Patents

Literature

1973results about "Maintainance of heating chambers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

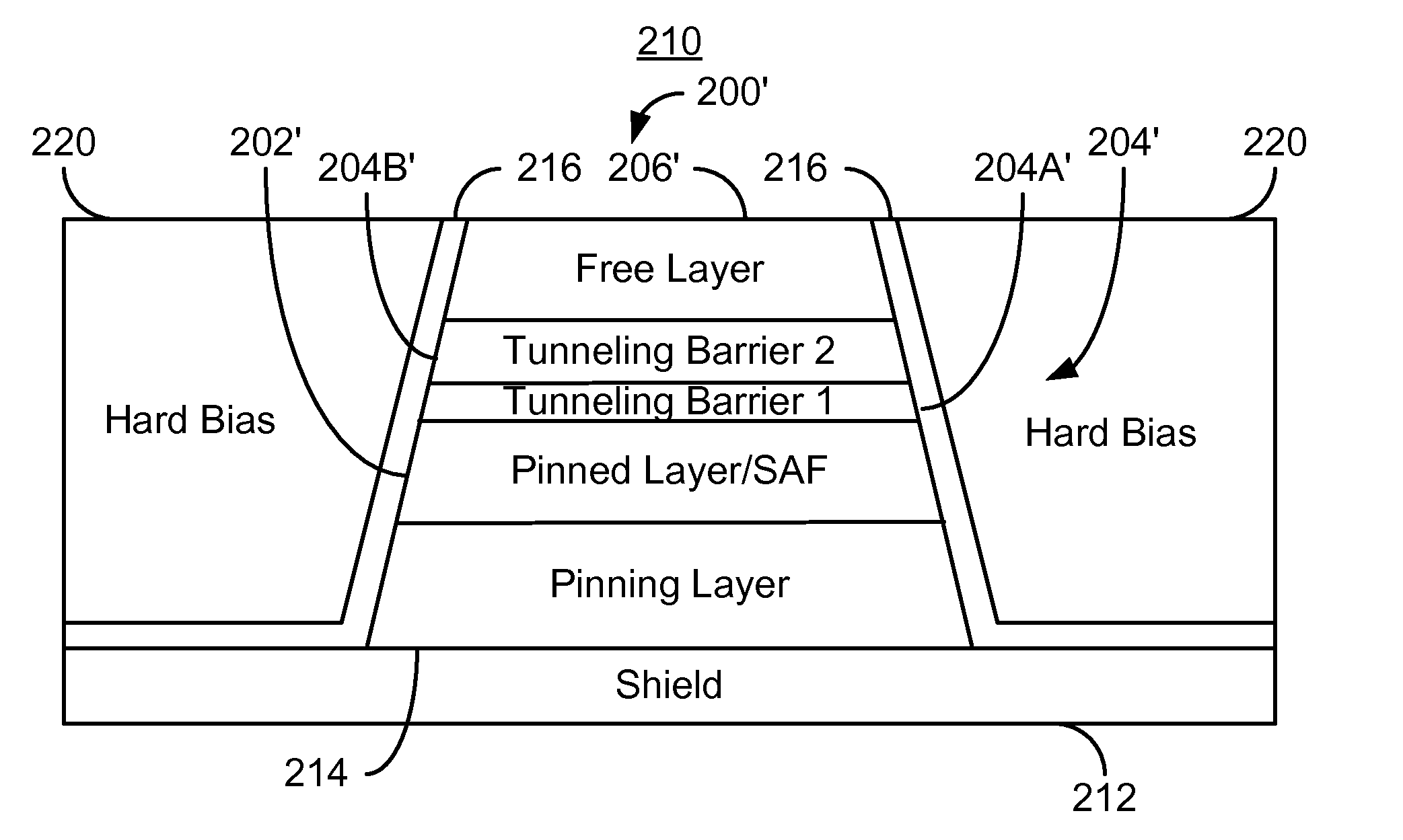

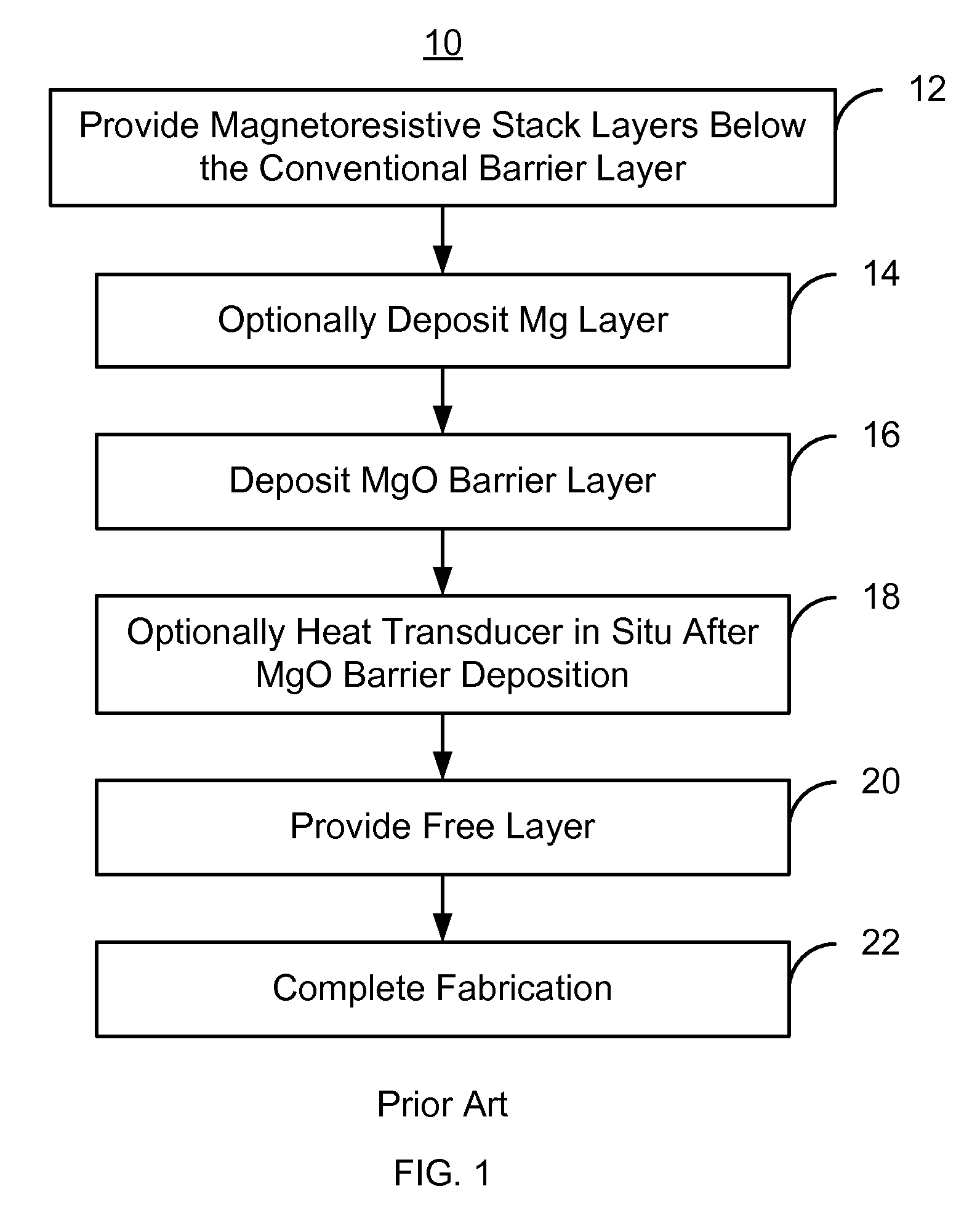

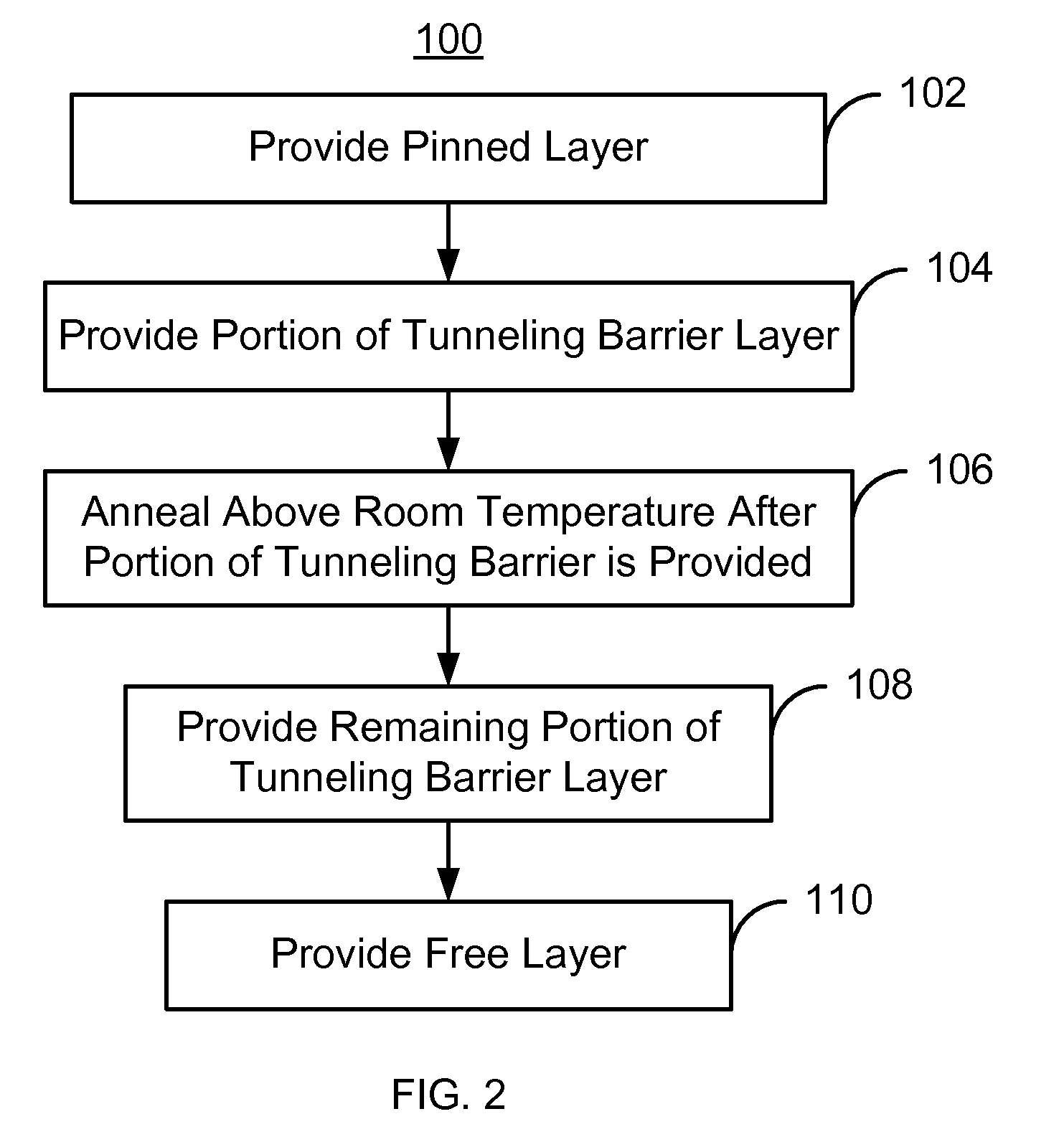

Method for providing a magnetic recording transducer

Owner:WESTERN DIGITAL TECH INC

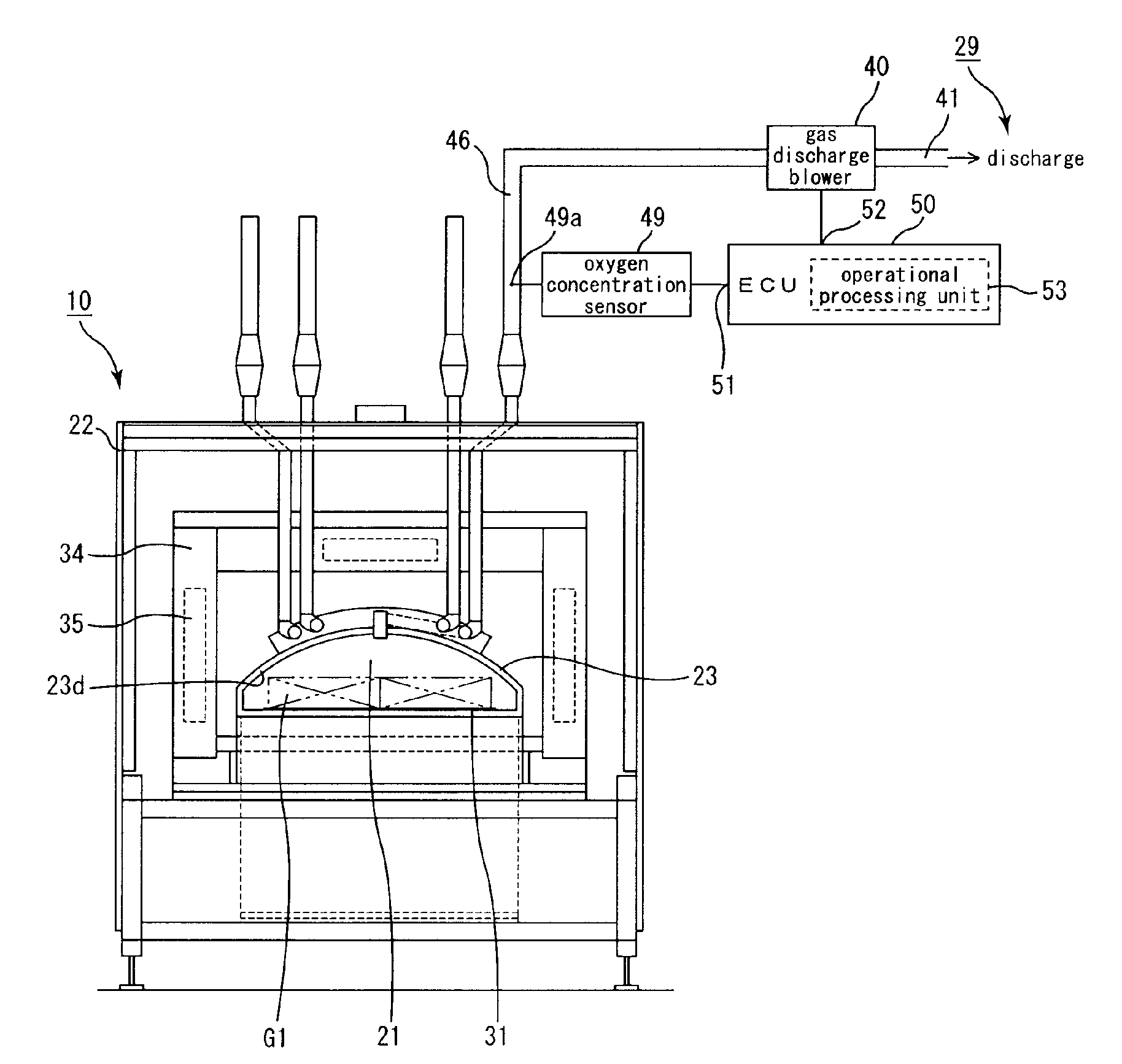

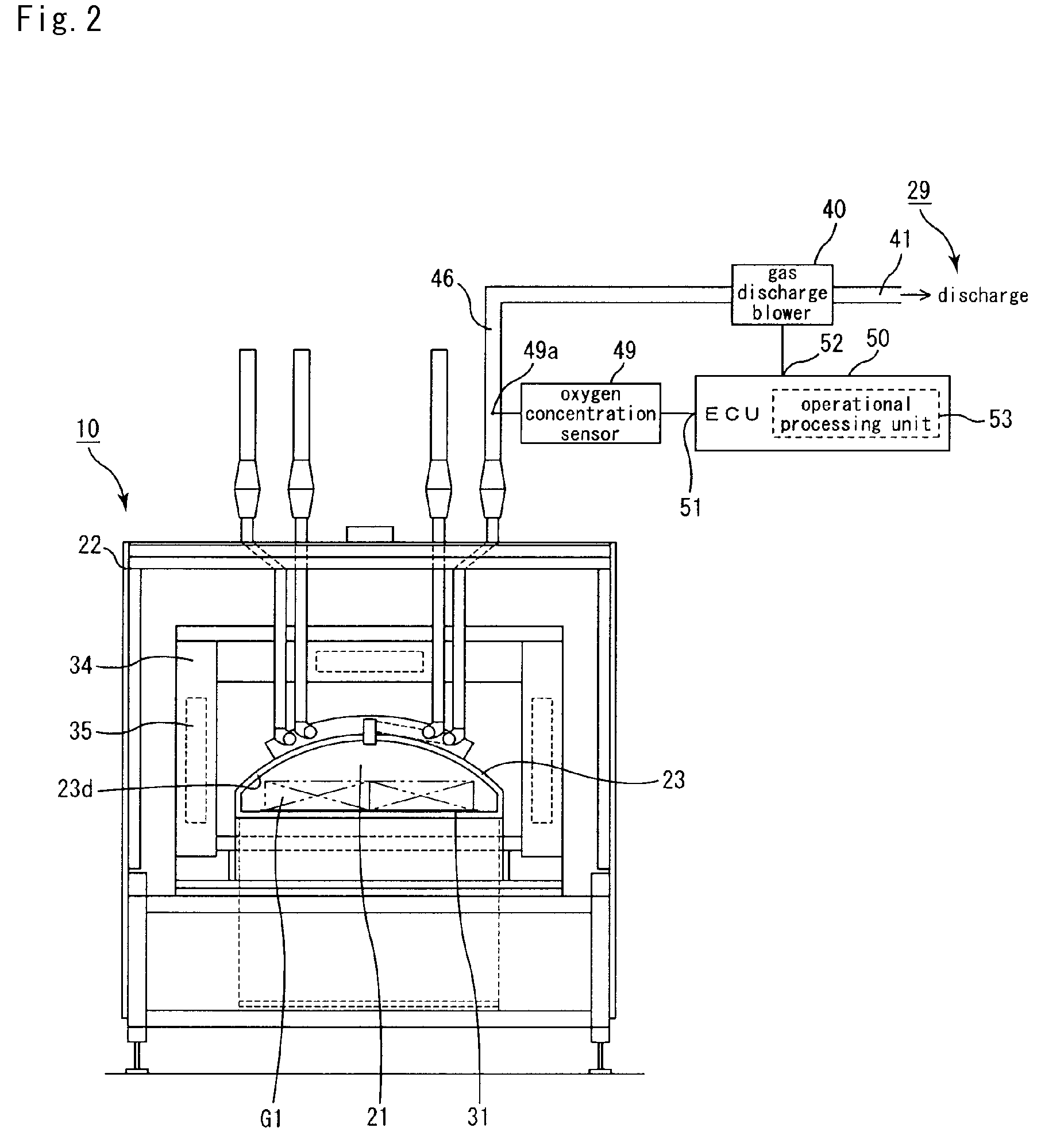

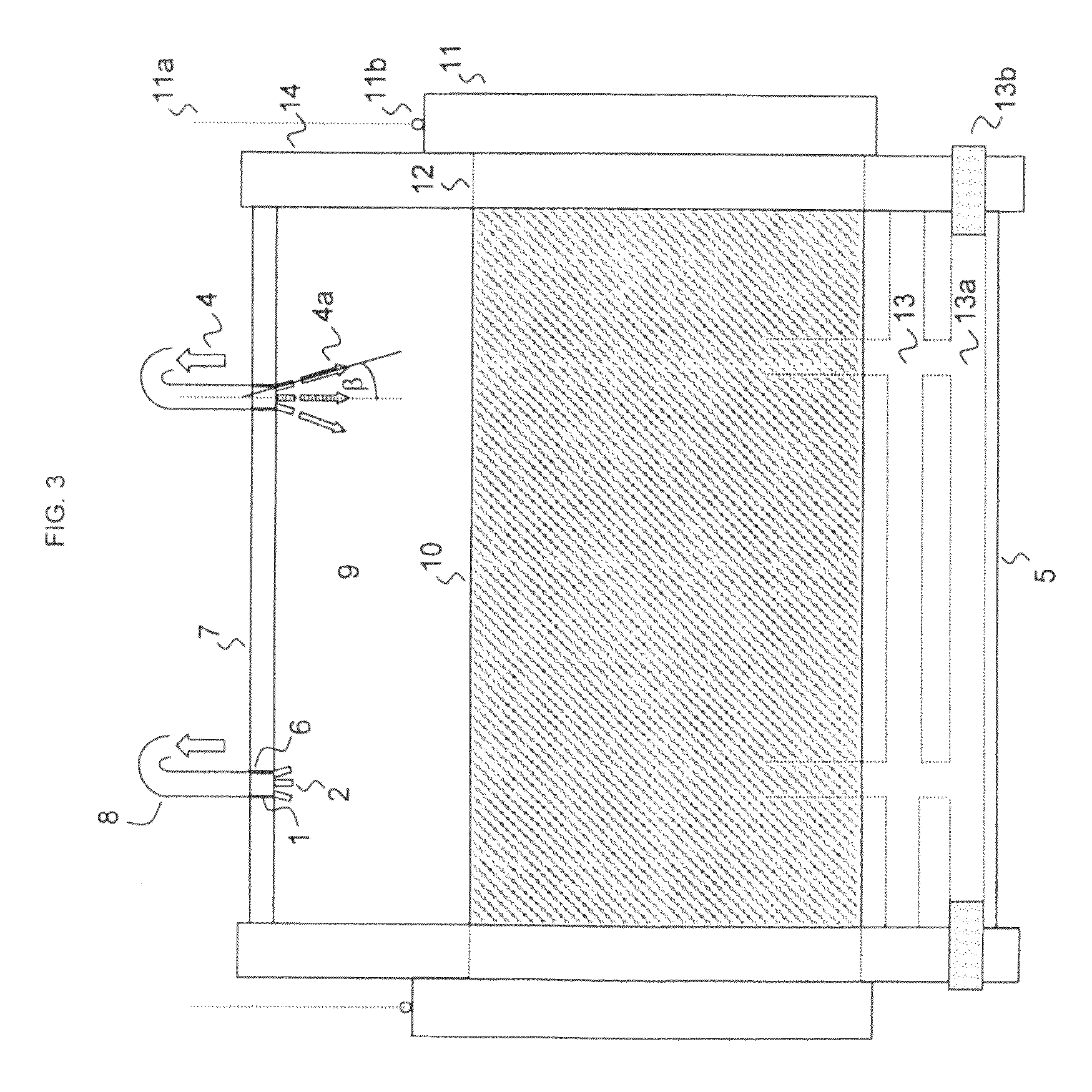

Heating furnace and method for manufacturing honeycomb structure

InactiveUS20080197544A1Increase temperatureMaintainance of heating chambersCeramic shaping apparatusMeasurement deviceHeating furnace

A heating furnace for calcining an object to be heated. The heating furnace includes a wall defining a furnace space and configured to receive the object in the furnace space, and a heating device configured to raise a temperature within the furnace space. The heating furnace also includes an oxygen supply channel configured to introduce gases containing oxygen into the furnace space. The oxygen supply channel is formed as an opening in a part of the wall surrounding the furnace space. The heating furnace further includes a gas discharge channel fluidly connected to the furnace space and configured to discharge gases in the furnace space to an outside of the furnace space, and a measurement device installed in the gas discharge channel and configured to measure properties of the gases passing through the gas discharge channel.

Owner:IBIDEN CO LTD

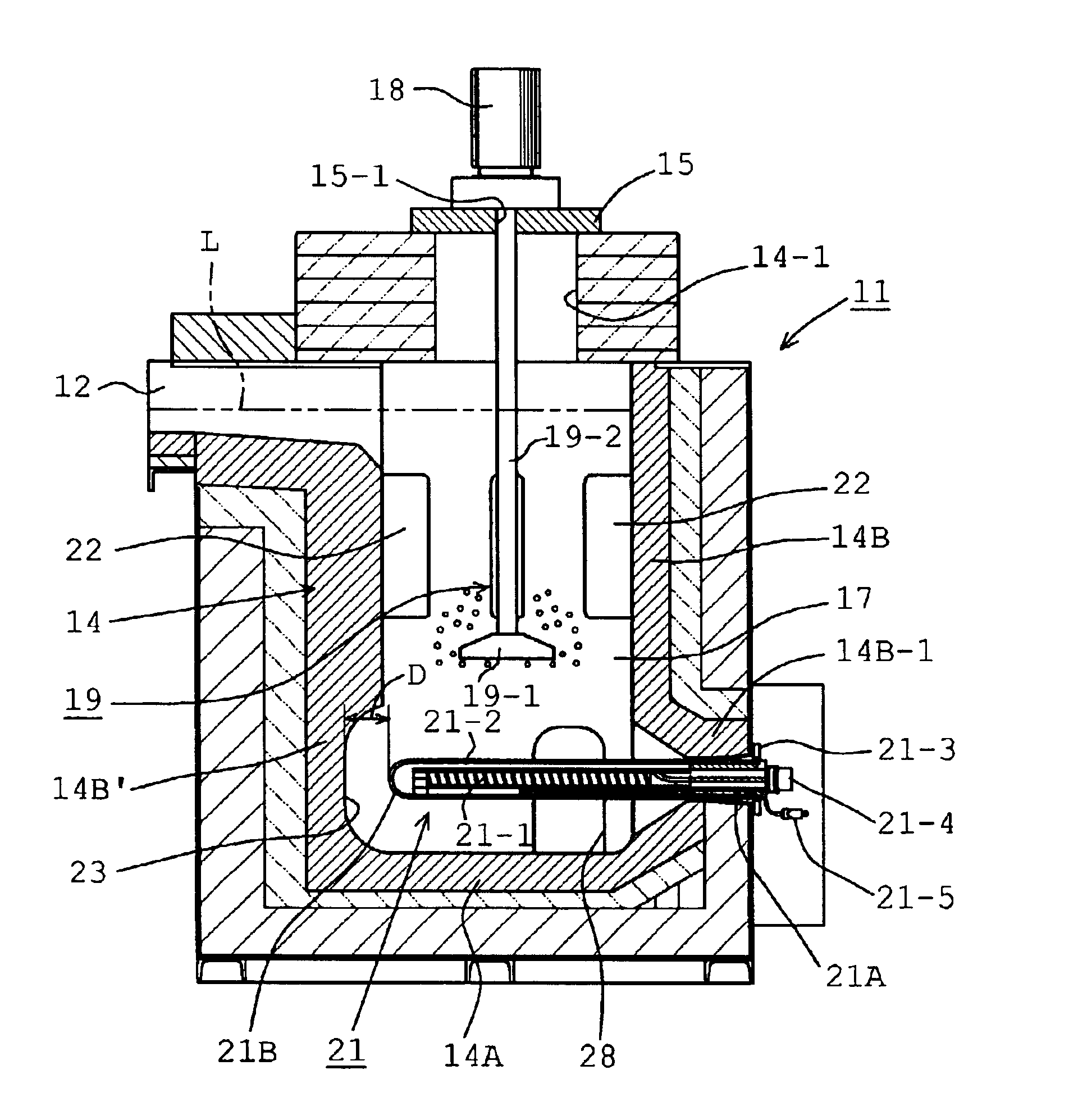

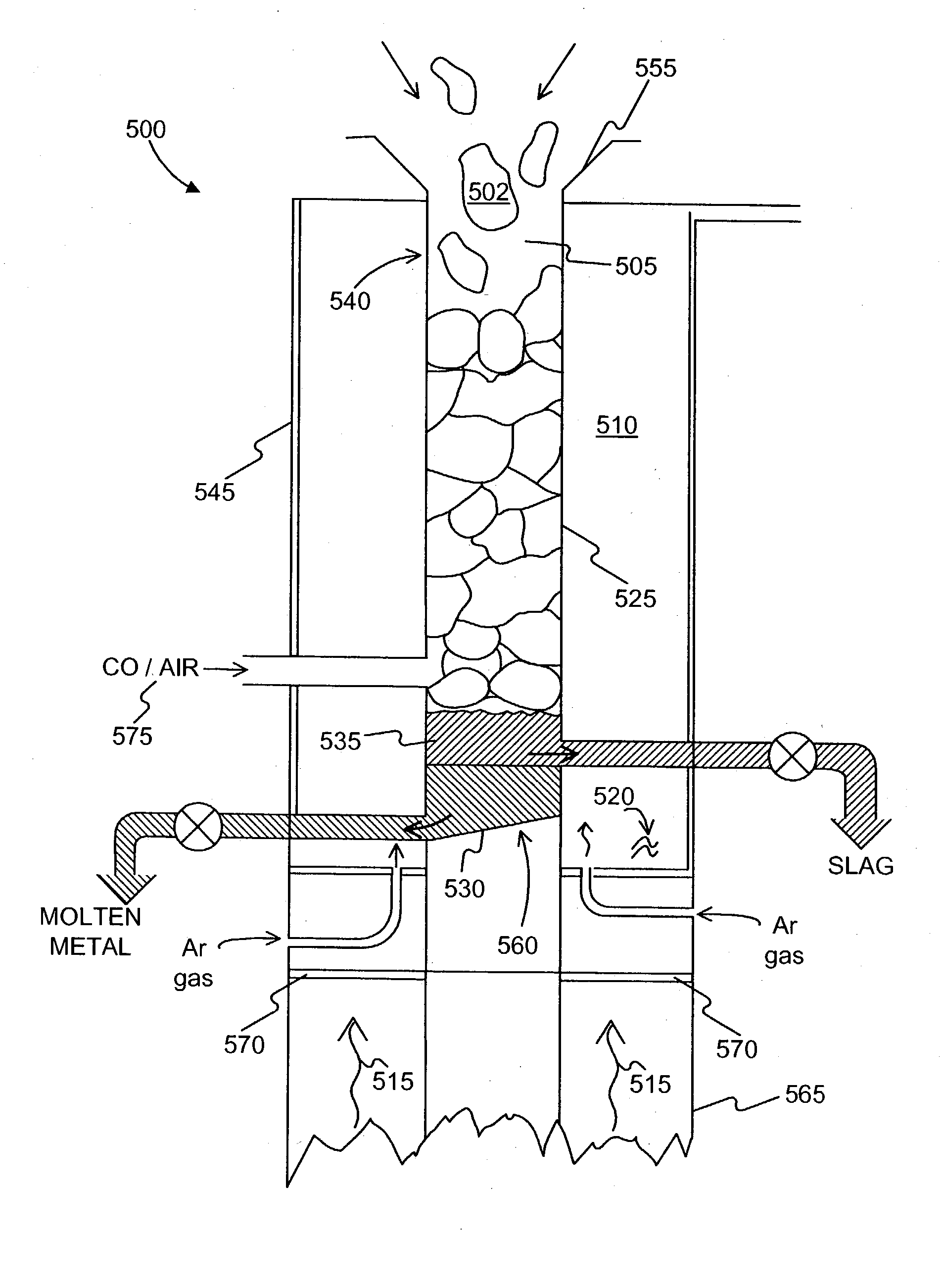

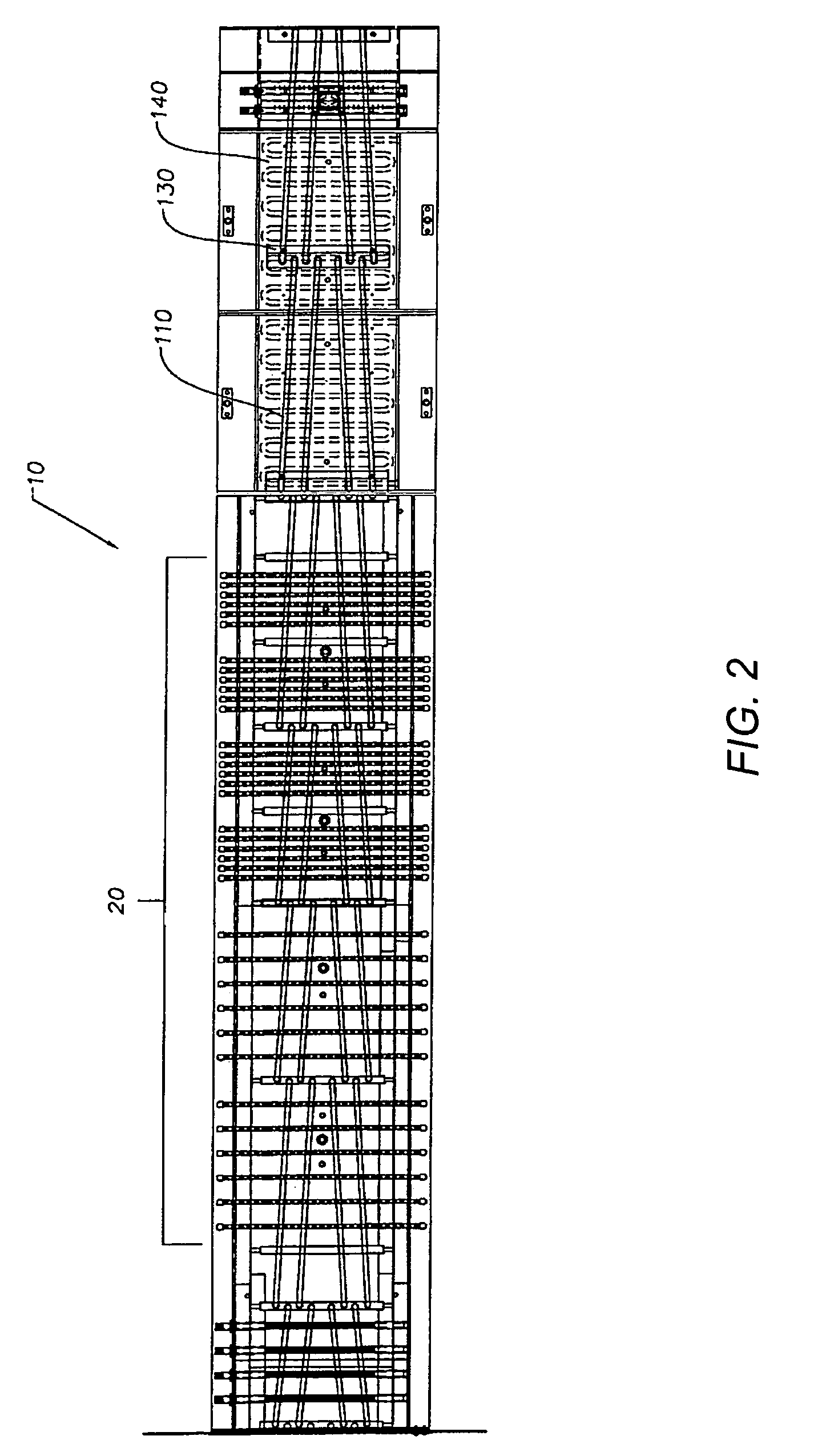

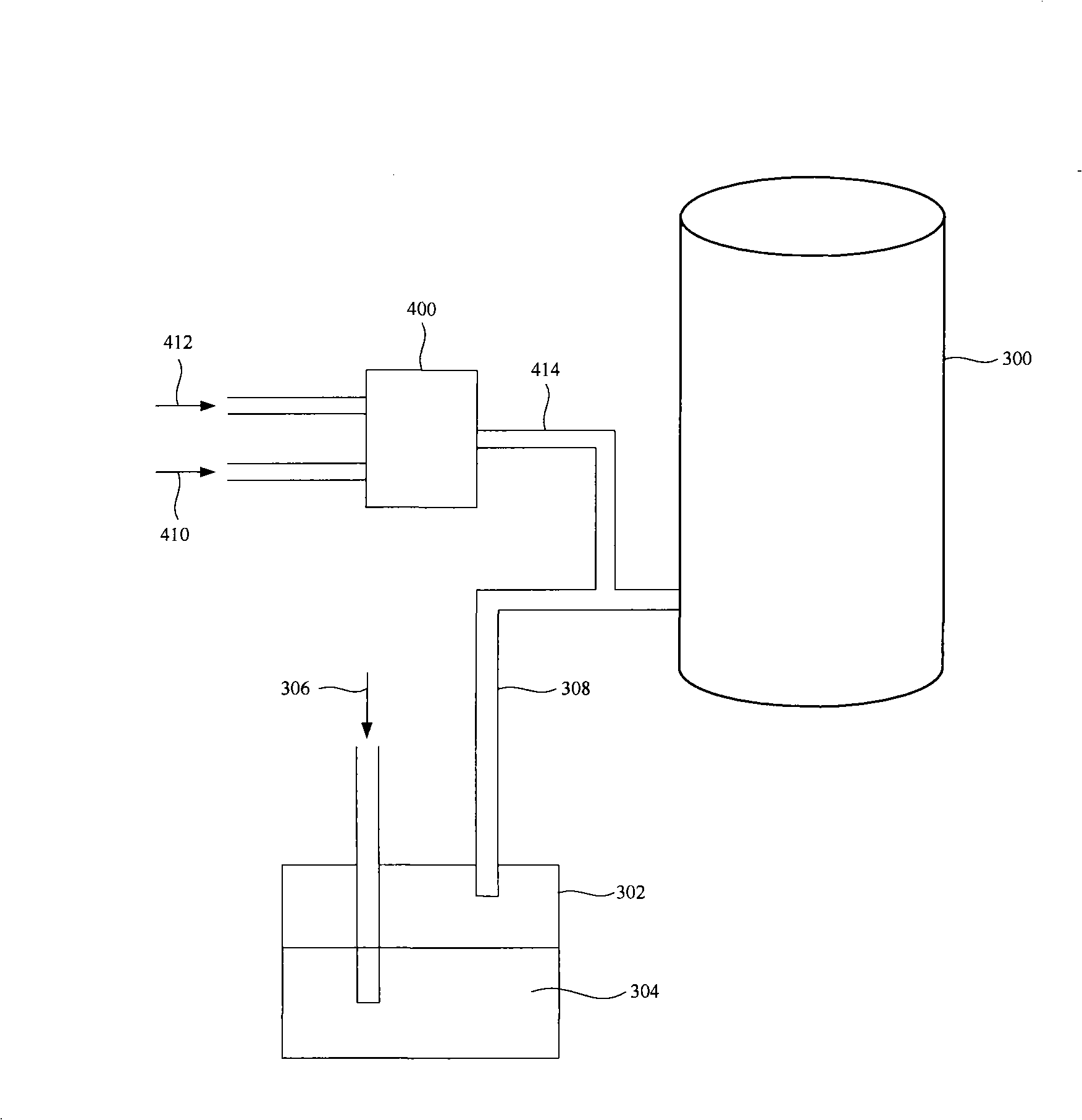

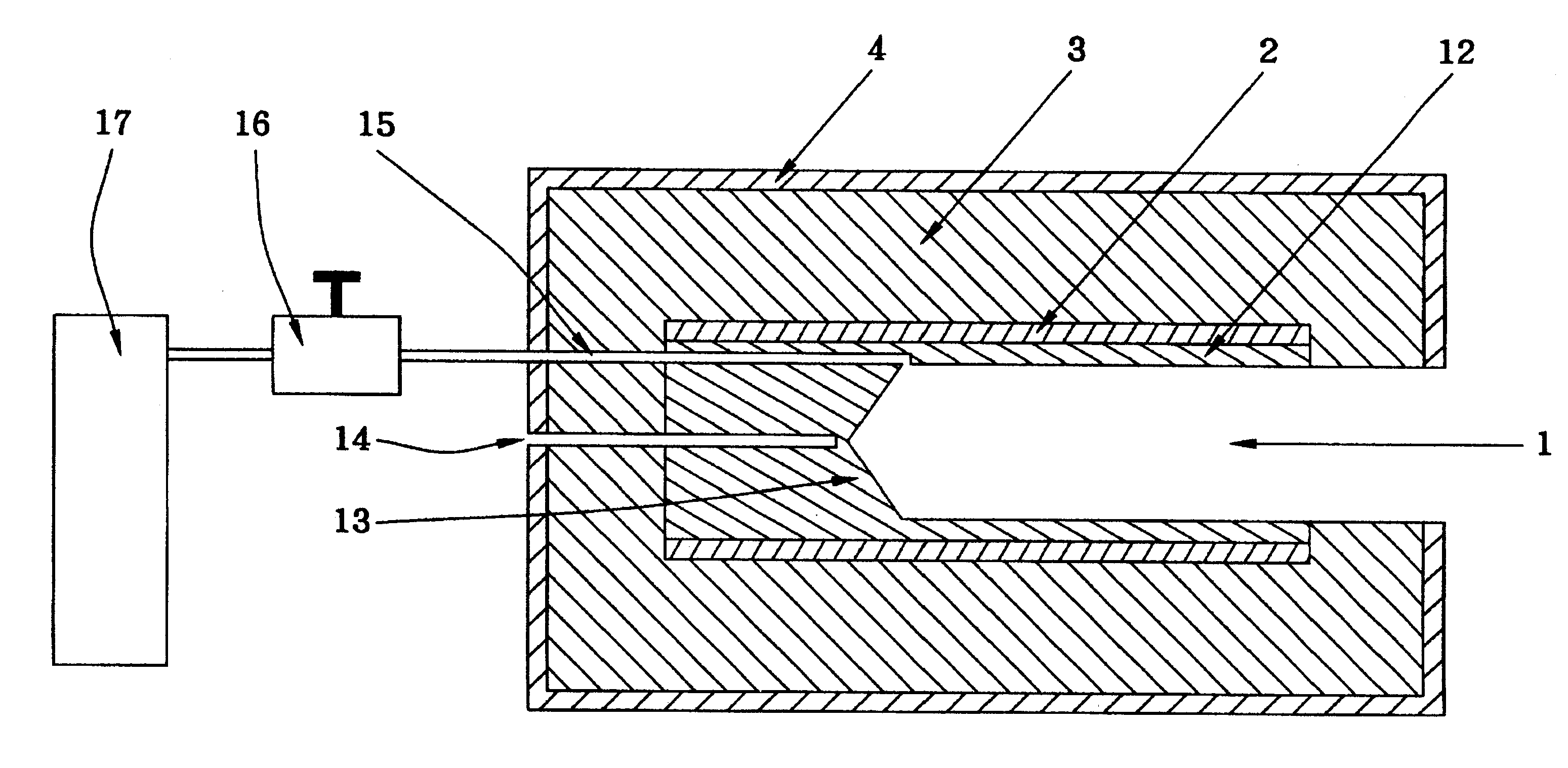

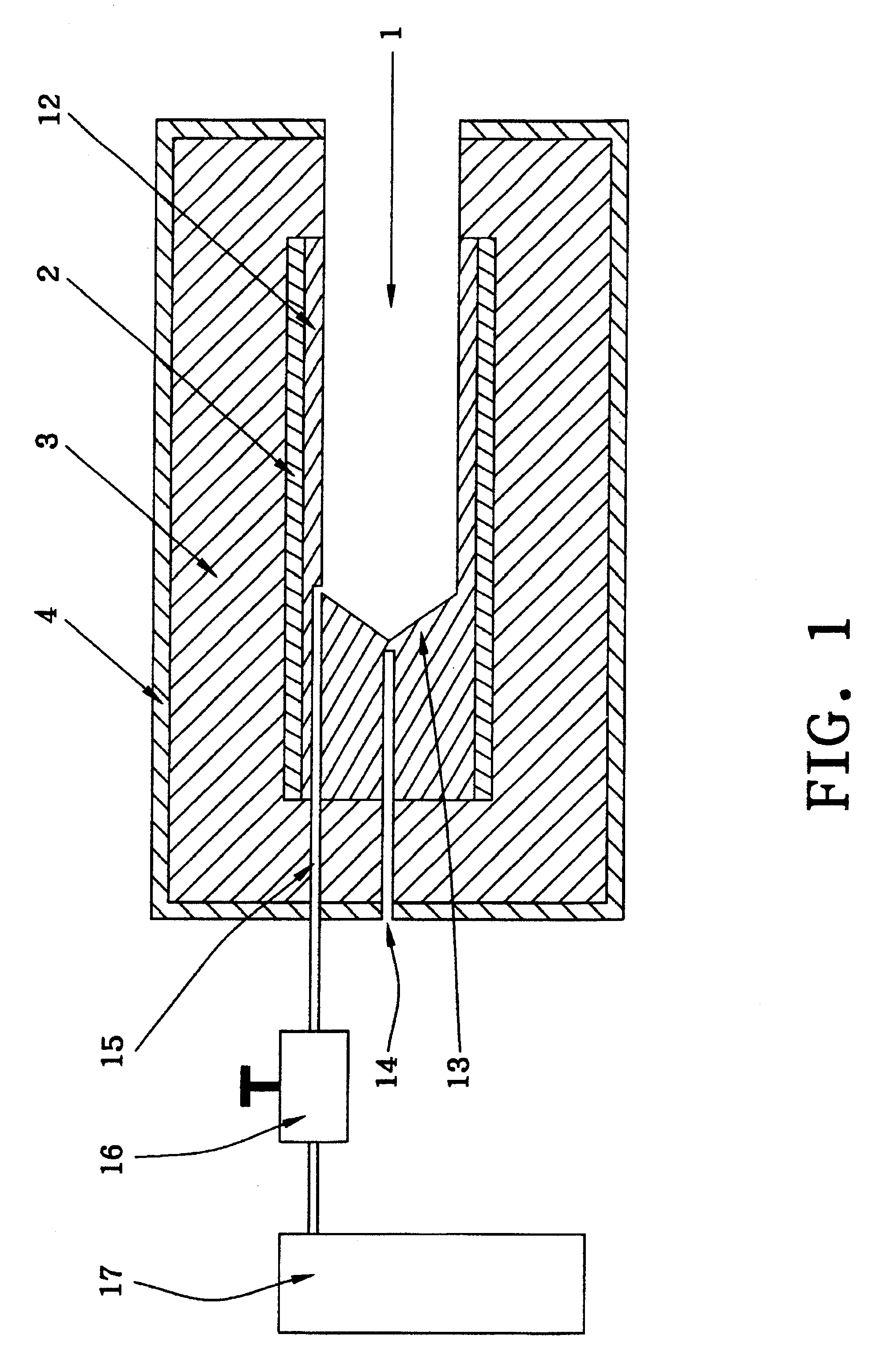

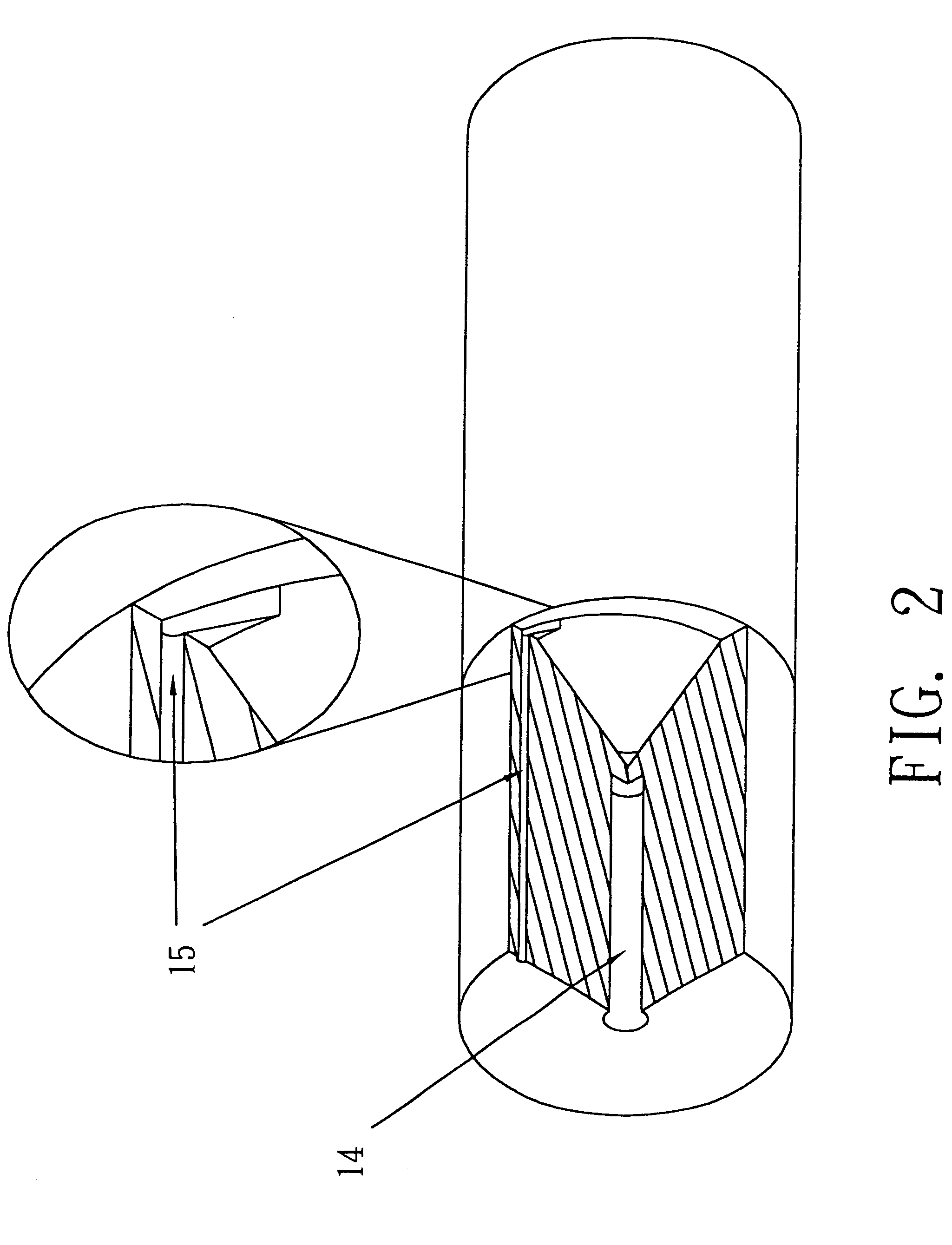

Inline degassing apparatus

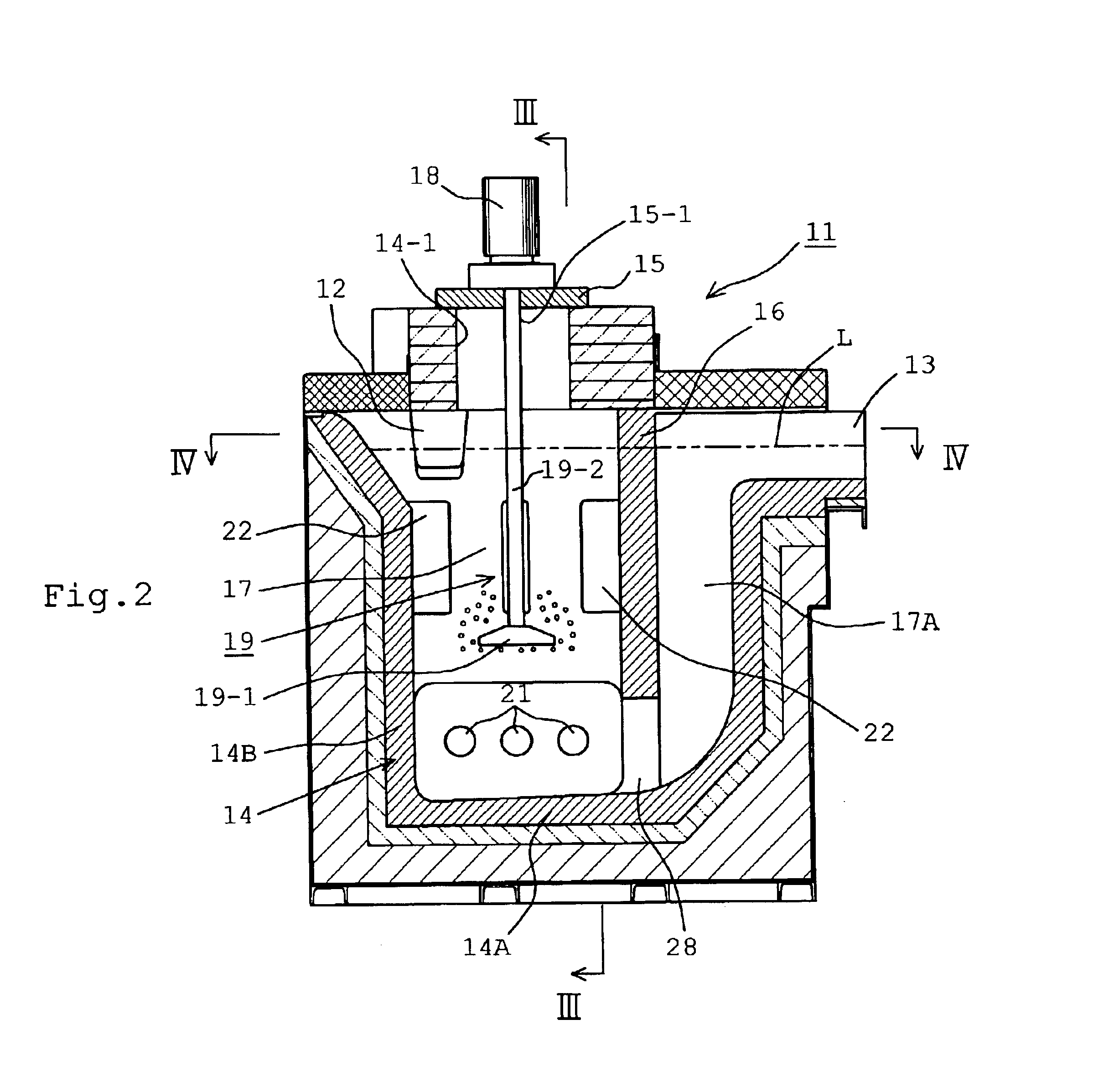

InactiveUS6887424B2Reduce the amount requiredSmall volumeMelt-holding vesselsMechanical apparatusNon-metallic inclusionsSolid solution

An inline degassing apparatus for removing solid solution gases as well as nonmetallic inclusions from molten metal in a degassing container, to which the molten metal is continuously introduced for degassing operation and from which the degassed molten metal is continuously removed. A rotary diffusing device is arranged in the degassing container for generating bubbles of inert gas diffused into the molten metal, thereby entrapping solid solution gases as well as nonmetallic inclusions into the bubbles, which are then floated and separated. Heaters are provided, which extend, in a cantilever fashion, from a side wall of container at a position adjacent the bottom wall of the container substantially parallel to the bottom wall.

Owner:PYROTEK JAPAN +1

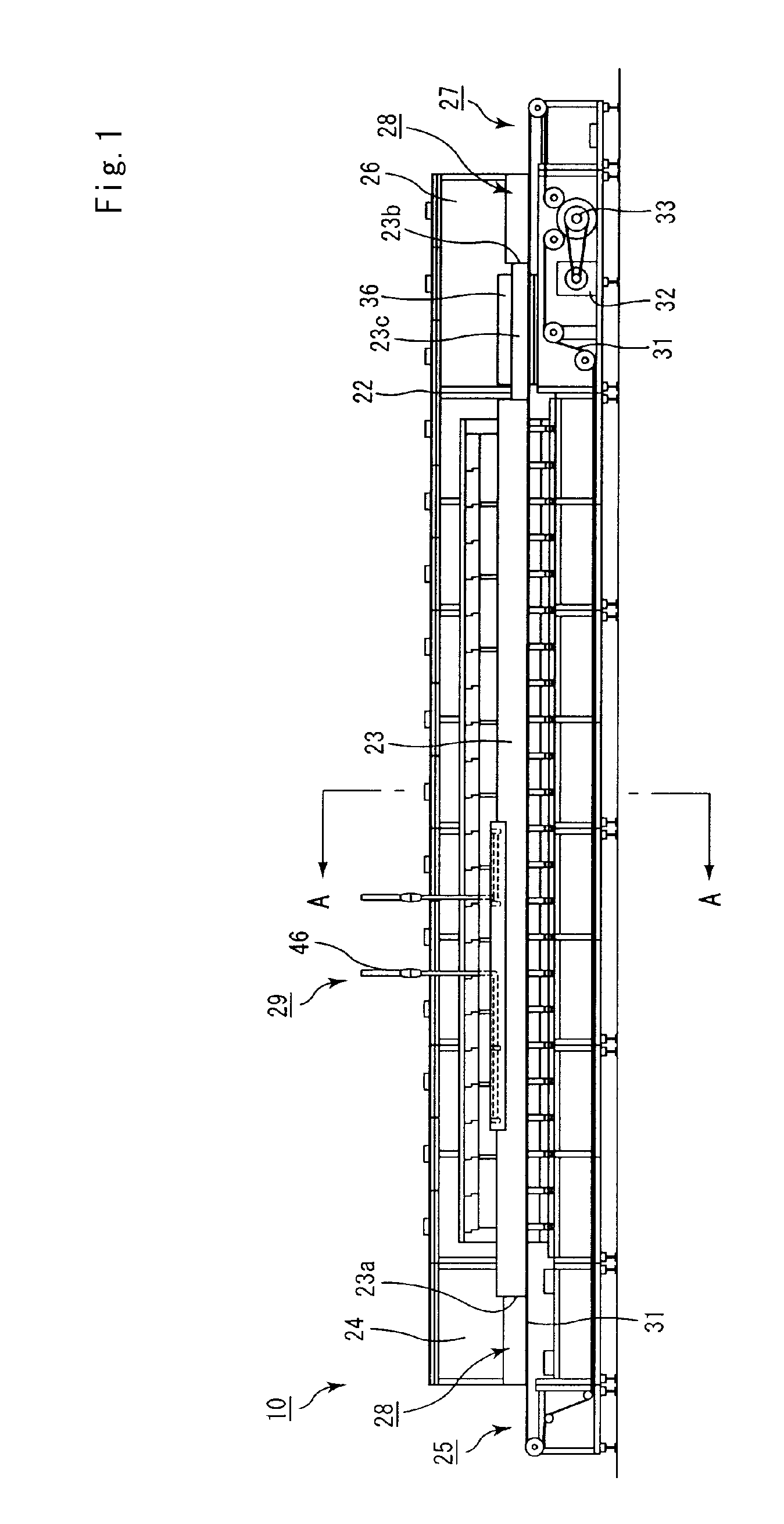

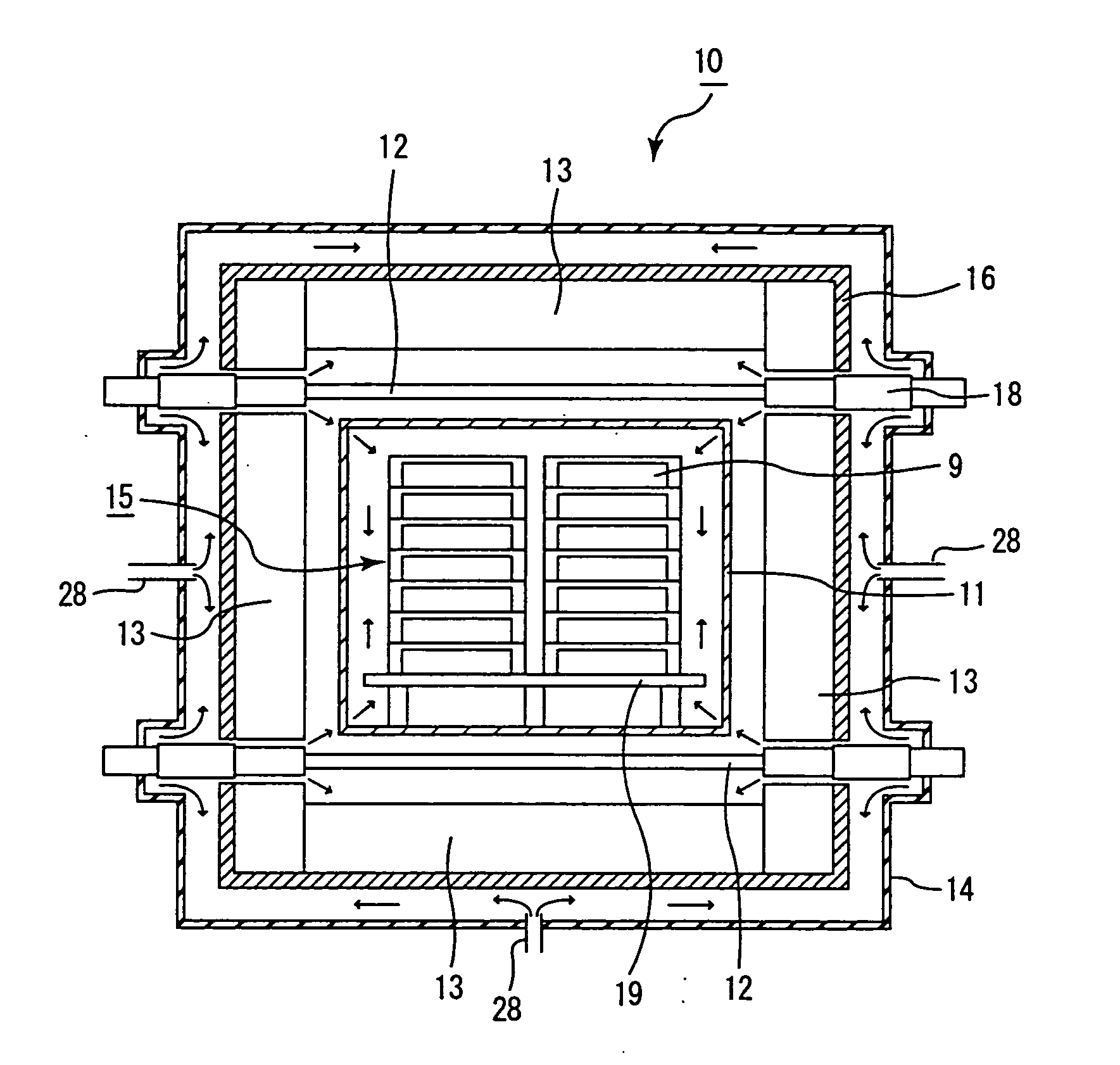

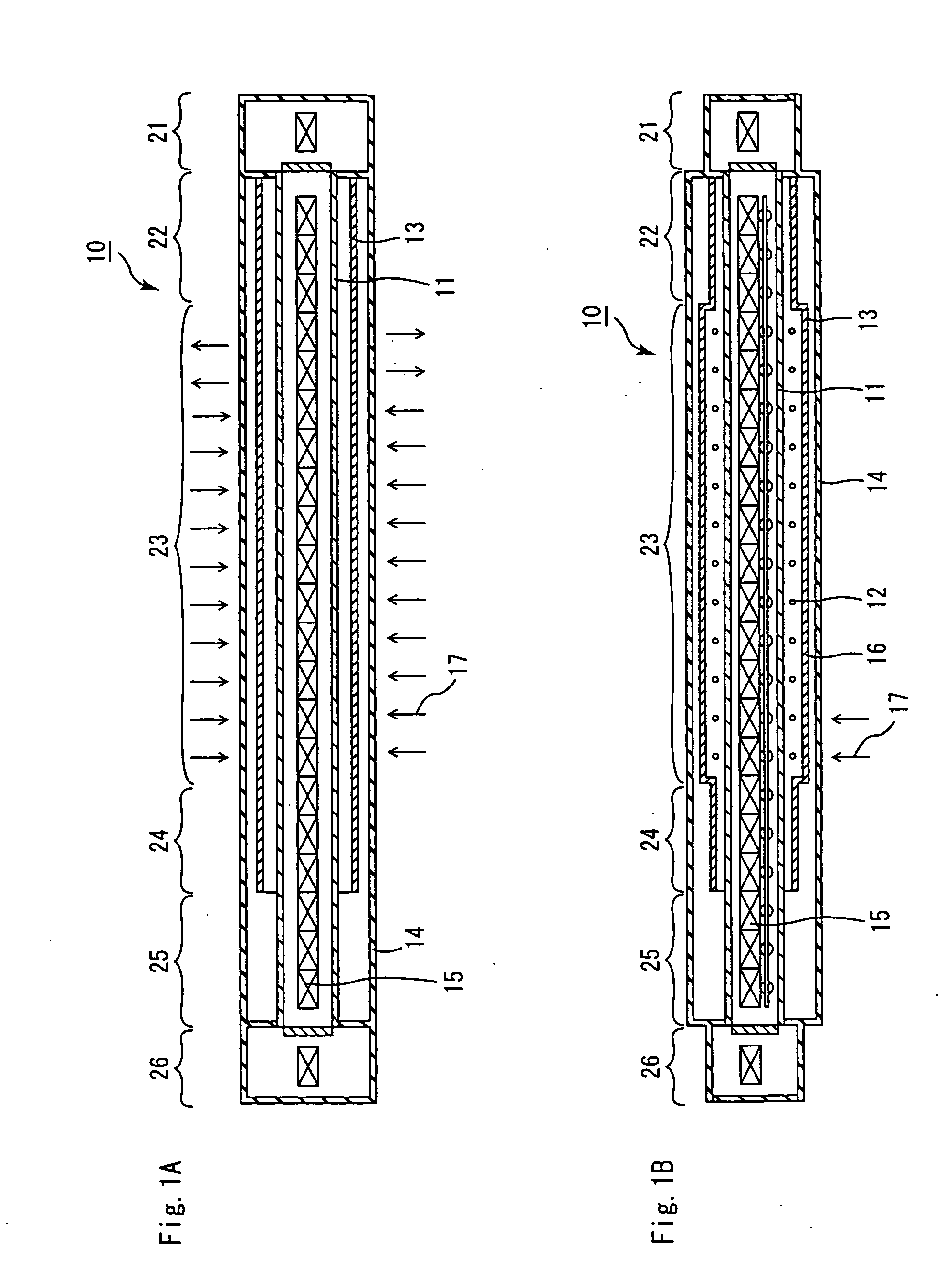

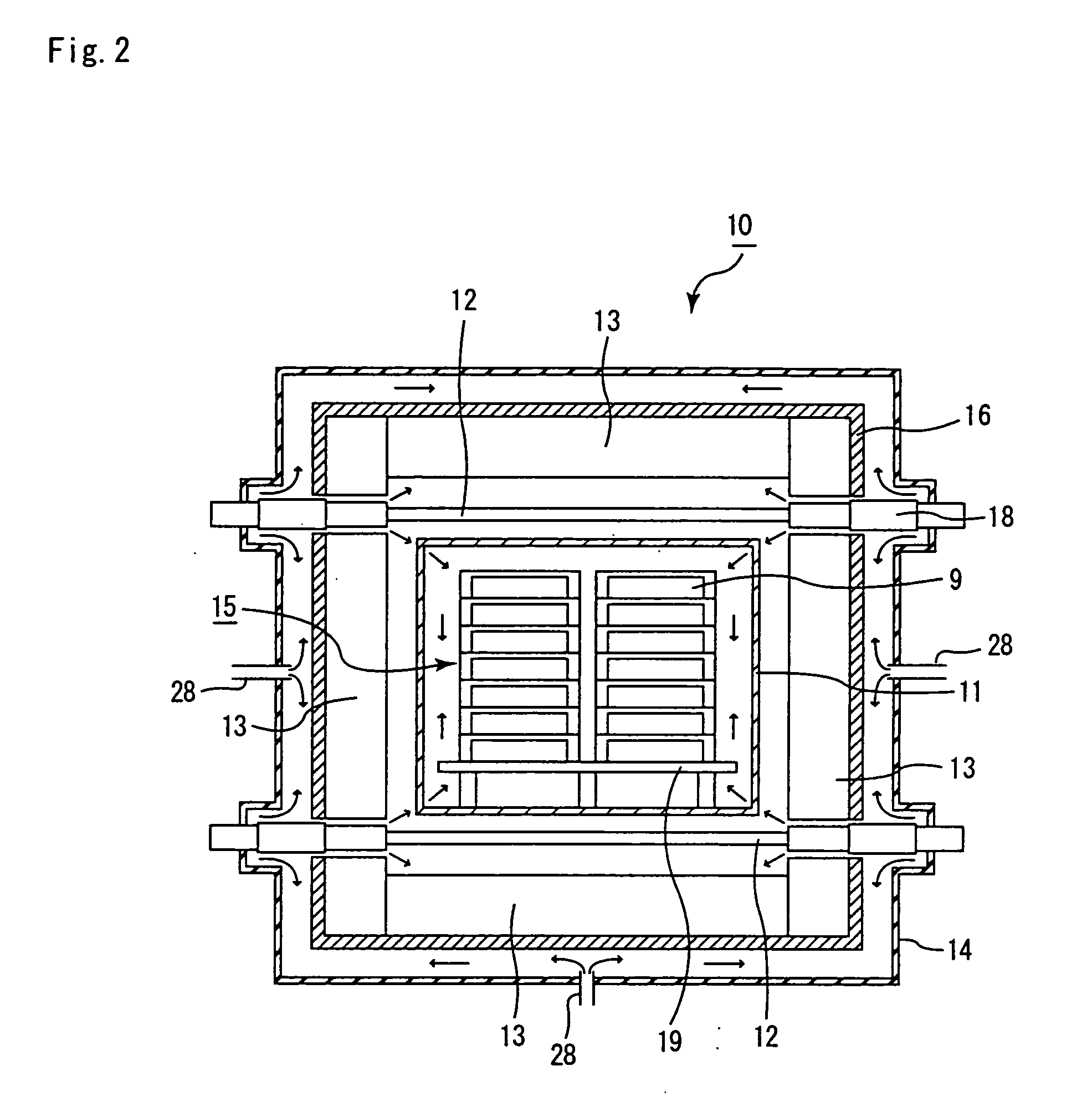

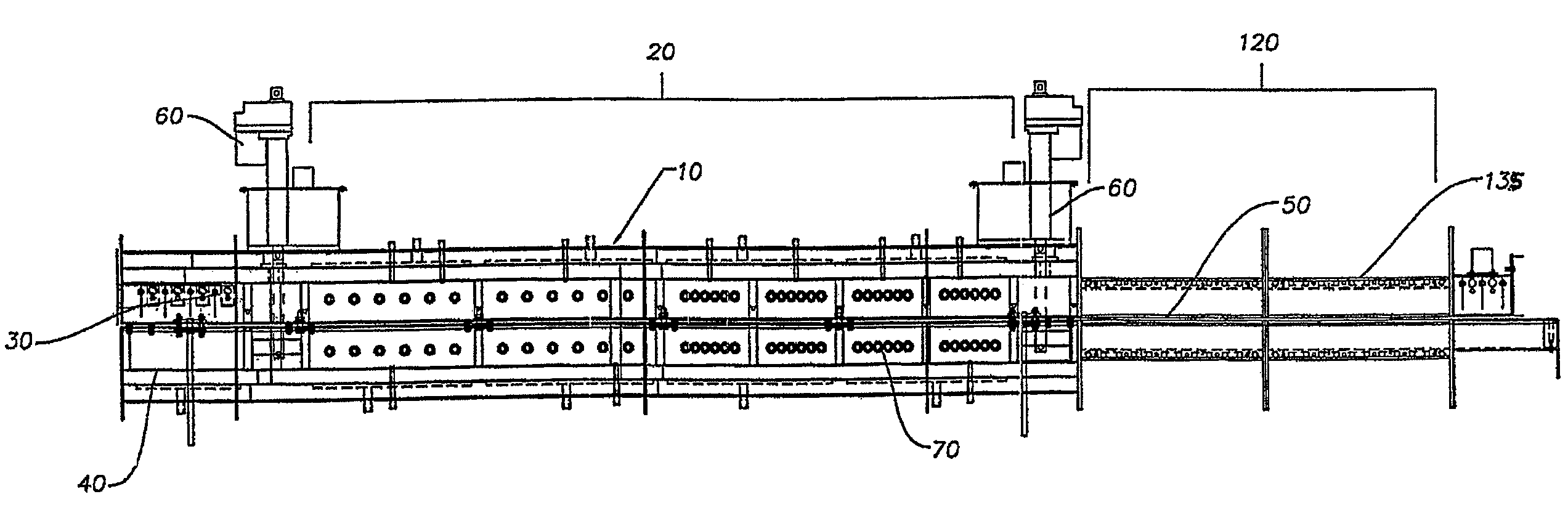

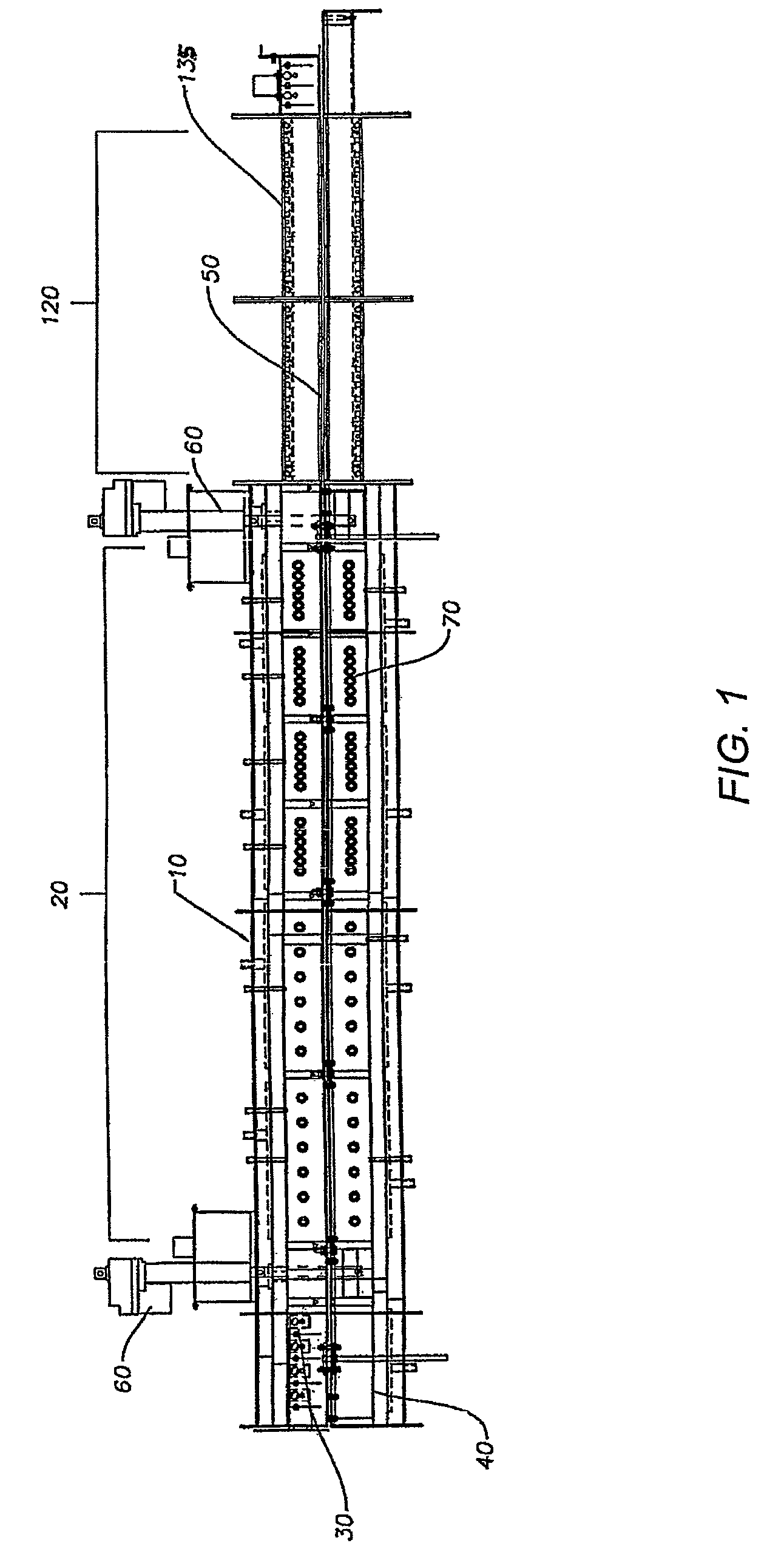

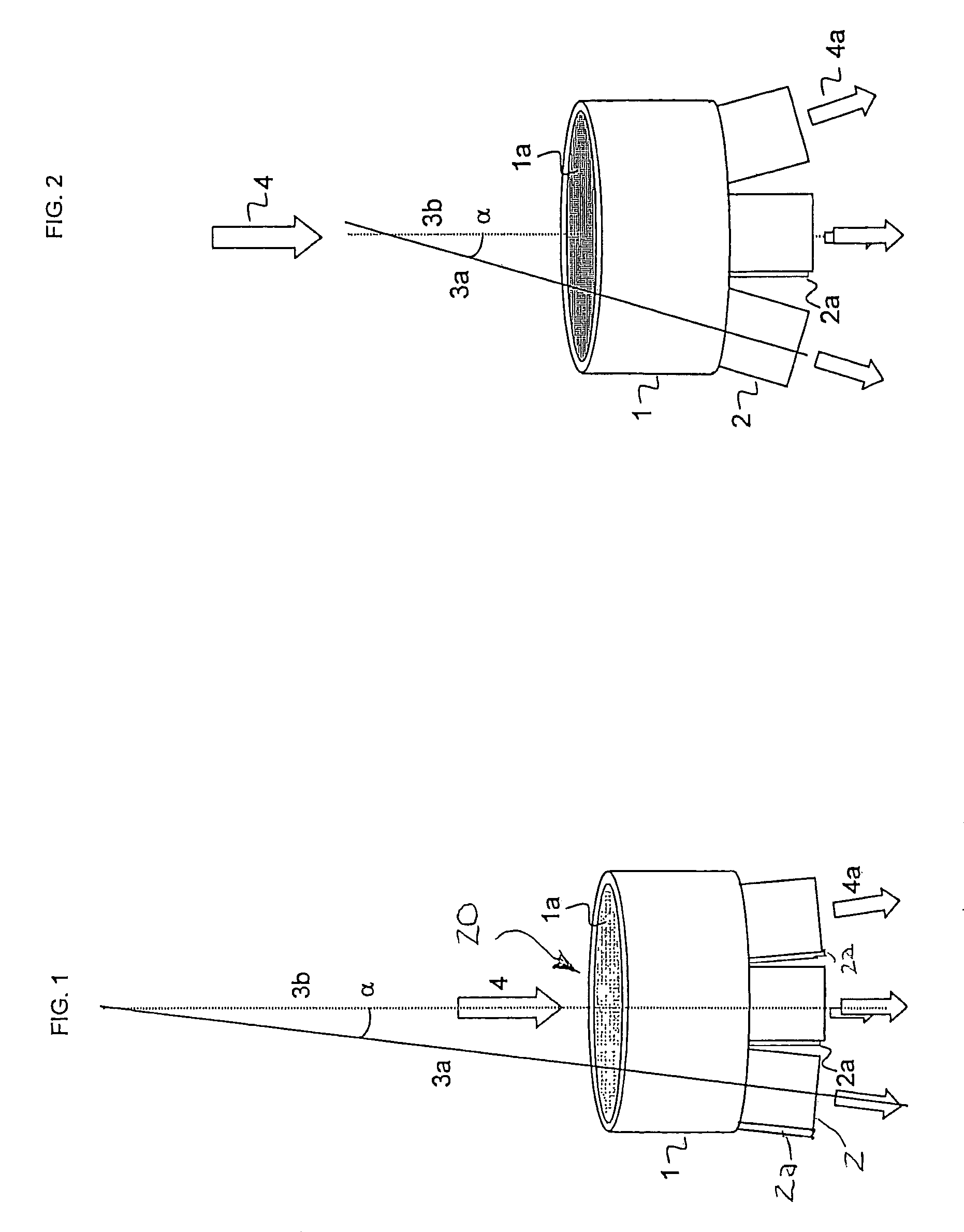

Continuous firing furnace, manufacturing method of porous ceramic member using the same, porous ceramic member, and ceramic honeycomb filter

InactiveUS20060029897A1Ensuring spaceMaintainance of heating chambersCharge manipulationMetallurgyPorous ceramics

A continuous firing furnace of the present invention comprises: a muffle formed into a cylindrical shape so as to ensure a predetermined space; a plurality of heat generators placed at the peripheral direction from the muffle; and a heat insulating layer formed in a manner so as to enclose said muffle and said heat generators therein, said continuous firing furnace being configured such that a formed body to be fired, which is transported from an inlet side, passes through the inside of said muffle at a predetermined speed in an inert gas atmosphere and, then, is discharged from an outlet so that said formed body is fired, wherein said inert gas flows through: a space between said muffle and said heat insulating layer; and a space inside the muffle, in sequence.

Owner:IBIDEN CO LTD

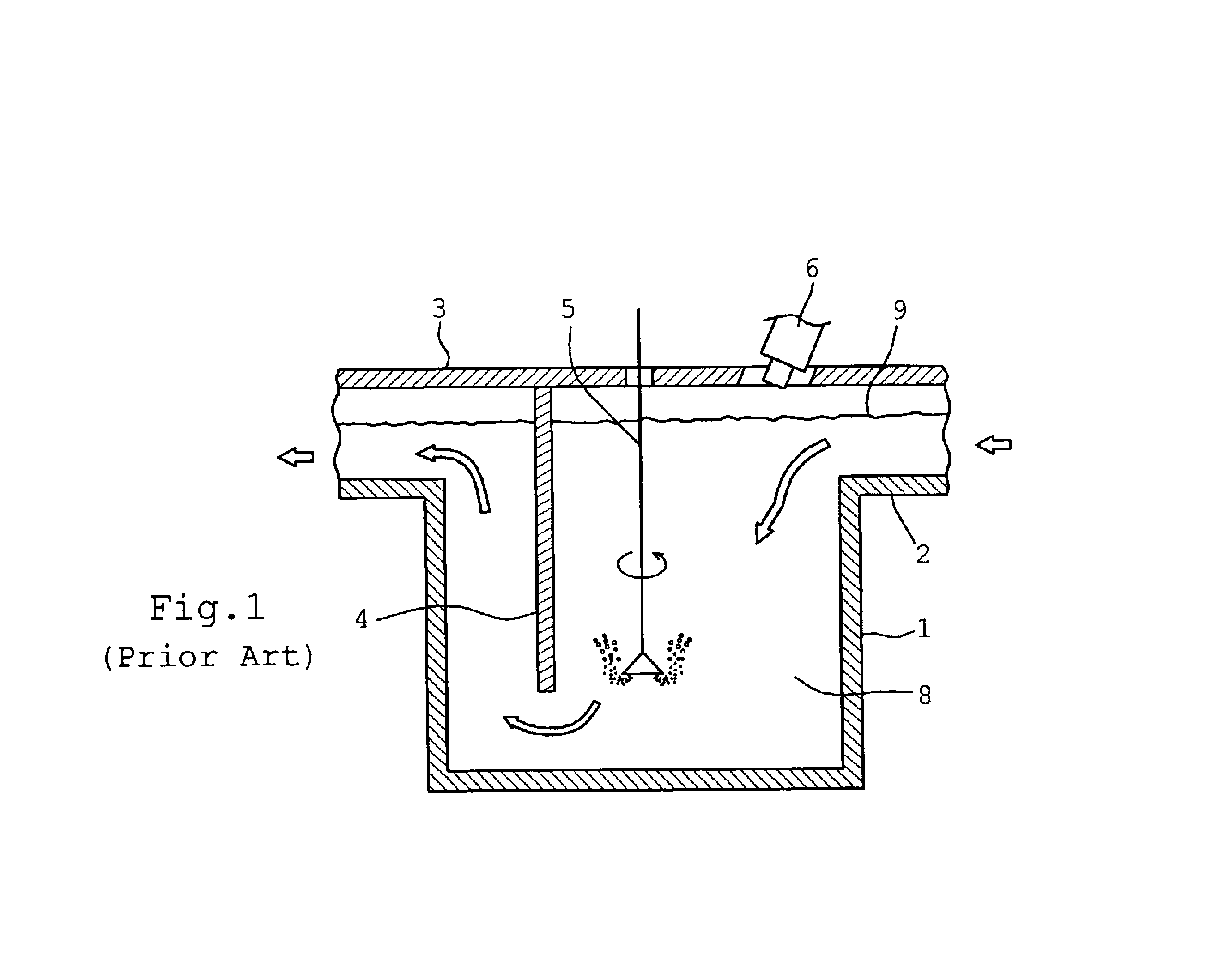

Method of retrofitting a furnace to provide oxygen enrichment

An oxygen enrichment system is provided which uses the existing air / fuel burners of a regenerative furnace to distribute additional oxygen to the burners for increased efficiency, and reduced nitrous oxide emissions. The centrally positioned cooling air lances in the burners of a regenerative furnace are modified to deliver oxygen when the burners are firing for oxygen enrichment. During the burmer firing cycle, oxygen is delivered from an oxygen supply through the oxygen lance to provide a central oxygen jet. The fuel is delivered concentrically around the oxygen jet. During the non-firing cycle of the burner, cooling air or other cooling fluid is delivered from the cooling air supply through the oxygen jet for cooling the offside of the furnace.

Owner:AIR LIQUIDE AMERICA INC

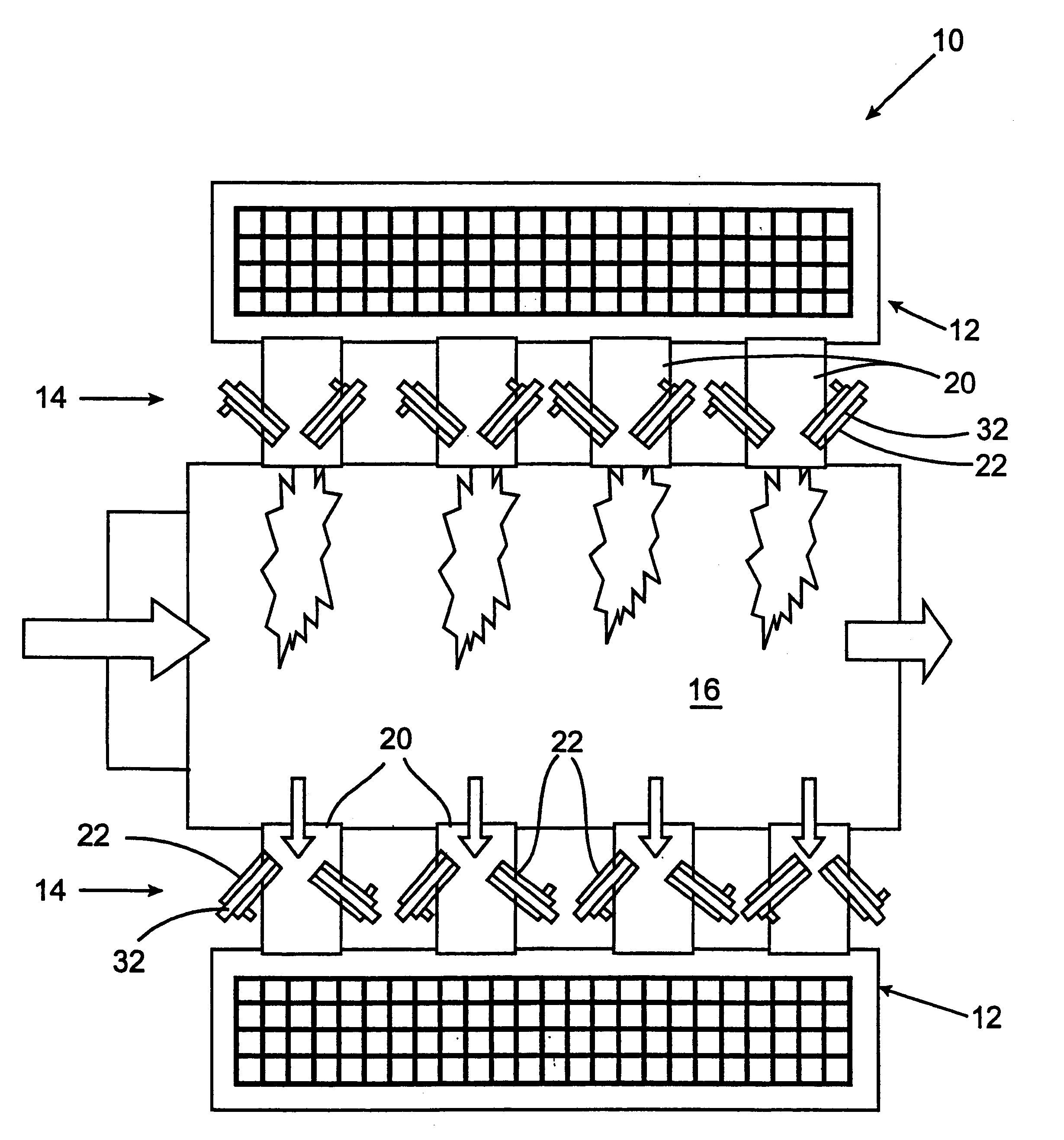

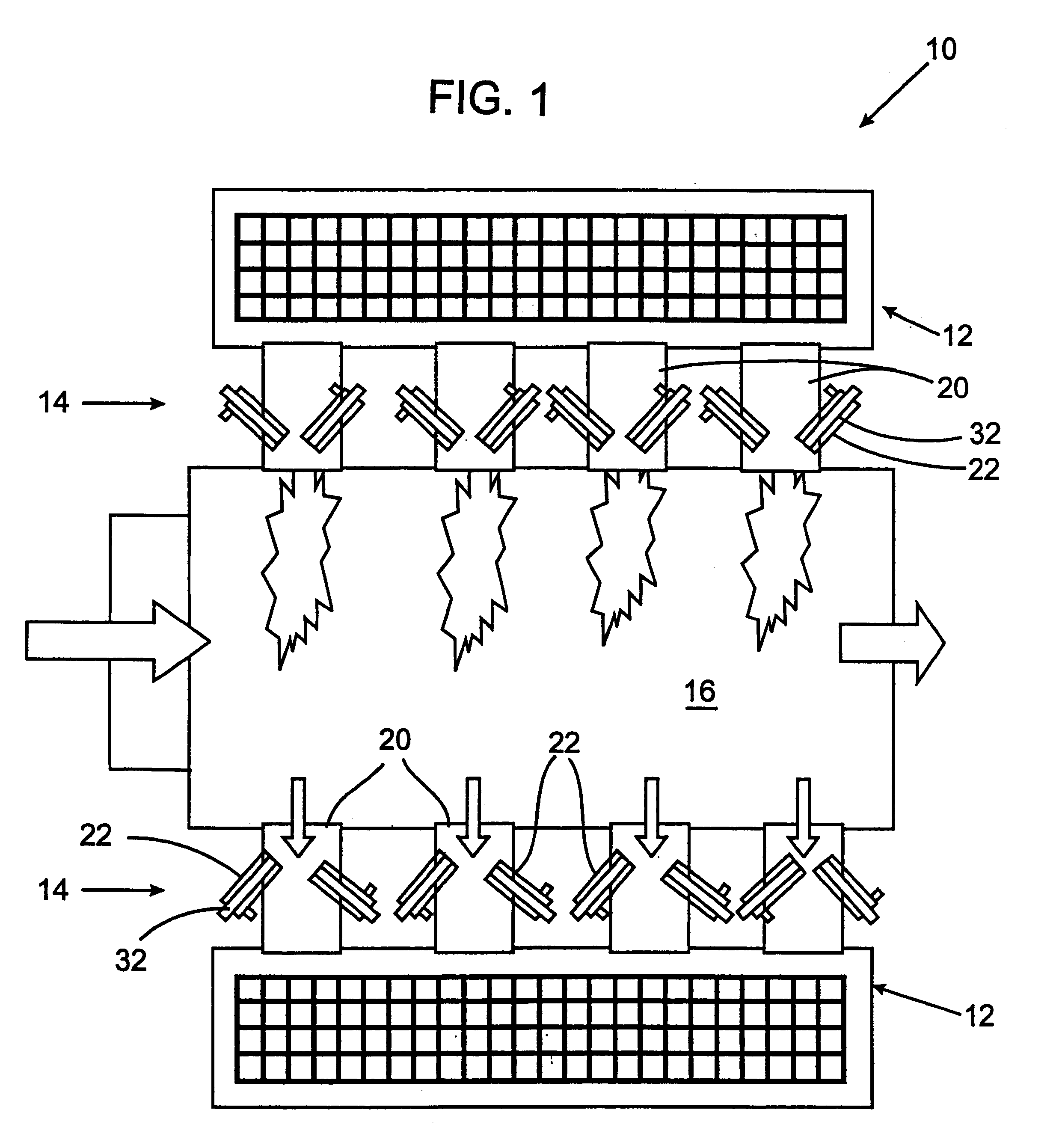

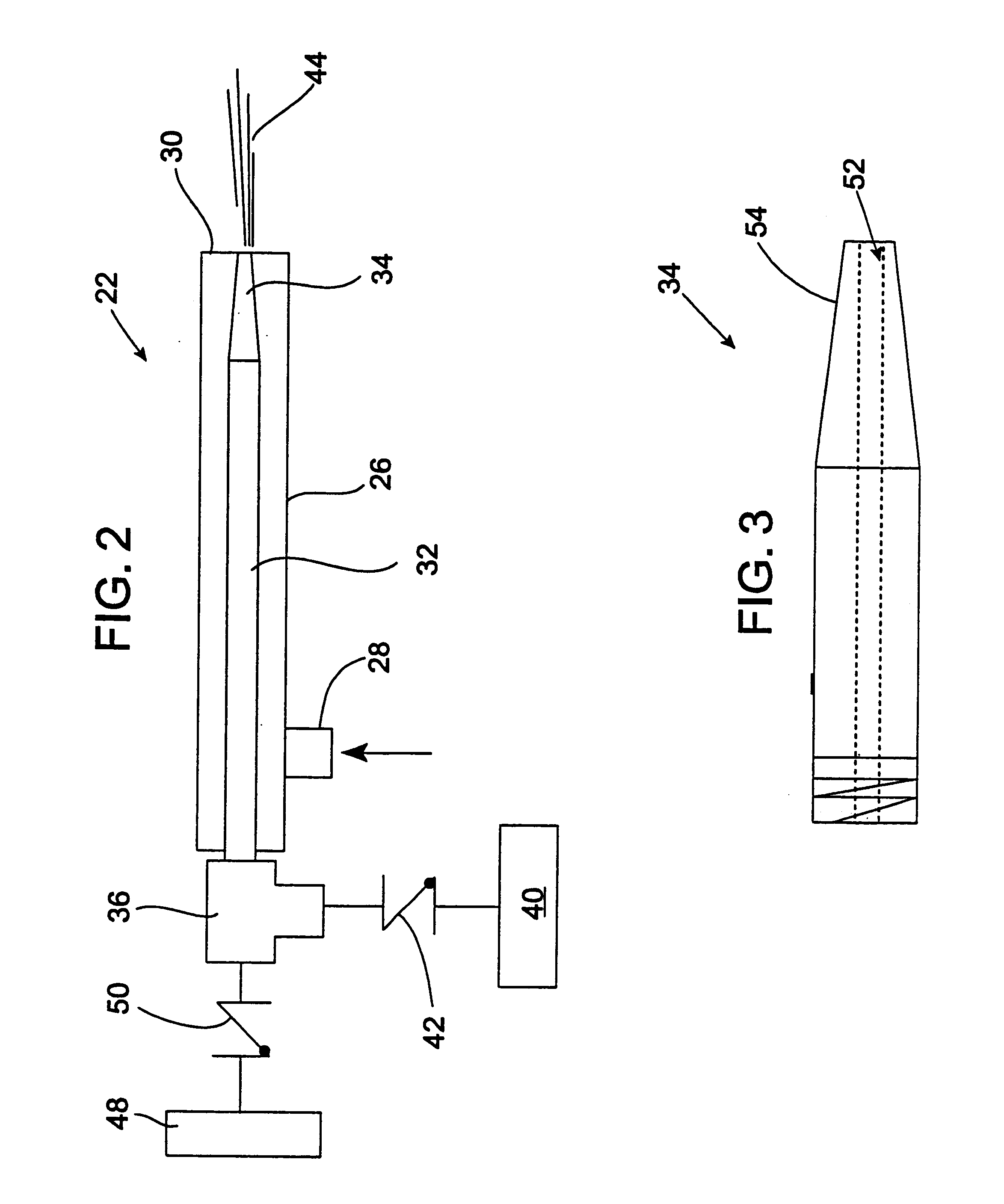

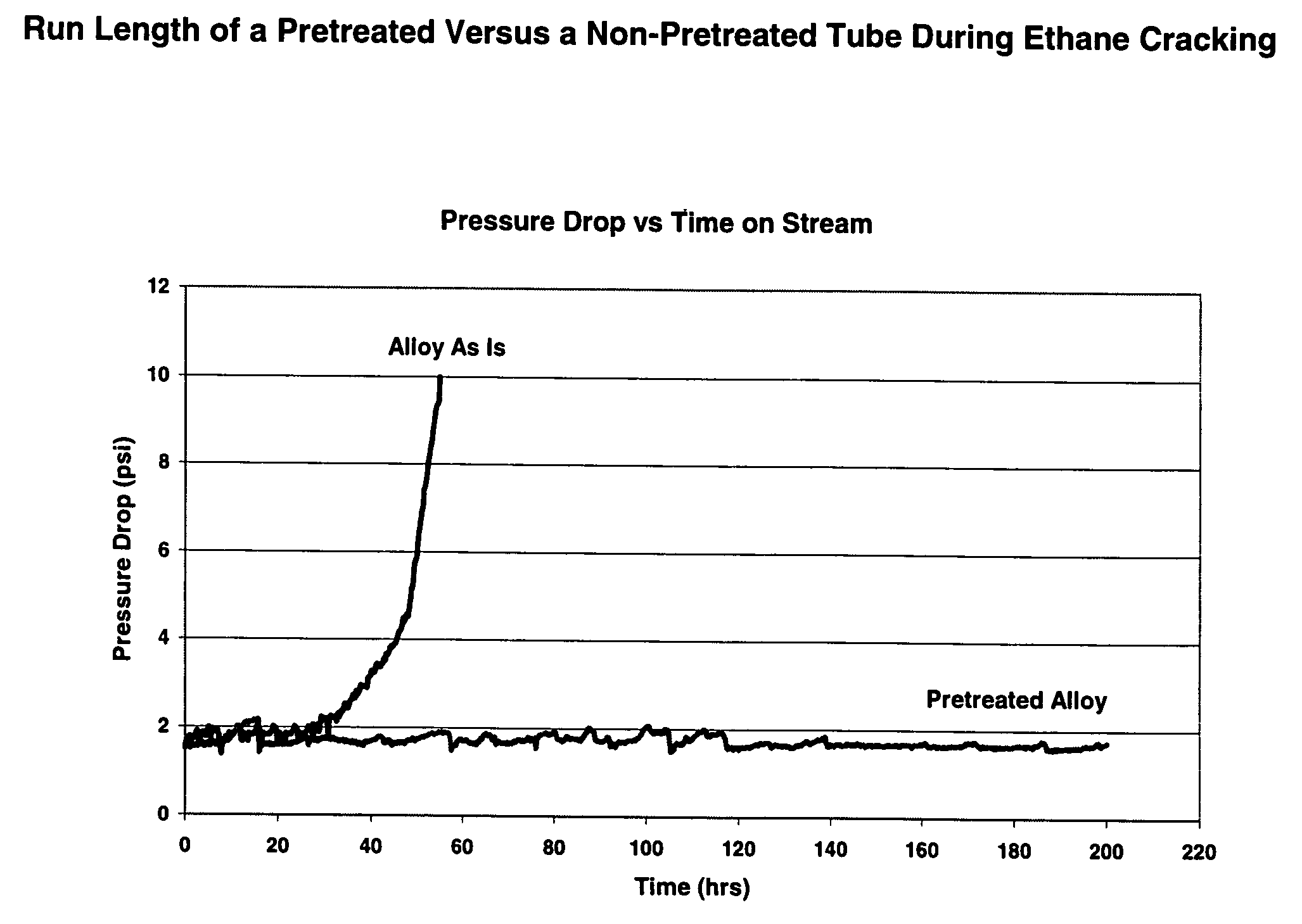

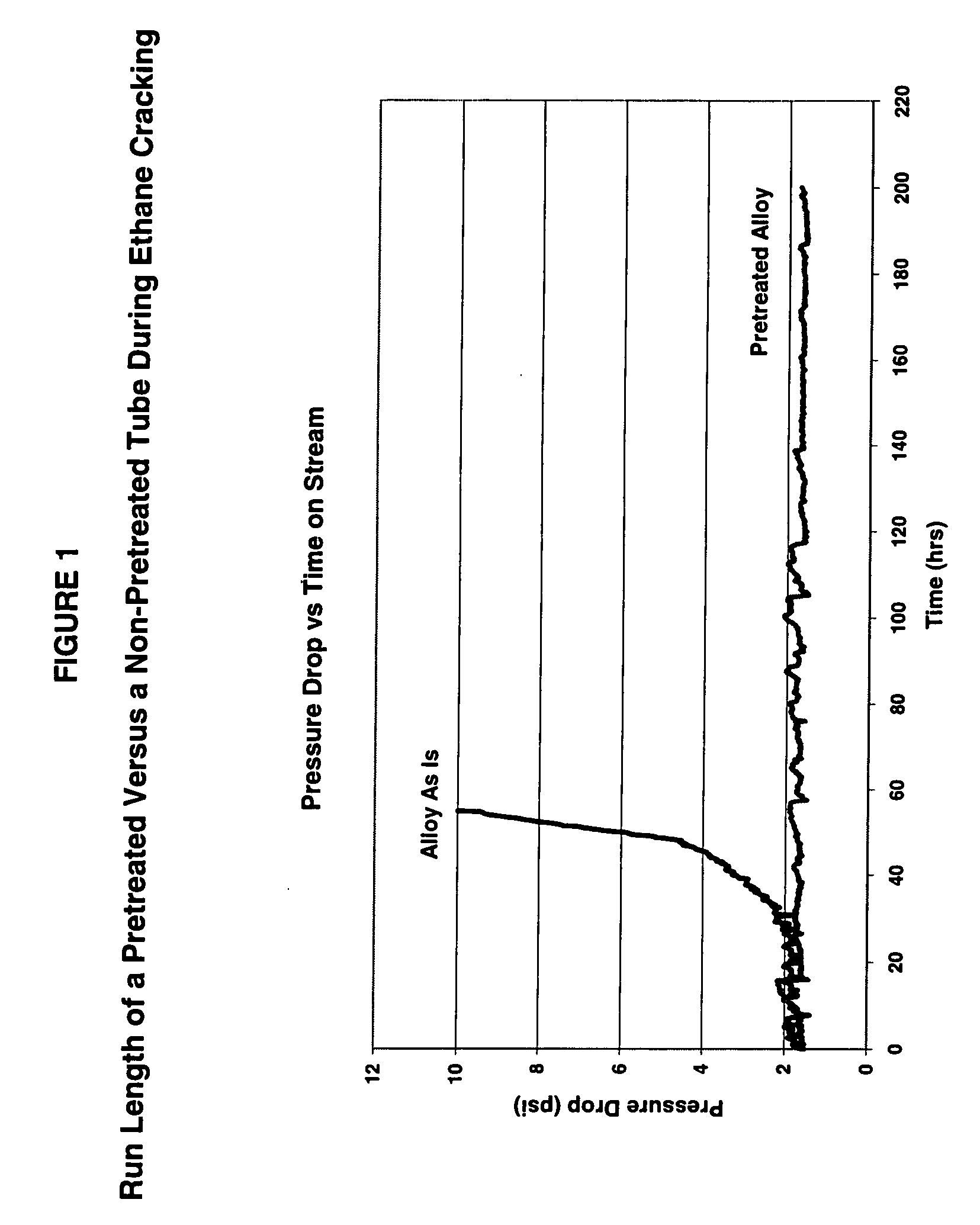

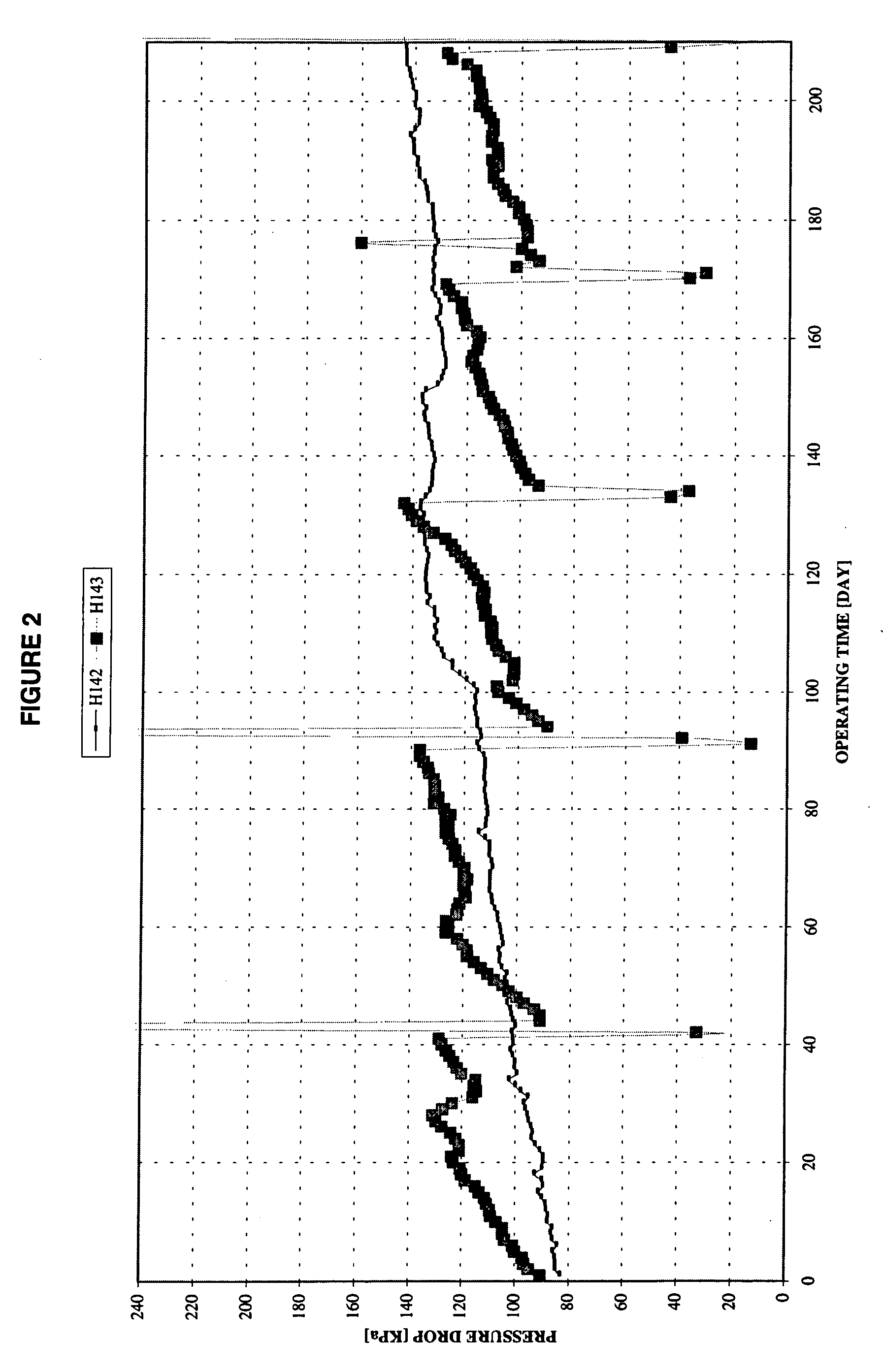

Thermal cracking process using tubes, pipes, and coils made of novel stainless steel matrix

A thermal cracking process using tubes, pipes, and coils made of.An outermost surface covering not less than 55% of stainless steel, said surface having a thickness from 0.1 to 15 microns and being a spinel of the formula MnxCr3-xO4 wherein x is from 0.5 to 2 is not prone to coking and is suitable for hydrocarbyl reactions such as furnace tubes for cracking.

Owner:NOVA CHEM (INT) SA

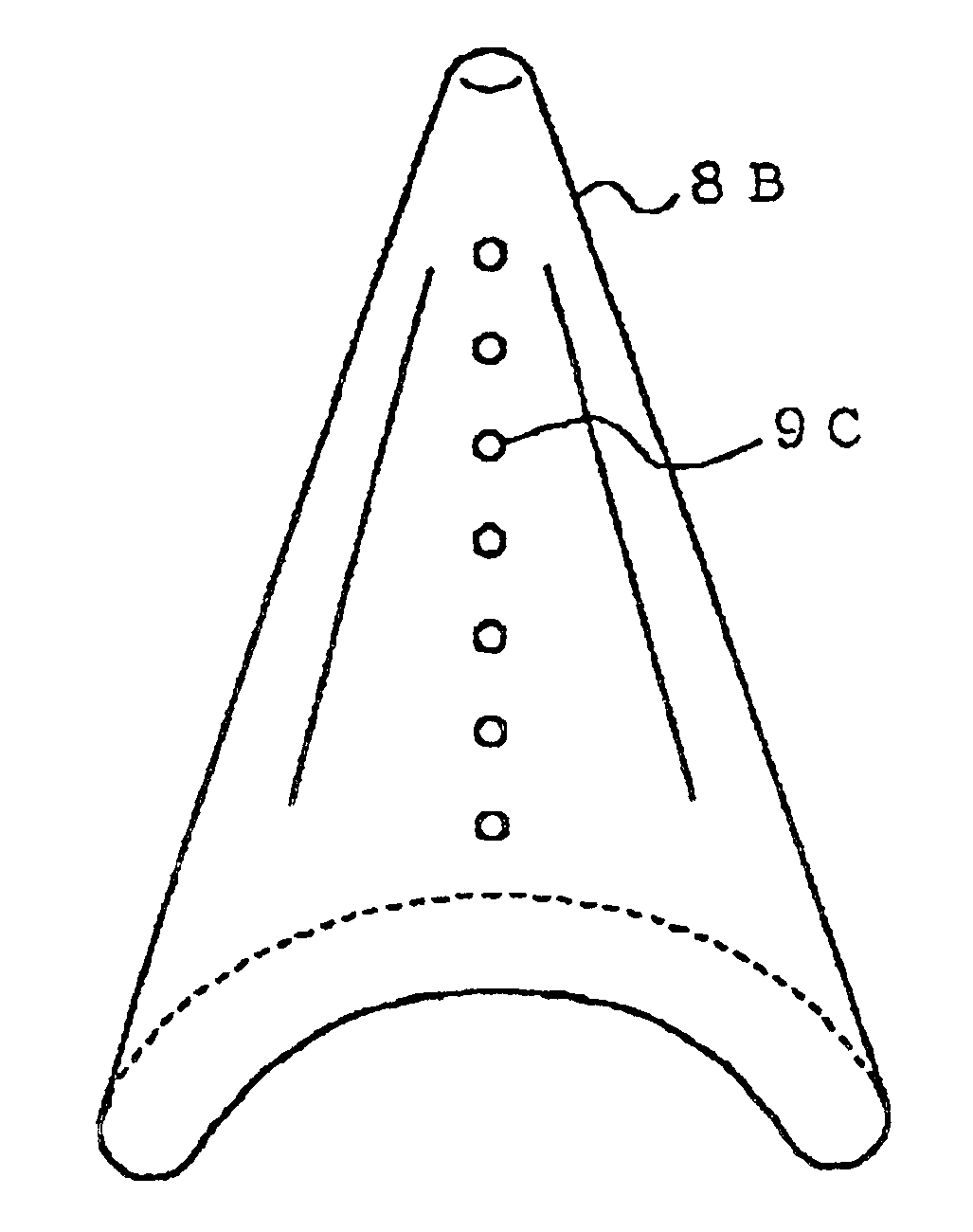

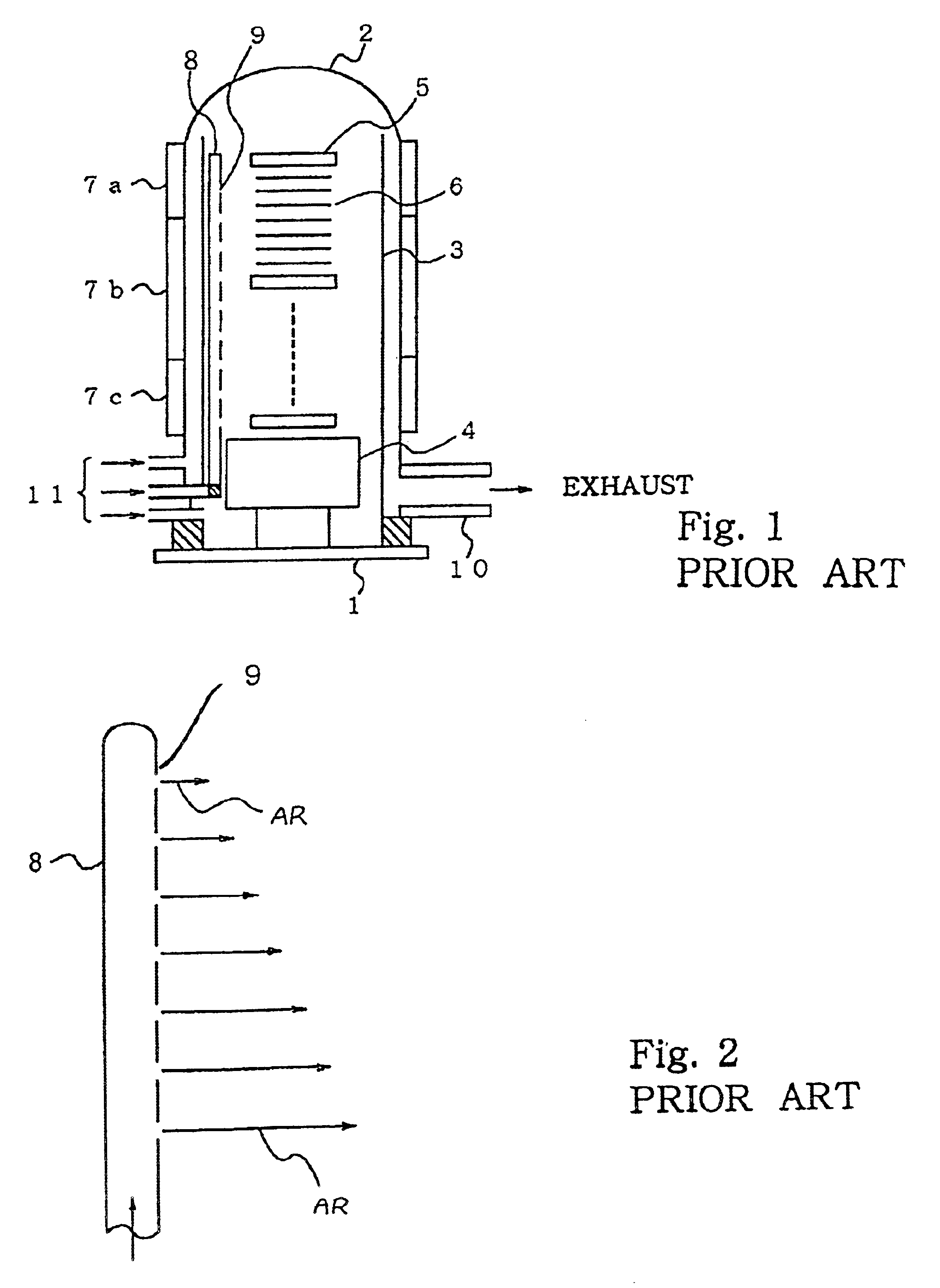

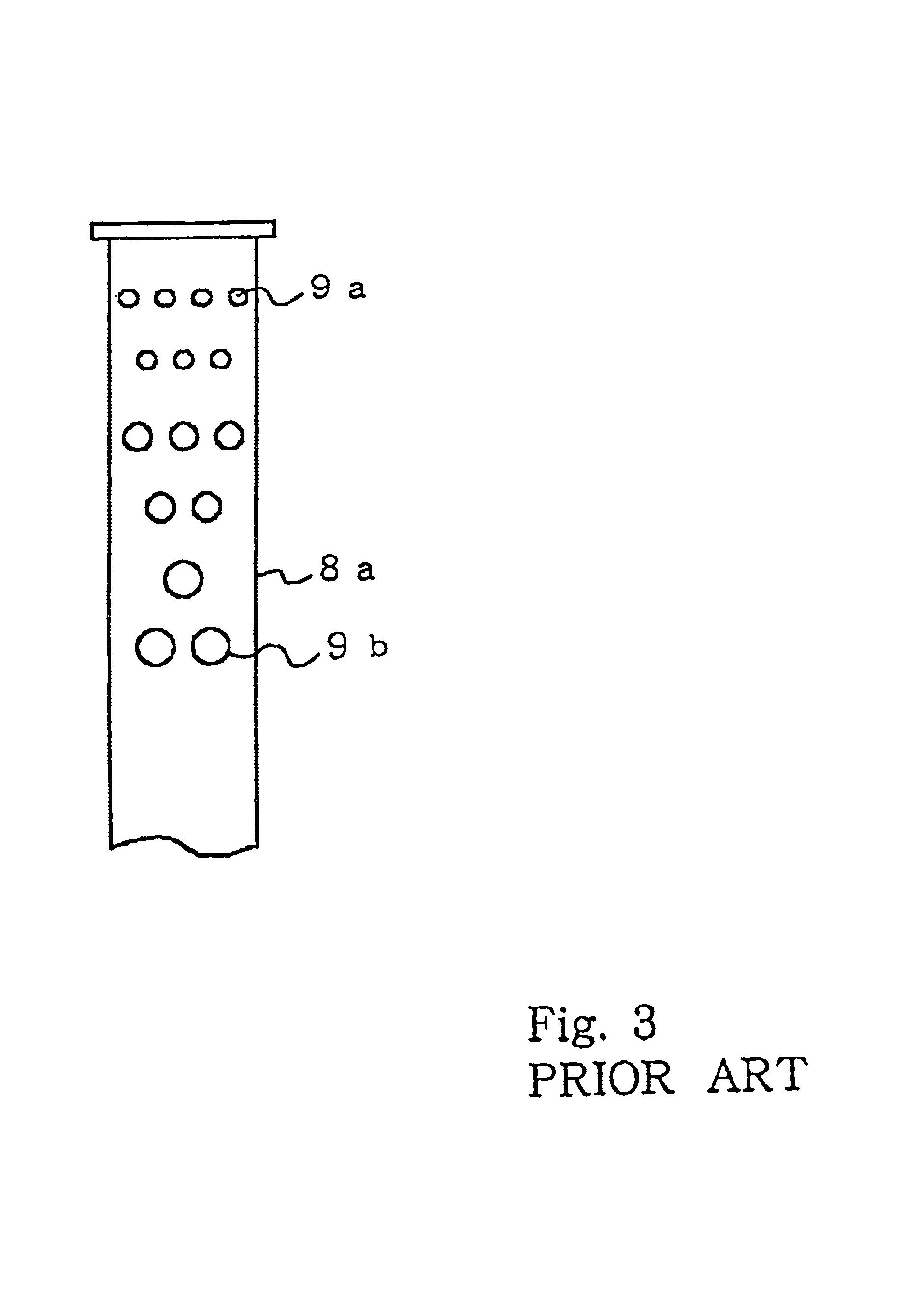

Air-tight vessel equipped with gas feeder uniformly supplying gaseous component around plural wafers

A reactor of a chemical vapor deposition system is equipped with a gas feeder for blowing dopant gas to plural semiconductor wafers supported by a wafer boat at intervals, and the gas feeder has a gas passage gradually reduced in cross section and gas outlet holes equal in diameter and arranged along the wafer boat for keeping the doping gas concentration substantially constant around the semiconductor wafers, whereby the dopant is uniformly introduced in material deposited on all the semiconductor wafers.

Owner:NEC ELECTRONICS CORP

Continuous firing furnace, manufacturing method of porous ceramic member using the same, porous ceramic member, and ceramic honeycomb filter

A continuous firing furnace of the present invention comprises: a muffle formed into a cylindrical shape so as to ensure a predetermined space; a plurality of heat generators placed at the peripheral direction from the muffle; and a heat insulating layer formed in a manner so as to enclose said muffle and said heat generators therein, said continuous firing furnace being configured such that a formed body to be fired, which is transported from an inlet side, passes through the inside of said muffle at a predetermined speed in an inert gas atmosphere and, then, is discharged from an outlet so that said formed body is fired, wherein said inert gas flows through: a space between said muffle and said heat insulating layer; and a space inside the muffle, in sequence.

Owner:IBIDEN CO LTD

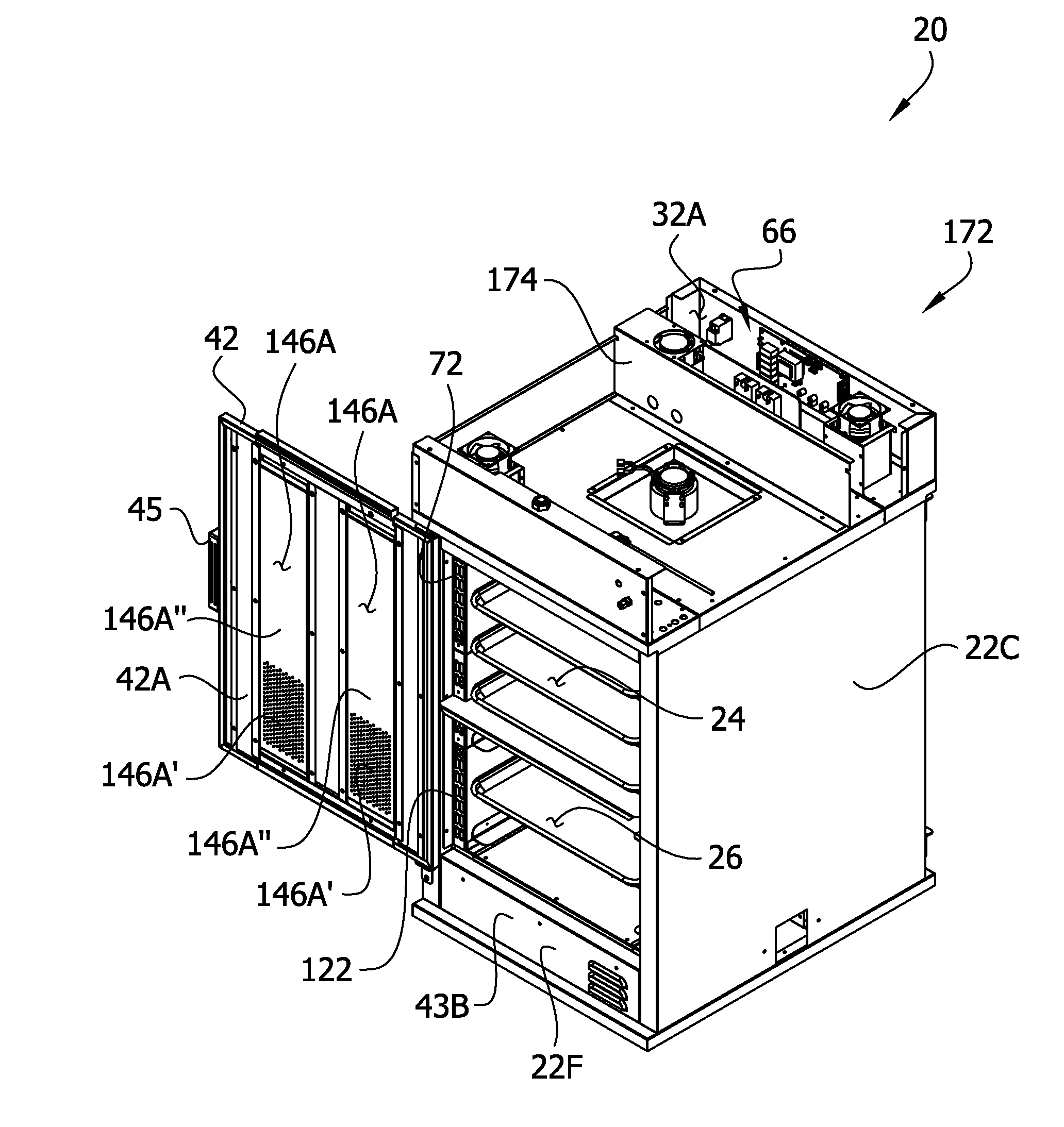

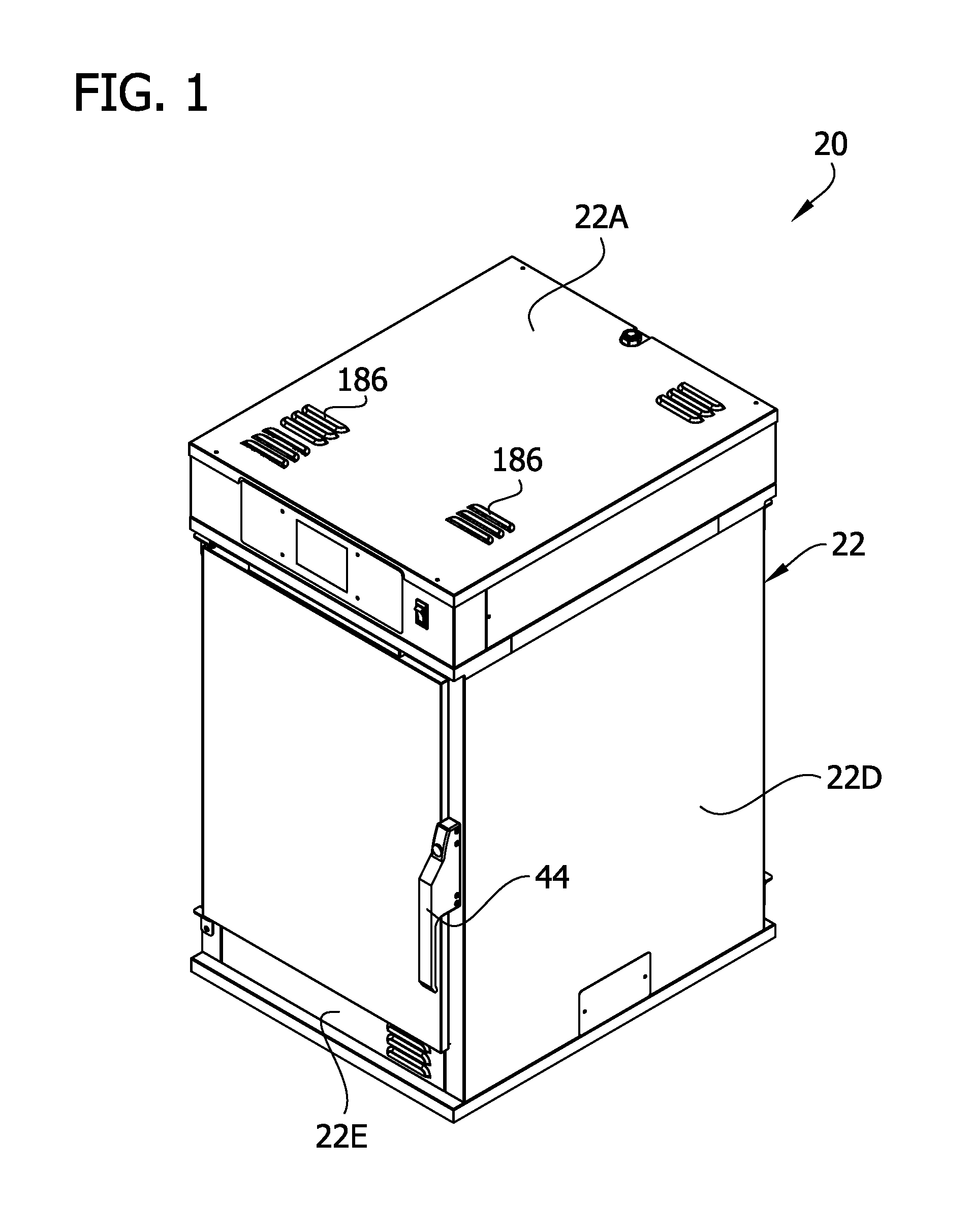

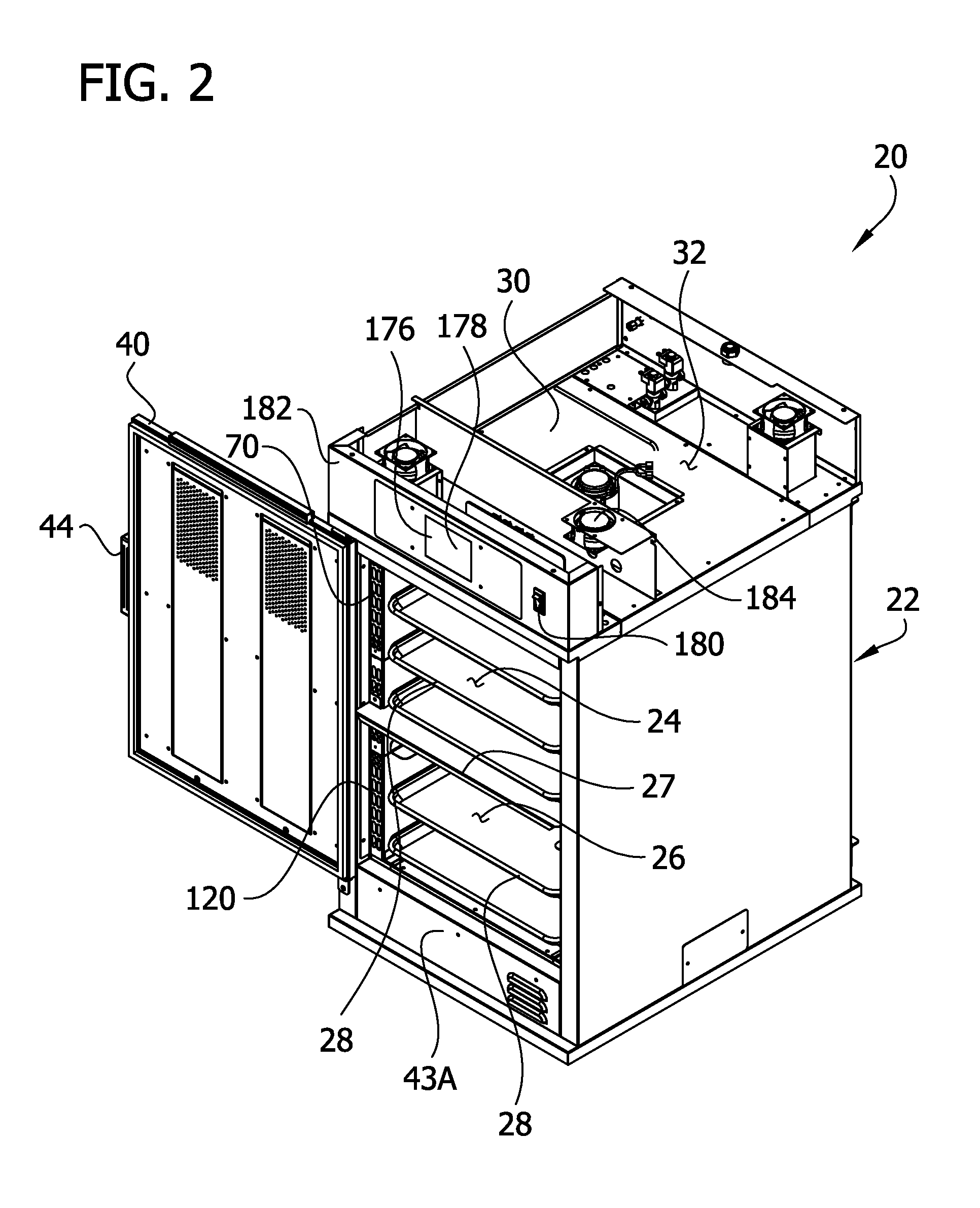

Holding oven

ActiveUS20140083309A1Maintain qualityQuick buildDomestic stoves or rangesOven air-treatment devicesWater vaporLaboratory oven

Methods, ovens, and associated apparatus. Ovens and methods are adapted for maintaining the quality of a pre-cooked food product. Rapid temperature and / or relative humidity restoration may be used. Ovens may include a partition movable to vary sizes of oven cavities. Ovens may include removable interior panels. Humidification mechanisms are adapted for generating water vapor which may be used to maintain the quality of a pre-cooked food product.

Owner:DUKE MANUFACTURING COMPANY

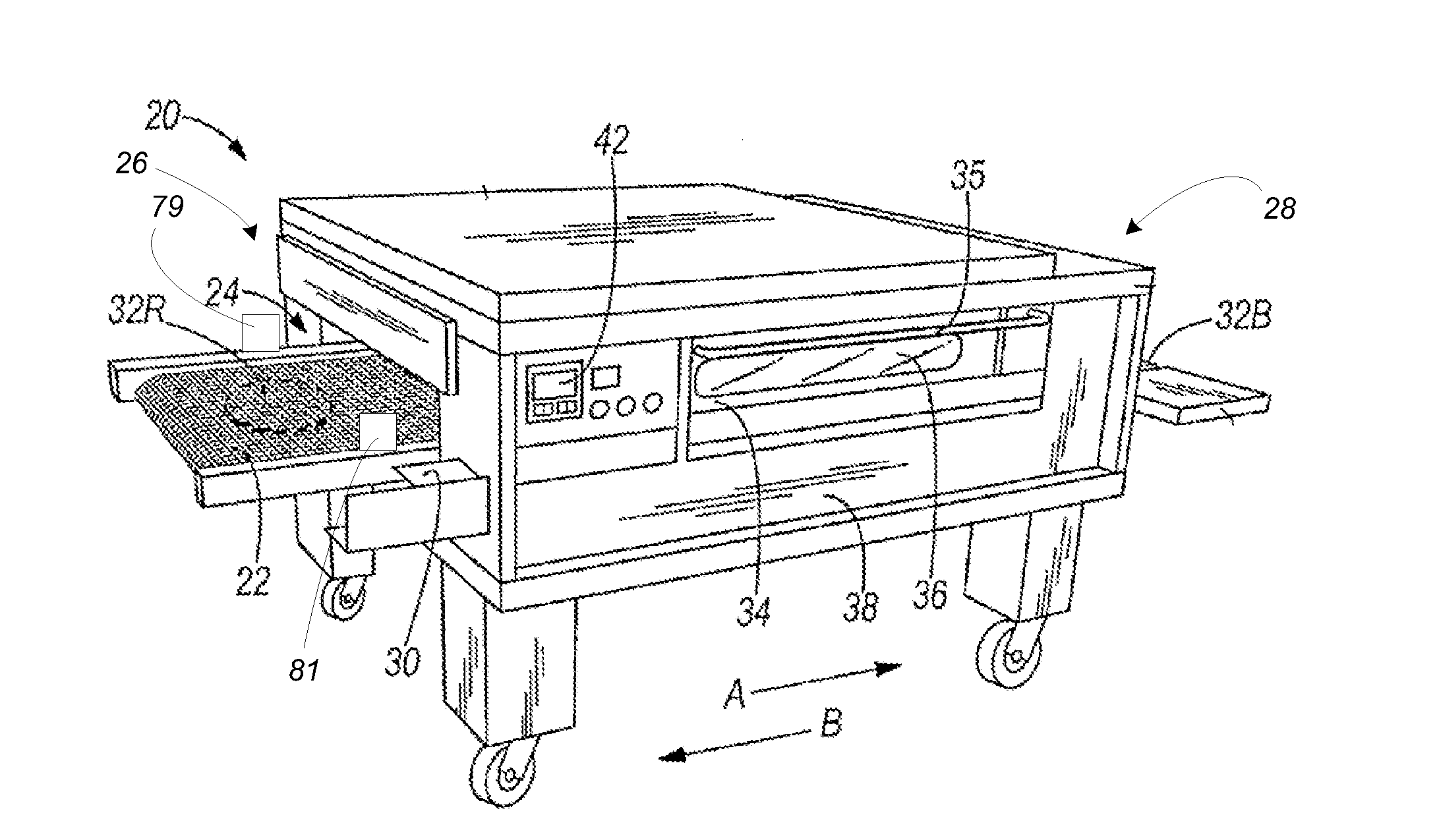

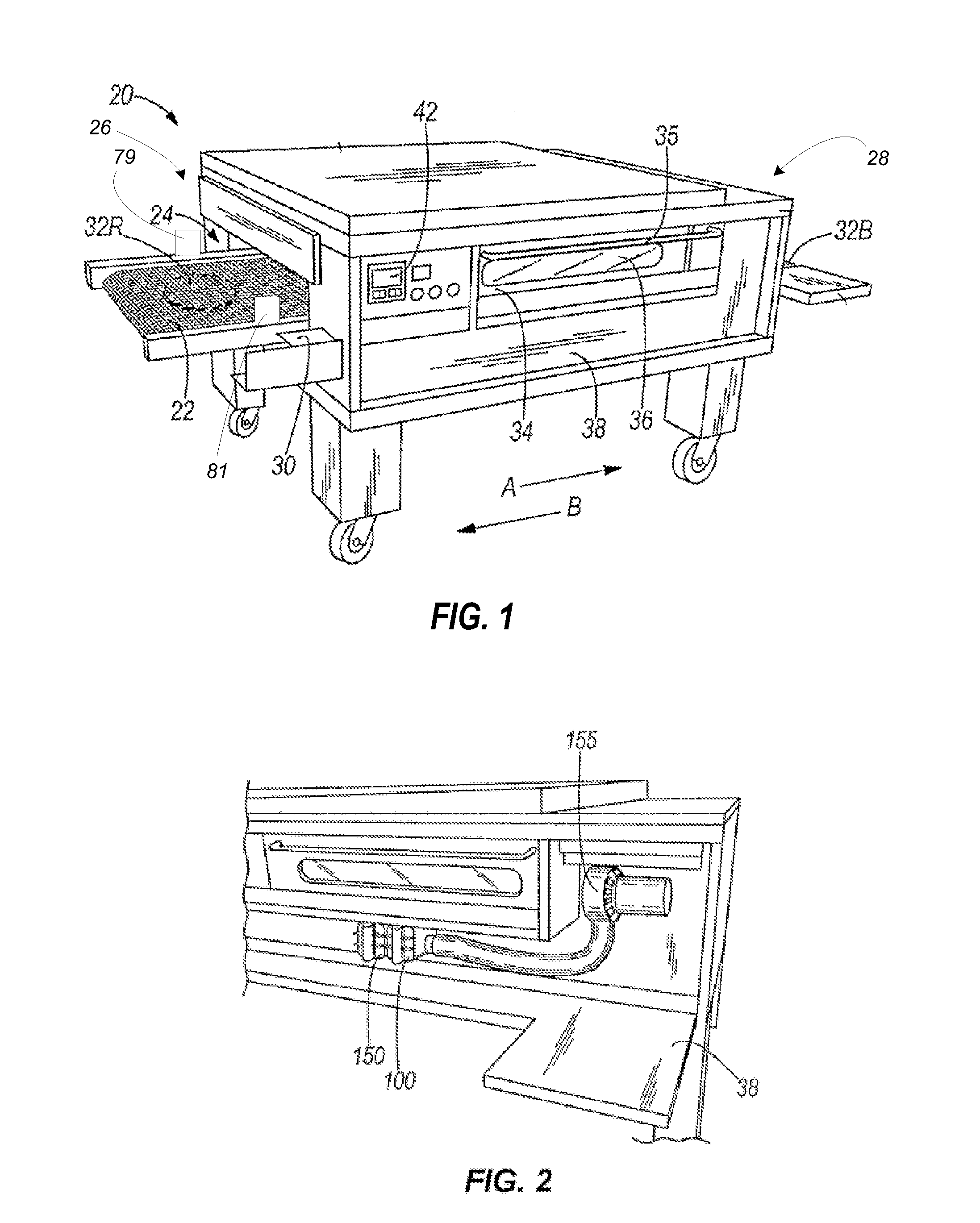

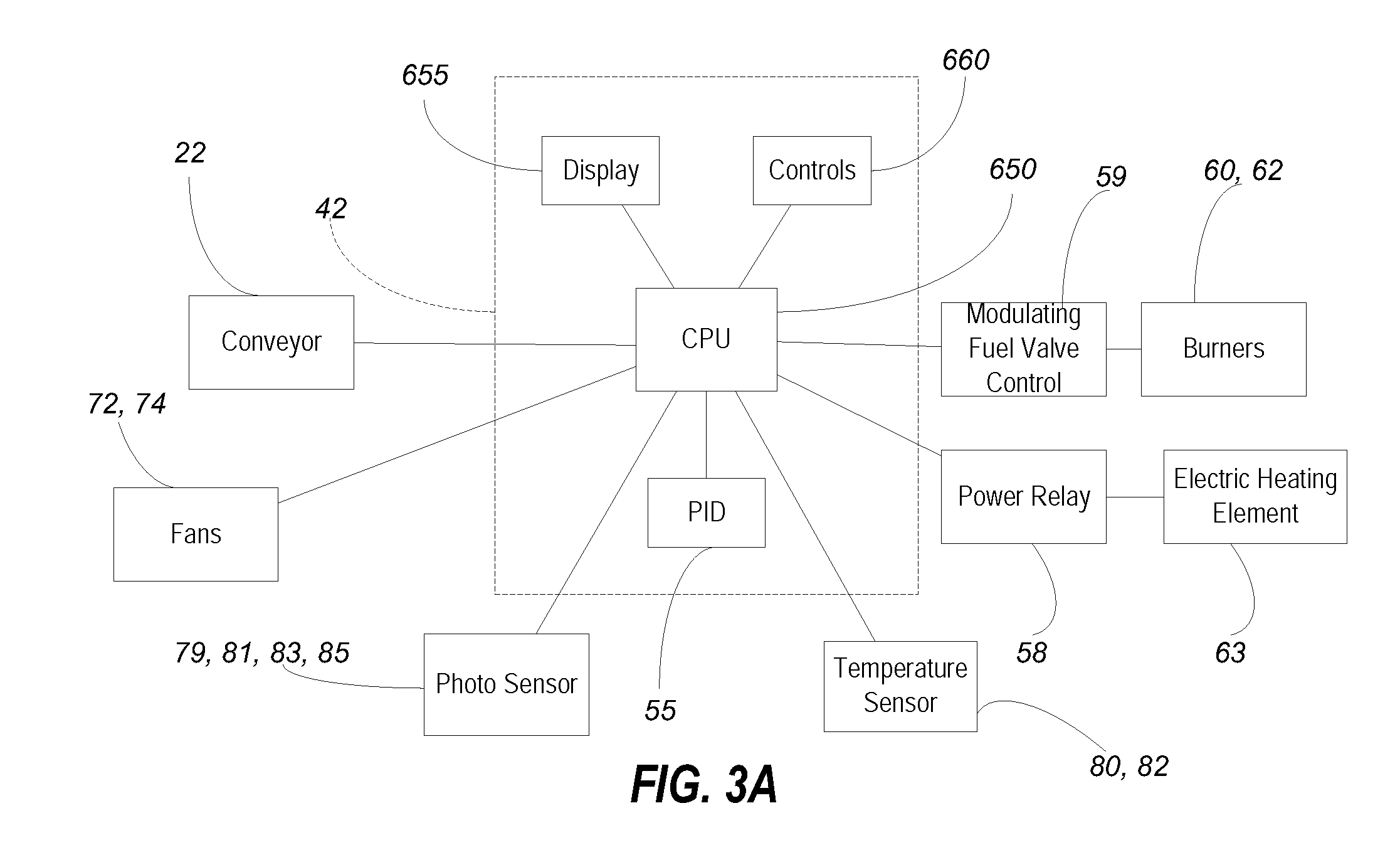

Conveyor oven apparatus and method

ActiveUS20110269085A1Increase productionReduce internal temperatureStoves/ranges foundationsDomestic stoves or rangesEngineeringInternal temperature

An oven with a sensor positioned to detect an event that will cause a decrease in the internal temperature of a tunnel. The oven includes a controller configured to increase the thermal output of a heating element in anticipation of the upcoming decrease in the internal temperature. In some embodiments, the oven is a conveyor over and the sensor is positioned to detect a food item approach the tunnel on a conveyor. In some embodiments, the amount of current provided to an electric heating element is increased by increasing the target temperature. In some embodiments, the amount of current provided to the electric heating element is increased by a predetermined offset.

Owner:MIDDLEBY CORPORATION

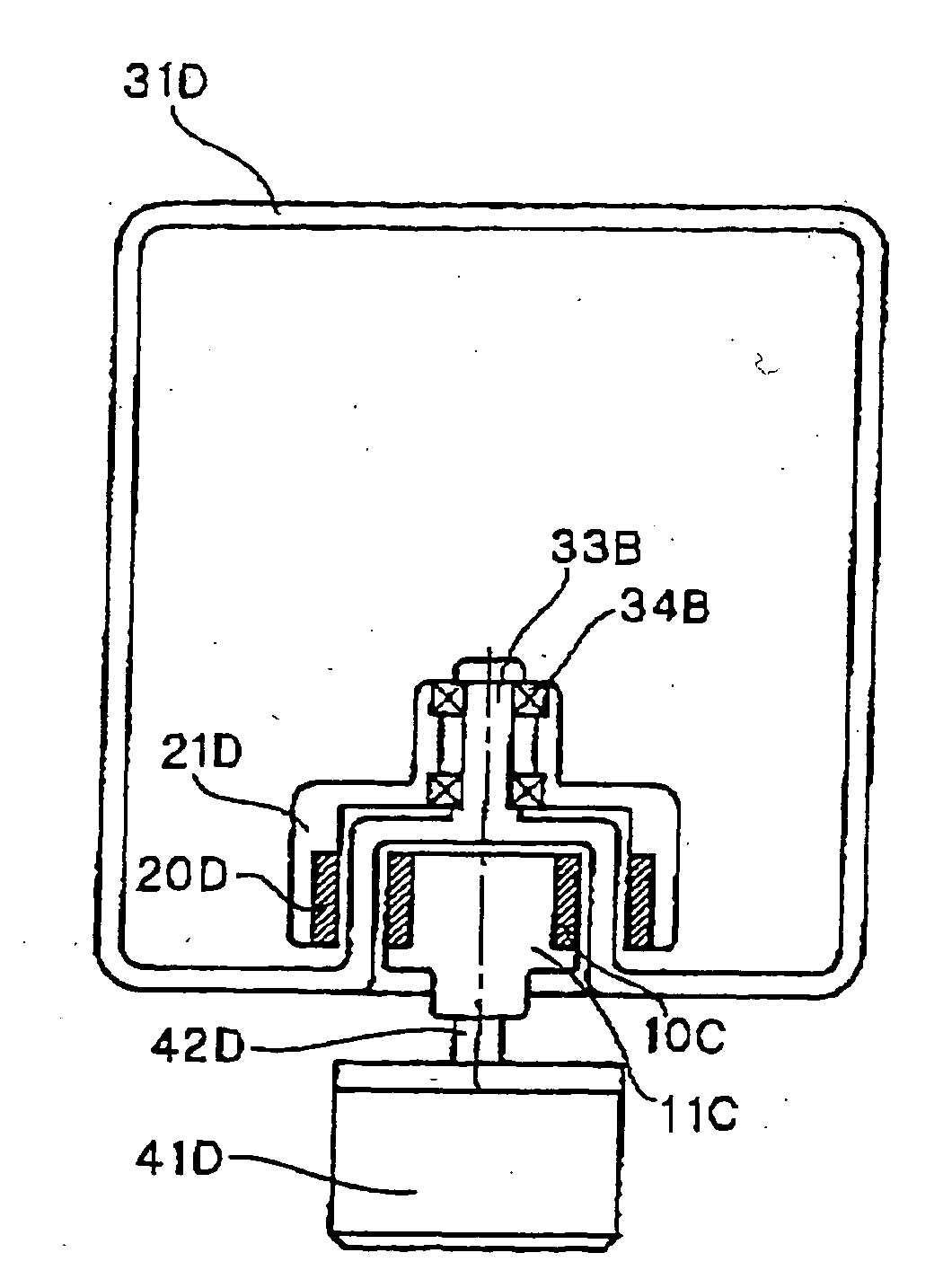

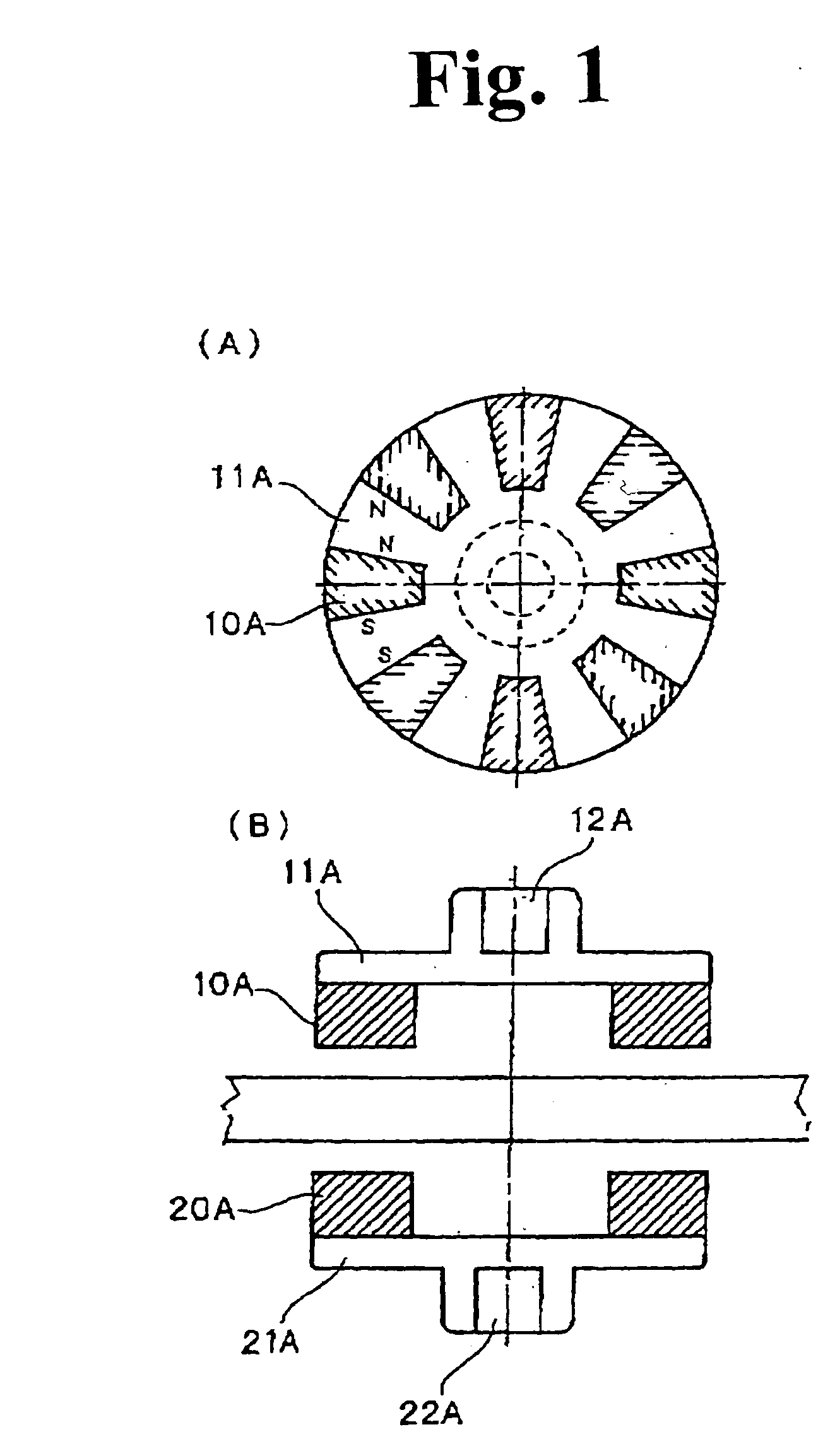

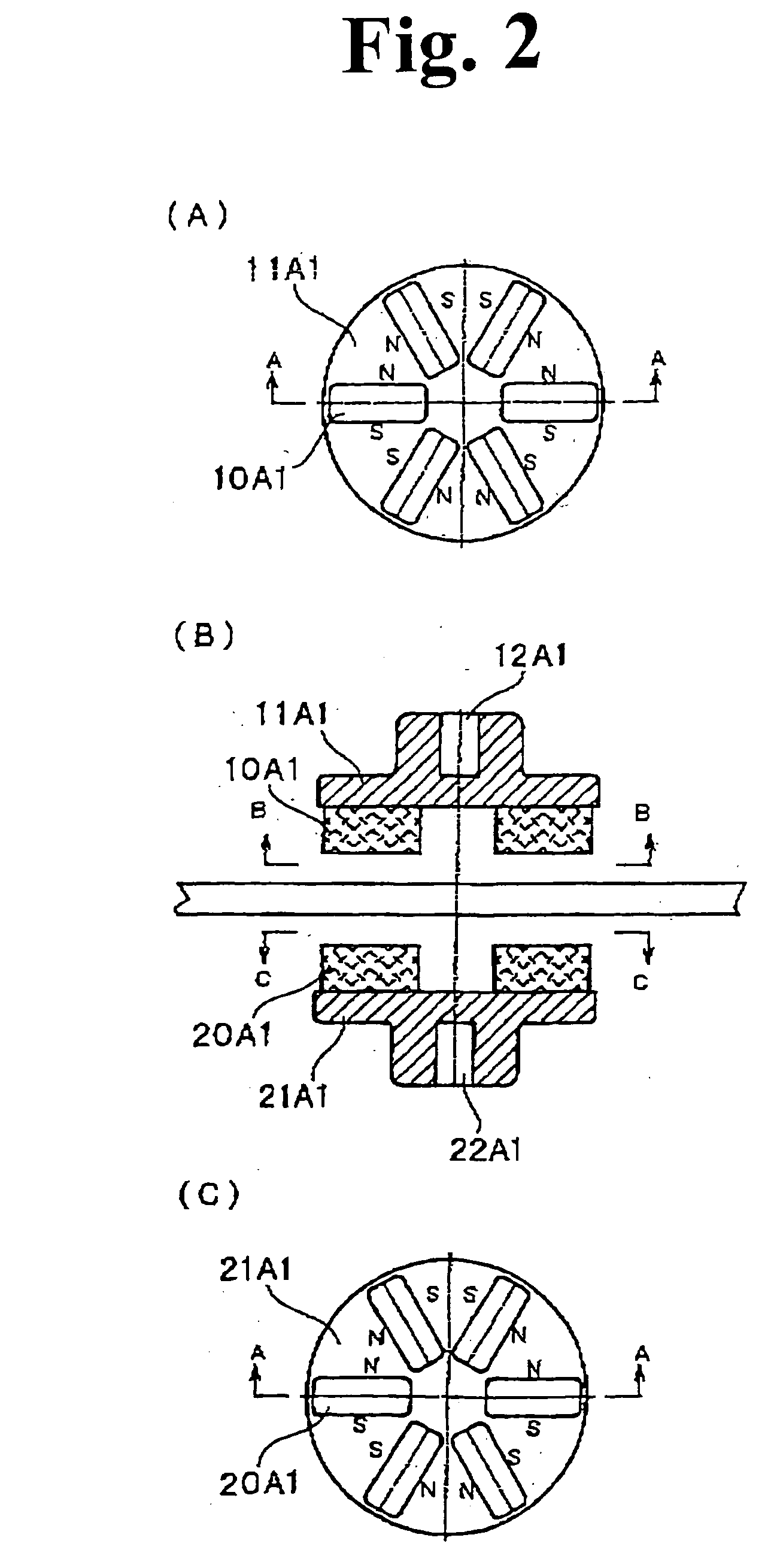

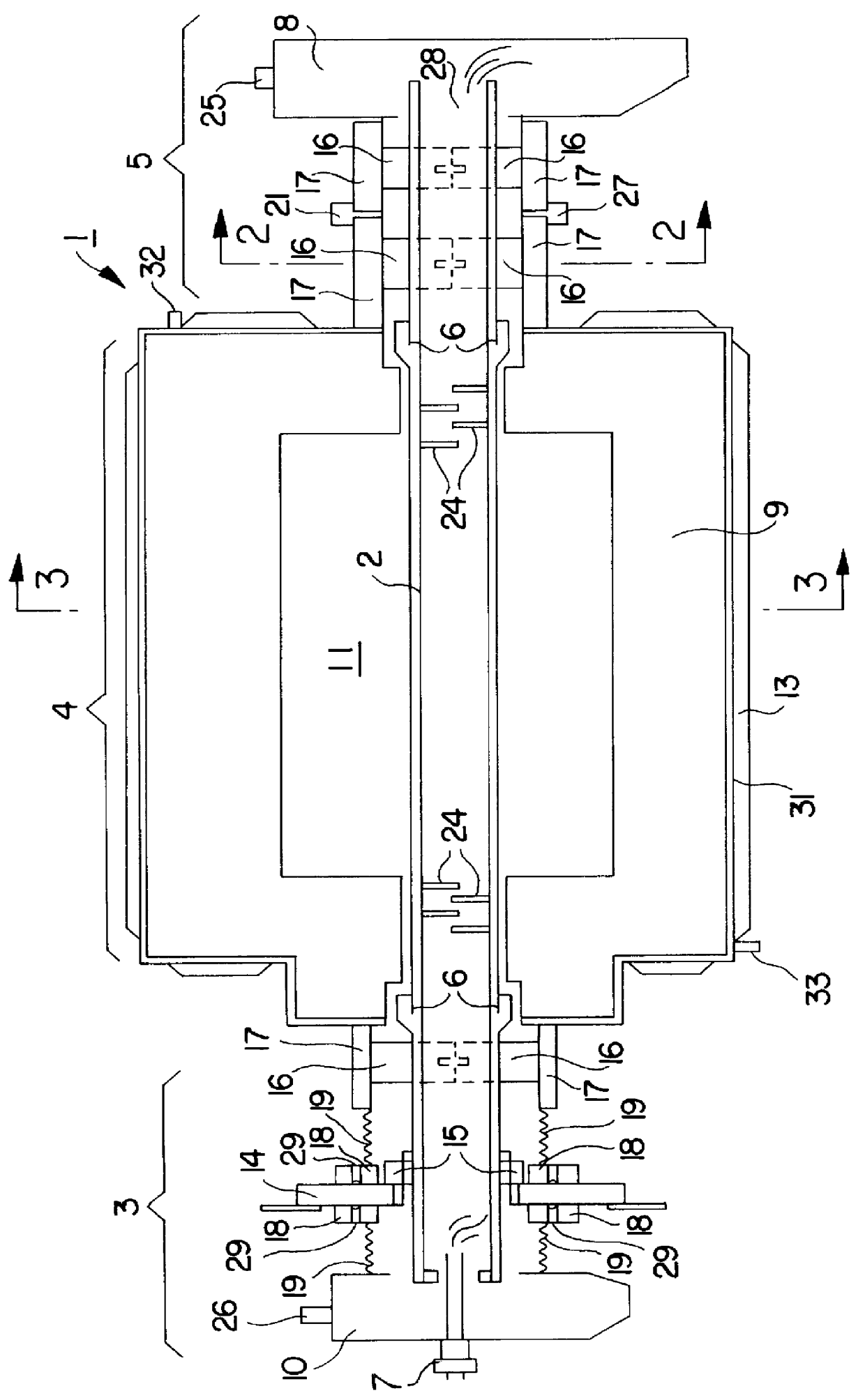

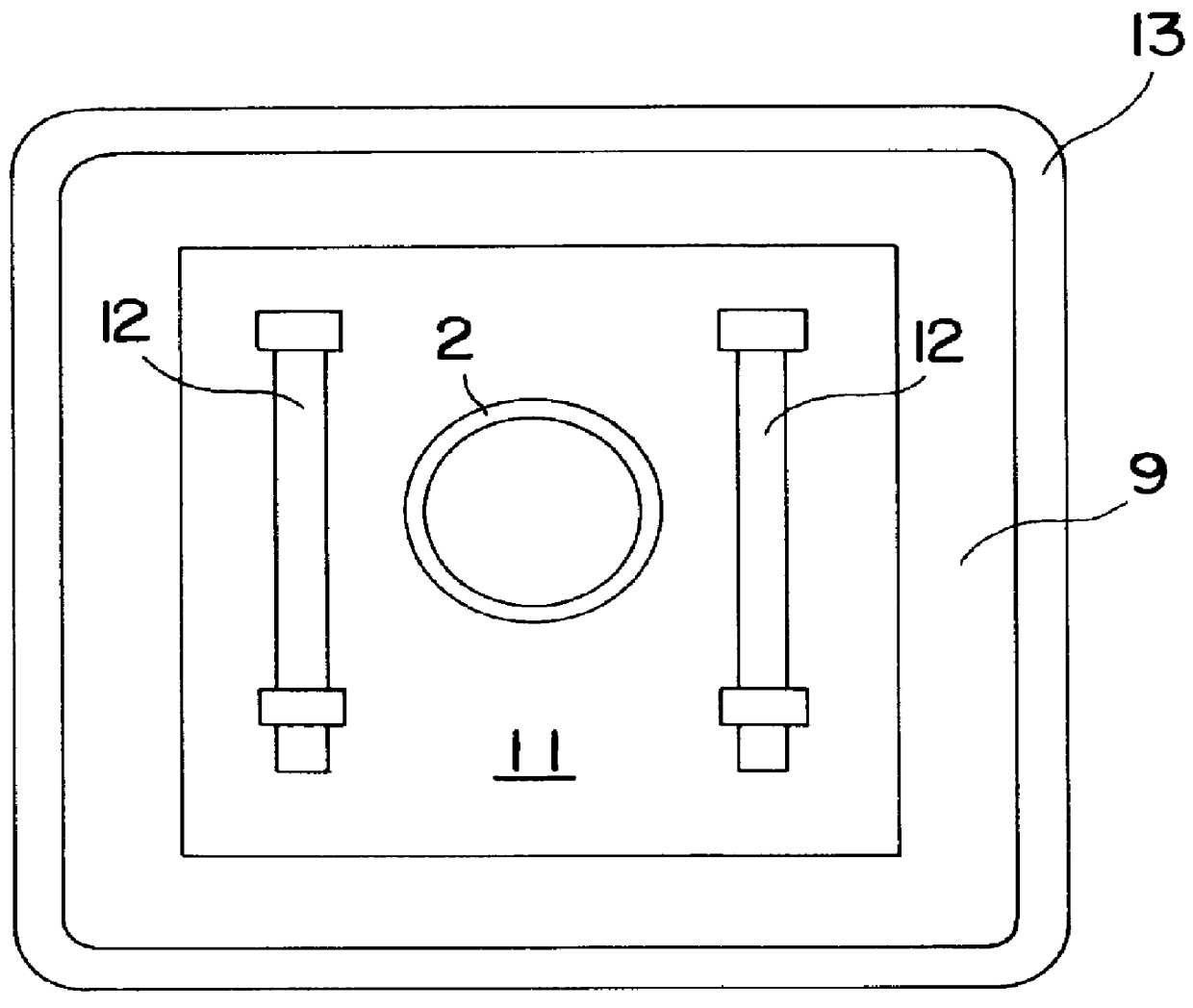

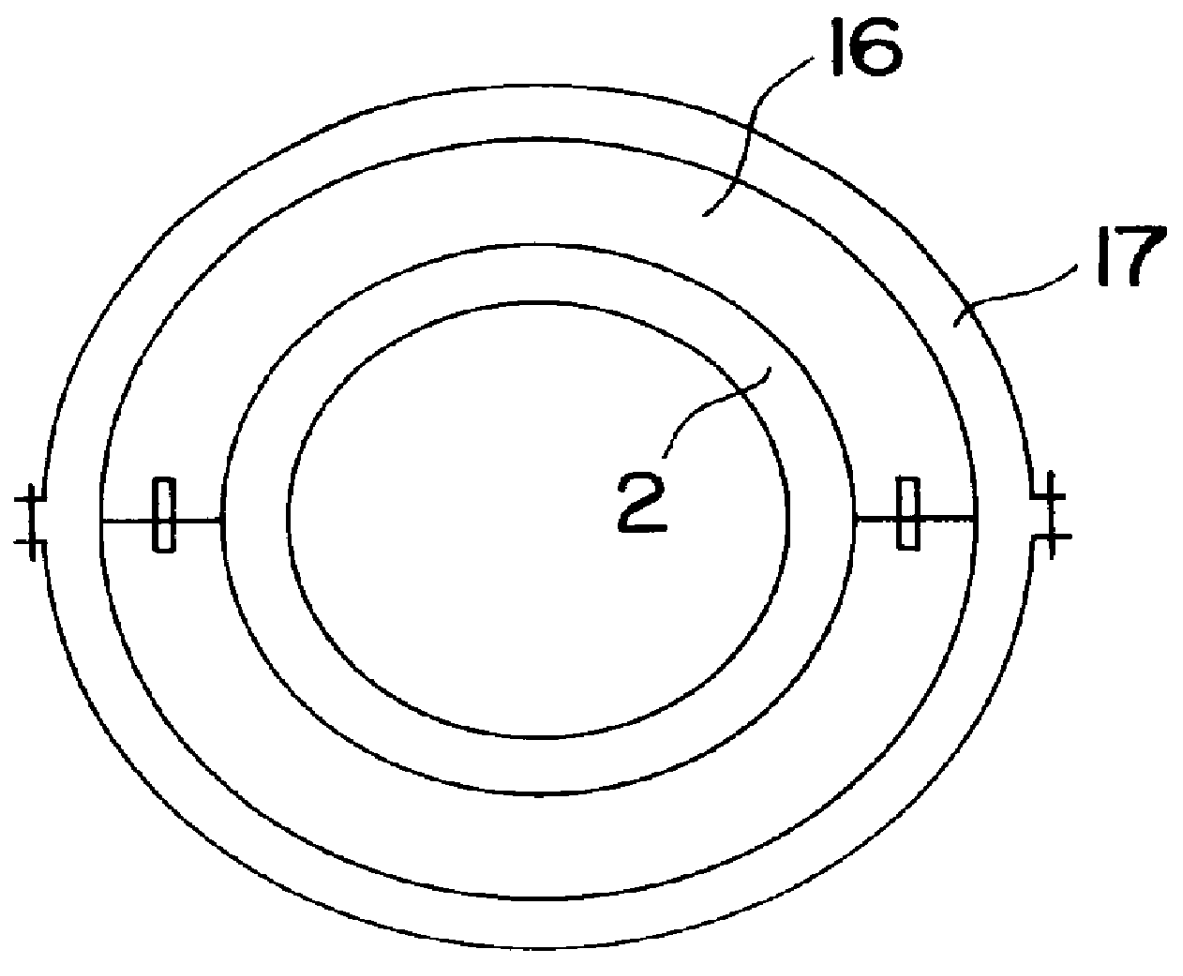

Magnetic rotation transmitting device, hermetic stirring unit, and electric furnace

InactiveUS20050206260A1Dynamo-electric brakes/clutchesRotary stirring mixersElectric arc furnaceMagnetic rotation

In order to provide a magnetic rotation transmitting device capable of obtaining a large transmitting torque without using a large-sized permanent magnet, in an axial-type magnetic rotation transmitting device, which includes a driving rotation body having one or plural magnetic line(s) in which plural first magnets (10A) are disposed in a circumferential direction on a first disk (11A) at almost equal intervals, a drive source rotationally driving a drive shaft of the driving rotation body, and a driven rotation body having one or plural magnet line(s) in which second magnets (20A) of the same number as the first magnets (10A) are disposed in the circumferential direction on a second disk (21A) at almost equal intervals, symmetrically disposed to, and magnetically coupled with the driving rotation body with a magnetic coupling gap and, which utilizes a magnetic operation and which allows the driven rotation body to rotate by rotationally driving the drive shaft by means of the drive source, the first magnet (10A) has a N-magnetic pole portion and a S-magnetic pole portion, and an extended surface of a boundary surface between the N-magnetic pole portion and the S-magnetic pole portion approximately overlaps with a driving center line as being a rotation center line of the driving rotation body, the second magnet (20A) has the N-magnetic pole portion and the S-magnetic pole portion, and the extended surface of the boundary surface between the N-magnetic pole portion and the S-magnetic pole portion approximately overlaps with a driven center line as being the rotation center line of the driven rotation body, adjacent and facing surfaces of the first magnets (10A) adjacent to each other on the first disk (11A) are disposed so that magnetic pole faces having the same polarity make pairs, and adjacent and facing surfaces of the second magnets (20A) adjacent to each other on the second disk (21A) are disposed so that the magnetic pole faces having the same polarity make pairs.

Owner:MAGUNEO

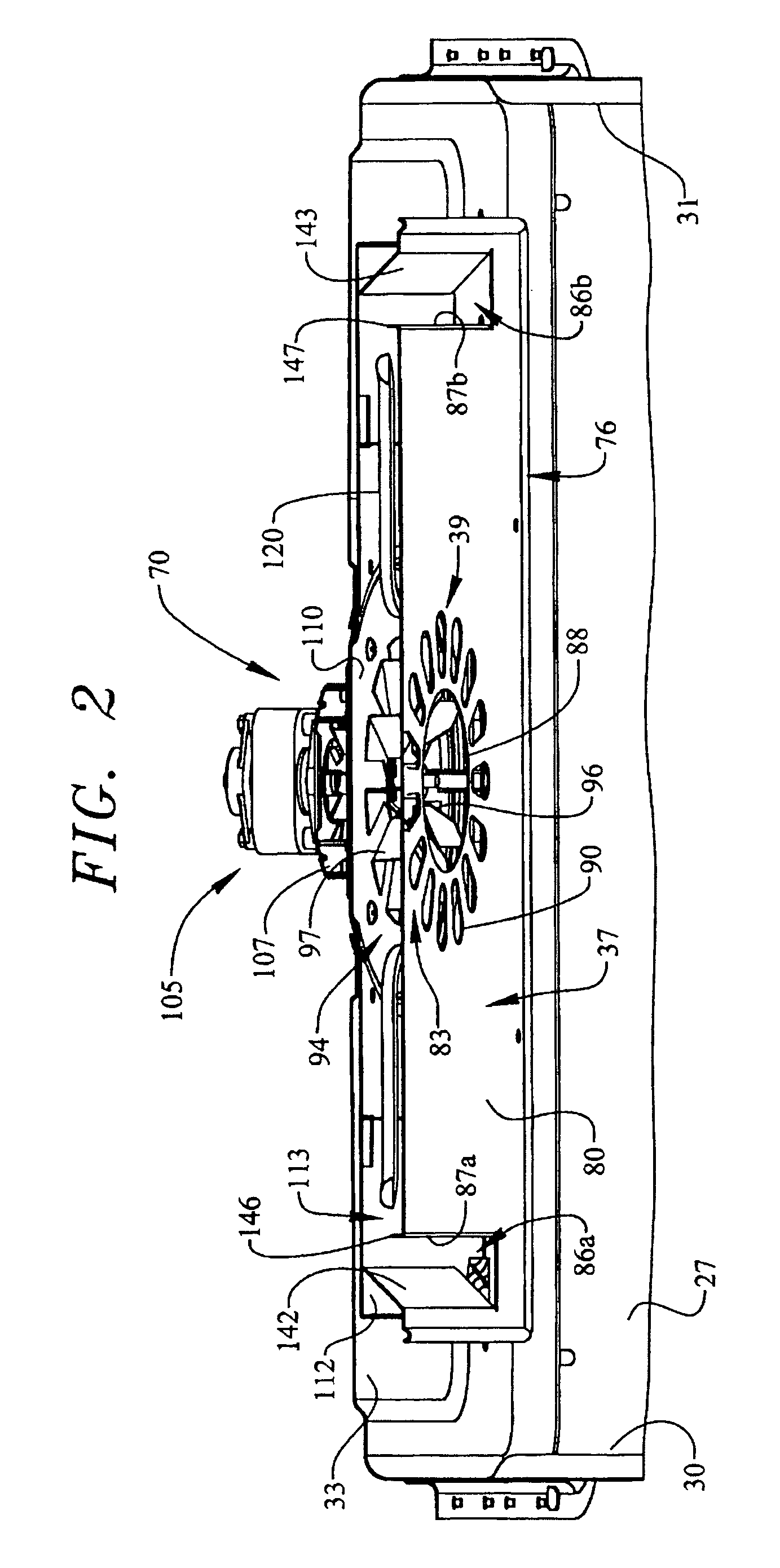

Graphite rotary tube furnace

InactiveUS6042370AMinimizing radiation heat lossStable temperatureRotary drum furnacesCharge supportsRadiative heat lossRadiant heat

A rotary tube furnace suitable for operation in controlled atmospheres at temperatures in the range of 1500 DEG to 2800 DEG comprises a generally horizontal rotatable graphite tube slidably supported on water-cooled split ring graphite bearings. The graphite tube is rotated by means of a stainless steel drive plate and is contained within a flexible atmospheric sealing assembly and enclosure for the containment of a selected atmosphere around and within the tube and allows for the co-current or counter-current flow of gas during operation. Radiation baffles in the interior of the graphite tube inhibit radiant heat loss at the ends of the tube. The graphite tube may be constructed in two or more sections having threaded ends for ease of installation as well as removal or replacement for maintenance purposes. A heating section of the tube is heated by a plurality of graphite electrical heating elements contained within an insulated heating chamber.

Owner:HARPER INT CORP

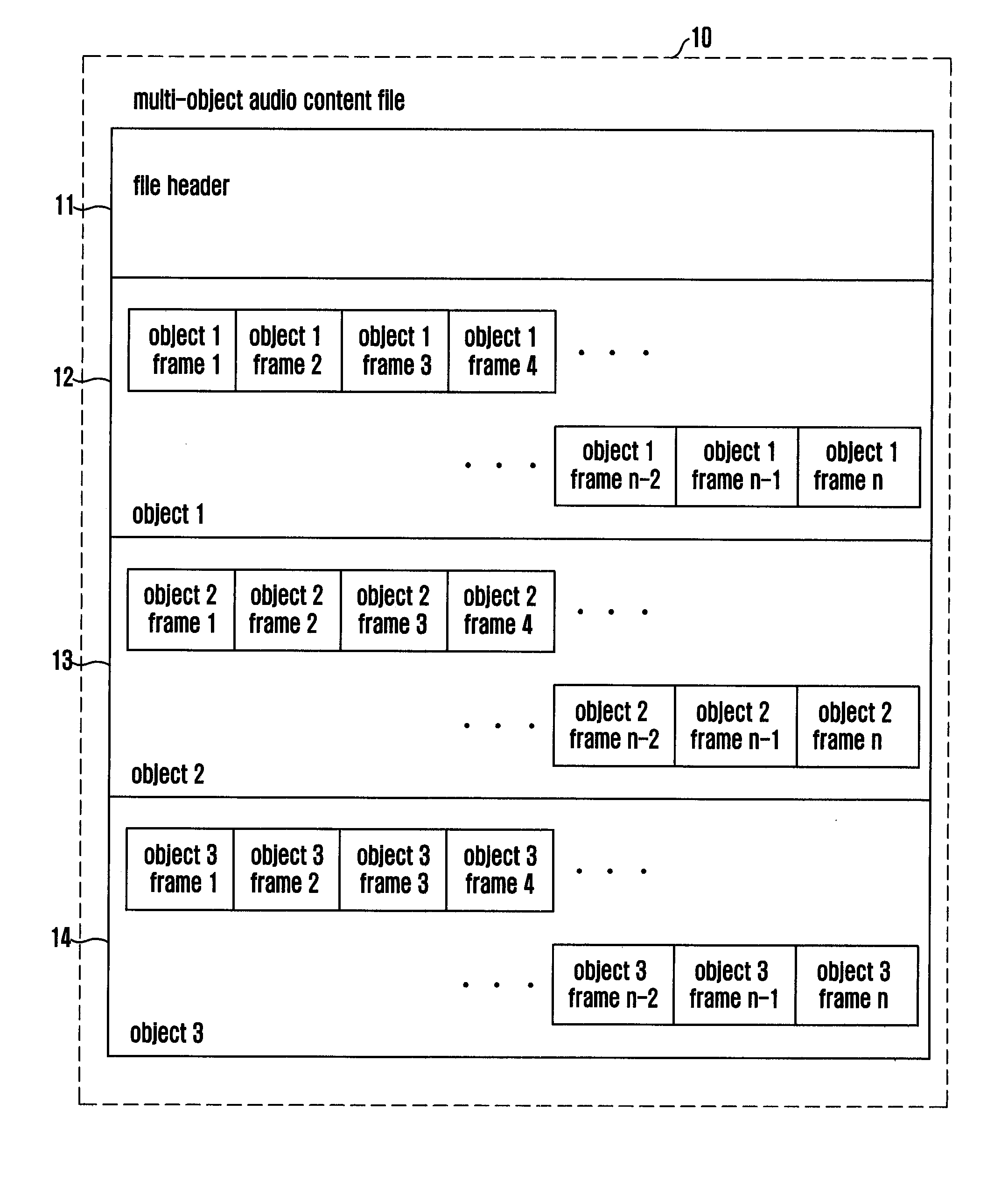

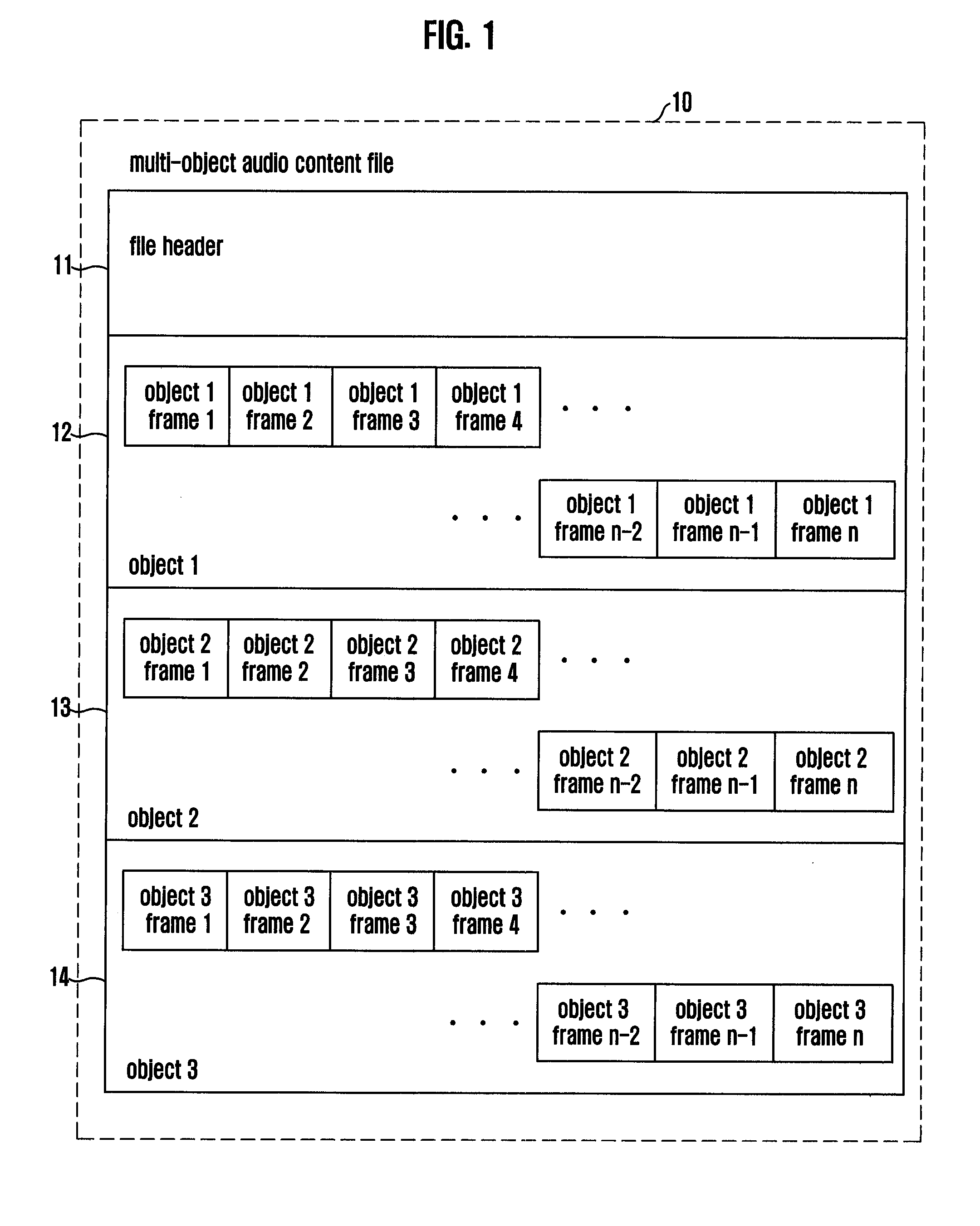

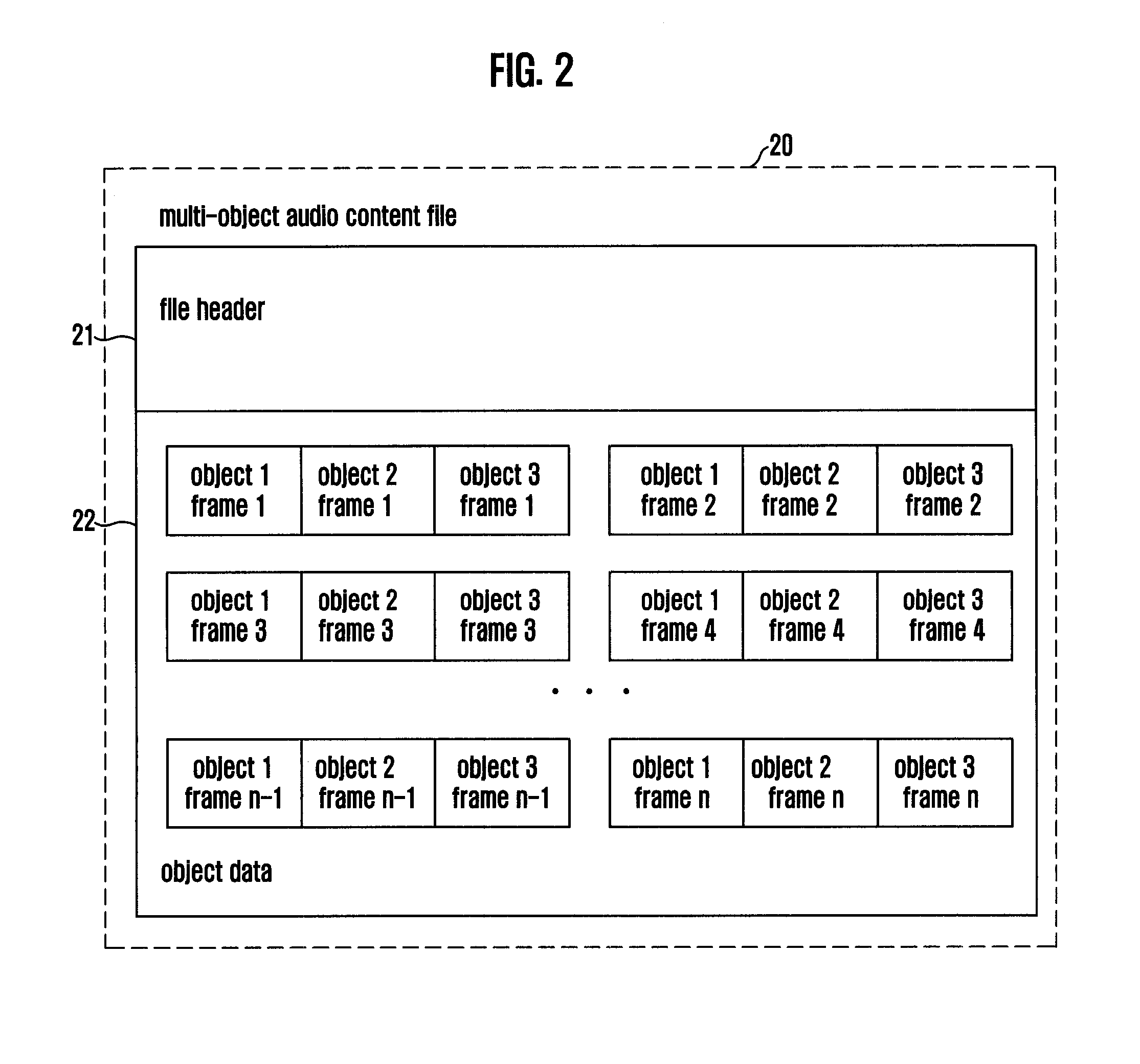

Method for creating, editing, and reproducing multi-object audio contents files for object-based audio service, and method for creating audio presets

ActiveUS20100076577A1Attenuation bandwidthEasy accessElectronic editing digitised analogue information signalsSpeech analysisObject basedSpeech recognition

Provided are a method for creating, editing and reproducing a multi-object audio content file for an object-based audio service and a method for creating audio presets. The multi-object audio content file creating method includes creating a plurality of frames for each audio object forming an audio content; and creating a multi-object audio content file by grouping and storing the frames according to each reproduction time. This invention can enhance functions of the object-based audio service and make it easy to access to each audio object of an audio content file.

Owner:ELECTRONICS & TELECOMM RES INST

Vacuum Insulation Body

ActiveUS20160178269A1Evacuated particularly easily and efficientlyMuffle furnacesThermal insulationPulp and paper industry

Owner:LIEBHERR HAUSGERATE LIENZ +1

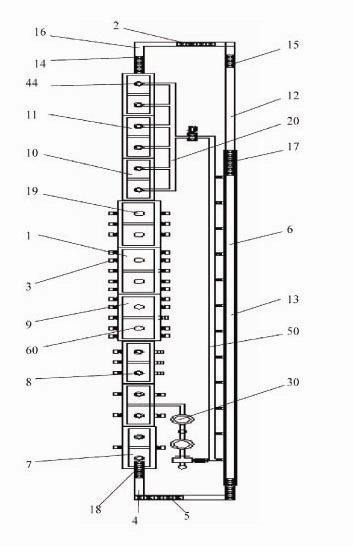

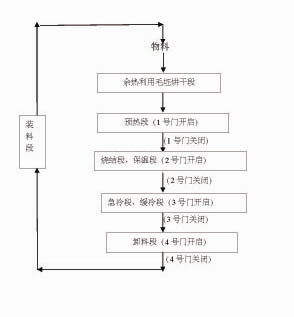

Fully-closed industrial microwave high-temperature roller continuous sintering kiln

InactiveCN102042749AConsistent shrinkageGood size consistencyMaintainance of heating chambersFurnace typesEnvironmental resistanceEngineering

The invention discloses a closed microwave high-temperature sintering roller kiln, in particular a tunnel roller kiln with length of 10 to 50meters, and hearth sectional area of 0.06 to 0.3m<2>. The kiln comprises a main kiln body, a microwave transmission system, a turning channel mechanism, a roller power system, and a kiln door interlocking opening and closing system; the main kiln body is formed by connecting a water draining section, a preheating section, a sintering section, a heat preservation section, a quick cooling section, and a slow cooling section in turn; the turning channel mechanism is mainly formed by a material loading and unloading section and a residual-heat utilization blank drying section and comprises a turning channel, a turning channel roller, and a power system; the power system can poke a pushing plate from the outlet of the main kiln body onto the turning channel and feed the pushing plate into the inlet of the main kiln body through the residual-heat utilization blank drying section; and an inner roller for transmitting the material pushing plate, which is driven by the roller power system, is arranged on the bottom of an inner cavity of the main kiln body. The closed microwave high-temperature sintering roller kiln saves energy and reduces consumption and is environmental-friendly, the shrinkage of the sintered products is consistent and the sintered products have high size consistency, the yield is high, the production efficiency is high and the production cost is low.

Owner:湖南航天有限责任公司

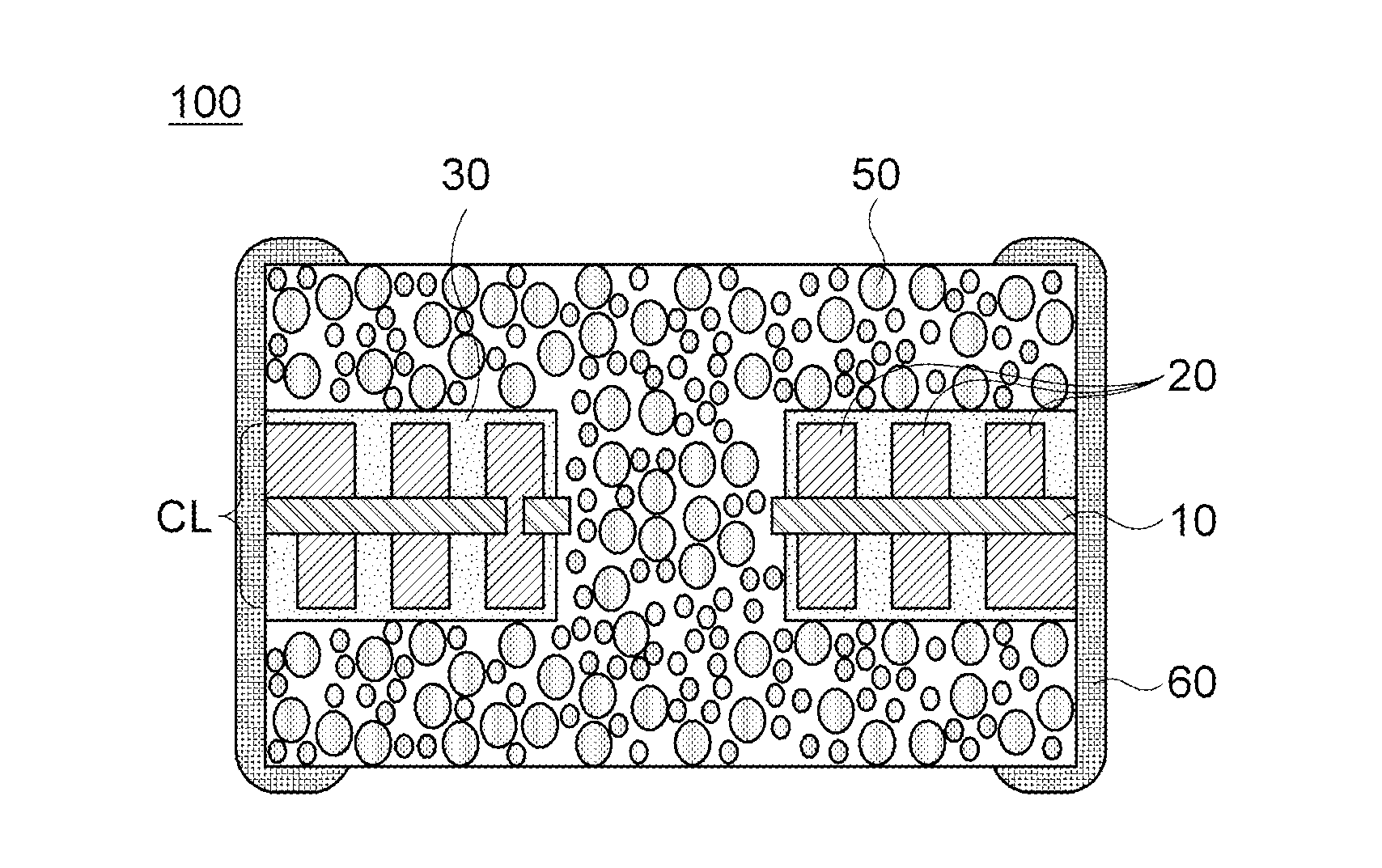

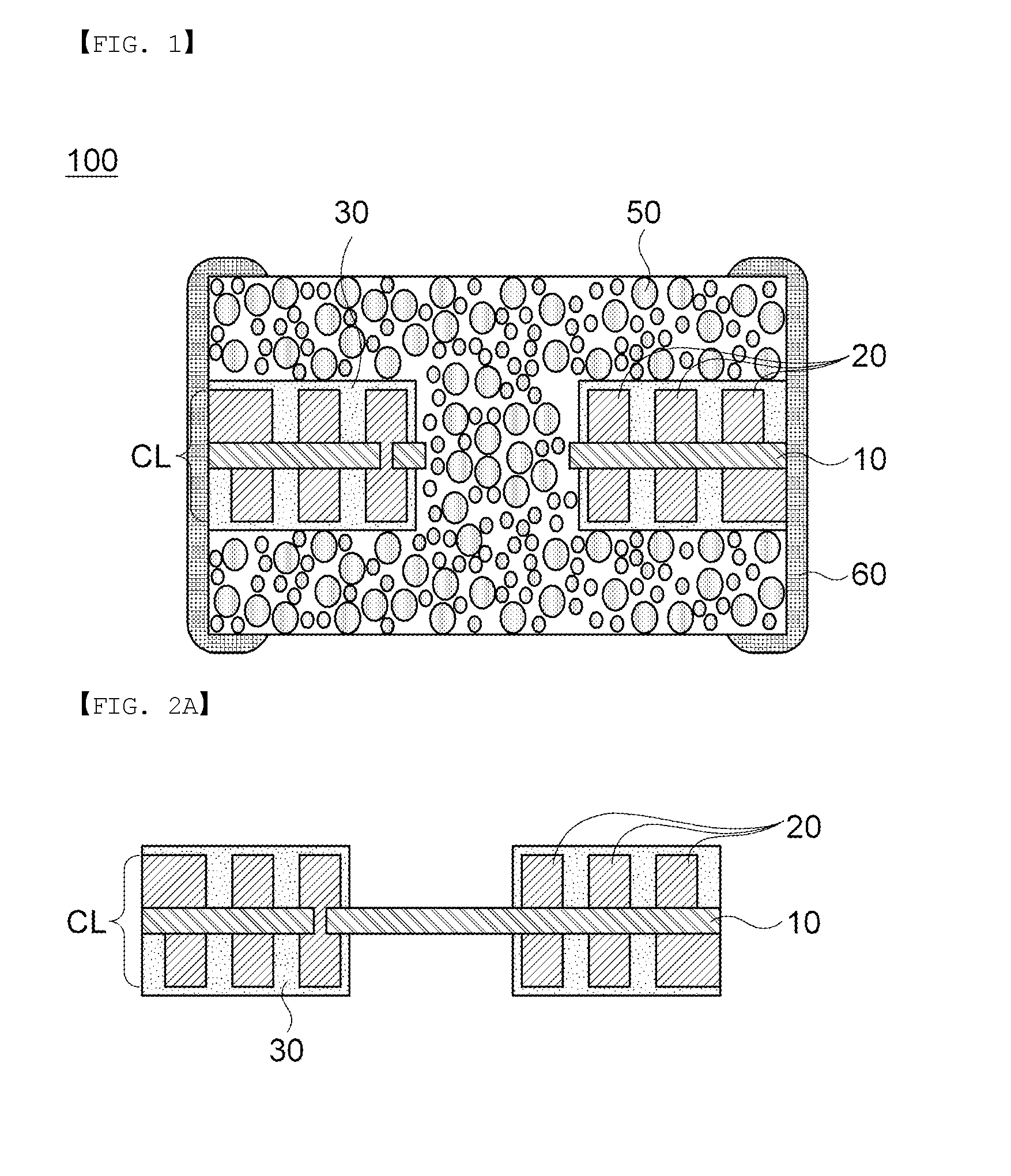

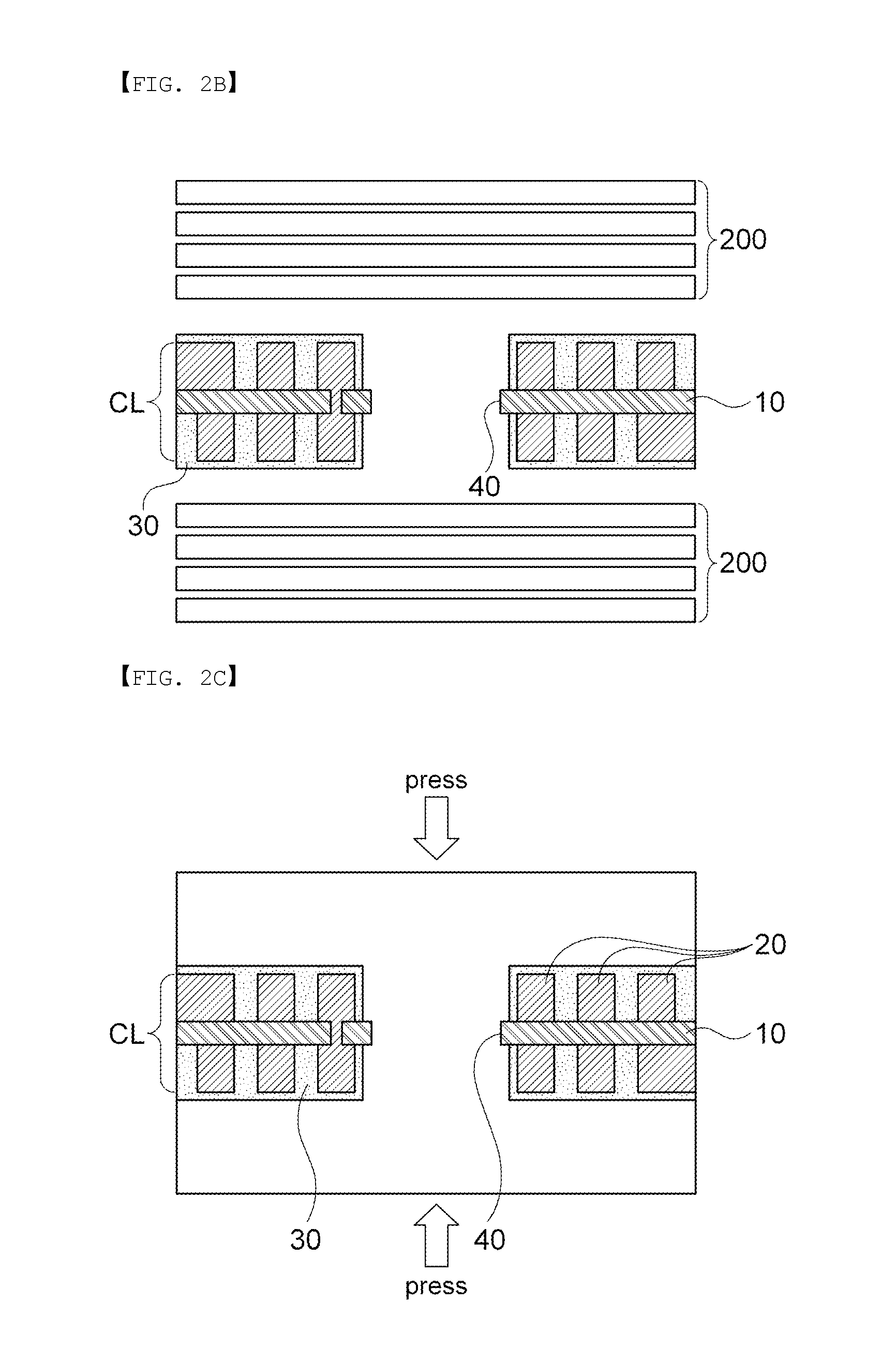

Metal-polymer complex film for inductor and method for manufacturing the same

Disclosed herein are a metal-polymer complex film for an inductor and a method for manufacturing an inductor, the inductor being manufactured by using the metal-polymer complex film for an inductor, including: a metal powder; and an amorphous epoxy resin, wherein the metal-polymer complex film is made in a film type by using a mixture where a weight ratio of the metal powder is 75˜98 wt %, so that a plurality of inductors can be simultaneously manufactured to thereby improve production efficiency and characteristic values of the inductor can be also improved.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

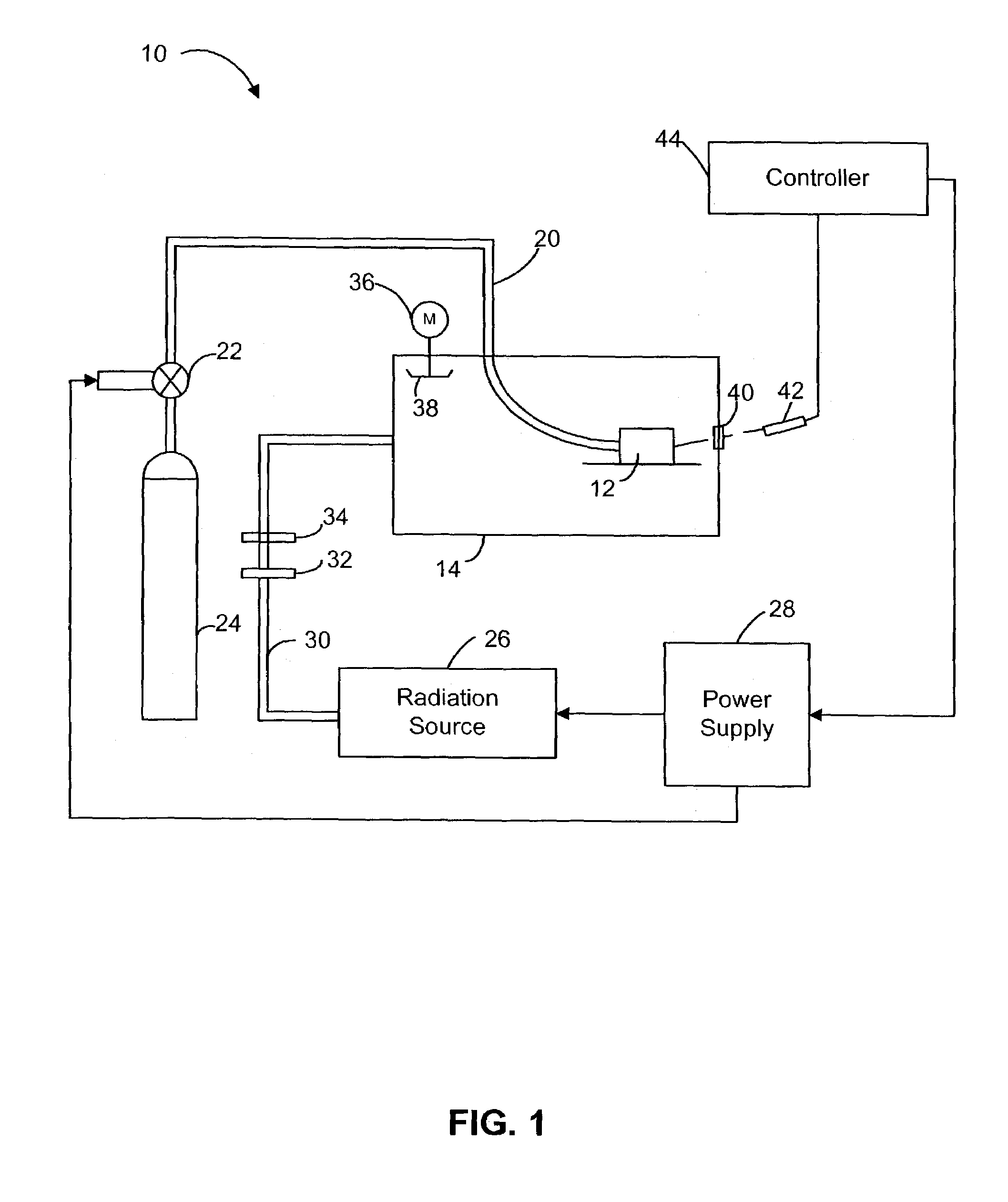

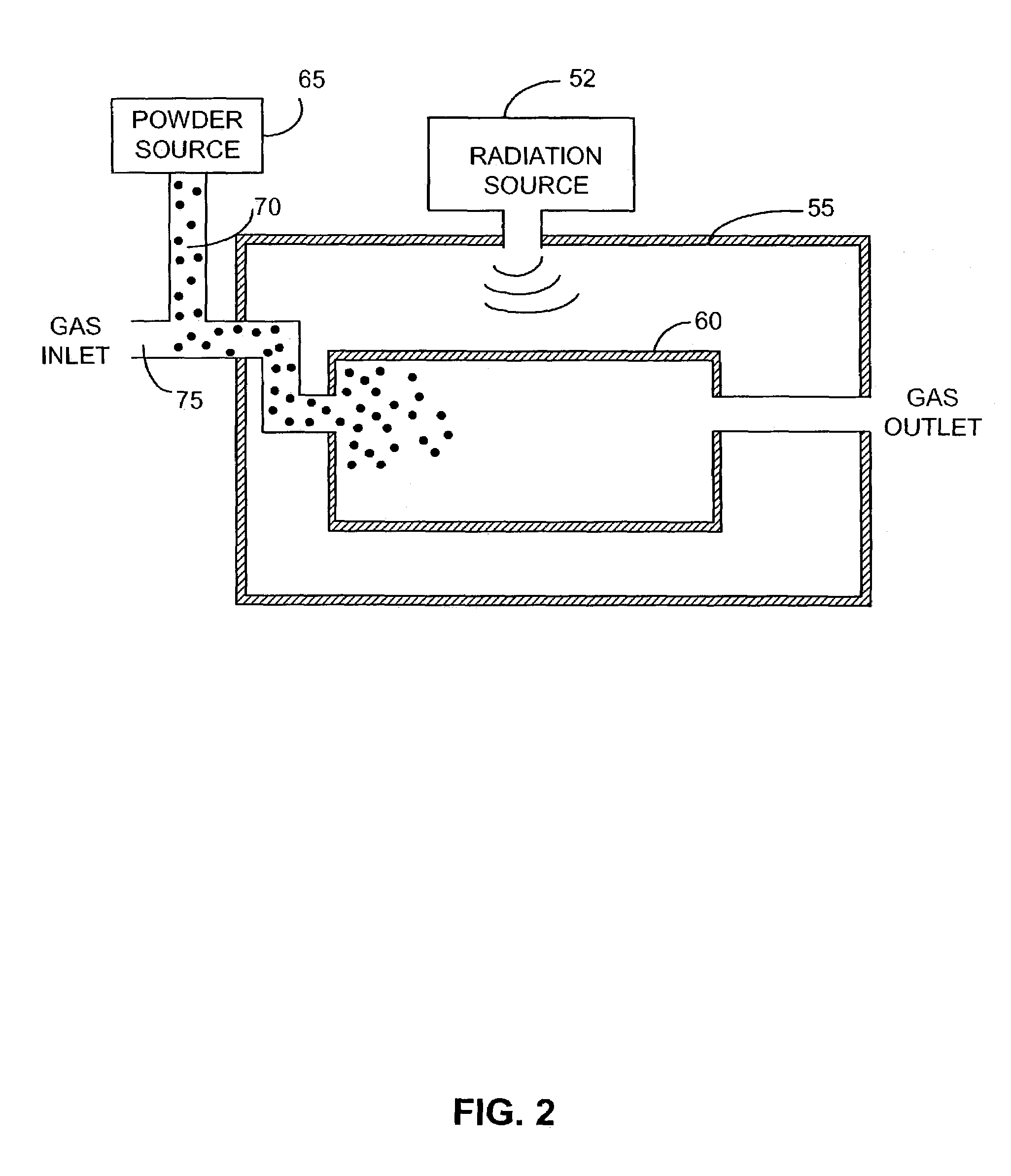

Plasma-assisted melting

Apparatus and methods for plasma-assisted melting are provided. In one embodiment, a plasma-assisted melting method can include: (1) adding a solid to a melting region, (2) forming a plasma in a cavity by subjecting a gas to electromagnetic radiation having a frequency less than about 333 GHz in the presence of a plasma catalyst, wherein the cavity has a wall, (3) sustaining the plasma in the cavity such that energy from the plasma passes through the wall into the melting region and melts the solid into a liquid, and (4) collecting the liquid. Solids that can be melted consistent with this invention can include metals, such as metal ore and scrap metal. Various plasma catalysts are also provided.

Owner:BTU INTERNATIONAL

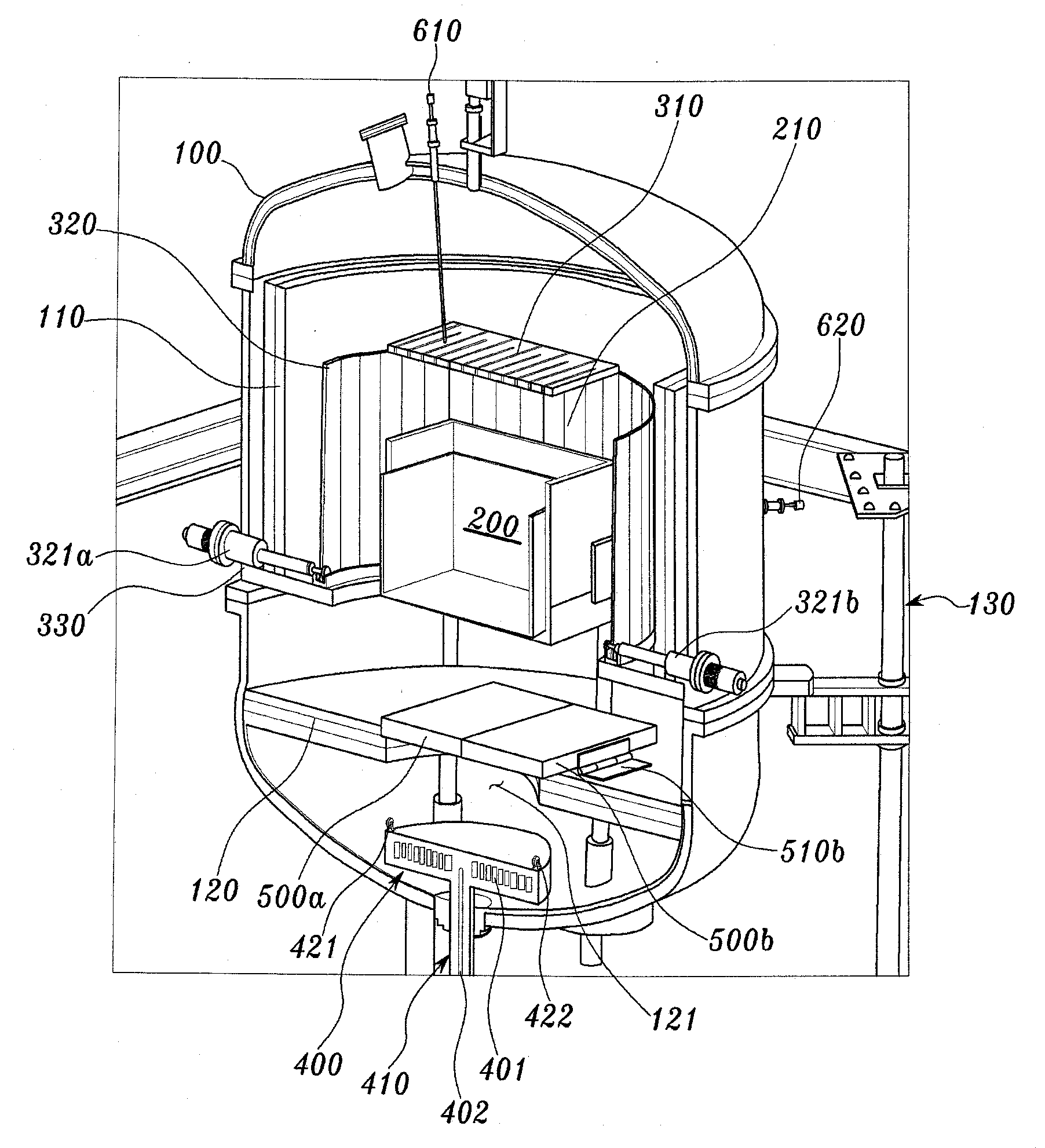

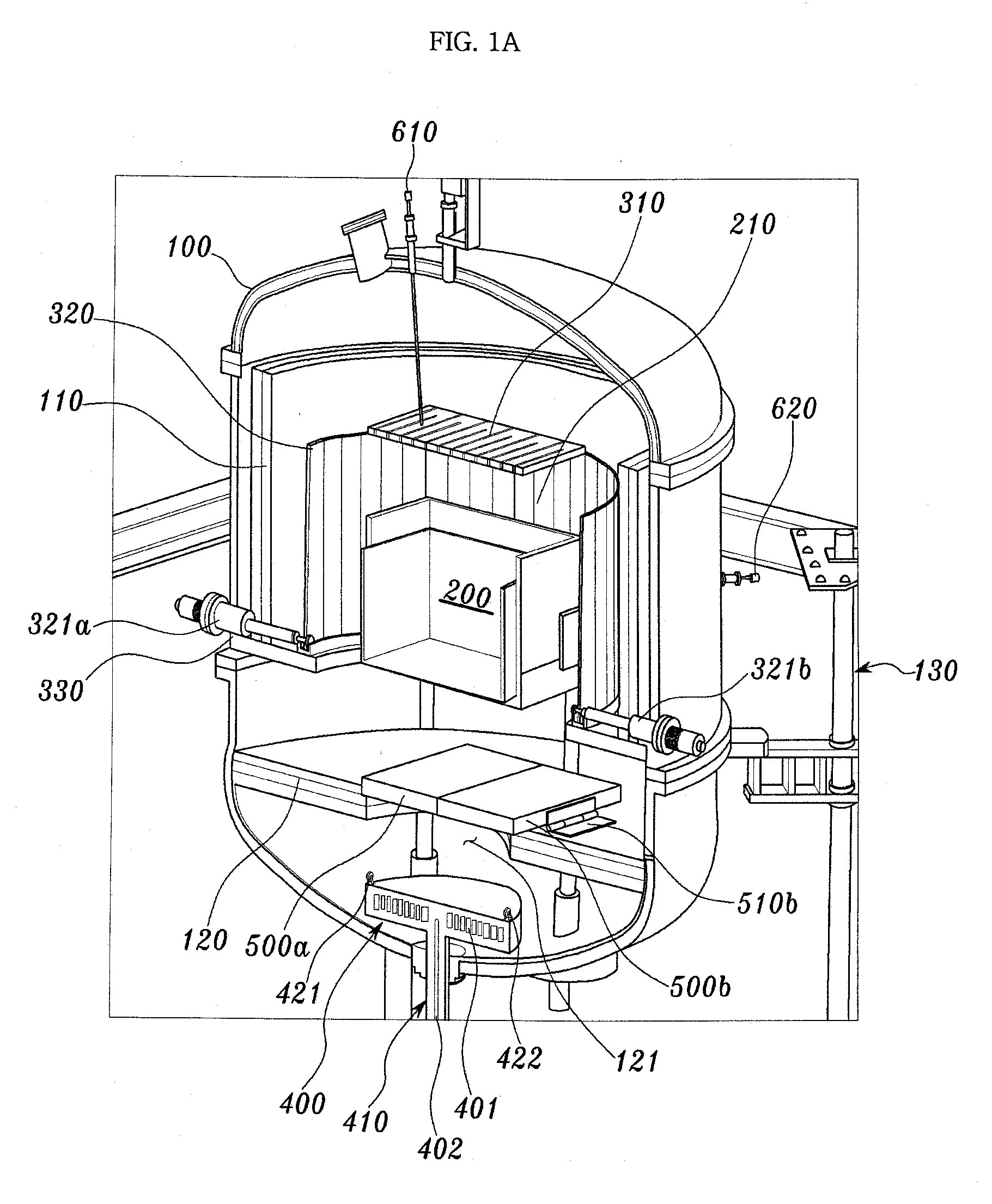

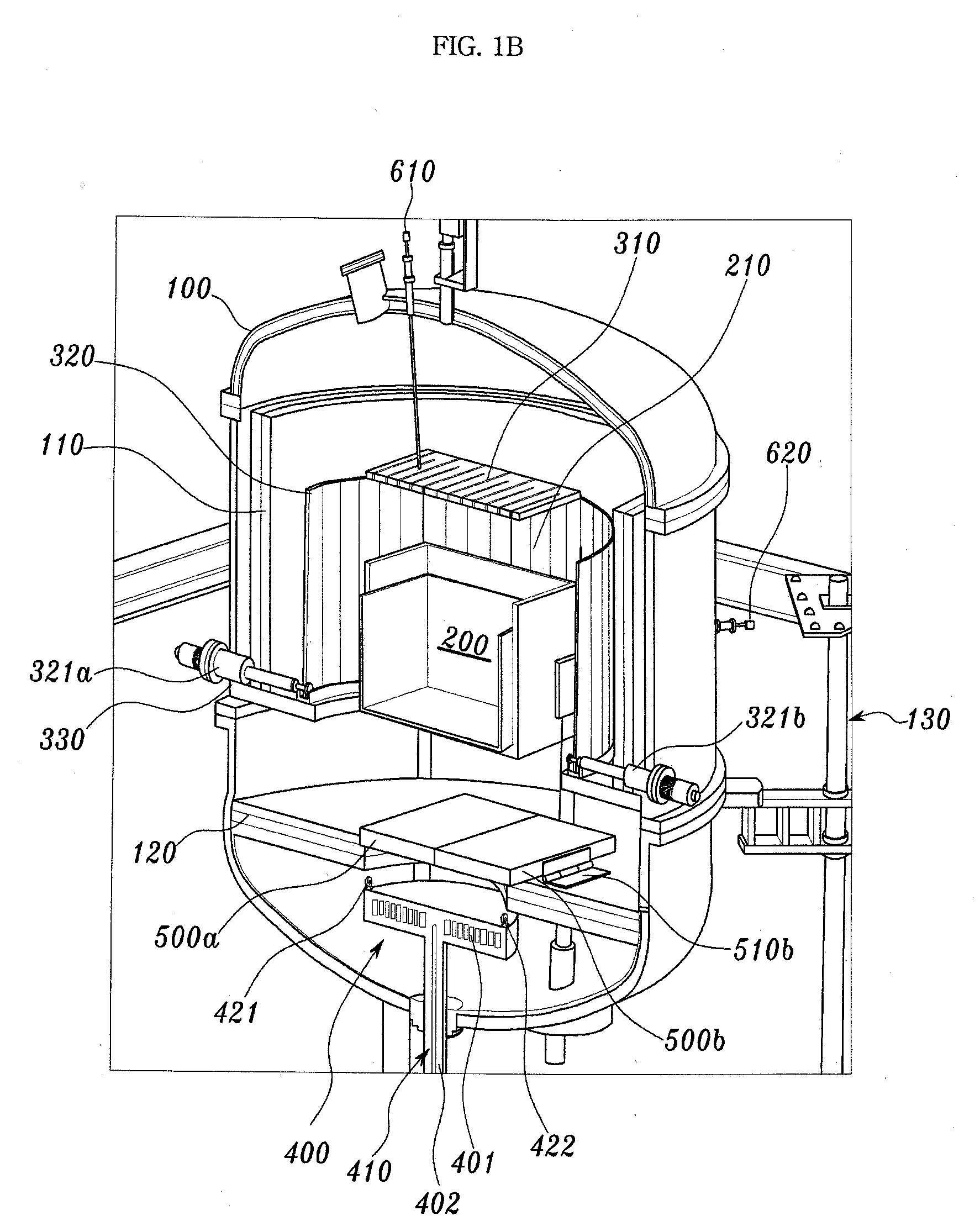

Apparatus for manufacturing poly crystaline silicon ingot for solar battery having door open/close device using hinge

InactiveUS20090090296A1Avoid scratchesBy zone-melting liquidsMaintainance of heating chambersSusceptorElectrical battery

Disclosed herein is an apparatus for manufacturing a polycrystalline silicon ingot for solar batteries having a door control device using a hinge. The apparatus includes a vacuum chamber, a crucible, a susceptor which surrounds the crucible, a heater which heats the crucible, and an insulation plate which is disposed below the susceptor and has an opening therein. The apparatus further includes a cooling plate which moves upwards through the opening of the insulation plate and comes into close contact with or approaches the lower end of the susceptor, a cooling plate moving unit which actuates the cooling plate, a temperature sensor which measures the temperature of the crucible, and a control unit which controls the temperature in the crucible and the cooling plate moving unit. Furthermore, a door is provided on the insulation plate to open or close the opening of the insulation plate. The hinge is provided between the door and the insulation plate. Thus, after the raw silicon material is melted, when the cooling plate moves upwards to cool the crucible and thus pushes the lower surface of the door upwards, the door is opened by the hinge in a swinging manner, and when the cooling plate approaches or comes into contact with the lower end of the susceptor, one end of the opened door is leaned on a corresponding surface of the cooling plate.

Owner:KOREA RES INST OF CHEM TECH

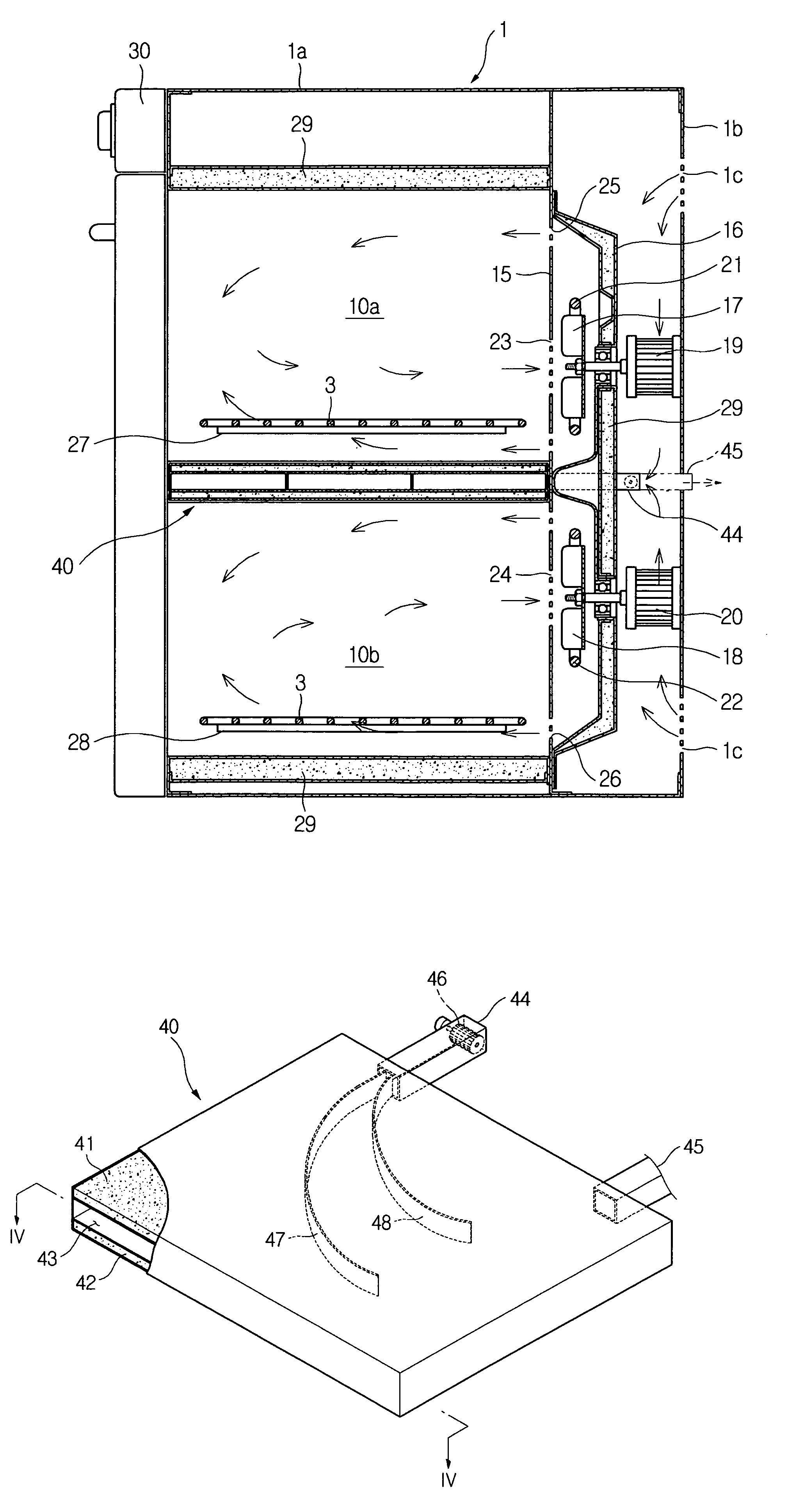

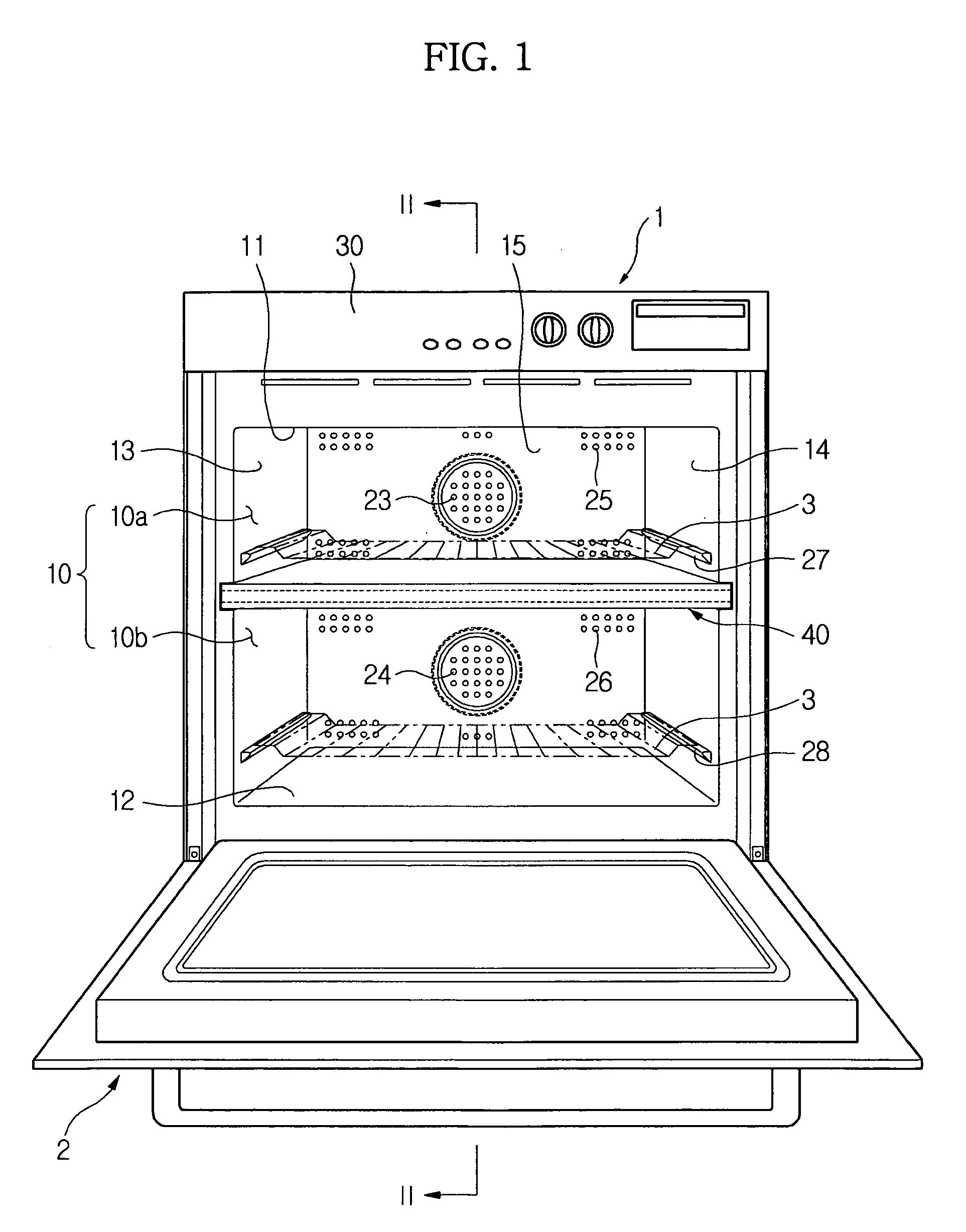

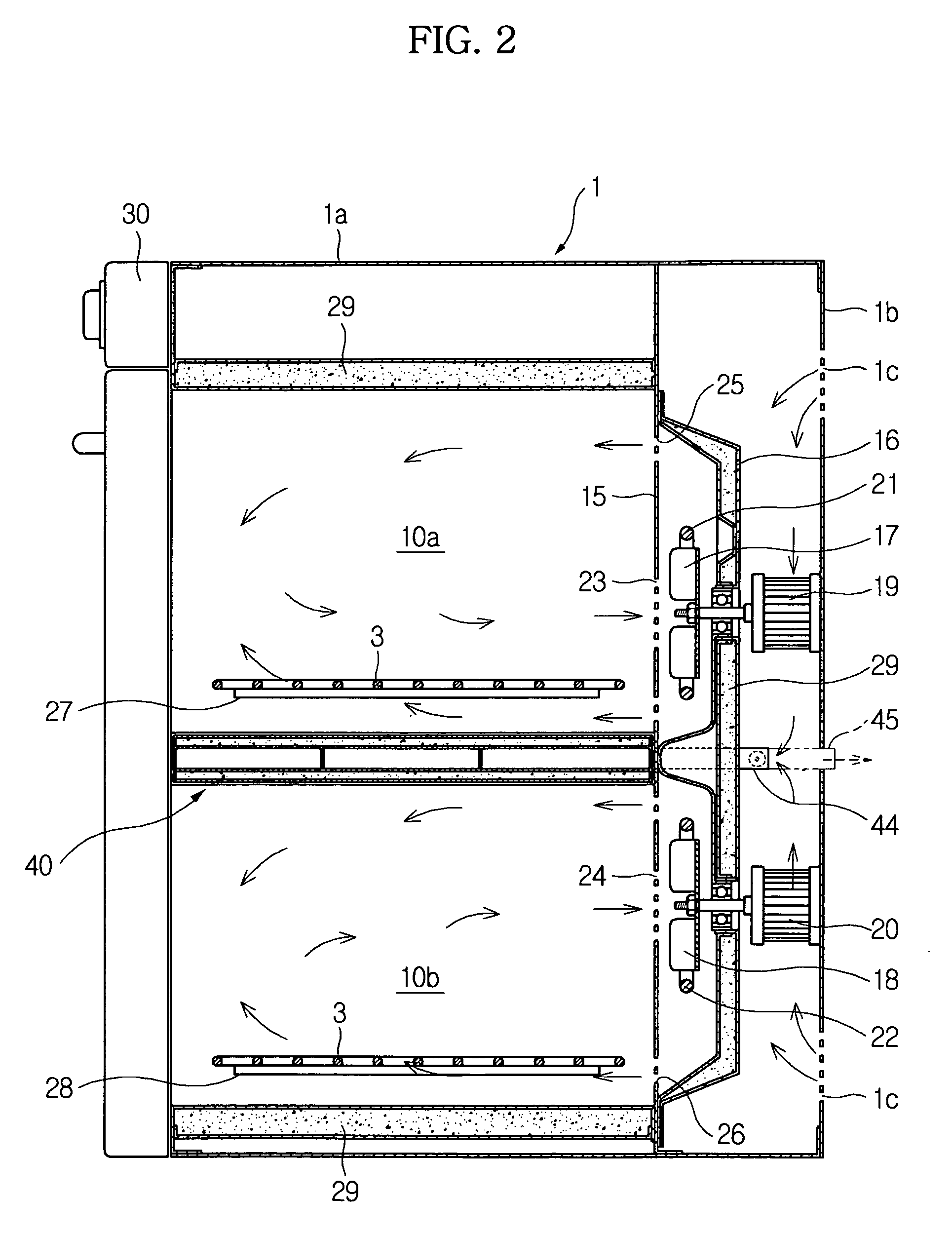

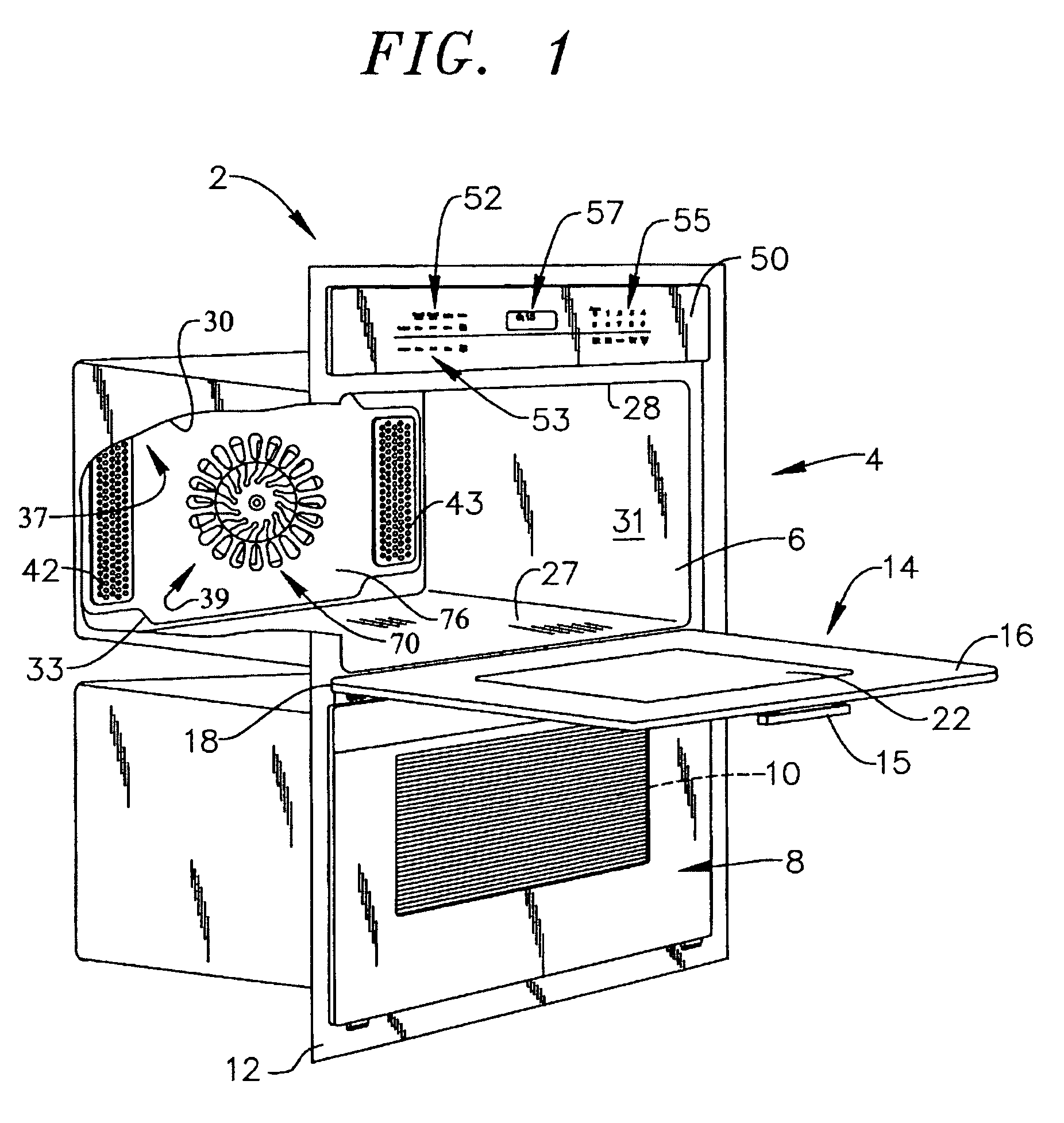

Oven

InactiveUS7129447B1Prevent heat transferDomestic stoves or rangesStoves/ranges shelves or racksAir layerElectrical and Electronics engineering

An oven having a partition unit to partition a cooking space into a plurality of independent cooking chambers wherein the partition unit has a heat-insulating structure to prevent heat transfer between the respective cooking chambers. The oven comprises a cabinet, a door to open and close an opened front surface of the cabinet, a partition unit to partition the interior of the cabinet into a plurality of independent cooking chambers, and electric heaters mounted in the cooking chambers. The partition unit includes first and second heat-insulating layers opposite to each other and an air layer disposed between the first and second heat-insulating layers. An inlet and an outlet are formed at the air layer, and a blowing fan is mounted at the inlet. Bent guide members are disposed in the air layer to guide air such that the air uniformly flows throughout the air layer.

Owner:SAMSUNG ELECTRONICS CO LTD

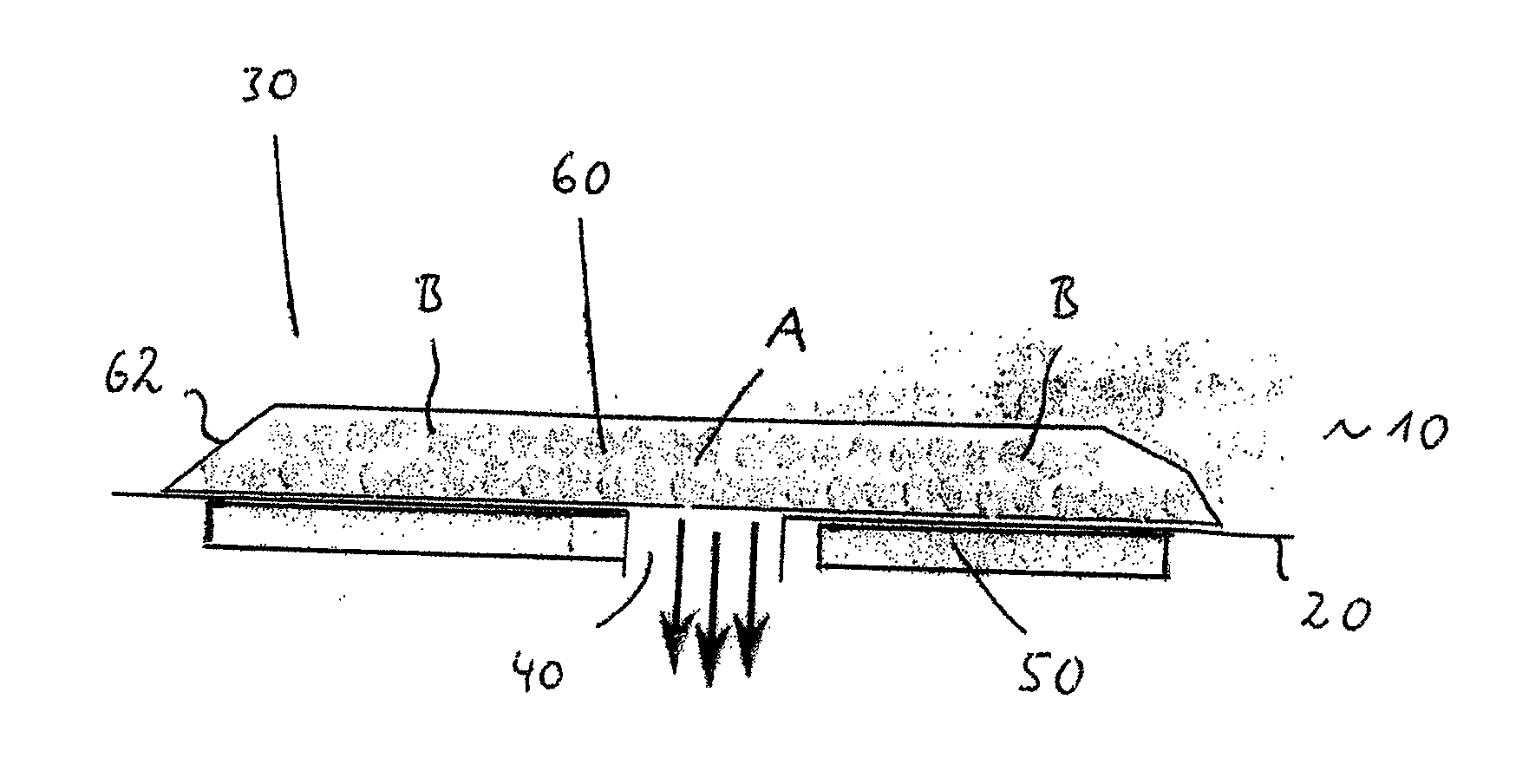

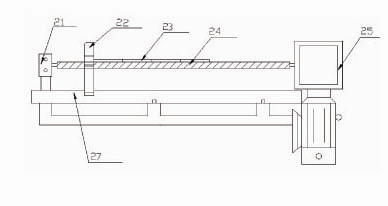

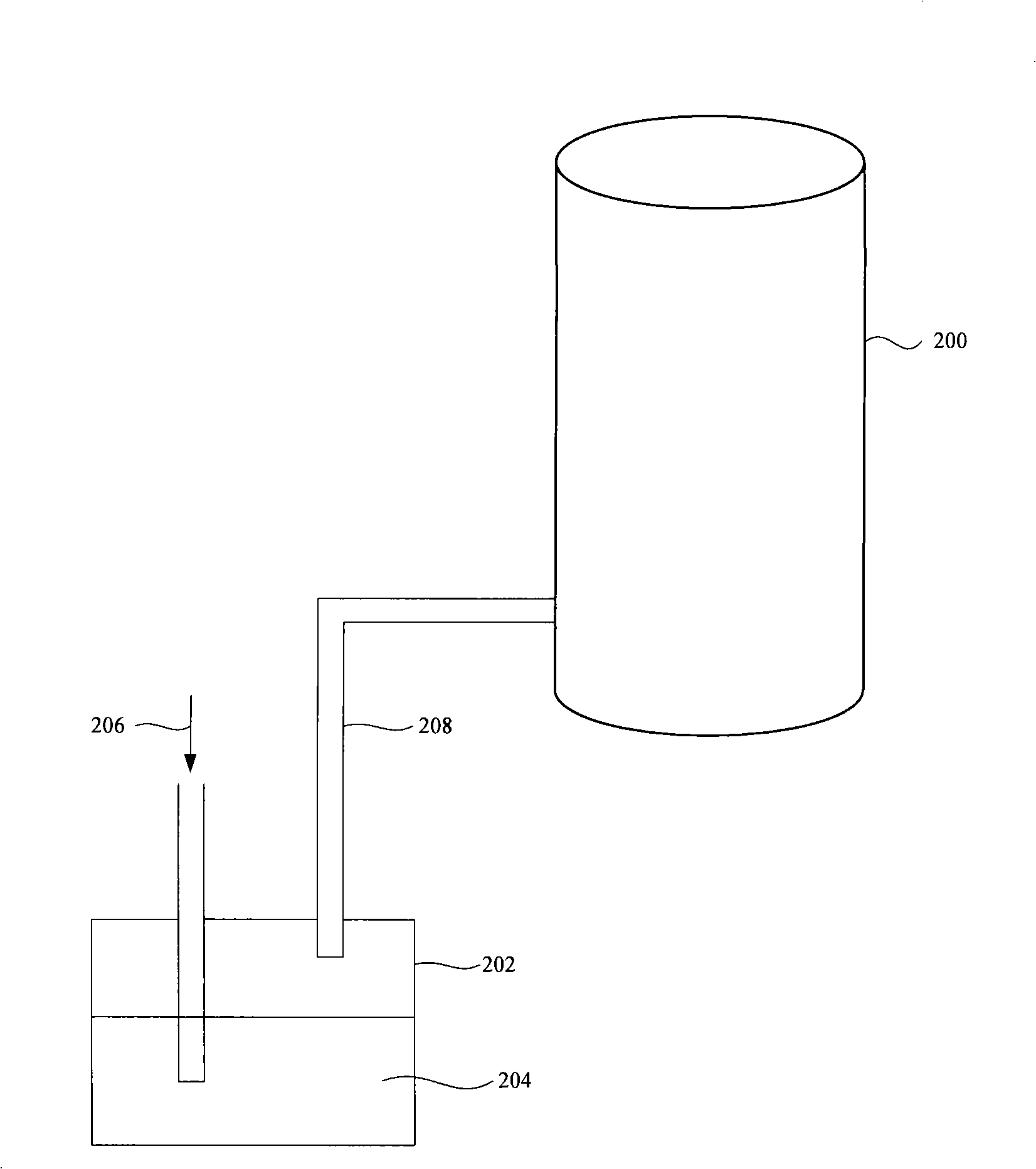

Continuous infrared furnace

A furnace of controlled heating and treatment of material using infrared radiation. The furnace is capable of continuous infrared treating of material with consistent radiation being applied to the material, ease of access to the furnace for maintenance cleaning and repair, excellent control of radiant cooling of the material to be treated, and ease of maintenance of a volatile component condenser.

Owner:ILLINOIS TOOL WORKS INC

Method and system for cleaning boiler tube

InactiveCN101327487AEasy to cleanHigh purityHollow article cleaningMaintainance of heating chambersEngineeringCleaning methods

The invention discloses a furnace tube cleaning system and method. Nitrogen gas enters into a cleaning agent tank, wherein, the cleaning agent carried by the nitrogen gas enters into the furnace tube via a pipeline to clean the furnace tube; hydrogen and oxygen are mixed to produce water vapor which enters into the furnace tube to clean the furnace tube. The furnace tube cleaning method of the invention is capable of effectively removing the metallic and non-metallic impurity sediments inside the furnace tubes in the semiconductor calcar pipes.

Owner:SEMICON MFG INT (SHANGHAI) CORP

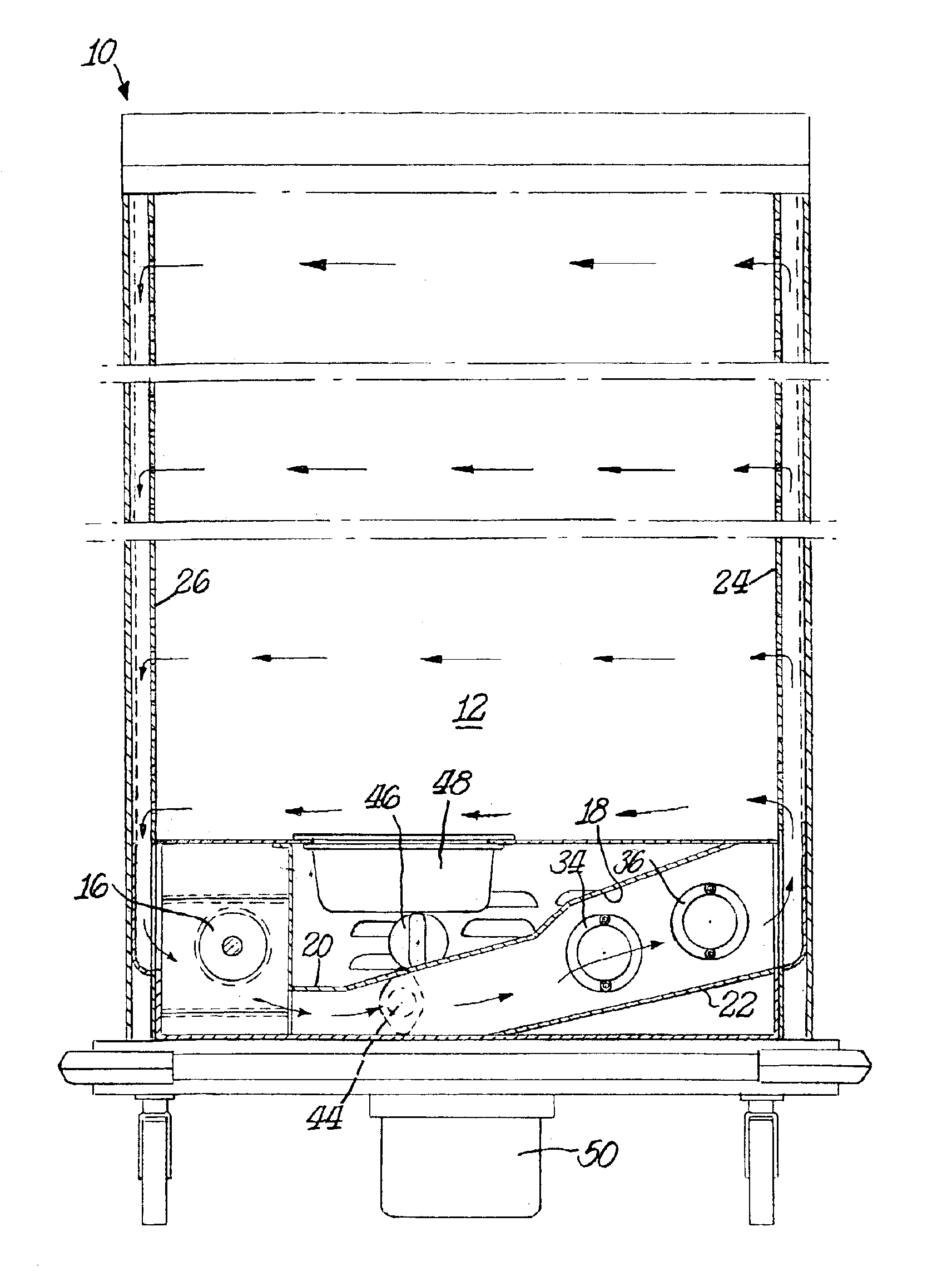

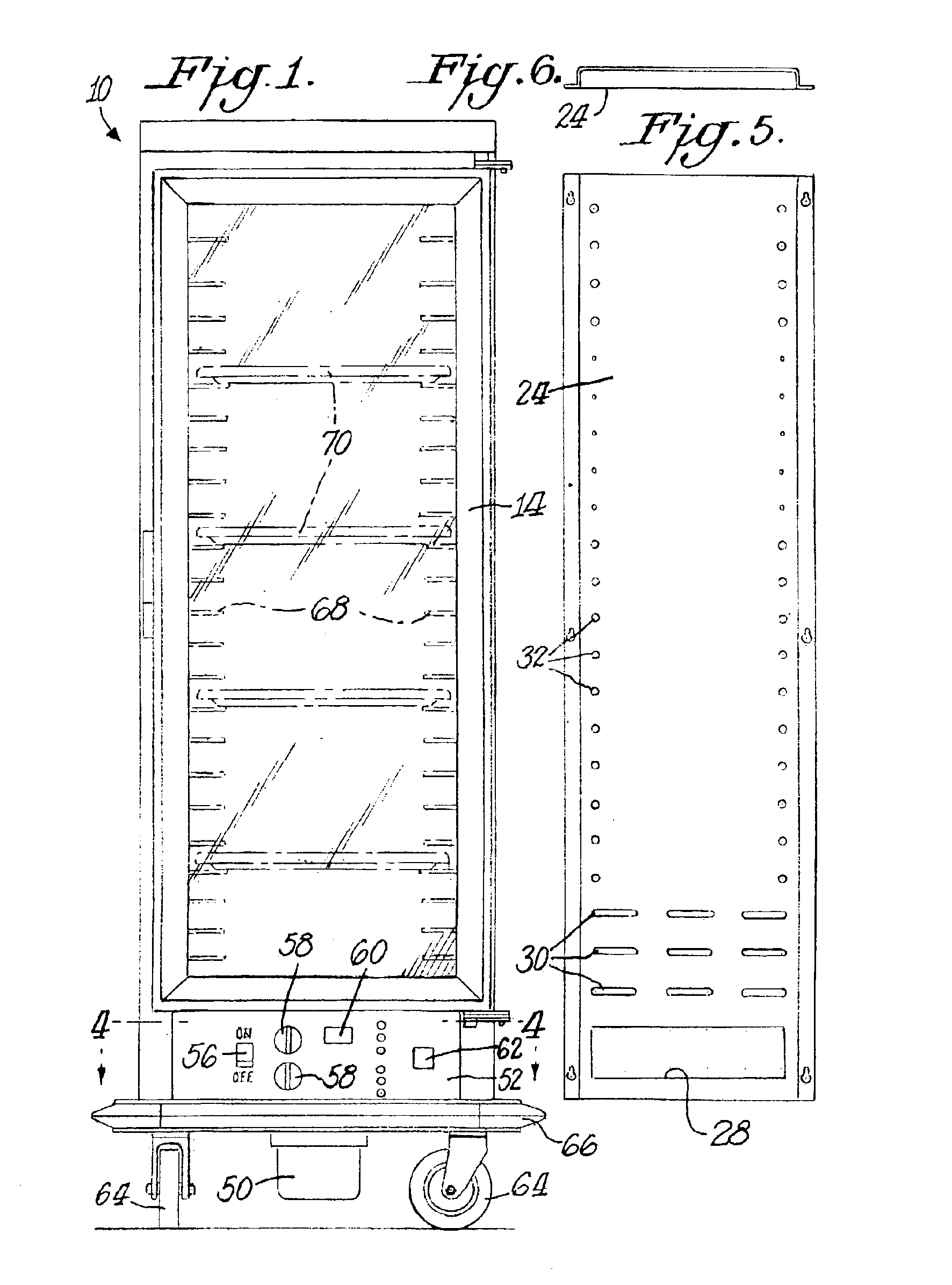

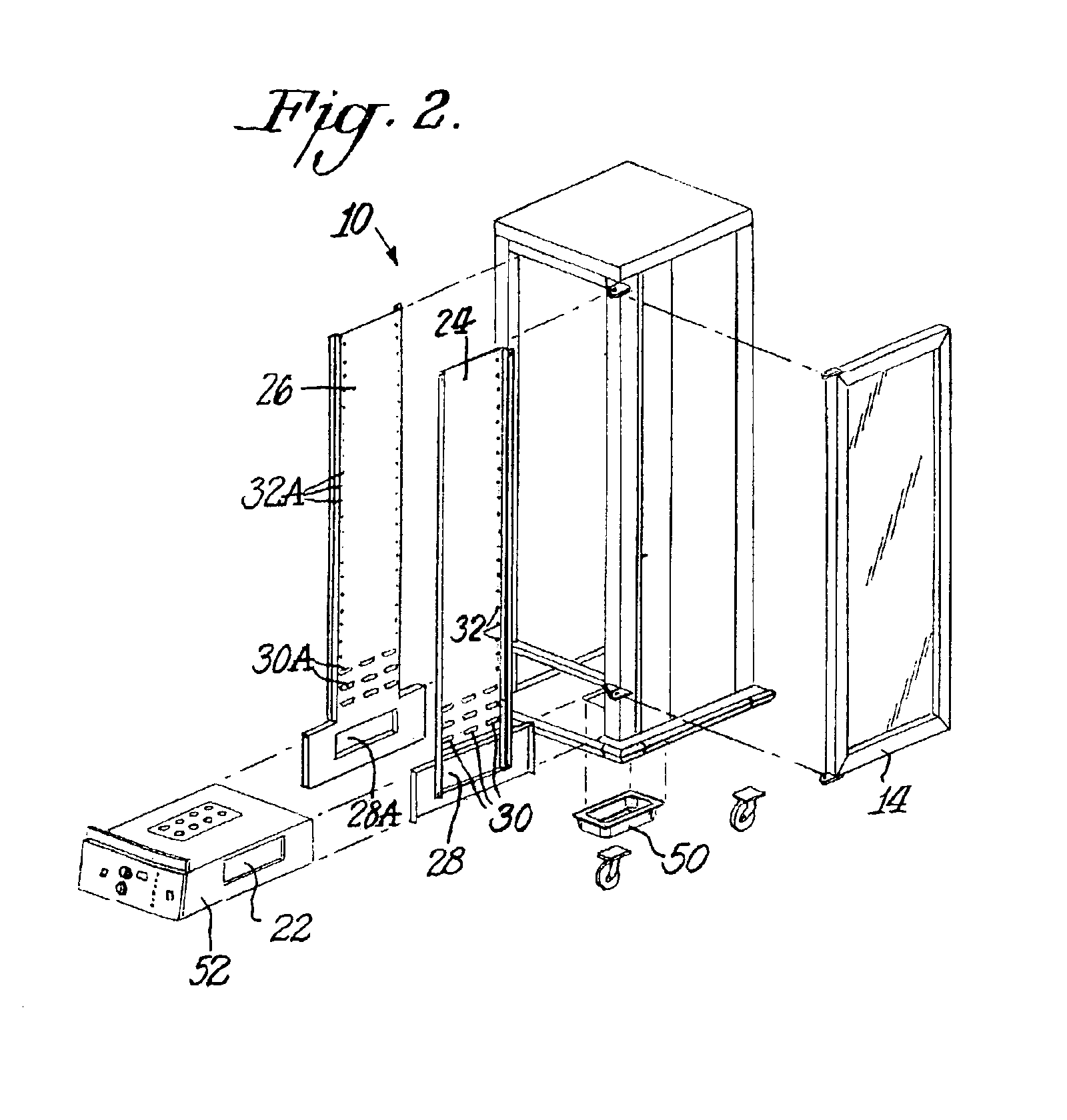

Heated proofing cabinet

InactiveUS6847013B2Increase air circulationEffective regulationAir-treating devicesDomestic stoves or rangesInterior spaceForced-air

A heated proofing cabinet with improved air flow and minimal air leakage comprises an enclosure having an interior space and an access door. A blower is positioned to supply forced air into the interior space of the enclosure and at least one heater is positioned to heat the air. A venturi air flow chamber has an entrance end connected to receive forced air from the blower and an exit end connected to deliver air to the interior space of the enclosure. A first air duct receives air from the exit end of the venturi air flow chamber and distributes the air to the interior space of the enclosure, and a second air duct receives air from the interior space of the enclosure and directs the air to the blower. Temperature and humidity levels within the interior space of the enclosure are controlled.

Owner:METAL MASTERS FOOD SERVICE EQUIP

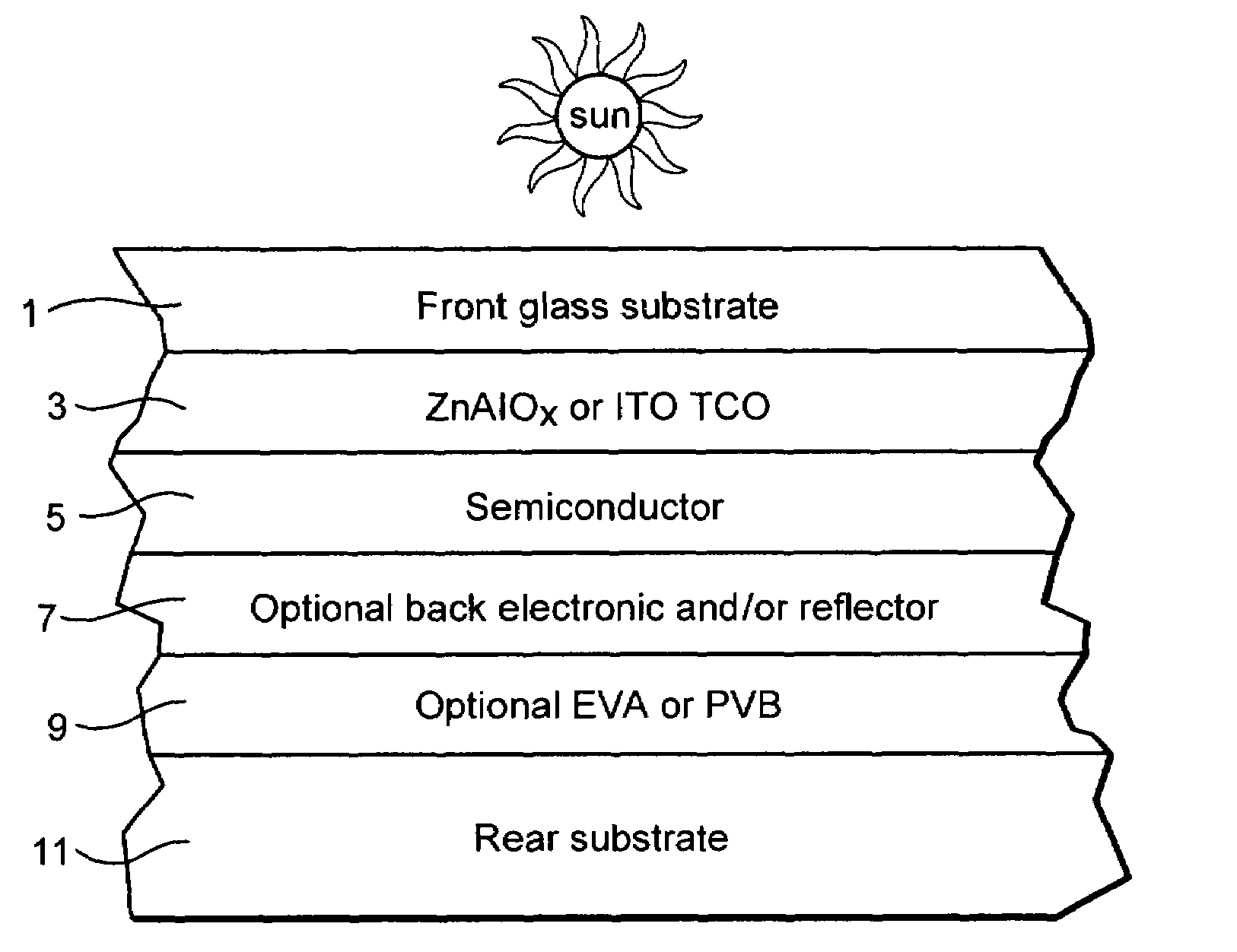

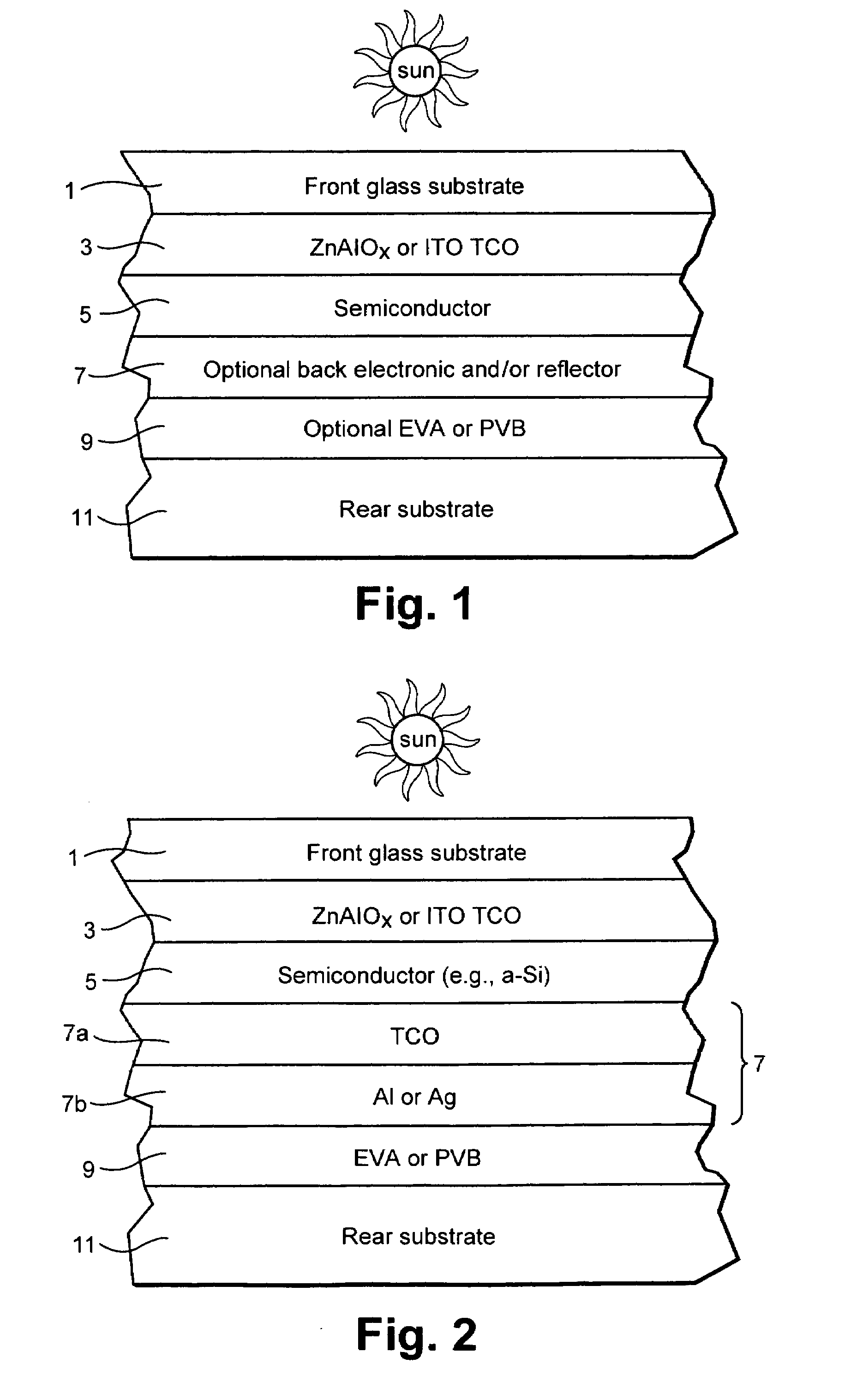

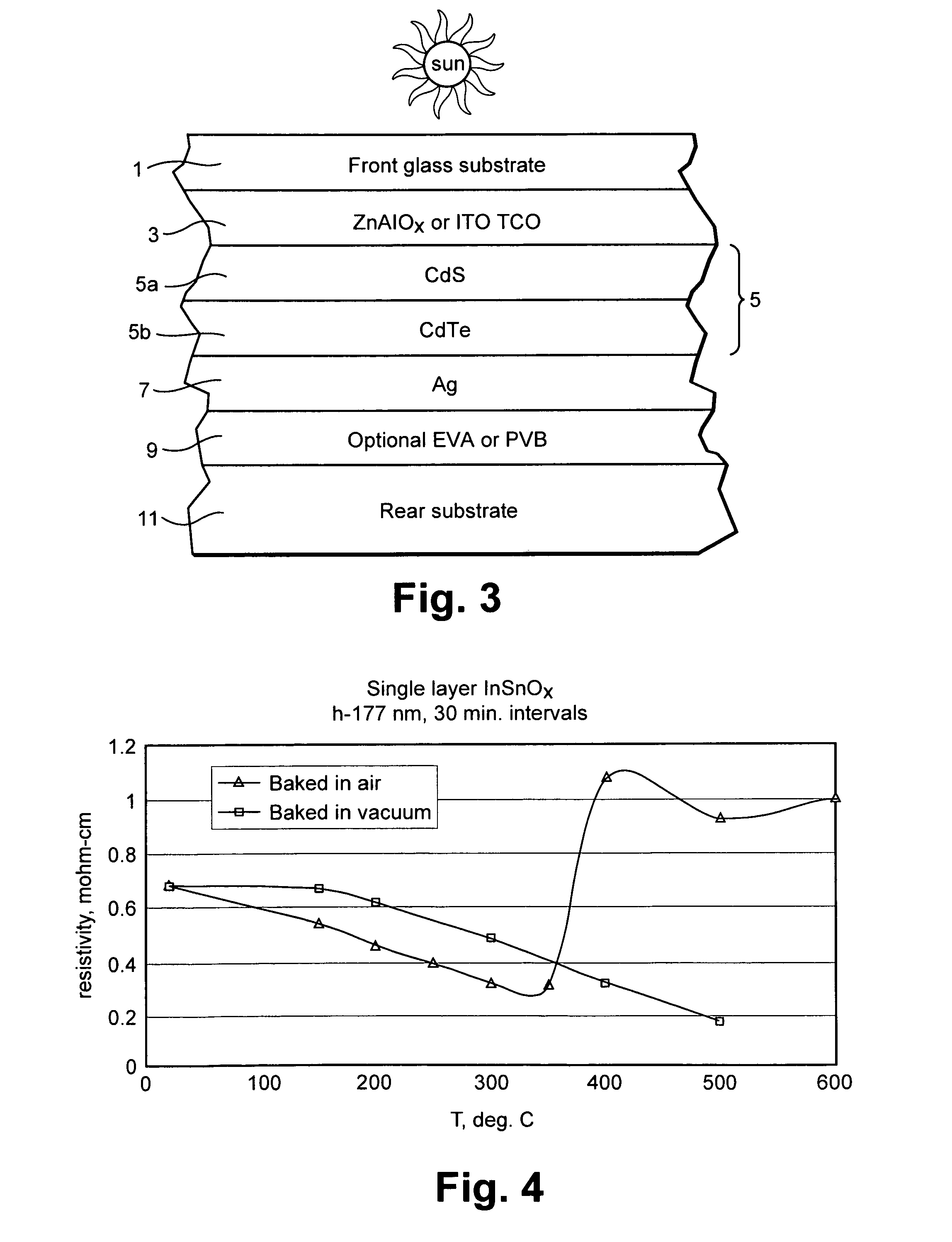

Method of enhancing the conductive and optical properties of deposited indium tin oxide (ITO) thin films

InactiveUS20100304523A1Improve conductivityReduce sheet resistanceMuffle furnacesMaintainance of heating chambersOptical propertyIndium tin oxide

Certain example embodiments of this invention relate to a method of activating an indium tin oxide (ITO) thin film deposited, directly or indirectly, on a substrate. The ITO thin film is baked in a low oxygen environment at a temperature of at least 450 degrees C. for at least 10 minutes so as to provide for (1) a post-baked resistivity of the ITO thin film that is below a resistivity of a corresponding air-baked ITO thin film, (2) a post-baked visible spectrum absorption and transmission of the ITO thin film that respectively are below and above the absorption and transmission of the corresponding air-baked ITO thin film, and (3) a post-baked infrared reflectivity of the ITO thin film that is above the reflectivity of the corresponding air-baked ITO thin film. The substrate with the activated ITO thin film may be used in a photovoltaic device, for example.

Owner:GUARDIAN GLASS LLC

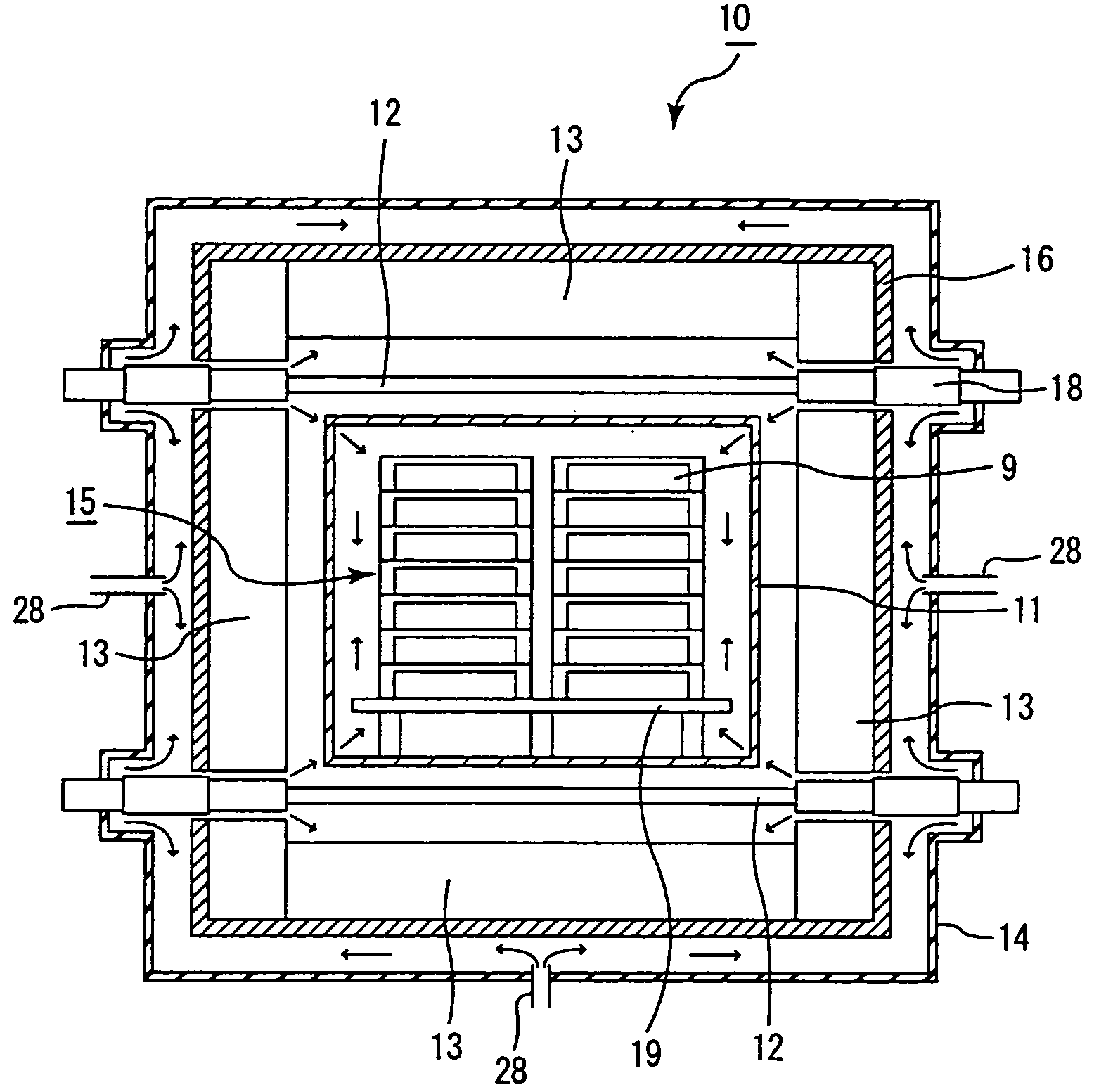

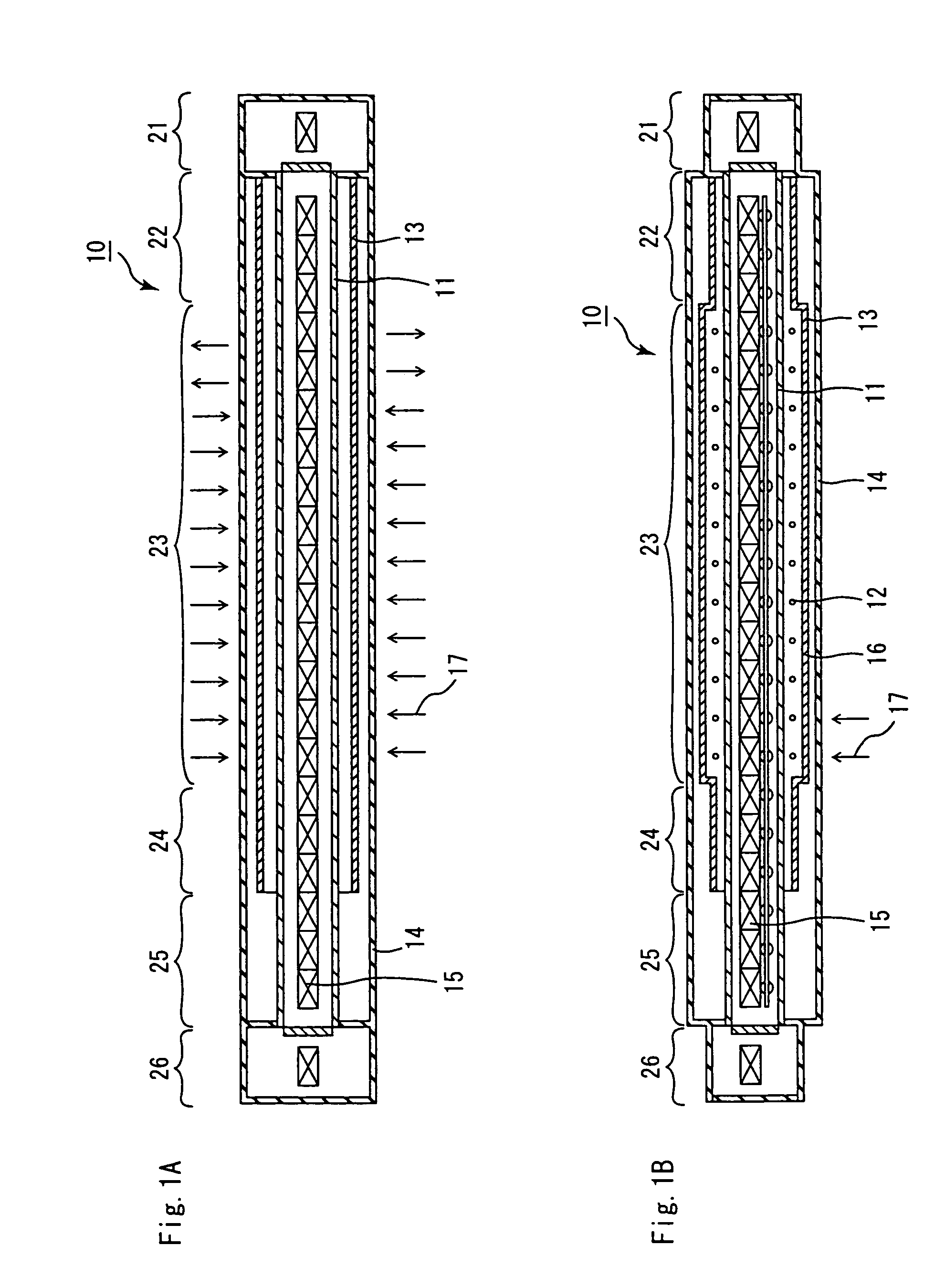

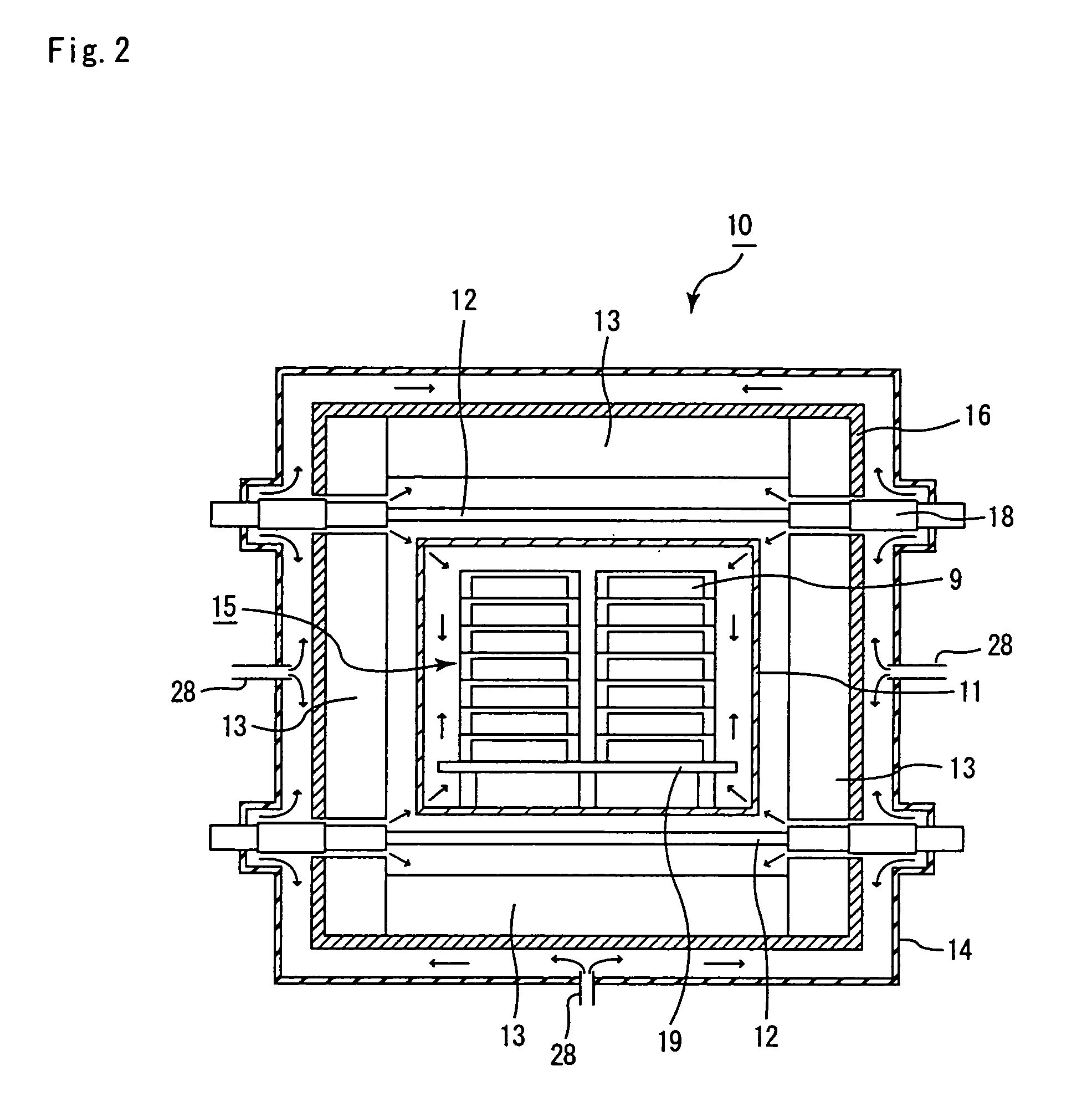

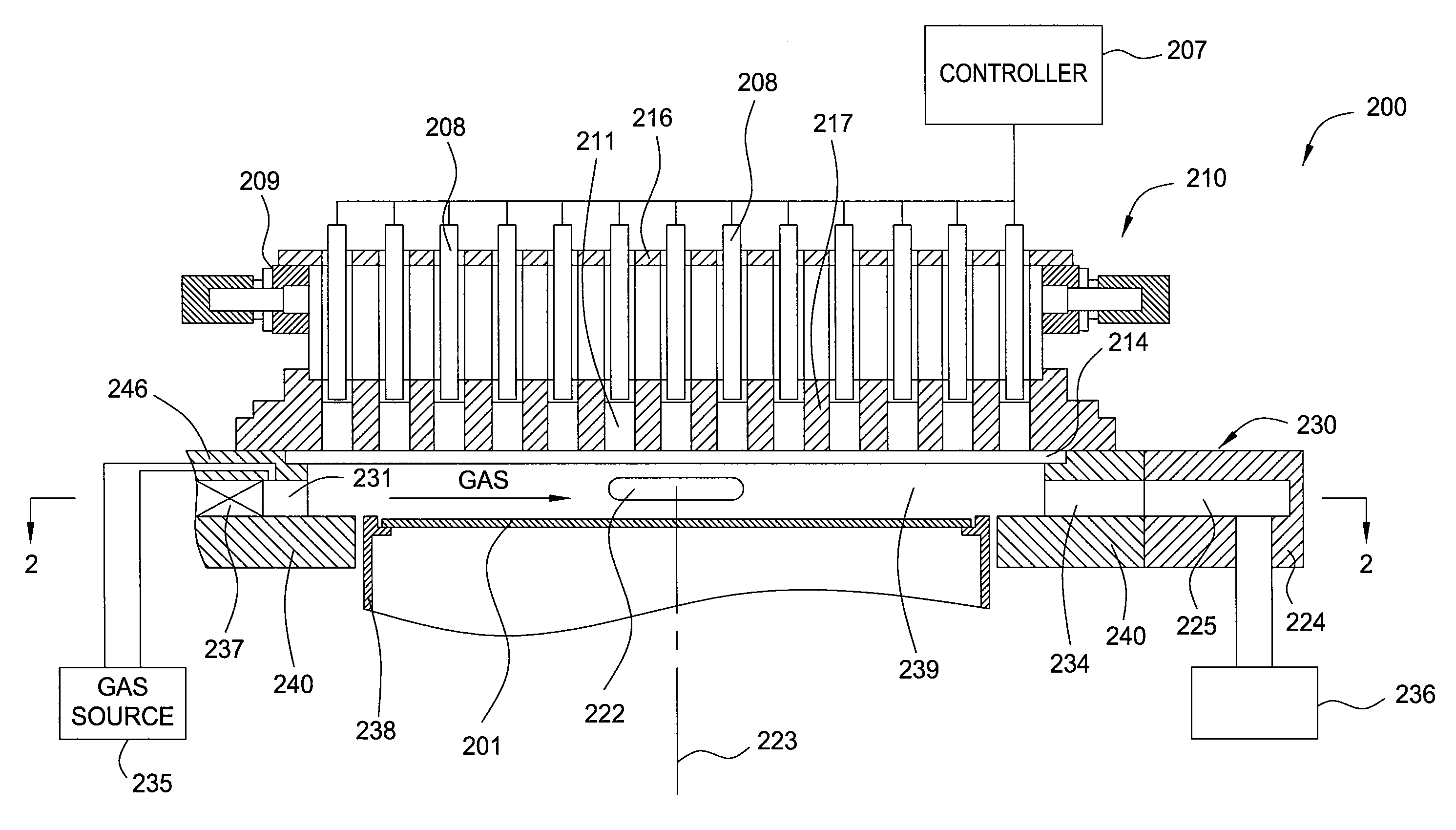

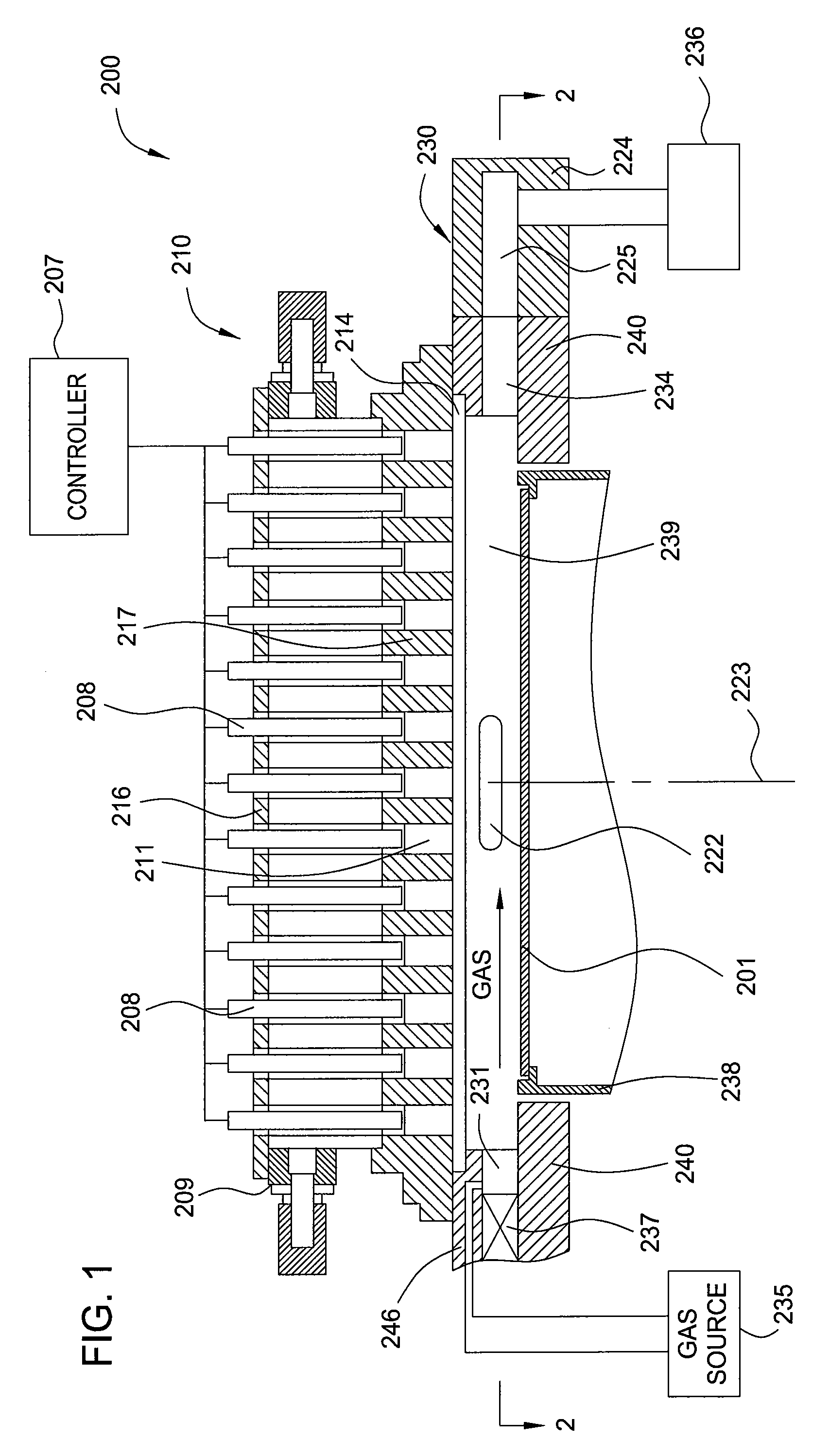

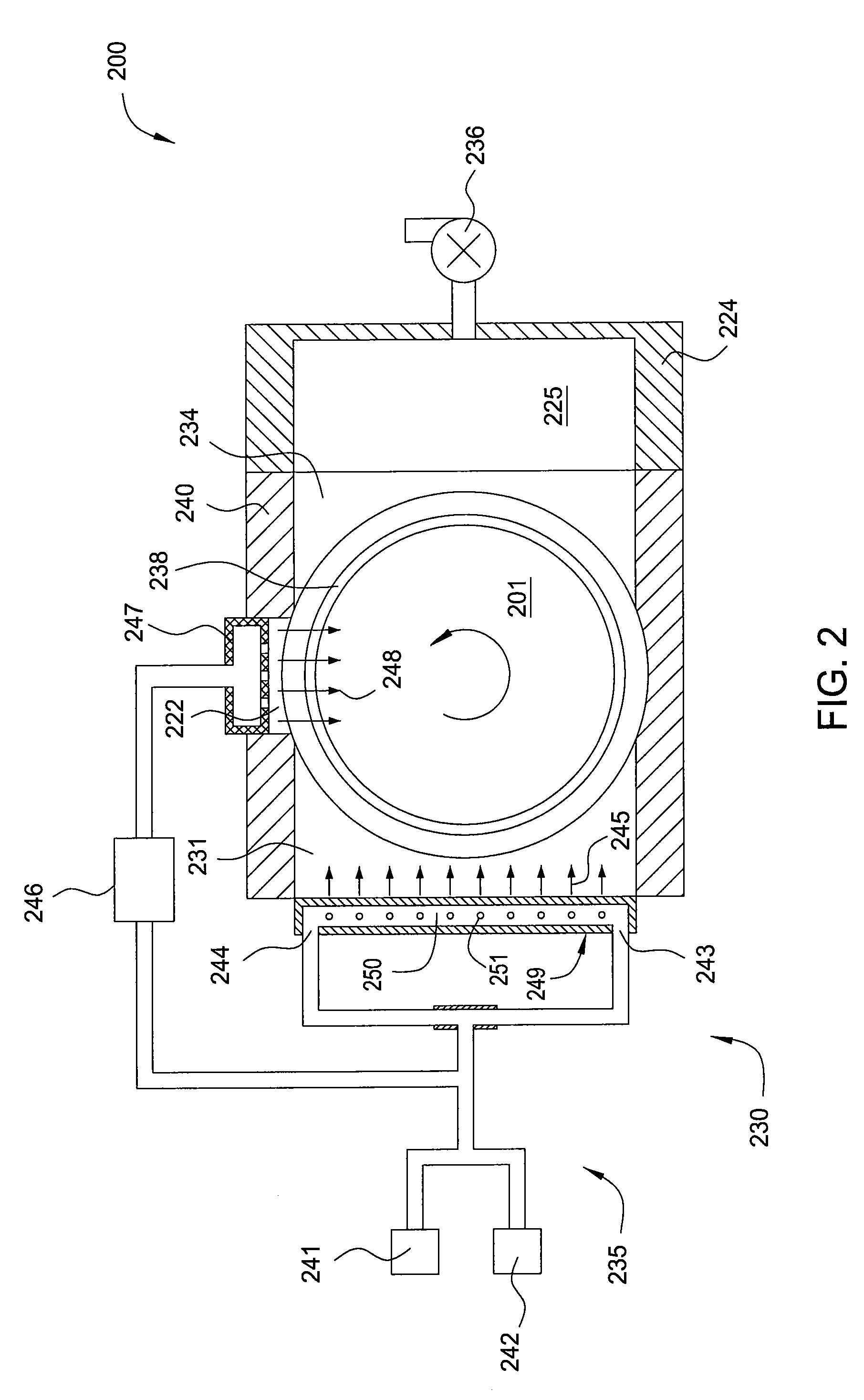

Thermal reactor with improved gas flow distribution

ActiveUS20090163042A1Improved gas distributionSemiconductor/solid-state device manufacturingMaintainance of heating chambersProcess engineeringHeat treated

Embodiments of the present invention provide apparatus and method for improving gas distribution during thermal processing. One embodiment of the present invention provides an apparatus for processing a substrate comprising a chamber body defining a processing volume, a substrate support disposed in the processing volume, wherein the substrate support is configured to support and rotate the substrate, a gas inlet assembly coupled to an inlet of the chamber body and configured to provide a first gas flow to the processing volume, and an exhaust assembly coupled to an outlet of the chamber body, wherein the gas inlet assembly and the exhaust assembly are disposed on opposite sides of the chamber body, and the exhaust assembly defines an exhaust volume configured to extend the processing volume.

Owner:APPLIED MATERIALS INC

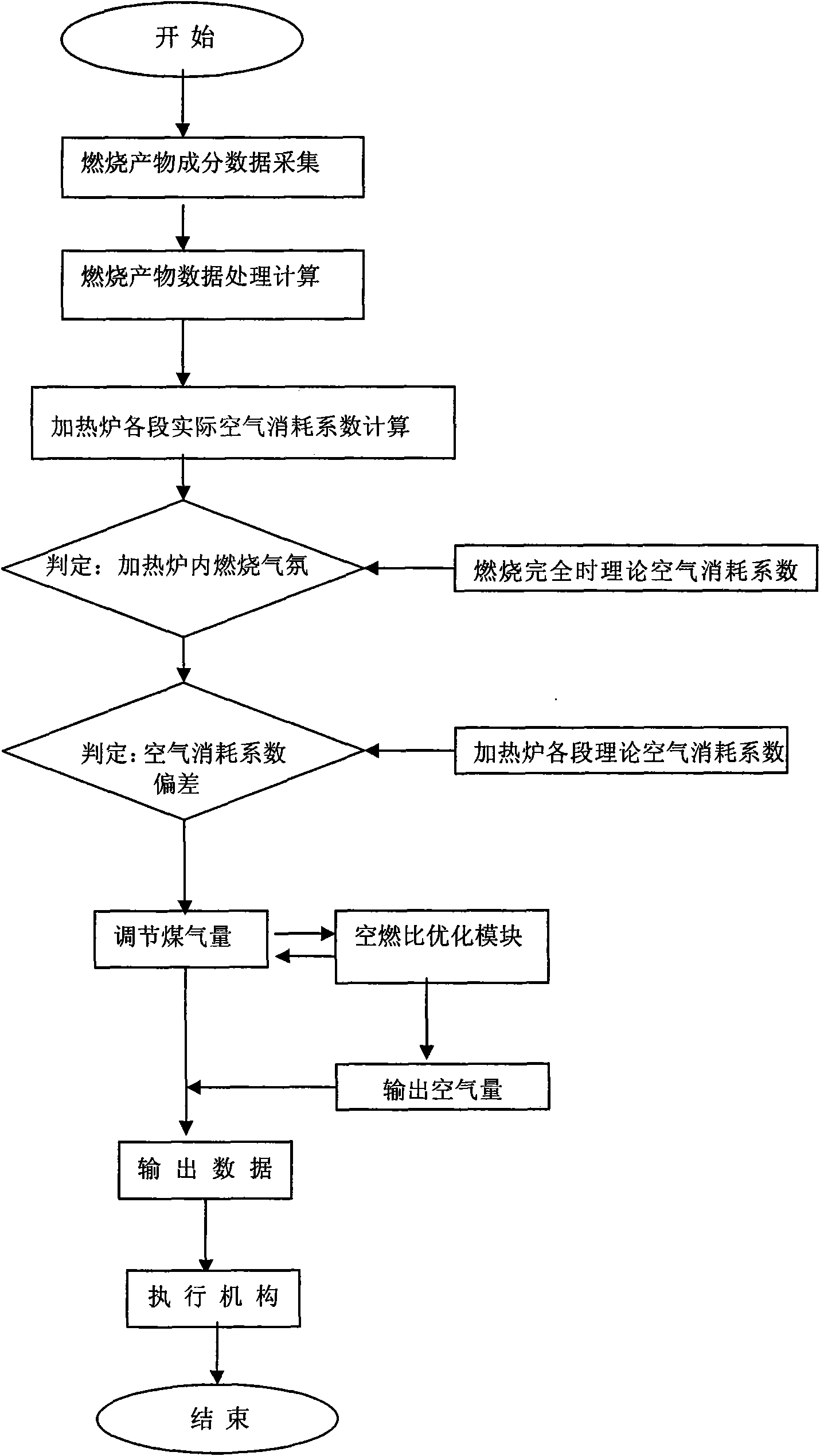

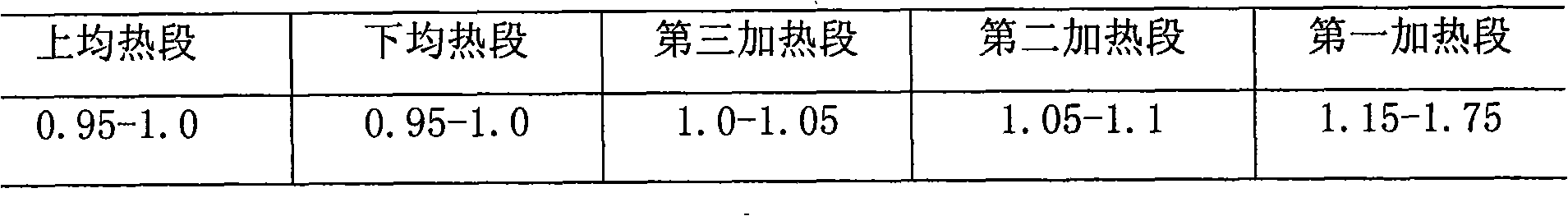

Method for controlling combustion atmosphere in large-scale walking beam type plate blank heating furnace

ActiveCN101561224AReduce burning rateReduce heat lossMaintainance of heating chambersFurnace typesFurnace temperatureComputer control system

The invention relates to a method for controlling combustion atmosphere in a large-scale walking beam type plate blank heating furnace, which belongs to the technical field of fuel combustion of industrial furnaces. A plate blank is heated through a preheating section, each heating section and a soaking section to finish the process of heating and temperature equilibrium; and in the process, a first-level computer control system and a second-level computer control system automatically generate a heating process and automatically set and control the furnace temperature in each section according to original data of the plate blank called from a database; and on the basis of an output control value of a residual oxygen analyzer, the computer control systems calculate the air consumption coefficient of each combustion area, perform dynamic track on the combustion atmosphere in the whole furnace along with the changes of thermal loads, correct the combustion atmosphere according to the actual air-fuel ratio of six combustion areas, adjust the proportion of combustion air and gas, and determine the reasonable air and gas flow to achieve the furnace temperature required by the heating process. The method has the advantages that the condition of furnace gas component changes in the furnace is quantificationally provided for a heating furnace operator in time, so that the combustion in the heating furnace reaches good state; and simultaneously, the energy-saving and environmental protection effects are remarkable.

Owner:SHOUGANG CORPORATION

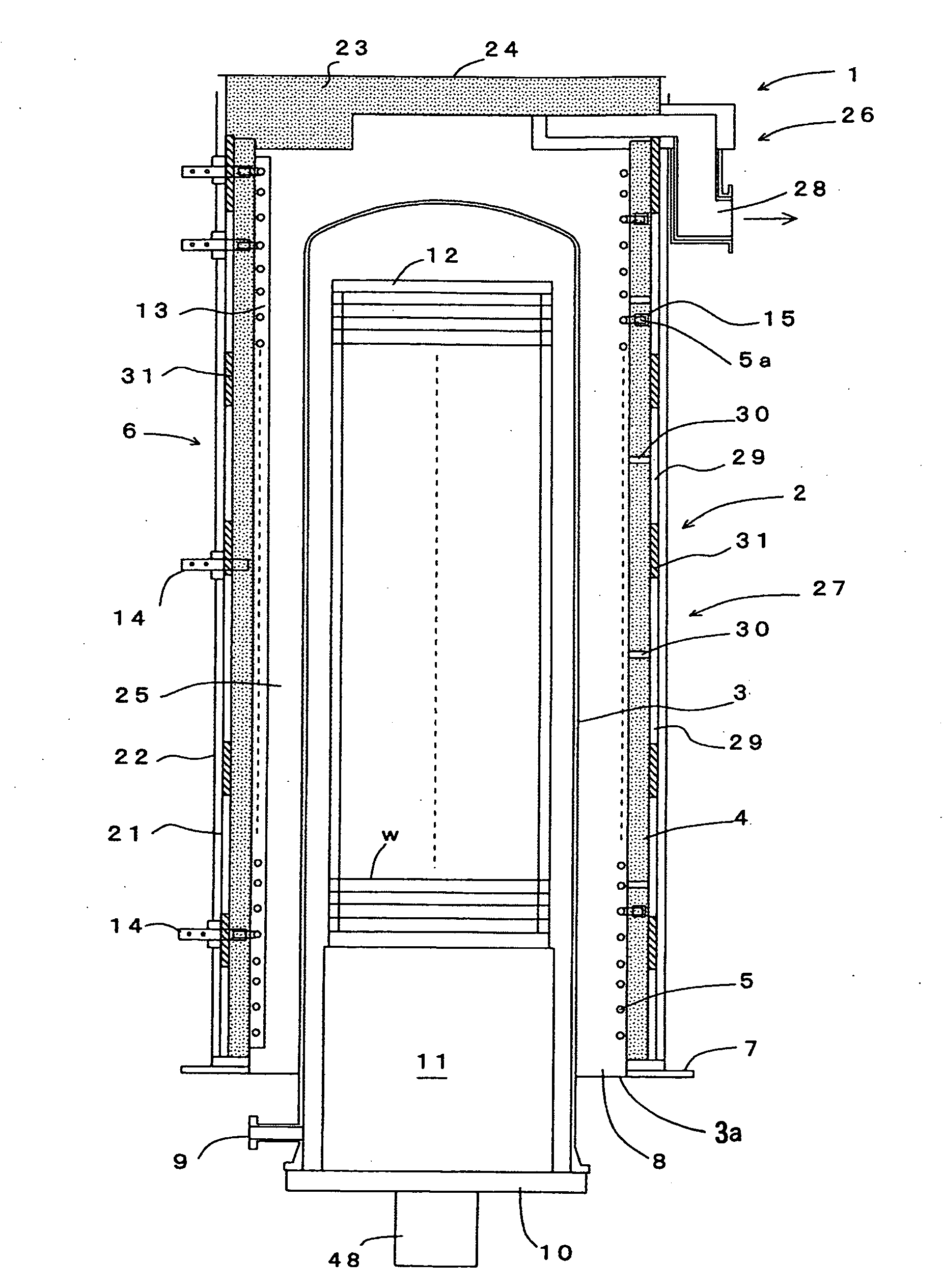

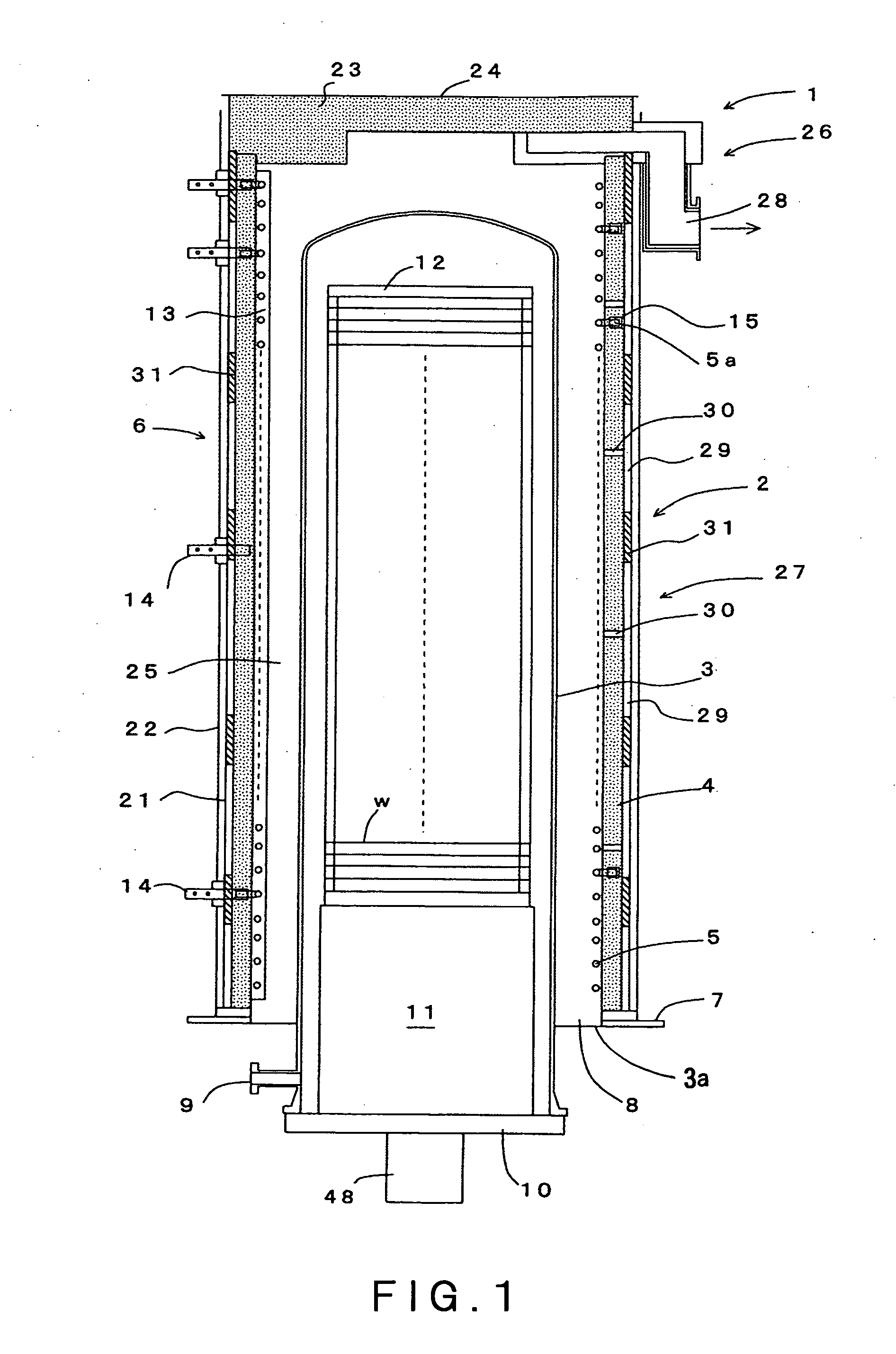

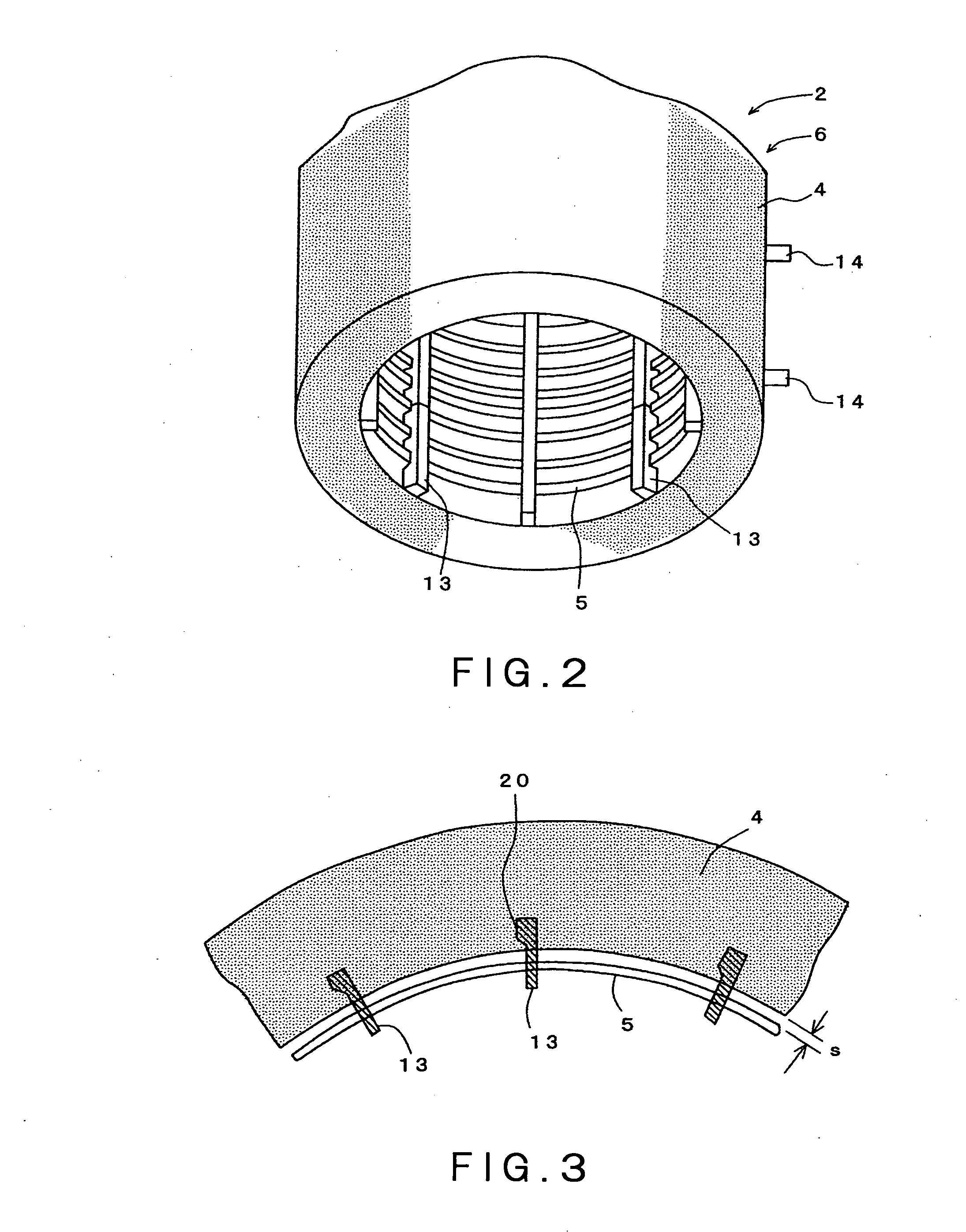

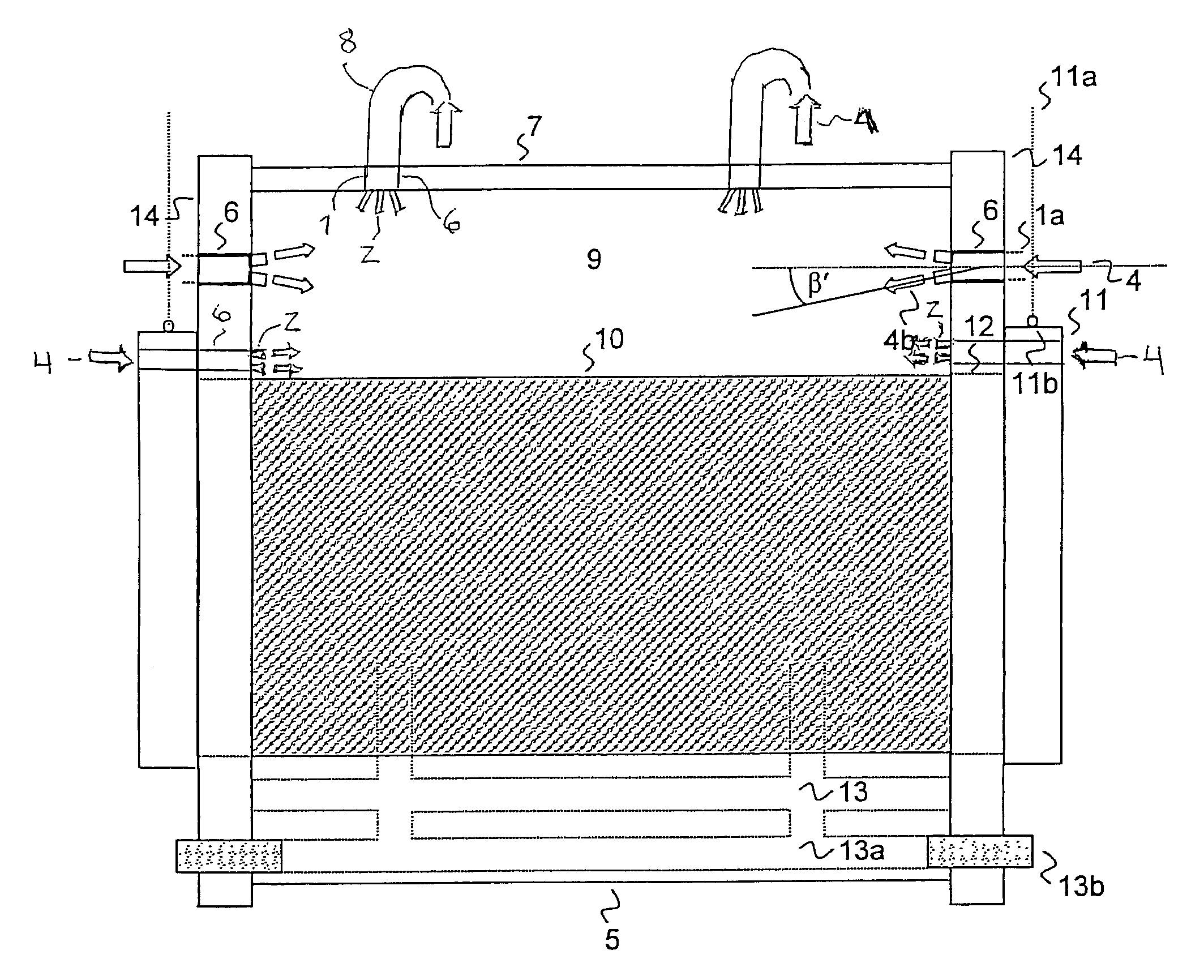

Heat processing furnace and method of manufacturing the same

ActiveUS20080296282A1Increased durabilityReduce frictional resistanceOhmic-resistance electrodesRotary drum furnacesCurve shapeEngineering

The object of the present invention is to reduce a frictional resistance which is generated between a support member and a heating resistor when the heating resistor is thermally expanded and thermally shrunk, whereby generation of a permanent deformation of the heating resistor caused by a residual stress thereof can be restrained, to thereby improve the durability. A heat processing furnace comprises: a processing vessel 3 capable of accommodating an object to be processed w and subjecting the object to be processed w to a heat process; a cylindrical heat insulation member 4 surrounding the processing vessel 3; a helical heating resistor 5 arranged along an inner peripheral surface of the heat insulation member 4; a support member 13 disposed on the inner peripheral surface of the heat insulation member 4 in parallel with an axial direction thereof, for supporting the heating resistor 5 at predetermined pitches along the axial direction; and a plurality of terminal plates 14 axially arranged on an outside of the heating resistor 5 at suitable intervals therebetween, the terminal plates 14 radially passing through the heat insulation member 4 so as to be extended outside. The support member 13 includes a base part 17 positioned on an inside of the heating resistor 5, and a plurality of support pieces 18 extending radially outward from the base part through spaces between adjacent portions of the heating resistor 5 so as to support the heating resistor 5, the support member 13 being formed to have a comb-like shape. An upper surface part of each of the support pieces 18 is formed to have a curved shape in order to reduce a frictional resistance generated when the heating resistor 5 is moved upon a thermal expansion and a thermal shrinkage thereof.

Owner:TOKYO ELECTRON LTD

Air distributing device for primary air in coke ovens

ActiveUS9404043B2Improved air distributionReduce formationCombustible gas coke oven heatingHorizontal chamber coke ovensCombustionCoke oven

A device for introduction of primary combustion air into the primary heating space of a coke oven chamber admits primary air through ports in the top of a oven chamber or in the oven chamber walls above the door or in the chamber door or in several or all of the mentioned positions These ports have inserts that are equipped with spouts, with the spouts having an opening through which primary air is conducted at a chamfered angle onto the coke cake. The primary air from the opening ports in the coke oven chamber top streams to the coke oven at an angle of less than 90° and primary air from the opening ports in the chamber wall above the door or in the door streams to the coke oven at an angle of greater than 0°. Also shown is a method for use with the described device.

Owner:THYSSENKRUPP IND SOLUTIONS AG

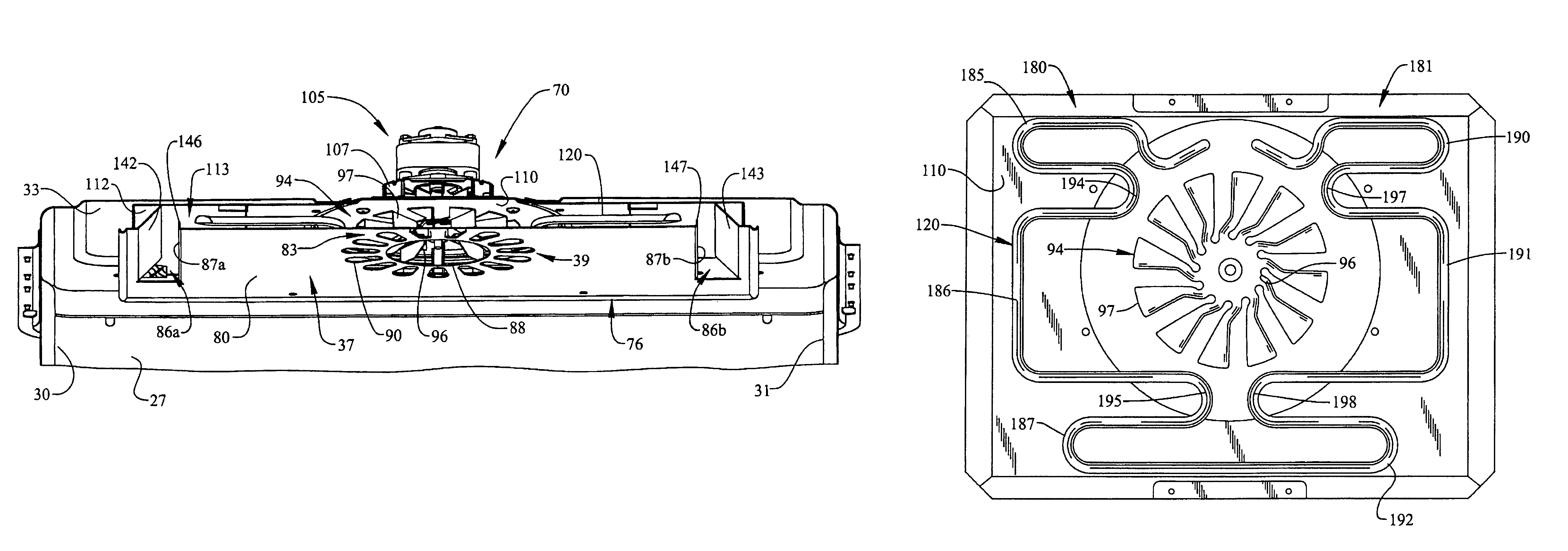

Airflow system for a convection oven

A convection cooking appliance includes a convection fan for establishing a convection airflow which is heated by a heating element including first and second sections that are symmetrically disposed about the convection fan substantially parallel to and downstream of the convection fan. Each of the first and second sections is formed so as to include at least three lobes and four 180° turns, while establishing a thin profile heating element. A convection fan cover extends across the convection fan and includes a main body portion having an outlet portion for directing the convection airflow into a cooking chamber of the appliance. The outlet portion includes an angled louver and a trip edge portion. The angled louver and trip edge portion cooperate to alter a direction of the convection airflow from being substantially parallel to the main body portion to being substantially perpendicular the main body portion.

Owner:MAYTAG

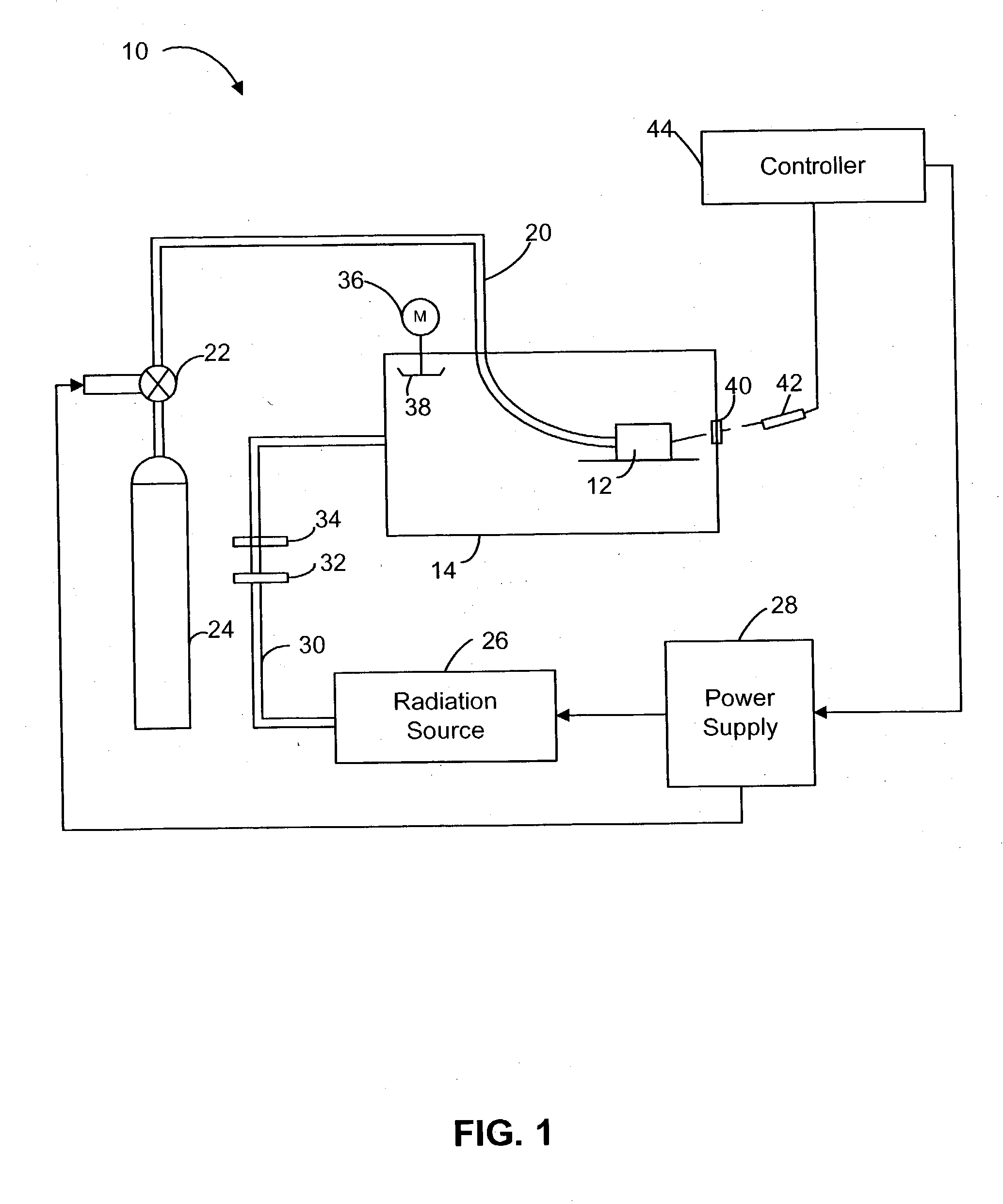

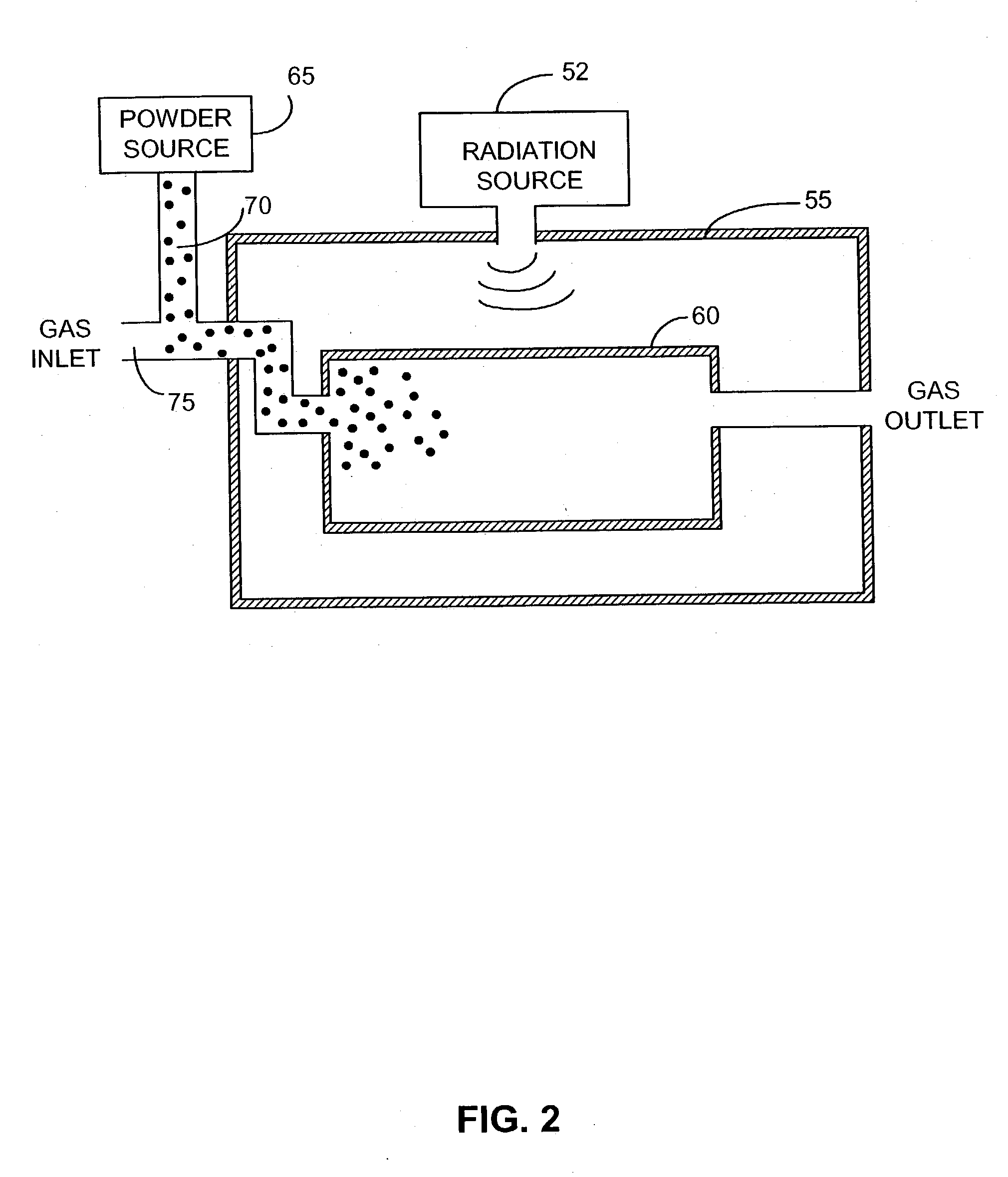

Plasma-assisted melting

InactiveUS7189940B2Electric discharge heatingExhaust apparatusElectromagnetic radiationMaterials science

Apparatus and methods for plasma-assisted melting are provided. In one embodiment, a plasma-assisted melting method can include: (1) adding a solid to a melting region, (2) forming a plasma in a cavity by subjecting a gas to electromagnetic radiation having a frequency less than about 333 GHz in the presence of a plasma catalyst, wherein the cavity has a wall, (3) sustaining the plasma in the cavity such that energy from the plasma passes through the wall into the melting region and melts the solid into a liquid, and (4) collecting the liquid. Solids that can be melted consistent with this invention can include metals, such as metal ore and scrap metal. Various plasma catalysts are also provided.

Owner:BTU INTERNATIONAL

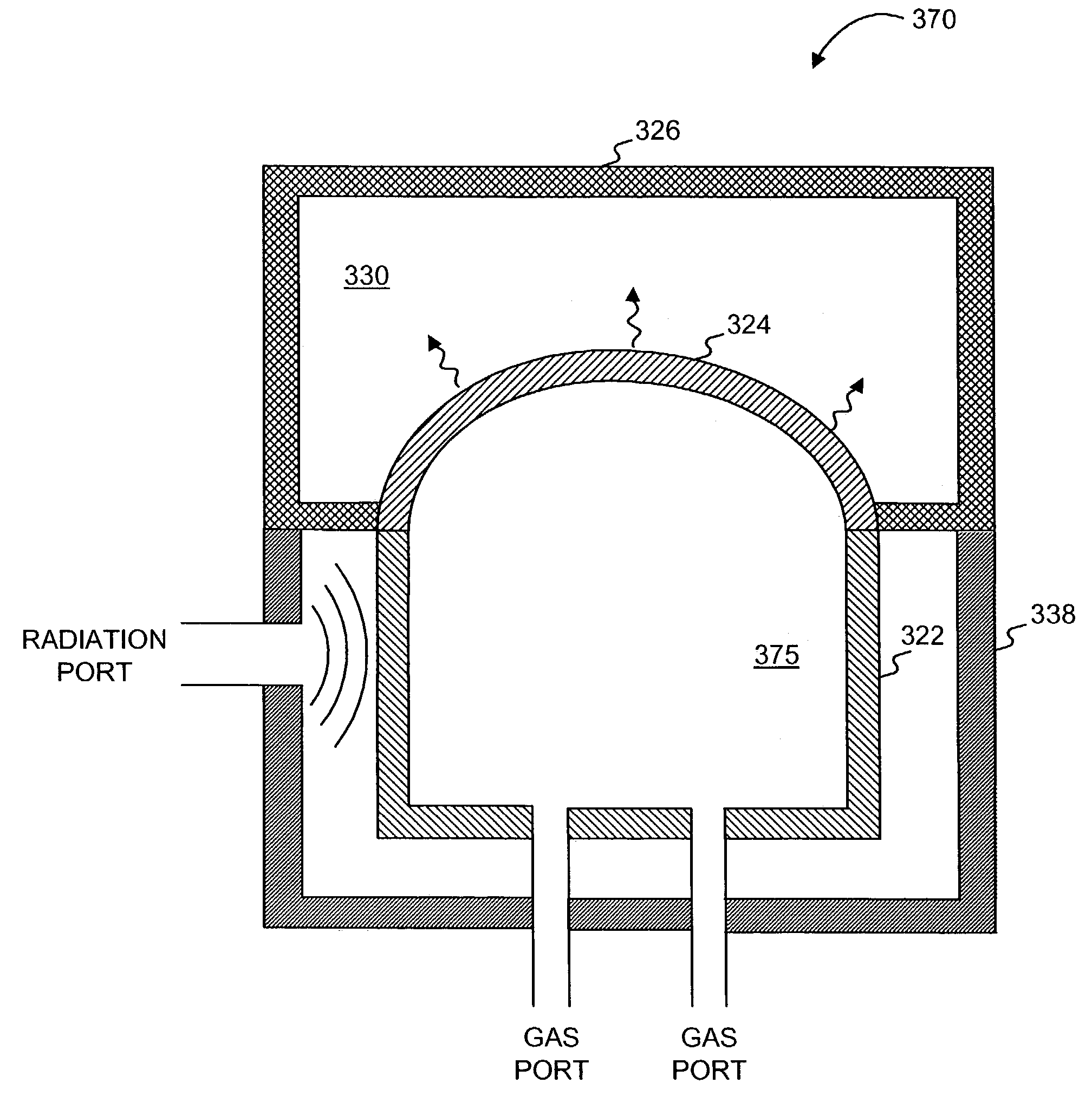

Blackbody furnace

InactiveUS6365877B1Improve cooling efficiencyReduce the temperatureRadiation pyrometryMuffle furnacesTemperature controlRoom temperature

A blackbody furnace, mainly comprising a radiation cavity, a thermally insulating layer, a heater, a housing, a temperature controller, an airflow controller and a high-pressure air source. Besides, a gas channel is provided at the bottom of the radiation cavity to conduct the interior of the furnace chamber with the exterior. In the process of lowering the temperature of the blackbody furnace, the airflow controller could be actuated by the temperature controller or by an operator. Therefore, the room-temperature high-pressure air will enter the radiation cavity through the gas channel to fast cool down the radiation cavity. Finally, heat air will be vented from an opening at the front end of the radiation cavity. The present invention utilizes forced convection to enhance the efficiency of heat dissipation to fast lower the temperature of the blackbody furnace.

Owner:IND TECH RES INST

Popular searches

Nanoinformatics Record information storage Inductances/transformers/magnets manufacture Automatic grinding control Galvano-magnetic device manufacture/treatment Electrical transducers Manufacture head surface Manufacturing heads with multiple gaps Manufacture unitary devices of plural heads Magnetic-field-controlled resistors

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com