Method and device for preheating batch by using waste heat of fume from pure-oxygen combustion glass furnace

A glass batching and preheating device technology, applied in glass production and other directions, can solve the problems of uneven preheating, short heat exchange time, uneven distribution of sticky material and material layer, etc., to reduce melting temperature and fuel consumption, increase Heat exchange time, avoid the effect of horizontal space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

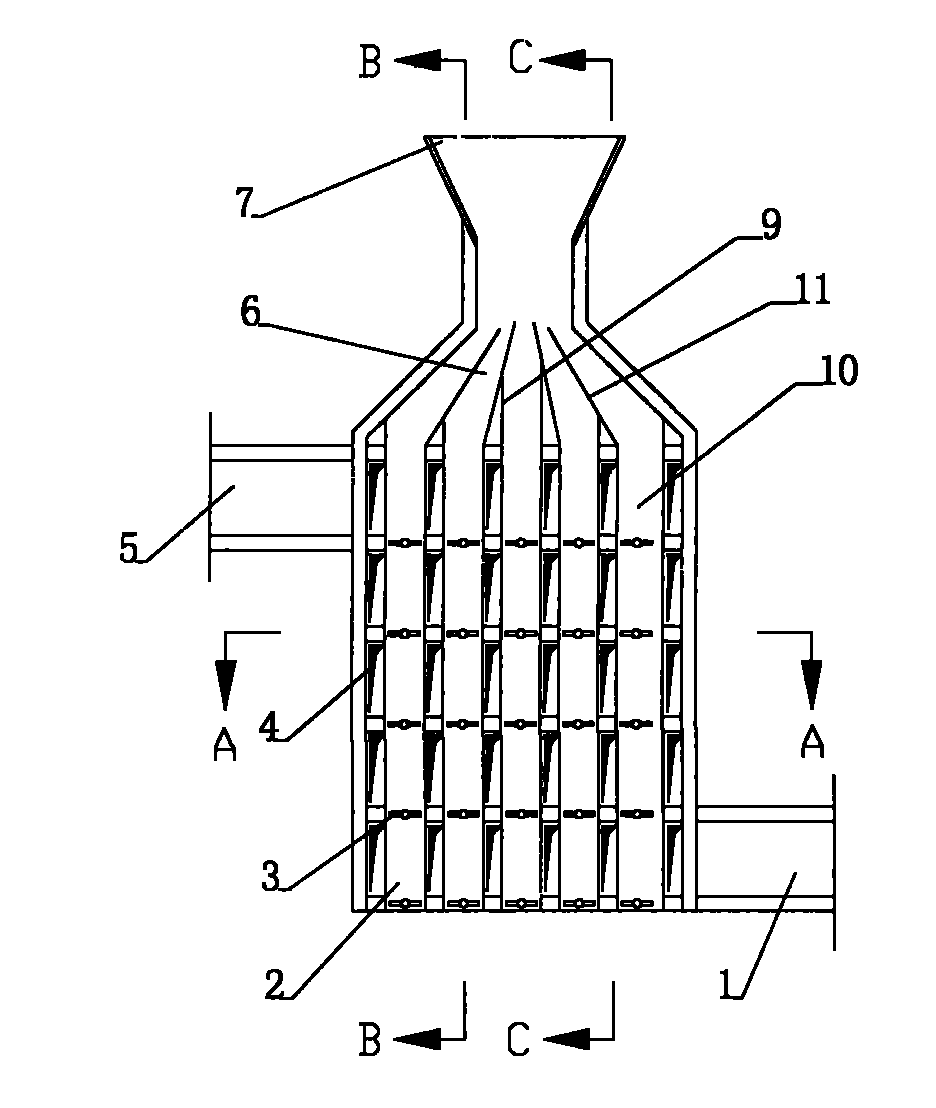

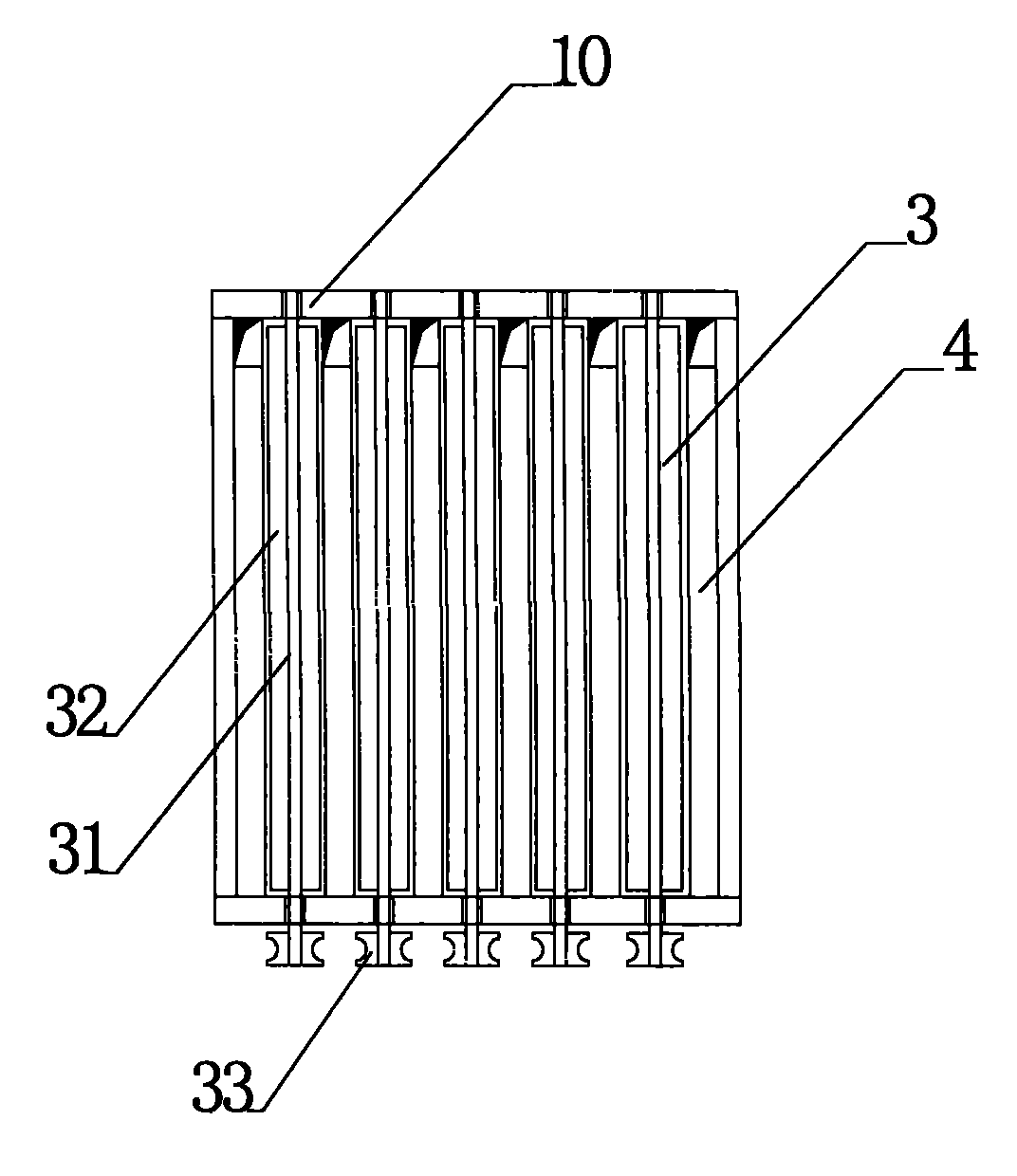

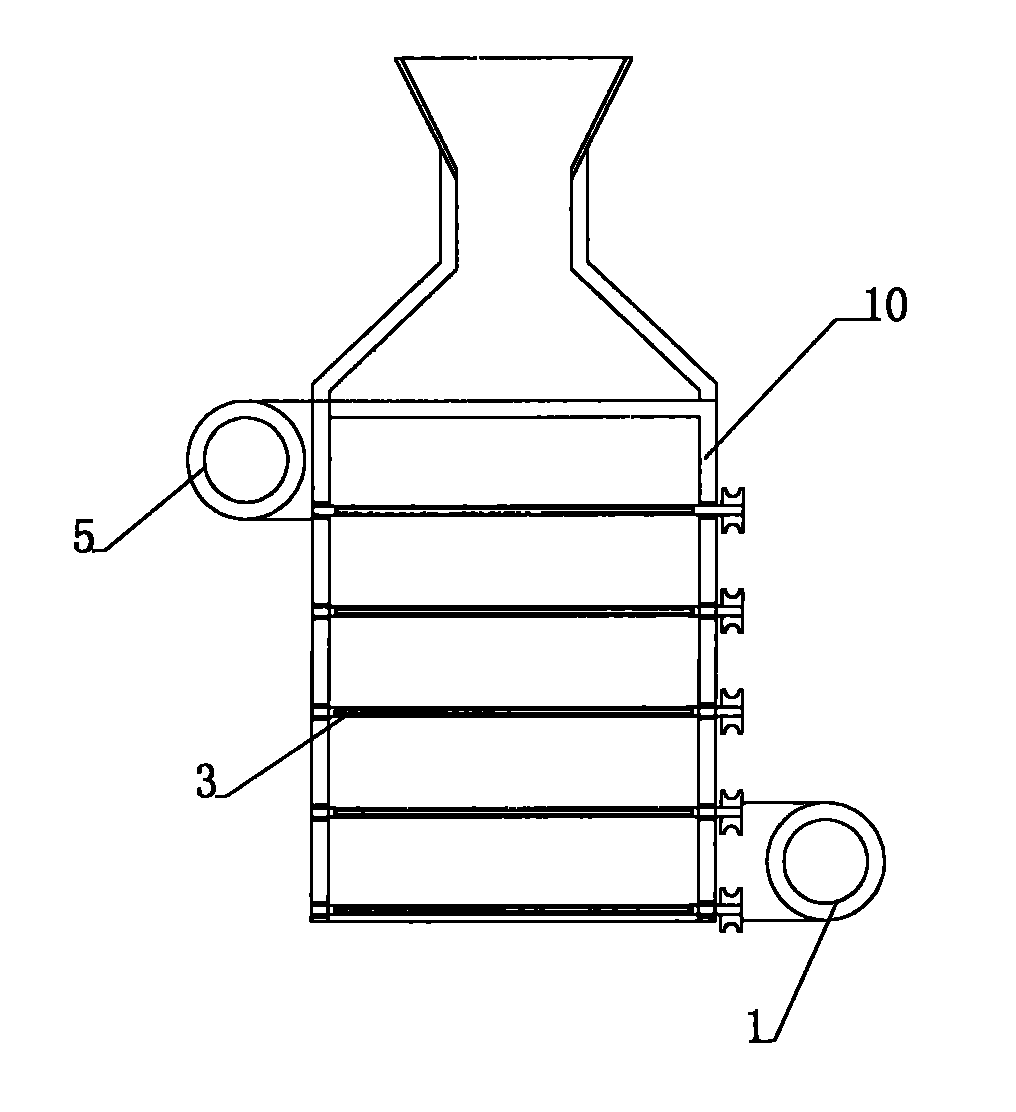

[0026] The invention relates to a method for preheating glass batch materials by utilizing high-temperature flue gas of an oxy-fuel combustion glass melting furnace and a special preheating device. in:

[0027] The method for preheating glass batch materials includes the process of preheating glass batch materials prepared by mixing various raw materials with high-temperature flue gas discharged from an oxy-fuel glass melting furnace; the specific steps are as follows:

[0028] 1) The glass batch material is granulated before entering the preheating process, and the particle size of the granulated material is 5-30mm;

[0029] 2) Before the high-temperature flue gas from the oxy-fuel combustion glass melting furnace enters the preheating process, a step of air dilution is also included to cool the high-temperature flue gas to below 900°C;

[0030] 3) After the granulated material in step 1) is dehydrated and dried, it is sent to a special preheating device; at the same time, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com