Patents

Literature

37results about How to "Improve heat transfer ability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

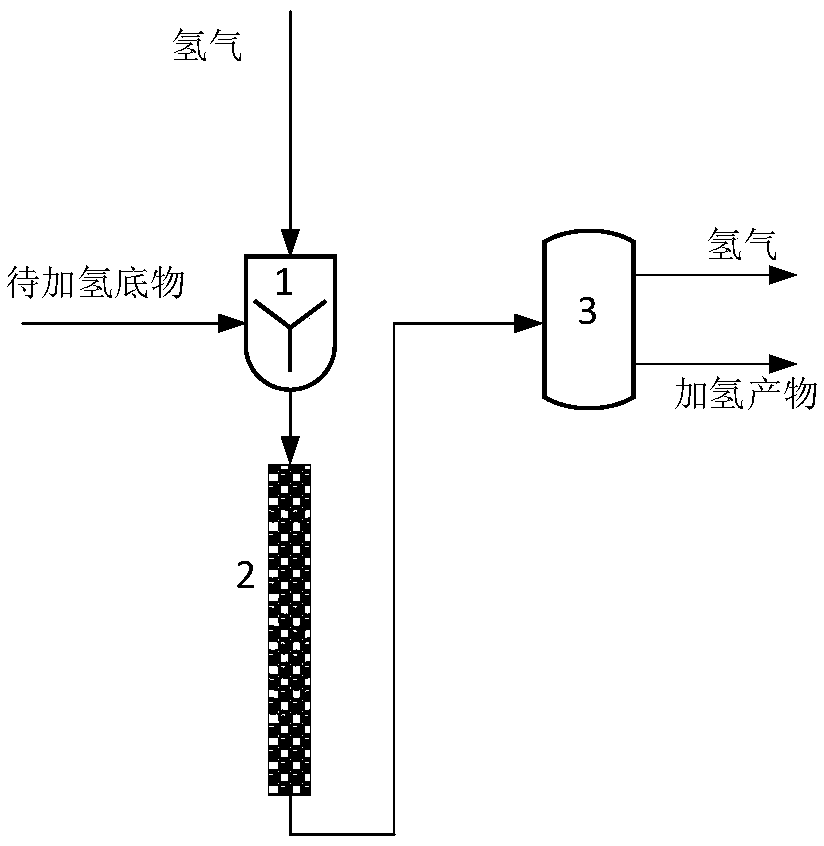

Hydrogenation reaction device in micropacked bed and method for hydrogenation reaction by using same

ActiveCN109225073AIncrease contact areaImprove mass transfer efficiencyChemical/physical processesPetrochemicalChemical reaction engineering

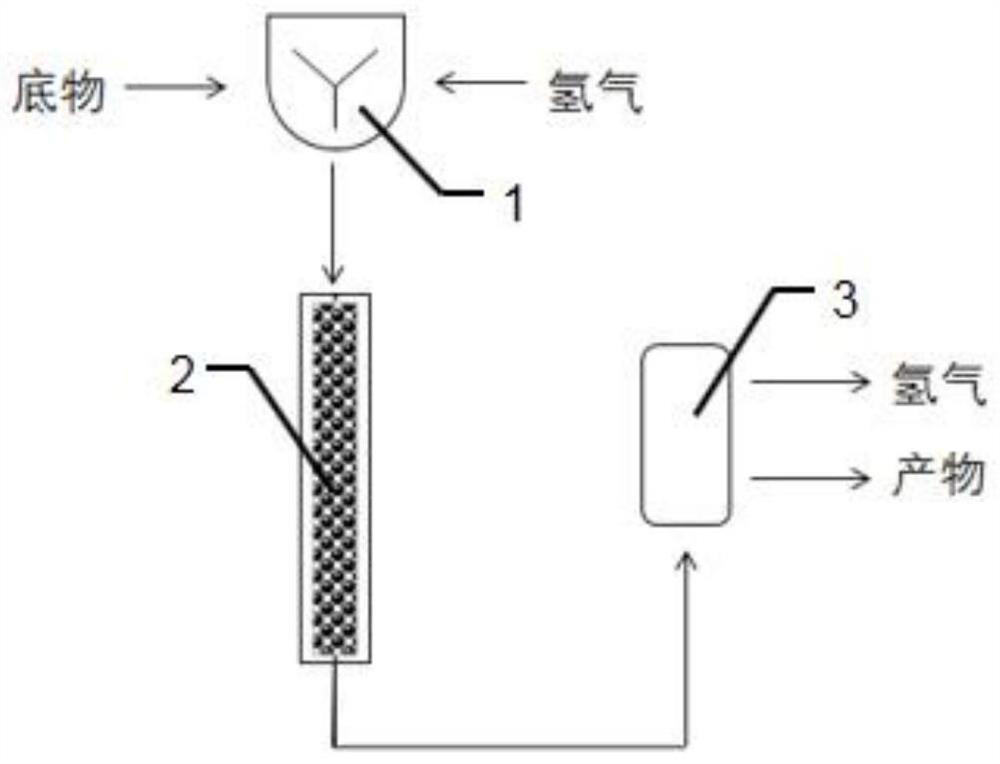

The invention discloses a hydrogenation reaction device in a micropacked bed and a method for a hydrogenation reaction by using the same in the technical field of chemical reaction engineering. The method comprises the steps: firstly, dispersing hydrogen into a solution containing a to-be-hydrogenated substrate by a micromixer to obtain a gas-liquid mixed fluid containing micro-scale bubbles; andthen, finishing a hydrogenation process on the gas-liquid mixed fluid by a micropacked bed filled with a hydrogenation catalyst. By using the method, the high mixing efficiency and excellent mass transfer and heat transfer performances of a microreactor are utilized, the gas-liquid and liquid-solid mass transfer in a hydrogenation reaction process is enhanced, the heat transfer capacity of the reactor is remarkably improved, and the size of a hydrogenation reactor can also be remarkably reduced; the hydrogenation reaction device has the advantages of high hydrogenation efficiency, safety, controllability and simplicity in amplification and can be widely applied to the technical fields such as petroleum and petrochemicals, fine chemical engineering, medicines, environments and foods.

Owner:TSINGHUA UNIV

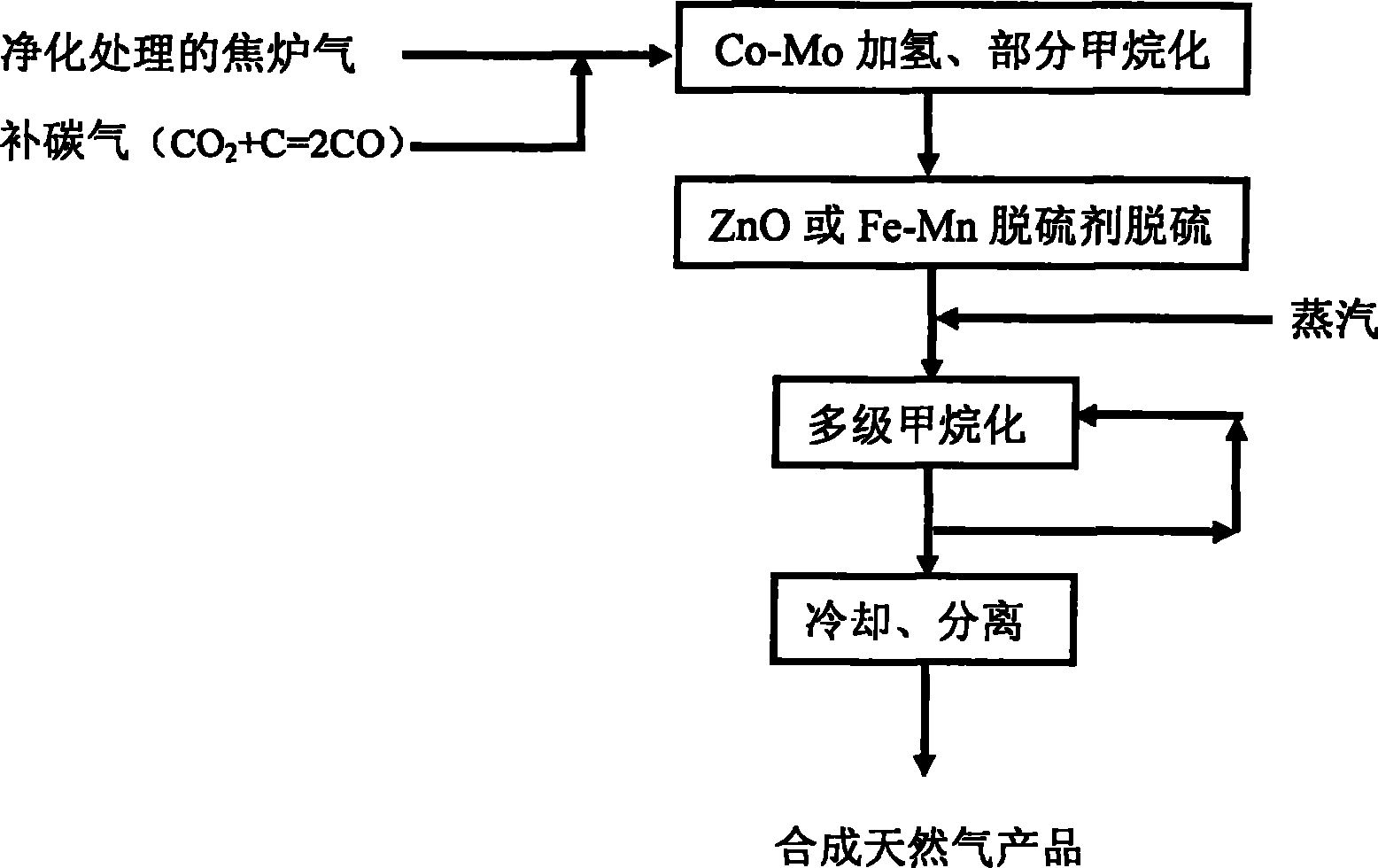

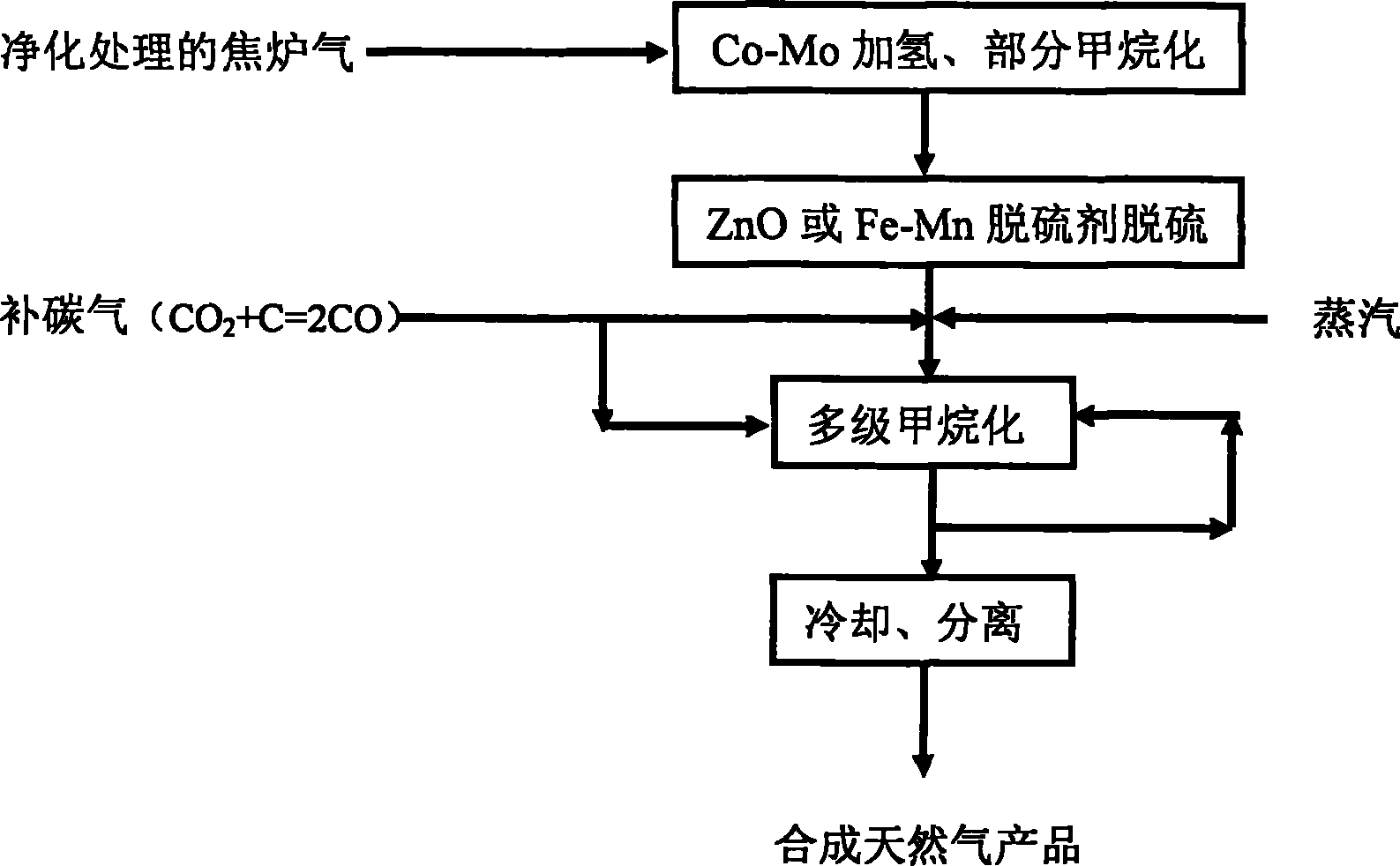

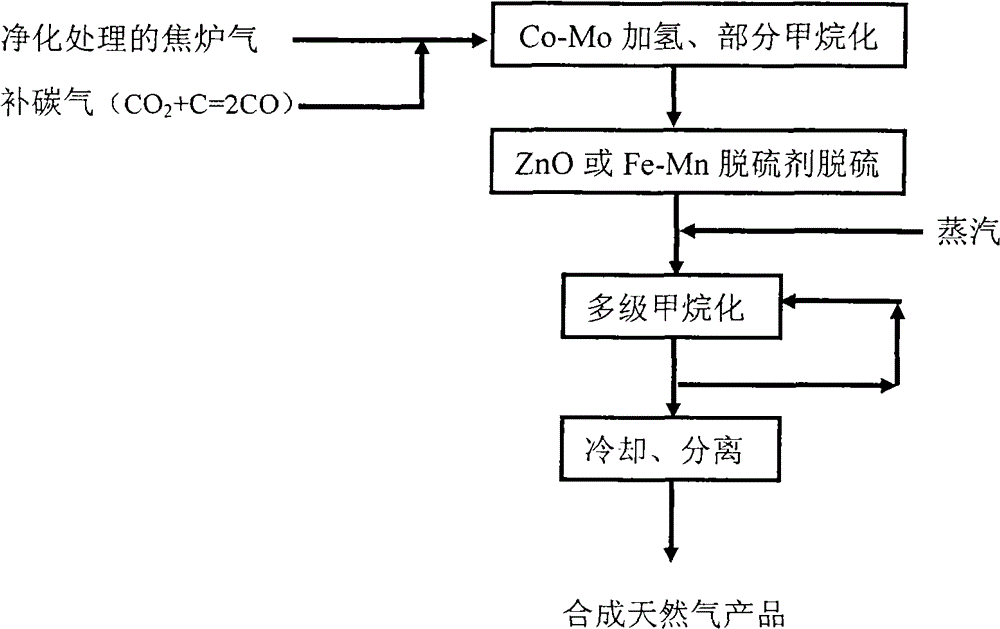

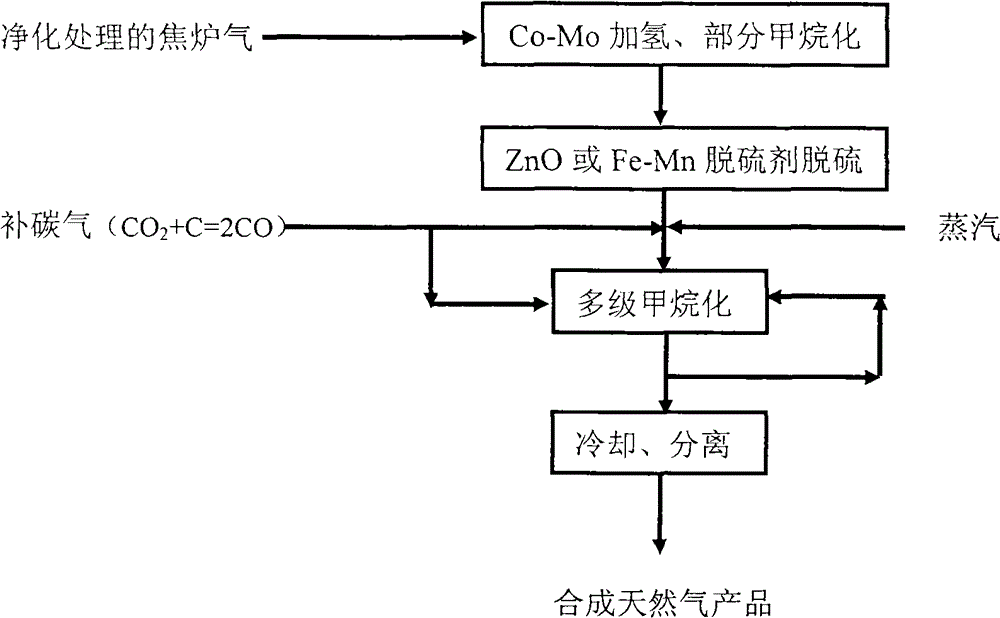

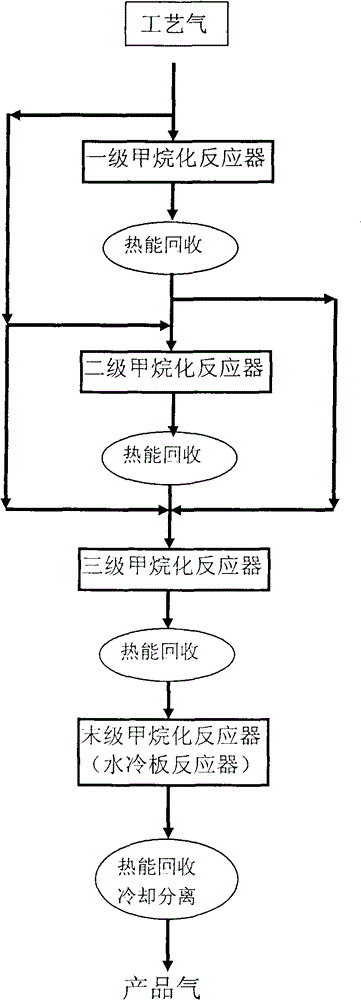

Novel process for making synthetic natural gas by using coke-oven gas

ActiveCN101818087APrevent sulfur poisoningGood recovery of waste heatGaseous fuelsChemistryCoke oven gas

The invention belongs to the field of the comprehensive utilization of coke-oven gas, and discloses a novel process for making synthetic natural gas by using the coke-oven gas. The qualified synthetic natural gas product is produced by the process comprising the steps of hydrodesulfurization, carbon compensation, multi-level methanation, cooling, separation and the like. The process can effectively prevent the temperature runaway phenomenon of a methanation reactor, can reasonably distribute the load of the methanation reactor, improves the conversion rate of CO and CO2, and provides a new method for making the synthetic natural gas by using the coke-oven gas.

Owner:NANJING GOODCHINA CHEM TECH

Annular space gas lifting type loop reactor

InactiveCN1605385AReduce production efficiencyAvoid entrainmentChemical/physical processesVapor–liquid separatorEngineering

The annular air-lift inner circulating reactor is one inner circulating reactor with high gas-liquid separating efficiency and excellent gas distributing effect. Technologically, the present invention features that the gas-liquid separator in funnel-fine pipe separating structure has complete gas-liquid separation; and that the sintered pipe gas distributor has relatively small initial bubble size resulting in excellent gas distributing effect. In order to improve flow and reinforce mass transfer, the annular air-lift pipe is provided with inner member; and in order to introduce out or in heat for reaction, the annular air-lift pipe is provided with heat exchange member of fingered or coiled pipe. The reactor has the features of high gas-liquid separating efficiency, high gas distributing effect, homogeneous radial gas distribution, homogeneous radial liquid speed distribution and no reverse fluid circulation.

Owner:TSINGHUA UNIV

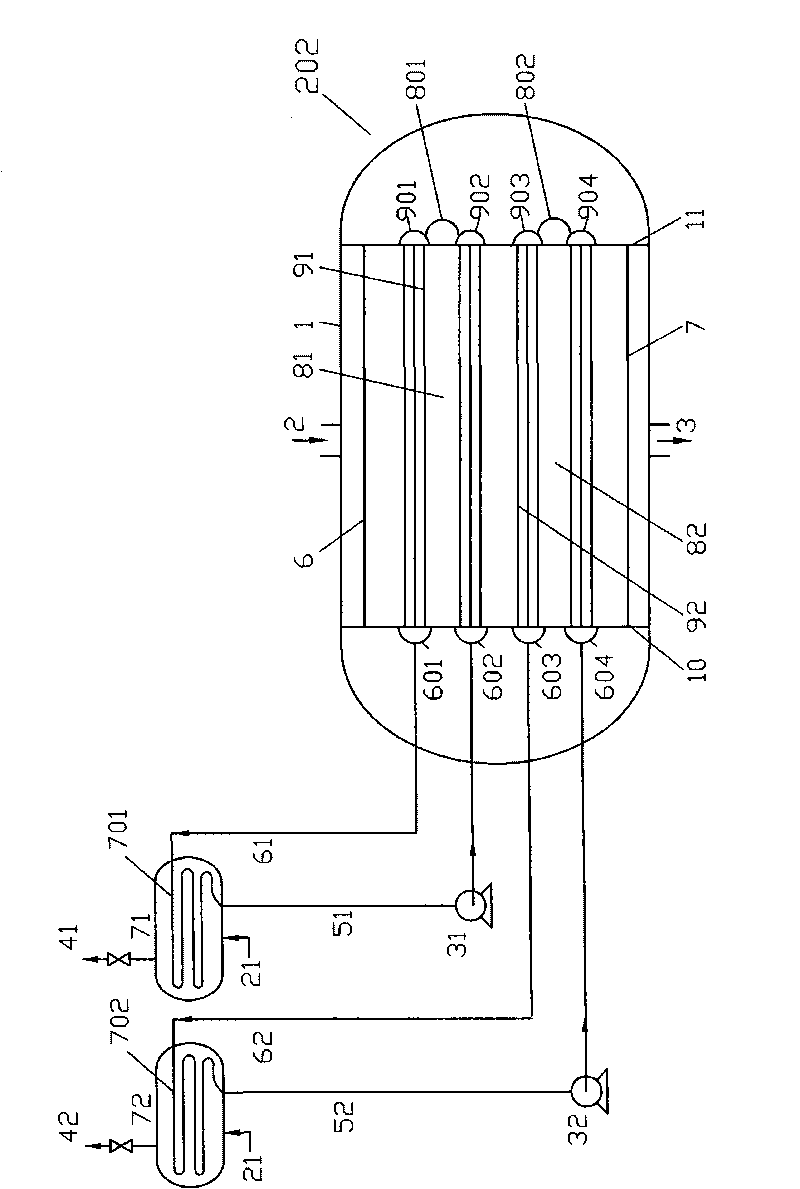

Method and equipment for preparing hydrocarbon by methyl alcohol or/ and dimethyl ether

ActiveCN101723775AImprove heat transfer abilityRelease more heat of reactionHydrocarbon from oxygen organic compoundsLiquid hydrocarbon mixture productionAlcoholFixed bed

The invention discloses a method and equipment for preparing hydrocarbon by methyl alcohol or / and dimethyl ether. The invention is mainly characterized in that raw material gases, such as methyl alcohol or / and dimethyl ether and the like pass through fixed bed reaction composition equipment for catalysis to generate hydrocarbon, wherein the fixed bed reaction combination equipment is at least provided with two reaction zones, and each reaction zone is provided with a heat exchange tube set capable of independently adjusting heat exchange medium temperature; after reaction gases separate target product hydrocarbon and water by heat exchange and cooling, expect that less chillout recycle gas is mixed with raw material gas, reaction for generating target product hydrocarbon is carried out.The invention has the beneficial effects of small catalyst layer temperature difference, low recycle ratio, high synthetic ratio, small investment, high output, energy saving and consumption reduction.

Owner:杭州林达化工技术工程有限公司

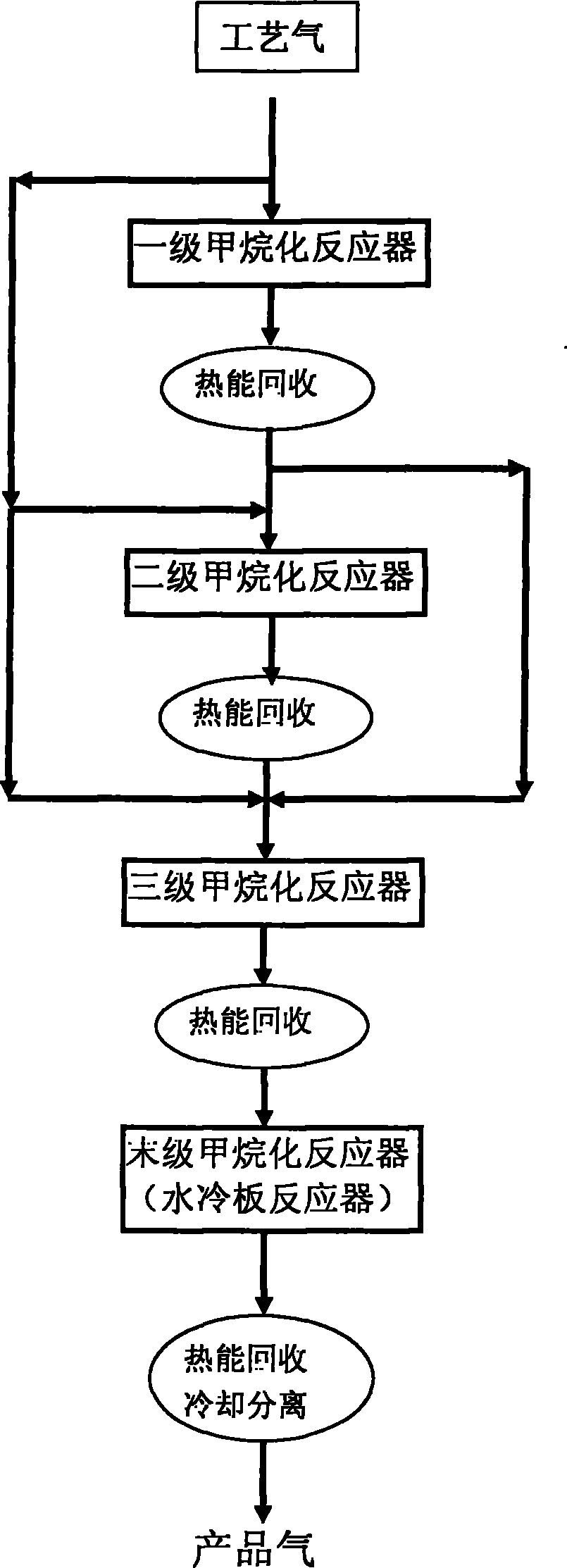

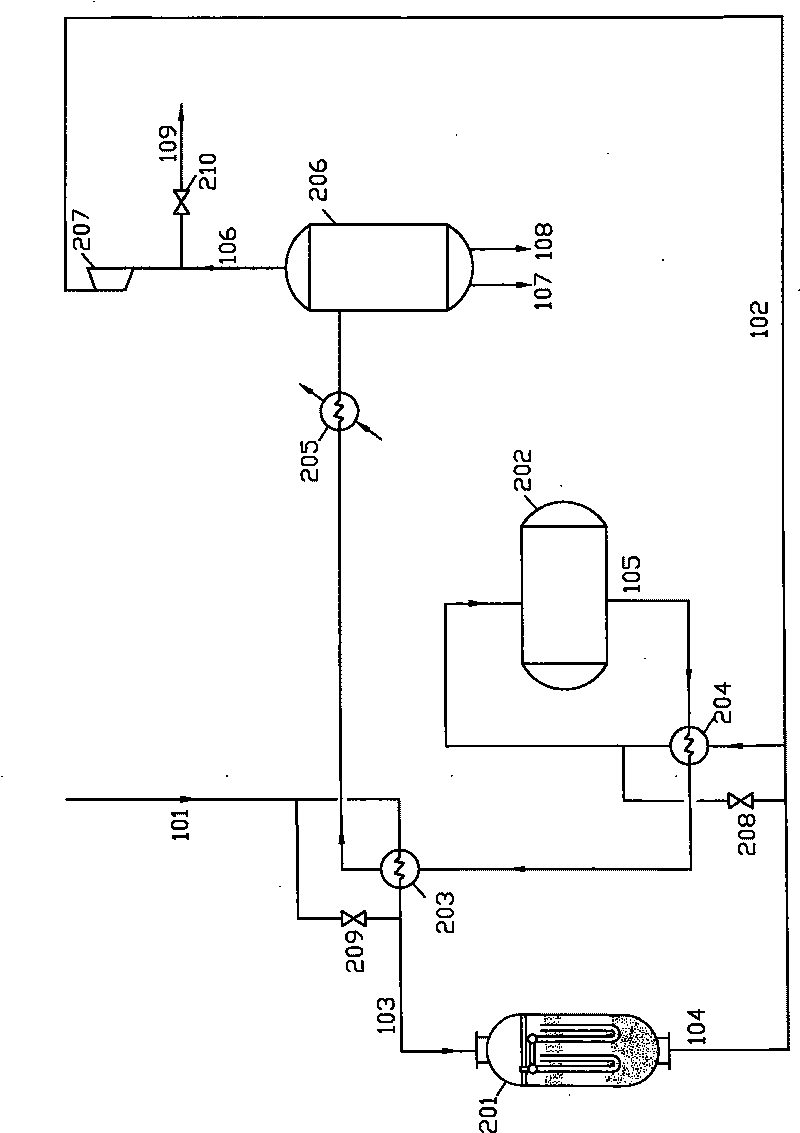

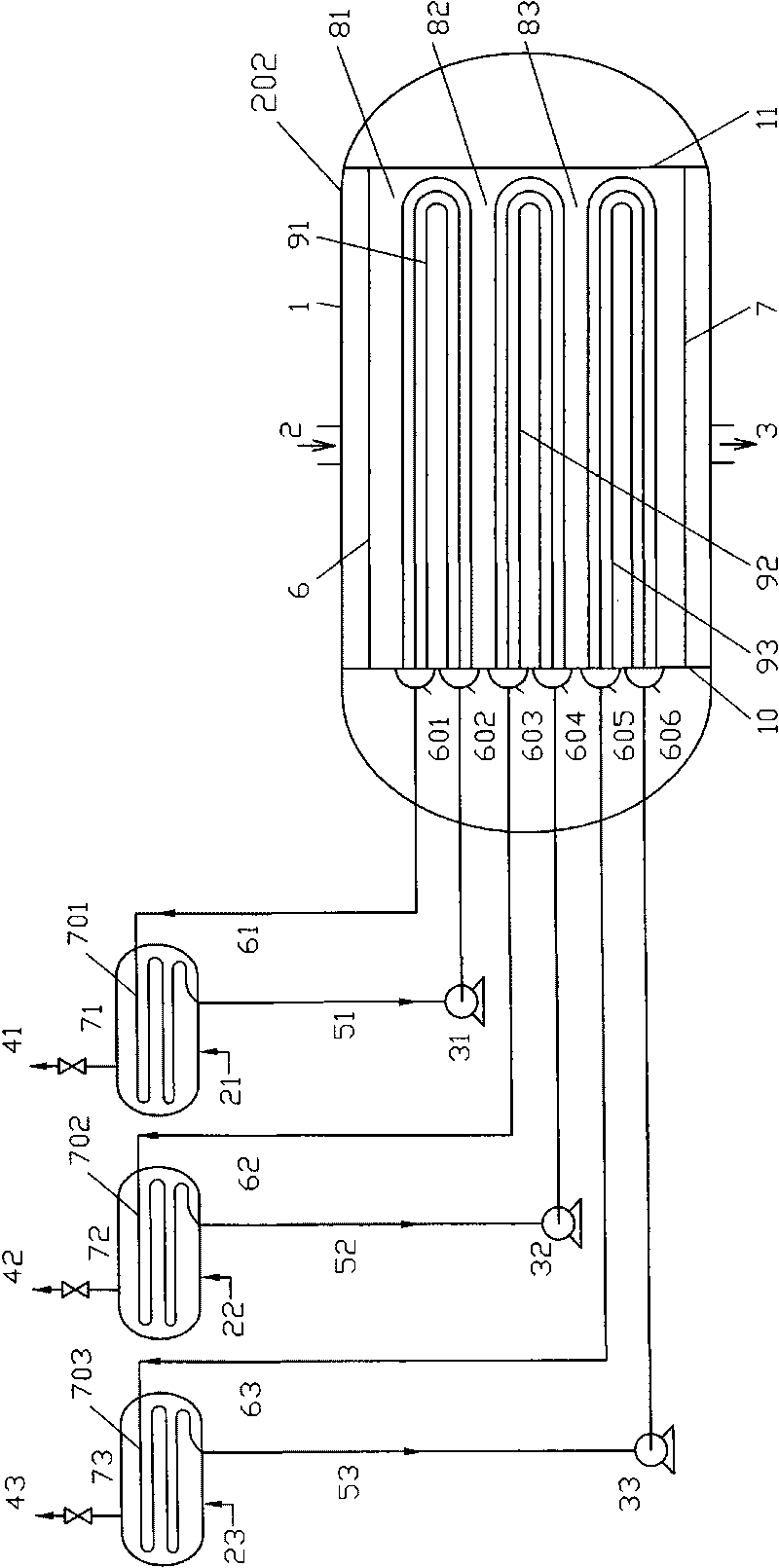

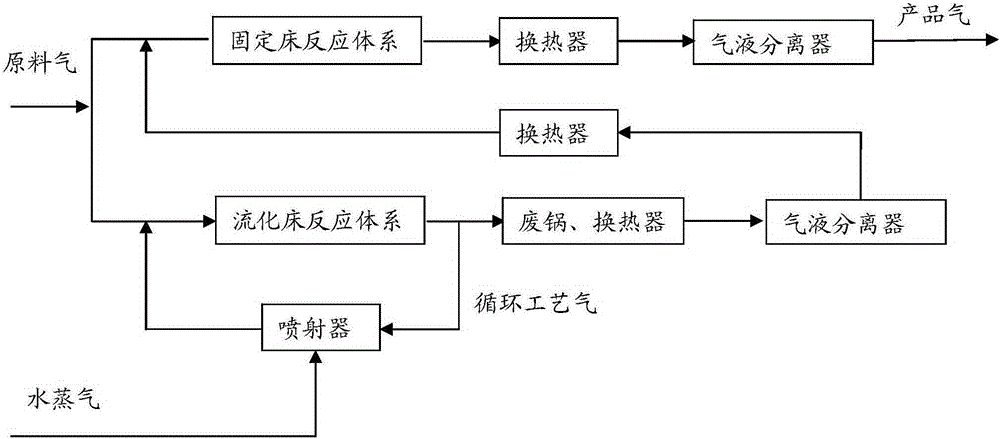

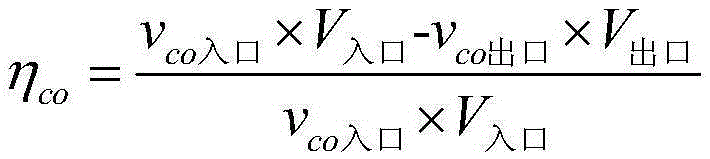

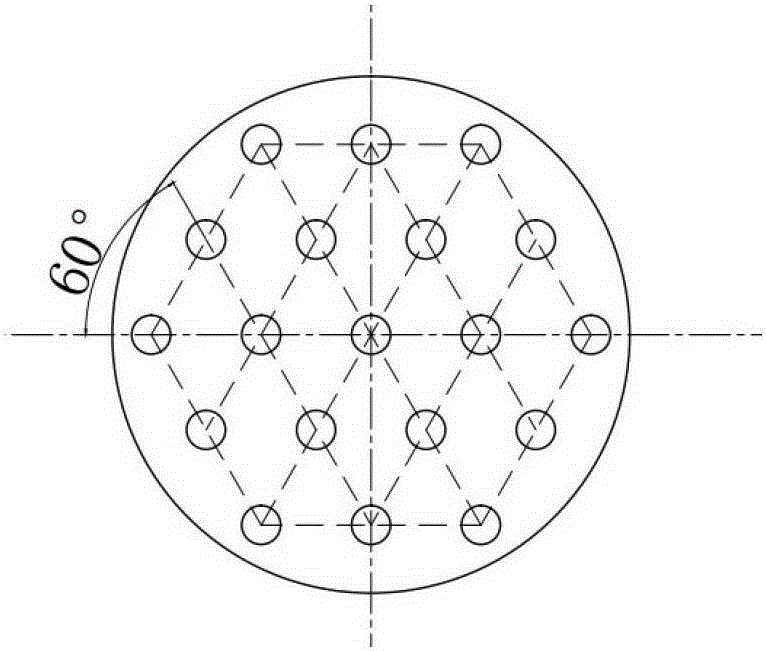

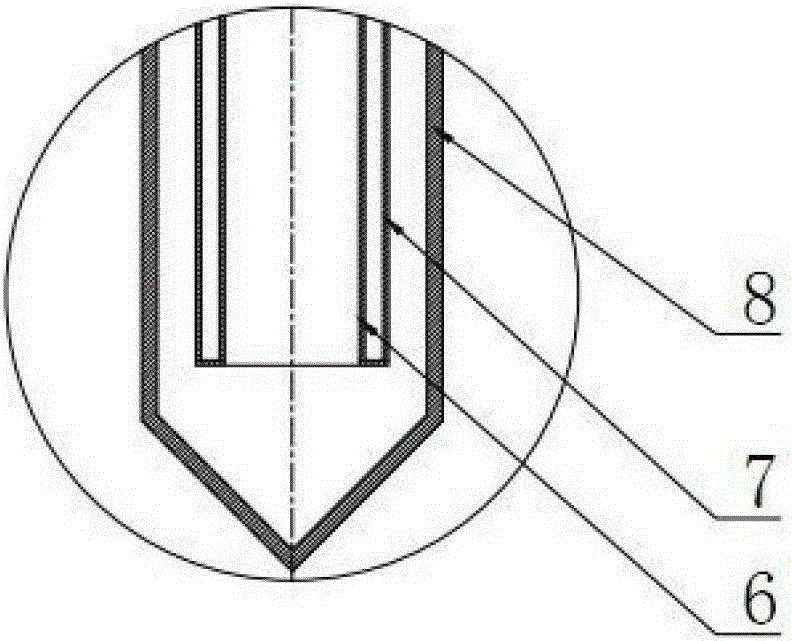

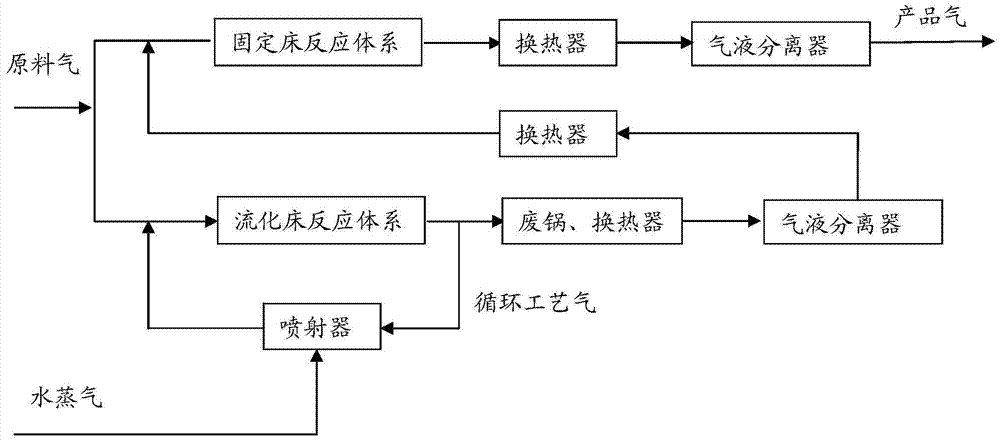

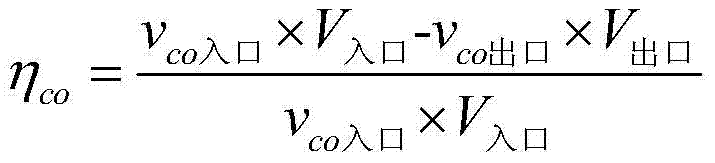

Fluidized bed and fixed bed combined methanation method

ActiveCN105255532AImprove heat transfer efficiencyImprove heat transfer abilityGaseous fuelsTemperature controlReactor system

The invention discloses a fluidized bed and fixed bed combined methanation method. The method comprises the steps that (1) a methanation feed gas is divided into two feed gases; one feed gas, water vapor and a recycle process gas from a fluidized bed methanation system enter the fluidized bed methanation system after being mixed to undergo methanation reaction under the action of a fluidized bed methanation catalyst; (2) a part of the outlet gas of the fluidized bed methanation system undergoes heat exchange, then is treated by a gas-liquid separator to separate condensed water and is mixed with the other feed gas; the gases enter a fixed bed methanation reaction system to undergo methanation reaction under the action of a fixed bed methanation catalyst; the other part of the outlet gas from the fluidized bed methanation system serves as the recycle process gas. Control of the temperature of the whole system is achieved by adding two system temperature control means, namely regulating the split ratio of the feed gases entering the two reactor systems and injecting the gas mixture of water vapor and the recycle process gas into the fluidized bed reaction system by an ejector.

Owner:CHINA NAT OFFSHORE OIL CORP +1

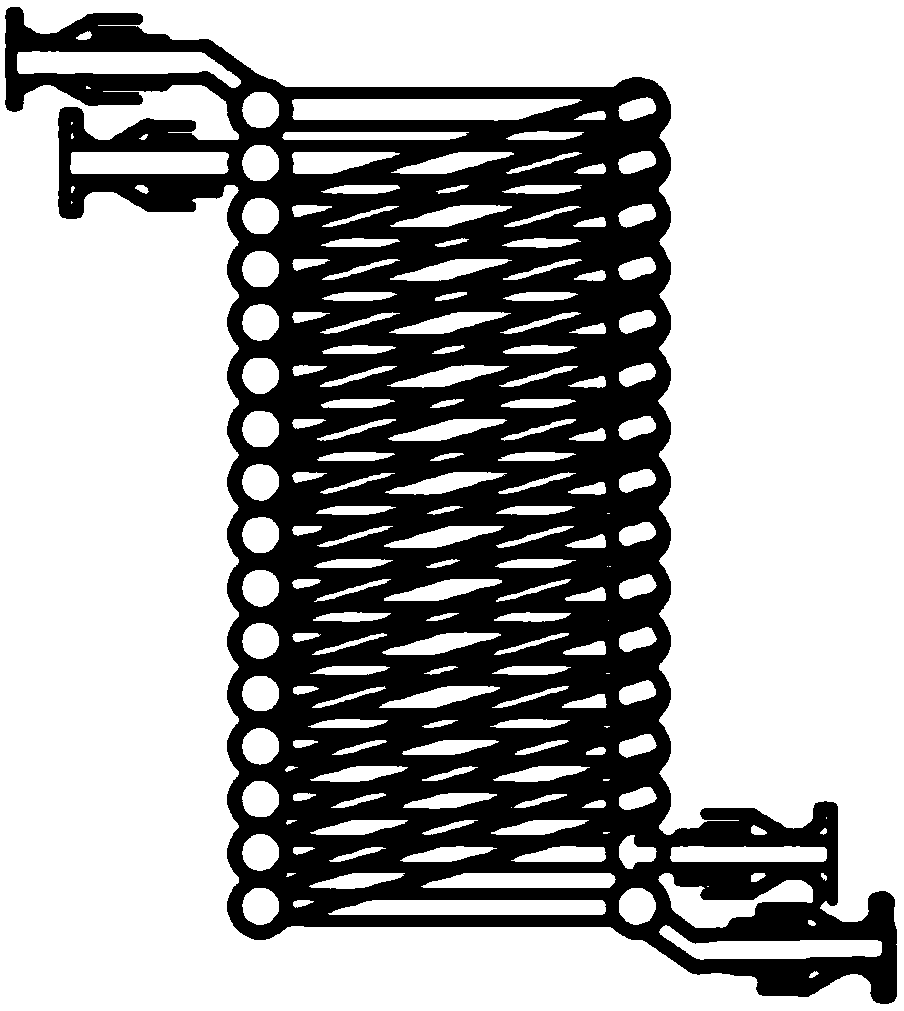

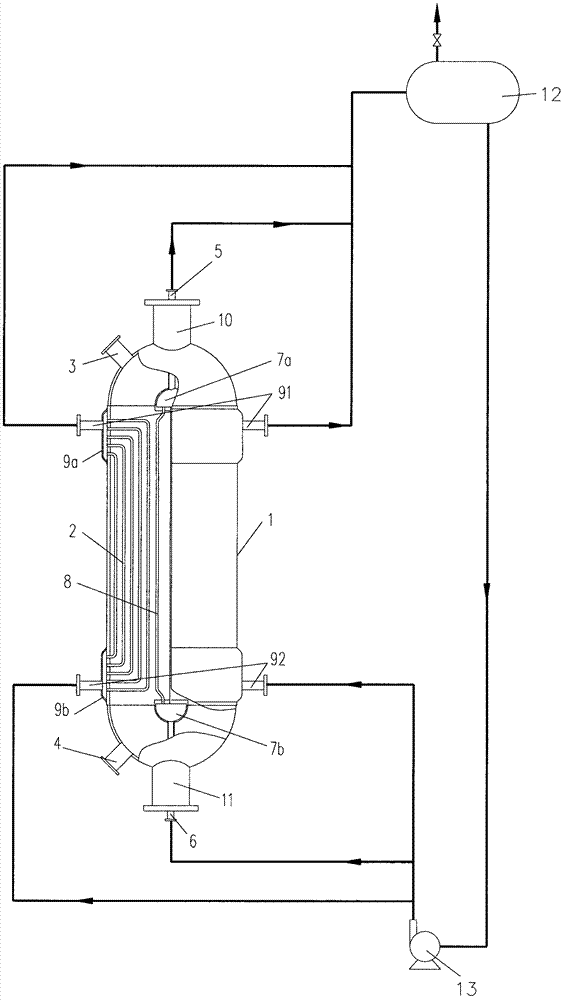

Straight pipe header coil pipe type reactor for waterway natural circulation

PendingCN106582455AImprove stability and securityReduce thermal stressOrganic compound preparationPreparation by carbon monoxide or formate reactionWater dischargeEngineering

The invention discloses a straight pipe header coil pipe type reactor for waterway natural circulation. The heat exchange pipe bundles comprise a water outlet pipe, an upper straight pipe header, coil pipes, a lower straight pipe header, branch pipes, annular pipes and a water inlet pipe, the water discharge pipe is connected to the top of a pressure-loaded housing, the upper straight pipe header is connected to an inlet of the water discharge pipe and outlets of the coil pipes respectively, the coil pipes are distributed in the axial direction of the pressure-loaded housing, the lower straight pipe header is connected to inlets of the coil pipes and outlets of the branch pipes respectively, the water inlet pipe is connected to the bottom of the pressure-loaded housing, and the annular pipes are connected to a water inlet pipe and the branch pipes respectively. According to the straight pipe header coil pipe type reactor for the waterway natural circulation, the coil pipes are adopted as a main heat exchange pipe bundle, the coil pipe bundle thoroughly removes thermal stress in the axial direction and the radial direction; an outer air cylinder and inner air cylinder technology are adopted to ensure air radically flow through a catalyst bed layer, and the flow directions of the air and water are in a perpendicular state; waterway circulation between the vapor bag and the coil pipe bundle is adopted as natural circulation, and the waterway circulation percentage is high; the catalyst is high in filling amount, strong in heat motion ability and easy for upsizing.

Owner:NANJING DUNXIAN CHEM TECH

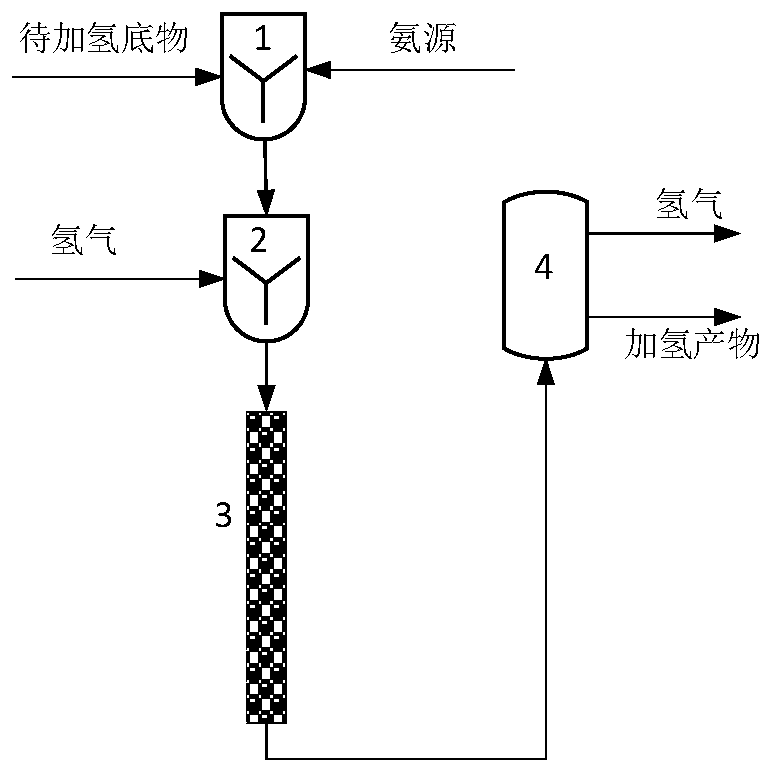

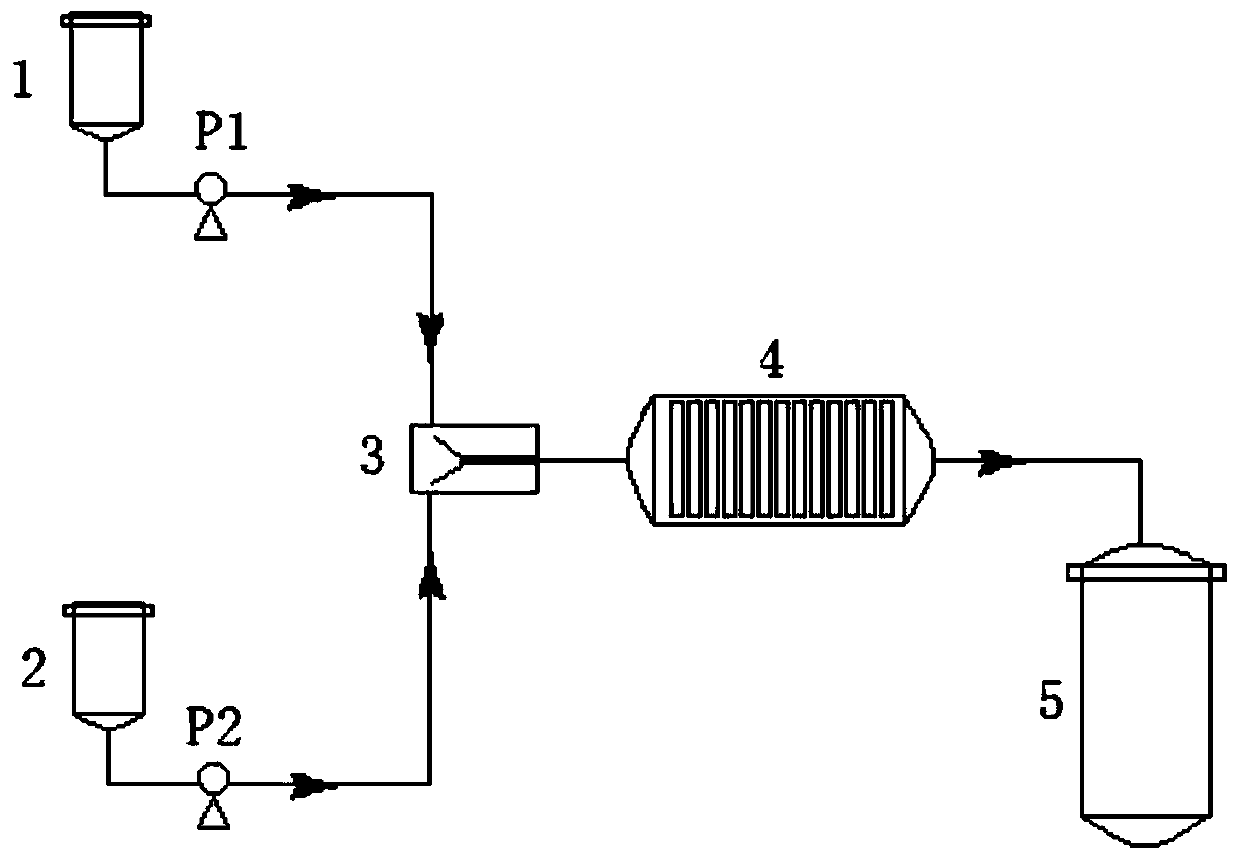

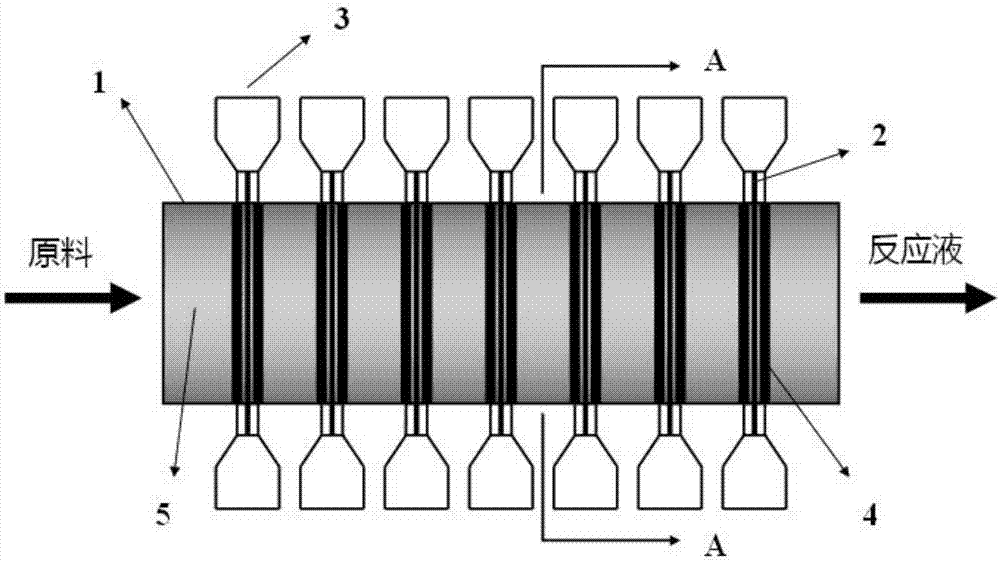

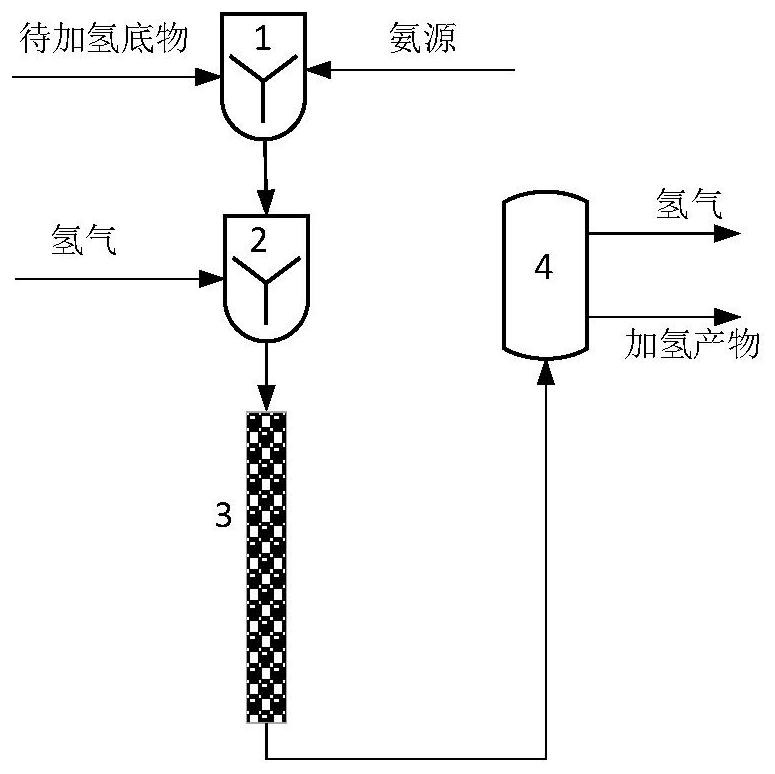

Device for continuous synthesis of benzylamine substance through heterogeneous hydrogenation in micro-reactor

ActiveCN110627650AIncrease contact areaImprove mass transfer efficiencyChemical/physical/physico-chemical microreactorsPreparation by reductive alkylationChemistryMICRO MIXER

Belonging to the technical field of chemical reaction, the invention particularly relates to a device for continuous synthesis of a benzylamine substance through heterogeneous hydrogenation in a micro-reactor. The device comprises: an inlet micro-mixer (1), an inlet micro-mixer (2), a micro-packed bed reactor (3) and an outlet split-phase tank (4). The device utilizes the efficient mixing and excellent mass and heat transfer performance of the micro-reactor to enhance the interphase mass transfer and heat removal capability in the reaction process, and can obviously reduce the volume of the reactor, improve the reaction yield, and enhance the production efficiency and safety. The method can solve the problems of low production efficiency, poor product purity, high device risk and the likein the hydrogenation kettle process, can realize continuous automatic operation of the process, and has the advantages of high yield, high safety and the like.

Owner:TSINGHUA UNIV

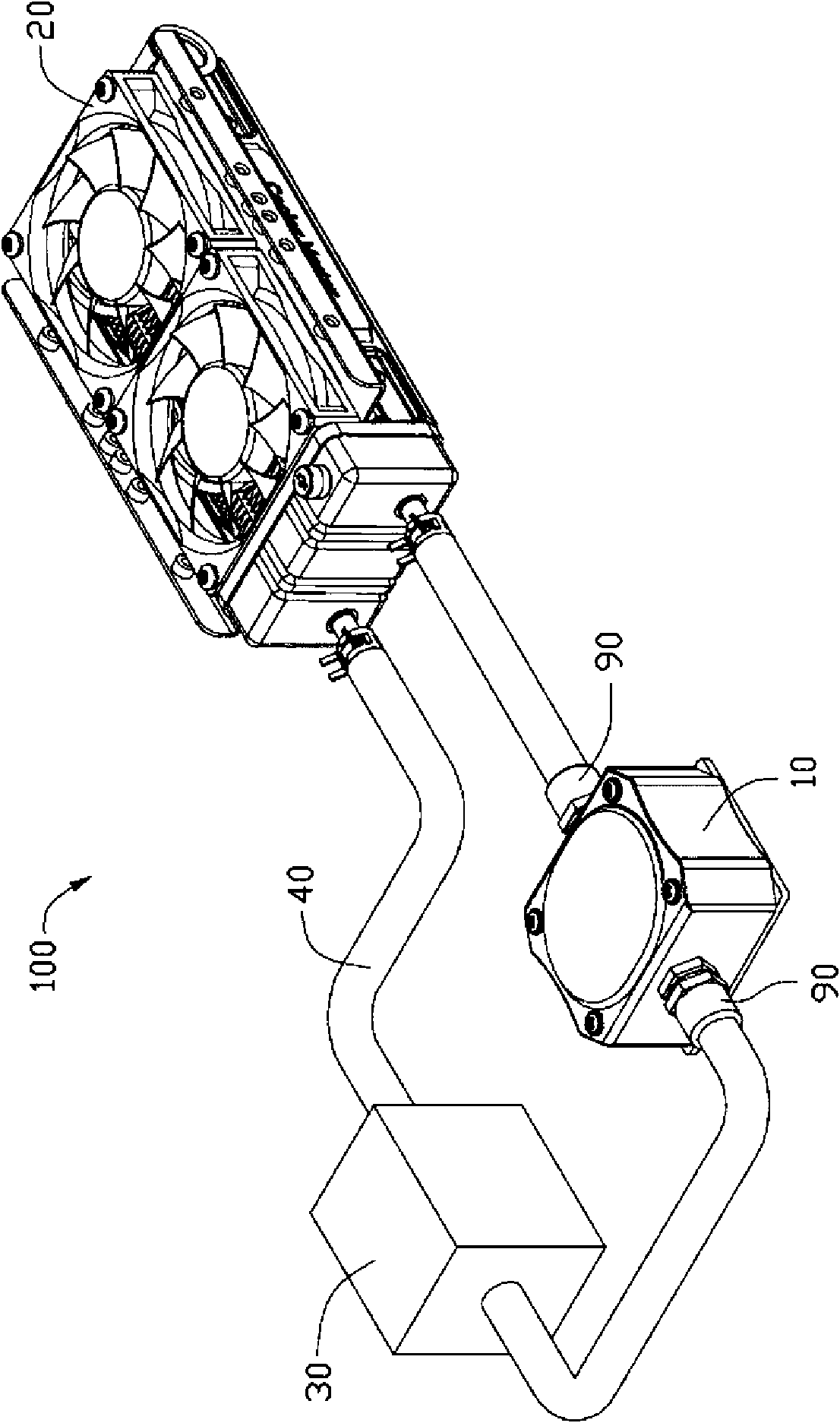

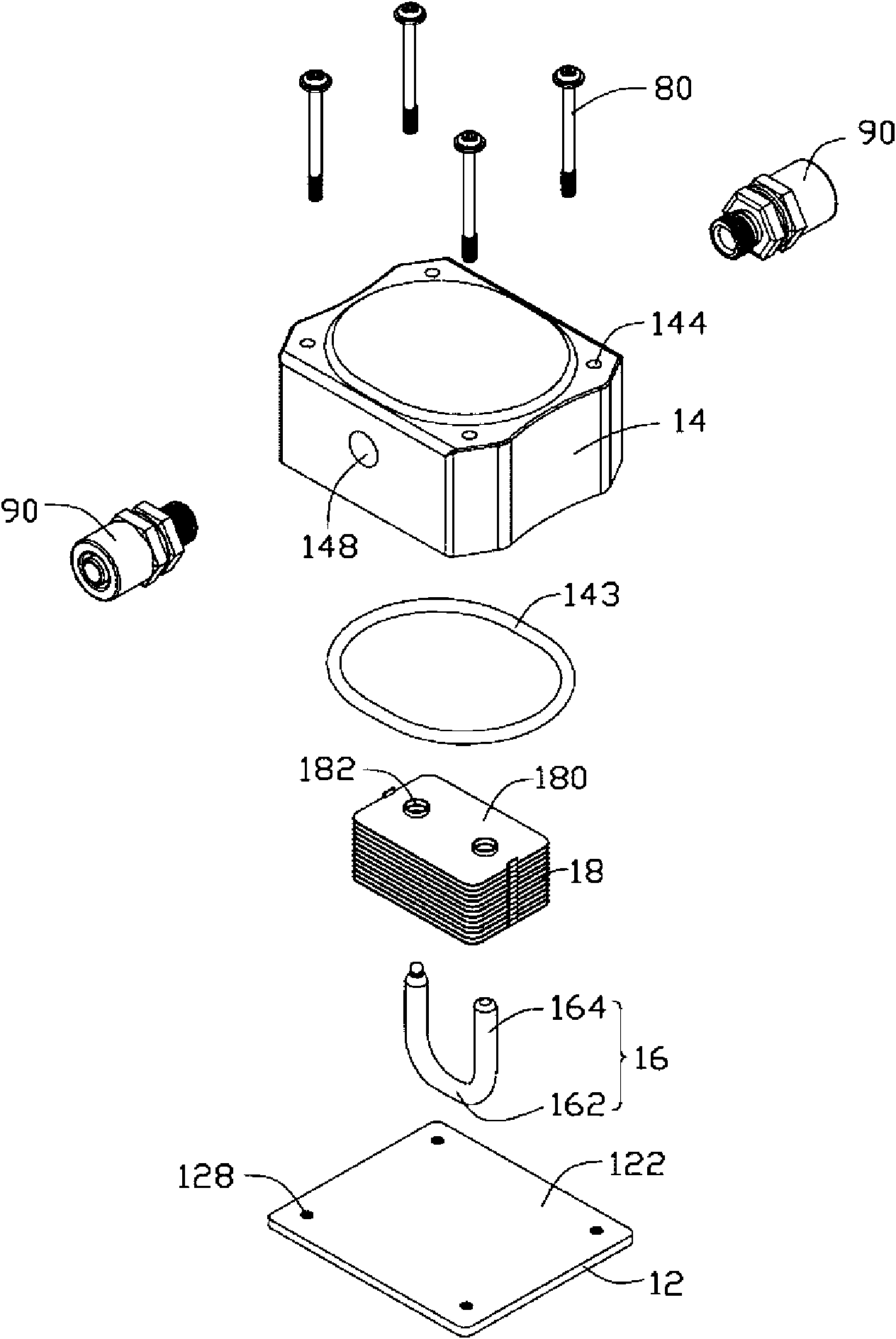

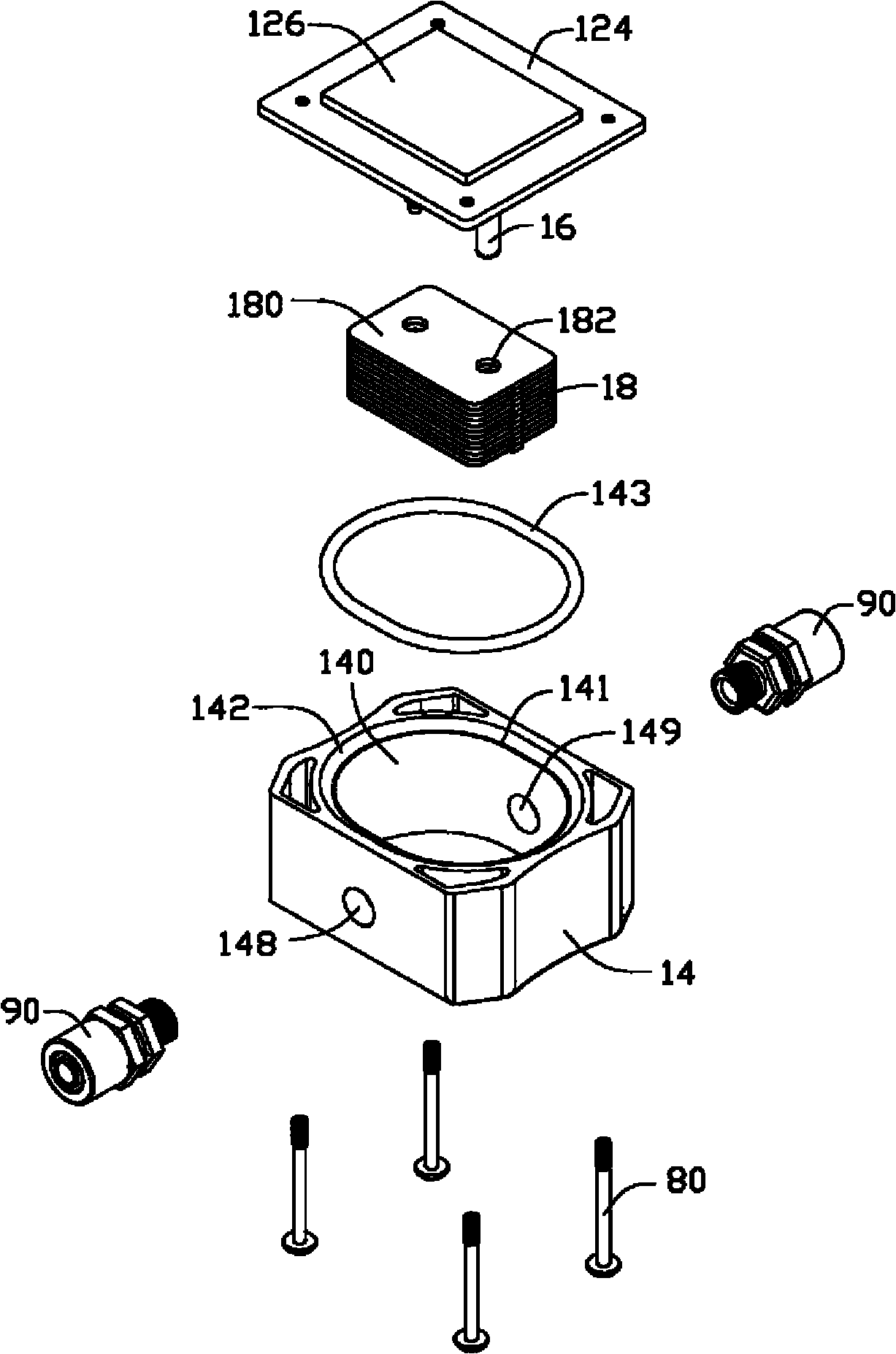

Liquid-cooling heat radiating device

InactiveCN102056459AImprove cooling effectImprove heat transfer abilityDigital data processing detailsSemiconductor/solid-state device detailsEngineeringCooling fluid

A liquid-cooling heat radiating device comprises a heat absorbing body, a heat radiating body and a driver, wherein the heat absorbing body, the heat radiating body and the driver are connected through a pipeline to form a loop; the loop is filled with cooling fluid; the driver drives the cooling fluid to flow circularly in the loop; the heat absorbing body comprises a heat absorbing plate, a radiator and a heat pipe; the interior of the heat absorbing body forms a cavity; the radiator and the heat pipe are accommodated in the cavity; and the heat absorbing plate is connected with the radiator through the heat pipe and used for being contacted with a heat source.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

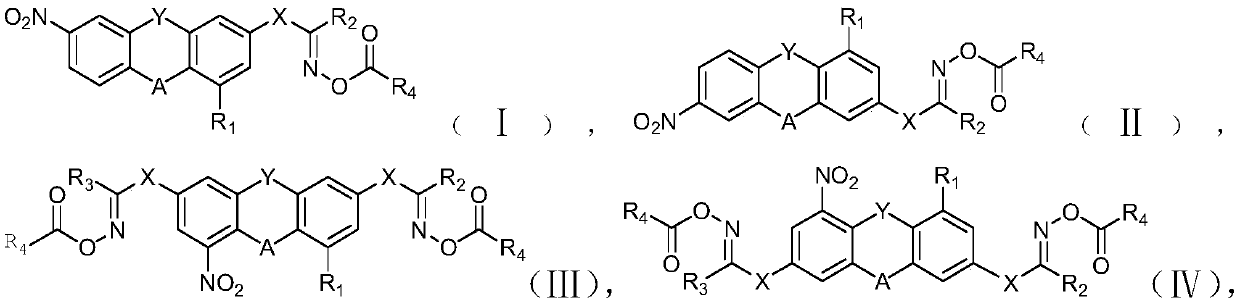

Method for preparing nitro-containing oxime ester photoinitiator by nitrification in micro-channel

PendingCN111233746AHigh product selectivityHigh product purityChemical/physical/physico-chemical microreactorsOximes preparationPhotoinitiatorAcetic anhydride

The invention belongs to the technical field of chemical reaction engineering, and relates to a method for preparing a nitro-containing oxime ester photoinitiator from an oxime ester initiator intermediate through a nitration reaction, and particularly provides a method for preparing the nitro-containing oxime ester photoinitiator through nitration in a micro-channel. According to the method, efficient mixing and excellent mass and heat transfer performance of a micro-channel are utilized, nitric acid serves as a dispersion phase in the micro-channel, an intermediate is dissolved in an inert solvent and acetic anhydride to serve as a continuous phase, the two phases are mixed to initiate a reaction, and the reaction is completed in the rear of the micro-channel. Compared with the reactionin the traditional reaction kettle, the conversion rate can be obviously improved, more importantly, the volume of the reactor can be obviously reduced, and the safety of the reaction process is improved.

Owner:泰兴先先化工有限公司

Production method of polyvinyl chloride with small pot suspension method

The invention relates to a polyvinyl chloride, in particular to a production method of the polyvinyl chloride with a small pot suspension method, belonging to the technical field of chemical industry, characterized in that: EHP (peroxydicarbonate-diethylhexyl ester) which has high activity, uniform heat generation, and light sticking is used, based on using the EHP, a composite initiator is used, heat exchange capability of the kettle is fully utilized to allow the reaction speed to be uniform, prevent the acceleration of the post reaction speed to guarantee the timely removal of polymerization heat, and reduce the polymerization time; a composite system of binary PVA (polyvinyl alcohol) with different alcoholysis degrees and a polybasic composite system of HPMC (hydroxypropyl methyl cellulose) and PVA are used; and a secondary water injection technology is used, so that viscosity of the materials is reduced, the heat removing capability of the polymerizing pot is improved, and the quality of the PVC products is increased. According to the invention, the polymerization time is reduced, the viscosity of the materials is reduced, the cleaning time of the polymerizing pot, and a low water-oil ratio can be used for filling, so that the production capacity is improved.

Owner:邱飞

Axial-radial reactor for synthesizing ethylene glycol by alkyl oxalate hydrogenation

InactiveCN109395669AHigh selectivityReduce the temperatureOrganic compound preparationHydroxy compound preparationOxalateReaction zone

The invention relates to an axial-radial reactor for synthesizing ethylene glycol by alkyl oxalate hydrogenation. The axial-radial reactor comprises a reactor body, wherein an axial-radial reaction zone is arranged in the reactor body, and an inner porous distribution barrel and an outer porous distribution barrel are arranged in the axial-radial reaction zone from inside to outside sequentially in a sleeving manner; holes I are fully distributed in the wall of the inner porous distribution barrel in the axial direction of the reactor body; holes II are formed in the end, opposite to a reaction gas inlet, of the outer porous distribution barrel in the axial direction of the reactor body; the wall, provided with the holes II, of the outer porous distribution barrel is shorter than the wall,provided with the holes I, of the inner porous distribution barrel, so that axial-radial flow and radial flow of reaction materials in a catalyst between the inner porous distribution barrel and theouter porous distribution barrel are realized. Compared with the prior art, the axial-radial reactor has the advantages that gas distribution is uniform, bed pressure drop is small, bed temperature distribution is reasonable, selectivity of ethylene glycol is high, production capacity of the reactor can be improved remarkably on the premise that diameter of the reactor is not increased, and the like.

Owner:PUJING CHEM IND SHA

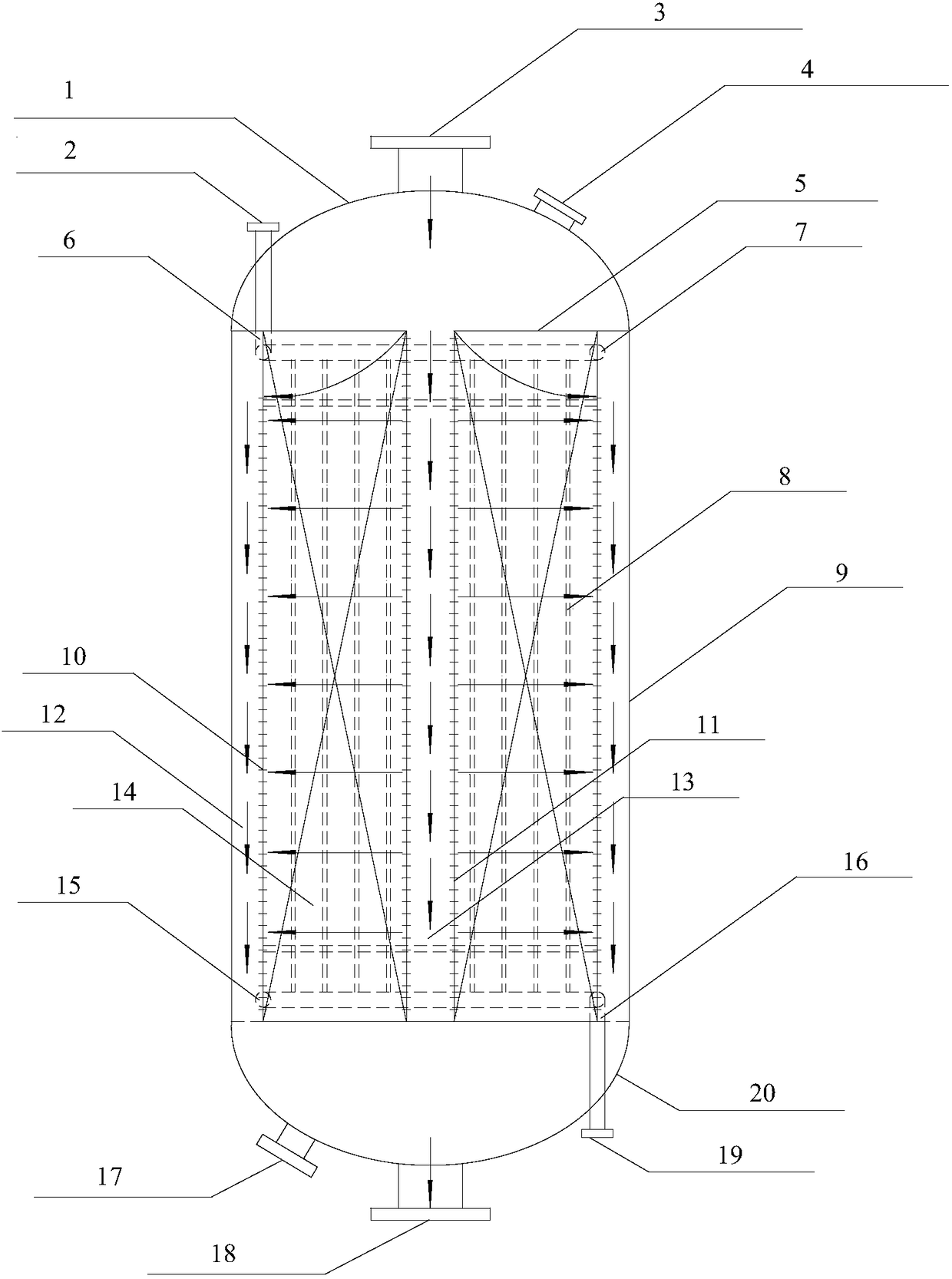

Downward chilling external heat removal pulverized coal pressurized gasification device

PendingCN109666512AImprove heat transfer abilityImprove the stability of safe operationGranular/pulverulent flues gasificationProcess engineeringCoal

The invention discloses a downward chilling external heat removal pulverized coal pressurized gasification device. The downward chilling external heat removal pulverized coal pressurized gasificationdevice comprises an external heat removal system, a gasification furnace casing and a pass partition plate arranged inside the gasification furnace casing, wherein the gasification furnace casing is separated by the pass partition plate into a top water wall mounting cavity and a bottom chilling chamber; the inside of the water wall mounting cavity is provided with a water wall, a gasification reaction chamber is formed inside the water wall, the inlet of an external heat removal system is communicated with the outlet of the water wall, the outlet of the external heat removal system is communicated with the inlet of the water wall, the inlet end of a burner nozzle is arranged inside the gasification furnace casing, the outlet end of the burner nozzle penetrates through the gasification furnace casing and is inserted into the gasification reaction chamber via the top of the gasification reaction chamber; circulating water inside the water wall of the downward chilling external heat removal pulverized coal pressurized gasification device is excellent in heat removal capacity, and meanwhile, the downward chilling external heat removal pulverized coal pressurized gasification device can effectively avoid various problems brought by vapor systems applied in the prior art.

Owner:HUANENG CLEAN ENERGY RES INST

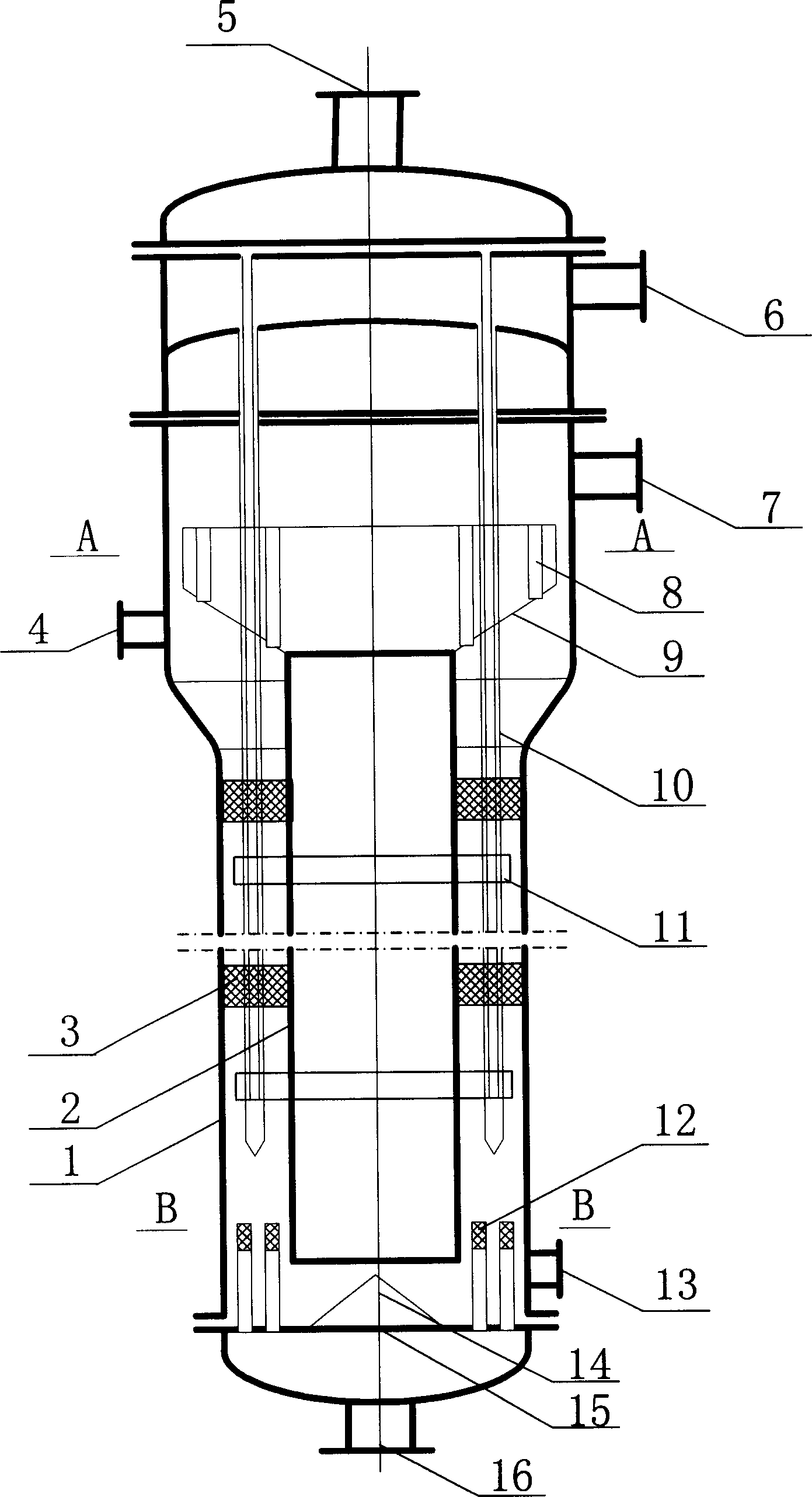

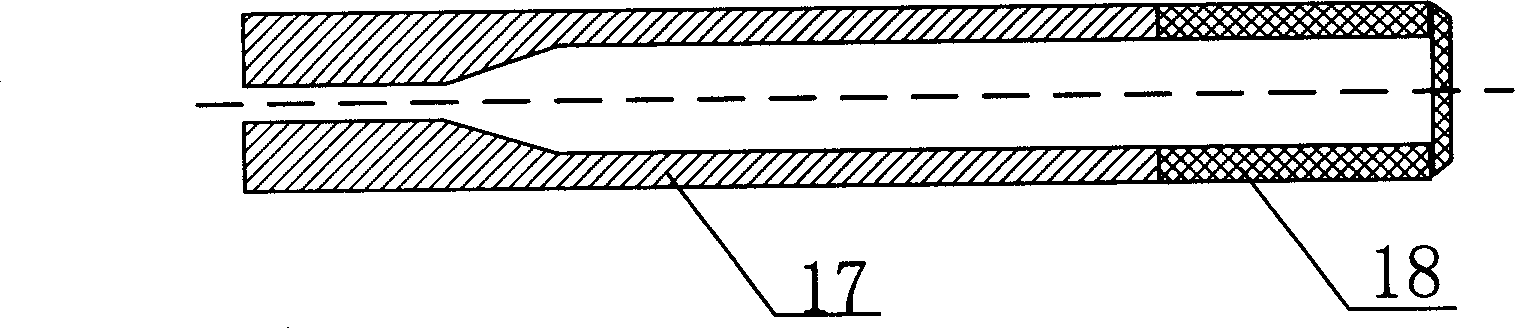

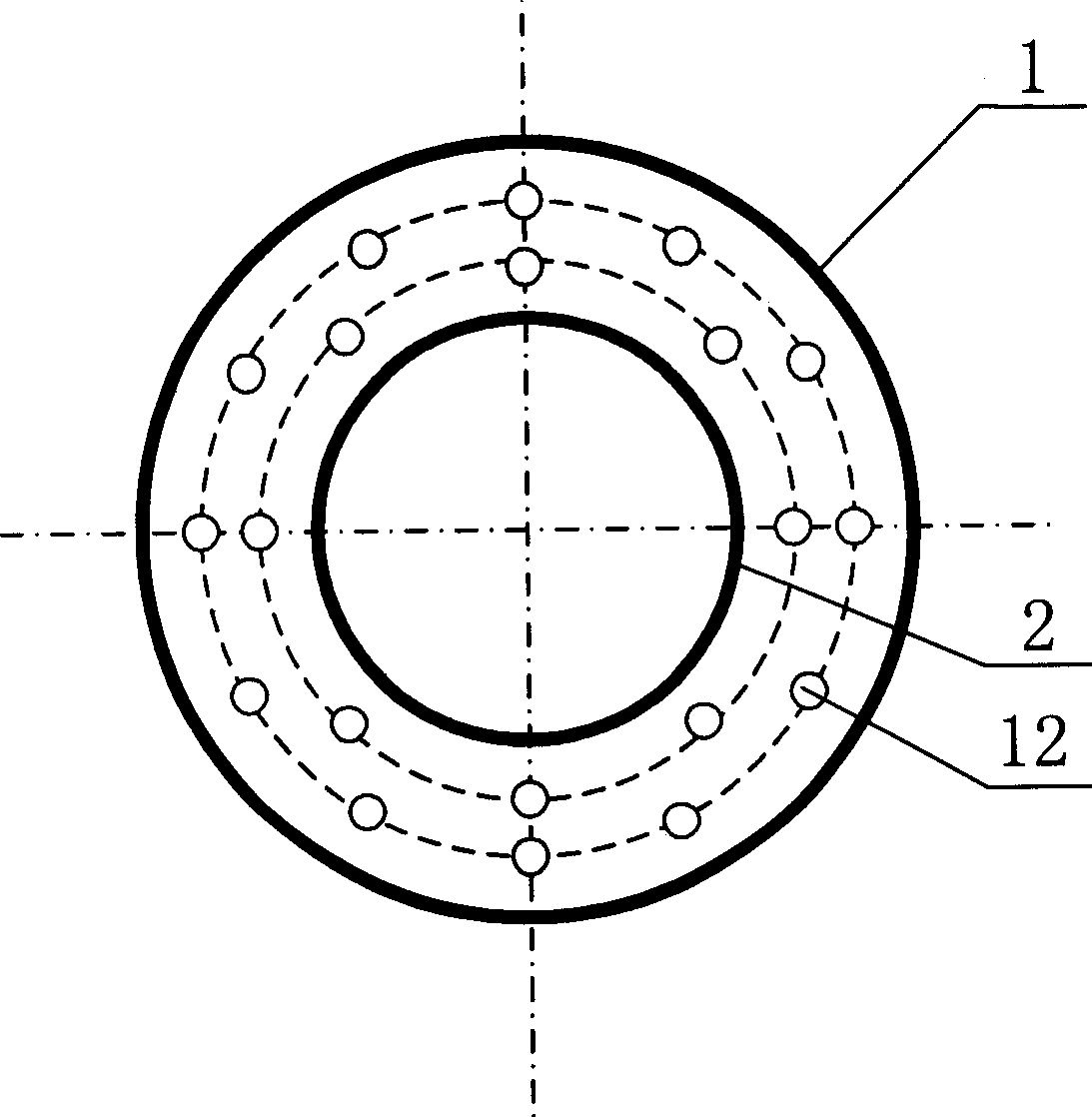

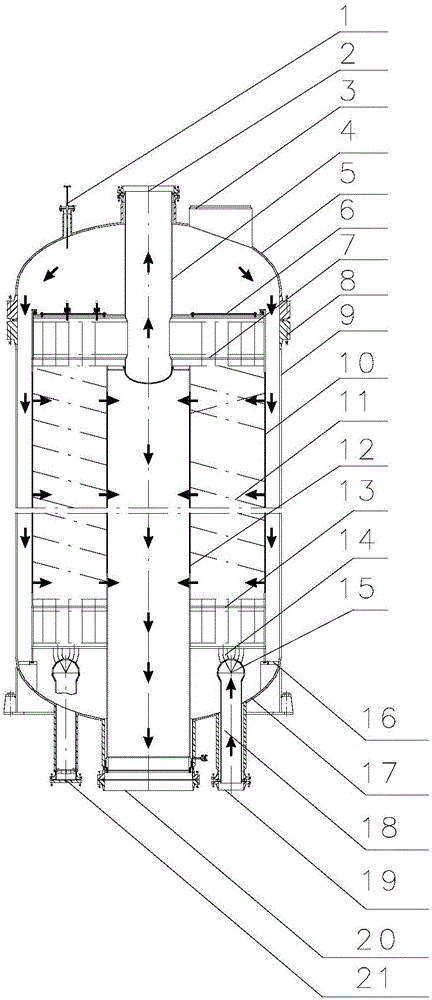

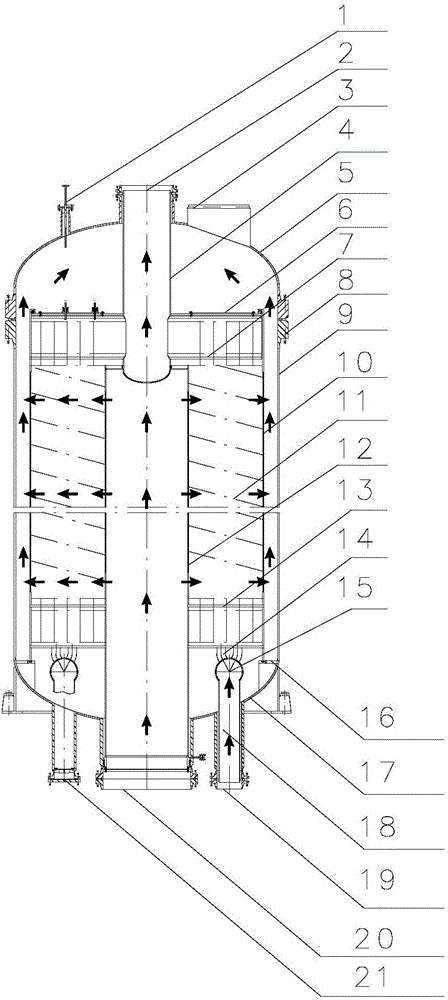

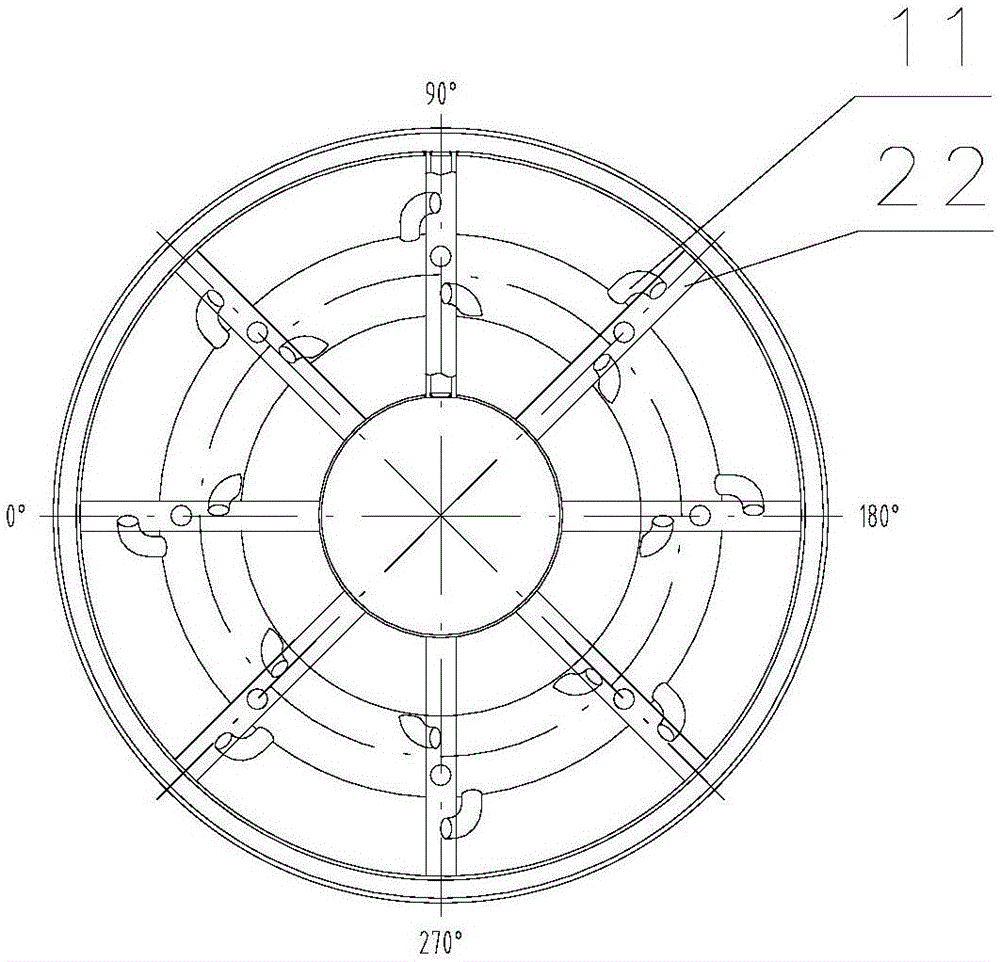

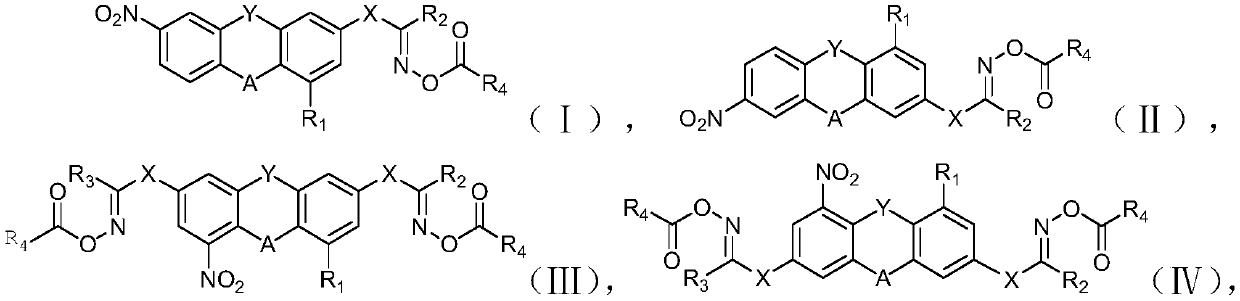

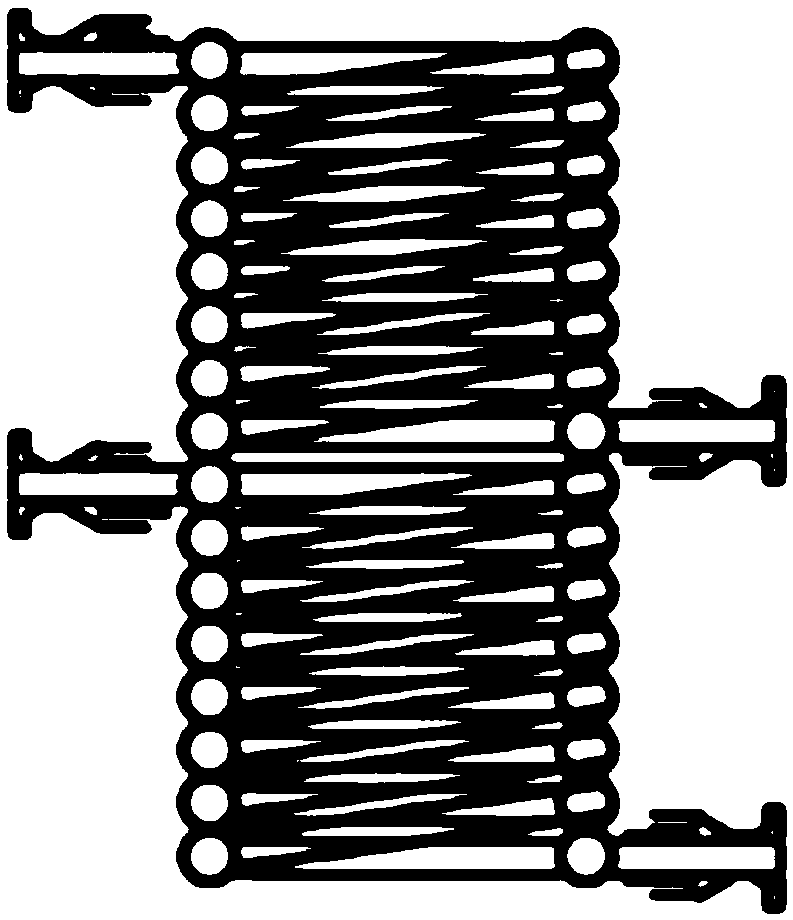

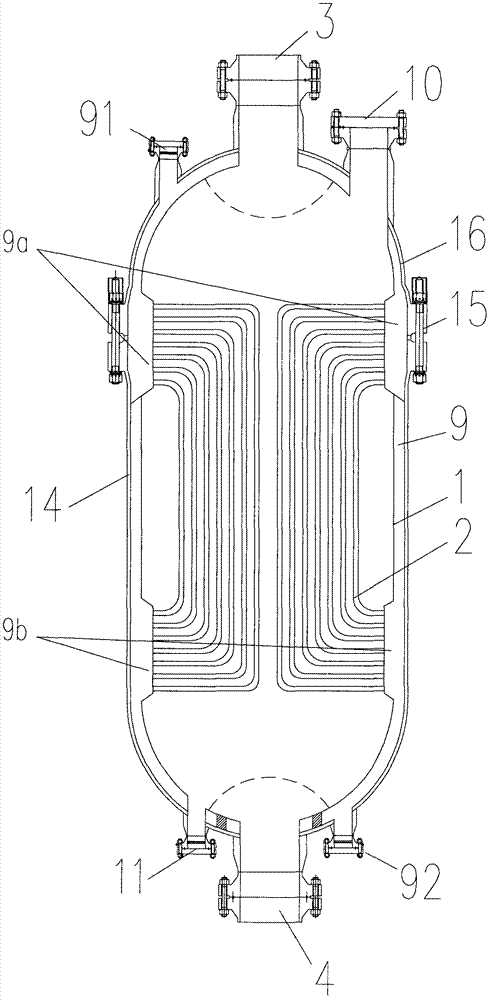

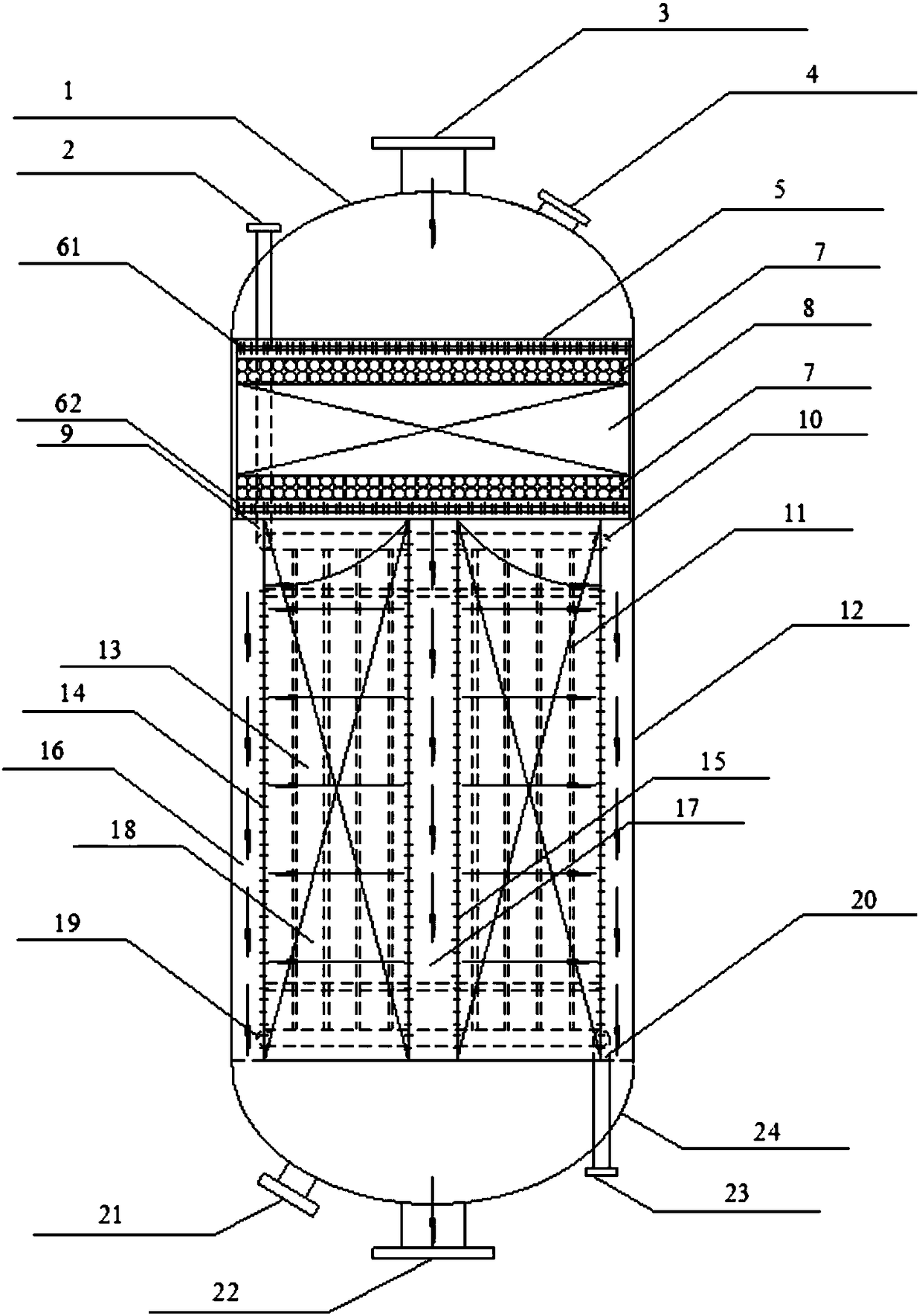

Spiral pipe jacket type axial reactor

PendingCN108654522ALarge amount of loadingImprove heat transfer abilityChemical/physical processesEngineeringWater jacket

The invention discloses a spiral pipe jacket type axial reactor. The spiral pipe jacket type axial reactor is characterized in that an upper seal head and a lower seal head are respectively fixedly arranged at the top part and bottom part of a cylinder body; a spiral heat exchange pipe is distributed in the axial direction of the cylinder body; an upper flat pipe plate header is communicated withthe water drain end of the spiral heat exchange pipe, and a lower flat pipe plate header is communicated with the water intake end of the spiral heat exchange pipe; the upper flat pipe plate header iscommunicated with a water collecting box, and the lower flat pipe plate header is communicated with a water distribution box; the upper flat pipe plate header and the lower flat pipe plate header arerespectively supported at the upper part and lower part of the cylinder body; both ends of a center fixed cylinder are respectively fixedly arranged on the upper flat pipe plate header and the lowerflat pipe plate header; a water jacket inner plate is covered onto the spiral heat exchange pipe along the outer wall of the spiral heat exchange pipe; a water jacket space is formed between the waterjacket inner plate and the cylinder body and is used for water to flow. The spiral pipe jacket type axial reactor has the advantage that by adopting the water jacket and spiral heat exchange pipe combination scheme, the whole catalyst bed layer can be uniformly cooled without overtemperature coking.

Owner:NANJING DUNXIAN CHEM TECH

Gas-solid phase catalytic reactor

InactiveCN103240035AMore pipesImprove heat transfer abilityChemical/physical processesGas solidFlange

The invention discloses a gas-solid phase catalytic reactor comprising a housing and heat exchanging internal parts, wherein an air inlet and an air outlet are formed in the top and the bottom of the housing respectively; the heat exchanging internal parts comprise a plurality of heat exchanging pipes; two ends of each heat exchanging pipe are connected with the inner wall of the housing respectively; jackets are arranged on the outer wall of the housing at the joints; and a central heat exchanging pipe group can be arranged in the internal center of the housing as required. Due to the housing with a flange coupling end socket, the gas-solid phase catalytic reactor also can be used for reconstruction of the conventional reactors with housings. Due to the special compact pipe arranging manner, the gas-solid phase catalytic reactor has the advantages that the heat exchanging capability is high; the structure is reliable; the manufacture is convenient to manufacture and maintain; the investment is low; and the suitability for new construction and reconstruction of the reactors is high.

Owner:杭州林达化工技术工程有限公司

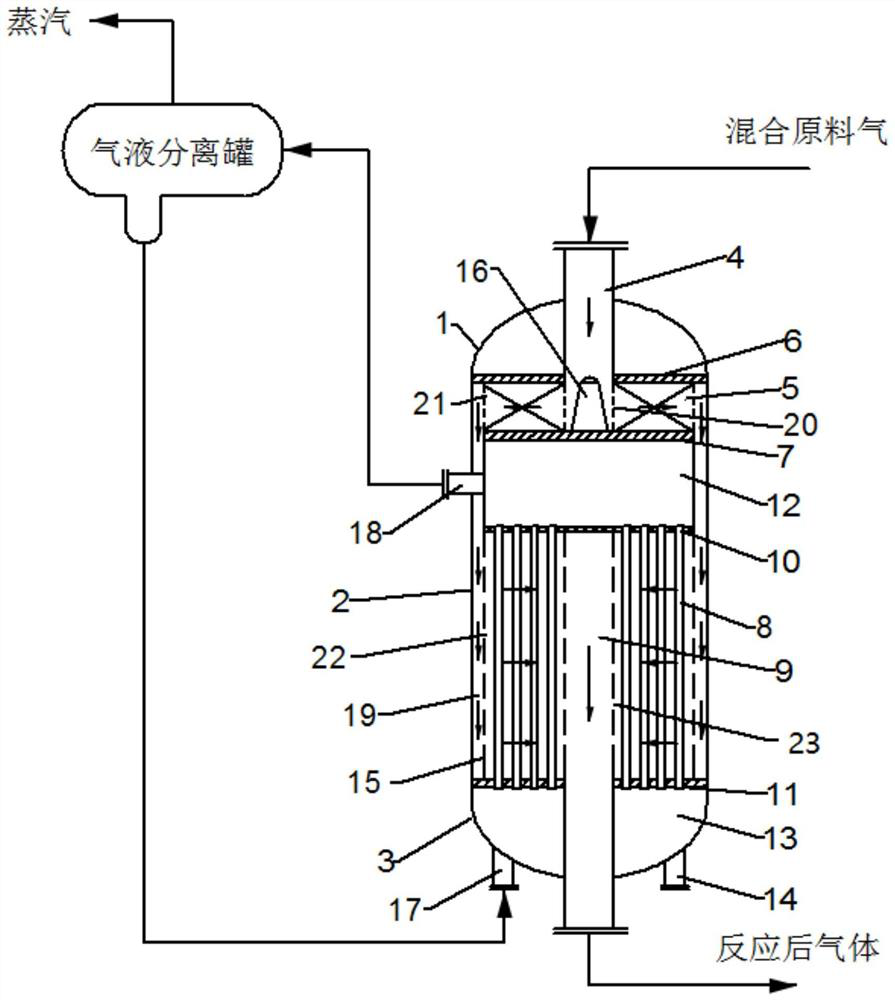

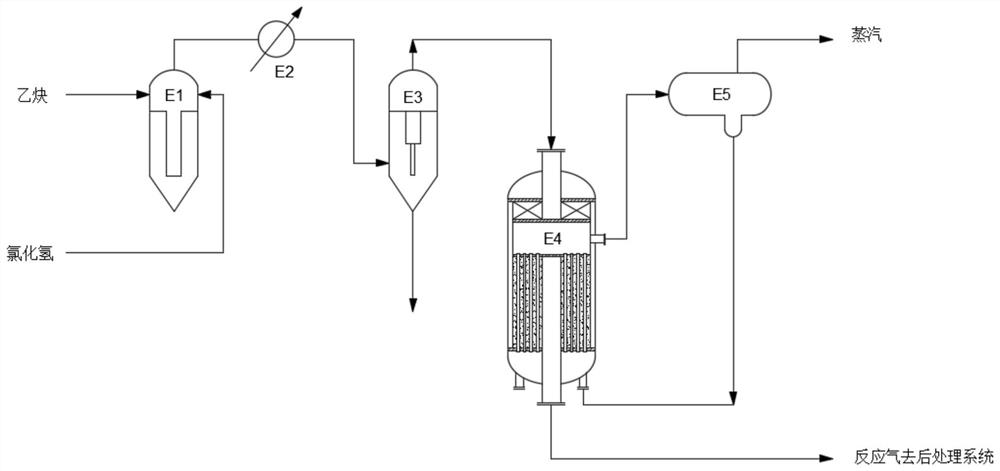

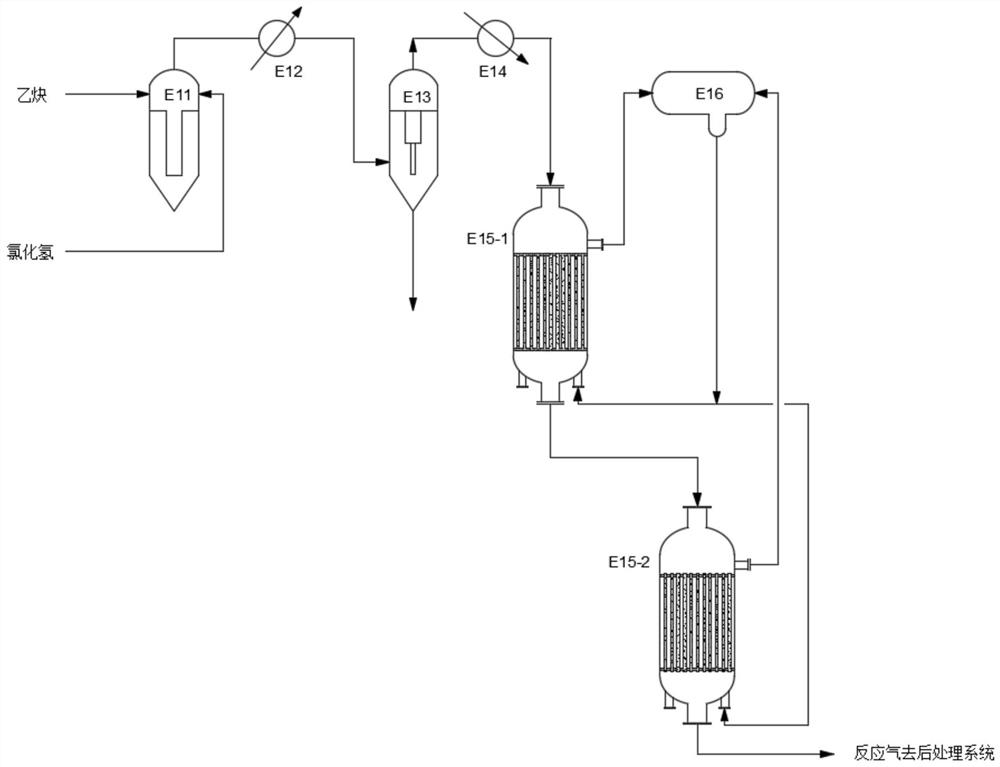

Acetylene method vinyl chloride synthesis reaction process

PendingCN112110788ASatisfy the temperature requirementRaise the reaction gas temperaturePreparation by halogen halide additionPtru catalystPhysical chemistry

The invention relates to a vinyl chloride synthesis reaction process, in particular to an acetylene method vinyl chloride synthesis reaction process which comprises the following steps: (1) carrying out adiabatic catalytic reaction on mixed raw material gas A to obtain mixed gas B; and (2) carrying out isothermal catalytic reaction on the mixed gas B to obtain mixed gas C containing vinyl chloride, and enabling the mixed gas C to enter a post-treatment system. Radial and two-stage catalytic reactions are adopted, an independent raw material gas preheater is omitted, the number of devices is reduced, the device investment is saved, the reaction pressure drop is reduced, the service life of the catalyst is prolonged, meanwhile, the subsequent reaction efficiency is improved, the conversion rate is larger than 98.5%, and the selectivity is larger than 99%.

Owner:鄂尔多斯市瀚博科技有限公司

Shallow geothermal application technology of passive building

InactiveCN106839207AReduce energy costsLow running costDucting arrangementsLighting and heating apparatusEvaporative coolerInlet channel

The invention discloses a shallow geothermal application technology of a passive building. The shallow geothermal application technology mainly includes preheating application and cooling application. A preheating process and a cooling process mainly include three steps: firstly, collecting outer air into an air inlet channel in the passive building, and filtering the collected air in the air inlet channel; secondly, transmitting the treated air into the passive building, and deeply burying the transmitted air into an underground ventilation pipeline, and preheating or cooling the air by the aid of formation depth and air temperature difference; thirdly, transmitting the treated air into an air supply pipeline distributed in the passive building, arranging a hot water heating coil or a direct evaporative cooler to treat the air again. According to the shallow geothermal application technology, structure is simple, the air in rooms is exchanged, the temperature of fresh air is adjusted, energy consumption is reduced, and the application technology has the advantages of low cost and energy consumption, wide application and the like in the use process.

Owner:新疆建筑设计研究院有限公司

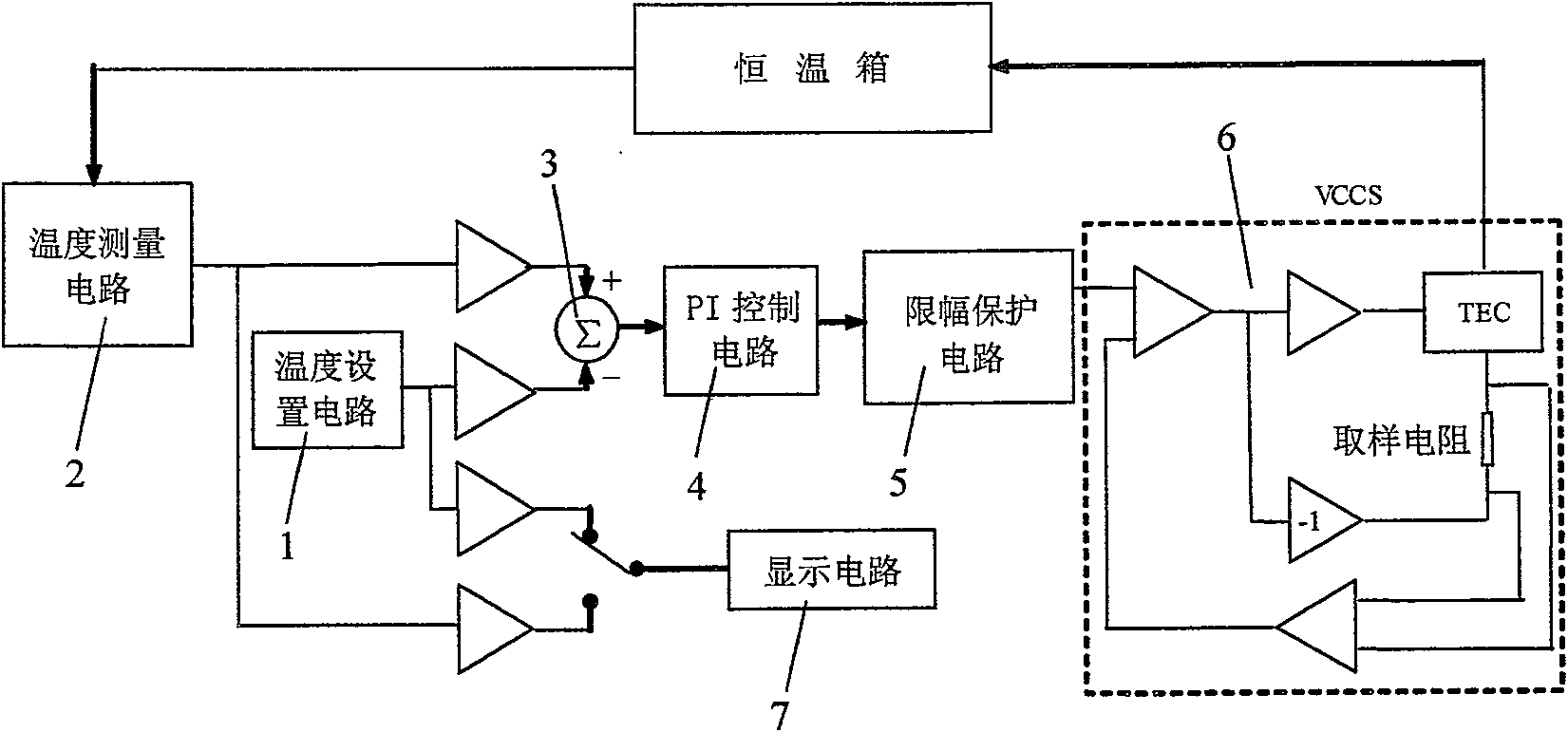

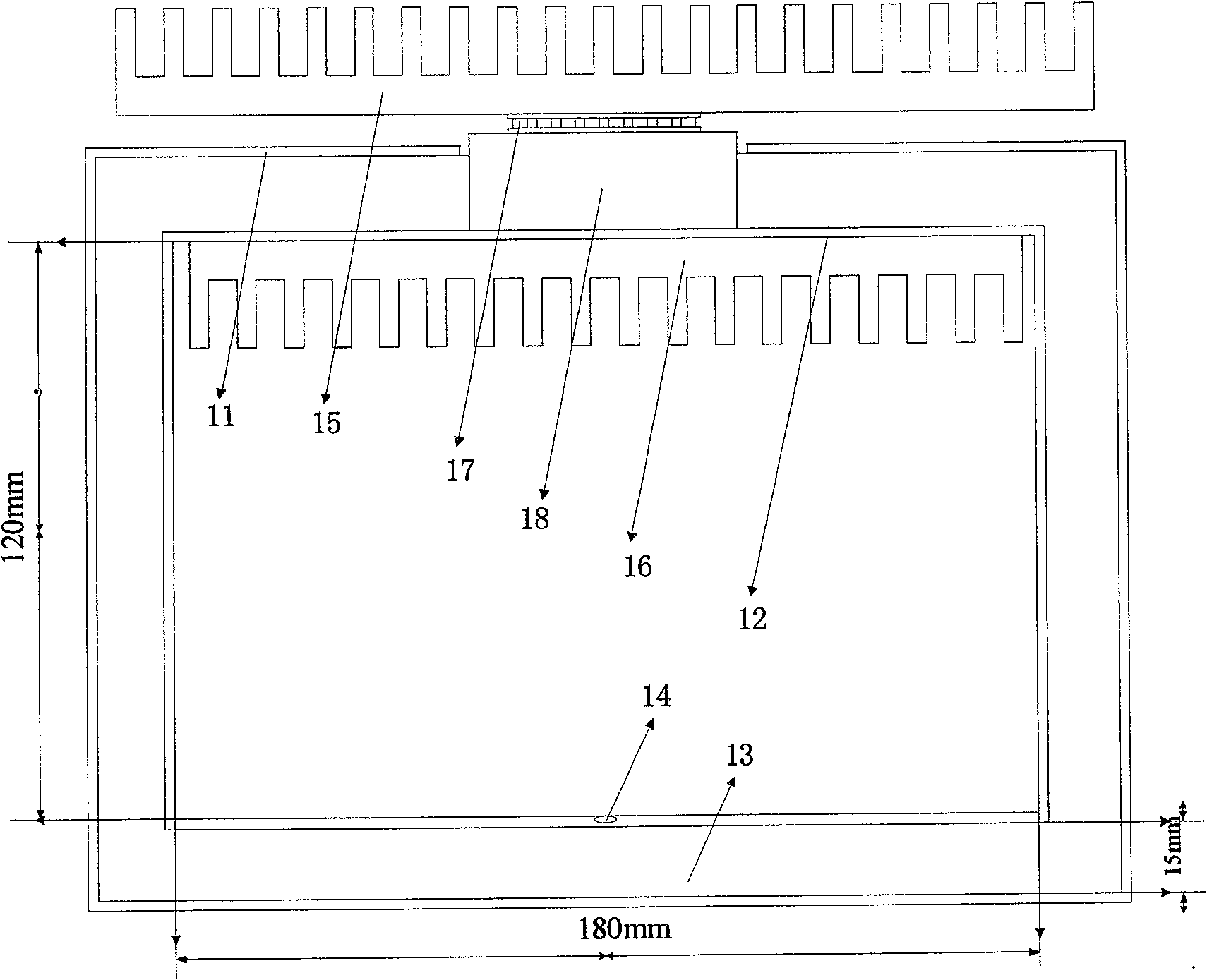

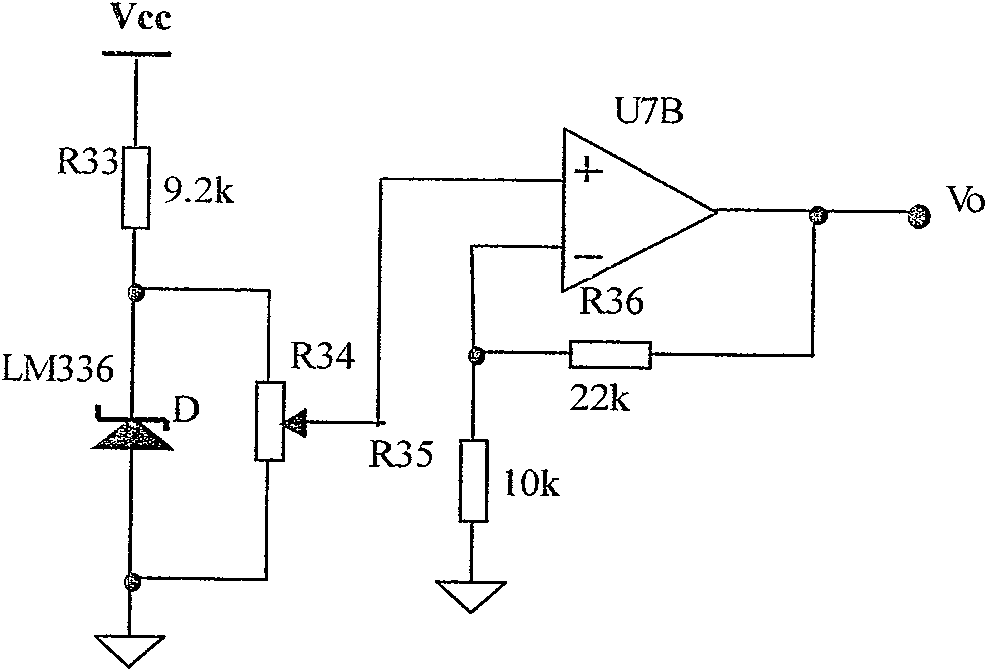

Precision thermostatic control laboratory box

InactiveCN100582987CImprove insulation effectImprove heat transfer abilityTemperature control using electric meansControllers with particular characteristicsMode locked fiber laserTemperature control

The invention provides a sophisticated and constant temperature control experiment box and belongs to the technological field of electronic equipment. The invention consists of an incubator (10) and a constant temperature controller. The incubator (10) comprises an insulation component and a thermal transfer component; the constant temperature controller consists of a temperature setting circuit (1), a temperature measurement circuit (2), a subtraction circuit (3), a PI control circuit (4), a limiting protection circuit (5), a TEC drives circuit (VCCS) (6) and a display circuit (7). The invention has the stable performance and the reliable work; the temperature control accuracy is 0.1 DEG C; the short-term stability is plus or minus 2.6*10<-3> DEG C; the long-term stability is plus or minus 0.024 DEG C; the temperature range at the normal temperature is 10 DEG C to 40 DEG C. The invention can not only be used for providing a constant-temperature environment for active lock-mold fiber laser experiment, but also can be used for measurement and testing on small occasions and for detection of gradually changed weak signals.

Owner:JILIN UNIV

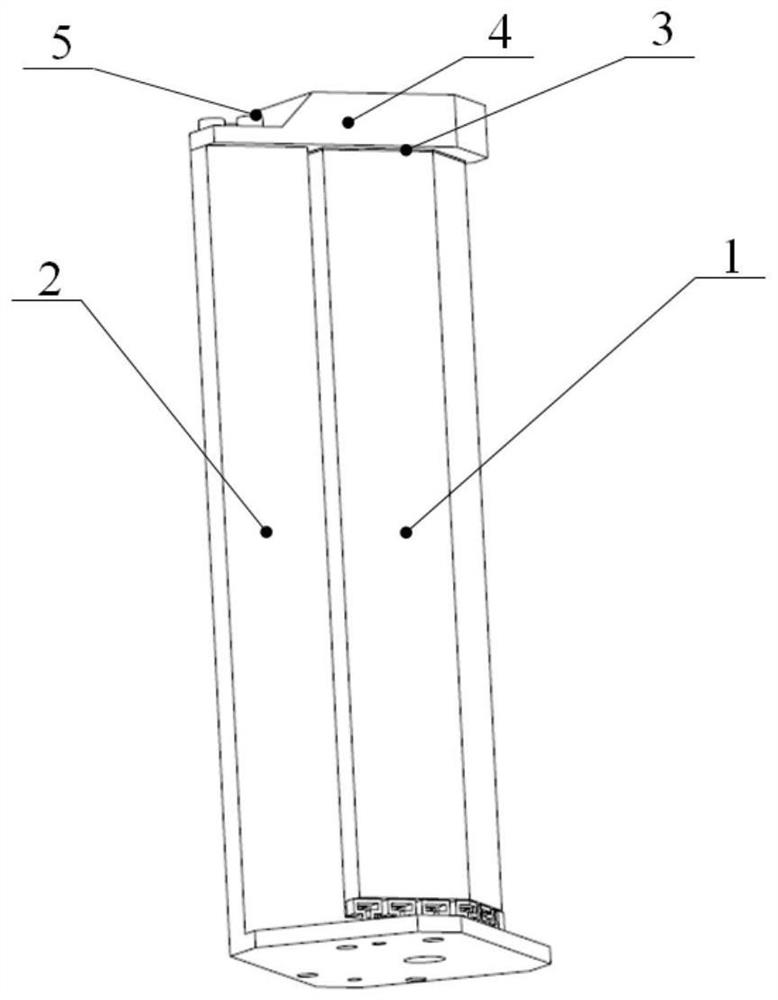

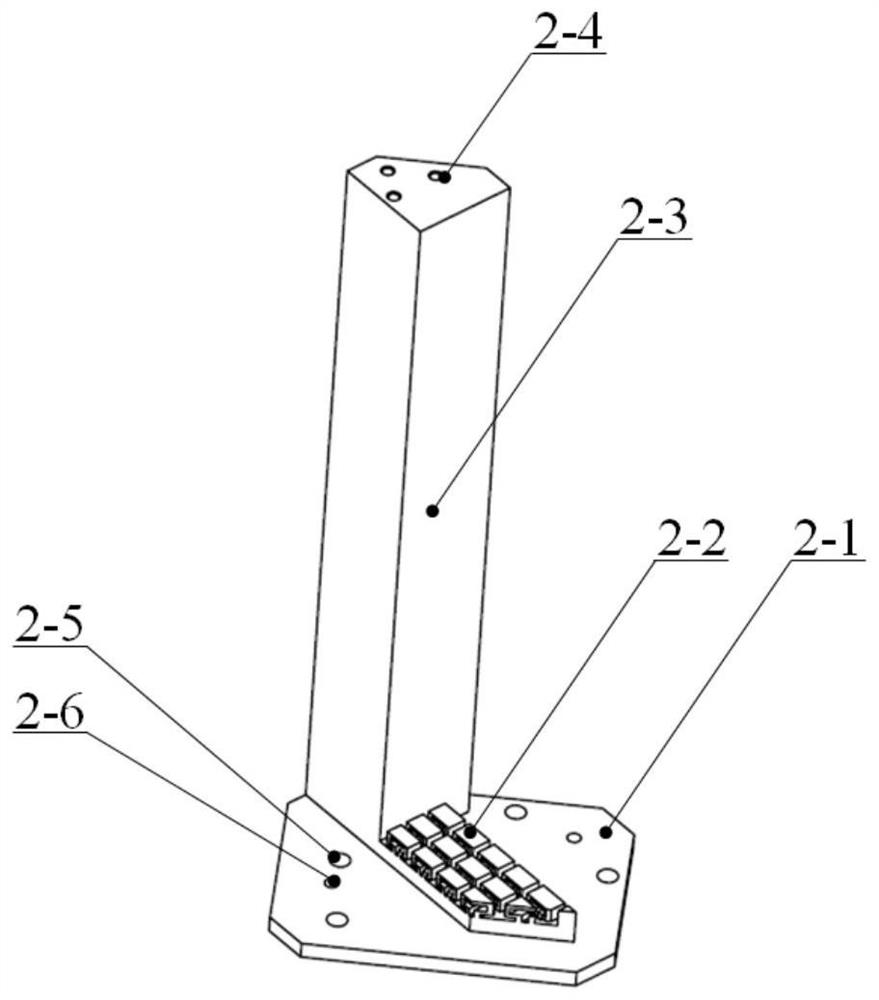

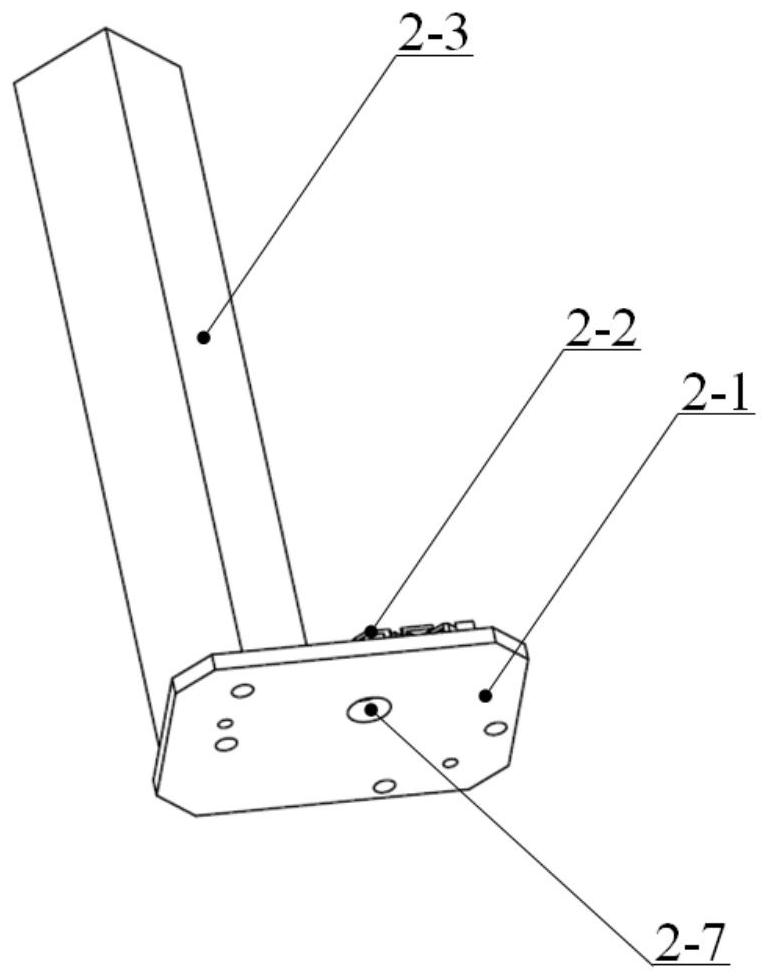

Flexible supporting structure of ultralow-temperature infrared optical reflecting prism

ActiveCN113655590AImprove deformation abilityImprove heat transfer abilityMountingsOptical reflectionImaging quality

The invention particularly relates to a flexible supporting structure for an ultralow-temperature infrared optical reflecting prism, and aims to solve the problem that the imaging quality is directly influenced by severe deformation of an optical reflecting mirror caused by large temperature difference between processing and assembling and actual working environments. The flexible supporting structure comprises a reflecting mirror base, a reflecting mirror end cover and a rubber block, wherein the reflecting mirror base is in an L shape, one side of the reflecting mirror end cover is fixedly connected with the other end of a base side support, the other side of the reflecting mirror end cover extends outwards and is kept parallel to the base of the base, the extension part is provided with the rubber block, a mounting area of the reflecting prism is formed among the rubber block, a flexible joint and the base side support, one end of the reflecting prism is connected with the flexible joint, the other end of the reflecting prism is connected with the rubber block, and the side part of the reflecting prism is connected with a vertical side beam.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

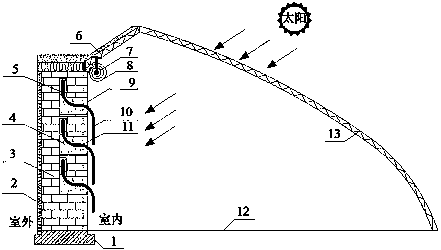

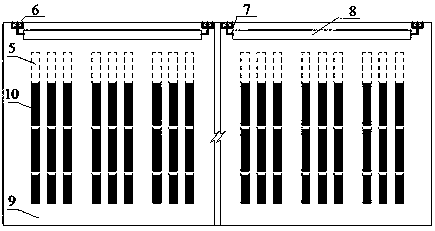

A solar greenhouse micro heat pipe array thermal storage wall

ActiveCN106234076BImprove heat storage efficiencyIncrease heat storageClimate change adaptationRenewable energy machinesInsulation layerBrick

The invention discloses a solar greenhouse micro-heat pipe array heat storage wall and a preparation method thereof and belongs to the technical field of agricultural facilities. The heat storage wall is sequentially composed of a heat insulation layer, a bearing building block layer, a micro-heat pipe module layer and a cement mortar layer from exterior to interior. The micro-heat pipe module layer is formed by building micro-heat pipe building blocks and building block bricks. Each micro-heat pipe building block is formed in the mode that condensation segments of a plurality of Z-shaped micro-heat pipes are arranged in parallel and inserted into a die and concrete is added for pouring and maintaining. Each micro-heat pipe is formed in the mode that an aluminum plate is stamped, a plurality of parallel micro-groove channels are formed in the aluminum plate and then filled with a proper amount of working medium and then sealing is carried out. By combining the requirements for uniformity of heat storing and releasing of the greenhouse wall, the micro-heat pipe building blocks are distributed in an arrayed mode, and the micro-heat pipe array heat storage wall is formed. By means of the micro-heat array technology, the diurnal solar energy is quickly transferred into the greenhouse wall, the heat storage capacity of the interior of the wall is improved, the stored heat energy is released in time at night according to needs of the heat environment in the greenhouse, and therefore the regulating capacity of the solar greenhouse wall for the heat environment in the greenhouse is improved, and the utilization rate of the solar energy by the greenhouse is increased.

Owner:LANZHOU JIAOTONG UNIV

Novel process for making synthetic natural gas by using coke-oven gas

ActiveCN101818087BAvoid poisoningPrevent "flying temperature" phenomenonGaseous fuelsMethanationHydrodesulfurization

The invention belongs to the field of the comprehensive utilization of coke-oven gas, and discloses a novel process for making synthetic natural gas by using the coke-oven gas. The qualified synthetic natural gas product is produced by the process comprising the steps of hydrodesulfurization, carbon compensation, multi-level methanation, cooling, separation and the like. The process can effectively prevent the temperature runaway phenomenon of a methanation reactor, can reasonably distribute the load of the methanation reactor, improves the conversion rate of CO and CO2, and provides a new method for making the synthetic natural gas by using the coke-oven gas.

Owner:NANJING GOODCHINA CHEM TECH

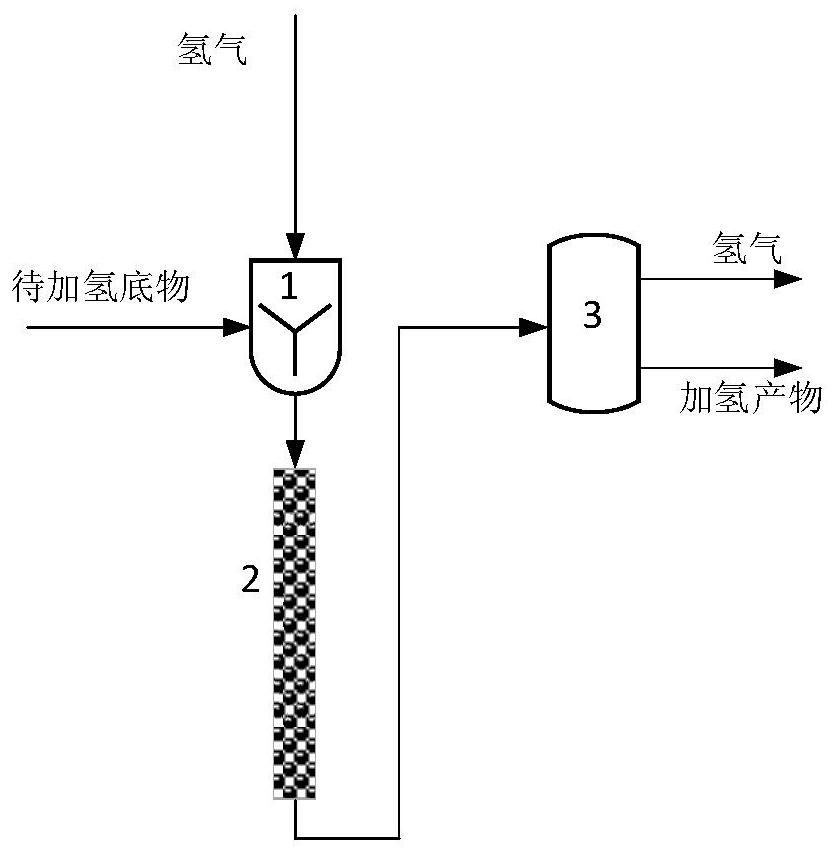

Method for one-step continuous hydrogenation synthesis of 1, 3-dimethyl-2-imidazolinone based on fixed bed microreactor

PendingCN114394937AImprove securityIncrease contact areaOrganic chemistryChemical/physical/physico-chemical microreactorsPtru catalystChemical reaction

The invention provides a method for one-step continuous hydrogenation synthesis of 1, 3-dimethyl-2-imidazolinone based on a fixed bed microreactor, and belongs to the technical field of chemical reaction engineering. The method comprises the following steps: firstly, mixing a substrate solution to be hydrogenated with formaldehyde to obtain a mixed solution, or adding homogeneous acid into the mixed solution, mixing with hydrogen in an inlet micromixer to obtain a gas-liquid mixed fluid, and then enabling the gas-liquid mixed fluid to pass through a micropacked bed filled with a catalyst to continuously finish a heterogeneous hydrogenation process by a one-step method. According to the method, efficient mixing and excellent mass and heat transfer performance of the microreactor are utilized, gas-liquid and liquid-solid mass transfer in the heterogeneous hydrogenation reaction process is enhanced, the heat transfer capacity of the reactor is improved, the volume of the reactor can be reduced, and the reaction yield is increased. The method can solve the problems of low production efficiency, poor product purity and high device risk in a hydrogenation kettle process, realizes continuous automatic operation of the process, and has the advantages of high yield, good safety and the like.

Owner:河北康壮环保科技股份有限公司 +1

A hydrogenation reaction device in a micro-packed bed and a method for hydrogenation reaction thereof

ActiveCN109225073BIncrease contact areaImprove mass transfer efficiencyChemical/physical processesPtru catalystChemical reaction

The invention discloses a hydrogenation reaction device in a micropacked bed and a method for a hydrogenation reaction by using the same in the technical field of chemical reaction engineering. The method comprises the steps: firstly, dispersing hydrogen into a solution containing a to-be-hydrogenated substrate by a micromixer to obtain a gas-liquid mixed fluid containing micro-scale bubbles; andthen, finishing a hydrogenation process on the gas-liquid mixed fluid by a micropacked bed filled with a hydrogenation catalyst. By using the method, the high mixing efficiency and excellent mass transfer and heat transfer performances of a microreactor are utilized, the gas-liquid and liquid-solid mass transfer in a hydrogenation reaction process is enhanced, the heat transfer capacity of the reactor is remarkably improved, and the size of a hydrogenation reactor can also be remarkably reduced; the hydrogenation reaction device has the advantages of high hydrogenation efficiency, safety, controllability and simplicity in amplification and can be widely applied to the technical fields such as petroleum and petrochemicals, fine chemical engineering, medicines, environments and foods.

Owner:TSINGHUA UNIV

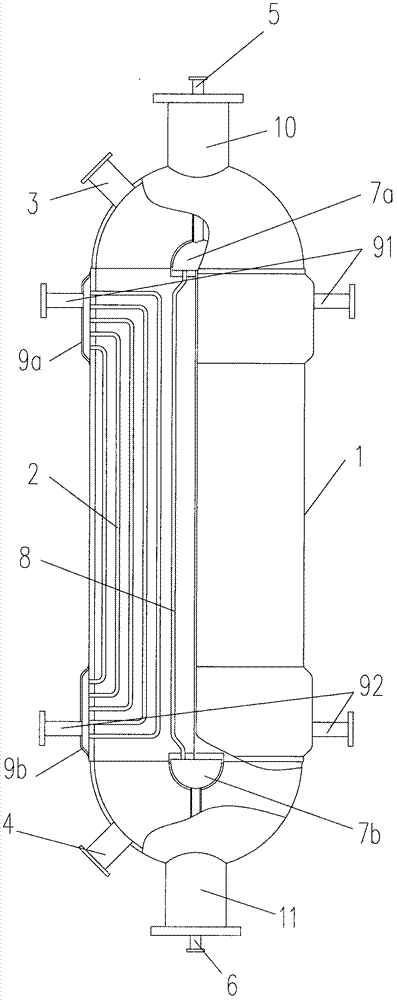

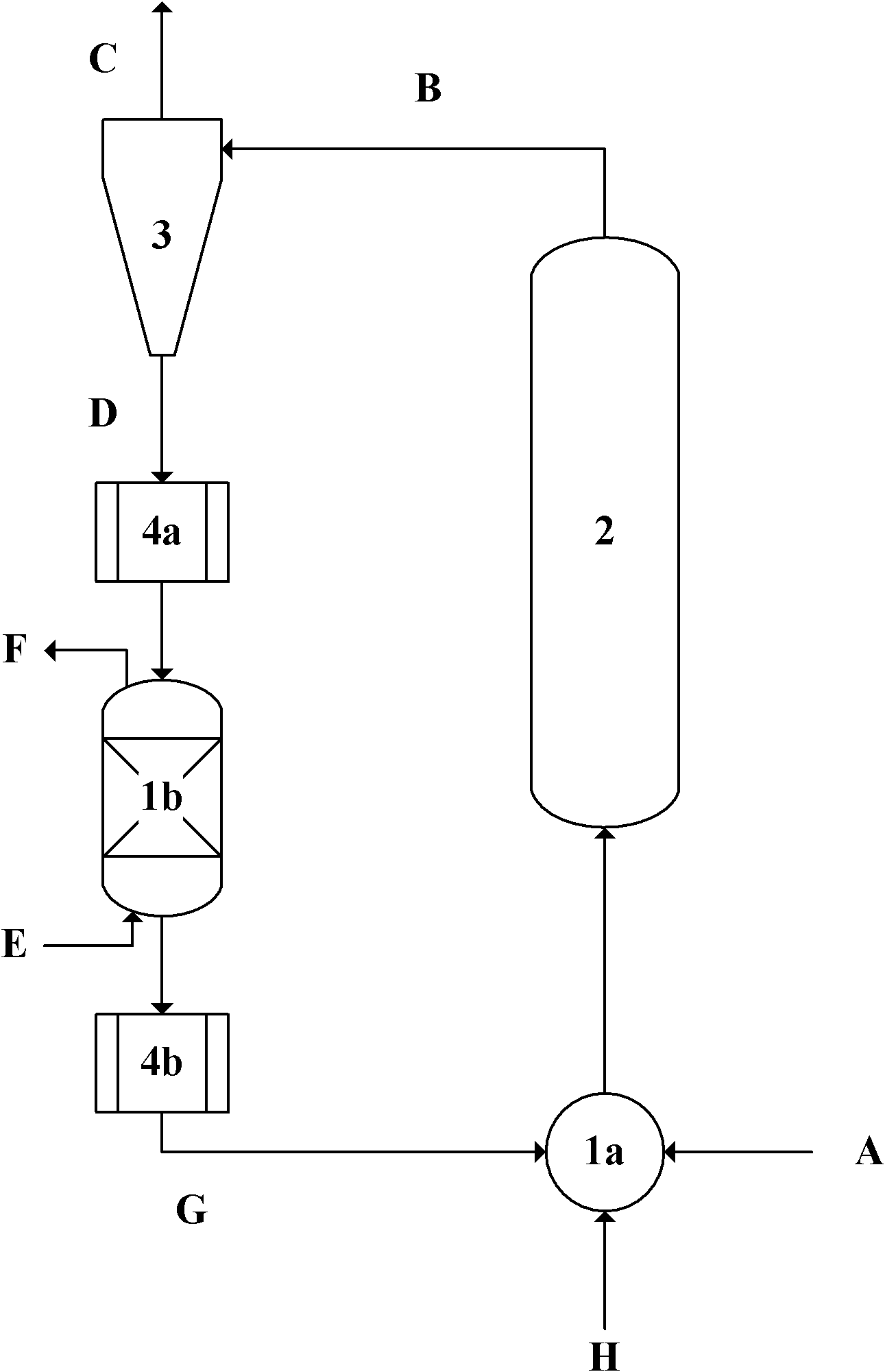

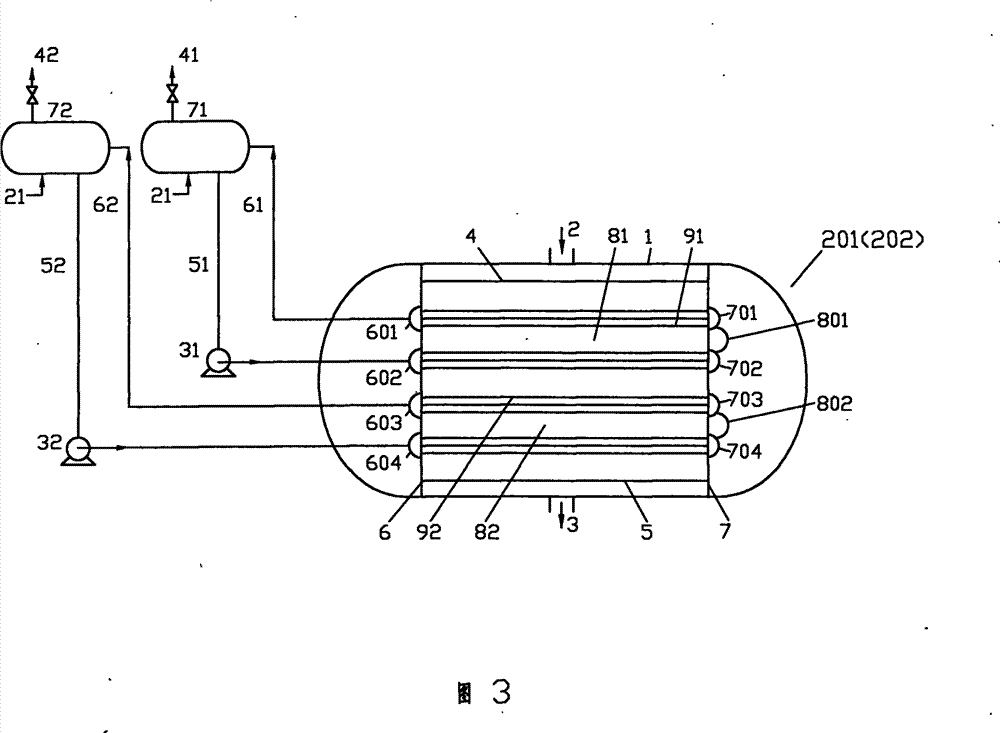

Device and method for complete methanation of synthesis gas

InactiveCN102180756BImprove heat transfer abilityImprove conversion rateHydrocarbon from carbon oxidesHeat carrierMethanation

The invention discloses a device and a method for complete methanation of synthesis gas, belonging to the technical field of coal chemical industry. The device consists of a mixer, a gas-solid-solid reactor, a cyclone separator, a heat recovery container, a first material seal and a second material seal. The method includes three main steps: complete methanation of synthesis gas consisting of feed gas carrying inert heat carrier particles, separation of product from the inert heat carrier particles, and recovering and recycling of the inert heat carrier particles, wherein the complete methanation of the synthesis gas consisting of the feed gas carrying the inert heat carrier particles can greatly reduce the reaction temperature, slow down the catalyst carbon deposit rate, and reduce the heat load of a material of a reactor, and the inert heat carrier particles are carried by reactant gas to pass through the reactor which can be continuously operated.

Owner:TSINGHUA UNIV

Method for continuous hydrogenation synthesis of 1, 3-dimethyl-2-imidazole based on serial microreactors

PendingCN114394936AImprove securityIncrease contact areaSequential/parallel process reactionsOrganic chemistryImidazolidinePtru catalyst

The invention discloses a method for continuous hydrogenation synthesis of 1, 3-dimethyl-2-imidazole based on serial microreactors, and belongs to the technical field of chemical reactions. The method comprises the following steps: dissolving 2-imidazolidone and formaldehyde in a solvent according to a certain ratio to prepare a mixed solution with a certain concentration, mixing the mixed solution with a solid acid catalyst to prepare an imine intermediate solution, then mixing the imine intermediate solution with hydrogen to obtain a gas-liquid mixed fluid, carrying out hydrogenation reduction, and finally carrying out gas-liquid separation on the gas-liquid mixture to obtain the 2-imidazolidone. The purity of the product is higher than 97%. The microreactor is used for mixing efficiently and has excellent mass and heat transfer performance, so that the heat transfer capacity of the reactor is improved, the volume of the reactor can be remarkably reduced, and the reaction yield is improved. The method can solve the problems of low production efficiency, poor product purity, high device risk and the like in a hydrogenation kettle intermittent synthesis process, can realize continuous automatic operation of the process, directly reduces the industrial cost, and realizes safe and environment-friendly production.

Owner:河北康壮环保科技股份有限公司 +1

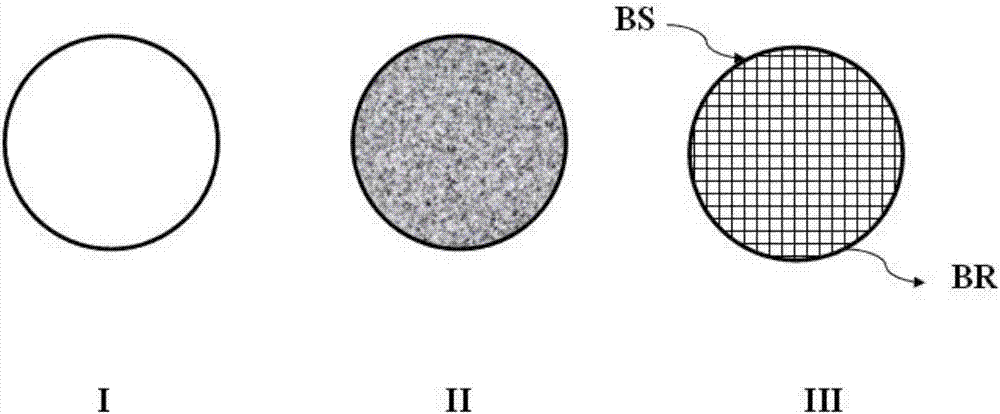

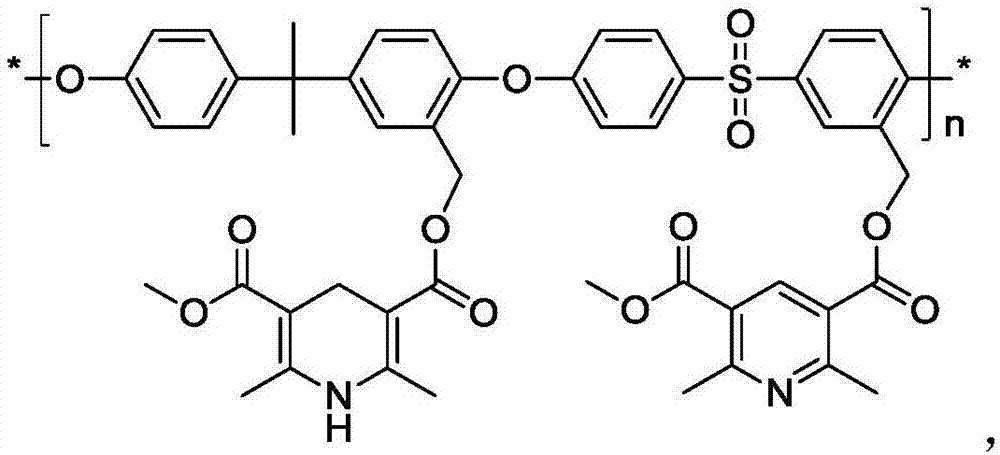

Catalyst, reactor using same and method for preparing beta-phenethyl alcohol

ActiveCN107952483ARealize continuous productionReduce processOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic reactionsStyrene oxidePhenethyl alcohol

The invention discloses a catalyst, a reactor using the same and a method for preparing beta-phenethyl alcohol. The catalyst is a polysulfone microporous membrane supported 1, 4-dihydropyridine Hantzsch nicotinamide coenzyme model compound molecule catalyst. The tubular membrane reactor comprises a tubular shell, a reaction cavity, a catalyst clamp and heat transfer grid tubes, the tubular shell is equally divided into a plurality of cavities, the catalyst clamp fixes the catalyst, and the heat transfer grid tubes cling to the catalyst and are mounted on two surfaces of the catalyst. The catalyst can hydrogenate styrene oxide in a high-selectivity and high-yield manner under the condition of room temperature to obtain the beta-phenethyl alcohol. The reactor can timely remove reaction heat,hydrogenation of styrene oxide can be performed without solvents, and desolvent energy consumption and production cost are reduced.

Owner:WANHUA CHEM GRP CO LTD

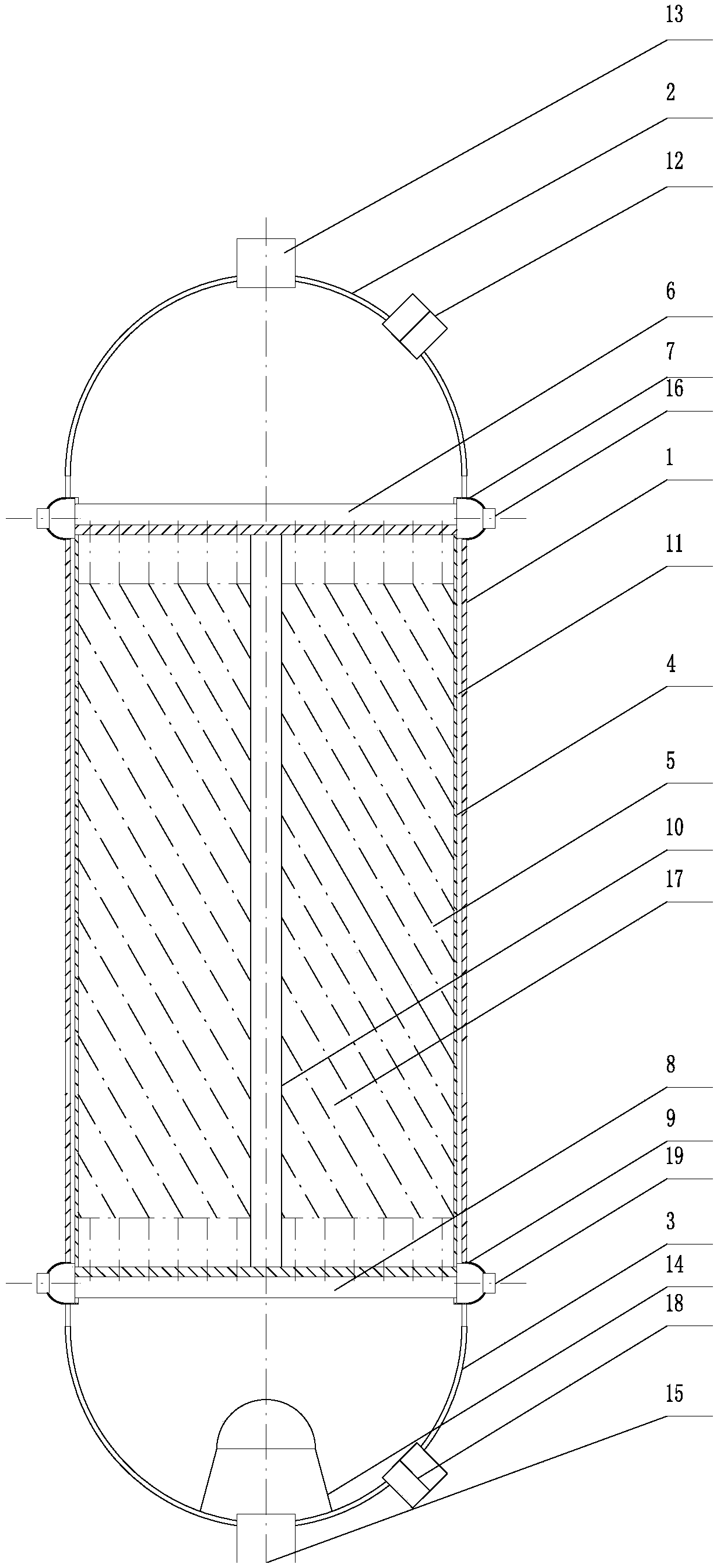

Coupling reactor for synthesizing ethylene glycol by alkyl oxalate hydrogenation

PendingCN109395668AAvoid influenceExtended service lifeOrganic compound preparationHydroxy compound preparationOxalateCoupling

The invention relates to a coupling reactor for synthesizing ethylene glycol by alkyl oxalate hydrogenation. The coupling reactor comprises an upper head, a lower head and a reactor shell arranged between the upper head and the lower head, wherein the upper head is provided with a reaction gas inlet, a refrigerant outlet and a manhole; the lower head is provided with a reaction gas outlet, a refrigerant inlet and a catalyst unloading port; a first gas distributor, an adiabatic reaction section, a second gas distributor and an axial-radial reaction section are arranged in the reactor shell fromtop to bottom sequentially. Compared with the prior art, the coupling reactor is simple and compact in overall structure, good in economic practicability, safe and stable, has the advantages that reaction gas is distributed uniformly, bed temperature distribution is reasonable, selectivity of ethylene glycol is high, and production capacity of the reactor can be improved remarkably on the premisethat diameter of the reactor is not increased, and has good industrial application prospect accordingly.

Owner:PUJING CHEM IND SHA

Method and equipment for producing hydrocarbon with synthetic gas

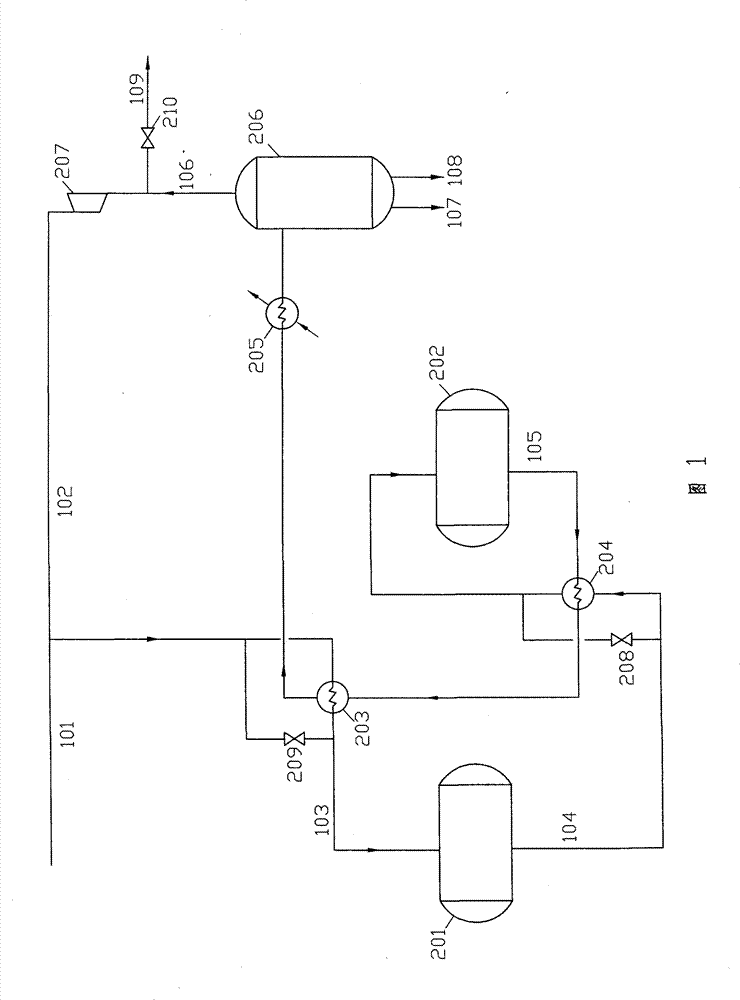

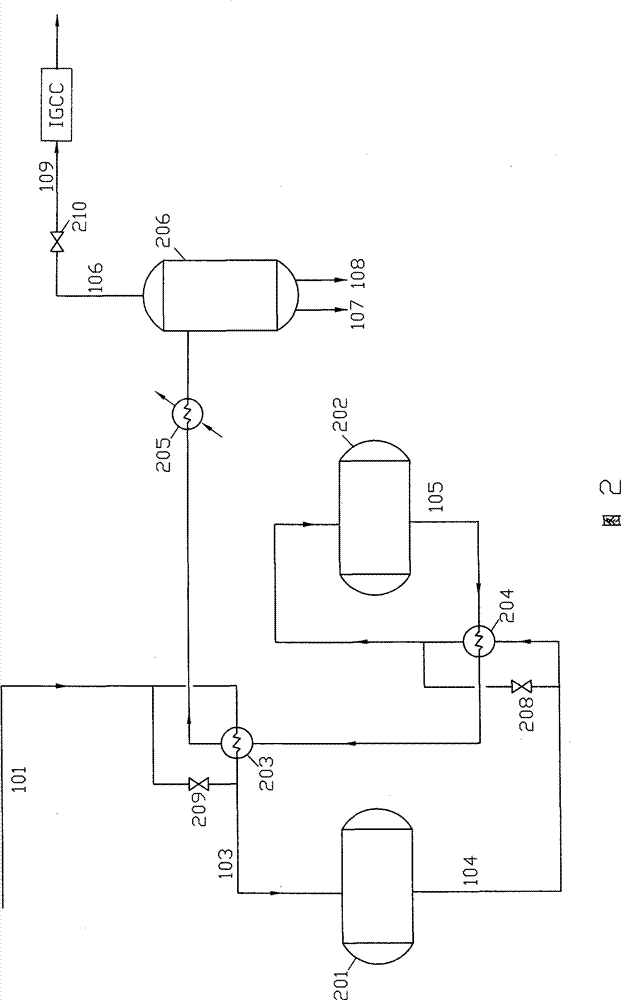

ActiveCN101519336BImprove heat transfer abilityRelease slows downOrganic compound preparationHydroxy compound preparationTowerIntegrated gasification combined cycle

The invention discloses a method for producing hydrocarbon with synthetic gas, which comprises essentially the steps as follows: methanol synthetic reaction of the pressurized synthetic gas is implemented in a methanol synthetic reactor, reaction gas is not separated after being output from a reaction tower and enters a methanol dehydrating reactor under the same pressure level so as to implement the methanol dehydrating reaction and generate the hydrocarbon product, the final reaction gas is cooled and separated so as to generate the hydrocarbon product, water and unreacted synthetic gas, and the separated synthetic gas is either discharged for gas-steam integrated gasification combined cycle (IGCC) or taken as recycled synthetic gas and mixed with the raw material synthetic gas in further methanol synthesis, methanol dehydration and product separation besides little discharge.

Owner:杭州林达化工技术工程有限公司

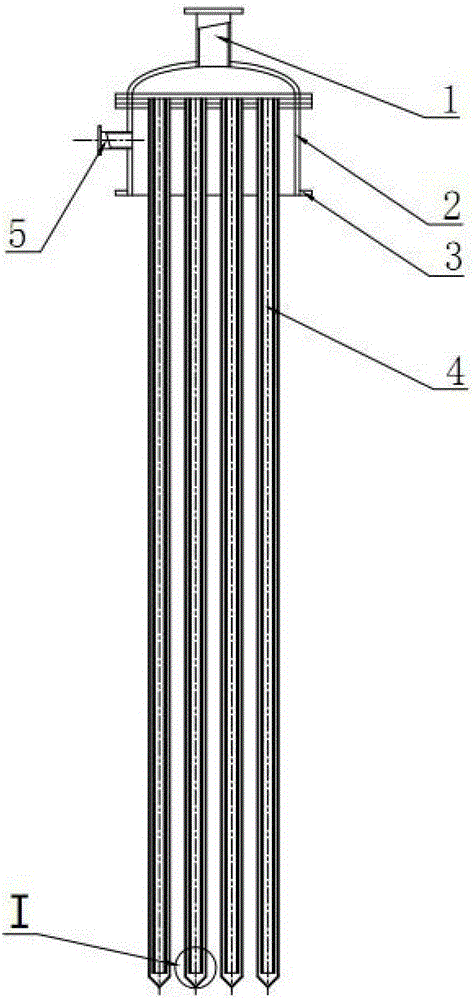

A finger heat exchanger with a three-tube structure used in a fluidized bed reactor for trichlorosilane synthesis

InactiveCN102910634BSimple structureEasy to manufactureHalogenated silanesPlate heat exchangerFluidized bed

The invention relates to a finger-type heat exchanger with a triple-sleeve structure used in a fluidized bed reactor for synthesizing trichlorosilane, which comprises a heat conduction oil inlet, an upper heat exchange tube seal head, a heat exchange tube connection flange, a plurality of finger-type triple-sleeve heat exchange tubes, and a heat conduction oil outlet, wherein each finger-type triple-sleeve heat exchange tube consists of an inner tube, a liner tube and an outer tube that are sequentially arranged from inside to outside, the upper end and the lower end of an annular interstice space between each inner tube and each liner tube are closed, and each annular interstice space is vacuumed to form a vacuum isolated layer. The heat exchanger solves the problem that oil temperature rises greatly as heat conduction oil enters the annular interstice spaces between the inner tubes and the outer tubes from the inner tubes, the temperature of a fluidized bed can be distributed uniformly, the reaction is stable, and the utilization ratio and the product purity of silicon powder are higher.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

A kind of methanation method combining fluidized bed and fixed bed

ActiveCN105255532BImprove heat transfer efficiencyImprove heat transfer abilityGaseous fuelsTemperature controlVapor–liquid separator

The invention discloses a fluidized bed and fixed bed combined methanation method. The method comprises the steps that (1) a methanation feed gas is divided into two feed gases; one feed gas, water vapor and a recycle process gas from a fluidized bed methanation system enter the fluidized bed methanation system after being mixed to undergo methanation reaction under the action of a fluidized bed methanation catalyst; (2) a part of the outlet gas of the fluidized bed methanation system undergoes heat exchange, then is treated by a gas-liquid separator to separate condensed water and is mixed with the other feed gas; the gases enter a fixed bed methanation reaction system to undergo methanation reaction under the action of a fixed bed methanation catalyst; the other part of the outlet gas from the fluidized bed methanation system serves as the recycle process gas. Control of the temperature of the whole system is achieved by adding two system temperature control means, namely regulating the split ratio of the feed gases entering the two reactor systems and injecting the gas mixture of water vapor and the recycle process gas into the fluidized bed reaction system by an ejector.

Owner:CHINA NAT OFFSHORE OIL CORP +1

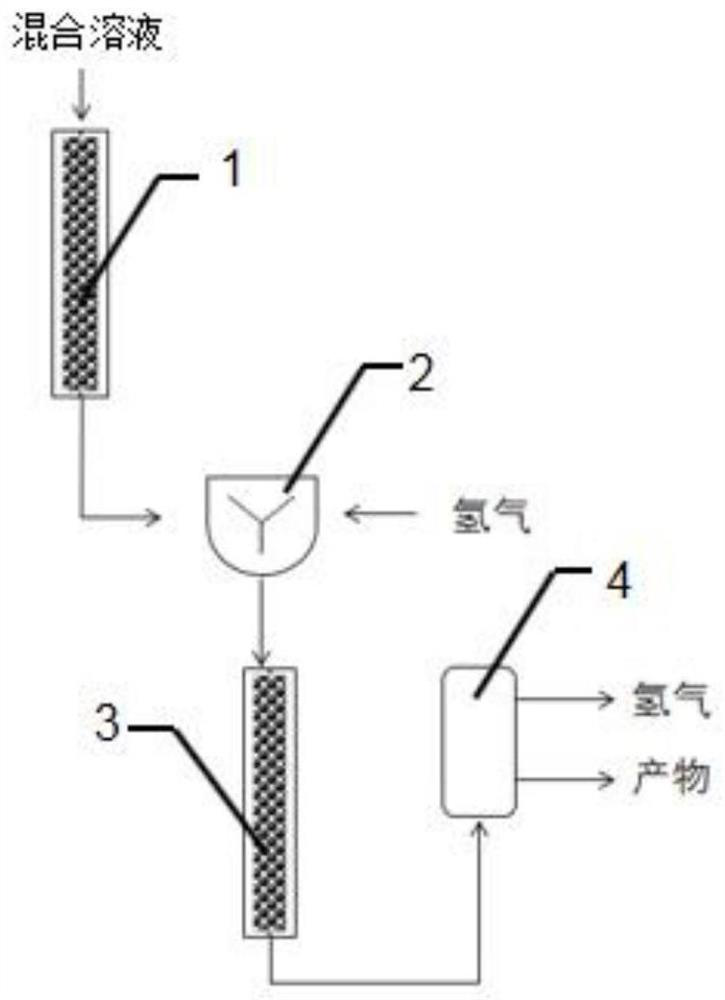

A device for continuously synthesizing benzylamines by heterogeneous hydrogenation in a microreactor

ActiveCN110627650BIncrease contact areaImprove mass transfer efficiencyChemical/physical/physico-chemical microreactorsPreparation by reductive alkylationMicroreactorChemical reaction

Belonging to the technical field of chemical reaction, the invention particularly relates to a device for continuous synthesis of a benzylamine substance through heterogeneous hydrogenation in a micro-reactor. The device comprises: an inlet micro-mixer (1), an inlet micro-mixer (2), a micro-packed bed reactor (3) and an outlet split-phase tank (4). The device utilizes the efficient mixing and excellent mass and heat transfer performance of the micro-reactor to enhance the interphase mass transfer and heat removal capability in the reaction process, and can obviously reduce the volume of the reactor, improve the reaction yield, and enhance the production efficiency and safety. The method can solve the problems of low production efficiency, poor product purity, high device risk and the likein the hydrogenation kettle process, can realize continuous automatic operation of the process, and has the advantages of high yield, high safety and the like.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com