Method for producing ultra-low phosphorous steel by converter double slag process

An ultra-low phosphorus steel and converter technology, applied in the field of metallurgy, can solve the problems of poor kinetic reaction conditions, exceeding the target range, difficult to reduce phosphorus content, etc., to reduce the melting point of slag, reduce the reaction temperature, and reduce the process of calcining into lime Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

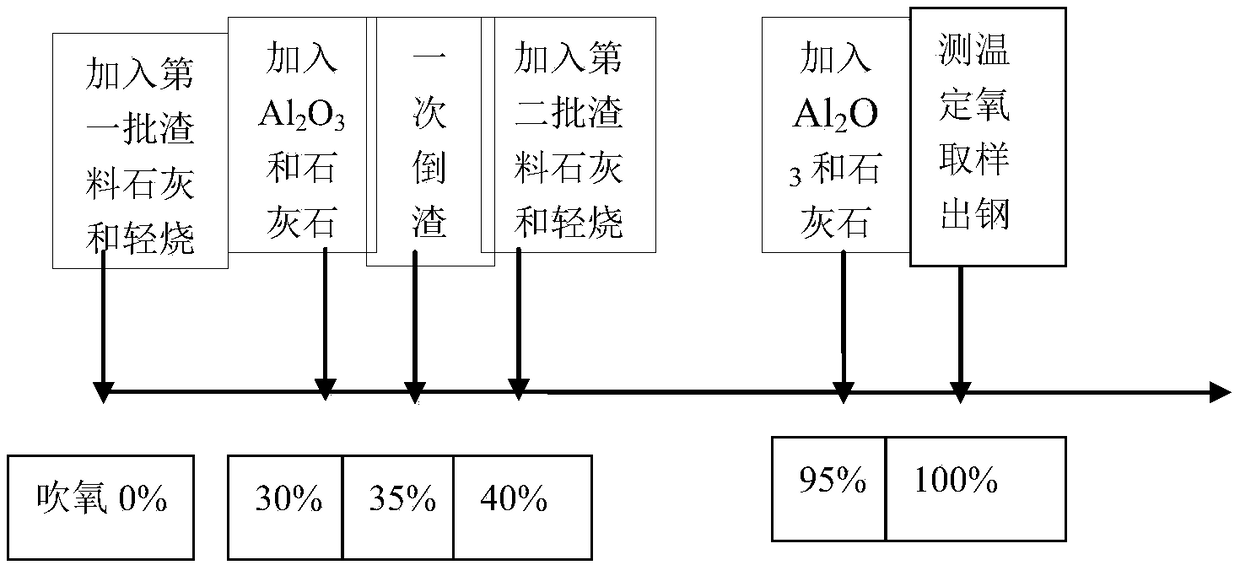

Embodiment 1

[0042] The method of producing ultra-low phosphorus steel in a 200t converter, 1) adding 0.103% of the molten iron [P] in the converter, using the conventional feeding process to add the first batch of slag lime and light burning; Join Al 2 o 3 300kg, limestone 200kg, when the oxygen blowing is 35%, stop the oxygen supply, lift the oxygen lance, and perform a slag dumping operation, the temperature of the molten steel is 1335°C, and the phosphorus content of the molten steel is 0.024%; after that, when the oxygen blowing is 40%, use conventional feeding The process adds the second batch of slag lime and light burning; 3) Al 2 o 3 200kg, 300kg of limestone, the temperature of the molten steel at the end of the converter is 1662°C, the phosphorus content of the molten steel is 0.0040%, and the steel is tapped to obtain ultra-low phosphorus steel.

Embodiment 2

[0044] The difference between embodiment 2 and embodiment 1 is: before the first slag dumping, Al is added when blowing oxygen at 25% 2 o 3 300kg, limestone 280kg, when the oxygen blowing is 32%, stop the oxygen supply, lift the oxygen gun, and perform a slagging operation. al 2 o 3 200kg, limestone 250kg, converter end point temperature 1671°C, molten steel phosphorus content 0.0045%.

Embodiment 3

[0046] The difference between Example 3 and Example 1 is: molten iron [P] 0.11%; before the first slag dumping, Al is added when blowing oxygen at 32% 2 o 3 280kg, limestone 180kg, when the oxygen blowing is 37%, stop the oxygen supply, lift the oxygen gun, perform a slagging operation, the temperature of the slagging is 1340°C, and analyze the phosphorus content of molten steel 0.021%; Al 2 o 3 150kg, limestone 350kg, converter end point temperature 1665°C, molten steel phosphorus content 0.0038%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com