Patents

Literature

915results about "Stirring devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

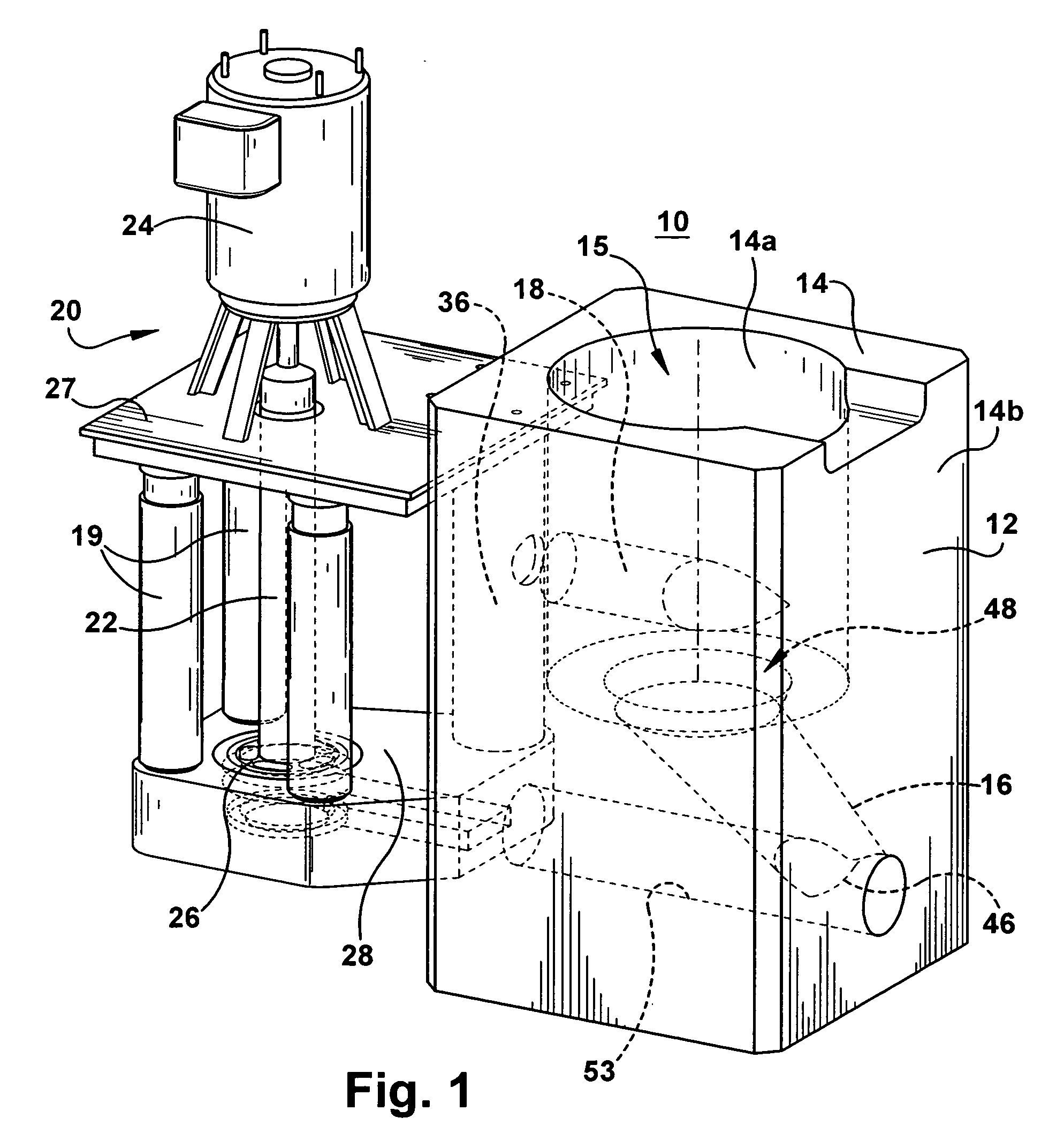

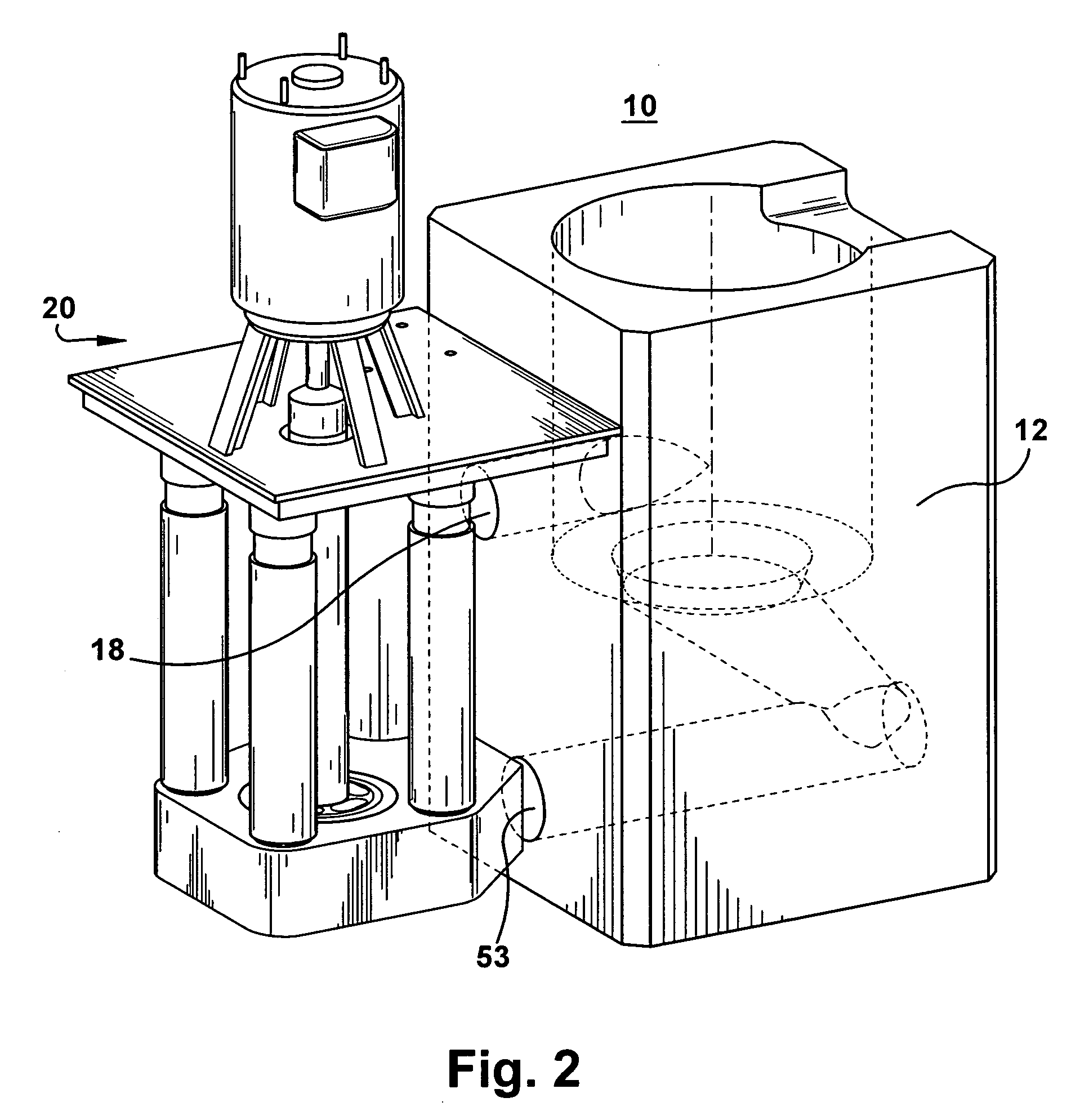

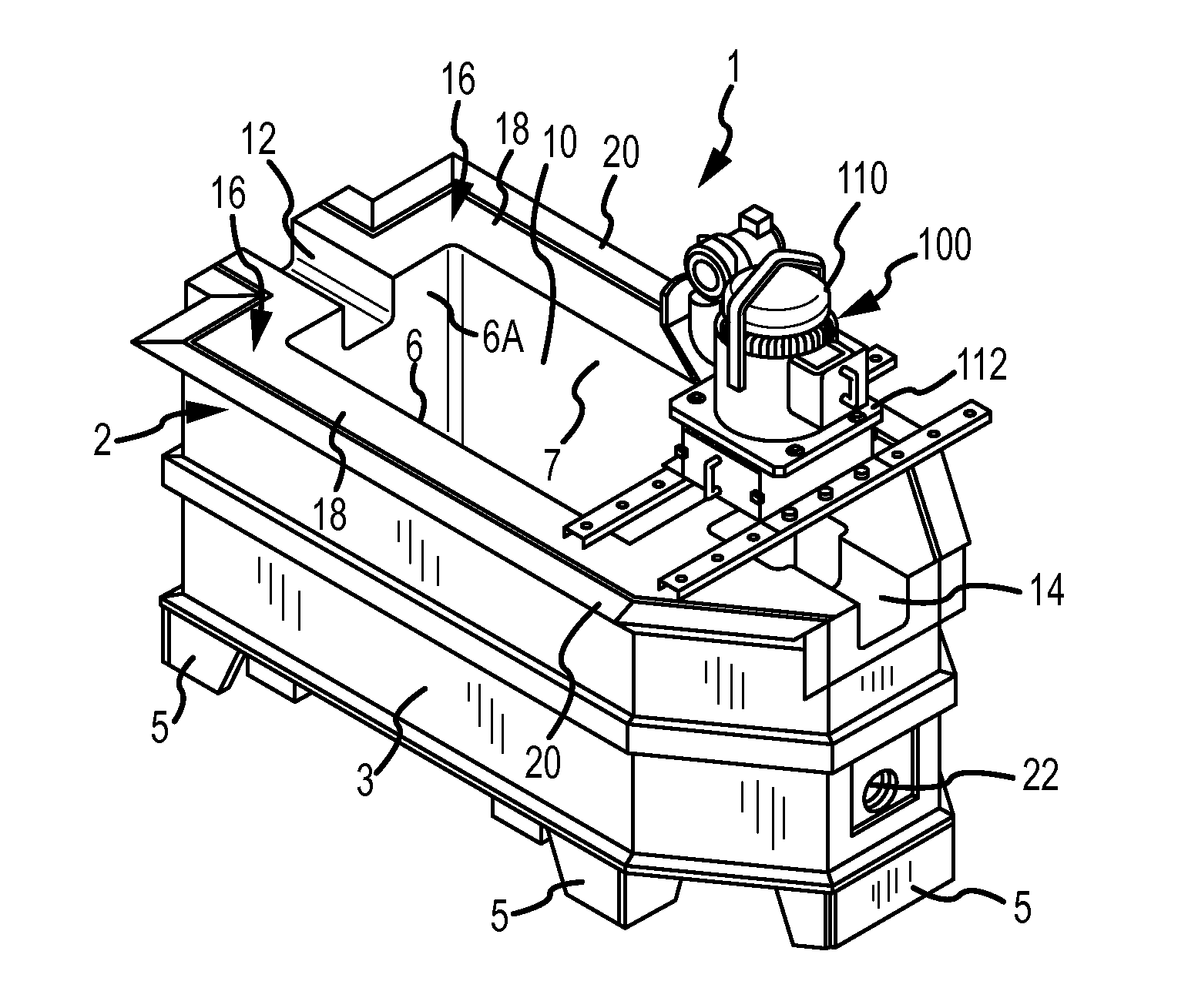

Vortexer apparatus

ActiveUS20060180963A1Facilitates submergence and meltingMaintain temperatureStirring devicesCharge manipulationImpellerPositive pressure

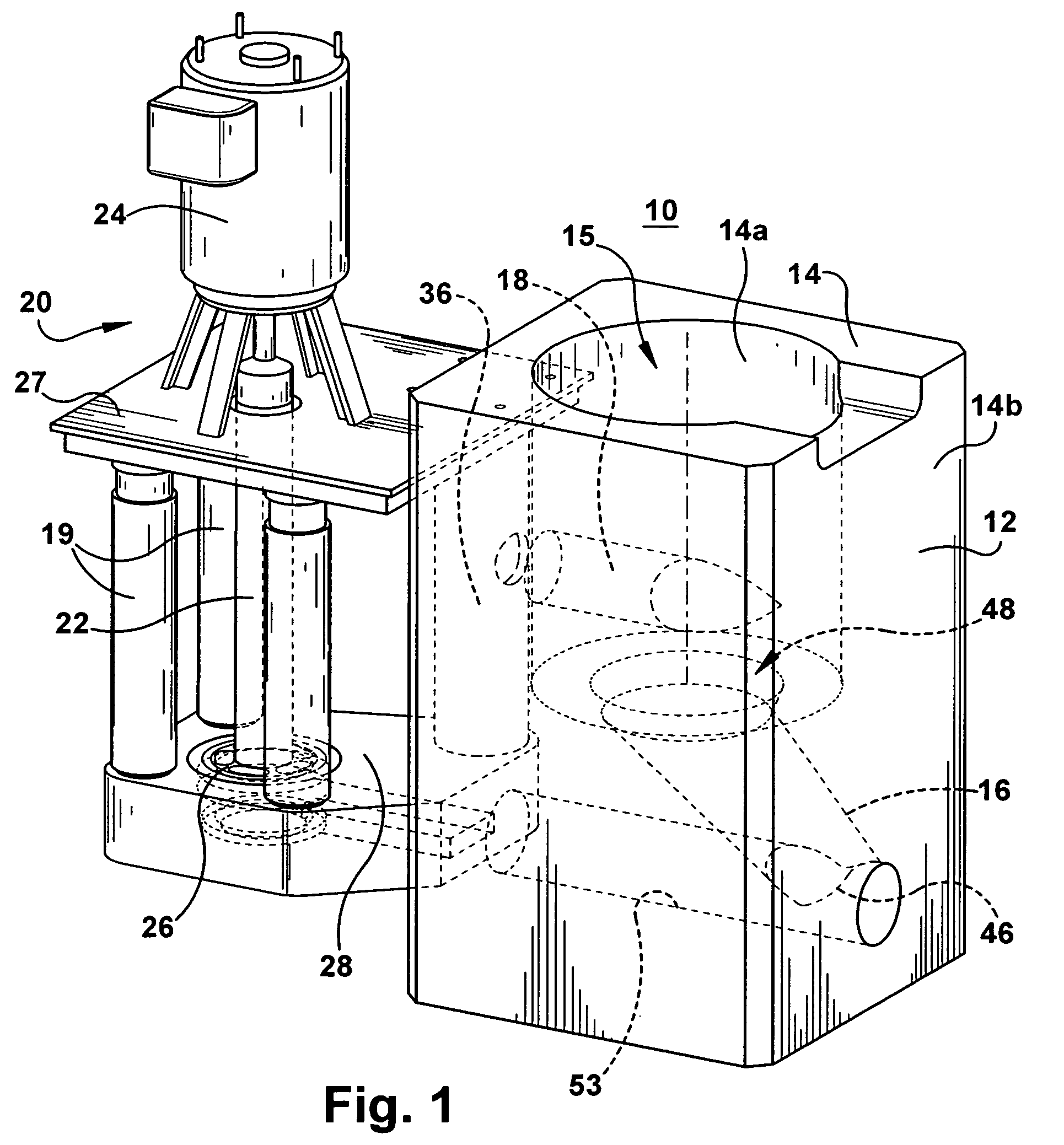

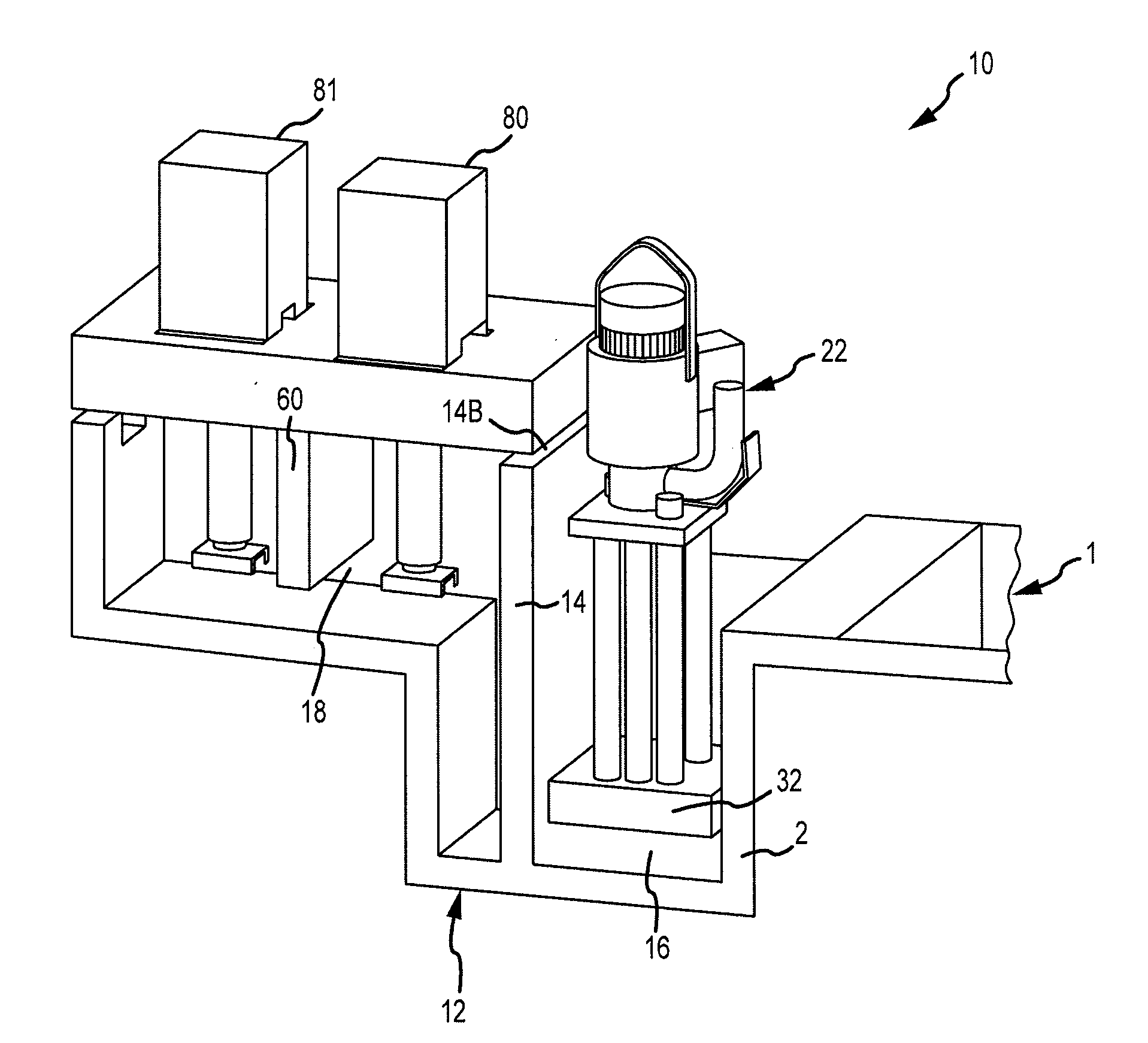

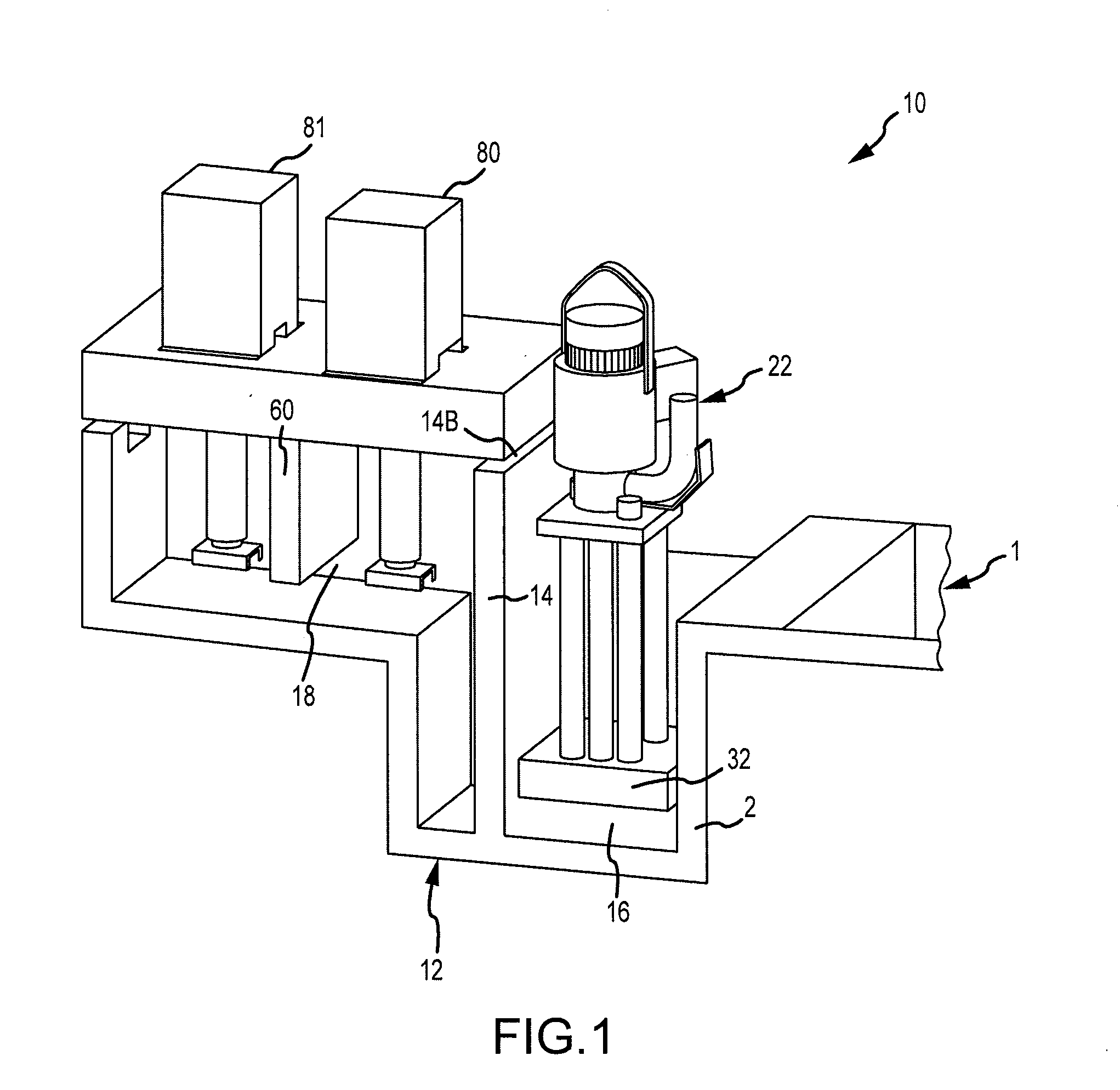

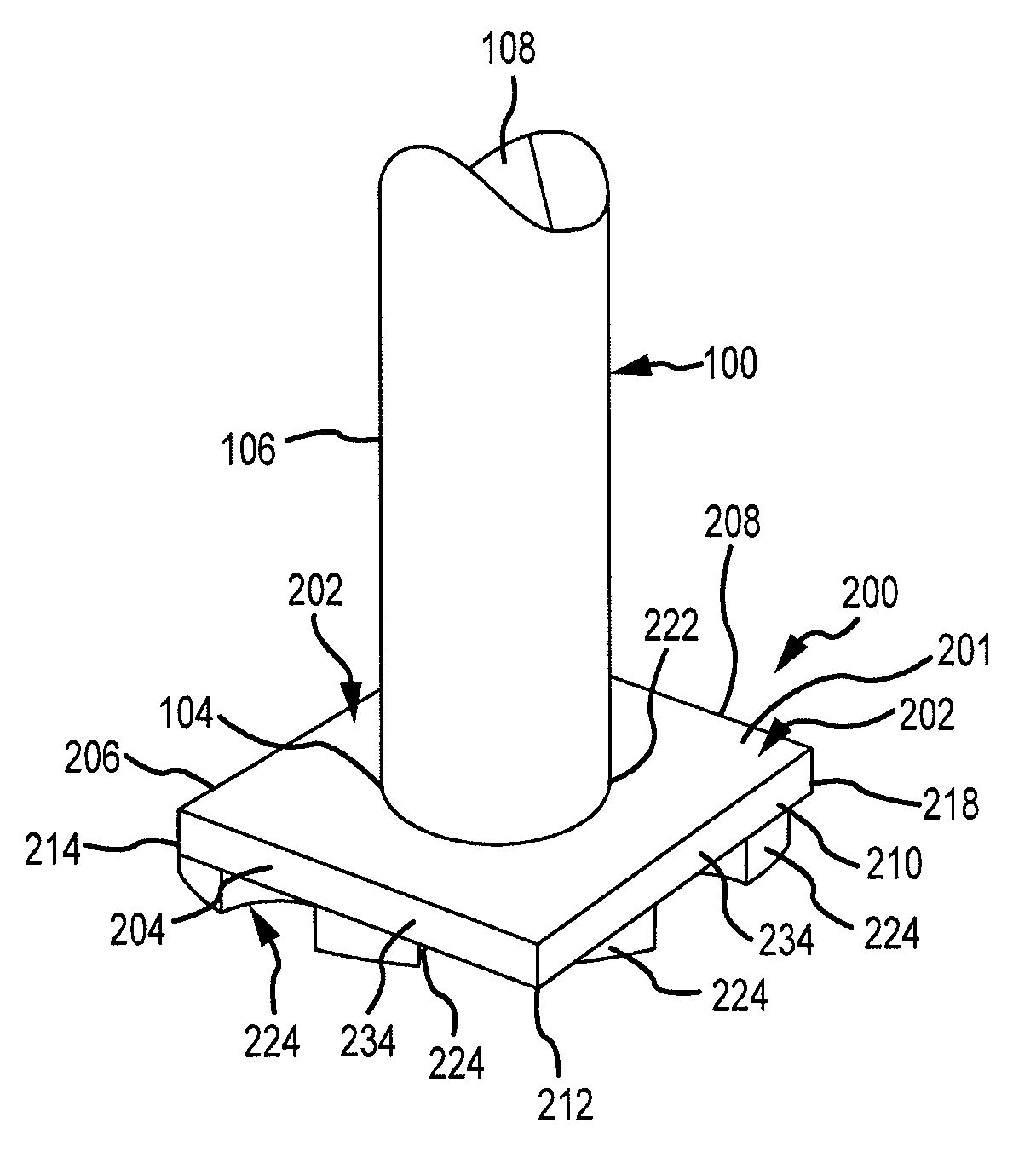

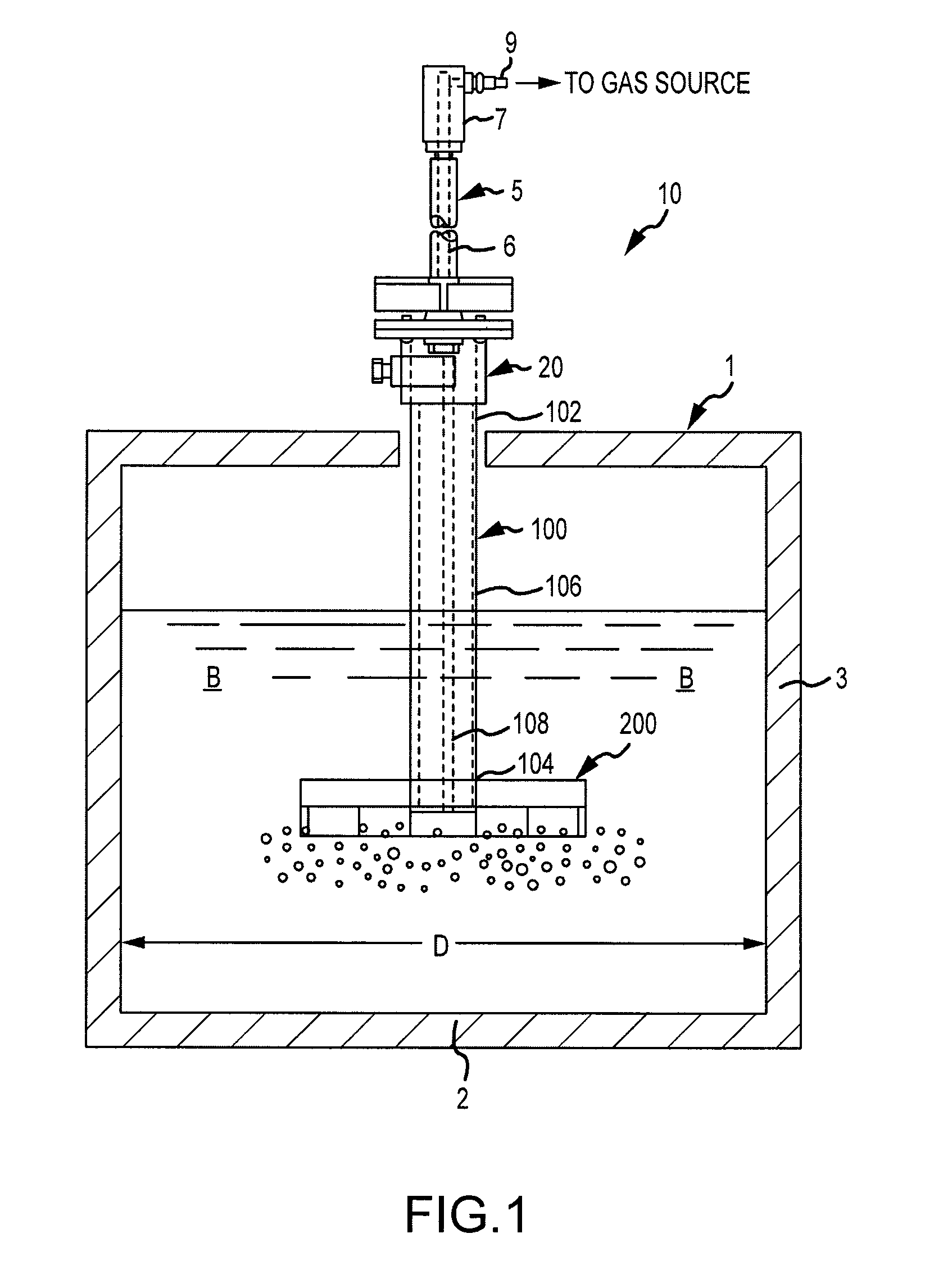

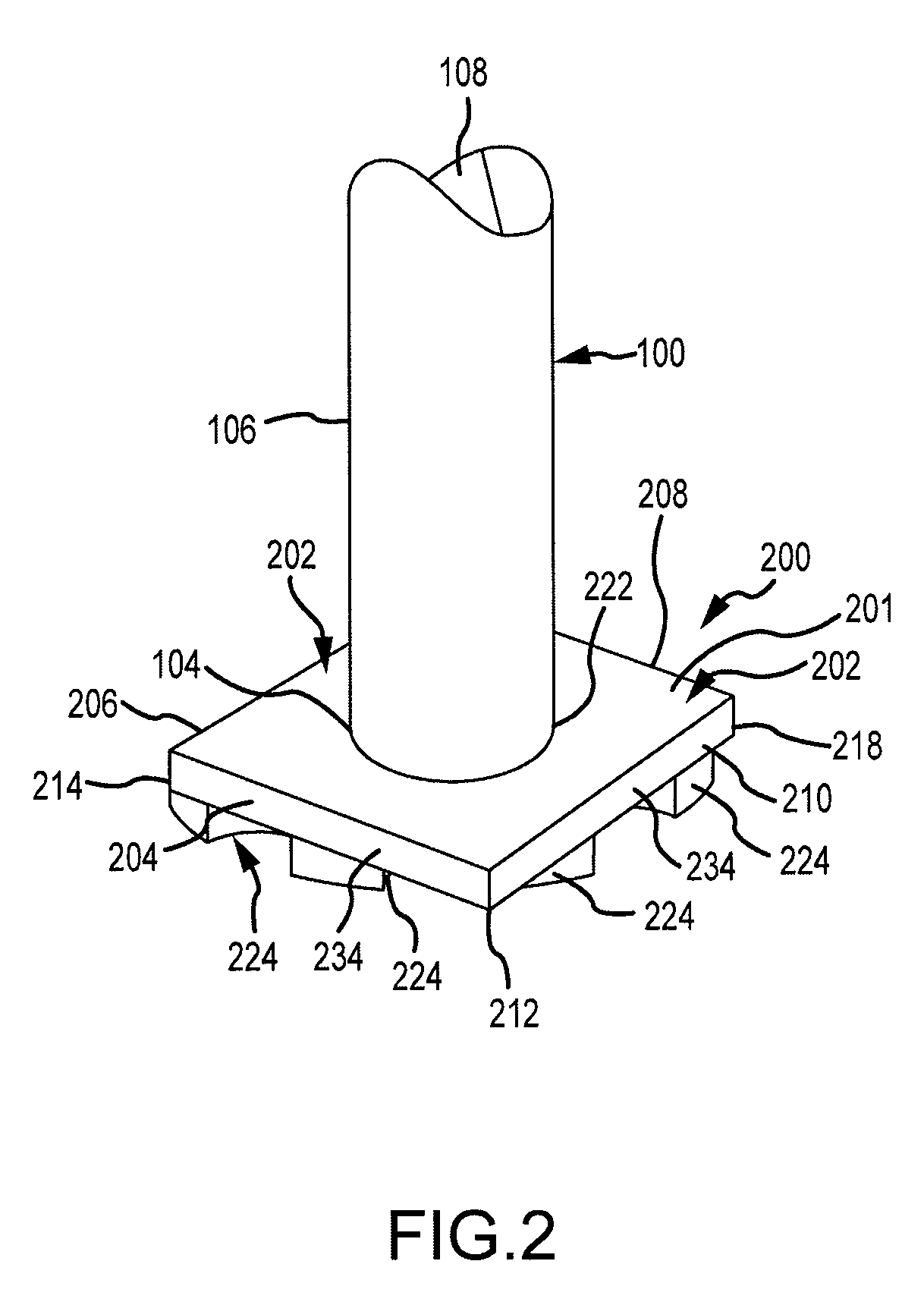

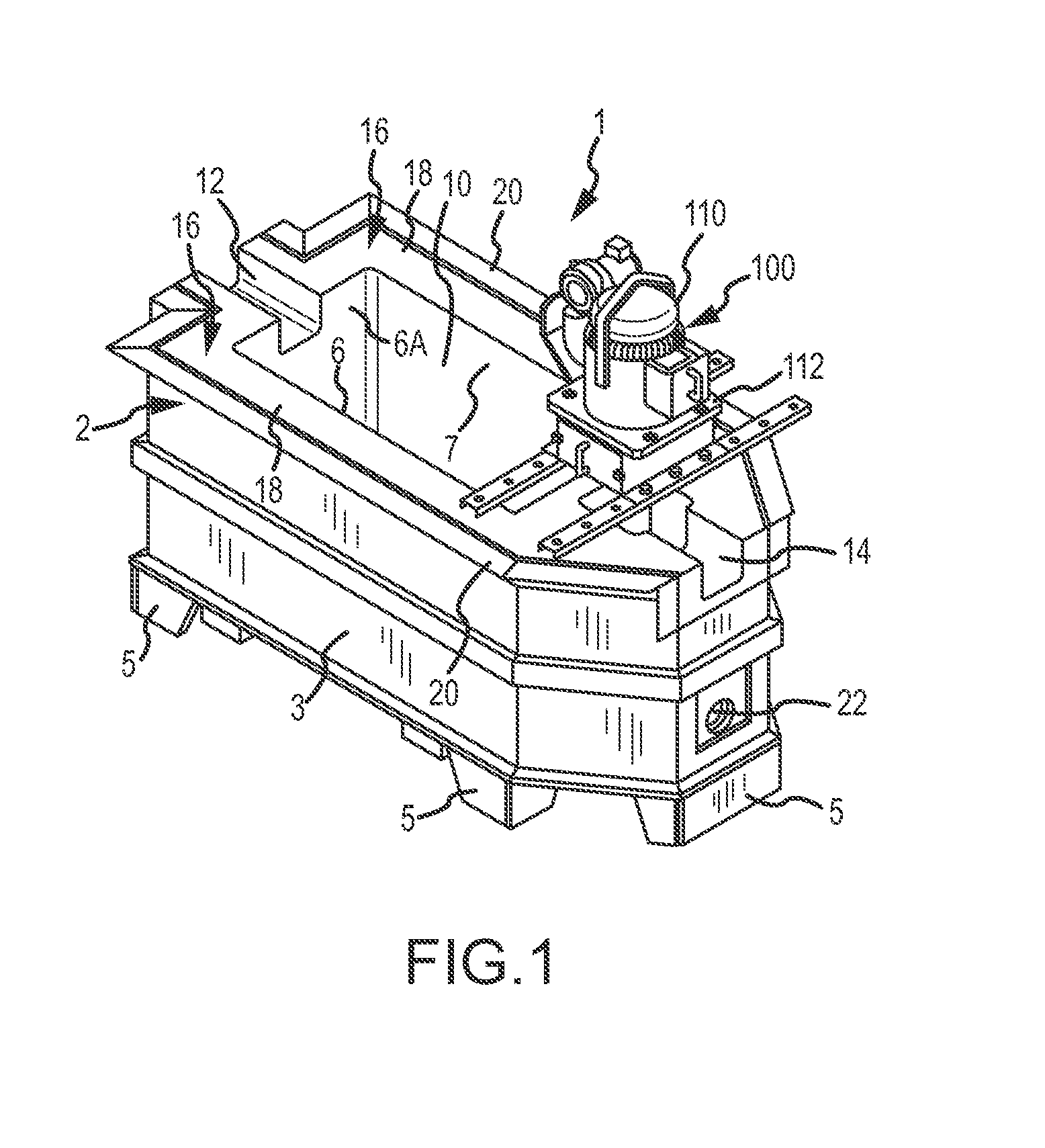

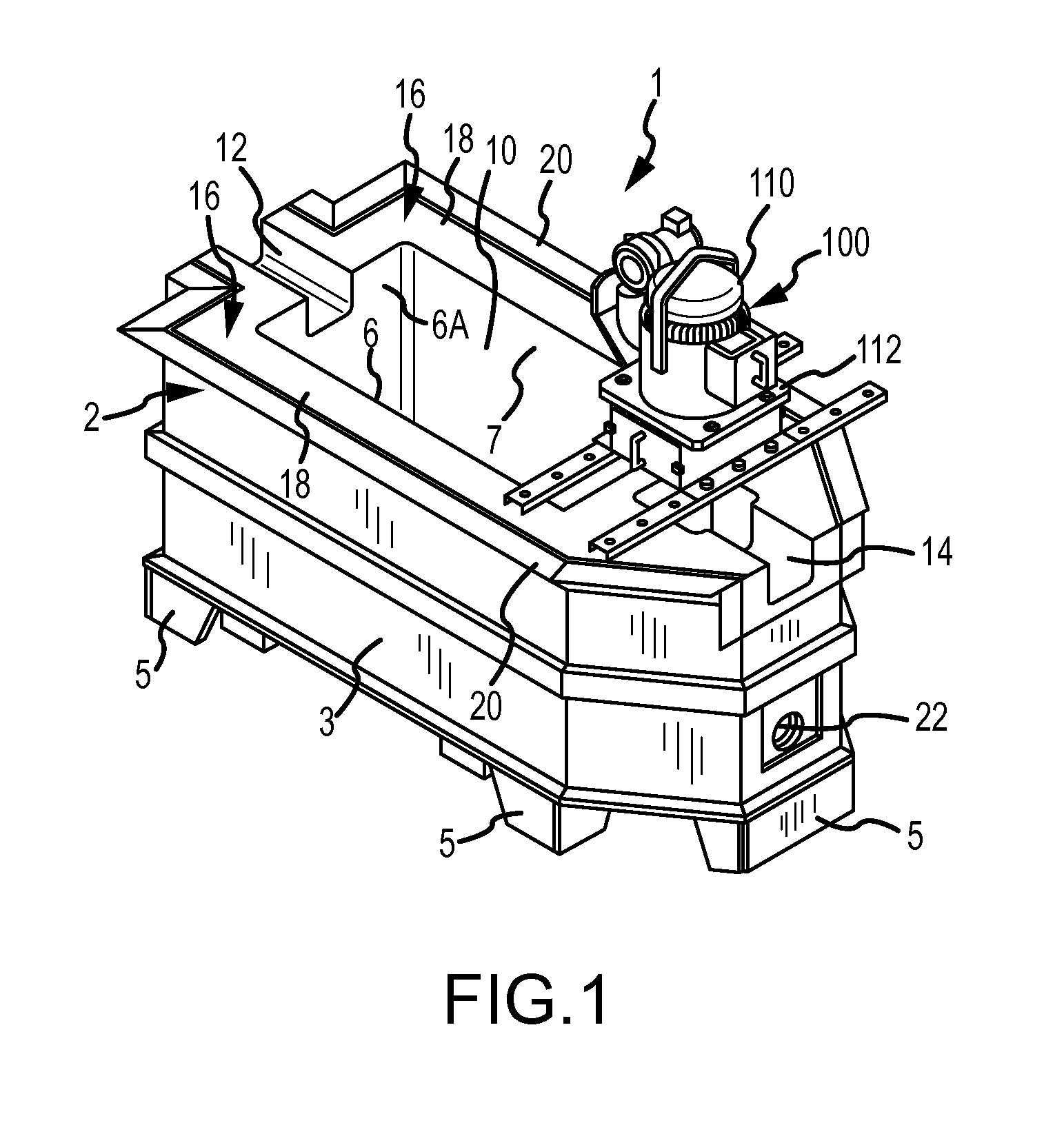

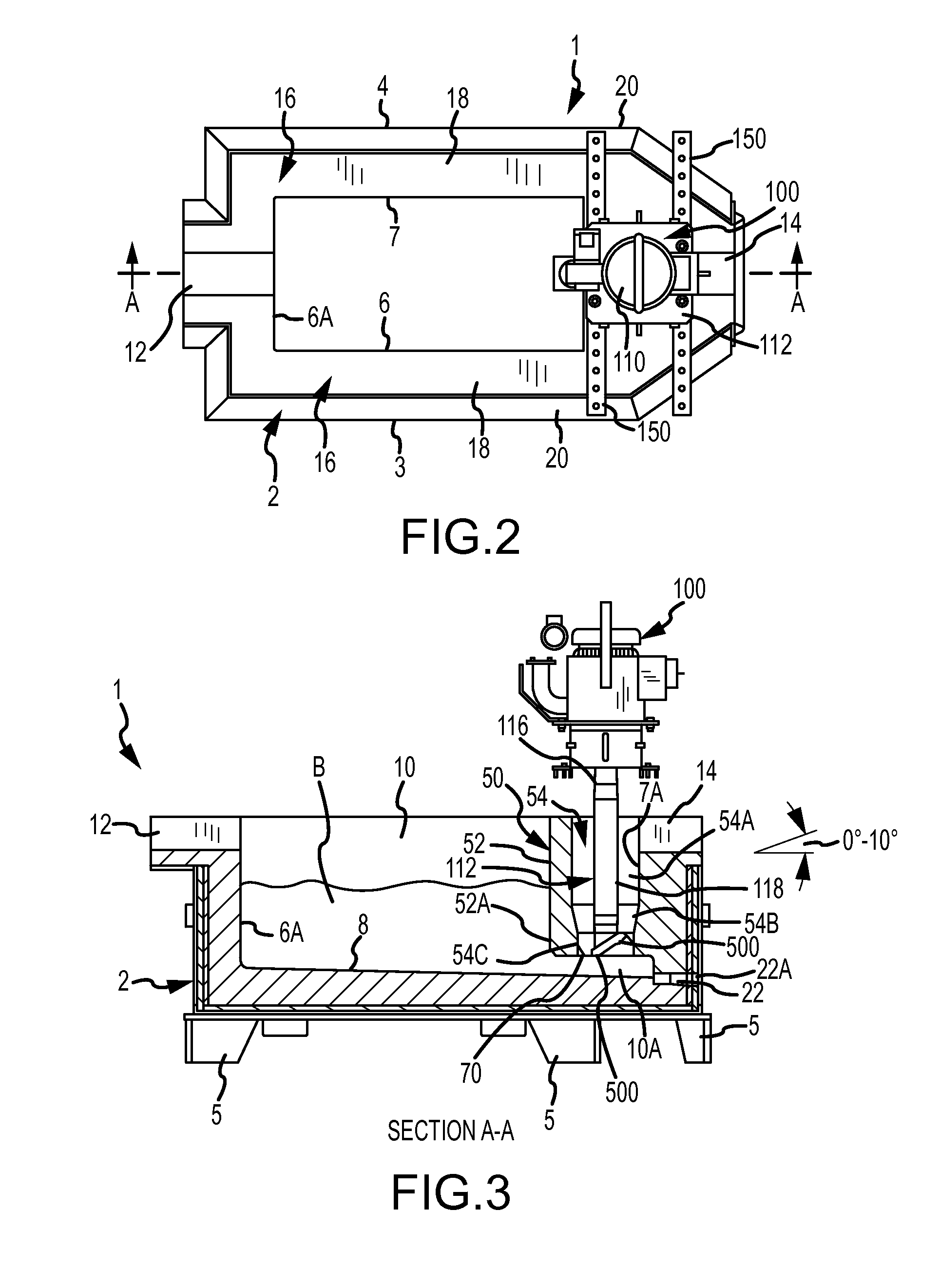

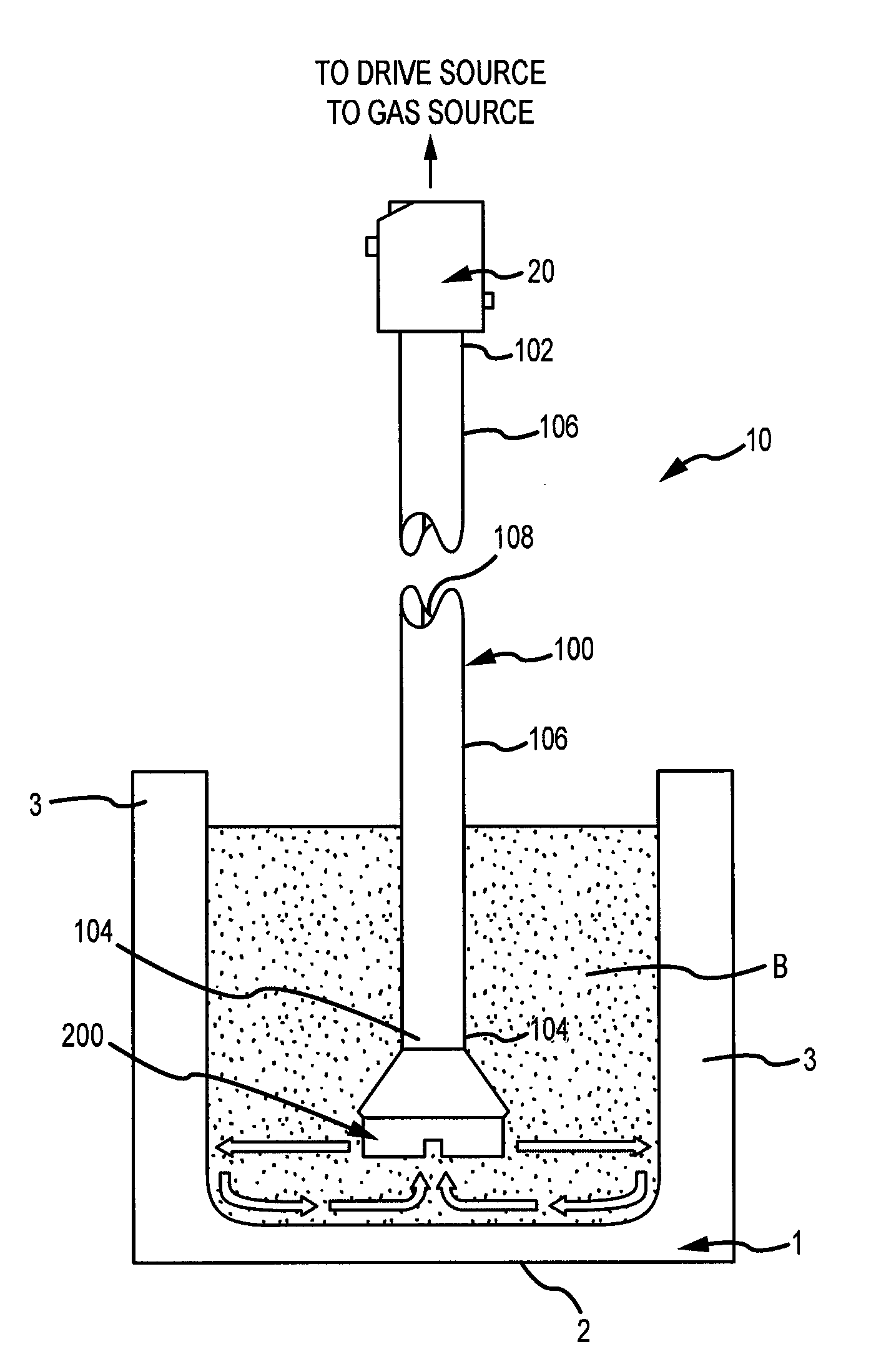

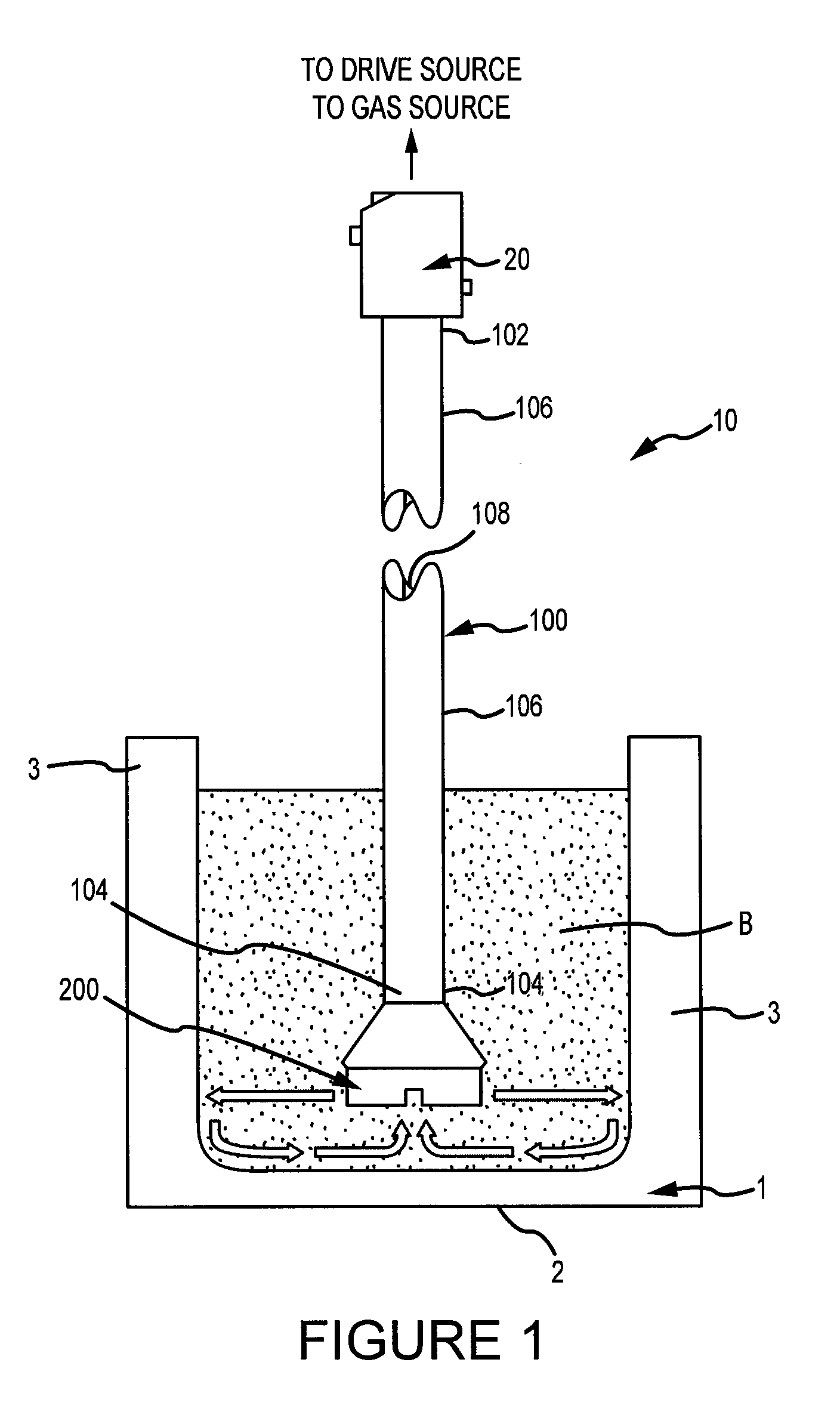

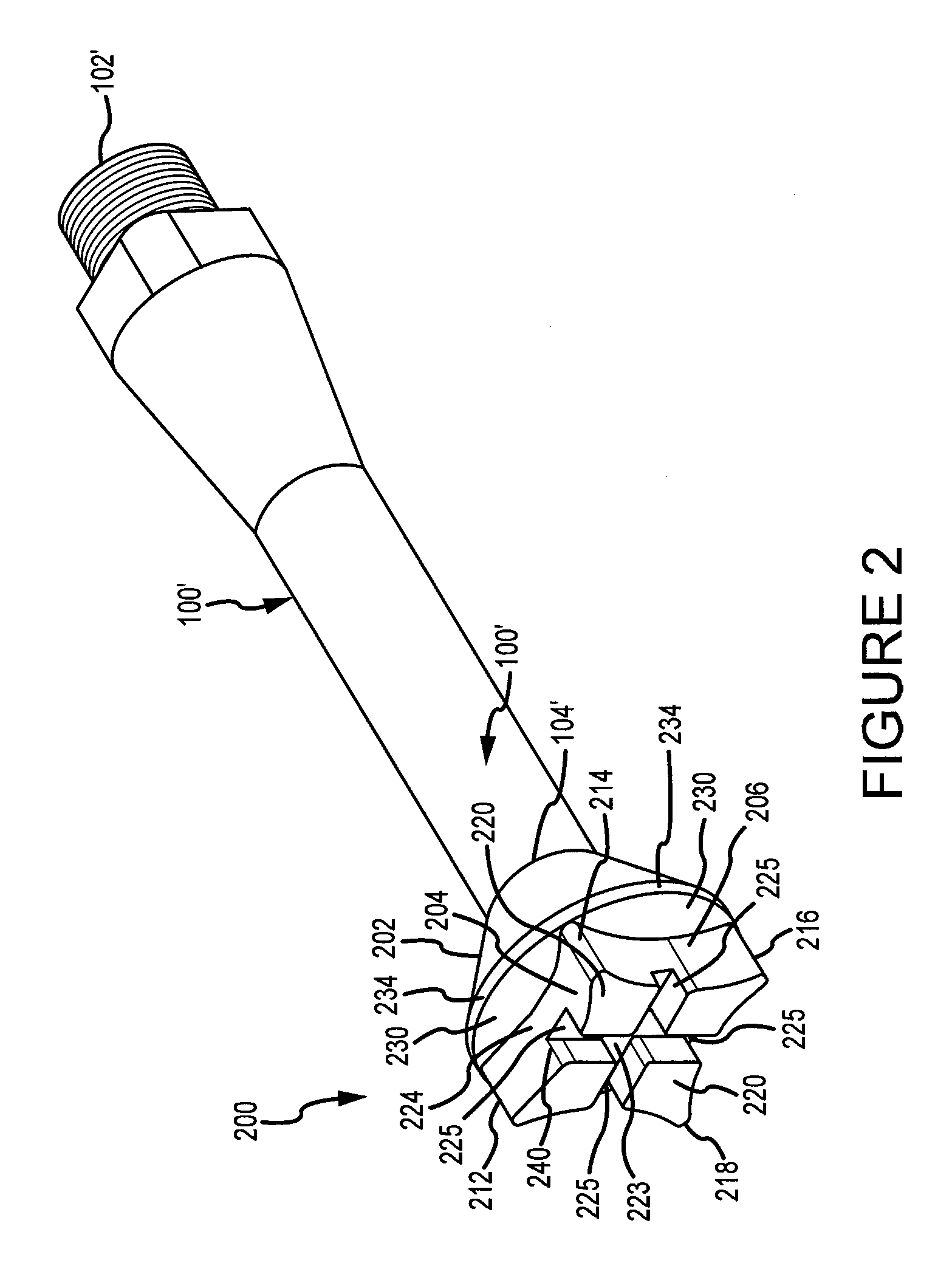

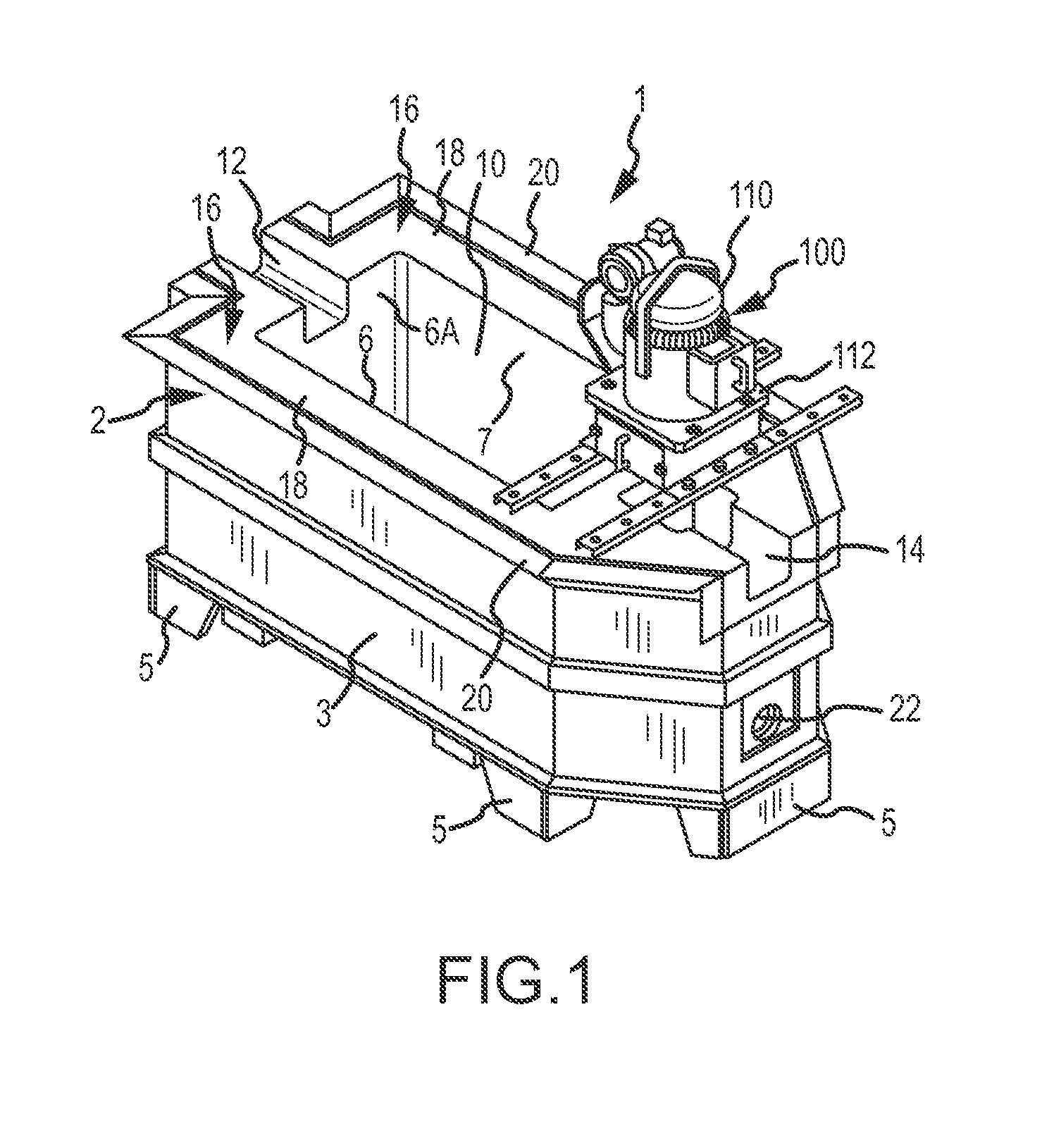

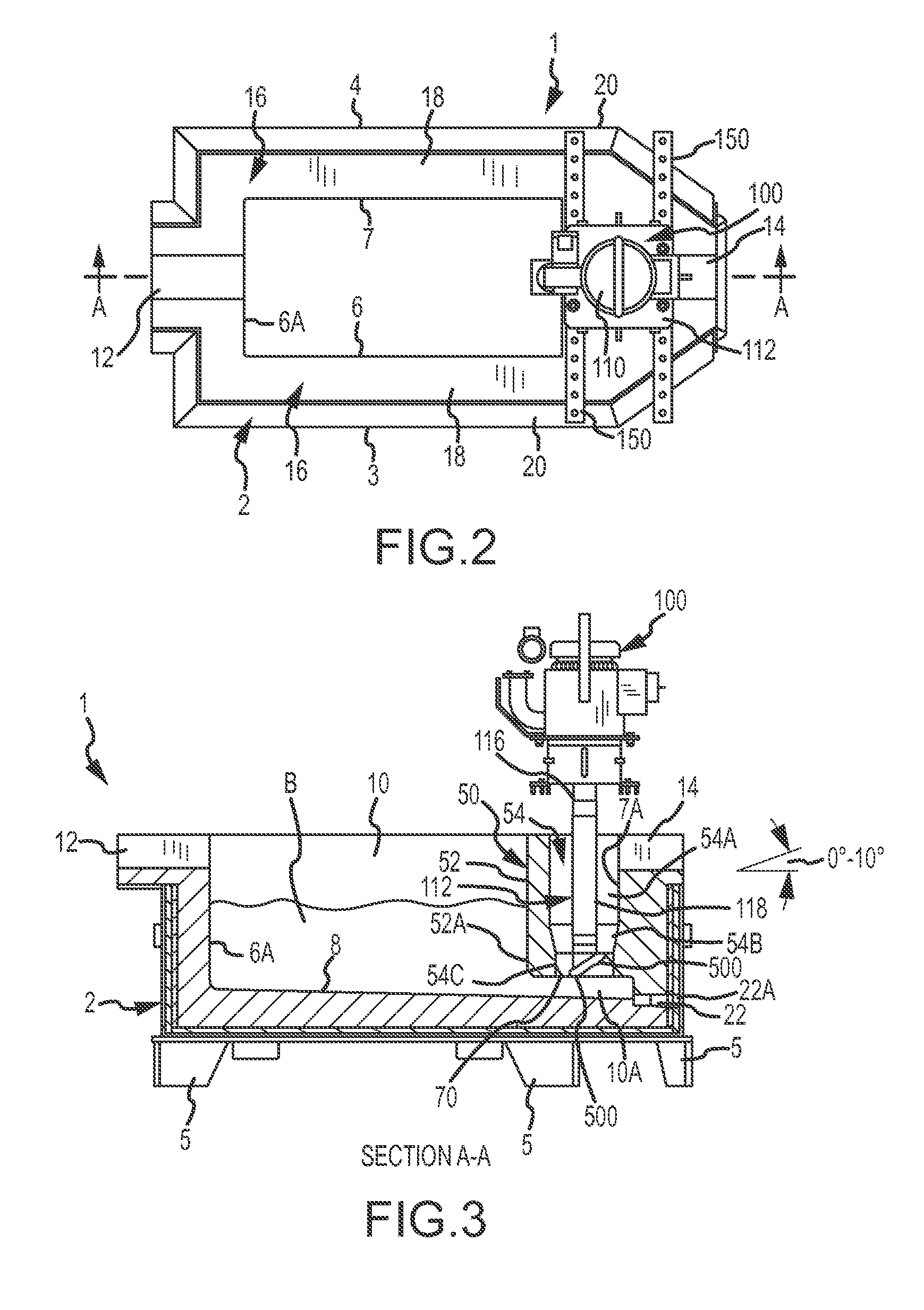

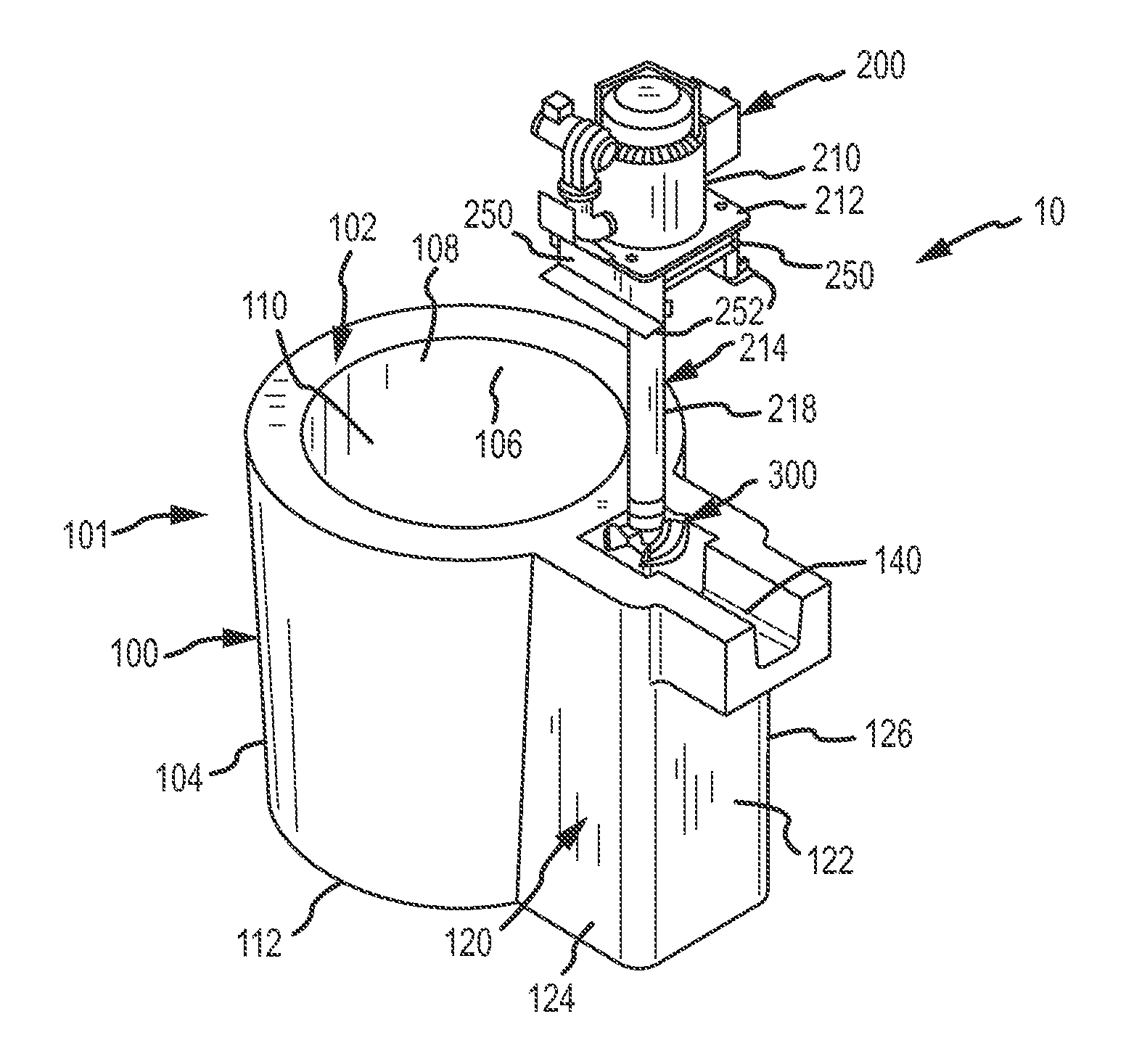

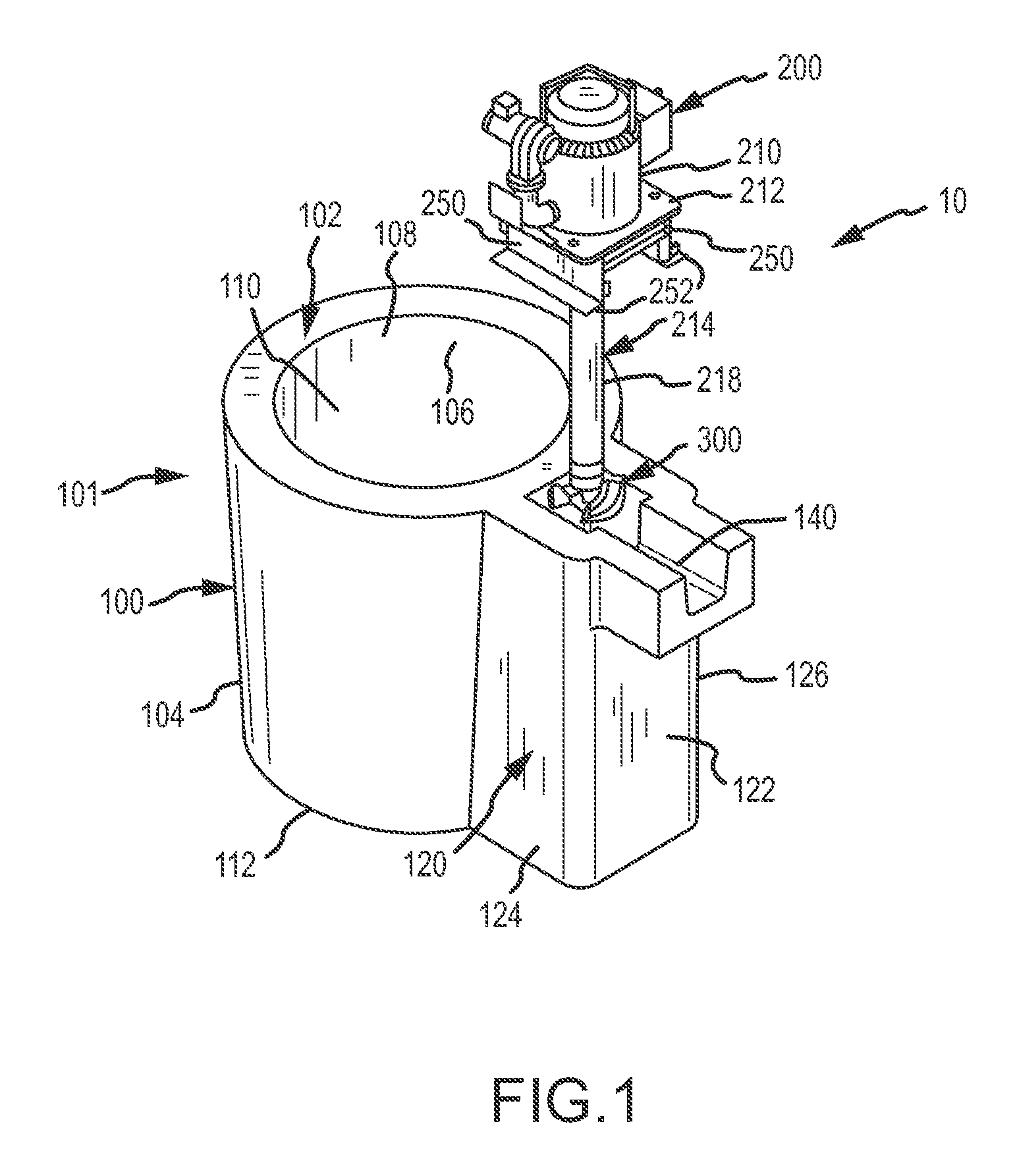

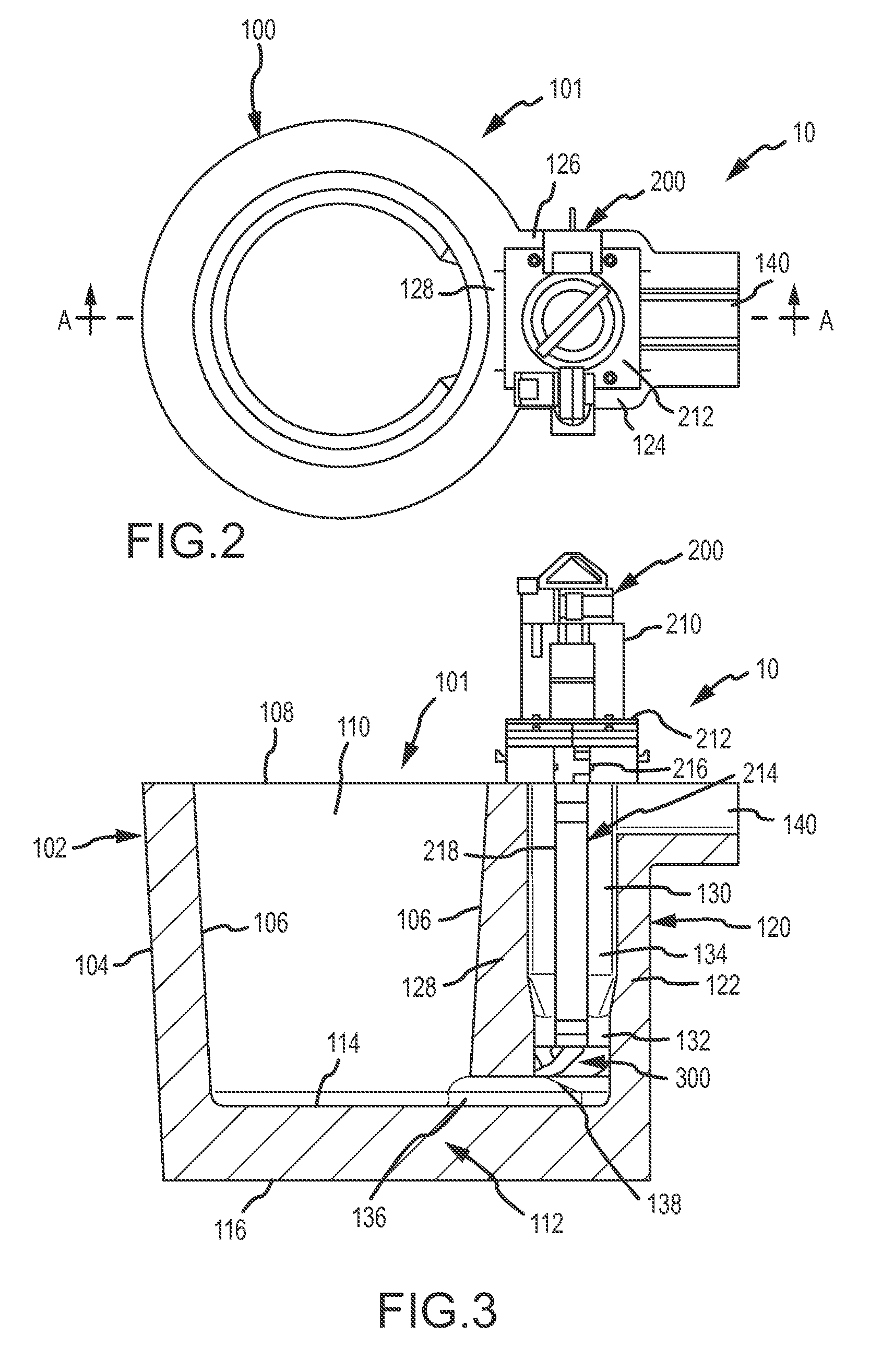

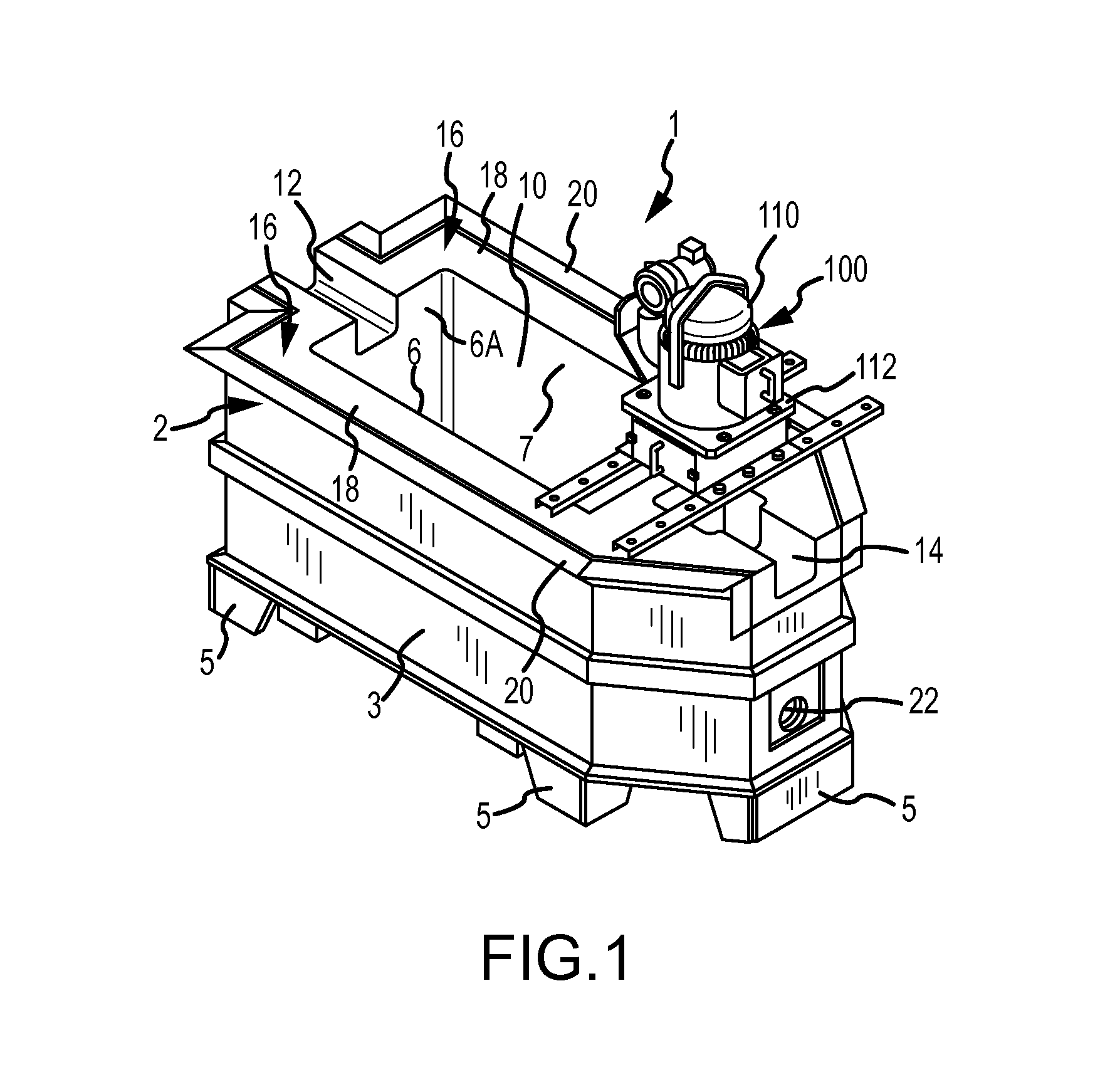

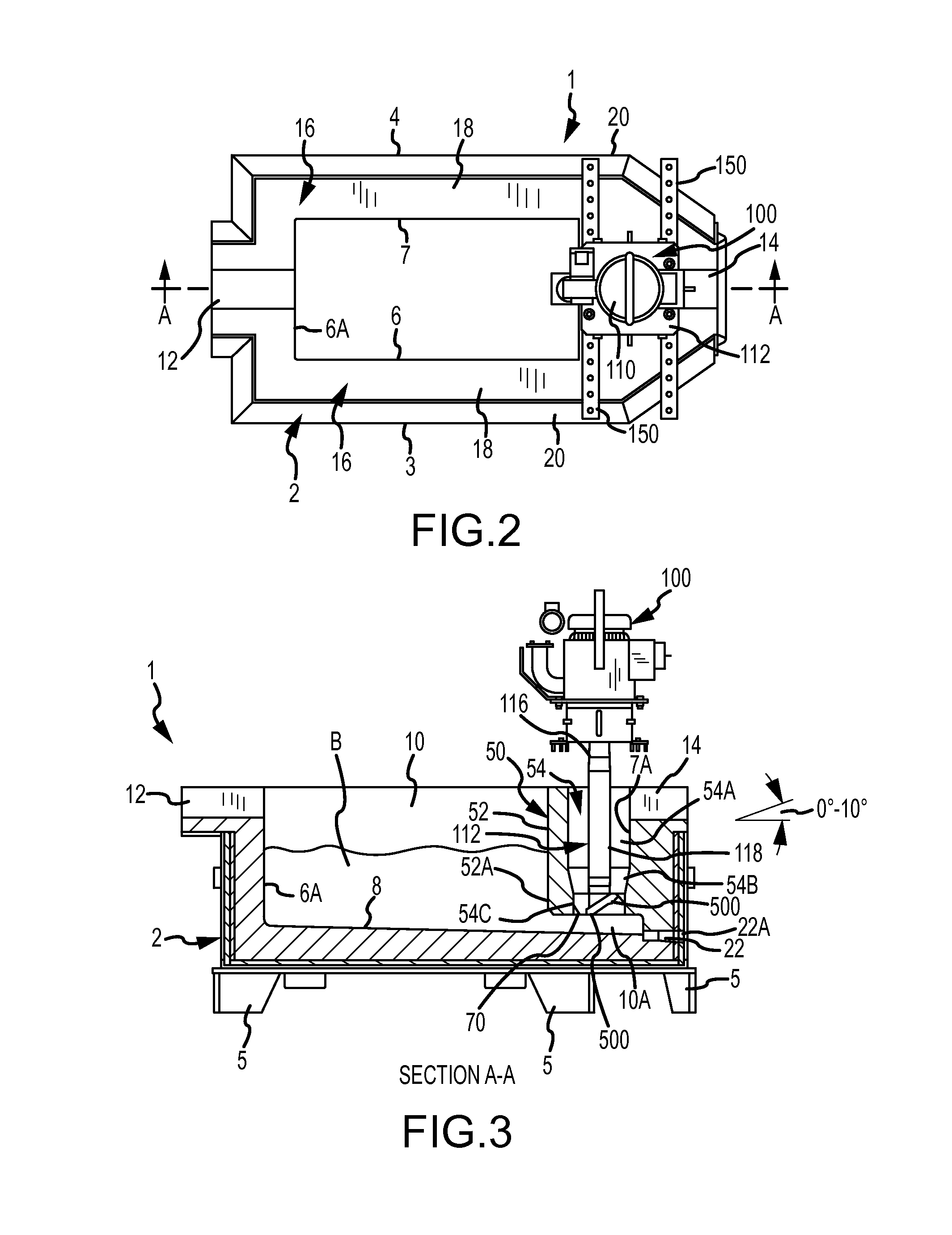

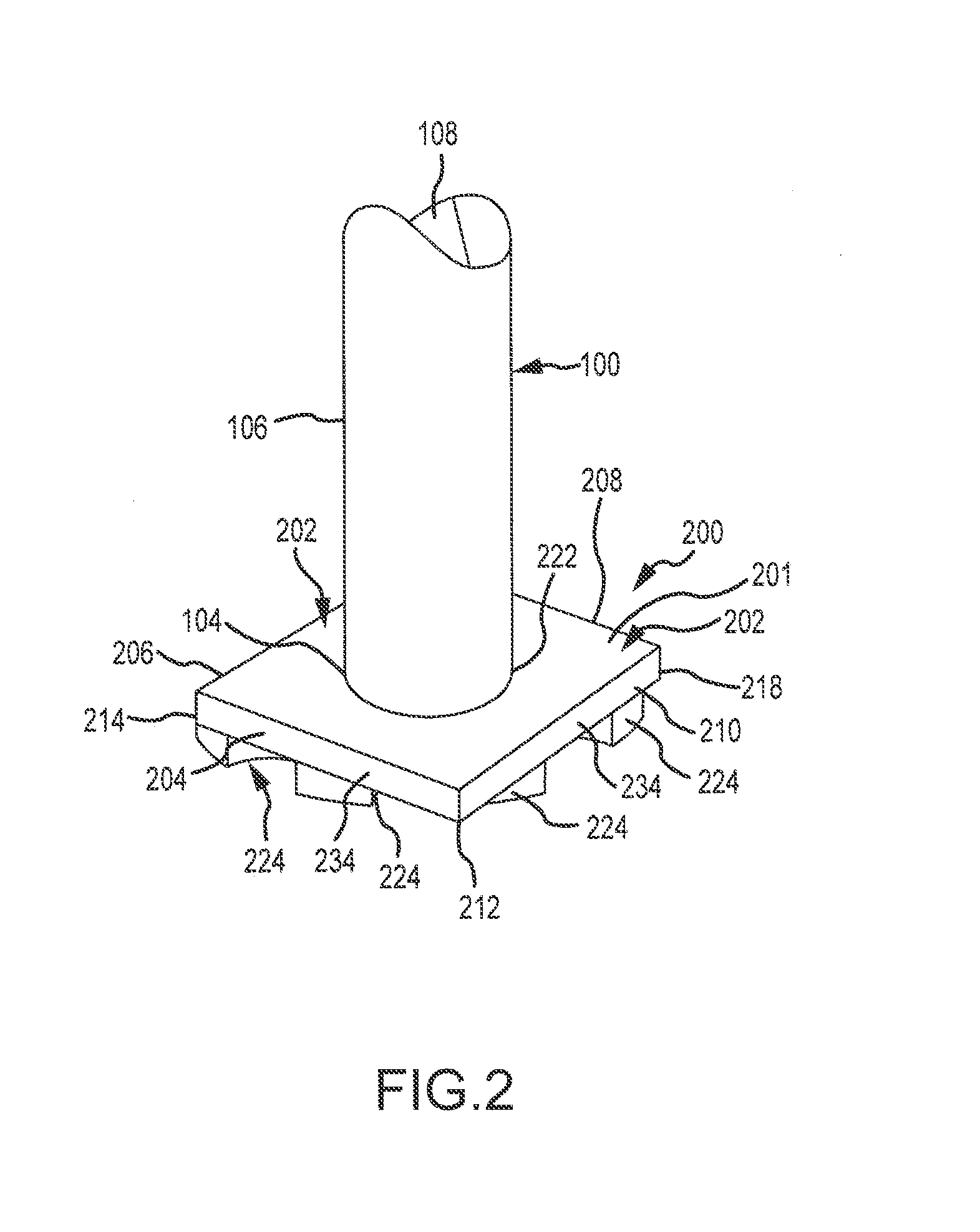

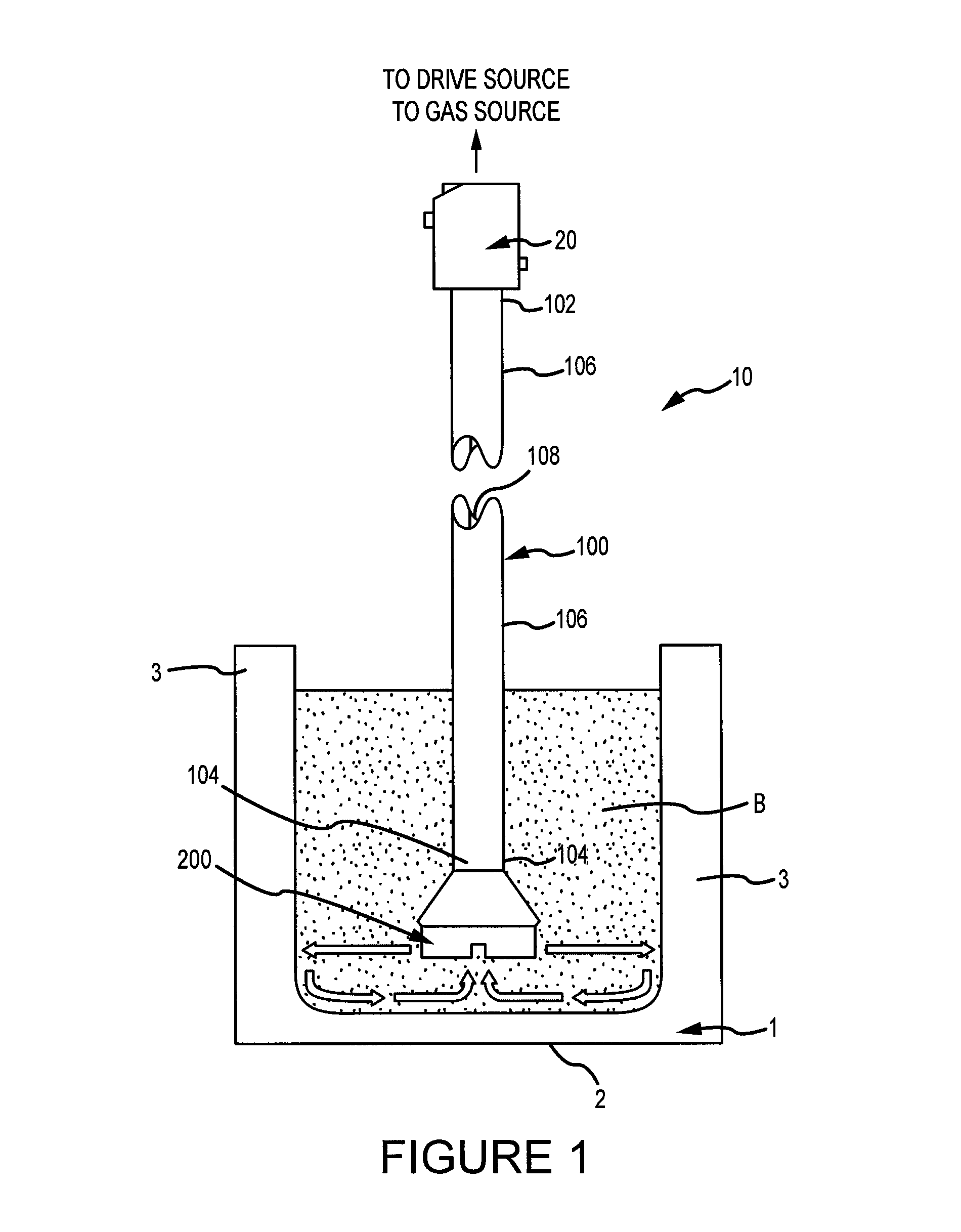

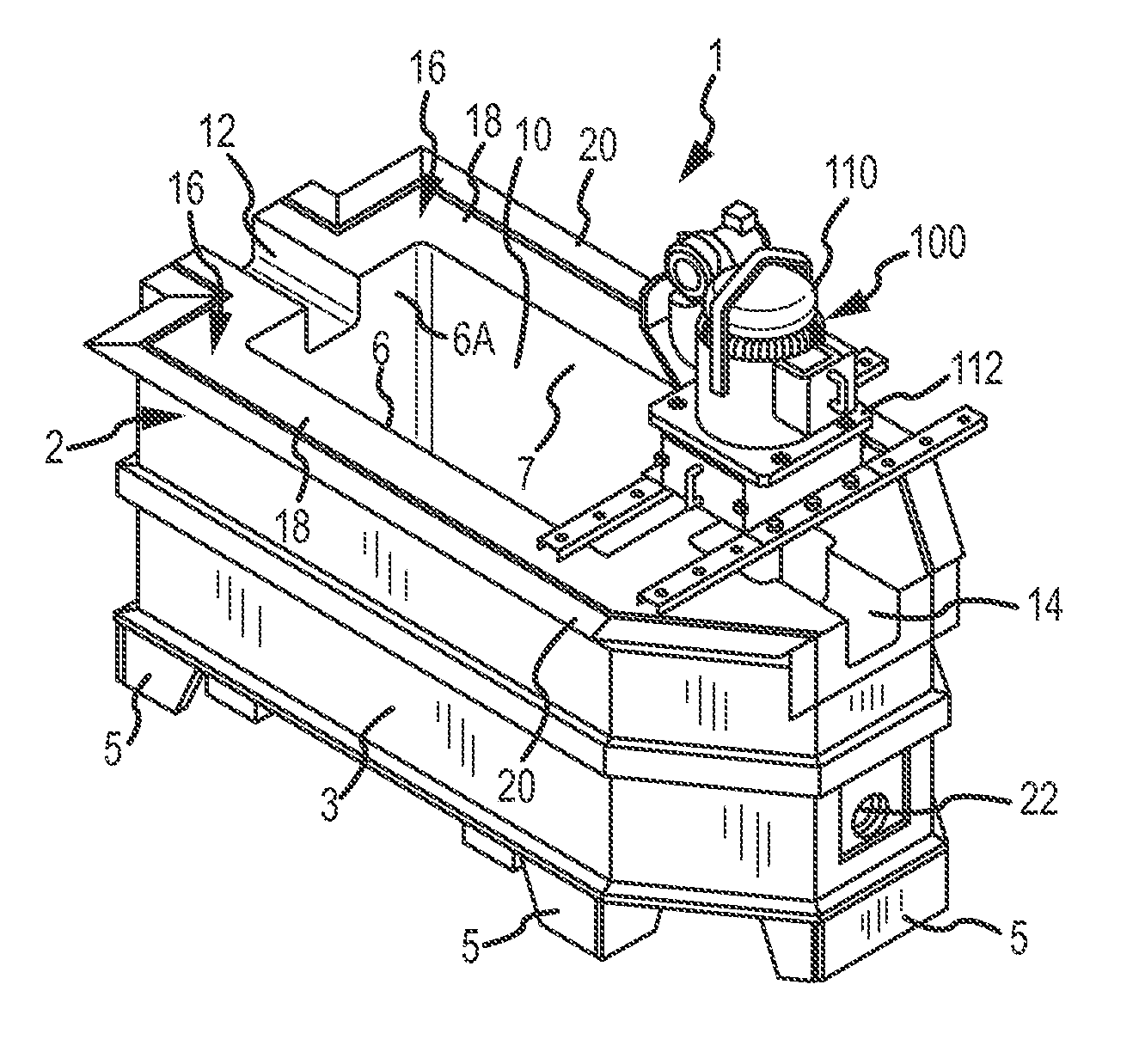

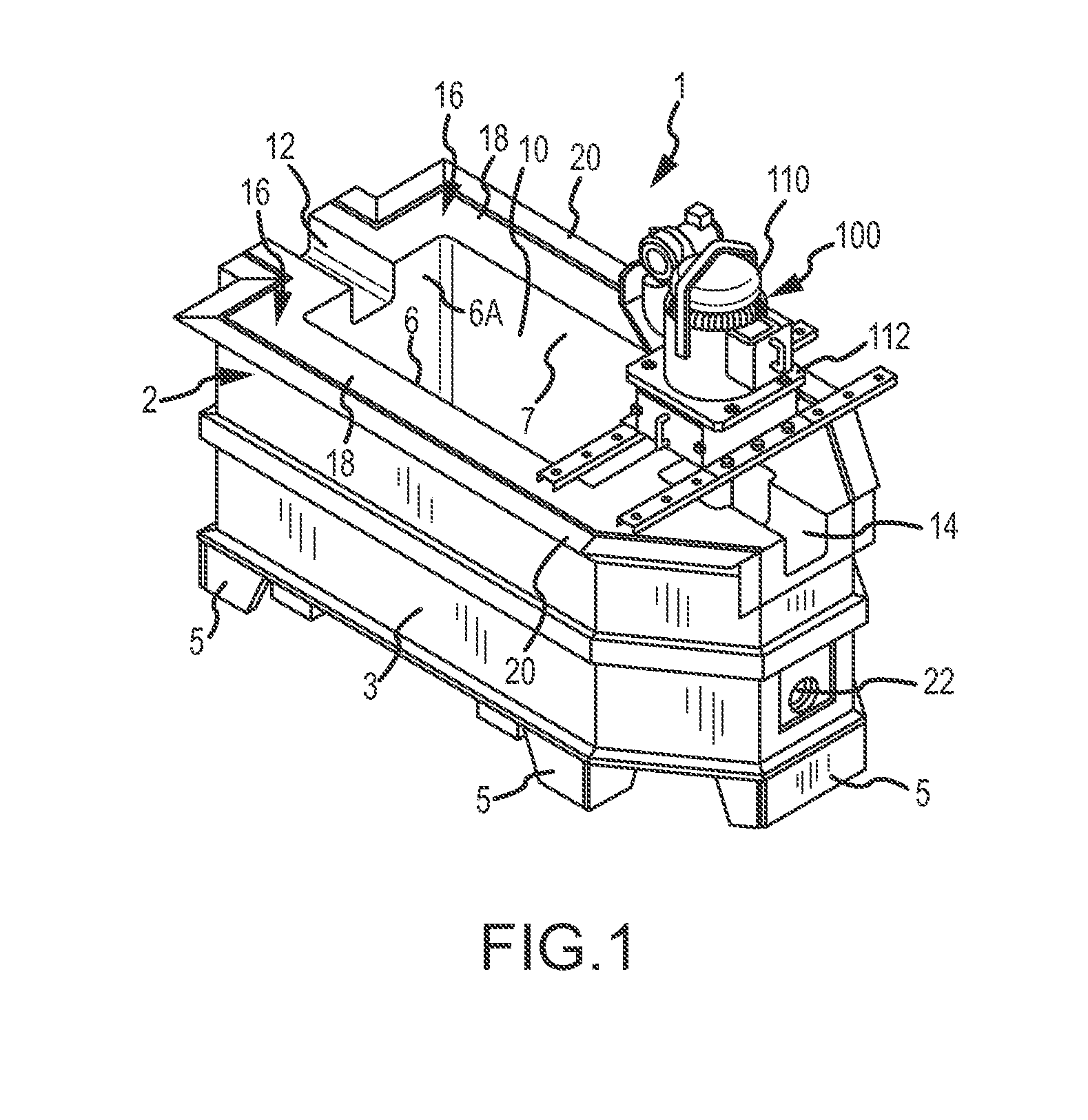

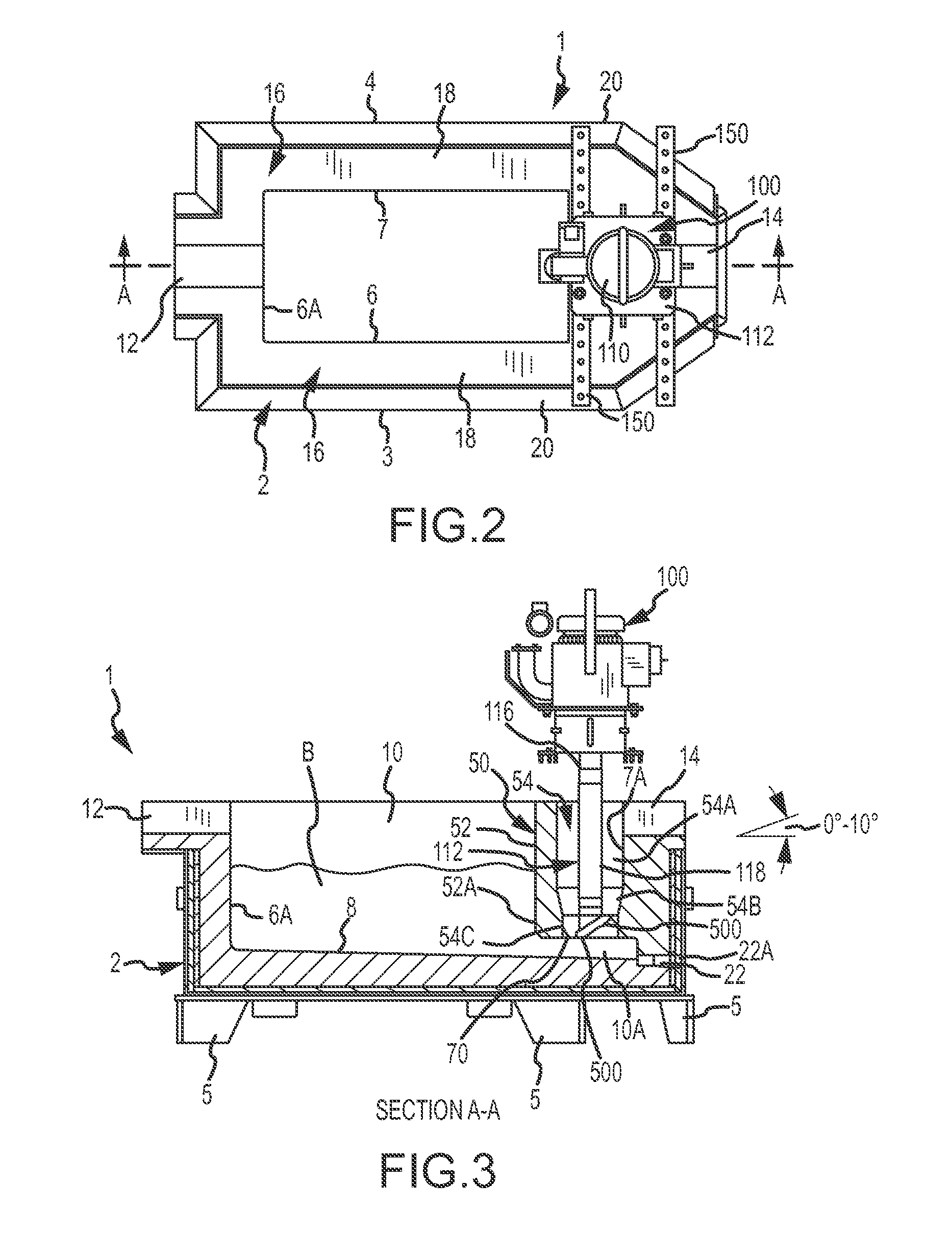

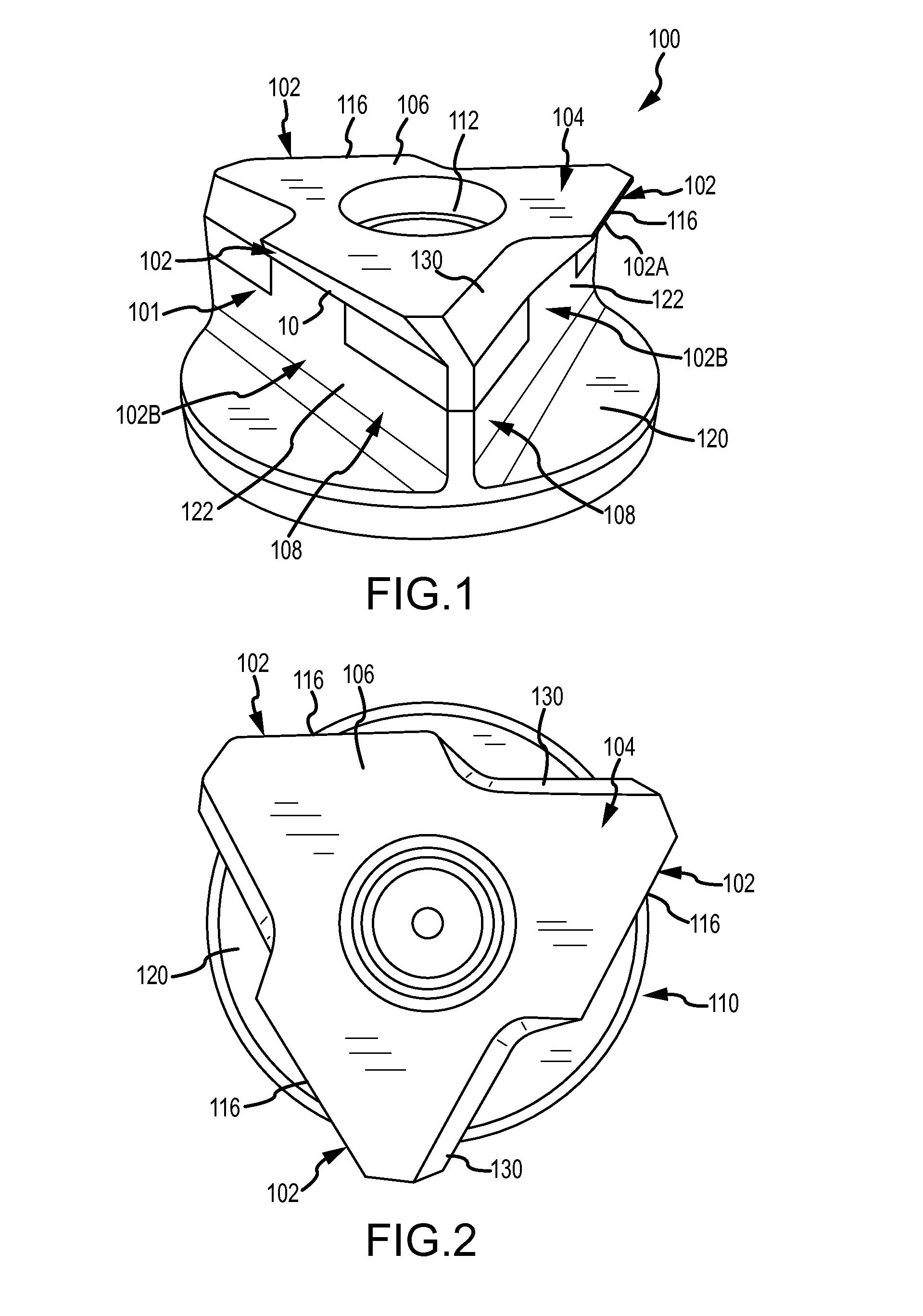

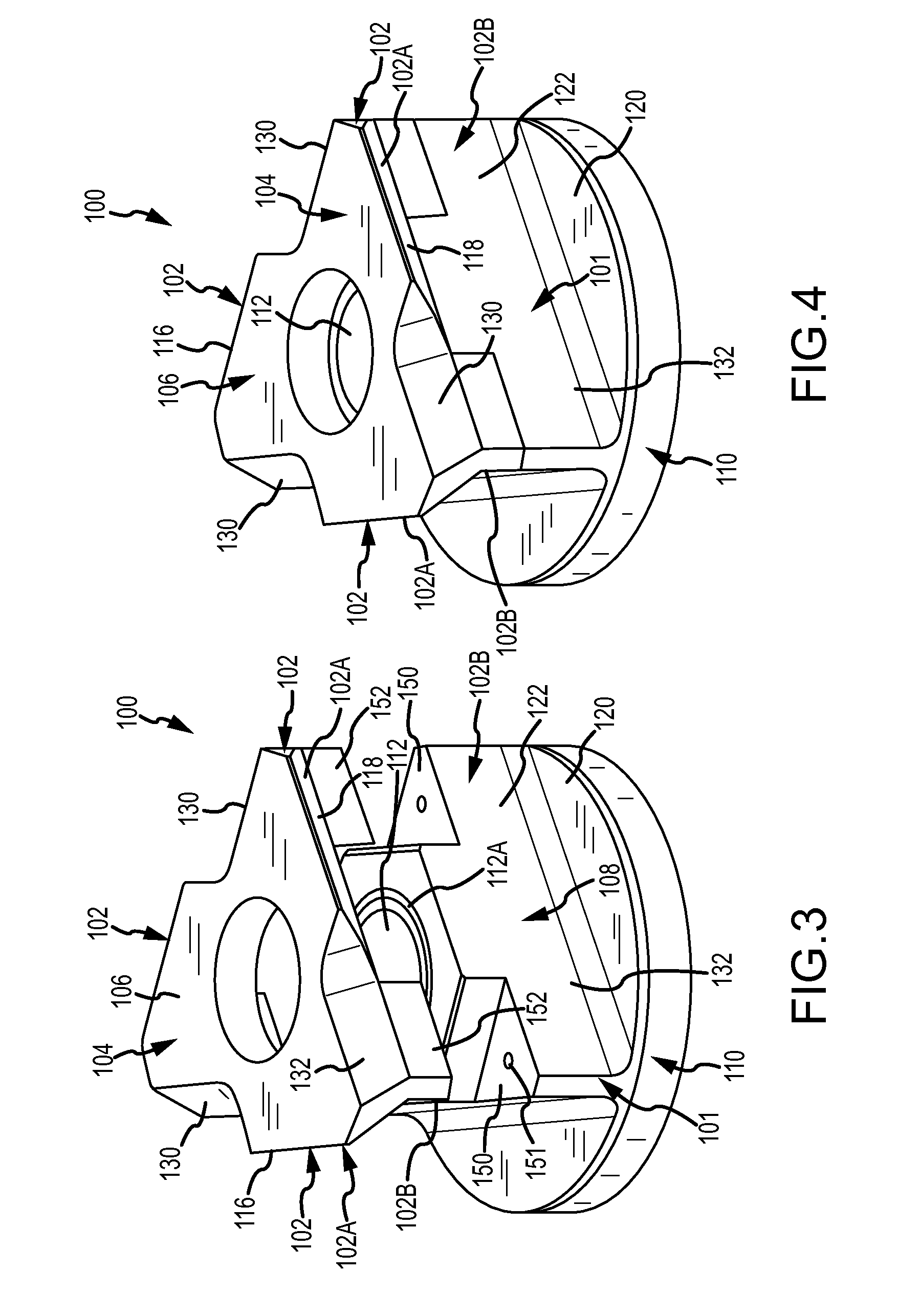

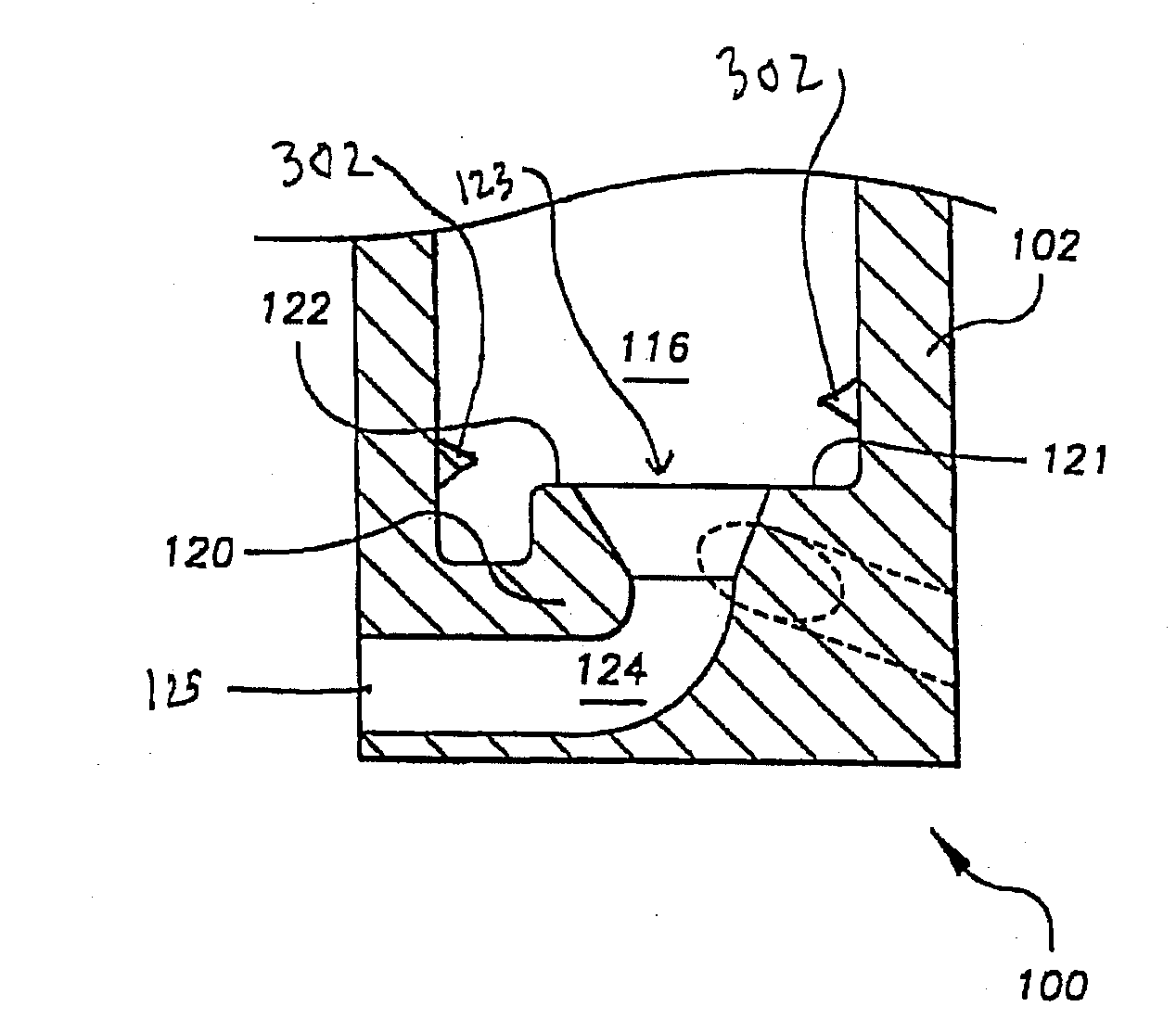

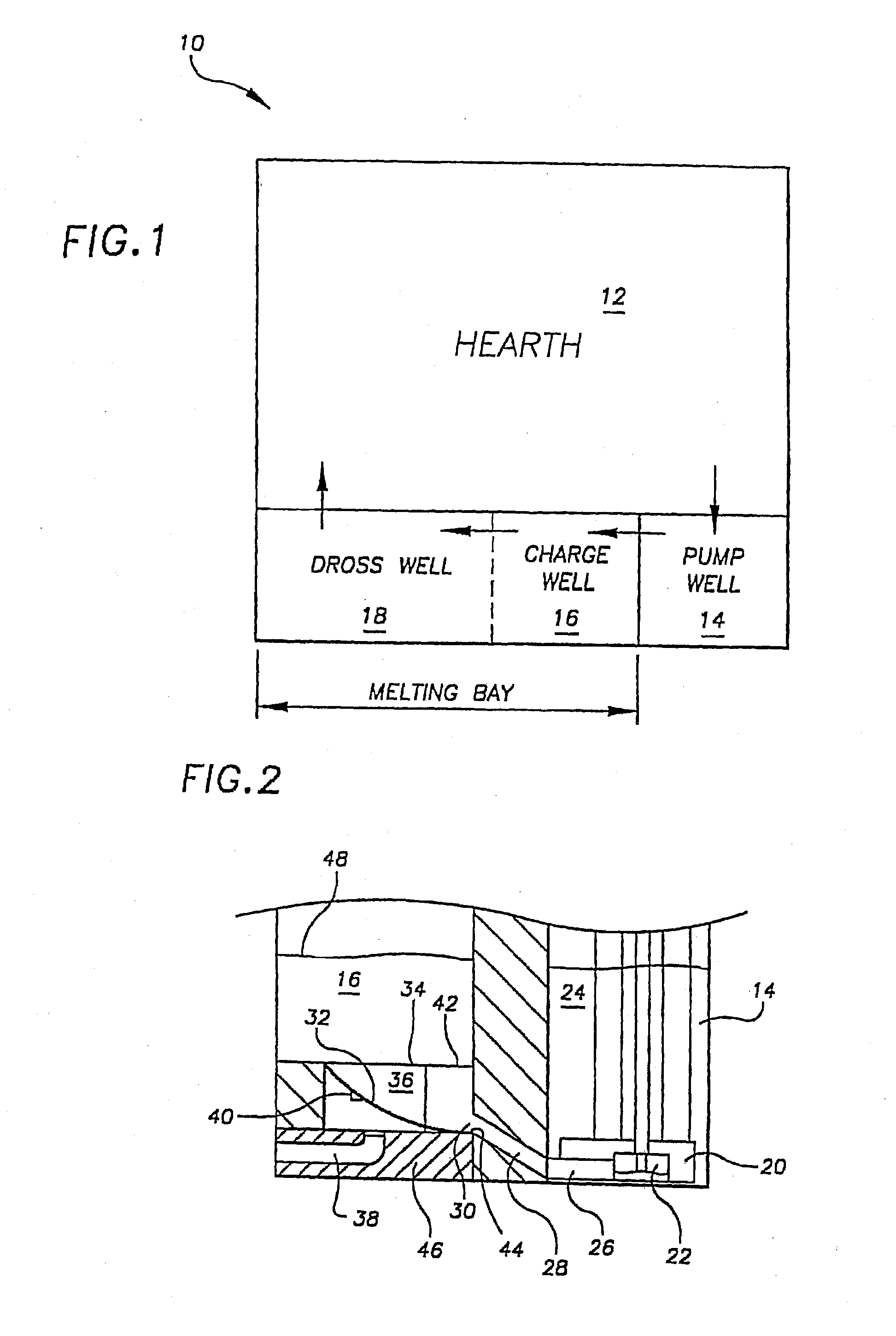

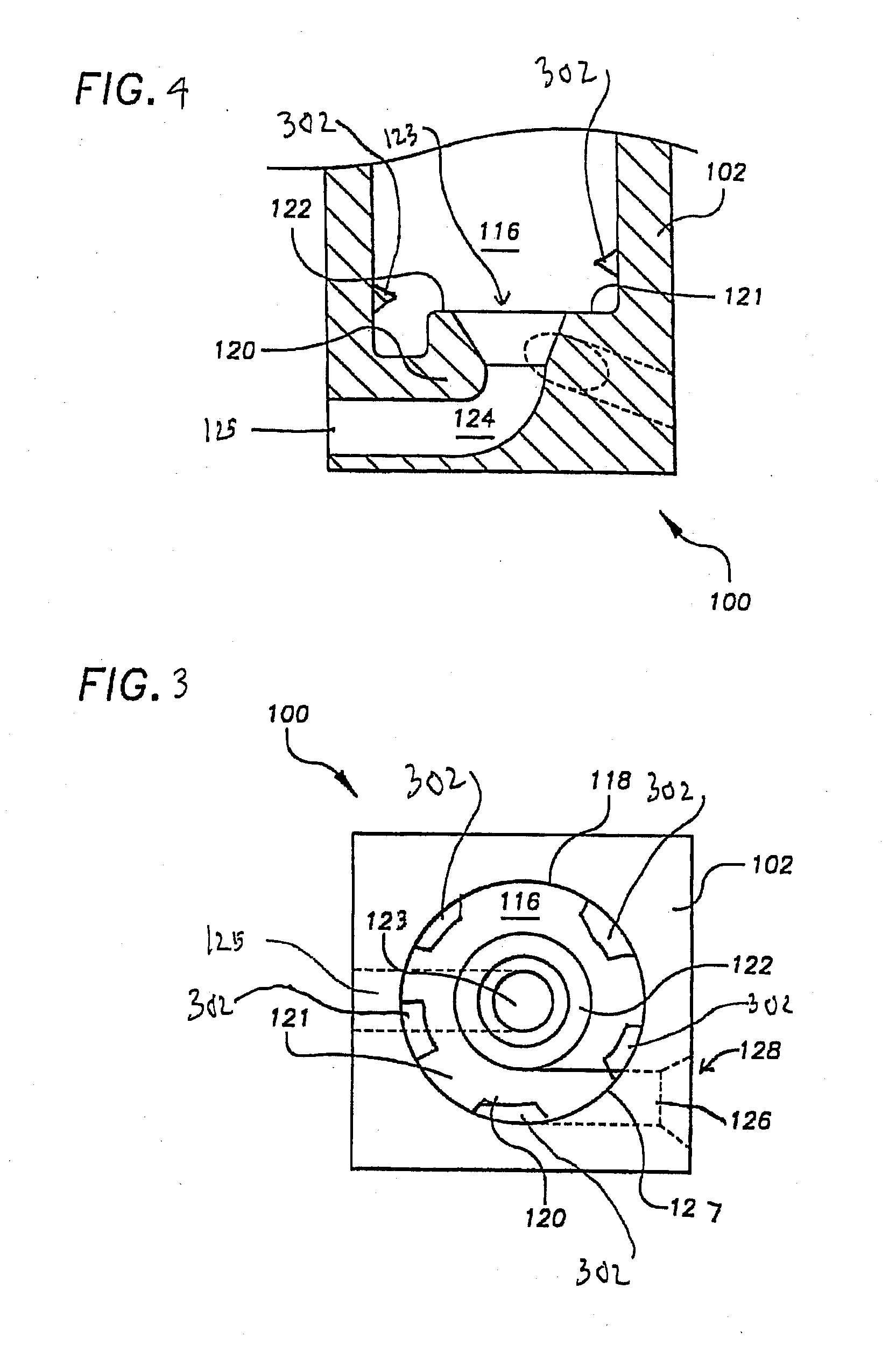

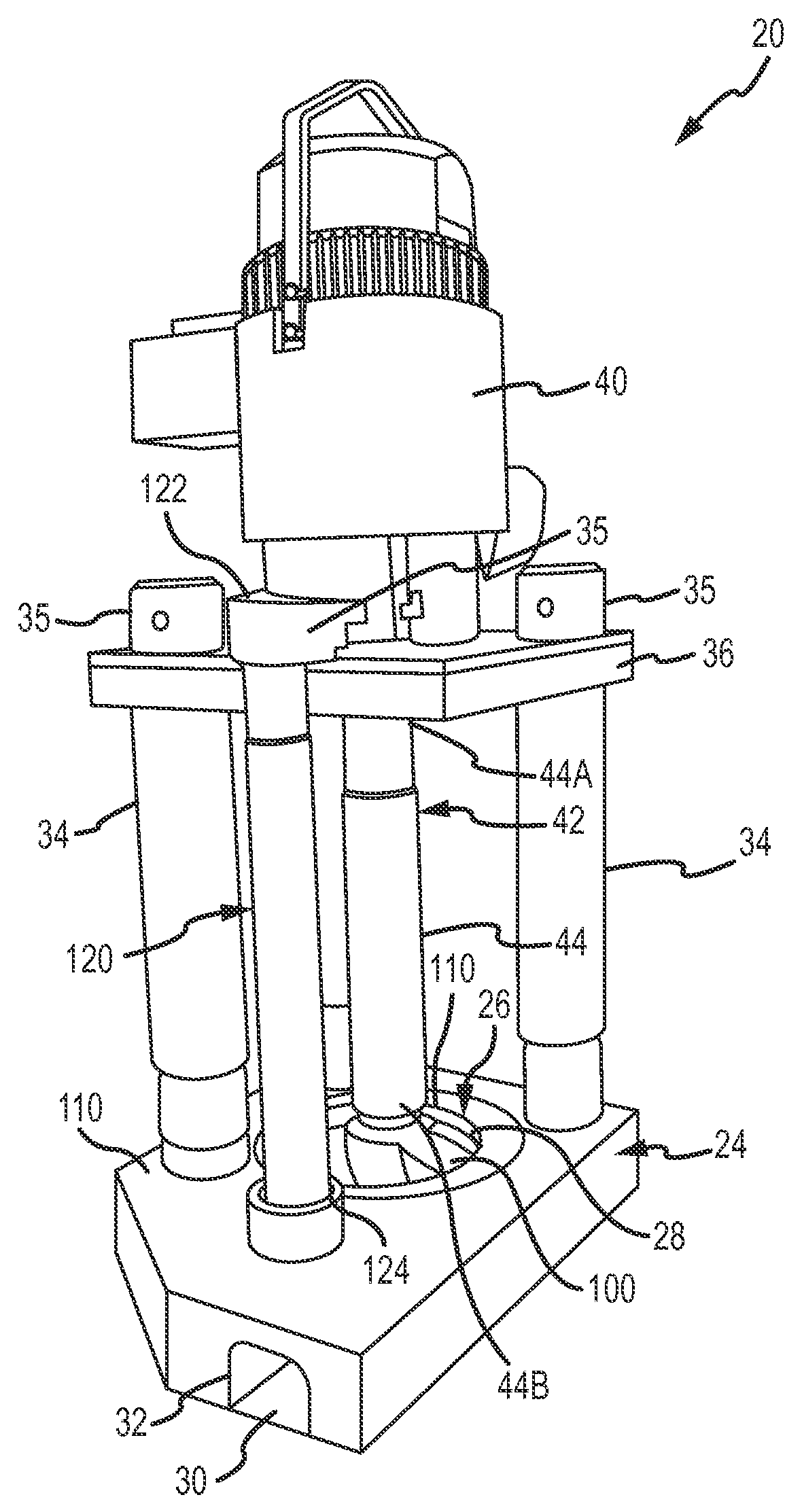

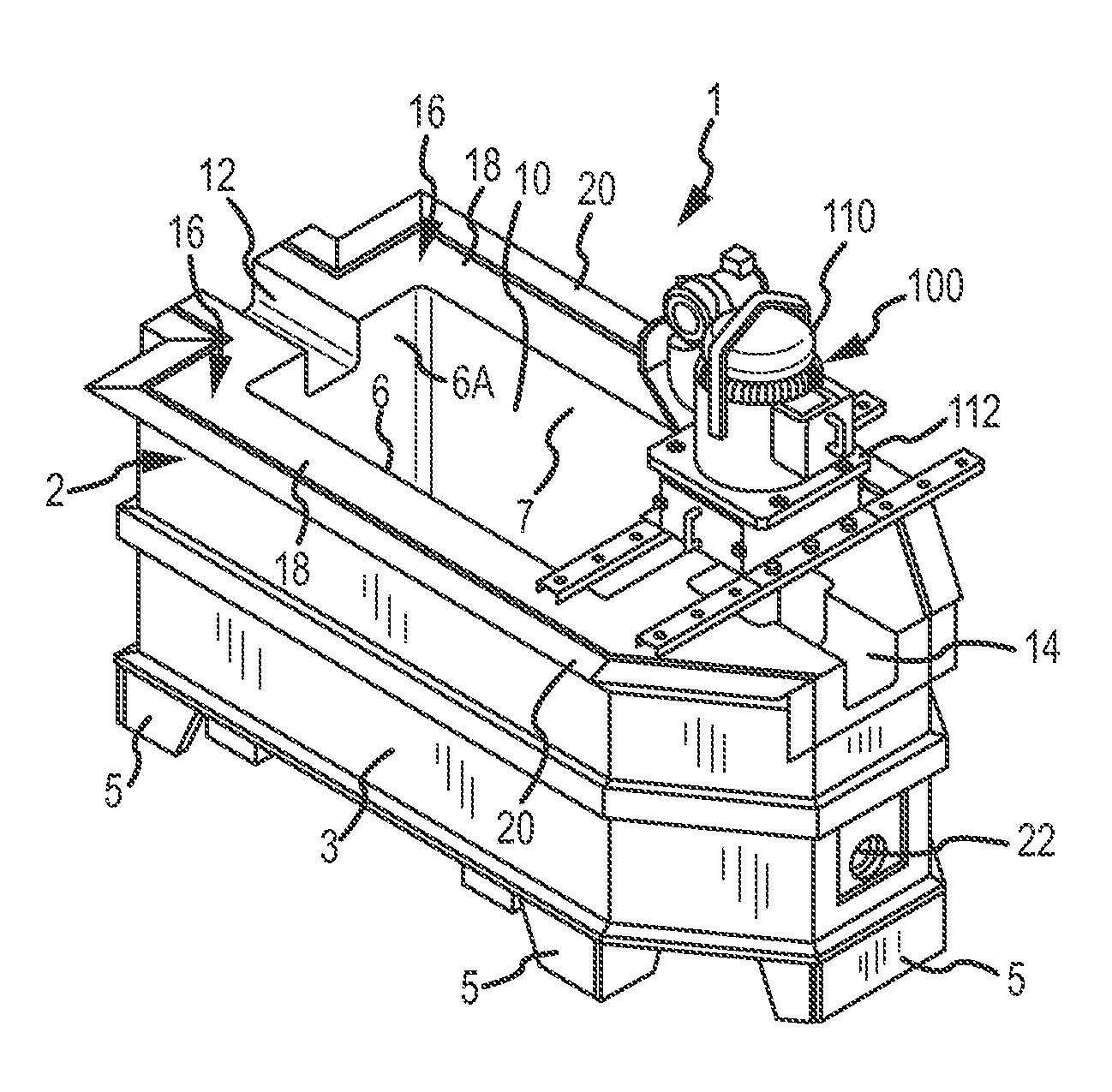

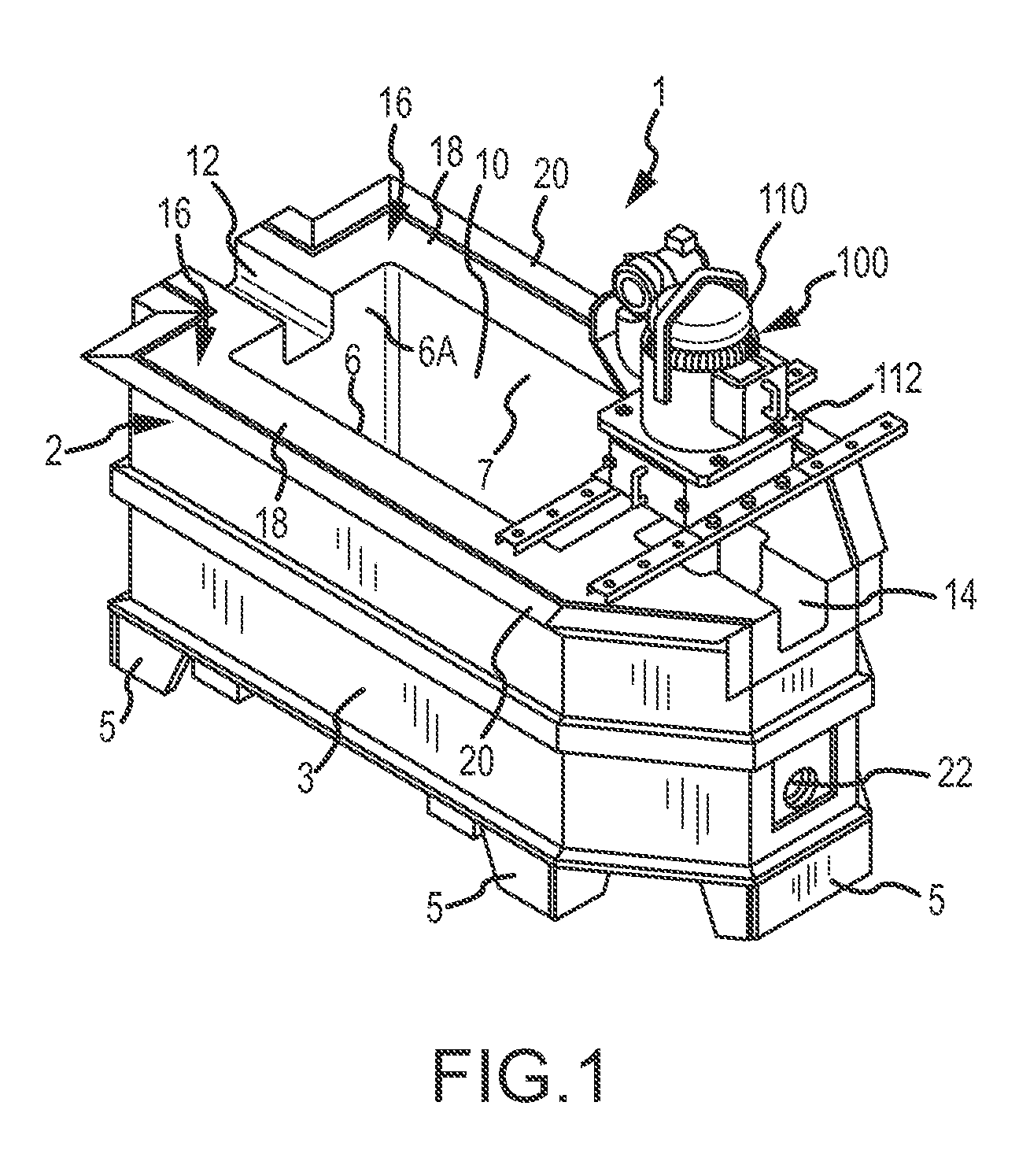

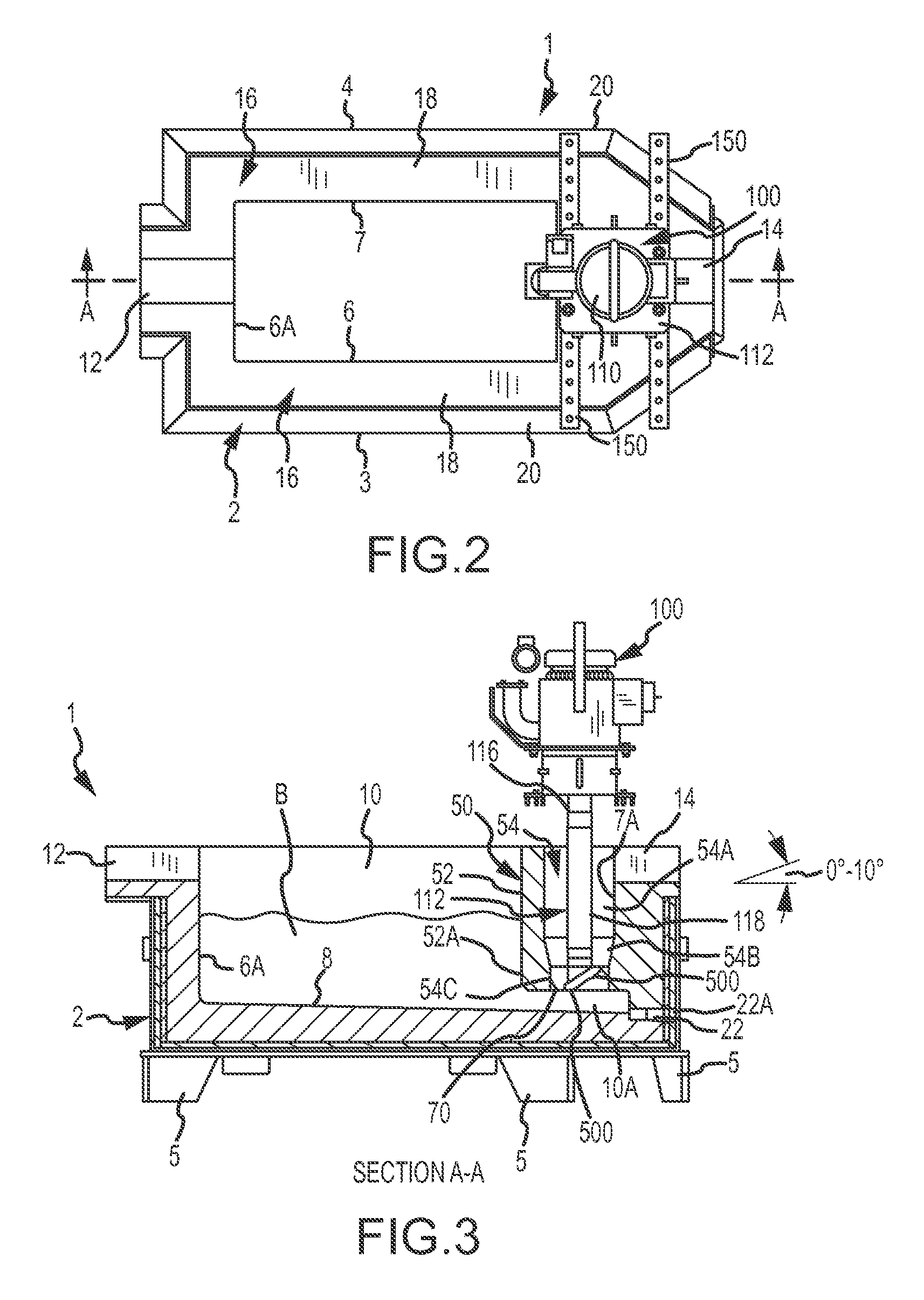

The present invention features a vortexer apparatus including a vessel comprising an exterior surface, an interior surface containing fluid and a mouth for receiving material at an upper end portion of the interior surface. In one application the material is metal scrap that is melted in molten metal as the fluid. All components that contact the molten metal are formed of refractory material. An outlet passageway extends downwardly from the interior surface. A vessel inlet opening is located between the exterior and interior surfaces above the outlet passageway. A center line passes through a center of the interior surface and the vessel inlet opening is disposed at a location offset from the center line. A pump is adapted to pump fluid into the vessel effective to form a vortex of fluid in the vessel. The base and impeller are configured and arranged effective to provide molten metal leaving the base outlet with a positive pressure. An outlet conduit extends from the base outlet to near the vessel inlet opening and can be maintained at a temperature above which molten metal solidifies, along its entire length. Instead of the vortexer vessel, the inventive vortexer apparatus may integrate a chamber of a furnace (e.g., a charge well). The chamber may be rectangularor include arcuate portions. Corner inserts may be used to provide the chamber with an oval or generally circular shape that may facilitate the vortex. One feature of the invention is a vortex vessel that includes an offset inlet opening and lower circulation opening. Also featured is a baffle impeller that may be vaned or barrel type. In addition, the invention features a pump having upper and lower impeller chambers separated by a web in the base, and impeller outlets that are isolated from fluid communication with each other.

Owner:THUT BRUNO H

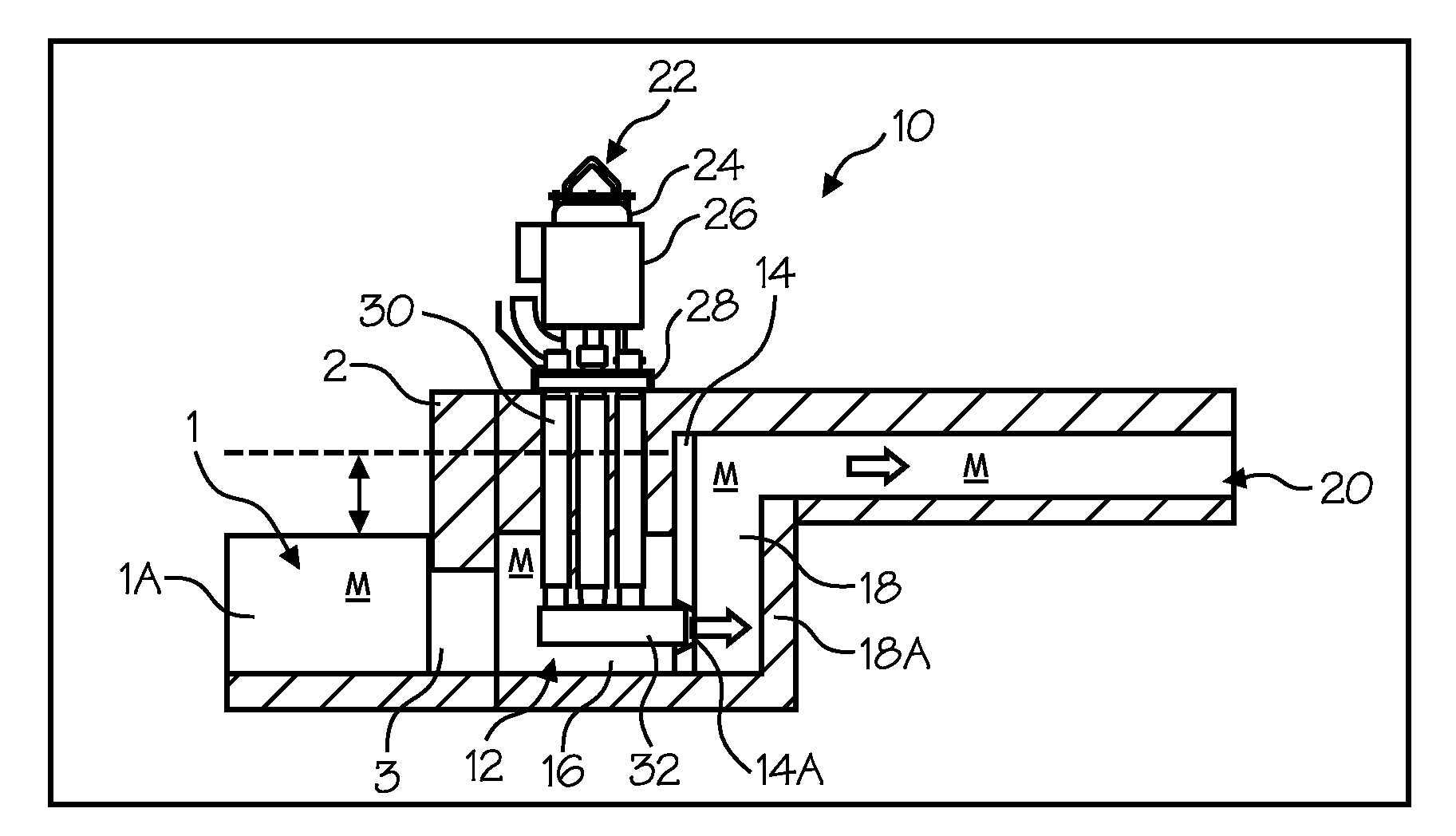

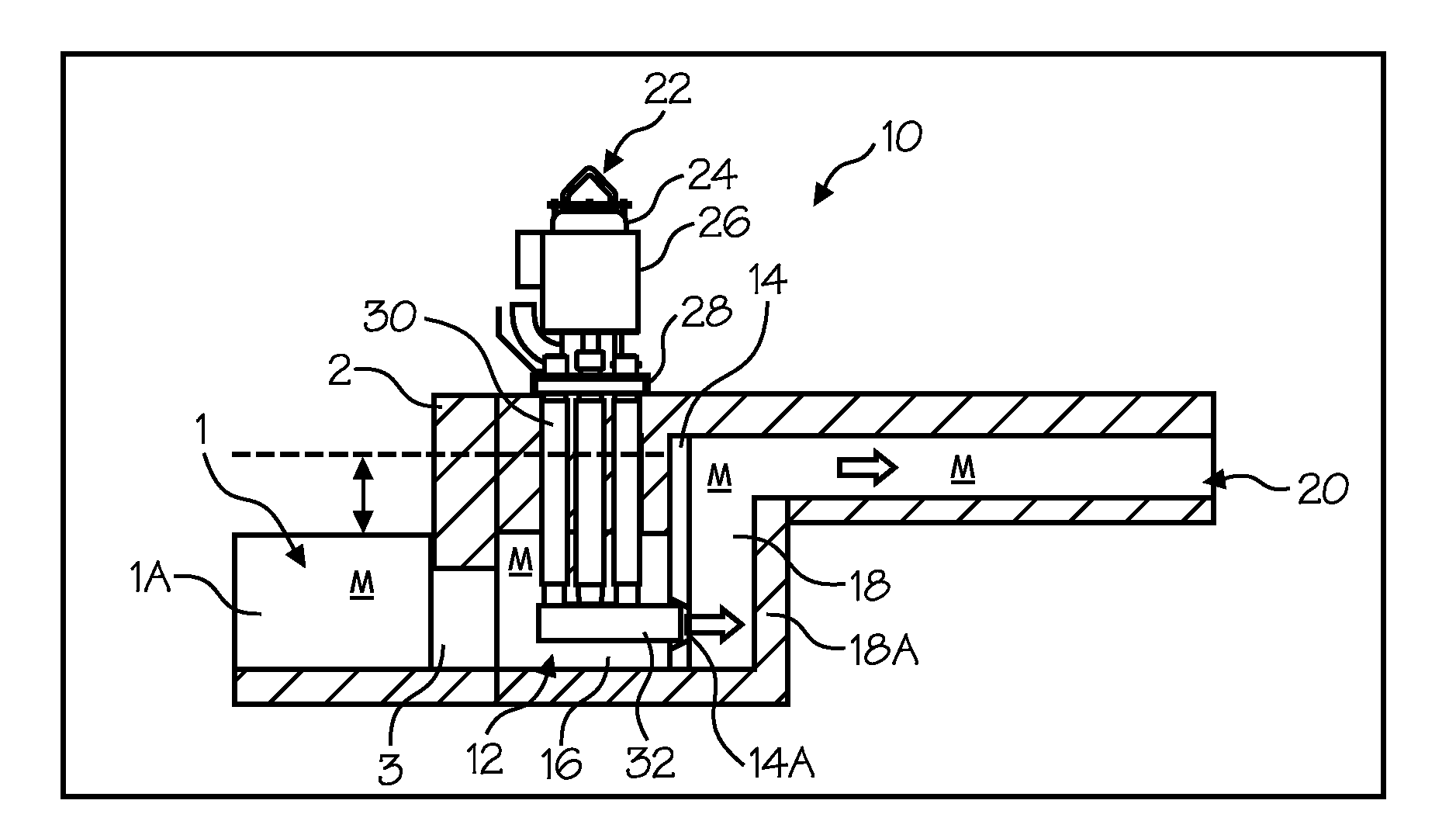

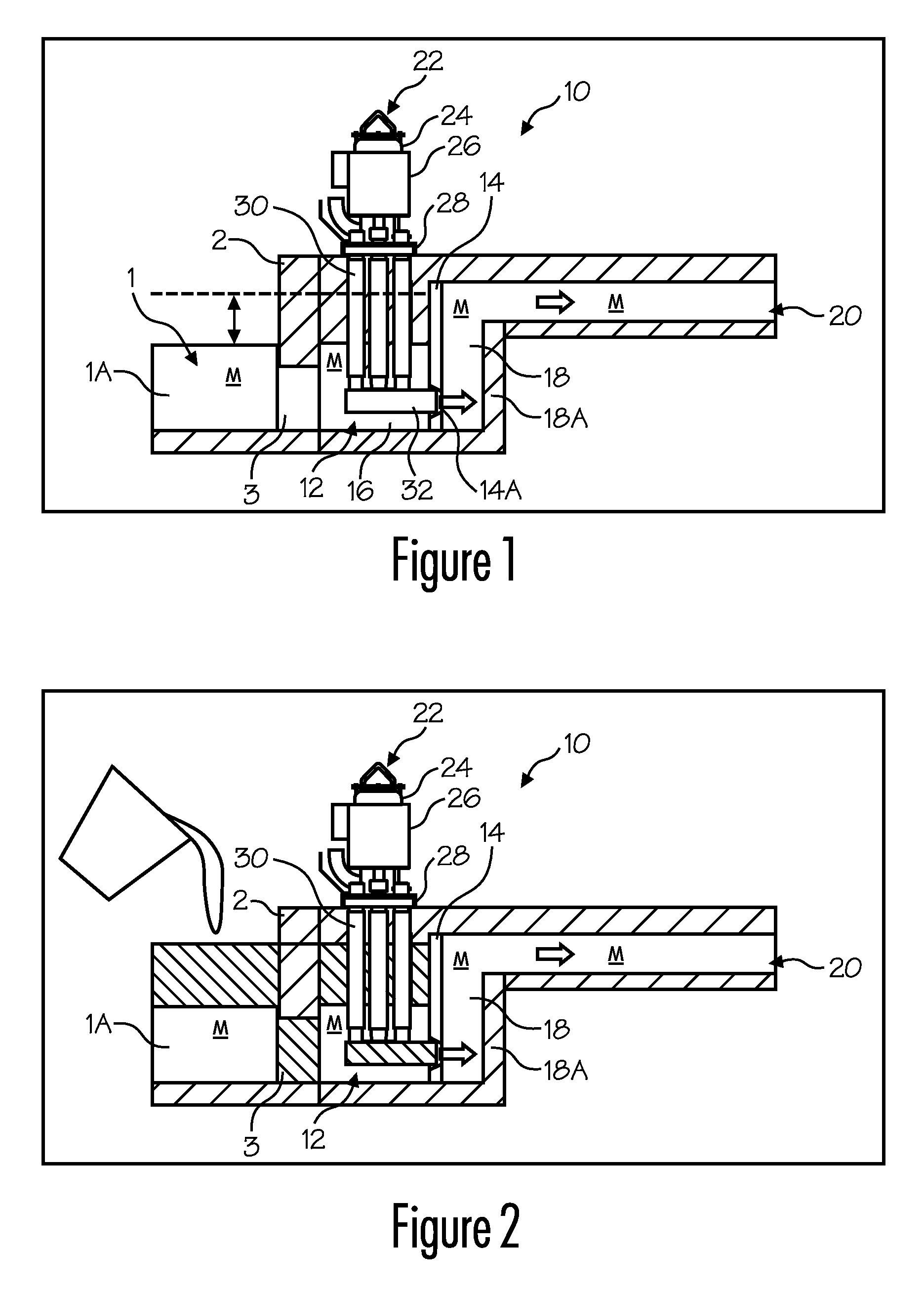

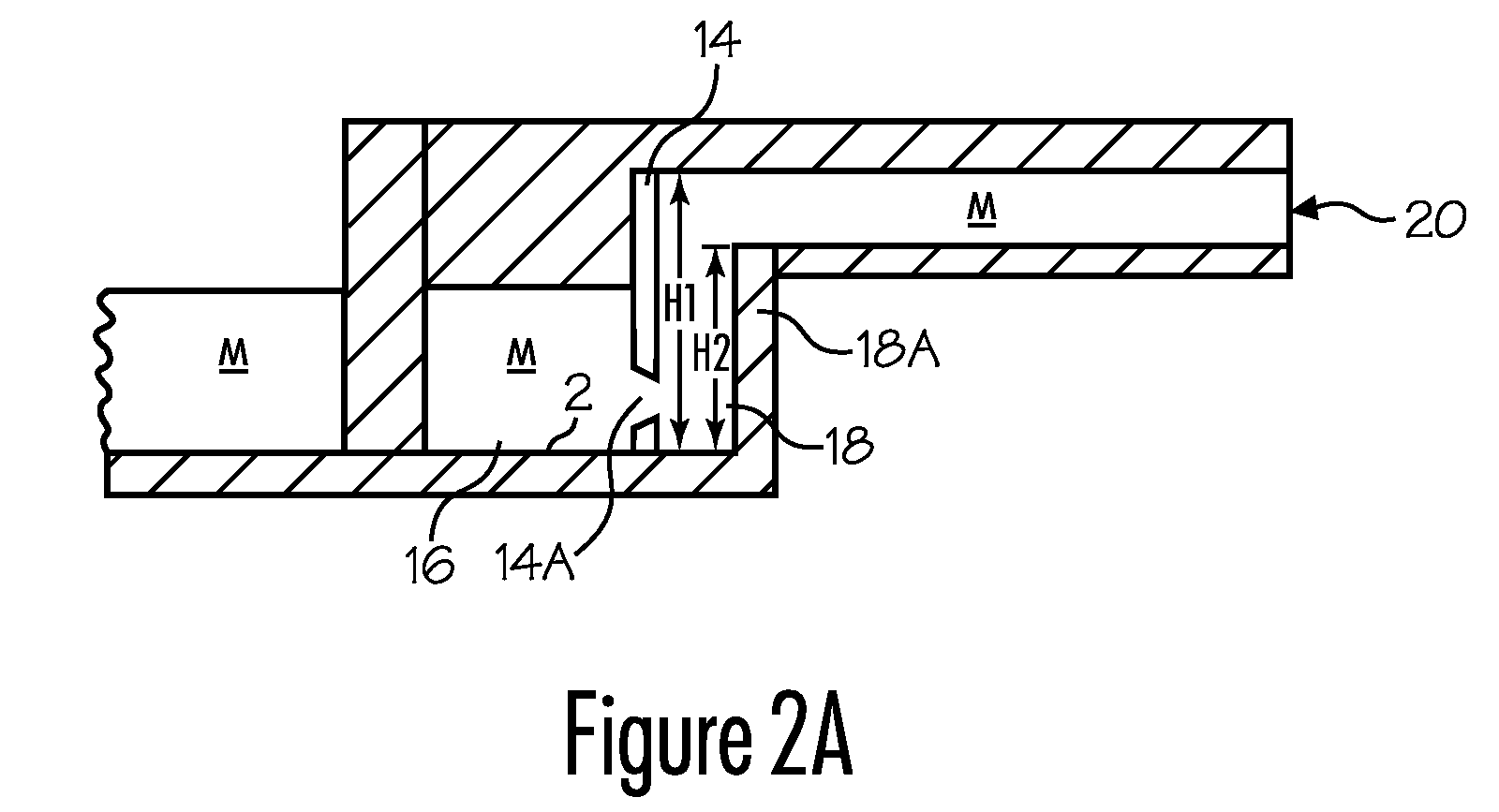

Transferring molten metal from one structure to another

ActiveUS20080314548A1Formation of dross in the ladle or launder are greatly reduced or eliminatedEliminate useMolten metal pouring equipmentsMolten metal supplying equipmentsDie castingMolten metal

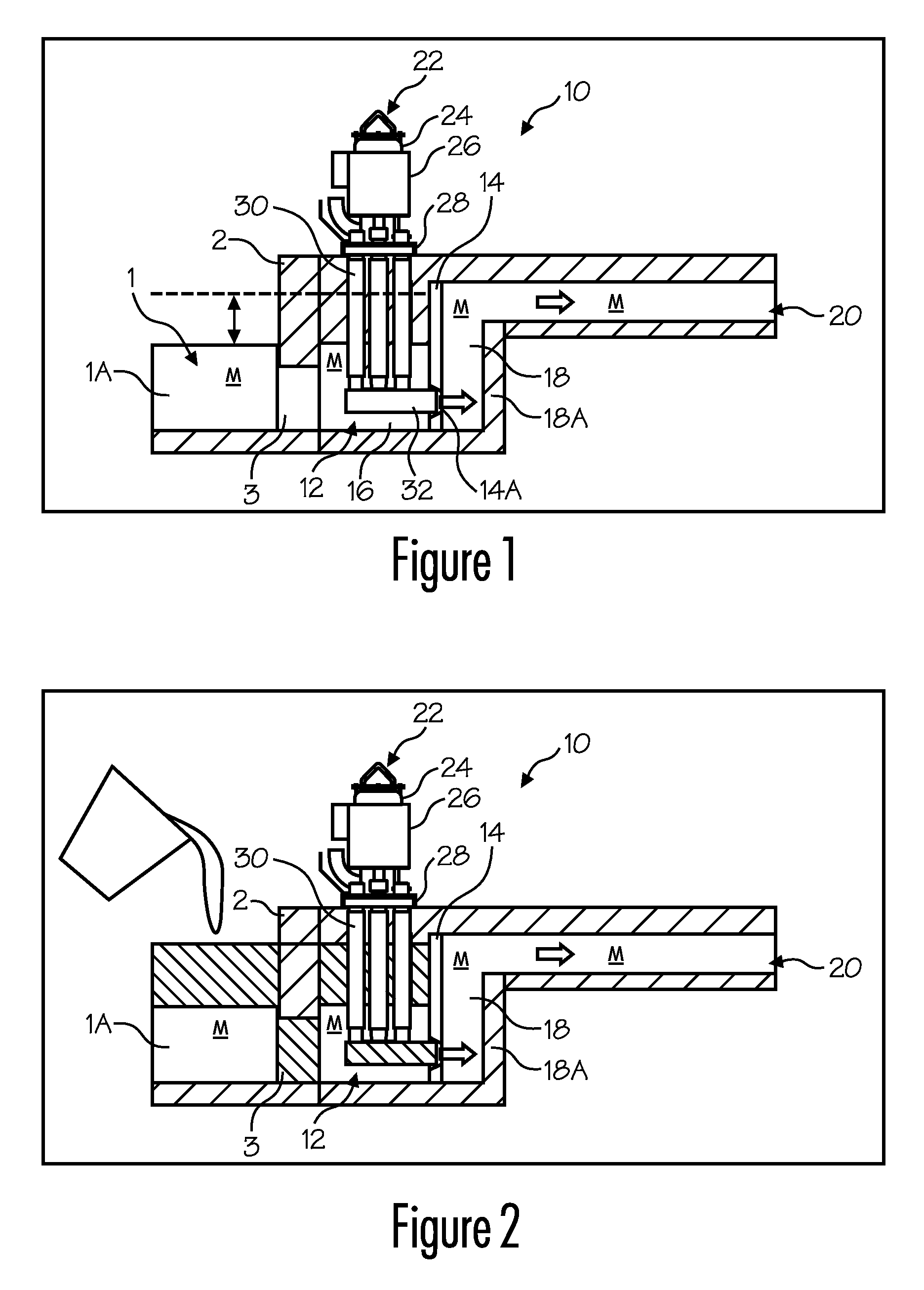

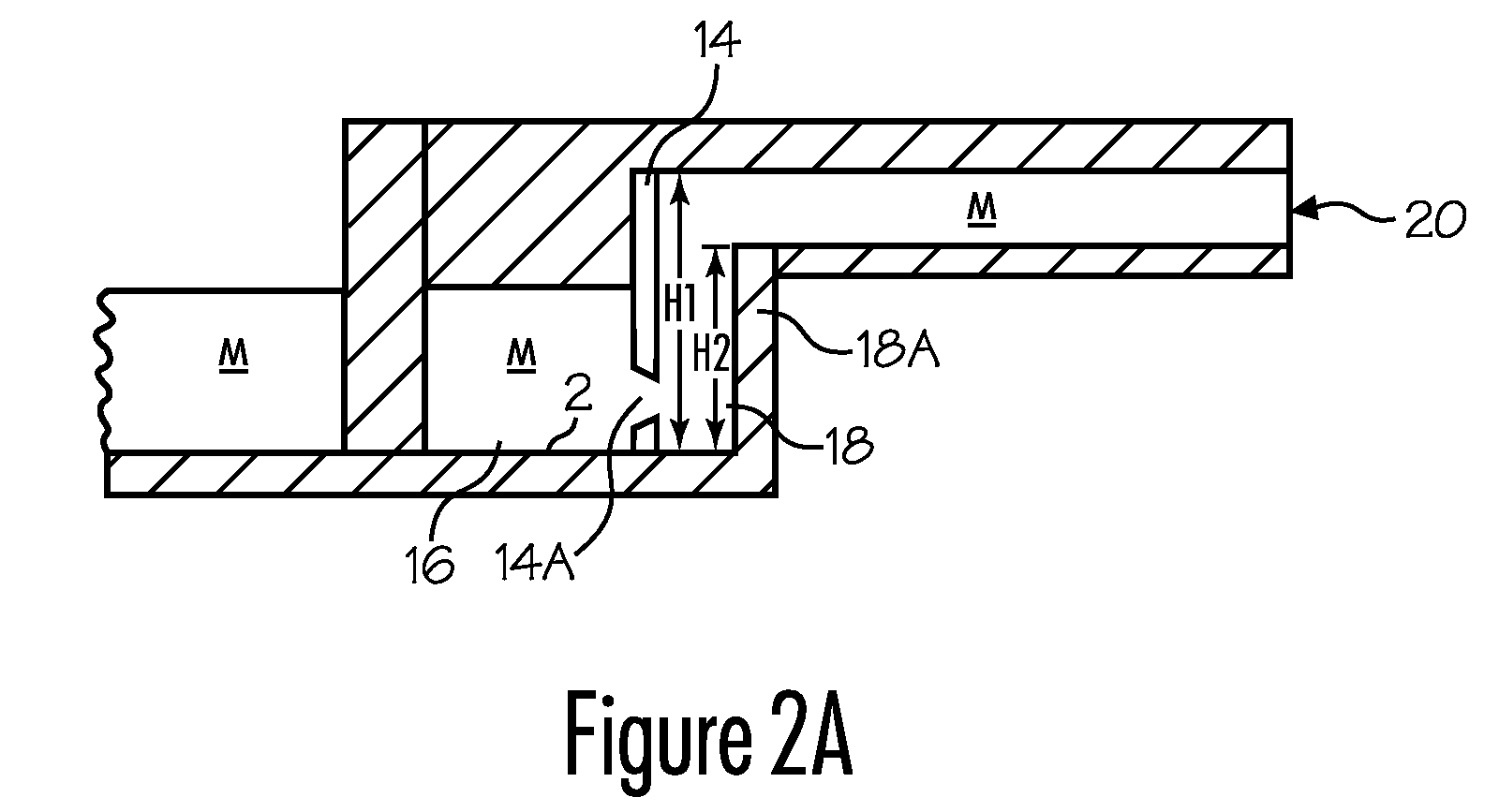

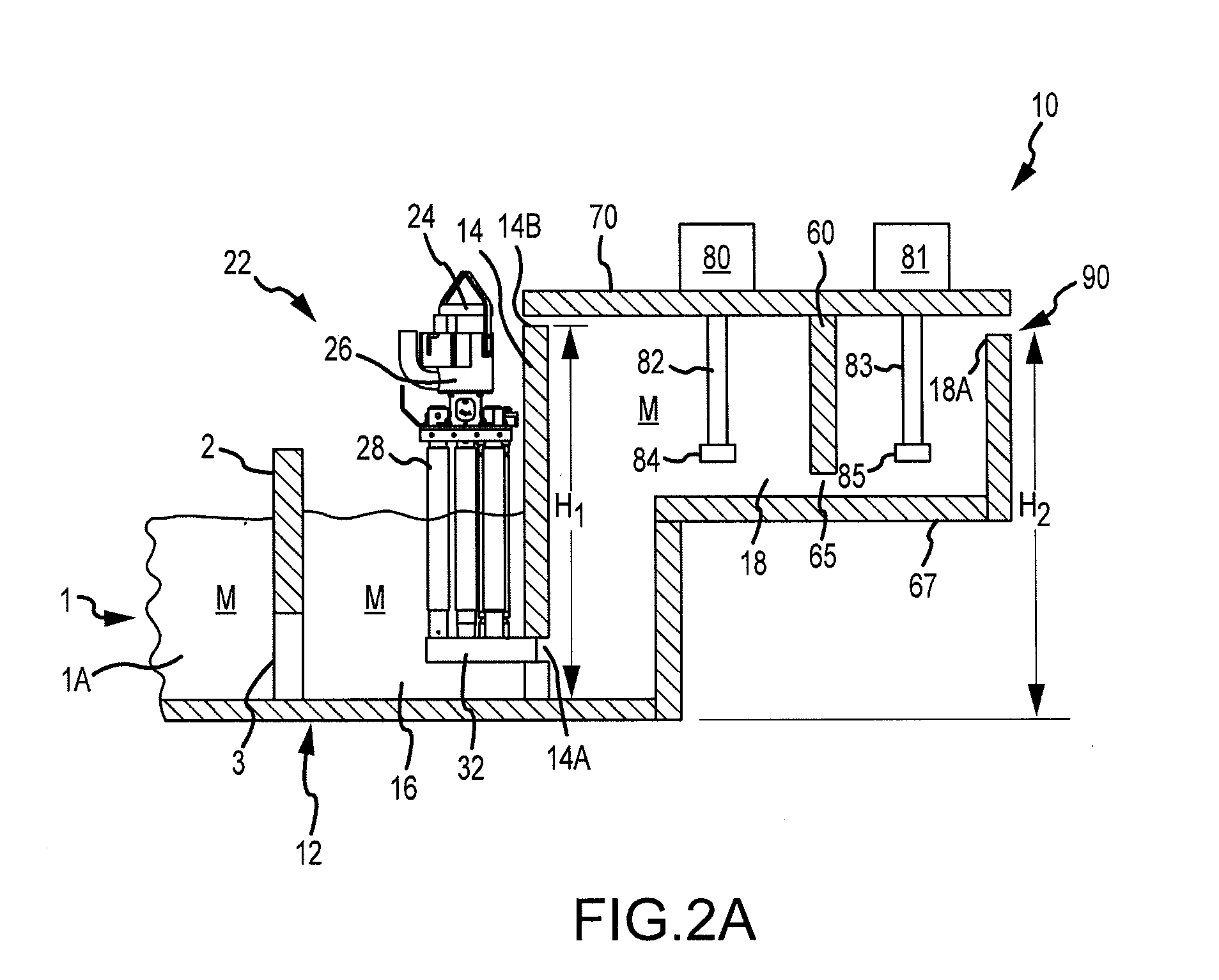

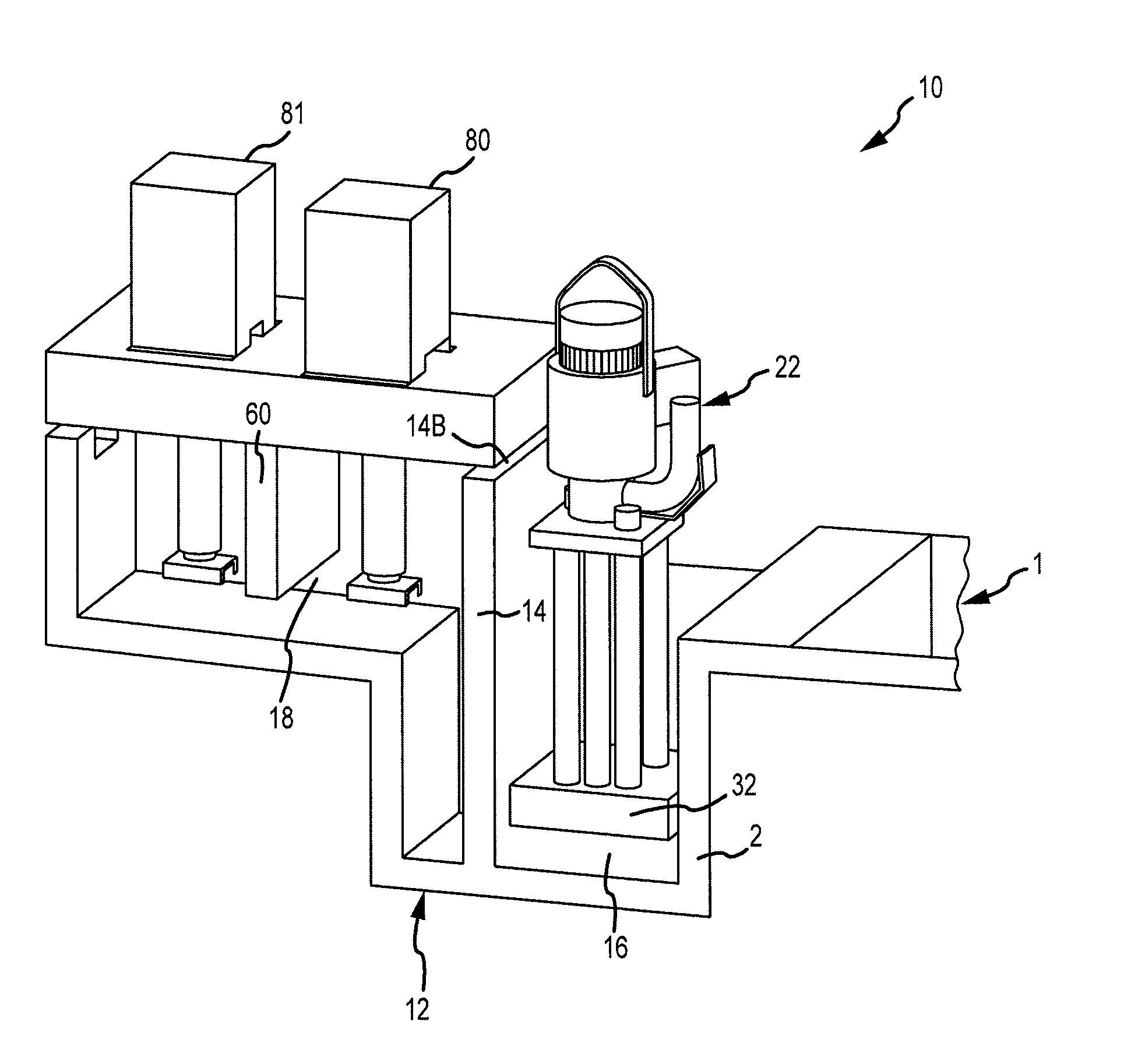

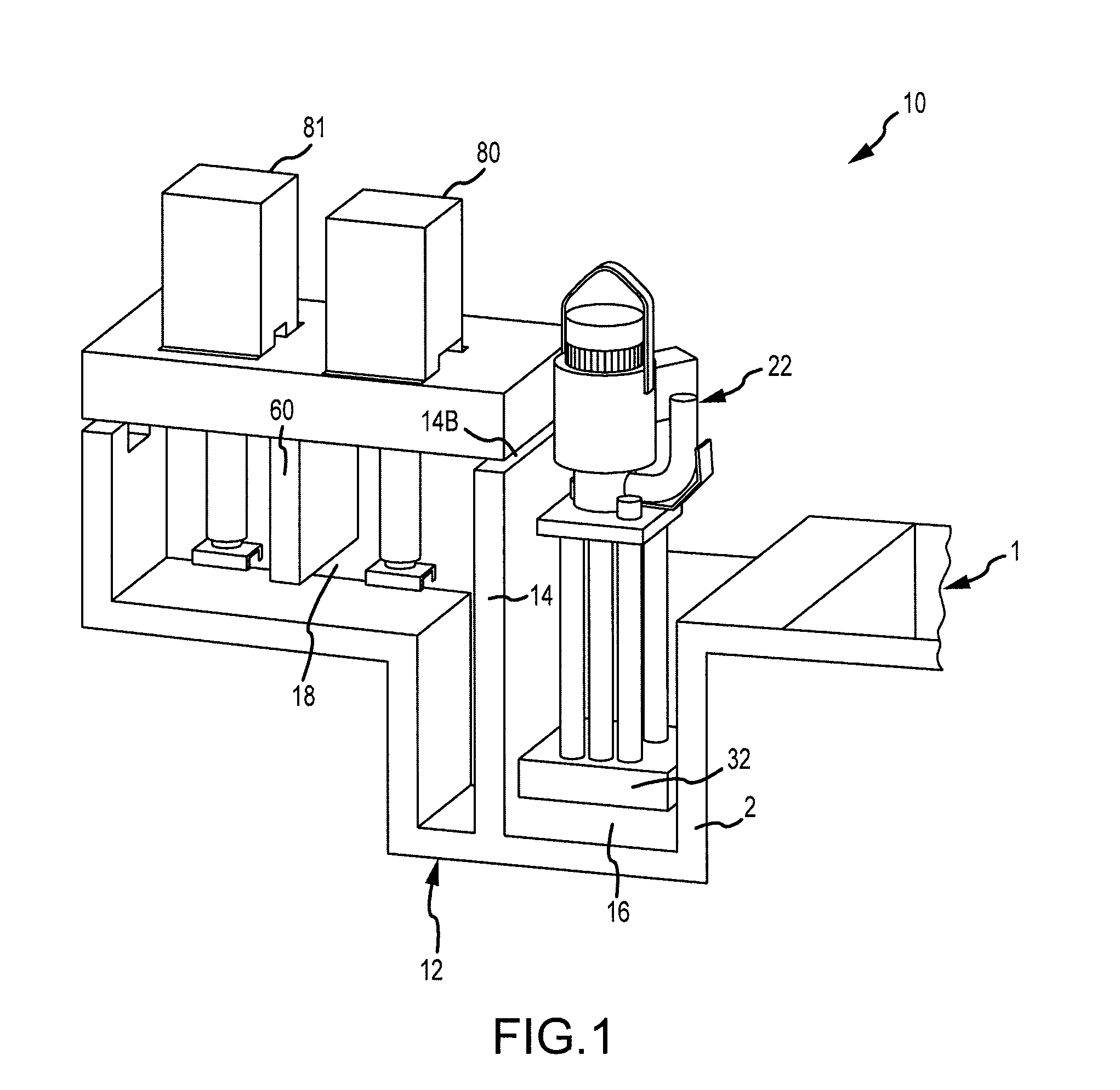

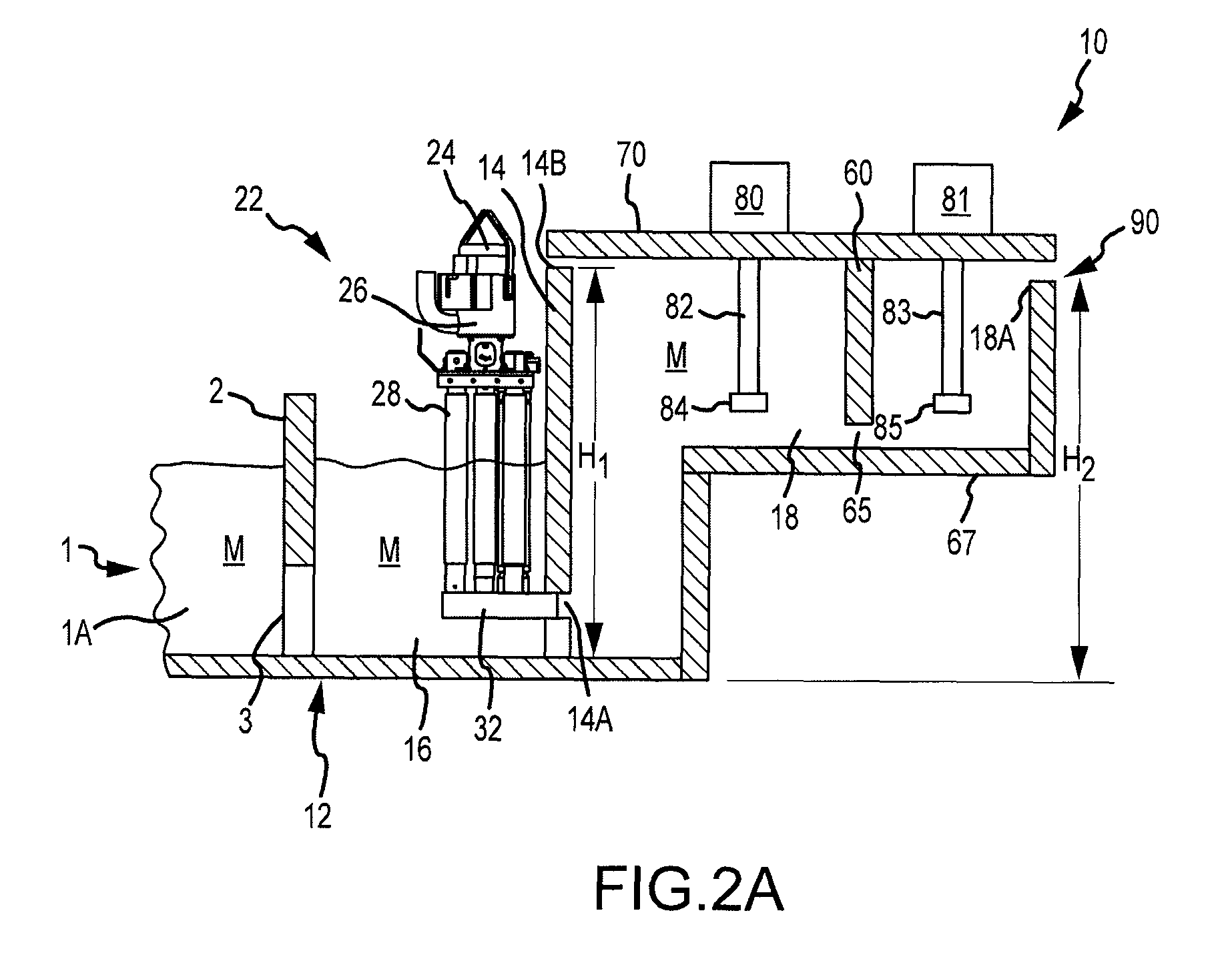

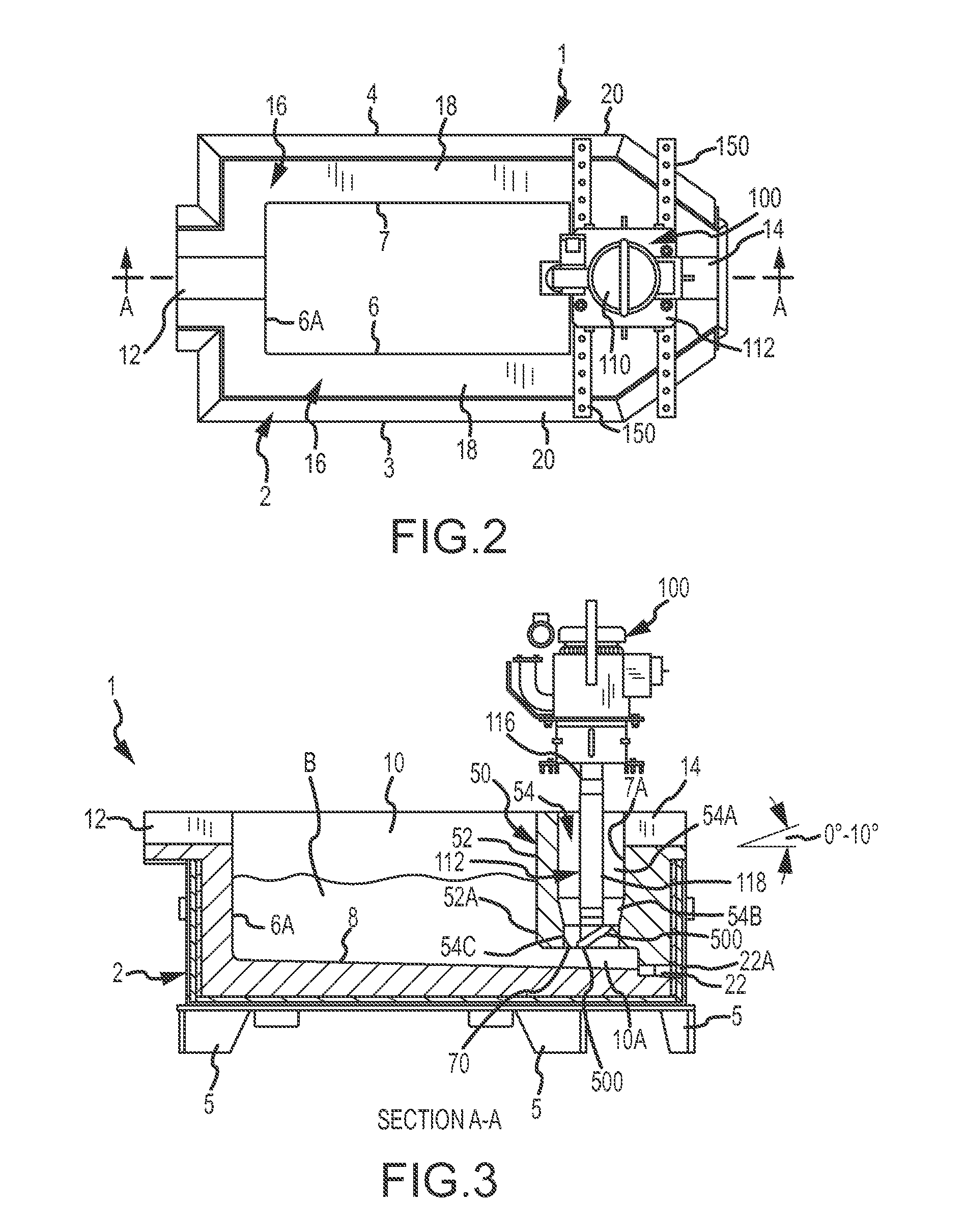

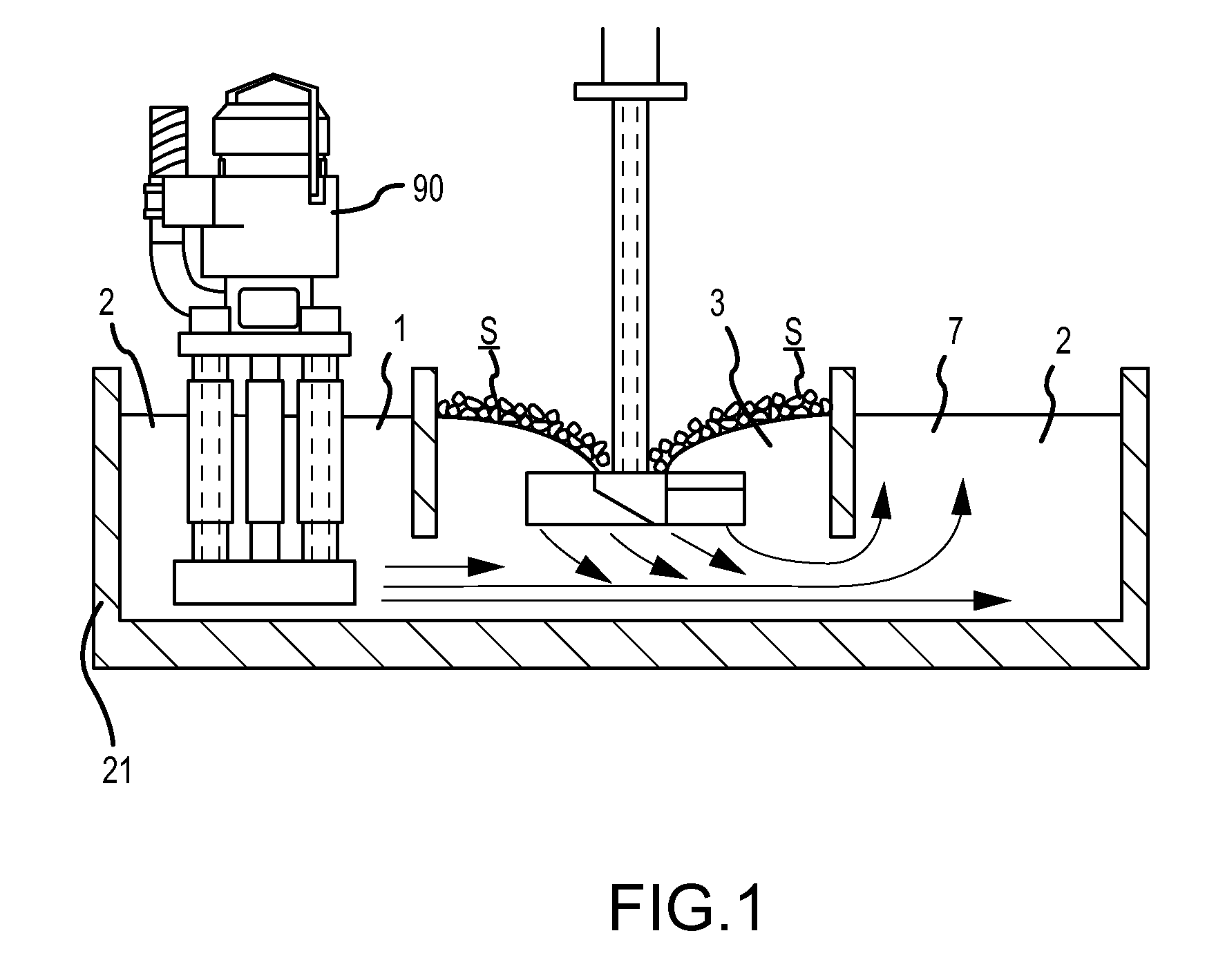

A system for transferring molten metal from a vessel and into one or more of a ladle, ingot mold, launder, feed die cast machine or other structure is disclosed. The system includes at least a vessel for containing molten metal, an overflow (or dividing) wall, and a device or structure, such as a molten metal pump, for generating a stream of molten metal. The dividing wall divides the vessel into a first chamber and a second chamber, wherein part of the second chamber has a height H2. The device for generating a stream of molten metal, which is preferably a molten metal pump, is preferably positioned in the first chamber. When the device operates, it generates a stream of molten metal from the first chamber and into the second chamber. When the level of molten metal in the second chamber exceeds H2, molten metal flows out of the vessel and into another structure, such as into one or more ladles and / or one or more launders.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

Vortexer apparatus

ActiveUS7497988B2Facilitates submergence and meltingMaintain temperatureStirring devicesCharge manipulationImpellerPositive pressure

Owner:THUT BRUNO H

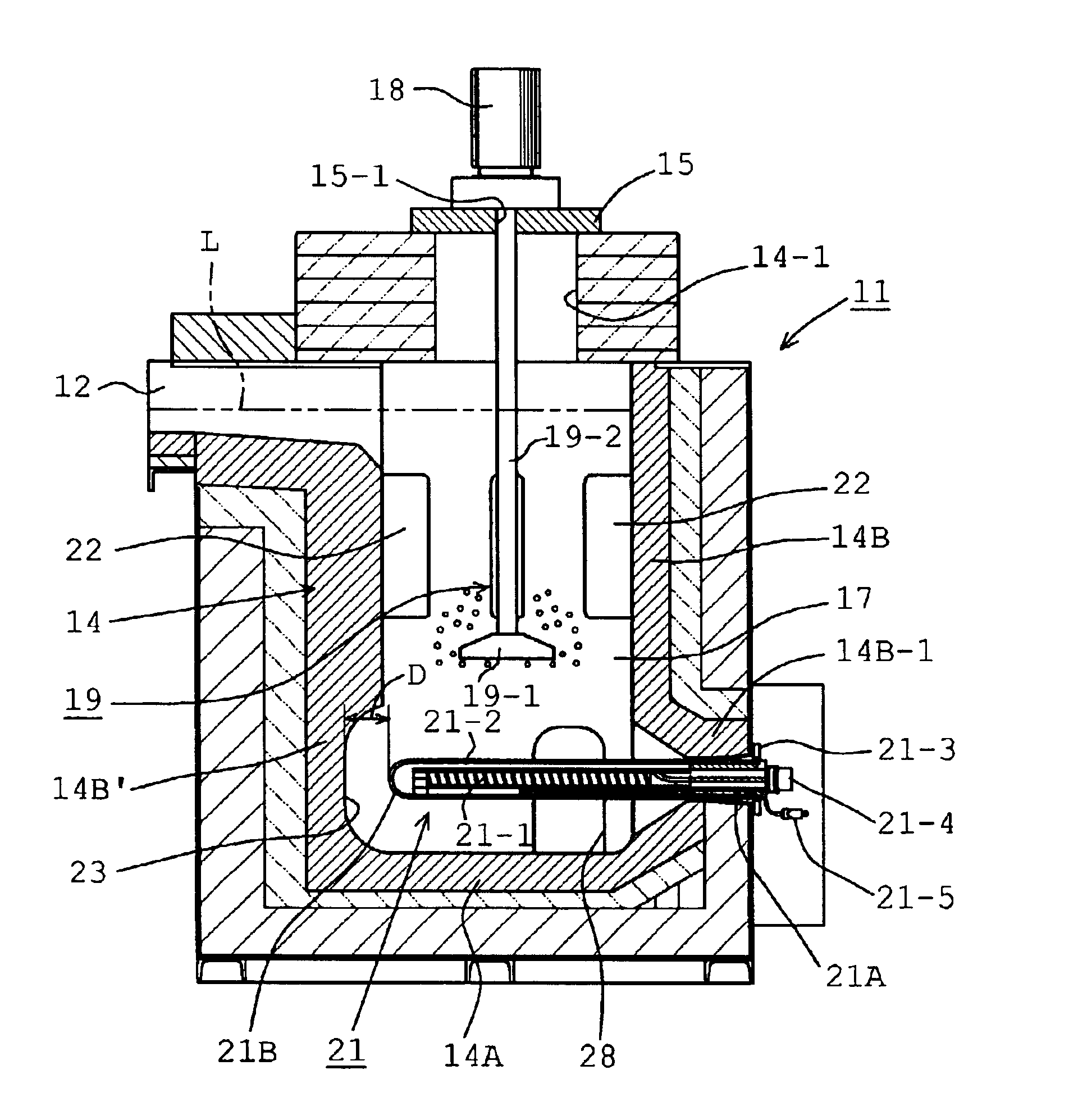

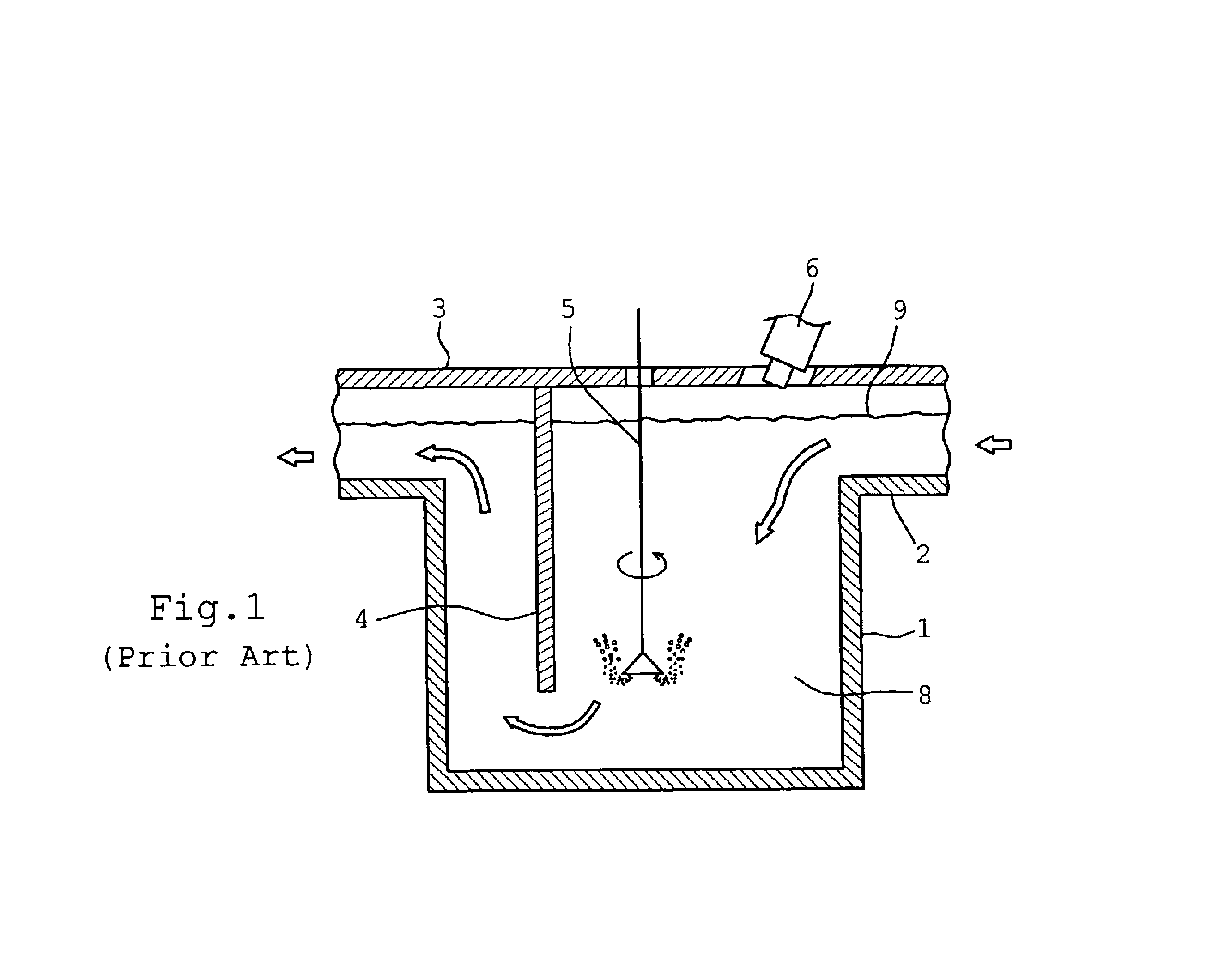

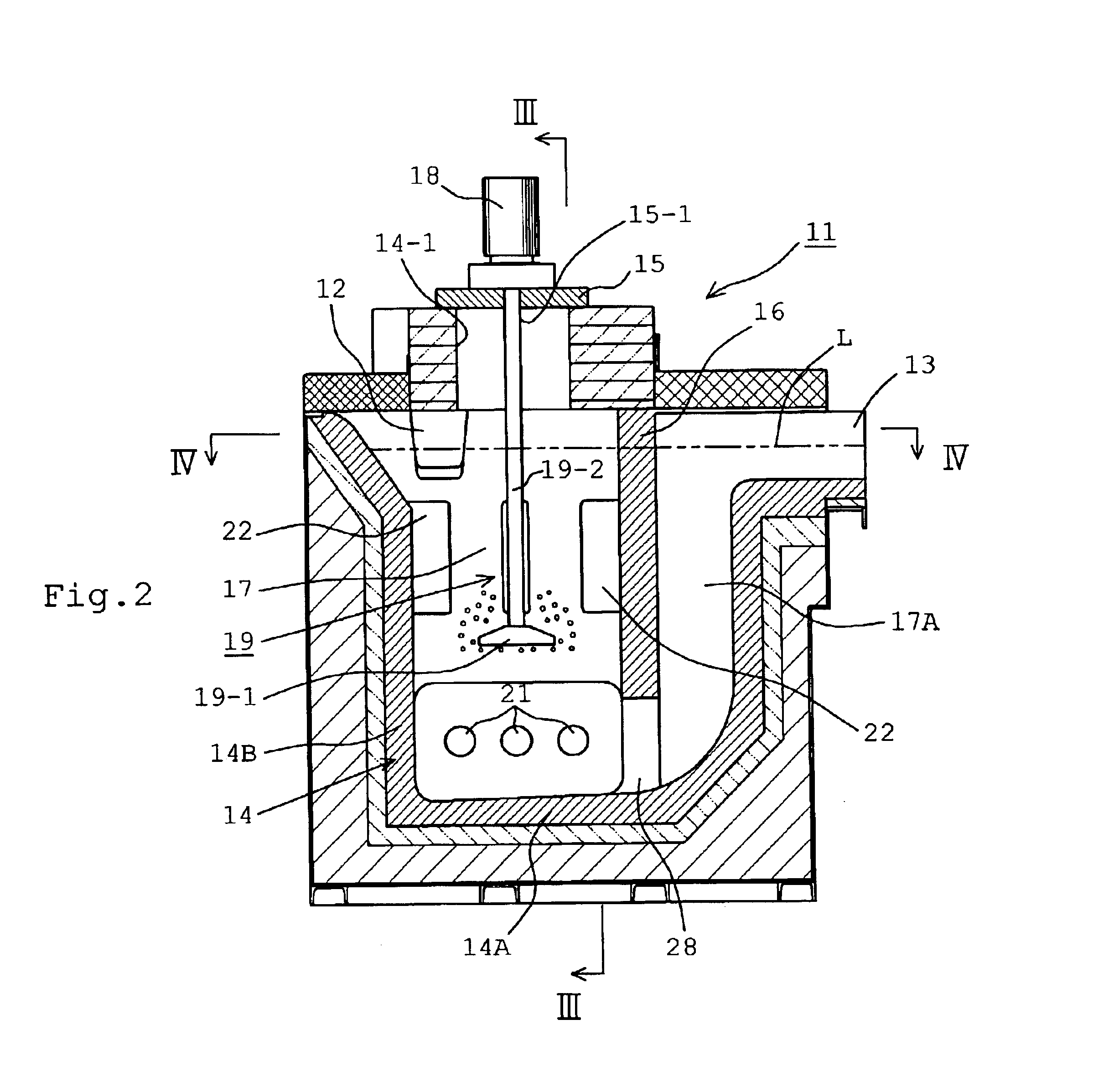

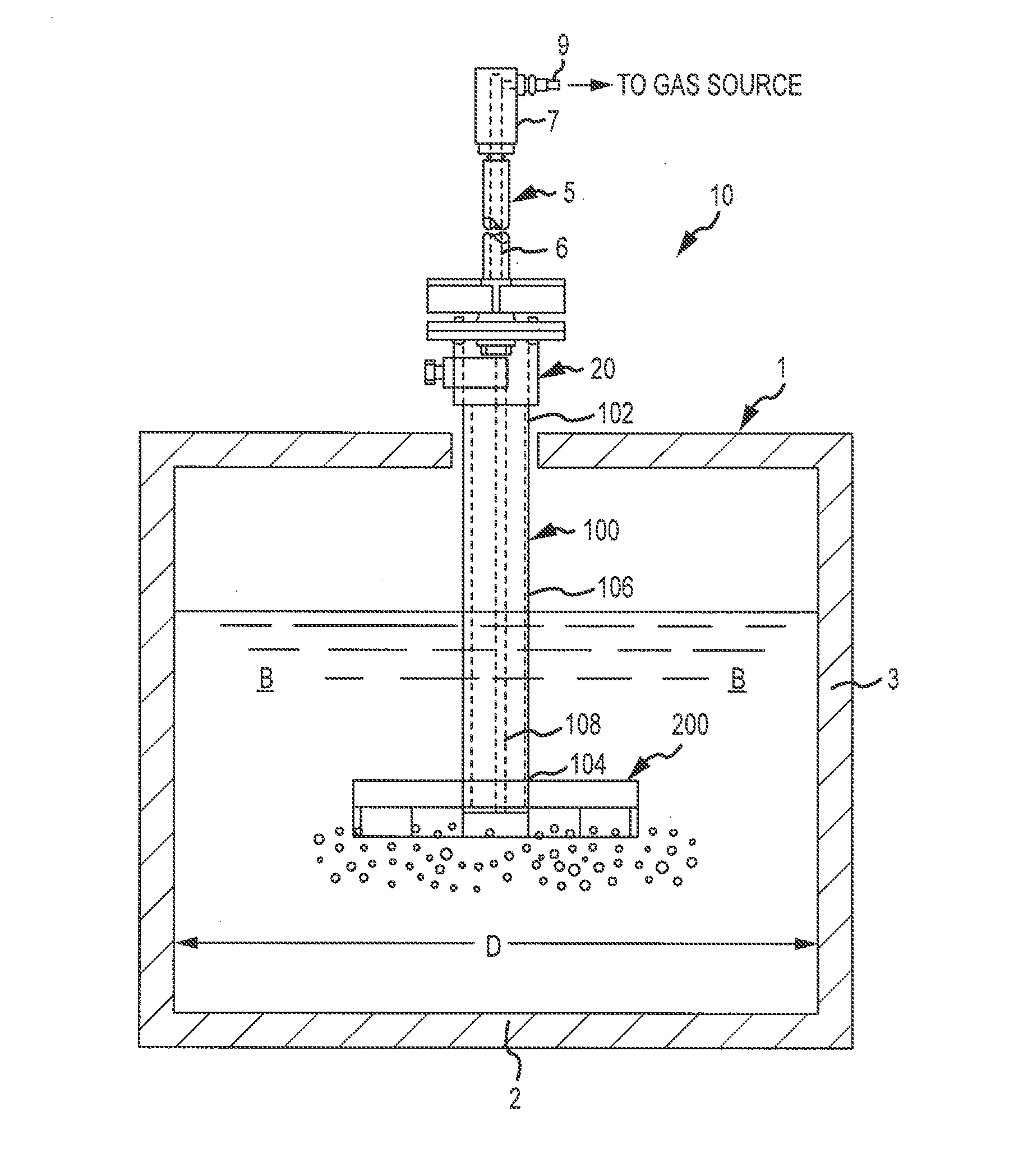

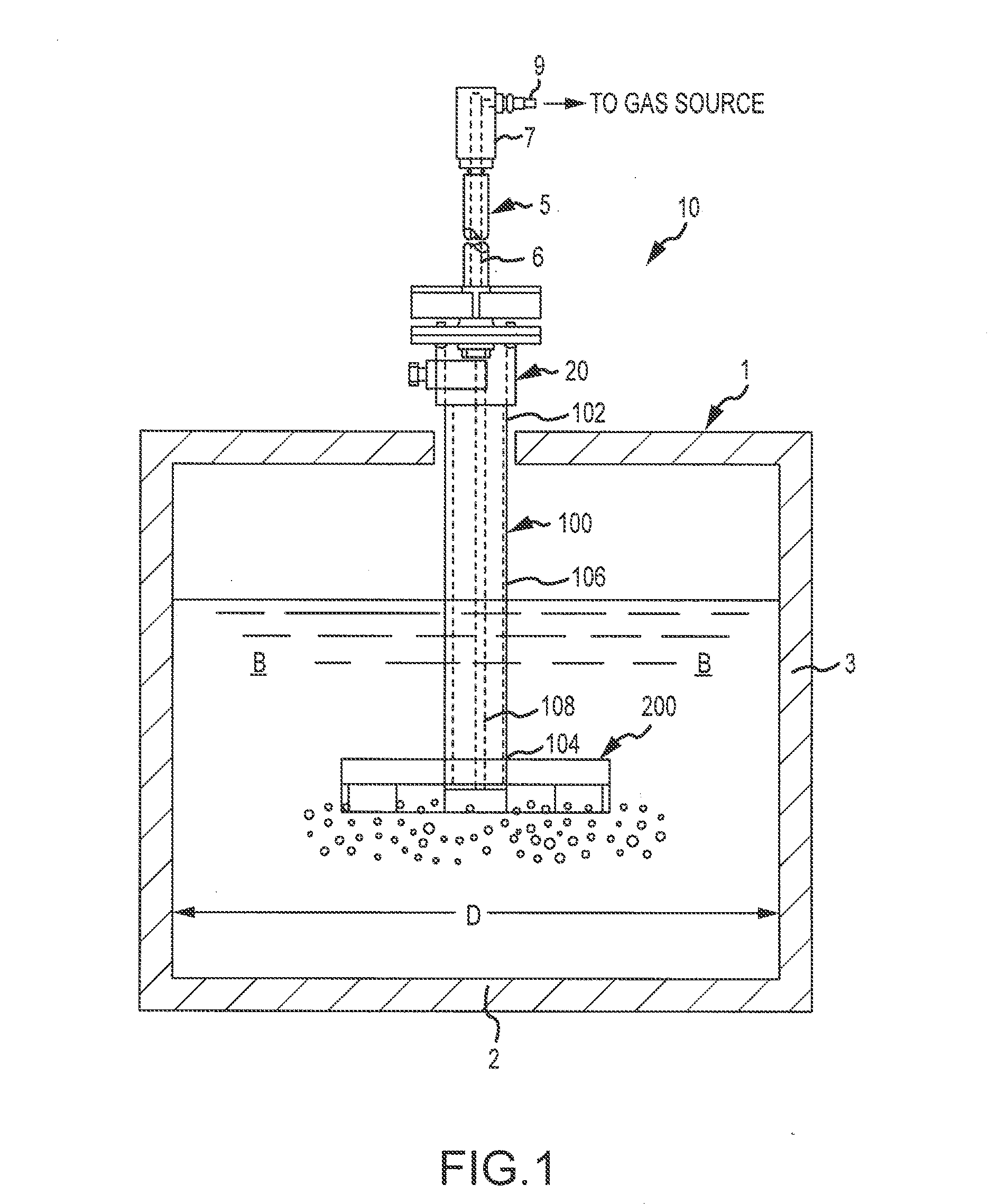

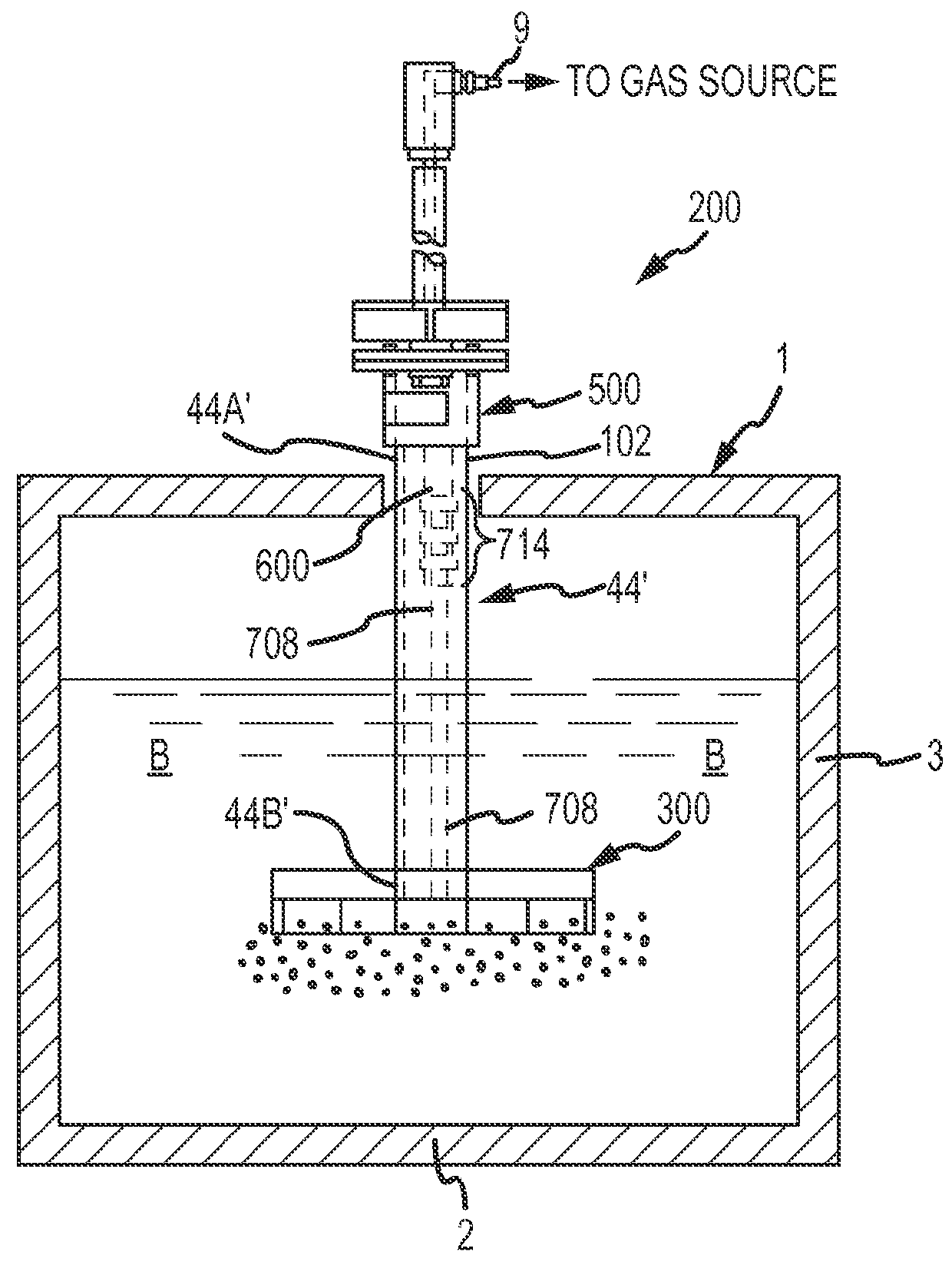

Inline degassing apparatus

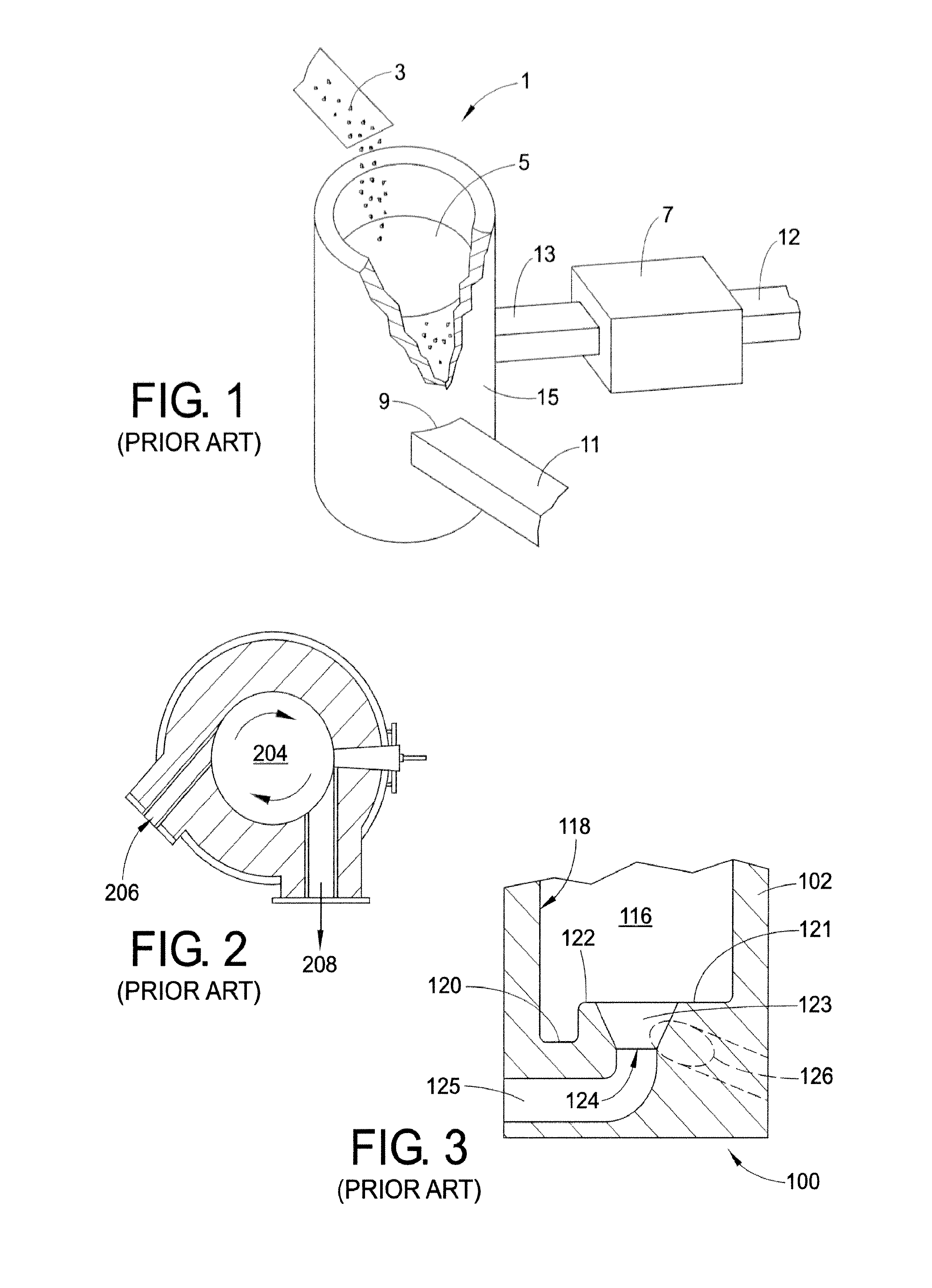

InactiveUS6887424B2Reduce the amount requiredSmall volumeMelt-holding vesselsMechanical apparatusNon-metallic inclusionsSolid solution

An inline degassing apparatus for removing solid solution gases as well as nonmetallic inclusions from molten metal in a degassing container, to which the molten metal is continuously introduced for degassing operation and from which the degassed molten metal is continuously removed. A rotary diffusing device is arranged in the degassing container for generating bubbles of inert gas diffused into the molten metal, thereby entrapping solid solution gases as well as nonmetallic inclusions into the bubbles, which are then floated and separated. Heaters are provided, which extend, in a cantilever fashion, from a side wall of container at a position adjacent the bottom wall of the container substantially parallel to the bottom wall.

Owner:PYROTEK JAPAN +1

System and method for degassing molten metal

A system for adding gas to and transferring molten metal from a vessel and into one or more of a ladle, ingot mold, launder, feed die cast machine or other structure is disclosed. The system includes at least a vessel for containing molten metal, an overflow (or dividing) wall, a device or structure, such as a molten metal pump, for generating a stream of molten metal, and one or more gas-release devices.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

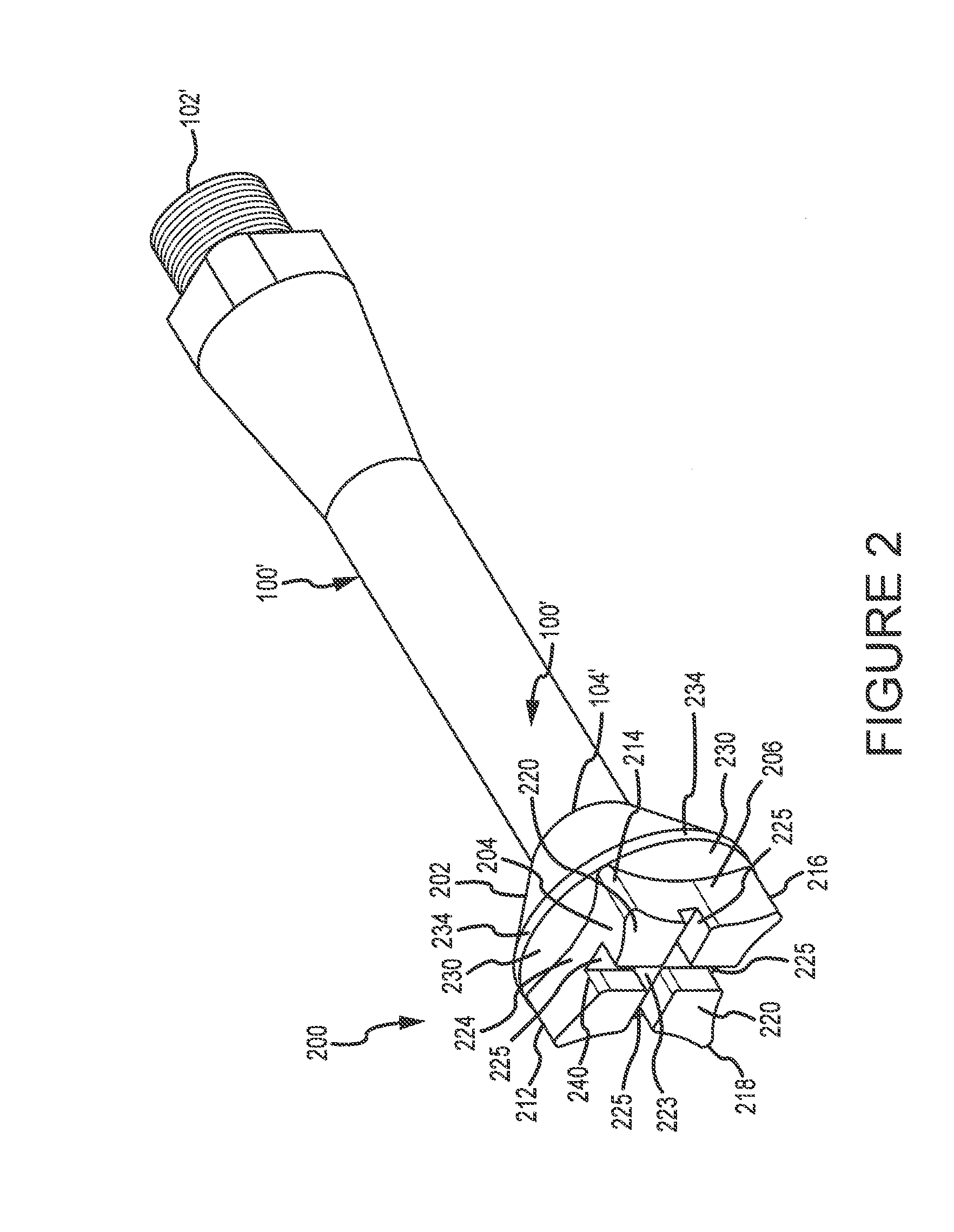

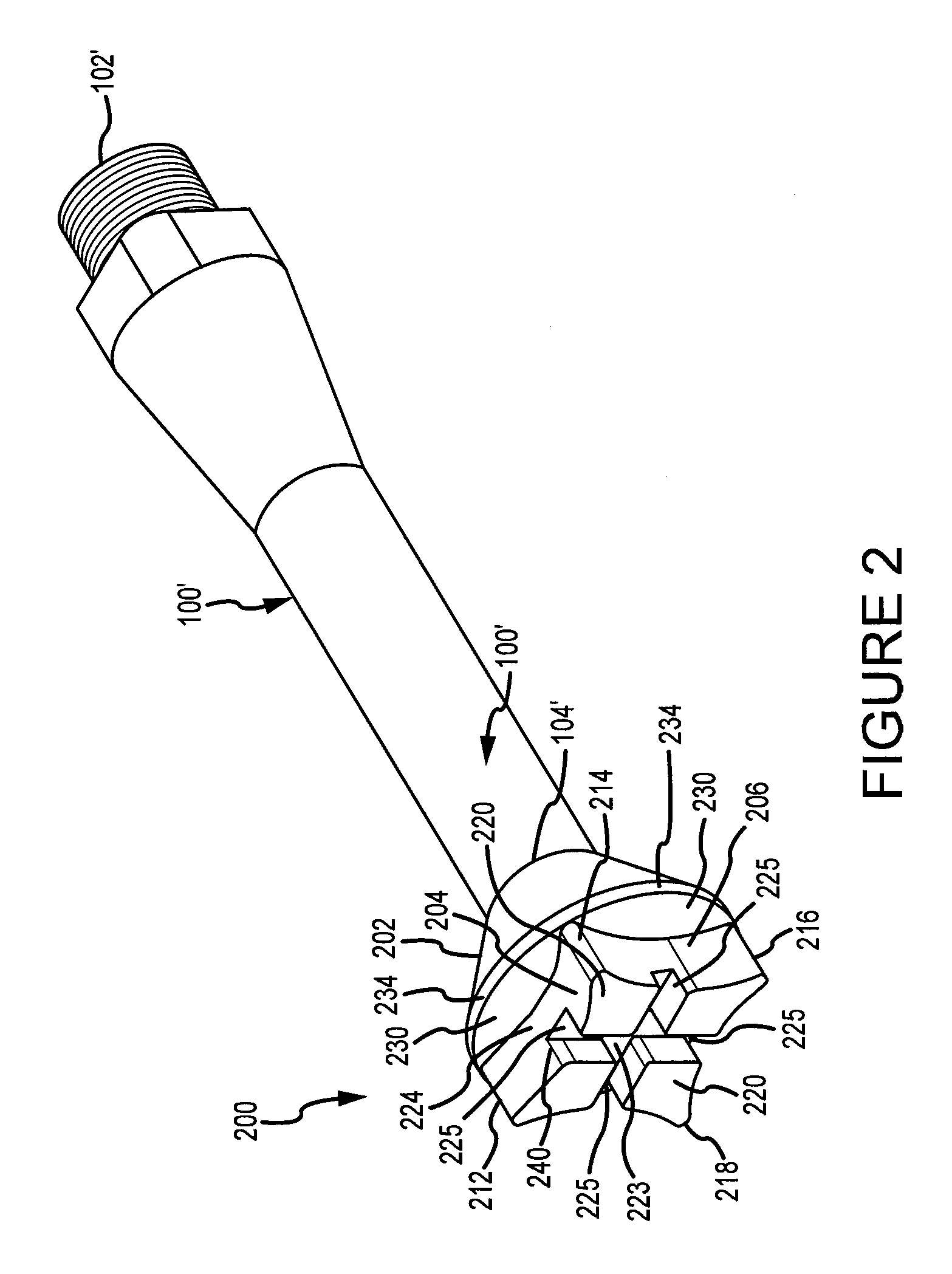

Scrap melter and impeller therefore

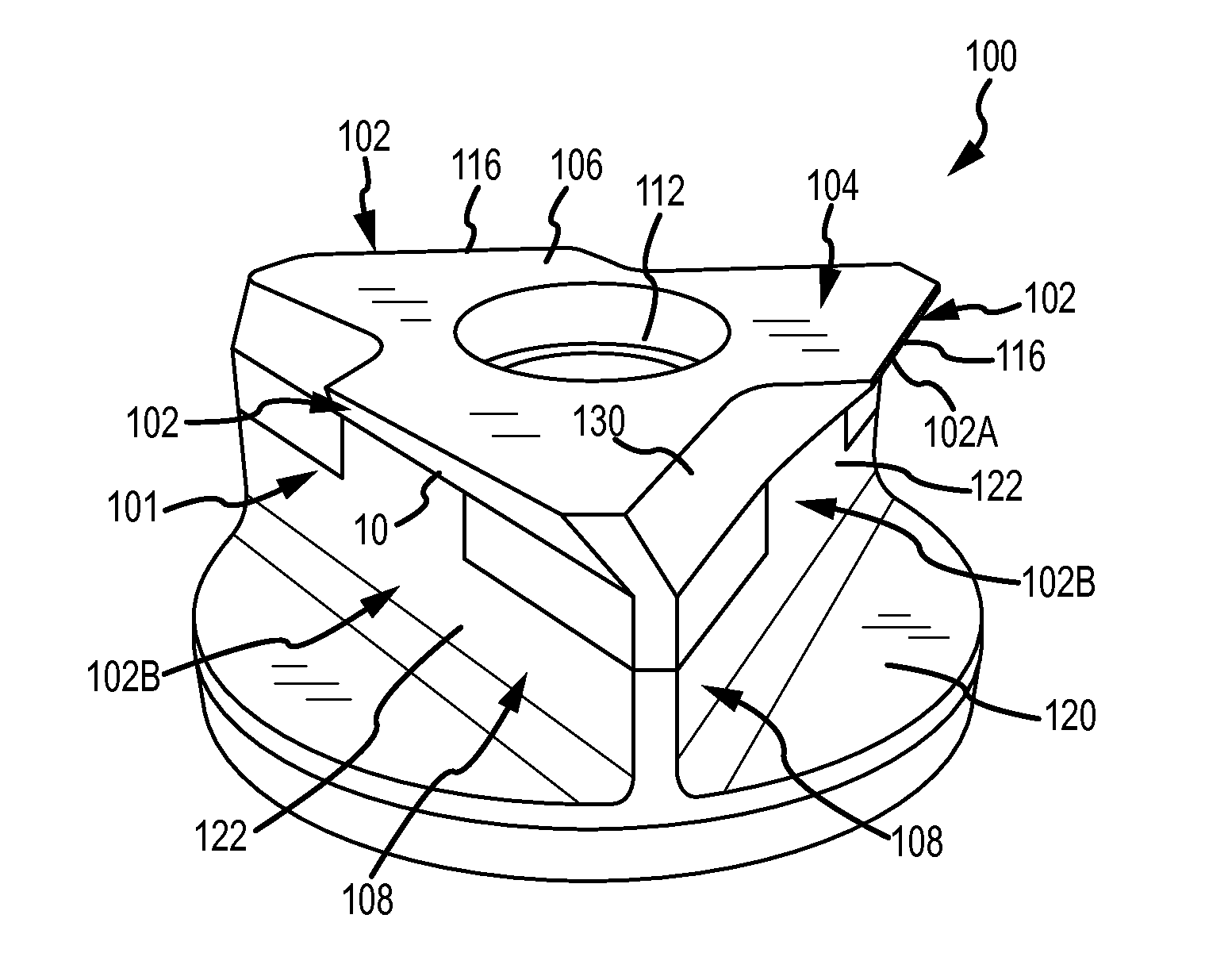

InactiveUS20080230966A1Reduce jammingReduce cloggingMelt-holding vesselsStirring devicesImpellerDrive shaft

A device for submerging scrap metal includes: (a) a drive source, (b) a drive shaft having a first end and a second end, the first end being connected to the drive source, and (d) an impeller connected to the second end of the drive shaft, the impeller preferably having two or more outwardly-extending blades. Preferably, each of the blades has a portion that directs molten metal at least partially downward. The impeller design leads to lower operating speeds, lower vibration, longer component life and less maintenance. Additionally, the impeller preferably has a connective portion. The connective portion is used to connect the impeller to the shaft and preferably comprises a nonthreaded, tapered bore extending through the impeller.

Owner:COOPER PAUL V

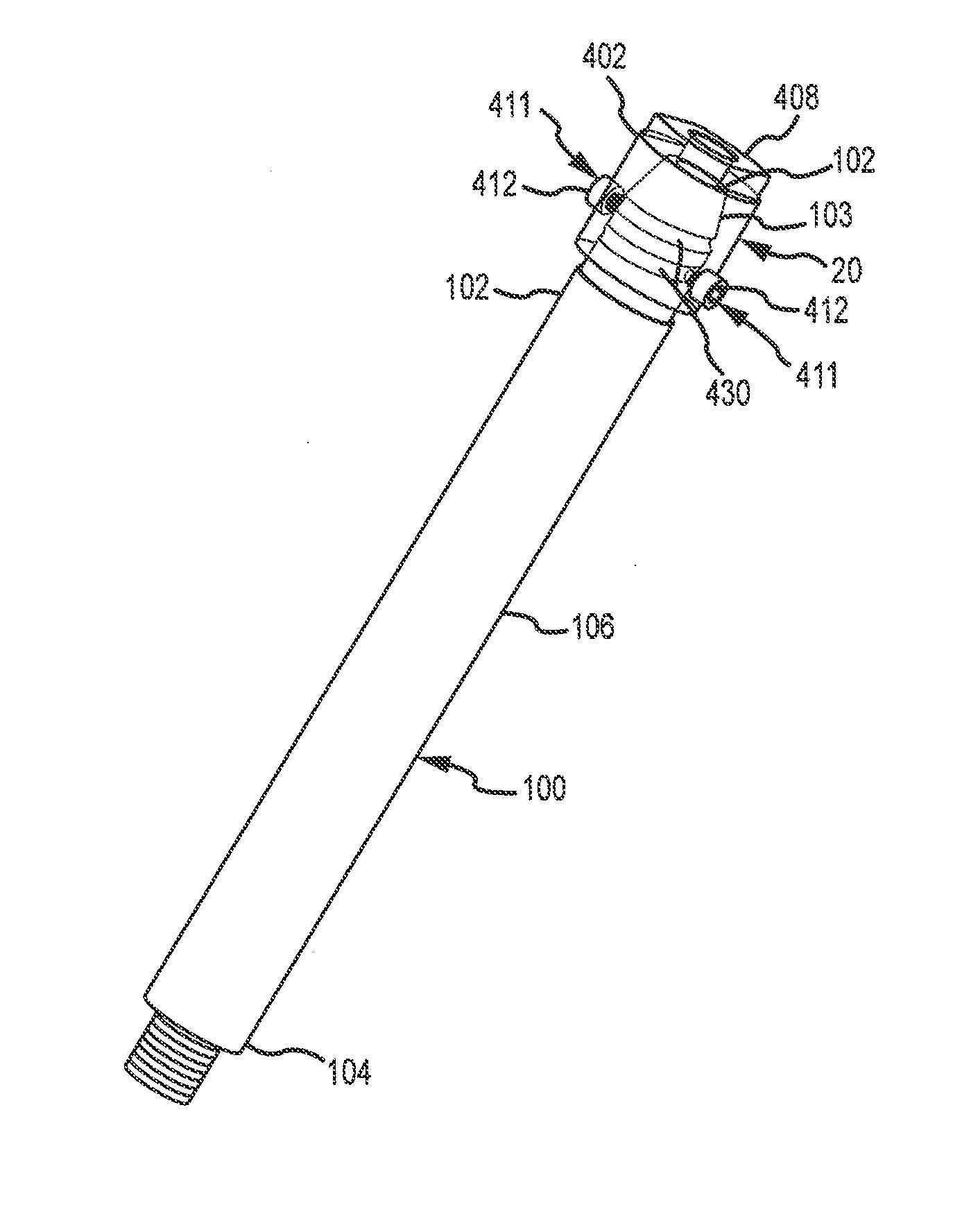

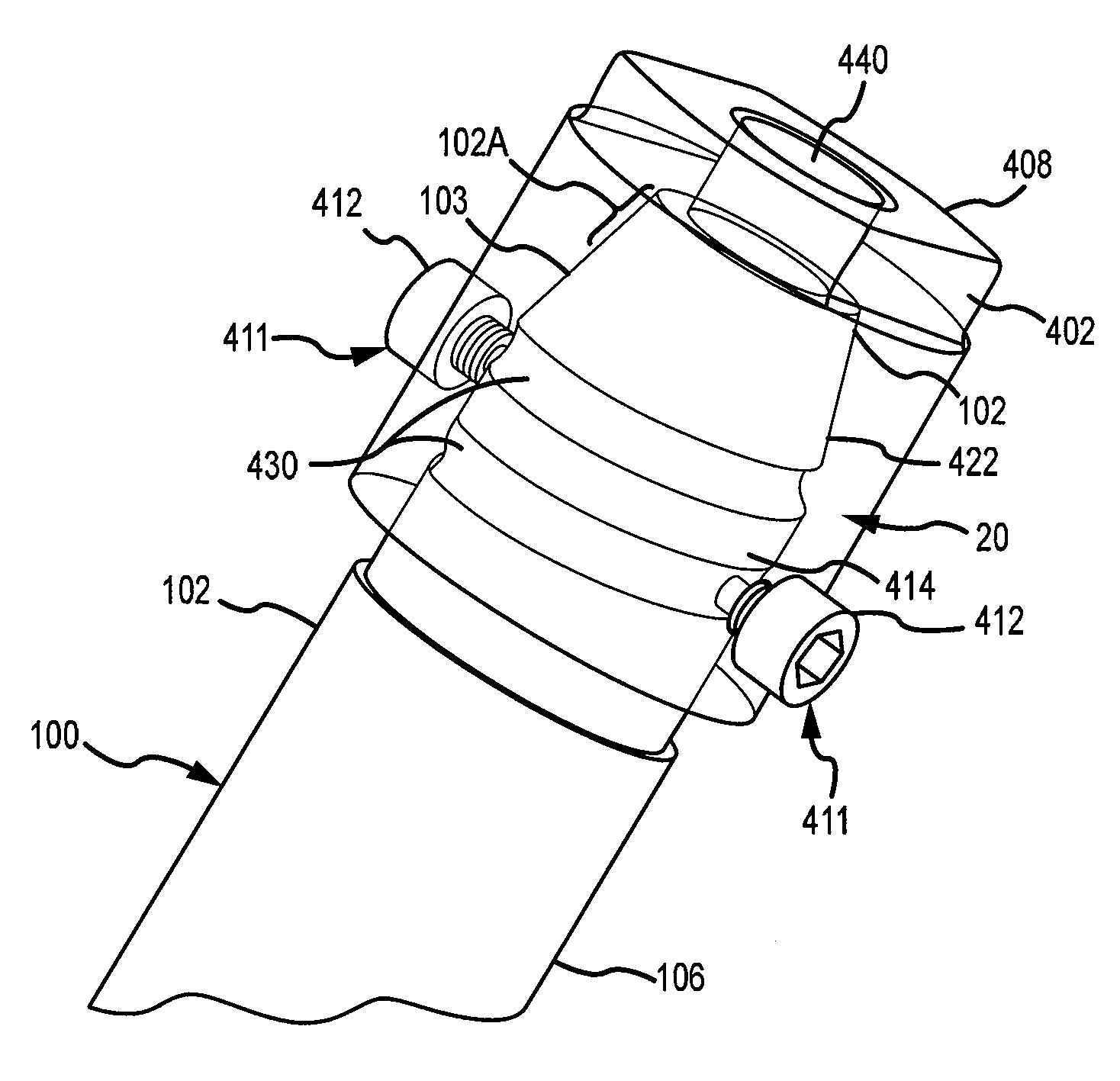

Rotary degassers and components therefor

Disclosed are degassers, couplings, impeller shafts and impellers for use in molten metal. One such coupling transfers gas into an impeller shaft, the coupling having a smooth, tapered internal surface to align with a corresponding surface on the impeller shaft and help prevent gas leakage and to assist in preventing damage to the impeller shaft. Improved impellers for shearing and mixing gas are also disclosed, as is a degasser including one or more of these components.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

Method of forming transfer well

ActiveUS20160082507A1Melt-holding vesselsMolten metal pouring equipmentsMarine engineeringMolten metal

The invention relates to systems for transferring molten metal from one structure to another. Aspects of the invention include a transfer chamber constructed inside of or next to a vessel used to retain molten metal. The transfer chamber is in fluid communication with the vessel so molten metal from the vessel can enter the transfer chamber. A powered device, which may be inside of the transfer chamber, moves molten metal upward and out of the transfer chamber and preferably into a structure outside of the vessel, such as another vessel or a launder.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

System and method for degassing molten metal

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

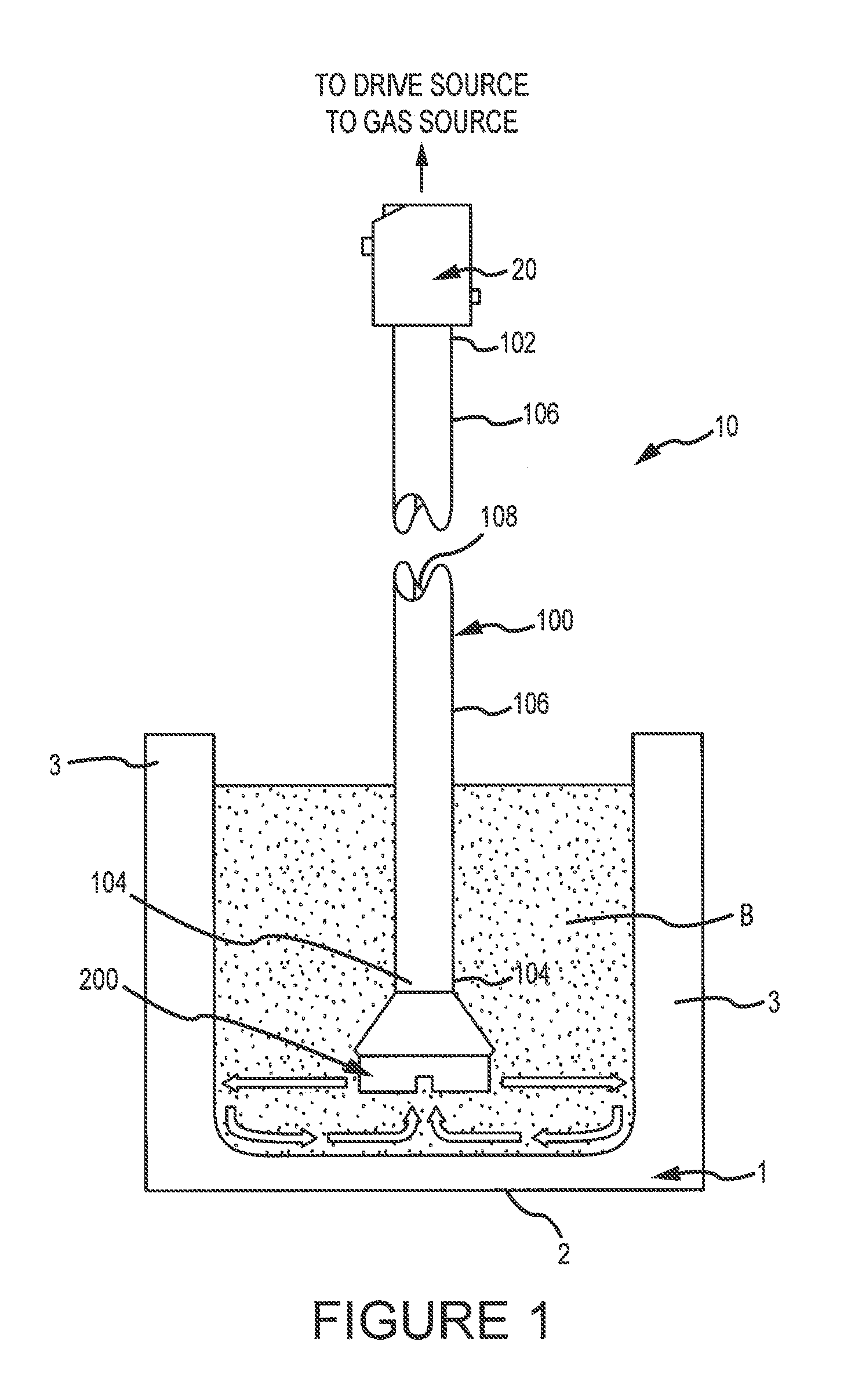

Rotary degasser and rotor therefor

ActiveUS8535603B2Efficiently circulatedWell mixedMelt-holding vesselsStirring devicesImpellerDegasser

A device for dispersing gas into molten metal includes an impeller, a drive shaft having a gas-transfer passage therein, and a first end and a second end, and a drive source. The second end of the drive shaft is connected to the impeller and the first end is connected to the drive source. The impeller includes a first portion and a second portion with a plurality of cavities. The first portion covers the second portion to help prevent gas from escaping to the surface without entering the cavities and being mixed with molten metal as the impeller rotates. When gas is transferred through the gas-transfer passage, it exits through the gas-release opening(s) in the bottom of the impeller. At least some of the gas enters the cavities where it is mixed with the molten metal being displaced by the impeller. Also disclosed are impellers that can be used to practice the invention.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

Transfer well system and method for making same

ActiveUS20130292426A1Melt-holding vesselsMolten metal pouring equipmentsMarine engineeringMolten metal

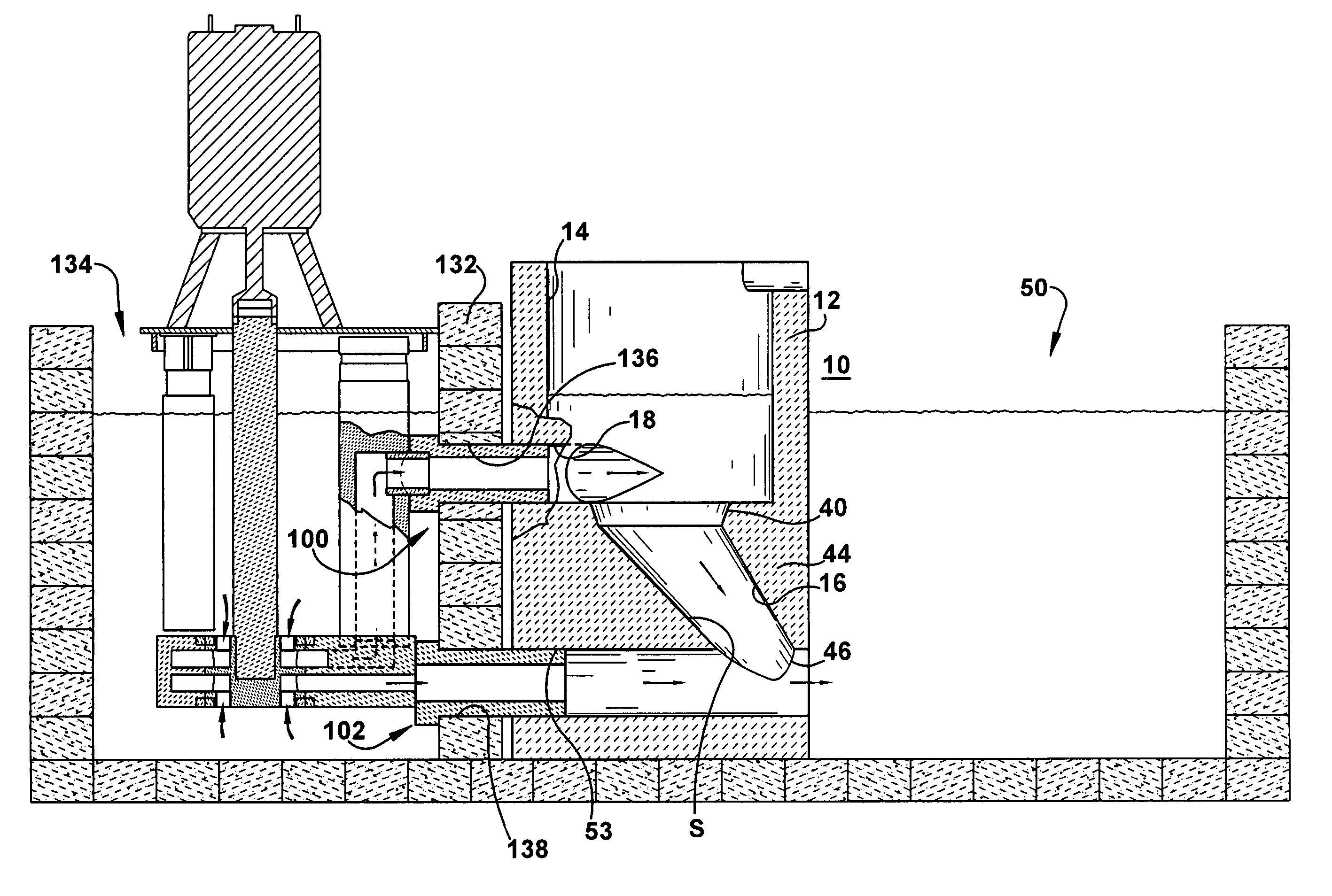

The invention relates to systems for transferring molten metal from one structure to another. Aspects of the invention include a transfer chamber constructed inside of or next to a vessel used to retain molten metal. The transfer chamber is in fluid communication with the vessel so molten metal from the vessel can enter the transfer chamber. A powered device, which may be inside of the transfer chamber, moves molten metal upward and out of the transfer chamber and preferably into a structure outside of the vessel, such as another vessel or a launder.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

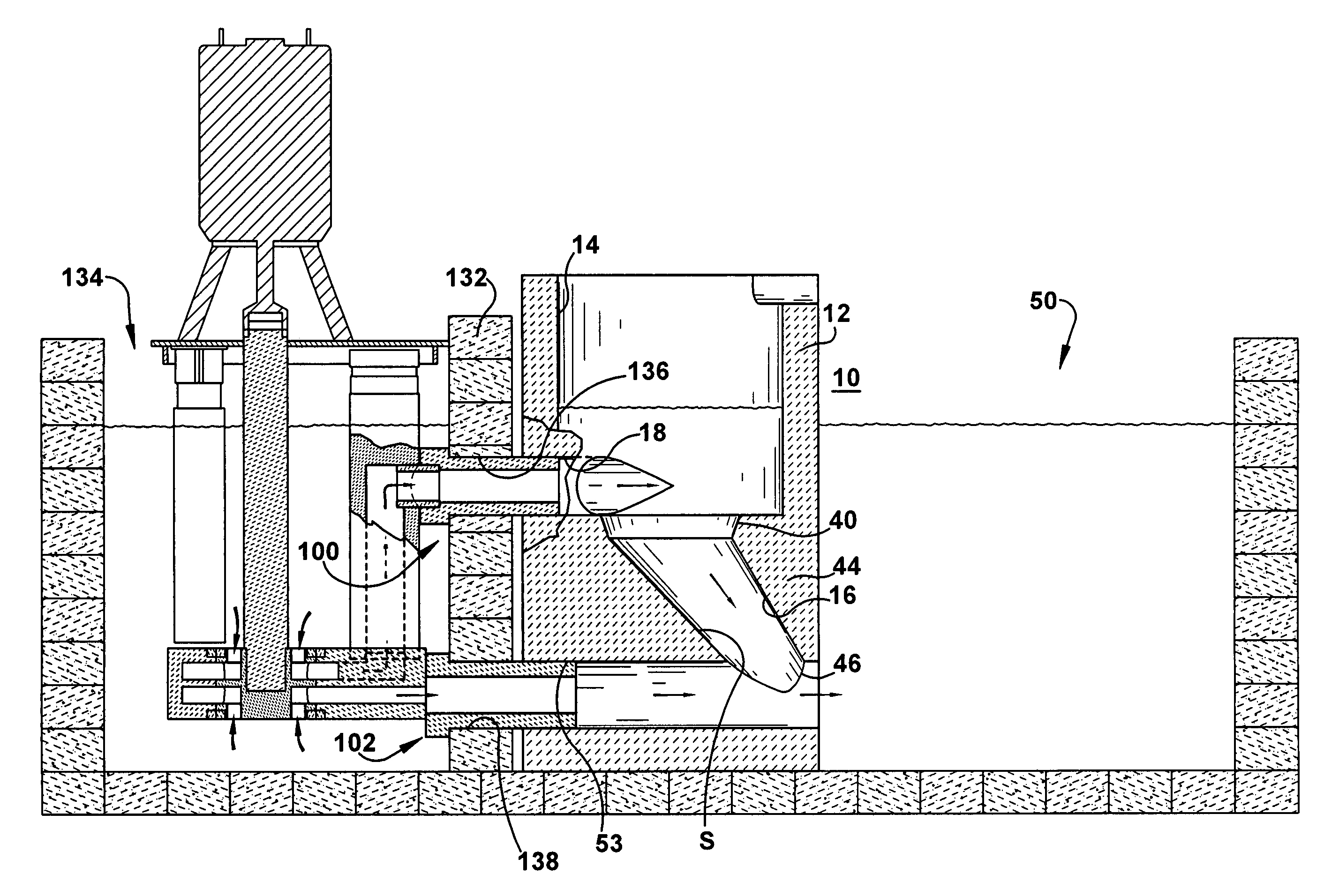

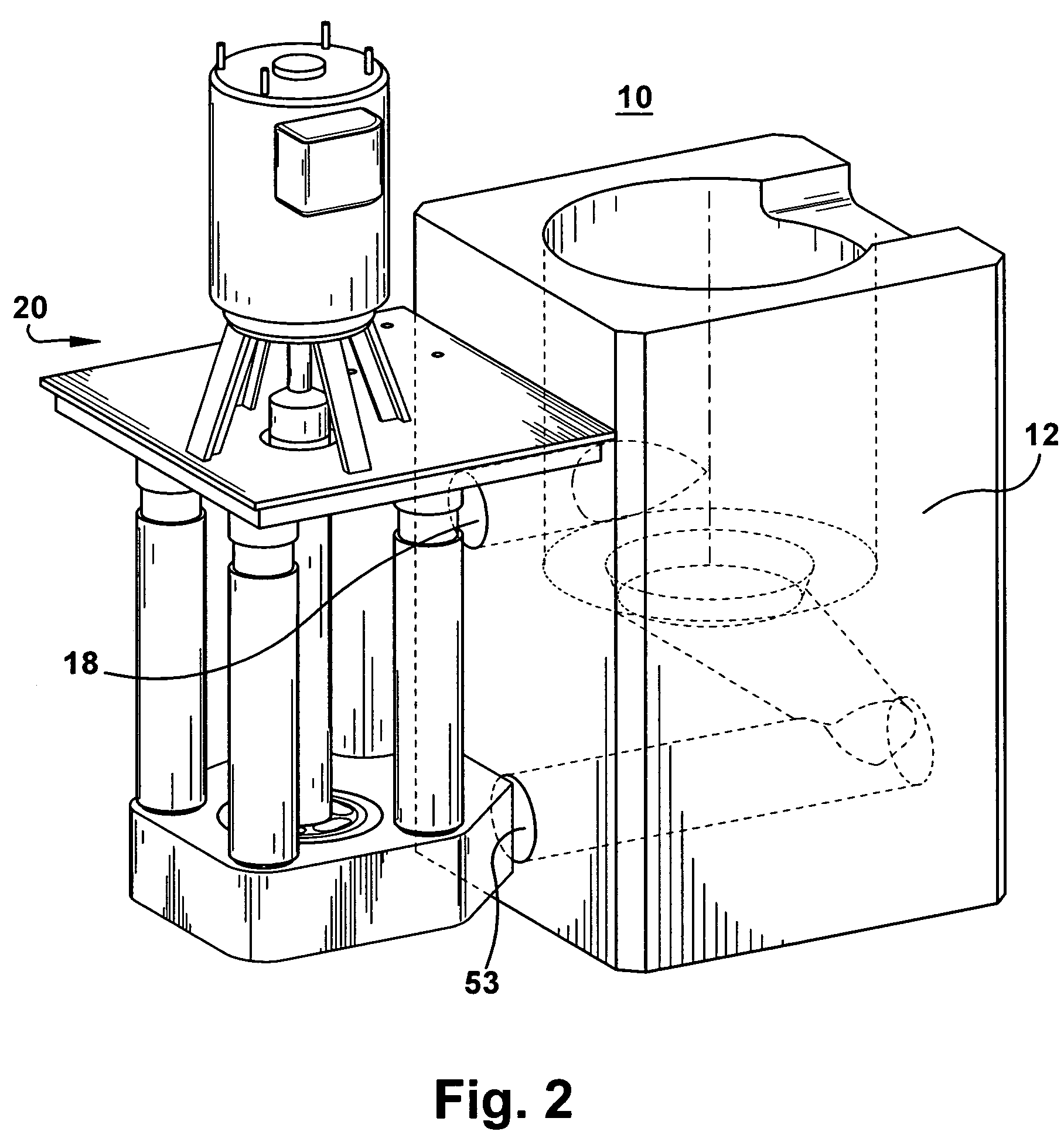

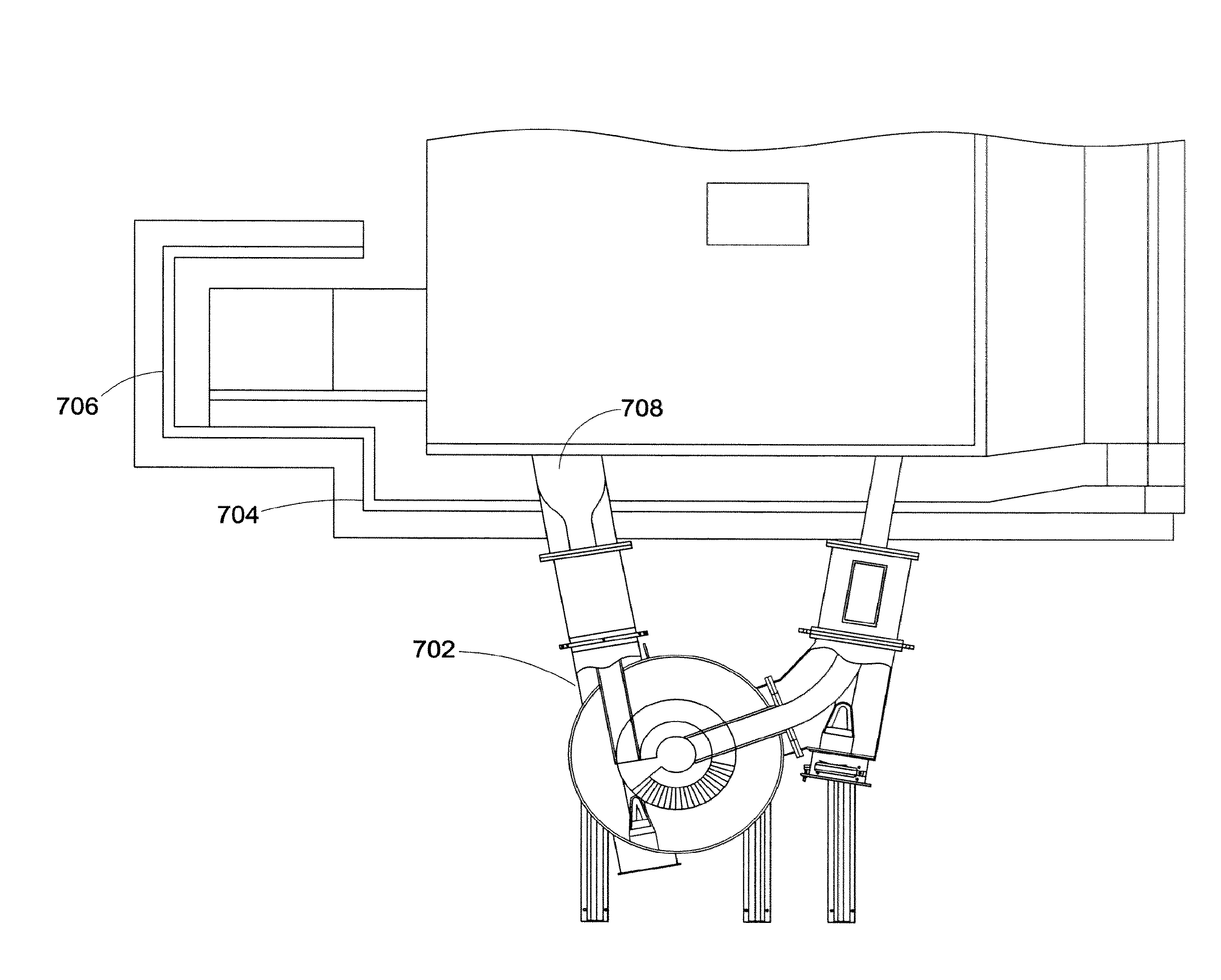

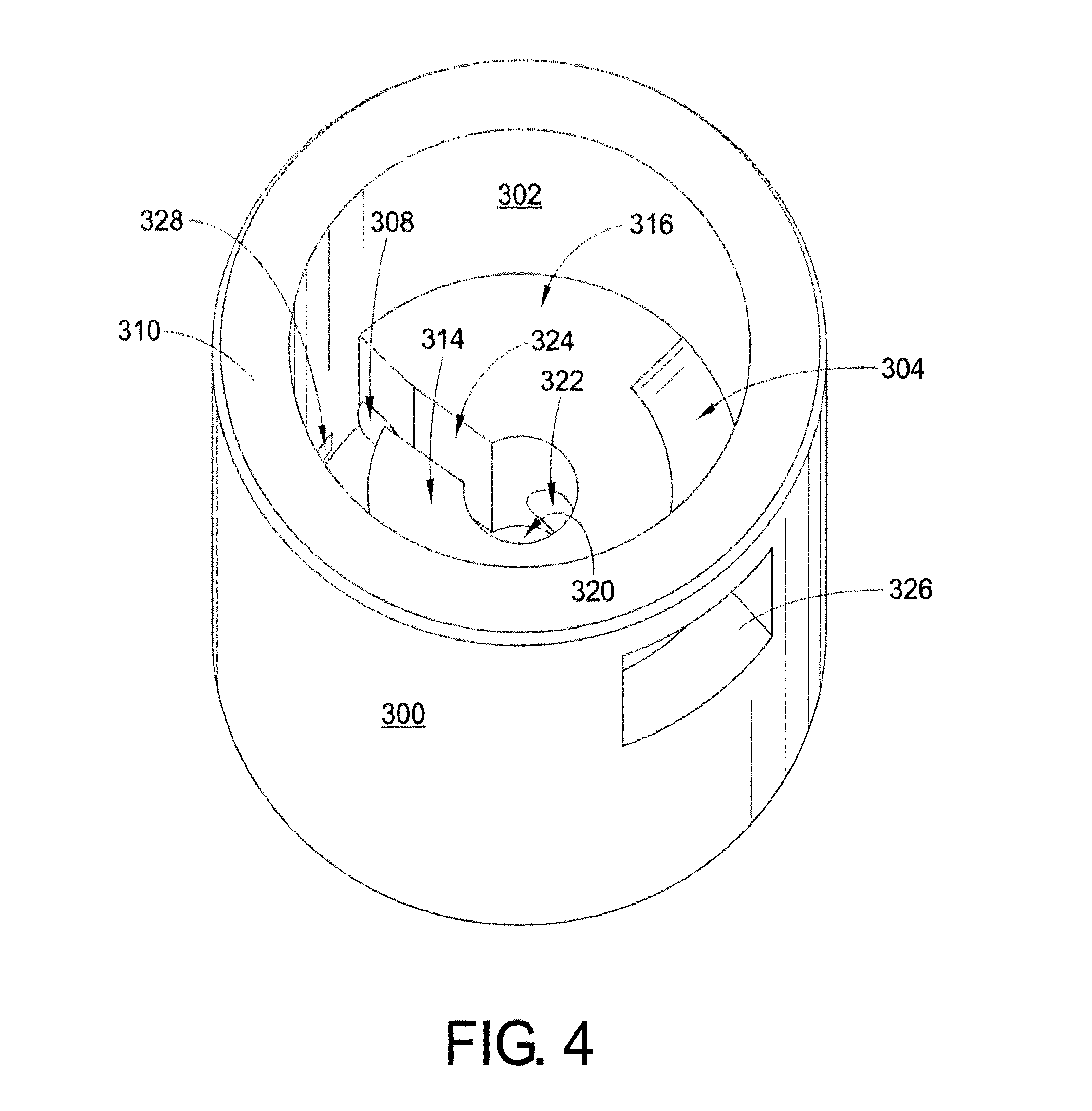

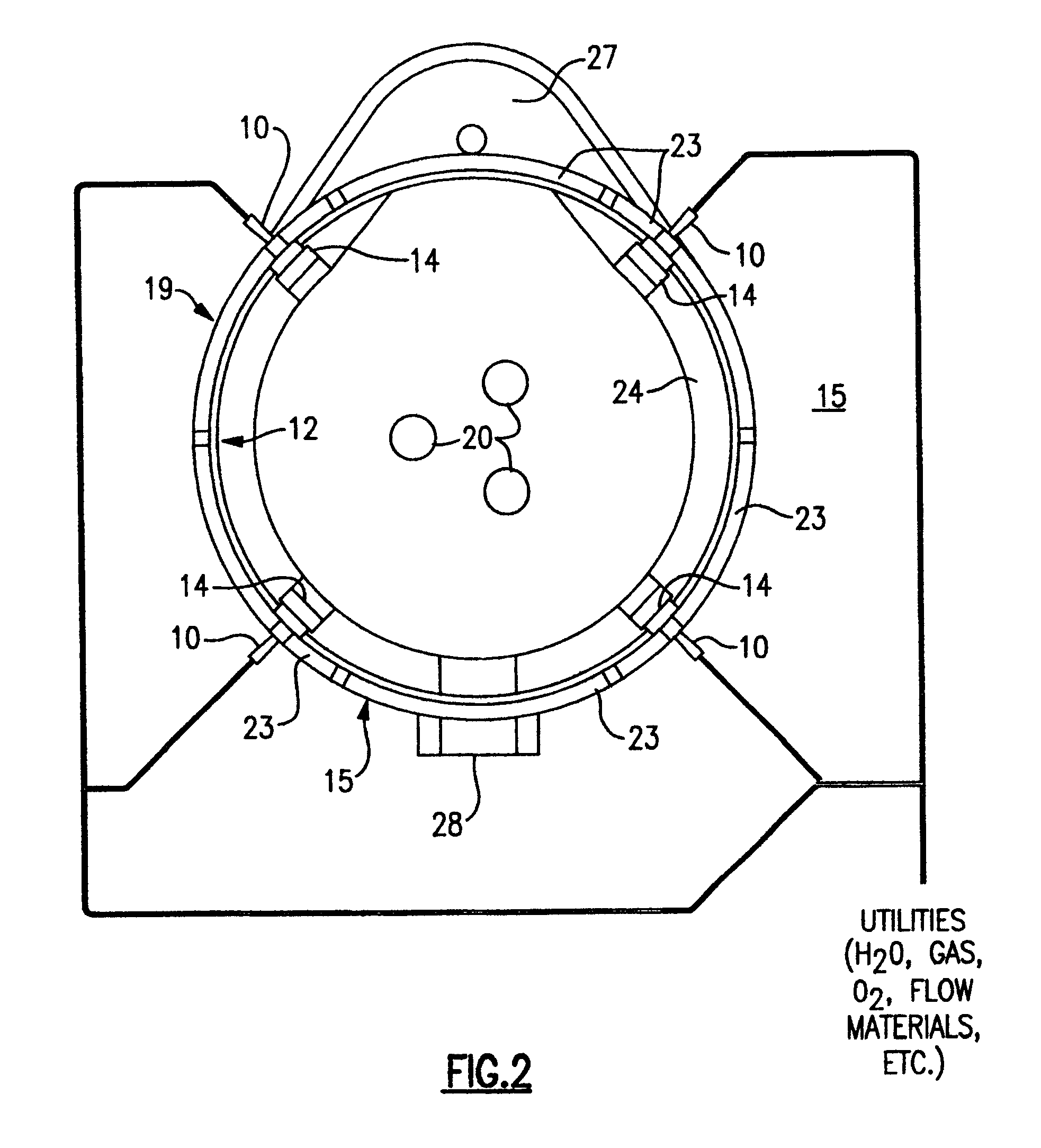

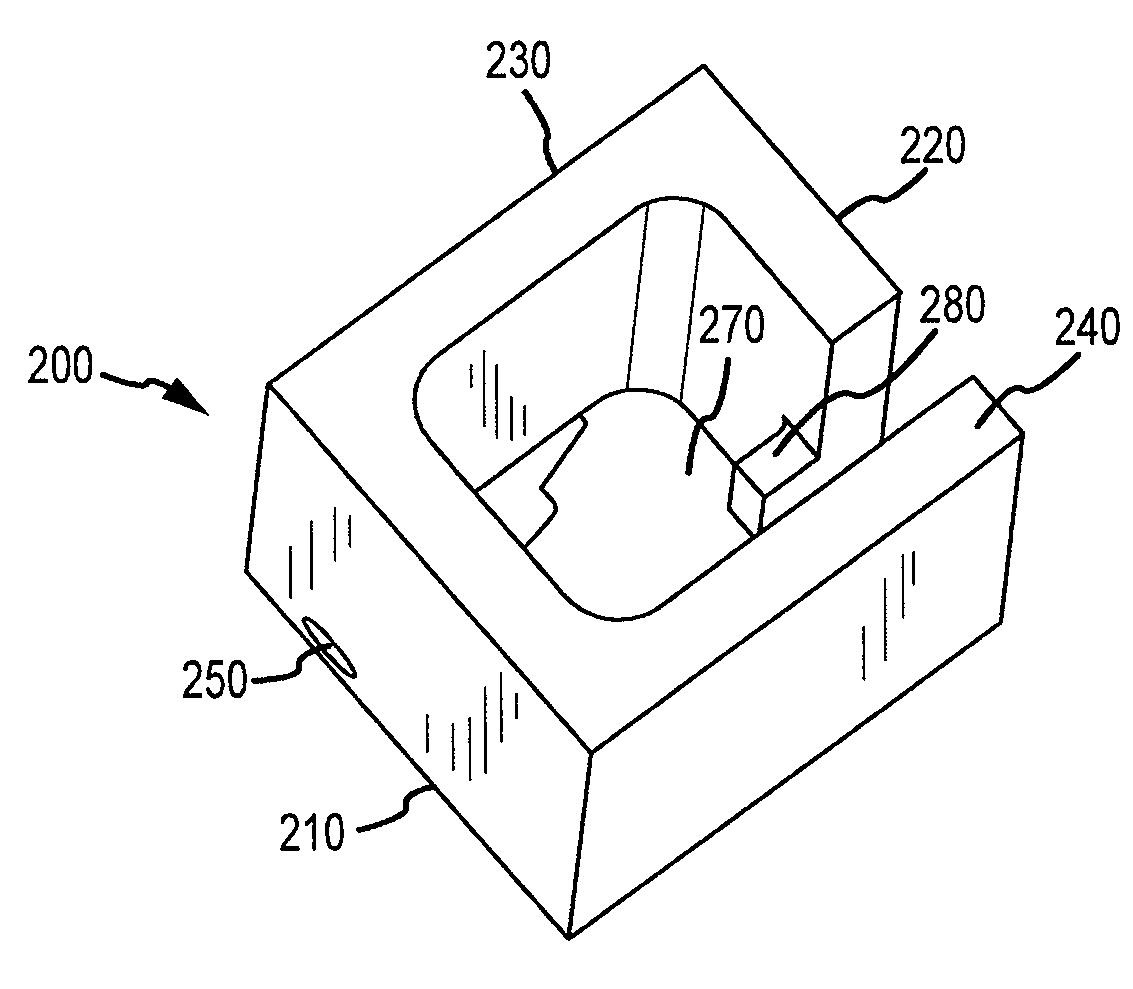

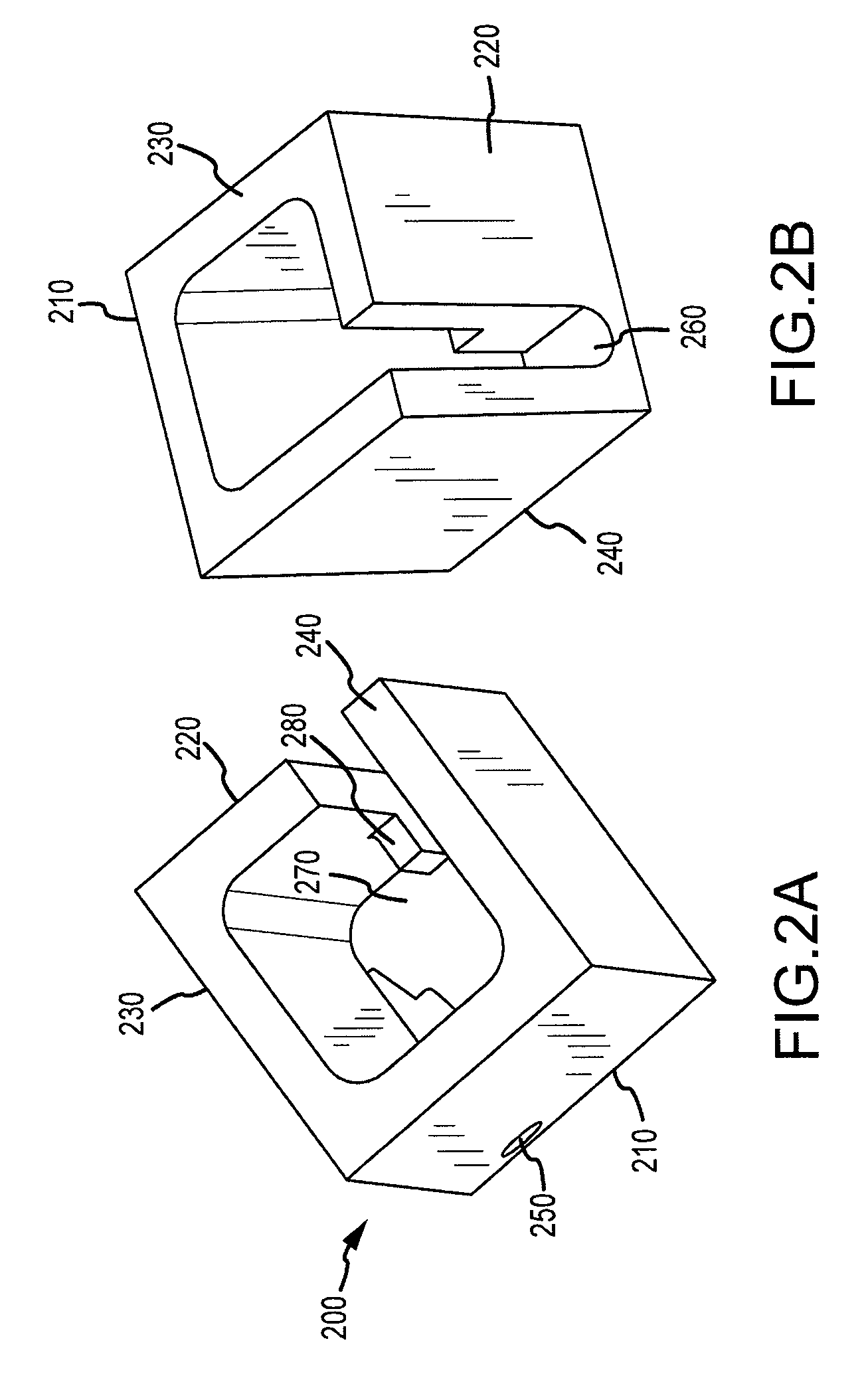

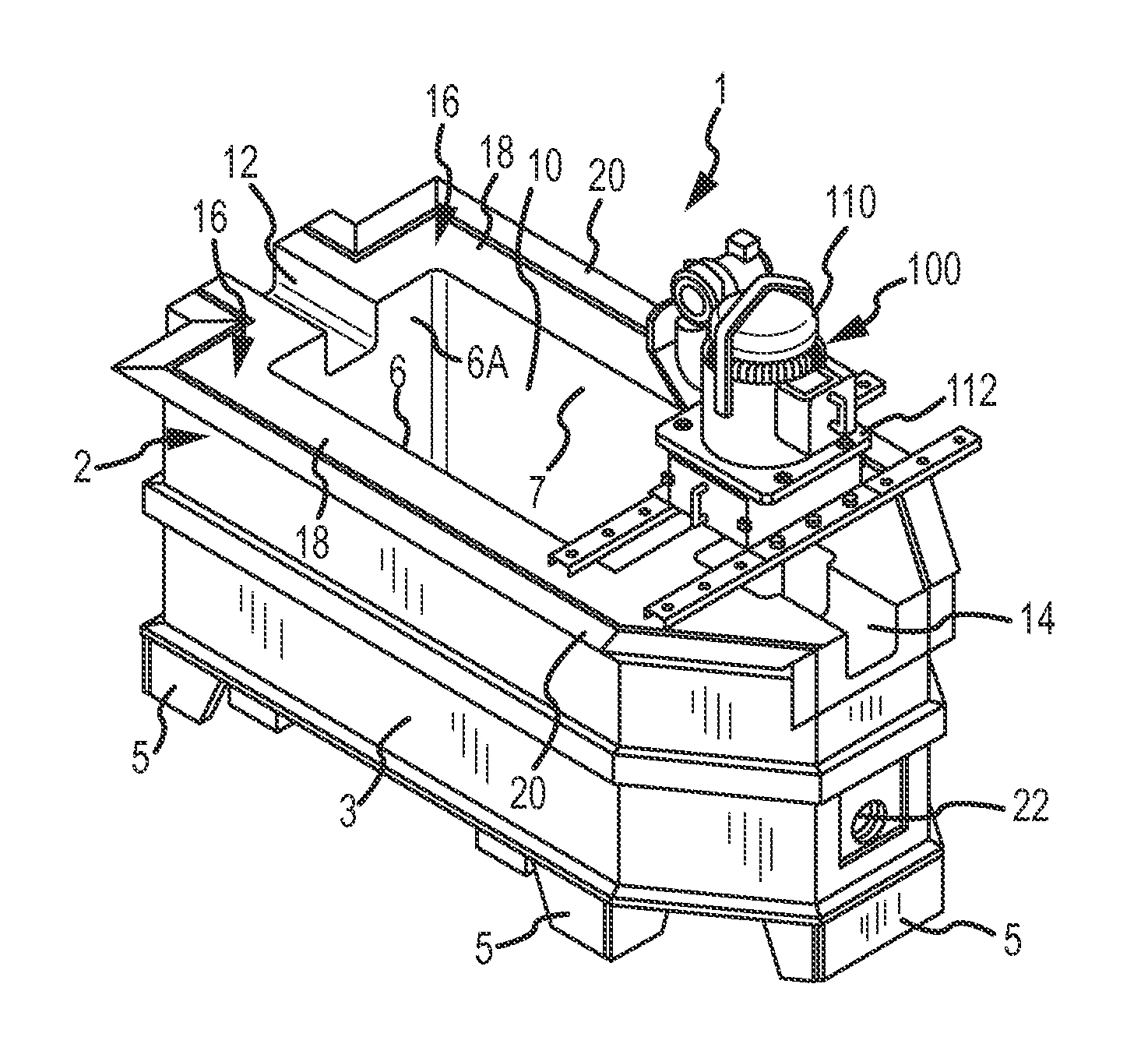

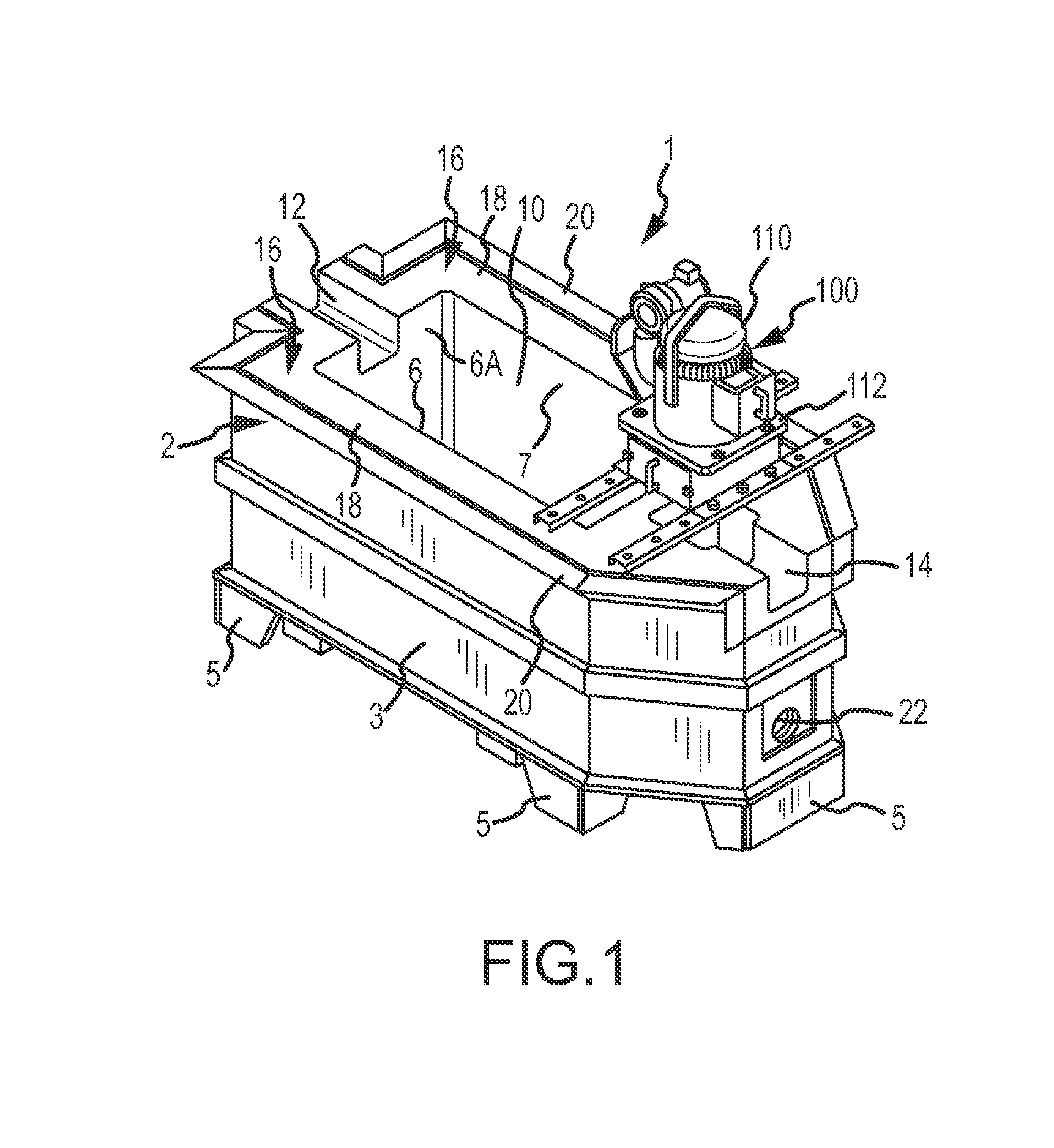

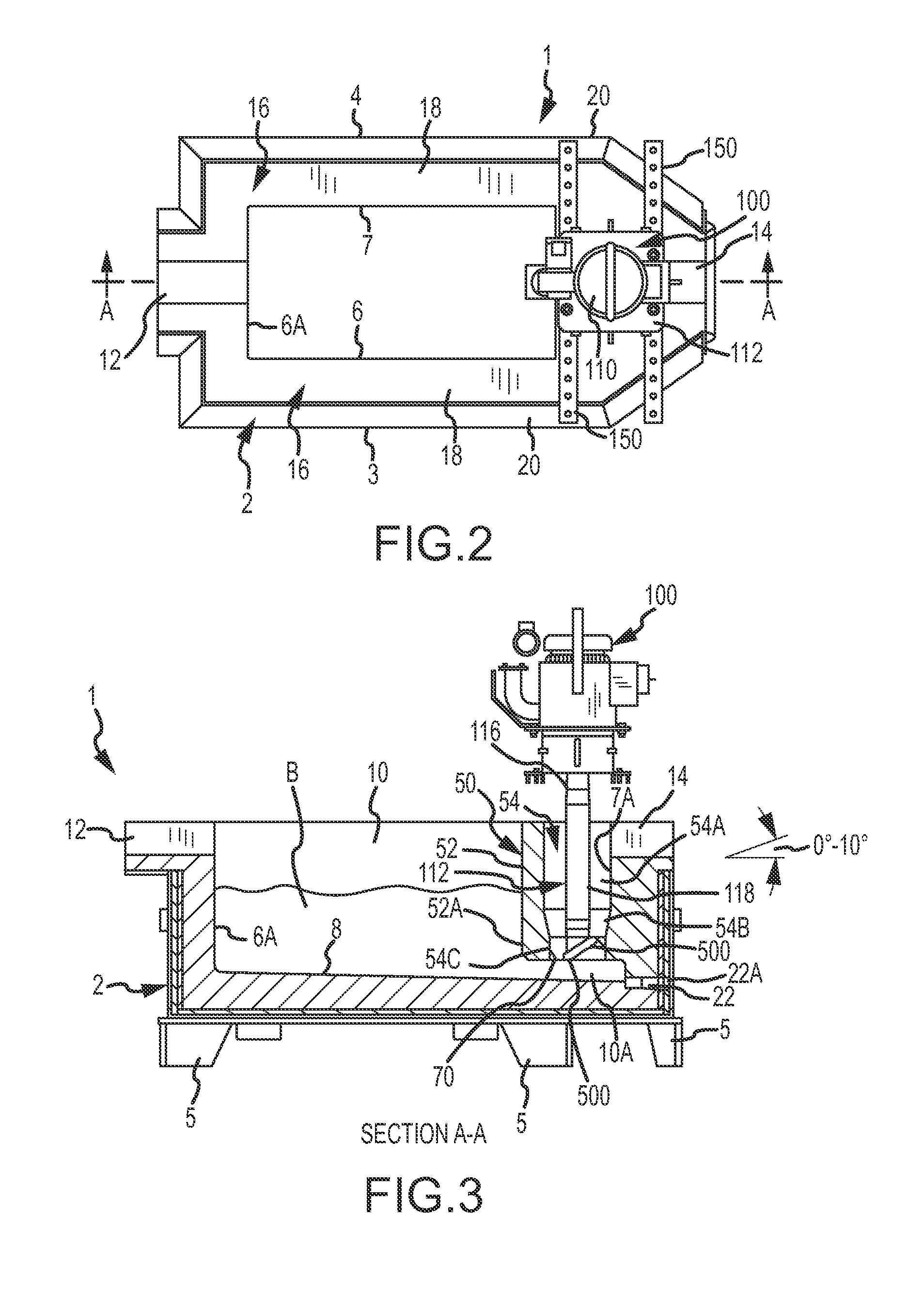

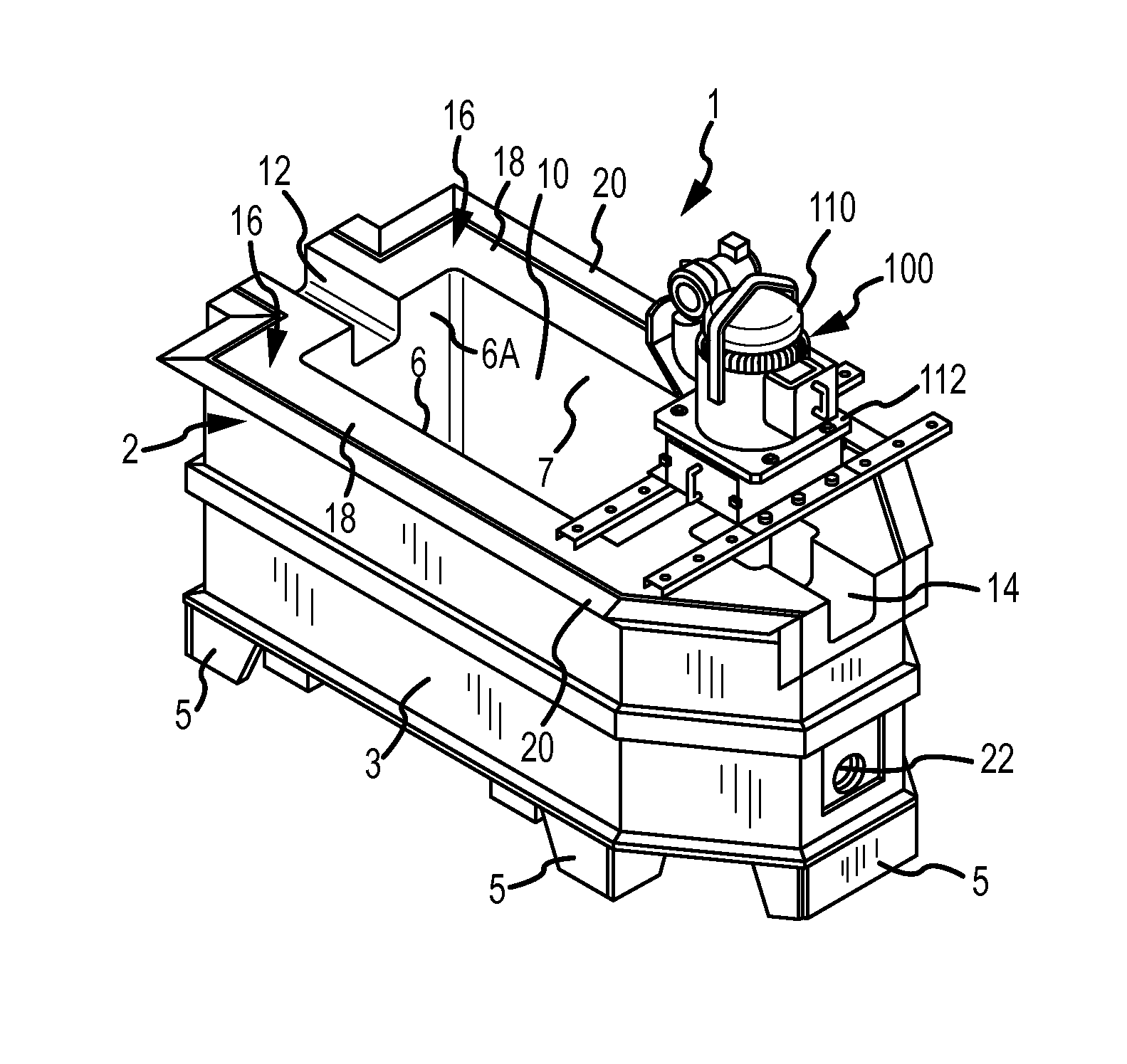

Scrap submergence system

ActiveUS20140232048A1Improve compatibilityStirring devicesManufacturing convertersMolten metalWaste management

In accordance with one aspect of an exemplary embodiment, a furnace including a charge well is provided. The charge well comprises an open top chamber including side and base walls of a heat resistant material. An inlet is provided in a side wall of the chamber for receiving molten metal. A ramp is provided adjacent the side wall and an inner wall forms a central cavity. The ramp is disposed between the inner wall and the side wall. The ramp is generally inclined from an intersection with the base wall to adjacent a top surface of the inner wall. The cavity is in fluid communication with an outlet. A passage in the inner wall provides fluid communication between the inlet and the cavity. The inlet and an outlet each receives a conduit and at least one of the conduits can include an elbow joint.

Owner:PYROTECK INC

Transferring molten metal from one structure to another

ActiveUS8337746B2Formation of dross in the ladle or launder are greatly reduced or eliminatedEliminate useMolten metal pouring equipmentsStirring devicesDie castingMolten metal

A system for transferring molten metal from a vessel and into one or more of a ladle, ingot mold, launder, feed die cast machine or other structure is disclosed. The system includes at least a vessel for containing molten metal, an overflow (or dividing) wall, and a device or structure, such as a molten metal pump, for generating a stream of molten metal. The dividing wall divides the vessel into a first chamber and a second chamber, wherein part of the second chamber has a height H2. The device for generating a stream of molten metal, which is preferably a molten metal pump, is preferably positioned in the first chamber. When the device operates, it generates a stream of molten metal from the first chamber and into the second chamber. When the level of molten metal in the second chamber exceeds H2, molten metal flows out of the vessel and into another structure, such as into one or more ladles and / or one or more launders.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

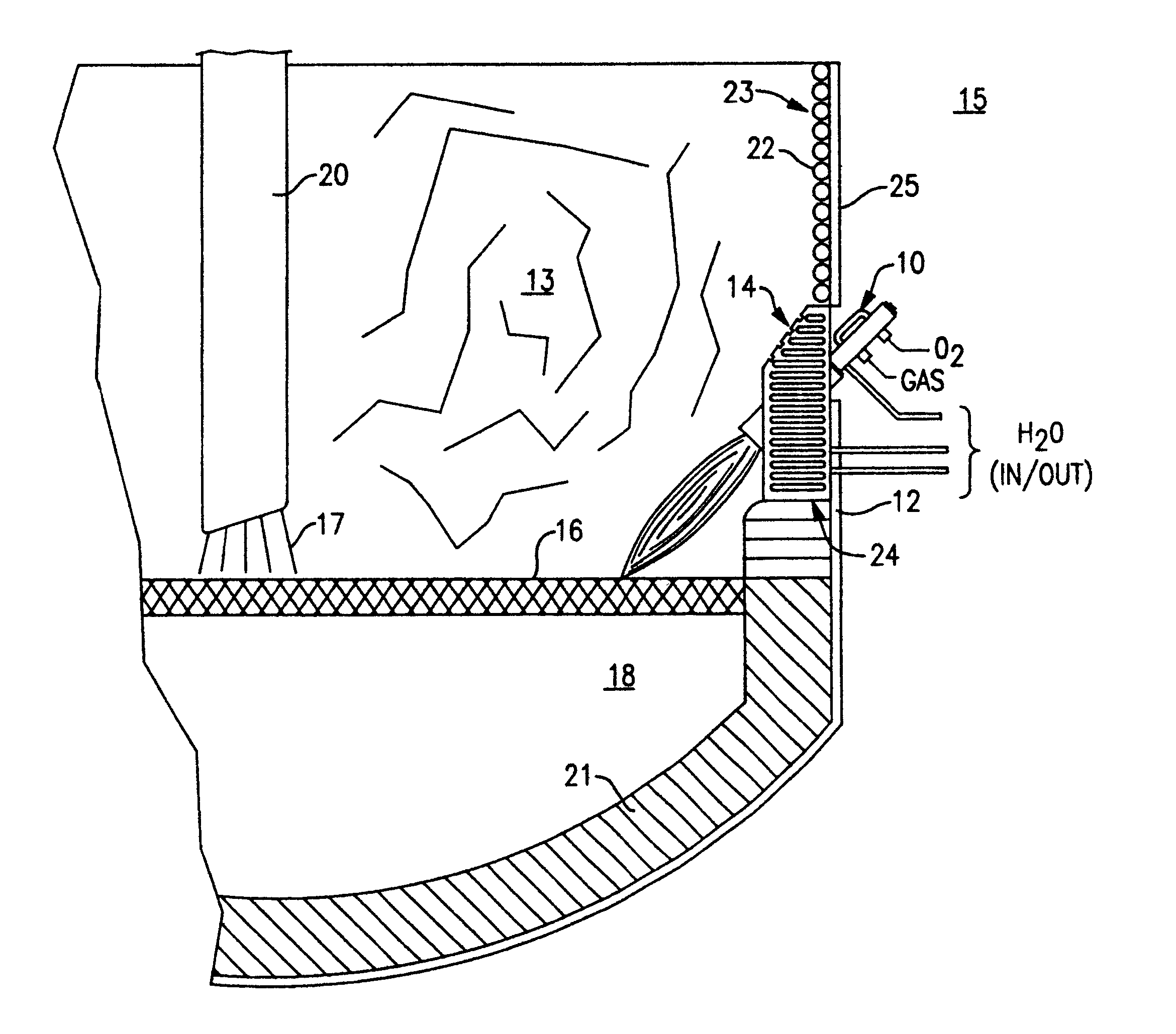

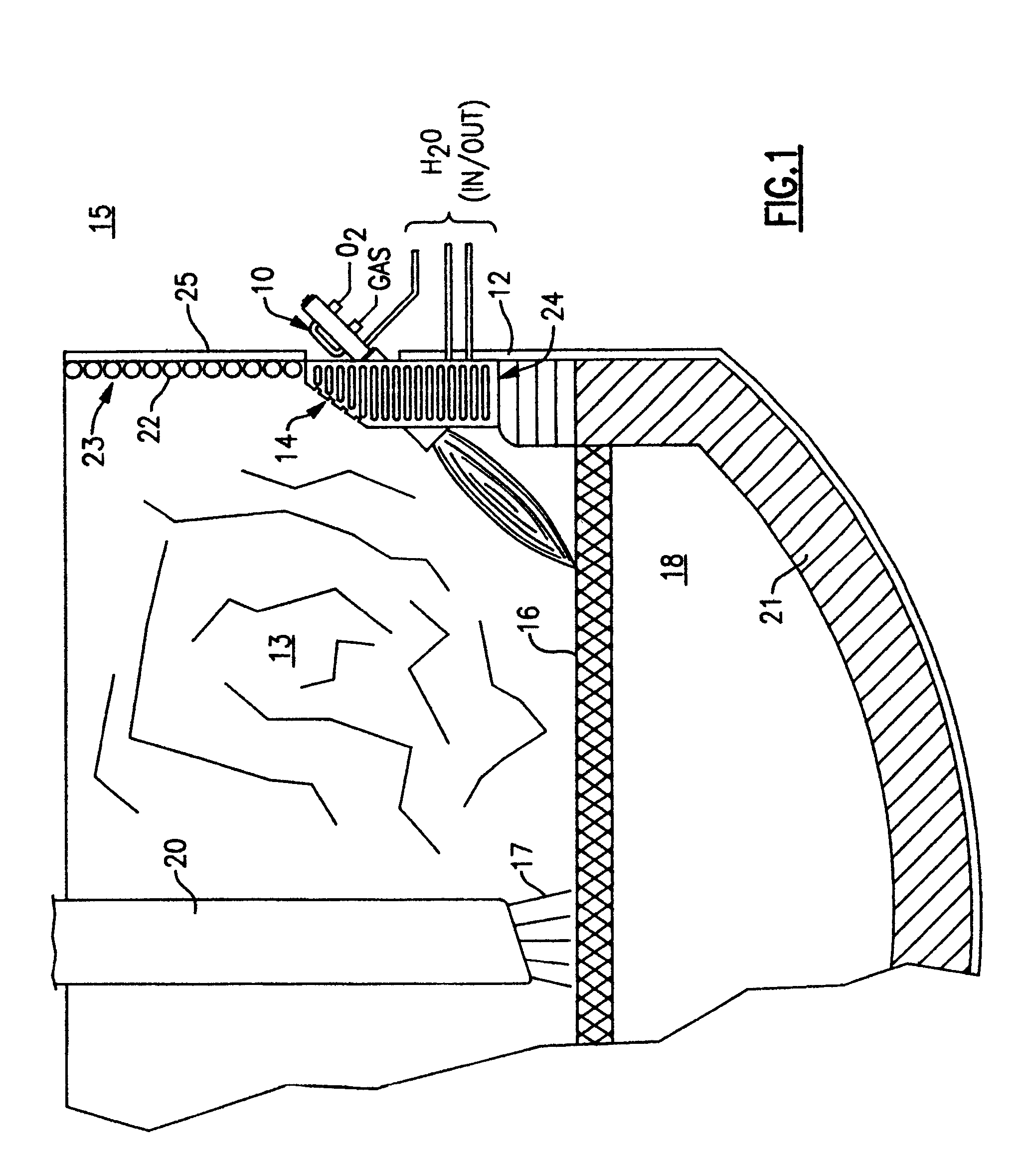

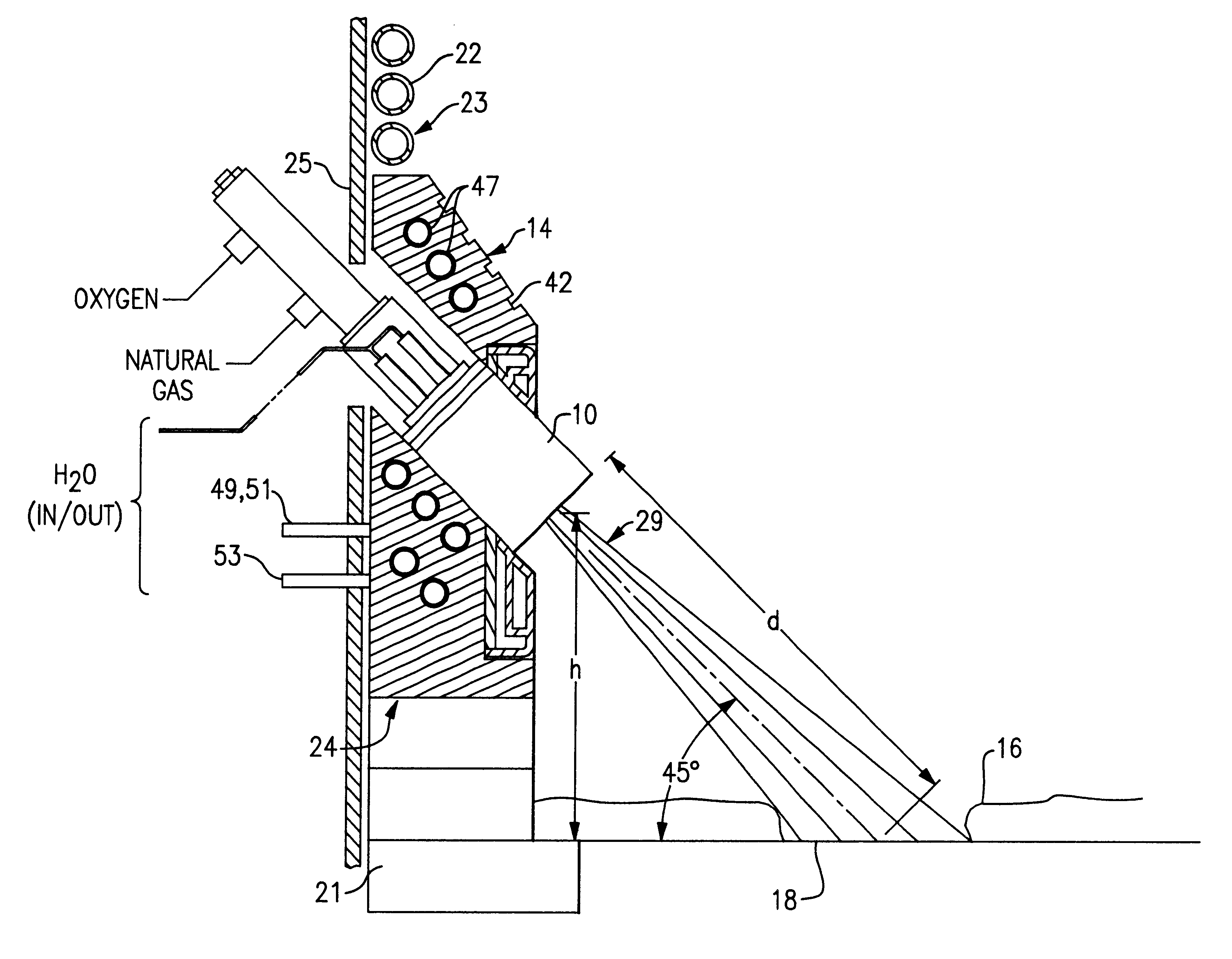

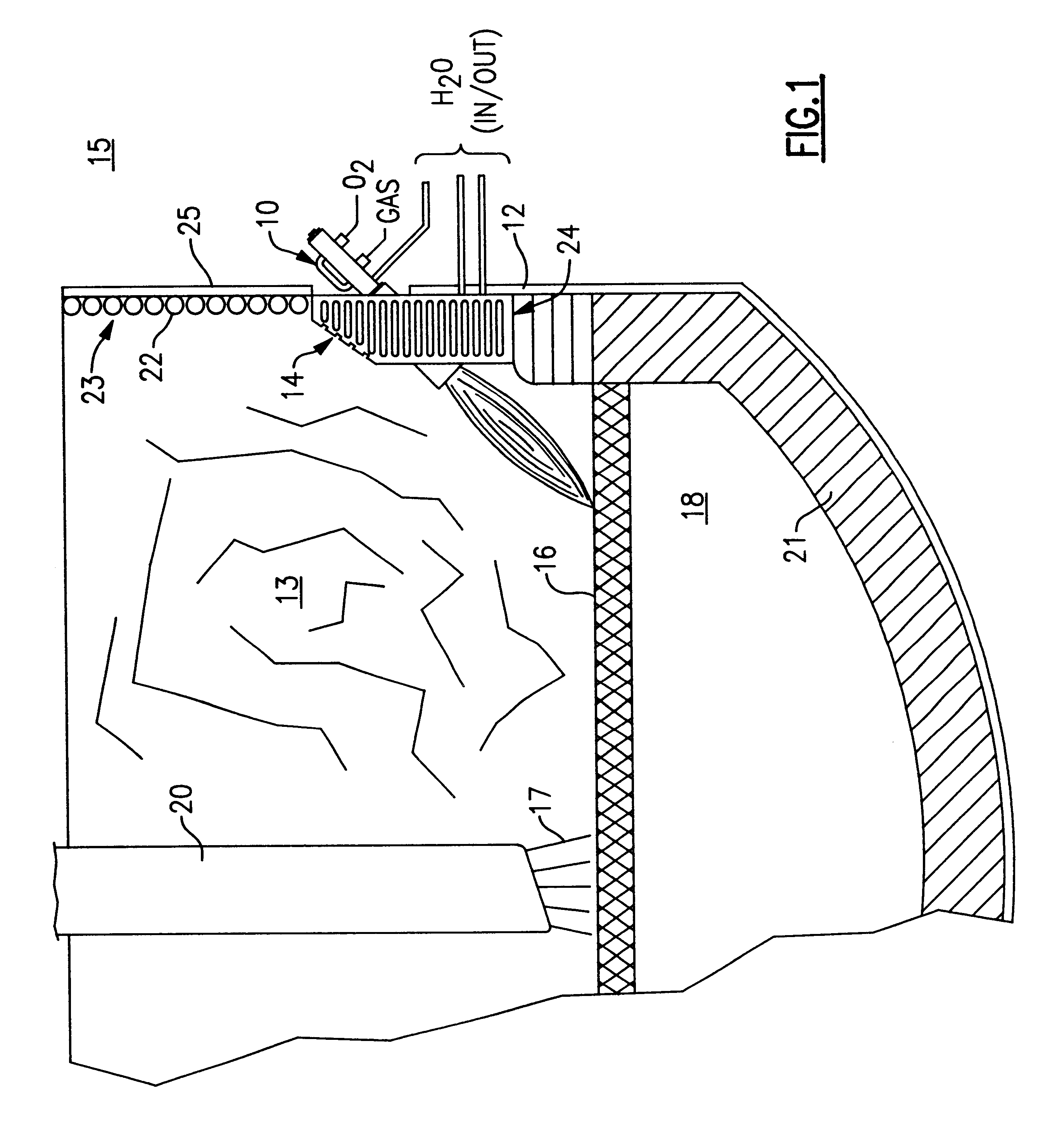

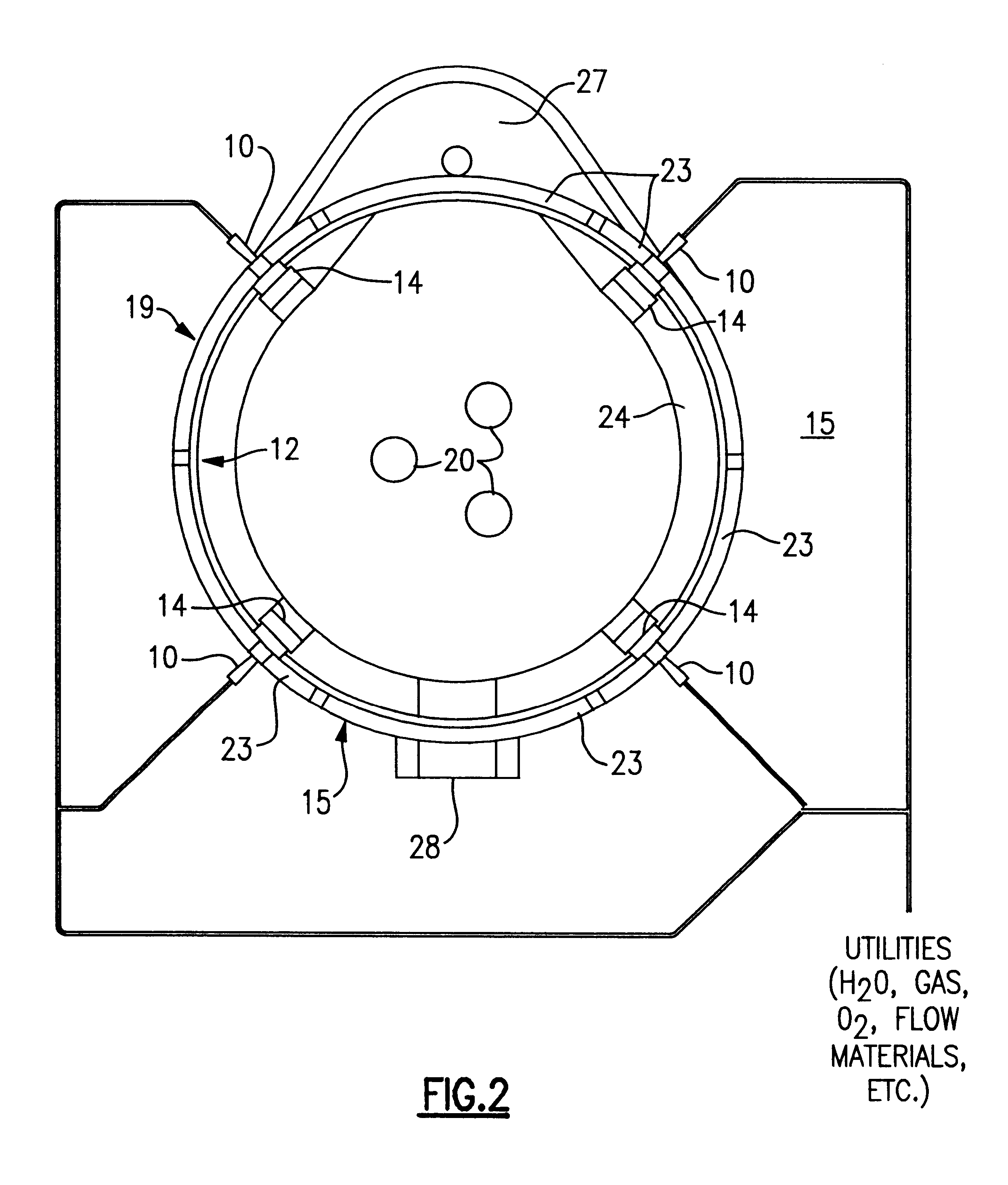

Mounting arrangement for auxiliary burner or lance

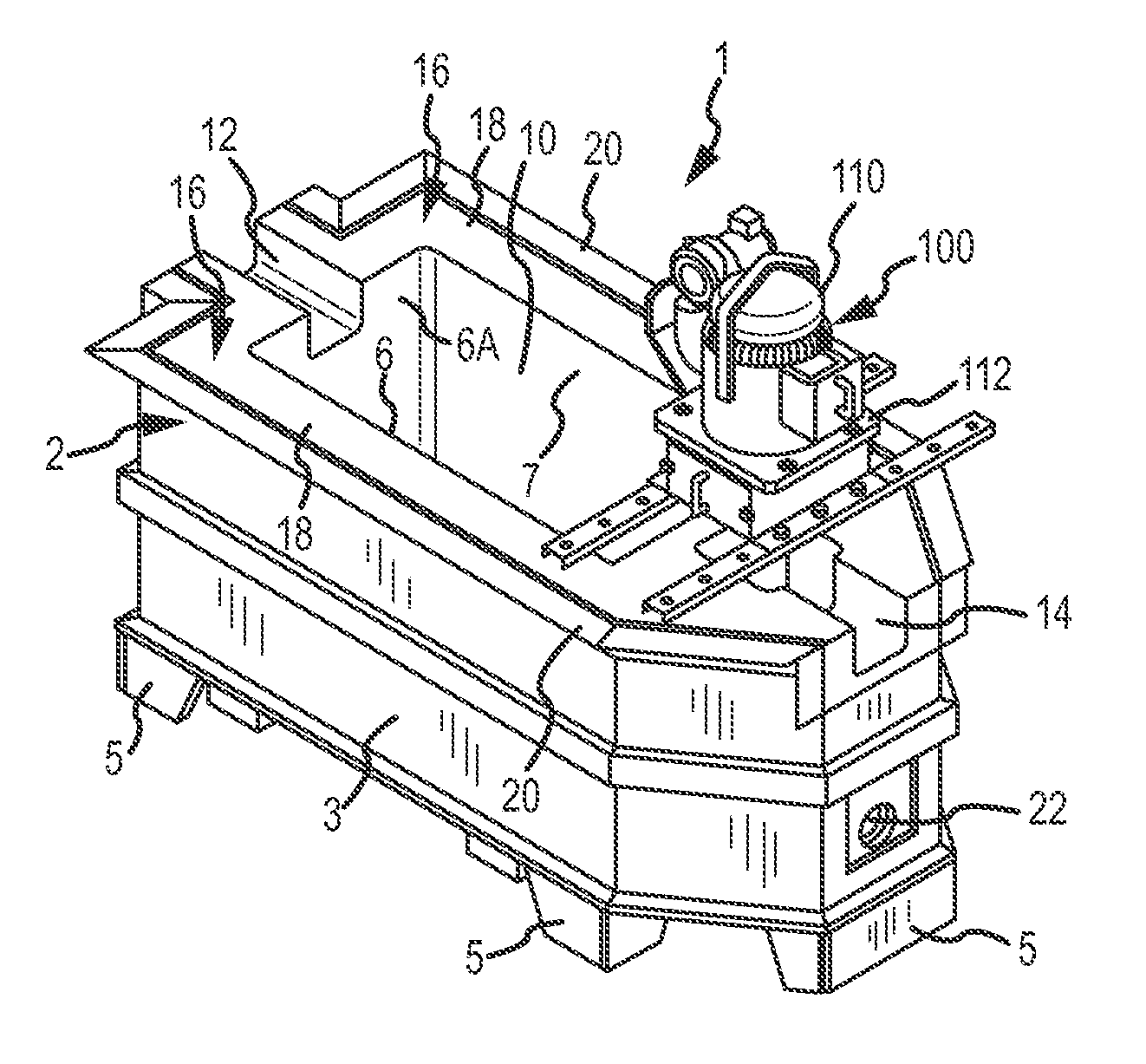

InactiveUS6614831B2Easy to produceImprove thermal conductivityElectric discharge heatingPeptide/protein ingredientsParticulatesElectric arc furnace

A mounting enclosure and an improved mounting arrangement for apparatus used in metal melting, refining and processing, particularly those apparatus adapted for steel making in an electric arc furnace, such as burners, lances and the like with supersonic oxygen lancing capability and injectors or the like for the introduction of particulate matter. The mounting enclosure is fluid cooled to survive the hostile environment of the electric arc furnace and is designed to occupy the step between the side wall and hearth of the furnace without any substantial change to the structure of the furnace. The mounting enclosure comprises a plurality of fluid cooling conduits surrounding an apparatus aperture and an injector aperture which are formed through the enclosure and adapted to mount an apparatus and an injector. The mounting arrangement includes utilizing the mounting enclosure to mount an apparatus with supersonic oxidizing gas lancing capability and an injector for particulate carbon in an electric arc furnace. Because the mounting enclosure is approximately the width of the step, the discharge openings of the apparatus and the injector are moved closer to the surface of the melt and toward the center of the furnace thereby providing increased efficiency. The discharge openings will now be extended to near the edge of the step so that the oxidizing gas flow pattern of the apparatus does not degrade the hearth material or other furnace equipment mounted nearby and the carbon flow pattern of the injector sufficiently agitates the slag to produce foaming.

Owner:PROCESS TECH INT

Molten metal transfer system and rotor

The invention relates to systems for transferring molten metal from one structure to another. Aspects of the invention include a transfer chamber constructed inside of or next to a vessel used to retain molten metal. The transfer chamber is in fluid communication with the vessel so molten metal from the vessel can enter the transfer chamber. A powered device, which may be inside of the transfer chamber, moves molten metal upward and out of the transfer chamber and preferably into a structure outside of the vessel, such as another vessel or a launder.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

Rotary degassers and components therefor

Disclosed are degassers, couplings, impeller shafts and impellers for use in molten metal. One such coupling transfers gas into an impeller shaft, the coupling having a smooth, tapered internal surface to align with a corresponding surface on the impeller shaft and help prevent gas leakage and to assist in preventing damage to the impeller shaft. Improved impellers for shearing and mixing gas are also disclosed, as is a degasser including one or more of these components.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

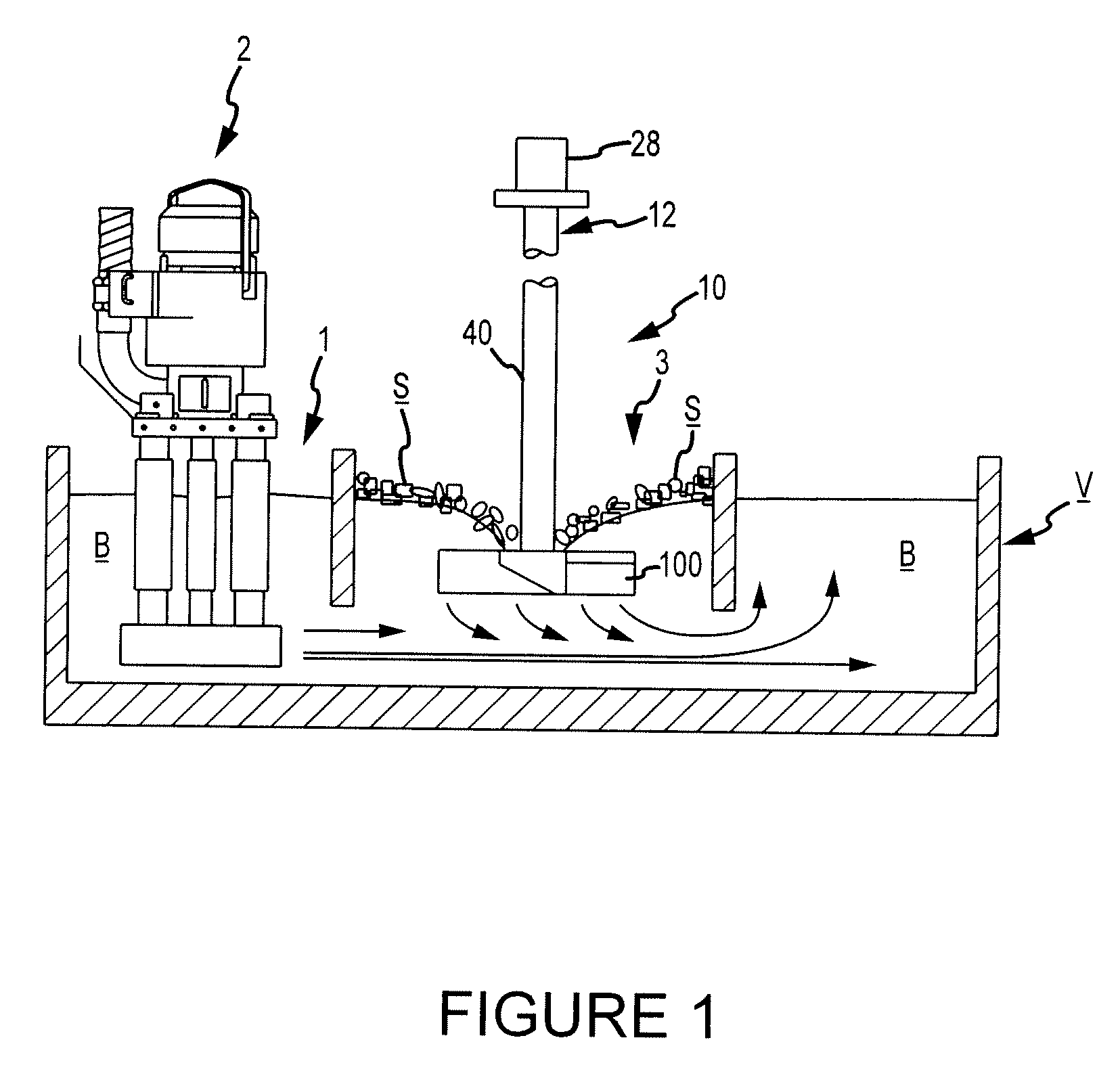

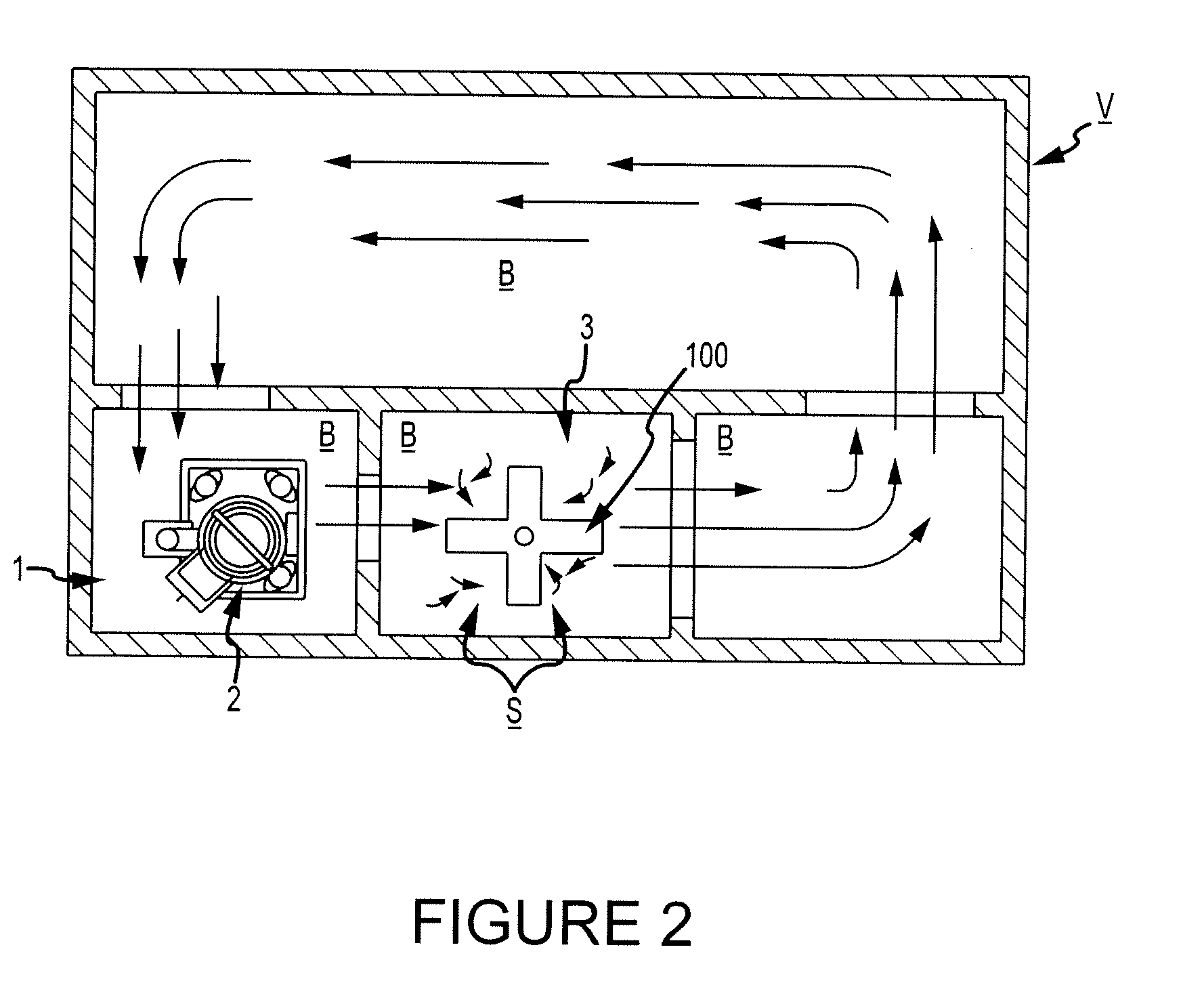

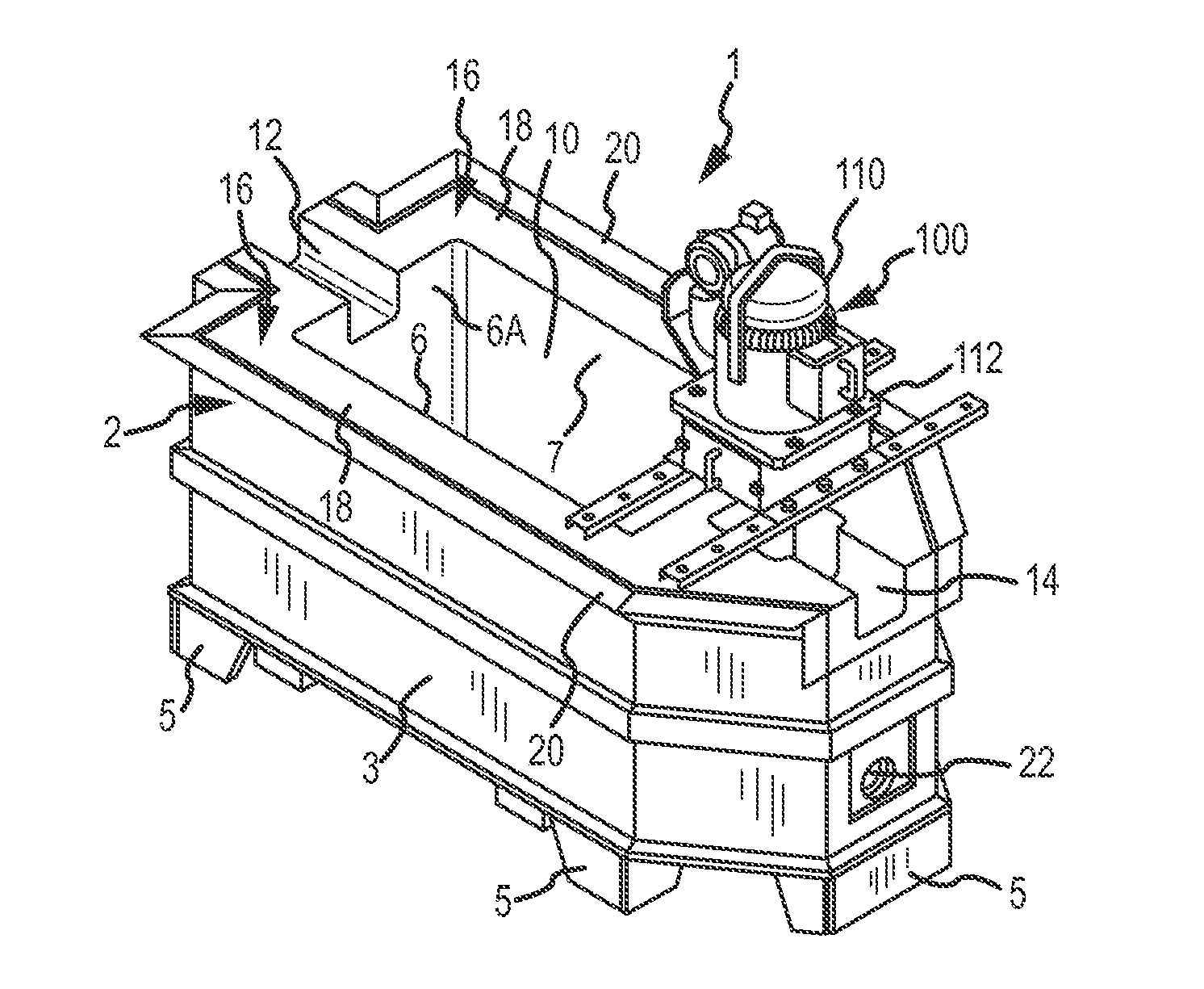

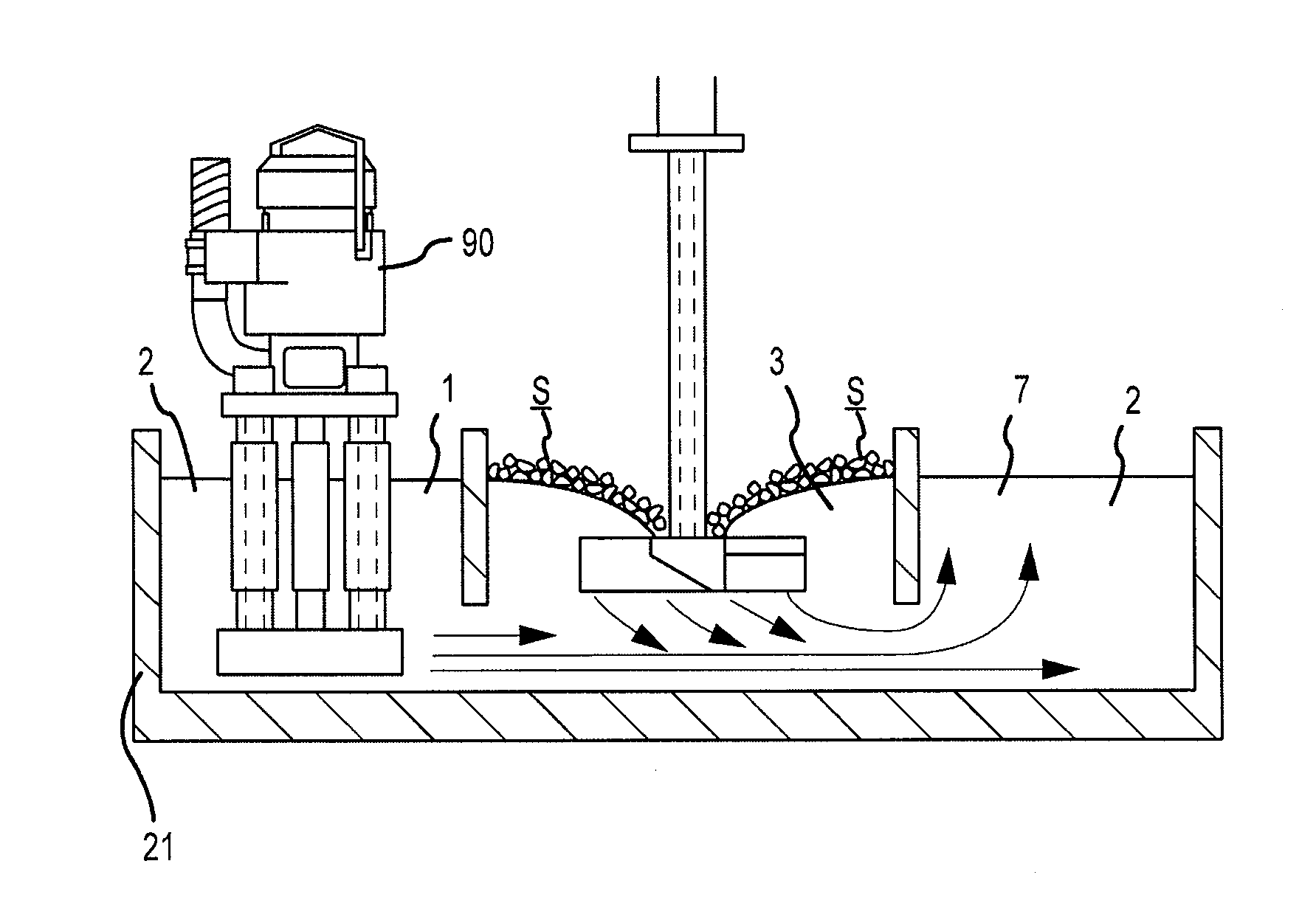

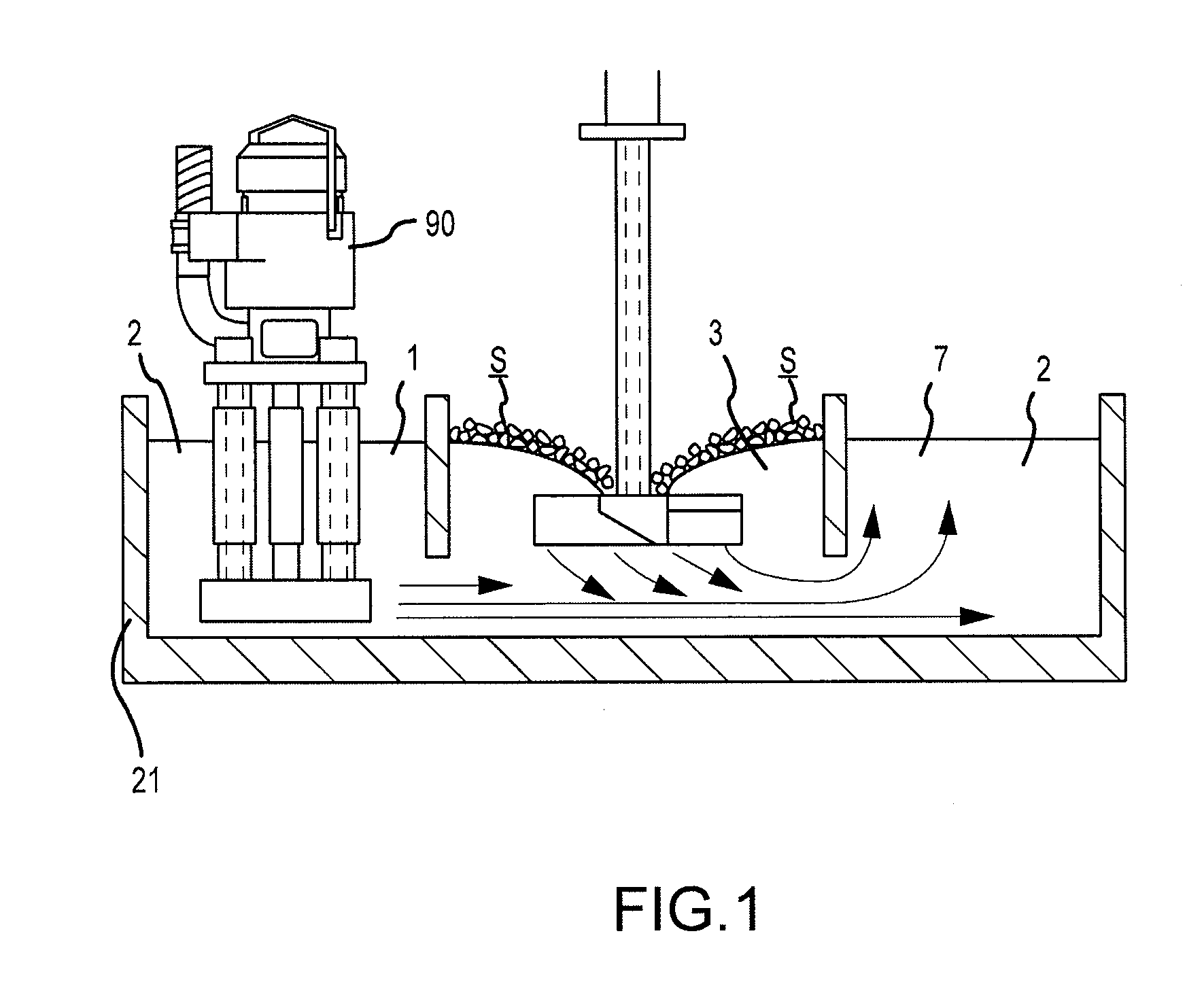

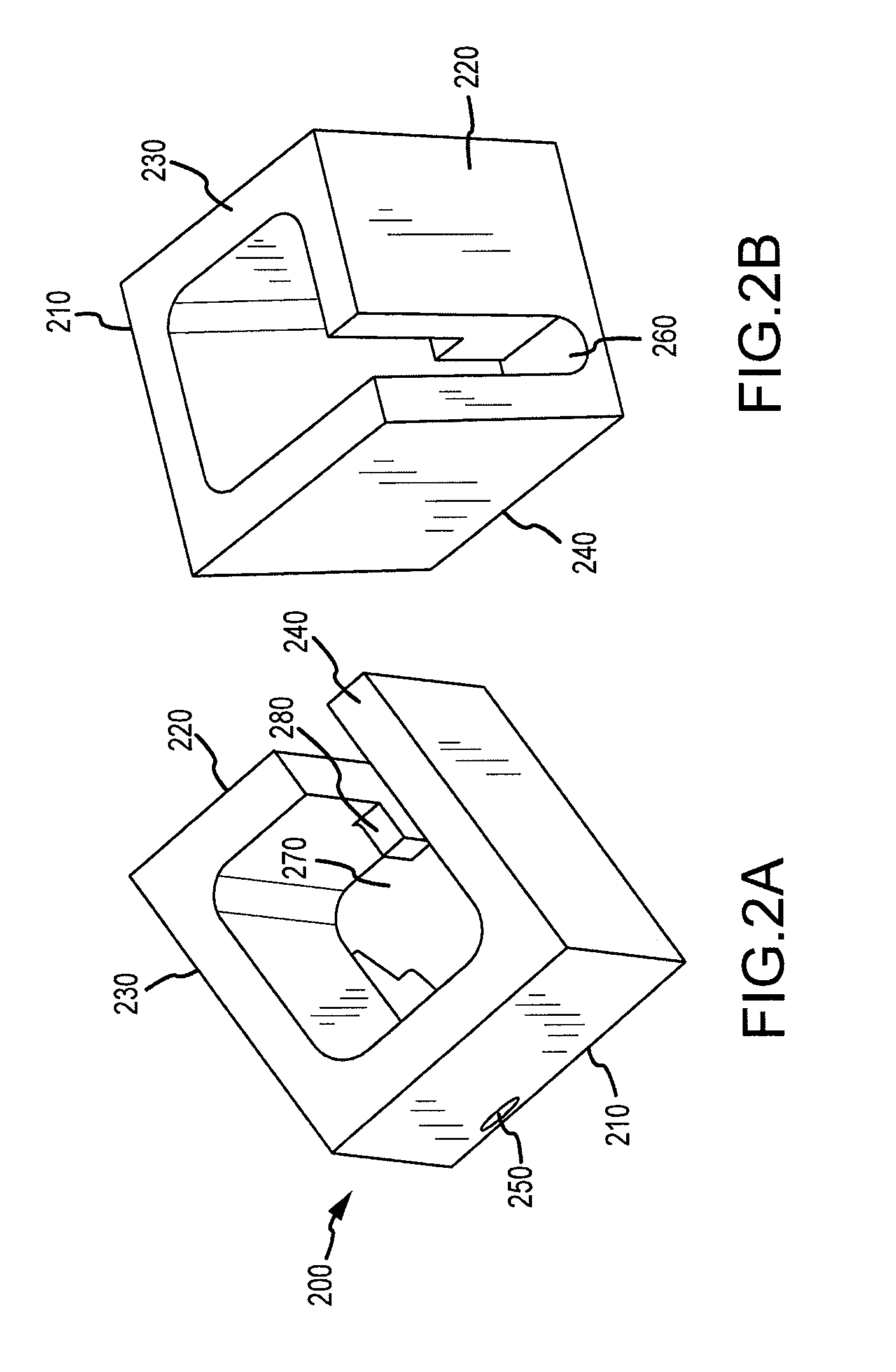

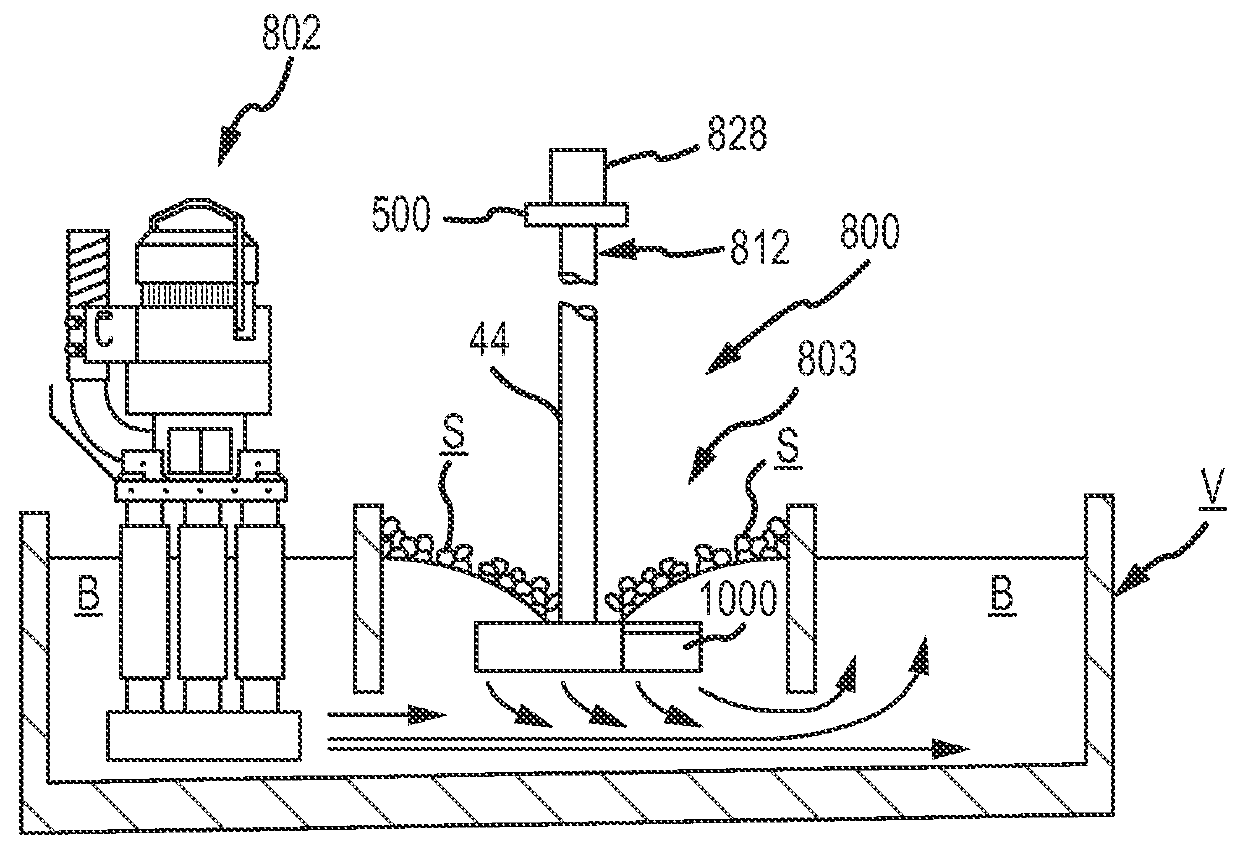

Systems and methods for melting scrap metal

ActiveUS8449814B2Soft and relatively easy to machineAvoid breakingStirring devicesProcess efficiency improvementMolten metalScrap

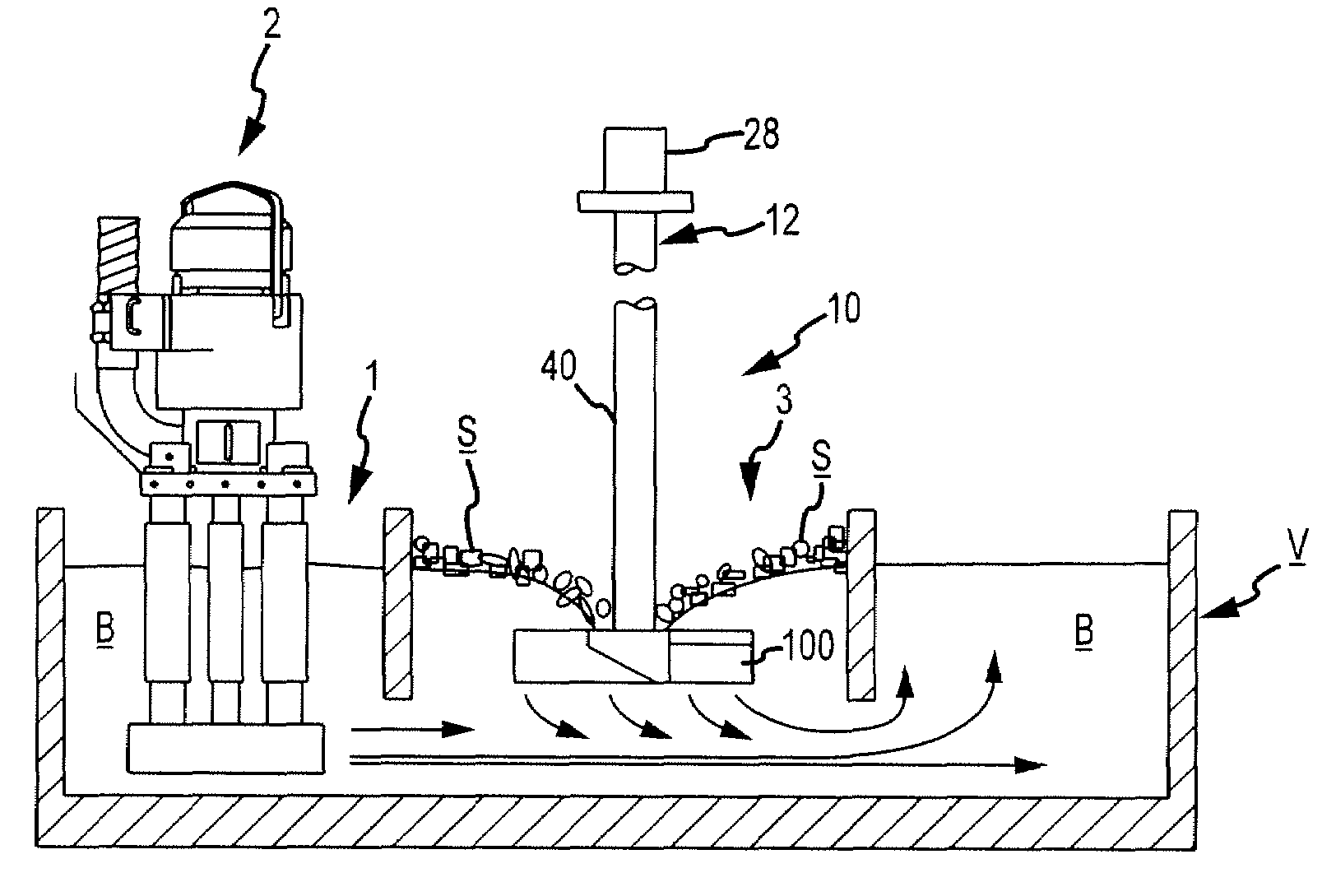

A scrap submergence vessel for melting scrap metal is disclosed. The vessel comprises a front wall comprising an inlet, a back wall (opposite the front wall) comprising an outlet, and a flow direction member that causes molten metal flowing into the inlet to be directed at least partially upward against a portion of the back wall. The movement of molten metal through the vessel creates a downward pull that draws metal scrap placed above or within the vessel downward into the molten metal bath where it melts.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

Mounting arrangement for auxiliary burner or lance

InactiveUS6289035B1Easy to produceImprove thermal conductivityElectric discharge heatingStirring devicesElectric arc furnaceCombustor

A mounting block and an improved mounting arrangement for apparatus used in metal melting, refining and processing, particularly those apparatus adapted to steel making in an electric arc furnace, such as burners, lances and the like with supersonic oxygen lancing capability. The mounting block is fluid cooled to survive the hostile environment of the electric arc furnace and is designed to rest on the step between the side wall and hearth of the furnace without any substantial change to the structure of the furnace. The mounting block comprises a plurality of fluid cooling conduits surrounding an aperture which is formed through the block and adapted to mount the apparatus. The mounting arrangement includes utilizing the mounting block to mount an apparatus with supersonic oxidizing gas or lancing capability in an electric arc furnace. The apparatus is mounted by passing it through an aperture in a water cooled side panel aligned with the mounting aperture in the mounting block. Because the mounting block is approximately the width of the step, the discharge opening of the apparatus is moved closer to the surface of the melt and toward the center of the furnace thereby providing increased efficiency. The discharge opening will now also extend past the inner edge of the step so that the oxidizing gas flow pattern does not degrade the hearth material and other furnace equipment mounted nearby.

Owner:PROCESS TECH INT

Molten metal transfer vessel and method of construction

ActiveUS20130299525A1Significant comprehensive benefitsFormation of dross in the ladle or launder are greatly reduced or eliminatedMelt-holding vesselsMolten metal pouring equipmentsMolten metalBuilding construction

The invention relates to systems for transferring molten metal from one structure to another. Aspects of the invention include a transfer chamber constructed inside of or next to a vessel used to retain molten metal. The transfer chamber is in fluid communication with the vessel so molten metal from the vessel can enter the transfer chamber. A powered device, which may be inside of the transfer chamber, moves molten metal upward and out of the transfer chamber and preferably into a structure outside of the vessel, such as another vessel or a launder.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

Systems and methods for melting scrap metal

ActiveUS20110133374A1Assist in the melting of scrap metalStirring devicesProcess efficiency improvementMolten metalScrap

A scrap submergence vessel for melting scrap metal is disclosed. The vessel comprises a front wall comprising an inlet, a back wall (opposite the front wall) comprising an outlet, and a flow direction member that causes molten metal flowing into the inlet to be directed at least partially upward against a portion of the back wall. The movement of molten metal through the vessel creates a downward pull that draws metal scrap placed above or within the vessel downward into the molten metal bath where it melts.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

Molten metal transfer and degassing system

ActiveUS20130306687A1Keep the flowReduce the possibilityMelt-holding vesselsMolten metal pouring equipmentsEngineeringMolten metal

Aspects of the invention include a transfer chamber constructed inside of or next to a vessel used to retain and degas molten metal. The transfer chamber is in fluid communication with the vessel so molten metal from the vessel is pulled through the vessel by the pump as it is degassed. This helps maintain a generally constant flow of molten metal through the degassing vessel. Other aspects relate to a system and method for efficiently performing maintenance on components positioned in a vessel.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

Ladle with transfer conduit

ActiveUS9011761B2Reduce the amount requiredReduce formationMelt-holding vesselsMolten metal supplying equipmentsMarine engineeringGuide tube

Disclosed is a transportable vessel for use in a factory for processing molten metal. The vessel is not connected to a reverbatory furnace and can be moved to different locations in the factory. The vessel includes a transfer conduit in communication with a cavity of the vessel. A molten metal pump can be positioned in the transfer conduit to move molten metal out of an outlet in communication with the transfer conduit and into another vessel without the need to tip or tilt the transportable vessel.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

Molten metal transfer system and rotor

The invention relates to systems for transferring molten metal from one structure to another. Aspects of the invention include a transfer chamber constructed inside of or next to a vessel used to retain molten metal. The transfer chamber is in fluid communication with the vessel so molten metal from the vessel can enter the transfer chamber. A powered device, which may be inside of the transfer chamber, moves molten metal upward and out of the transfer chamber and preferably into a structure outside of the vessel, such as another vessel or a launder.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

Rotary degasser and rotor therefor

ActiveUS20140008849A1Efficiently circulatedWell mixedStirring devicesBlade accessoriesImpellerDegasser

A device for dispersing gas into molten metal includes an impeller, a drive shaft having a gas-transfer passage therein, and a first end and a second end, and a drive source. The second end of the drive shaft is connected to the impeller and the first end is connected to the drive source. The impeller includes a first portion and a second portion with a plurality of cavities. The first portion covers the second portion to help prevent gas from escaping to the surface without entering the cavities and being mixed with molten metal as the impeller rotates. When gas is transferred through the gas-transfer passage, it exits through the gas-release opening(s) in the bottom of the impeller. At least some of the gas enters the cavities where it is mixed with the molten metal being displaced by the impeller. Also disclosed are impellers that can be used to practice the invention.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

Rotary degassers and components therefor

Disclosed are degassers, couplings, impeller shafts and impellers for use in molten metal. One such coupling transfers gas into an impeller shaft, the coupling having a smooth, tapered internal surface to align with a corresponding surface on the impeller shaft and help prevent gas leakage and to assist in preventing damage to the impeller shaft. Improved impellers for shearing and mixing gas are also disclosed, as is a degasser including one or more of these components.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

Transfer well system and method for making same

The invention relates to systems for transferring molten metal from one structure to another. Aspects of the invention include a transfer chamber constructed inside of or next to a vessel used to retain molten metal. The transfer chamber is in fluid communication with the vessel so molten metal from the vessel can enter the transfer chamber. A powered device, which may be inside of the transfer chamber, moves molten metal upward and out of the transfer chamber and preferably into a structure outside of the vessel, such as another vessel or a launder.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

Molten metal rotor with hardened top

Embodiments of the invention are directed to a rotor for a molten metal pump and a molten metal pump including the rotor. The rotor has a main body and a top comprised of a material that is at least twice as hard as the main body. The top, among other things, may form a first portion of each rotor blade wherein the first portion directs molten metal into a pump chamber or other structure in which the rotor is mounted.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

Molten metal scrap submergence apparatus

A metal scrap submergence device comprising an open top chamber including walls of a heat resistant material, an inlet positioned in a side wall of the chamber, an outlet positioned in the base of said chamber, and a ramp adjacent said side wall of the chamber. The side wall further includes a feature affecting molten metal flow. The feature can include, for example, a baffle, a vane, a passage, a diverging or converging shape and combinations thereof. Similarly, the molten metal flow can be affected by slanting the ramp inwardly or outwardly.

Owner:PYROTECK INC

Rotor and rotor shaft for molten metal

A molten metal rotor receives and retains an end of a molten metal rotor shaft. The rotor shaft has one or more projections at the end received in the rotor. The rotor has an inner cavity, a top surface with an opening leading to the inner cavity, and at least one abutment. The opening includes one or more portions for allowing each projection to pass through the opening and into the inner cavity. The rotor and / or shaft are then rotated so at least one of the outwardly-extending projections is under the top surface of the rotor and is against an abutment. A molten metal pump, rotary degasser scrap melter or other device used in molten metal may utilize a rotor / shaft combination as disclosed herein.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

Molten metal transfer vessel and method of construction

ActiveUS9409232B2Formation of dross in the ladle or launder are greatly reduced or eliminatedEliminate useMelt-holding vesselsMolten metal pouring equipmentsMolten metalBuilding construction

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com