Patents

Literature

589results about "Damper arrangement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

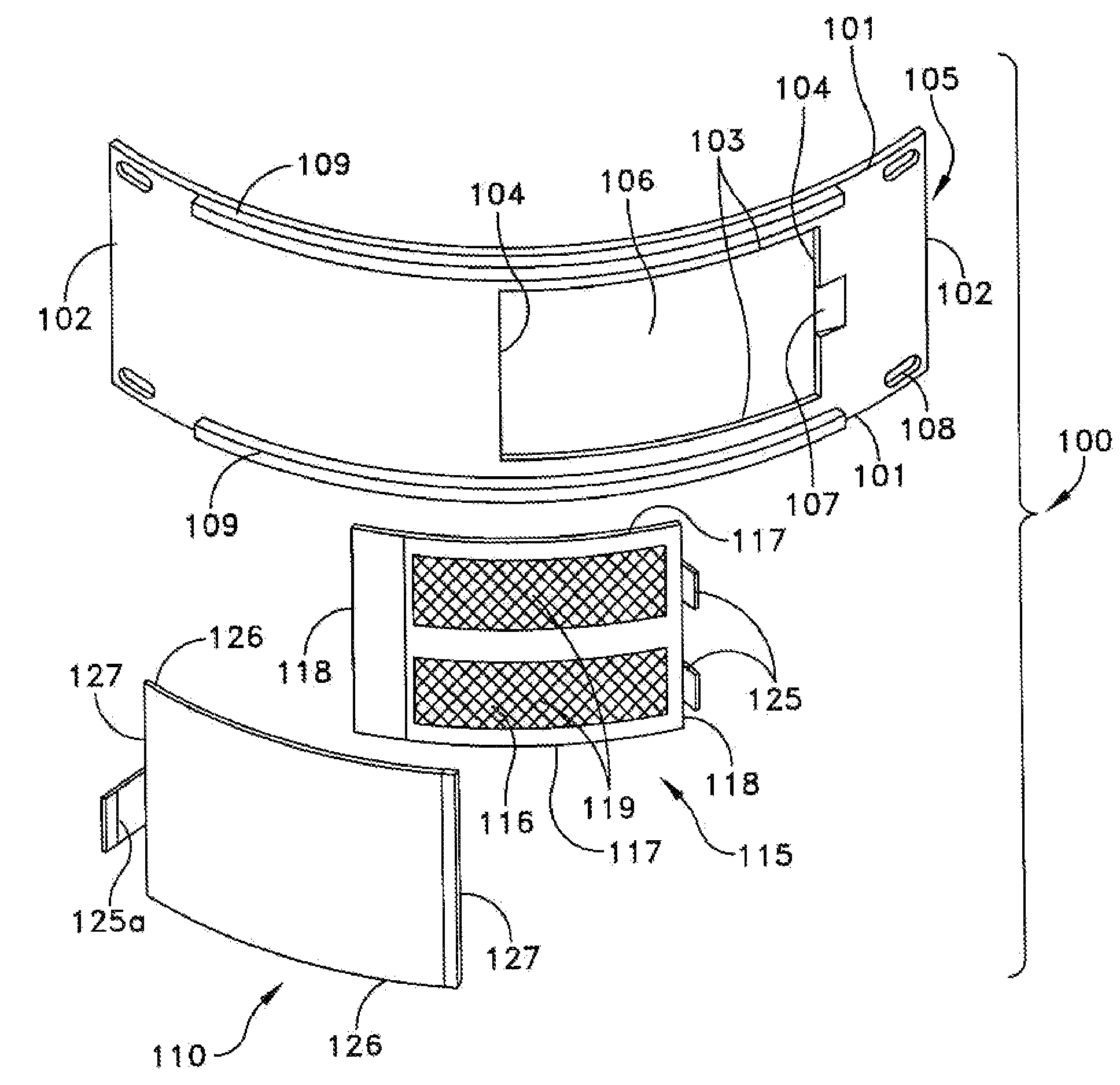

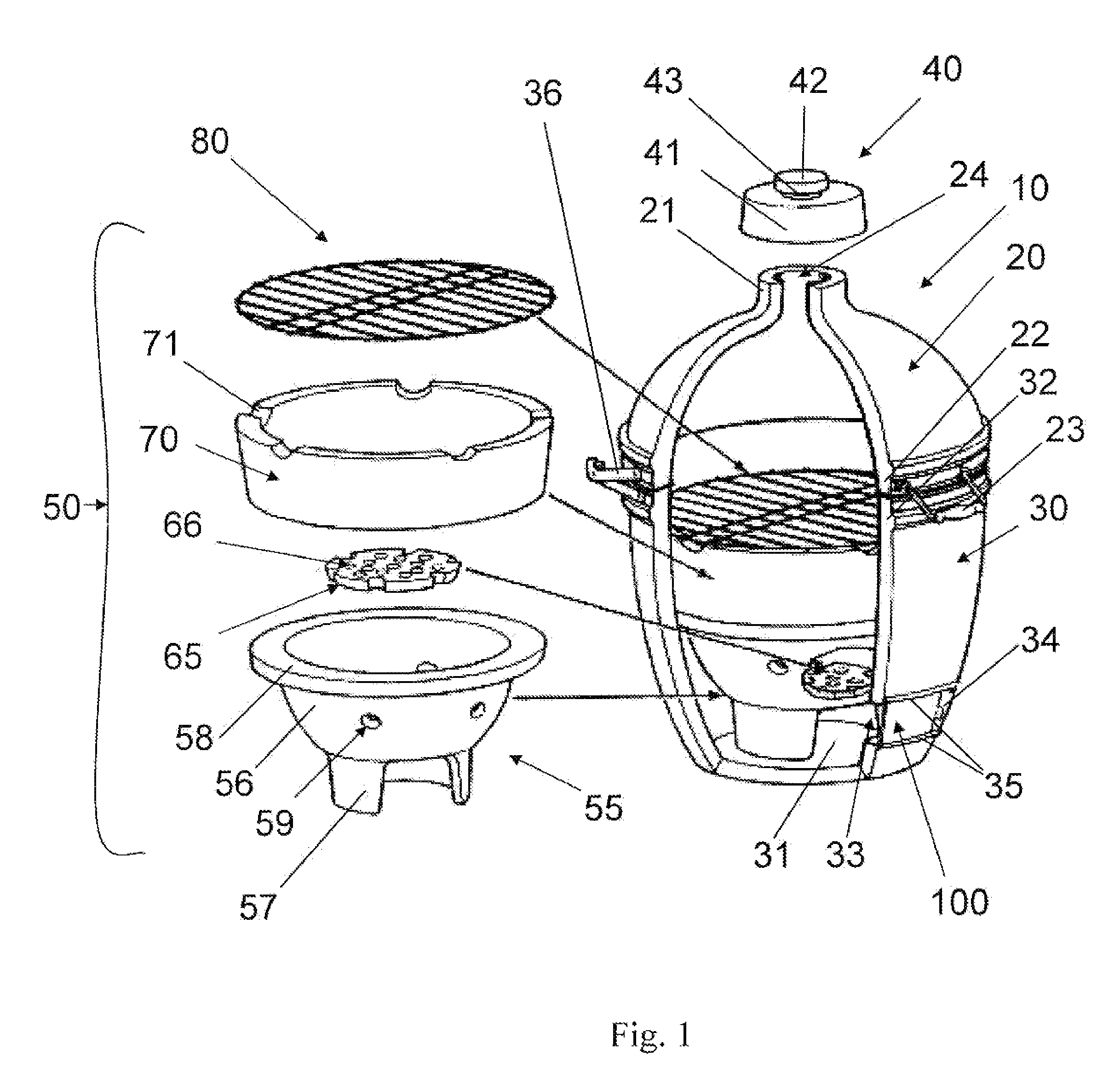

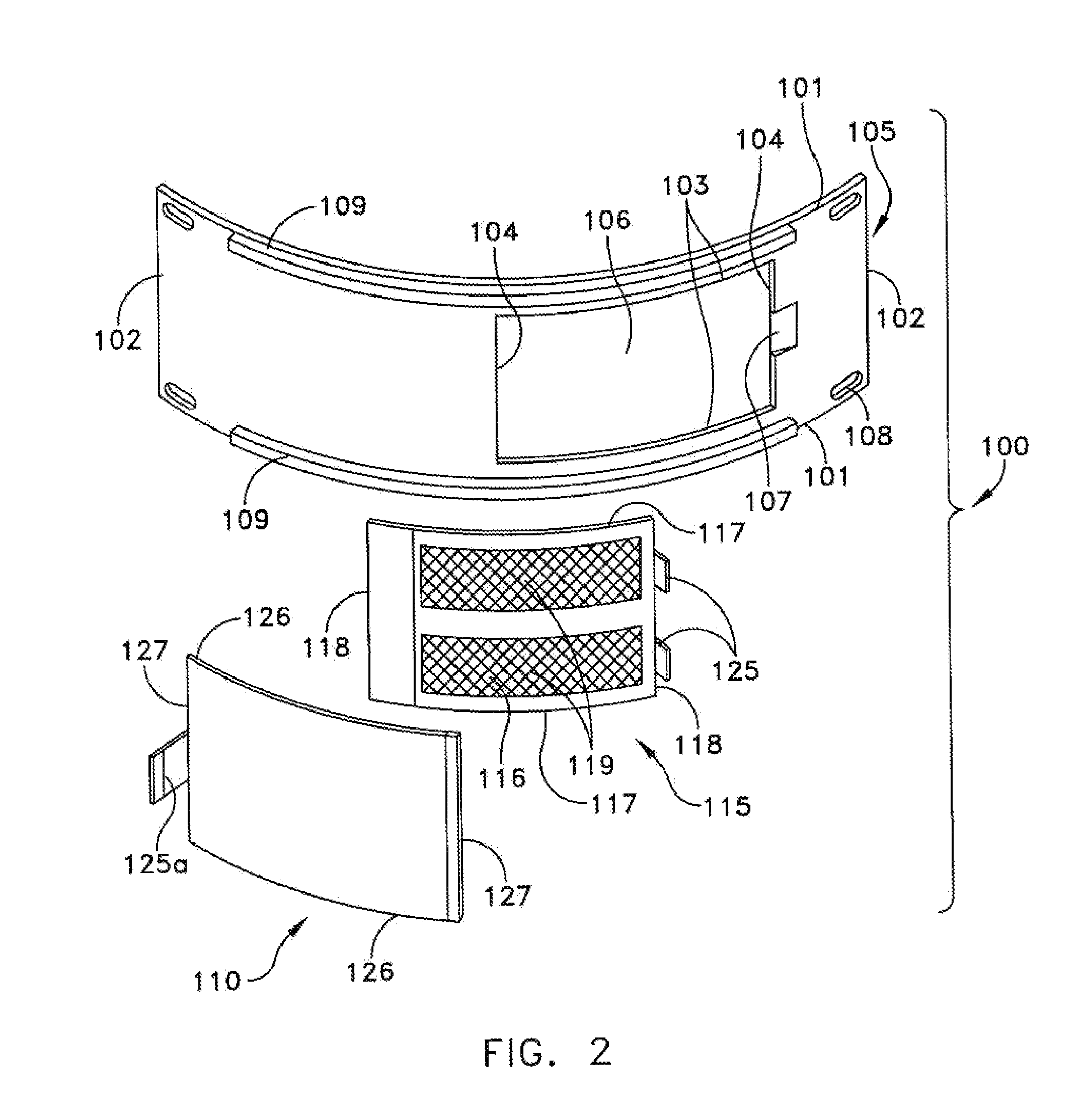

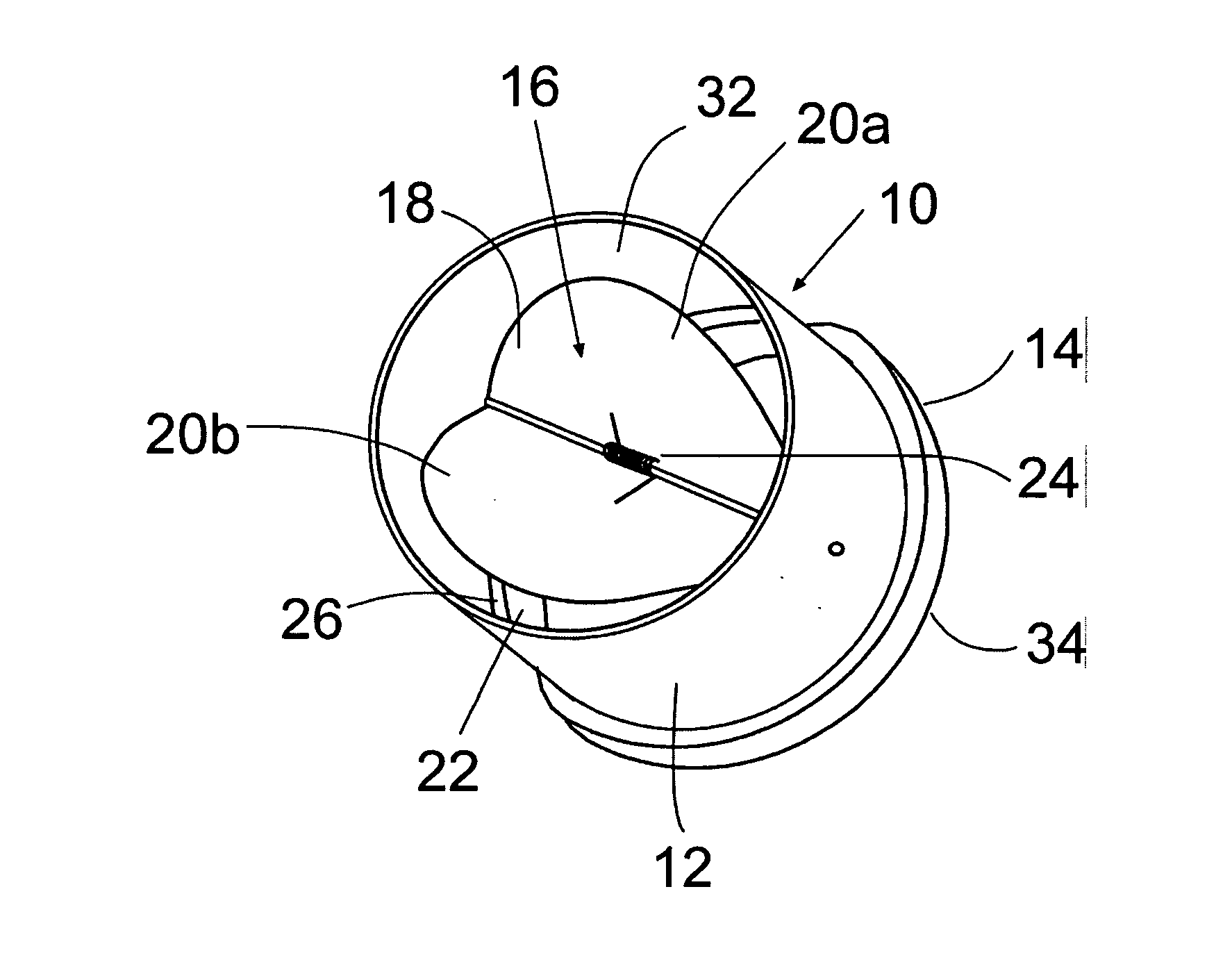

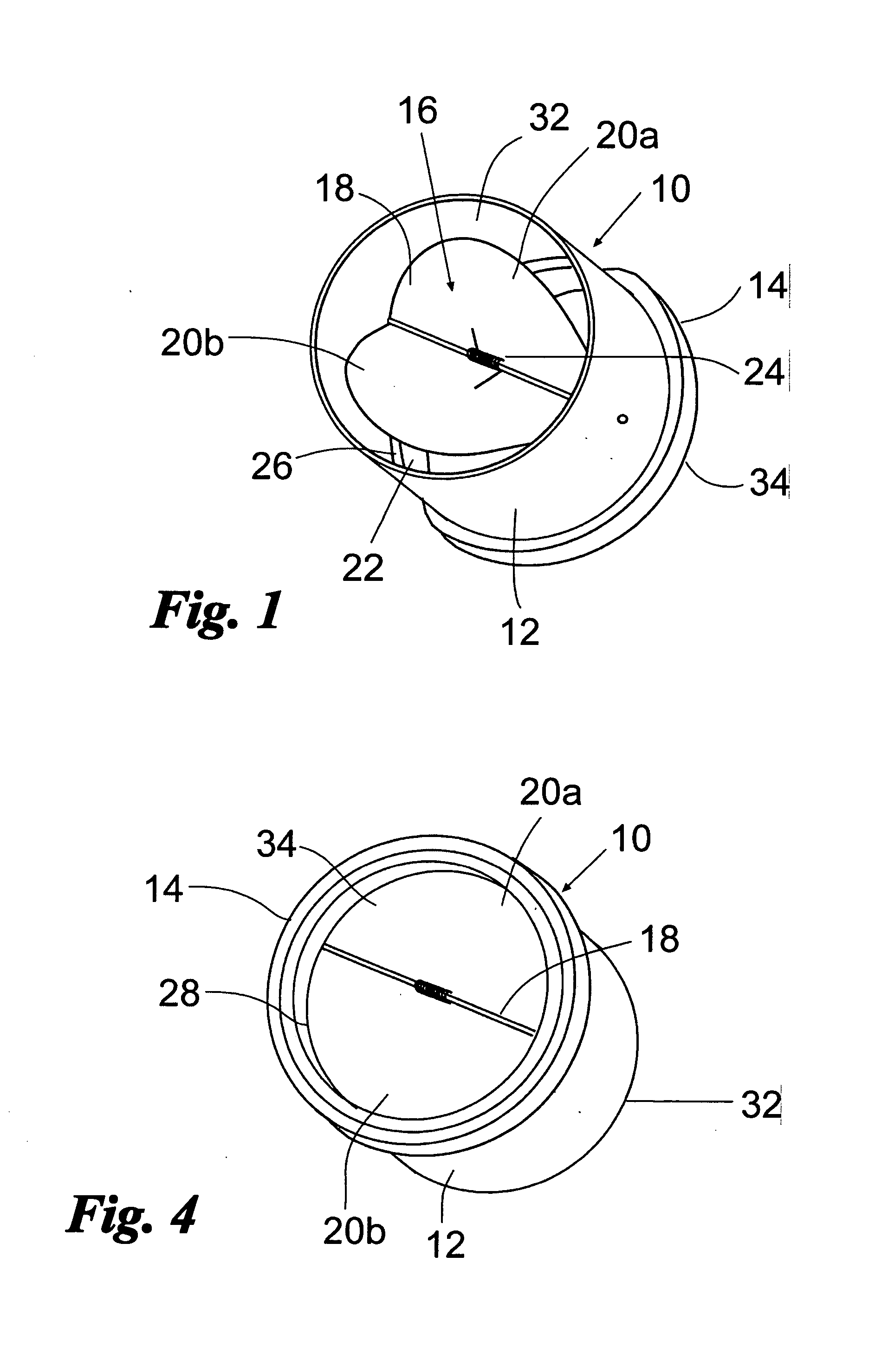

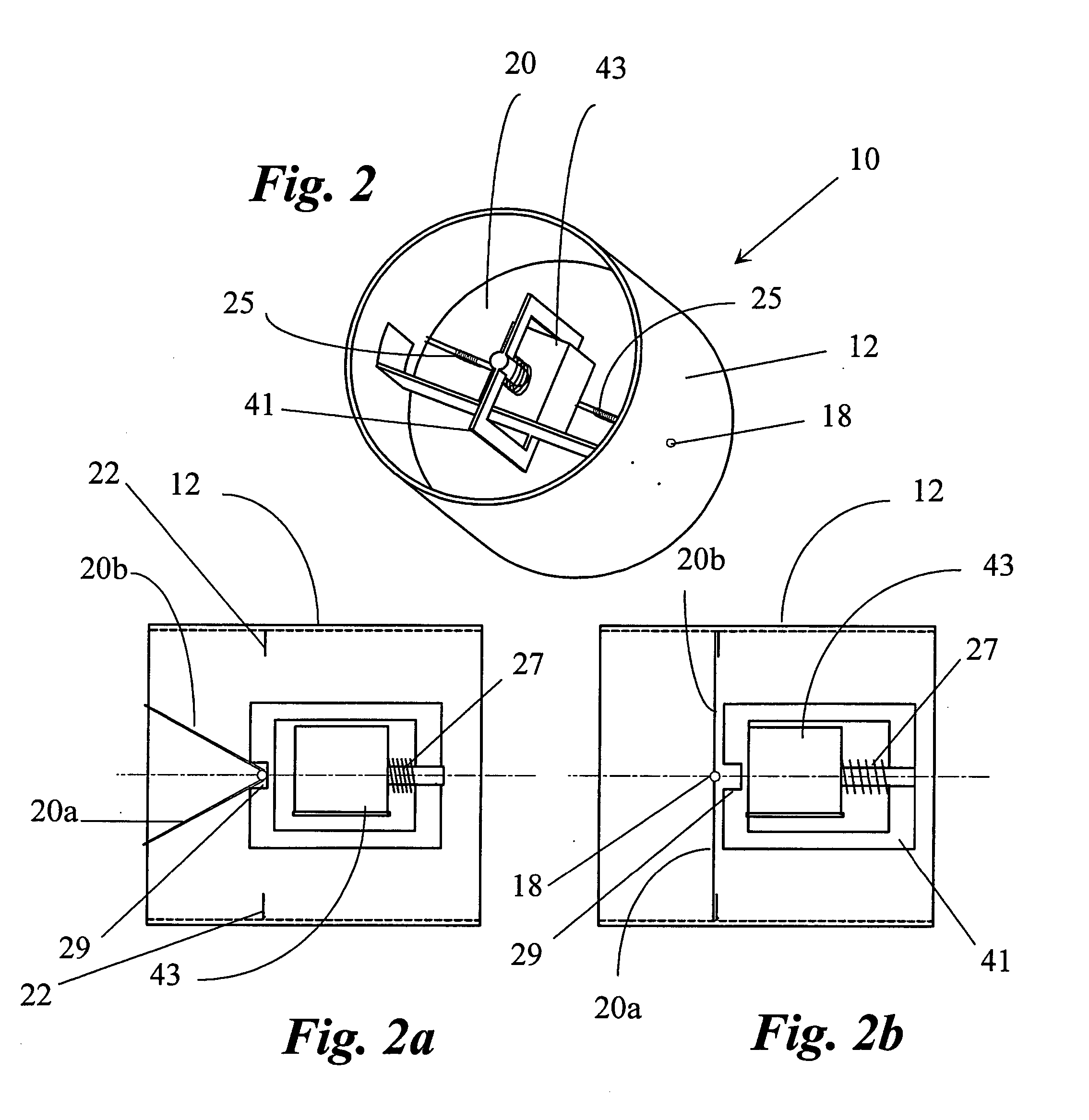

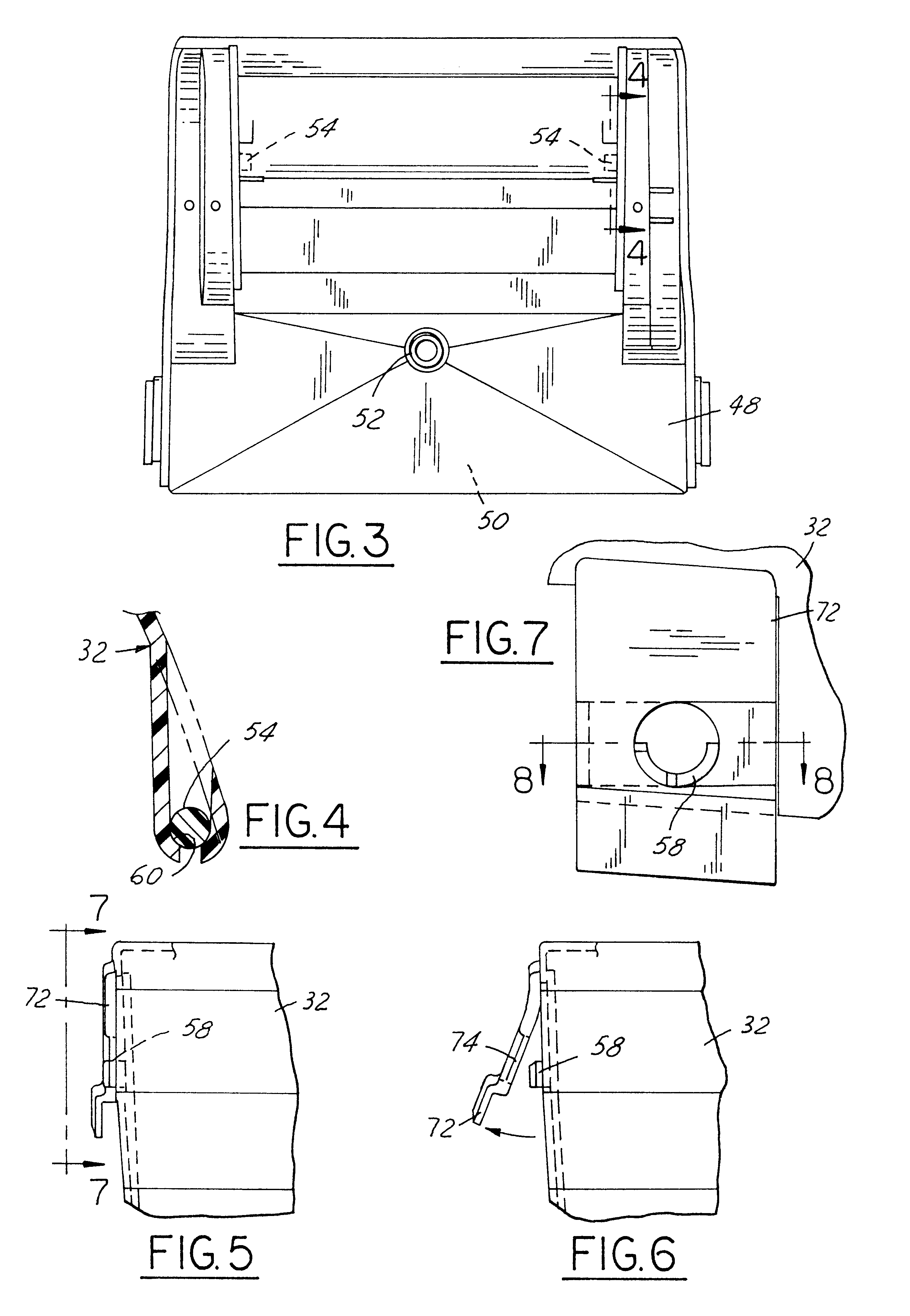

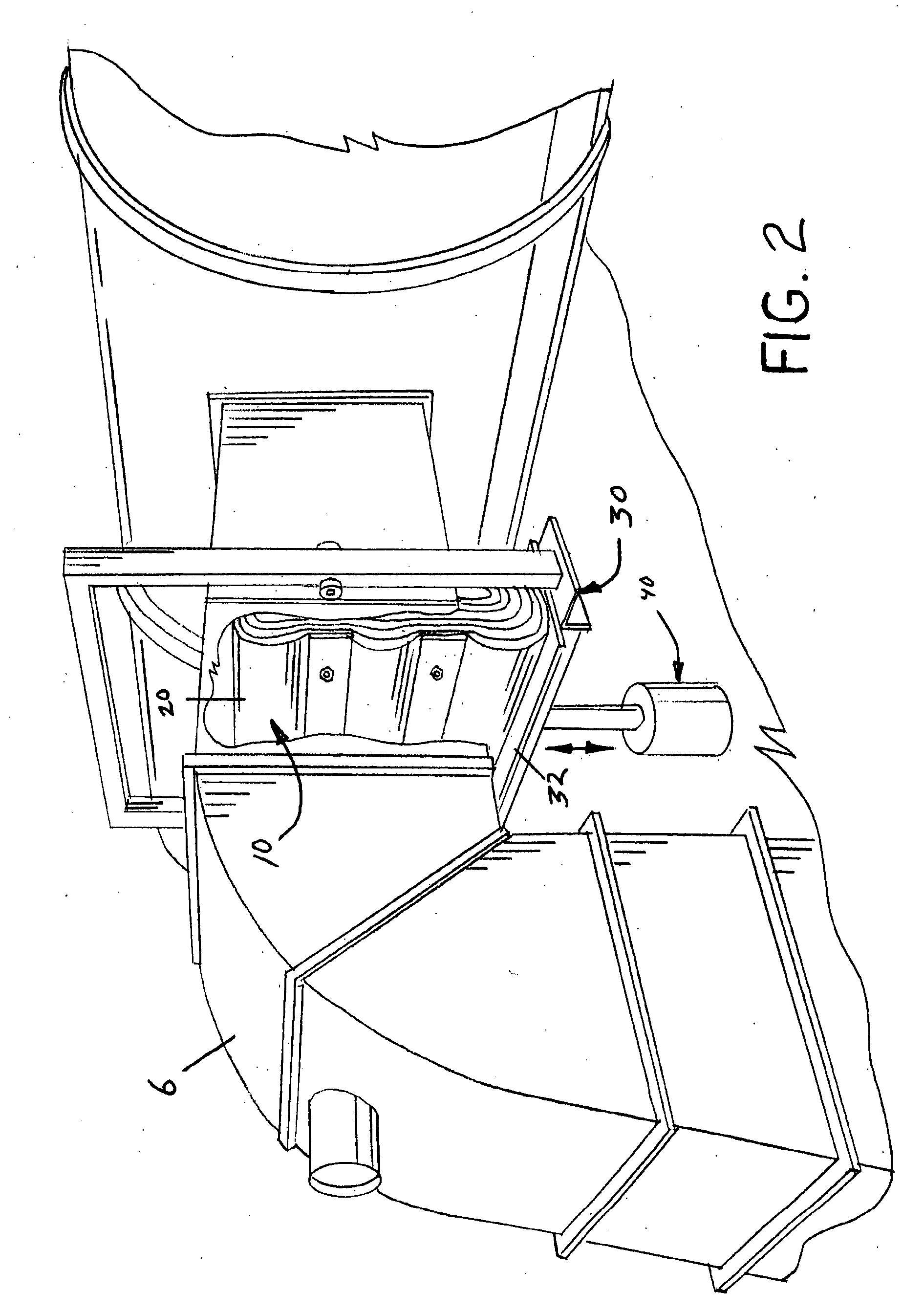

Spark arrestor and airflow control assembly for a portable cooking or heating device

ActiveUS7644711B2Easy to adjustEasy to controlDomestic stoves or rangesBaking ovenSpark arrestorEngineering

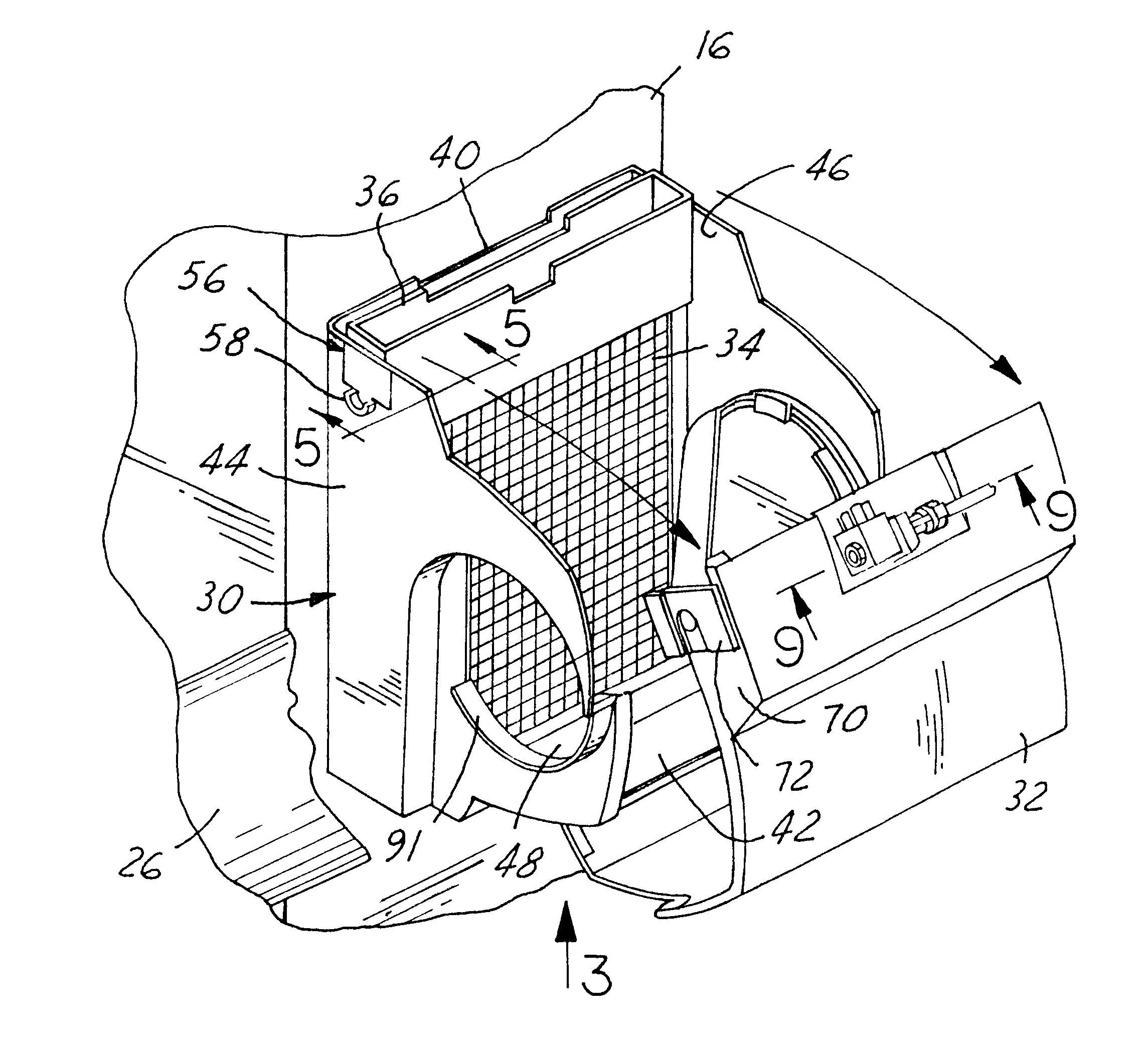

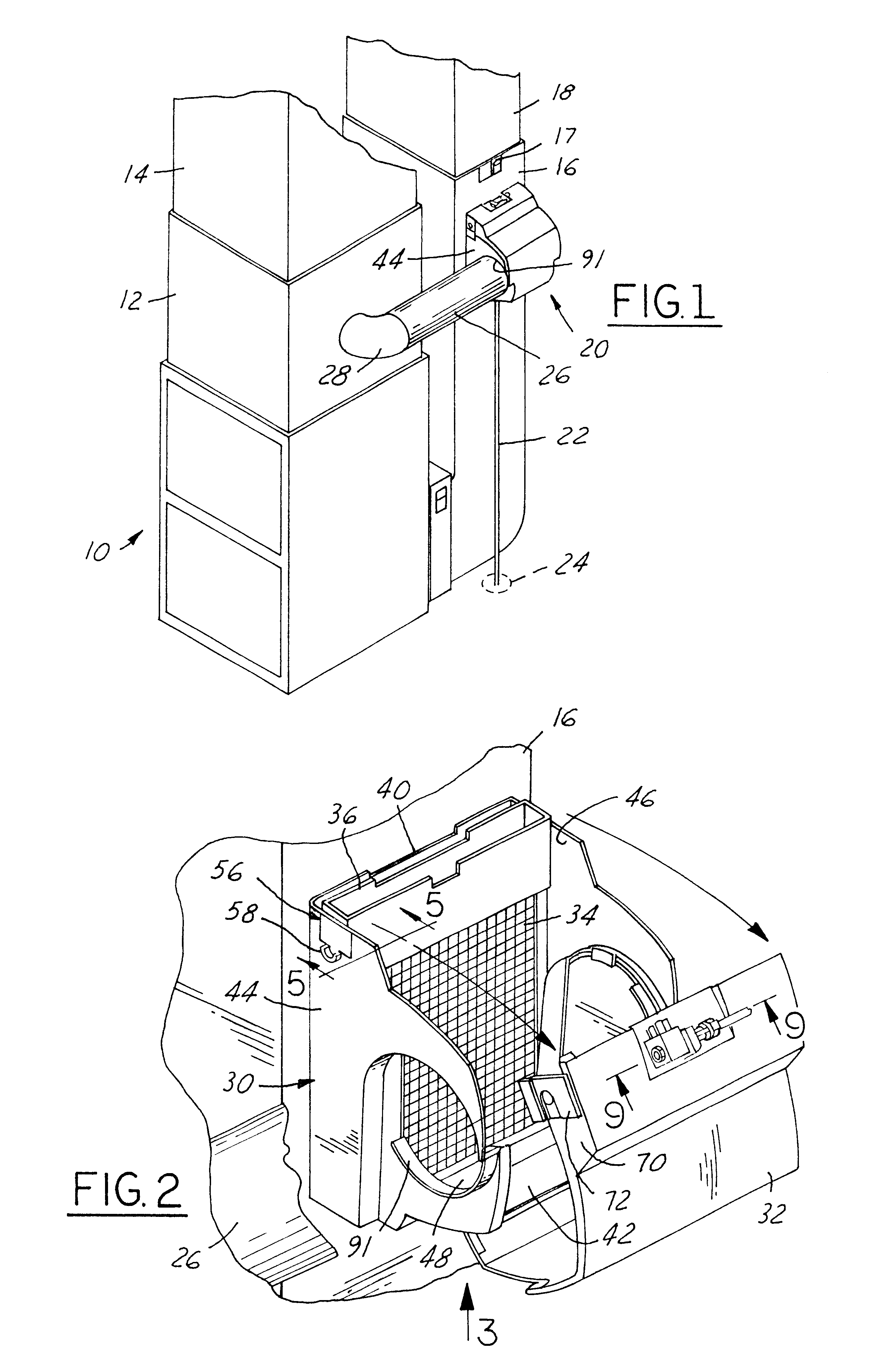

A device for arresting spark and ash issuing from, and precisely controlling the ventilation of and temperature inside, a heat source-containing vessel such as a cooking grill, stove, oven, cooker, fireplace, heater, or firebox. The device comprises a spark arrestor assembly including a base plate, a cover plate, and a spark arrestor. The base plate defines an opening. The cover plate and spark arrestor are slidably mated in two channels formed in the base plate around the opening. The cover plate and spark arrestor may be adjusted to extend across or only partway across the opening as selected by a user of the device. Tabs are provided on the cover plate and spark arrestor for easy adjustment thereof. Tabs in the base plate are positioned to define a range of slidable motion of the cover plate and spark arrestor. The spark arrestor assembly engages a fire-containing or heat source-containing vessel over an opening defined by the vessel so that the vessel opening cooperates with the spark arrestor assembly opening.

Owner:THE BIG GREEN EGG

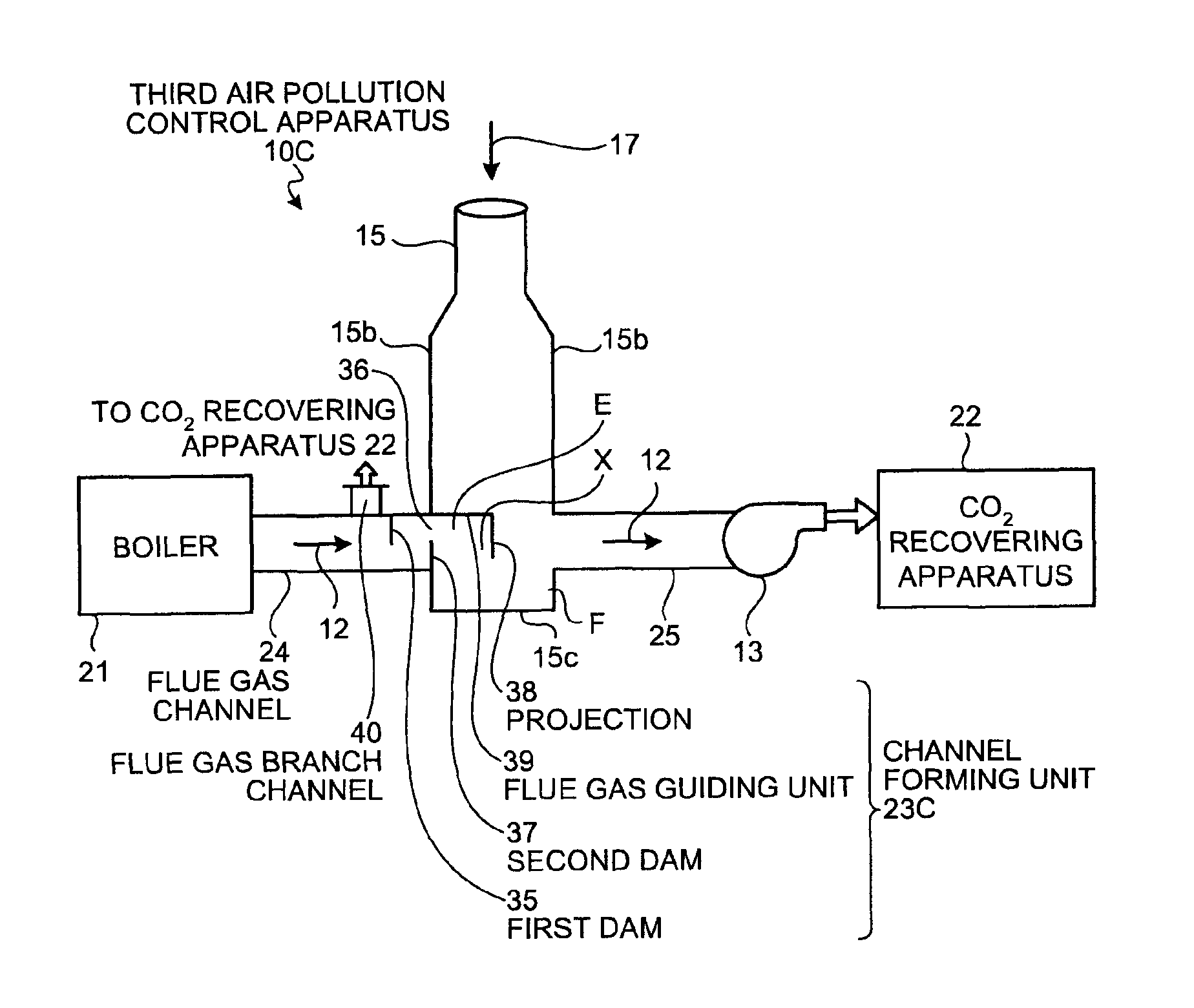

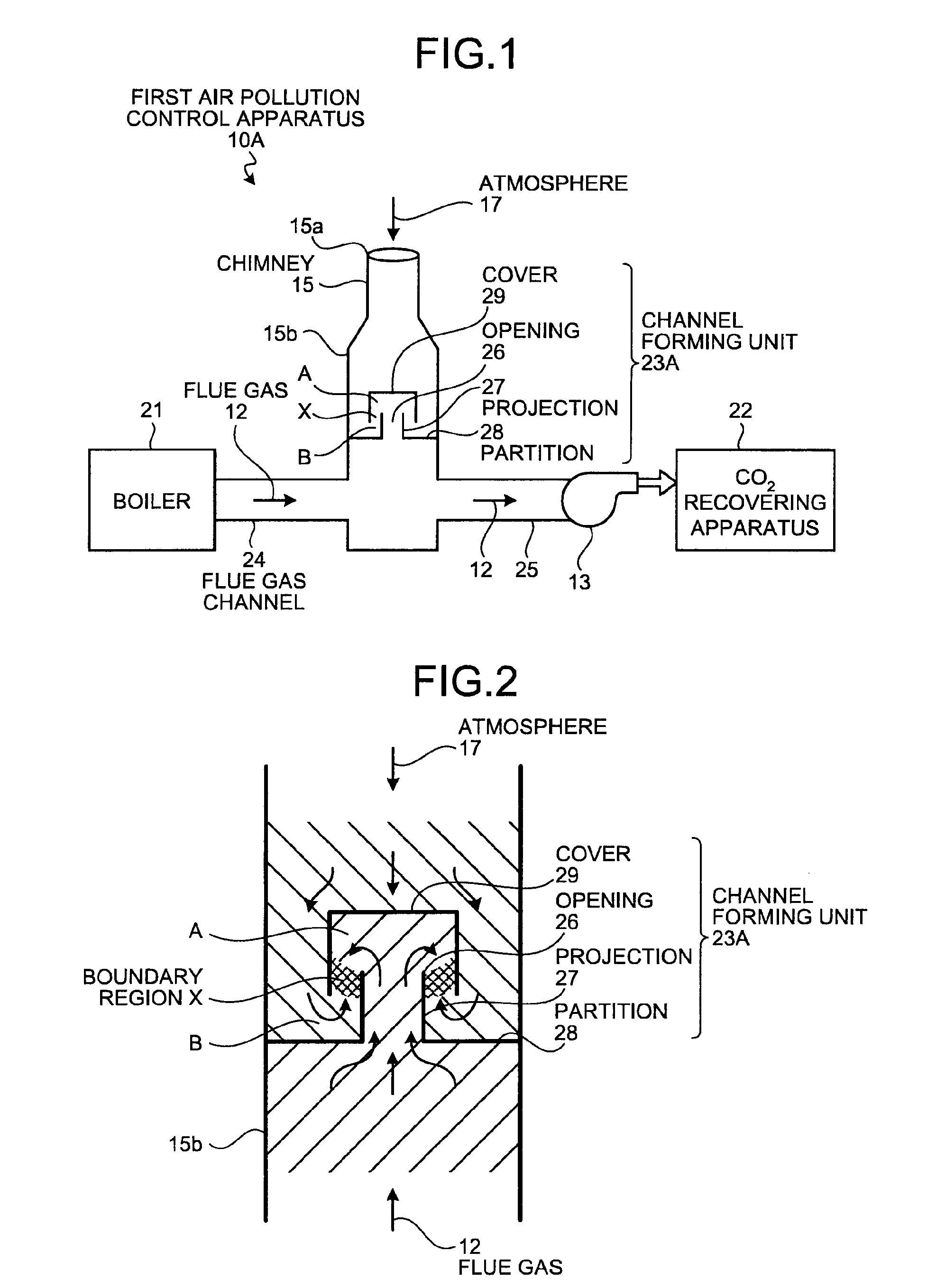

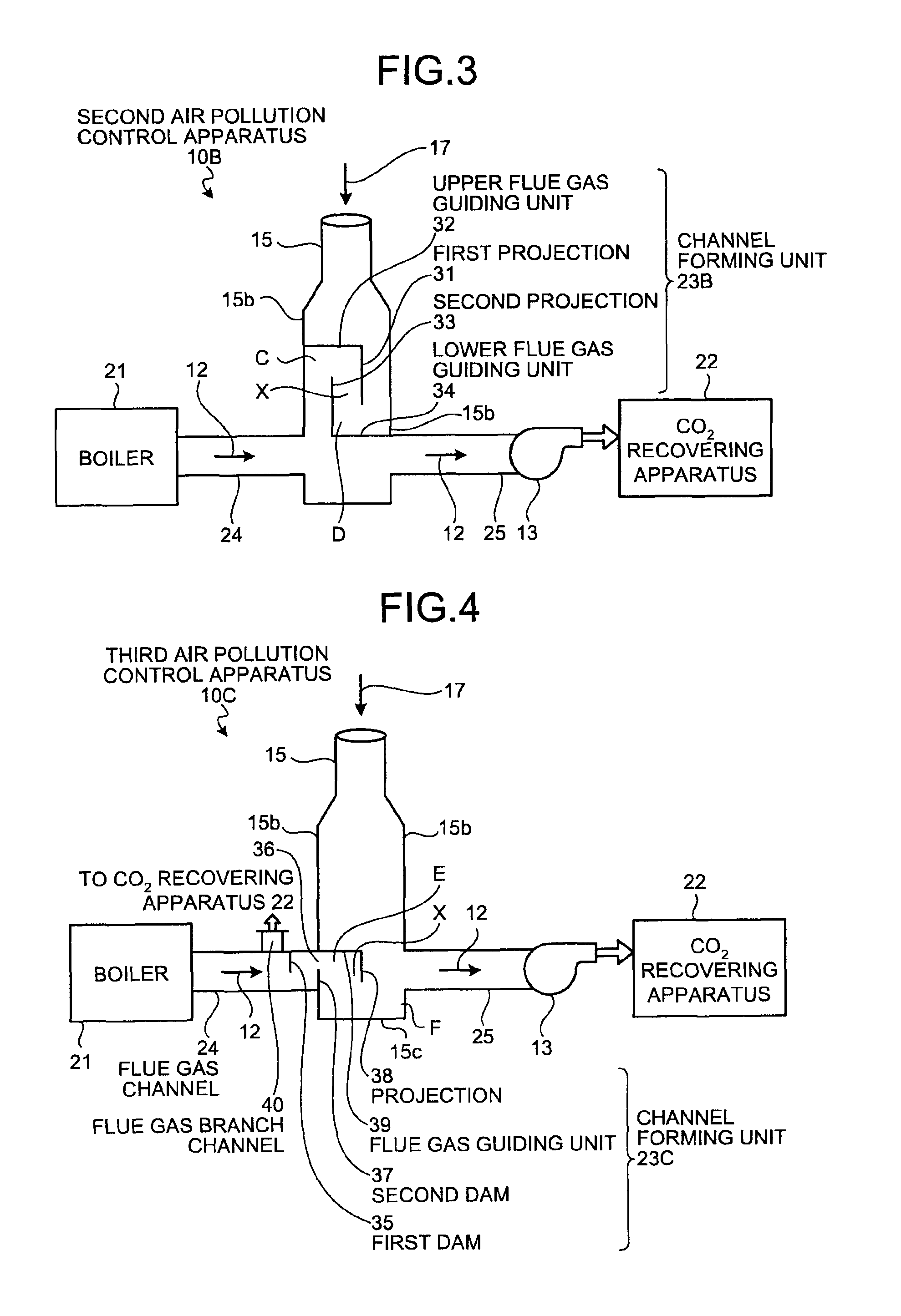

Air pollution control apparatus and air pollution control method

An air pollution control apparatus according to an embodiment of the present invention includes: a stack that discharges flue gas discharged from a boiler outside; a blower that is provided downstream of the stack and draws in the flue gas; and a CO2 recovering apparatus that recovers CO2 in the flue gas drawn in by the blower. The stack includes a controlling unit that suppresses release of the flue gas outside from the stack and suppresses inflow of atmosphere to the stack, and the controlling unit is a channel forming unit that forms a serpentine channel through which the flue gas and the atmosphere in the stack flow.

Owner:MITSUBISHI HEAVY IND ENG LTD

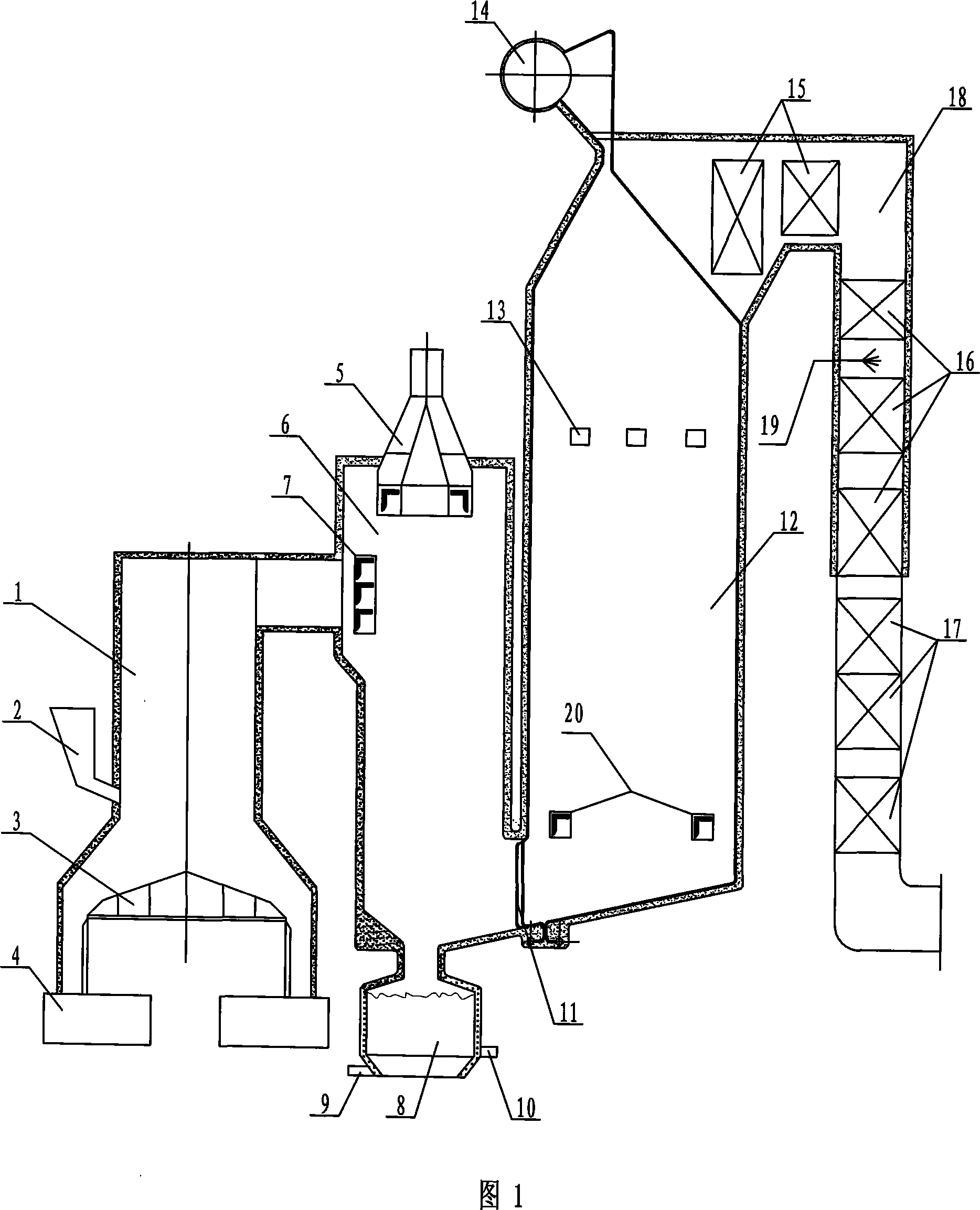

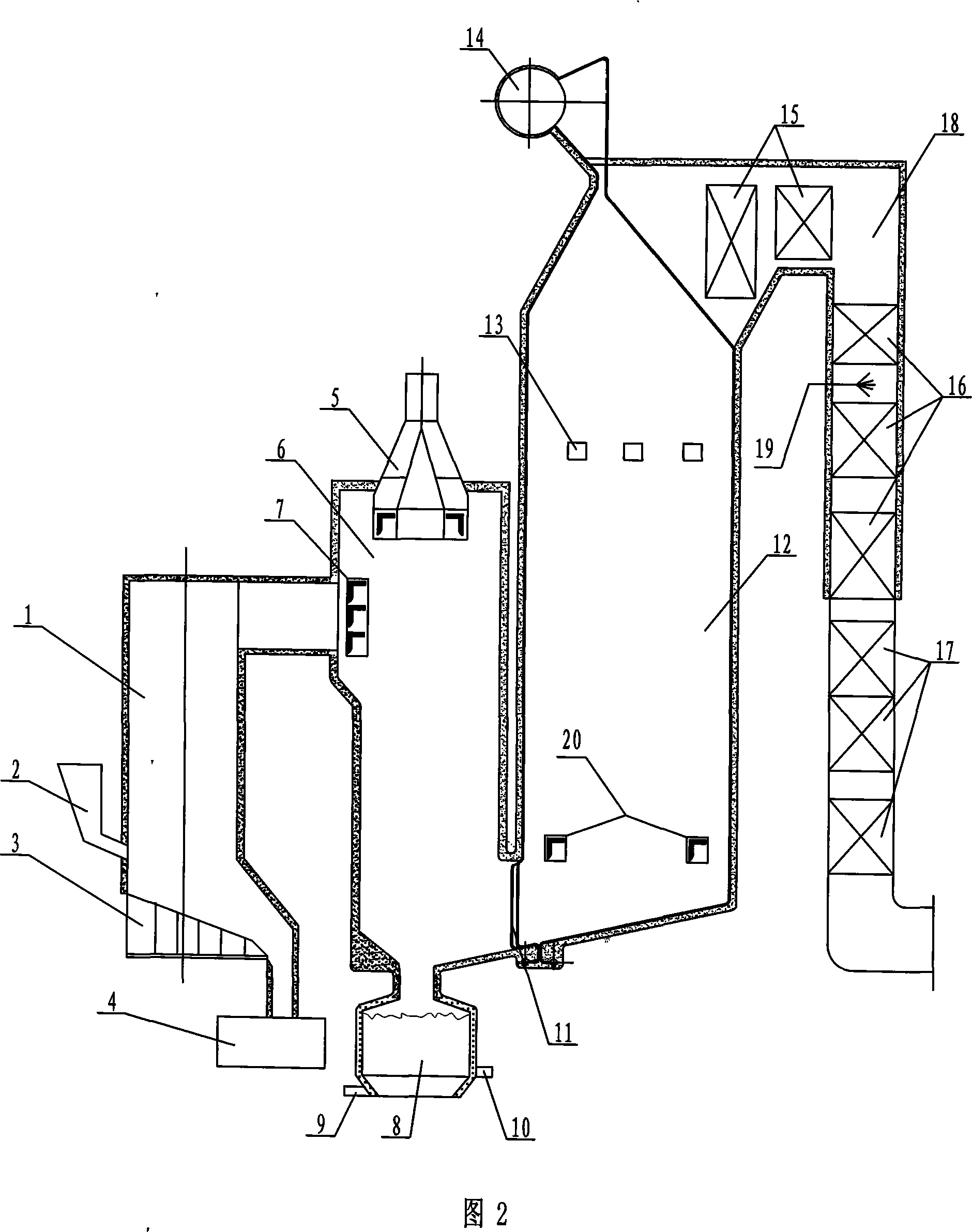

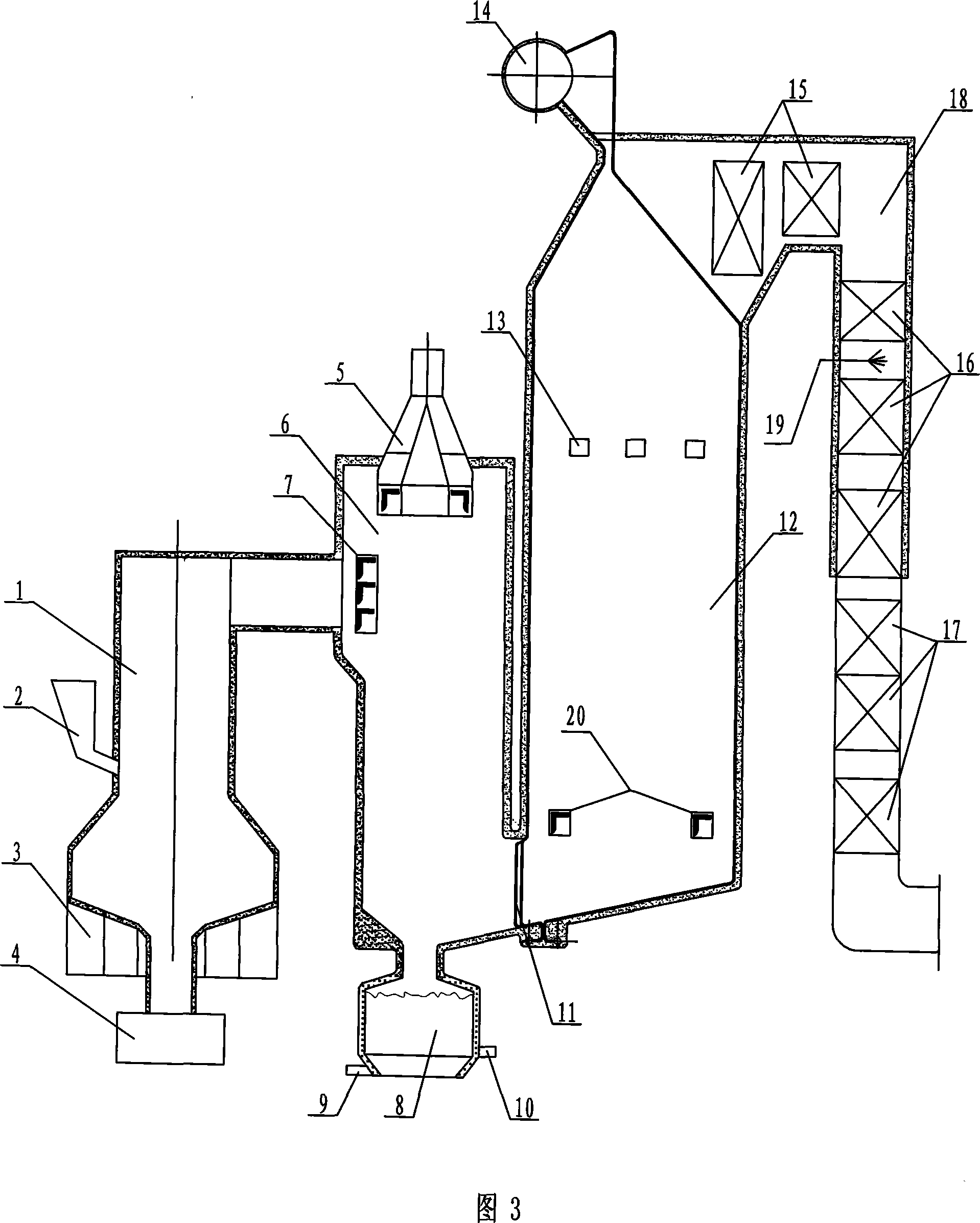

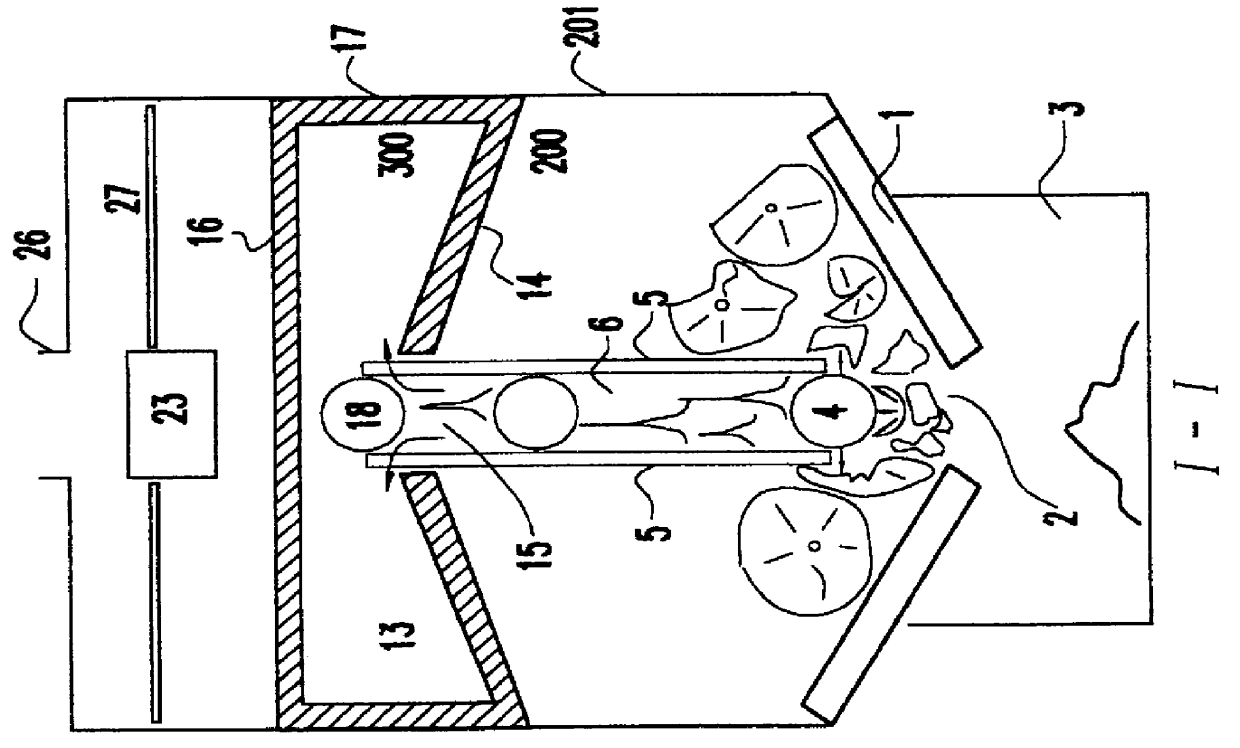

Apparatus and method for gasification of refuse and hyperthermia melt processing of flying ash

ActiveCN101201167AWith waste heat utilizationHigh heat intensity of combustionDamper arrangementIndirect carbon-dioxide mitigationAir preheaterEngineering

A device and method for garbage gasification and flying ash high temperature melting treatment relates to an integrated technology for garbage gasification and flying ash high temperature melting. The invention aims at solving the problem that the heavy metals and dioxins in the ash collected by a hop-pocket in an incinerator for garbage gasification exceeds the standard limits greatly. The device is formed in the way that a fluidized bed gasifier is communicated with a cyclone furnace; the cyclone furnace is communicated with a burnt chamber and the burnt chamber is communicated with a flue. The method includes that the smoke and gas generated by the gasification of the garbage in the fluidized bed gasifier enters the cyclone furnace and burns with the help of coal powder; the heavy metals in the flying ash are reduced to metals and recycled; the dioxins in the flying ash are decomposed; the exhaust smoke and gas enters a tail gas treatment device after entering the burnt chamber, a superheater, a coal saving device and an air preheater. The invention leads the smoke and gas generated by the gasification and burning of the garbage in the fluidized bed gasifier to enter the cyclone furnace for high temperature melting treatment so as to lead the dioxins in the tail gas collecting ash and in the tail gas to be respectively lower than 50ng-TEQ / kg, 0.1ng-TEQ / m{3}.

Owner:HARBIN INST OF TECH

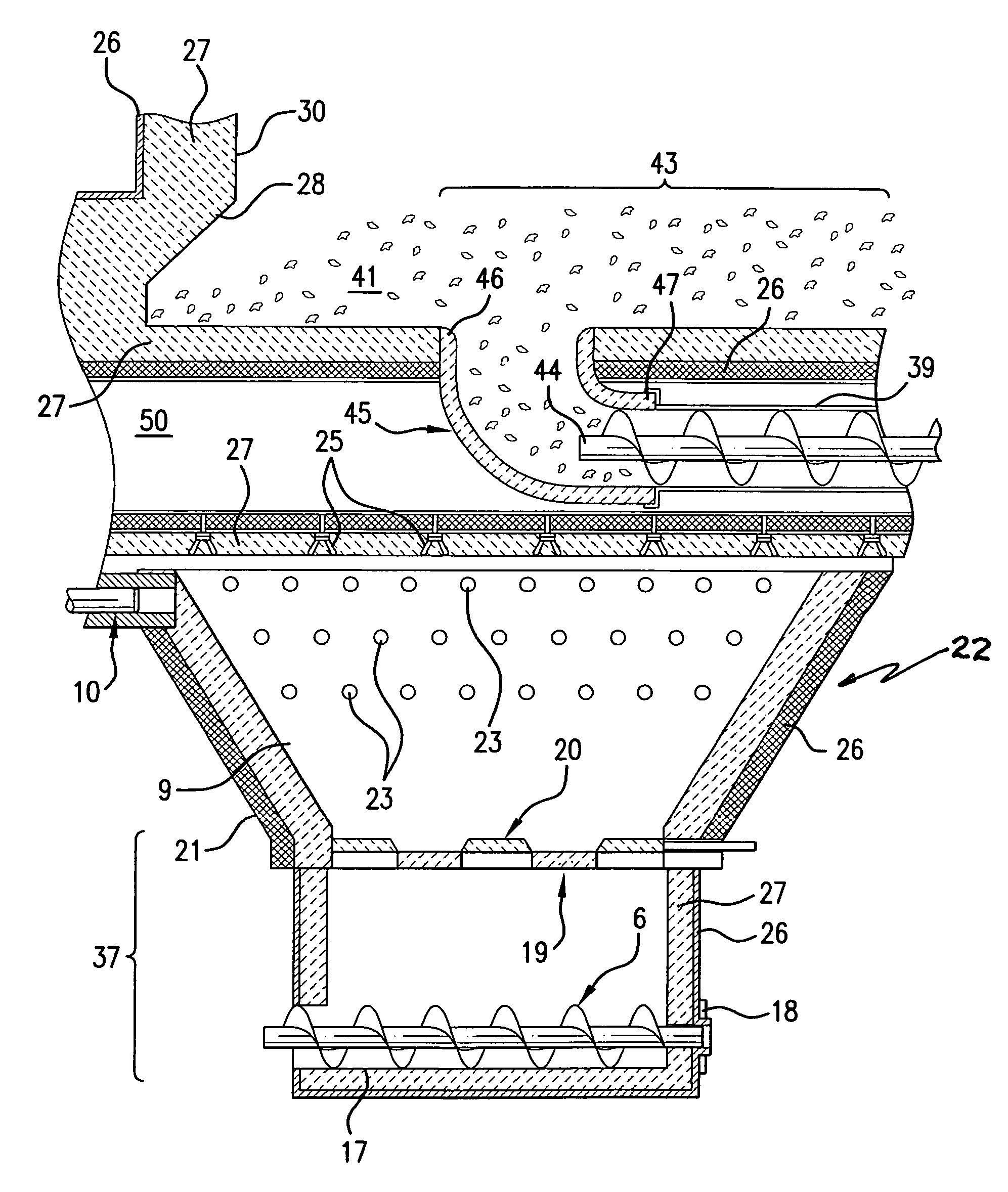

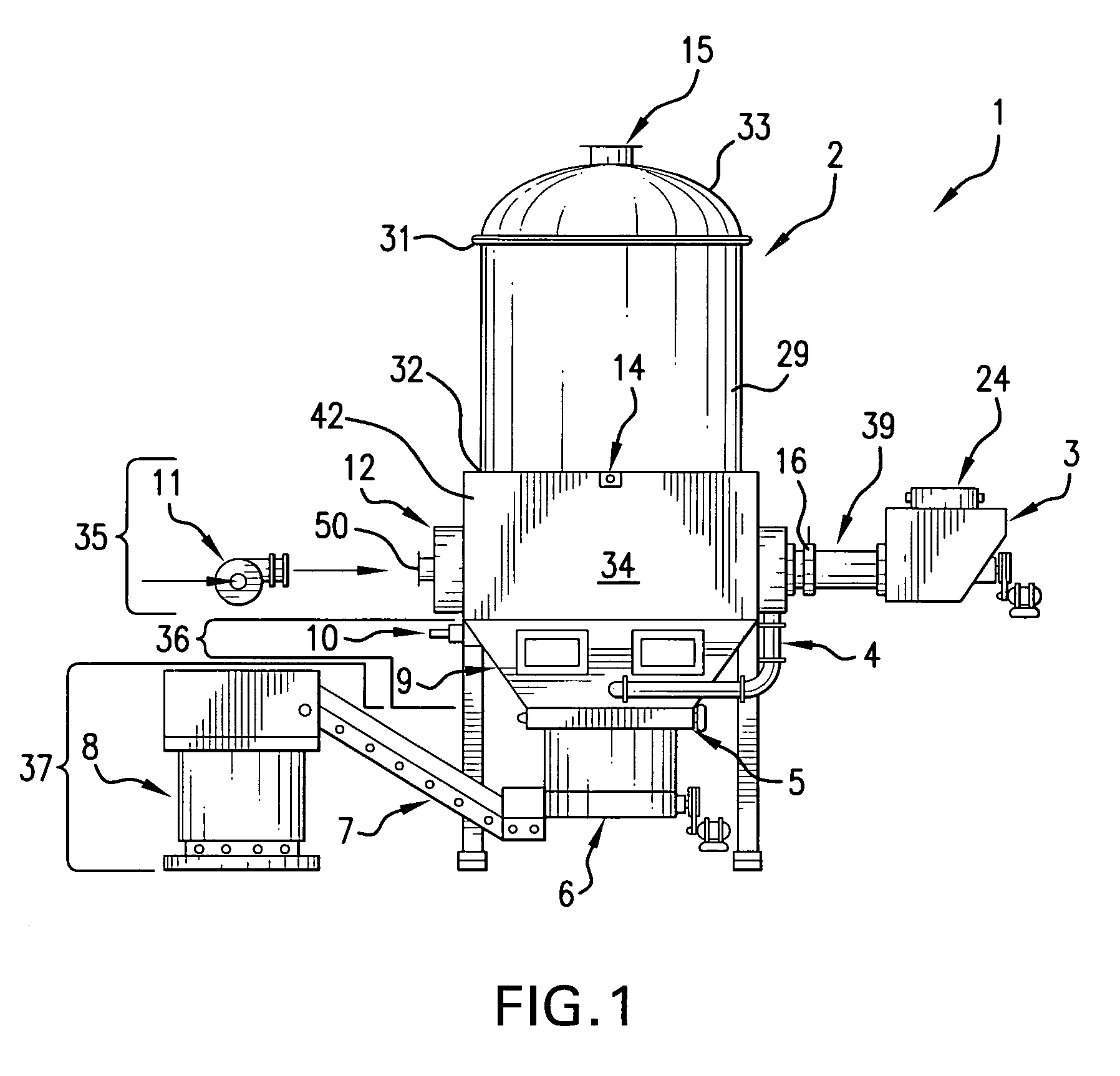

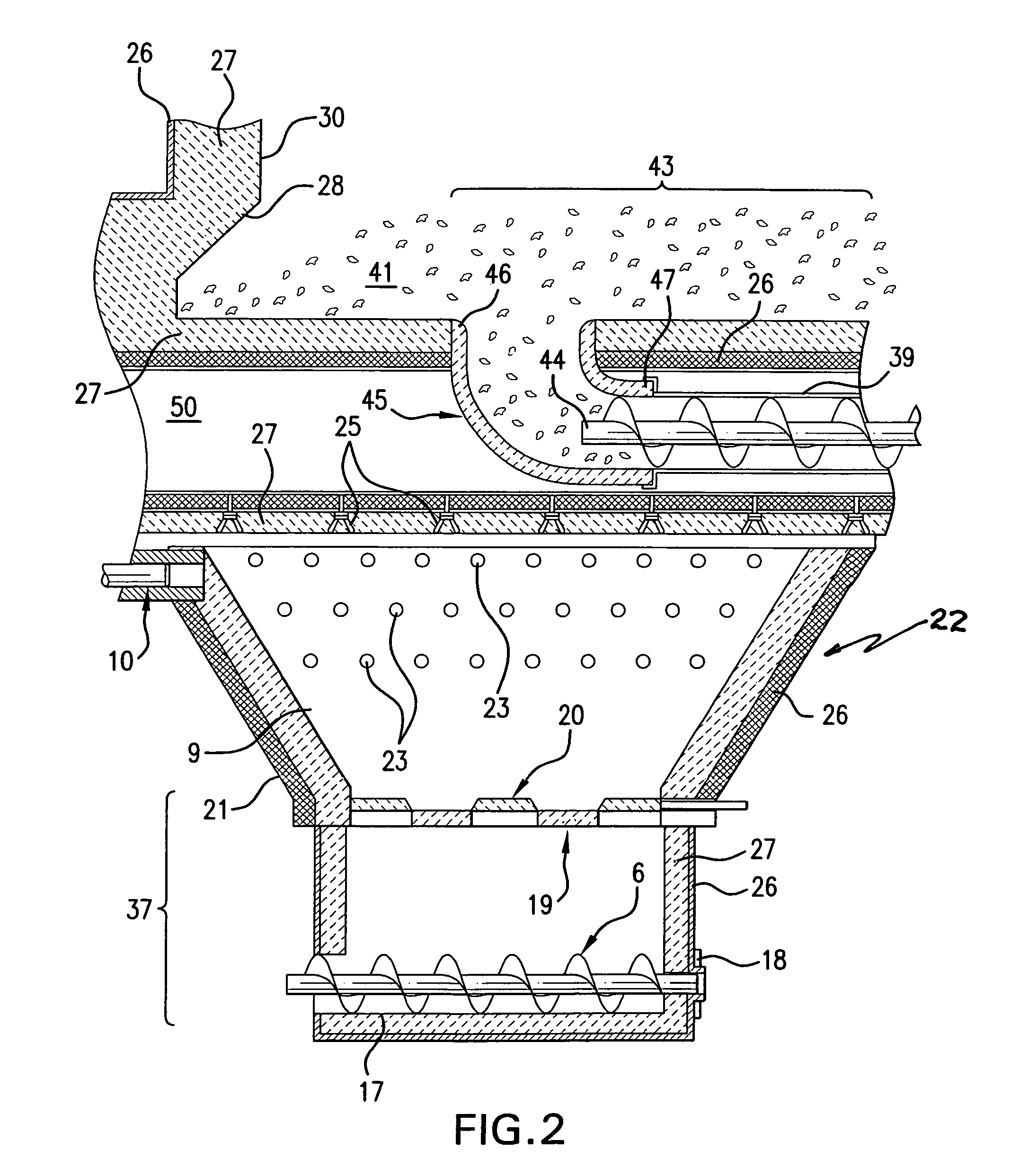

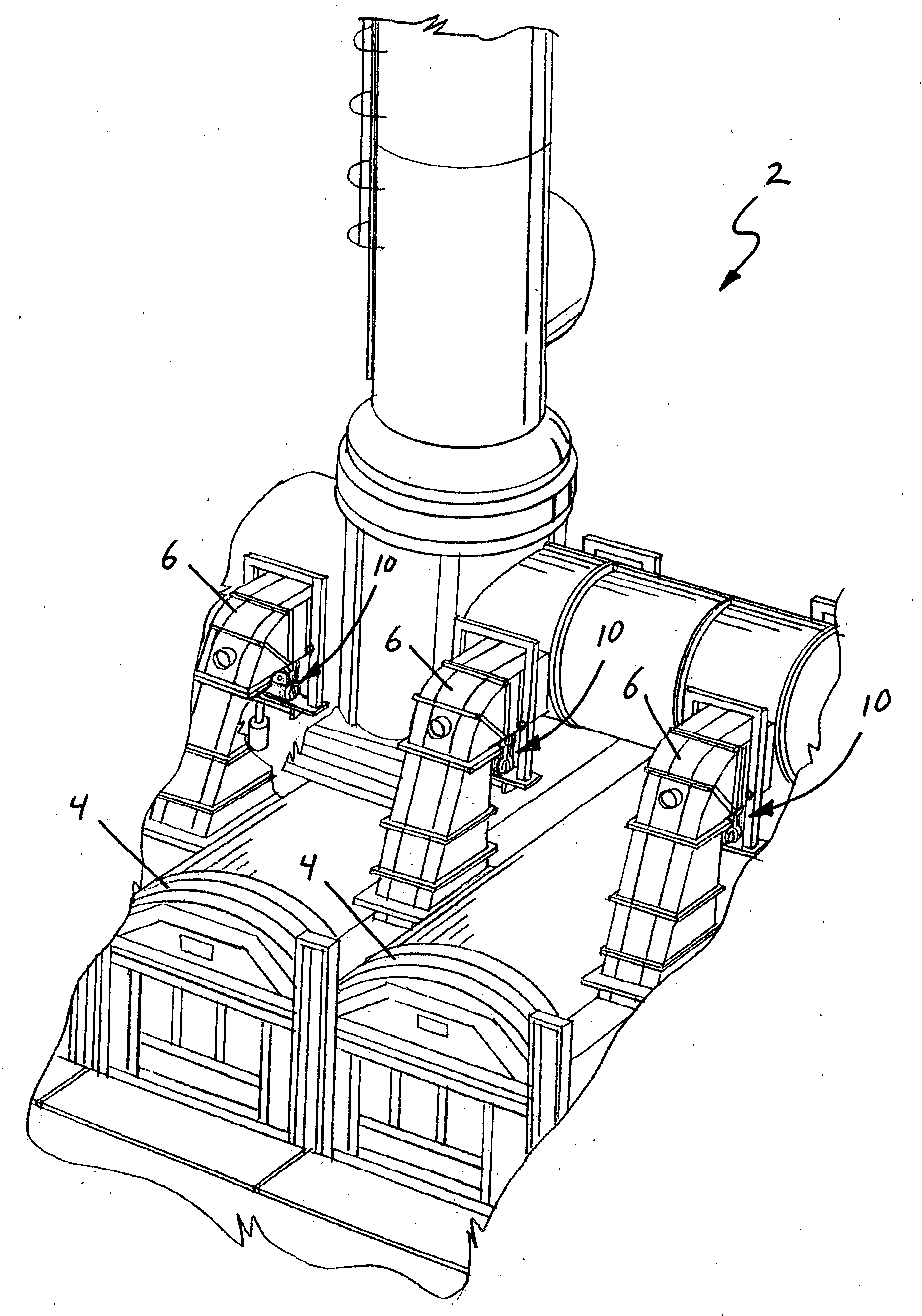

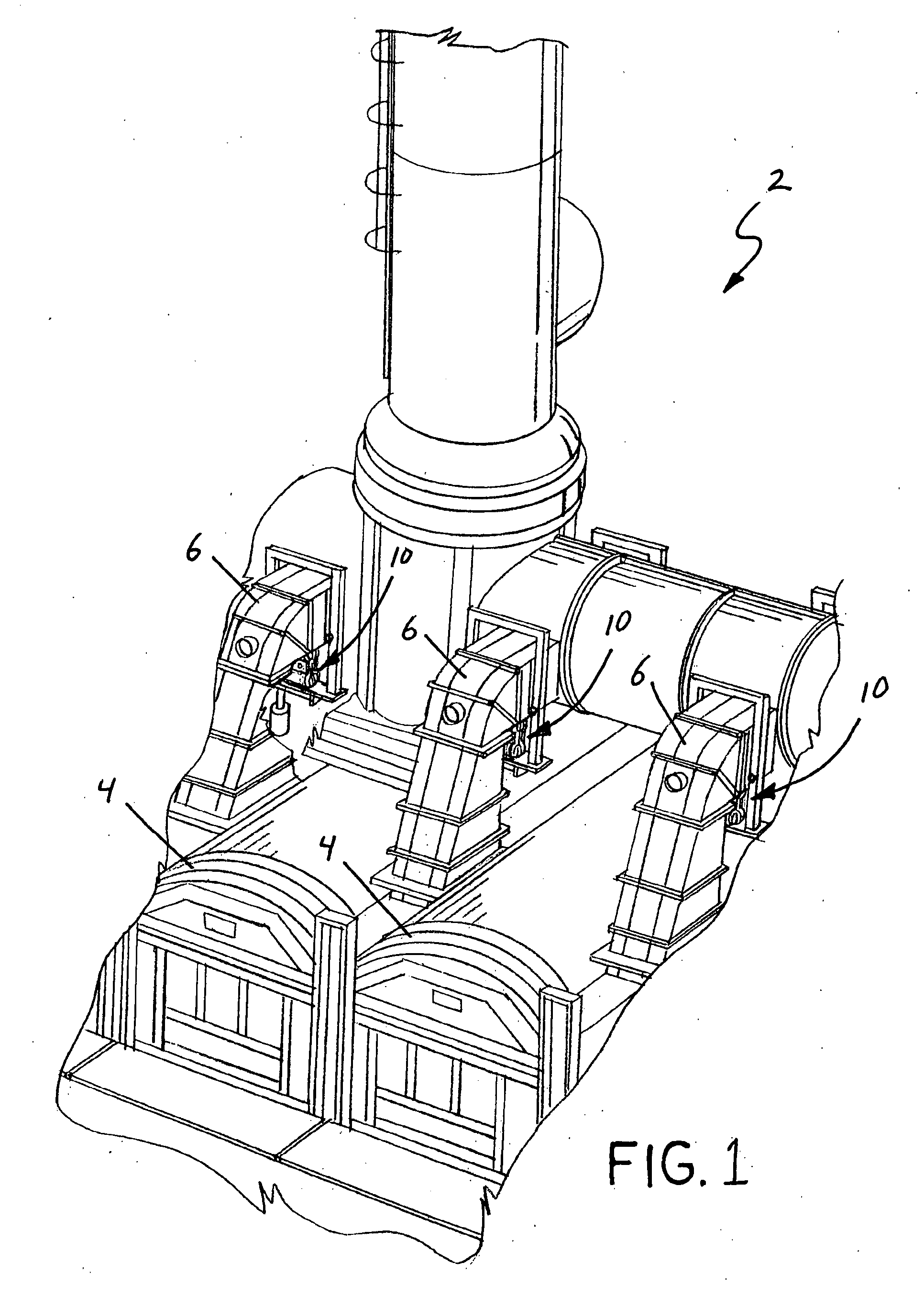

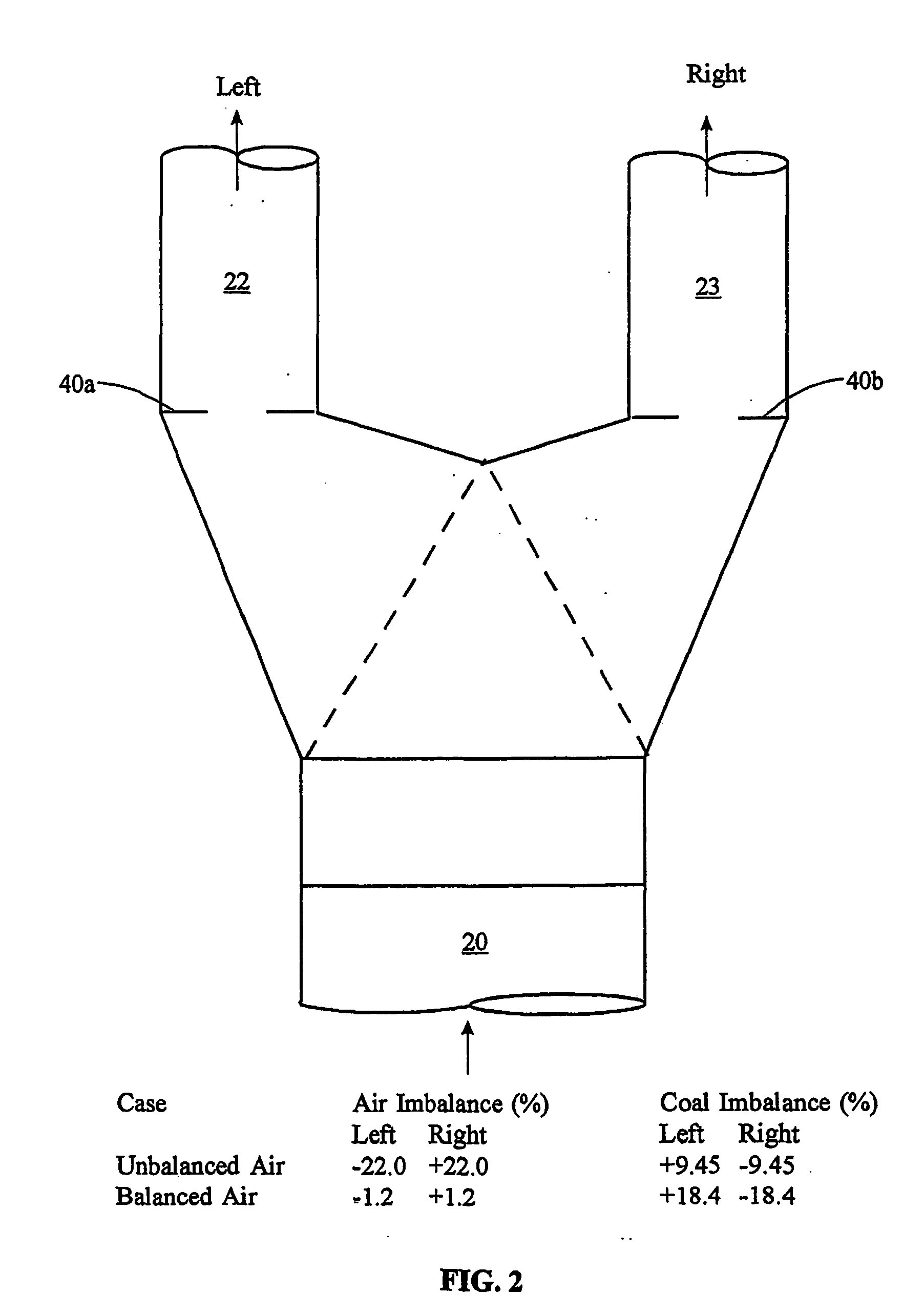

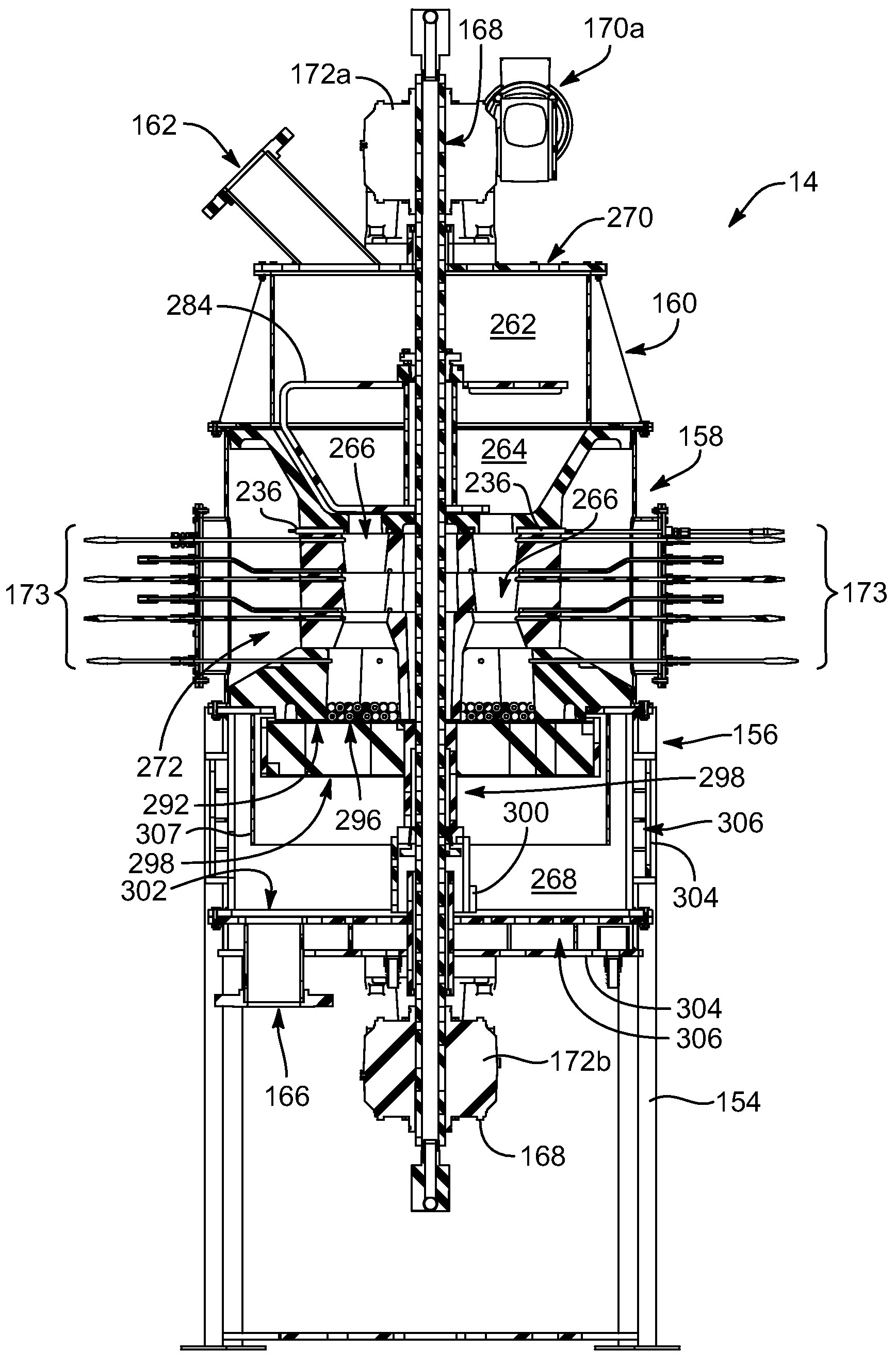

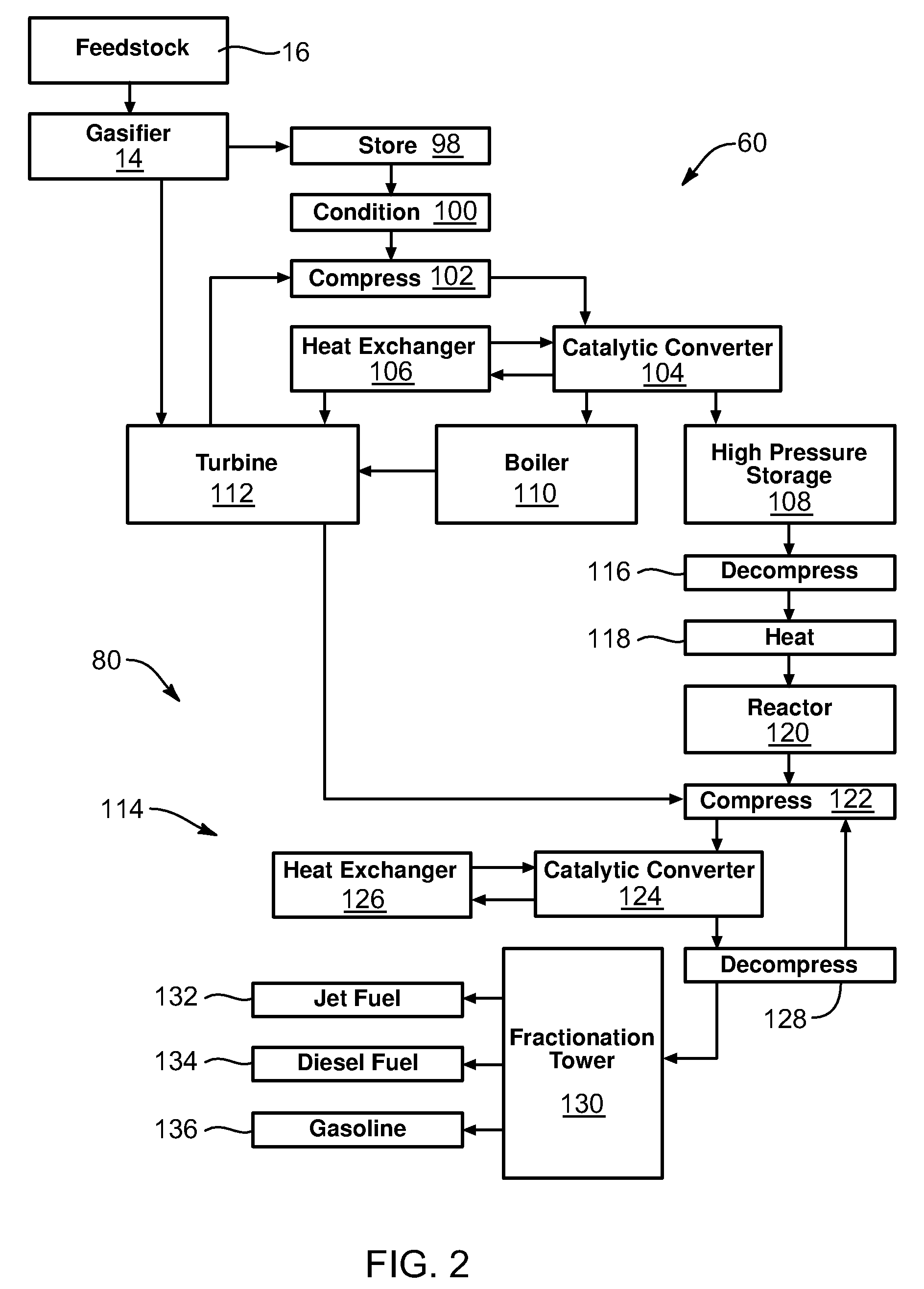

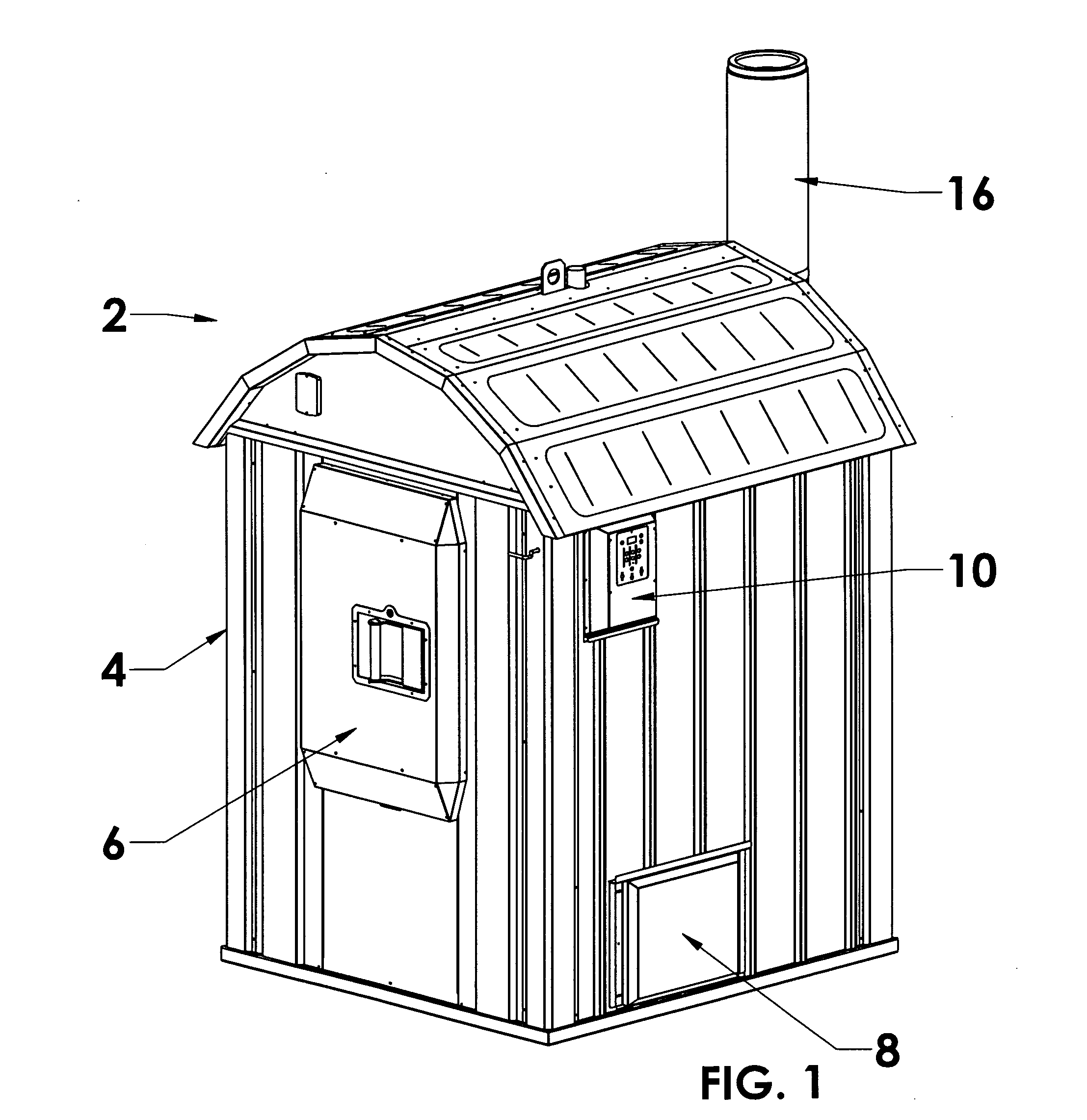

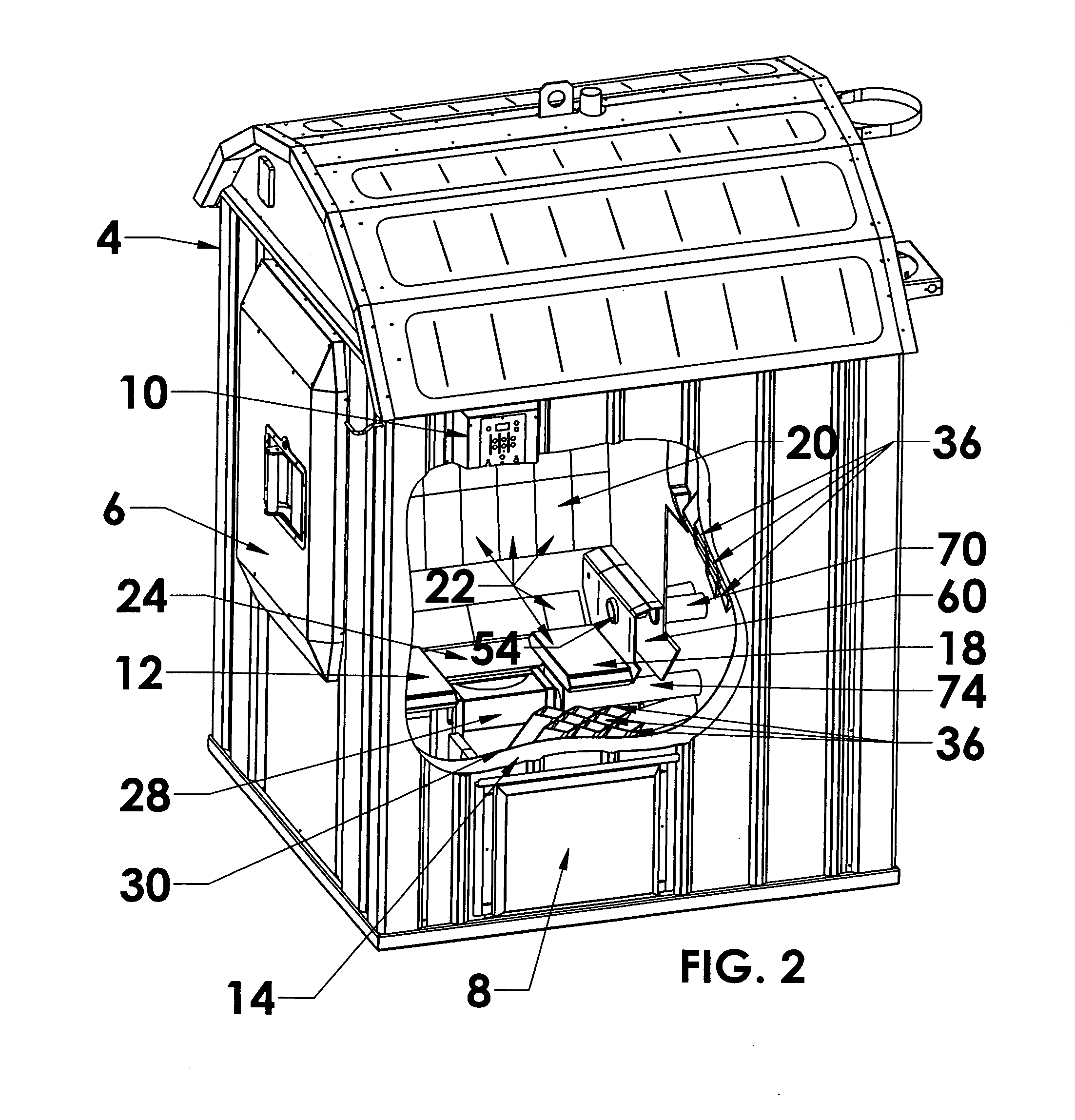

Gasifier and gasifier system for pyrolizing organic materials

InactiveUS7976593B2Lower buildCost of operationMuffle furnacesGasifier mechanical detailsMechanical engineeringEngineering

A gasifier and gasifier system based on the gasifier, which contains as a major component, a novel feed system for feeding organic materials into the burn pile of the gasifier. The gasifier feed system is a horizontal auger driven feed system that feeds directly through a ceramic elbow into the furnace without having to auger the feed through significant vertical elevations.

Owner:HEAT TRANSFER INT

Air inlet damper apparatus

InactiveUS20070044787A1Prevents uncontrolled intrusionAvoid problemsDomestic stoves or rangesCombustion valves/nozzle/pumpsCombustionCoupling

An air inlet damper apparatus for minimizing the entrance of outside air into a poultry house when the ventilation exhaust fans are running and the radiant tube heater is not operating. The apparatus has a housing with a passage and a coupling flange; a pin that spans the passage and divides the apparatus into a low pressure side and an outside high pressure side, where the low pressure side is in fluid communication with a blower supplying combustion air to the tube heater; a damper blade connected to the pin; a stop; and a means for controlling the damper blade. The controlling means is responsive to pressure. The damper blade pivotally opens away from the stop when there is a static pressure differential that is higher than the negative pressure created by the ventilation exhaust fans, or when the controlling means electromechanically actuates the damper blade.

Owner:GAS FIRED PRODS

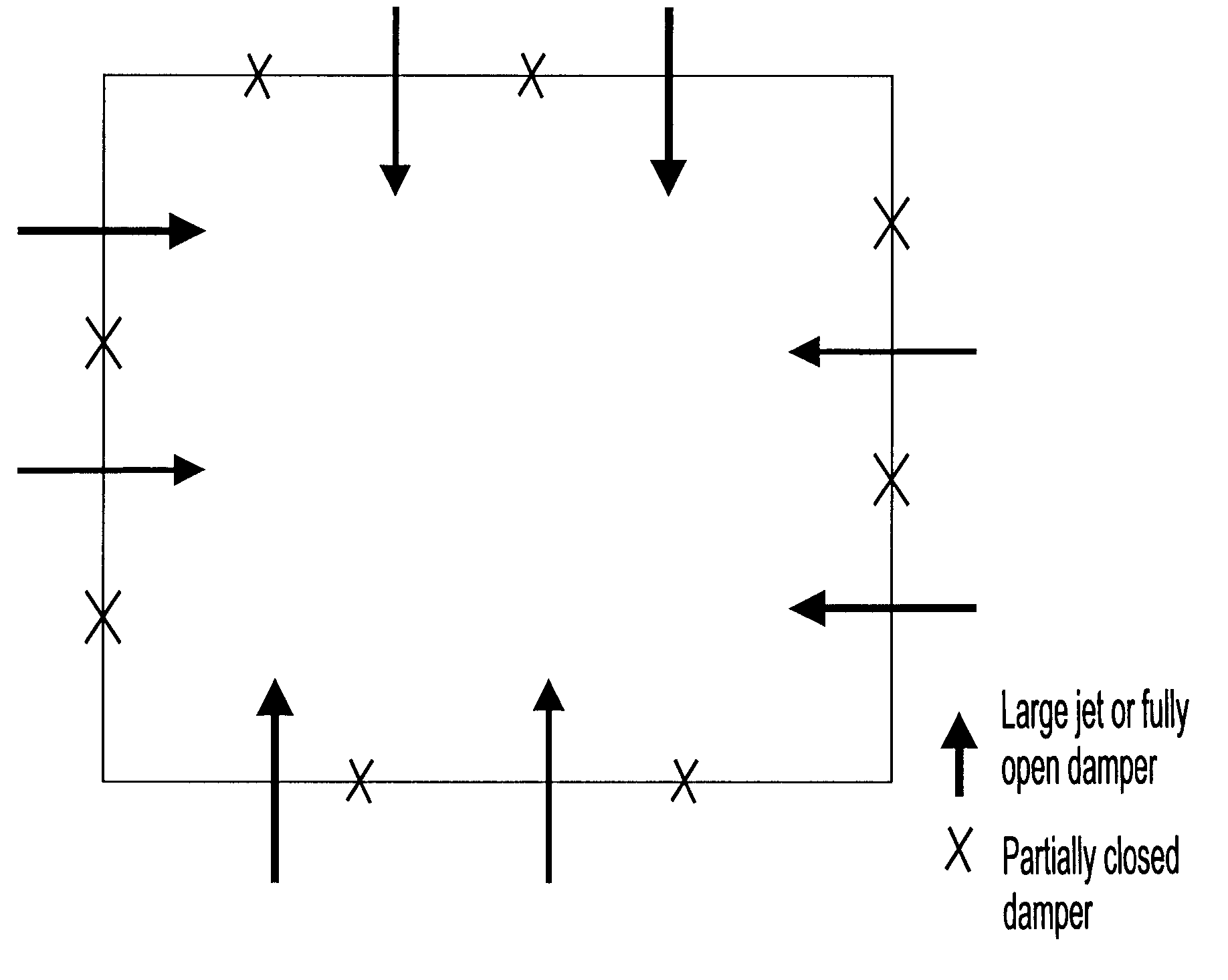

Method and apparatus for optimizing the combustion air system in a recovery boiler

InactiveUS6279495B1Improve boiler efficiencyAvoid costly modificationPulp liquors combustionSolid fuel combustionParticulatesChemical recovery

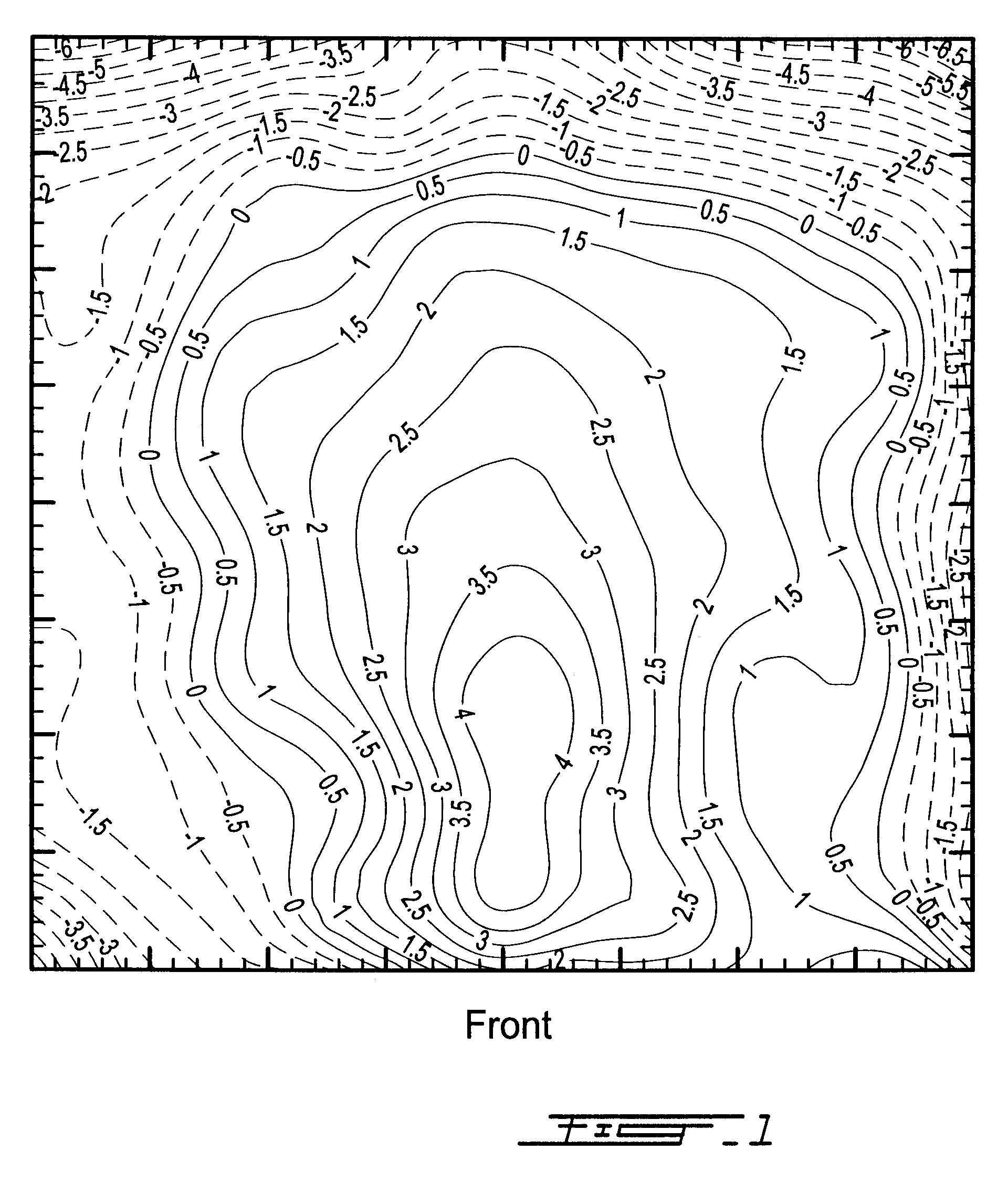

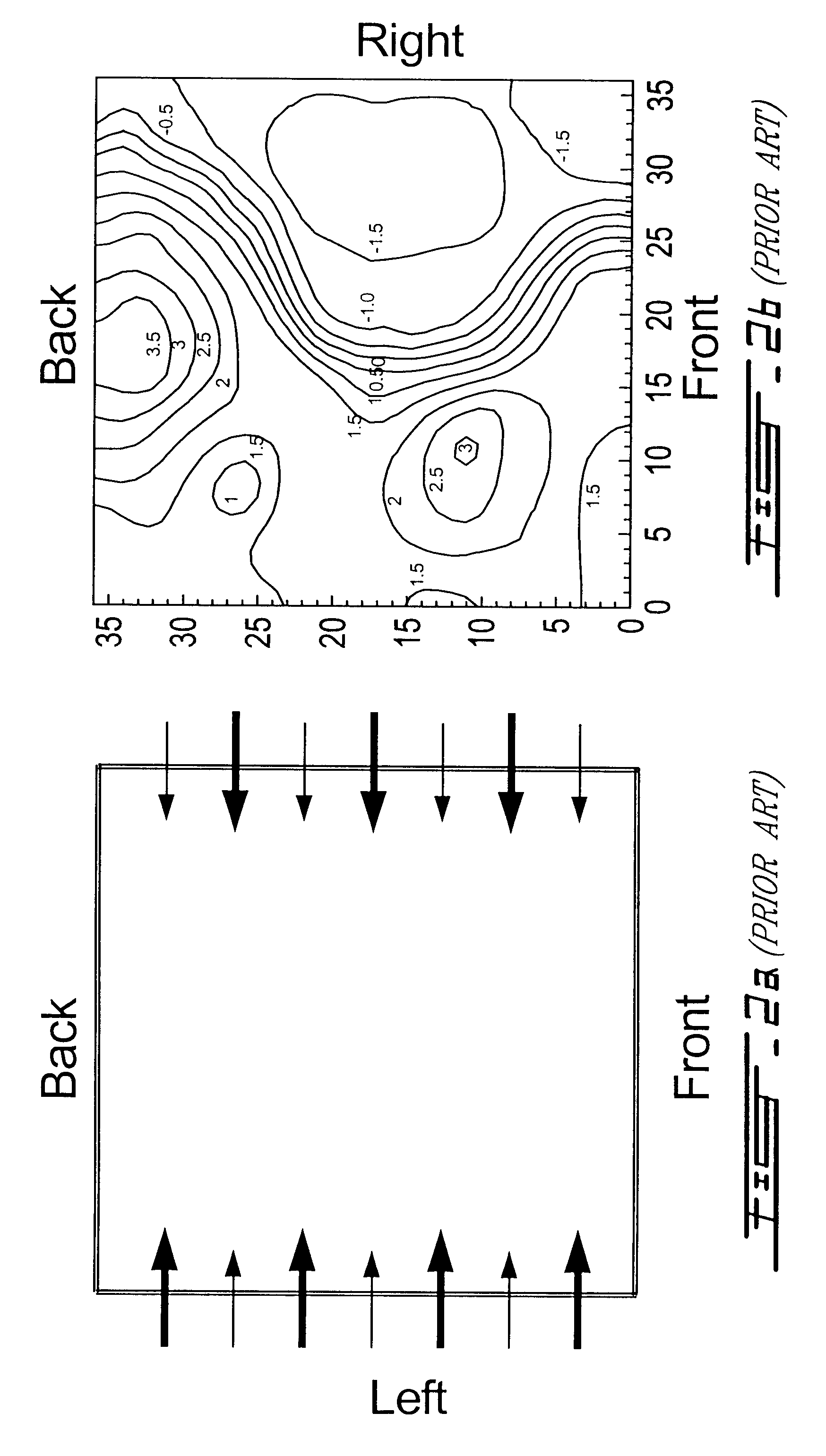

A method and an apparatus for optimizing the combustion air system in a power boiler or chemical recovery boiler by improving fluid flow and gas mixing are disclosed, whereby one can increase boiler capacity and combustion uniformity and reduce particulate and gaseous emissions. The method involves interlacing of the secondary and, where applicable, the tertiary air supply through opposing air ports on all four walls of the boiler, and is implemented by alternately opening wide or partially closing a port damper on one side, while partially closing or opening wide a port damper on the opposite side, such that a 70-100% open damper on one side opposes a partially closed (10-40% open) damper on the other and vice versa in an alternating fashion, along opposing walls. In a preferred embodiment, the optimization is further enhanced by balancing primary air flow, achieved by adjusting port dampers and windbox pressures so that the primary air flow is evenly distributed between opposite walls, between all four walls of the boiler and between individual airports on each wall. Windbox pressure and other key measurements of boiler operation ensure proper balancing and an adequate interlacing of air flows at the primary, secondary and tertiary elevations, respectively.

Owner:FPINNOVATIONS INC

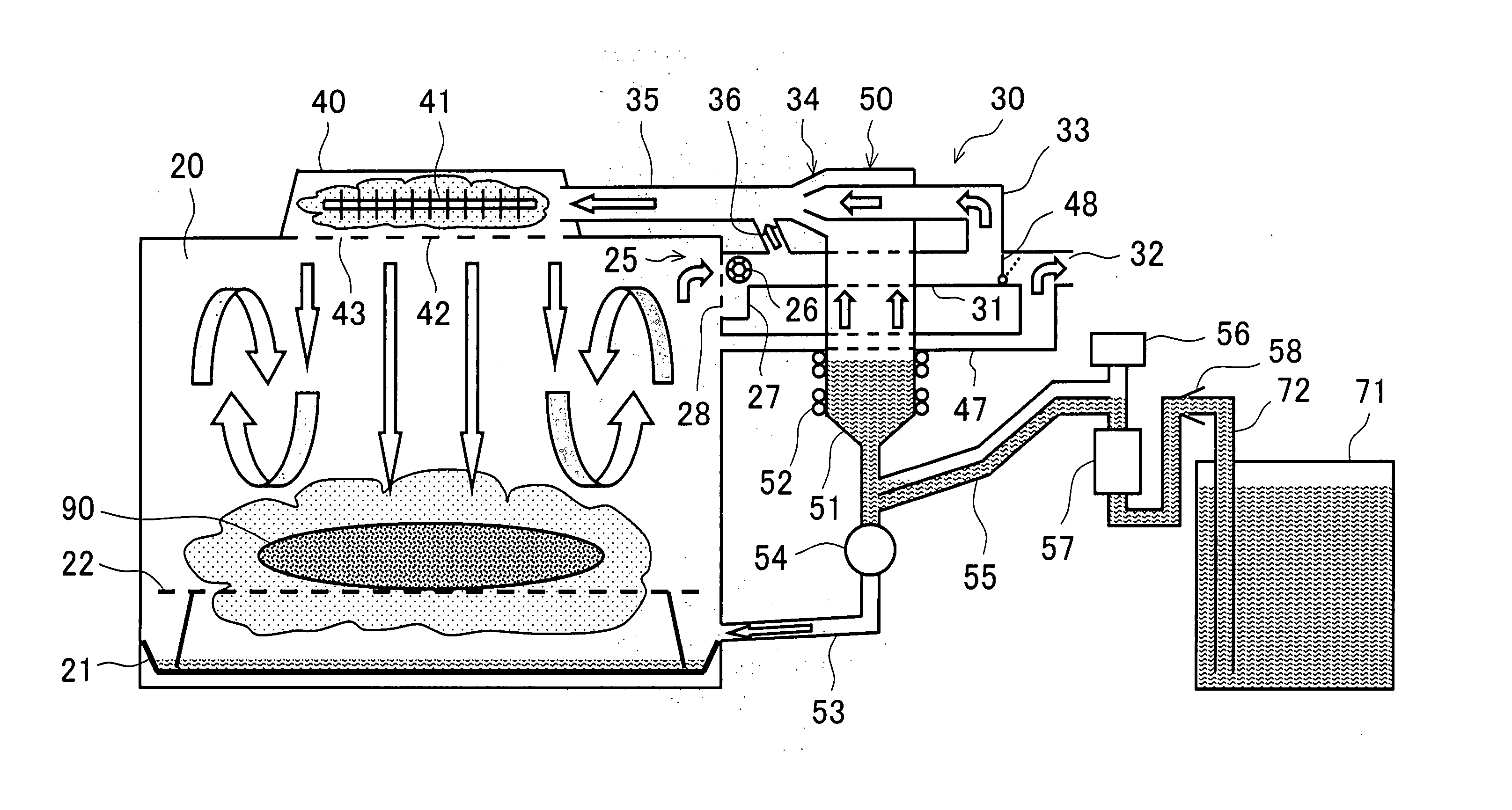

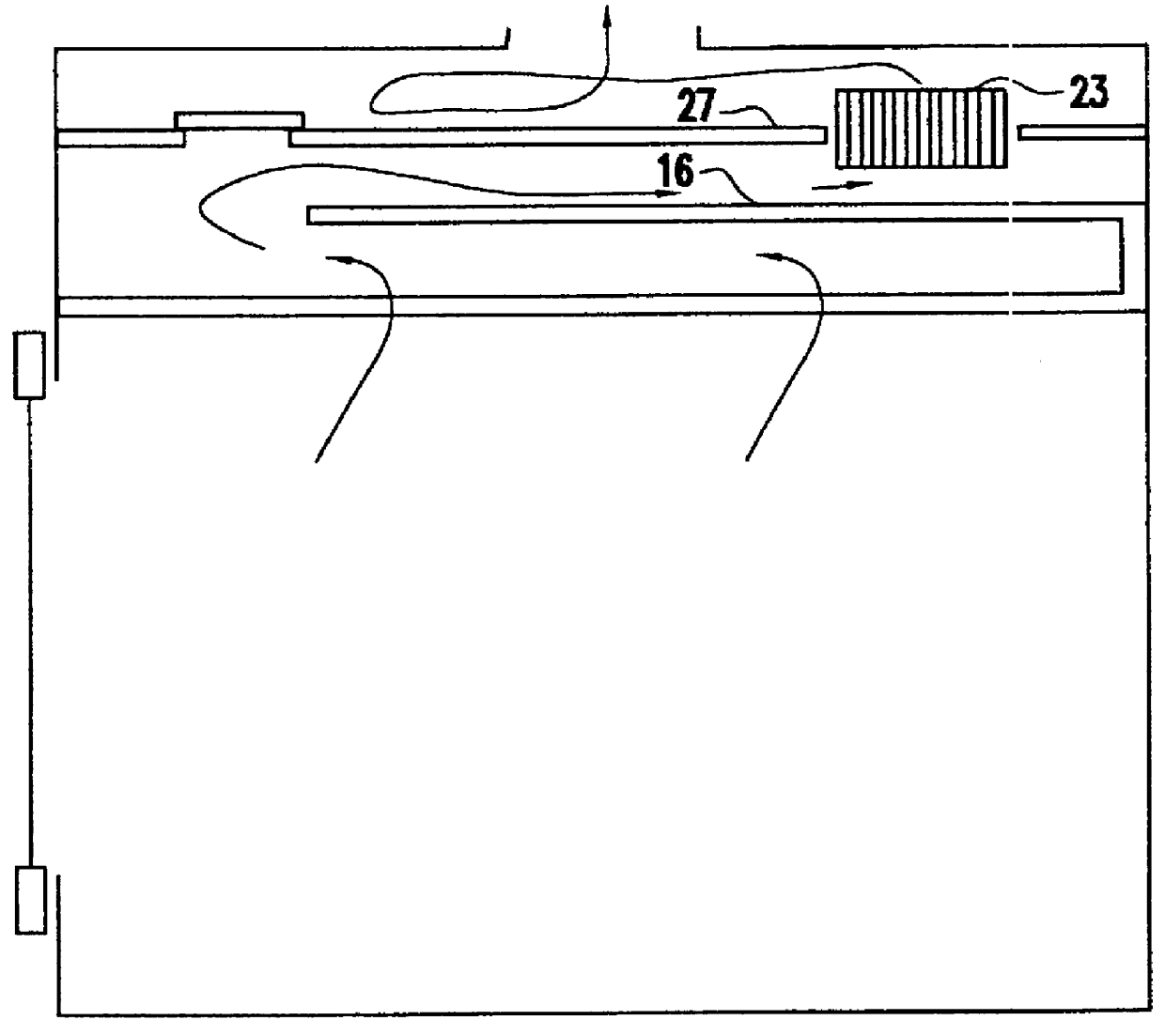

Humidifier with swingable cover

InactiveUS6588734B2Easy accessEasy constructionMixing methodsUsing liquid separation agentWater flowSump

The humidifier includes a cabinet having a rear wall, a front wall, a pair of side walls, a bottom wall and a sump defined in part by the walls at the bottom of the cabinet. The cabinet has in the interior thereof means providing communication with an air system. Retainer ears are provided on the outer surfaces of the side walls near the top thereof. An evaporator pad is mounted in the cabinet adjacent and parallel to the rear wall. A water distribution trough is disposed in the interior of the cabinet adjacent the rear wall and is located above the evaporator pad for providing a substantially uniformly distributed flow of water to the evaporator pad. A pair of mounting elements are provided on the inner surfaces of the side walls near the bottom thereof. A swingable cover is provided for opening and closing the cabinet and has a top end and a bottom end. The cover at the bottom end is provided with a pair of bearing portions which are engageable with and pivotally mounted on the mounting elements. Fastening means are secured to the sides of the top end of the cover and are engageable with the retainer ears when the cabinet is closed. The cover when the fastening means are disengaged from the retainer ears being swingable relative to the mounting elements for opening the cover to permit access to the evaporator pad and to the interior of the cabinet.

Owner:GENERAL FILTERS

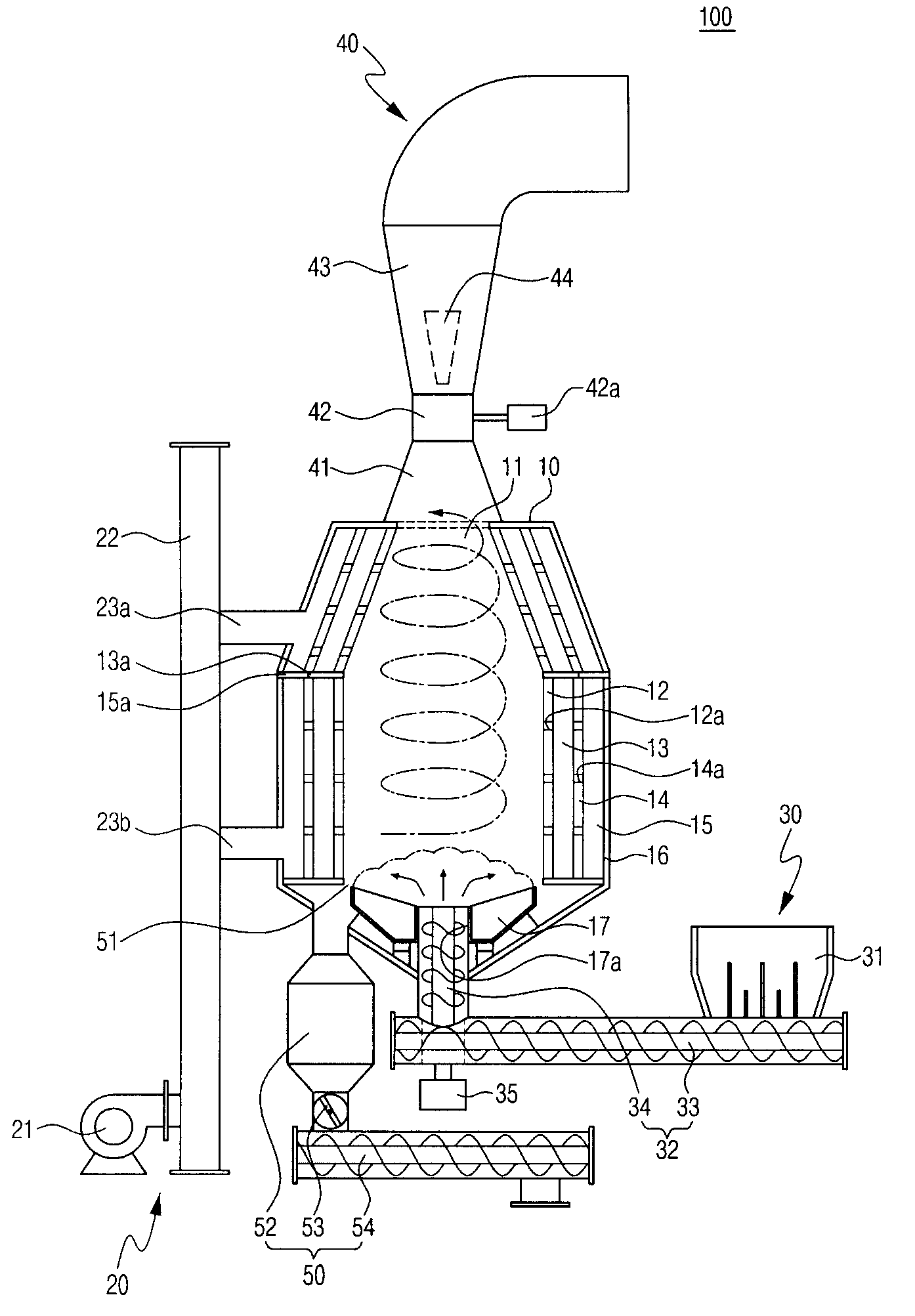

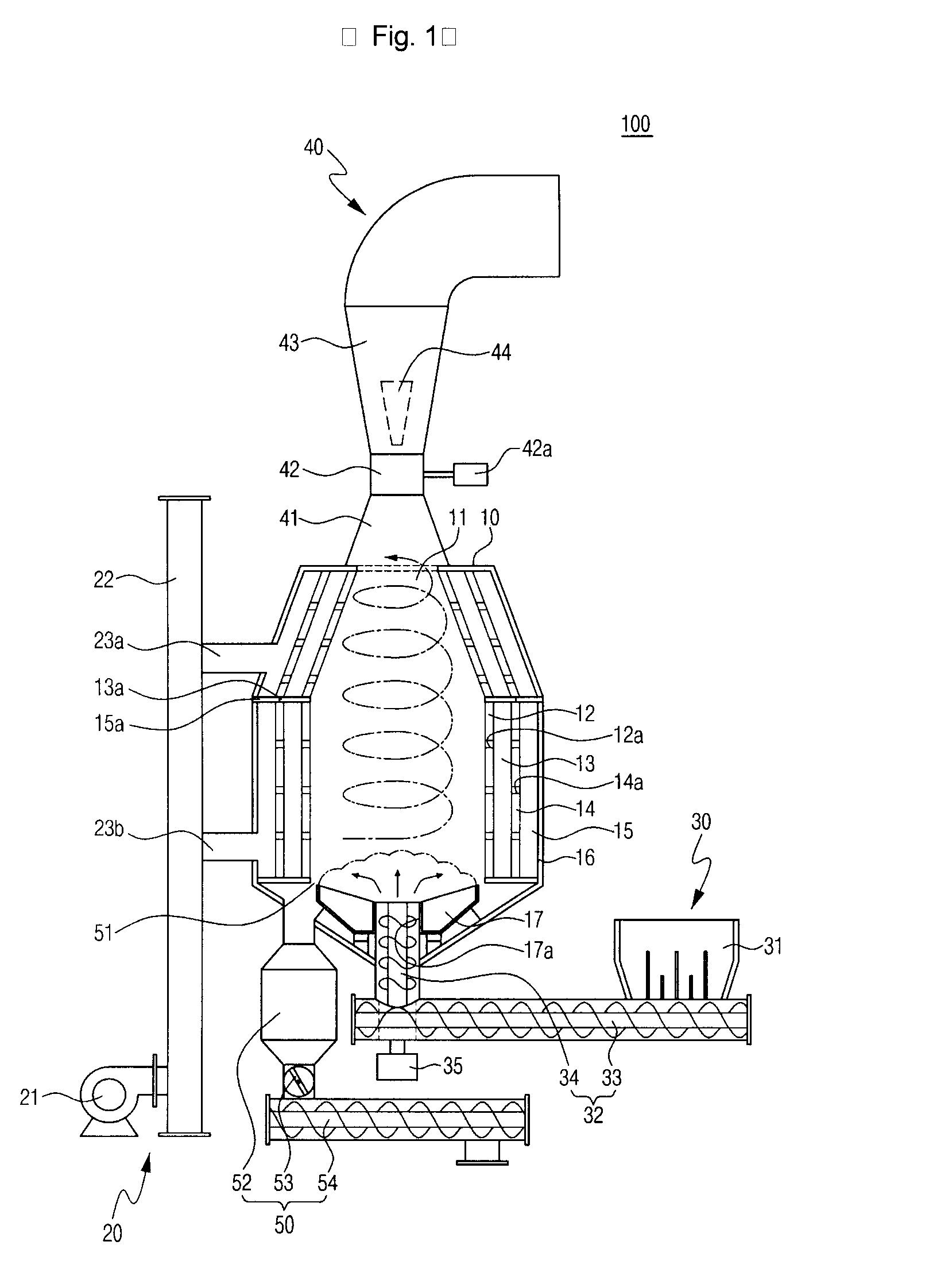

Combustion Apparatus For Recovering Heat

InactiveUS20090126607A1Low costReduce generationPulverulent fuel combustion burnersDamper arrangementCombustion chamberHeat losses

A combustion apparatus for recovering heat according to the present invention comprising a combustion tank for burning fuel contained in the interior by combustion air supplied from the exterior, characterized in that: a combustion chamber surrounded by an inner wall for burning fuel is defined in said combustion tank; a swirl flow supply chamber for supplying a combustion air into said combustion chamber is defined around the outer circumference of the inner wall of said combustion tank; a combustion air supply passage for supplying combustion air from said swirl flow supply chamber into said combustion chamber is defined on the inner wall of said combustion tank; said combustion air supply passage is slanted at a predetermined angle to the vertical direction of the inner face of the inner wall in said combustion tank; and the combustion air generates a swirl flow in the combustion chamber. Furthermore, the combustion apparatus for recovering heat according to the invention characterized in that; an air cooling chamber for supplying combustion air supplied from the exterior into said swirl flow supply chamber is defined around the outer circumference of said swirl flow supply chamber in said combustion tank, and the combustion air supplied from the exterior is supplied through said cooling chamber into the swirl flow supply chamber to decrease a heat loss and to improve a thermal efficiency.

Owner:ENERONE

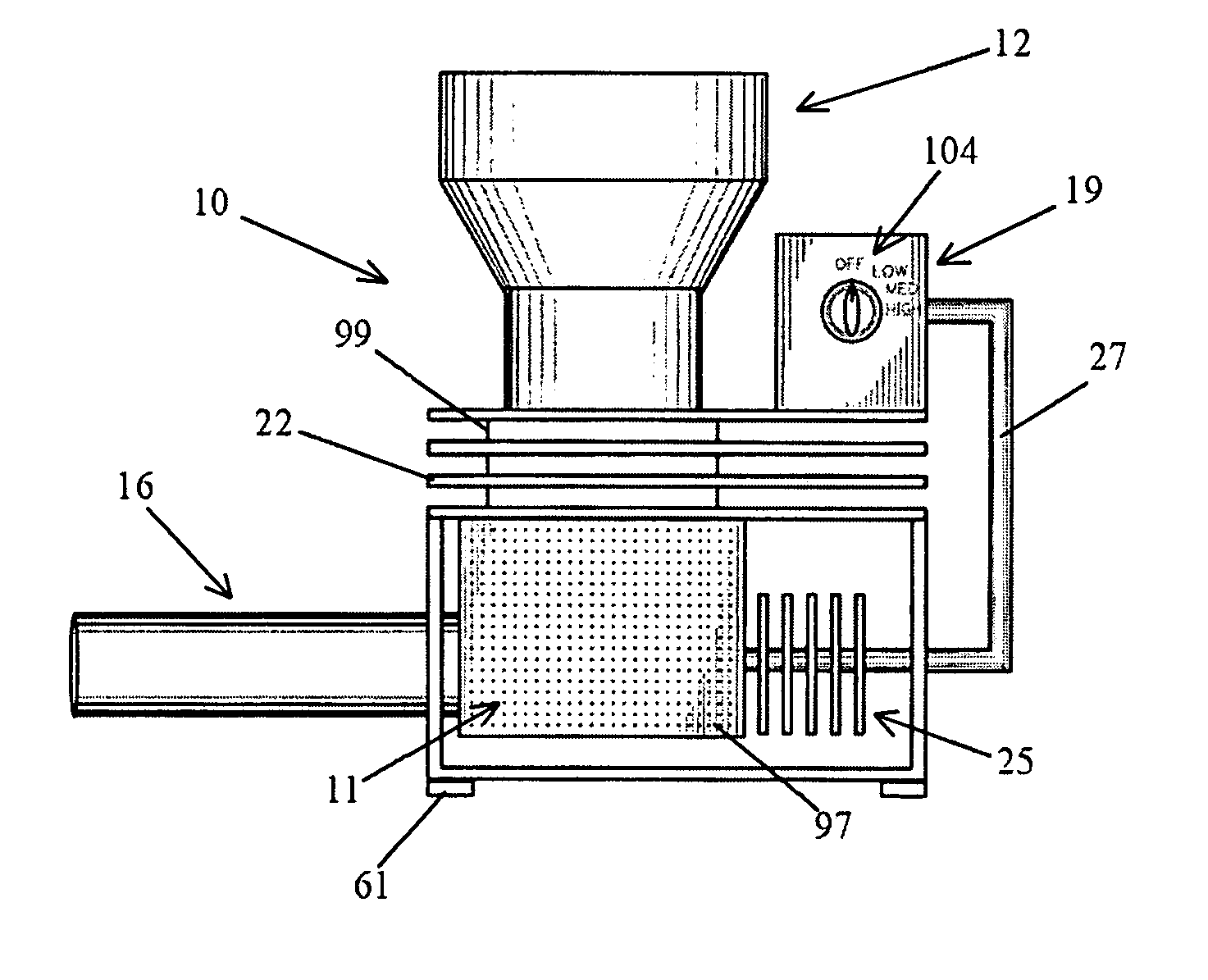

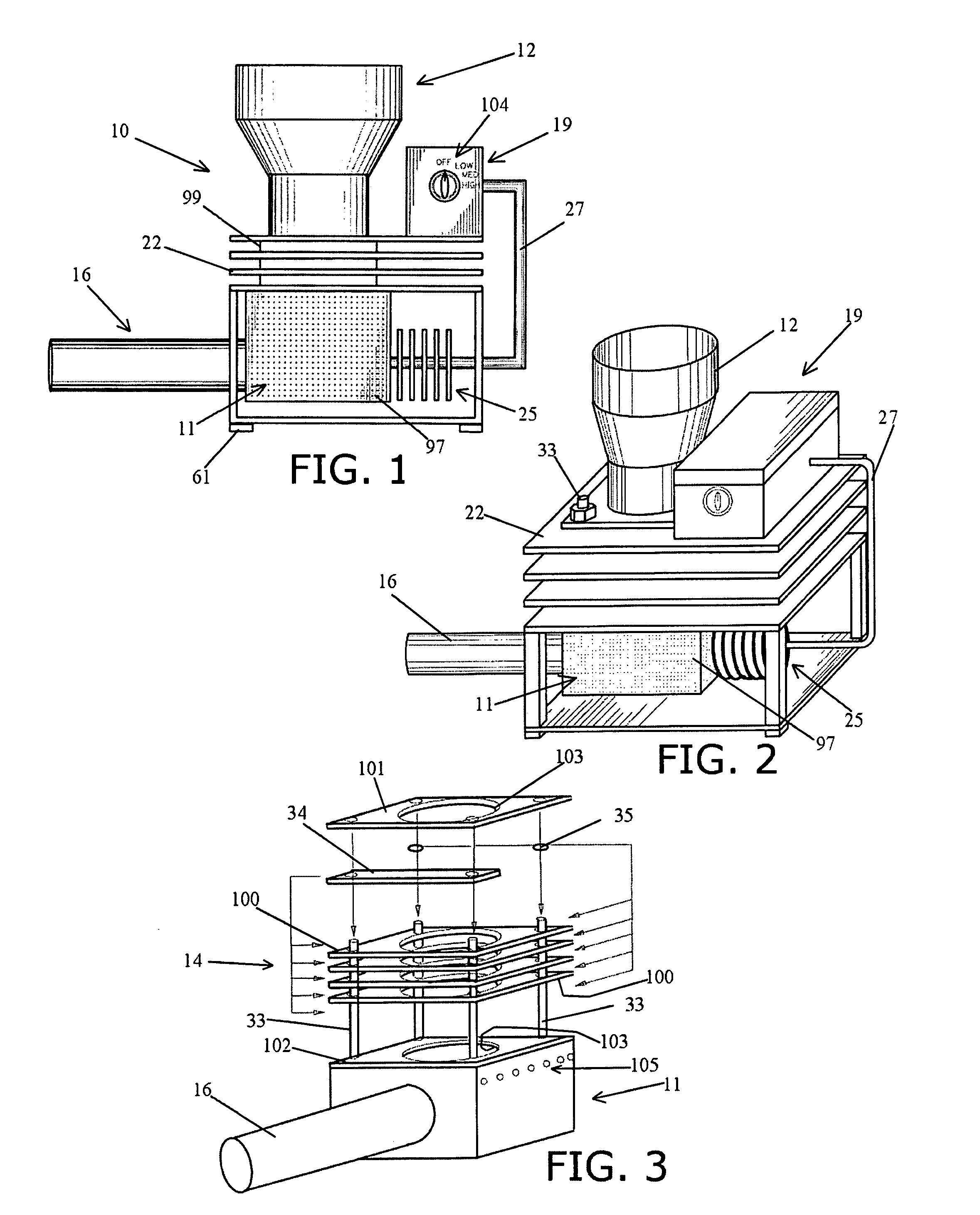

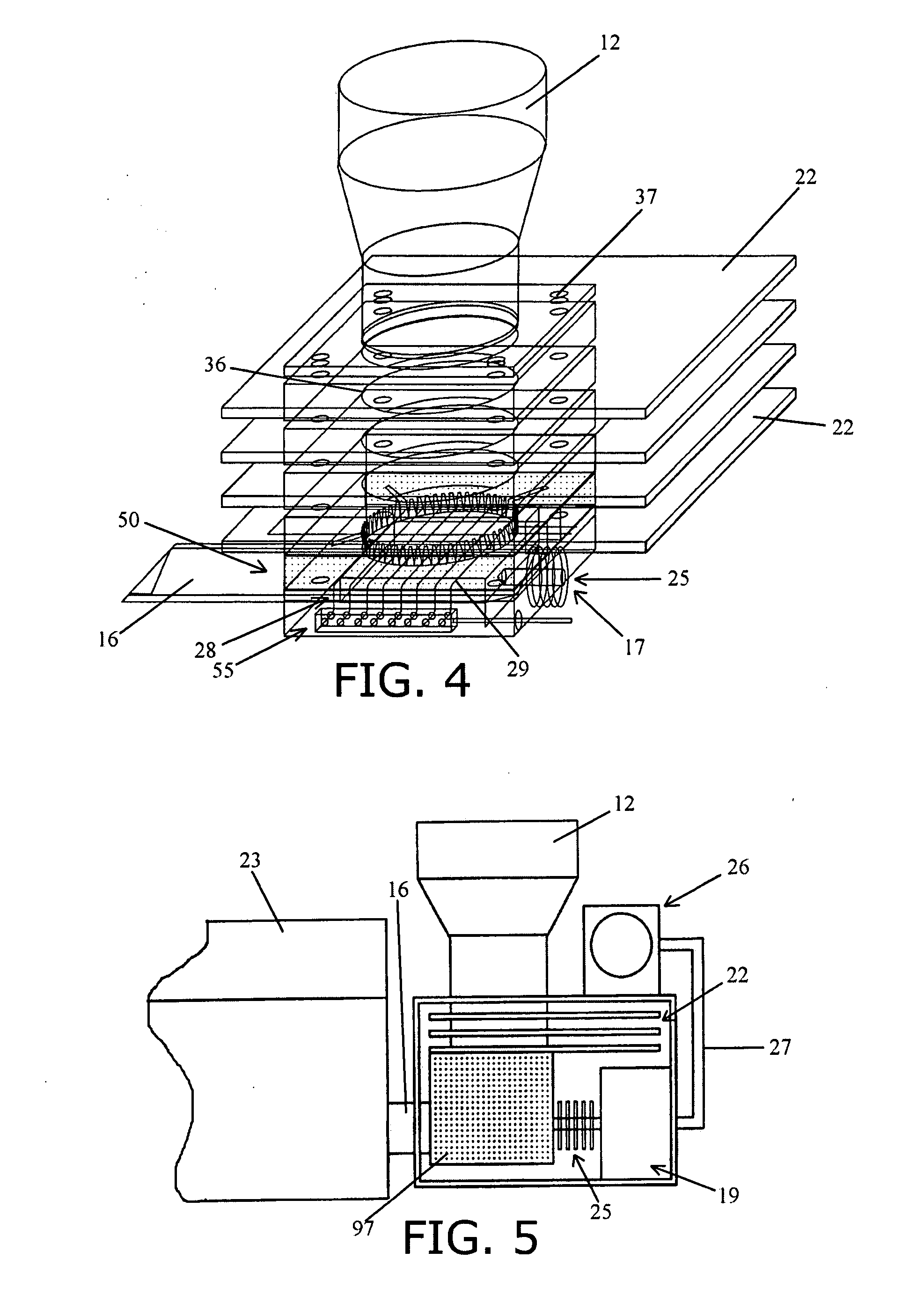

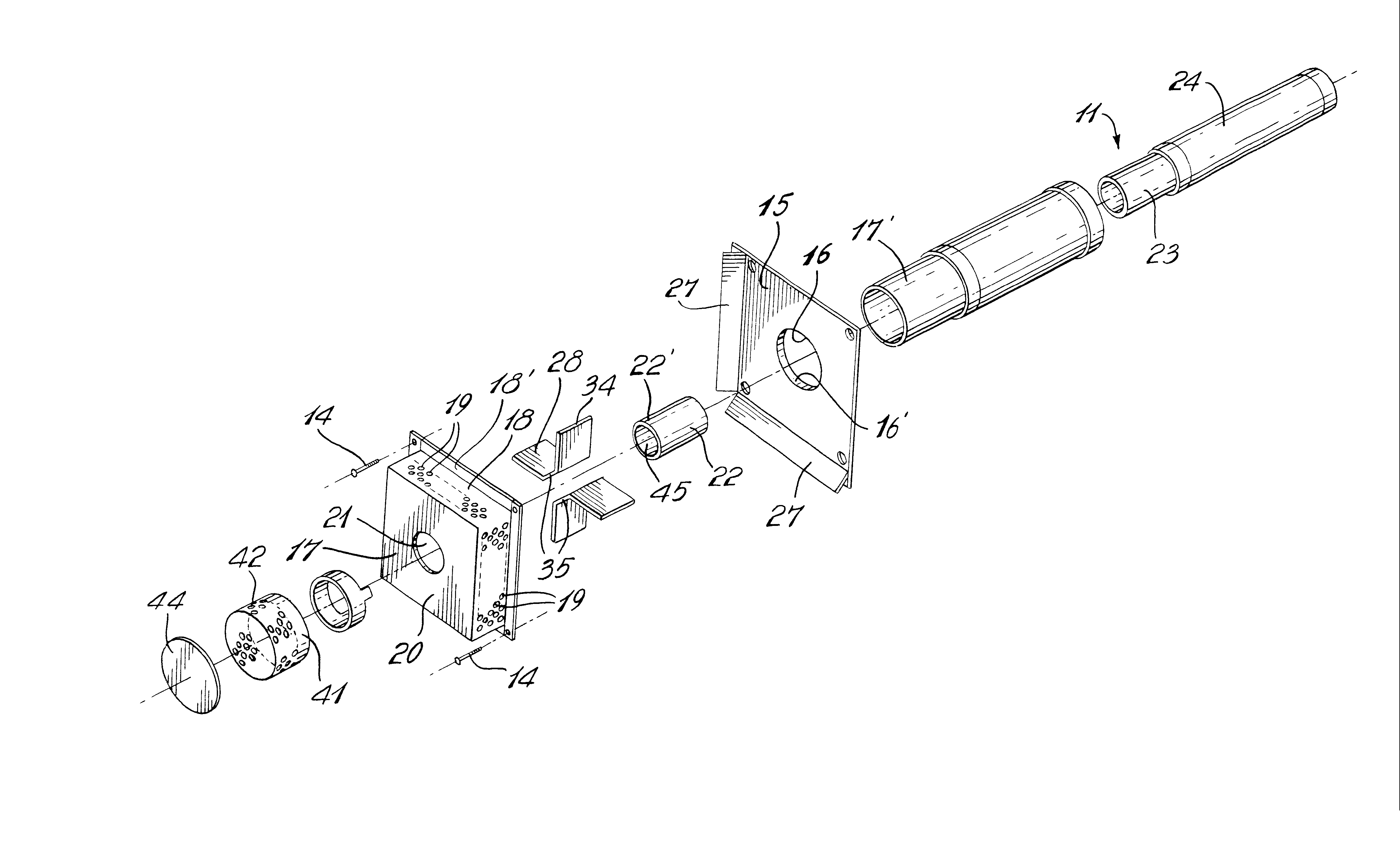

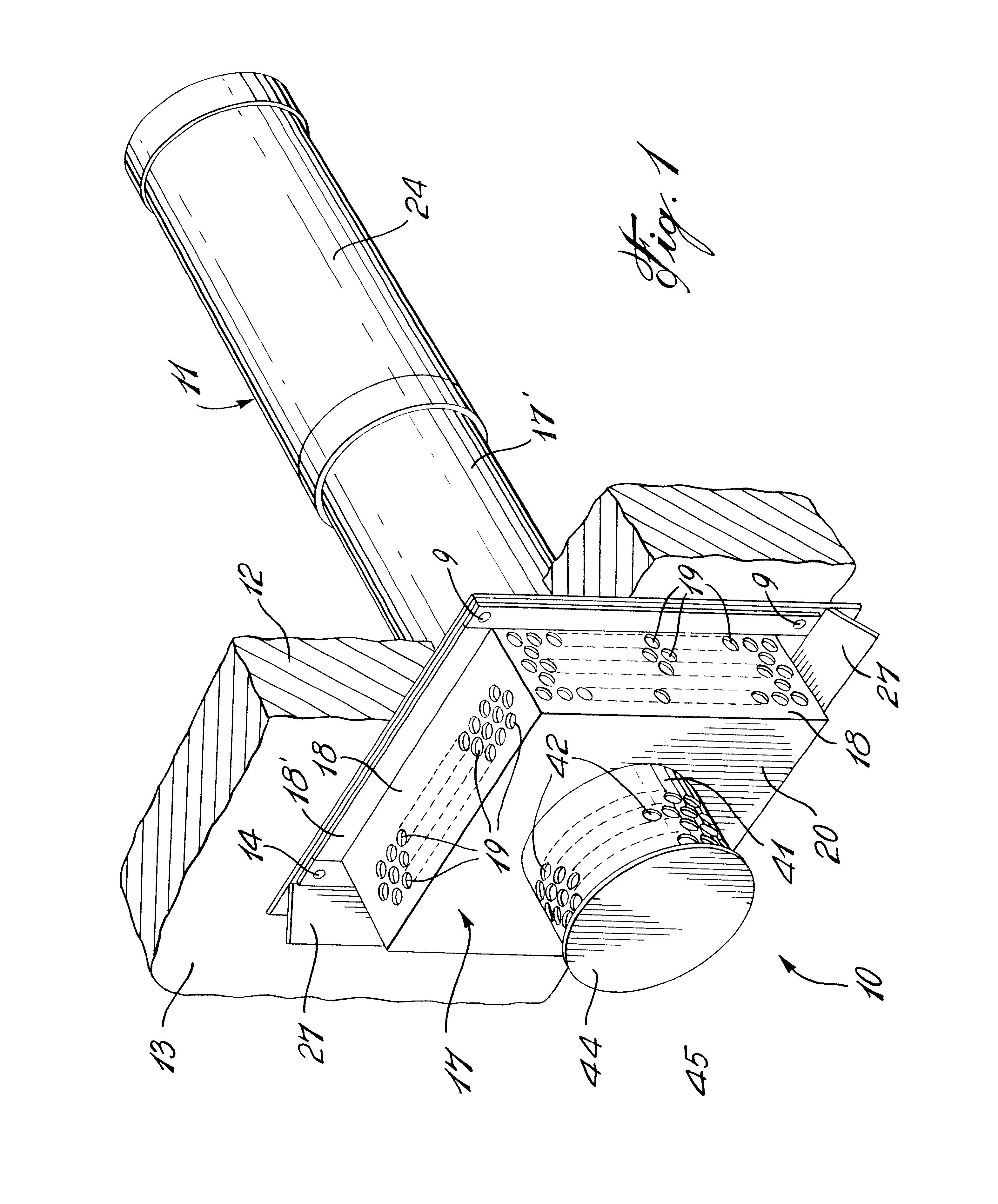

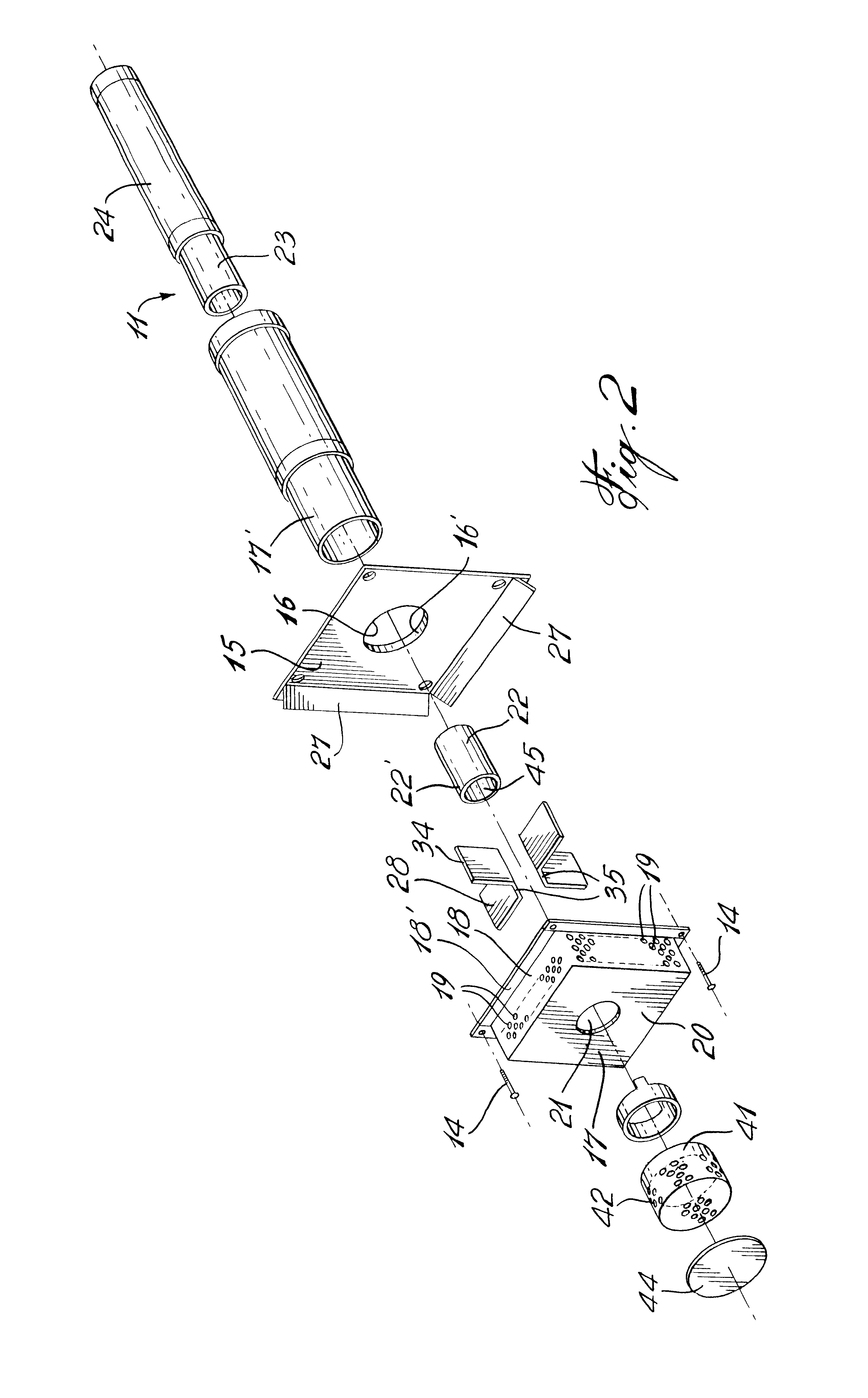

Pellet burning heating assembly

ActiveUS20080060632A1Low costShort cooking timeStoves/ranges with convection heatingCombustion-air/flue-gas circulation for stovesAtmospheric airWood gas

A portable pellet fired heating element for mounting to a grill or stove and comprising a gravity fed pellet holder, a unitary tubular structure having a burner, an air intake and an exhaust chute. Fuel may be supplied to the pellet holder by various supply means such as a conveyer, ramp, scooped, held in bulk in a hopper, and like pellet supply structures and methods. Fuel is fed to the air-cooled insulated burner area onto a decomposer grate, which defines the primary combustion area and which is partially open to the atmosphere for air intake. An adjustable high-pressure flow of gas or vapor is introduced to the primary exhaust chute below the decomposer grate to create a low pressure flow above the grate and which upon ignition, cause flames to be pulled into the pellet mass on the grate. In operation, air from the primary air intake maintains hot charcoal in the primary combustion area, and the secondary combustion area provides a steady flow of wood gas that mixes with a predetermined or adjustable amount of air supplied by the secondary air intake to maintain the flame. The super heated gasses and any ash are provided to the grill or stove by means of the exhaust chute. For cleaning purposes, an electrical / mechanical device may be provided to move the decomposer grate or to provide a sudden burst of high gas pressure.

Owner:GRILLSON

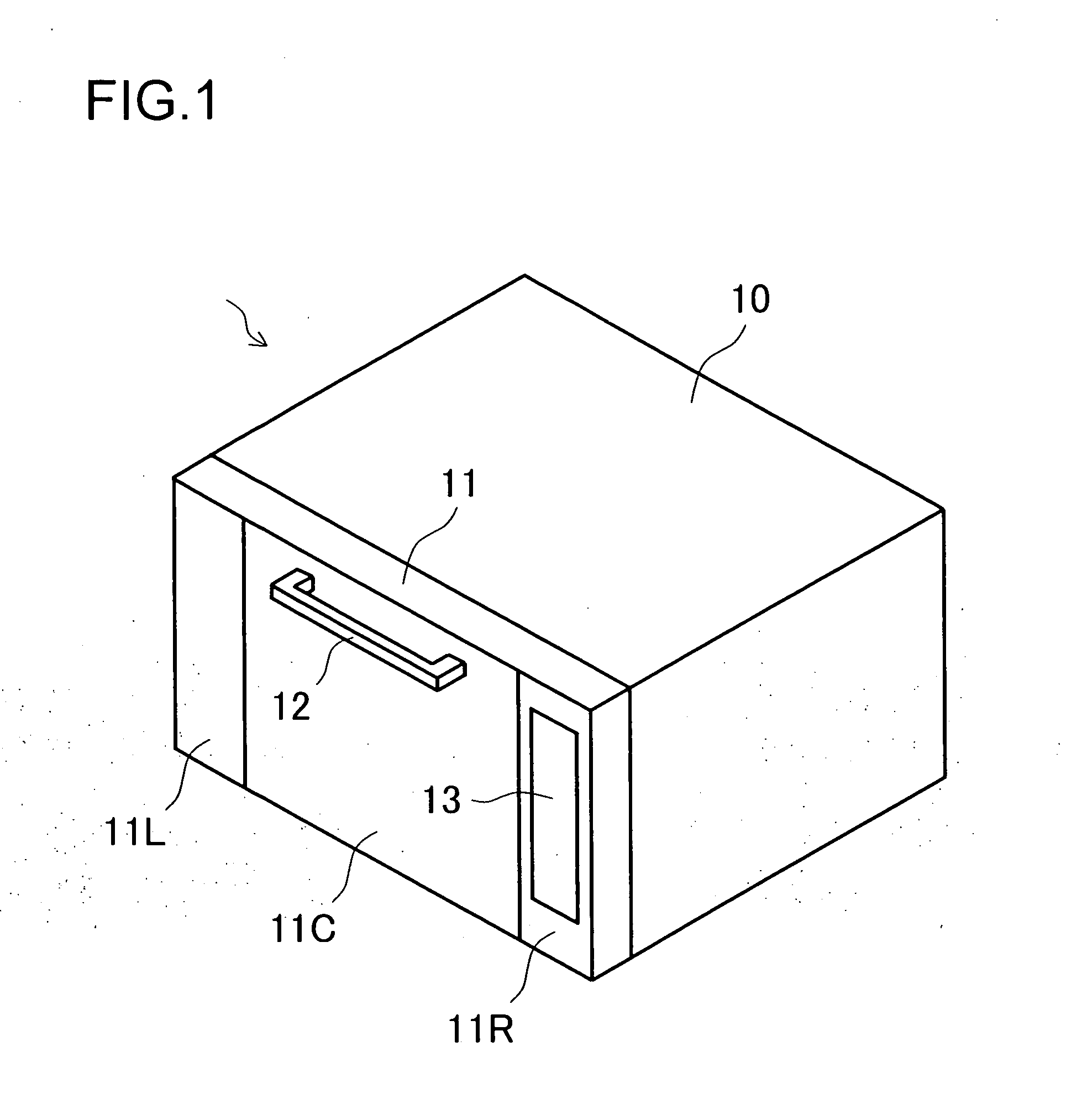

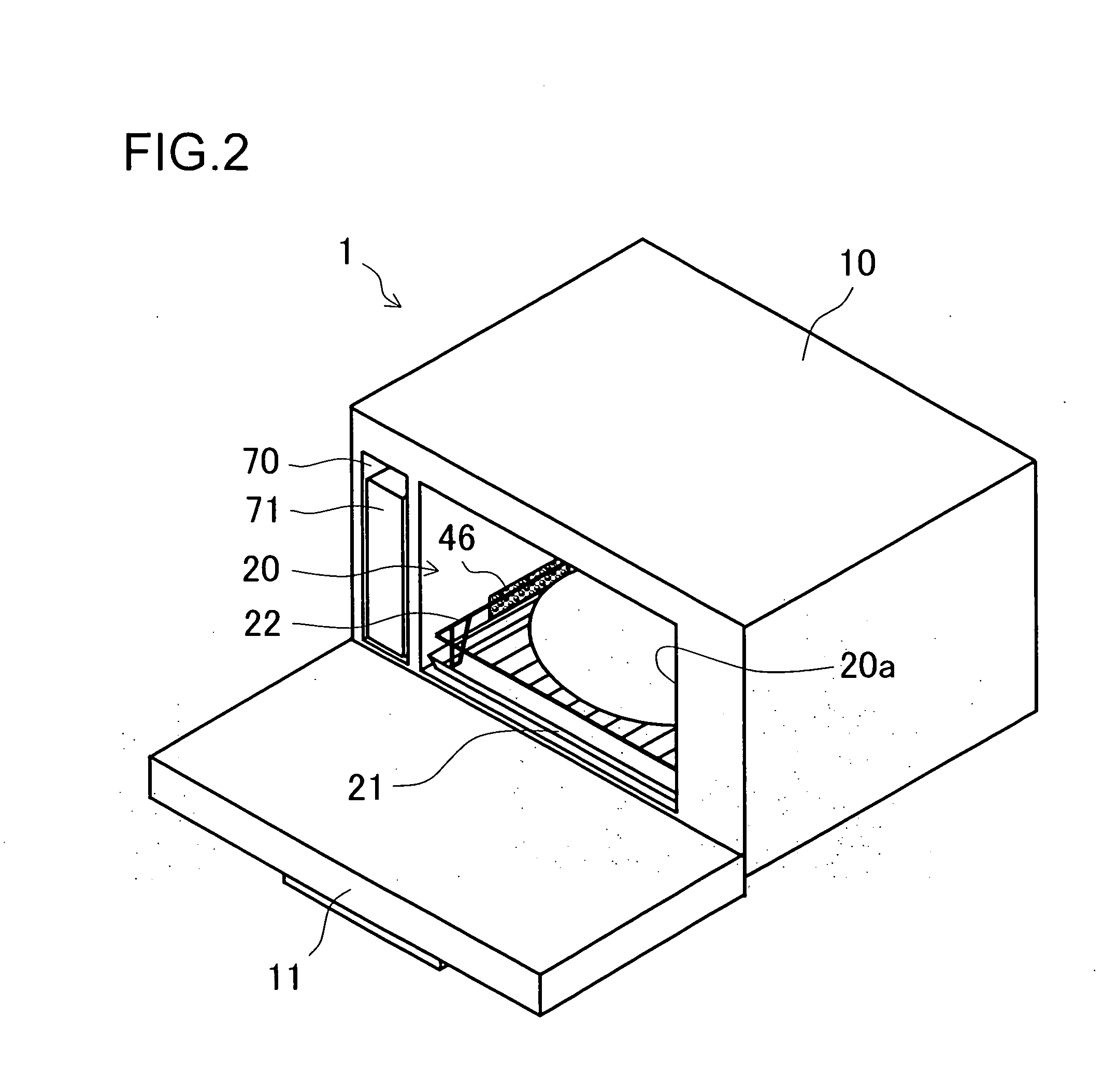

Heat-cooking apparatus

InactiveUS20070163567A1Reduce the temperatureImprove efficiencyAir-treating devicesDoors for stoves/rangesEngineeringHigh heat

Owner:SHARP KK

Damper baffle for a coke oven ventilation system

InactiveUS20090032385A1Fuel supply regulationCombustible gas coke oven heatingVehicle frameCoke oven

The damper baffle includes a U-shaped sub-frame and a temperature resistant insulation damper mat draped over and secured upright to the sub-frame for use in the ventilation system of a coke oven. The damper mat is a thick sheet of silica needle mat, which provides the thermal barrier of the damper baffle. The sub-frame is a bent high temperature steel rod which is bolted directly to the base plate of a conventional lift frame and lift mechanism. Two pairs of support plates secure and support the mat over the sub-frame in an upright orientation. The damper baffle seeks to provide a light-weight damper baffle for use in coke ovens, which eliminates the need for the heavy and cumbersome refractory baffle blocks.

Owner:ENGLE BRADLEY G

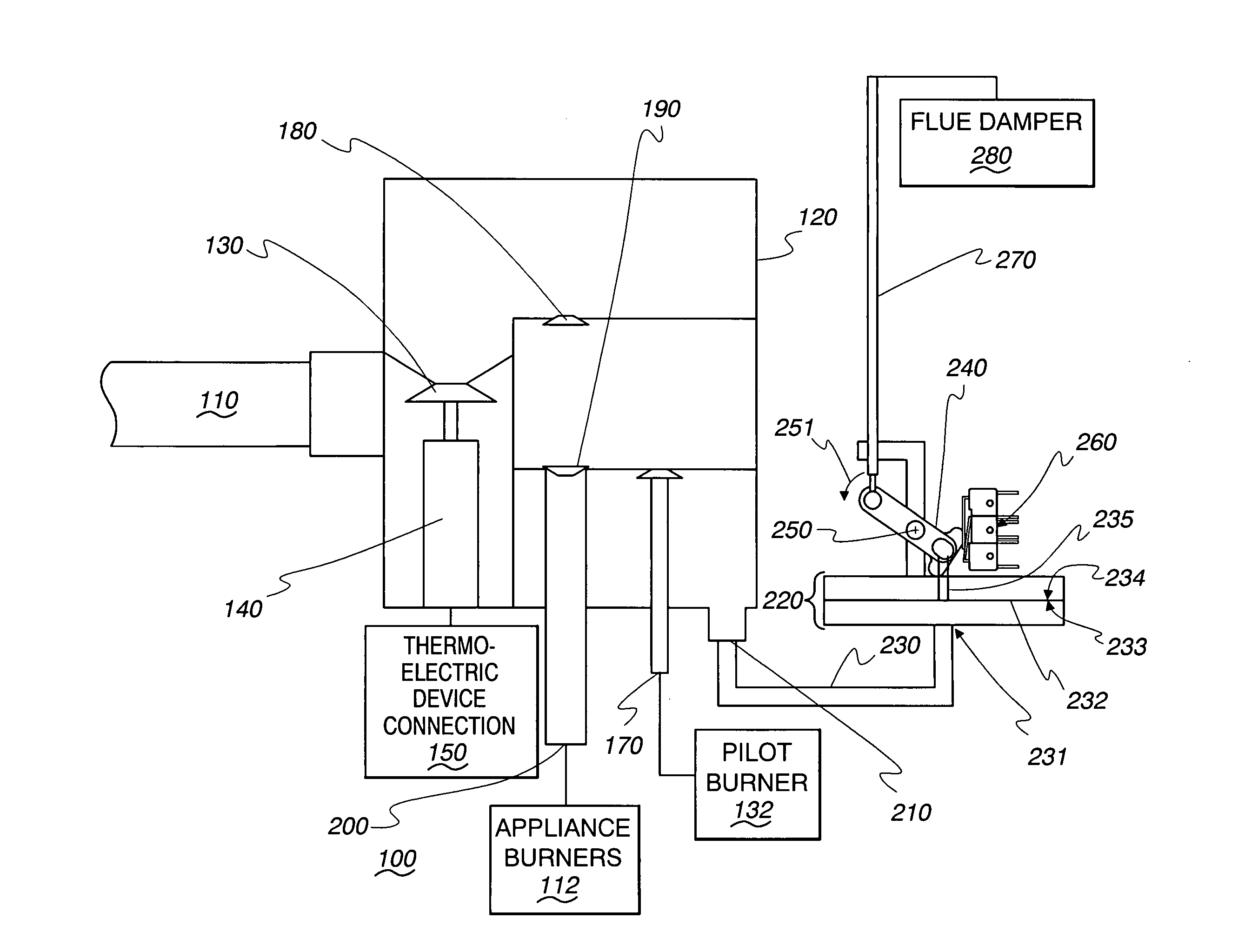

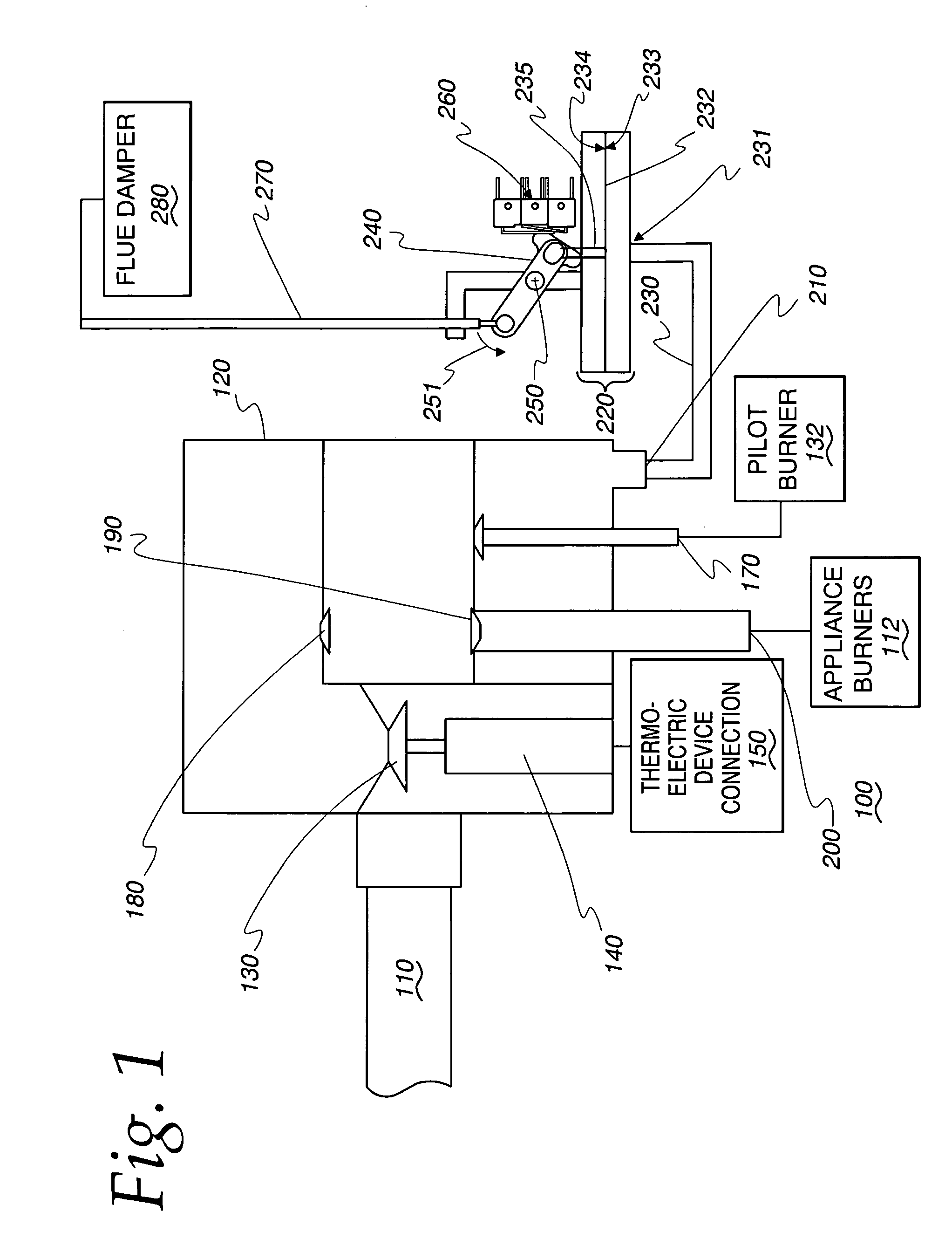

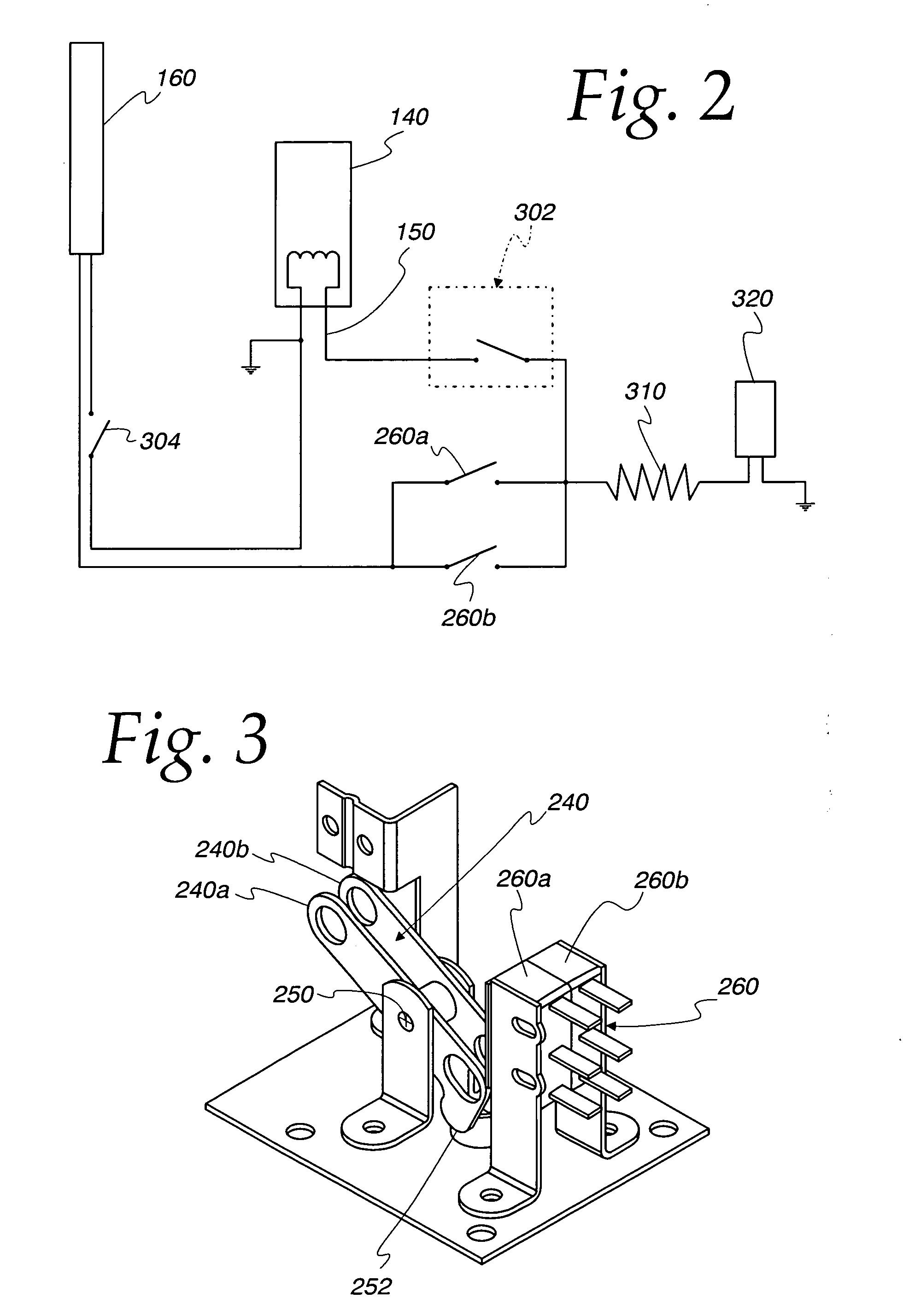

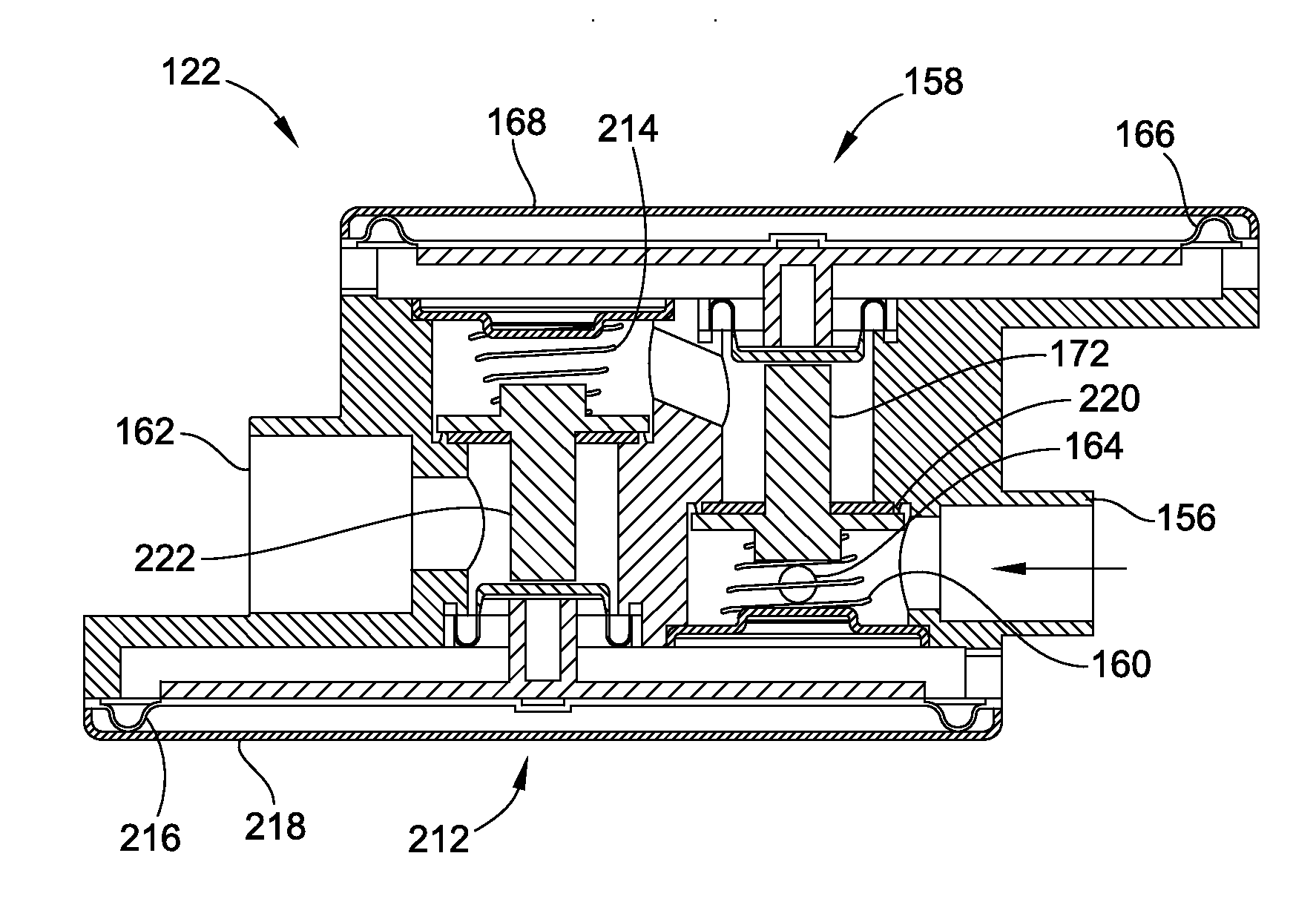

Apparatus and method for controlling a damper in a gas-fired appliance

A damper mechanism for a gas-fired appliance is disclosed. The damper mechanism is mechanically operated in response to changes in pressure within a portion of the appliance. Changes in gas pressure operate to displace a diaphragm, thereby moving a linkage attached to a flue damper, such that the damper can be moved between open and closed positions. An interim damper control activation arm can pivot in response to movement of the linkage to actuate electrical switches, which act to close a magnetic pilot valve when the damper is in a partially-opened or partially-closed position.

Owner:FIELD CONTROLS

Apparatus and method of automatically regulating intake of air into heating unit

InactiveUS6041771ACounteracting forceDischarge cleaningCombustion-air/flue-gas circulation for stovesCheck valvesCombustion chamberGas pressure

This invention relates to a novel apparatus and method for automatically and dynamically regulating the intake of air into the combustion chamber of a heating unit such as a wood burning stove, furnace, or fireplace to ensure even and efficient burning of fuel. More particularly, this invention pertains to a method and apparatus that uses negative gas pressure in the heating unit's flue, and no additional temperature or pressure sensors, to automatically and dynamically control a damper regulating intake of air into the combustion chamber in inverse relation to changes in negative flue gas pressure. This method and apparatus are especially useful in combination with a heating unit having two combustion chambers, one chamber for combustion of solid fuel and a second chamber for further combustion of exhaust gases and other byproducts from combustion in the first chamber. The two-stage combustion in a dual chamber heating unit is an especially dynamic situation where traditional static controls are not very effective.

Owner:HAYES CECIL JOSEPH

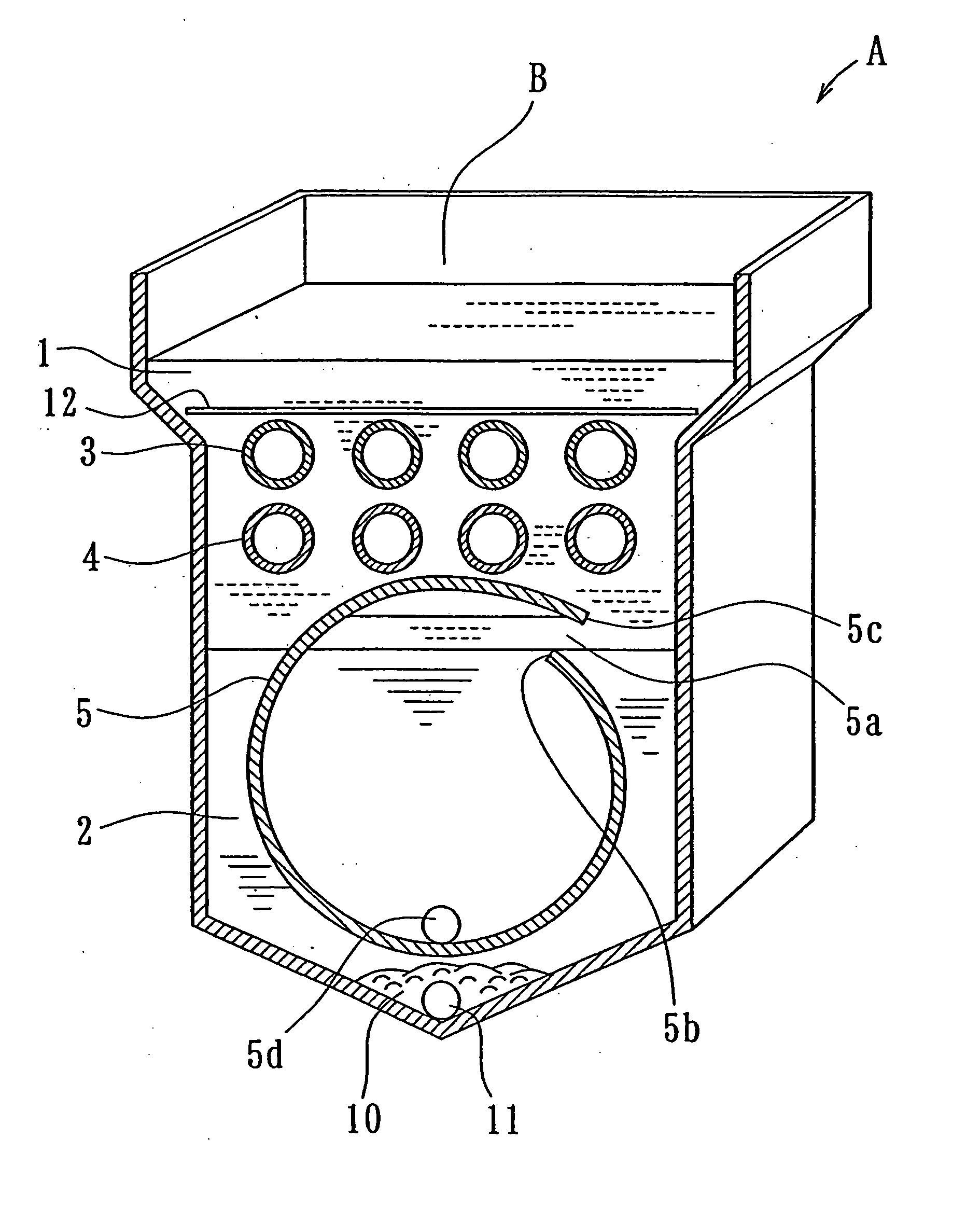

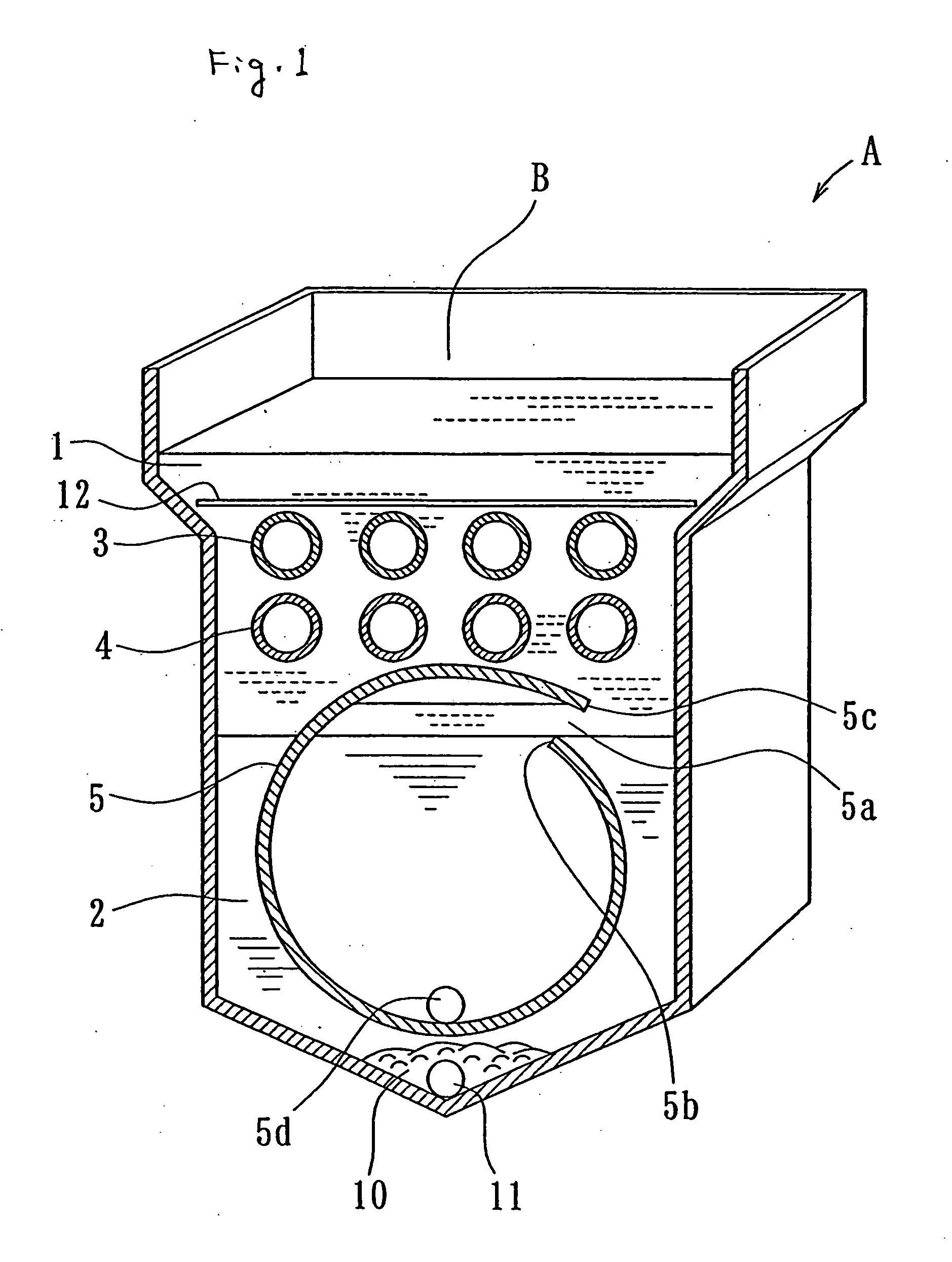

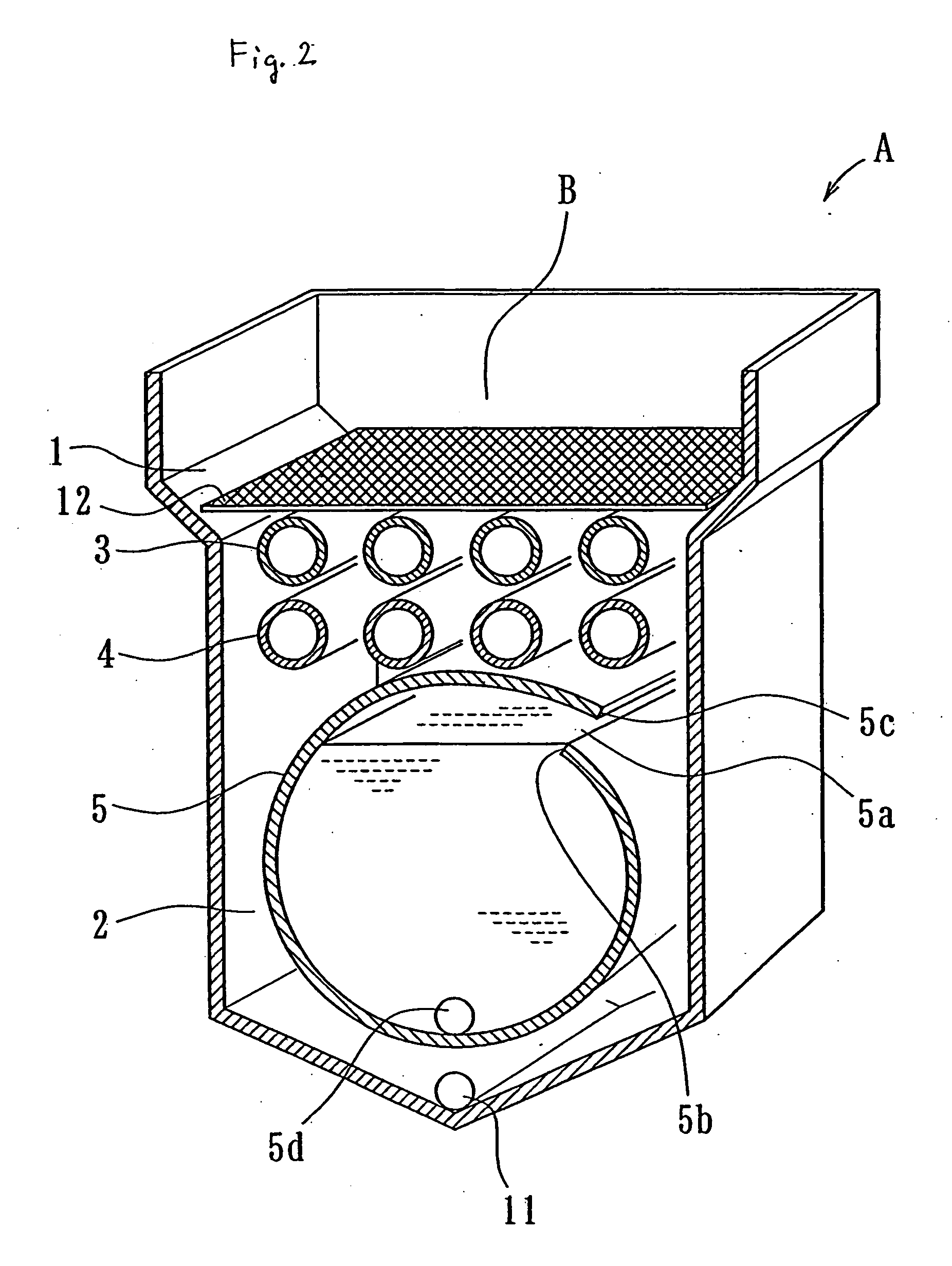

Food fryer

ActiveUS20050252506A1Easy to operateRepeat usageBoiling over preventionDamper arrangementFuel tankIngested food

A food fryer allowing a fried food tank to be safely and efficiently cleaned, wherein an opening part (5a) is formed in the side upper part of an oil storage tank (5) so that an upper end part (5c) covers a lower end part (5b) a cock (5d) is installed at the bottom part of the tank, the opening part (5a) is positioned near a boundary between an oil tank area (1) and a water tank area (2), a cover part is not provided for the opening part, after a food frying operation is completed, first oil in the oil tank area (1) is stored in the oil storage tank (5) through the opening part (5a) by the opening and closing operation of the cock (5d) and then a cock (11) is opened to drain the oil from those portions other than the oil storage tank of the fried food tank (B), and the tank is cleaned, and when the next frying operation is started, the oil in the oil storage tank (5) is moved to the oil tank area (1) due to a difference in gravity between the oil and water by merely feeding the water into the fried food tank (B).

Owner:SATO

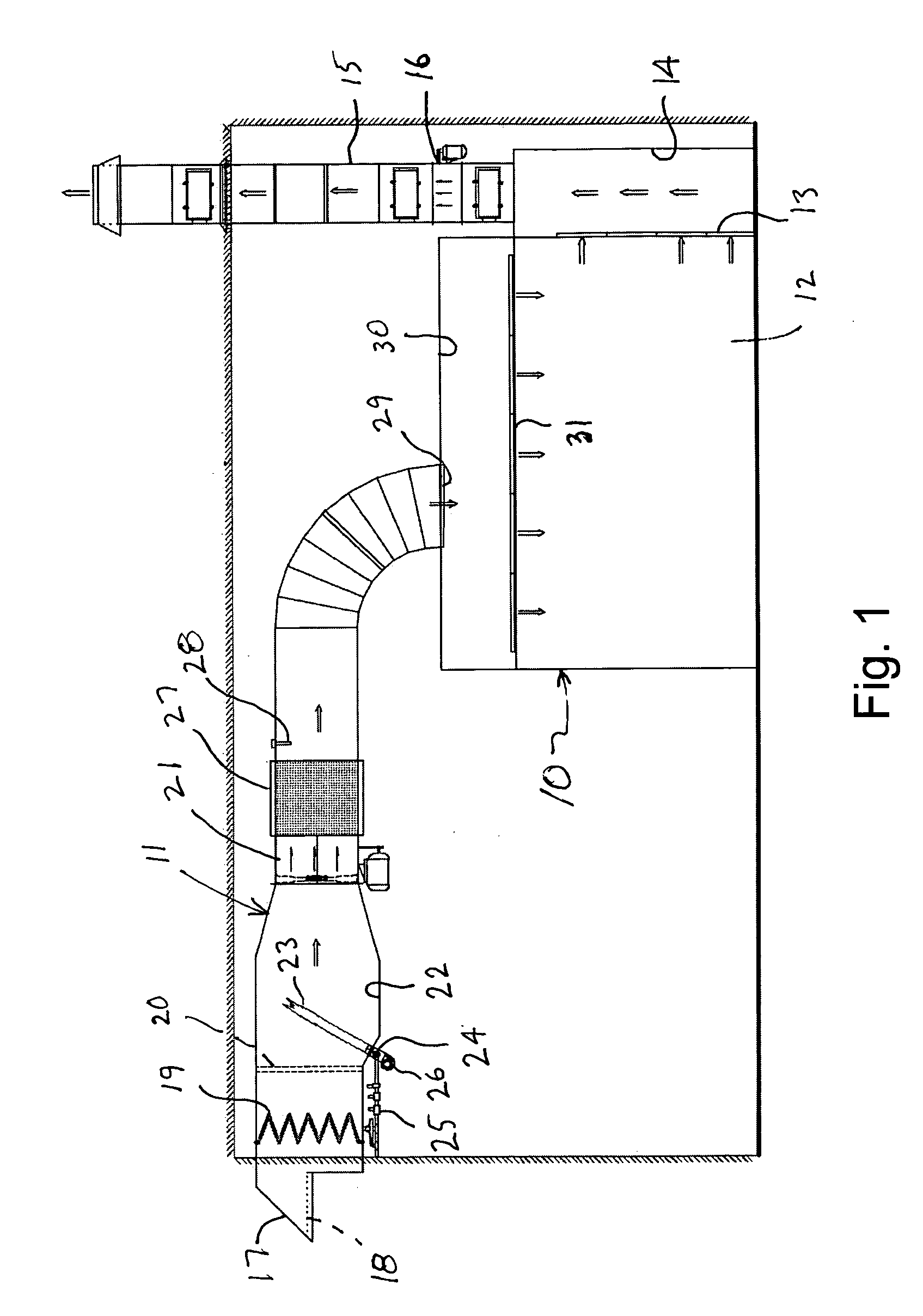

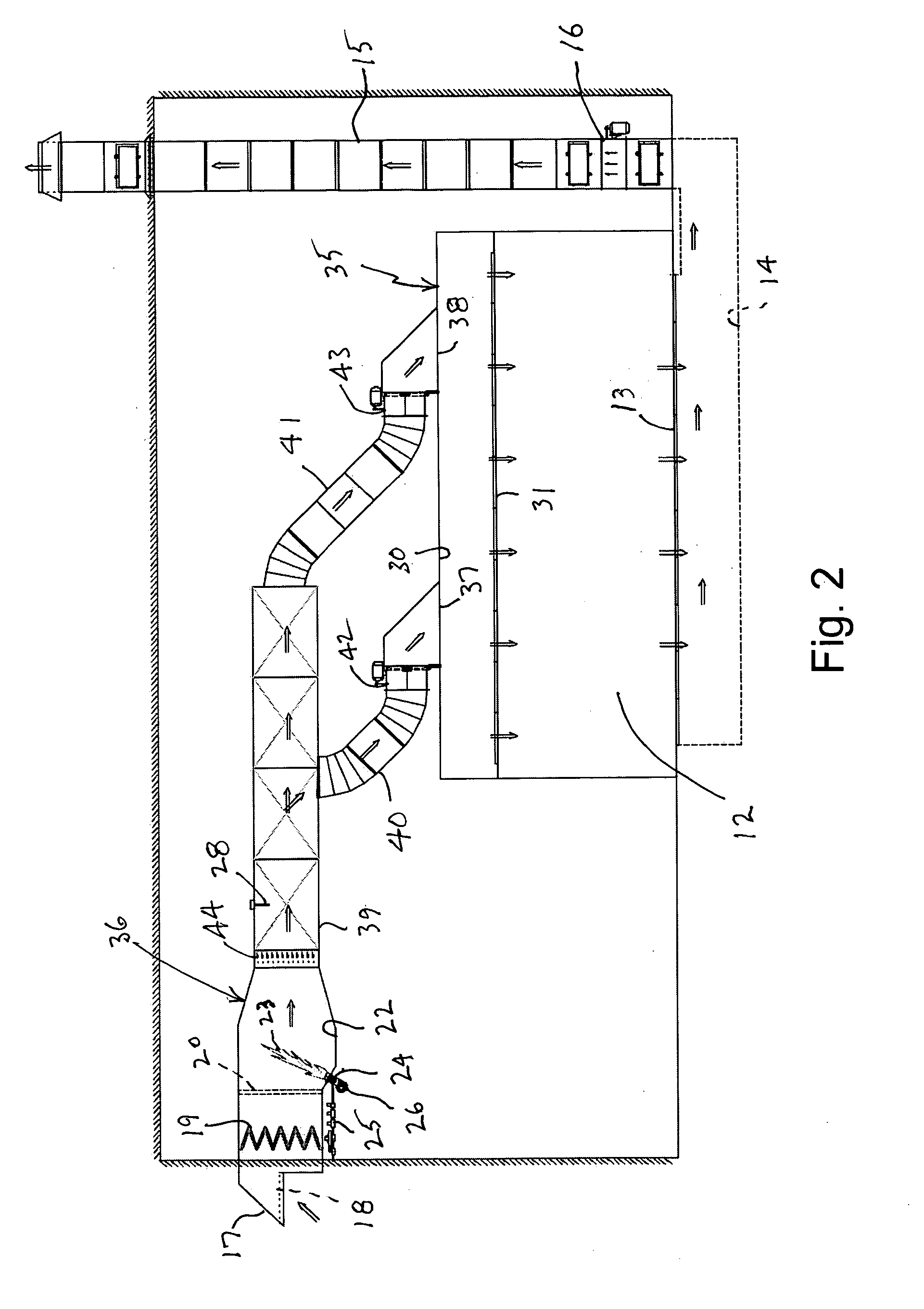

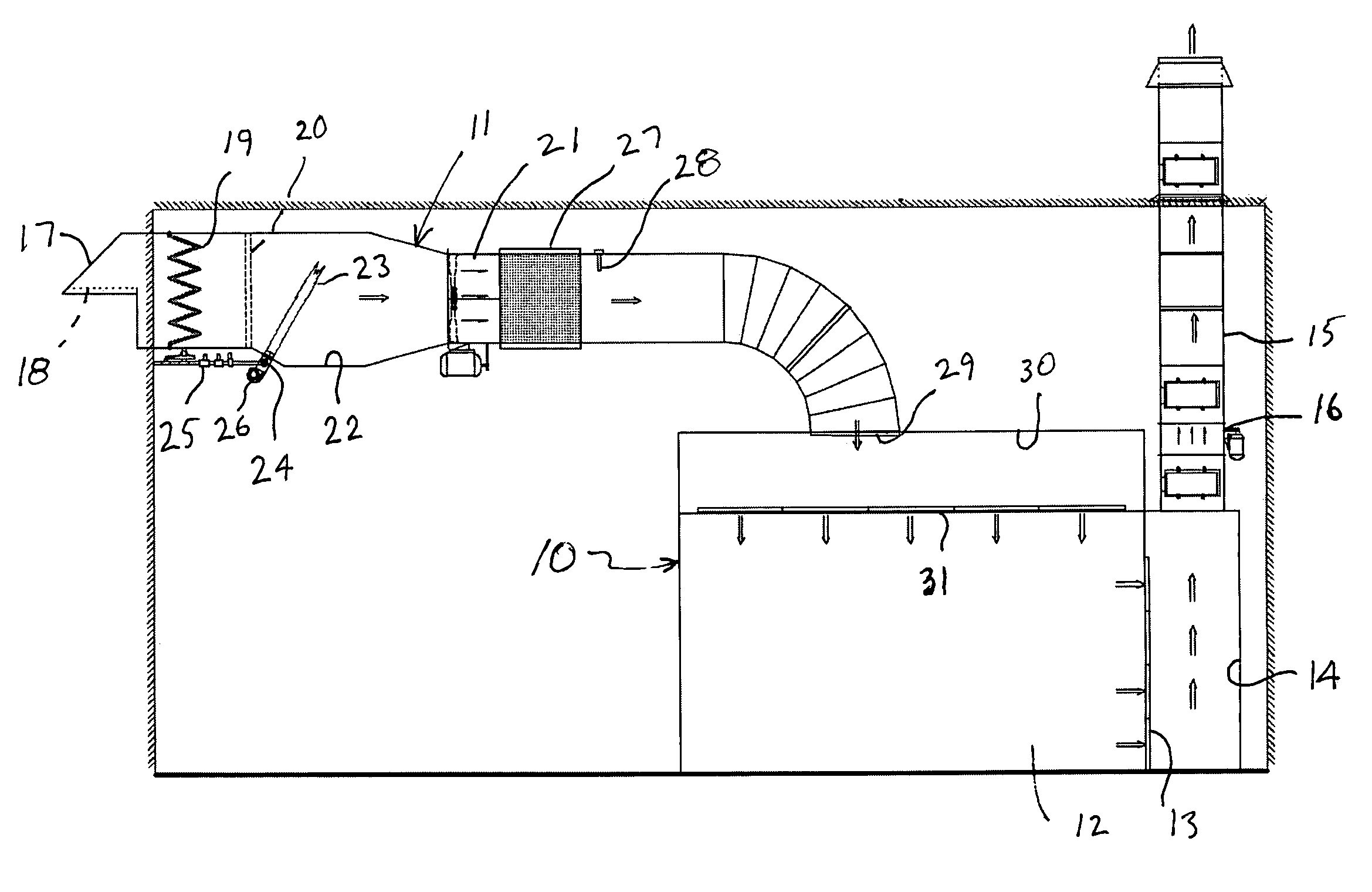

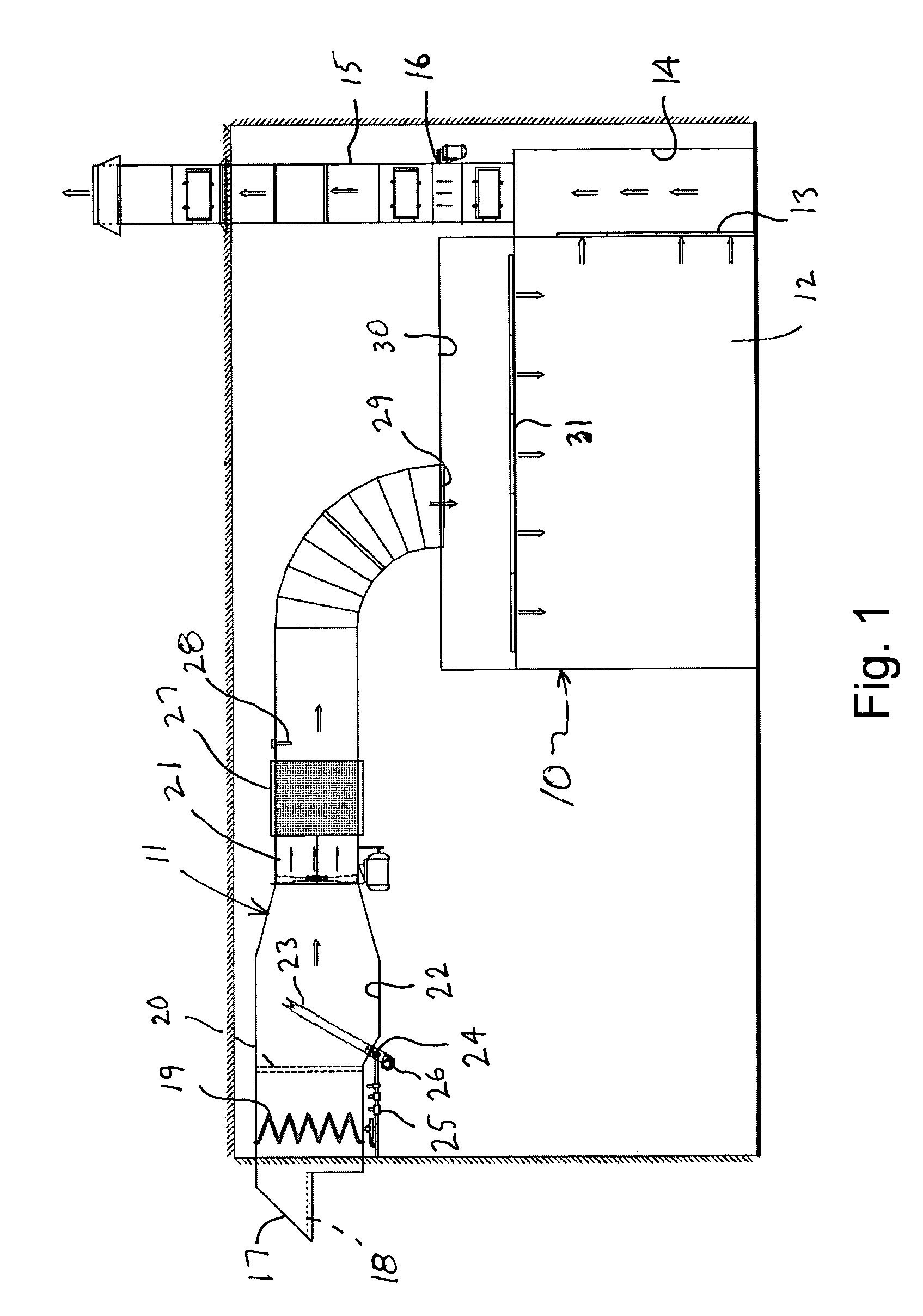

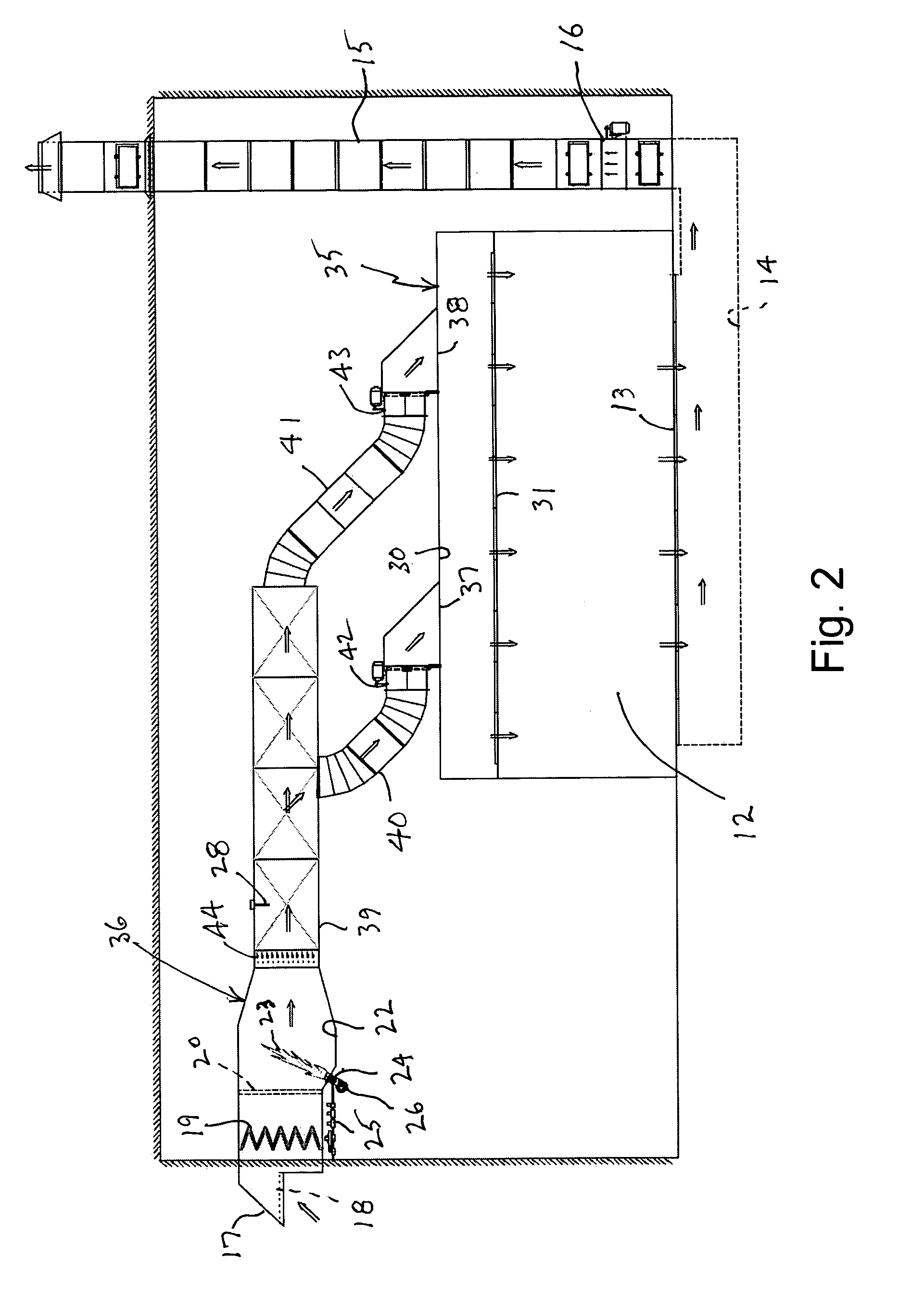

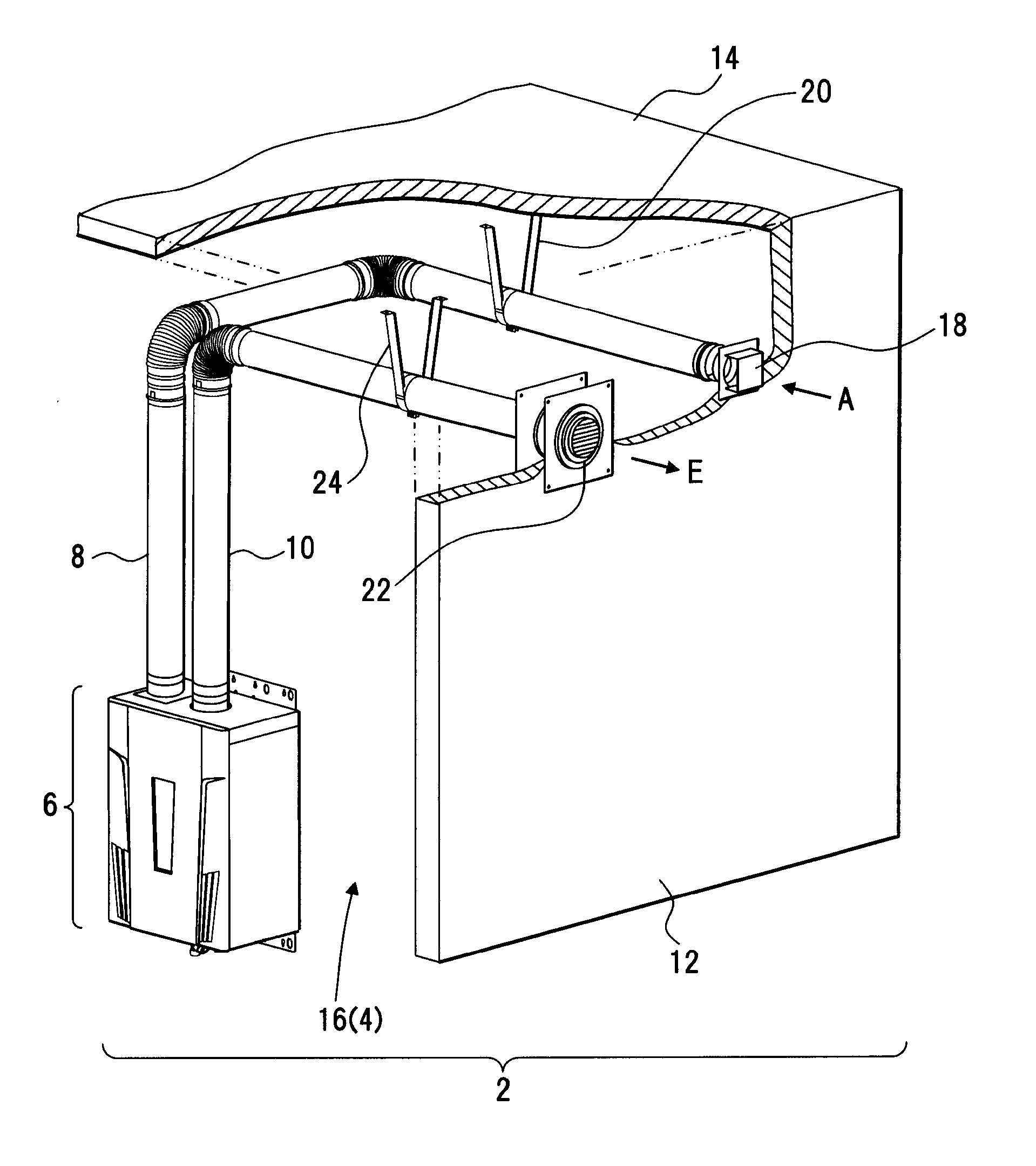

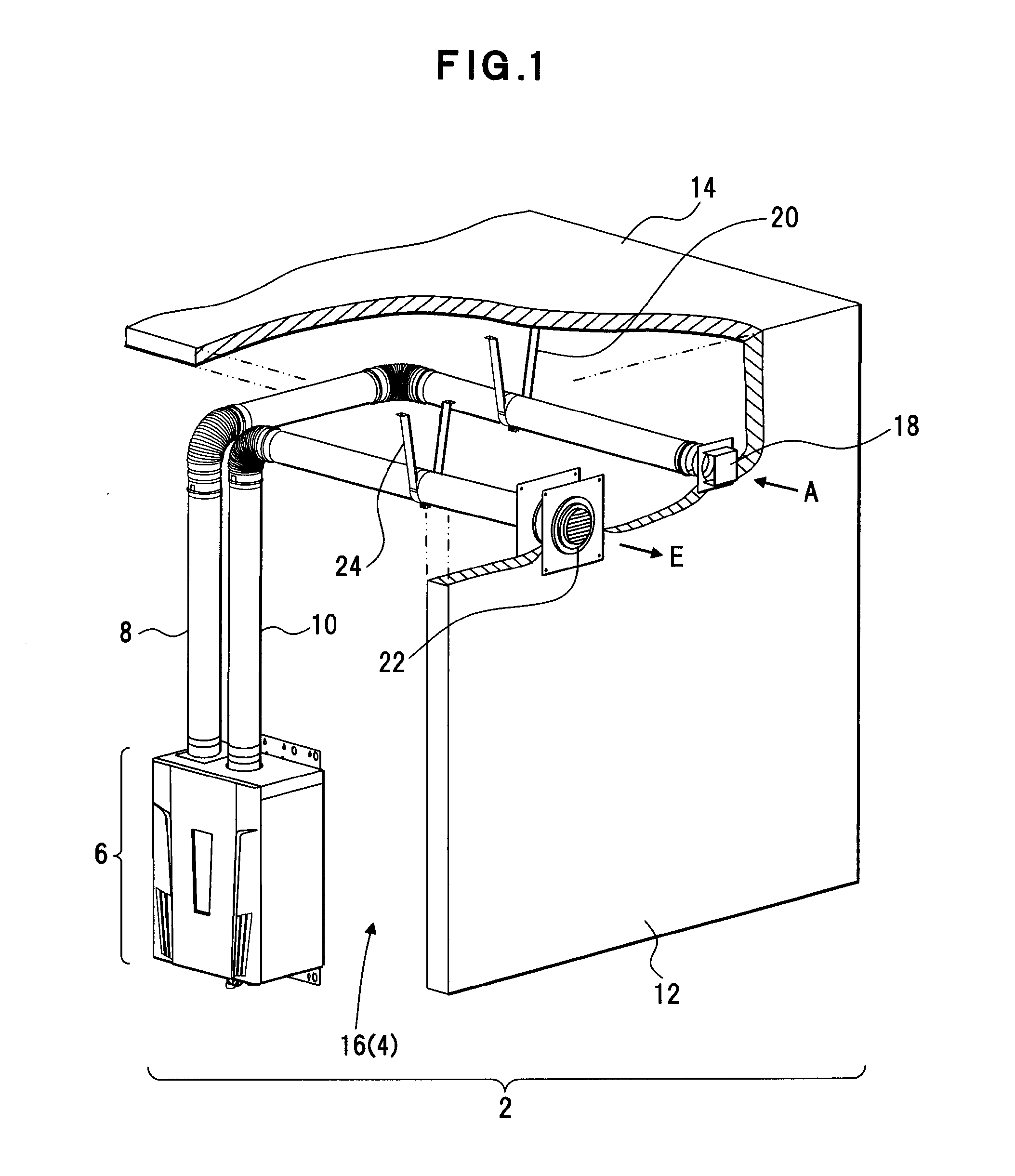

Heated replacement air system for commercial applications

ActiveUS20050229921A1Improve transmission efficiencyEmission reductionLiquid surface applicatorsDomestic stoves or rangesCombustorEngineering

Apparatus and a method for providing heated replacement air to a paint spray booth or other commercial process which requires heated make-up air to replace exhausted air. A blower draws outside air through a filter and an injection chamber prior to delivering the air to the process. Hot gases from a burner are injected into the injection chamber and mixed with the replacement air to adjust the temperature of the replacement air. The burner uses combustion air which is separate from the replacement air. The flow rate of the exhaust air and the replacement air can be adjusted to meet changing needs of the process. The BTU output from the burner is adjusted to maintain a desired replacement air temperature.

Owner:SUPPLIER SUPPORT INT

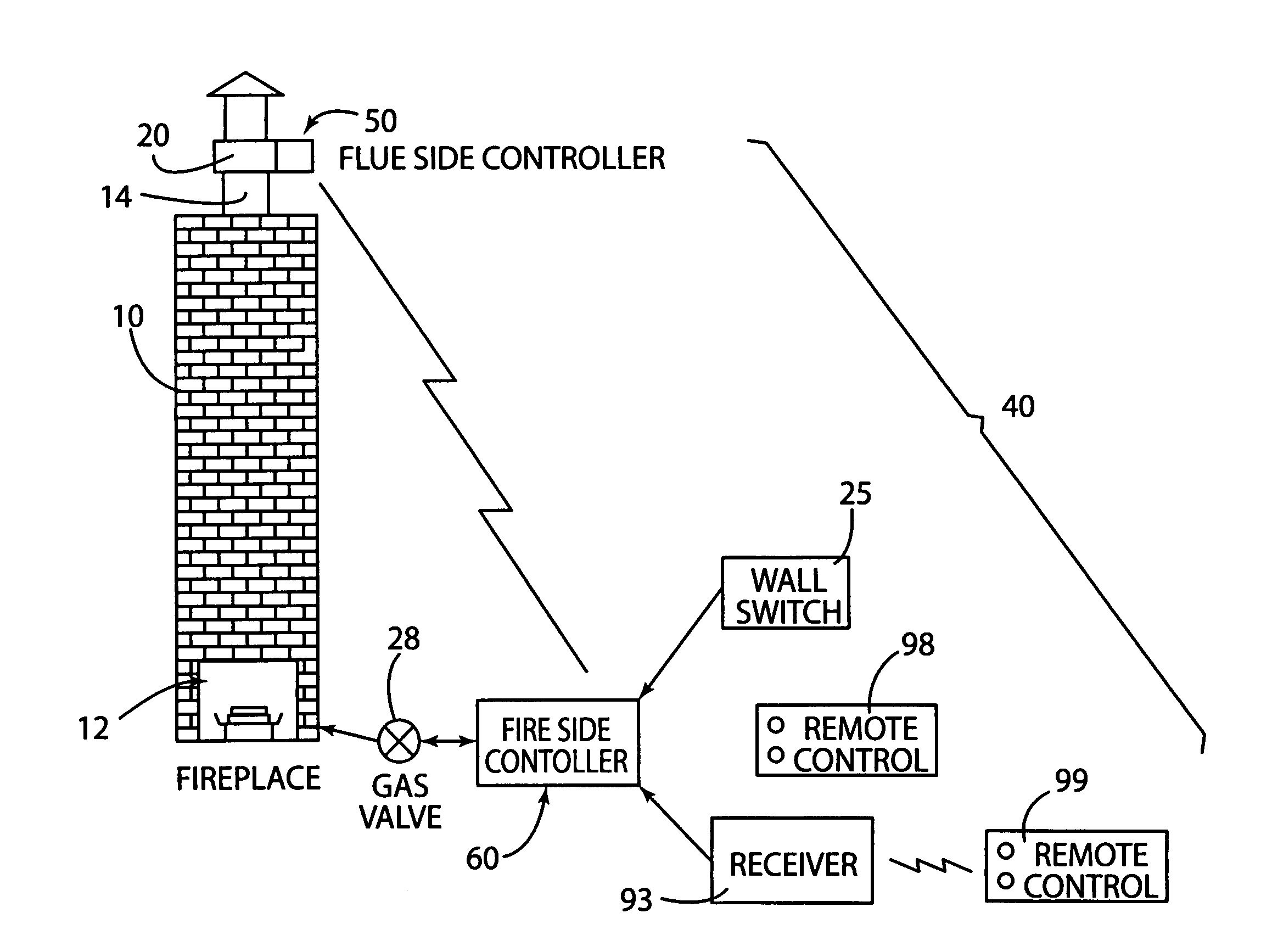

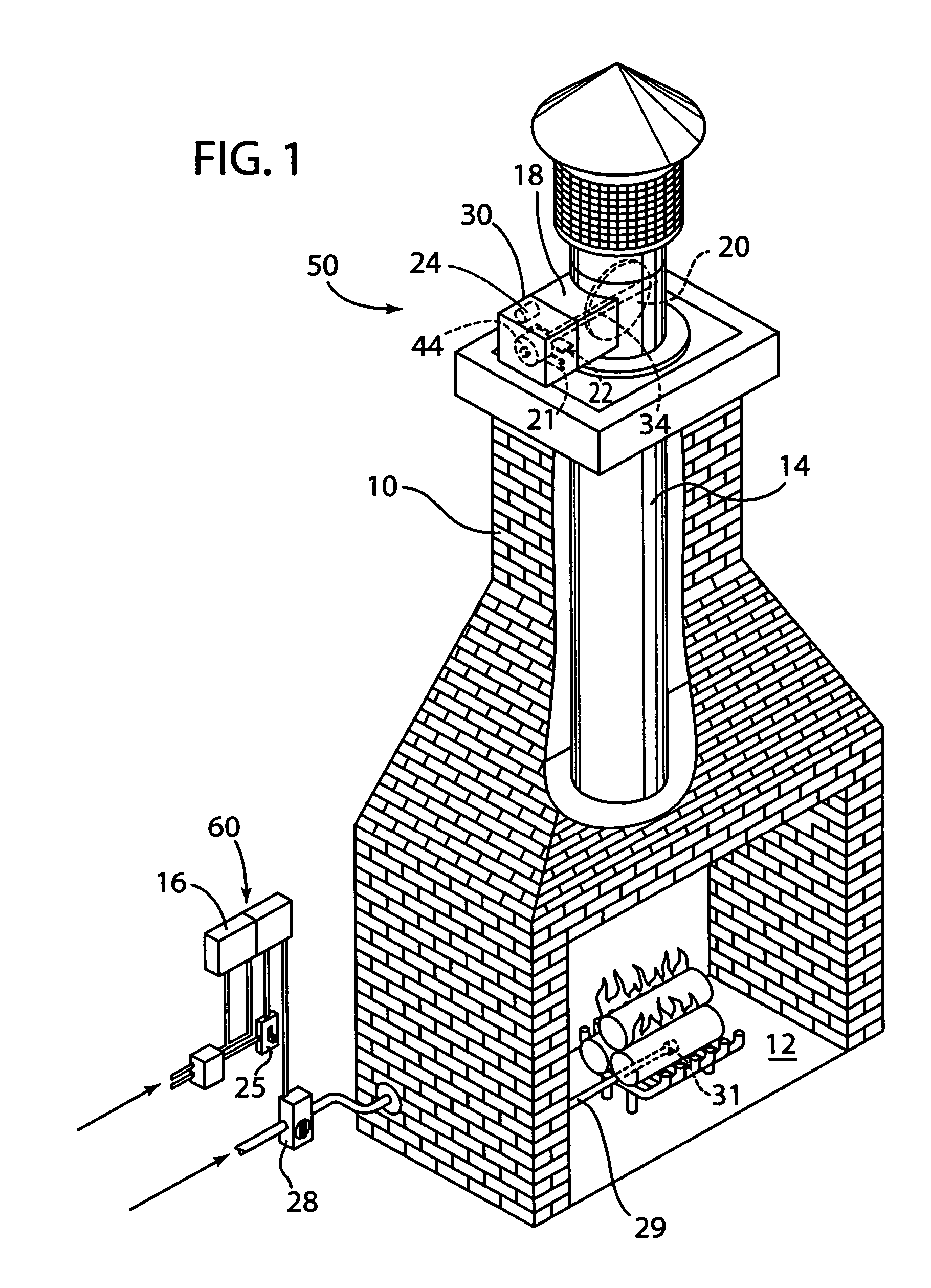

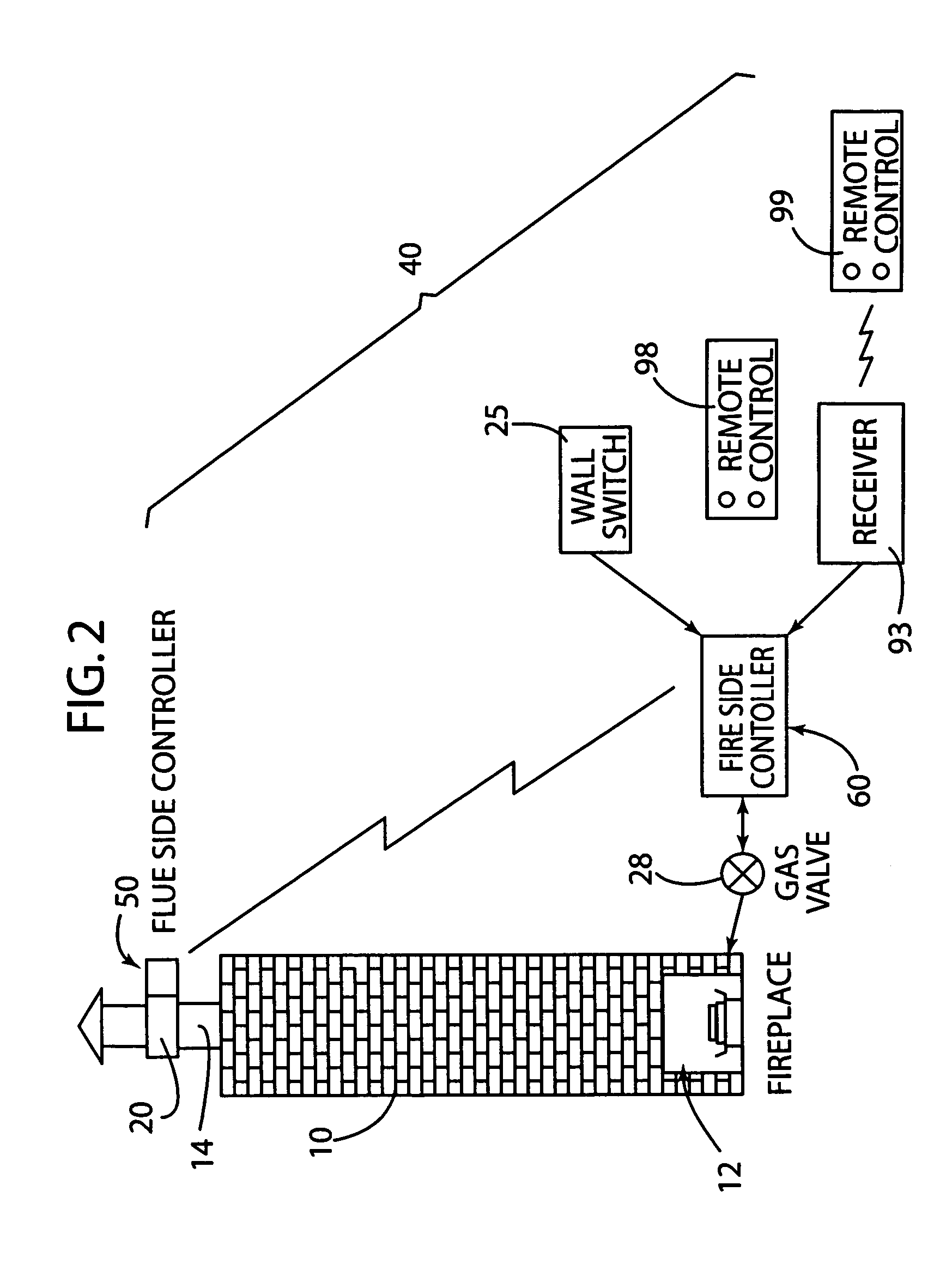

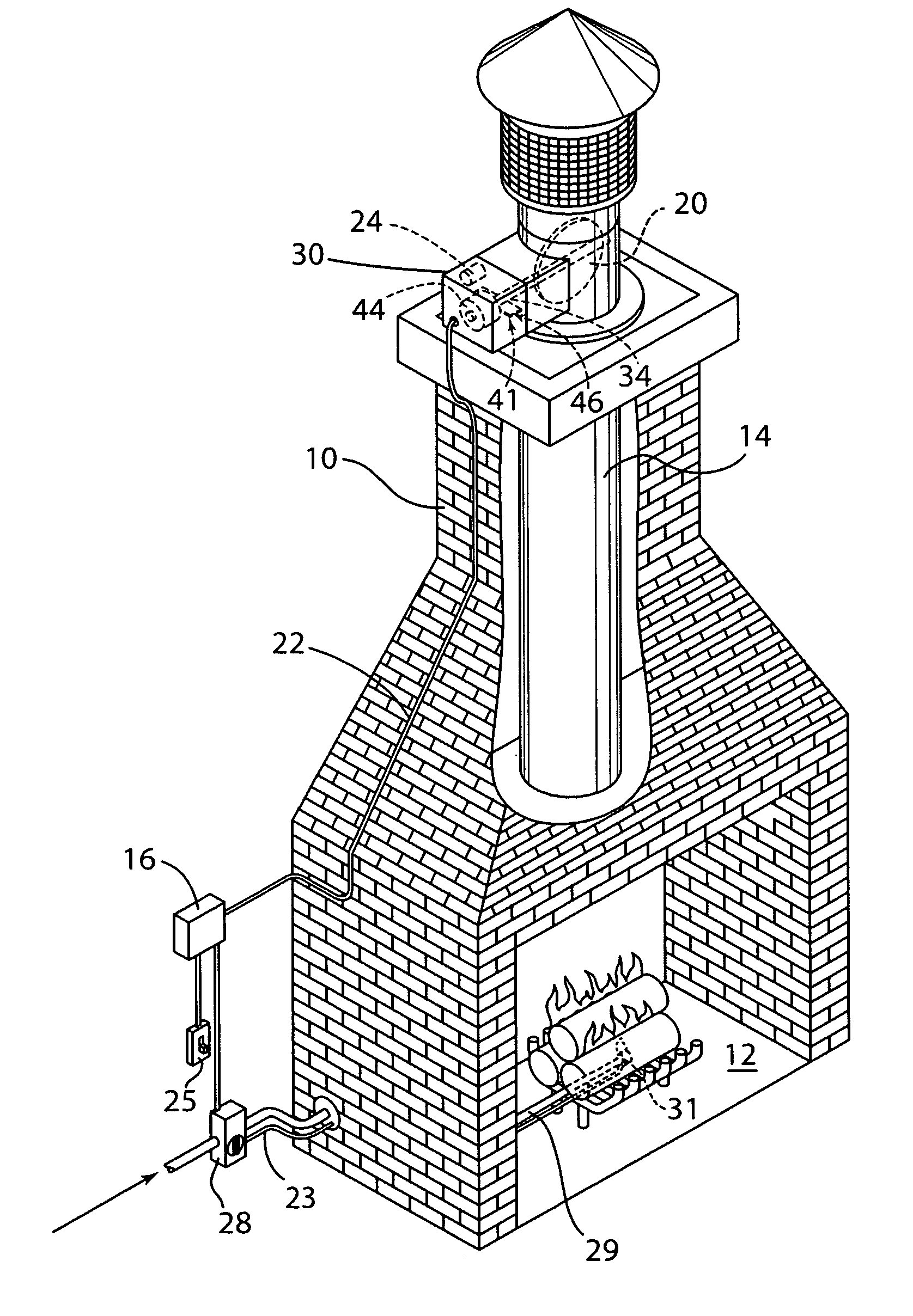

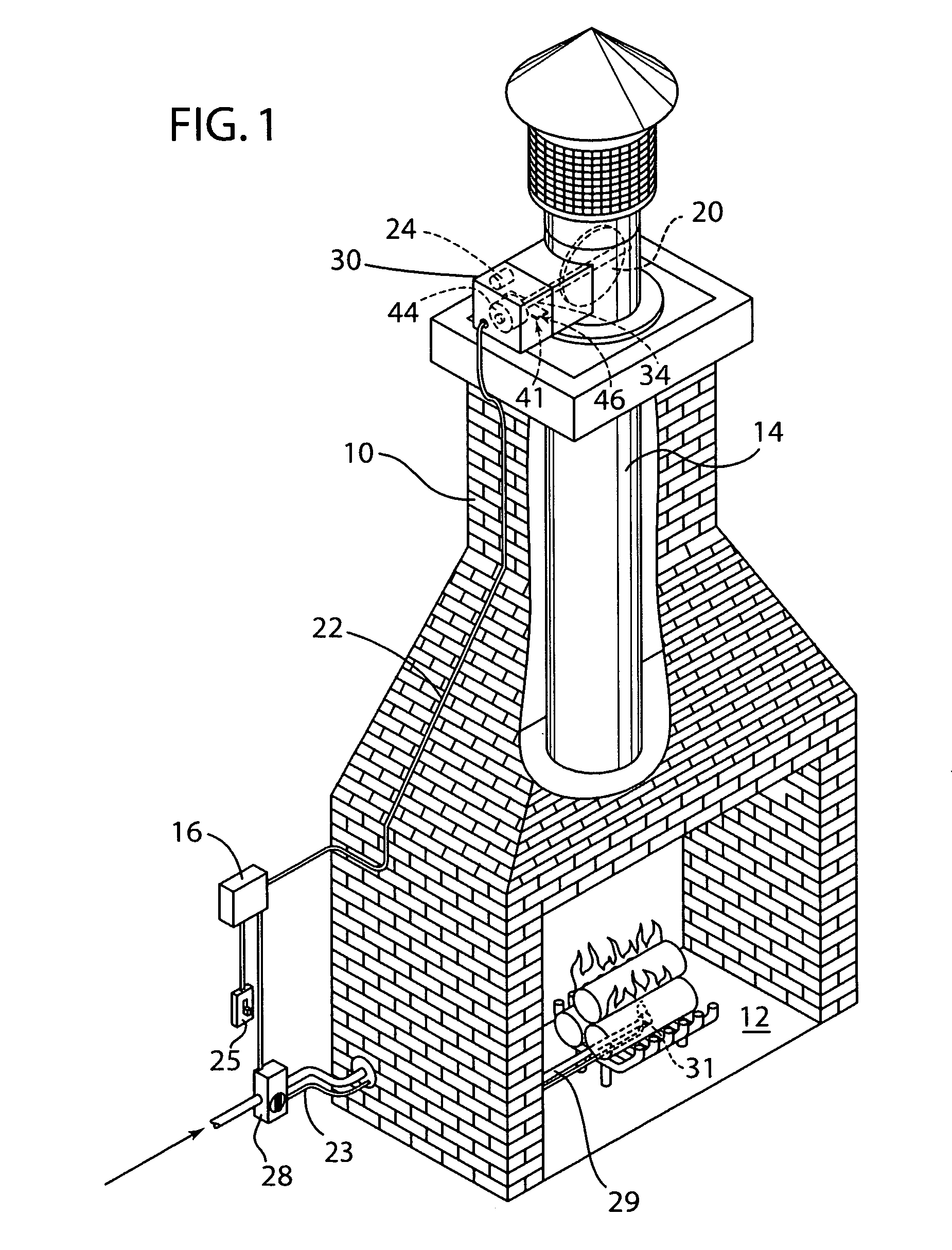

Wireless fireplace damper control device

Owner:FLUE SENTINEL

Millivolt damper control device

InactiveUS20050247304A1Quality improvementDomestic stoves or rangesAir supply regulationComparators circuitsVoltage reference

A millivolt damper control device comprises a damper movable between a closed position where a flue is blocked and an open position, a thermoelectric device having an input voltage, a battery having a voltage, and a controller comprising a comparator circuit which compares the input voltage with a reference voltage based upon the voltage of the battery. When the input voltage is greater than or equal to the reference voltage, the comparator circuit transmits a damper signal to move the damper to the open position.

Owner:FLUE SENTINEL

Termination unit for a coaxial flue pipe

A termination unit for a through-the-wall horizontal vent of a gas combustion device having a combustion chamber and a burner, is described. The termination unit comprises a wall mounting plate which is secured to a vertical wall outer surface and about an outer sleeve of a coaxial flue pipe. A fresh air chamber is secured to the wall mounting plate. An exhaust end of an exhaust flue pipe extends through the wall mounting plate and the fresh air chamber to exit through an outer wall of the chamber. Air intake ports are provided in an outer peripheral wall of the chamber to supply fresh air to a coaxial passage between the exhaust flue pipe and the outer sleeve to feed the combustion chamber. An air baffle is provided in the chamber about the exhaust end of the flue pipe and extends through the chamber. Wind deflector flanges are disposed in spaced relationship about the air intake ports of the chamber.

Owner:MICLAU S R I

Combustion system

InactiveUS6067979AAvoid quenchingIncrease gasification rateSolid bar grateCombustion-air/flue-gas circulation for stovesCombustion systemCombustion chamber

A combustion system includes a primary combustion chamber divided into left and right sides by fuel-retaining standards defining a canyon or void extending into a secondary combustion chamber is provided. The floor of the primary combustion chamber and the fuel-retaining standards direct the burning solid fuel toward the lower part of the canyon, while at the same time retaining the non-burning solid fuel on either side of the fuel-retaining standards. The combustion system further includes an air delivery system having a lower air tube supplying high and low velocity air and an upper air tube. The lower air tube is positioned proximate to a firebox floor, while the upper air tube is positioned within the secondary chamber. Automatic air setting mechanisms are provided so that proper air settings can be maintained during various phases of a fire. The combustion system further includes a loading door having openings and a bypass system preventing the loading door from being fully closed unless the bypass is in the completely closed position. The secondary combustion chamber includes at least fuel protecting baffles and a secondary combustion chamber ceiling which extends partially over the entire length of the secondary combustion chamber or includes openings. A catalyst mounting system which minimizes canning and masking and a radiant catalyst heating system are also provided.

Owner:JAASMA DENNIS R

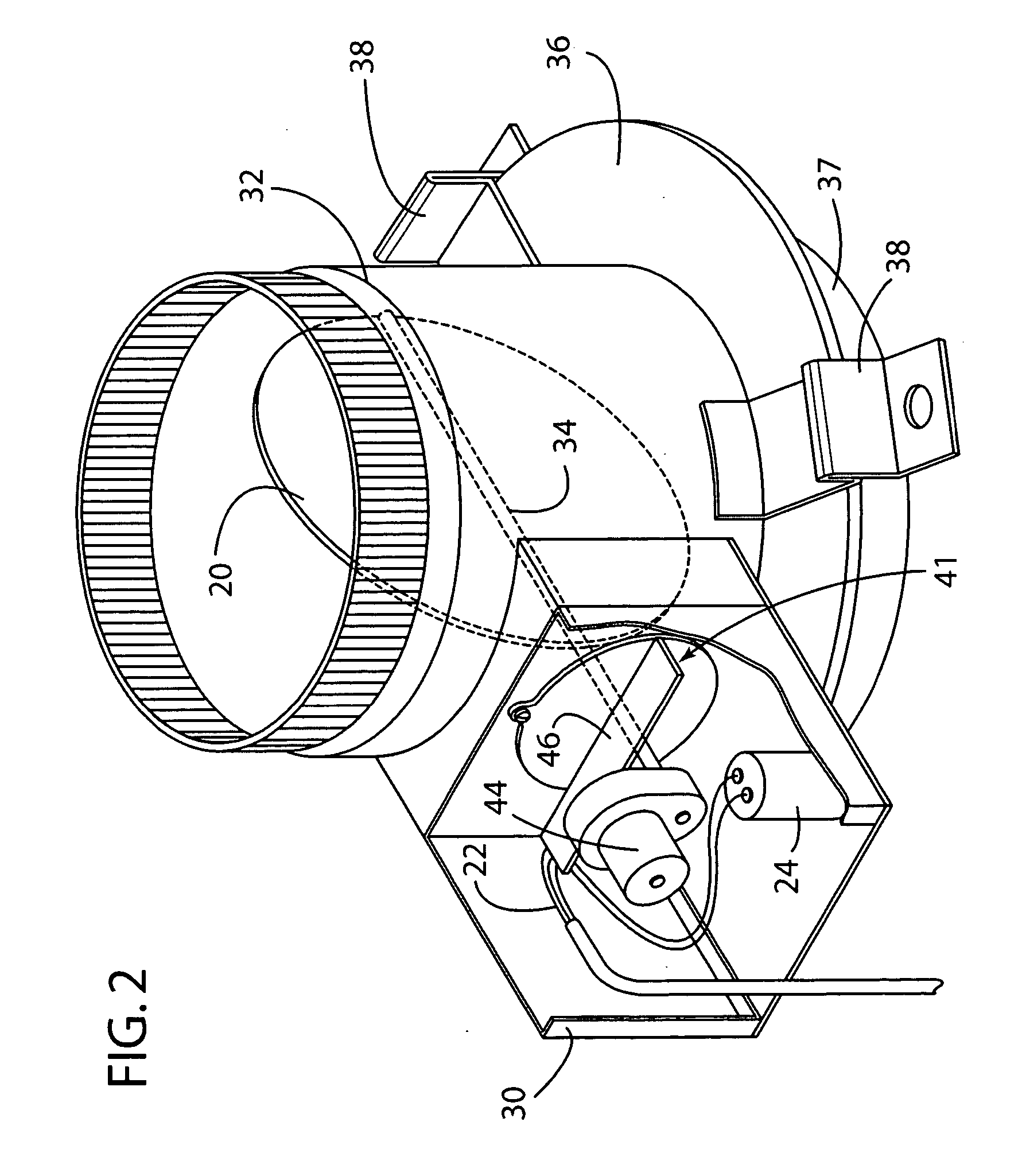

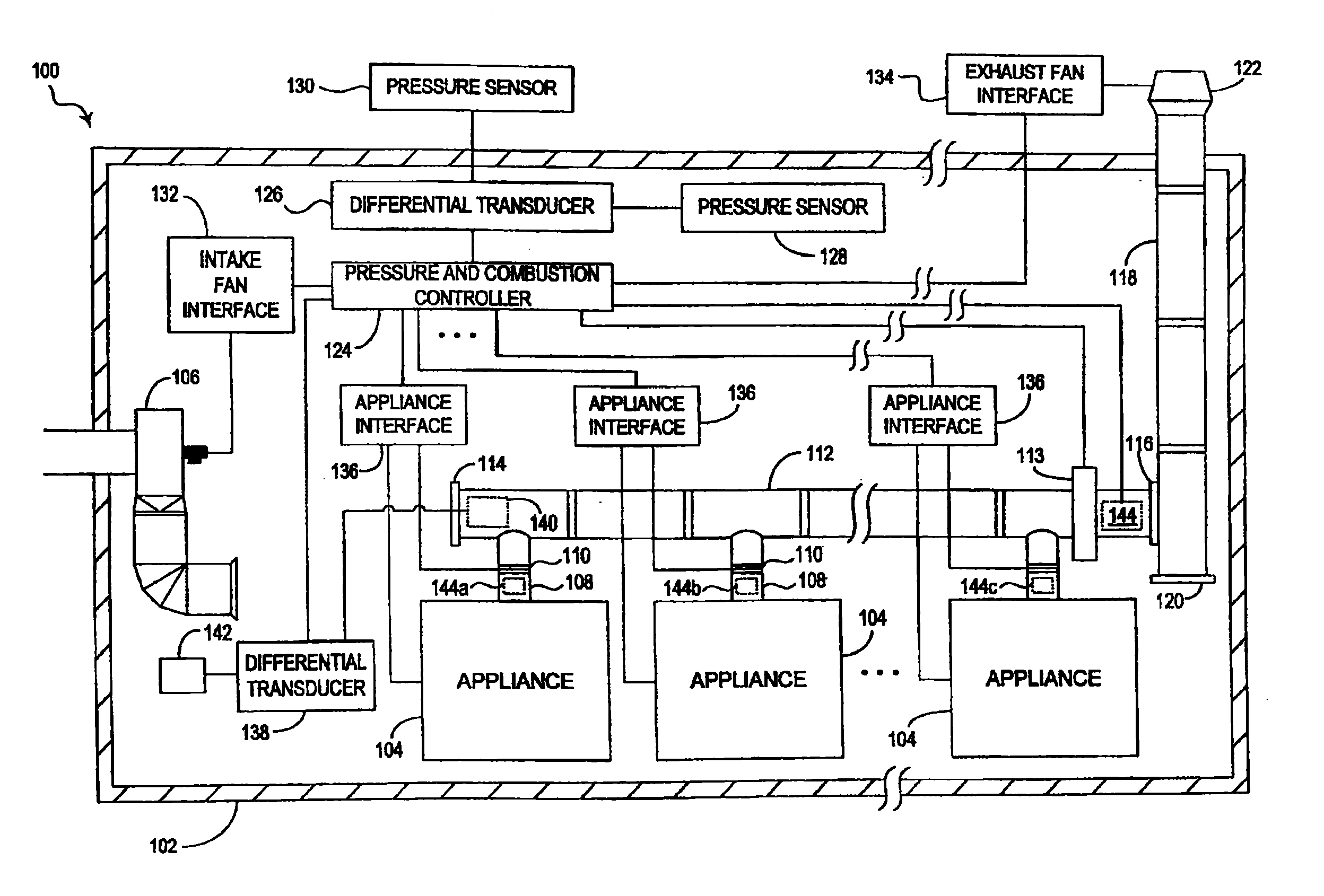

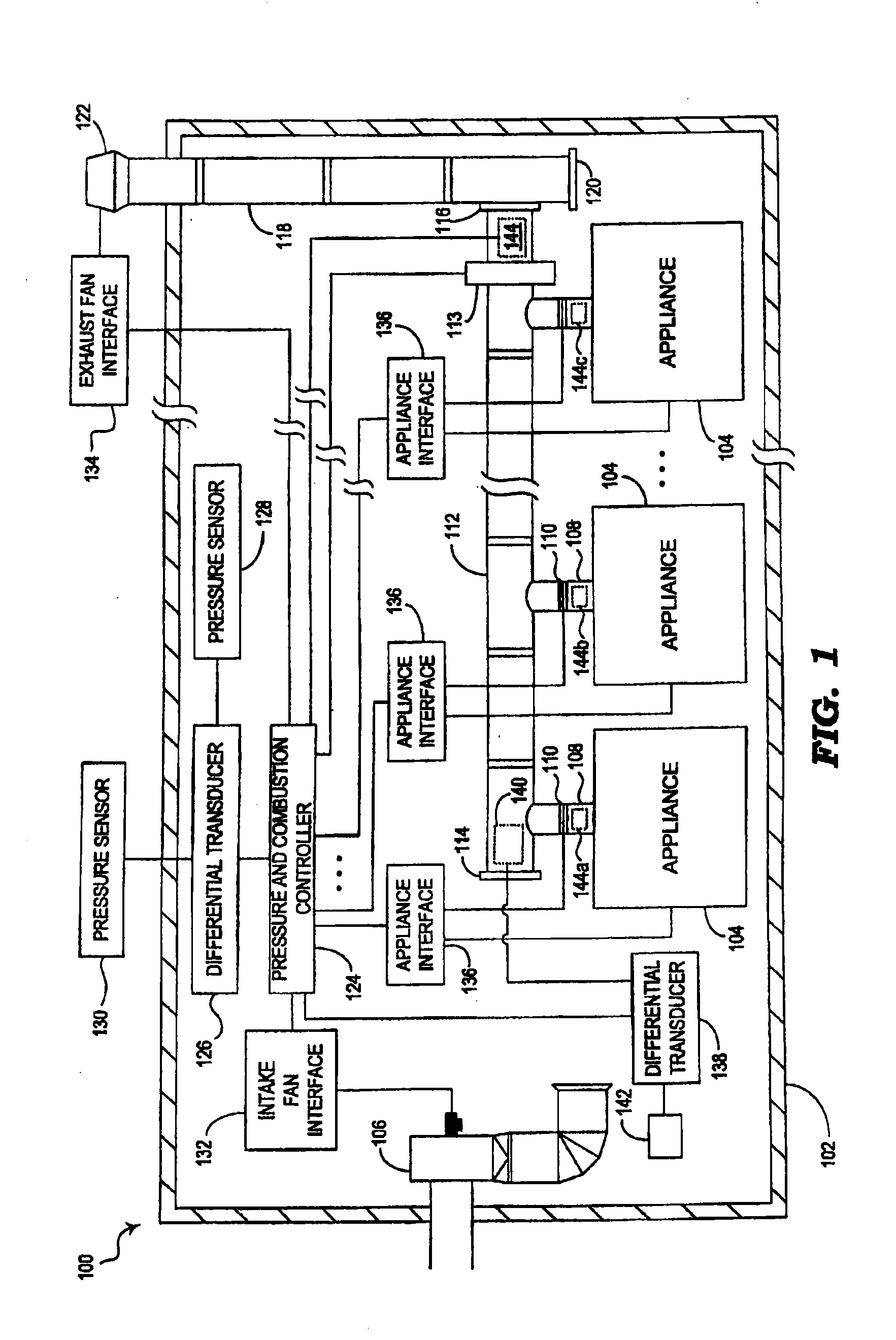

Mechanical draft systems

A representative mechanical draft system for drawing exhaust gasses from a chimney includes: an exhaust fan assembly having: a housing defining a chamber and having opposing openings, the opposing openings having a centerline extending therebetween, a first of the openings being operative to intake a flow of gasses, a second of the openings being operative to exhaust the flow of gasses from the chamber; and a centrifugal fan having a motor and an impeller, the motor being mounted external to the housing, the impeller being positioned within the chamber, a rotational axis of the impeller being inclined with respect to the centerline extending between the openings of the housing.

Owner:ENERVEX

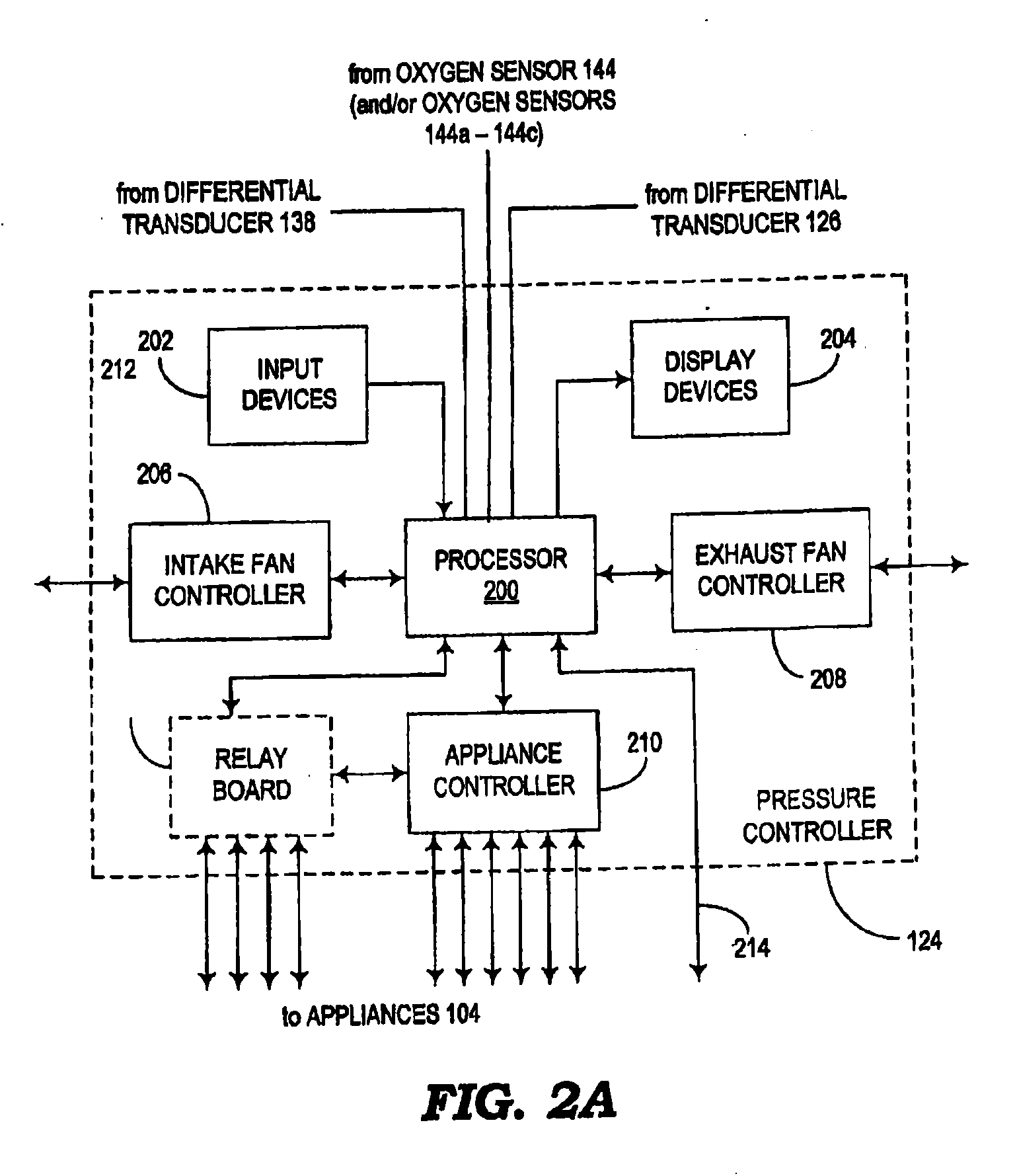

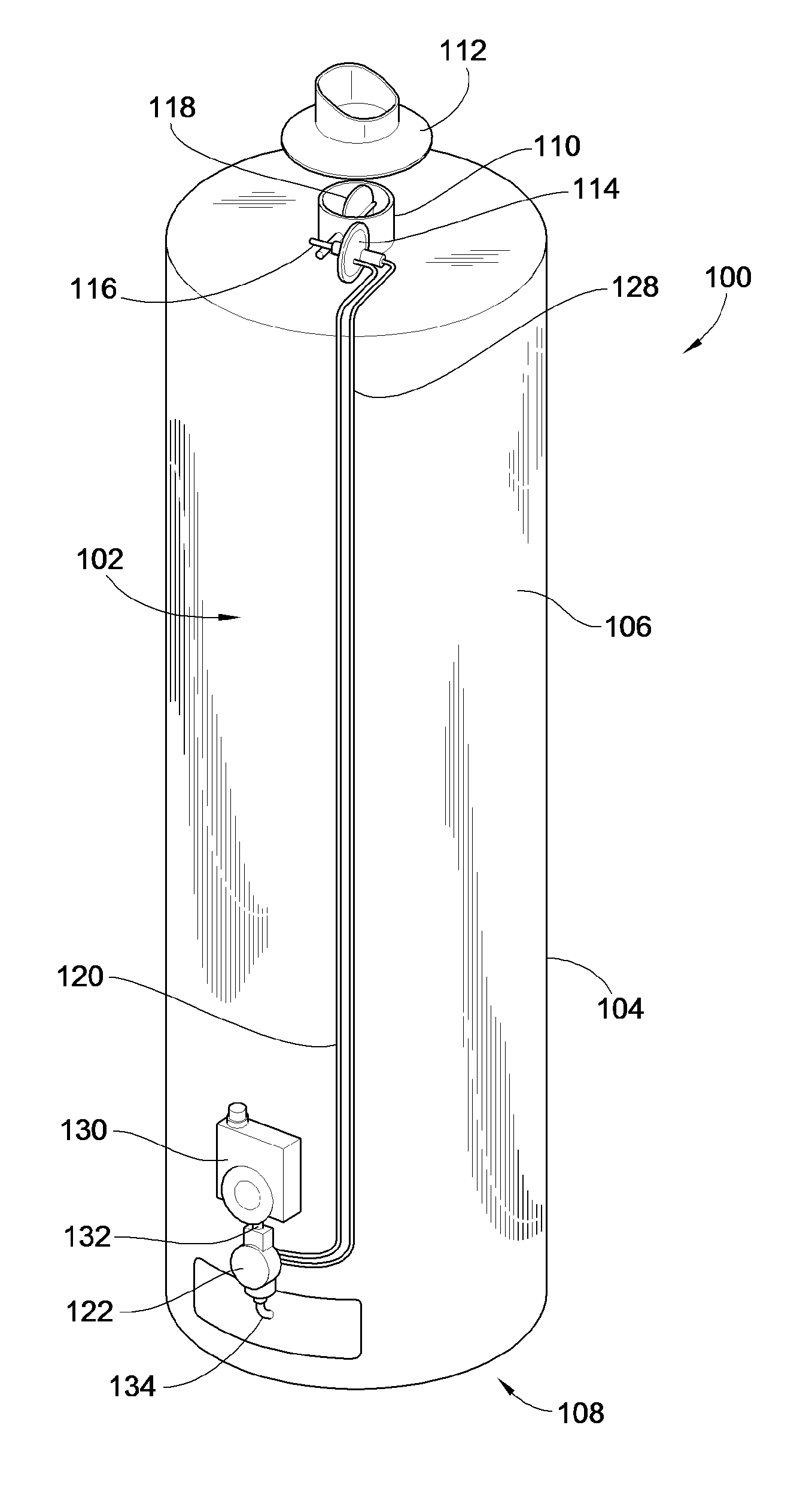

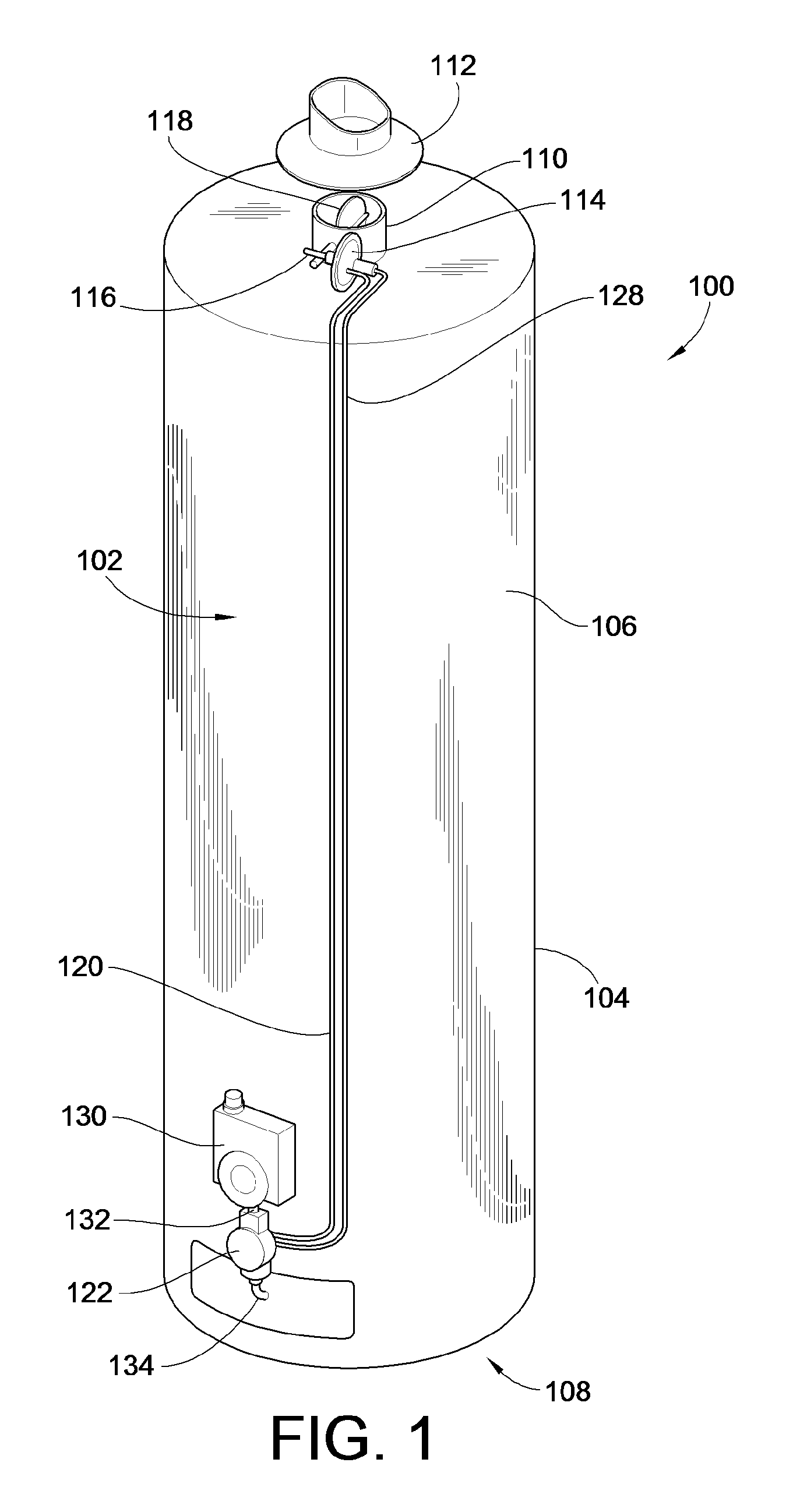

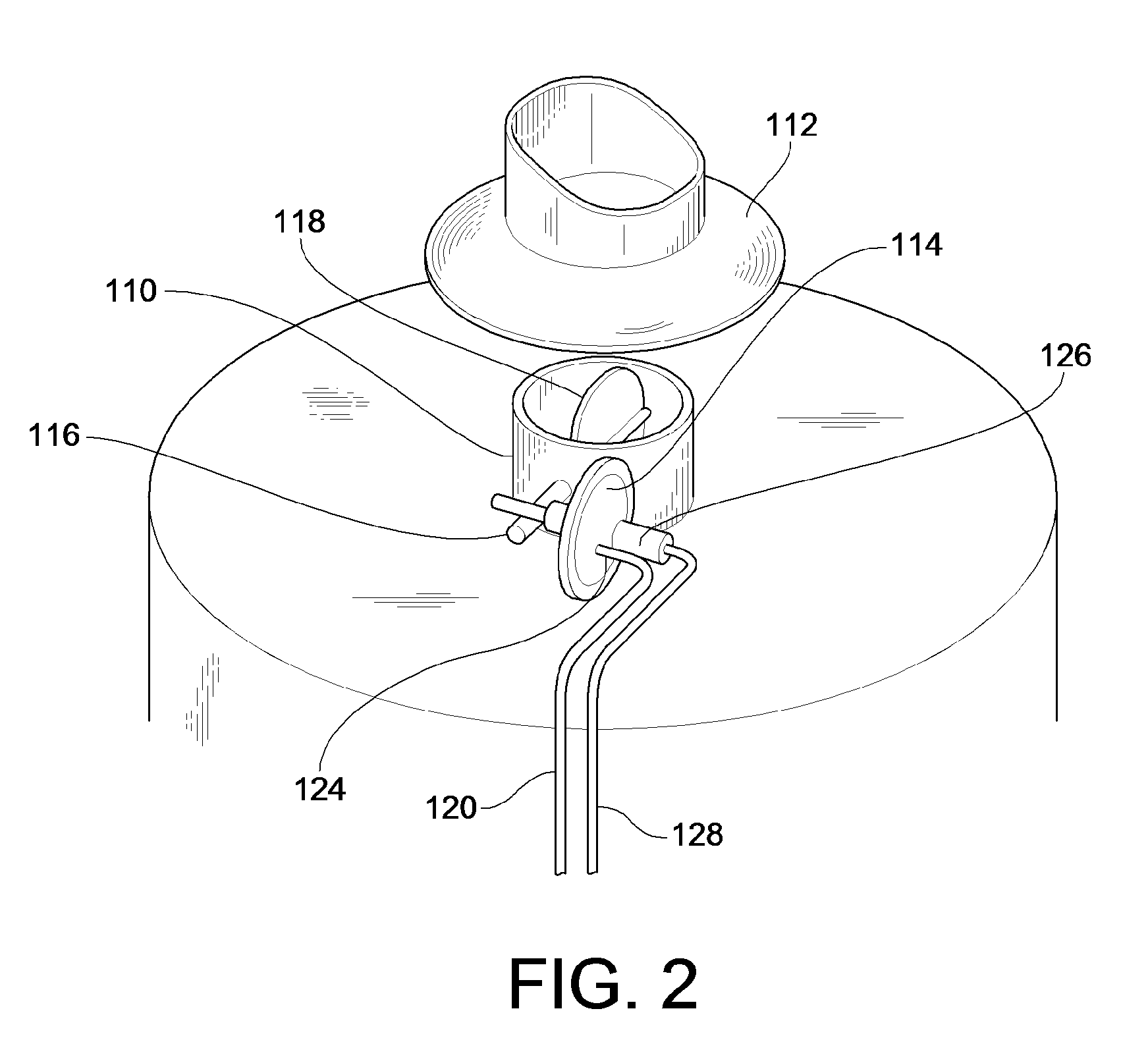

System and Method to Reduce Standby Energy Loss in a Gas Burning Appliance and Components for Use Therewith

ActiveUS20110168284A1Reducing greenhouse gasReduces standby heat lossOperating means/releasing devices for valvesAir supply regulationRelay valveCombustor

A system to reduce standby losses in a hot water heater is presented. The system utilizes a dual safety relay valve between the combination gas controller and the burner. The dual safety relay valve bypasses gas to a rotary damper actuator valve to position a damper flapper valve located over / inside the flue pipe. Once the flapper valve has opened to ensure combustion, the gas is allowed to flow back to the dual safety relay valve. Some of the bypass gas may be diverted to boost the pilot or to supply a booster. The dual safety relay valve is then opened to allow the gas supply to the burner. Once the burner is turned off, bypass gas bleeds out of the rotary damper actuator valve to close the damper flapper valve to reduce standby losses through the flue pipe, and to allow the dual safety relay valve to close tightly.

Owner:INVENSYS CONTROLS AUSTRALIA

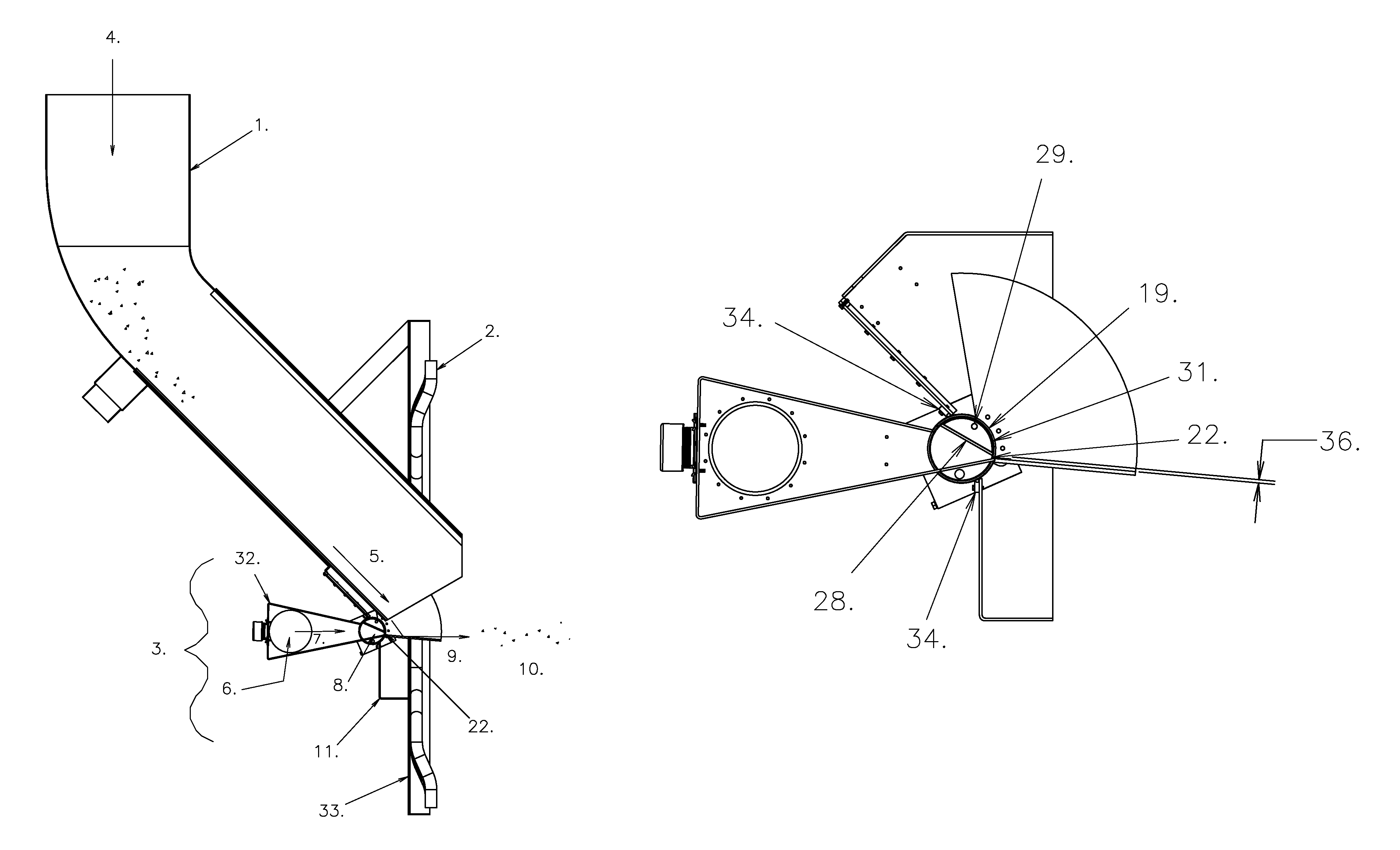

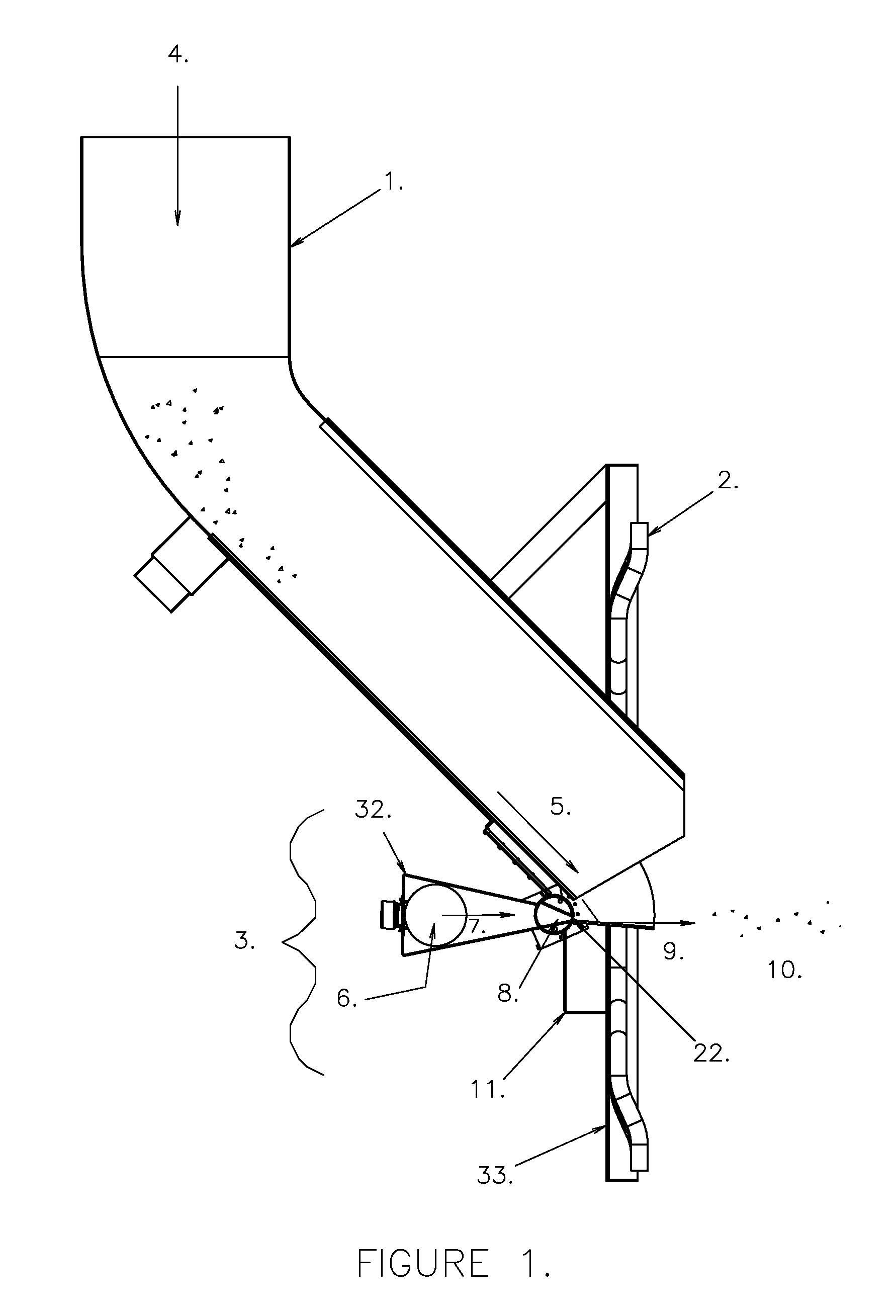

Pneumatic fuel distributor for solid fuel boilers

InactiveUS8276528B1Efficiently controls flowImprove fluid flowPulverulent fuel combustion burnersDamper arrangementSpray nozzleSolid fuel

A pneumatic fuel distributor for solid fuel boilers is described incorporating in various embodiments one or more of the following features: a converging nozzle section, a converging adjustable orifice section and an integral trajectory plate. The nozzle, orifice and trajectory plate are preferably all interconnected and rotate together about a common axis. The orifice damper is, in one embodiment, a rotating convergent section and independently adjustable. The unit preferably incorporates a viewing glass and access port and the rotating components are preferably removable for maintenance. The unit is preferably reversible for left or right hand installation and the trajectory plate is easily replaceable.

Owner:SULLIVAN HIGGINS & BRION PPE LLC

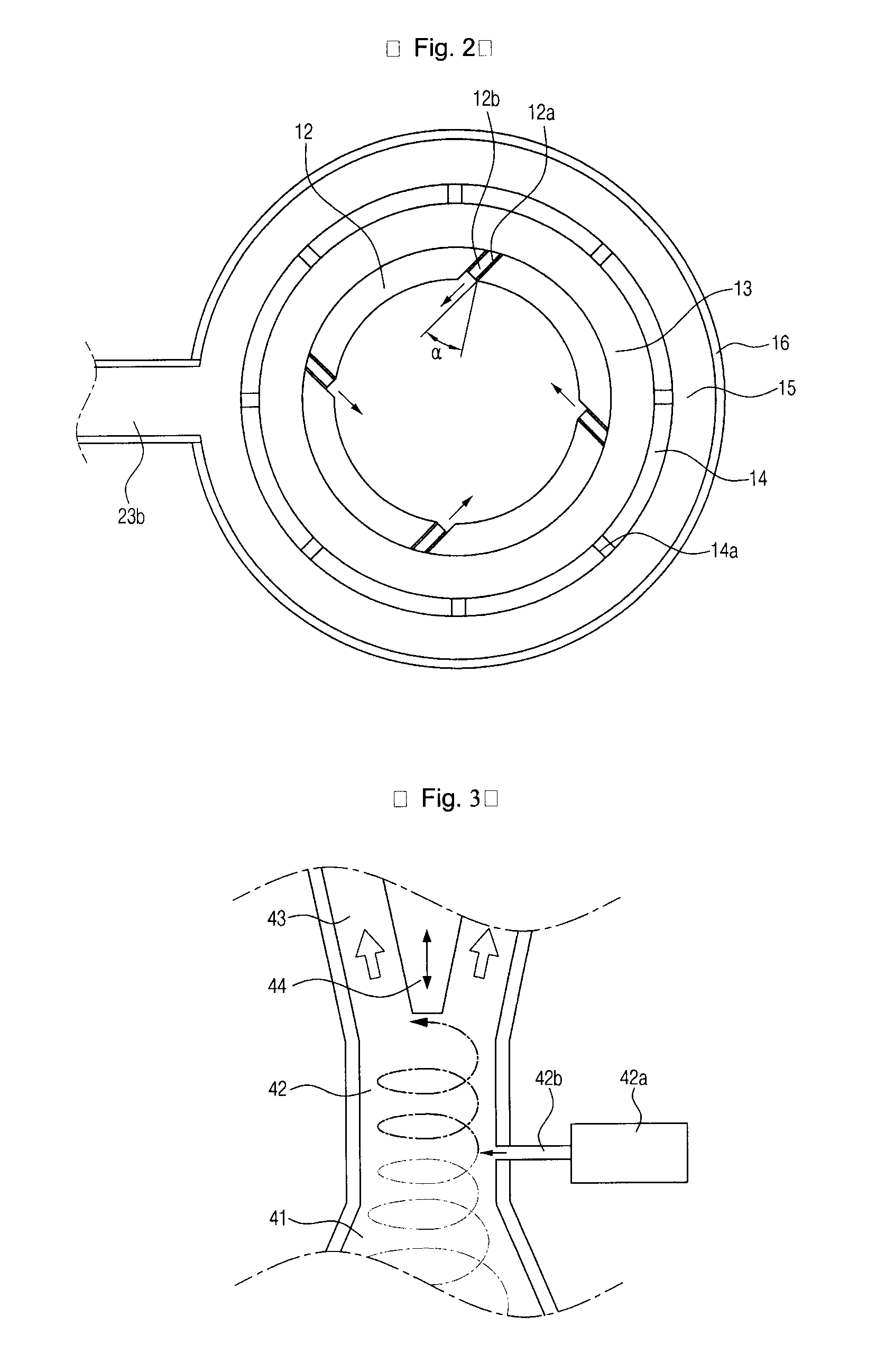

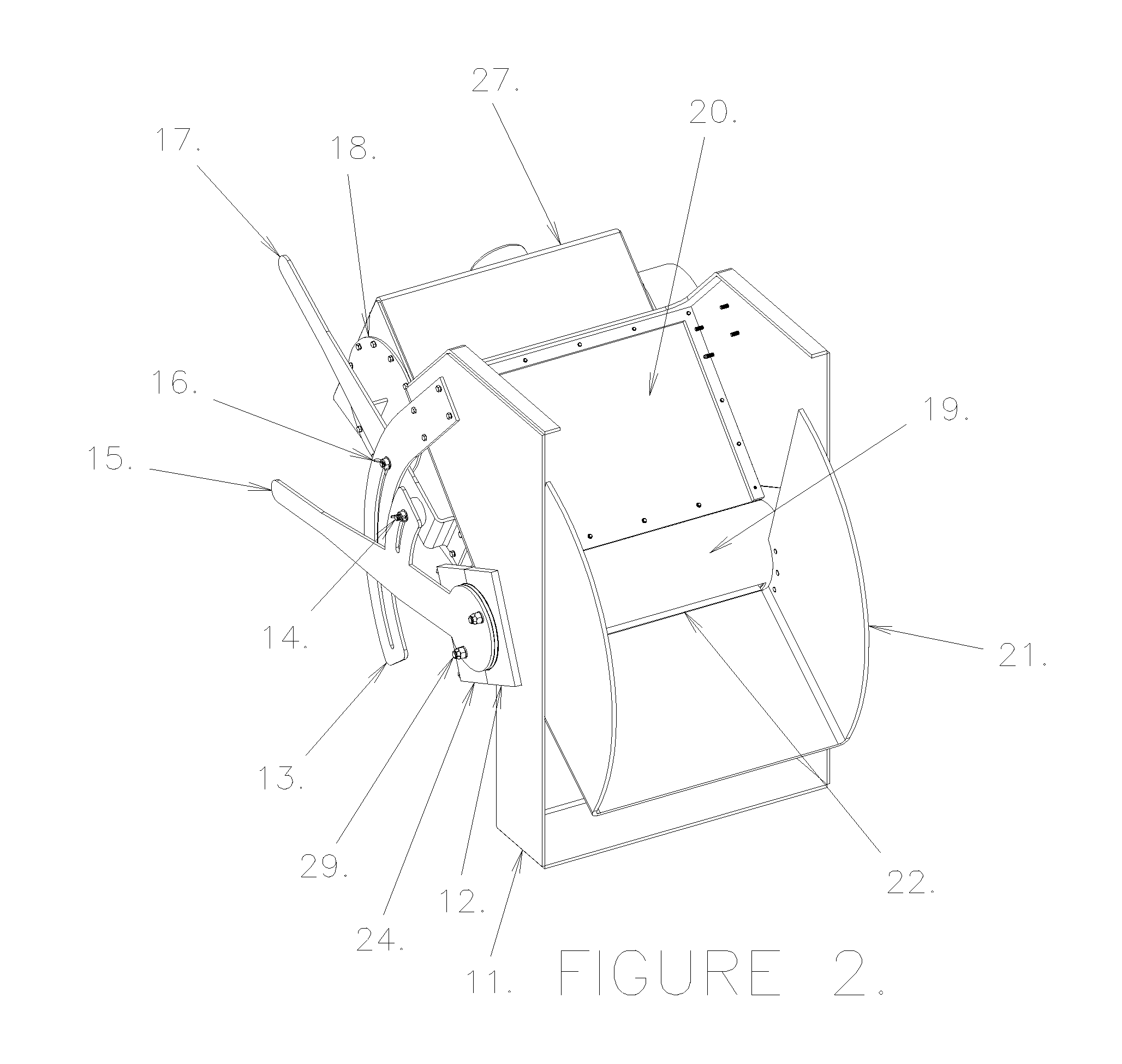

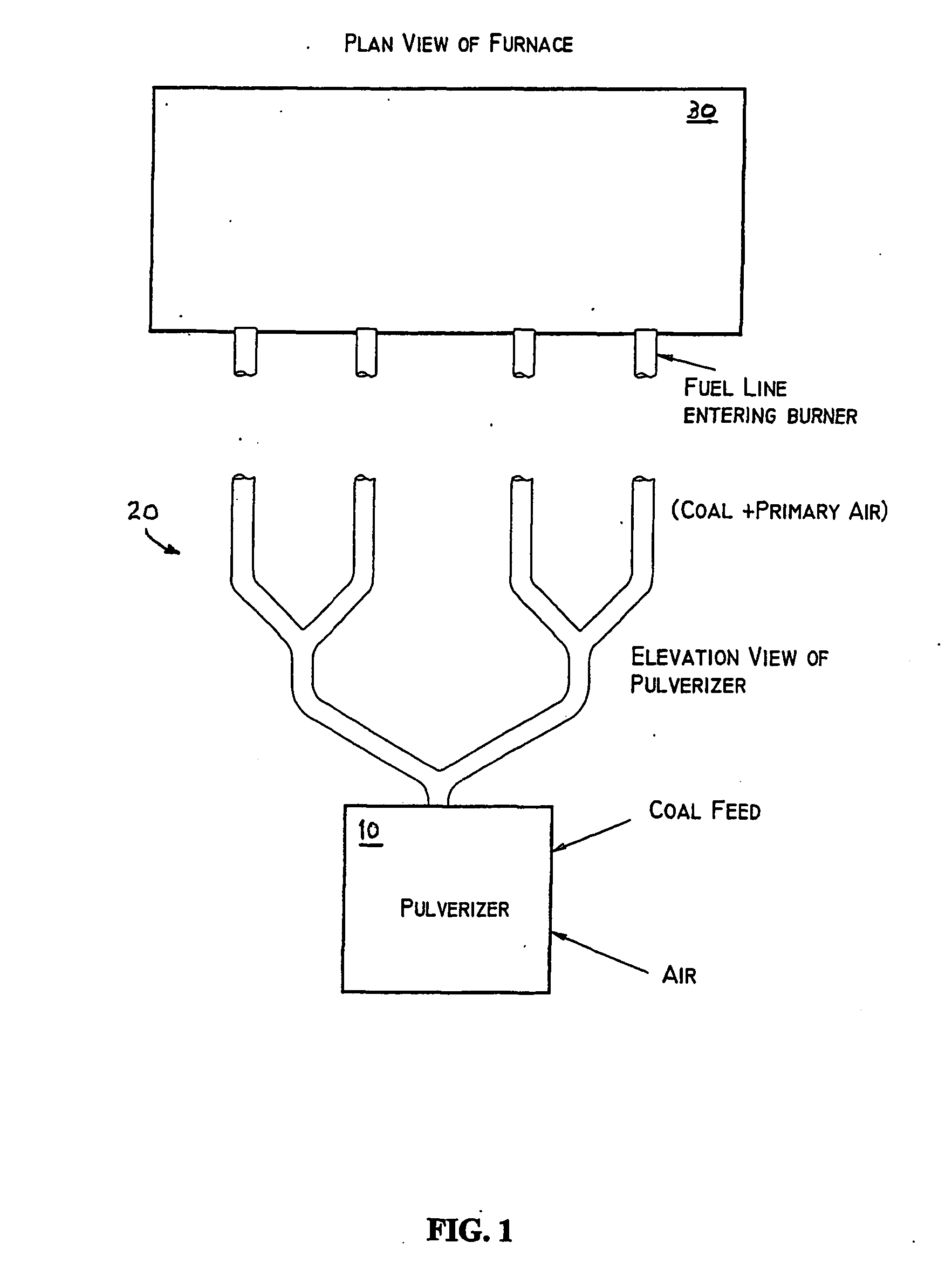

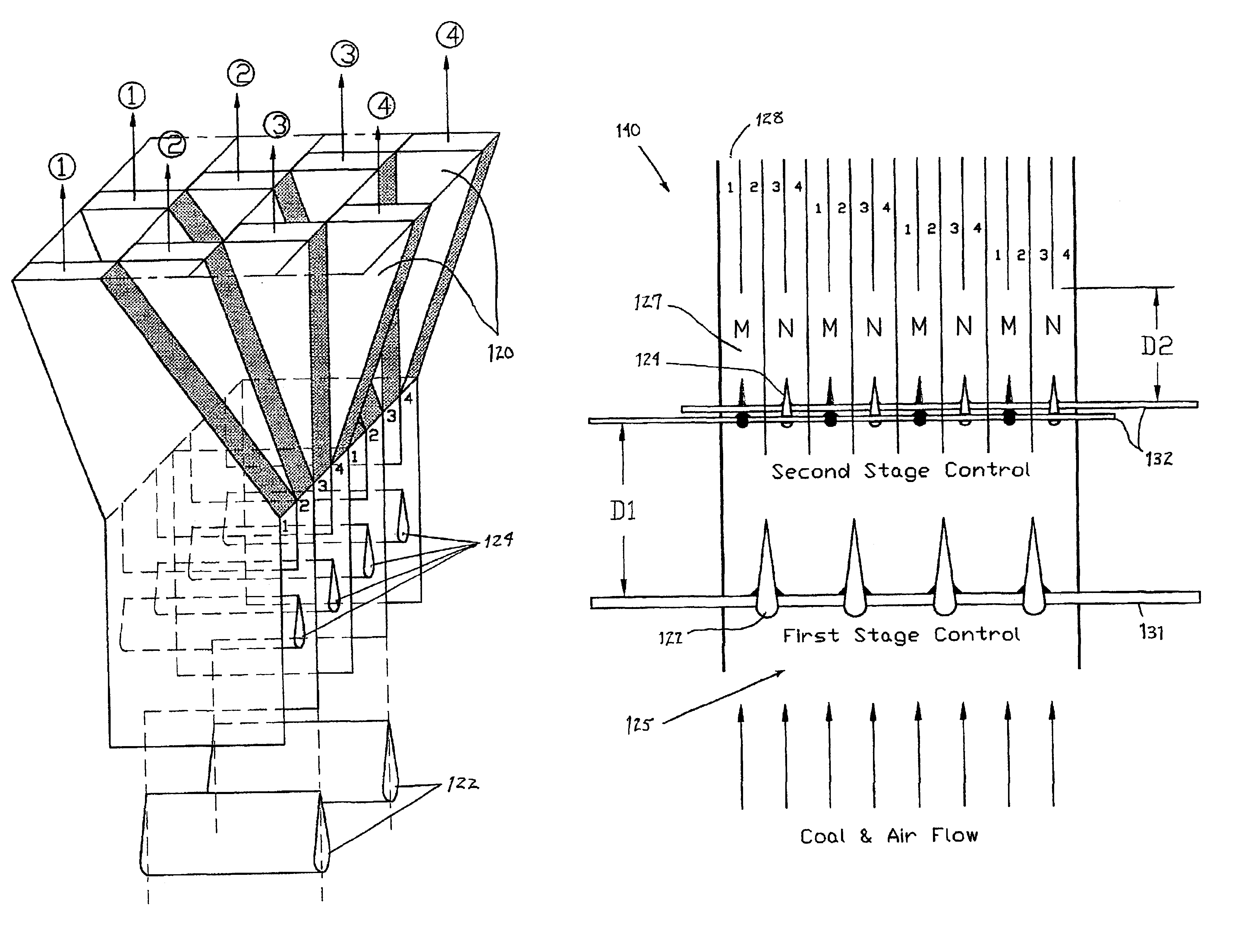

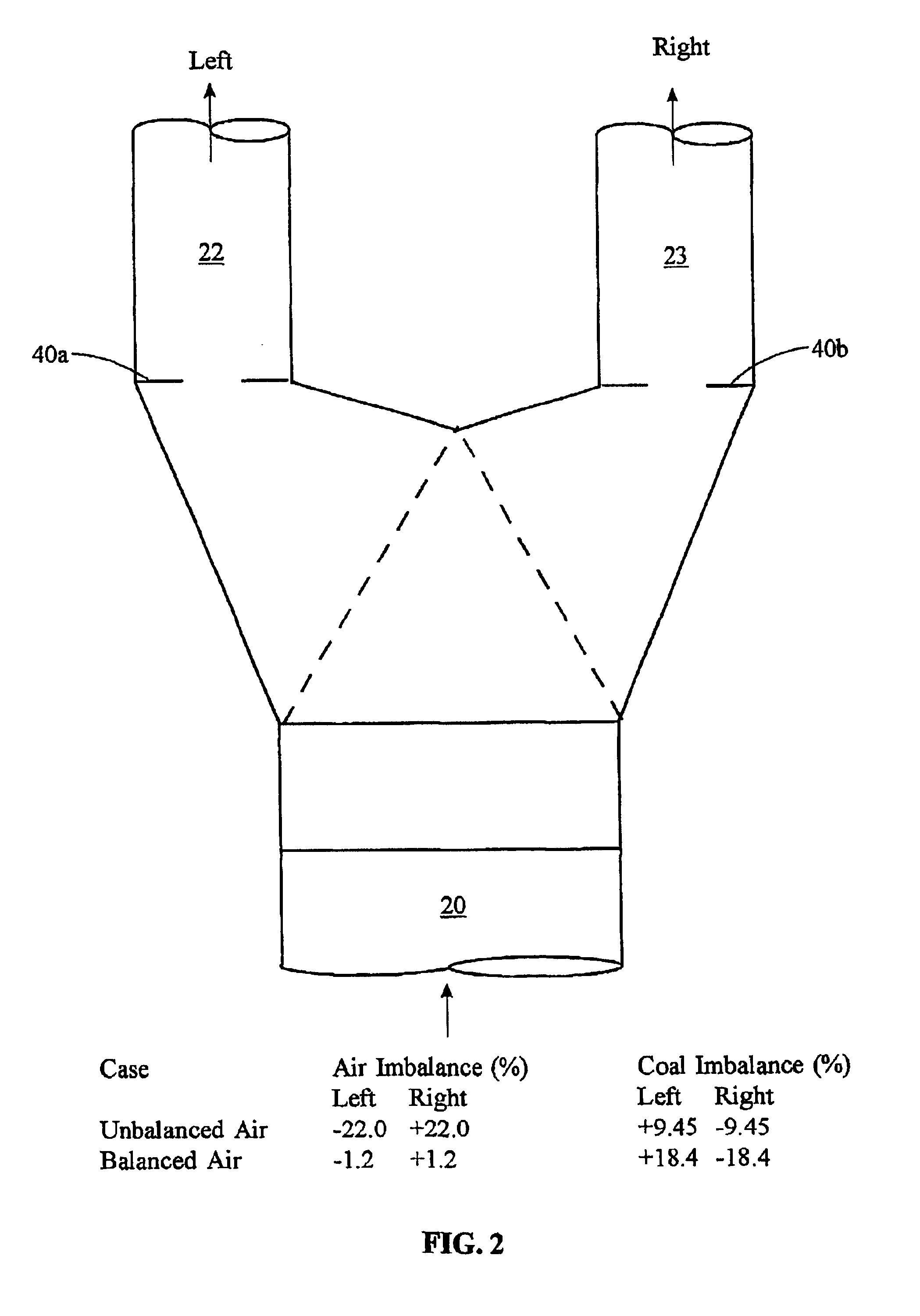

Adjustable air foils for balancing pulverized coal flow at a coal pipe splitter junction

InactiveUS20050042043A1Coal flow imbalanceIncreasing and decreasing flowFuel feeding arrangementsDamper arrangementPollutant emissionsCoal

An adjustable device installed at the inlet of conventional junctions / splitters (116) for on-line control of the distribution of coal among the outlet pipes is herein disclosed. The device includes a plurality of wake inducing airfoils (60) each positioned upstream of a plurality of flow channels in the riffler (50) for directing coal flow to the outlet pipes. Each wake-inducing airfoil has a cross-section defined by a width W that varies along its length H for creating upstream turbulence, and a particle wake that preferentially diverts the coal flow to one of the outlet pipes at the splitter junction without affecting primary air flow. For example, each wake inducing airfoil may comprise a rounded convex edge leading to straight tapered sides. The surfaces of the sides may be roughened or textured (63) for promoting turbulent boundary layers. In addition, conventional fixed or variable orifices may be used in combination with the wake inducing airfoils for balancing primary air flow rates. The device allows fine-adjustment control of coal flow rates when used in combination with the slotted riffler, yet it has negligible effect on the distribution of primary air, resulting in closely balanced coal flow, reduced pollutant emissions and improved combustion efficiency.

Owner:LEVY EDWARD KENNETH +3

Parallel path, downdraft gasifier apparatus and method

ActiveUS20090119993A1Rapid and precise control of environmentFor fast and precise controlGasifier mechanical detailsGas modification by gas mixingOxidation zoneDowndraft gasifier

A method for using a downdraft gasifier comprising a housing and a refractory stack contained within the housing. The refractory stack may comprise various sections. Apertures in the sections may be aligned to form multiple columnar cavities. Each columnar cavity may comprise an individual oxidation zone. The method of use may include the steps of placing a feedstock into an upper portion of the refractory stack, measuring the temperature of each columnar cavity, and adjusting the flow of oxygen to a particular columnar cavity to maintain the temperature of the particular columnar cavity within a particular range.

Owner:STRATEAN

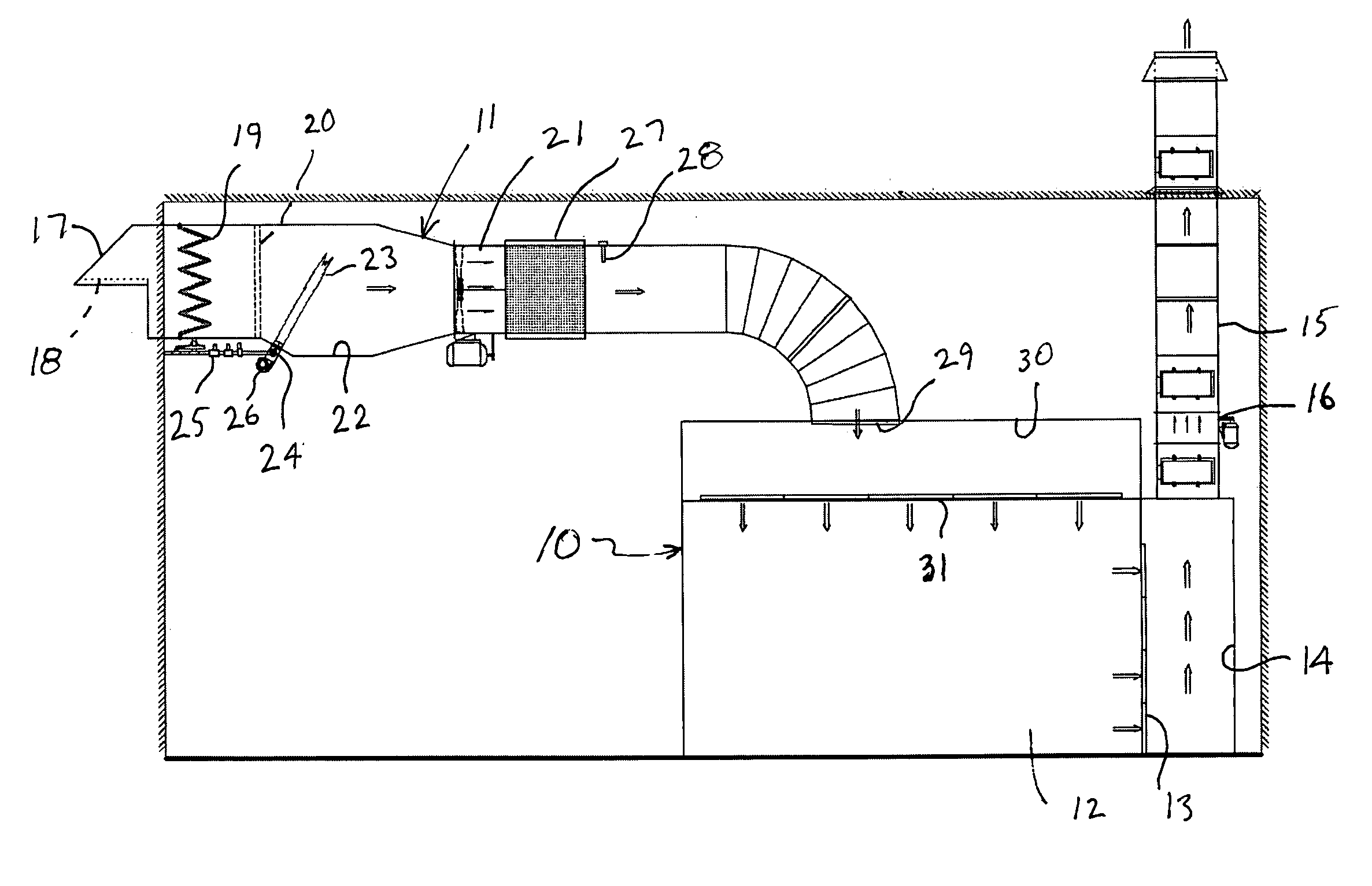

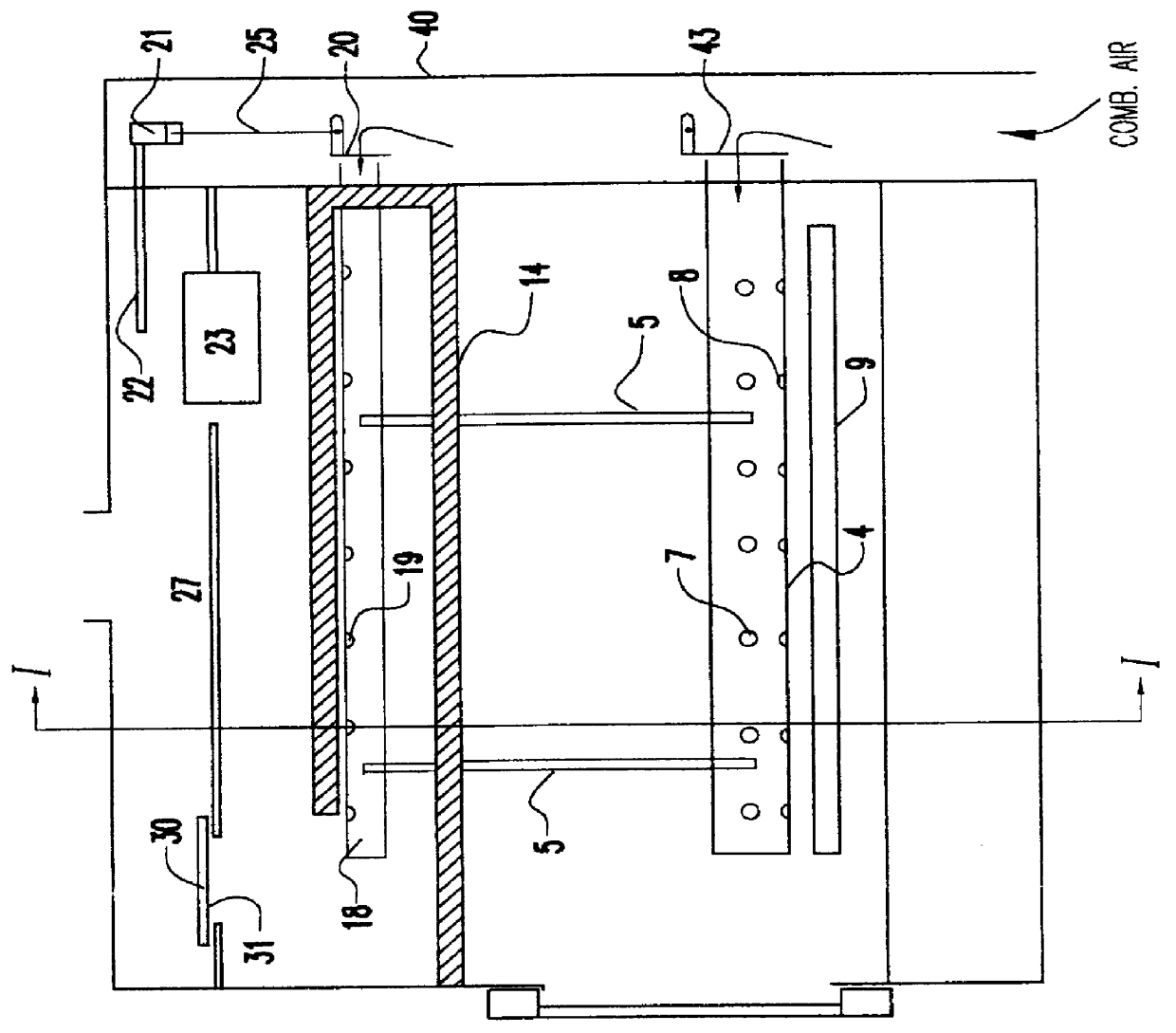

Heated replacement air system for commercial applications

ActiveUS7360534B2Improve transmission efficiencyEmission reductionLiquid surface applicatorsDomestic stoves or rangesCombustorEngineering

Apparatus and a method for providing heated replacement air to a paint spray booth or other commercial process which requires heated make-up air to replace exhausted air. A blower draws outside air through a filter and an injection chamber prior to delivering the air to the process. Hot gases from a burner are injected into the injection chamber and mixed with the replacement air to adjust the temperature of the replacement air. The burner uses combustion air which is separate from the replacement air. The flow rate of the exhaust air and the replacement air can be adjusted to meet changing needs of the process. The BTU output from the burner is adjusted to maintain a desired replacement air temperature.

Owner:SUPPLIER SUPPORT INT

Heating apparatus with fan

InactiveUS20120031392A1Reduced temperature external surfaceLiquid heating fuelCombustion-air/flue-gas circulation for stovesInterior spaceCombustion chamber

Owner:DENG DAVID

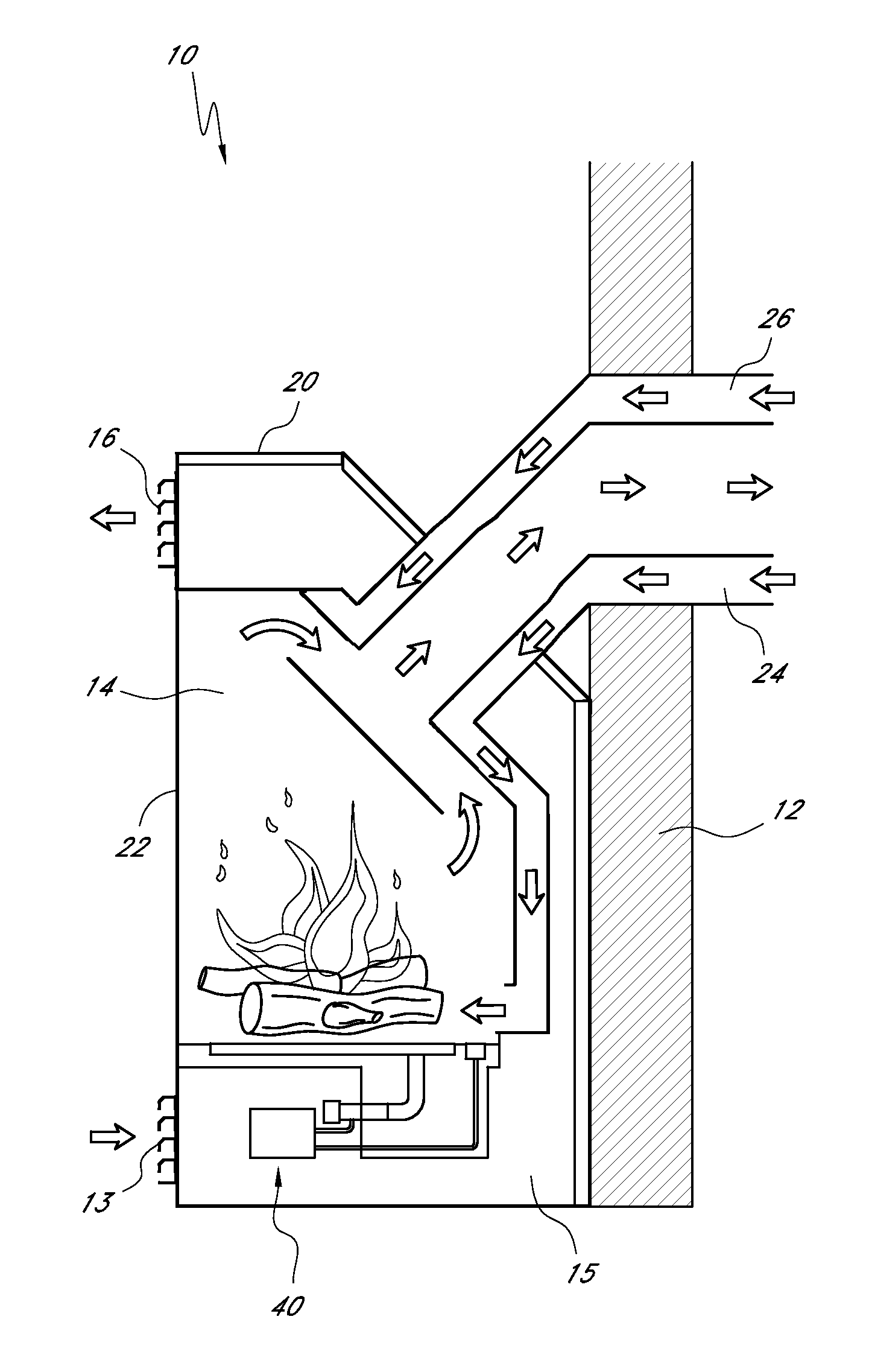

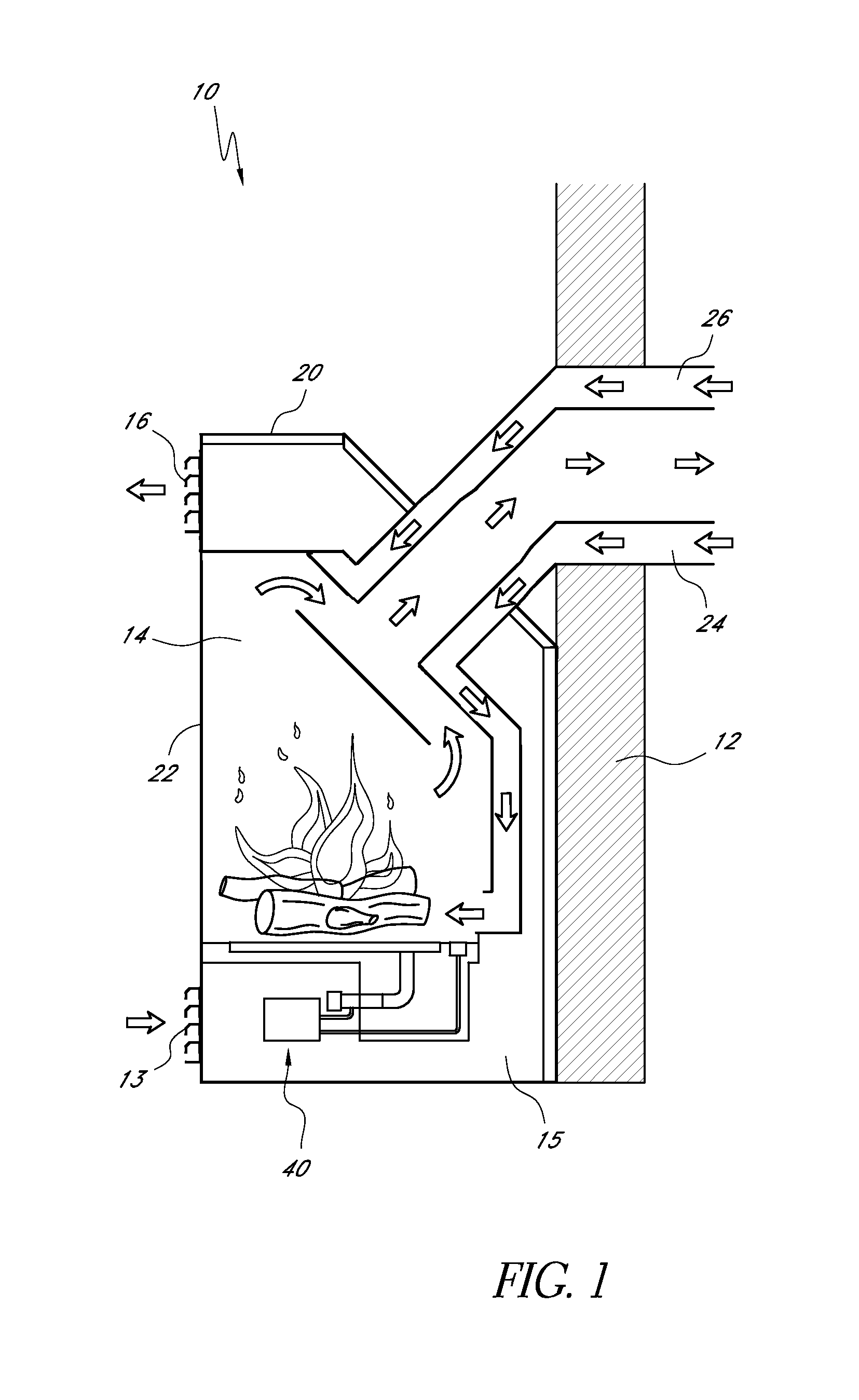

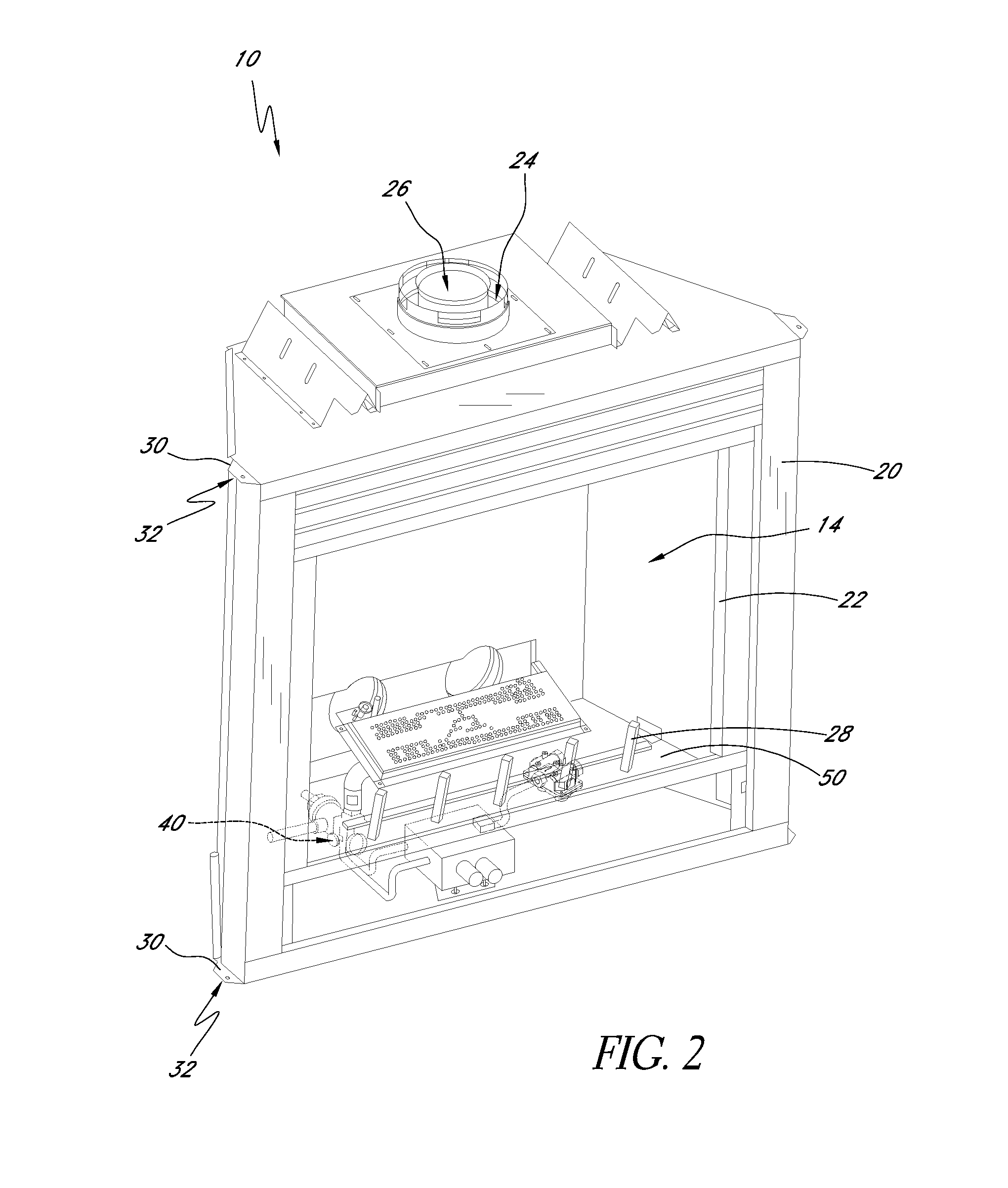

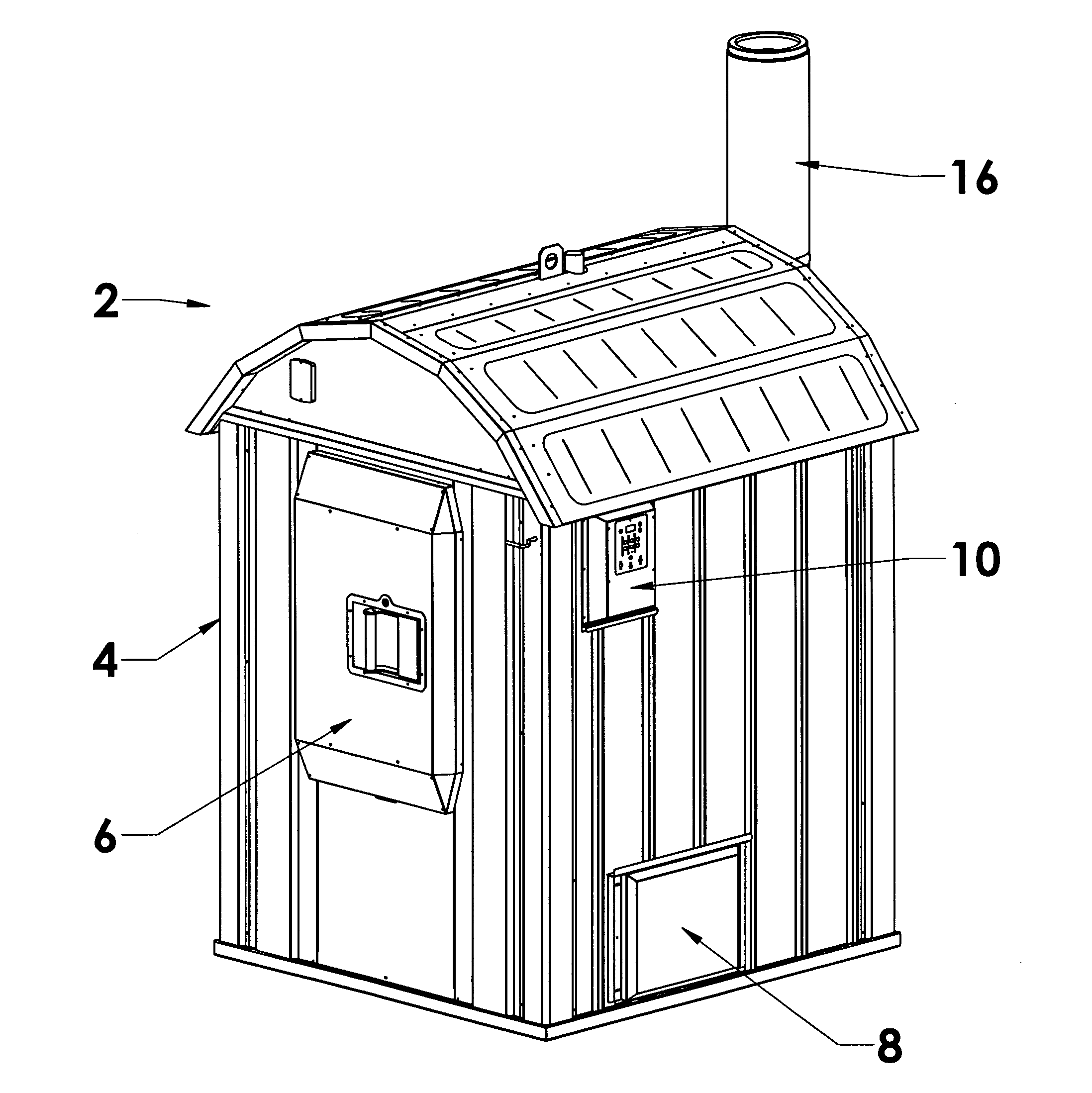

Wood fired boiler

ActiveUS20080223266A1Facilitates carbon removalFacilitate cold startFurnace componentsDomestic stoves or rangesCombustion chamberCombustor

A bio-mass fueled boiler operating at delivered efficiencies in excess of 90%. Pre-heated, pressurized primary combustion air is supplied to a primary burn chamber via horizontal and vertical orifice containing conduits. Exhaust gases are directed past a reflective secondary burner supplying pre-heated, pressurized secondary combustion air into a secondary burn / ash collection chamber. Exhaust gases are directed from the secondary burn chamber via exhaust conduits having axial and cross-sectional shapes and wall geometries that promote internal turbulence and heat transfer. One or more gas / oil fired burners are fitted to or between the primary and secondary combustion chambers. Several operating modes are provided via associated blowers, air baffles, liquid and gas fuel conduits, pumps and sundry stove sensors and servos coupled to microprocessor control circuitry.

Owner:CENTRAL BOILER

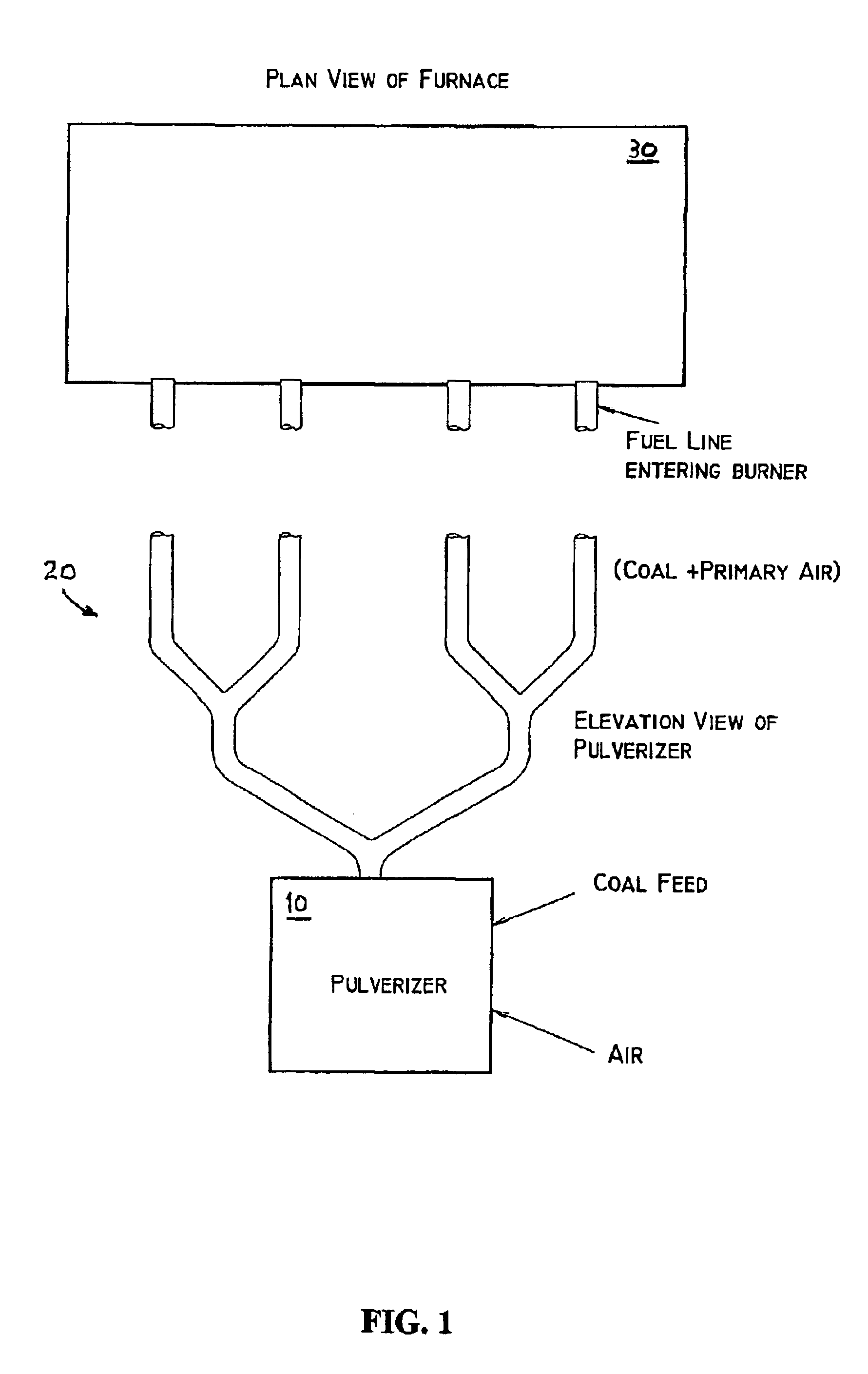

Adjustable flow control elements for balancing pulverized coal flow at coal pipe splitter junctions

InactiveUS6789488B2Lower Level RequirementsImprove combustion efficiencyFuel feeding arrangementsPulverulent fuel combustion burnersCombined usePollutant emissions

An adjustable device installed at the inlet of conventional junctions / splitters (116) for on-line control of the distribution of coal among the outlet pipes is herein disclosed. The device includes a plurality of flow control elements (60) each positioned upstream of a plurality of flow channels in the riffler (50) for directing coal flow to the outlet pipes. Each flow control element preferably comprises a rounded convex edge leading to straight tapered sides (FIG. 9). The surfaces of the sides may be roughened or textured (63) for promoting turbulent boundary layers (FIG. 9). In addition, conventional fixed or variable orifices may be used in combination with the flow control elements for balancing primary air flow rates. The device allows fine-adjustment control of coal flow rates when used in combination with the slotted riffler, yet it has negligible effect on the distribution of primary air. The combination of the riffler assembly and the coal flow control elements (60) results in closely balanced coal flow. Balanced coal flow is imperative to the optimization of the operation of pulverized coal boiler systems (i.e. reduced pollutant emissions, improved combustion efficiency).

Owner:LEVY EDWARD KENNETH +2

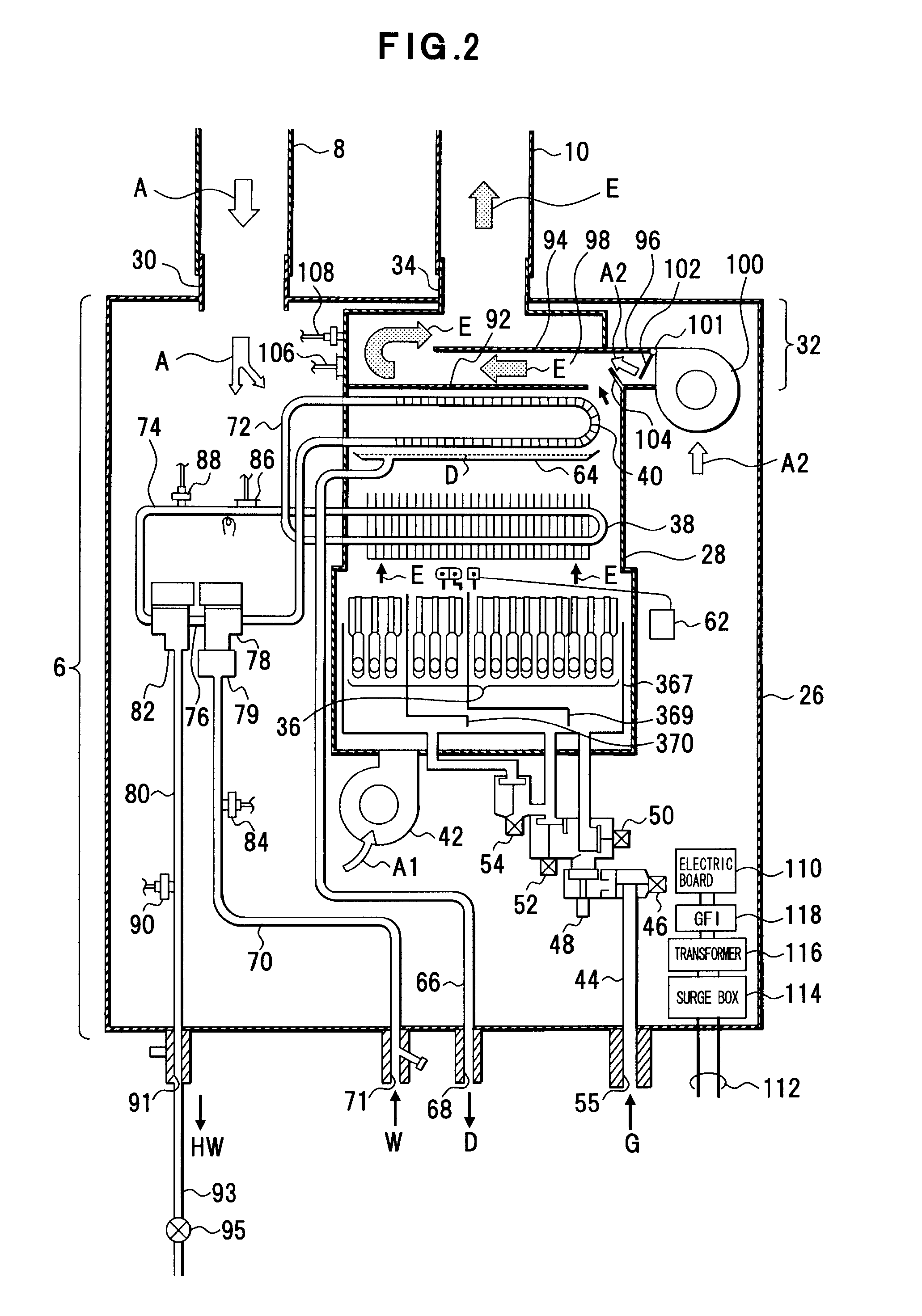

Combustion apparatus, method for combustion control, combustion control board, combustion control system and water heater

InactiveUS20120037096A1Equipment miniaturizationCompact apparatusFuel supply regulationMechanical apparatusCombustionControl system

A combustion apparatus includes combustion means generating combustion exhaust by combustion of fuel, heat exchange means exchanging heat of the combustion exhaust, and exhaust dilution unit supplying dilution air after the heat exchange by the heat exchange means and diluting the combustion exhaust after the heat exchange, and controls a temperature of the combustion exhaust after the heat exchange below a predetermined temperature by dilution by air supply.

Owner:PURPOSE CO LTD

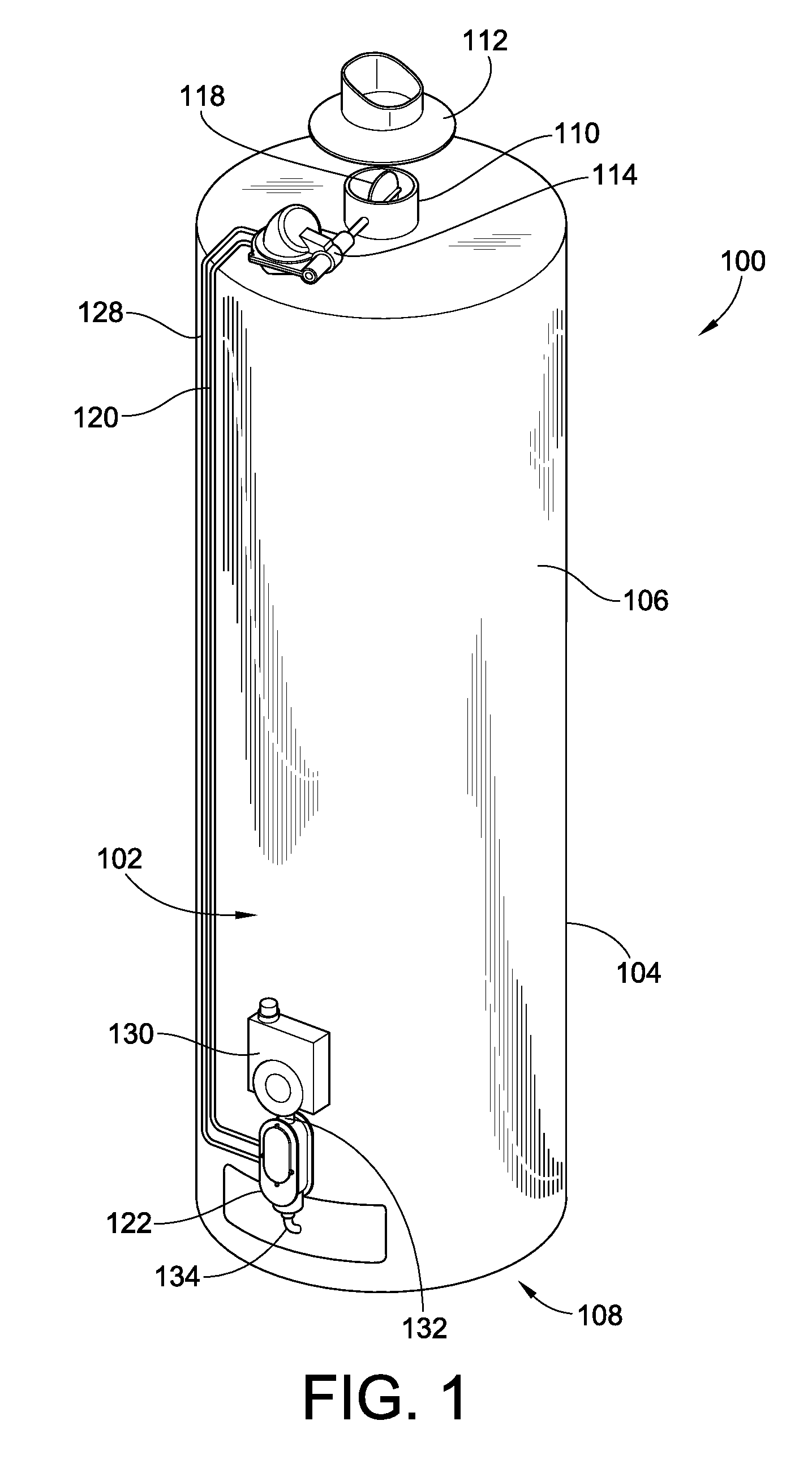

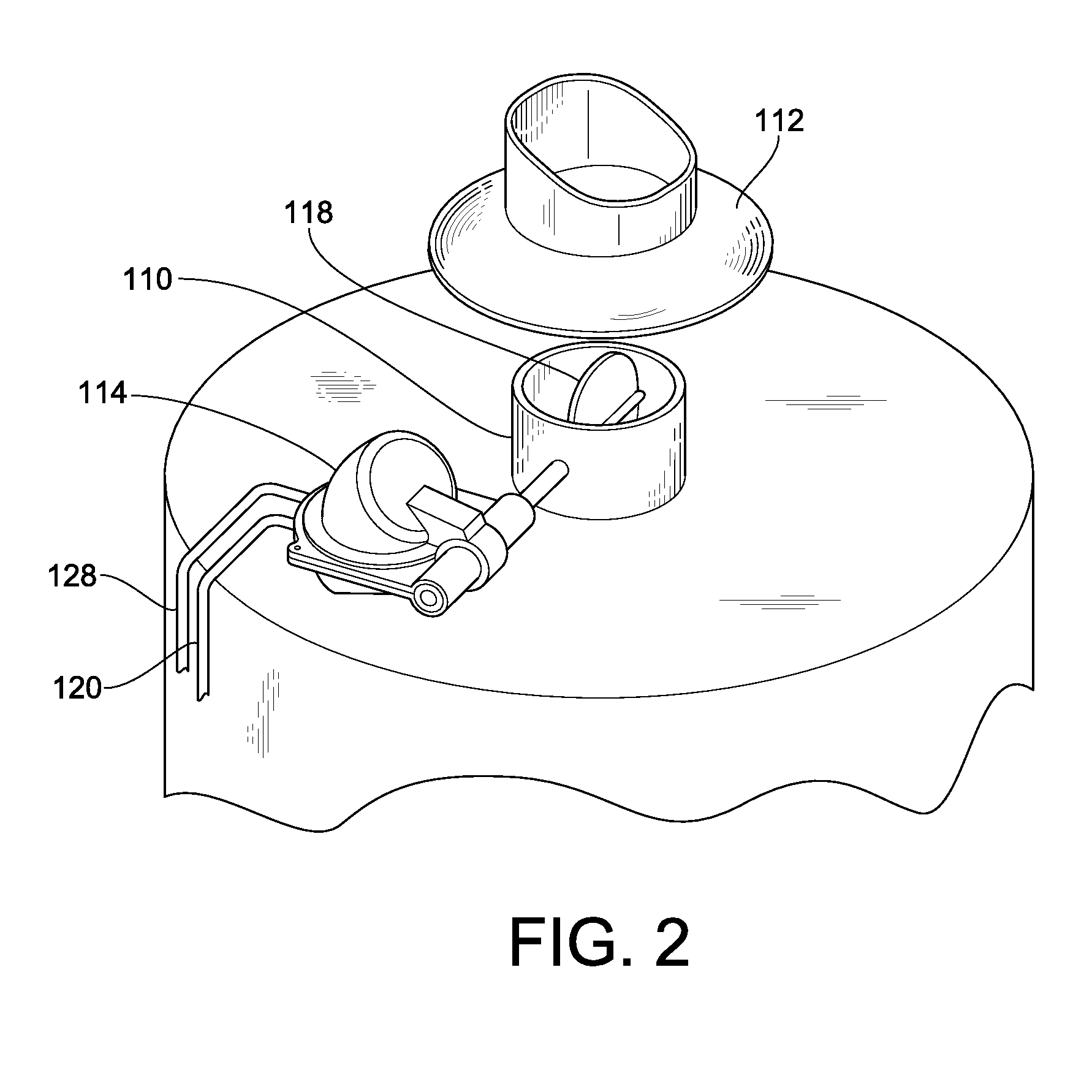

System and Method to Reduce Standby Energy Loss in a Gas Burning Appliance

ActiveUS20100012048A1Reducing greenhouse gasReduces standby heat lossAir supply regulationDamper arrangementRelay valveCombustor

A system to reduce standby losses in a hot water heater is presented. The system utilizes a safety relay valve between the combination gas controller and the burner. The safety relay valve bypasses gas to a damper actuator valve to position a flapper valve located over the flue pipe. Once the flapper valve has opened to ensure combustion, the gas is allowed to flow back to the safety relay valve. Some of the bypass gas may be diverted to boost the pilot or to supply a booster. The safety relay valve is then opened to allow the gas supply to the burner. Once the burner is turned off by the combination gas controller, the small amount of bypass gas bleeds out of the damper actuator valve to close the flapper valve to reduce standby losses through the flue pipe, and to allow the safety relay valve to close tightly.

Owner:INVENSYS CONTROLS AUSTRALIA

Popular searches

Emergency protective arrangement details Solid heating fuel Overvoltage protection resistors Emergency protective arrangements for limiting excess voltage/current Arrangements responsive to excess voltage Carbon compounds Dispersed particle filtration Isotope separation Pipeline systems Direct carbon-dioxide mitigation

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com