Method for synthesizing metal matrix composition using metal reaction under the coupling action of magnetic field and ultrasonic field

A composite material and ultrasonic field technology, applied in the field of synthesis and preparation of new composite materials, can solve problems such as unsatisfactory effects, and achieve improved dynamic conditions and good composite effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

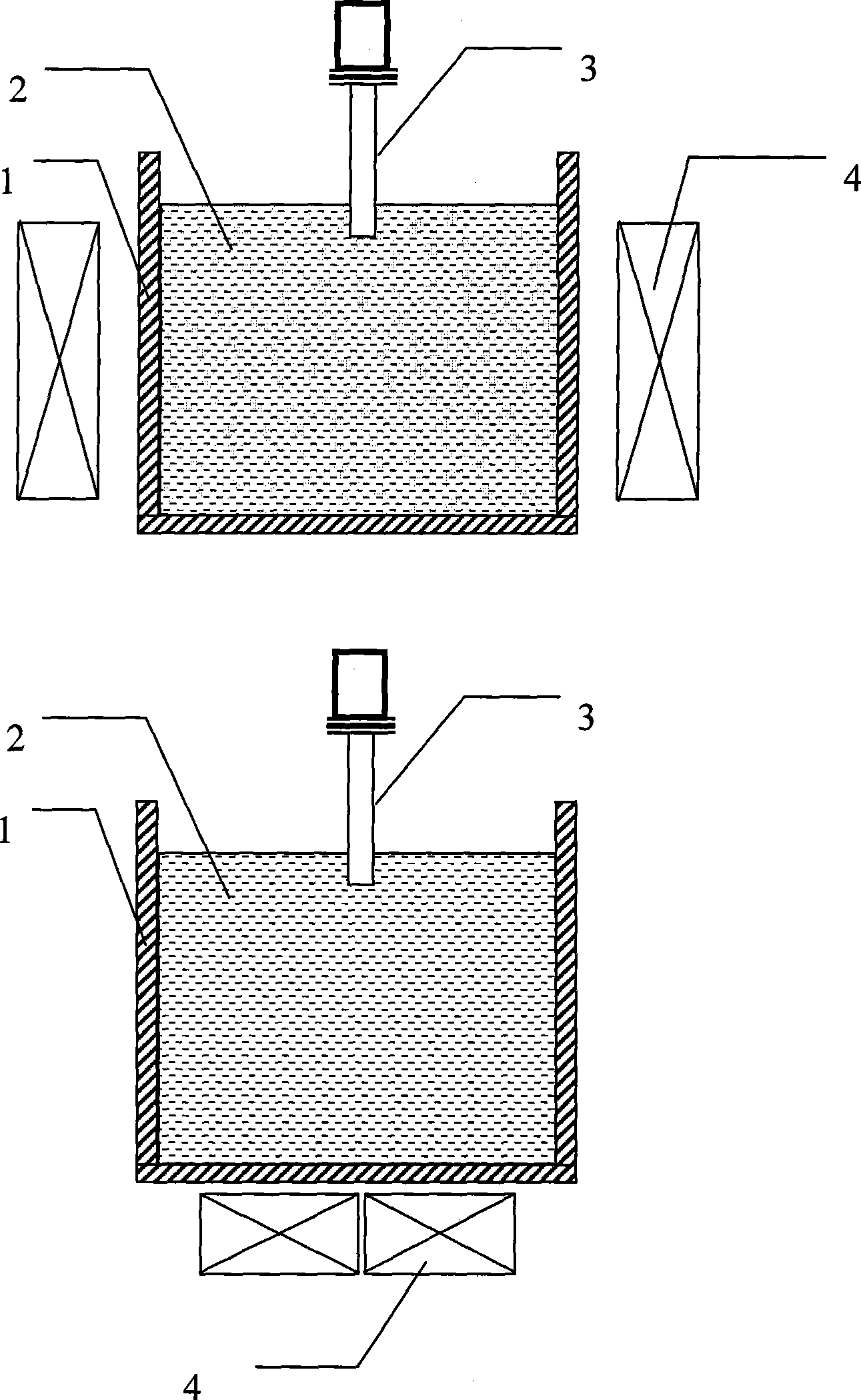

Method used

Image

Examples

Embodiment 1

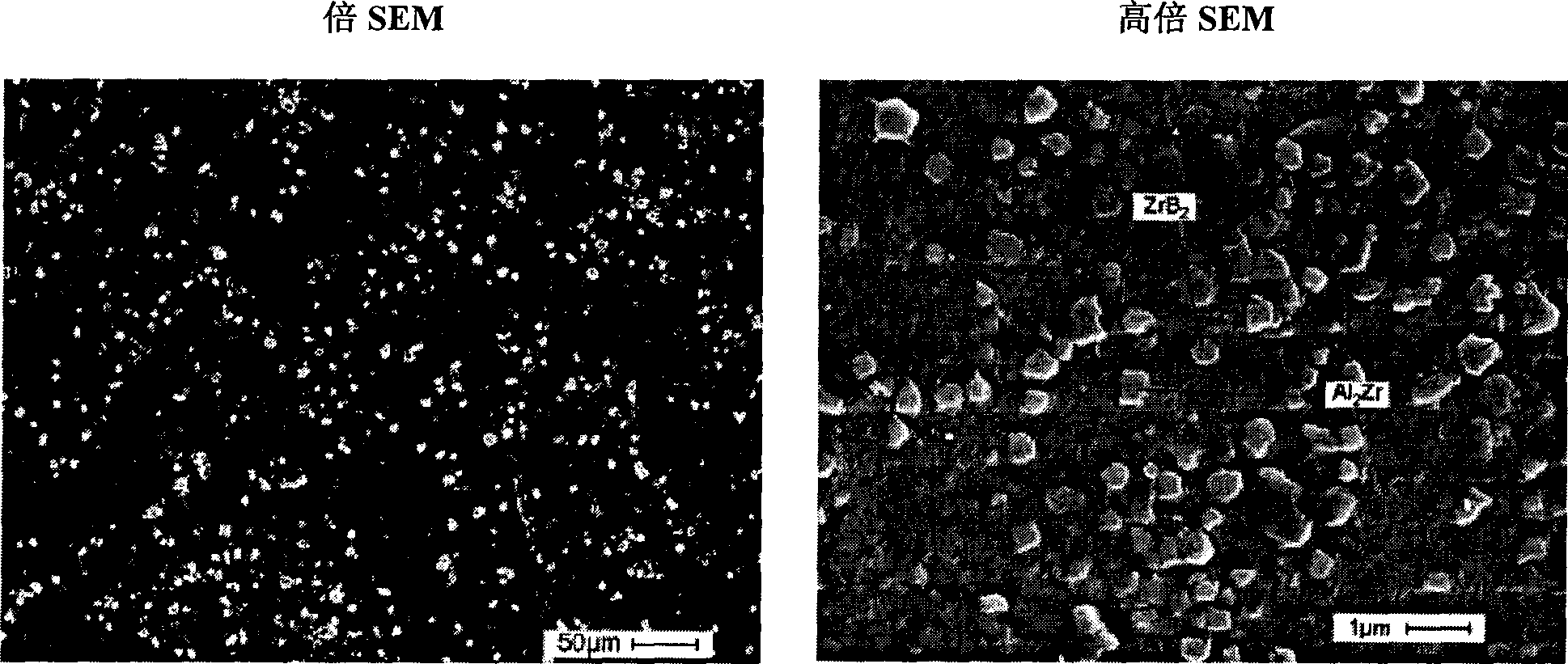

[0042] Embodiment 1: Preparation under the coupling action of strong pulsed magnetic field and ultrasonic field (Al 3 Zr (s) +ZrB 2(s) ) particle reinforced Al-based composites

[0043] Raw material: base metal: pure Al; reaction salt: K 2 ZrF 6 +KBF 4 Powder, refining degassing agent and slag removal agent;

[0044] The preparation process is divided into two steps:

[0045] (1): Metal smelting and powder preparation:

[0046] 50Kg of pure Al is melted in a 60kW resistance furnace and heated up to 900°C for degassing and slag removal. All reagents used are fully dried at 250°C to 300°C, of which K 2 ZrF 6 +KBF 4 , ground into fine powder (particle size less than 200 mesh), weighed and wrapped with aluminum foil for later use, K 2 ZrF 6 +KBF 4 The powder is added in an amount of 20% of the weight of the metal.

[0047] (2): In situ reaction synthesis to prepare composite material melt:

[0048] The molten metal that has been refined and meets the requirements ...

Embodiment 2

[0050] Embodiment 2: Preparation under the coupling effect of high-frequency oscillating magnetic field and ultrasonic field (Al 3 Zr (s) +ZrB 2(s) ) particle reinforced Al-based composites

[0051] Raw material: base metal: pure Al; reaction salt: K 2 ZrF 6 +KBF 4 Powder, refining degassing agent and slag removal agent;

[0052] The preparation process is divided into two steps:

[0053] (1): Metal smelting and powder preparation:

[0054] 50Kg of pure Al is melted in a 60kW industrial frequency aluminum melting furnace and heated up to 900°C for degassing and slag removal. The reagents used are fully dried at 250°C to 300°C, among them, K 2 ZrF 6 +KBF 4 The powder is ground into a fine powder (particle size less than 200 mesh), weighed and put into the spray tank, K 2 ZrF 6 +KBF 4 The powder is added in an amount of 20% of the weight of the metal.

[0055] (2): In situ reaction synthesis to prepare composite material melt:

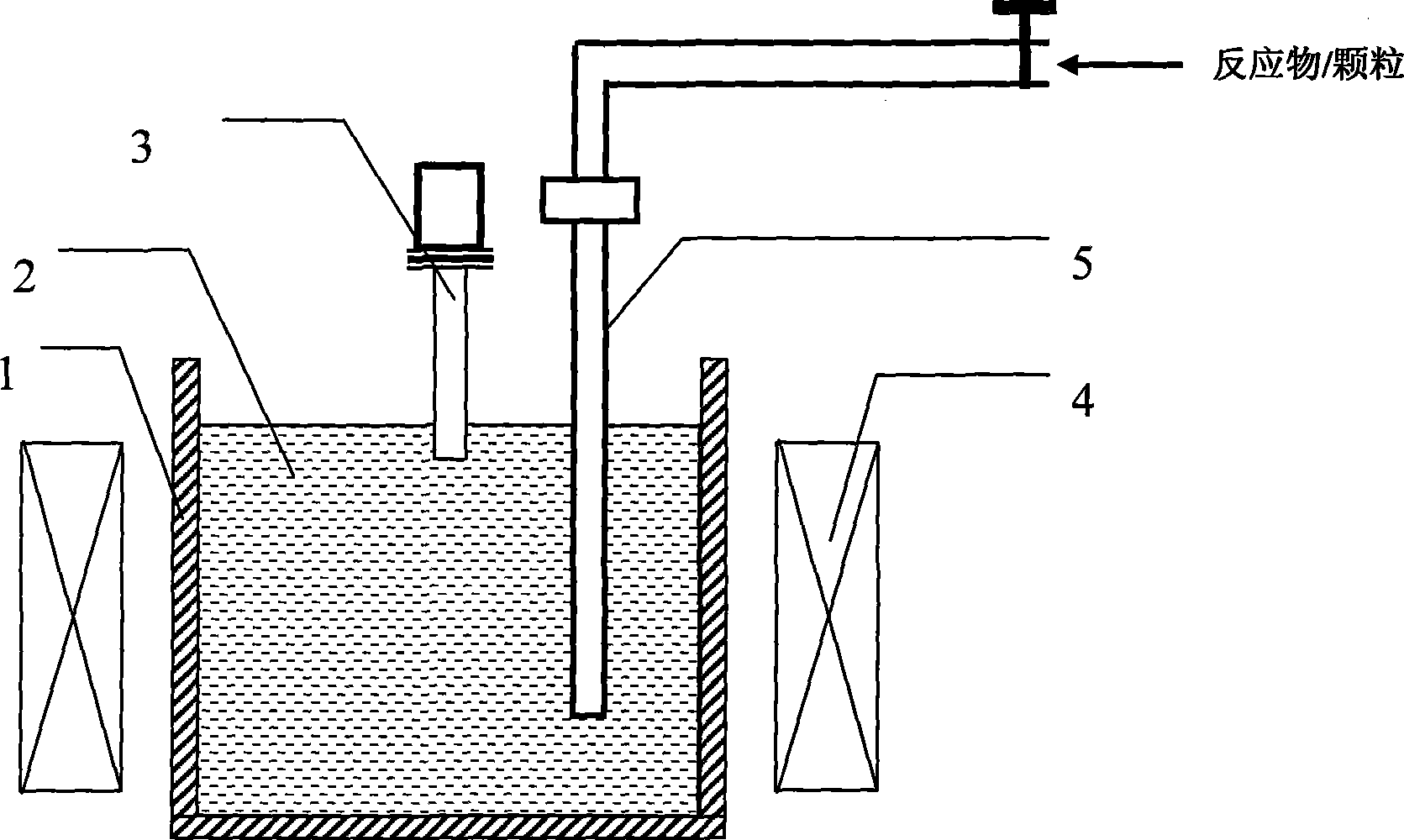

[0056] device such as figure 2 , ...

Embodiment 3

[0058] Embodiment 3: preparation (Al 3 Zr (s) +Al 2 o 3(s) ) particle reinforced Al-based composites

[0059] Raw materials: base metal: pure Al; solid powder: industrial zirconium carbonate (Zr(CO 3 ) 2 ) powder, refining degassing agent and slag removal agent;

[0060] The preparation process is divided into two steps:

[0061] (1): Metal smelting and powder preparation:

[0062] 50Kg of pure Al is melted in a 60kW industrial frequency aluminum melting furnace and heated up to 900°C for degassing and slag removal. All reagents used were fully dried at 250°C to 300°C, among which Zr(CO 3 ) 2 Grind into fine powder (particle size less than 200 mesh), weigh and put into blowing tank, Zr(CO 3 ) 2 The added weight is 20% of the metal weight.

[0063] (2): In situ reaction synthesis to prepare composite material melt:

[0064] The molten metal that has been refined and meets the requirements of the initial reaction temperature (900°C) is poured from the metal refining...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com