Forming process of resin-based three-dimensional braided composite material

A technology of three-dimensional weaving and composite materials, which is applied in the field of material forming, can solve the problems of inability to ensure the penetration of prefabricated parts, and achieve the effect of good surface quality, low energy consumption and good surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to further understand the advantages of the present invention, the efficacy of the present invention will be illustrated through specific examples below.

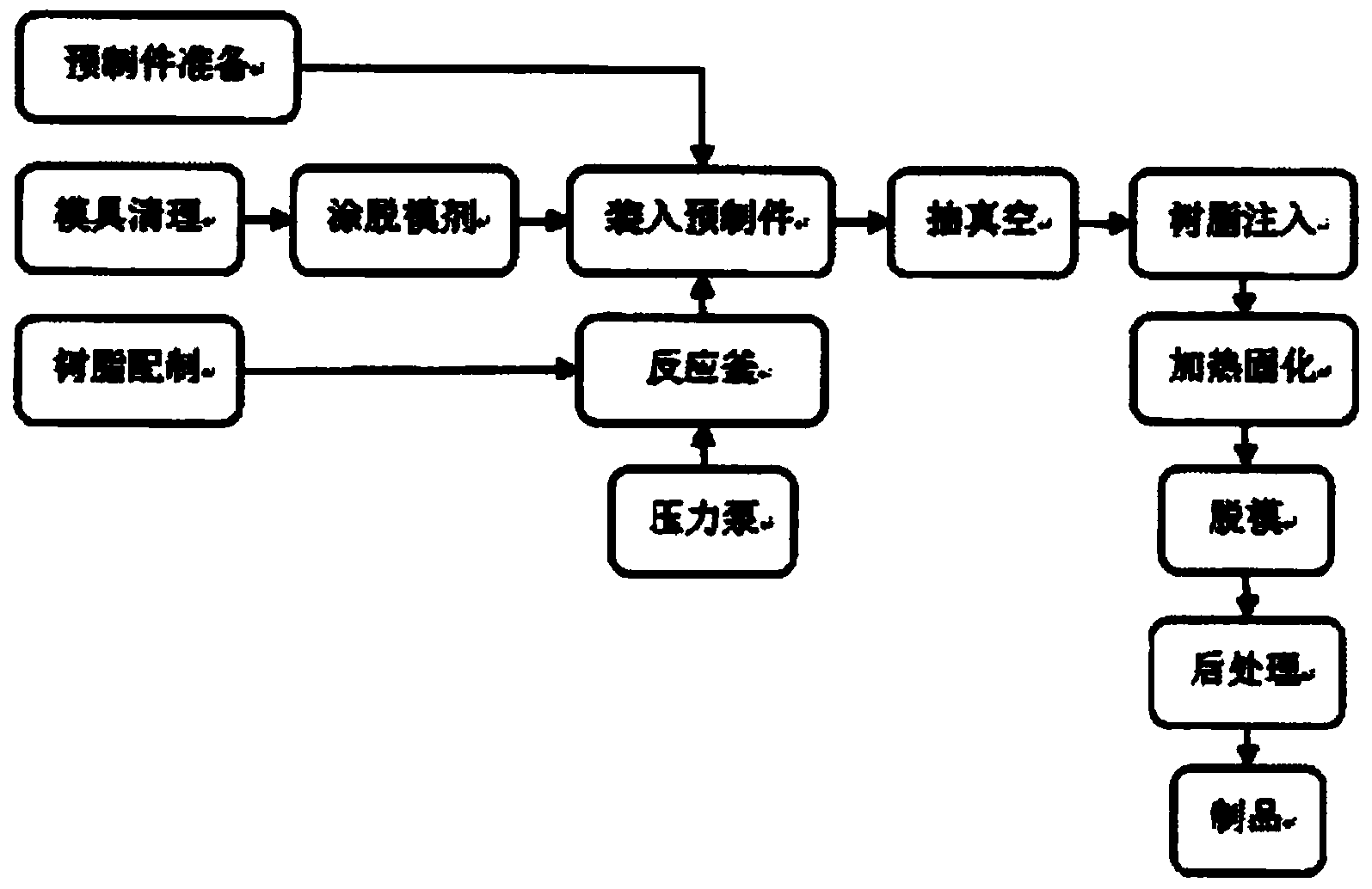

[0017] as attached figure 1 Shown: a resin-based three-dimensional braided composite material molding process, including the following steps:

[0018] (1) Preparation of prefabricated parts: Before loading the mould, place the three-dimensional woven prefabricated part in an oven to heat and dry to remove the moisture in it, so as to prevent the moisture in the prefabricated part from affecting the effect of the release agent, and at the same time avoid the internal Bubbles are generated, the oven temperature is 120°C, and the time is 2 to 3 hours. After drying, take out the preform and cut it into the required size, and then weigh it;

[0019] (2) Mold preparation: Before loading the mold, the mold must be cleaned. Use blades, sandpaper, acetone, etc. to remove impurities such as residual resin and rust sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com