Patents

Literature

183 results about "Braided composite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

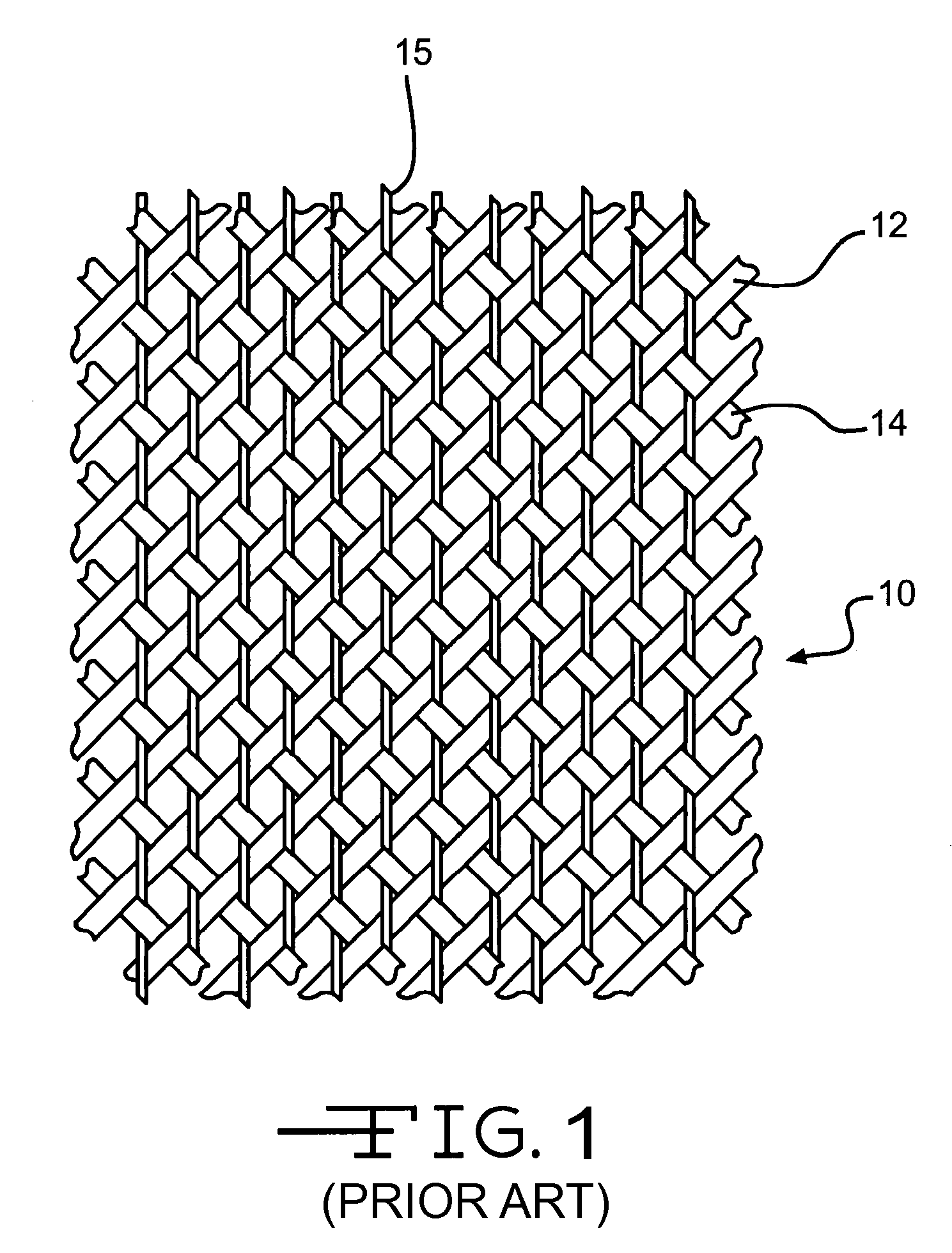

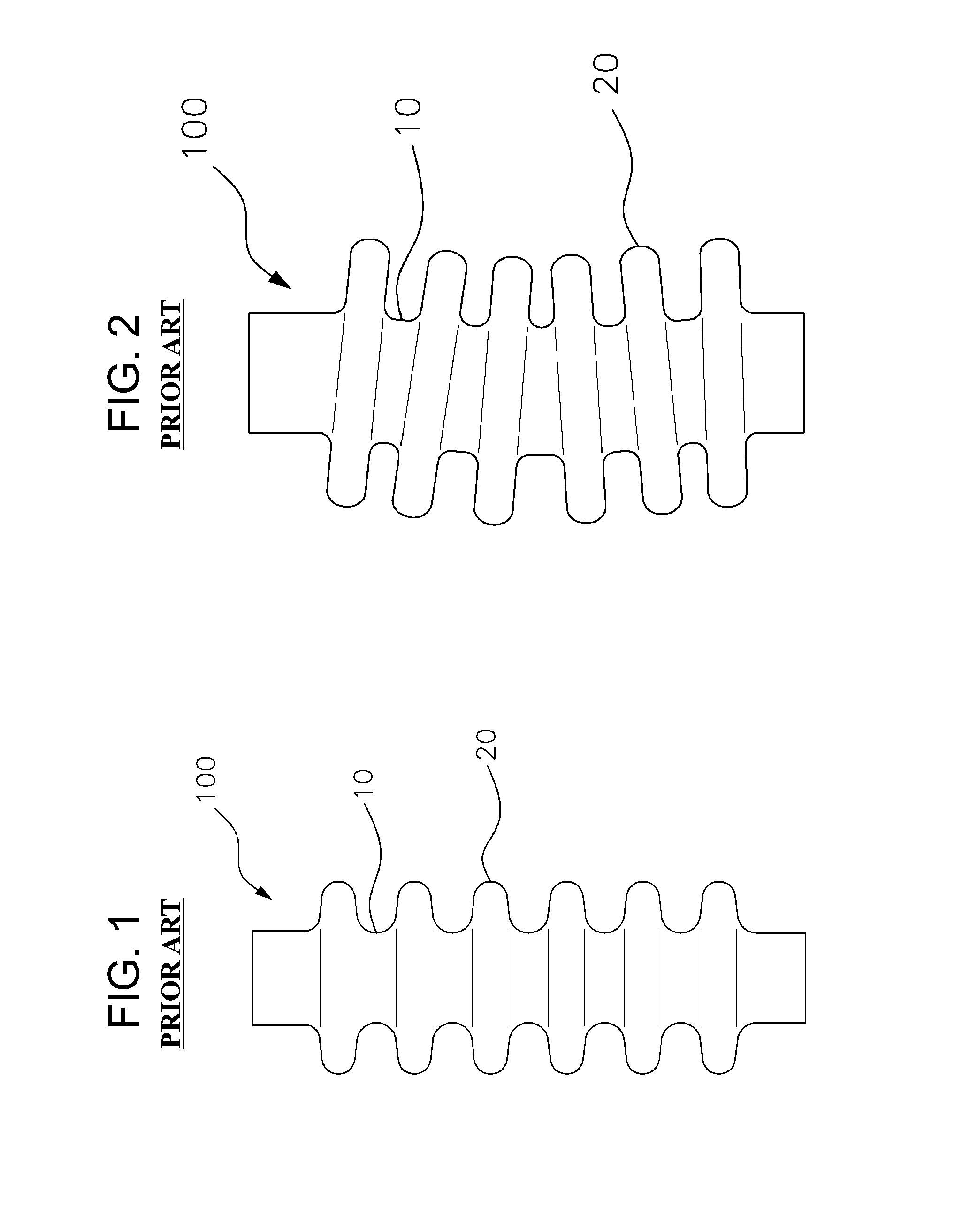

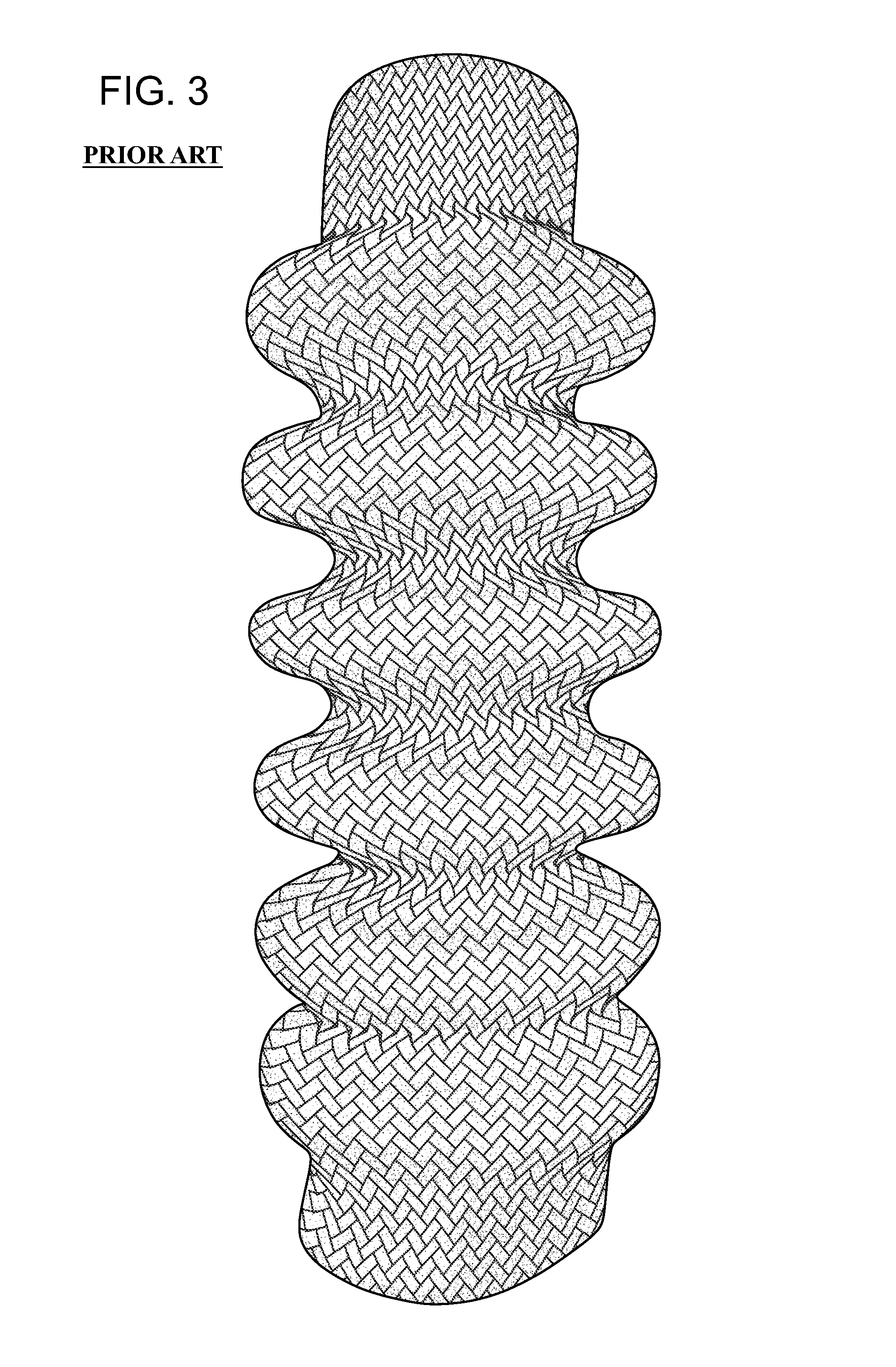

Braided composite prosthesis

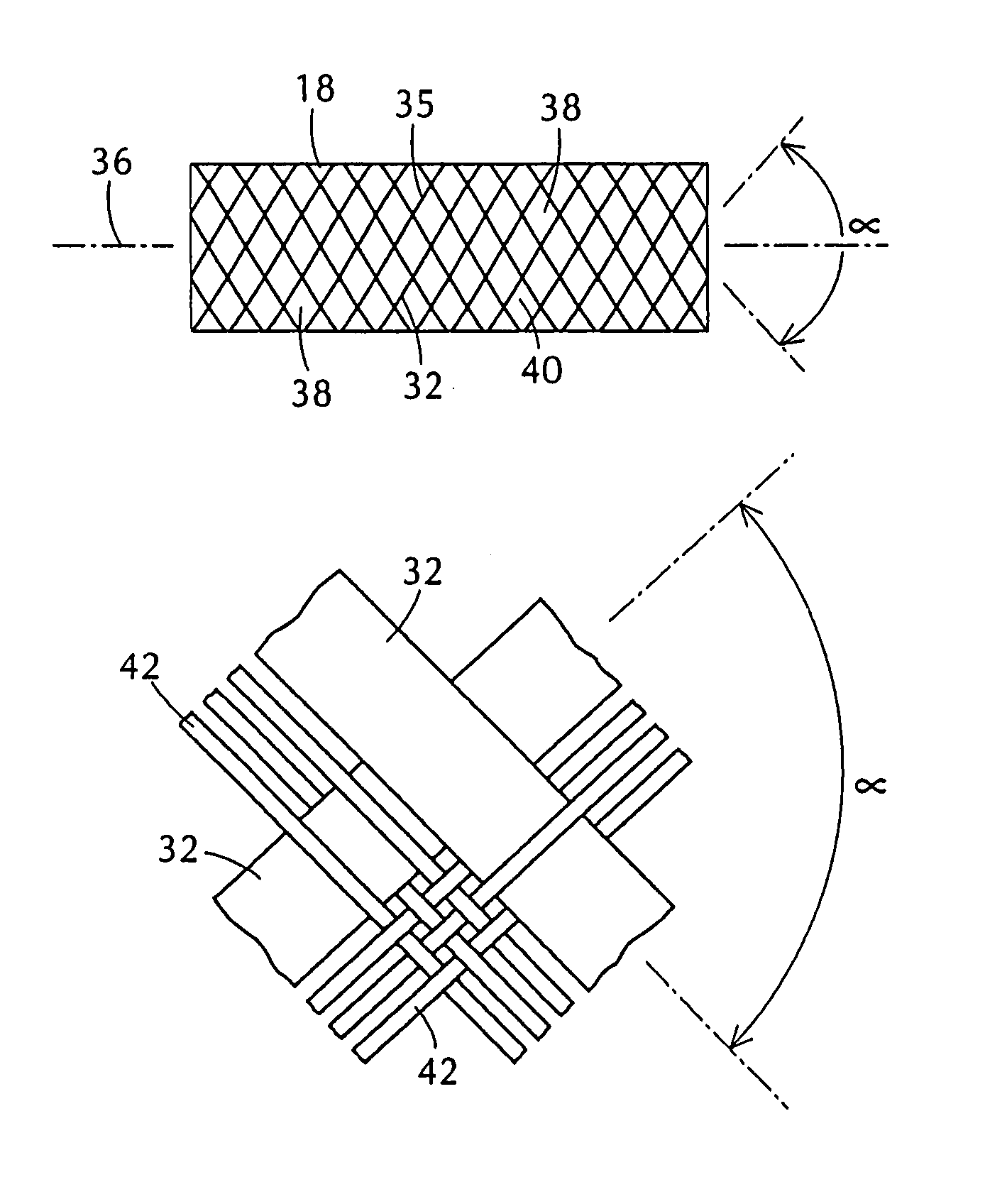

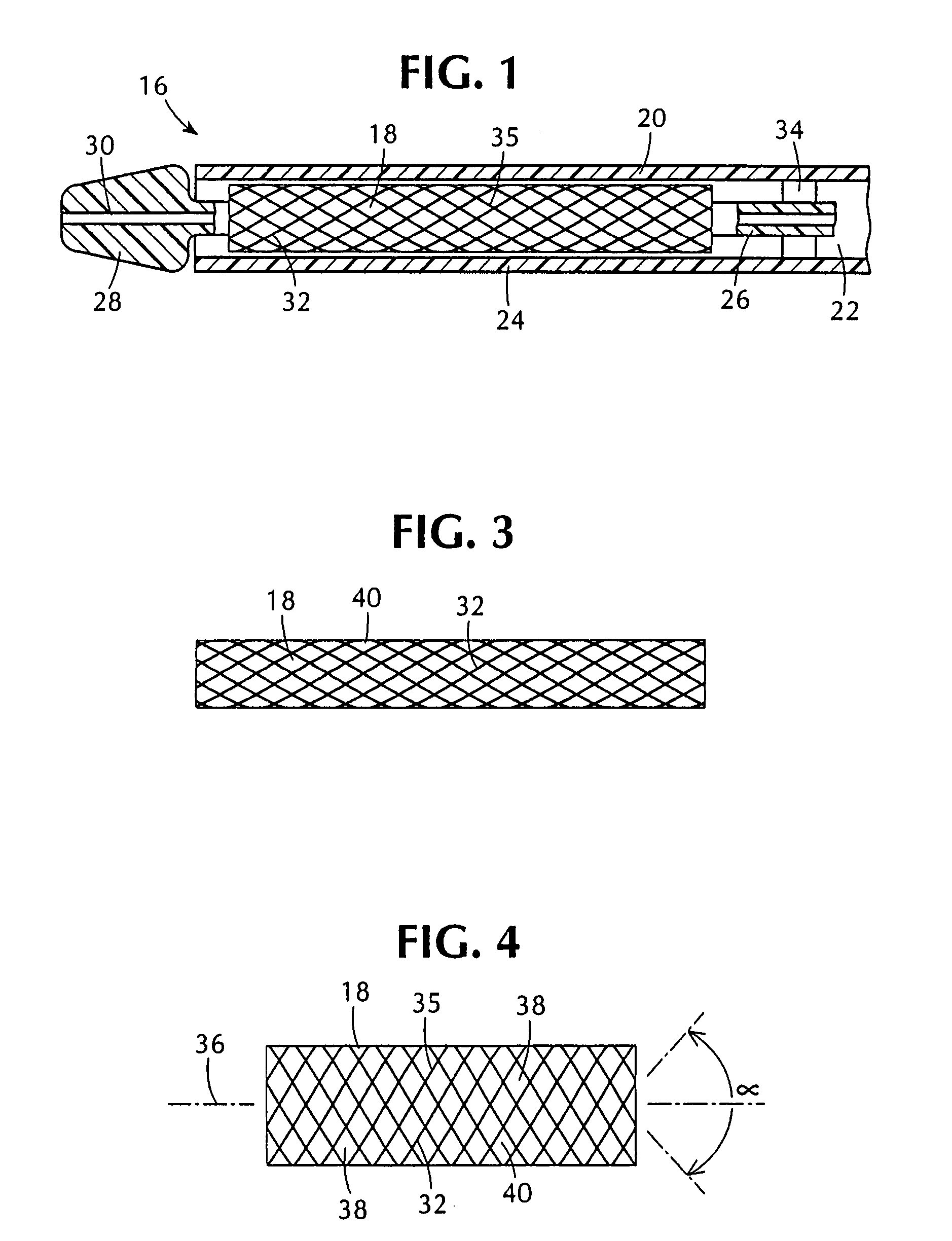

A prosthesis for transluminal implantation consists of a flexible tubular interbraided structure of metal or polymeric monofilaments, and polymeric multifilament yarns. The prosthesis can be elastically deformed to reduce its diameter through axial elongation. The monofilaments and multifilament yarns are arranged in axially spaced apart helices, concentric on a common central axis of the prosthesis. The monofilaments are selectively shaped before their interbraiding with the multifilament yarns, either by an age-hardening or other heat-setting stage, or a cold-working stage that controllably plastically deforms the strands. The shaped structural strands cooperate to impart to the prosthesis its nominal shape and resilience. The textile strands cooperate to provide a sheeting that occupies interstices between adjacent structural strands, to reduce permeability and thereby enhance the utility of the prosthesis as a vascular graft. An alternative embodiment prosthesis includes elastically and plastically deformable structural strands, selectively plastically deformed by cold-working then interbraided to form the prosthesis.

Owner:LIFESHIELD SCI

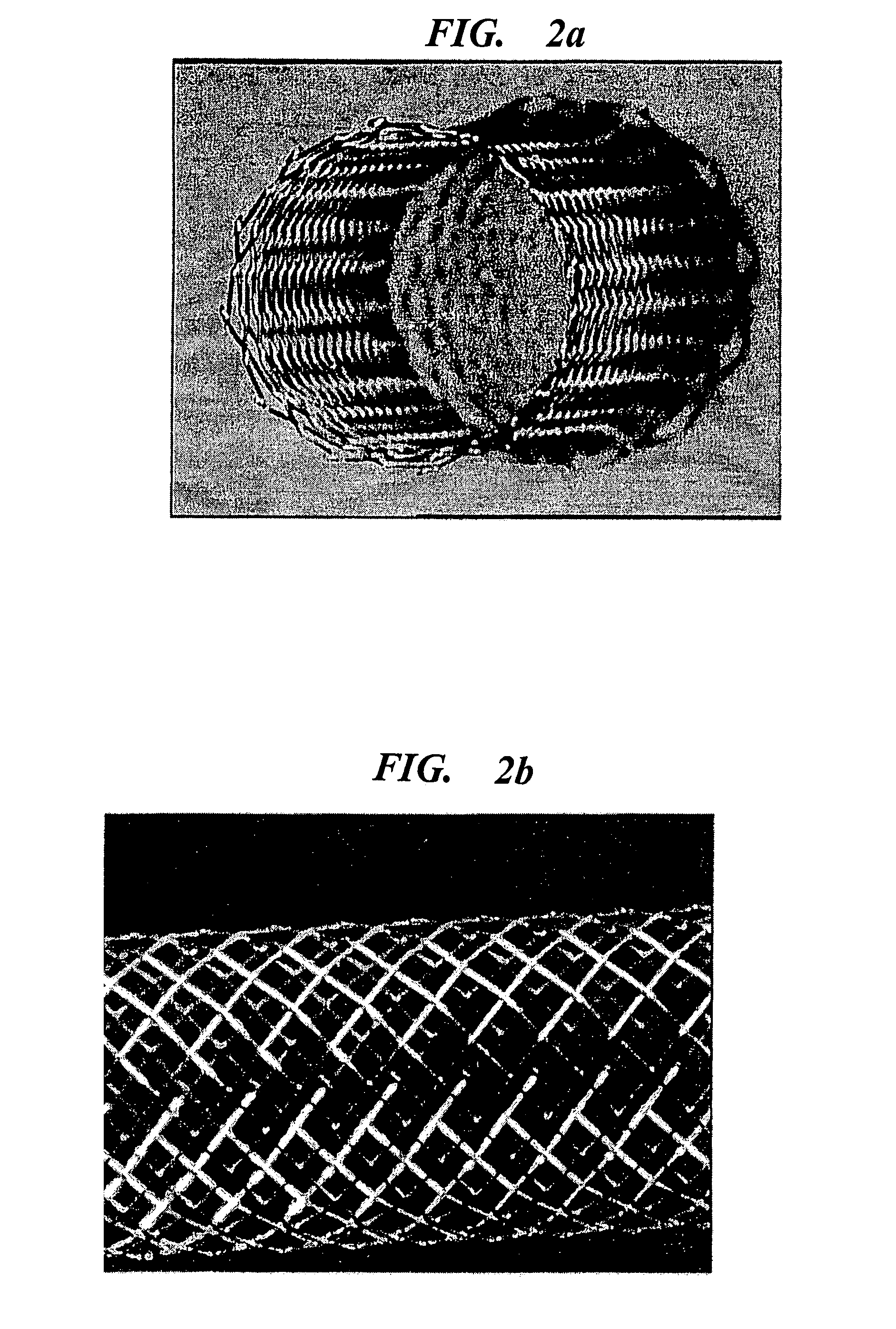

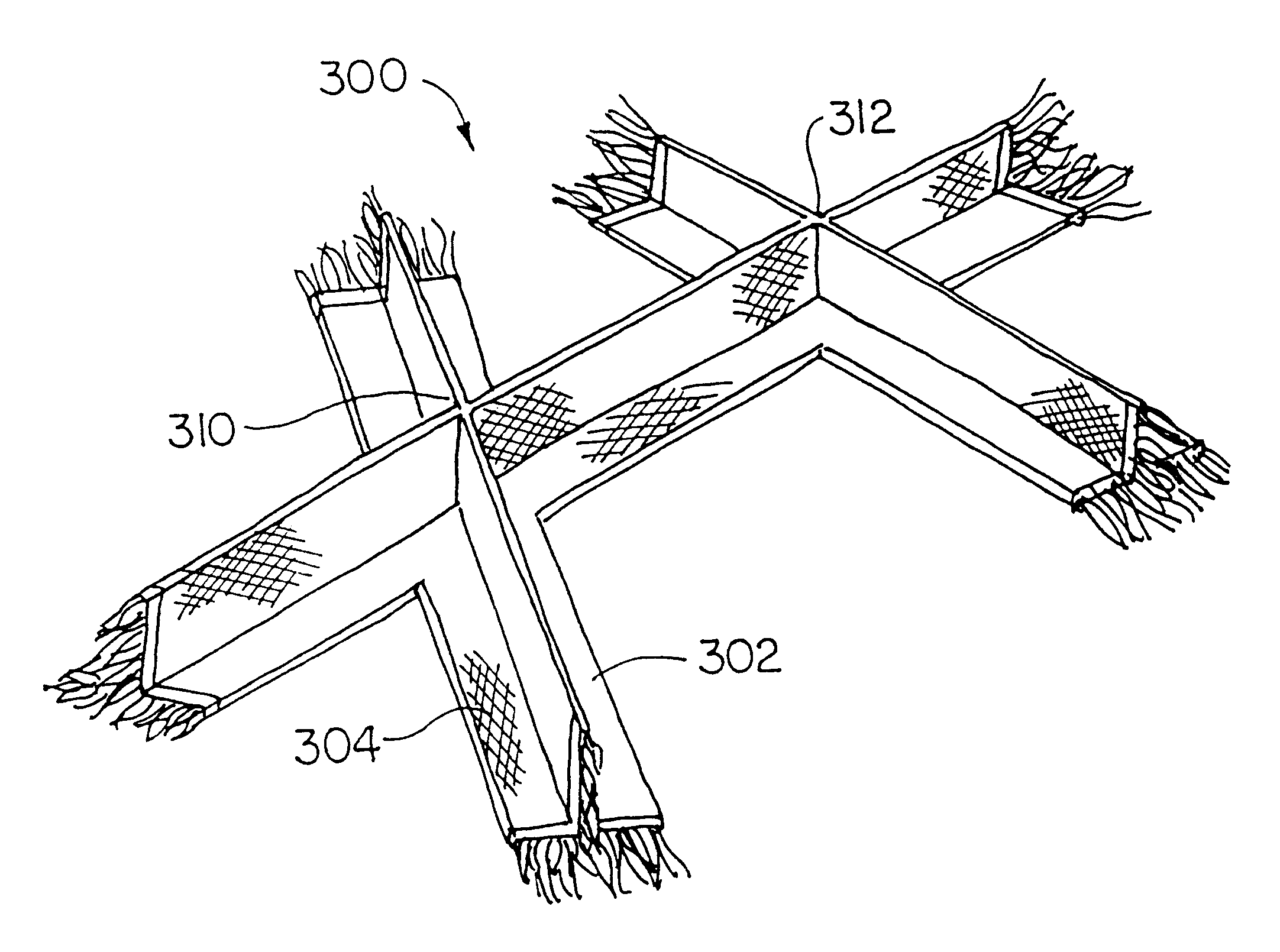

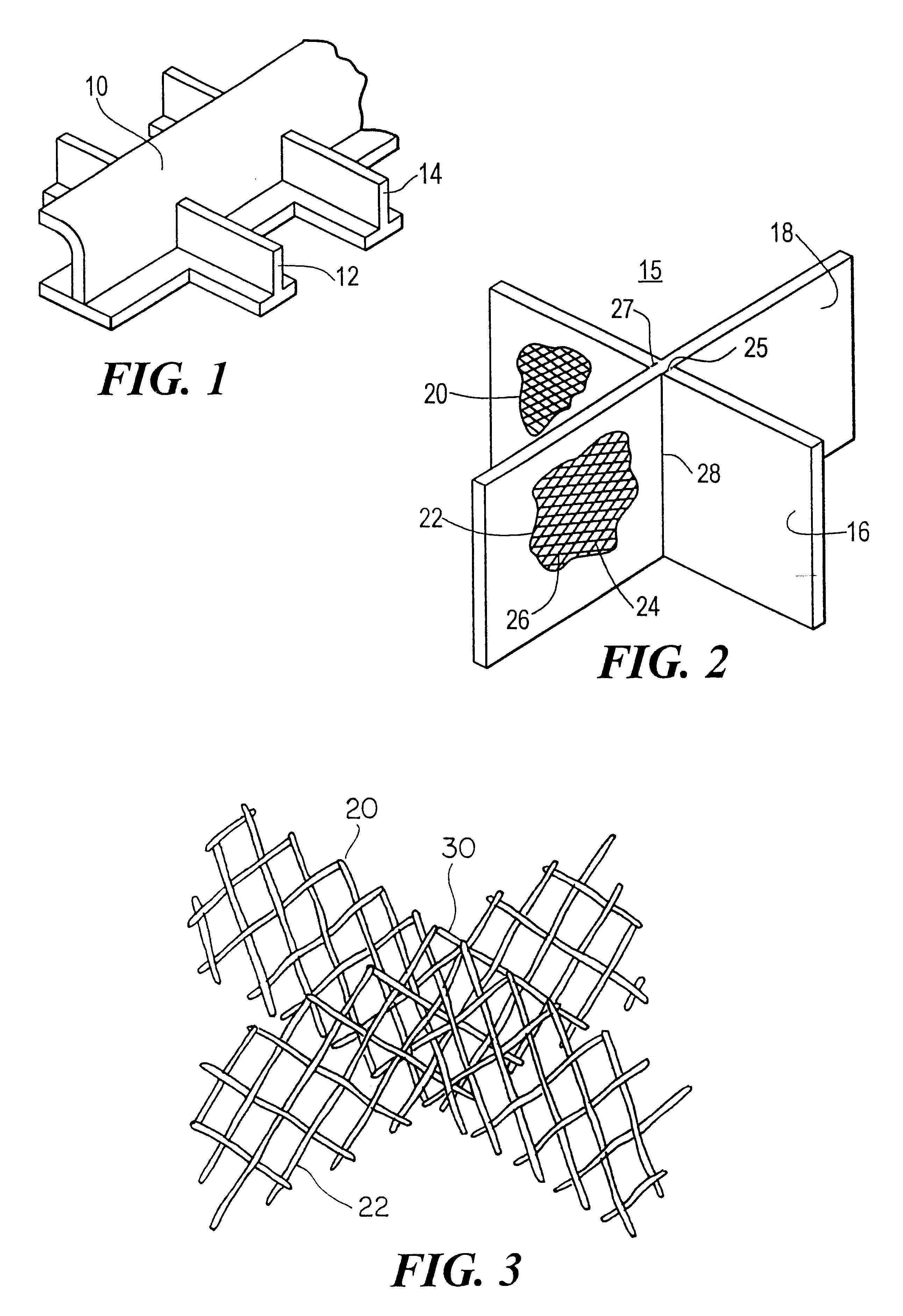

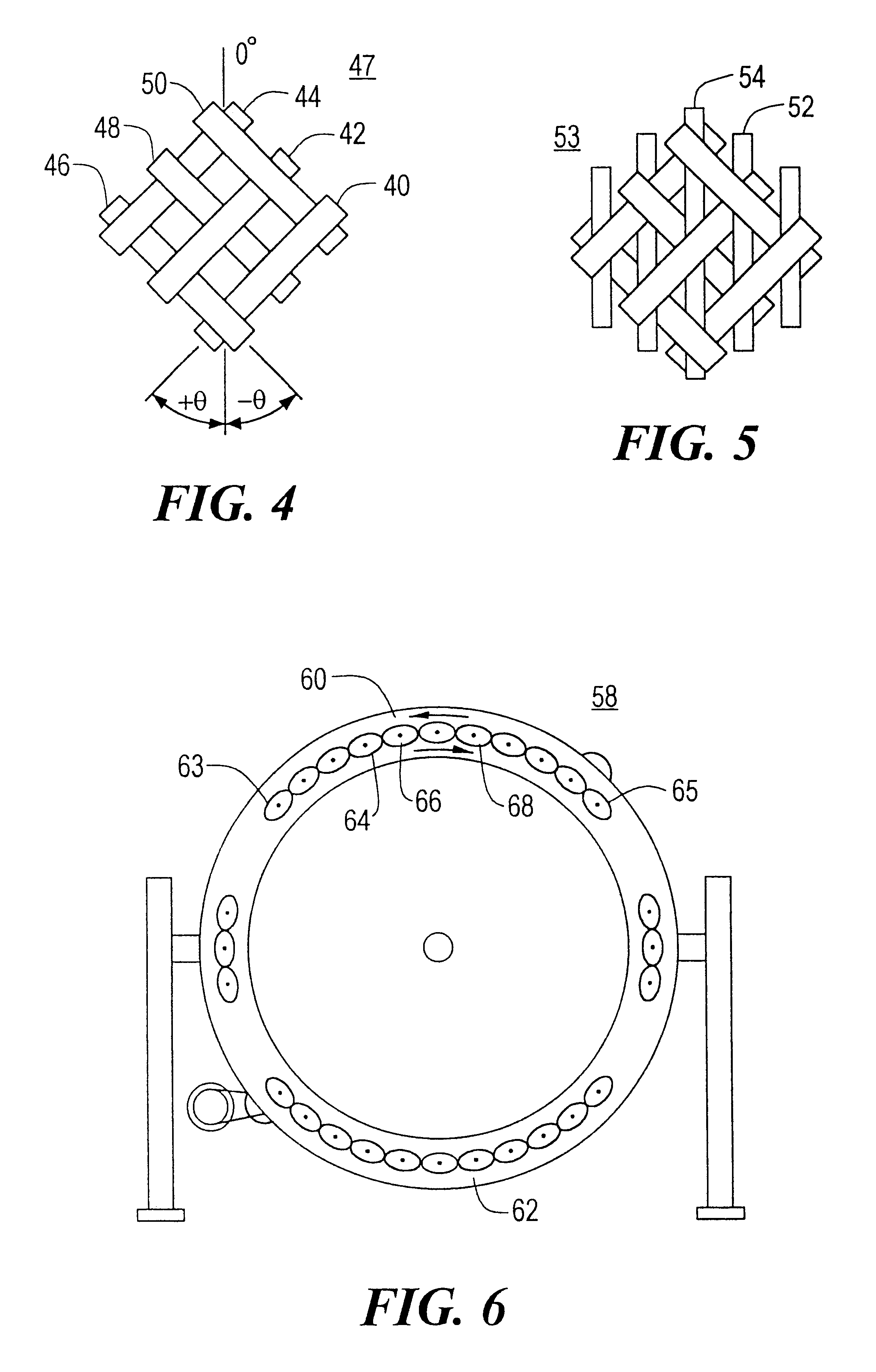

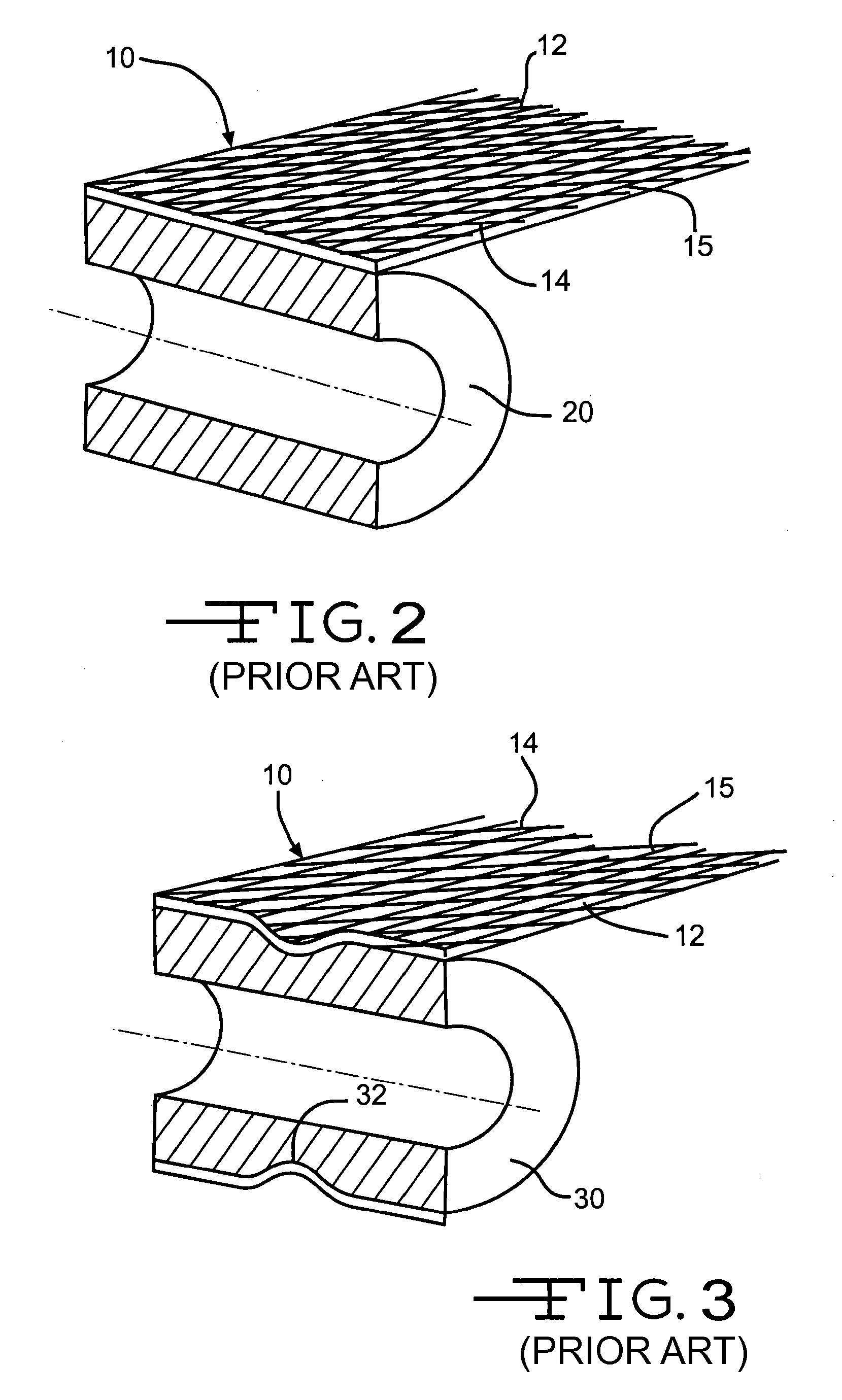

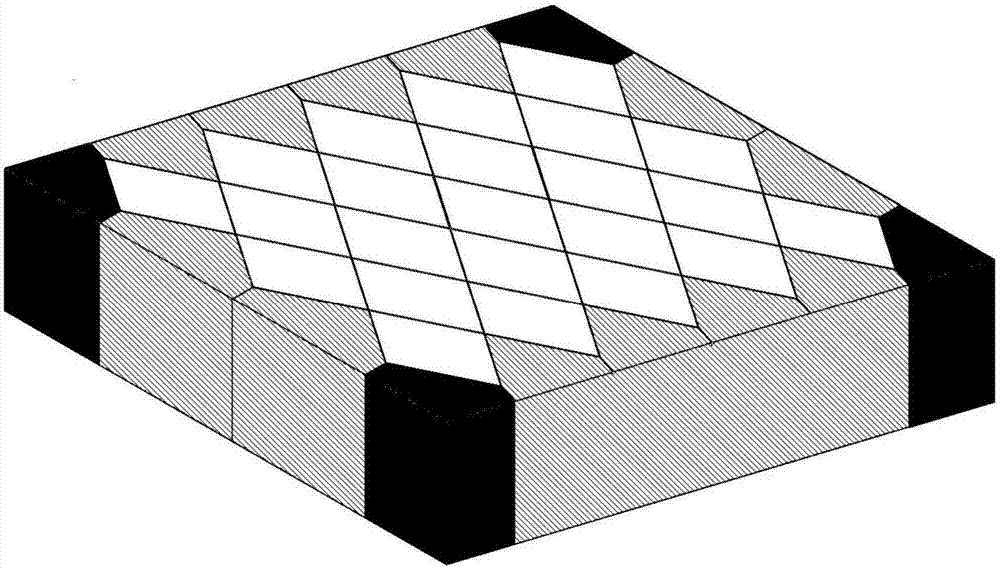

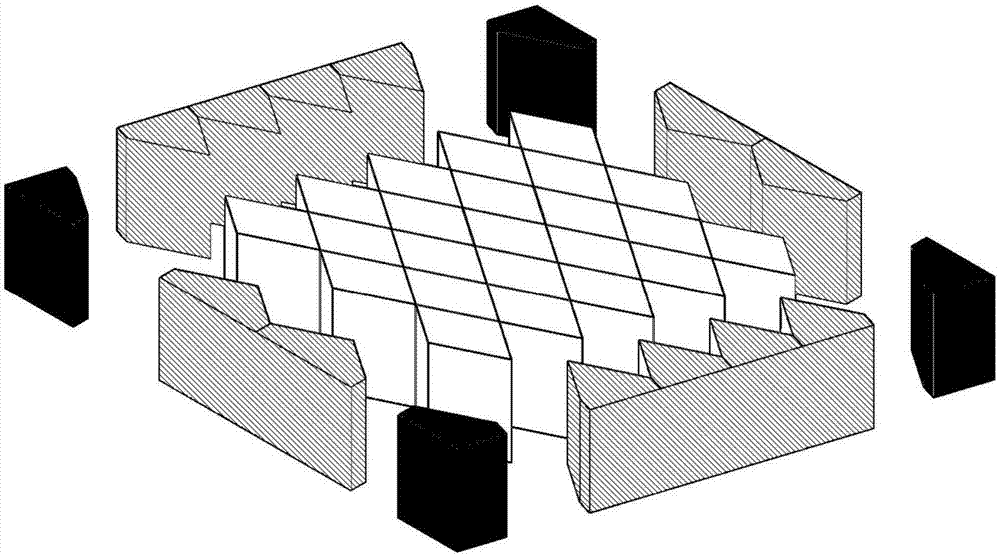

Continuous intersecting braided composite structure and method of making same

InactiveUS6647852B1Eliminate needIncrease laborLayered productsDyeing processBraided compositeMaterials science

A continuous intersecting braided composite preform including a first member with at least one ply of biased fibers and a second member also with at least one ply of biased fibers. The first member intersects with the second member and passes continuously through the second member such that the biased fibers of the first member are interstitially arranged with respect to the biased fibers of the second member at the intersection.

Owner:FREITAS GLENN +2

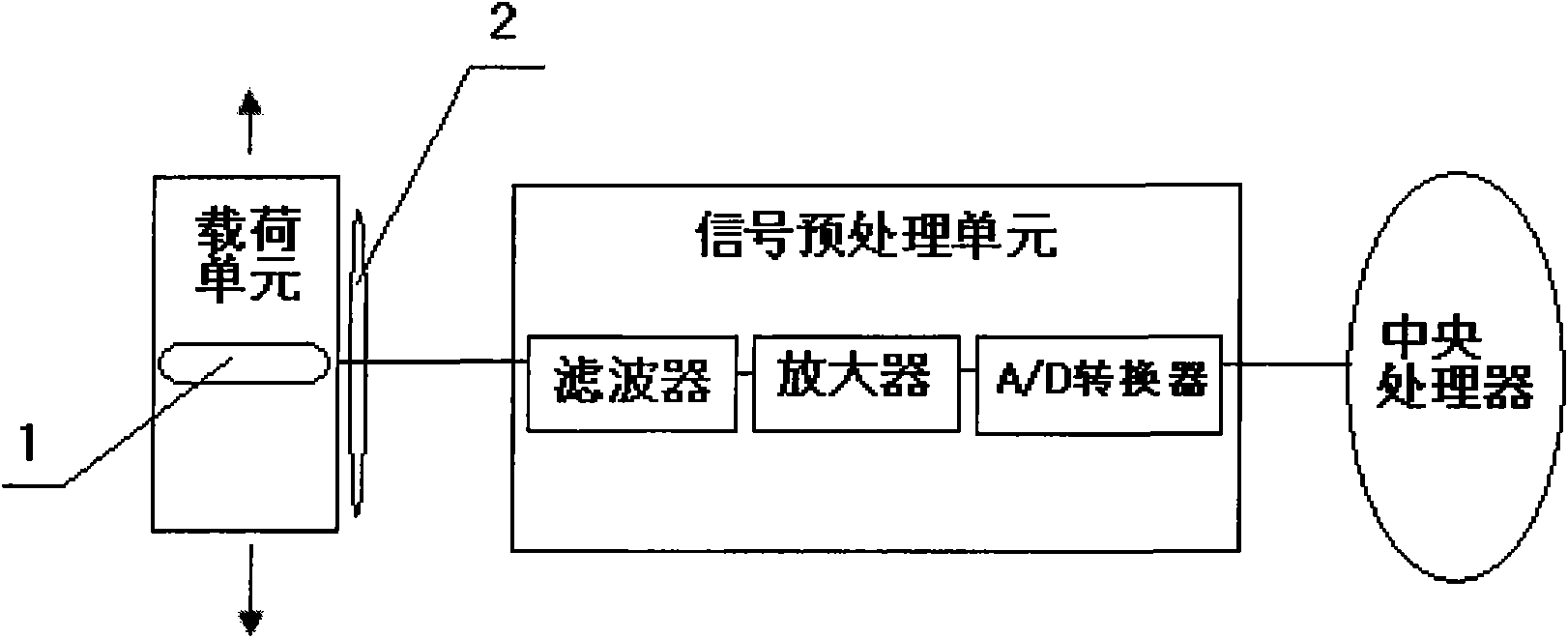

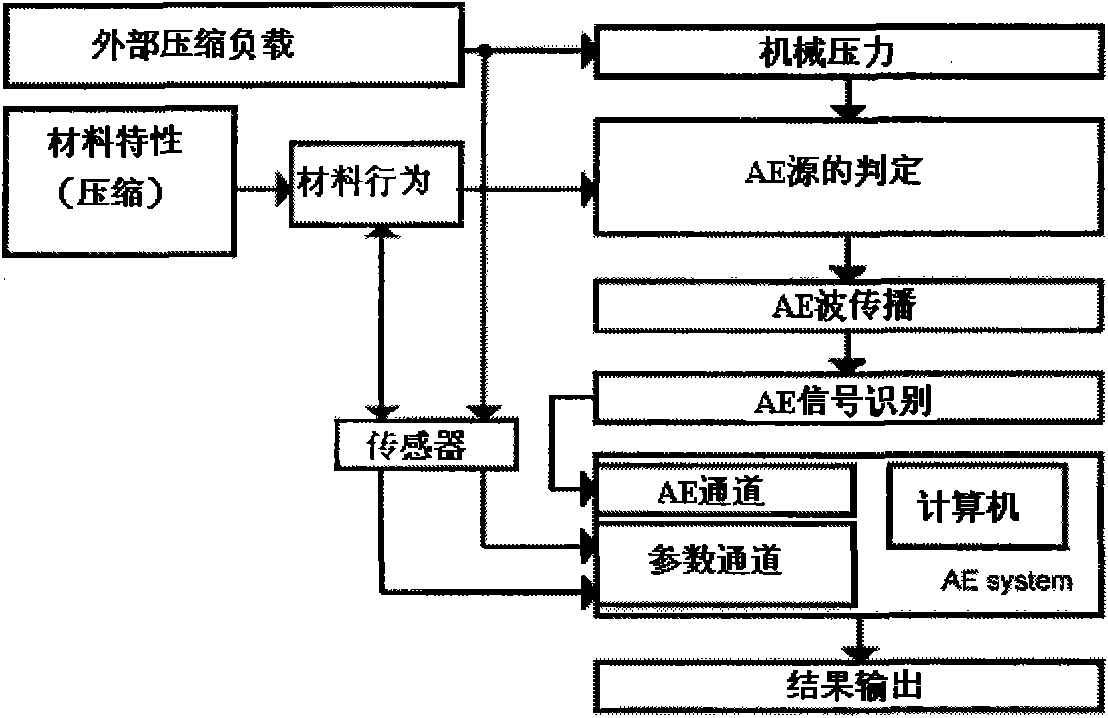

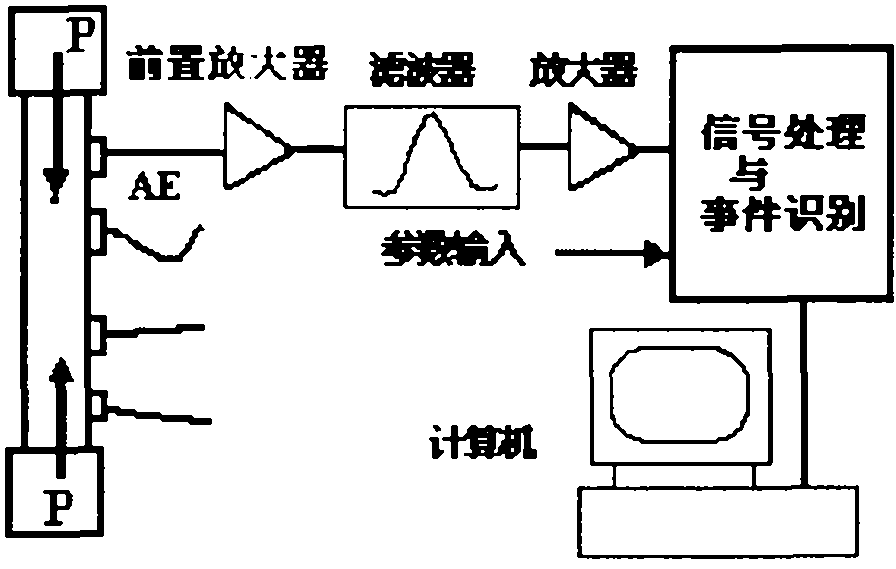

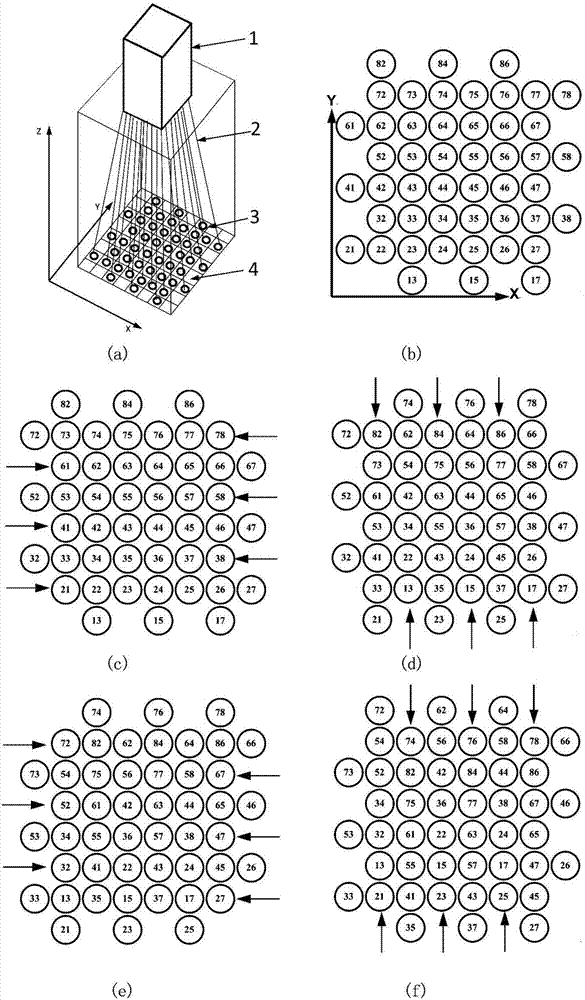

Nondestructive testing system and testing analysis method for three-dimensional braided composite material

InactiveCN102109498ARealize the whole dynamic monitoringShow damage characteristicsMaterial analysis using acoustic emission techniquesFrequency spectrumAcoustic emission

The invention provides an acoustic-emission-technology-based nondestructive testing system and an acoustic-emission-technology-based nondestructive testing method for a three-dimensional braided composite material. In the method, an acoustic emission signal generated by the composite material under external loading is received by an acoustic emission sensor and then is digitized, and the damaged condition of the material is further analyzed. By the method, a unilateral stretching experiment of the carbon fiber three-dimensional braided composite material is dynamically monitored all the way by the acoustic emission technology; and the method proves that the number of the acoustic emission events has good correlation with damage evolution of the carbon fiber composite material; through the spectrum analysis of the carbon fiber three-dimensional braided composite material, the final damage to the material is caused by fibrous fracture and damage frequencies show the damage characteristics of the material; different types of damage modes are well described through the spectrum analysis, and frequency ranges of all peak values can be detailed further, so that more detailed explanation for damage types and mechanisms can be given; and the fracture modes of the material can be analyzed by using acoustic emission characteristic parameters.

Owner:TIANJIN POLYTECHNIC UNIV

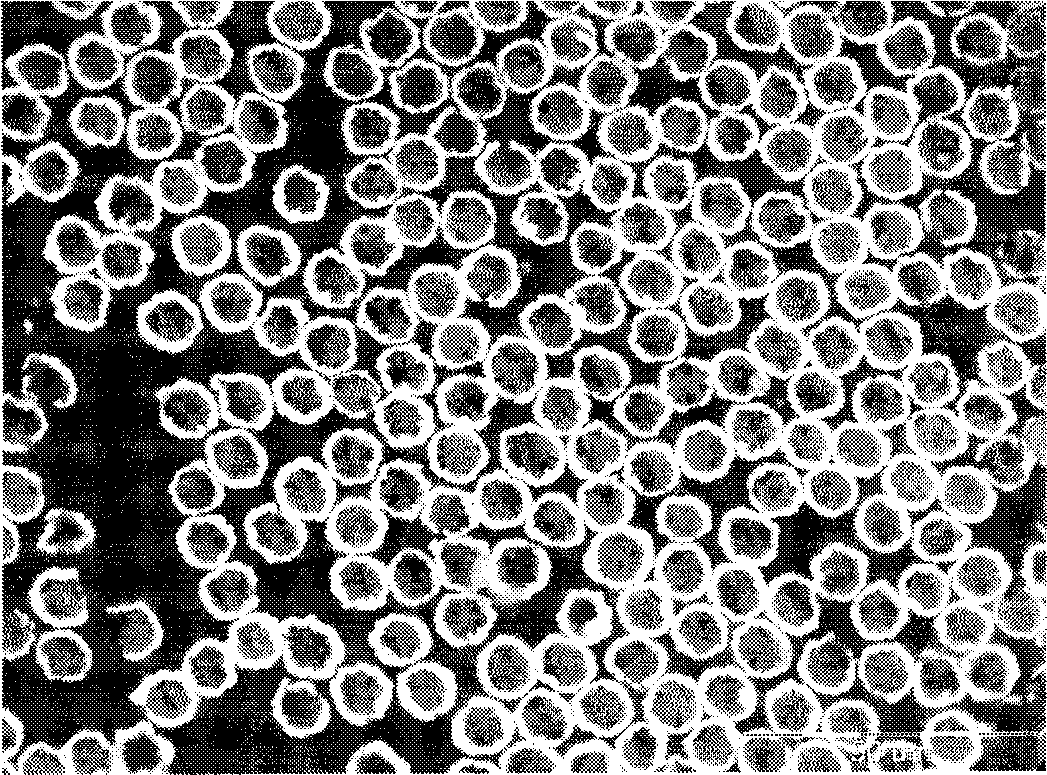

Electromagnetic shielding compound material made from three-dimensional braided nickel-plated carbon fiber and epoxy resin and method for preparing same

InactiveCN101531804AImprove performanceGood electromagnetic shieldingOther chemical processesFiberEpoxy

The invention relates to an electromagnetic shielding compound material made from three-dimensional braided nickel-plated carbon fiber and epoxy resin and a method for preparing same. The method comprises the following steps: carbon fiber surface treatment, carbon fiber nickel-electroplating, nickel-plated carbon fiber three-dimensional braiding, and compound material preparation on the basis of RTM (resin transfer molding) method and electromagnetic shielding effectiveness test. In the invention, the nickel-plated carbon fiber / epoxy resin braided compound material is prepared through the following steps: plating the carbon fiber with nickel, the metal; carrying out three-dimensional four-directional braiding; and then, compounding the nickel-plated carbon fiber braid and the epoxy resin. Owing to the good conductivity of the carbon fiber braid and the nickel-plated layer and the ferromagnetism of the nickel-plated layer, the braided compound material has good electromagnetic shielding performance. According to the test results based on the flange co-axial method, the electromagnetic shielding level of the braided compound material reaches 70dB to 80dB.

Owner:TIANJIN UNIV

Three-dimensional braided carbon fiber reinforced polyetheretherketone composite material and preparation method thereof

InactiveCN102134372AAvoid difficultiesGood mechanical propertiesCarbon fibresPoly ether ether ketoneDistilled water

The invention relates to a three-dimensional braided carbon fiber reinforced polyetheretherketone composite material and a preparation method thereof. Carbon fiber reinforced polyetheretherketone fiber, and carbon fiber which is used as the raw material and accounts for 18-54% by volume, are mixed and braided in a three-dimensional five-direction mode to obtain the three-dimensional braided carbon fiber reinforced polyetheretherketone composite material. The three-dimensional braided carbon fiber reinforced polyetheretherketone composite material is prepared from fibers by a braiding and hot compaction combined technique. The technological process comprises the following steps: carrying out three-dimensional mixing and braiding on the polyetheretherketone fiber and carbon fiber, carrying out solution oxidation pretreatment on the mixed fabric, repeatedly flushing with distilled water, drying, putting the mixed fabric into a die, and carrying out hot compaction. The invention can effectively overcome the difficulties in the preparation of the three-dimensional braided composite material due to the thermoplastic property of the polyetheretherketone, thereby obtaining the three-dimensional braided carbon fiber reinforced polyetheretherketone composite material which has the advantages of sufficient fiber immersion and excellent mechanical properties.

Owner:江苏飞荣达新材料科技有限公司

Three-dimensional braided composite material mechanical arm and manufacturing method thereof

ActiveCN105602200AImprove performanceImprove rigidityLamination ancillary operationsSynthetic resin layered productsHigh intensityConductor Coil

The invention discloses a three-dimensional braided composite material mechanical arm and a manufacturing method thereof. The mechanical arm sequentially comprises a body rigid structure layer, an anti-impact layer and a surface machining assembly layer from inside to outside. The body rigid structure layer comprises a three-dimensional braided structure and a resin layer, wherein the three-dimensional braided structure is manufactured from high-modulus fibers, and the resin layer is solidified on the three-dimensional braided structure in a dipping mode. The anti-impact layer comprises a three-dimensional braided structure and a resin layer, wherein the three-dimensional braided structure is manufactured from hybrid fibers composed of high-modulus fibers and organic fibers, and the resin layer is solidified on the three-dimensional braided structure in a dipping mode. The surface machining assembly layer comprises a two-dimensional winding layer fabric structure and a resin layer, wherein the two-dimensional winding layer fabric structure is manufactured from high-strength fibers, and the resin layer is solidified on the two-dimensional winding layer fabric structure in a dipping mode. The mechanical arm has the advantages of being high in strength, high in rigidity, low in weight, not prone to deformation and high in designability, machinability and assembling ability, the weight of components is reduced, the power of a motor is reduced, energy consumption is reduced, and stability and quality of products are guaranteed.

Owner:SHANDONG ZHONGHENG CARBON FIBER TECH DEV CO LTD

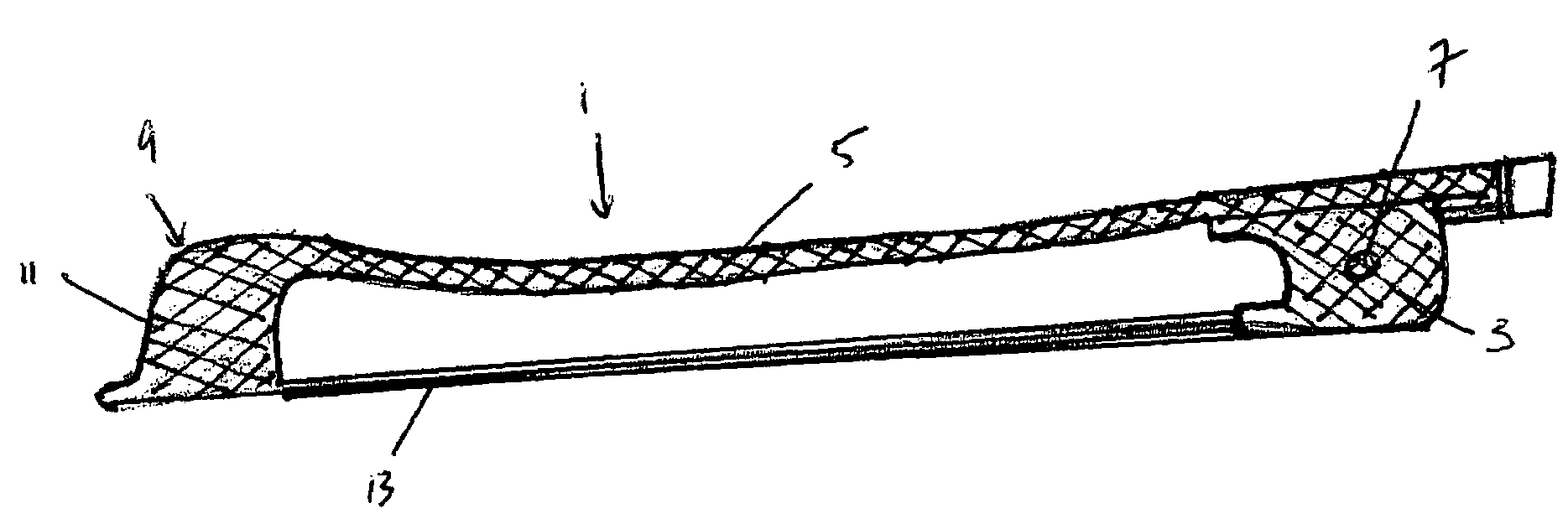

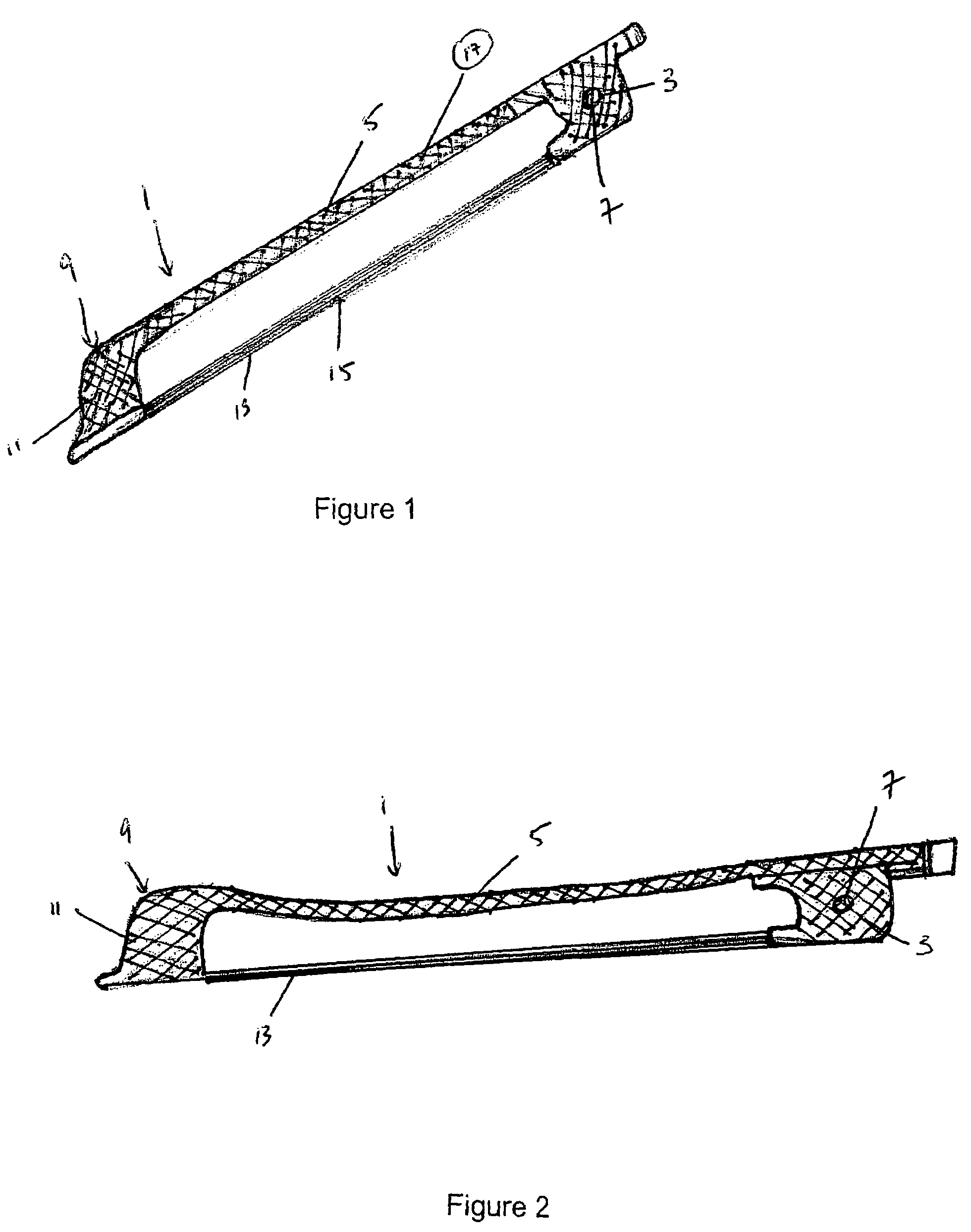

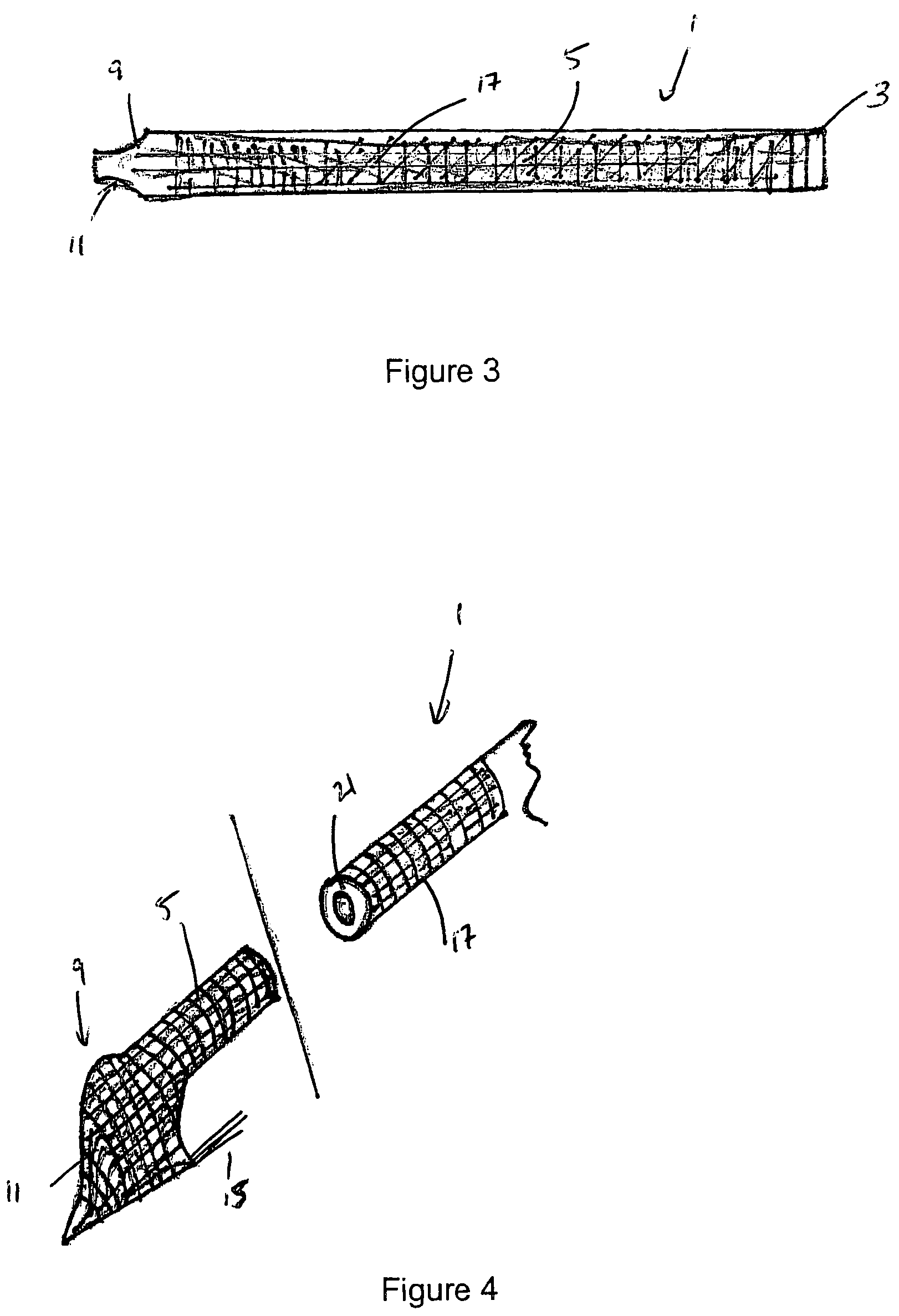

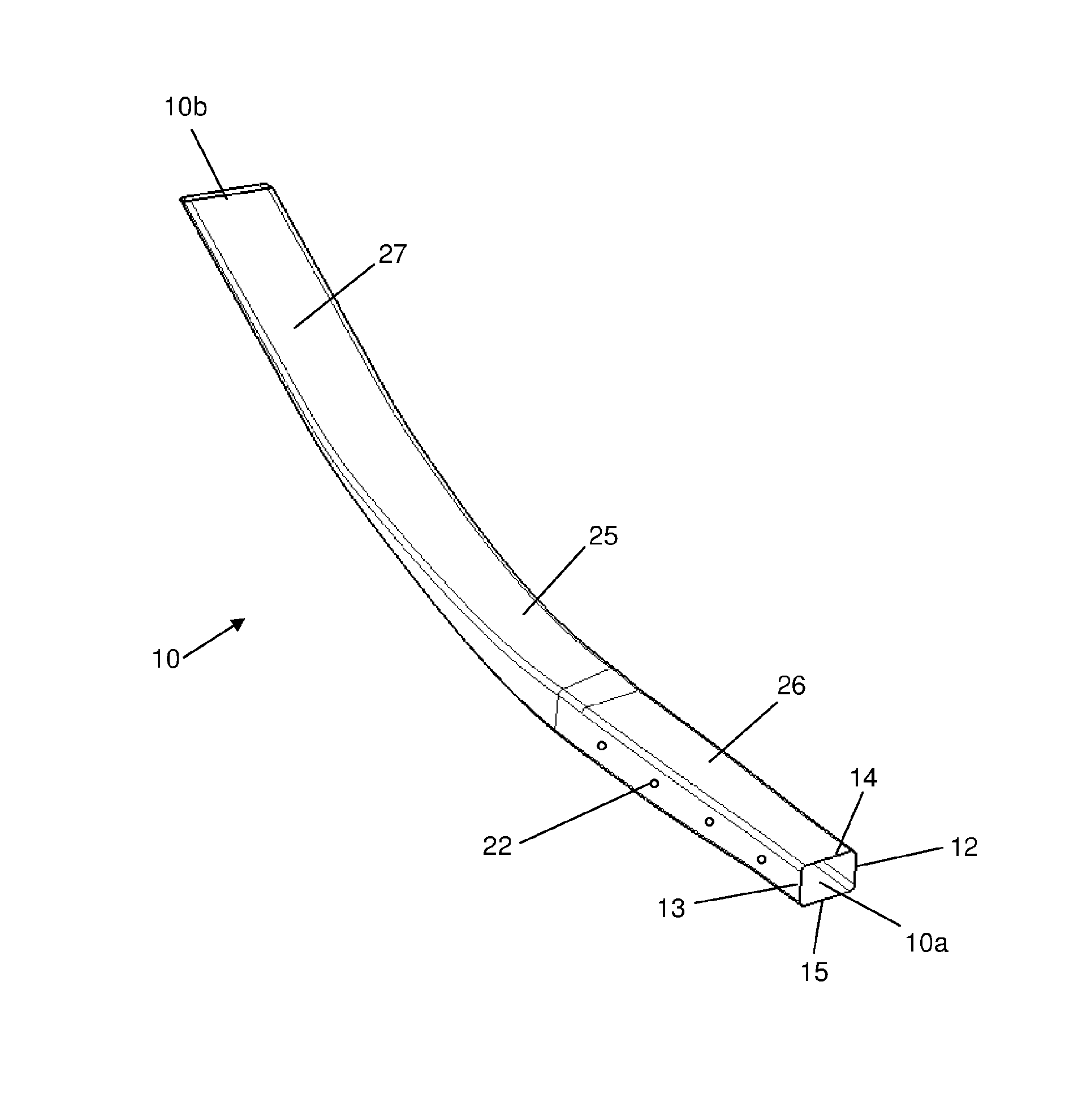

Braided composite stringed instrument bow

A new and improved instrument bow for use with a stringed instrument is provided. A unique new instrument bow is provided that may be constructed with a braided material and / or composite to form the instrument bow. Additionally, the new instrument bow using a braided composite to form a single piece construction instrument bow for use in conjunction with a stringed instrument. The instrument bow may be a combination of a synthetic material covered with a braided material in a single piece construction that will provide the instrument bow with increased resilient and strength without the necessity for reinforcement and / or repair.

Owner:GLASSER ANDREW

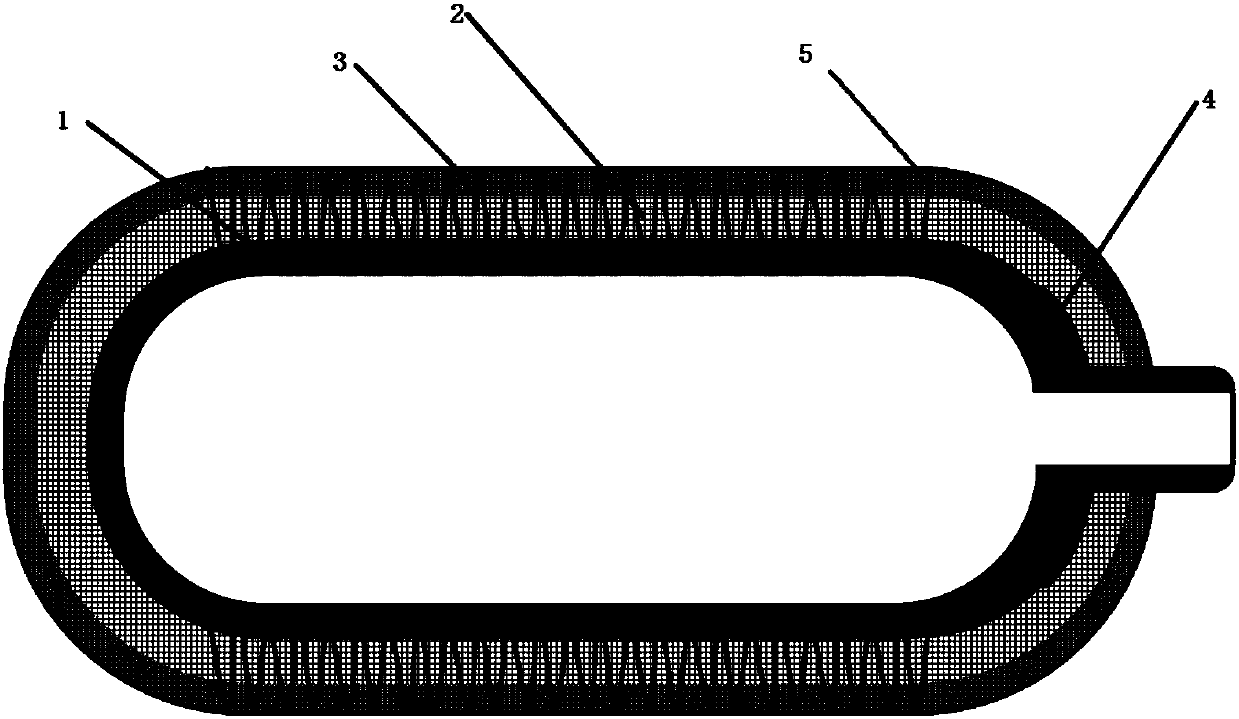

Three-dimensionally braided pressure gas bottle and preparation method thereof

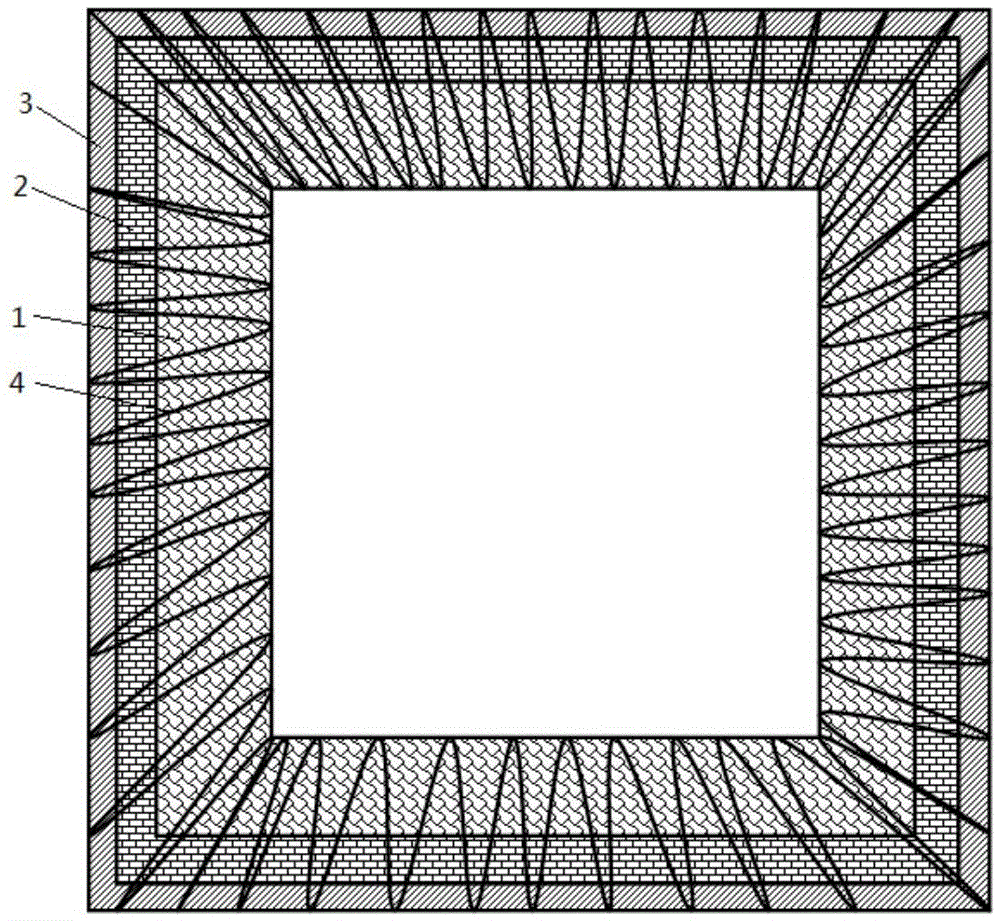

The invention discloses a three-dimensionally braided pressure gas bottle and a preparation method thereof. The pressure gas bottle comprises a metal liner layer, a medium inlet / outlet and a three-dimensionally braided composite outer layer, wherein the medium inlet / outlet is formed at an opening in one end of the metal liner layer, and the medium inlet / outlet and the metal liner layer form an inner gas bottle layer, so that gas can enter and exit from the metal liner layer through the medium inlet / outlet; the three-dimensionally braided composite outer layer enwraps the inner gas bottle layer; the three-dimensionally braided composite outer layer is formed by repeatedly impregnating and compounding three-dimensionally braided three-dimensional fabric and resin; the three-dimensionally braided three-dimensional fabric sequentially comprises a three-dimensionally braided composite inner layer and a three-dimensionally braided composite surface layer from inside to outside; the three-dimensionally braided composite inner layer and the three-dimensionally braided composite surface layer are reinforced by seaming through a two-dimensionally seaming reinforcing structure. The pressure gas bottle is made of a novel mixed material, adopts a novel structure, can be adapted to different pressure-resistant environments, can be adapted to different application climate environments, and effectively solves a problem of pressure container damage caused by interlayer weakness.

Owner:SHANDONG ZHONGHENG CARBON FIBER TECH DEV CO LTD

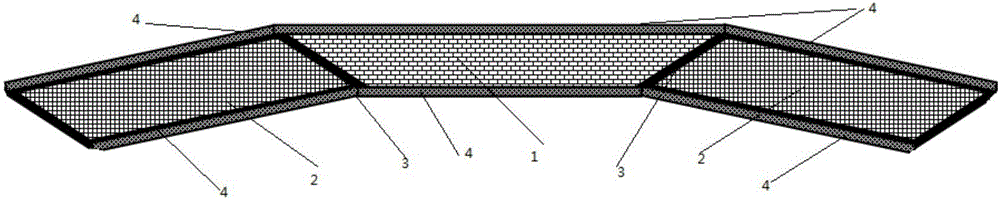

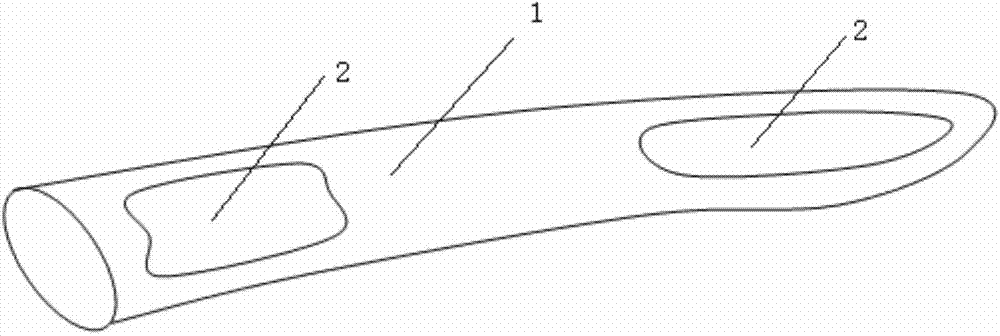

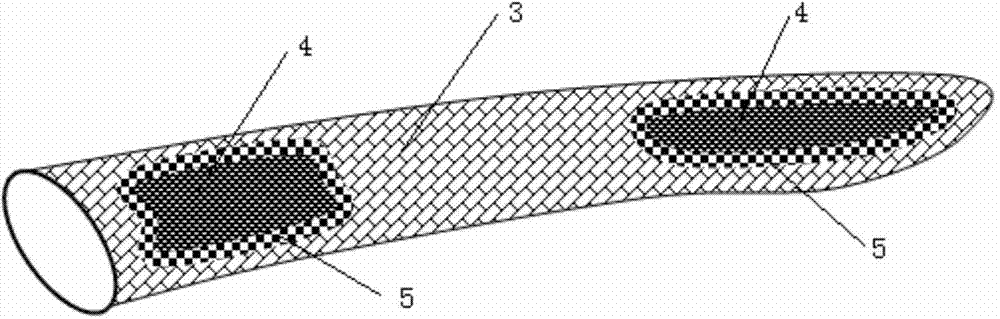

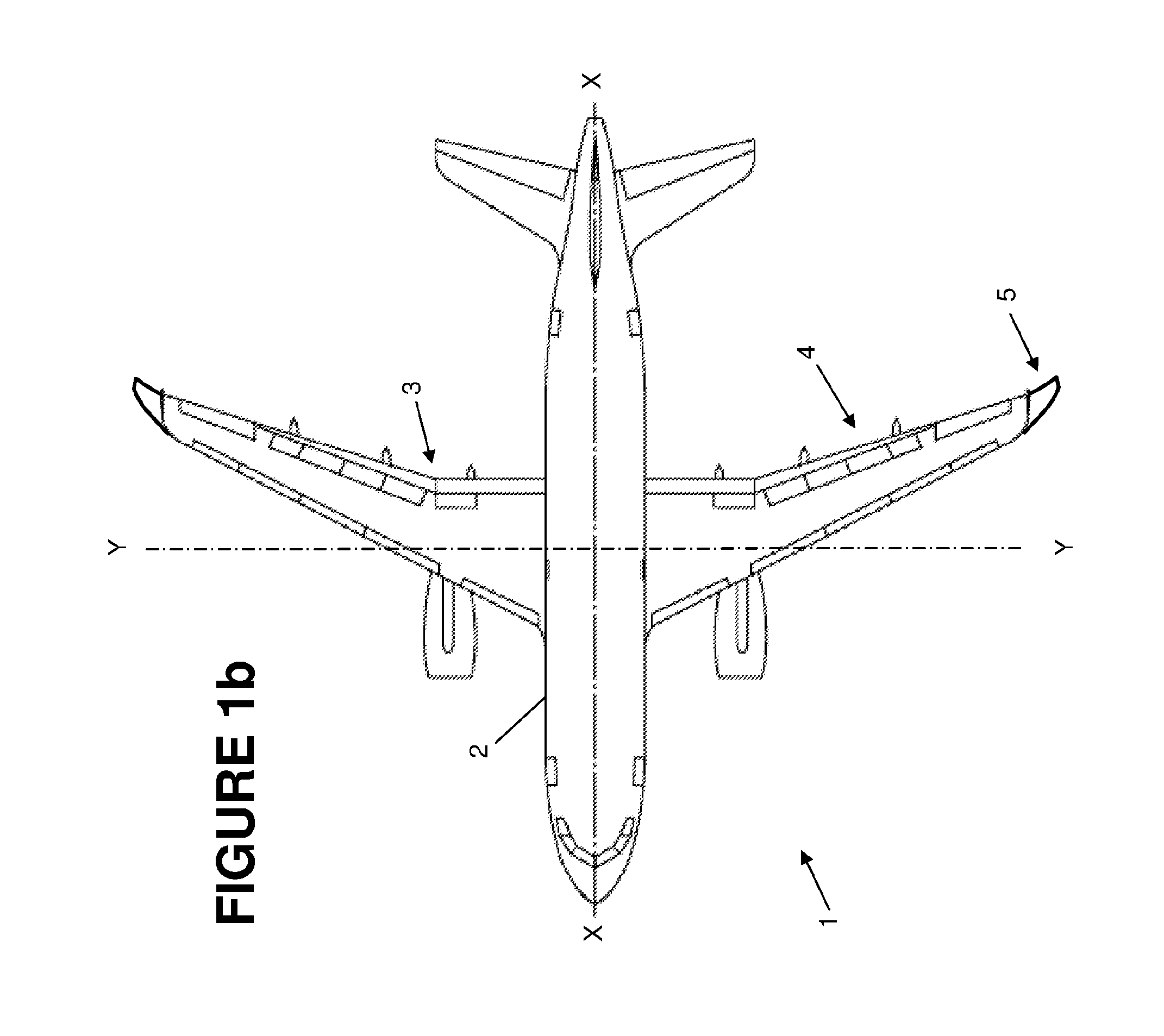

Automobile plate spring of three-dimensional braided composite material and preparation method thereof

The invention discloses an automobile plate spring of three-dimensional braided composite material and a preparation method thereof. The plate spring is of a three-dimensional fabric structure which is formed by combining and waving hybrid fibers, the material of fibers, the amount of tows and the structure of the fabric are adjusted to make the important part of the plate spring higher in strength and fatigue rigidity and longer in use durability, and simultaneously a resin vacuum transfer moulding technology is cooperated to uniformly soak, cure and shape the special composite resin, so as to obtain the heavy truck plate spring of three-dimensional braided composite material, the heavy truck plate spring is light in weight, strong in fatigue resistance, high in strength, rigidity and dimensional stability and relatively long in service life, and the problems of the common plate spring of two-dimensional laminated structure composite material such as interlayer fracture under fatigue loading condition are conquered.

Owner:山东宽原新材料科技有限公司

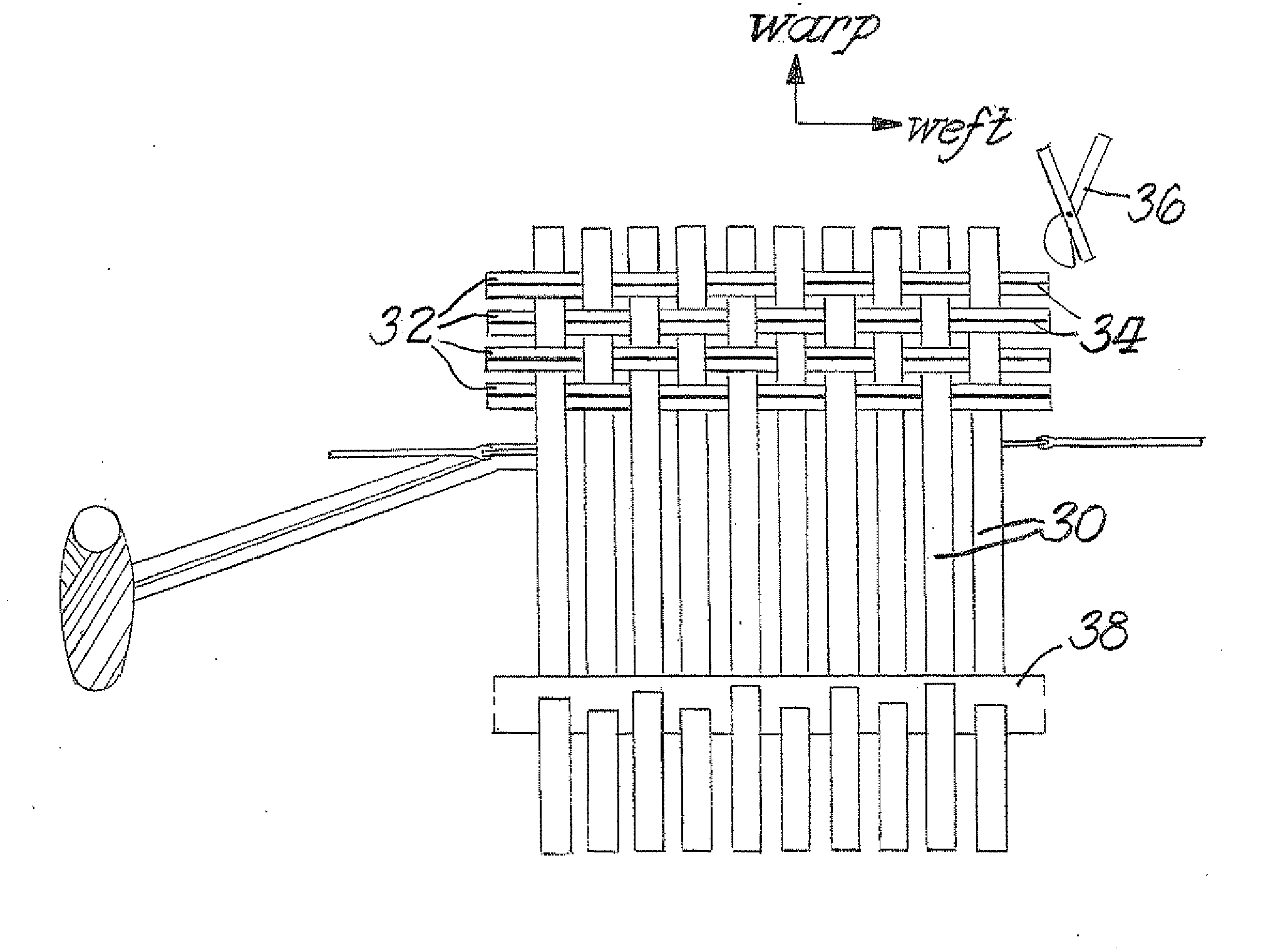

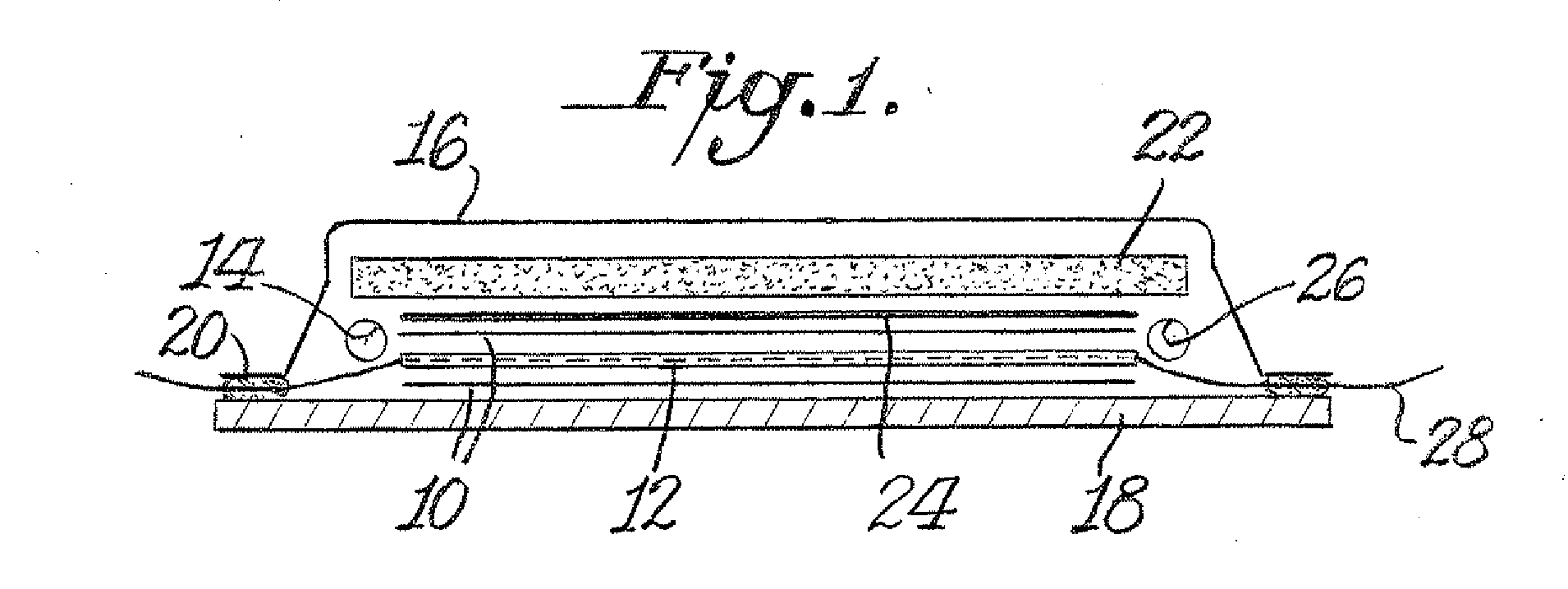

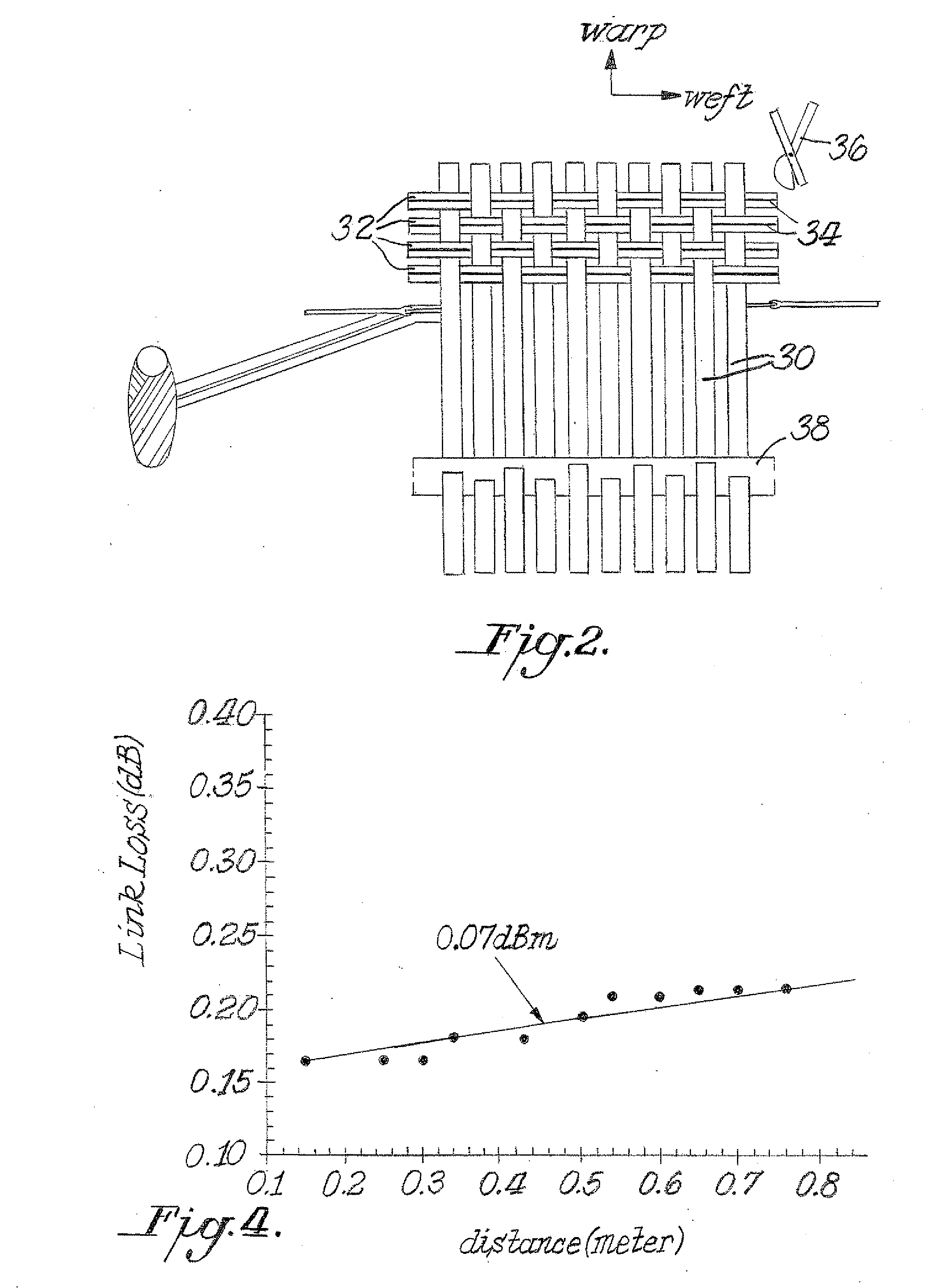

Automated process for embedding optical fibers in woven composites

InactiveUS20070103928A1Increased complexityIncrease laborProtective fabricsAuxillary apparatusEngineeringOptical fiber

An automated process for embedding optical fiber in woven composites includes embedding a woven fabric in resin using a vacuum infusion process to create a structural composite with integrated optical conduit with less than 0.8413 optical loss. The optical fiber is embedded in the woven fabric in both warp and weft directions. Optical fiber connectorization is done without polishing.

Owner:UNITED STATES OF AMERICA +1

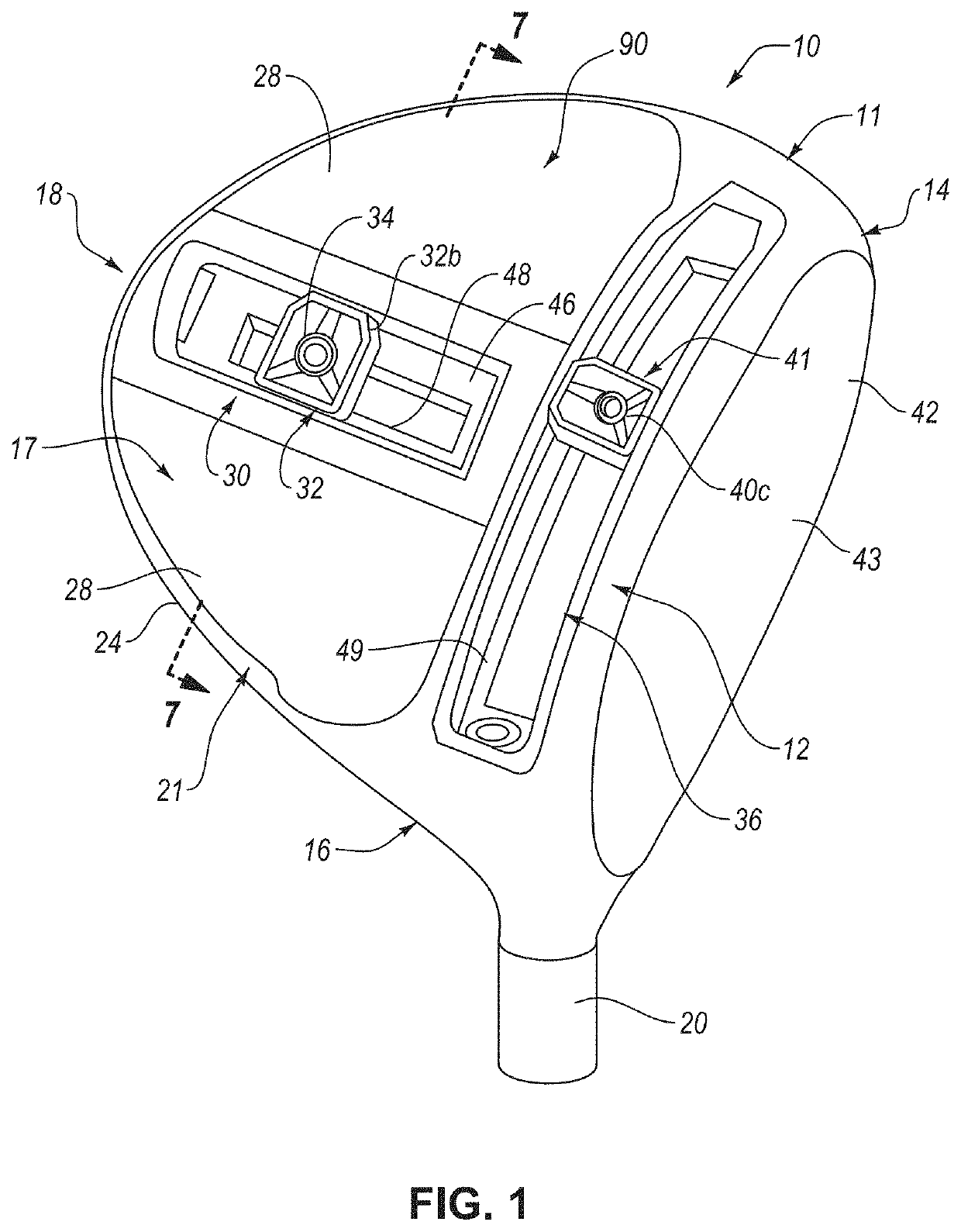

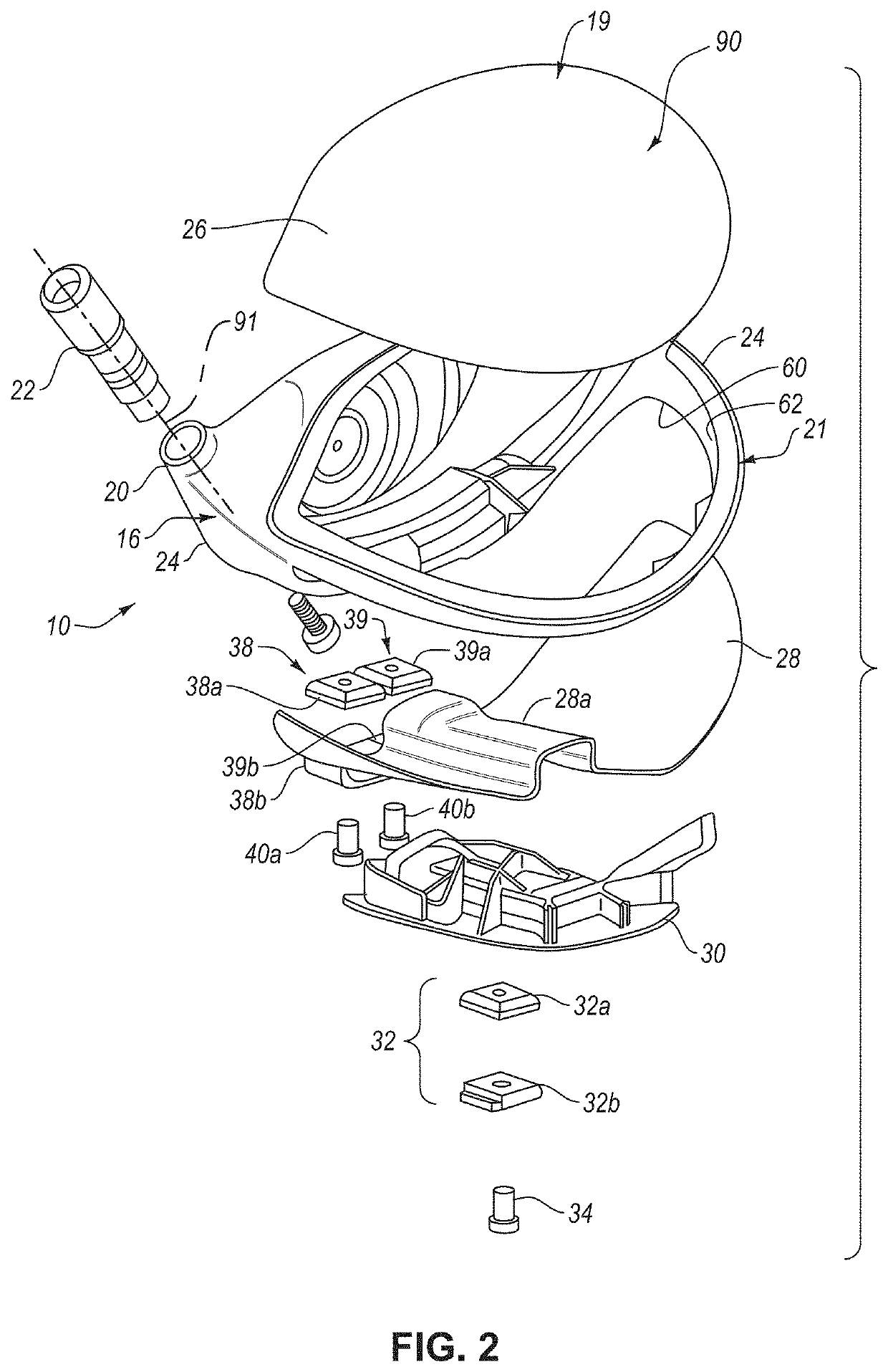

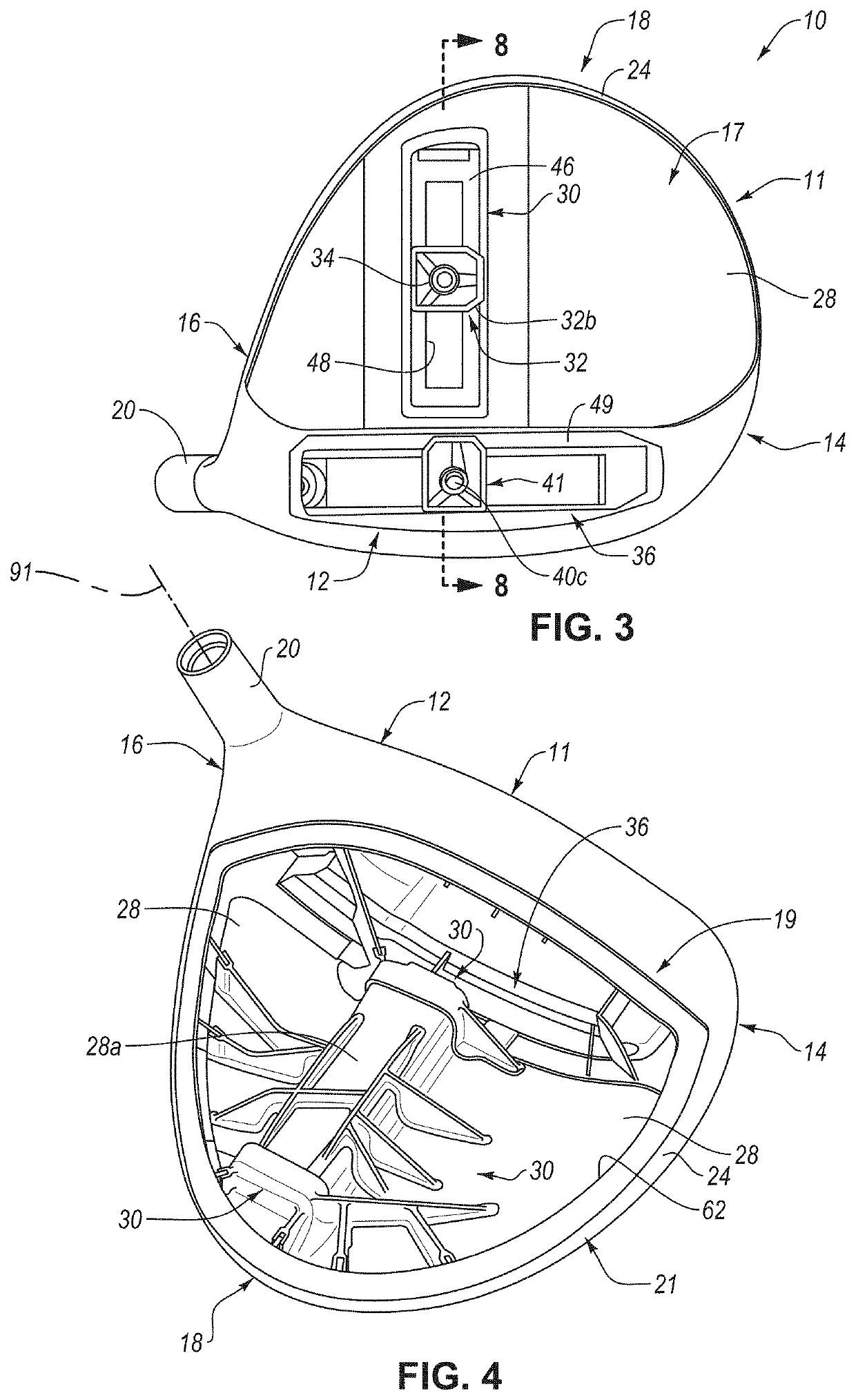

Golf club including composite material with color coated fibers and methods of making the same

A golf club including at least one component with a construction that includes a composite material with color / metallic coated fibers. In some embodiments, at least a portion of an outer surface of the golf club head is defined by a layered structure including color / metallic coated fibers. The layered structure may include a non-woven composite layer comprising a plurality of unidirectional fiber composite plies and woven composite layer disposed over the non-woven fiber composite layer and including color / metallic coated fibers. In some embodiments, an optically transparent coating may be disposed over the woven composite layer. In some embodiments, the color / metallic coated fibers may be electroplated fibers.

Owner:TAYLOR MADE GOLF

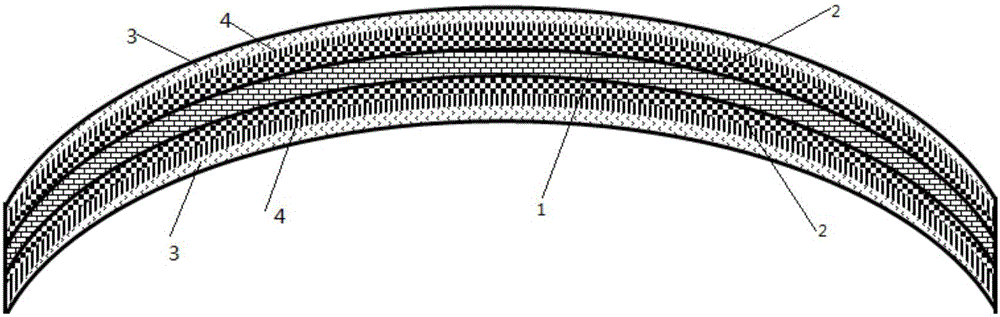

Plate spring of interlayer reinforced two-dimensional/three-dimensional braided composite material and preparation method thereof

InactiveCN105128357AHigh strengthReduce weightLeaf springsResilient suspensionsWhole bodyTransfer molding

The invention discloses a plate spring of interlayer reinforced two-dimensional / three-dimensional braided composite material and a preparation method thereof. A monolayer fabric of different fiber materials is formed by three-dimensional stereo braiding, the monolayer of the special fiber material and in the three-dimensional braided structure is designed on the special part in relatively high rigid or strength requirements, and finally the layers are vertically seamed to make the laminated monolayer structure form a whole body. Finally, the fabric of the two-dimensional / three-dimensional composite structure and resin are repeatedly soaked and composited through a resin vacuum transfer moulding technology, and the novel automobile plate spring of composite material which is high in strength and rigidity, small in deformation amount, large in fatigues resistance, long in service life and high in high-low temperature environment adaptability is prepared through gradient heating and curing. The plate spring uses the novel structure and the structure form to satisfy the use requirements of different loading capacities especially automobiles with heavy loads, and the problems such as interlayer fracture caused by relatively low fatigue load strength of the common plate spring of two-dimensional laminated structure composite material are conquered.

Owner:SHANDONG UNIV

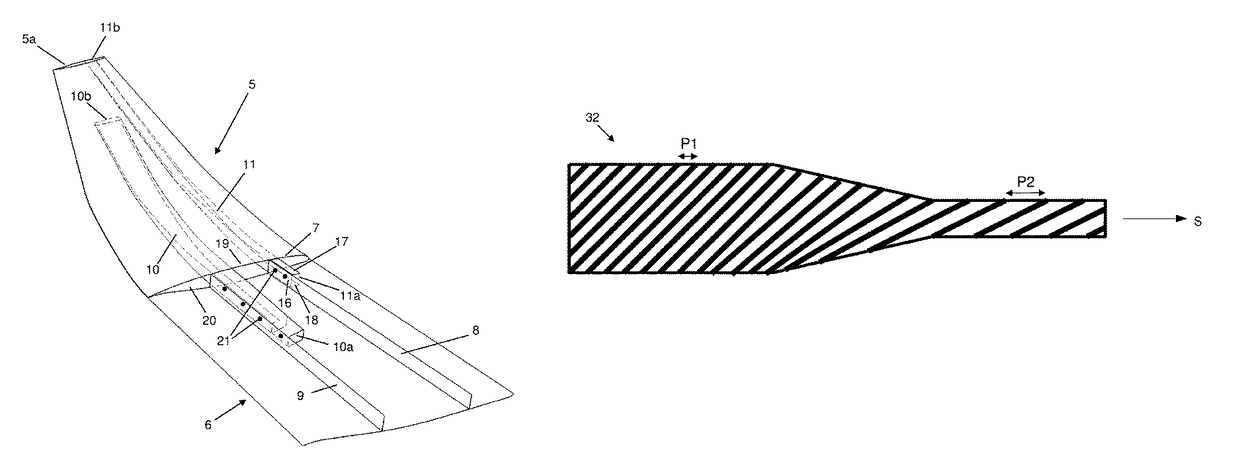

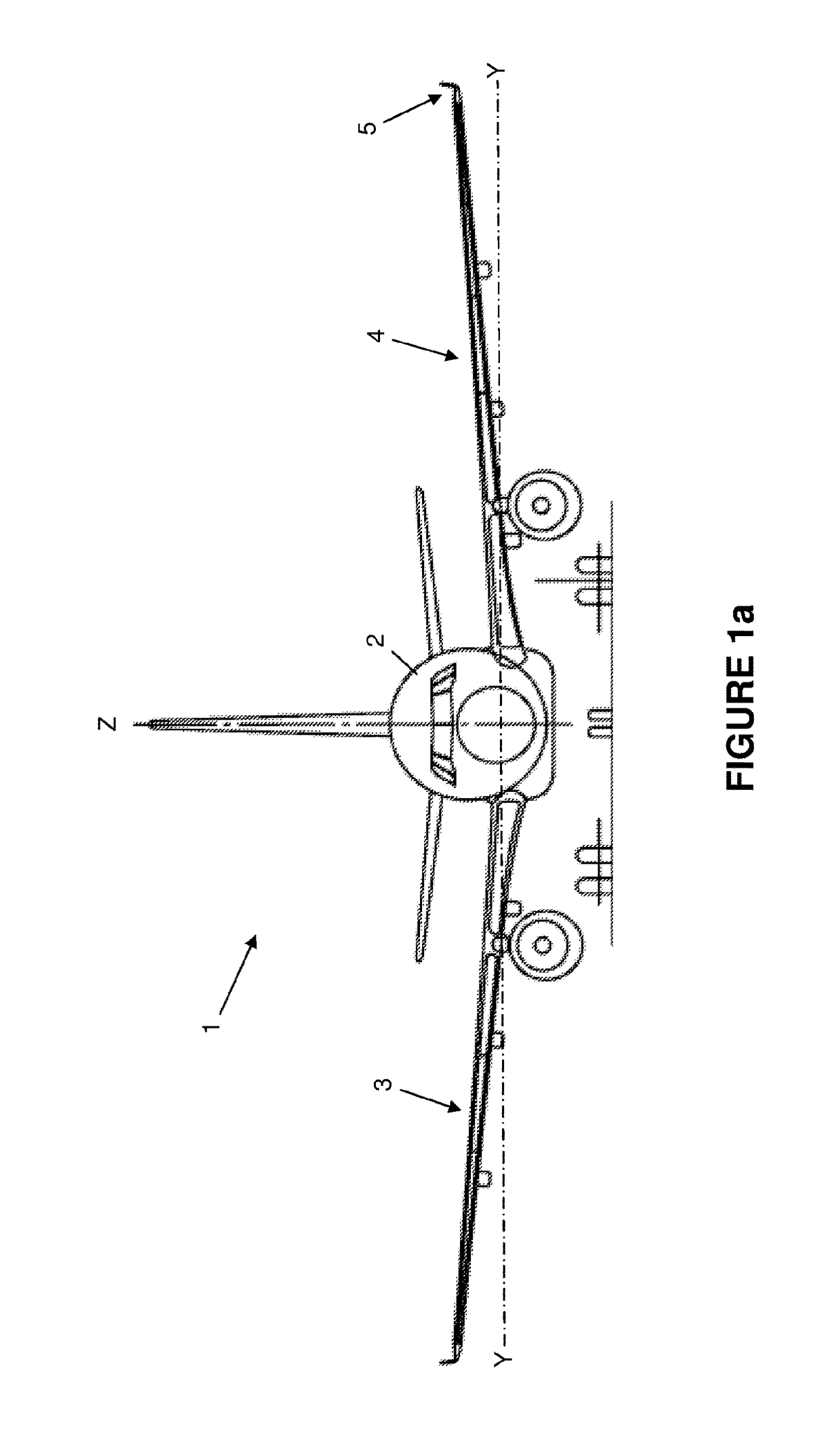

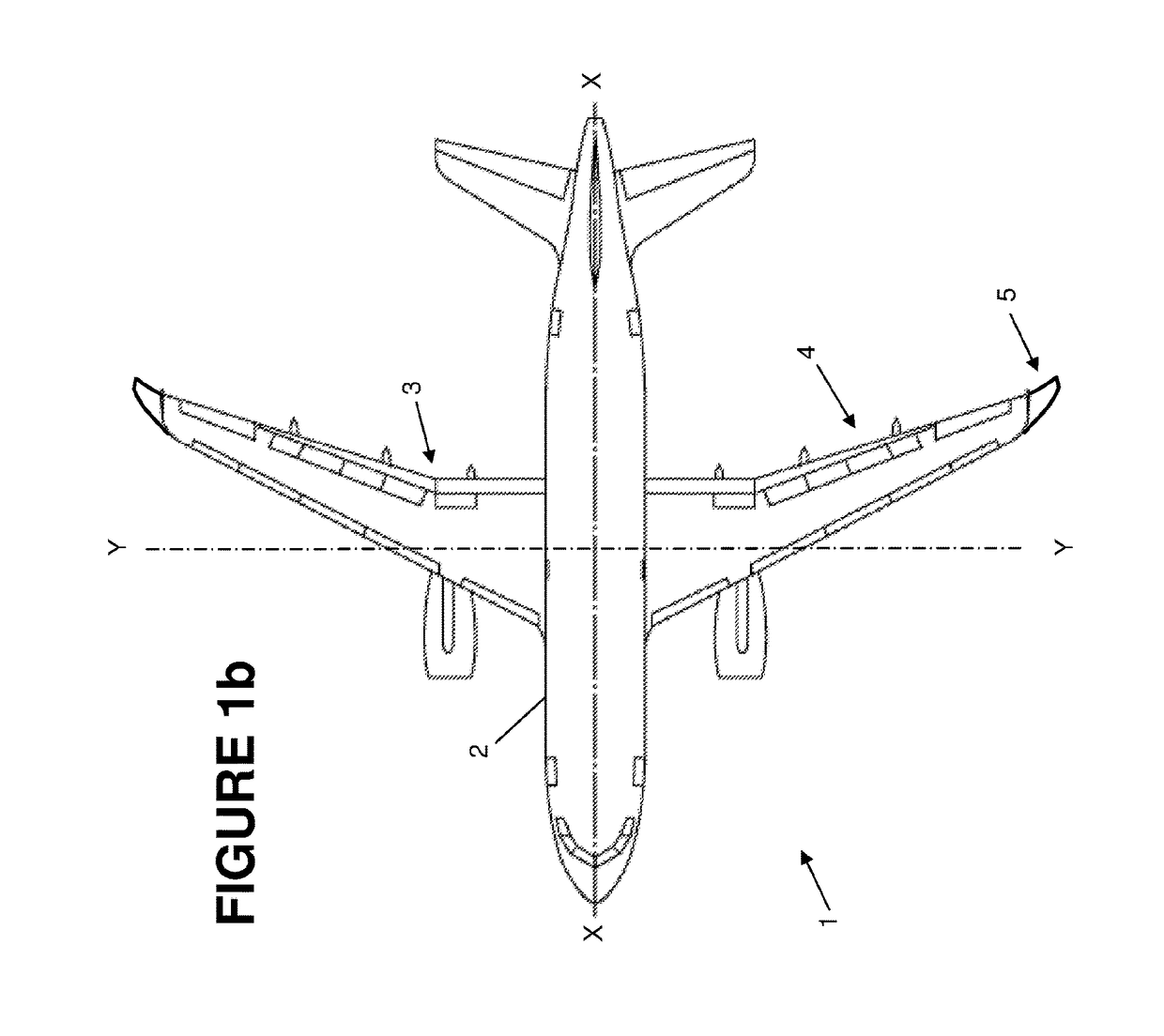

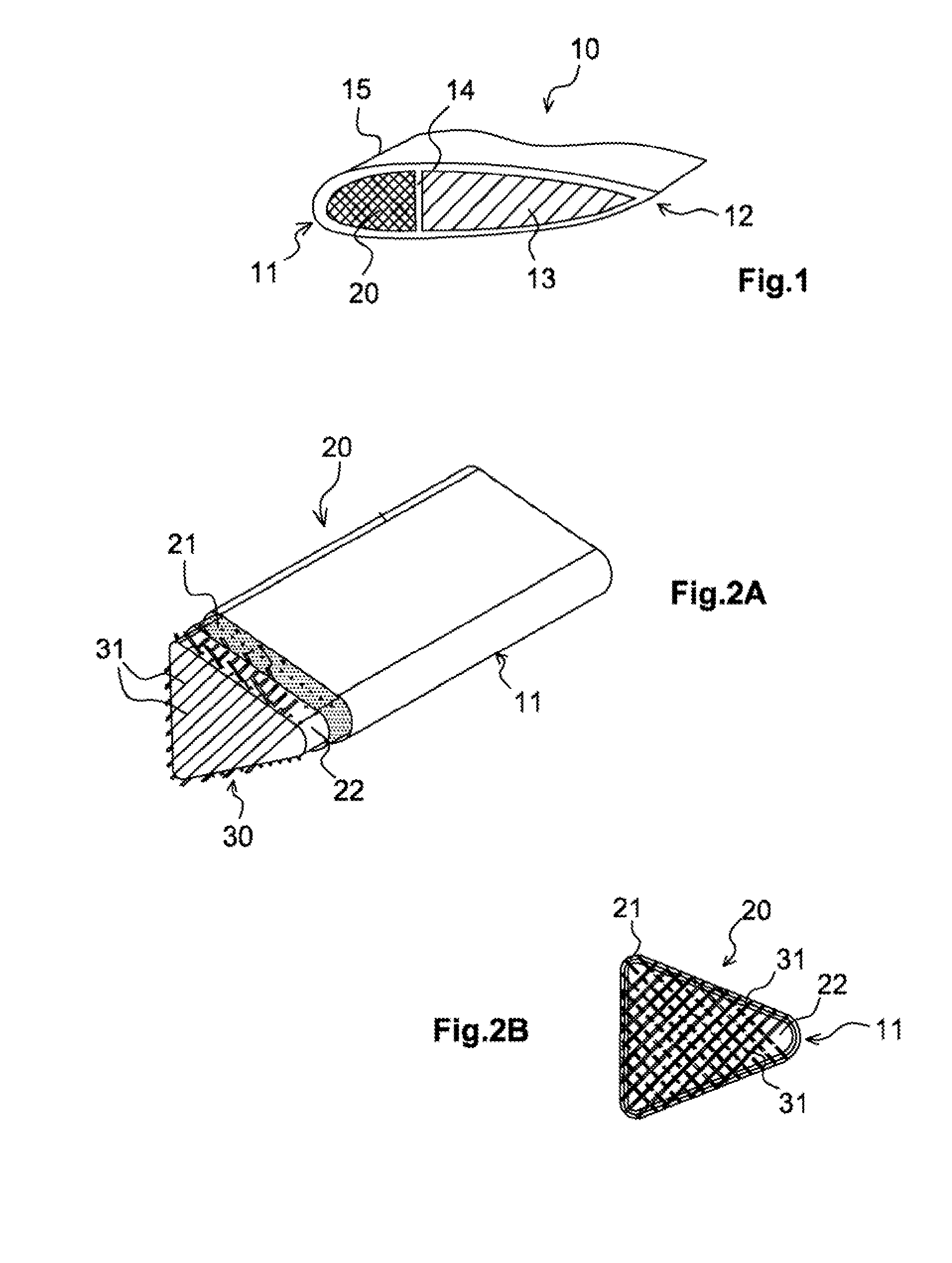

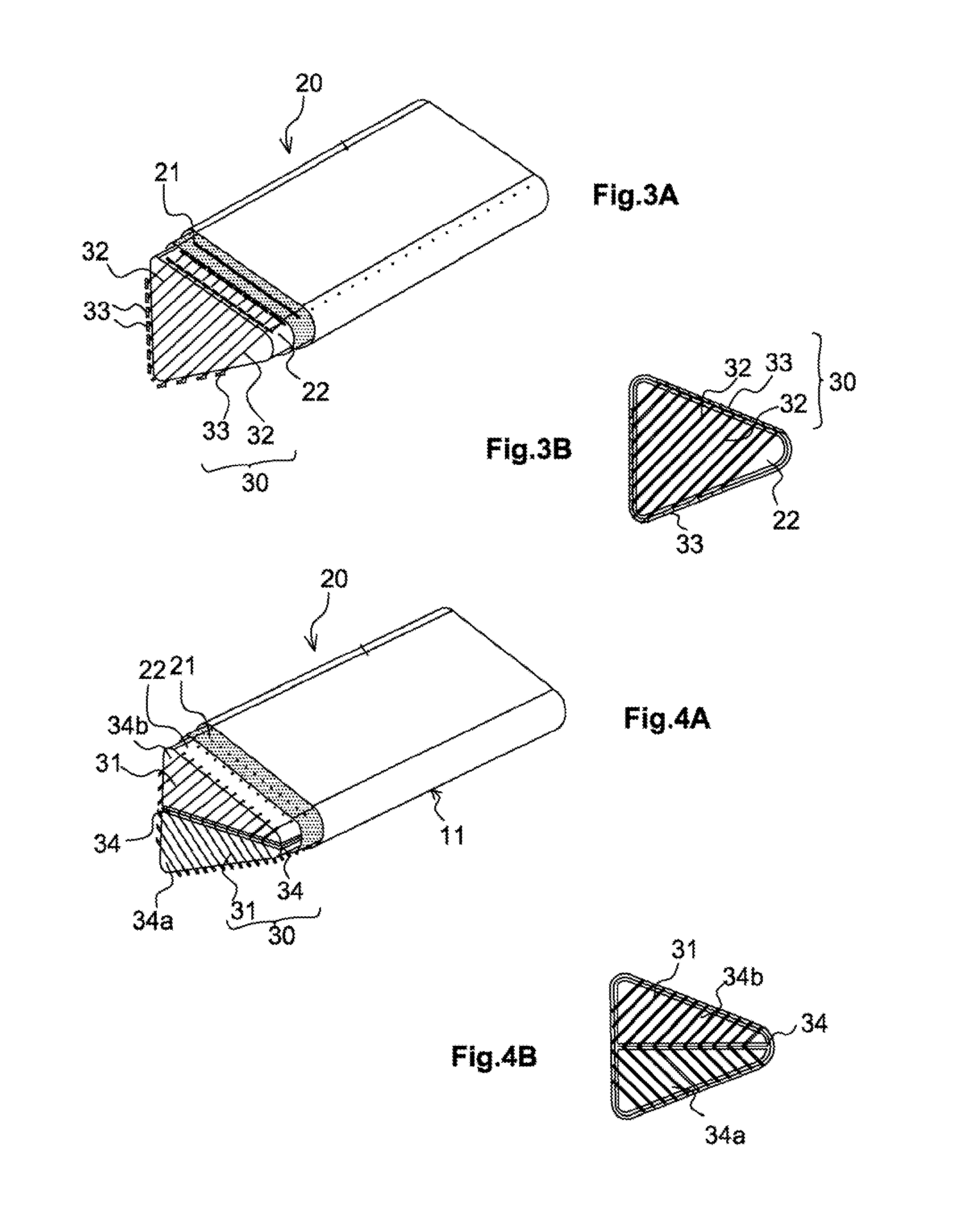

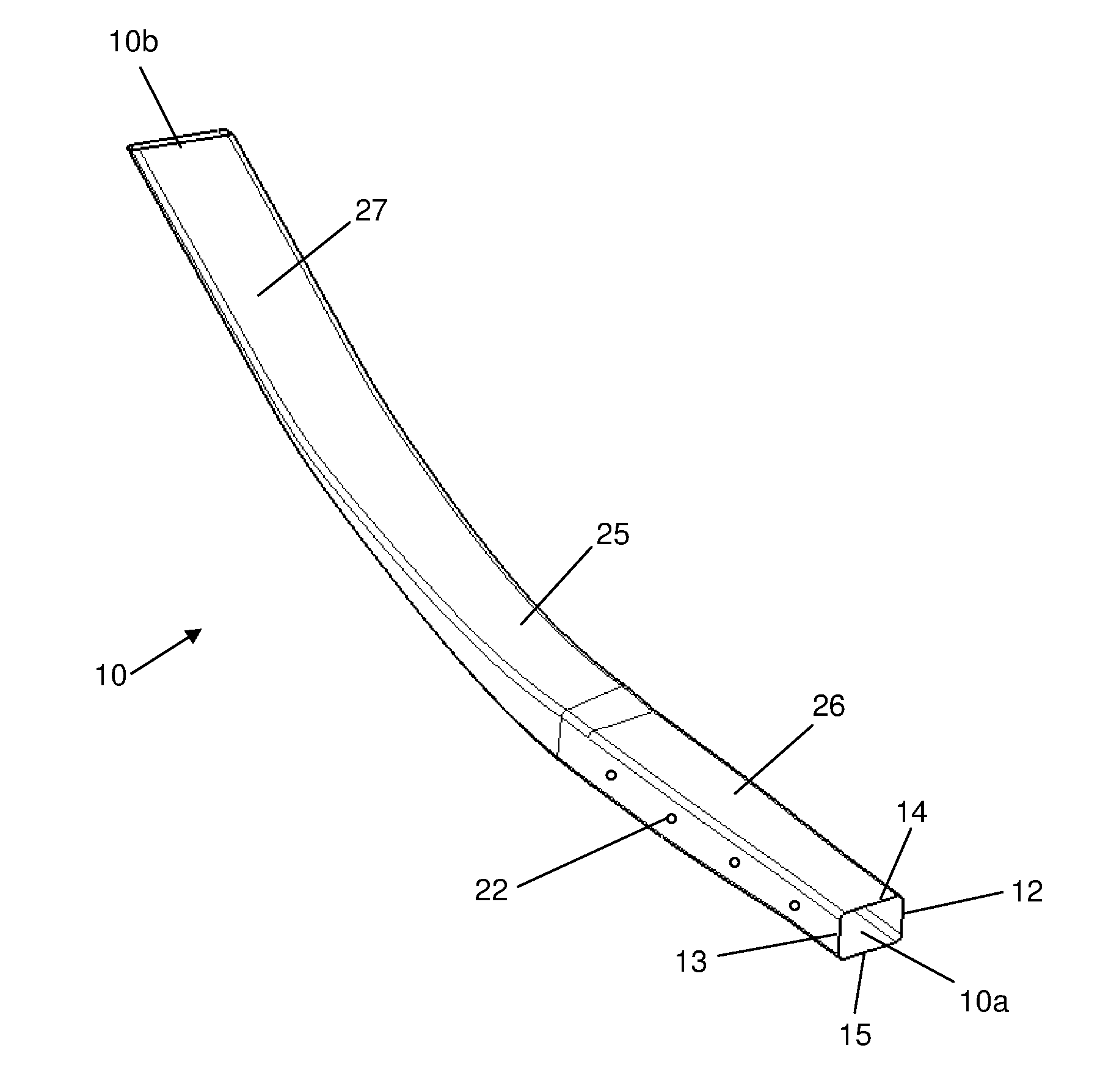

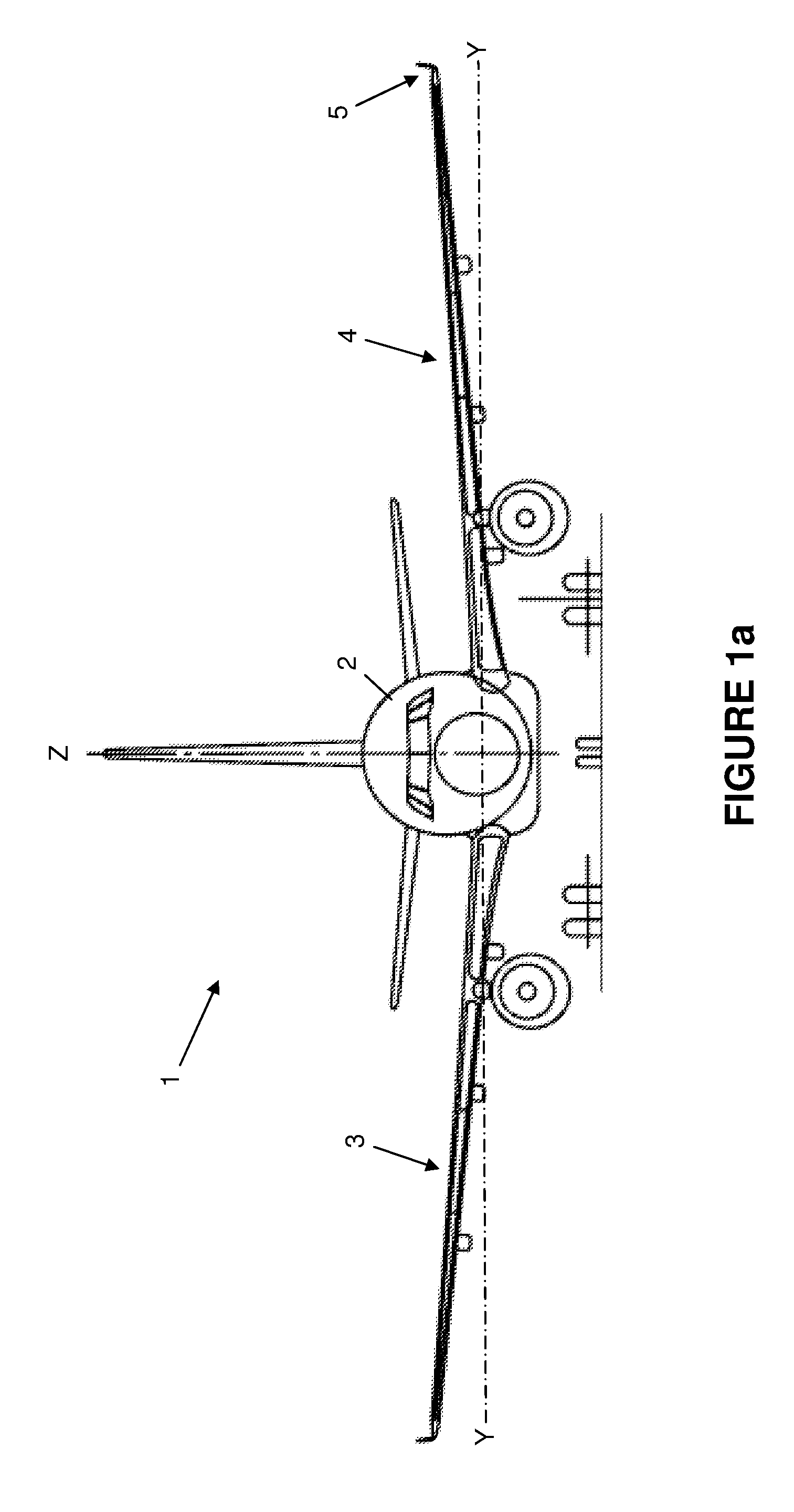

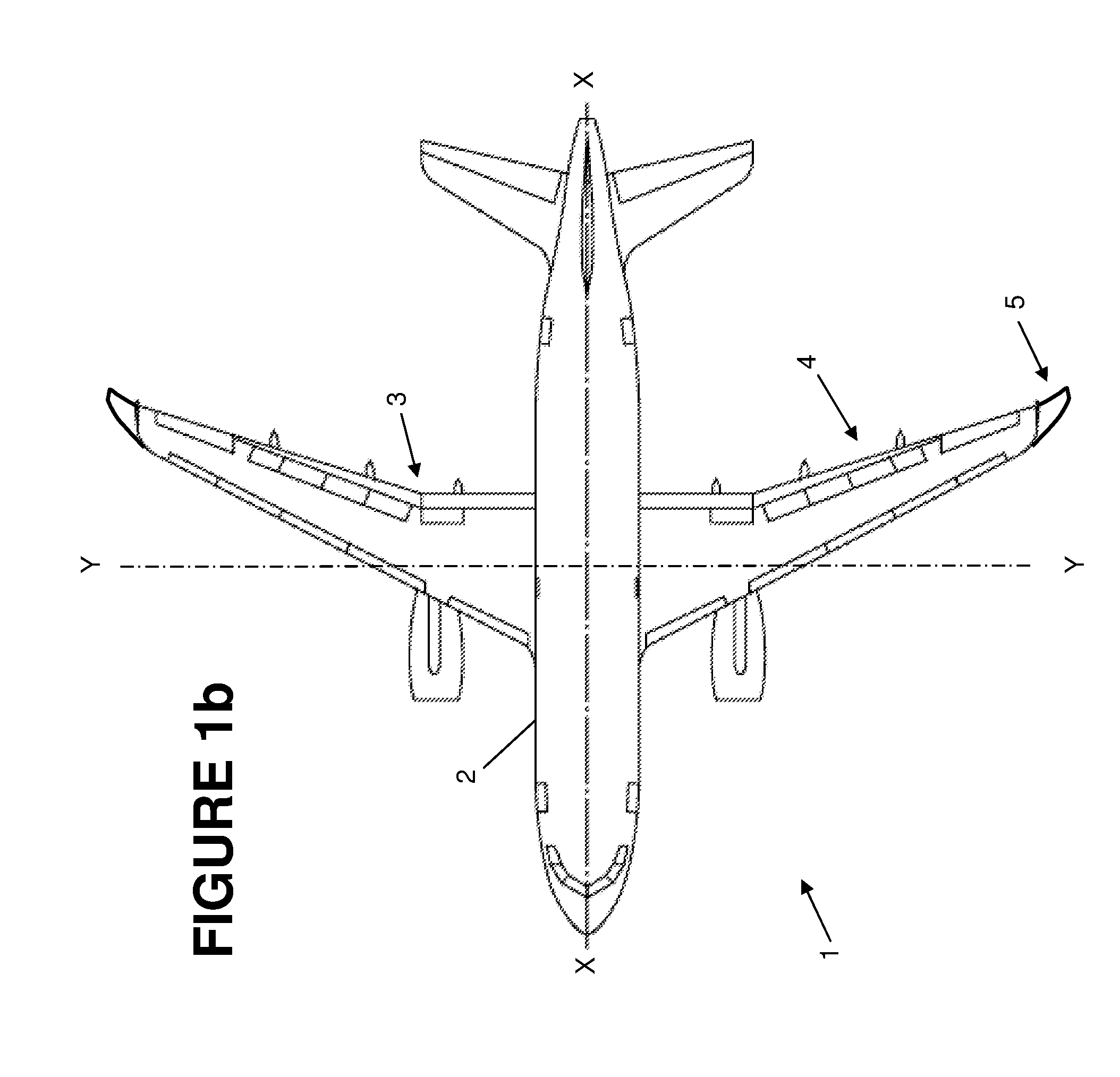

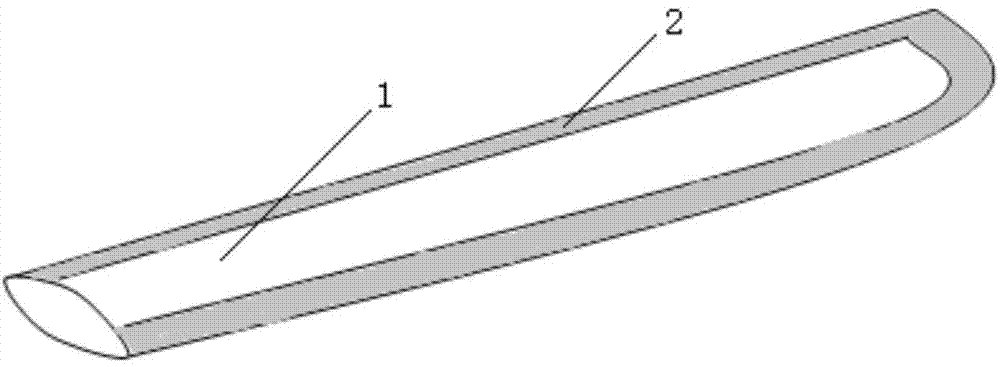

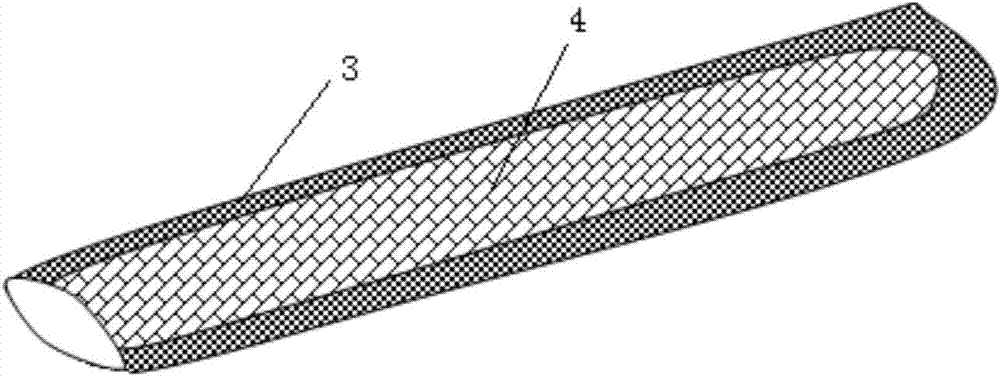

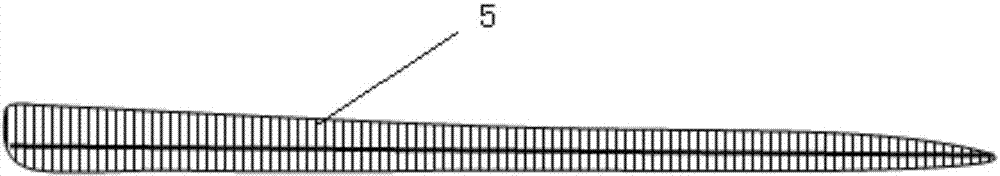

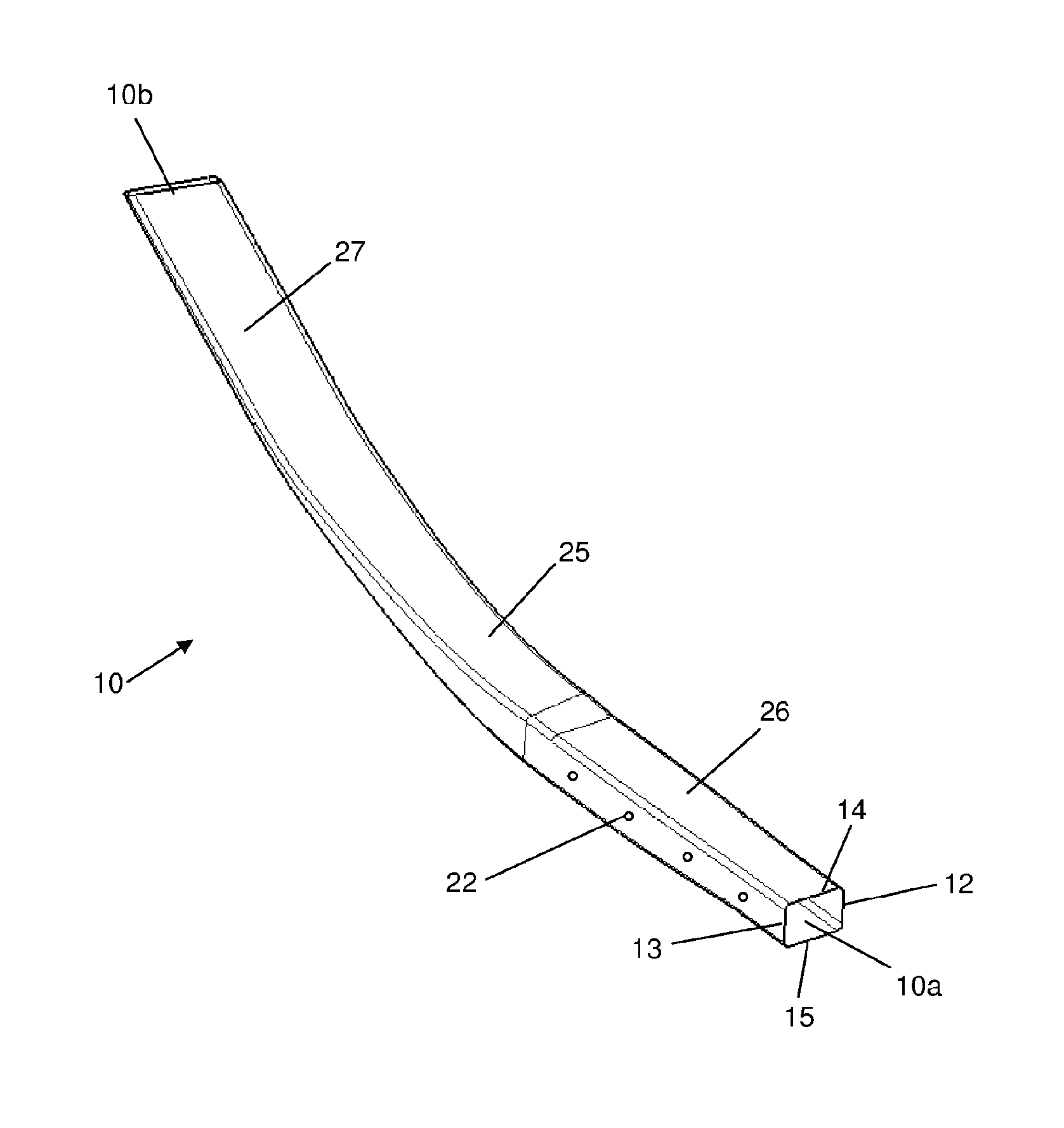

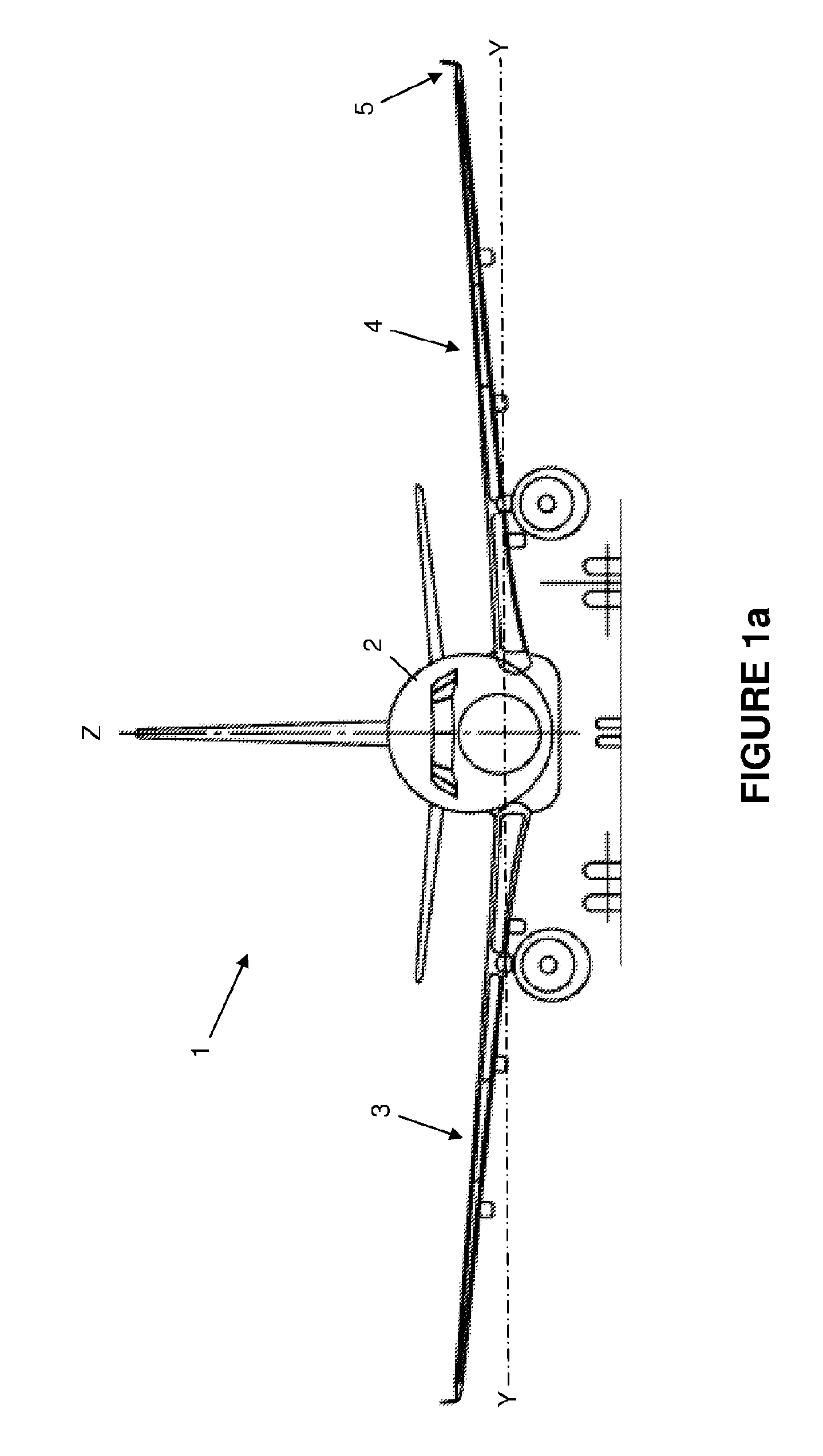

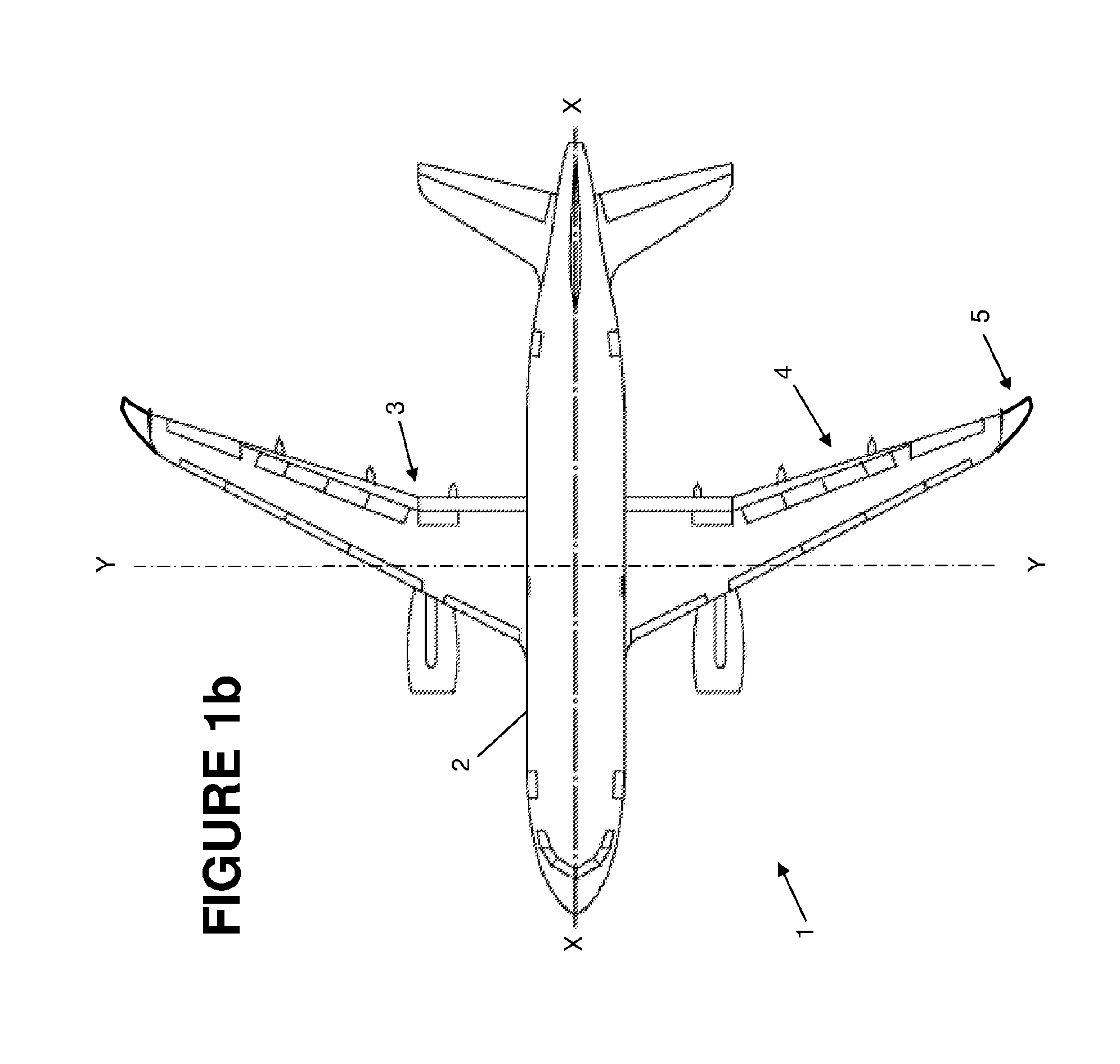

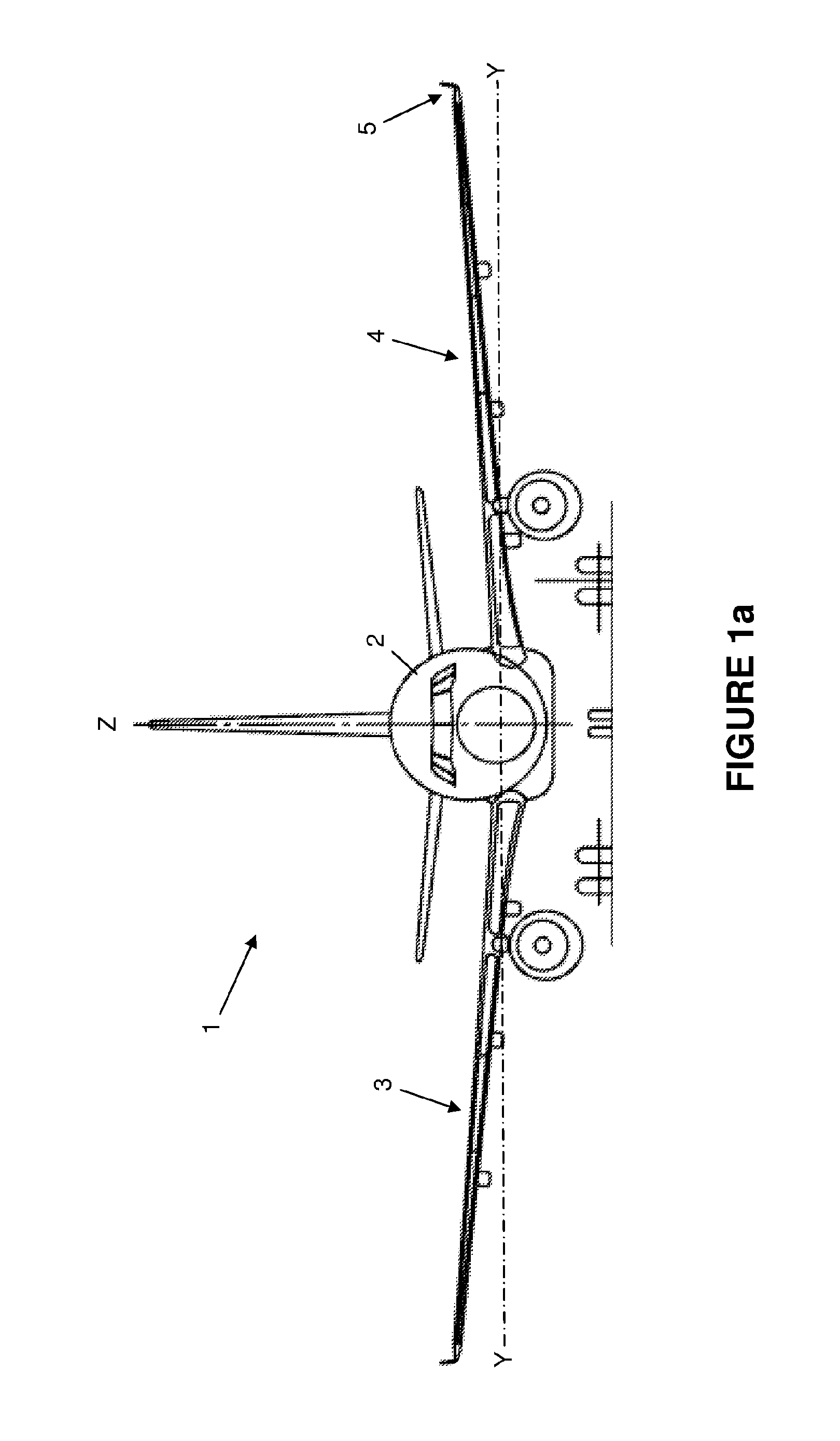

Braided composite spar

ActiveUS9896186B2Increasing the fibre pitchReducing circumferenceInfluencers by generating vorticesLamination ancillary operationsClockwiseBraided composite

A braided composite spar or preform for a braided composite spar with a plurality of tubular plies of braided fibers. Each ply has a first set of fibers which wind in a clockwise direction in a first series of turns with a pitch between each adjacent pair of turns, and a second set of fibers which wind in an anti-clockwise direction in a second series of turns with a pitch between each adjacent pair of turns. The first and second sets of fibers in each ply are intertwined to form a braided structure. The spar or preform extends lengthwise from a root to a tip and has a tapered portion which tapers inwardly towards the tip. Each ply has a circumference in the tapered portion which reduces as it tapers inwardly. For at least one of the plies the pitches of the first and second sets of fibers increase continuously as the ply tapers inwardly in the tapered portion. The spar or preform can be used to provide a tubular main spar for a winglet. The winglet also has a front spar with a front spar web, an upper front spar cap, and a lower front spar cap. An upper skin of the winglet is joined to the braided spar and the upper front spar cap. A lower skin of the winglet is joined to the braided spar and the lower front spar cap.

Owner:AIRBUS OPERATIONS LTD

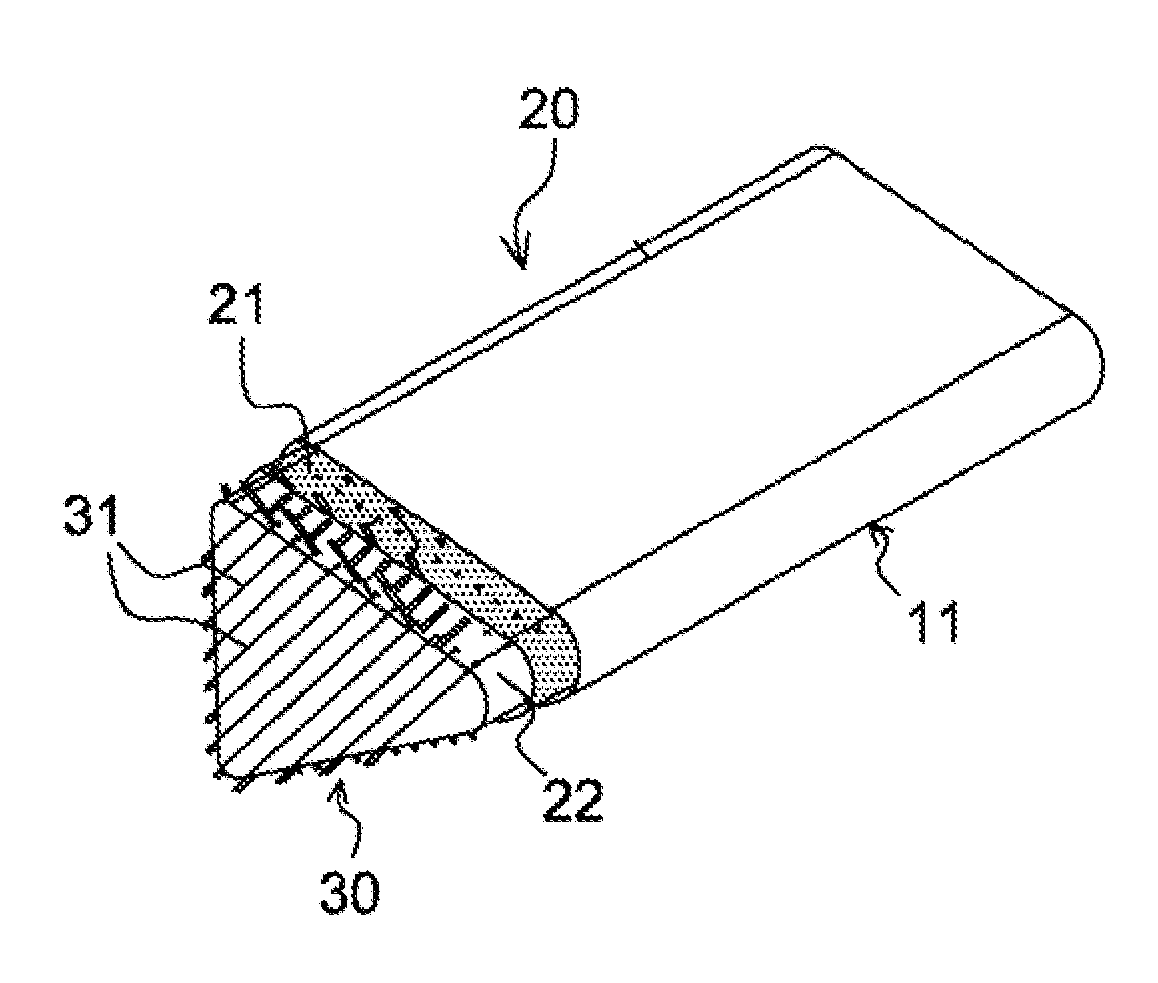

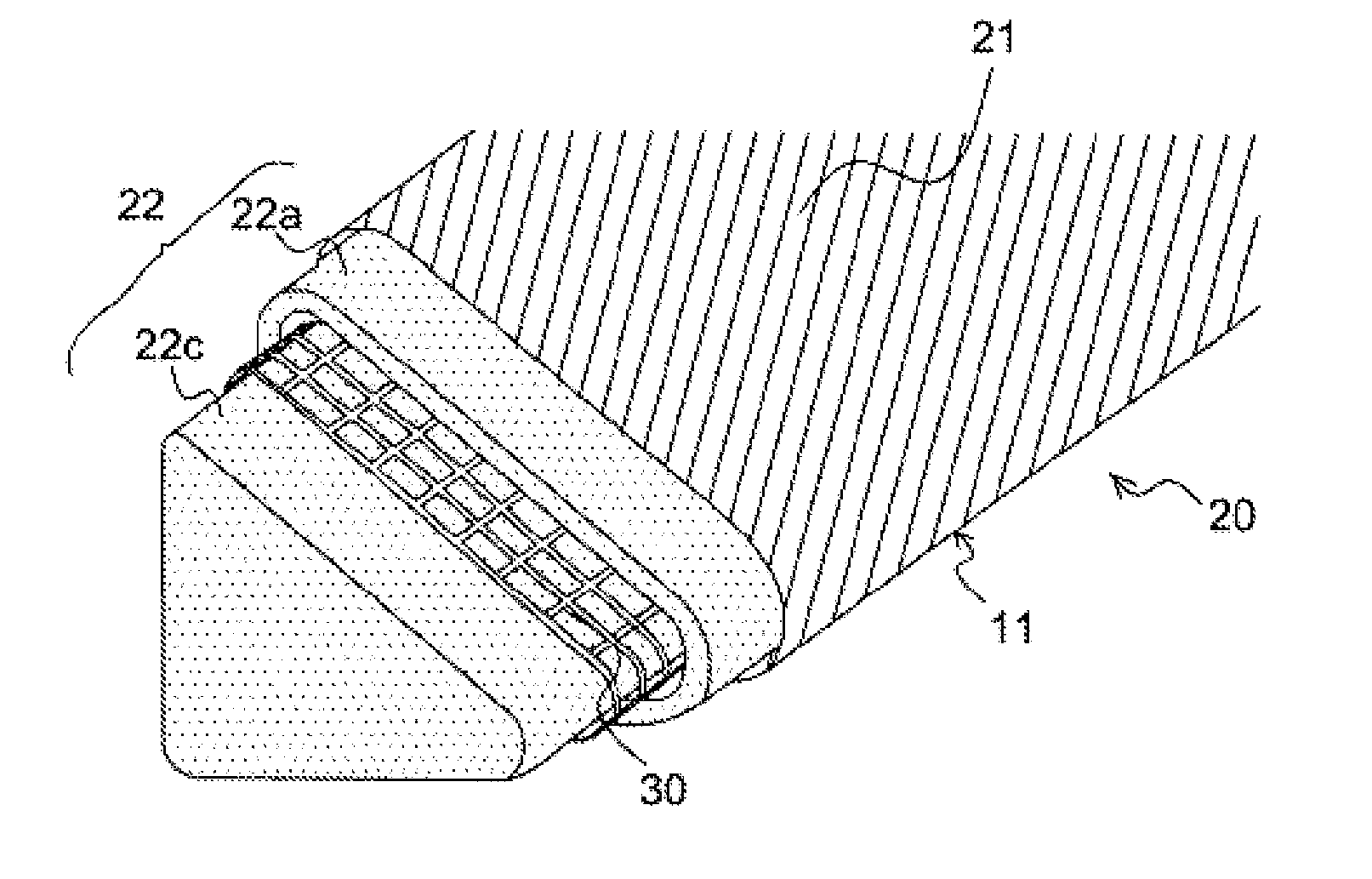

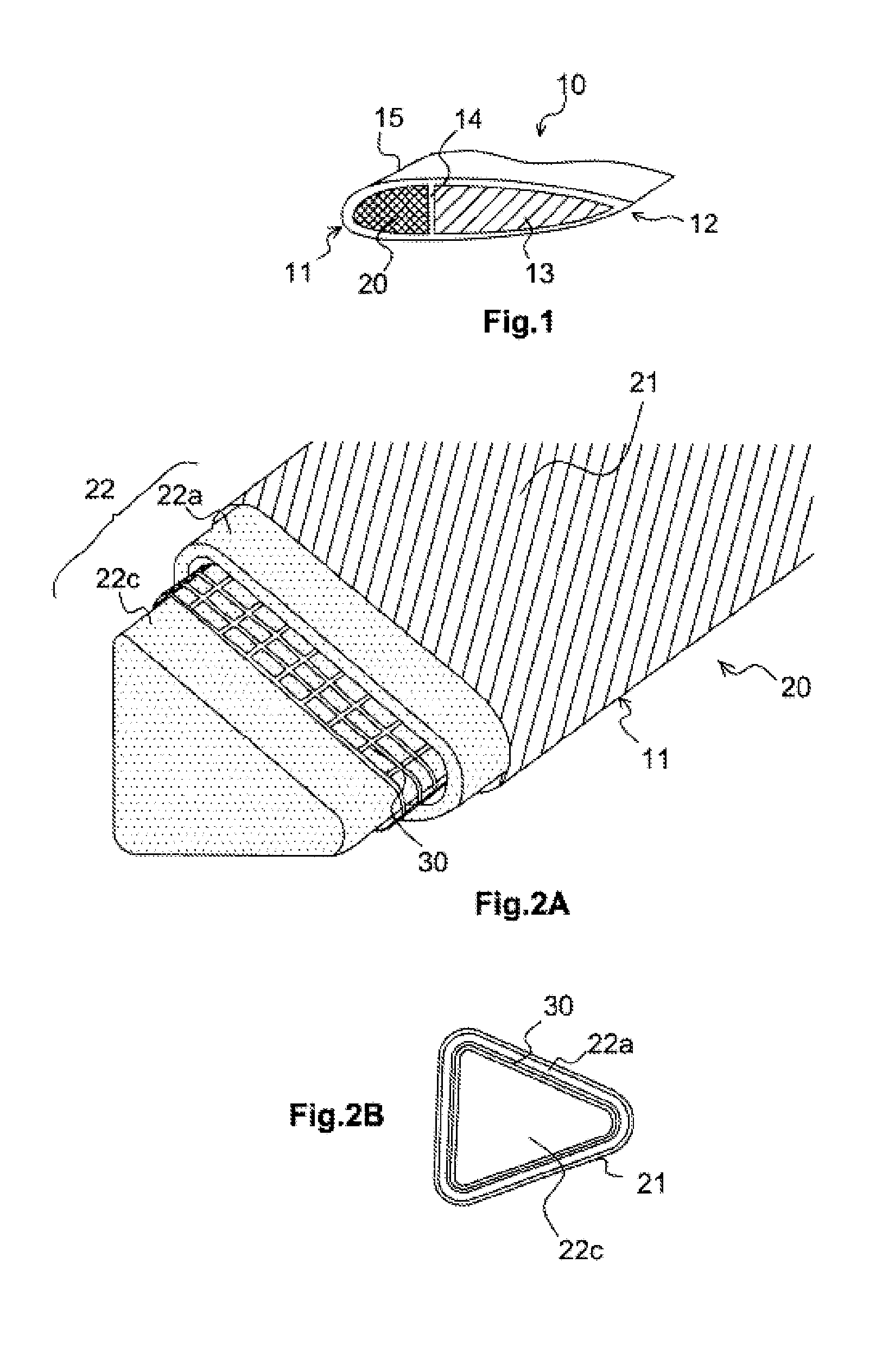

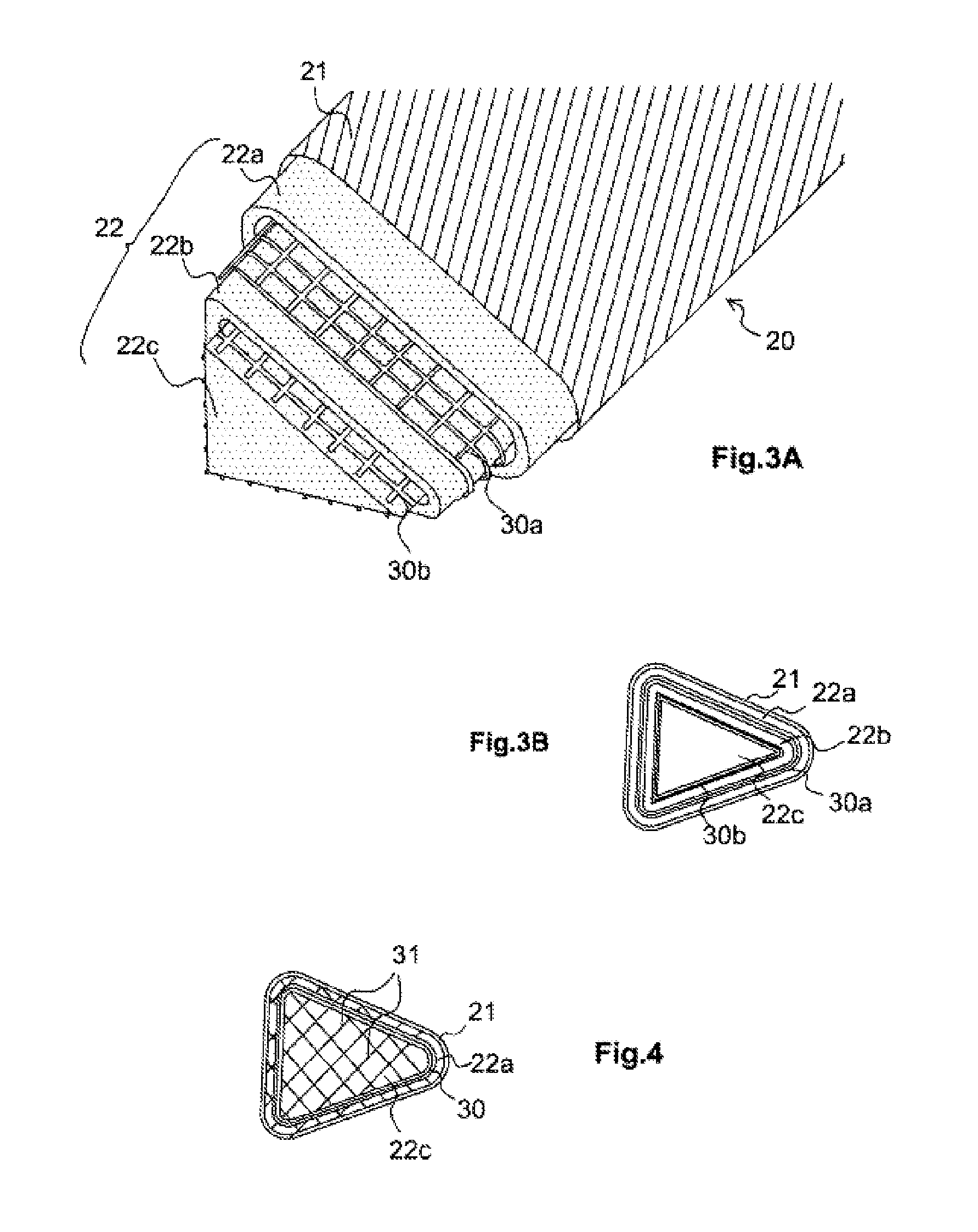

Energy absorption device for aircraft structural element

ActiveUS20150344125A1Reduce threatOvercome disadvantagesPropellersLayered productsNuclear engineeringEnergy absorption

A device for absorbing kinetic energy for an aircraft structural element undergoing a dynamic impact. The device includes an outer enclosure made from a braided composite material configured to preserve its integrity after an impact, a foam core, contained in the outer enclosure and to at least partially fill the outer enclosure. The foam core is configured to at least partially absorb the kinetic energy generated by the impact. Reinforcing elements are integrated at least partially into the foam core to dissipate, combined with the form core, the kinetic energy generated by the impact. The reinforcing elements includes discontinuous threads inserted into the foam core by stitching, and each discontinuous thread includes an L- or T-shaped head, folded down outside the outer enclosure.

Owner:EURON AERONAUTIC DEFENCE & SPACE

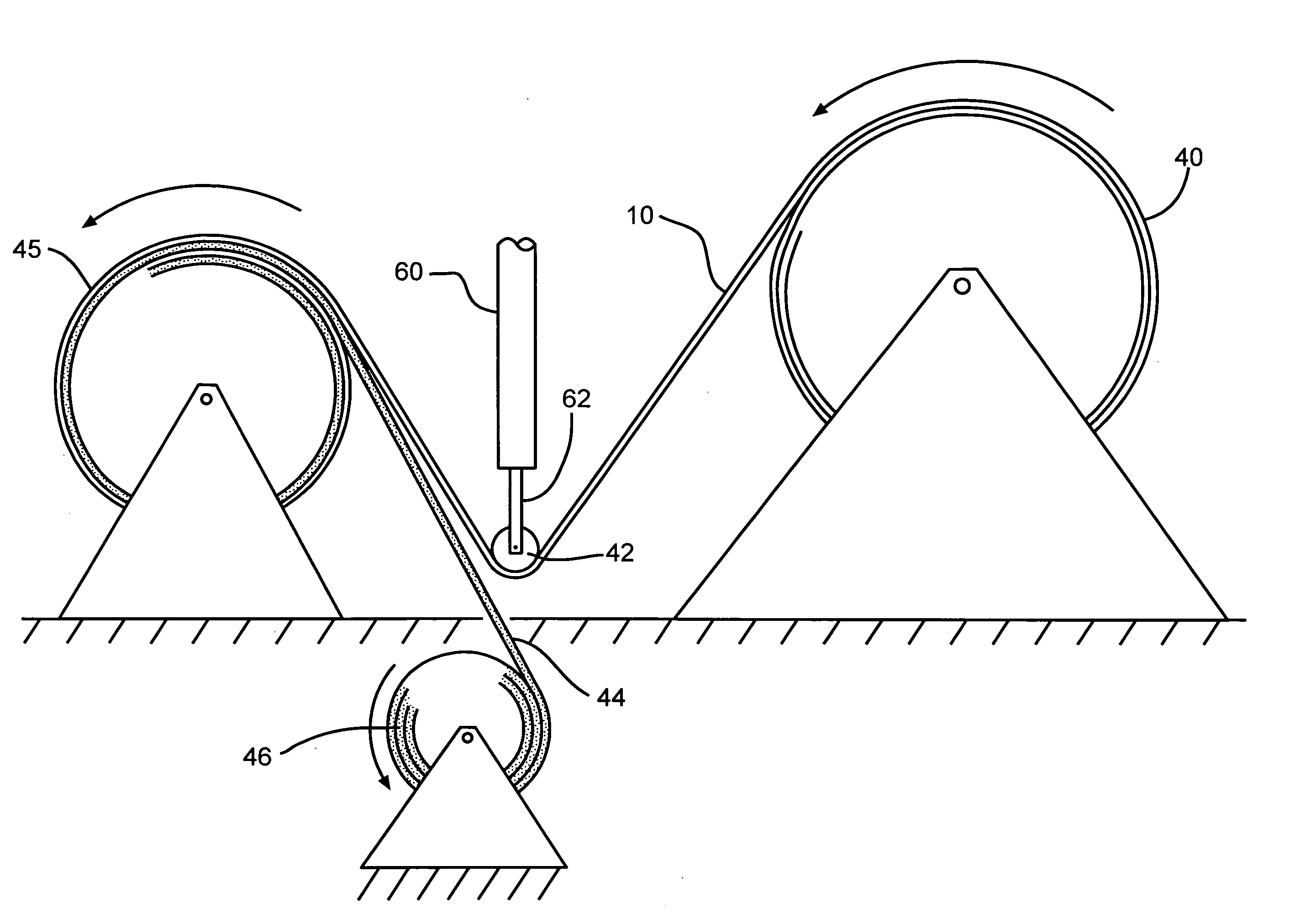

Method and apparatus for shipping braided composite reinforcing fabric

By the present invention method and apparatus is disclosed whereby a triaxial braided composite reinforcing fabric having axial yarns of varying length may be wrapped about a cylindrical shipping spool without deformation of the braided fabric. A tensioning device is interposed between the braiding tool and shipping or storage spool whereby the individual variable length axial yarns are subjected to constant tensioning. As the braided fabric is wound upon a cylindrical shipping spool, a conformable foam layer is interposed between each layer of braided fabric thereby permitting each axial yarn to seek out its own diameter by compressing the layer of conformable foam upon which it is wrapped.

Owner:A&P TECH

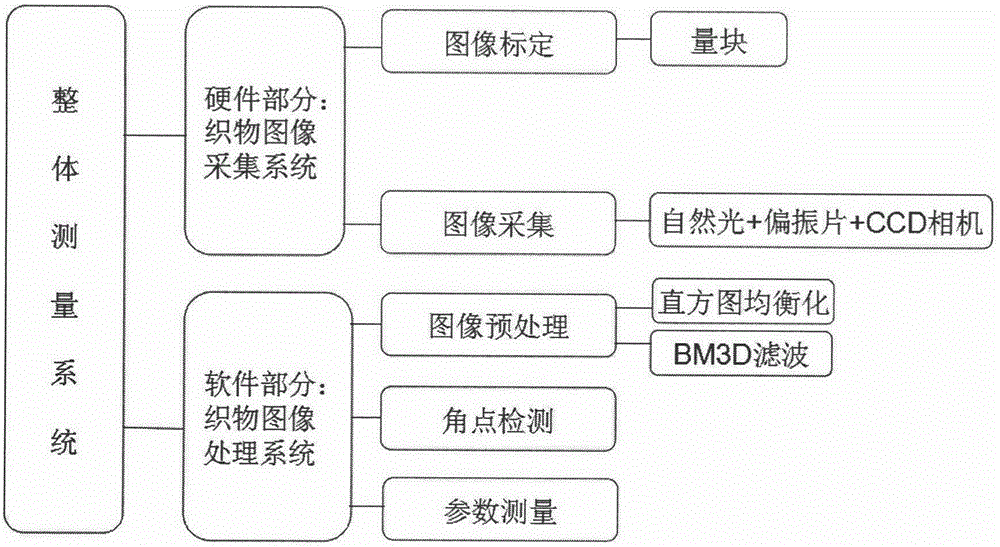

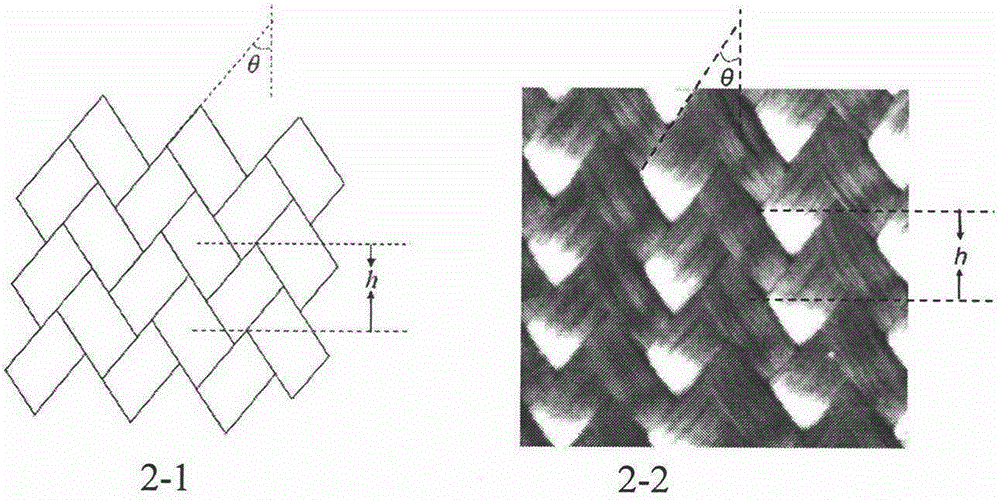

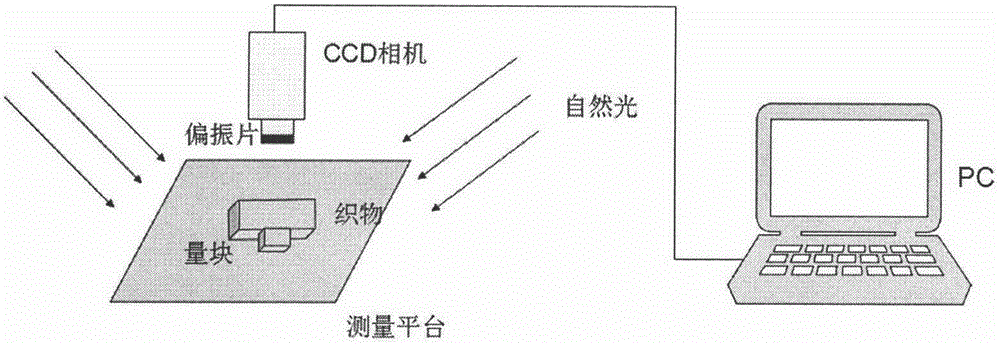

Automatic measurement system for surface parameters of prefabricated component of three-dimension braiding composite material

The invention relates to an automatic measurement system for the surface parameters (the braiding angle and the pitch) of a prefabricated component of a three-dimension braiding composite material. The system comprises a hardware portion and a software portion; The hardware portion serves as a collection system of fabrics, and comprises image calibration based on a gauge block and image collection based on a natural light plus Polaroid plus CCD camera scheme; and the software portion serves as a processing system of fabrics images, and comprises image preprocessing with histogram equalization and BMED (block matching 3D) filter, angular point detection and parameter measurement. The Polaroid principle is combined with the CCD camera to effectively reduce adverse influence, caused by surface reflection of the prefabricated component of the carbon fiber material, on image processing; the angular point detection algorithm, in which clone connection, least square fitting, autocorrelation and ACSS are combined, improves the accuracy of ACSS angular point detection algorithm; and each braiding angle and each pitch of images of the prefabricated component of the three-dimension braiding composite material can be measured automatically.

Owner:思腾合力(天津)科技有限公司

Three-dimensional braided composite material propeller blade of ship and manufacturing method thereof

The invention discloses a three-dimensional braided composite material propeller blade of a ship and a manufacturing method thereof. A design of a core mode for supporting of a preform is conducted according to the requirement of marine power, and the design comprises determination of a blade main structure and specific strengthening part structures; according to the structure of the core mode and the strengthening design requirement, the category of a high performance fiber and a key characteristic of hybrid fiber yarn are determined, and the manufacturing of the hybrid fiber yarn is performed; the hybrid fiber yarn is adopted and the three-dimensional braided technology is applied to conduct continuous braiding forming of the propeller blade hybrid fiber preform; thermosetting resin adhesive glue solution is taken as a substrate, a vacuum infusion technology and a thermosetting process are adopted to conduct resin impregnation and vacuum solidification treatment on the hybrid fiber blade preform, and the three-dimensional braided propeller blade of the ship is obtained. The application of the three-dimensional braided structure and the combined process of the vacuum infusion and the thermosetting improve the strength of the propeller blade, and the production efficiency of the blade is effectively improved.

Owner:山东宽原新材料科技有限公司

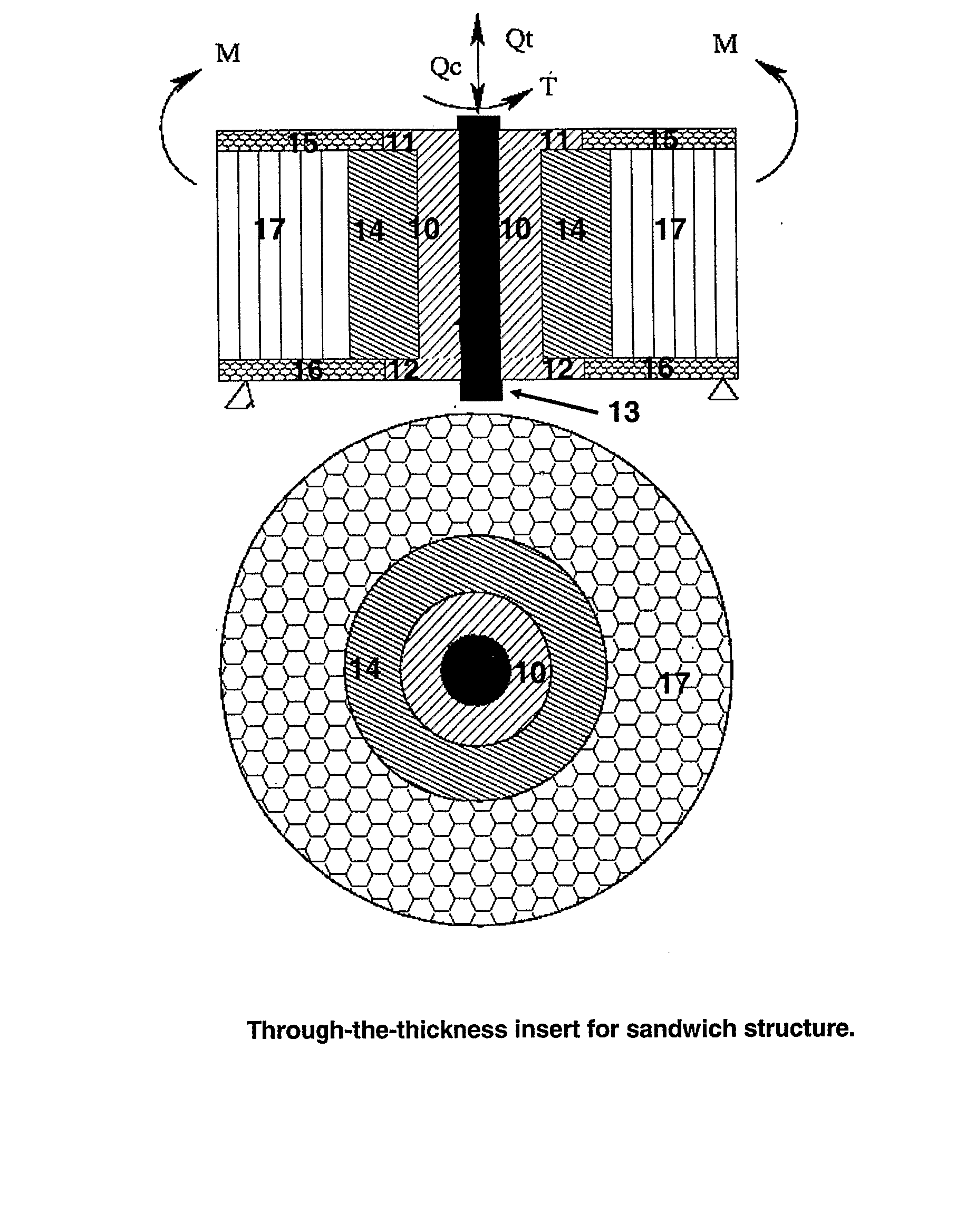

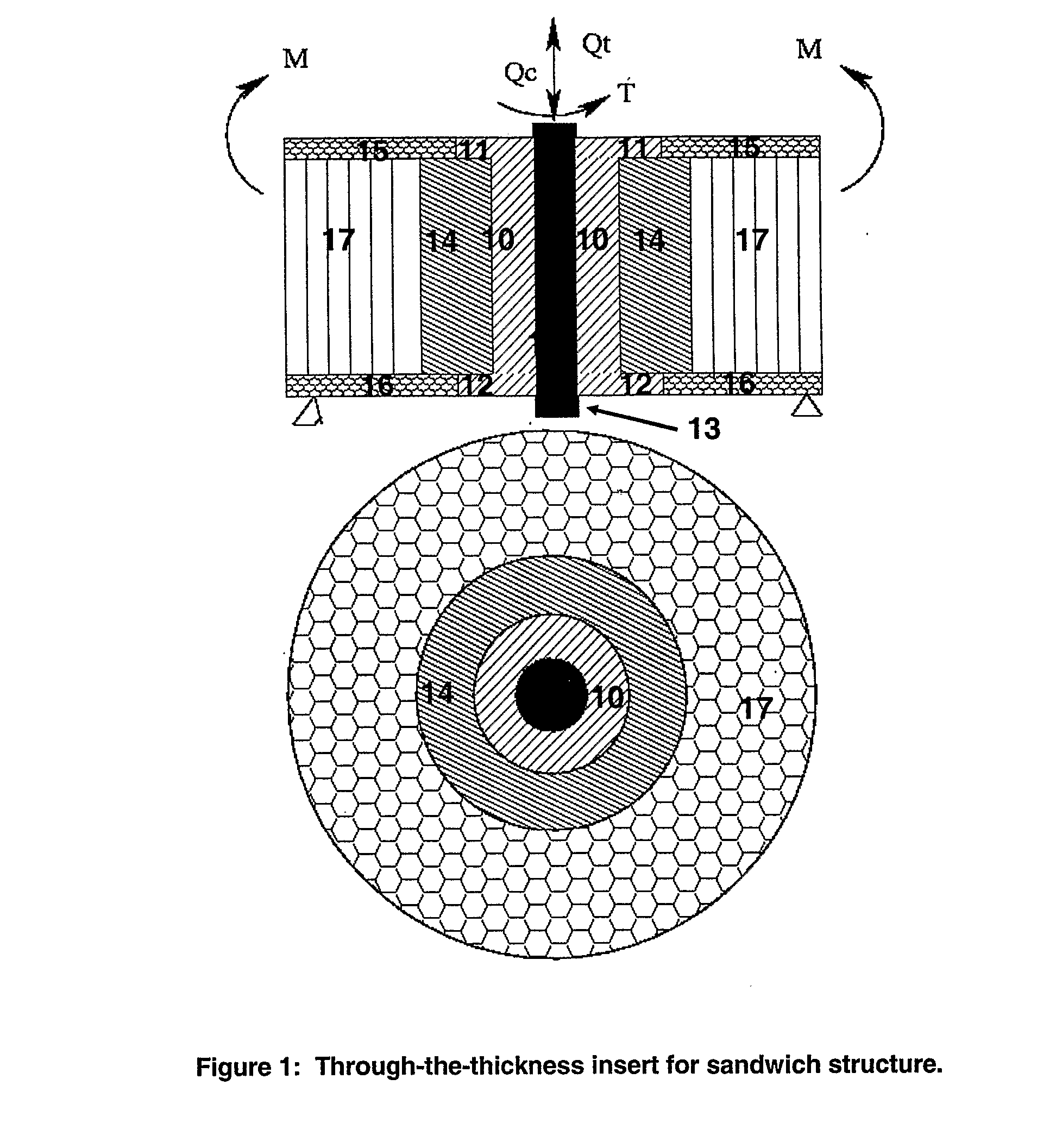

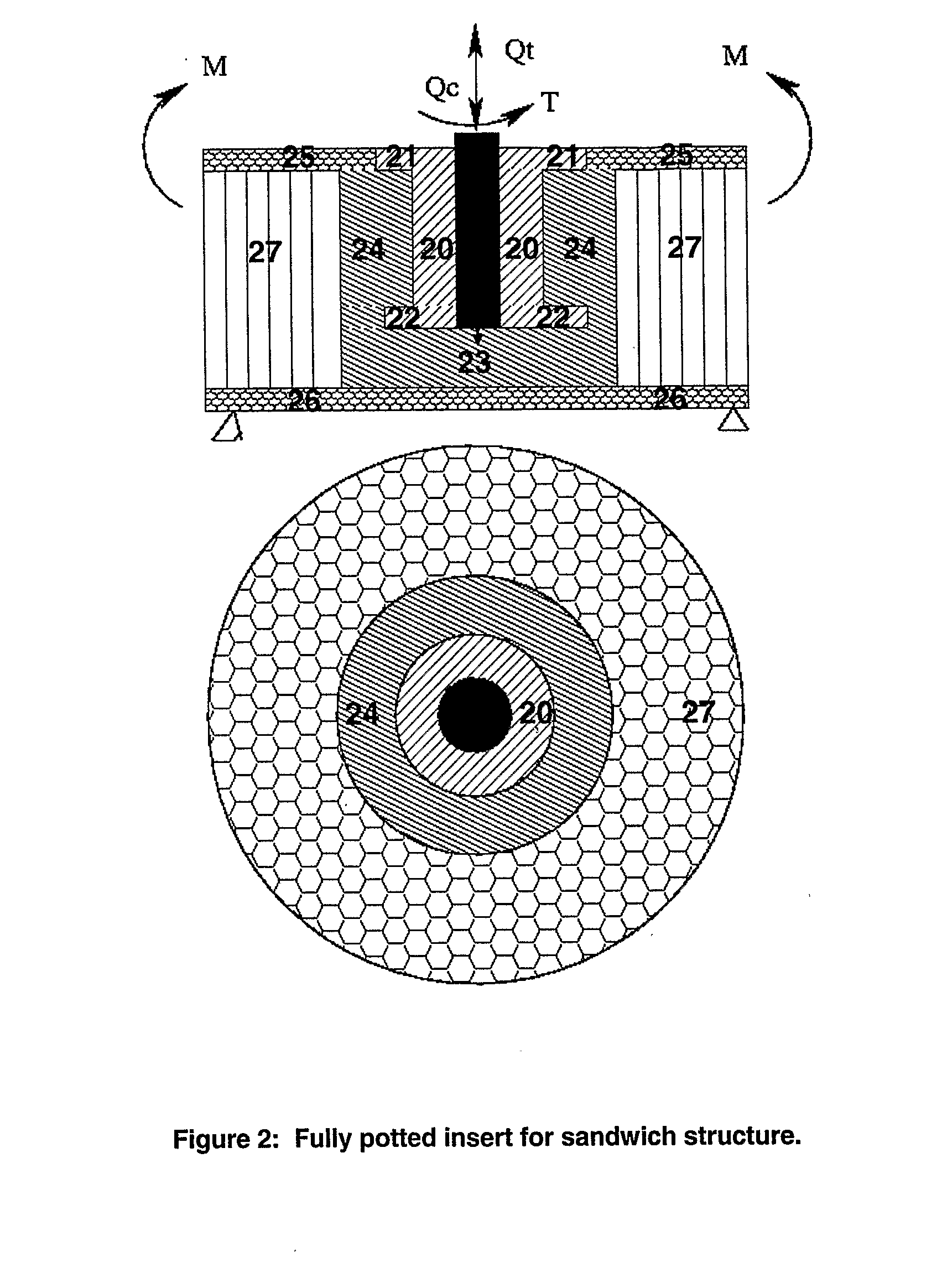

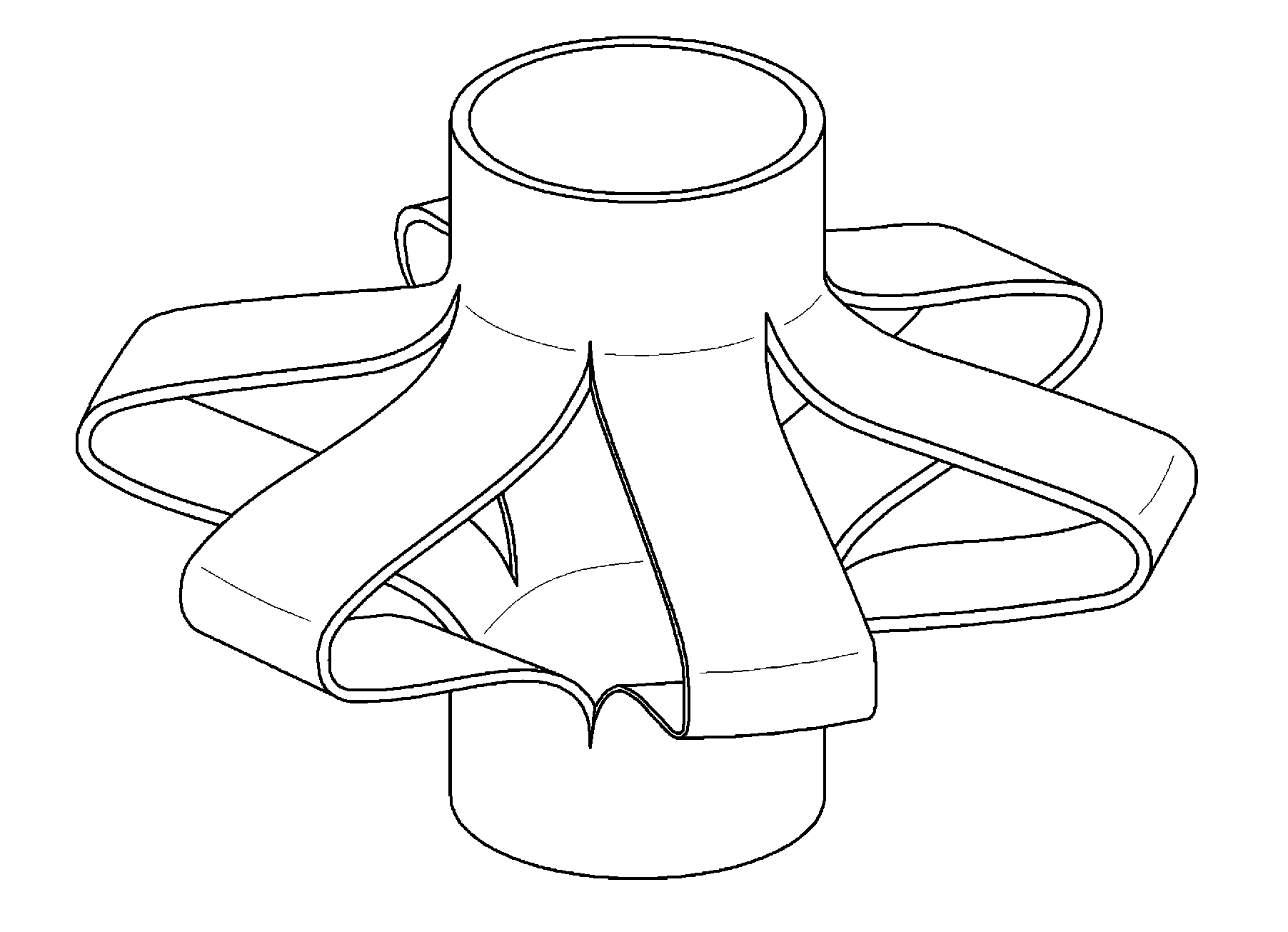

Novel Strength Enhancing Insert Assemblies

InactiveUS20080008521A1Reduce stress concentrationHigh strengthSheet joiningBranching pipesStress concentrationStress distribution

Insert assemblies of high specific strengths to reduce stress concentration at locations where Multidirectional stresses act on sandwich structures have been designed based on mapping stress distribution and failure initiation. The insert assembly comprises of insert (10, 20, 30), potting material (14, 24, 34), core (17, 27, 37), lower face plate (16, 26, 36), Upper face-plate (15, 25, 35) and attachment (13, 23, 33). The insert materials are selected from 2D woven composites, 3D thermoelastic isotropic woven composites, 3D woven composites, 3D woven composites with multiple inserts and 3D functionally gradient woven composites. Specific strengths of inserts (10, 20, 30) of present invention are higher than the inserts of prior art.

Owner:INDIAN INSTITUTE OF TECHNOLOGY BOMBAY

Method of manufacturing corrugated preform using braiding process

Owner:HYUNDAI MOTOR CO LTD +1

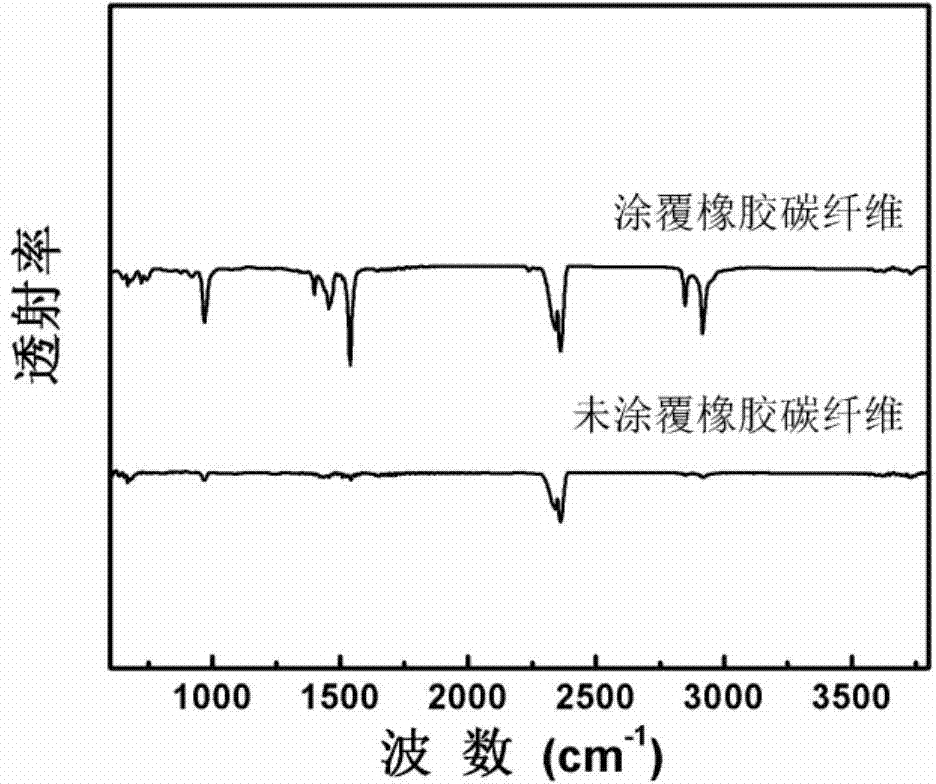

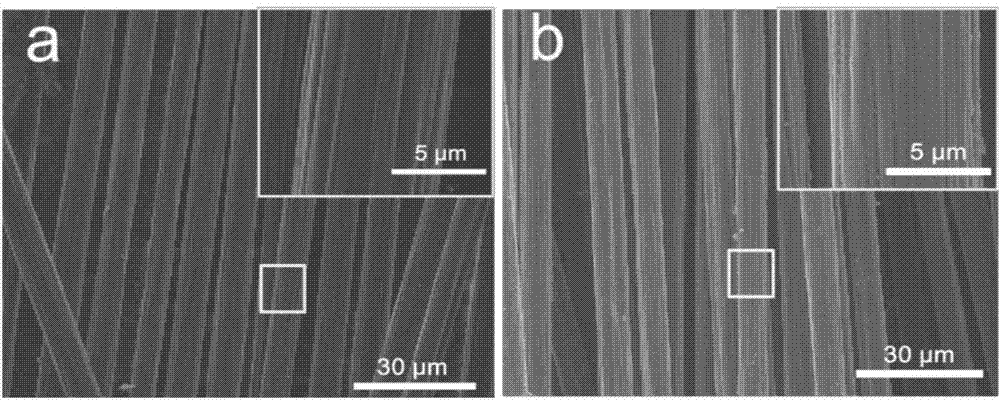

Preparation method of three-dimensional woven rubber coating carbon-fiber-reinforced composite material

The invention provides a preparation method of a three-dimensional woven rubber coating carbon-fiber-reinforced composite material, which comprises the following steps: preparing filler mixed powder; preparing a filler mixed solution; preparing an unvulcanized nitrile-butadiene rubber mixed solution; preparing nitrile-butadiene rubber mixed rubber cement; taking the dissolved unvulcanized nitrile-butadiene rubber mixed solution, and pouring the filler mixed solution while stirring; sequentially adding plasticizers DOA and DOS to obtain yellow viscous nitrile-butadiene rubber mixed rubber cement; preparing a rubber coating carbon fiber fabric; and preparing a damping composite material. The behaviors of the fiber-rubber interface and rubber-base interface are adjusted to implement the organic connection between the fiber and base, thereby obtaining the three-dimensional woven composite material with excellent damping characteristic.

Owner:TIANJIN UNIV

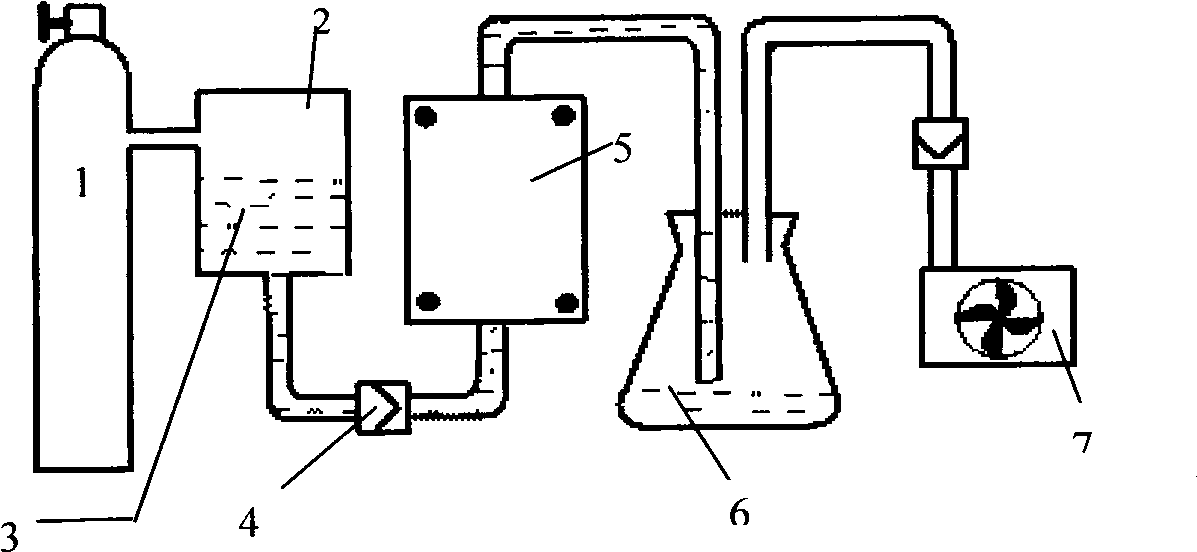

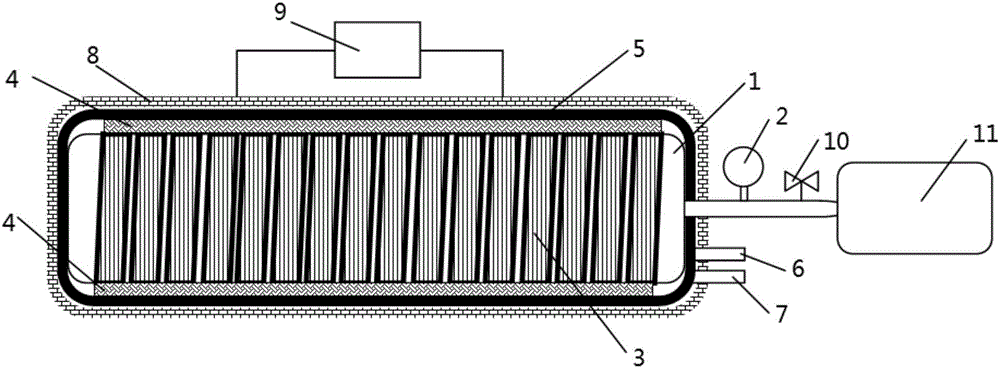

Forming device and forming method for tubular three-dimensional braided composite product

The invention relates to a forming device and a forming method for a tubular three-dimensional braided composite product. The forming device comprises a flexible core mold, an inward-contracting demolding device, a flexible RTM outer mold, a mold curing device and a medium circulation device, wherein the inward-contracting demolding device is arranged between the flexible RTM outer mold and the flexible core mold; the flexible curing device is arranged on the outer side of the flexible RTM outer mold; and the flexible core mold is connected with the medium circulation device. The forming device is applicable to forming of the tubular three-dimensional braided composite product; by adoption of the forming device, a curved tubular three-dimensional braided composite with various uniform interfaces and various irregular variable cross sections can be prepared; meanwhile, after preform fabric is subjected to braided molding, resin RTM impregnation and rapid curing molding can be performed continuously; and besides, the forming device has the function of quickly demolding the tubular three-dimensional braided composite product. Accordingly, the problem that a conventional metal or wood core mold is cumbersome in molding process, single in function and relatively low in production efficiency can be effectively solved.

Owner:SHANDONG UNIV

Braided composite spar

ActiveUS20160075425A1Reduce the overall heightIncreasing the fibre pitchInfluencers by generating vorticesLamination ancillary operationsEngineeringMechanical engineering

A braided composite spar or preform for a braided composite spar, comprising a plurality of tubular plies of braided fibres, wherein the spar or preform has a centre line which extends lengthwise from a root to a tip, and at least part of the centre line follows a curved path which does not lie in a single plane. The spar or preform can be used to provide a tubular main spar for a winglet. The winglet also has a front spar with a front spar web, an upper front spar cap, and a lower front spar cap. An upper skin of the winglet is joined to the braided spar and the upper front spar cap. A lower skin of the winglet is joined to the braided spar and the lower front spar cap.

Owner:AIRBUS OPERATIONS LTD

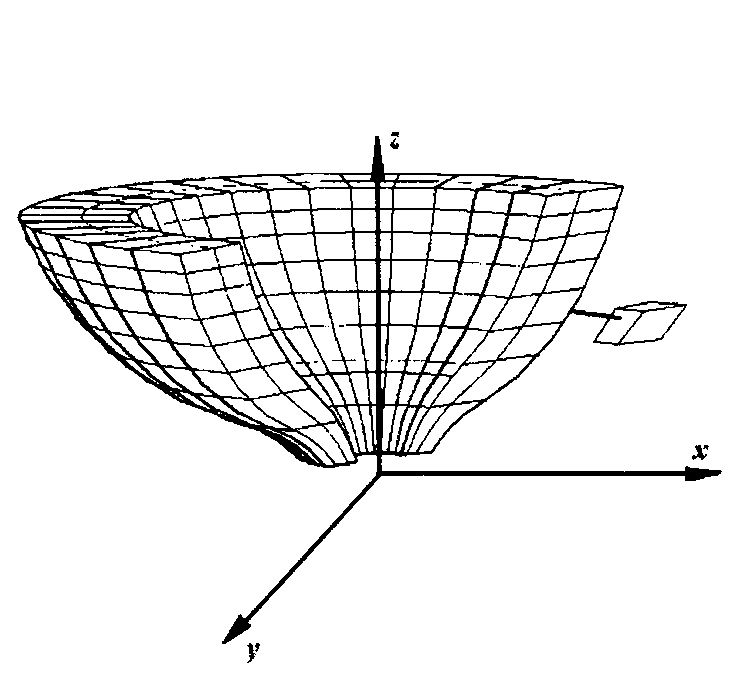

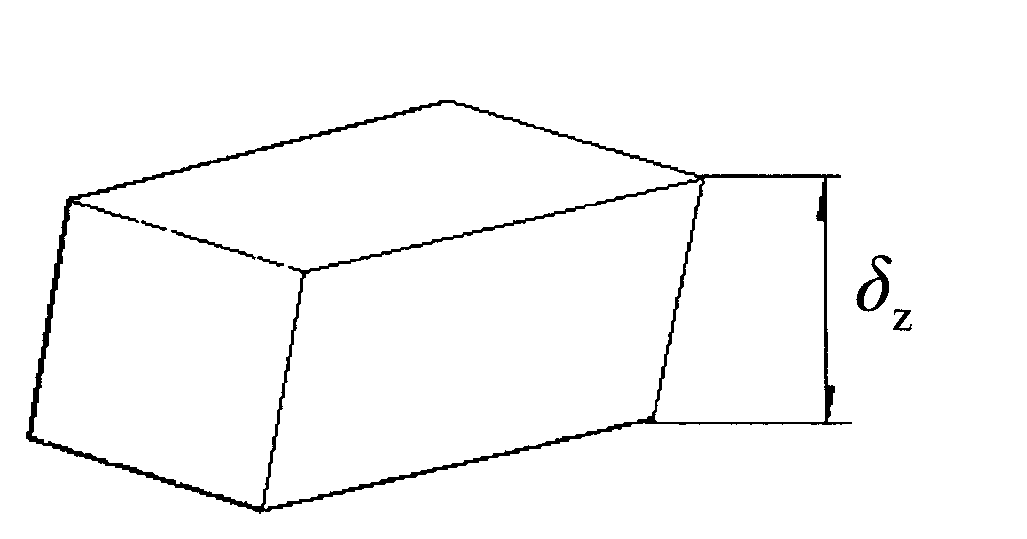

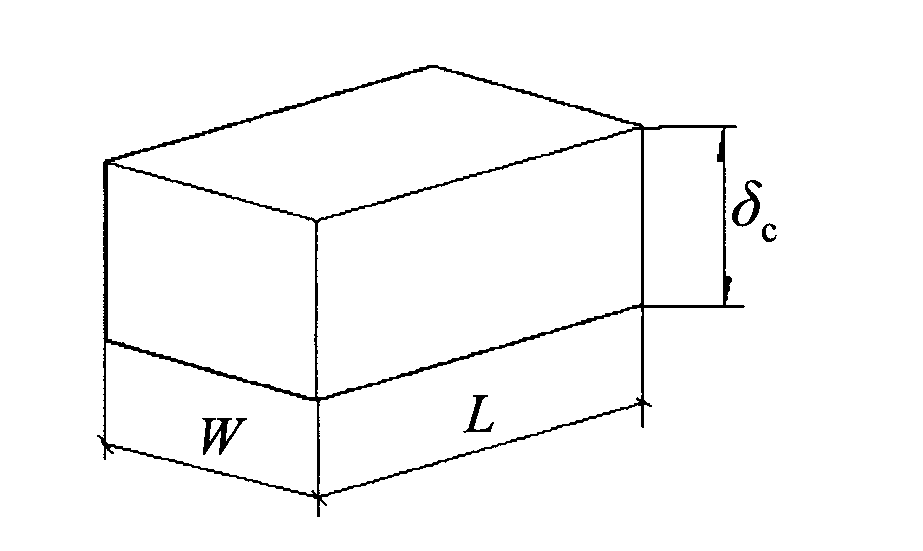

Self-adaption unit analyzing method for performance of three-dimensional woven compound material

ActiveCN102938019ASolving performance prediction problemsImprove forecast accuracySpecial data processing applicationsFiberEngineering

The invention relates to a self-adaption unit analyzing method for performance of a three-dimensional woven compound material. The self-adaption unit analyzing method comprises the following steps of: 1) defining a unit of a three-dimensional woven compound material with an abnormal section, namely a self-adaption unit; 2) equalizing the self-adaption unit to be a cuboid unit; 3) determining the volume percentage composition of whole fibers of the three-dimensional woven compound material with the abnormal section based on a self-adaption unit method; and 4) analyzing the elastic performance of the three-dimensional woven compound material with the abnormal section based on the self-adaption unit method. Aiming at the gradient of the performance of the three-dimensional woven compound material with the abnormal section, the invention provides the self-adaption unit capable of accurately predicating the performance and an equal method for accurately predicating the performance; and the invention provides a step length control method for digitally describing the performance, namely a model calculation precision can be improved through thinning step lengths of different coordinate directions. Compared with a predication model based on a single-cell method, the self-adaption unit analyzing method has the advantages that the problem of predicating the performance of the three-dimensional woven compound material with a complicated geometrical shape is effectively solved and the predication precision is higher.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD

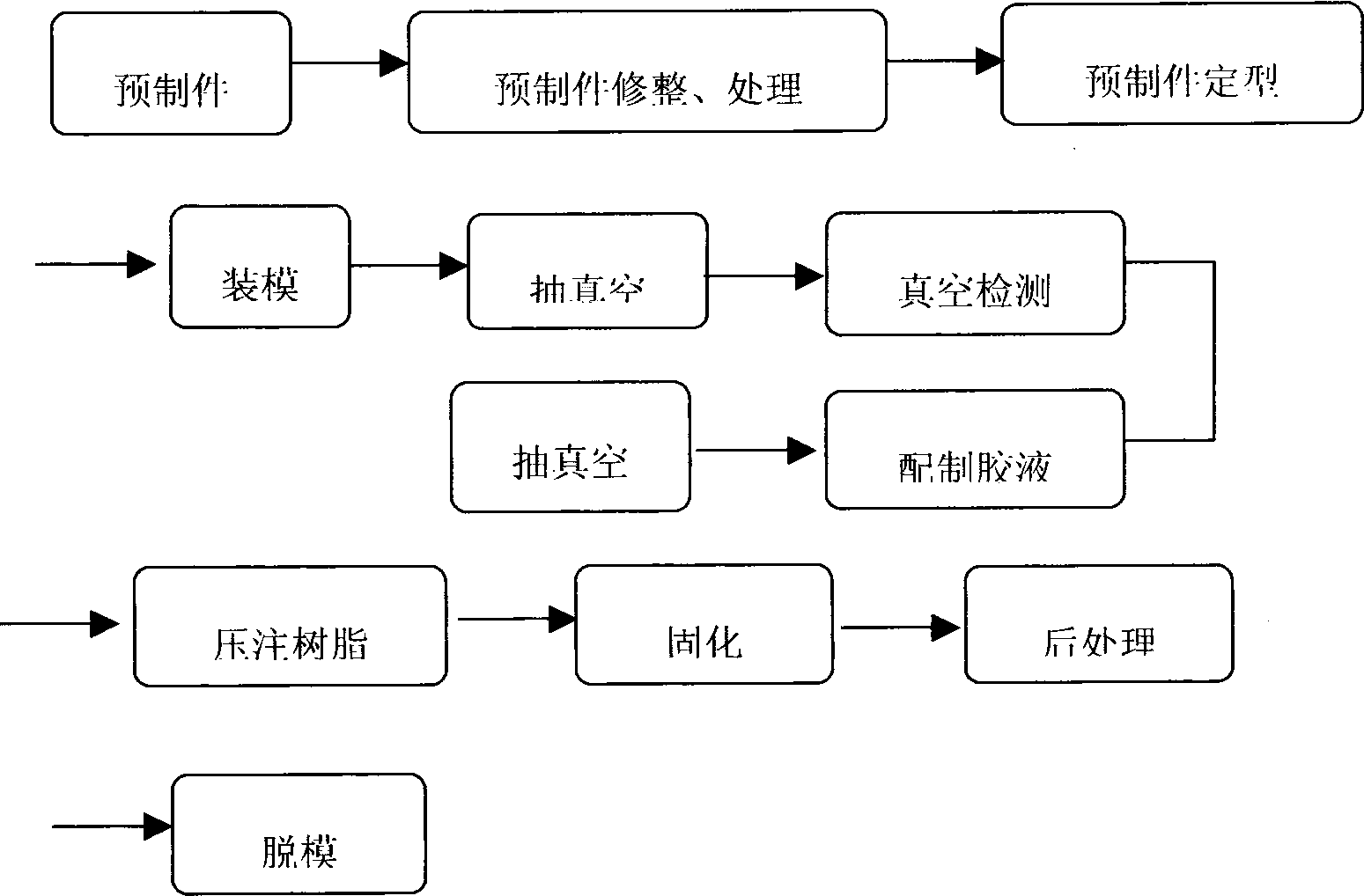

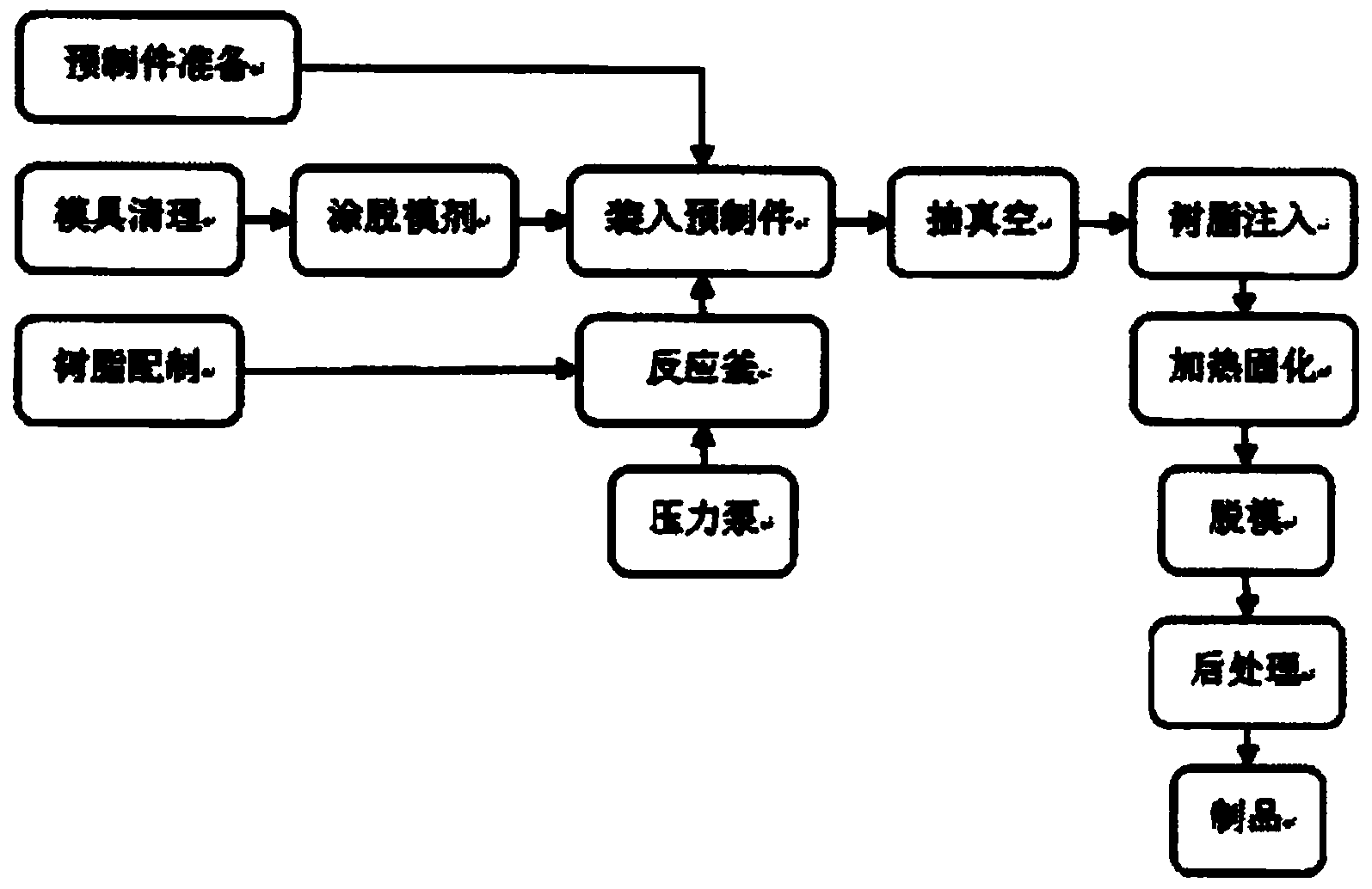

Forming process of resin-based three-dimensional braided composite material

The invention relates to a forming process of a resin-based three-dimensional braided composite material. The forming process comprises the following steps of (1) preparing prefabricated elements; (2) preparing a mold; (3), assembling the mold; (4) preparing resin; (5) injecting glue; (6) curing; and (7) opening the mold. The forming process of the resin-based three-dimensional braided composite material has the characteristics of low energy consumption, less environment pollution, accurate product size, good surface quality, high stability, high finished product rate, and capability of forming products with complex shapes. The mold manufacture and material selection are high in flexibility, and complex constructional elements with favorable surface quality and high dimension accuracy can be manufactured; the fiber volume of the composite material is high; the composite material product is low in porosity; the formed three-dimensional braided composite material generally is not required to be subjected to mechanical processing, and therefore, not only is the additional expense reduced, but also the fiber damage caused by post processing is also prevented. The forming process of the resin-based three-dimensional braided composite material is widely applied to the fields of aerospace, national defense, war industry, traffic transportation, buildings, civil industry and the like.

Owner:KUNSHAN WANFENG GARMENT

Energy absorption device for aircraft structural element

ActiveUS20150353185A1Reduce threatOvercome disadvantagesArmourPropellersEnergy absorptionNuclear engineering

A device for absorbing kinetic energy for an aircraft structural element undergoing a dynamic impact. The device includes an outer enclosure made from a braided composite material configured to preserve its integrity after an impact, and a foam core contained in the outer enclosure and to at least partially fill the outer enclosure. The foam core configured to at least partially absorb the kinetic energy generated by the impact. Reinforcing elements include at least one dry composite fiber preform integrated into the foam core to dissipate, in combination with the foam core, the kinetic energy generated by the impact. A method for integrating the device for absorbing kinetic energy.

Owner:AIRBUS

Three-dimensional braided composite material propeller blade for airplane and manufacturing method of propeller blade

The invention discloses a three-dimensional braided composite material propeller blade for an airplane and a manufacturing method of the propeller blade. The preparation method comprises the following steps: designing the blade mold appearance, comprising the operation of designing the specific reinforcing parts of different strength and rigidity requirements; performing integral braiding on the blade main body and the specific reinforcing parts of the blades by adopting a carbon fiber three-dimensional preform multi-part combined braiding technology, thereby obtaining a three-dimensional braided structure; performing secondary suture reinforcement treatment along the thickness direction of the three-dimensional braided structure after the preparation of the three-dimensional braided structure is finished, thereby obtaining a secondary suture structure; by taking thermosetting resin glue liquid as a matrix, finishing the resin compounding process of the three-dimensional stereoscopic braided structure by adopting the process of combining vacuum infusion and rapid thermocuring, and finally, manufacturing the carbon fiber composite material propeller blade. By utilizing the multiple three-dimensional stereoscopic braided structures, the secondary suture technology and the process of combining vacuum infusion and rapid thermocuring, the strength of the propeller blade is enhanced, and the production efficiency of the blade is effectively improved.

Owner:山东宽原新材料科技有限公司

Automatic generating method of three-dimensional woven composite hexahedron finite element model

ActiveCN107330148AFast establishment of finite element model functionRemoving Barriers to Mesostructural CharacterizationDesign optimisation/simulationSpecial data processing applicationsElement modelFiber bundle

The invention discloses an automatic generating method of a three-dimensional woven composite hexahedron finite element model. The method includes the following steps that a space trajectory in the fiber bundle center weaving process is calculated, and position coordinates of the center of each fiber bundle are obtained; position coordinates of space trajectories of center points of the fiber bundles are read, in other words, the position coordinates of each tightened fiber bundle are read, and geometric creation, direction grouping and hexahedron meshing are carried out. By means of the method, the rapid finite element model establishment function of a complex geometric structure three-dimensional woven composite can be achieved only by inputting multiple simple macroparameters. In combination with the geometric structure and finite element modeling, grouping is carried out according to fiber bundle center direction vectors, material spindle direction setting of transverse isotropy materials of the fiber bundles is convenient, the change of internal zone, surface zone and corner zone fiber bundle sections is considered, and transverse isotropy finite element model establishment of the large-size three-dimensional woven composite can be achieved in reality from being manually feasible theoretically.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Braided composite spar

ActiveUS20160075426A1Increasing fibre pitchReducing circumferenceInfluencers by generating vorticesLamination ancillary operationsEngineeringMechanical engineering

A braided composite spar or preform for a braided composite spar, comprising a plurality of tubular plies of braided fibres, wherein the spar or preform extends lengthwise from a root to a tip, and the spar or preform has a tapered portion in which each ply has a height which reduces and a width which increases as it extends toward the tip. The spar or preform can be used to provide a tubular main spar for a winglet. The winglet also has a front spar with a front spar web, an upper front spar cap, and a lower front spar cap. An upper skin of the winglet is joined to the braided spar and the upper front spar cap. A lower skin of the winglet is joined to the braided spar and the lower front spar cap.

Owner:AIRBUS OPERATIONS LTD

Carbon fiber composite material bone fracture plate and preparation method thereof

ActiveCN110585491AStrong penetrating powerImprove bindingPhosphorus compoundsBone platesBiocompatibility TestingNonwoven fabric

The present invention provides a carbon fiber composite material bone fracture plate and a preparation method thereof. The bone fracture plate is composed of a continuous carbon fiber braided composite material layer and a carbon fiber nonwoven fabric composite material layer in a superposed manner; carbon fibers between the continuous carbon fiber braided composite material layer and the carbon fiber nonwoven fabric composite material layer are filled with a silicon carbide matrix or a silicon carbide-carbon matrix and hydroxyapatite. The composite material has characteristics of light weight, good biocompatibility, good chemical stability, mechanical properties close to human body bones, good fatigue, strong designability, no artifacts, etc., and besides, surface pores and surfaces are stably adhered with the hydroxyapatite which can improve biological activity of the composite material, promotes bone growth and induces bone proliferation.

Owner:HUNAN TANKANG BIOTECH CO LTD

Braided composite spar

ActiveUS20160075427A1Increasing the fibre pitchReducing circumferenceInfluencers by generating vorticesLamination ancillary operationsClockwiseBraided composite

A braided composite spar or preform for a braided composite spar with a plurality of tubular plies of braided fibres. Each ply has a first set of fibres which wind in a clockwise direction in a first series of turns with a pitch between each adjacent pair of turns, and a second set of fibres which wind in an anti-clockwise direction in a second series of turns with a pitch between each adjacent pair of turns. The first and second sets of fibres in each ply are intertwined to form a braided structure. The spar or preform extends lengthwise from a root to a tip and has a tapered portion which tapers inwardly towards the tip. Each ply has a circumference in the tapered portion which reduces as it tapers inwardly. For at least one of the plies the pitches of the first and second sets of fibres increase continuously as the ply tapers inwardly in the tapered portion. The spar or preform can be used to provide a tubular main spar for a winglet. The winglet also has a front spar with a front spar web, an upper front spar cap, and a lower front spar cap. An upper skin of the winglet is joined to the braided spar and the upper front spar cap. A lower skin of the winglet is joined to the braided spar and the lower front spar cap.

Owner:AIRBUS OPERATIONS LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com