Glomerocryst cubic boron nitride composite sheet and preparation method for same

A technology of polycrystalline cubic boron nitride, applied in chemical instruments and methods, layered products, metal layered products, etc., can solve the problems of short service life and low chipping efficiency of polycrystalline cubic boron nitride composite sheets, Achieve the effect of increased cutting depth, extended service life, and no desoldering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: a kind of preparation method of polycrystalline cubic boron nitride composite sheet is characterized in that it is carried out according to the following steps:

[0023] A. Mix 70g of cubic boron nitride micropowder, 10g of metal bond and 10g of ceramic additive, the particle size of the cubic boron nitride micropowder is 20~30um, the particle size of metal bond is less than or equal to 10um, and the particle size of ceramic additive is less than Equal to 10um;

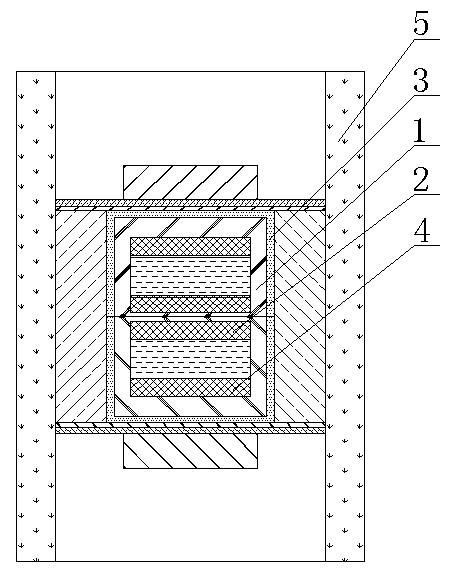

[0024] B. Put the mixture 4 and the cemented carbide substrate 2 into the molybdenum cup 1 isolated by the shielding layer of the salt pipe 3, wherein the mixture is placed on both sides of the cemented carbide substrate 2, and the installed salt pipe 3 is put into the molybdenum cup 1. Graphite mould, put the graphite mold into the pyrophyllite block 5, put the pyrophyllite block into the cubic boron nitride six-sided top press for pressing and sintering, the sintering process is as follows, firs...

Embodiment 2

[0029] Embodiment 2: a kind of preparation method of polycrystalline cubic boron nitride composite sheet is carried out according to the following steps:

[0030] A. Mix 75g of cubic boron nitride micropowder, 14g of metal bond and 9g of ceramic additive, the particle size of the cubic boron nitride micropowder is 20 ~ 30 um, the particle size of metal bond is less than or equal to 10um, and the particle size of ceramic additive is less than Equal to 10um;

[0031] B. Put the mixture and the cemented carbide substrate into the molybdenum cup isolated by the shielding layer of the salt tube, wherein the mixture is placed on both sides of the cemented carbide substrate, put the installed salt pipe into the graphite mold, and put the graphite mold Put it into the pyrophyllite block, put the pyrophyllite block into the cubic boron nitride six-sided top press for pressing and sintering. Cooling starts after ~2min, synthesis takes 6min~15min. The synthesis time includes heating ti...

Embodiment 3

[0036] Embodiment 3: a kind of preparation method of polycrystalline cubic boron nitride composite sheet is carried out according to the following steps:

[0037] A. Mix 80g of cubic boron nitride micropowder, 15g of metal bond and 8g of ceramic additive, the particle size of the cubic boron nitride micropowder is 20 ~ 30 um, the particle size of metal bond is less than or equal to 10um, and the particle size of ceramic additive is less than Equal to 10um;

[0038] B. Put the mixture and the cemented carbide substrate into the molybdenum cup isolated by the shielding layer of the salt tube, wherein the mixture is placed on both sides of the cemented carbide substrate, put the installed salt pipe into the graphite mold, and put the graphite mold Put it into the pyrophyllite block, put the pyrophyllite block into the cubic boron nitride six-sided top press for pressing and sintering. Cooling starts after ~2min, synthesis takes 6min~15min. The synthesis time includes heating ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com