Thermo-mechanical-environmental coupling effect testing device and application from room temperature to ultrahigh temperature

A test device, ultra-high temperature technology, applied in the direction of testing material strength by applying stable bending force, testing material strength by applying stable tension/compression, and weighing by removing certain components, which can solve the problem of poor test repeatability , Heating body and sample fixtures are difficult to withstand ultra-high temperature, uneven temperature field of materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

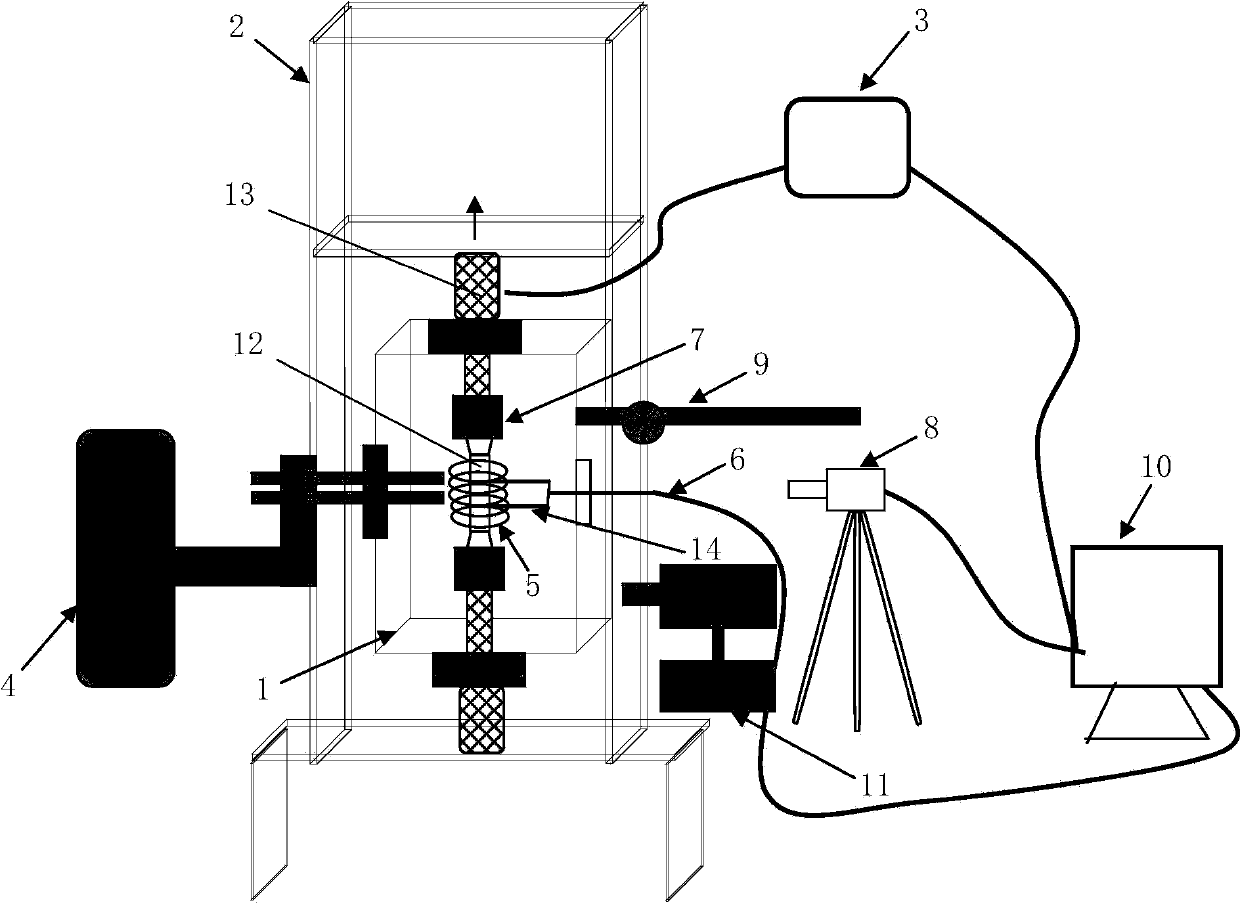

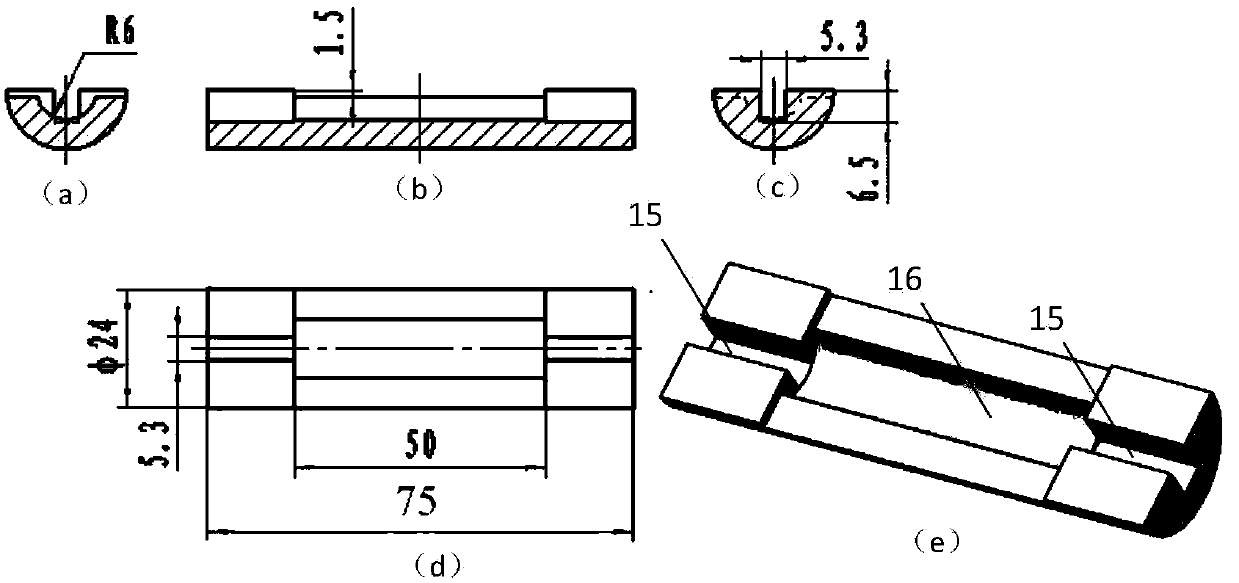

[0081] Example 1: Testing the ultra-high temperature tensile strength of oxidation-resistant carbon / carbon composites

[0082] In the tensile strength test, the length of the gauge section of the sample is 30mm, the width of the sample is 10mm, and the thickness is 5mm. The test device is as follows: figure 1 As shown, fix the two ends of the sample in the upper and lower fixtures respectively to ensure that the sample is perpendicular to the loading direction, adjust the power of the induction power supply to heat the sample to the target temperature of 2200 ° C, and adjust the pressure control system at the same time to keep the air in the vacuum chamber up to 20KPa Ambient atmosphere, the sample was kept warm for 1800s.

[0083] The loading control system loads the sample at a speed of 1mm / min through the loading device until the sample breaks. When the sample breaks, the load recorded by the loading control system will decay rapidly, so it can be judged that the maximum lo...

Embodiment 2

[0084] Example 2: Testing the high-temperature flexural strength of carbon / silicon carbide composites and a ternary layered machinable ceramic

[0085] The bending strength sample size is 3.02mm×3.98mm×40.1mm. Fix the sample on the rollers of the ultra-high temperature ceramic fixture, and the span between the two lower rollers is 20mm; adjust the power of the induction power supply to heat the carbon / silicon carbide composite to 1600°C and keep it in air for 600s.

[0086] The loading control system loads the sample at a speed of 0.5 mm / min through the loading device until the sample breaks, and records the strength-displacement curve, such as Figure 4 As shown, the strength of the sample when it breaks is 260MPa.

[0087] For the test of the bending strength of ternary layered machinable ceramics, the sample size is as above, and the test temperature distribution is selected as 1000°C, 1200°C and 1400°C, Figure 5 are the intensity-displacement curves at three temperature...

Embodiment 3

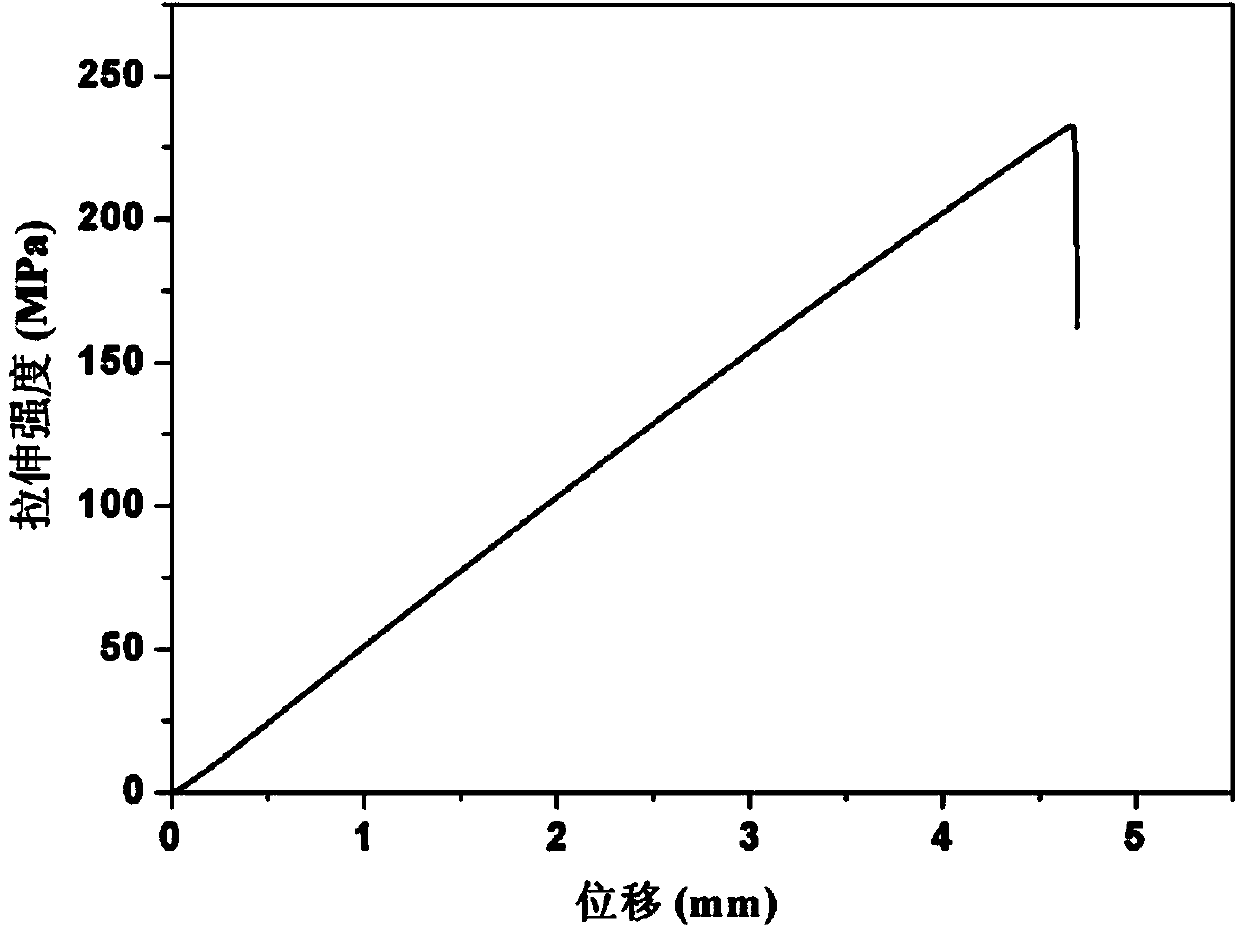

[0088] Example 3: Testing the ultra-high temperature compressive strength of a three-way braided composite

[0089] The compressed sample is a three-way braided composite material with a size of 4.02mm×5.0mm×39.8mm. The sample is fixed on the ultra-high temperature ceramic lower pressure rod along the length direction, and the upper pressure rod connected to the pressure sensor is in contact with the upper end of the sample. Apply a preload of about 5N and adjust the power of the induction power supply to heat the compressed sample to 1600°C.

[0090] The loading control system loads the sample at a speed of 0.5mm / min through the loading device until the sample is broken, and records the strength-displacement curve, such as Figure 6 As shown, the strength of the sample when it breaks is 235MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com