Phase change heat accumulation system for generating steam directly and preparation method of phase change heat accumulation agent

A technology of phase change heat storage and steam, which is applied in the direction of steam generation method using heat carrier, heat storage equipment, indirect heat exchanger, etc., to achieve the effects of high heat transfer efficiency, improved efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

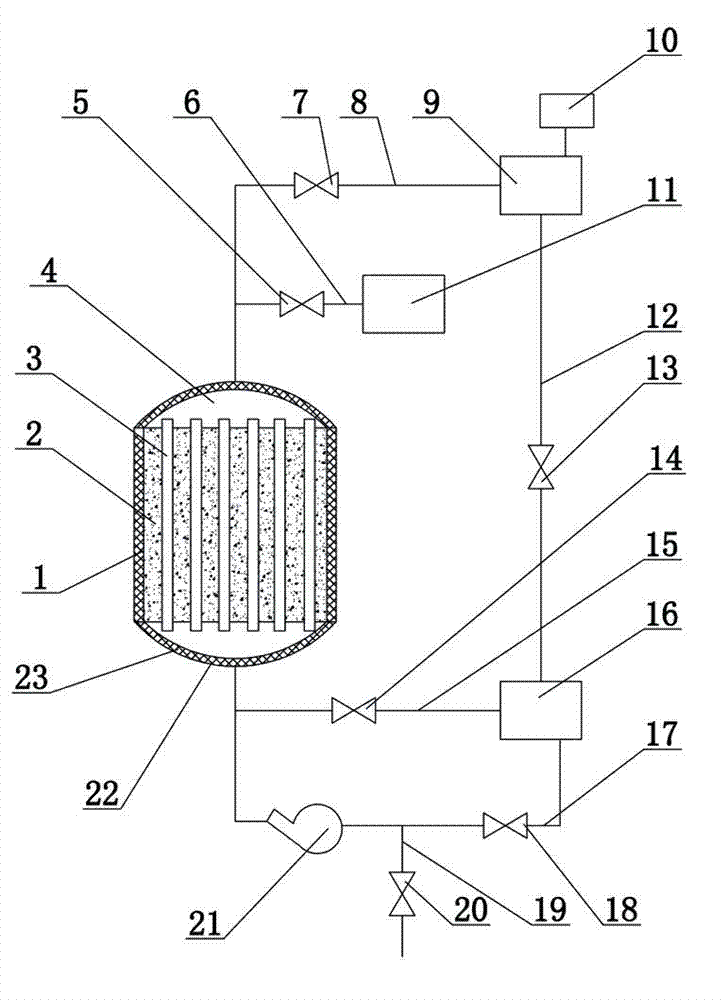

[0044] Such as figure 1 As shown, a phase change heat storage system that directly generates steam includes a heat storage tank 1, a heat exchange tube 3 and a phase change heat storage agent 2. The heat exchange tube 3 passes through the heat storage tank 1 vertically, and the heat exchange tube 3 The upper end of the upper end is connected with the upper head 4, and the lower end of the heat exchange tube 3 is connected with the lower head 22. The upper end 4 and the lower head 22 are both oval heads. Between the heat exchange tubes 3, between the heat exchange tubes 3 and the The inner wall of the heat storage tank 1 is filled with a phase-change heat storage agent 2, the upper head 4 is connected to the heat source 11 through the first pipeline 6, the first pipeline 6 is provided with a first steam valve 5, and the upper head 4 passes through the second pipeline 8 Connect the gas-liquid separator 9, the second pipeline 8 is provided with a second steam valve 7, the gas ou...

Embodiment 2

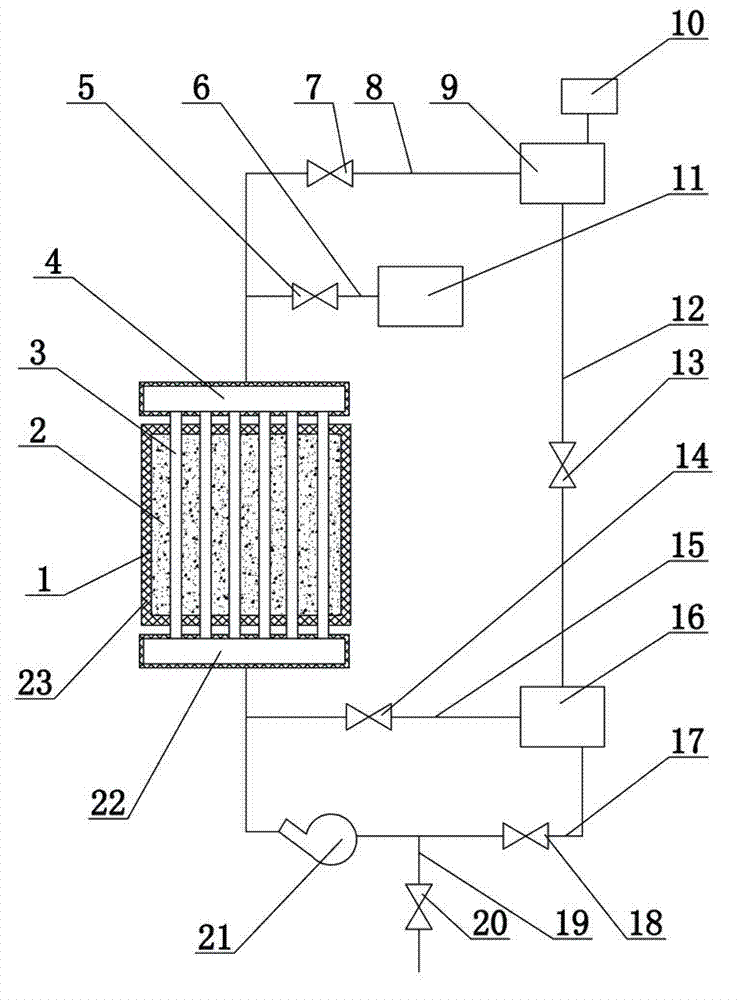

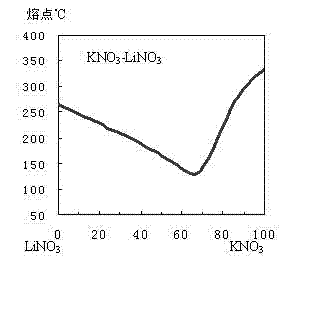

[0064] Such as figure 2 , 3, repeating Example 1, there are the following differences: the upper head 4 and the lower head 22 are rectangular heads, and the binary eutectic salt adopts KNO3-LiNO3 with a melting point of 270°C. The phase change heat storage agent 2 is a composite phase change heat storage agent 2 of KNO3-LiNO3 and graphite foam, the graphite foam has a porosity of 0.84 and a pore diameter of 300 mm.

[0065] The preparation method of the composite phase change heat storage agent 2 of KNO3-LiNO3 and graphite foam comprises the following process steps:

[0066] 1. Determine the mass fraction of the two components of the binary eutectic salt

[0067] The mass fraction of KNO3 required to prepare KNO3-LiNO3 at 270°C is 85%, and the mass fraction of LiNO3 is 15%;

[0068] 2. Preparation:

[0069] Prepare KNO3 and LiNO3 according to the ratio of KNO3 mass fraction 85%, LiNO3 mass fraction 15%,

[0070] Prepare a graphite foam with a pore size of 300 mm and a por...

Embodiment 3

[0081] Such as Figure 4 As shown, repeating Example 1, there are the following differences: In this embodiment, two heat storage tanks 1 connected in series are used, and the series operation of heat storage tanks 1 can significantly improve the heat storage and release performance of the system, and more effectively carry out heat storage.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com