Patents

Literature

3079 results about "Surface reflection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

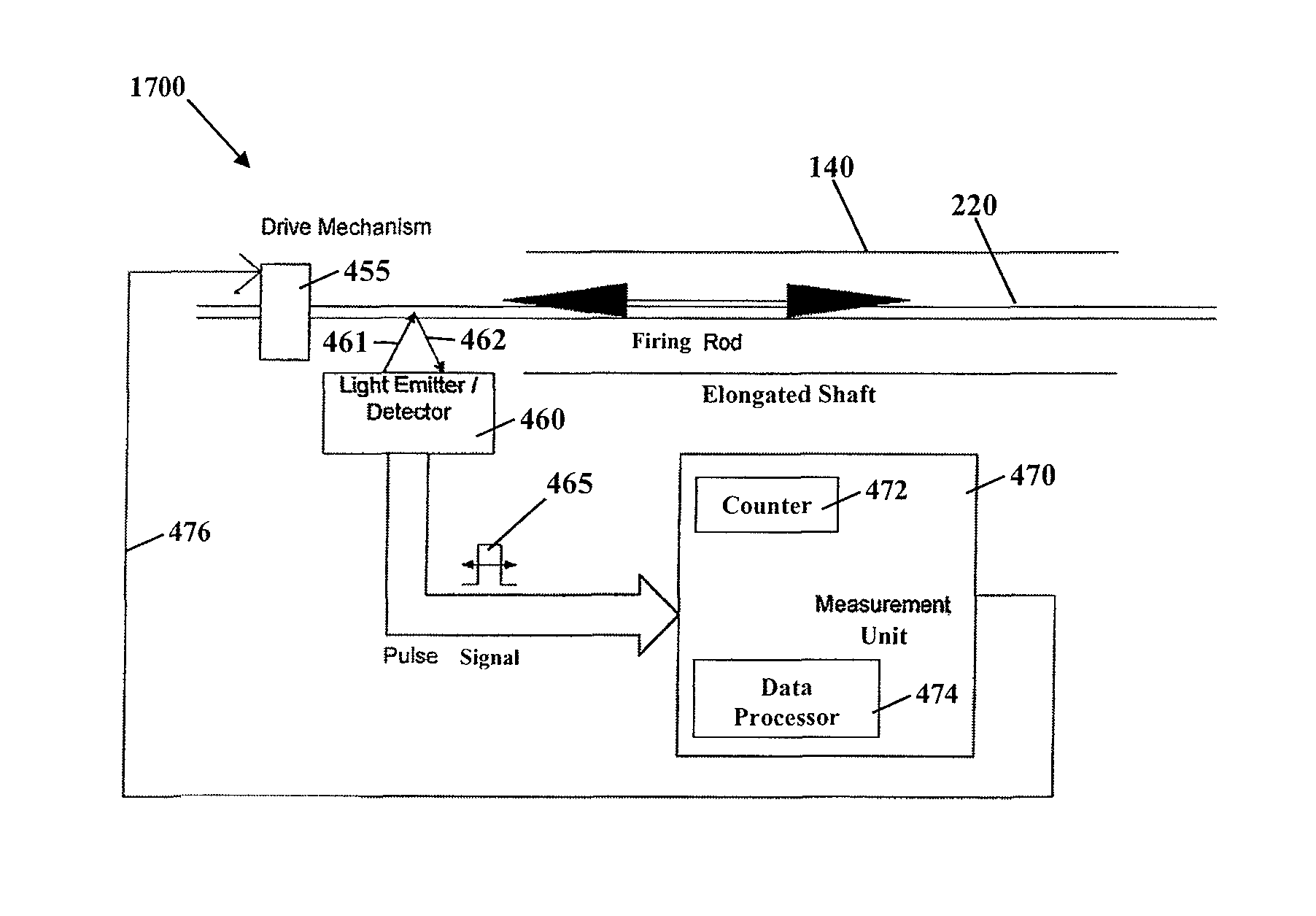

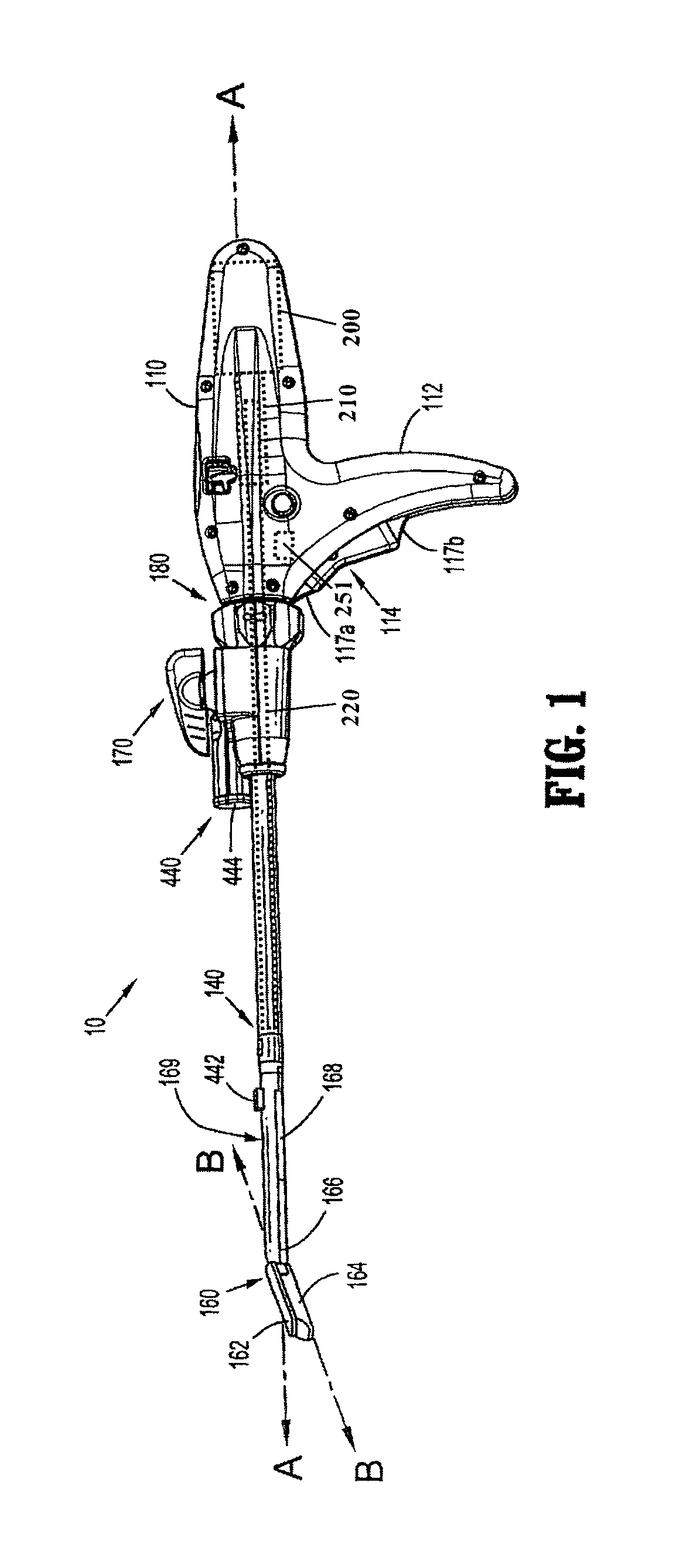

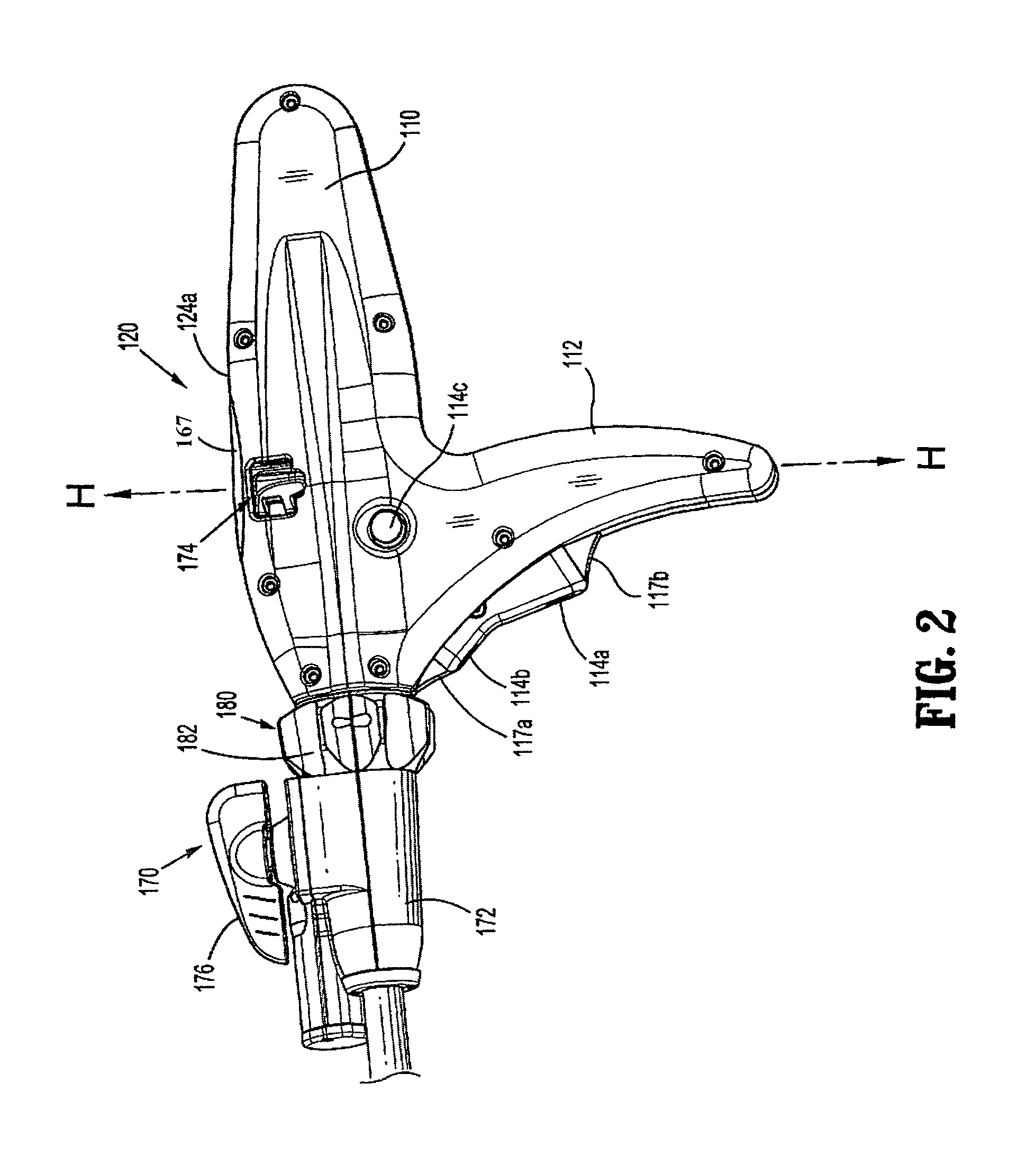

Method and apparatus for determining parameters of linear motion in a surgical instrument

ActiveUS8967443B2Reduce mechanical wearMinimized in sizeSuture equipmentsStapling toolsLinear motionMotion parameter

A surgical instrument and method of controlling the surgical instrument are disclosed. The surgical instrument includes a housing and an elongated shaft that extends distally from the housing and defines a first longitudinal axis. The surgical instrument also includes a firing rod disposed in the elongated shaft and a drive mechanism disposed at least partially within the housing. The drive mechanism mechanically cooperates with the firing rod to move the firing rod. A sensor senses a parameter of light reflected from the surface of the firing rod, which includes markings that change the reflectivity of the firing rod. The measurement unit determines a parameter of the motion of the firing rod, such as the position and speed of the firing rod, based on the sensed parameter of the light reflected from the surface of the firing rod.

Owner:TYCO HEALTHCARE GRP LP

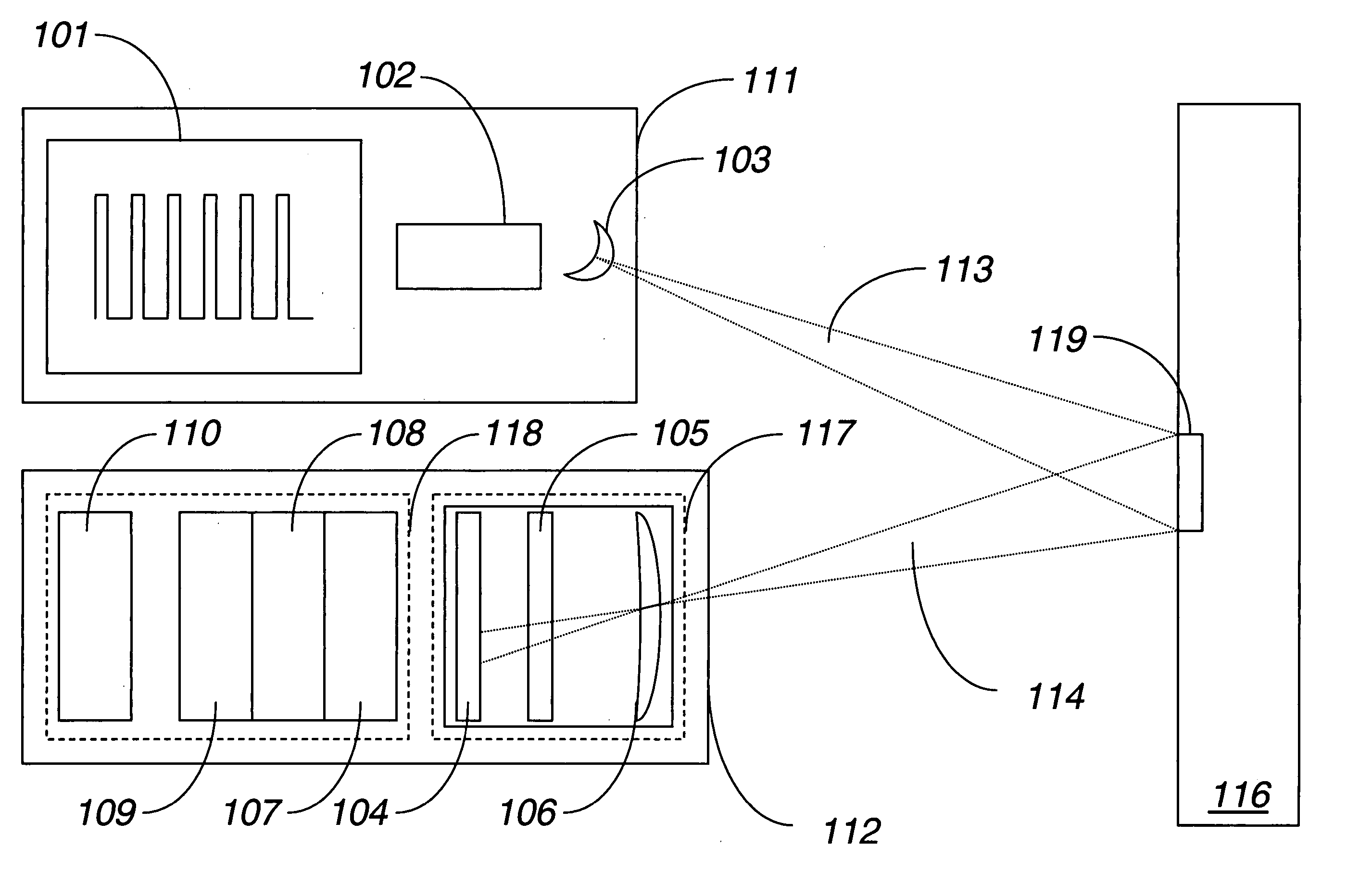

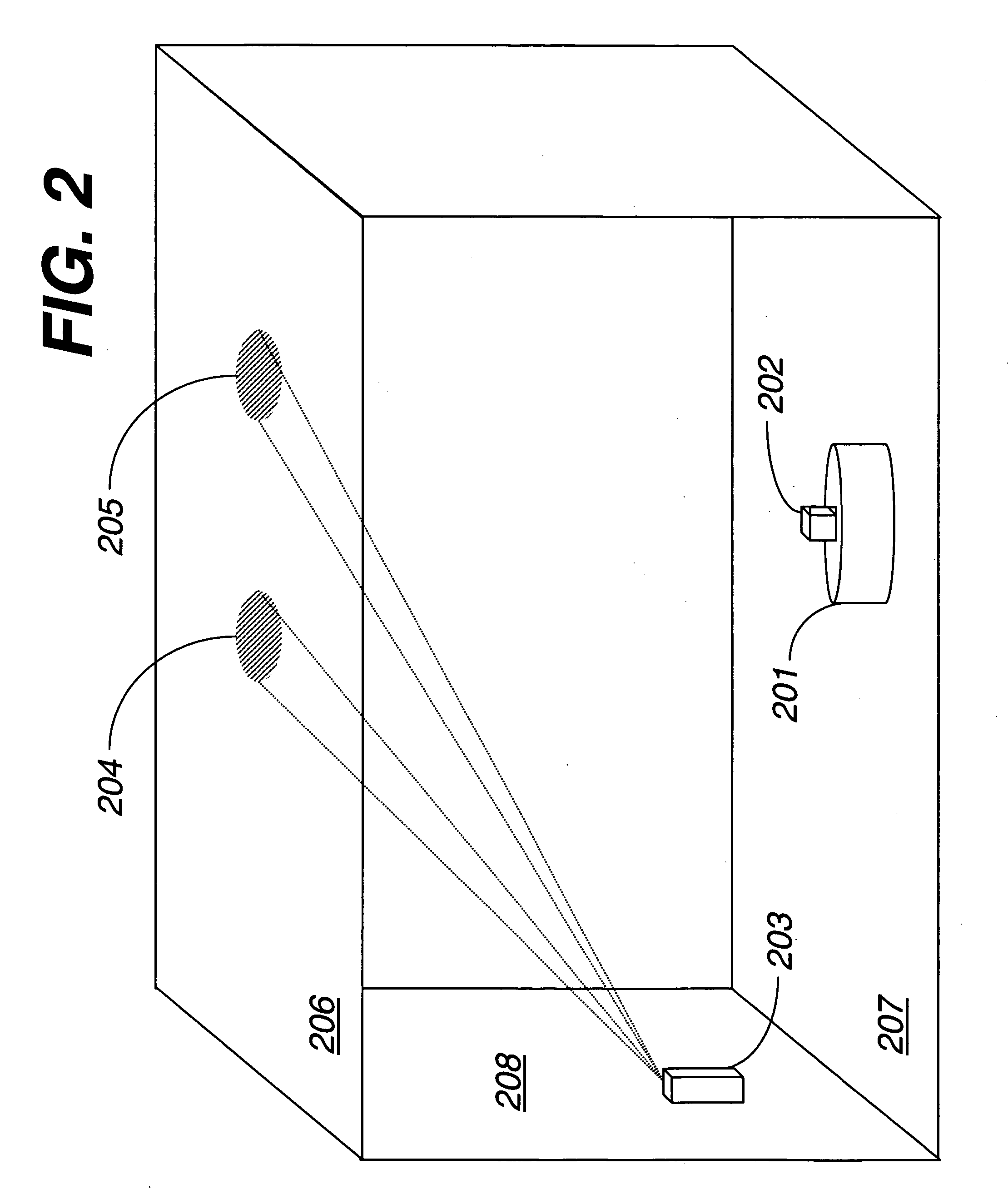

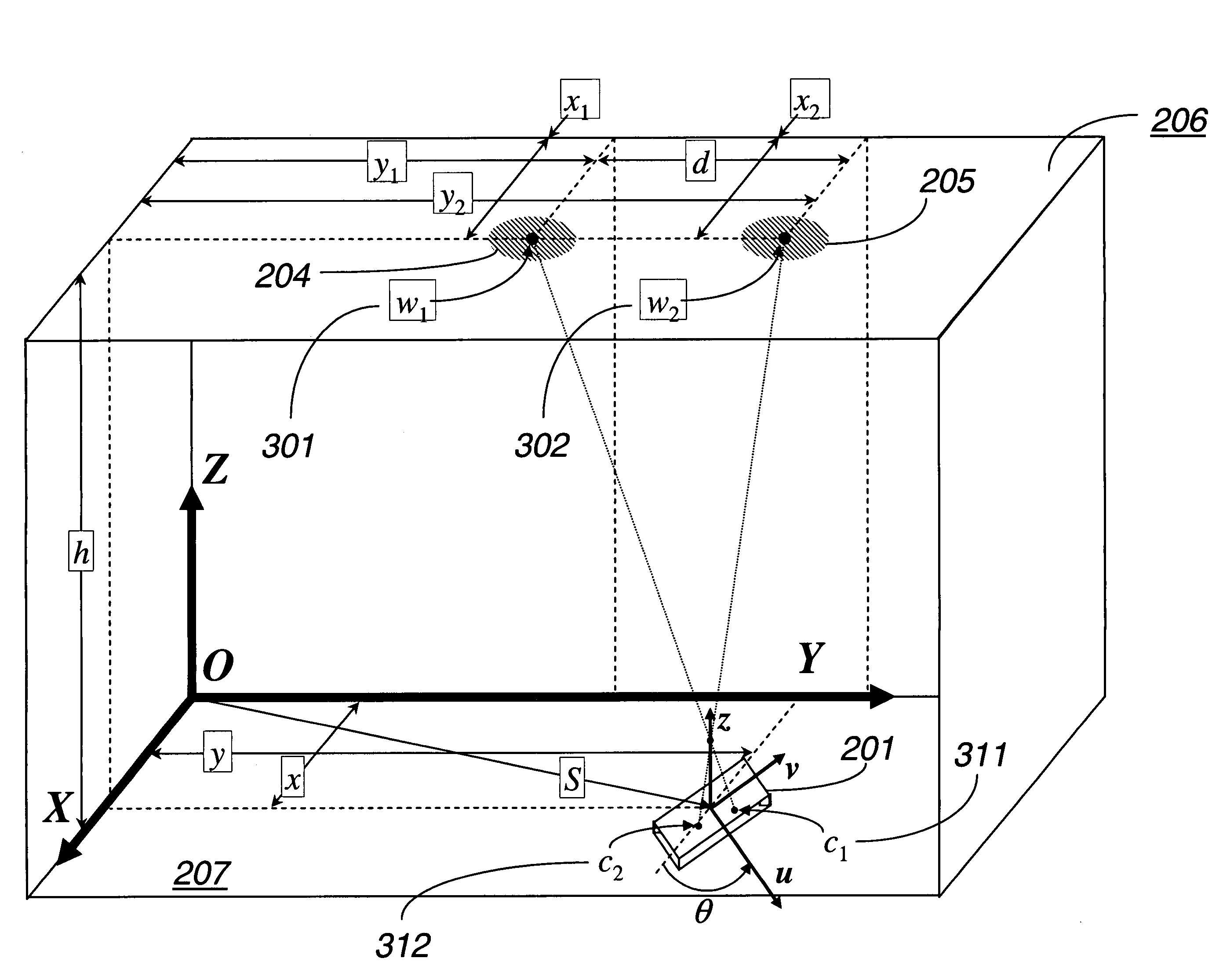

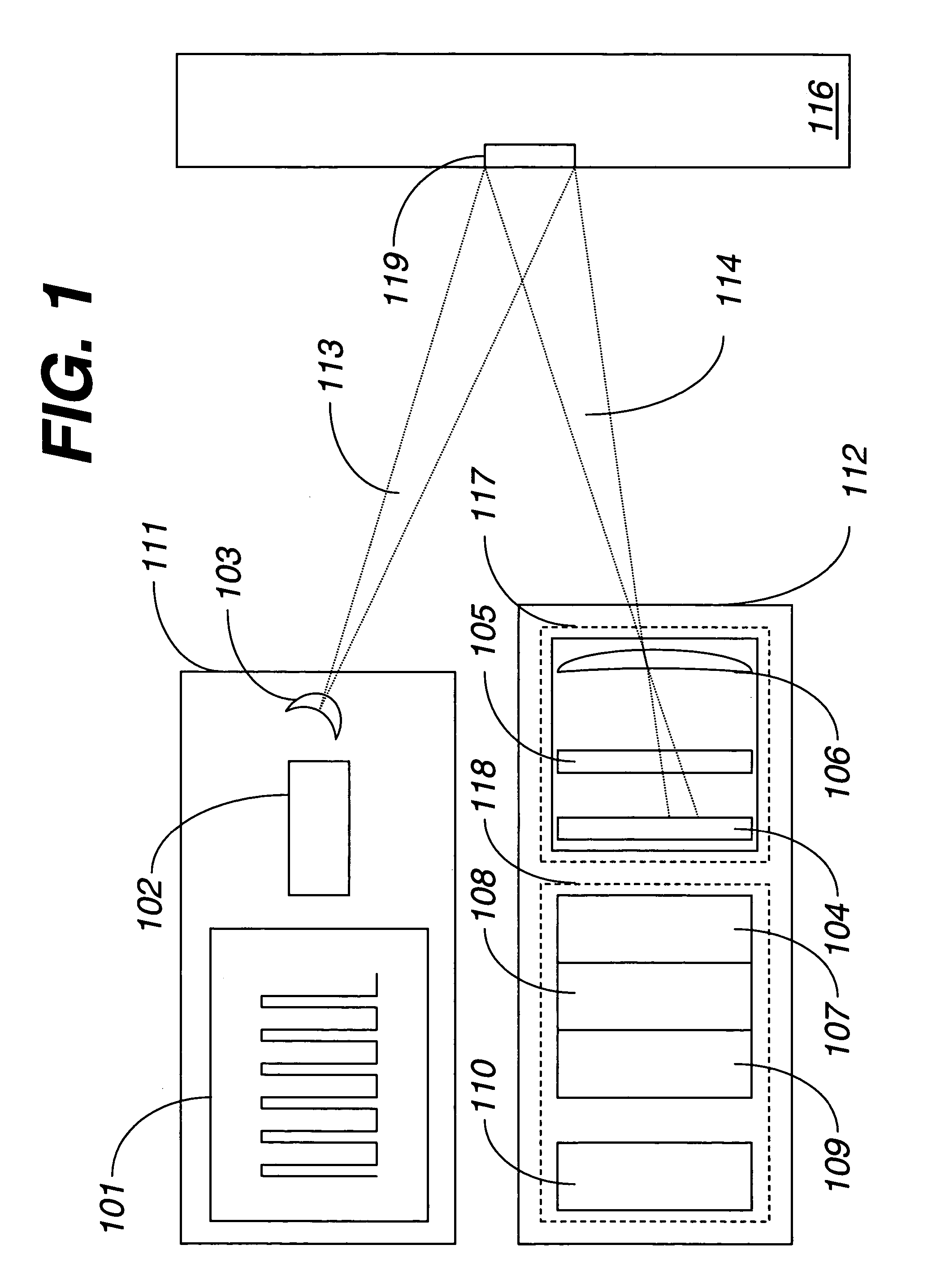

Methods and apparatus for position estimation using reflected light sources

InactiveUS20050213082A1Angle measurementOptical rangefindersSignal processing circuitsCompanion animal

The invention is generally related to the estimation of position and orientation of an object with respect to a local or a global coordinate system using reflected light sources. A typical application of the method and apparatus includes estimation and tracking of the position of a mobile autonomous robot. Other applications include estimation and tracking of an object for position-aware, ubiquitous devices. Additional applications include tracking of the positions of people or pets in an indoor environment. The methods and apparatus comprise one or more optical emitters, one or more optical sensors, signal processing circuitry, and signal processing methods to determine the position and orientation of at least one of the optical sensors based at least in part on the detection of the signal of one or more emitted light sources reflected from a surface.

Owner:IROBOT CORP

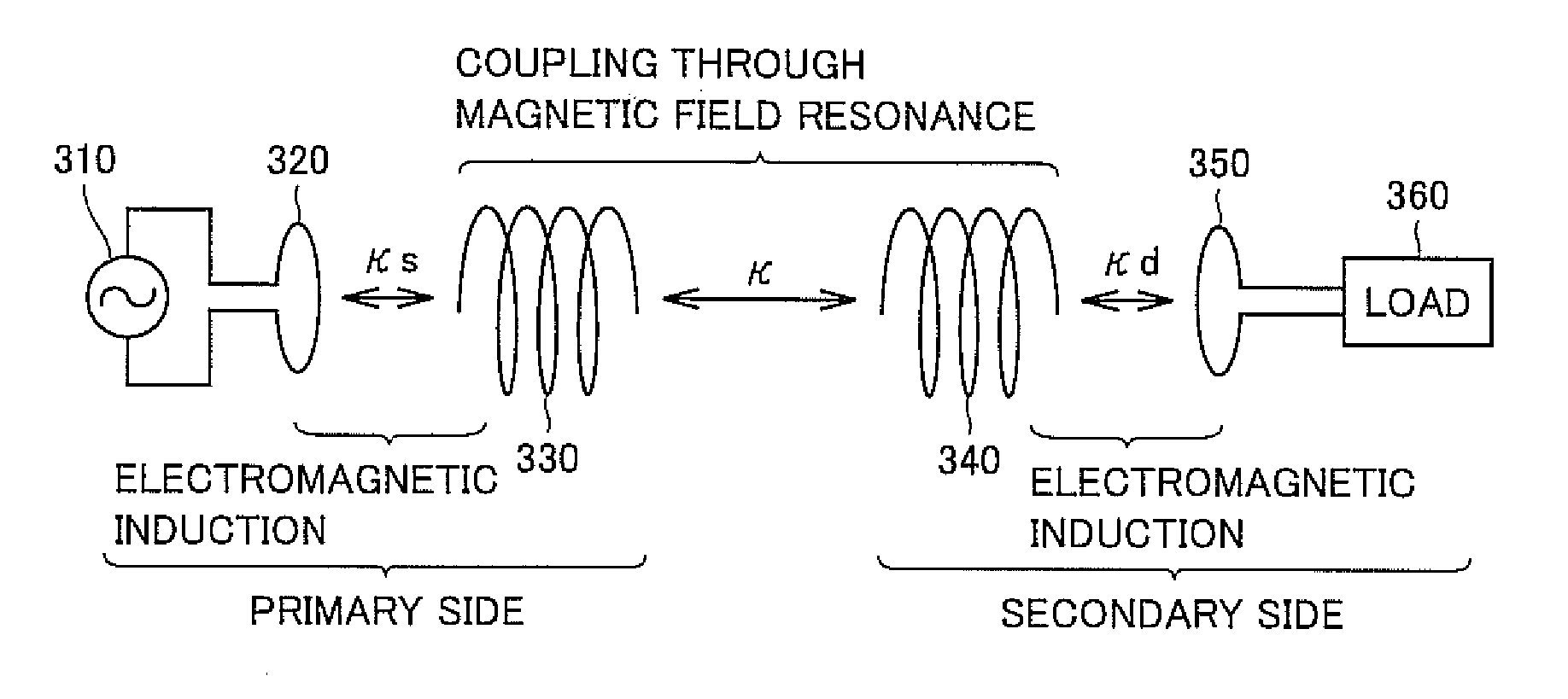

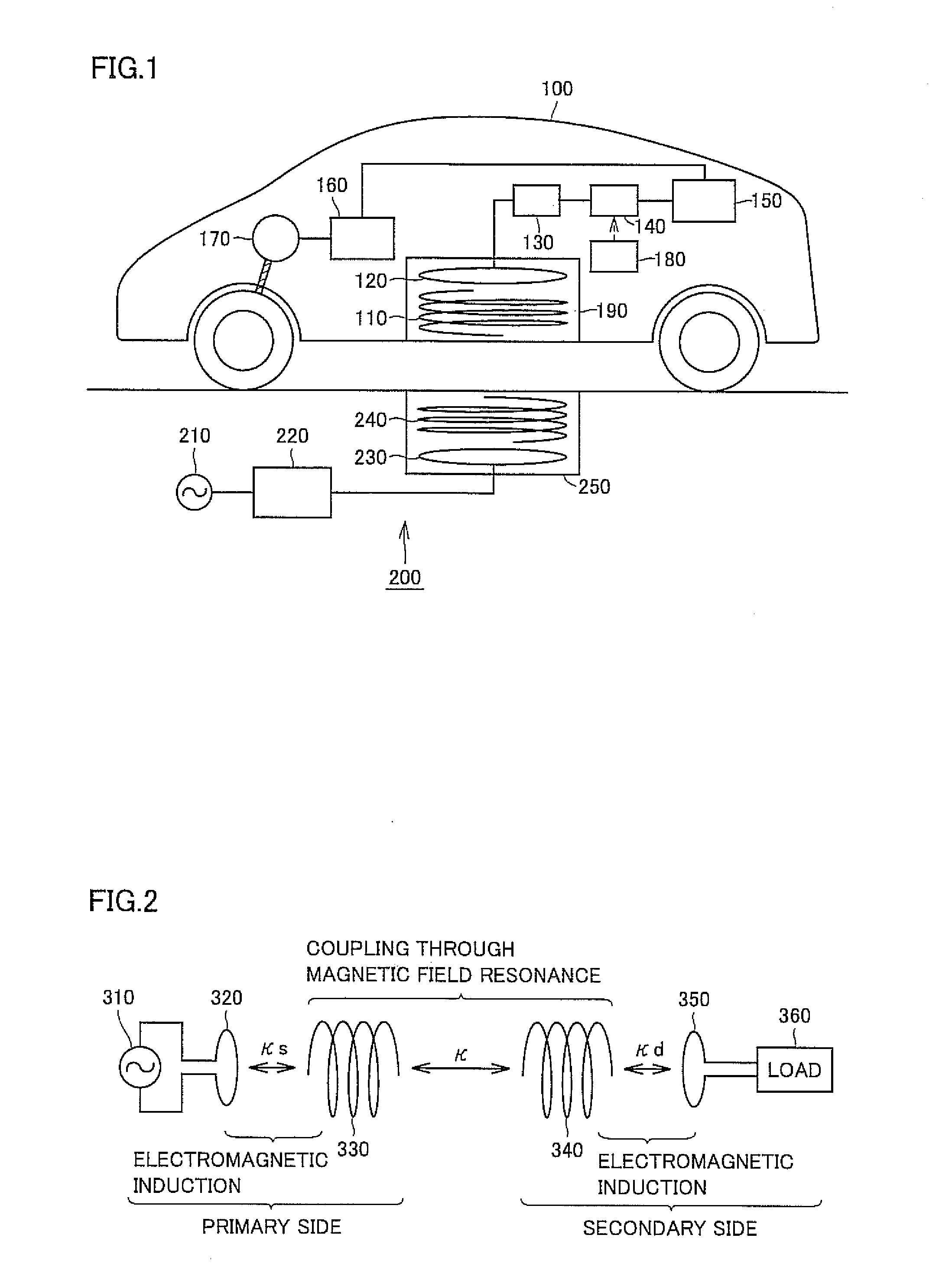

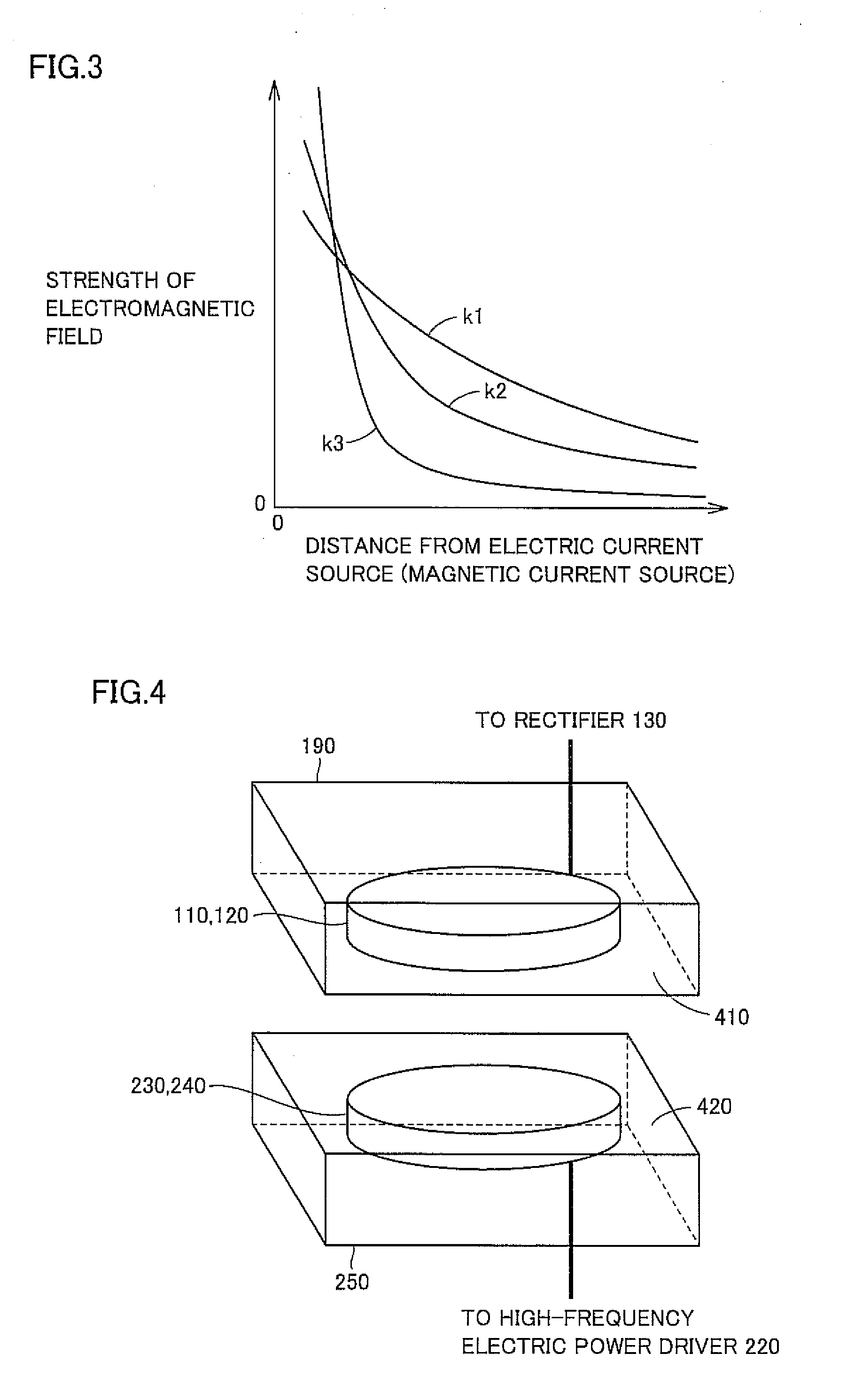

Noncontact electric power receiving device, noncontact electric power transmitting device, noncontact electric power feeding system, and electrically powered vehicle

A first shielding box is disposed so that its first surface can be opposite to an electric power feeding unit. The first surface has an opening and remaining five surfaces thereof reflect, during reception of electric power from the electric power feeding unit, a resonant electromagnetic field (near field) generated in the surroundings of the electric power receiving unit. The electric power receiving unit is provided in the first shielding box to receive the electric power from the electric power feeding unit via the opening (first surface) of the first shielding box. A second shielding box has a similar configuration, i.e., has a second surface with an opening and remaining five surfaces thereof reflect the resonant electromagnetic field (near field) generated in the surroundings of the electric power feeding unit.

Owner:TOYOTA JIDOSHA KK

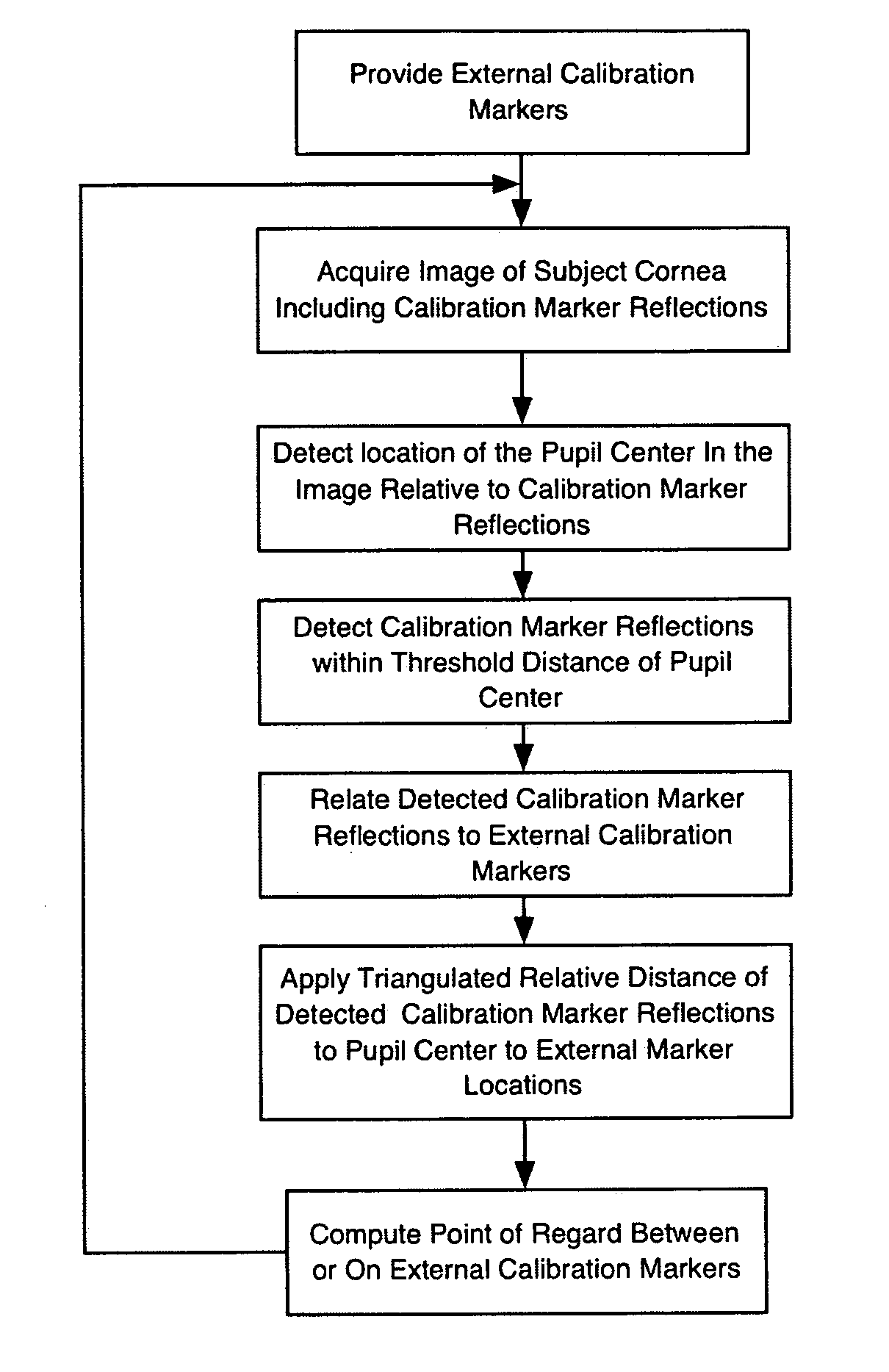

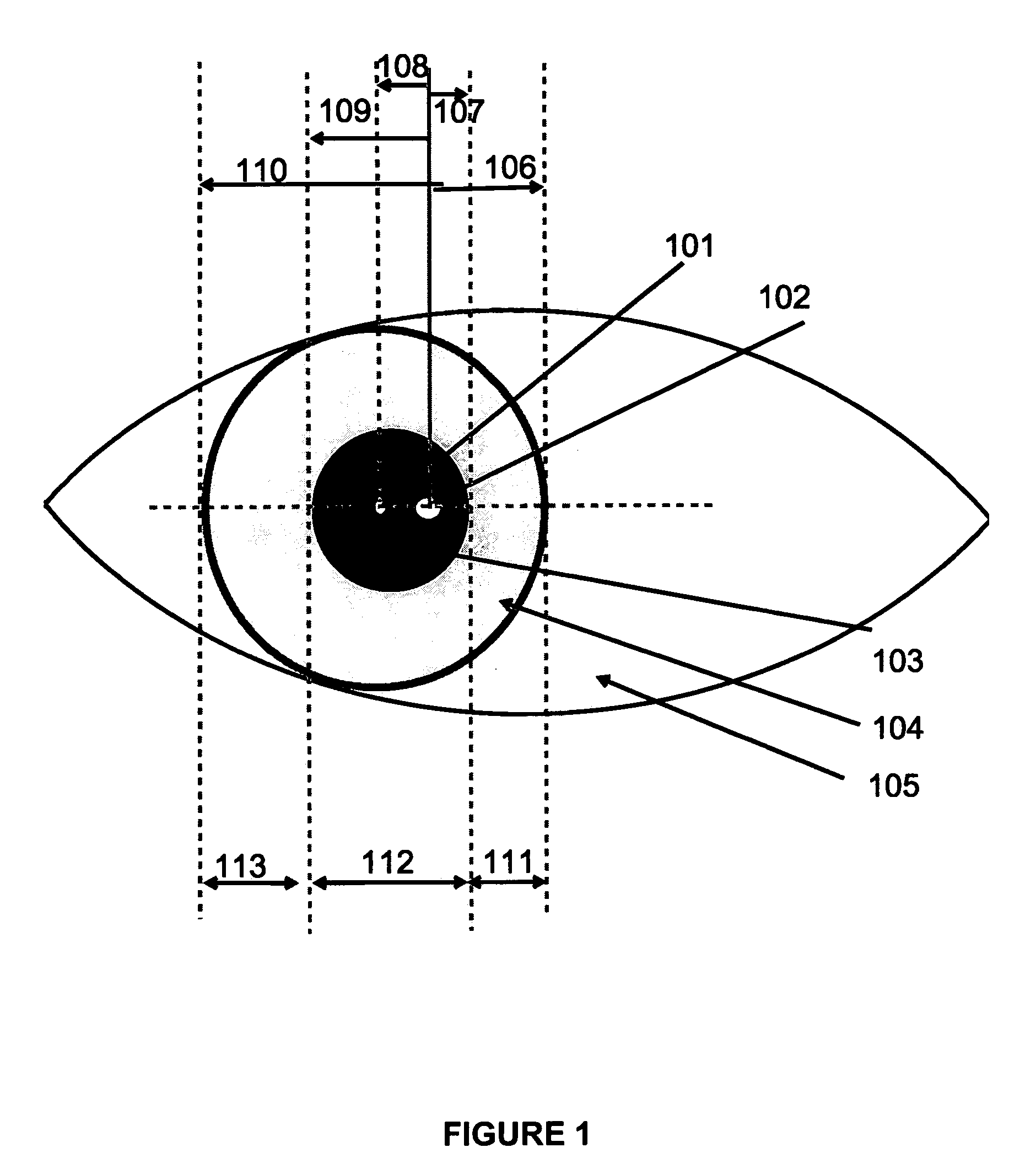

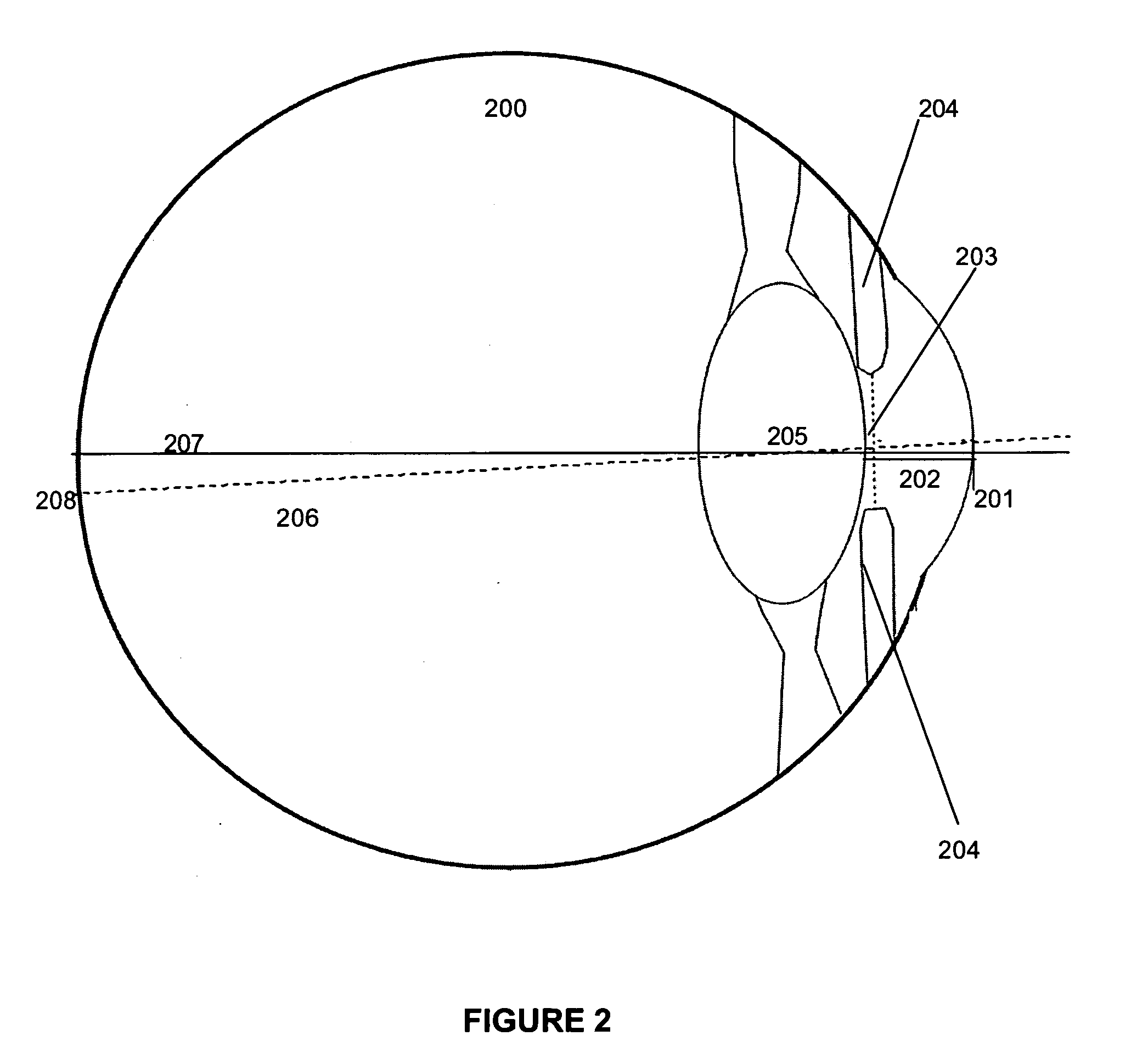

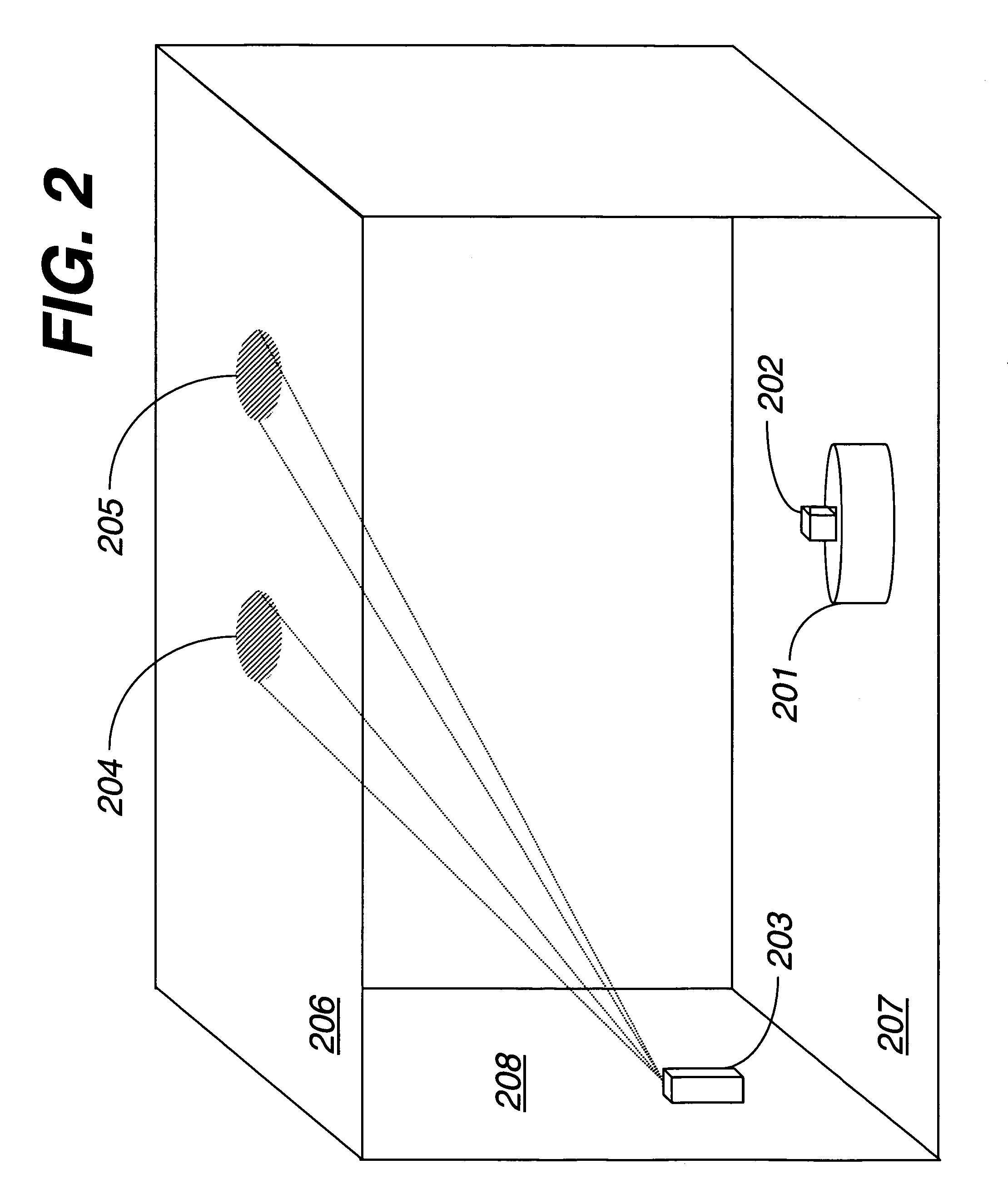

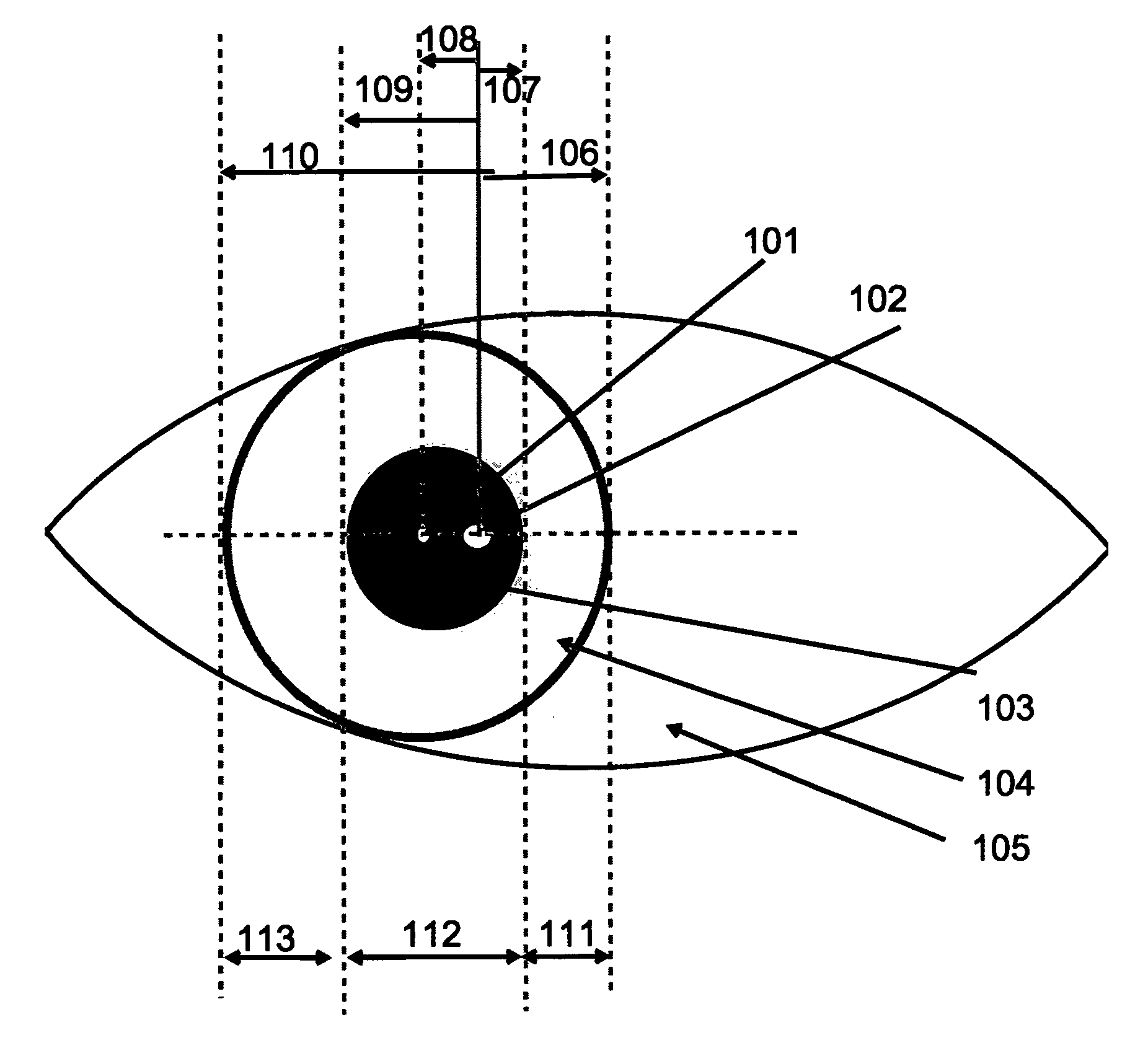

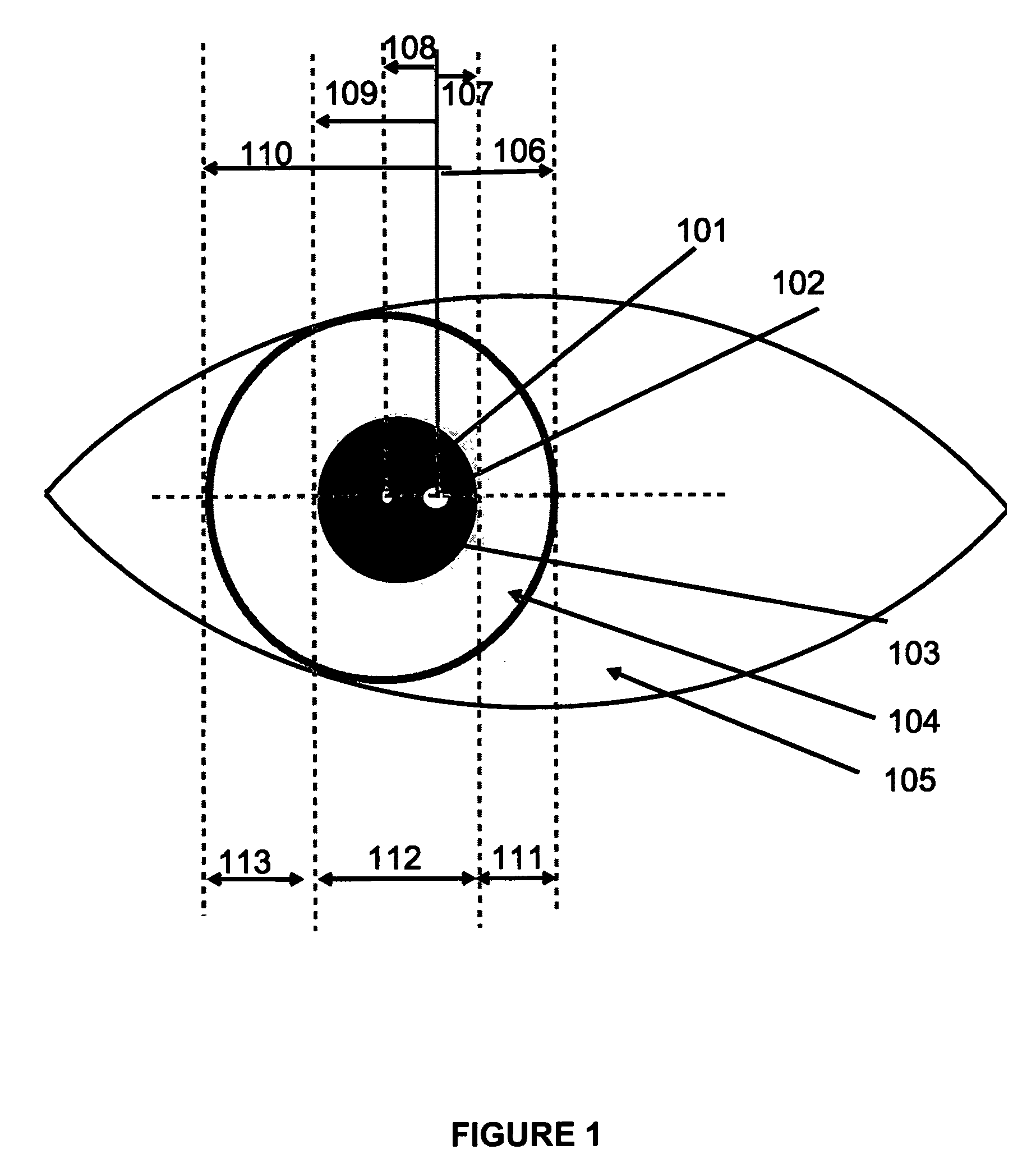

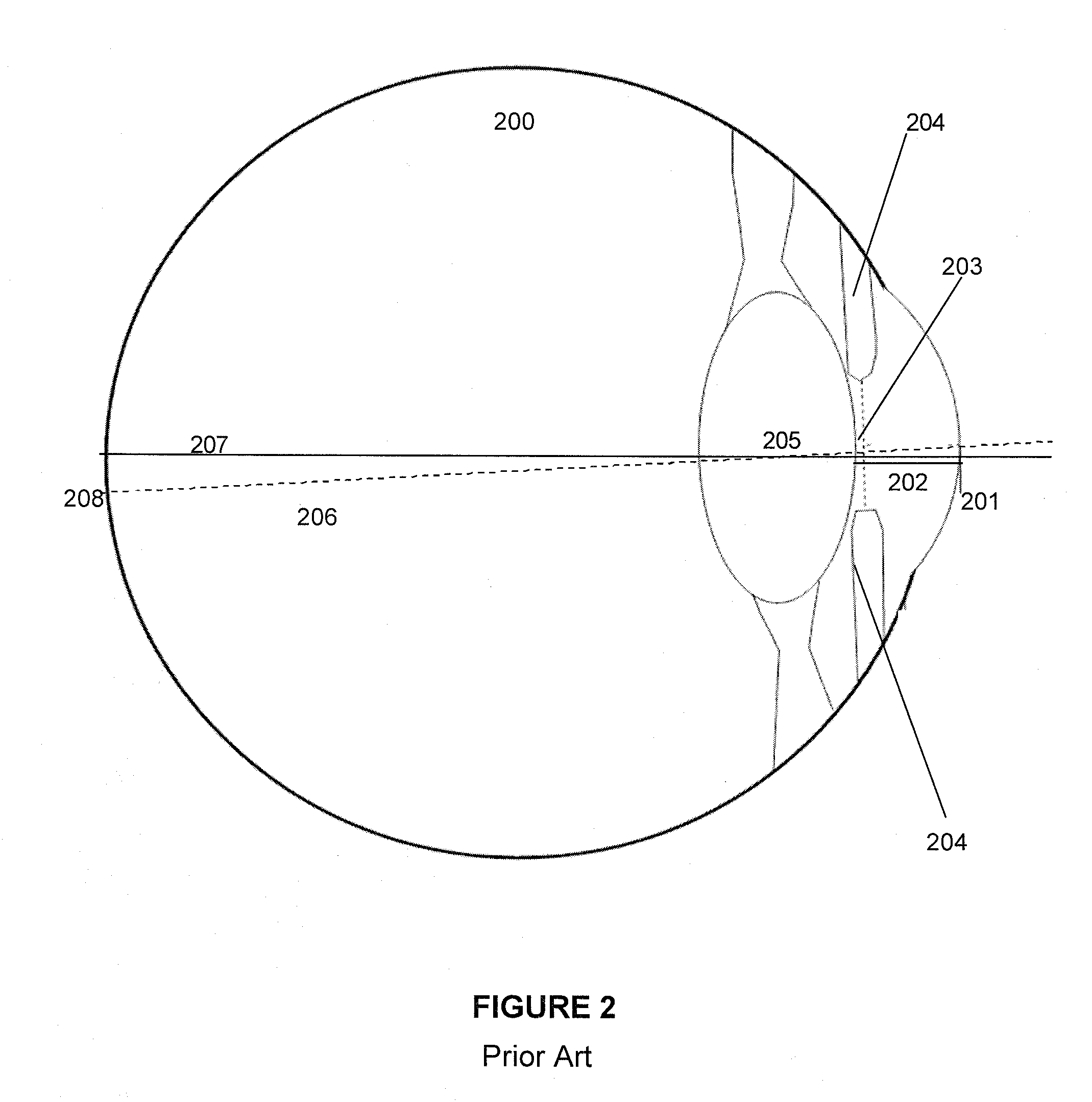

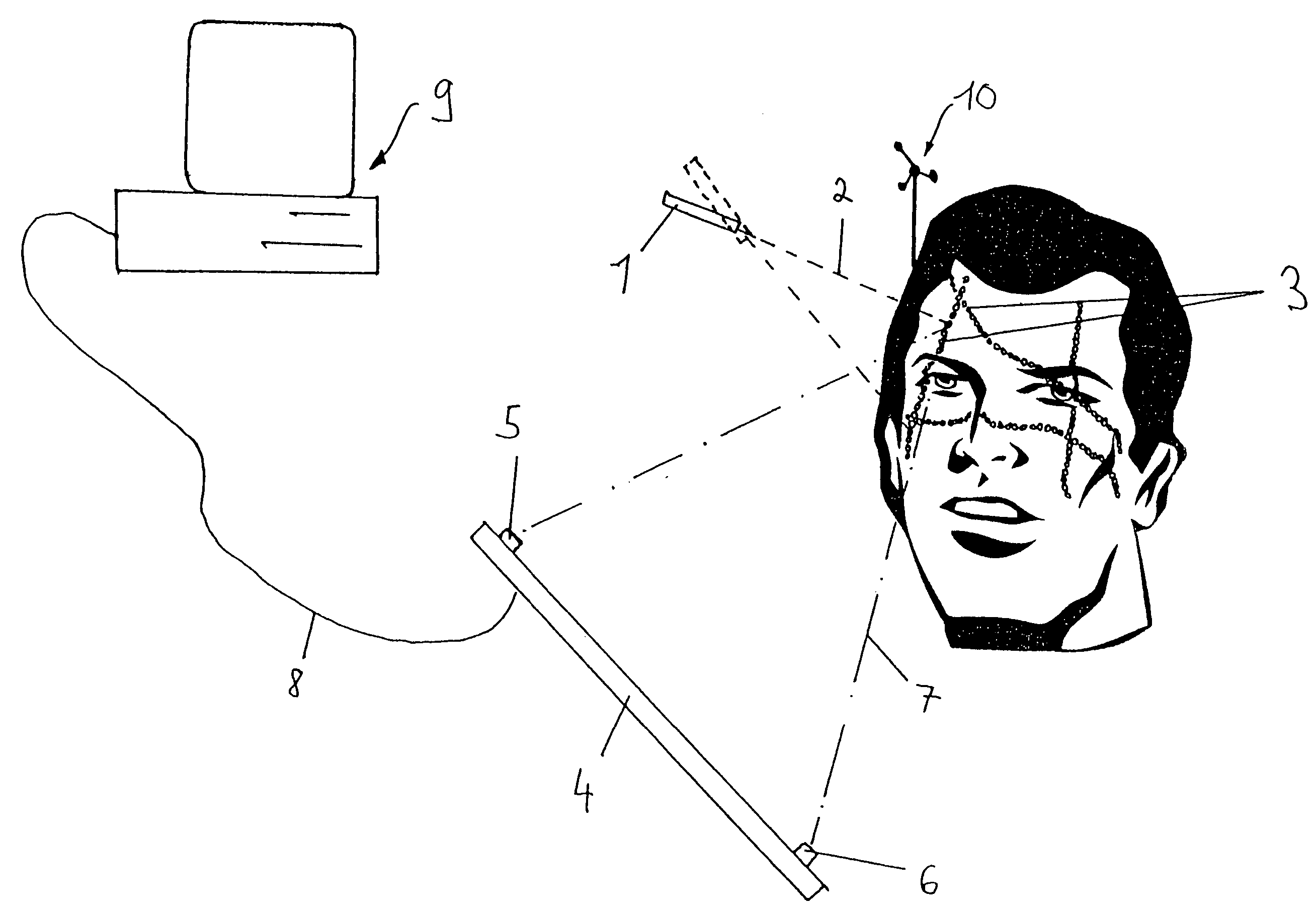

Method and apparatus for calibration-free eye tracking using multiple glints or surface reflections

InactiveUS20050175218A1Input/output for user-computer interactionImage enhancementCorneal surfaceAngular distance

A system and method for eye gaze tracking in human or animal subjects without calibration of cameras, specific measurements of eye geometries or the tracking of a cursor image on a screen by the subject through a known trajectory. The preferred embodiment includes one uncalibrated camera for acquiring video images of the subject's eye(s) and optionally having an on-axis illuminator, and a surface, object, or visual scene with embedded off-axis illuminator markers. The off-axis markers are reflected on the corneal surface of the subject's eyes as glints. The glints indicate the distance between the point of gaze in the surface, object, or visual scene and the corresponding marker on the surface, object, or visual scene. The marker that causes a glint to appear in the center of the subject's pupil is determined to be located on the line of regard of the subject's eye, and to intersect with the point of gaze. Point of gaze on the surface, object, or visual scene is calculated as follows. First, by determining which marker glints, as provided by the corneal reflections of the markers, are closest to the center of the pupil in either or both of the subject's eyes. This subset of glints forms a region of interest (ROI). Second, by determining the gaze vector (relative angular or cartesian distance to the pupil center) for each of the glints in the ROI. Third, by relating each glint in the ROI to the location or identification (ID) of a corresponding marker on the surface, object, or visual scene observed by the eyes. Fourth, by interpolating the known locations of each these markers on the surface, object, or visual scene, according to the relative angular distance of their corresponding glints to the pupil center.

Owner:CHENG DANIEL +3

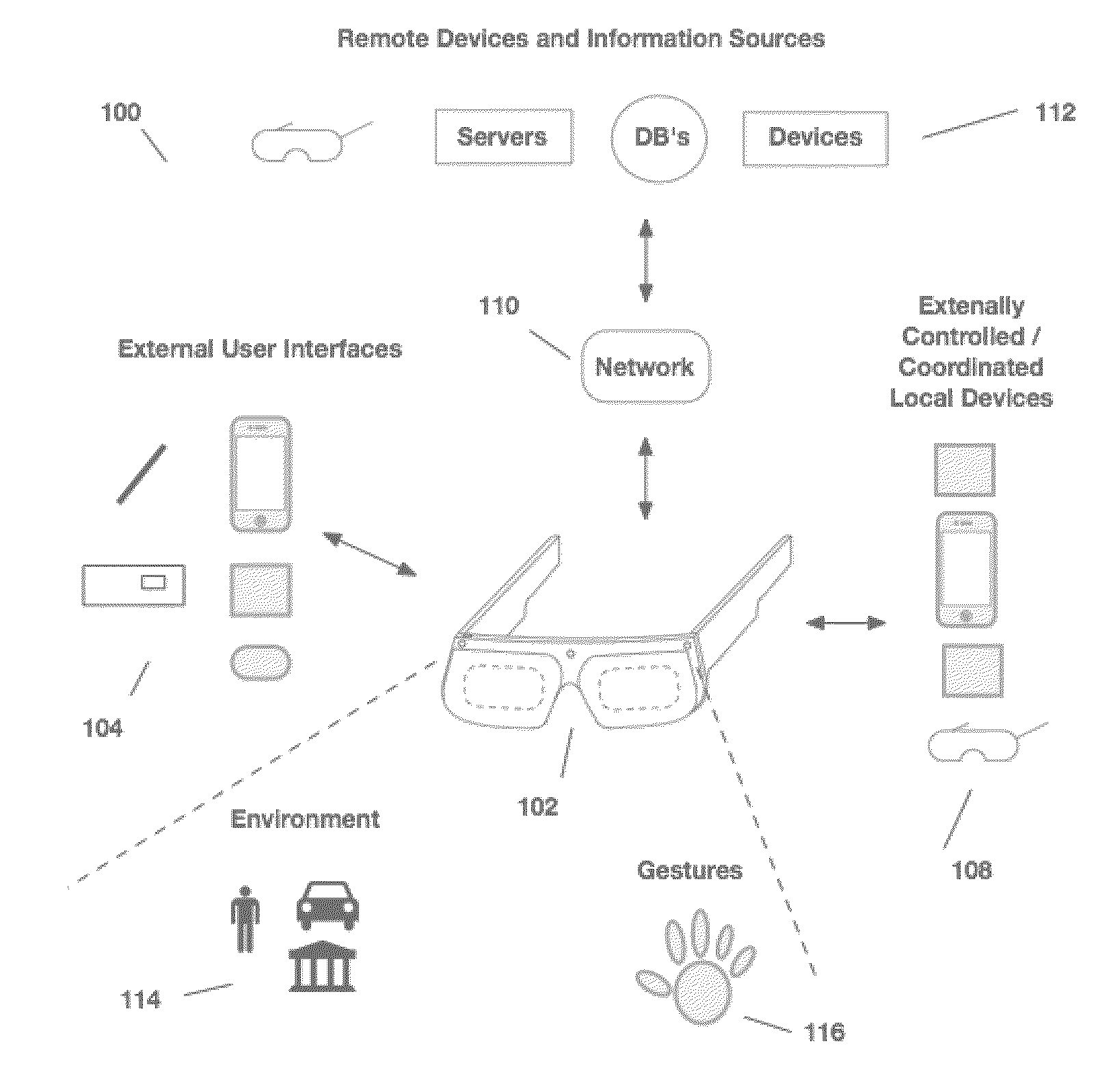

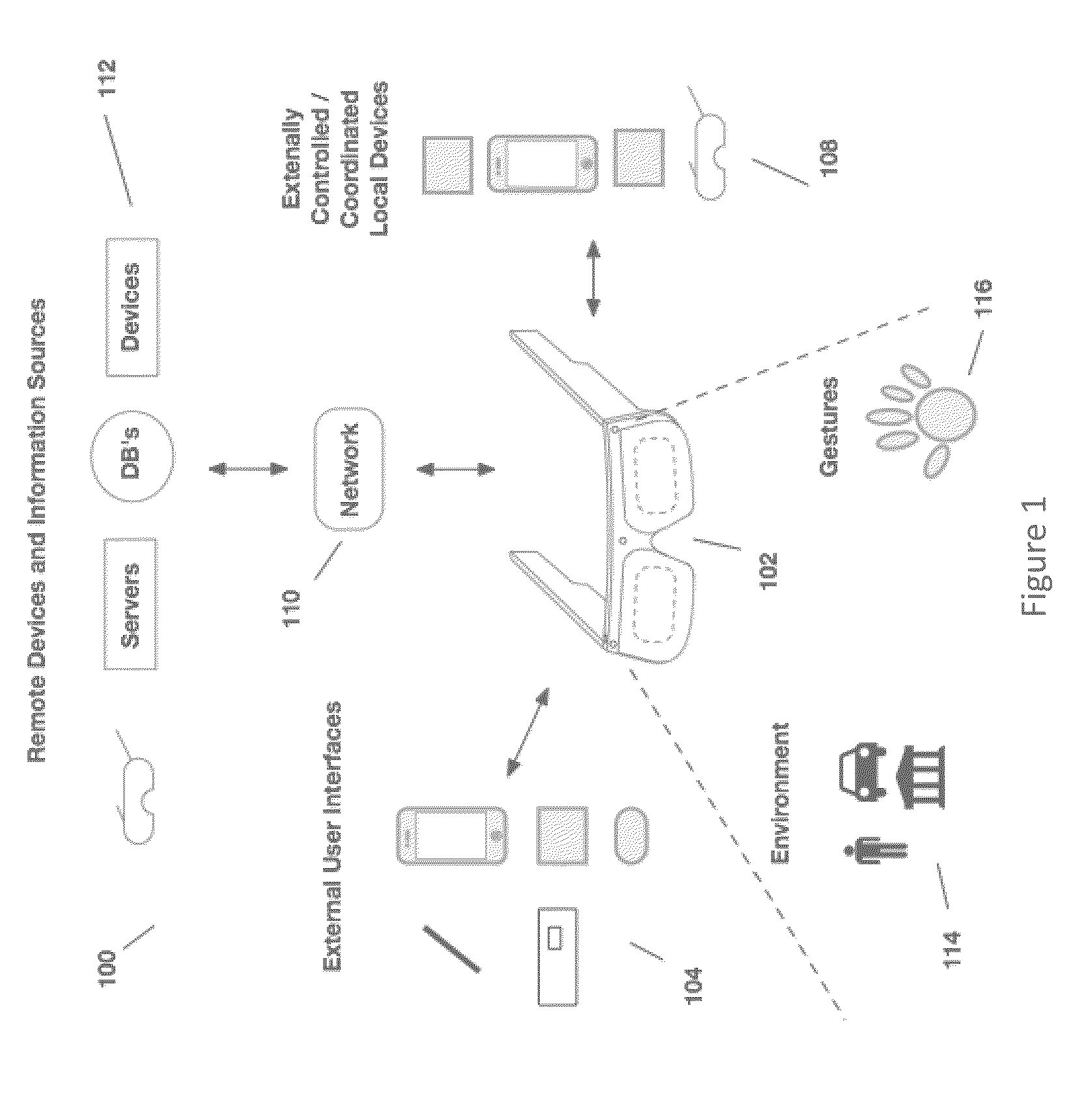

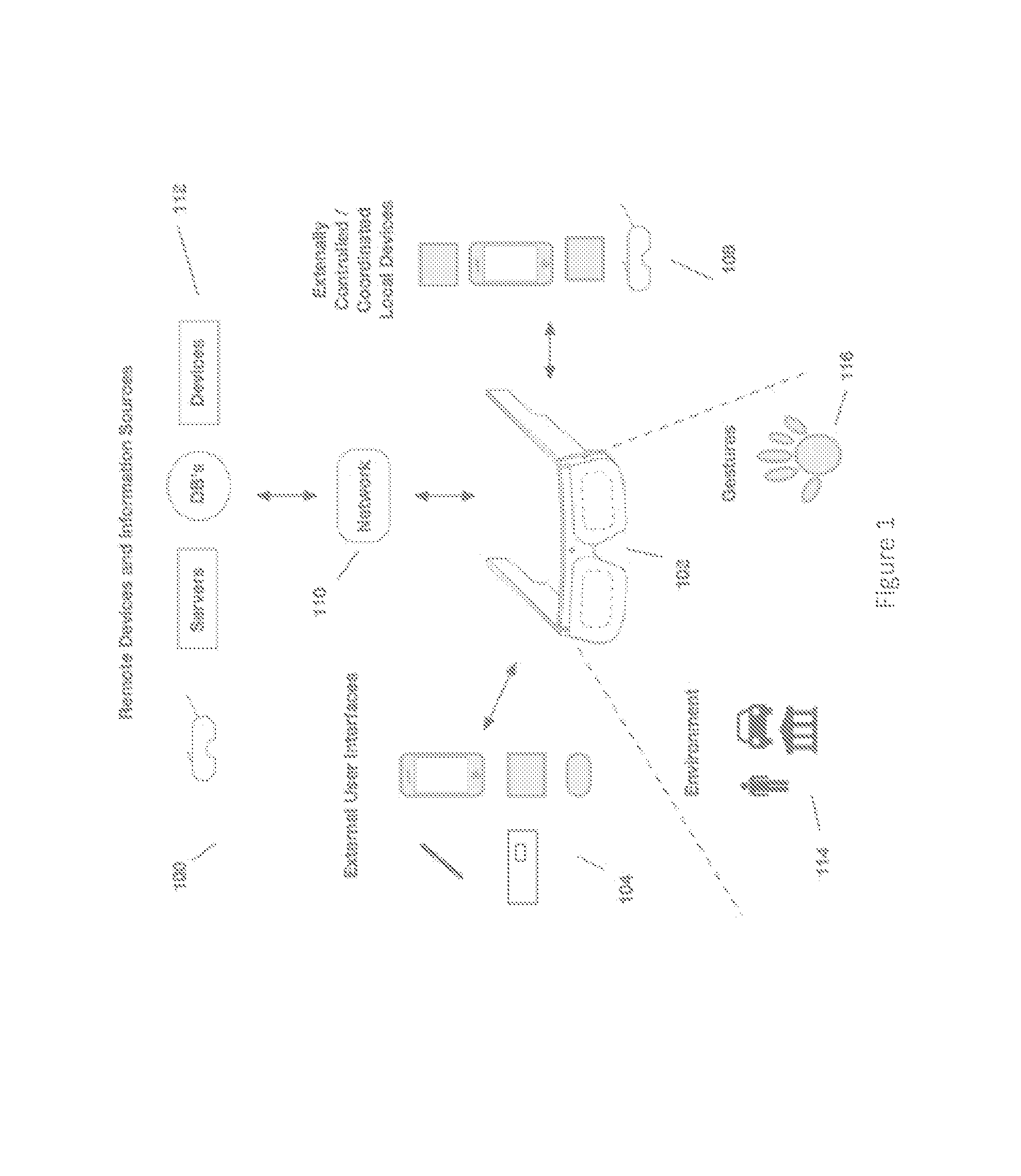

Eye glint imaging in see-through computer display systems

ActiveUS20160116979A1Improve transmittanceInput/output for user-computer interactionAcquiring/recognising eyesDisplay deviceComputer science

Owner:OSTERHOUT GROUP INC

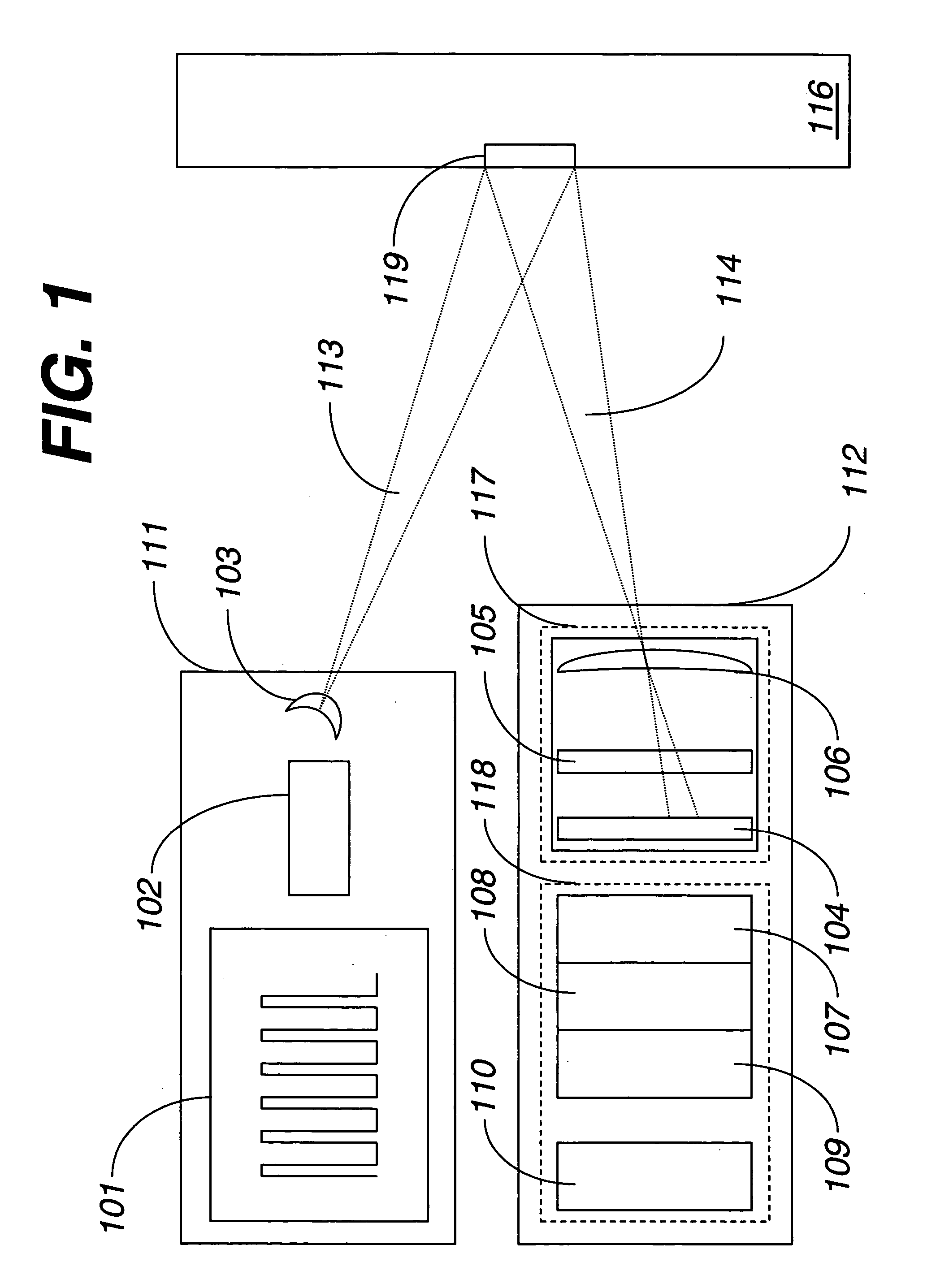

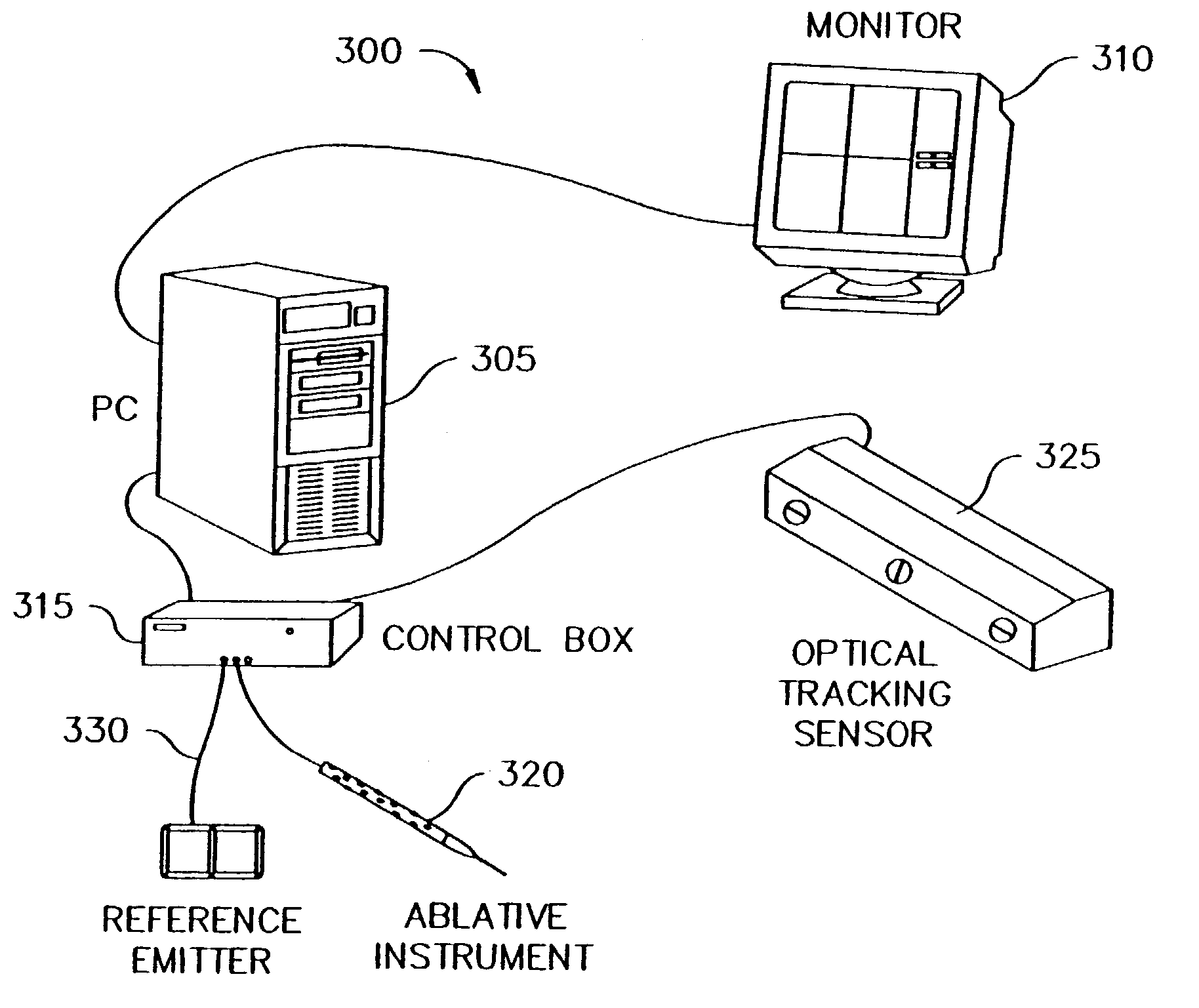

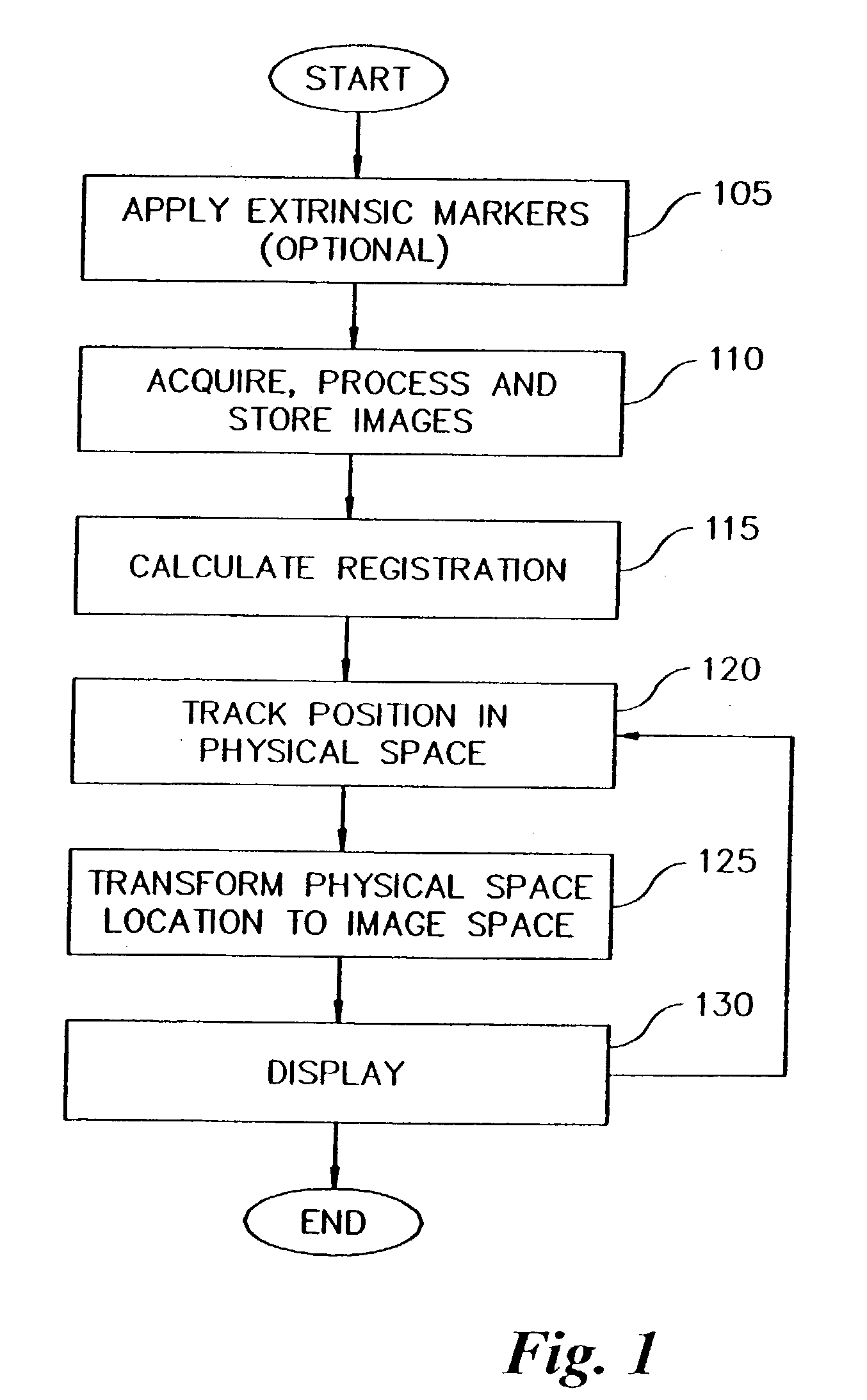

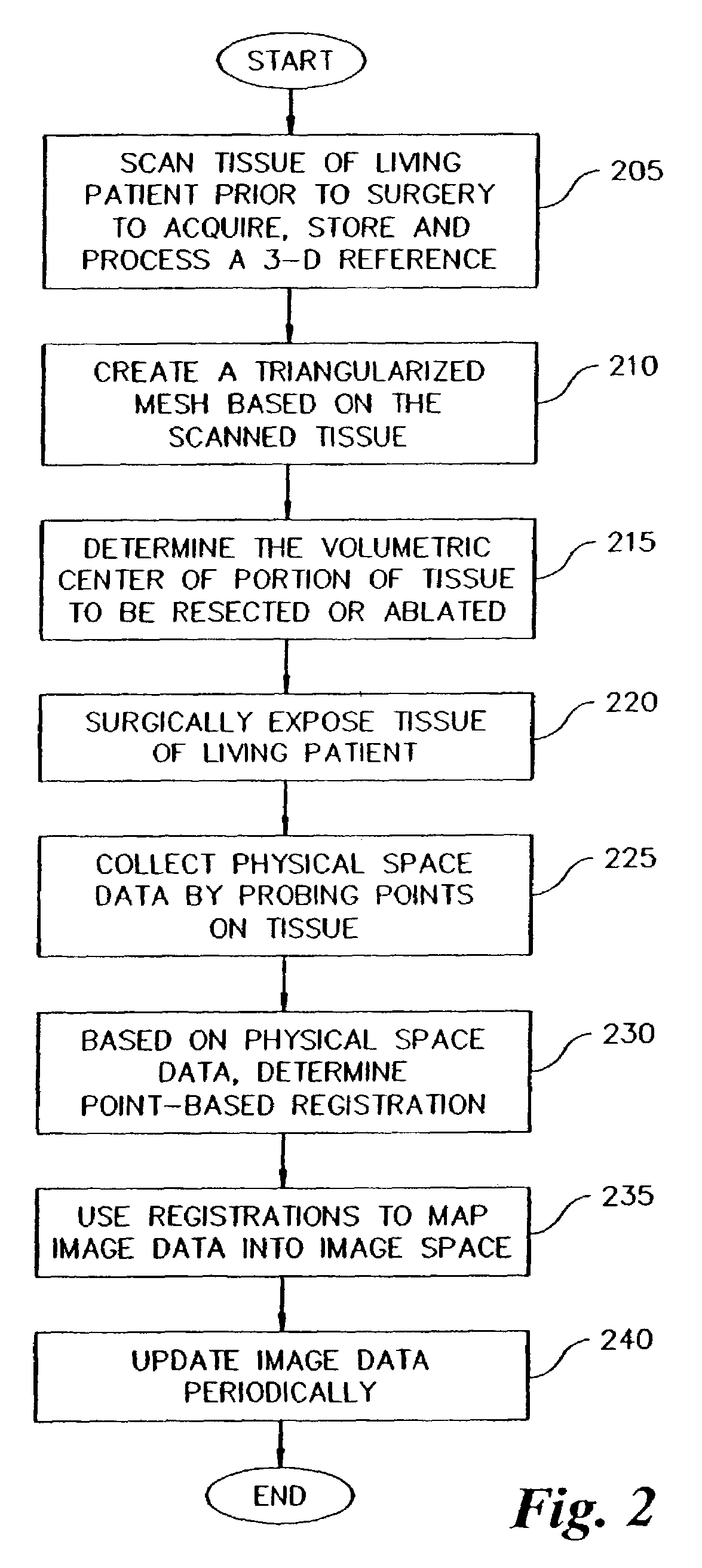

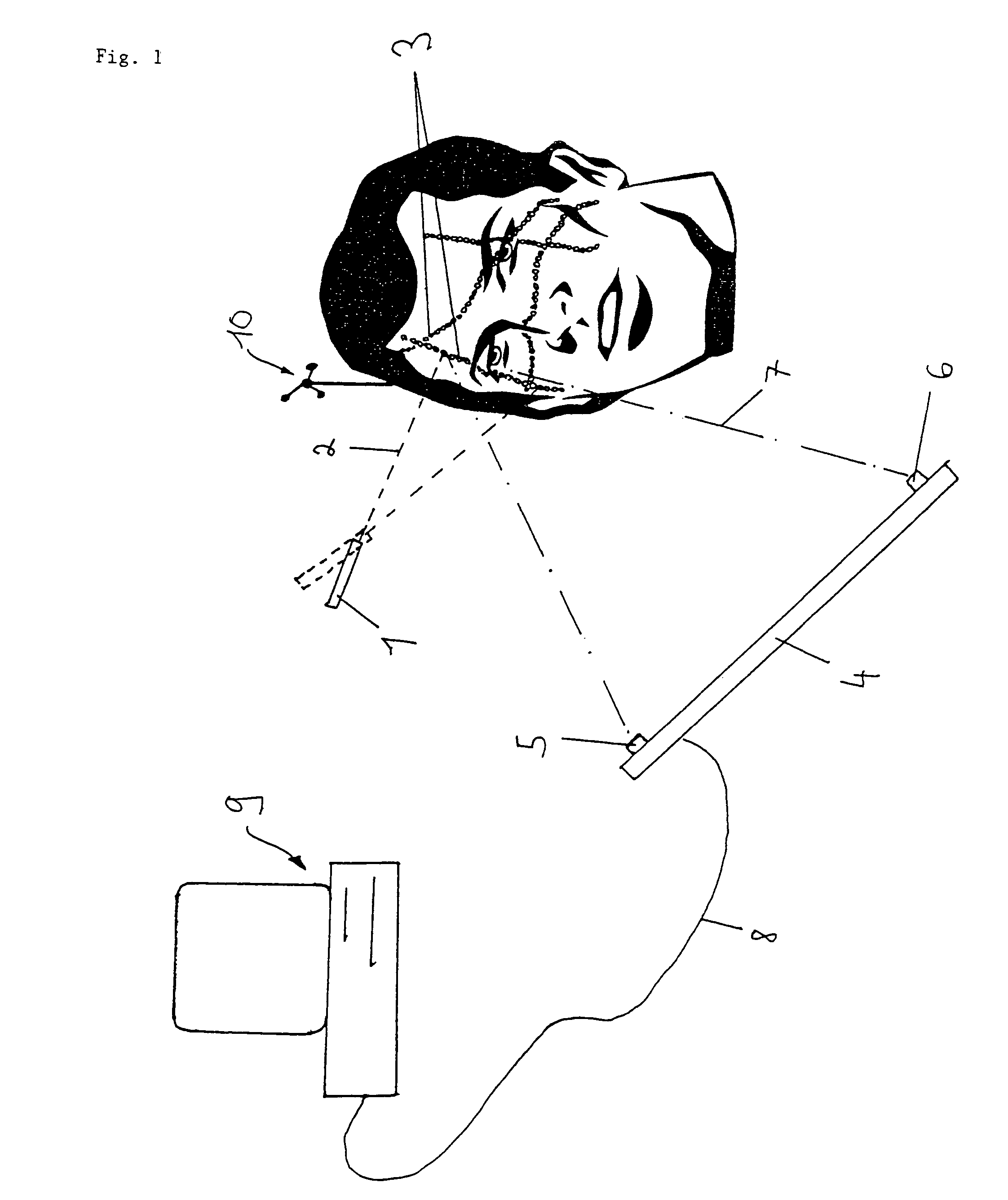

Method and apparatus for collecting and processing physical space data for use while performing image-guided surgery

InactiveUS7072707B2Ultrasonic/sonic/infrasonic diagnosticsSurgical navigation systemsPhysical spaceLaser light

A method and apparatus for collecting and processing physical space data used while performing image-guided surgery is disclosed. Physical space data is collected by probing physical surface points of surgically exposed tissue. The physical space data provides three-dimensional (3-D) coordinates for each of the physical surface points. Based on the physical space data collected, point-based registrations used to indicate surgical position in both image space and physical space are determined. In one embodiment, the surface of surgically exposed tissue of a living patient is illuminated with laser light. Light reflected from the illuminated surface of the exposed tissue is received and analyzed. In another embodiment, one or more magnetic fields of known shape and size are established in the proximity of the exposed tissue. Data associated with the strength of the magnetic fields is acquired and analyzed.

Owner:VANDERBILT UNIV

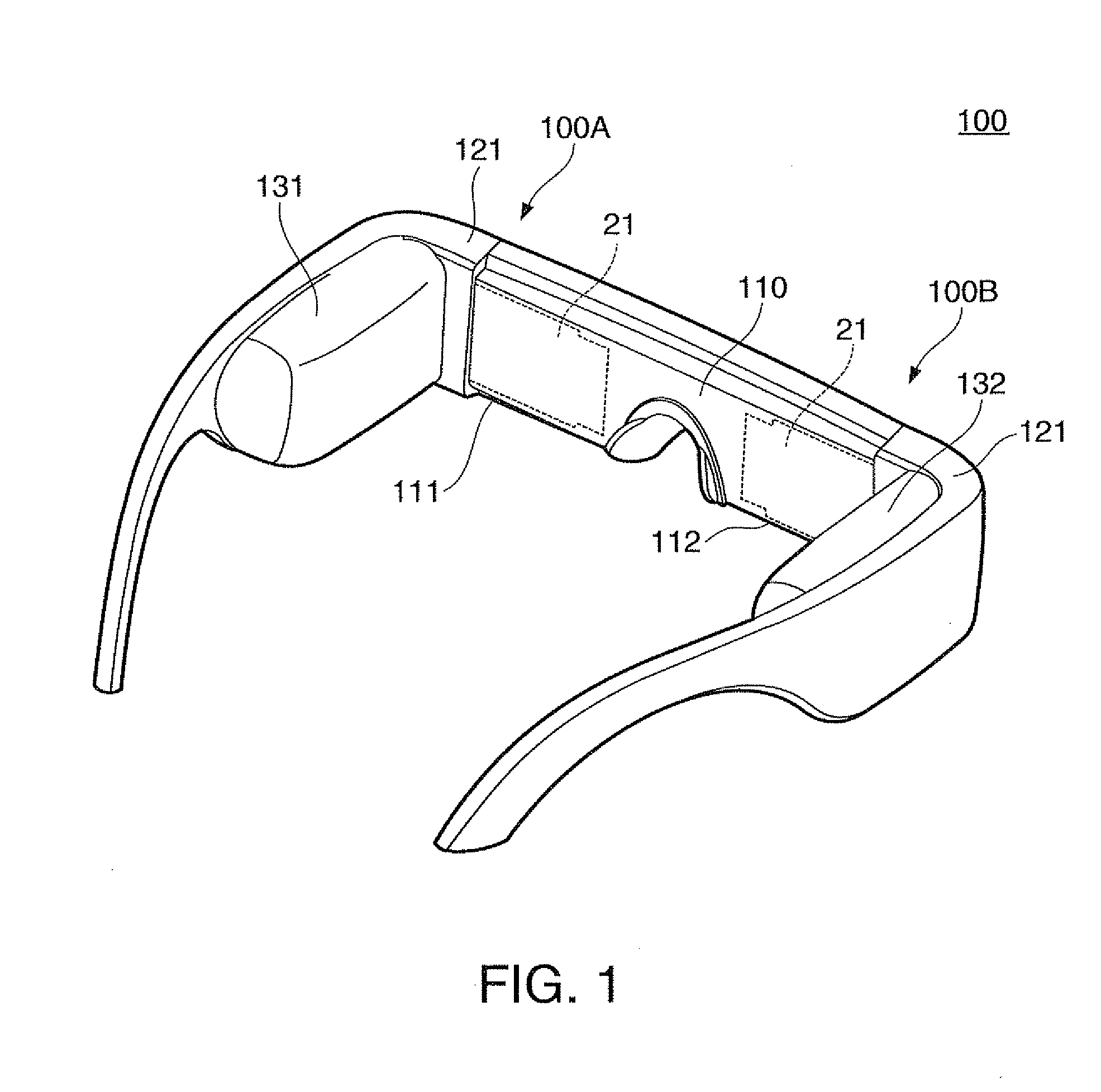

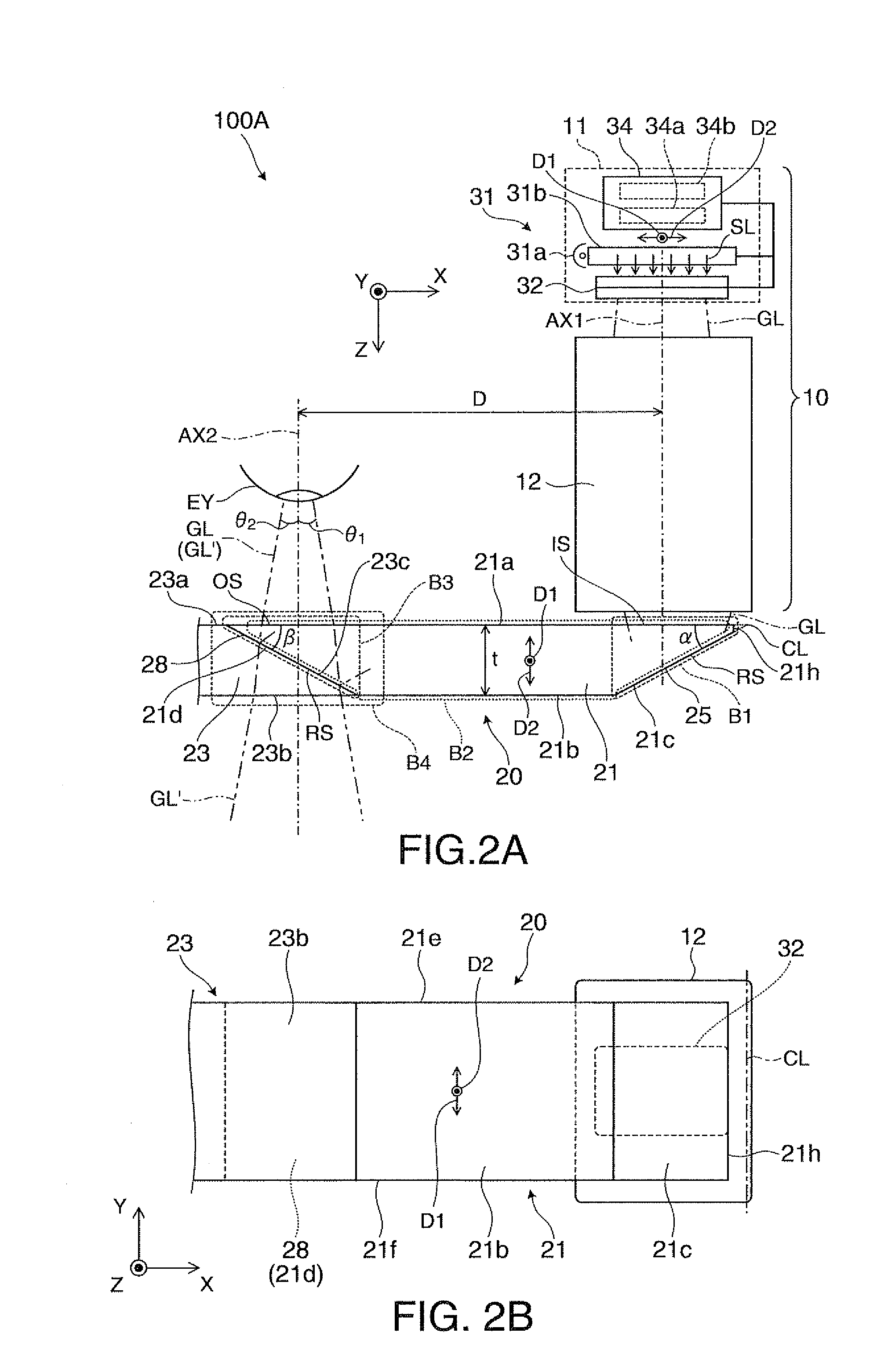

Virtual image display device

ActiveUS8564883B2Simple configurationMake up bulkyCathode-ray tube indicatorsOptical light guidesDisplay deviceLight beam

Owner:SEIKO EPSON CORP

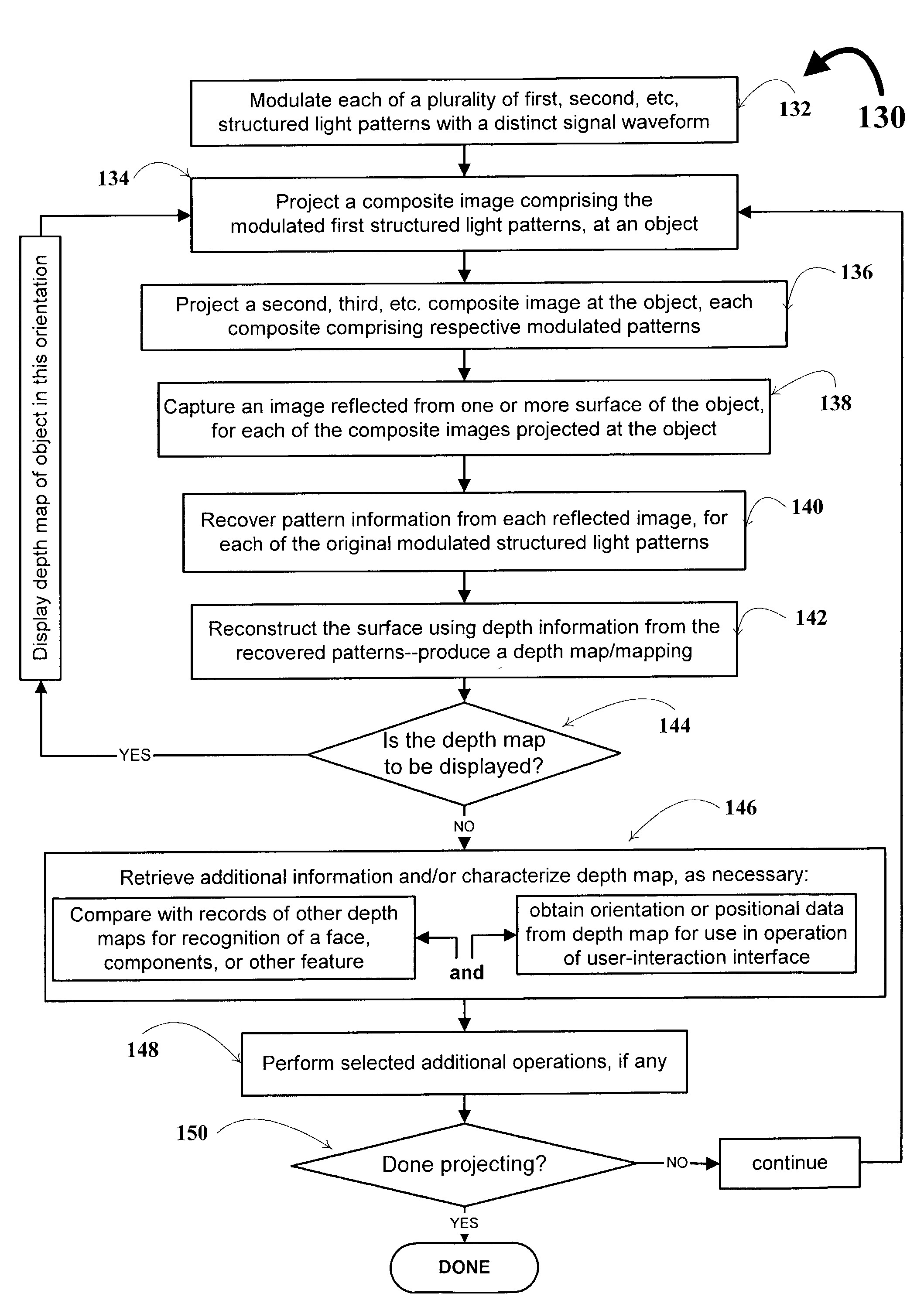

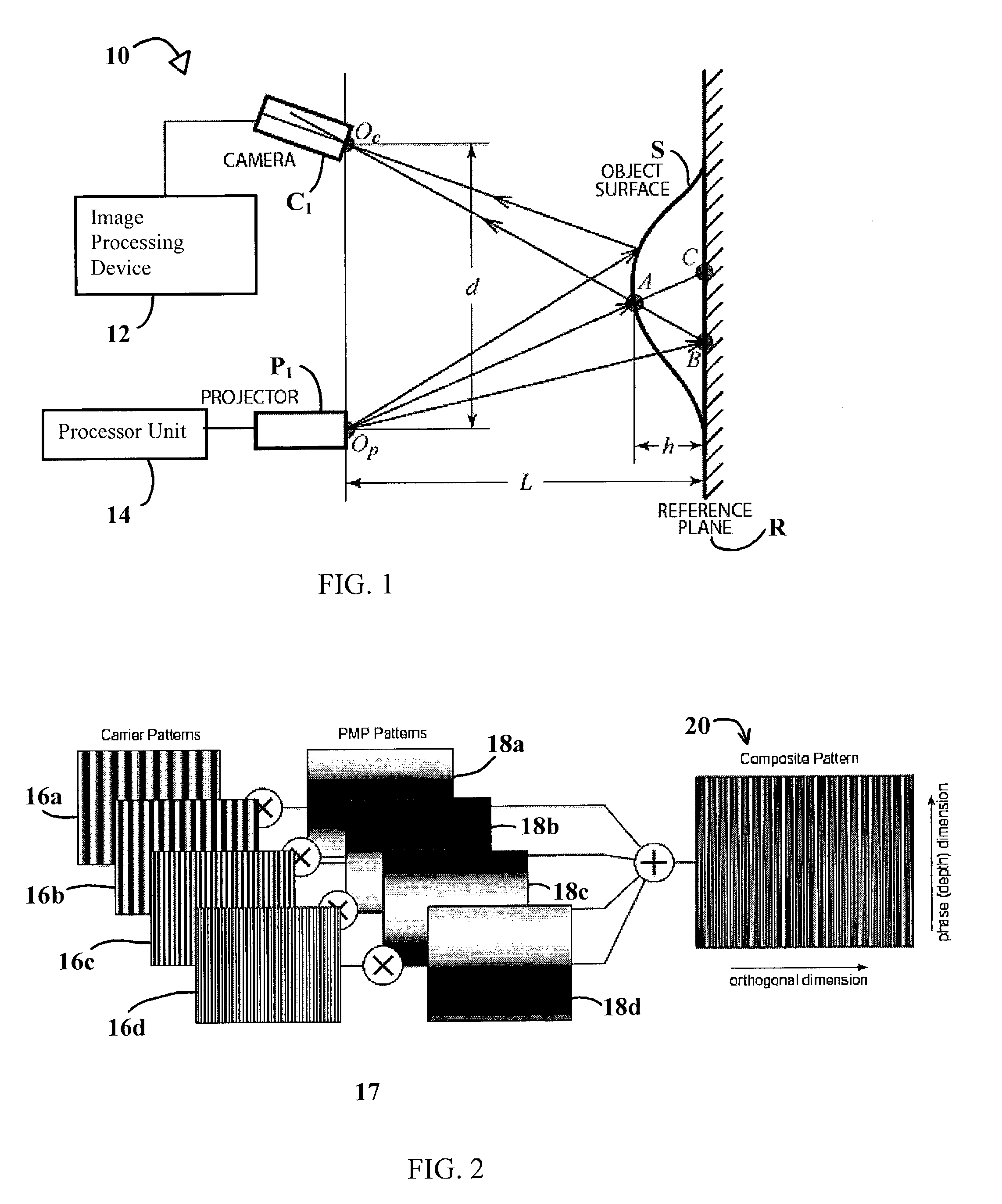

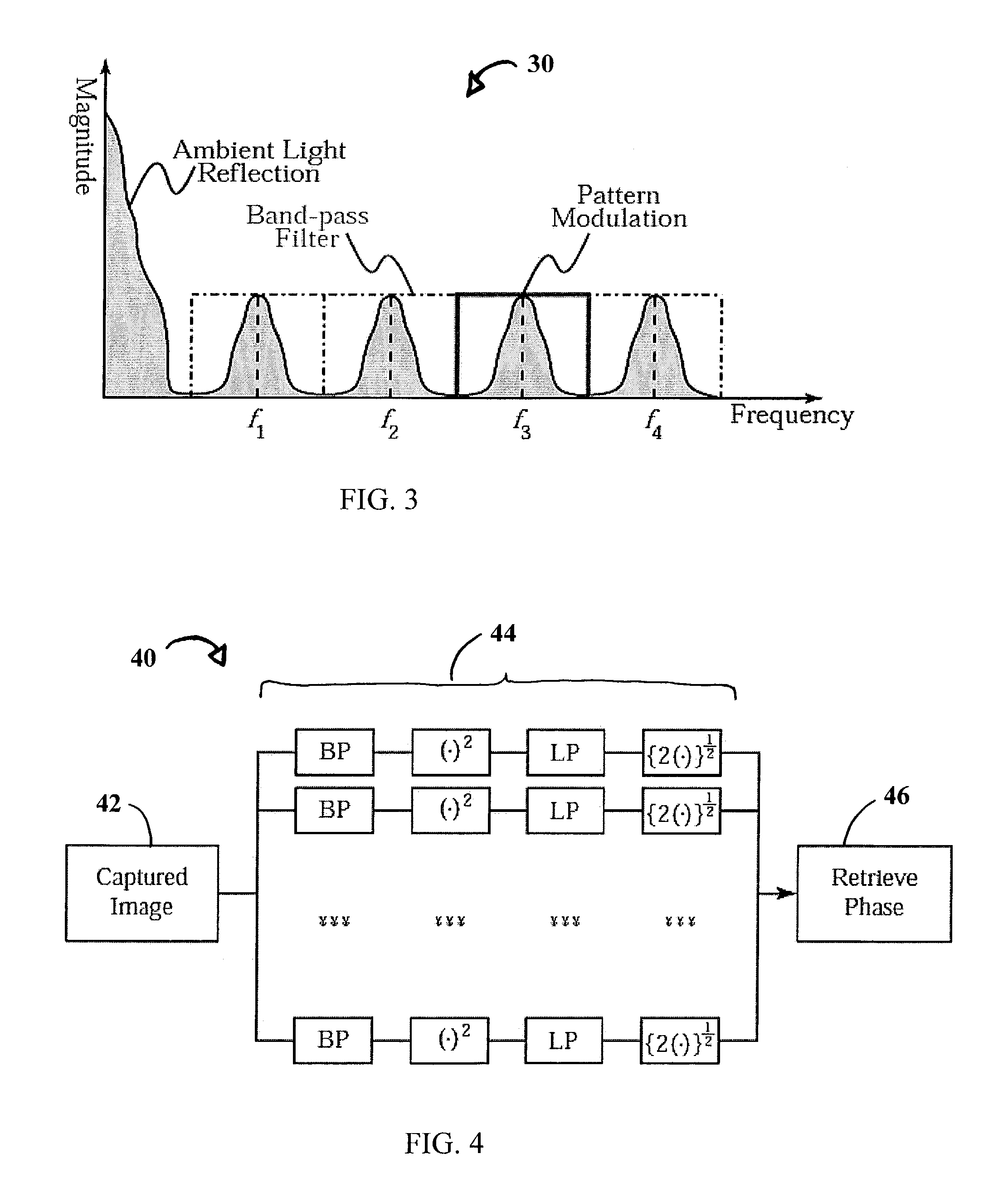

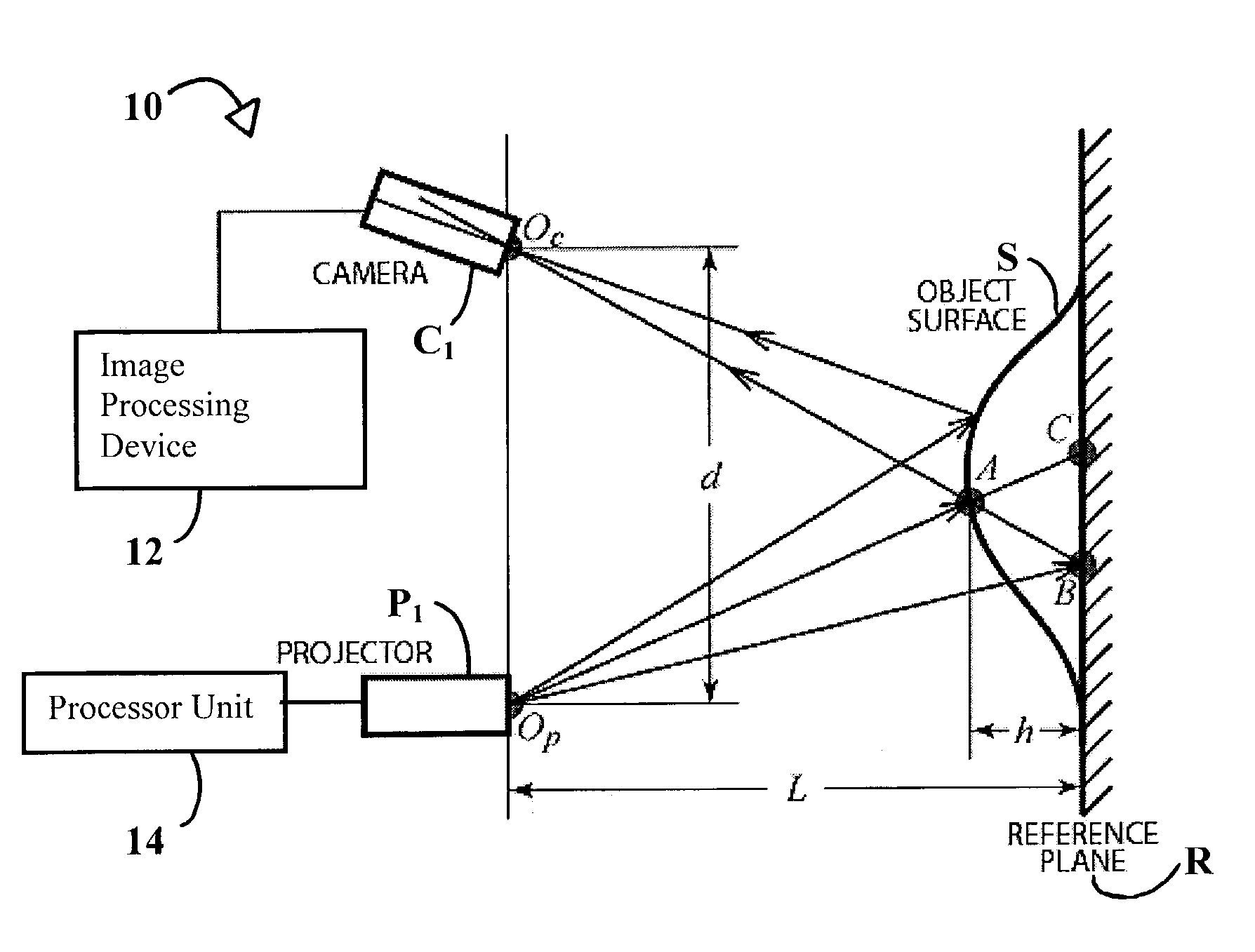

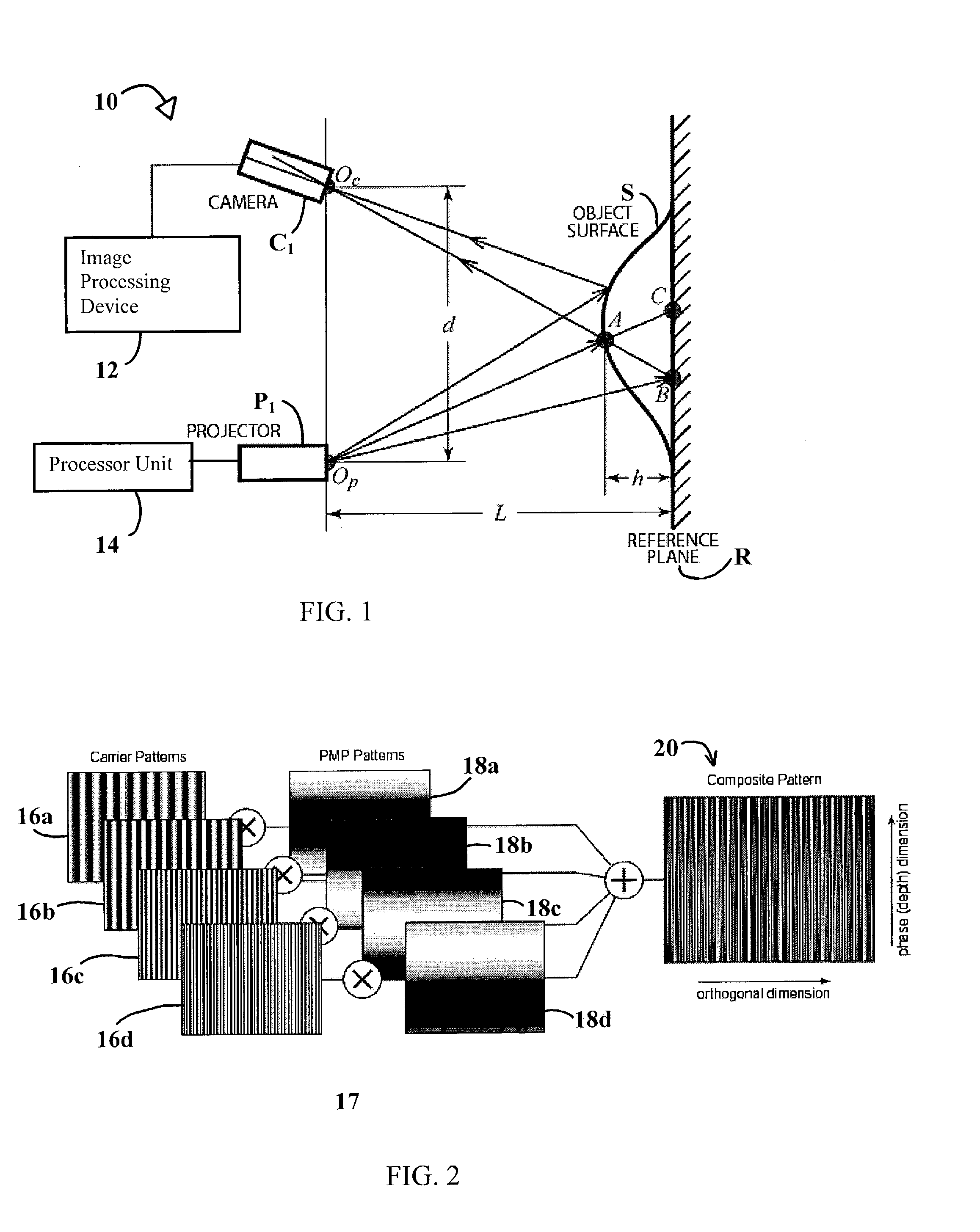

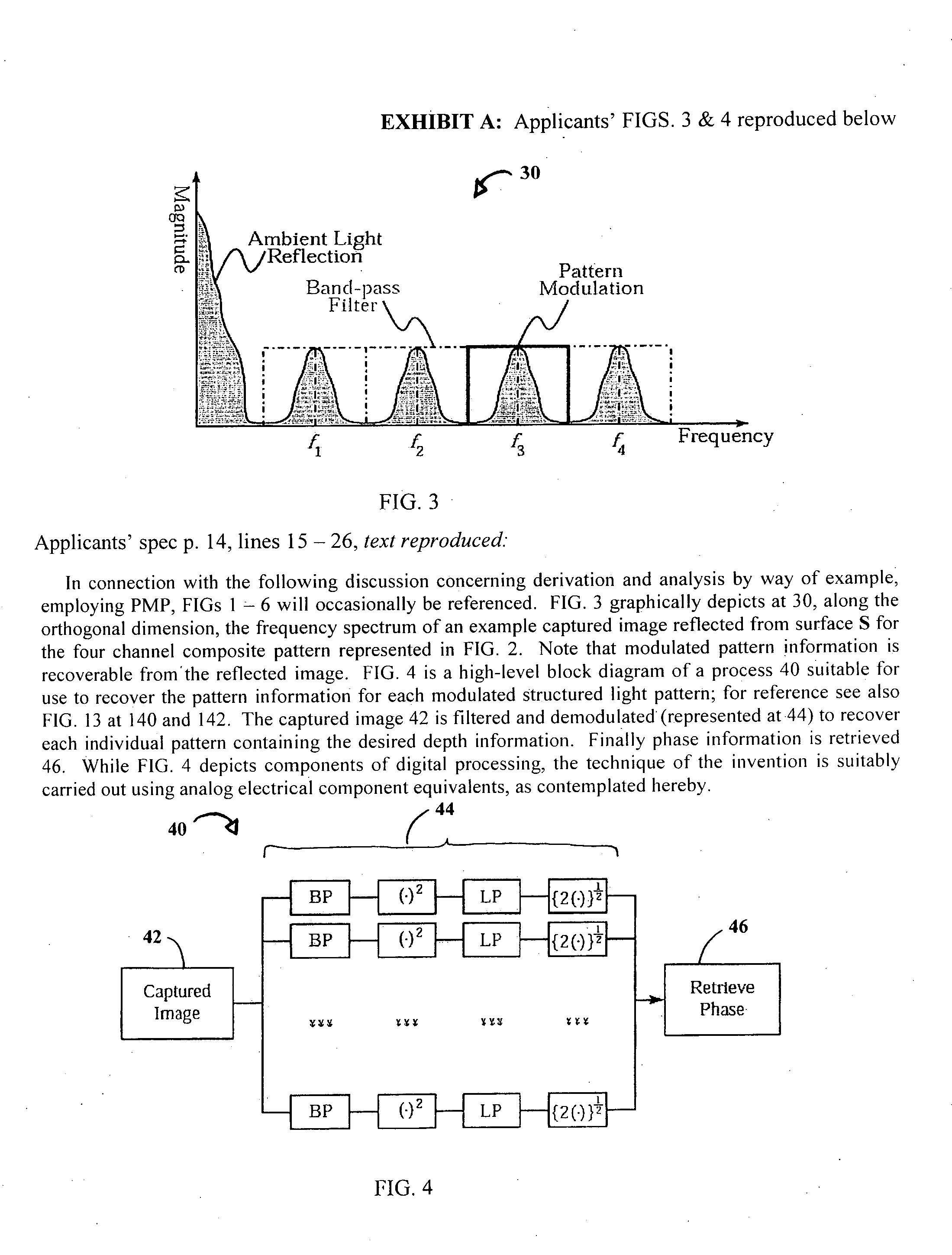

System and technique for retrieving depth information about a surface by projecting a composite image of modulated light patterns

InactiveUS7440590B1More detailed and large depth mappingLimited bandwidthProjectorsCathode-ray tube indicatorsInteraction interfaceTelecollaboration

A technique, associated system and program code, for retrieving depth information about at least one surface of an object. Core features include: projecting a composite image comprising a plurality of modulated structured light patterns, at the object; capturing an image reflected from the surface; and recovering pattern information from the reflected image, for each of the modulated structured light patterns. Pattern information is preferably recovered for each modulated structured light pattern used to create the composite, by performing a demodulation of the reflected image. Reconstruction of the surface can be accomplished by using depth information from the recovered patterns to produce a depth map / mapping thereof. Each signal waveform used for the modulation of a respective structured light pattern, is distinct from each of the other signal waveforms used for the modulation of other structured light patterns of a composite image; these signal waveforms may be selected from suitable types in any combination of distinct signal waveforms, provided the waveforms used are uncorrelated with respect to each other. The depth map / mapping to be utilized in a host of applications, for example: displaying a 3-D view of the object; virtual reality user-interaction interface with a computerized device; face—or other animal feature or inanimate object—recognition and comparison techniques for security or identification purposes; and 3-D video teleconferencing / telecollaboration.

Owner:UNIV OF KENTUCKY RES FOUND

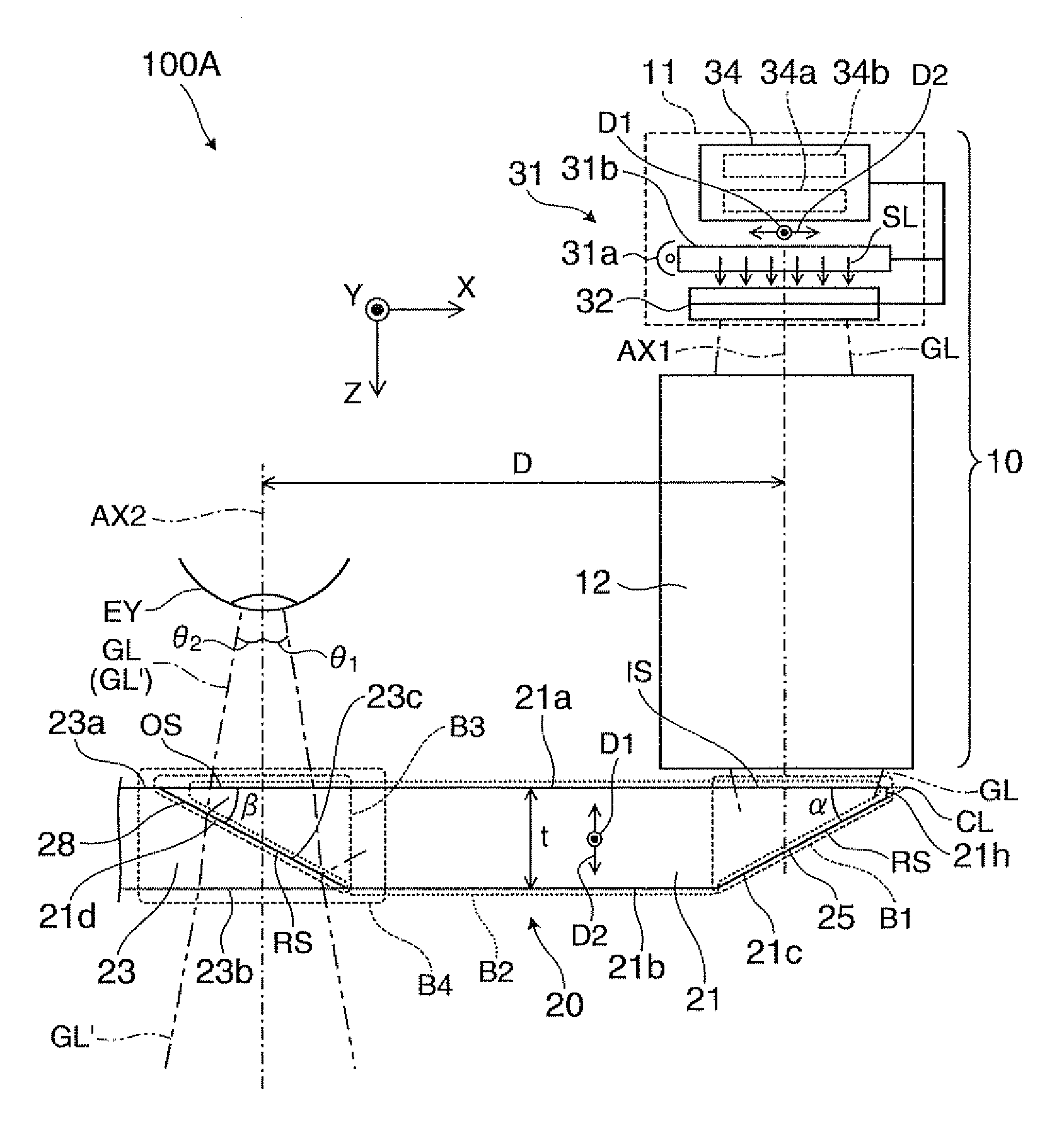

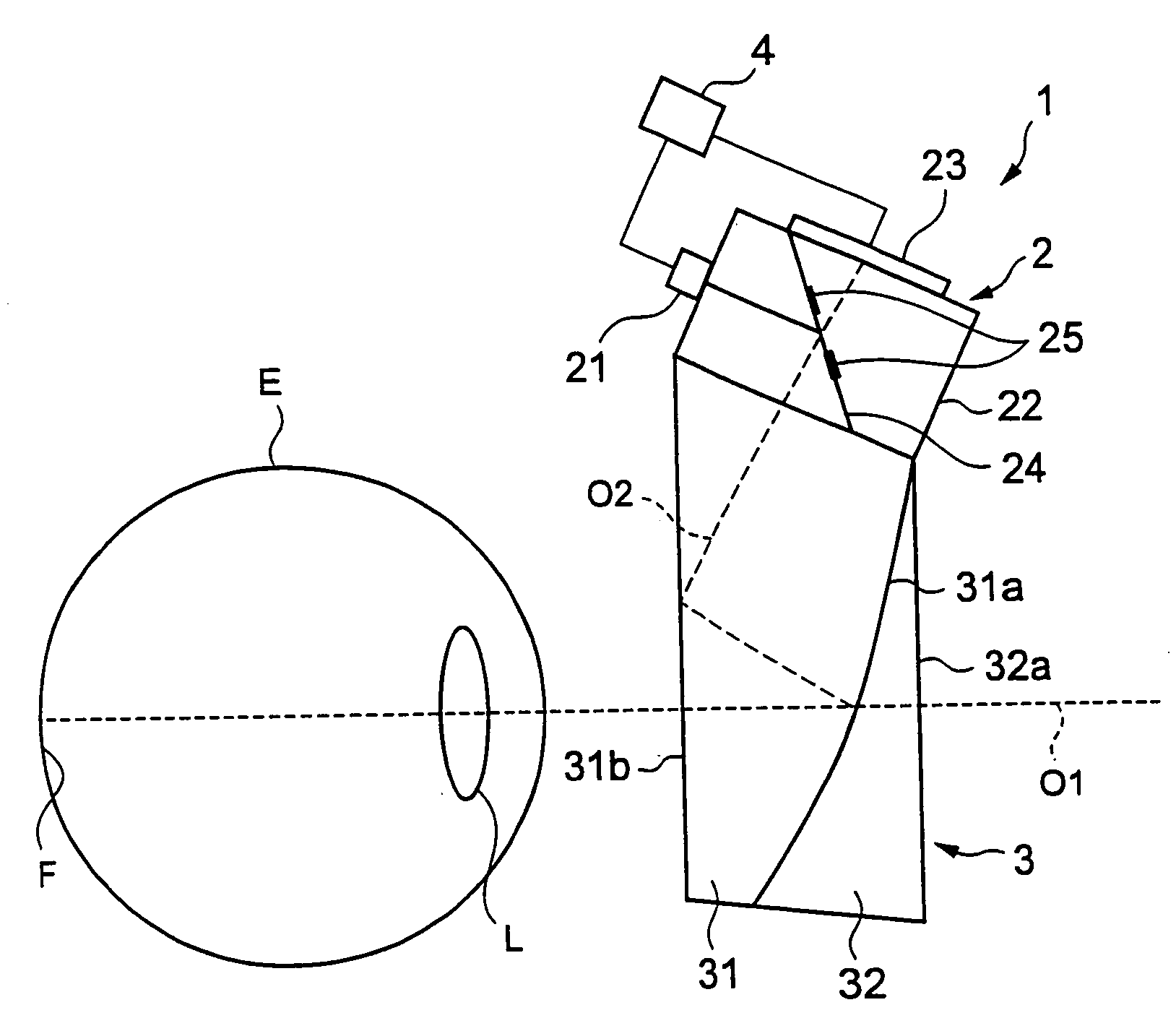

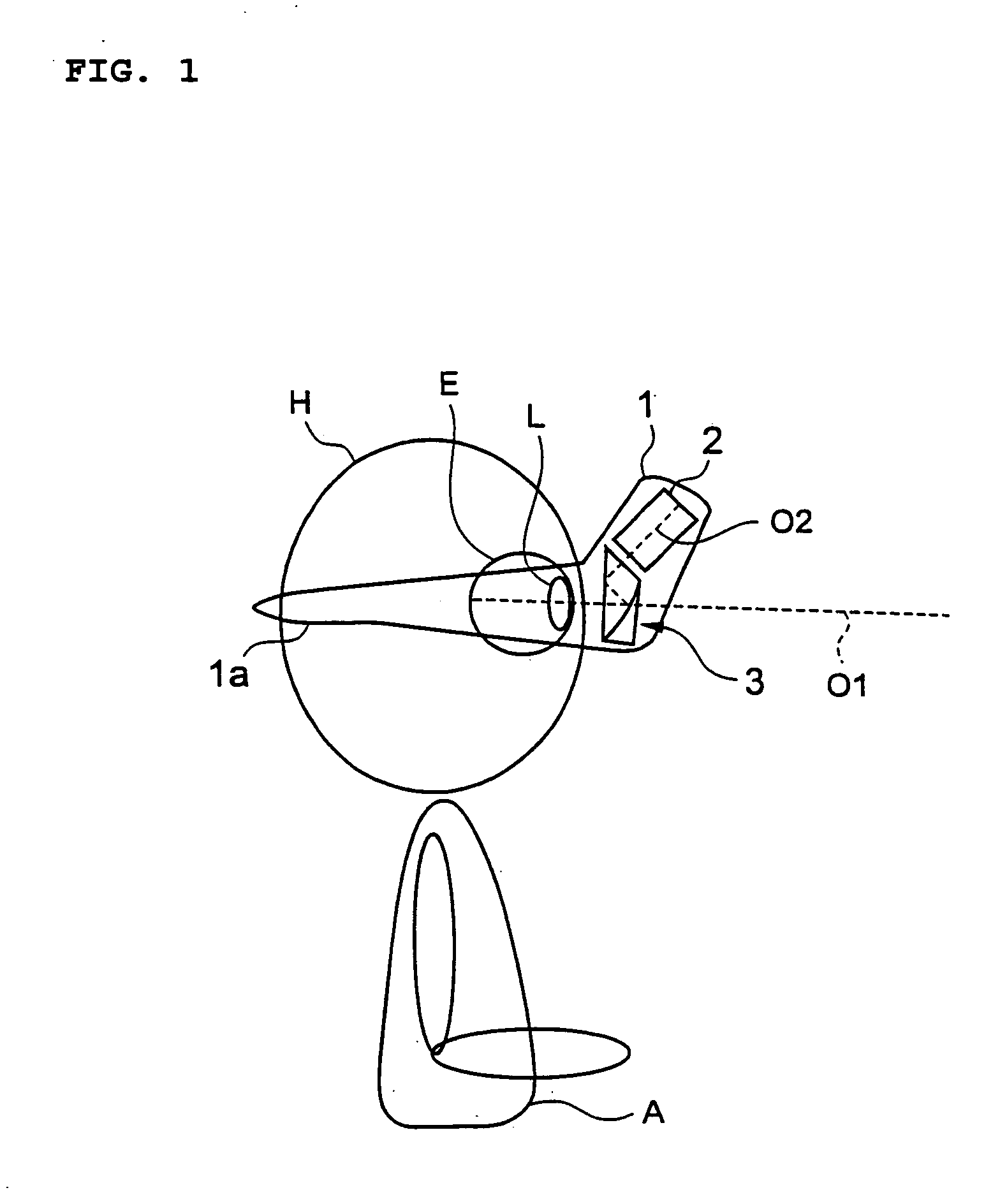

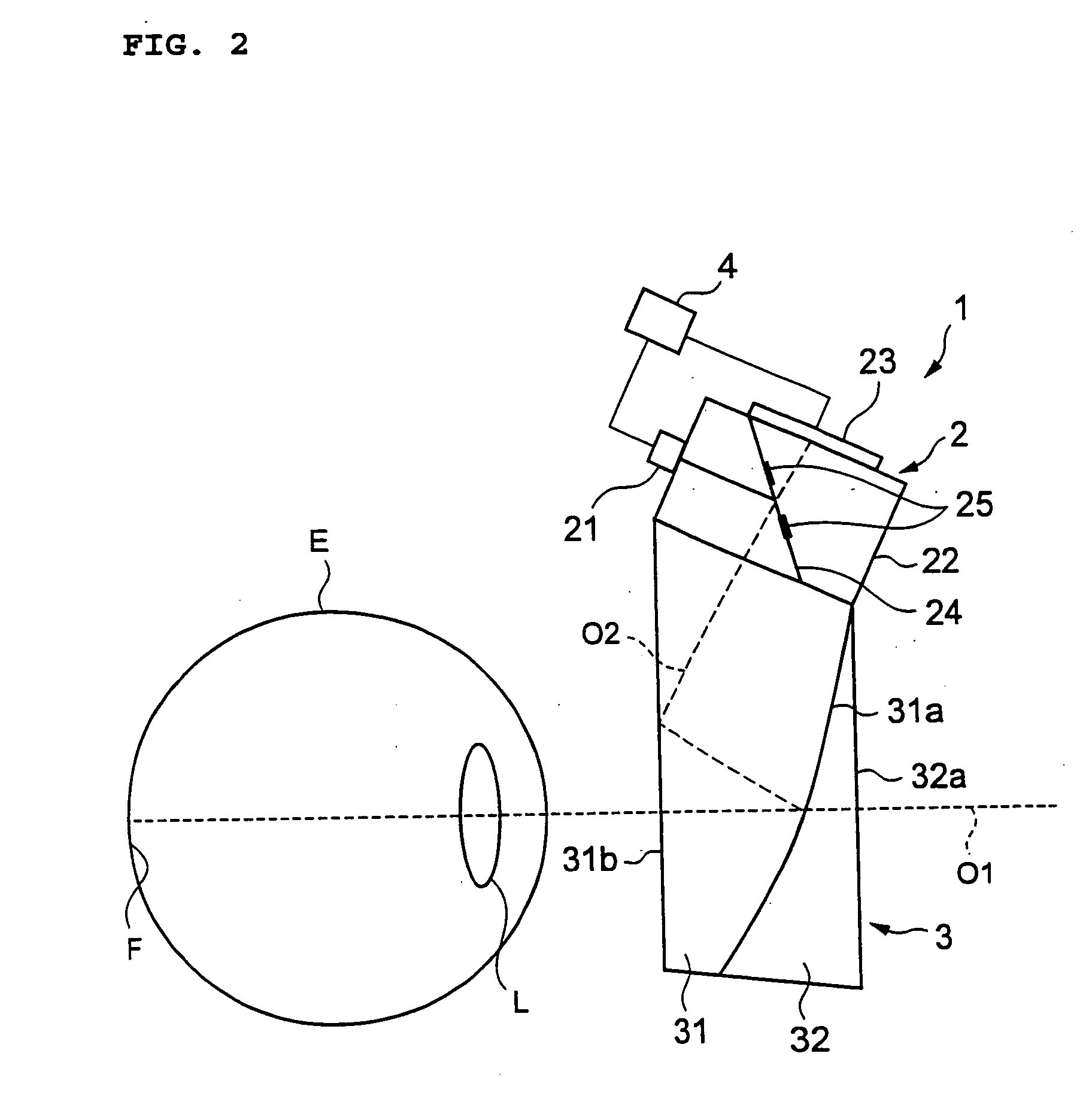

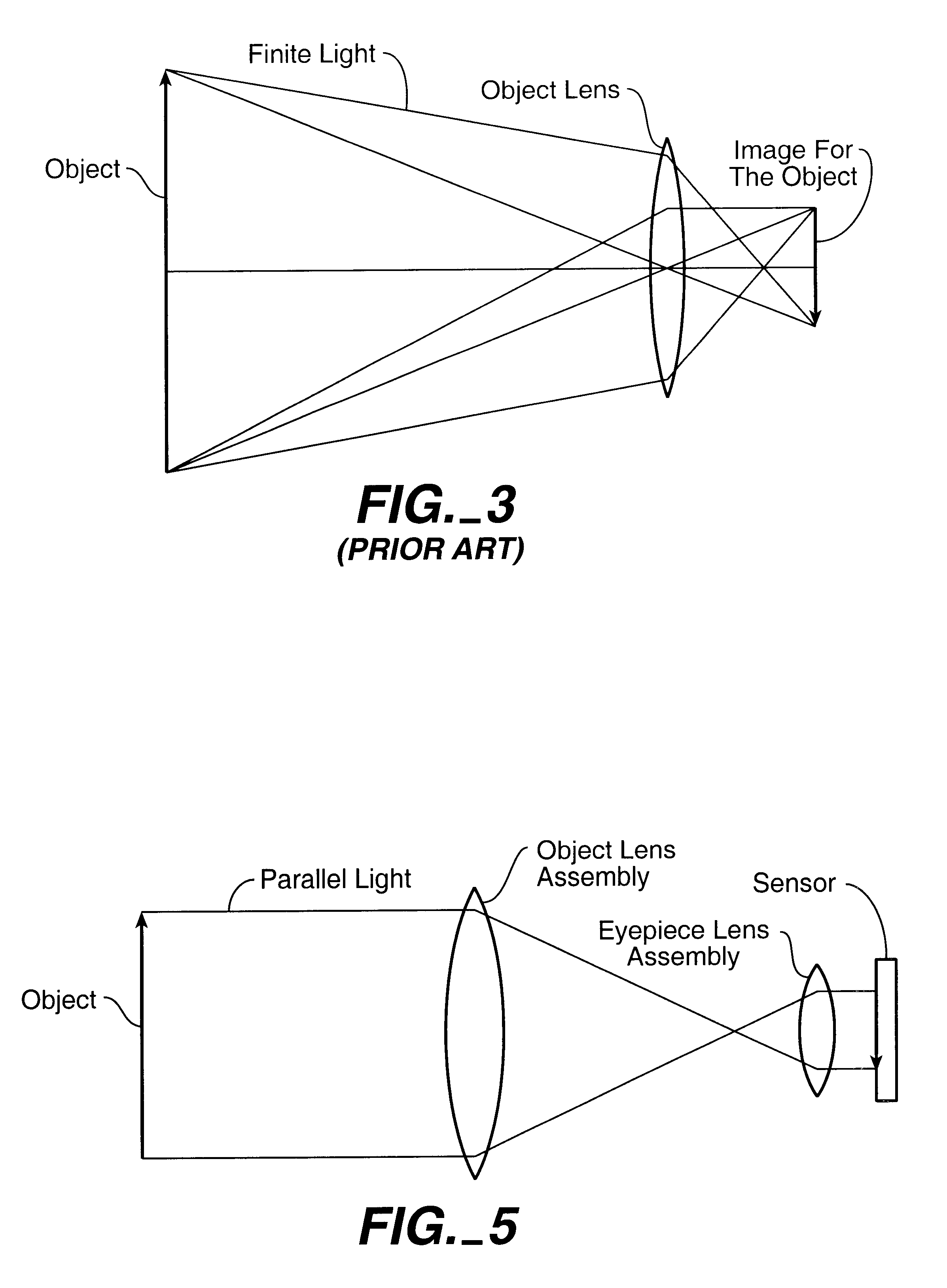

Refraction measuring instrument

InactiveUS20060215111A1Small sizeReduce weightRefractometersSkiascopesMeasuring instrumentBeam splitting

A refraction measuring instrument for measuring the refraction of an eye to be examined while the subject is viewing an external object in a more natural posture. A measuring light beam from a light source 21 is reflected from a mirror 25, shaped into a beam with a ring cross section, directed to a free curved surface prism 31 along an optical axis O2, reflected from a surface 31b and a beam splitting surface 31a, guided to an eye E along an optical axis O1 together with the visible light from outside the instrument, and form a ring pattern on the fundus F. The measurement beam reflected from the fundus F is received by a CCD 23 through the free curved surface prism 31 and a prism 22, and a ring pattern is imaged. A calculation control device 4 analyzes the imaged ring pattern and calculates the sphericity, the degree of astigmatism, and the astigmatic axis angle. For measurement, the subject A wears the refraction measuring instrument 1 on the head H through a wearing section 1a.

Owner:KK TOPCON

Methods and apparatus for position estimation using reflected light sources

The invention is generally related to the estimation of position and orientation of an object with respect to a local or a global coordinate system using reflected light sources. A typical application of the method and apparatus includes estimation and tracking of the position of a mobile autonomous robot. Other applications include estimation and tracking of an object for position-aware, ubiquitous devices. Additional applications include tracking of the positions of people or pets in an indoor environment. The methods and apparatus comprise one or more optical emitters, one or more optical sensors, signal processing circuitry, and signal processing methods to determine the position and orientation of at least one of the optical sensors based at least in part on the detection of the signal of one or more emitted light sources reflected from a surface.

Owner:IROBOT CORP

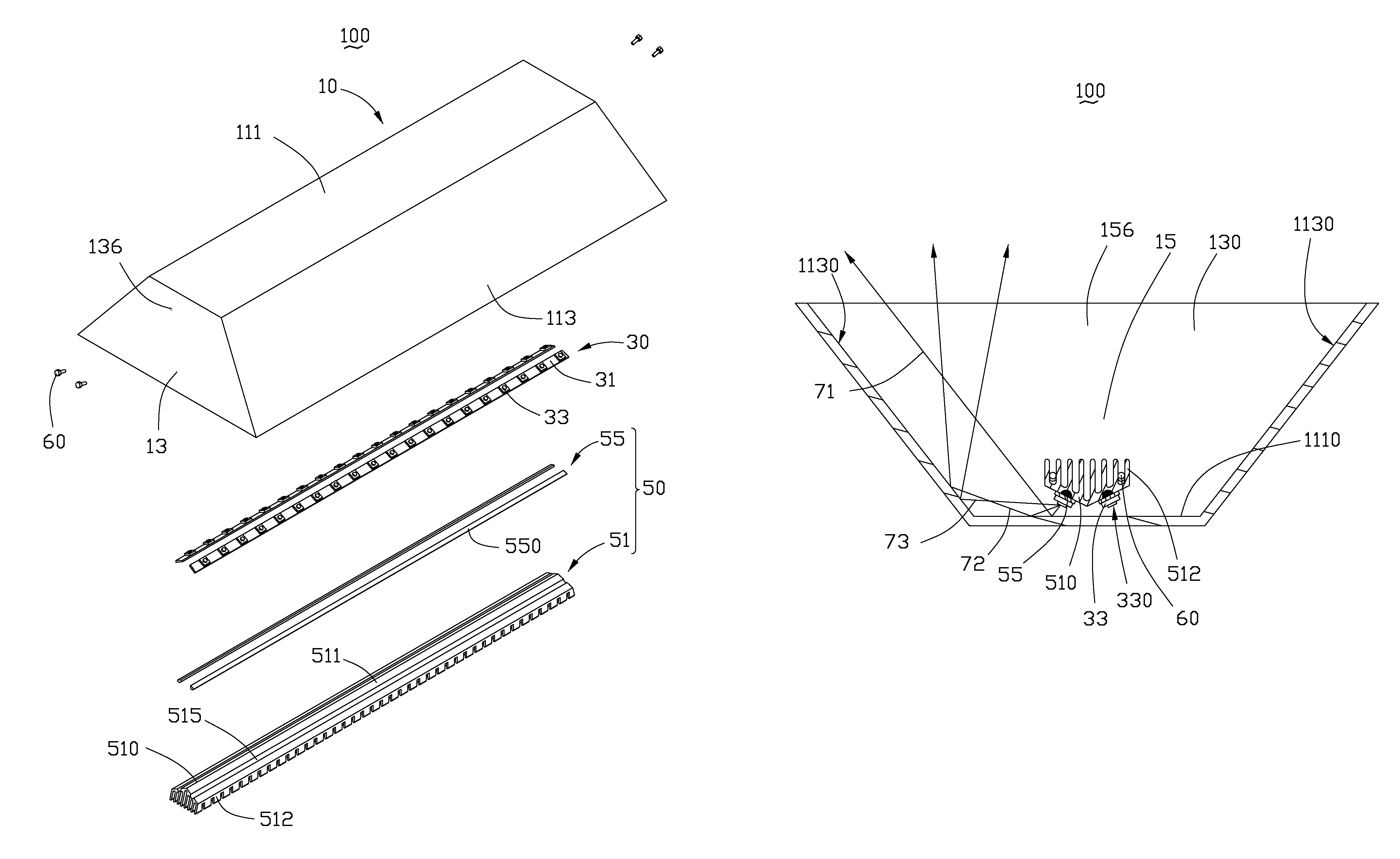

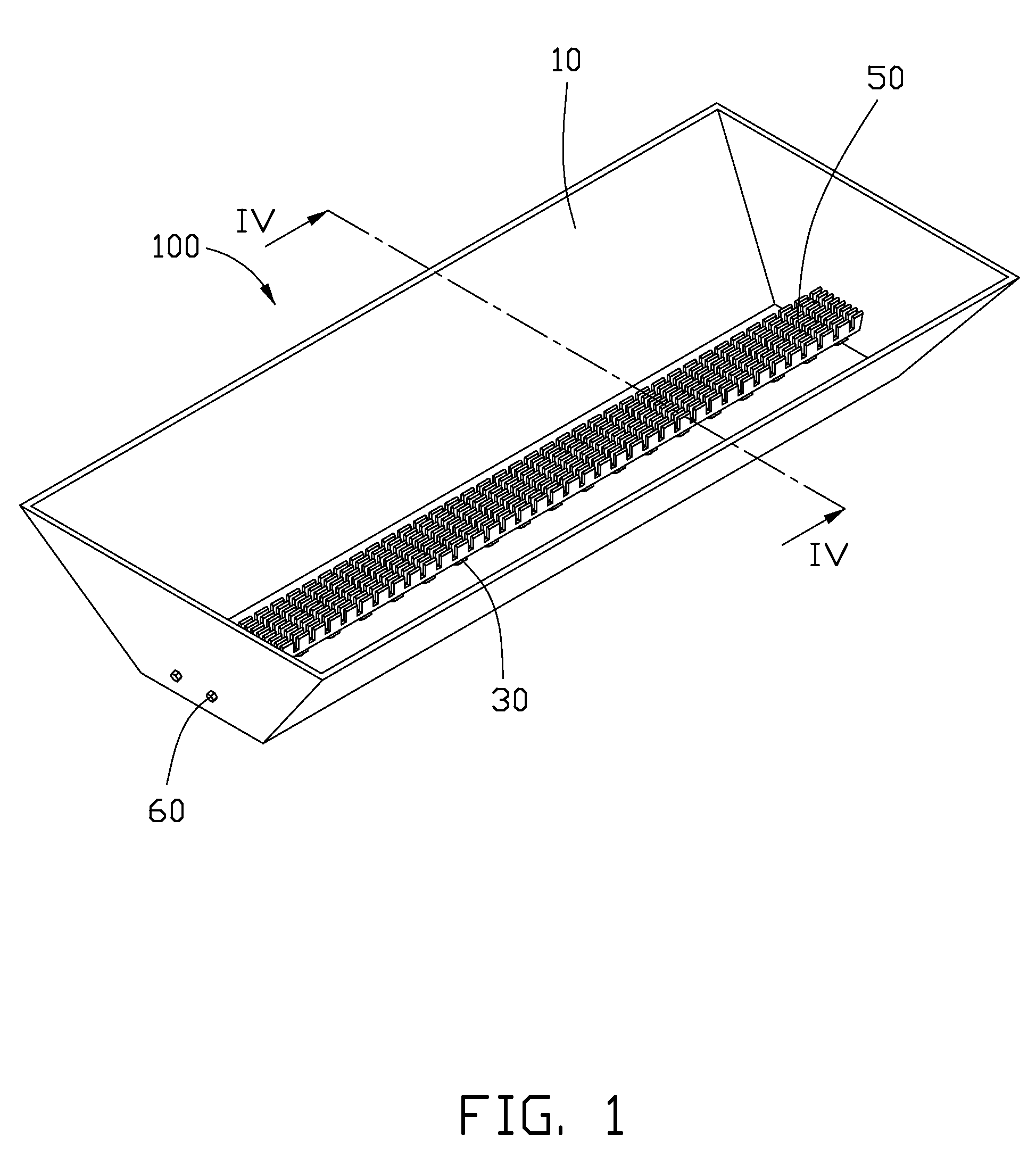

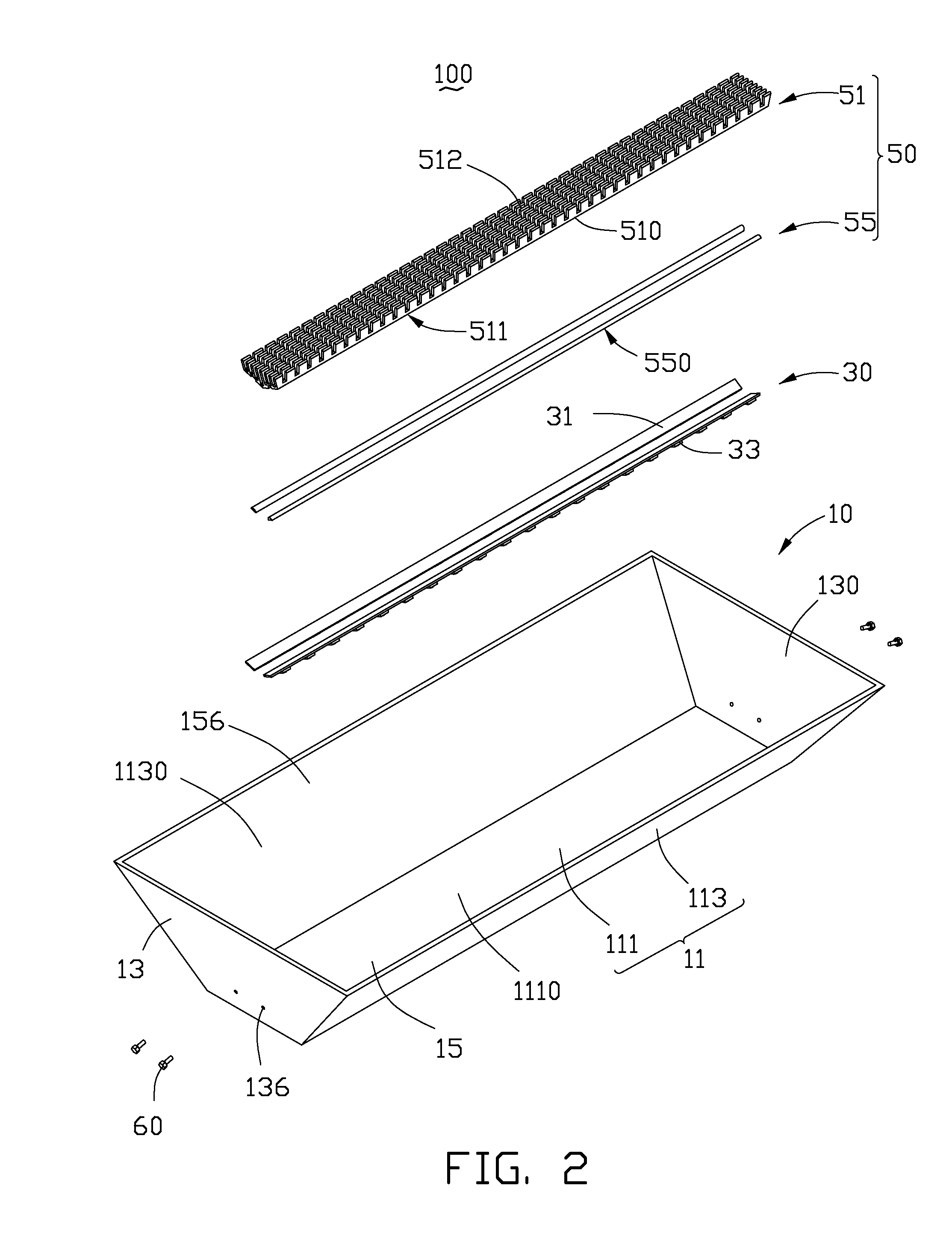

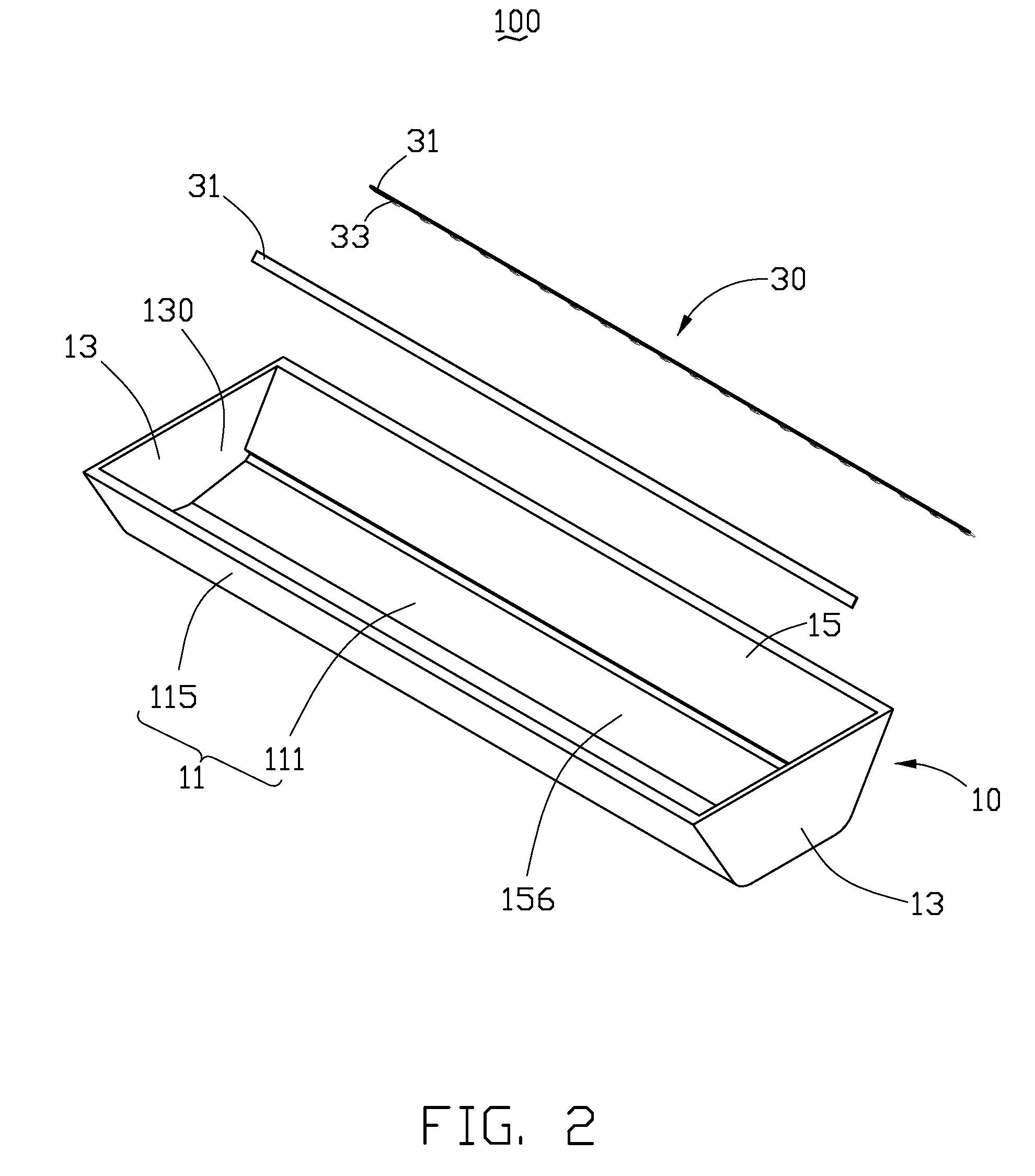

LED lamp

An LED lamp (100) includes a lamp enclosure (10), a heat sink (51) and two LED modules (30). The lamp enclosure has a recess (15) and an opening (156). The heat sink is received in the recess of the lamp enclosure. The LED modules are attached to a bottom of the heat sink and oriented downwardly and outwardly towards an internal surface (1110) of the lamp enclosure. Light emitted by the LED module is firstly directed to the internal surface and other internal surfaces (130, 1130), and then reflected from the internal surfaces to an outside of the LED lamp through the opening.

Owner:FU ZHUN PRECISION IND SHENZHEN +1

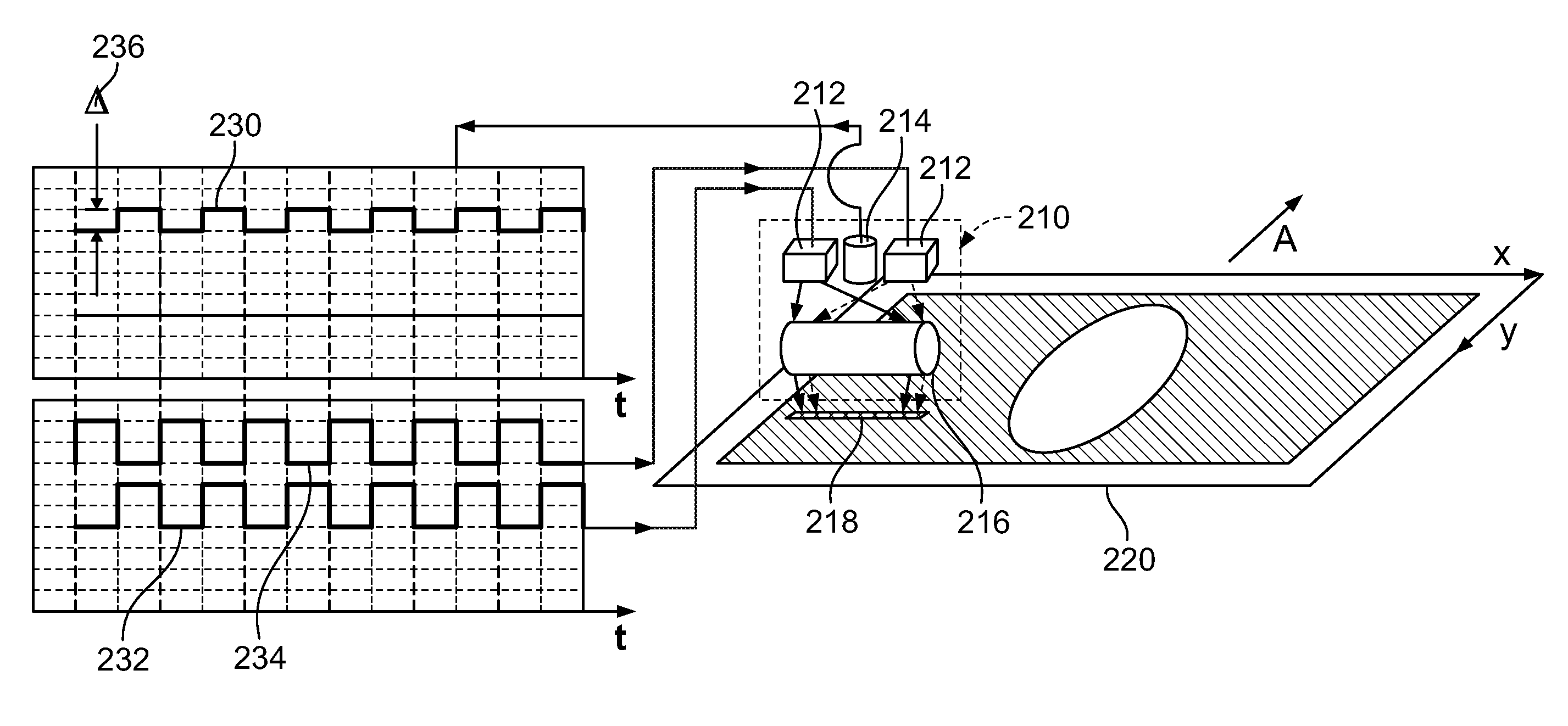

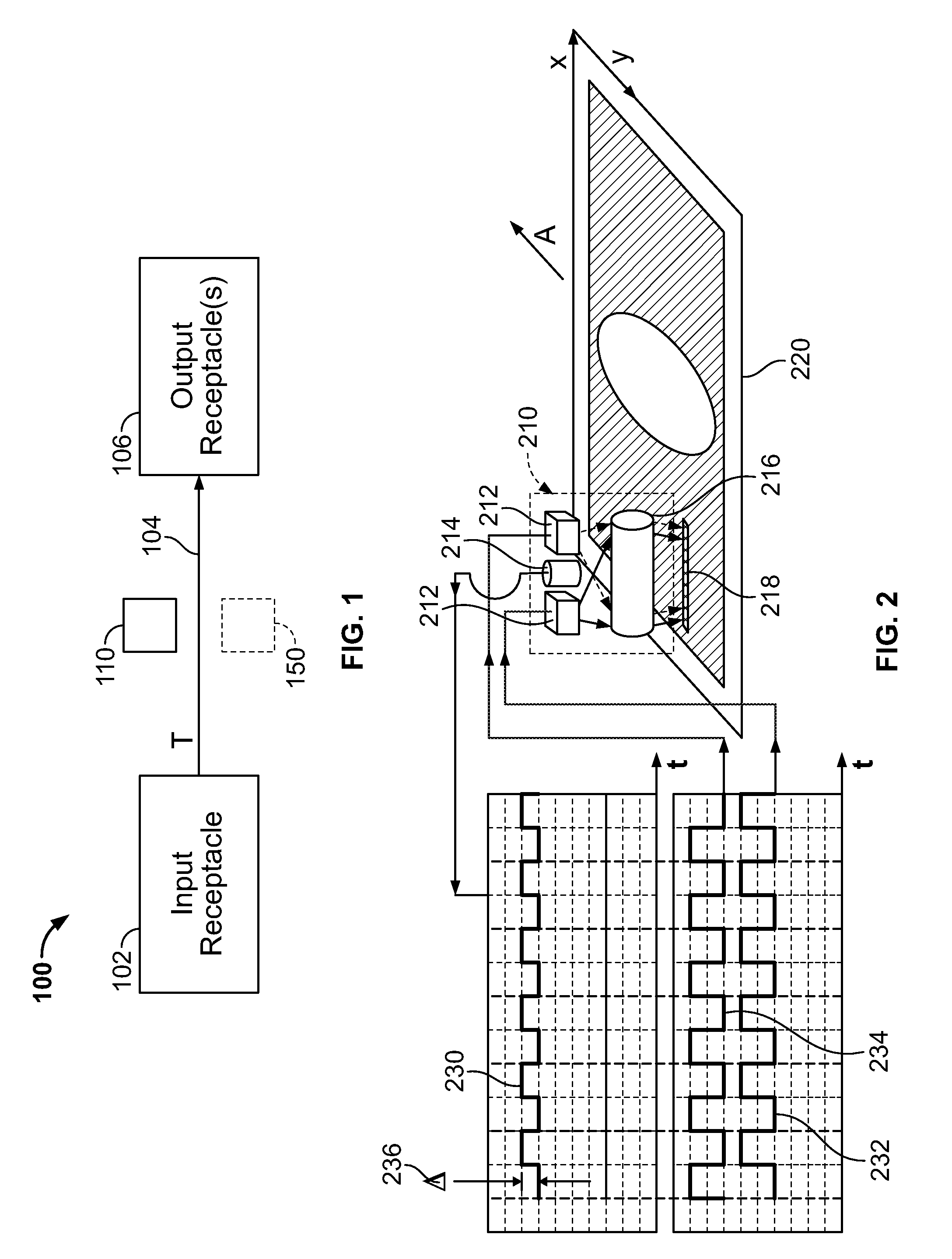

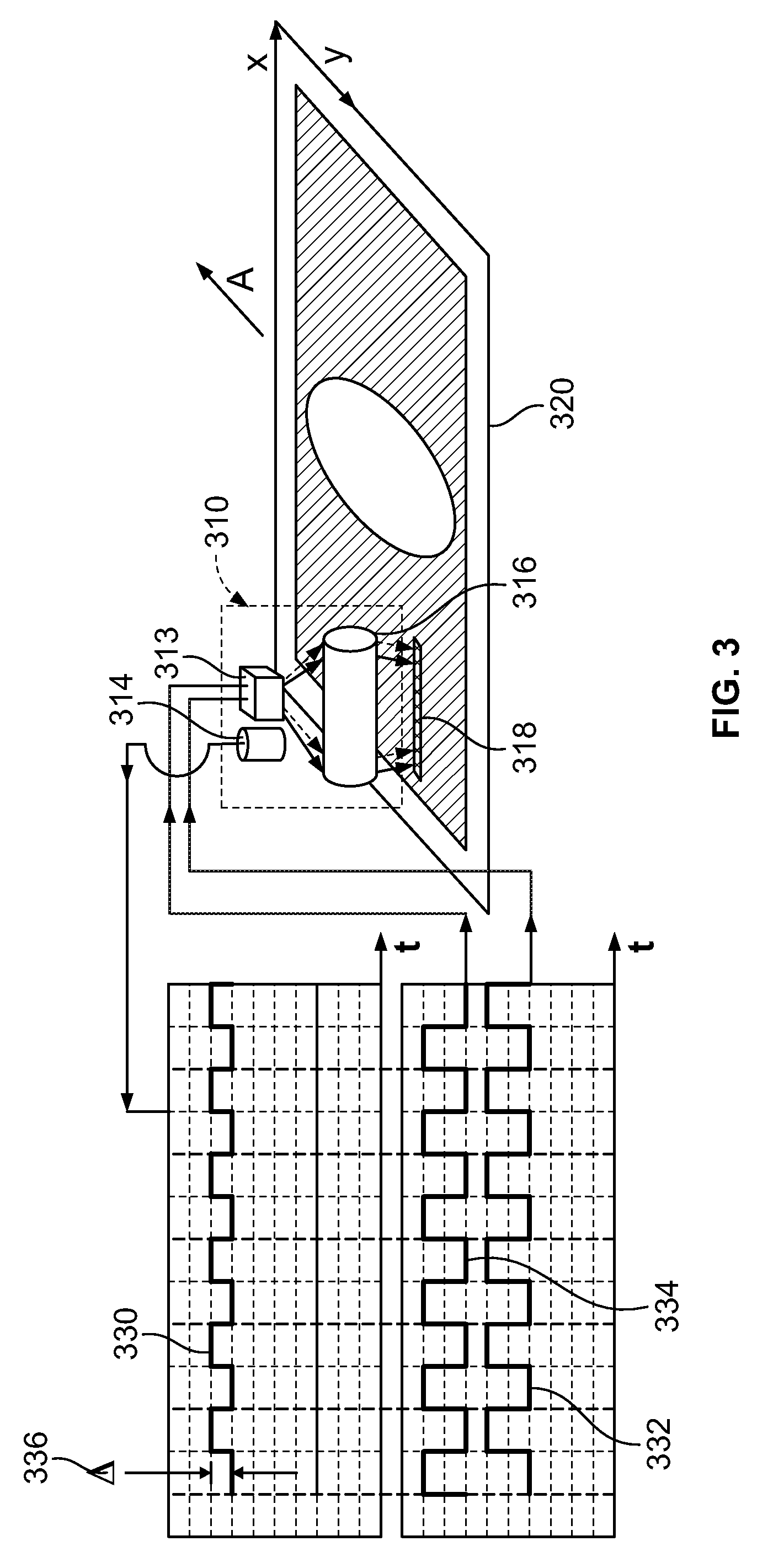

Currency bill sensor arrangement

ActiveUS20090022390A1Paper-money testing devicesCoin/currency accepting devicesPhotovoltaic detectorsPhotodetector

A currency processing device for receiving a stack of U.S. currency bills and rapidly processing all the bills in the stack, the device comprising: an input receptacle adapted to receive a stack of U.S. currency bills of a plurality of denominations, the currency bills having a wide dimension and a narrow dimension; a transport mechanism positioned to transport the bills, one at a time, in a transport direction from the input receptacle along a transport path at a rate of at least about 1000 bills per minute with the narrow dimension of the bills parallel to the transport direction; a currency bill sensor arrangement positioned along the transport path, the currency bill sensor comprising: i) a multi-wavelength light source configured to emit a first wavelength of light and a second wavelength of light; ii) a cylindrical lens positioned to receive the first and second wavelengths of light from the multi-wavelength light source, the cylindrical lens illuminating an elongated strip of light on a surface of one of the plurality of currency bills, the cylindrical lens being configured to receive light reflected from the surface of the one of the plurality of currency bills; iii) a photodetector positioned to receive the reflected light, the photodetector generating an electrical signal in response to the received reflected light; iv) a processor configured to receive the electrical signal generated by the photodetector; wherein, the processor is configured to determine whether the surface of the one of the plurality of currency bills is a primary surface or a secondary surface based on the electrical signal.

Owner:CUMMINS-ALLISON CORP

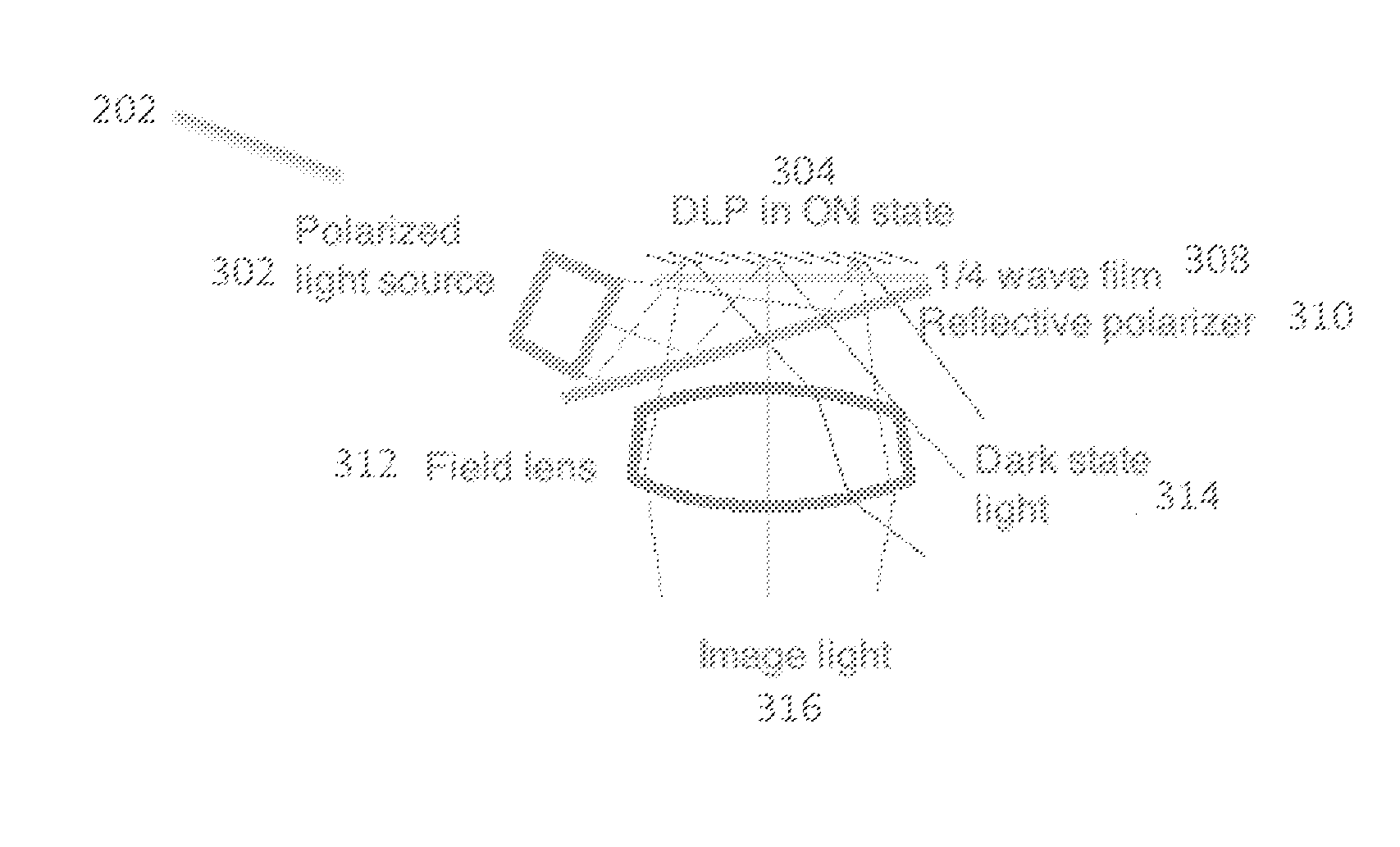

Compact optical system with improved contrast uniformity

ActiveUS20160216516A1Increase contrastLow costElectrical apparatusStatic indicating devicesDisplay deviceOptic system

An optical system for a head-worn computer may include a light source positioned within the head-worn computer and adapted to project non-polarized illuminating light towards a partially reflective partially transmissive surface such that the illuminating light reflects through a field lens and towards a reflective display and a polarizing film adjacent to a surface of the reflective display that polarizes the illuminating light after it passes through the field lens. The illuminating light reflects off a surface of the reflective display, forming image light which is then analyzed by the polarizing film prior to being transmitted through the field lens and then through the partially reflective partially transmissive surface to a non-polarizing lower display optical system adapted to present the image light to an eye of a user wearing the head-worn computer.

Owner:OSTERHOUT GROUP INC

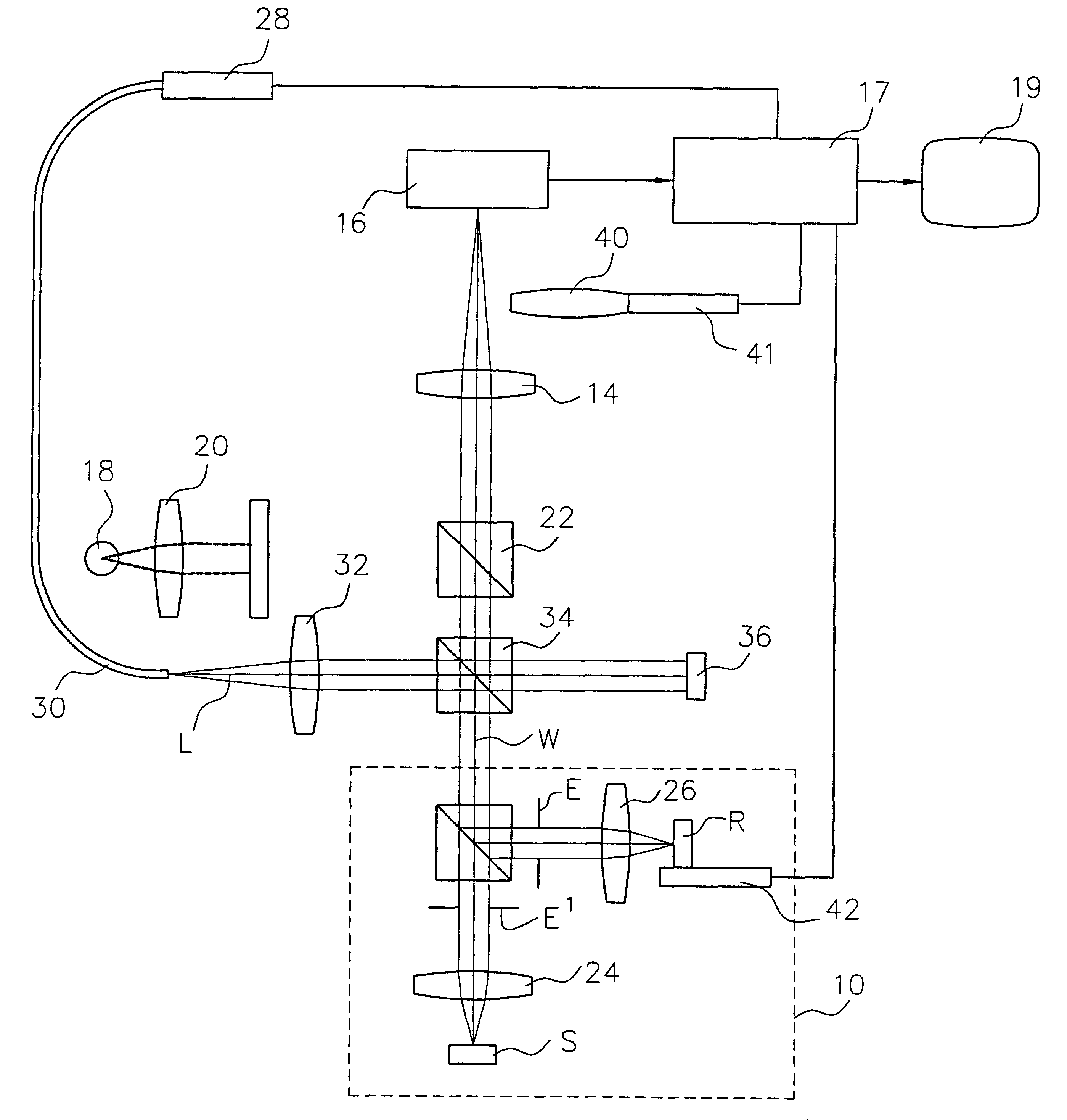

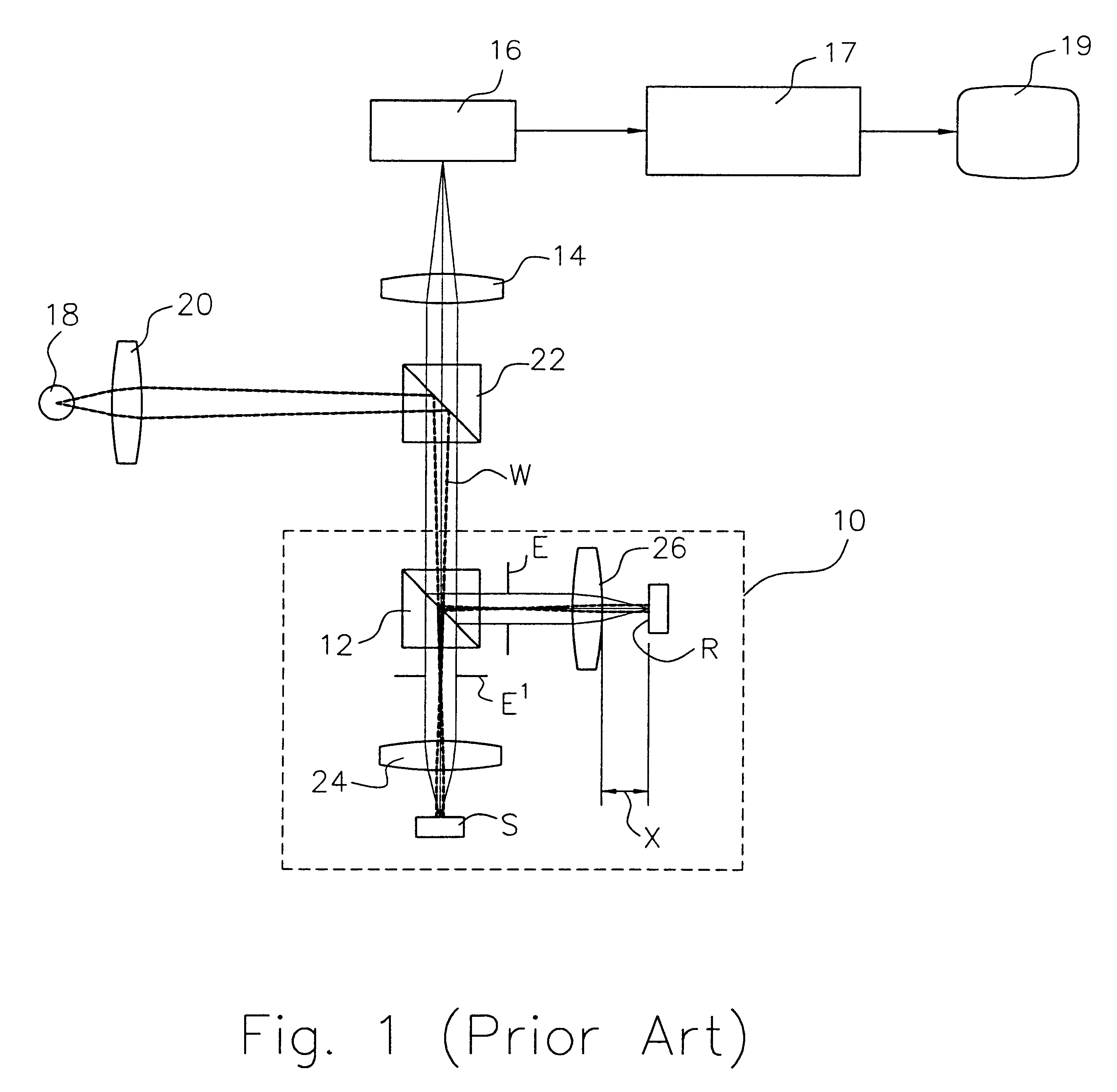

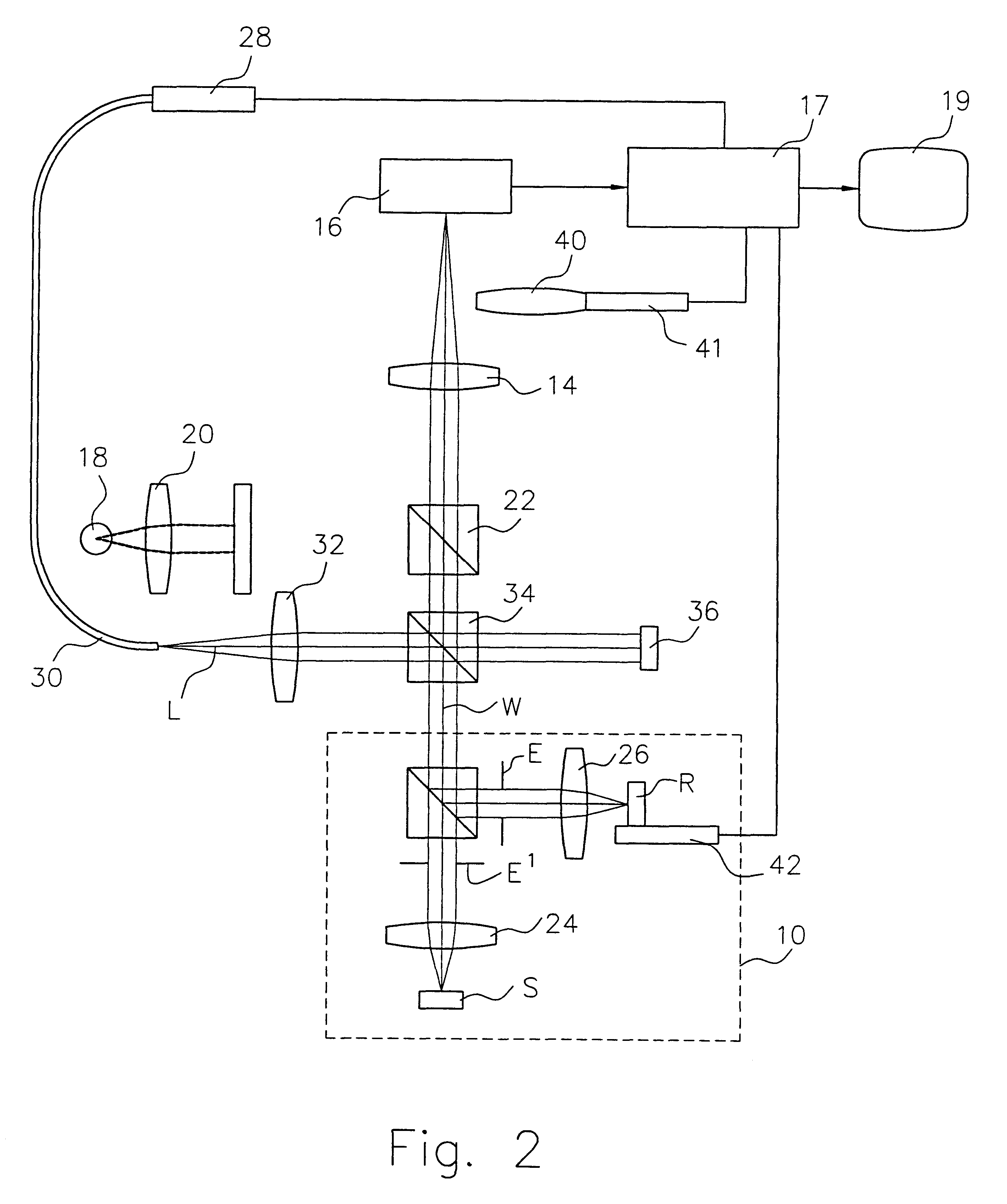

Embedded interferometer for reference-mirror calibration of interferometric microscope

InactiveUS6545761B1Implemented easily and economicallyAccurately determineInterferometersUsing optical meansClosed loopOptoelectronics

A laser interferometer is embedded into an interference microscope to precisely determine the in-focus position of the microscope objective's reference mirror. A collimated laser beam is introduced into the microscope system and split into two beams directed toward a calibration reference surface and the interference objective. The light reflected from the calibration reference surface is returned to the camera. The light into the interference objective is focused onto the reference mirror and returned to the camera. For the purpose of calibration, the two beams are combined at the camera to produce interference fringes. When the reference mirror is in focus, the returned beam is collimated; if the mirror is on either side of focus, the beam is either converging or diverging. Accordingly, the interferogram produced at the camera reflects the in-focus or out-of-focus condition of the reference mirror. The curvature of the wavefront returned from the reference mirror is determined electronically by analyzing the interference fringes produced with the beam returned from the calibration reference surface. By minimizing the curvature of the reference-mirror wavefront as the mirror is translated along the optical path, the reference mirror can be focused with an accuracy greater than possible by visual observation. Furthermore, by automating the focusing system with a precise translation mechanism driven by closed-loop control, operator-to-operator variations are completely eliminated.

Owner:BRUKER NANO INC

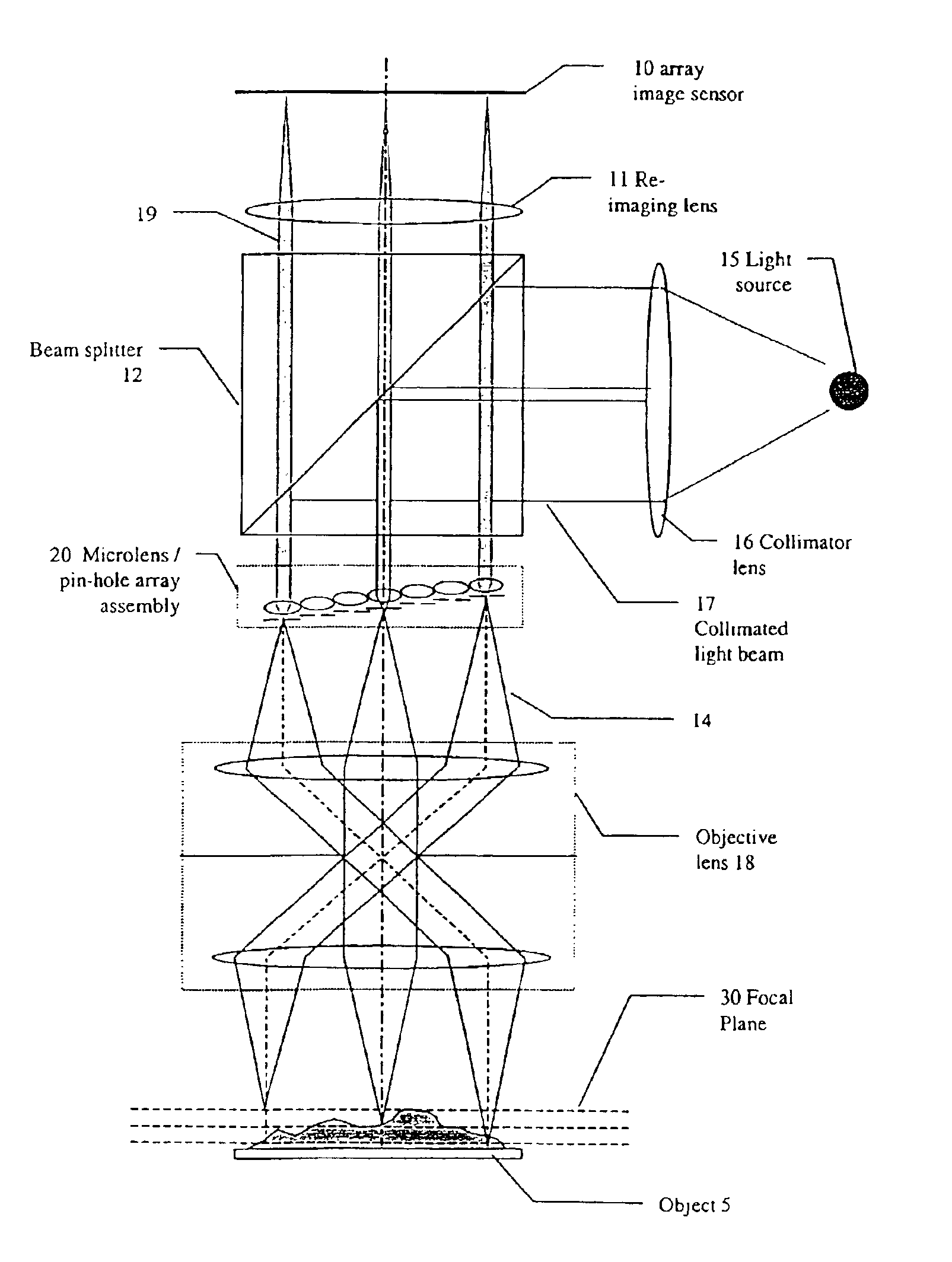

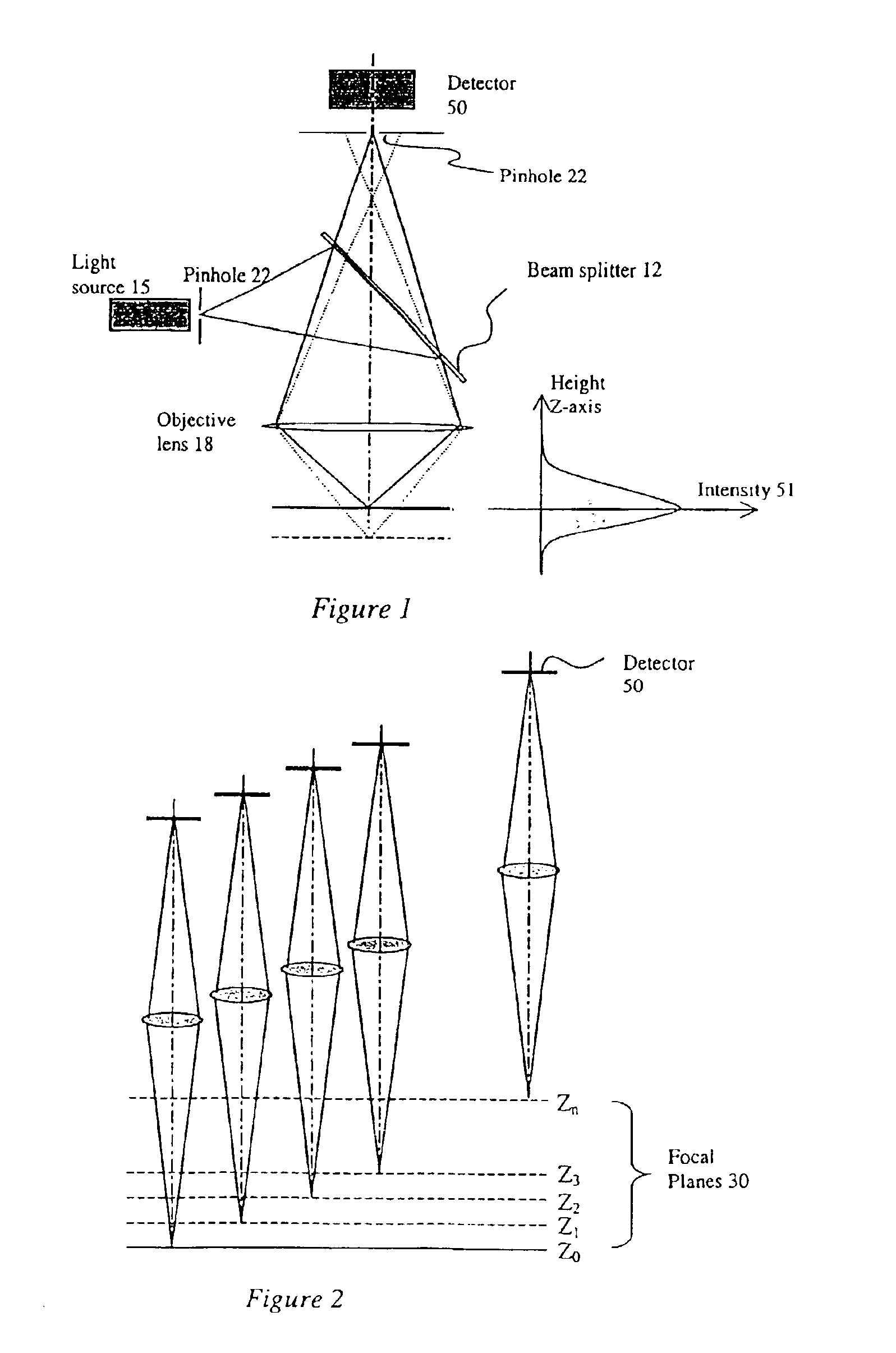

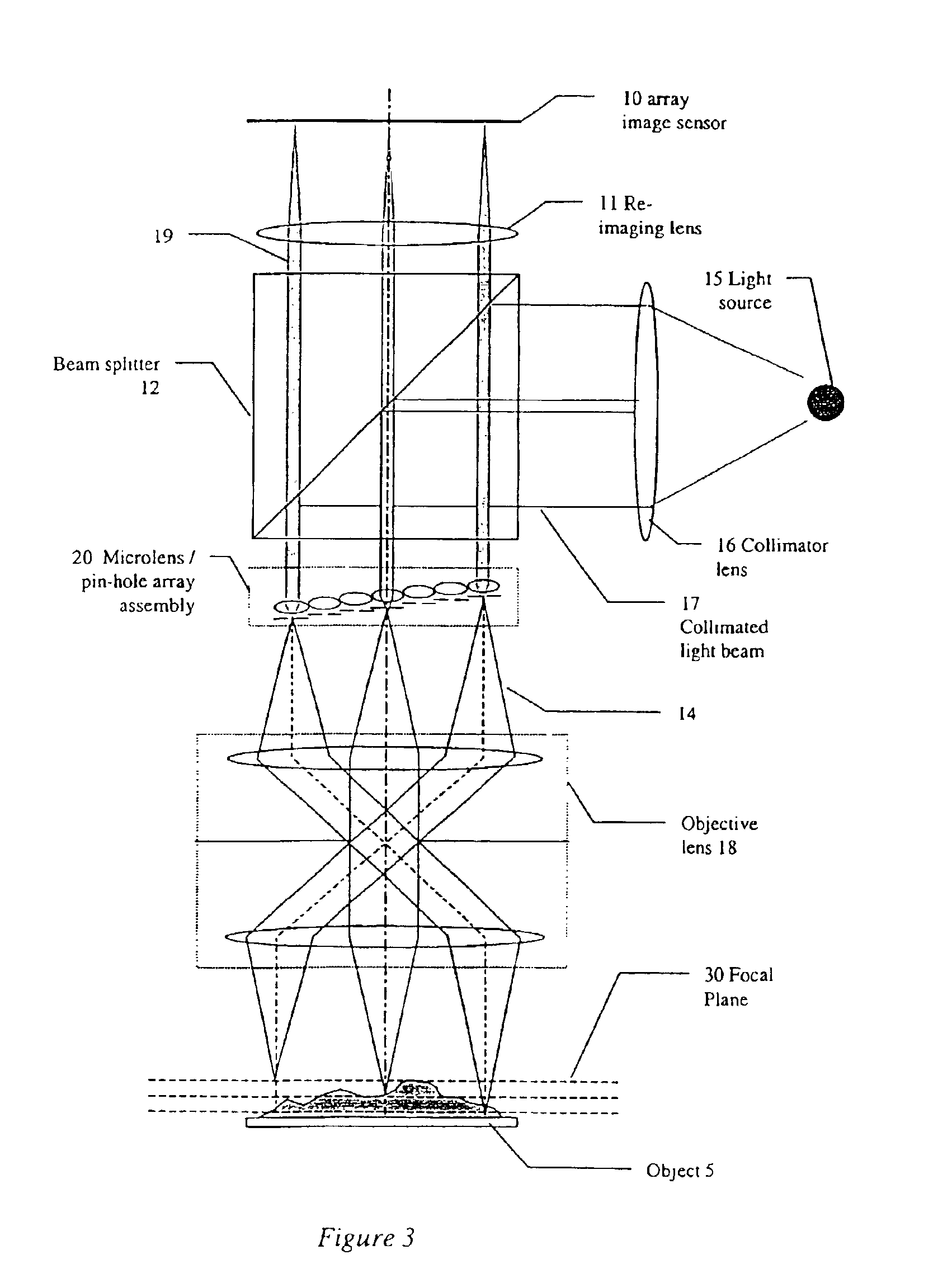

Confocal imaging

InactiveUS6838650B1Increase flexibilityImprove programmabilitySolid-state devicesMaterial analysis by optical meansConfocal imagingPhysics

A confocal imaging system for imaging a surface. The system includes an area array sensor having rows of sensors for detecting light reflected from the surface, and an optical system arranged to focus light from different focal planes on the surface to different sensor rows of the area array sensor.

Owner:AGILENT TECH INC

System and technique for retrieving depth information about a surface by projecting a composite image of modulated light patterns

InactiveUS20080279446A1Reduce system costInformation can be reducedUsing optical meansAquisition of 3D object measurementsInteraction interfaceTelecollaboration

Owner:UNIV OF KENTUCKY RES FOUND

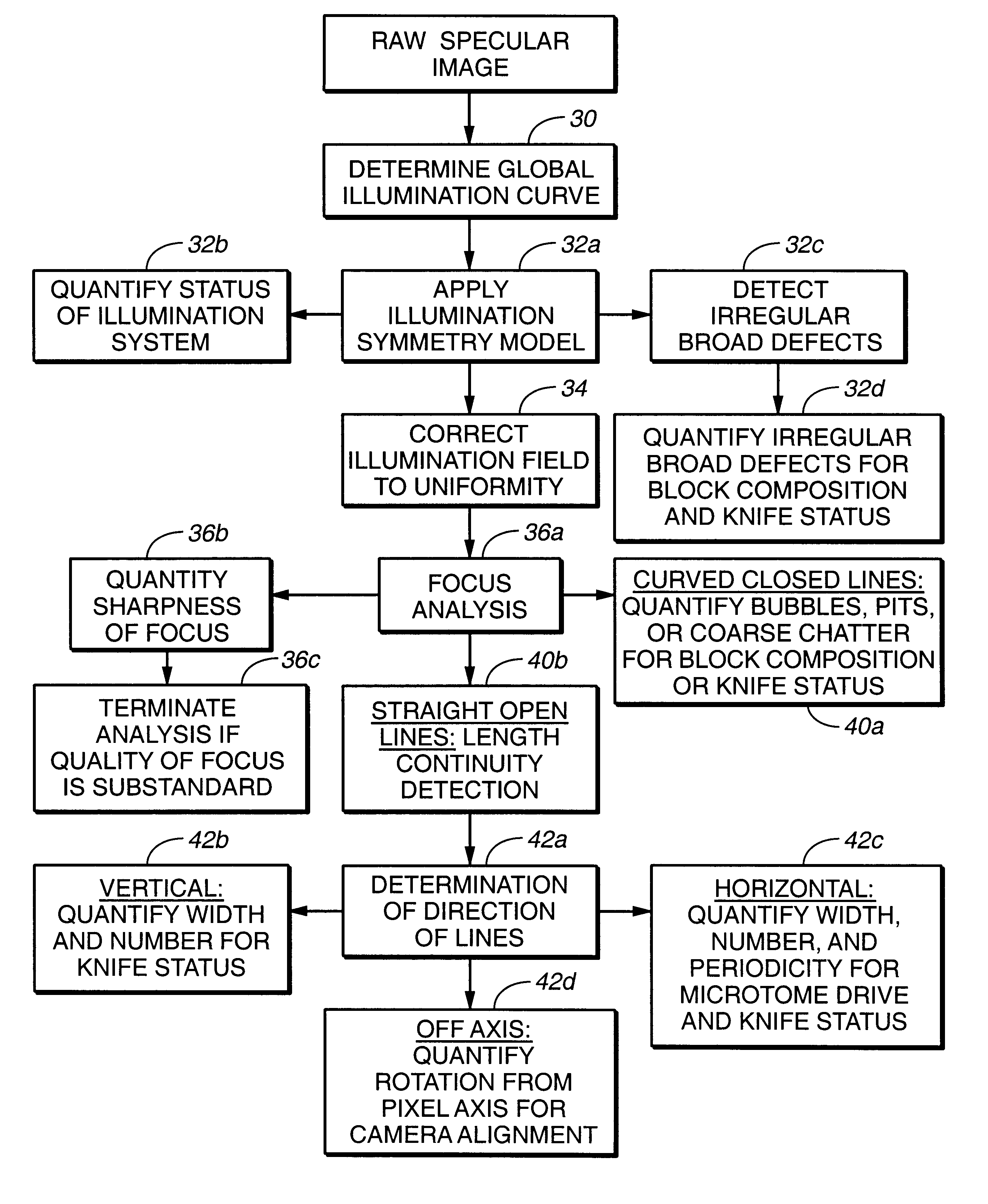

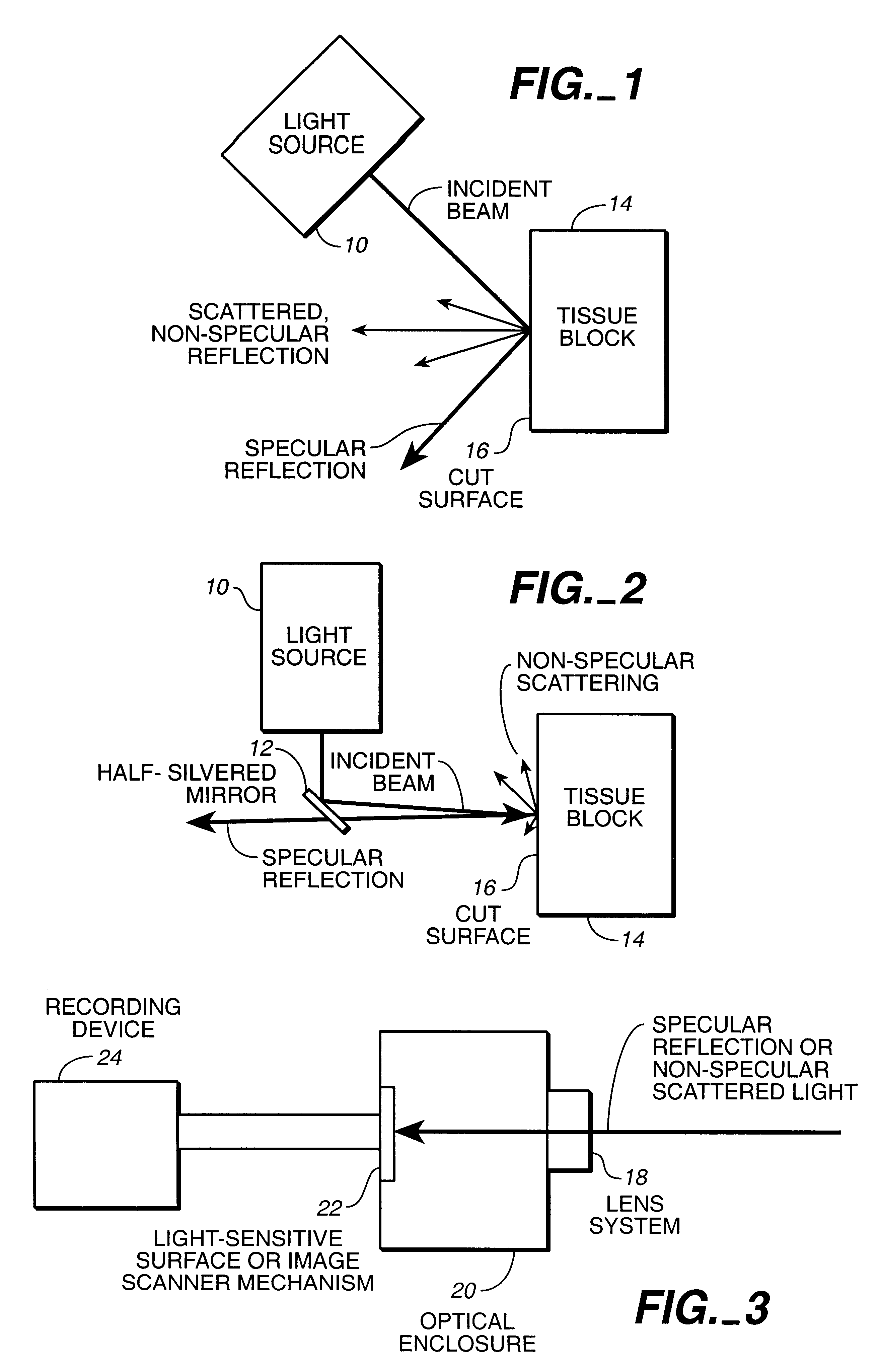

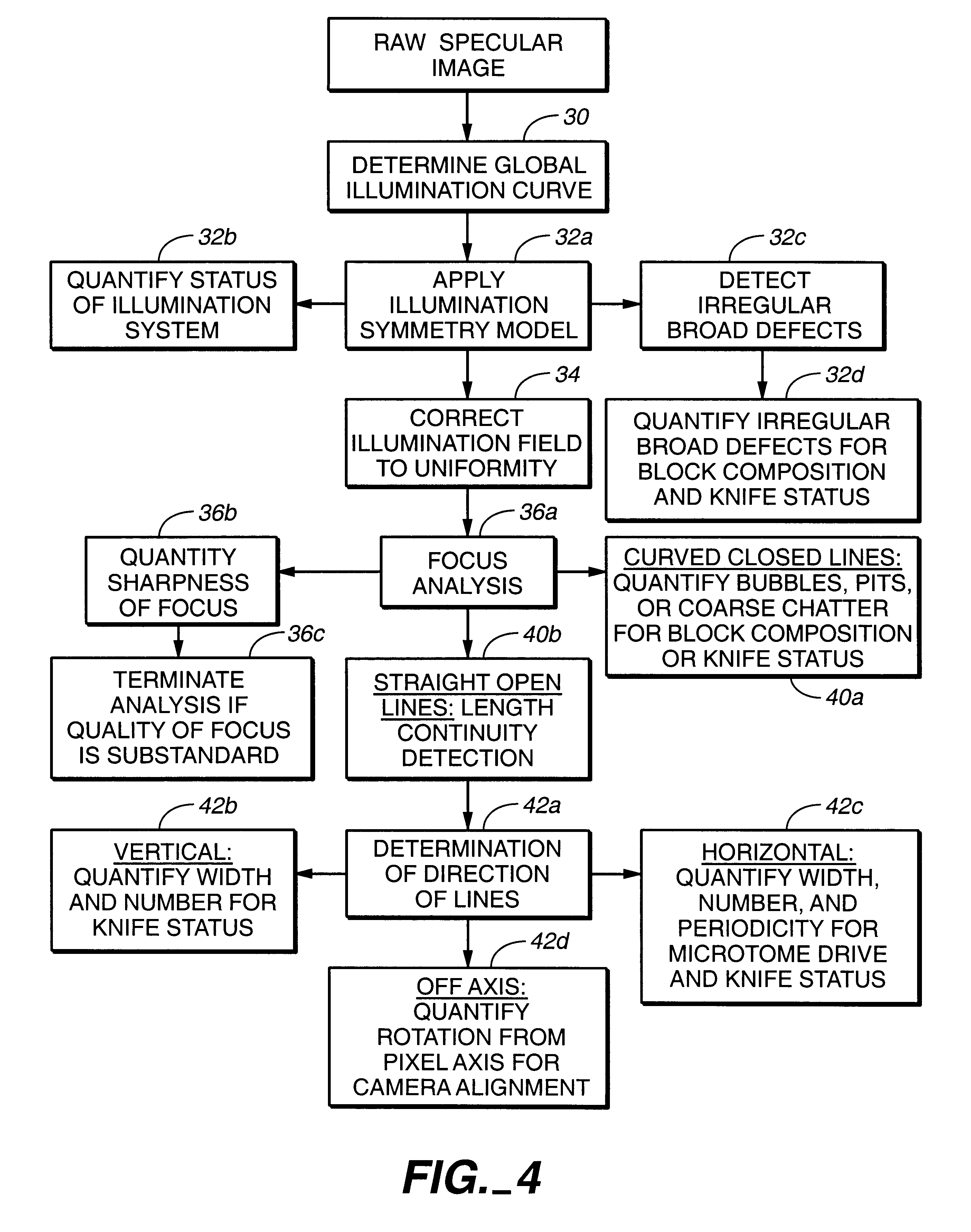

Method and apparatus for measurement of microtome performance

A method and apparatus for monitoring and evaluating the performance and condition of histology laboratory microtomes and microtome accessories including knives, motor drives, and illumination devices. Irregularities in an image of the surface of a block mounted on the microtome are detected and characterized, the block having been subjected to mechanical sectioning by the microtome to produce a cut block face. The image of light reflected from the surface of the block, either specular or non-specular, is recorded and subjected to graphical analysis to extract, quantify, and interpret patterned features, including those indicating anomalies in the function of the microtome, its accessories, or the tissue block itself.

Owner:MICROSCI GROUP

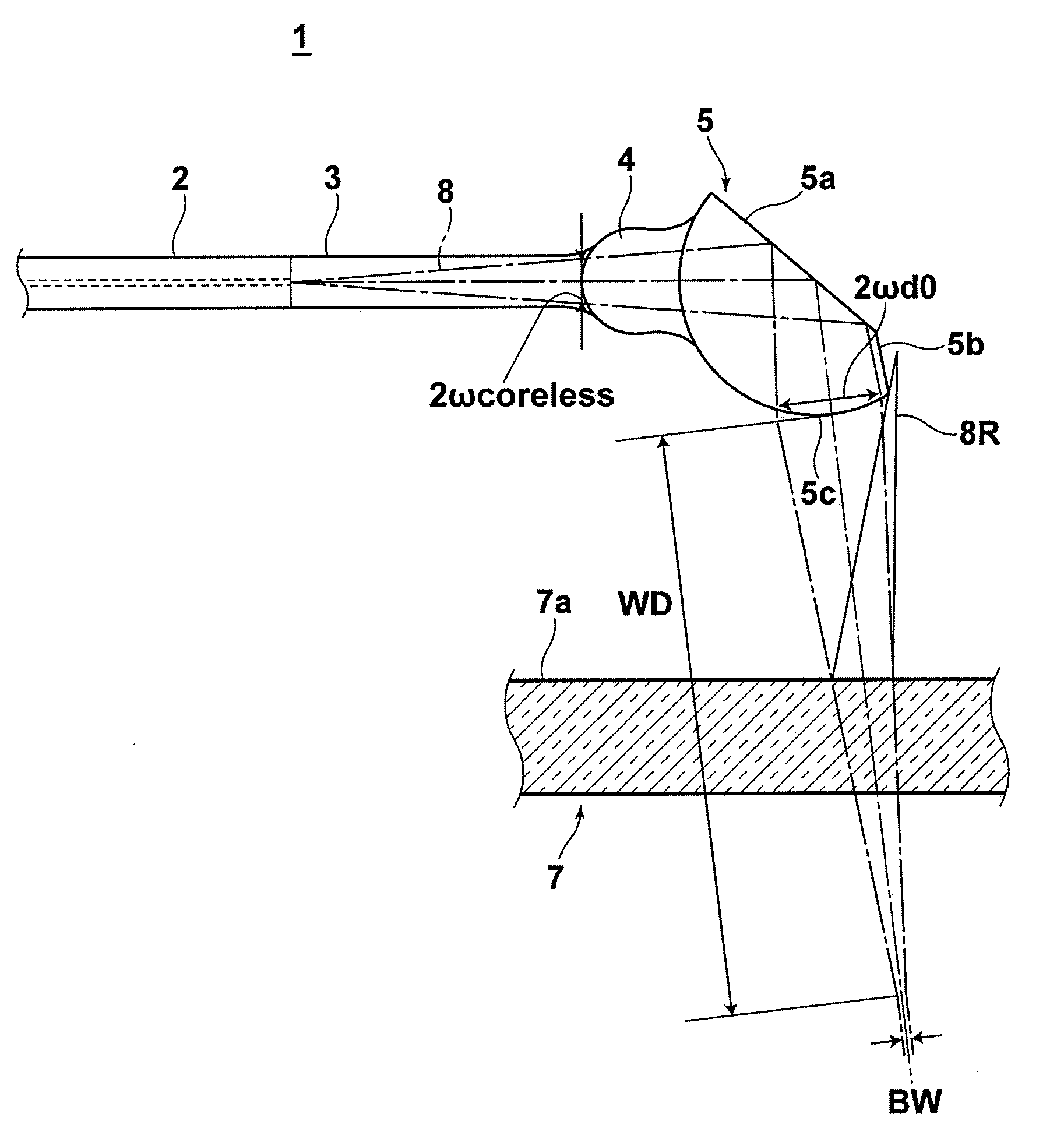

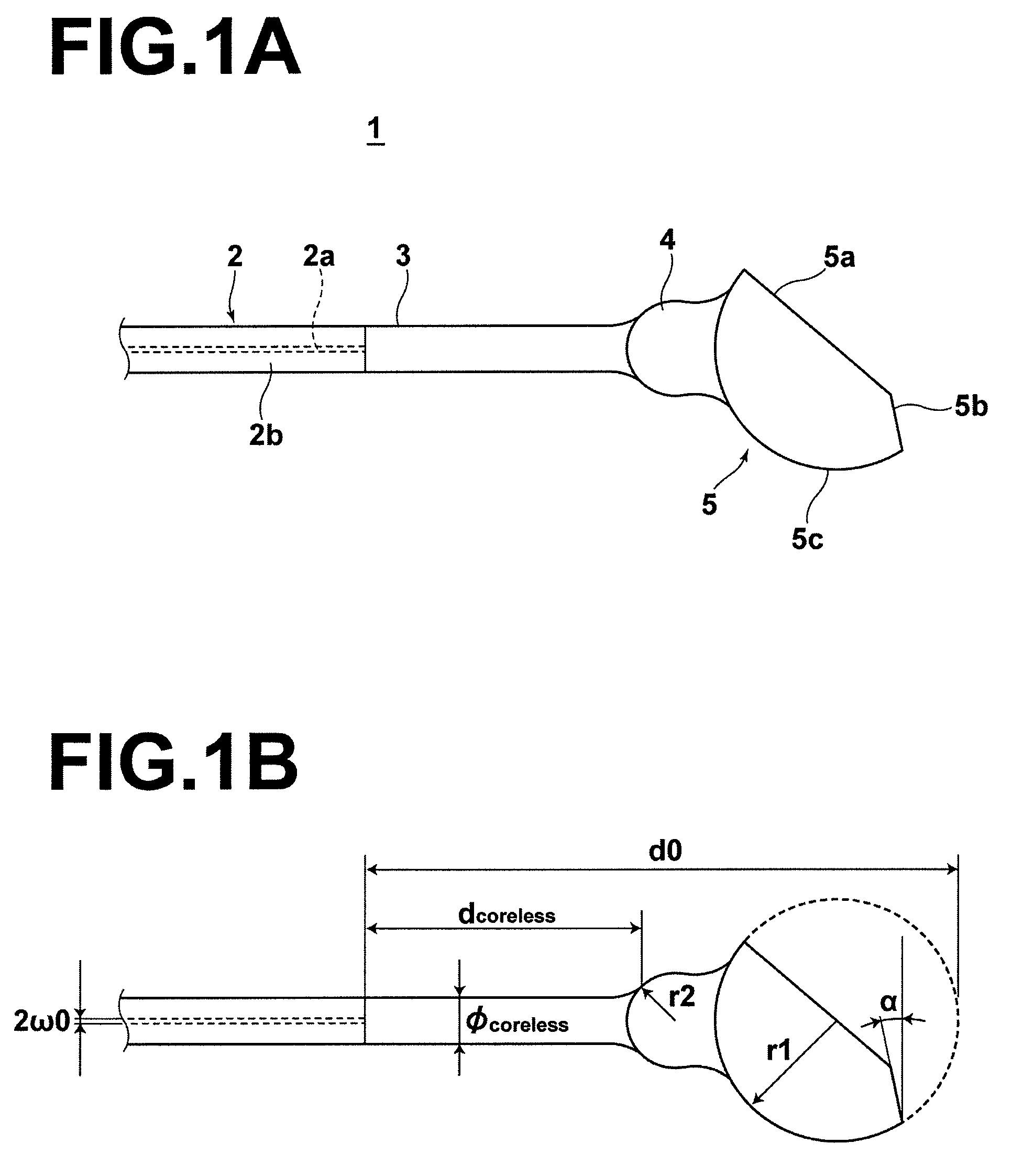

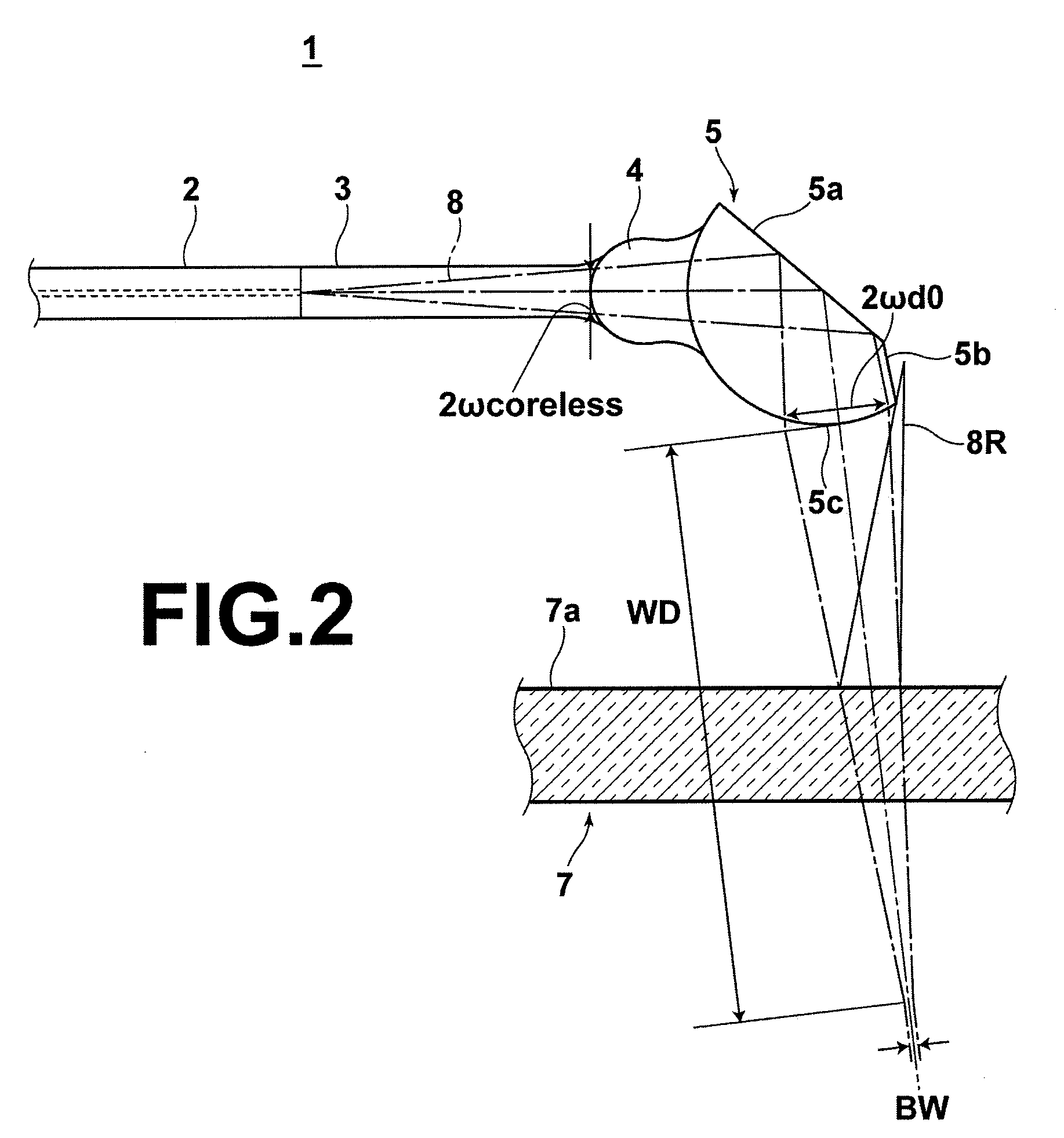

OCT probe for eliminating ghost images

InactiveUS7805034B2Reduce the overall diameterIncrease the working distanceMaterial analysis by optical meansCatheterPhoto irradiationMedicine

An OCT probe has a sheath to be inserted into a subject; and an optical system within the sheath, for changing the direction of light which propagates from a light source through an optical fiber to irradiate the light onto the subject through a transparent portion of the sheath, and for reflecting the light beam, which is reflected by the subject, to guide the light into the optical fiber. A light output surface, for causing the light to be output from the reflecting surface in a direction obliquely inclined with respect to the inner surface of the sheath, and a reflected light sheath entrance preventing portion, for preventing light reflected by the inner surface of the sheath from entering the optical fiber, are provided in the optical system. The reflected light sheath entrance preventing portion may be formed by providing a cut planar surface portion on the lens.

Owner:NAMIKI PRECISION JEWEL CO LTD

Method and apparatus for calibration-free eye tracking using multiple glints or surface reflections

InactiveUS7809160B2Input/output for user-computer interactionImage enhancementCorneal surfacePoint of gaze

Apparatus and method for eye gaze tracking in human or animal subjects without calibration of cameras, specific measurements of eye geometries or the tracking of a cursor image on a screen by the subject through a known trajectory. One embodiment includes one uncalibrated camera for acquiring video images of the subject's eye(s) and optionally having an on-axis illuminator, and a surface, object, or visual scene with embedded off-axis illuminator markers. The off-axis markers are reflected on the corneal surface of the subject's eyes as glints. The glints indicate the distance between the point of gaze in the surface, object, or visual scene and the corresponding marker on the surface, object, or visual scene.

Owner:CHENG DANIEL +3

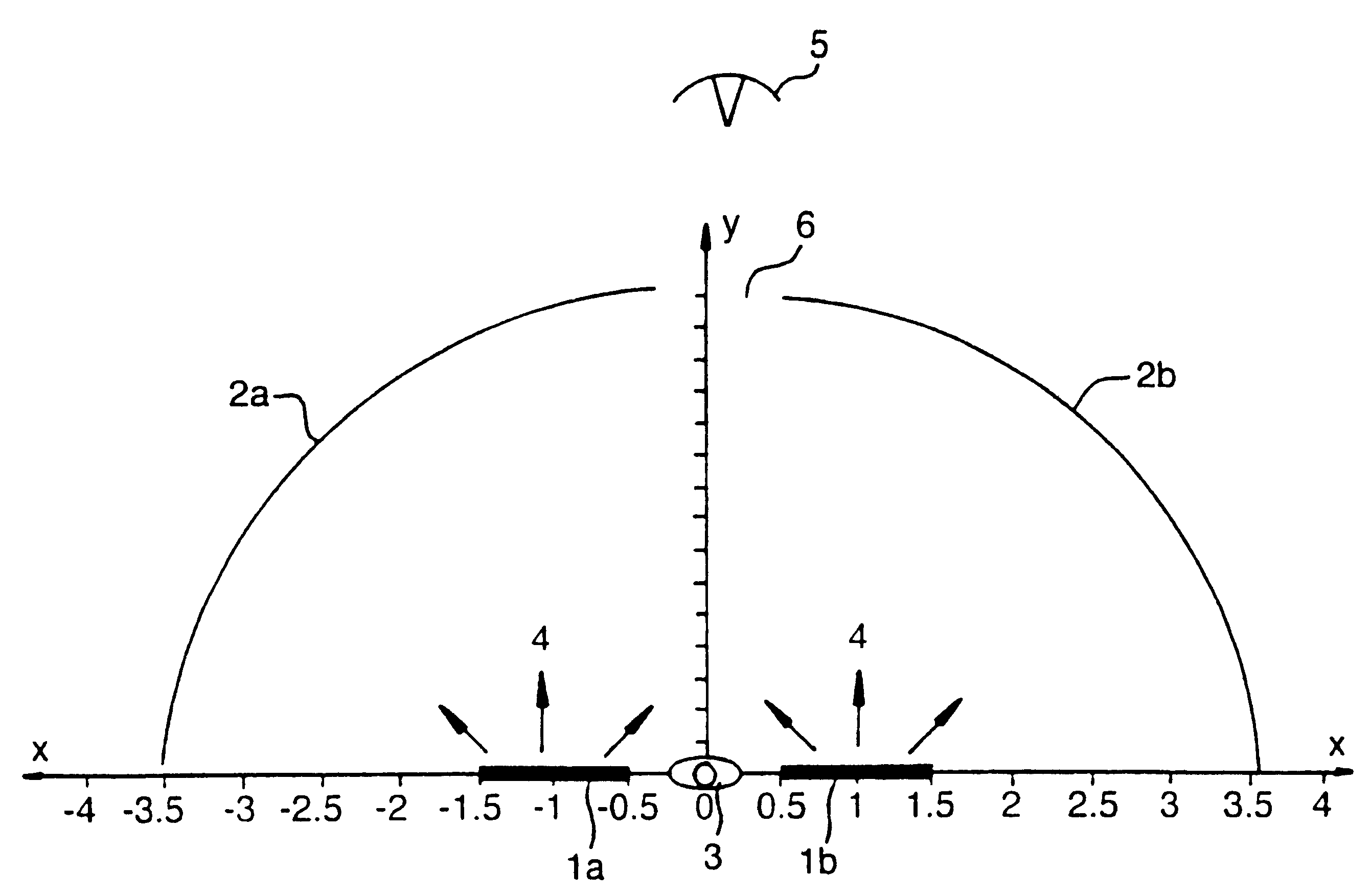

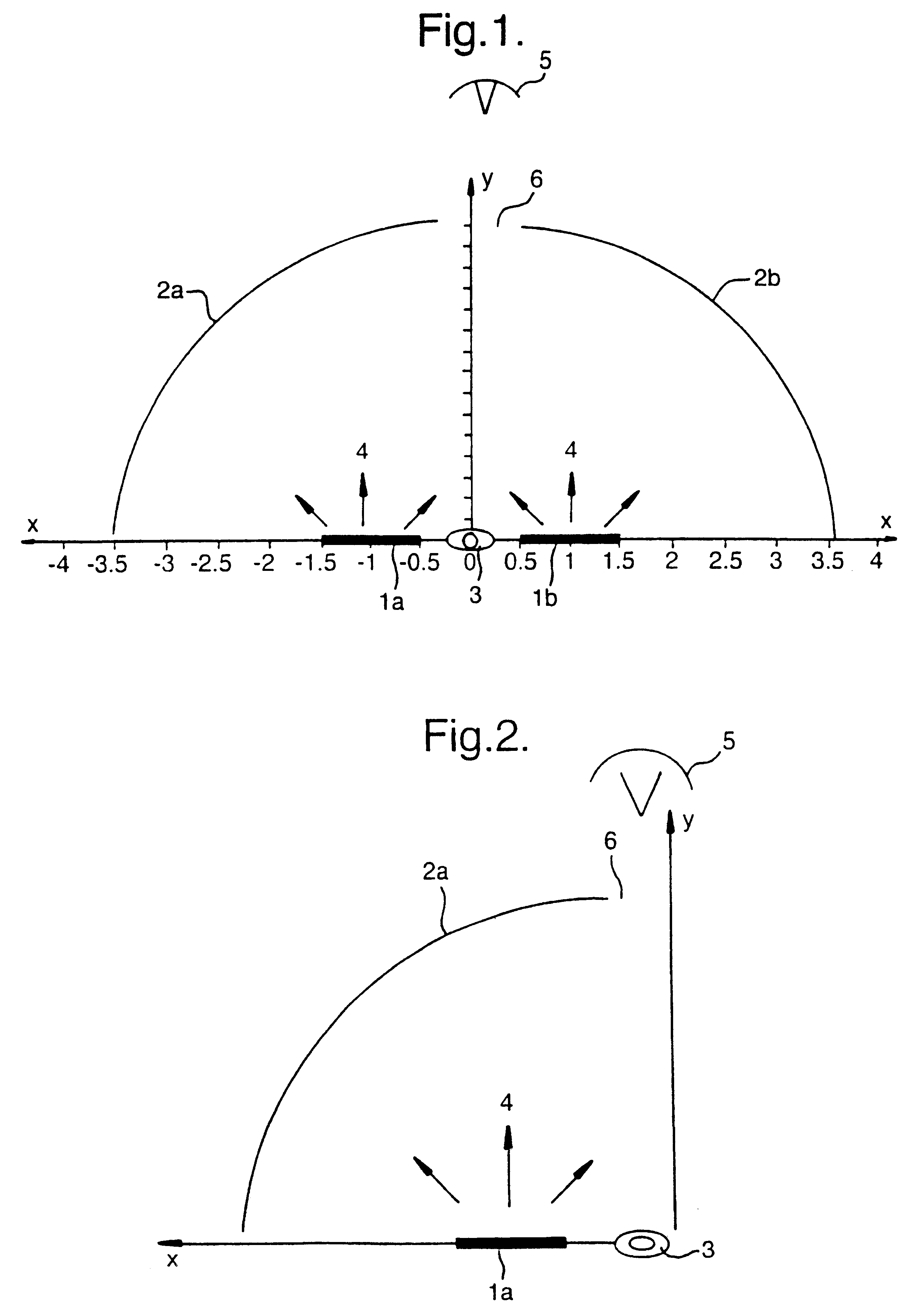

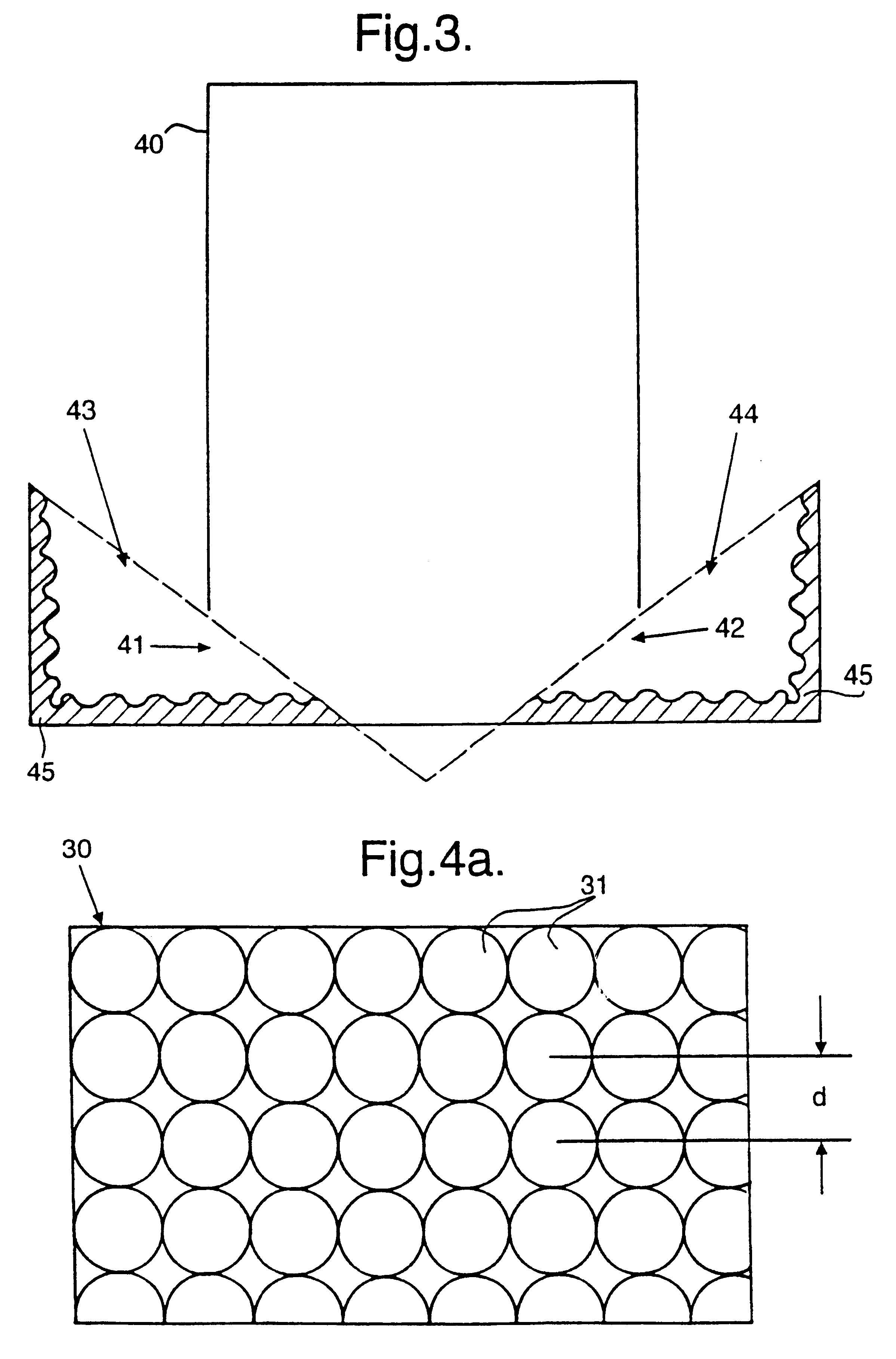

Millimeter wave imaging apparatus

InactiveUS6353224B1Maximises emissionEmission reductionGeological detection using milimetre wavesMaterial analysis using microwave meansMillimetre waveLength wave

Millimeter wave imaging apparatus for use, in articular, as an indoor security system to identify objects concealed under the clothing of a person in a background scene, including means for generating a millimetric temperature contrast between the person to be imaged and the surroundings in scene. This may be a "hot" or "cold" source for producing a flux, and a relatively smaller flux respectively, of incoherent millimeter wavelength radiation. The apparatus may also include at least one partial ellipsoid reflective enclosure for reflecting millimeter wavelength radiation emitted from the "hot" and "cold" source so as to generate non-localized and uniform illumination of the person. The enclosure may have a metallic inner surface on which a dimpled pattern may be embossed to diffuse the millimeter wavelength radiation reflected from the metallic inner surface. The apparatus also includes one or more millimeter wavelength imaging cameras for detecting the millimeter wavelength radiation at one or more millimeter wave center frequencies, which may be mounted inside or outside the reflective enclosure. An image of the objects may be generated on a television monitor from the detected radiation.

Owner:QINETIQ LTD

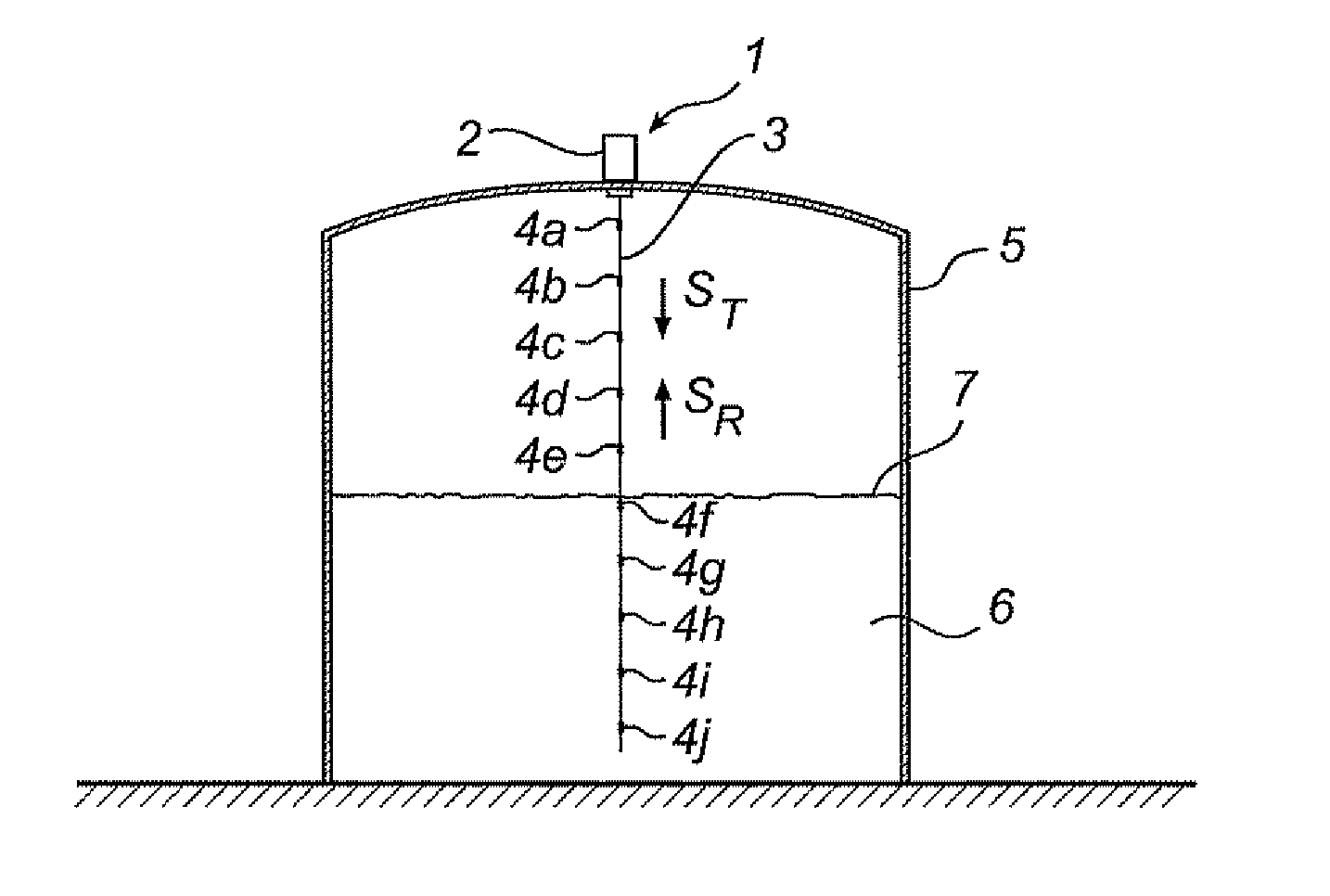

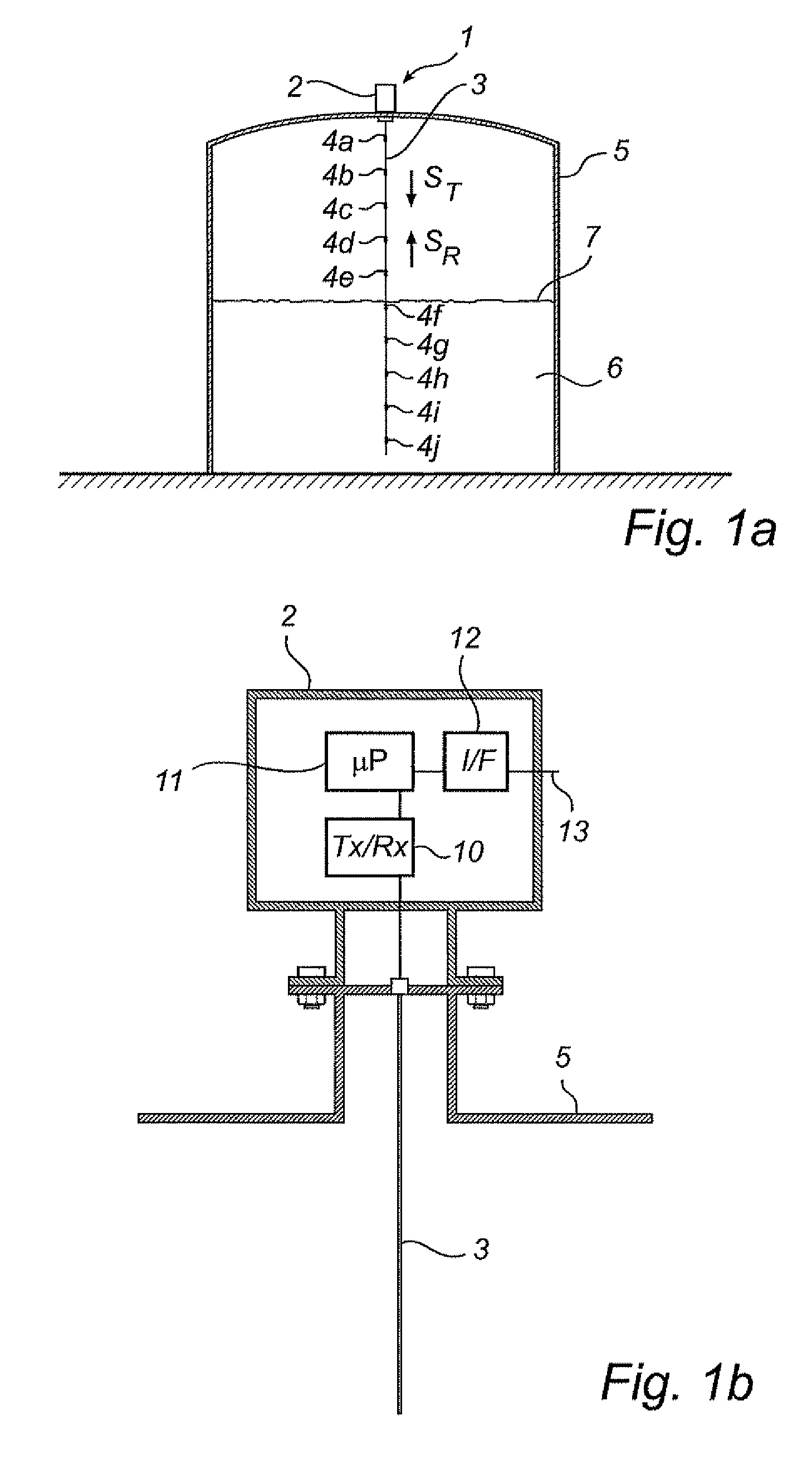

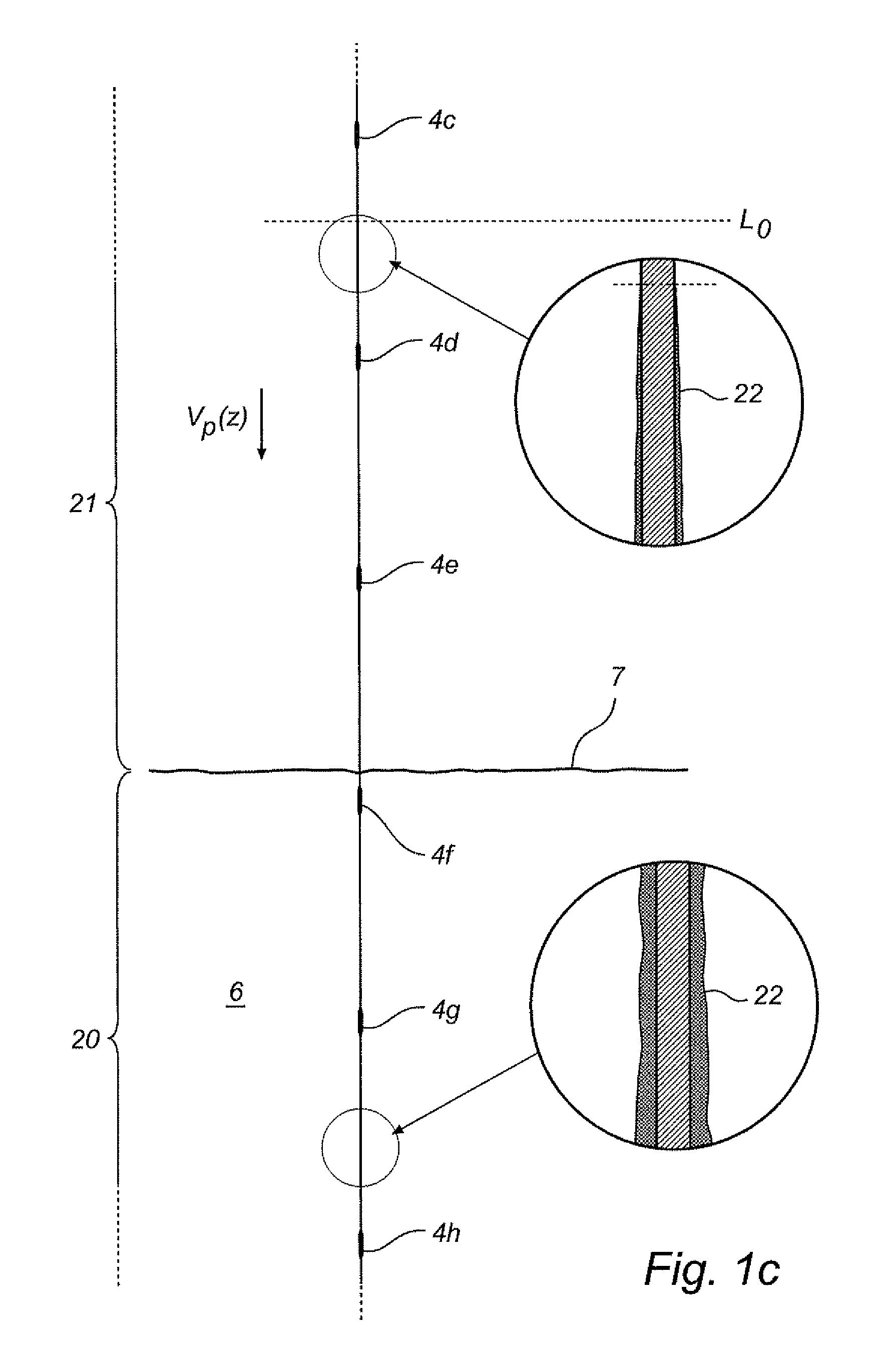

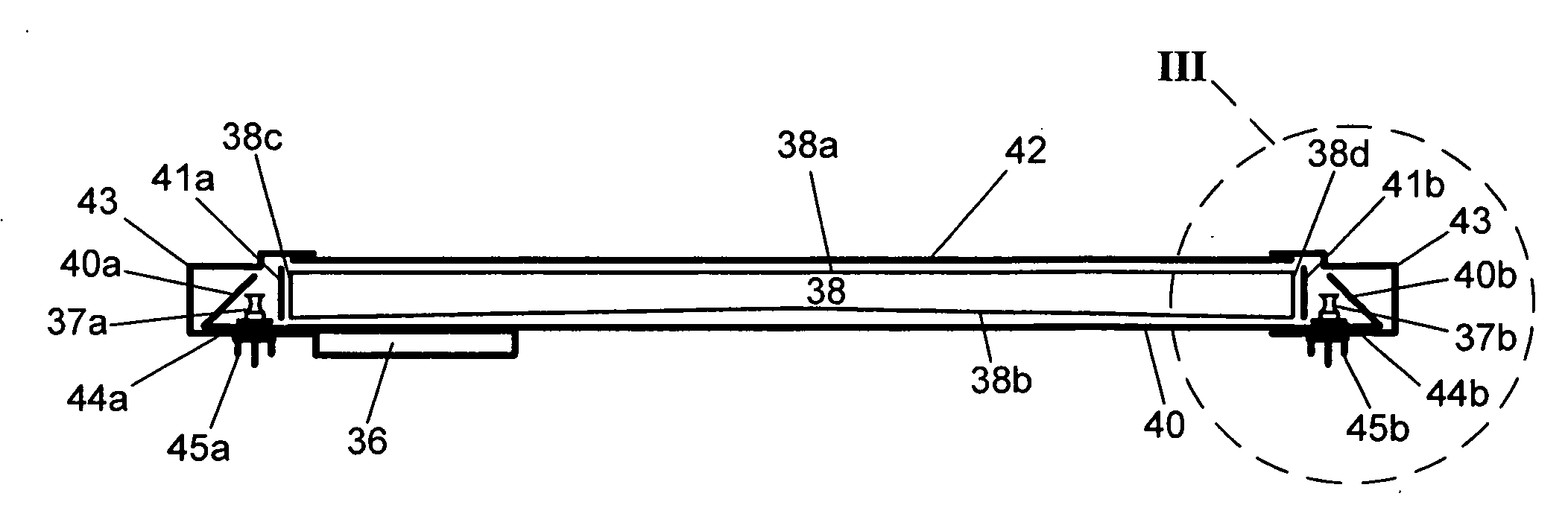

System and method for filling level determination

A method for determining a filling level of a product contained in a tank, by means of a radar level gauge system comprising a transceiver for generating, transmitting and receiving electromagnetic signals; a probe connected to the transceiver and arranged to guide a transmitted electromagnetic signal from the transceiver towards and into the product inside the tank, and to return a reflected electromagnetic signal resulting from reflection of the transmitted electromagnetic signal by a surface of the product back towards the transceiver; and a plurality of reference reflectors each being arranged at a respective known position along the probe and being configured to reflect a portion of the transmitted electromagnetic signal back towards the transceiver. The method comprises the steps of identifying, based on received electromagnetic signals reflected by the reference reflectors, a set of reference reflectors located above the surface of the product; selecting first and second reference reflectors comprised in the set of reference reflectors; determining a propagation velocity compensation factor based on a known distance between the first and second reference reflectors and a distance therebetween determined using received electromagnetic signals reflected by the first and second reference reflector, respectively; and determining the filling level based on a received electromagnetic signal reflected by the surface of the product, and the propagation velocity compensation factor.

Owner:ROSEMOUNT TANK RADAR

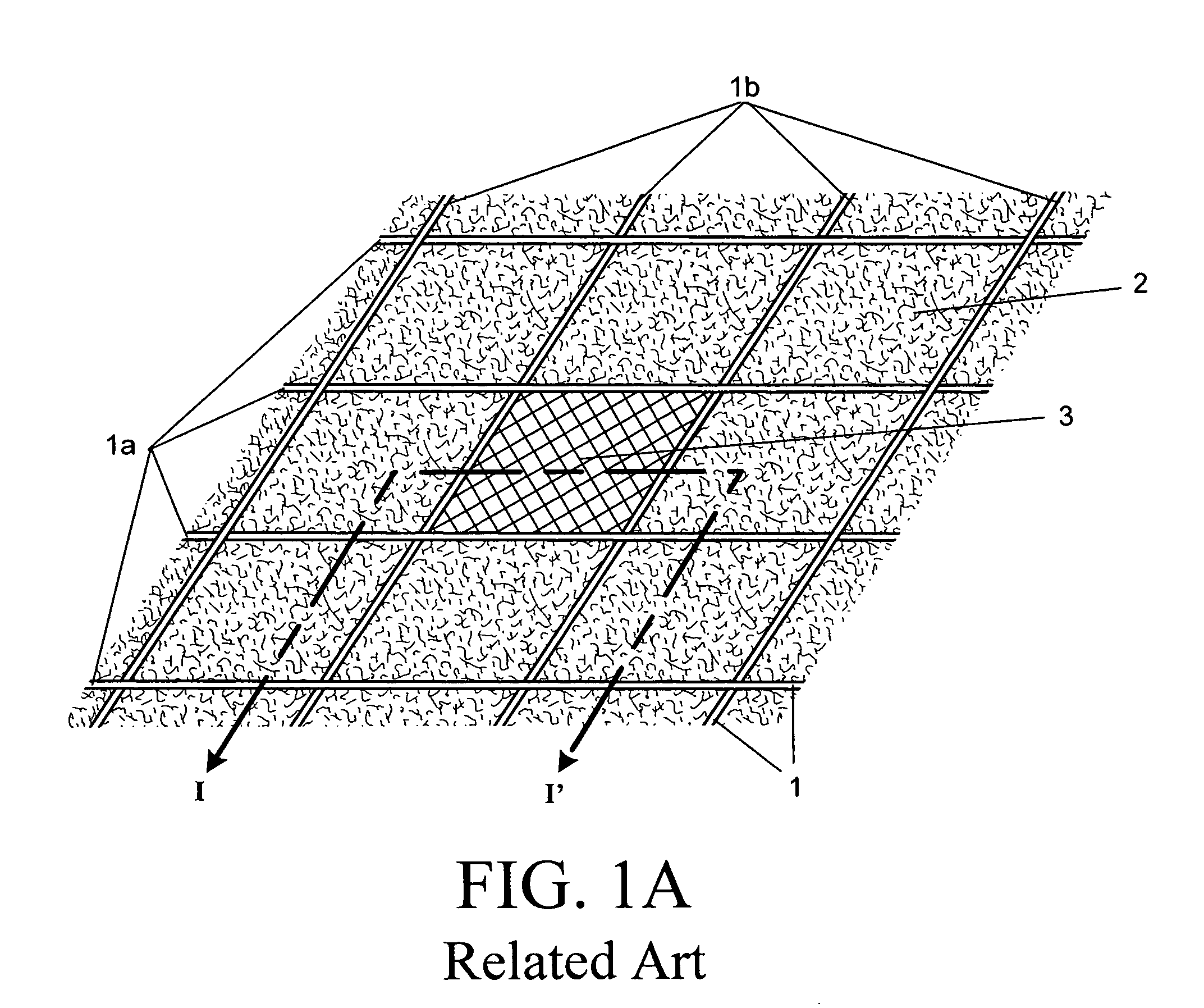

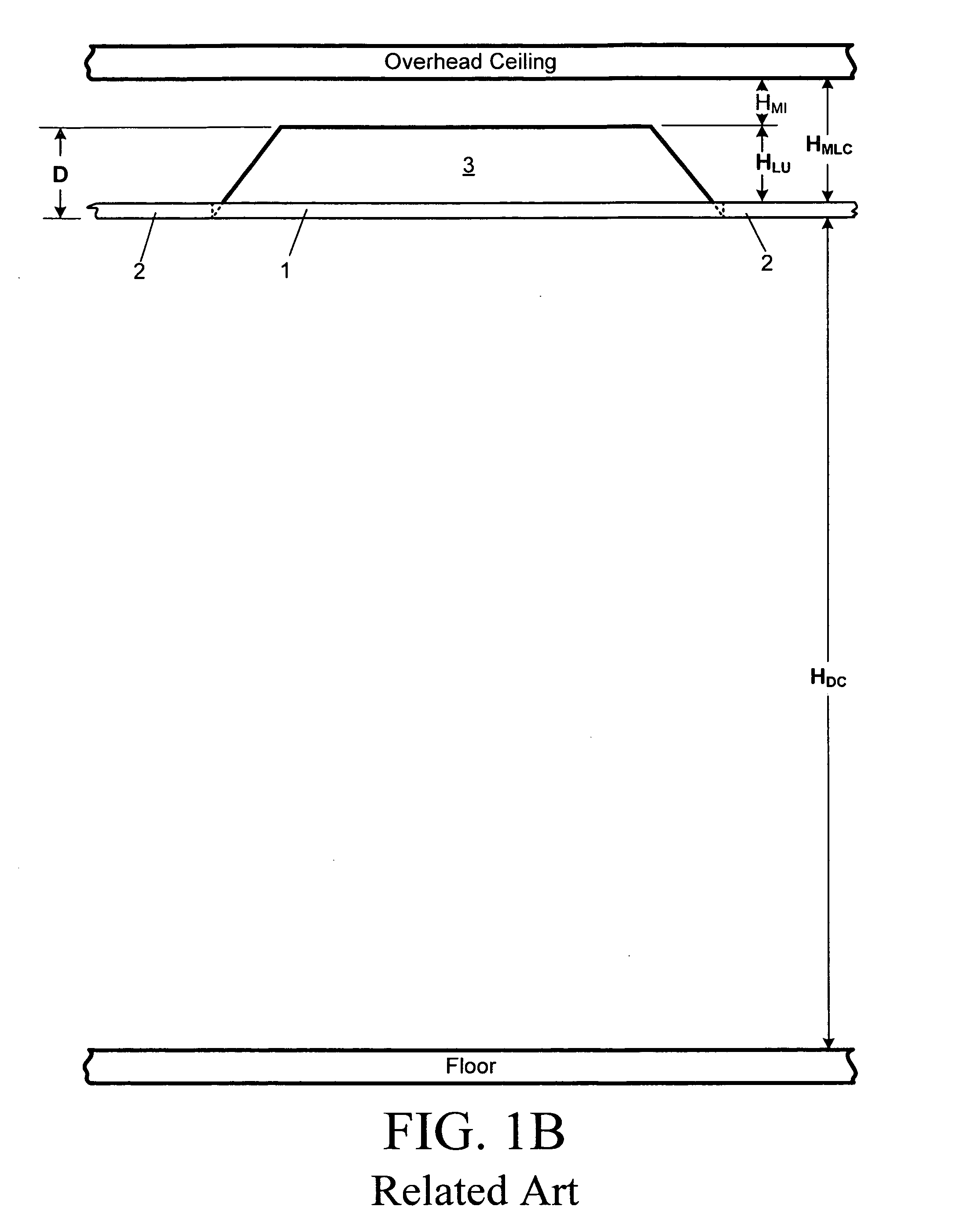

Low-clearance light-emitting diode lighting

InactiveUS20090237958A1Low overhead clearanceImprove cooling effectPlanar light sourcesNon-electric lightingLight guideMetal framework

A low-clearance light-emitting diode lighting includes a light guide panel having side surfaces and a front surface opposing a back surface, a plurality of light-emitting diodes positioned on at least two side surfaces of the light guide panel, a reflecting plate at the back surface of the light guide panel, reflectors having an inclined angle, and a metal frame for supporting the reflecting plate and the light guide panel, wherein each of the plurality of light-emitting diodes is positioned between one of the at least two side surfaces and one of the reflectors such that light from the plurality of light-emitting diodes is reflected toward the at least two side surfaces.

Owner:LED FOLIO CORP

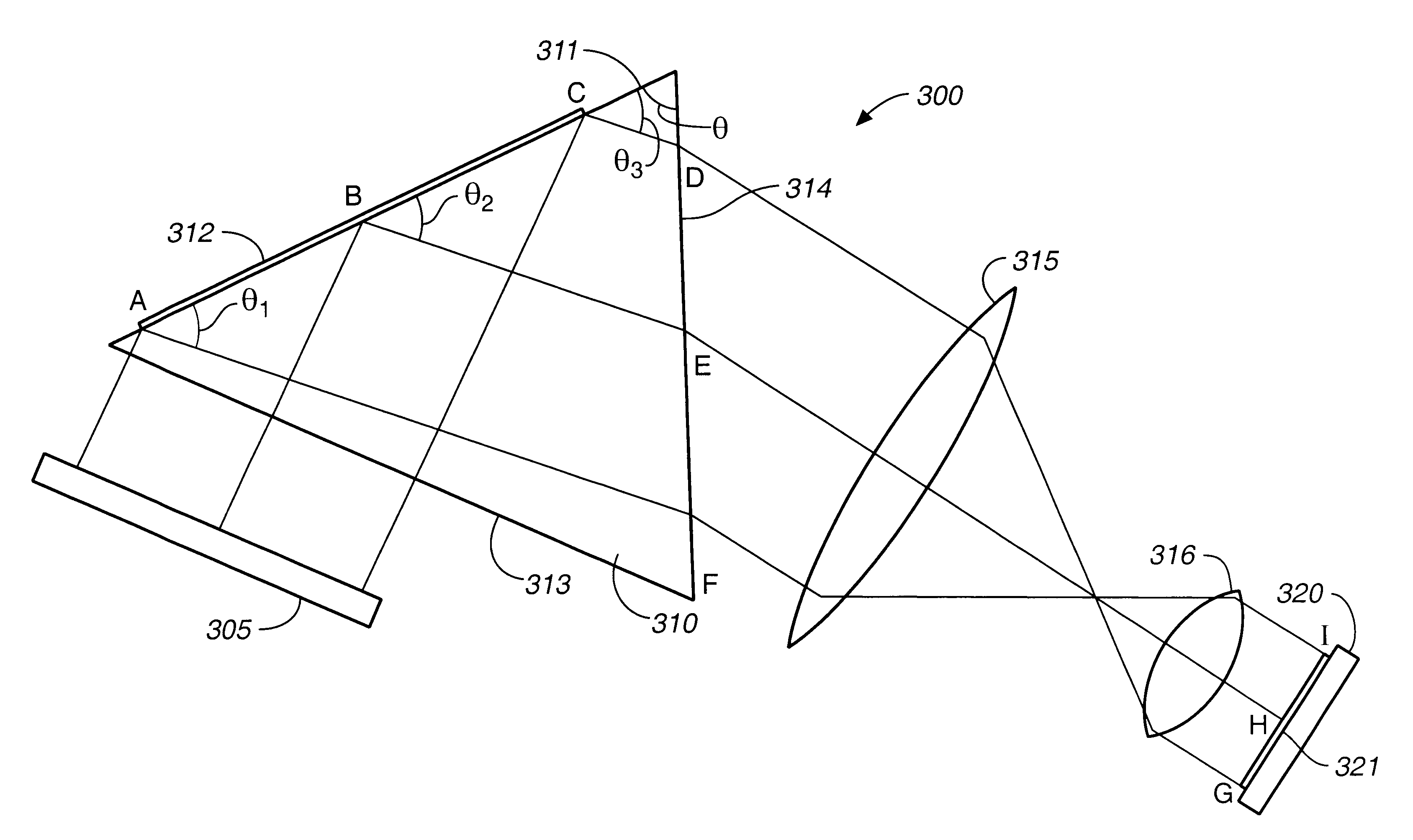

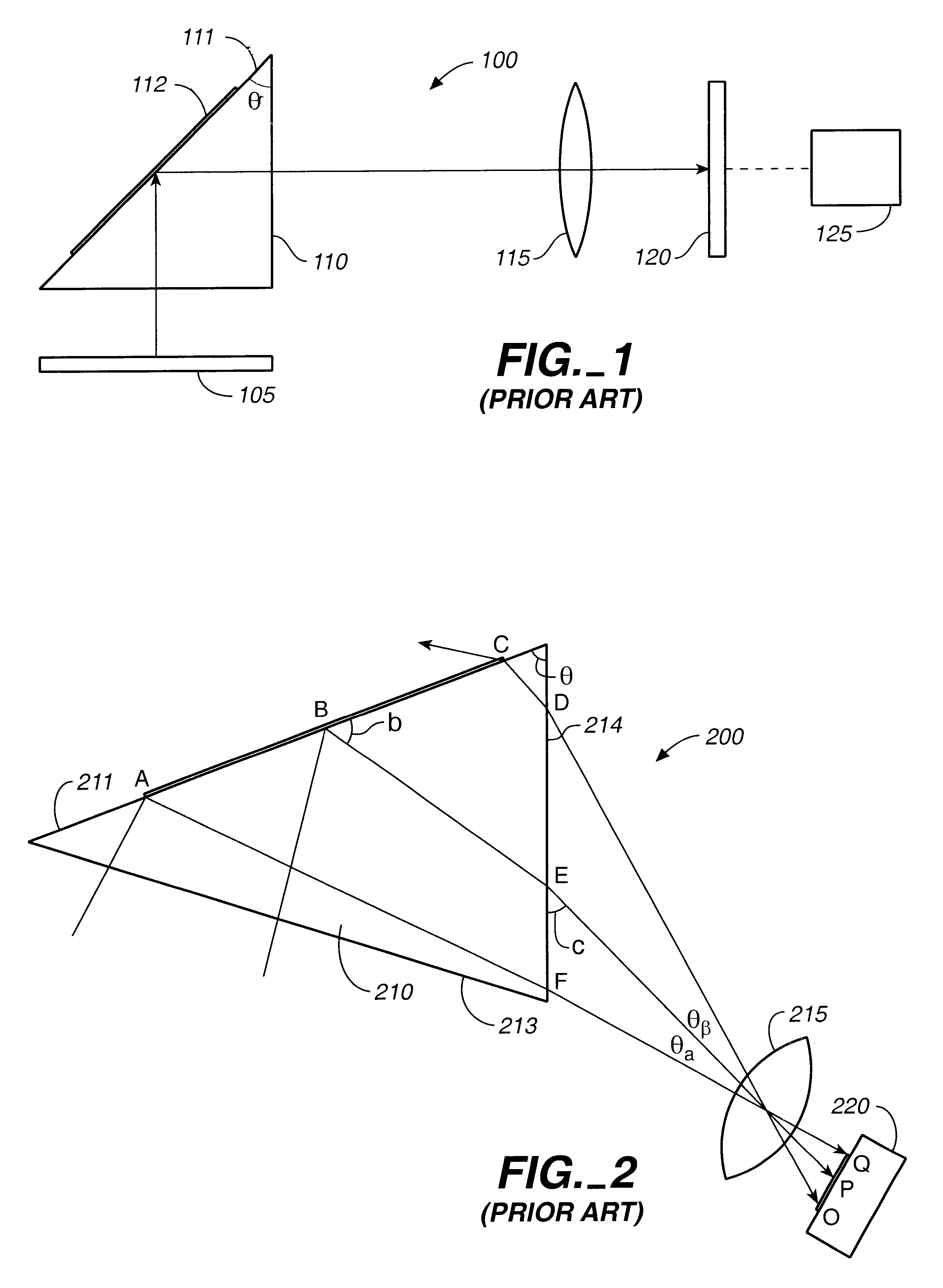

Compact optical fingerprint capturing and recognition system

InactiveUS6870946B1Solve bulkyImprove simplicityCharacter and pattern recognitionUsing optical meansRecognition systemFingerprint

An apparatus and method for acquiring an image of a patterned object such as a fingerprint including a light refracting device, a focusing lens, a light source, and a biometric circuit for detecting the presence of a patterned object such as a fingerprint at the light refracting device. Incident light from the light source is projected through a light receiving surface of the light refracting device and is directly reflected off an imaging surface. The resulting image is projected through the focusing lens. The focusing lens has a diameter which is larger than the projection of the patterned object through the light refracting device.

Owner:SECUGEN CORP

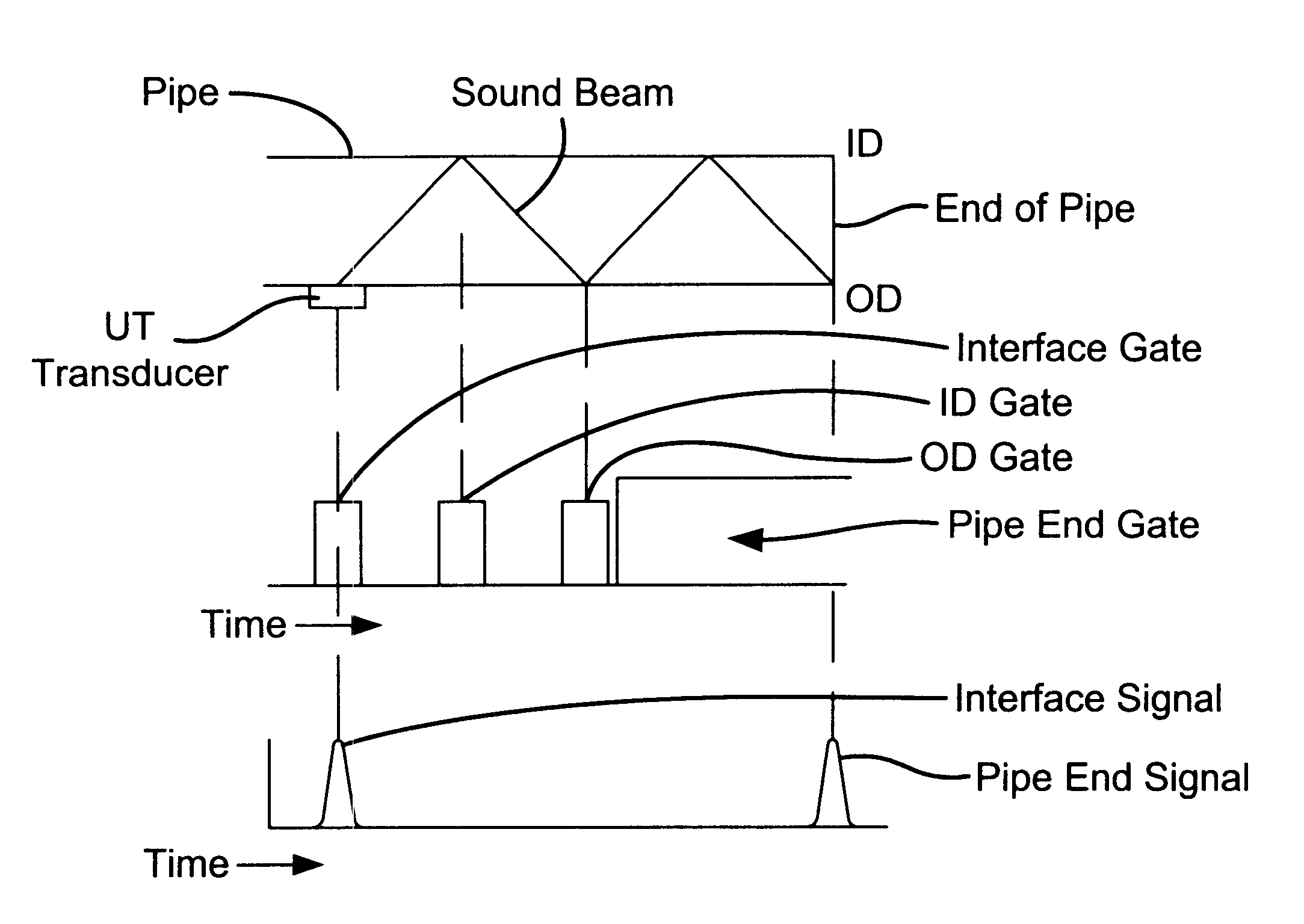

Ultrasonic detection of flaws in tubular members

InactiveUS6578422B2Efficient and effective inspectionAnalysing solids using sonic/ultrasonic/infrasonic wavesResponse signal detectionTransducerEngineering

Owner:VARCO I P INC

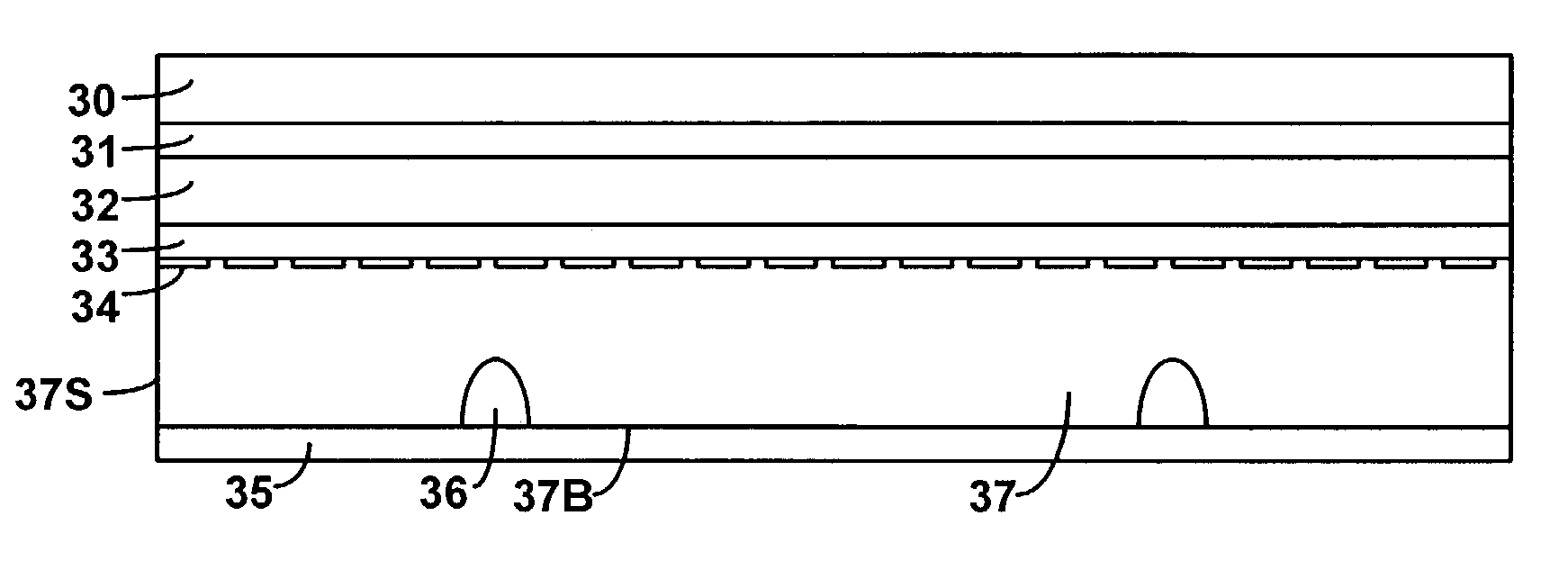

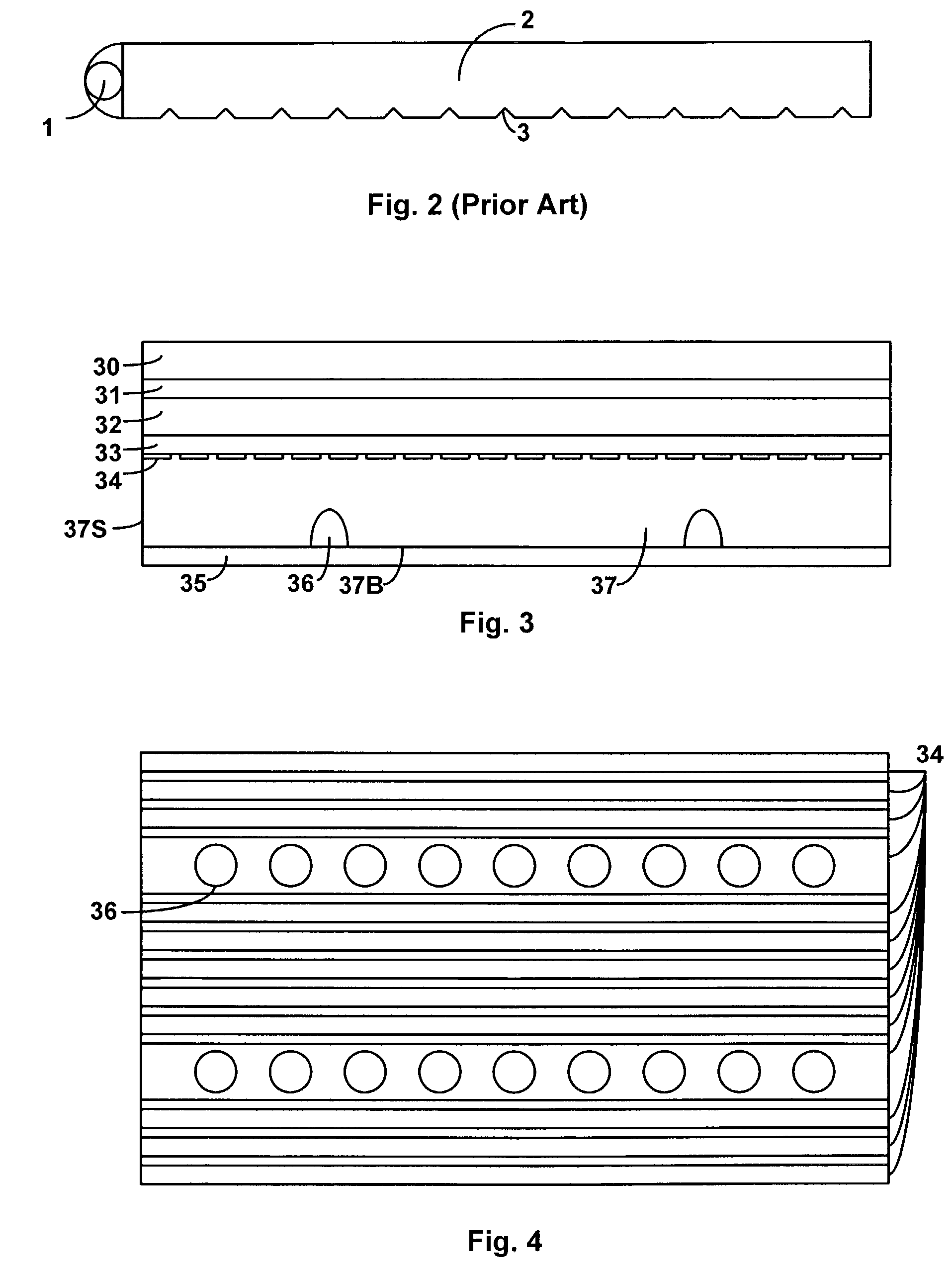

Devices for creating brightness profiles

InactiveUS6974229B2Mechanical apparatusPoint-like light sourceLight-emitting diodeBrightness perception

A mixing chamber includes a first surface and a second surface opposite the first surface. At least two light emitting diodes are disposed along the first surface. At least a portion of the first surface is reflective, and the second surface includes a reflective region and a plurality of openings formed in the reflective region. In some embodiments, the first surface and the second surface are separated by at least one side surface. Light emitted from the light emitting diodes is reflected off the first surface, reflective region of the second surface, and side surfaces of the mixing chamber until it is emitted from the openings of the second surface.

Owner:LUMILEDS LIGHTING U S

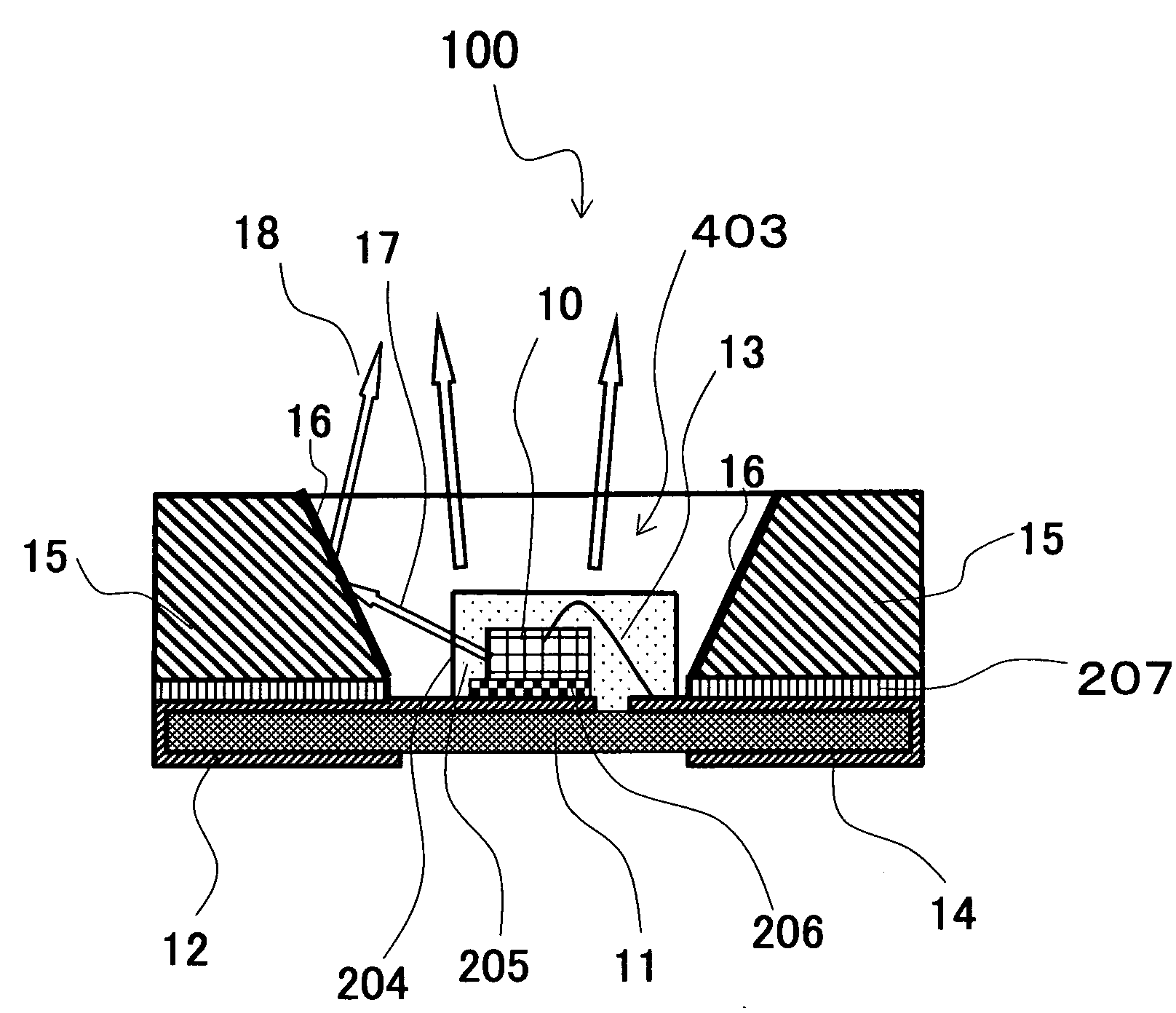

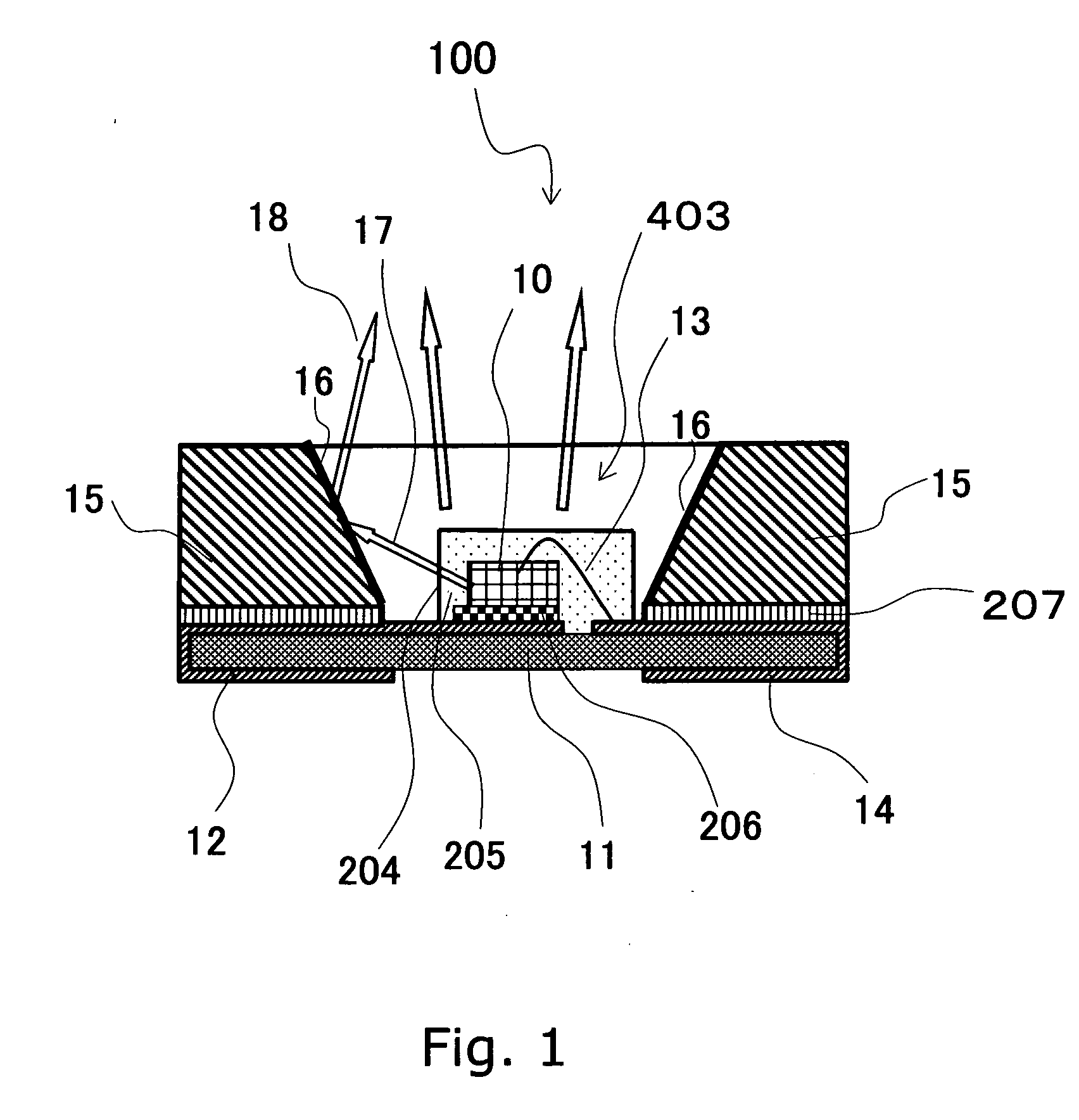

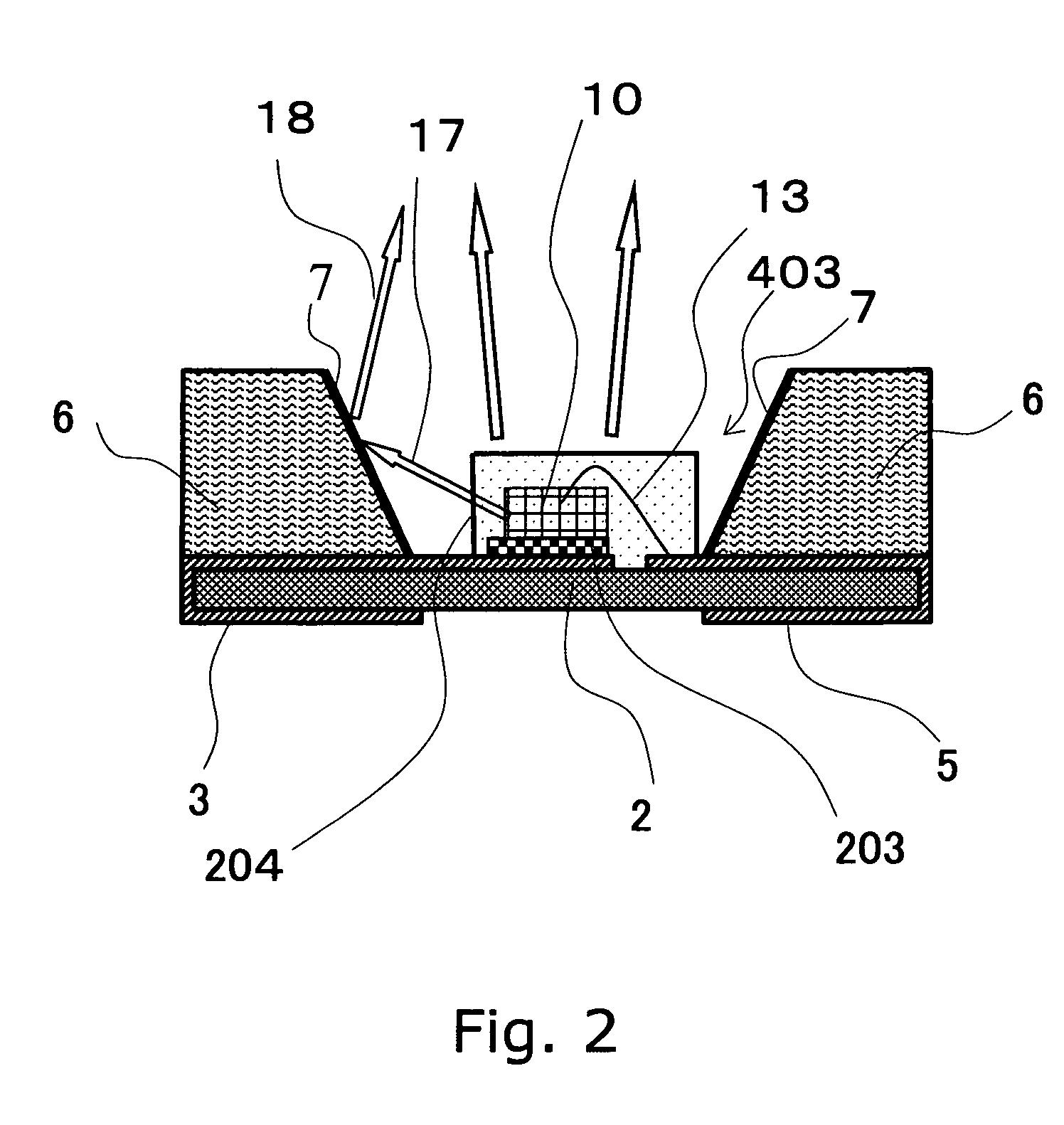

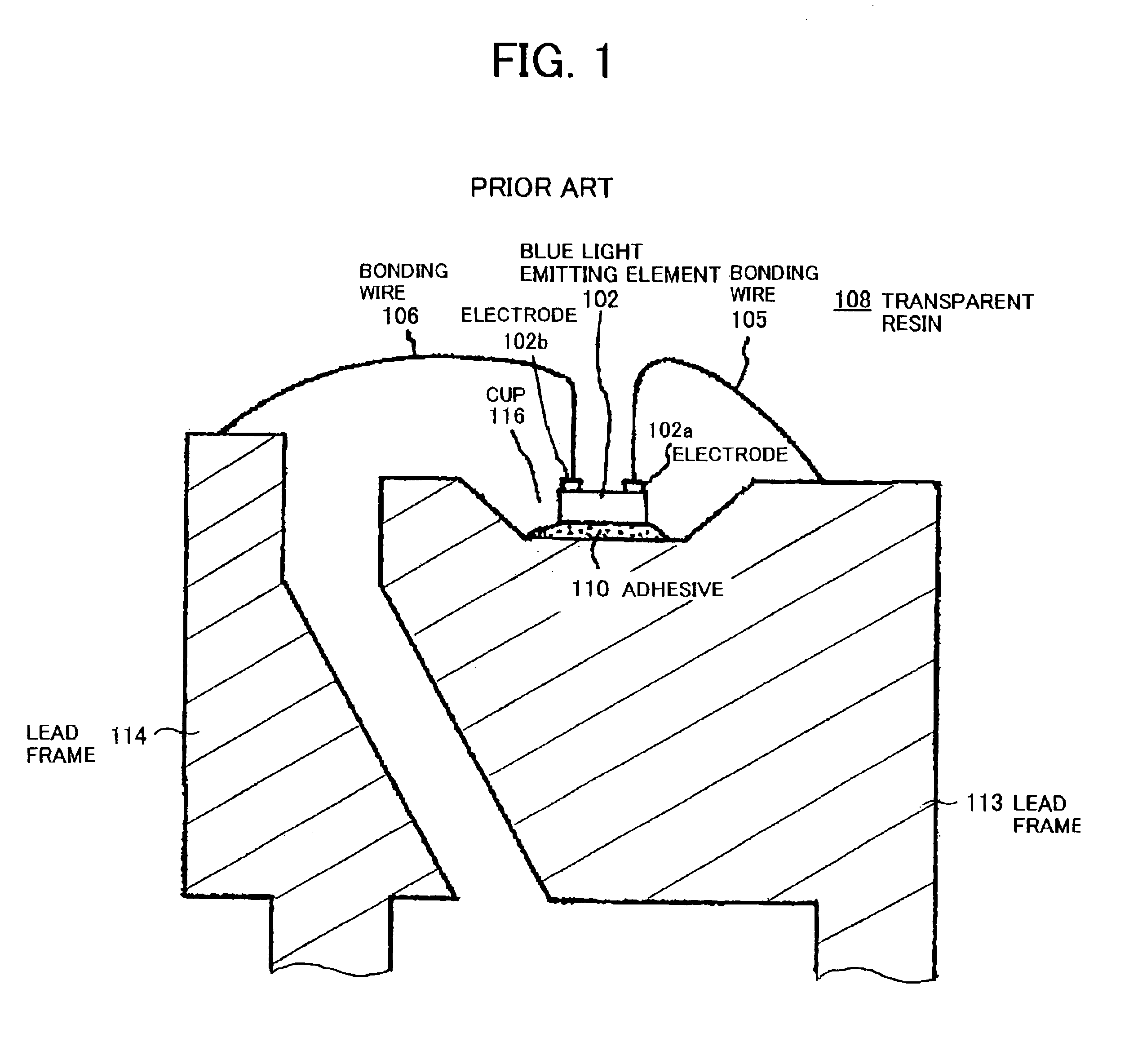

Semiconductor light emitting device

Various semiconductor light emitting devices are described. In one aspect, the semiconductor light emitting device may include, an insulating substrate having an electrode pattern; a metal body provided on the insulating substrate, the metal body having a through-hole; an adhesive layer provided between the insulating substrate and the metal body; a semiconductor light emitting element provided in the through-hole of the metal body, provided on the insulating substrate and electrically connected to the electrode pattern; and a resin configured to seal the semiconductor light emitting, wherein an inner surface of the through-hole faces the semiconductor light emitting element. The inner surface may have a slanted surface and at least a part of the light emitted from the semiconductor light emitting element reflected by the inner surface.

Owner:KK TOSHIBA

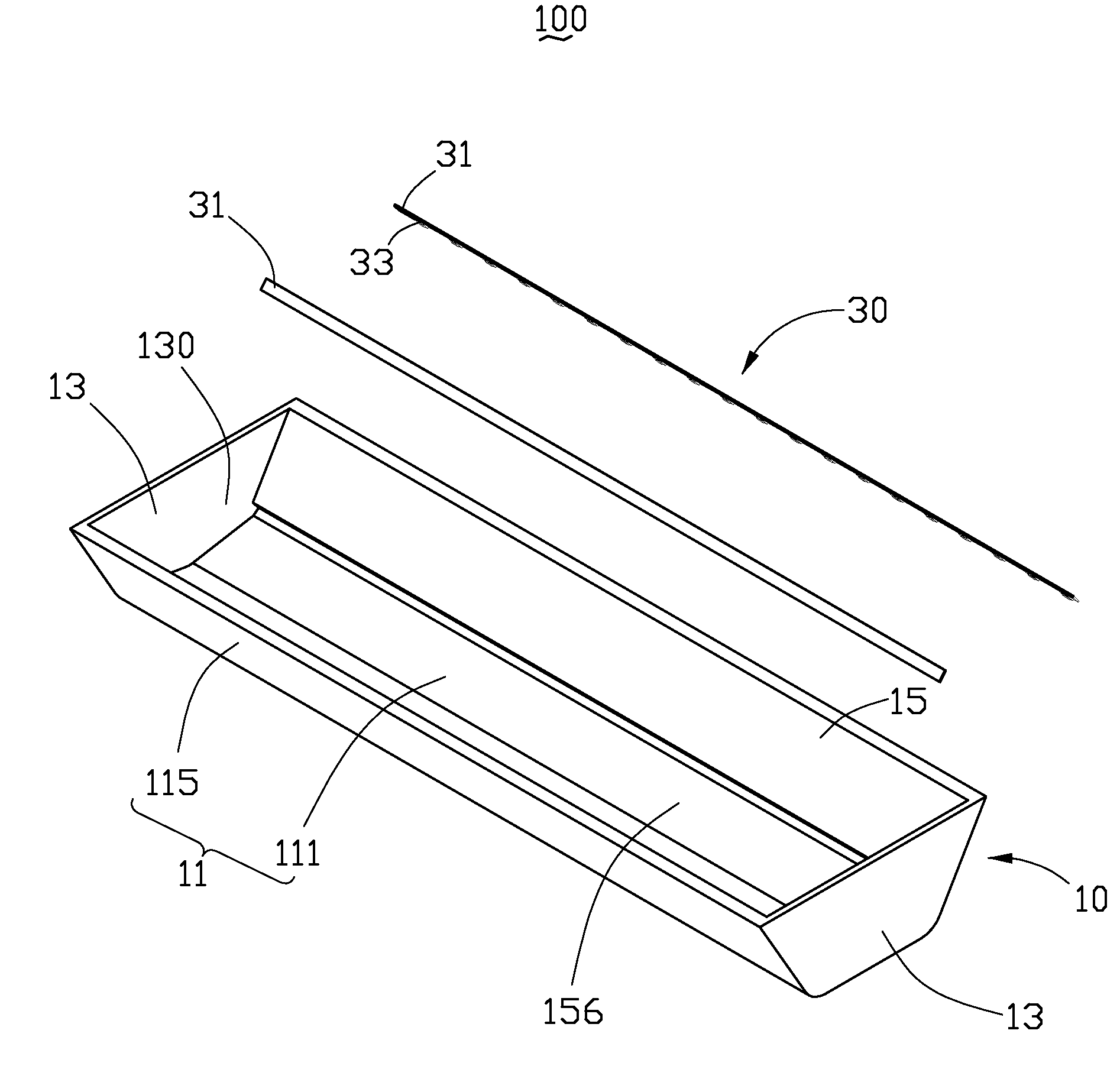

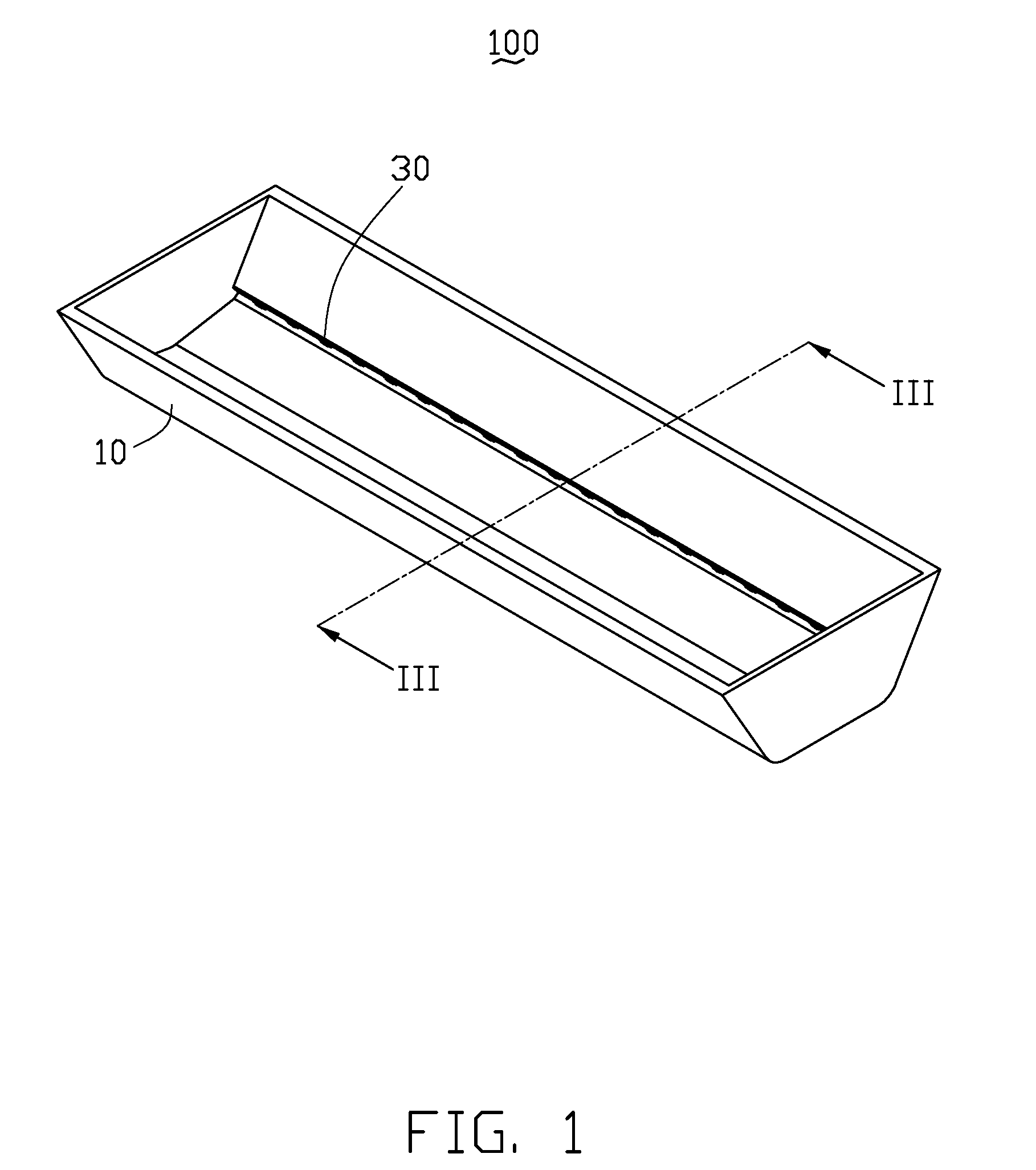

LED lamp

An LED lamp (100) includes a lamp enclosure (10) and two LED modules (30). The lamp enclosure has a concave housing (11). The housing includes an elongated bottom plate (111) and two lateral plates (115) extending upwardly from two opposite lengthwise sides of the bottom plate respectively. An opening (156) is defined at a top side of the lamp enclosure. The LED modules each are mounted at a joint between the bottom plate and a corresponding of the lateral plates in such a manner that at least a portion of lights emitted by the LED modules is firstly directed to and reflected by an internal surface of the bottom plate, and then directed to an outside through the opening.

Owner:FU ZHUN PRECISION IND SHENZHEN +1

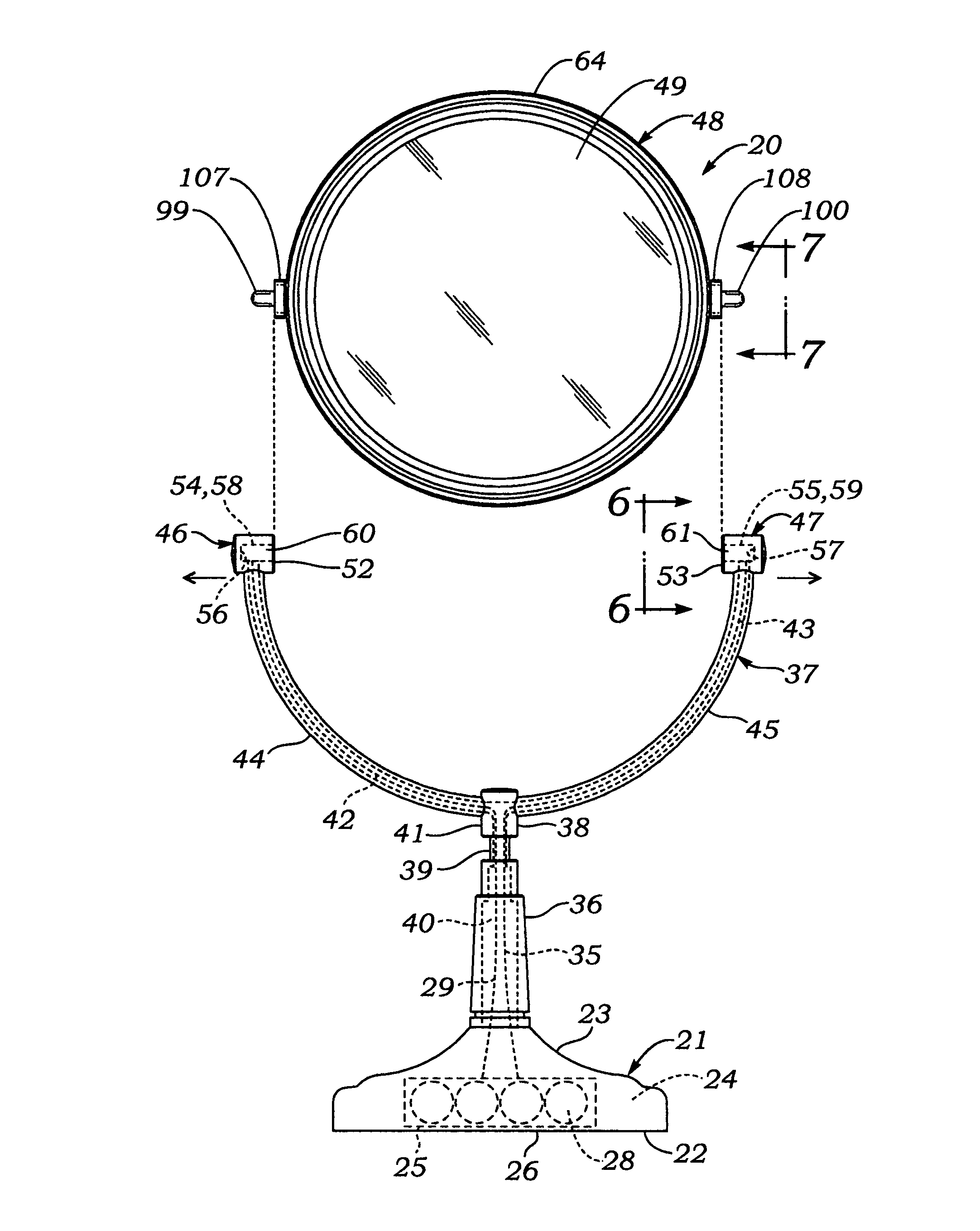

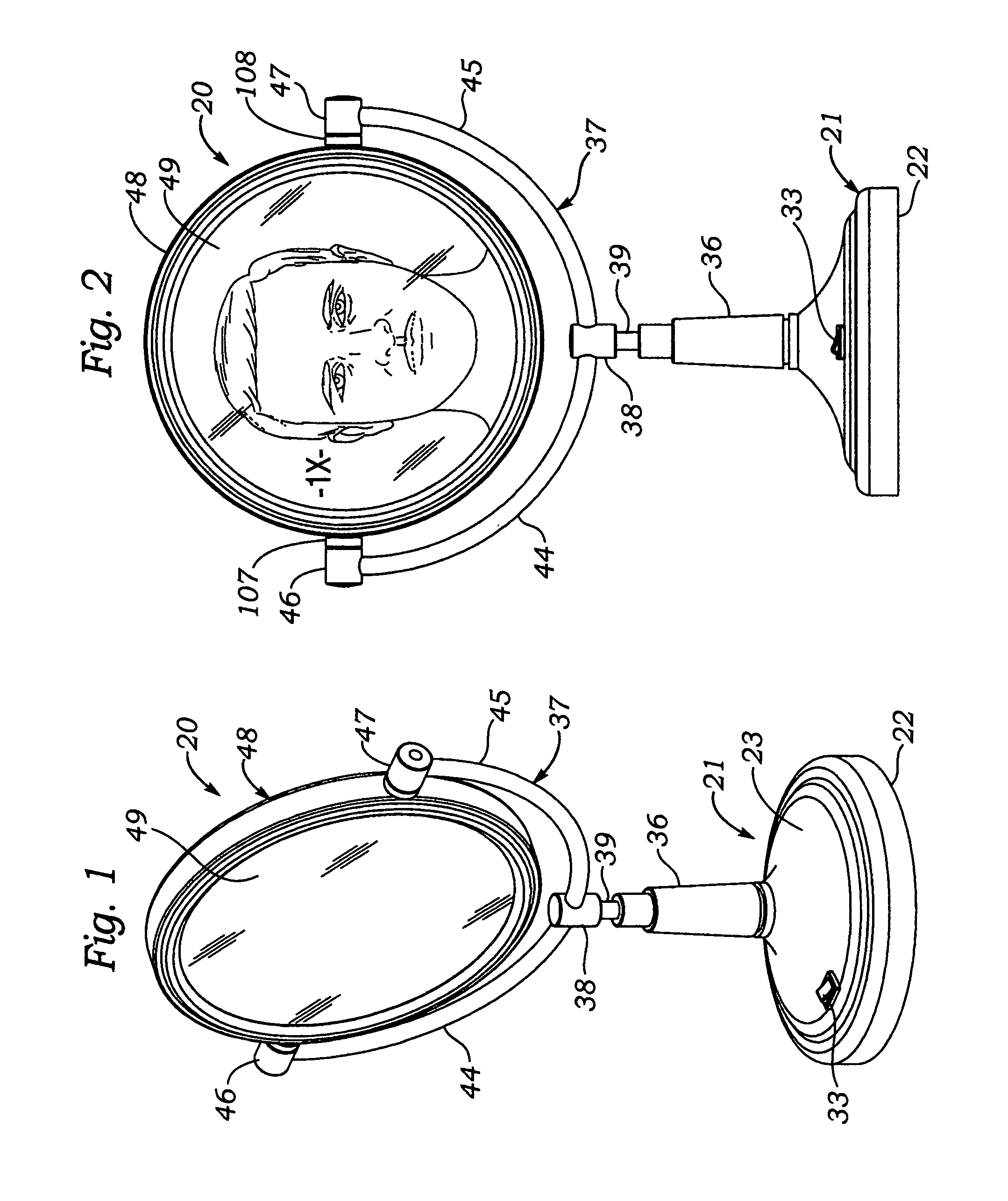

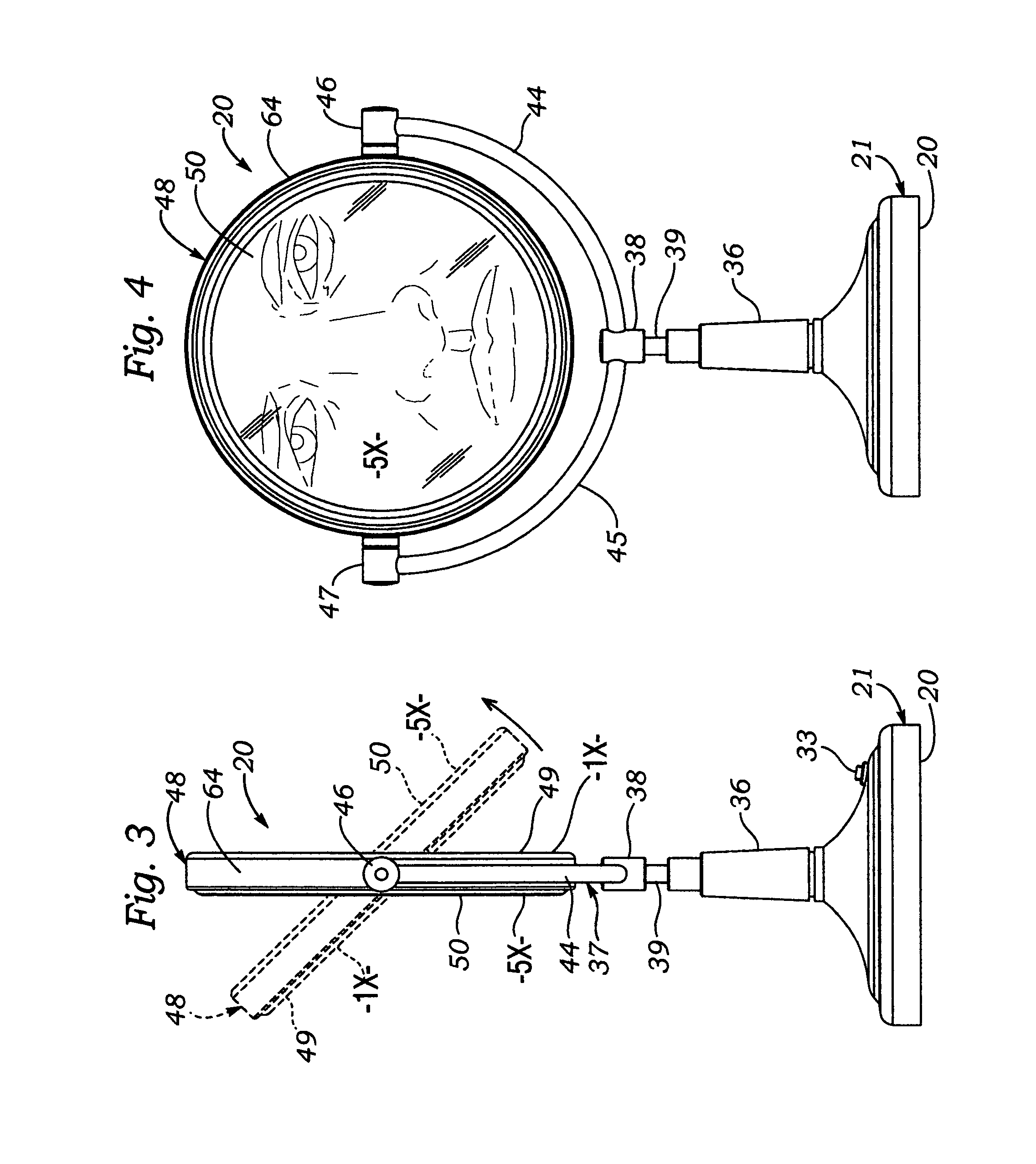

Illuminated continuously rotatable dual magnification mirror

ActiveUS8162502B1Efficient and uniform illuminationEfficient illuminationLighting support devicesLighting elementsMagnifying glassMagnification

A mirror for facilitating appearance related functions includes a circular ring-shaped frame holding therein back-to-back reflective mirror plates having different magnification factors, e.g. 1× and 5×, each plate having a circular central imaging reflective area and an outer concentric light transmissive window area. Continuously rotatable pivot joints support the frame between opposed arms of a yoke protruding upwardly from a stanchion and base for placement on a table, or an arm and wall bracket for mounting on a wall, enabling the frame to be rotated to interchangeably orient 1× and 5× mirror plates in a forward facing use position. A ring-shaped, printed circuit board with circumferentially spaced apart light emitting diodes (LED's) protruding radially outwards of an outer circumferential edge of the board is located between inner facing surfaces of the mirror plates. Illumination of objects in front of the mirror plates is effected by direct LED rays emitted forwardly through the light transmissive windows, and intensified by indirect LED rays reflected from reflective inner facing surfaces of the mirror plates. Electrical power is supplied to the LED's from a battery power supply in the base of the mirror by electrically conductive pins which protrude radially outwards from opposite sides of the frame, the pins being rotatably supported in electrically conductive cups located in opposed arms of the yoke, the cups being connected to the power supply via wires disposed through the yoke arms and stanchion to the power supply.

Owner:ZADRO INC

Referencing or registering a patient or a patient body part in a medical navigation system by means of irradiation of light points

InactiveUS7577474B2Improve accuracyEasy to correctTelevision system detailsSurgical navigation systemsThree-dimensional spaceLight beam

Owner:BRAINLAB

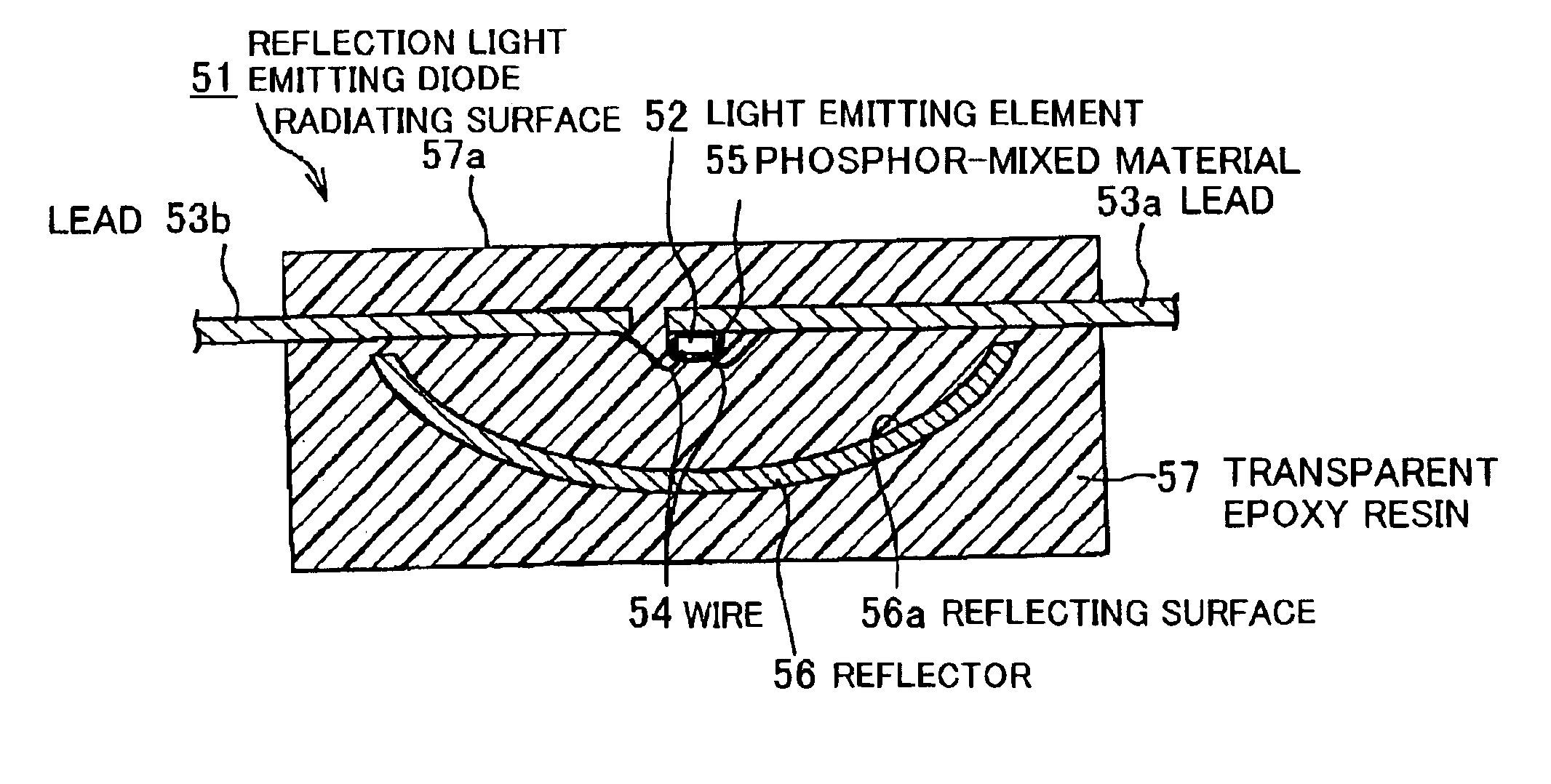

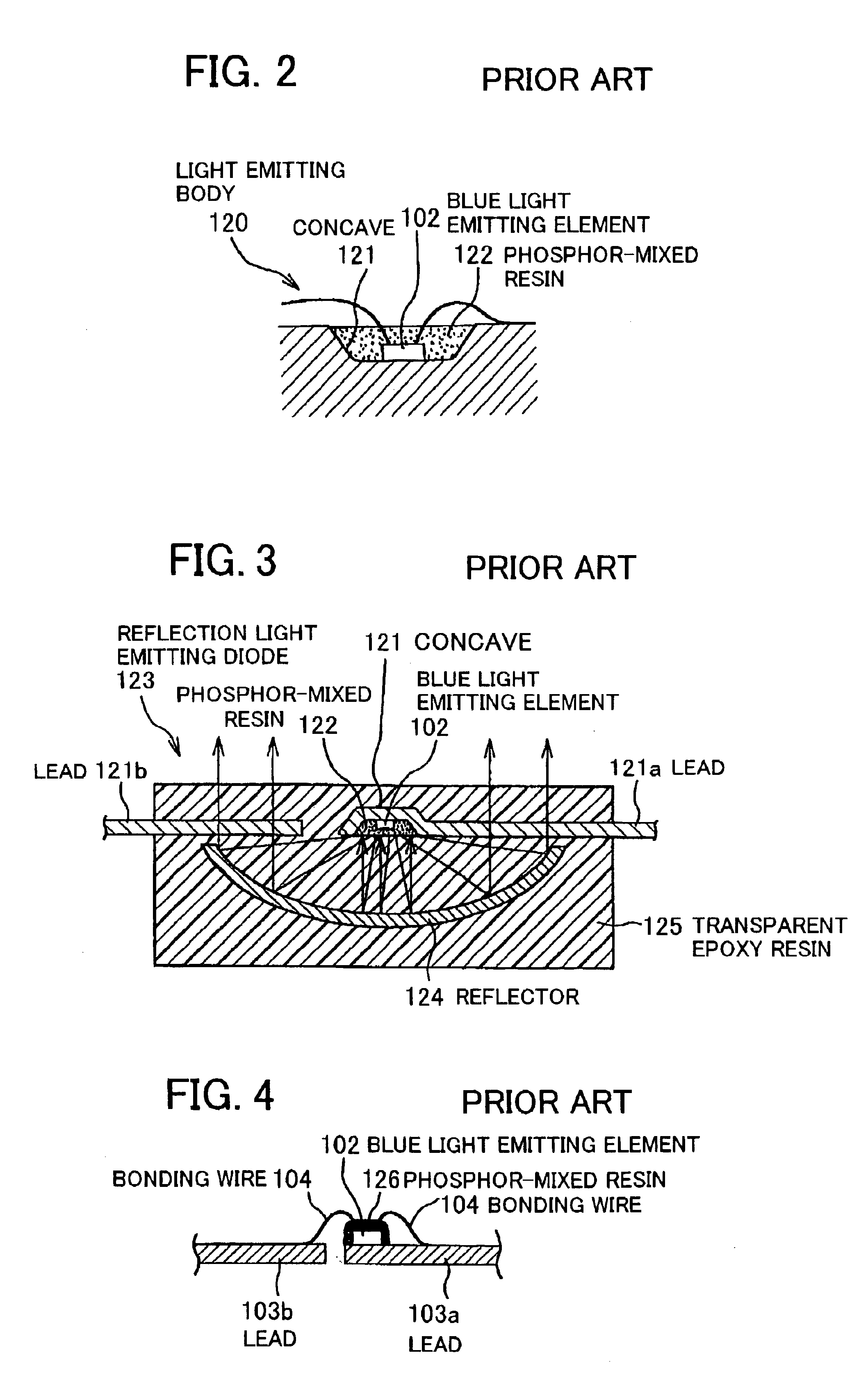

Light emitting diode

InactiveUS6943379B2Improve efficiencyEfficient light emissionSemiconductor/solid-state device detailsSolid-state devicesPhosphorLight-emitting diode

In a light emitting diode, a blue light emitting element is mounted on a base having a cup through a phosphor-containing mount so that the light emitting element is located within the cup and is mounted on the bottom of the cup through the phosphor-containing mount. The light emitting diode includes a light emitting element and a p electrode. By virtue of the above construction, blue light emitted from the light emitting element can be reflected from the lower surface of the p electrode without being radiated directly from the upper surface of the light emitting element to the outside of the light emitting diode. As a result, the blue light emitted from the light emitting element can be efficiently mixed with yellow light given off from the phosphor in the phosphor-containing mount to provide white light which is radiated to the outside of the light emitting diode with high efficiency. The white light can be perceived by a viewer to be uniformly radiated from the light radiating surface of the light emitting diode.

Owner:TOYODA GOSEI CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com