Remanent service life prediction method of steam turbine high-temperature component

A high-temperature component and life prediction technology, which is applied in the fields of power engineering and steam turbines, can solve the problems of inability to deal with the remaining life prediction, and does not consider the factors of creep fracture and crack, so as to achieve the effect of improving accuracy and reliability and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] An in-service medium and high pressure rotor in a power plant is made of CrMoV steel. During routine inspection, some internal defects were found. Due to the limitation of production and manufacturing time of the rotor, the equipment needs to continue running for a period of time before it can be overhauled.

[0067] In order to ensure the reliability of the rotor during the period of time thereafter, the remaining life prediction method of the present invention is used to predict the remaining life of the rotor and give a safety judgment.

[0068] Determining Material Properties

[0069] Using the CT sample of CrMoV steel, using the electronic creep fatigue testing machine, using the direct current potential method, the material properties of CrMoV steel are obtained, as follows:

[0070] Fatigue crack growth constant C at room temperature 0 =1.43×10 -8 , the crack growth exponent n 0 = 2.7;

[0071] At the working temperature (522°C), the creep crack growth coef...

Embodiment 2

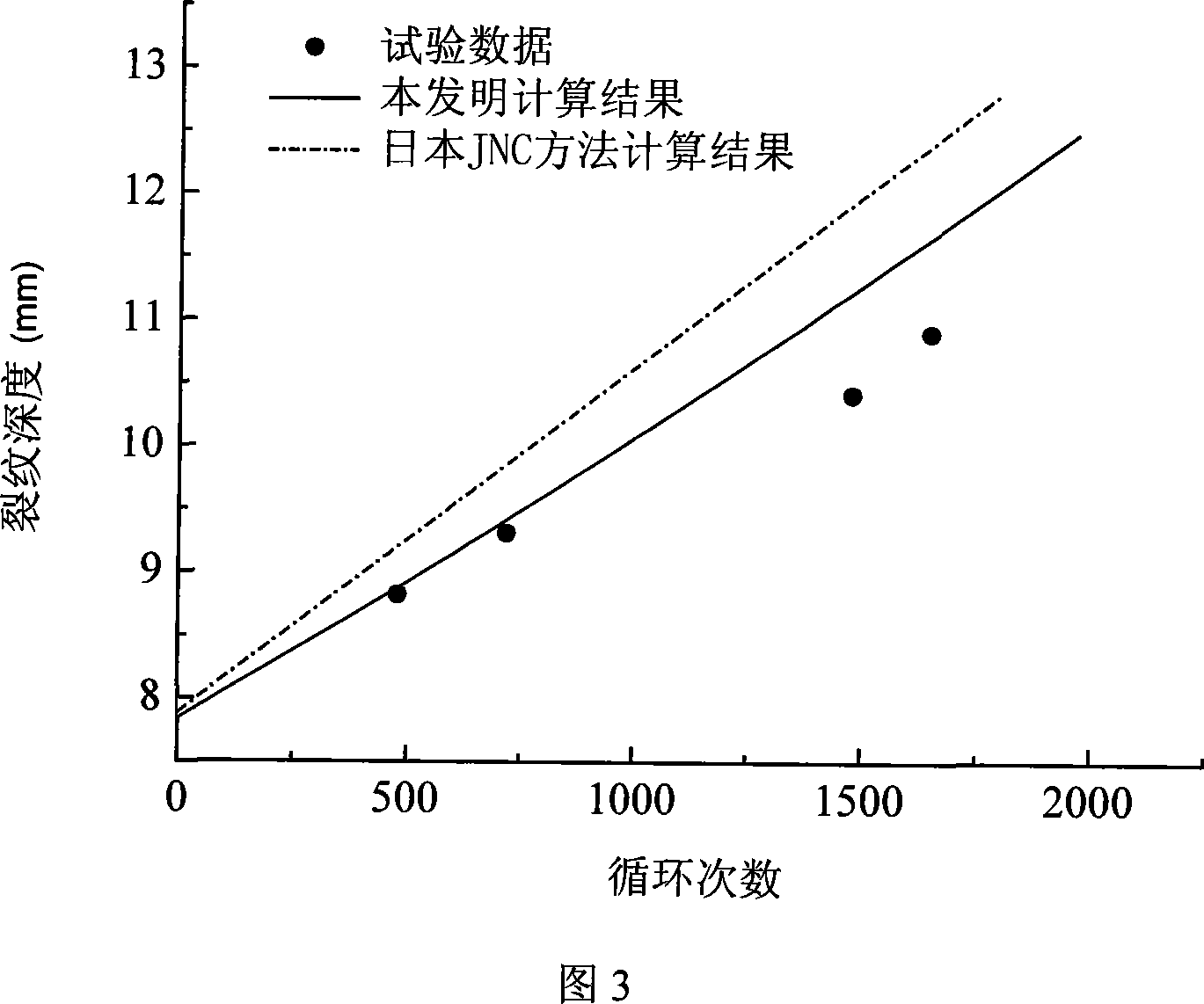

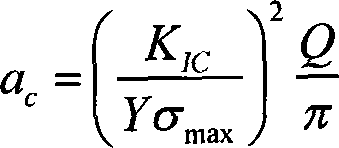

[0096] According to the test data of foreign researchers, the test results, the life predicted by the Japanese JNC method and the life predicted by the method of the present invention are compared.

[0097] The sample material is a 361L stainless steel plate with a thickness of 24.5mm and a half oval surface crack, the crack length is 2c=87.2mm, the depth is a=7.9mm, the test temperature is 650°C, and the fatigue crack growth constant is C 0 =6.2×10 -8 , the crack growth exponent n 0 =2.46; Creep crack growth coefficient B=0.0071, expansion index q=0.73, holding time is 1h, maximum stress σ max =141.5MPa, stress amplitude Δσ=283MPa.

[0098] Since the size and shape of the crack and the stress distribution of the sample have been determined, the calculation of the number of cycles can be performed directly. In the calculation, the crack increment is taken as Δa=0.01mm, and the critical crack size is taken as a c = 12.7 mm. Comparing the calculation results with the test d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Stress | aaaaa | aaaaa |

| Crack length | aaaaa | aaaaa |

| Maximum stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com