Switching valve seal

一种环状密封、阀口的技术,应用在阀装置、阀的操作/释放装置、升阀等方向,能够解决增加泄露、分隔器泄露、压力波动等问题,达到节省成本、良好密封、低压力波动的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

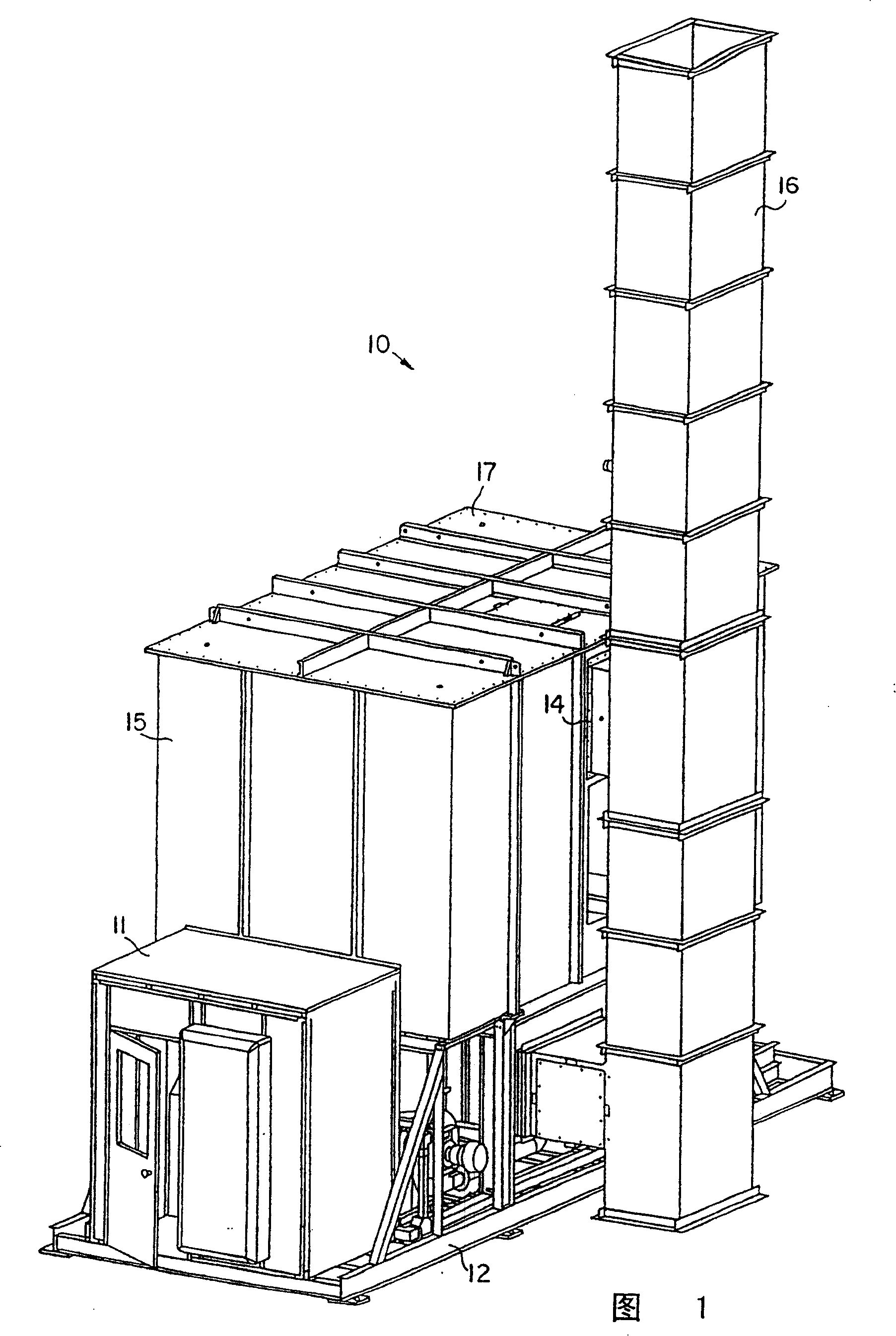

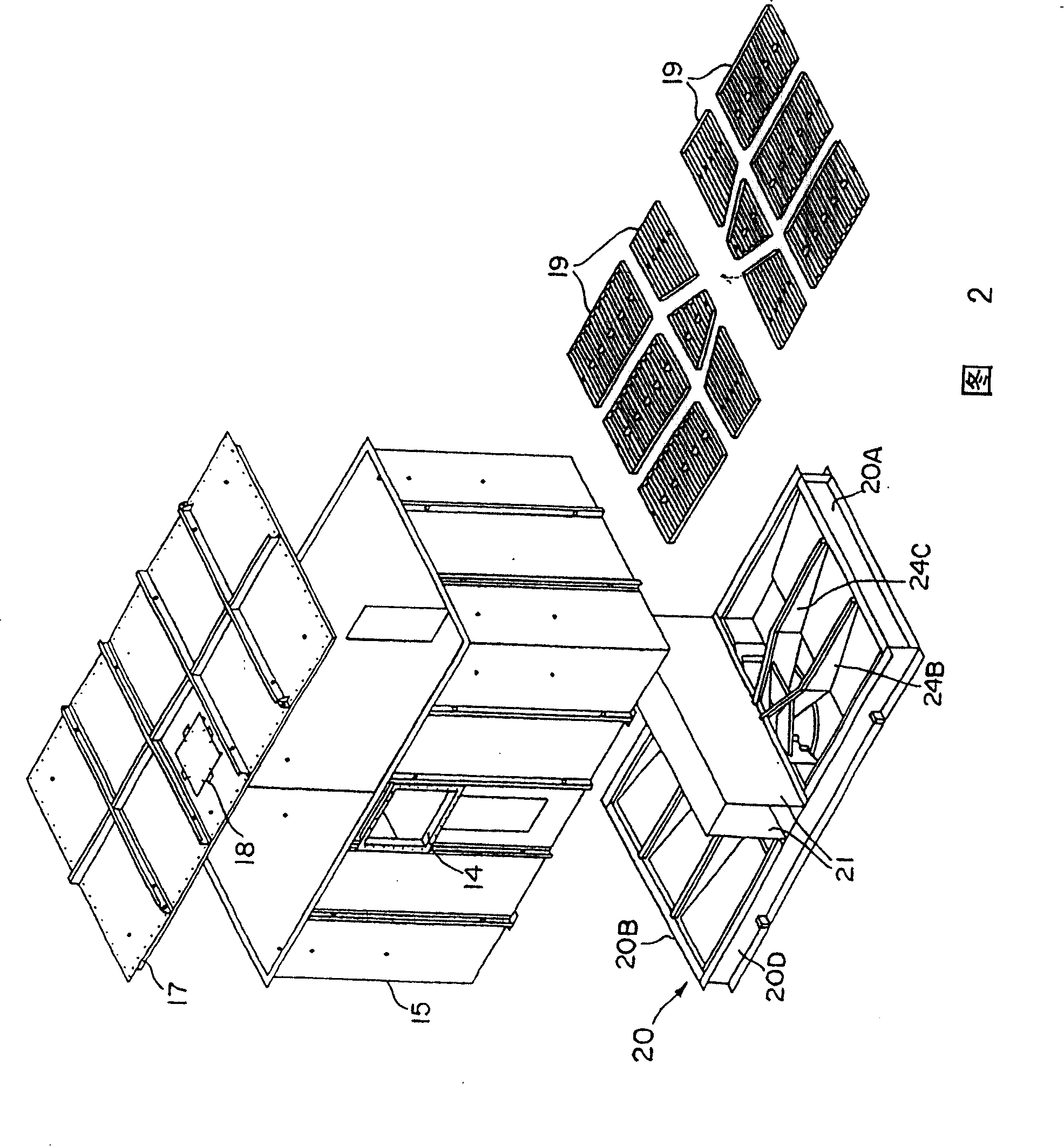

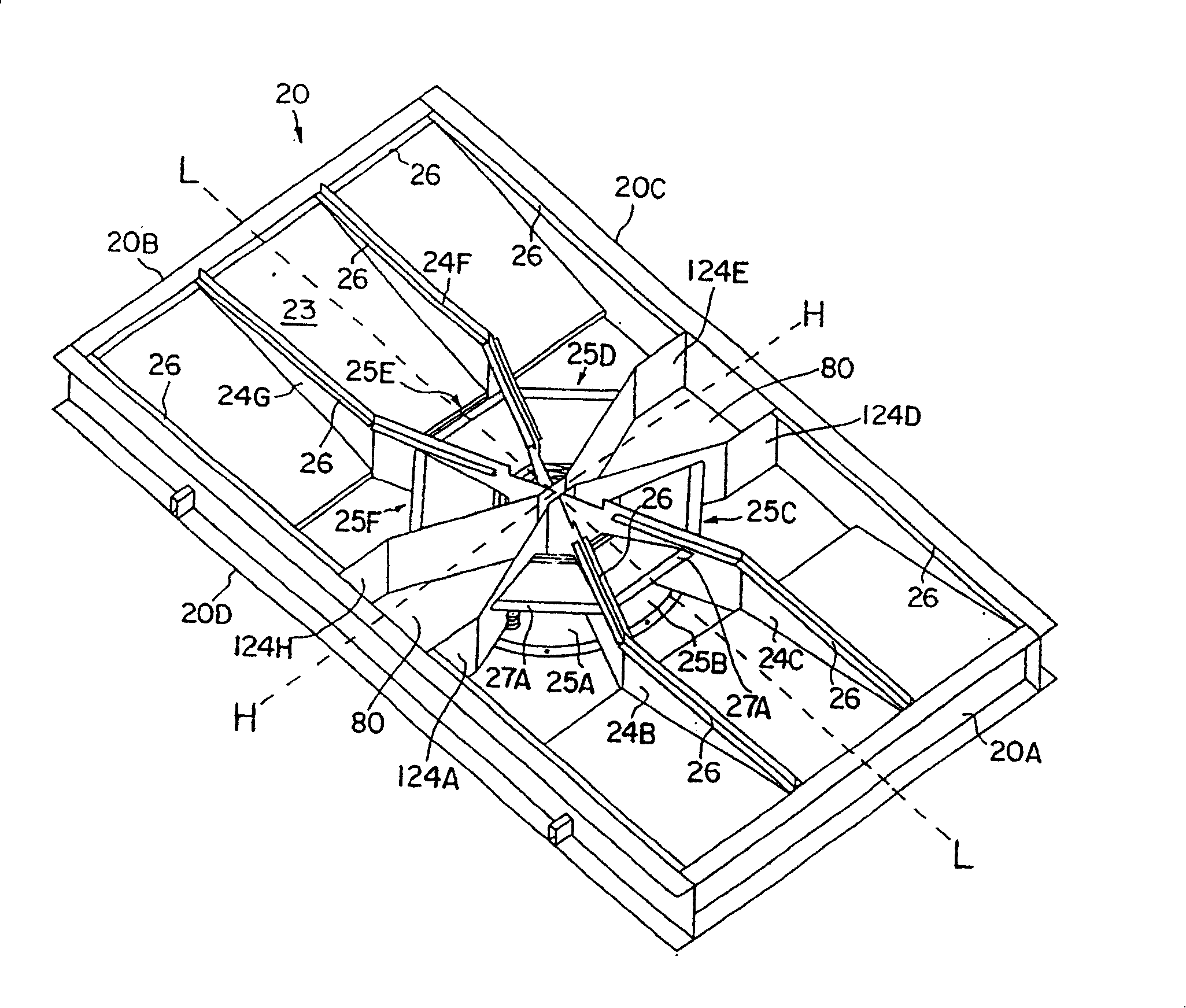

[0040]Referring first to Figures 1 and 2, a dual chamber regenerative thermal oxidizer 10 (catalytic or non-catalytic oxidizer) supported on a support 12 is shown. The oxidizer 10 includes an enclosure 15 within which are first and second heat exchange chambers in communication with a centrally mounted combustion zone to which a burner (not shown) can be connected and which can A combustion blower is supported on the frame 12 for supplying combustion air to the burner. The combustion zone includes a bypass outlet 14 in fluid communication with an exhaust stack 16 which is normally open to atmosphere. A control compartment 11 houses the controls for the device and is preferably also mounted on a stand 12 . Opposite the control chamber 11 is a fan (not shown) supported on a frame 12 to deliver process gas into the oxidizer 10 . Housing 15 includes an upper chamber or roof 17 having one or more access hatches 18 to allow operator access to housing 15 . Those skilled in the art...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com