Straight pipe header coil pipe type reactor for waterway natural circulation

A tubular reactor, natural circulation technology, applied in the fields of carbon monoxide or formate reaction preparation, chemical instruments and methods, preparation of organic compounds, etc. problems, to achieve the effect of convenient and simple filling and self-unloading, high overall heat transfer coefficient, and reduced floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

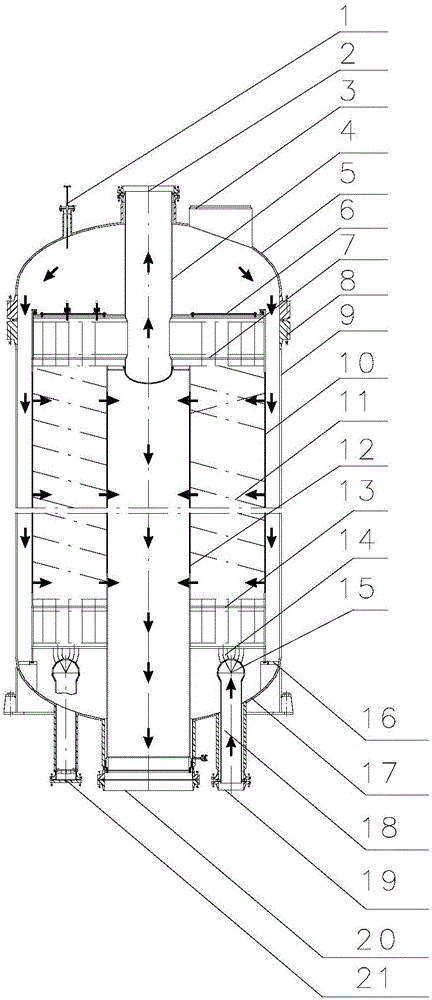

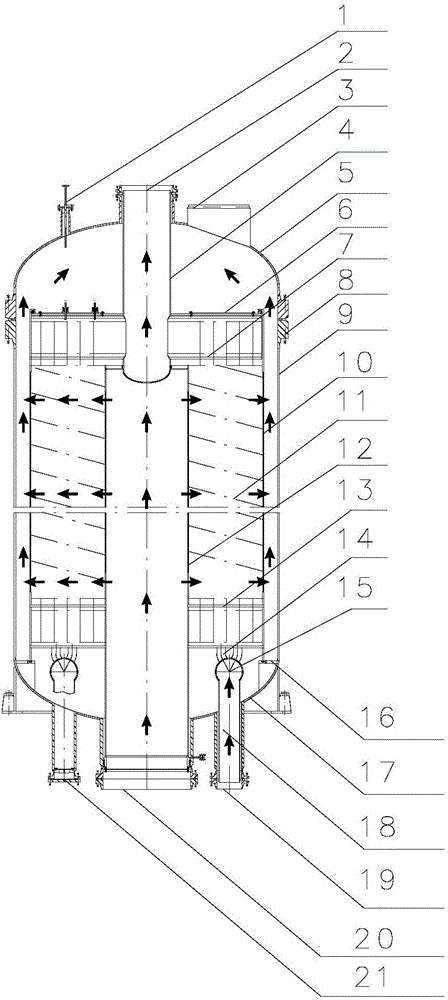

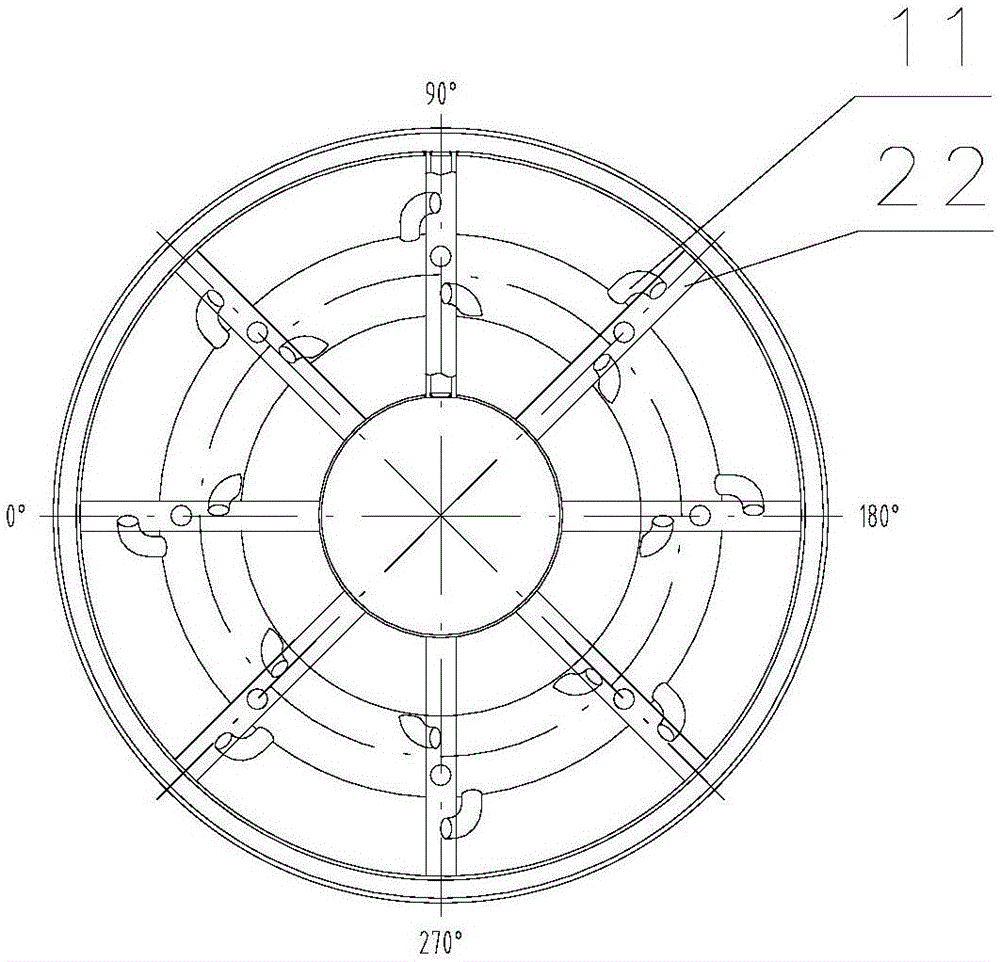

[0036] like figure 1As shown, this embodiment includes a pressure-bearing shell, a catalyst frame and a heat exchange tube bundle, and the catalyst frame and heat exchange tube bundle are respectively arranged in the pressure-bearing shell; the heat exchange tube bundle includes an outlet pipe 4, an upper straight pipe Header 7, snake pipe 11, lower straight pipe header 13, branch pipe 14, ring pipe 15 and water inlet pipe 18, the outlet pipe 4 is connected to the top of the pressure-bearing shell, and the upper straight pipe header 7 is respectively connected to the The inlet of the water pipe 4 and the outlet of the coil pipe 11, the coil pipe 11 is distributed along the axial direction of the pressure-bearing shell, the lower straight pipe header 13 is respectively connected to the inlet of the coil pipe 11 and the outlet of the branch pipe 14, the inlet The water pipe 18 is connected to the bottom of the pressure housing, and the annular pipe 15 is respectively connected t...

Embodiment 2

[0045] like figure 2 Shown, the present embodiment uses reactor to carry out the method for carbonylation reaction, comprises the following steps:

[0046] (21) Palladium series catalyst is filled in the catalyst frame;

[0047] (22) In the coiled pipe 11, water flows from bottom to top, and the lower gas port 20 enters the reaction gas, passes through the catalyst bed in the radial direction through the inner gas cylinder 12 to the outer gas cylinder 10, and carbonylation reaction occurs;

[0048] (23) After the reaction, the water phase change in the coiled pipe 11 absorbs heat, and the heat of the carbonylation reaction in the catalyst frame is removed, and the gas is collected by the outer gas cylinder 10, and then discharged through the upper gas port 3 and takes away the heat.

[0049] Using the reactor of this embodiment, 2CH can be completed 3 ONO+2CO=CH 3 OCOCOCH 3 O+2NO+Q 放 、2CH 3 ONO+CO=CH 3 OCOCH 3 O+2NO+Q 放 、2CH 3 ONO=HCHO+CH 3 OH+2NO+Q 放 Waiting for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com