Patents

Literature

67 results about "Iron storage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Storage Of Iron In Human Body. According to the doctors, 26 percent of iron in our body is stored as ferritin, which are found in cells and then transmitted to the other parts of the body. It is said that male body has around 1000 mg of iron stored in it which is enough for about 3 years.

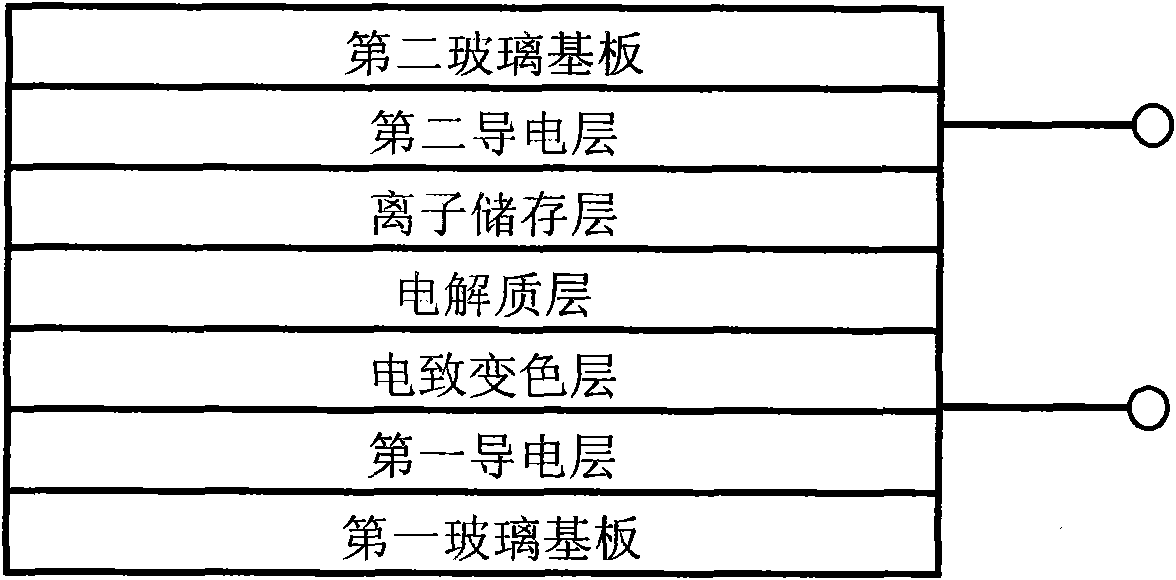

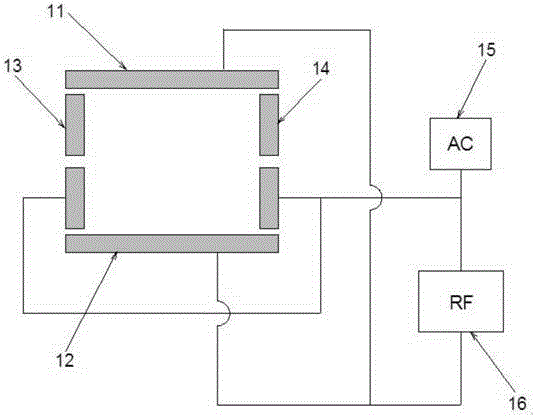

Intelligent dimming glass

InactiveCN101833211AHigh electrochromic efficiencyLow external voltageNon-linear opticsOptical elementsFiberOptoelectronics

The invention discloses intelligent dimming glass comprises a first glass base plate and a second glass base plate which are stacked at the top and the bottom, a first conductive layer, an electrochromic layer, an electrolyte layer, an iron storage layer and a second conductive layer are sequentially arranged between the first glass base plate and the second glass base plate; one ends of the first conductive layer and the second conductive layer are respectively connected with an anode and a cathode; and the first conductive layer and the second conductive layer are conductive films having infrared reflection performance, and the surfaces of the conductive films are coated with active carbon fibers. Compared with the prior art, the intelligent dimming glass has the characteristics of infrared reflection effect, high electrochromic efficiency, lower required external voltage and the like, can not only reduce indoor heat losses and realize the purpose of saving energy sources, but also prolong the service life of the intelligent dimming glass, thereby meeting the requirements of daily life and architectural decoration of people.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Method for laying protection layer on surface of iron storage tank

InactiveCN102991024AImprove bindingExtended use timeSynthetic resin layered productsGlass/slag layered productsGlass fiberSand blasting

The invention discloses a method for laying a protection layer on the surface of an iron storage tank. The technical scheme of the invention is characterized in that the method comprises the following steps: carrying out sand blast treatment of the metal surface to make the surface reach an Sa2.5 grade effect, carrying out isodirectional brush coating of a primer resin of the metal surface, allowing the obtained coat to solidify, carrying out isodirectional brush coating of the primer resin again, allowing the obtained new coat to solidify, laying a layer of a resin mortar on the surface of the coat, laying a reinforcement layer obtained through laying glass fiber clothes in an alternated manner to a required thickness of 3-5mm, laying a resin-rich layer, laying a layer of a plastic film on the surface, allowing to solidify, and uncovering the plastic film. The method for laying the protection layer on the surface of the iron storage tank has the characteristics of strong adhesion of the metal and the glass fiber reinforced plastic protection layer, long use time, no cracking, no exfoliation, and flattened and beautiful surface.

Owner:JIANGXI COPPER

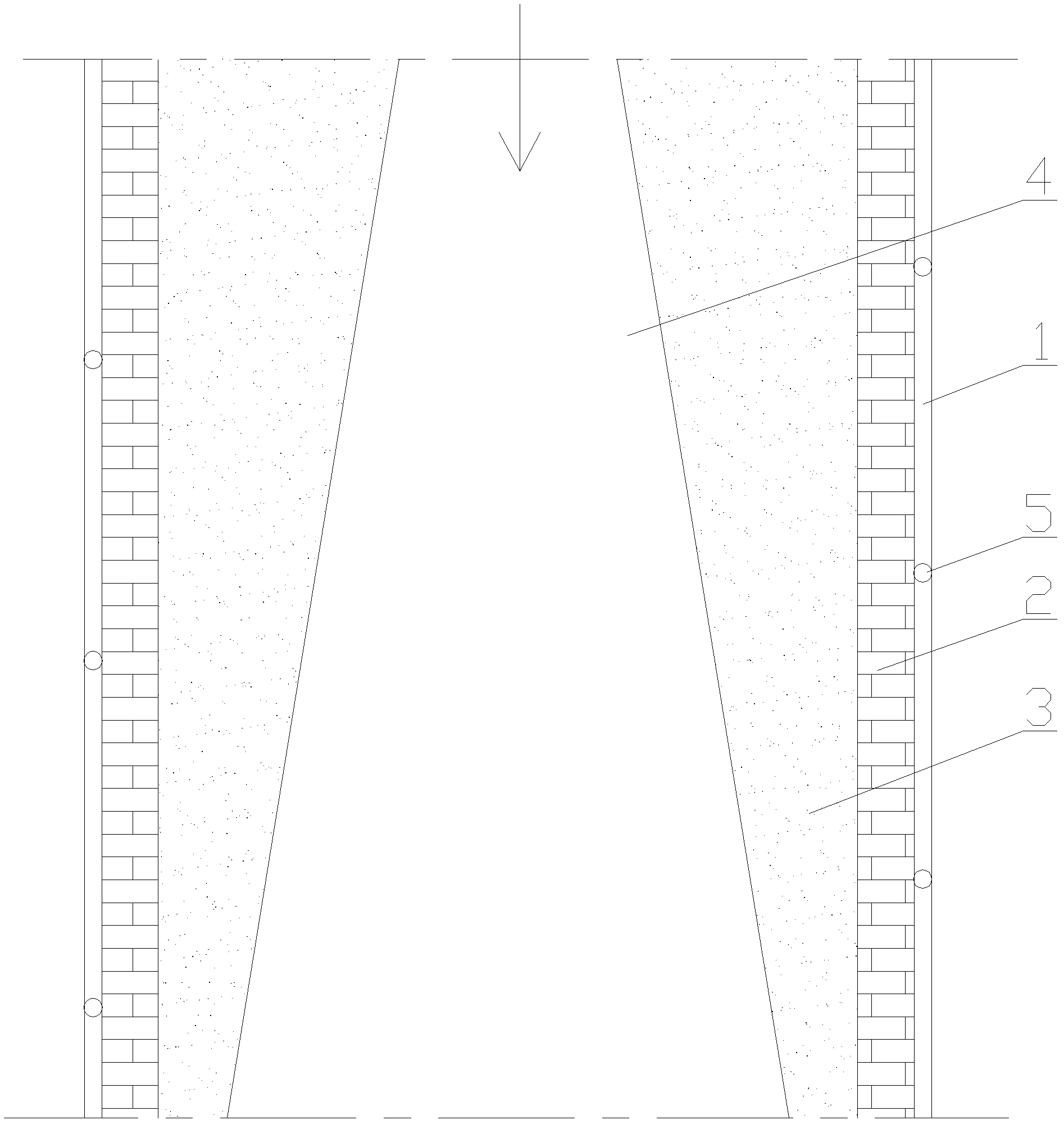

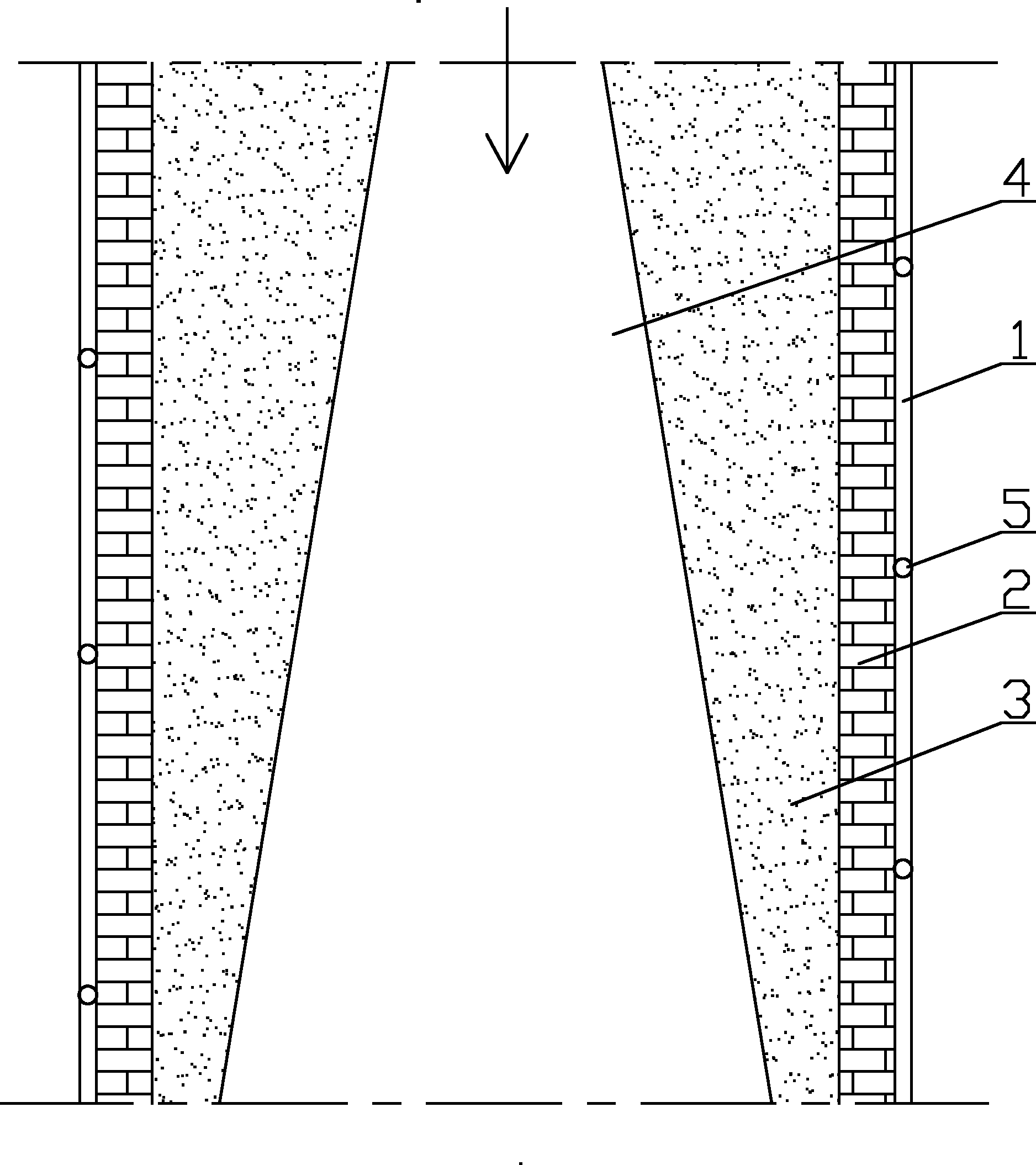

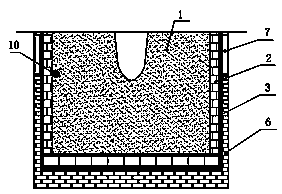

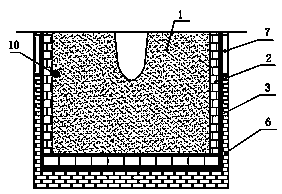

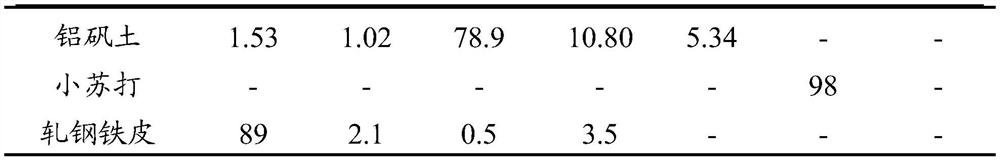

Pouring material and single-iron notch blast furnace iron storage type tapping main channel using same

The invention discloses a pouring material and a single-iron notch blast furnace iron storage type tapping main channel using the same; the single-iron notch blast furnace iron storage type tapping main channel comprises a steel mould, a brick layer and the pouring material, wherein the brick layer is laid at the inner side of the steel mould; and the pouring material is poured at the inner side of the brick layer. The single-iron notch blast furnace iron storage type tapping main channel is characterized in that a channel is arranged at the inner side of the pouring material, so that the width of the channel is gradually increased from front to back. According to the invention, the scouring force of molten iron for the main channel can be reduced, the labor intensity of workers pushing slag can be reduced, and the front half part and rear half part of the main channel can be repaired synchronously, so that the waste can be avoided. The repairing material can be saved by about 40-50 tons every year, so that the cost is greatly saved; and about 10 ton of material can be saved for a new main channel which is poured for the first time after the structural design is improved, so that the material cost is greatly saved, the annual total cost is greatly saved, and the economic benefit is greatly improved.

Owner:CHANGXING MINGTIAN FURNACE CHARGE

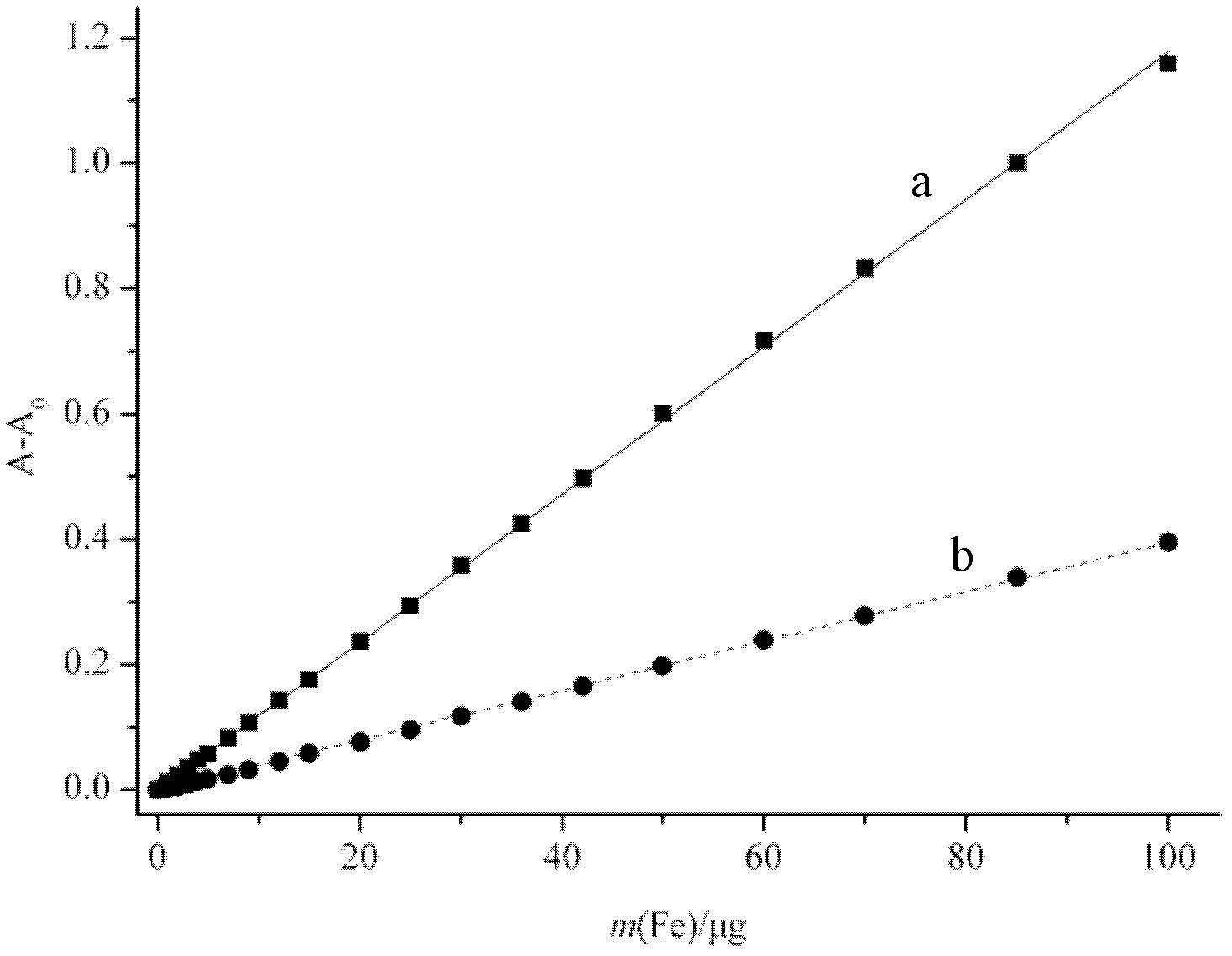

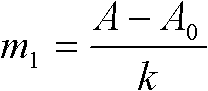

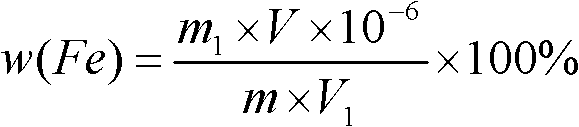

Method for measuring iron content in kaolin through using spectrophotometer

InactiveCN102621090AHigh sensitivityHigh precisionColor/spectral properties measurementsVolumetric flaskAbsorbance

The invention relates to a method for measuring iron content in inorganic mineral, particularly relates to a method for measuring iron content in kaolin through using a spectrophotometer, and the method is simple and convenient in operation, and rapid and accurate. The method comprises the following steps: melting a test sample with sodium hydroxide at a high temperature, and acidifying with hydrochloric acid to obtain a sample solution; placing ammonium ferrous sulfate hexahydrate in a beaker, adding hydrochloric acid and water, dissolving, placing into a volumetric flask, adding water to a constant volume to obtain a standard iron storage solution, and diluting to obtain a standard iron solution; transferring standard iron solutions of different volumes into a set of 50mL volumetric flasks, diluting with water to about 15mL, adding a mixed color development solution, adding water to a constant volume, transferring into an absorption vessel after 15min, measuring absorbance with a spectrophotometer at a wavelength of 510nm, and calculating the slope of a standard iron working curve; and measuring absorbance and blank absorbance of the sample solution, and then calculating the iron content in kaolin.

Owner:XIAMEN UNIV

Iron-storage type casting material for iron tapping channel, and preparation method thereof

The invention discloses an iron-storage type casting material for an iron tapping channel. The casting material is composed of brown corundum, dense corundum, silicon carbide, ball asphalt, alpha-Al2O3, pure calcium aluminate cement, silica micropowder, silicon metal powder, Guangxi white mud, aluminium metal powder, an explosion-proof fiber and FDN. The invention also provides a preparation method of the iron-storage type casting material for the iron tapping channel. The method comprises the steps of mixing the above-mentioned raw materials according to a proportion; stirring the mixture for 10 minutes in a stirring machine; discharging the mixture and packaging. Compared with a conventional technology, the method has the beneficial effects that the casting material is manufactured by employing Al2O3-SiC-C material and a carbon-containing polymer, and has good high-temperature wear resistance, good slag-resistant chemical corrosion performance, high and good oxidation resistance, good thermal shock-resistant stability, good high-temperature volume stability, good explosion resistance, high iron content, high safety coefficient and high slag resistance, sticks no slag iron, is convenient for production, and reduces labor intensity.

Owner:王振江

Impact-resistance and low temperature-resistance transparent polypropylene composition and preparation method for transparent polypropylene composition

The invention relates to a polypropylene modified material, in particular to a impact-resistance and low temperature-resistance semi-transparent polypropylene composition and a preparation method for the semi-transparent polypropylene composition. The impact-resistance and low temperature-resistance semi-transparent polypropylene composition comprises the following components in weight percent: 75-85 percent of polypropylene, 5-10 percent of fire retardant, 5-15 percent of toughening agent, 0.1-0.5 percent of antioxygen and 0.1-0.3 percent of core transparent agent. The preparation method comprises the following steps of: adding to a mixing machine in proportion and evenly mixing; then, performing extruding granulation by using a twin-screw extruder, wherein the extruding granulation temperature is controlled to be 180-225 DEG C. The modified polypropylene has the advantages of low temperature resistance, ageing resistance, flame resistance and semitransparency, especially has very high low-temperature impact resistance and is capable of meeting the functional requirements of display panels of high-iron storage battery slot bodies and submarines. Meanwhile, the impact-resistance and low temperature-resistance semi-transparent polypropylene composition can be widely applied to the field of aviation, aerospace, electronics, military project and the like.

Owner:MIANYANG HONGQI NEW MATERIAL SCI & TECH

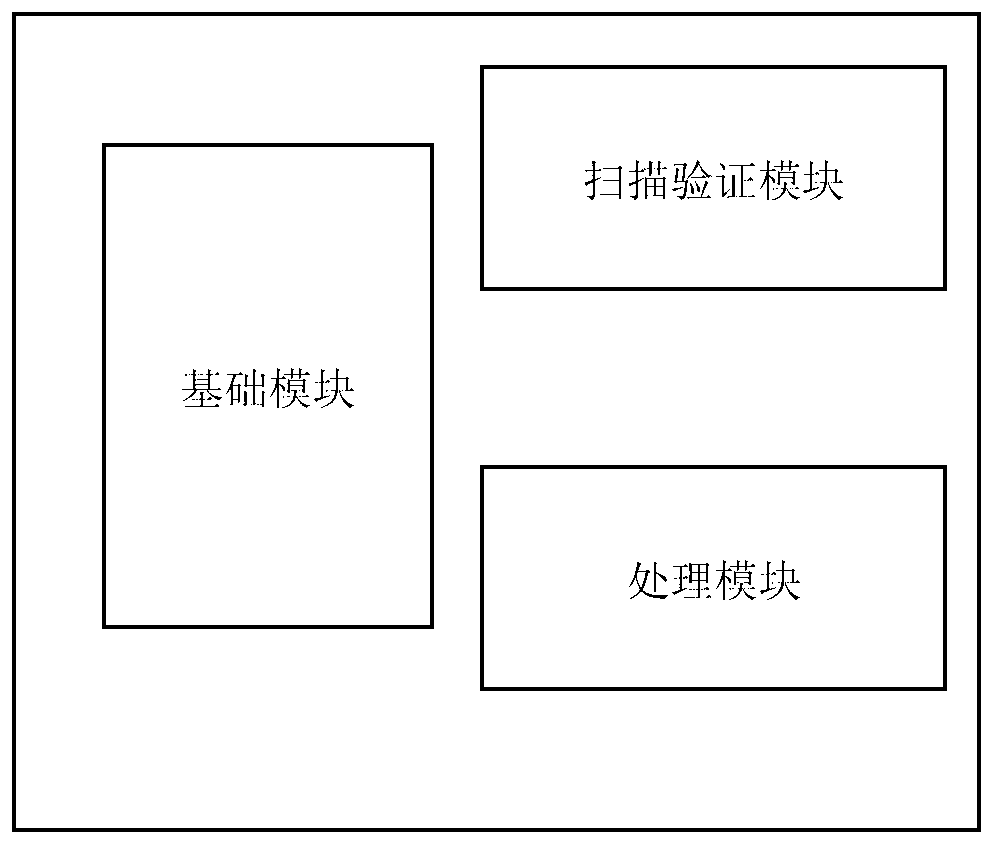

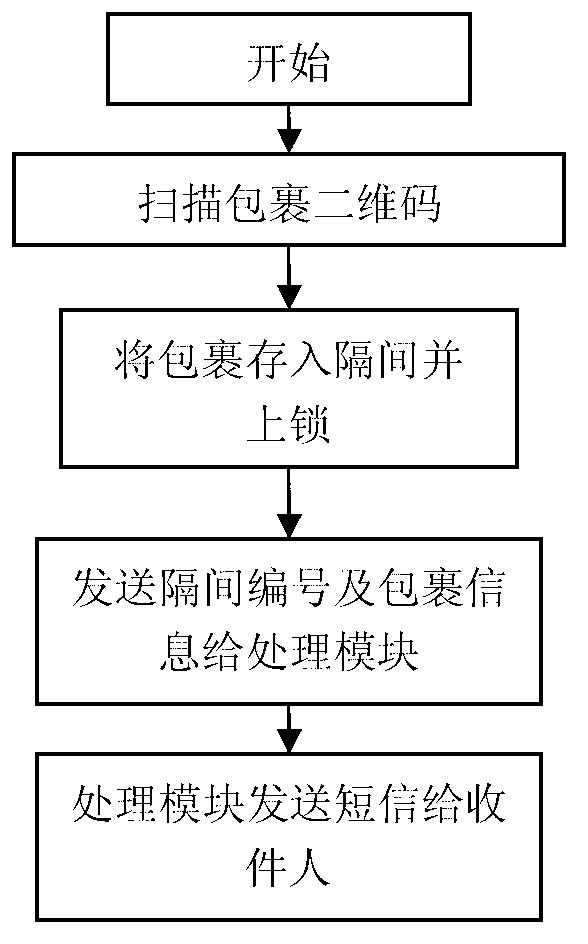

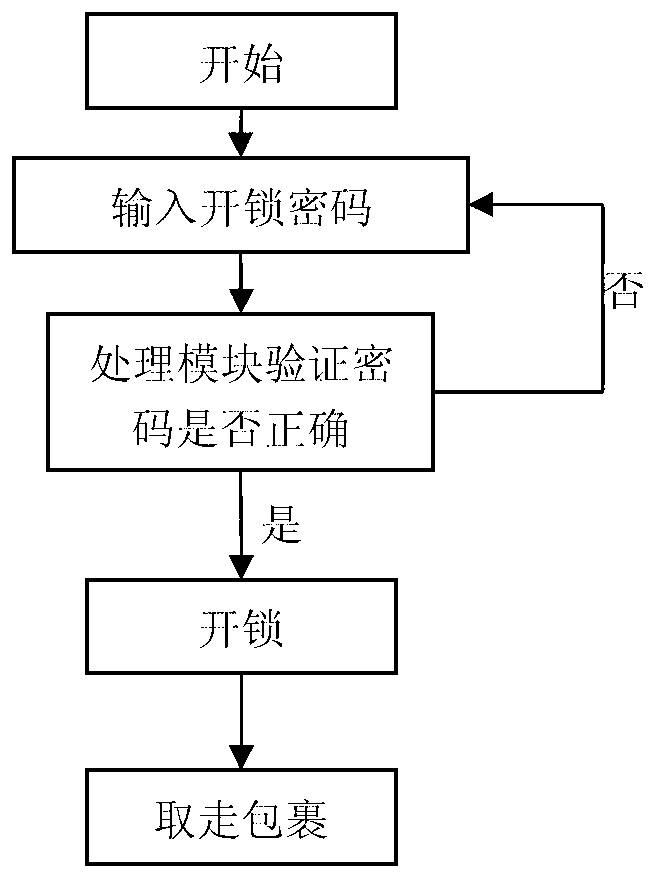

Intelligent express delivery cabinet

InactiveCN103279851AEfficient delivery phaseSecurity during deliveryService system furnitureIndividual entry/exit registersComputer moduleComputer science

The invention relates to an intelligent express delivery cabinet. The intelligent express delivery cabinet comprises a basic module, a scanning and verification module and a processing module. The basic module is composed of an iron storage cabinet, which is provided with a plurality of storage cells of a specification A, a specification B, a specification C and a specification D. The scanning and verification module is used for acquiring the authentication and identification data of users, and is composed of a two-dimensional code scanner and a number input keyboard. The processing module is used for receiving and processing the data sent back by the scanning and verification module to obtain the information of parcels and users. The intelligent express delivery cabinet simplifies the last stage of flow of express delivery, so that express delivery men do not need to manually send short messages to notify addressees any more, consequently, the process of delivery is more efficient, and meanwhile, troubles which are caused when express delivery men send wrong short messages are prevented.

Owner:HANGZHOU DIANZI UNIV

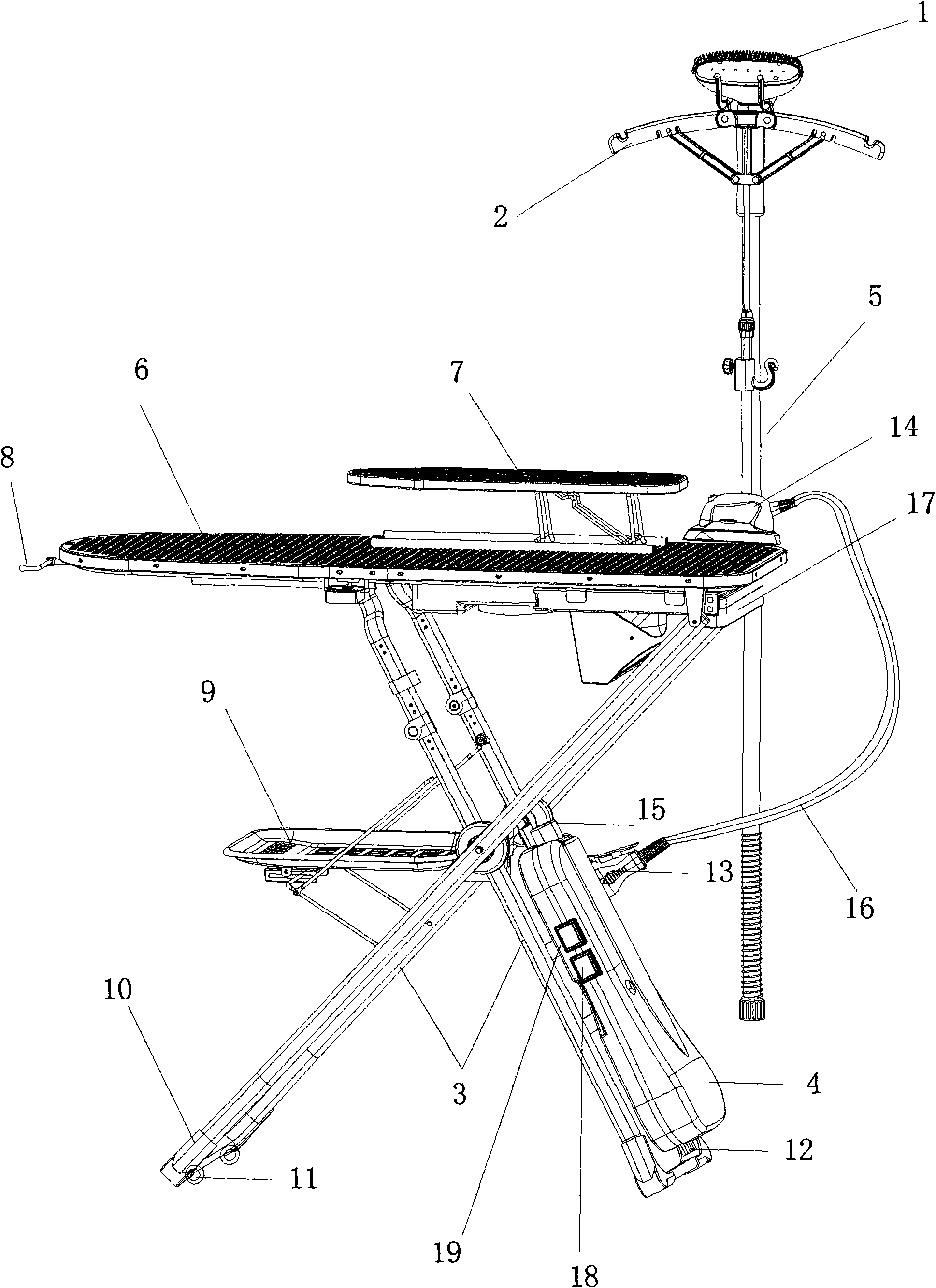

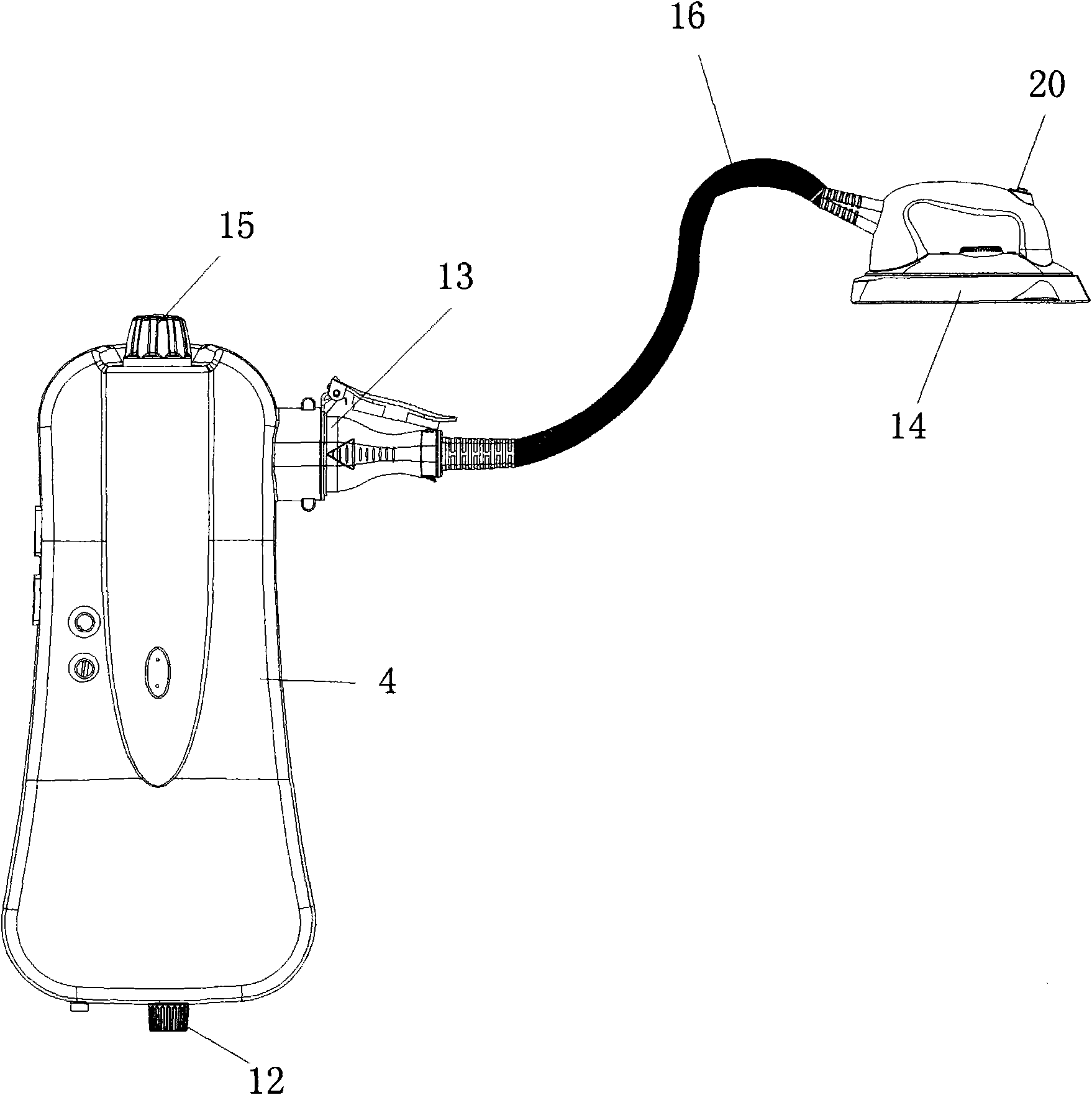

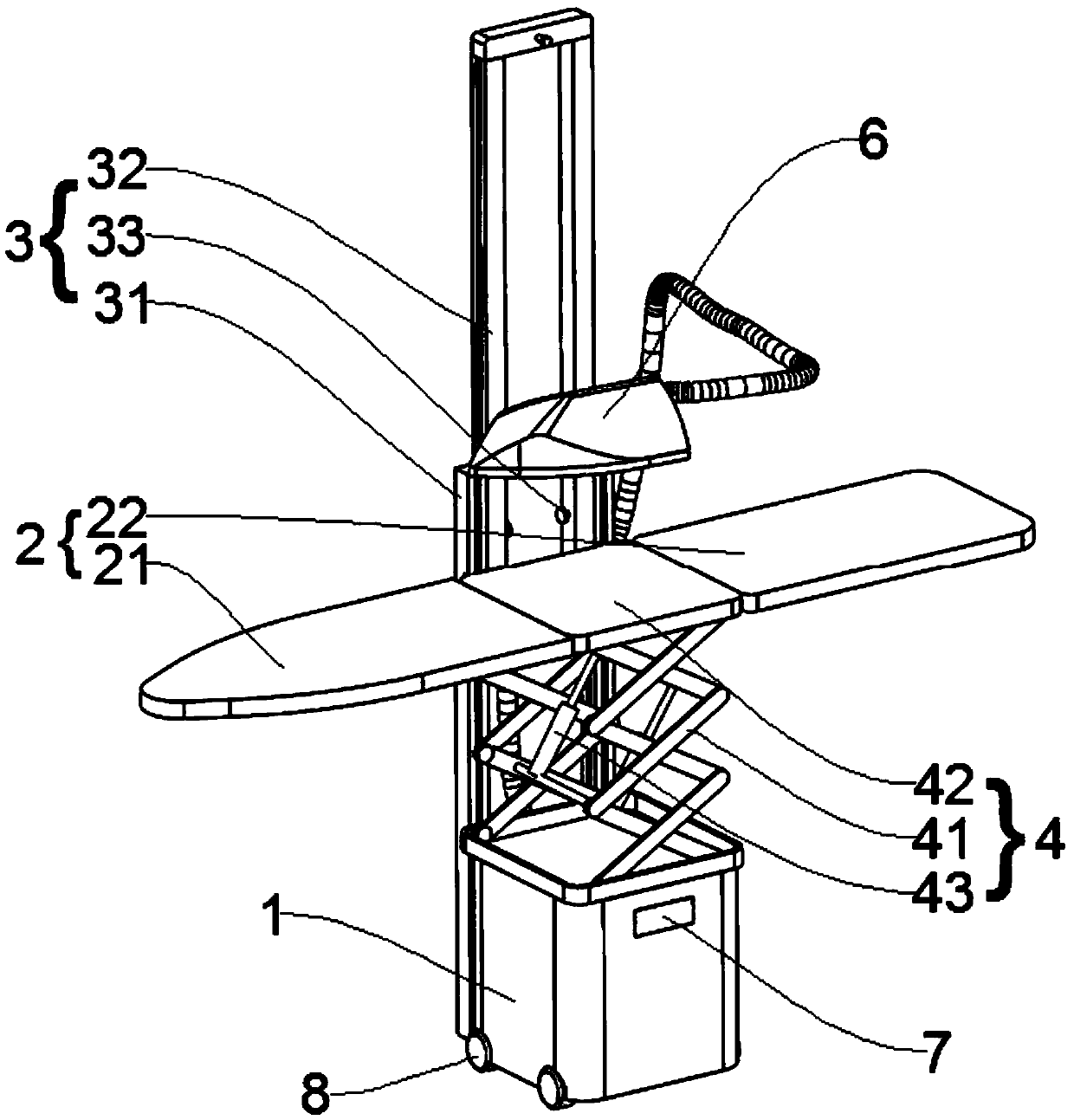

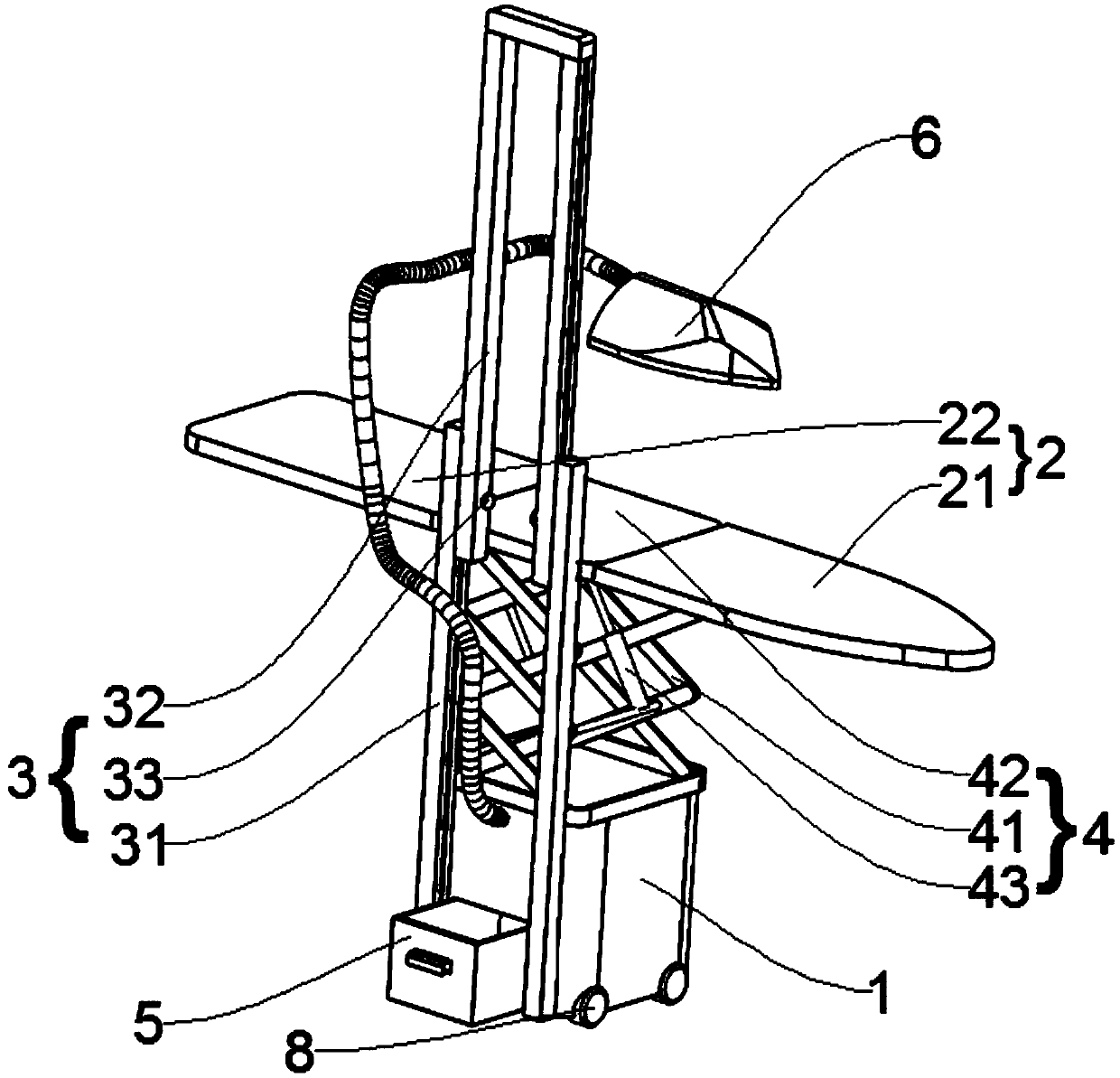

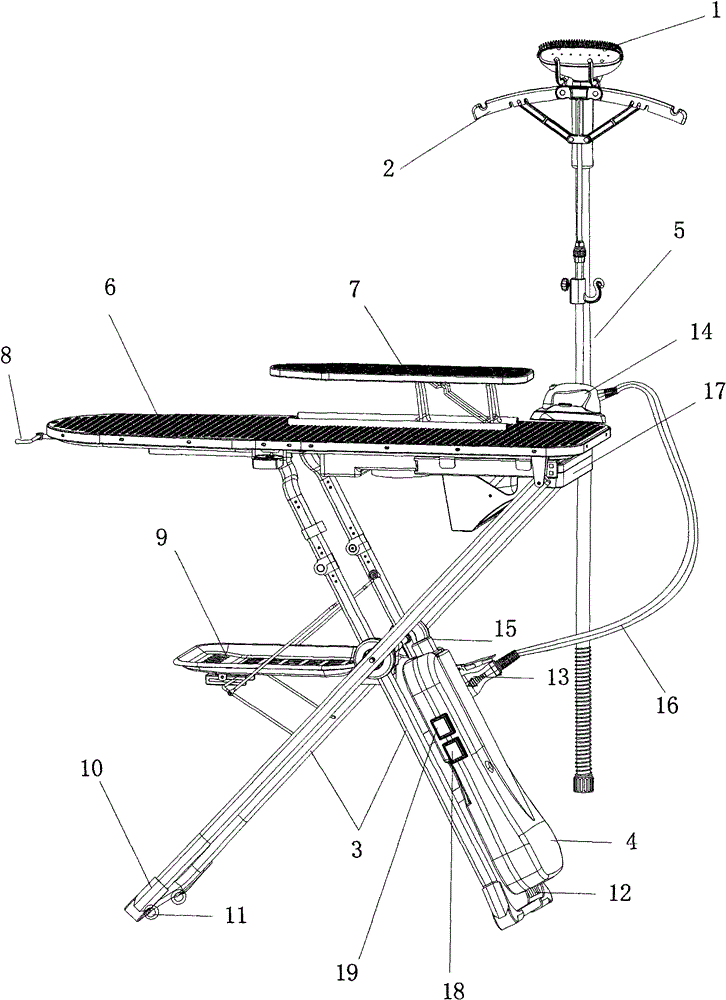

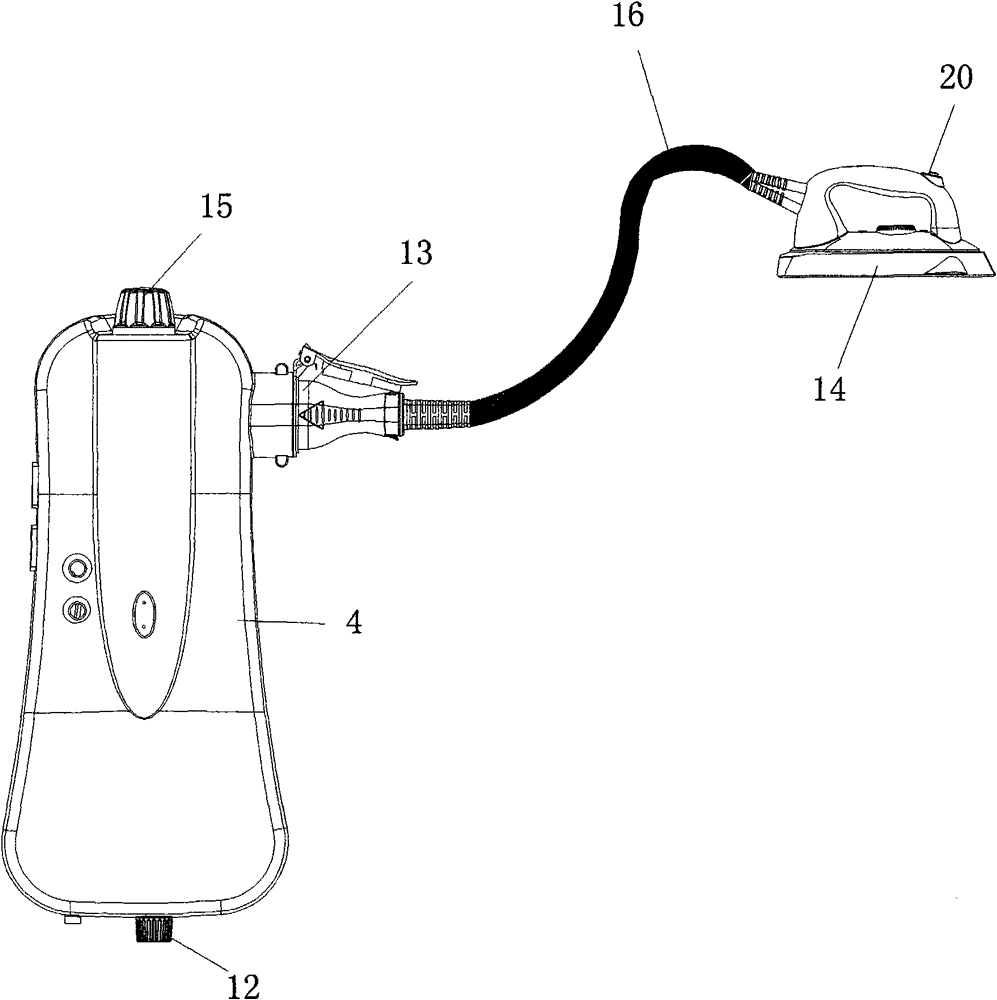

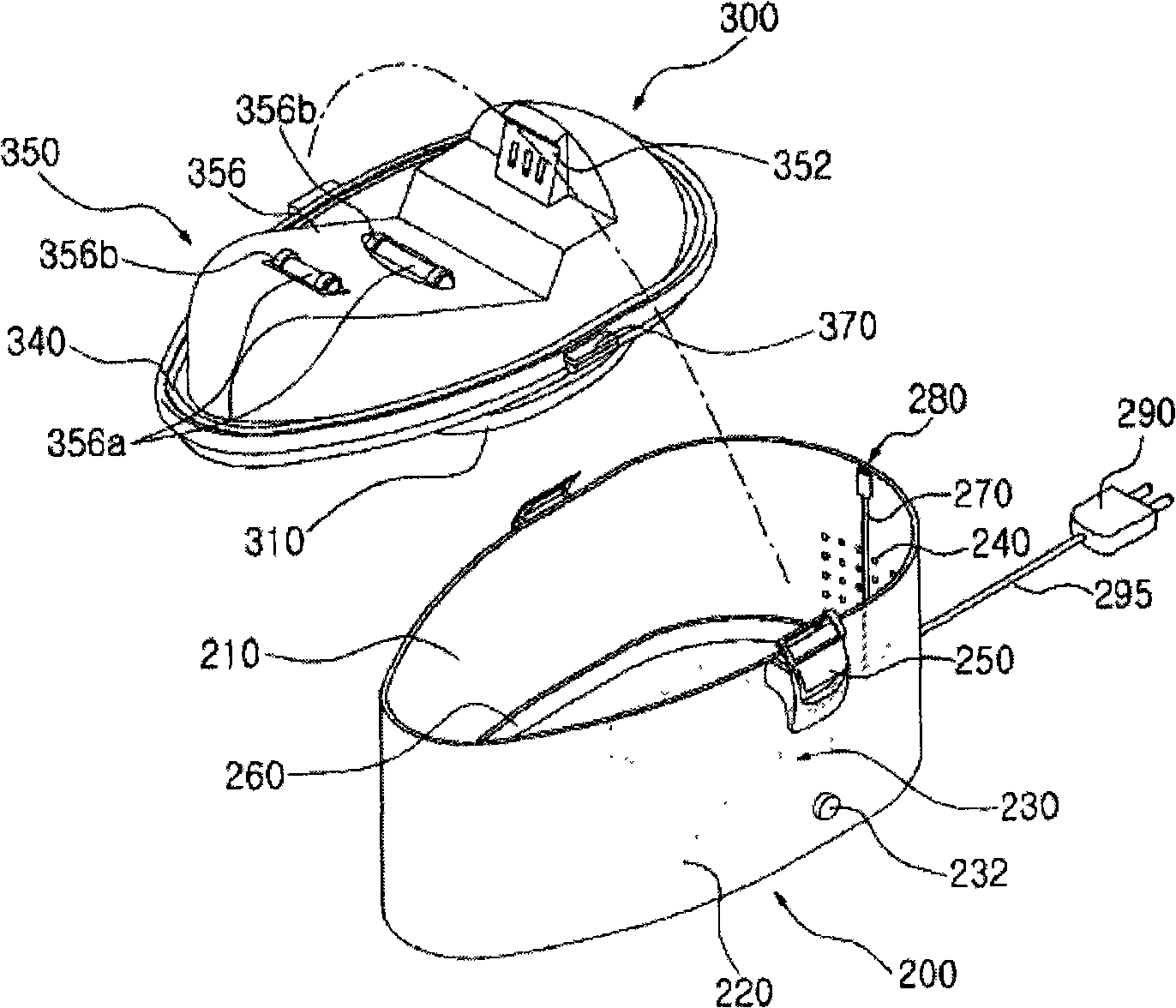

Steam ironing device assembly

ActiveCN101858031ATransportation safetySafe and reliable delivery automationIroning boardsHand ironCouplingEngineering

The invention discloses a steam ironing device assembly, which comprises a steam suspended ironing head, a suspended ironing hanger, a folding support frame, a steam generator, a steam suspended ironing pipe, an ironing board, a sleeve ironing board, a lifting device, a storage tray, an electric steam iron and an iron storage box. The electric steam iron is provided with an automatic lock switching push button; the steam generator is provided with a quick coupling, the inside of the steam generator is provided with an electromagnetic valve and a pressure switch, and the bottom of the steam generator is provided with a drain valve; and the bottom of the folding support frame is provided with a V-shaped shoe and a caster. The steam iron is provided with the automatic lock switch, the steam generator is provided with the electromagnetic valve, the pressure switch and a safety head, and a multiple safety protection device is adopted, so the personal safety of a user can be protected to the maximum, and the safety of the whole product is improved to the possibly high level; besides, the steam generator is provided with the quick coupling and the drain valve and the bottom of the folding support frame is provided with the caster, so the design of the whole product is more humanized and the use is more convenient.

Owner:JINBO CHUBAO ELECTRIC IND ZHONGSHAN CITY

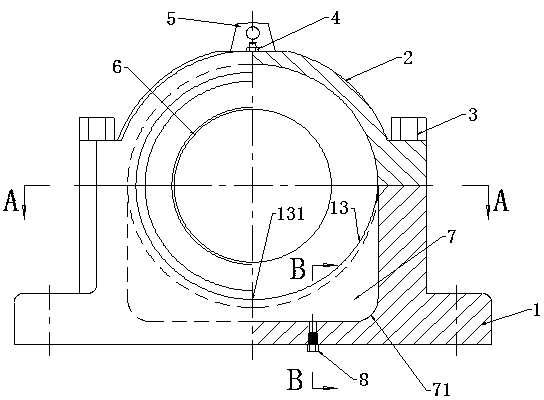

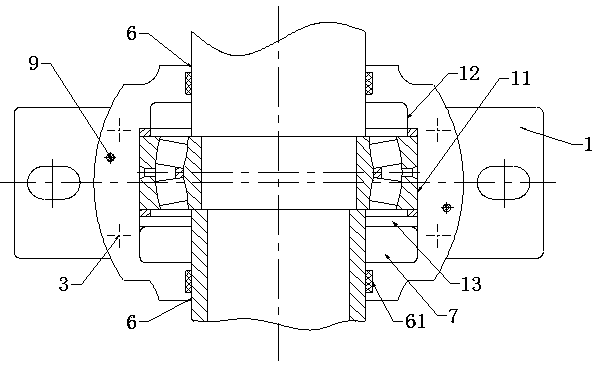

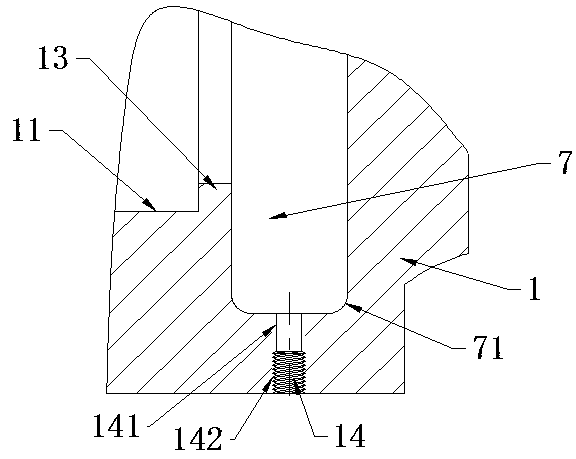

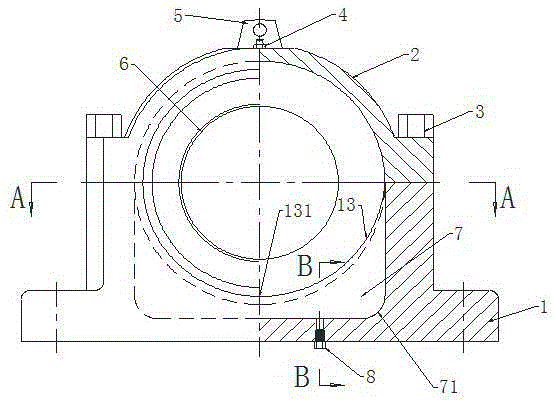

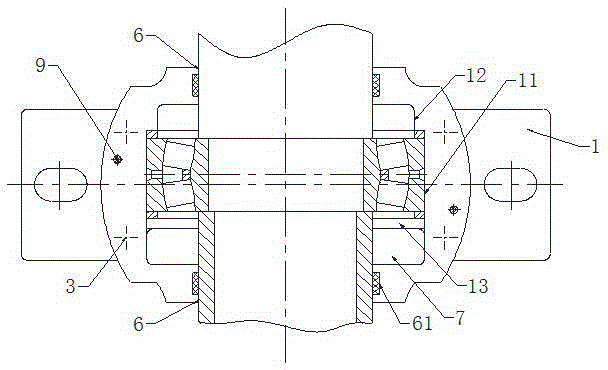

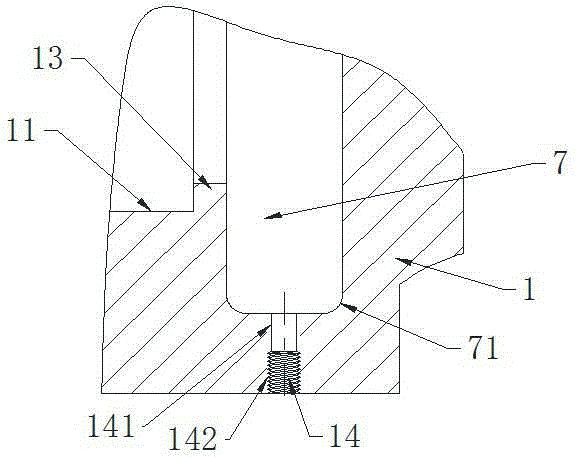

Disassembly-free scrap-iron-cleanable bearing seat, cleaning method and mining industry engineering machine

ActiveCN103939481AExtended service lifeReduce impurity concentrationScrewsLubrication elementsWorking environmentEngineering

The invention discloses a disassembly-free scrap-iron-cleanable bearing seat. The bearing seat comprises a bearing seat body and a bearing cap which is arranged on the bearing seat body, wherein an oil storage cavity is formed in the bearing seat body and the bearing cap, the oil storage cavity is located between a bearing hole and one of shaft holes, a scrap iron storage bolt is arranged below the oil storage cavity, and the scrap iron storage bolt has a function of collecting scrap irons in the oil cavity. By adopting the structure, the bearing seat disclosed by the invention has the advantages of being easy to use, process and manufacture, low in cost and long in life, and the service life of the bearing is prolonged, and the working environment of the bearing is improved and the like. In addition, the invention also discloses a cleaning method of scrap irons based on the disassembly-free scrap-iron-cleanable bearing seat, and the method has the advantages of being simple in operation and high in efficiency and the like; and in addition, the invention also discloses a mining industry engineering machine which comprises the disassembly-free scrap-iron-cleanable bearing seat, and the mining industry engineering machine has the advantages that the bearing is simple to maintain and has a long service life, so that the overhaul period of the mining industry engineering machinery is prolonged.

Owner:常州裕腾机械有限公司

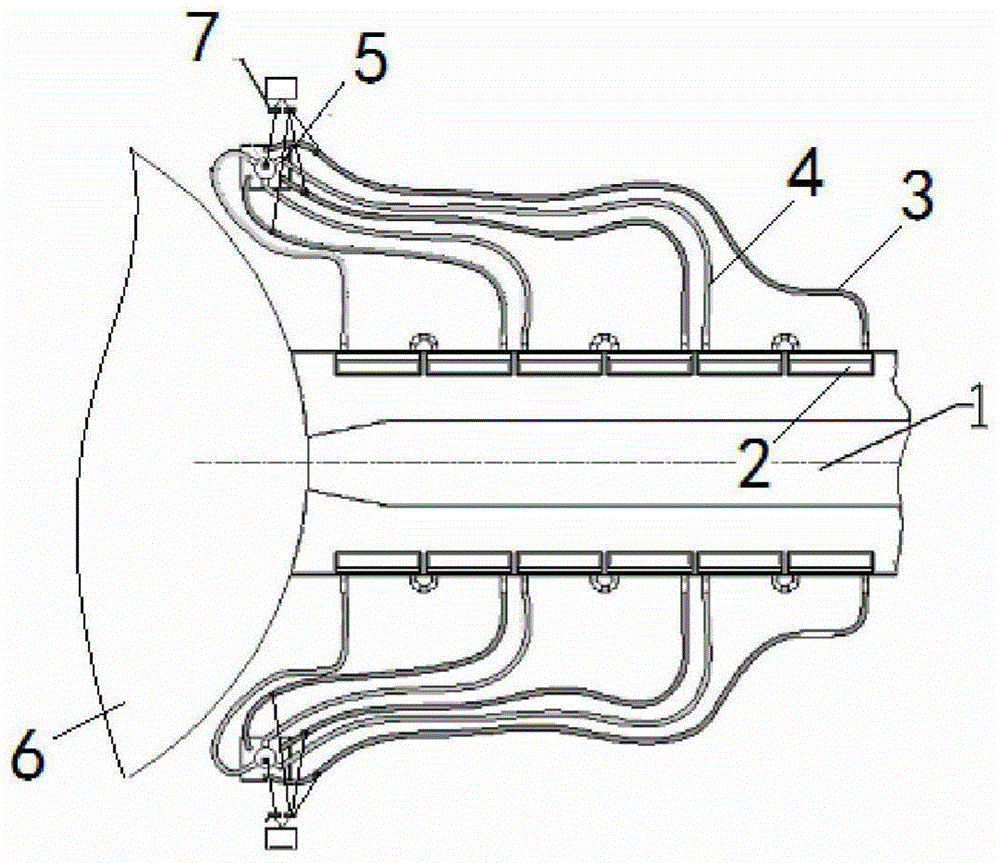

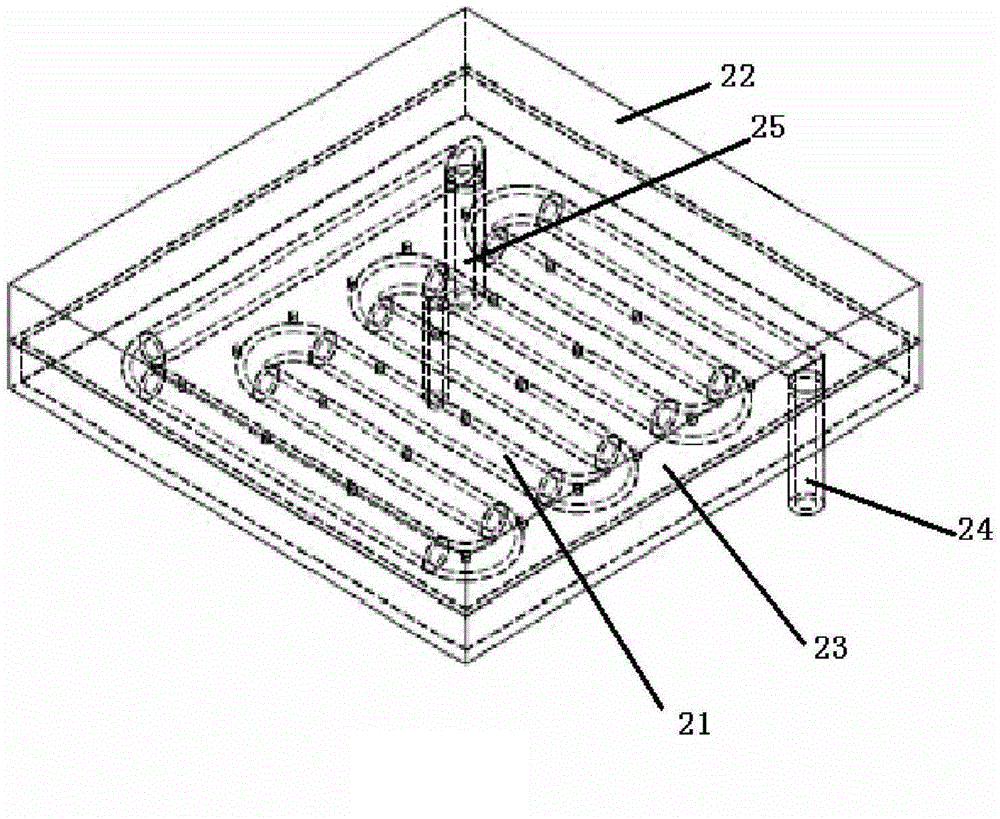

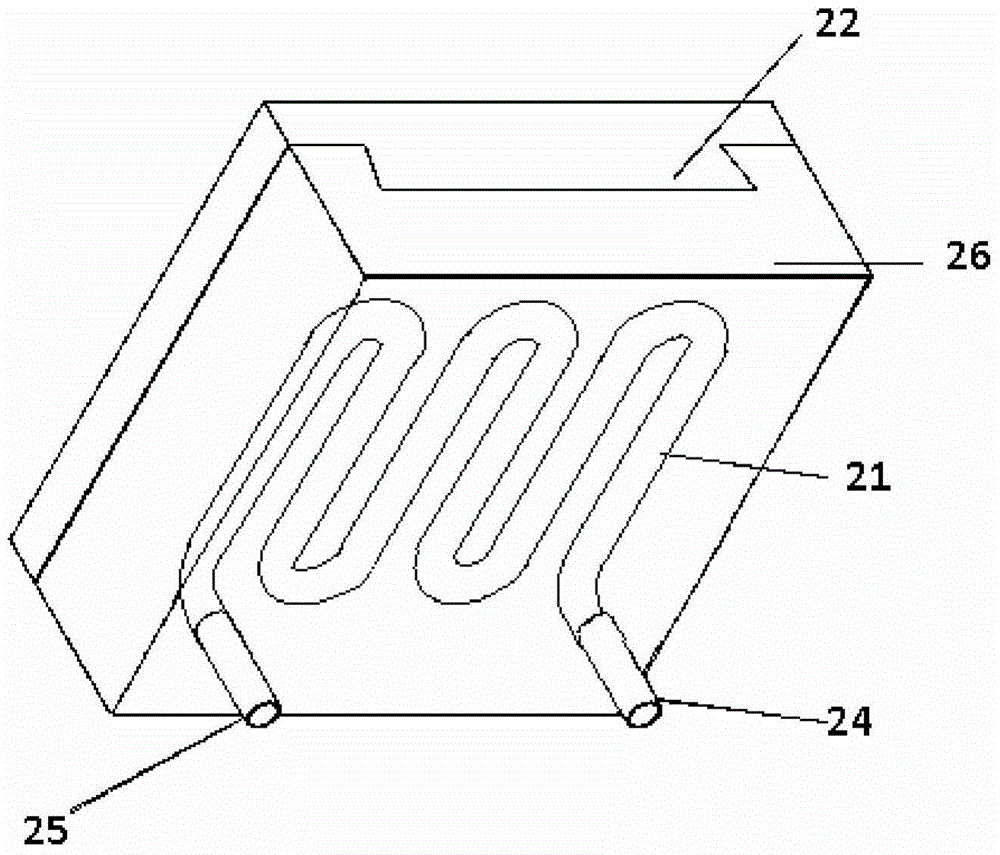

Water-cooled iron storage type iron runner and cooling method thereof

ActiveCN104313221APrevent iron seeping explosion accidentsPrevent leakageDischarge devicesChecking devicesMonitoring systemWater flow

The invention discloses a water-cooled iron storage type iron runner and a cooling method thereof, and belongs to the technical field of blast furnace iron tapping runners. A water-cooled assembly is arranged on the inner side wall of the front half section of an iron runner groove (close to an iron falling point of a blast furnace tap hole) and is in direct contact with a lining casting material; cooling water introduced from a blast furnace cooling water system is introduced into the water-cooled assembly to cool a lining on the side wall of the iron runner, the cooling water flowing out of the water-cooled assembly flows to a blast furnace platform circulating water collecting bowl to form a circulating water passage; and a temperature measurement monitoring system monitors the inlet water temperature and the outlet water temperature of the water-cooled assembly to judge the working state of the water-cooled assembly, so as to timely take necessary safety measures and prevent iron permeation blast accidents of the iron runner. The service life of the water-cooled iron storage type iron runner is greatly prolonged and can reach half a year or a longer time, and the effects of reducing cost, increasing benefits and reducing consumption and emission can be achieved.

Owner:北京联合荣大工程材料股份有限公司

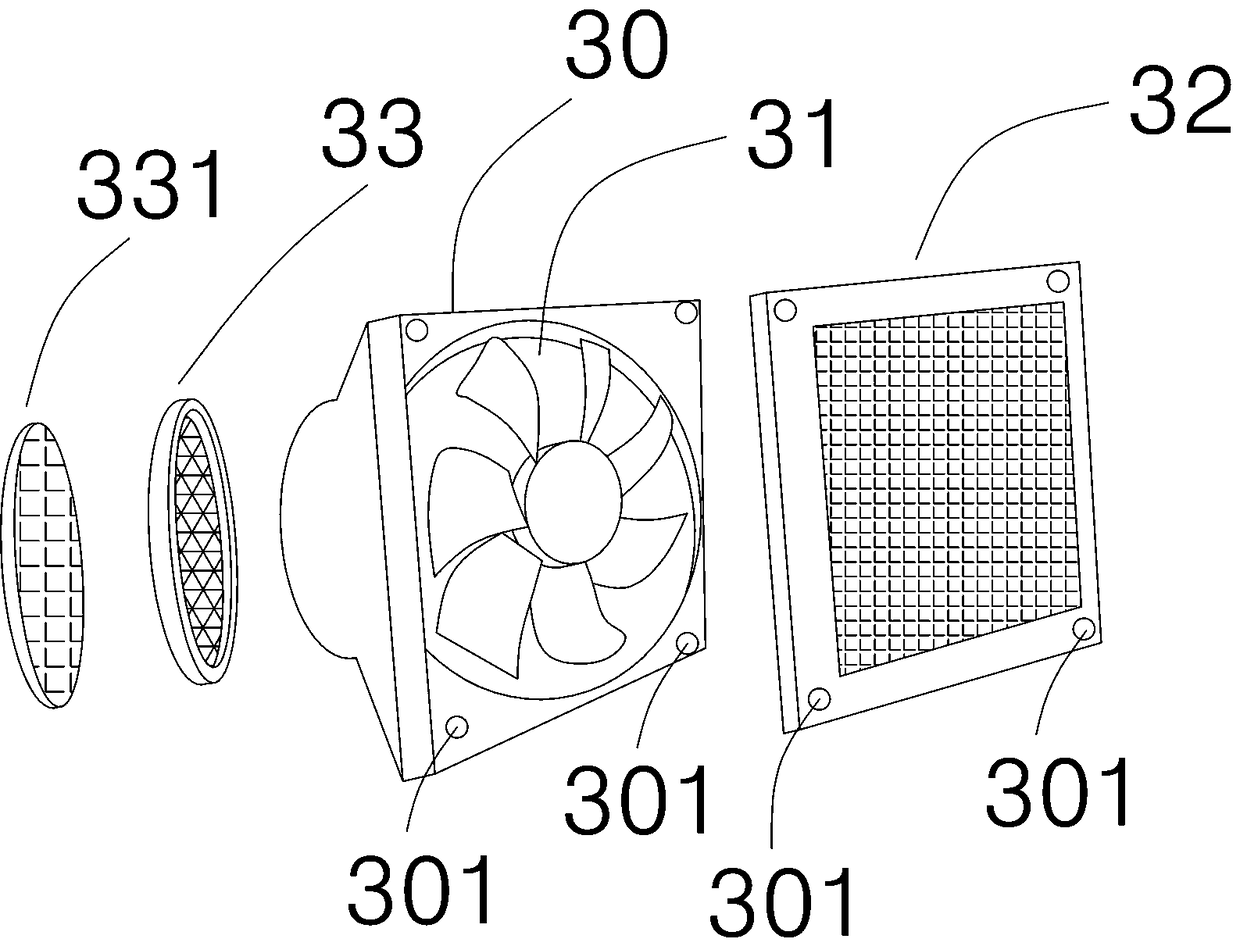

Mechanical workpiece dust-removal device

InactiveCN109317469AImprove adsorption capacityEasy to take outMagnetic separationCleaning using gasesEngineeringIron storage

The invention relates to a mechanical workpiece dust-removal device. The mechanical workpiece dust-removal device comprises a supporting framework, wherein a dust adsorbing tube for adsorbing dust isarranged in the supporting framework; the end part of the dust adsorbing tube is connected with one end of a dust channel through a first jointing channel; the other end of the dust channel is connected with a suction end through a second jointing channel; the bottom of the second jointing channel is connected with an scrap iron adsorbing bin; an electromagnet is arranged on the bottom in the scrap iron adsorbing bin; a scrap iron storage box for accommodating scrap iron is arranged on a position, on the upper part of the electromagnet, in the scrap iron adsorbing bin; the bottom of the scrapiron storage box fits to the electromagnet; a control box is arranged on the bottom of the mechanical workpiece dust-removal device; the control box is connected with a power line; and an electromagnetic switch and a fan switch which are electrically connected with the control box are arranged outside the control box. The invention provides the mechanical workpiece dust-removal device which can quickly adsorb scrap iron, and conveniently take out the adsorbed scrap iron.

Owner:苏州创而丰五金科技有限公司

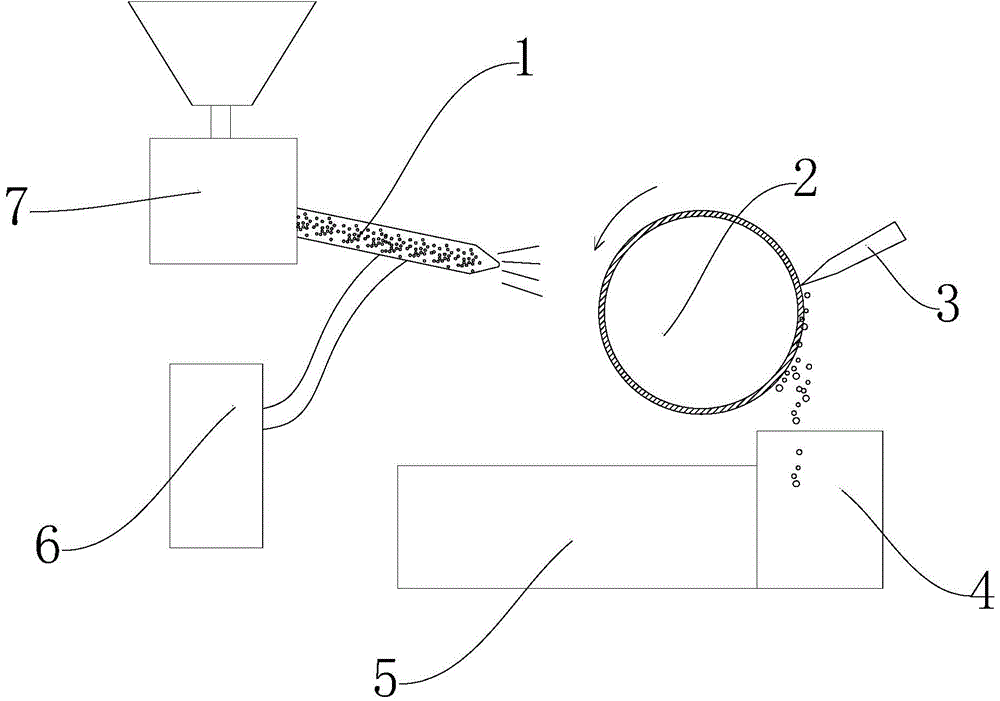

Sand-iron separation device

InactiveCN106031944AEasy to separateSimple structureMould handling/dressing devicesAir compressorIron storage

The invention discloses a sand-iron separation device. The sand-iron separation device comprises a discharging device and a round roller, wherein the discharging device comprises a feeding cylinder and an air compressor, the feeding cylinder is connected with a spray gun, the air compressor is connected with the spray gun, and the round roller is coated with a magnet layer; the discharging device is located above the left side of the round roller, and an outlet of the discharging device inclines towards the round roller; a sand storage device is arranged below the round roller, a scraper blade is arranged above the right side of the round roller, and an iron storage device is arranged below the scraper blade. The sand-iron separation device is simple in structure, and iron and sand can be separated out quickly.

Owner:CHONGQING DONGHONGXIN TECH

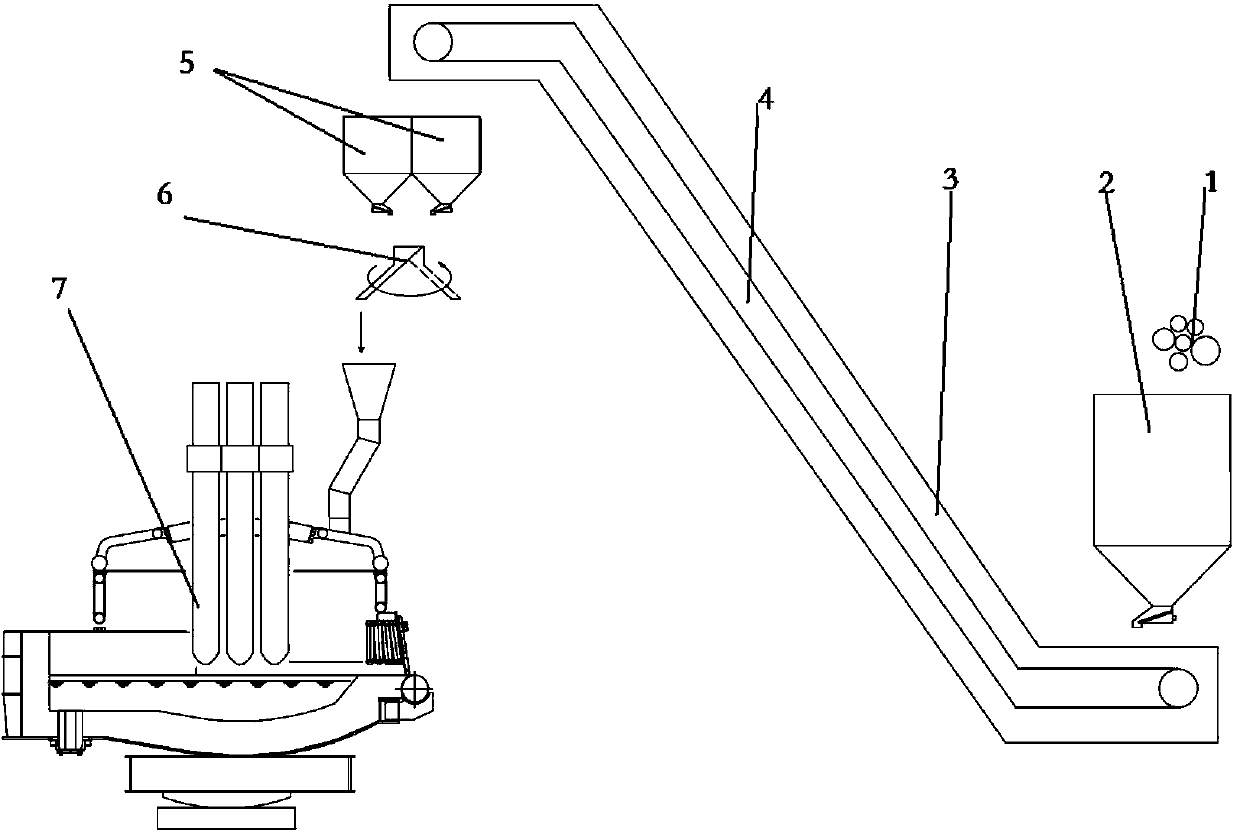

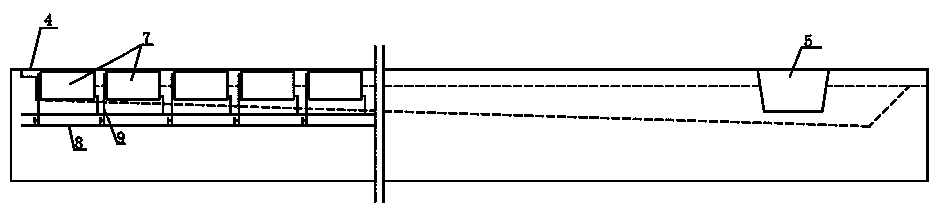

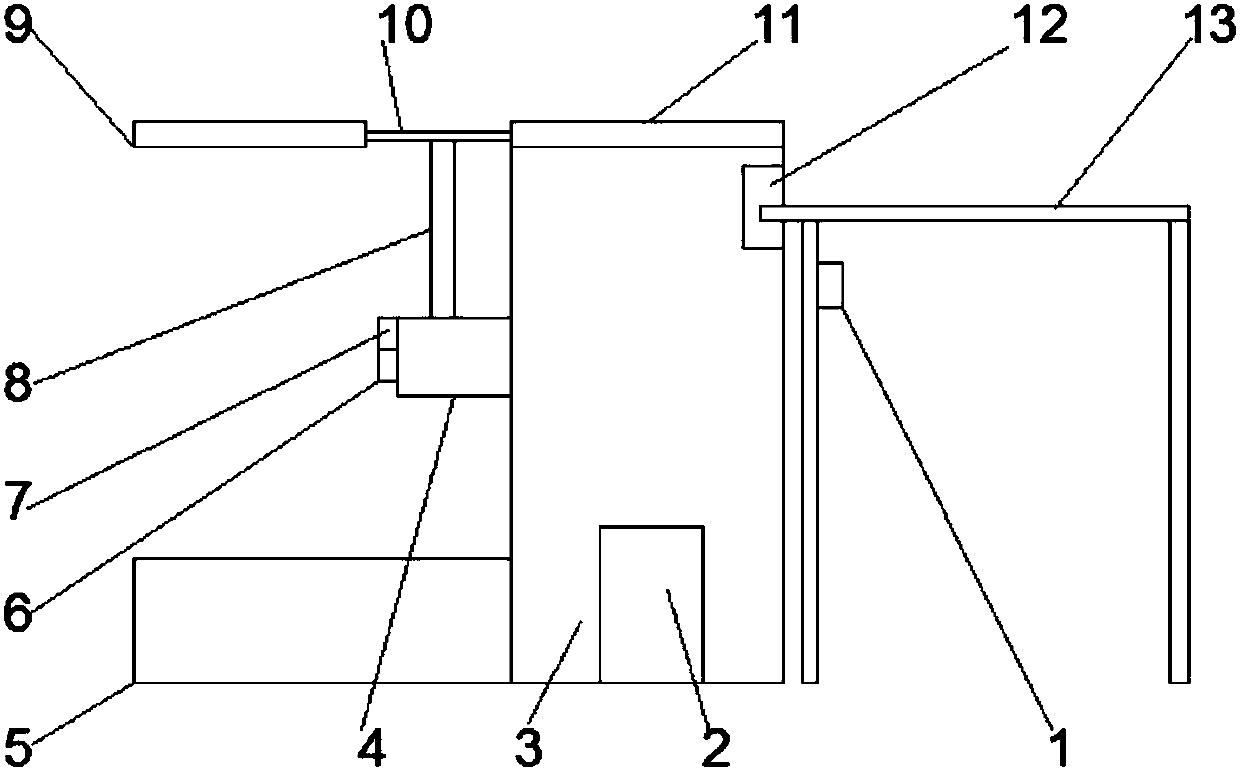

Direct reduction iron hot-charging method by use of chain conveyer

ActiveCN103805727AReduce breakageAvoid secondary oxidationFluidised-bed furnacesThermodynamicsProcess engineering

The invention relates to a direct reduction iron hot-charging method by use of a chain conveyer, belonging to the field of direct reduction iron hot-charging technology. The method comprises the processes of discharging hot direct reduction iron into a direct reduction iron storage tank, conveying the direct reduction iron to an electric furnace shop and discharging in a transitional material tank on the furnace top by the chain conveyer, and charging into an electric furnace through a feeding chute. The method has the advantages that the direct reduction iron hot-charging method adopts a mechanical transportation mode, and compared with pneumatic transportation, pneumatic conveying equipment is not required to be constructed, therefore, the investment is low, the energy consumption is low, the equipment is convenient to maintain, and damage of the direct reduction iron during conveying can be reduced; inert gas is introduced for protection during loading of direct reduction iron, so that secondary oxidation of the direct reduction iron can be effectively prevented; the angle of the chain conveyer can be adjusted according to the height of the direct reduction iron production equipment, and is not limited by the height of the direct reduction iron production equipment, therefore, the chain conveyer can be suitable for various production flows.

Owner:BEIJING SHOUGANG INT ENG TECH

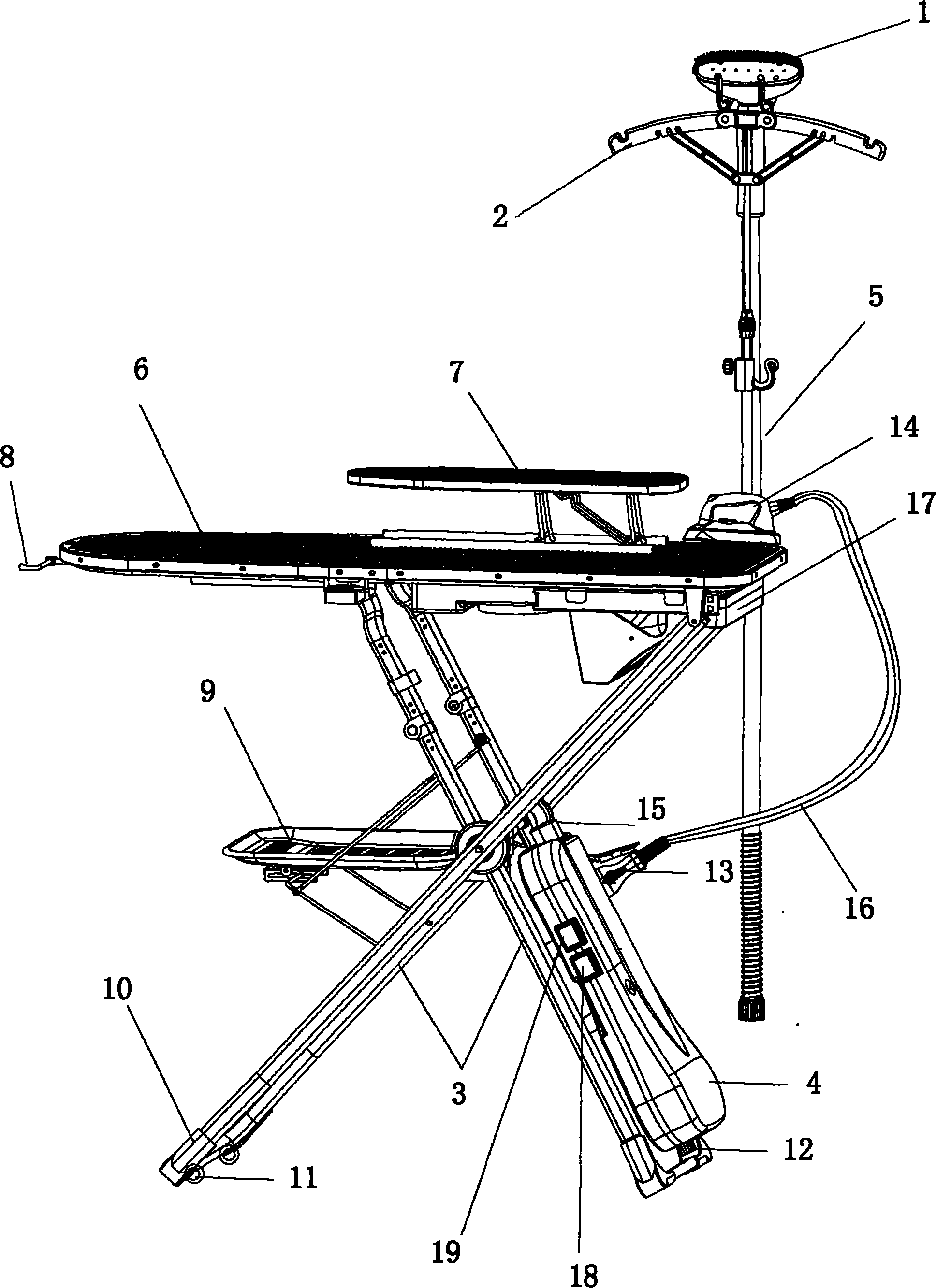

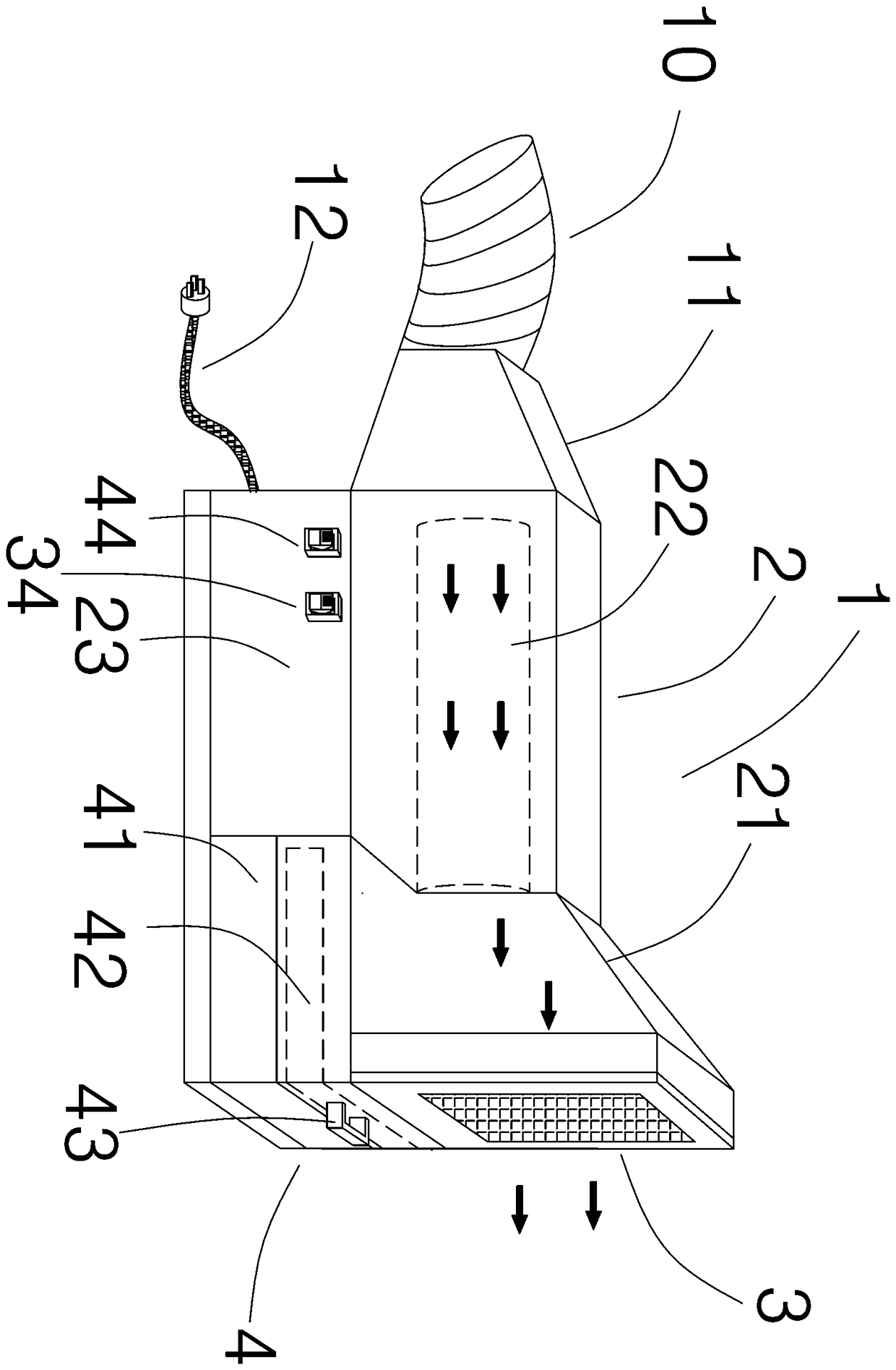

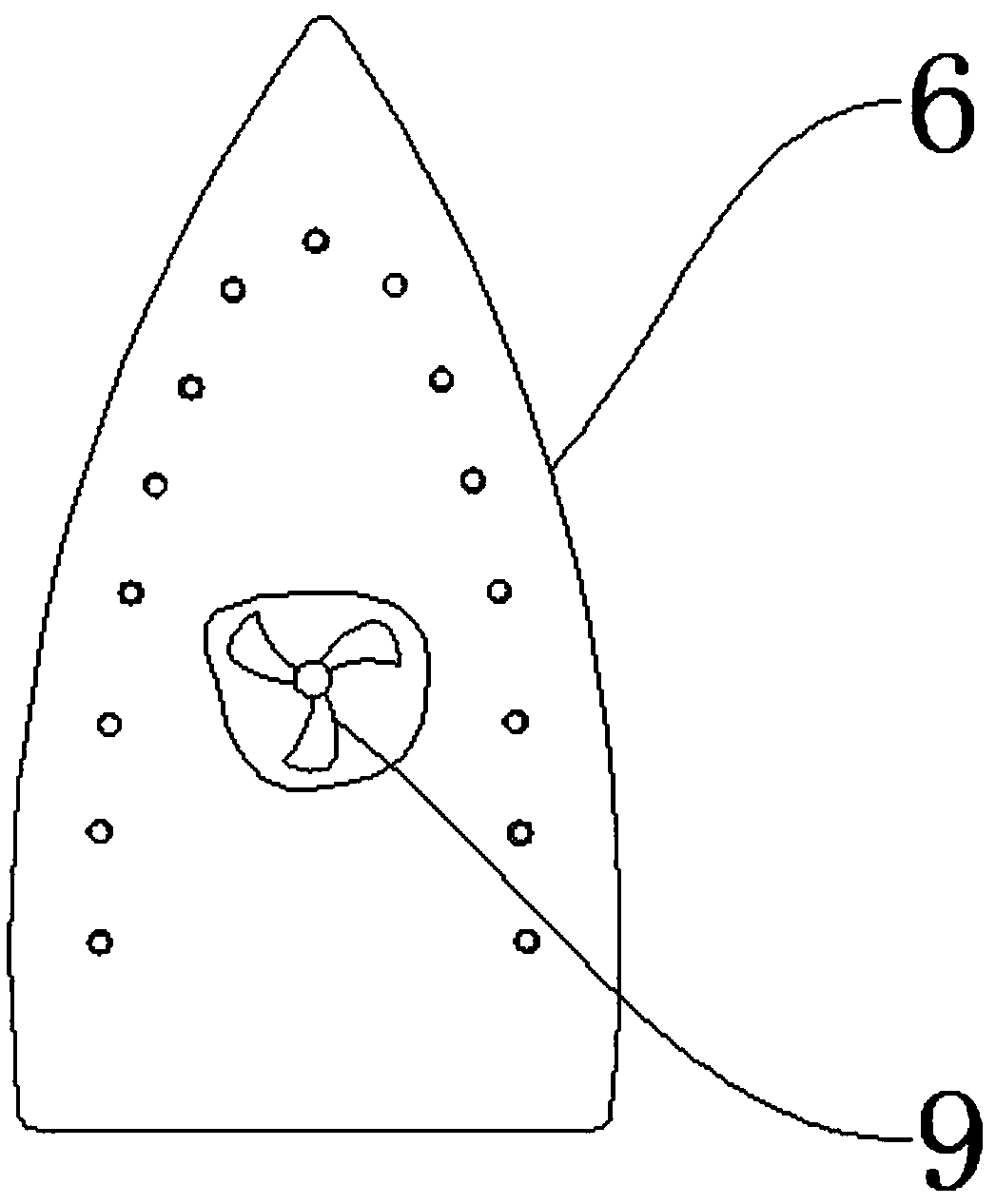

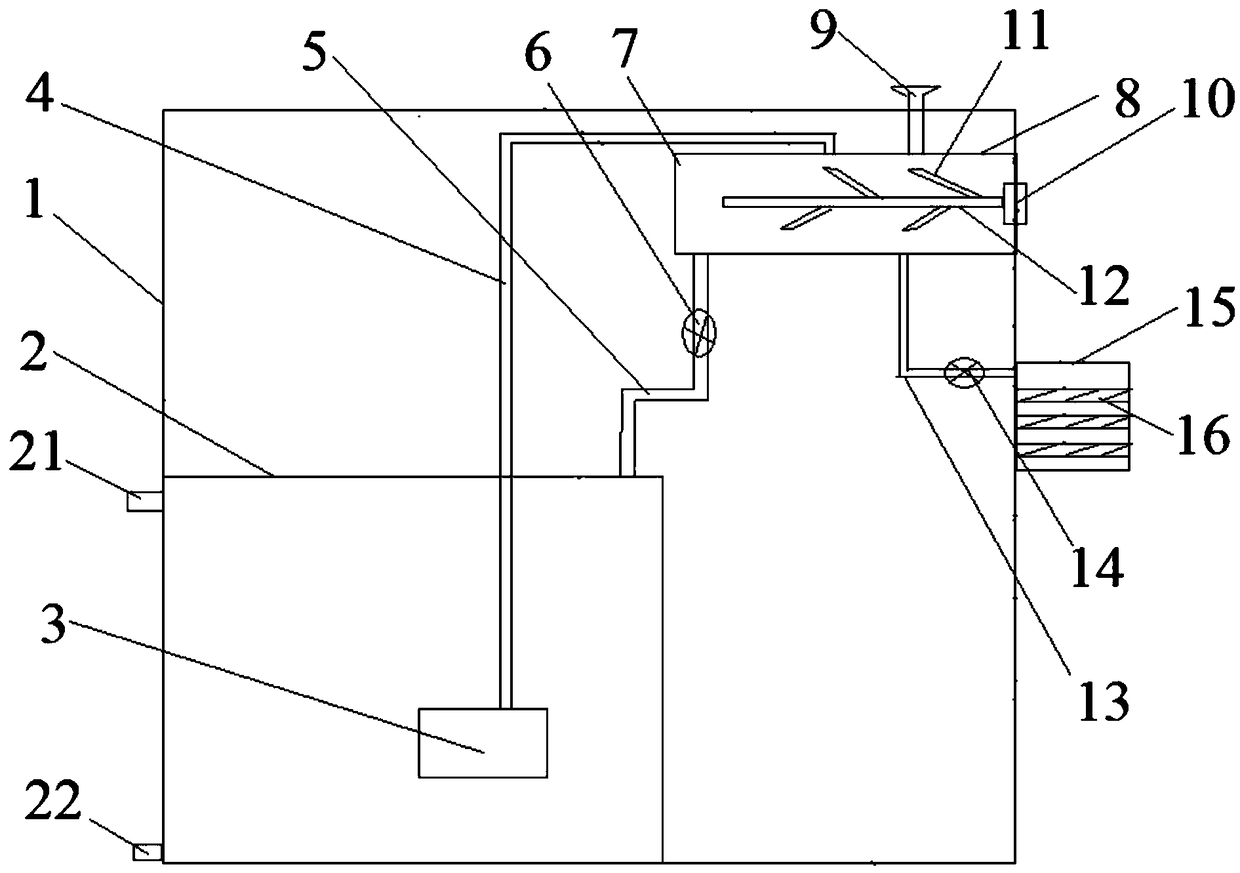

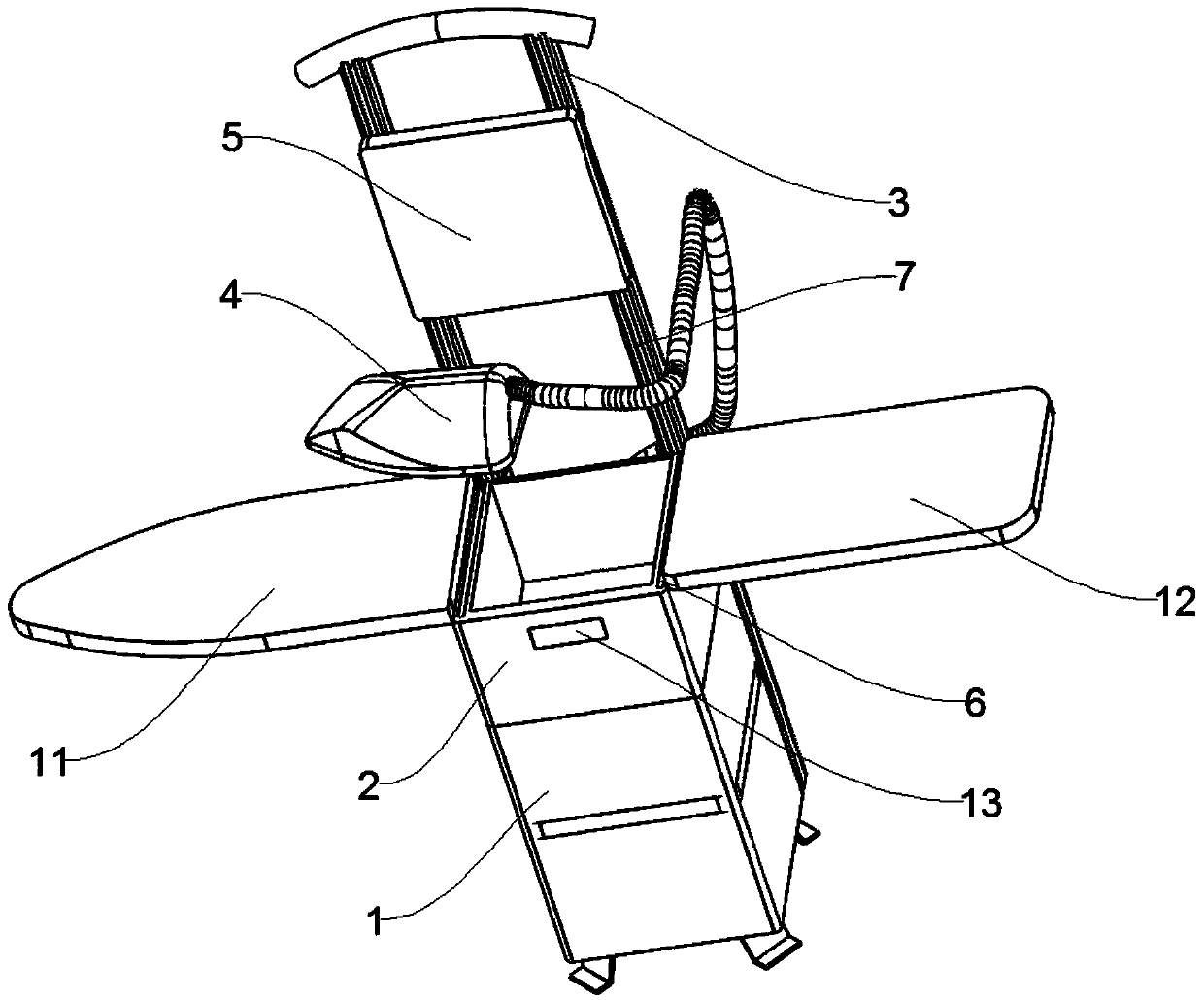

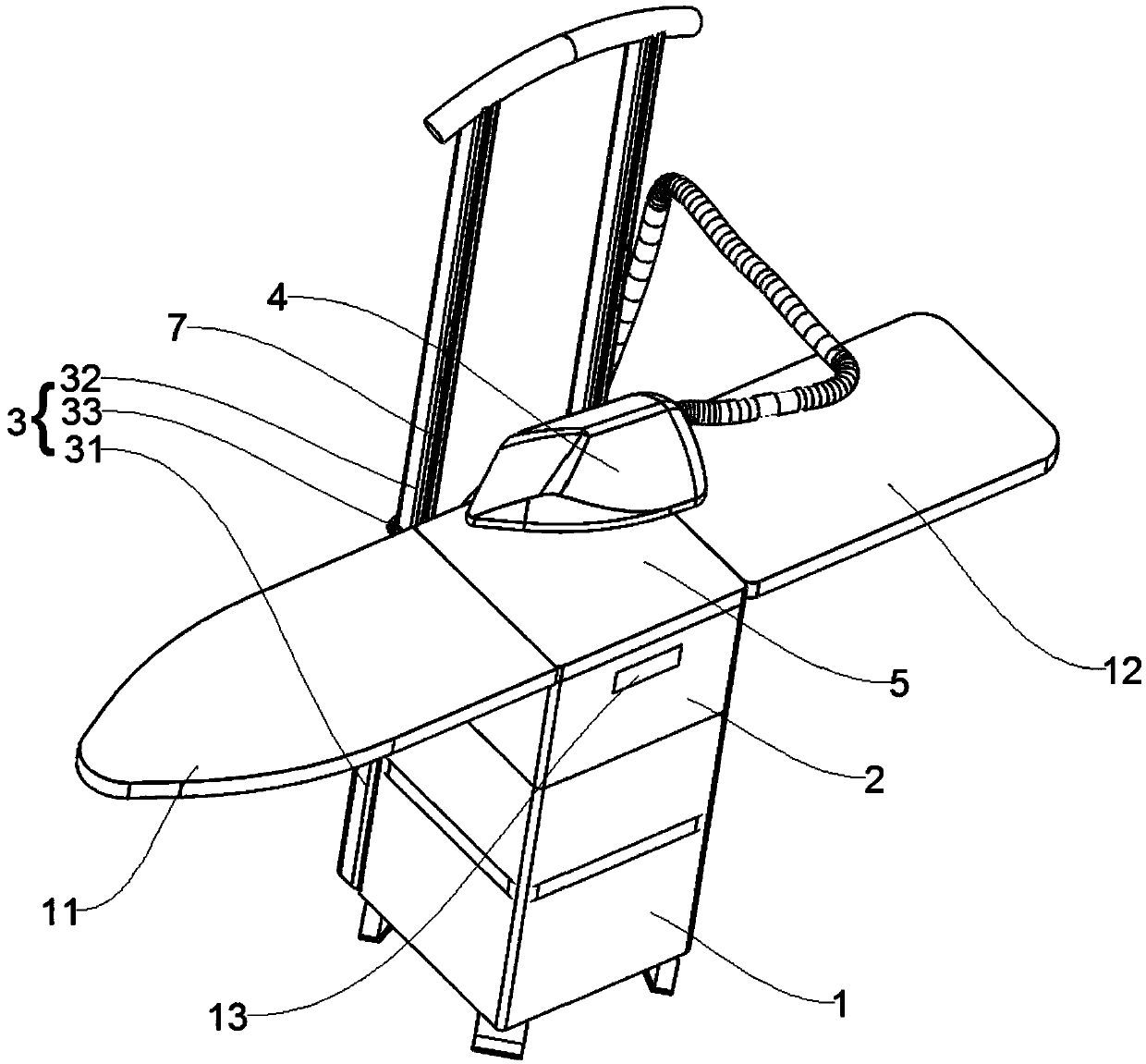

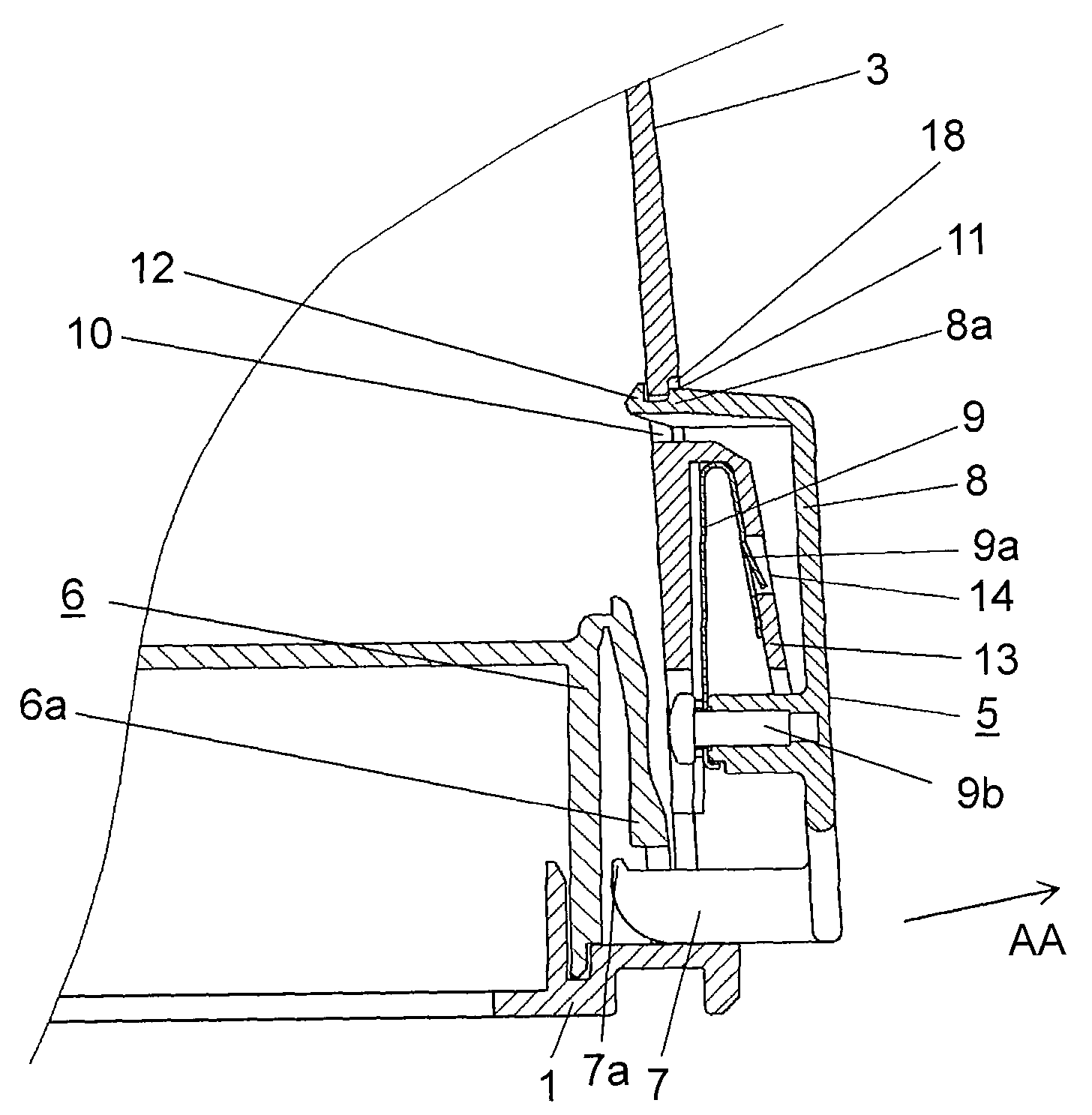

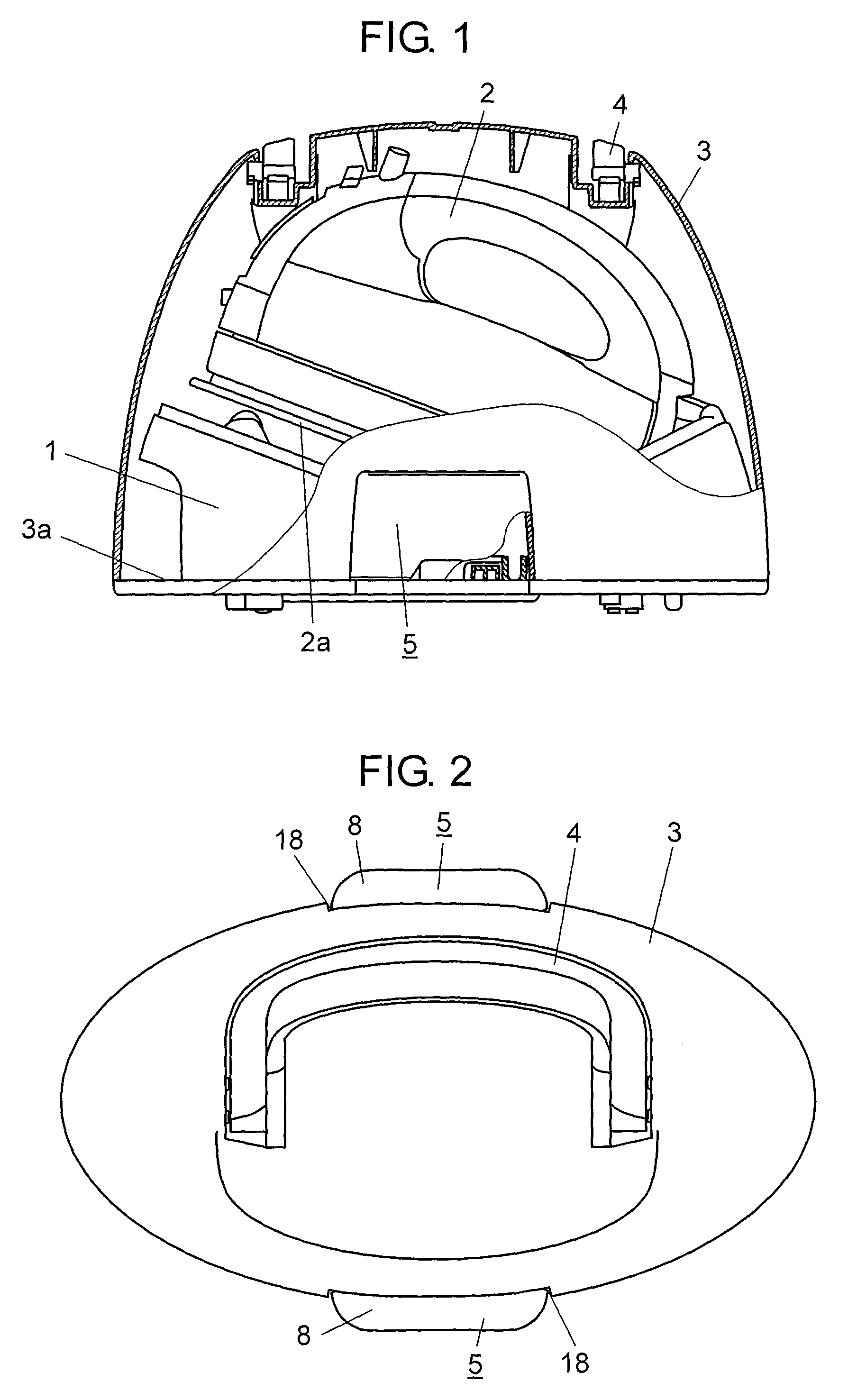

Ironing equipment

PendingCN111254679AFunctionalSmall footprintIroning boardsHand ironMechanical engineeringIron storage

The invention provides ironing equipment, and belongs to the technical field of ironing. The ironing equipment aims to solve the problem of large occupied space caused by the fact that a flat ironingdevice and a hanging ironing device need to be purchased correspondingly if a user wants to have the flat ironing function and the ironing function at the same time in existing ironing devices. The ironing equipment comprises a machine body, a flat ironing assembly, a hanging ironing assembly, a height adjusting assembly, an iron storage assembly and a steam iron, the iron storage assembly is arranged on the machine body and used for storing the steam iron, the hanging ironing assembly and the height adjusting assembly are both arranged on the machine body, the flat ironing assembly is arranged on the height adjusting assembly, the height adjusting assembly is arranged to be capable of driving the flat ironing assembly to ascend and descend, the flat ironing assembly is arranged to be capable of being unfolded and folded, and the hanging ironing assembly is arranged to be capable of ascending and descending. The ironing equipment has the flat ironing function and the hanging ironing function at the same time, does not occupy too much space, meanwhile, can store the iron, prevents the iron from being soaked by impurities such as dust, and improves the user experience.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

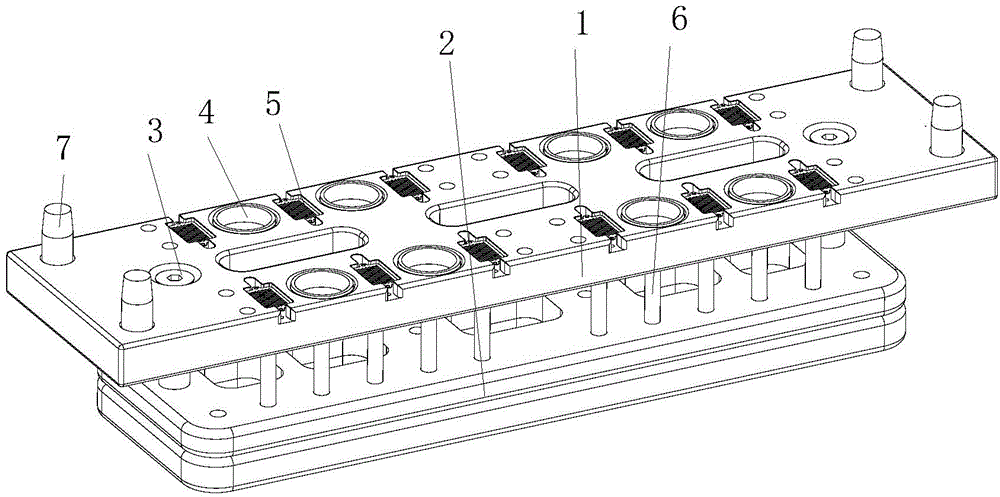

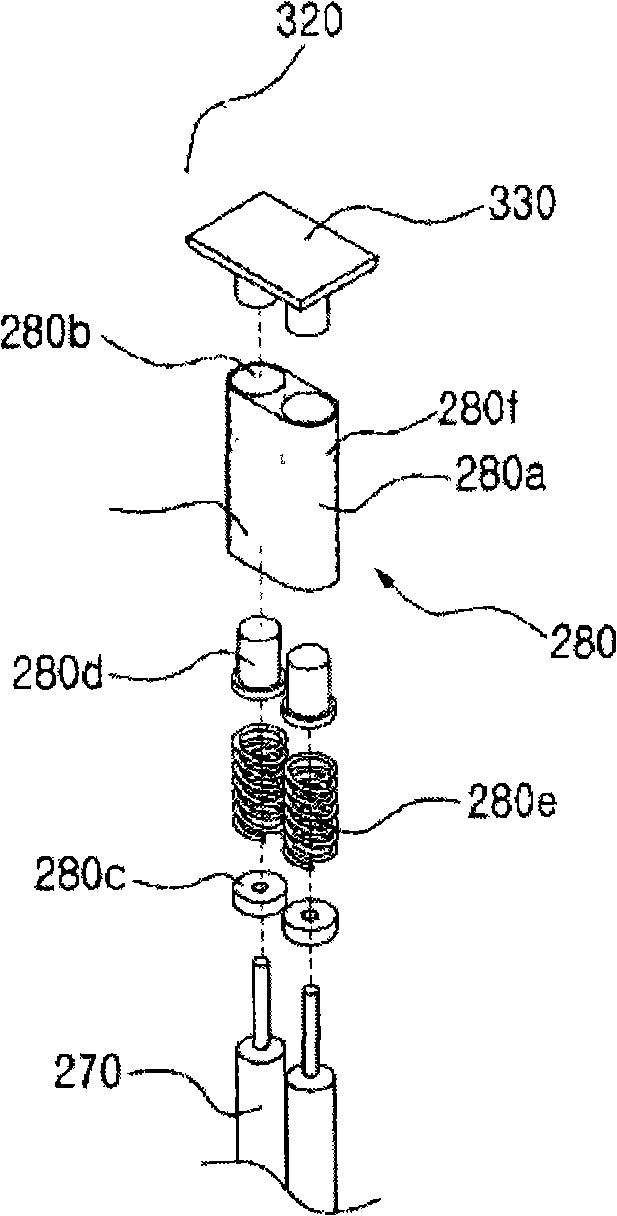

Metal insert loading fixture for plastic mold

InactiveCN104416742AReduce labor intensityQuick placementDomestic articlesEngineeringUltimate tensile strength

The invention relates to the technical field of auxiliary devices of injection molding equipment and in particular relates to a metal insert loading fixture for a plastic mold. The metal insert loading fixture is characterized by comprising a base plate and a bottom plate, wherein the base plate is positioned above the bottom plate; the base plate is movably connected with the bottom plate by virtue of a connecting post; a reset spring is arranged on the connecting post in a sleeving manner; a U-shaped iron storage tank used for storing U-shaped iron and a mesh storage tank used for storing meshes are arranged on the base plate; and support pillars are arranged on the bottom plate corresponding to the lower sides of the U-shaped iron storage tank and the mesh storage tank. The loading fixture disclosed by the invention is simple in structure, the original method for manually putting the U-shaped iron and meshes into cavities on plastic package molds one by one is changed, the mold is used, and the operating speed is greatly improved, so that the yield is improved, the fixture has high consistency and reliability, and the product quality is guaranteed; the labor intensity of workers is reduced; and moreover, a metal insert can be rapidly arranged in the mold by using the device, and the risk of burns is avoided.

Owner:TIANJIN CHANGLE ELECTRONICS SCI & TECH

Iron scrap removal and collection equipment

PendingCN108706696AEasy to handleWater contaminantsWater/sewage treatment by magnetic/electric fieldsSewageSewage treatment

The invention discloses iron scrap removal and collection equipment which comprises a shell, wherein a sewage containing tank and an iron scrap treatment tank are respectively arranged on the left lower side and the right upper side of the shell; a sewage inlet and a sewage outlet are respectively formed in the upper part and the lower part of the side surface of the sewage containing tank; a circulation water pump is arranged inside the sewage containing tank; a water outlet of the circulation water pump is connected with the upper side of the iron scrap treatment tank through a water inlet tube; the lower end of the iron scrap treatment tank is connected with the upper side of the sewage containing tank; a first electromagnetic valve is arranged at the water outlet tube; a water inlet funnel is arranged on the iron scrap treatment tank; a stirring shaft for driving a motor to rotate is arranged inside the iron scrap treatment tank; stirring blades are arranged on the stirring shaft;electromagnetic iron layers are arranged on surfaces of the stirring blades; the lower side of the iron scrap treatment tank is connected with the upper side of the iron storage treatment tank throughan iron scrap water outlet tube; a second electromagnetic valve is arranged on the iron scrap water outlet tube; a magnetic layer is arranged inside the iron scrap treatment tank; and water through holes are formed in the magnetic layer. By adopting the iron scrap removal and collection equipment disclosed by the invention, iron scrap removal and collection are firstly carried out before sewage with iron scrap is treated.

Owner:苏州瑞沁精密机械有限公司

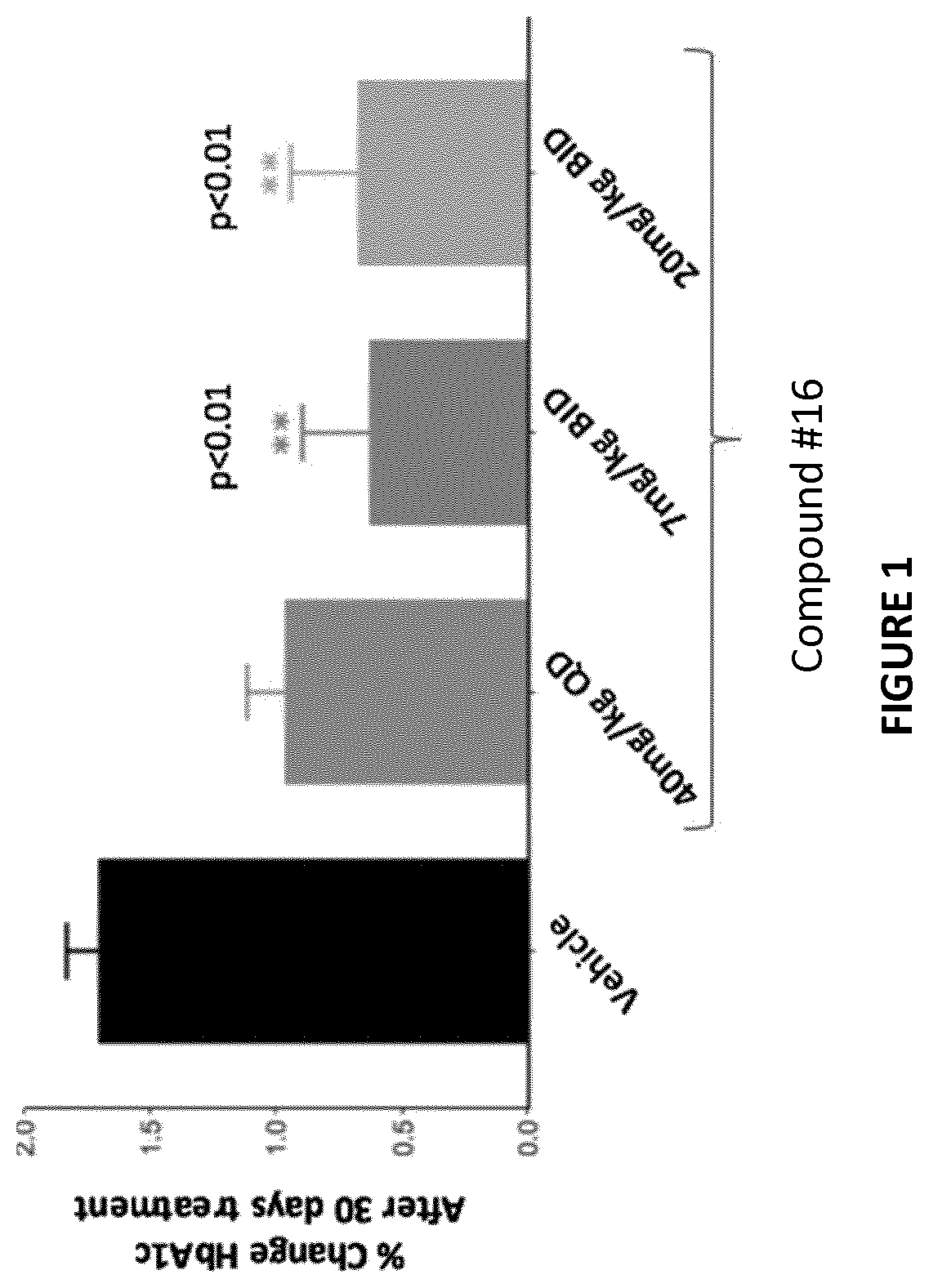

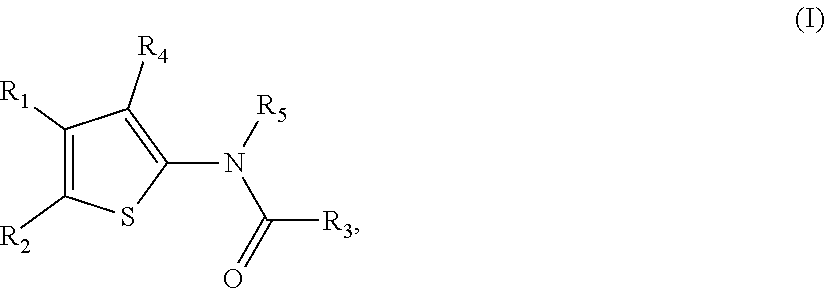

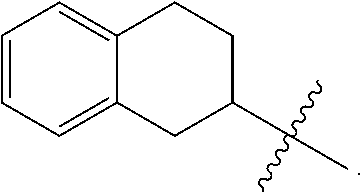

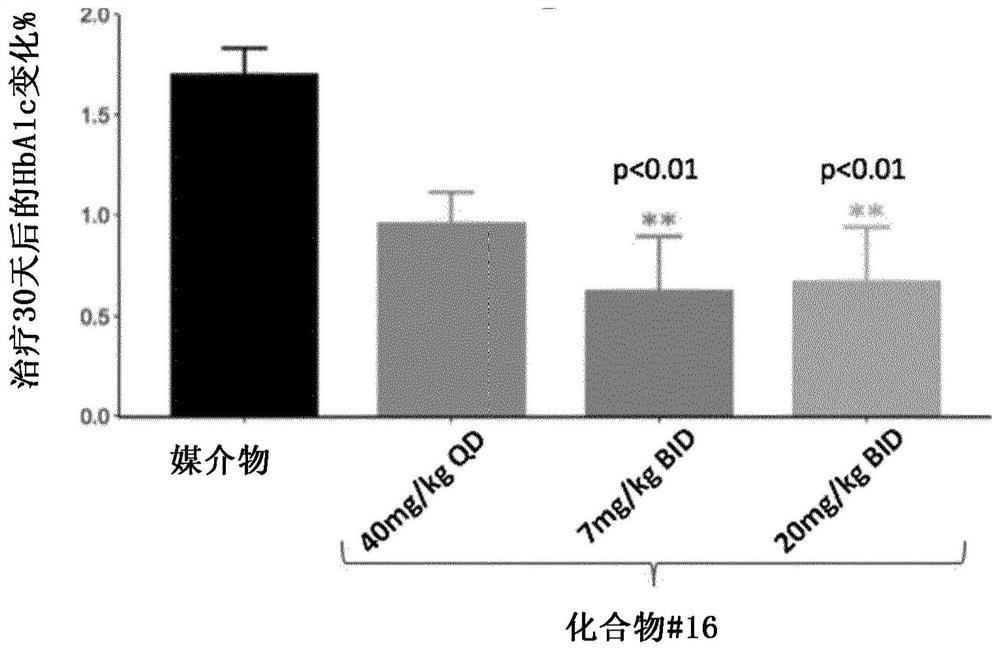

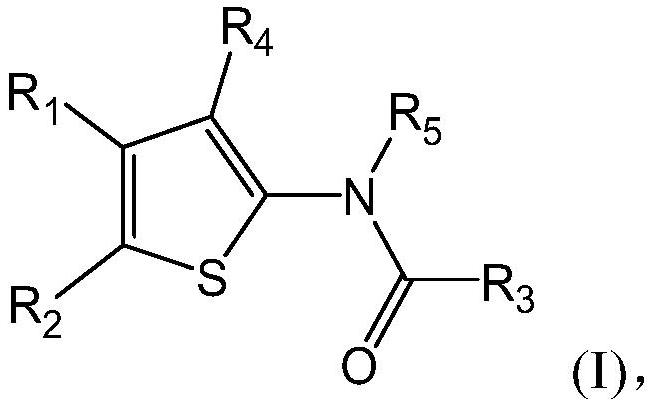

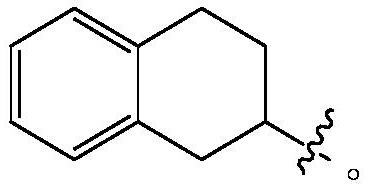

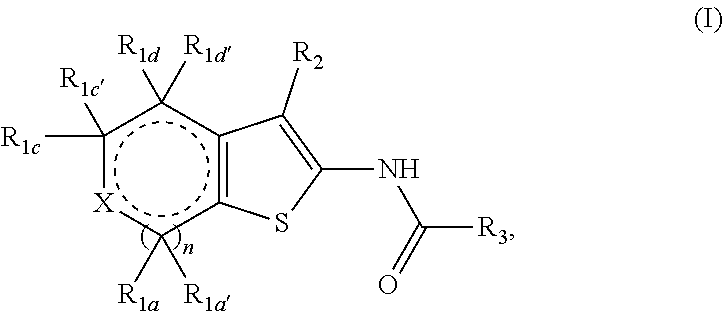

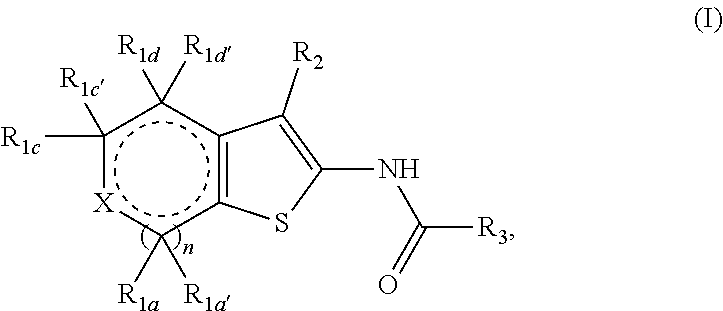

Non-fused thiophene derivatives and their uses

PendingUS20210040059A1Antibacterial agentsOrganic active ingredientsThiophene derivativesCardio vascular disease

The present invention relates to a new class of non-fused thiophene derivatives and their uses for treating diseases such as infection, cancer, metabolic diseases, cardiovascular diseases, iron storage disorders and inflammatory disorders.

Owner:ENYO PHARMA

Steam ironing device assembly

The invention discloses a steam ironing device assembly, which comprises a steam suspended ironing head, a suspended ironing hanger, a folding support frame, a steam generator, a steam suspended ironing pipe, an ironing board, a sleeve ironing board, a lifting device, a storage tray, an electric steam iron and an iron storage box. The electric steam iron is provided with an automatic lock switching push button; the steam generator is provided with a quick coupling, the inside of the steam generator is provided with an electromagnetic valve and a pressure switch, and the bottom of the steam generator is provided with a drain valve; and the bottom of the folding support frame is provided with a V-shaped shoe and a caster. The steam iron is provided with the automatic lock switch, the steam generator is provided with the electromagnetic valve, the pressure switch and a safety head, and a multiple safety protection device is adopted, so the personal safety of a user can be protected to the maximum, and the safety of the whole product is improved to the possibly high level; besides, the steam generator is provided with the quick coupling and the drain valve and the bottom of the folding support frame is provided with the caster, so the design of the whole product is more humanized and the use is more convenient.

Owner:JINBO CHUBAO ELECTRIC IND ZHONGSHAN CITY

Ironing device

ActiveCN111254680AImprove functionalityAvoid dippingIroning boardsIroning apparatusEngineeringMachine

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

Non-fused thiophene derivatives and their uses

The present invention relates to a new class of non-fused thiophene derivatives and their uses for treating diseases such as infection, cancer, metabolic diseases, cardiovascular diseases, iron storage disorders and inflammatory disorders.

Owner:ENYO PHARMA

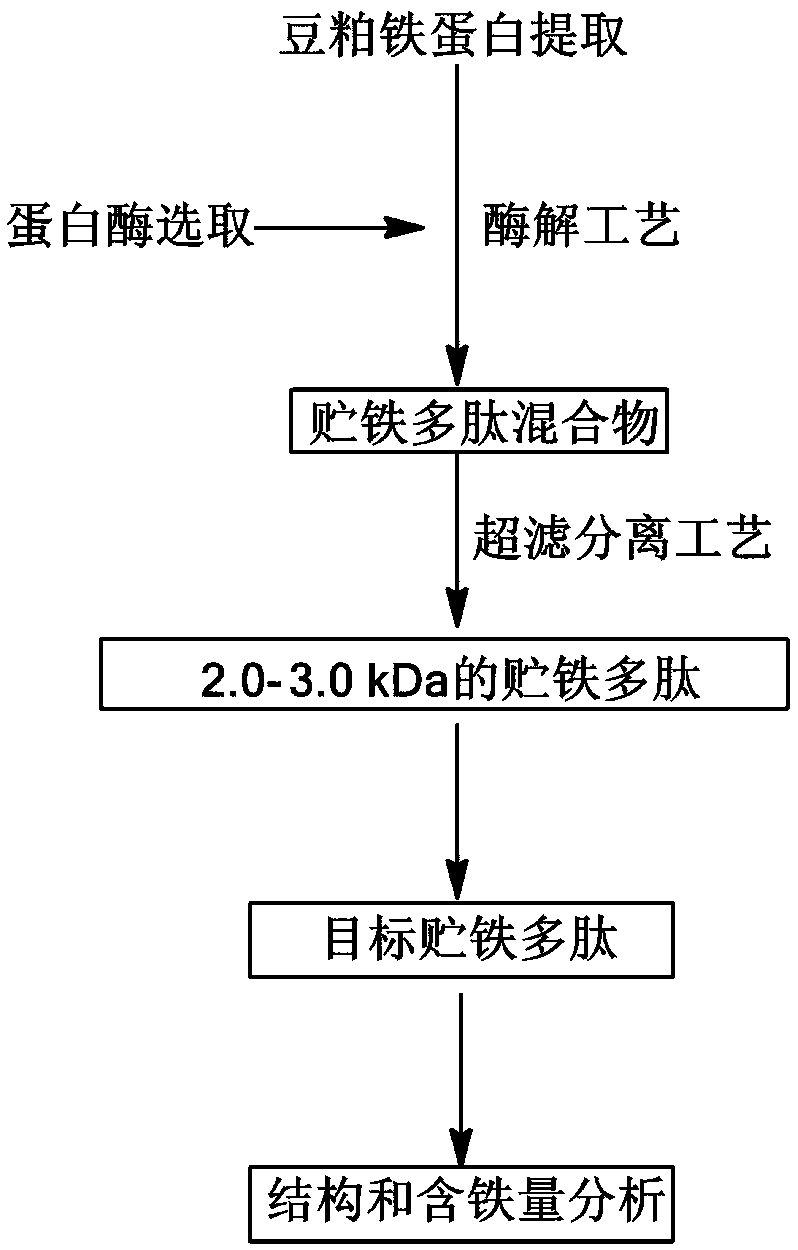

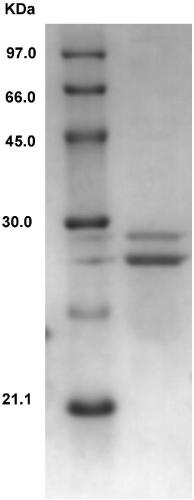

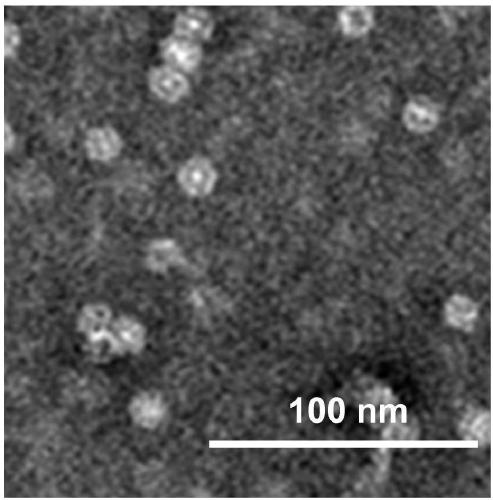

Method for preparing degreased soybean meal iron storage polypeptide by protease and application

ActiveCN109438552ABroad development potentialBroad application prospectsAccessory food factorsPeptide preparation methodsFood additiveAdditive ingredient

The invention relates to a method for preparing a degreased soybean meal iron storage polypeptide by protease. The method includes the steps: taking degreased soybean meal as a raw material; extracting and separating ferroprotein; acquiring iron-containing polypeptide components with molecular weight of 2.0-3.0kDa by the aid of a proteolysis technique; preparing the iron storage polypeptide with an iron component by the aid of an ultra-filtration technology. According to the method, a novel iron supplement source based on the polypeptide is developed, a polypeptide structure and iron content are researched and illuminated, and reference is provided for development of future iron supplement products. The iron storage polypeptide prepared by the method and development of related products ofthe polypeptide have wide development potential and application prospects in the industries such as food additives, feed and health food, and the method explores a new path for utilization of soybeanmeal resources.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

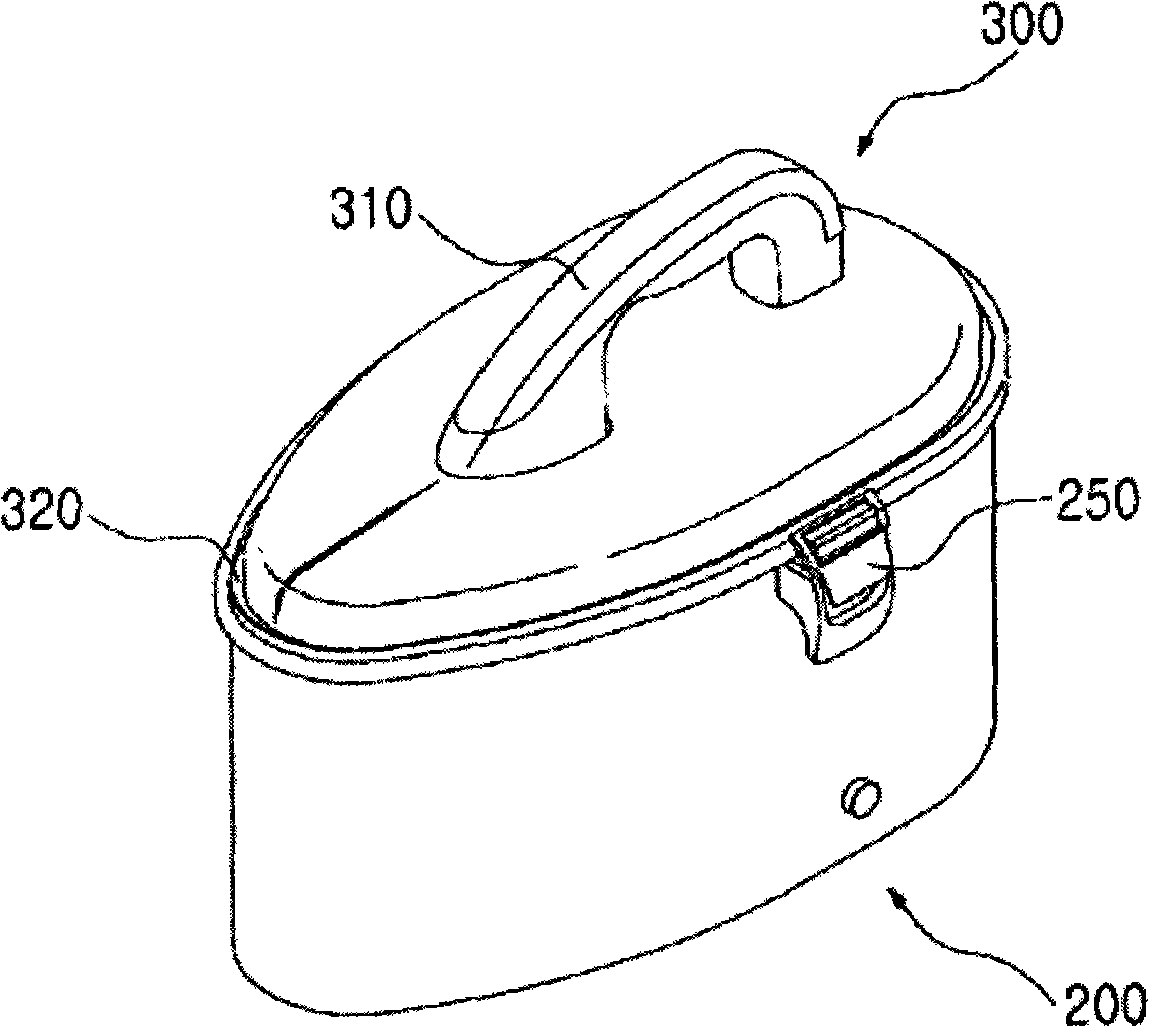

Box for storing wireless iron

Provided is a cordless iron storage case with a cover that reverses to double as a stand for a cordless iron and a power supply unit formed at the rear of the case to allow the iron to be used while seated on the case, and capable of safely storing the cordless iron within. The case forms a storage compartment for storing the cordless iron, a cord winder on a floor plate inside its lower end, and a power supply unit formed at the rear. The cover, for opening and closing the case, has a handle formed on its top and a sliding portion, a power connector, and a protruding portion formed on its bottom. The cordless iron storage case not only allows convenient use of the cordless iron, but also easy storage of the cordless iron on its heat resistant floor plate when its hot plate is still hot and easy stowage of its power cord due to its cord winder.

Owner:金星伯

Water cooling type iron storage type iron runner structure

PendingCN111139328AExtended service lifeStable temperatureCooling devicesDischarge devicesCarbon compositesBrick

The invention discloses a water cooling type iron storage type iron runner structure which comprises a working layer, a permanent layer and a steel shell. The working layer makes direct contact with ahigh temperature mixed solution. The permanent layer coats the working layer. The permanent layer is formed by building carbon composite bricks. A water cooling device is arranged at the portion, corresponding to the height of an iron runner groove, of the outer side wall of the steel shell. The water cooling device is arranged at the outer attached wall of the steel shell. High-alumina castableor high-aluminum bricks for traditional iron storage type iron runner permanent layers are changed into carbon composite brick building with the good heat conducting performance, cooling water flowingin inner circulation of the water cooling device is used for driving away abundant heat of the iron runner, the temperature inside the iron runner is kept constant, and the permeation, abrasion, erosion and other damage effects influenced by iron scraps on a linear of the iron runner are kept within the reasonable range. Meanwhile, the water cooling device is installed at the outer side of the iron runner steel shell, even if water leakage is caused, water cannot enter the iron runner, and therefore it is ensured that water cannot meet water, and security water cooling is achieved.

Owner:REWELL REFRACTORY ZHENGZHOU CO LTD

Transformation method of device for treating molten iron backflow

PendingCN114657301APass safelyPass smoothlyBlast furnace detailsExhaust gas handlingSlagIron storage

The invention relates to the technical field of metallurgical enterprise blast furnace production slag iron treatment, and discloses a transformation method of a device for treating molten iron backflow, which comprises the following steps: S1, cleaning residual materials in a main channel and a skimmer by using a tool; s2, the widths of the pits on the two sides of the main channel of the skimmer are increased by 30-32 cm, and the depths are increased by 18-20 cm; s3, according to the specific size, steel large and small well passage molds are manufactured again; and S4, the steel mold is installed, and the skimmer is dropped by 10-12 cm. According to the invention, the molten iron can safely and smoothly pass through, the phenomenon of molten iron recharge is eliminated, the phenomenon that the molten iron flows into the slag runner to cause blasting hidden danger is avoided, the impact and erosion strength of the wall body of the small well of the skimmer is reduced, and the molten iron leakage accident caused by local burnthrough of the iron storage device is avoided.

Owner:SHANDONG LAIGANG YONGFENG STEEL & IRON

Iron removing device for calcite

The invention discloses an iron removing device for calcite in the technical field of ore screening. The iron removing device comprises an iron removing structure and a vertical material storing cylinder, the upper portion of the material storing cylinder is provided with an opening, a conveyer belt used for feeding materials into the material storing cylinder is arranged at the opening, the conveyer belt runs in the conveying direction from right to left, and a first controller used for controlling the conveyer belt to work is electrically connected to the conveyer belt; the iron removing structure comprises a vertical supporting rod and a motor arranged at the periphery of the material storing cylinder, the motor is used for driving the supporting rod to rotate, and a second controller used for controlling the motor to work is electrically connected to the motor; and a transverse cross beam is connected to the top of the supporting rod, a first electromagnet is connected to the leftside of the cross beam, a second electromagnet is connected to the right side of the cross beam, the distance between the first electromagnet and the supporting rod is equal to that between the secondelectromagnet and the supporting rod, and the first electromagnet is located over the opening. By adopting the scheme, iron removing treatment can be continuously conducted.

Owner:遵义市繁枝矿业有限公司

Fused thiophene derivatives and their uses

ActiveUS20200361924A1Antibacterial agentsOrganic active ingredientsThiophene derivativesCardio vascular disease

The present invention relates to a new class of fused thiophene derivatives and their uses for treating diseases such as infection, cancer, metabolic diseases, cardiovascular diseases, iron storage disorders and inflammatory disorders.

Owner:ENYO PHARMA

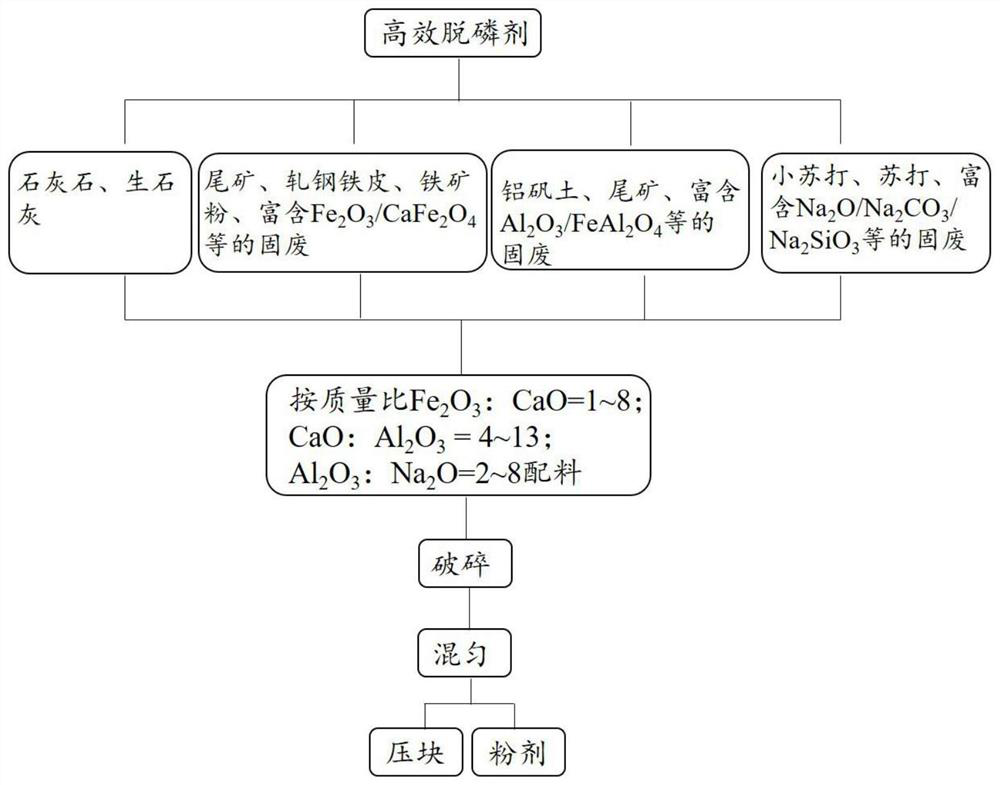

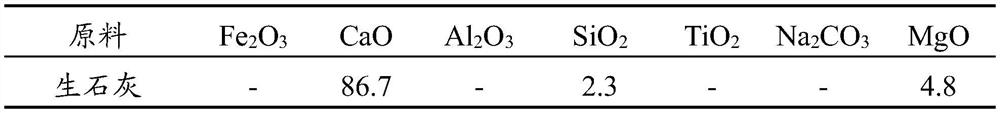

Dephosphorizing agent and application thereof

PendingCN114657326ALow melting pointImprove liquidityProcess efficiency improvementSteelmakingIron storage

The invention provides a dephosphorizing agent for pre-dephosphorizing medium-high phosphorus molten iron as well as a preparation method and application of the dephosphorizing agent, and belongs to the technical field of metallurgy. The dephosphorizing agent disclosed by the invention is low in slag system melting point, extremely fast in slag forming, good in fluidity, high in phosphorus capacity and high in dephosphorizing efficiency. The dephosphorizing agent can achieve a dephosphorizing rate of 70% or more in a short time from molten iron storage and transportation to a converter process. After the dephosphorizing agent is used for pre-dephosphorizing the molten iron, more than 70% of dephosphorization is completed before the molten iron enters a converter, on one hand, the dephosphorizing agent can be suitable for the molten iron with the initial [P] content up to about 0.25%, and compared with an existing blast furnace burden structure, the application proportion of inferior iron ore resources with high phosphorus content in a blast furnace is remarkably increased; on the other hand, the smelting efficiency in the converter steelmaking process is effectively improved, emission of slag and the like is remarkably reduced, and economic benefits and environmental benefits are huge.

Owner:UNIV OF SCI & TECH BEIJING

Disassemble-free bearing seat with scrap iron removing function, removing method and mining engineering machine

InactiveCN105257716AExtended service lifeReduce impurity concentrationScrewsLubrication elementsWorking environmentIron storage

The invention discloses a disassembly-free bearing seat with a scrap iron removing function. The disassembly-free bearing seat with the scrap iron removing function comprises a bearing seat body and a bearing cap arranged on the bearing seat body. An oil storage cavity is formed in the bearing seat body and the bearing cap and located between a bearing hole and one shaft hole. A scrap iron storage bolt is arranged below the oil storage cavity and has the function of collecting scrap iron in the oil cavity. The bearing seat of the structure has the advantages that using and machining are easy, the cost is low, the service life is long, the service life of a bearing is prolonged, and the working environment of the bearing is improved. In addition, the invention discloses a removing method for scrap iron in the disassembly-free bearing seat with the scrap iron removing function. The removing method has the advantages that operation is easy and the efficiency is high. Furthermore, the invention discloses a mining engineering machine comprising the disassembly-free bearing seat with the scrap iron removing function. The mining engineering machine has the advantages that maintenance of the bearing is easy and the service life is long, and accordingly the overhaul period of the mining engineering machine is prolonged.

Owner:长沙贤正益祥机械科技有限公司

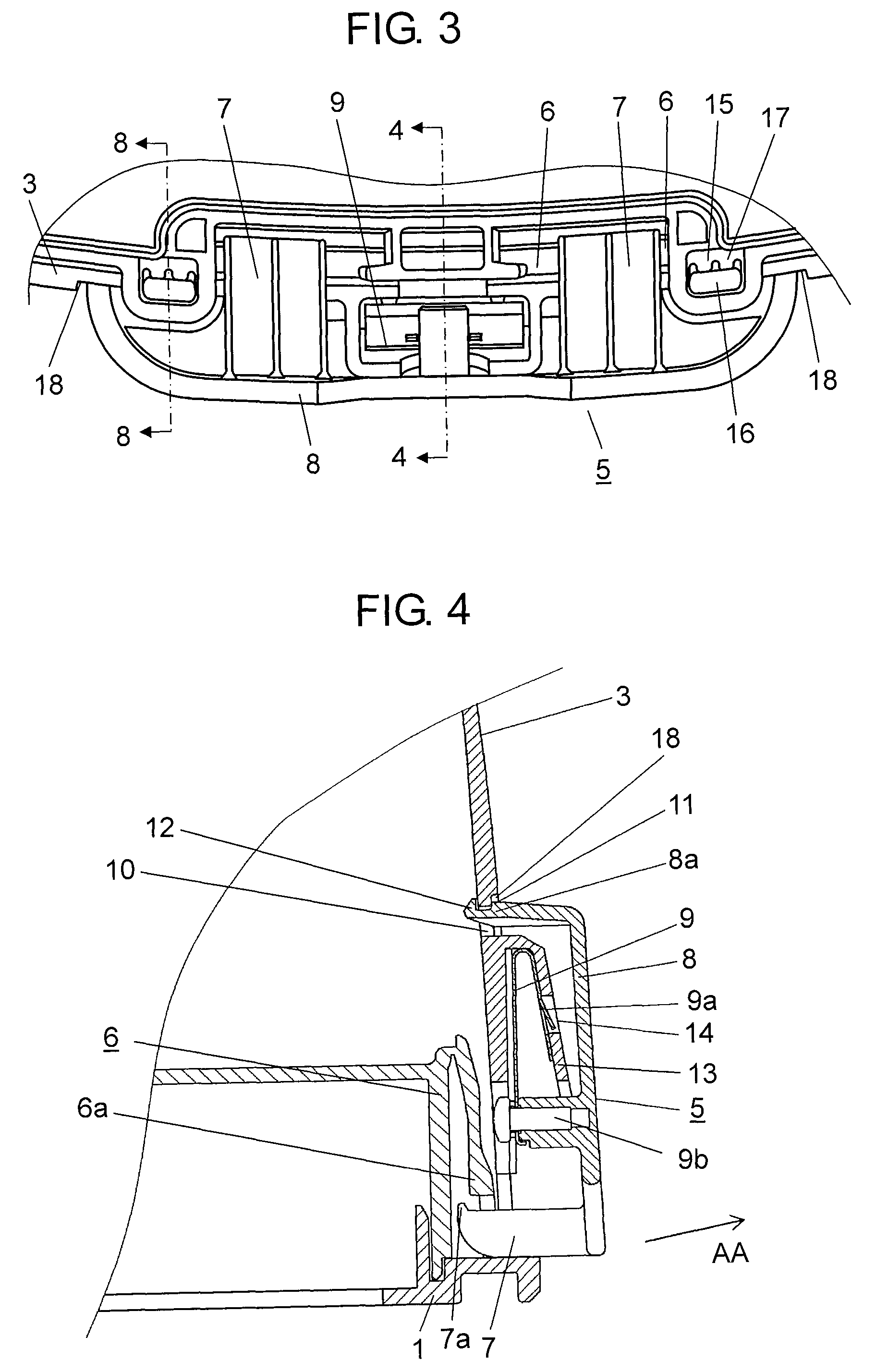

Clothes iron storage case

ActiveUS8985325B2Avoid failureAlleviate external shockIroning boardsHand ironLocking mechanismEngineering

An iron case includes: a table where an iron is placed; a receiving case that surrounds the iron and has a lower opening that is closed by the table; and a locking mechanism that detachably combines the table with the receiving case, in which the locking mechanism includes: a locking portion formed on the sides of the table; a locking body formed at the receiving case and engaged with the locking portion; an operating button disposed to be movable outwardly on the outer surface of the receiving case and operating the locking body; and a locking spring disposed in the receiving case and biasing the operating button to the table. Therefore, malfunction of the locking mechanism is prevented while usability when the receiving case is separated is improved.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

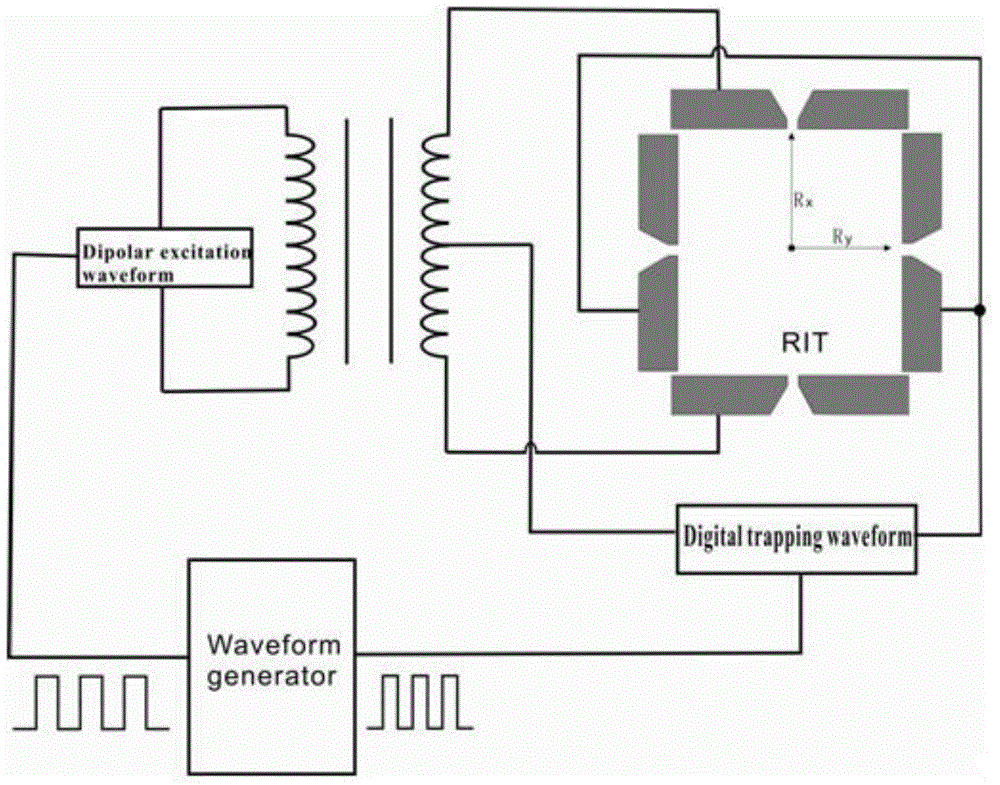

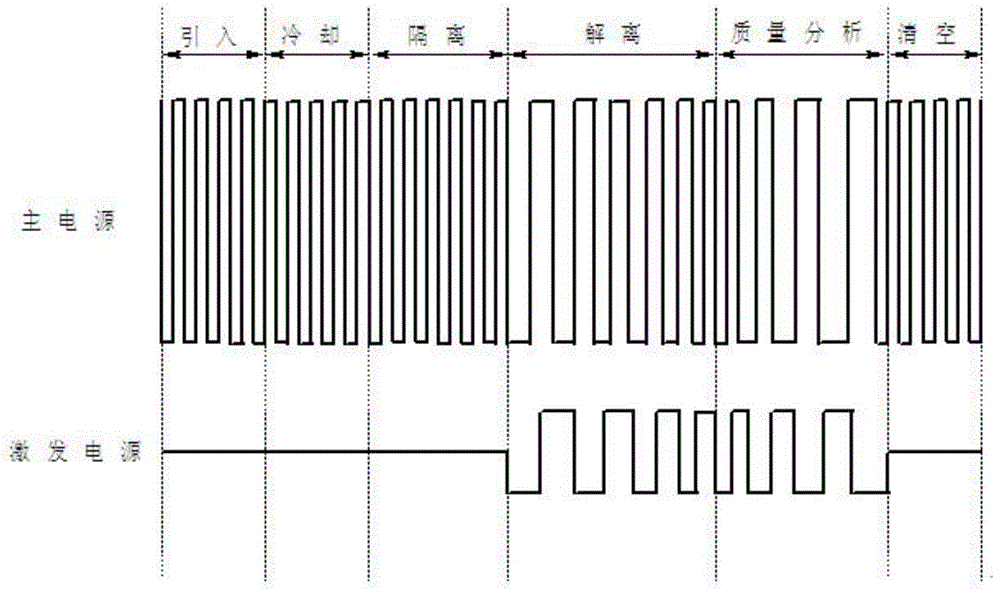

Method for improving low mass cutoff value of ion trap mass spectrometer

ActiveCN104916520ARealize analysisImprove performanceStability-of-path spectrometersIon sources/gunsIon trap mass spectrometryHigh energy

The invention relates to a method for improving a low mass cutoff value of an ion trap mass spectrometer. A driving working power supply of an iron trap is a digital square wave power supply. The method comprises the steps of: (1) fixing voltage and periods T of the digital square wave power supply for carrying out iron storage and mass selection; (2) entering a collision-induced dissociation CID process of ions, and reducing the periods T of the digital square wave power supply gradually in the CID process so that the selected parent ions are excited to a high energy state and can further perform collision-induced dissociation with neutral molecules in the iron trap to produce fragment ions; (3) and then scanning the periods T of the digital square wave power supply from small to large so as to realize mass analysis of the ions. All the processes are controlled by a computer. The method provided by the invention can solve the problem of limitation of 1 / 3 low mass cutoff value in tandem mass spectrum analysis, realizes the analysis of low mass fragment ions, and significantly improves performance of the digital ion trap mass spectrometry.

Owner:常州磐诺仪器有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com