Fluidized bed and fixed bed combined methanation method

A methanation and fluidized bed technology applied in the field of methanation to achieve the effects of simplifying process flow and control, prolonging catalyst life and reducing instantaneous impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The experimental methods used in the following examples are conventional methods unless otherwise specified.

[0034] The materials and reagents used in the following examples can be obtained from commercial sources unless otherwise specified.

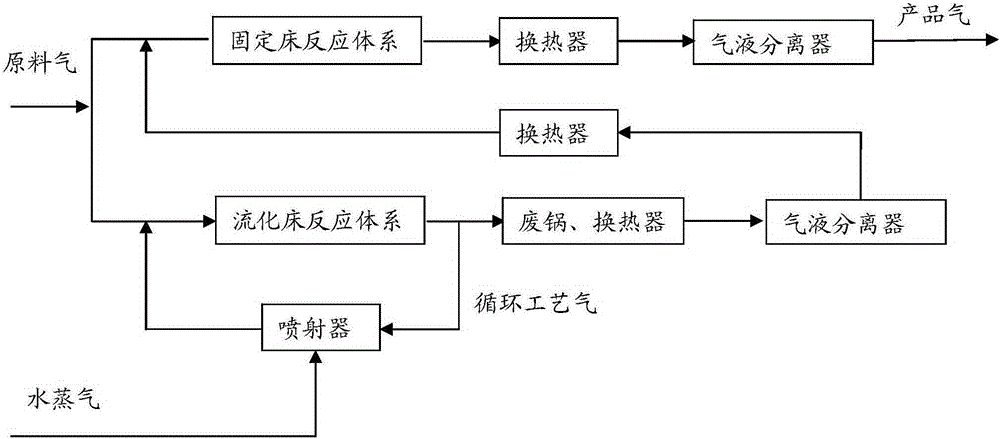

[0035] according to figure 1 The process scheme shown carries out the methanation of the feed gas.

[0036] The pressure is 3.5MPa, 100000Nm 3 / h of synthesis gas (for coal-based natural gas) and the total sulfur in the synthesis gas is less than 0.1ppm, f=(n H2 -n CO2 ) / (n CO +n CO2)=3.005 (n represents mole), and the composition (volume fraction, wet base) of concrete synthesis gas is: H 2 : 64.00, CH 4 : 14.30, CO: 20.10, CO 2 : 0.90, N 2 : 0.50, H 2 O: 0.30.

[0037] According to the volume ratio of 0.85 and 0.15, the above raw material gas is divided into two streams and enters the fluidized bed reaction system and the fixed bed reaction system respectively, wherein there are 2 parallel fluidized bed methanation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com