Patents

Literature

297results about How to "Shorten melting time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low melting polyester polymers

ActiveUS20060046004A1Less energyShorten melting timeEnvelopes/bags making machineryLayered productsCarboxylic acidBottle

A bulk of polyester polymer particles comprising polyester polymer comprising greater than 75% virgin polyester polymer, the particles having: A) an It.V. of at least 0.72 dl / g, and B) 10 ppm or less of residual acetaldehyde; and C) at least two melting peaks, wherein one of said at least two melting peaks is a low peak melting point within a range of 140° C. to 220° C. and having a melting endotherm area of at least the absolute value of 1 J / g. The particles may also have a degree of crystallinity within a range of 20% and a maximum degree of crystallinity Tcmax defined by the equation: Tcmax=50%−CA−OH where CA is the total mole % of all carboxylic acid residues other than terephthalic acid residues, based on 100 mole % of carboxylic acid residues, and OH is the total mole % of all hydroxyl functional compound residues other than ethylene glycol residues, based on 100 mole % of hydroxyl functional compounds residues. The preforms and bottles made from these particles can be obtained by melt processing these particles at either lower overall power, faster screw speeds, lower residence time, or lower overall cycle time to thereby reduce the level of residual acetaldehyde generated in the melt.

Owner:ALPEK POLYESTER SA DE CV

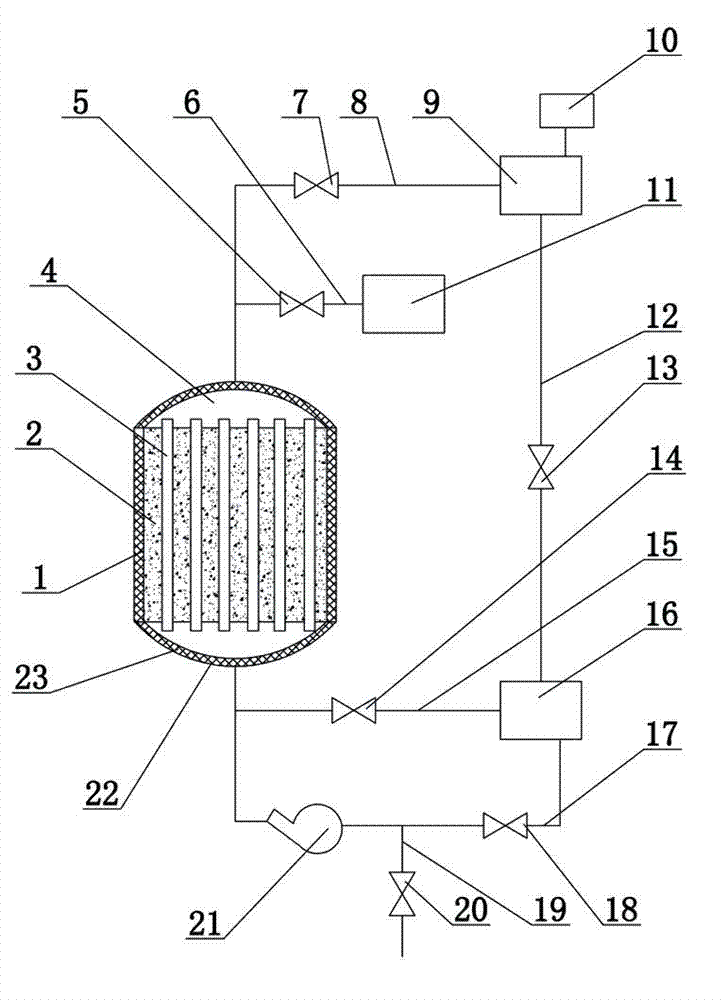

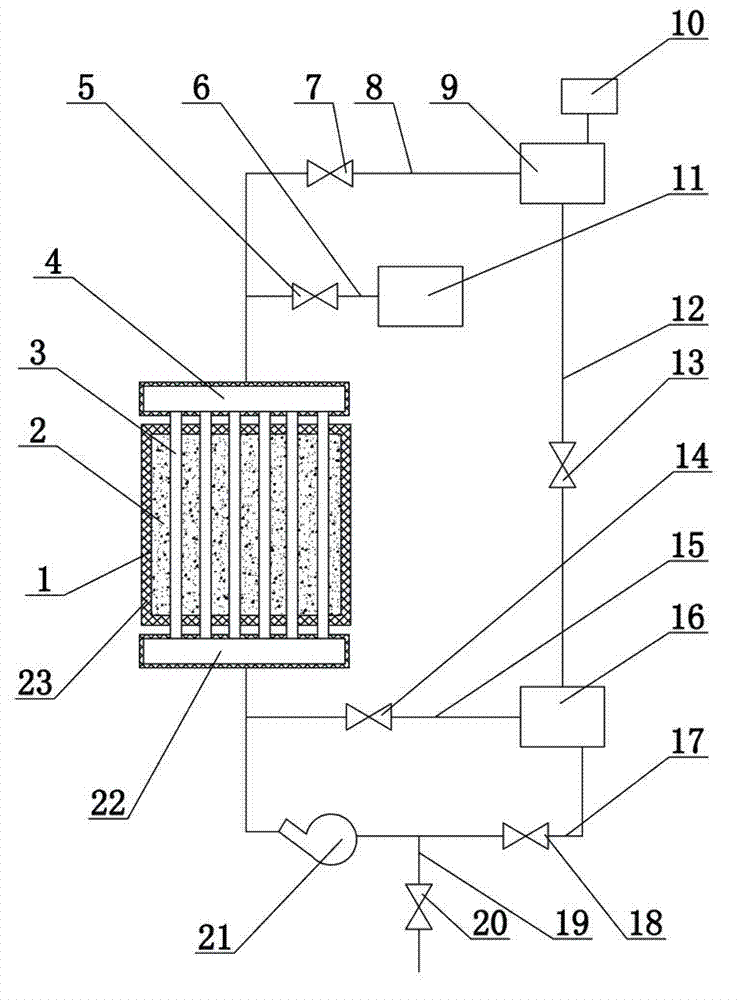

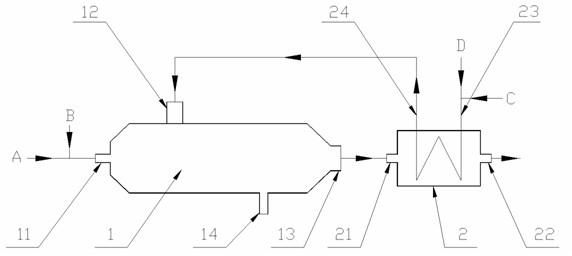

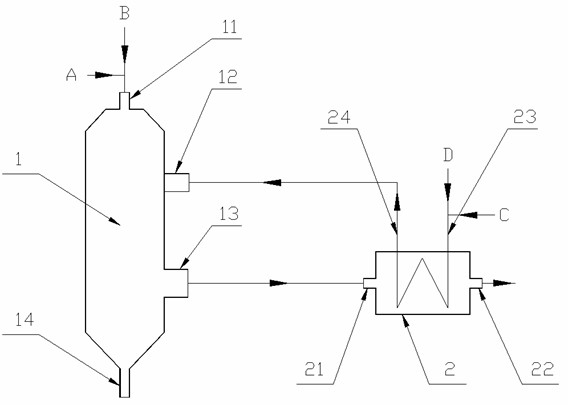

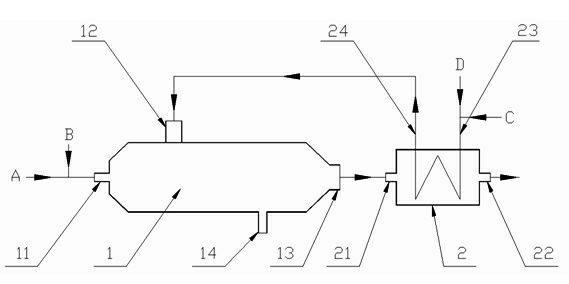

Phase change heat accumulation system for generating steam directly and preparation method of phase change heat accumulation agent

InactiveCN102777874AImprove efficiencyImprove heat transfer coefficientHeat storage plantsChemical industryPorous mediumToxic industrial waste

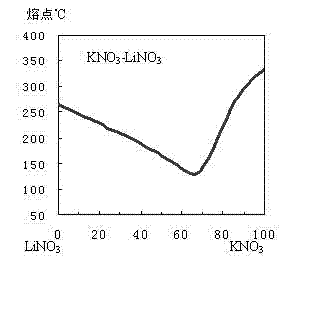

The invention relates to a phase change heat accumulation system for generating steam directly and a preparation method of a phase change heat accumulation agent. A phase change material is enhanced with graphite foam, and is absorbed in a porous medium of the graphite foam, so that a binary eutectic salt / graphite foam material is prepared and is used as a composite phase change material of a heat accumulation device, the composite phase change material is high in heat conduction coefficient, therefore under the same design condition, the phase change heat accumulation system provided by the invention is applied to systems of a focusing type solar thermal power generation system, an industrial waste heat recovery system and the like, and has the characteristics of high heat transfer efficiency, small volume, low cost and the like. In addition, the phase change heat accumulation system for generating steam directly can flexibly adopt a parallel connection or serial connection mode according to the temperature of high-temperature waste heat steam and the requirement of a steam user; and during serial connection, the binary eutectic salt / graphite foam composite phase change material can be combined in a cascaded manner according to a melting point, thus the efficiency of an energy accumulation system is increased, and the energy can be greatly accumulated.

Owner:ZHENGZHOU UNIV

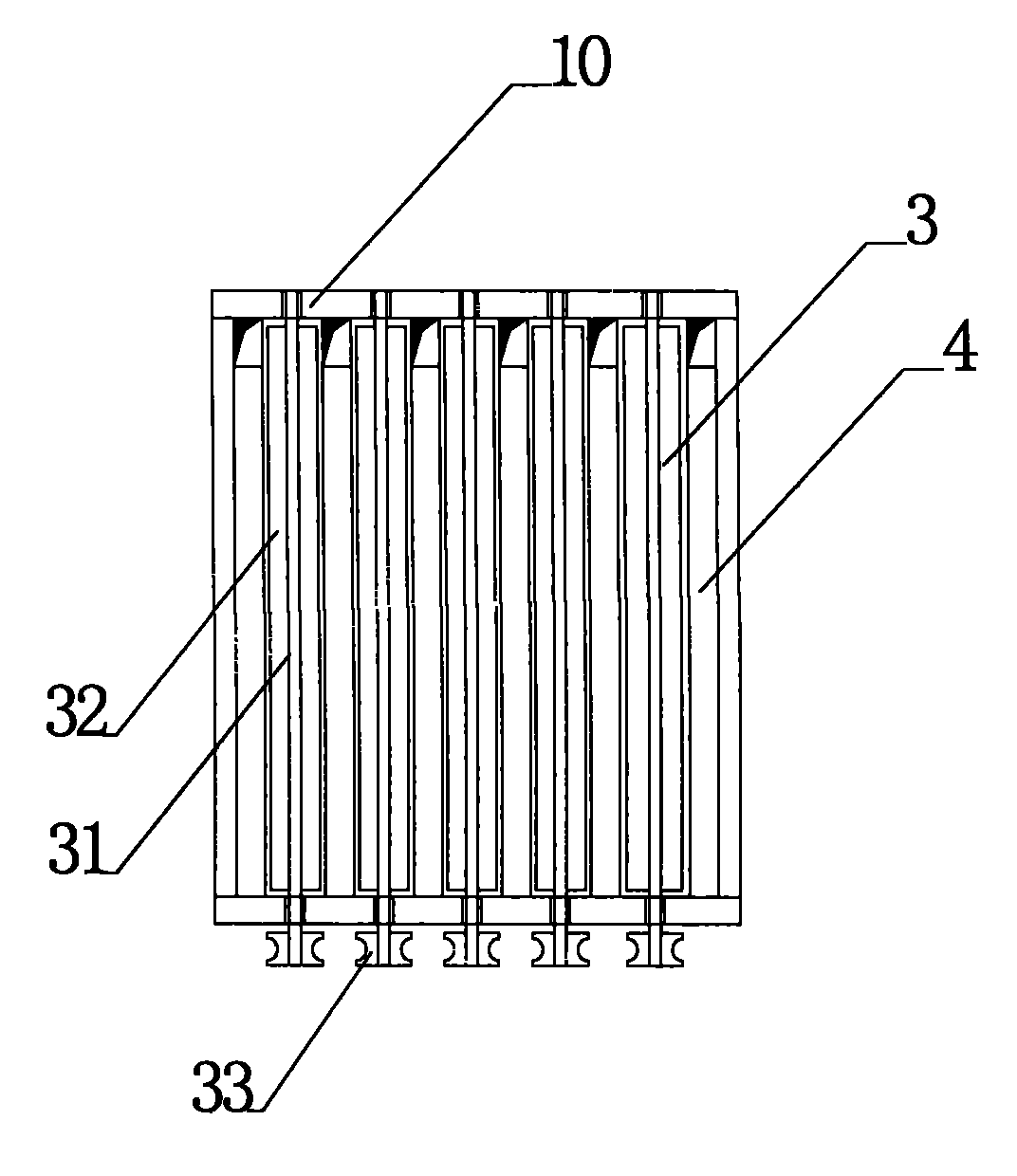

Precast piece for busbar of storage battery and method for welding same with polar plates of storage battery

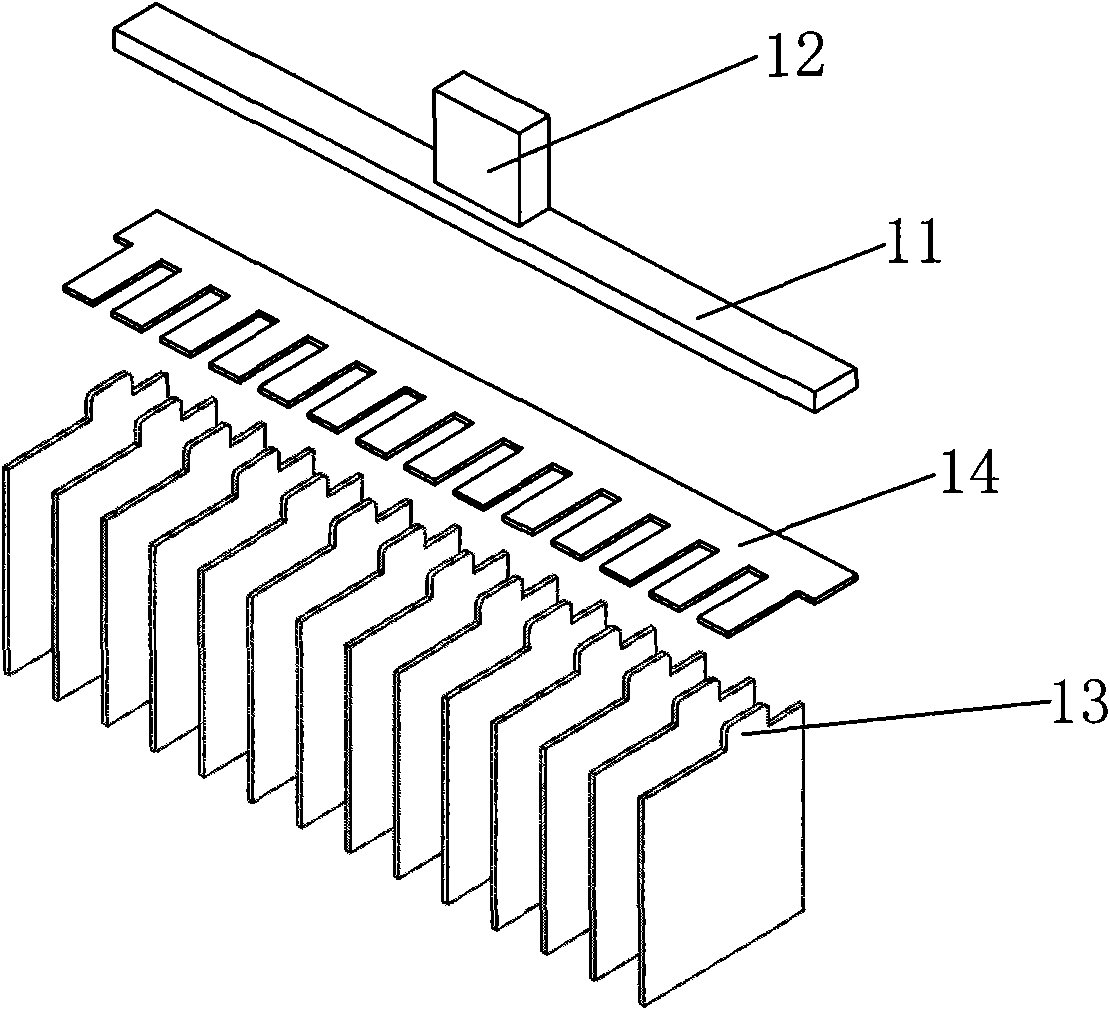

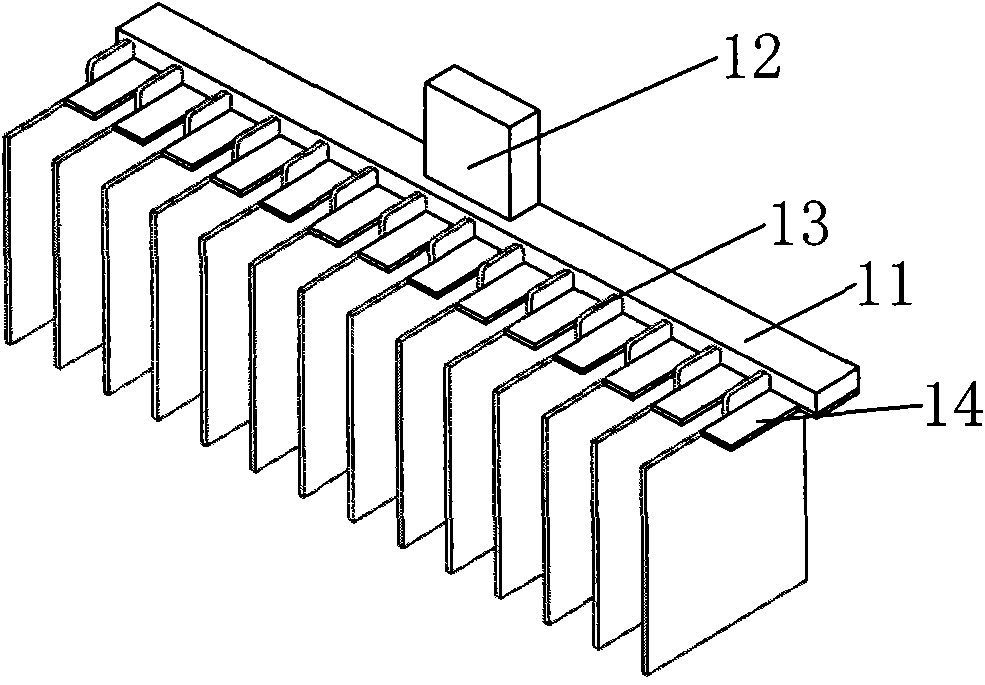

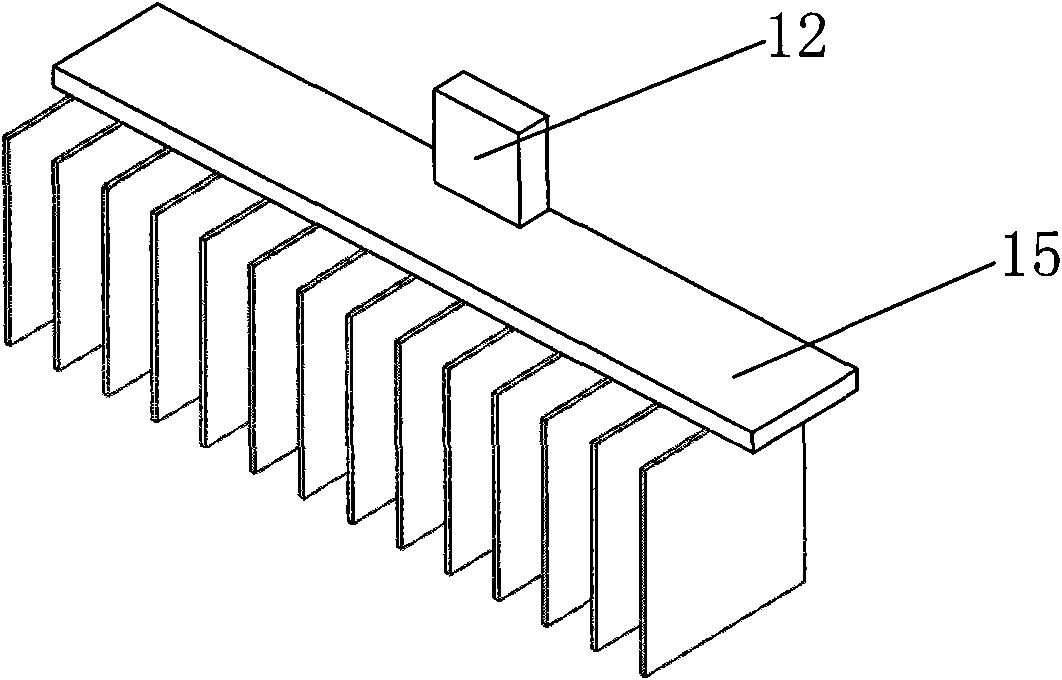

ActiveCN101593822ACompact structureIncrease contact areaArc welding apparatusCell component detailsBusbarElectrical polarity

The invention provides a precast piece for a busbar used in a high-capacity lead-acid storage battery, parallelly connecting polar plates with the same polarity in the storage battery and leading the polar plates to electrode terminals. The precast piece comprises a connecting main board which is respectively welded with lugs of the polar plates of the storage battery; the connecting main board is strip-shaped; the middle of the connecting main board is provided with a post vertical to the connecting main board; and a pectinate material preparing threaded rod is extended along the lateral surface of a longer side of the connecting main board. Due to the existence of the pectinate material preparing threaded rod, the precast piece for the busbar can greatly reduce the melting time of workpieces and the feed amount of alloy solder in the welding, can complete solder sides for one time in short time, can reduce the air contacting opportunity of a lead alloy to the utmost, ensure the quality of weldments, and ensures that the busbar has compact structure to prolong the service life of the storage battery. The invention also provides a method for connecting the precast piece for the busbar and the lugs of the polar plates of the storage battery, which has simple operation and can obtain good welding quality by means of the prior welding conditions.

Owner:GUANGDONG DYNAVOLT NEW ENERGY TECH CO LTD

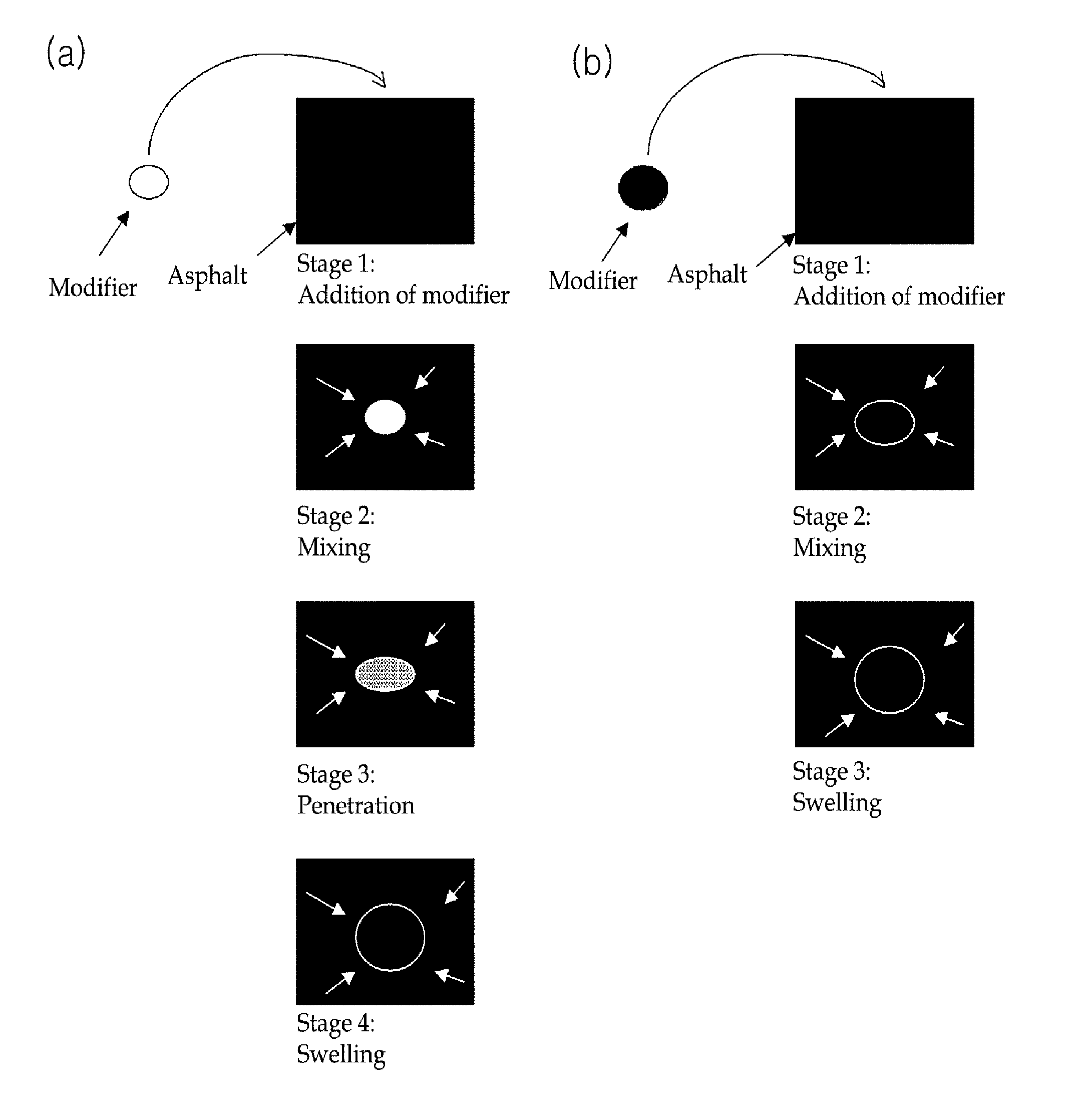

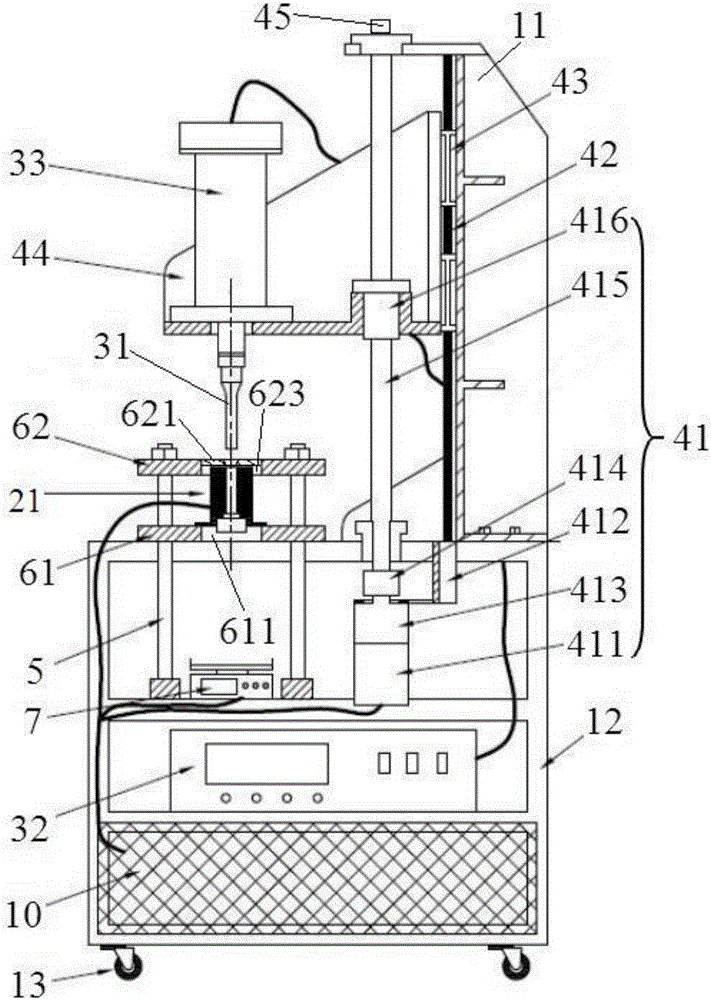

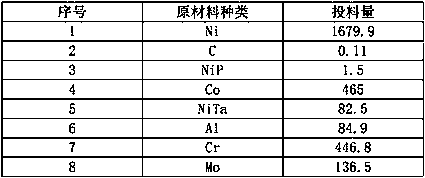

Asphalt modifier compositions with an improved melting rate and modified asphalt prepared using the same

ActiveUS20100273915A1Increase melting rateShorten melting timeBuilding insulationsProduction rateButadiene-styrene rubber

The present invention relates to a pellet type SBS-asphalt master batch modifier composition comprising styrene-butadiene-styrene (SBS) block copolymer and asphalt, and modified asphalt prepared by melting and mixing the pellet type SBS-asphalt master batch modifier composition with asphalt. The modified asphalt prepared thereof has advantages that deterioration of physical properties and thermal oxidation can be prevented while productivity can be improved due to reduced melting time of modifier.

Owner:KOREA KUMHO PETROCHEMICAL CO LTD

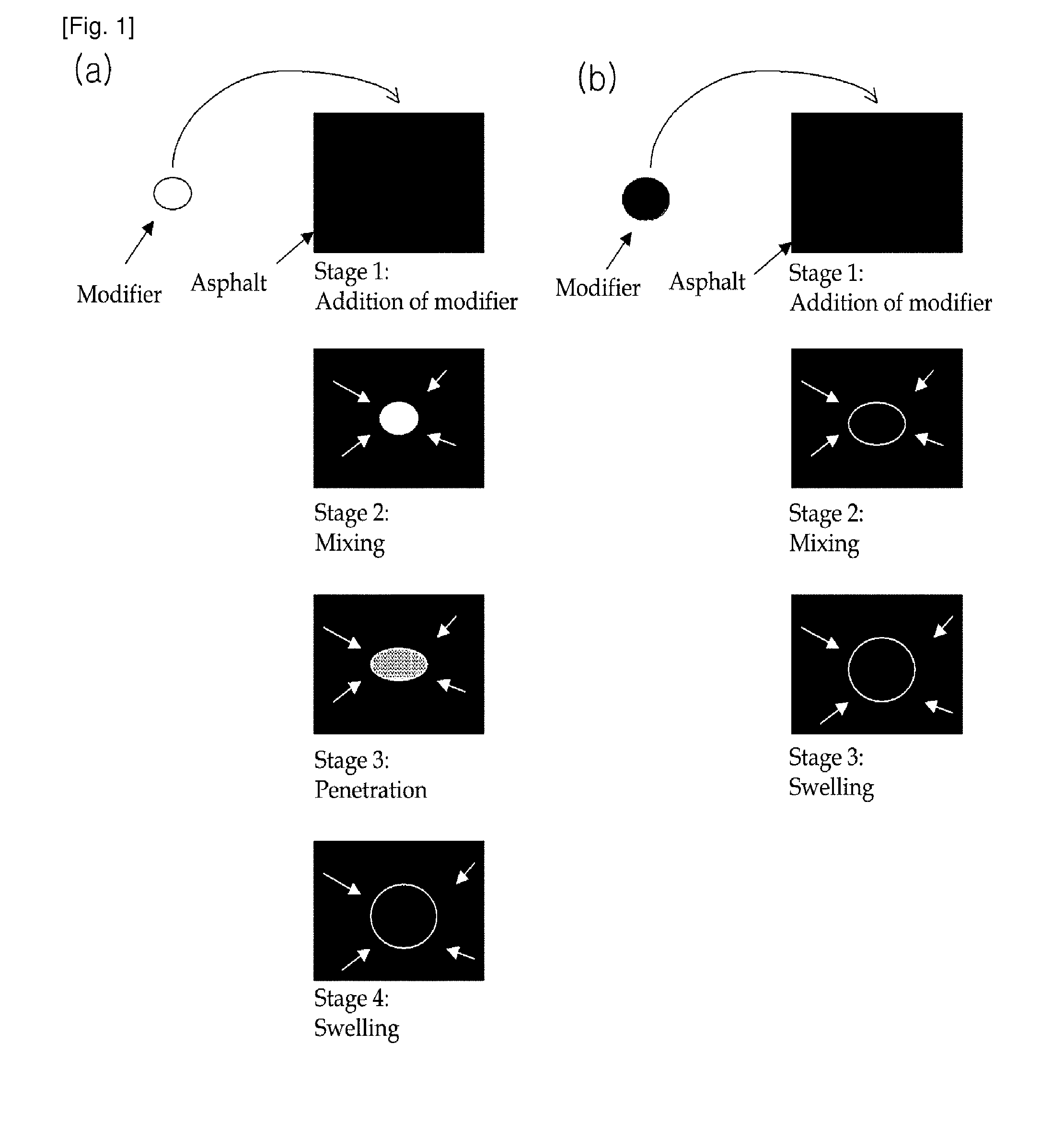

Low density and small pore size powder metallurgy foam aluminum composite structure preparation method

The present invention relates to a low density and small pore size powder metallurgy foam aluminum composite structure preparation method, and belongs to the technical field of porous metal materials. The method comprises: adopting a vibration sieve screening manner to select TiH2 powder with the same size as a foaming agent; then uniformly mixing aluminum powder, magnesium powder, silicon powder and the foaming agent according to a certain ratio, and carrying out extrusion forming to prepare the foamable preform; and finally placing the foamable preform into a mold capable of being compounded with the foamable preform, preheating for a certain time, quickly transferring to a thermal insulation furnace to carry out thermal insulation foaming, and cooling to prepare the foam aluminum composite structure. The foam aluminum material prepared by using the method has characteristics of low density, small pore size, less pore structure defects, high strength and good energy absorption capability, and is suitable for promotion application.

Owner:SHENYANG POLYTECHNIC UNIV

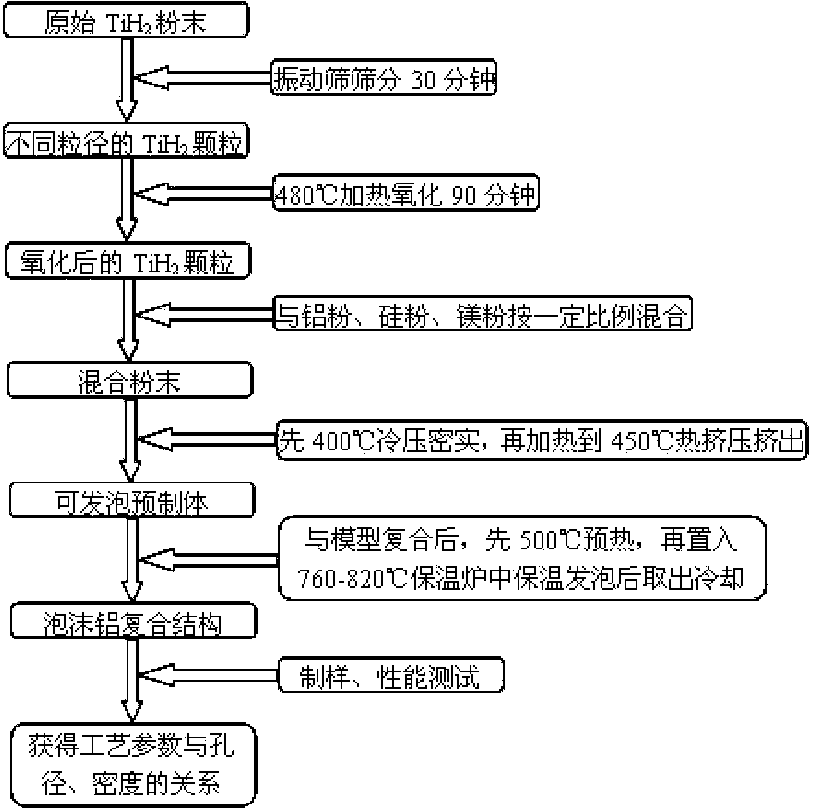

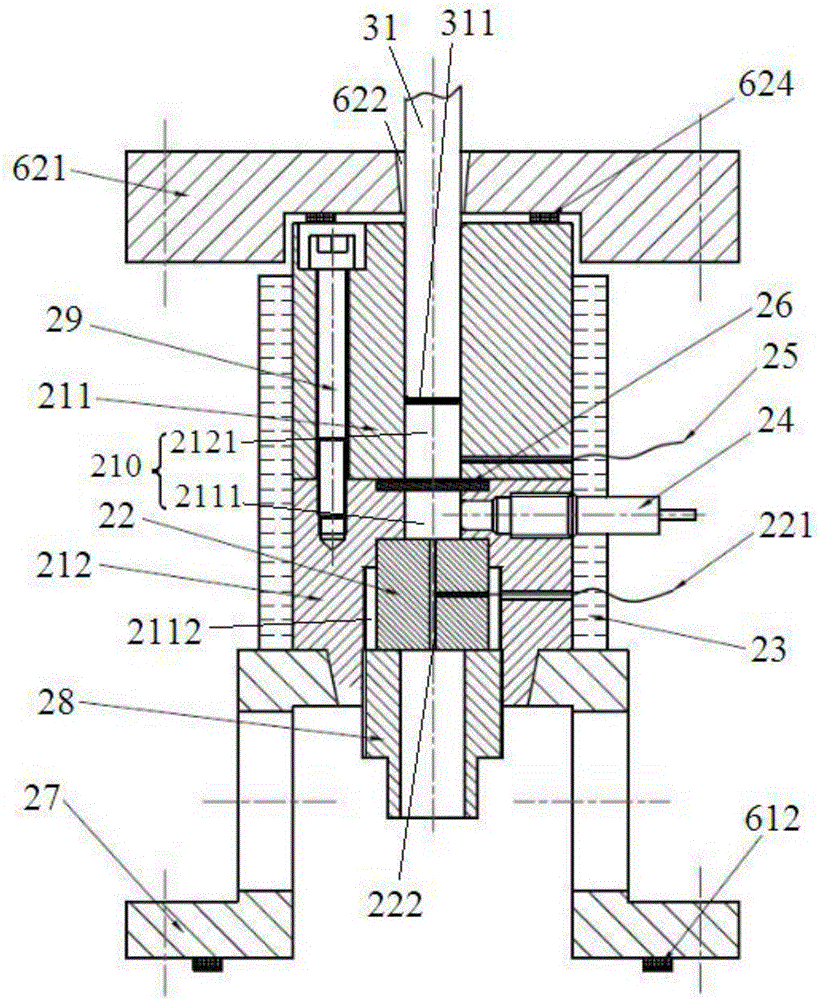

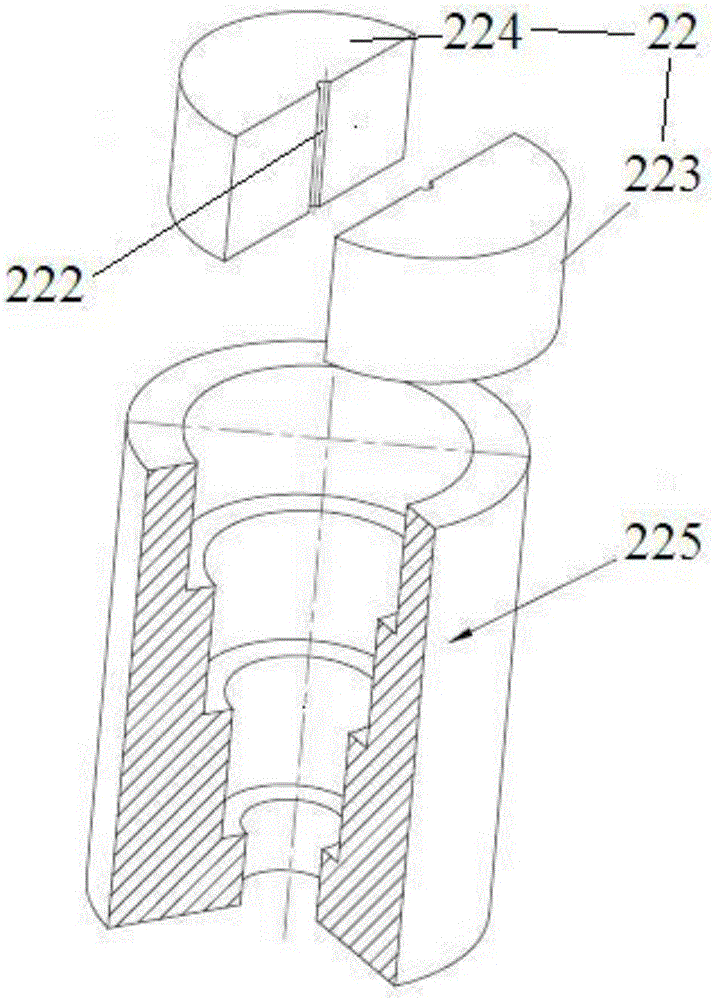

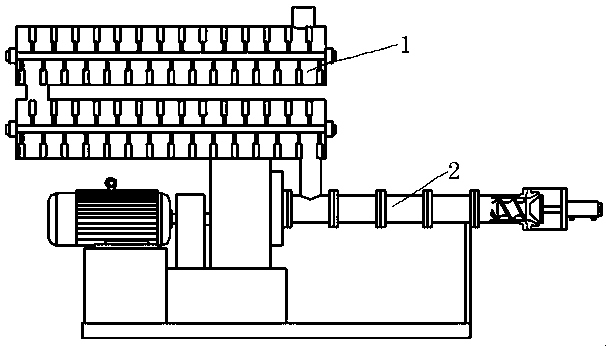

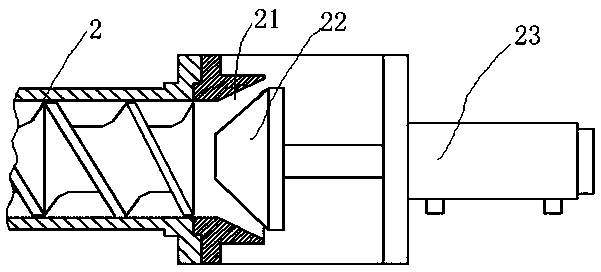

Ultrasonic plasticizing capillary rheometer and viscosity test method

ActiveCN106124362AImprove liquiditySimplify the delivery pathIndirect flow property measurementEngineeringPolymer

An ultrasonic plasticizing capillary rheometer comprises a frame, a rheological test unit, an ultrasonic vibration apparatus, and a tool head moving and loading unit. The ultrasonic vibration apparatus is provided with an ultrasonic tool head capable of extending into a plasticizing chamber along an axial direction, providing extrusion force for polymer in the plasticizing chamber, and providing ultrasonic wave energy required by the polymer for fusion from a solid state to a liquid state. In the ultrasonic plasticizing capillary rheometer, three steps including heating fusion, ultrasonic vibration for fluidity increase, and material extrusion are completed through the ultrasonic tool head and in the plasticizing chamber, thereby simplifying the conveying path. A heating ring providing the required initial temperature for the plasticizing process sleeves a material canister, provides a constant material canister temperature for the rheometer, and reduces the test error. A filter screen is arranged in the material canister, centralizes fused polymer, and improves the test accuracy. During a test process, a viscosity test method is accurate in heating, short in fusion time, and wide in application range, is slightly affected by the external environment, and can provide viscosity data high in accuracy.

Owner:CENT SOUTH UNIV

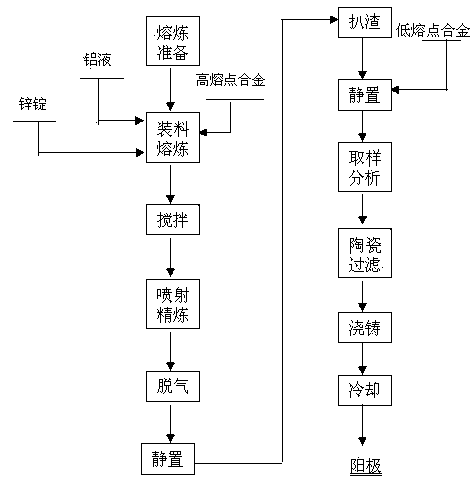

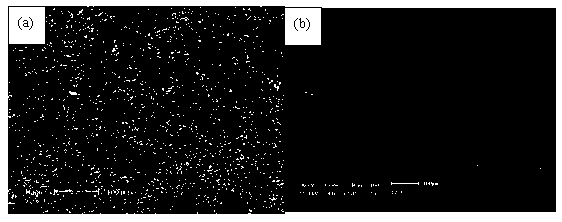

Casting method of aluminum alloy sacrificial anode

The invention belongs to the technical field of corrosion and prevention, and in particular relates to a casting method of an aluminum alloy sacrificial anode. The casting method comprises the following steps: adding basic electrolytic molten aluminum to a resistance furnace; then adding a zinc ingot to obtain molten aluminum alloy; performing jet refining on the molten aluminum alloy by adopting an argon located refining agent; charging argon to refined aluminum alloy melt to degas; drossing oxidizing scum on the surface of the aluminum alloy melt through a drossing tool; adding a low melting point metallic element to drossed aluminum alloy melt; electromagnetically agitating the melt after pressing the low melting point metal; carrying out ceramic filtering; pouring and casting the aluminum alloy melt to a preheated iron anode mould at an even casting speed under the temperature of 700 to 740 DEG C until the mould is full of the aluminum alloy melt; and moving the aluminum alloy melt out of the mould after cooling, solidifying and molding, so as to obtain the aluminum alloy sacrificial anode. The casting method has the characteristics of being short in smelting time, small in loss of iron scale, high in degassing and purifying performances, and low in smelting cost.

Owner:NORTHEASTERN UNIV +1

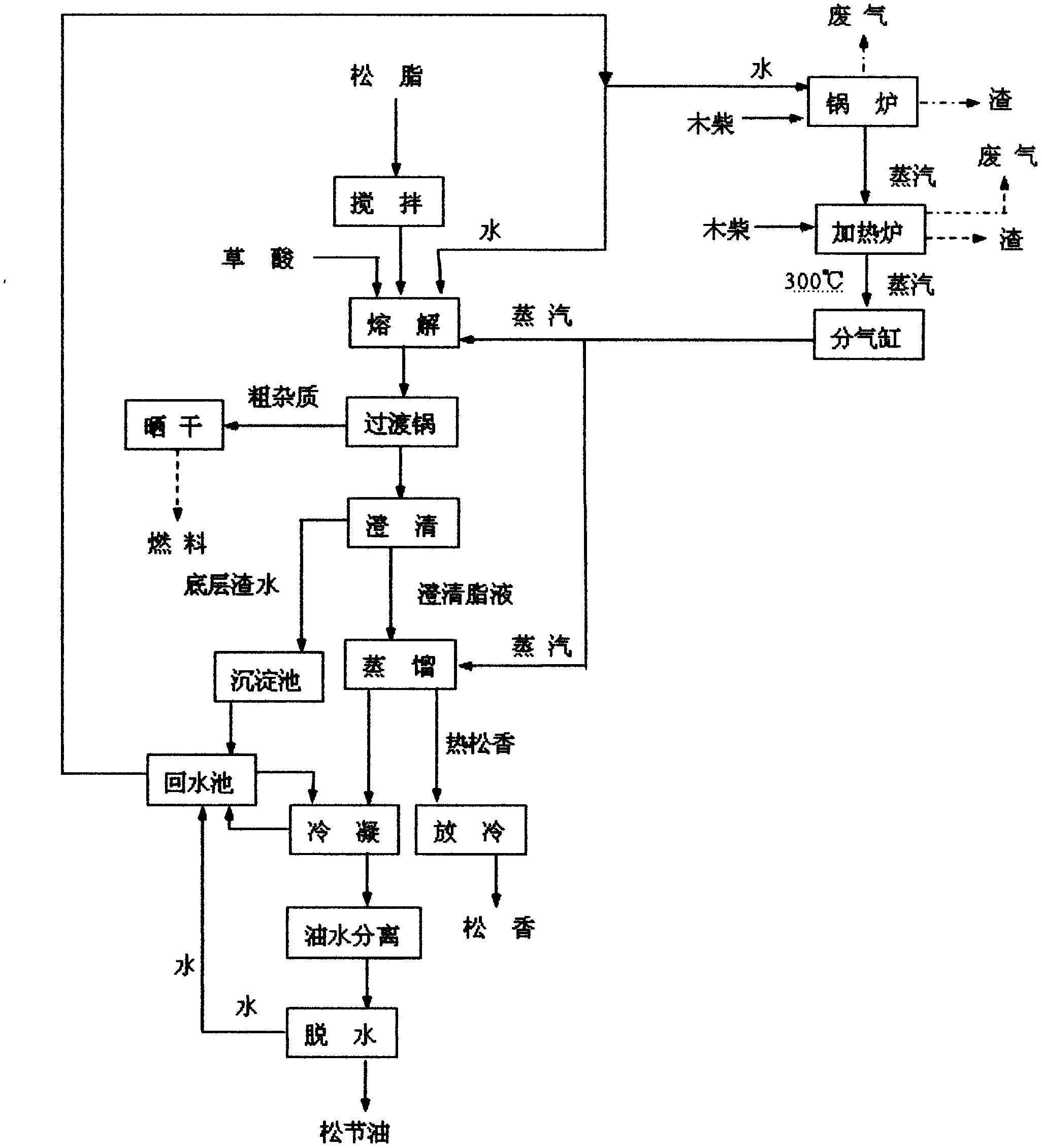

Rosin production technology process

InactiveCN104342034AImprove melting abilityThere will be no meltingChemical industryTurpentine spiritsSteam pressureTurpentine

The invention discloses a rosin production technology process. The process comprises the following steps: conveying turpentine to a melting boiler, adding water, turpentine oil, and oxalic acid, wherein the weight ratio of turpentine to water to turpentine oil is 2-4:1-2:1, and the oxalic acid accounts for 0.1 to 0.3% of the turpentine weight; heating the boiler to melt the mixture in the boiler; transferring the melt mixture to a transition boiler; introducing the melt mixture into a clarifying boiler after precipitation in the transition boiler, then transferring the liquid to a steaming boiler to carry out steaming, wherein during the steaming process, water and turpentine oil are continuously steamed out from the liquid. The provided rosin production technology process has the following advantages: the turpentine is fully stirred before melting so as to grind the turpentine, thus the turpentine melting effect is improved, at the same time the phenomenon that some turpentine is not melted during the melting process is avoided, and thus the yield is increased; moreover, the metling is reduced, the energy consumption is reduced, and the rosin color will not turn darker; the condensed hot water can be directly applied to the boiler so as to reduce the temperature difference between the inlet water and outlet water, the boiler efficiency is improved, the steam pressure is more stable, and more energy is saved.

Owner:琼中森富松香加工厂有限公司

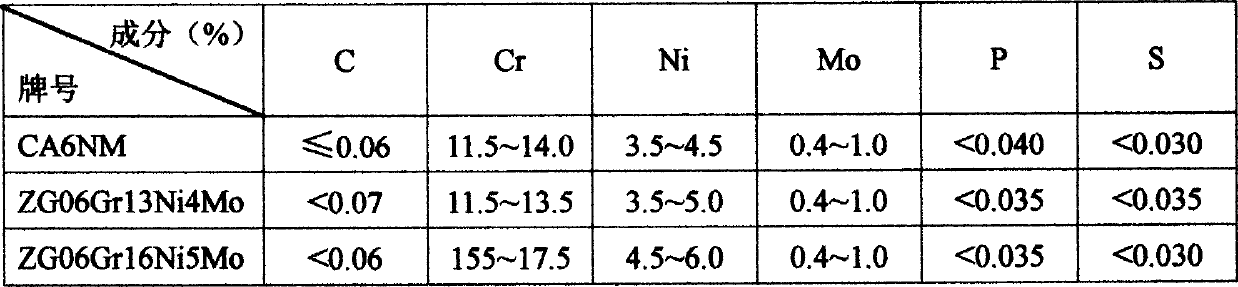

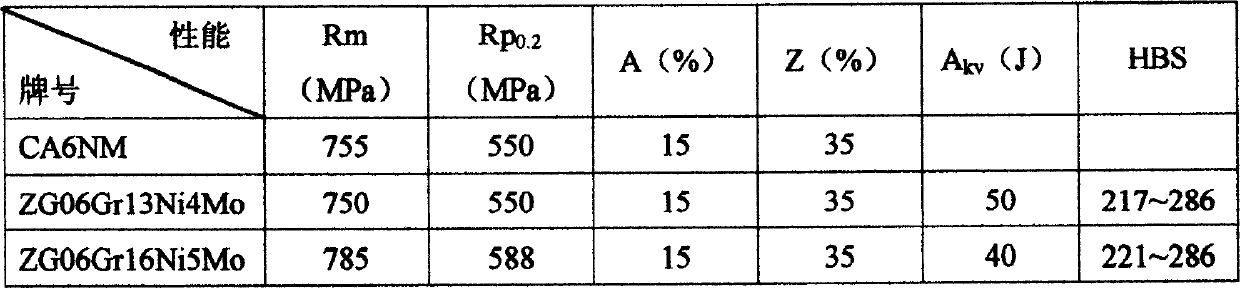

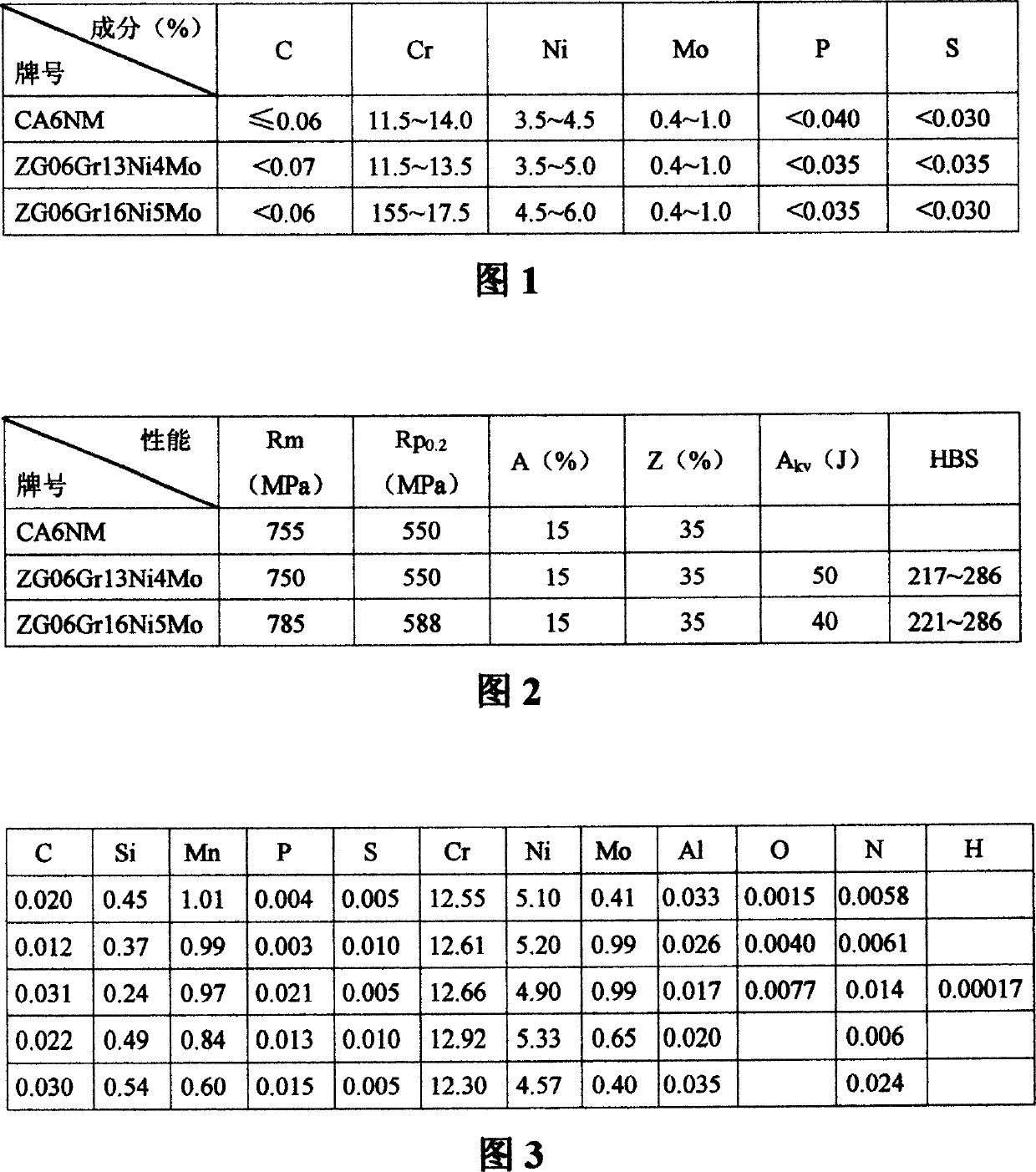

High-yield-ratio, high-strong toughness cast martensite stainless steel and production method thereof

The invention is martensitic stain less steel with high yield ratio and high ductility, the character is that it contains: C is not more than 0.06%, Cr 11-16.5%, Ni 3.50-6.0%, Mn is not more than 2%, Mo 0.5-2%, Si is less than 1%, the residue are Fe and a little impurity. The impurity includes Al, [O], [N], [H], S, P, the content of then are Al <0.15%, [O]<0.01%, [N]<0.03%, [H] is not more than 0.0005%, S is not more than 0.020%, P is not more than 0.025%. The invention can enhances the synthesis performance index (high density, high rigidity, high ductility and yield ratio, excellent welding processing property, and fatigue preventing property under water) greatly, it can ensure that the stress of large wheel is smaller than 1 / 3 of material yield ratio, the stress of large welding wheel is smaller than 1 / 2 of material yield density. It maintains the higher etching preventing property and sand grinding resisting property.

Owner:SHENYANG RES INST OF FOUNDRY

Oil composition for reducing generation of polar compounds of frying oil

ActiveCN104171029AExtended service lifeSuppress or reduce harmful substancesEdible oils/fatsChemical compositionTriglyceride

The invention provides an oil composition for reducing the generation of polar compounds of frying oil. Triglyceride comprises 48-65wt% of SUS type triglyceride, 5-10wt% of SSU type triglyceride, 0.5-15wt% of SSS type triglyceride, 15-31wt% of SU2 type triglyceride and 0-10wt% of U3 type triglyceride, and saturated fatty acids in the oil composition account for 42-58% weight of the weight of total fatty acids; and the SUS type triglyceride with the unsaturated fatty acids being oleic acid accounts for 70-90% of the weight of all the SUS type triglyceride. The oil composition obtained in the invention has the characteristics of slow color change, few generated polar compounds, and fast fusing speed as frying oil.

Owner:WILMAR SHANGHAI BIOTECH RES & DEV CENT

Li2O-Al2O3-SiO2-BASED CRYSTALLIZED GLASS

ActiveUS20130130887A1Large degree of influenceLower melting temperatureOptical elementsMaterials science

Provided is a Li2O—Al2O3—SiO2-based crystallized glass, comprising, as a composition in terms of mass %, 55 to 75% of SiO2, 20.5 to 27% of Al2O3, 2% or more of Li2O, 1.5 to 3% of TiO2, 3.8 to 5% of TiO2+ZrO2, and 0.1 to 0.5% of SnO2, and satisfying the relationships of 3.7≦Li2O+0.741MgO+0.367ZnO≦4.5 and SrO+1.847CaO≦0.5.

Owner:NIPPON ELECTRIC GLASS CO LTD

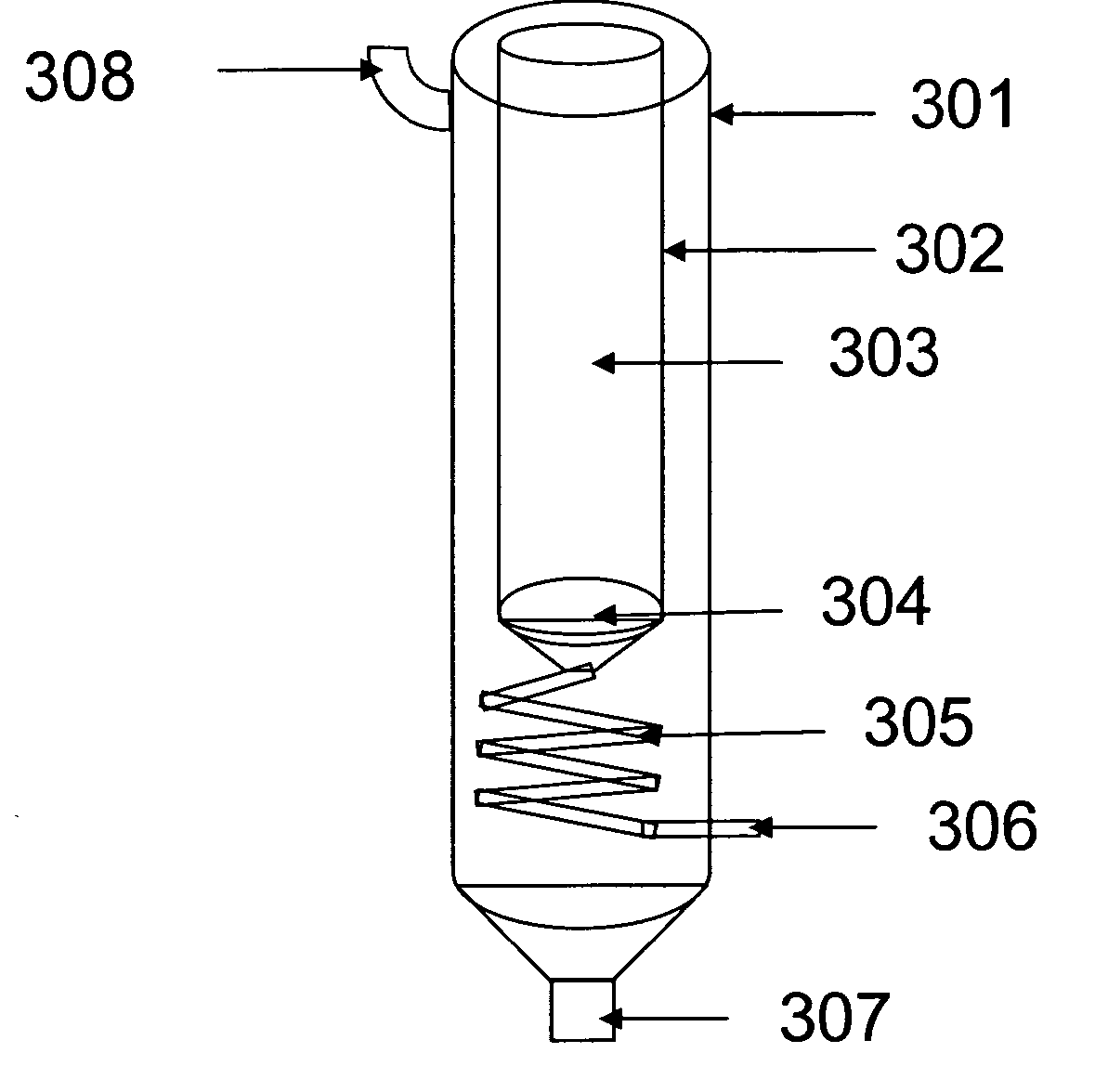

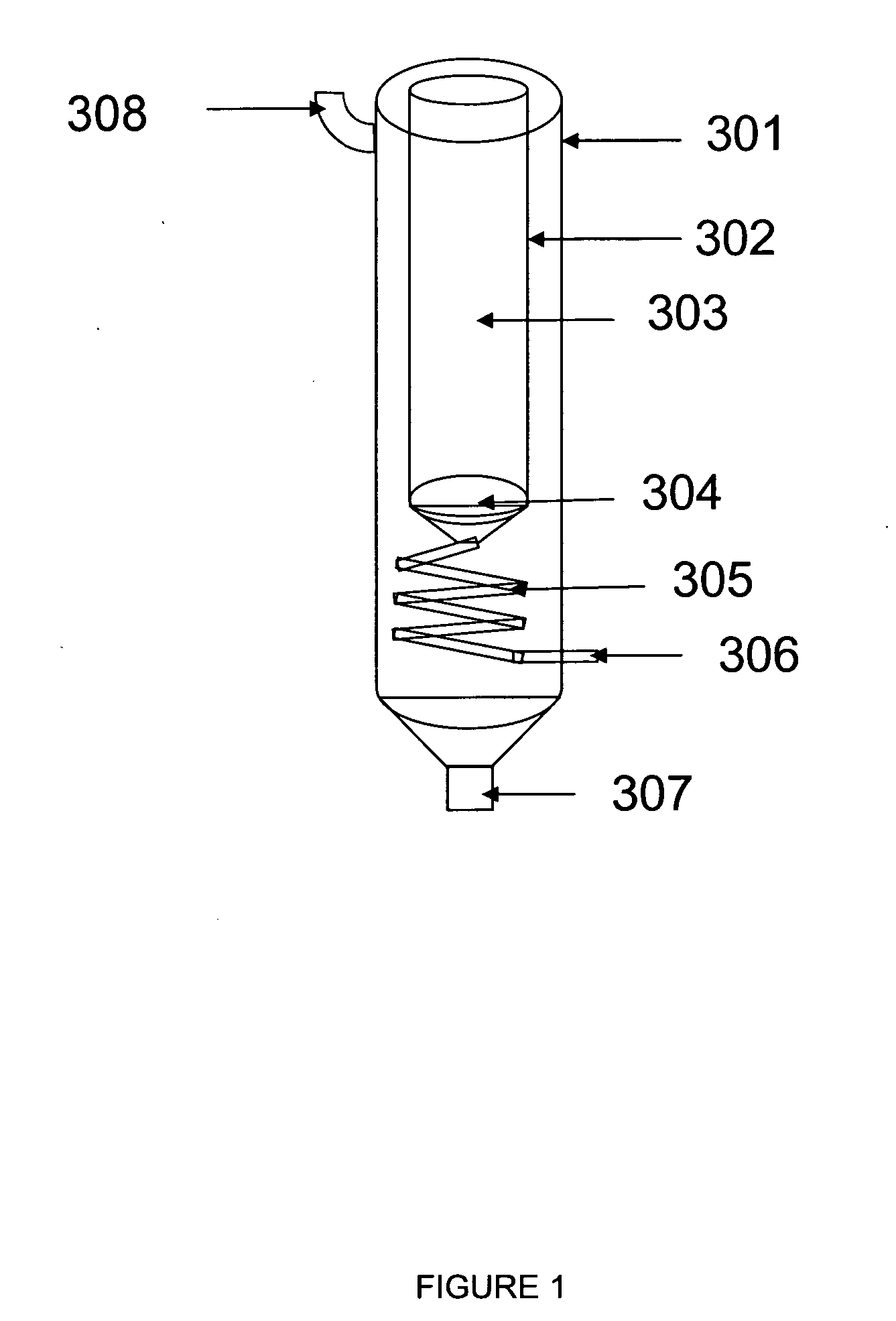

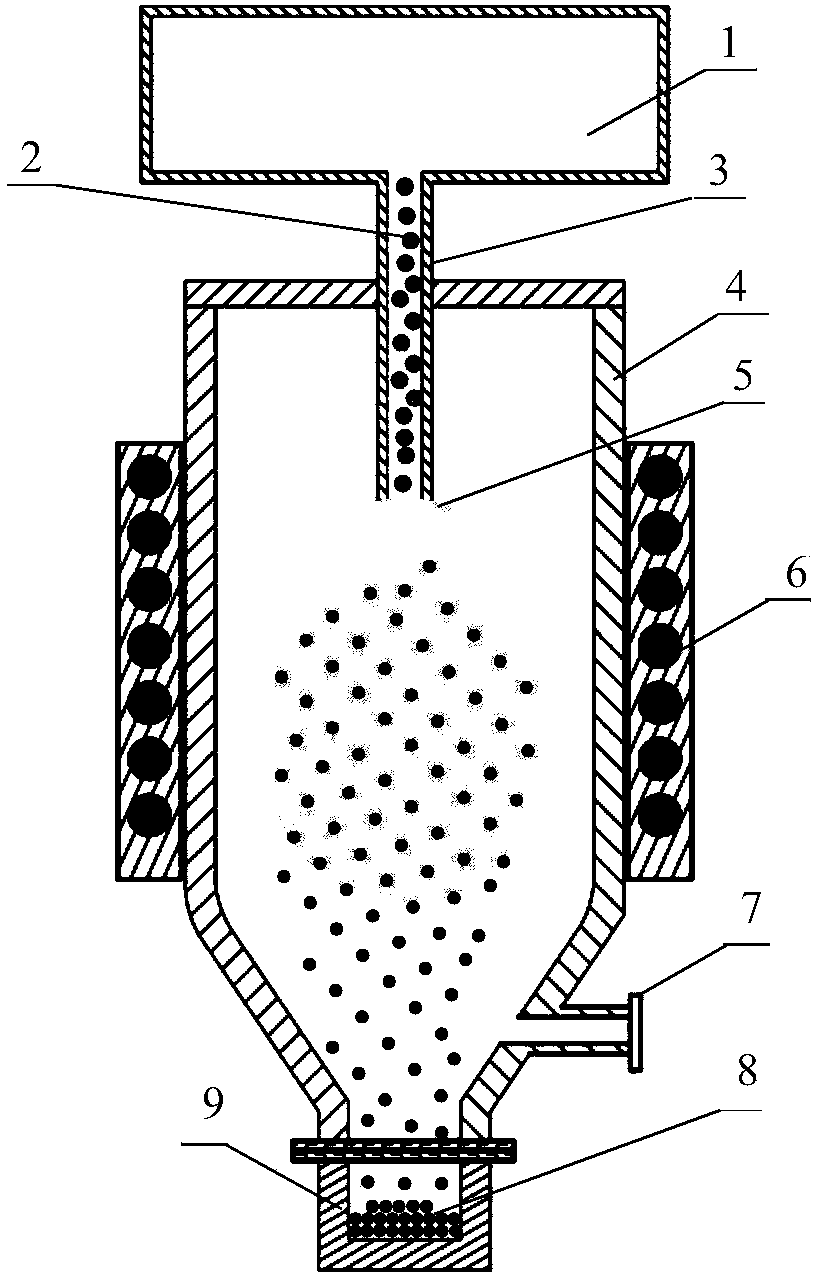

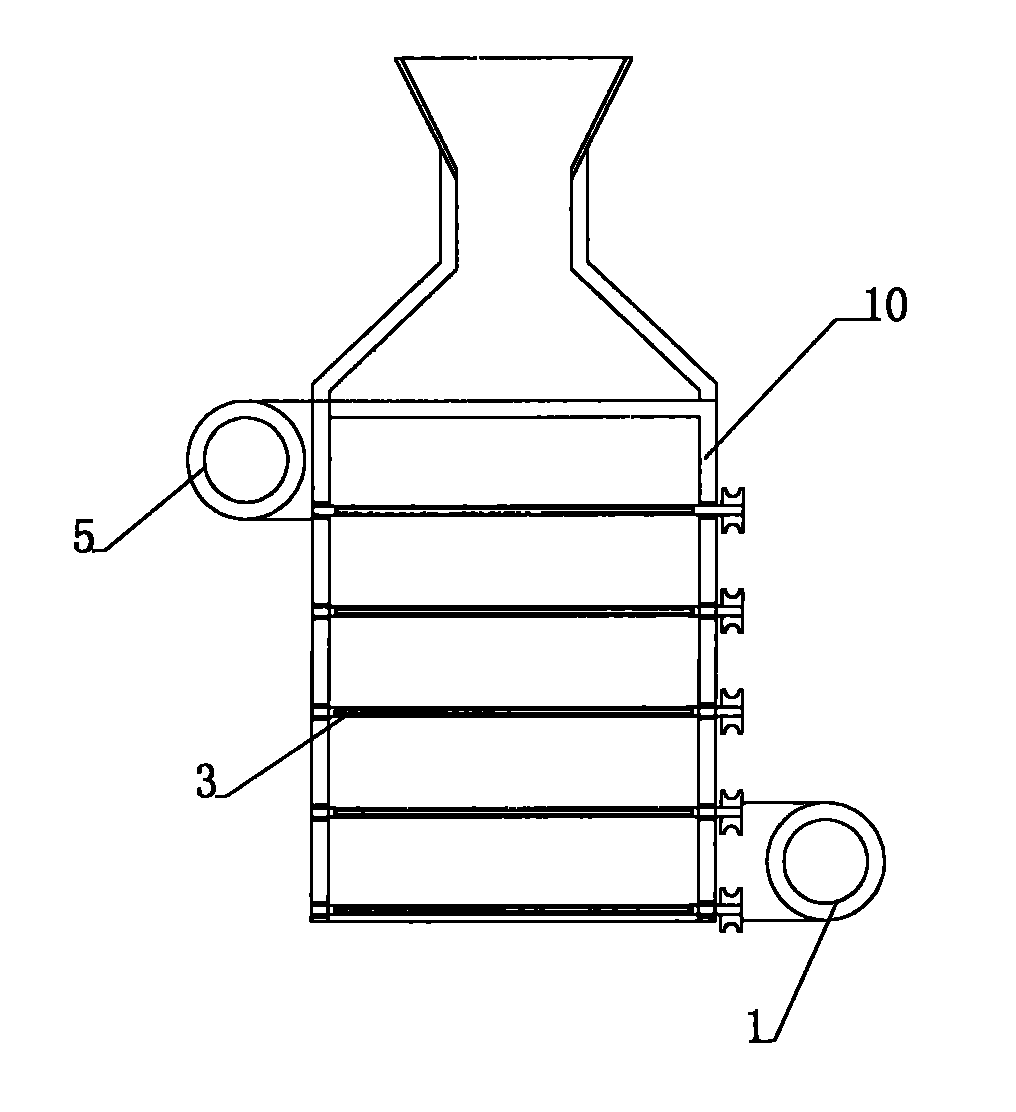

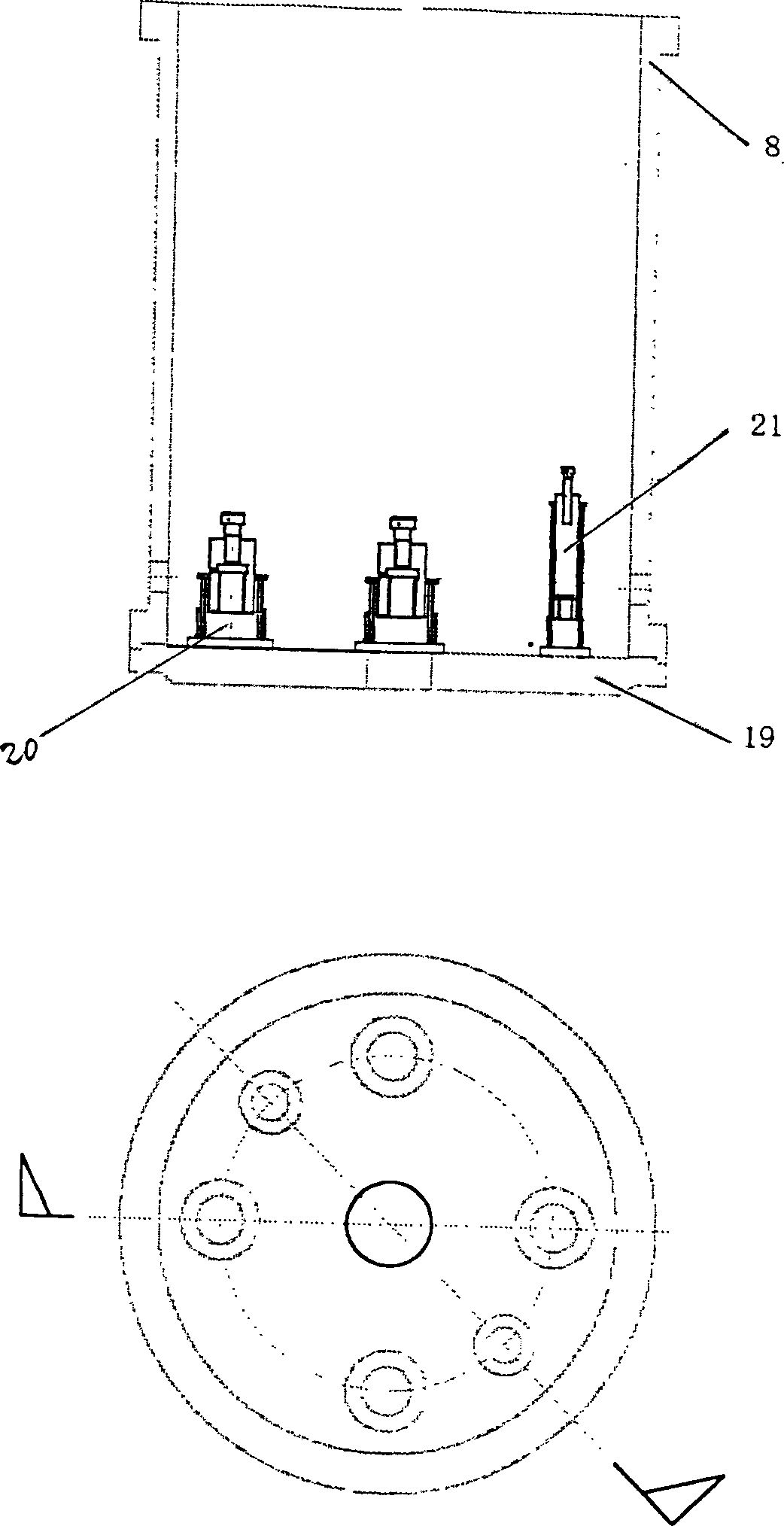

Cyclone melting device and method for fly ash preheating

InactiveCN102620299AImprove leaching rateLow melting slag collection rateIncinerator apparatusThermodynamicsLiquid slag

The invention discloses a cyclone melting device and a cyclone melting method for fly ash preheating, particularly relates to a device and a method for fly ash melting treatment. The device comprises a cyclone furnace and a fly ash preheater, wherein a smoke outlet of the cyclone furnace is connected with a hot smoke inlet of the fly ash preheater, and a working medium outlet of the fly ash preheater is communicated with a secondary air tangential inlet of the cyclone furnace. The method comprises the steps as follows: mixing the primary air with coal powders; spraying into the front end of the cyclone furnace from a primary air inlet of the cyclone furnace; carrying fly ashes into the fly ash preheater through the secondary air for the combustion of the coal powders through adopting the pneumatic transmission technology, enabling high-temperature smoke generated by combustion in the cyclone furnace to enter the fly ash preheater for heating the secondary air and the fly ashes, enabling the fly ashes after heated through the high-temperature smoke to enter the cyclone furnace, quickly heating the fly ashes to reach the fly ash melting temperature, rotating the secondary air in the cyclone furnace at a high speed, throwing the fly ashes to the wall surface of the cyclone surface under the action of a centrifugal force, quickly melting the fly ashes through the high-temperature wall surface, and discharging the molten fly ashes in the form of liquid slags from a liquid deslagging hole at the bottom of the cyclone furnace.

Owner:NANJING XINYE ENERGY TECH

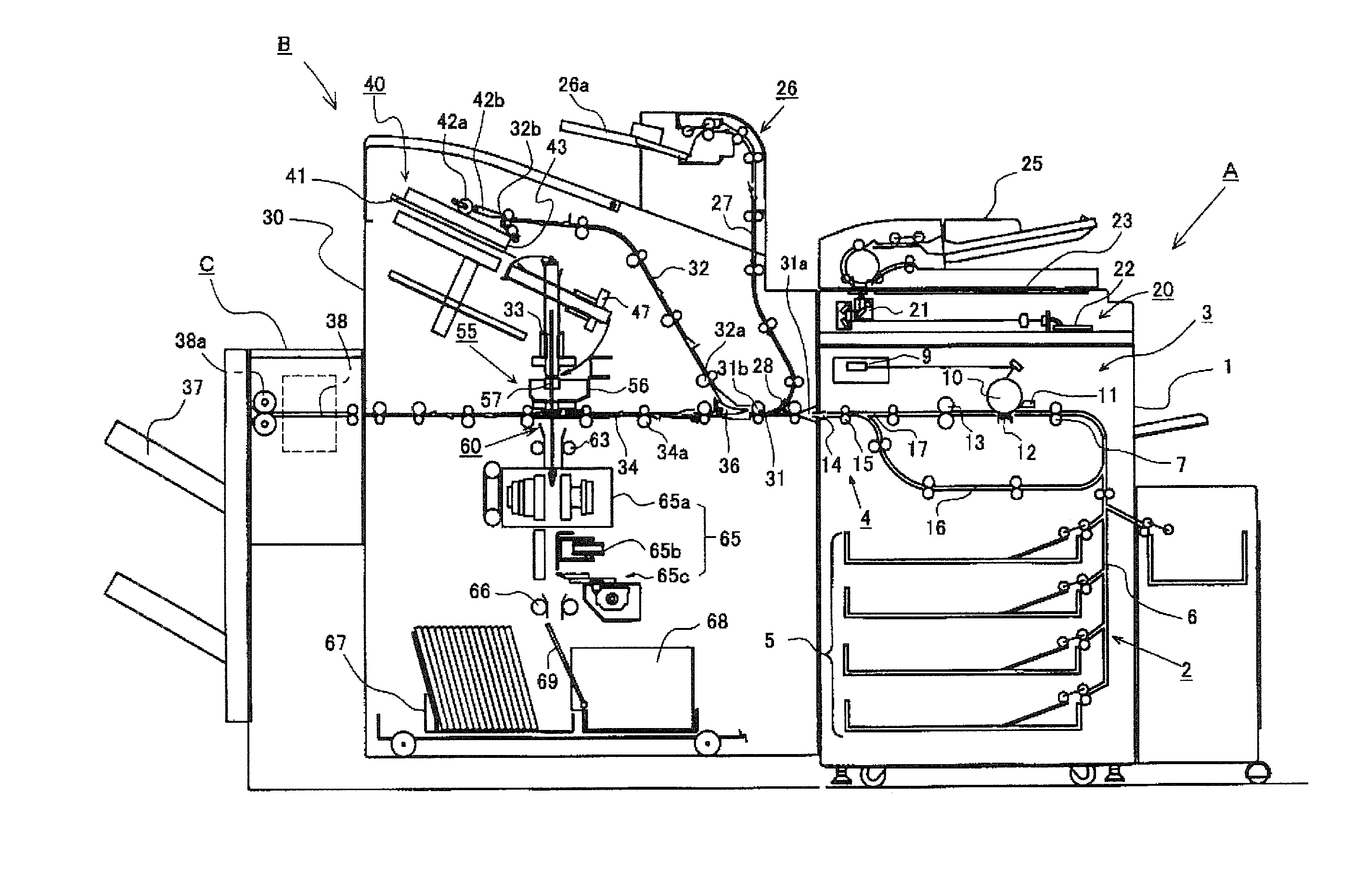

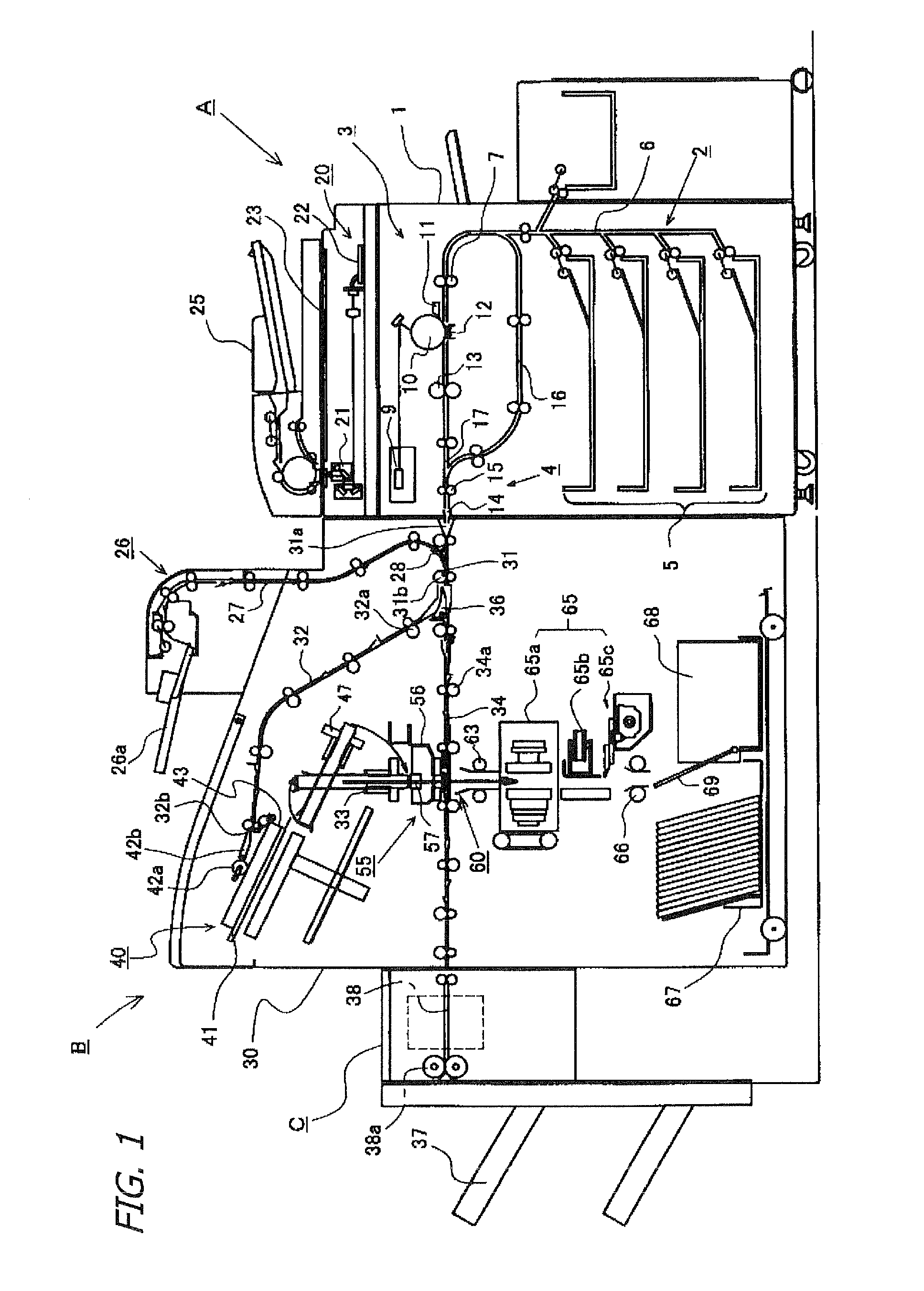

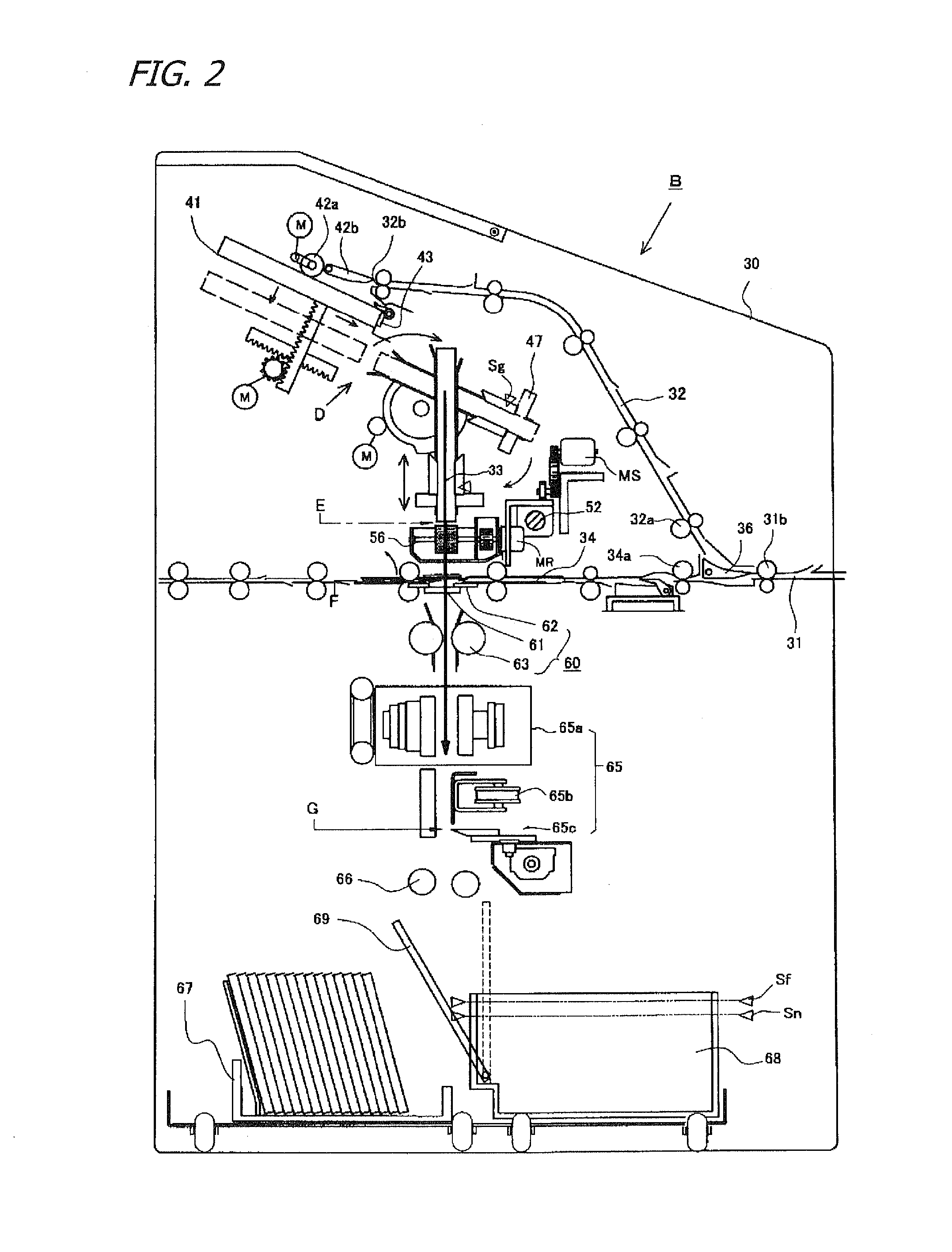

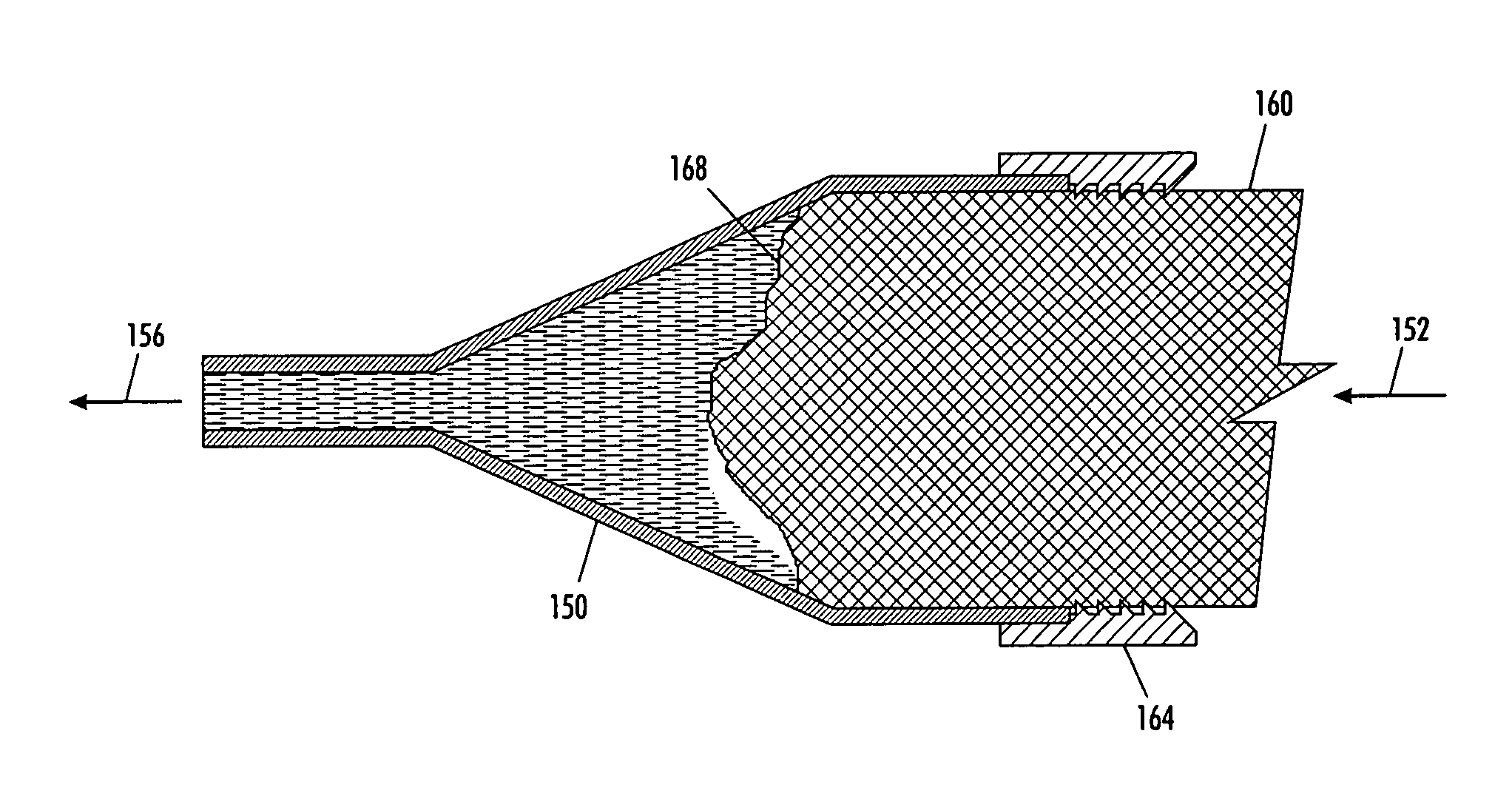

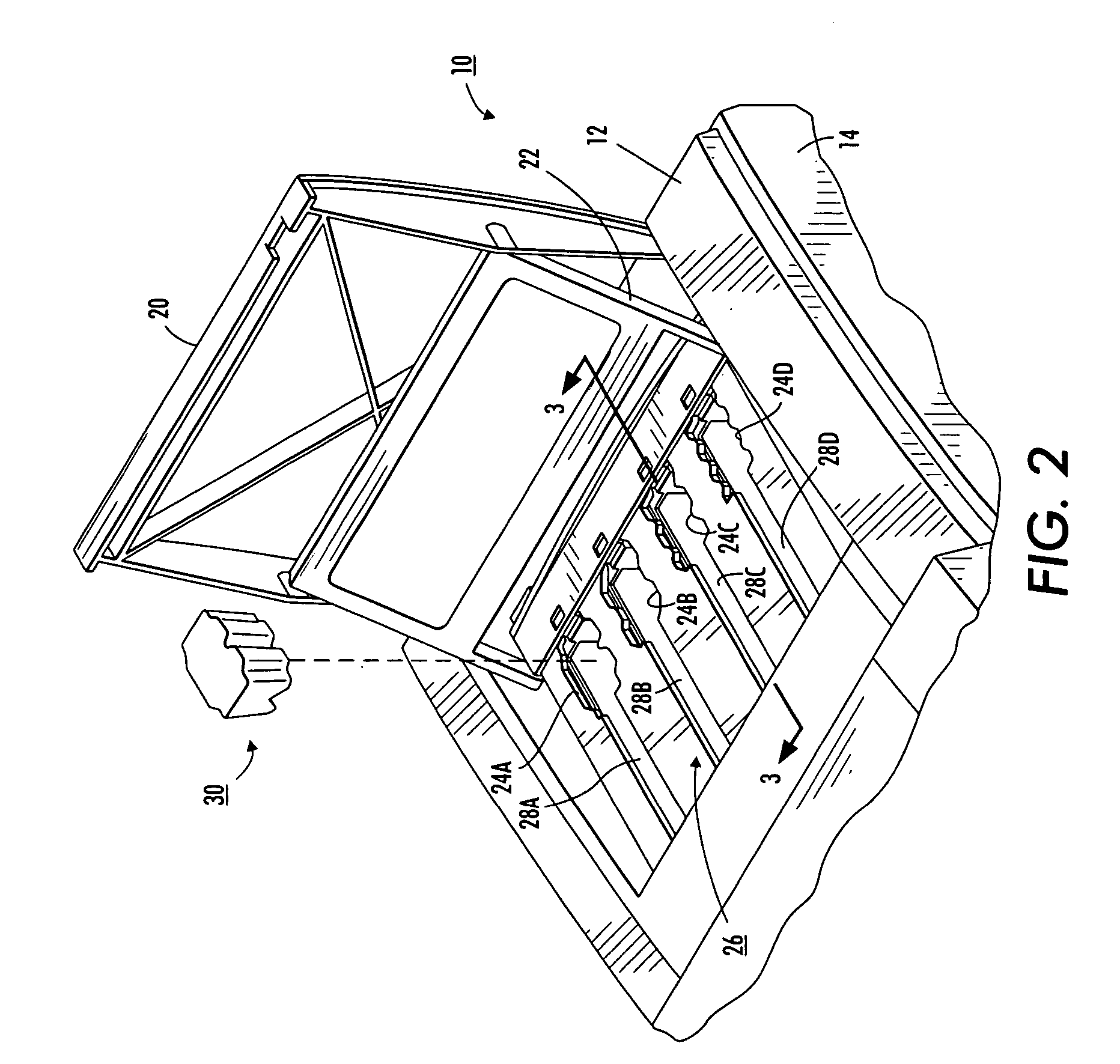

Adhesive Applicator, and Bookbinding Apparatus and Image-Forming System Equipped with the Applicator

ActiveUS20080056735A1Stable supplyShorten melting timeLiquid surface applicatorsBook making processesTemperature controlEvaporation

In replenishing a glue container with hot-melt glue, to enable stable supply of the glue in solid form without it clogging the resupply path from the hopper, provided are: a sheet retaining unit for retaining a sheaf in a glue application position; a glue applier in a hot-melt-glue-receiving container, disposed in the glue application position, for applying glue to an endface of a sheaf there; a heater, disposed in the glue container, for heating / melting the glue inside; a heater temperature controller; a resupply hopper above the glue container for replenishing it with solid glue; a vacuum ducting unit above the container and adjoining the resupply hopper, for suctioning up glue evaporation derivatives; and a control unit configured to run the vacuum ducting unit when the glue container is being replenished with glue, to prevent or mitigate invasion of evaporation derivatives into the resupply hopper.

Owner:NISCA KK

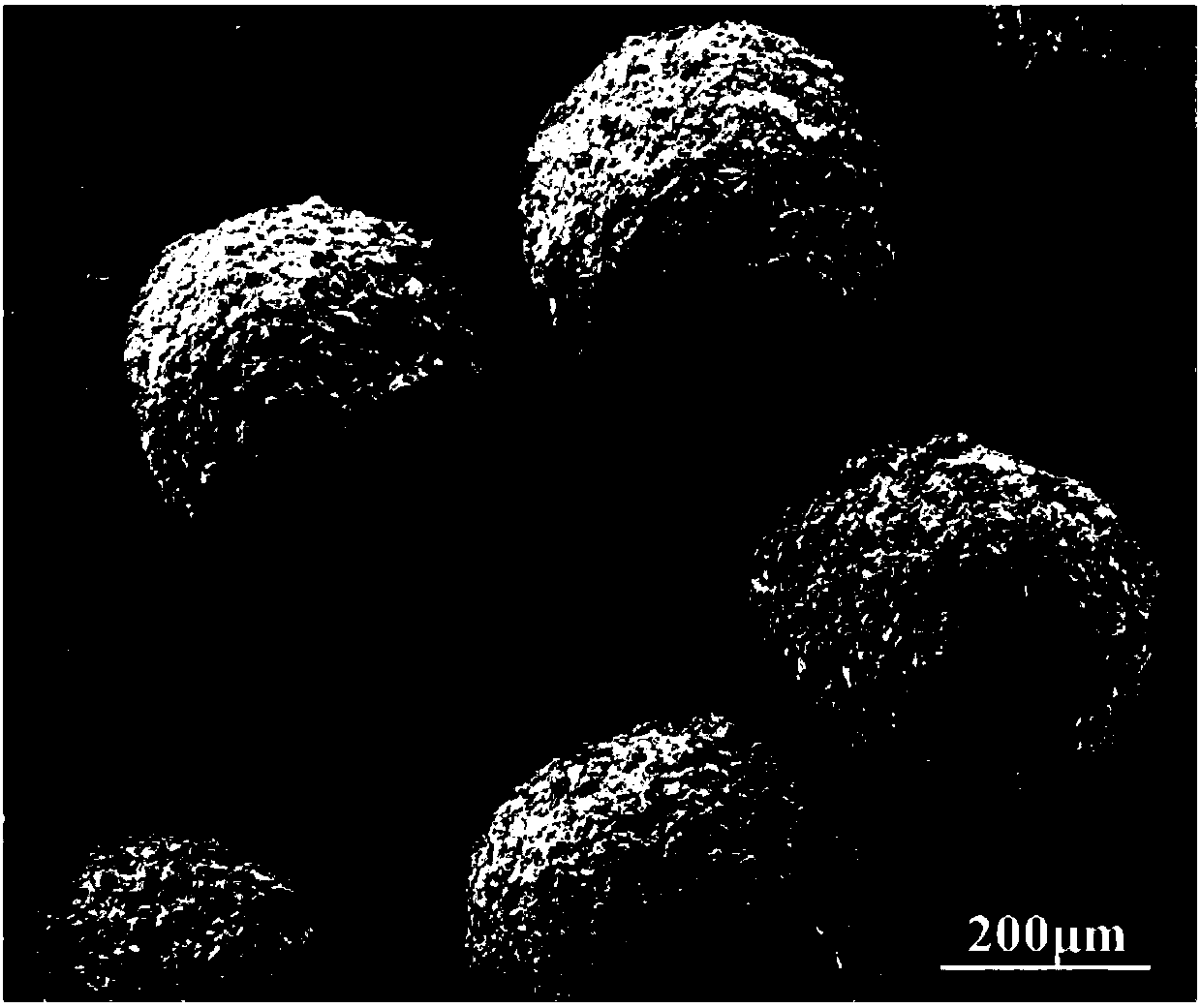

Preparation method of spherical powder of refractory material

The invention discloses a preparation method of spherical powder of a refractory material. The method includes the steps that firstly, raw material powder of the refractory material and an adhering agent are mixed uniformly, then pelleting is performed, and prefabricated granules are obtained; secondly, the prefabricated granules are subjected to vacuum sintering or hydrogen atmosphere protectingsintering, and a prefabricated granule blank body is obtained; and thirdly, the prefabricated granule blank body is contained into a quantitative powder feeding device of a plasma device, and is fed into a high temperature area of a plasma generating device through a conveying pipeline under the gas effect to be molten and shrink so as to generate a compact sphere, then the compact sphere falls into a collecting tank, and the spherical powder of the refractory material is obtained. According to the preparation method of the spherical powder of the refractory material, the raw material powder of the refractory material is sintered after being subjected to pelleting, then plasma is adopted, the raw material powder of the refractory material is made to be molten rapidly, the spherical powderis generated through fast shrinking and nodulizing, the sphericity degree of the powder is improved, and generation of satellite powder and hollow powder is avoided, and finally the compact and uniform spherical powder, smooth and clean in surface and high in sphericity degree, of the refractory material is obtained.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

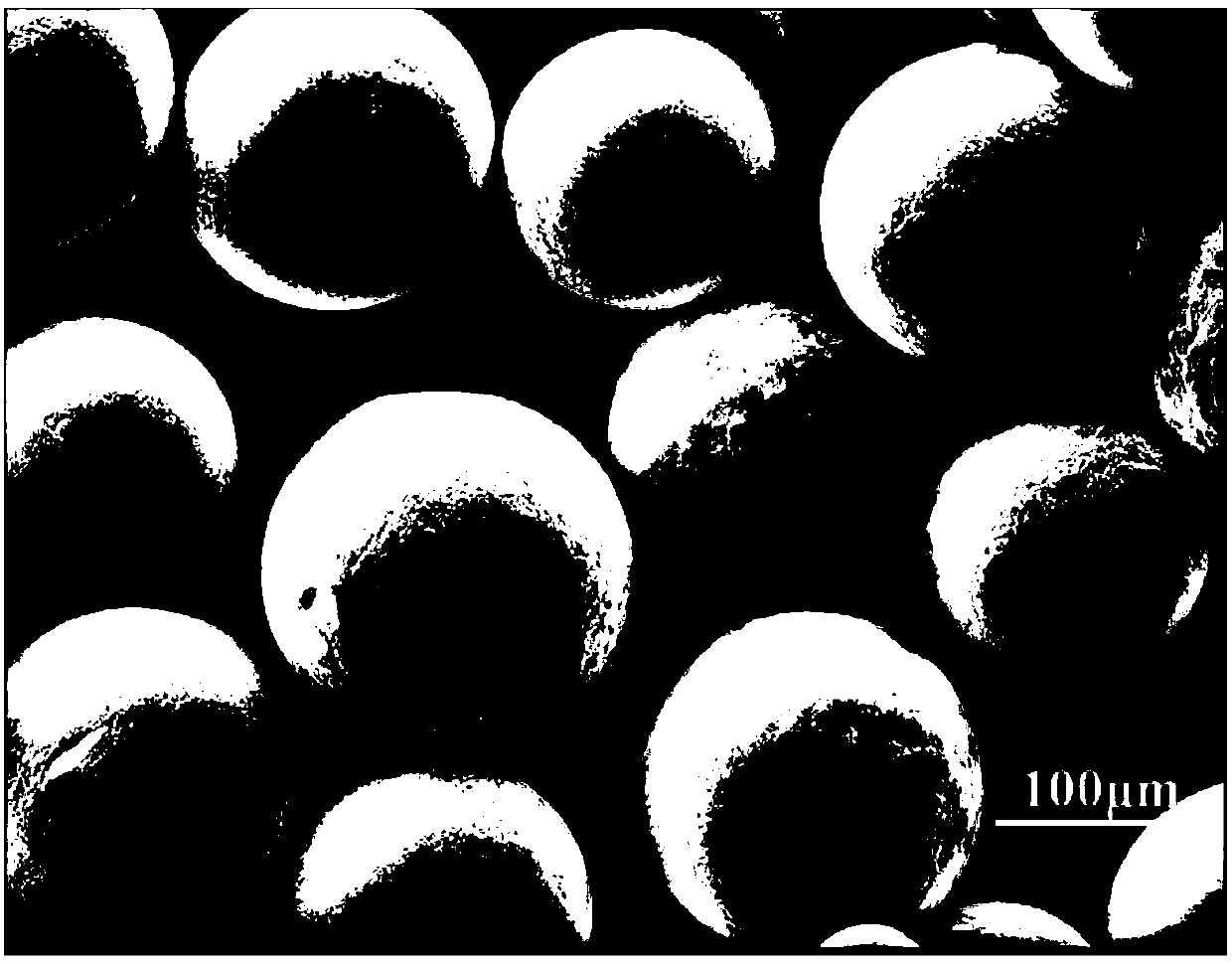

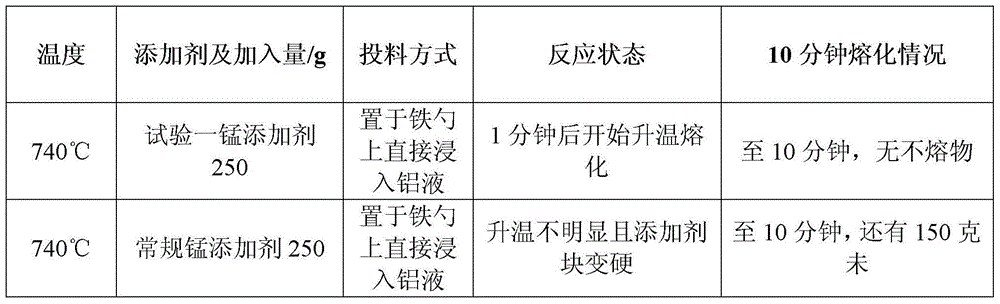

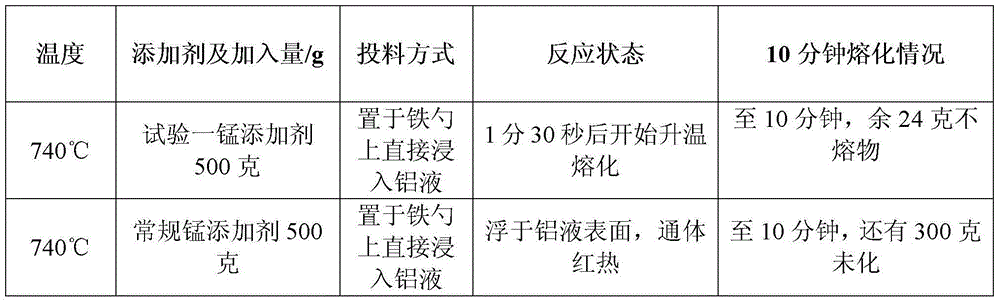

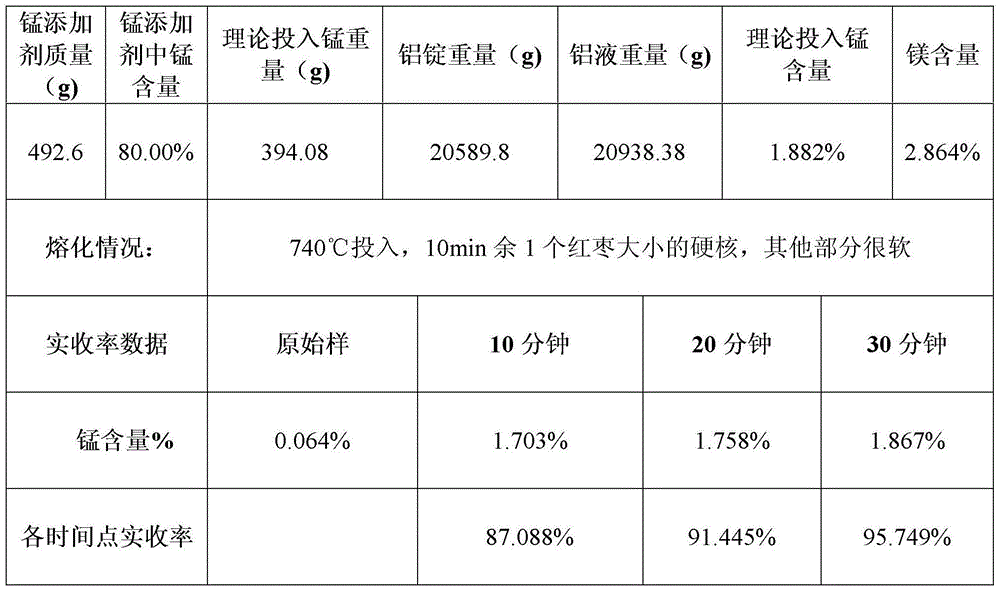

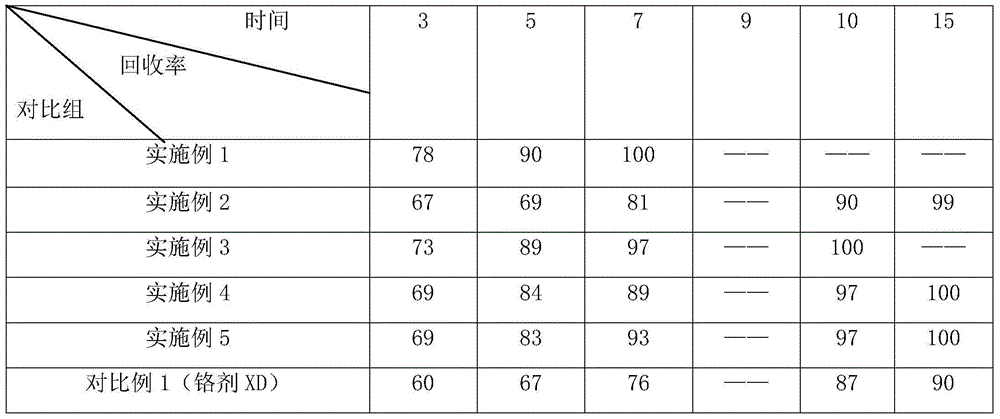

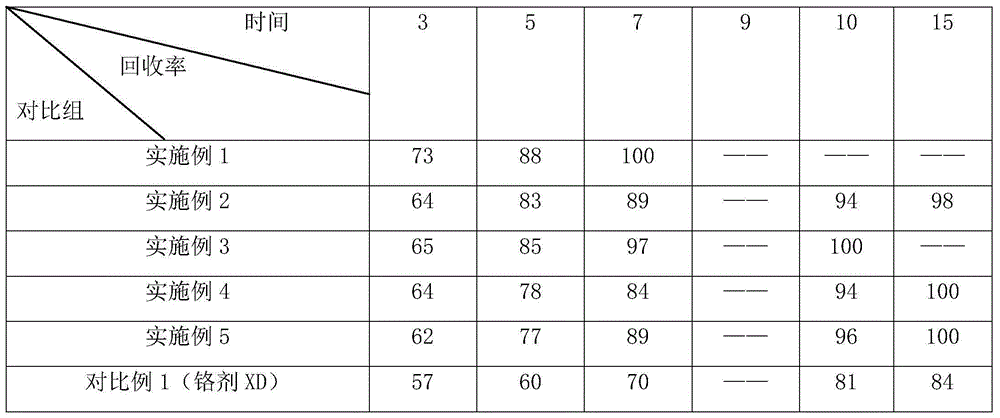

Manganese additive for casting aluminum magnesium alloy and preparation method of manganese additive

The invention discloses a manganese additive for casting aluminum magnesium alloy and a preparation method of the manganese additive, relates to an additive for casting aluminum magnesium alloy and a preparation method of the additive, and aims at solving the problems that a conventional manganese additive is low in melting rate or infusible, low in casting yield, high in smelting temperature, long in smelting time and high in energy consumption under the existing environment with high content of magnesium. The manganese additive disclosed by the invention is prepared from manganese powder and a fluxing agent. The method disclosed by the invention comprises the following steps: mixing the manganese powder with the fluxing agent, and pressing into a cake at the pressure intensity of 7-8MPa, so as to obtain the manganese additive. The manganese additive is low in melting temperature, high in melting rate and high in casting yield, and can be completely molten at 740 DEG C; the melting rate is over 50% greater than that of the conventional manganese additive; the additive which is fed to molten aluminum magnesium alloy over 740 DEG C can be rapidly molten and can be absorbed by molten aluminum within 8-10 minutes; and the casting yield of a manganese element within 20 minutes can be up to over 90%.

Owner:哈尔滨东盛金材科技(集团)股份有限公司

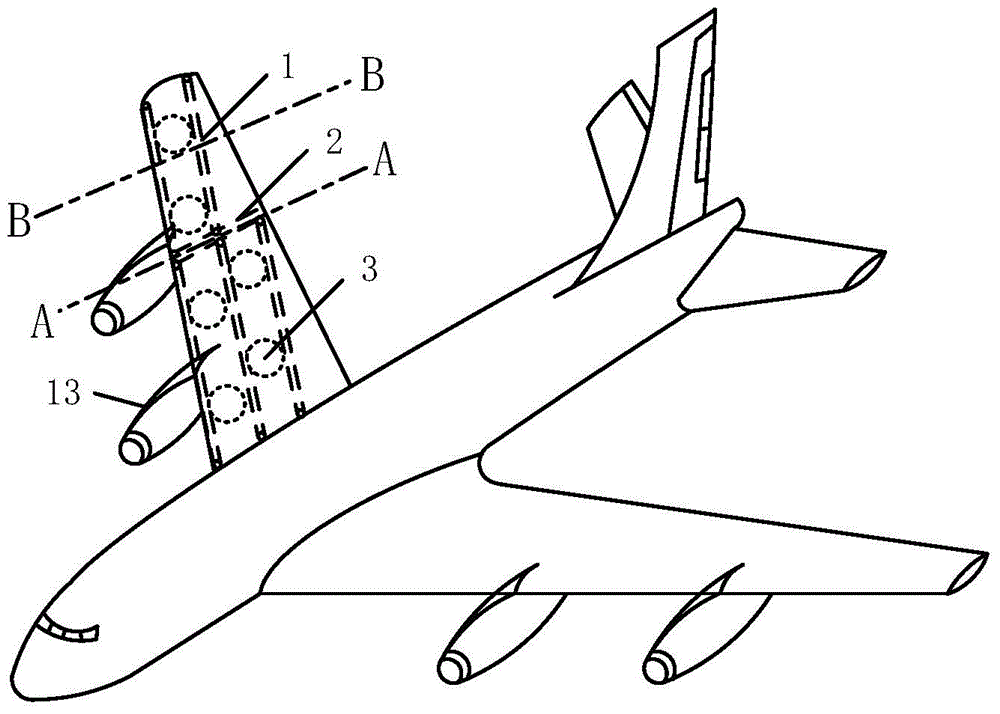

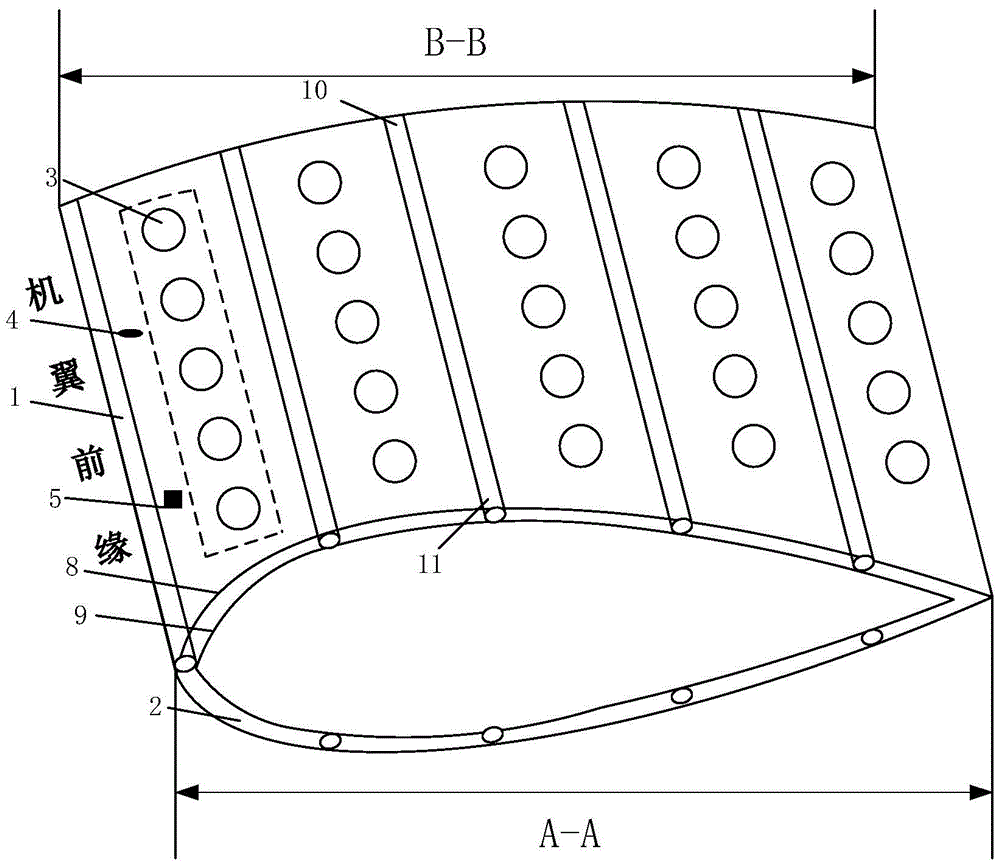

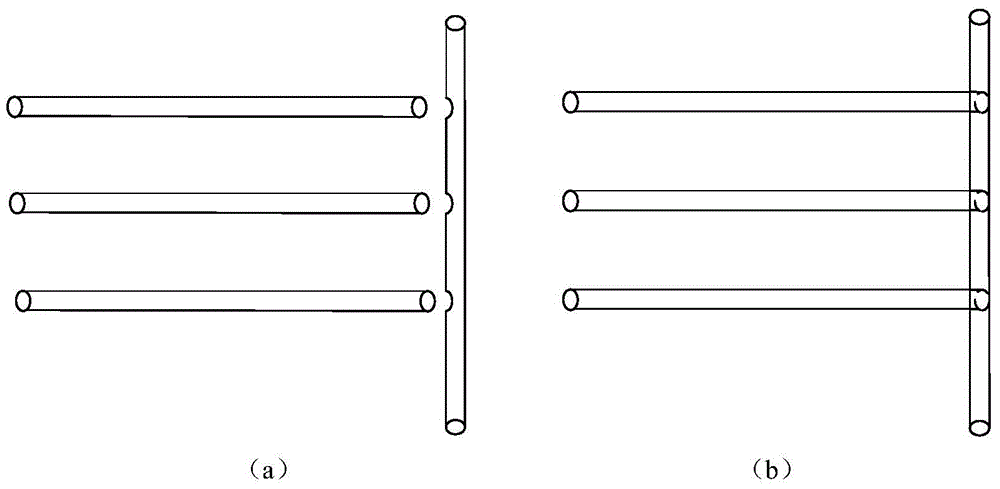

Heat pipe and ultrasonic wave combined ice preventing and removing device and method utilizing waste heat of aircraft engine

InactiveCN105691620APrevent freezingStable anti-icing temperatureDe-icing equipmentsEvaporationAtmospheric temperature

The invention provides a heat pipe and ultrasonic wave combined ice preventing and removing device and method utilizing waste heat of an aircraft engine. The device comprises a heat pipe ice-preventing system, an ultrasonic oscillation ice removing system, a program control system, an atmospheric temperature sensor and an icing strength annunciator. The heat pipe ice-preventing system comprises a communicating pipe installed at the tail portion of the engine to absorb exhaust waste heat and a heat pipe bank bundle with an evaporation section connected with the communicating pipe. The ultrasonic oscillation ice removing system comprises an ultrasonic generator and an ultrasonic transducer unit connected with the output end of the ultrasonic generator through a connecting cable. The program control system automatically controls on and off between the heat pipe bank bundle and the communicating pipe and starting or stopping of the ultrasonic generator according to a temperature signal and an icing strength signal. By means of the synergistic effect of heat pipes and ultrasonic waves, preventing and removing can be combined, compared with a method for removing ice simply through ultrasonic waves, the icing phenomenon of wings is greatly reduced, the flying stability of an aircraft is ensured, and a system is safe and reliable.

Owner:NANJING NORMAL UNIVERSITY

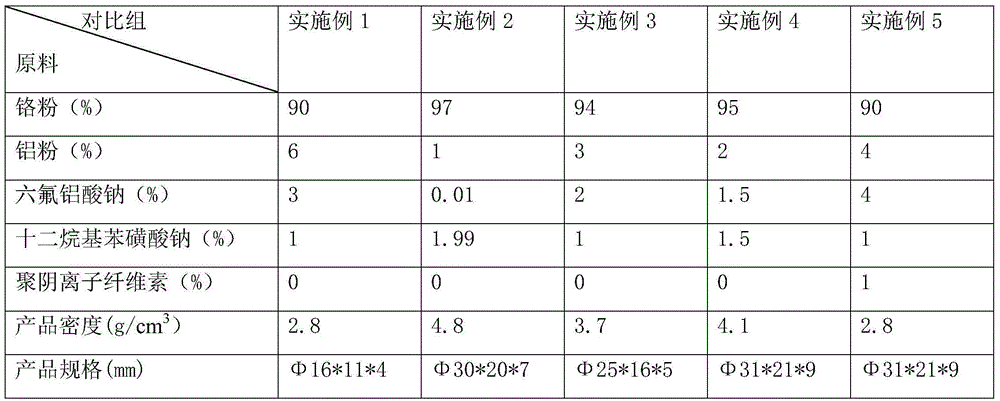

High-content chromium metal additive for aluminum alloy production and preparation method thereof

The invention belongs to the field of aluminum alloy additives, and discloses a high-content chromium metal additive for aluminum alloy production and a preparation method thereof. The high-content chromium metal additive takes the shape of a cake or a rugby mainly pressed by chromium powder, aluminum powder and a fluxing agent, wherein the chromium powder and the aluminum powder are respectively crushed under the protection of inert gas. The high-content chromium metal additive further comprises a surface active agent; and the mass percentages of all the components are as follows: 90-97% of chromium powder, 0-9.38% of aluminum powder, 0.01-5% of fluxing agent, and 0.5-2% of surface active agent. In the additive, the content of the chromium metal element is highest to 97%; the chromium additive is low in melting temperature; the melting temperature is low to 670 DEG C; the melting time is short; the melting can be realized by 10-15 minutes; and the recovery rate of the chromium metal element is high above 98%.

Owner:CHONGQING RUNJI YUANDONG NEW MATERIAL TECH

Blast furnace-intermediate frequency furnace duplexing smelting short process production technology

The invention provides a short flow manufacturing technique for the duplex smelting of a blast furnace-intermediate frequency furnace, relating to the blast furnace-intermediate frequency sensing electric stove smelting technique. The short flow manufacturing technique is characterized in that the liquid iron produced by an ironmaking blast furnace is directly added into the intermediate frequency sensing electric stove, the temperature is increased to adjust materials, and a cast piece is poured. In the material adjusting process, a liquid iron nucleating agent is added to accelerate the crystallization. The nucleating agent comprises the compositions in weight percentage: 65 to 70 percent of silicon, 0.5 to 2.5 percent of calcium, 0.0 to 6.0 percent of barium, 0.2 to 2.0 percent of aluminum, 0.05 to 0.2 percent of bismuth, and the balancing being iron. The short flow manufacturing technique has the advantages that the process of melting iron ingot for the second time is saved, the overheating efficiency of the sensing electric stove is high, the adjustment of components and the control of the temperature are convenient, the high temperature liquid iron which has good quality and meets the requirement for the cast piece is obtained; and the technique can be applied to spheroidal graphite casting to produce parts of an automobile, parts of wind power equipment, engineering plant cast pieces and other cast pieces, the product quality is improved, the energy is saved, the production efficiency and the production benefits are improved, and the environmental pollution is reduced.

Owner:LINZHOU HEXIN CASTING CO LTD

Li2O—Al2O3—SiO2—based crystallized glass

ActiveUS9126859B2Large degree of influenceLower melting temperatureOptical elementsMaterials scienceSilicon dioxide

Provided is a Li2O—Al2O3—SiO2-based crystallized glass, comprising, as a composition in terms of mass %, 55 to 75% of SiO2, 20.5 to 27% of Al2O3, 2% or more of Li2O, 1.5 to 3% of TiO2, 3.8 to 5% of TiO2+ZrO2, and 0.1 to 0.5% of SnO2, and satisfying the relationships of 3.7≦Li2O+0.741MgO+0.367ZnO≦4.5 and SrO+1.847CaO≦0.5.

Owner:NIPPON ELECTRIC GLASS CO LTD

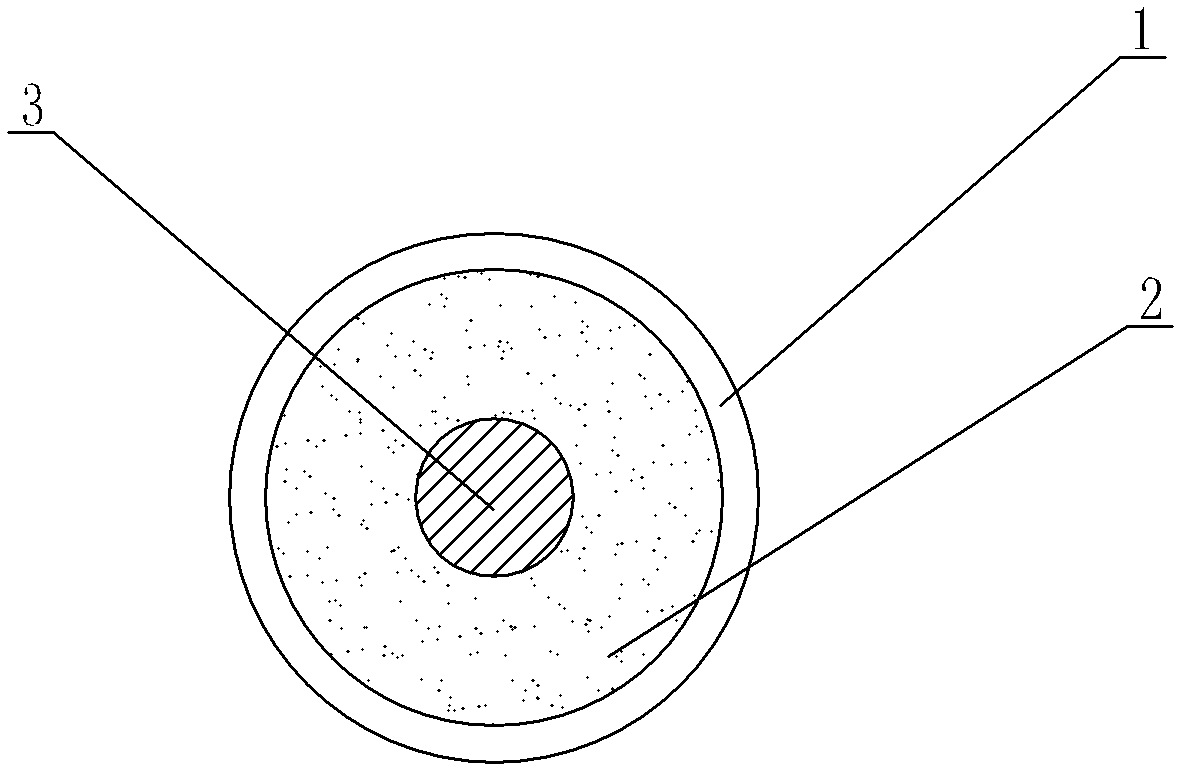

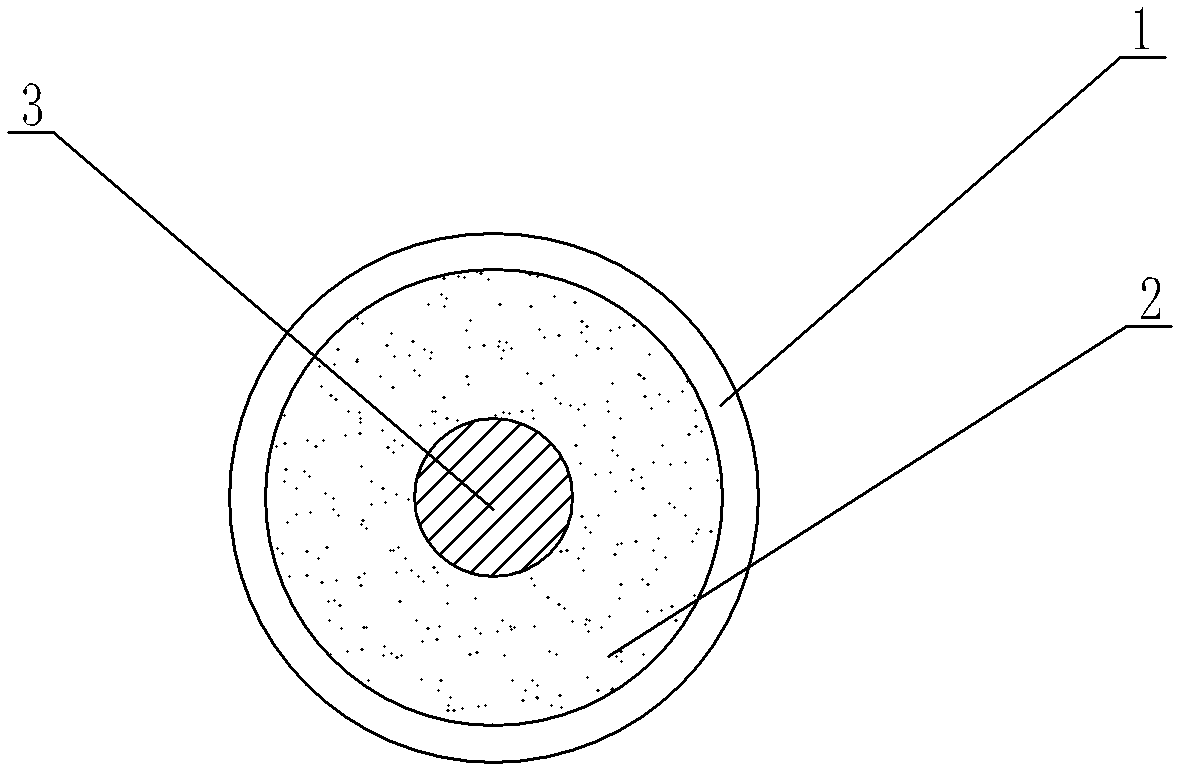

High binding force nano-amorphous sprayed welding wire

InactiveCN102284804AHigh strengthImprove bindingWelding/cutting media/materialsSoldering mediaMolten stateNiobium

The invention relates to a nano-amorphous sprayed welding wire with high binding force, which comprises a strip matrix located on the surface, and filling powder is filled in the strip matrix; the feature is that there is a central welding wire in the center of the filling powder. The strip substrate is an iron-based strip or a nickel-based strip. The iron-based strip is made of low carbon steel or austenitic ferritic stainless steel, and the nickel-based strip is made of pure nickel or nickel-chromium. The filling powder is a mixture of ferroboron, ferrotungsten and / or tungsten powder, ferroniobium and / or niobium powder. The central welding wire is aluminum welding wire, aluminum magnesium welding wire or aluminum silicon welding wire. The welding wire of the present invention has twice the intensity of the coating formed by spraying the amorphous coating formed by spraying the traditional welding wire; the welding wire of the present invention has added a central welding wire in the center of the amorphous powder, and the central welding wire It has a low melting point and is easy to melt, thereby reducing the melting time of the amorphous powder and the matrix strip, prolonging the melting state of Ni3Al and Fe3Al, and obtaining a nano-amorphous coating with high bonding force.

Owner:WUXI APPLIED MATERIALS

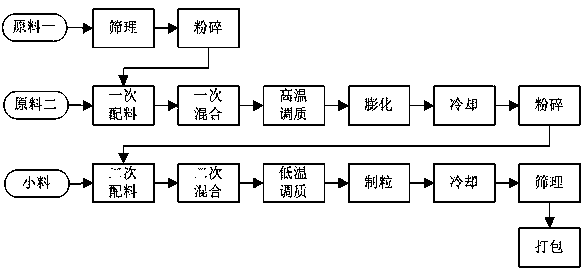

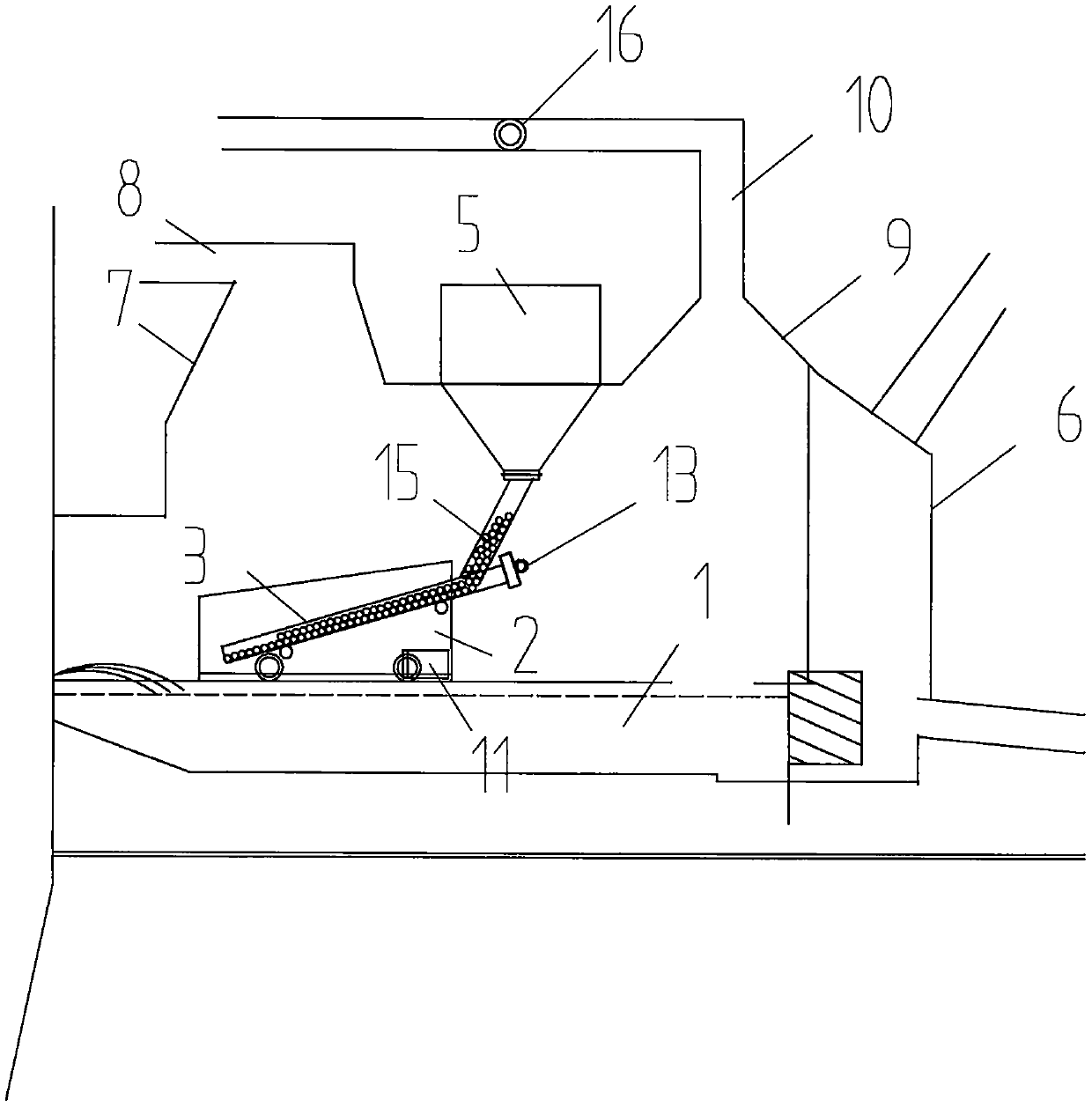

Livestock and poultry feed processing technology and device

InactiveCN105494956AHigh degree of gelatinizationIncrease bubble volumeWorking-up animal fodderAdditive ingredientMixed materials

The invention discloses a livestock and poultry feed processing technology and device. The livestock and poultry feed processing technology includes the steps that raw materials are screened and smashed; then primary blending is carried out, and raw materials not needing to be smashed are added in the primary blending process; primary mixing is carried out after primary blending; the primarily-mixed materials are subjected to high-temperature tempering and puffing, wherein the temperature of high-temperature tempering is 90-100 DEG C, the time of high-temperature tempering reaches 30 s or longer, and the pressure range of a puffing cavity in puffing is 0-10 MPa; the puffed materials are independently cooled and smashed; then secondary blending and secondary mixing are carried out, and thermosensitive ingredients lost in high-temperature tempering and puffing are replenished in secondary blending; low-temperature tempering and granulating are carried out after secondary mixing, wherein the temperature of low-temperature tempering is 40-70 DEG C. The gelatinization degree of the materials is effectively increased through high-temperature tempering and puffing, thermosensitive nutritional ingredients in the raw materials are seriously lost after high-temperature tempering and puffing, the thermosensitive ingredients are replenished in secondary blending, and therefore nutritional ingredients of feed are increased.

Owner:JIANGSU MUYANG HLDG

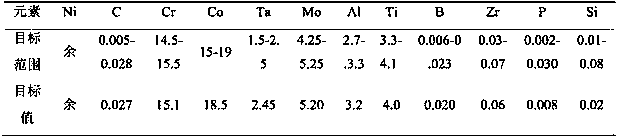

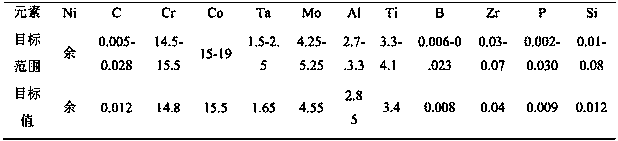

Novel powder high-temperature alloy and preparing method thereof

The invention relates to novel powder high-temperature alloy and preparing method thereof. The novel powder high-temperature alloy comprises, by weight percent, 14.00 to 15.00% of Cr, 14.50 to 19.50%of Co, 4.5 to 5.5% of Mo, 3.25 to 4.10% of Ti, 2.50 to 3.10% of Al, 1.45 to 2.50% of Ta, 0.55 to 1.55% of Hf, 0.045 to 0.068% of Zr, 0.005 to 0.030% of C, 0.006 to 0.023% of B, 0.002 to 0.030% of P, 0.01 to 2.0% of Re, 0.1 to 2.0% of W, 0.1 to 1.0% of Nb, smaller than 0.5% of Y, smaller than 0.3% of V, smaller than 0.5% of Fe, smaller than 0.15% of Si, smaller than 0.12% of Mn, and the balance Ni.The gamma' phase content in the l powder high-temperature alloy is about 40 to 50%. The novel powder high-temperature alloy prepared through the preparing method has the good room temperature strength, high temperature strength and high temperature creep properties, and the use temperature is up to 750 DEG C.

Owner:西部超导材料科技股份有限公司

Asphalt modifier compositions with an improved melting rate and modified asphalt prepared using the same

ActiveUS8173725B2Increase melting rateShorten melting timeBuilding insulationsProduction rateAsphalt

The present invention relates to a pellet type SBS-asphalt master batch modifier composition comprising styrene-butadiene-styrene (SBS) block copolymer and asphalt, and modified asphalt prepared by melting and mixing the pellet type SBS-asphalt master batch modifier composition with asphalt. The modified asphalt prepared thereof has advantages that deterioration of physical properties and thermal oxidation can be prevented while productivity can be improved due to reduced melting time of modifier.

Owner:KOREA KUMHO PETROCHEMICAL CO LTD

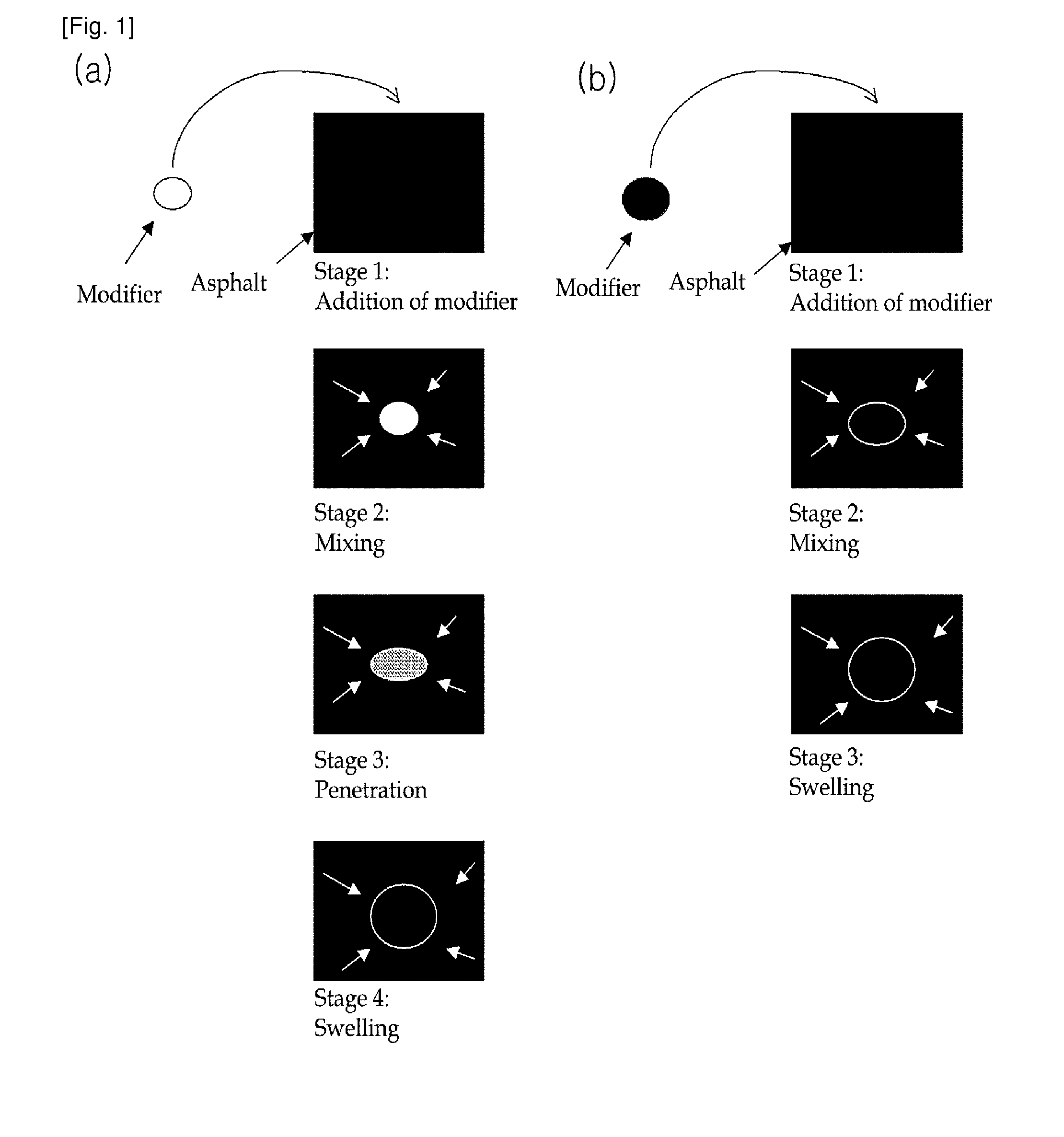

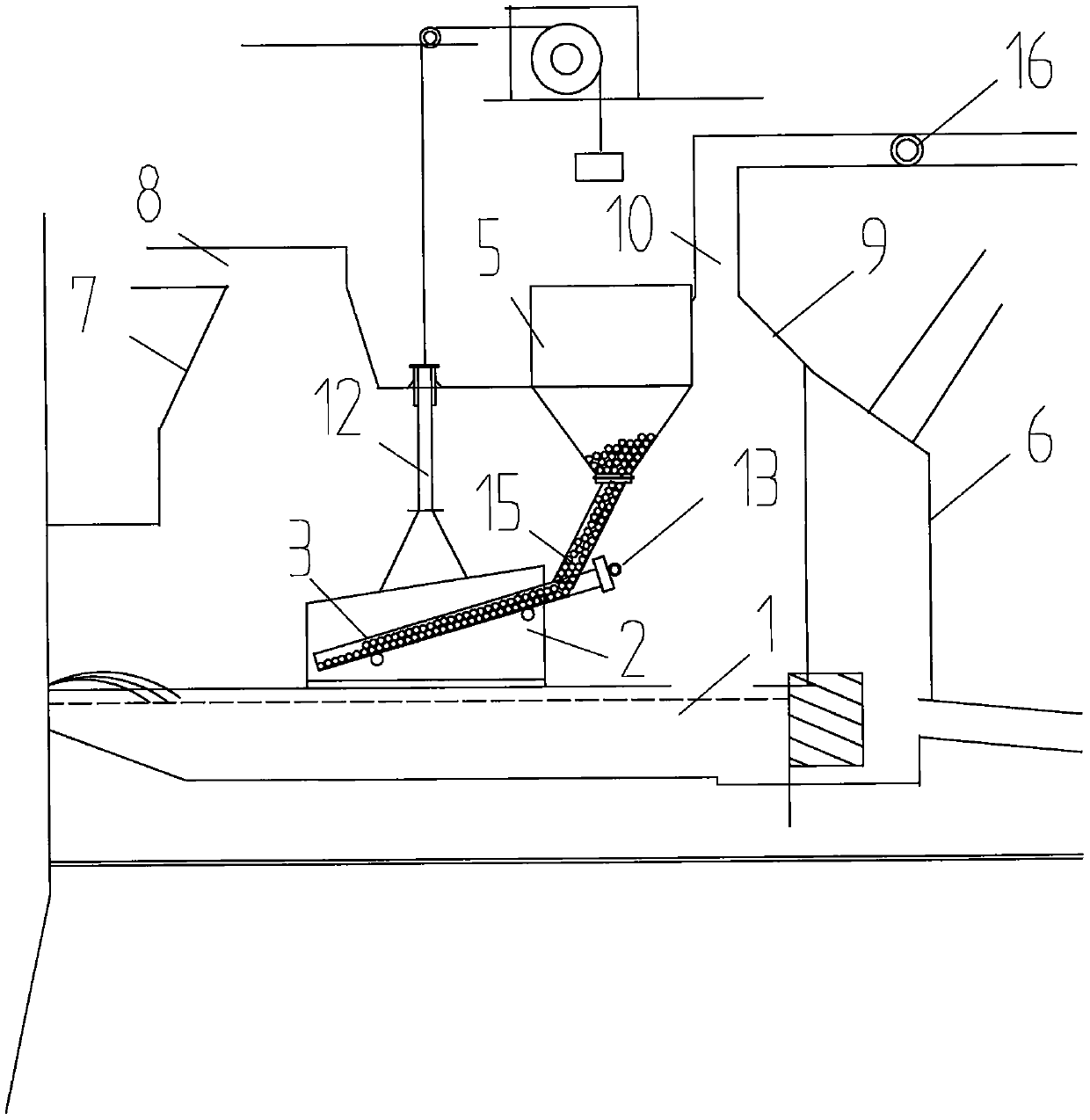

Method and device for preheating batch by using waste heat of fume from pure-oxygen combustion glass furnace

InactiveCN101830628AShorten melting timeRaise the preheat temperatureGlass productionCombustionGlass furnace

The invention relates to a method and a special device for preheating a batch by using the waste heat of fume from a pure-oxygen combustion glass furnace. The method comprises the following steps: granulating the glass batch; dehydrating and drying the grains; and preheating the grains by using a multilayer vertical turning plate preheating mode, wherein the glass batch and the hot fume are contacted indirectly, namely the fume radiates heat to the glass batch by convection, and the glass batch is preheated by a multilayer turning plate preheater to above 400 DEG C and then is delivered to the next process step. Multiple layers of turning plates and multiple flues are arranged in the preheating device, a fume inlet communicated with the flues is positioned on the outer side of the side water on the lower part of the preheater, a fume outlet communicated with the flues is positioned on the outer side of the other side wall on the upper part of the preheater, and the fume inlet and the fume outlet are arranged diagonally; the special preheating device is used to preheat the glass batch, the utilization rate of the waste heat of the high-temperature fume is high, no smoke dust pollution is produced; under self suction, the fume rises along the flues, so no power is consumed; the vertical structure occupies small floor area, so the replacement of space for time is realized; and the promotion and implementation of the device are easy.

Owner:QINHUANGDAO GLASS IND RES & DESIGN INST

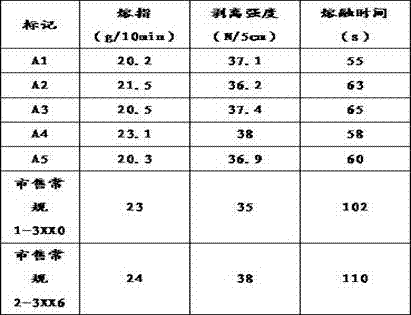

Rapid-melted copolyester hot melt glue and preparation method thereof

InactiveCN107236509AShorten melting timeGuaranteed bonding effectAdhesivesPolymer scienceAntioxidant

The invention discloses rapid-melted copolyester hot melt glue and a preparation method thereof. Main materials of the rapid-melted copolyester hot melt glue comprise diacid and diol, wherein diacidis prepared from a mixture of terephthalic acid, isophthalic acid and 1,6-adipic acid in a mole ratio being 1:(0.3-0.4):(0.15-0.3), diol is prepared from a mixture of 1,4-butanediol, ethanediol, diglycol and 1,6-hexanediol in a mole ratio being 1:(0.2-0.4):(0.5-0.7):(0.15-0.2), and a mole ratio of diacid to diol is 1:1.5; auxiliary materials of the rapid-melted copolyester hot melt glue comprise a catalyst and an antioxidant. By means of design for a unique raw material ratio, especially a ratio of the main materials, and no addition of novel additives, a copolyester hot melt glue product is directly prepared through conventional one-step esterification and a one-step polycondensation reaction, the melting time of the copolyester hot melt glue product is greatly shortened on the premise that the binding performance of the product is guaranteed and industrial coating is facilitated, so that the copolyester hot melt glue product is more suitable for being applied to the field of textile lining cloth, production efficiency of the application implementing field is improved, and energy consumption is reduced.

Owner:KUNSHAN TIANYANG HOT MELT ADHESIVE CO LTD +2

Energy-saving and production-increasing method of preheating pellet materials by blast furnace tap drain hot smoke

PendingCN110607407AReduce heat radiationQuick responseBlast furnace detailsExhaust gas handlingSocial benefitsCombustion

The invention discloses an energy-saving and production-increasing method of treating pellet materials such as carbon-iron-zinc-containing dust sludge pellets and / or waste steel and slag steel to increase the production of molten iron by using a blast furnace tap drain and preheating the pellet materials by using hot smoke generated during the separation and recycling of zinc powder and belongs tothe field of dust sludge solid waste treatment and energy conservation and emission reduction. The method is characterized in that a large amount of hot smoke generated by tap drain high-temperatureslag iron during blast furnace tapping and a large amount of hot smoke generated by flame combustion during treating the carbon-iron-zinc-containing dust sludge pellets are utilized, a device for heating and preheating the pellet materials such as the carbon-iron-zinc-containing dust sludge pellets and the waste steel and slag steel is installed on the blast furnace tap drain, and the temperatureof the pellet materials added to the tap drain is greatly improved. The method has the advantages that the pellet materials are heated to the high temperature then to be added into the tap drain, partial pre-reduction can occur in advance, the reaction speed is remarkably accelerated, the reaction time and the melting time are greatly shortened, the treatment amount of the pellet materials added into the tap drain can be remarkably improved, the energy is effectively saved, the yields of the molten iron and the grain slag are improved, and the economic and social benefits are increased.

Owner:湖南建鑫冶金科技有限公司

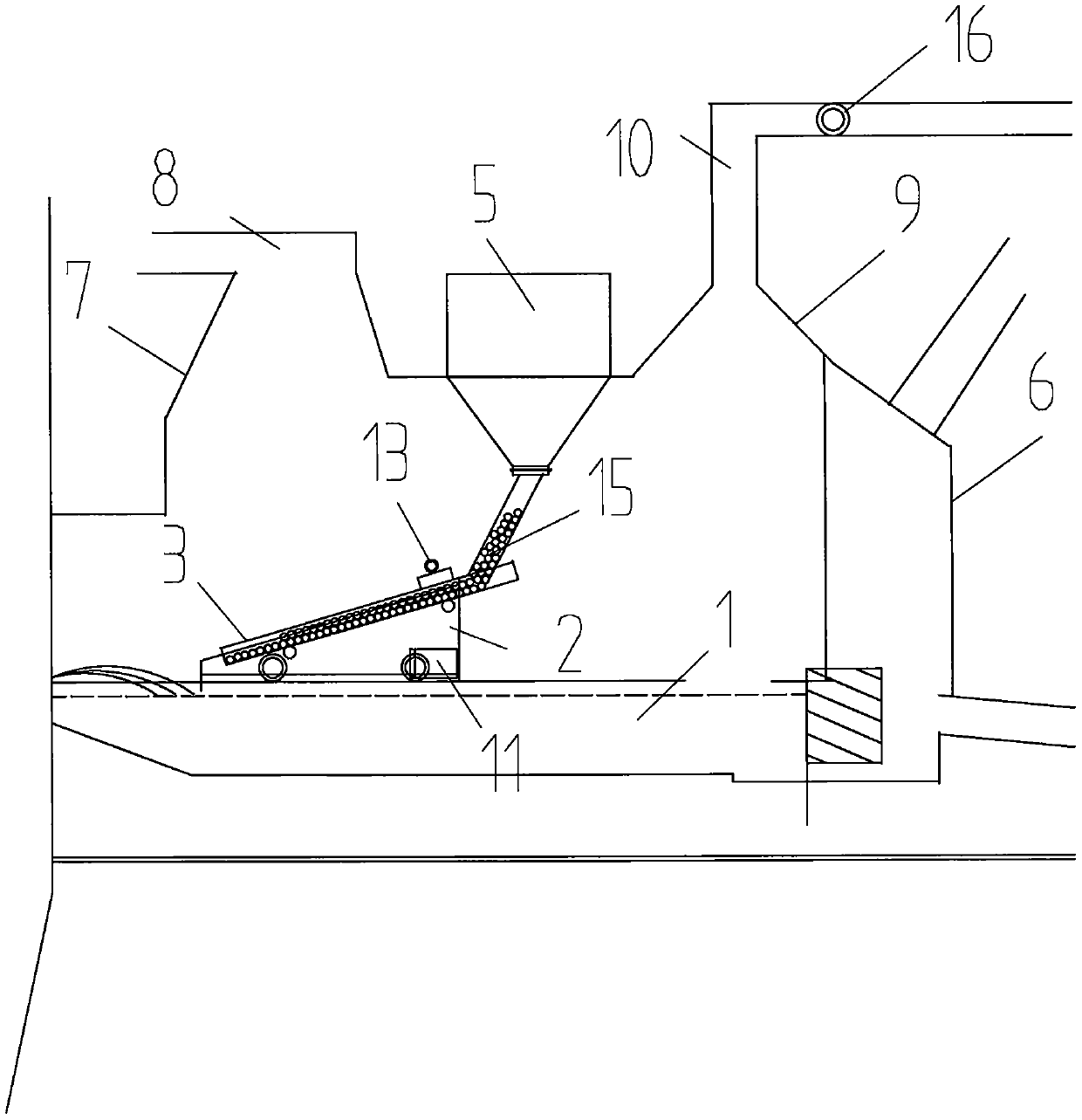

System and method for melting solid ink sticks in a phase change ink printer

InactiveUS20070252876A1Shorten melting timeIncreased melted ink exit flow rateMeasurement apparatus componentsPrintingInk printerEngineering

A solid ink stick melting apparatus is incorporated in a phase change printer to provide melted ink under pressure to a print head. The solid ink stick melting apparatus includes an ink stick melt chamber having an enclosure with at least one heated wall, an inlet for receiving an ink stick, and an outlet for melted ink flow from the enclosure, and a seal mounted proximate the inlet to engage an ink stick passing through the seal so that the seal and the ink stick form a barrier and retain melted ink within the enclosure.

Owner:XEROX CORP

Method for smelting magnesium alloy

A method for smelting magnesium alloy contains the following steps: preparing material, heating the preheating furnace, melting furnace, alloying furnace and standing holding furnace respectively, and introducing protective gas respectively, preheating magnesium ingot to 120-600DEG C in preheating furnace, adding into the melting furnace for several times for melting, keeping the temperature at 660-780DEG C, introducing the magnesium fusing liquid into the alloying furnace, keeping the temperature at 660-780DEG C, melting other alloy elements with the melting furnace, refining, keeping the temperature of the melting liquid at 720-730DEG C, introducing into the alloying furnace to mix with magnesium fusing liquid, blowing argon for refining, transferring into standing holding furnace, keeping the temperature of the melting liquid at 680-860DEG C, casting magnesium alloying melting liquid to ingot, or cast continuously or semi-continuous. The invention can prevents oxidization and loss of the metal, reduced impurities in magnesium alloy, and improves the quality and performance of magnesium alloy.

Owner:GRIMAT ENG INST CO LTD

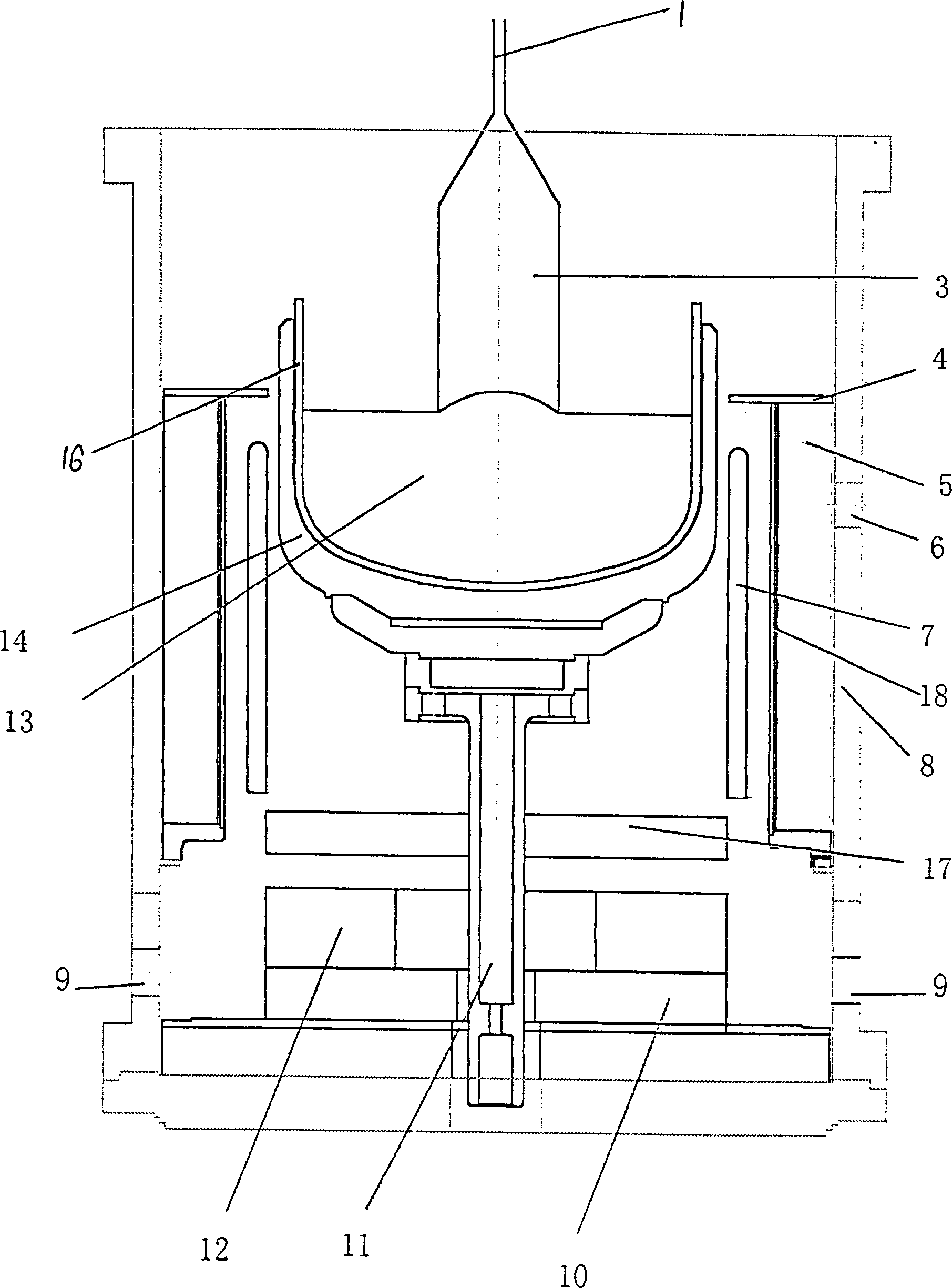

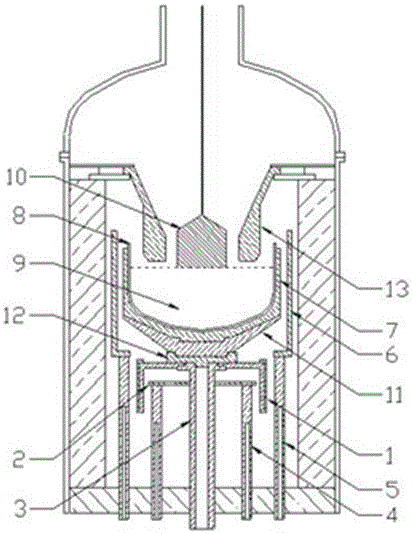

Method of speeding smelting of polycrystalline material and bottom heater for pulling monocrystal

InactiveCN1417388AIncrease temperatureChange the heating methodBy pulling from meltDc currentEngineering

The present invention relates to a method of speeding melting of polycrystalline raw material and the bottom heater for pulling monocrystal. The method comprises leading DC current to bottom heater while leading DC current to the main heater, so that the quartz crucible is heated from both lateral side and bottom. The bottom heater comprises one disc heating body and two electrodes. The present invention can short the melting time of polycrystalline material and save electric power, and thus increase the yield of monocrystal silicon or germanium.

Owner:GRINM SEMICONDUCTOR MATERIALS CO LTD

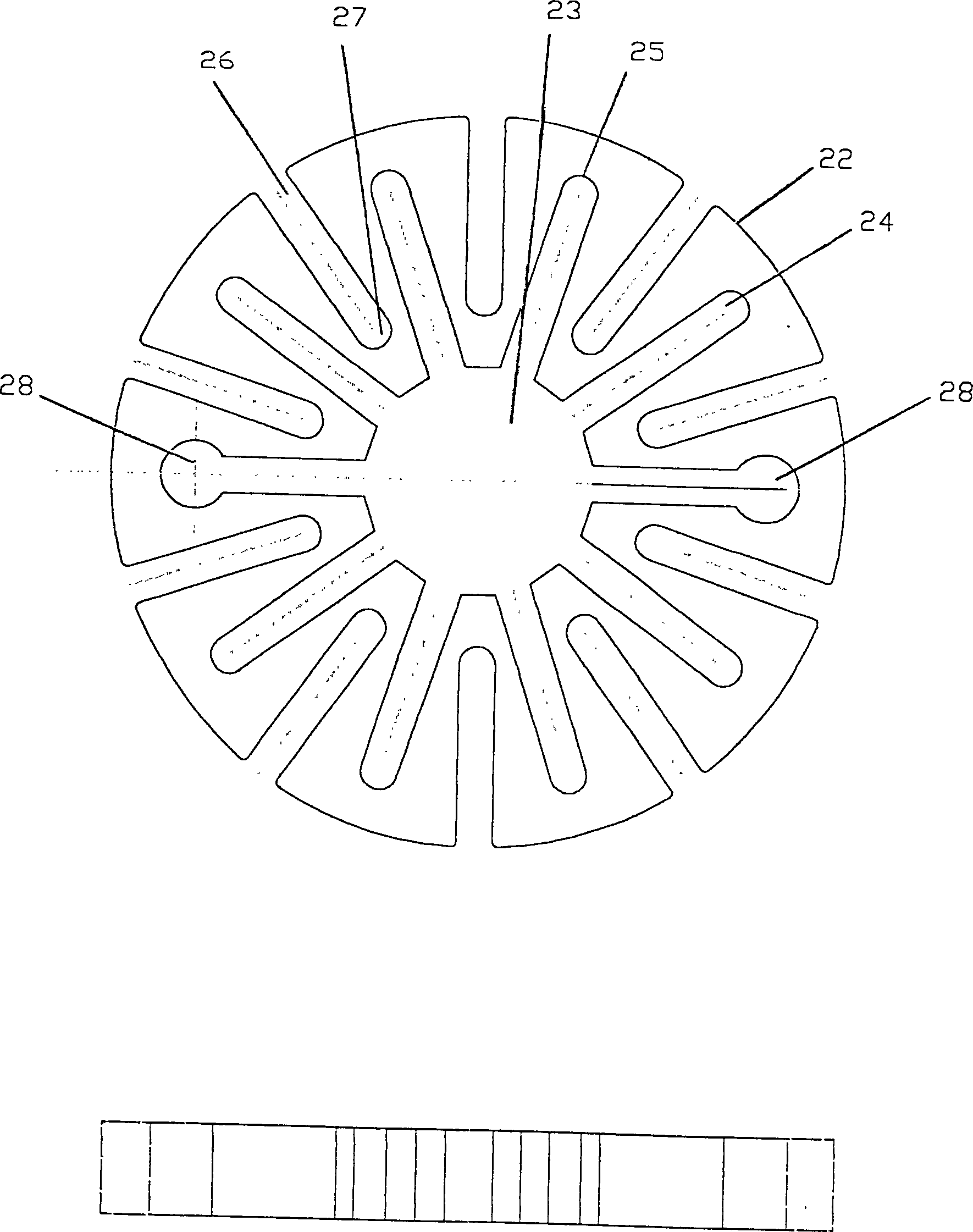

Silicon single-crystal pulling equipment and growing method

ActiveCN105887186ASpeed up meltingReduce melting timePolycrystalline material growthBy pulling from meltCrucibleSingle crystal

The invention provides silicon single-crystal pulling equipment. An auxiliary heat shield is arranged under a crucible tray support. A bottom heater is arranged in the auxiliary heat shield and supported and cooled through a water-cooling electrode. The bottom heater is made of a graphite material. The auxiliary heat shield is of an inverted-U-shaped structure. The horizontal part of the upper part of the auxiliary heat shield only comprises single-layer graphite. The vertical parts of the two sides of the auxiliary heat shield comprise double-layer graphite. The double-layer graphite is formed in the mode that a layer of outer layer graphite is added on the basis of single-layer graphite on the inner layer. The heat conductivity of the outer layer graphite is not smaller than 0.1 W / m / k and not larger than 20 W / m / K, and the heat conductivity of the inner layer graphite material is not smaller than 75 W / m / K and not larger than 200 W / m / K. The invention further provides a method for carrying out silicon single-crystal growing through the silicon single-crystal pulling equipment. By means of the equipment, melting time for polycrystalline silicon raw materials can be shortened greatly, the silicon single-crystal pulling growth rate is increased, the growth cycle of silicon single crystals is shortened, the cost is saved, and the production efficiency is improved.

Owner:SHANGHAI ADVANCED SILICON TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com