Patents

Literature

102results about How to "High volume content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

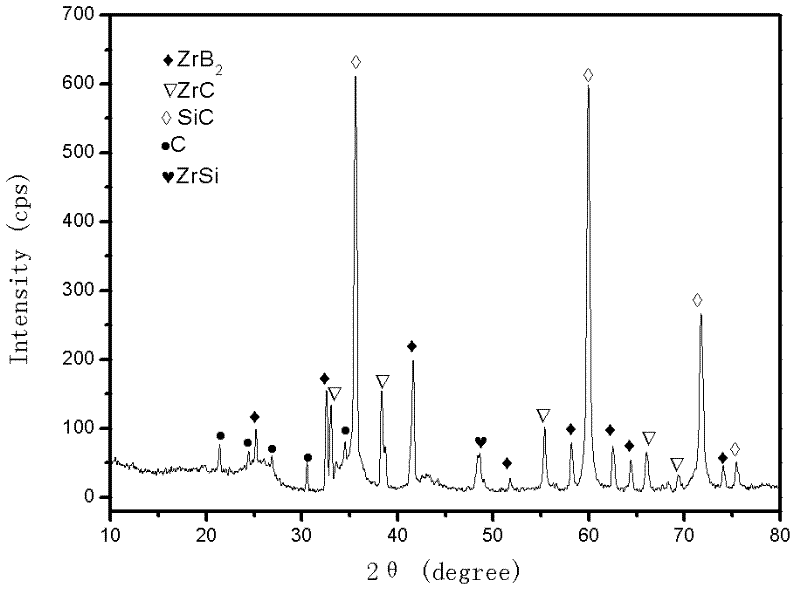

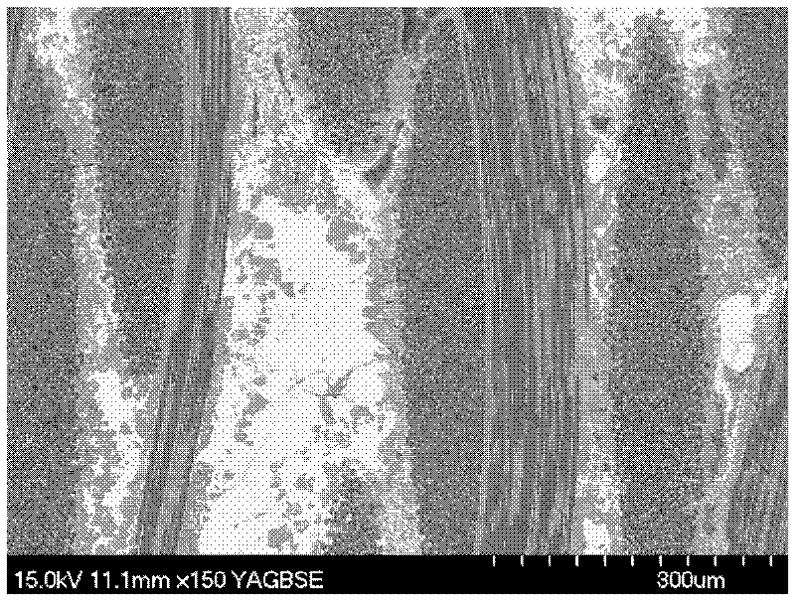

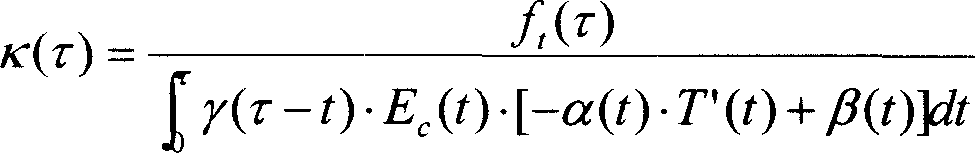

Preparation method of C/SiC-ZrB2-ZrC ultrahigh-temperature ceramic-based composite material

ActiveCN102515870AGuaranteed mechanical propertiesHigh volume contentVacuum pressureUltrahigh temperature ceramics

The invention relates to a preparation method of a C / SiC-ZrB2-ZrC ultrahigh-temperature ceramic-based composite material. According to the invention, B4C and a C organic precursor are introduced into a C / SiC composite material with a vacuum pressure impregnation method; the obtained material is cured and is subject to a heat treatment, such that the C organic precursor is cracked, and pores sealed by the C organic precursor are opened; with a reactive melt infiltration method, under a condition that a temperature is higher than that of silicozirconium alloy, silicozirconium alloy is subject to a reaction with B4C and C, such that in-situ productions of SiC, ZrB2, and ZrC are realized, and the C / SiC-ZrB2-ZrC composite material is prepared. According to the invention, with the vacuum pressure impregnation method, B4C and the C organic precursor are introduced into the C / SiC composite material; with the reactive melt infiltration method, silicozirconium alloy is subject to a reaction with B4C and C, such that in-situ productions of SiC, ZrB2, and ZrC are realized. The produced ZrB2 and ZrC are advantaged in fine grains and high volume content. The ablation resistance and mechanical properties of the composite material are effectively improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

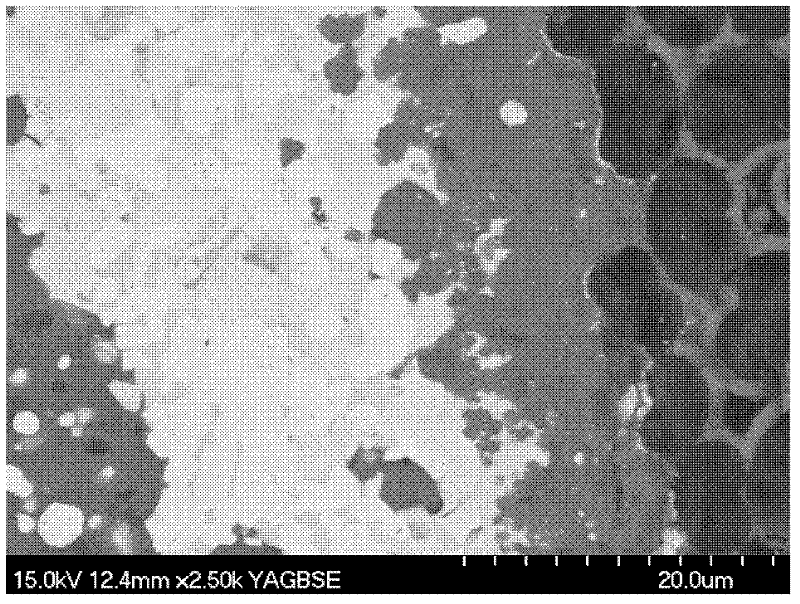

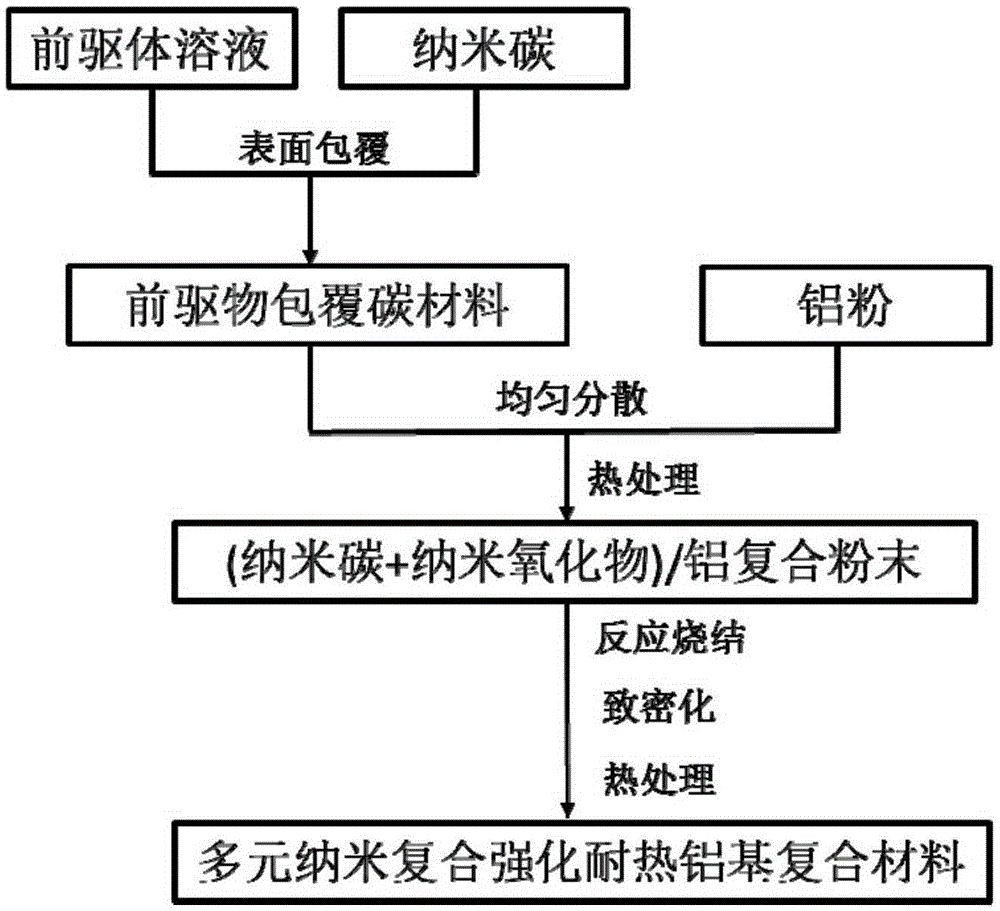

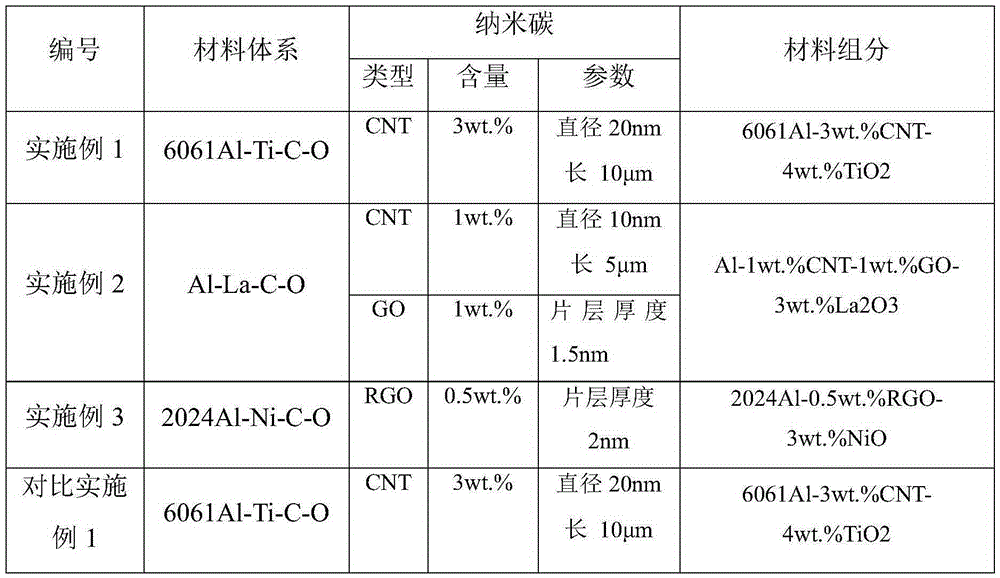

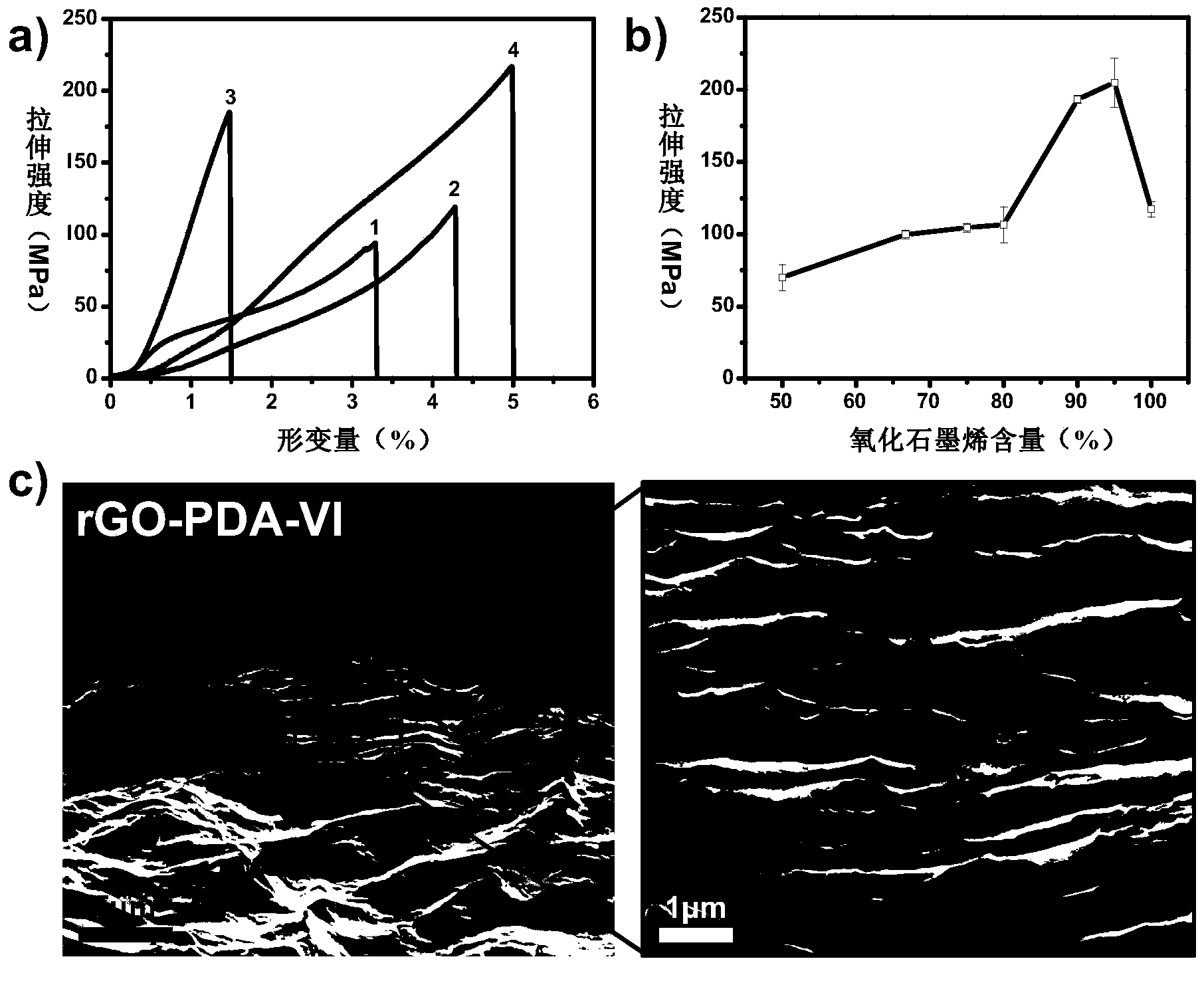

Preparing method of multielement nanometer composite strengthening thermal-resisting aluminum matrix composite

The invention provides a preparing method of a multielement nanometer composite strengthening thermal-resisting aluminum matrix composite. The surface of nanocarbon is coated with a metal ion precursor in advance, the nanocarbon is evenly scattered in aluminum powder, the precursor is converted into oxide through thermal treatment, reactive sintering and densifying treatment are carried out on the obtained composite powder, and the multielement nanometer strengthening aluminum matrix composite is obtained. The nanocarbon has the high specific surface area, the feature size of the nanocarbon is far larger than that of the nanometer oxide, and therefore a proper amount of nanometer oxide can be loaded and evenly led into the aluminum powder, metallic oxide, carbide, an intermetallic compound and other multielement nanometer strengthening phases are generated through the in-situ reaction, and the tissue stability and the thermal resistance of the aluminum matrix composite are improved coordinately. The method achieves the purposes of even leading of high-volume-content multielement nanometer strengthening phases and the space occupation control, and the conventional powder metallurgy technology can be adopted for preparing the multielement nanometer composite strengthening thermal-resisting aluminum matrix composite.

Owner:SHANGHAI JIAO TONG UNIV

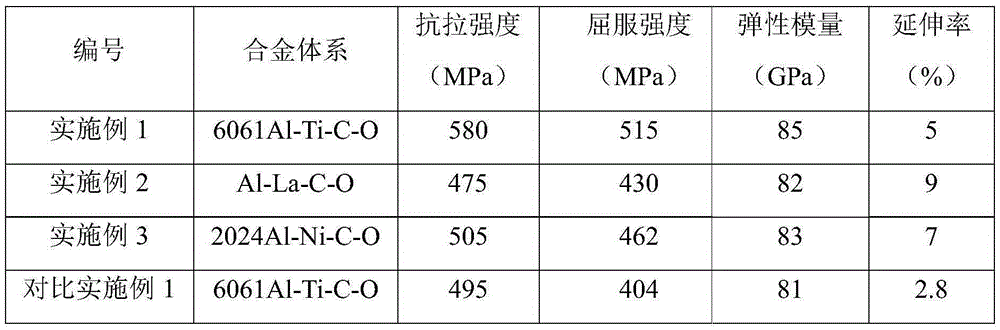

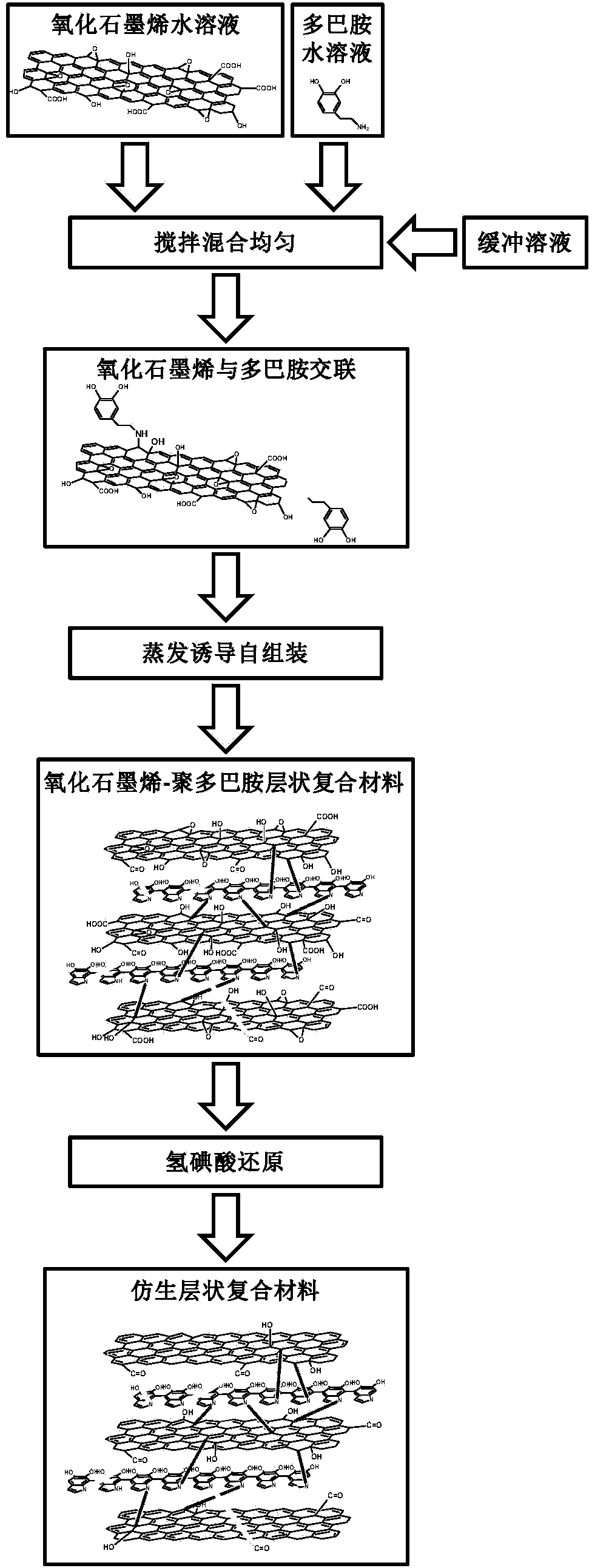

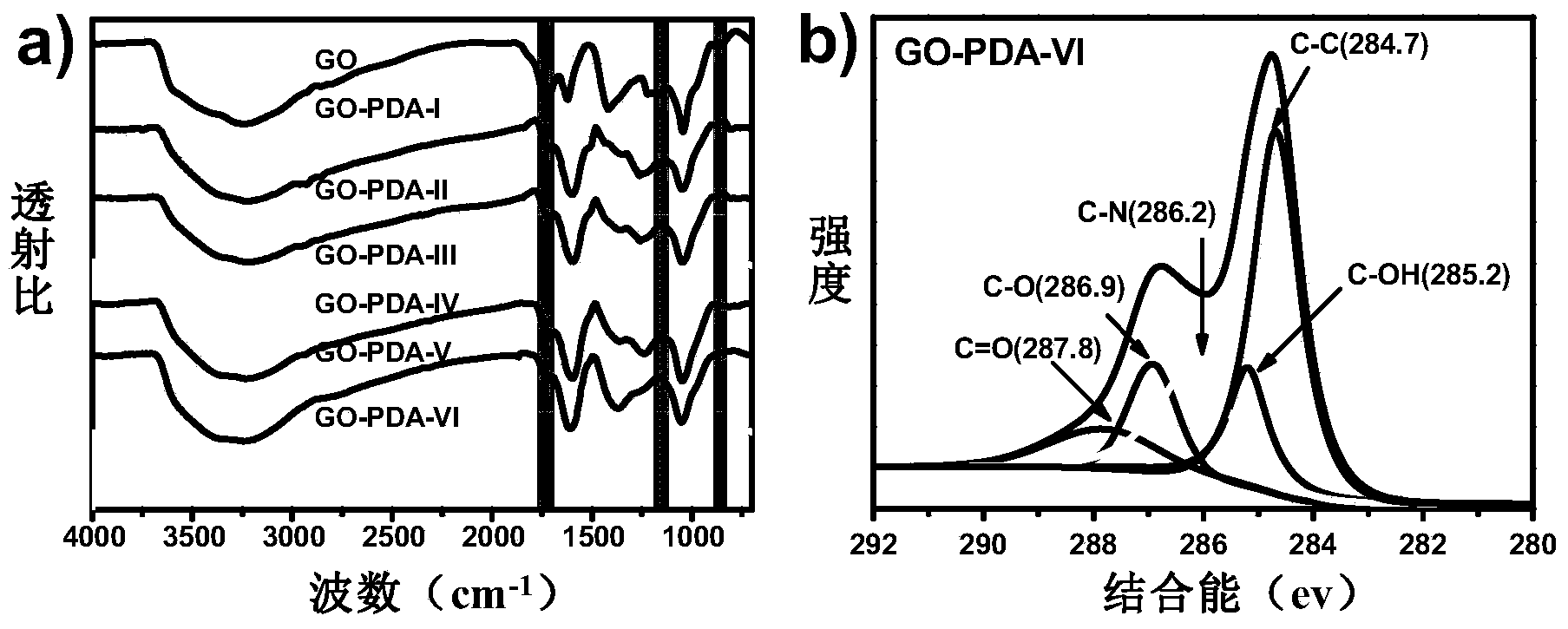

Method for preparing tough integrated biomimetic layered graphene composite material

The invention discloses a method for preparing a tough integrated biomimetic layered graphene composite material. Inorganic graphene oxide and organic dopamine are formed into a bionic building layered graphene composite material by an evaporation-induced self assembly method under the inspiration of a natural abalone shell organic-inorganic micro-nano multi-stage layered assembly structure and organic-inorganic crosslinking. The obtained imitated abalone shell layered composite material not only has high strength, but also has high toughness, the strength is twice of that of the natural abalone shell, the toughness is 1.5 times of that of the natural abalone shell, and meanwhile, the biomimetic layered graphene composite material also has excellent conductivity, and has potential application in the fields such as aviation and aerospace, tissue engineering, capacitor electrodes and the like.

Owner:BEIHANG UNIV

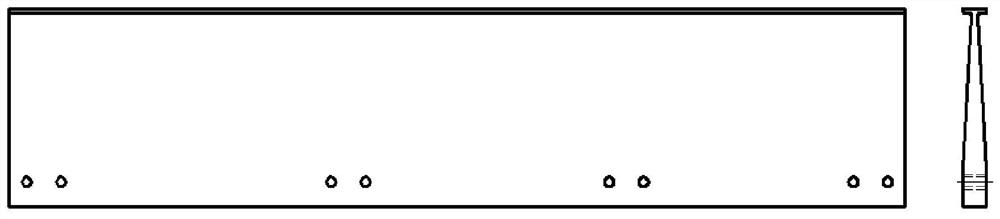

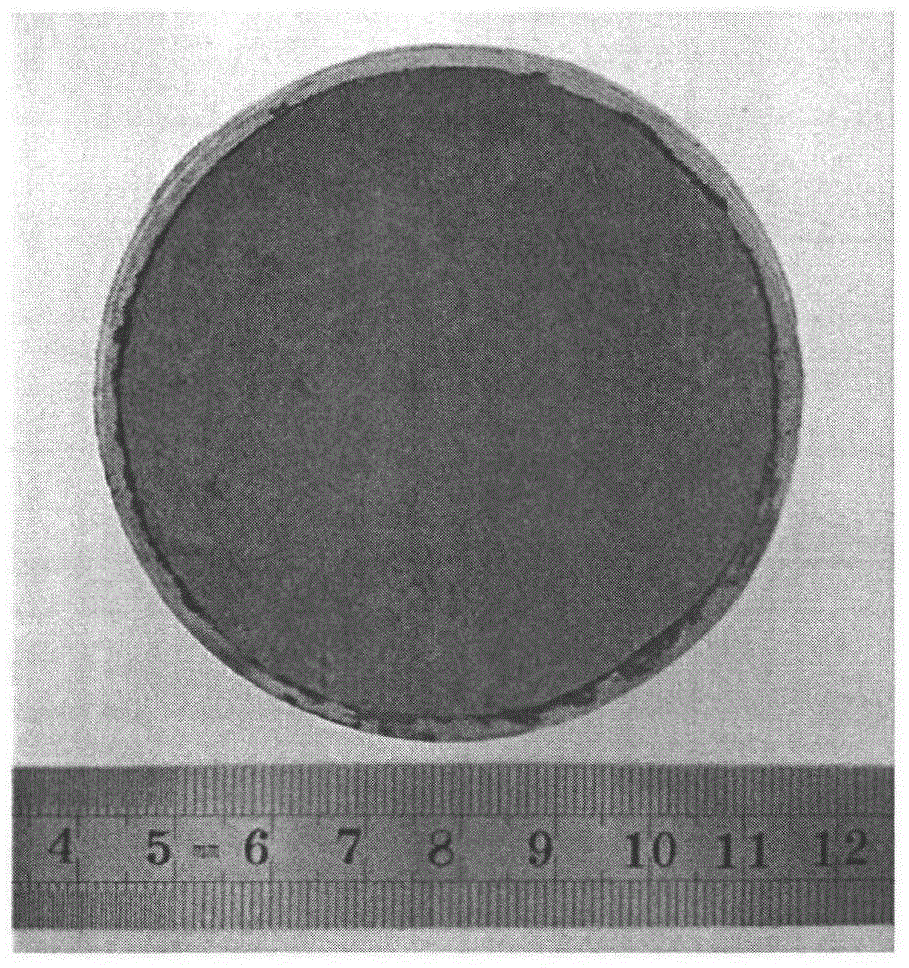

Method for manufacturing needle-punched carbon fiber pseudo-three-dimensional preform

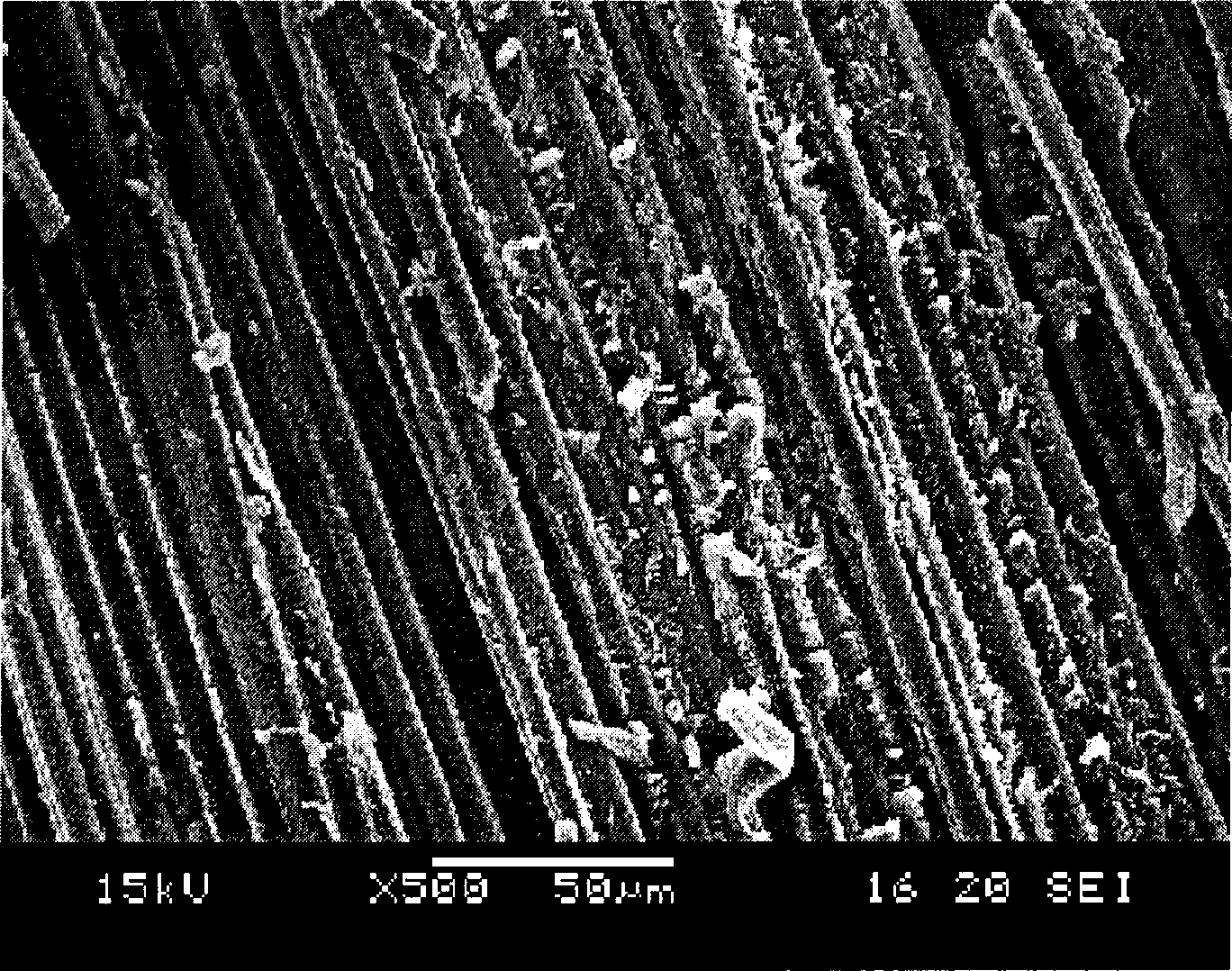

InactiveCN101575766AImprove wear resistanceExtended service lifeNeedling machinesCarbon compositesCarbon fibers

The invention relates to a method for manufacturing a needle-punched carbon fiber pseudo-three-dimensional preform, which comprises the following steps: adopting alternating laminations of continuous carbon fibers and short carbon fiber mesh carcasses, wherein the laminations of the continuous carbon fibers are paved alternately with included angles between 0 and 30 degrees; and introducing longitudinal fortifying fibers through a needle-punching process in the axial direction of the short carbon fiber mesh carcasses and the continuous carbon fiber laminations, and controlling the needling density to between 36 to 44 needles / cm so as to manufacture a full carbon fiber pseudo-three-dimensional structural preform with the volume density of between 0.55 and 0.82g / cm. The preform manufactured by the method has the most important characteristics of high volume content of the carbon fibers, evener continuous carbon fiber laminations, high needling density, high mechanical property of a manufactured carbon / carbon composite material and good wear resistance, and is applicable to manufacturing aircraft carbon brake disc materials with high torque characteristics.

Owner:XIAN CHAOMA SCI TECH

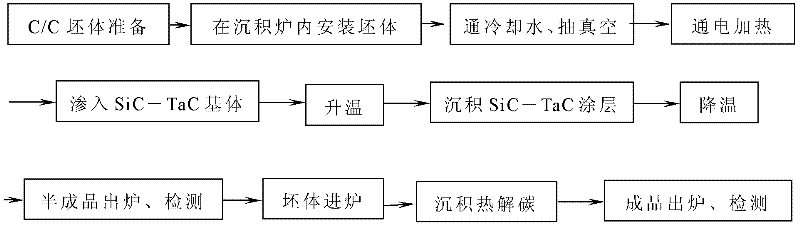

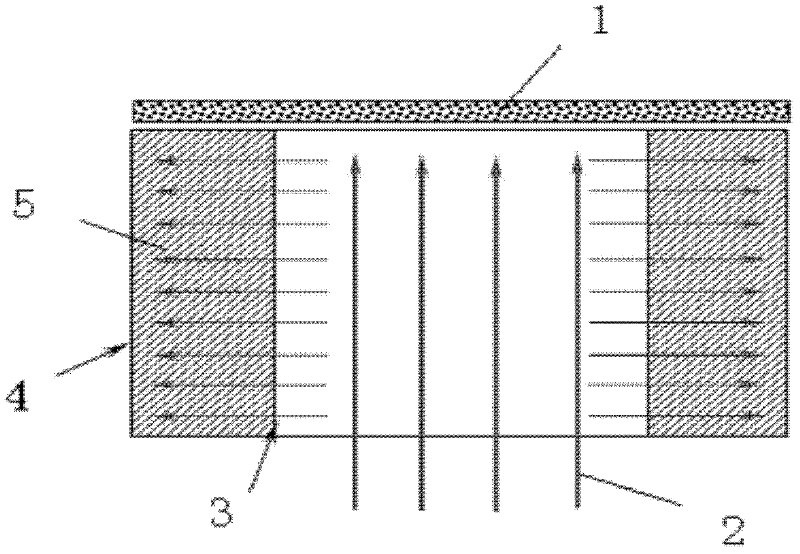

A kind of sic-tac coating/matrix synergistically modified c/c composite material and preparation method thereof

ActiveCN102295474AMitigate Thermal MismatchHigh coefficient of thermal expansionSurface layerHigh density

The invention discloses a SiC-TaC coating / matrix collaborative modified C / C composite material and its preparation method. The composite material provided by the invention comprises two parts. The portion below the surface of the C / C composite material is the matrix modified portion with the thickness being 0.1-10mm. In addition, carbide in the C / C composite material emerges in gradient distribution. The portion which is deposited on the surface of a carbon material is a coating portion with the thickness being 10-300 microns. The preparation method of the composite material comprises the following steps of: cutting a C / C green body at the density of 0.80g / cm<3>-1.60g / cm<3> into an annular shape or a plate shape, followed by ultrasonic cleaning and drying, placing into a multifunctional CVD furnace, depositing carbide on the surface layer and surface of the C / C green body by controlling deposition parameters, further densifying the green body by the use of pyrolytic carbon so as to obtain the high-density coating / matrix collaborative modified C / C composite material. The main advantages of the invention are as follows: by the penetration of carbide through the surface layer of the C / C composite material, the thermal expansion coefficient of the matrix is raised, the interfacial bonding state is improved, a continuous transition of carbide is formed between the coating and the matrix, and the metallurgical bonding is accomplished between the coating and the matrix.

Owner:CENT SOUTH UNIV

Flake diamond-reinforced metal matrix composite and preparation method

ActiveCN105220049AHigh volume contentImprove production efficiencyHeat conductingSurface modification

The invention provides a flake diamond-reinforced metal matrix composite and a preparation method. The composite is formed by arranging diamond sheets in a matrix metal, and the diamond sheets and the matrix metal are in metallurgical bonding. The preparation method comprises the steps that one of the casting, infiltration, cold-press sintering, hot-press sintering and plasma sintering processes is adopted, the matrix metal or the matrix metal containing surface modification diamond particles and the diamond sheets are compounded, and the flake diamond-reinforced metal matrix composite with the diamond sheets and the matrix metal in metallurgical bonding is obtained. As flake diamond frameworks are distributed in the matrix metal, a certain number of diamond particles are added in the matrix metal, and the diamond sheets are subjected to surface modification through the sandwich structure that a graphene layer is clamped between bottom metal film and surface metal film, the composite has the excellent heat conducting property and can be taken as electronic packaging and heat sink materials and the like, and package of high-temperature, high-frequency and large-power electronic devices is achieved.

Owner:CENT SOUTH UNIV

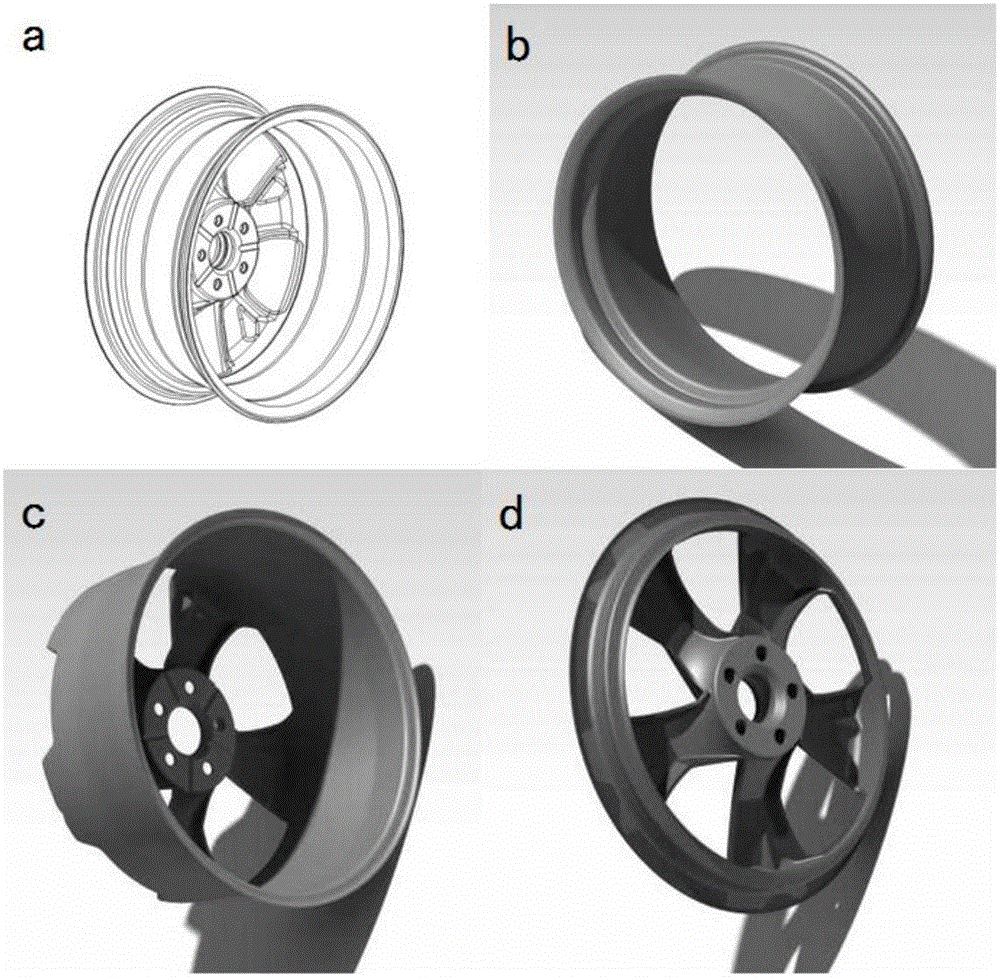

Manufacturing method for composite hub

The invention relates to a manufacturing method for a composite hub. The manufacturing method comprises the following steps that a reinforced fiber perform is manufactured in advance; a sealed die cavity is filled with the reinforced fiber perform, and then is vacuumized; a resin system is injected in the die cavity with compressed air; and the composite hub is obtained after curing. The resin system is injected in a die with the compressed air, and pressure is maintained for a certain time after injection is completed, so that the acceptable volume content of a reinforced material is increased, the purpose that the volume content of the reinforced material is controllable is achieved, and the mechanical strength of the hub is controlled and improved. The composite hub, manufacturing according to the manufacturing method, is extremely low in void ratio and high in fiber content, fibers are uniformly distributed in a composite material structure, without folds, and since the perform is manufactured in a blocked manner, a complex product is split into simple components, the production efficiency is high, and the quality is controllable and stable.

Owner:HARBIN FRP INST

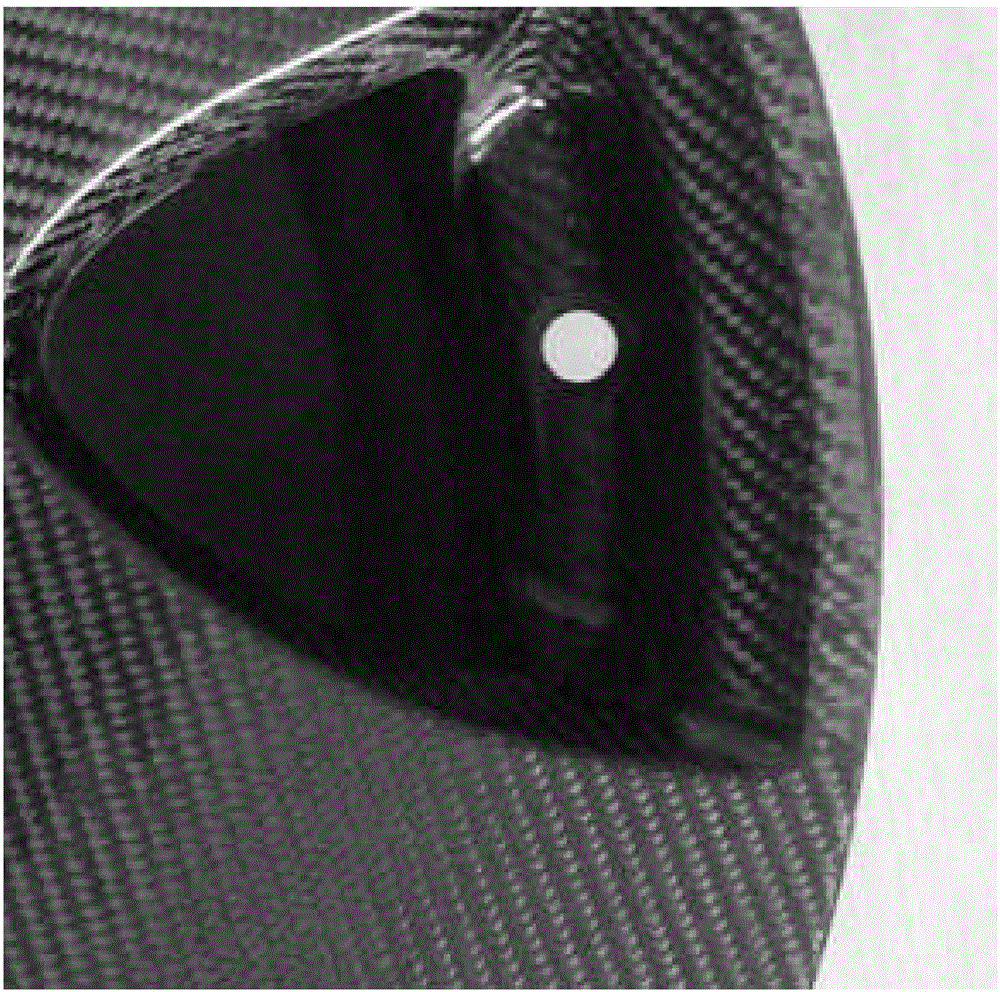

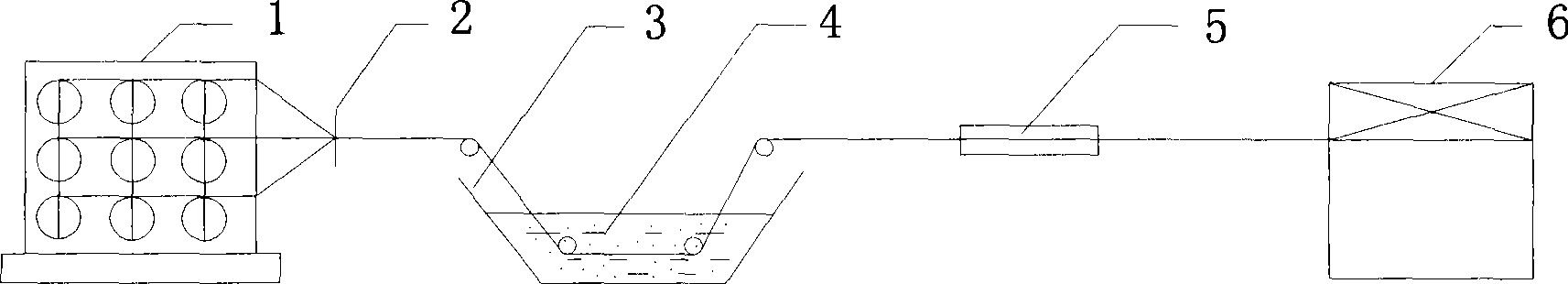

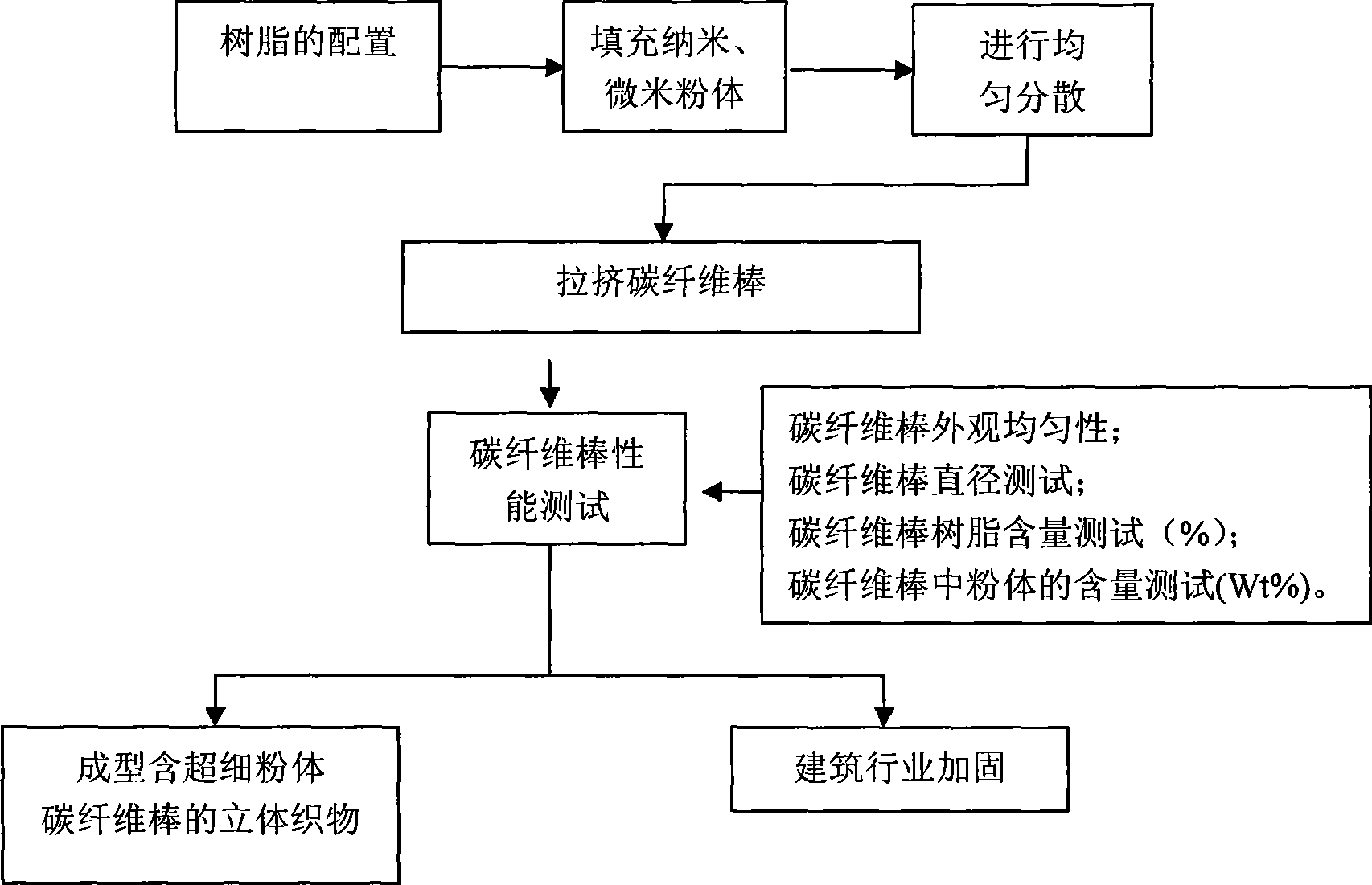

Carbon fibre bar containing super fine and preparation thereof

The invention relates to a carbon fiber stick containing ultra-thin powder and a preparation method thereof. The carbon fiber stick is compounded and prepared by taking carbon fibers, ultra-thin powder and thermosetting resins; wherein, the content of the carbon fiber is larger than 55 percent; the content of the ultra-thin powder filled in the carbon fibers is within 10 percent and the rest is the thermosetting resins. The preparation method thereof includes the following steps: 1) the thermosetting resins are used as a substrate, the carbon fibers are used as reinforcement and an accessory ingredient corresponding to the resin liquid is added in the resin liquid to prepare a pre-mixed liquid; 2) after the ultra-thin powder is completely dipped by a coupling agent, the ultra-thin powder is uniformly dispersed into the pre-mixed liquid to prepare a mixed liquid; 3) after the carbon fibers are completely dipped in the mixed liquid, the carbon fiber stick containing the ultra-thin powder is manufactured by adopting a pultrusion method. A solid fabric shaped by the carbon fiber stick can form a prefabricated part of compound materials containing the ultra-thin powder. The carbon fiber stick can be applied to the construction reinforcement industry as well.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD

Liquid pressure forming method of composite material

The invention belongs to a resin based composite material liquid forming technique, and relates to a composite material liquid pressure forming method. The periphery of a predetermined mold body is filled with resin, and the predetermined mold body is continuously pressurized and cured successively by resin via a first pressure source and a second pressure source. According to the invention, the predetermined mold body is pressurized and cured continuously by resin; a molded composite material product not only has high fiber volume content equivalent to a composite material molded by a prepreg / autoclave technique, but also has the high precision equal to the composite material molded by an RTM technique; the applicable range of the composite material molded by a liquid forming technique is expanded; the molding efficiency is improved obviously; the manufacturing cost is reduced.

Owner:AVIC COMPOSITES

High volume stability marine concrete and its preparation method

The present invention relates to marine engineering concrete and its preparation process. The marine engineering concrete with high volume stability consists of fine synthetic fiber in 0.05-0.15 vol%, cementing material in 400-500 kg / cu m, crushed stone in 1000-1300 kg / cu m, sand in 600-1000 kg / cu m, and plasiticizer accounting for 0.5-2.0 wt% of the cementing material. The cementing material includes Portland cement, ground ore slag and silica fume. The marine engineering concrete with high volume stability has high anticorrosion capacity to sulfate and chloride in sea water, low hydration heat, high microscopic compatibility, high strength, low cost, greatly raised volume stability and durability and raised resistance to environment temperature and humidity change.

Owner:TONGJI UNIV

Compositional type reclaiming agent

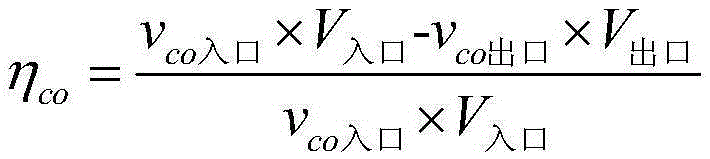

InactiveCN101322900AHigh volume contentReduce circulationDispersed particle separationAntifoam agentChemistry

The invention relates to a high-effective remover of hydrogen sulfide at normal temperature and a preparation method thereof, in particular to a compound high-effective sulfur remover and the preparation method thereof. The sulfur remover contains N-methyl diethanol amine with the content of 93.5 weight percent to 96 weight percent, and the other components are an anti-foaming agent, a corrosion inhibitor, an antioxidant and an intensifier. The preparation method of the sulfur remover is that 93.5 portions to 96 portions (all portions are weight portions) of N-methyl diethanol amine, 0.05 portion to 0.2 portion of anti-foaming agent, 0.02 portion to 0.05 portion of corrosion inhibitor, 0.05 portion to 0.2 portion of antioxidant and 3 portions to 6 portions of intensifier are stirred in a stirring kettle into uniform solution, that is, the compound sulfur remover. The compound sulfur remover of the invention solves the problem that the present MDEA compound sulfur remover can affect the sulfur removing effect by reacting with CO2.

Owner:顾泽元

Moulding process of carbon fiber composite heavy-wall pipe

InactiveCN103737942AExpand the scope of applicationAccelerateTubular articlesCarbon fiber compositeExternal pressure

The invention provides a moulding process which uses carbon fiber prepregs to manufacture a heavy-wall pipe and belongs to the field of the moulding process of composite materials. The carbon fiber composite heavy-wall pipe is prepared through carrying out cutting, stacking, pipe reeling, band winding and solidifying on the carbon fiber prepregs. The moulding process can make the laying design of the pipe be unrestricted, the distribution amounts of the fibers in different directions can be precisely controlled, and the angles of the fibers can be designed. Environmental pollution is not caused during preparation, and later period processing is not needed after moulding. The prepared heavy-wall pipe has the advantages of light weight, low porosity, high fiber content and strong carrying capacity. The moulding process uses the Level T700 carbon fiber epoxy type prepregs to produce the heavy-wall pipe which can resist the external pressure of more than 80MPa, and the specification of the heavy-wall pipe is the inner diameter phi of 37 mm, the outer diameter phi of 49 mm, and the length of 1200 mm.

Owner:SICHUAN XIN WAN XING CARBON FIBER COMPOSITES

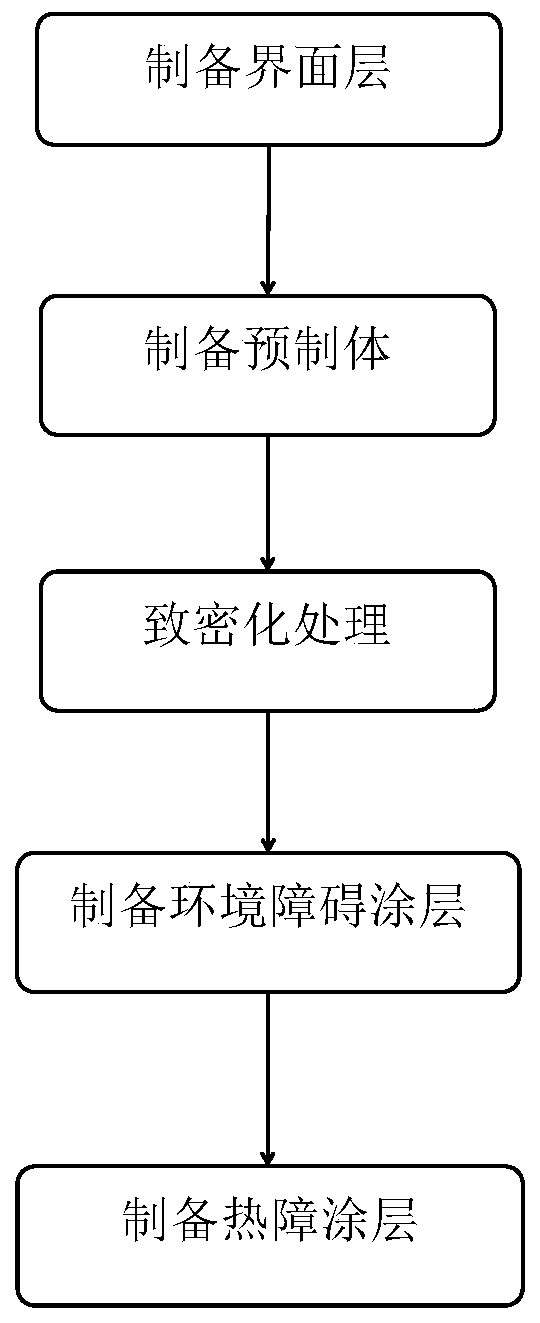

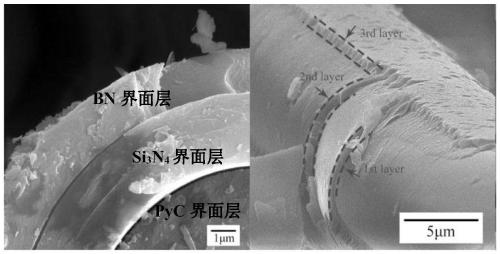

SiCf/SiC composite material flame tube and automatic preparation method thereof

ActiveCN110330353AHigh mechanical strengthCorrosion protectionContinuous combustion chamberCeramic layered productsPolymer scienceGas phase

The invention discloses an automatic preparation method of a SiCf / SiC composite material flame tube. The preparation method comprises the following steps: preparing an interface layer from SiC fibersby adopting chemical vapor deposition, so as to obtain SiC fibers with a continuous interface layer; performing unidirectional tape laying and filament winding on the SiC fibers with the continuous interface layer according to the fiber volume and fiber orientation obtained by simulation calculation, so as to obtain net size forming preform; performing densifying treatment on the obtained preformby adopting a reactive melt infiltration process and the chemical vapor deposition process; preparing an environmental barrier coating on the surface of the obtained preform; finally, continuously preparing a thermal barrier coating on the surface, thereby fully intelligently obtaining the high-density SiCf / SiC composite material flame tube. The SiCf / SiC composite material flame tube prepared withthe method disclosed by the invention has the characteristics of high temperature resistance and long service life and also has the advantages such as low thermal expansion coefficient, high thermalconductivity, high thermal shock resistance and excellent mechanical property. Meanwhile, the preparation method is high in degree of automation, short in production cycle, low in cost and controllable in quality.

Owner:CENT SOUTH UNIV

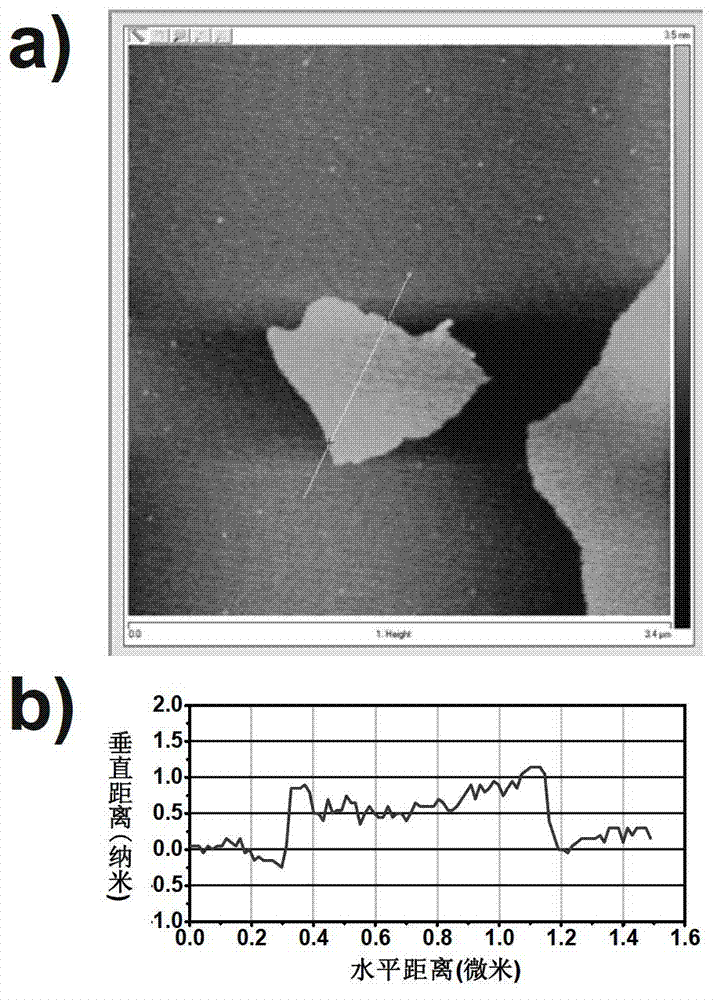

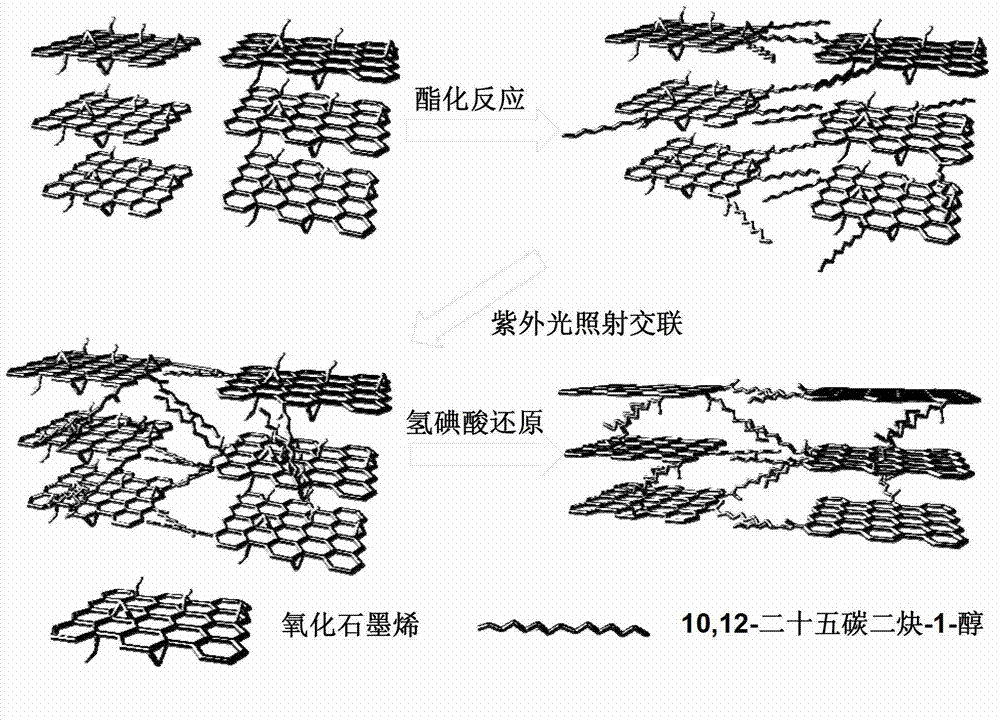

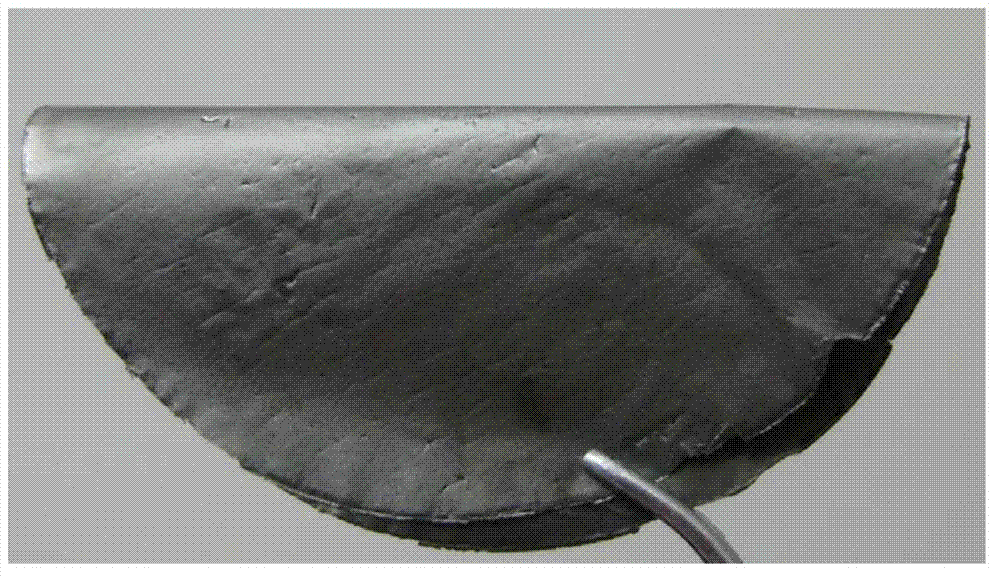

Preparation method of conducting shell-like layered graphene composite material

ActiveCN102924274AImprove mechanical propertiesHigh volume contentOrganic compound preparationCarboxylic acid esters preparationAqueous solutionCvd graphene

Provided is a preparation method of a conducting shell-like layered graphene composite material. Inorganic oxidized graphene and small organic molecule 10,12-pentacosadiyn-1-OL (PCDO) are orderly assembled to form the layered graphene composite material. The preparation method comprises preparation of oxidized grapheme uniformed aqueous solution, assembly of an oxidized grapheme film, esterification of the PCDO and the oxidized grapheme and cross-linking of the PCDO and reduction of the oxidized grapheme. The toughness of the shell-like layered composite material prepared by the method is twice that of a natural shell, and simultaneously the conducting shell-like layered graphene composite material has excellent conductivity and is widely applied to the fields of artificial muscle, tissue engineering, capacitor electrodes and aerospace and the like.

Owner:BEIHANG UNIV

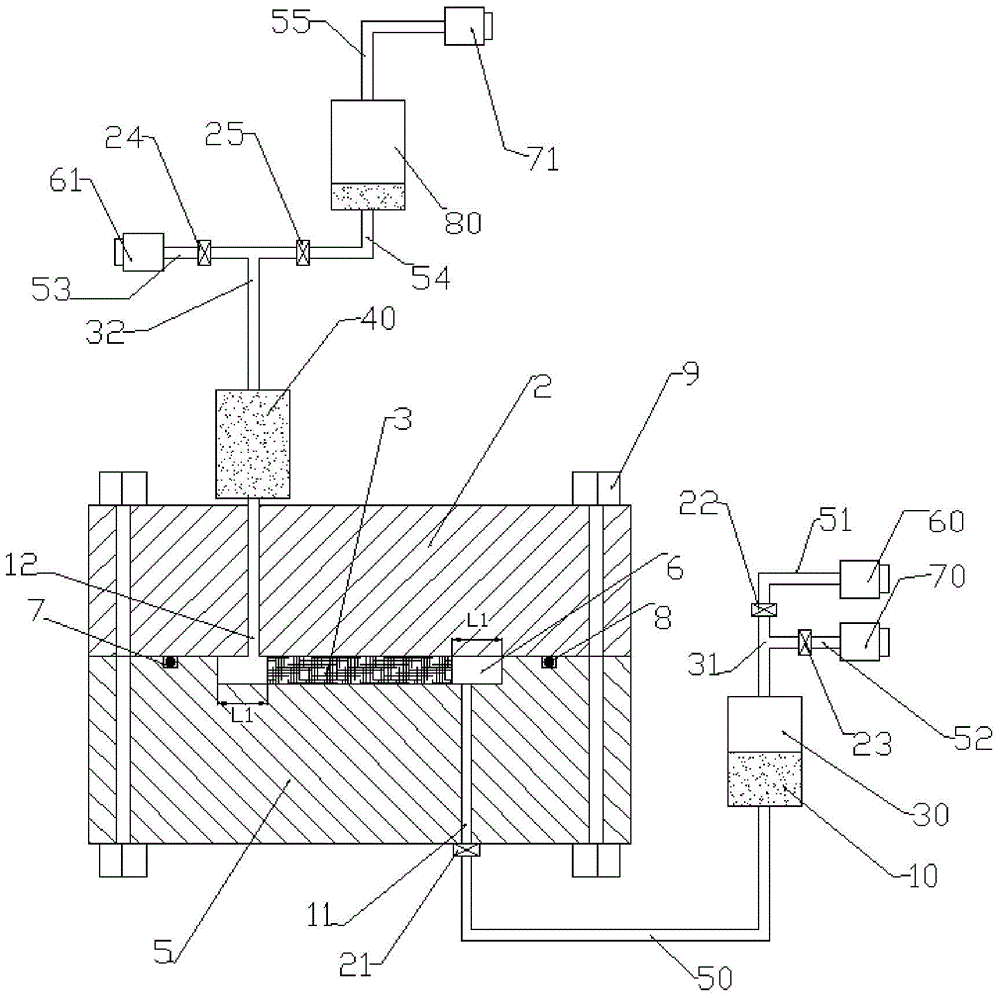

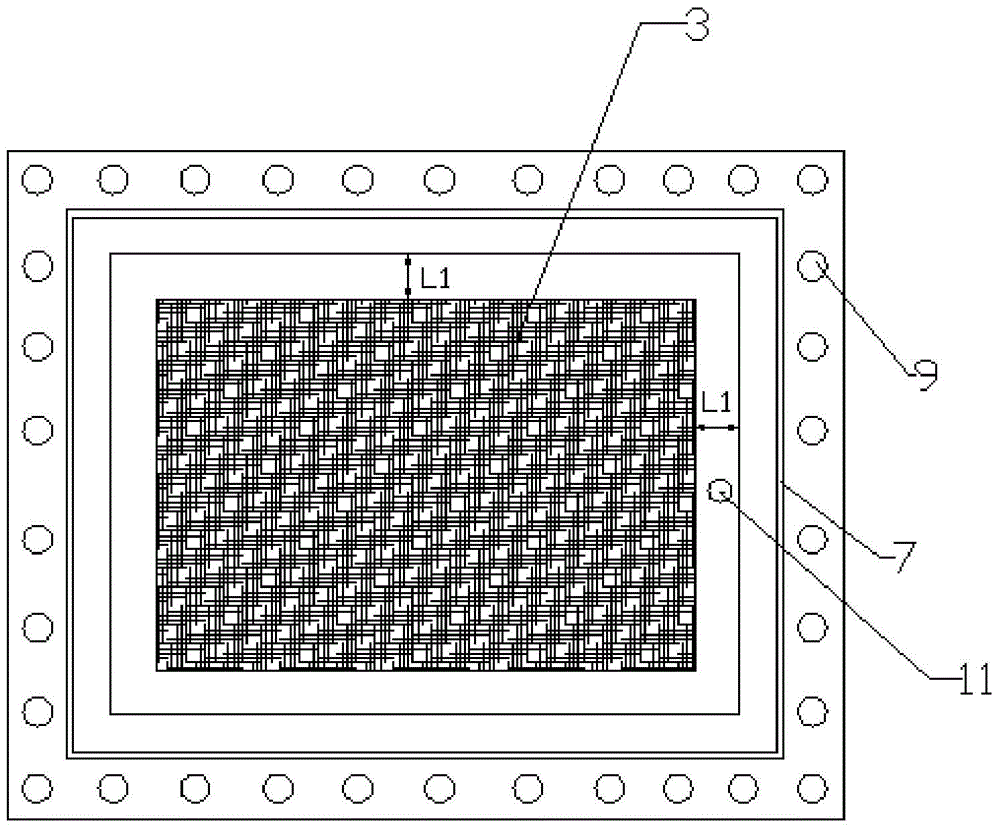

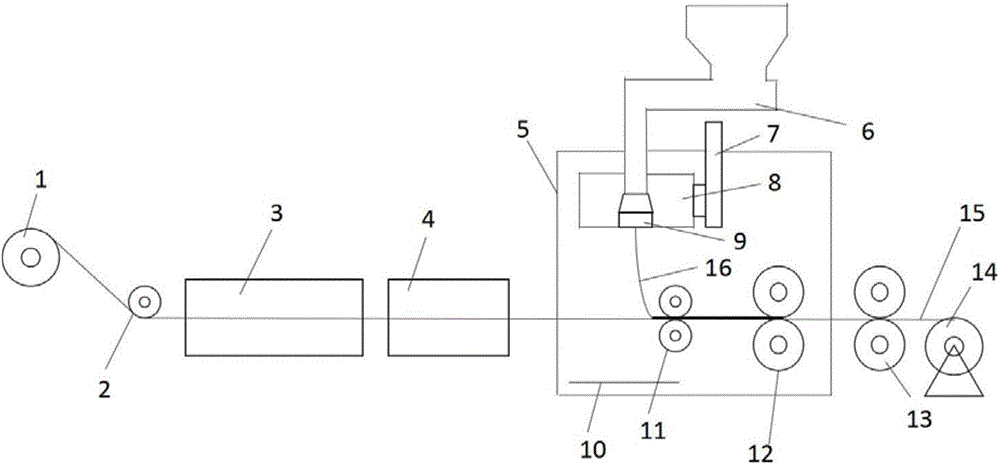

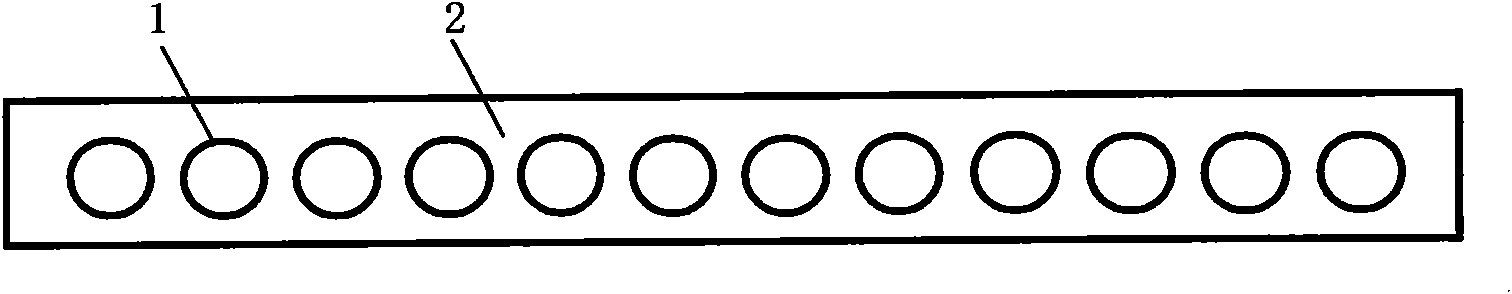

Device for manufacturing continuous fiber reinforced thermoplastic prepreg tape

The invention relates to a device for manufacturing a continuous fiber reinforced thermoplastic prepreg tape. The device comprises a creel, a yarn guide roll, a fiber splitting device, a pre-heating oven, a melting, spinning and coating device, a heating device, a hot compression roll set, cold compression rolls and a wind-up roll which are sequentially arranged; the melting, spinning and coating device and the hot compression roll set are simultaneously heated by the heating device; the melting, spinning and coating device comprises a screw extruder, a numerical-control sliding table, a spinning assembly, a spinneret plate, bonding rolls and a collecting device; the screw extruder, the bonding rolls and the collecting device are arranged from top to bottom; and the spinneret plate and the bonding rolls are separately positioned in rear and front of a moving direction of a one-way continuous reinforced fiber band; the spinneret plate is parallel to the one-way continuous reinforced fiber band; and the collecting device is positioned below the spinneret plate. The device realizes one-step forming of melting, spinning and coating and prepreg preparing, so that process steps are simplified and efficiency is improved; and the manufactured continuous fiber reinforced thermoplastic prepreg tape is uniform in distribution, is stable in dimension and is low in porosity.

Owner:DONGHUA UNIV

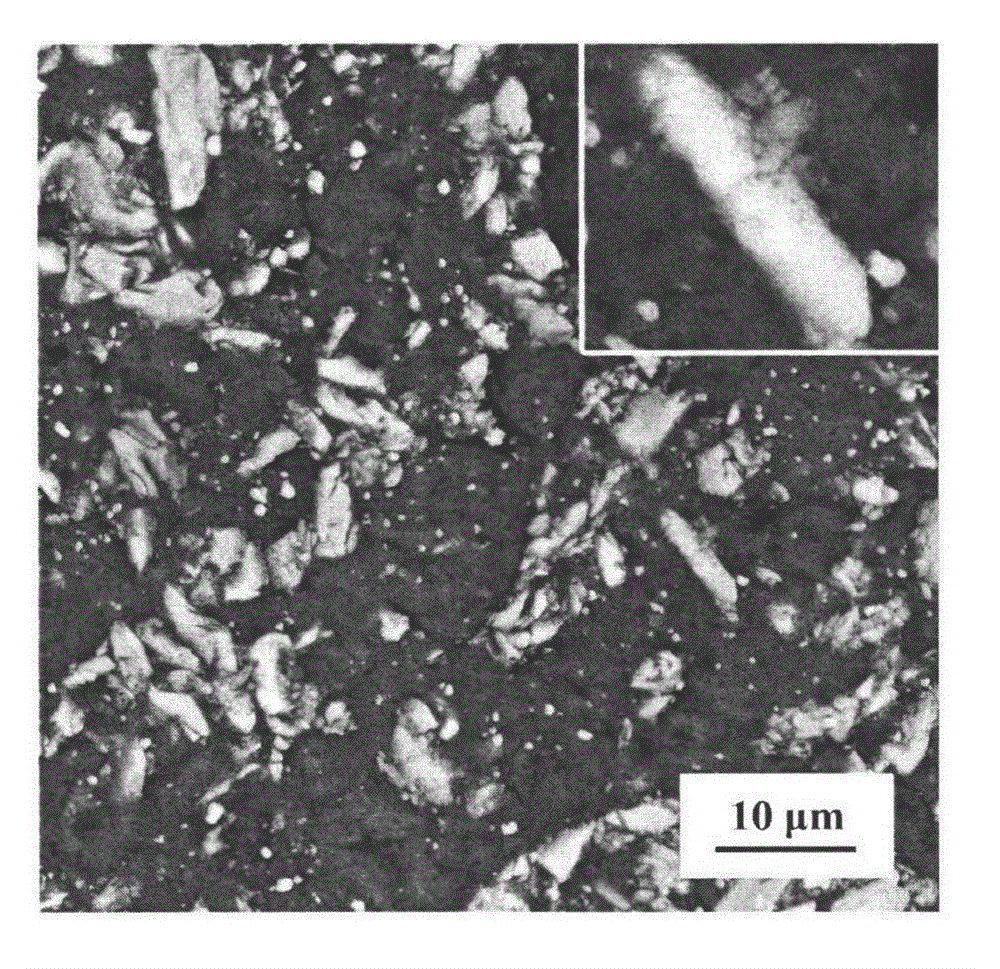

Preparation method of carbon nanotube (CNT) enhanced SiC based nano composite material film

ActiveCN104291826AExcellent thermal and electrical conductivityHigh volume contentBuckypaperFiltration

The invention discloses a preparation method of a carbon nanotube (CNT) enhanced SiC based nano composite material film. The preparation method comprises the following steps: dispersing CNTs, B4C micro-powder and elemental silicon powder into water to prepare a suspension liquid, taking TritonTM X-100 as a dispersing agent, then performing pressure filtration on the suspension liquid by using a pressure filtration device, soaking a CNTs Buckypaper preform obtained by virtue of pressure filtration in a thermoplastic phenolic resin solution, and then sequentially performing soft curing, hard curing and post-curing to obtain a curing sample; and then carbonizing the curing sample under the protection of nitrogen, and finally sintering to obtain the CNT enhanced SiC based nano composite material film. The nano composite material film prepared by using the method disclosed by the invention is high in CNT volume content and good in dispersion performance, has good preferred orientation in arrangement of the CNTs, has good combination between the CNTs and a matrix, and is smooth and warping-free in film surface, uniform and compact in microscopic structure, good in thermal and electrical conduction properties, good in strength and toughness, short in period and low in cost.

Owner:XIAN XINGUI CERAMIC COMPOSITE MATERIAL CO LTD

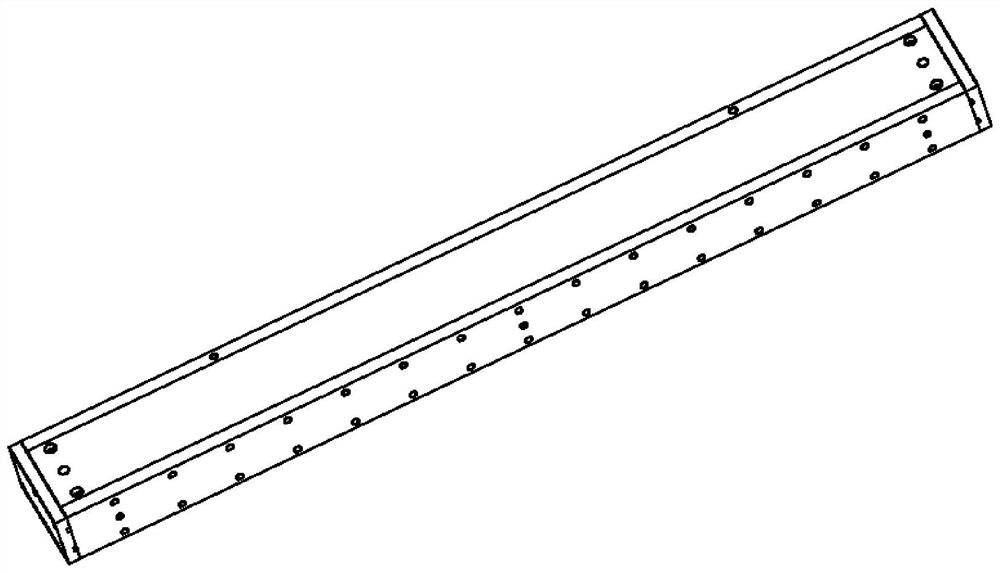

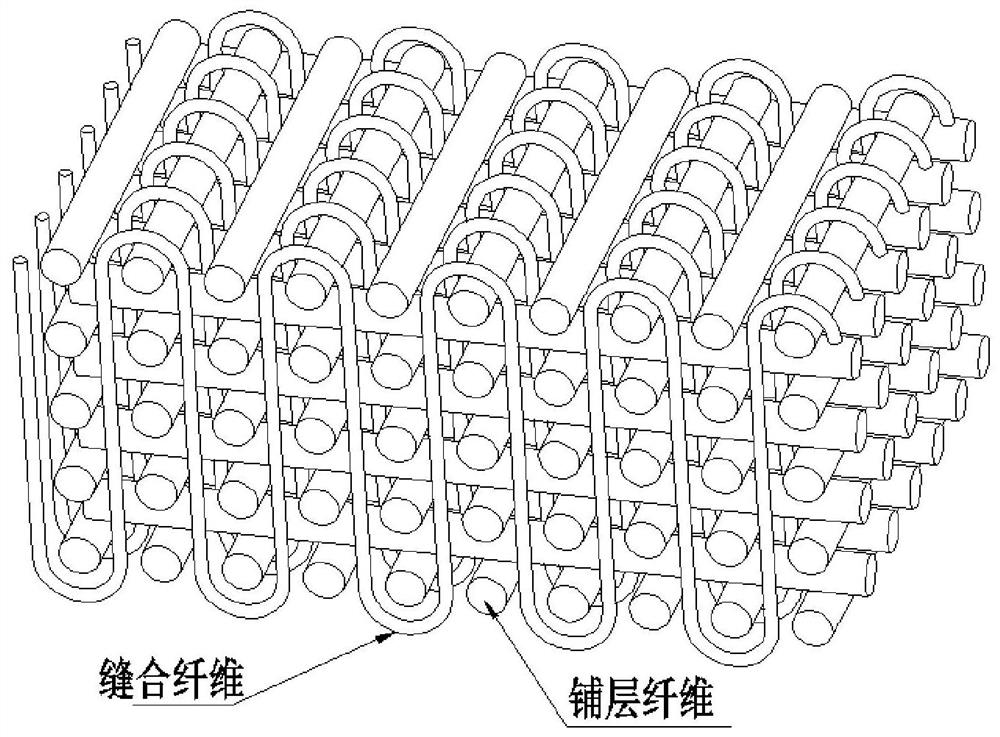

Z direction continuous carbon fiber prefabricated body

The invention relates to an improvement on Z direction continuous carbon fiber prefabrication, which is characterized in that: a planar laminated carbon fiber fabric is weftless carbon fiber cloth formed by arranging long fibers in an interlaminar crossing way. A Z direction structure is stable, and basically undamaged continuous carbon fibers are arranged in the three-dimensional direction of the prefabricated body, so that the isotropy of the prefabricated body is enhanced, and a three-dimensional structural framework is formed. A chopped fiber web in which fibers are randomly distributed is introduced between adjacent layers, and a plurality of holes are distributed randomly, so that the introduction and uniform distribution of matrix carbon are facilitated. Due to the adoption of the weftless fabric, the needle threading resistance is reduced, the Z direction continuous fiber interval can be enlarged, and the Z direction continuous fiber introducing efficiency is improved; and large K-beam carbon fibers can be adopted, so that the cost can be lowered by 40-60 percent. The prefabricated body provided by the invention can be taken as a structural material, a functional material and a structural-functional material.

Owner:JIANGSU TIANNIAO HIGH TECH

Traction transmission belt and preparation method thereof

ActiveCN101982672AStrong weightGood mechanical propertiesRope making machinesDriving beltsEngineeringMechanical property

The invention discloses a method for preparing a traction drive belt which comprises the following steps: firstly obtaining carbon fiber composite slender rods with diameter of 0.5-5mm after molding and curing carbon fiber beams which are doped with a resin adhesive solution under the action of attraction through a pultrusion mold; then arranging a plurality of carbon fiber composite slender rods in parallel along a length direction of a belt base, introducing into a belt building machine and recombining with elastic materials forming the belt base, forming a traction drive belt; finally performing a post-treatment according the use of the traction drive belt. Compared with the prior art, the preparation method of the invention has low cost, can satisfy the industry actual demand with continuous production. The characteristics of light weight, favorable toughness, corrosion resistance, fatigue resistance, favorable mechanical properties and the like of the carbon fibers are given full play, so that the prepared traction drive belt has the advantages of light dead weight and high operating efficiency, thereby lowering the energy consumption and saving the operating cost.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

High-fiber volume content polylactic acid homopolymer composite material and preparation method thereof

ActiveCN106671545AImprove mechanical propertiesRenewable resourcesSynthetic resin layered productsPolymer scienceEthylene Homopolymers

The invention discloses a high-fiber volume content polylactic acid (PLA) homopolymer composite material and a preparation method thereof. A reinforced phase is a PLA fiber of which the content of a dextrolactic acid structure unit (D-LA) is 0-10mol% and a matrix is PLA of which the content of the dextrolactic acid structure unit (D-LA) is 10-50mol%, or the reinforced phase is an isotactic composite polylactic acid (sc-PLA) fiber, wherein sc-PLA is a mixture of poly L-lactic acid (PLLA) and poly D-lactic acid (PDLA), the weight ratio of the PLLA to the PDLA is 1:1 and the matrix is PLA of which the D-LA content is 0-100mol%; and the volume content of the strengthened phase is 5-90mol%. The preparation method of the corresponding composite material comprises the steps of (1) processing the PLA fiber of a skin-core structure into fiber assemblies; (2) overlaying 1-1,000 layers of PLA fiber assemblies of the skin-core structure; and (3) forming a PLA homopolymer composite material through hot pressing of the PLA fiber assemblies of the skin-core structure on a hot press under the conditions that the pressure is 1-20MPa and the temperature is 100-210 DEG C. The obtained PLA homopolymer composite material can be applied to the fields of packaging, automobiles and the like.

Owner:JIANGNAN UNIV

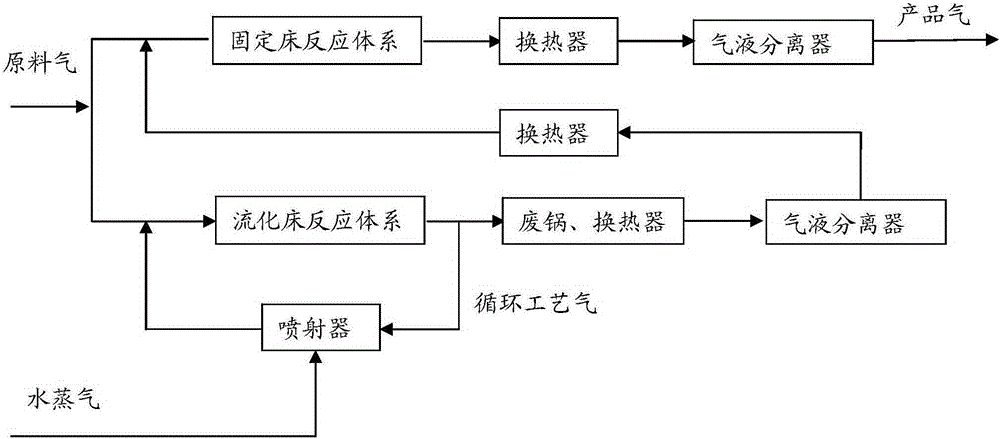

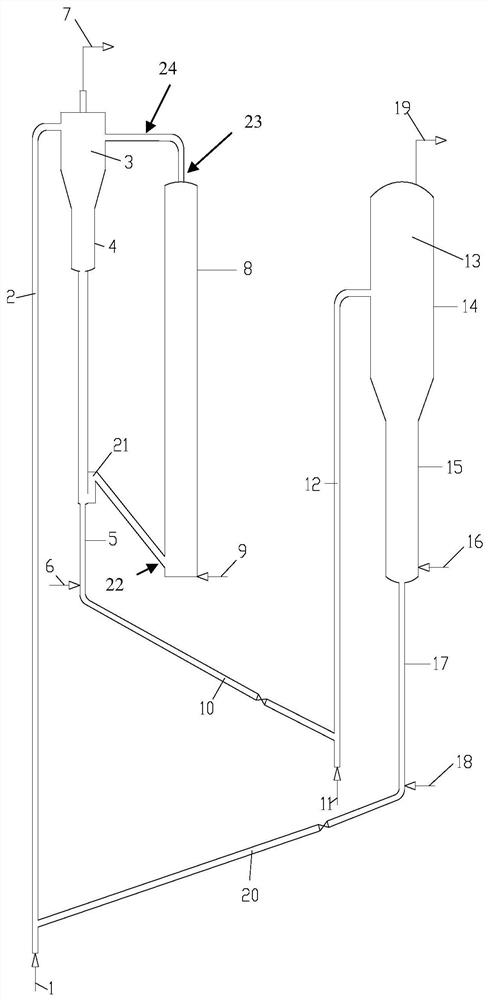

Fluidized bed and fixed bed combined methanation method

ActiveCN105255532AImprove heat transfer efficiencyImprove heat transfer abilityGaseous fuelsTemperature controlReactor system

The invention discloses a fluidized bed and fixed bed combined methanation method. The method comprises the steps that (1) a methanation feed gas is divided into two feed gases; one feed gas, water vapor and a recycle process gas from a fluidized bed methanation system enter the fluidized bed methanation system after being mixed to undergo methanation reaction under the action of a fluidized bed methanation catalyst; (2) a part of the outlet gas of the fluidized bed methanation system undergoes heat exchange, then is treated by a gas-liquid separator to separate condensed water and is mixed with the other feed gas; the gases enter a fixed bed methanation reaction system to undergo methanation reaction under the action of a fixed bed methanation catalyst; the other part of the outlet gas from the fluidized bed methanation system serves as the recycle process gas. Control of the temperature of the whole system is achieved by adding two system temperature control means, namely regulating the split ratio of the feed gases entering the two reactor systems and injecting the gas mixture of water vapor and the recycle process gas into the fluidized bed reaction system by an ejector.

Owner:CHINA NAT OFFSHORE OIL CORP +1

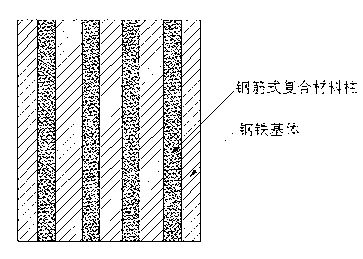

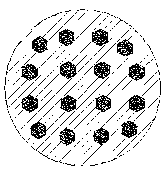

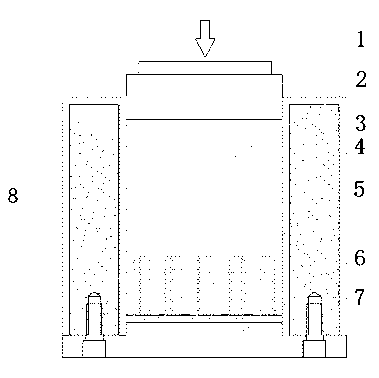

Steel-based composite and preparation method and preparation device thereof

The invention relates to a steel-based composite and a preparation method and a preparation device thereof, and belongs to the technical field of steel-based composites. The steel-based composite comprises a steel base and reinforced composite columns parallelly arranged in the steel base, and is prepared by processes of pressing, sintering, pouring, condensing and the like. The preparation device of the steel-based composite comprises a mould base, a composite mould casing and a pressing head, wherein the composite mould casing is in the shape of a hollow cylinder with the lower end connected with the mould base and consists of a low-heat-conduction ceramic layer and hot-work die steel, the low-heat-conduction ceramic layer is packaged by the hot-work die steel on the periphery, the pressing head is disposed inside the composite mould casing and capable of moving freely along the inner wall, and the size of the pressing head is matched with the inner diameter of the composite mould casing. The steel-based composite has excellent bearing capacity and wear resistance. The preparation method is easy in processing, short in production cycle and facilitates mechanical batch production. The preparation device is reusable, and accordingly production cost is reduced.

Owner:KUNMING UNIV OF SCI & TECH

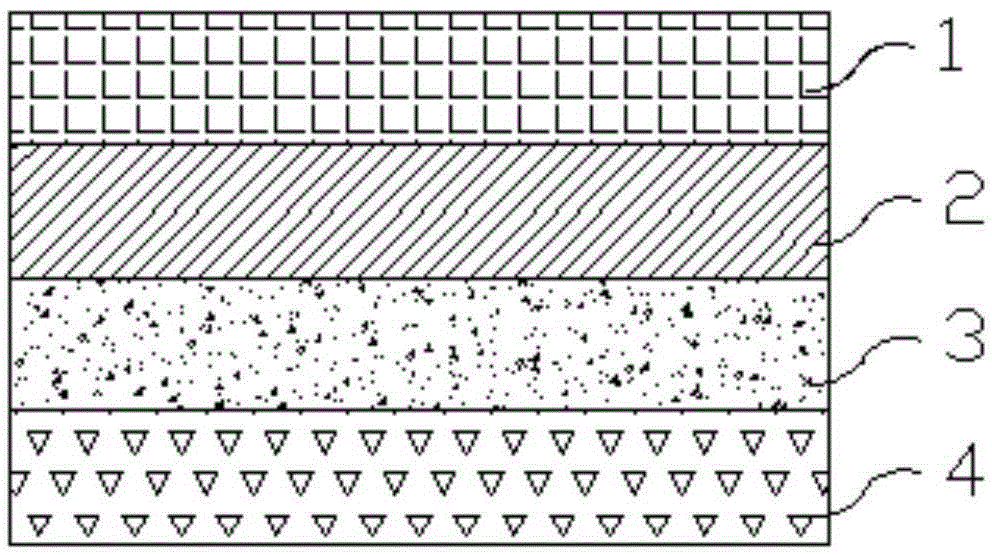

Edging slender composite material airfoil and forming method thereof

ActiveCN111746000AImprove layer performanceMake up for the shortcomings of weak interlayer performanceDomestic articlesCarbon fibersFibrous body

The invention provides an edging slender composite material airfoil and forming method thereof. The edging slender composite material airfoil is subjected to ladder-like symmetrical overlaying with asection center through a carbon fiber UD cloth, after overlaying, Z-direction seaming is executed for toughening, and an autoclave / VARTM combined technology of injecting resin into a prefabricated reinforcement and curing based on the autoclave is used to realize forming. According to the invention, for the edging slender composite material airfoil, integral overlaying integrated forming is used,seaming for toughening is executed in overlaying Z direction, forming is realized through the autoclave / VARTM technology, a defect of relatively weaker interlayer performance of a product prepared through the conventional overlaying technology is made remedied, interlayer performance is improved, relatively higher fiber volume content and product forming quality are kept, and comprehensive performance of the composite material airfoil is guaranteed.

Owner:SHANGHAI COMPOSITES SCI & TECH CO LTD

Heating-layer pavement for cold region and construction technology thereof

The invention discloses a heating-layer pavement for a cold region. The heating-layer pavement comprises a pavement structure layer, a roadbed structure layer, a foam light layer and an original frozen soil layer, wherein the pavement structure layer is arranged at the top part of the roadbed structure layer in parallel; the roadbed structure layer covers the top part of the foam light layer; the foam light layer is arranged at the top part of the original frozen soil layer in parallel and is arranged in a position which is 0.8 to 2.0 m apart from the bottom part of the pavement structure layer; the foam standard density of the foam light layer is 50kg / m<3>. According to the heating-layer pavement for the cold region, disclosed by the invention, in foam light soil, the volume percentage of foam is up to 40 to 70 percent, the content of the foam is high, the volume weight is small, the shock absorption performance is good, a heat conductivity coefficient is small, heat insulation and sound insulation effects are good, and the anti-freezing-and-thawing performance is strong; when the heating-layer pavement is used as a heat insulation layer between frozen soil and an earth fill embankment in the cold region, energy exchange between original frozen soil and the exterior can be well switched off, heat insulation and heat preservation effects are achieved, and the problem of frost failures in the cold region can be effectively solved.

Owner:JIANGSU ZHAOTONG ENG TECH CO LTD

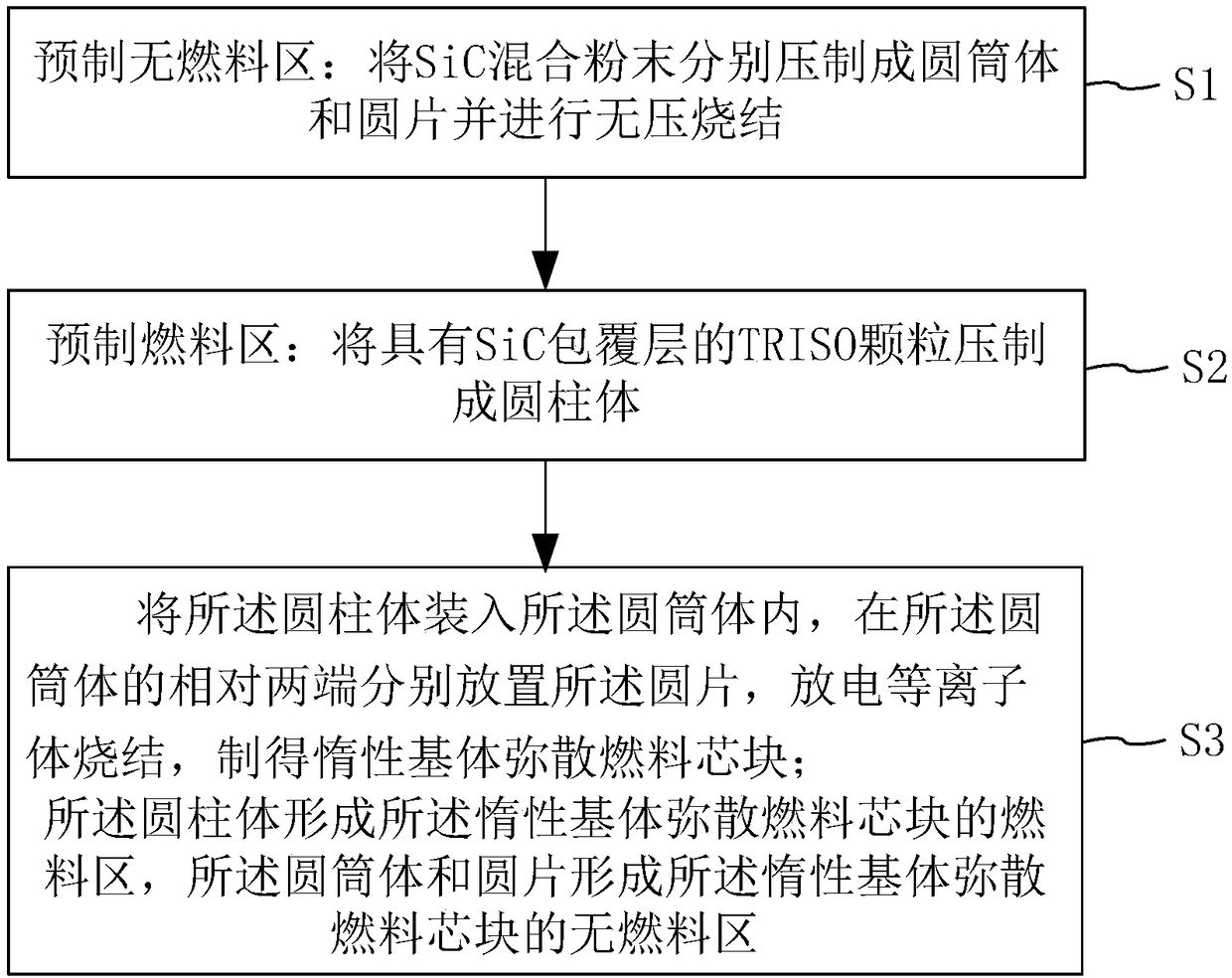

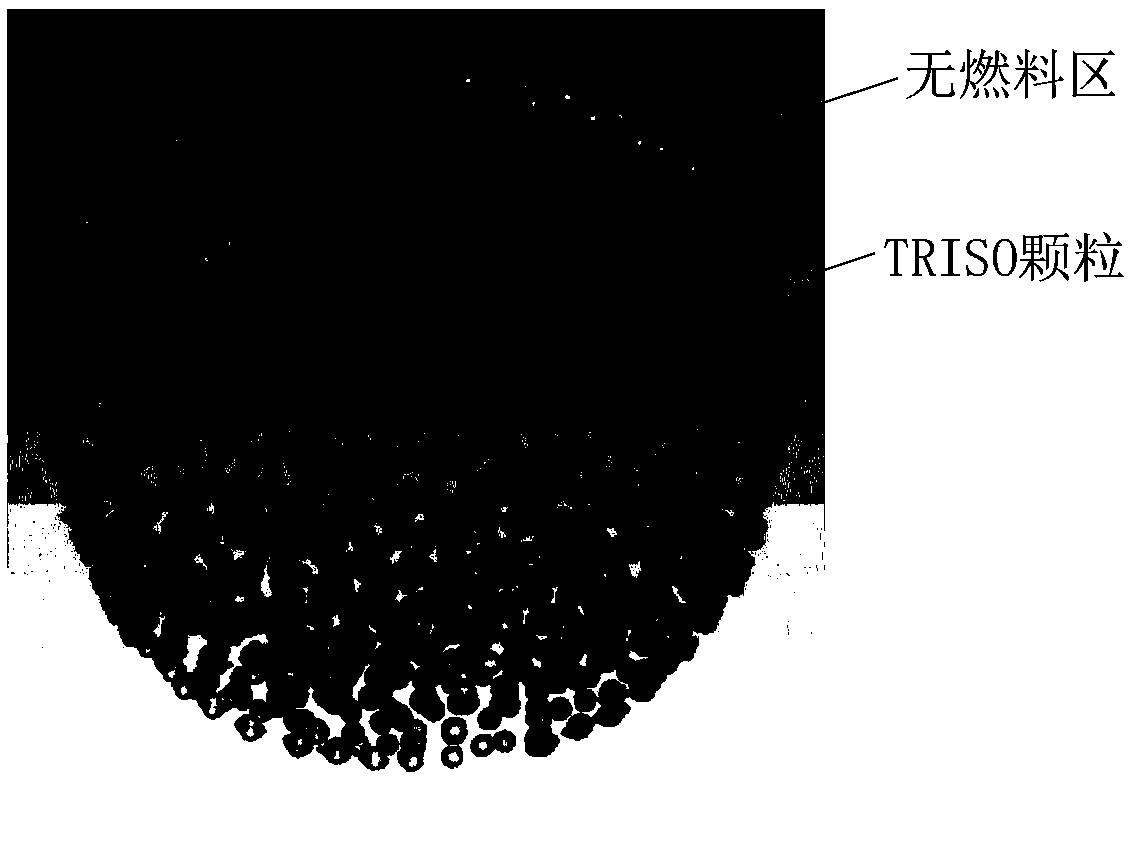

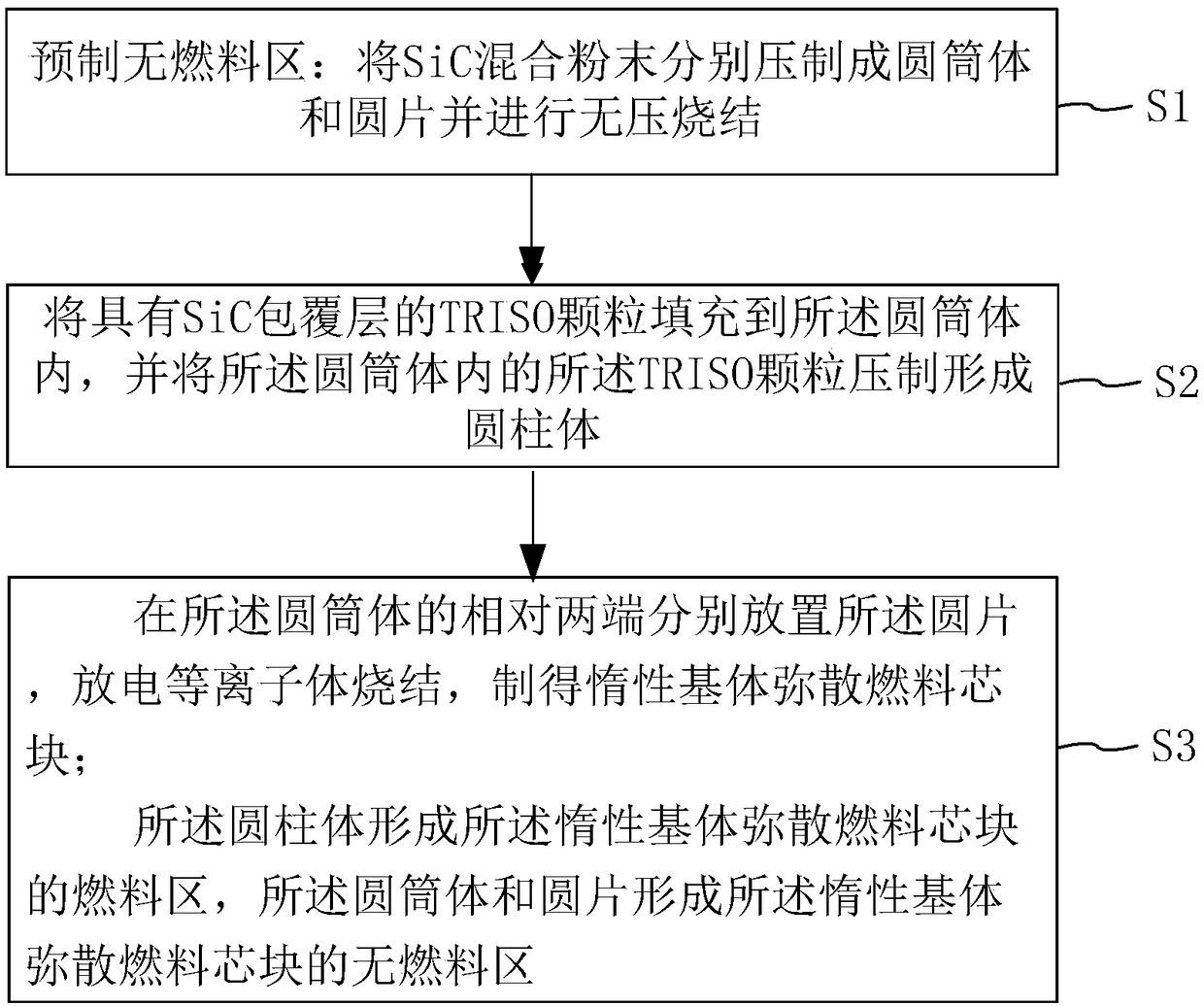

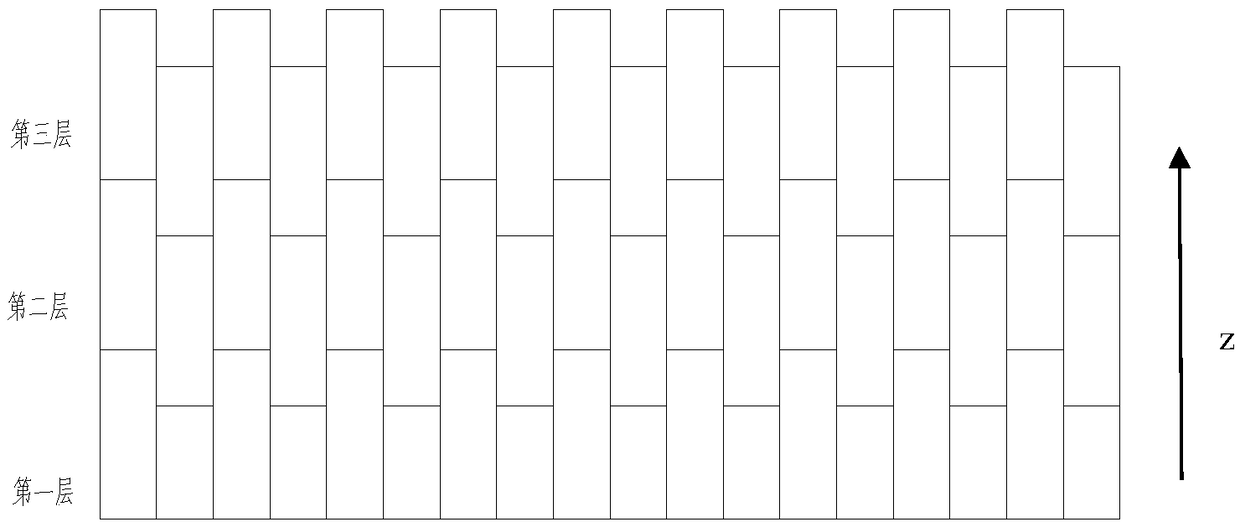

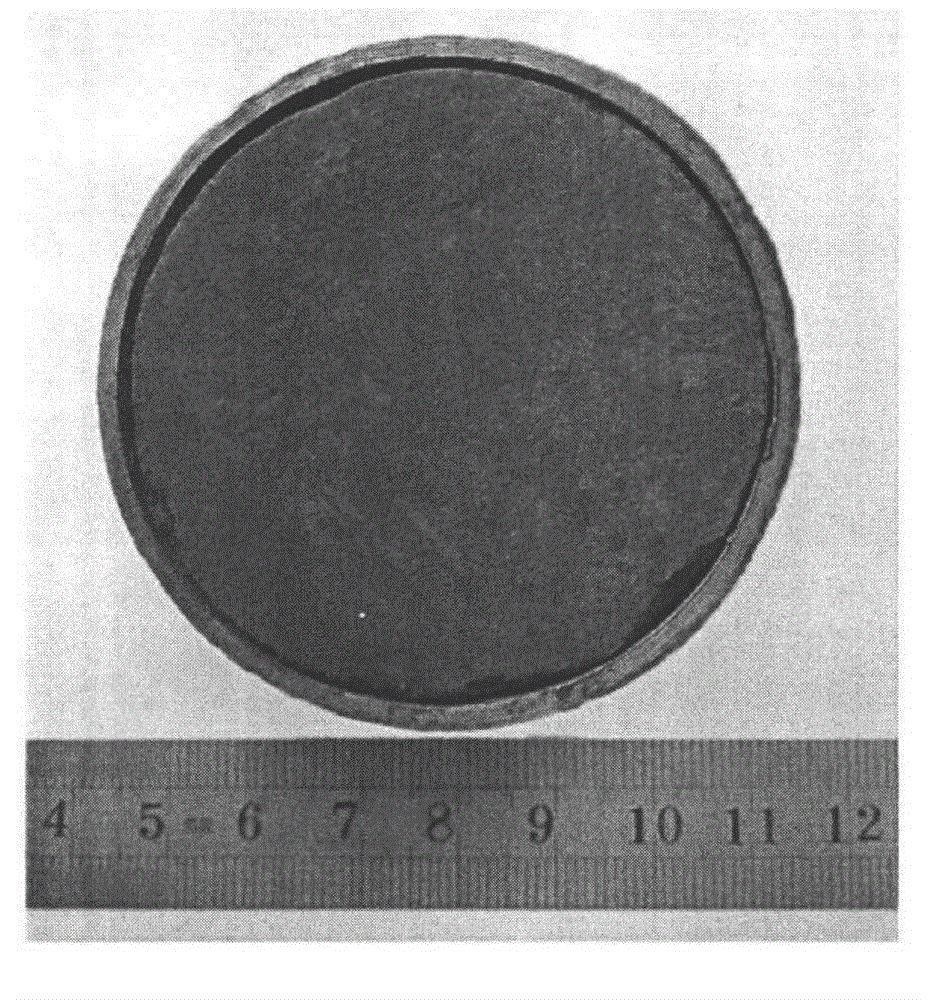

Inert matrix dispersion fuel pellet and preparation method thereof

ActiveCN109461509ASmall density differenceHigh volume contentNuclear energy generationReactors manufacturePressureless sinteringDensity difference

The invention discloses an inert matrix dispersion fuel pellet and a preparation method thereof. The preparation method includes: S1, prefabricating a fuel-free area, specifically, pressing SiC mixedpowder into a tubular shape or a disc shape, and performing pressureless sintering; S2, prefabricating a fuel area, specifically pressing TRISO (tri-structural iso-tropic) particles with SiC coatingsinto a cylindrical shape; S3, filling the cylindrical-shaped materials into the tubular-shaped materials, then placing the disc-shaped materials at the opposite both ends of the tubular-shaped materials, performing discharge plasma sintering to obtain the inert matrix dispersion fuel pellet, wherein the cylindrical-shaped materials form the fuel area of the inert matrix dispersion fuel pellet, andthe tubular-shaped materials and the disc-shaped materials form the fuel-free area of the inert matrix dispersion fuel pellet. According to the preparation method of the inert matrix dispersion fuelpellet, by prefabricating the fuel-free area, the density of the fuel-free area is controlled to be close to that the pressed fuel area, the density difference between the fuel area and the fuel-freearea of the sintered inert matrix dispersion fuel pellet can be reduced, the peripheral contour structure of TRISO particles inside the fuel area can be improved, the fuel area can be expanded, the overall TRISO volume content of the inert matrix dispersion fuel pellet can be increased, and the comprehensive performance of the inert matrix dispersion fuel pellet can be further enhanced.

Owner:CHINA NUCLEAR POWER TECH RES INST CO LTD +4

Preparation method of surface hyperbranched modified steel fiber and ultra-high performance concrete based on modified steel fiber

ActiveCN114656181AImprove toughnessIncrease roughnessSolid waste managementPolymer scienceHydrolysate

The invention discloses a preparation method of surface hyperbranched modified steel fibers and ultra-high performance concrete based on the modified steel fibers. The preparation method of the surface hyperbranched modified steel fiber comprises the steps that pretreated steel fiber is placed in silane coupling agent hydrolysate for a reaction, and silane coupling agent modified steel fiber is obtained; and placing the silane coupling agent modified steel fiber in a mixed solution of tetraethoxysilane, absolute ethyl alcohol and deionized water to obtain the surface hyperbranched modified steel fiber. Hyperbranched modification is carried out on the surface of the steel fiber through the method, the corrosion resistance is improved, meanwhile, multidirectional matrix embedding and cohesiveness strengthening are achieved, the toughening, strengthening and crack resisting performance of the steel fiber on the UHPC is improved, the cost is low, the operation method is simple, toxicity is avoided, harm to the environment is avoided, and batch treatment can be carried out on materials.

Owner:山东鲁桥建材有限公司

3D printing raw material and 3D printing method and 3D printing workpiece adopting same

ActiveCN109049687AGuaranteed mechanical propertiesPrint single layer thickness increasedAdditive manufacturing apparatus3D object support structuresEngineeringAdhesive

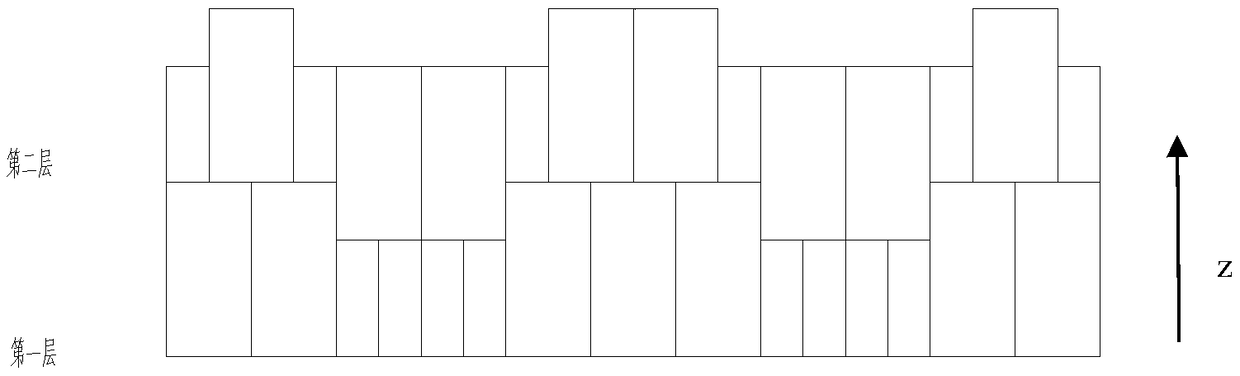

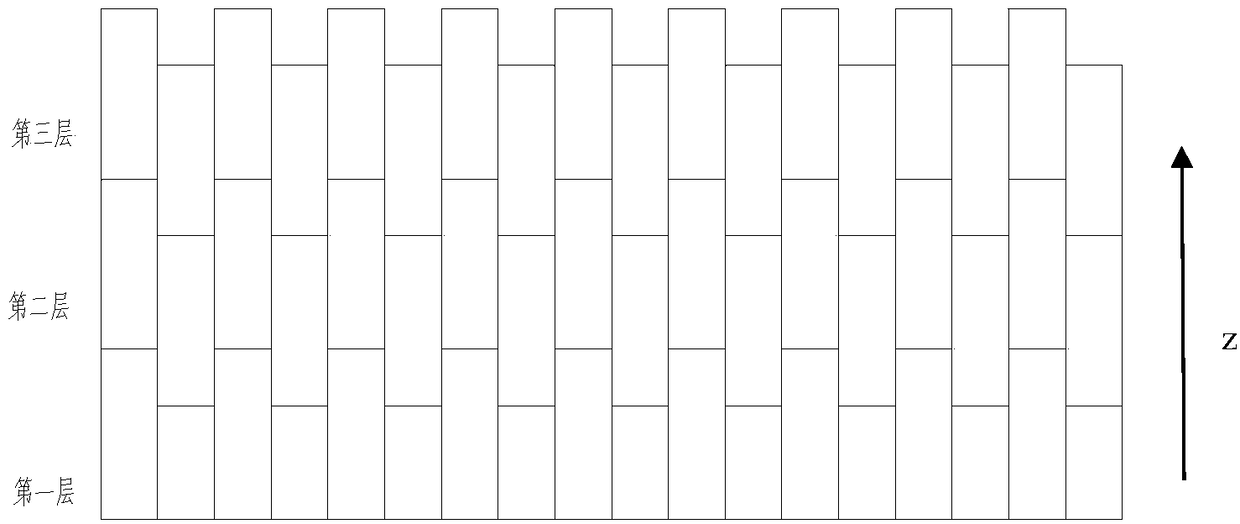

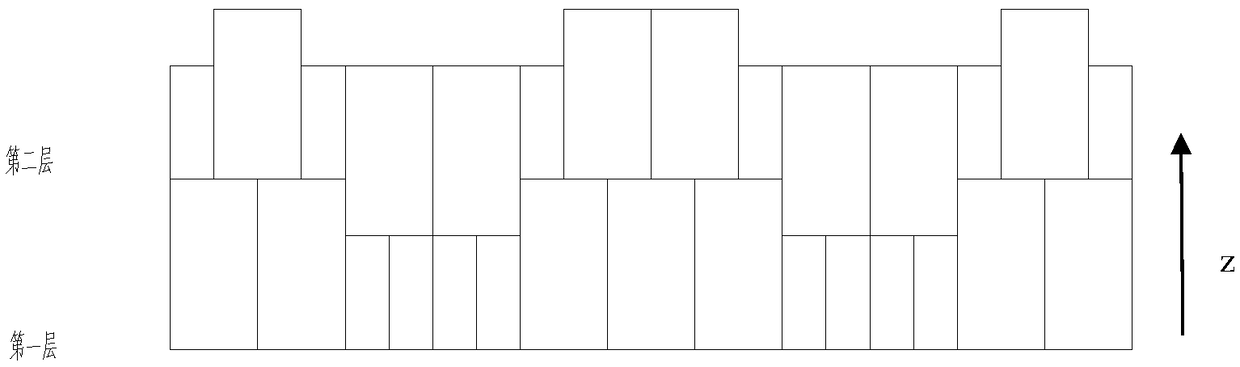

The invention provides a 3D printing raw material and a 3D printing method and 3D printing product adopting the same. The printing raw material comprises a plurality of block units, wherein a materialof one random block unit is a fiber reinforced thermoplastic resin material. The method comprises: S1, preparing the 3D printing raw material, which comprises: using the block units as 3D printing units, and according to slice analysis of a to-be-printed component, obtaining the block units which need to be used by each printing layer; forming the blocking units of each printing layer; and coating the surfaces of all the formed block units with an adhesive or arranging welding lines on the surfaces of all the block units; S2, according to the obtained block units of each printing layer, sequentially printing each printing layer layer by layer, and carrying out adhesion connection by the adhesive or carrying out welding connection by the welding lines among the printing layers. The invention can solve the technical problems that when a continuous fiber reinforced material is adopted to prepare the 3D printing product currently, the obtained product is poor in mechanical property and for a large product, a printing speed is low.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

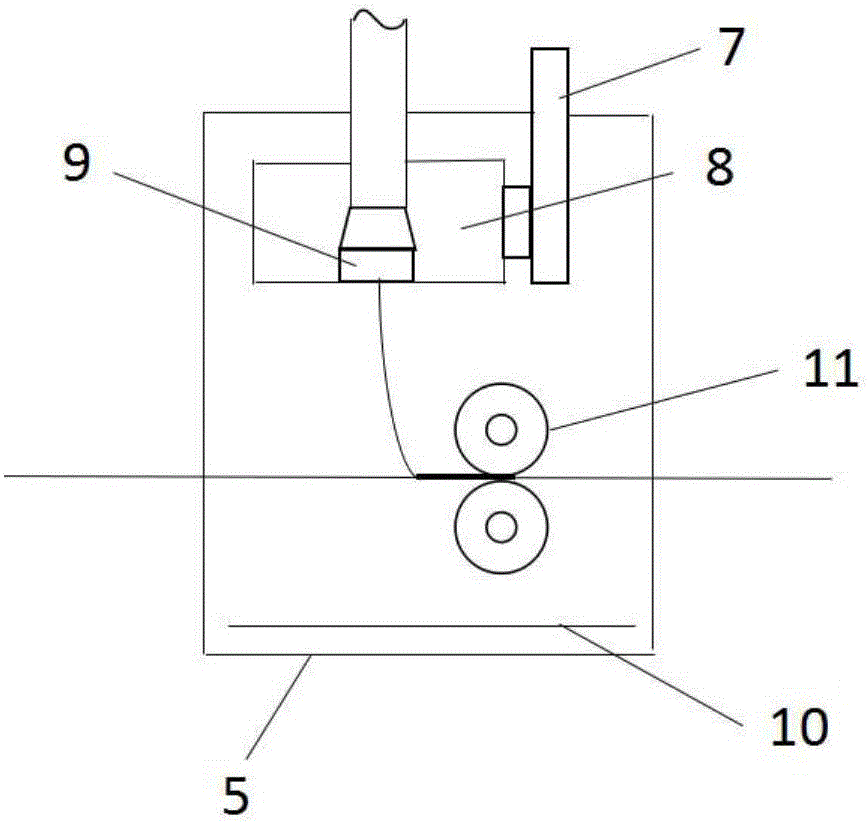

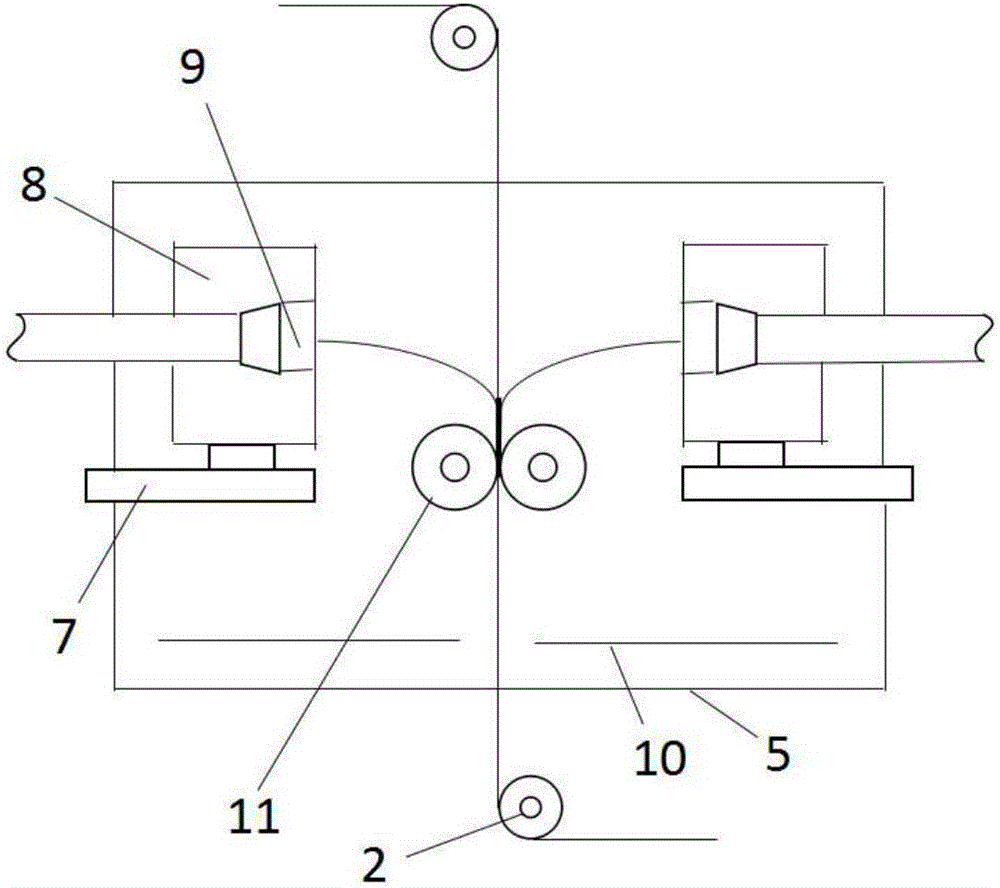

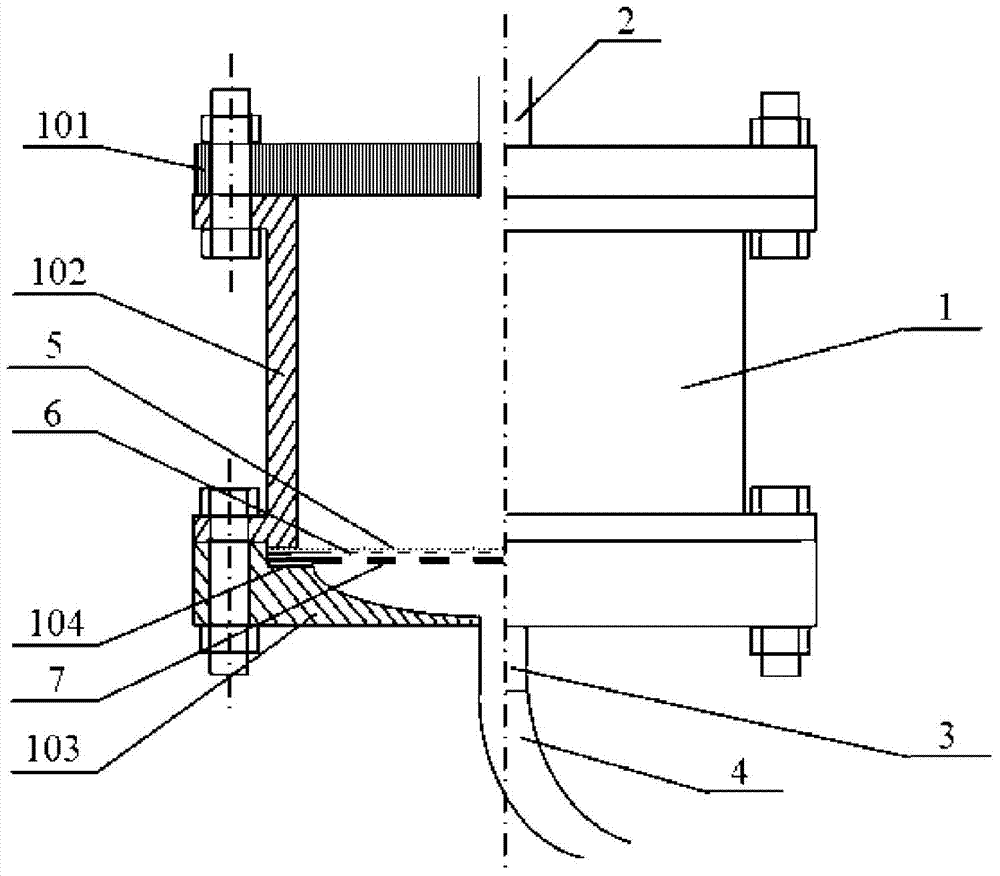

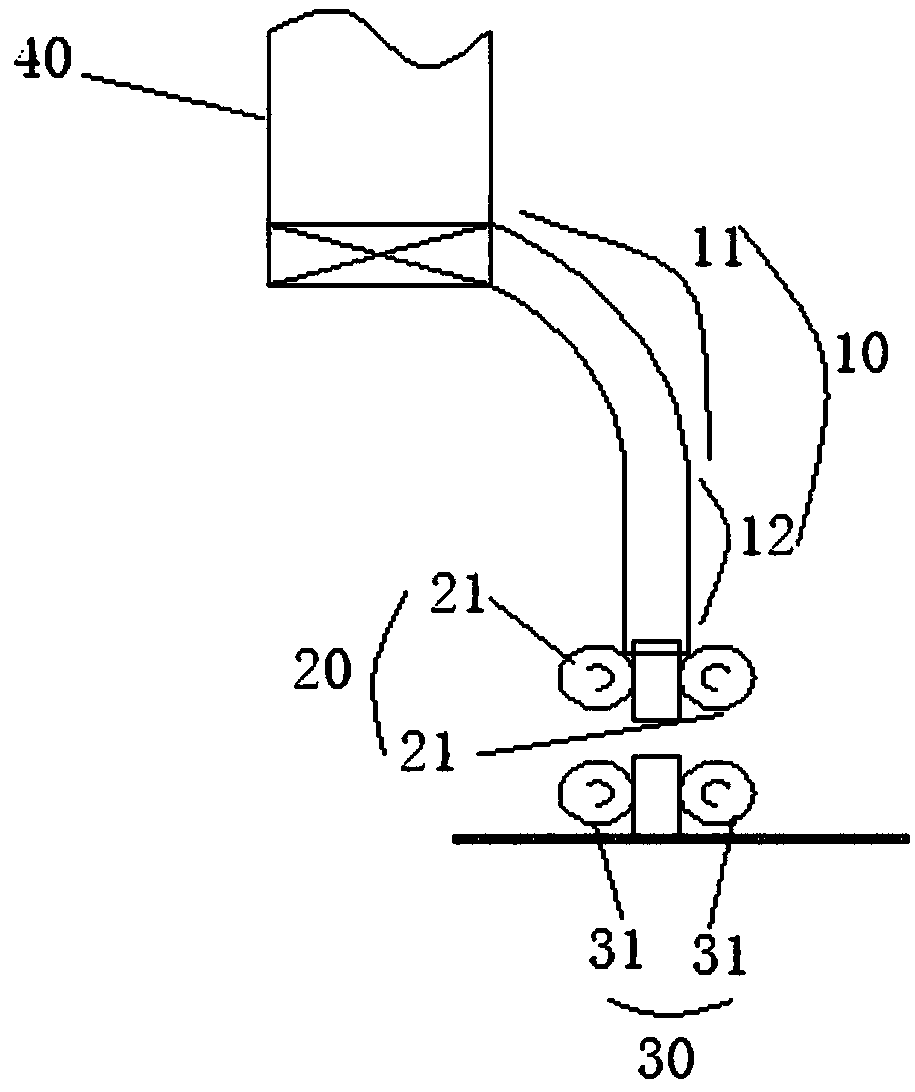

3D printing device using block unit

ActiveCN109049688AIncreasing the thicknessGuaranteed mechanical propertiesAdditive manufacturing apparatus3D object support structuresFiberReciprocating motion

The invention provides a 3D printing device using a block unit, and the block unit is made of fiber reinforced thermoplastic resin. The 3D printing device comprises a first bracket, a driving part, aconveying pipe, a first pair of rotary roller assemblies and a second pair of rotary roller assemblies, wherein the first bracket has a first operating state of a reciprocating motion in a horizontaldirection and a second operating state of a reciprocating motion in a vertical direction by virtue of the driving part; the conveying pipe is arranged on the first bracket and is used for conveying the block unit; the first pair of rotary roller assemblies are arranged on the first bracket and below the conveying pipe and are used for conveying the block unit output by the conveying pipe below; and the second pair of rotary roller assemblies are arranged on the first bracket and below the first pair of rotary roller assemblies and are used for outputting the block unit output by the first pairof rotary roller assemblies to a pre-printed surface and applying pressure in a Z direction. According to the 3D printing device, the technical problems of poor mechanical properties of 3D printing workpieces prepared from continuous fiber reinforced materials and low printing speed of large workpieces at present can be solved.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

PHBV mono-polymer composite material having high fiber volume content and preparation method thereof

ActiveCN106626535AImprove mechanical propertiesRenewable resourcesSynthetic resin layered productsLaminationPolymer compositesPolymer composite materials

The invention discloses a poly(3-hydroxybutyrate-co-3-hydroxyl pentanoate) (PHBV) mono-polymer composite material having high fiber volume content and a preparation method thereof. A reinforcing phase in the composite material is PHBV fiber with the 3-hydroxybutyrate (HV) content of 0-20 mol%, a substrate is the PHBV with the HV content of 10-100 mol%, and the volume content of the reinforcing phase fiber is 5%-90%. A preparation method of the composite material comprises the steps that 1, the PHBV fiber with a skin-core structure is processed into a fiber aggregate; 2, 1-1000 layers of PHBV fiber aggregates with the skin-core structures are superposed together; 3, the PHBV fiber aggregates with the skin-core structures are hot-pressed into the PHBV mono-polymer composite material on a hot-pressing machine under the pressure of 1-20 MPa and the temperature of 100-160 DEG C. The obtained PHBV mono-polymer composite material can be used in the fields of packaging, automobiles and the like.

Owner:JIANGNAN UNIV

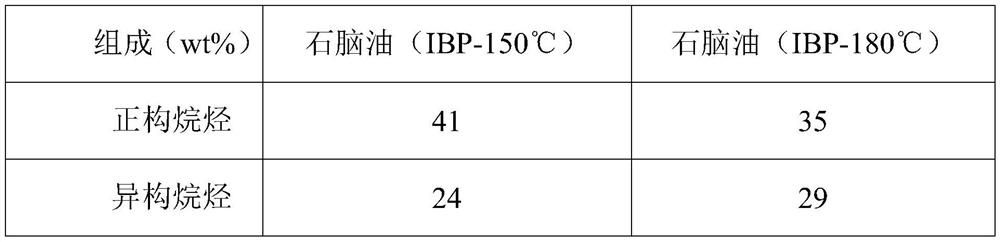

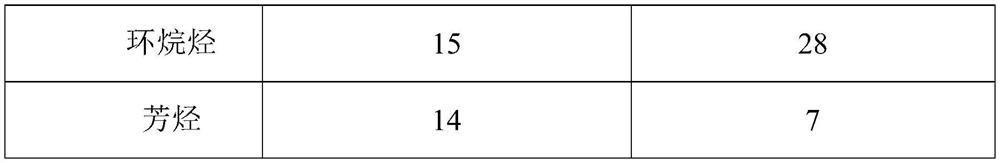

A method for converting raw materials containing naphtha into light olefins and/or aromatics

ActiveCN111484387BHigh volume contentAct quicklyMolecular sieve catalystCatalystsPtru catalystNaphtha

The application discloses a method for converting a raw material containing naphtha into light olefins and / or aromatics, which is characterized in that it comprises the following steps: a) passing the raw material containing naphtha into a fast fluidized bed reactor , contact with the catalyst to obtain the product gas and the catalyst to be regenerated; the product gas is separated to obtain light olefins and / or aromatics; b) the catalyst to be regenerated enters the regenerator for regeneration to obtain the regenerated catalyst; c) the regenerated catalyst returns to the fast Fluidized bed reactor. The method reduces the influence of the thermal cracking reaction in the naphtha catalytic cracking technology, and reduces the yield of methane in the product.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

Preparation method of controllable volume fraction Ti2AlCp/Al base composite material

InactiveCN105219981ASimple preparation processThe content is easy to controlControllabilityMaterials science

The invention discloses an extrusion casting method of a controllable volume fraction Ti2AlCp / Al composite material, relates to a preparation method of a reinforcement prefabricated block, and belongs to the field of aluminum base composite materials. The invention solves the problem of difficult preparation of a particle reinforced aluminum base composite material prefabricated block, realizes the reinforcement content controllability, and proposes a brand new extrusion casting method of the controllable volume fraction Ti2AlCp / Al composite material. The preparation process comprises preparation of a reinforcement prefabricated block raw material, cold pressing formation of a prefabricated block, and extrusion casting preparation of a Ti2AlCp / Al aluminum base composite material. The method for preparing the reinforcement prefabricated block is simple in process, needs no complex adhesive screening process, is excellent in particle dispersibility of the prefabricated block, and is controllable in reinforcement content.

Owner:江苏华旺新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com