Patents

Literature

114results about How to "Improve dephosphorization efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

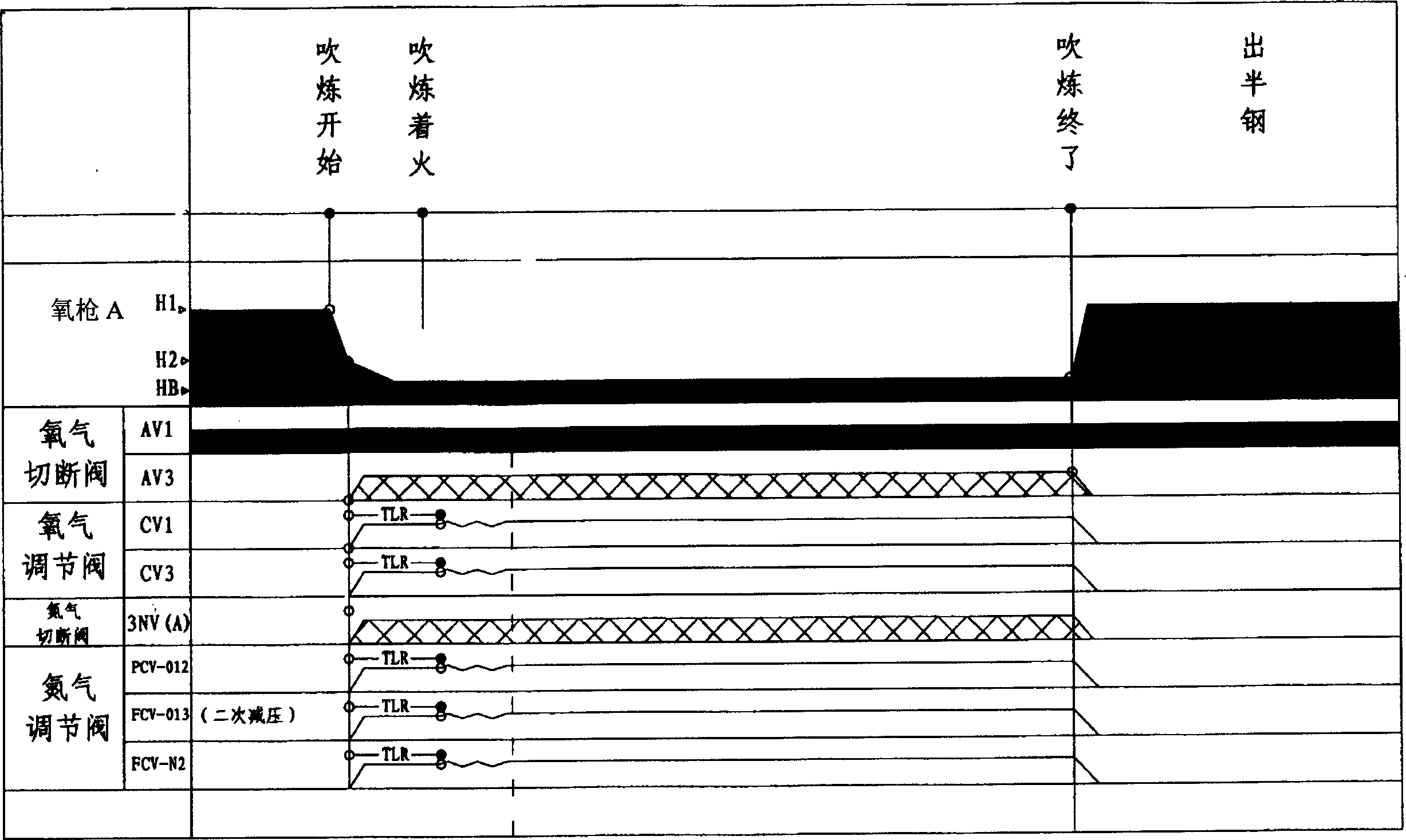

Converter oxide and nitrogen top-blown dephosphorizing method

InactiveCN1552919AHigh carbon contentInhibition of decarburization reactionsManufacturing convertersSputteringSlag

An oxygen-nitrogen top blowing converter process for desulfurization is carried out by blowing oxygen-nitrogen at its top while blowing nitrogen or inertial gases at its bottom to desulfurise. Its top blowpipe controls oxygen blowing to desulfurise in two modes, with mixed gases at some ratio or with pure oxygen switched with pure nitrogen, in order to inhibit sputtering and to enhance stirring in smelting pool when sputter occurs by excessive oxidation, so that balance of (P) / [P] in dynamics is improved. It desulfurises better when bottom blowing is weak, can inhibit decarbonise reaction effectively with >70% recovery of Mn in molten iron, also, strengthen blowing at top to stir strongly and shorten pre-treat time, increase rate of desulfurization, control slag elimination in procedure effectively to prevent sputtering, and increase stability and security.

Owner:BAOSHAN IRON & STEEL CO LTD

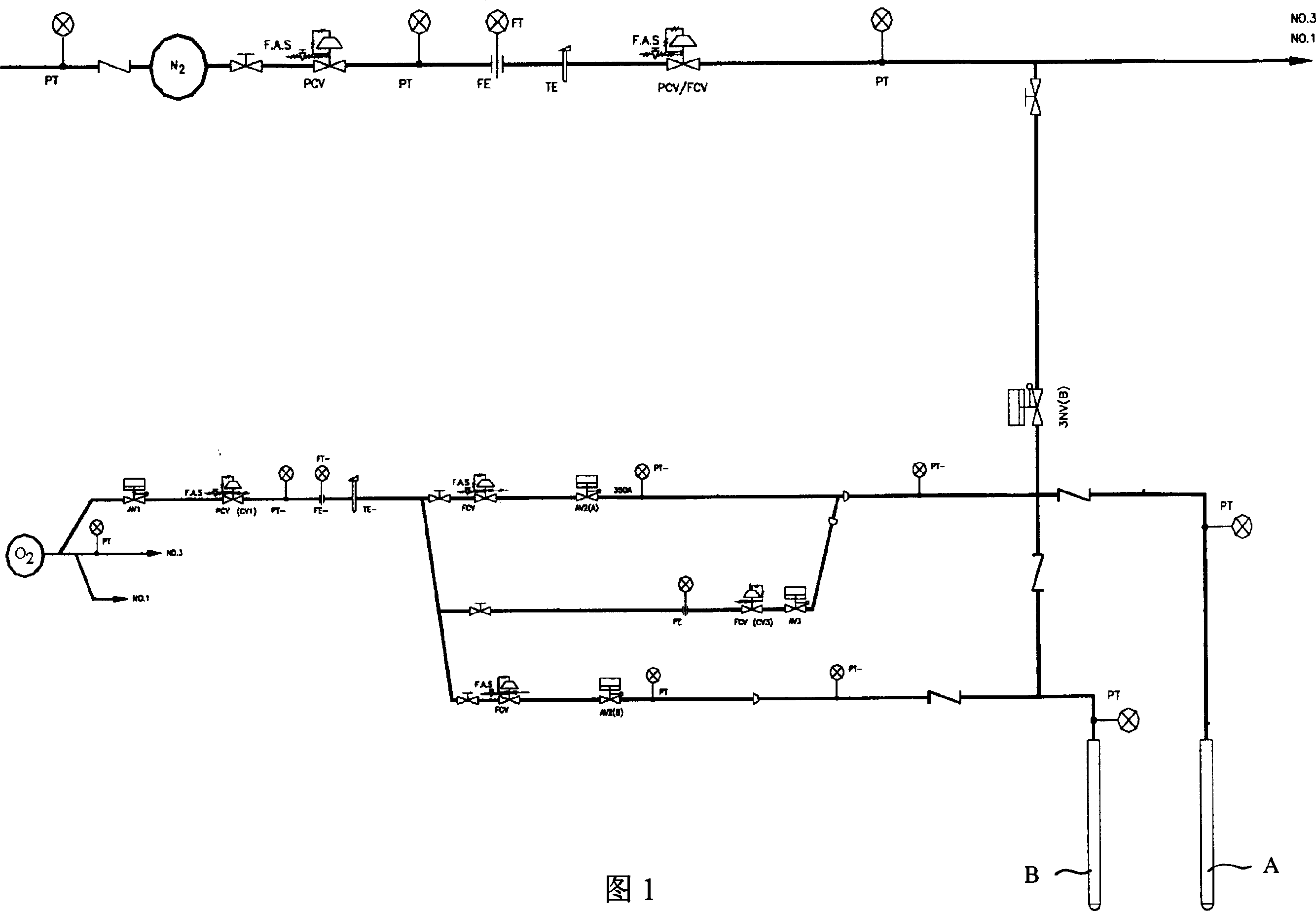

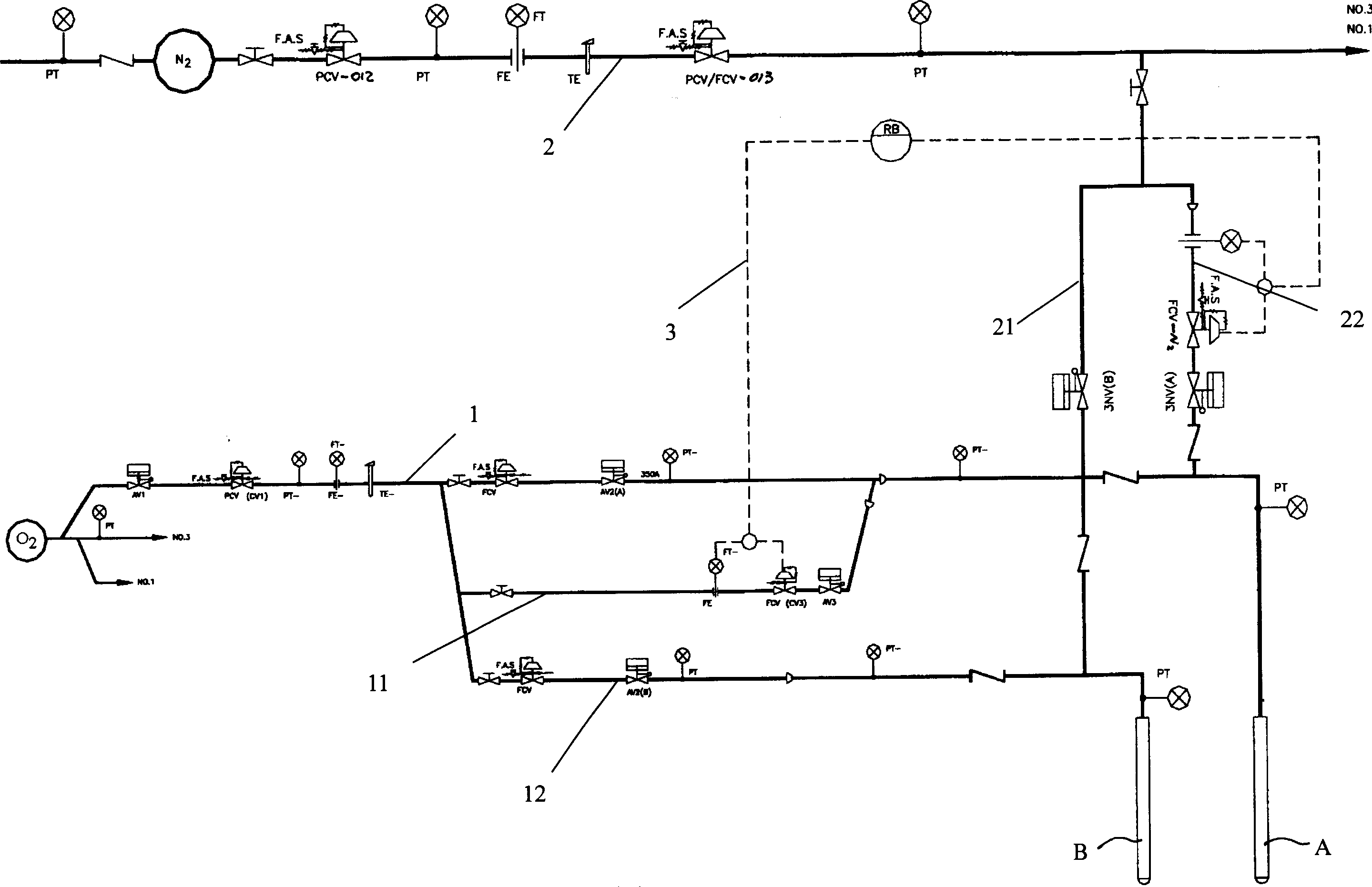

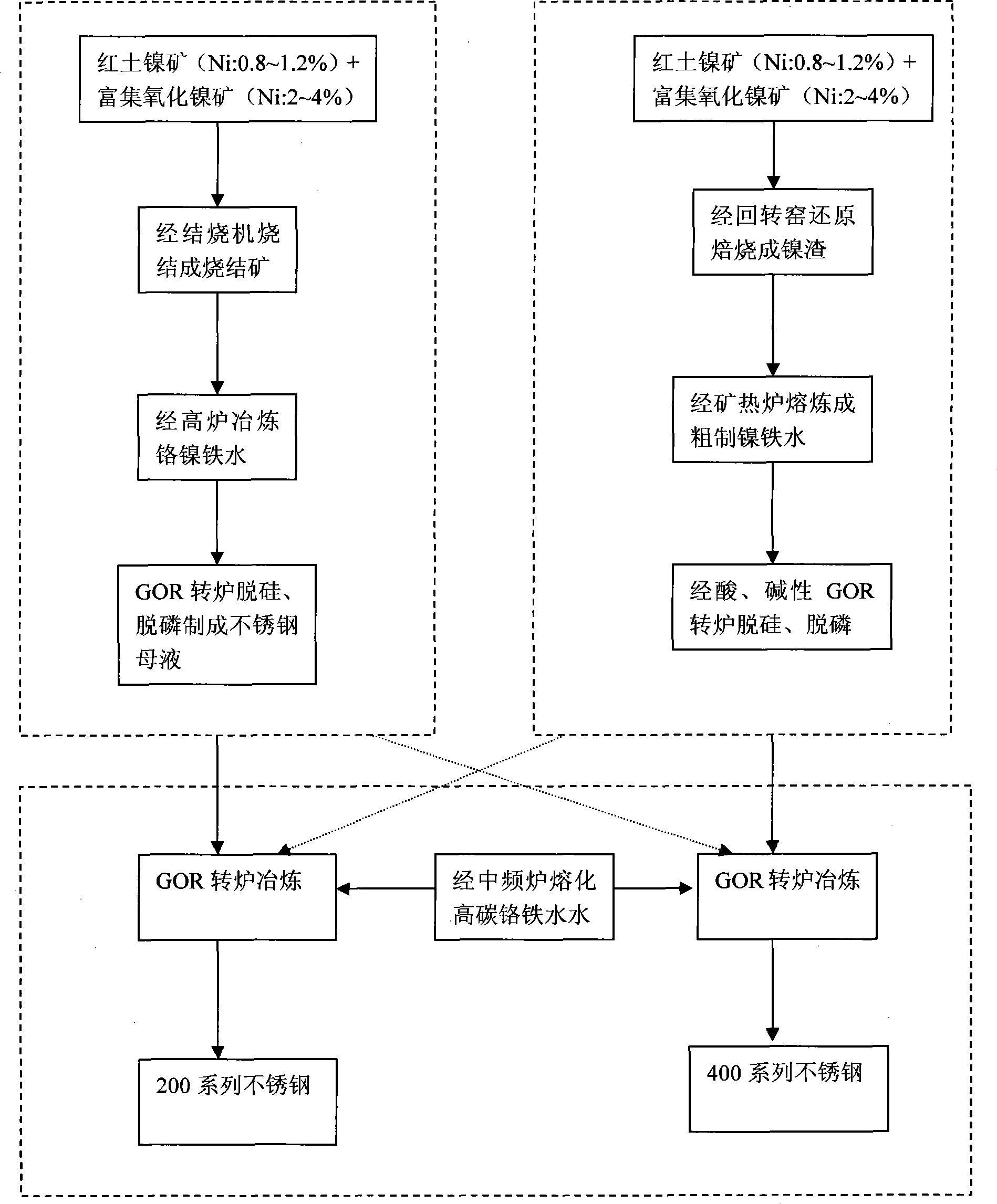

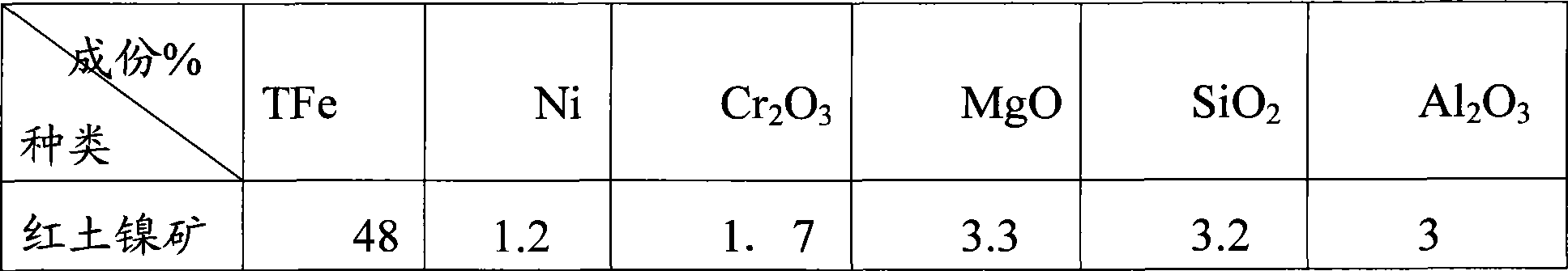

Process for directly producing austenitic stainless steel by utilizing oxide nickel

ActiveCN101445845AImprove dephosphorization efficiencyHigh yieldBlast furnace detailsElectric arc furnaceFerrochrome

The invention relates to a technological process for stainless steel smelting, in particular to a process for directly producing austenitic stainless by utilizing oxide nickel. The process has the following advantages: oxide nickel of various grades is adopted to obtain different ingredients of molten nickel iron by smelting in a blast furnace and a submerged arc furnace, an electric arc furnace is cancelled as a melting unit, the chemical heat of the molten iron is utilized to melt all or part of chromium and manganese alloy, and a bottom-blowing argon-oxygen converter is utilized to dephosphorize so as to improve the dephosphorization efficiency of molten chromium iron and the obtainment yield of chromium, thereby the following series and trademarks of products, i.e. 200 series of 201, 202, J4, and the like, 300 series of 304,304L, 316,321,329, and the like, are produced; and meanwhile, all links in the whole production flows are organically combined, and various energy sources, such as coal gas, steam, afterheat, and the like are fully utilized and recycled, thereby the energy consumption is low, the secondary waste gas discharge amount not great, the production cost and the raw material cost are low, and the investment and the occupied area are not great.

Owner:陈法官 +1

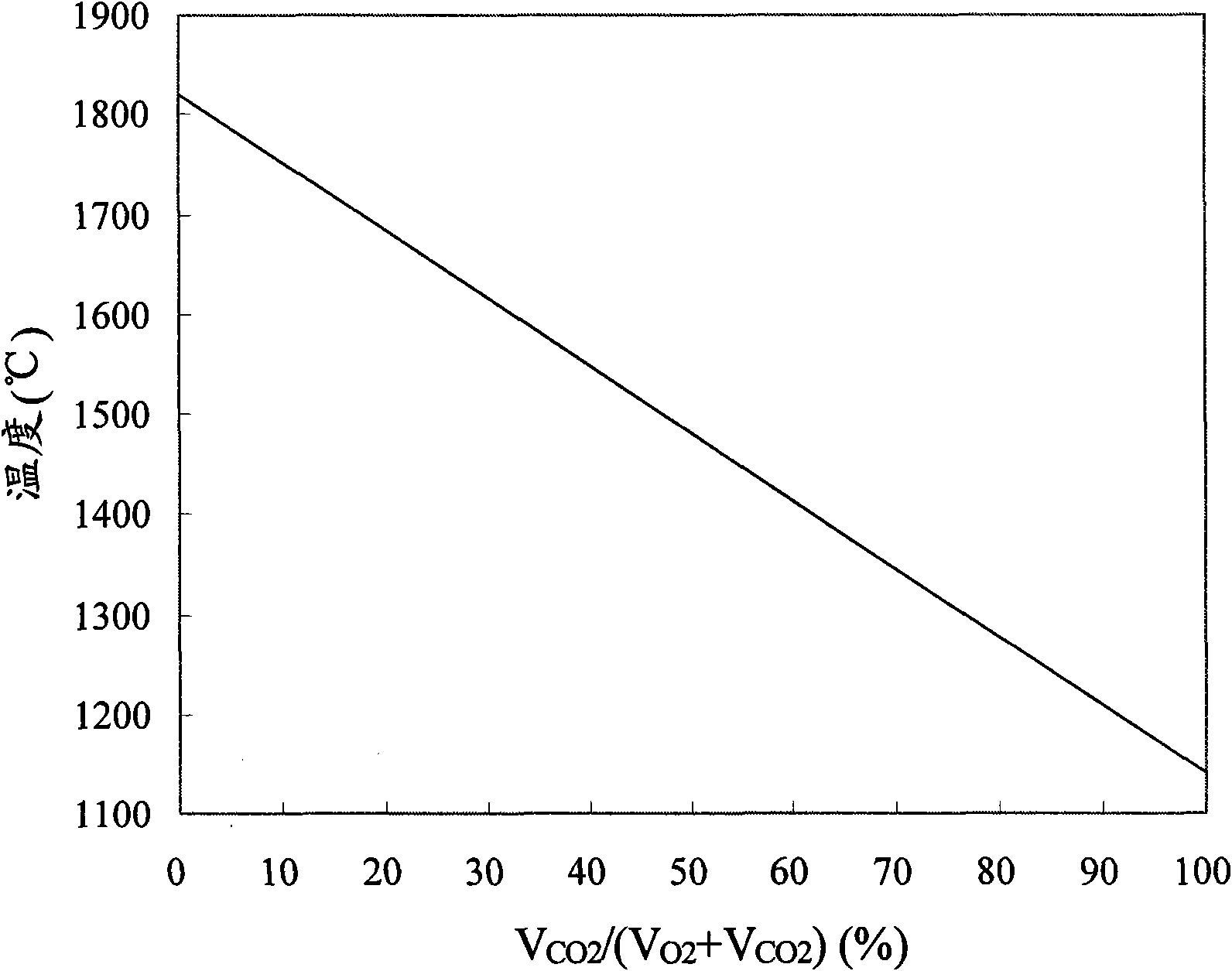

Method for controlling temperature of steelmaking melting pool of converter by blowing CO2 gas

InactiveCN101608250AAchieve diversificationEffective temperature controlManufacturing convertersSteelmakingMelting tank

The invention discloses a method for controlling temperature of a steelmaking melting pool of a converter by blowing CO2 gas, which belongs to the filed of convertor steel making and relates to a converter dephosphorization technology. The invention sprays CO2 gas (or mixed gas of CO2-O2) into the melting pool of the converter and realizes the smooth temperature increase of the melting pool by regulating the proportion of V[CO2] / (V[O2]+V[CO2]). The proportion of V[CO2] / (V[O2]+V[CO2]) is controlled at 10%-100% at the early and middle stages of melting (3-5min), the total flow rate of the blowing gas is 100-80000Nm / h, bottom blowing and strong stirring are adopted at this time, and the temperature is controlled between 1300 DEG C and 1400 DEG C. The proportion of V[CO2] / (V[O2]+V[CO2]) is adjusted and controlled at 10%-50% at the middle stage of melting according to desilication and dephosphorization situation and the temperature of the melting pool, and the flow rate of the blowing gas is 100-80000Nm / h. The method is applicable to the converter steel making of 30-300 tons, the dephosphorization rate can achieve 85%-95% by adopting the method, and the rephosphorization rate after slag dumping is lower than 3%.

Owner:UNIV OF SCI & TECH BEIJING

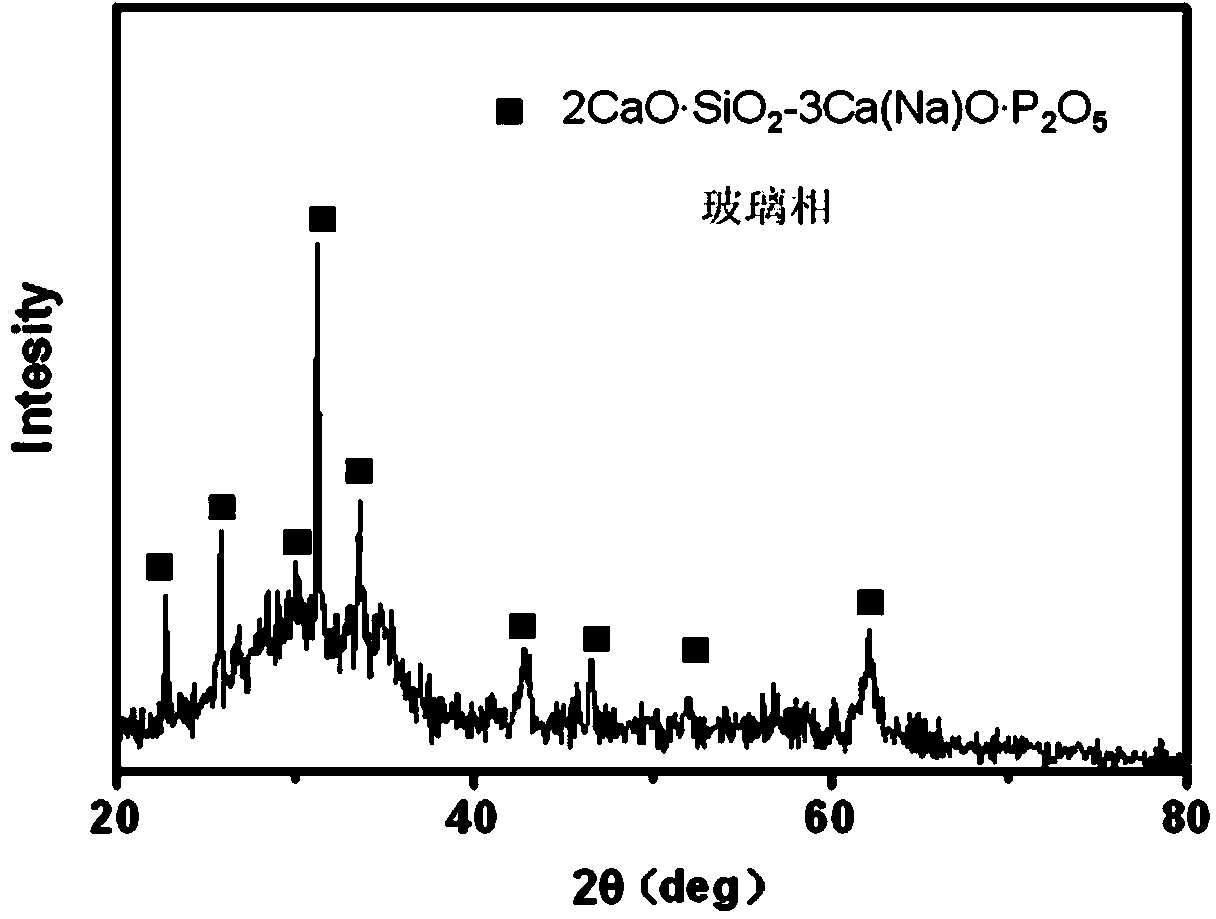

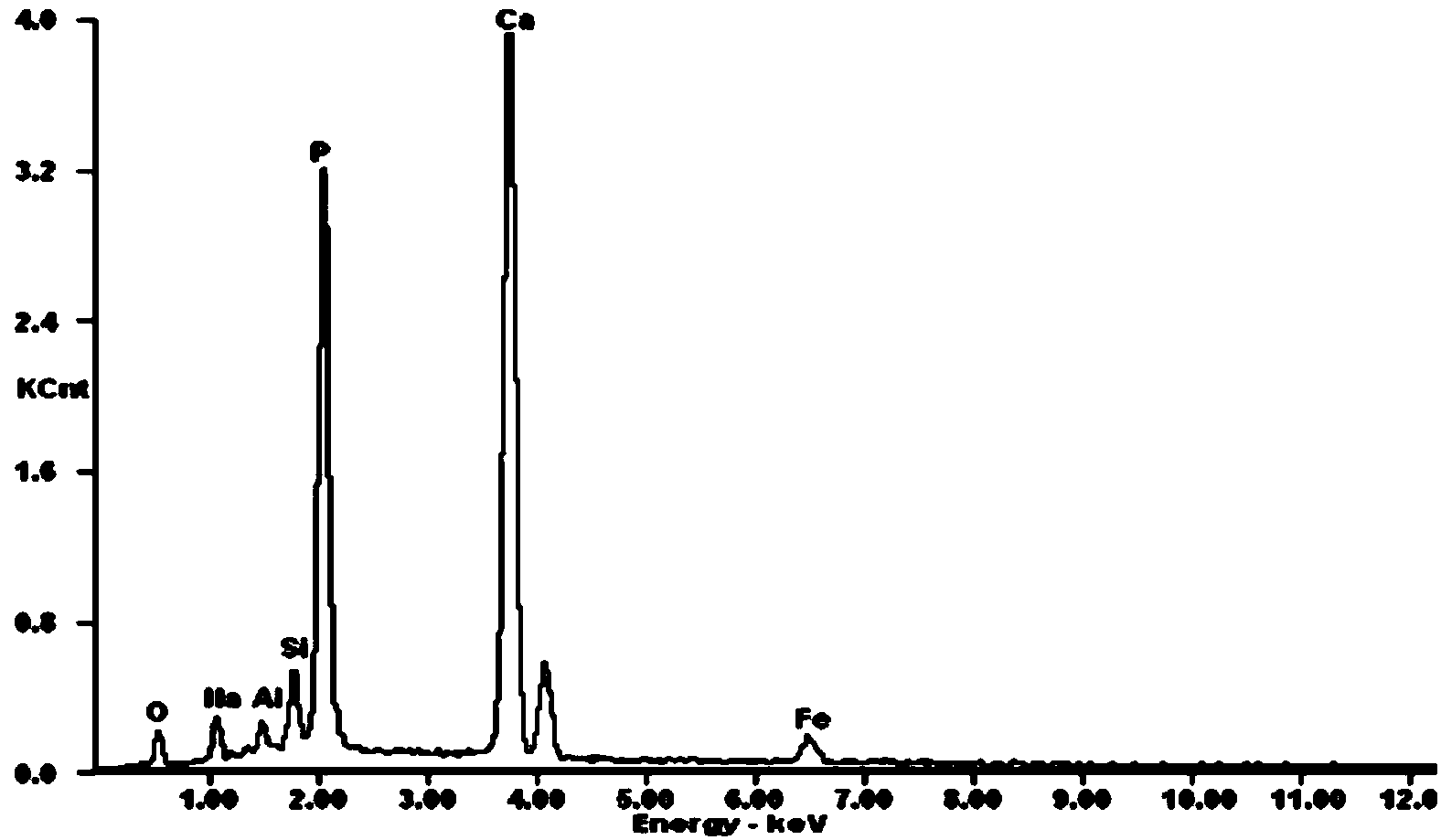

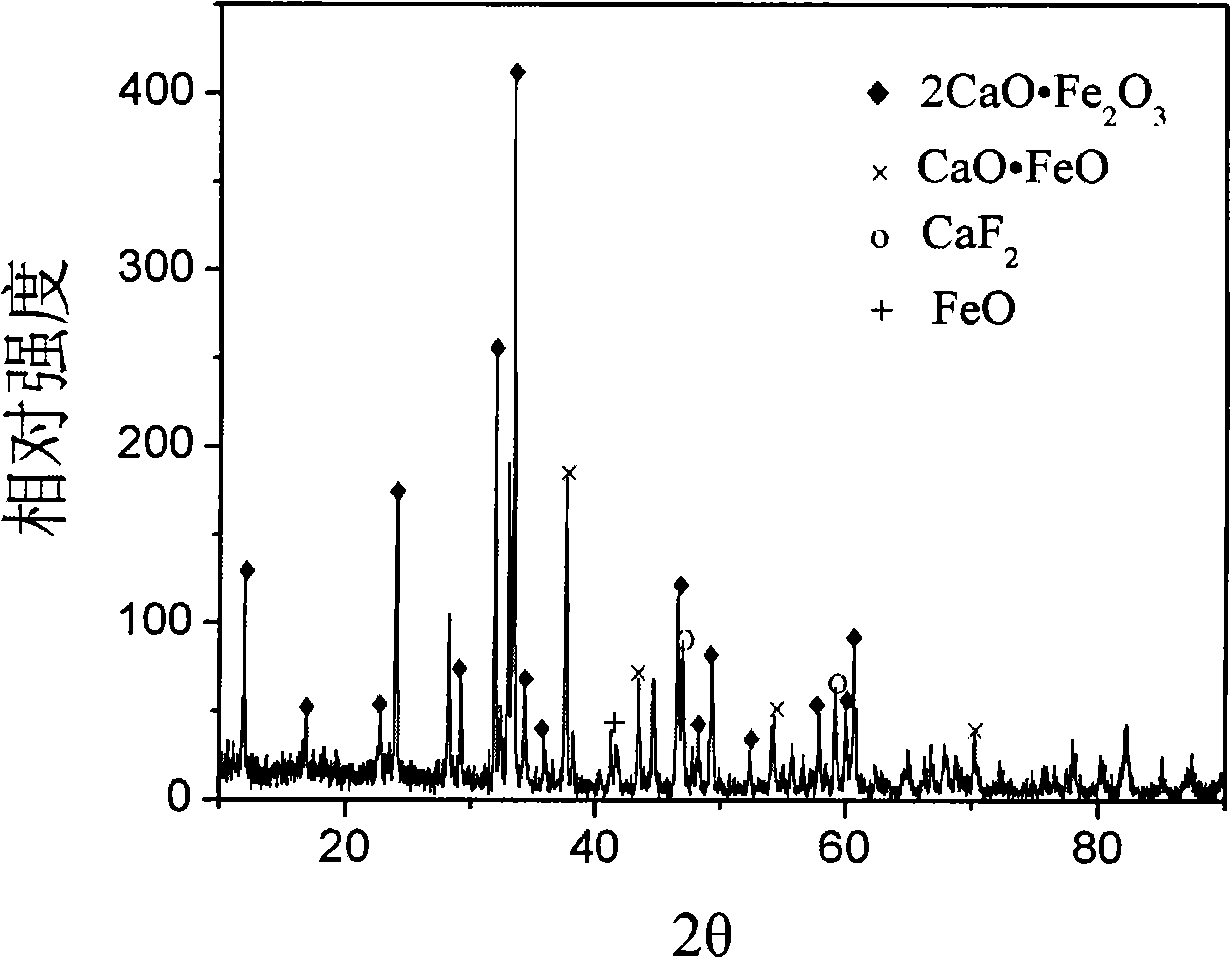

Dephosphorizing agent and application thereof

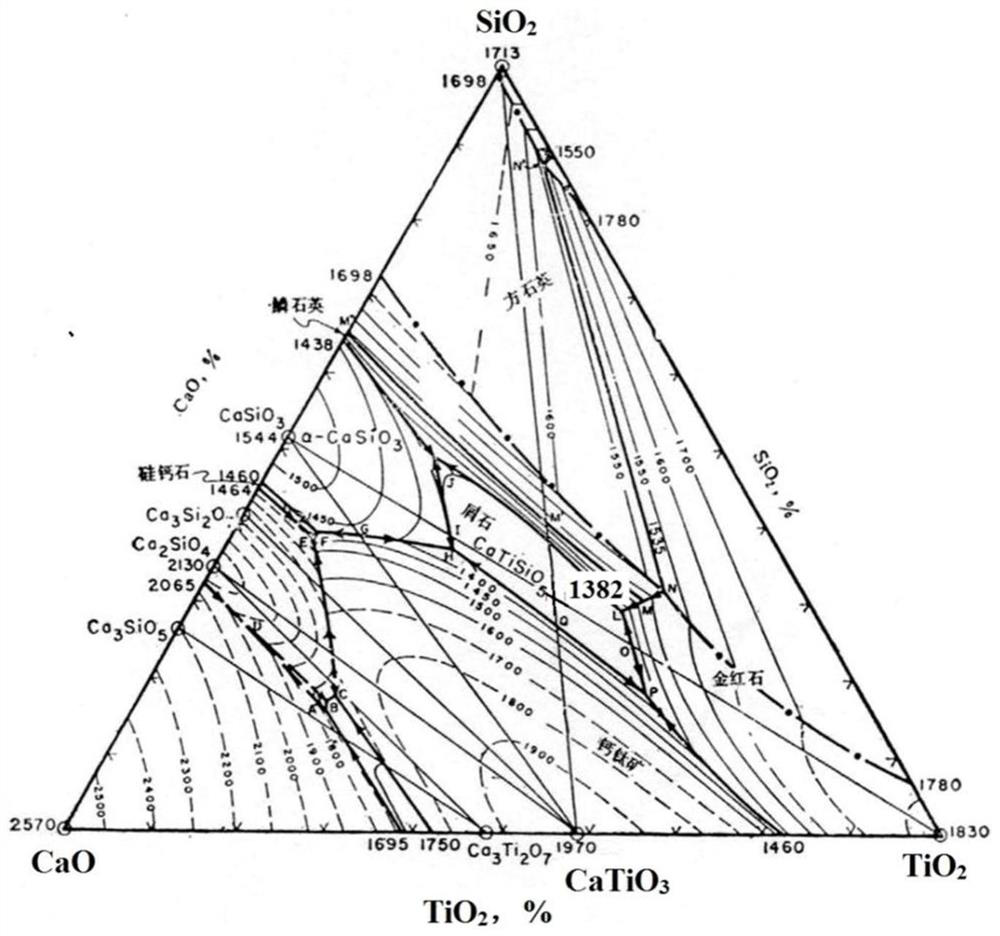

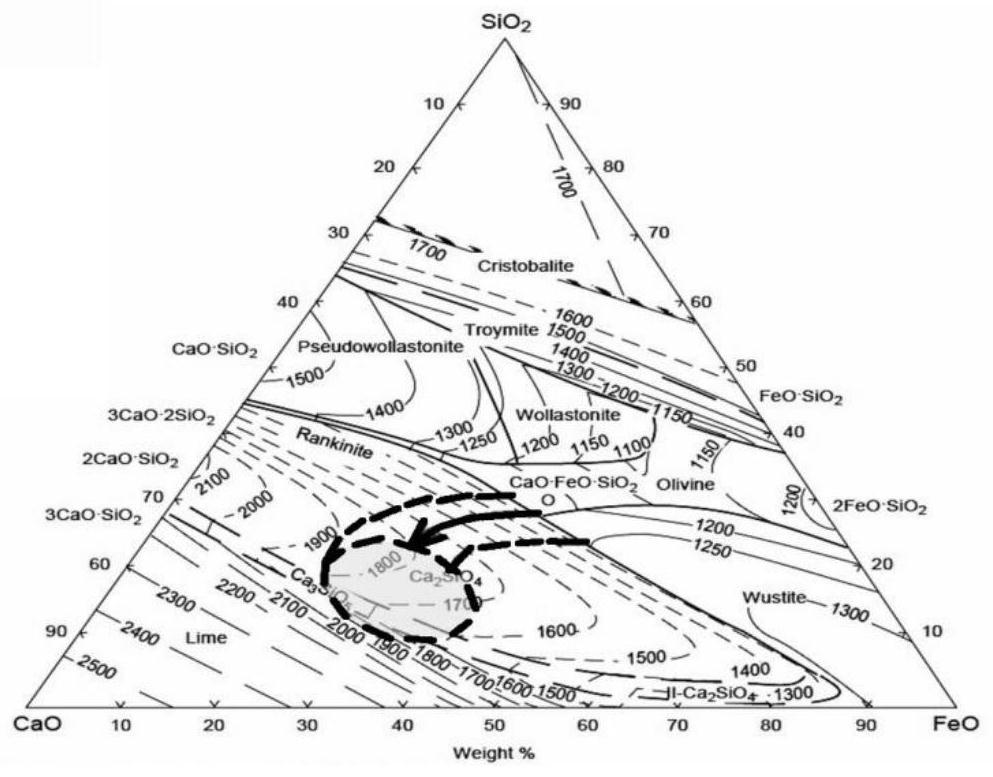

The invention relates to a dephosphorizing agent and application thereof, belonging to the technical field of ferrous metallurgy. The dephosphorizing agent solves the problems of low dephosphorizing efficiency, high residue consumption, environment pollution and difficulty in resource comprehensive utilization in the existing calcium-oxide-based molten iron pretreatment dephosphorizing agent. The dephosphorizing agent comprises the following components in percentage by mass: 25-50% of FeOt, 20-45% of CaO, 15-30% of SiO2, 2-10% of Na2O and 3-12% of Al2O3. After being molten, the molten iron dephosphorizing can form a solid-phase / liquid-phase coexistent multiphase residue system at 1300-1400 DEG C, wherein the solid phase is a 2CaO.SiO2 phase capable of providing a place for enriching oxidized phosphorus in molten iron, so that the dephosphorizing agent has the characteristics of favorable dephosphorizing effect, low slag consumption, no fluorine and small environmental pollution and is beneficial to comprehensive utilization of dephosphorizing slag.

Owner:CENT SOUTH UNIV

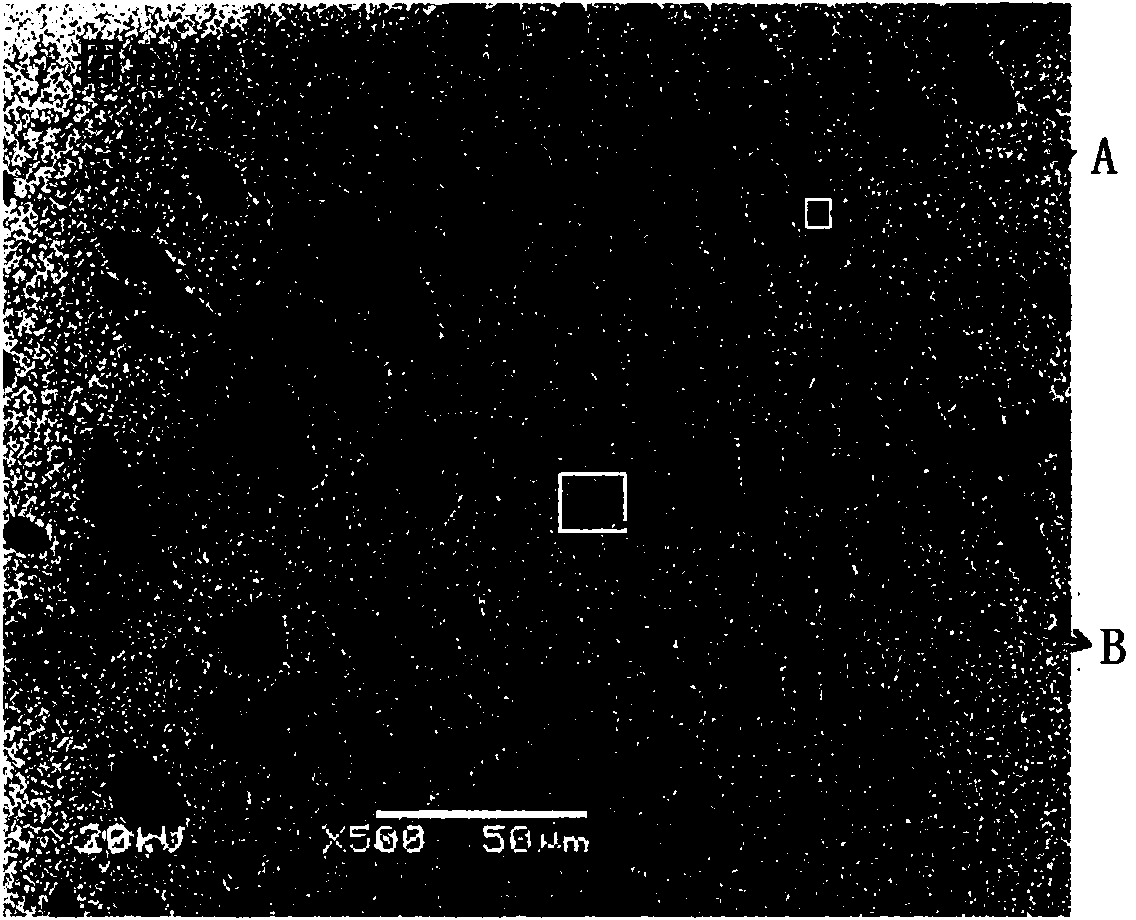

Compound dephosphorization agent with converter slag as raw material and preparing method thereof

The invention discloses a molten iron pretreatment compound dephosphorization agent with converter slag as the raw material, and the compound dephosphorization agent contains the following raw materials by weight: 45 to 55 percent of converter slag, 3 to 5 percent of quartz sand, 22 to 34 percent of steel-rolling iron sheet, 3 to 6 percent of bauxite, 10 to 14 percent of soda and 0 to 5 percent of fluorite; the raw materials meeting the ingredient demands are evenly mixed according to the proportions after being crushed, and then the product with the diameter being 20 to 50mm is produced after ball-milling, screen separation, palletizing and drying. The compound dephosphorization agent realizes cyclic utilization of the converter slag which accounts for 45 to 55 percent, thus reducing the produced slag amount in the steel-making process and the environmental load; the converter slag contains plenty of CaO and FeO, which can reduce consumption of lime to a certain degree, thus increasing the metal yield rate and reducing the steel-making cost; the compound dephosphorization agent has low melting point, slag can be formed fast, the liquidity is good, thus shortening the treatment time, the dephosphorizing efficiency is high, and the dephosphorized final slag has low alkalinity and low melting point.

Owner:CHONGQING UNIV

Slagging constituent for semisteel converter steelmaking and manufacturing method thereof

ActiveCN102912068AFast slagEfficient productionManufacturing convertersProcess efficiency improvementSteelmakingSludge

The invention discloses a slagging constituent for semisteel converter steelmaking and a preparation method thereof, wherein the slagging constituent for semisteel converter steelmaking comprises the following compounds in percentage by weight: 45-55% of SiO2, 2-8% of CaO, 5-15% of Al2O3, 2-8% of MnO, 5-15% of MgO, 5-10% of FeO and 10-20% of Fe2O3; the manufacturing method thereof comprises the following steps: scattering quartz sand, manganese ore, corundum slag and converter sludge and grinding till the granularity is below 1mm; and mixing with a bonding agent to obtain a mixture, wherein the mixture is pressed for palletizing and then baked for manufacturing the slagging constituent. The slagging constituent disclosed by the invention has the advantages of being quick in slagging speed, relatively low to control converter gun position integrally, easier to control in sladding process, low in melting point of converter final slag, relatively low for TFe in the slag, high in dephosphorization efficiency, and the like; the efficient production of semisteel converter steelmaking can be ensured; the solid waste of corundum slag is further utilized so that the corundum slag becomes a secondary resource for steelmaking and the cyclic utilization of waste resource is realized; therefore, the slagging constituent for semisteel converter steelmaking and the manufacturing method thereof have better economic value and social value.

Owner:PANGANG GRP PANZHIHUA STEEL & VANADIUM

Operation technology for electric furnace converter

ActiveCN102634637ANo power consumptionZero consumption productionProcess efficiency improvementElectric furnaceTemperature controlOxygenate

The invention discloses an operation technology for an electric furnace converter. A furnace burden structure containing 85-95% of molten iron and 5-15% of steel scrap is adopted; after a furnace lid of an electric furnace is opened, the steel scrap is added at one time through a material basket; molten iron is continuously blended at a speed of 2.0-4.0 tons per minute by utilizing an iron blending device, and meanwhile, an oxygen flow is jetted into the furnace through three furnace-wall praxair carbon oxygen guns which are mounted on the furnace wall; the oxygen supply strength is adjusted according to a blowing condition in the furnace and the carbon content in the furnace stabilized at 0.40-0.80% is ensured; lime, return mine and limestone are added while oxygen is blown; slagging is performed and temperature of the molten steel in the furnace is adjusted; during a blowing process, the temperature of the molten steel in the electric furnace is controlled within a range of 1500 DEGC to 1560 DEG C and the stability of carbon oxygen reaction in the furnace is ensured; and the temperature of the molten steel is controlled within the range of 1600 DEG C to 1650 DEG C at end point of the electric furnace, thereby finishing electric furnace smelting. According to the operation technology provided by the invention, the problems of serious splashing and difficulty in dephosphorization of electric furnace converter production are solved, the splashing is light, the time of electric furnace smelting is short, and energy conservation and cost reduction are realized.

Owner:ZENITH STEEL GROUP CORP +1

Production method for smelting clean steel from full-scrap steel using duplex electric arc furnaces

ActiveUS20180363077A1Improve cleanlinessLow melting pointManufacturing convertersElectric furnaceSteelmakingElectric arc furnace

A production method for smelting clean steel from full-scrap steel using duplex electric arc furnaces, which belongs to the field of electric arc furnace steelmaking. This method makes electric arc furnaces located in two positions be connected in series, wherein the electric arc furnace in a first position is dephosphorization electric arc furnace, and the electric arc furnace in a second position is decarbonization electric arc furnace.

Owner:UNIV OF SCI & TECH BEIJING +1

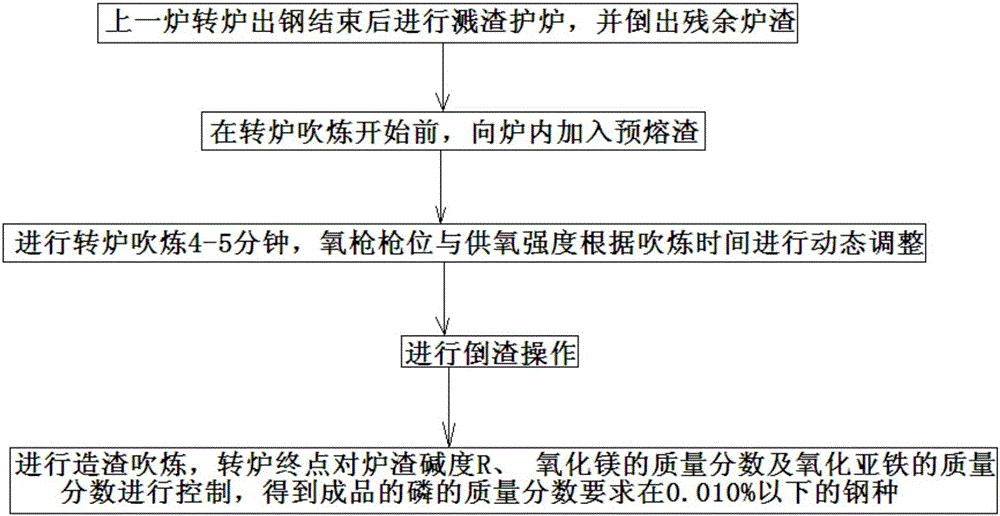

Smelting method of converter efficient dephosphorization

ActiveCN105671248AImprove dephosphorization efficiencyReduce phosphorus contentManufacturing convertersProcess efficiency improvementSlagFerrous metallurgy

The invention discloses a smelting method of converter efficient dephosphorization and belongs to the technical field of ferrous metallurgy. The smelting method of converter efficient dephosphorization comprises the following steps that after the last time of converter steel tapping, slag splashing furnace protection is conducted, and residual slag is poured out; before converter blowing is started, pre-melted slag is added into a converter; converter blowing is conducted for 4-5 minutes, the oxygen lance position and the oxygen supply intensity are adjusted dynamically according to blowing time; slag pouring operation is conducted; and slag-forming blowing is conducted, at the converter endpoint, the slag basicity R, the mass fraction of magnesium oxide and the mass fraction of ferrous oxide are controlled, and finished steel of which the phosphorus mass fraction is required to be 0.010% or below is obtained. Through the smelting method of converter efficient dephosphorization, the converter dephosphorization efficiency can be effectively improved, the phosphorus content at the converter endpoint is lowered, and the cost is low.

Owner:SHOUGANG CORPORATION

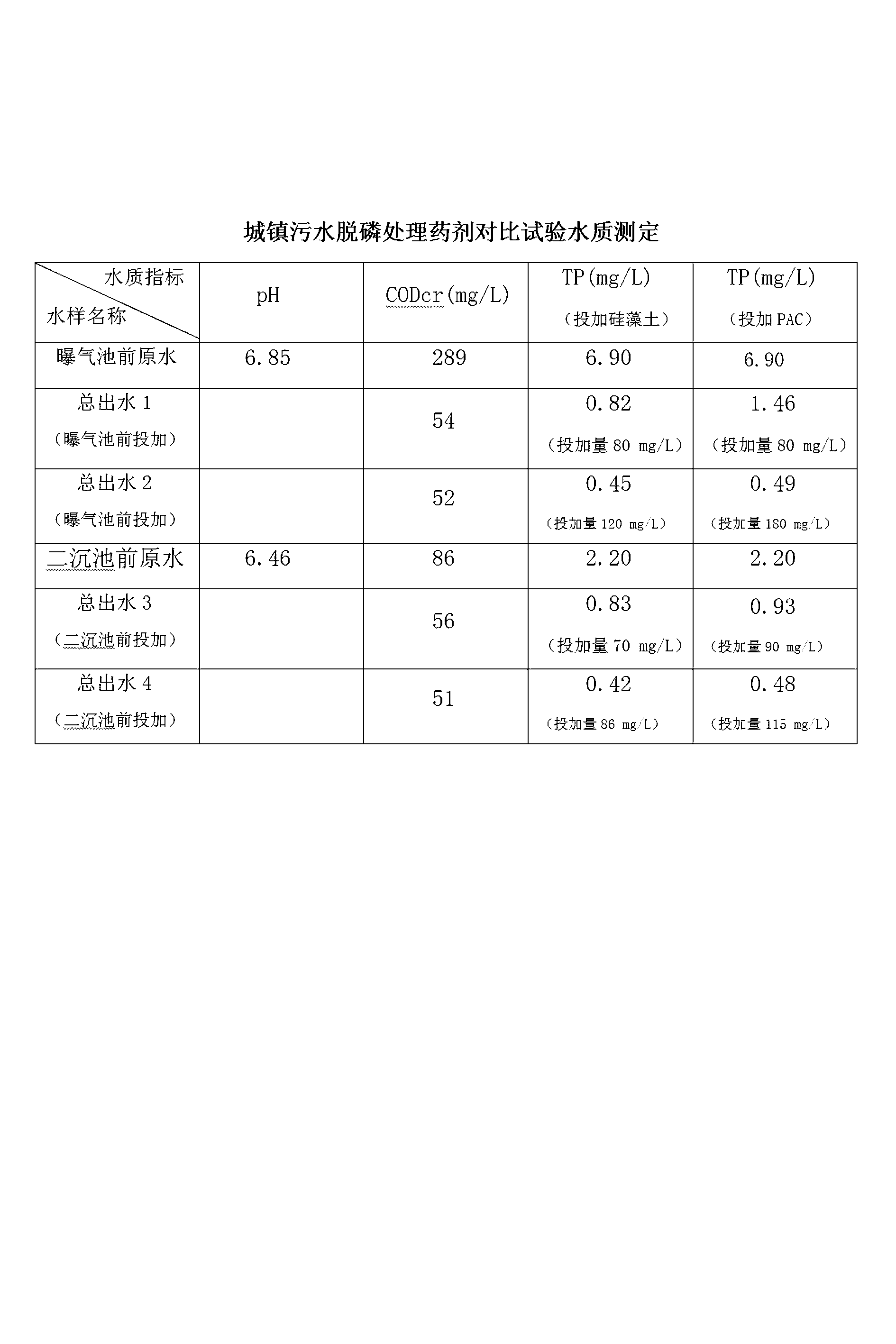

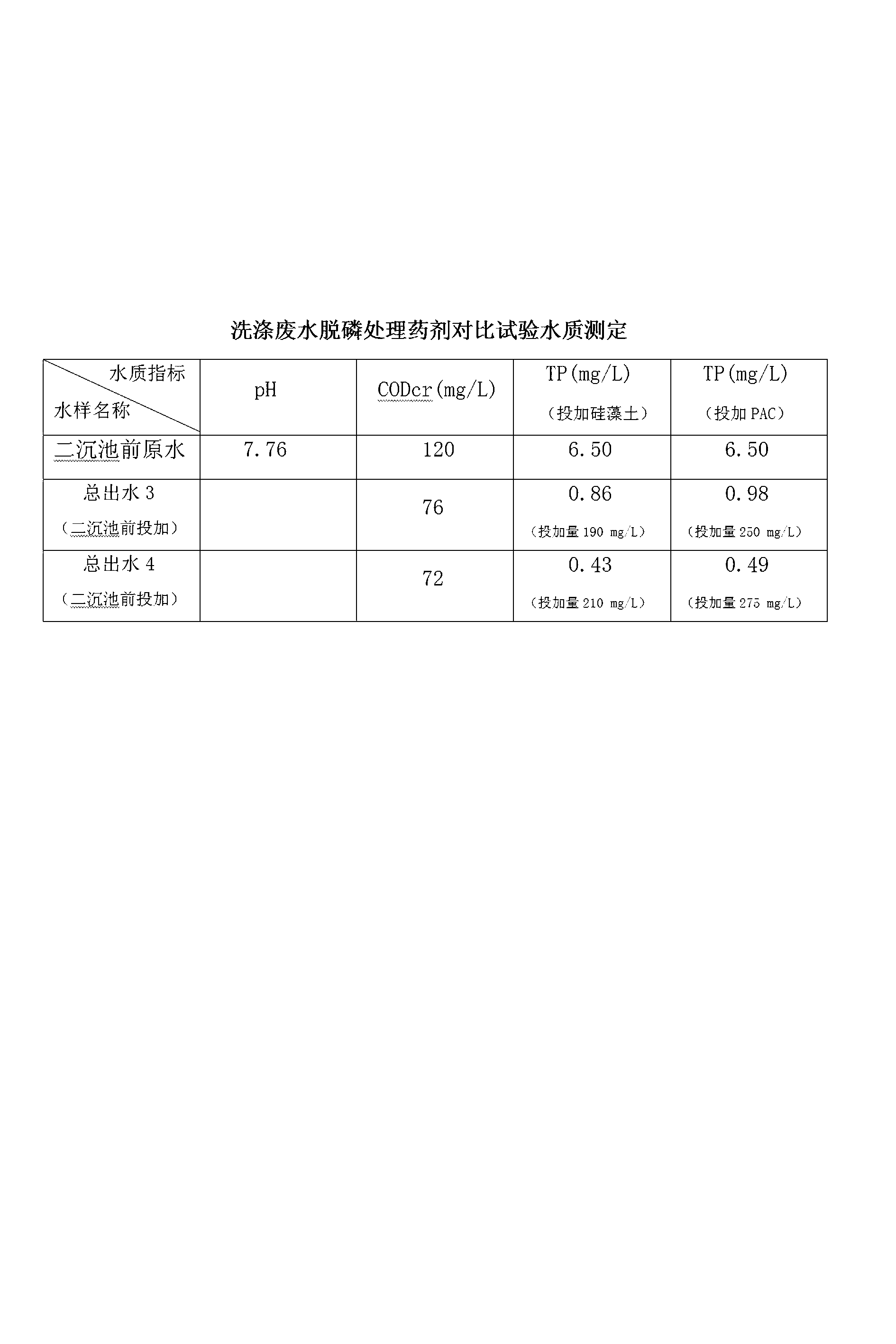

Compound refined diatomite sewage dephosphorization agent

ActiveCN102976458AImprove dephosphorization efficiencyGive full play to the adsorption effectWater/sewage treatment by flocculation/precipitationWater/sewage treatment by sorptionFlocculationSewage

The invention discloses a compound refined diatomite sewage dephosphorization agent. The compound refined diatomite sewage dephosphorization agent comprises 67-75% of modified refined diatomite, 24-32% of a polymeric diacid flucculant and 1-2% of a cationic organic polymer flocculant. The compound refined diatomite sewage dephosphorization agent has the advantages that the modified diatomite has efficient adsorption effects and the polymeric diacid flucculant and the cationic organic polymer flocculant are conducive to obvious improvement of aggregation and flocculation effects of suspended sludge blankets in a biological aeration tank or a sedimentation tank, thus the dephosphorization efficiency of sewage treatment is greatly improved; and compared with the traditional chemical dephosphorization technology only adopting an aluminium salt or a ferric salt, a technology adopting the compound refined diatomite sewage dephosphorization agent has higher treatment efficiency and a lower operation cost.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP +1

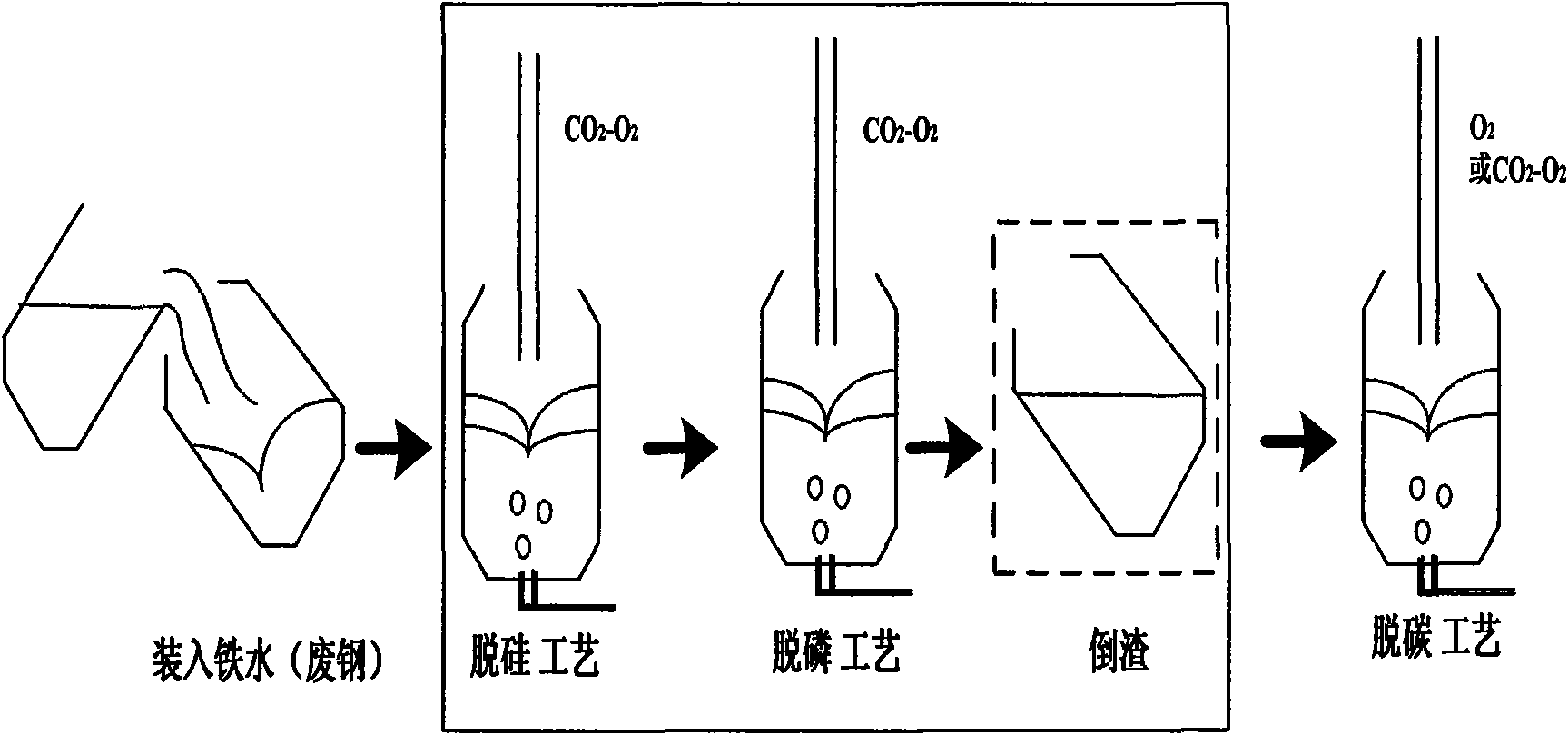

Converter steelmaking process for recycling converter final slag

InactiveCN103882178AHigh yieldReduce usageManufacturing convertersProcess efficiency improvementSteelmakingMaterials science

The invention relates to a converter steelmaking process for recycling converter final slag, belonging to the technical field of converter steelmaking. The converter blowing process is divided into two steps including a dephosphorizing step and a decarbonising step; before the beginning of blowing in the dephosphorizing step, 0-70 kg / t of converter final slag in a cooled state is added firstly; then, bowing in the dephosphorizing step is carried out by adding iron and waste steel; slag having low FetO content is produced in the blowing process; deslagging is carried out after blowing; then, blowing in the decarbonising step is carried out; carbon catching and steel tapping are carried out after blowing in the decarbonising step; and converter final slag is remained in the converter and used for an underfired furnace to blow in the dephosphorizing step. The converter steelmaking process for recycling converter final slag disclosed by the invention has the advantages that the best use of converter slag is ensured to the most extent; and loss of steel materials is further reduced for smelting low-TFe dephosphorization slag.

Owner:SHOUGANG CORPORATION

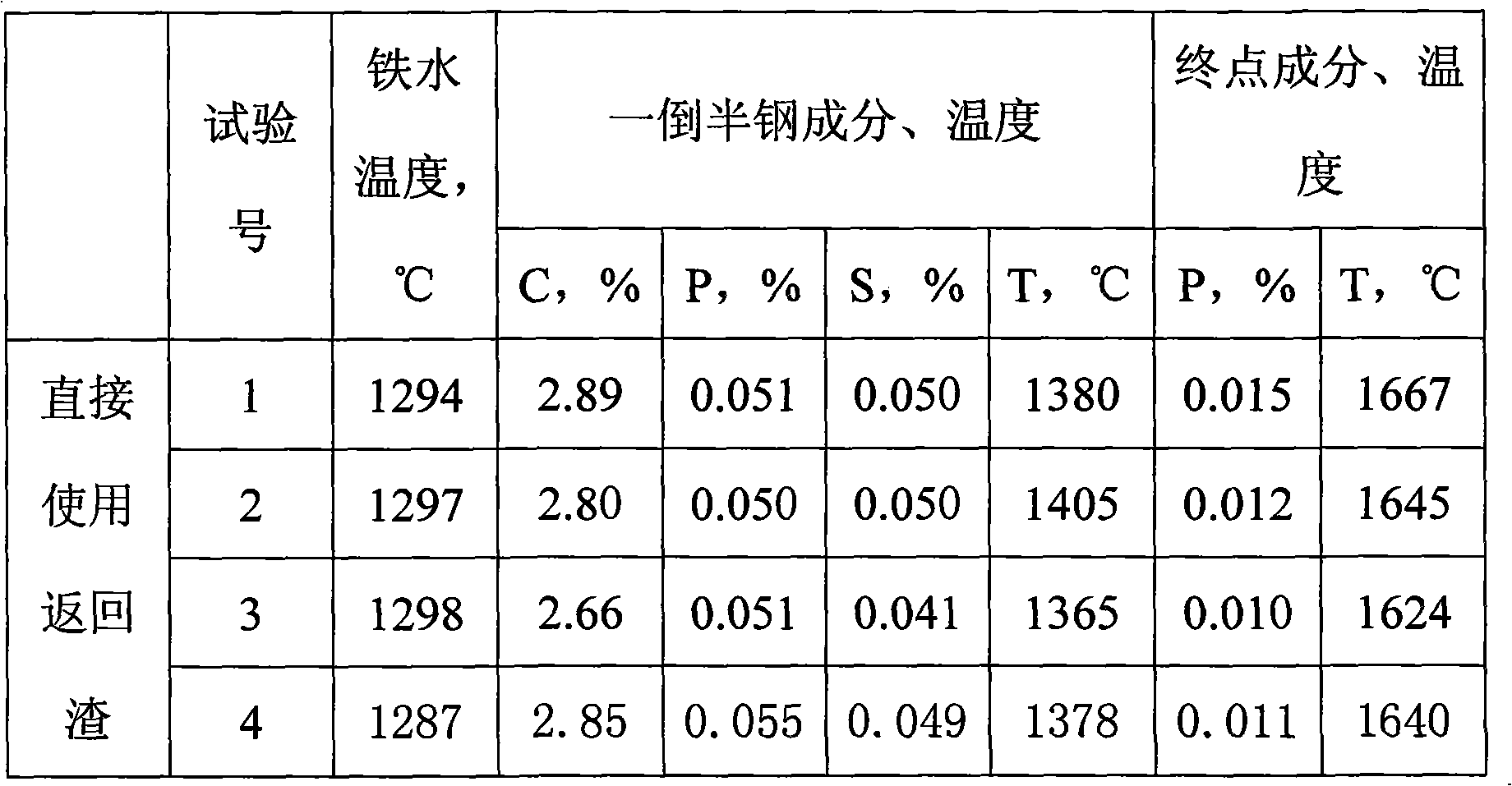

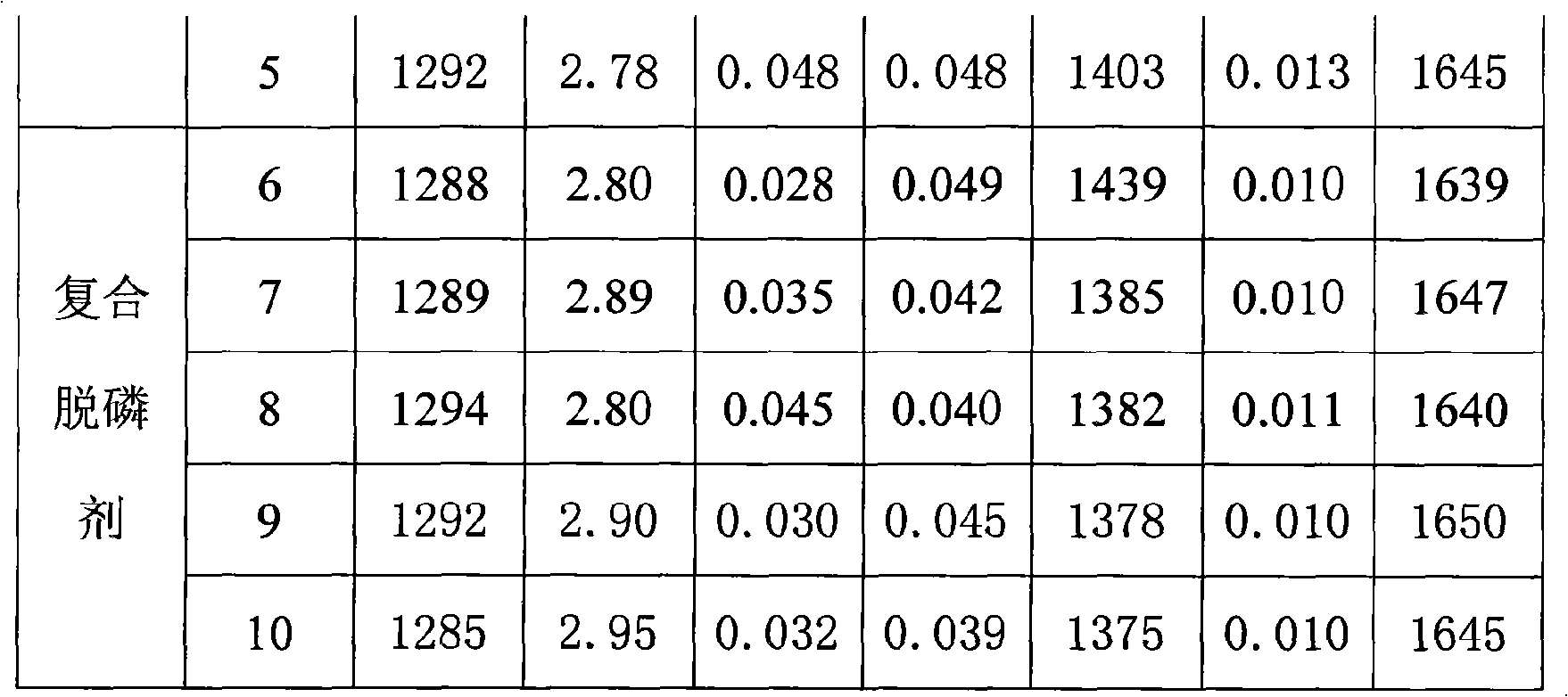

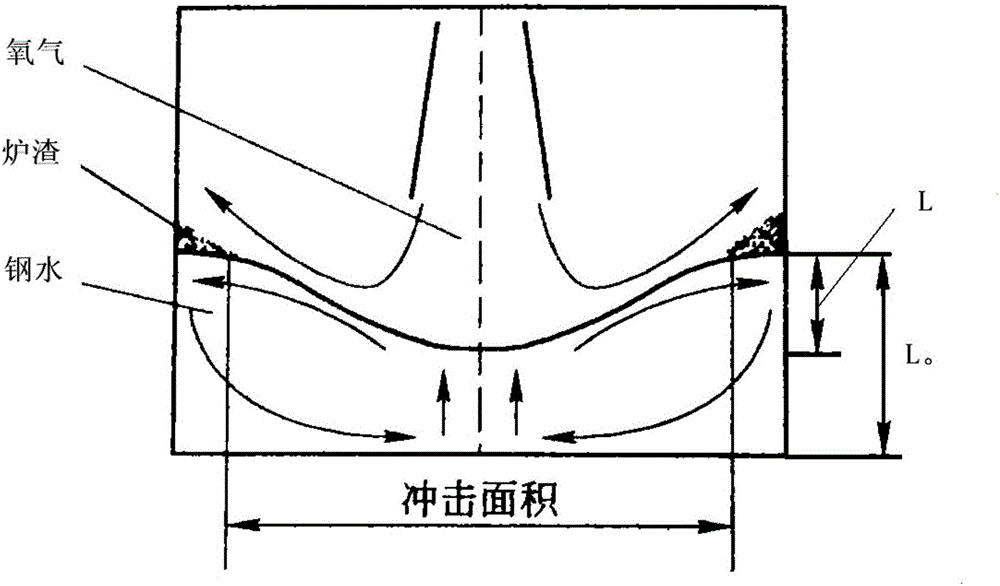

Molten iron pre-dephosphorization method by utilizing top and bottom combined blown converter

The invention relates to a molten iron pre-dephosphorization method by utilizing a top and bottom combined blown converter, belonging to the technical field of molten iron pre-dephosphorization. In the method, generally used molten iron pre-dephosphorization raw and auxiliary materials, such as lime, iron ores and fluorite, are adopted; through controlling the gun position and oxygen flow of a dephosphorization oxygen gun, the fast heating at an earlier stage of smelting is achieved, the slagging effect is improved, the dephosphorization efficiency is improved to above 80%; through the oxygengun, oxygen is supplied to a molten iron bath surface from the top, and a stirred gas is supplied to the inside of molten iron through a converter bottom gas supplying system; and through controllingthe gun position and oxygen flow of the oxygen gun, the dephosphorization efficiency is improved, and the emission load of waste slag in the steel-making process is reduced.

Owner:SHOUGANG CORPORATION

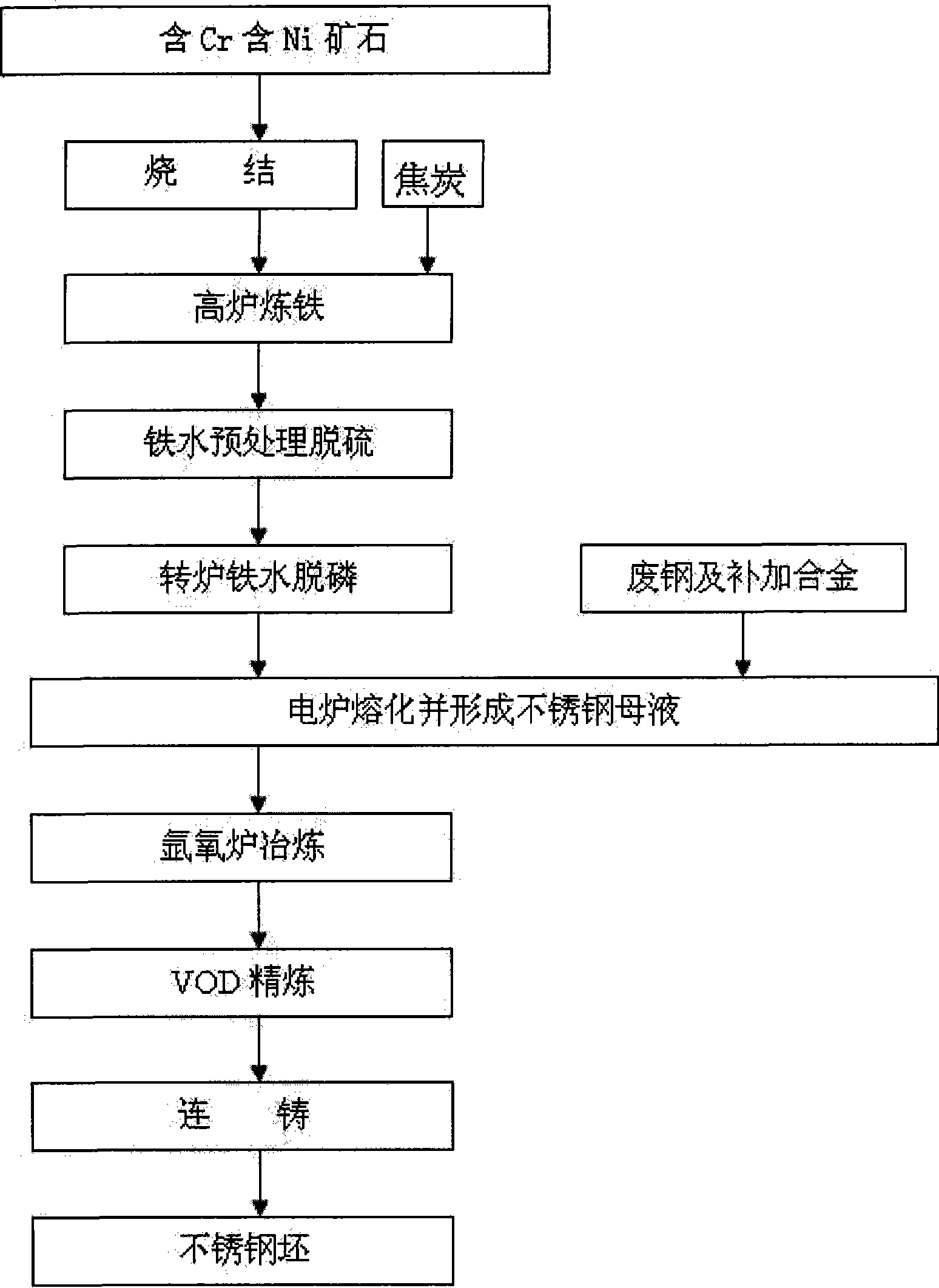

Ni-containing stainless steel smelting method

The invention discloses a method for smelting stainless steel containing Ni, which is characterized in that the method mainly comprises the following steps: low-grade nickel-containing chromium-containing ore is dried and then is sintered; the sintered ore is smelted into molten iron containing the Ni in a blast furnace; the molten iron is subject to pretreatment desulfurization and dephosphorization to form a stainless steel mother solution; iron alloy is melted in an electric furnace; the refining is performed in a stainless steel smelting furnace and a VOD furnace; and a stainless steel billet is obtained by continuous casting. The low-grade nickel-containing chromium-containing ore is used to substitute for chromium and nickel alloy to smelt the stainless steel, so the cost for the stainless steel is reduced greatly. At the same time, the method can fully utilize the low-grade ore, ensure that the idle scarce resource is fully utilized, and can reduce cost.

Owner:SHEN KAN QINHUANGDAO GENERAL ENG DESIGN & RES INST CORP MCC

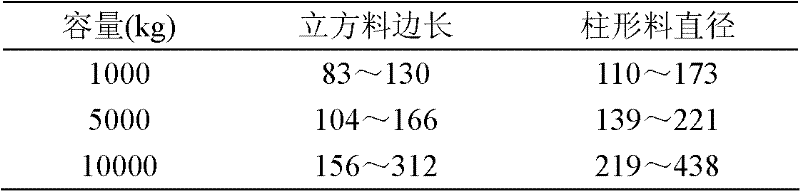

Arc furnace deep dephosphorization technology and deep dephosphorization agent thereof

InactiveCN101892352AImprove dephosphorization effectImprove dephosphorization efficiencyProcess efficiency improvementElectric furnaceSlagIron oxide

The invention relates to arc furnace deep dephosphorization technology and a deep dephosphorization agent thereof. The arc furnace deep dephosphorization technology comprises the following steps of: melting steel by using slag, performing deep dephosphorization and preparing foamed slag, and is characterized in that lime and the deep dephosphorization agent are added after the addition of scrap steel and before complete melting of the scrap steel in parts so as to enhance the deep dephosphorization effect. The deep dephosphorization agent consists of the following components in percentage by weight: 25 to 40 percent of lime, and 60 to 75 percent of ferric oxide powder. The method for preparing the dephosphorization agent comprises the following steps of: smashing the raw materials into 100 to 150 meshes and uniformly mixing; and premelting the materials at the high temperature of between 1,200 and 1,550 DEG C, cooling and processing into granules with the diameter of 3 to 50 mm. Compared with the prior art, the invention has the advantages that: the deep dephosphorization technology and the deep dephosphorization agent are adopted for deep dephosphorization, the lime is not added before charging, and the lime and the deep dephosphorization agent are added after charging and before complete melting of the materials in parts to enhance the deep dephosphorization effect, so that the tapping phosphorus is reduced to 0.0030 percent or even lower.

Owner:辽宁中汇环保科技有限公司

Hot metal pre-dephosphorization method

ActiveCN106282487AIncrease end point carbon contentReduce consumptionSteelmakingUltimate tensile strength

The invention provides a hot metal pre-dephosphorization method and belongs to the technical field of hot metal treatment in steelmaking. During loading of hot metal, the proportion of the hot metal is 92-100% and the proportion of scrap steel is within 8%; during slag formation, the slag basicity R is 1.6-2.6, feeding of lime and dolomite for slag formation is started within 40 seconds after blowing; when 7 minutes before oxygen supply, the oxygen supply flow Q is 1 / 4 to 1 / 2 of the oxygen flow of a decarburization furnace, and the later-period oxygen supply flow is 0.85-1.0 time of the early-stage oxygen supply flow Q; the maximal bottom-blowing air supply intensity is not less than 0.020Nm<3> / min.t; the final temperature of a dephosphorization furnace is not higher than 1380 DEG C, and the dephosphorization rate is higher than 80%. The method provided by the invention has the advantages that the dephosphorization efficiency of hot iron pre-dephosphorization based on an existing converter is not less than 85%; heating materials are not needed to be added for a following decarburization furnace, so that the converter production cost is greatly lowered.

Owner:北京北科中钢工程技术有限公司

Low-phosphorous steel smelting method of mixed blowing of oxygen and nitrogen of top blowing oxygen lance of converter

InactiveCN103160637AGas supply intensity does not decreaseLow oxygen supplyManufacturing convertersProcess efficiency improvementMelting tankSteelmaking

The invention relates to a low-phosphorous steel smelting method of mixed blowing of oxygen and nitrogen of a top blowing oxygen lance of a converter, and belongs to the technical field of converter steelmaking. The low-phosphorous steel smelting method of mixed blowing of the oxygen and the nitrogen of the top blowing oxygen lance of the converter includes the following steps that firstly, blowing of a dephosphorizing phase is conducted in the converter, blowing time is controlled in 6-9min, and normal blowing is conducted after deslagging; top-blowing air is mixed gas of the nitrogen and the oxygen in the dephosphorizing phase of the converter; and raw materials which are used by steelmaking are melted iron scrap steel, and scrap ratio is 5%-15%. The low-phosphorous steel smelting method of mixed blowing of the oxygen and the nitrogen of the top blowing oxygen lance of the converter has the advantages that a part of nitrogen is mixed into the top-blowing gas in the dephosphorizing phase, so that low oxygen supply is reached, and simultaneously top-blowing gas supply strength is not reduced (top-blowing mixing intensity is not reduced). Control of molten bath temperature1300DEG C-1380DEG C in the dephosphorizing phase is reduced, and dephosphorizing rate of the dephosphorizing phase is improved, low-phosphorou and extremely low-phosphorous steel with fished phosphorous content lower than 60ppm is achieved. High-phorphorous molten iron can be adopted to smelt, blowing is stable, and dephosphorizing efficiency is high.

Owner:SHOUGANG CORPORATION

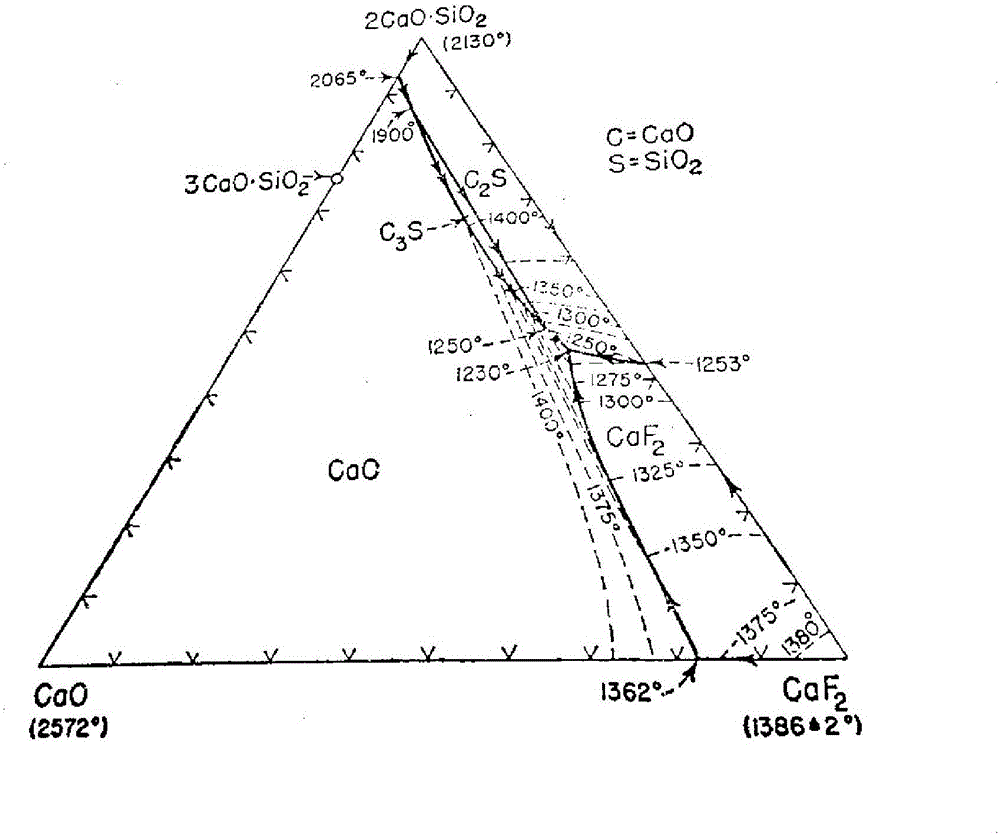

Premelting molten iron pretreatment dephosphorization agent

The invention discloses a pre-melted dephosphorizing agent that is used for preprocessing liquid iron in the field of metallurgy of iron and steel, and is particularly applicable to the smelting techniques that have bad raw material condition of the liquid iron and large fluctuation of initial phosphorus content or are used for producing low-phosphorus steel and ultra-low phosphorus steel. The pre-melted dephosphorizing agent that is used for preprocessing liquid iron is smashed into particles after a complete pre-melting processing at the temperature of 1250 to 1400 DEG C, and consists of following raw materials and weight percentages thereof: 35 to 50 percent of activated lime, 40 to 60 percent of iron oxide and 6 to 15 percent of fluorite. The pre-melted dephosphorizing agent that is used for preprocessing liquid iron has higher content of CaO and Fe2O3, meets the requirements of high basicity and high oxidizing slag of the dephosphorizing in the liquid iron preprocessing, can quickly reduce the phosphorus content in the liquid iron below 0.01 percent; consequently by adopting the pre-melted dephosphorizing agent that is used for preprocessing liquid iron of the invention, the phosphorus content in the liquid iron which has bad raw material condition of the liquid iron, high phosphorus content in the initial liquid iron and large fluctuation of initial phosphorus content can be reduced to a lower level, and the low-phosphorus liquid iron that is required for smelting the low-phosphorus steel and the ultra-low phosphorus steel can be provided.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Dephosphorization method of converter oxygen tapping

The invention discloses a dephosphorization method of converter oxygen tapping. The method is characterized in that after converter smelting is finished, oxygen tapping is carried out, in the tapping process, lime, fluorite and a modifier are added, and after tapping is finished, steel ladle dephosphorization is carried out through stirring. On the premise that the technology path is not changed, the dephosphorization capacity of steel ladle slag is utilized fully, the dephosphorization efficiency of a production line is improved by 2% to 4%, the dephosphorization effect of the converter-RH technology is stably improved, the converter dephosphorization pressure is reduced, the component judgment drop caused by phosphorus content standard exceeding of a steel ladle is avoided, the cost is low, and the efficiency is high.

Owner:TANGSHAN STAINLESS STEEL +1

Method for gasifying, dephosphorizing and steel-making in converter steel slag furnace

InactiveCN108754062AImprove dephosphorization efficiencyReduce phosphorus contentManufacturing convertersProcess efficiency improvementMaterial consumptionSemi-steel

The invention relates to a method for gasifying, dephosphorizing and steel-making in a converter steel slag furnace, and belongs to the technical field of metallurgy. The method comprises the following steps of: first furnace smelting: blowing gas, adding a slag-making material into a first furnace while starting to blow, controlling alkalinity of end-point slag until blowing is ended, adding first anthracite before tapping, splashing slag after tapping, gasifying, dephosphorizing and keeping all steel slag; second furnace smelting: reducing dosage of the slag-making material by one half, keeping one half of the slag after tapping, splashing the slag, and keeping the residual steel slag; and the rest of the steps which are the same with the first furnace smelting step; the third to the tenth furnace smelting: reducing 20-30wt% of the dosage of the slag-making material on the basis of the first furnace, keeping one half of the slag after tapping, and splashing the slag; and the rest ofthe steps which are the same with the first furnace smelting step. The method is simple, can reduce content of phosphor in steel slag, increases steel slag circulating times, reduces material consumption, improves converter dephosphorizing efficiency, relieves the problem that a semi-steel smelting heat source is insufficient, and reduces steel slag discharge amount.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Freon-free slagging agent for rotating furnace

The invention discloses a freon-free slagging agent for a rotating furnace, mainly comprising the following materials in parts by weight: 5-30 parts of manganese (Mn), 0-20 parts of silicon dioxide (SiO2) and 10-50 parts of total iron (TFe). The freon-free slagging agent is prepared into 5-50mm particles and the adding amount thereof is determined according to the silicon content in molten iron and is controlled to be within 5-7kg / t steel. The freon-free slagging agent has the advantages of prolonging the service life of a rotating furnace body, reducing the wastage rate of fettling material, accelerating the joint concentration of steelmaking of the rotating furnace, and reducing the time of daily maintenance and overhauling. Under the condition that the materials and the status of equipment are not changed, after the rotating furnace is added with the freon-free slagging agent, the technical indexes are all improved with different degrees, also the blowing is stable, the slagging is good, the phenomenon that the slag is re-dried is avoided, the operating conditions of steelmaking of the rotating furnace are improved, certain main consumption indexes of the rotating furnace take on downward trend, and the effects of dephosphorization and desulfurization are superior to that of other slagging agents.

Owner:郑州市鑫磊冶金材料有限公司

Dephosphorization method of high-phosphorous chromium-nickel pig iron

The invention relates to a dephosphorization method of high-phosphorous chromium-nickel pig iron. The method comprises the following steps in order: I. EAF (electric arc furnace) preliminary desilication, adding the high-phosphorous chromium-nickel pig iron into an EAF for fusing so as to realize preliminary desilication, with silicon in the desiliconized molten iron up to 0.05-1.0% by weight; II. removing electric furnace slag and blending the molten iron into an AOD (argon oxygen decarburization) furnace or converter, with the molten iron at a temperature of 1400-1550DEG C; III. dephosphorization, adding 6-45kg / ton steel of lime and 1-34kg / ton steel of fluorite into the blended molten iron, leaving the alkalinity R being 1-5, blowing a mixed gas of oxygen and nitrogen that are in a ratio of 2:1-5:1, when the gas allocation amounts to 0.5-3Nm<3> / ton steel. min. and the content of molten steel P is less than or equal to 0.04%, removing oxidized slag, thus obtaining low-phosphorous molten iron. In another method, a ladle and molten iron dephosphorization pretreatment is conducted after removing electric furnace slag following EAF preliminary desilication in step I. The dephosphorization method of high-phosphorous chromium-nickel pig iron in the invention is characterized by low cost and short time. The dephosphorization process is shortened to 6-10min, thus enhancing the dephosphorization efficiency.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Manganese-base vanadium-containing MnAlV alloy smelted by high-phosphorus manganese ores and smelting method thereof

The invention relates to a manganese-base vanadium-containing MnAlV alloy smelted by high-phosphorus manganese ores and a smelting method thereof. The MnAlV alloy comprises the following chemical components by mass percentage: 30%-50% of Mn, 20%-40% of Al, 10%-20% of Si, 1%-10% of V, not more than 0.08% of P and the balance of Fe and other impurity elements. The needed main raw materials for smelting the alloy comprise the high-phosphorus manganese ores, manganese-enriched residues, coke, blue coke, silica, ferrovanadium, pure aluminum as well as a corresponding dephosphorizing agent and a slag forming constituent. The smelting method comprises the following steps: according to the design requirements for alloy components, firstly weighing the needed raw materials based on per unit weightof alloy; smelting the raw materials into a silicon-manganese alloy mother liquid; dephosphorizing, alloying and casting; and finally cooling to obtain the MnAlV alloy. The manganese-base vanadium-containing MnAlV alloy smelted by the method has high aluminum content, high vanadium content and low phosphorus content; the alloy can be stored under various weather conditions and has a stale structure without chalking; and a crystal structure and a carbide shape of the alloy are improved so as to enhance steel performances such as yield strength, tensile strength, heat resistance and cold workability.

Owner:重庆中盛裕康冶金有限公司

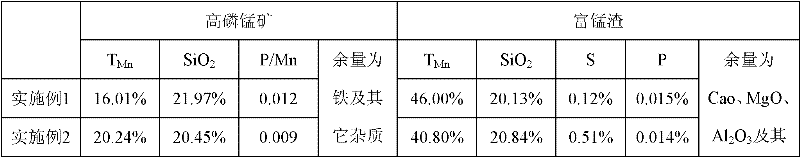

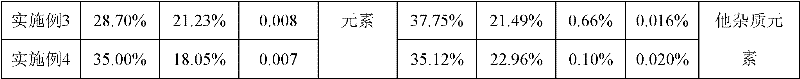

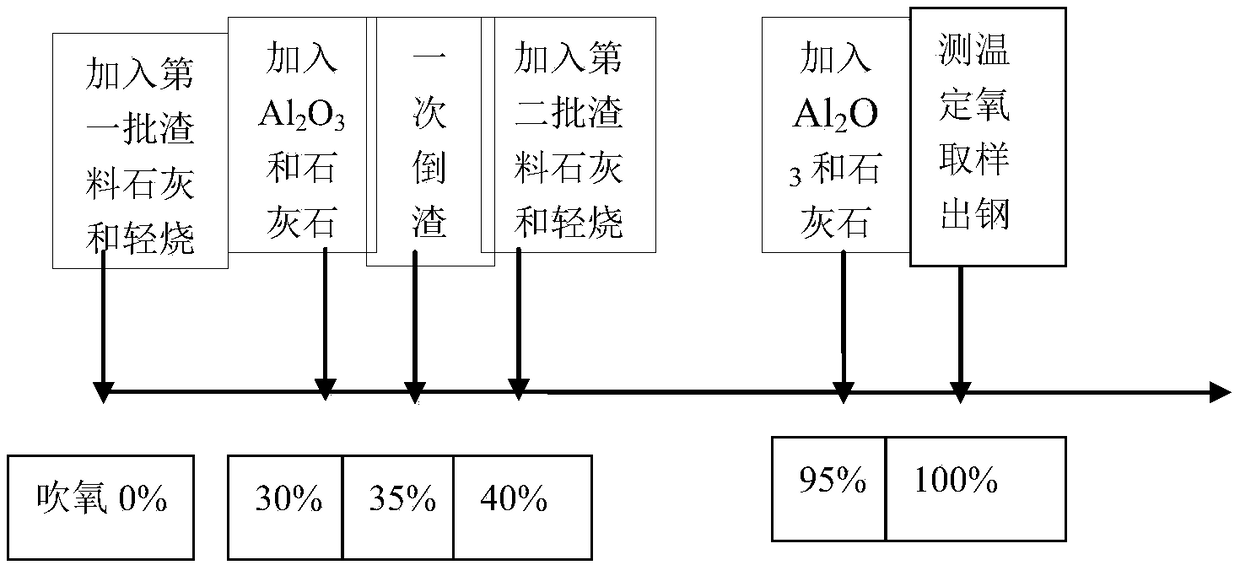

Method for producing ultra-low phosphorous steel by converter double slag process

ActiveCN108085449ALow melting pointImprove liquidityManufacturing convertersSlagReaction temperature

The invention belongs to the field of iron and steel, and particularly relates to a method for producing ultra-low phosphorous steel by a converter double slag process. The method comprises the following steps: 1) adopting a conventional feeding process in the early stage of blowing, and when the amount of oxygen to be blown accounts for 25 to 35% of total required blown oxygen amount, adding 1 to2 Kg / t of Al2O3 and 0.75 to 1.5kg / t of limestone into a converter; 2) when the amount of oxygen to be blown accounts for 30 to 40% of the total required blown oxygen amount, performing a deslagging operation, and then adopting the conventional feeding process; 3) when the amount of oxygen to be blown accounts for 90 to 100% of the total required blown oxygen amount, adding 0.75 to 1.5kg / t of Al2O3 and 1 to 2kg / t of limestone into the converter, thus obtaining the ultra-low phosphorous steel after the converter blowing is finished. The Al2O3 and the limestone are added to make slag during primary deslagging, so that the melting point of slag can be reduced, the fluidity of the slag is increased, the dephosphorization efficiency before deslagging is improved, and the phosphorus content is reduced to 0.025% or less during primary deslagging; the Al2O3 and the limestone are added at an end point of the converter to improve the flowability and foaming of the slag, the temperature of moltensteel is not reduced, and the slag-steel interface reaction temperature is reduced to improve the dephosphorization efficiency, so that the phosphorus content can be reduced to 0.005% at the end point of the converter.

Owner:武汉钢铁有限公司

Smelting method of low phosphate steel

InactiveCN108950127AReduce splashingExtend dephosphorization timeManufacturing convertersProcess efficiency improvementPhosphateSlag

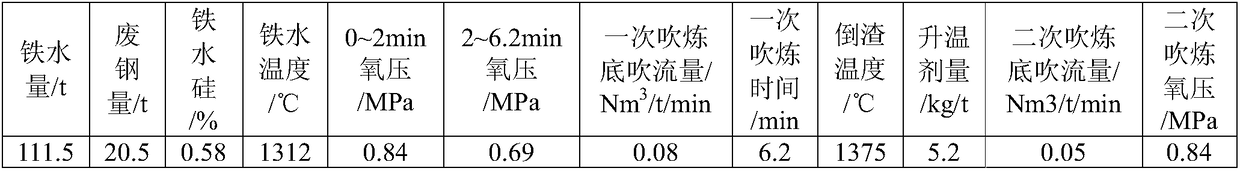

The invention relates to a smelting method of low phosphate steel. The method comprises the steps of molten iron desulphurization, waste steel adding and molten iron adding, converter primary blowing,deslagging, converter secondary blowing, and deslagging tapping. A double slag process is used for smelting, particularly, through control over the furnace inlet molten iron ratio and adoption of a material adding method, an oxygen supply method and a bottom blowing method which are matched, smelting of high-temperature high-carbon low phosphate steel is achieved; the smelting molten iron ratio is controlled according to the molten iron temperature and the molten iron silicon content, the primary blowing time is controlled to range from 5 min to 7 min, the variable gun variable oxygen pressure oxygen blowing mode is adopted, according to the molten iron silicon content, the lime adding amount is controlled, before secondary blowing gun lowering, a certain amount of temperature rising agent is added, the tapping temperature is controlled to be above 1670 DEG C, the tapping carbon content is controlled to above 0.1%, the process structure is adopted for producing, and the content of converter end point phosphorus is stably controlled to below 0.008%.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE +2

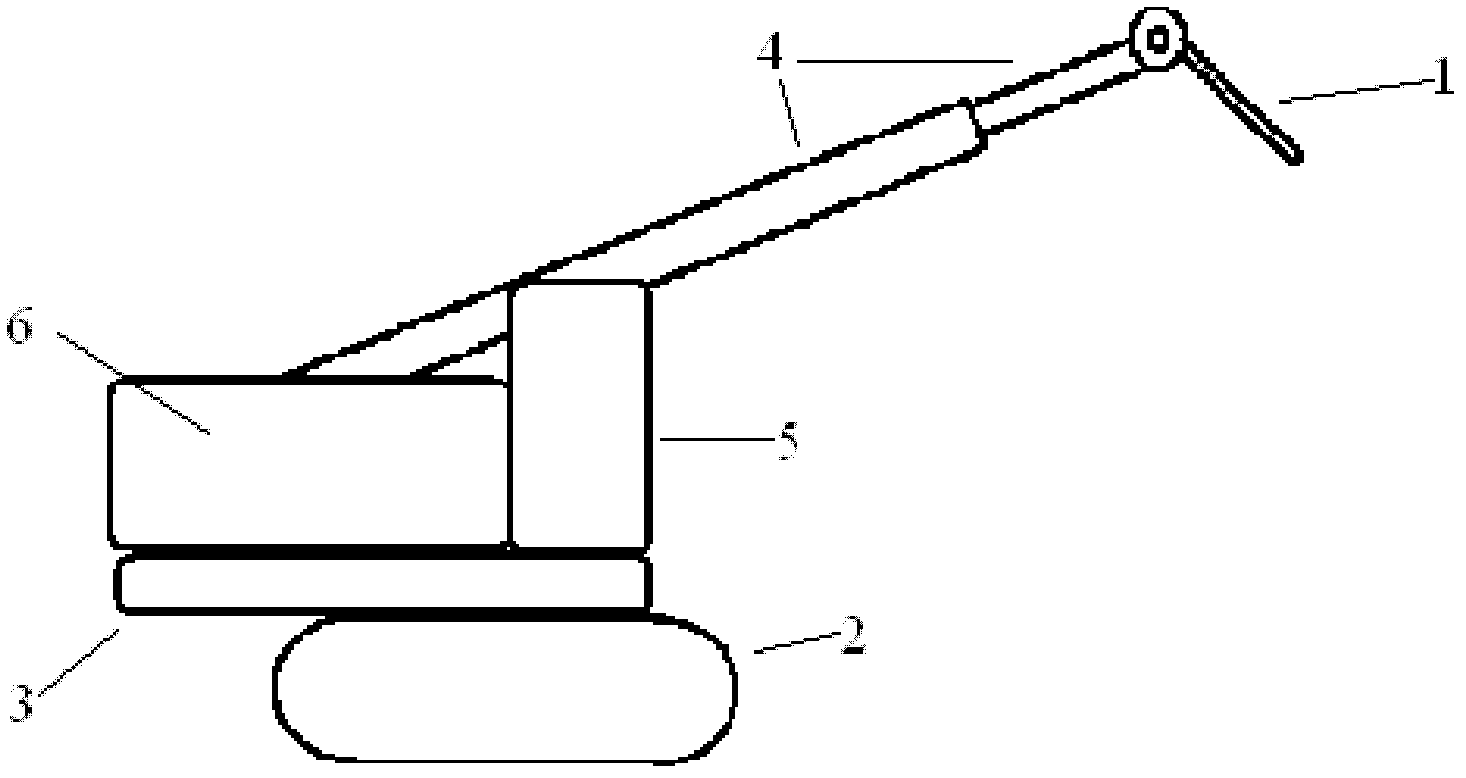

Vehicle-mounted slag-raking machine for converter, and use method

InactiveCN102559992AIncrease alkalinityReduce consumptionManufacturing convertersCasting cleaning apparatusSteelmakingEngineering

The invention relates to a vehicle-mounted slag-raking machine for a converter, and a use method, and belongs to the field of steelmaking slag-raking technology. The vehicle-mounted slag-raking machine for the converter comprises a slag-raking plate, a walking chassis, a rotary central disk, a telescopic working arm, a cab and a power system, wherein the rotary central disk is arranged above the walking chassis, and the power system is arranged at the left side over the rotary central disk; the cab is arranged at the right side over the rotary central disk, and the power system is adjacent to the cab; and one end of the telescopic working arm is connected onto the power system, and the other end of the telescopic working arm is connected with the slag-raking plate. The slag-raking is started in 4minutes to 7minutes after the start of converting, and the slag-raking machine is driven to a converter mouth, and is rightly opposite to the converter; and in a deslagging process, the slag-raking plate is fed into the converter by the telescopic working arm to slag off. The vehicle-mounted slag-raking machine for the converter has the advantages that: the use is flexible and convenient, and one slag-raking machine can be used for multiple converters; most of converter slag can be fast and effectively racked out, the decarburization slag basicity can be effectively improved by raking out a large number of dephosphorization slag, the dephosphorization efficiency can be improved, the lime consumption of the converter can be reduced, and the consumption of iron and steel materials can be reduced.

Owner:SHOUGANG CORPORATION

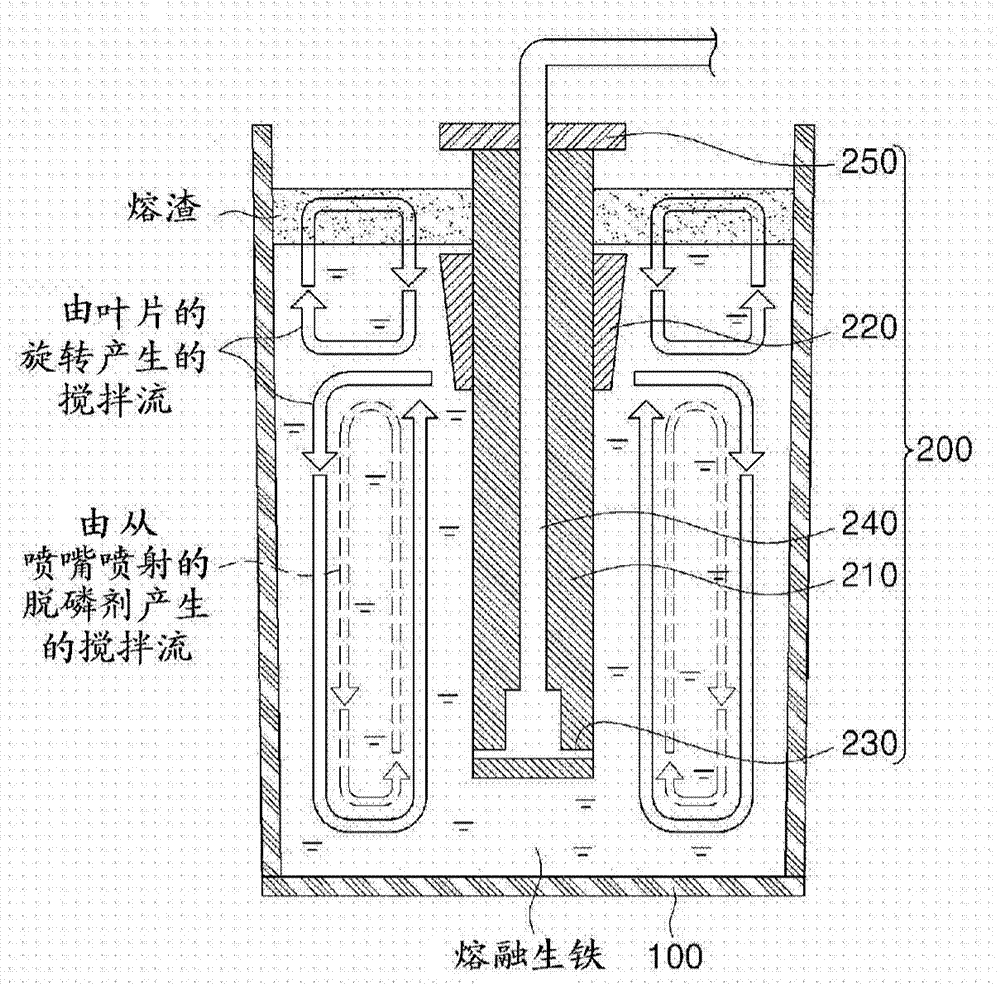

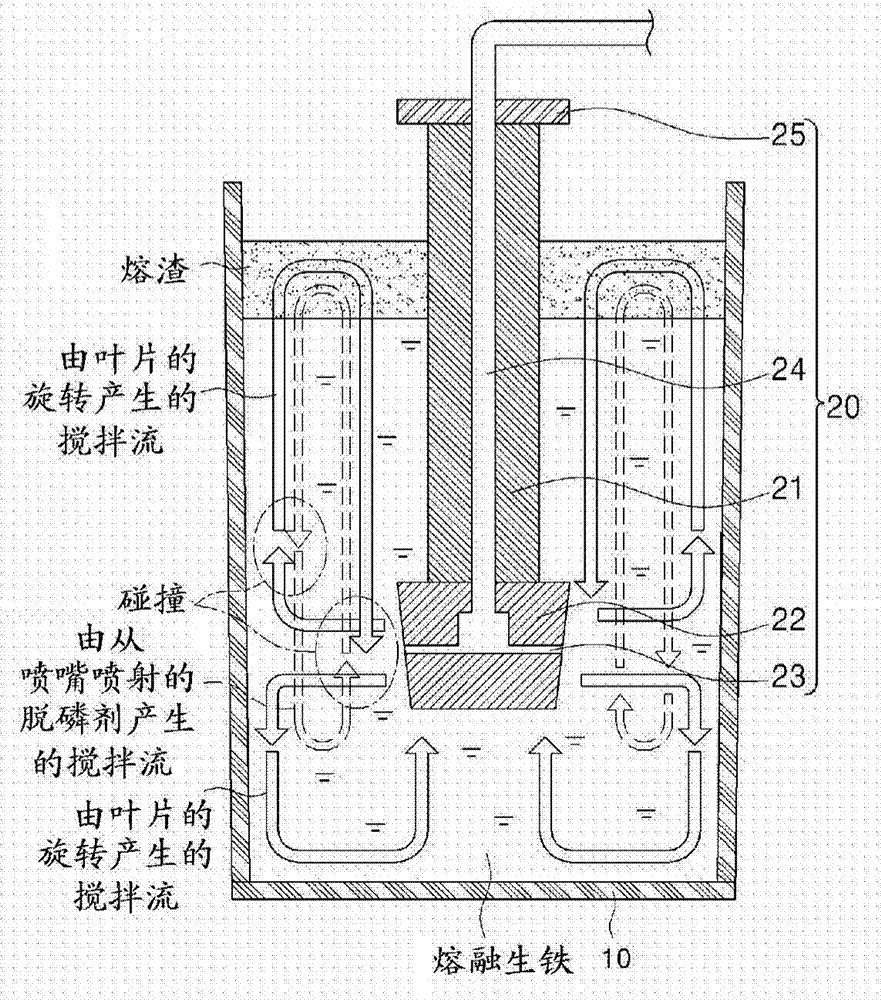

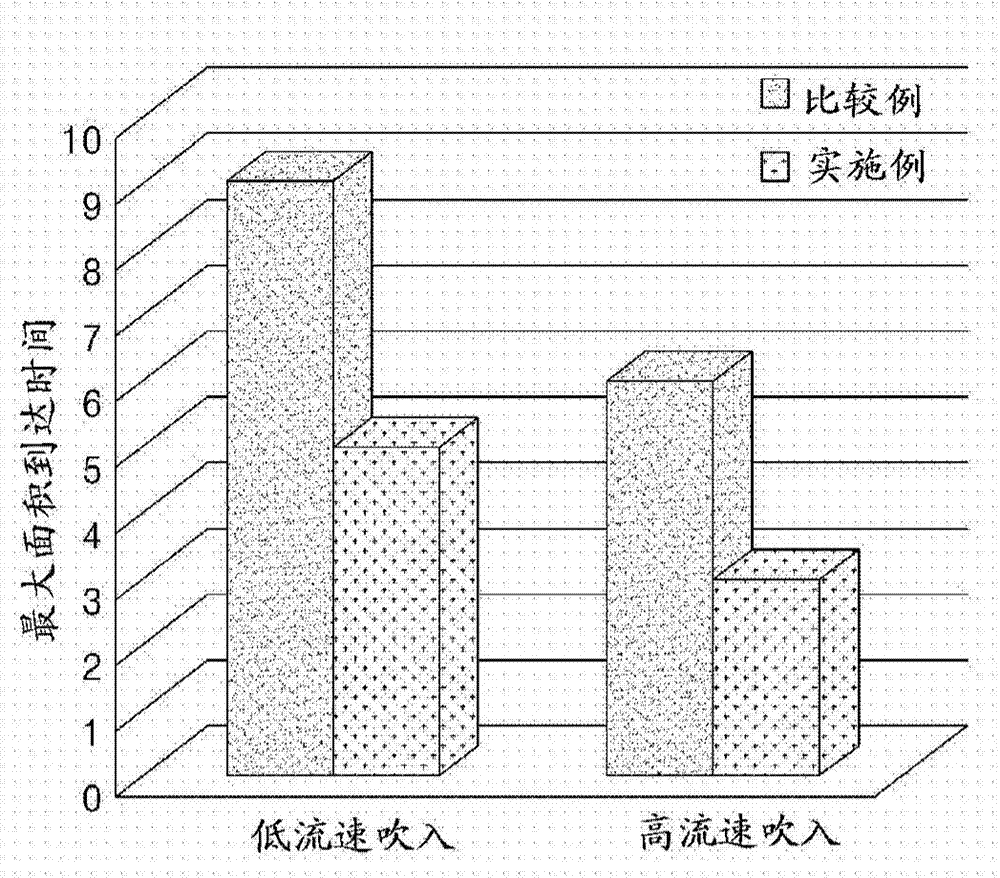

Impellor and melt-pool processing method using same

InactiveCN104755634AIncrease reaction rateIncrease total agitation flowStirring devicesImpellerMelting tank

The present invention concerns an impellor for stirring a melt pool and concerns a melt-pool processing method using same. The impellor comprises: an impellor body extending in the length direction; an intake nozzle which is provided in such a way as to pass through one part at the bottom end of the impellor body; and a blade provided on the upper part of the impellor body. As a result, when embodiments of the present invention are used, a stirring flow produced due to the blade and a stirring flow due to substances taken in to the melt pool via the intake nozzle are united with each other, and the two flows are combined such that the overall stirring force is improved. Consequently, it is possible to improve the efficiency of stirring by the impellor as compared with hitherto, and, as a result, refining efficiency in a refining step is improved as the rate of reaction between the melt pool and additives is increased.

Owner:POSCO

Titanium-containing molten iron converter dephosphorization method

The invention provides a titanium-containing molten iron converter dephosphorization method, which comprises the following steps of obtaining the Nth converter slag; wherein in the Nth converter slag,the mass fraction of FeO is 15-25%; mixing the converter slag of the Nth converter, titanium-containing molten iron to be smelted and scrap steel, and top-blown oxygen at the flow rate of 2.95-3.35 Nm < 3 > / min / t is used to carry out first-stage smelting to obtain smelted molten steel; and the flow of top-blown oxygen of the smelted molten steel is increased to a target value, conducting second-stage smelting, obtaining the converter slag of the N+1th converter and dephosphorized molten steel, and N is a positive integer. By adopting the method provided by the invention, the dephosphorizationrate of the titanium-containing molten iron can reach 80.31-90.70%, and the iron content of the converter slag at the smelting end point of the converter is obviously reduced.

Owner:SHOUGANG CORPORATION

Method for producing ultra-low phosphoretic steel by molten steel dephosphorising outside furnace

The invention provides a method to produce ultra low phosphorus steel by out-of-furnace dephosphorization, in particular to a controlling method to control phosphorus in steel during ultra low phosphorus steel production process. The invention is done according to the following steps: (1) when converter tapping, the weight percent of end phosphorus content is less than 0.013 percent and dephosphorization flux is added along with steel flow stream to ladle at the same time; (2) slag-stopping and non-deoxidation tapping is adopted; (3) after tapping, remove dephosphorization flux in the ladle; (4) after flux removal, refining treatment such as heating, deoxidation alloying and desulphurization; (5) continuous casting is done. The invention is convenient for operation, high efficiency of dephosphorization, short time consumption, and stable dephosphorization effect which can satisfy dephosphorization requirement of different content ultra low phosphorus molten steel by dephosphorization during the tapping without increase treatment time.

Owner:SHOUGANG CORPORATION

Hot metal pretreatment dephosphorization agent and preparation method thereof

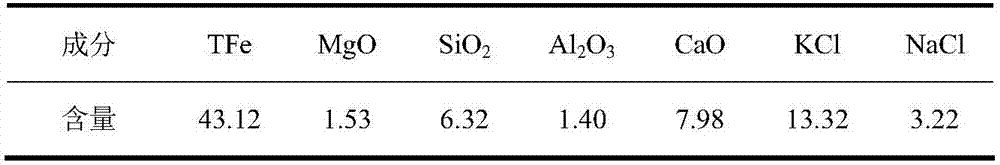

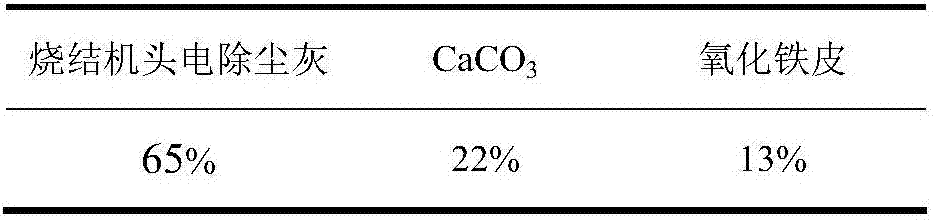

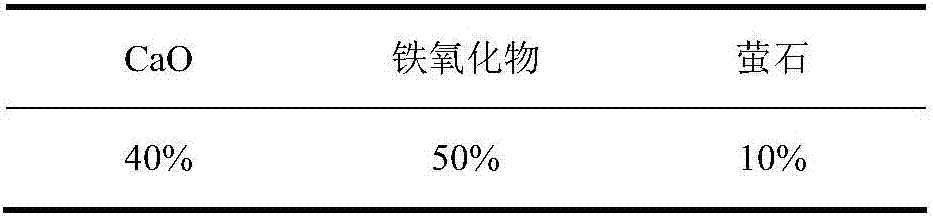

The invention discloses a hot metal pretreatment dephosphorization agent and a preparation method thereof. In mass percent, a formula of the dephosphorization agent comprises: 30-70% of drying sintering nose electric precipitation ash, 10-30% of lime CaCO3 and 10-40% of iron oxide; binary basicity CaO / SiO2 of the hot metal pretreatment dephosphorization agent is 3-4, and alkali chloride content is 5-15%; in mass percent, the total content of four substances, namely CaO, Fe, KCl and NaCl, in the dry sintering nose electric precipitation ash is not less than 60%, wherein the content of alkali chlorides is not less than 10%; and the iron oxide is one or more of sintered ore, iron ore powder, converter dust, electric furnace dust and oxidized scale. Ingredients of the formula of the dephosphorization agent are dried and treated and then are ground until particle size is below 1mm, and uniform mixing is carried out.

Owner:ANGANG STEEL CO LTD

Composite sphere for manufacturing ultra-low phosphoretic steel with outside-stove refining dephosphorization and its manufacturing method

The invention relates to a method for controlling phosphorus in the production of ultra-low phosphorous steel by microalloy steel and special steel, in particular to a compound sphere for producing the ultra-low phosphorous steel by external refining dephosphorization and a preparation method thereof. The compound sphere consists of a spherical core and a shell, wherein, the spherical core mainlycomprises dephosphorizing flux, calcium carbonate, magnesium carbonate or a mixture of the calcium carbonate and the magnesium carbonate, and the shell mainly comprises one of calcium oxide or magnesium oxide or a mixture of the calcium oxide and the magnesium oxide; and the compound sphere is prepared by material mixing, drying, and compound sphere preparation on sphere preparation equipment. The method has scientific formula and simple and reasonable process, can realize the quick refining dephosphorization of molten steel until the content of the phosphorus is lower than 0.0030 percent proven by application, is high in efficiency, steady and short in time, remedies the defect that the prior converter smelting is difficult to achieve the content of the phosphorus in the steel less than 0.01 percent, can meet the requirements of different molten steel on the content of the phosphorus, greatly improves the quality of refining steel, and reduces smelting cost.

Owner:ANGANG STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com