Dephosphorizing agent and application thereof

A technology of dephosphorization agent and phosphorus content, applied in the field of dephosphorization agent, can solve the problems of poor dephosphorization kinetic conditions, limited use range of phosphorus content, low lime dissolution efficiency, etc., to expand the available range, improve smelting efficiency, The effect of increasing phosphorus capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

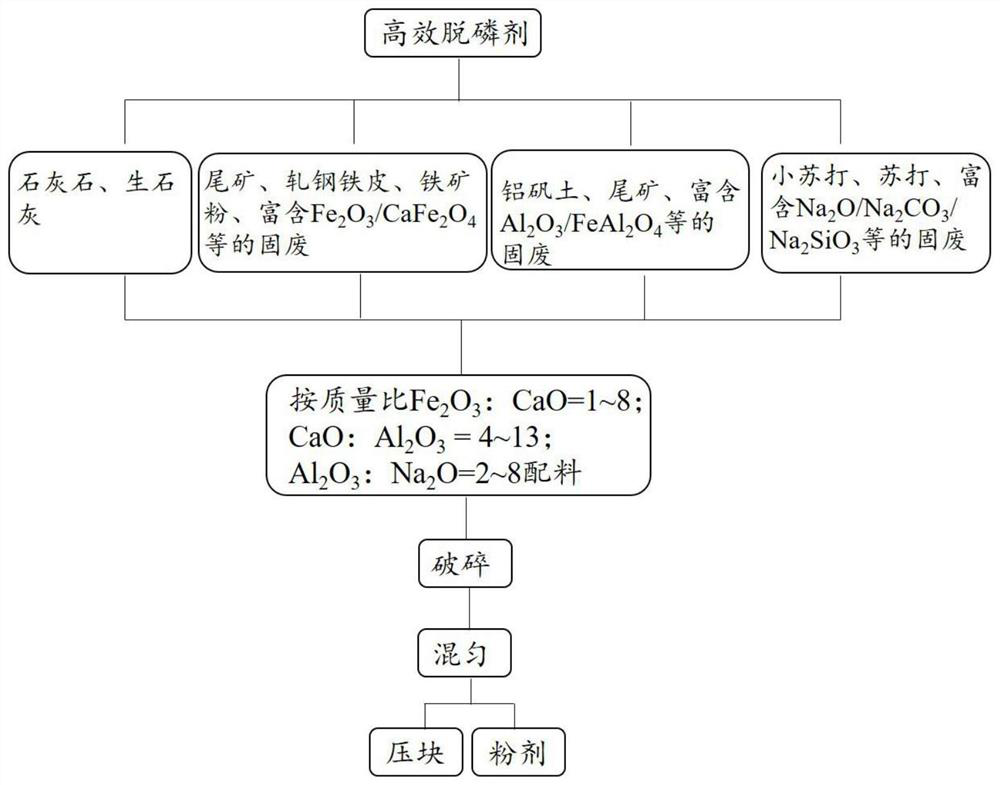

[0030] The present invention has no special requirements for the preparation method of the dephosphorization agent. The corresponding raw materials are directly prepared according to the mass ratio of the metal oxides in the dephosphorization agent, and then crushed and mixed to prepare the spray powder, pellets or pressed powders. block, the specific preparation flow chart is as follows figure 1 shown.

[0031] When the dephosphorizing agent is spray powder, the particle size of the spray powder is preferably 0.5 mm to 2 mm; when the dephosphorizing agent is pellets or briquette, the particle size of the pellet or briquette is preferably 10 mm ~20mm.

[0032] In the present invention, if a certain material can provide Fe at the same time 2 O 3 and Al 2 O 3 , such as FeAl containing 2 O 4 materials, when converting raw materials, FeAl 2 O 4 Converted to Fe at the same time 2 O 3 and Al 2 O 3 .

[0033] The present invention provides the application of the dephosp...

Embodiment 1

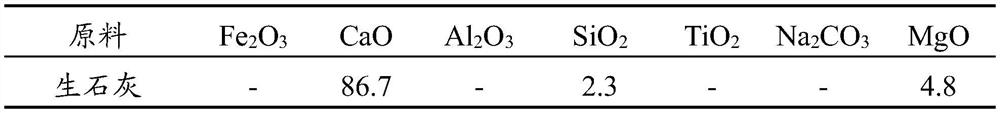

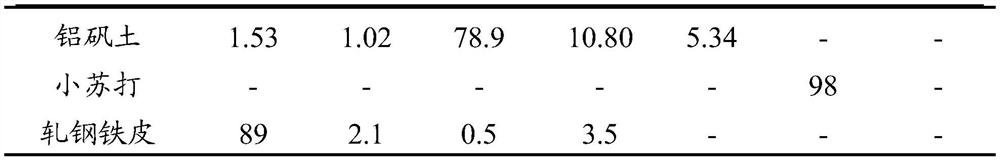

[0038] The raw materials such as quicklime, bauxite, baking soda and rolled steel skin are taken, fully mixed and ground to prepare a briquette with a particle size of 15mm. Among them, Fe in the dephosphorization agent according to the mass ratio 2 O 3 : CaO is 4.1:1, mass ratio CaO:Al 2 O 3 8.5:1, mass ratio Al 2 O 3 : Na 2 O is 5.1:1.

[0039] Table 1 Example 1 Main components of each raw material (wt%)

[0040]

[0041]

[0042] Take 2.20Kg of pig iron blocks with an initial [C] content of 4.3 wt% and a [P] content of 0.23 wt% for dephosphorization test, control the temperature to 1410 °C, add 150 g of dephosphorization agent to the furnace respectively, and carry out dephosphorization for 10 min. [P] 0.060 wt%, [C] 3.2 wt% molten iron. The dephosphorization rate was 73.9%.

Embodiment 2

[0044] The raw materials limestone, bauxite, baking soda and iron-containing tailings are taken, fully mixed and finely ground to prepare a powder with a particle size of 1 mm. Among them, in the dephosphorization agent according to the mass ratio of Fe 2 O 3 : CaO is 2.3:1, mass ratio CaO:Al 2 O 3 8.4:1, mass ratio Al 2 O 3 : Na 2 O is 4.3:1.

[0045] Table 2 The main components of each raw material in Example 2 (wt%)

[0046]

[0047] Take 2.15Kg of pig iron blocks with an initial [C] content of 4.5wt% and a [P] content of 0.24wt% for pre-dephosphorization test, control the temperature to 1410℃, add 148g of dephosphorization agent to the furnace respectively, and carry out dephosphorization for 10min. [P] 0.064 wt%, [C] 4.0 wt% of molten iron was obtained. The dephosphorization rate was 73.3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com