Patents

Literature

41results about How to "Improved gas distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

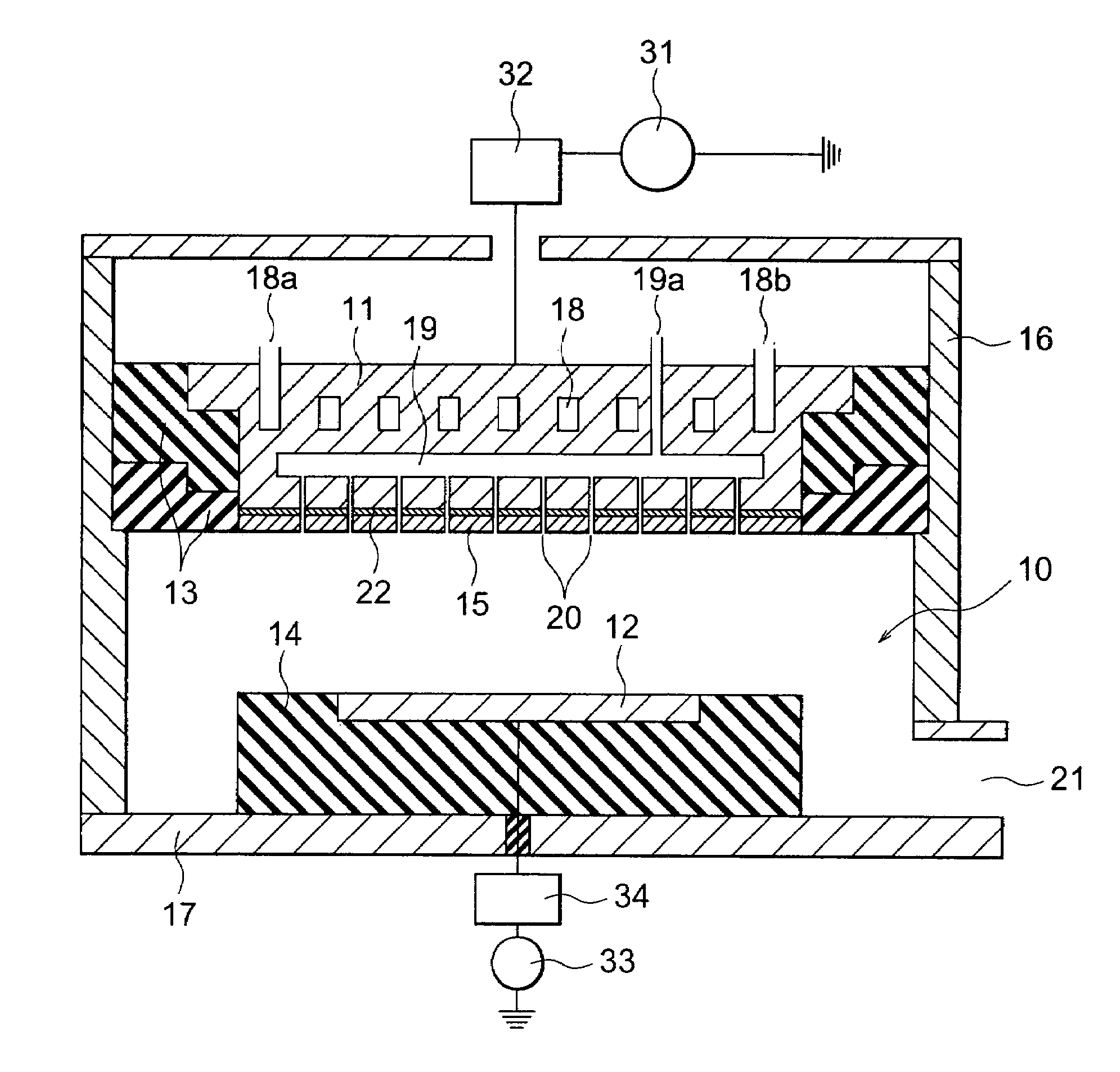

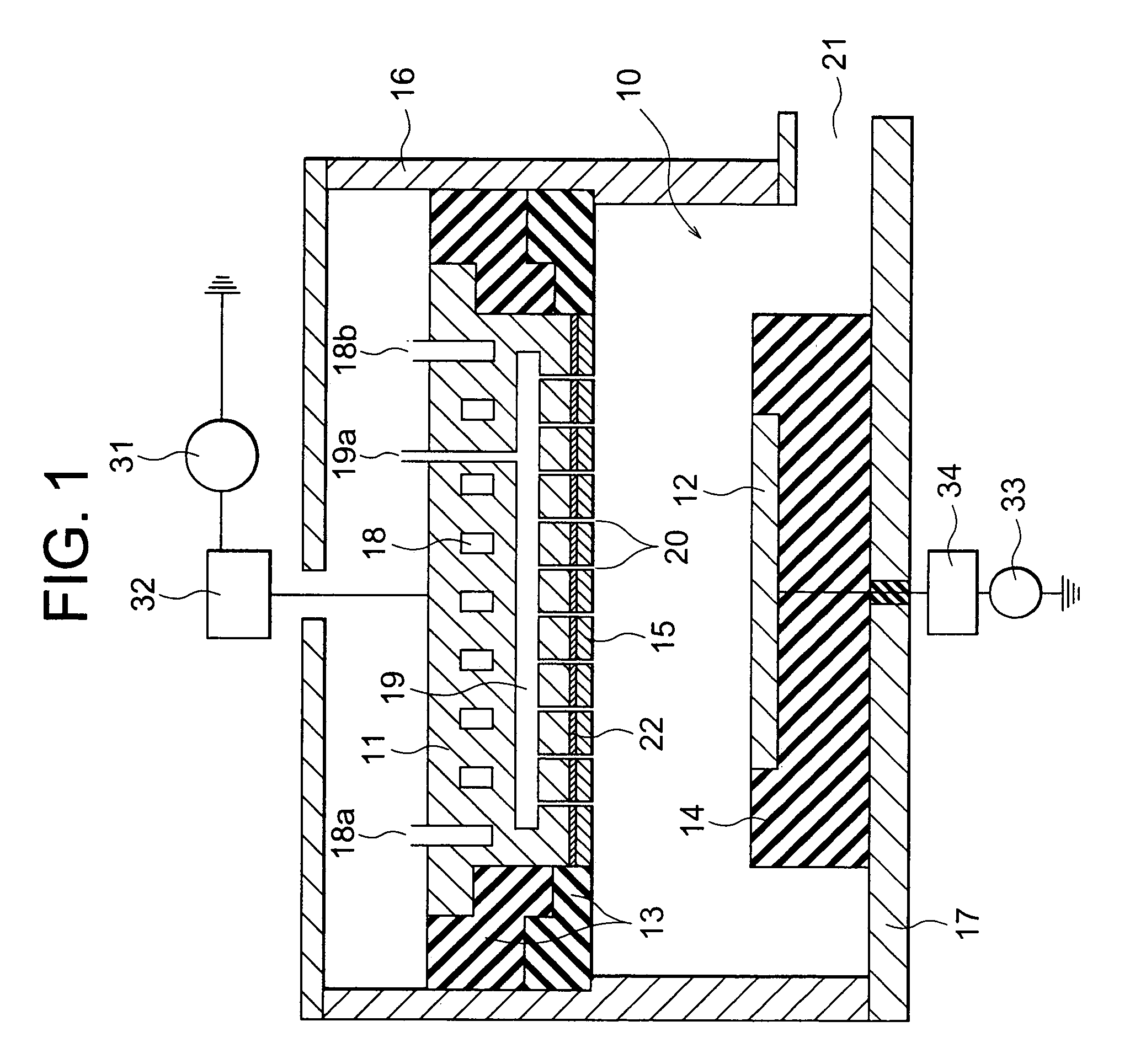

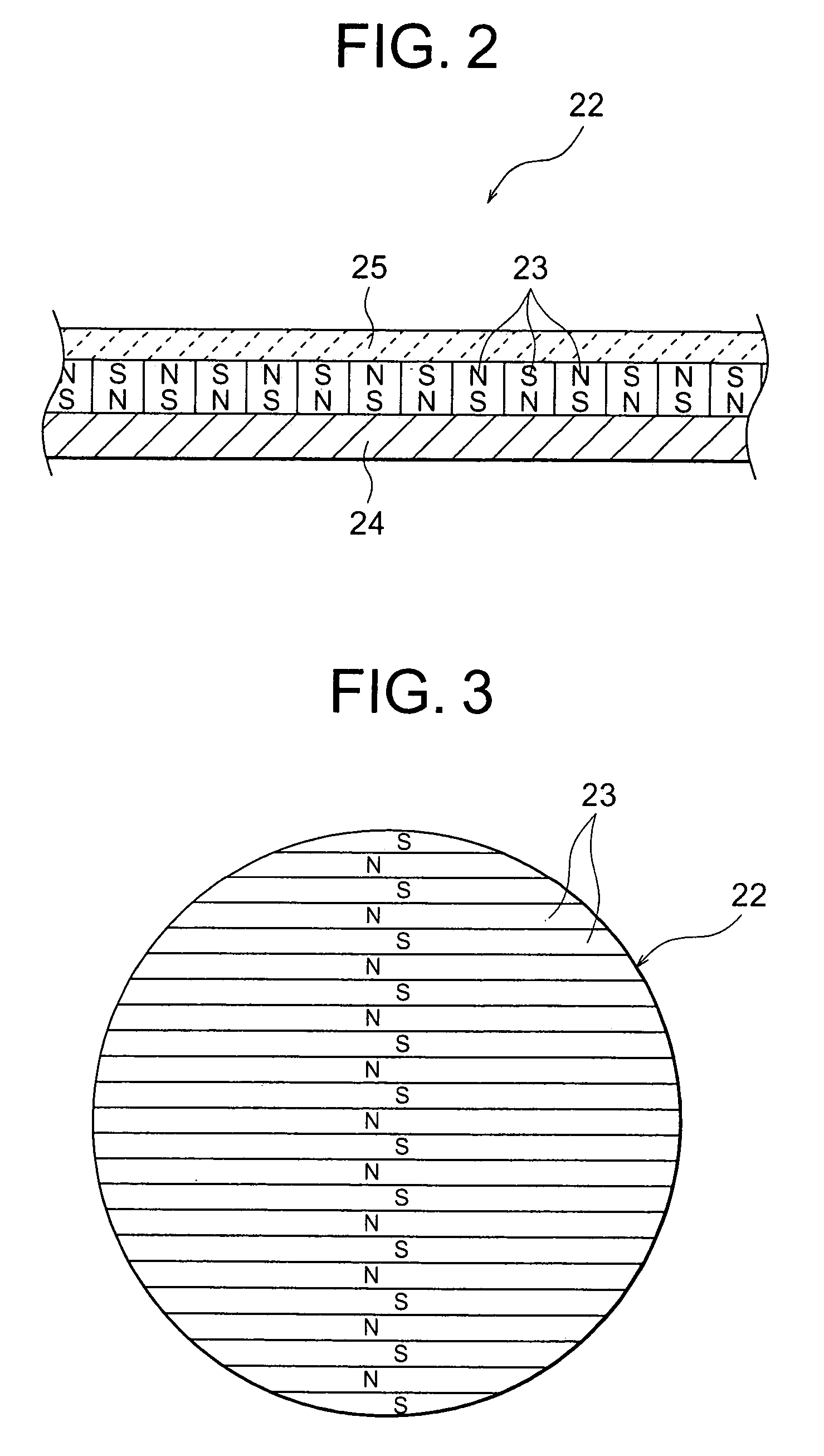

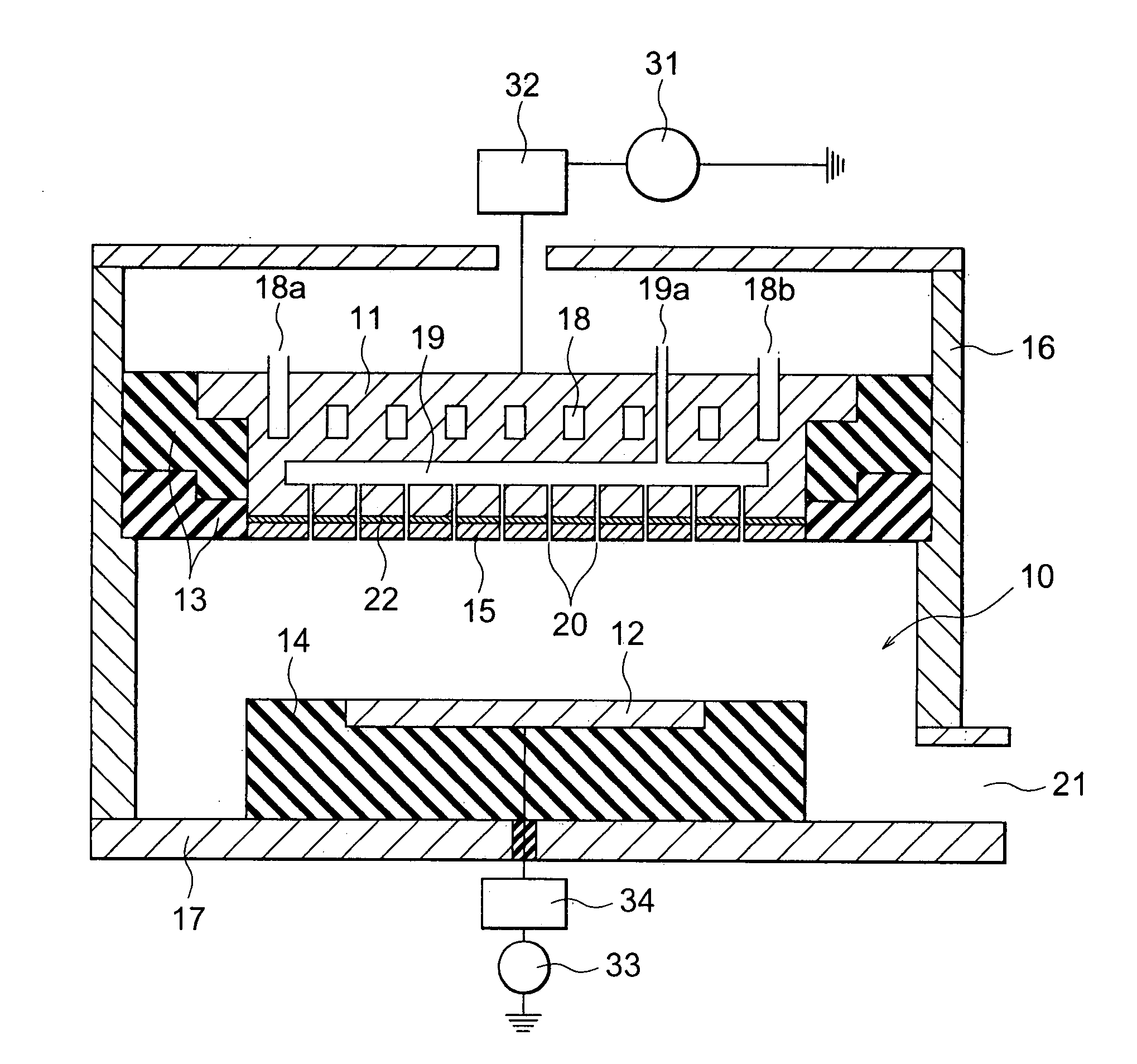

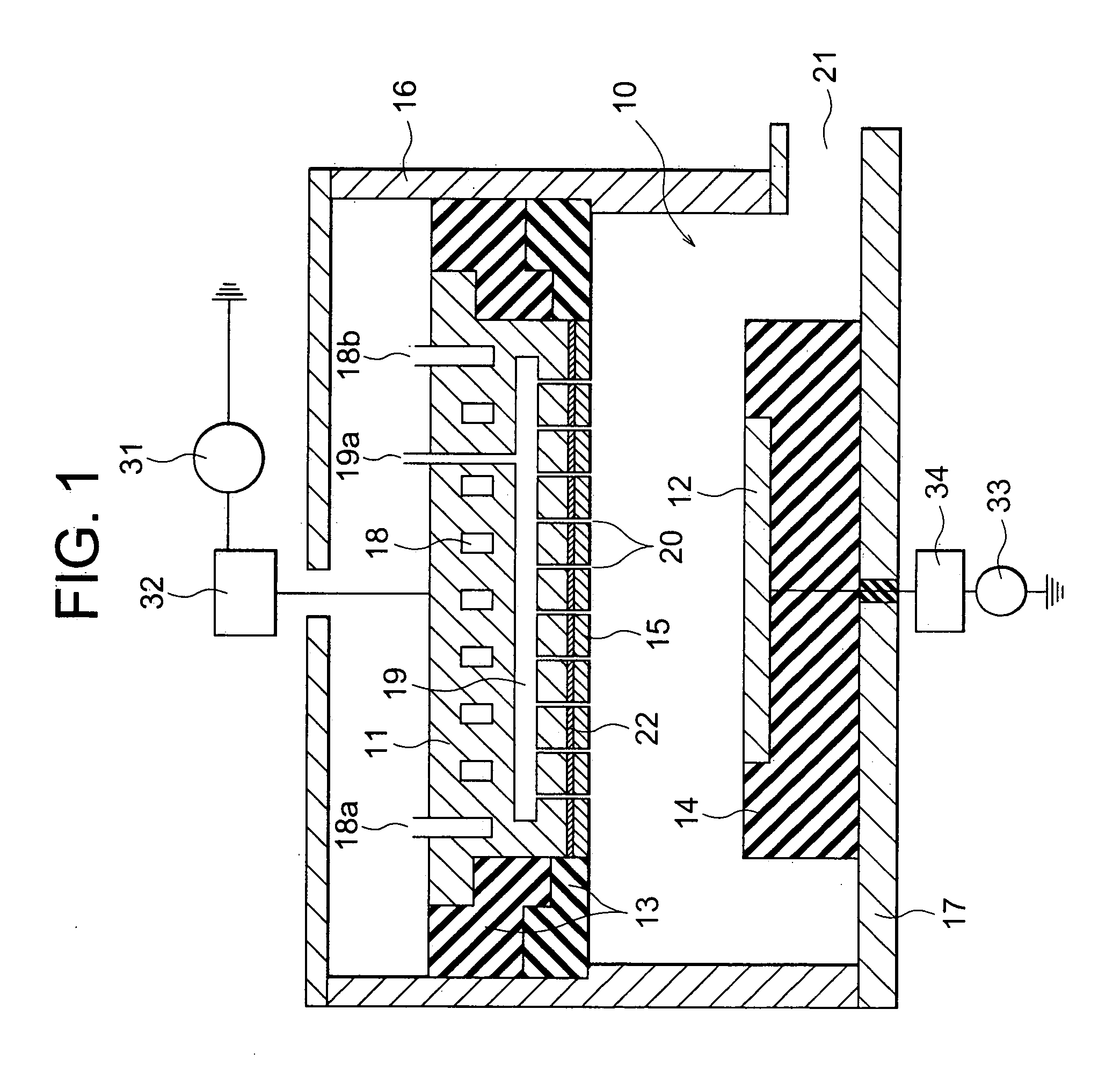

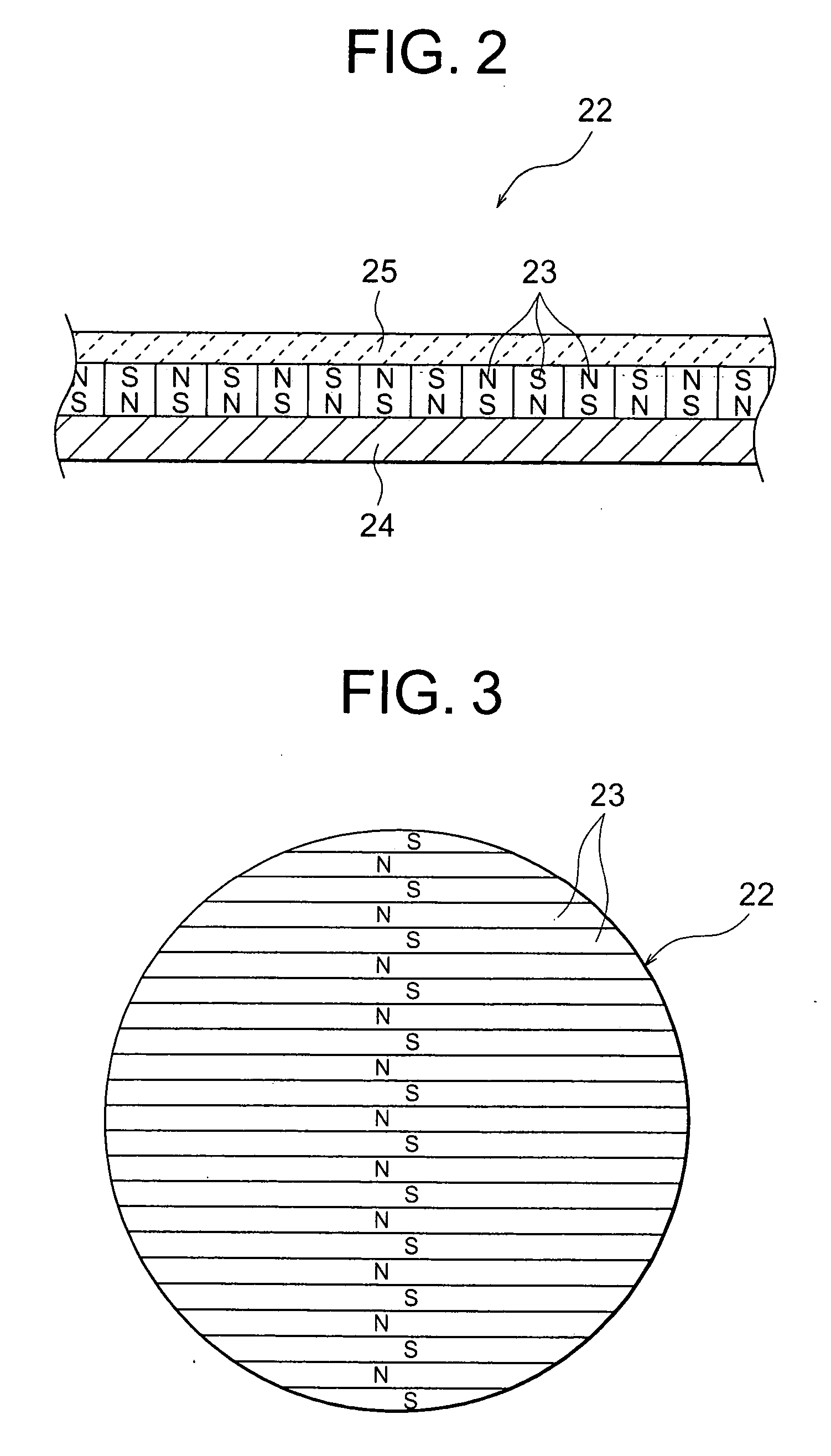

Device for fixing a gas showerhead or target plate to an electrode in plasma processing systems

InactiveUS7159537B2Improving the thermal conductance from the showerheadImproved gas distributionCellsElectric discharge tubesMetal alloyMetal sheet

A plasma processing system includes a reactor, a top electrode made of a magnetic or ferromagnetic metal or a metal-alloy, wherein a RF or DC power is applied to generate plasma within the reactor; a gas showerhead fixed to the top electrode; a sheet-like magnetic assembly bound to the upper surface of the gas showerhead, which includes a plurality of separate magnets, a metal sheet made of a ferromagnetic metal, and a deformable film.

Owner:ANELVA CORP

Device for fixing a gas showerhead or target plate to an electrode in plasma processing systems

InactiveUS20050028935A1Increased contact surface areaImprove temperature uniformityCellsElectric discharge tubesMetal alloyEngineering

A plasma processing system includes a reactor, a top electrode made of a magnetic or ferromagnetic metal or a metal-alloy, wherein a RF or DC power is applied to generate plasma within the reactor; a gas showerhead fixed to the top electrode; a sheet-like magnetic assembly bound to the upper surface of the gas showerhead, which includes a plurality of separate magnets, a metal sheet made of a ferromagnetic metal, and a deformable film.

Owner:ANELVA CORP

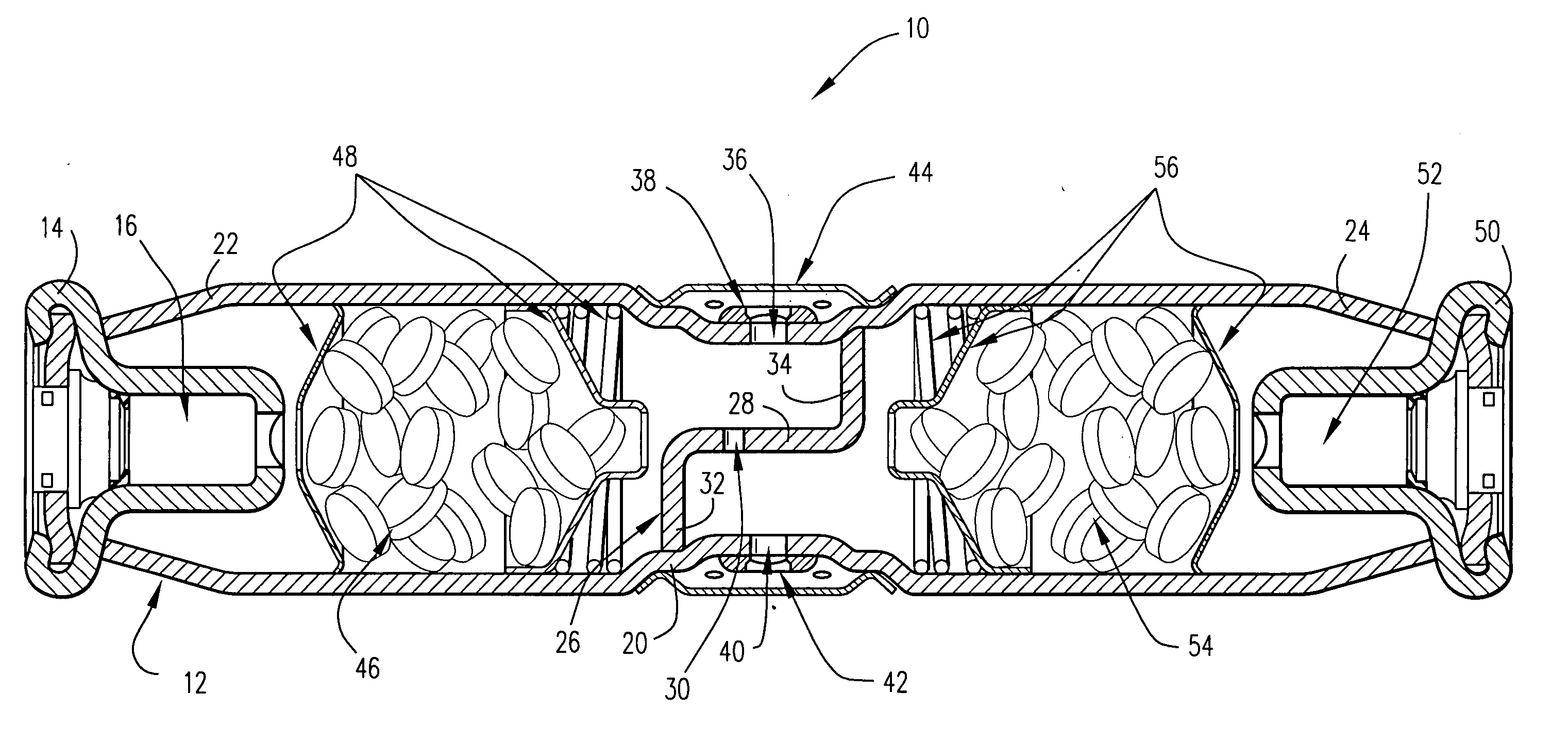

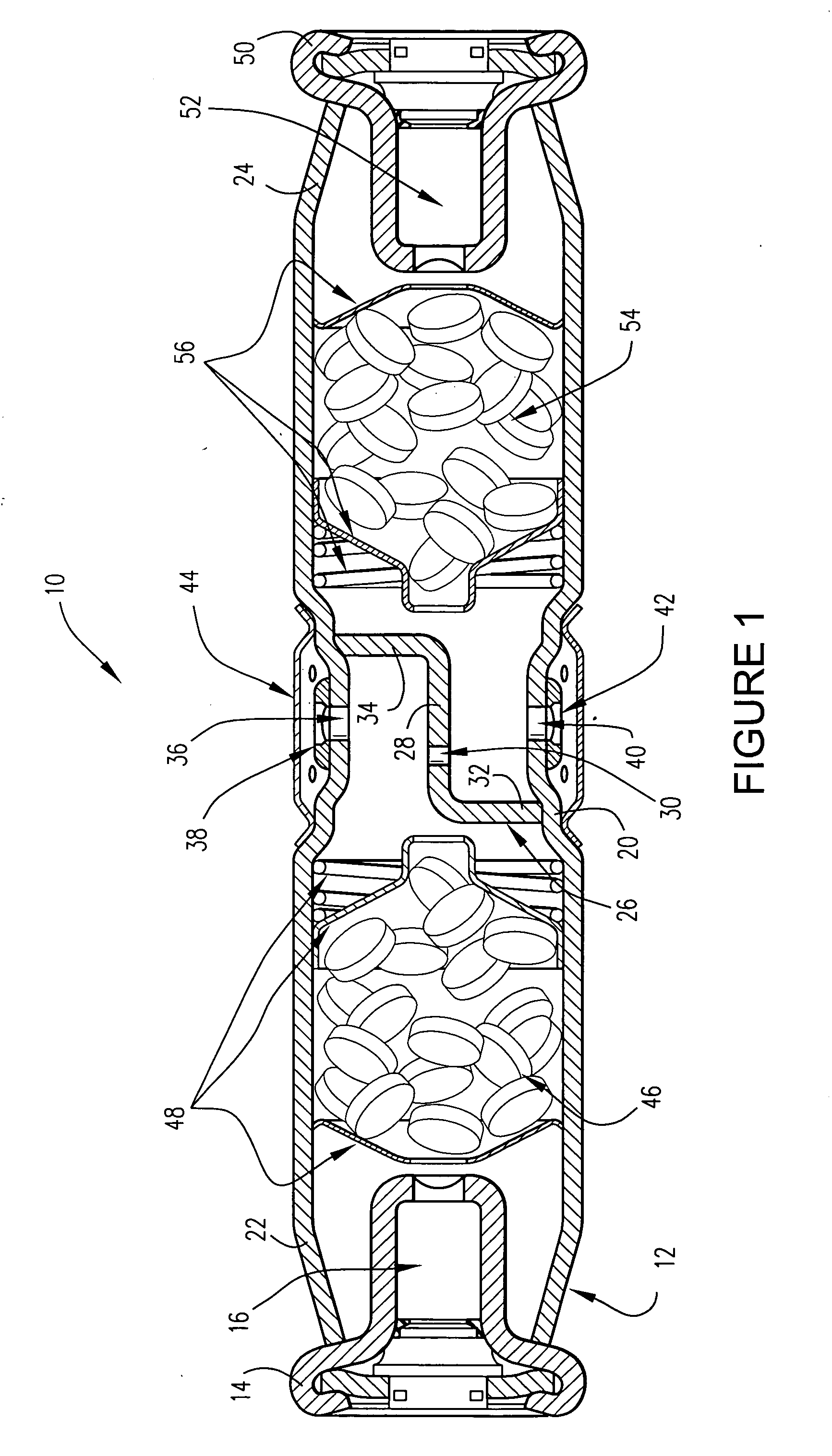

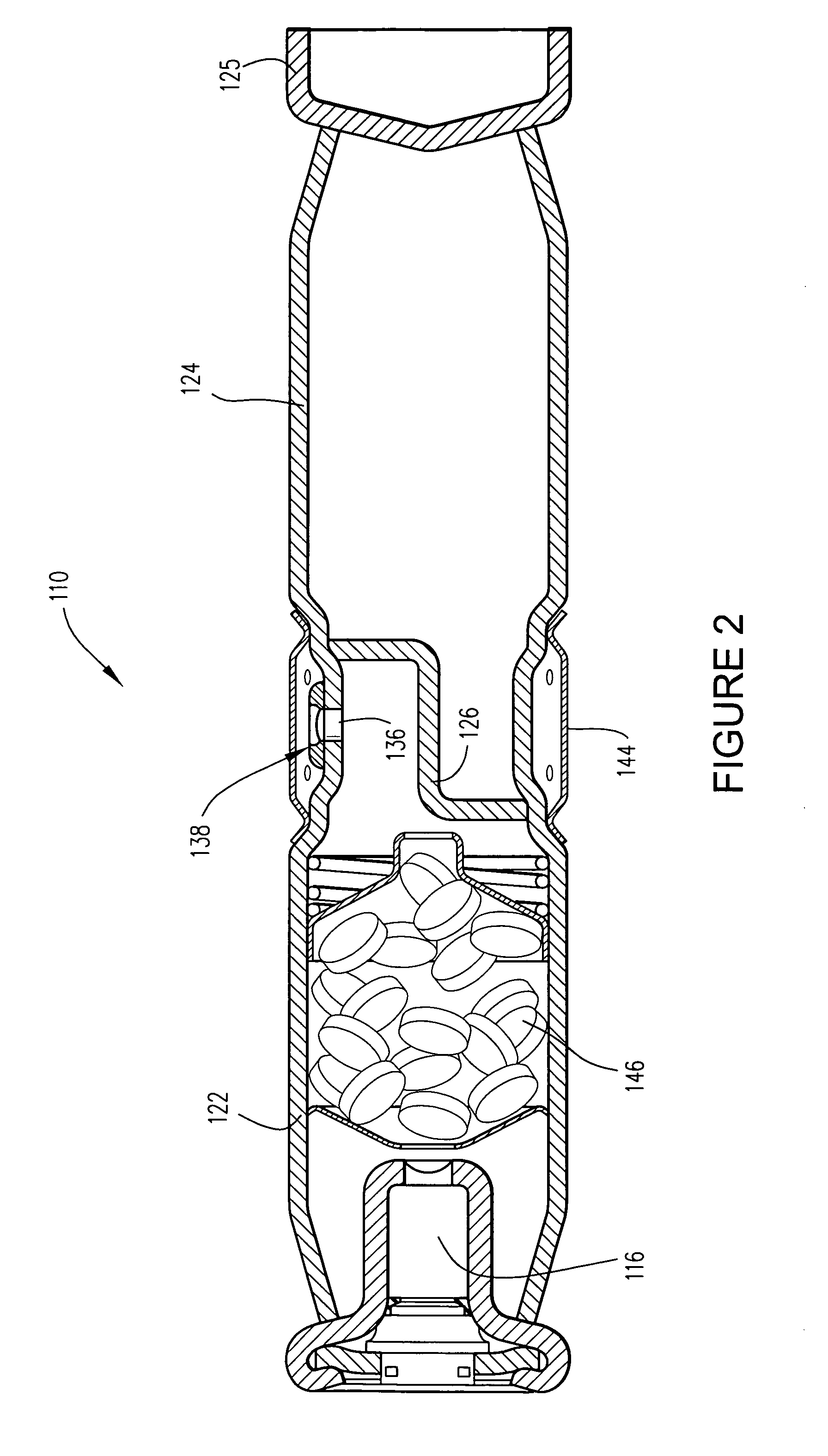

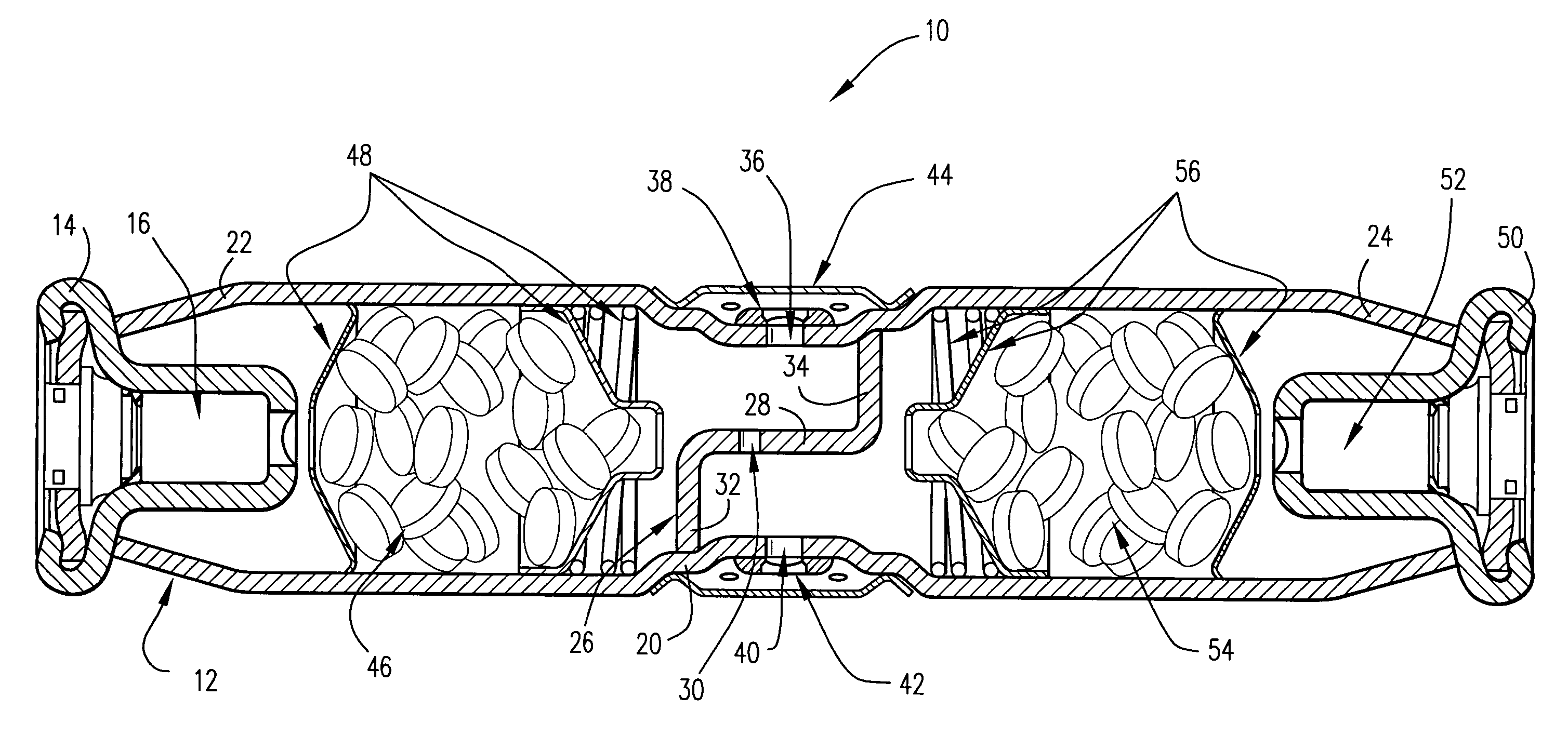

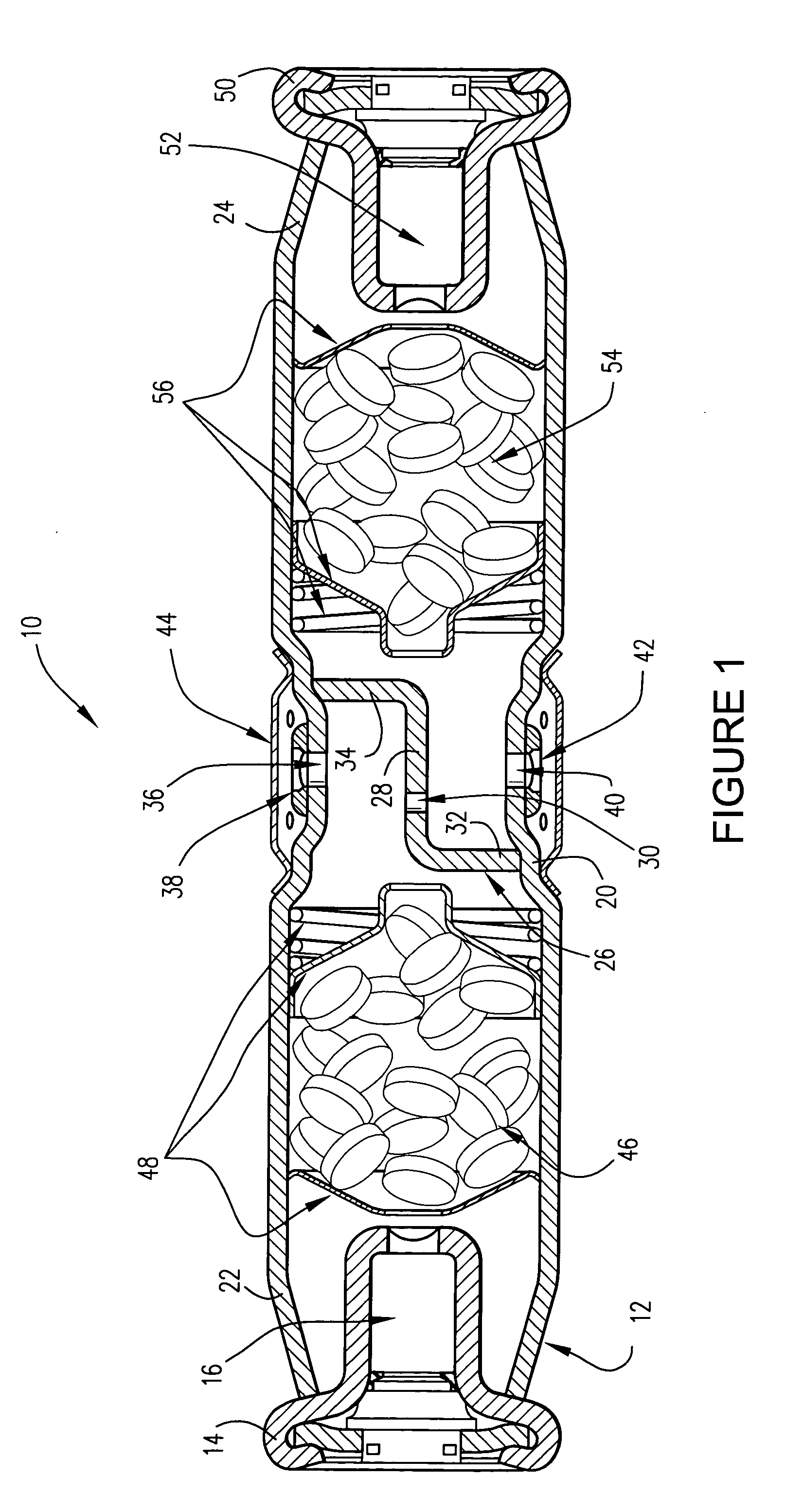

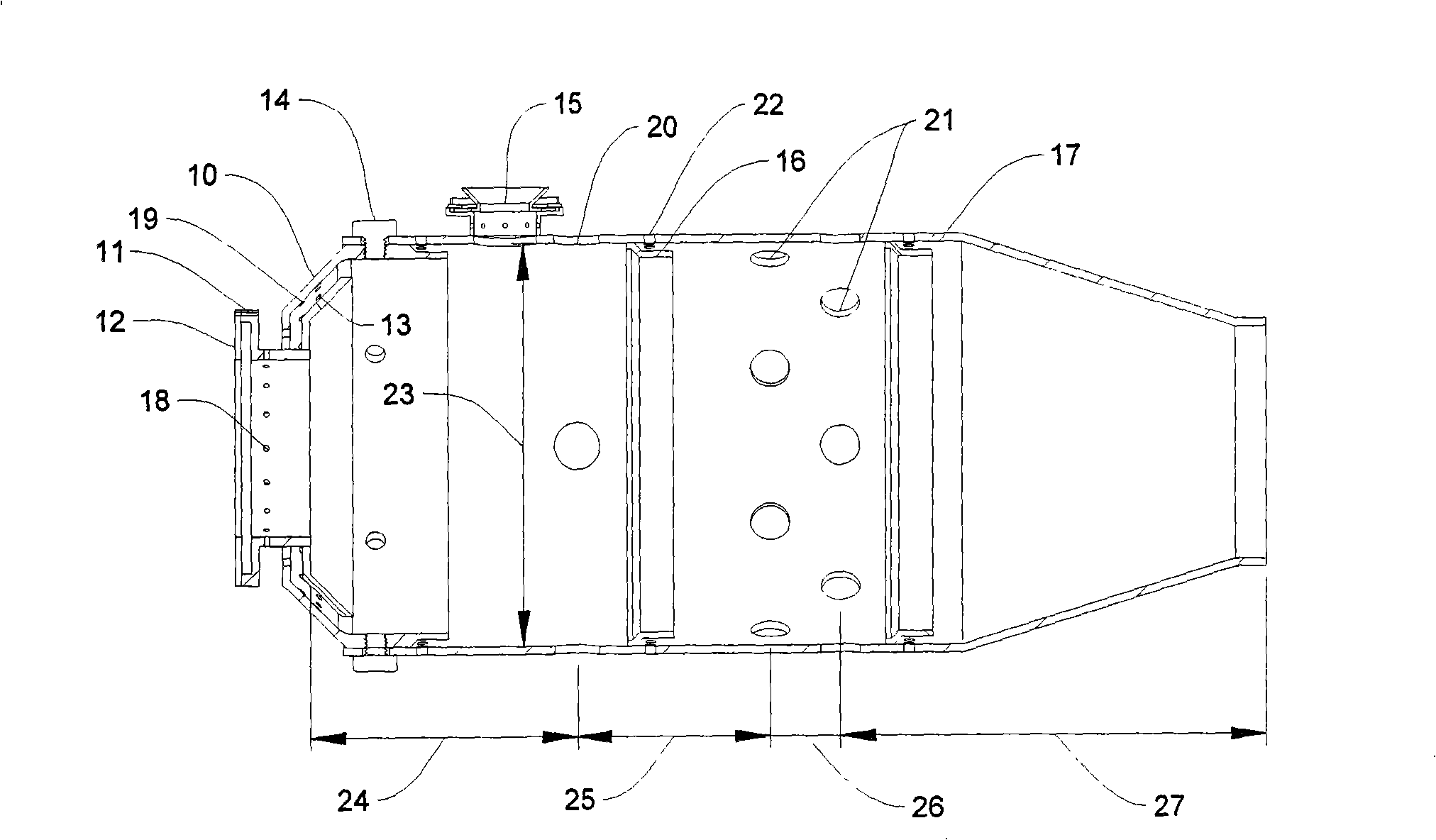

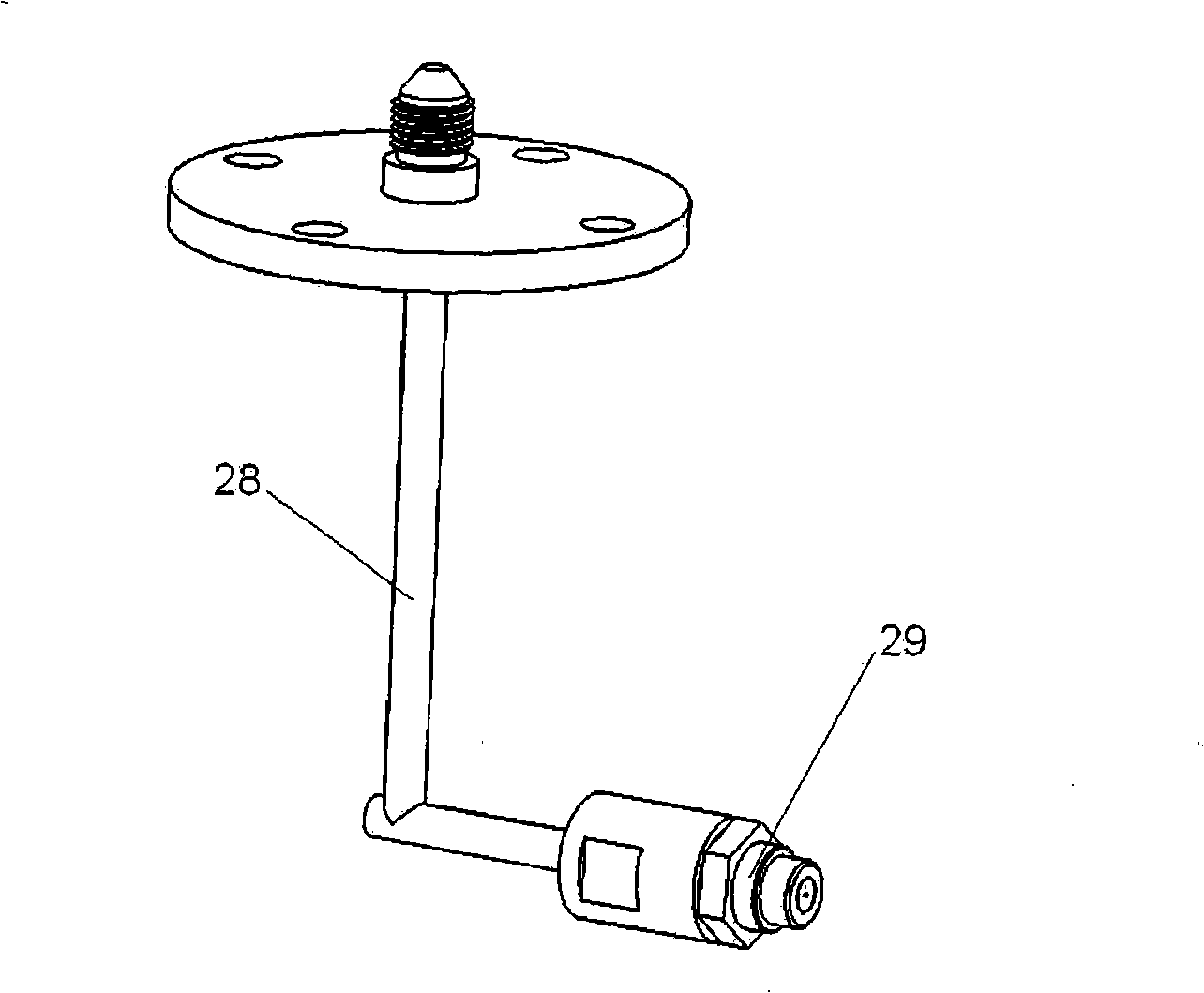

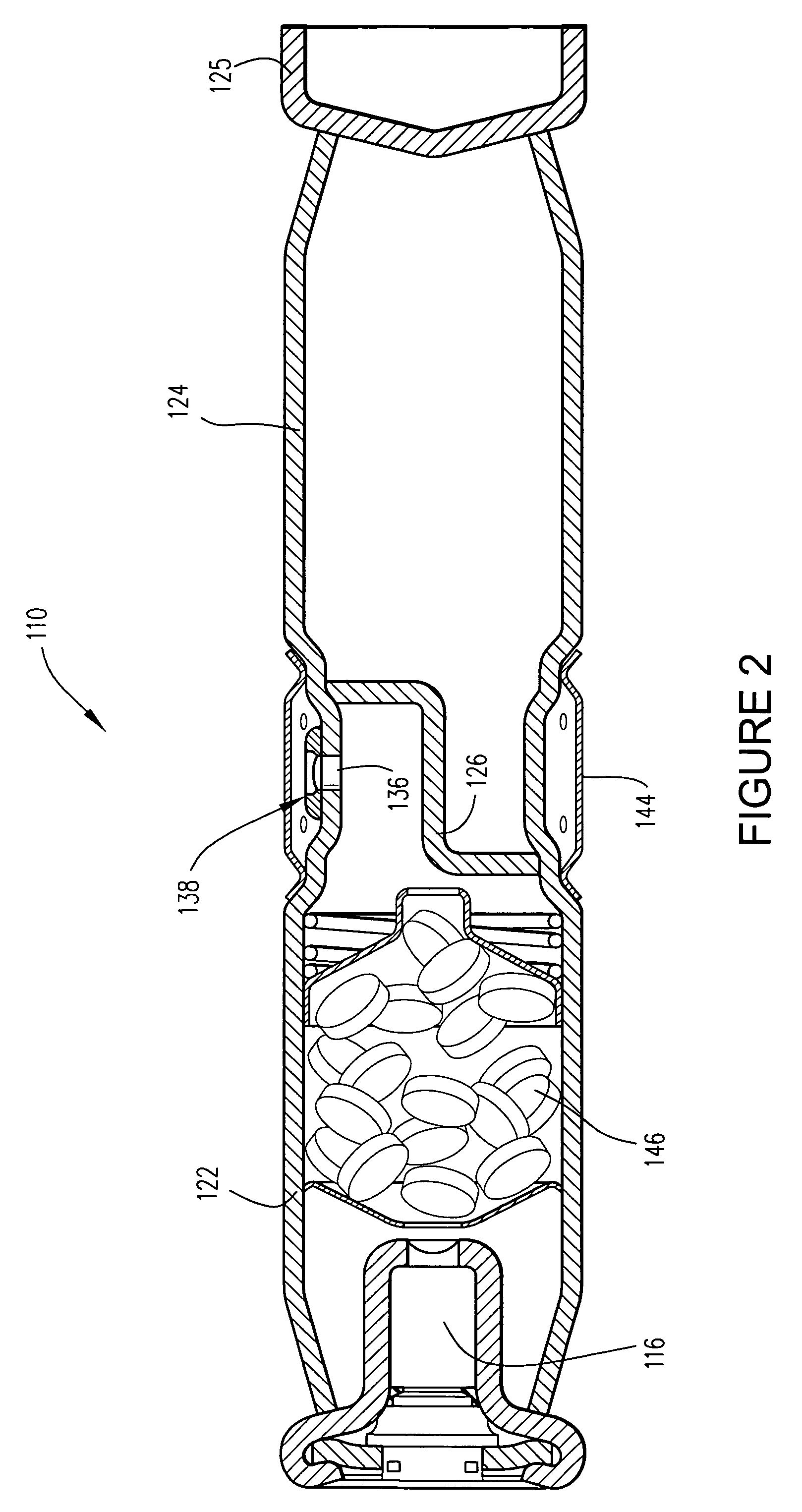

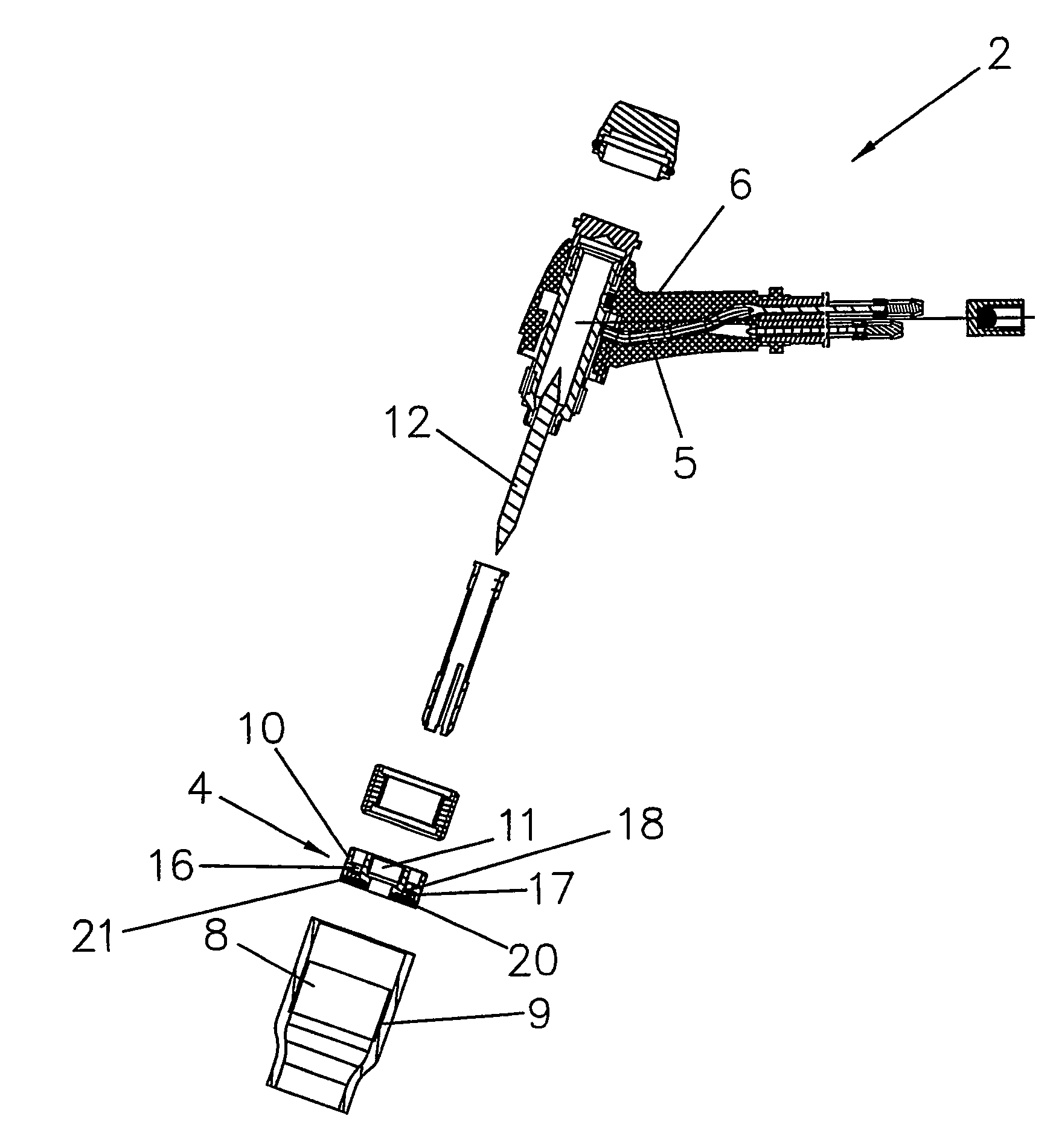

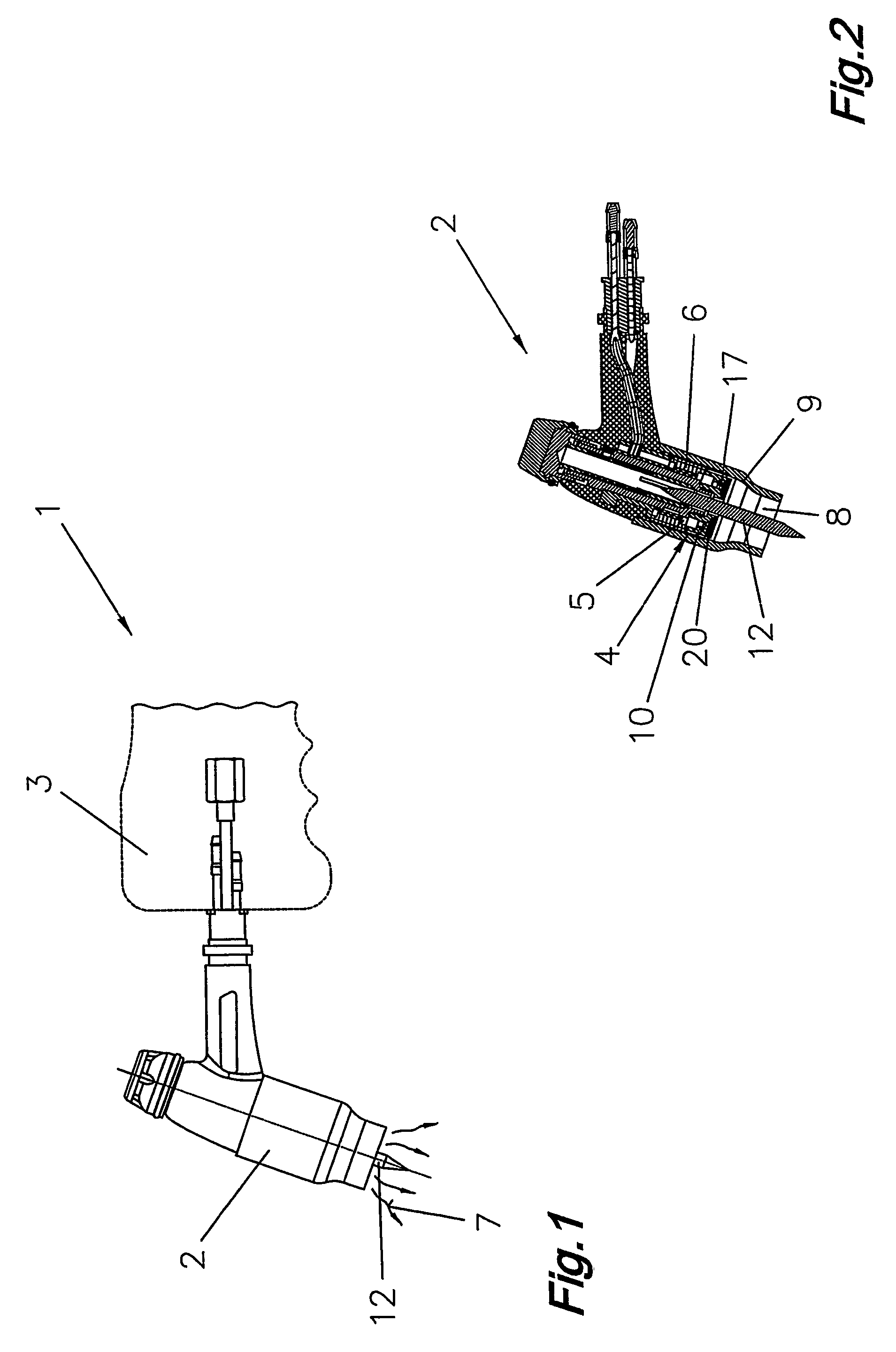

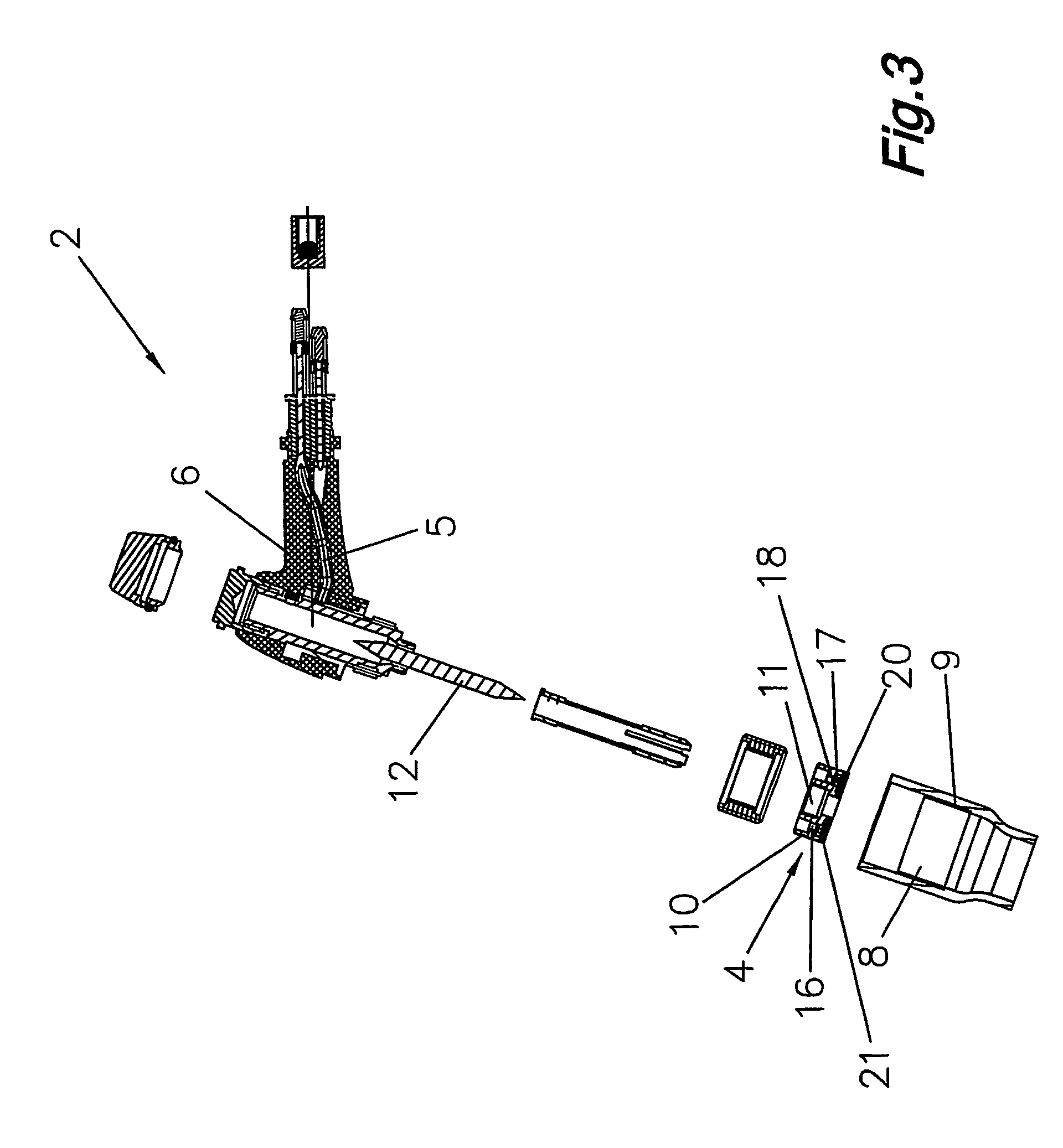

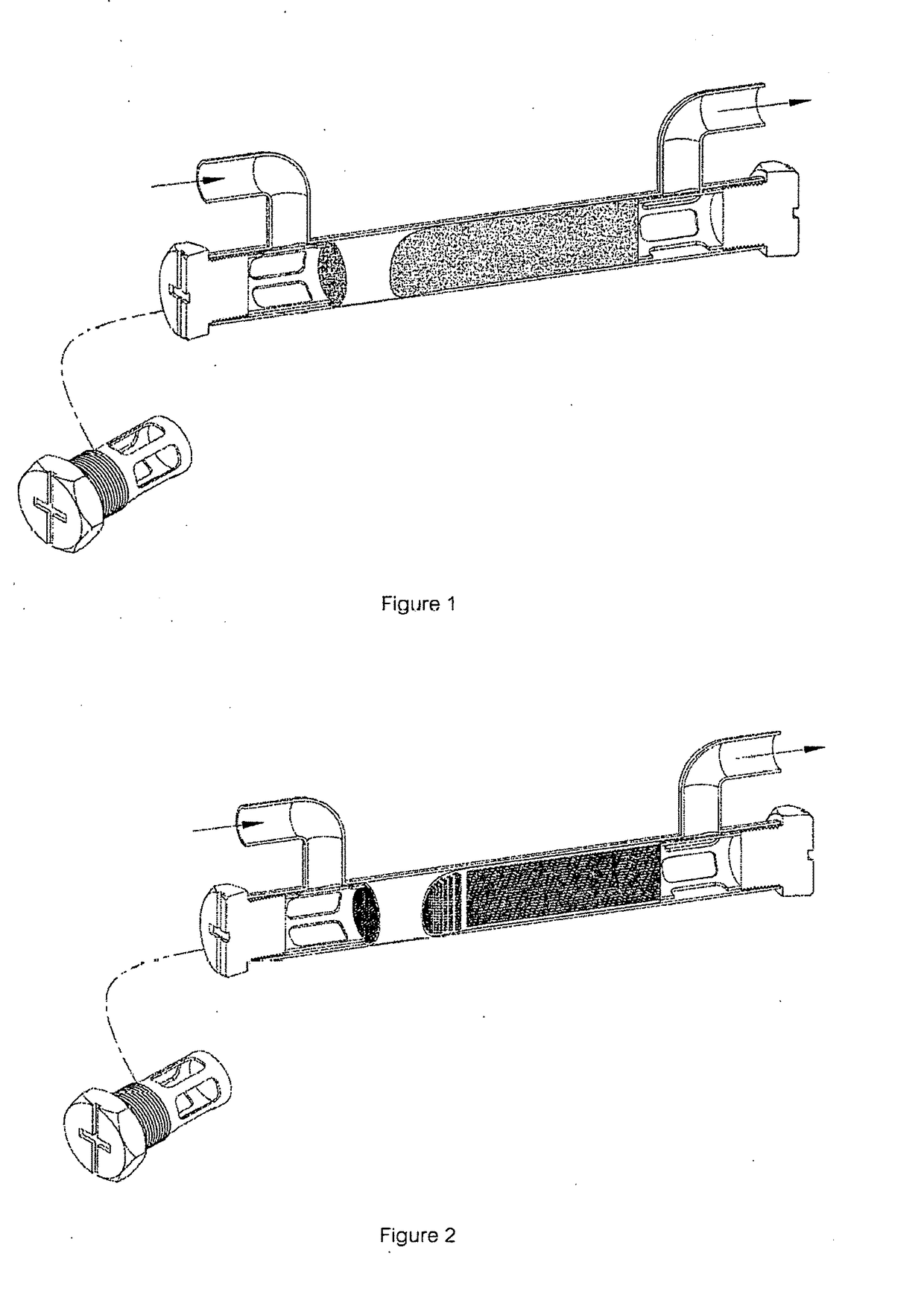

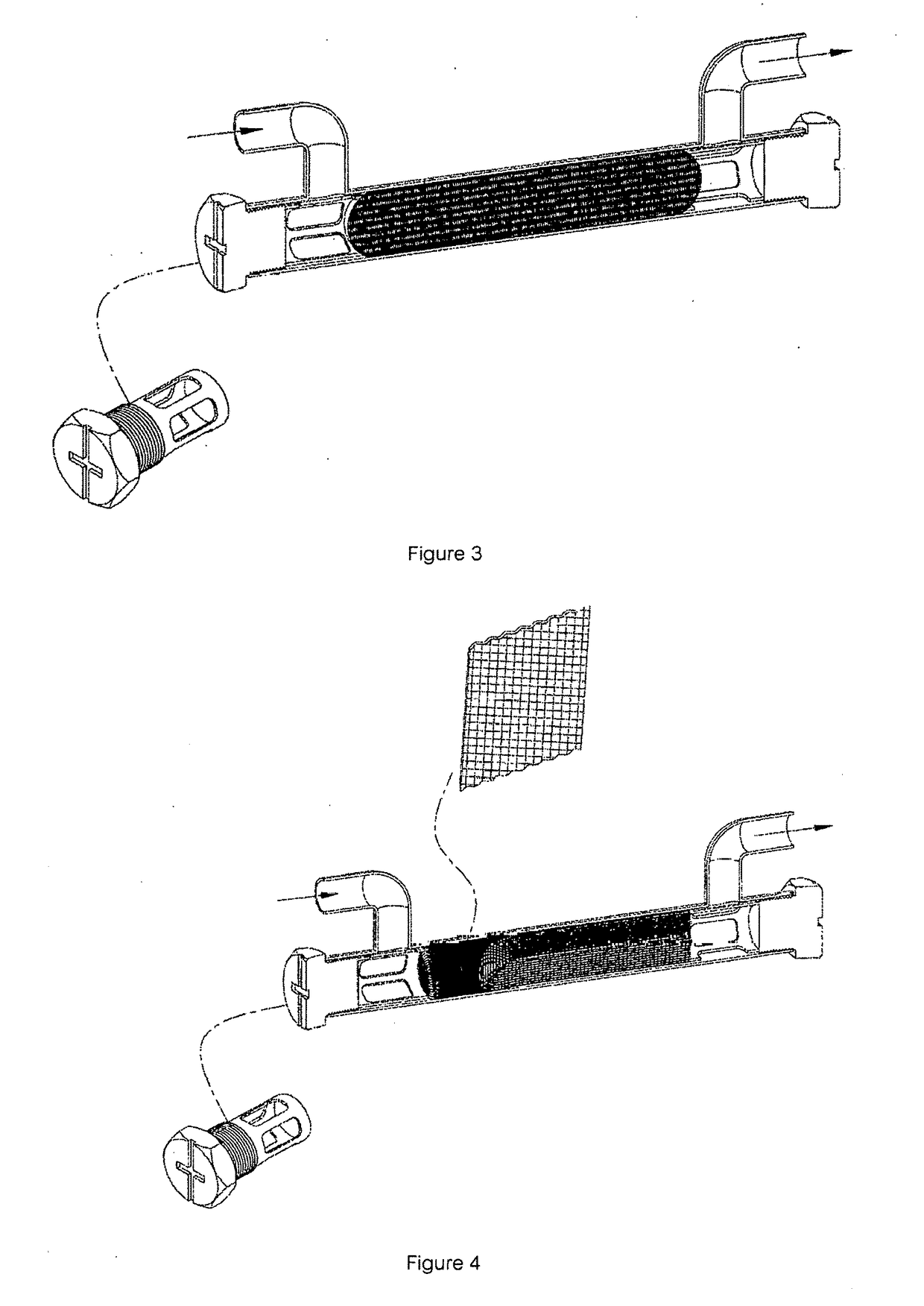

Compact multi-level output gas generator

ActiveUS20050161922A1Easy constructionEasy to assemblePedestrian/occupant safety arrangementEngineeringEnergy device

A multi-level gas inflator for an air bag or other safety device, comprising an elongated pressure vessel having a primary gas generant portion with a first open end and a secondary portion with a second open end. The primary gas generant portion has a primary ignition device and primary gas generating energetics disposed therein. The primary ignition device is mounted on and closes the pressure vessel at the first open end thereof. The secondary portion may have a secondary ignition device and secondary gas generating energetics disposed therein. The secondary ignition device may be mounted on the pressure vessel at the second open end thereof. A suitable gas under a predetermined pressure is present in the primary and secondary portions. One or more separate dividers or divider walls are disposed within the midportion of the pressure vessel to separate the primary and secondary portions. The pressure vessel may have a primary exit orifice in the midportion thereof that is in communication with the primary gas generant portion, and a secondary exit orifice in the midportion thereof that is in communication with the secondary portion. A primary rupture disk is disposed over the primary exit orifice, and a secondary rupture disk is disposed over the secondary exit orifice. A diffuser may be mounted on and surround the pressure vessel midportion and the primary and secondary exit orifices. Each divider or divider wall may have a communication port therethrough.

Owner:ARC TECH HLDG LTD

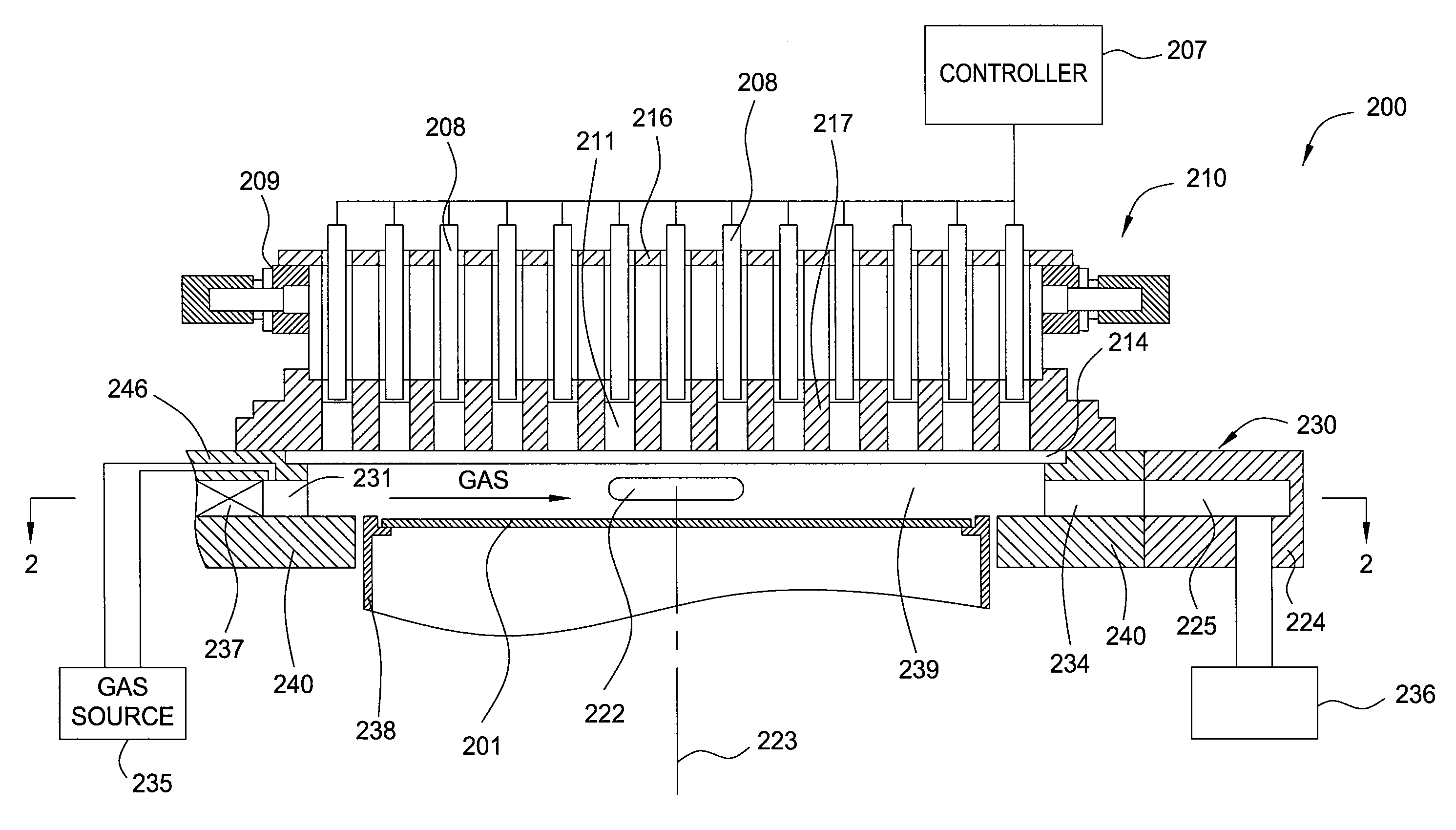

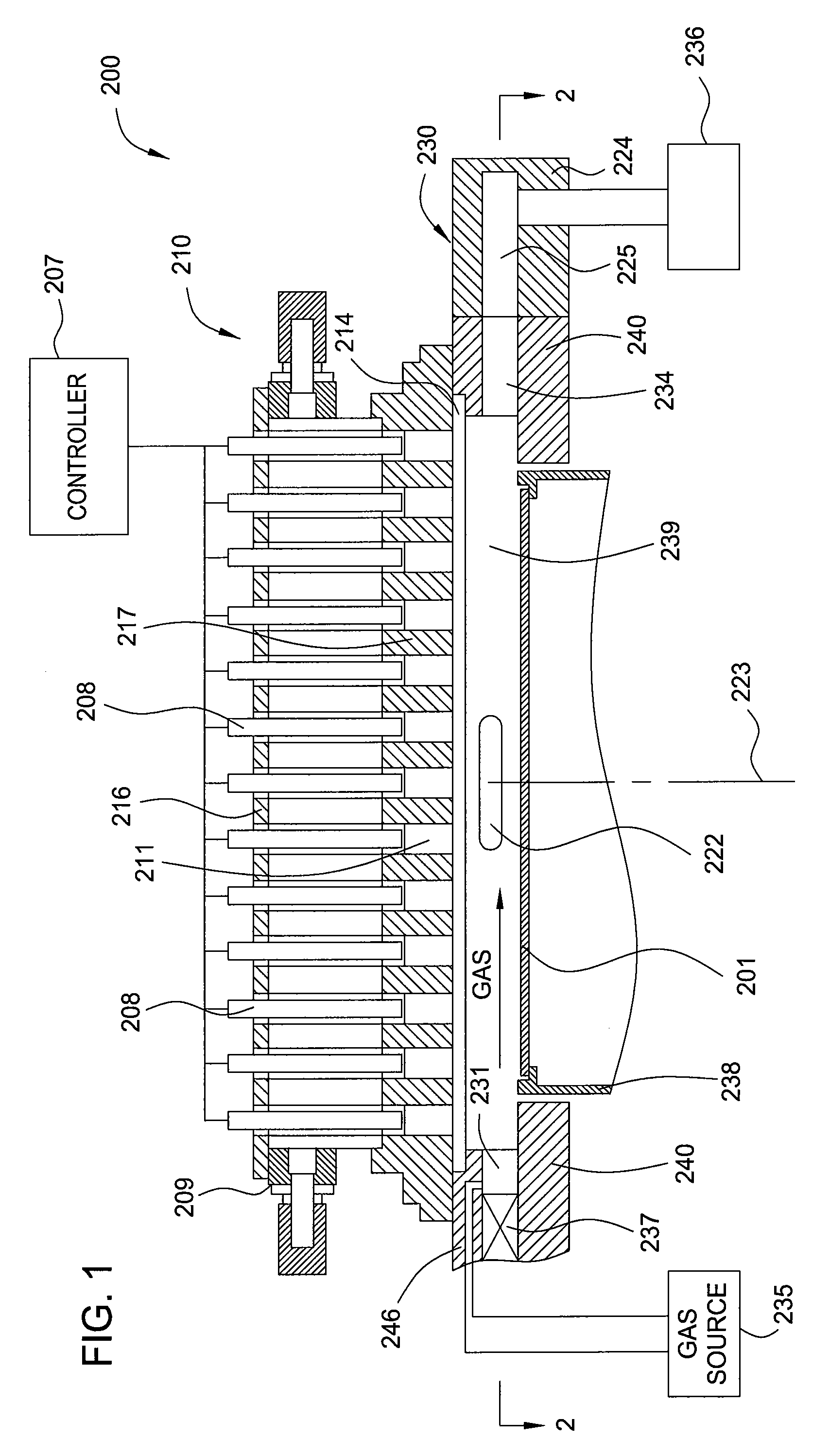

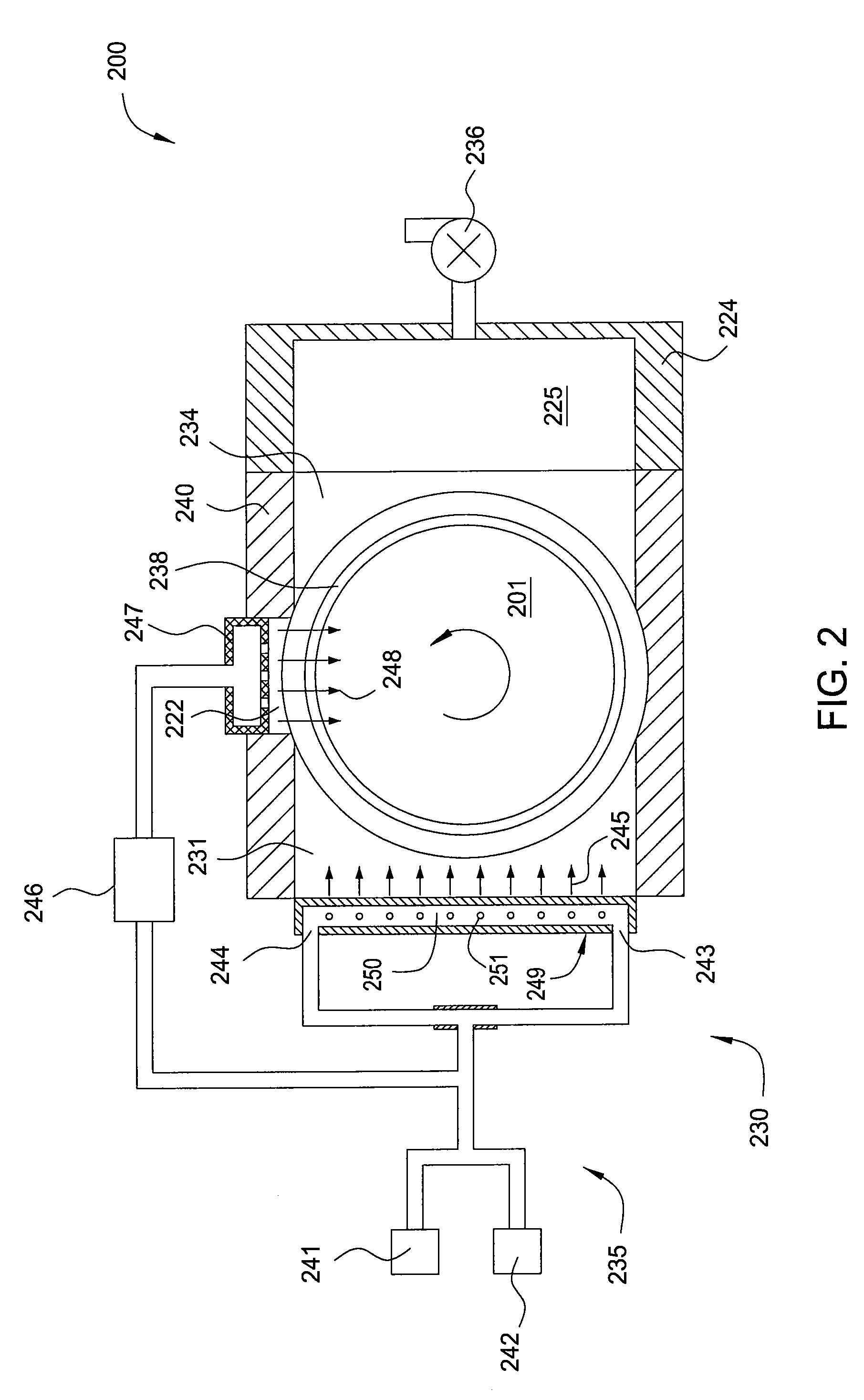

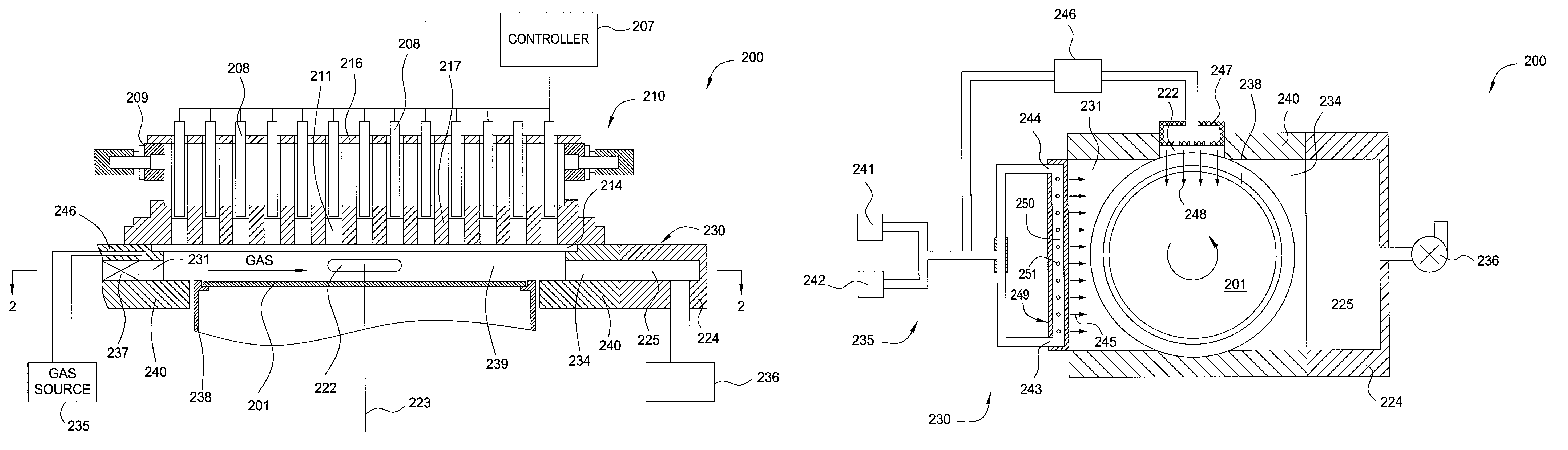

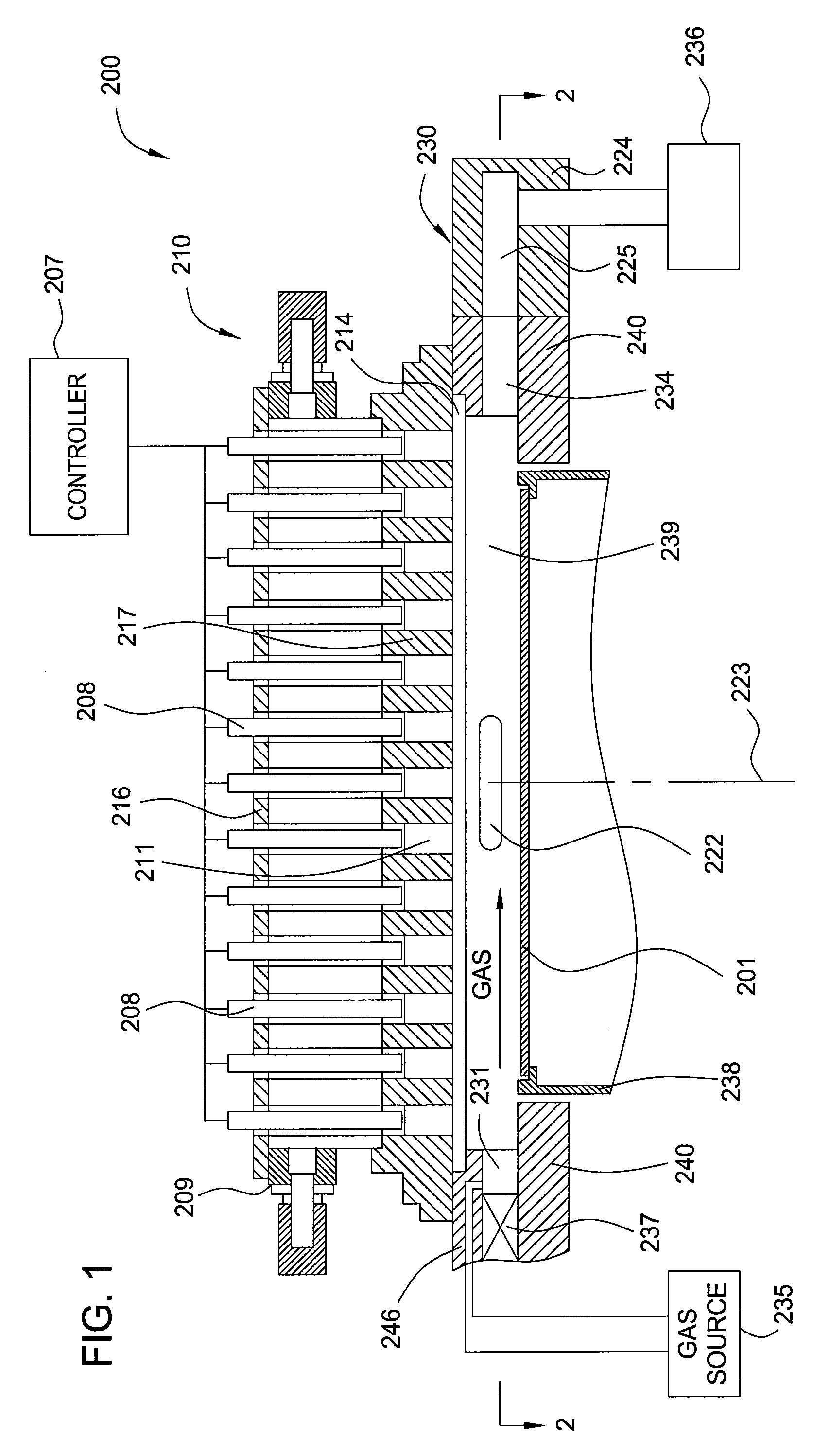

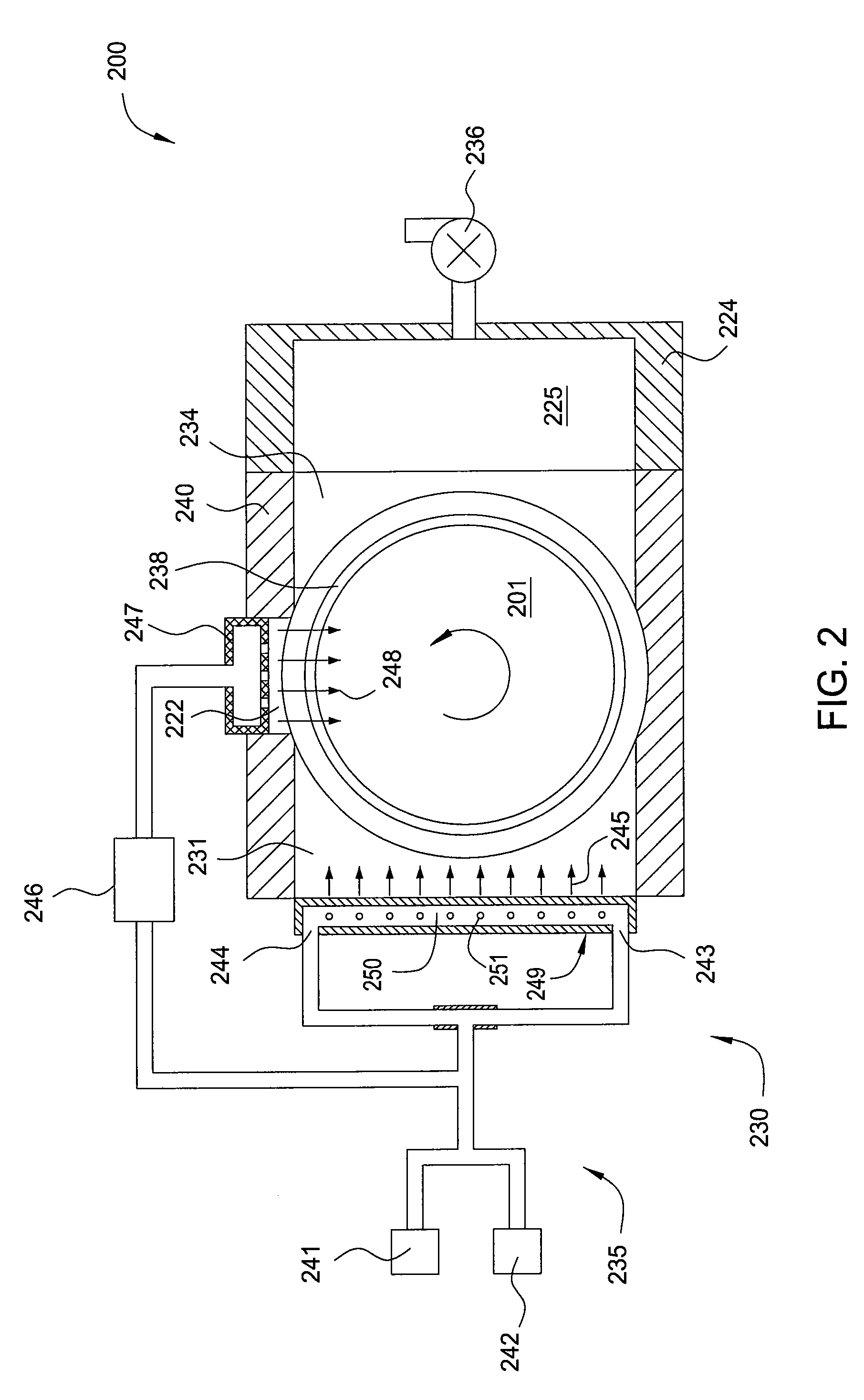

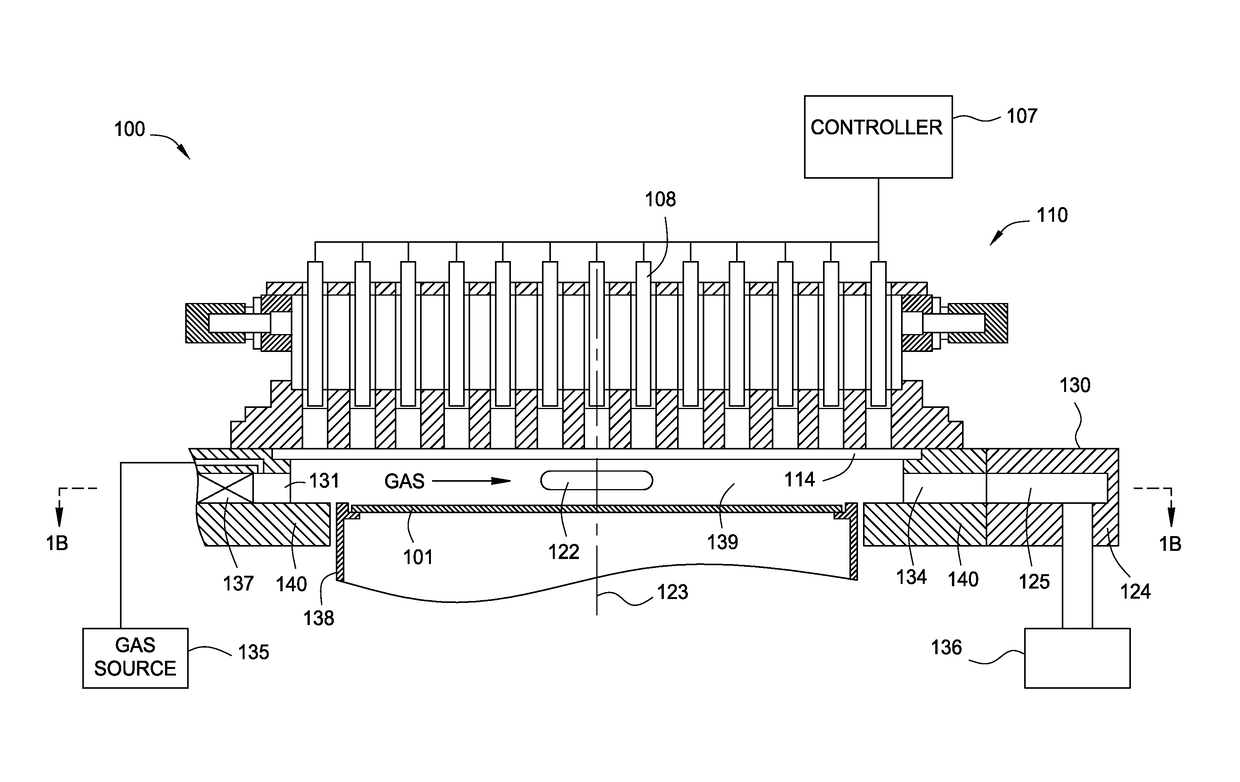

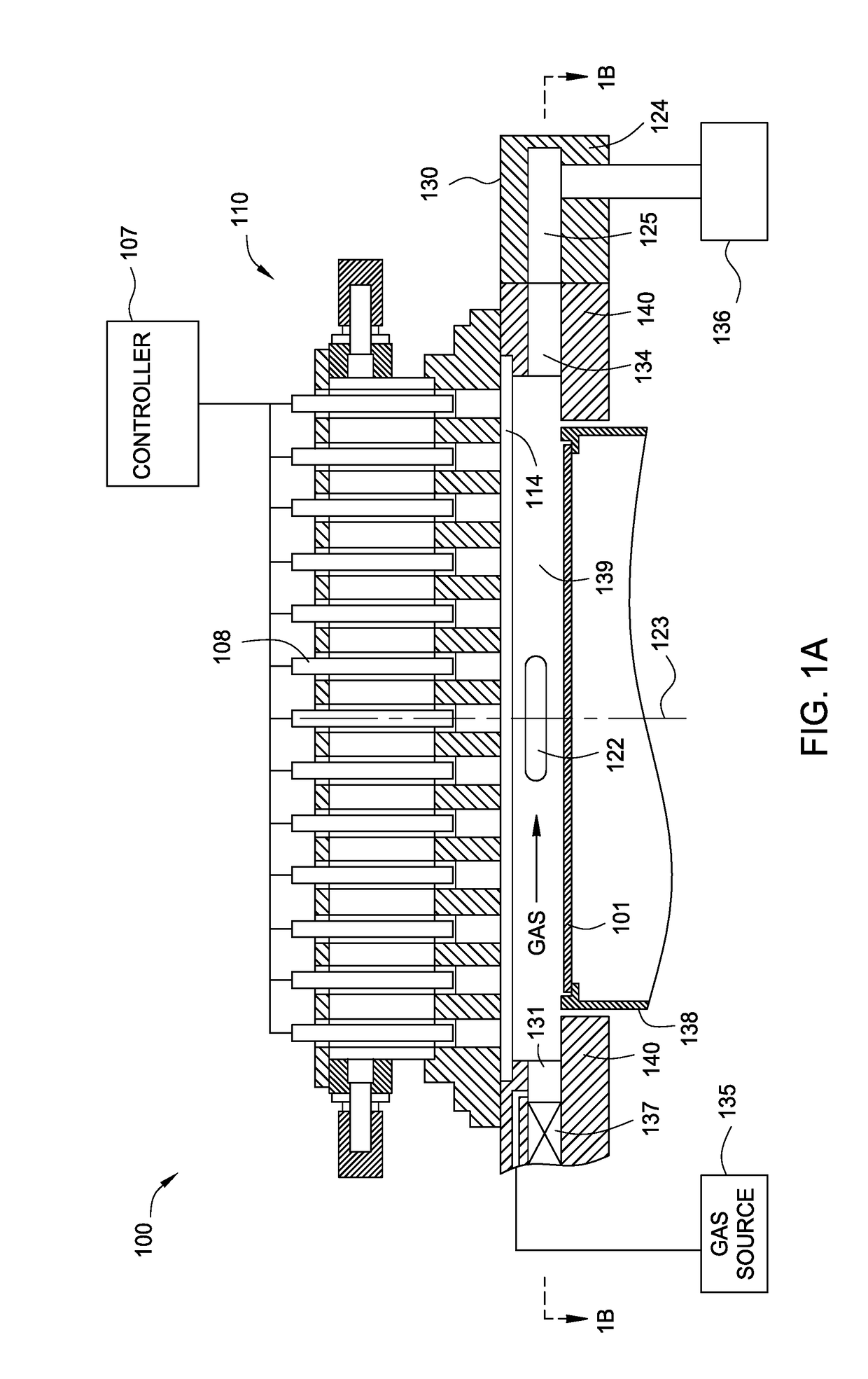

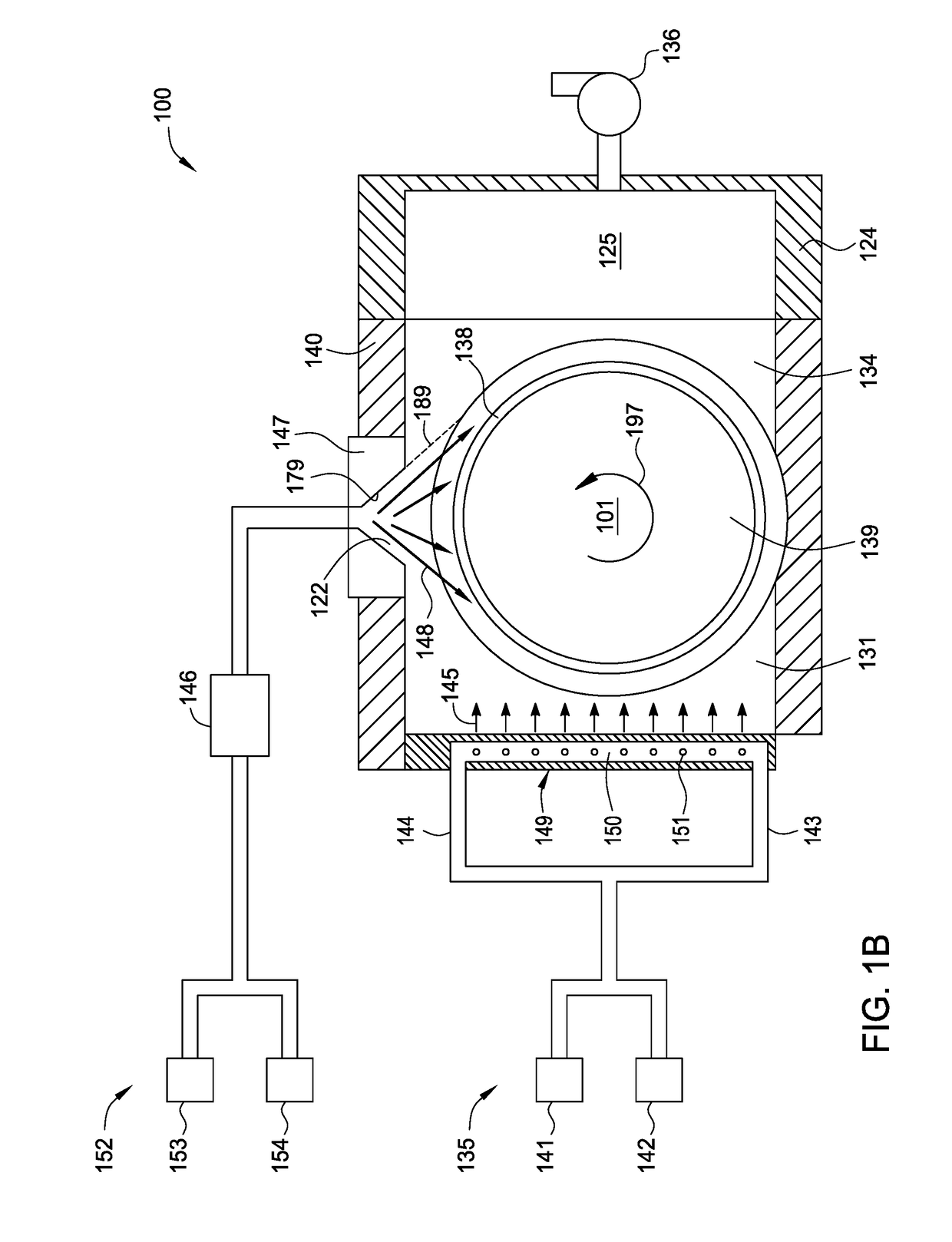

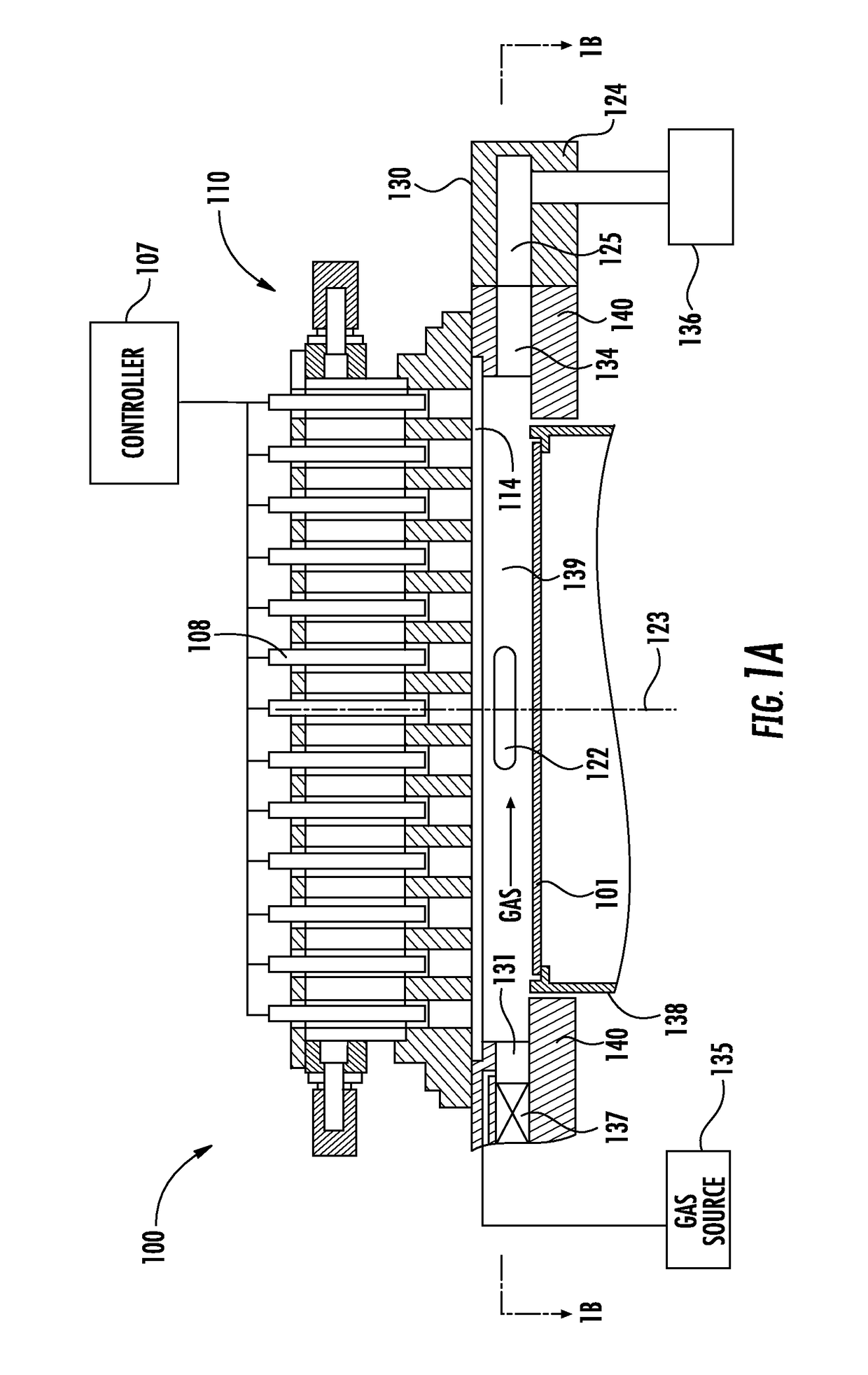

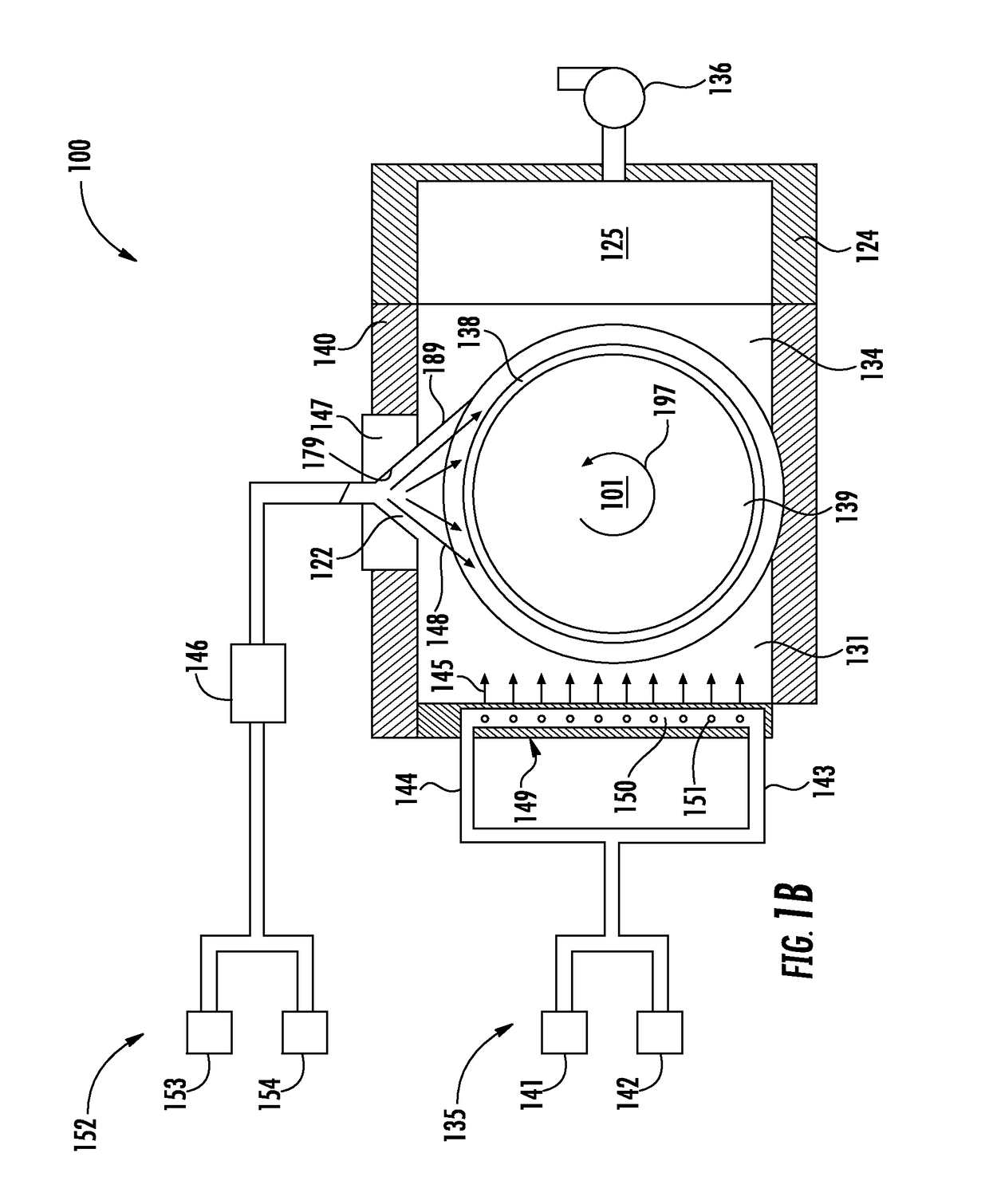

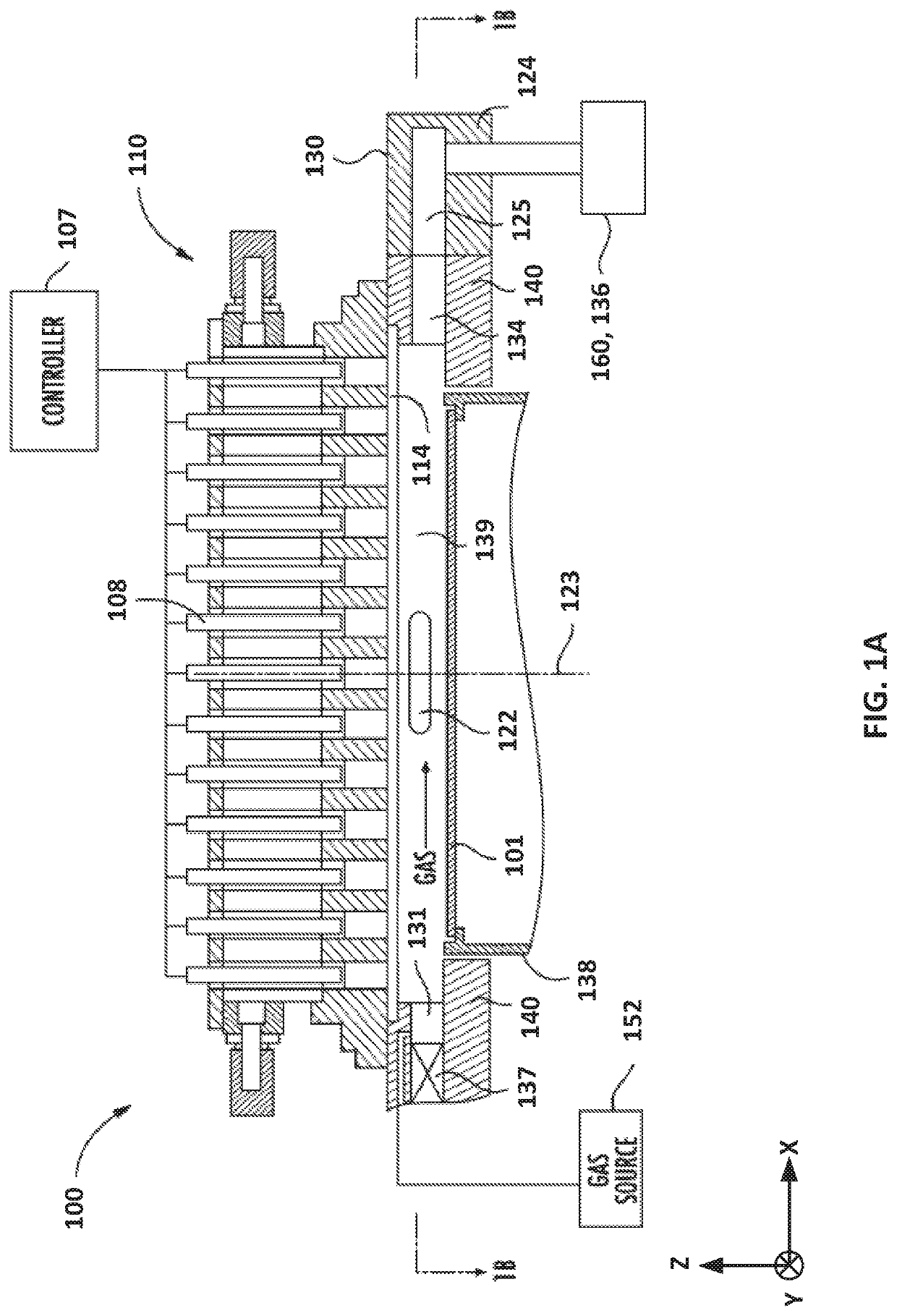

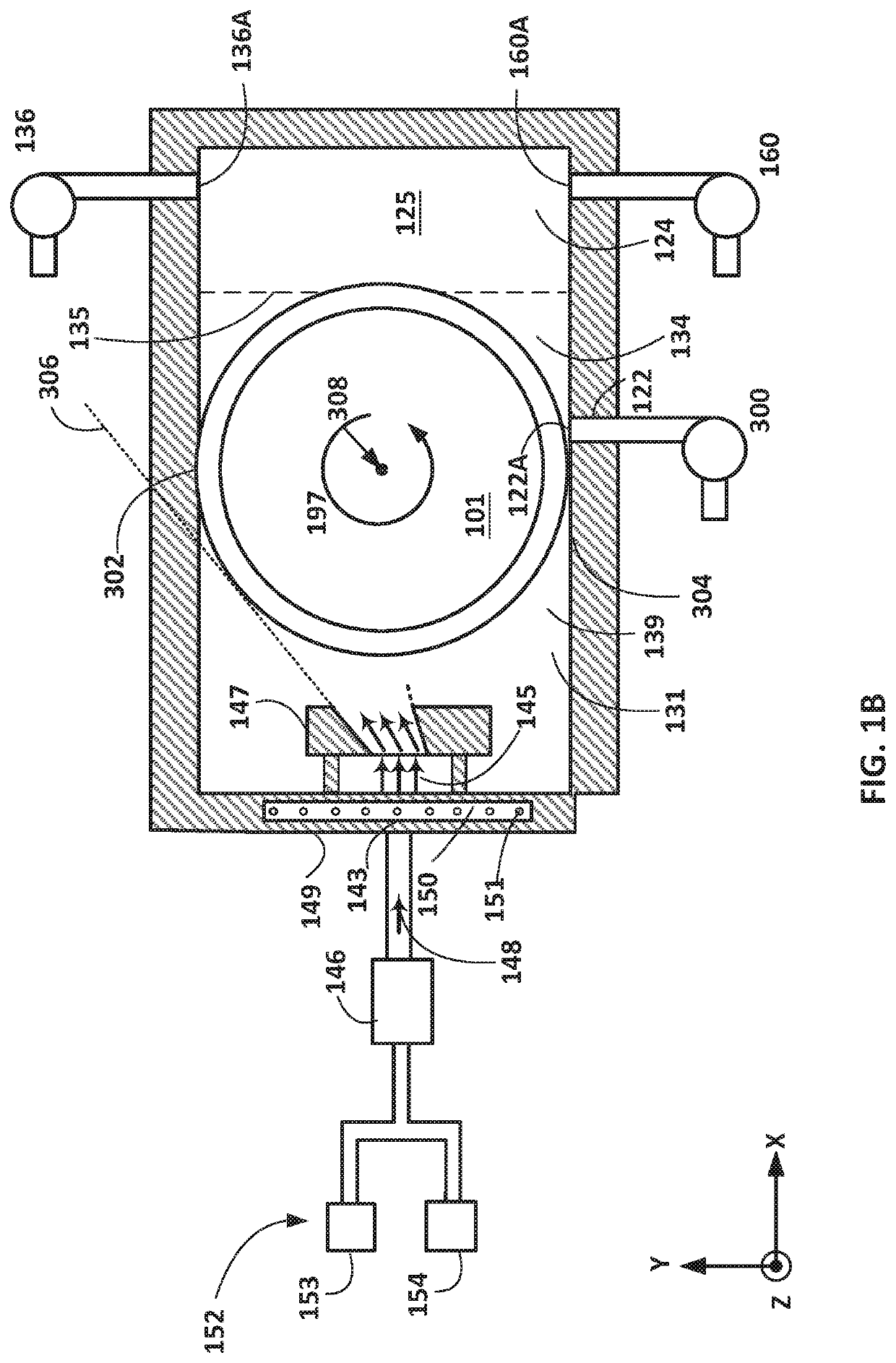

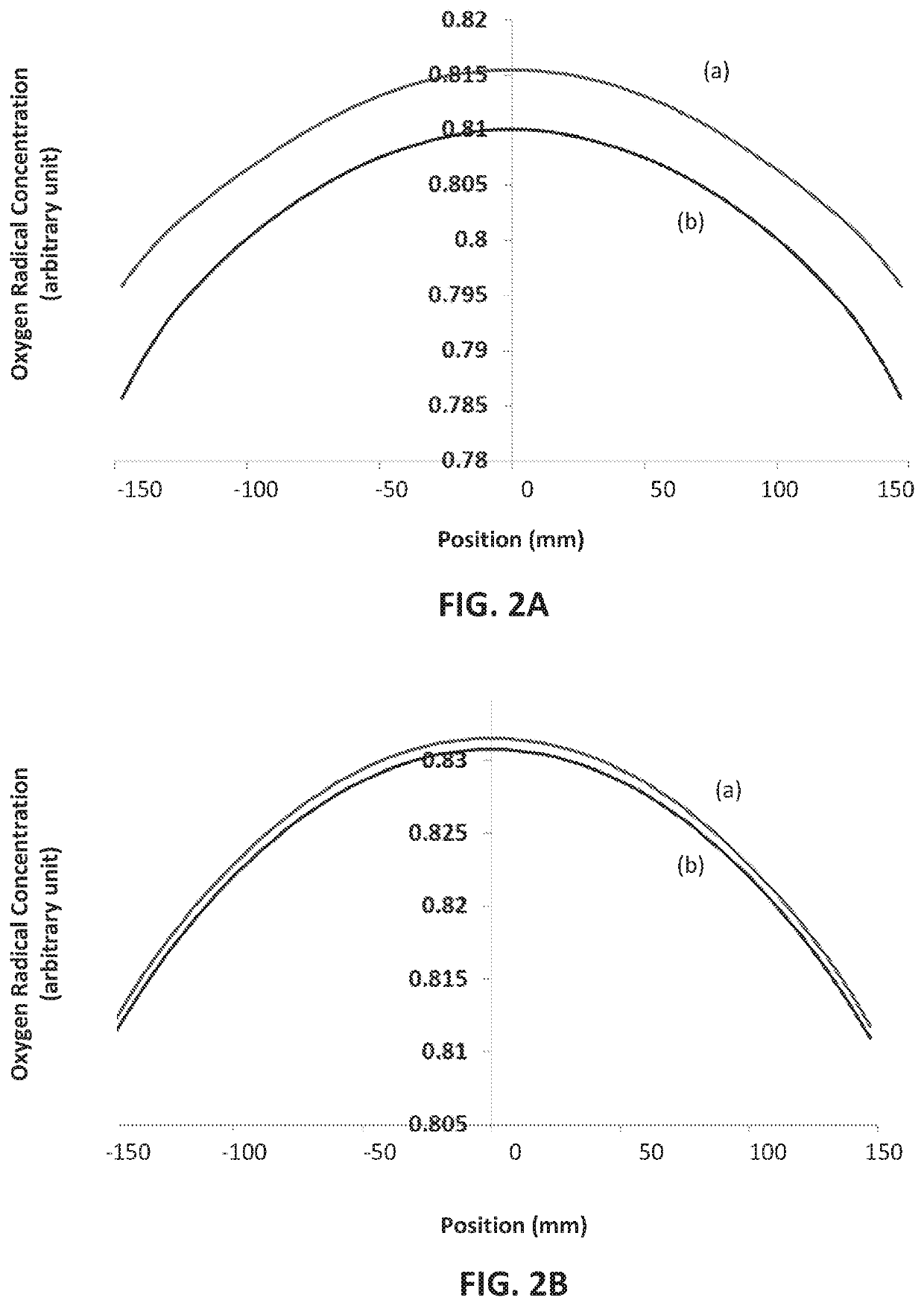

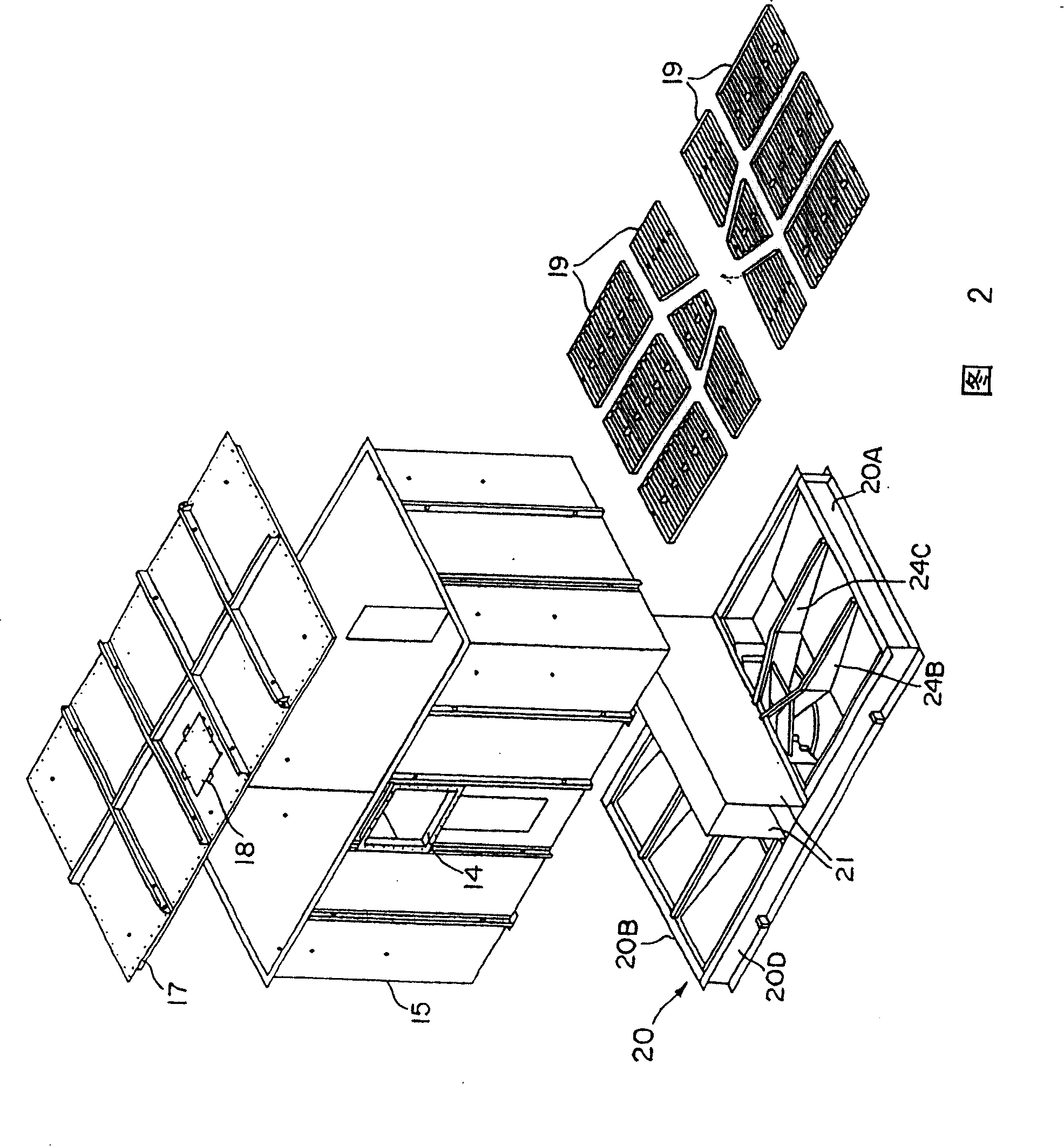

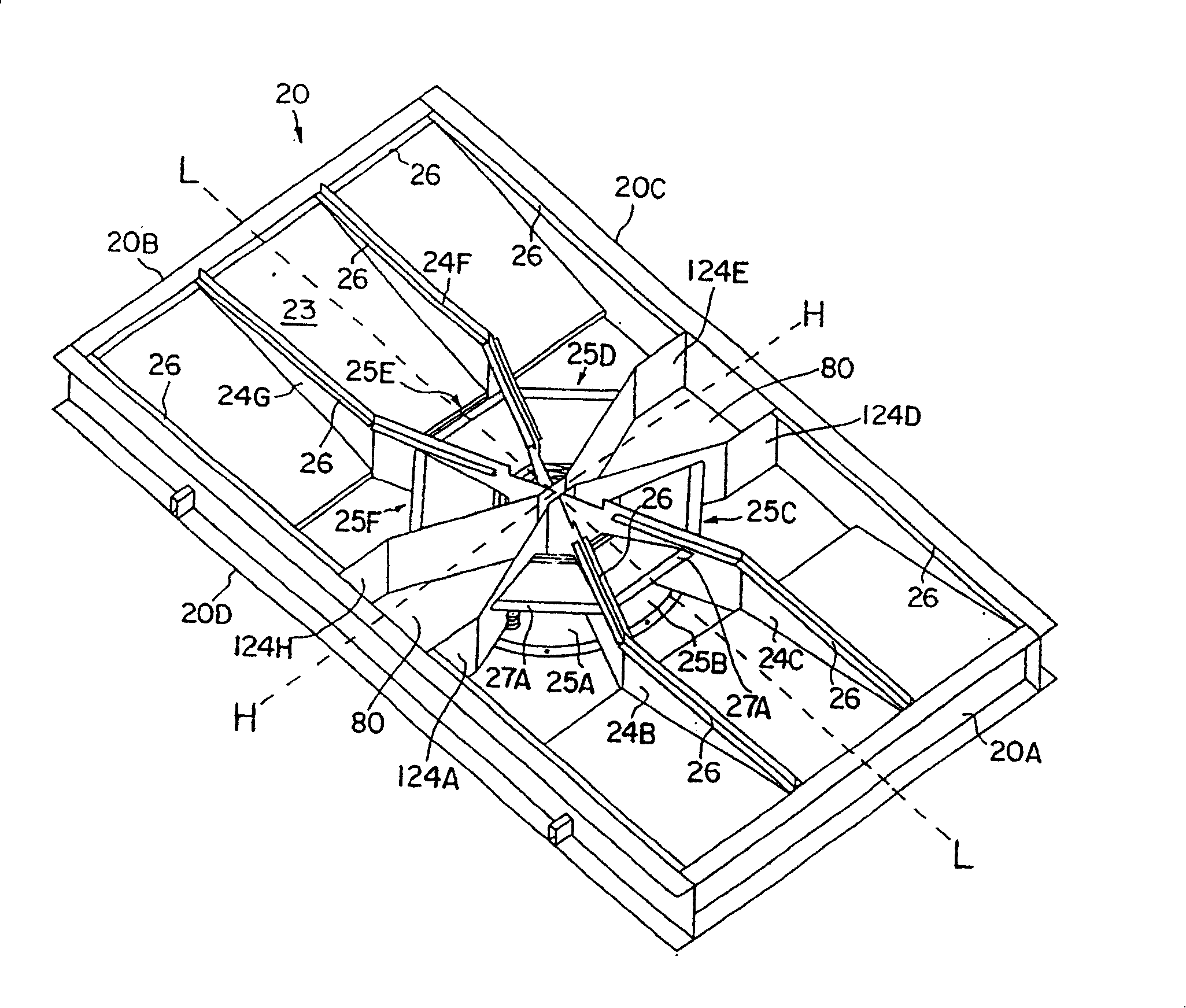

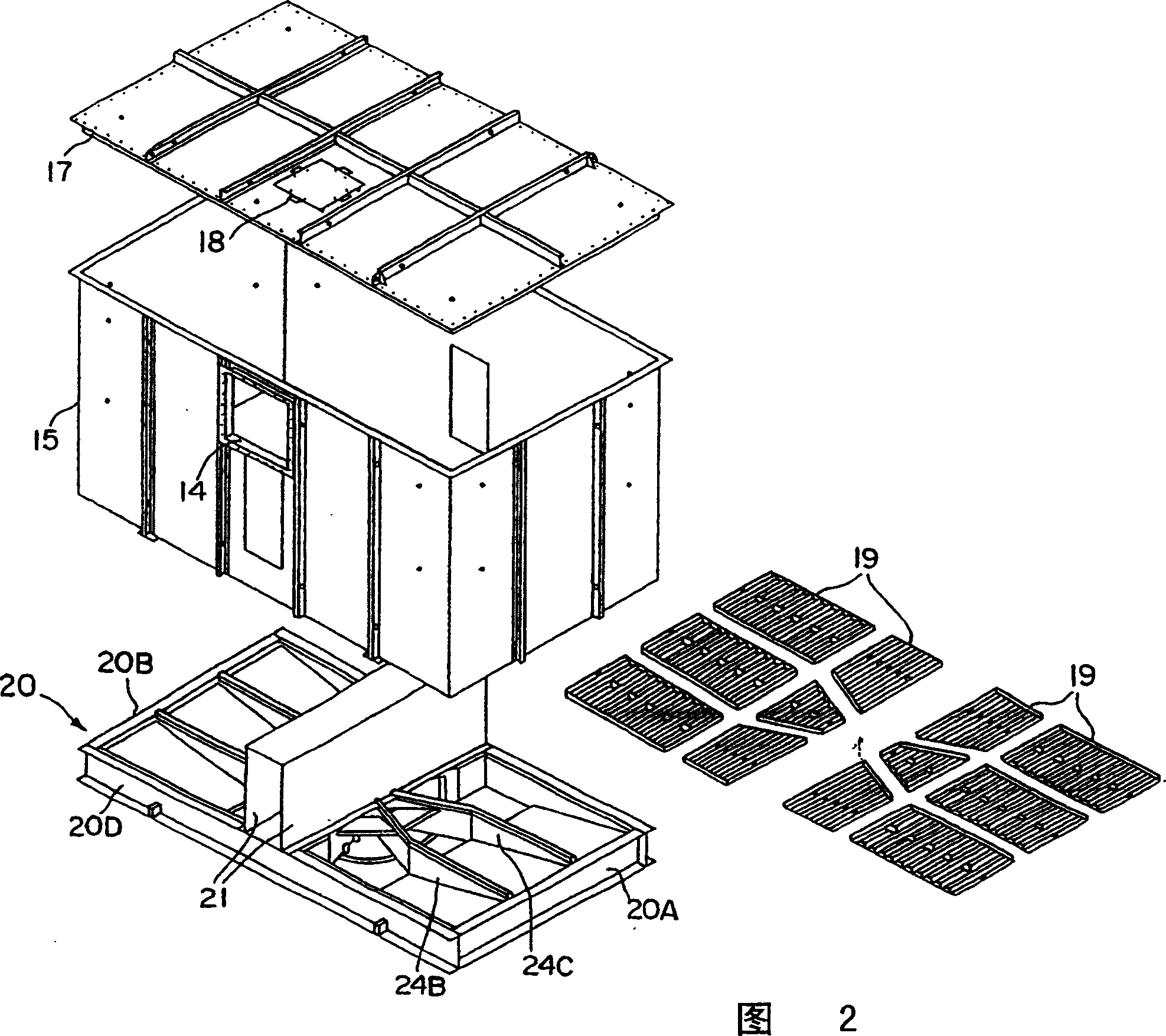

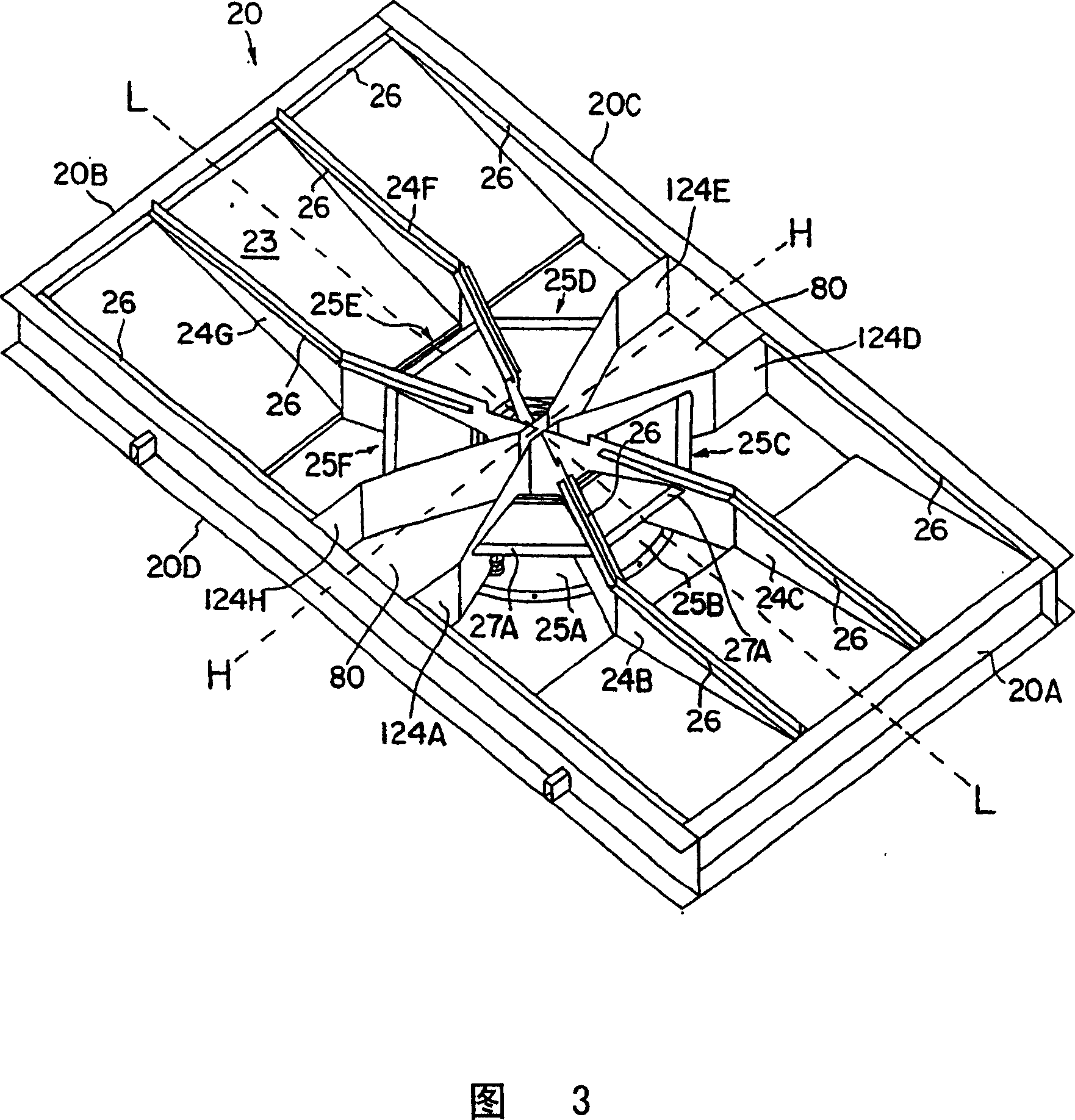

Thermal reactor with improved gas flow distribution

ActiveUS20090163042A1Improved gas distributionSemiconductor/solid-state device manufacturingMaintainance of heating chambersProcess engineeringHeat treated

Embodiments of the present invention provide apparatus and method for improving gas distribution during thermal processing. One embodiment of the present invention provides an apparatus for processing a substrate comprising a chamber body defining a processing volume, a substrate support disposed in the processing volume, wherein the substrate support is configured to support and rotate the substrate, a gas inlet assembly coupled to an inlet of the chamber body and configured to provide a first gas flow to the processing volume, and an exhaust assembly coupled to an outlet of the chamber body, wherein the gas inlet assembly and the exhaust assembly are disposed on opposite sides of the chamber body, and the exhaust assembly defines an exhaust volume configured to extend the processing volume.

Owner:APPLIED MATERIALS INC

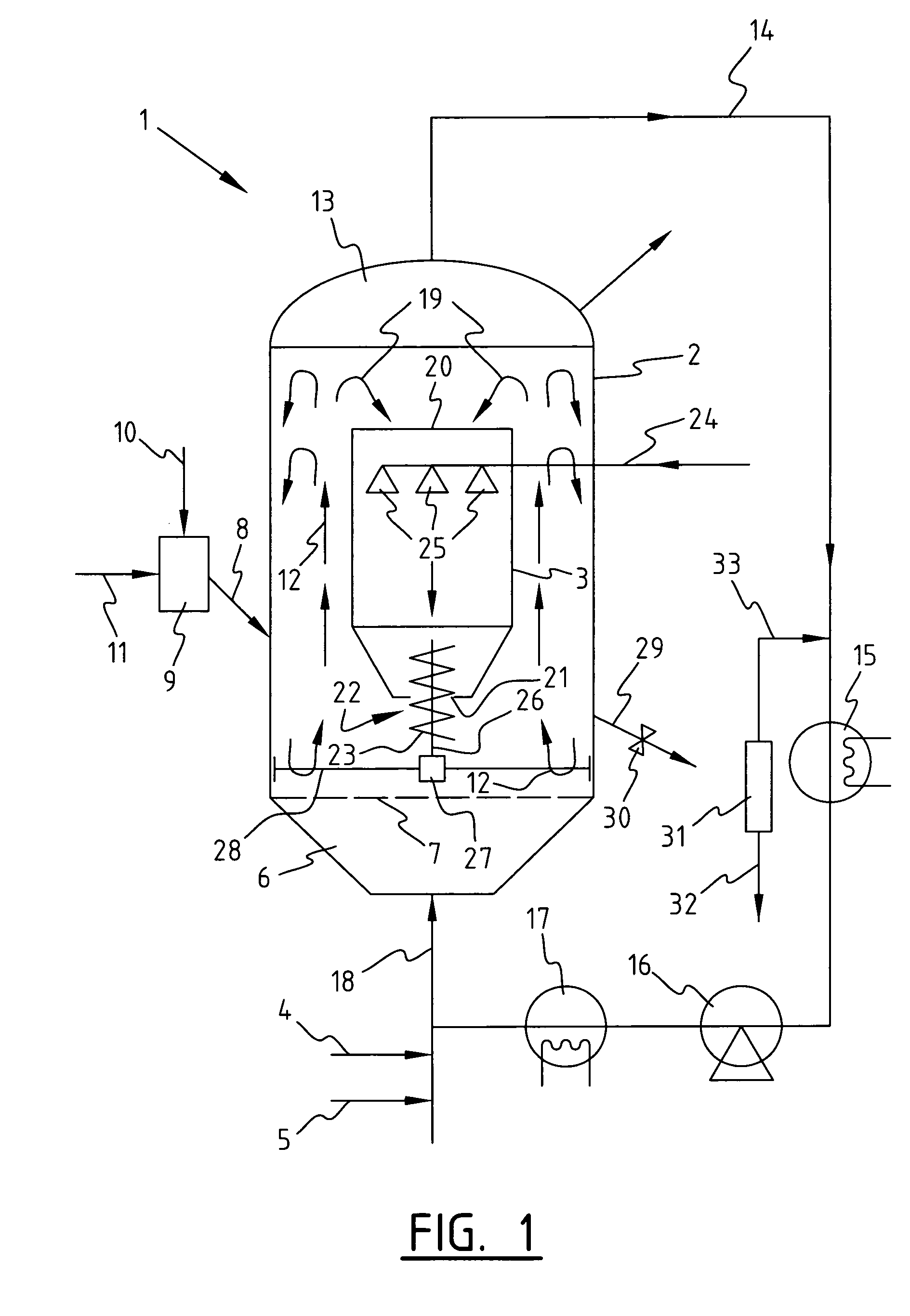

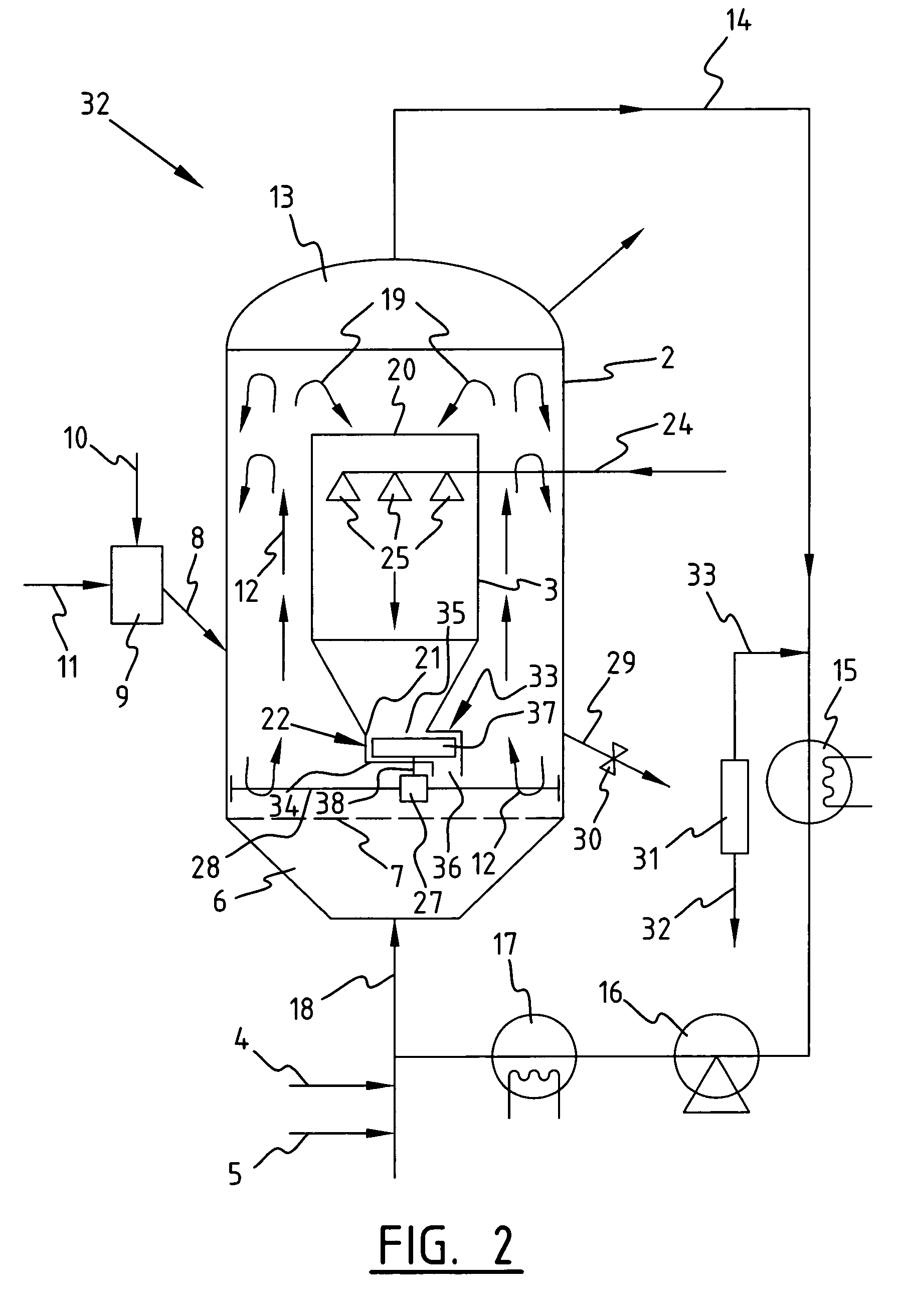

Reactor system and process for the catalytic polymerization of olefins, and the use of such reactor system in catalytic polymerization of olefins

InactiveUS8354483B2Easy to controlReduce gas velocityChemical/physical/physico-chemical stationary reactorsFluidised-bed furnacesReactor systemFluidized bed

The invention relates to a reactor system and process for the catalytic polymerization of olefin monomer and optionally comonomer(s), having one or more inlets for olefin monomer, catalyst, optionally for comonomer, chain growth controllers or chain transfer agents, and / or inert gas, an outlet for gas and an outlet for polymerized particles. The reactor system has at least one fluidized bed unit and at least one moving bed unit, wherein the fluidized bed unit has means for maintaining a fluidized bed in the fluidized bed unit and wherein the moving bed unit is provided with an inlet and an outlet which are connected to the fluidized bed unit, wherein the outlet of the moving bed unit is provided with means for displacing metered quantities of polymerized particles from the moving bed unit into the fluidized bed unit, and to the use of such reactor system.

Owner:BOREALIS TECH OY

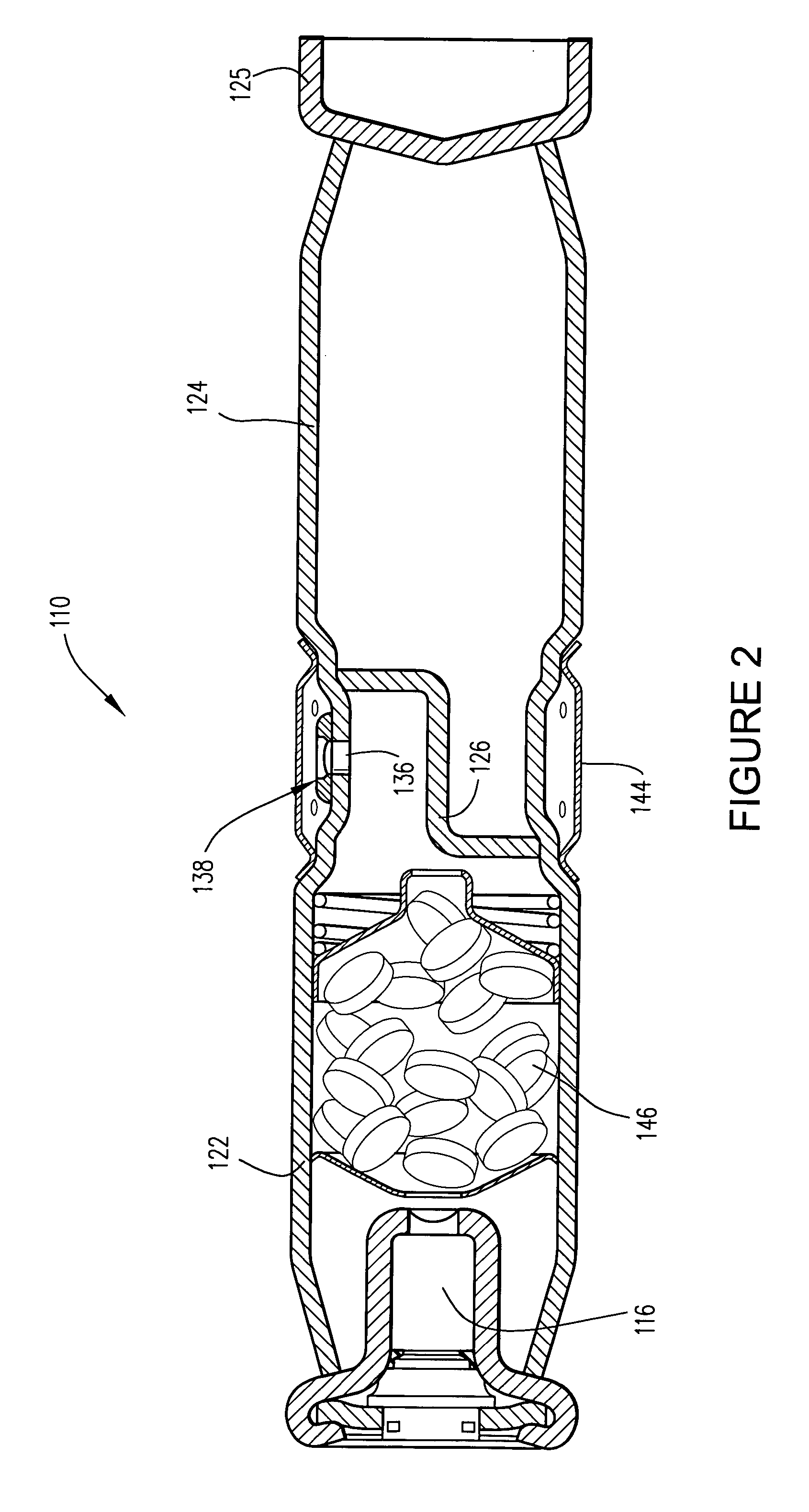

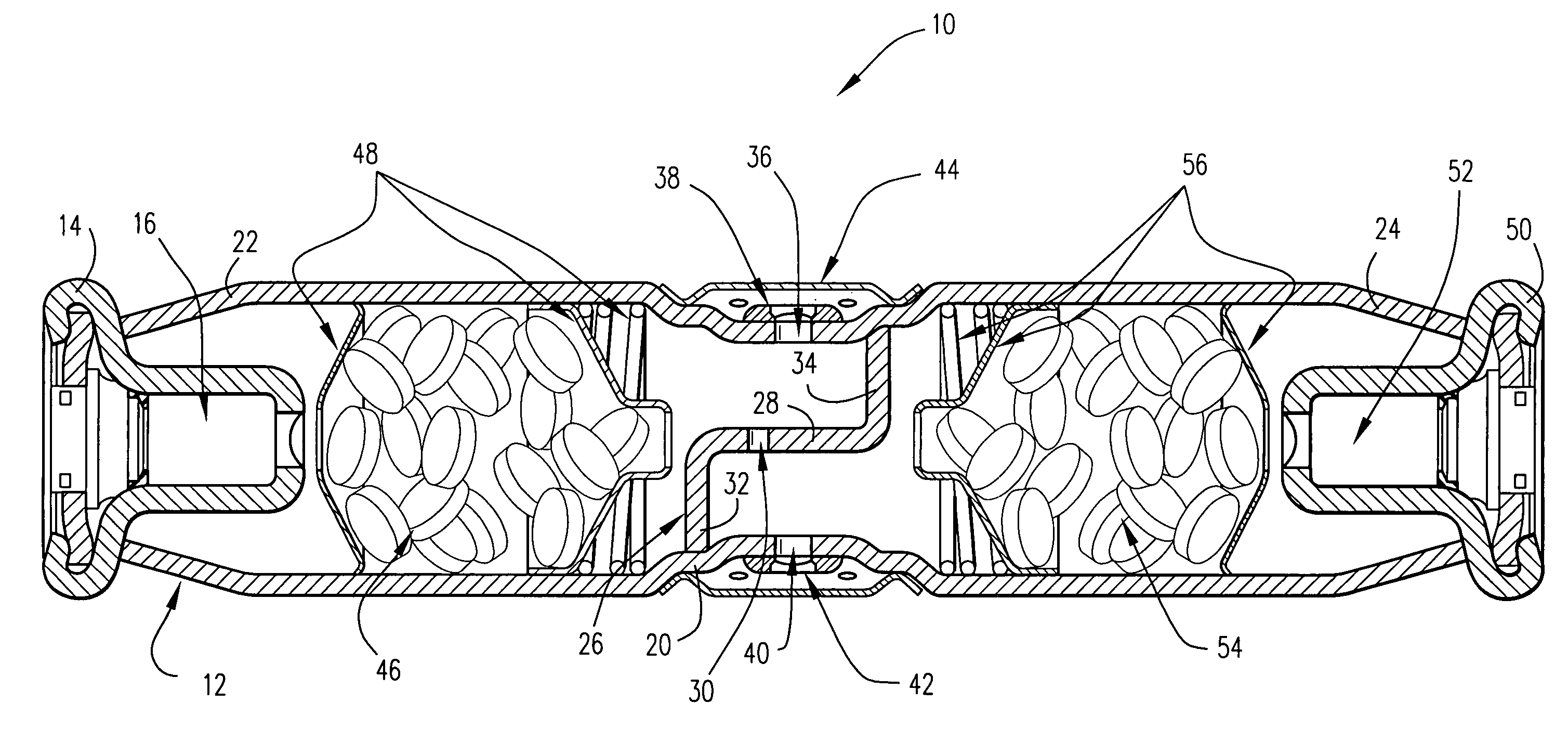

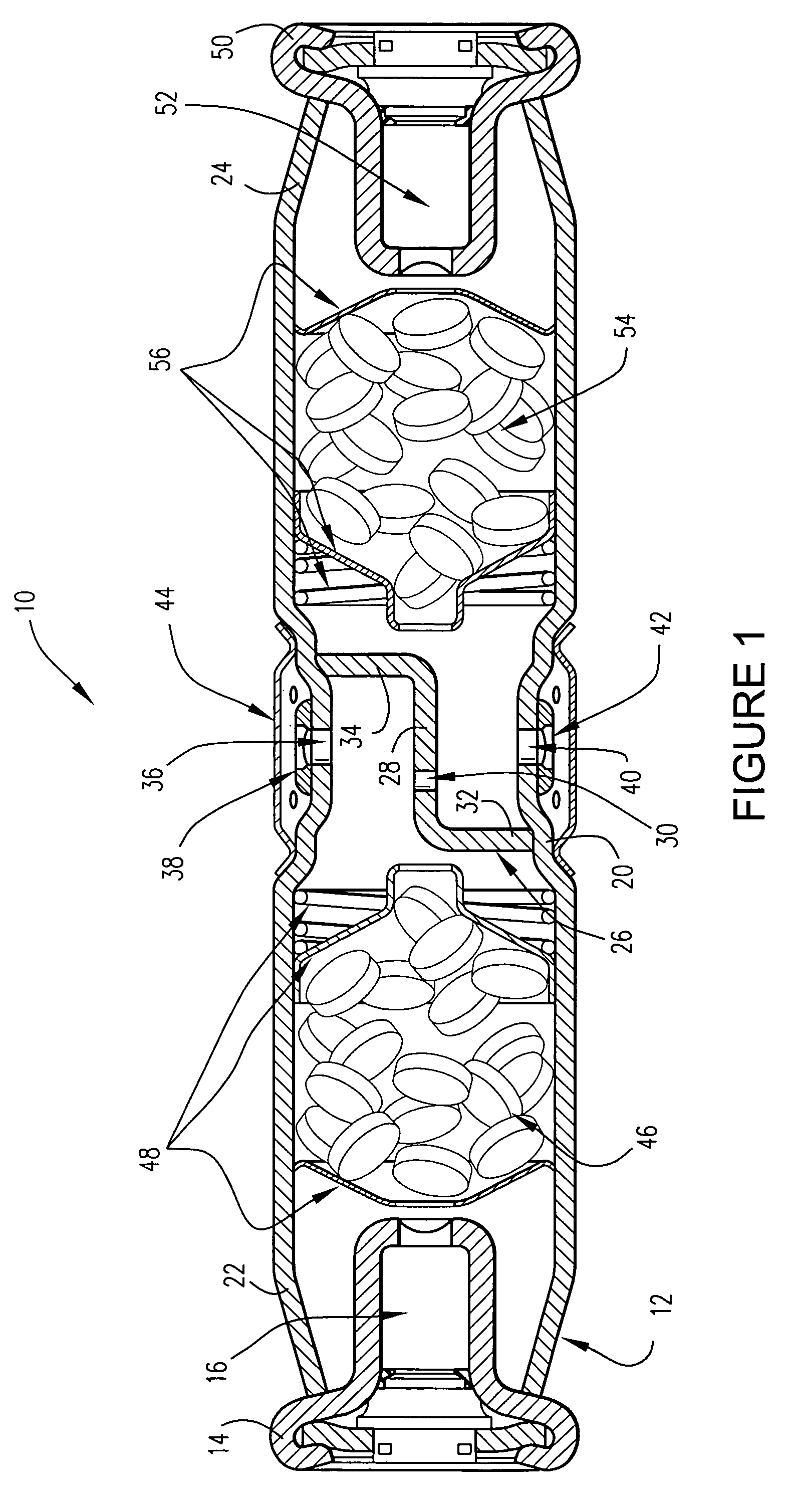

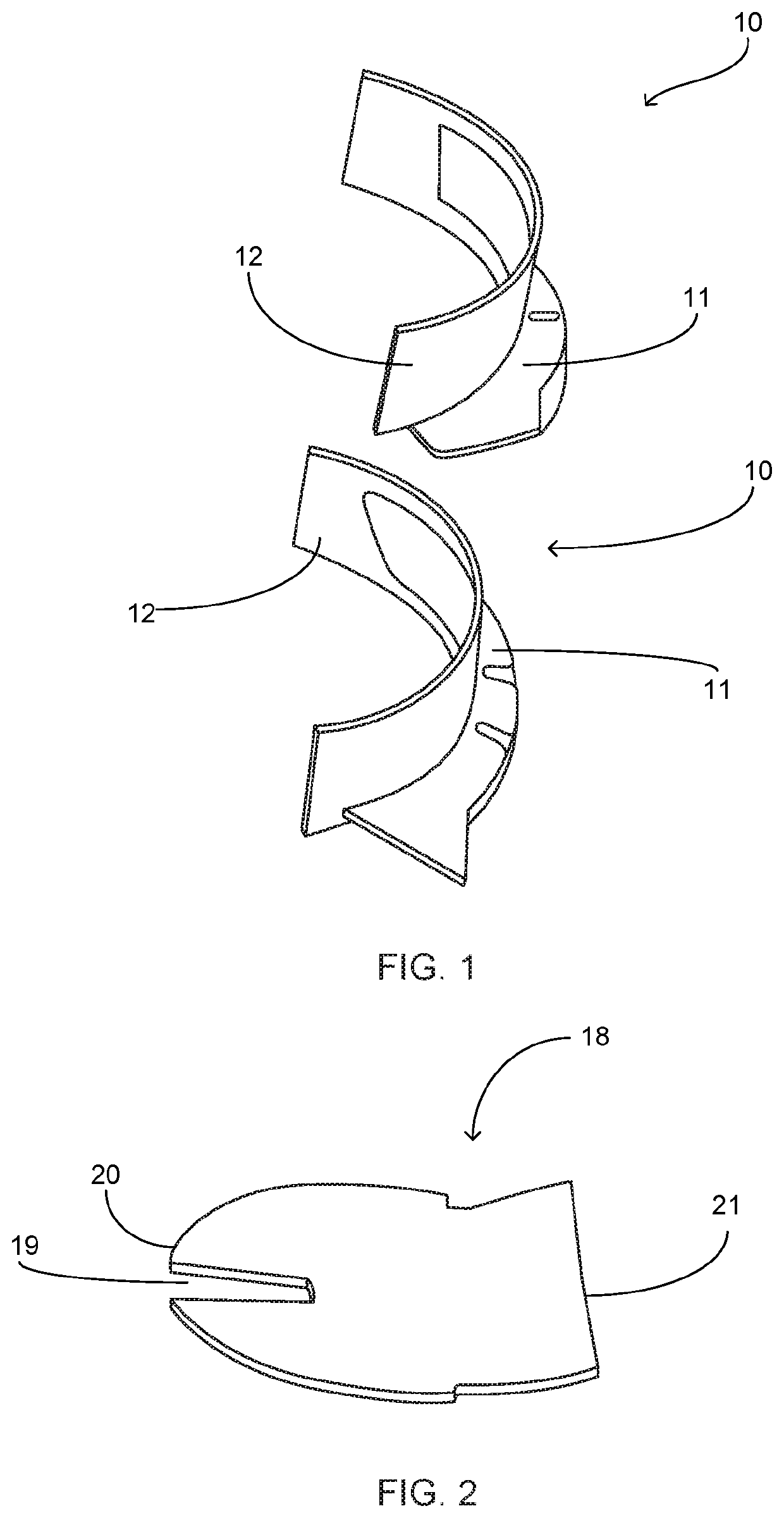

Compact multi-level output hybrid gas generator

InactiveUS20050029785A1Cost-effectiveGuaranteed uptimePedestrian/occupant safety arrangementVehicle design optimisationEnergeticsSingle level

A multi-level gas inflator for an air bag or other safety device, comprising an elongated pressure vessel having a primary gas generant portion with a first open end and a secondary gas generant portion with a second open end. The primary gas generant portion has a primary ignition device and primary gas generating energetics disposed therein. The primary ignition device is mounted on and closes the pressure vessel at the first open end thereof. The secondary gas generant portion has a secondary ignition device and secondary gas generating energetics disposed therein. The secondary ignition device is mounted on and closes the pressure vessel at the second open end thereof. A suitable gas under a predetermined pressure is present in the primary and secondary gas generant portions. One or more dividers or divider walls are disposed within the midportion of the pressure vessel to separate the primary and secondary gas generant portions. The pressure vessel has a primary exit orifice in the midportion thereof that is in communication with the primary gas generant portion, and a secondary exit orifice in the midportion thereof that is in communication with the secondary gas generant portion. A primary rupture disk is disposed over the primary exit orifice, and a secondary rupture disk is disposed over the secondary exit orifice. A diffuser is mounted on and surrounds the pressure vessel midportion and the primary and secondary exit orifices. The diffuser is in communication with the air bag for the inflation thereof. The inflator can be easily converted to a single level output inflator by omitting the secondary ignition device and the secondary gas generating energetics.

Owner:ARC AUTOMOTIVE

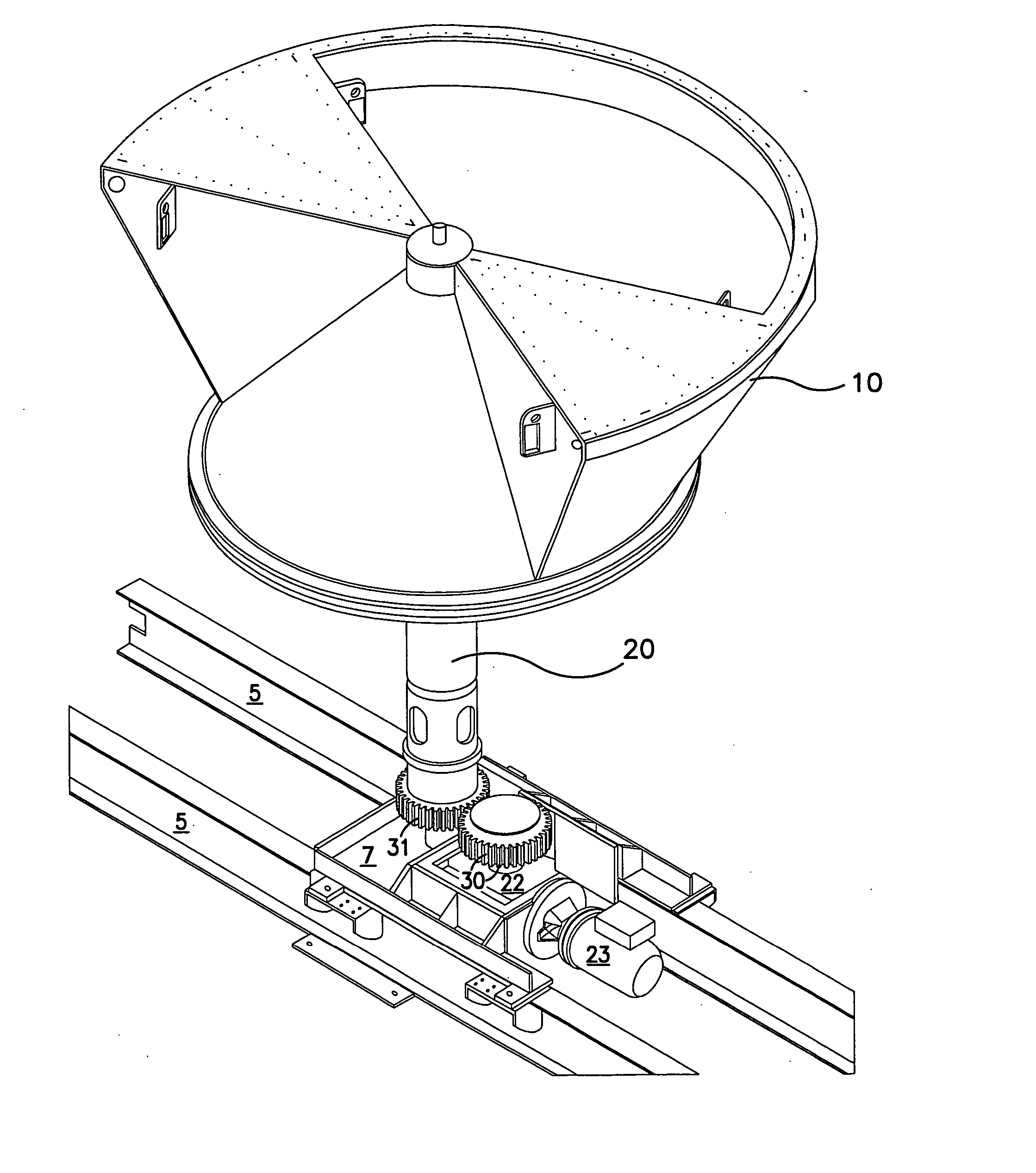

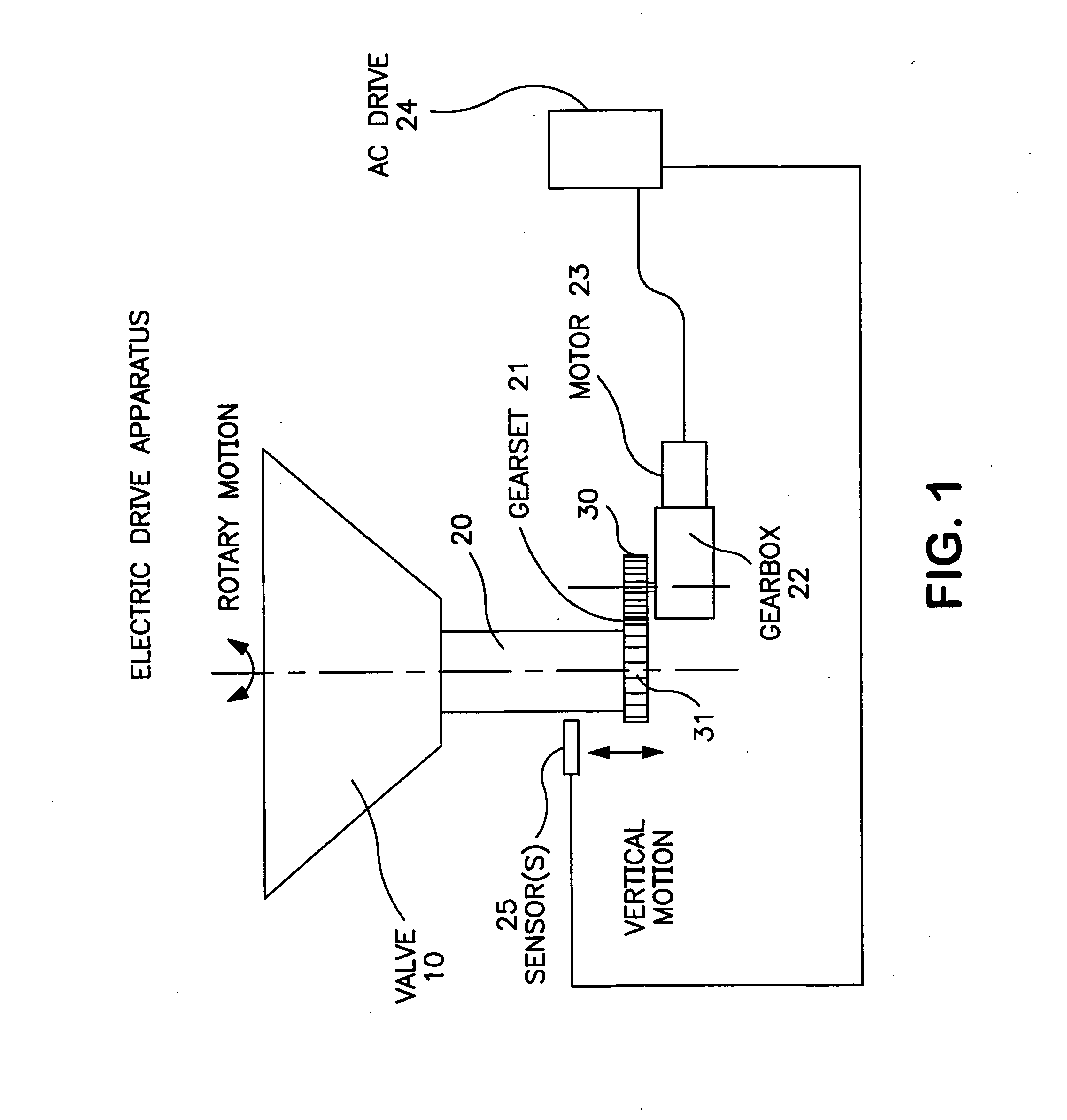

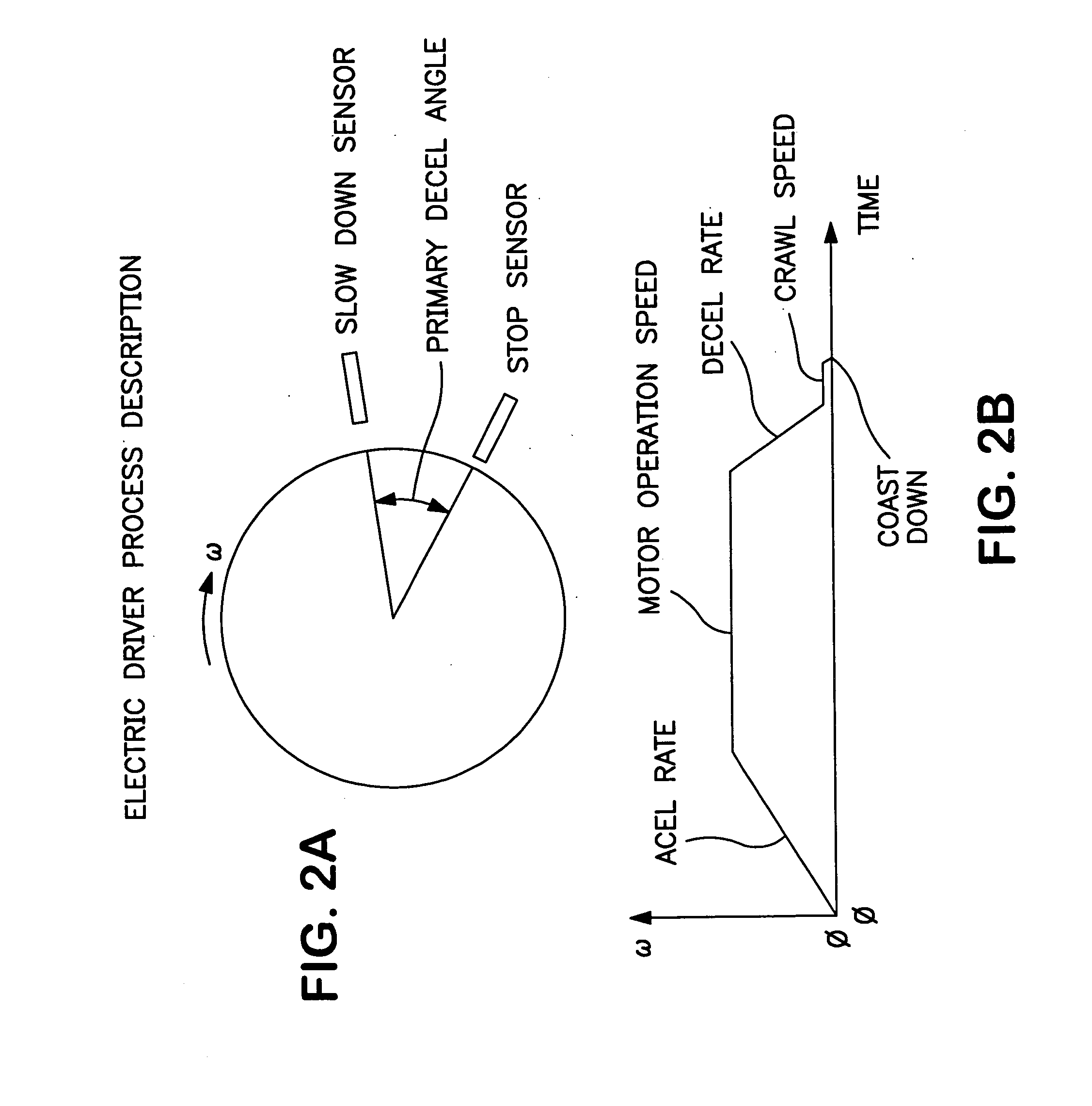

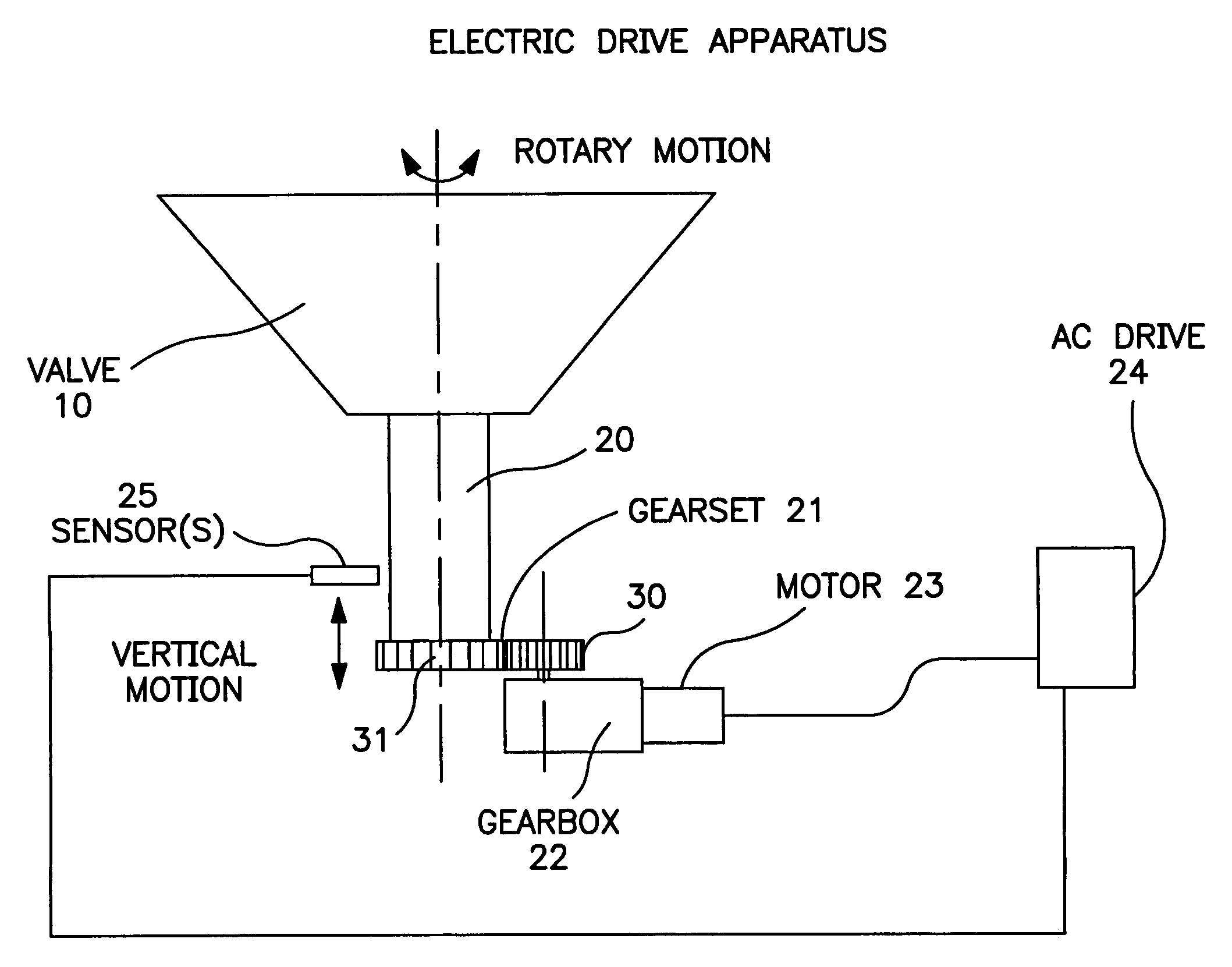

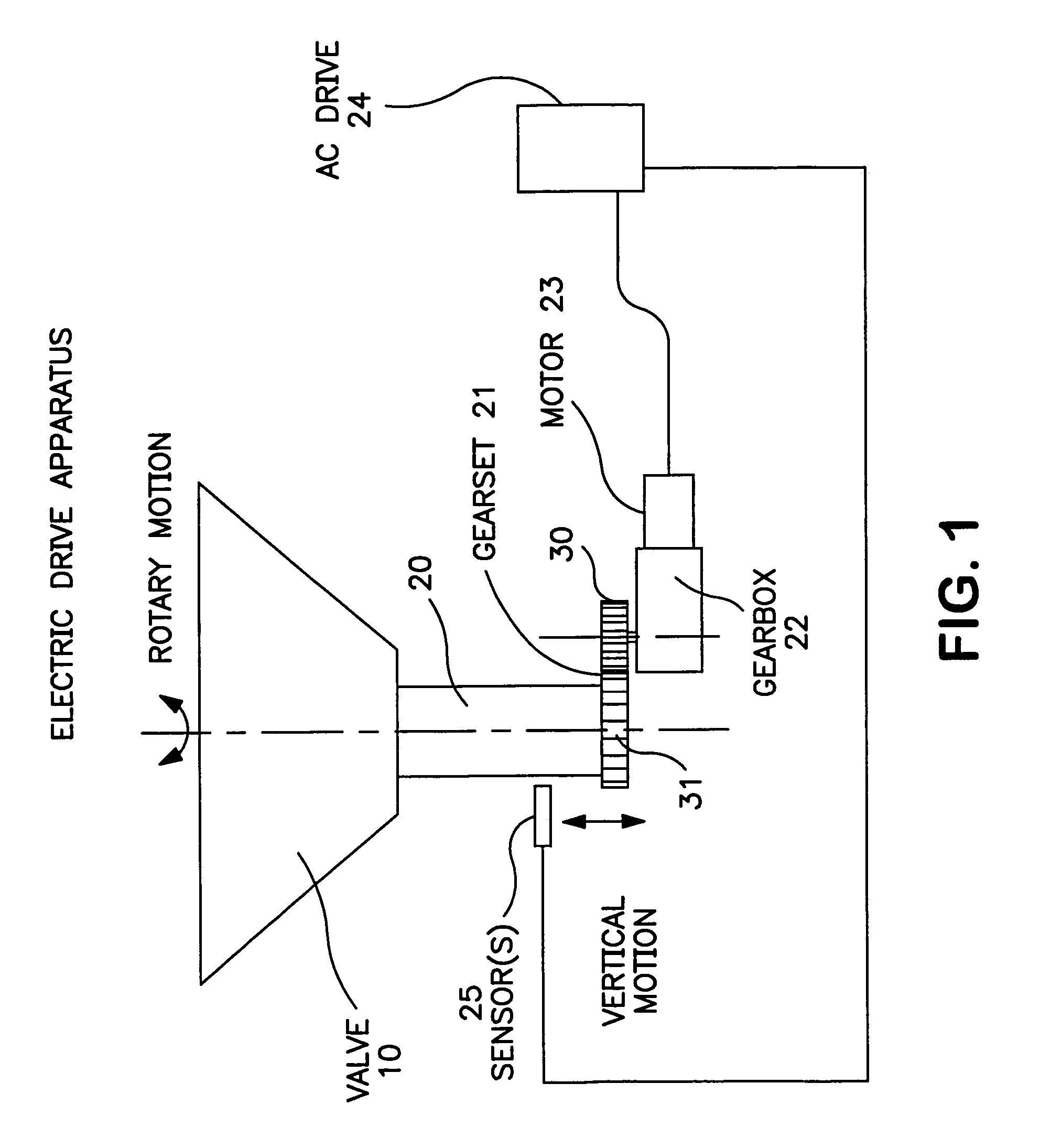

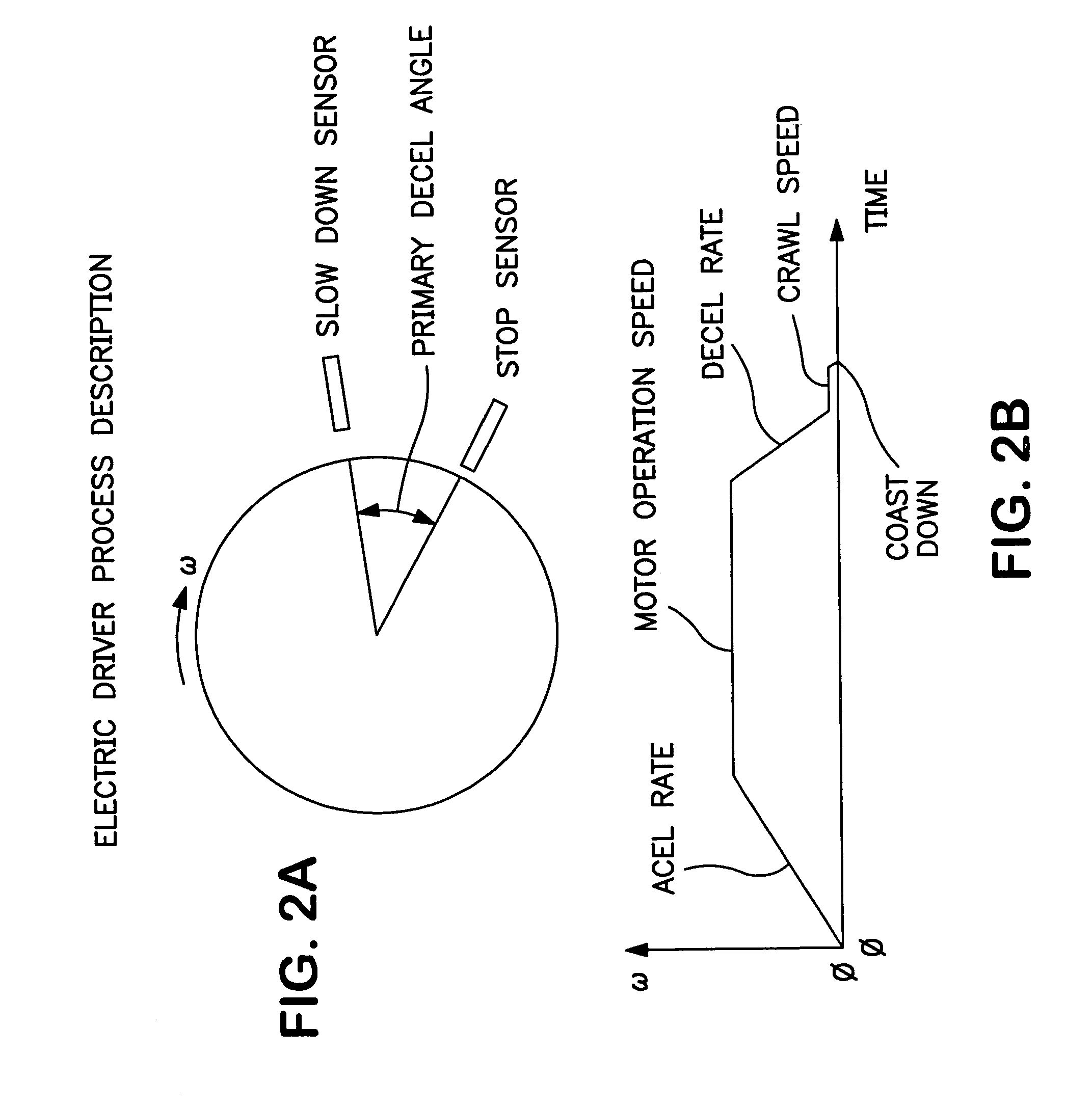

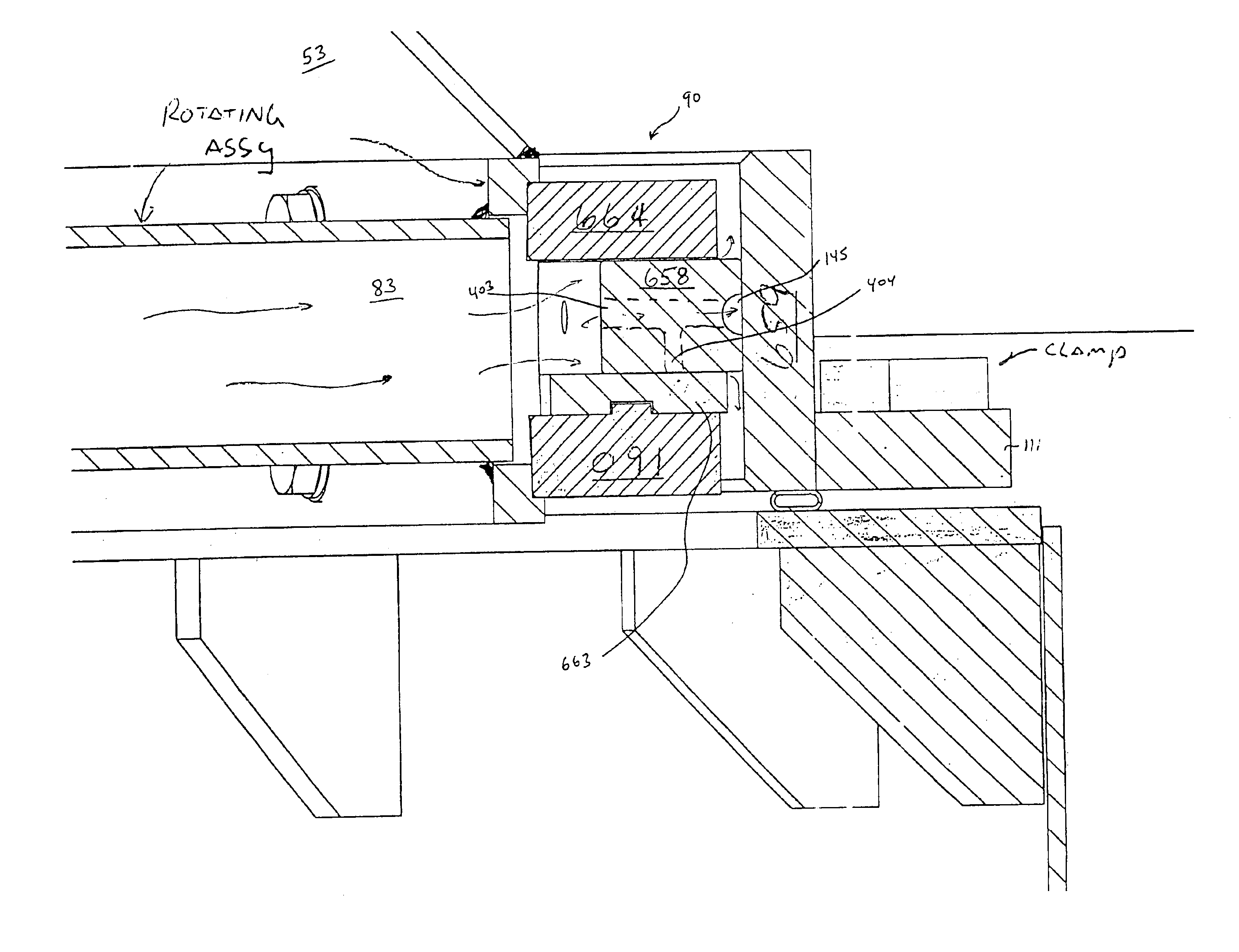

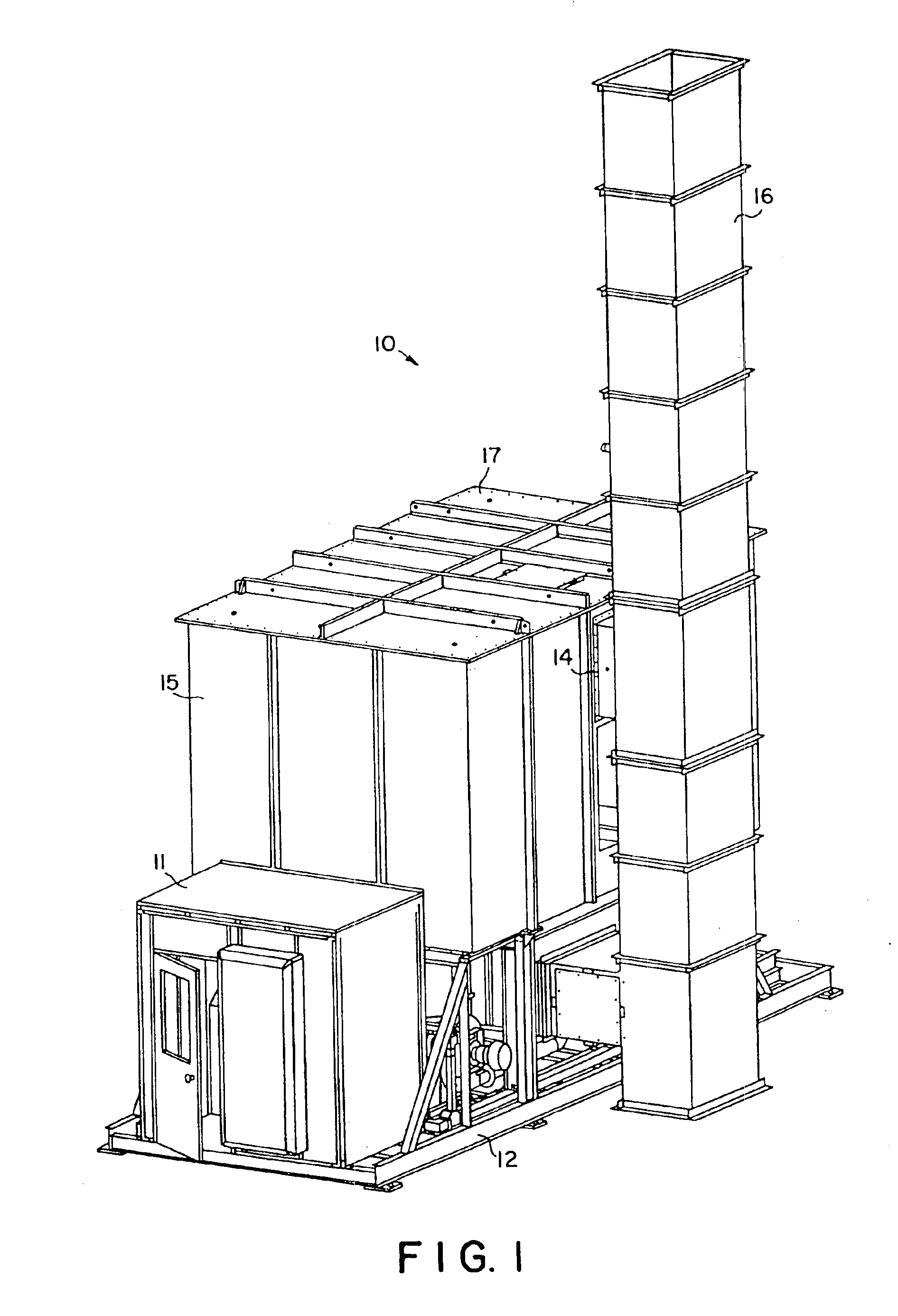

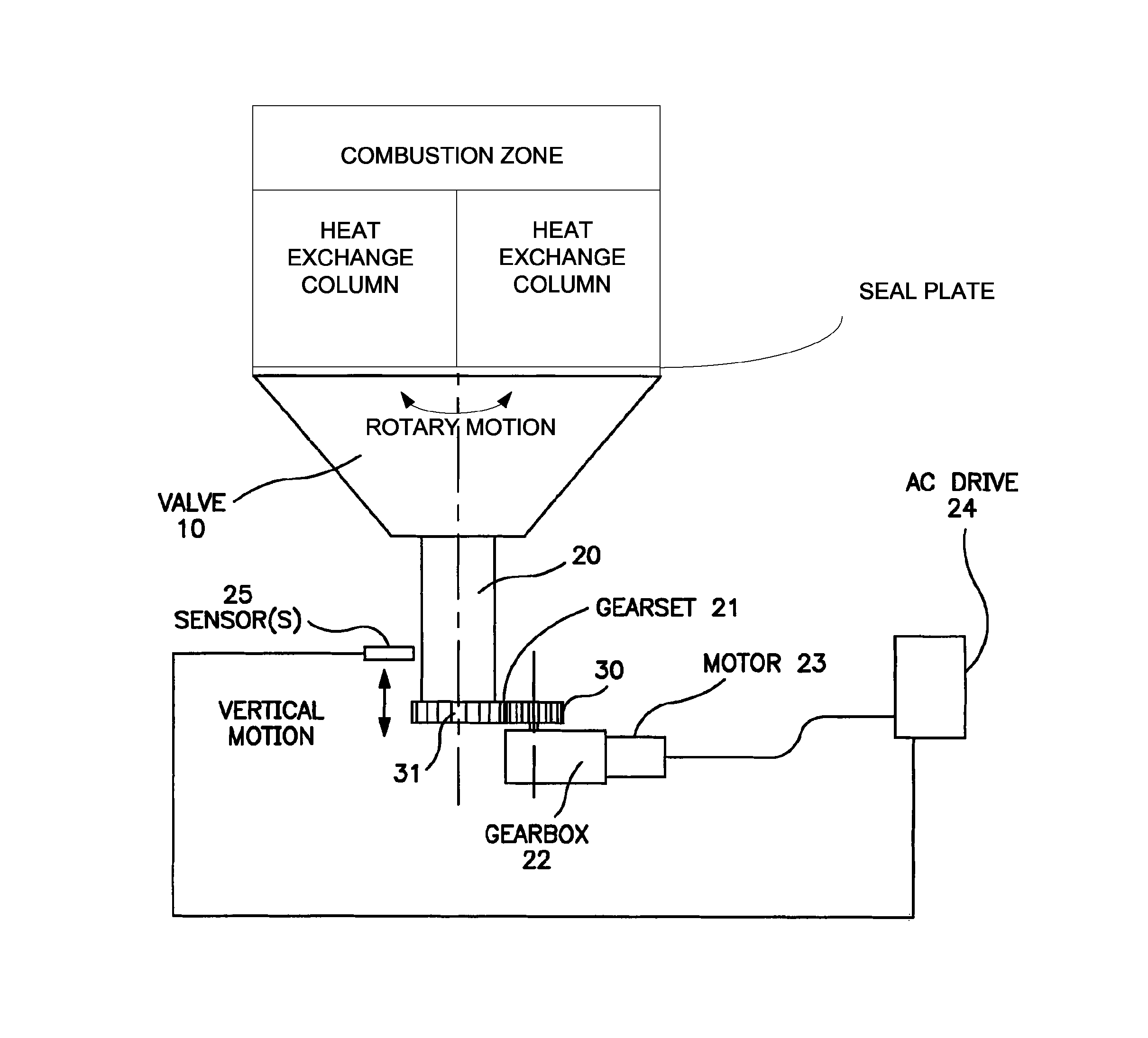

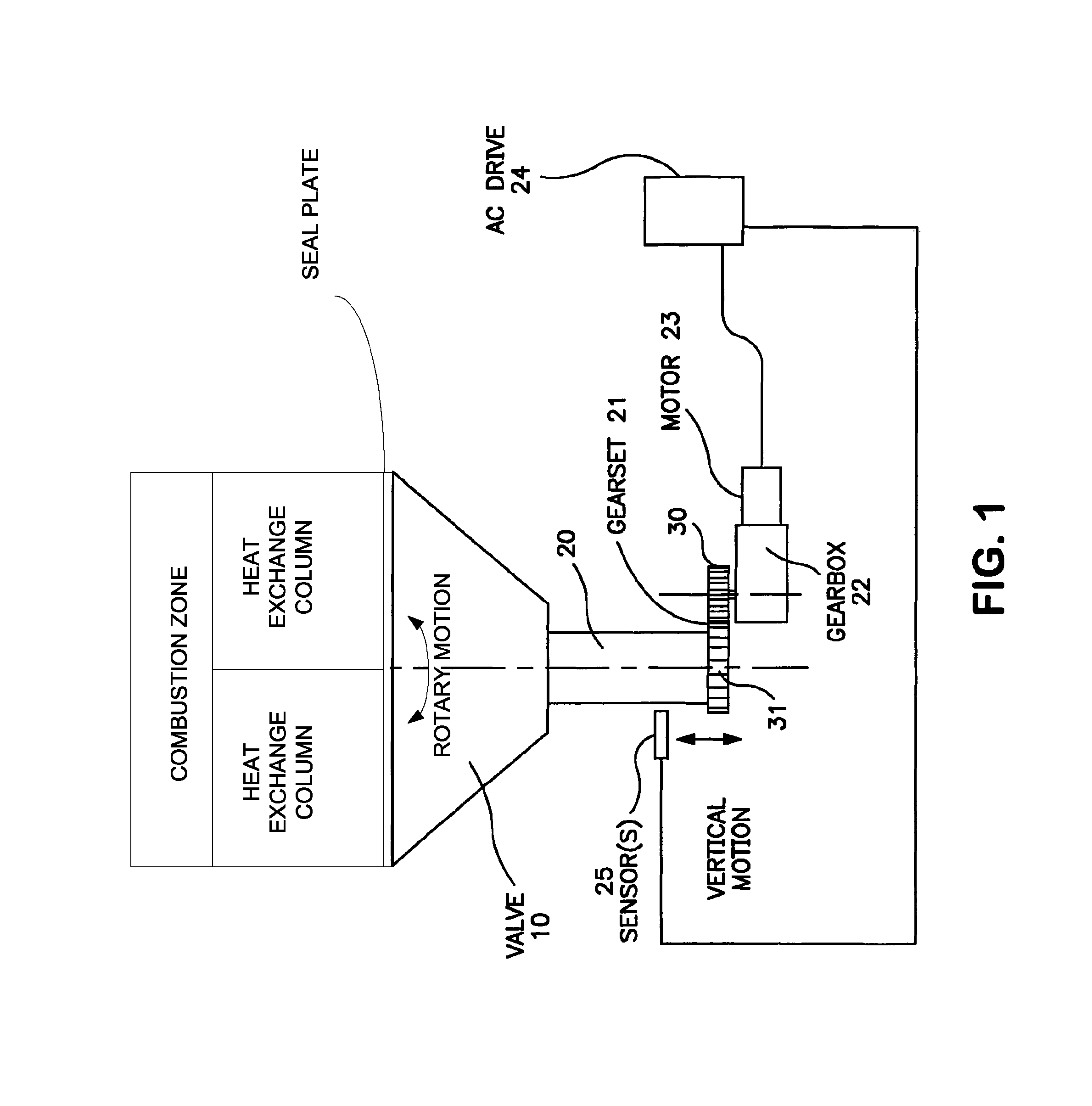

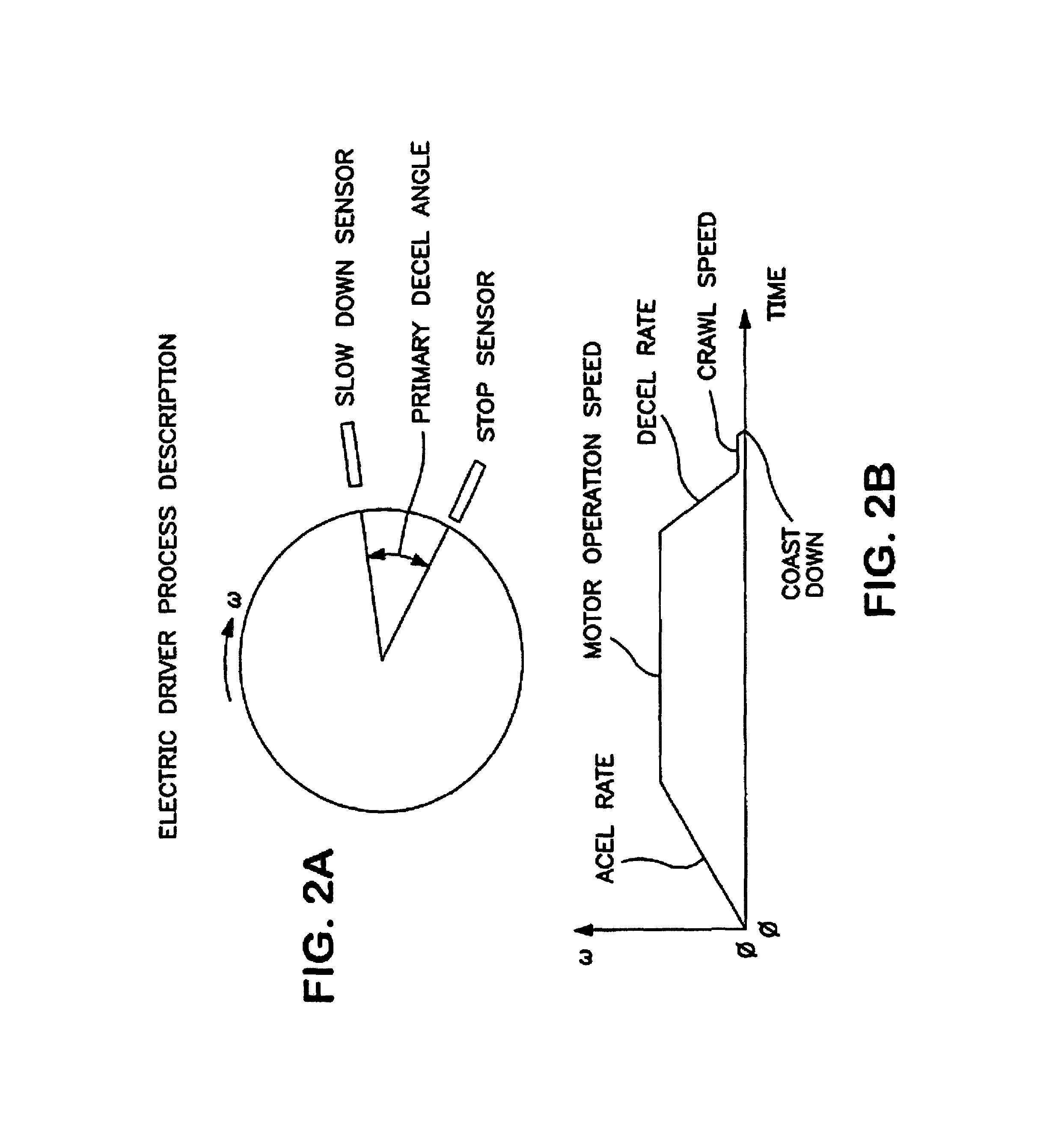

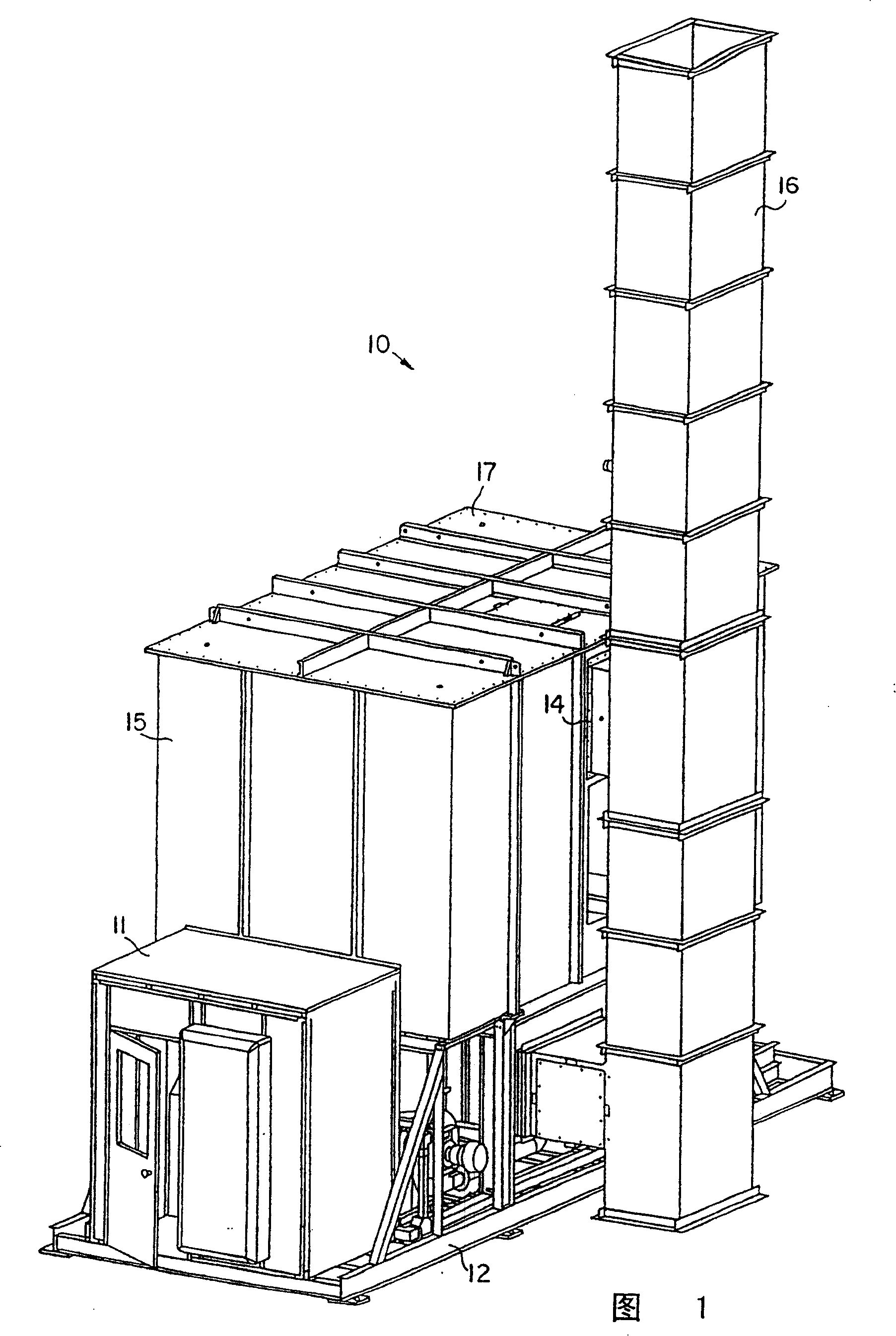

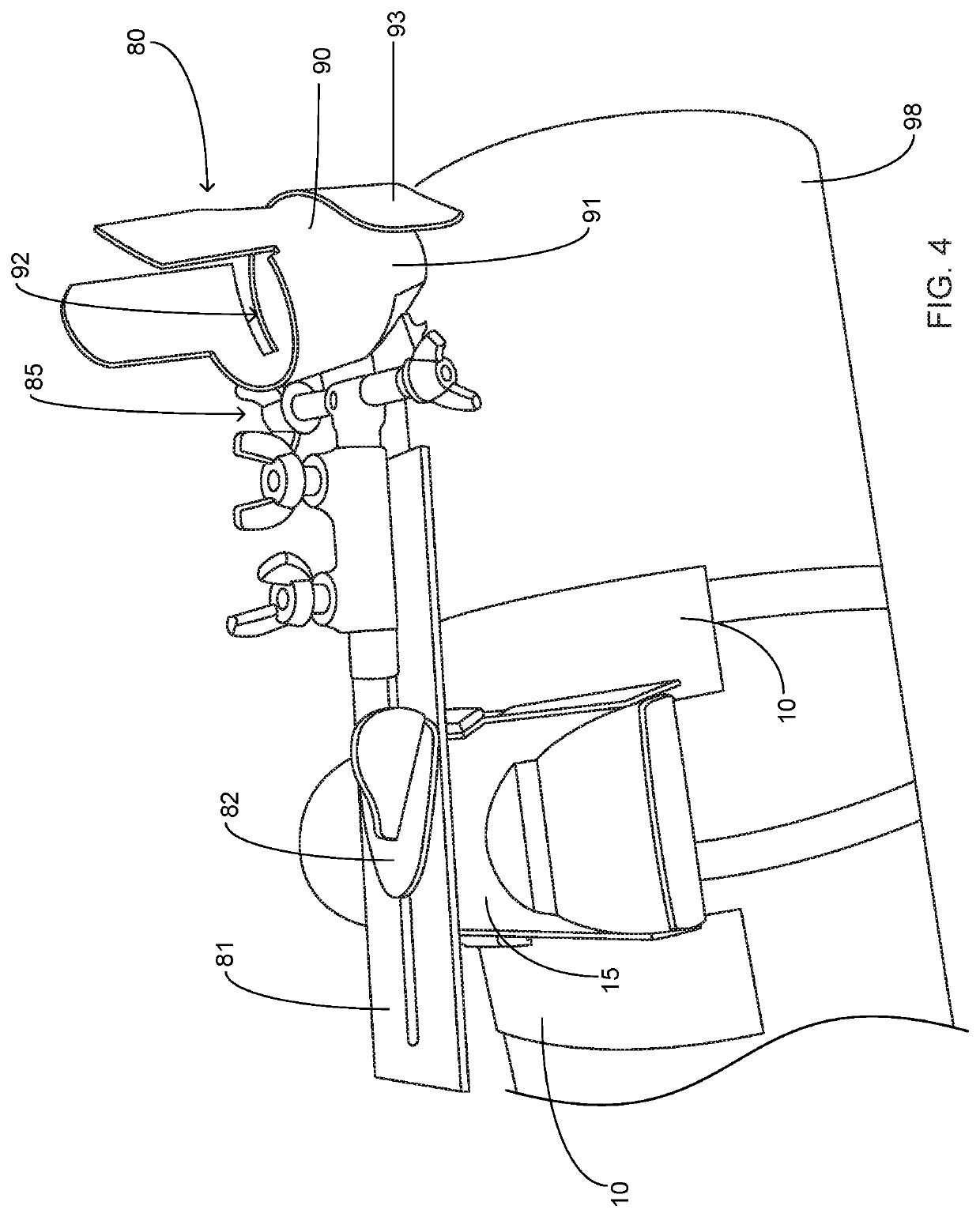

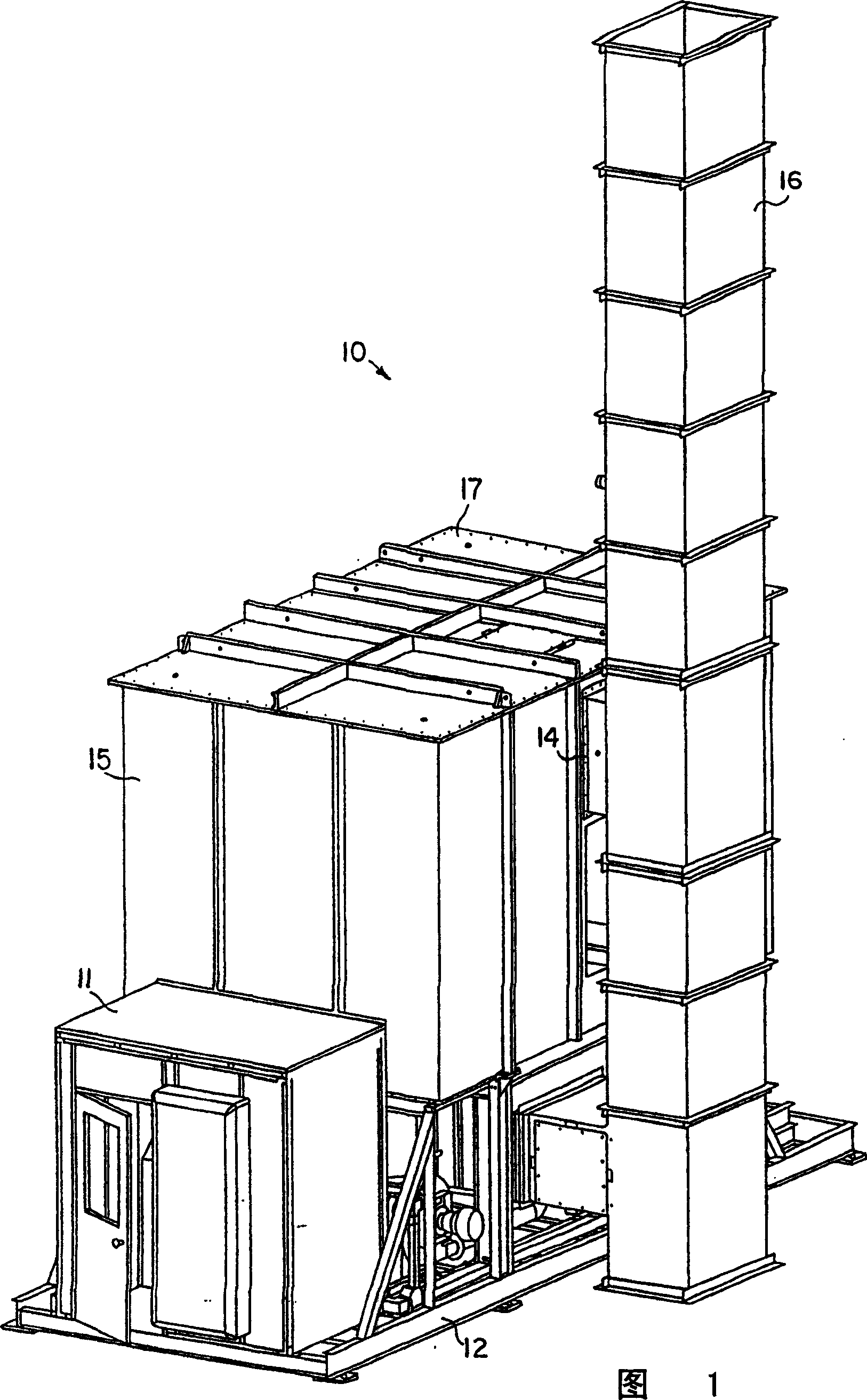

Electric gear motor drive for switching valve

ActiveUS20060102864A1Precise positioningDissipate energyOperating means/releasing devices for valvesValve members for heating/coolingMotor driveGear wheel

Electric drive for a switching valve, the switching valve having such a drive, and a regenerative thermal oxidizer including the switching valve and drive system. The electric drive system allows for the starting and stopping of the rotation of a rotary valve with accurate positioning. The stopping of the valve includes dissipation of the kinetic energy of the valve by electric means. The valve is allowed to move vertically and oscillating rotary motion is possible. The drive system preferably includes a gear, gearbox, variable speed drive and at least one positioning sensor. Valve acceleration and deceleration can be carried out in a controlled fashion and with repeatability, so that the final end position of the valve is consistent. The accommodation of vertical movement of the valve is also within the scope of the present invention.

Owner:DURR SYST INC

Thermal reactor with improved gas flow distribution

ActiveUS8056500B2Improved gas distributionSemiconductor/solid-state device manufacturingMaintainance of heating chambersThermodynamicsProcess engineering

Embodiments of the present invention provide apparatus and method for improving gas distribution during thermal processing. One embodiment of the present invention provides an apparatus for processing a substrate comprising a chamber body defining a processing volume, a substrate support disposed in the processing volume, wherein the substrate support is configured to support and rotate the substrate, a gas inlet assembly coupled to an inlet of the chamber body and configured to provide a first gas flow to the processing volume, and an exhaust assembly coupled to an outlet of the chamber body, wherein the gas inlet assembly and the exhaust assembly are disposed on opposite sides of the chamber body, and the exhaust assembly defines an exhaust volume configured to extend the processing volume.

Owner:APPLIED MATERIALS INC

Electric gear motor drive for switching valve

ActiveUS7308904B2Precise positioningDissipate energyOperating means/releasing devices for valvesValve members for heating/coolingMotor driveGear wheel

Electric drive for a switching valve, the switching valve having such a drive, and a regenerative thermal oxidizer including the switching valve and drive system. The electric drive system allows for the starting and stopping of the rotation of a rotary valve with accurate positioning. The stopping of the valve includes dissipation of the kinetic energy of the valve by electric means. The valve is allowed to move vertically and oscillating rotary motion is possible. The drive system preferably includes a gear, gearbox, variable speed drive and at least one positioning sensor. Valve acceleration and deceleration can be carried out in a controlled fashion and with repeatability, so that the final end position of the valve is consistent. The accommodation of vertical movement of the valve is also within the scope of the present invention.

Owner:DURR SYST INC

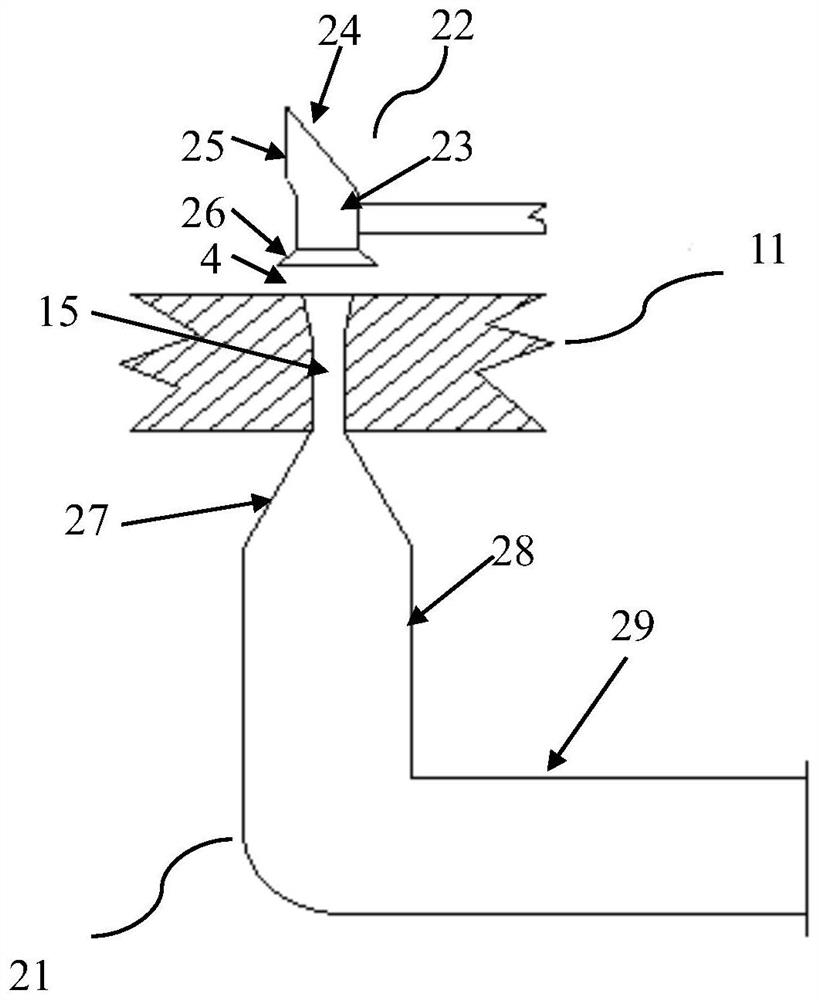

Gas turbine combustion-chamber for combusting ethanol fuel

InactiveCN101307916AAchieve energy saving and emission reductionImproved gas distributionContinuous combustion chamberCombustion chamberEvaporation

The invention discloses a combustion chamber of a gas turbine burning ethanol fuel. The combustion chamber of the gas turbine burning ethanol fuel adopts a single tube cylinder combustion chamber structure which is formed by a combustion chamber cartridge receiver and a flame tube; an inlet of the combustion chamber is welded with the combustion chamber cartridge receiver, which is used for introducing air current; the flame tube is welded or connected by threads between an outlet and the combustion chamber cartridge receiver; liquid ethanol is supplied to the combustion chamber through an ethanol supply path, and a fuel preparation system is formed by the ethanol supply path and a rotational flow device to complete atomization and evaporation of the ethanol; an electric spark lighter is inserted in the flame tube to realize ignition startup of the ethanol combustion chamber; the whole process of ethanol combustion is completed in the flame tube so as to exhaust high temperature fuel gas from the outlet at the end of the combustion chamber; air current distribution of the combustion chamber of the gas turbine is adjusted to adapt to and exert characteristics and advantages of the ethanol fuel to the maximum extent, thereby improving combustion efficiency of the ethanol combustion and reducing pollution emission, and contributing to realizing the aims of energy conservation and environmental protection; and the combustion chamber is a key part of a micro-gas turbine with biomass fuel, which can enlarge fuel adaptability and is convenient for popularization and application.

Owner:BEIHANG UNIV

Compact multi-level output gas generator

ActiveUS7438313B2Cost-effectiveGuaranteed uptimePedestrian/occupant safety arrangementEngineeringMajor and minor

A multi-level gas inflator for an air bag or other safety device, comprising an elongated pressure vessel having a primary gas generant portion with a first open end and a secondary portion with a second open end. The primary gas generant portion has a primary ignition device and primary gas generating energetics disposed therein. The primary ignition device is mounted on and closes the pressure vessel at the first open end thereof. The secondary portion may have a secondary ignition device and secondary gas generating energetics disposed therein. The secondary ignition device may be mounted on the pressure vessel at the second open end thereof. A suitable gas under a predetermined pressure is present in the primary and secondary portions. One or more separate dividers or divider walls are disposed within the midportion of the pressure vessel to separate the primary and secondary portions. The pressure vessel may have a primary exit orifice in the midportion thereof that is in communication with the primary gas generant portion, and a secondary exit orifice in the midportion thereof that is in communication with the secondary portion. A primary rupture disk is disposed over the primary exit orifice, and a secondary rupture disk is disposed over the secondary exit orifice. A diffuser may be mounted on and surround the pressure vessel midportion and the primary and secondary exit orifices. Each divider or divider wall may have a communication port therethrough.

Owner:ARC TECH HLDG LTD

Side inject nozzle design for processing chamber

ActiveUS20170314126A1Improved gas distributionSemiconductor/solid-state device manufacturingChemical vapor deposition coatingProduct gasEngineering

Implementations of the present disclosure provide apparatus and method for improving gas distribution during thermal processing. One implementation of the present disclosure provides an apparatus for processing a substrate comprising a chamber body defining a processing volume, a substrate support disposed in the processing volume, wherein the substrate support has a substrate supporting surface, a gas source assembly coupled to an inlet of the chamber body, an exhaust assembly coupled to an outlet of the chamber body, and a side gas assembly coupled to a sidewall of the chamber body, wherein the side gas assembly comprises a gas inlet pointed in a direction that is tangential to the edge of the substrate supporting surface, and wherein the gas inlet, the inlet of the chamber body, and the outlet of the chamber body are angularly offset at about 90° with respect to each other, and the gas inlet, the inlet of the chamber body, and the outlet of the chamber body are intersected by a common plane.

Owner:APPLIED MATERIALS INC

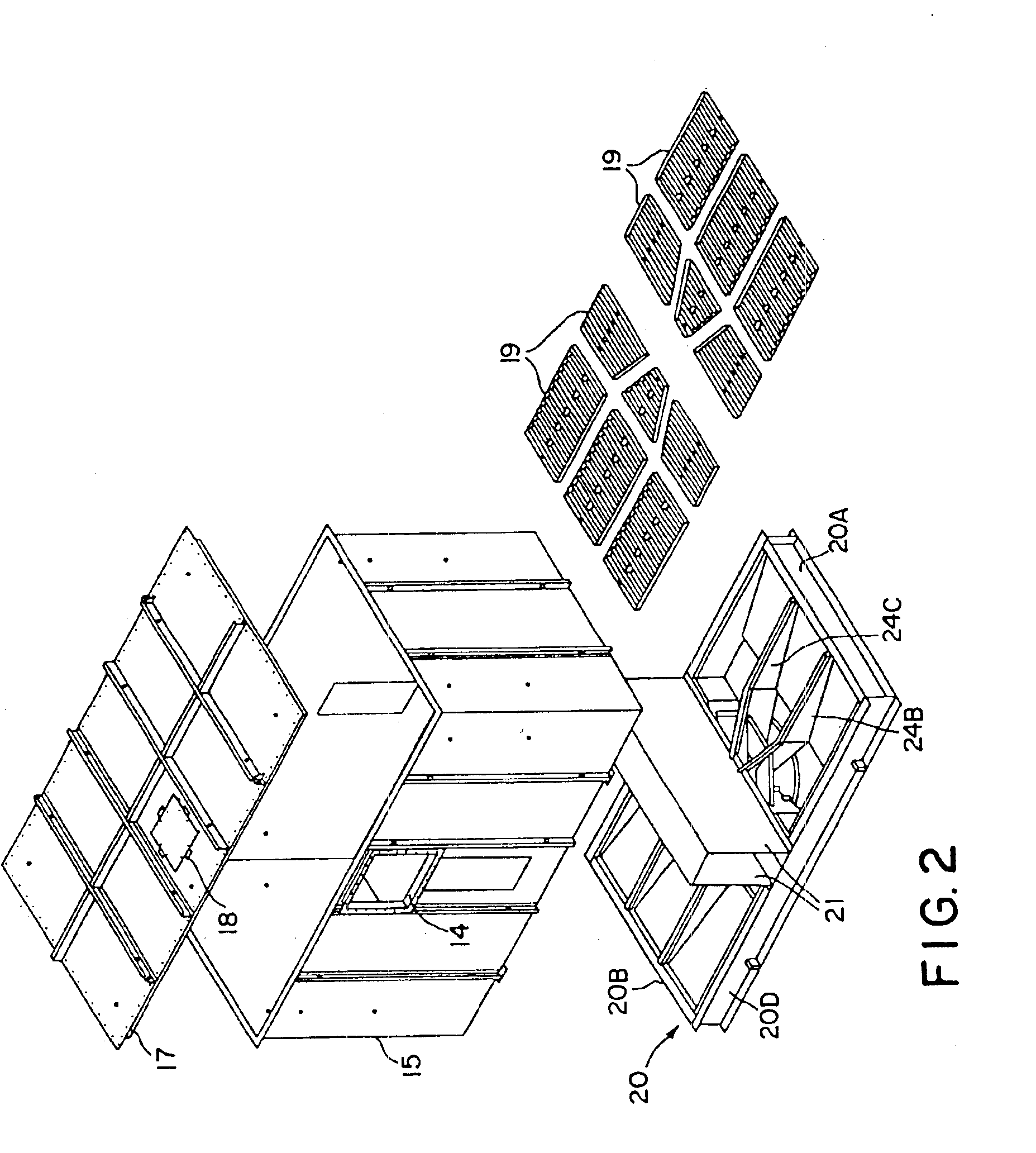

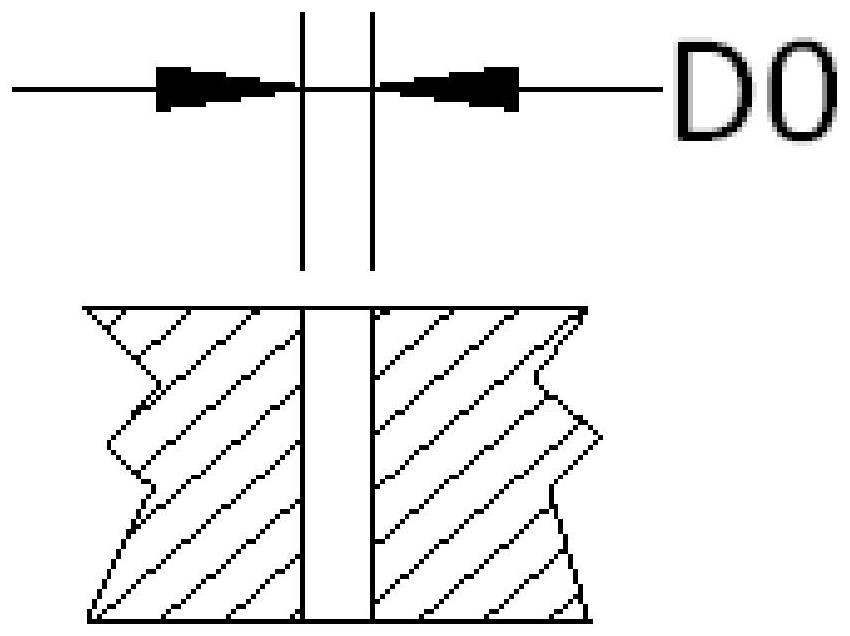

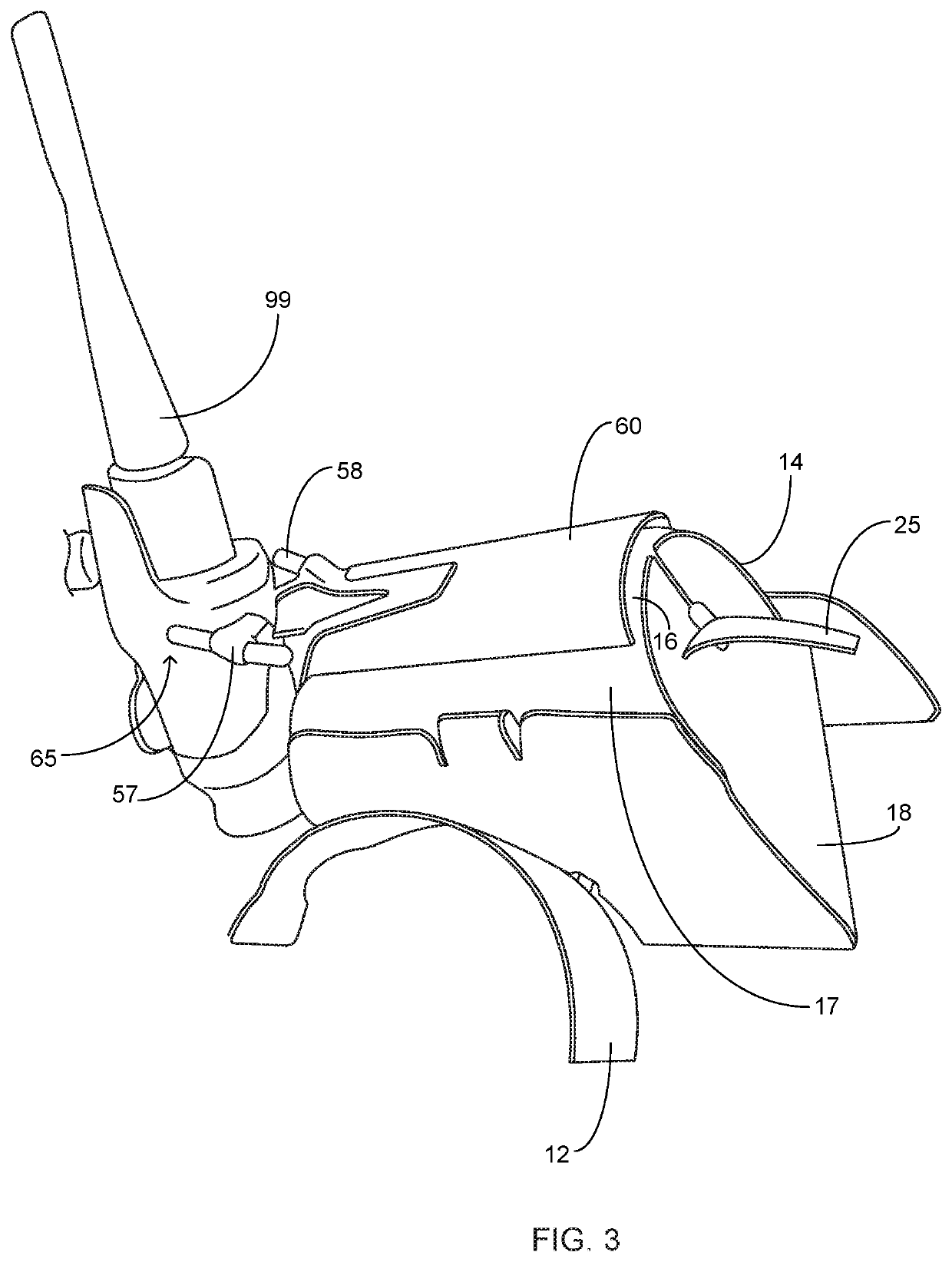

Switching valve seal

InactiveUS6899121B2Improve sealingImprove sealing propertiesExhaust apparatusMachines/enginesEngineeringDistributor

Switching valve utilizing a rotatable seal suitable for use in a regenerative thermal oxidizer, and oxidizer including the switching valve. The valve of the present invention exhibits excellent sealing characteristics and minimizes wear. The valve has a seal plate that defines two chambers, each chamber being a flow port that leads to one of two regenerative beds of the oxidizer. The valve also includes a switching flow distributor that provides alternate channeling of the inlet or outlet process gas to each half of the seal plate. The valve operates between two modes: a stationary mode and a valve movement mode. In the stationary mode, a tight gas seal is used to minimize or prevent process gas leakage. The gas seal also seals during valve movement.

Owner:DURR SYST INC

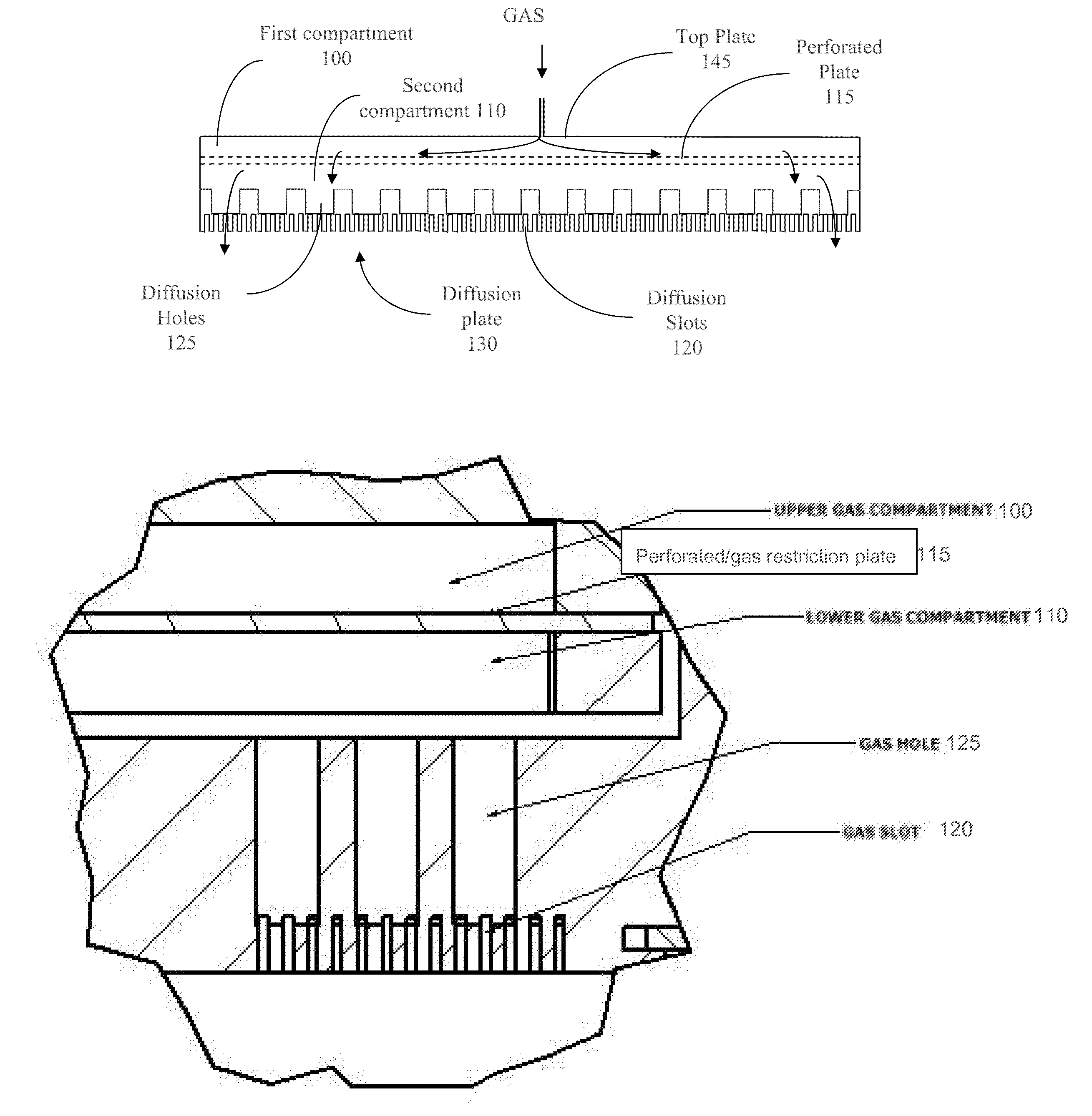

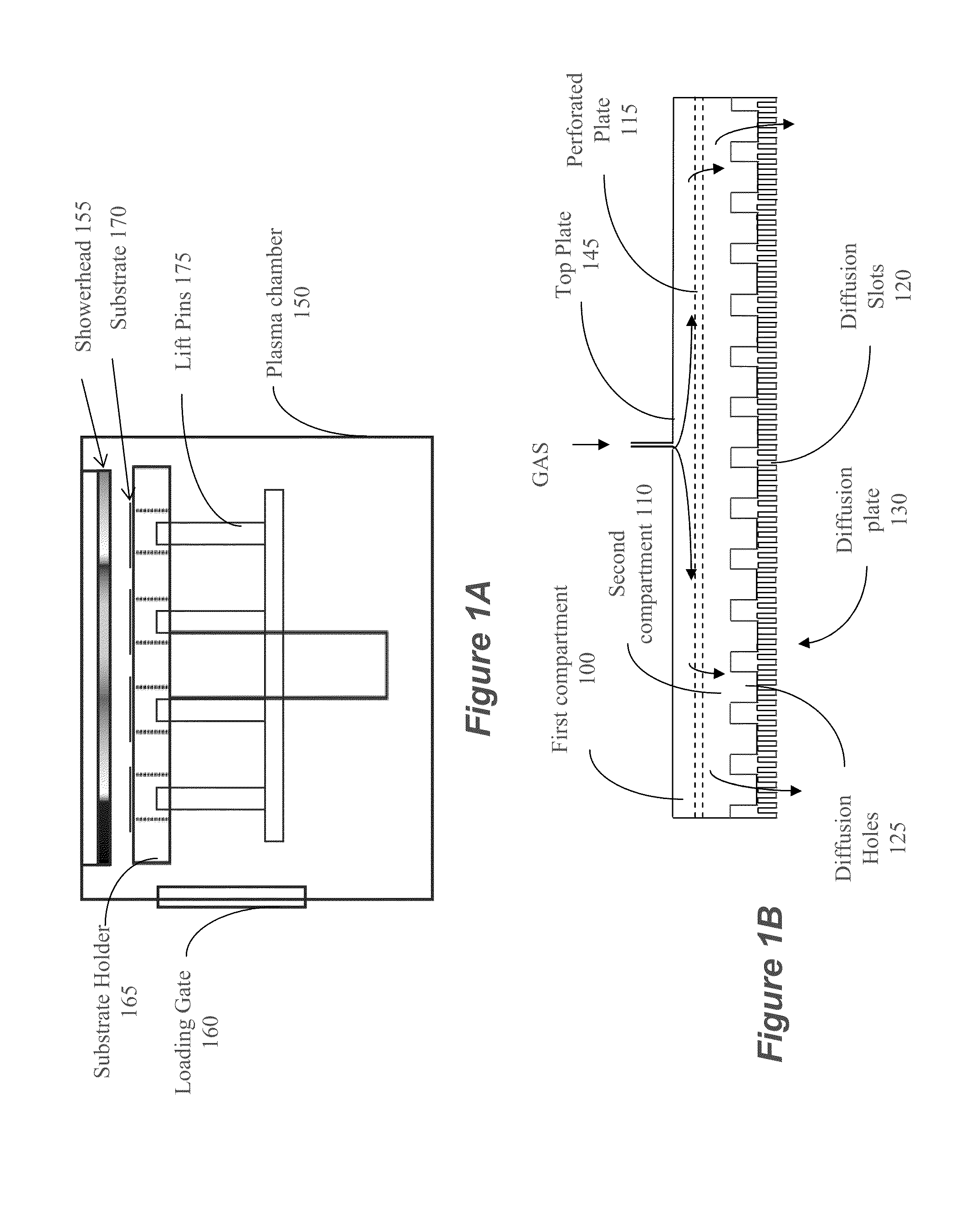

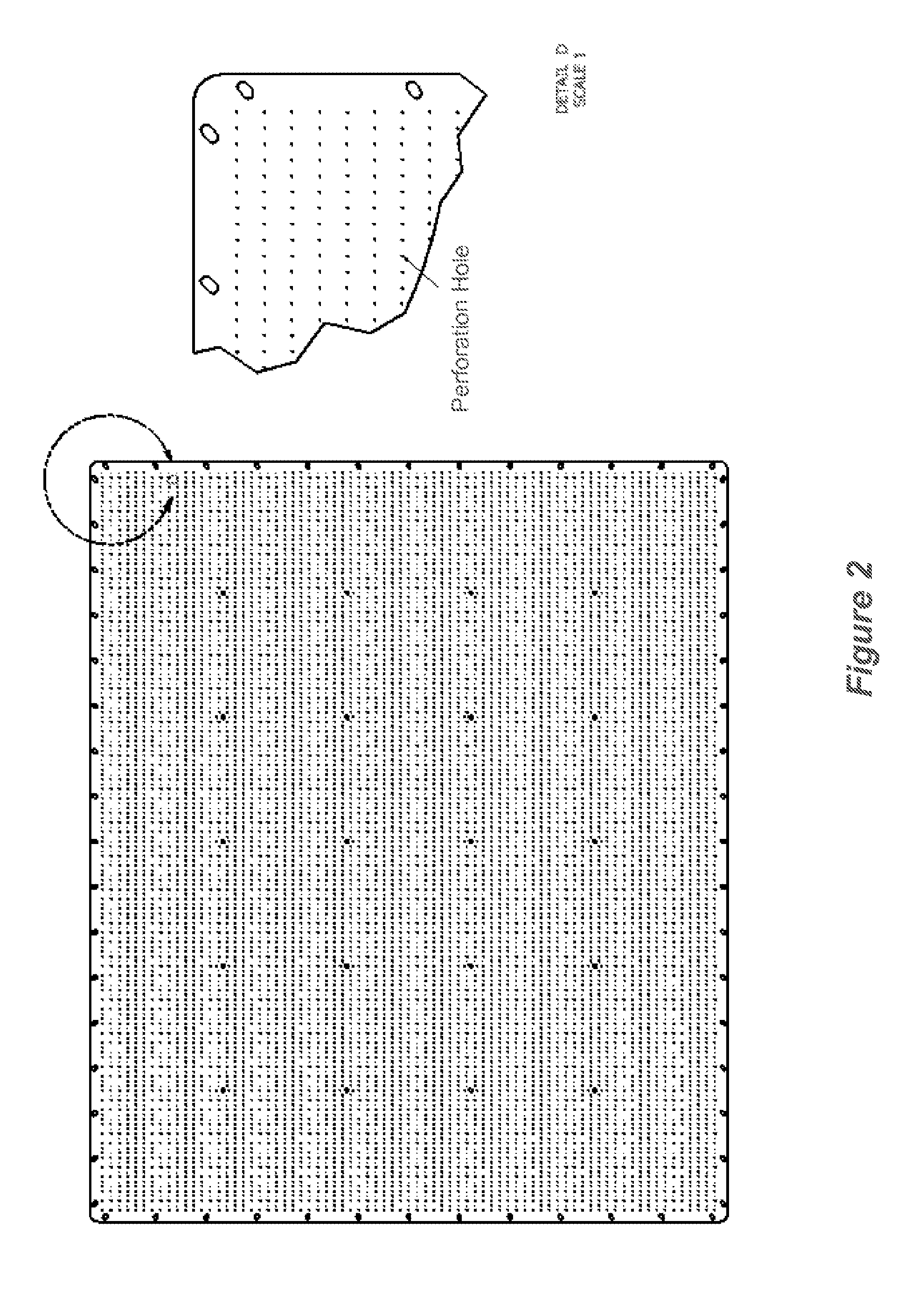

Showerhead assembly for plasma processing chamber

ActiveUS8617349B2Easy and significantly less-expensive to manufactureImproved gas distributionElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringPlasma processing

A showerhead for a plasma process apparatus for processing substrates, comprising a showerhead body comprising a top plate and a bottom plate defining a cavity in between; a gas inlet formed in the top plate; a perforated plate positioned between the top plate and the bottom plate and dissecting the cavity into an upper gas compartment and a lower gas compartment; and, wherein the bottom plate comprises a plurality of elongated diffusion slots on its lower surface and a plurality of diffusion holes on its upper surface, each of the diffusion holes making fluid connection from the lower gas compartment to more than one of the diffusion slots.

Owner:KLA CORP

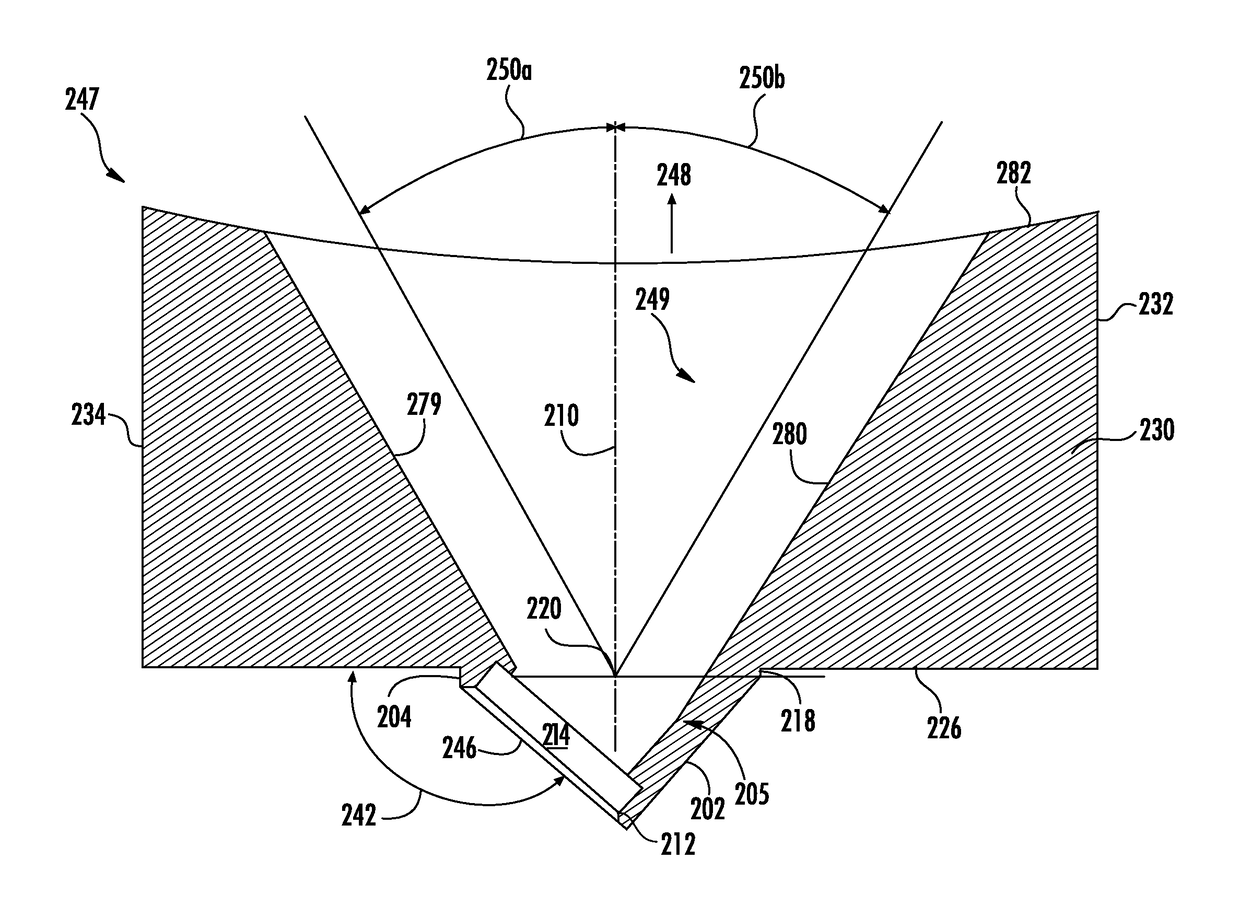

Half-angle nozzle

ActiveUS20180223426A1Improved gas distributionElectric discharge tubesSemiconductor/solid-state device manufacturingSpray nozzleEngineering

Implementations of the present disclosure provide an apparatus for improving gas distribution during thermal processing. One implementation of the present disclosure provides an apparatus for thermal processing a substrate. The apparatus includes a body, an angled gas source assembly, and a gas injection channel. The gas injection channel has a first half-angle and a second half-angle. The first half-angle is different from the second half-angle. The use of an improved side gas assembly in a processing chamber to direct gas towards the edge of the substrate advantageously controls growth uniformity throughout the substrate, i.e., from the center to the edge. Surprisingly, directing gas through a gas channel with non-uniform half-angles will significantly increase the reaction at or near the edge of the substrate, thereby leading to an improved overall thickness uniformity of the substrate.

Owner:APPLIED MATERIALS INC

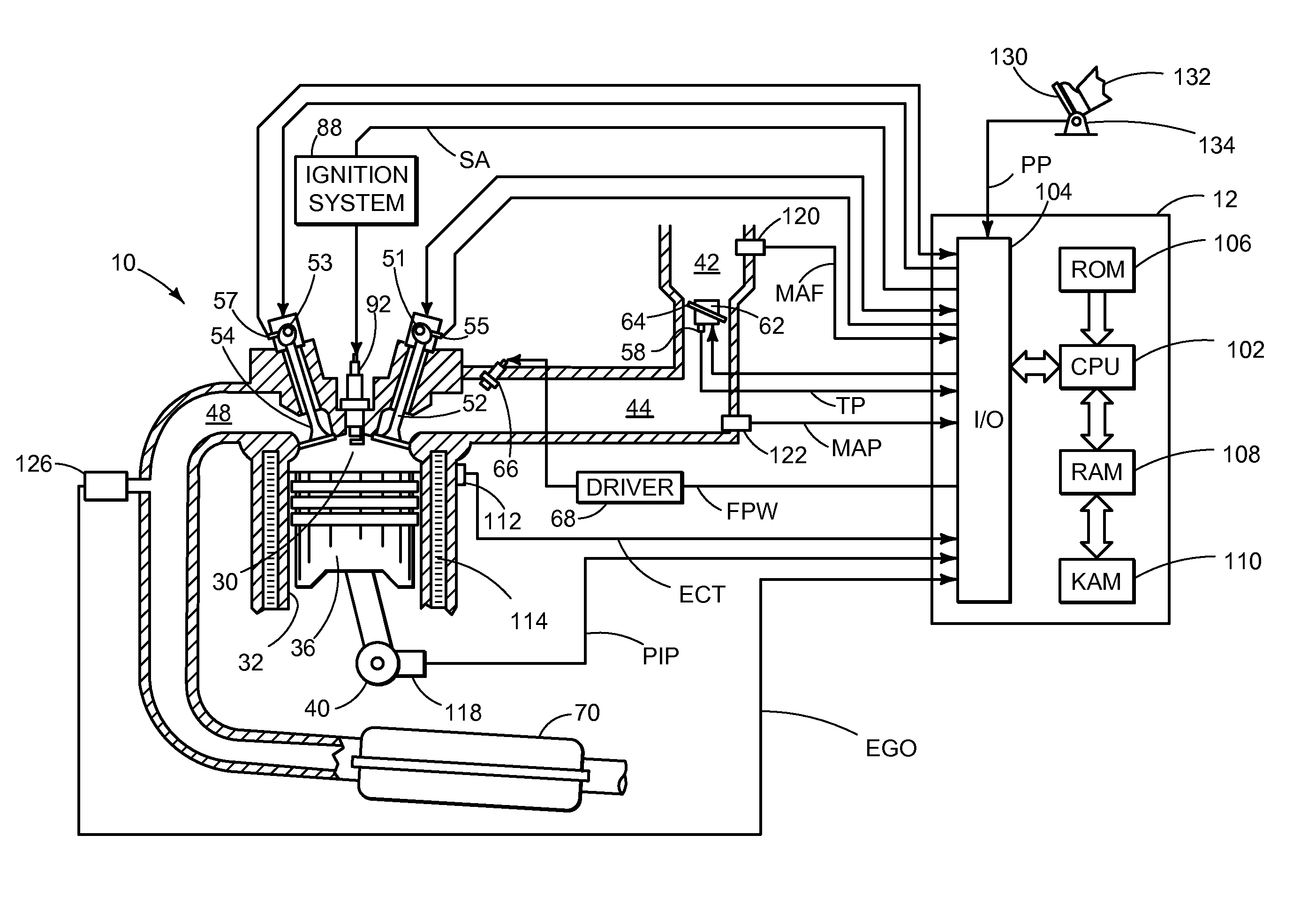

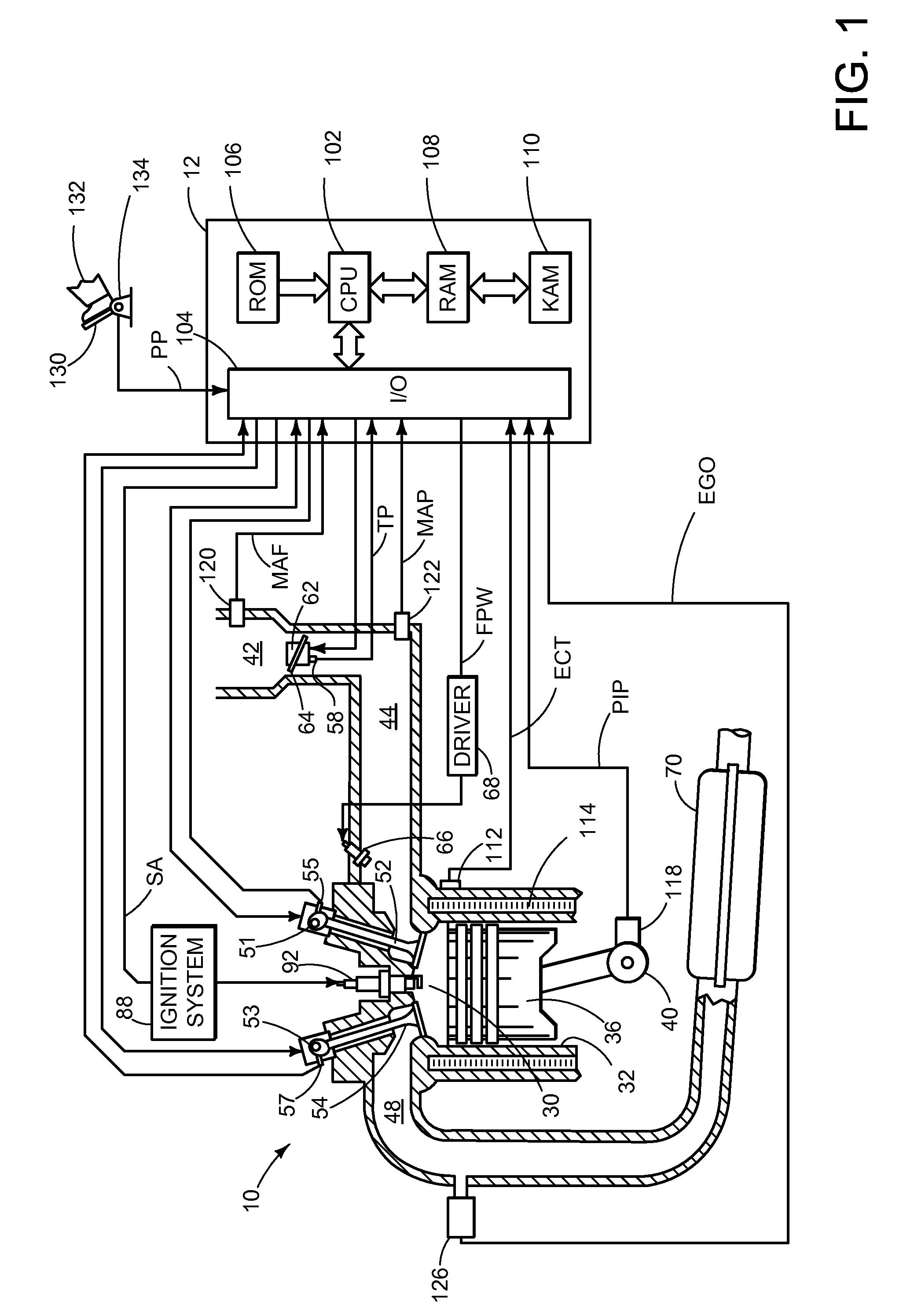

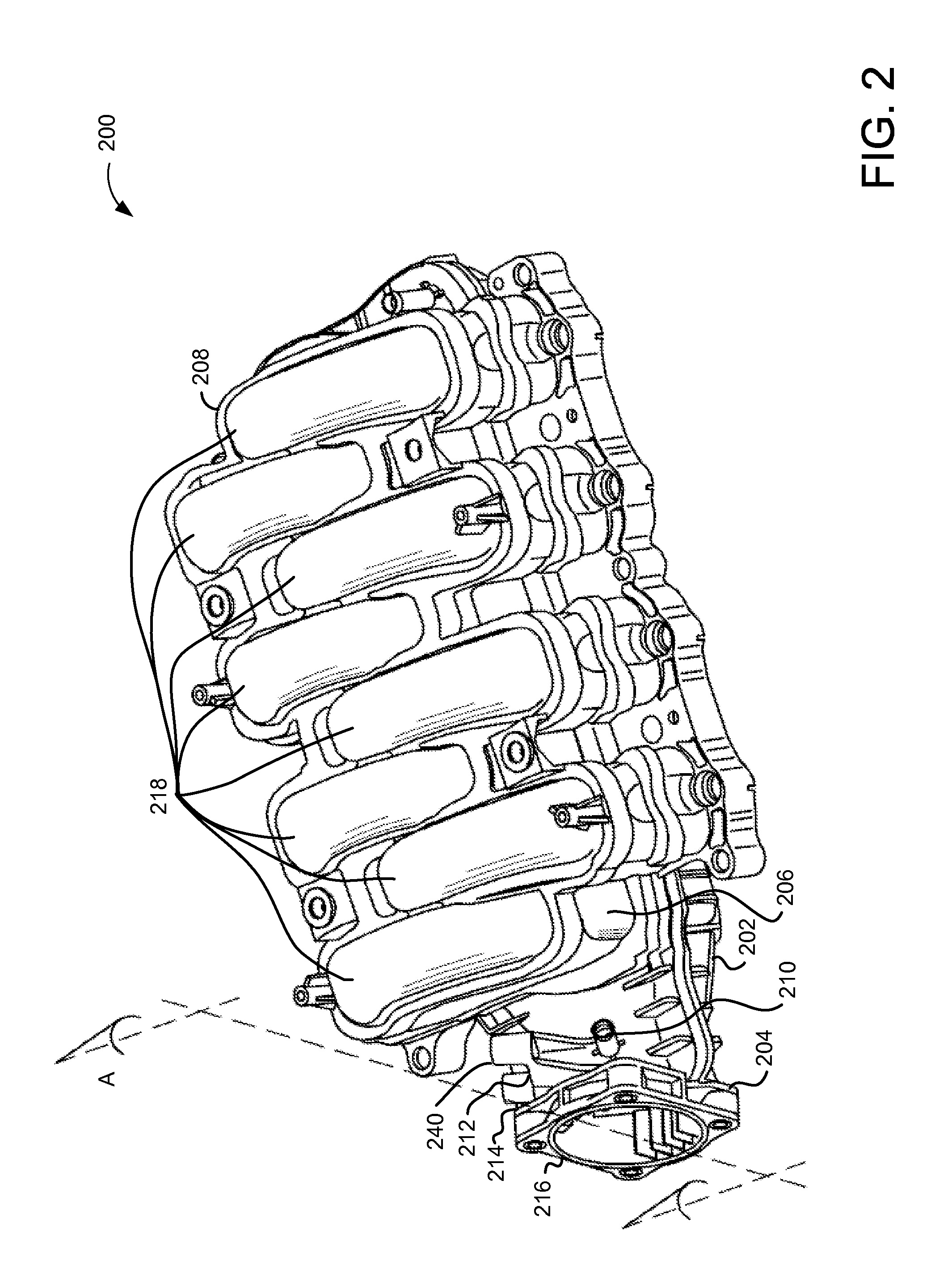

System for improving gas distribution in an intake manifold

ActiveUS8191525B2Optimize allocationImproved gas distributionMachines/enginesAir intakes for fuelProcess engineeringInlet manifold

Owner:FORD GLOBAL TECH LLC

Insertion element, gas lens with such an insertion element, and welding torch with such a gas lens

ActiveUS8809723B2Improved gas distributionFaster and quick spreadingSupport devices with shieldingCooled electrode holdersEngineeringRadial deviation

For a WIG / TIG welding torch, gas distribution across a cross-section of the gas lens and / or the gas nozzle, is improved and as small a size and as low a weight of the components as possible can be achieved, when an insertion element with a bore in the center through which an electrode is to be guided is arranged, with fan-shaped flow elements being positioned around the bore and twisted relative to the plane of the bore so as to provide for radial deviation of a gas flowing therethrough. The gas lens consists of a base body having a gas distribution channel with at least one gas-lens filter, with an above-described insertion element being arranged in the gas-distribution channel, and with a gas-lens filter, seen in the out-flow direction of the gas, being arranged downstream of the insertion element.

Owner:FRONIUS INTERNATIONAL GMBH

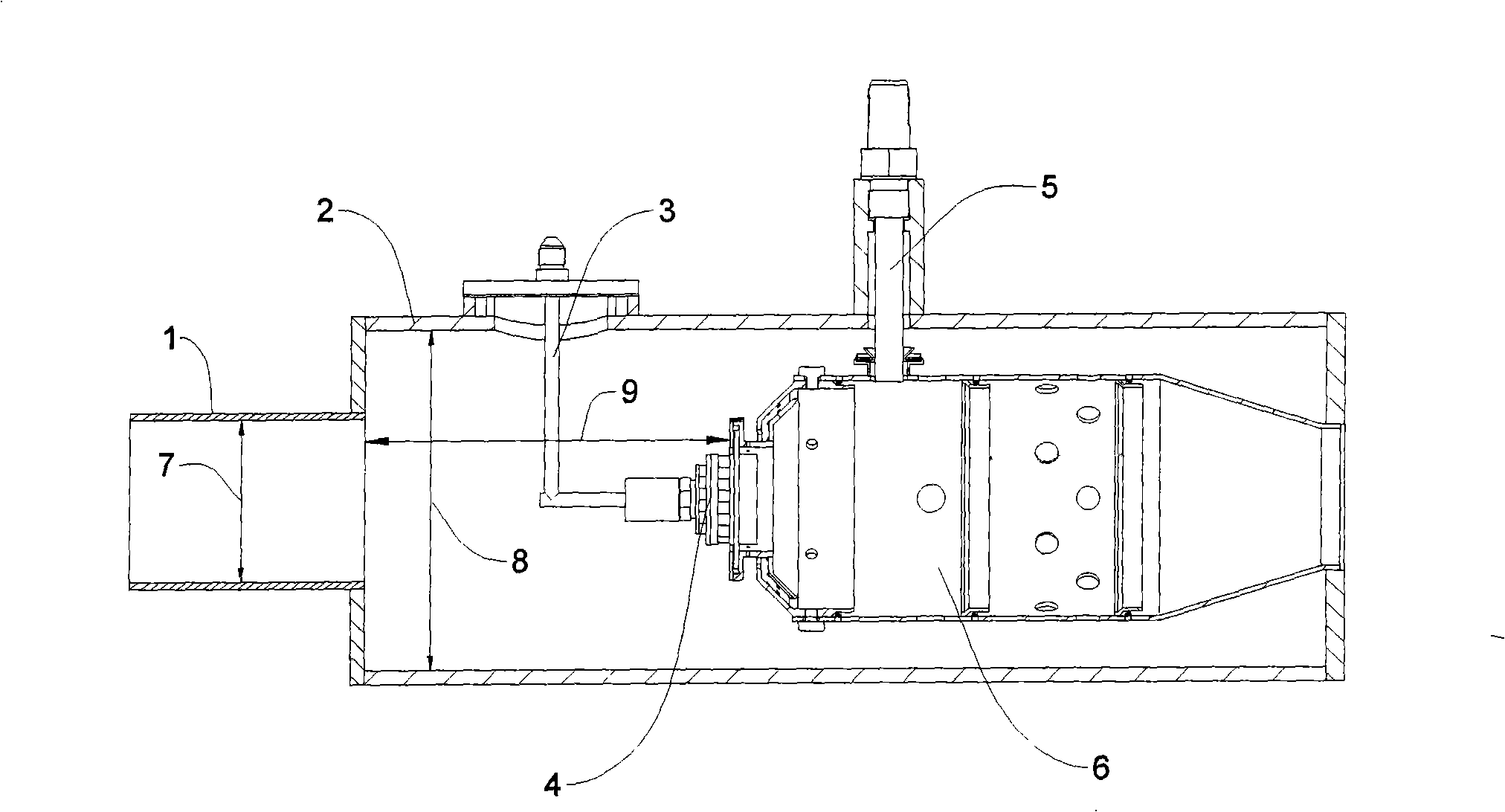

Electric valve left mechanism

InactiveUS8758693B2Precise positioningSmall volumeCombination devicesOperating means/releasing devices for valvesRotary valveTorque motor

A valve lift mechanism for actuating a valve in the vertical direction, and a regenerative thermal oxidizer including the valve and lift mechanism is disclosed. The valve is allowed to move vertically and oscillating rotary motion is possible. Vertical movement is achieved using the valve lift mechanism without the use of compressed air. In certain embodiments, the valve lift mechanism includes a torque motor. Preferably, a non self-locking screw jack is used to adjust the vertical height of the valve. Vertical movement can reduce the torque needed to rotate the valve, and also facilitates servicing of the valve. For example, if the valve experiences high temperature, and consequently expands, rotating the valve against the mating seal plate can be difficult, if not impossible. By lowering the valve slightly, the frictional forces between the valve and the mating seal plate are reduced, allowing freer rotational movement of the valve.

Owner:BABCOCK & WILCOX MEGTEC LLC

Asymmetric injection for better wafer uniformity

ActiveUS20200240014A1Improved gas distributionSemiconductor/solid-state device manufacturingSolid state diffusion coatingPhysicsInjector

A gas injector for processing a substrate includes a body having an inlet connectable to a gas source that is configured to provide a gas flow in a first direction into the inlet when processing a substrate on a substrate support disposed within a processing volume of a processing chamber, and an a gas injection channel formed in the body. The gas injection channel is in fluid communication with the inlet and configured to deliver the gas flow to an inlet of the processing chamber. The gas injection channel has a first interior surface and a second interior surface that are parallel to a second direction and a third direction. The second and third directions do not intersect a center of the substrate, and are at an angle to the first direction towards a first edge of the substrate support.

Owner:APPLIED MATERIALS INC

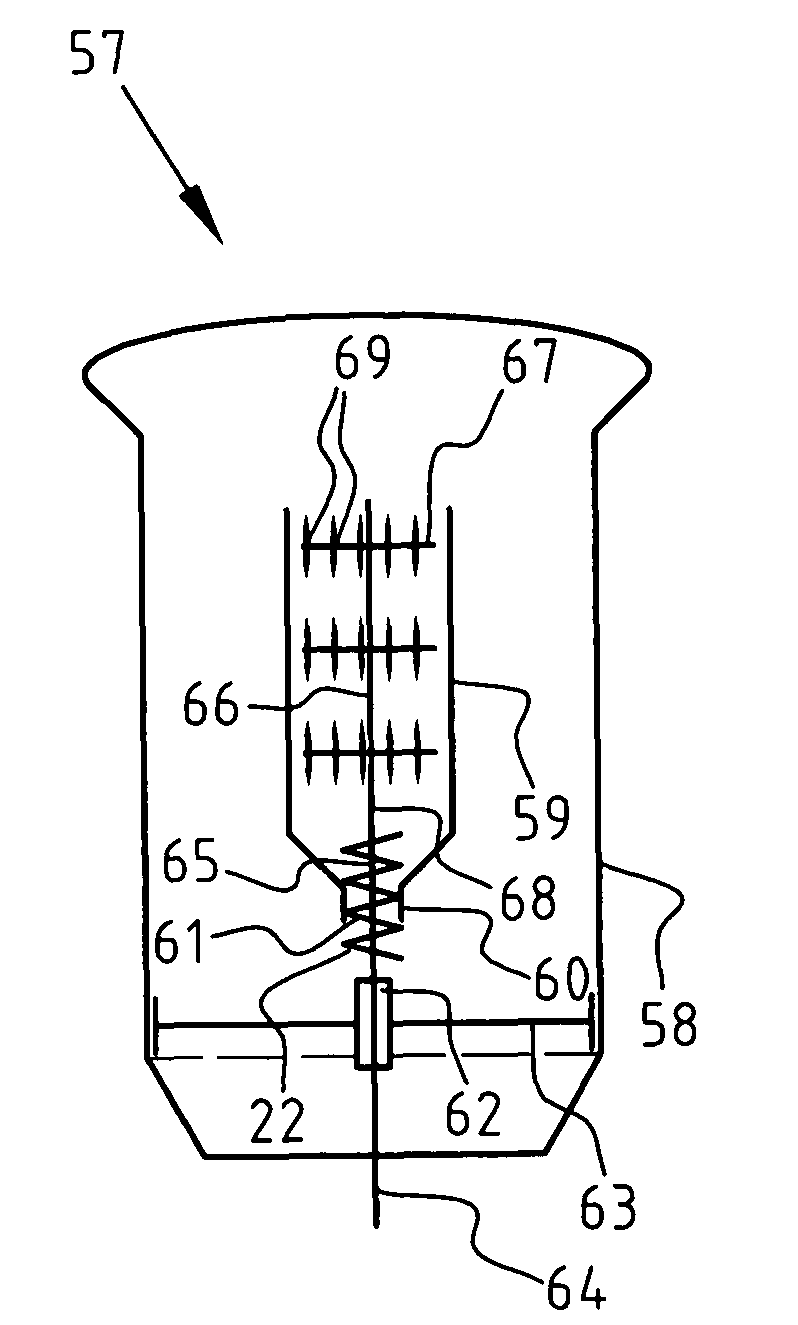

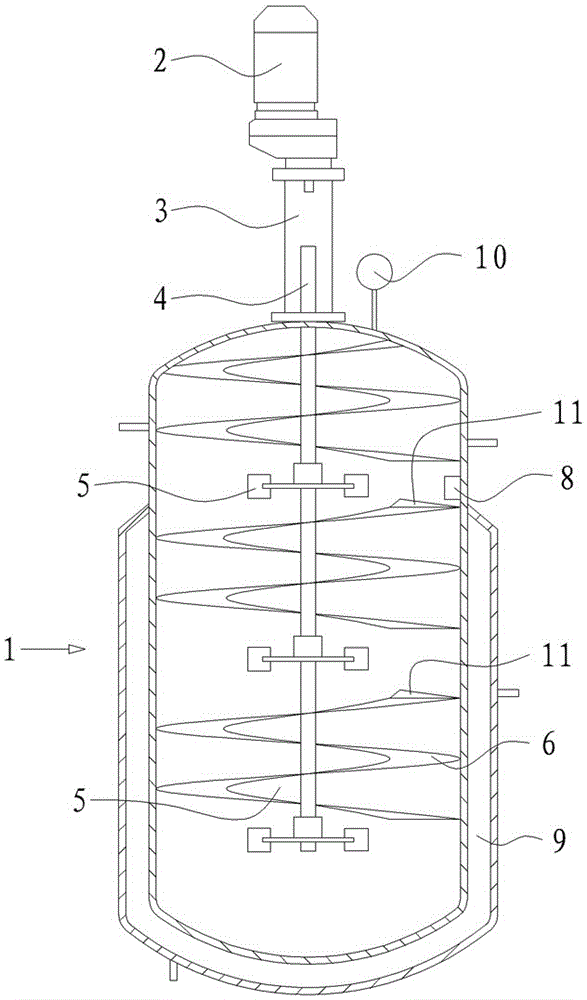

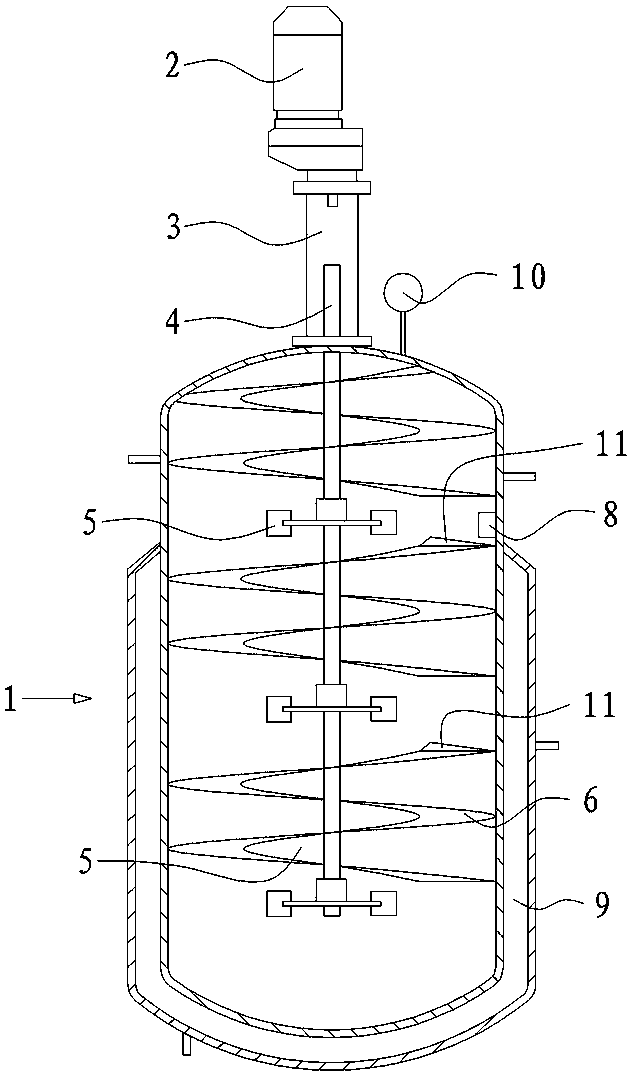

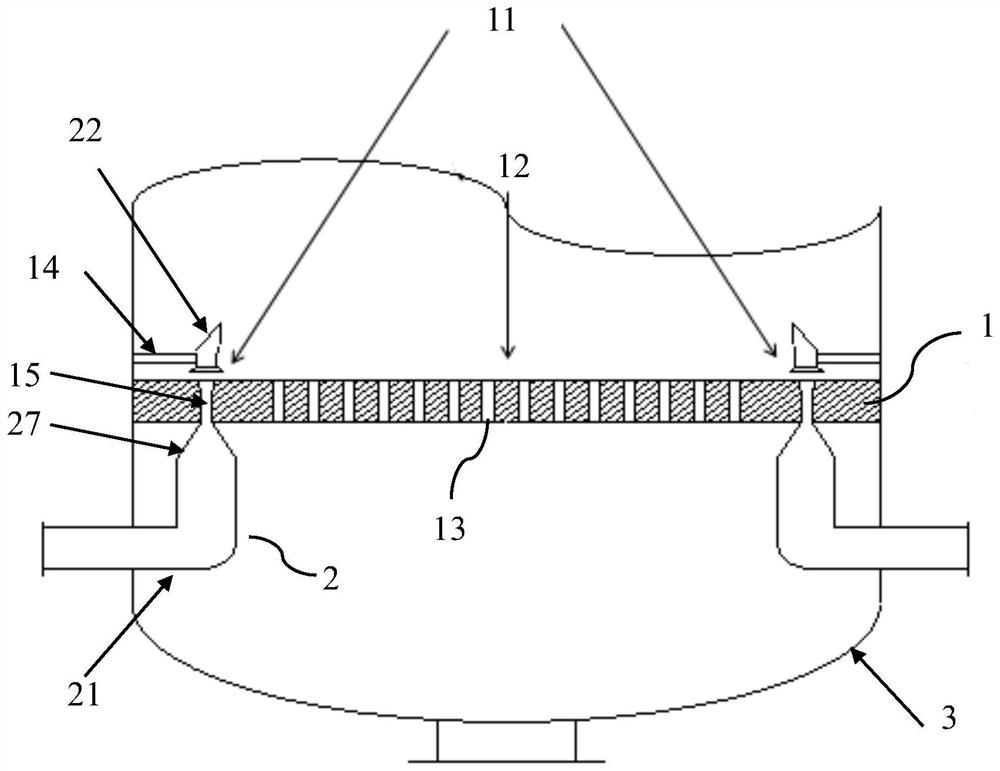

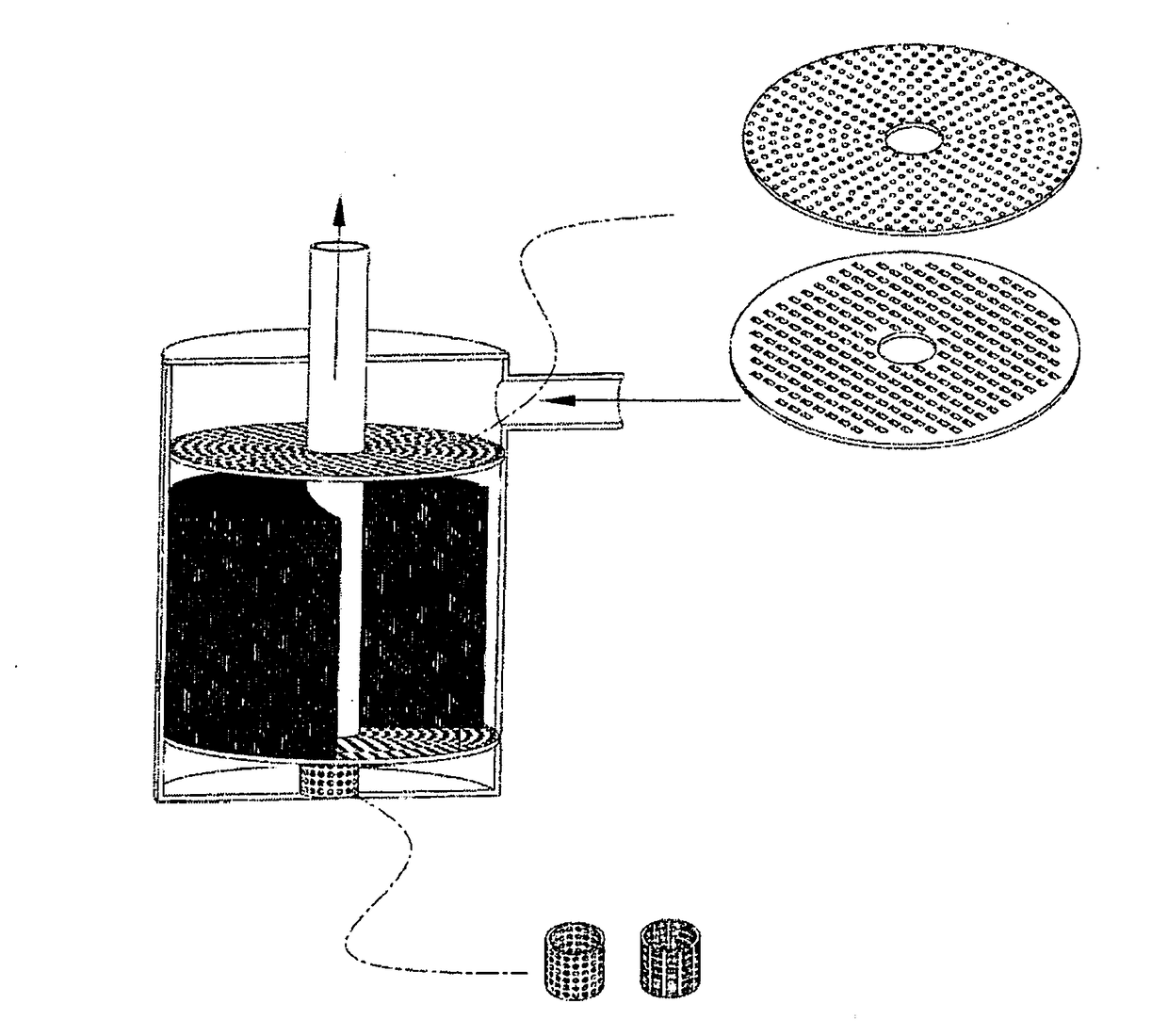

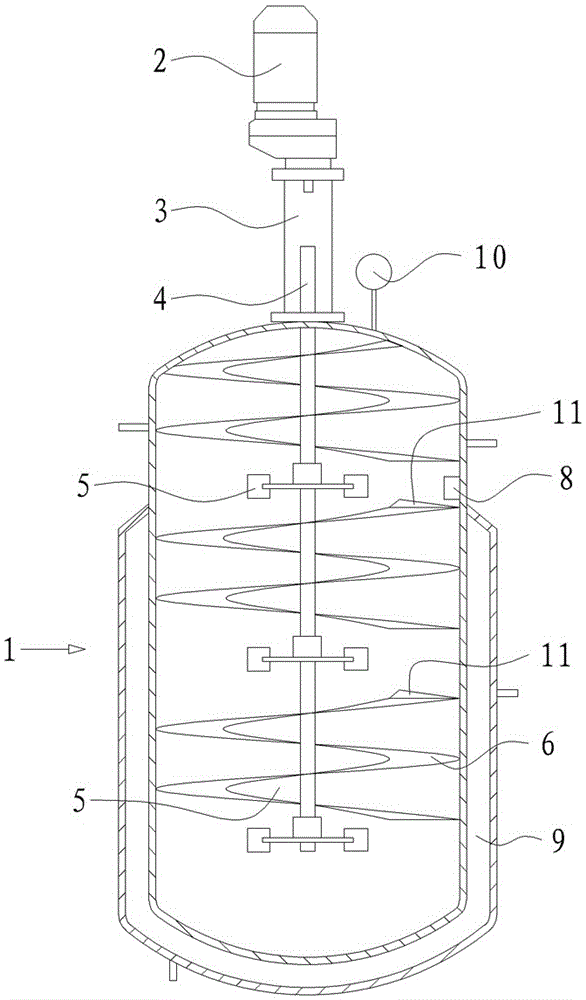

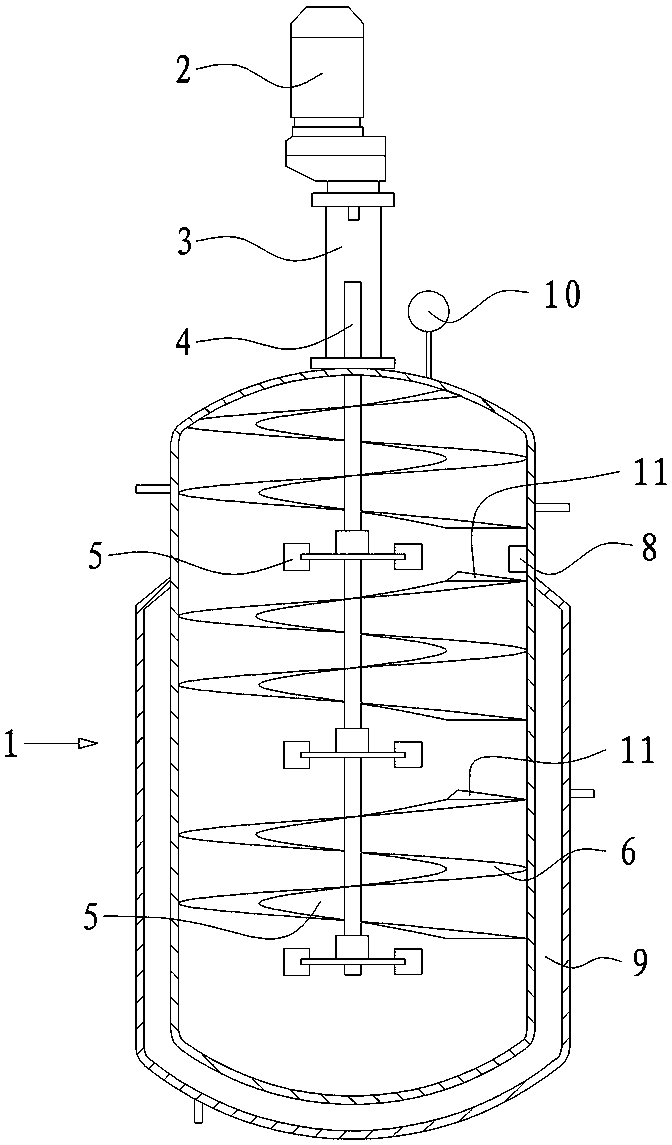

Efficient and vertical fermentation tank

ActiveCN106281979APromote growthReduce metabolic damageBioreactor/fermenter combinationsBiological substance pretreatmentsHelical bladeEngineering

The invention relates to an efficient and vertical fermentation tank and belongs to the technical field of fermentation devices. The fermentation tank comprises a vertical tank body, a motor, a speed reducer driven by the motor and a stirring shaft, wherein the lower end of the stirring shaft penetrates into the tank body, multiple stirring blades are arranged at the lower end of the stirring shaft at intervals, multiple helical channels sequentially are formed in the inner wall of the tank body from top to bottom, each helical channel is formed by splicing multiple helical blades fixed to the inner wall of the tank body along the central axis of the tank body in a surrounding mode and is provided with a through channel for containing the corresponding stirring blades, one stirring blade is located at the lower end of the corresponding helical channel and is same as the corresponding helical channel in helix angle, a zooming plate inclining towards the stirring shaft is arranged at the upper end of the helical channel, and the surfaces of the helical blades and the zooming plates are coated with continuous polytetrafluoroethylene coatings. The fermentation tank has the advantages that the structure is simple, and the oxygen dissolution rate can be remarkably improved without increase of stirrer diameter and rotation speed.

Owner:扬中市威柯特生物工程设备有限公司

High-efficiency vertical fermentation tank

ActiveCN106281979BPromote growthReduce harmBioreactor/fermenter combinationsBiological substance pretreatmentsHelical scanHelical blade

The invention relates to an efficient and vertical fermentation tank and belongs to the technical field of fermentation devices. The fermentation tank comprises a vertical tank body, a motor, a speed reducer driven by the motor and a stirring shaft, wherein the lower end of the stirring shaft penetrates into the tank body, multiple stirring blades are arranged at the lower end of the stirring shaft at intervals, multiple helical channels sequentially are formed in the inner wall of the tank body from top to bottom, each helical channel is formed by splicing multiple helical blades fixed to the inner wall of the tank body along the central axis of the tank body in a surrounding mode and is provided with a through channel for containing the corresponding stirring blades, one stirring blade is located at the lower end of the corresponding helical channel and is same as the corresponding helical channel in helix angle, a zooming plate inclining towards the stirring shaft is arranged at the upper end of the helical channel, and the surfaces of the helical blades and the zooming plates are coated with continuous polytetrafluoroethylene coatings. The fermentation tank has the advantages that the structure is simple, and the oxygen dissolution rate can be remarkably improved without increase of stirrer diameter and rotation speed.

Owner:扬中市威柯特生物工程设备有限公司

Switching valve seal

InactiveCN100408919CGood sealing featureReduce or prevent leakageOperating means/releasing devices for valvesSlide valveStatic modeEngineering

Switching valve utilizing a rotatable seal suitable for use in a regenerative thermal oxidizer (10), and oxidizer (10) including the switching valve (20). The valve (20) of the present invention exhibits excellent sealing characteristics and minimizes wear. The valve (20) has a seal plate (100) that defines two chambers, each chamber being a flow port (25) that leads to one of two regenerative beds of the oxidizer (10). The valve (20) also includes a switching flow distributor (50) that provides alternate channeling of the inlet or outlet process gas to each half of the seal plate. The valve operates between two modes: a stationary mode and a valve movement mode. In the stationary mode, a tight gas seal is used to minimize or prevent process gas leakage. The gas seal also seals during valve movement.

Owner:DUERR SYST GMBH

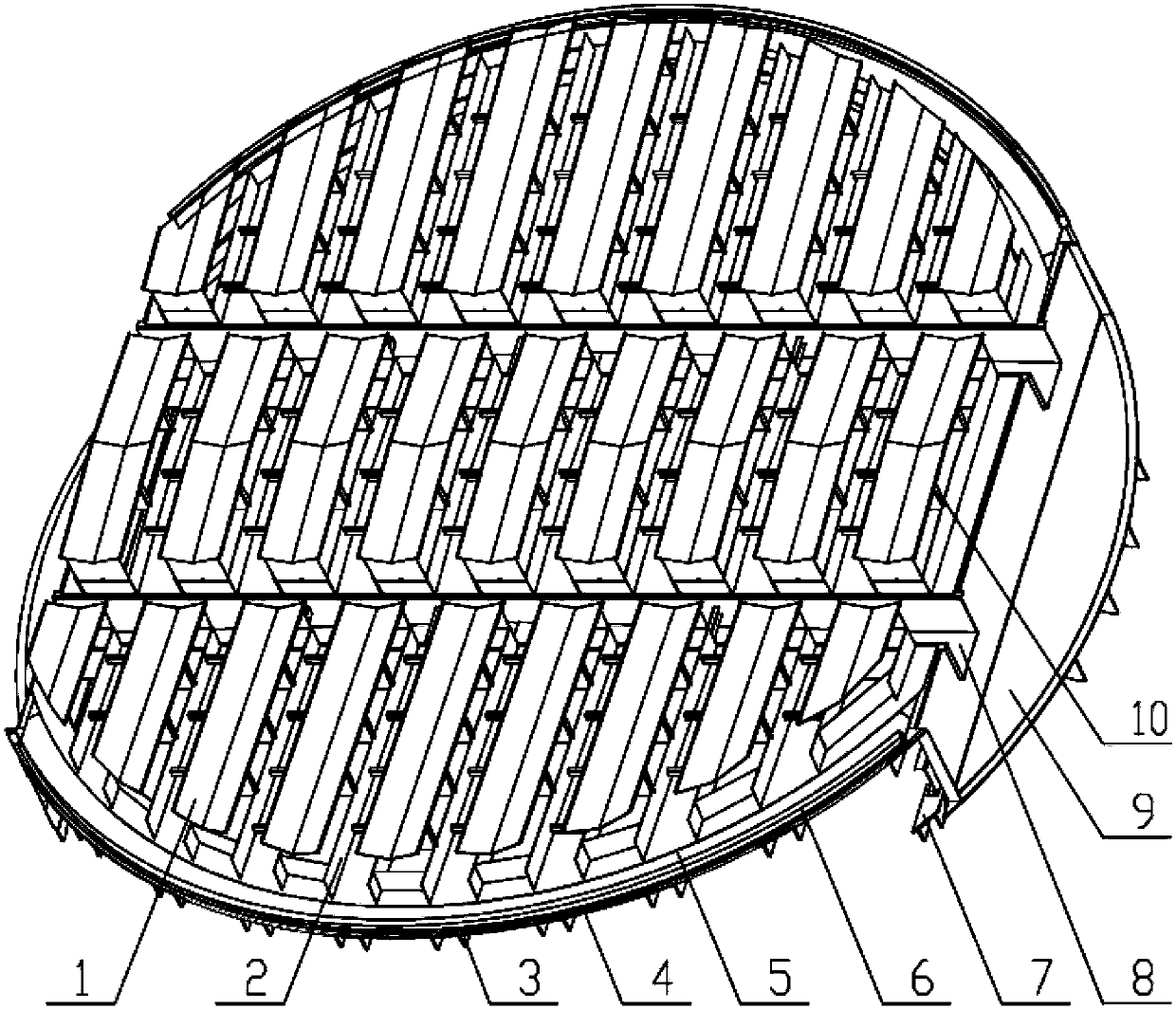

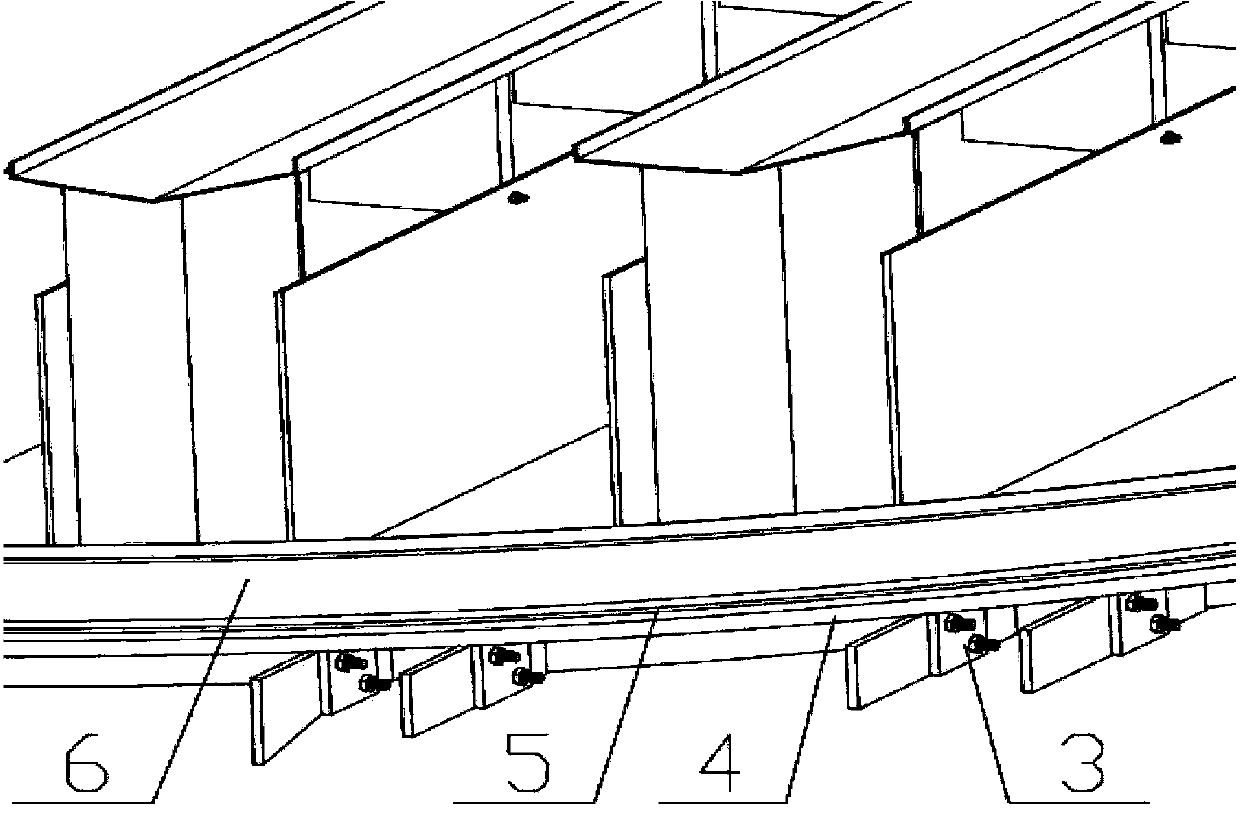

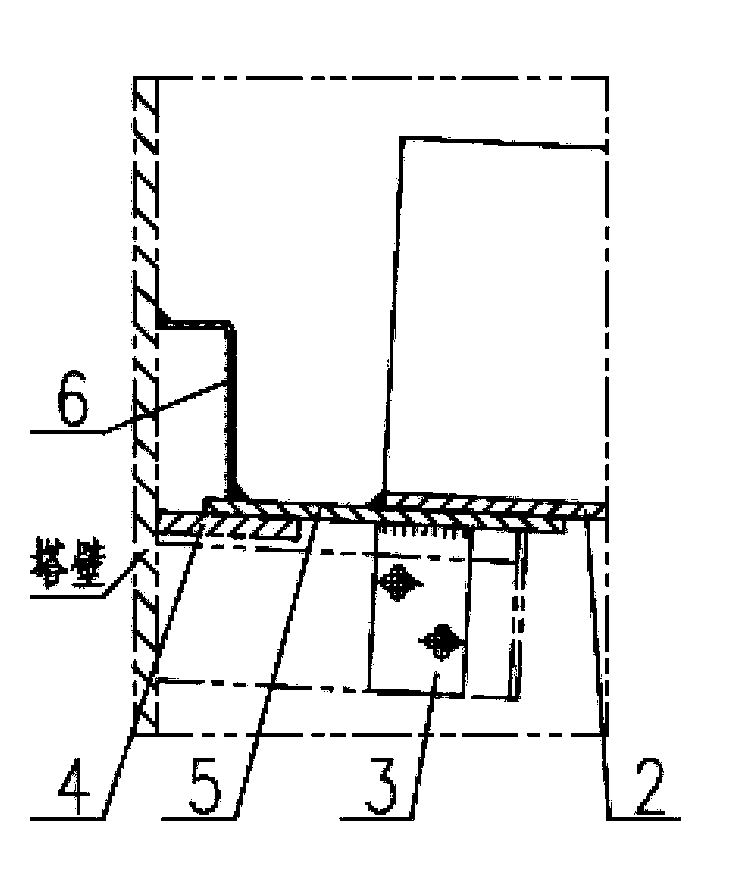

Gas Spargers and Silicone Fluidized Bed Reactors for Silicone Fluidized Beds

ActiveCN111569790BImproved gas distributionPrevent sinteringChemical/physical processesFluidized bedEngineering

The invention provides a gas distributor and an organic silicon fluidized bed reactor for an organosilicon fluidized bed. The gas distributor provided by the invention is used in an organic silicon fluidized bed, which is beneficial to eliminate accumulation dead zones in side wall regions At the same time, it can also promote particle shearing and collision, thereby realizing the surface renewal of particles and improving the reactivity in the fluidized bed. The gas distributor for an organosilicon fluidized bed provided by the present invention includes a gas distribution plate and a particle guide device, wherein the gas distribution plate is divided into a central area and a side wall area located on the periphery of the central area, and the central There are a plurality of vertical air holes distributed in the side wall area; the particle flow guiding device is installed in the side wall area, and the particle flow guiding device is used to suck the particles deposited in the side wall area and move them in a horizontal direction or roughly The spray is injected horizontally above the gas distribution plate and at least above the central region.

Owner:WANHUA CHEM GRP CO LTD +1

Welding shield

InactiveUS20210146467A1Improved gas distributionEasy to weldShielding gas supply/evacuation devicesSupport devices with shieldingEngineeringWeld seam

A welding shield that is configured to provide improved gas distribution adjacent a weld seam during the welding process so as to improve the weld quality. The welding shield includes a central member wherein the central member includes contiguously formed sidewalls and a top wall operable to create an interior volume. Mounted within the interior volume is a gas distribution module that is operably coupled to a gas source. A clip member is mounted to the central member and is configured to provide retention of the gas distribution module. A torch retention member is movably mounted to the top wall of the central member. The torch retention member is configured to receive and secure a welding torch and further provide rotational and pivotal movement thereof. A plasma cutter holding member is further included and is operable to releasably retain a plasma cutter.

Owner:PETTERSSON CARL +1

Apparatus for enhancing performance of fuel combustion

InactiveUS20170138594A1Reduce static chargeImprove performanceLiquid fuel feeder/distributionSpecial fuel supply arrangementsCombustionMetallic materials

This invention demonstrate the apparatus for enhancing the performance of fuel combustion having tubes comprised of woven filaments in the form of a net made of metal or non-metal materials having the property of reducing static charges between molecules. The invention as disclosed herein will allow the better distribution of gas mass. The spaces between molecules of gas mass can enhance its flammable property and allow complete combustion. With the same amount of gas used, the heat and energy obtained will also increase.

Owner:TOWIWAT DHITI

Switching valve seal

InactiveCN101004269AGood sealing featureReduce or prevent leakageOperating means/releasing devices for valvesDamper arrangementStatic modeEngineering

Switching valve utilizing a rotatable seal suitable for use in a regenerative thermal oxidizer (10), and oxidizer (10) including the switching valve (20). The valve (20) of the present invention exhibits excellent sealing characteristics and minimizes wear. The valve (20) has a seal plate (100) that defines two chambers, each chamber being a flow port (25) that leads to one of two regenerative beds of the oxidizer (10). The valve (20) also includes a switching flow distributor (50) that provides alternate channelling of the inlet or outlet process gas to each half of the seal plate. The valve operates between two modes: a stationary mode and a valve movement mode. In the stationary mode, a tight gas seal is used to minimize or prevent process gas leakage. The gas seal also seals during valve movement.

Owner:MEGTEC SYST INC

Vertical fermenting tank

ActiveCN106282005AIncrease dissolved oxygen ratePromote fermentationBioreactor/fermenter combinationsBiological substance pretreatmentsSpiral bladeEngineering

The invention relates to a vertical fermenting tank, and belongs to the technical field of zymology-device chemistry. The fermenting tank comprises a vertical tank body, a motor, a speed reducer driven by the motor and a stirring shaft; the lower end of the stirring shaft penetrates through the tank body, a plurality of stirring paddles are arranged at the lower end of the stirring shaft at intervals, a plurality of spiral channels are sequentially formed in the inner wall of the tank body at intervals from top to bottom, each spiral channel is defined and jointed by a plurality of spiral blades fixed on the inner wall of the tank body in the central axis of the tank body, the spiral lifting angle of each spiral channel ranges from 15 degrees to 20 degrees, a through channel for containing the stirring paddles is formed in each spiral channel, each stirring paddle is located at the lower end of the corresponding spiral channel and has the angle same as the angel of the spiral lifting angle of the corresponding spiral channel, and a lifting plate slanting towards the stirring shaft with the angle of 30 degrees to 40 degrees is arranged at the upper end of the spiral channel. The fermenting tank has the advantages that the structure is simple, the diameter and the rotating speed of the stirring device do not need to be increased, and the dissolved oxygen rate can be remarkably increased.

Owner:扬中市威柯特生物工程设备有限公司

vertical fermenter

ActiveCN106282005BIncrease dissolved oxygen ratePromote fermentationBioreactor/fermenter combinationsBiological substance pretreatmentsSpiral bladeEngineering

The invention relates to a vertical fermenting tank, and belongs to the technical field of zymology-device chemistry. The fermenting tank comprises a vertical tank body, a motor, a speed reducer driven by the motor and a stirring shaft; the lower end of the stirring shaft penetrates through the tank body, a plurality of stirring paddles are arranged at the lower end of the stirring shaft at intervals, a plurality of spiral channels are sequentially formed in the inner wall of the tank body at intervals from top to bottom, each spiral channel is defined and jointed by a plurality of spiral blades fixed on the inner wall of the tank body in the central axis of the tank body, the spiral lifting angle of each spiral channel ranges from 15 degrees to 20 degrees, a through channel for containing the stirring paddles is formed in each spiral channel, each stirring paddle is located at the lower end of the corresponding spiral channel and has the angle same as the angel of the spiral lifting angle of the corresponding spiral channel, and a lifting plate slanting towards the stirring shaft with the angle of 30 degrees to 40 degrees is arranged at the upper end of the spiral channel. The fermenting tank has the advantages that the structure is simple, the diameter and the rotating speed of the stirring device do not need to be increased, and the dissolved oxygen rate can be remarkably increased.

Owner:扬中市威柯特生物工程设备有限公司

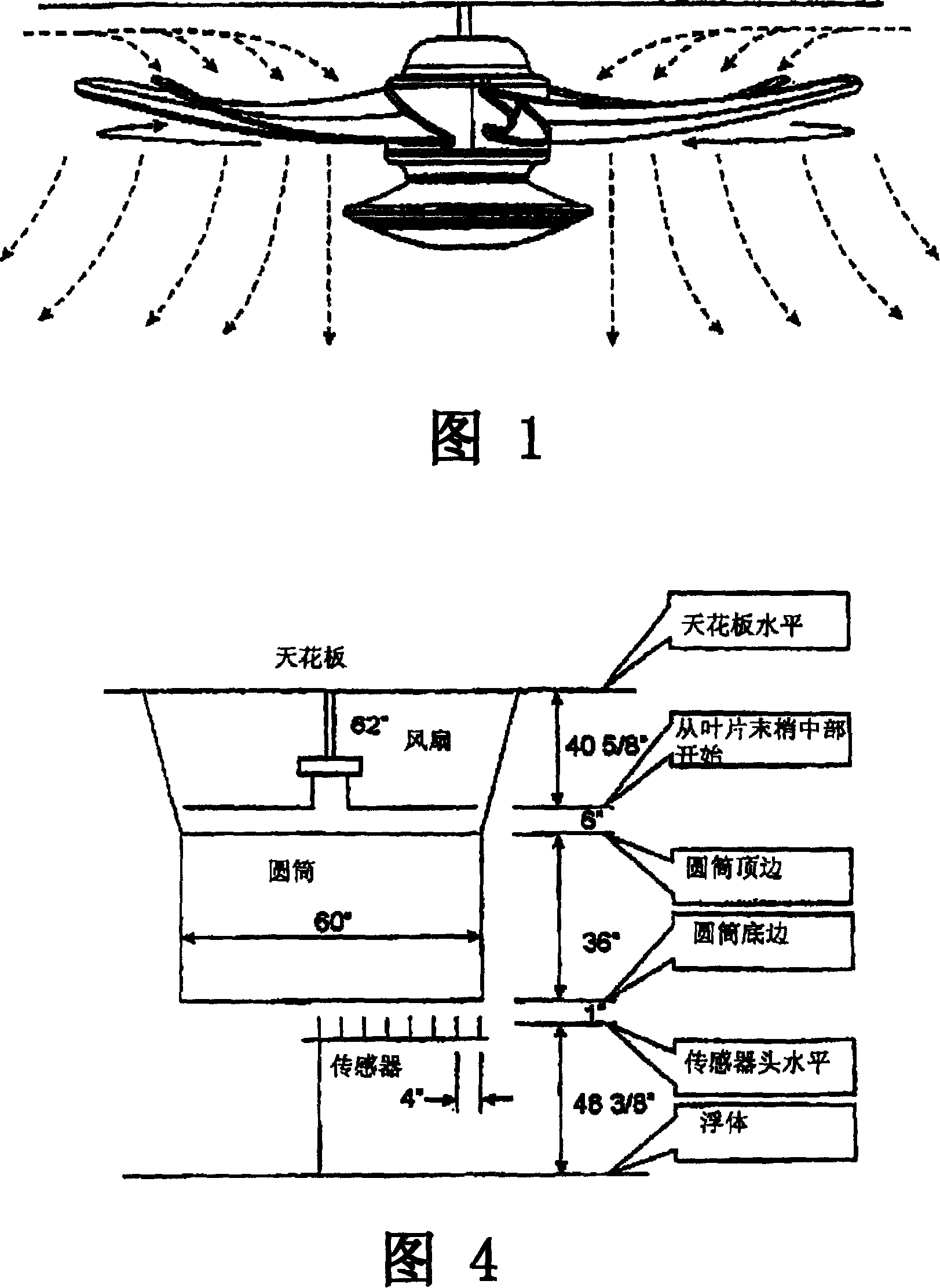

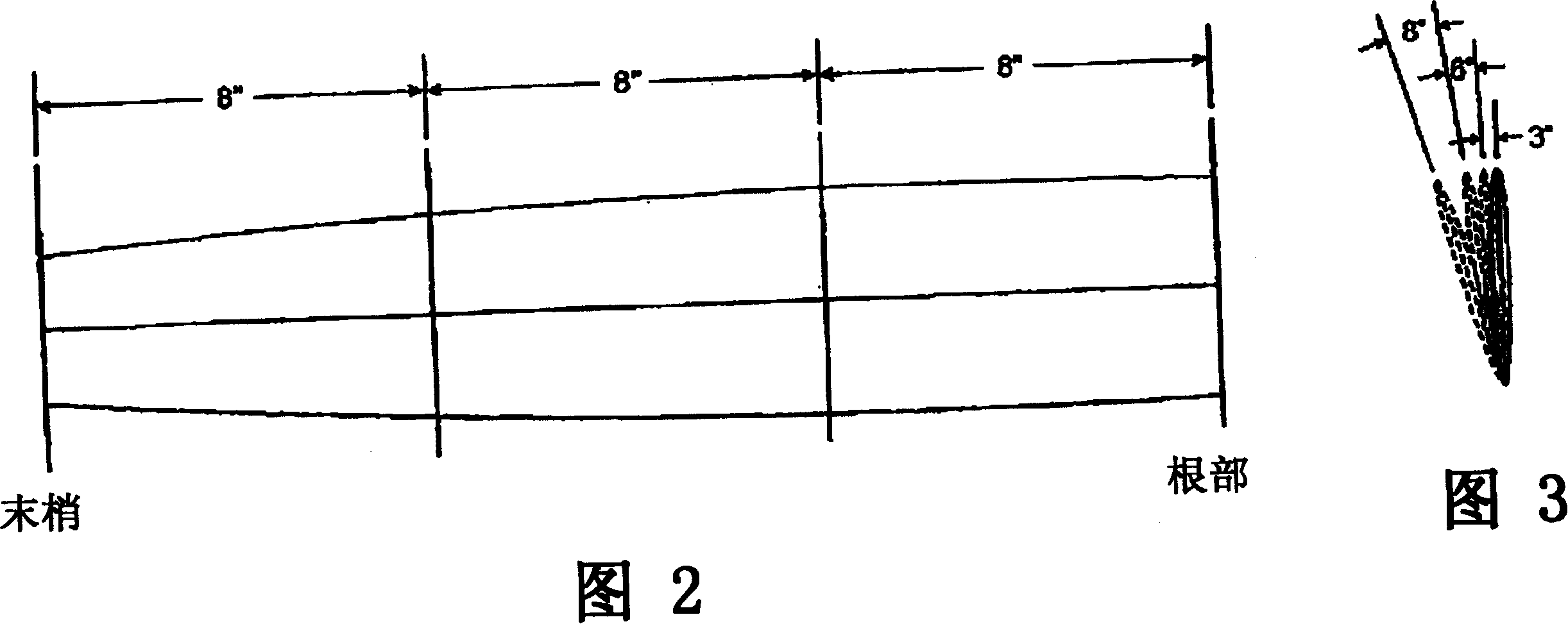

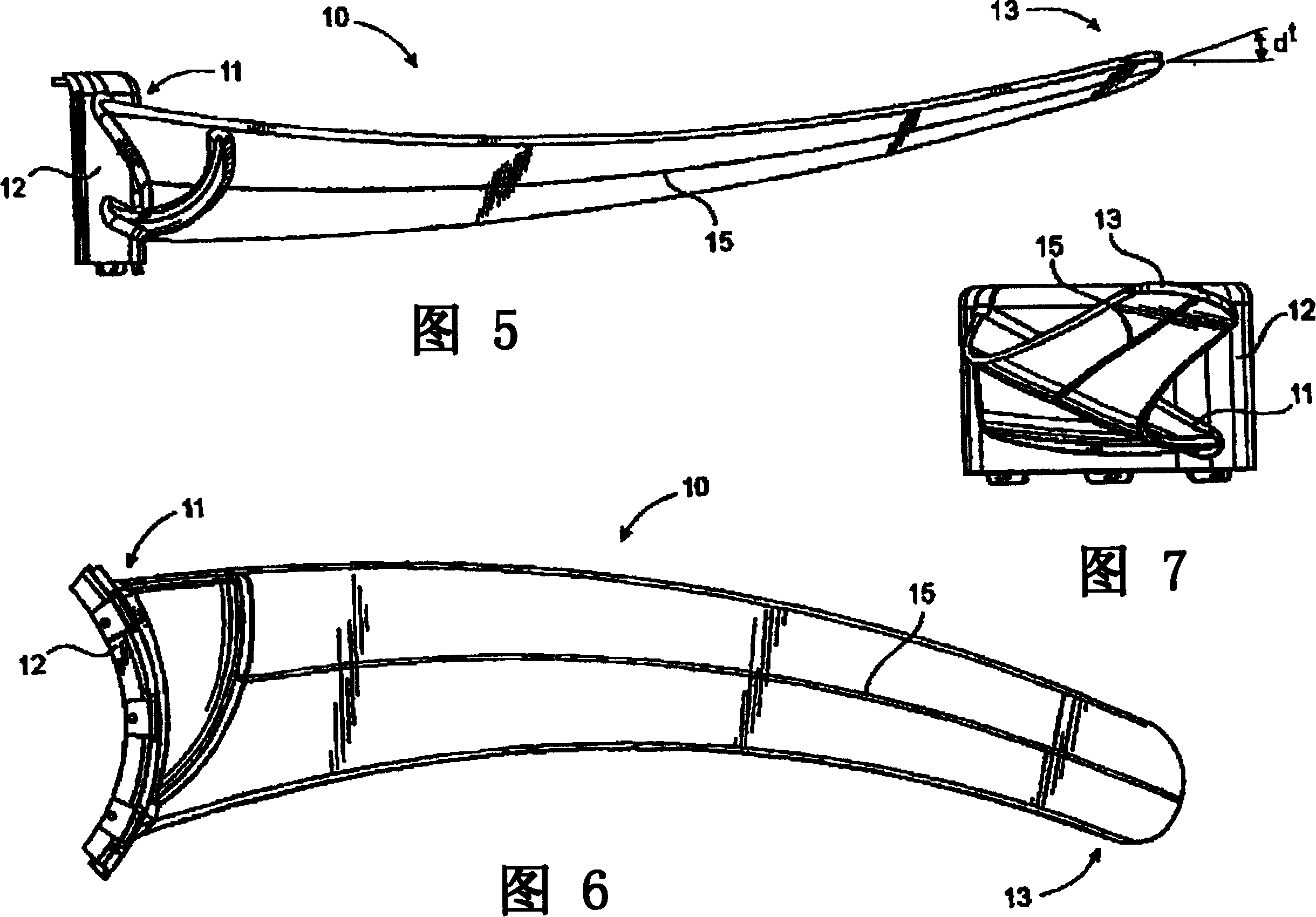

Ceiling fan

InactiveCN100374731CImprove efficiencyImproved air distributionPump componentsPumpsCeiling fanHigh rate

Ceiling fan energy consumption efficiency is enhanced with fan blades that have an angle attack that decreases from root end to tip end at higher rates of decrease nearer their tip ends than at their root ends. Air flow distribution is enhanced with at least a portion of the blades having a dihedral that continuously increases.

Owner:HUNTER FAN

Oil collection tank having expansion ring, and application thereof

Owner:TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com