Smelting method of converter efficient dephosphorization

A smelting method and converter technology, which is applied in the field of iron and steel metallurgy, can solve the problems of not being able to effectively improve the dephosphorization efficiency of the converter, and cannot reduce the phosphorus content and cost at the end of the converter, and achieve low cost, low phosphorus content, and improved dephosphorization efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

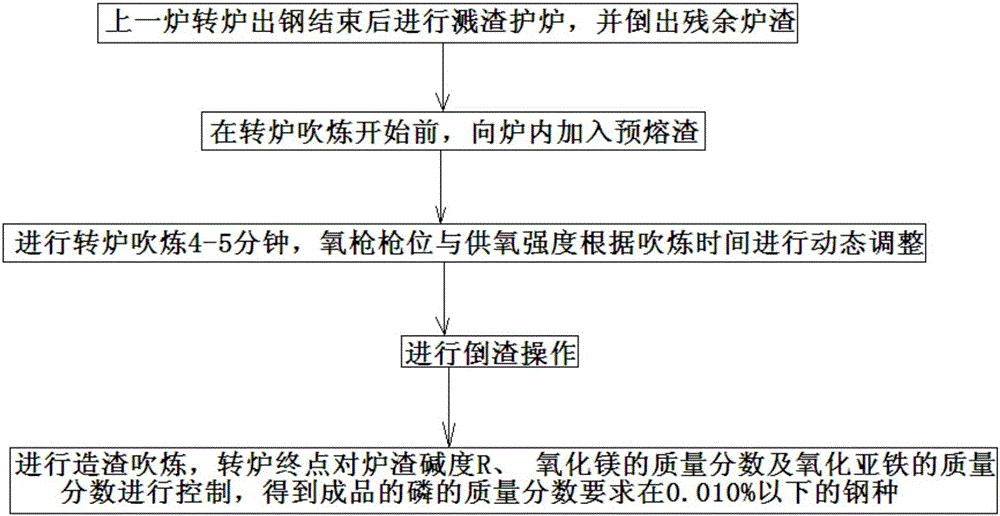

[0012] see figure 1 The embodiment of the present invention provides a high-efficiency converter dephosphorization smelting method, which is mainly used for smelting molten iron with a mass fraction of phosphorus of 0.080-0.200%, and finally reaching steel grades with a mass fraction of phosphorus of less than 0.010% in the finished product. Suitable for 180-250 ton converters, the smelting method includes the following steps:

[0013] Step 1, carry out slag splashing to protect the furnace, and pour out the residual slag.

[0014] Step 2, adding pre-melted slag into the furnace.

[0015] Step 3: Carry out converter blowing for 4-5 minutes, and the oxygen lance position and oxygen supply intensity are dynamically adjusted according to the blowing time.

[0016] Step 4, carry out the slag dumping operation.

[0017] Step 5: Carry out slagging and blowing, and control the basicity R of slag, the mass fraction of magnesium oxide and the mass fraction of ferrous oxide at the en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com