Patents

Literature

1992results about How to "Improve heat transfer coefficient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

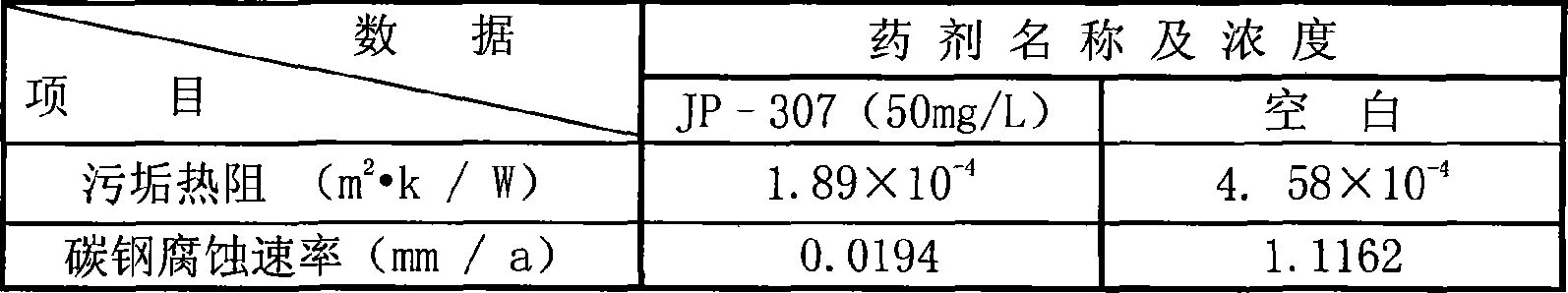

No-phosphate corrosion and scale inhibitor and its application

InactiveCN101066811AExcellent corrosion inhibition performanceIncrease polarityScale removal and water softeningNon-contaminated water treatmentPolyaspartic acidPhosphate

The present invention relates to no-phosphate corrosion and scale inhibitor and its application. The no-phosphate corrosion and scale inhibitor consists of polyaspartic acid and / or polyepoxy succinic acid 10-20 wt%, polymaleic anhydride 20-30 wt%, copolymer of acrylic acid and 2-acrylamido-2-methyl propenyl sulfonic acid 15-20 wt%, zinc salt 3-5 wt%, natural organic high molecular compound 5-12 wt%, molybdate 5-8 wt%, and other components 5-20 wt%. It has excellent corrosion retarding performance, high scale inhibiting performance and environment friendship.

Owner:WUHAN JINPO CHEM TECH

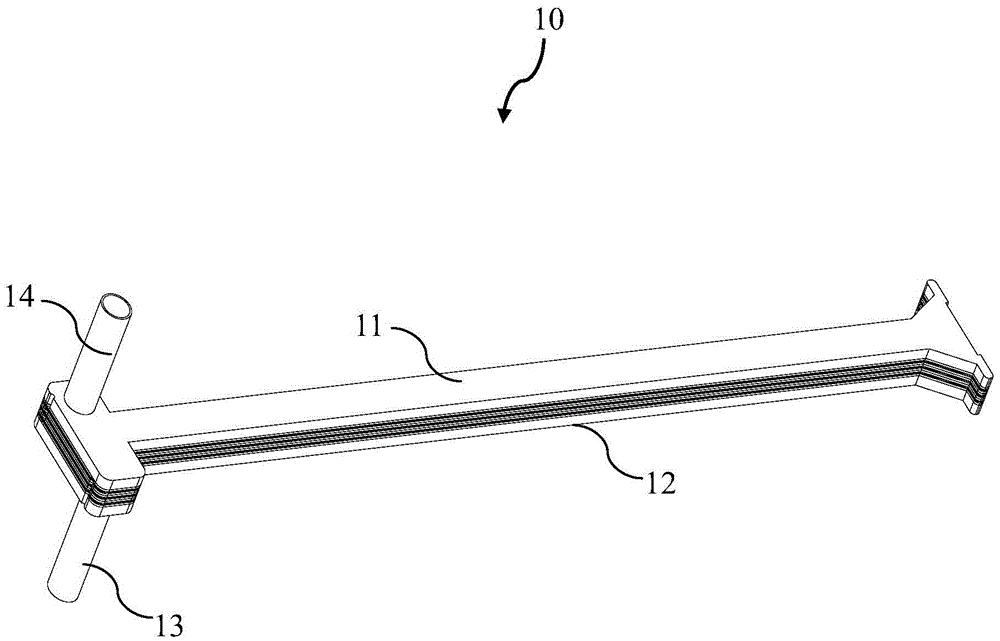

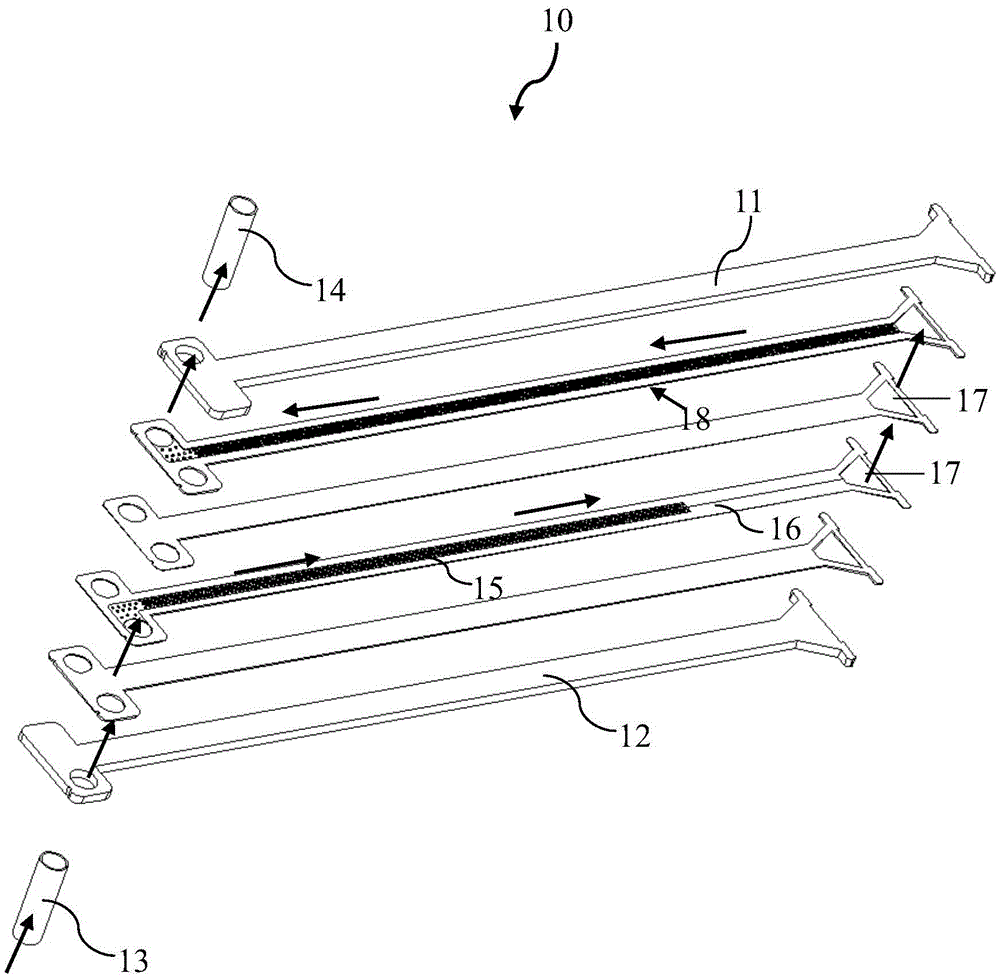

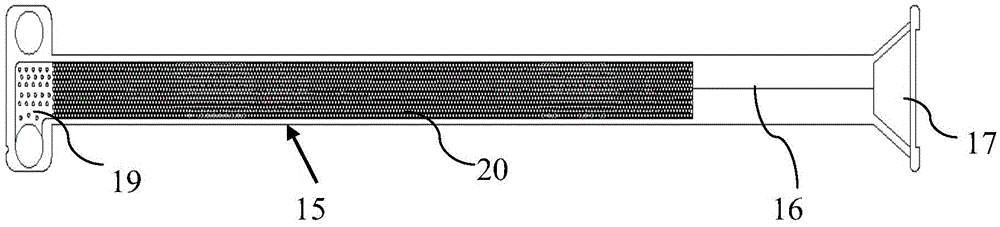

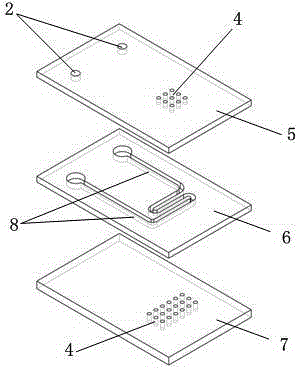

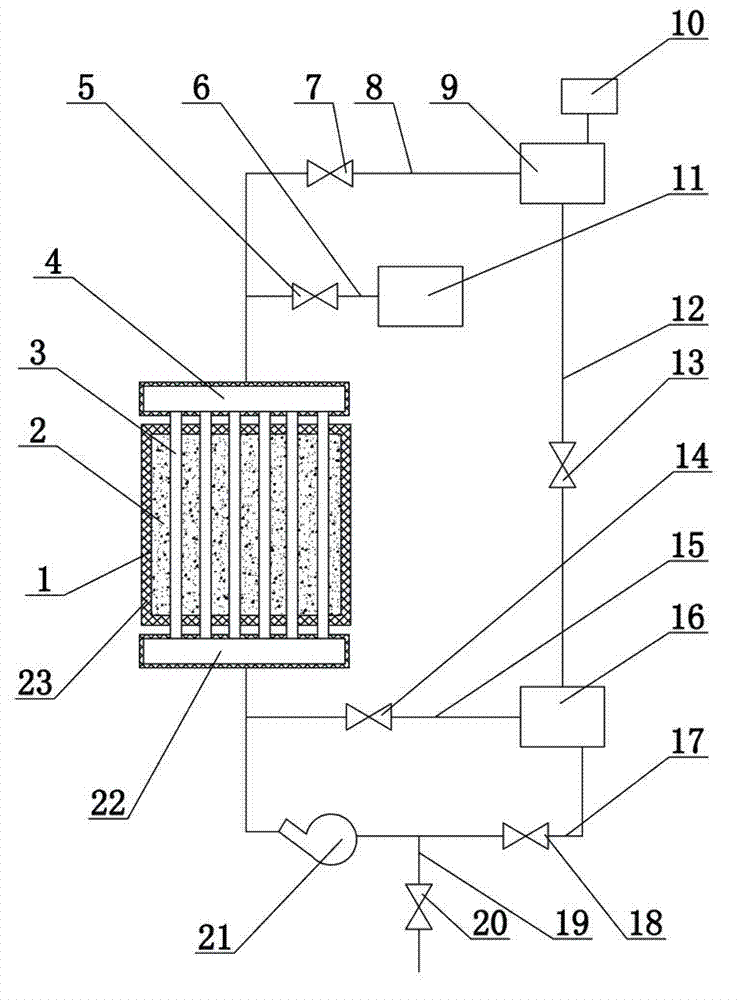

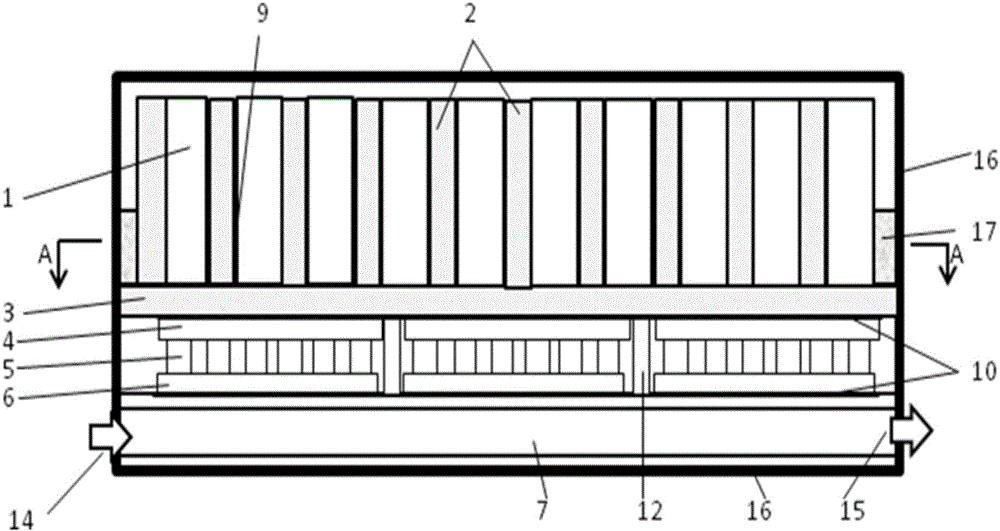

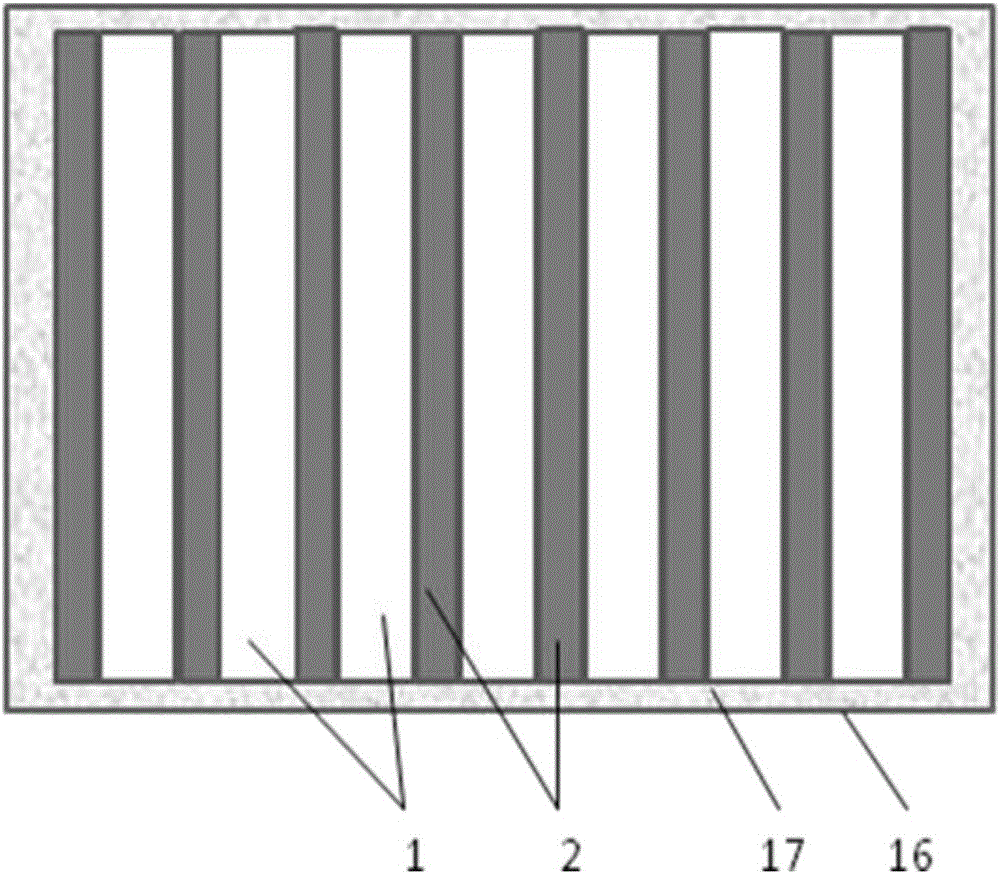

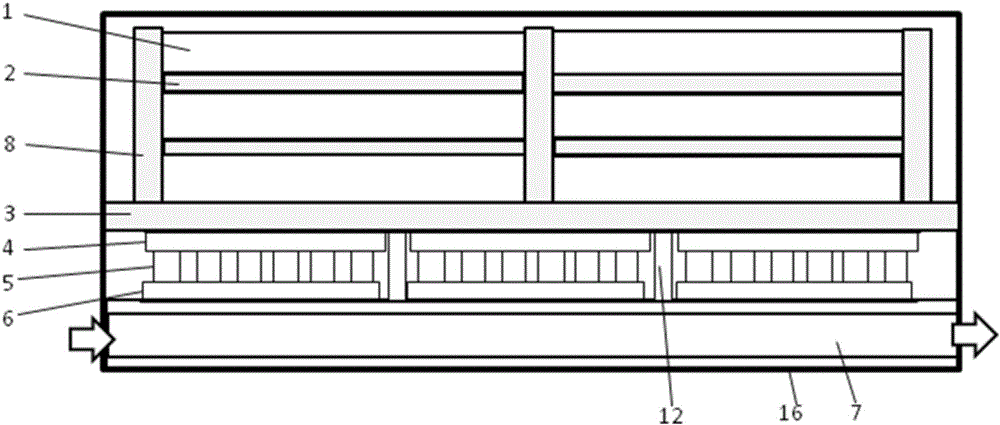

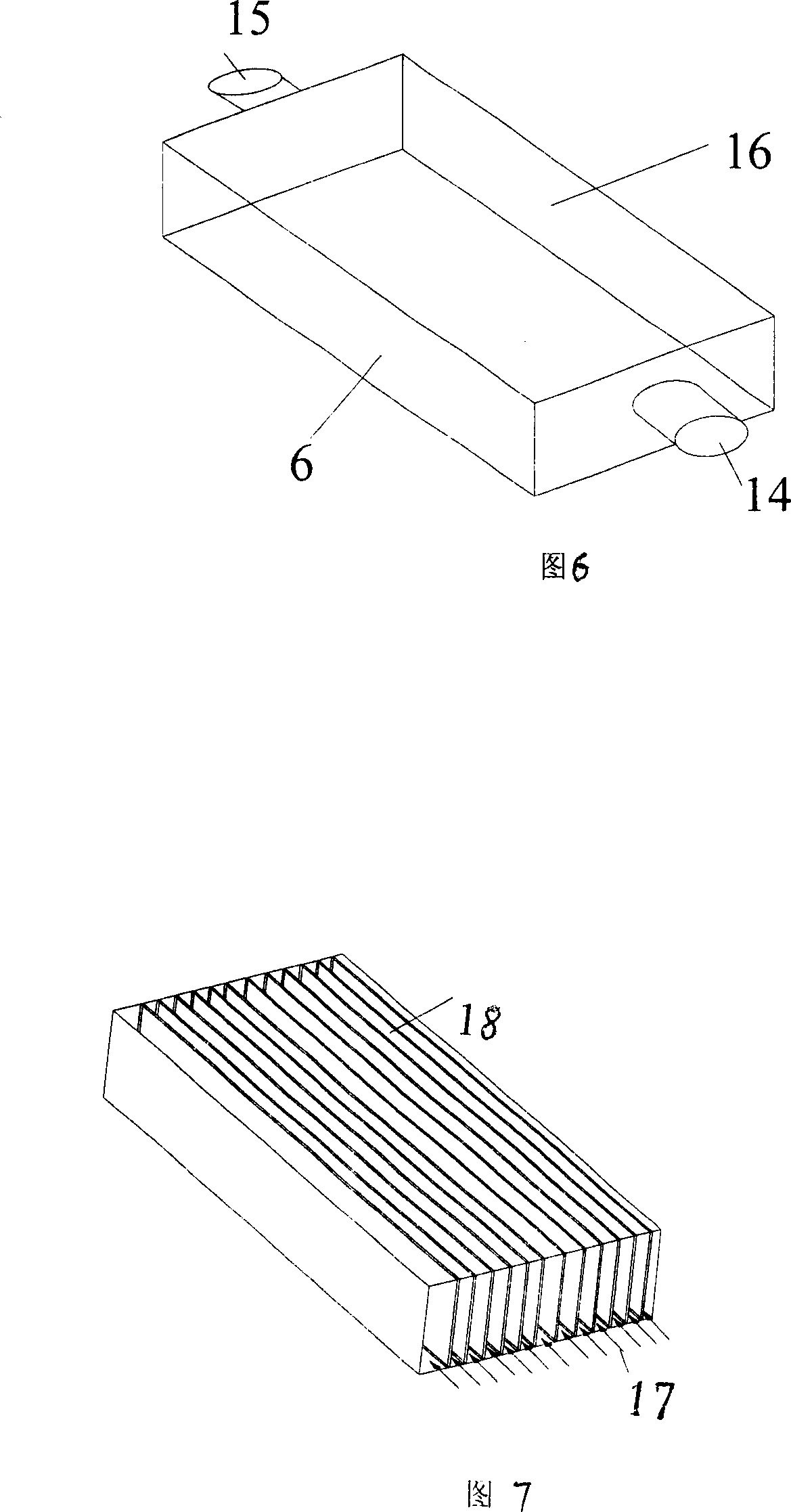

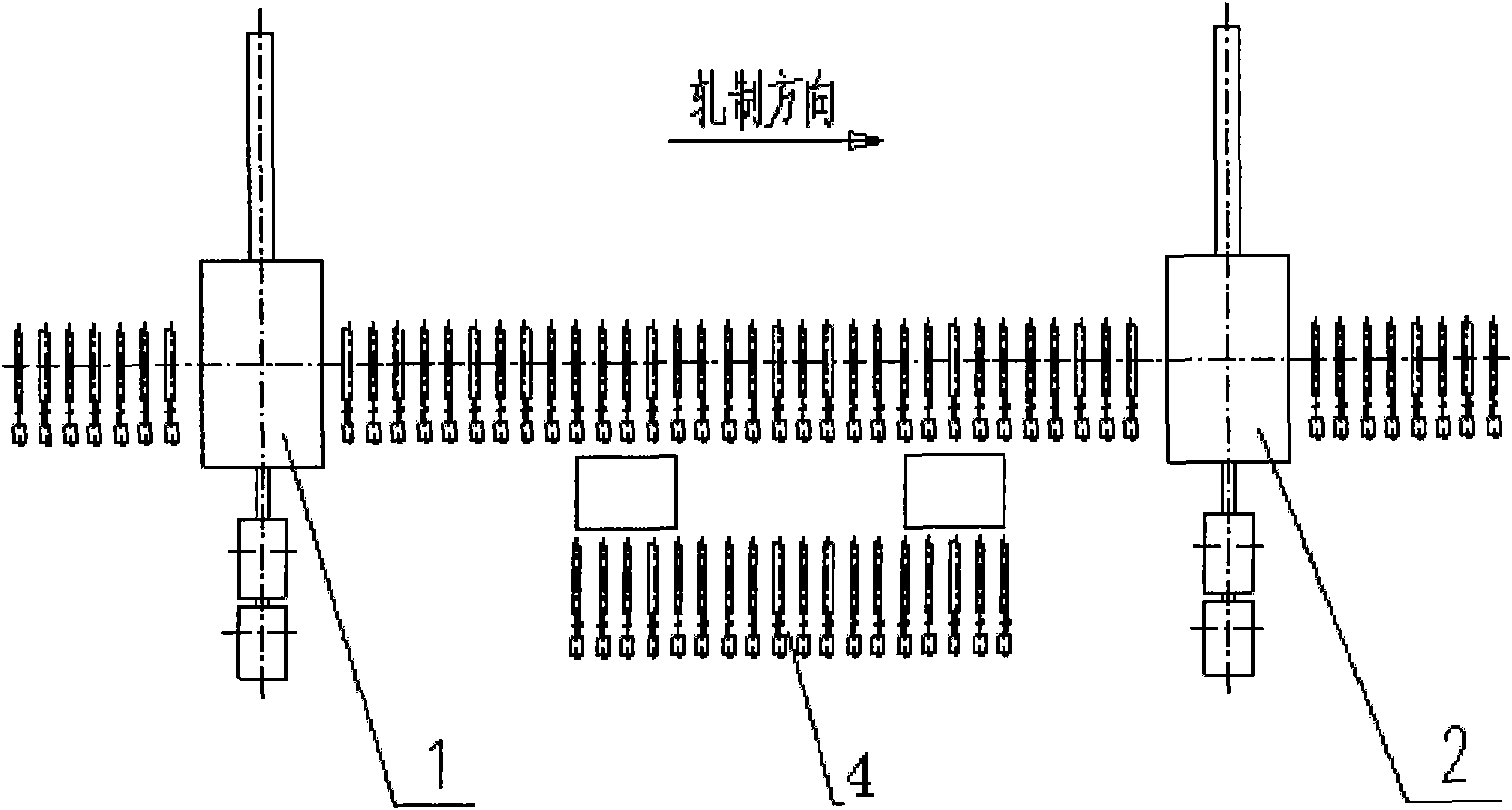

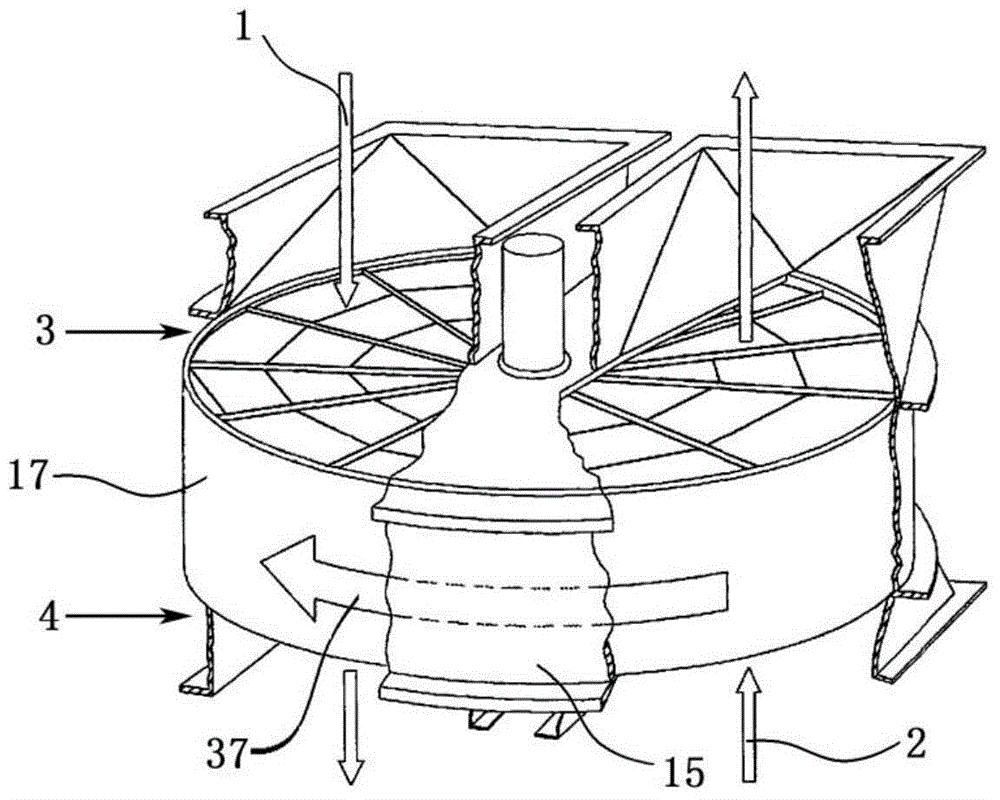

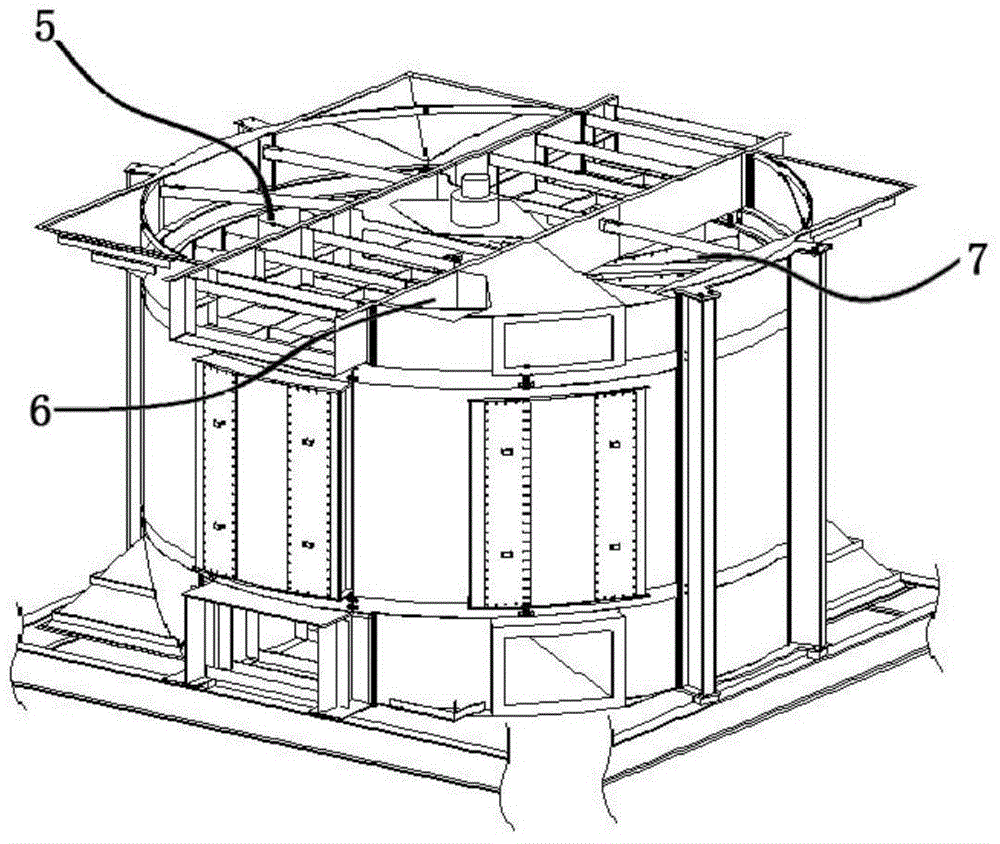

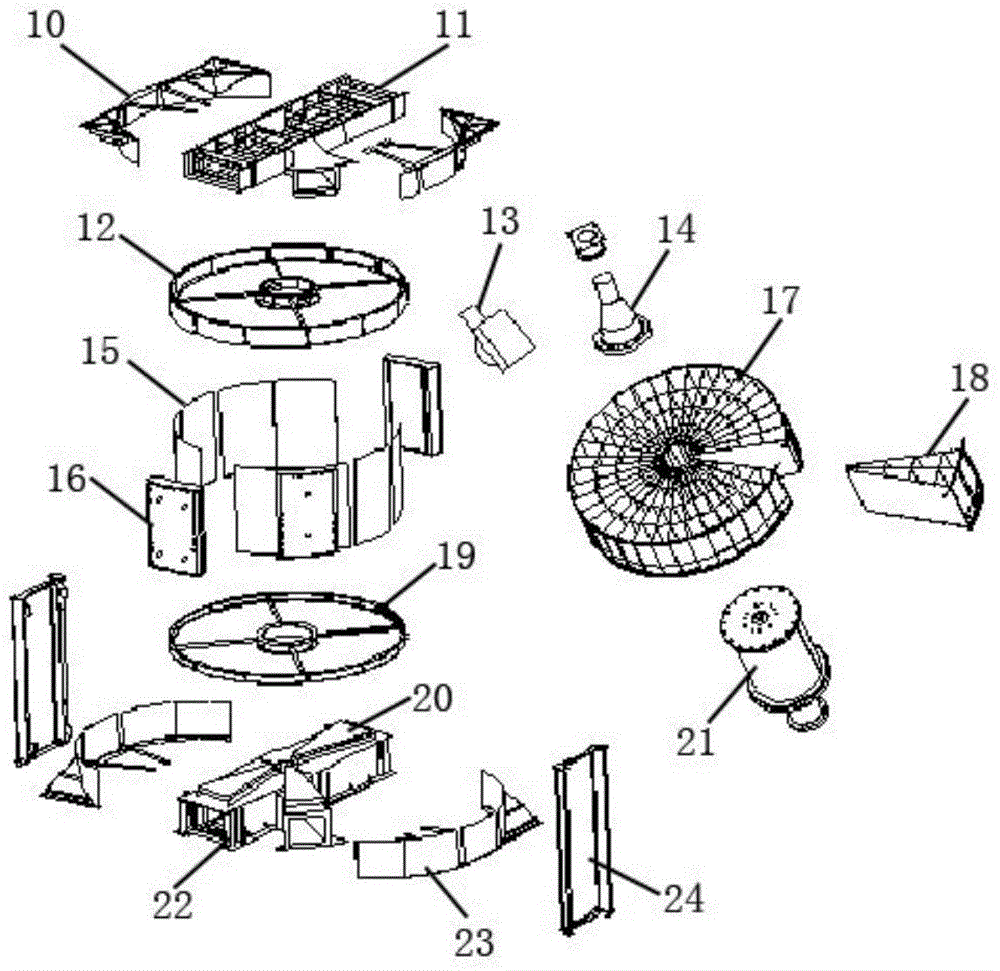

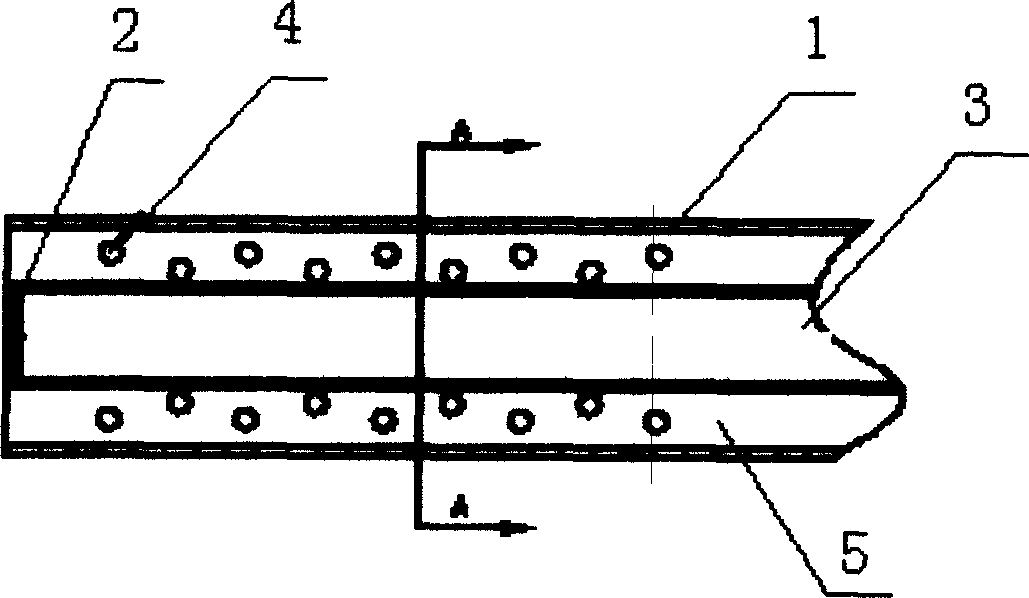

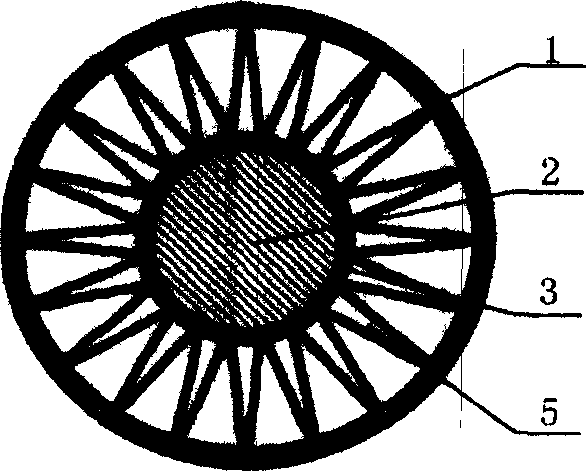

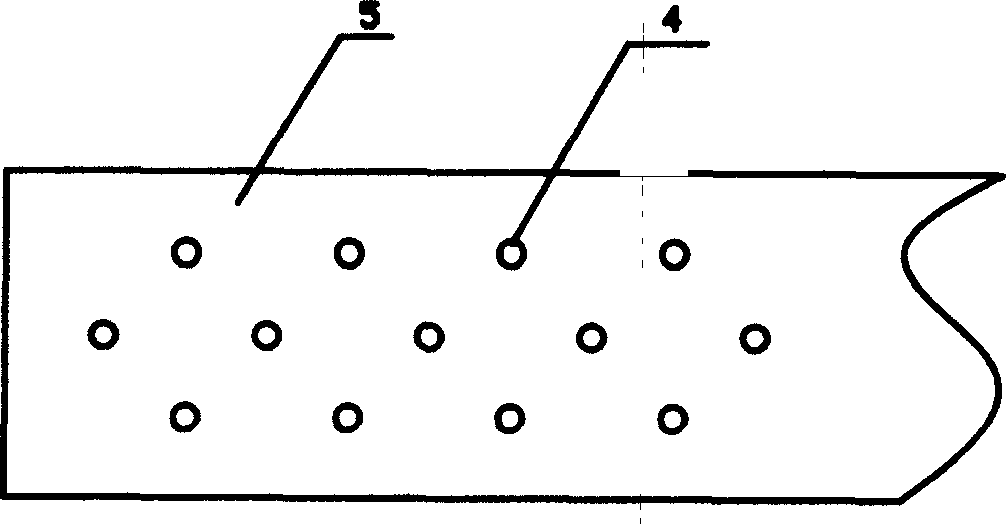

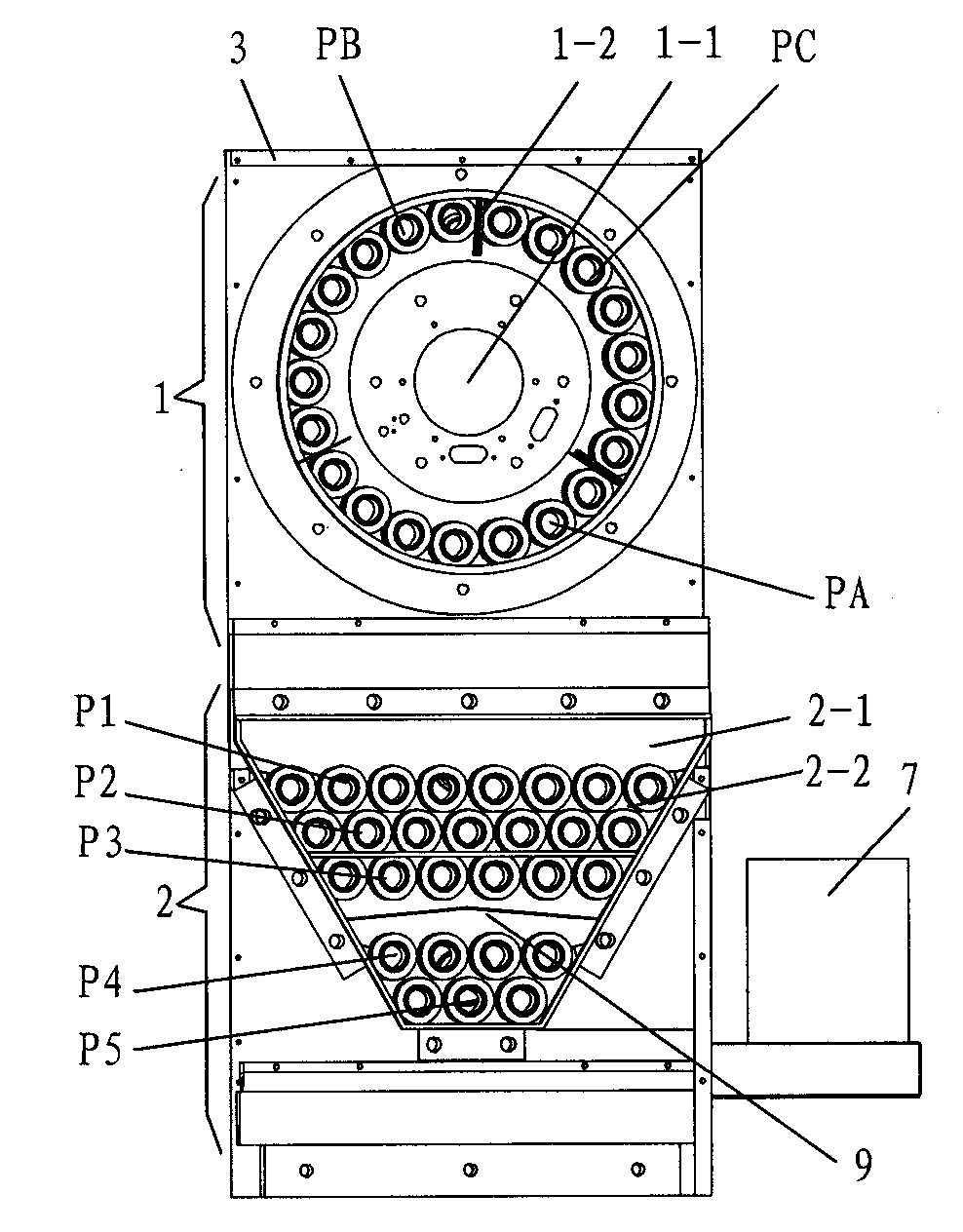

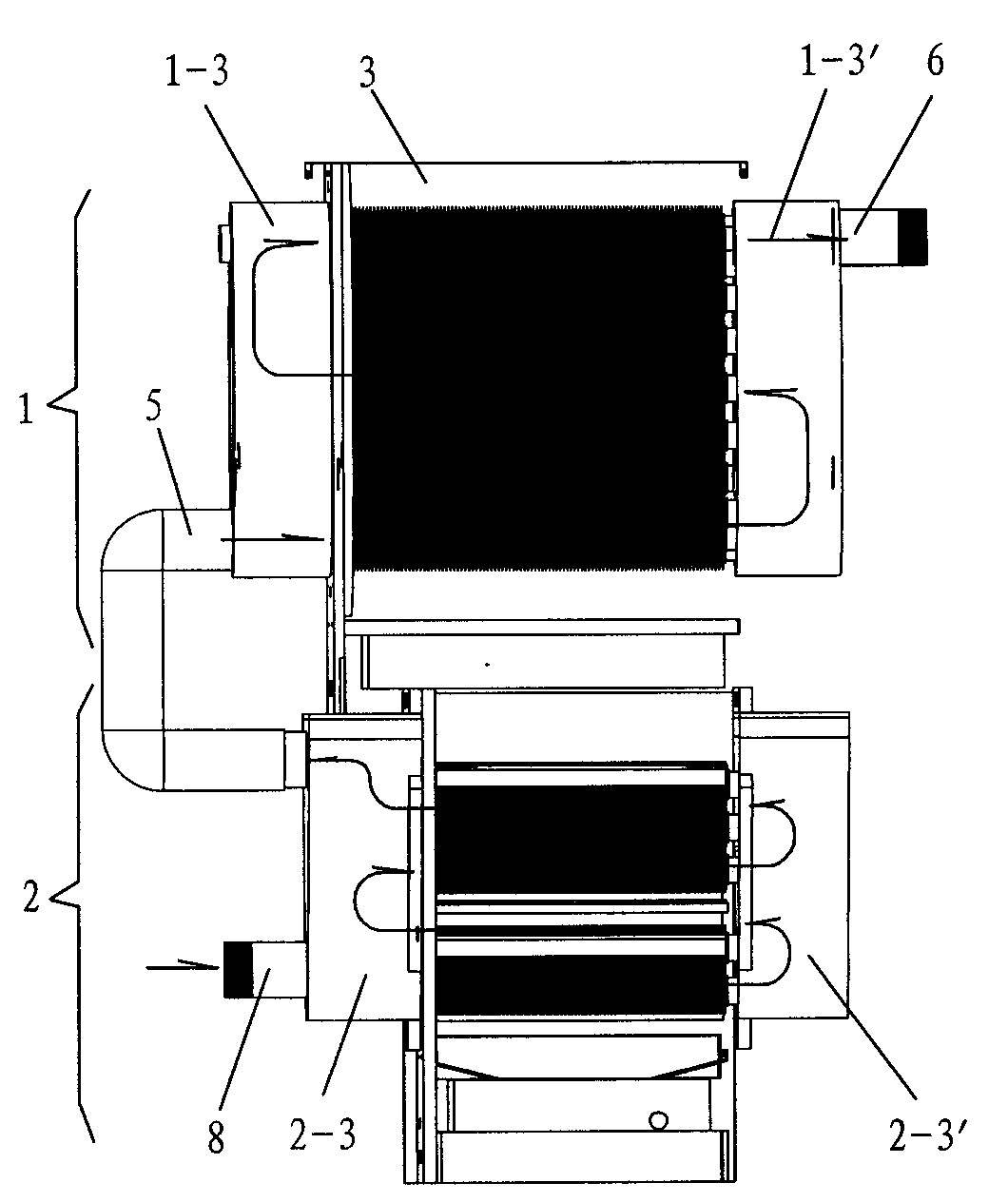

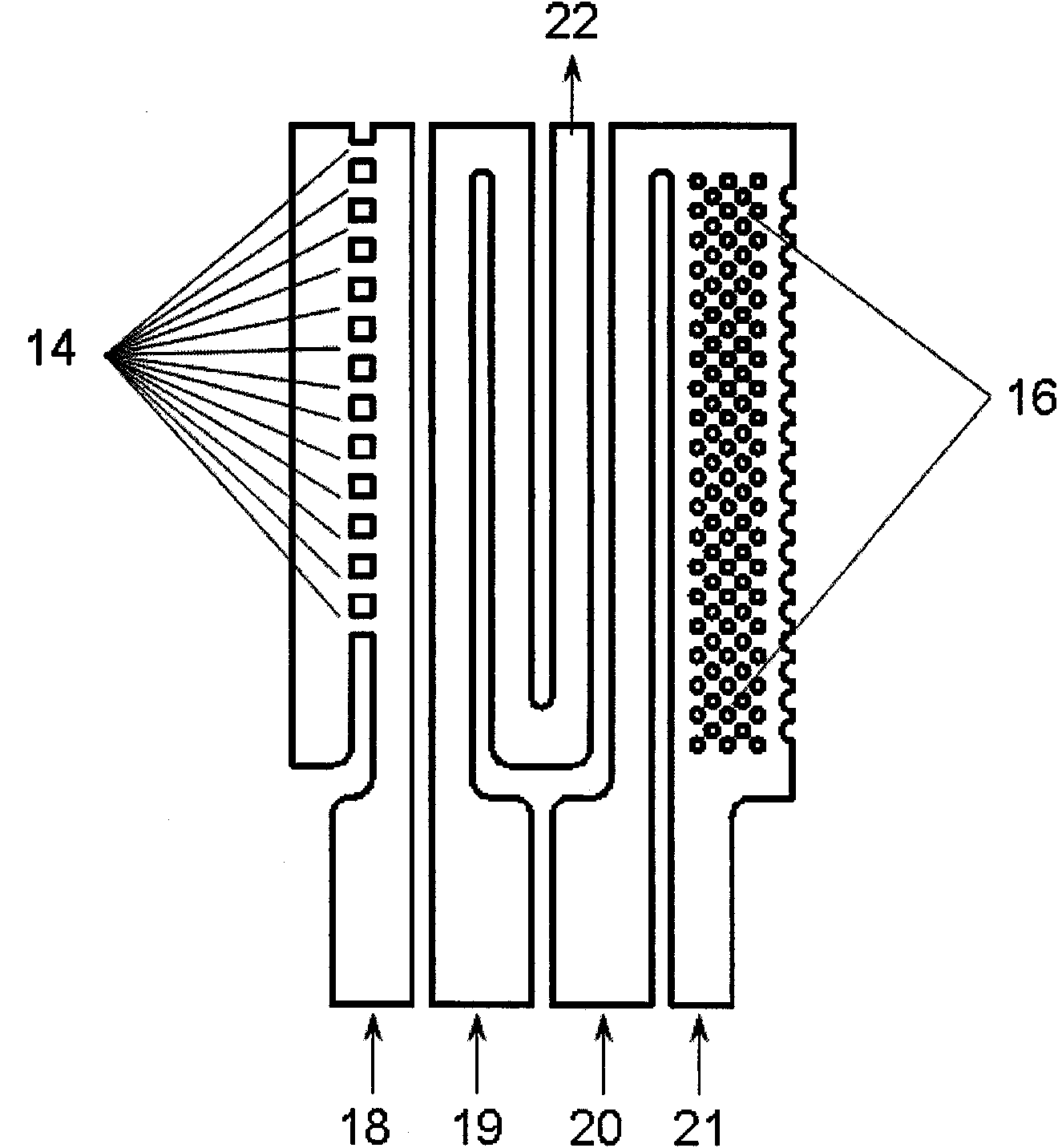

Refrigerating device for cylinder clustered printed circuit board type micro-channels

InactiveCN105627609AImprove compactnessIncrease heat transfer area densityCompression machinesRefrigeration componentsEngineeringHigh pressure

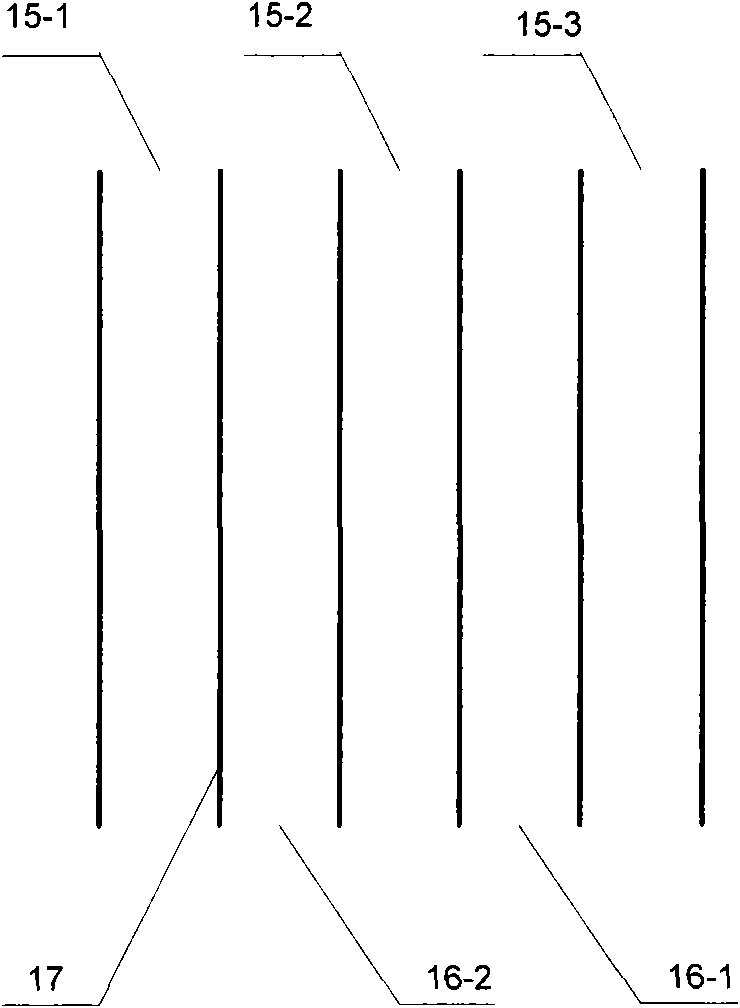

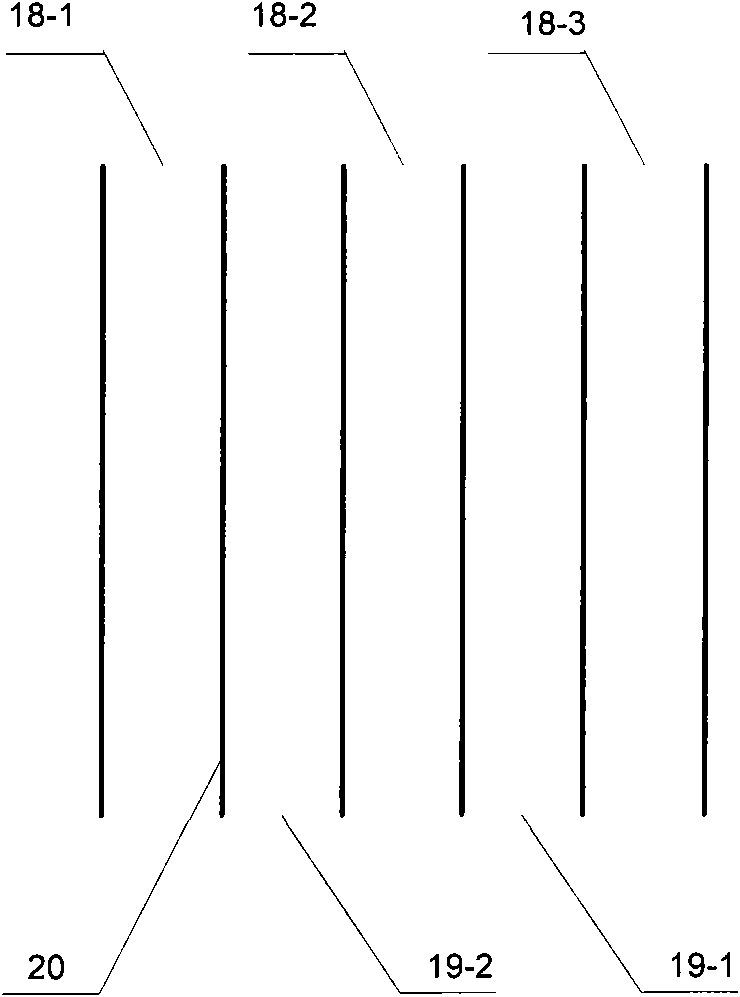

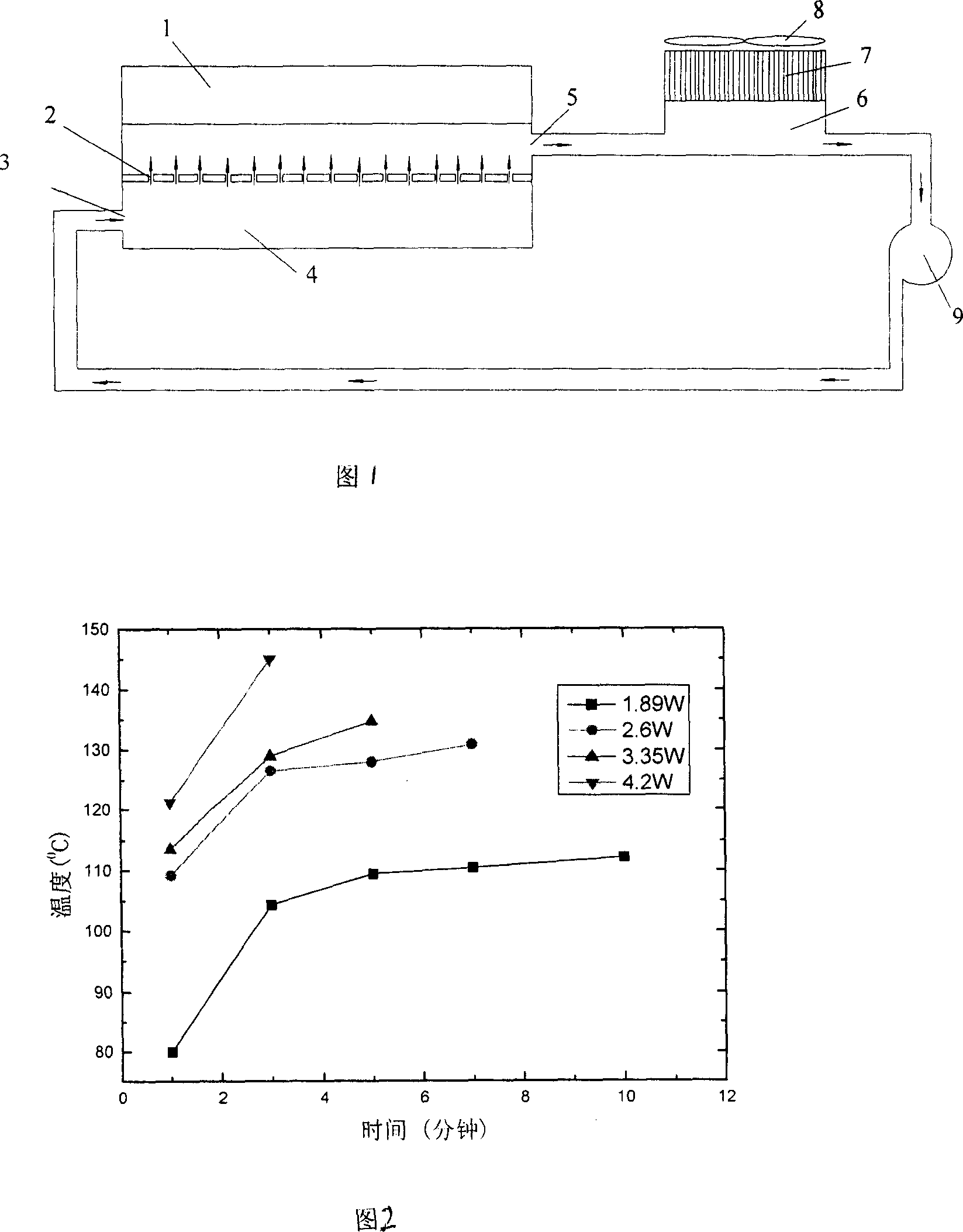

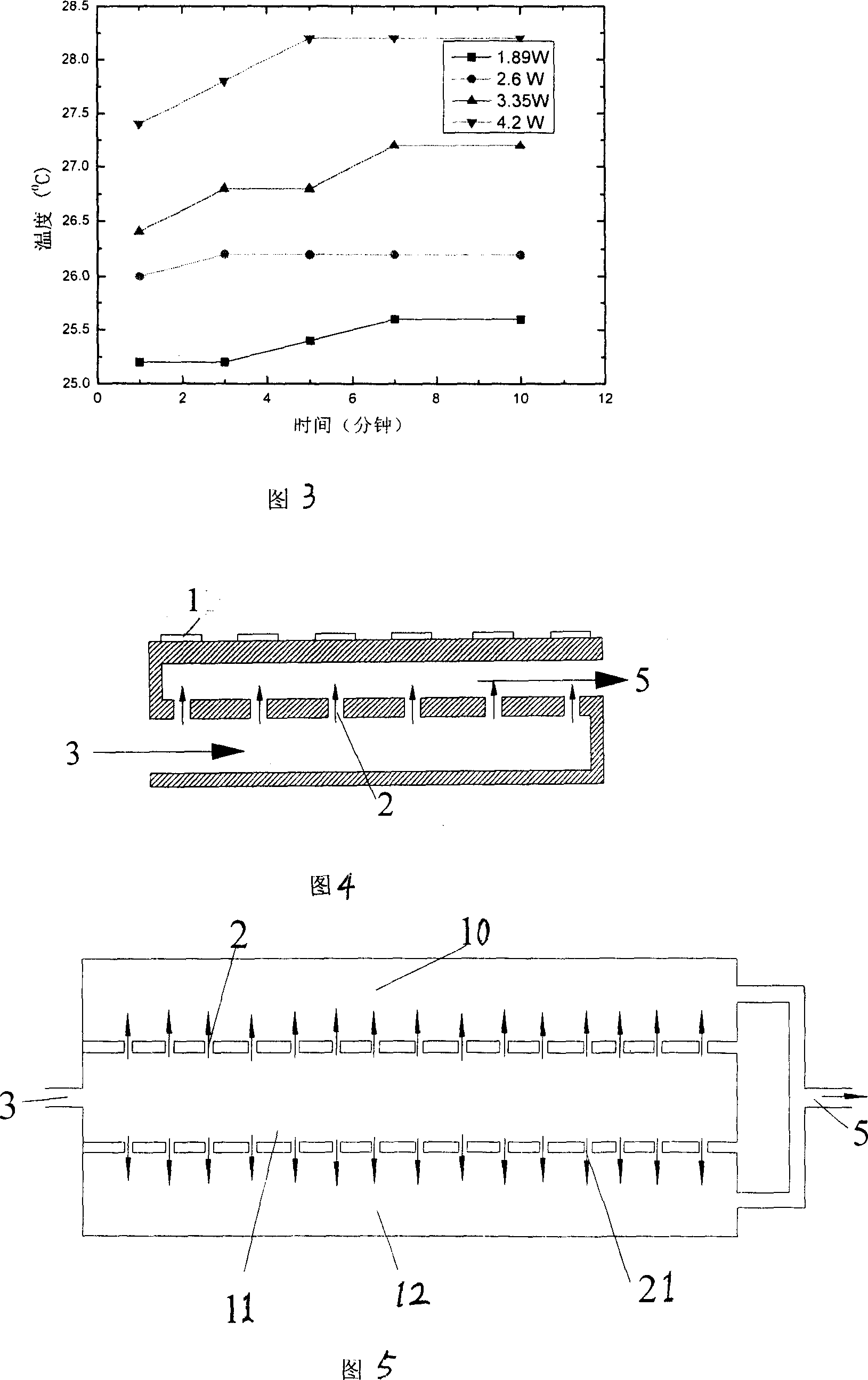

The invention provides a refrigerating device for cylinder clustered printed circuit board type micro-channels, comprising a medium feeding unit, a high-pressure micro-channel unit used for guiding a high-pressure gas refrigerating medium to flow, a throttling unit used for throttling the high-pressure gas refrigerating medium flowing through the high-pressure micro-channel unit, an evaporating unit used for enabling a low-temperature low-pressure gas refrigerating medium to absorb heat of external environment, and a low-pressure micro-channel unit arranged above the high-pressure micro-channel unit and used for guiding the low-temperature low-pressure gas refrigerating medium after heat exchanger to flow, and a medium discharge unit. Runners of the high-pressure micro-channel unit and the low-pressure micro-channel unit are all in cylinder clustered form, so that a medium can generate certain disturbance in flowing, thus enhancing heat transfer coefficients between a sheet bar and the medium and weakening the axial heat conduction of a refrigerator.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

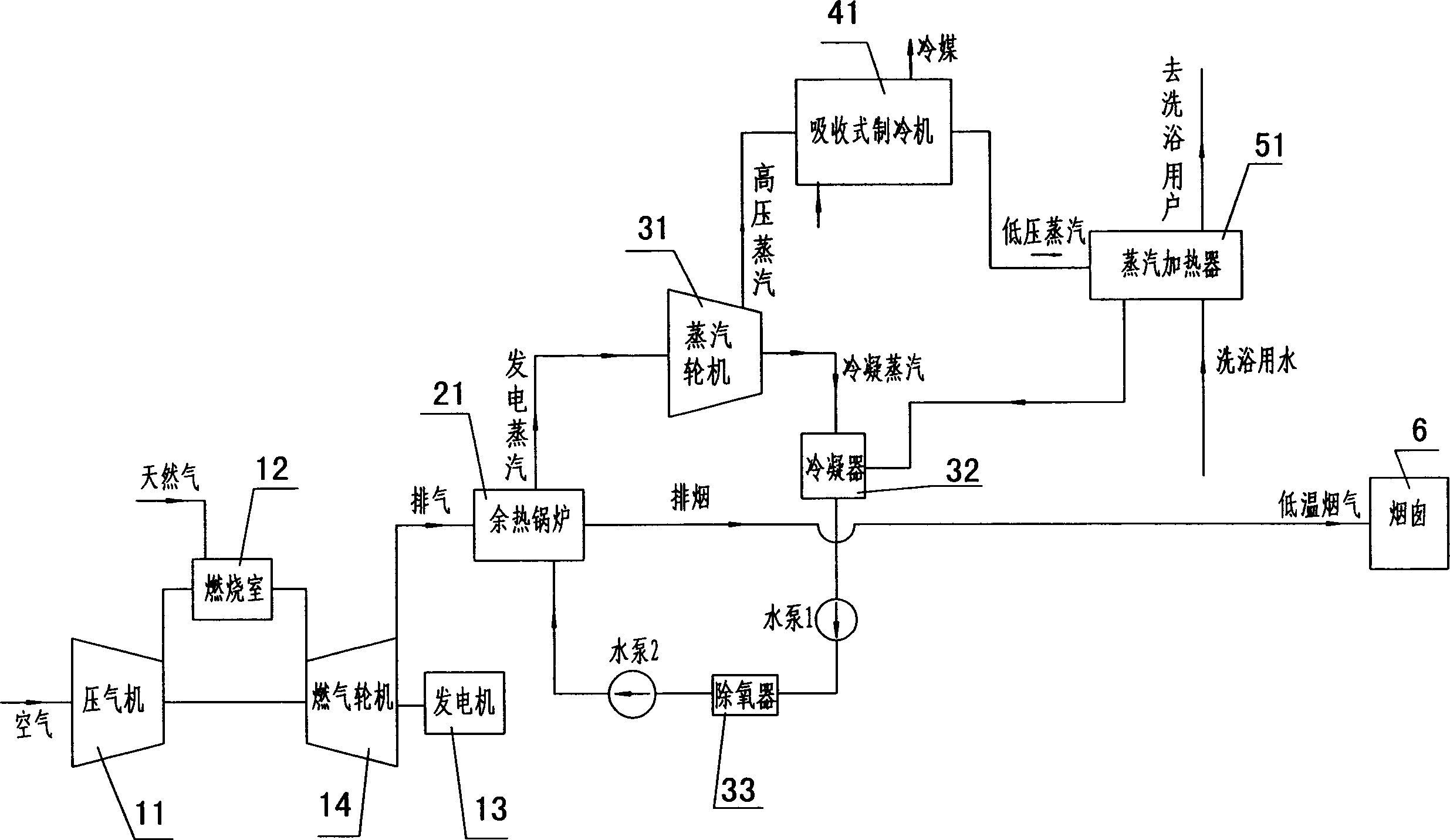

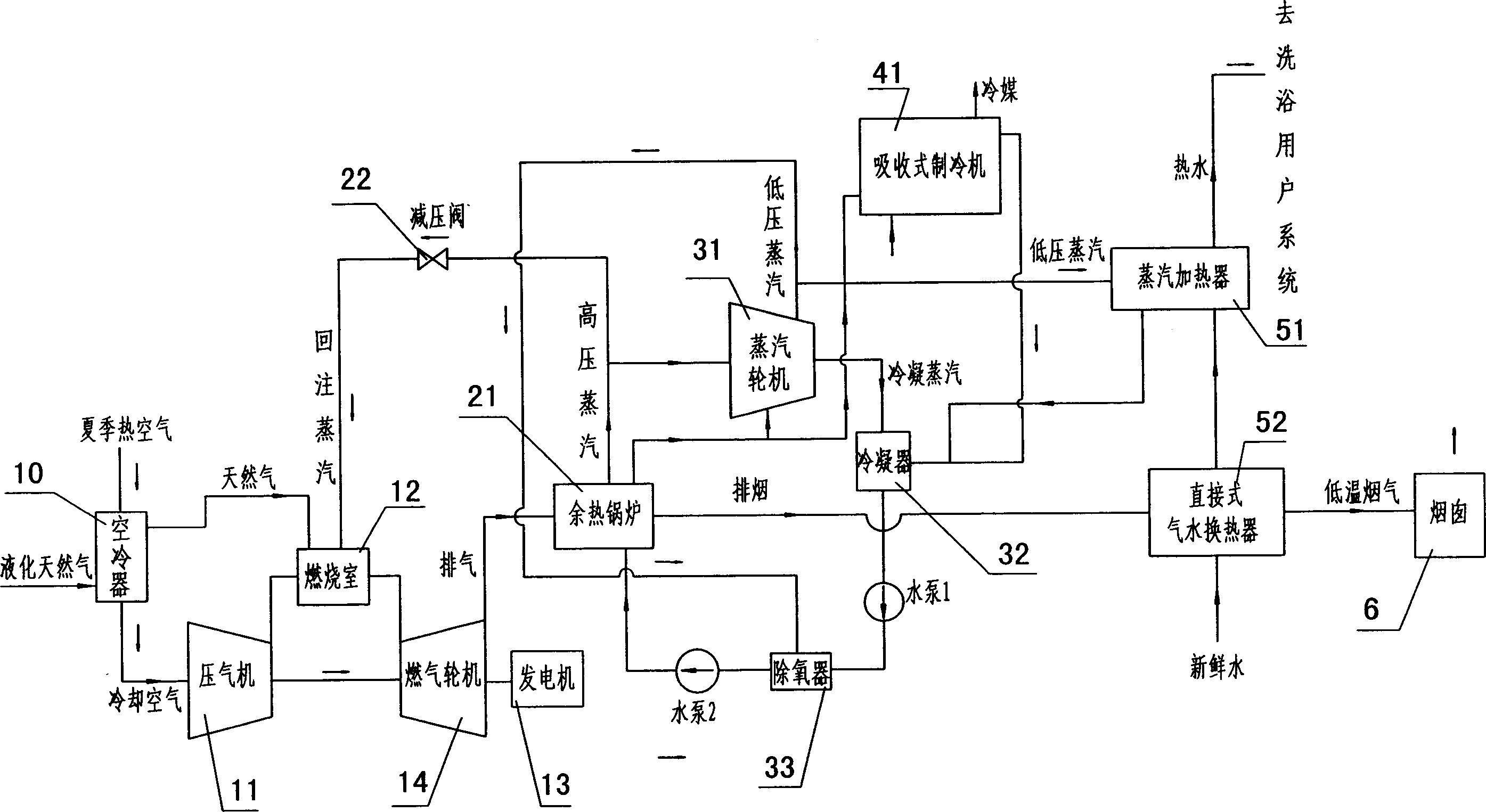

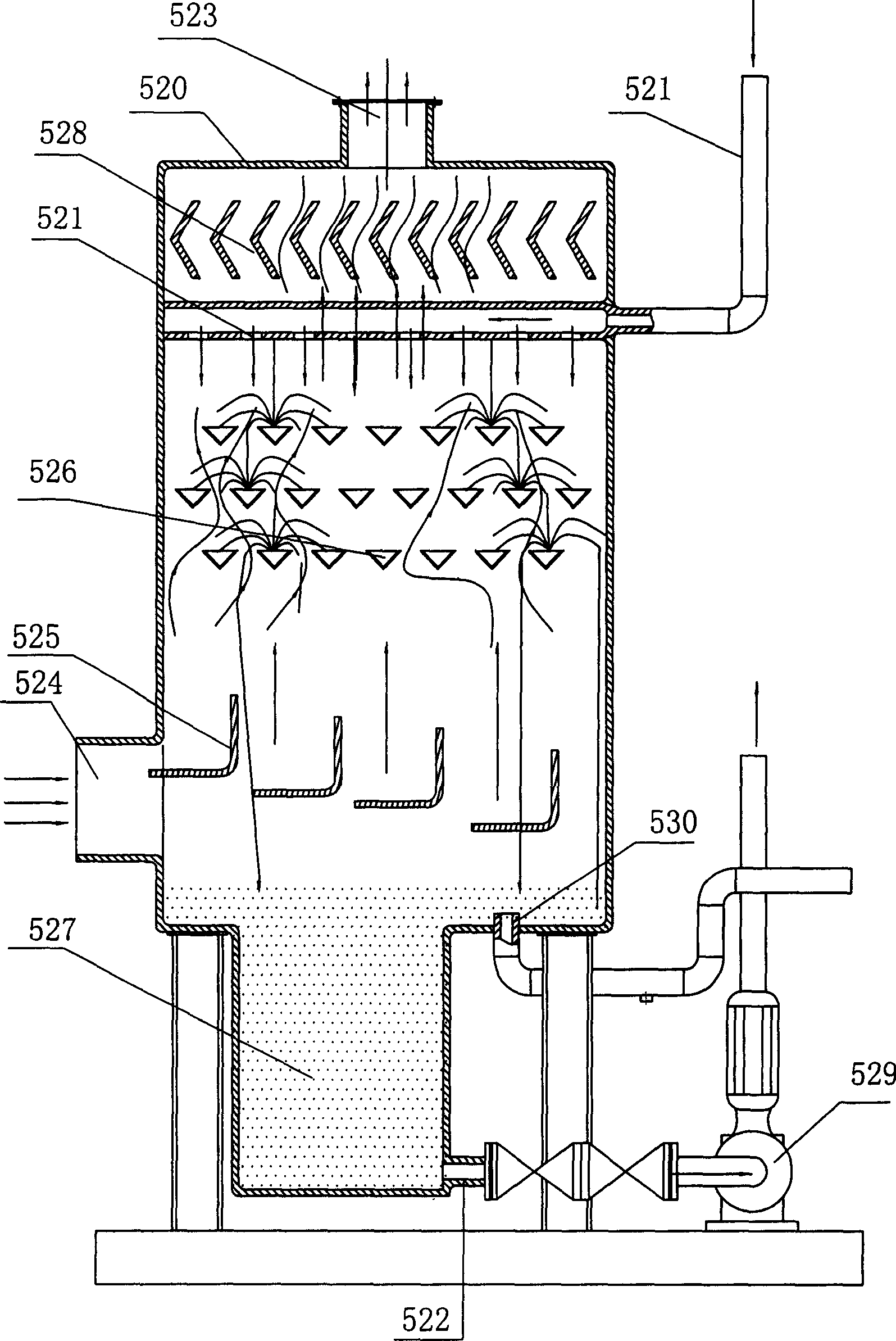

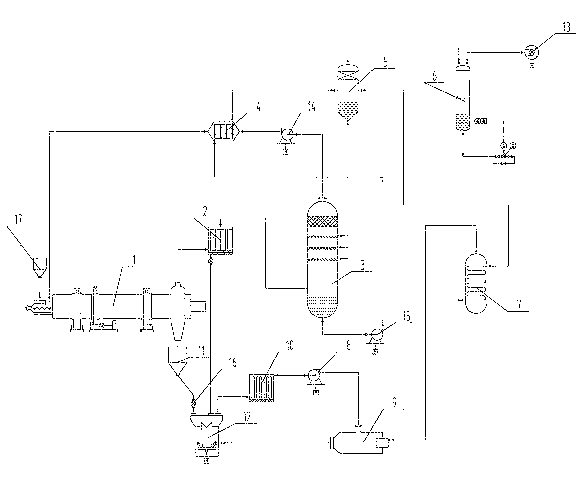

Smoke low-temperature residual heat utilization system with natural gas cooling-heating combined power device and operating method thereof

InactiveCN1807860AIncrease flexibility and economyRaise the outlet temperatureClimate change adaptationGas turbine plantsCombustion chamberHeating efficiency

The invention relates to a smoke low-temperature heat utilization system of natural gas cold-heat electric supply and relative operation method. Said system comprises a fuel gas generator, a waste heat boiler, an adsorption refrigerator, and a heating water supply device. Wherein, the heating water supply device comprises a direct gas-water heat exchanger which contains a gondola water faucet whose water channel forms the smoke channel; the smoke outlet of waste heat boiler is connected to the chimney via the direct gas-water heat exchanger; the water inlet and outlet pipes of direct gas-water heat exchanger are serially connected to the pipe of life hot water or water supply; the gas transmission pipe of waste heat boiler has a branch of the reflux gas pipe connecting the burning of fuel gas generator; and the reflux gas pipe is serially connected with a depressurizing device. The invention has simple heat transmission device, lower cost, improved heat efficiency and improved economic benefits.

Owner:SOUTH CHINA UNIV OF TECH

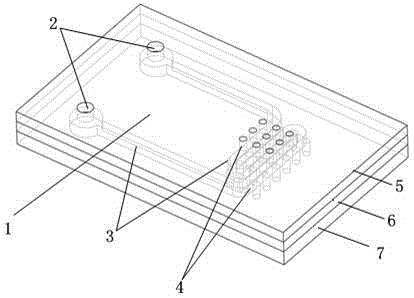

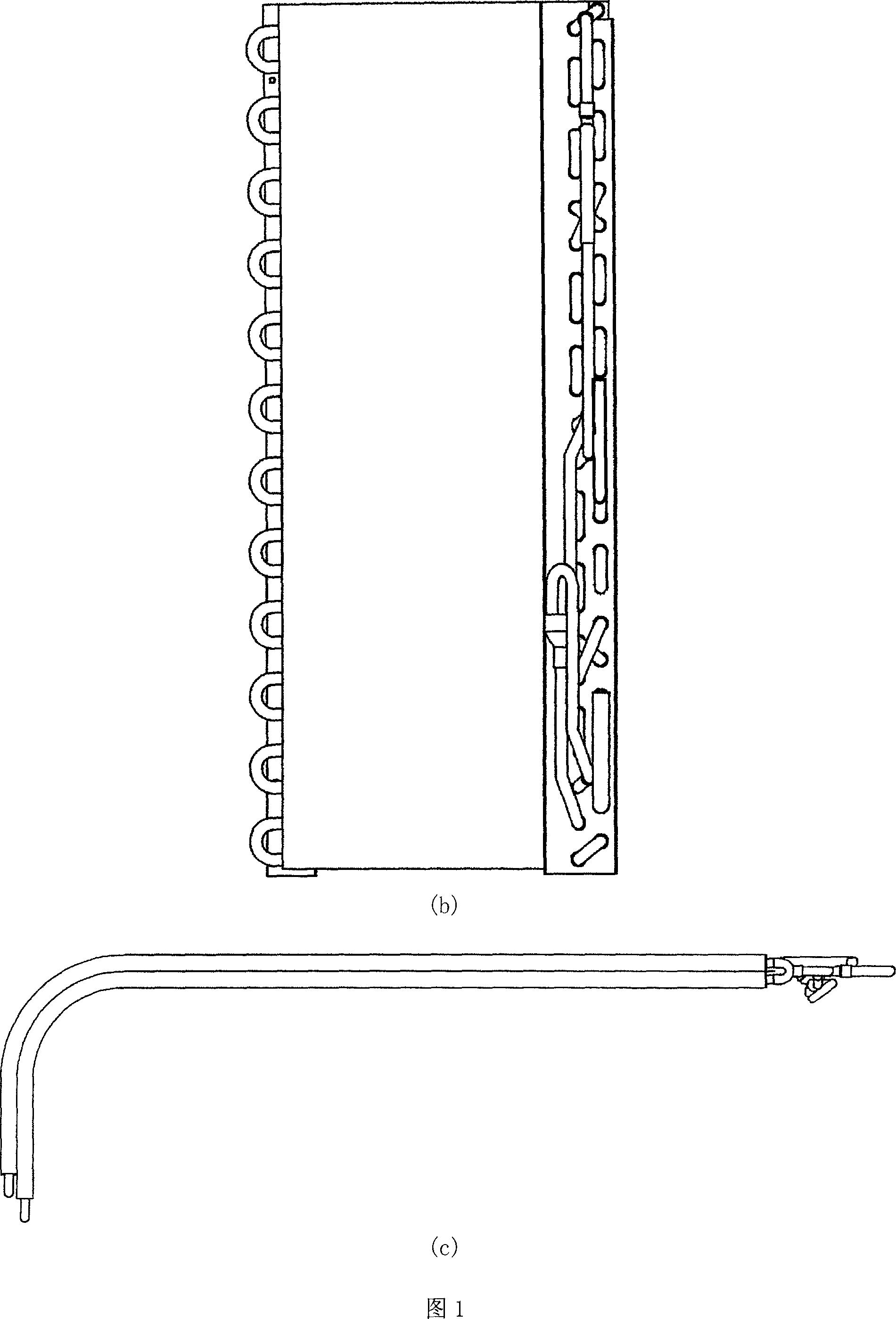

Printed circuit board embedded runner liquid cooling heat exchange device

ActiveCN105188260AImprove heat transfer coefficientLower working temperaturePrinted circuit aspectsCircuit fluid transportPrinted circuit boardConductive materials

The invention discloses a printed circuit board embedded runner liquid cooling heat exchange device. The heat exchange device comprises a top PCB layer, a middle PCB layer and a bottom PCB layer, wherein a runner is laid on the middle PCB layer, and an embedded runner is formed after the runner is sealed by the top PCB layer and the bottom PCB layer. An inlet and an outlet of the runner are formed in the top PCB layer or the bottom PCB layer simultaneously, or positioned in the top PCB layer and the bottom PCB layer respectively. A plurality of metal conduction holes are formed in the top PCB layer or the bottom PCB layer provided with a heating device, the metal conduction holes are positioned under the installation position of the heating device and filled with a conductive material, and the conductive material is a good conductor of heat simultaneously. The printed circuit board embedded runner liquid cooling heat exchange device disclosed by the invention is capable of effectively solving the problem of heat dissipation of a high-power device in a printed circuit board, and is smaller in volume and higher in integration and reliability.

Owner:CHINA ELECTRONICS TECH GRP NO 26 RES INST

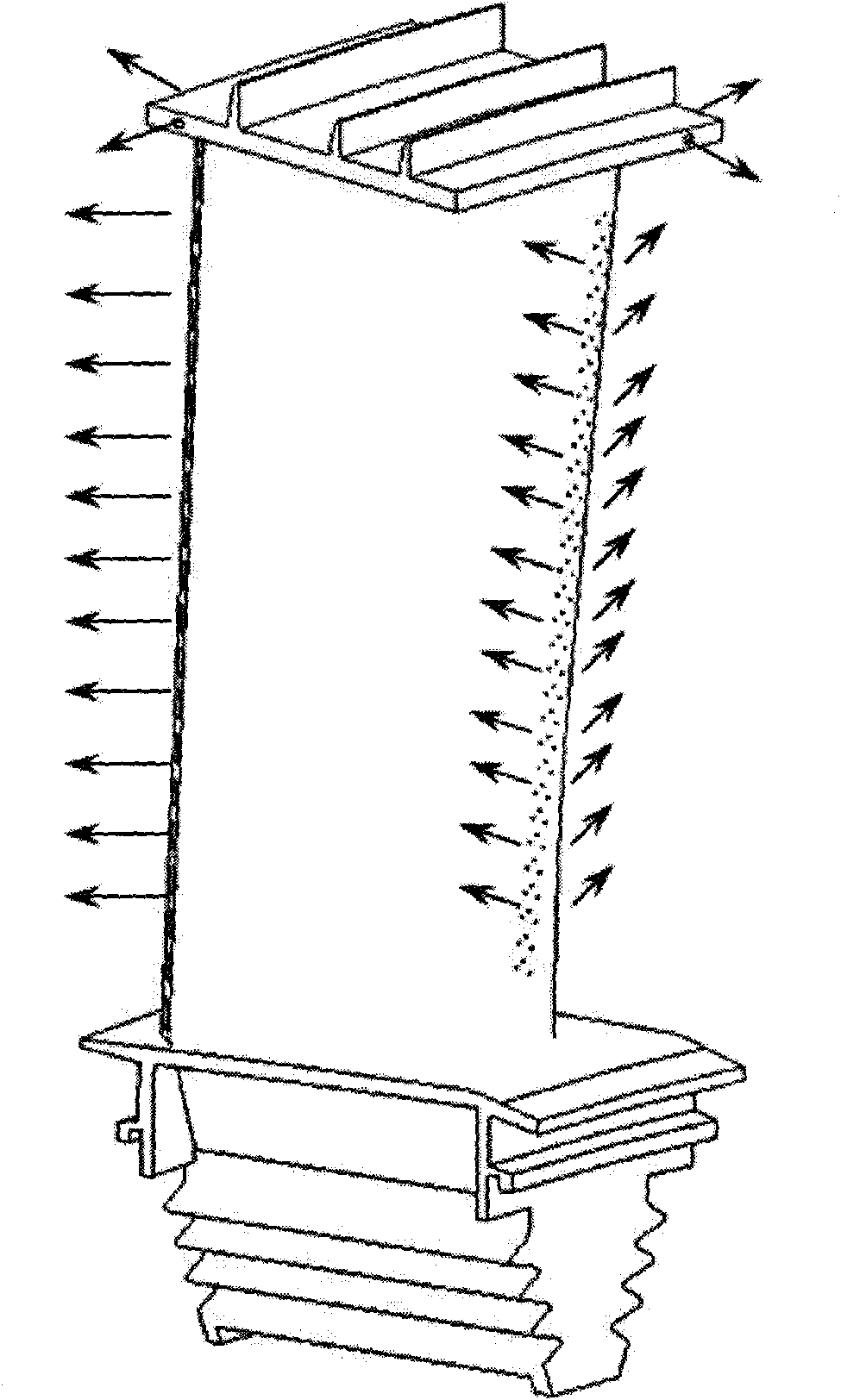

Liquid separating air condenser

InactiveCN1975311ANo steam leakage or short circuitReduce thicknessEvaporators/condensersSteam/vapor condensersCondensation processSuper cooling

A liquid-air-condenser belongs to thermal equipment technical fields. comprising steam inlet, heat exchange tube, fin, j cascade box, discharge pipe, three-limb tube, condensate outlet, single-pass pipe, shell; Steam from the steam inlet enter into the first cascade box and condense through the first group heat exchange tube, the vapor-liquid mixture flows into the second cascade box, vapor and liquid are separated: the liquid is ejected into the next cascade box by discharge pipes between cascade boxes , while steam enter into the next heat exchange tube group; collected by three-limb tube in the end and flow out through condensate outlet. The invention condense with stepped steam, separate by middle automatic vapor-liquid and drain fluid associate with super-cooling technology by the condensate concentrations, guarantee that each tube pass is entered with pure steam and cooled, effectively reduce the thickness of the liquid film in condensation process and eliminate the adverse biphasic flow pattern; compared with traditional condenser, save 30% material and reduce the condenser production and operation cost, and simple in production.

Owner:TSINGHUA UNIV

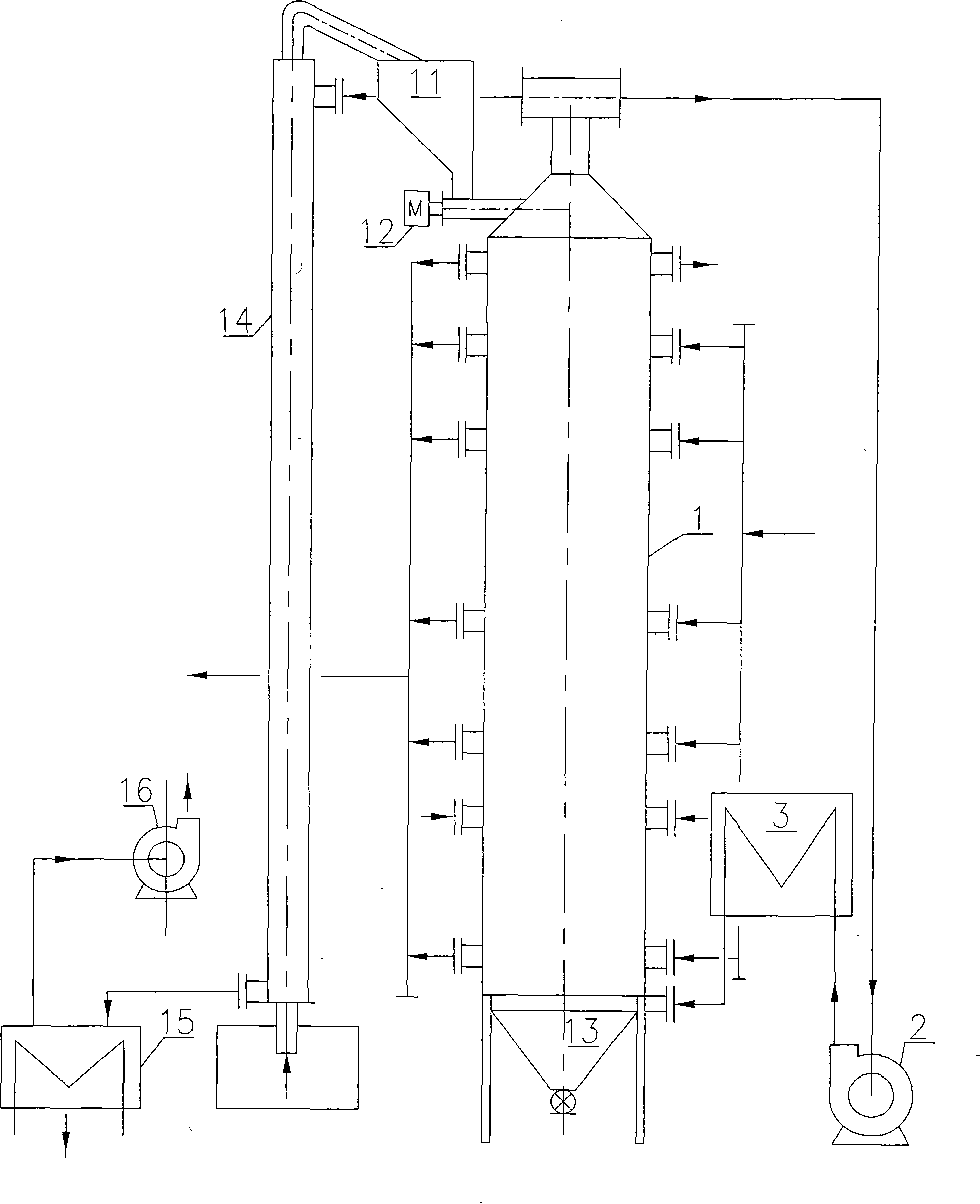

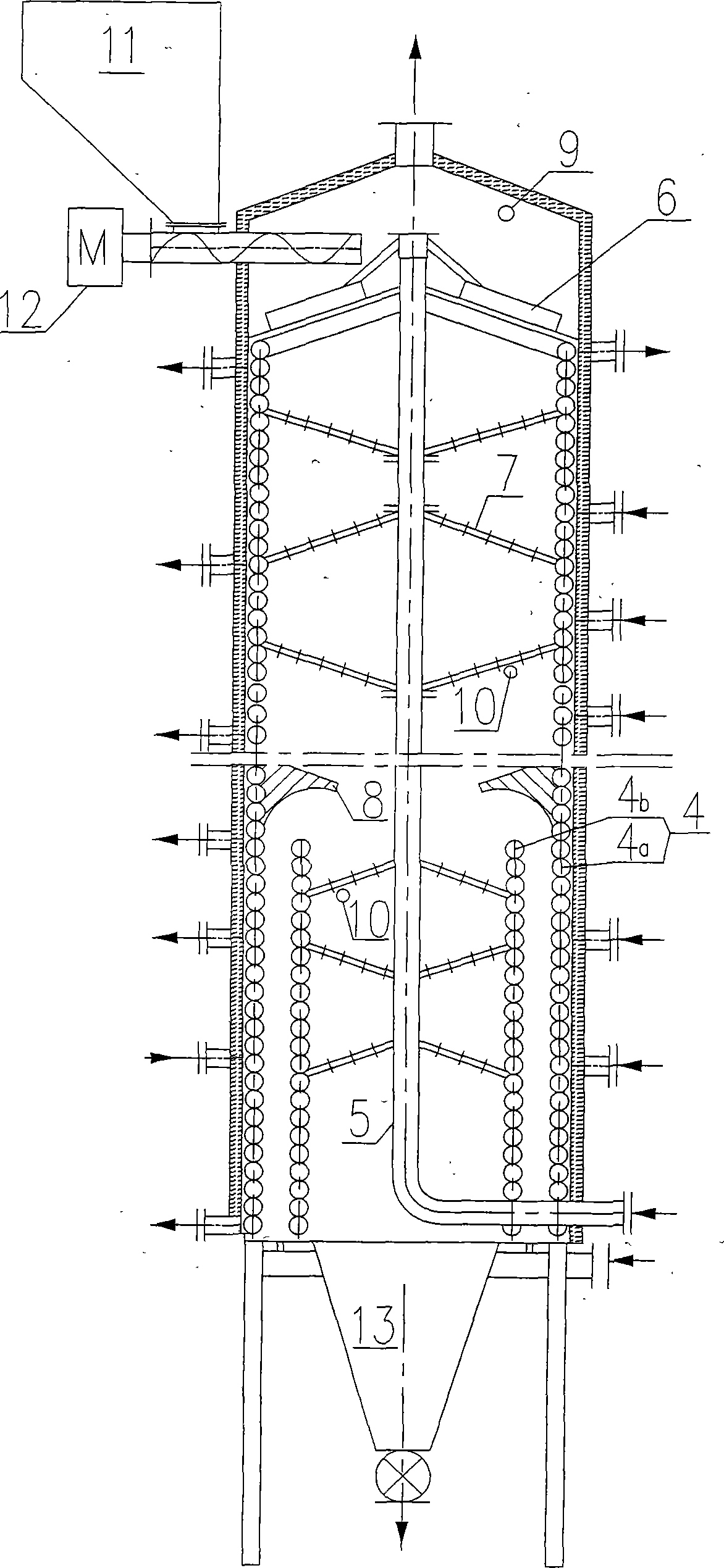

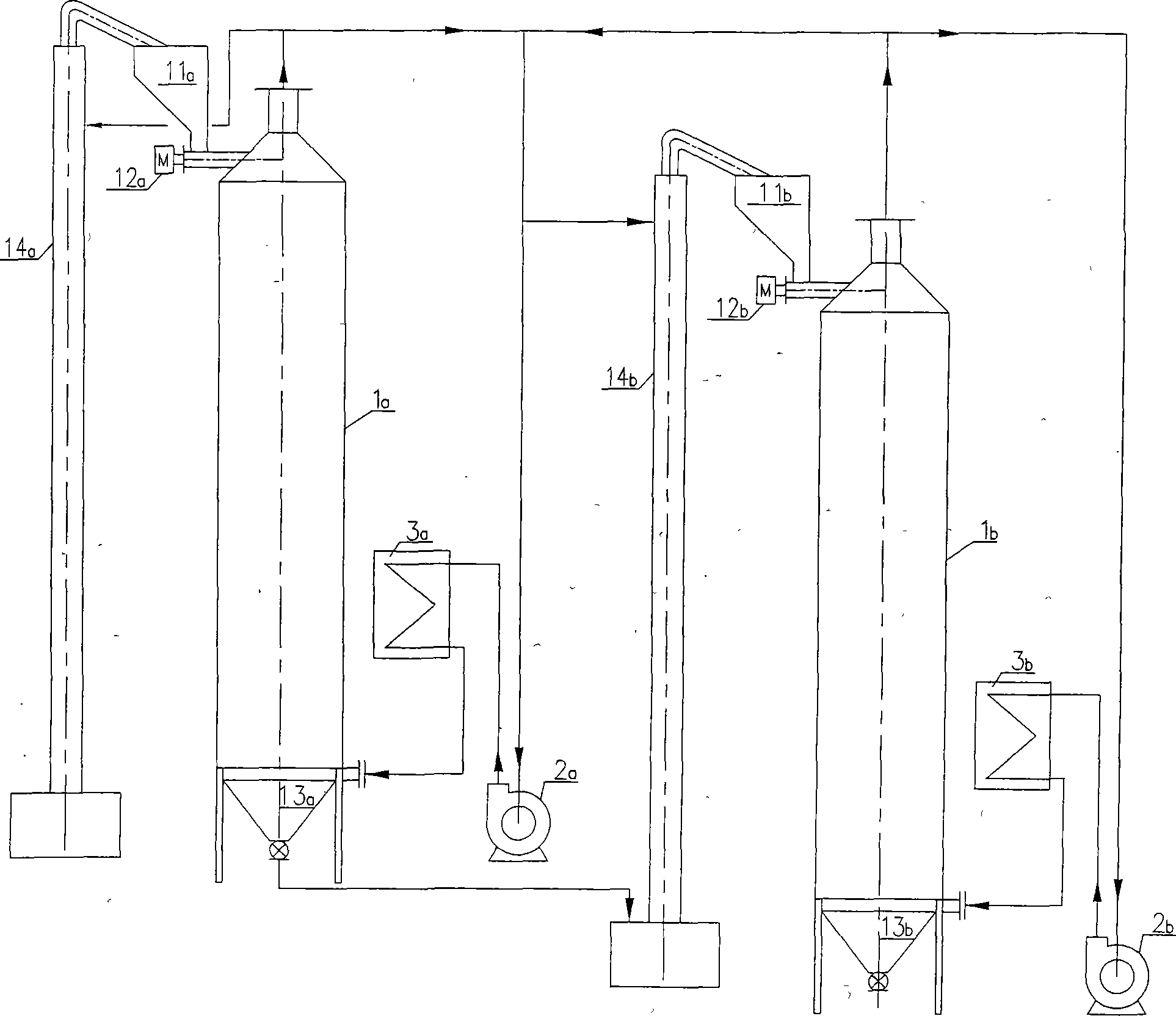

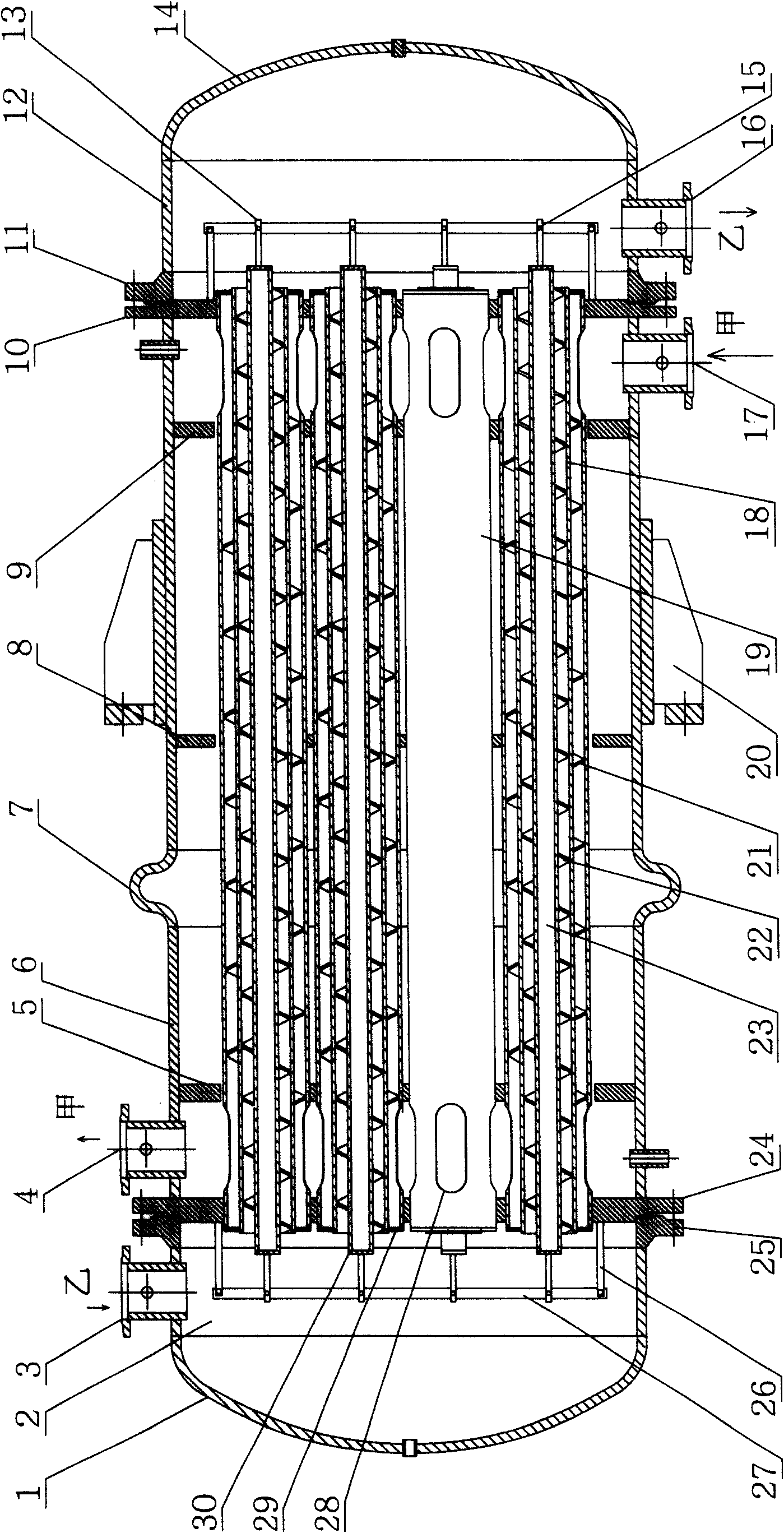

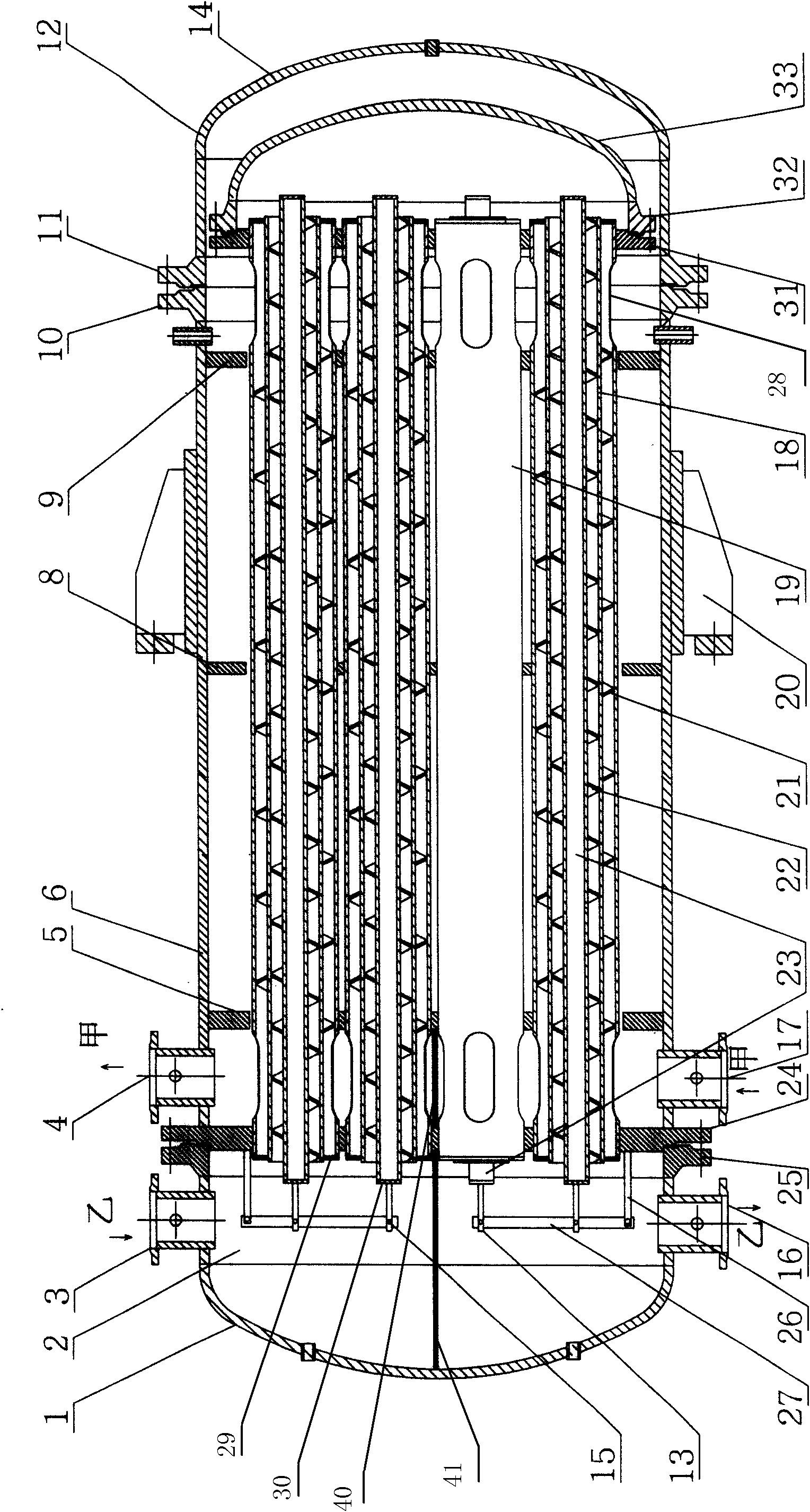

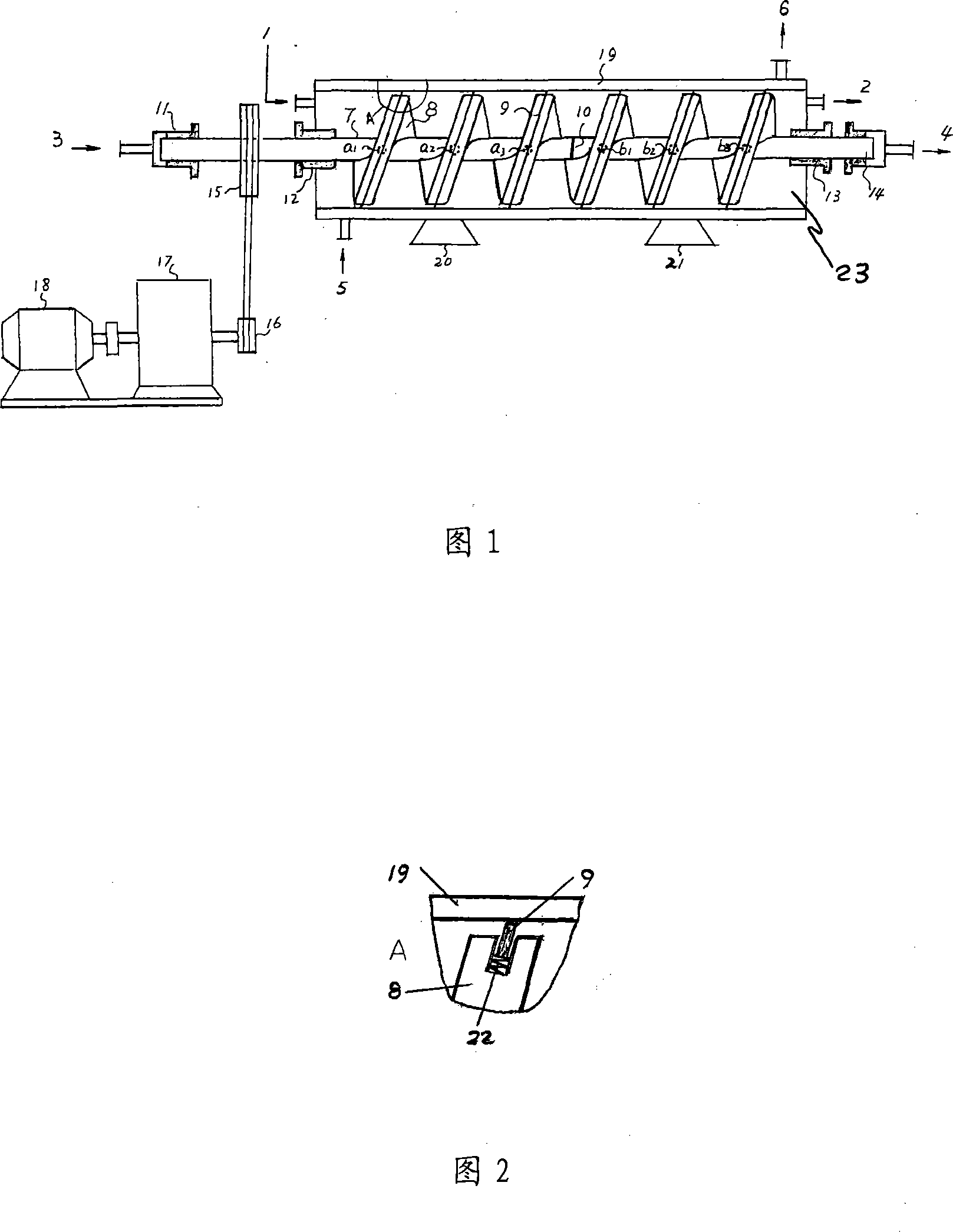

Lignite drying device by aid of low-pressure superheated steam and method

ActiveCN102564095AImprove heat transfer coefficientReduce mass transfer resistanceDrying solid materials with heatDrying gas arrangementsAutomatic controlProcess engineering

Owner:天津格物兴业热能科技有限责任公司

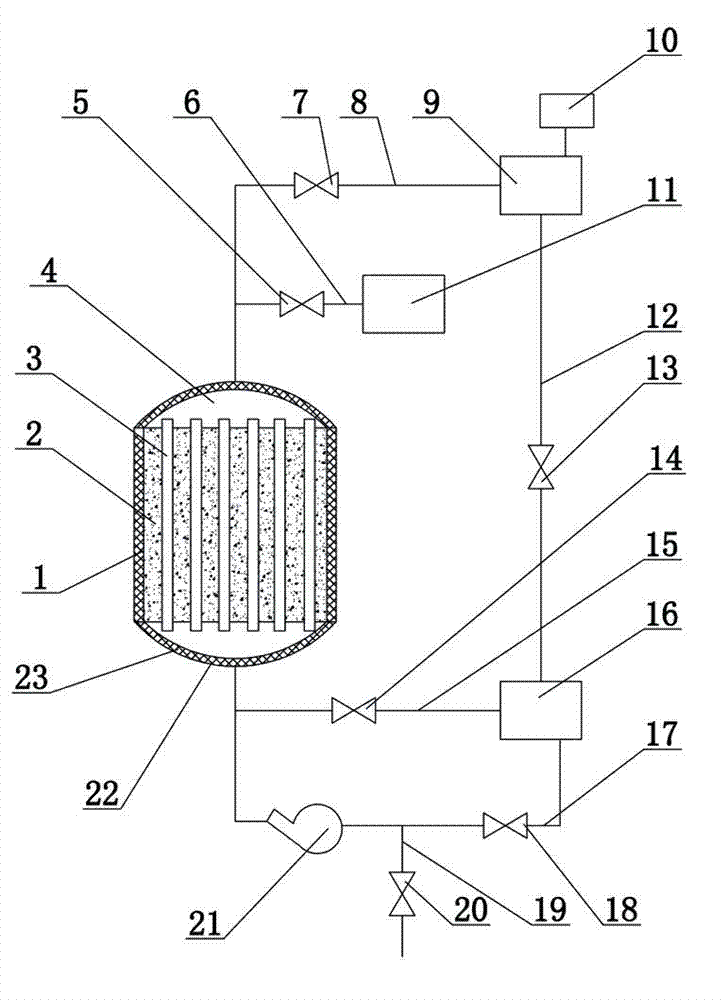

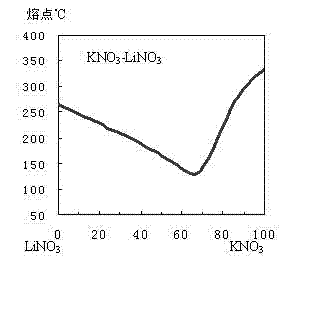

Phase change heat accumulation system for generating steam directly and preparation method of phase change heat accumulation agent

InactiveCN102777874AImprove efficiencyImprove heat transfer coefficientHeat storage plantsChemical industryPorous mediumToxic industrial waste

The invention relates to a phase change heat accumulation system for generating steam directly and a preparation method of a phase change heat accumulation agent. A phase change material is enhanced with graphite foam, and is absorbed in a porous medium of the graphite foam, so that a binary eutectic salt / graphite foam material is prepared and is used as a composite phase change material of a heat accumulation device, the composite phase change material is high in heat conduction coefficient, therefore under the same design condition, the phase change heat accumulation system provided by the invention is applied to systems of a focusing type solar thermal power generation system, an industrial waste heat recovery system and the like, and has the characteristics of high heat transfer efficiency, small volume, low cost and the like. In addition, the phase change heat accumulation system for generating steam directly can flexibly adopt a parallel connection or serial connection mode according to the temperature of high-temperature waste heat steam and the requirement of a steam user; and during serial connection, the binary eutectic salt / graphite foam composite phase change material can be combined in a cascaded manner according to a melting point, thus the efficiency of an energy accumulation system is increased, and the energy can be greatly accumulated.

Owner:ZHENGZHOU UNIV

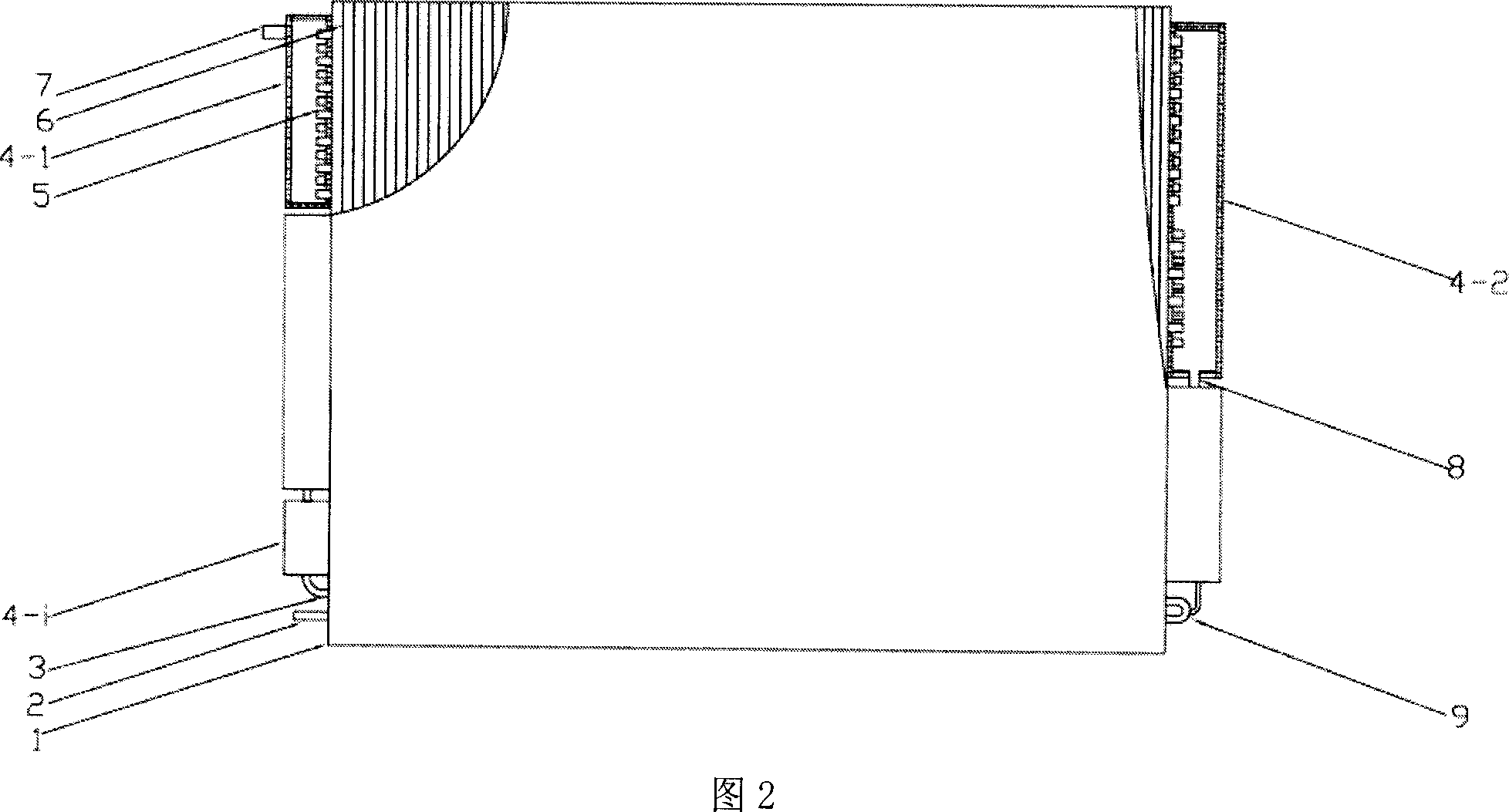

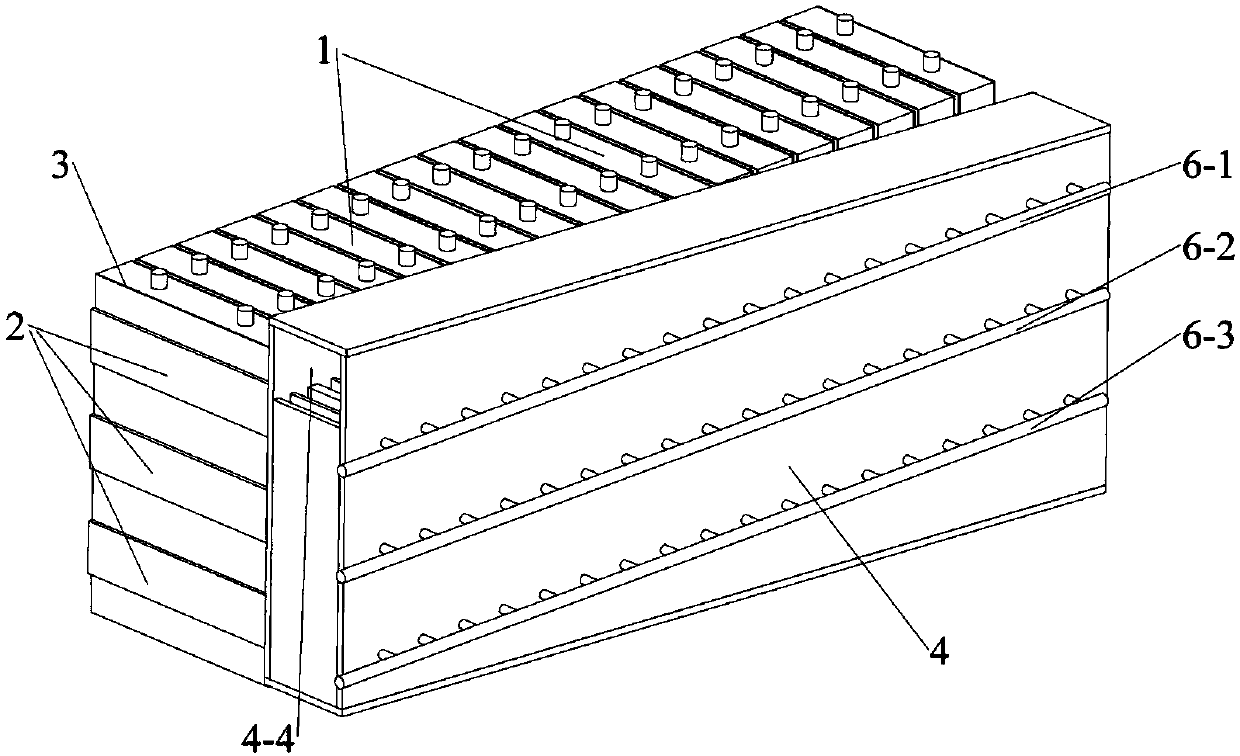

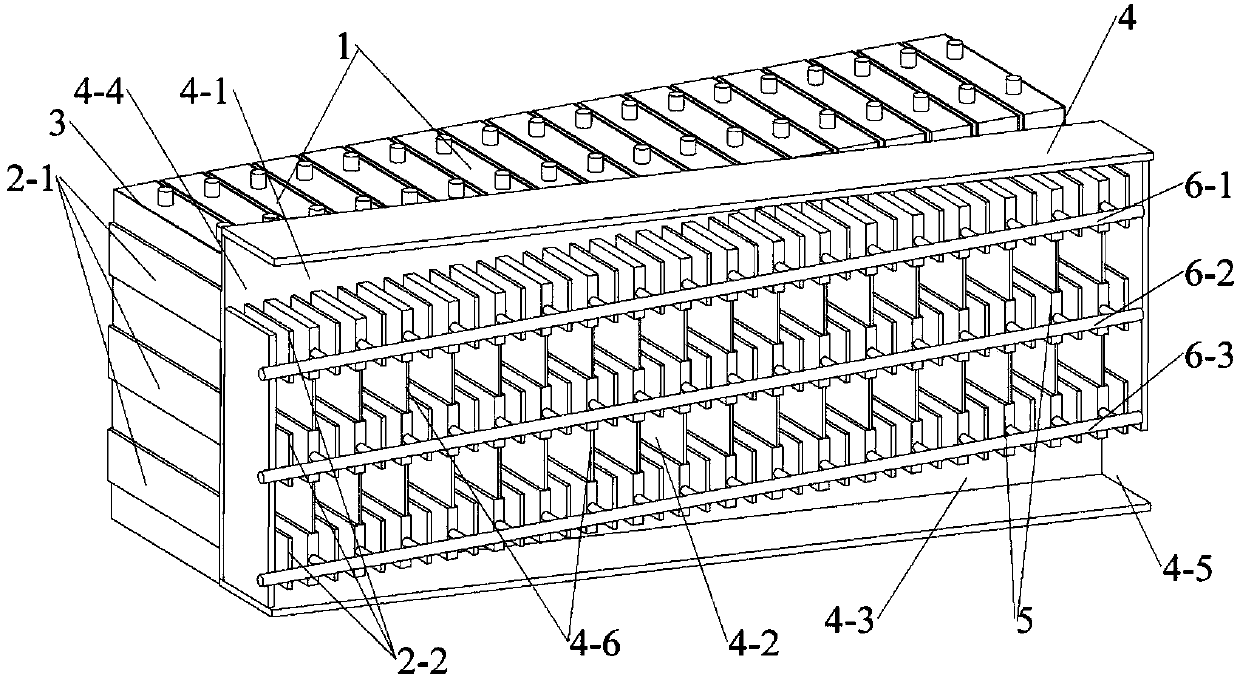

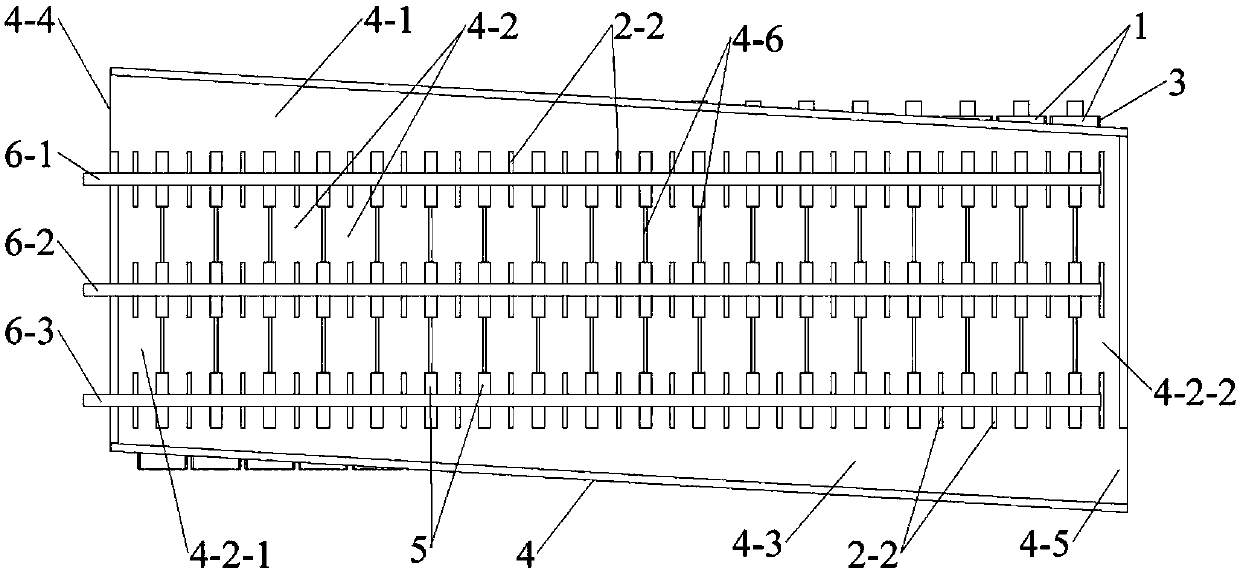

Battery module heat management method and apparatus based on thermo-electric effect

ActiveCN106374162AImprove heat transfer coefficientFast thermal responseSecondary cellsElectrical batteryOperating temperature range

The invention discloses a battery module heat management method and apparatus based on a thermo-electric effect. A battery module, heat conductors, semiconductor thermal-electric assemblies and a liquid heat conducting channel form a heat conducting path in a battery pack box; the battery module heat management method comprises two working modes, including a refrigerating mode executed in a high-temperature environment and a heating mode executed in a low-temperature environment, wherein in the refrigerating mode, the temperature of the upper part of each semiconductor thermal-electric assembly is reduced to be lower than the environment temperature to form a refrigerating surface; the temperature of the lower part of the semiconductor thermal-electric assembly is increased to form a heat dissipation surface; the generated heat is discharged through the liquid heat conducting channel; in the heating mode, the temperature of the upper part of each semiconductor thermal-electric assembly is increased to form a heating surface; the battery module is heated through the heat conduction of the heat conductors to achieve a normal working temperature range; and meanwhile, the temperature of the lower part of each semiconductor thermal-electric assembly is reduced to form a heat absorption surface. The battery module heat management method and apparatus, by integrating refrigerating and heating into one body, is compact in structure and efficient in heat exchange, thereby ensuring that the battery can constantly work in the optimal temperature environment; and therefore, the battery module heat management method and apparatus have high application prospect.

Owner:SHANGHAI UNIV OF ENG SCI

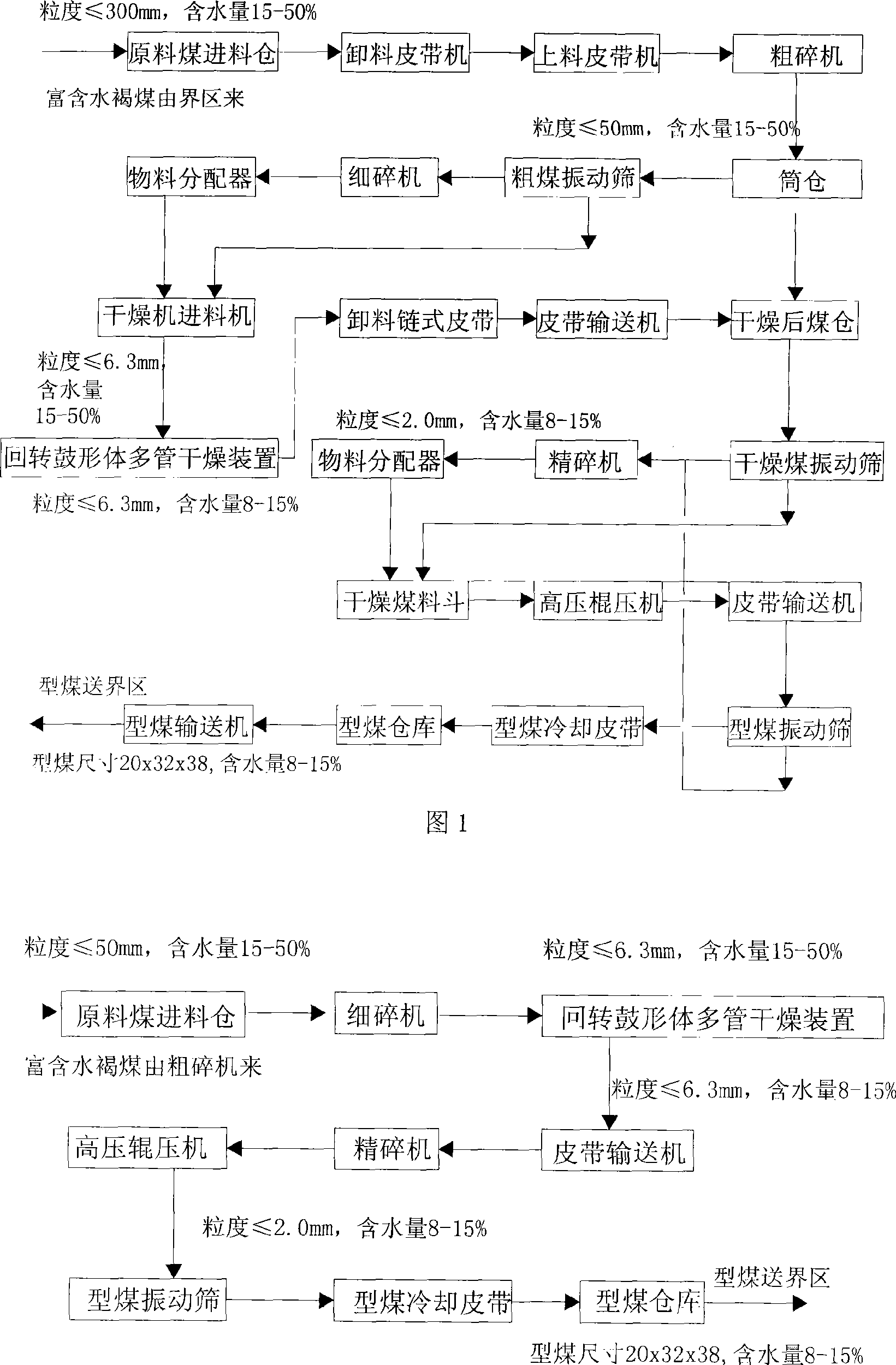

Process for dryness, formation and further processing of water-enriched lignite

ActiveCN101519614AIncrease contact areaImprove heat transfer coefficientSolid fuelsMaterial transferHot press

The invention provides a process for dryness, formation and further processing of water-enriched lignite. The process mainly comprises storage of the lignite, material transfer, crushing of lignite grains, rotary drum-shaped body multi-pipe drying, refined crushing, heating, hot pressing forming, screening and material return. The products can be used in process engineering in the fields of transportation, smelting, combustion, power generation or aerification. In the drying process, a rotary drum-shaped body multi-pipe drying device is used, and low-pressure vapor is indirectly used in the drying process, thereby avoiding the explosion due to the reaction of volatile compounds and oxygen, which is caused by too high temperature in the drying process; and in the forming process, little amount of internal water in capillary tubes of the lignite is used as a bonding agent, at certain temperature and grain size and under a certain pressure, gaps between lignite grains are filled by hot pressing so as to strengthen the contact between the lignite grains for forming. Because the hot pressing damages the structure of the capillary tubes of the lignite, the capillary tubes of the lignite are difficult to restore the original spongy property, thereby reducing the secondary adsorption water of the lignite grains. The process has the advantages of improving economic values of the lignite and causing little environmental pollution, along with safe drying and forming process.

Owner:CHINA NAT CHEM ENG GRP CORP LTD +1

On-line quenching production technique for high toughness thick steel plate

InactiveCN101215624AShort production cycleLow costFurnace typesHeat treatment furnacesSteel platesQuenching

A press quenching manufacturing technique process of high strength and ductility thick steel plate belongs to low alloying steel manufacturing technique field, which comprises heating up steel billet to 1100 DEG C to 1250 DEG C, rolling steel plate through two stages of austenite recrystallization zone and non recrystallization zone with 860 DEG C to 950 DEG C of final rolling temperature, realizing steel plate press quenching through adopting two cooling ways of aerial fog and water-curtain with 25-45 DEG C / s of average cooling speed in cooling region, stopping the quenching when temperature reduced to 150 DEG C to 300 DEG C, and drawing the steel plate after quenched under high temperature. The invention overcomes the weaknesses of long productive cycle of current modified treatment method, high cost and unfavorable stability of high strength and ductility steel plate property which is manufactured by TMCP technique, and can manufacture 20mm-50mm high strength and high ductility steel plate with stable property. And the invention has the advantages of short production line and low energy consumption, which can be extensively applied to manufacture steel plate which is needed in the industries of metallurgy, petrifaction, hydroelectricity and marine and the like.

Owner:SHANDONG IRON & STEEL CO LTD

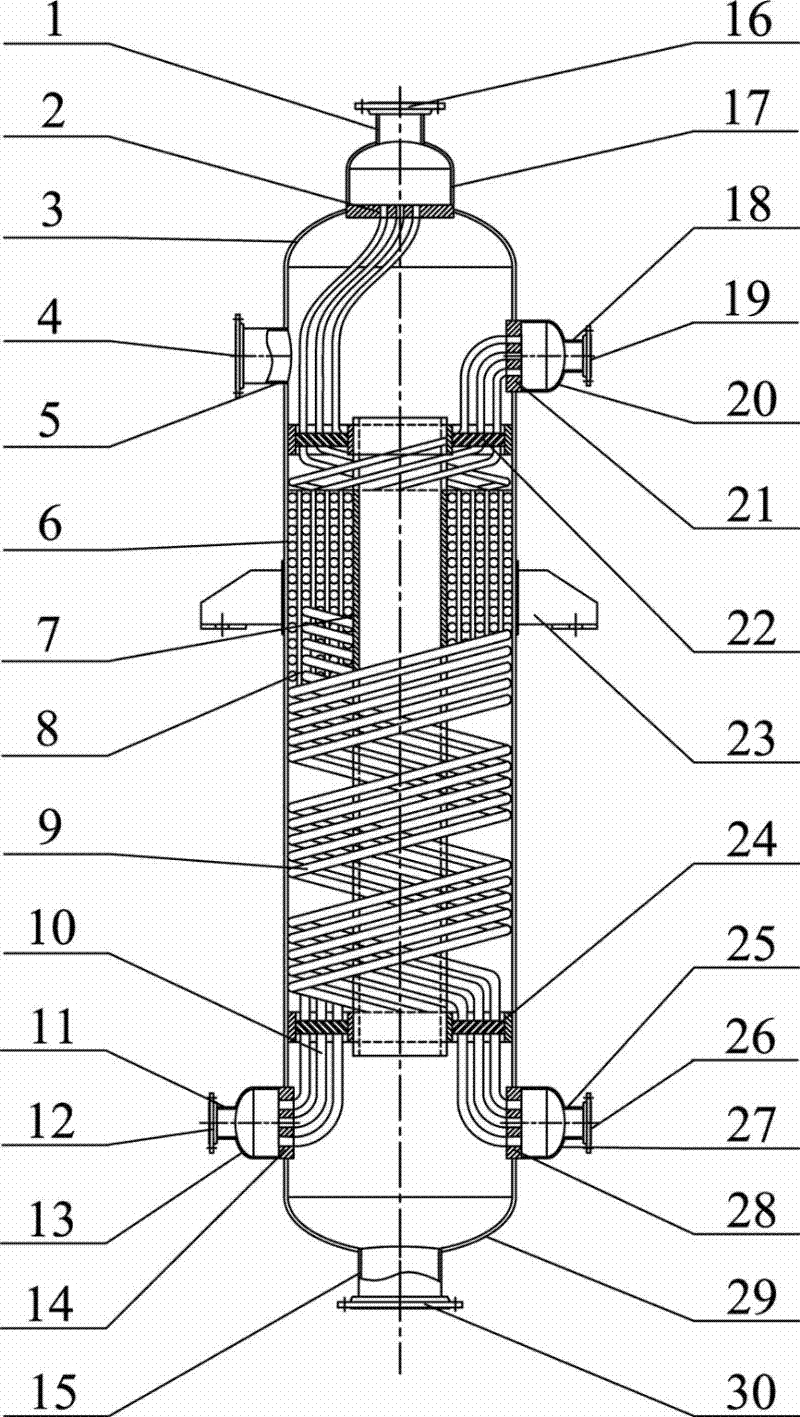

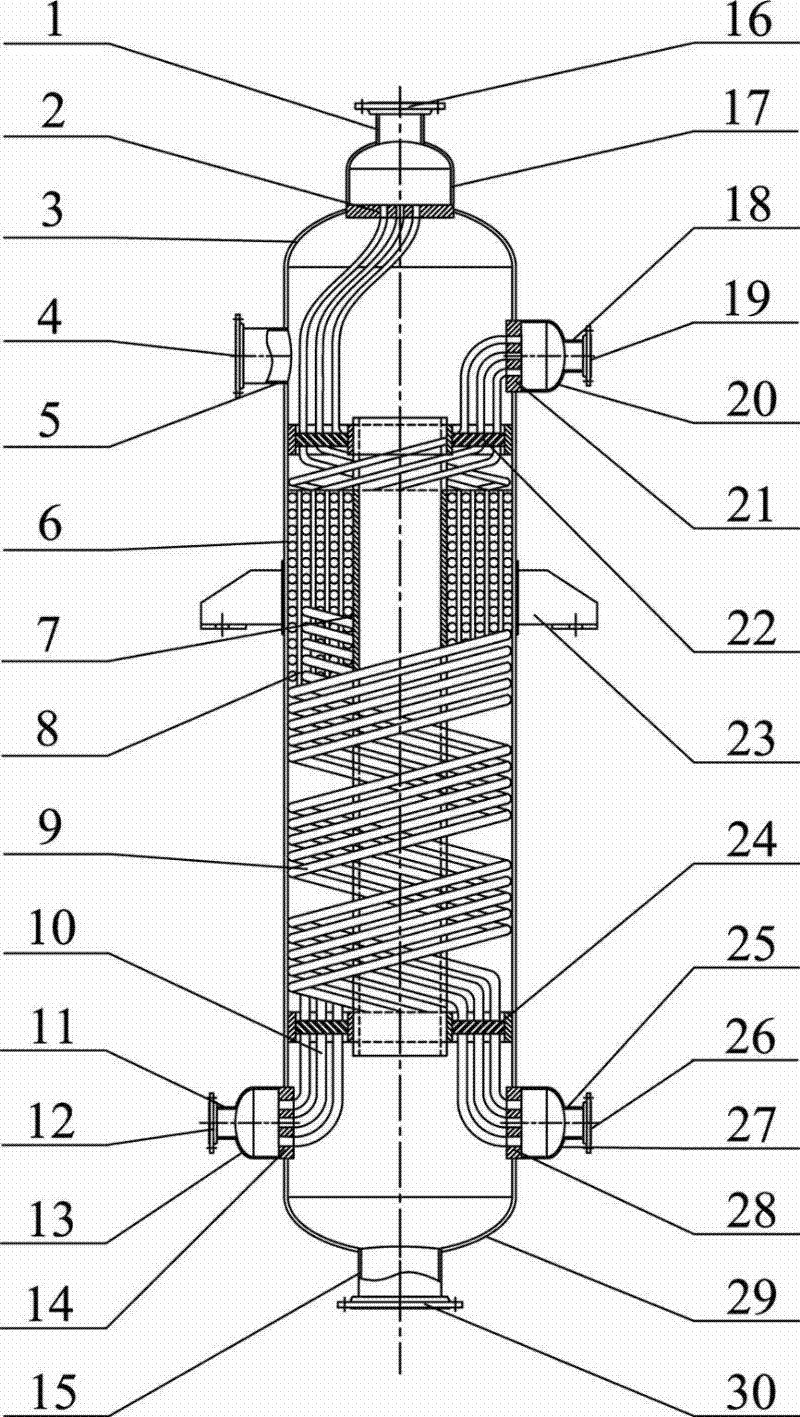

Composite sleeve double-helix heat exchanger

InactiveCN101566437AImprove circulationImprove heat transfer coefficientStationary tubular conduit assembliesViscous flowEngineering

The invention relates to a composite sleeve double-helix heat exchanger. At present, a plate type heat exchanger has high coefficient of heat transfer but can bear lower working pressure; a pipe shelltype heat exchanger is of a pressure-resisting structure but has very low coefficient of heat transfer; and a pipe type heat exchanger is formed by a single heat exchanging pipe or a heat exchange pipe bundle and has low heat transfer rate due to thick viscous flow layer of liquid inside the pipe and poor circulation state due to very low flow rate of liquid outside the pipe. In a double-helix three-sleeve heat exchanging pipe bundle of the composite sleeve double-helix heat exchanger, a middle pipe and a hollow inner pipe form an inner flow passage; inner helical blades are arranged in an annular gap of the middle pipe and the inner pipe; an outer pipe and the middle pipe form an outer flow passage; outer helical blades with opposite handedness with the inner helical blades are arranged in an annular gap of the middle pipe and the outer pipe; and two-phase liquid fast forms an annular lamella in the pipe to flow forwards in a helical scouring way. The structure not only has strong structure, but also can greatly improve the heat-transfer characteristic of the heat exchanger.

Owner:赵文阁

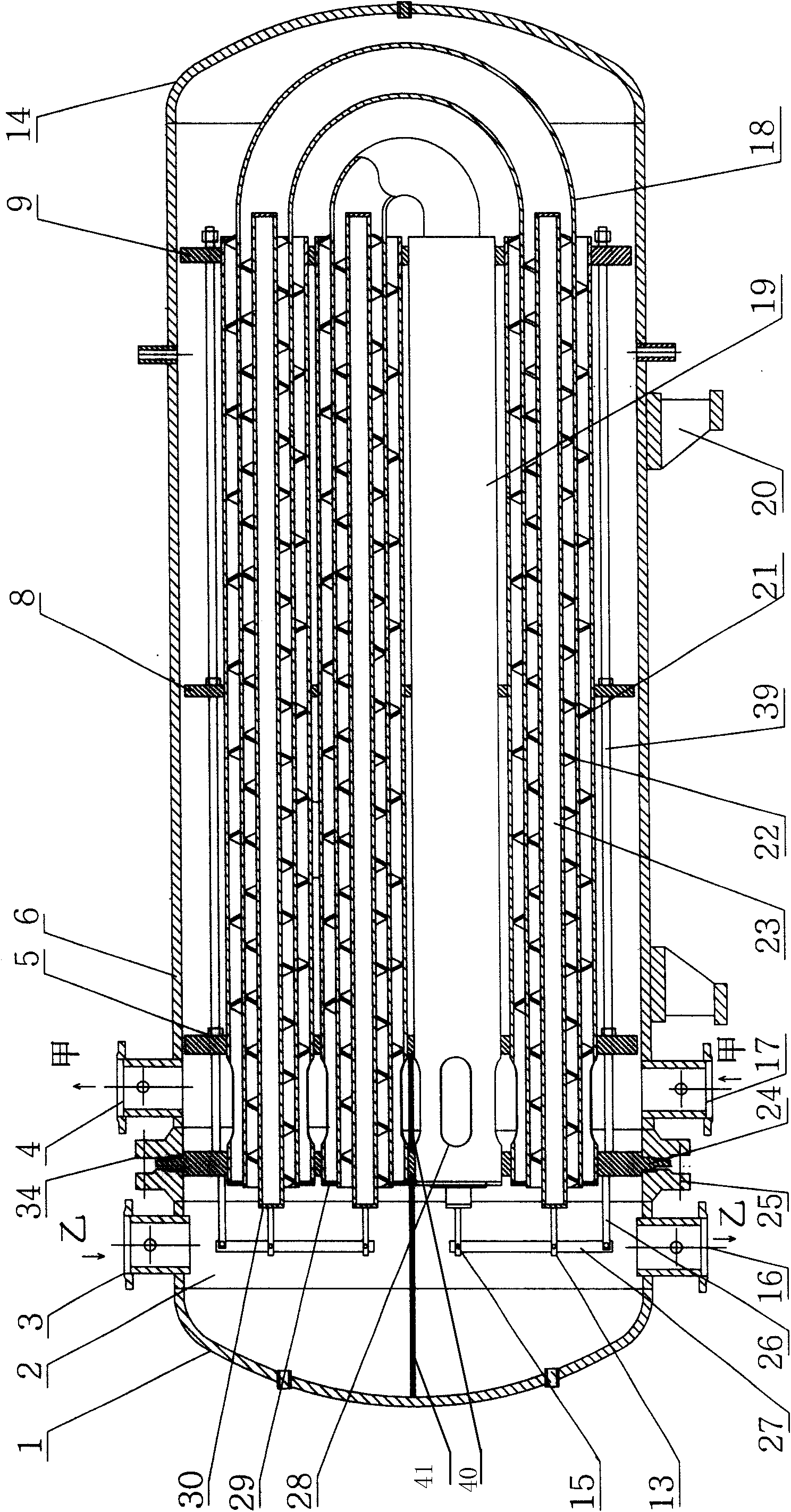

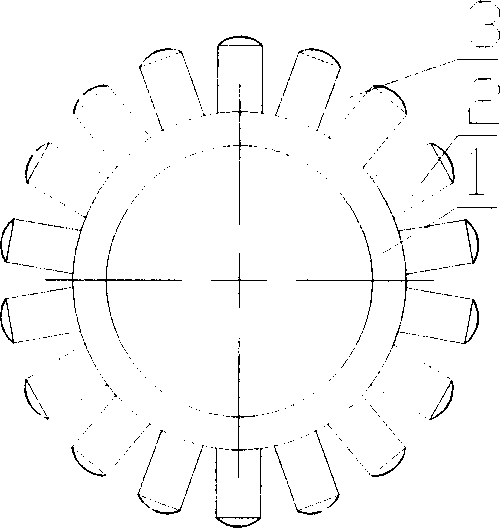

Liquefied natural gas (LNG) low temperature liquefied three-level refrigeration spiral wound tube type heat exchanger

InactiveCN102538387AWith self-tightening adjustment functionReduce volumeSolidificationLiquefactionThree levelSpiral wound

The invention belongs to the field of natural gas low temperature liquefied technology, and relates to a liquefied natural gas (LNG) three-level low temperature liquefied process device and a mixed refrigerant refrigeration technology, which cools 6.0MPa, -120DEG C natural gas into -164DEG C to be liquefied in two-steam spiral wound tube type heat exchanger by applying a certain proportion of non-azeotropic N2-CH4 mixed refrigerant, thereby being convenient for LNG to be stored in a surpercooling mode and being convenient to transport. The non-azeotropic N2-CH4 mixed refrigerant is firstly precooled and liquefied by a three-level refrigerant spiral wound tube type heat exchanger, and is throttled to a shell pass after being liquefied to cool a LNG tube bundle and a N2-CH4 mixed refrigerant precooling tube bundle from a secondary outlet in -120DEG C, thereby leading natural gas and precoolded refrigerant in the tube pass to be liquefied, and achieving the purpose of precooling mixed refrigerant before throttling and liquefying nature gas at low temperature. The LNG three-level low temperature liquefied process device is compact in structure and high in heat exchange efficiency, can be used to exchange heat for mixed gas with low-temperature phase transition, solves the difficult problem of LNG three-level low temperature technology, and increases low temperature heat exchange efficiency of a LNG system.

Owner:张周卫

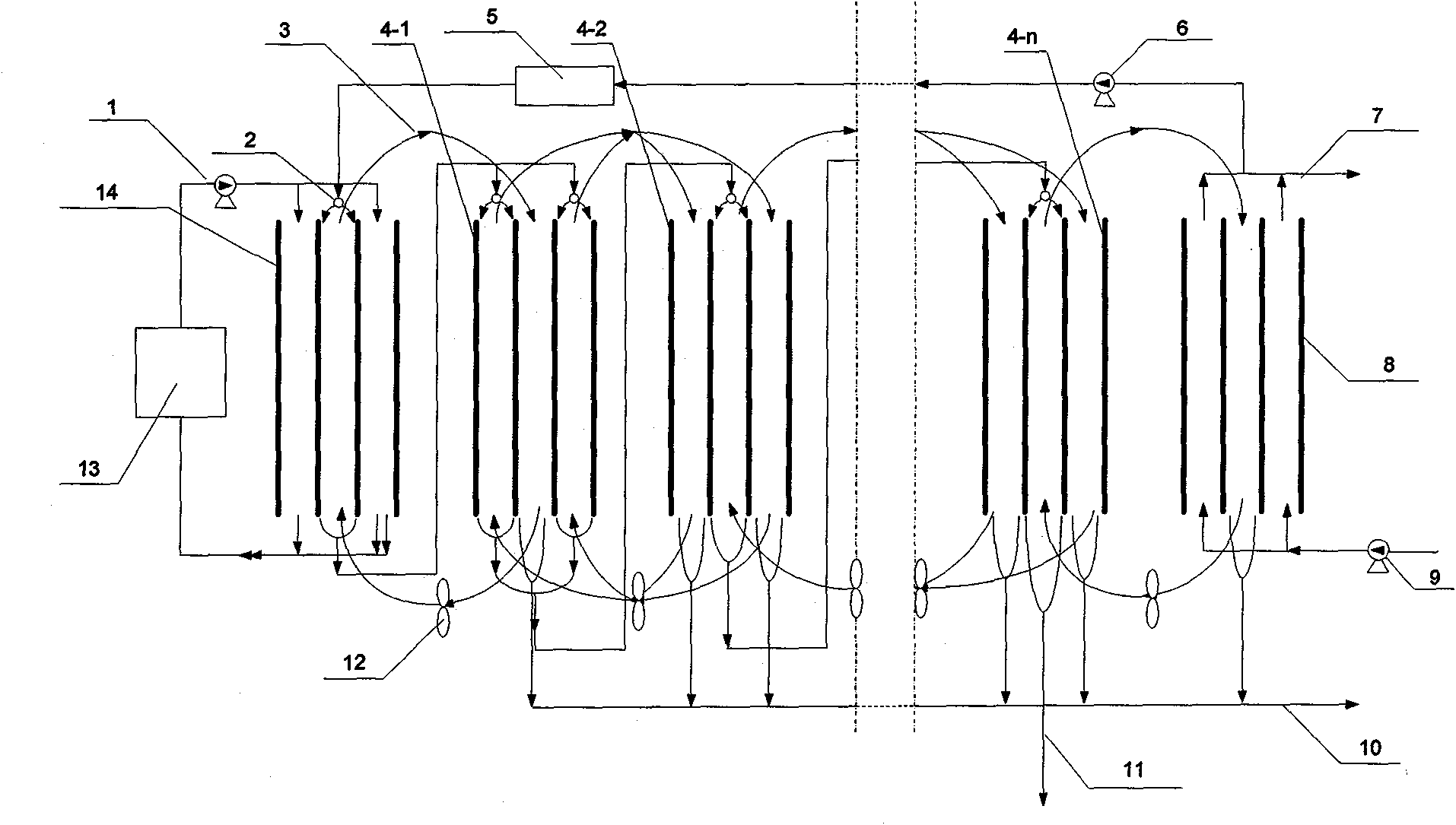

Constant-pressure multiple-effect evaporation condensation sea water desalination device with air medium

InactiveCN101921036AReduce consumptionImprove performanceSeawater treatmentMultistage water/sewage treatmentWater desalinationEnergy recovery

The invention discloses a constant-pressure multiple-effect evaporation condensation sea water desalination device with an air medium, which mainly comprises a low-and-medium temperature heat source (13), a first-stage heating evaporator (14), an evaporation condenser (4) and a last-stage condenser (8). The first-stage heating evaporator (14), the evaporation condenser (4) and the last-stage condenser (8) are installed in sequence closely, and the low-and-medium heat source (13) and the first-stage heating evaporator (14) are connected together. The first-stage heating evaporator (14), the evaporation condenser (4) and the last-stage condenser are all formed by combining a plurality of heat exchange plates which are arranged from left to right in sequence, and a gap is reserved between every two adjacent heat exchanging plates to form a flow channel for heat exchange fluid. By adopting the plate-type heat exchange principle, the sea water desalination device realizes multiple-effect air humidification and dehumidification evaporation and condensation for sea water desalination under constant pressure. Heat and moisture transfer is performed between sprayed sea water and overflowing air, and the condensation latent heat of fore effect heat and moisture air can be absorbed at the same time, and therefore, energy recovery is realized and the fore effect heat and moisture air can be condensed to obtain fresh water.

Owner:GUANGDONG FIVESTAR SOLAR ENERGY

Micro-jet-flow water-cooling system for luminuous diode LED

InactiveCN1979825AEffective coolingImprove heat transfer coefficientSemiconductor/solid-state device detailsLighting heating/cooling arrangementsJet flowEngineering

The system includes LED chip, micro jet ejector, water tank with cooling unit, and tiny pump. Base seat of LED chip is installed on shell of the micro jet ejector. A cavity is setup inside the micro jet ejector. There is clapboard with multiple tiny nozzles inside the cavity. Through tubes, inlets and outlets setup on two sides of the clapboard are connected to tiny pump and water tank. Heat sink and fan in up part of the water tank, and micro flute channels inside the water tank form a close internal circulation cooling system. Using impaction heat exchange, the system possesses large heat transfer coefficient. Advantages are: flexible control for setting cooling direction. The invention is suitable to cool LED where condition is changed quite often.

Owner:刘胜

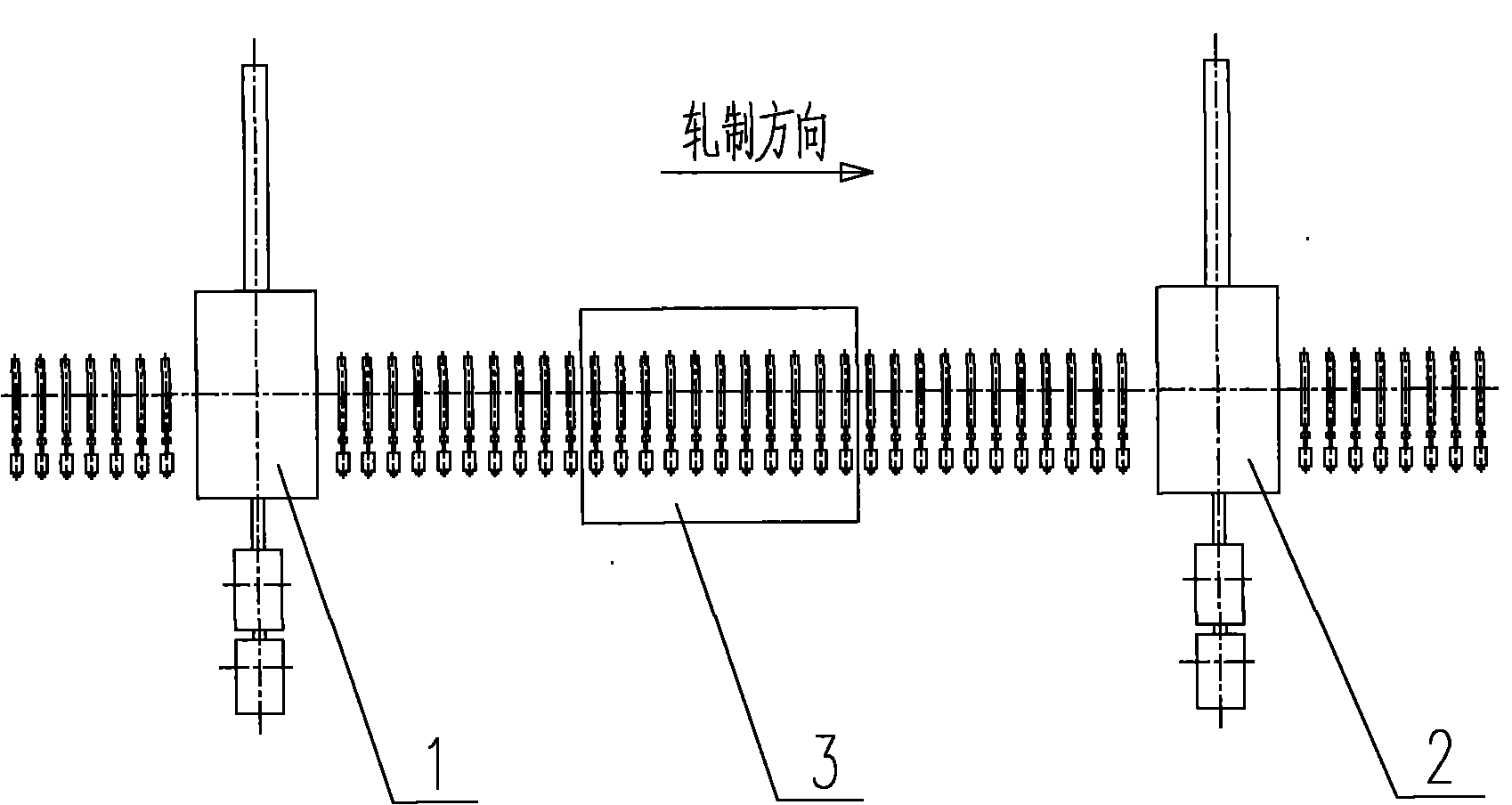

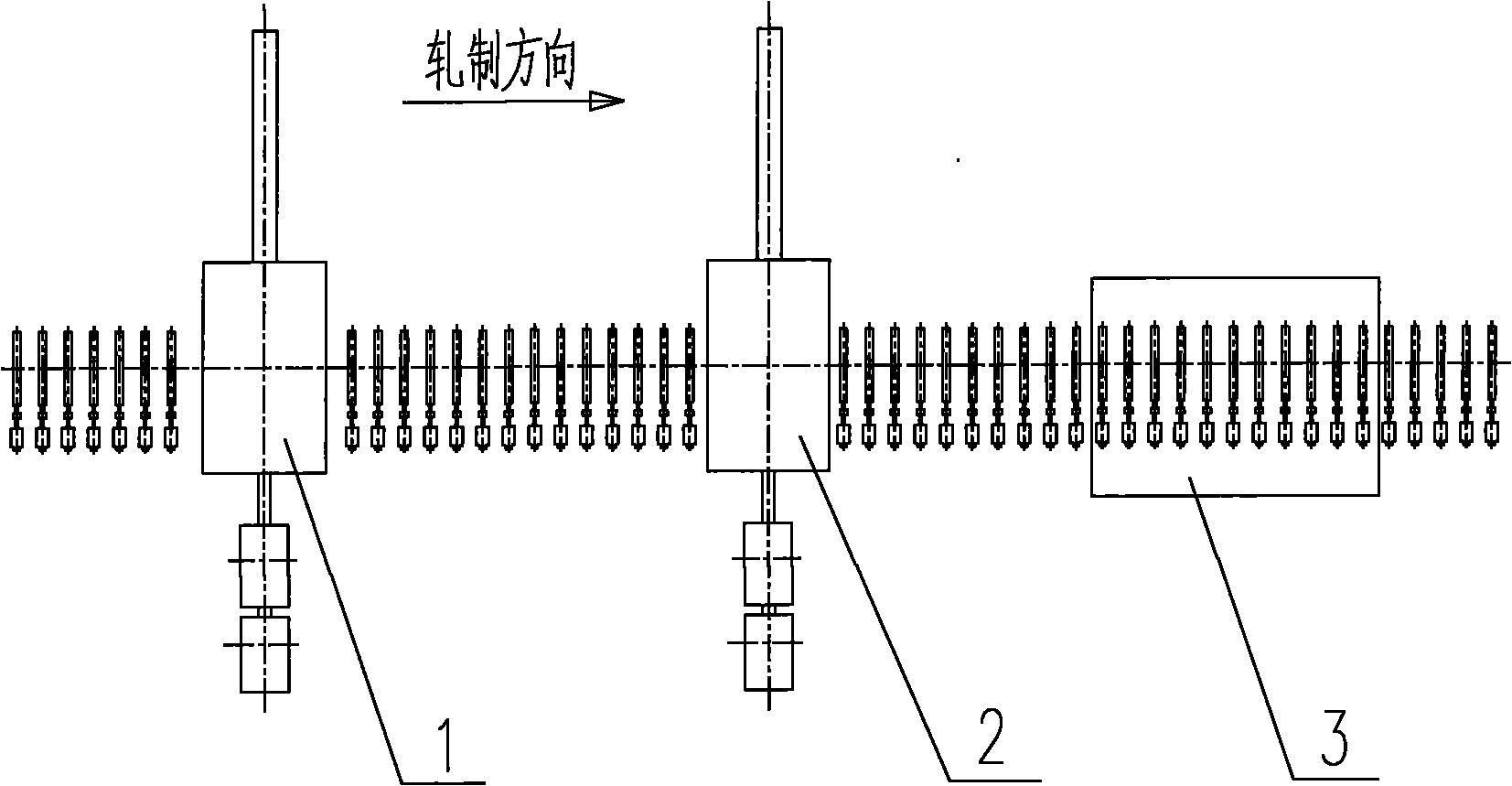

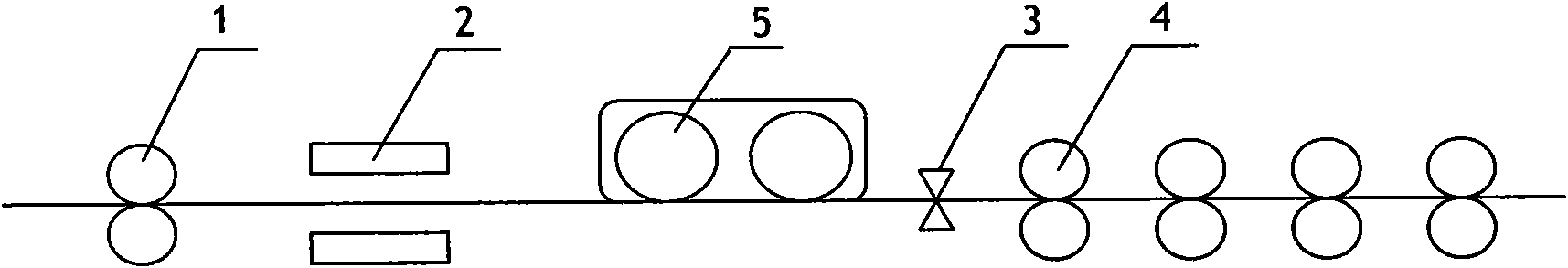

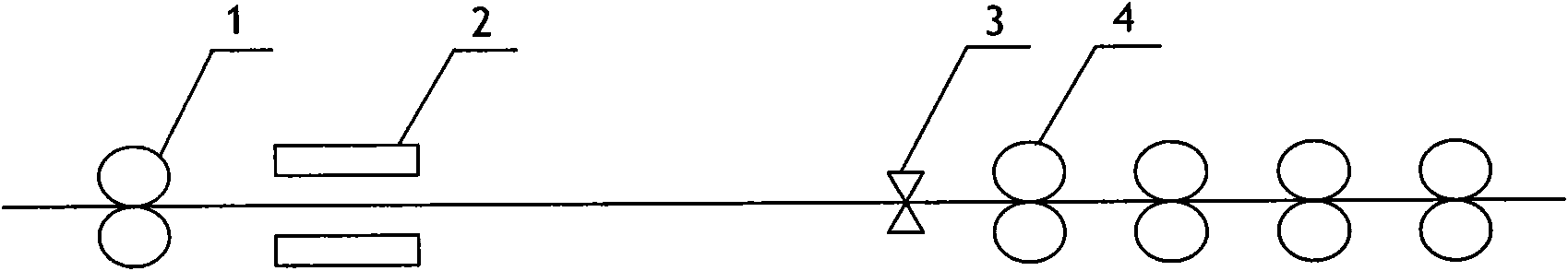

Cooling method of heavy and medium plate controlled rolling intermediate blank

InactiveCN101829688ALess investmentImprove applicabilityTemperature control deviceWater qualityWater cycling

The invention belongs to a producing and cooling technique of rolled steel, relating to a cooling method of a heavy and medium plate controlled rolling intermediate blank, which can be realized by both a single-stand heavy and medium plate roll and a double-stand heavy and medium plate roll. The cooling method comprises the following steps of: transmitting a roughly rolled intermediate blank with the thickness range of 30-110 mm in an austenite recrystallization zone into an intermediate controlled cooling zone from a transmission roller way for rapidly cooling to 800-950 DEG C, and then transmitting the intermediate blank into the roll for rolling in a non- recrystallization zone after short-time air cooling and temperature evening. In the intermediate cooling process, an upper collecting pipe and a lower collecting pipe with high density or ultra-high density are adopted to impact, jet and cool the intermediate blank, and specific technological parameters are accurately controlled by a computer. Water is cooling water for the roll with the pressure of 0.3-1.0 MPa in a common water circulating system for workshops. The intermediate cooling holding time is 30-70% shorter than that of the conventional process so that the production efficiency is improved, and due to austenite grain refinement after intermediate controlled cooling, the mechanical properties of a steel plate can be improved.

Owner:UNIV OF SCI & TECH BEIJING

Rotary air preheater dust-blocking-prevention synergy sealing method and system

ActiveCN104949149AExtend your lifeEasy to implementCombustion processHeat exhanger sealing arrangementAir preheaterLiquid state

The invention discloses a rotary air preheater dust-blocking-prevention synergy sealing method and system. The dust-blocking-prevention synergy sealing method includes the steps that air leaked from the heat end is guided or extracted to the cold end from the heat end, and local heat exchange elements are purged and heated. The rotary air preheater dust-blocking-prevention synergy sealing system comprises a heat end primary air / smoke side sector sealing box, a heat end primary air / secondary air side sector sealing box and a cold end secondary air / smoke side sector sealing box, and further comprises a heat air leakage air flue; the heat end primary air / smoke side sector sealing box and the heat end primary air / secondary air side sector sealing box are each provided with an air inlet, one end of the heat air leakage air flue is in butt joint with the air inlets, and the other end of the heat air leakage air flue extends to a cold end secondary air highest-temperature module. By means of the rotary air preheater dust-blocking-prevention synergy sealing method and system, H2SO4 drops and liquid state NH4HSO4 are gasified while the air leaked from a preheater is reduced, and the aim of removing accumulated dust is achieved; the rotary air preheater dust-blocking-prevention synergy sealing method and system have the advantages of reducing the boiler smoke discharging temperature, restraining the accumulated dust of the preheater, reducing the air leakage rate, prolonging the service life of the heat exchange elements and the like.

Owner:南京博沃科技发展有限公司

Helix stirred reactor with cryogen gong through inside, application, and technical method of polyreaction

ActiveCN101091901AReasonable workmanshipReduce manufacturing costRotating receptacle mixersTransportation and packagingTextile fiberPolymer science

The invention relates to a screw agitation reactor of the freezing mixture and the use and the polyreaction technique. The reactor includes the support, the tubular material trough which has the material entrance and the export circle, the bearing, the spiral stirrer, the gland seal and the power dragging turning gear. It is suitable for producing polymer by the solution polymerization method technological process like synthetic rubber, the plastic and the textile fiber, especially suitable for synthesizing isoprene rubber and cis-butadiene rubber in the rare earths catalysis system. It replaces the complete mixing flow type of the completely backmixing by the plug flow type of no backmixing, strengthened the polyreaction process and the heat transfer process, the reactor volume is reduced obviously, the energy consumption is reduced largely, the polymer performance is enhanced.

Owner:FUSHUN YIKESI NEW MATERIAL

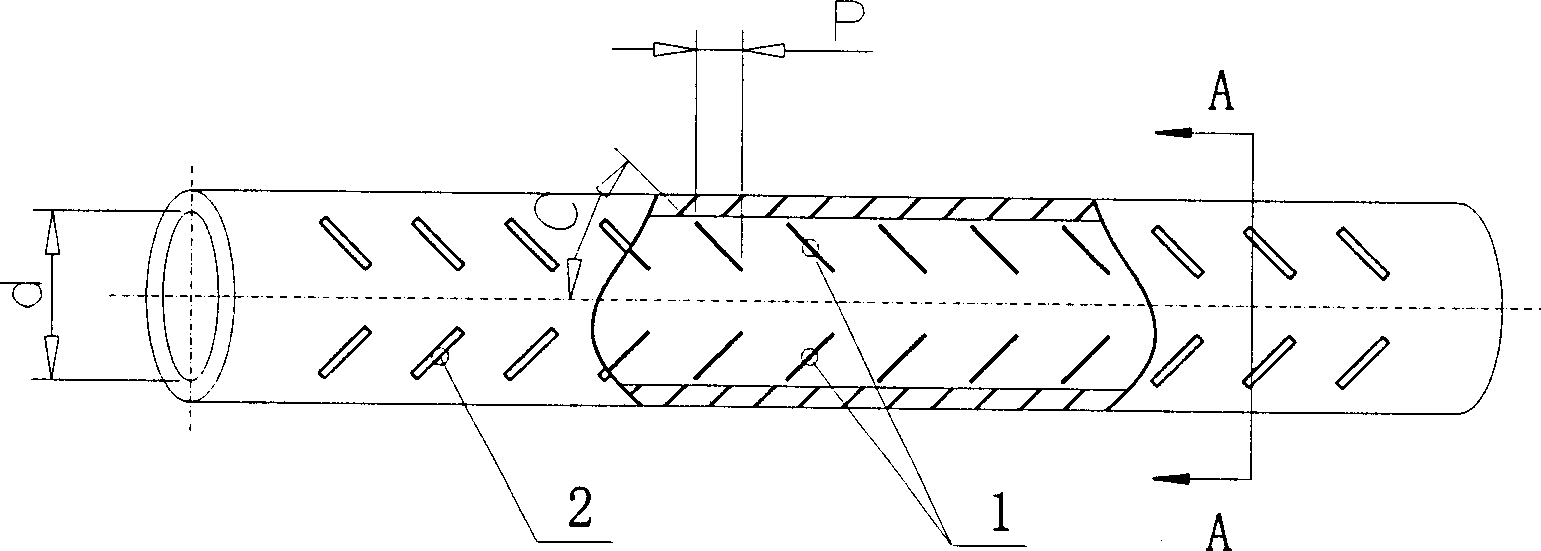

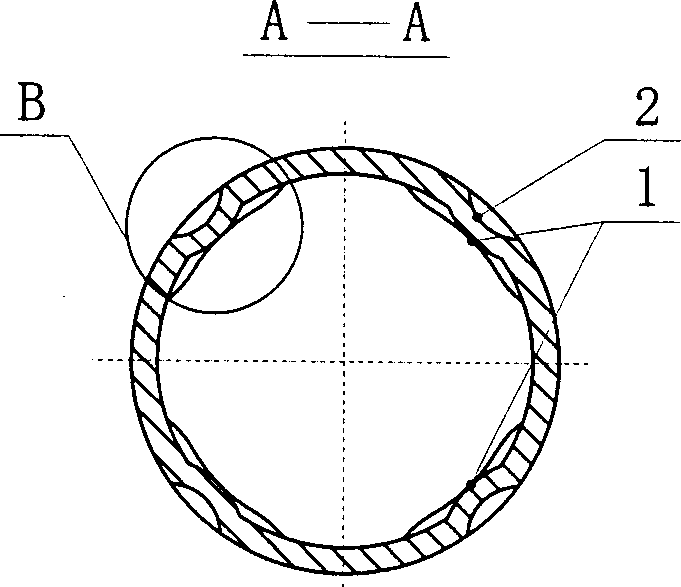

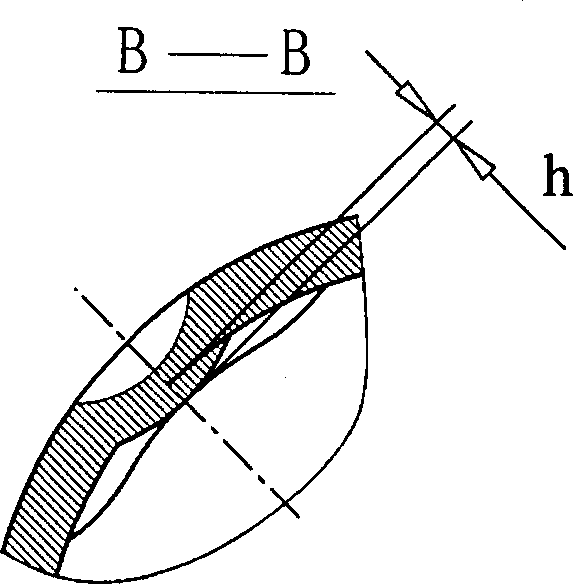

Non-continuous double diagonal internal rib reinforced heat exchange tube

InactiveCN1451937ASignificant effect of enhanced heat transferSmall flow resistanceHeat exchanger casingsTubular elementsEngineeringHigh heat

A heat exchanging tube is characterized by that on its inner surface there are discontinuous internal ribs which have a certain included angle (5-85 deg.) relative to axis of tube and are inclined intwo directions. Its advantages are high heat exchange efficiency, low flow resistance and not scaling.

Owner:TSINGHUA UNIV

Powder coal gasification powder processing and water recovery integrated system for high-moisture coal and method of system

ActiveCN103234214AReduce water dischargeTake advantage ofDrying solid materials with heatIndirect carbon-dioxide mitigationMoistureVacuum pump

The invention relates to a powder coal gasification powder processing and water recovery integrated system for high-moisture coal. The system comprises a steam indirect heat transfer drying machine, an absorption tower, a flash tower, a vacuum pump / Venturi injection pump and a raw coal bunker. The steam indirect heat transfer drying machine is connected with the raw coal bunker, a bag-type dust collector I and a surge bunker; the surge bunker is connected with a coal mill; the coal mill is connected with a hot blast heater, and a bag-type dust collector II and a delivery pipe II are arranged at the top of the coal mill respectively; the top of the absorption tower is connected with a carrier gas initial heater, a circulating pump is arranged at the bottom, and the side of the absorption tower is connected with the flash tower; the circulating pump is connected with an air heater and connected with the carrier gas initial heater; the air heater is connected with the flash tower and the hot blast heater respectively; the flash tower is connected with a condenser which is connected with the vacuum pump / Venturi injection pump; and the flash tower is connected with the carrier gas initial heater. The invention further discloses an application method of the system. According to the system and the method, the investment is small, and energy consumption can be reduced effectively.

Owner:TIANHUA INST OF CHEM MACHINERY & AUTOMATION

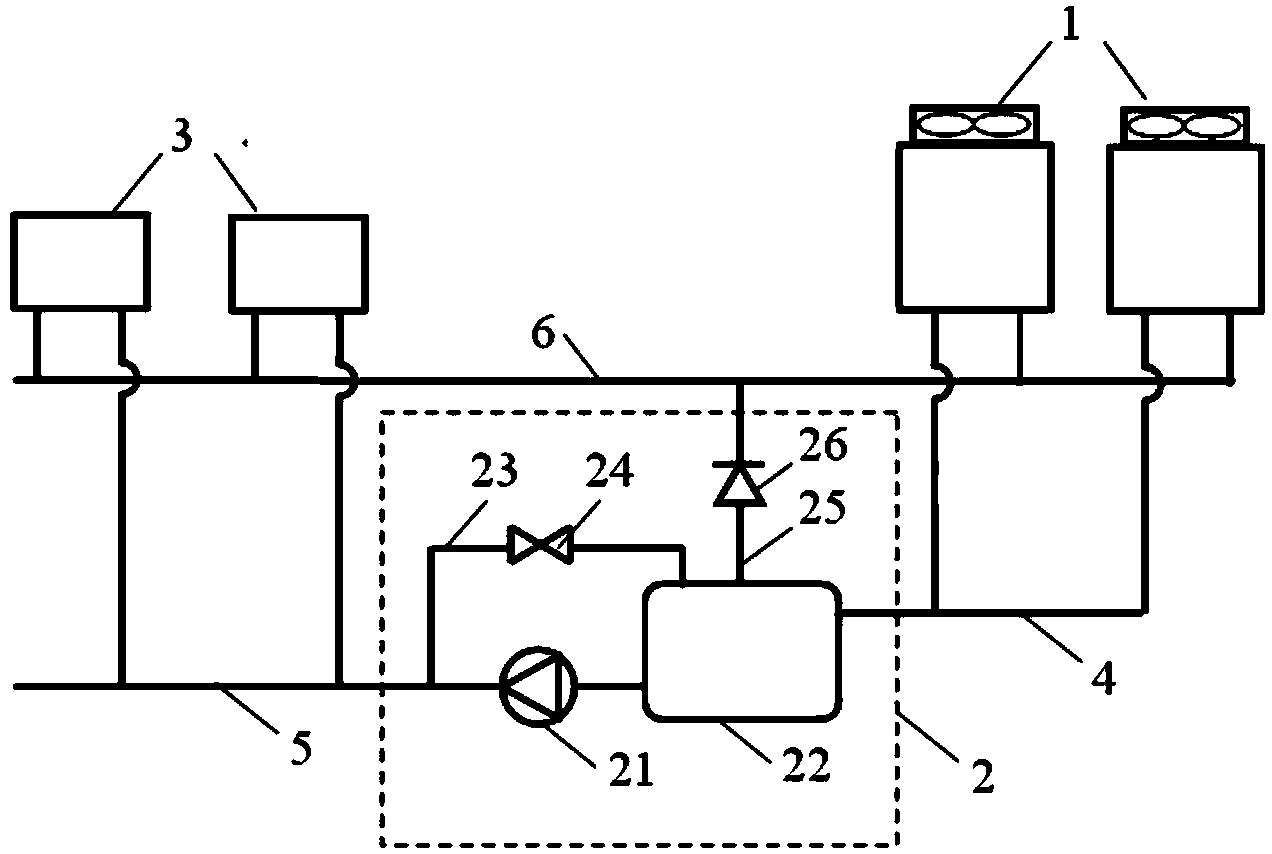

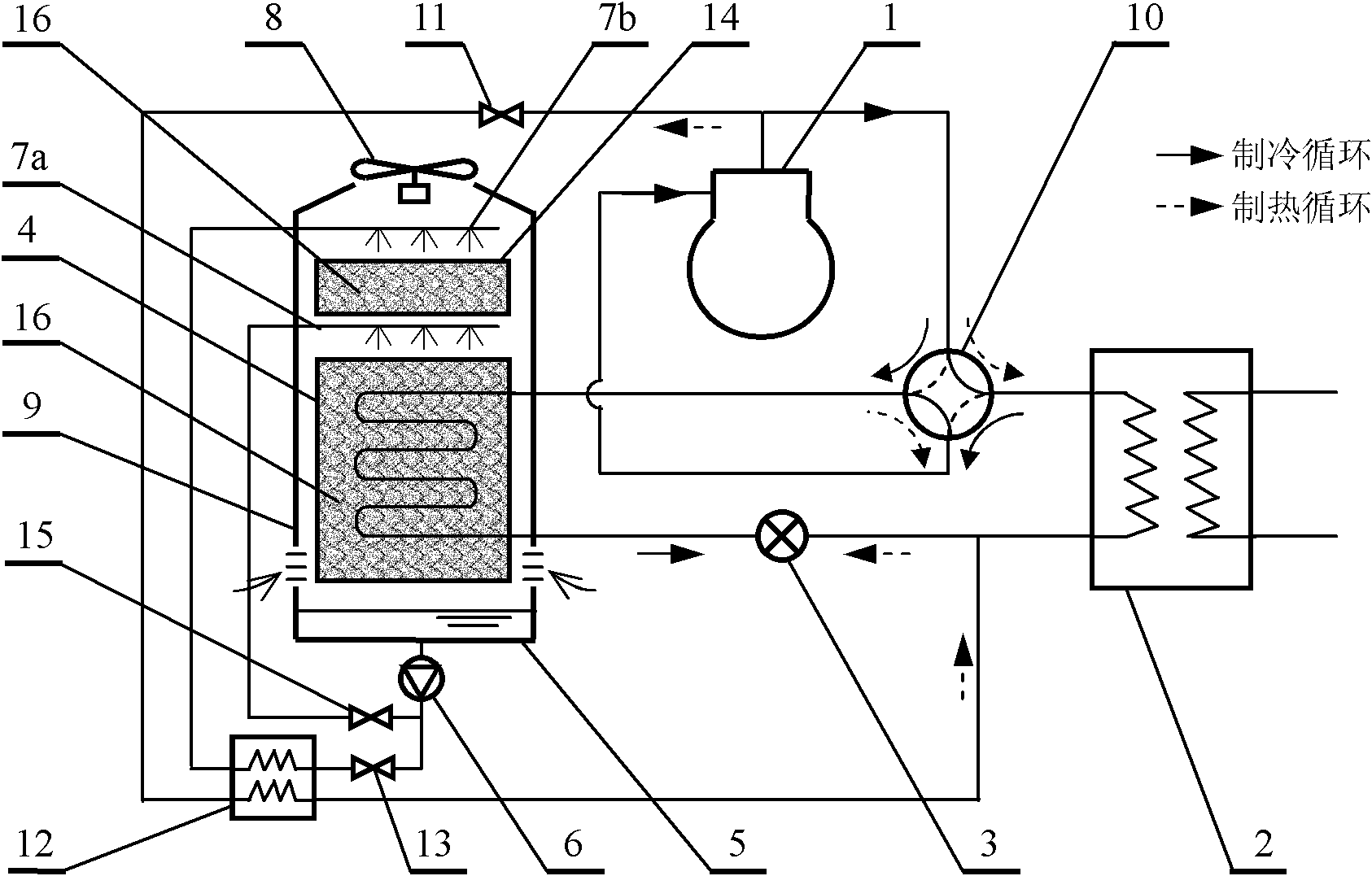

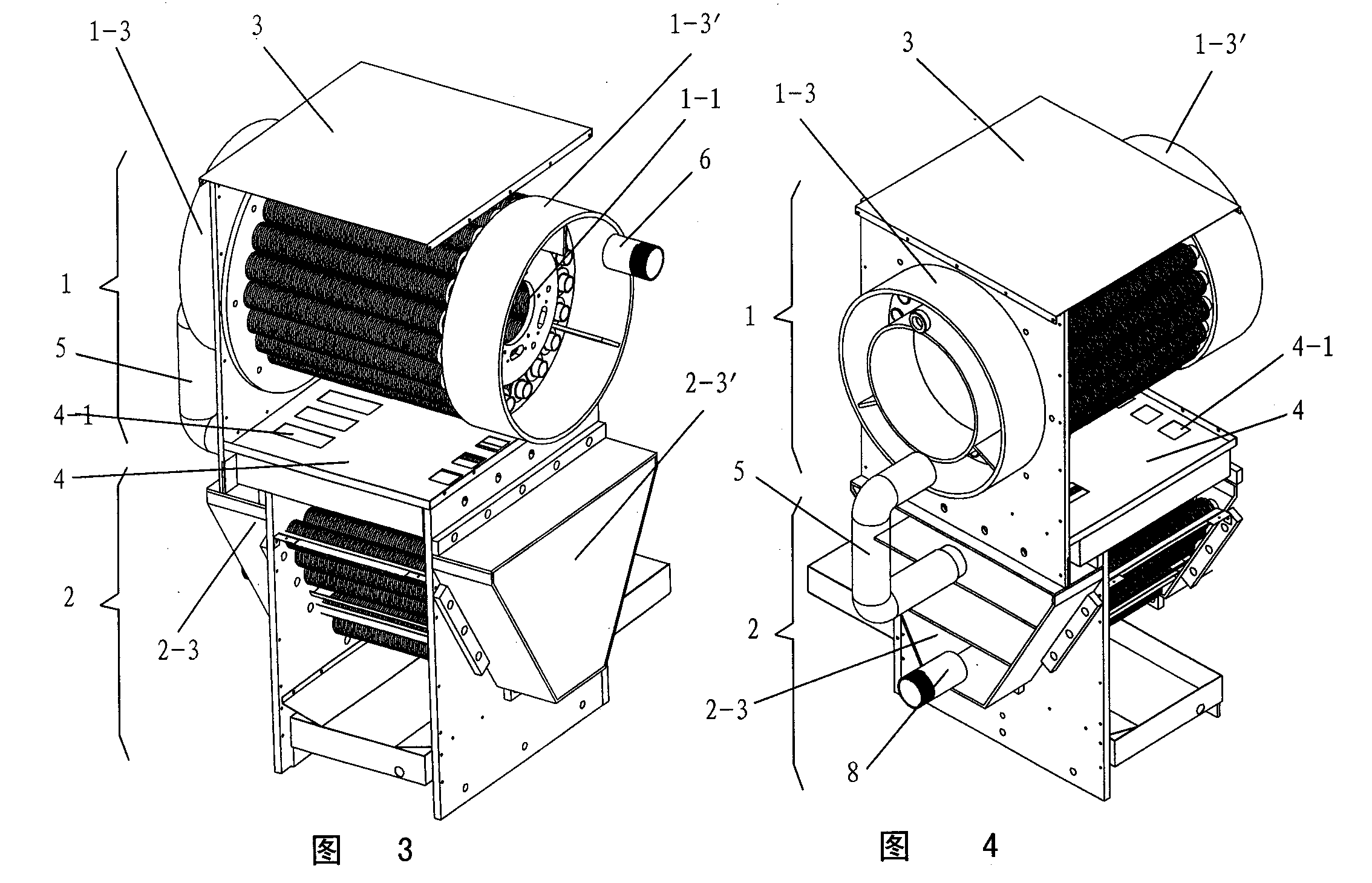

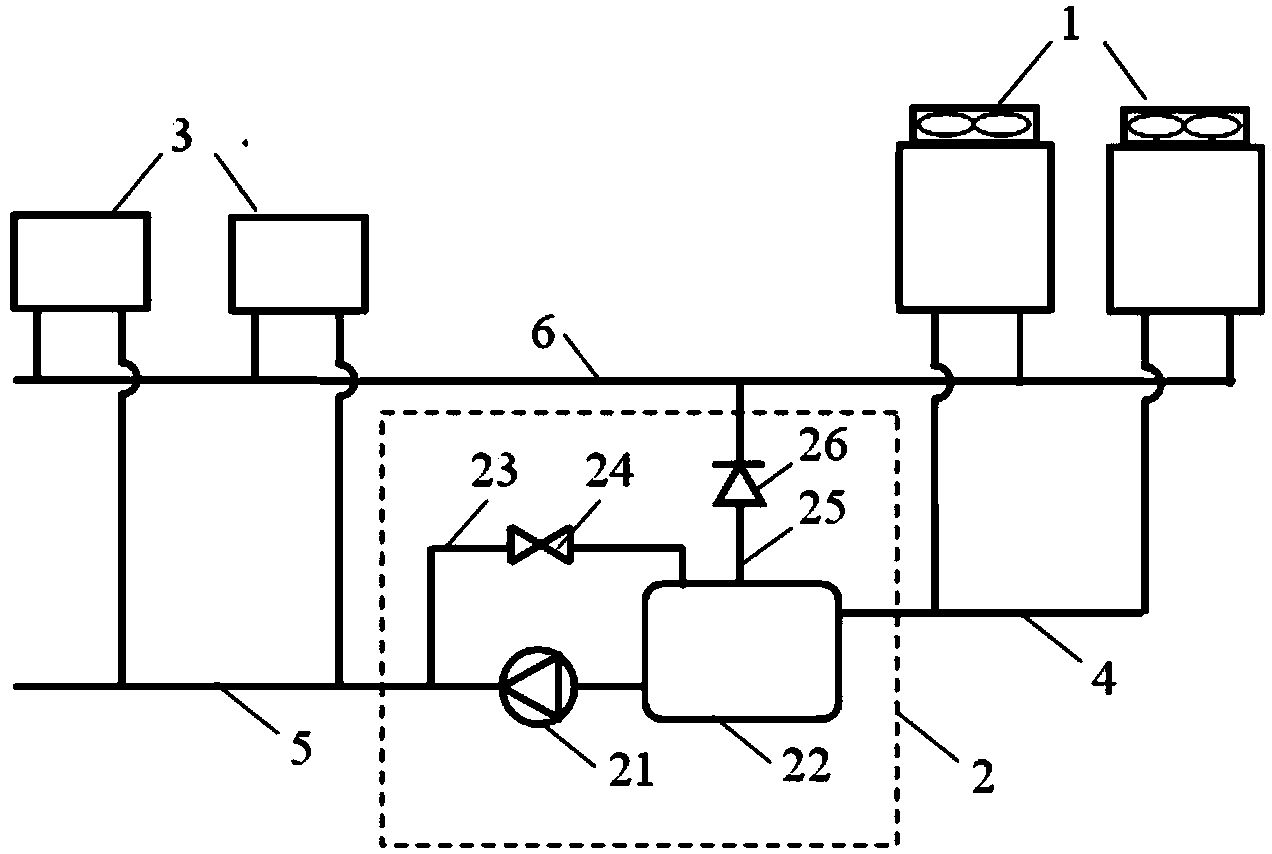

Control method for combined refrigerating multi-split air conditioner system

InactiveCN104266314ALarge working temperature zoneEasy to increase capacityMechanical apparatusSpace heating and ventilation safety systemsIndoor airTransition season

The invention discloses a control method for a combined refrigerating multi-split air conditioner system. The multi-split air conditioner system is characterized in that two or more outdoor combined refrigerating modules are arranged the outdoor side to form a cold source system of the multi-split air conditioner system, each outdoor combined refrigerating module is composed of a first refrigerant vapor compression and refrigeration circulating loop and a second refrigerant circulating loop, one or more direct evaporation type indoor air cooler modules are arranged at the indoor side, and a refrigerant storing and conveying unit is connected with the part between each outdoor combined refrigerating module and the corresponding indoor air cooler module to form a closed circulating system through a liquid collecting tube, a main liquid supply tube and a main air return tube. According to the control method for the combined refrigerating multi-split air conditioner system, the number of the indoor and outdoor modules is decided according to the designed thermal load of an air conditioner, and the control method precisely regulates the refrigerating capacity to meet the heat control needs of round-the-clock running data machine rooms and electronic equipment; the control method for the combined refrigerating multi-split air conditioner system is capable of making the maximum use of the natural cold source of the day and night, transition season and winter so as to realize the great energy conservation and emission reduction of the air conditioner system.

Owner:CHINA YANGZI GRP CHUZHOU YANGZI AIR CONDITIONERCO

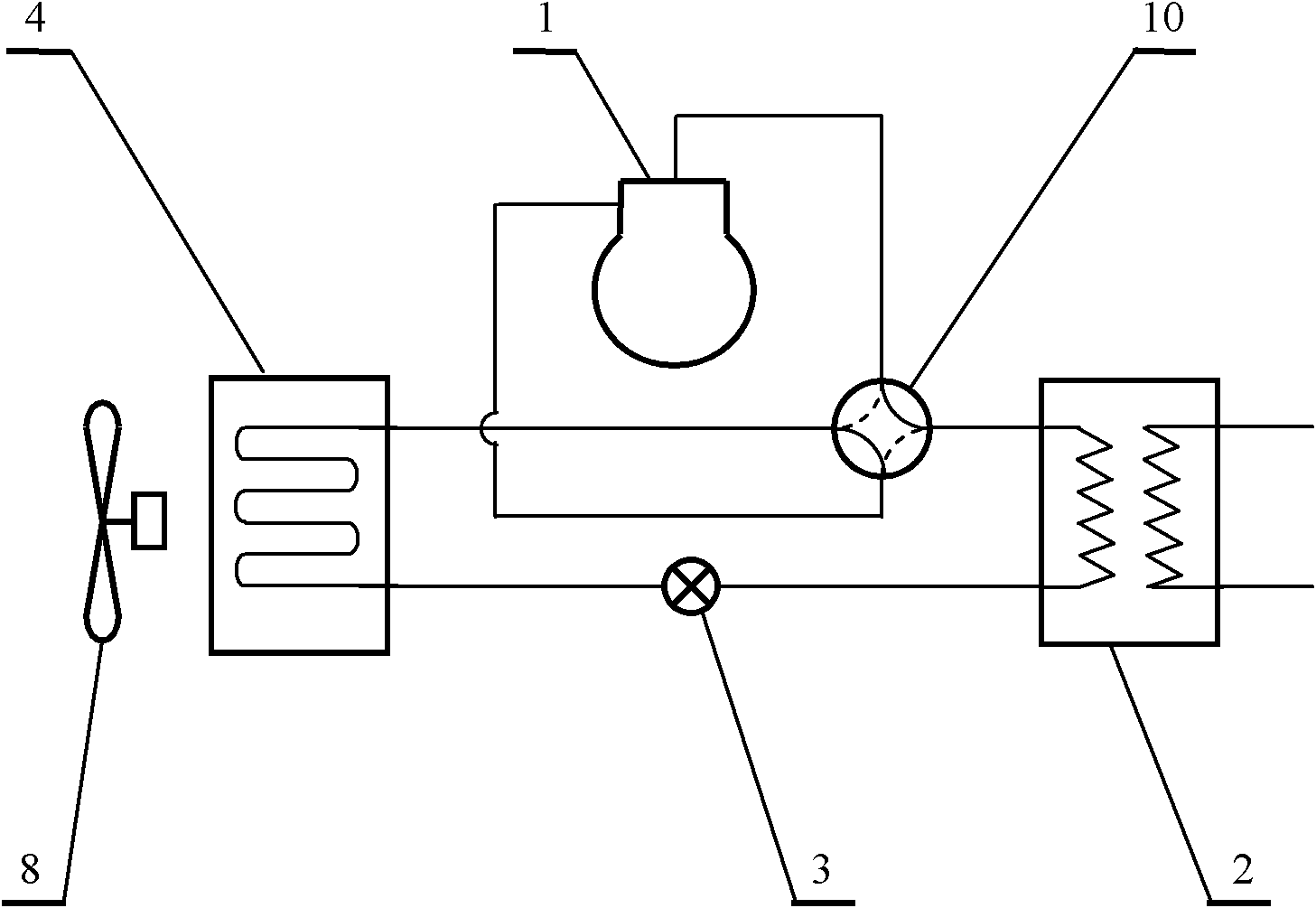

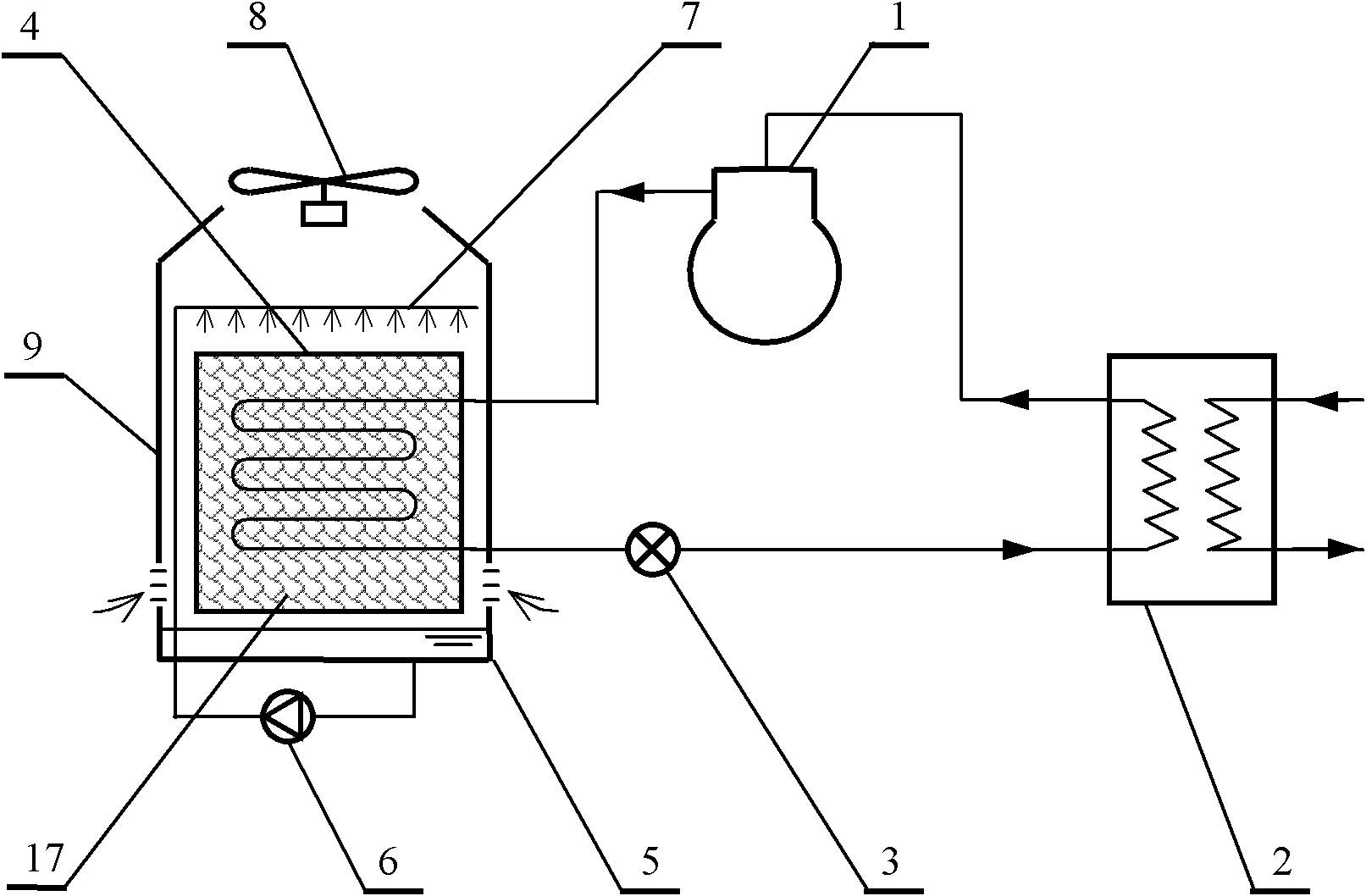

Solution-spraying type air-conditioner heat pump unit

InactiveCN102141279ASolve defrosting problemsGuaranteed comfortLighting and heating apparatusAir conditioning systemsEngineeringAir conditioning

The invention discloses a solution-spraying type air-conditioner heat pump unit, belonging to the field of refrigerating air-conditioning equipment. The solution-spraying type air-conditioner heat pump unit is technically characterized in that with the adoption of the solution spraying, the unit diffuses condensation heat to the environment in summer and takes heat from the outdoor air environment in winter; and the solution is regenerated by the using of exhausted gas of the compressor or hot water manufactured by the unit. Compared with an air source heat pump unit, the solution-spraying type air-conditioner heat pump unit has the obvious characteristics that the refrigeration efficiency is high, the continuous heating operation can be realized without defrosting in winter and the heating efficiency is high, and in addition, the structure of the unit is compact and the early-investment of the equipment is low.

Owner:GUANGZHOU WIDE IND +1

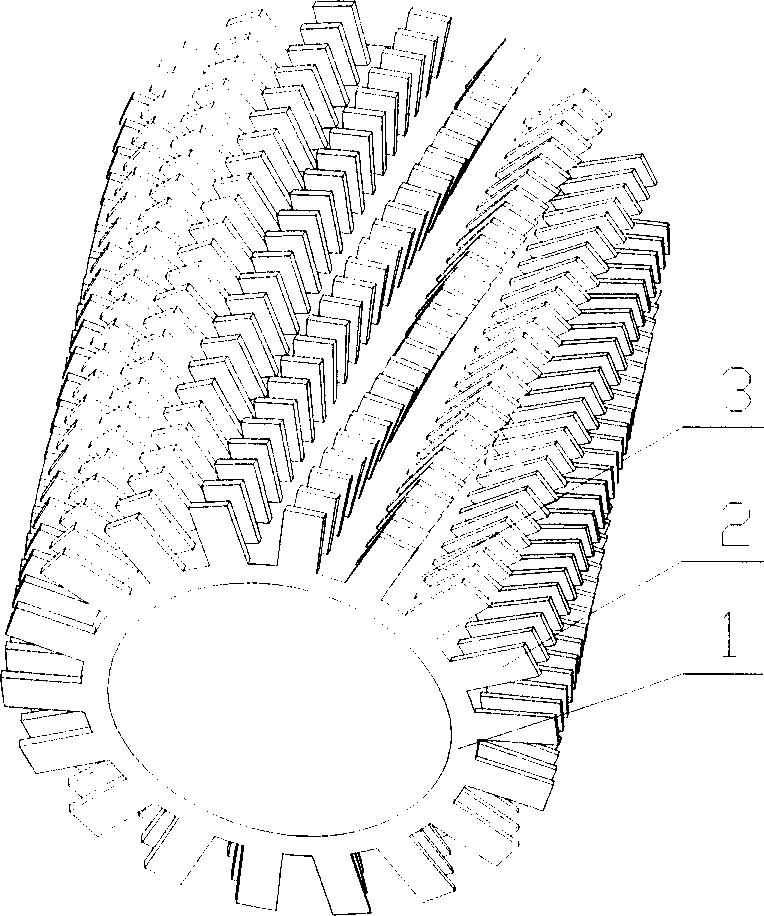

Integral external finned tube and method for manufacturing the same

This invention relates to one integral fin tube, which comprises base tube, fin slice, tank channel, wherein, the tanks are distributed on the base tube surface at 45 to 90 degree angle to the rotation angle; the tanks are distributed with parallel fin slices. The integral fin tube process method comprises the following steps: heat crushing, and cold grinding and processing tank channel by other casting method; then using tolls to cut down base tube between tanks to form fin slice; through heat crushing and cold crushing or other casting method to form fin by cutting the base tube between tanks.

Owner:SOUTH CHINA UNIV OF TECH

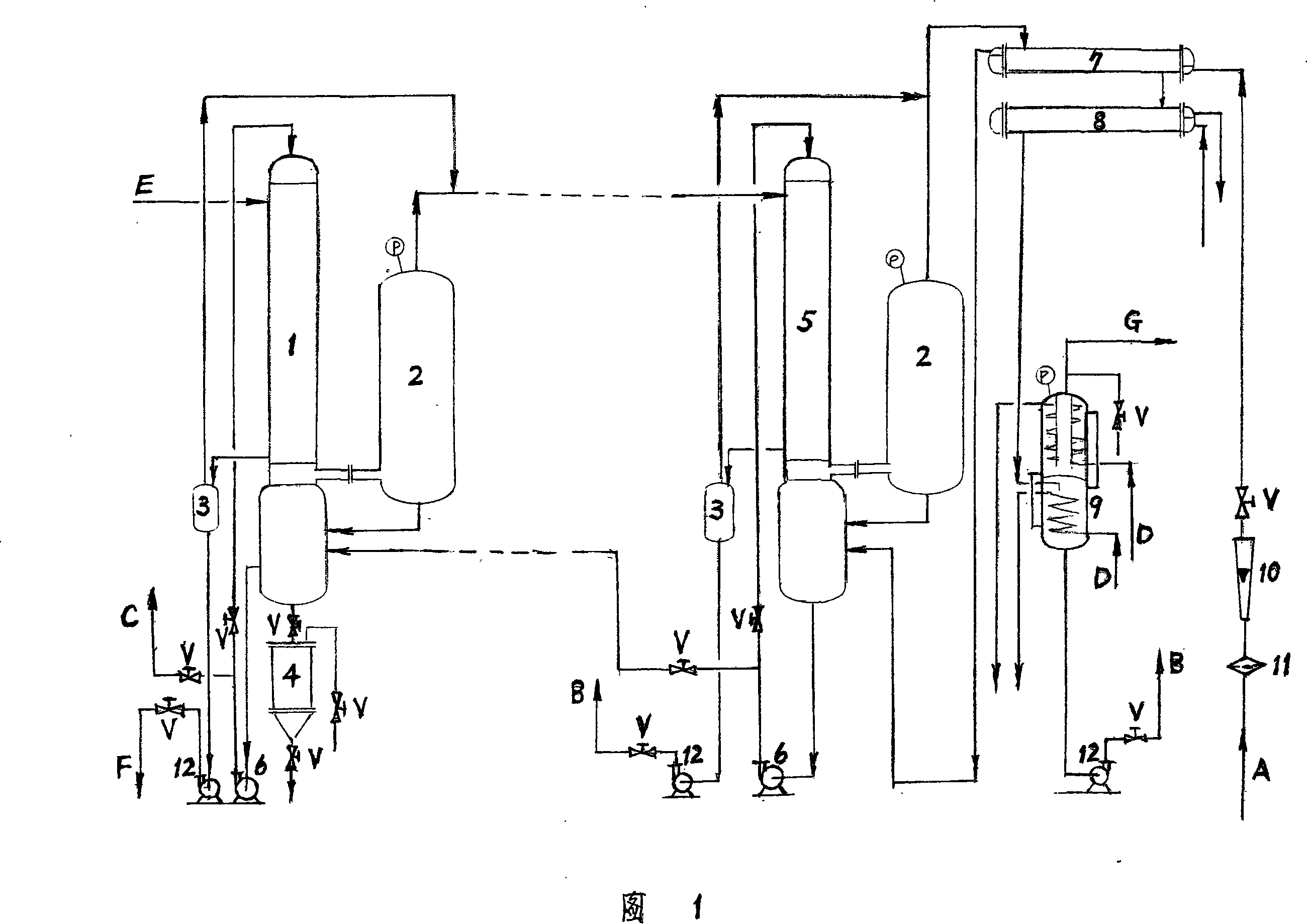

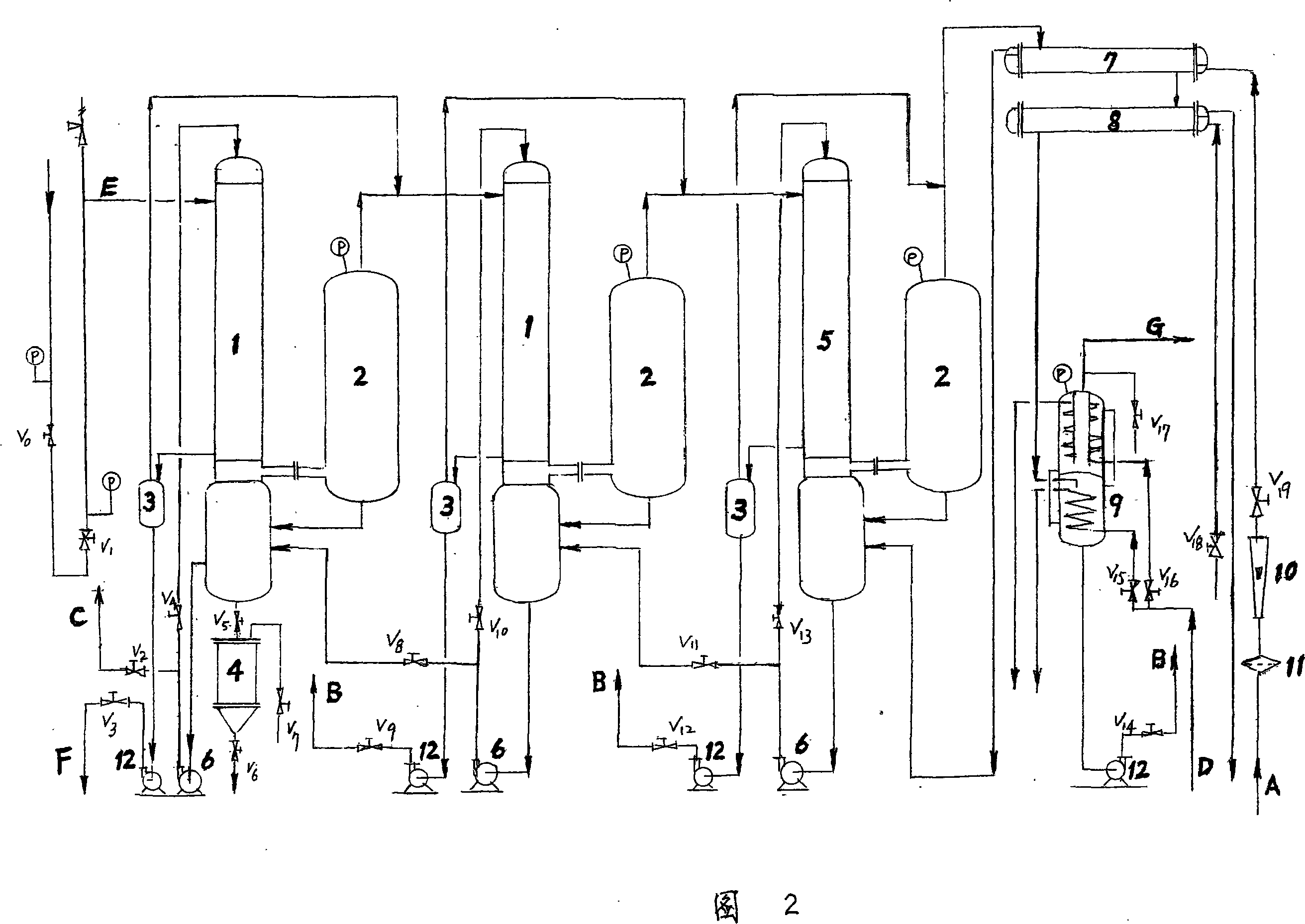

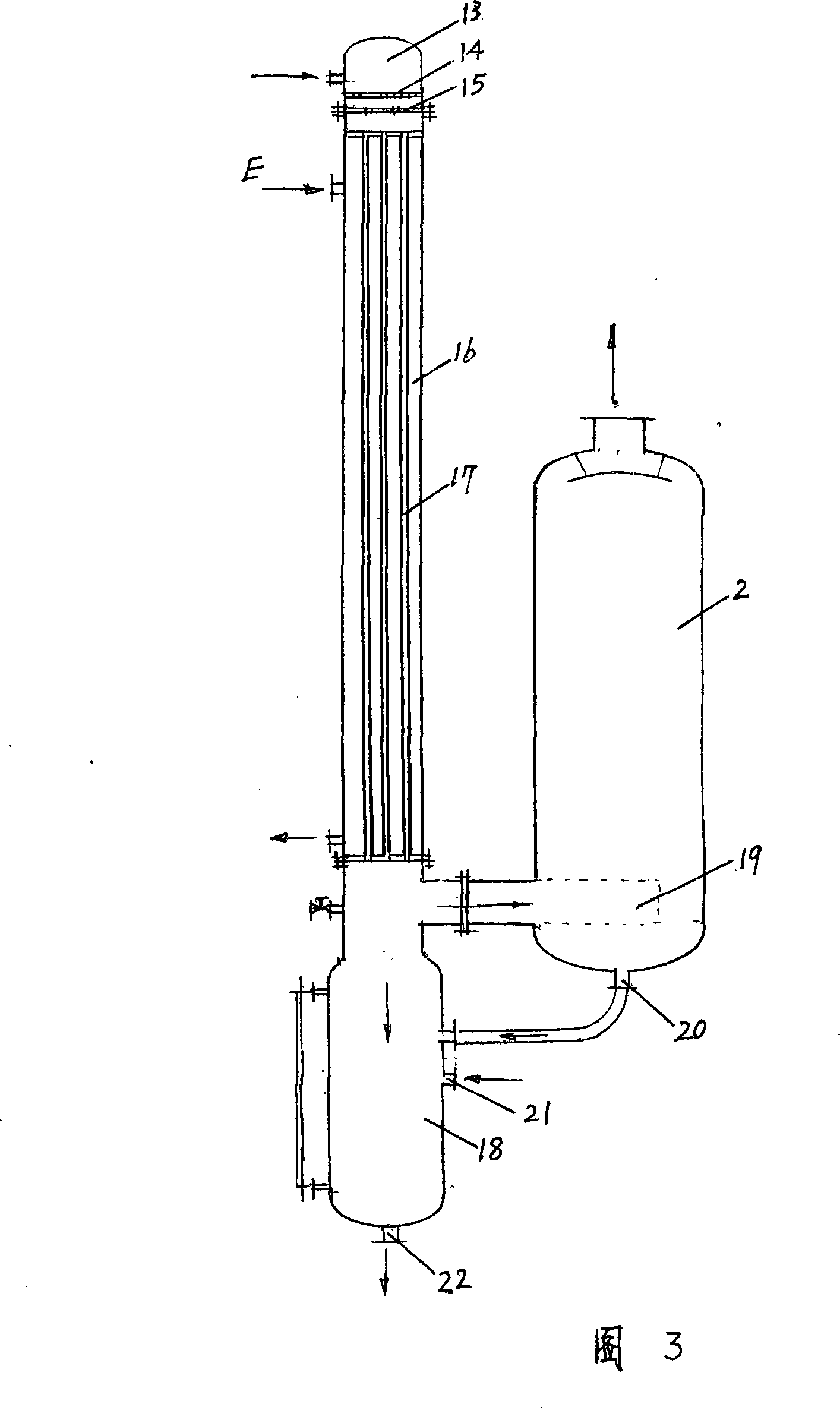

Pleietrepie counter current falling film evaporator of organic solvent recycle

InactiveCN101229449AControl circulation volumePromote circulationMultiple-effect evaporationSteam condensationGas phase

The invention provides a multiple effective reflux falling film evaporation system used for recycling organic solvent. The invention is mainly used for recycling the solvent in water solution of the organic solvent during the concentration production process of plant extractions in food industry and biopharmaceutical industry. The invention adopts falling film evaporators with high heat transmission coefficient and small terminal temperature difference to form the multiple effective evaporation system. Each evaporator is provided with a solution circulating pump which increases down-flow quantity in a heat transfer tube and avoids dry wall of a heat transfer surface and enhances heat transferring, thus having great evaporation ability and high efficiency. The condensate of each evaporator enters into a corresponding condensate tank respectively and is discharged by the pump and recycled. A gas-phase communicating pipe is arranged between the condensate tank and a gas-liquid separator, which guarantees the discharge of noncondensable gas under vacuum operation condition, thus being beneficial for improving condensing and heat transferring efficiency. The invention is a new technique, new technology and new device used in concentration process of the extractions of the organic solvent and used for recycling solvent, which has high recycling rate, little energy consumption and convenient operation and can use a vacuum low temperature evaporation concentration production device in continuous and intermittent production operation.

Owner:DALIAN UNIV OF TECH

Forced heat exchange tube

InactiveCN1677044AIncrease heat transfer areaImprove heat transfer coefficientTubular elementsHeat conductingEngineering

The invention disclose a intensive heat conducting tube applied to high mucosity liquor cooler, heater or cooling device in air compressor on energy, power, fossil, chemistry fields. It comprises exterior basal tube, inner core tube with two ends jamming and wave wing fins set between the inner core tube and exterior basal tube arranged along inner core tube uniformly. Set two or more through holes on the side wall of the wave wing fins. In consequence that there are holes on the wave wing fins, the inner flowing channel of the tube is a non-complete-separated round flowing channel. The inner wing fin with holes increases the flowing speed gradient with disturbing the border layer improving the association between fluid speed and the temperature gradient. Meanwhile due to the number of fins and the holes on the fins, the heat exchanger performance is enhanced so to lower the size of heat exchanging device and lower the production cost.

Owner:XI AN JIAOTONG UNIV

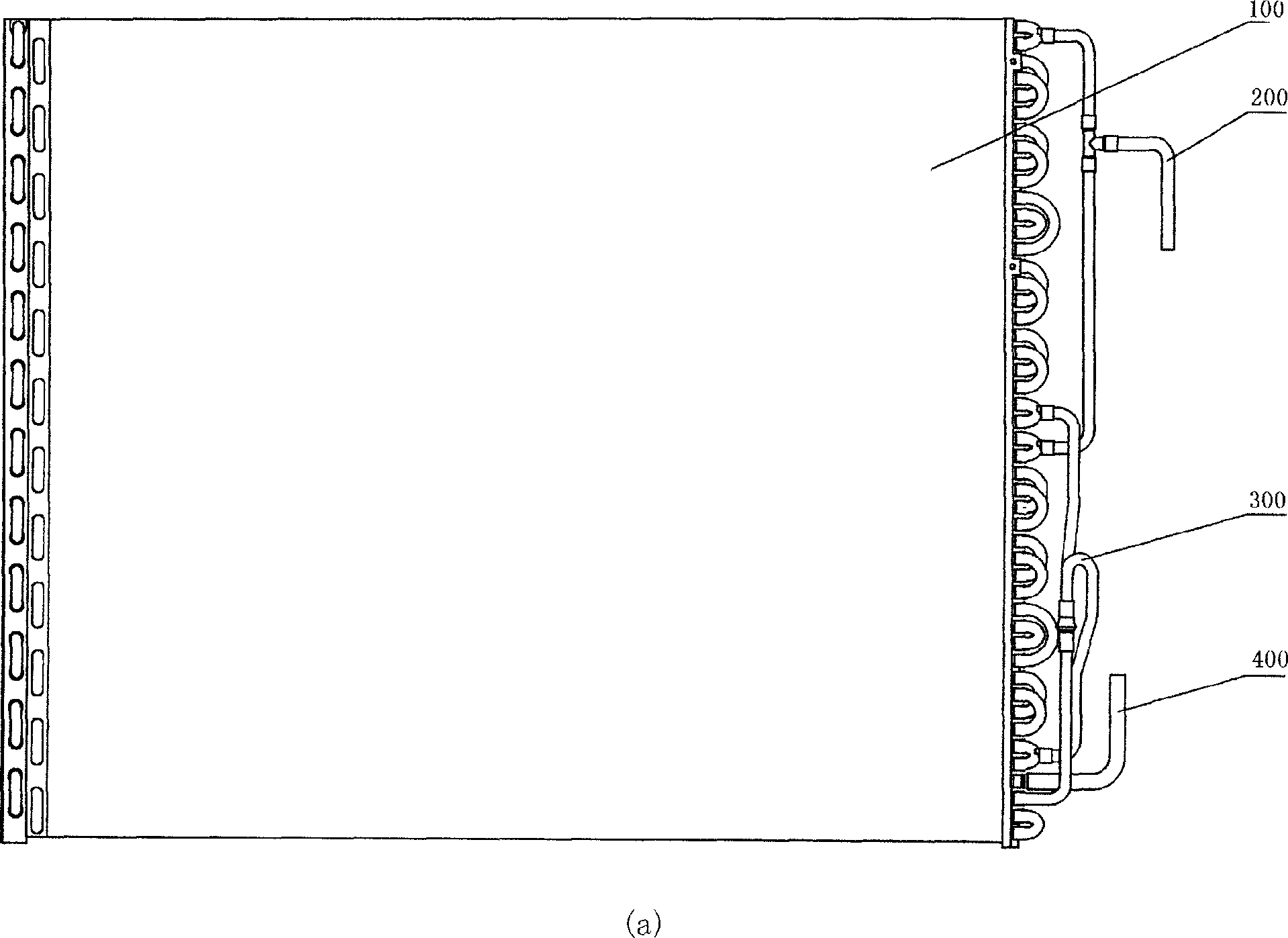

Efficient thermal management system for large-scale power battery and control method

ActiveCN107768773AConducive to jet heat transferTimely deliverySecondary cellsVehicular energy storageControl mannerEvaporation

The invention discloses an efficient thermal management system for a large-scale power battery and a control method. The efficient thermal management system comprises a battery pack and multiple flatheat pipe, wherein a cooling air box is arranged at one side of the battery pack; the multiple flat heat pipes are divided into multiple rows of heat pipe arrays, all the evaporation sections are respectively and orderly clamped by battery cells and fit between the battery cells respectively, and all the cooling sections orderly pass through a wallboard of the cooling air box and are inserted intothe interior of the cooling air box; a partition board is arranged between every two cooling sections in the cooling air box, and an independent branch cooling channel for each cooling section is formed; and the system is also provided with a jet flow heat exchange system, a wind-heat heat exchange system and other systems. According to the system and the method, which are disclosed by the invention, the technical problems of heat dissipation of the battery under different working conditions, reduction of temperature difference of a large-scale battery pack and rapid preheating of the batterycan be solved; meanwhile, the working performance of the system is stable, a control mode is flexible, mounting and maintenance are convenient, and the optimization space is large, so that the systemis consistent with the development trend of battery thermal management systems and electric vehicles, and the battery thermal management system disclosed by the invention has good application prospect.

Owner:SOUTH CHINA UNIV OF TECH

Condensing gas boiler

InactiveCN101782270AGuaranteed flow rateSufficient heat exchangeCorrosion preventionWater heatersCombustorCombustion chamber

The invention relates to a condensing gas boiler, which belongs to the technical field of heat exchange facilities. The condensing gas boiler mainly comprises a burner and a heat exchange device with smoke and water passages, wherein the heat exchange device comprises a horizontal heat exchanger and a V-shaped heat exchanger which are mutually connected in series; a first group of water pipes forming a roundabout flow passage are distributed at the circumference of the horizontal heat exchanger, and the middle part of the horizontal heat exchanger is provided with a cylindrical combustion chamber; the burner is arranged at one end of the cylindrical combustion chamber, and the smoke passes through the horizontal heat exchanger and enters the V-shaped smoke passage of the V-shaped heat exchanger through a downward through hole; a second group of water pipes forming a roundabout flow passage are distributed in the V-shaped smoke passage at intervals; and reverse heat exchange is formed between the water first flowing through the second group of water pipes and then the first group of water pipes and the smoke coming from the combustion chamber and flowing through the V-shaped smoke passage. The heat exchange is sufficient, the flow rate of the cooled smoke can be kept to ensure the heat exchange efficiency, and the condensing gas boiler has a reasonable structure and occupies small area.

Owner:A O SMITH CHINA WATER HEATER CO LTD

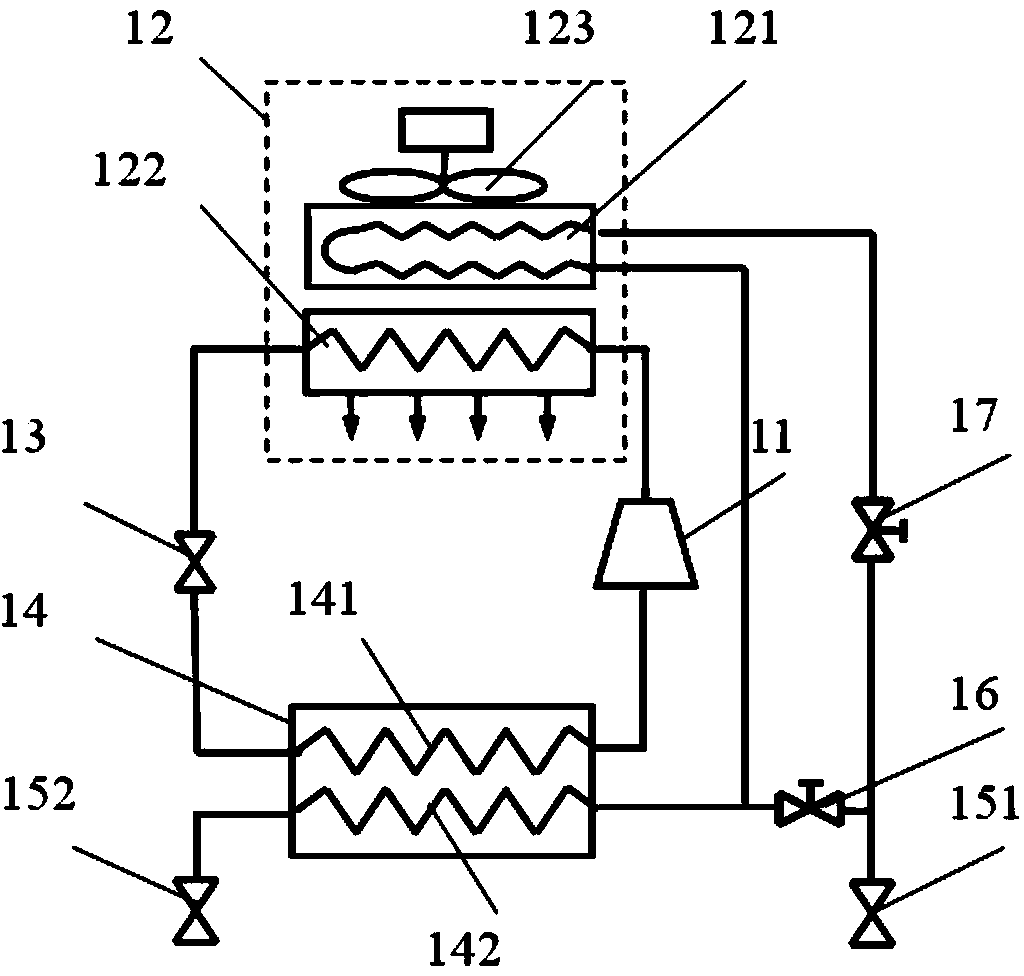

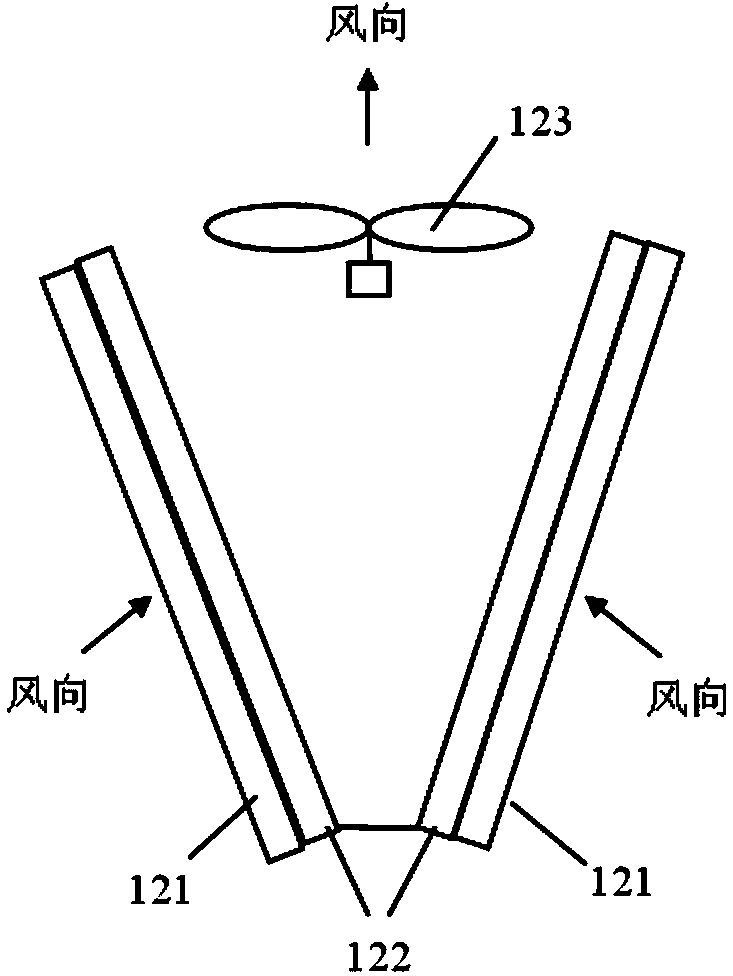

Combined type refrigeration and multi-connected air conditioning system

ActiveCN104251529ALarge working temperature zoneMaximize utilizationMechanical apparatusSpace heating and ventilation safety systemsEngineeringTransition season

The invention discloses a combined refrigeration and multi-connected air conditioning system which is characterized in that a cold source system of the multi-connected air conditioning system, which is composed of two or more than two outdoor composite refrigeration modules is arranged outdoors; each outdoor combined refrigeration module is formed by compositing a first refrigerant vapor compression refrigeration cycle loop and a second refrigerant cycle loop; one or more direct evaporative indoor air cooler modules are arranged indoors, and a refrigerant storage and transmission unit is connected between each outdoor composite refrigeration module and the corresponding indoor air cooler module to form a closed cycle system through a liquid collecting pipe, a liquid supply main pipe and a return air main pipe. According to the combined refrigeration and multi-connected air conditioning system, the number of the indoor and outdoor modules is set according to the design heating loads of air conditioning objects, refrigerating capacity is precisely regulated, the thermal control demands of various all-weather running data rooms and electronic devices are met, and natural cold sources in days and nights, transition seasons and winters can be used to the maximum extent to realize energy conservation and emission reduction of the air conditioning system.

Owner:CHINA YANGZI GRP CHUZHOU YANGZI AIR CONDITIONERCO

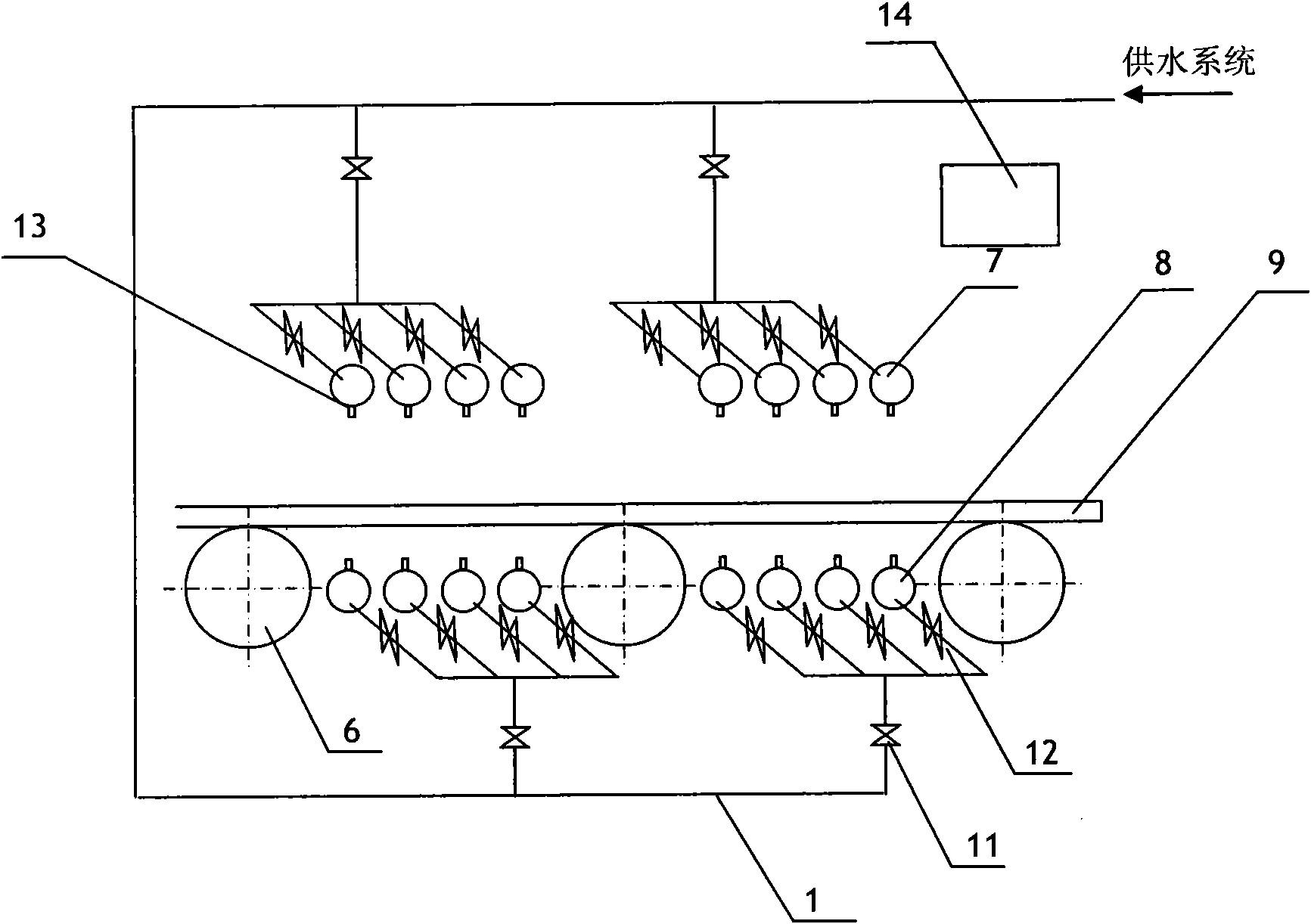

Device and method for cooling intermediate rolled blank of hot rolled strip

ActiveCN101972782ALess prone to overcoolingCool evenlyTemperature control deviceWork treatment devicesPipe waterWater quality

The invention provides a device and method for cooling an intermediate rolled blank of a hot rolled strip. The device comprises an upper collecting pipe arranged above roller beds and a lower collecting pipe arranged between the roller beds, wherein the upper collecting pipe and the lower collecting pipe are both provided with nozzles and opening and closing control valves and are connected with a workshop circulating water system through collecting pipe water supply pipelines; and the collecting pipe water supply pipelines are provided with flow control valves. The opening and closing control valves and the flow control valves are controlled by a programmable controller. A plurality of groups of cooling collecting pipes which can be independently controlled to open and close and has smaller flow are arranged between every two roller beds, the intermediate blank is cooled by adopting water jet, and the cooling speed is correspondingly dynamically controlled according to the transmission speed of the intermediate blank. The invention has the advantages of relatively simple structure of the device, low requirement for water quality, good flow stability and high production efficiency, and is convenient to maintain and free of limit of speed raising of a roughing mill and deceleration of throwing steel; rolling mill cooling water is adopted and a single water supply and drainage system is not needed; and grains of the intermediate blank are remarkably refined, and the mechanical property of a steel plate is improved.

Owner:UNIV OF SCI & TECH BEIJING

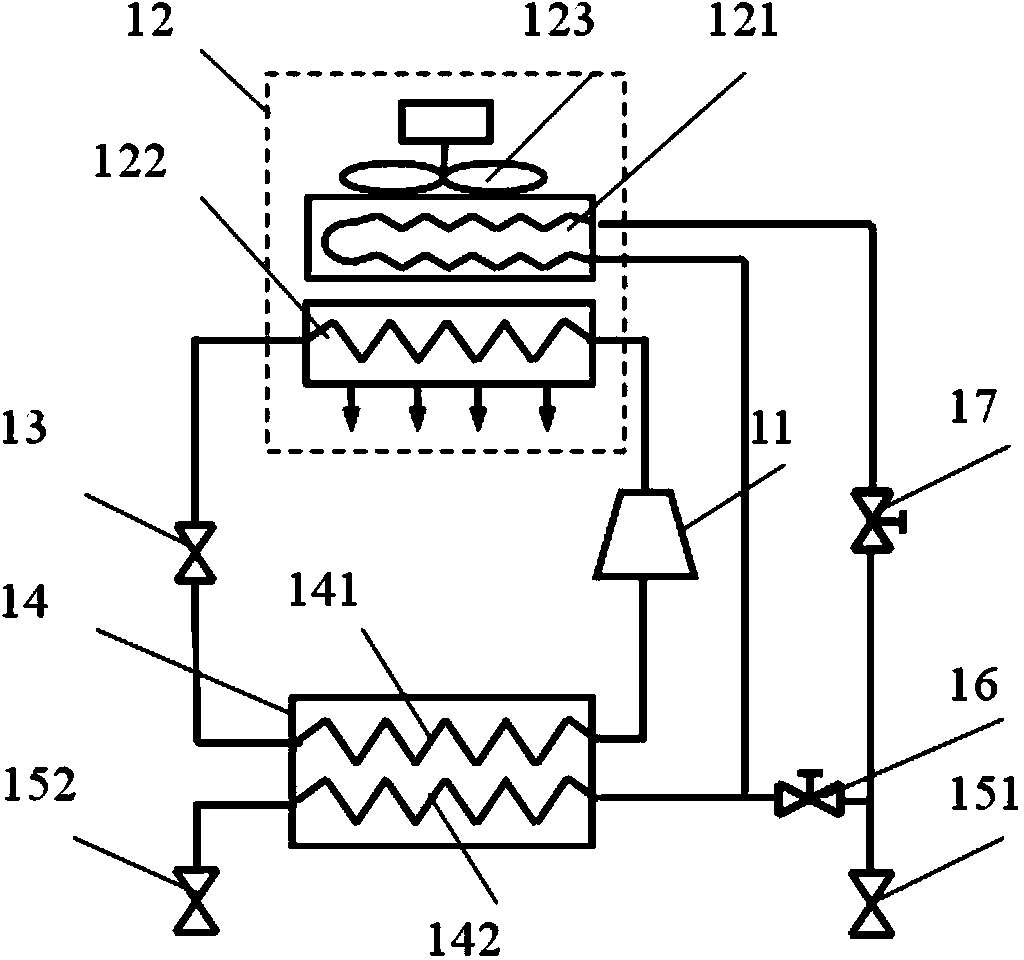

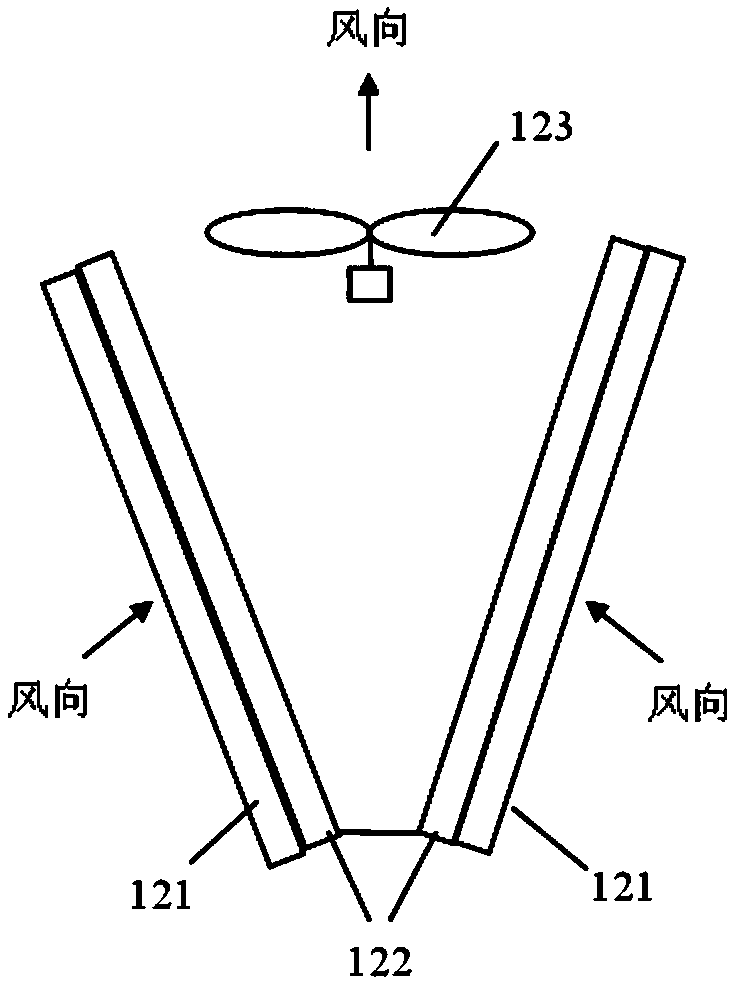

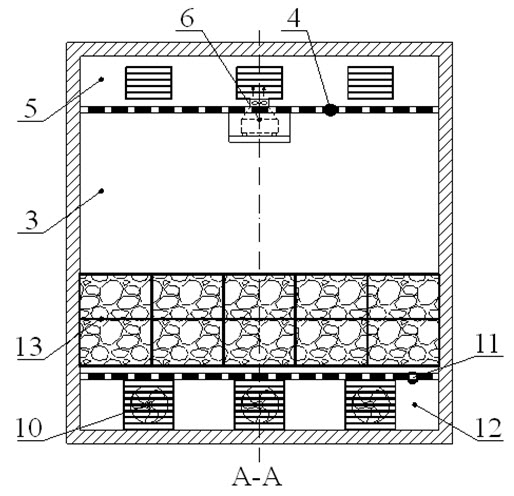

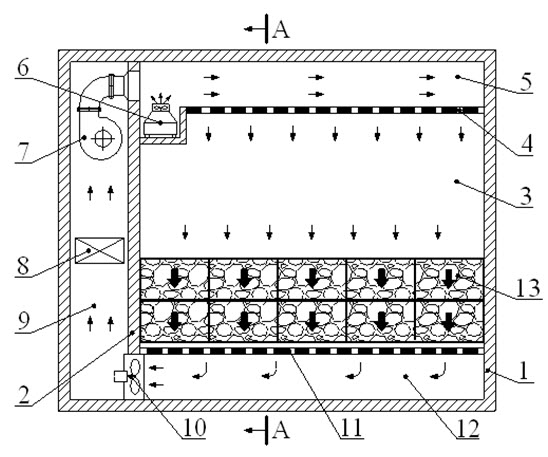

Heat pump type pressure gradient fruit vegetable heat treatment library

ActiveCN101919436AReduce heat treatment energy consumptionShorten the timeFood processingFruits/vegetable preservation by heatingThermodynamicsAir treatment

The invention discloses a heat pump type pressure gradient fruit vegetable heat treatment library. The library is composed of a library entry, a heat pump system, a circulation air system and a humidifying system, the library entry is divided into four parts of air treatment, air supply plenum, fruit vegetable heat treatment and return air plenum. The upper end and the lower end of the clapboard are respectively provided with three centrifugal fans and three pressure gradient fans, an air supply homogenizing plate and a return air floor plate are respectively arranged at the upper part and the lower part in the library, and a fruit vegetable heat treatment chamber is formed between the two plates. An air supply plenum chamber is formed between the air supply homogenizing plate and the upper top wall of the library entry, and a return air plenum chamber is formed between the return air floor plate and the lower bottom of the library entry. The condenser of the heat pump system is arranged in an air treatment chamber, a centrifugal humidifier is arranged above the right side of the clapboard, and the return air floor plate is placed with a fruit vegetable box. Pressure gradient air supply is adopted, so that treatment time can be reduced. The invention adopts heat pump heat source, the heat pump can supply 3-5 units of heat into the library while a compressor consumes every 1 unit electricity; compared with the electric heating method, fruit vegetable heat treatment energy consumption can be obviously reduced, and energy conservation effect of the system is obvious.

Owner:TIANJIN UNIV

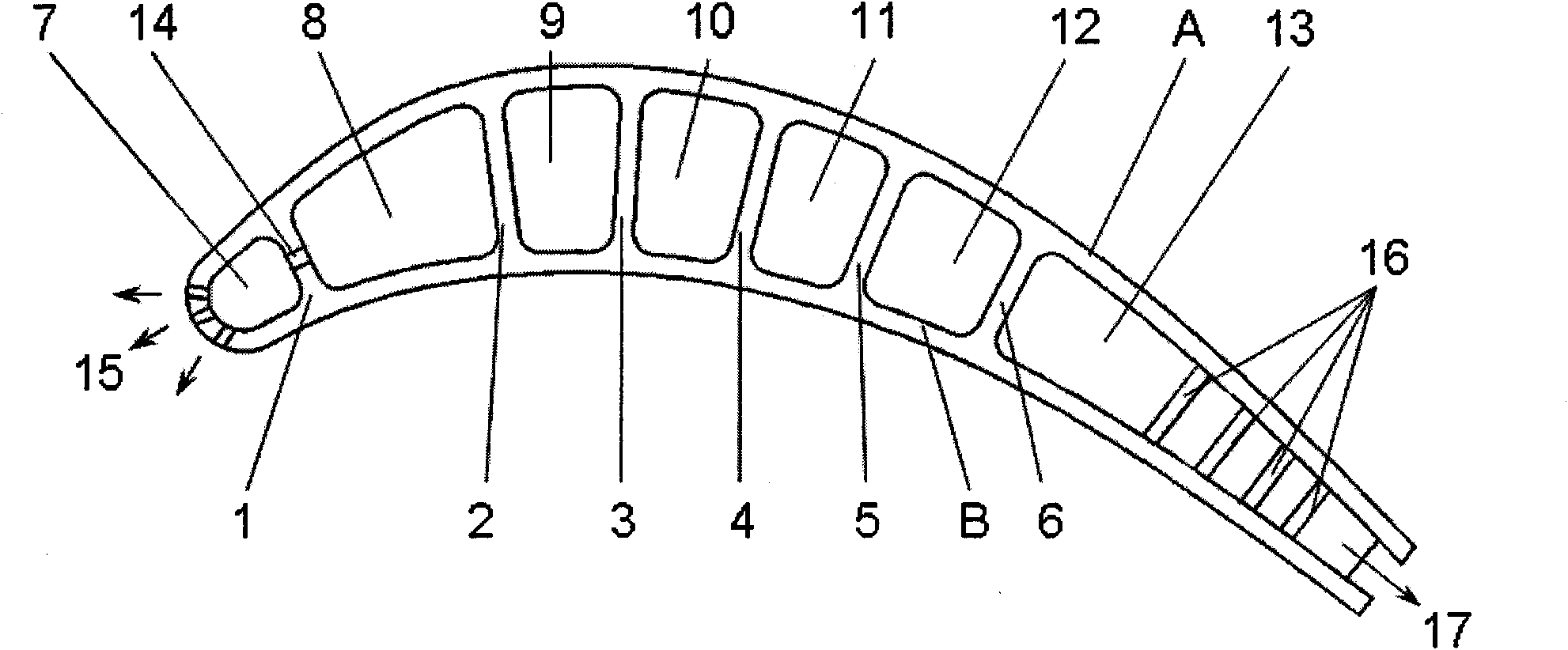

Gas turbine cooling blade with crown

InactiveCN102128055AReduce air leakage lossImprove overall machine efficiencyBlade accessoriesMachines/enginesLeading edgeTurbine blade

The invention discloses a gas turbine cooling blade with a crown. A plurality of clapboards which are arranged along the radial direction respectively are arranged from the leading edge of a blade body to the tail edge on the inner wall of the blade body; the inner cavity of the blade body is divided into three return flow type cooling channels which are formed along the longitudinal direction of the blade body; a clapboard at the headmost end is provided with impingement cooling holes, and the leading edge of the blade body is provided with air film holes; the tail end of a cooling channel on the middle part of the blade body is connected with a blade crown cooling cavity; partition ribs and turbulent flow posts are arranged and air vent holes are formed in the blade crown cooling cavity; an air vent seam is formed at the tail edge of the blade; and the turbulent flow posts are arranged in the air vent seam. The blade has a simple structure; and by the blade, the cooling efficiency is improved, the temperatures of the blade body and the blade crown are reduced, the loss of air leakage of a blade tip is reduced, and the properties of the turbine blade and the complete machine are improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com