Oil collection tank having expansion ring, and application thereof

A technology of expansion ring and oil collection tank, which is applied in the field of full-communication disc type oil collection tank with expansion ring, which can solve the problems of affecting normal operation, thermal deformation and damage of the connection between the sump of the oil collection tank and the tower ring, and large thermal deformation. Achieve the effects of reduced residence time, excellent gas distribution and liquid collection, and prevention of coking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

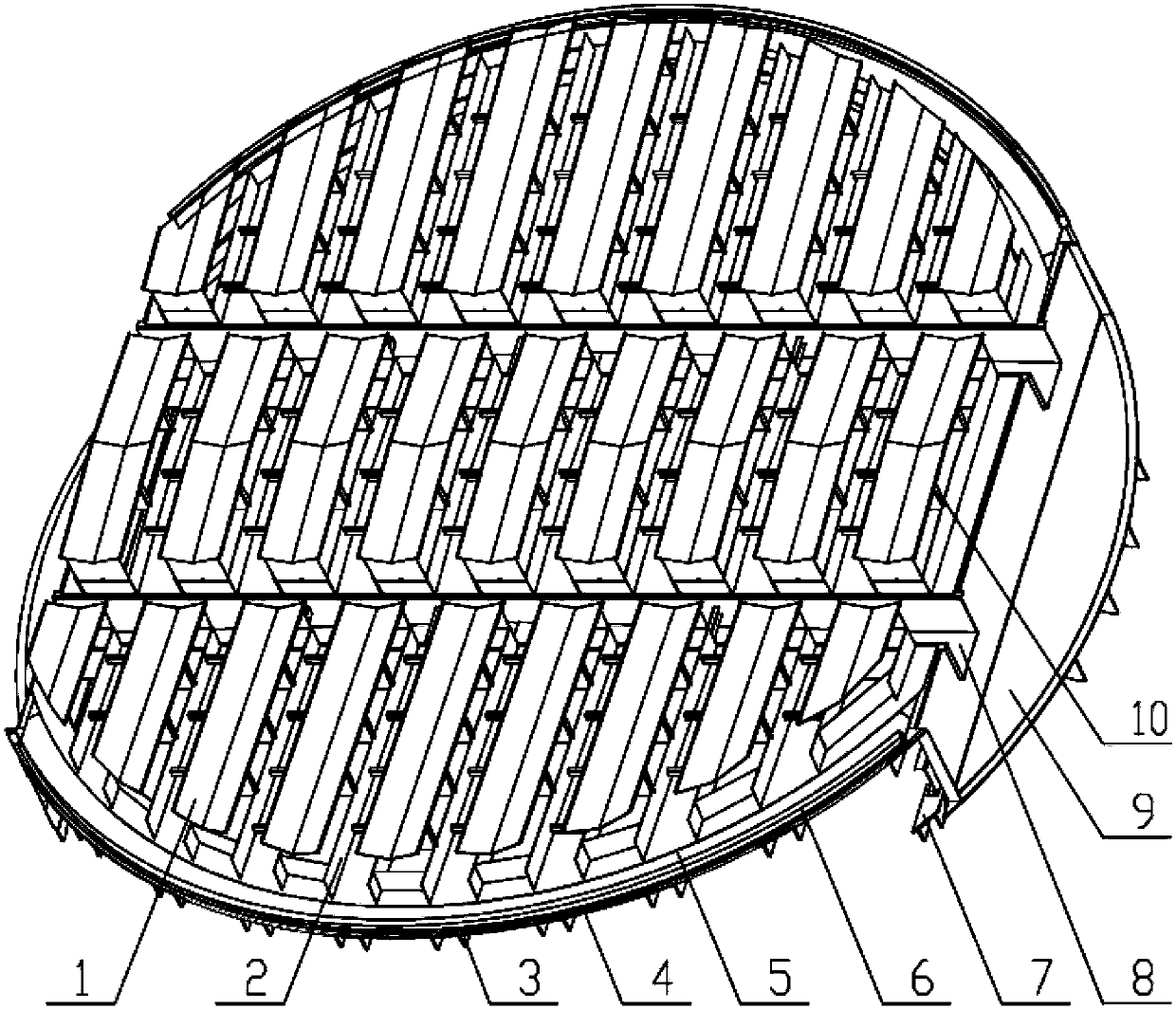

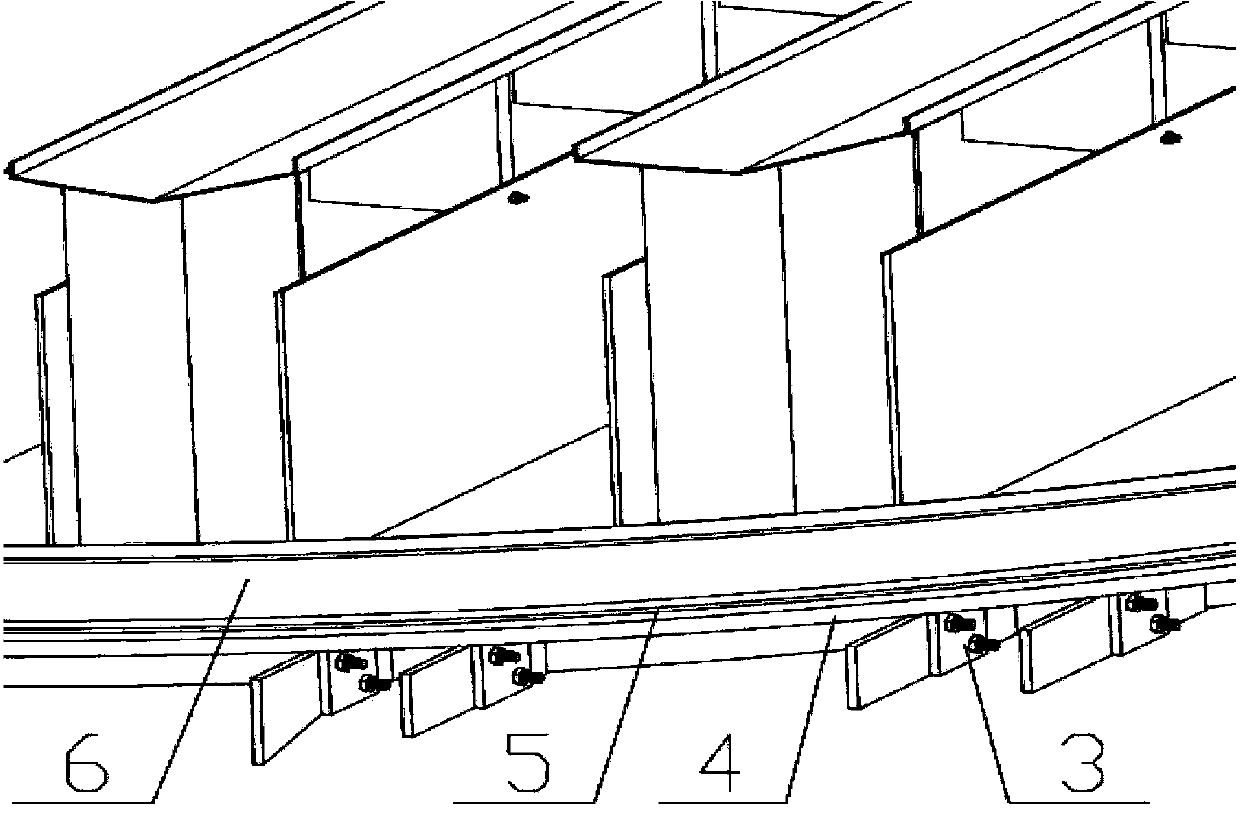

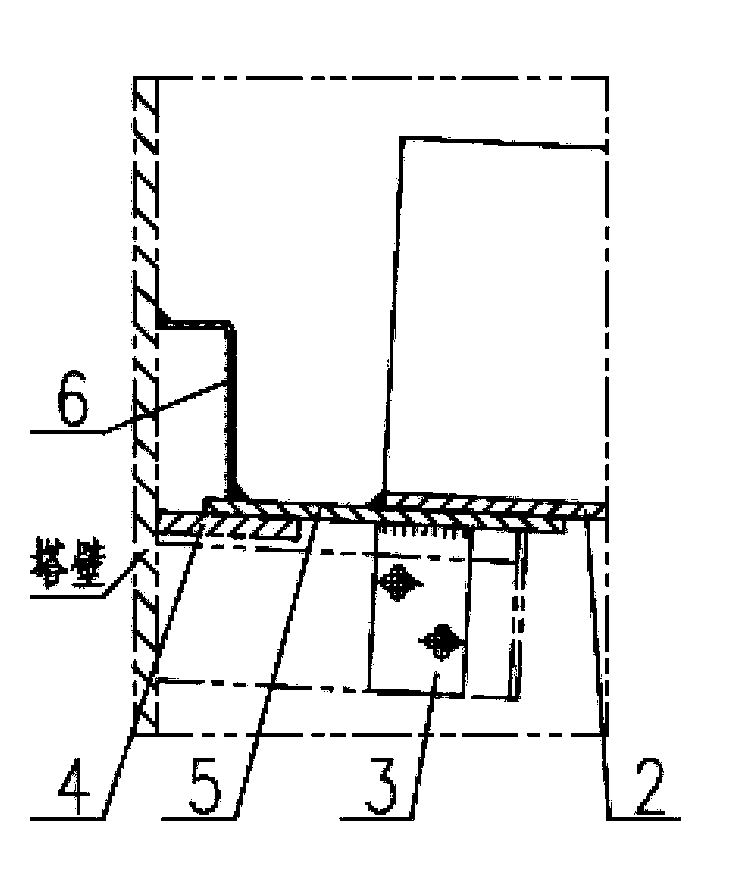

[0023] Such as figure 1 As shown, the oil collection tank with expansion ring includes liquid collection cap 1, liquid collection tank 2, liquid collection tank limiter 3, tower ring 4, backing plate 5, L-shaped limit expansion ring 6, support 7, liquid collection tank Canal 8, extraction bucket 9 and supporting ribs 10 and other components (wherein the tower ring 4 and the support 7 are common parts in the tower, which will not be described in detail in the present invention), the two ends of the liquid collection channel 8 are fixed on the extraction bucket 9; one end of the liquid collection tank 2 is fixed on the liquid collection channel 8, and the other end is fixed on the backing plate 5, and the backing plate 5 and the tower ring 4 are connected by an L-shaped limit expansion ring 6, and the liquid collection tank is limited The device 3 is connected with the backing plate 5; the liquid collecting cap 1 is connected above the two liquid collecting tanks by the support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com