Automatic measurement system for surface parameters of prefabricated component of three-dimension braiding composite material

A composite material and automatic measurement technology, applied in the direction of measuring devices, instruments, optical devices, etc., can solve the problems of low degree of automation and strong subjective dependence, and achieve the effect of simple method, easy implementation and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

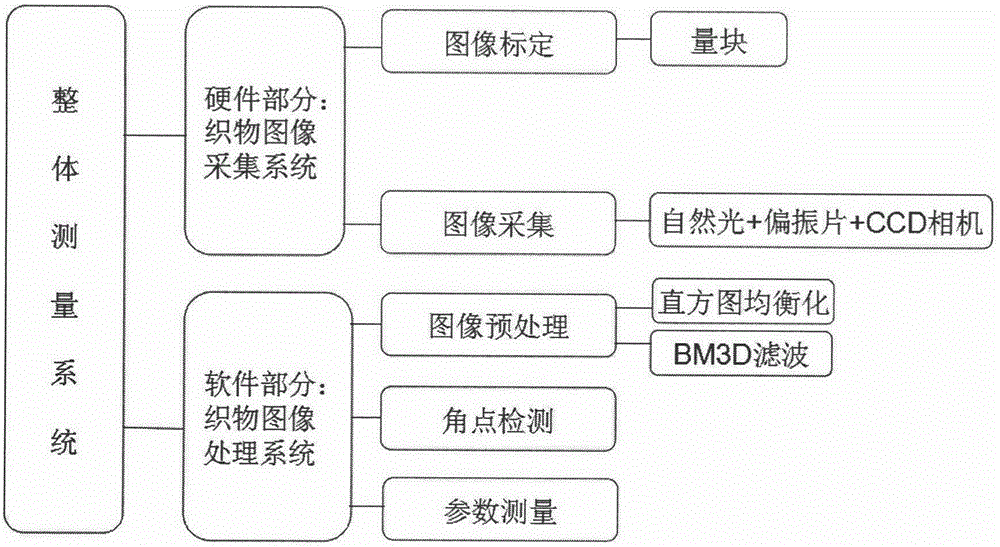

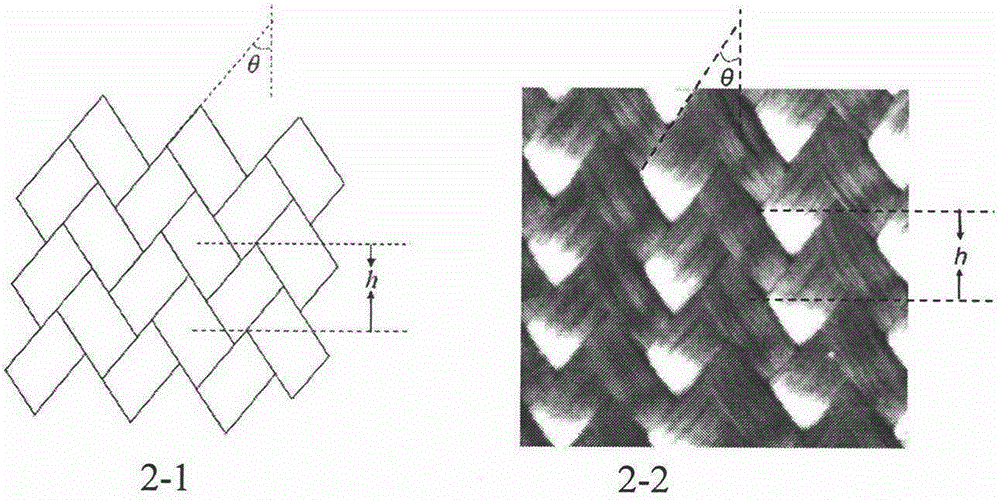

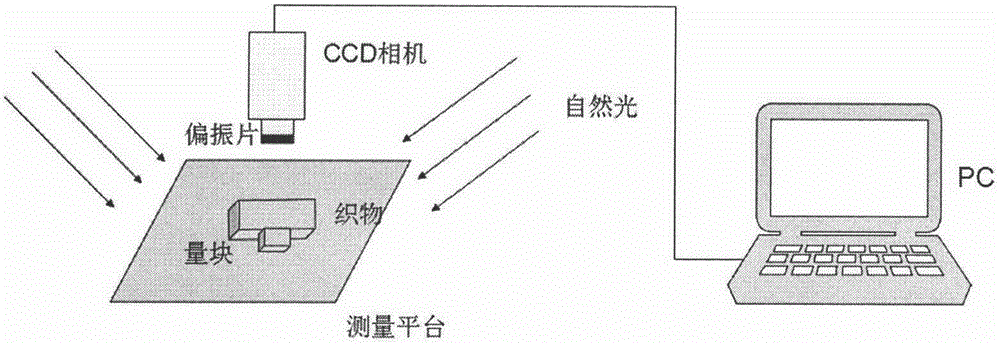

[0041] Overall system design of the present invention such as figure 1 As shown, the system is divided into two parts: the hardware part and the software part. The hardware part is mainly the fabric acquisition system, including image calibration based on gauge blocks and image acquisition based on "natural light + polarizer + CCD camera". The software part is mainly the fabric image processing system, including image preprocessing, corner detection and parameter measurement combined with the four algorithms of clone connection, least square fitting, autocorrelation and ACSS corner detection. The specific implementation process of the technical solution of the present invention will be described below in conjunction with the accompanying drawings.

[0042] 1. Hardware part (fabric image acquisition system)

[0043] Including image calibration and image acquisition.

[0044] 1.1 Image Calibration

[0045]A standard 3cm gauge block is used to calibrate the image of the fabr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com