Milling process parameter optimization method

A technology of process parameter optimization and process parameters, which is applied in the field of cutting processing technology, can solve problems such as not being able to meet high-speed cutting processing, affecting the machining accuracy of parts, the service life of machine tool spindles and tools, and restricting cutting processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

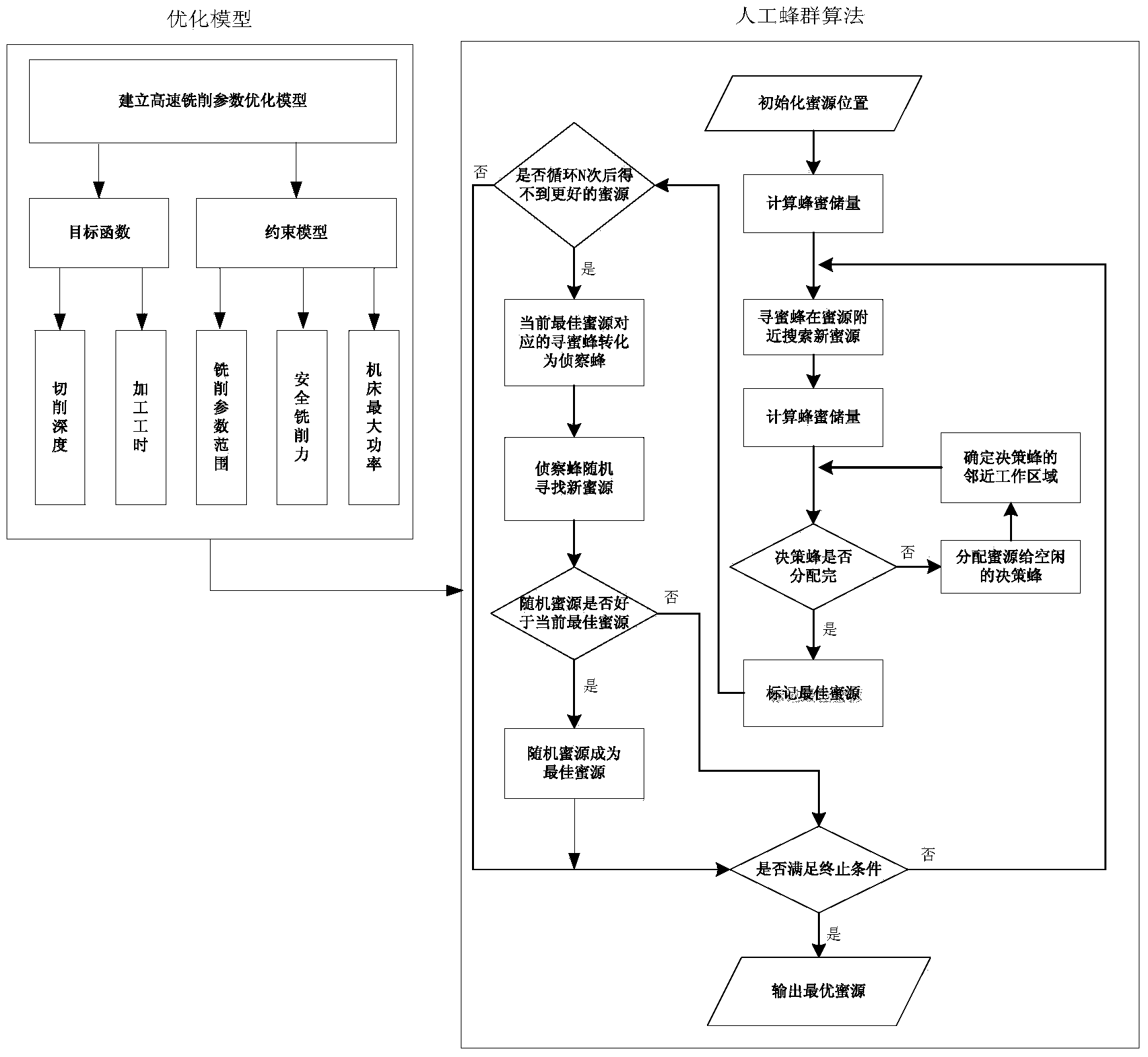

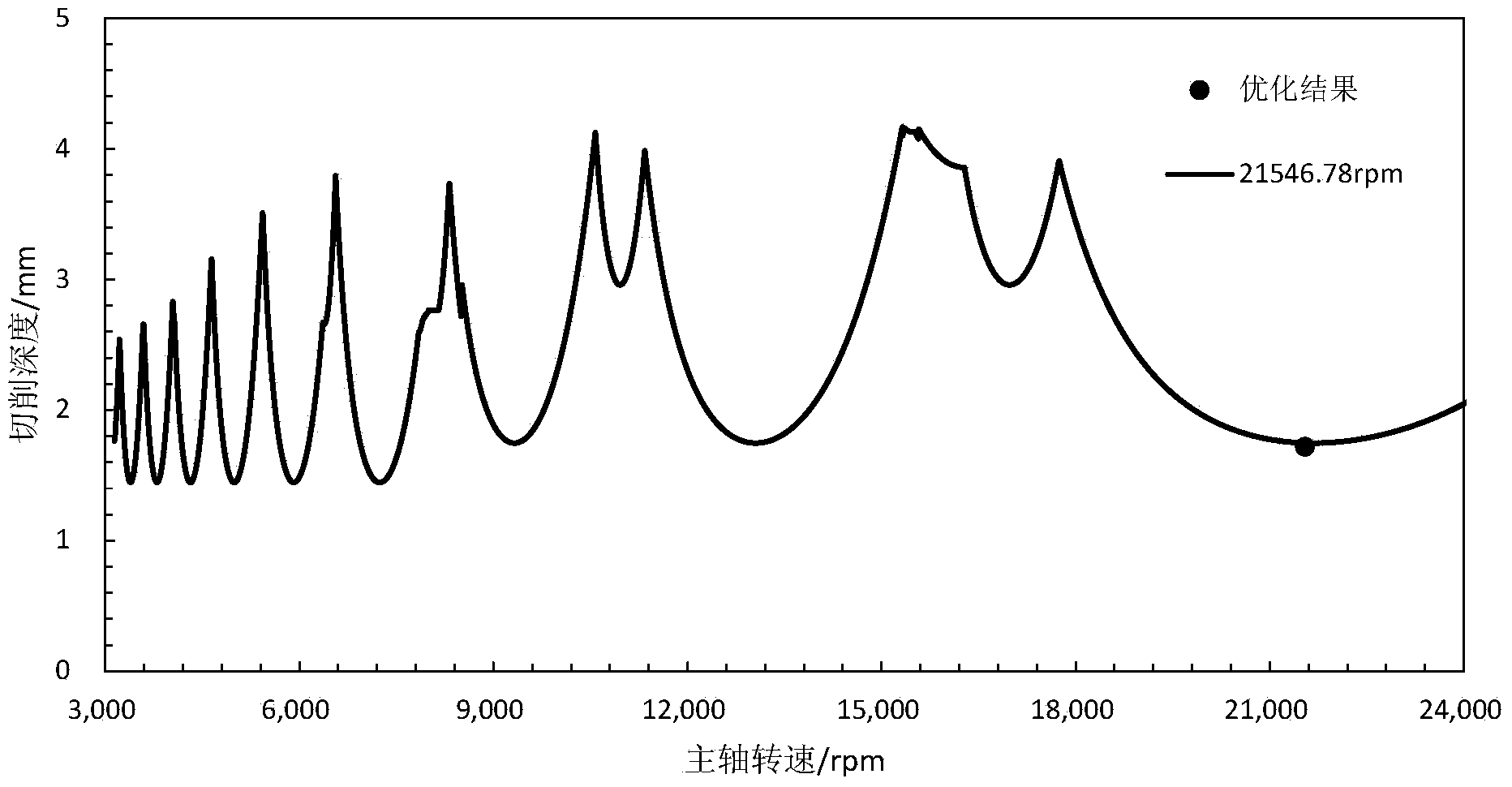

[0045] Aiming at the deficiencies of the prior art, the present invention proposes a milling process parameter optimization method based on cutting stability and applicable to the high-speed milling process for the fields of aerospace, automobiles and moulds. The method first establishes a high-speed milling process parameter optimization model , and then according to the artificial bee colony algorithm, the established optimization model is calculated to obtain the optimal combination of milling process parameters that can obtain the maximum productivity in the non-chatter state (that is, the cutting stable state).

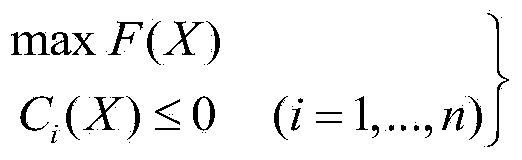

[0046] In order to achieve the purpose of the invention, the high-speed milling process parameter optimization model in the present invention considers cutting stability and productivity, and the model satisfies the following relat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com