Energy-saving and production-increasing method of preheating pellet materials by blast furnace tap drain hot smoke

A technology of hot flue gas and agglomeration, applied in blast furnace details, blast furnace, furnace and other directions, can solve the problems of energy waste, heat is not well utilized, etc., to reduce the temperature in the hood, great economic and environmental benefits , the effect of reducing heat radiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

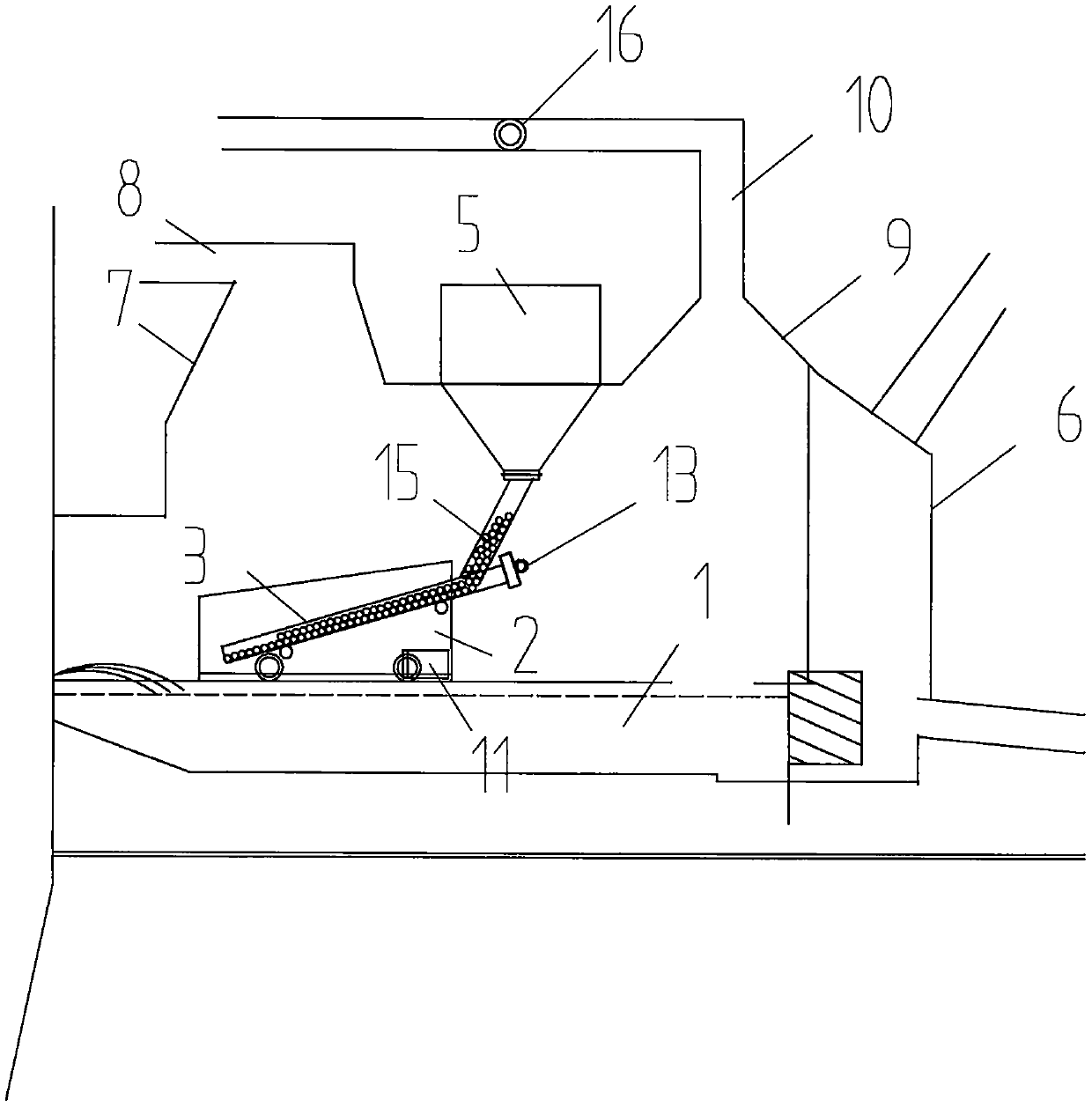

[0014] Embodiment 1: at 2600M 3 In the main ditch of blast furnace No. 1 casting yard, carbon-containing blast furnace bag gas ash and zinc-containing steelmaking converter dust are used to form carbon-containing agglomerates containing iron and zinc. The agglomerate is about 40mm. Add 300 kg of agglomerate 15 to the slag high-temperature molten pool, see figure 1 . When opening the tap hole to tap iron, according to the molten iron and slag conditions, continuously add carbon-containing iron-zinc agglomerates and slag steel granular iron material 15 to the high-temperature molten pool of molten iron slag before the iron drop point of main ditch 1 for processing, and at the same time, Move the trolley-type agglomerate material heating and preheating device 2 with a fume hood forward to the dust and mud pellet adding position by relying on the trolley driving mechanism 11, and cover the main ditch 1 with the dust in the ball adding treatment area, and the smoke or dust moves b...

Embodiment 2

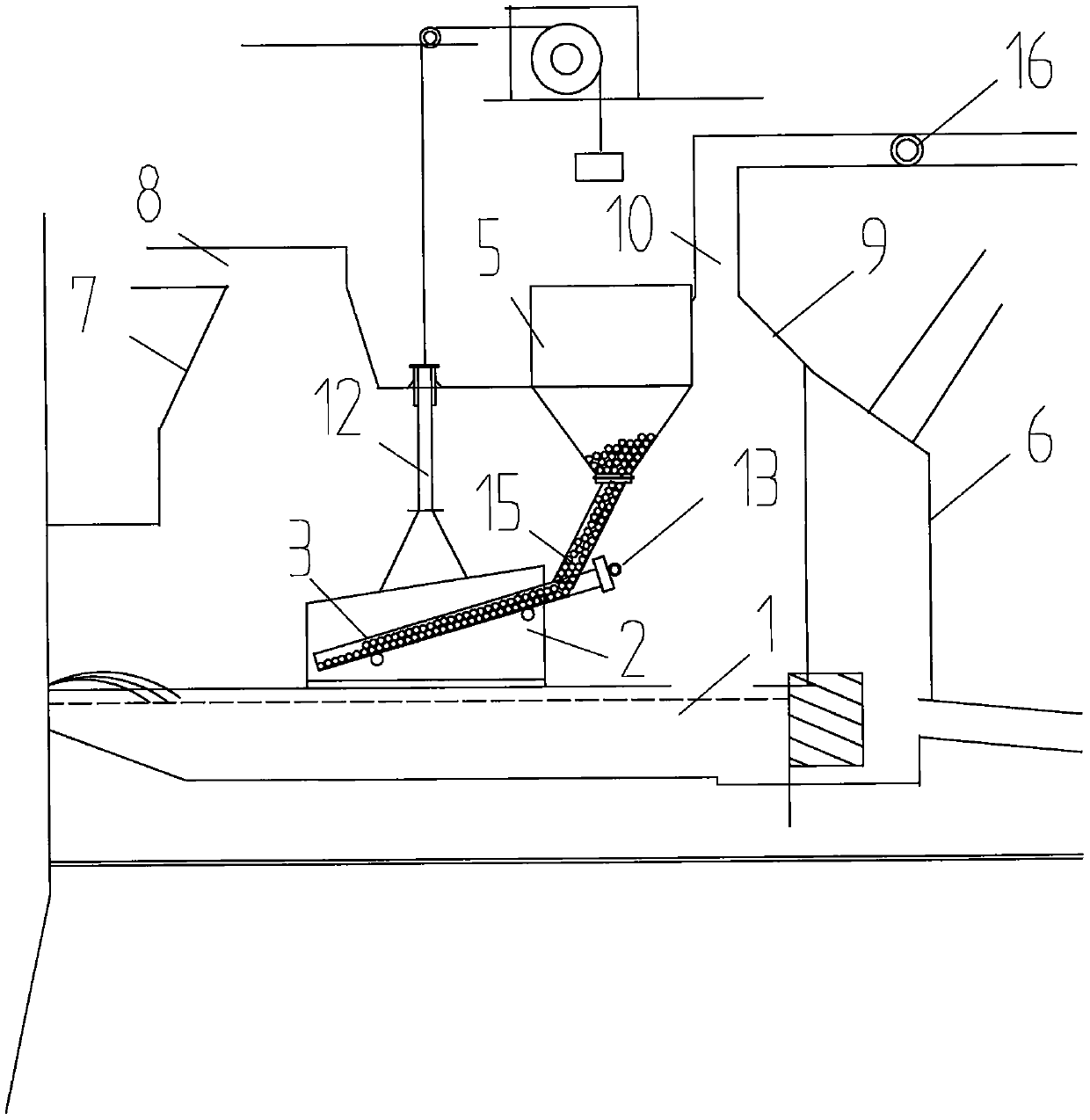

[0015] Embodiment two: at 1800M 3 In the main ditch of blast furnace No. 2 casthouse, carbon-containing and iron-containing agglomerates made of coking carbon-containing dust removal ash, electric furnace dust removal ash with high zinc content, and red mud are used. The lump size is about 40mm. Add 200 kg lump 15 to the high temperature molten pool, see figure 2 . When opening the taphole to tap iron, according to the molten iron and slag conditions, continuously add carbon-containing iron-containing agglomerates, magnetically separated iron briquettes, and red mud incineration fly ash and other iron-containing dust into the high-temperature molten iron slag bath in the front section of the main ditch. The carbon-containing agglomerate material 15 pressed with coal powder is processed, and at the same time, the belt fume hood suspended on the top of the main ditch 1 is lifted and the vibration feeding type heating and preheating device 2 is lowered, and the heating and preh...

Embodiment 3

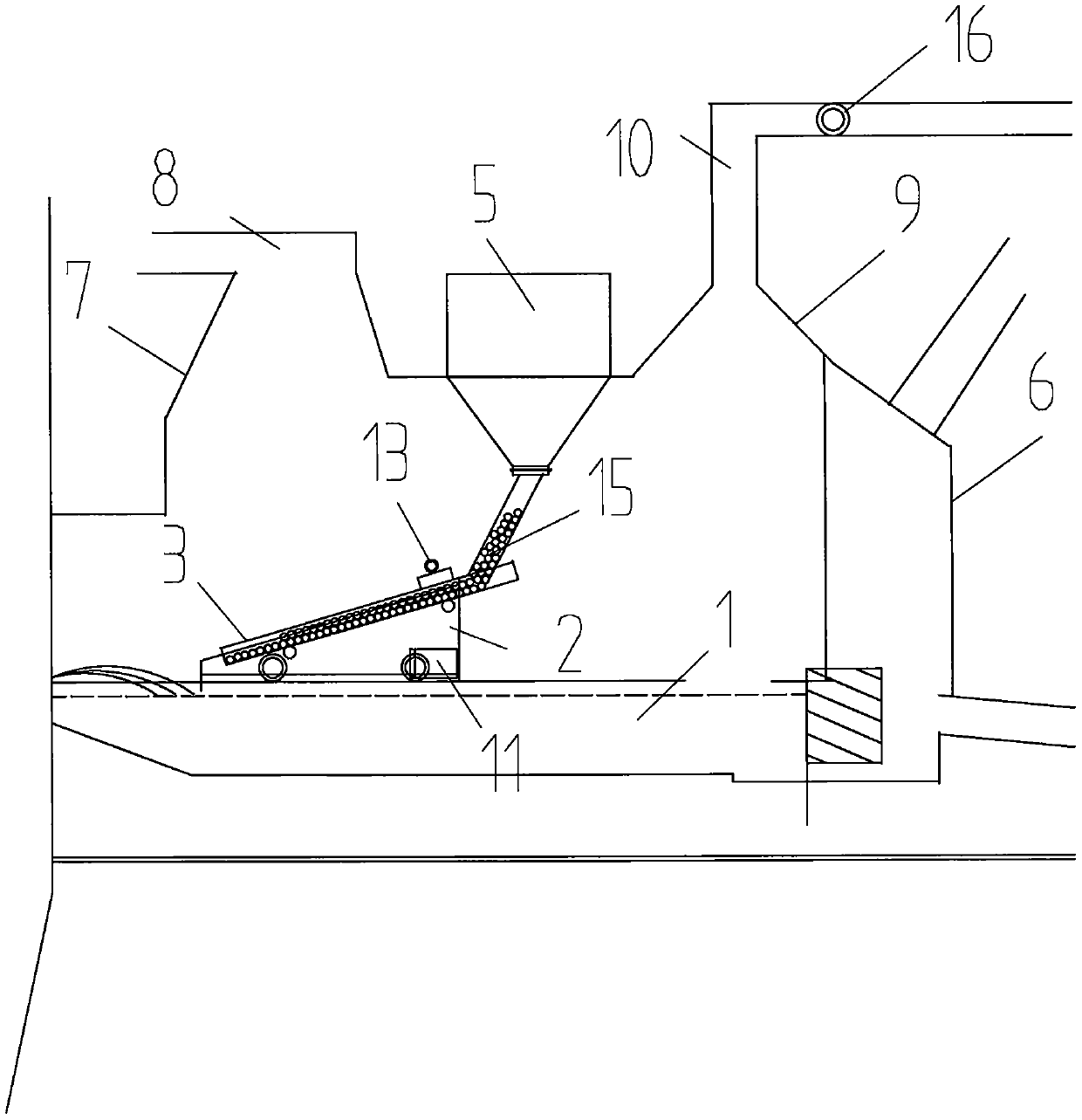

[0016] Embodiment 3: At 1080M 3 Carbon-containing iron and zinc agglomerates made of carbon-containing blast furnace gas ash and high-zinc-containing electric furnace dust in the main ditch of blast furnace No. Figure 4 . When opening the taphole to tap iron, according to the molten iron and slag conditions, continuously add carbon-containing iron-zinc agglomerates, direct reduced iron nuggets, dust sludge, waste incineration fly ash, etc. The compressed agglomerate material 15 is processed, and at the same time, the mobile trolley-type cylindrical heating and preheating device 2 with a smoke hood is moved forward to the position of adding dust and mud pellets by relying on the trolley driving mechanism 11, and the heating and preheating device 2 will Add ball treatment area fume cover, flue gas or flue dust flows backward, open newly added zinc-containing flue gas pipeline valve 16. Similar to Embodiment 1, the agglomerate material heating and preheating device 2 installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com