Patents

Literature

2032 results about "Coupling effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The coupling effect states that test data sets that detect simple types of faults are sensitive enough to detect more complex types of faults. This paper describes empirical investigations into the coupling effect over a specific domain of software faults. All the results from this investigation support the validity of the coupling effect.

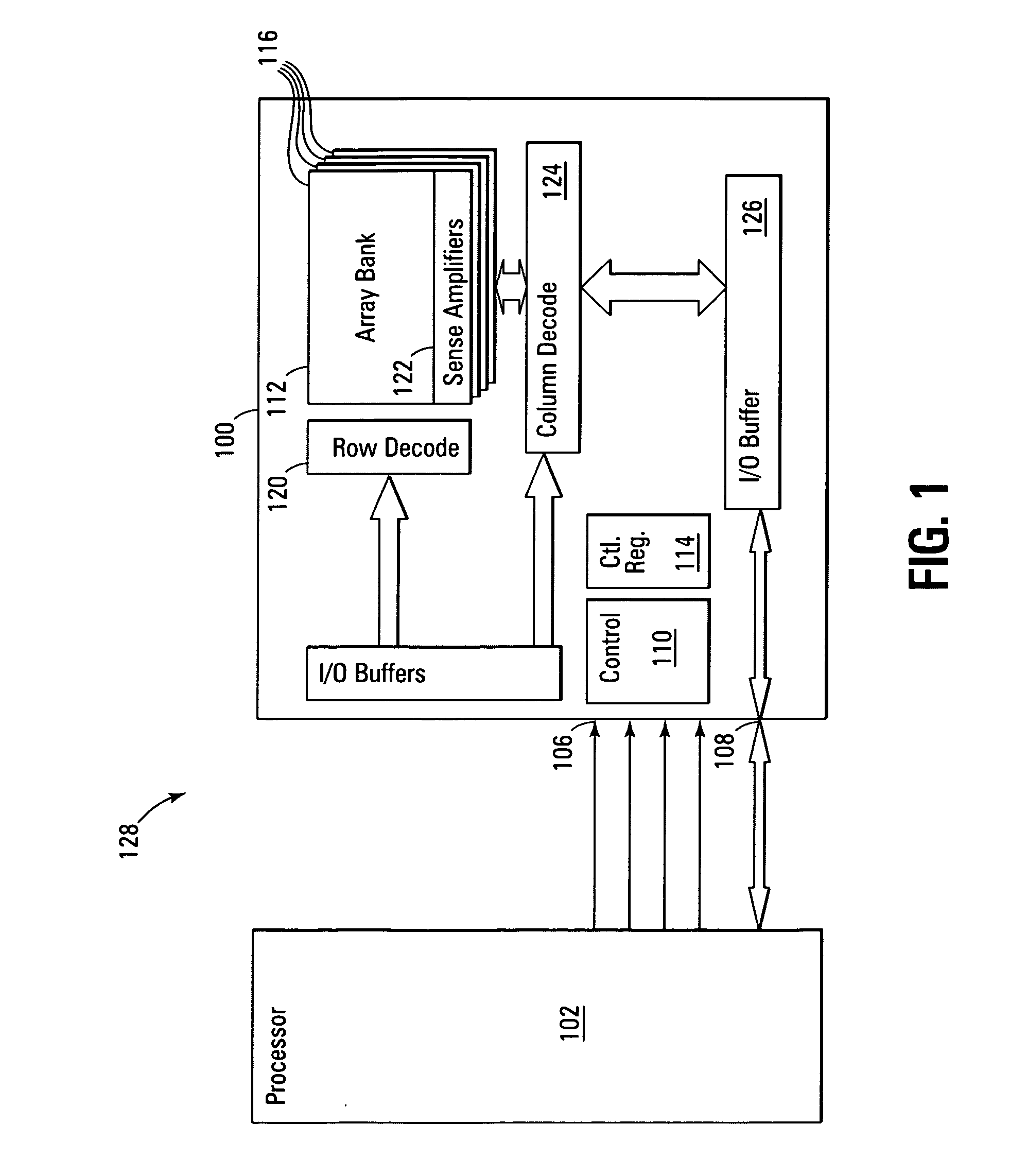

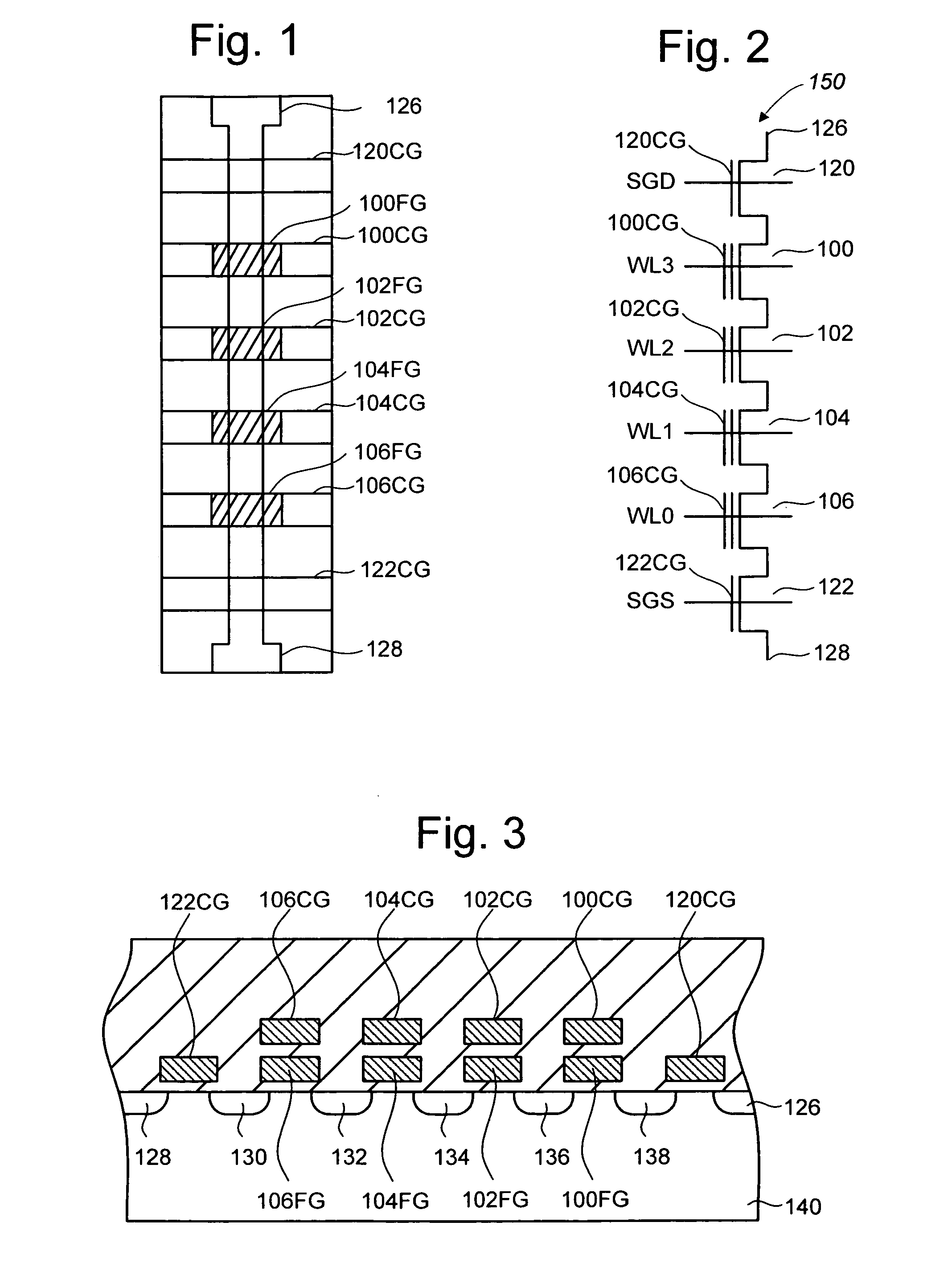

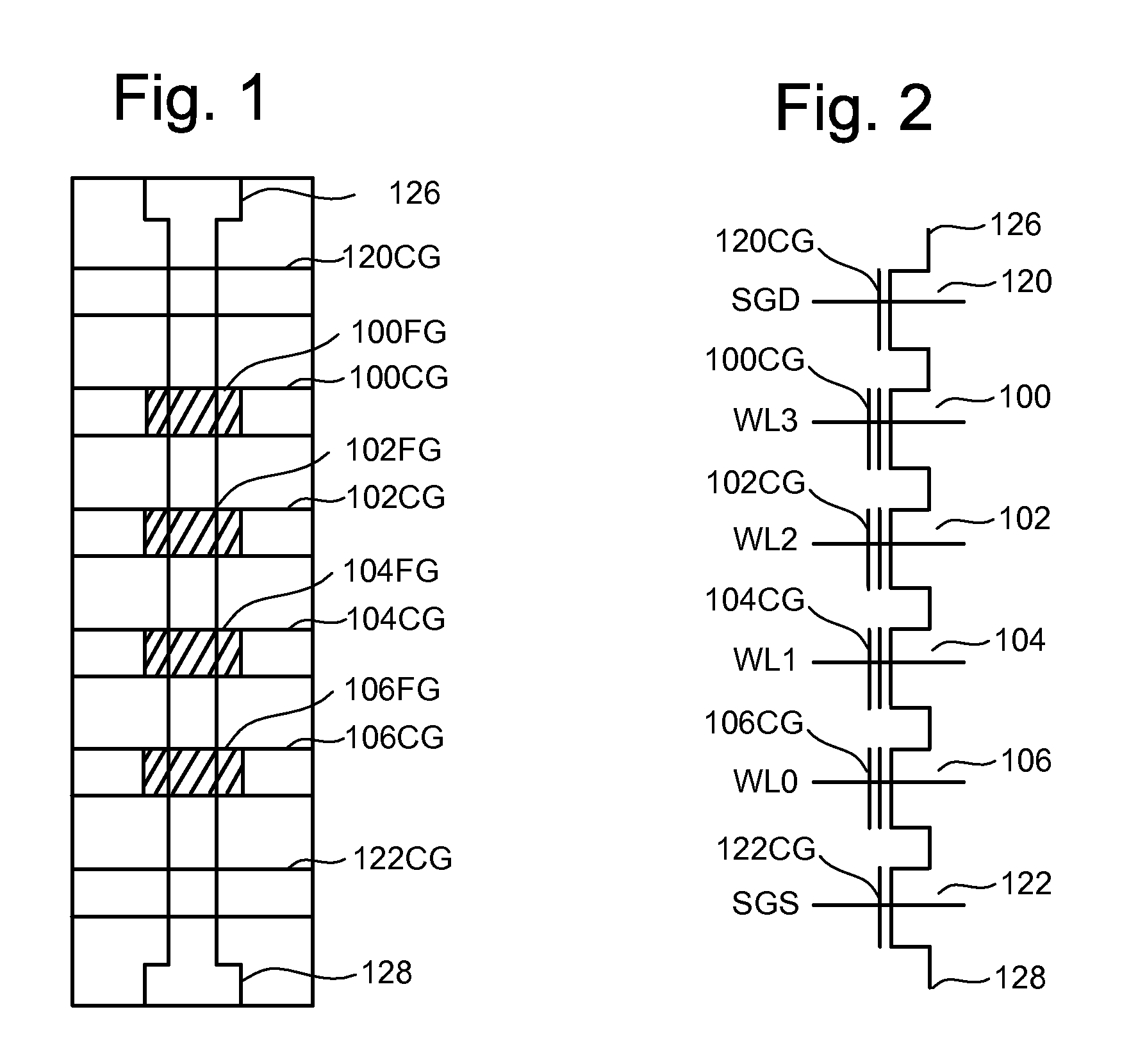

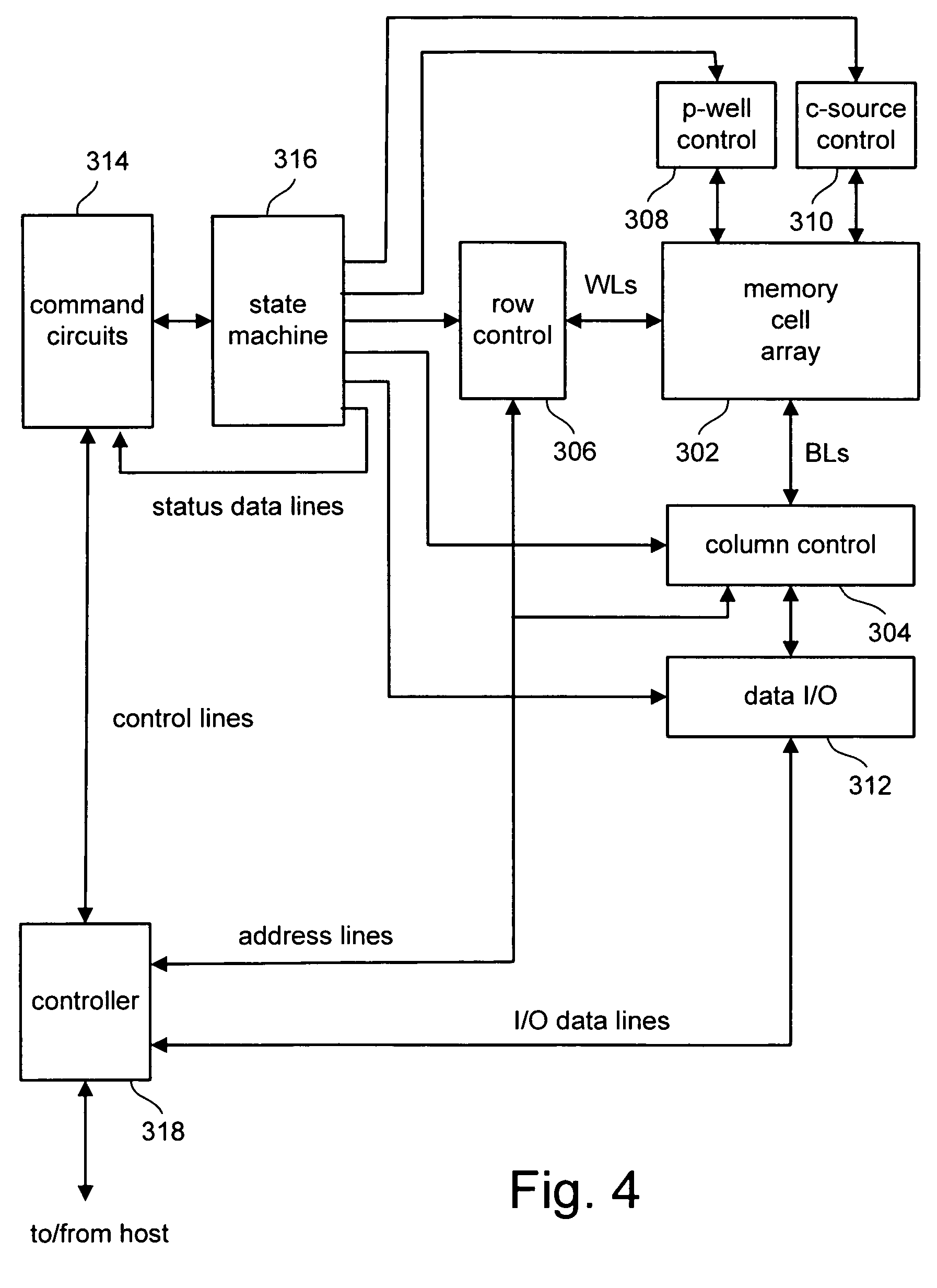

Programming method to reduce gate coupling interference for non-volatile memory

Owner:MICRON TECH INC

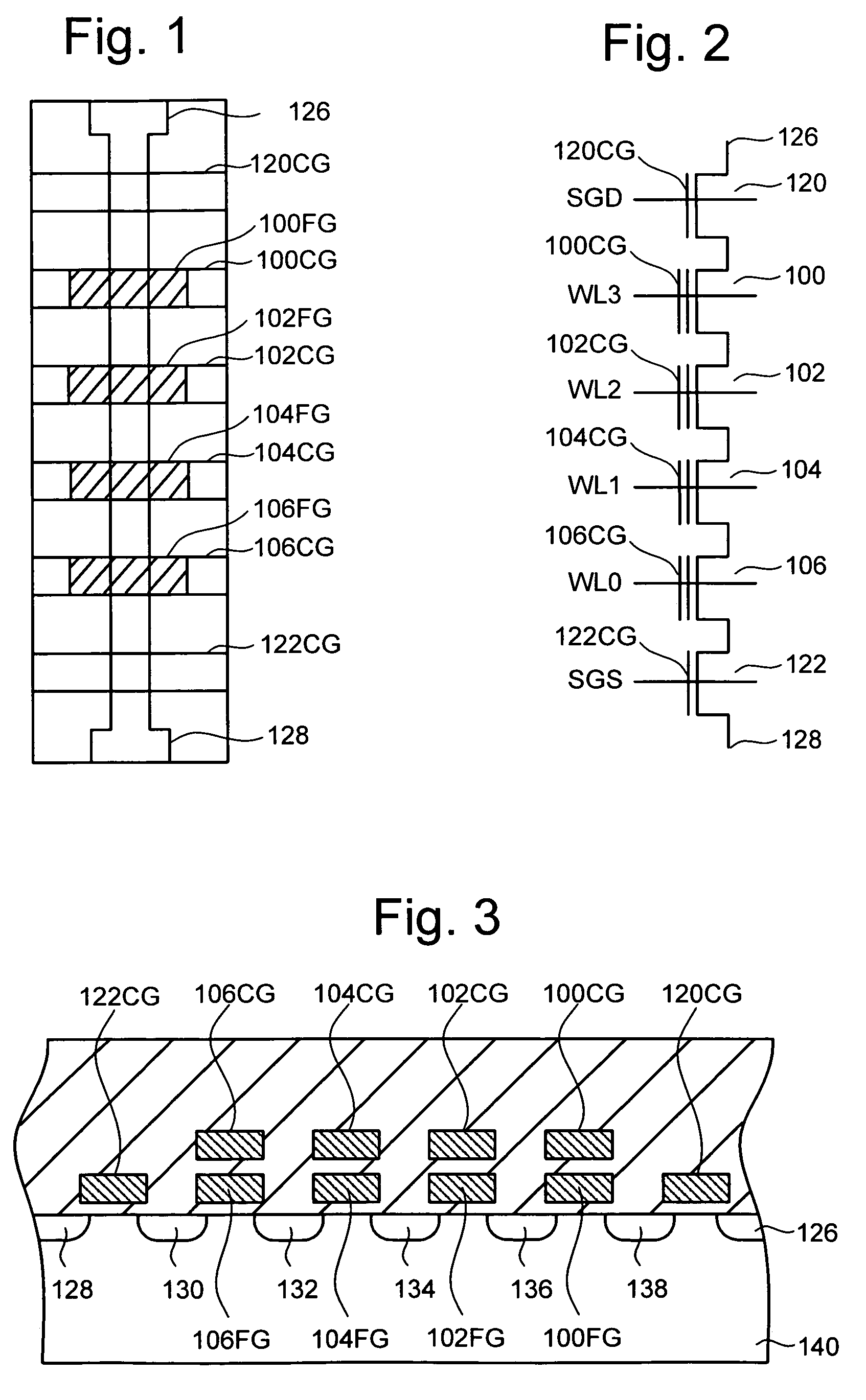

Programming method to reduce gate coupling interference for non-volatile memory

ActiveUS20070189073A1Reduce the impactReduce impactRead-only memoriesDigital storageGoal programmingEngineering

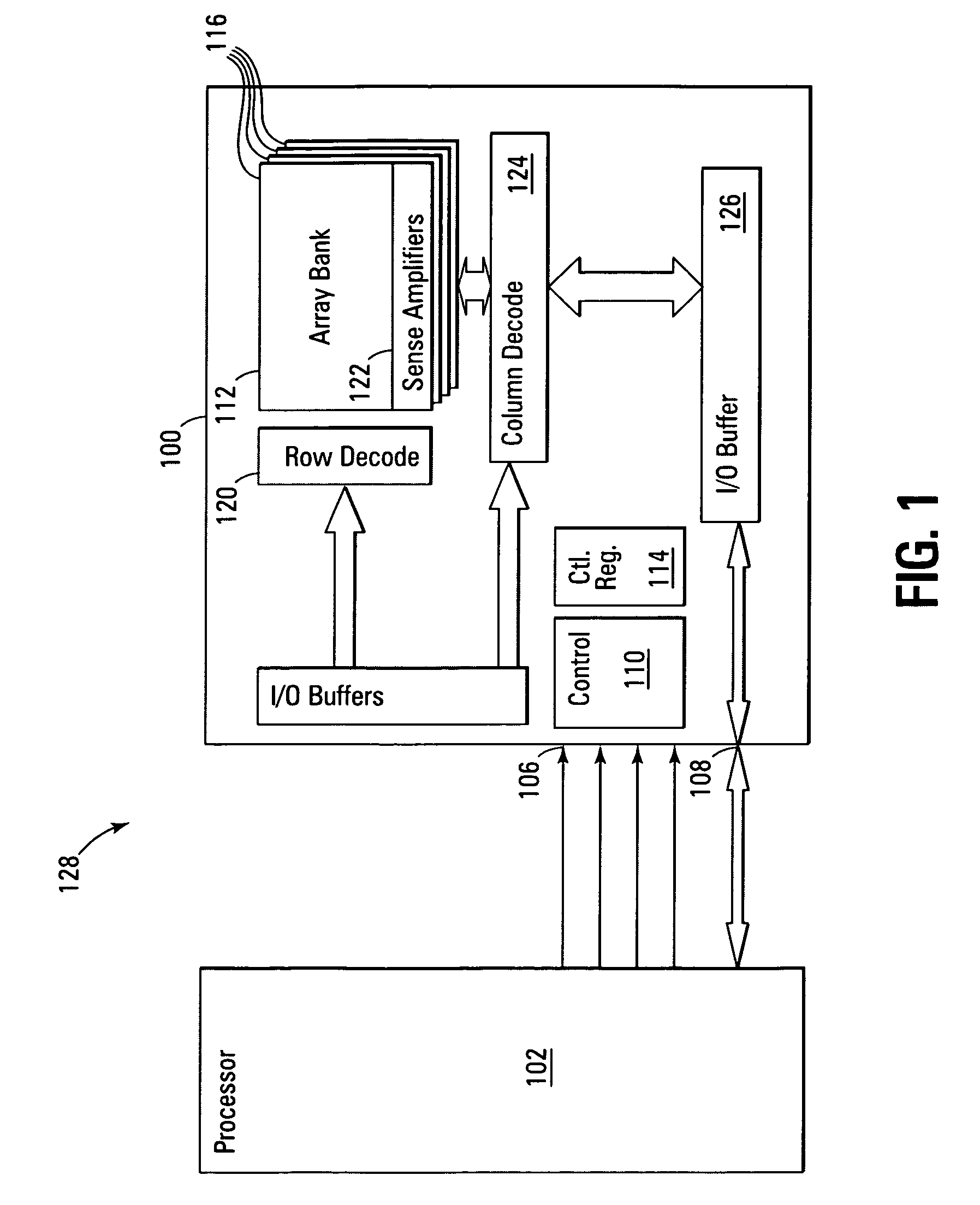

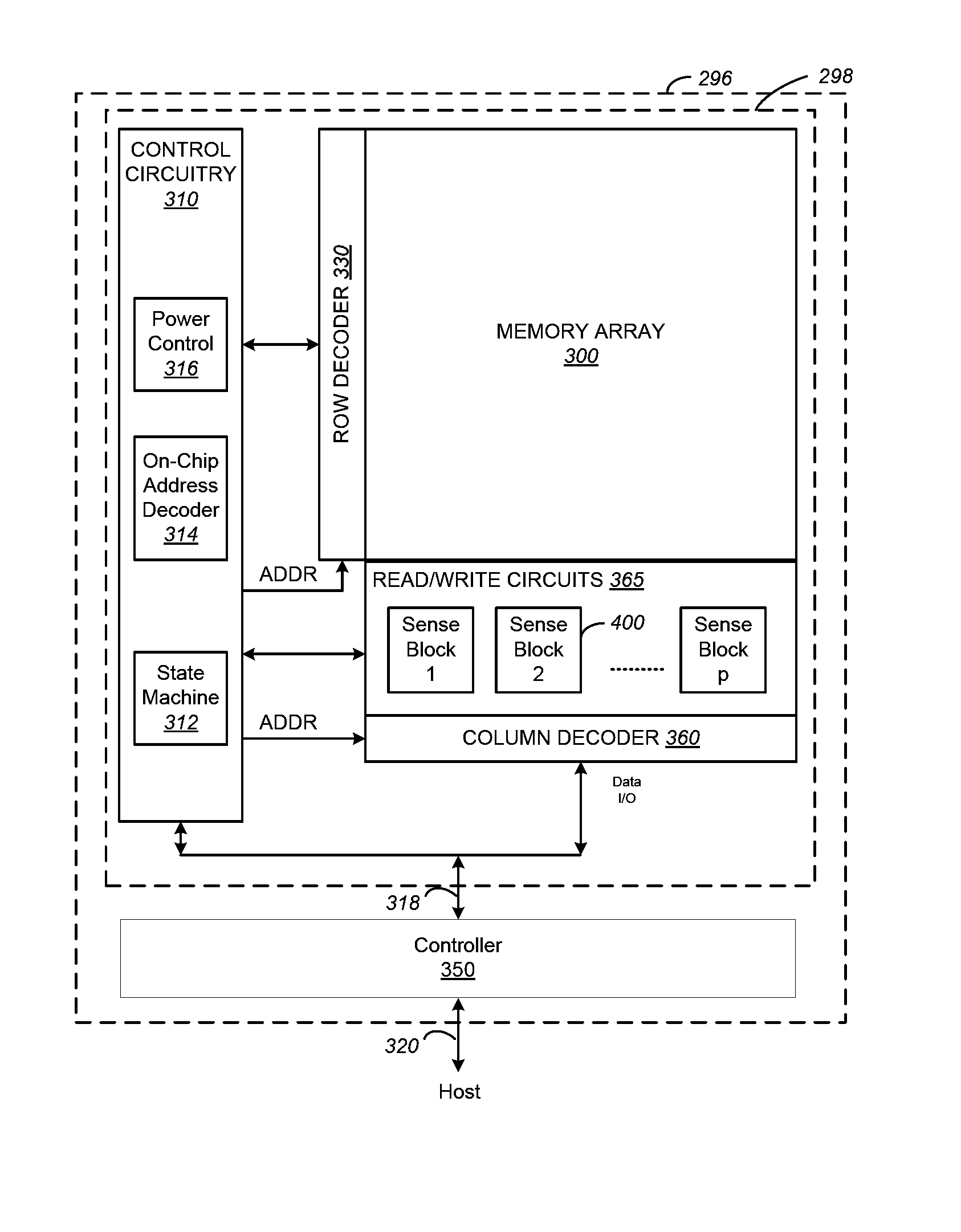

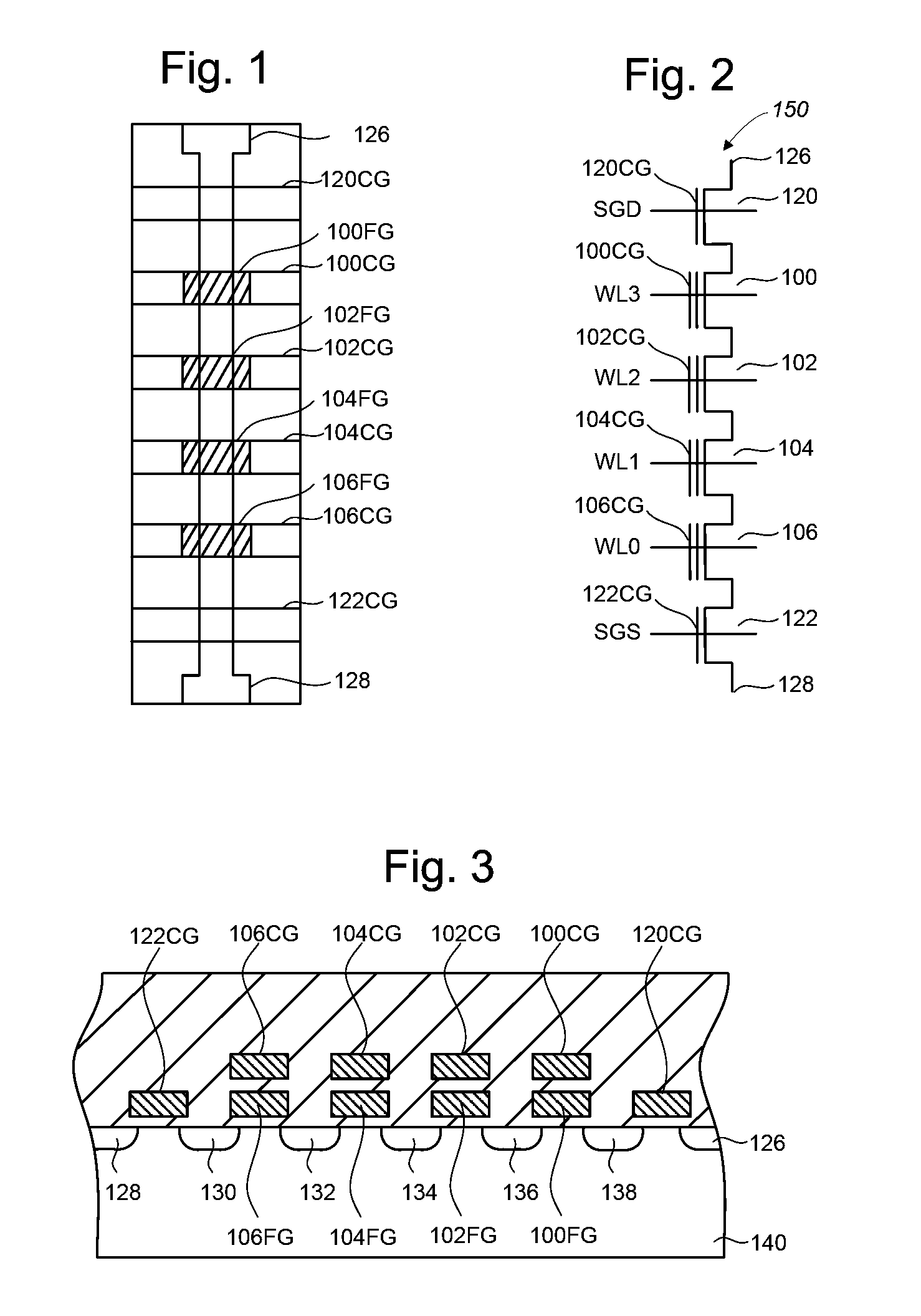

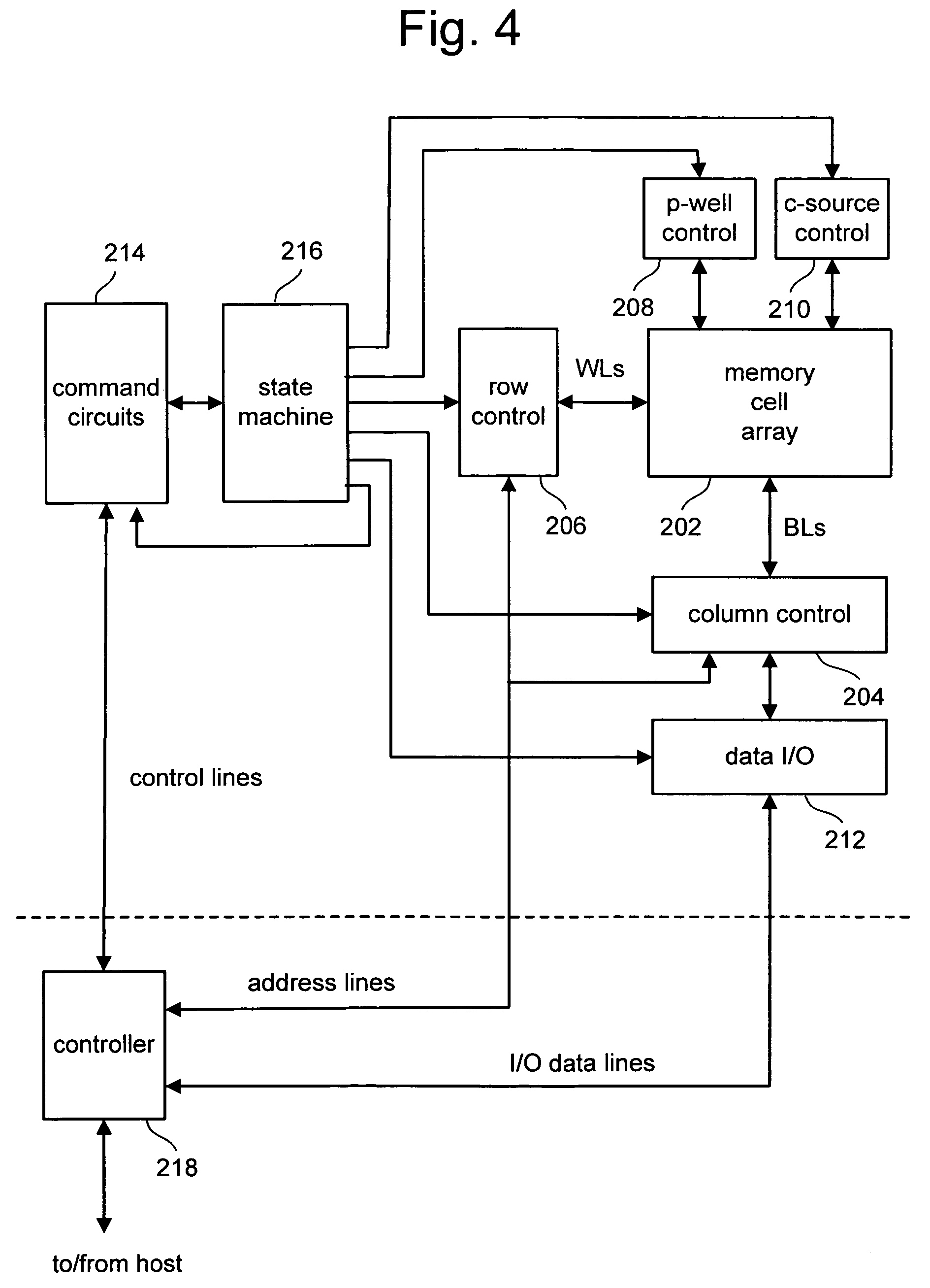

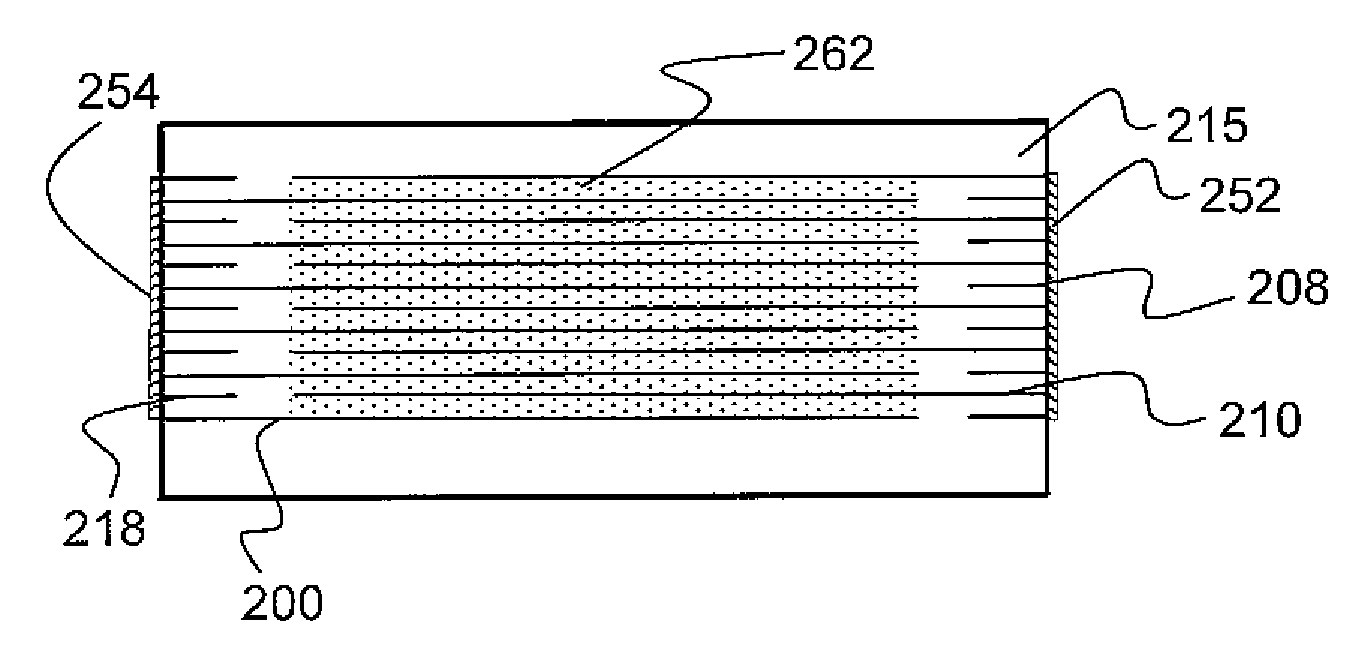

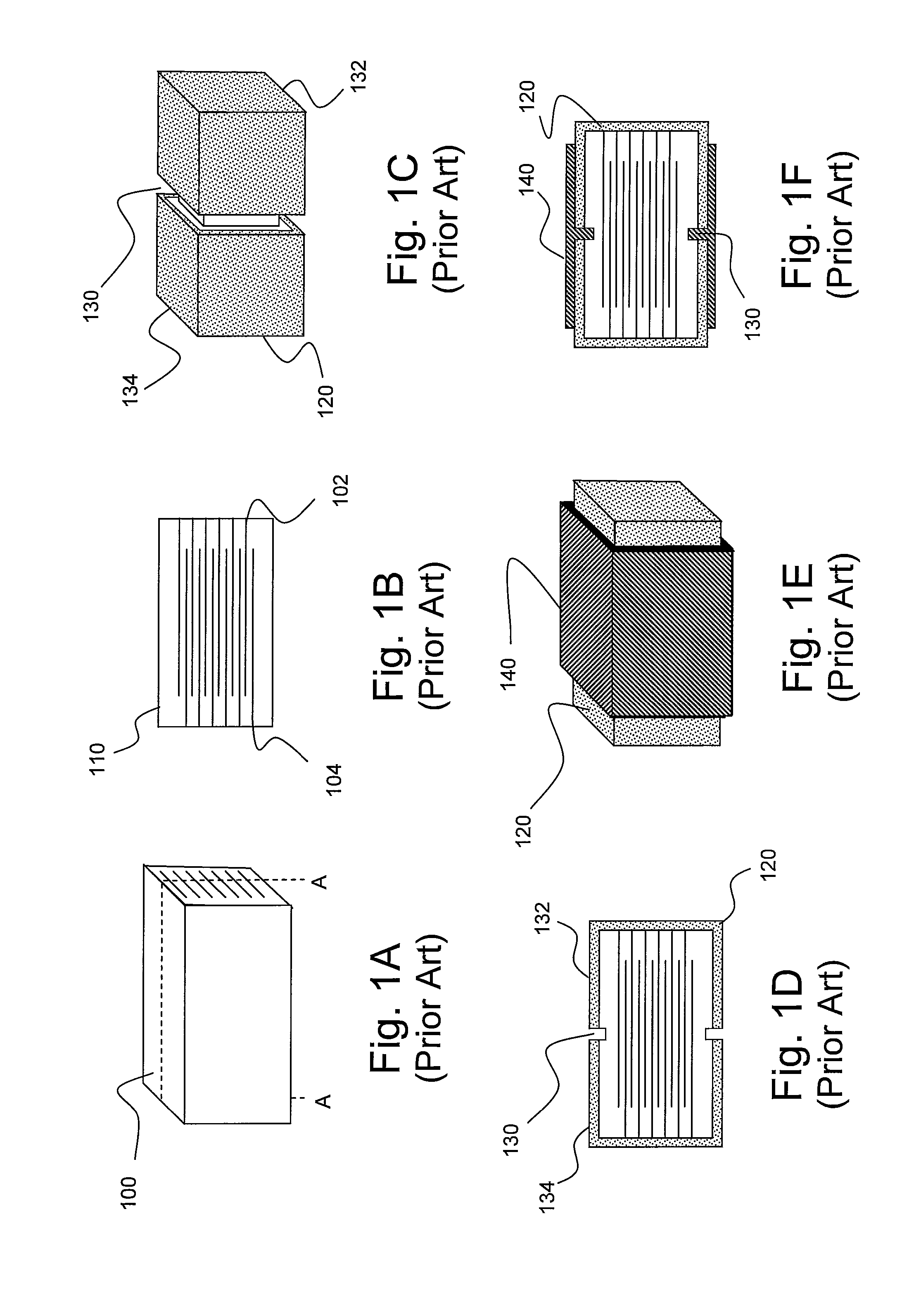

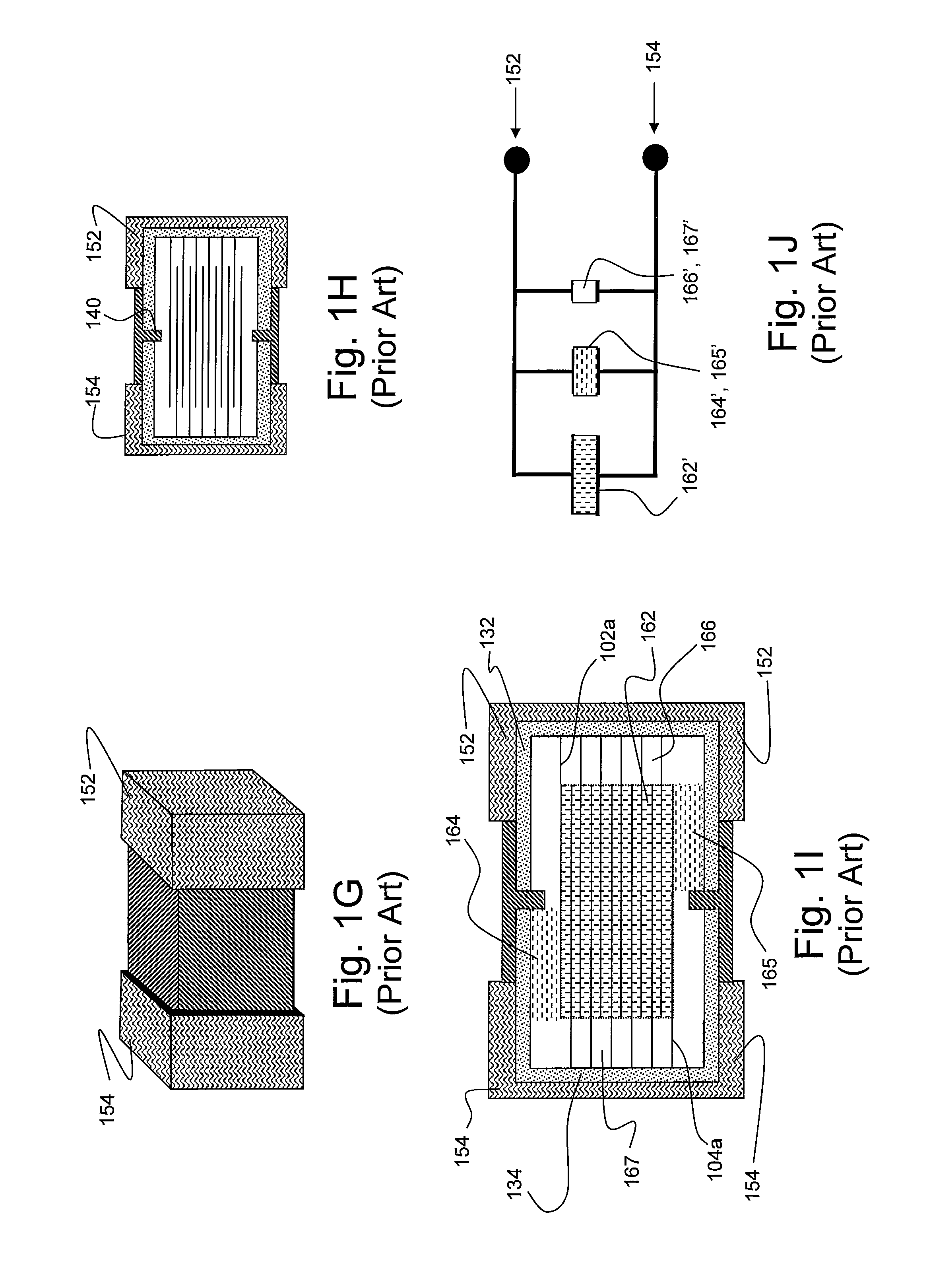

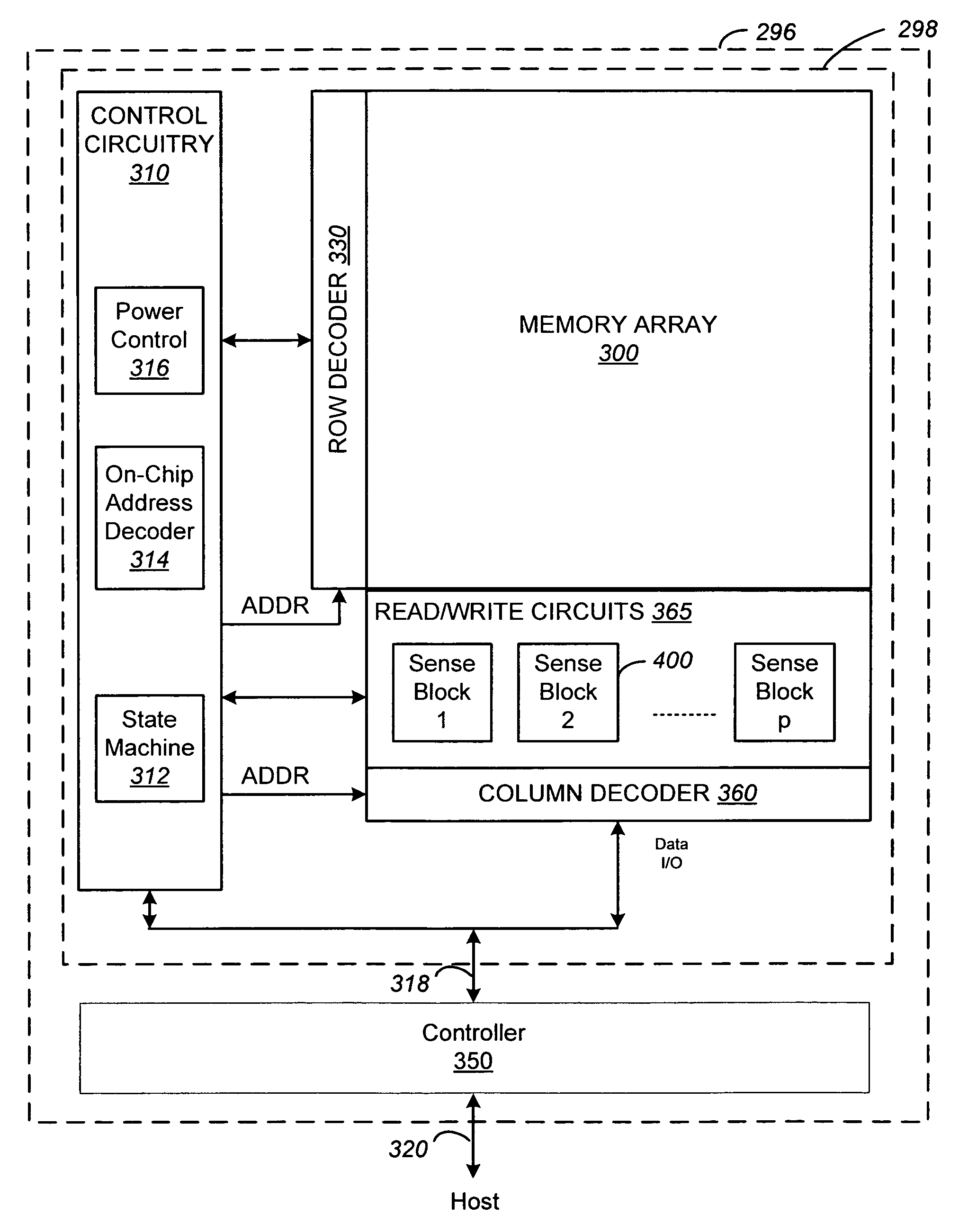

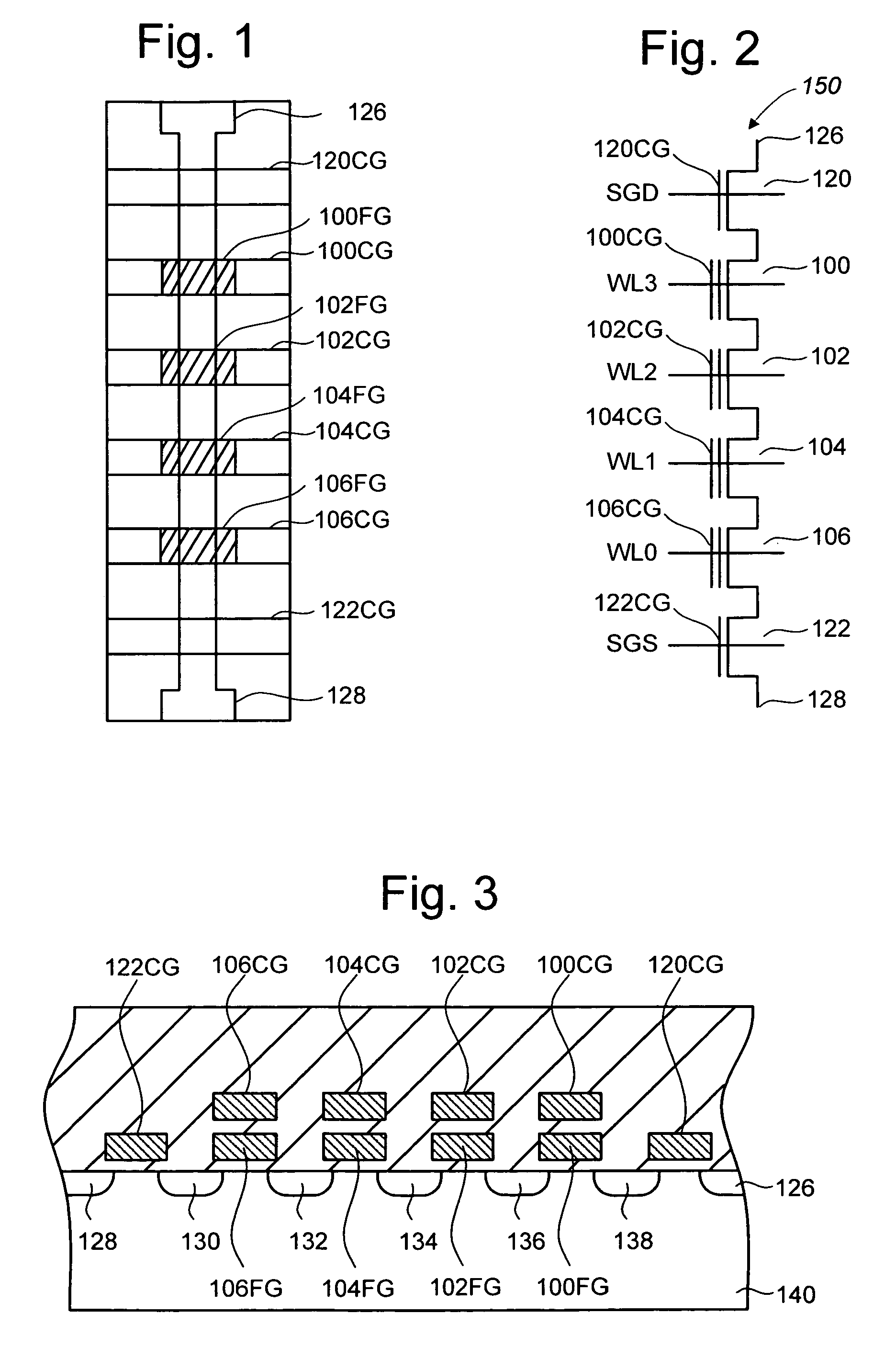

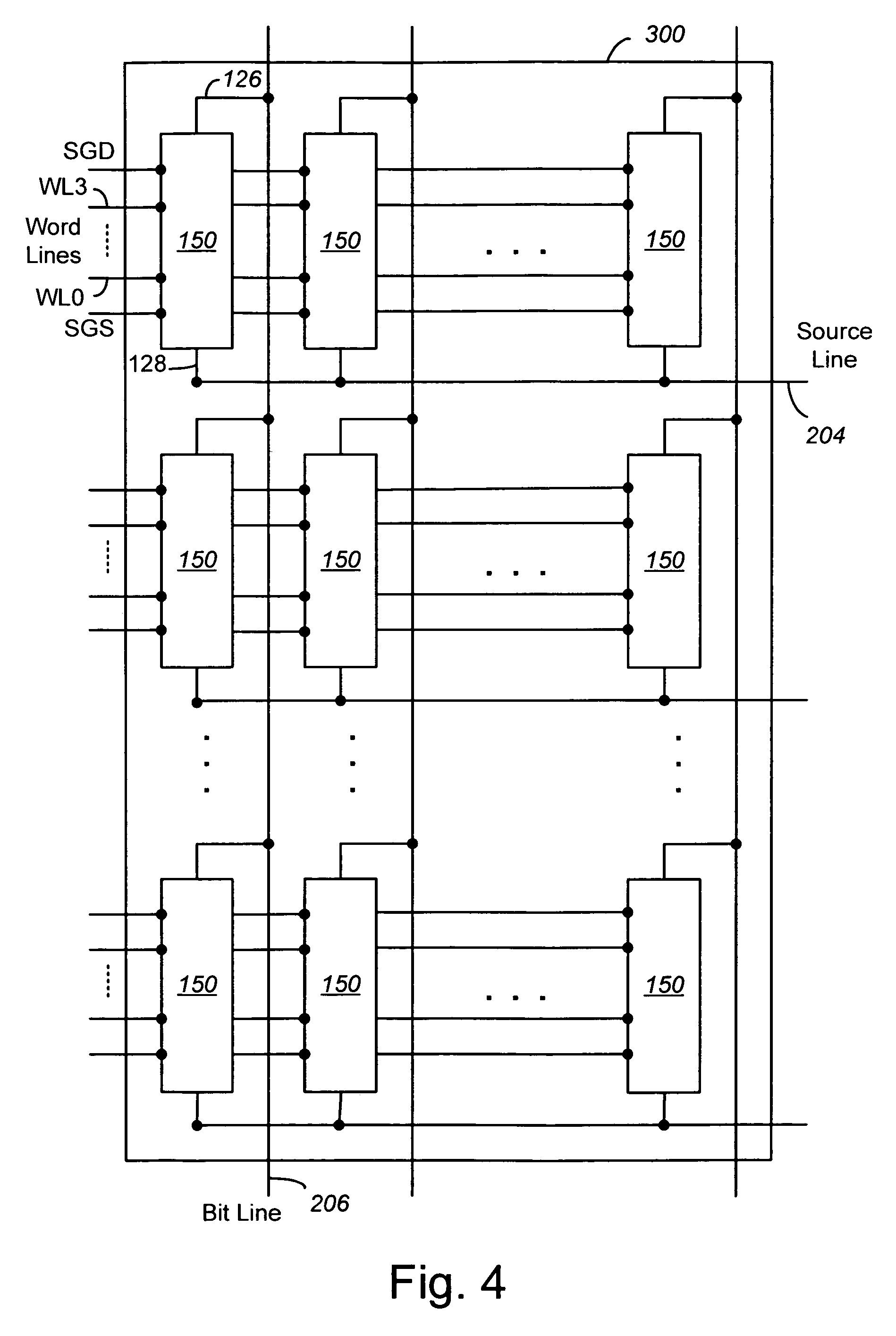

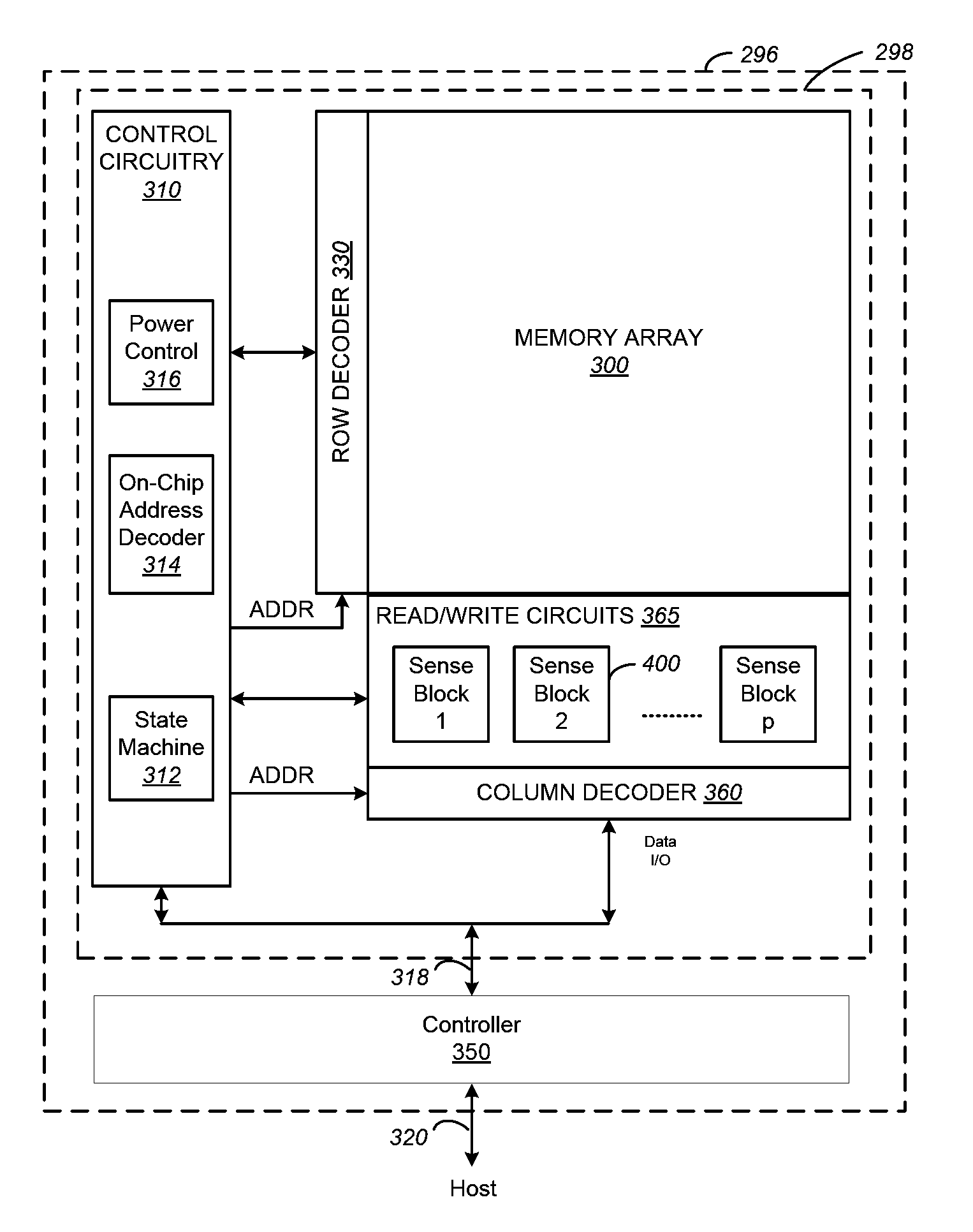

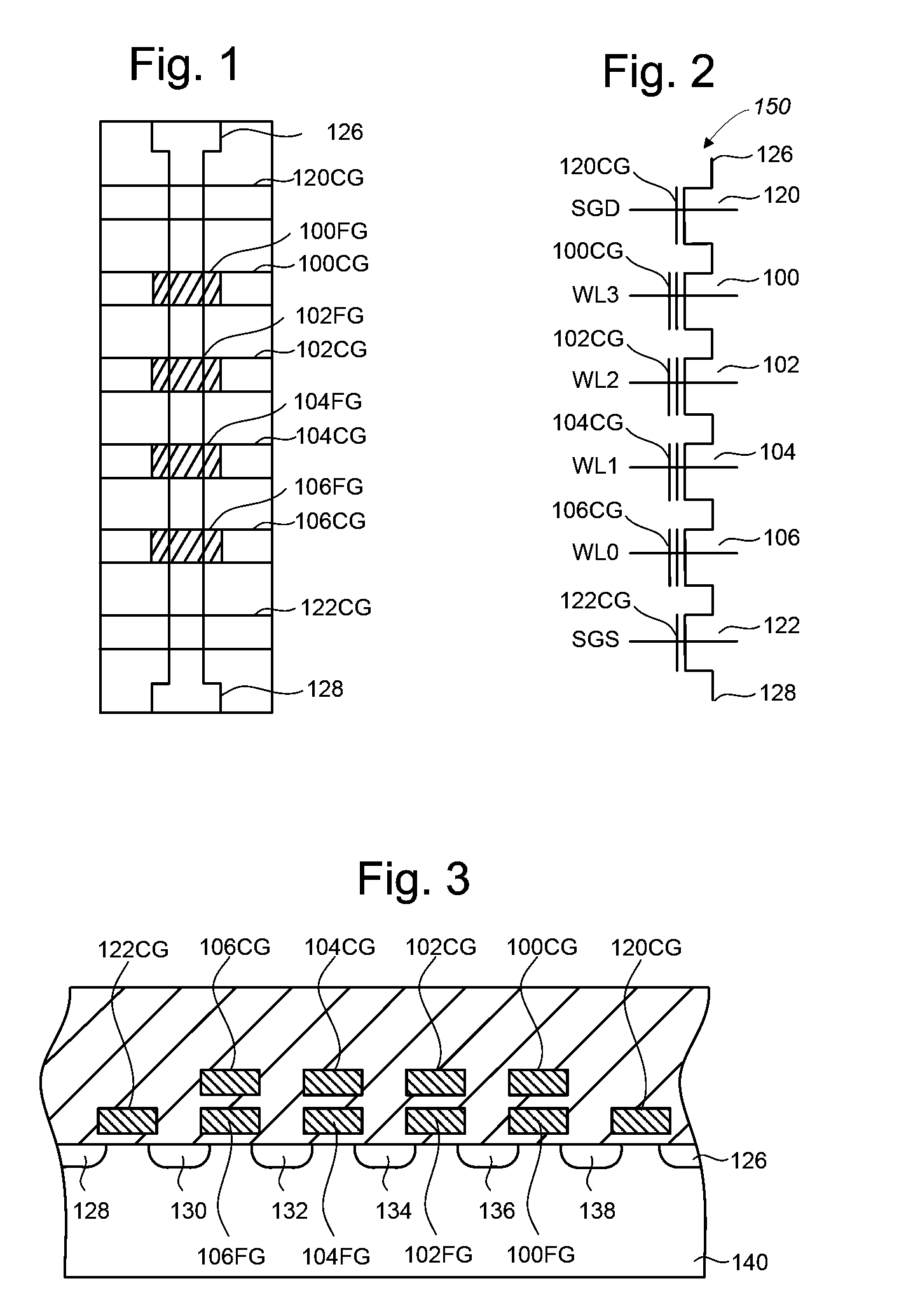

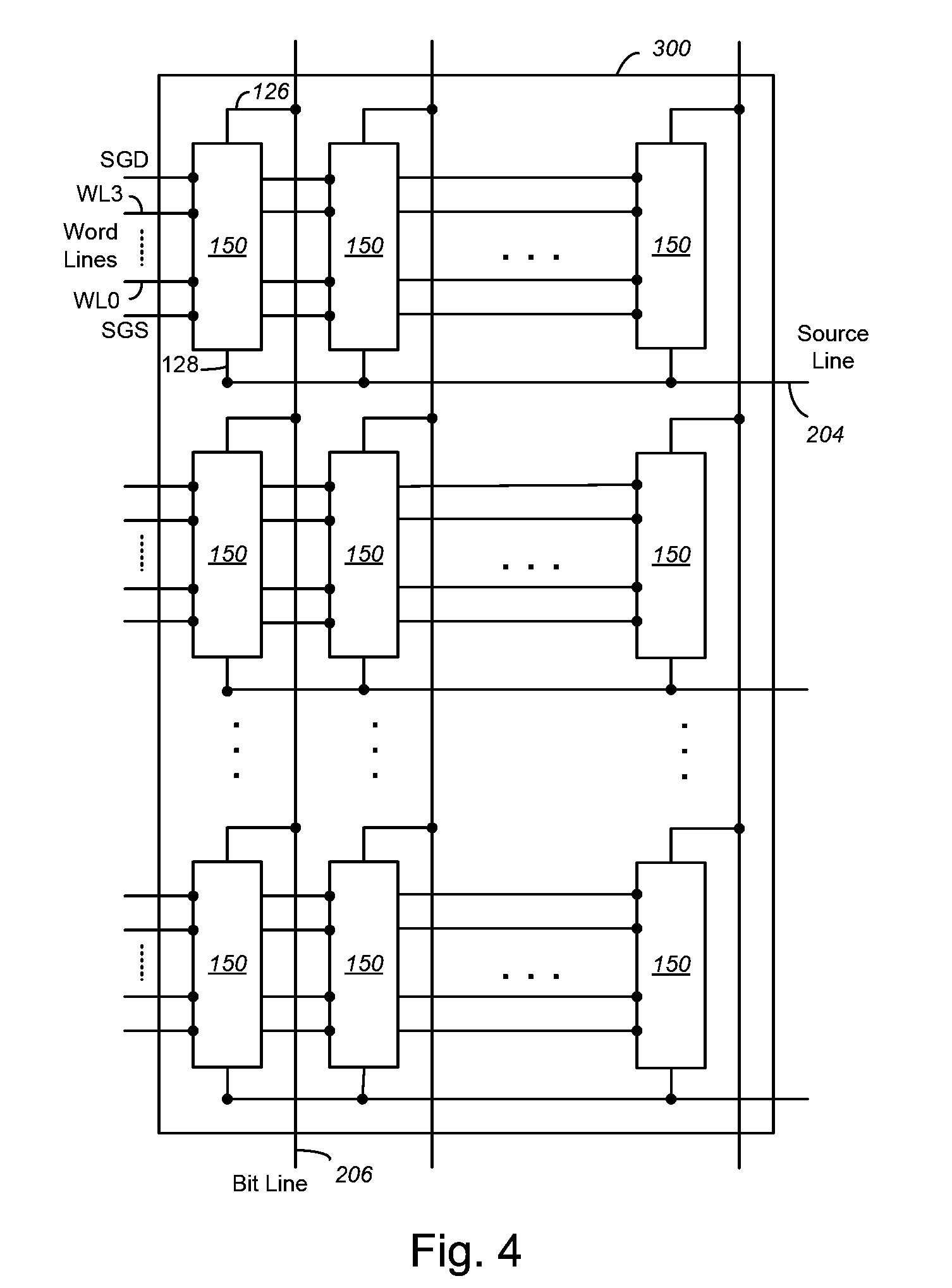

A non-volatile memory device and programming process is described that compensates for coupling effects on threshold gate voltages of adjacent floating gate or non-conductive floating node memory cells by adjusting the threshold voltage level programmed in view of the data being programmed on a following programming cycle into adjacent memory cells, so that the coupling effect results in the desired target threshold voltages for the cells. In one embodiment of the present invention, memory cell coupling is compensated for by adjusting programming level of one or more memory cells of a first page a memory array to a higher or lower threshold verify target voltage given the data / programming level to be written to directly adjacent memory cells of a second page, so that coupling between the directly adjacent memory cells of the first and second pages brings the memory cells of first page to their final target programming level.

Owner:MICRON TECH INC

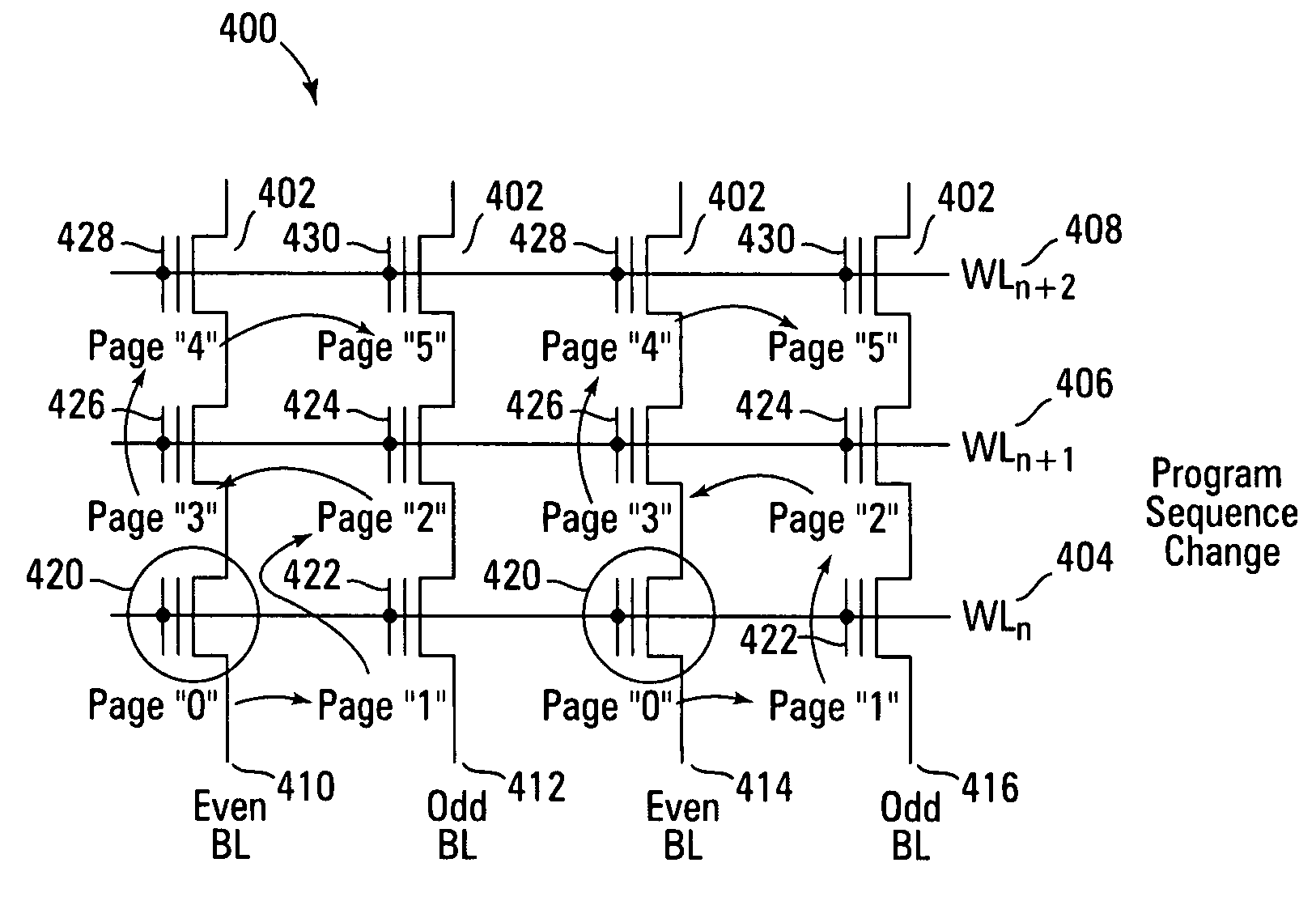

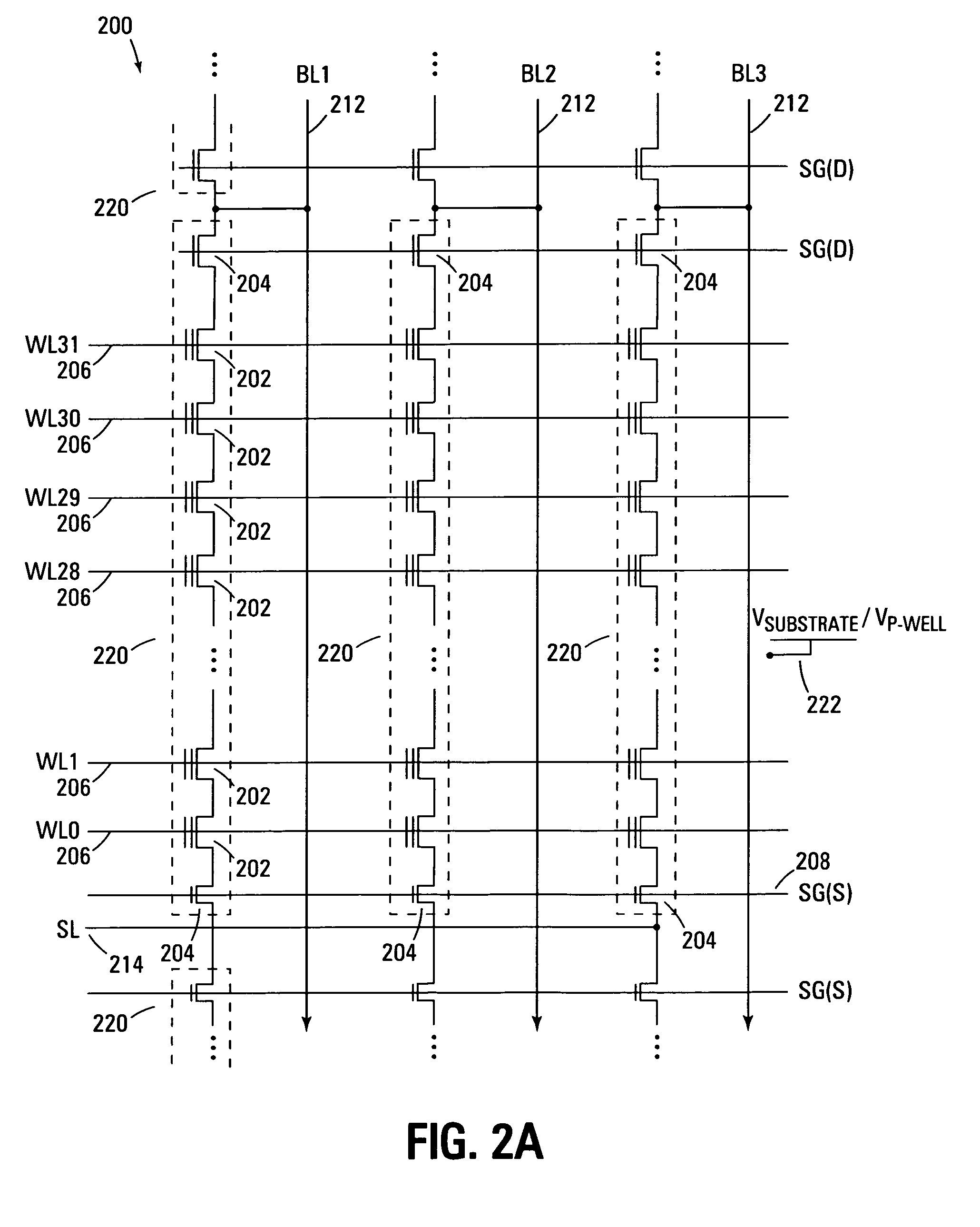

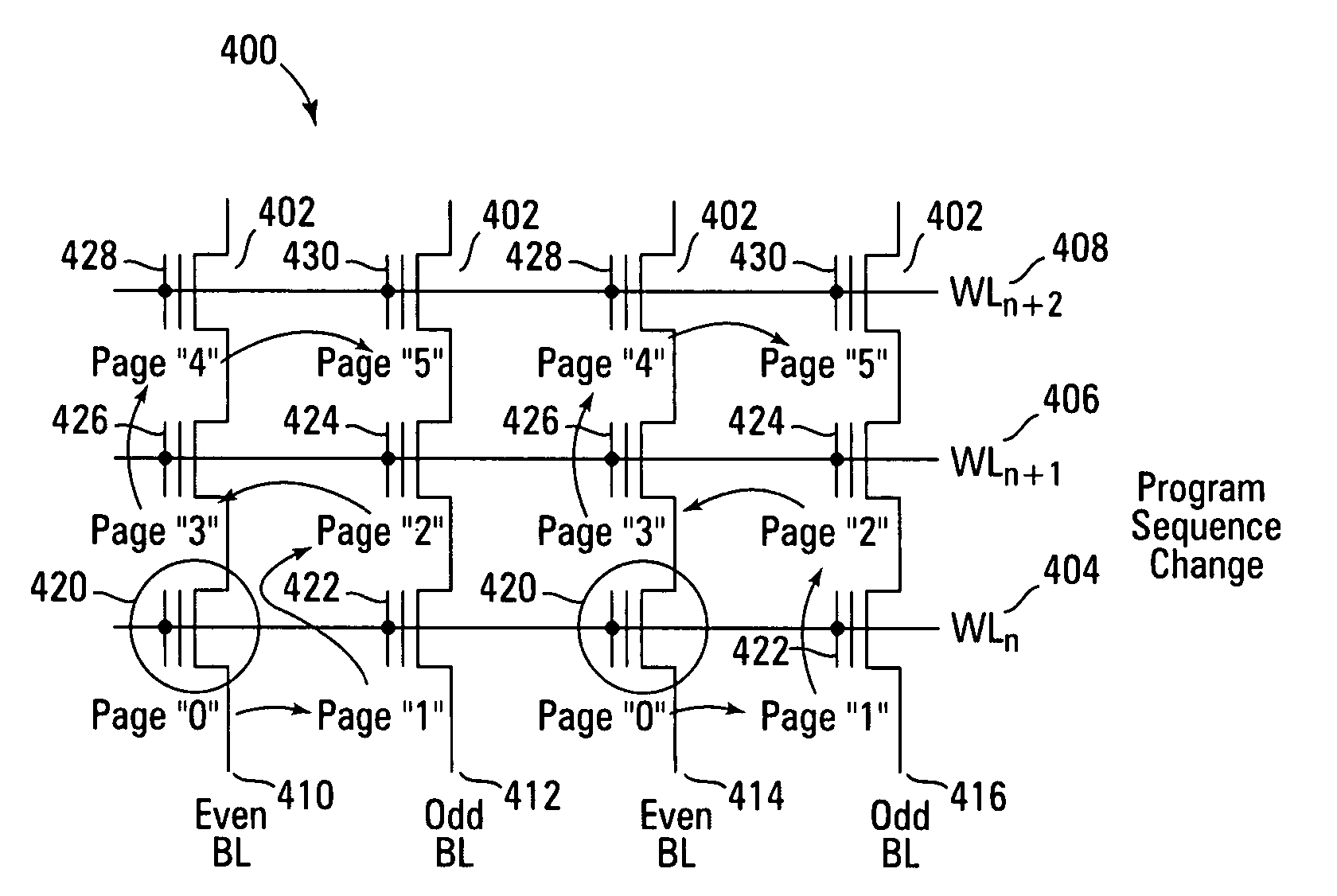

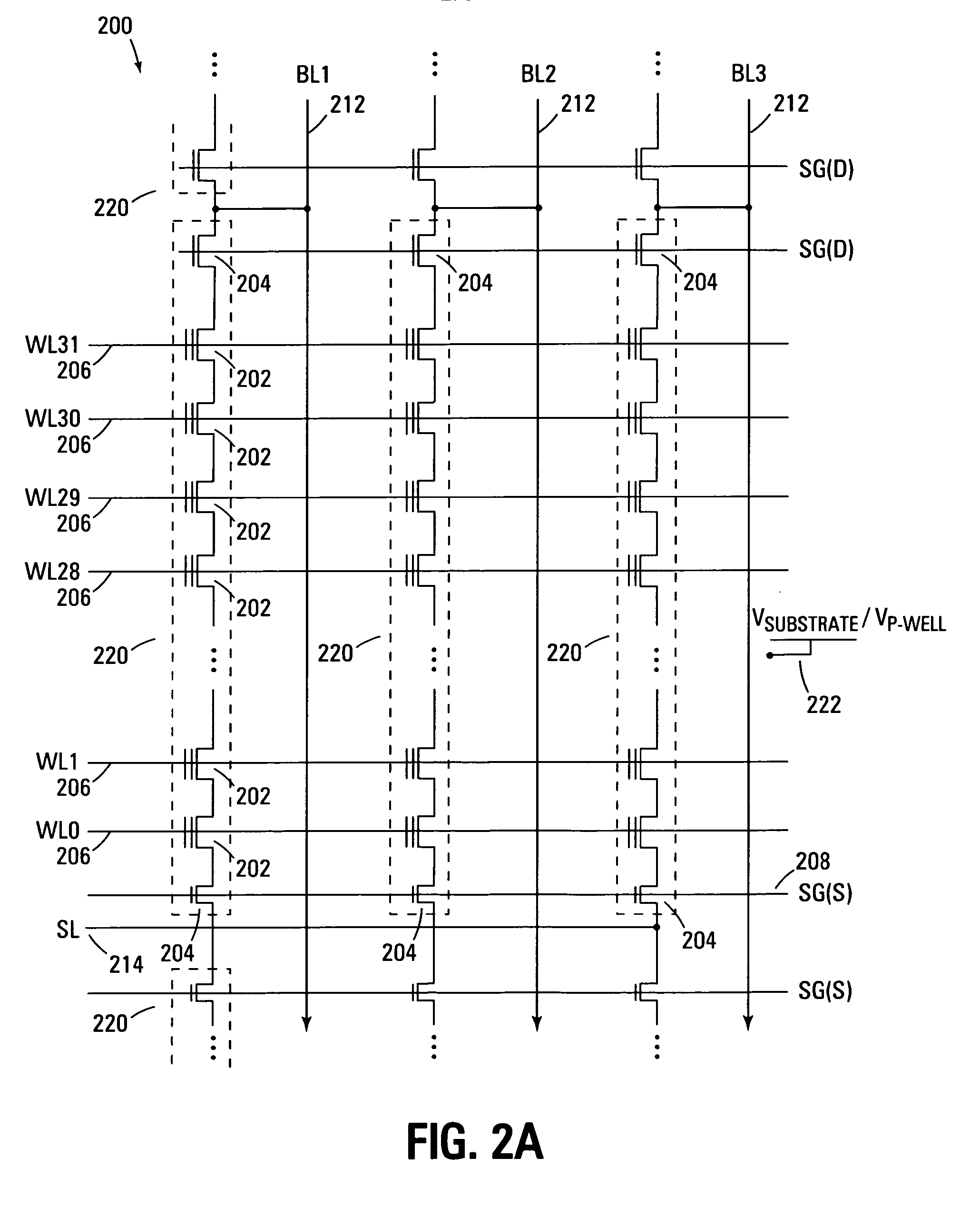

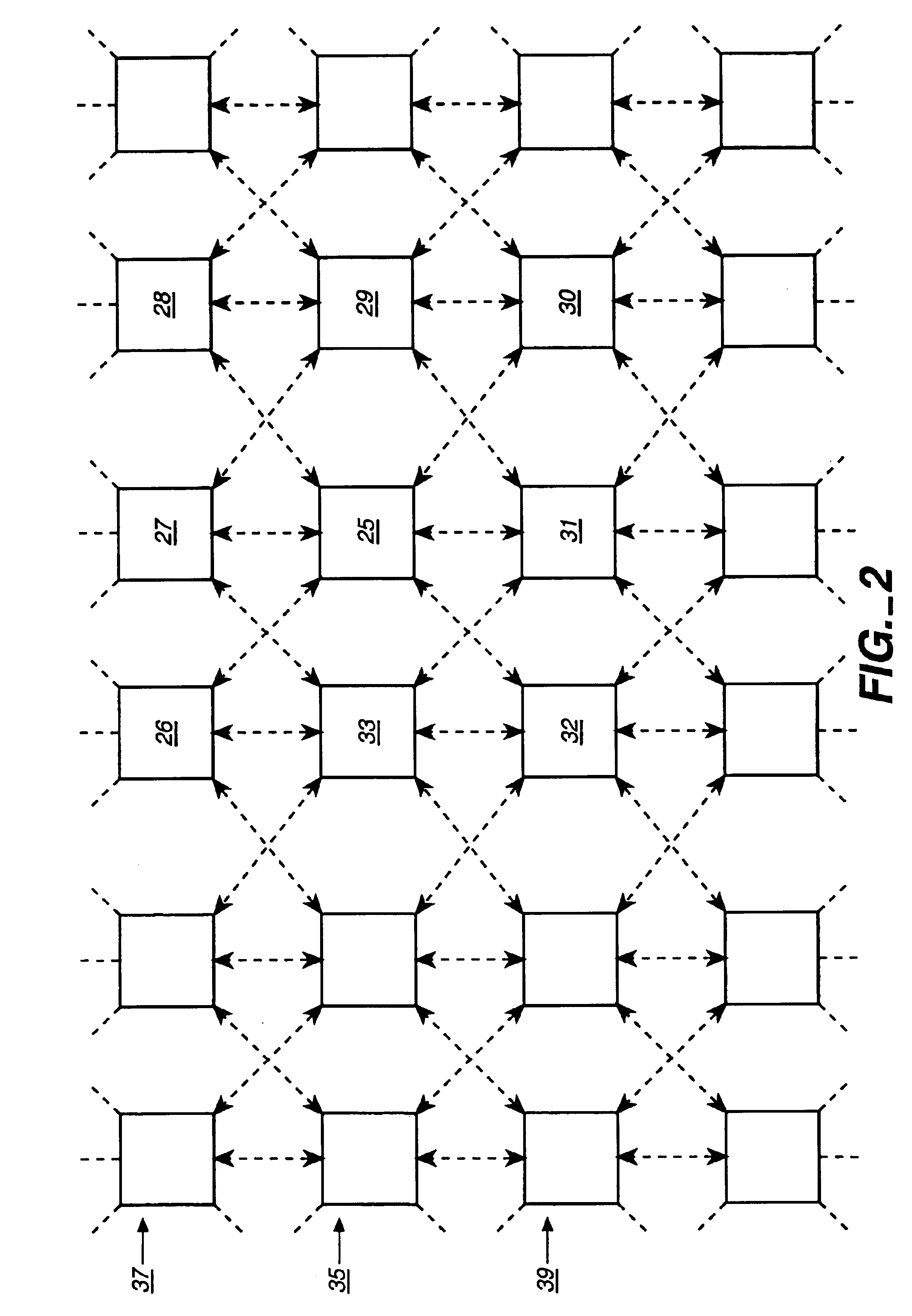

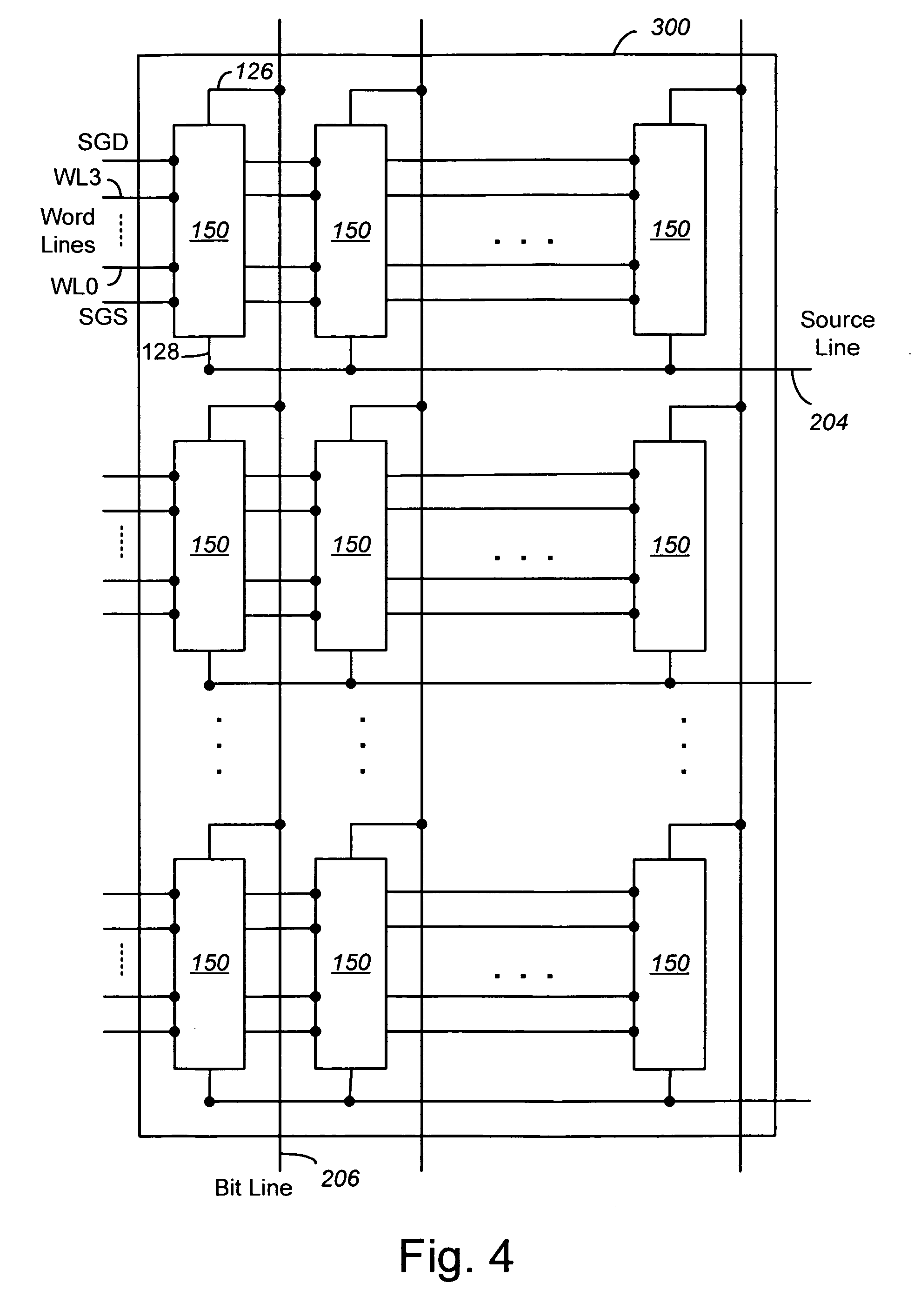

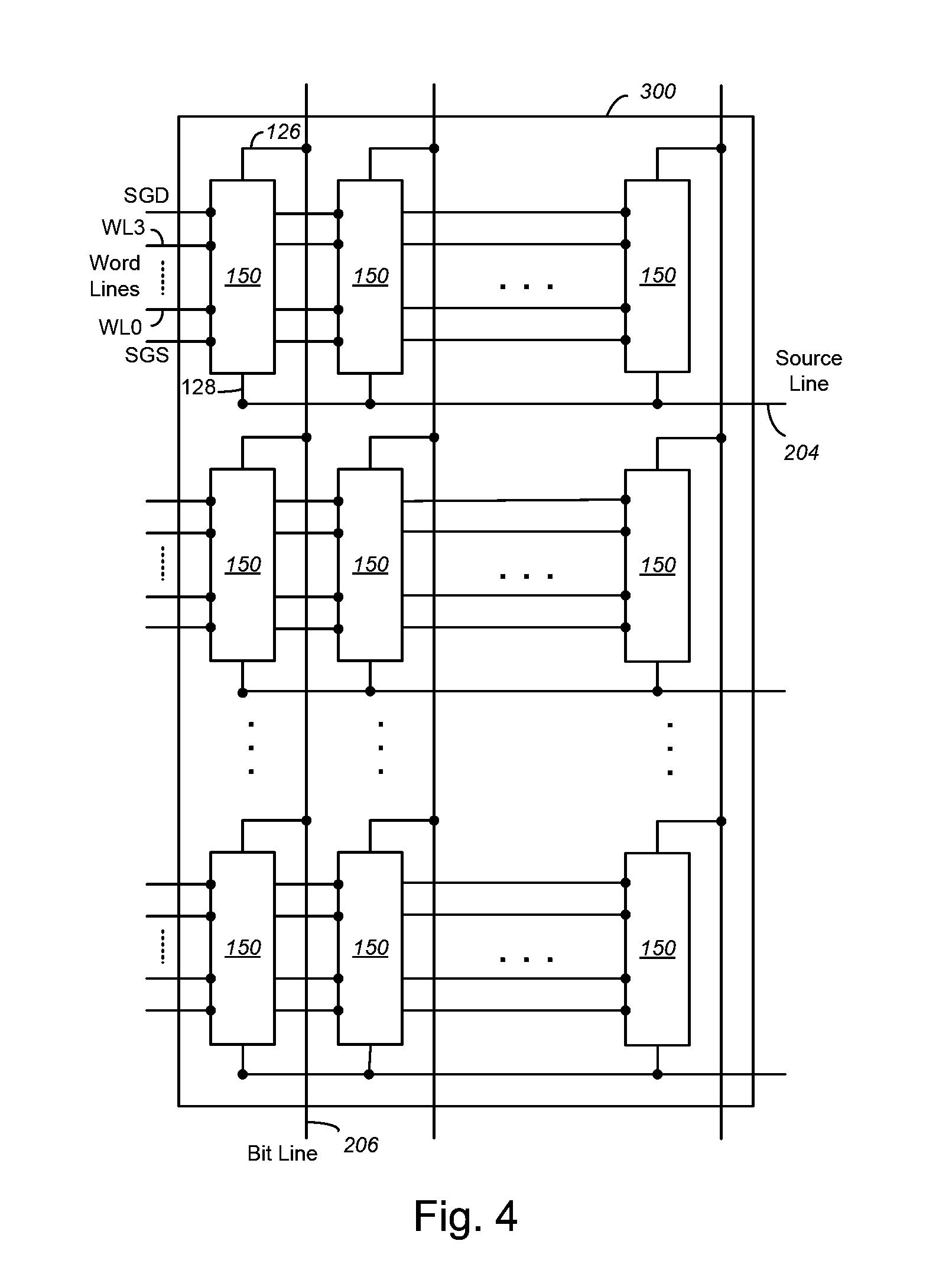

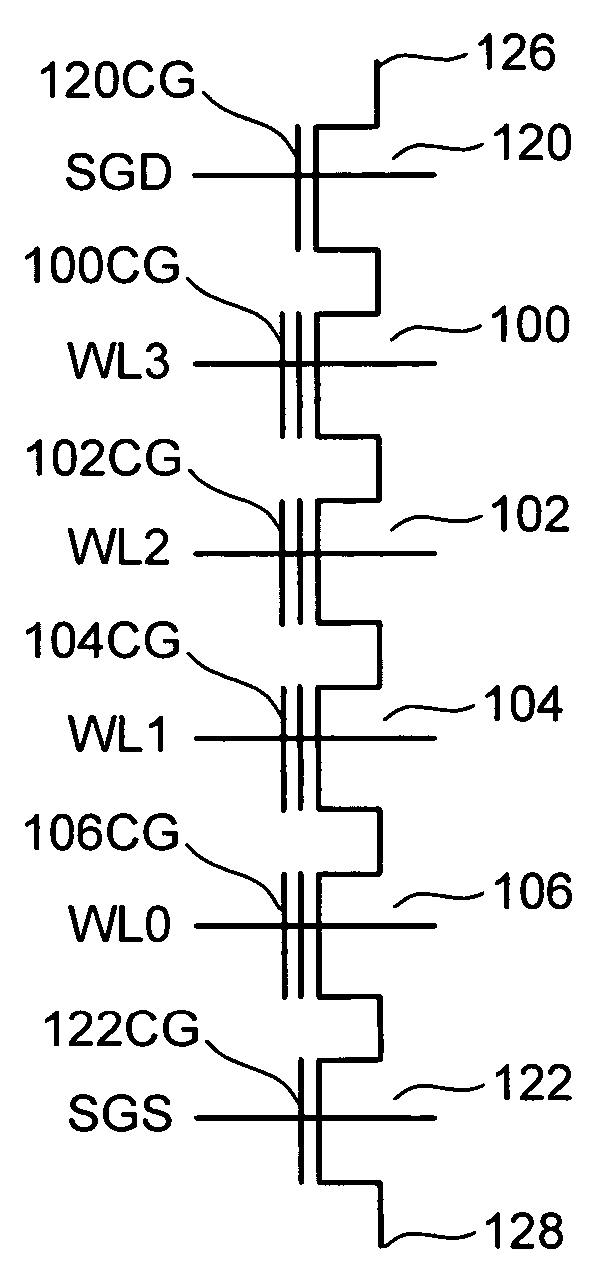

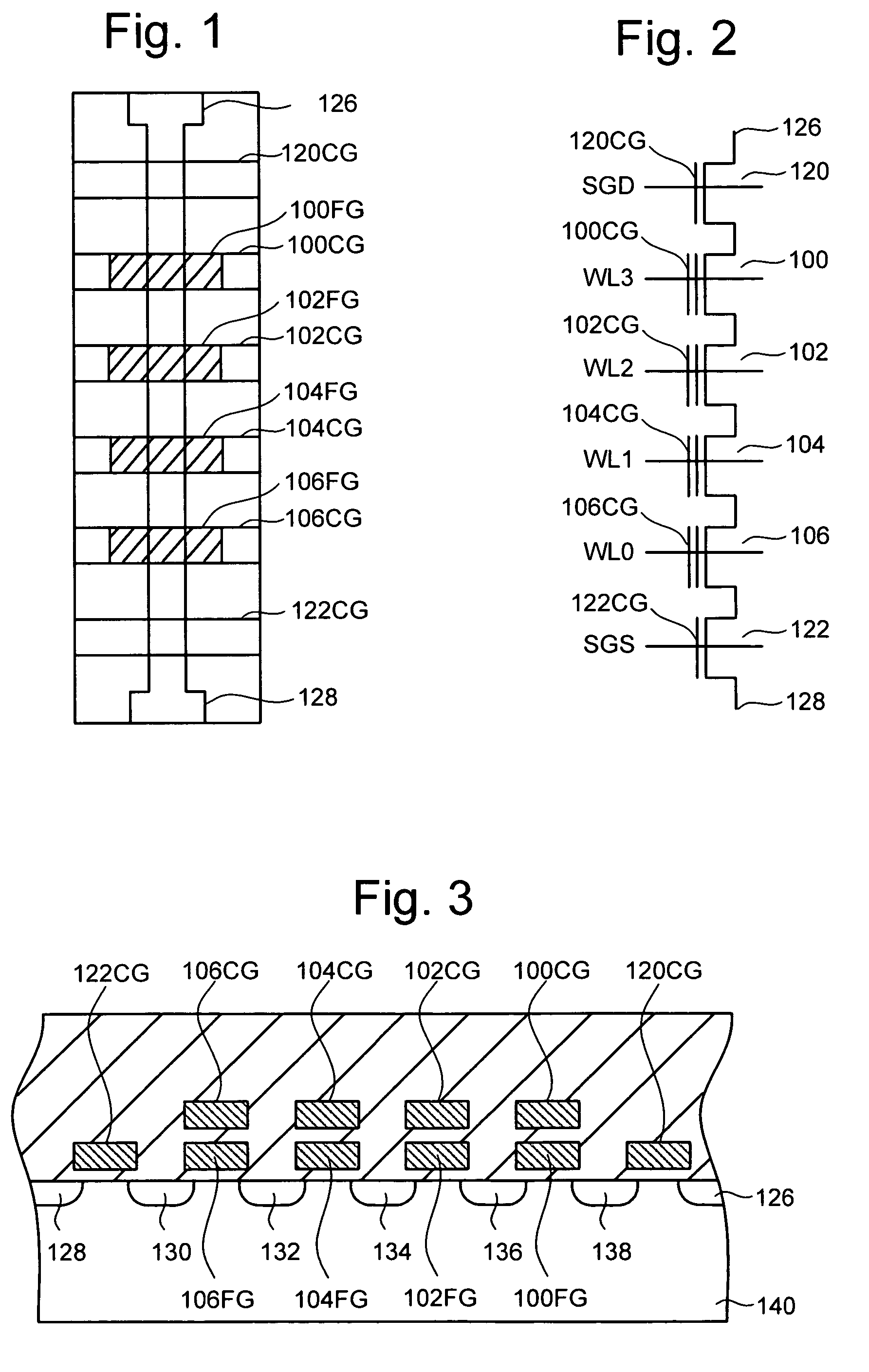

Techniques for reducing effects of coupling between storage elements of adjacent rows of memory cells

Techniques of reducing erroneous readings of the apparent charge levels stored in a number of rows of memory cells on account of capacitive coupling between the cells. All pages of a first row are programmed with a first pass, followed by programming all pages of a second adjacent row with a first pass, after which the first row is programmed with a second pass, and then all pages of a third row are programmed with a first pass, followed by returning to program the second row with a second pass, and so on, in a back-and-forth manner across the rows of an array. This minimizes the effect on the apparent charge stored on rows of memory cells that can occur by later writing data into adjacent rows of memory cells.

Owner:SANDISK TECH LLC

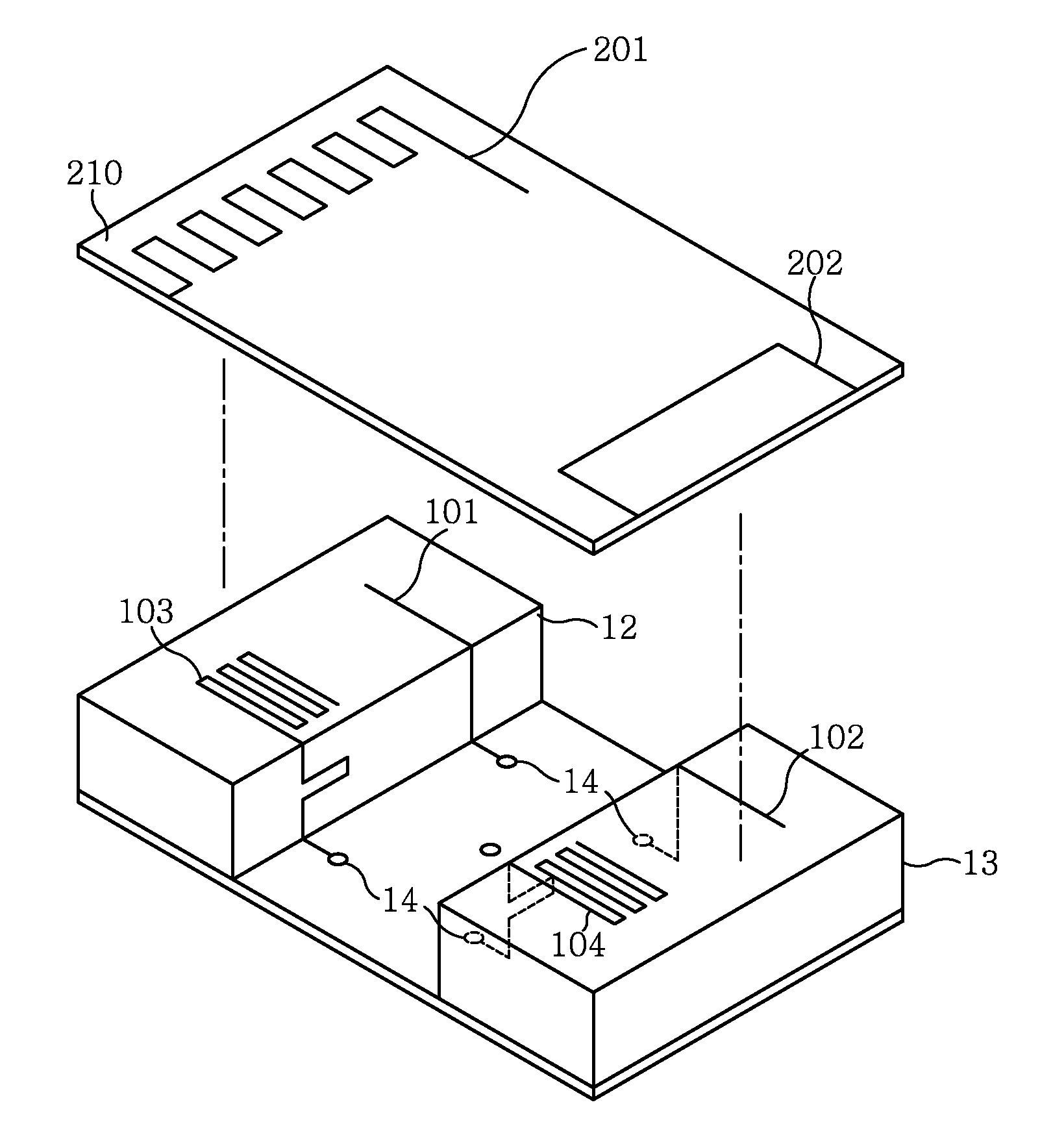

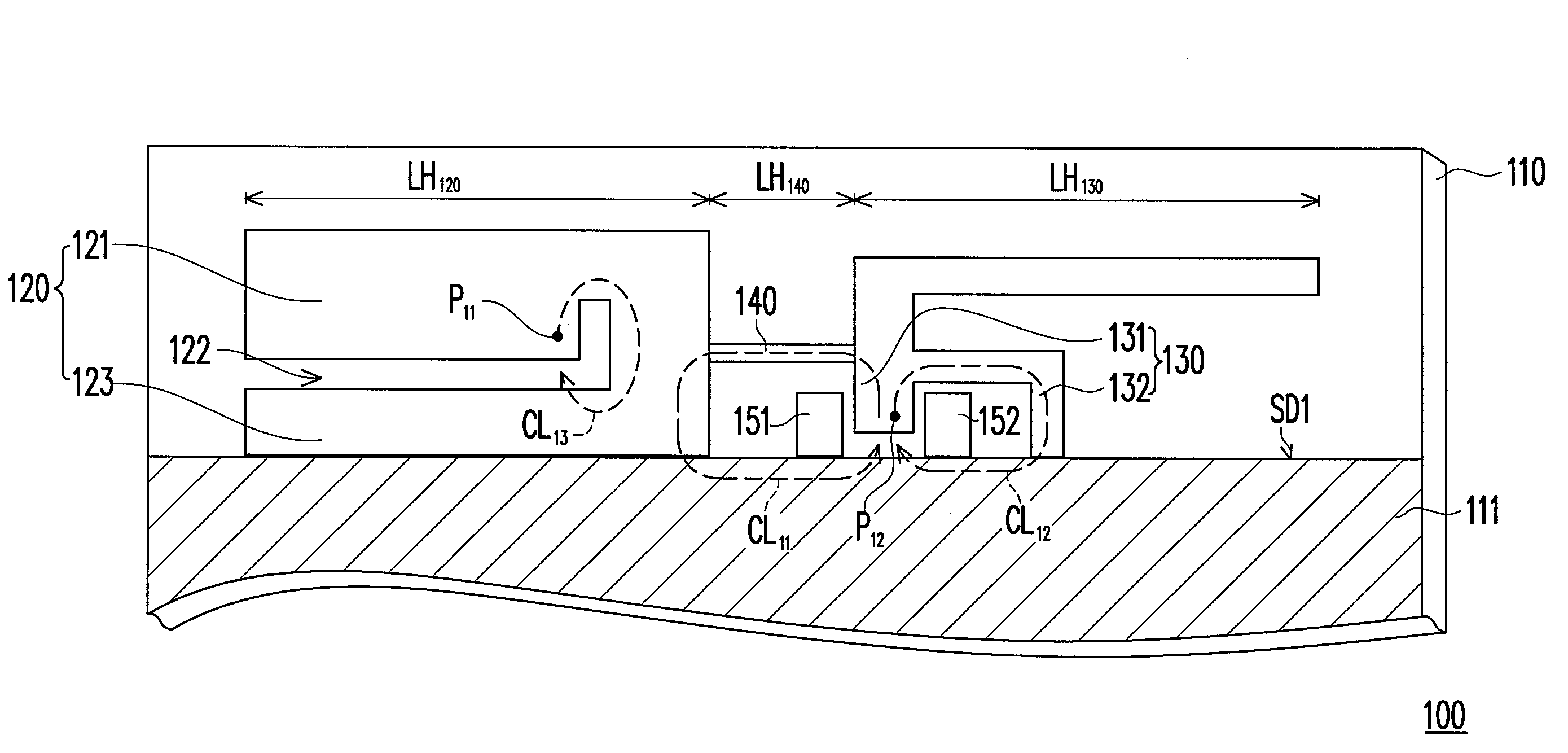

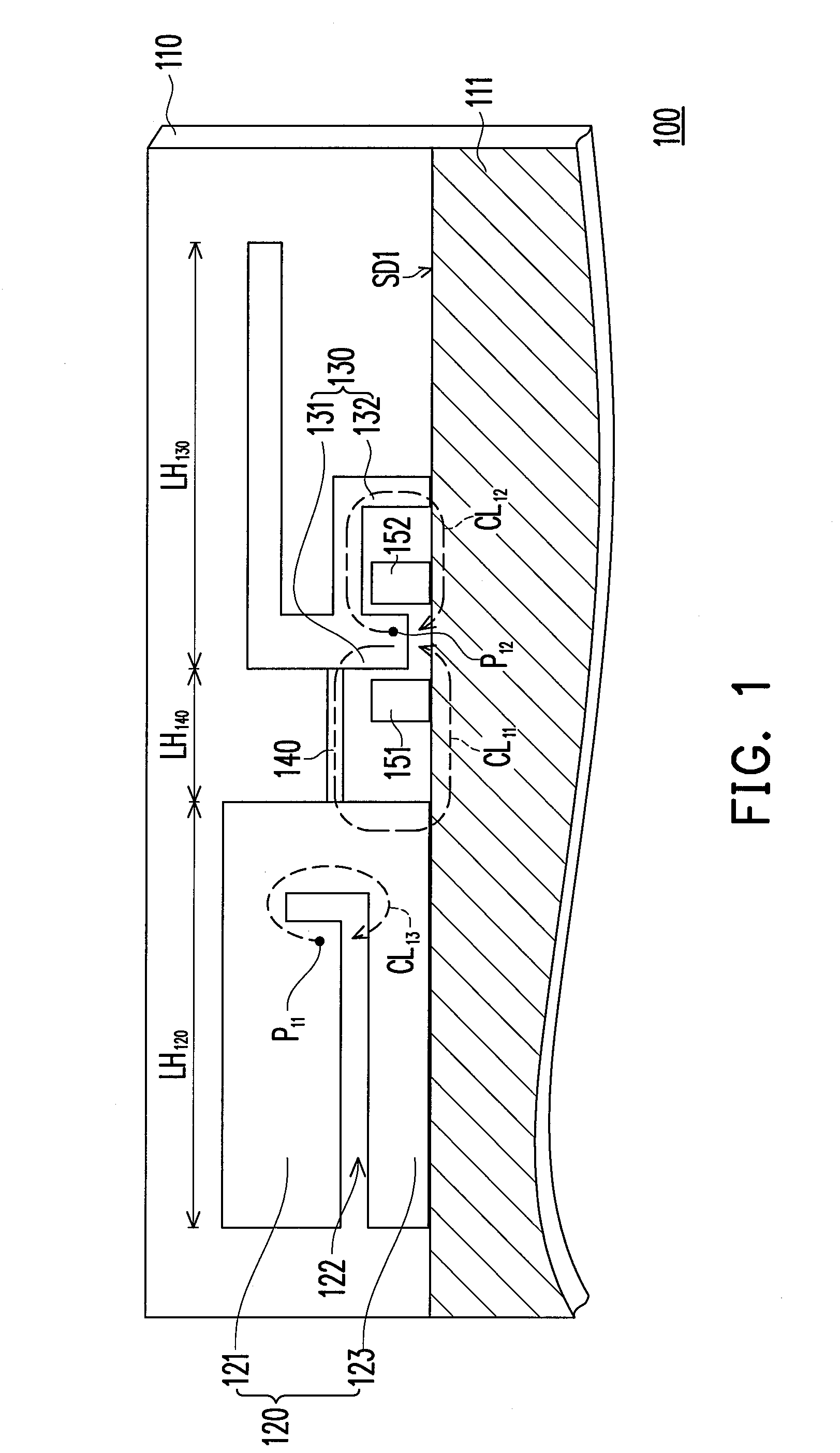

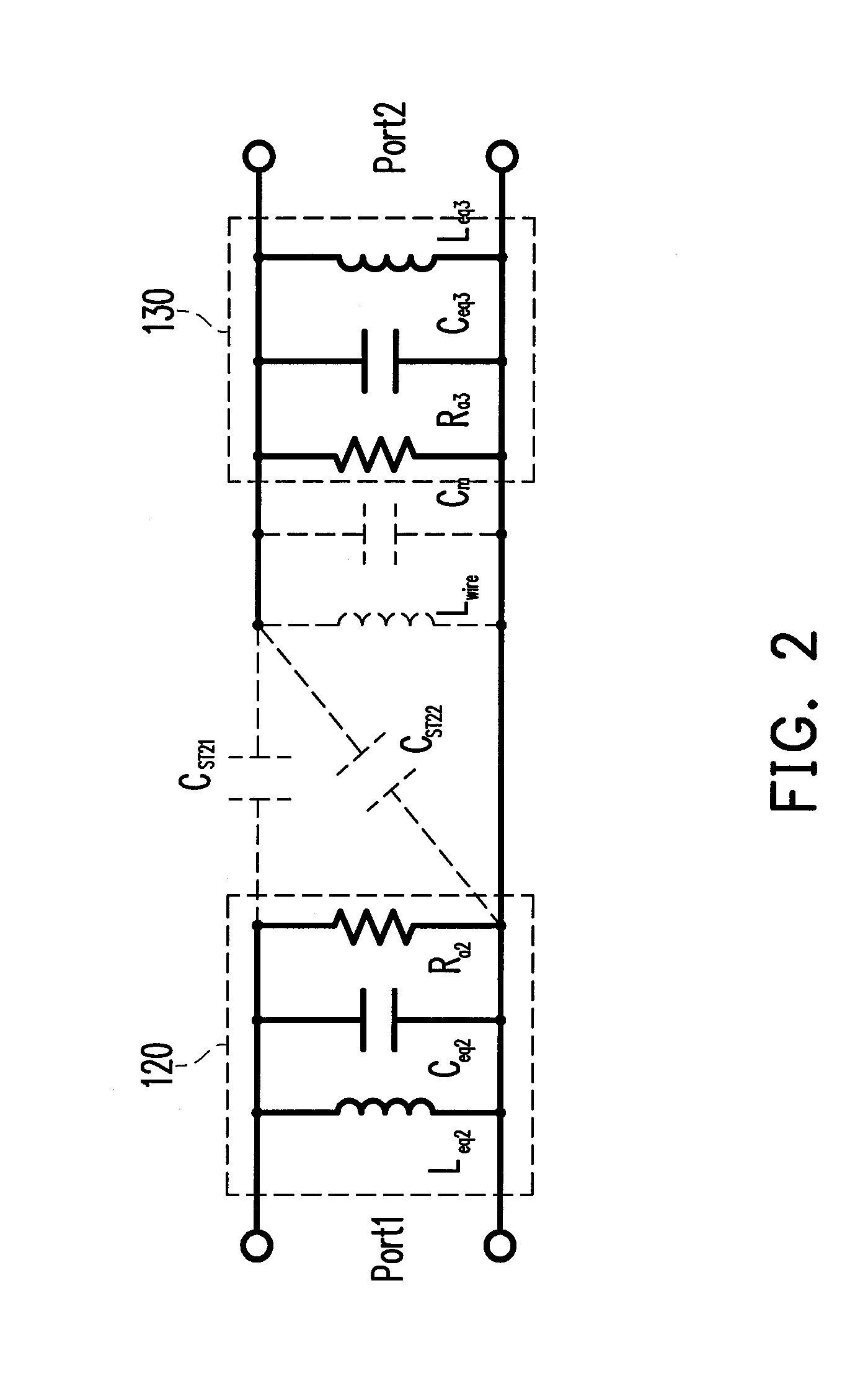

Multi-Input Multi-Output antenna with multi-band characteristic

InactiveUS20120319904A1Improve isolationAvoid lostSpatial transmit diversitySimultaneous aerial operationsMulti inputMulti band

The present invention relates to a multi-input multi-output (MIMO) antenna with a multi-band characteristic which includes a plurality of MIMO antenna, each having a pair of antenna elements, to support multiple bands, and is capable of guaranteeing high antenna efficiency for different bands by minimizing an interference between antenna elements of each MIMO antenna to improve an isolation characteristic. The MIMO antenna system having a multi-band characteristic, which includes two pairs of antenna patterns to support different band and coupling antenna parts separated from and coupled with the pairs of antenna patterns, can improve an isolation through the coupling antenna parts and guarantee an antenna gain. Moreover, since signal interference caused by the coupling effect can be cancelled to guarantee a band width with no change in antenna characteristics, it is possible to constructing two or more antennas to support a multi-band while guaranteeing stable operation of the antennas.

Owner:KIM BOBAE

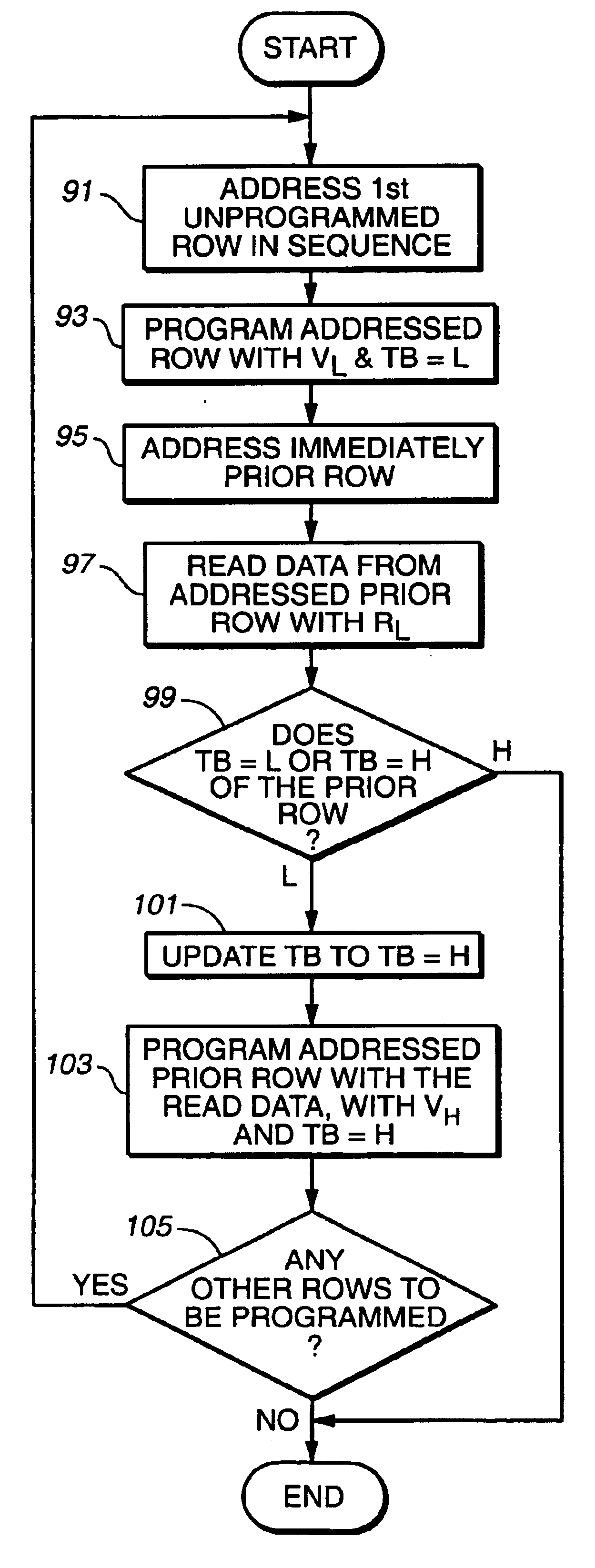

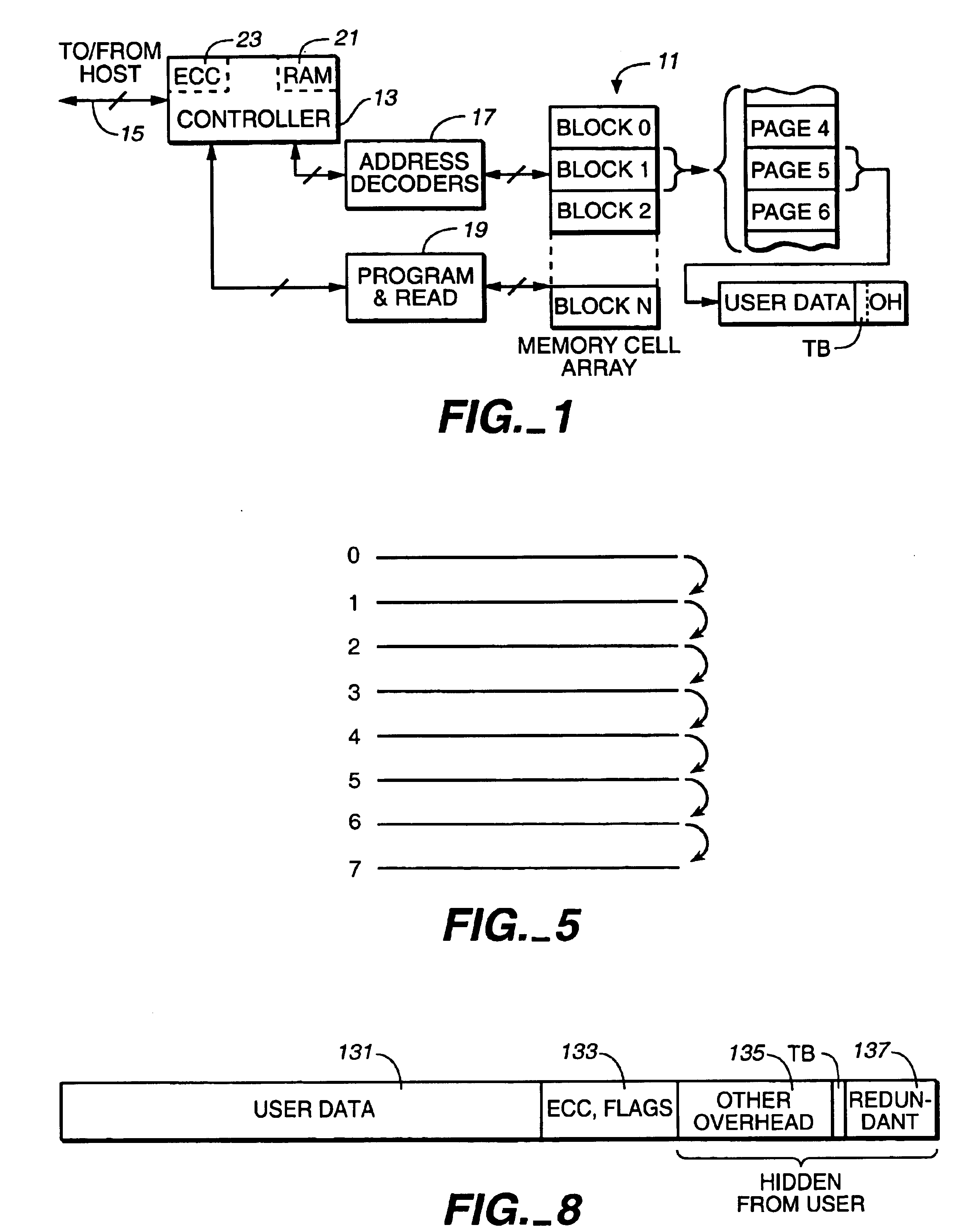

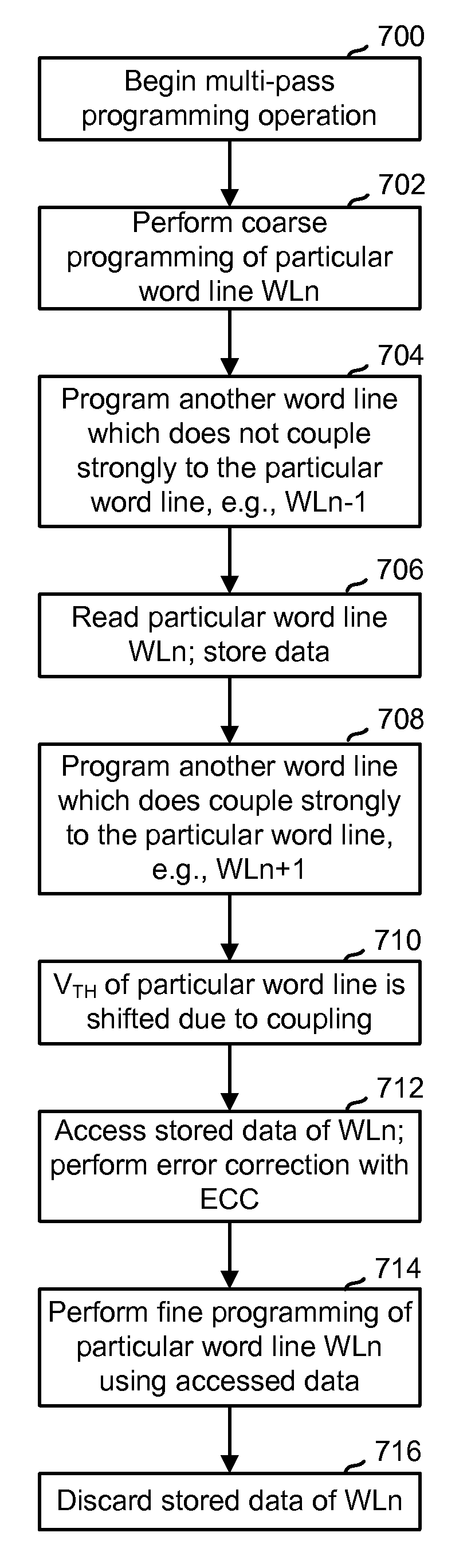

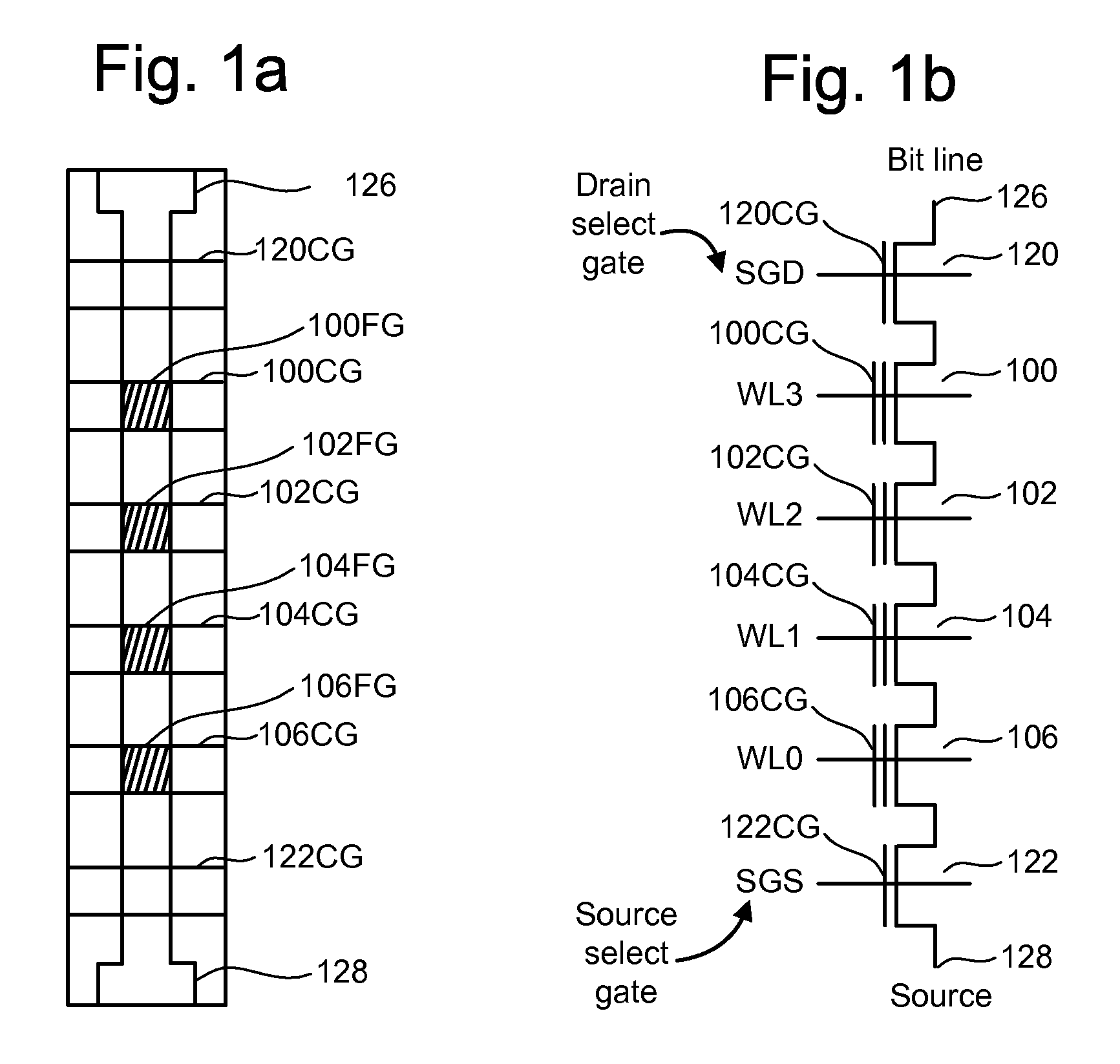

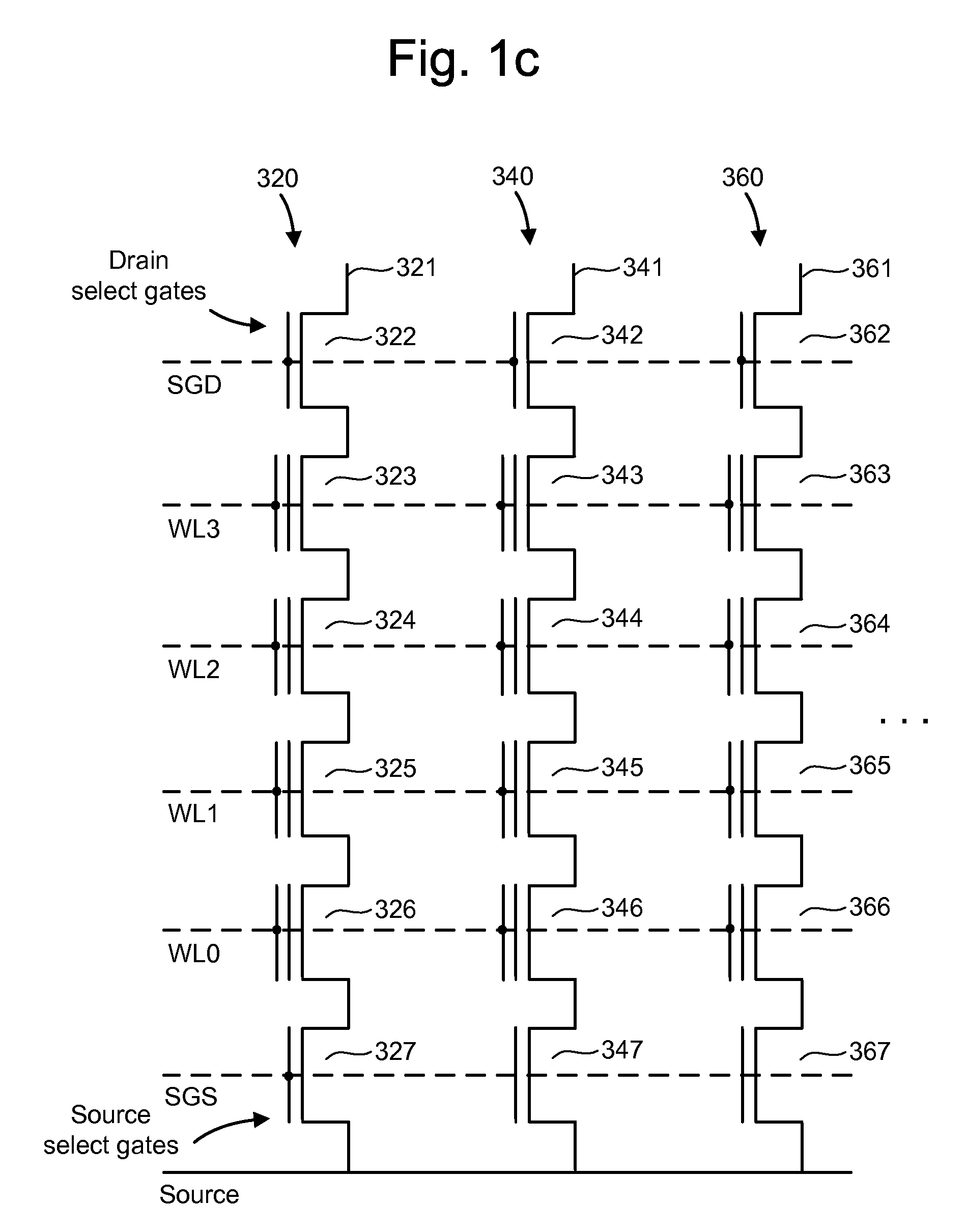

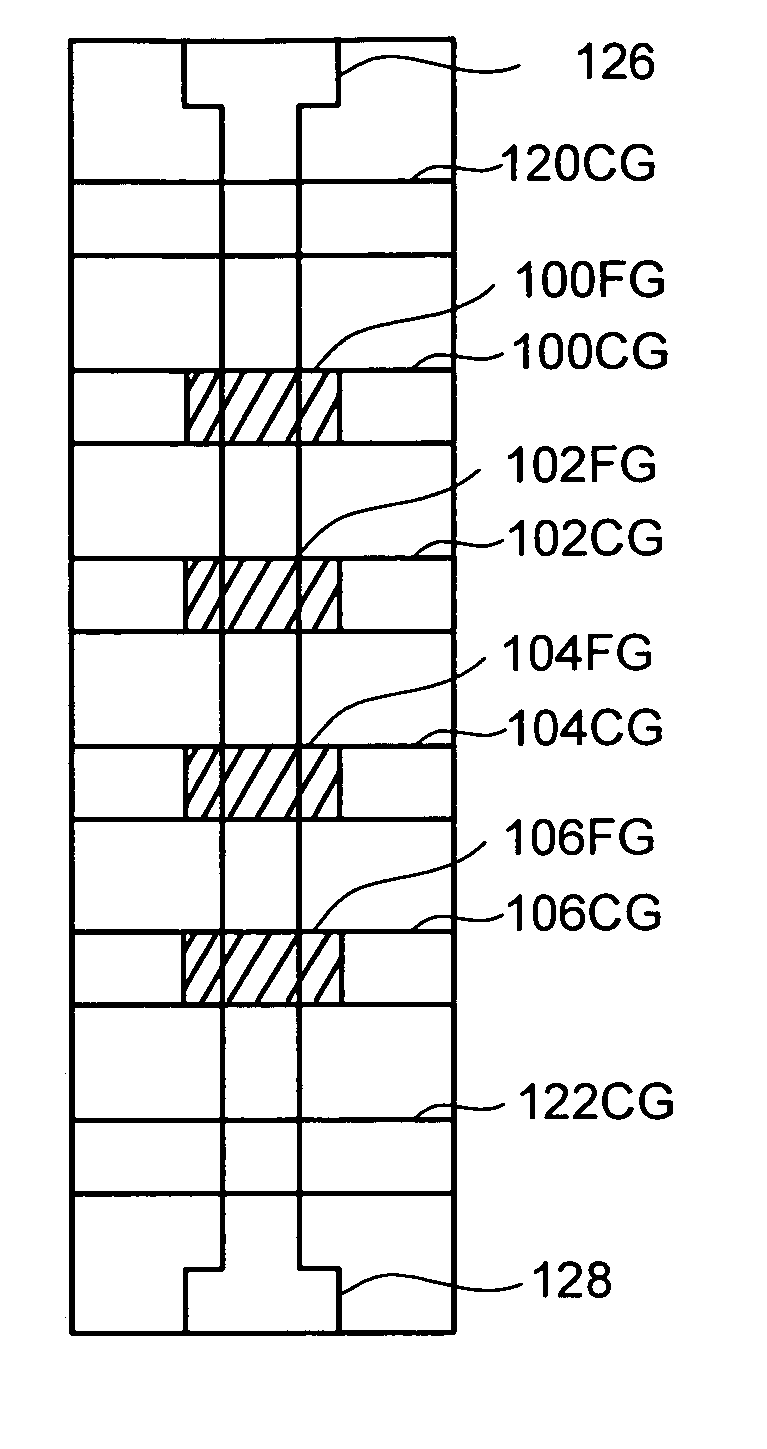

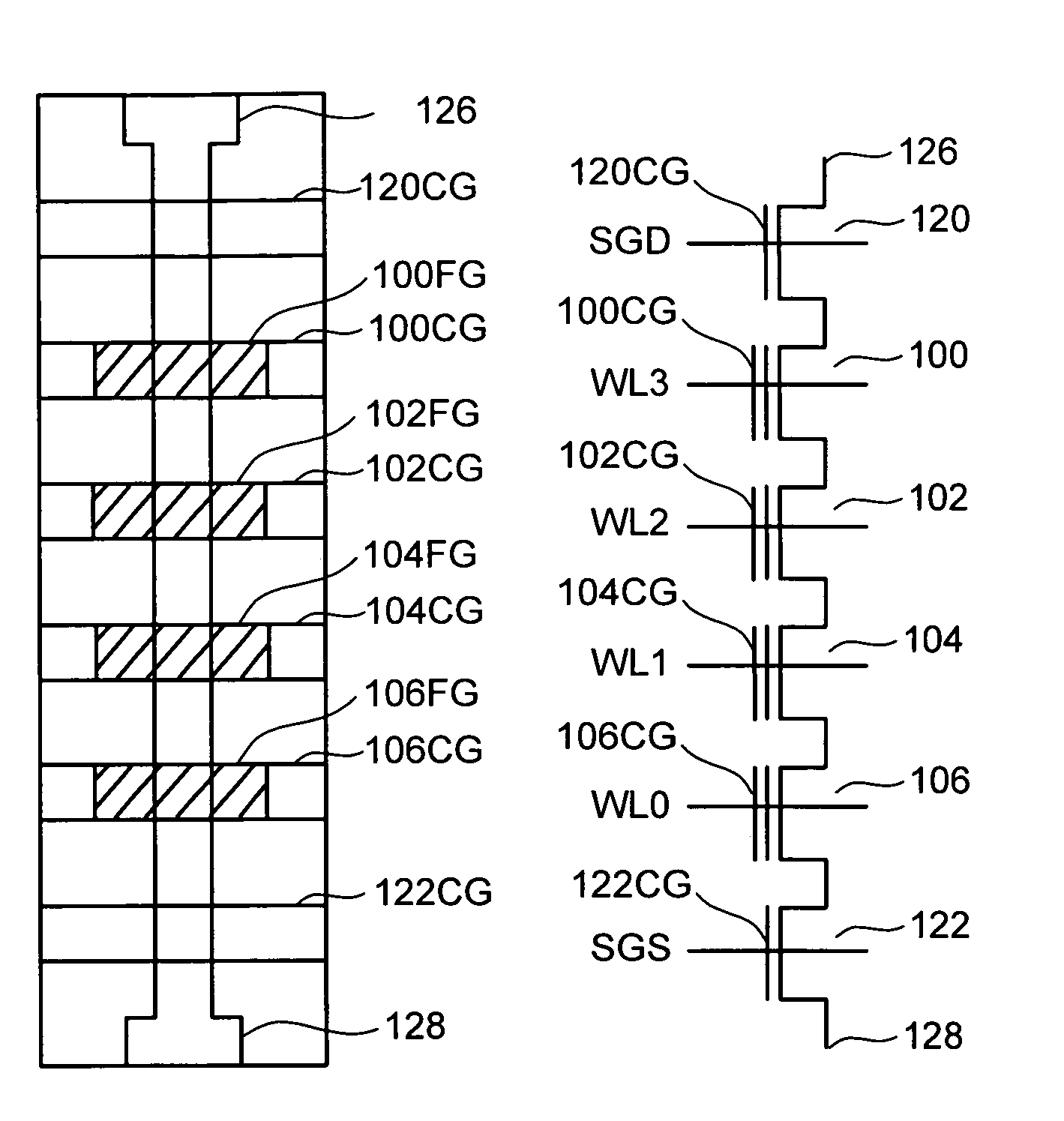

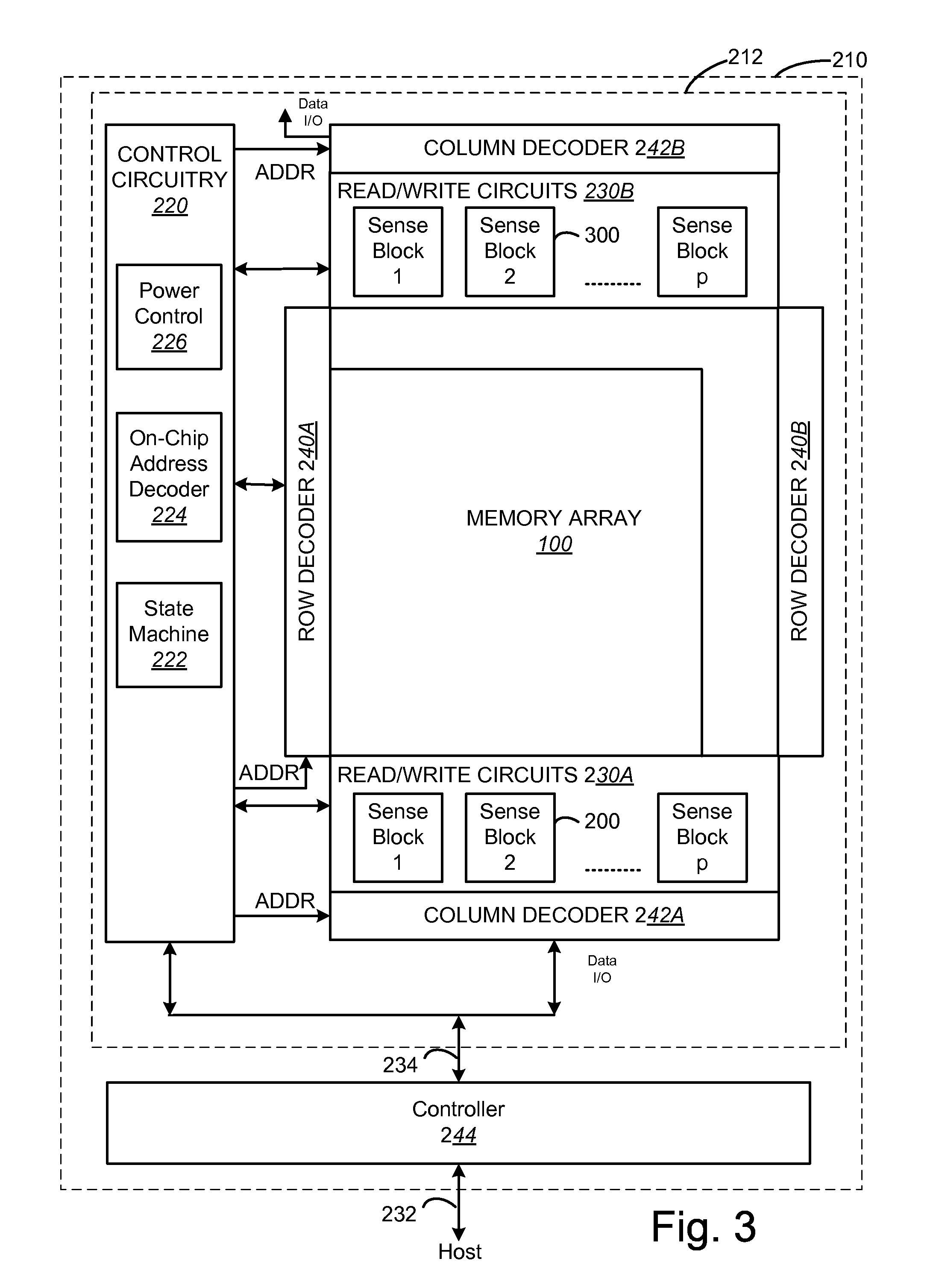

Multi-pass programming for memory with reduced data storage requirement

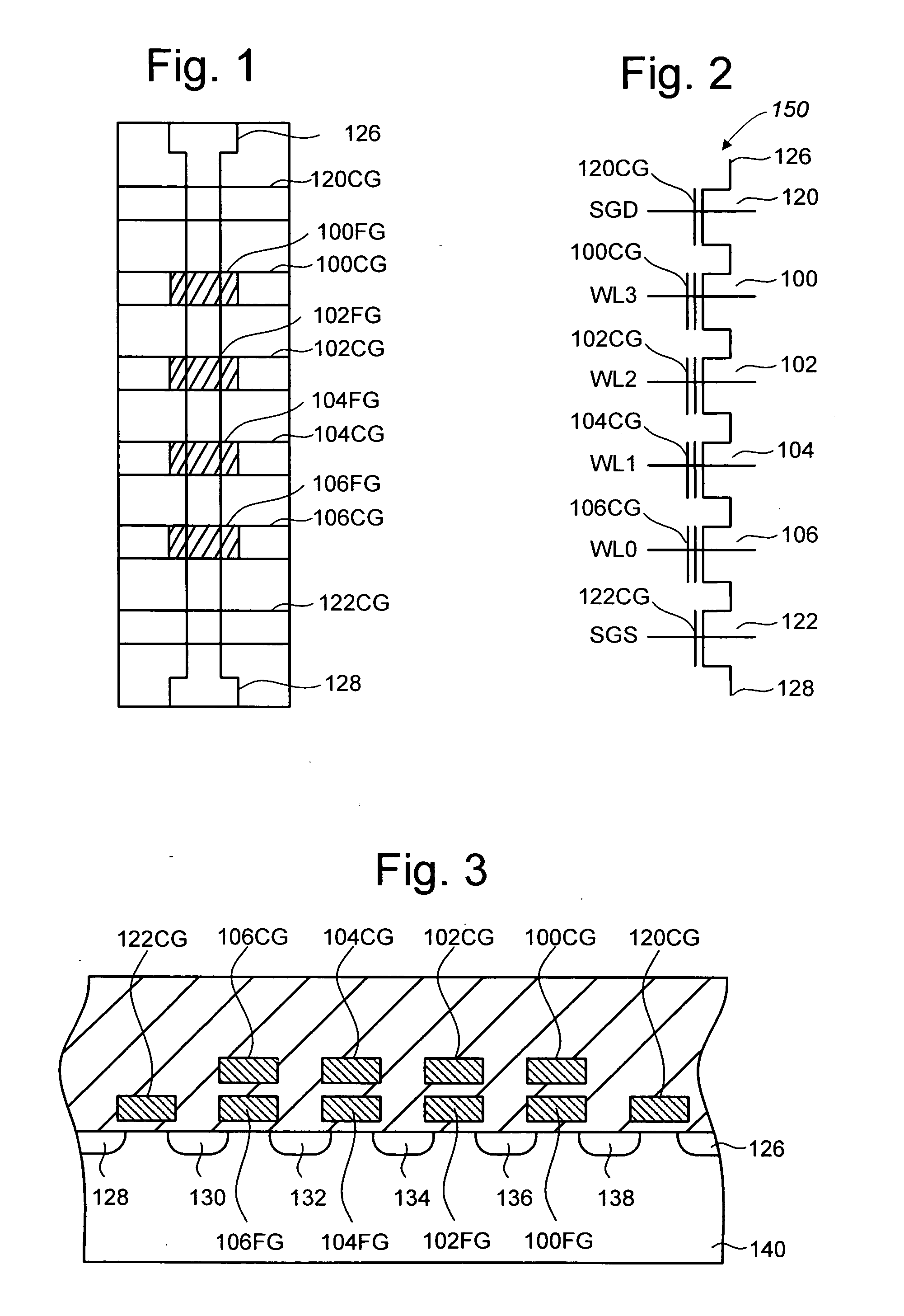

Coupling effects between adjacent floating gates in a non-volatile storage device are reduced in a multi-pass programming operation, while reducing program data storage requirements. In one approach, storage elements are programmed in an out of sequence or zigzag word line order. A particular word line is programmed with a coarse program pass, after which another word line is programmed with a fine program pass, after which the particular word line is read. The particular word line is read before another word line is programmed with a coarse program pass which causes coupling interference to storage elements of the particular word line. The read data is subsequently used to perform a fine program pass for the particular word line. This avoids the need to store program data of multiple word lines concurrently, so that storage hardware can be reduced in size along with power consumption.

Owner:SANDISK TECH LLC

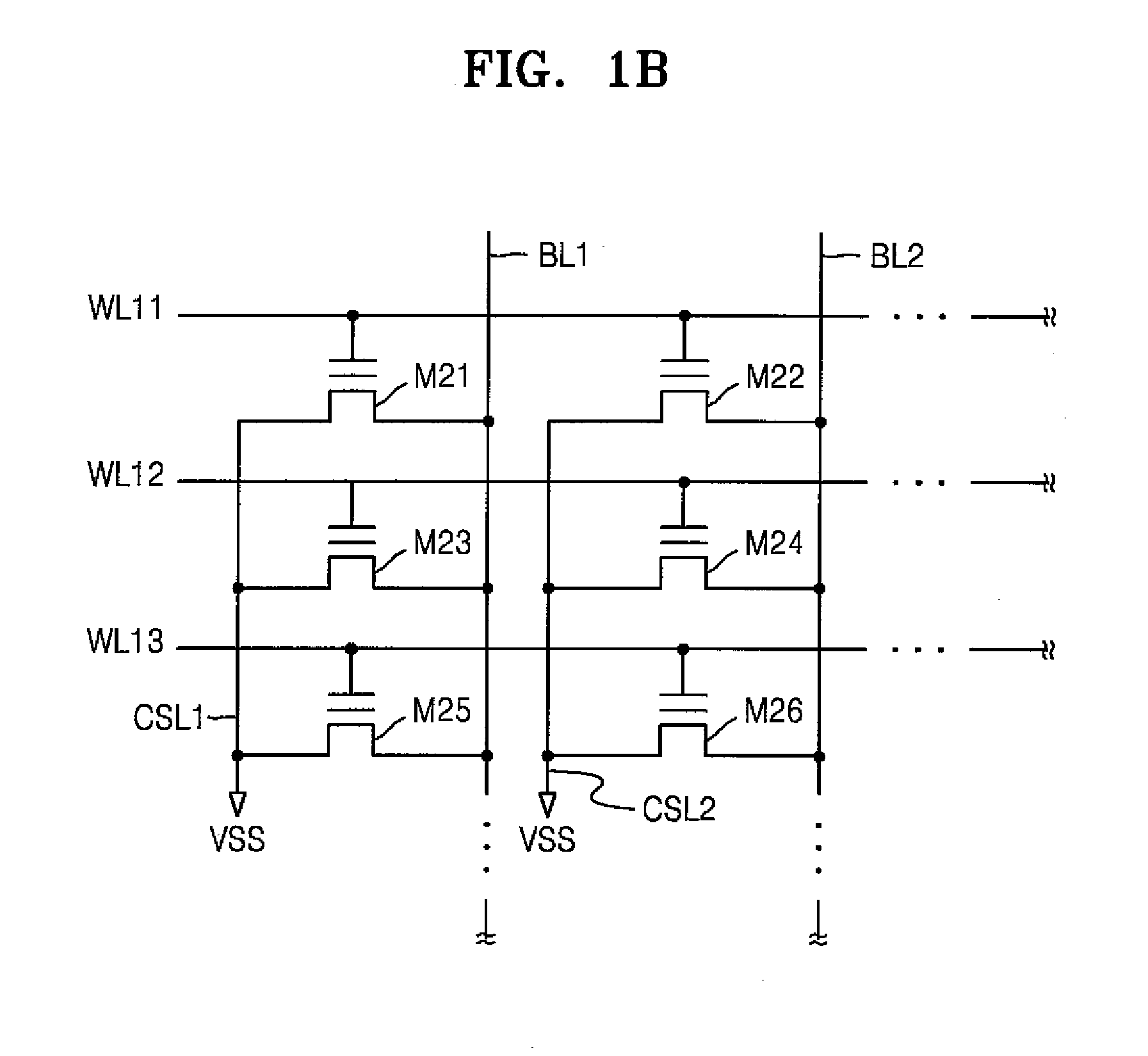

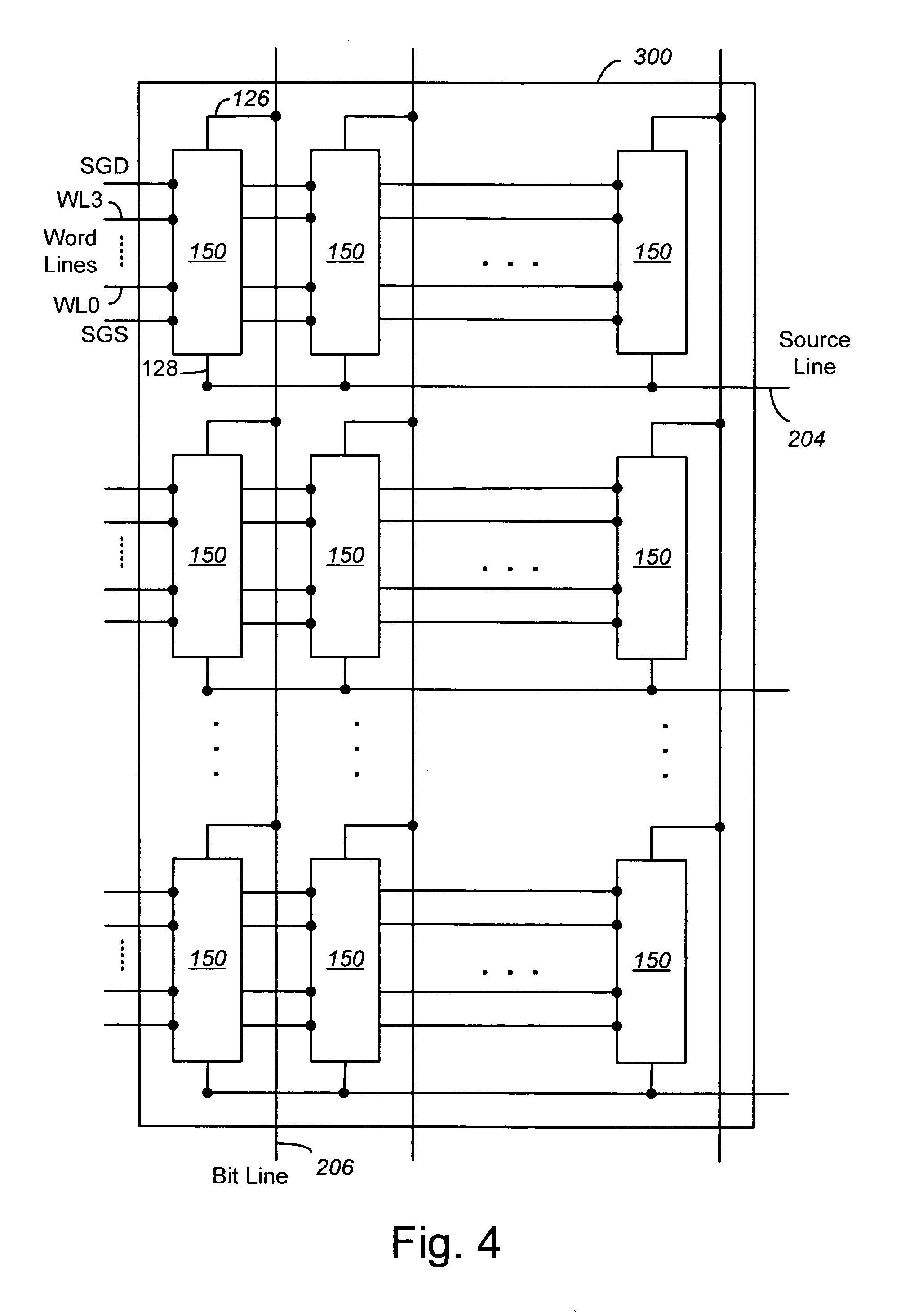

System for performing read operation on non-volatile storage with compensation for coupling

ActiveUS20070206426A1Reduce coupling effectSolid-state devicesRead-only memoriesComputer scienceElectric field

Shifts in the apparent charge stored on a floating gate (or other charge storing element) of a non-volatile memory cell can occur because of the coupling of an electric field based on the charge stored in adjacent floating gates (or other adjacent charge storing elements). The problem occurs most pronouncedly between sets of adjacent memory cells that have been programmed at different times. To account for this coupling, the read process for a particular memory cell will provide compensation to an adjacent memory cell in order to reduce the coupling effect that the adjacent memory cell has on the particular memory cell.

Owner:SANDISK TECH LLC

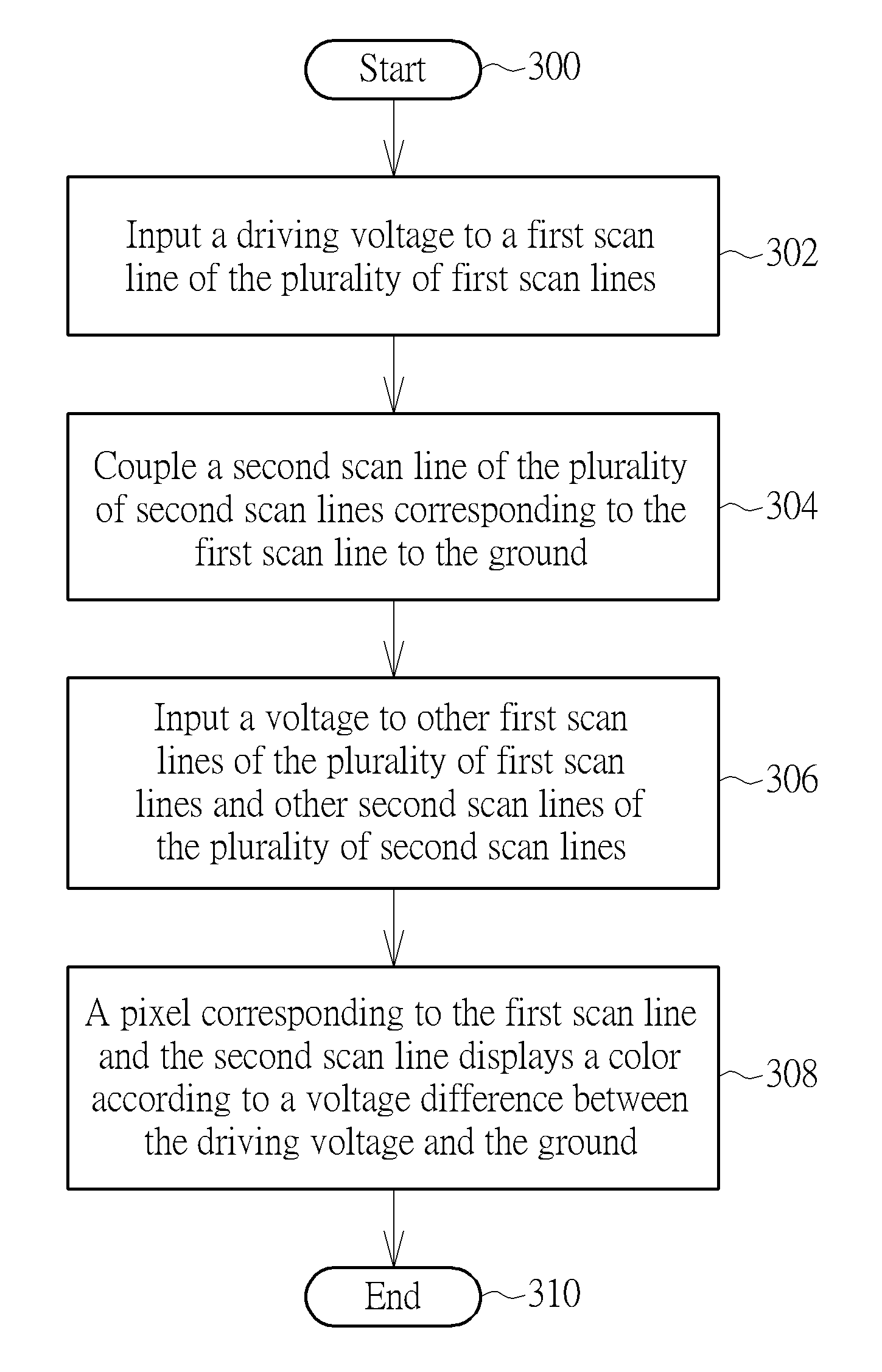

Electrophoretic display capable of reducing passive matrix coupling effect and method thereof

Owner:YUANHAN MATERIALS INC

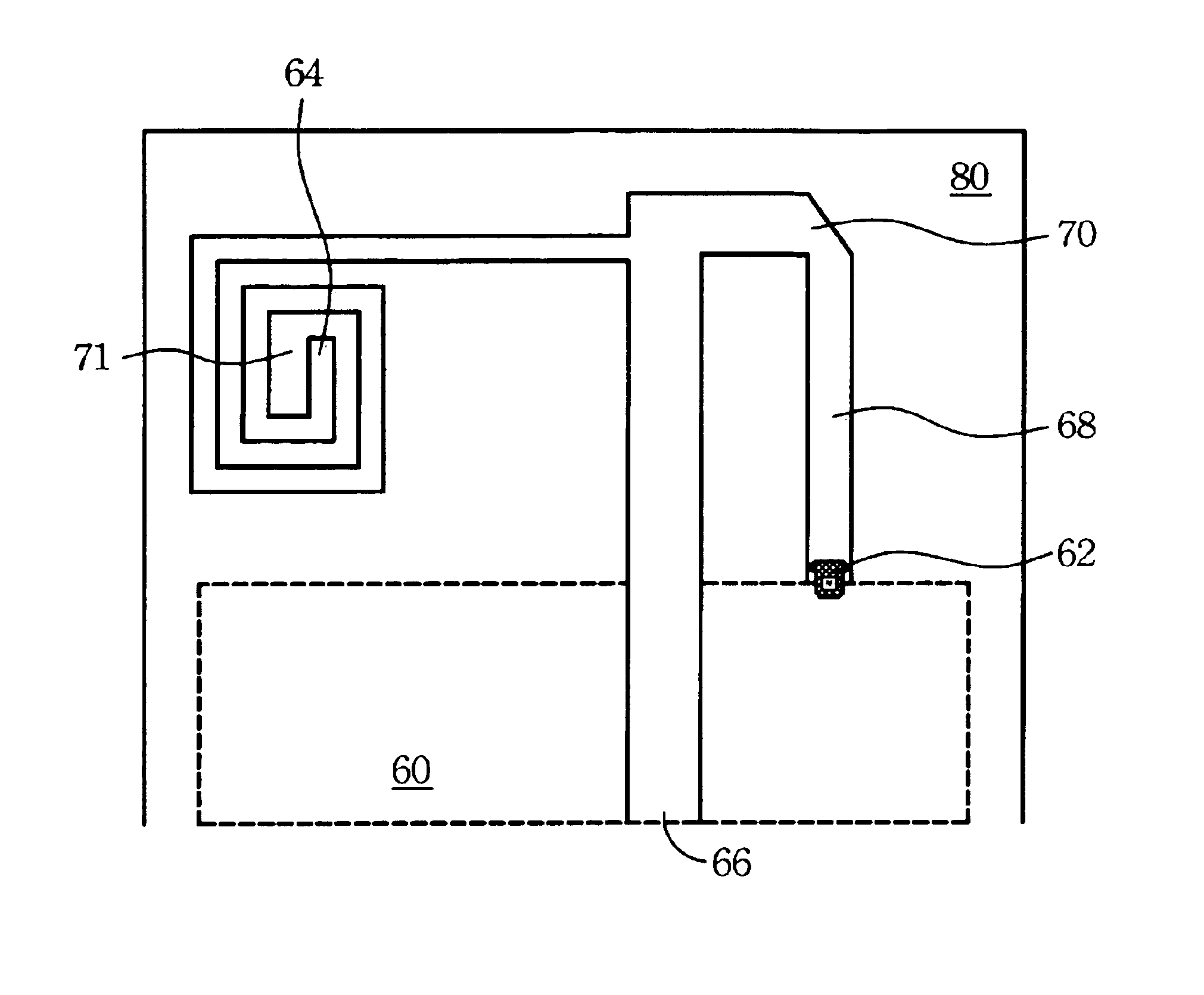

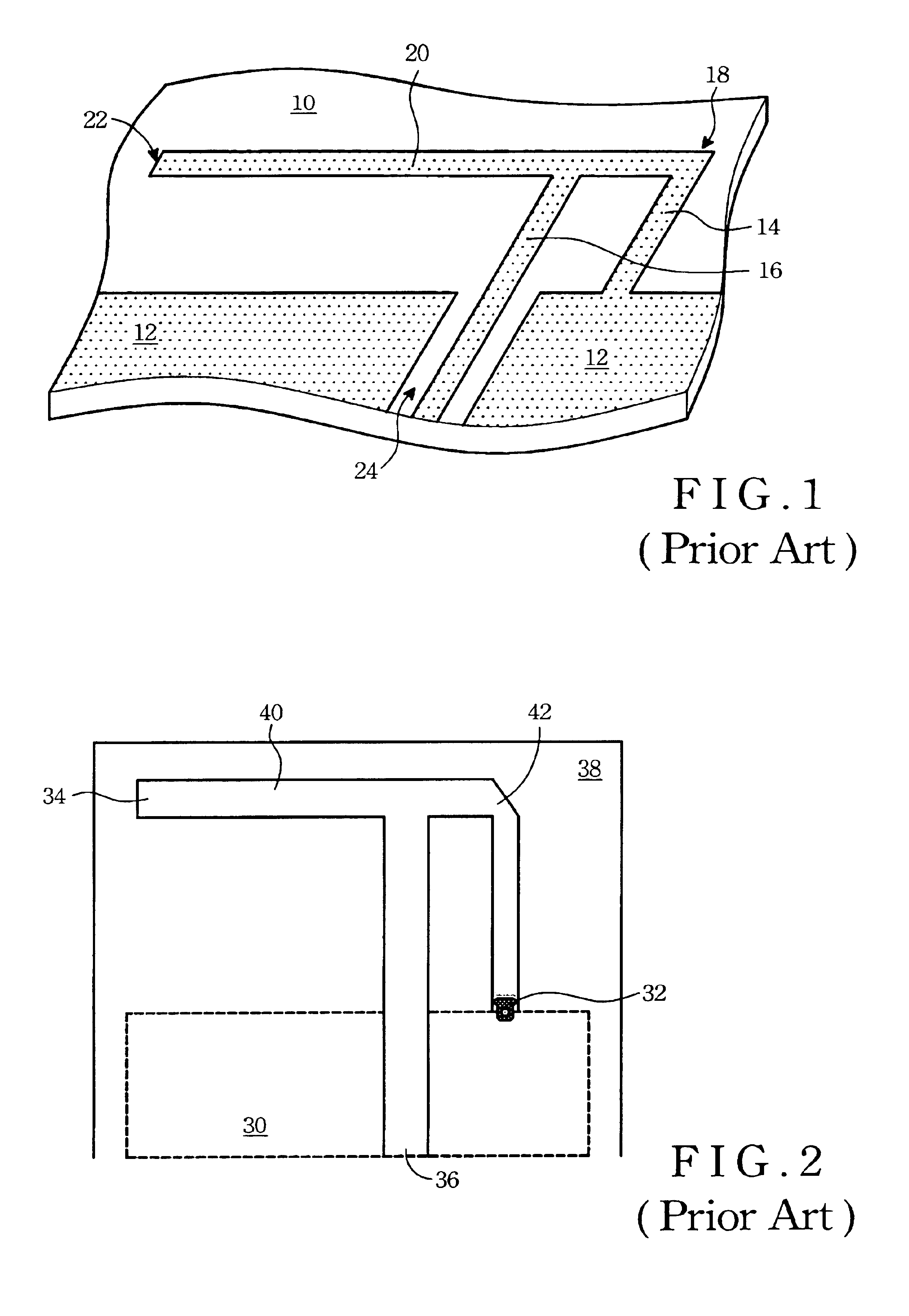

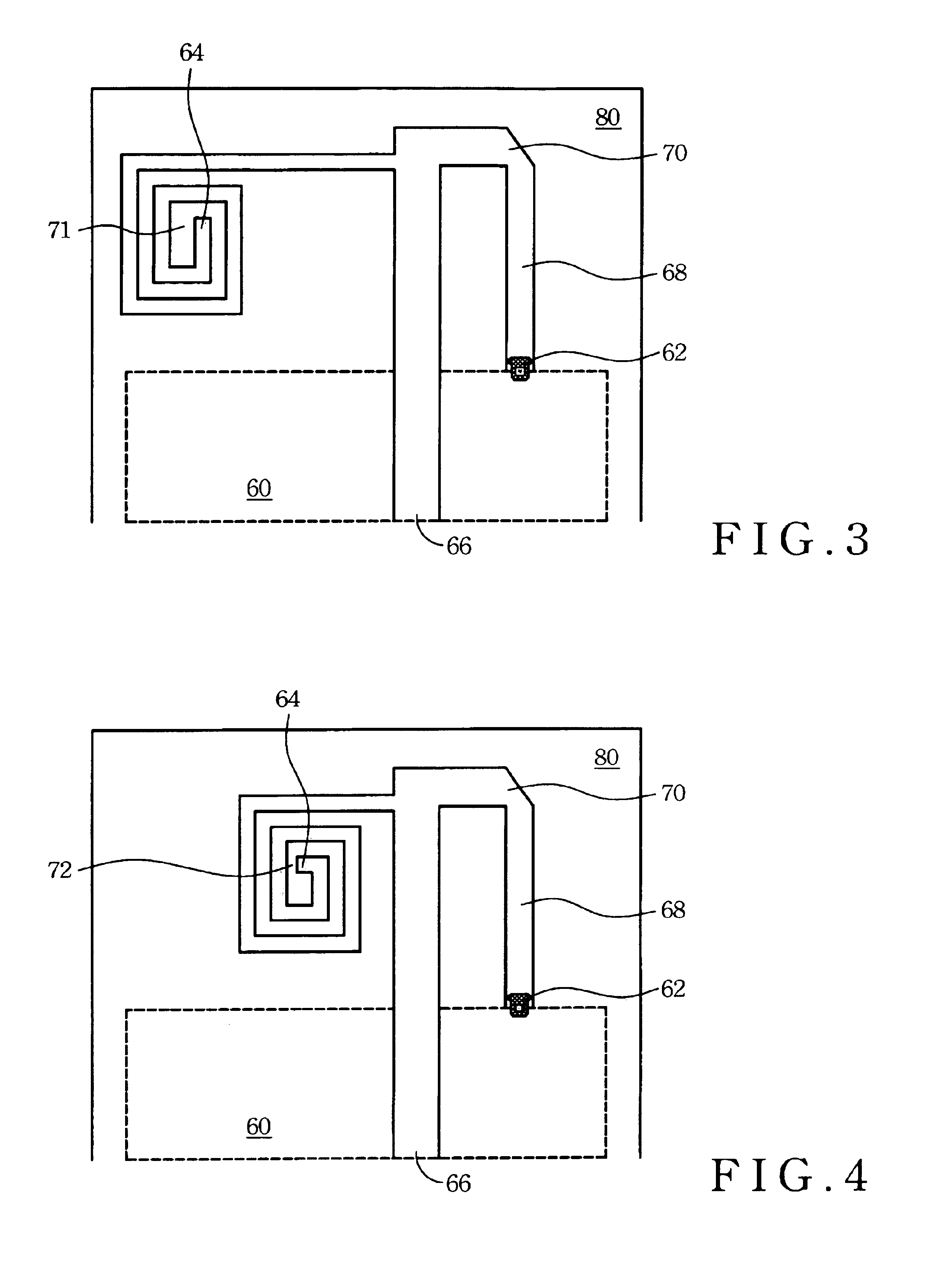

Dual frequency band inverted-F antenna

ActiveUS6930640B2Lower resonance frequencySimultaneous aerial operationsAntenna supports/mountingsDual frequencyResonance

A dual frequency band inverted-F antenna used for communicating a low frequency signal and a high frequency signal includes a substrate, a ground metal, a vortical metal structure, a short circuit leg, a feeding leg, and a terminal micro strip. The ground metal and the terminal micro strip are formed on the lower surface of the substrate. The vortical metal structure, formed on the upper surface of the substrate, further has a short circuit end and an open circuit end. The short circuit leg connects electrically the short circuit end of the vortical metal structure with the ground metal. The feeding leg extends along a predetermined direction of the vortical metal structure to couple with a feeding circuit on the substrate. The terminal micro strip connects electrically to the open circuit end through a first conductive aperture. By increasing the encircling number of the vortical metal structure, the coupling effect is generated so that the equivalent wavelength of the high frequency signal can be longer, thus the resonance frequency thereof can be reduced, and so a first frequency can be still kept communicating at a lower frequency band and a second frequency can also be added for communicating at a higher frequency band.

Owner:GEMTEK TECH CO LTD

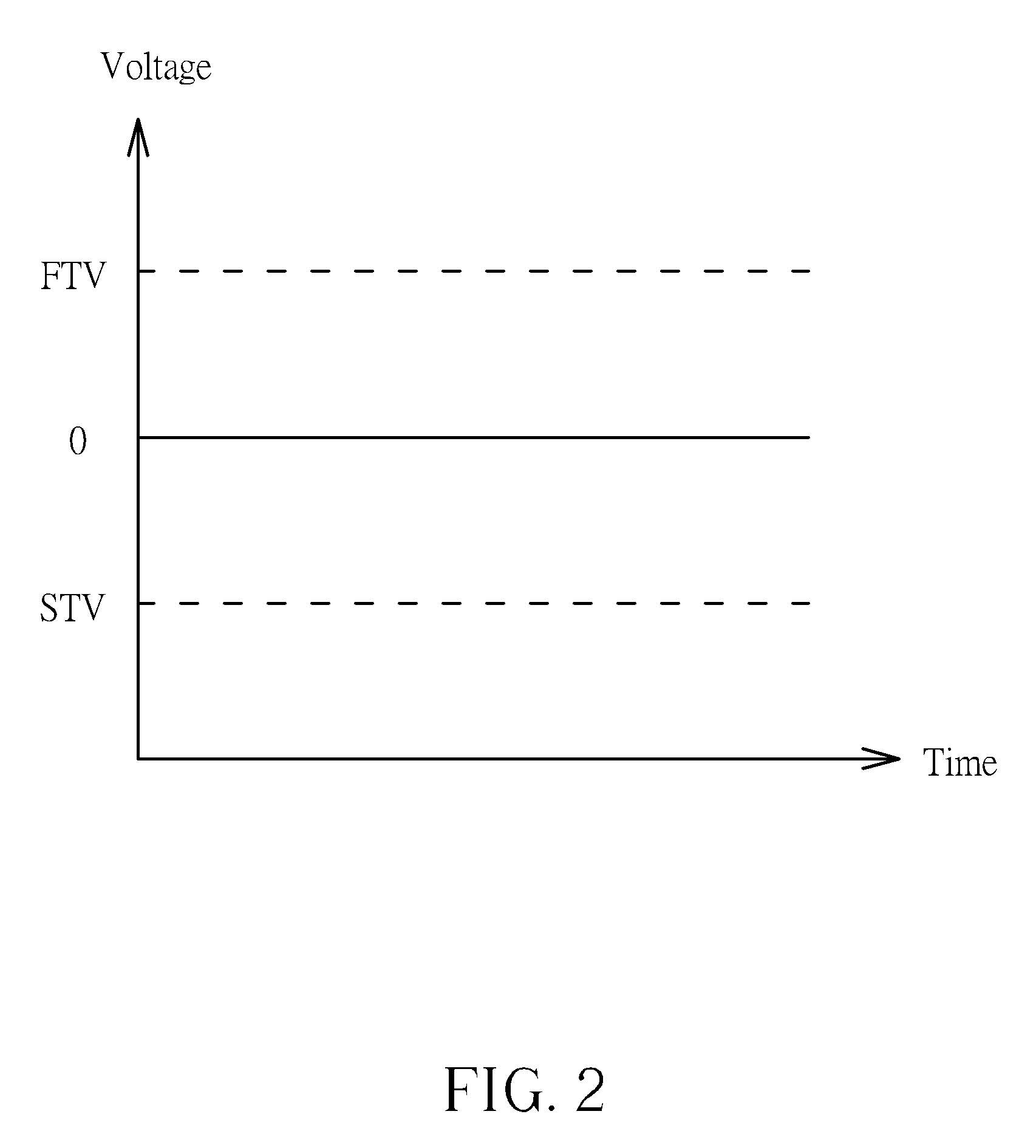

System for performing data pattern sensitivity compensation using different voltage

ActiveUS7310272B1Reduce coupling effectExact searchRead-only memoriesDigital storageCapacitanceCapacitive coupling

Errors can occur when reading the threshold voltage of a programmed non-volatile storage element due to at least two mechanisms: (1) capacitive coupling between neighboring floating gates and (2) changing conductivity of the channel area after programming (referred to as back pattern effect). To account for coupling between neighboring floating gates, the read process for a particular memory cell will provide compensation to an adjacent memory cell in order to reduce the coupling effect that the adjacent memory cell has on the particular memory cell. To account for the back pattern effect, a first voltage is used during a verify operation for unselected word lines that have been subjected to a programming operation and a second voltage is used for unselected word lines that have not been subjected to a programming operation. The combination of these two techniques provides for more accurate storage and retrieval of data.

Owner:SANDISK TECH LLC

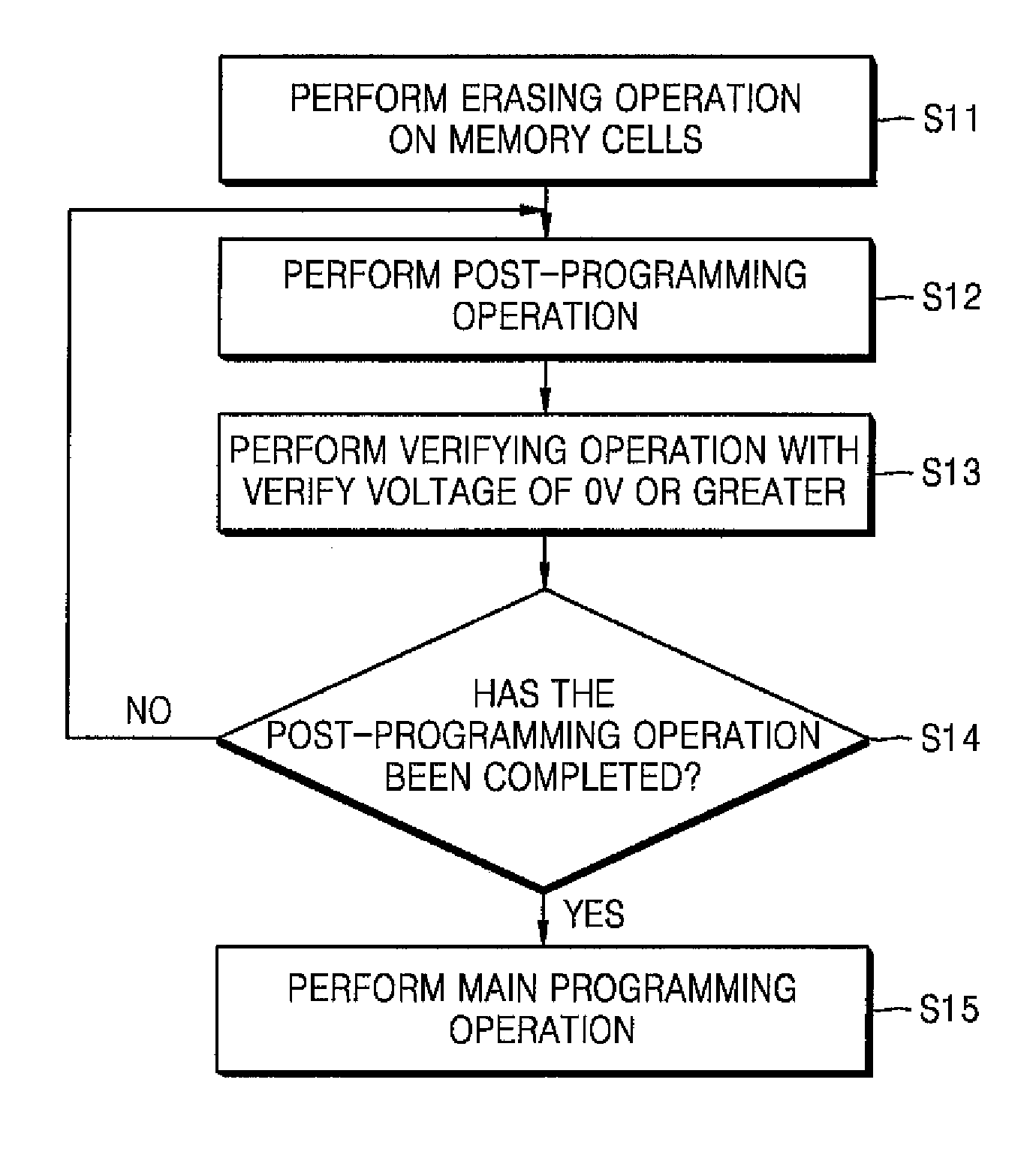

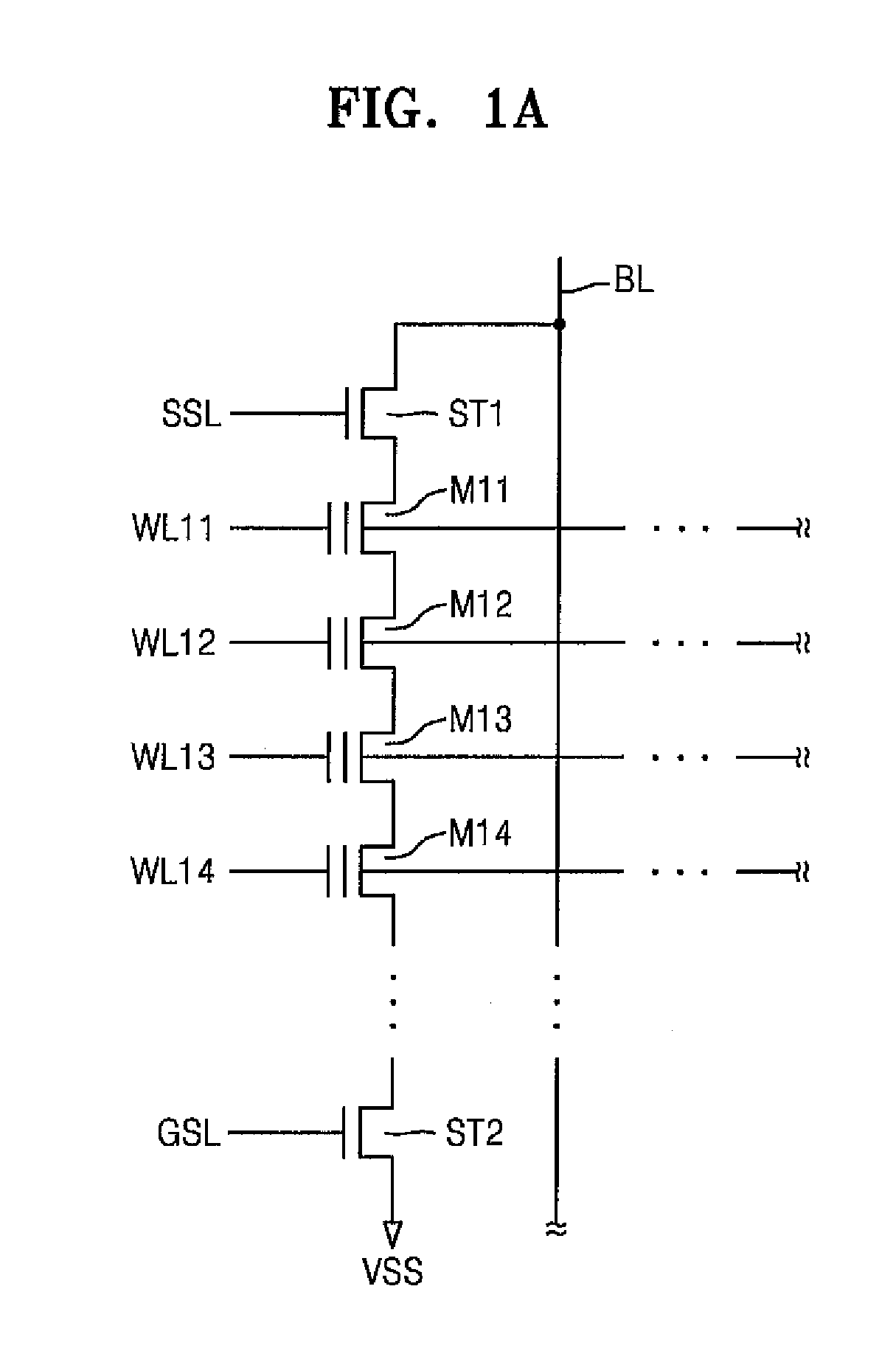

Flash memory device with reduced coupling effect among cells and method of driving the same

ActiveUS20080225599A1Improve reliabilityMinimize coupling effectRead-only memoriesDigital storageComputer scienceThreshold voltage

Embodiments of the invention provide a flash memory device that can improve the reliability of a reading operation by minimizing a variation in the threshold voltage distribution that occurs due to coupling between cells, and a method of driving the flash memory device. In an embodiment of the invention, the method of driving the flash memory includes: performing an erasing operation on memory cells; after the performing the erasing operation, performing a post-programming operation to control a threshold voltage of the memory cells; and after performing the post-programming operation, performing a main programming operation on the memory cells, wherein the performing of the post-programming operation comprises increasing the threshold voltage of the memory cells in an erased state, thereby reducing a difference in the threshold voltage between the memory cells in the erased state and the memory cells in the programmed state.

Owner:SAMSUNG ELECTRONICS CO LTD

Reverse coupling effect with timing information for non-volatile memory

Shifts in the apparent charge stored on a floating gate (or other charge storing element) of a non-volatile memory cell can occur because of the coupling of an electric field based on the charge stored in neighboring floating gates (or other neighboring charge storing elements). The problem occurs most pronouncedly between sets of adjacent memory cells that have been programmed at different times. To compensate for this coupling, the read process for a given memory cell will take into account the programmed state of a neighbor memory cell if the neighbor memory cell was programmed subsequent to the given memory cell. Techniques for determining whether the neighbor memory cell was programmed before or after the given memory cell are disclosed.

Owner:SANDISK TECH LLC

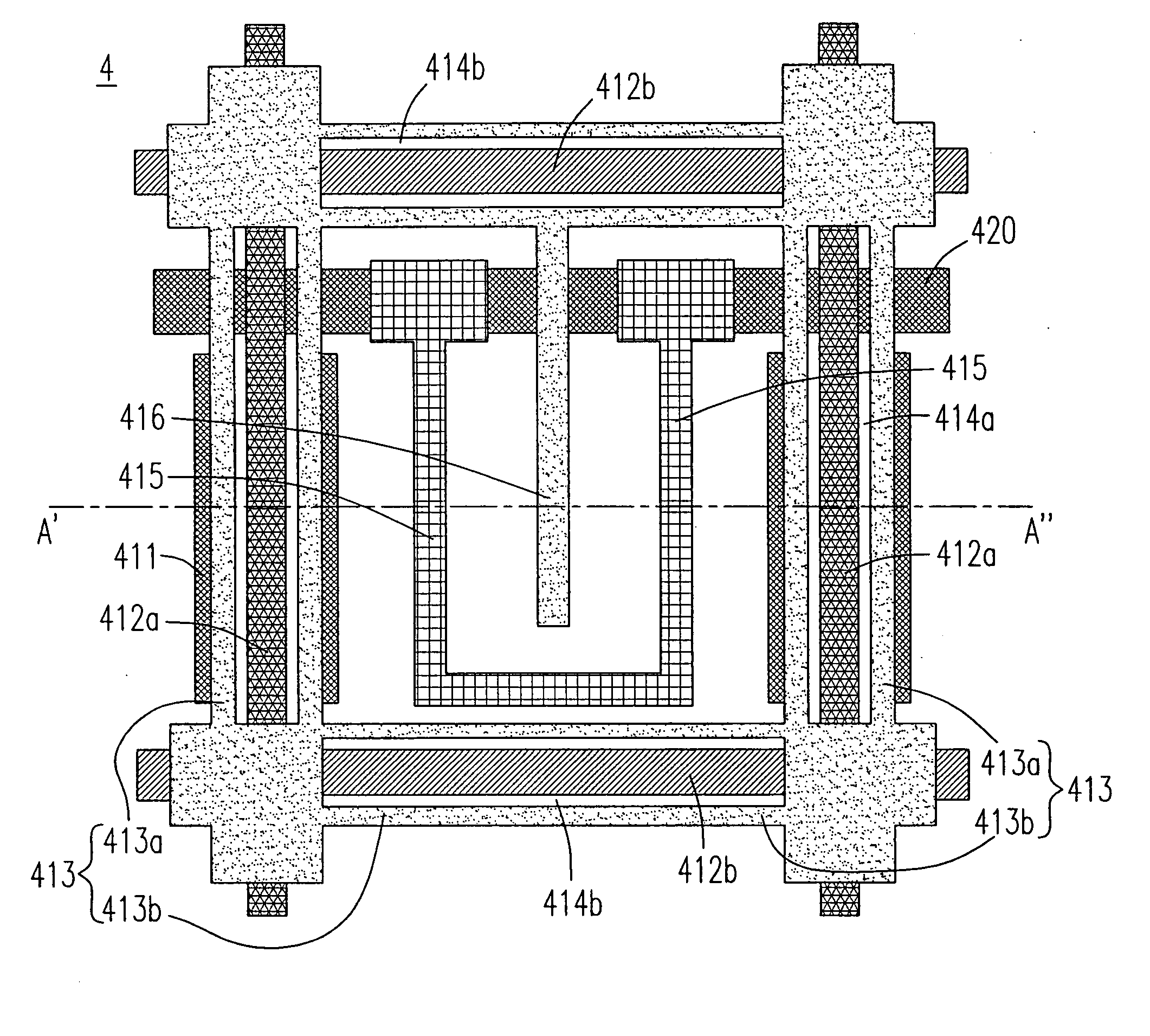

Ultra broadband capacitor

ActiveUS20100039749A1Efficient and less-expensiveReduce in quantityFixed capacitor electrodesFixed capacitor dielectricUltra-widebandBroadband

Disclosed are apparatus and methodology for inexpensive realization of one or more secondary capacitors within a monolithic body that already includes a first, larger capacitor to provide ultra wideband structures. Alternating layers of electrodes are provided with arm portions that embrace portions of adjacent electrode layers so as to create additional coupling effects within the capacitor structure thereby producing multiple additional equivalent capacitor structures within the device.

Owner:KYOCERA AVX COMPONENTS CORP

Data pattern sensitivity compensation using different voltage

ActiveUS7450421B2Reduce coupling effectExact searchRead-only memoriesDigital storageCapacitanceCapacitive coupling

Owner:SANDISK TECH LLC

Apparatus with alternating read mode

ActiveUS7440324B2Reduce coupling effectRead-only memoriesDigital storageParallel computingElectric field

Shifts in the apparent charge stored on a floating gate (or other charge storage element) of a non-volatile memory cell can occur because of the coupling of an electric field based on the charge stored in adjacent floating gates (or other charge storing elements). To account for this coupling, the read process for a targeted memory cell will provide compensation to an adjacent memory cell (or other memory cell) in order to reduce the coupling effect that the adjacent memory cell has on the targeted memory cell. The compensation applied is based on a condition of the adjacent memory cell. To apply the correct compensation, the read process will at least partially intermix read operations for the adjacent memory cell with read operations for the targeted memory cell.

Owner:SANDISK TECH LLC

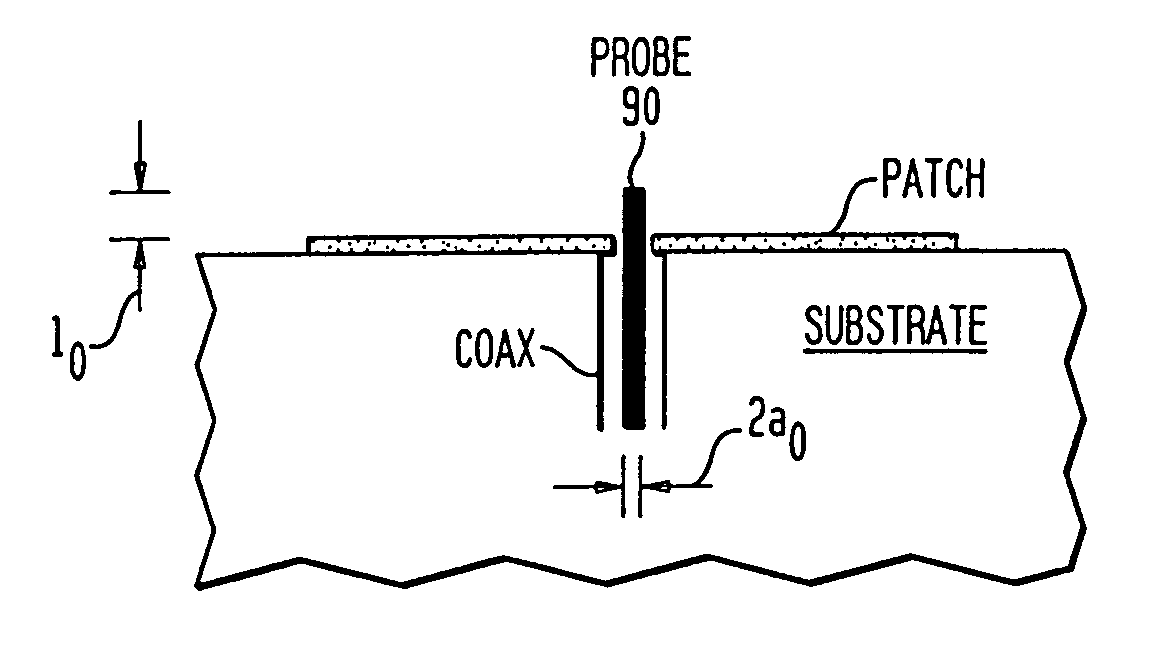

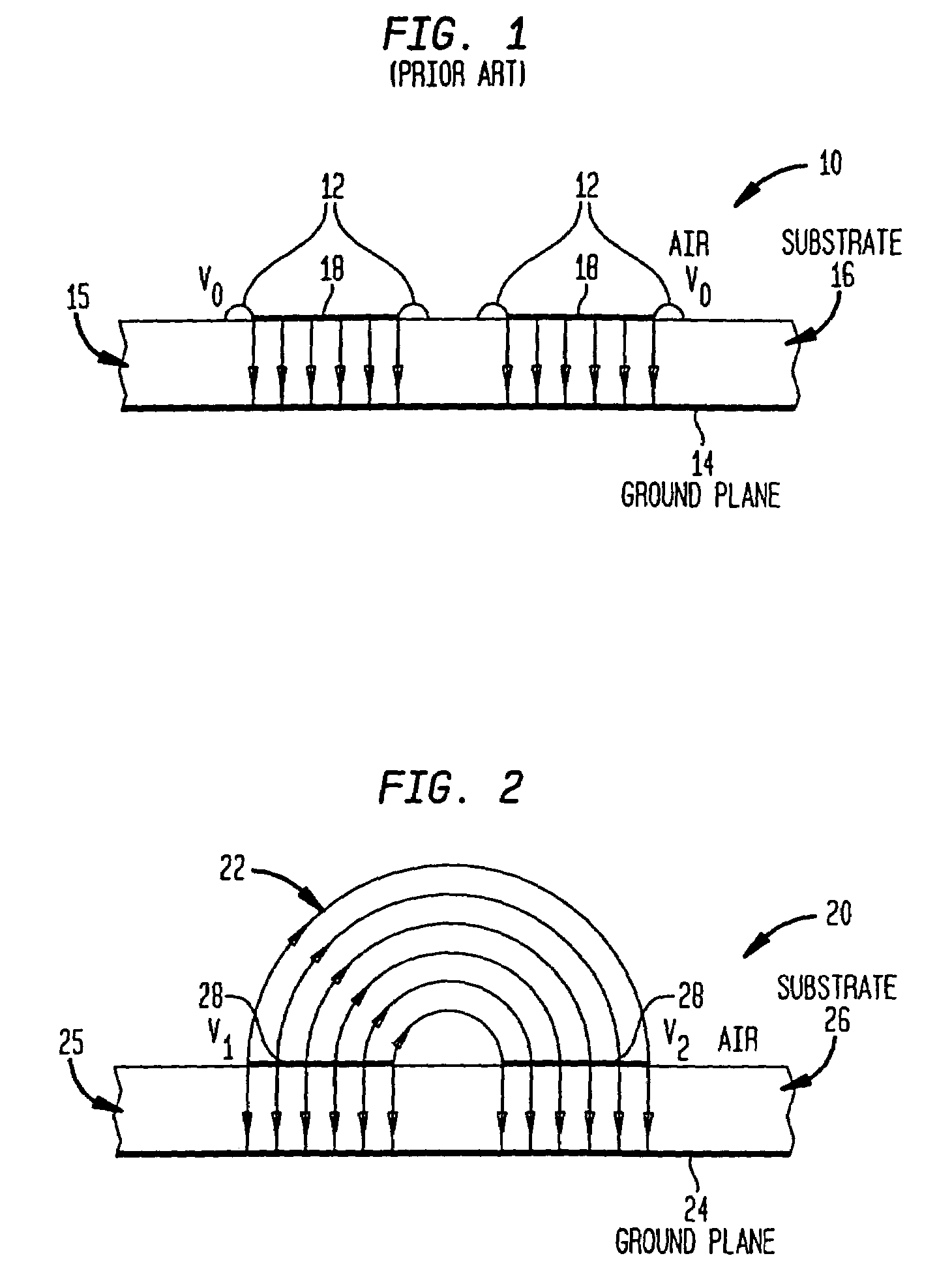

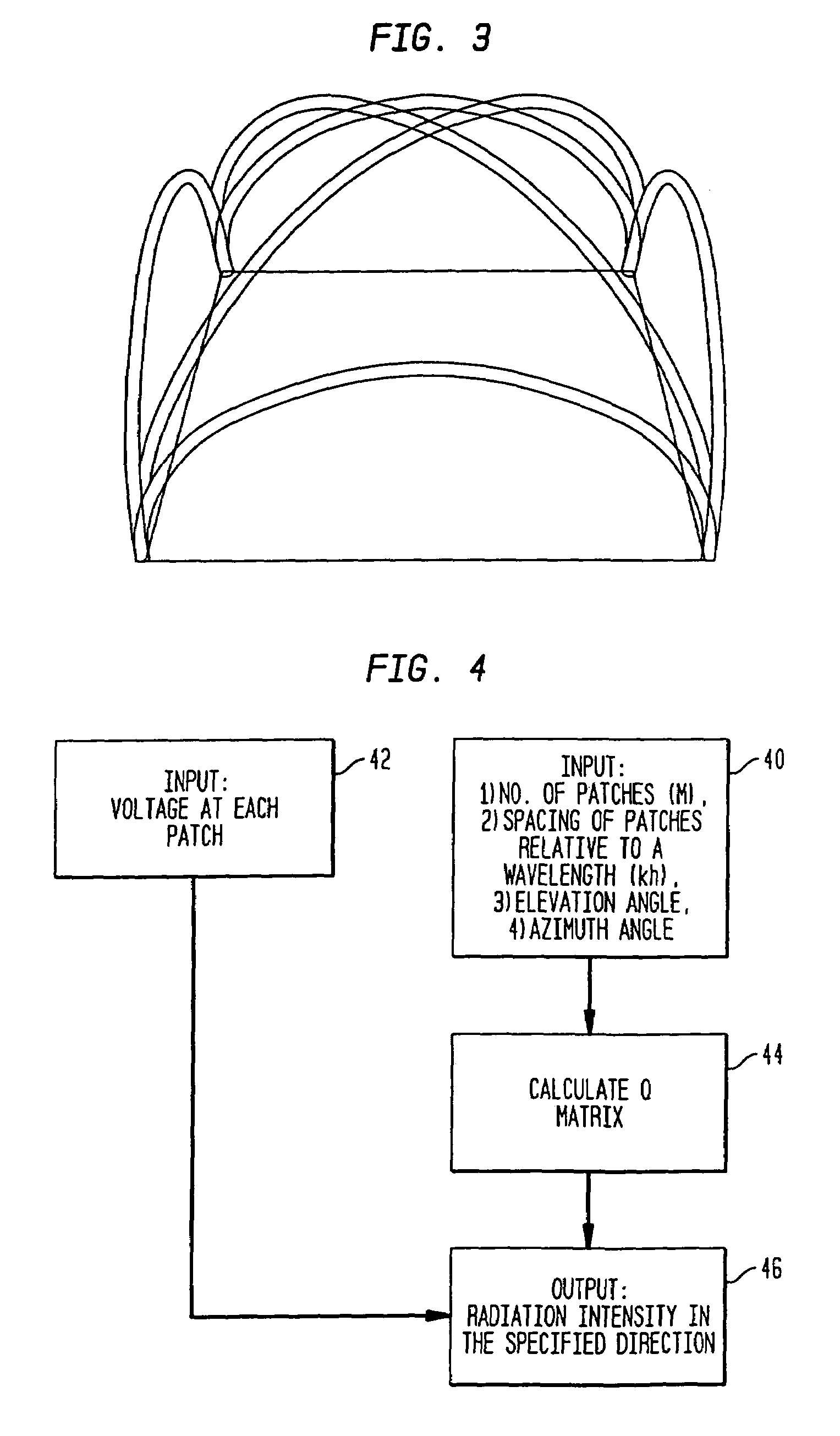

Systems and methods for providing optimized patch antenna excitation for mutually coupled patches

InactiveUS7298329B2Enhanced radiationImprove efficiencyParticular array feeding systemsSimultaneous aerial operationsMicrostrip patch antennaLight beam

An antenna array (e.g., microstrip patch antenna) operates in a manner that exploits the particular susceptibility of the mutual coupling effects between radiating elements in the array. Various differential-mode excitation schemes are provided for determining optimal differential-mode voltages or optimal differential-mode currents that are applied to the radiating elements (e.g., microstrip patches) to thereby achieve certain desirable radiation characteristics including, for example, aiming a radiated beam in a prescribed direction, steering the beam, shaping the radiated beam, and / or optimizing the gain of the antenna in a specified direction.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

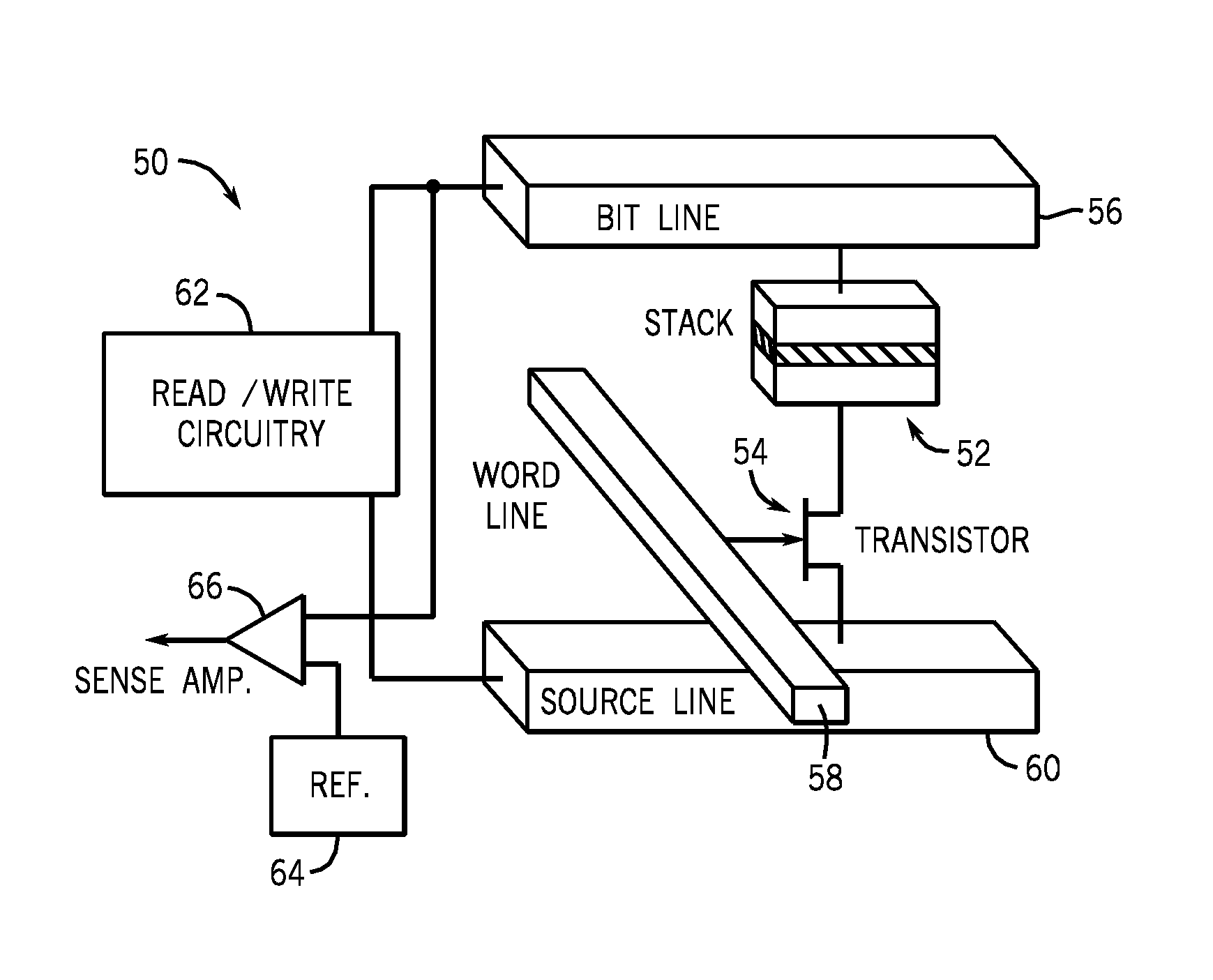

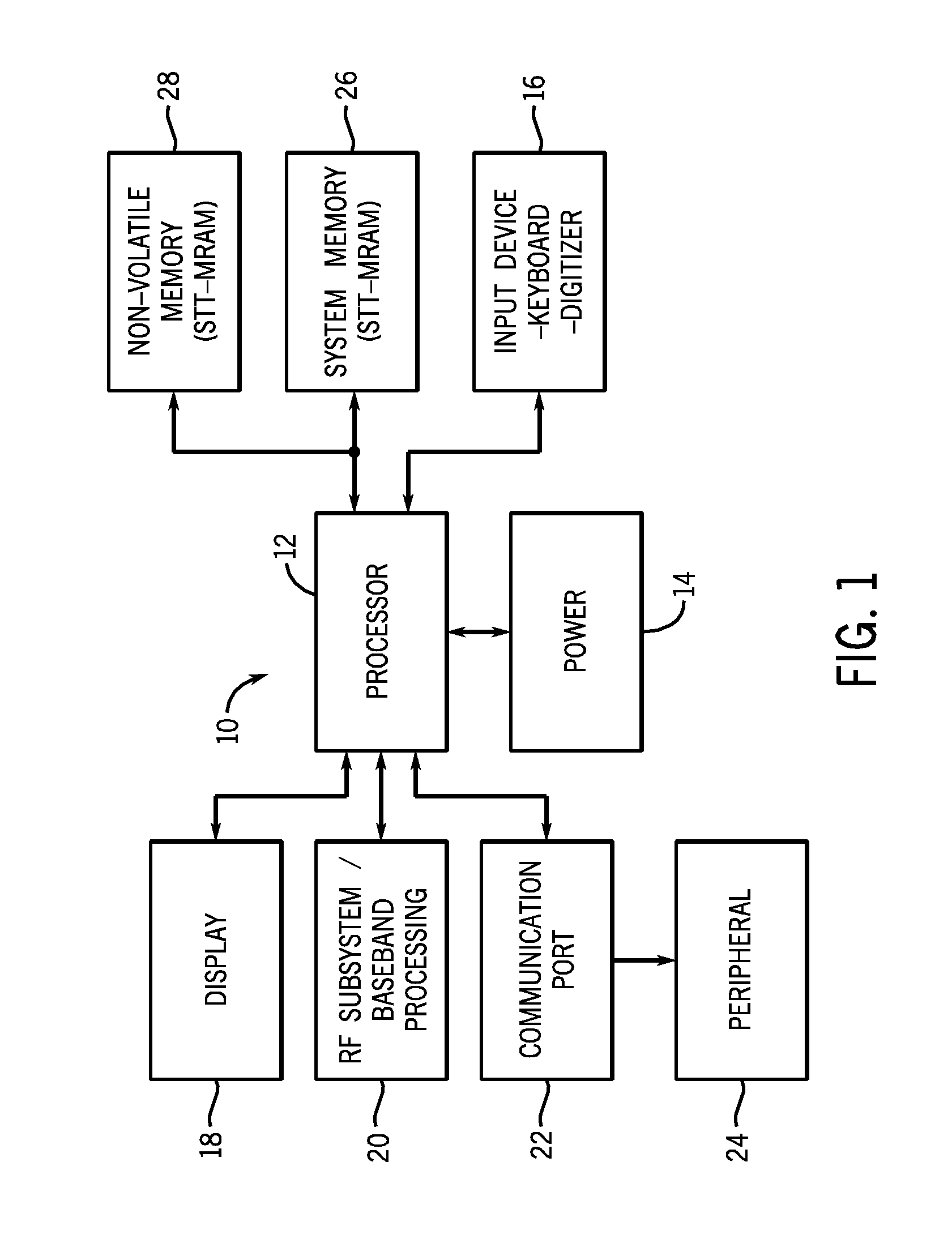

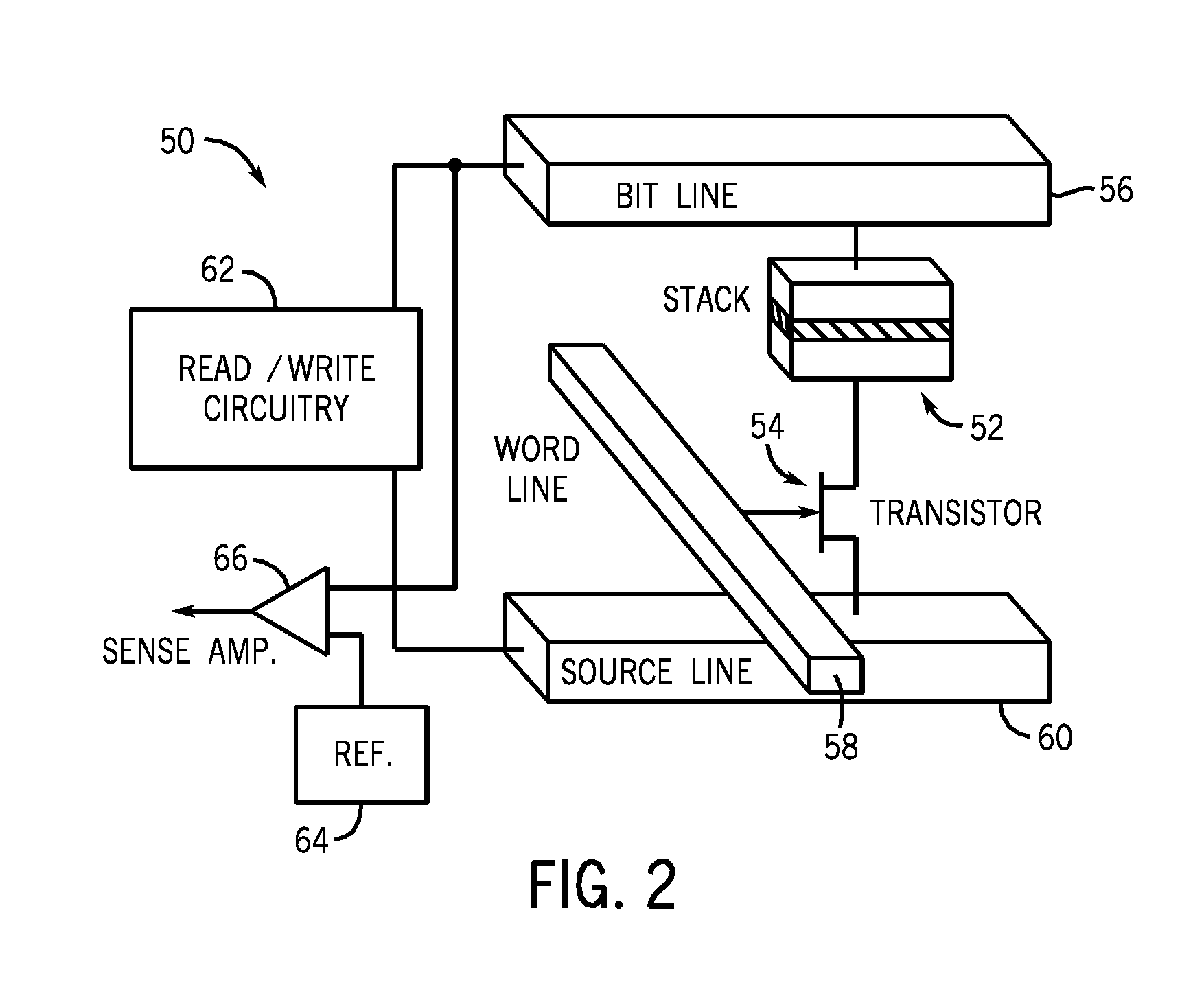

Spin torque transfer cell structure utilizing field-induced antiferromagnetic or ferromagnetic coupling

A magnetic memory cell including a soft magnetic layer and a coupling layer, and methods of operating the memory cell are provided. The memory cell includes a stack with a free ferromagnetic layer and a pinned ferromagnetic layer, and a soft magnetic layer and a coupling layer may also be formed as layers in the stack. The coupling layer may cause antiferromagnetic coupling to induce the free ferromagnetic layer to be magnetized in a direction antiparallel to the magnetization of the soft magnetic layer, or the coupling layer may cause ferromagnetic coupling to induce the free ferromagnetic layer to be magnetized in a direction parallel to the magnetization of the soft magnetic layer. The coupling layer, through a coupling effect, reduces the critical switching current of the memory cell.

Owner:OVONYX MEMORY TECH LLC

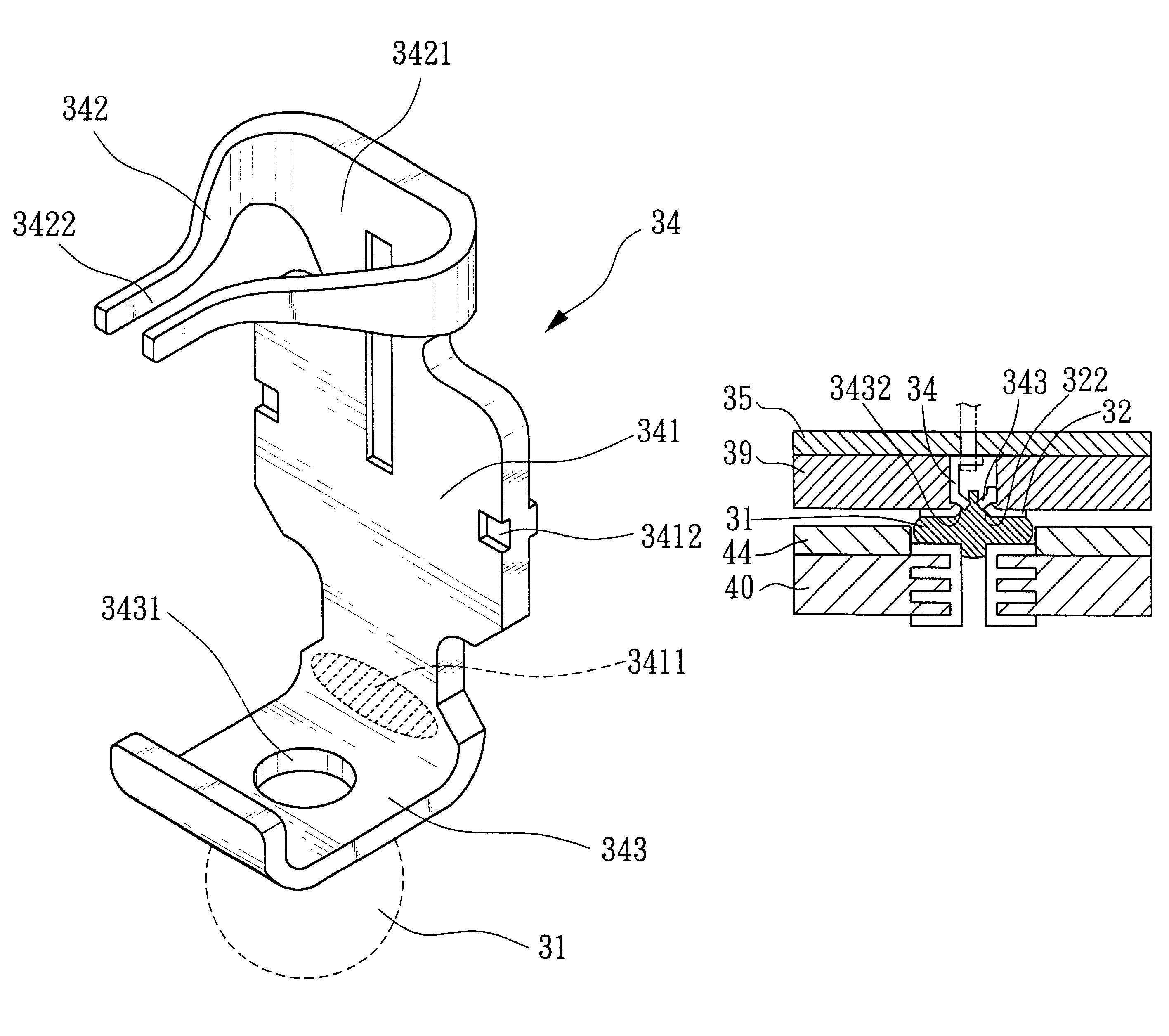

Electrical connection device

InactiveUS6692265B2Printed circuit assemblingFinal product manufactureElectricityElectrical connection

An electrical connection device comprises a socket, a plurality of electrical conducting holder in between, a contact ring and a plurality of solder balls. A plurality of pin holes are placed on the socket to provide the insert function for the pins of a IC package. The electrical conducting holder is placed in the pin holes and comprises an extensional part, a holder on the top of the extension part and a solder pad on the bottom part of the extension part to combine the solder ball. At least one 2D or 3D geometrical structure such as the hole, the convex and concave part or the slope on the bottom surface of the solder pad is formed. The geometrical structure will make the bottom surface of the solder pad not the flat plane. With the geometrical structure and the contact ring, the contact area of the solder pad and the contact ring will be enlarged during the solder reflow process. The coupling effect will be better and meanwhile improve the characteristics of the electricity, the intensity of the structure, the production yield and the characteristics of the co-planarity.

Owner:VIA TECH INC

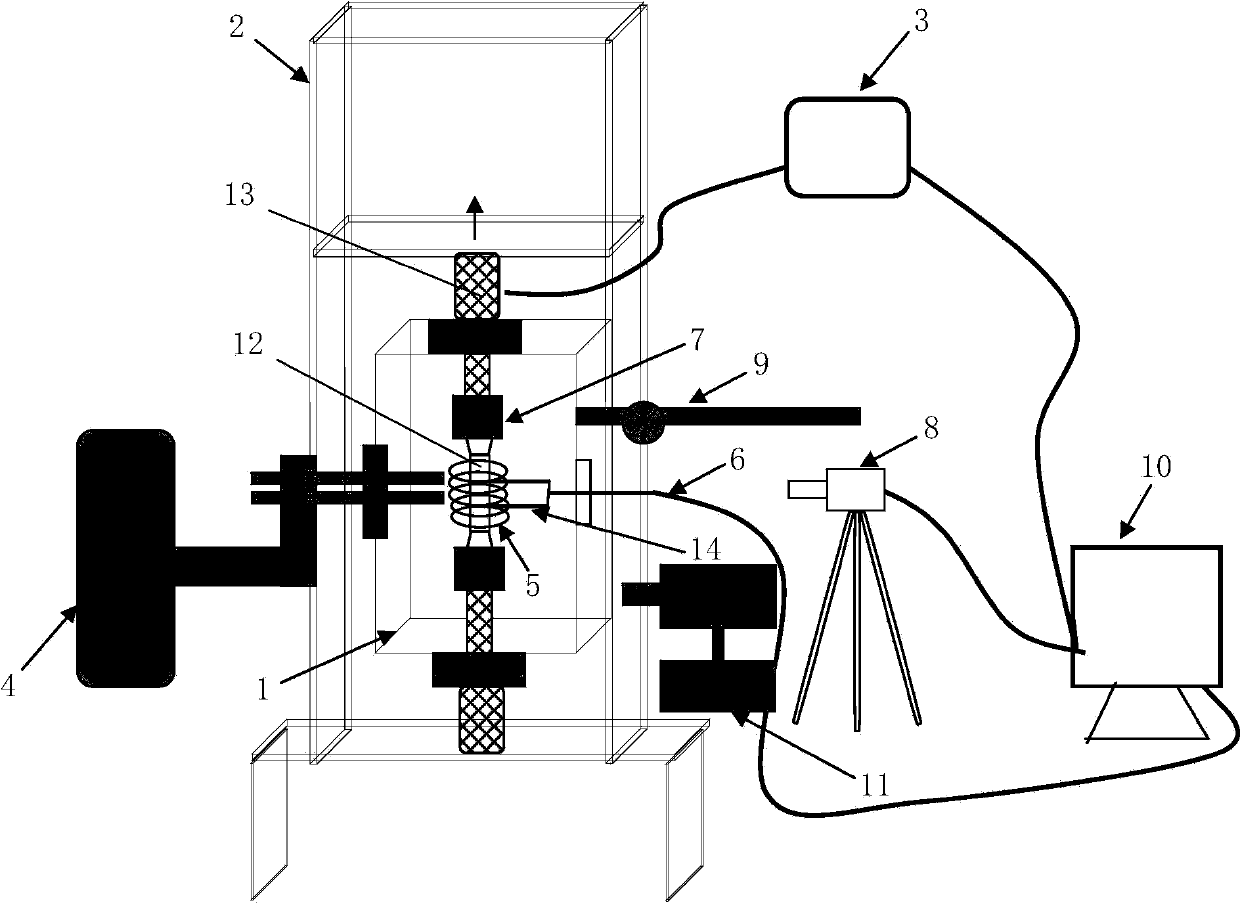

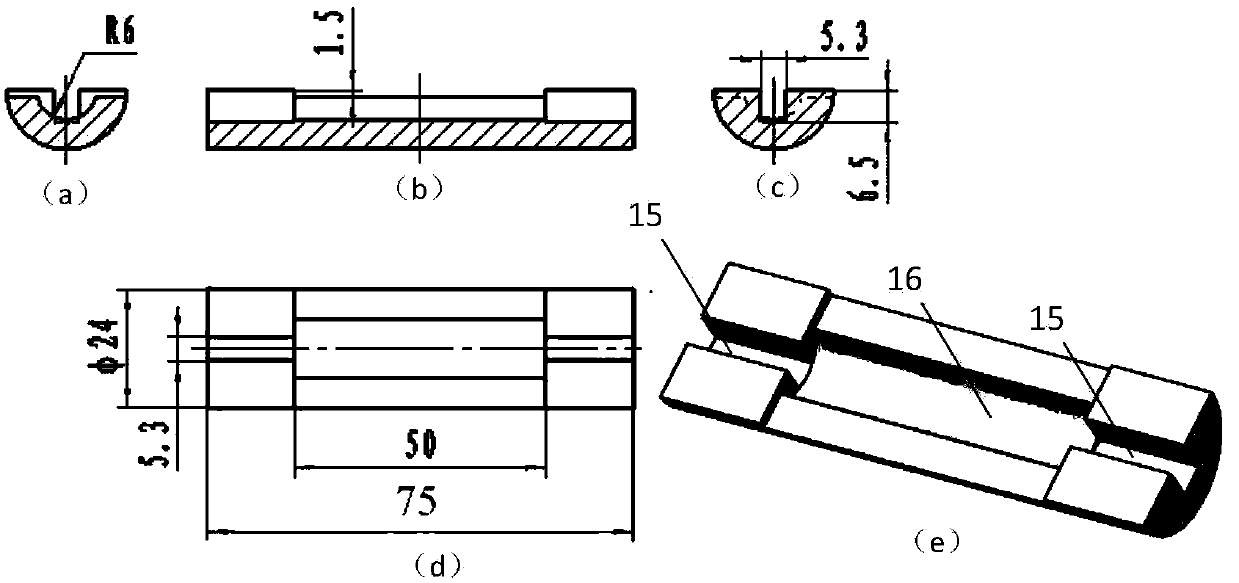

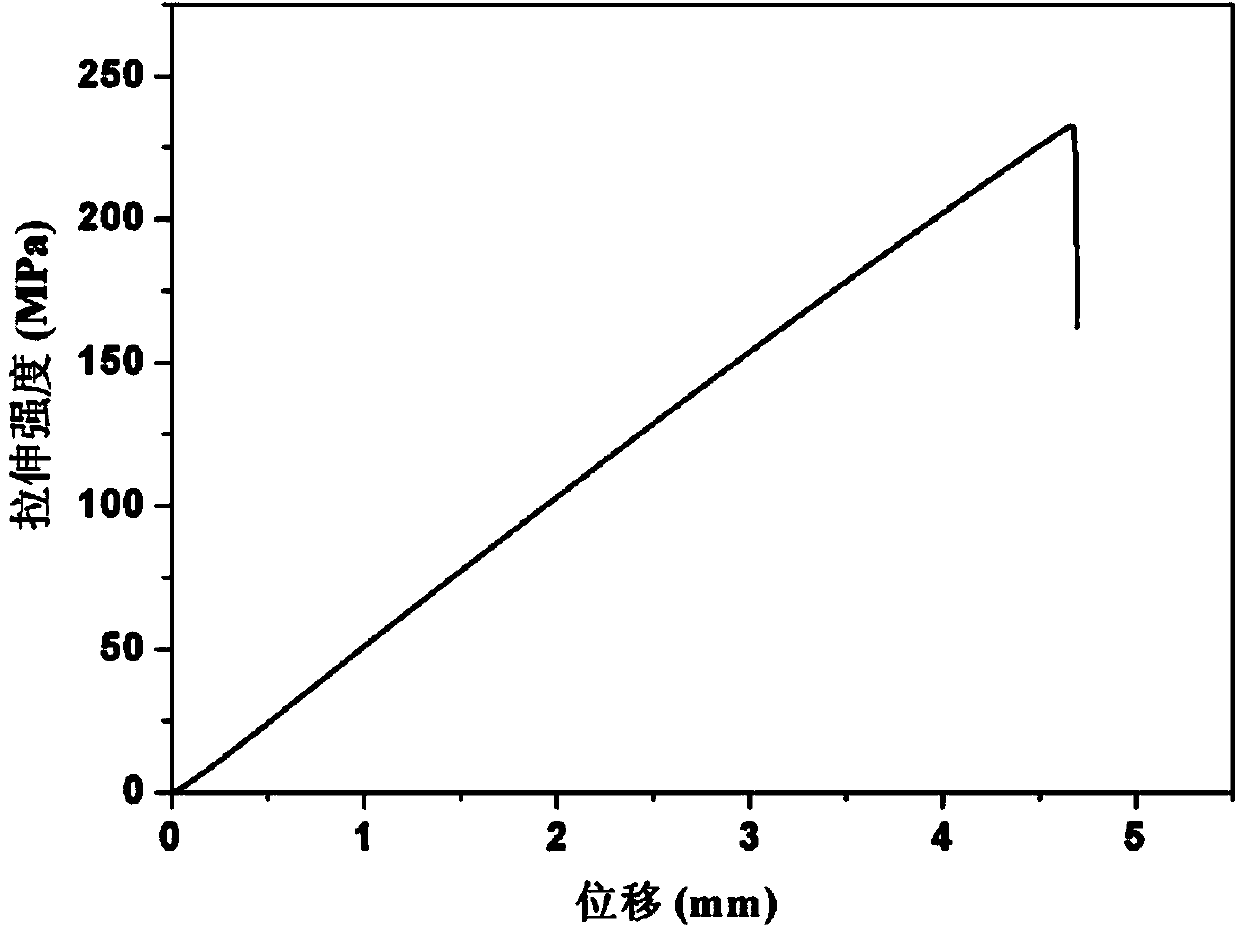

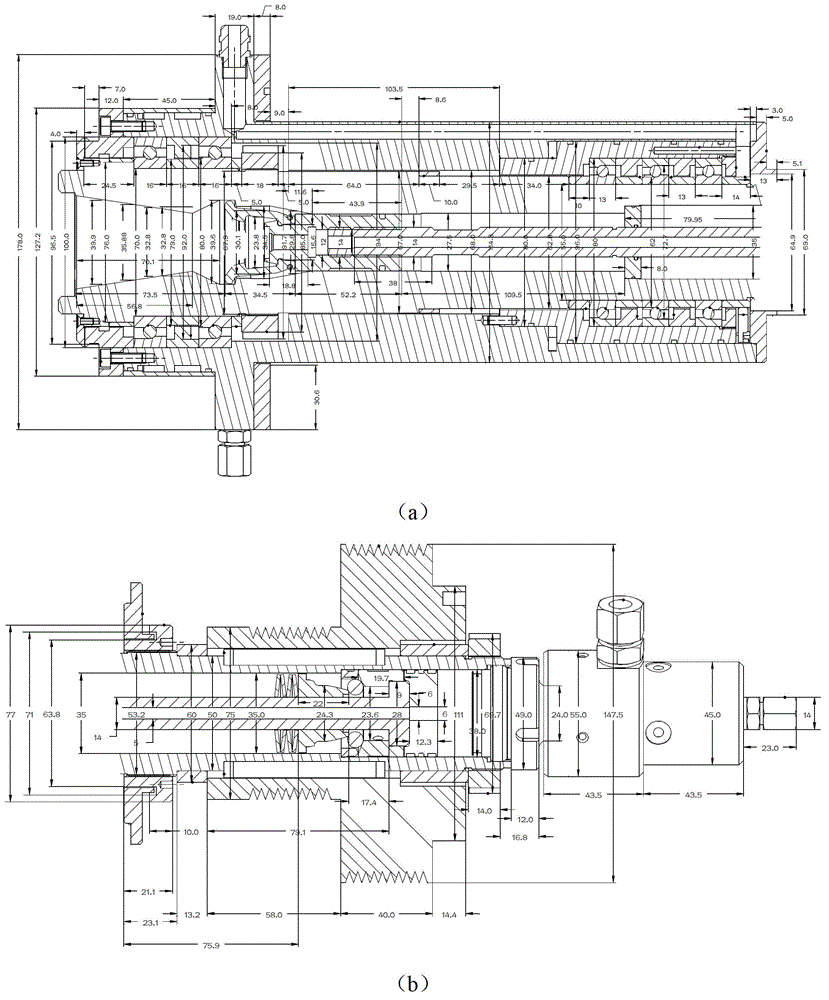

Thermo-mechanical-environmental coupling effect testing device and application from room temperature to ultrahigh temperature

ActiveCN104215521APrecise temperature controlTestable tensile strengthWeighing by removing componentMaterial strength using tensile/compressive forcesPower control systemTest fixture

The invention relates to the field of test of mechanical properties of materials and in particular relates to a thermo-mechanical-environmental coupling effect testing device and application from room temperature to ultrahigh temperature. The device comprises an electronic universal testing machine, a loading control system, a power supply control system, an induction heater, a strain measurement system, a sample clamp, a temperature measuring system, a pressure control system, a display and analysis system and a vacuum system, wherein a vacuum cavity in the electronic universal testing machine is in a fully water-cooled design, and various functional windows, such as a sensor connector of the clamp and the electronic universal testing machine, an infrared or thermocouple temperature measuring opening of the temperature measuring system, a pressure control opening of the pressure control system, an induction power supply introduction opening of the power supply control system, an extensometer introduction opening of the strain measurement system and a connector of the vacuum system and the vacuum cavity, are reserved in different parts of the vacuum cavity. The device disclosed by the invention can quantitatively research the thermo-mechanical-environmental coupling effect and has the advantages of diversified tested mechanical property parameters, high sample heating and cooling speed and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

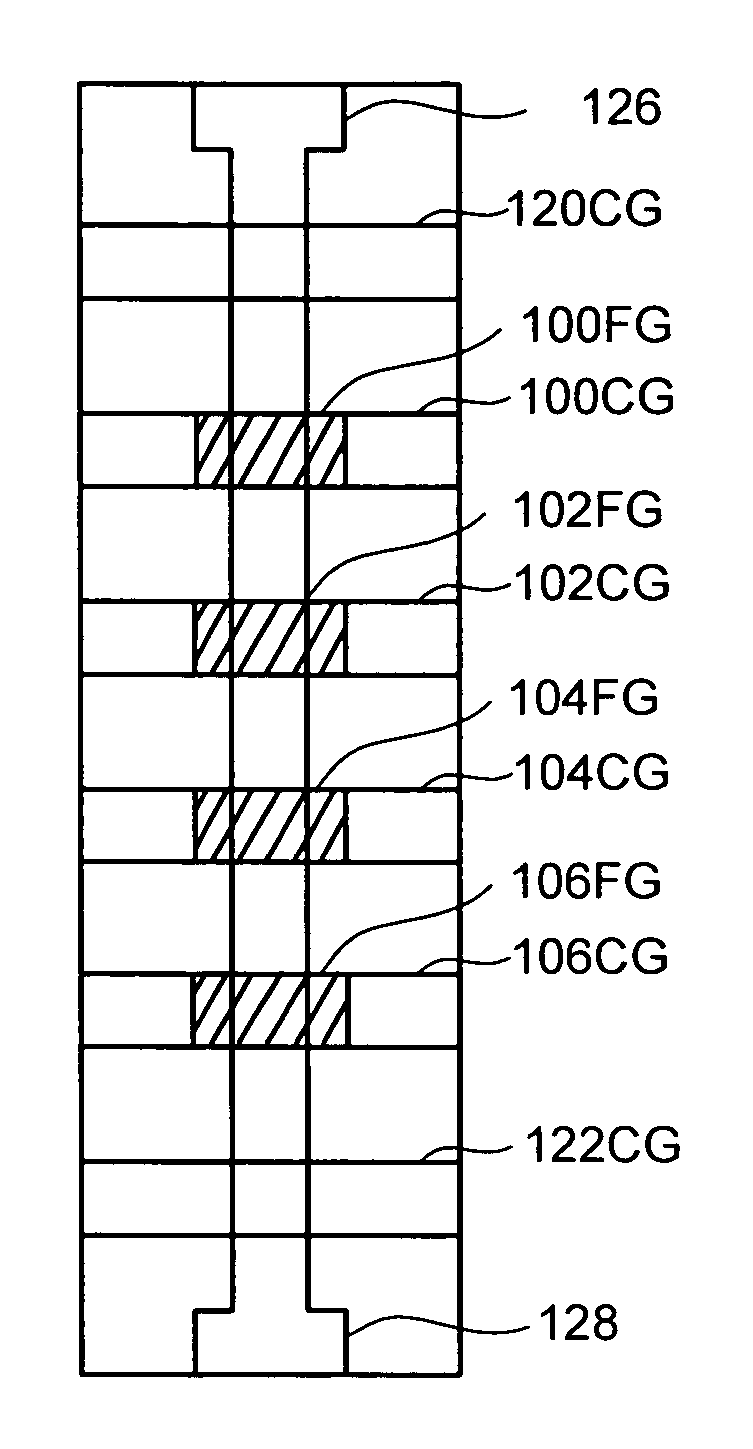

Reducing floating gate to floating gate coupling effect

InactiveUS20060140011A1Weakening rangeReduce voltageRead-only memoriesDigital storageEngineeringThreshold voltage

For a non-volatile memory system, compressing the erase threshold voltage distribution into the lowest threshold voltage state will decrease the valid data threshold voltage window. Decreasing the valid data threshold voltage window reduces the floating gate to floating gate coupling effect. The compression can be performed as part of the erase process or part of the programming operation.

Owner:SANDISK TECH LLC

Waterproof sealing paste producing chemical crosslinking and physical mortising with cement

ActiveCN103304862AImprove adhesionStrong tear resistanceOther chemical processesBuilding insulationsPlasticizerAdsorption effect

The invention provides waterproof sealing paste producing chemical crosslinking and physical mortising with cement. The sealing paste is characterized by comprising the following raw materials in parts by weight: 40-60 parts of synthesized rubber latex, 20-30 parts of rubber modified emulsified asphalt, 1-2 parts of a functional additive, 10-30 parts of filler, 0.5-5 parts of plasticizer, 1-3 parts of a thickener and 2-5 parts of water. A principle is that part of molecules in the synthesized rubber and the asphalt are coupled into macromolecules with reactivity under the coupling effect of the functional additive; when the macromolecules are contacted with a basic surface, the non-reactivity molecule sections of the rubber and the asphalt form a physical adsorption effect with the basic surface, and the reactivity molecule sections react with the basic surface to form a chemical bonding effect so as to generate a powerful bonding force; and the bonding effect is difficultly influenced by outside environment factors after the bonding operation is finished. Therefore, the sealing paste is very excellent in waterproof performance.

Owner:XI NIU PI WATERPROOFING TECH CO LTD

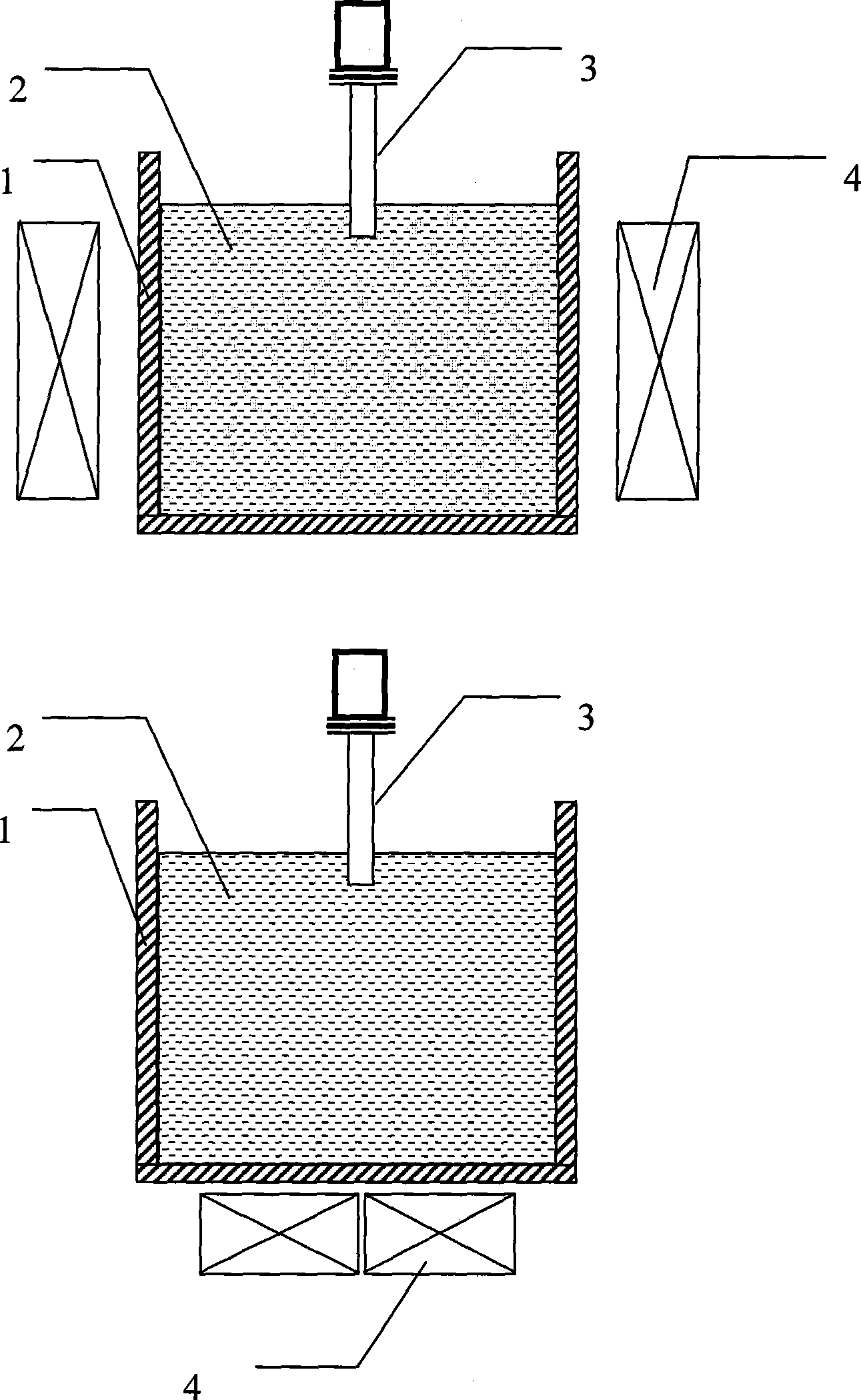

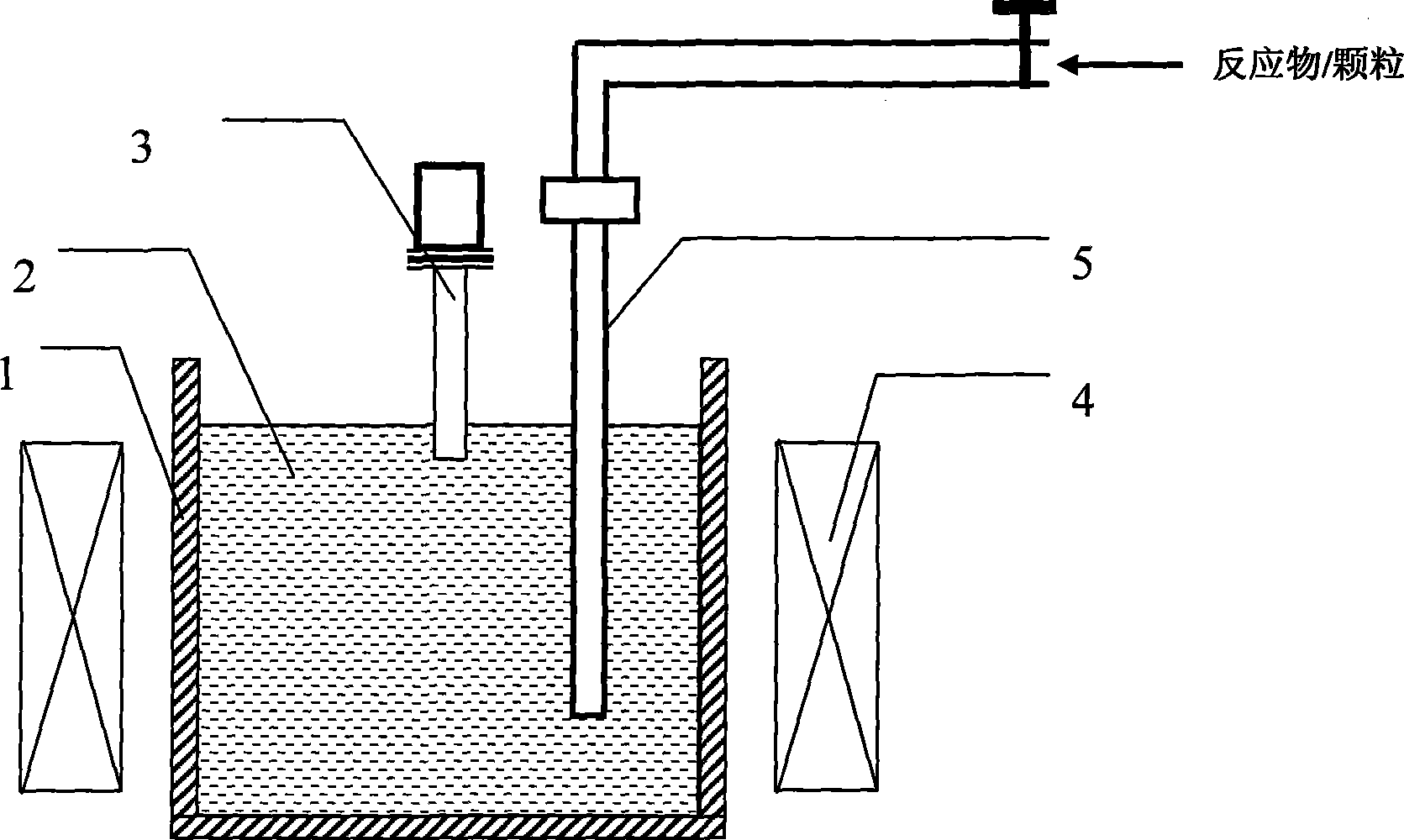

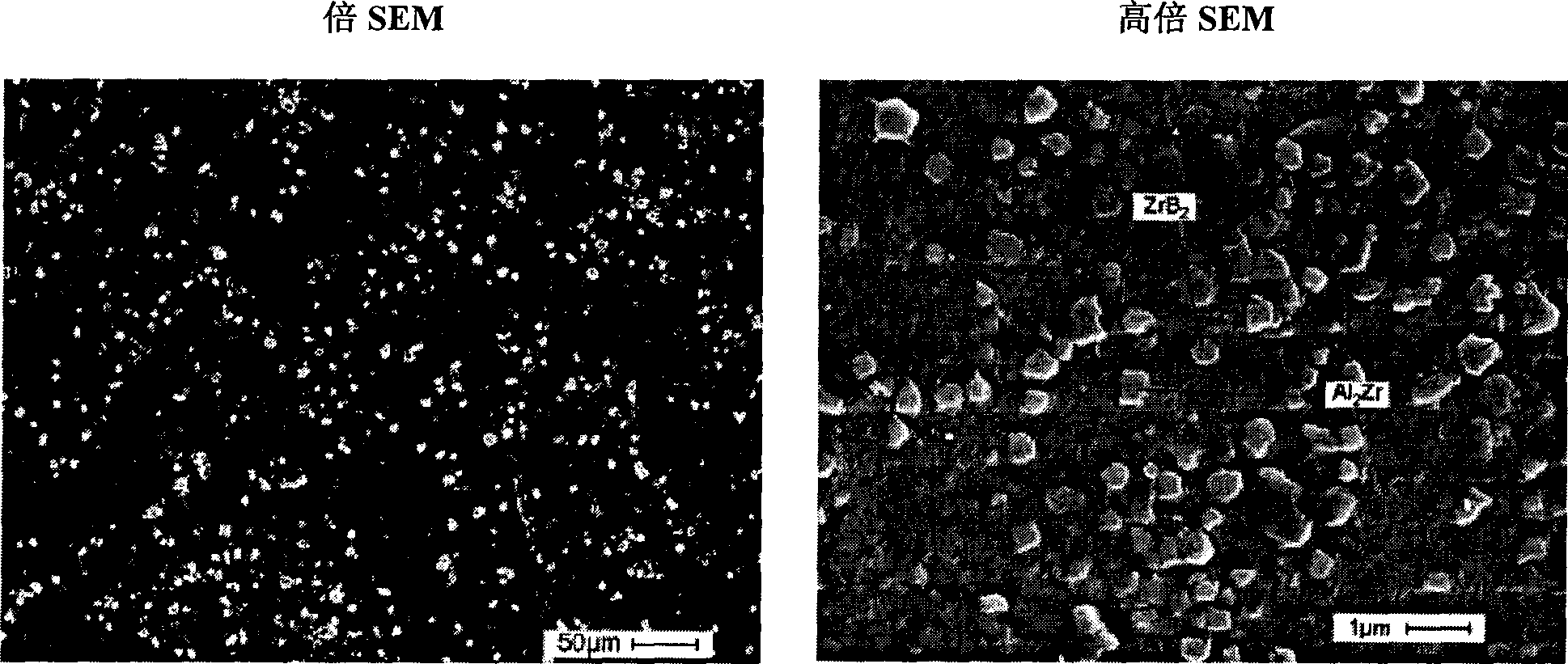

Method for synthesizing metal matrix composition using metal reaction under the coupling action of magnetic field and ultrasonic field

The invention relates to a method for preparing endogenetic particle reinforced metal matrix composites under the coupling effect of a magnetic field and supersonic waves. The method comprises: adjusting the temperature of a metal matrix fused mass to the reaction initial temperature after refining, adding a reactant which can generate a particle phase with the fused mass through the reaction in situ for implementing the synthesis reaction, standing the mixture after the reaction is over, and cooling the mixture to the pouring temperature for pouring; and the method is characterized in that: the magnetic field and the high-intensity ultrasonic field are simultaneously exerted in the reaction synthesis process to realize the synthesis of endogenetic particle reinforced metal matrix composites under the coupling effect of the magnetic field and the high-intensity ultrasonic field. The magnetic field can be an intense pulse magnetic field, a high frequency oscillation magnetic field or a low frequency alternating magnetic field. In the method, the coupling effect of the magnetic field and the ultrasonic field makes the particle sizes be thinned and dispersed evenly; the ultrasonic vibration agitation and electromagnetic stirring functions improve the composite dynamic condition, and the compounding of the particle phase and a base metal interface is better; and the co-action of magnetochemistry and sonochemistry improves the thermodynamic condition of the reaction in situ, as well as speeding up the reaction in situ and controlling the growth of the particle phase.

Owner:JIANGSU UNIV

System for performing read operation on non-volatile storage with compensation for coupling

Shifts in the apparent charge stored on a floating gate (or other charge storing element) of a non-volatile memory cell can occur because of the coupling of an electric field based on the charge stored in adjacent floating gates (or other adjacent charge storing elements). The problem occurs most pronouncedly between sets of adjacent memory cells that have been programmed at different times. To account for this coupling, the read process for a particular memory cell will provide compensation to an adjacent memory cell in order to reduce the coupling effect that the adjacent memory cell has on the particular memory cell.

Owner:SANDISK TECH LLC

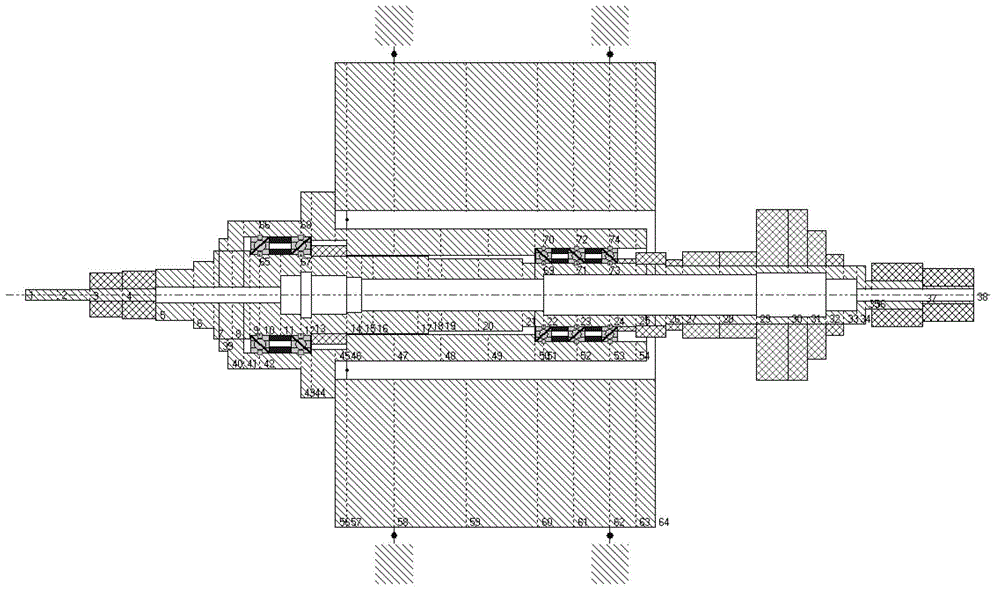

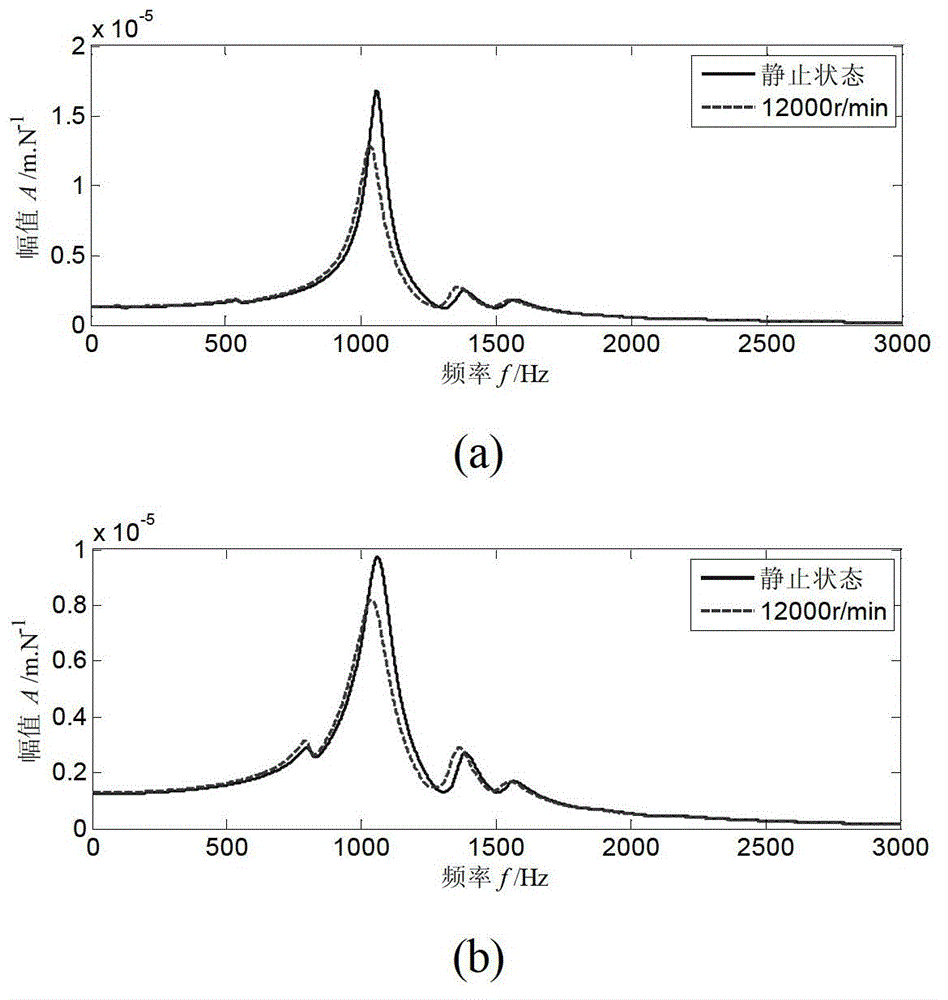

High-speed milling process parameter optimizing method based on dynamic model

ActiveCN102873381AImprove accuracyHigh removal rateMilling machinesSpecial data processing applicationsDynamic modelsSystem dynamics model

The invention relates to a high-speed milling process parameter optimizing method based on a dynamic model. The optimizing method includes 1) inputting structure parameter and initial cutting condition of a spindle-cutter system; 2) building a dynamic model of the spindle-cutter system, calculating a frequency response function of the cutter nose position according to the model and determining cutting force coefficient; 3) building a high speed spindle-cutter dynamic characteristic and milling interaction process model to obtain the characteristic equation of a closed loop dynamic milling system; 4) calculating a high-speed milling machining shimmy stability leaf picture; 5) selecting lathe spindle rotating speed and cutting depth to achieve high-speed milling parameter optimization with the lower bound curve of the high-speed milling machining shimmy stability leaf picture as the constraint condition and with maximum material removing rate as the optimization target. The method considers centrifugal force and gyroscopic couple effect of the cutter-cutter system in the high-speed rotating state, approaches actual work condition, improves accuracy of stability prediction, and provides effective technology for optimization of high-speed milling process parameter optimization.

Owner:XI AN JIAOTONG UNIV

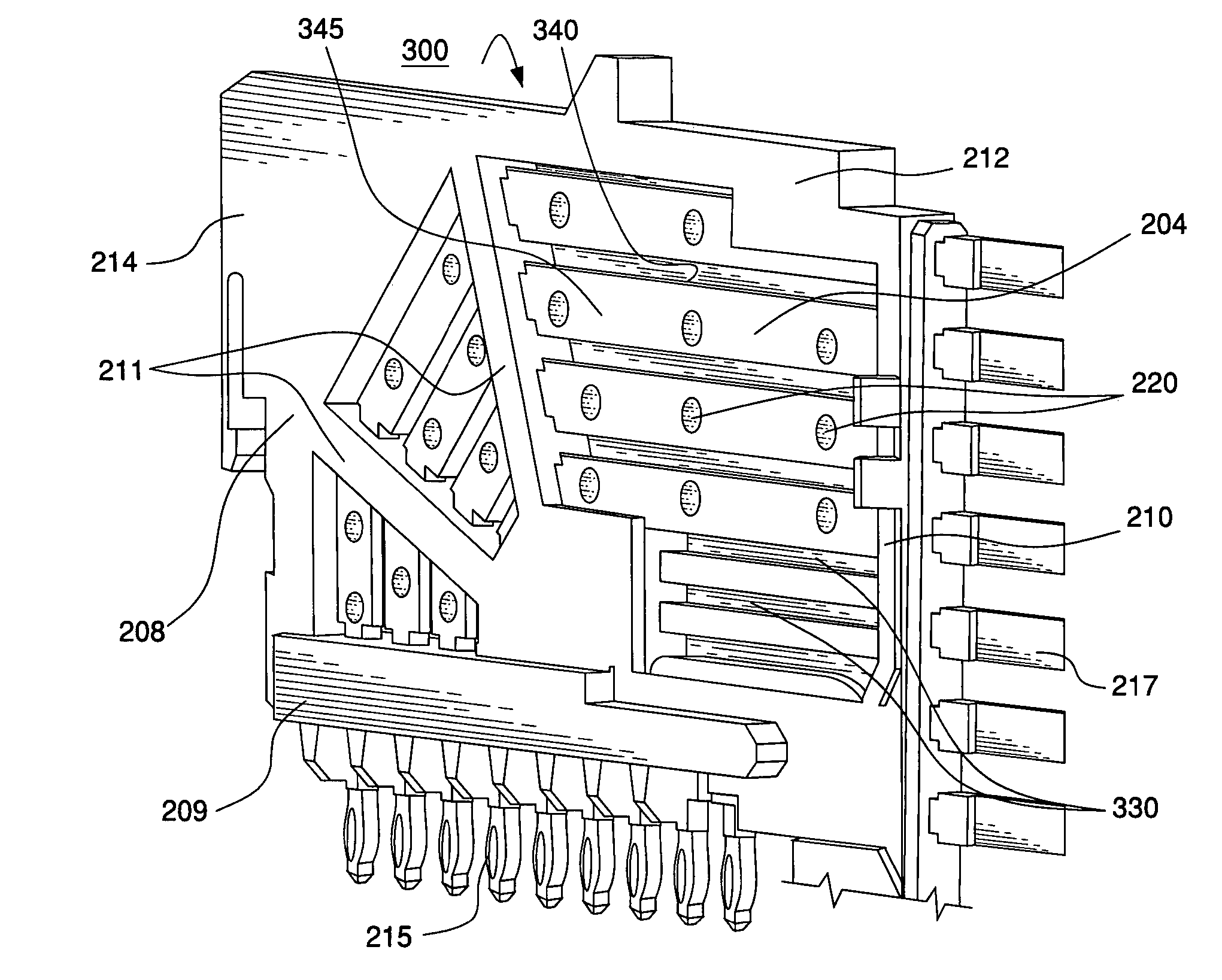

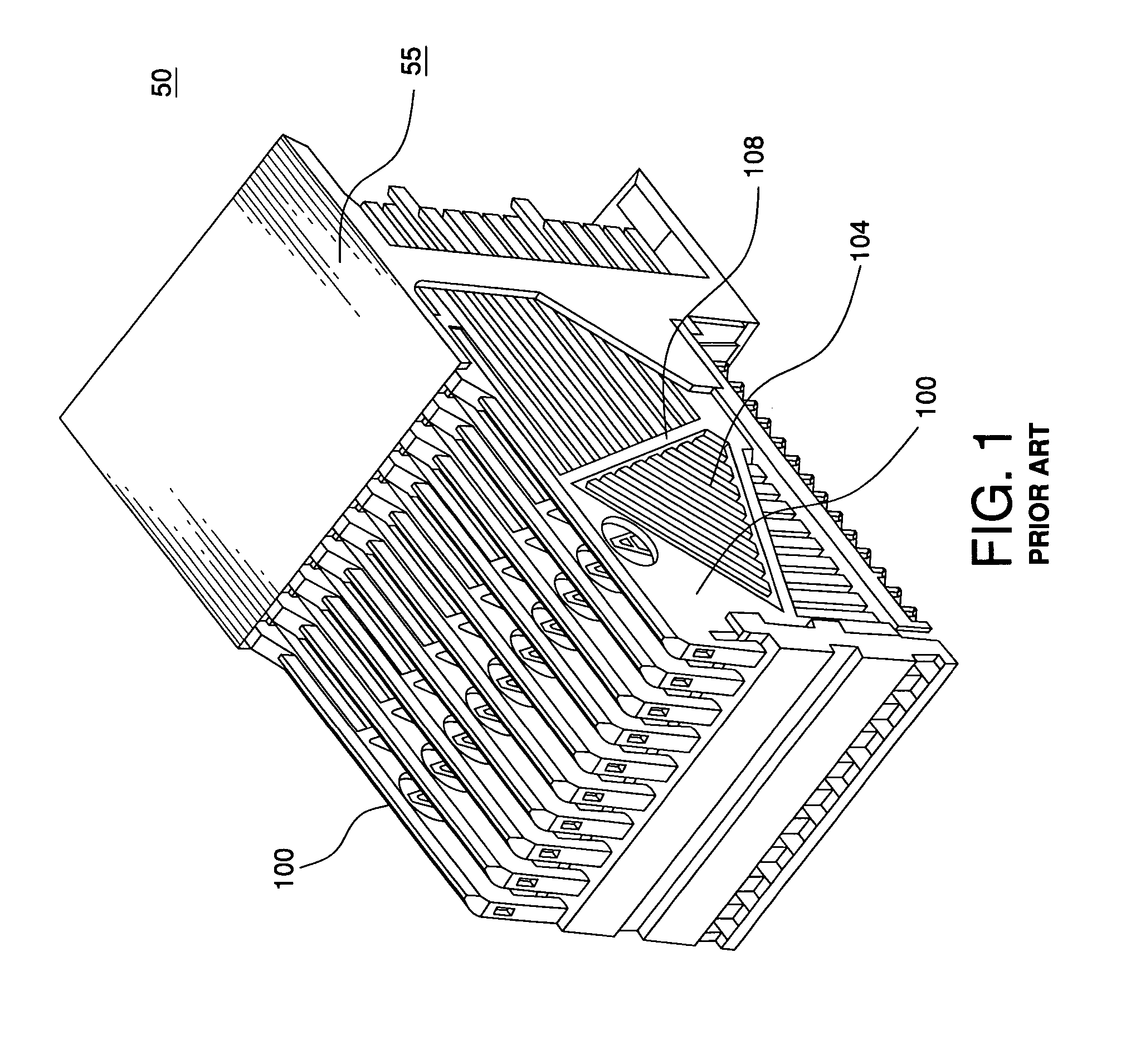

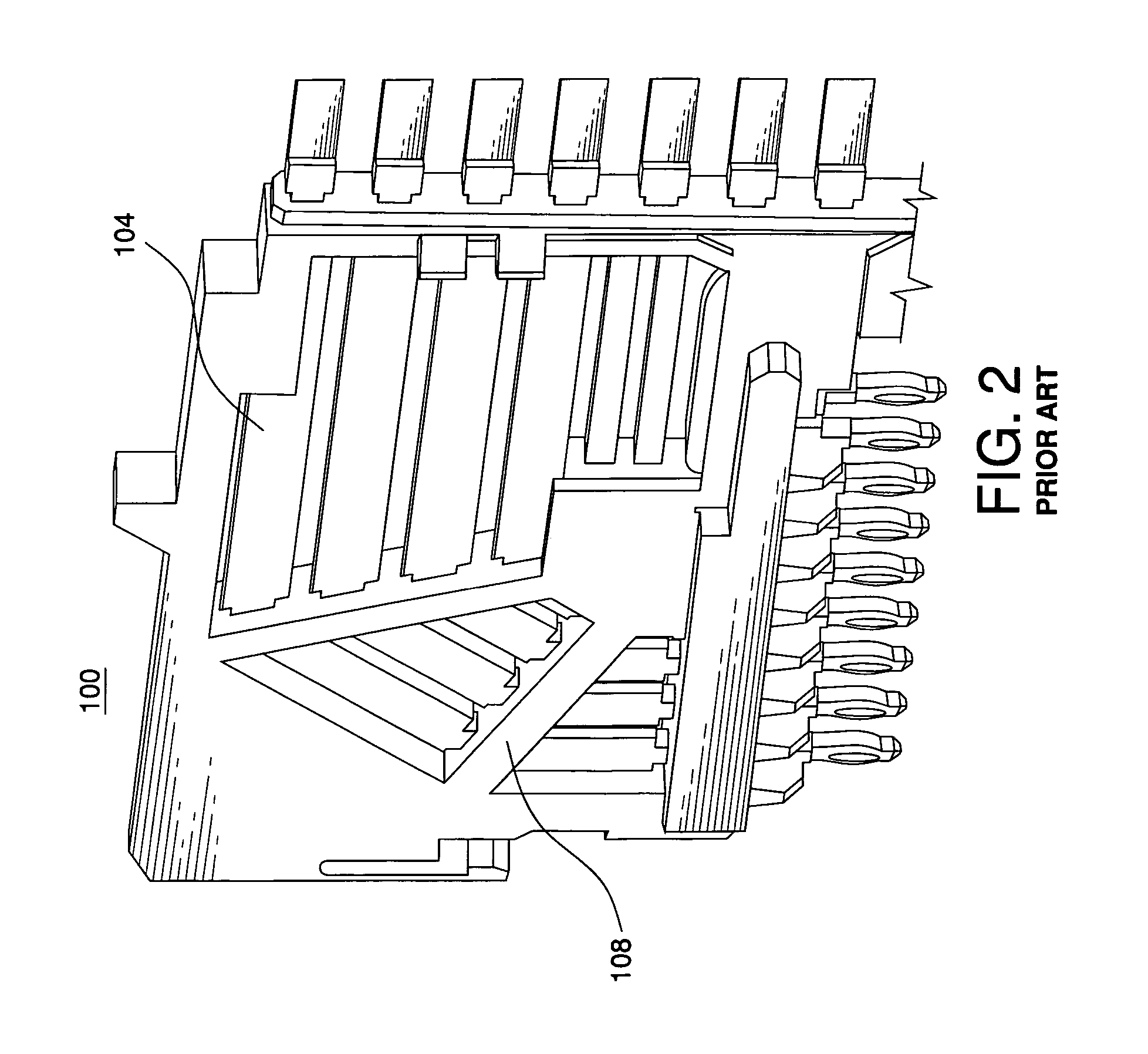

Mechanically robust lead frame assembly for an electrical connector

ActiveUS7347740B2Improve robustnessHigh strengthElectrically conductive connectionsCoupling protective earth/shielding arrangementsDifferential signalingEngineering

A lead frame assembly is disclosed in which holes may be formed in contacts of the assembly and a dielectric material extends along a length of the contact. The dielectric material may be further secured to the contact by filling the hole. The dielectric material may span across two or more contacts of the lead frame assembly and also across gaps formed between the contacts, or may span across an entire side of a lead frame assembly. The dielectric material may add mechanical strength and robustness to the lead frame assembly while helping to reduce dust accumulation on electrical contacts of the assembly. The dielectric material may abut only one side of one or more contacts in the lead frame assembly and thus may not affect edge-coupling effect of contacts that form differential signal pairs.

Owner:FCI AMERICAS TECH LLC

Read operation for non-volatile storage with compensation for coupling

ActiveUS20070206421A1Reduce coupling effectRead-only memoriesDigital storageComputer scienceElectric field

Shifts in the apparent charge stored on a floating gate (or other charge storing element) of a non-volatile memory cell can occur because of the coupling of an electric field based on the charge stored in adjacent floating gates (or other adjacent charge storing elements). The problem occurs most pronouncedly between sets of adjacent memory cells that have been programmed at different times. To account for this coupling, the read process for a particular memory cell will provide compensation to an adjacent memory cell in order to reduce the coupling effect that the adjacent memory cell has on the particular memory cell.

Owner:SANDISK TECH LLC

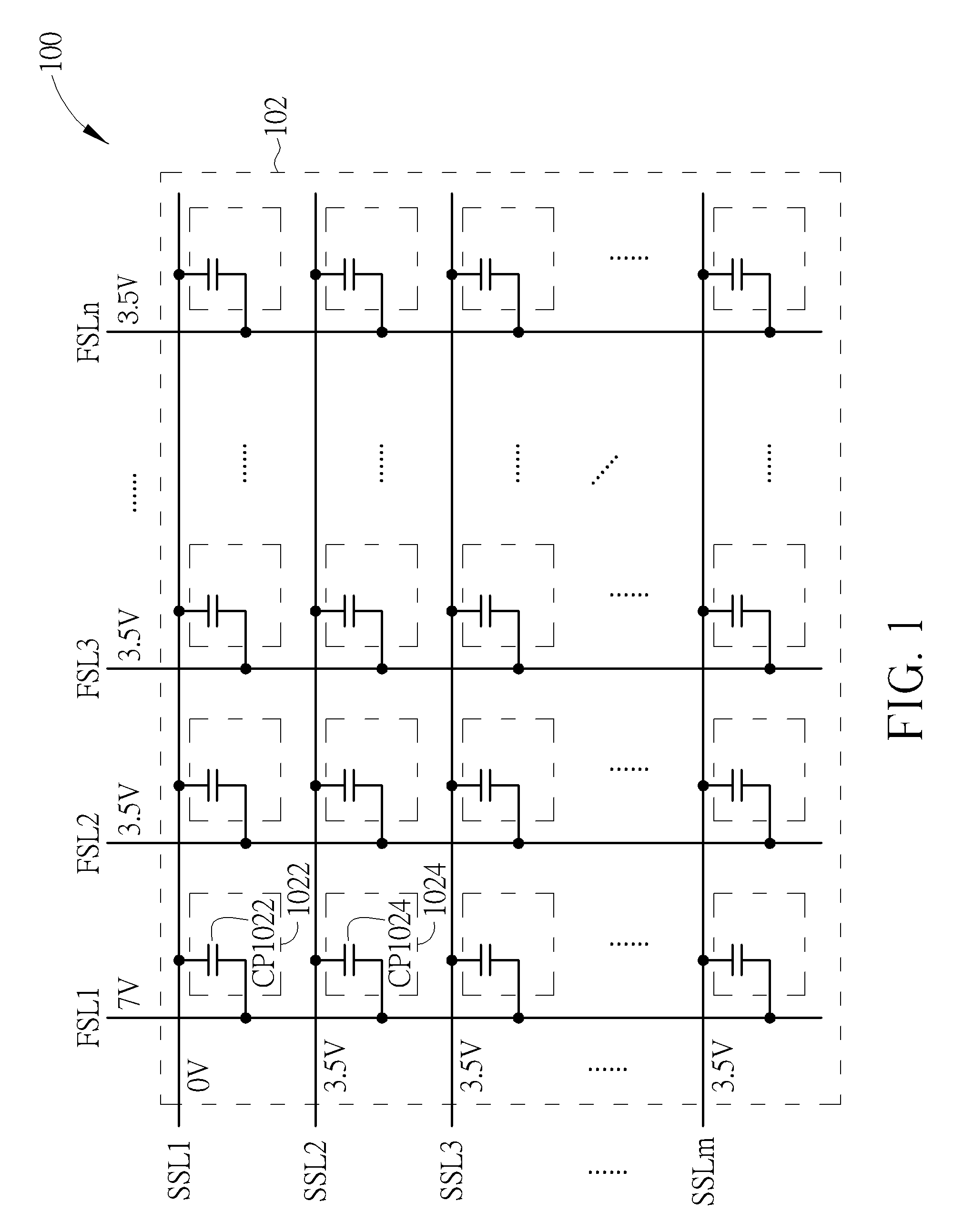

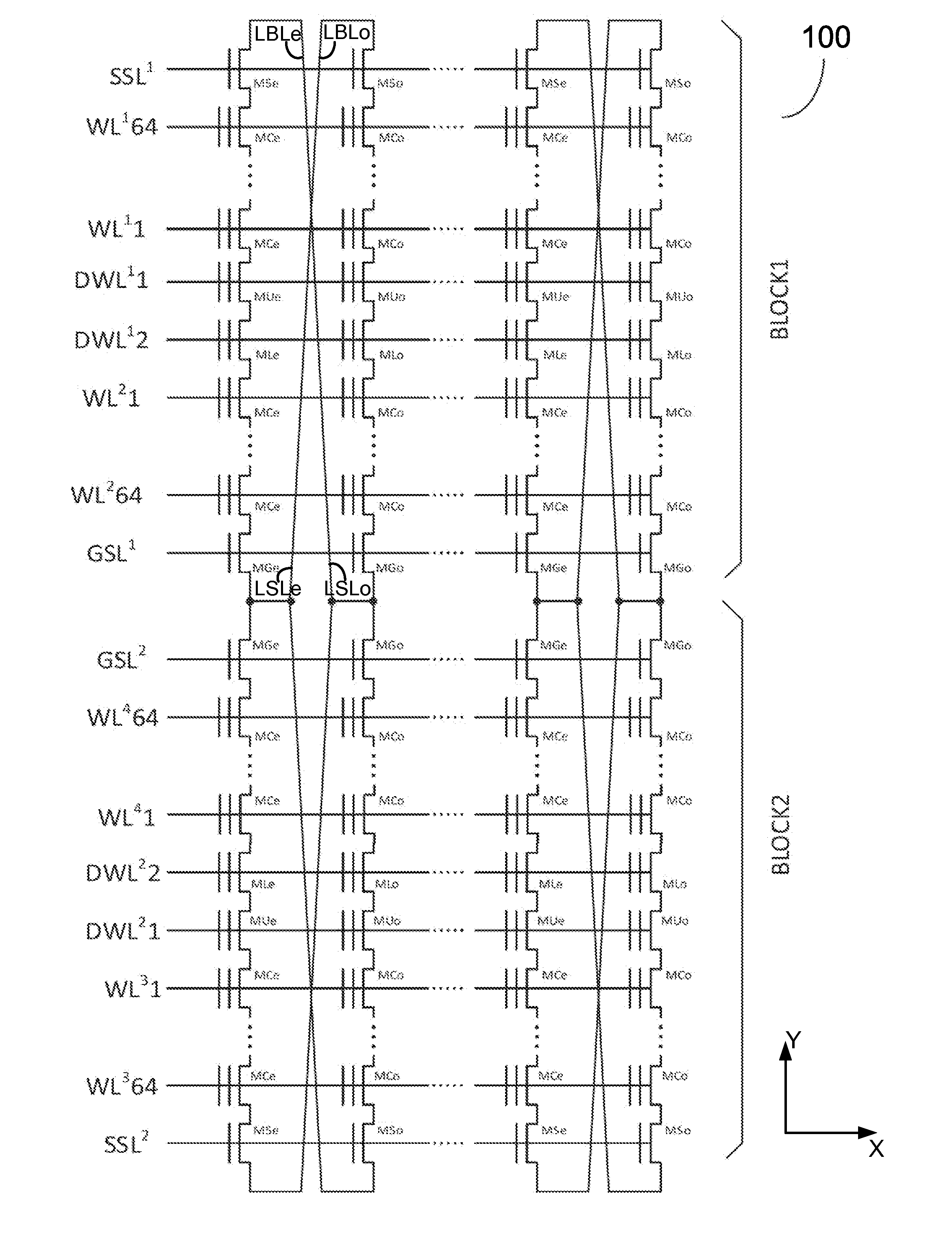

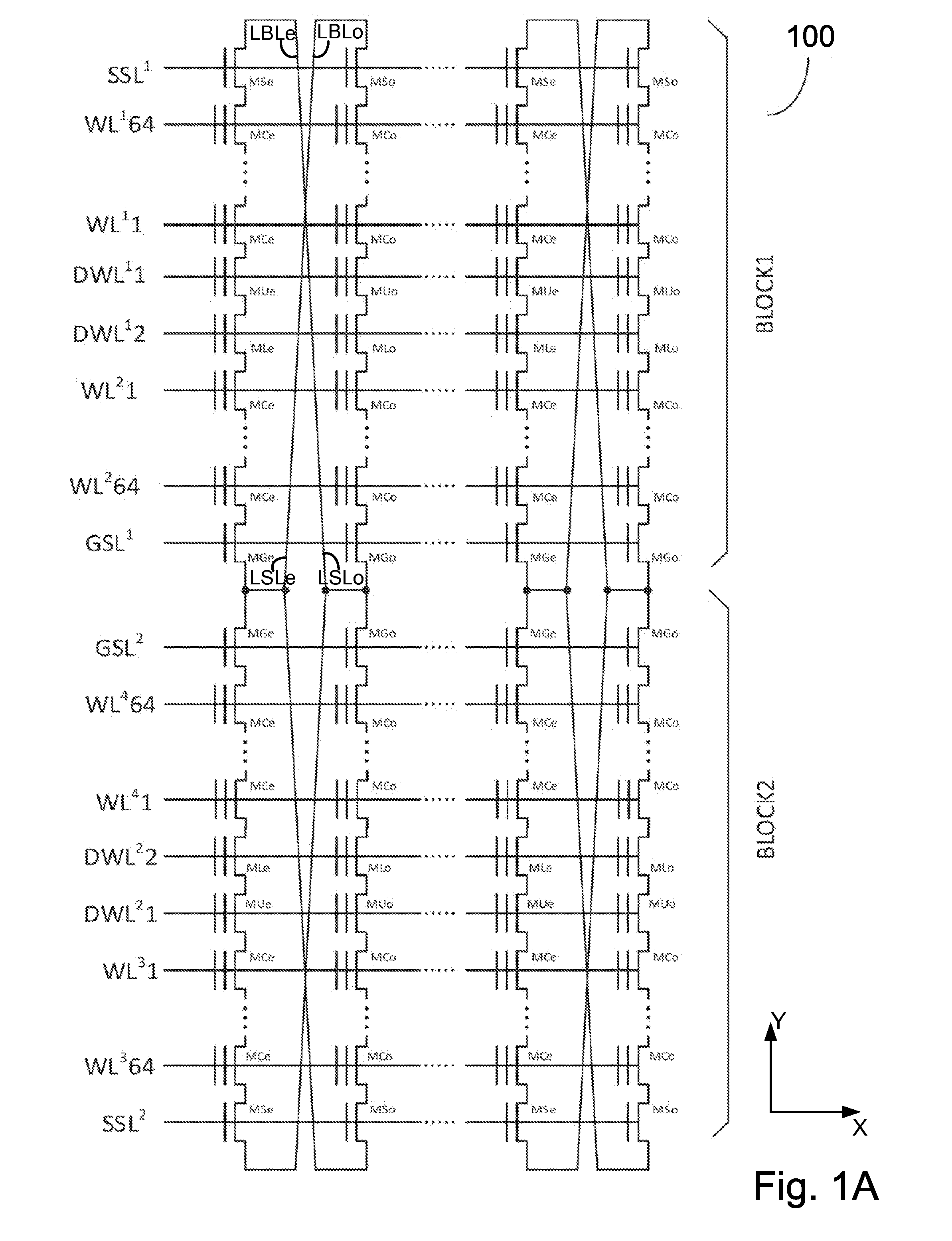

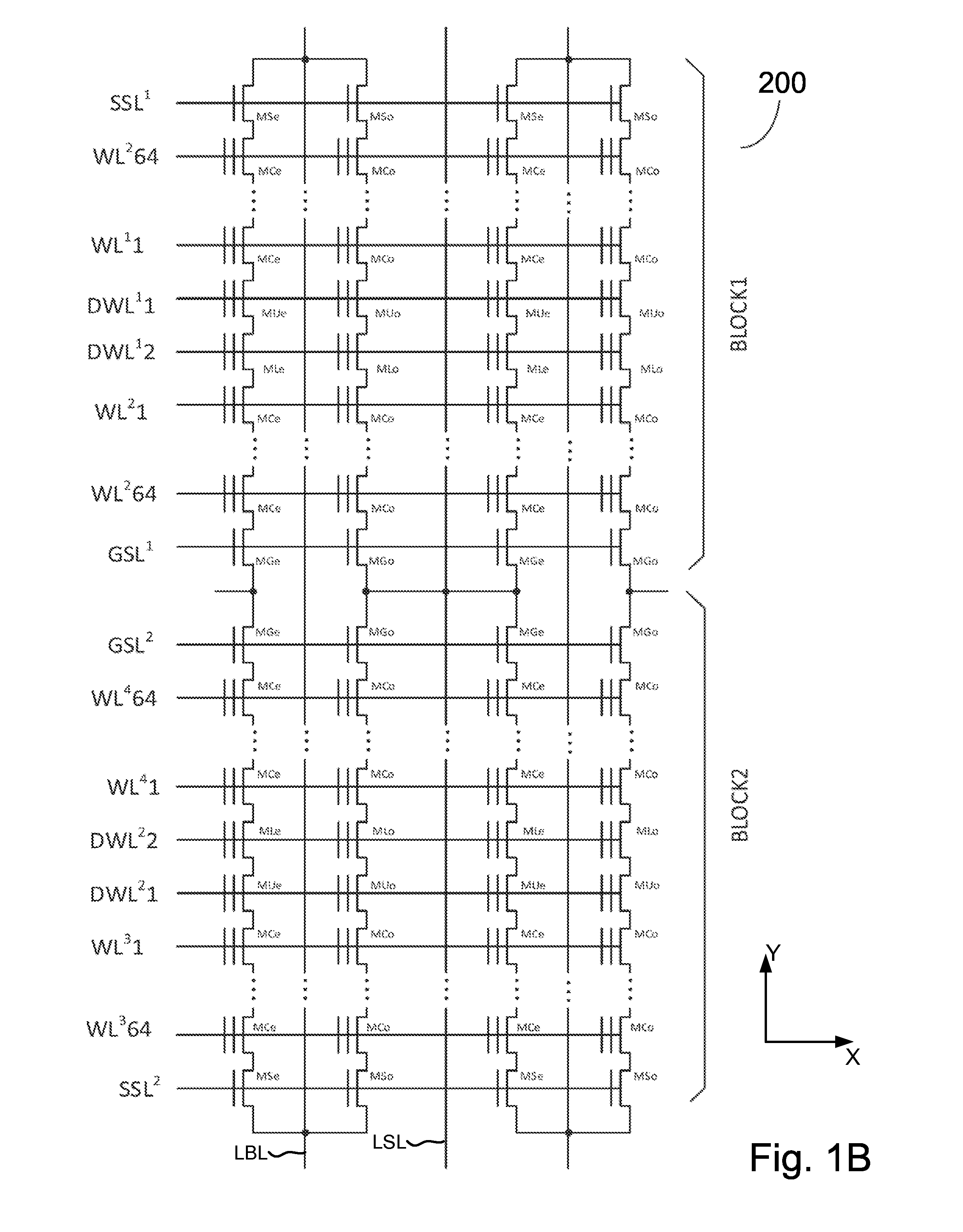

YUKAI VSL-BASED Vt-COMPENSATION FOR NAND MEMORY

ActiveUS20160027504A1Less Yupin coupling effectLess capacitanceRead-only memoriesDigital storageVirtual cellBatch processing

A YUKAI NAND array comprising multiple strings associated with hierarchical global / local bit lines (GBL / LBL) and each string being associated with one LBL and having adjacent LBL as a dedicated local source line (LSL) without a common source line to connect all strings. Each of the LBLs is interleavingly associated with either an Odd or Even string selected via one pair of dummy cells inserted in each string and is used as one on-chip PCACHE register with full BL-shielding without wasting extra silicon area to allow batch-based multiple concurrent MLC All-BL, All-Vtn-Program and Alternative-WL program, Odd / Even read and verify operations with options of providing individual and common VSL-based Vt-compensation and VLBL compensations to mitigate high WL-WL and BL-BL coupling effects. Bias conditions in each string are provided to correctly sense highly-negative erase-verify voltage, multiple negative program-verify voltages and without VDS punch-through, breakdown and body-effect in both boundary and non-boundary WLs cells.

Owner:LEE PETER WUNG

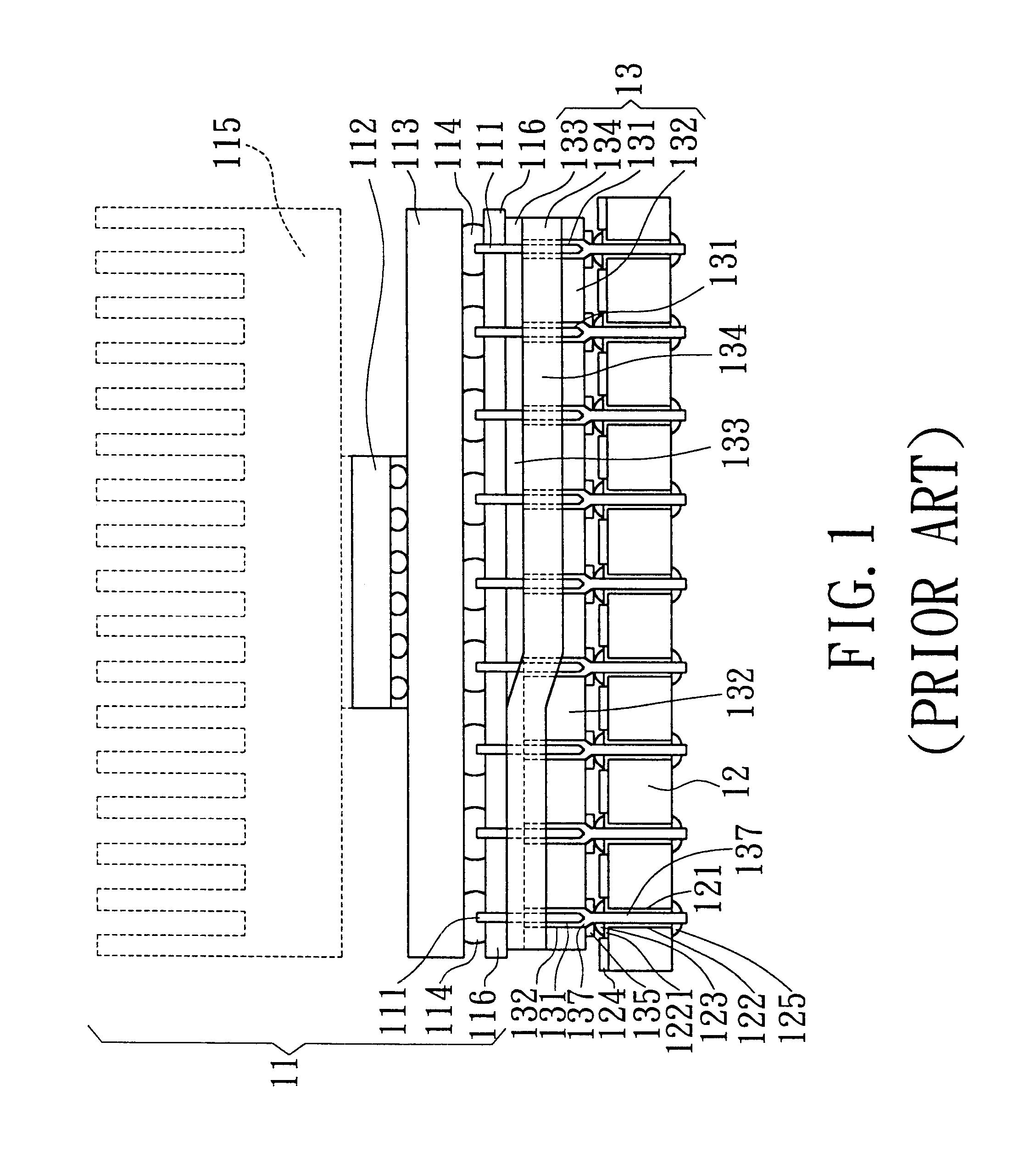

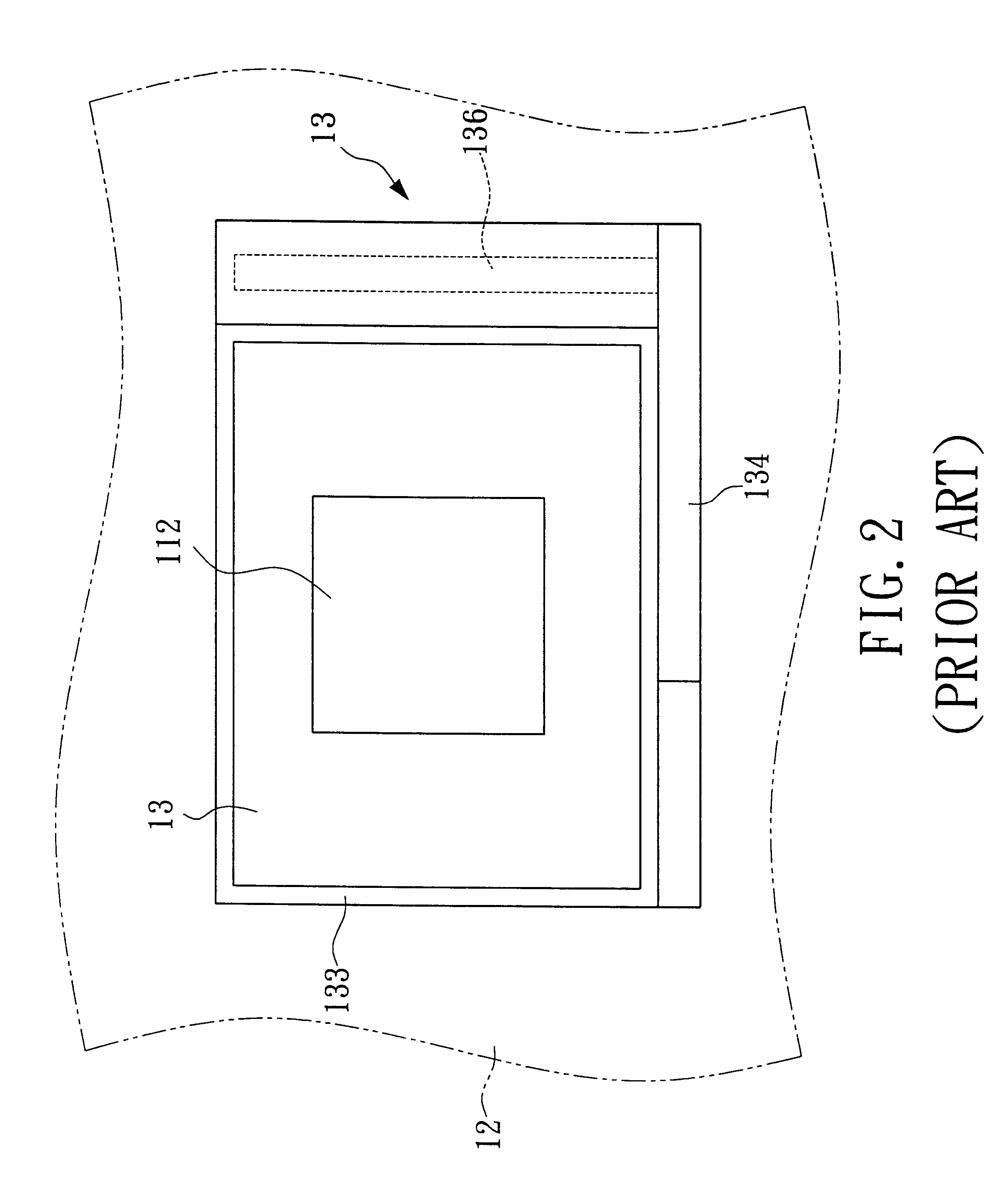

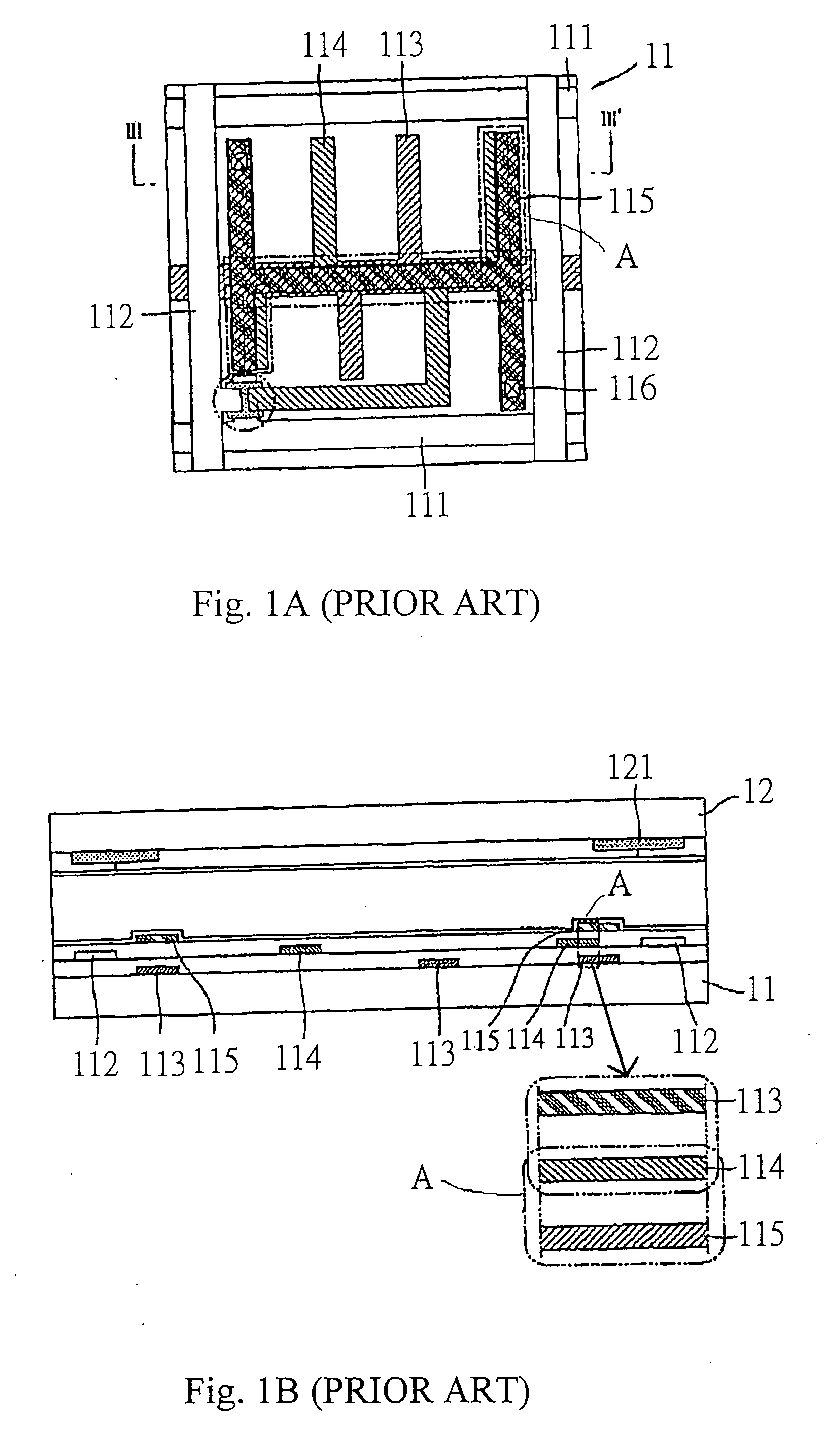

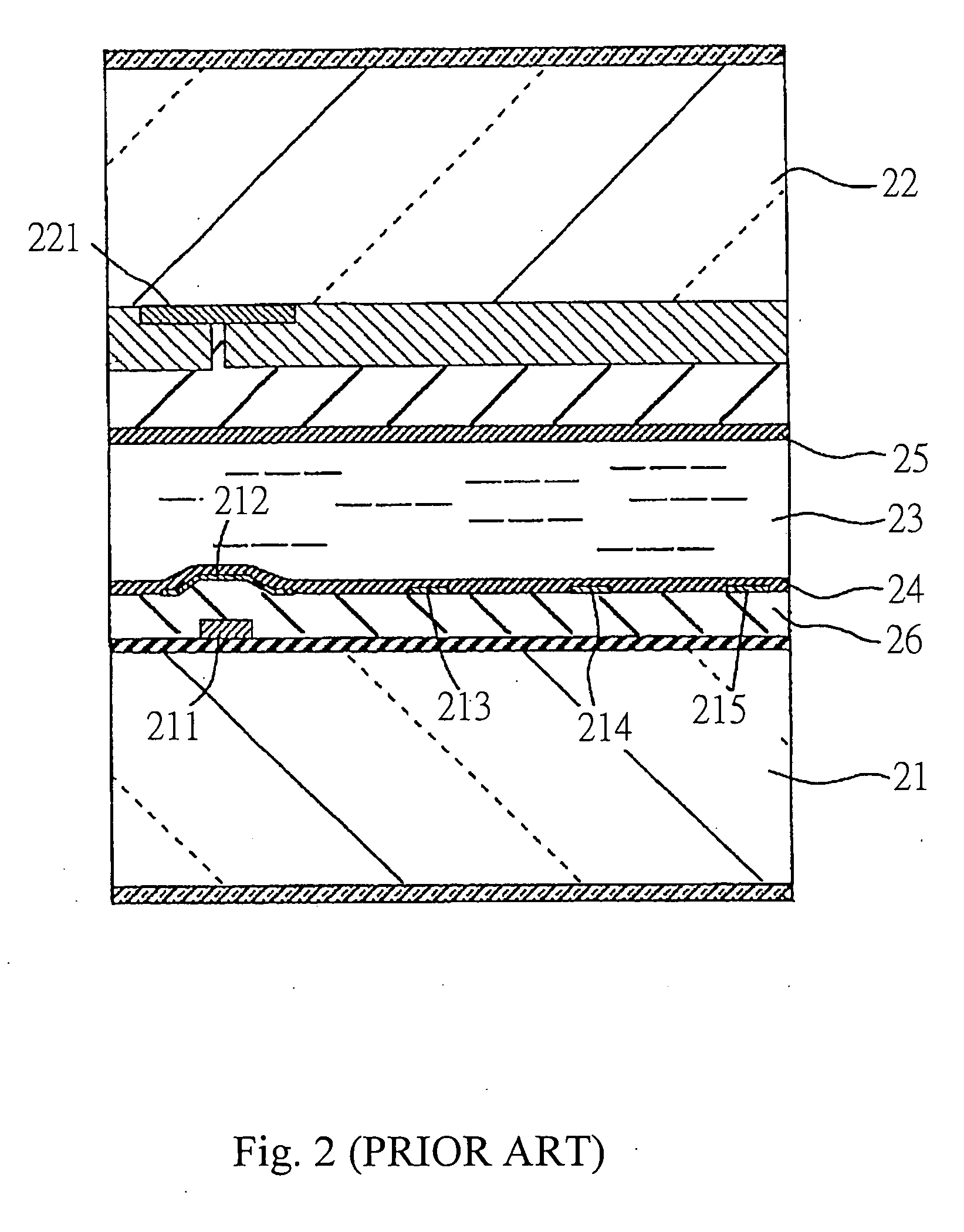

In-plane switching liquid crystal display

ActiveUS20070052899A1Low production costIncrease opening ratioNon-linear opticsLiquid-crystal displayEngineering

An in-plane switching liquid crystal display, especially relative to an in-plane switching liquid crystal display with the absence of an overcoat layer is provided. The in-plane switching liquid crystal display having a first substrate, a second substrate and a liquid crystal layer sandwiched therebetween, a plurality of gate lines and data lines disposed on the first substrate, a counter electrode disposed on the second substrate and corresponding to one of the data lines, a pixel having a pixel electrode, a pair of shielding electrodes and a common electrode also disposed on the first substrate. Through the arrangement of shielding electrodes as well as the counter electrode, the coupling effect of the applied pixel voltage on the data lines is shielded.

Owner:HANNSTAR DISPLAY CORPORATION

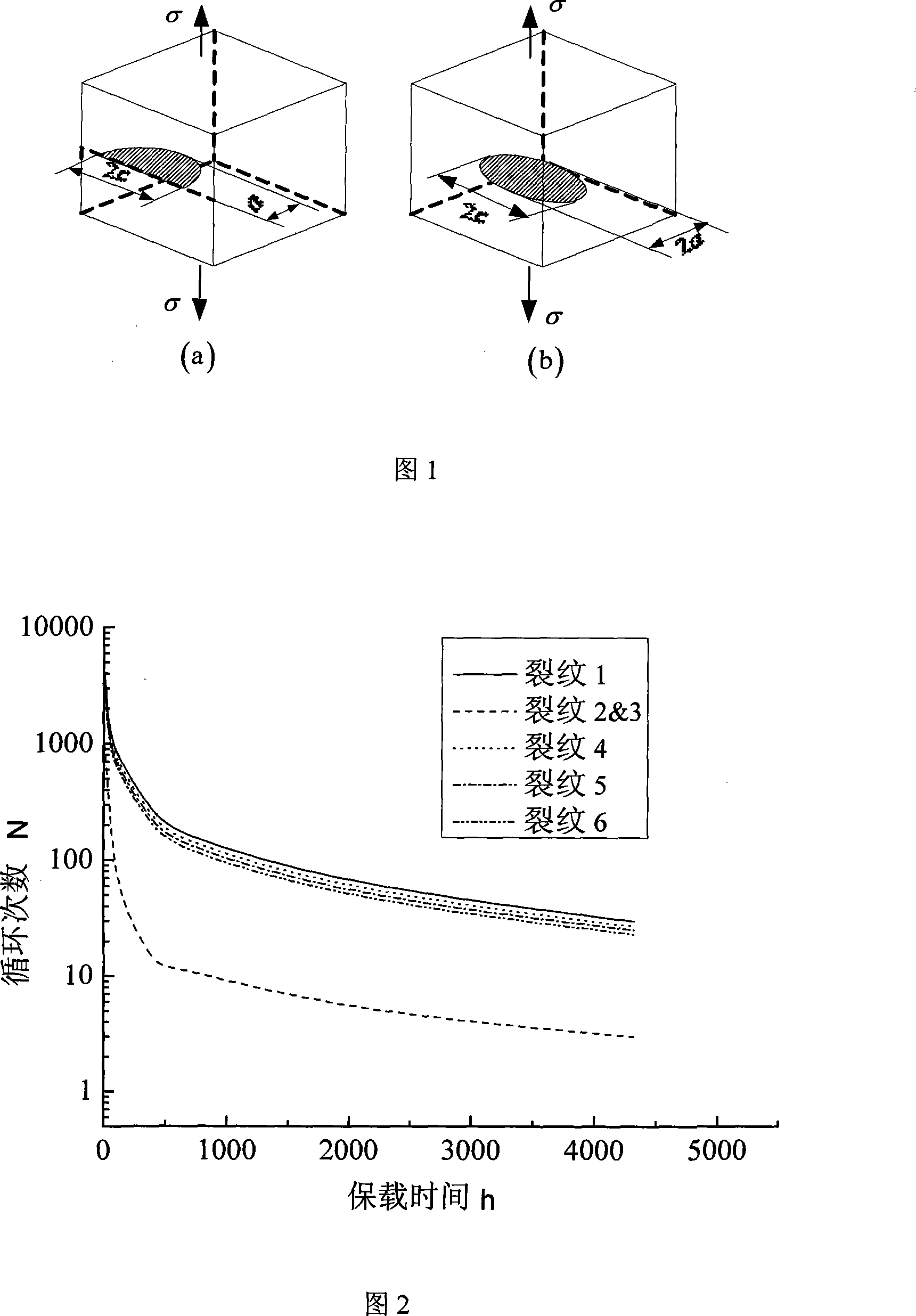

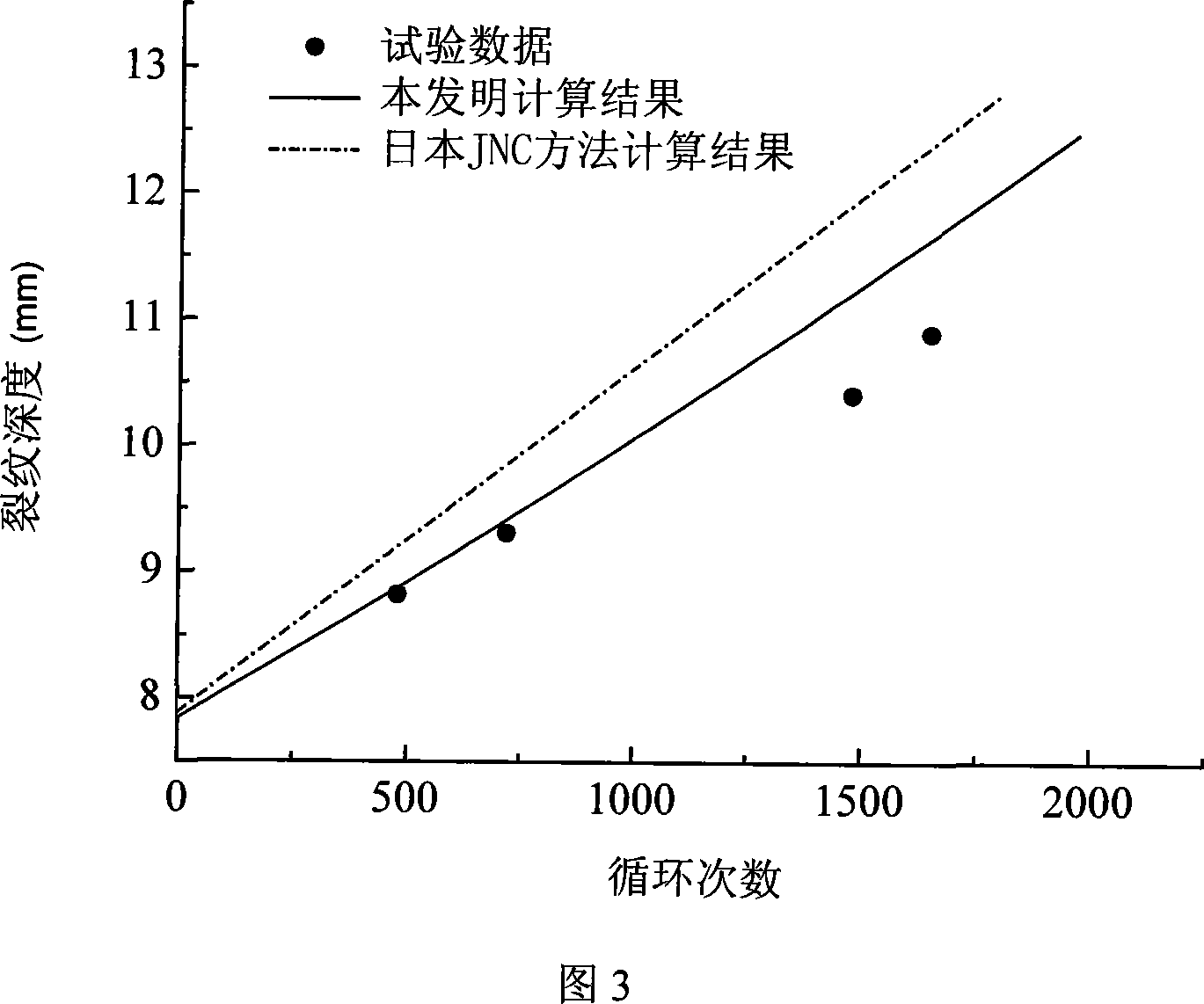

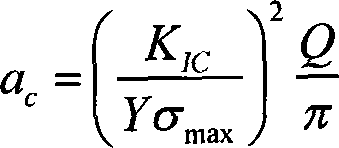

Remanent service life prediction method of steam turbine high-temperature component

InactiveCN101162234AHigh precisionImprove reliabilityEngine testingComplex mathematical operationsLife timeCoupling effect

The invention discloses a method for predicting the remaining lifetime of a high-temperature part of a steam turbine after defects are found, including the following steps of: obtaining the material property of the material of the high-temperature part of the steam turbine at different temperatures; performing nondestructive flaw detection on the high-temperature part of the steam turbine; regularizing cracks obtained by nondestructive flaw detection as elliptic type cracks; analyzing and evaluating the interference and communication between cracks; analyzing the stress of the high-temperature part; predicting the remaining lifetime of the high-temperature part of the steam turbine. The invention has the advantages of taking reasonably the coupling effect of fatigue and creep deformation on the lifetime into consideration, realizing the judgment of cracks interference and combination, improving the calculation accuracy of the remaining lifetime of the high-temperature part of the steam turbine; therefore, the invention can be used to support the analysis of safety performance of defects and the prolonging of the service life of the high-temperature part in the manufacturing process and to guide the reasonable making of repair schedule.

Owner:EAST CHINA UNIV OF SCI & TECH

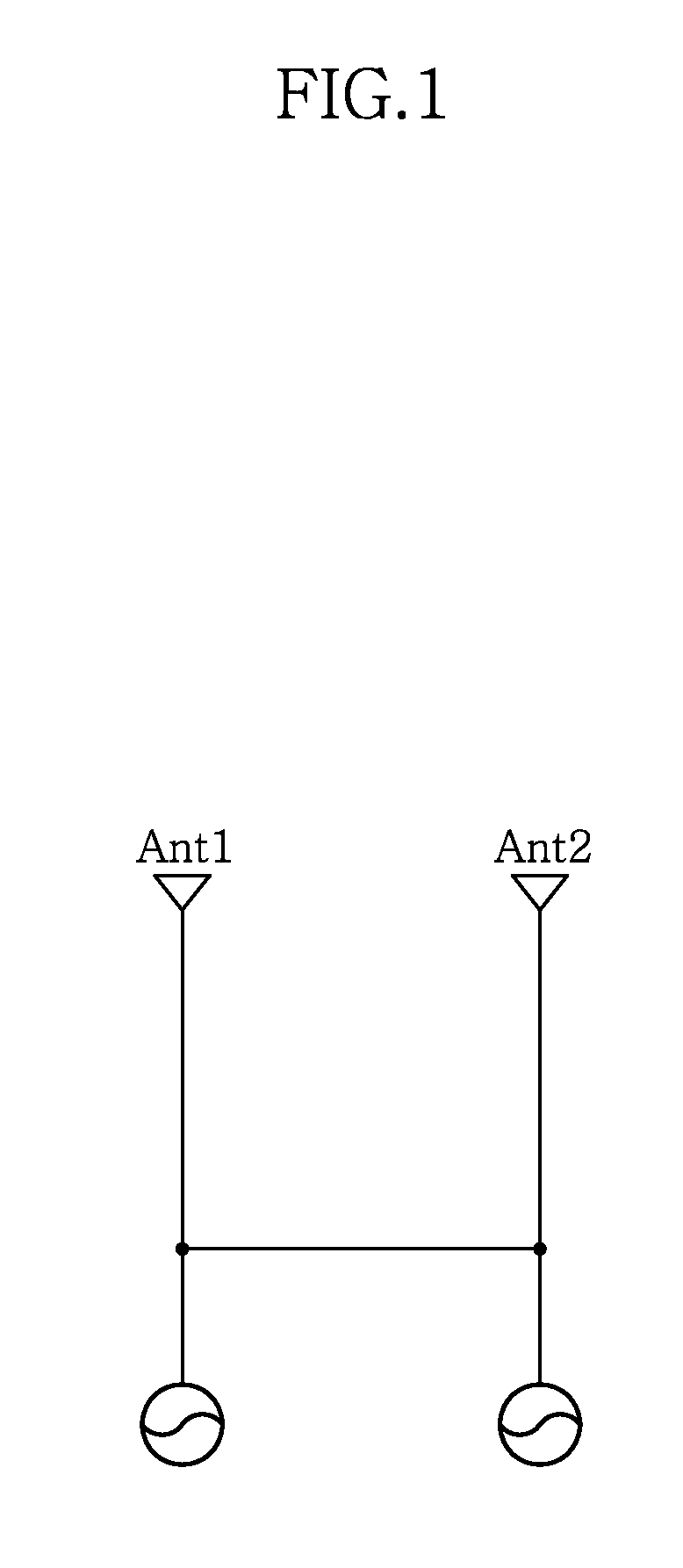

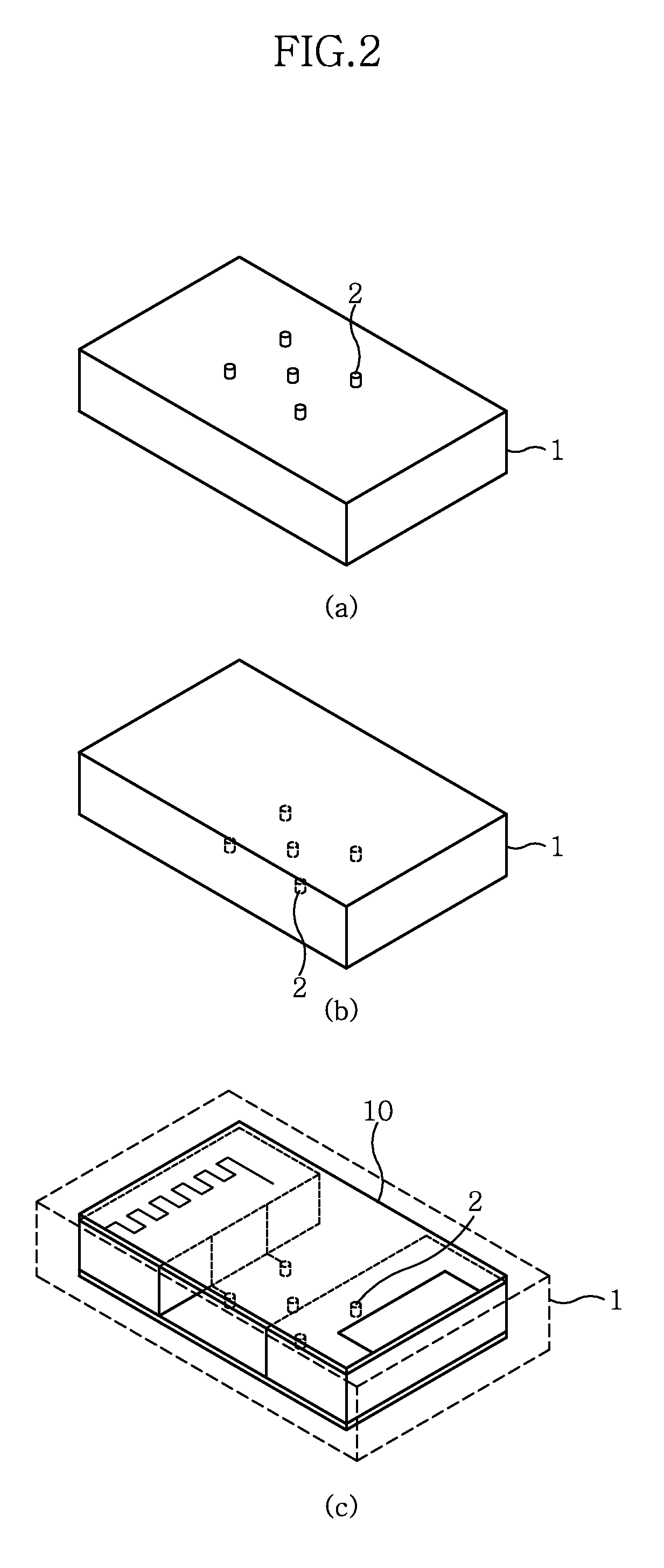

Antenna apparatus

InactiveUS20090322639A1Reduce coupling effectDistanceSimultaneous aerial operationsRadiating elements structural formsElectromagnetic shieldingCoupling effect

An antenna apparatus including a metal layer, a first planar antenna, a second planar antenna and a conducting wire is provided. The first planar antenna has a first ground terminal electrically connected to the metal layer. The second planar antenna has a second ground terminal electrically connected to the metal layer. The conducting wire is connected between the first planar antenna and the second planar antenna. In the whole operation, electromagnetic signals transmitted by the first planar antenna and the second planar antenna are in the same frequency band, and the coupling effect of the first planar antenna and the second planar antenna is reduced along with the formation of a current loop of the conducting wire.

Owner:ASUSTEK COMPUTER INC

System for performing data pattern sensitivity compensation using different voltage

ActiveUS20070279995A1Reduce coupling effectExact searchRead-only memoriesDigital storageCapacitanceCapacitive coupling

Errors can occur when reading the threshold voltage of a programmed non-volatile storage element due to at least two mechanisms: (1) capacitive coupling between neighboring floating gates and (2) changing conductivity of the channel area after programming (referred to as back pattern effect). To account for coupling between neighboring floating gates, the read process for a particular memory cell will provide compensation to an adjacent memory cell in order to reduce the coupling effect that the adjacent memory cell has on the particular memory cell. To account for the back pattern effect, a first voltage is used during a verify operation for unselected word lines that have been subjected to a programming operation and a second voltage is used for unselected word lines that have not been subjected to a programming operation. The combination of these two techniques provides for more accurate storage and retrieval of data.

Owner:SANDISK TECH LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com