Patents

Literature

188results about How to "Increase gasification rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

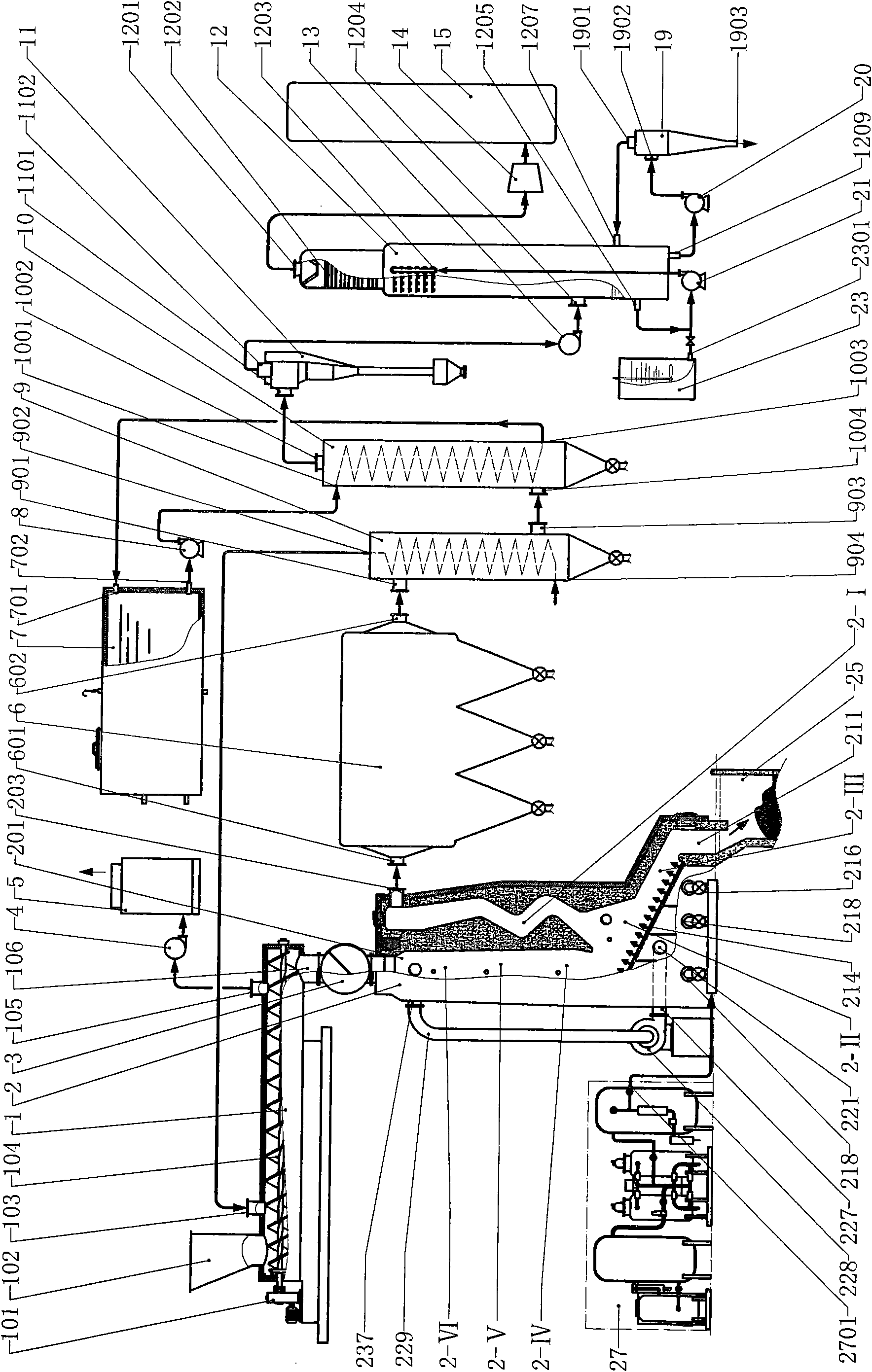

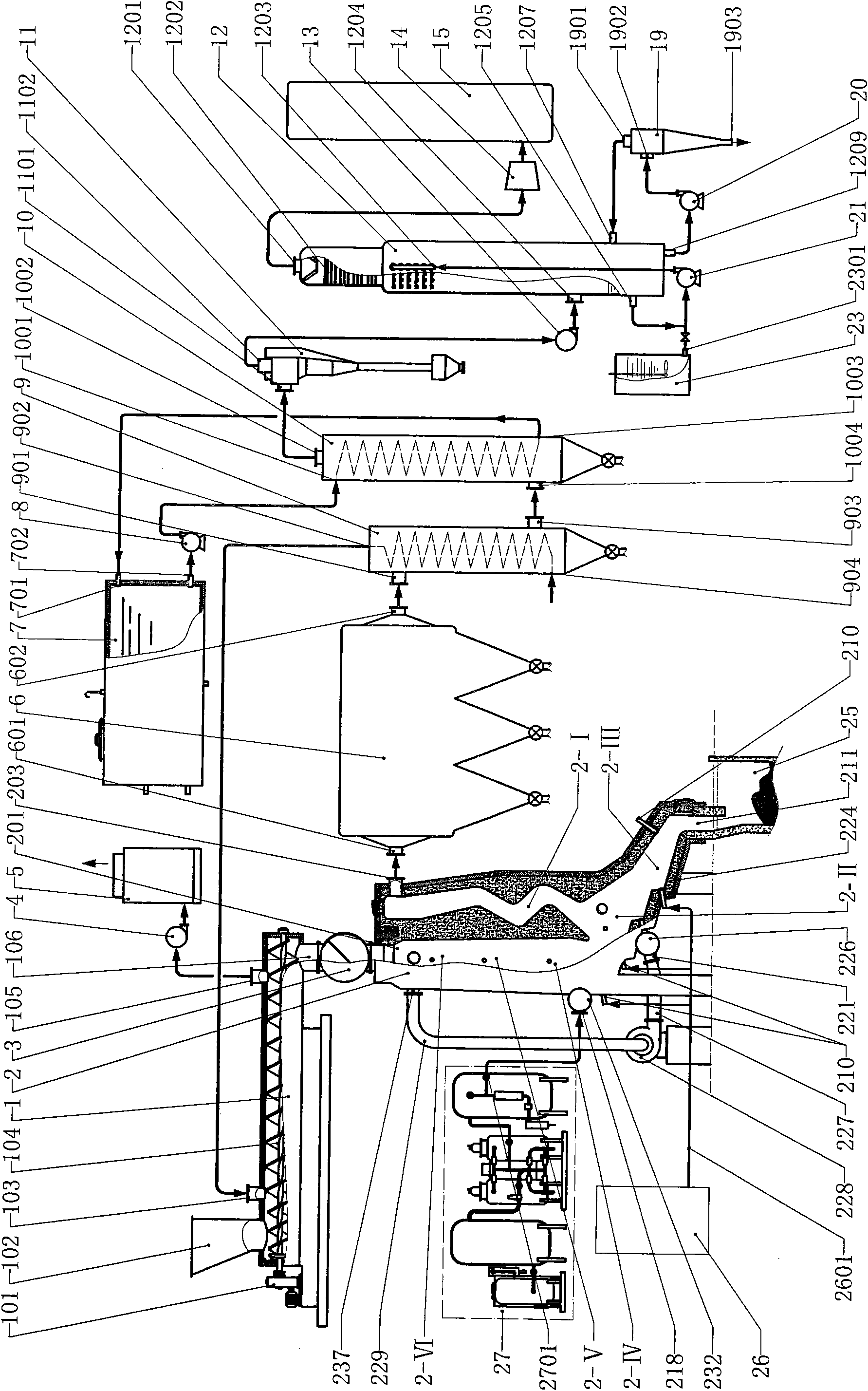

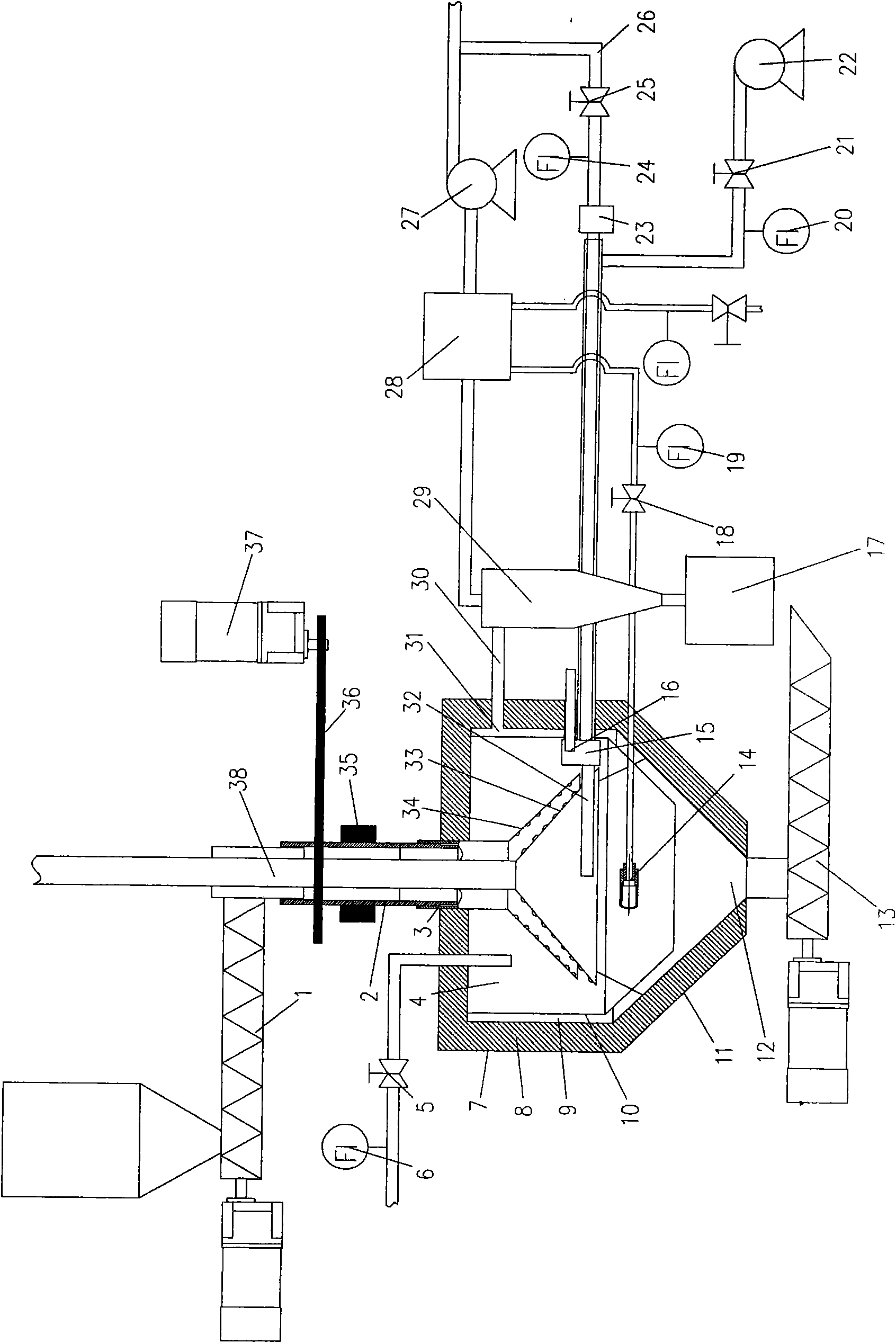

Biomass castoff supercritical water fluid bed partial oxidation hydrogen-preparation device and method

ActiveCN101058404AImprove heat transfer efficiencyConducive to centralized processing and resource utilizationSolid waste disposalHydrogen productionBiomassChemistry

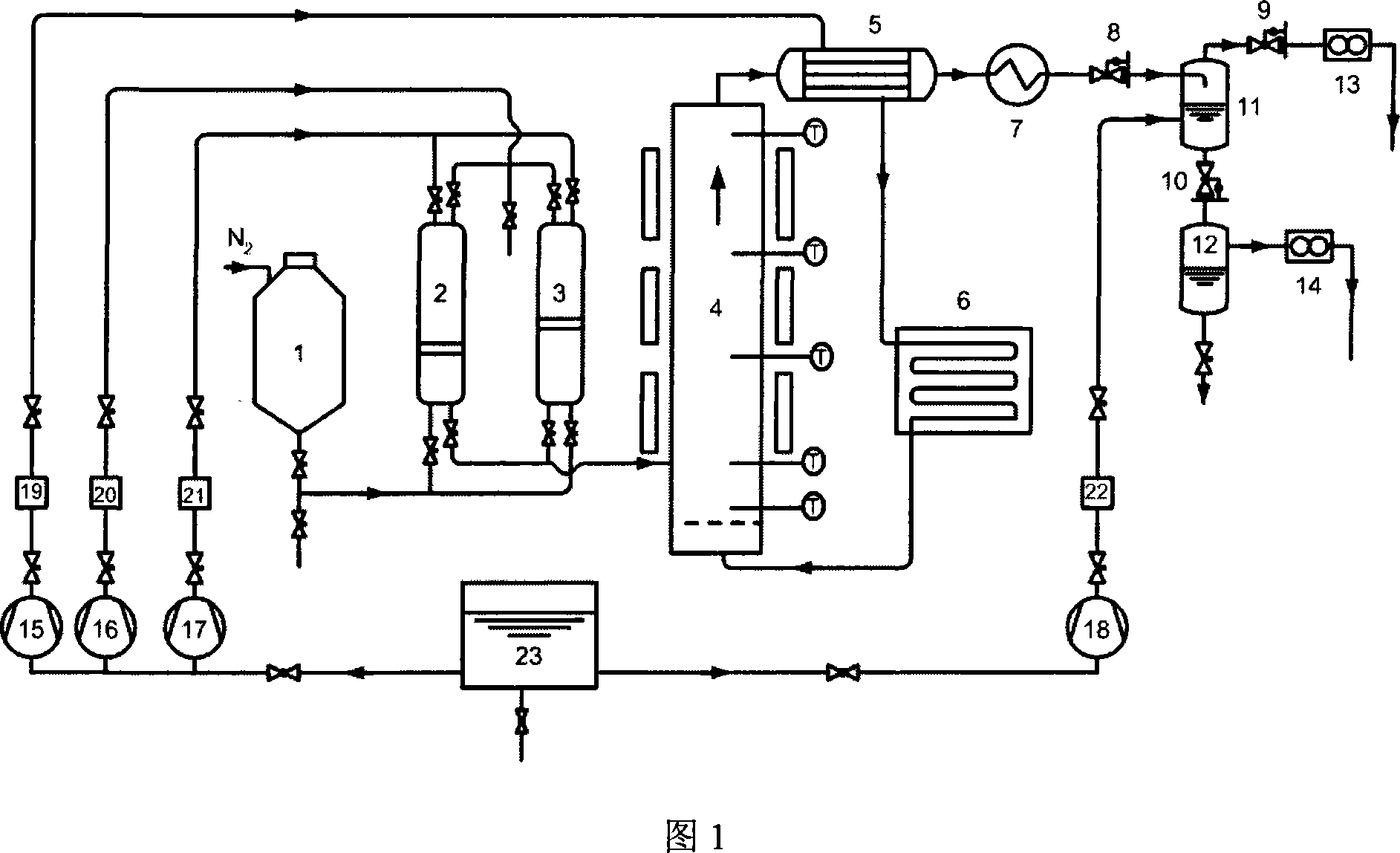

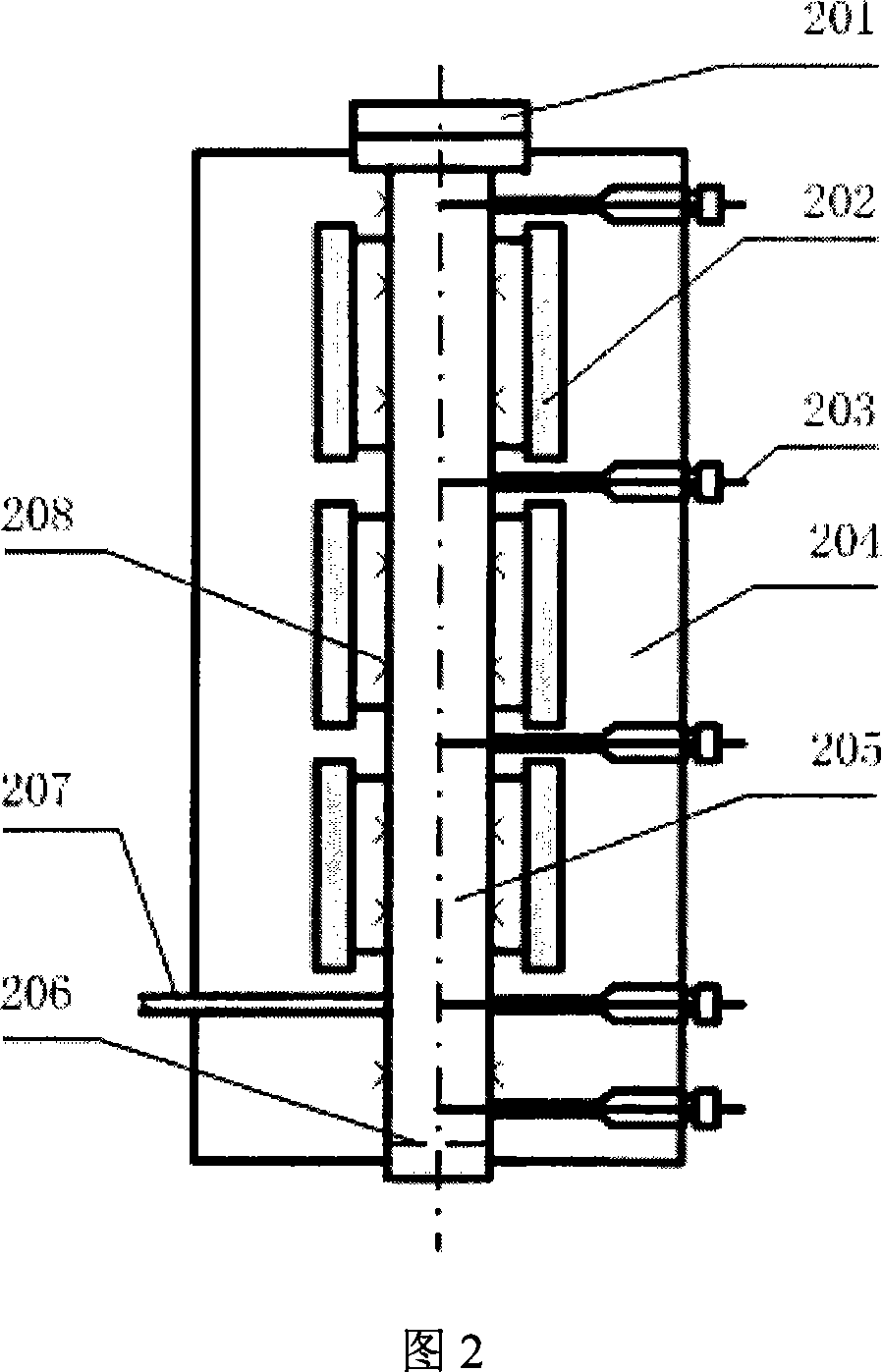

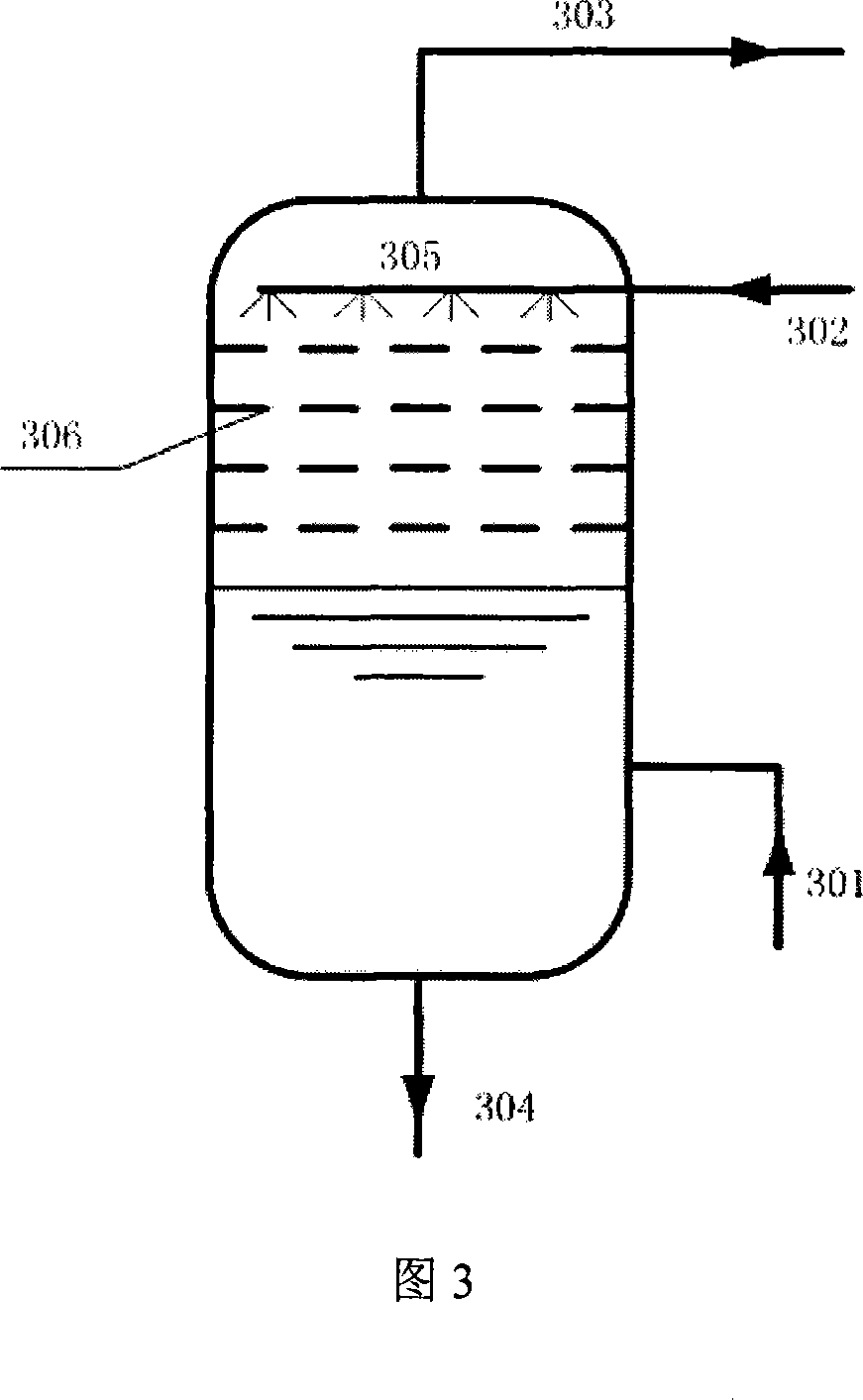

The invention discloses an oxidizing and gasifying hydrogen-making device and method of hypercritical water fluid-bed part of the biological waste, which is characterized by the following: adopting hypercritical water fluid-bed reactor to prevent slagging and blocking problem in the pipe flow reactor; using high-pressure separator to generate high-pressure water to adsorb carbon dioxide in the gas product; realizing the separation of the hydrogen from the carbon dioxide; making the separated high-density carbon dioxide concentrate to be disposed and do resoursing usage conveniently; compacting the device structure; simplifying and conveniencing the operation; improving the gasifying rate of the biological waste with less pollution in the liquid product; realizing the oxidizing and gasifying fusion in the reactor; improving the biological mass transmitting rate and system energy transmitting efficiency; transmitting the biological waste into high-quality hydrogen through the method; reducing the environmental pollution; realizing the dual goals to harness pollution and make hydrogen.

Owner:陕西中核交大超洁能源技术有限公司

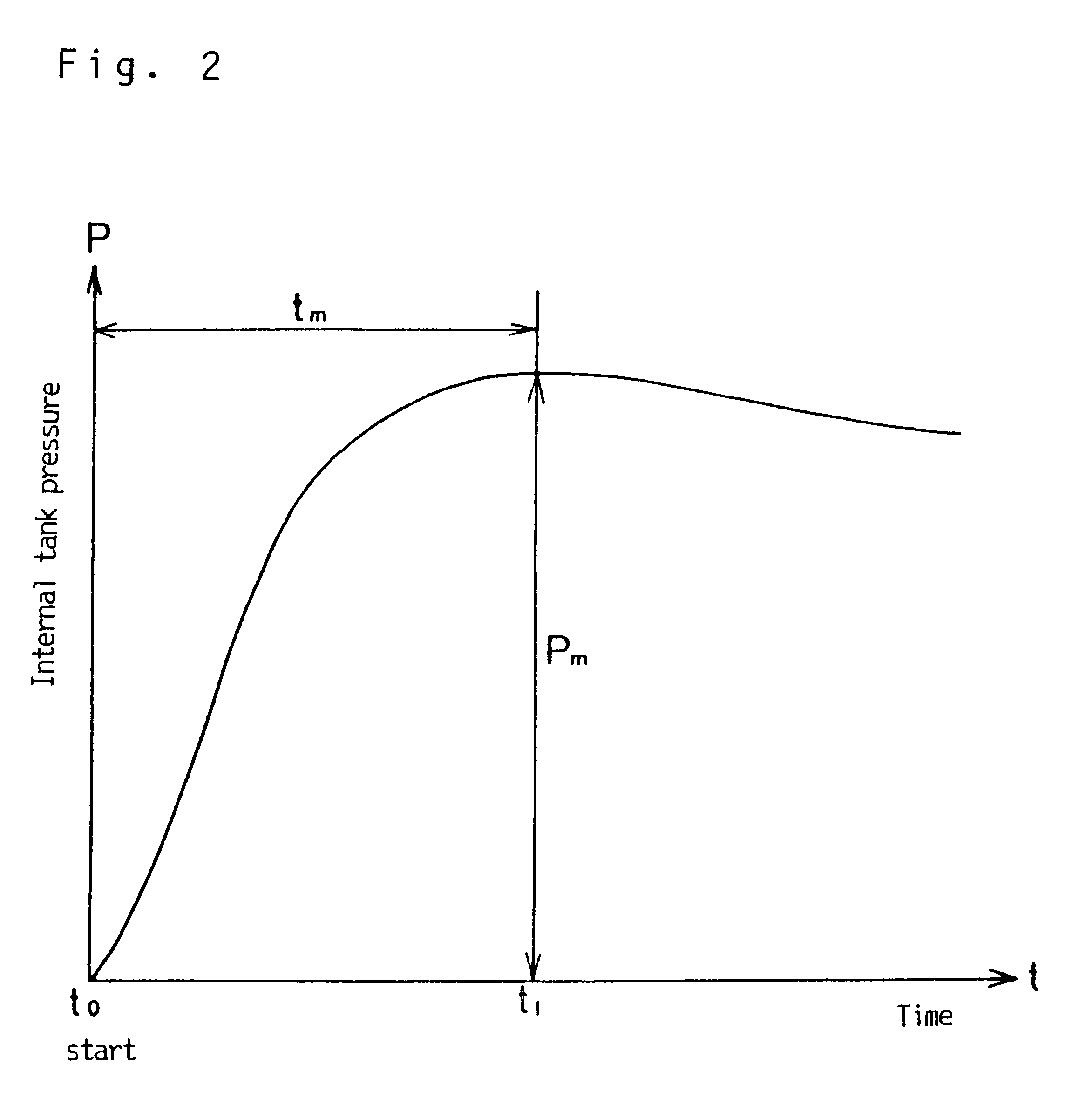

Spontaneous firing explosive composition for use in a gas generator for an airbag

InactiveUS6177028B1More securityEnsure safetyDetergent bleaching agentsNitrated explosive compositionsCombustionEngineering

A spontaneous firing explosive composition for use in a gas generator for an airbag containing a fuel, an oxidizer, a combustion modifier, and a binder.

Owner:NIPPON KAYAKU CO LTD +1

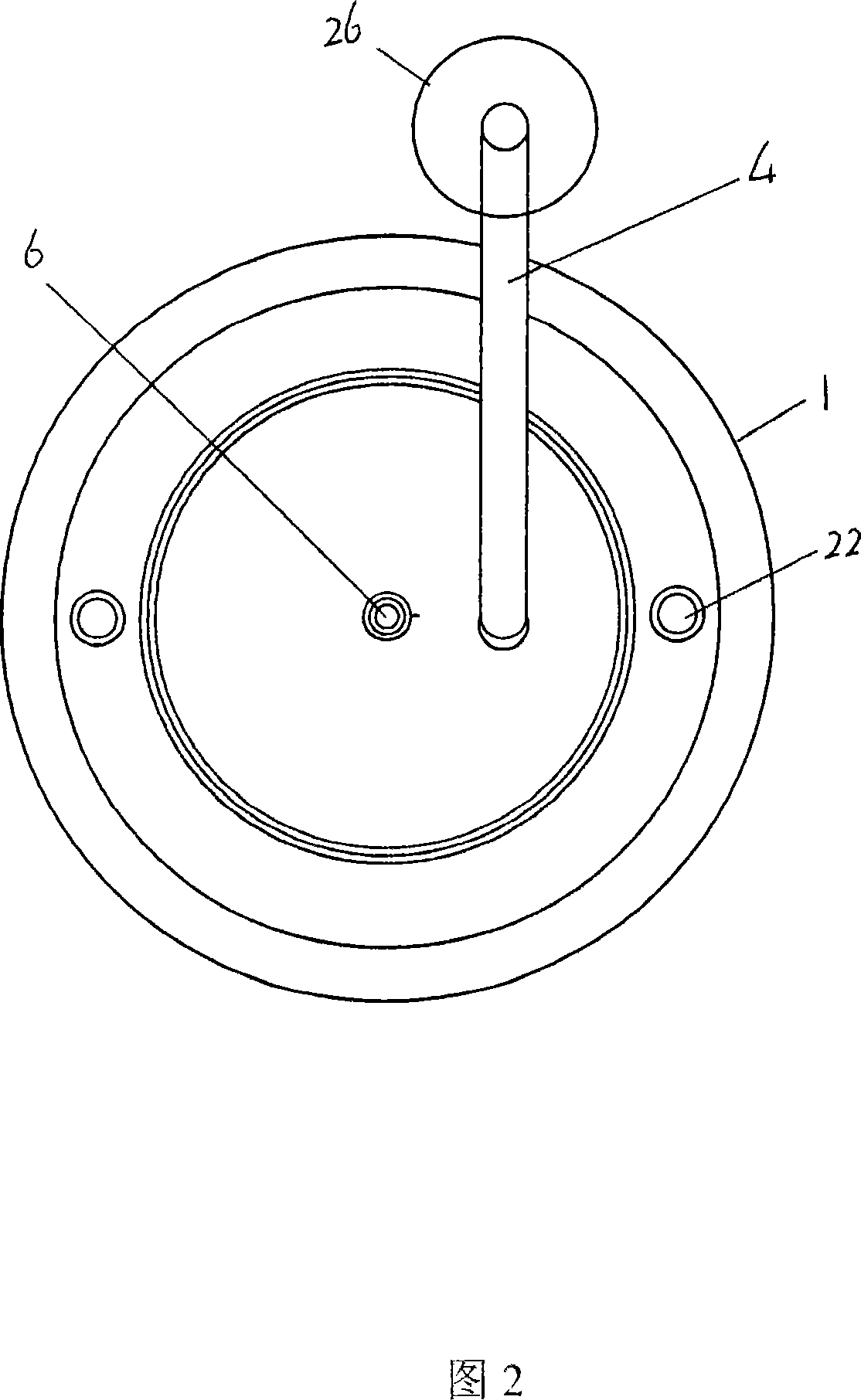

Internal-combustion heating type biomass gasification furnace

ActiveCN101021334AImprove biomass gasification rate and gas calorific valueImprove gasification efficiencyDomestic stoves or rangesLighting and heating apparatusNitrogen gasEngineering

The present invention relates to an internal combustion heated biomass gasification furnace. Its structure is characterized by that it adopts a cylindrical furnace body, in the furnace body interior a coiled internal combustion pipe is set, the internal combustion pipe inlet is positioned in the lower portion of said cylindrical furnace body, and its outlet is extended to the exterior of furnace body from the top portion of cylindrical furnace body, its igniter is positioned in the internal combustion pipe inlet; over the cylindrical furnace body a helical feeding mechanism is set, its helical feeding hole is positioned on the eccentric position of cylindrical furnace body top portion, on the centre axis position of said cylindrical furnace body a stirring shaft with stirring blades is set, on the inside wall of cylindrical furnace body several layers of baffle plates are set, the combustion-supporting air inlet is set in the top portion of said cylindrical furnace body, and the gas outlet in the furnace body is positioned in the lower portion of said furnace body.

Owner:ANHUI WEIDA ENVIRONMENTAL PROTECTION TECH

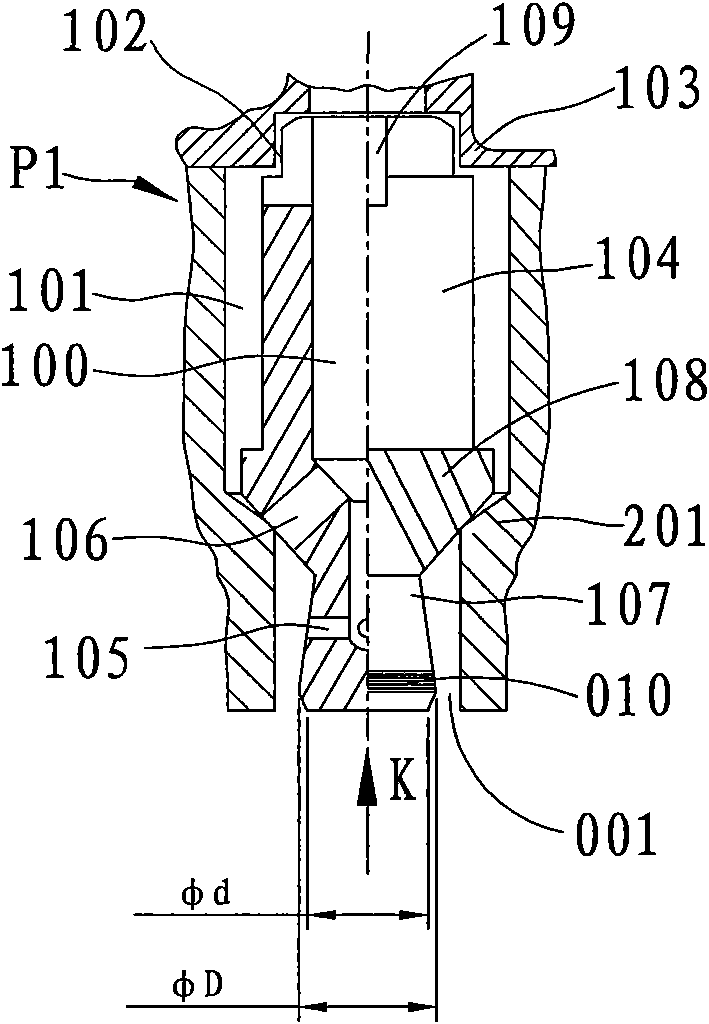

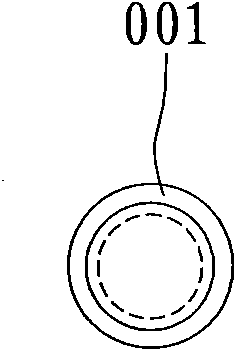

Rotary annular-seam spray nozzle and spraying device thereof

InactiveCN102039228AEasy ultra-fine atomizationUltra-fine atomization promotionSpray nozzlesLiquid spraying apparatusSpray nozzleFineness

The invention discloses a rotary annular-seam spray nozzle comprising a core seat, a rotary core and a rotary annular-seam spray hole, wherein a core cavity is arranged in the core seat, an inlet and an outlet which are communicated with the core cavity are arranged on the core seat, a core seat inlet is communicated with a pressure flow source, the rotary core can be sleeved into the core cavity in positioning and rotating modes and is concentric with the core cavity, a rotation-promoting flow path is arranged on the rotary core or / and the wall of the core cavity in order to mutually rotate the rotary core and the core cavity by using flow power, one end of the rotary core is penetrated into the core seat outlet, and the penetrating end forms the rotary annular-seam spray hole with the inner wall of the core seat outlet. The cross section of the spray hole of the rotary annular-seam spray nozzle is an annular seam, the annular seam and a diameter can be set to respectively and conveniently control the fineness and the flow of pressure spray and make liquid drop sizes more evenly and finely distributed. The rotary annular-seam spray nozzle has a self-cleaning function, is not easy to block and is in a self-closing dust-resisting type; the rotary annular-seam spray nozzle is arranged on a spray head body or the core seat of the rotary annular-seam spray nozzle is connected with the spray head body, the spray head body is communicated with the pressure flow source, and therefore, the spray device with the rotary annular-seam spray nozzle can be formed.

Owner:韩铁夫

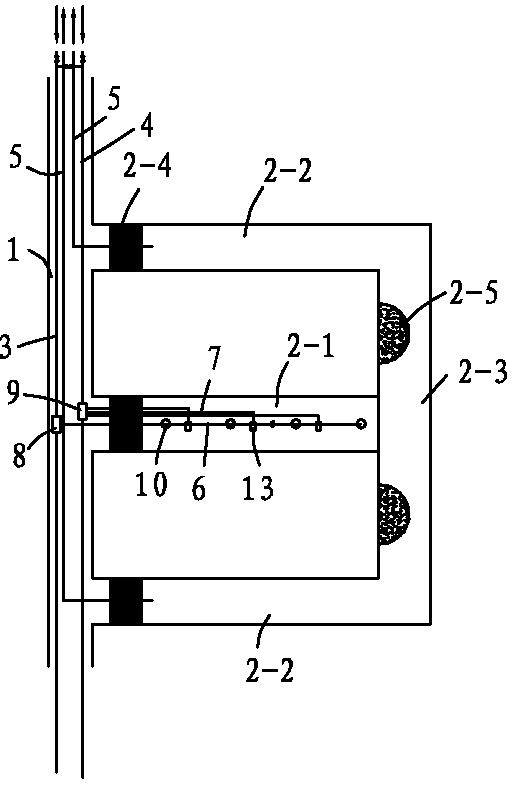

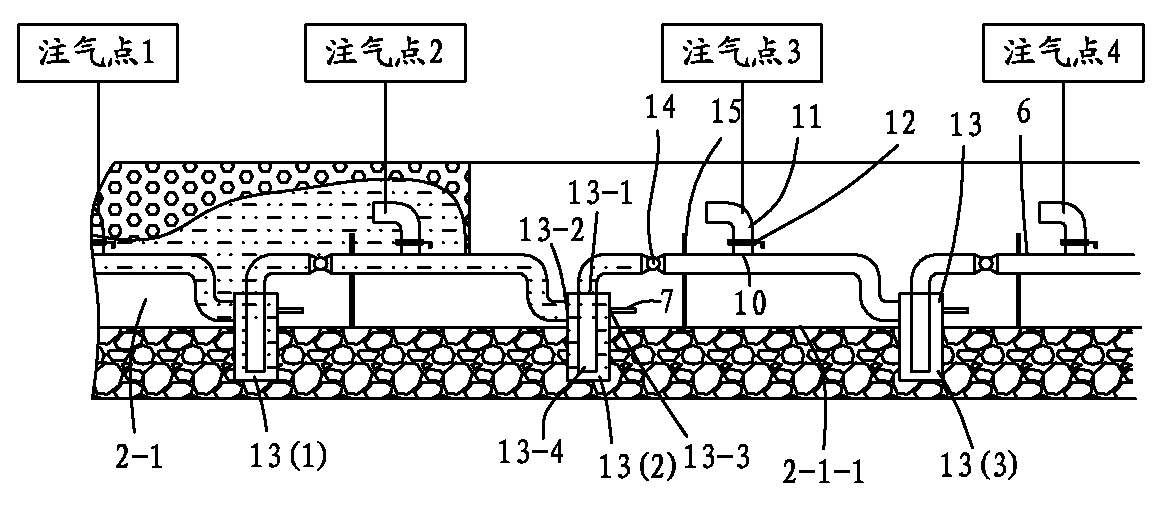

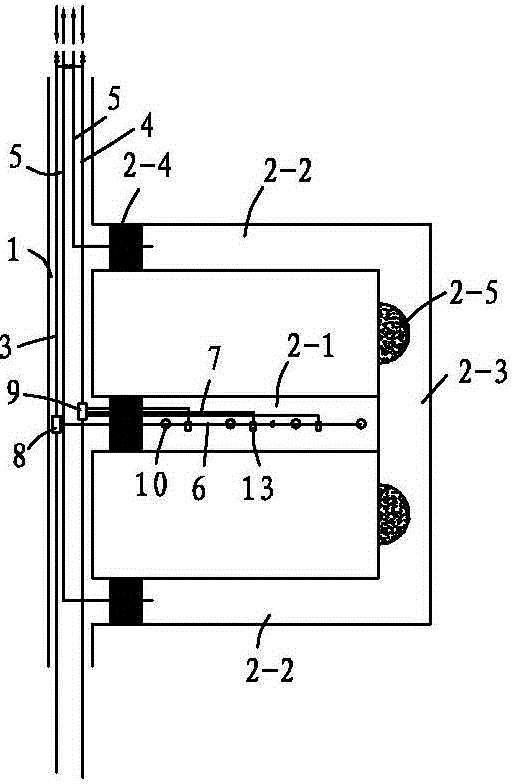

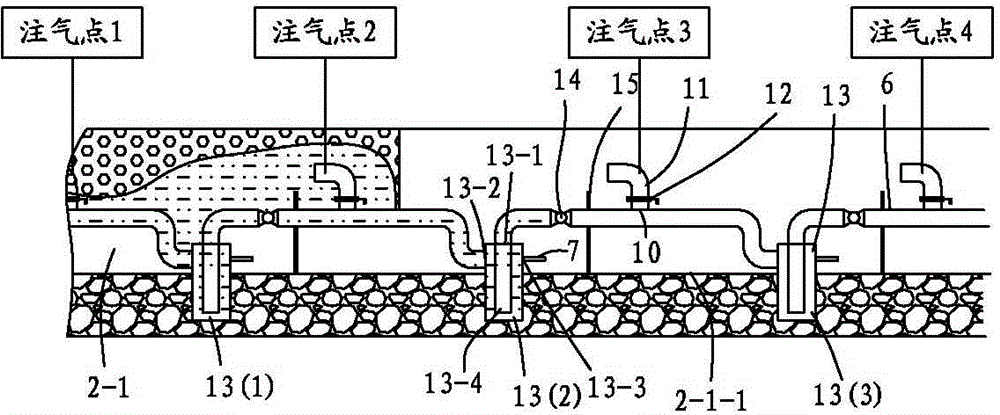

Gas injection point retreating type coal underground gasification system and process

InactiveCN103277082AAvoid cloggingPrevent backflowConstructionsCoal gasificationThermodynamicsCombustion

The invention discloses a gas injection point retreating type coal underground gasification system and process. The gas injection point retreating type coal underground gasification system comprises an airway arranged in a coal layer and multiple coal underground gasification units, wherein the airway is connected to the multiple coal underground gasification units; and the technical steps are sequentially as follows: a step of cold-state testing, a step of ignition on a gasification working surface, a step of debugging of the gasification working surface and a step of gasification normal production process. According to the invention, mud can be prevented from blocking the gas injection point efficiently, and the coal layer can be exploited to the maximum extent, so that possibility of thoroughly cutting off the leakage of a gasification agent to a combustion space area is realized while safe retreating in the coal underground gasification process is realized, filling of the combustion space area is realized, collapse of the ground surface caused by the gasification is removed, stability of the gasification channel structure is guaranteed, problem of the short circuit of the gasification agent caused by a channel which is resulted from collapse of a coal layer plate in the gasification area in the early stage and the gasification channel at the later stage of the underground gasification is solved, the quality of the coal gas is improved, and safe and reliable coal gas production and high gasification rate are achieved.

Owner:HENAN ZHONGKUANG KENENG COAL CHEM

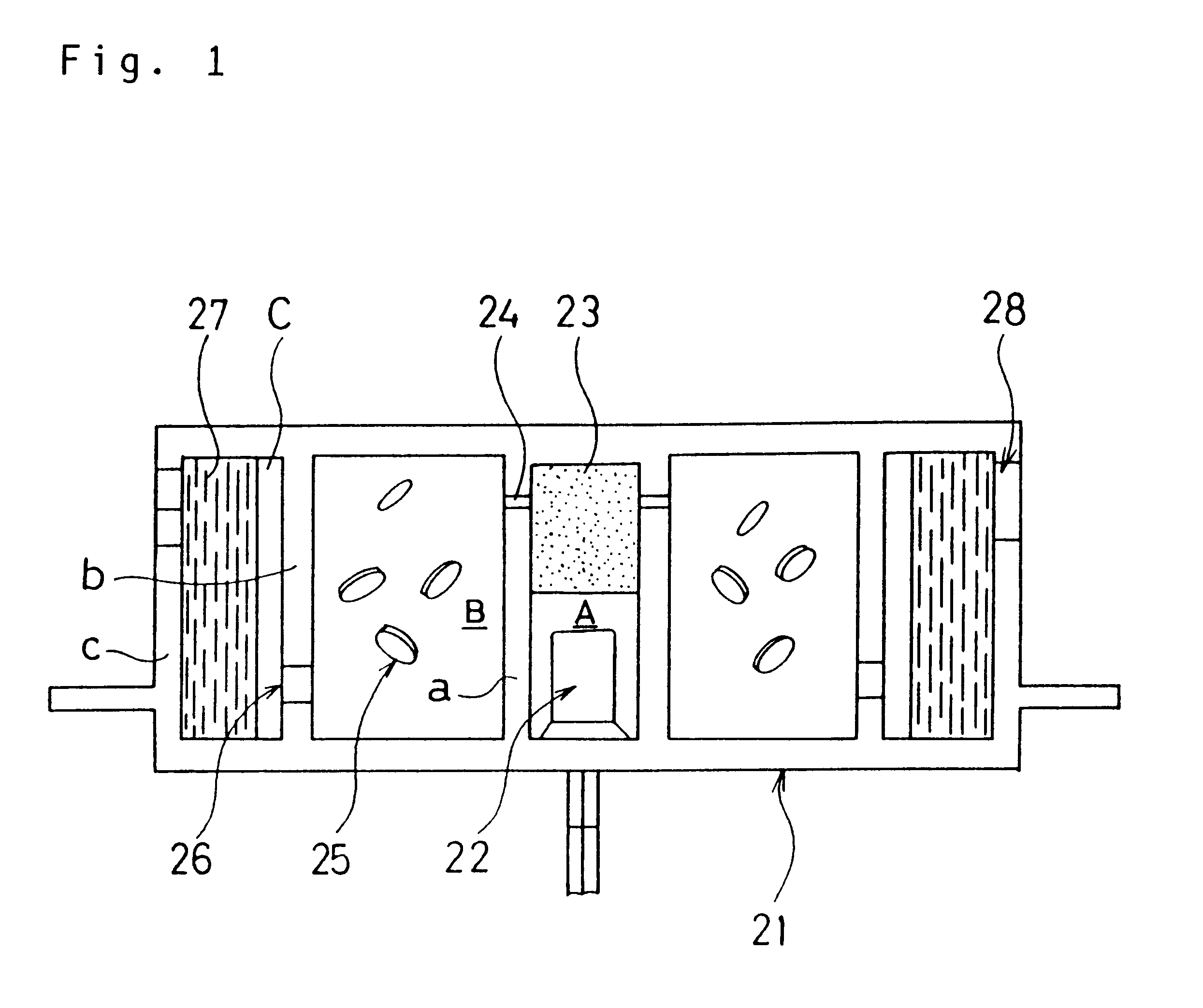

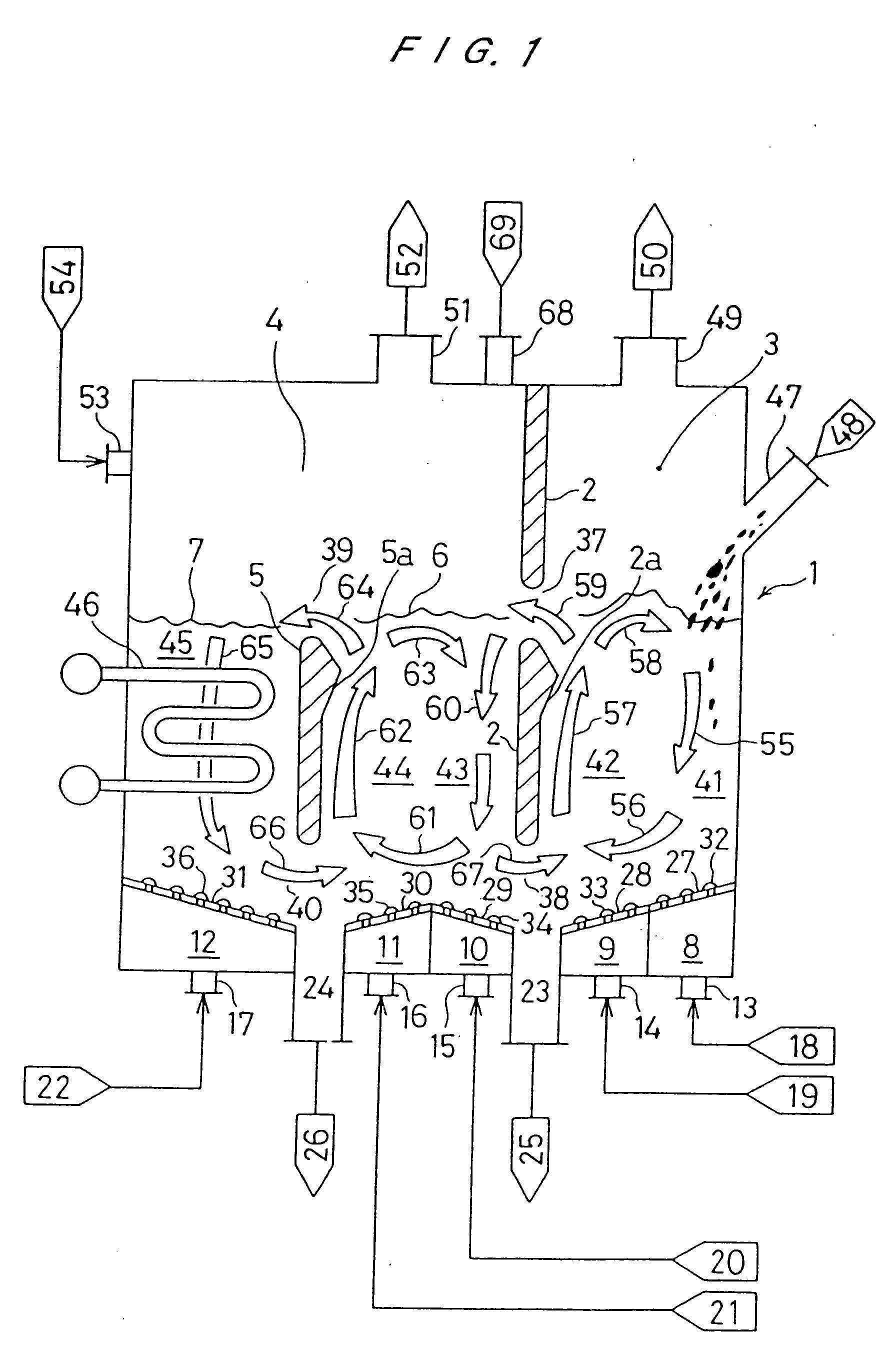

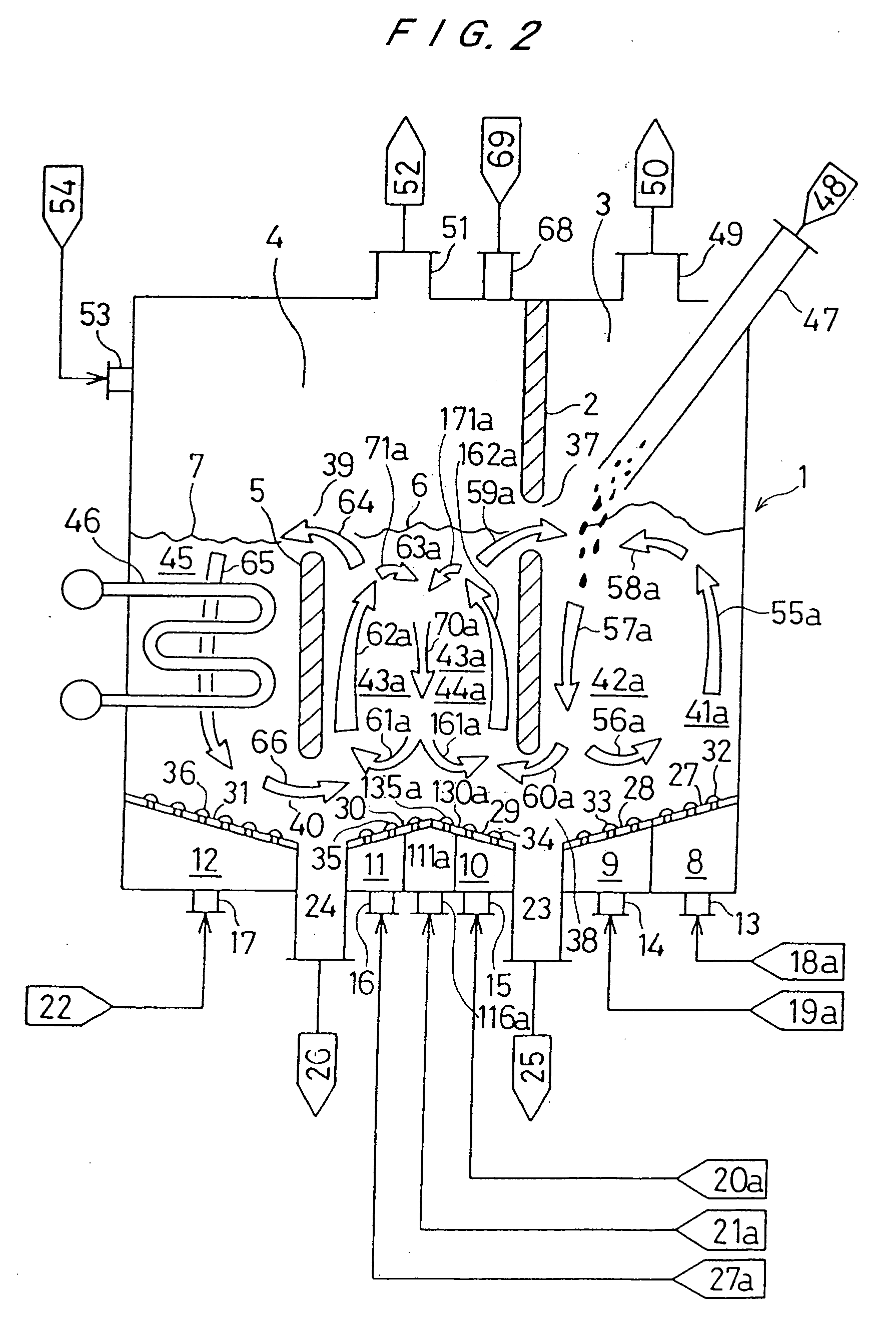

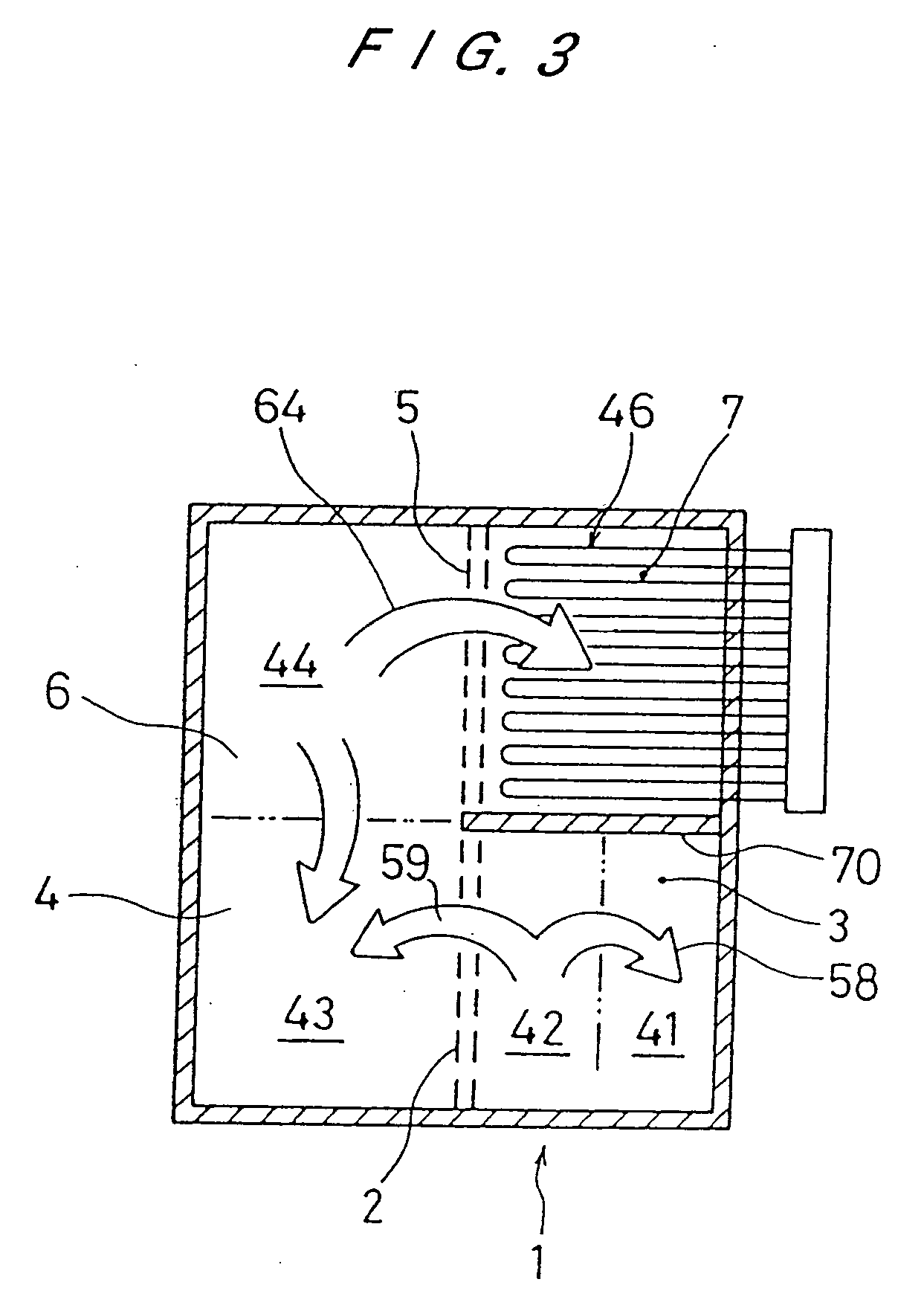

Fluidized-bed gasification and combustion furnace

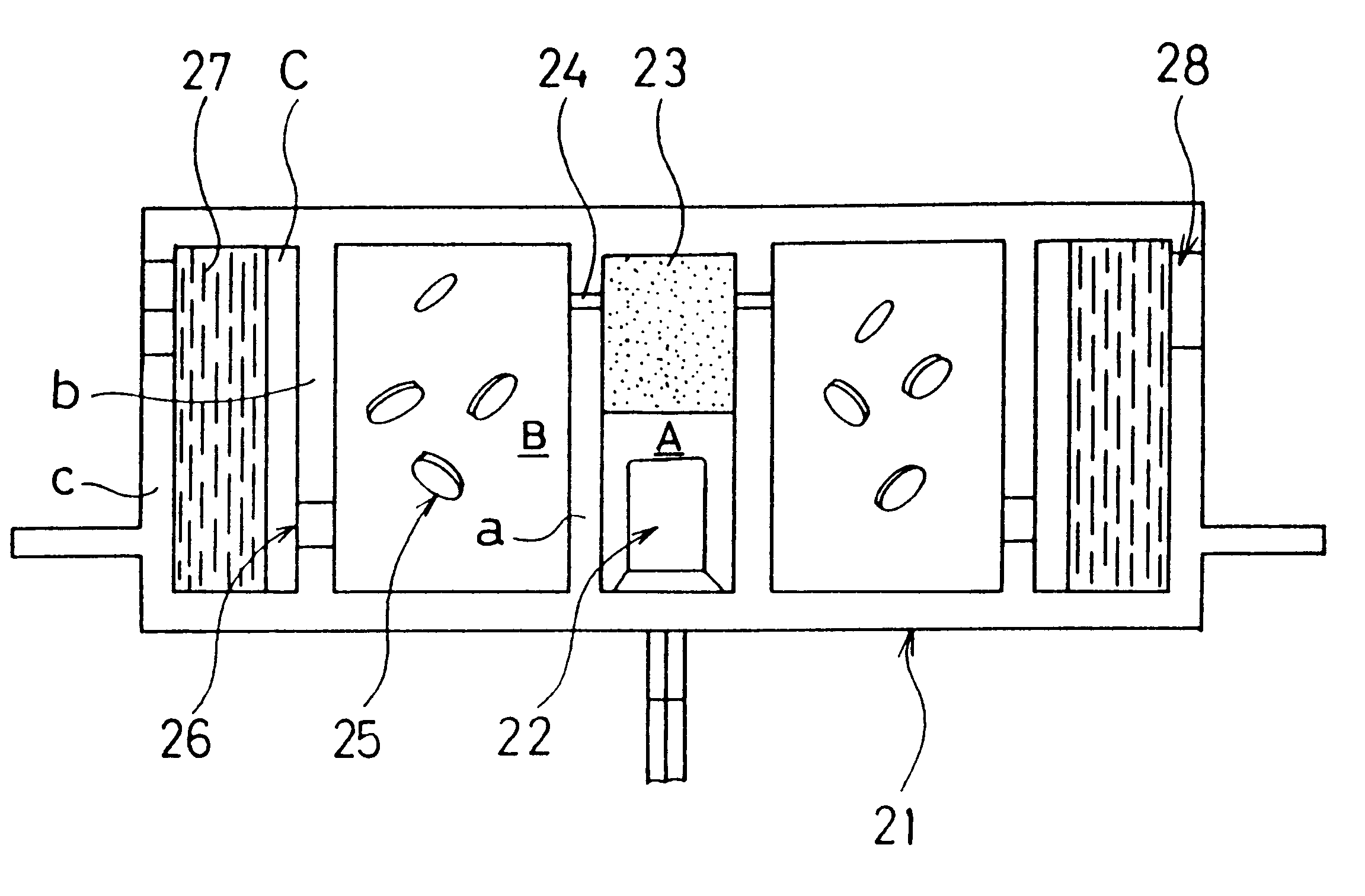

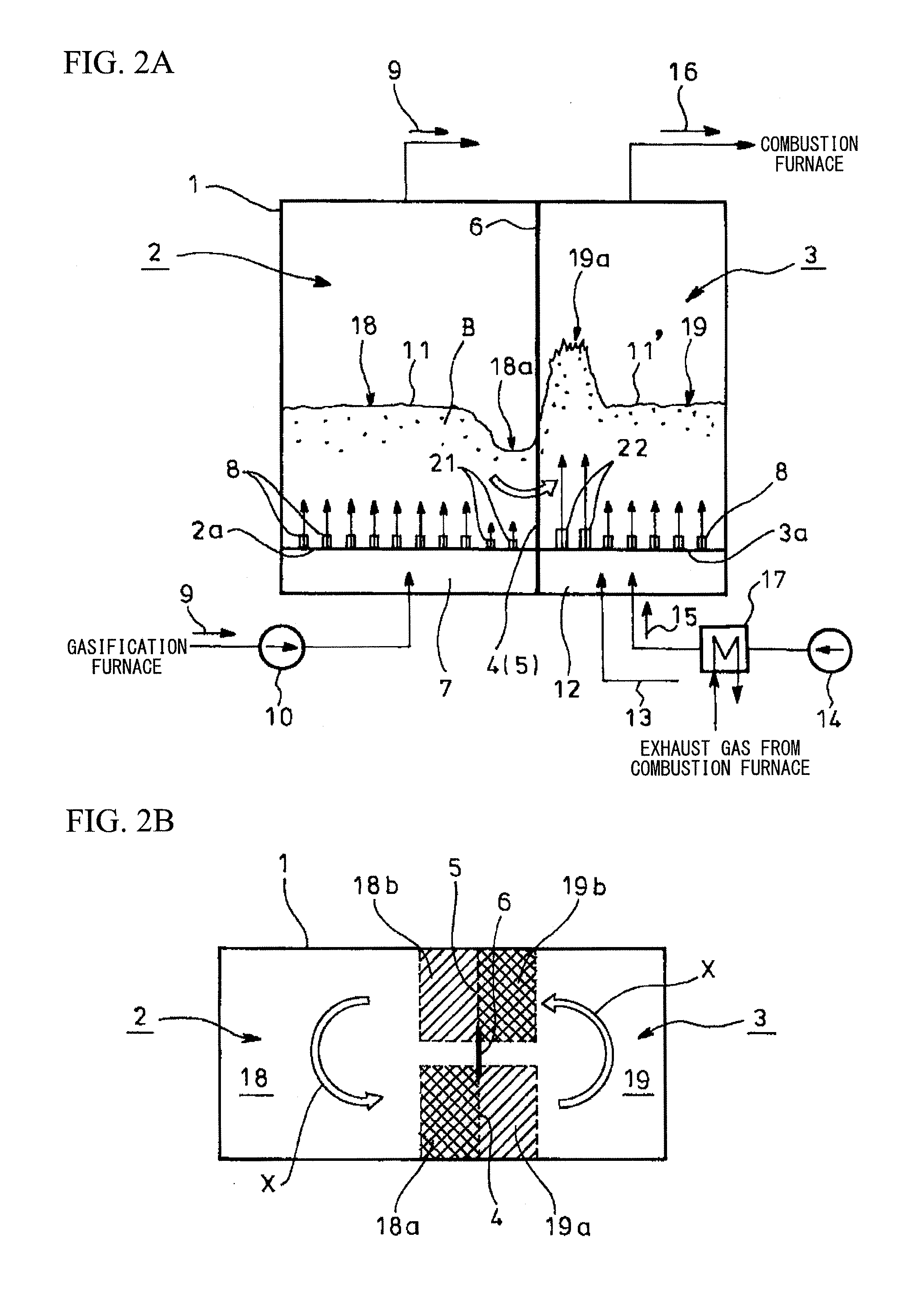

InactiveUS20060000143A1Reduce amount of airIncrease gasification rateHydrogenGasifier mechanical detailsCombustion chamberEngineering

A gasification furnace and a combustion furnace are integrated with each other to form a single fluidized-bed gasification and combustion furnace in which unburned char generated in the gasification furnace is combusted in the combustion furnace, and the thus generated heat of combustion is utilized as a heat source for gasification. The fluidized-bed gasification and combustion furnace (1) comprises a gasification furnace (3) and a combustion furnace (4) which are divided by a first partition wall (2). In the gasification furnace (3), a revolving flow of the fluidized medium is formed by diffusion devices (32, 33) provided on furnace bottoms, and an upward flow of the fluidized medium partly flows in the combustion furnace (4). The combustion furnace (4) is divided into a main partition wall (5). In the main combustion chamber (6), a revolving flow of the fluidized medium is formed by diffusion devices (34, 35) provided on furnace bottoms, and an upward flow of the fluidized medium partly flows in the heat recovery chamber (7).

Owner:EBARA CORP

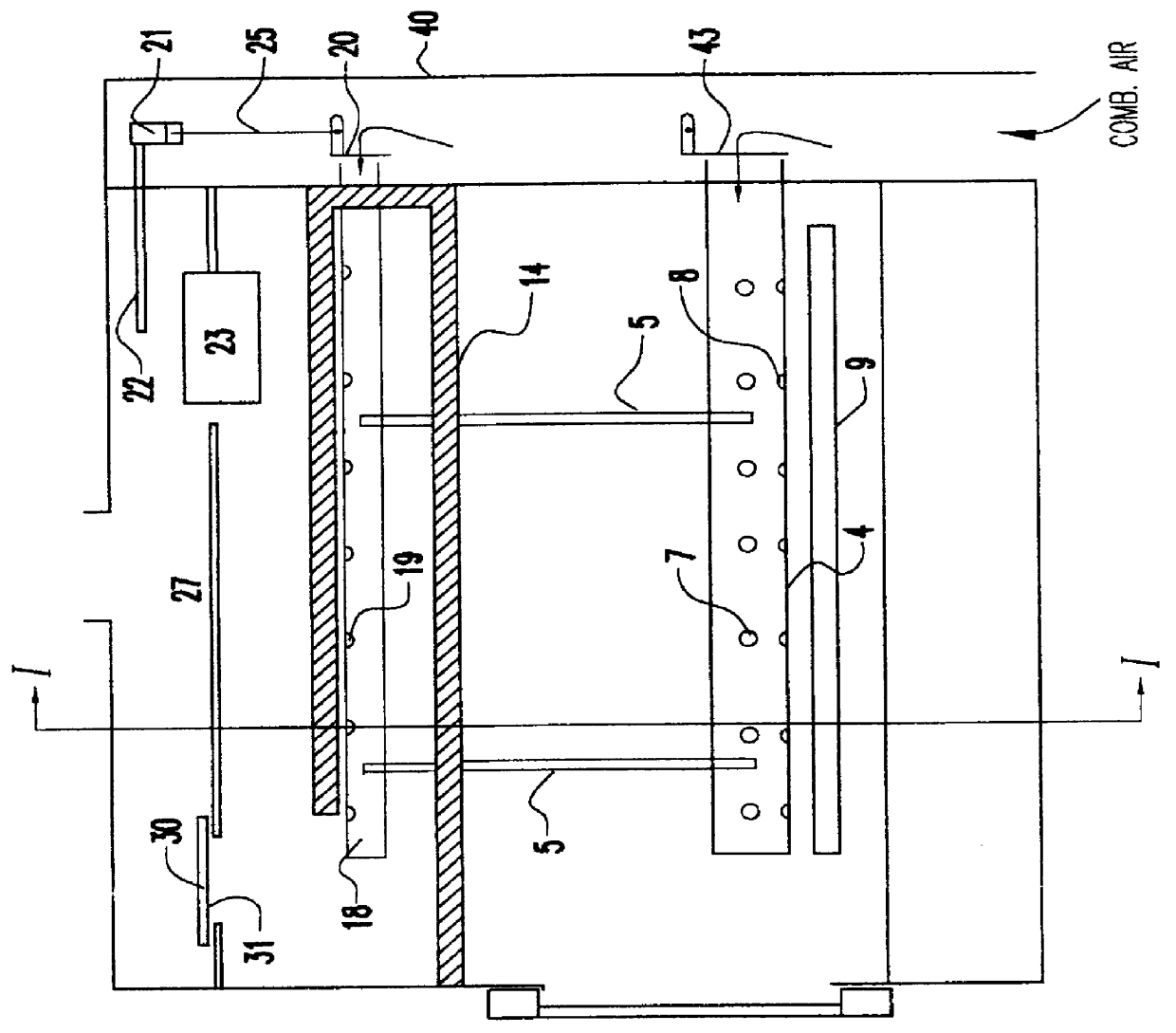

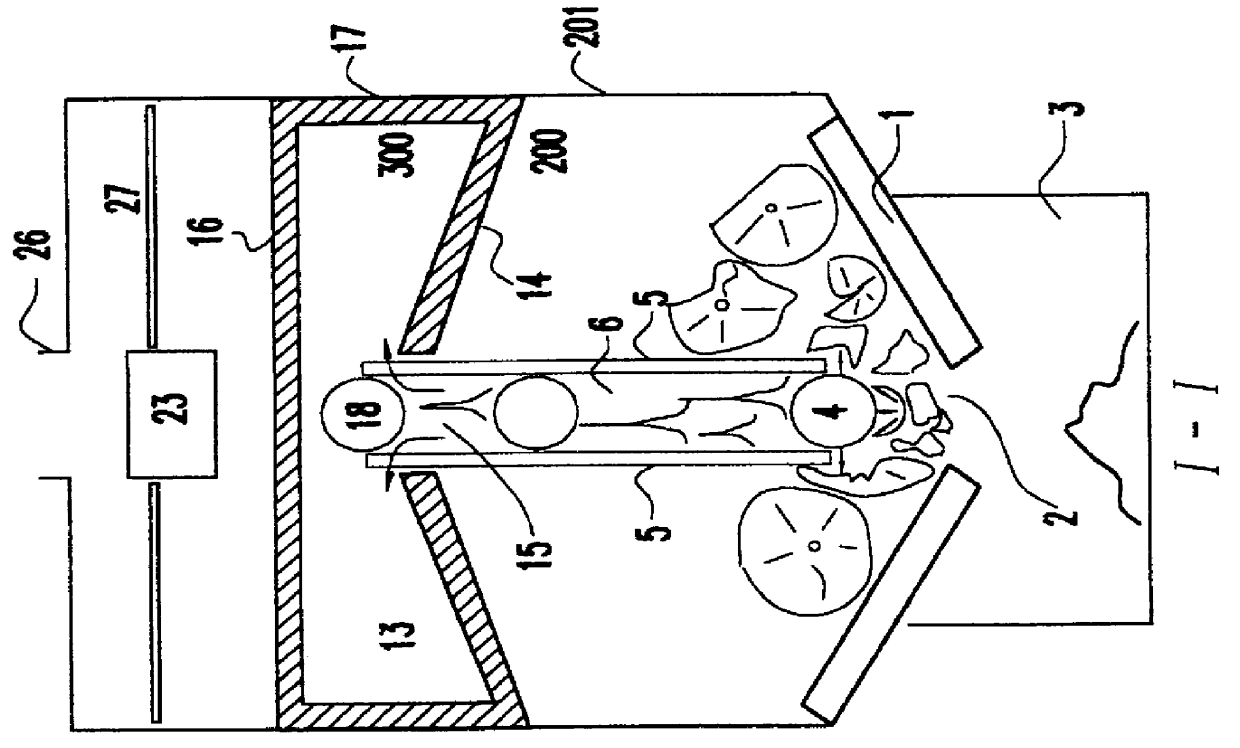

Combustion system

InactiveUS6067979AAvoid quenchingIncrease gasification rateSolid bar grateCombustion-air/flue-gas circulation for stovesCombustion systemCombustion chamber

A combustion system includes a primary combustion chamber divided into left and right sides by fuel-retaining standards defining a canyon or void extending into a secondary combustion chamber is provided. The floor of the primary combustion chamber and the fuel-retaining standards direct the burning solid fuel toward the lower part of the canyon, while at the same time retaining the non-burning solid fuel on either side of the fuel-retaining standards. The combustion system further includes an air delivery system having a lower air tube supplying high and low velocity air and an upper air tube. The lower air tube is positioned proximate to a firebox floor, while the upper air tube is positioned within the secondary chamber. Automatic air setting mechanisms are provided so that proper air settings can be maintained during various phases of a fire. The combustion system further includes a loading door having openings and a bypass system preventing the loading door from being fully closed unless the bypass is in the completely closed position. The secondary combustion chamber includes at least fuel protecting baffles and a secondary combustion chamber ceiling which extends partially over the entire length of the secondary combustion chamber or includes openings. A catalyst mounting system which minimizes canning and masking and a radiant catalyst heating system are also provided.

Owner:JAASMA DENNIS R

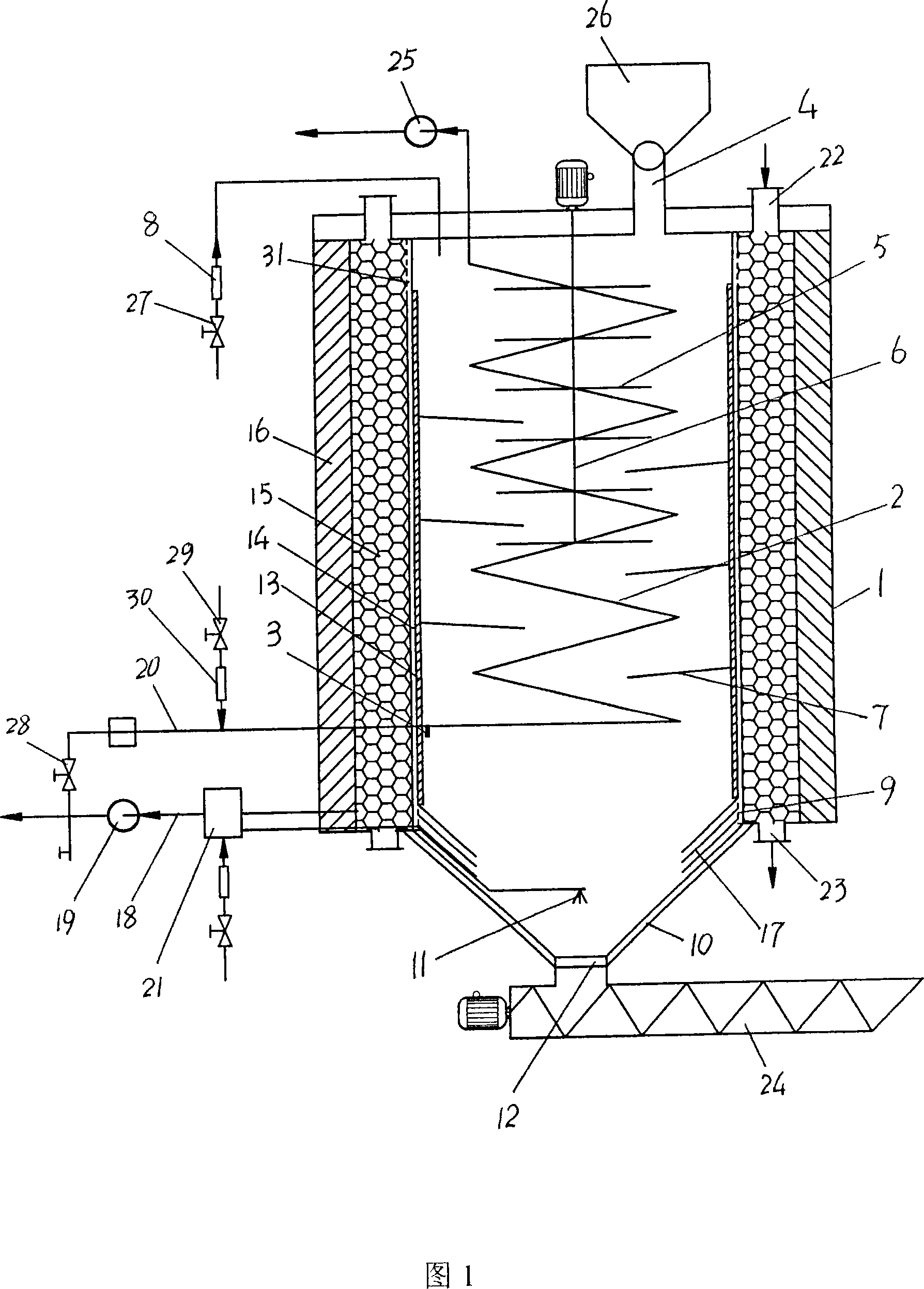

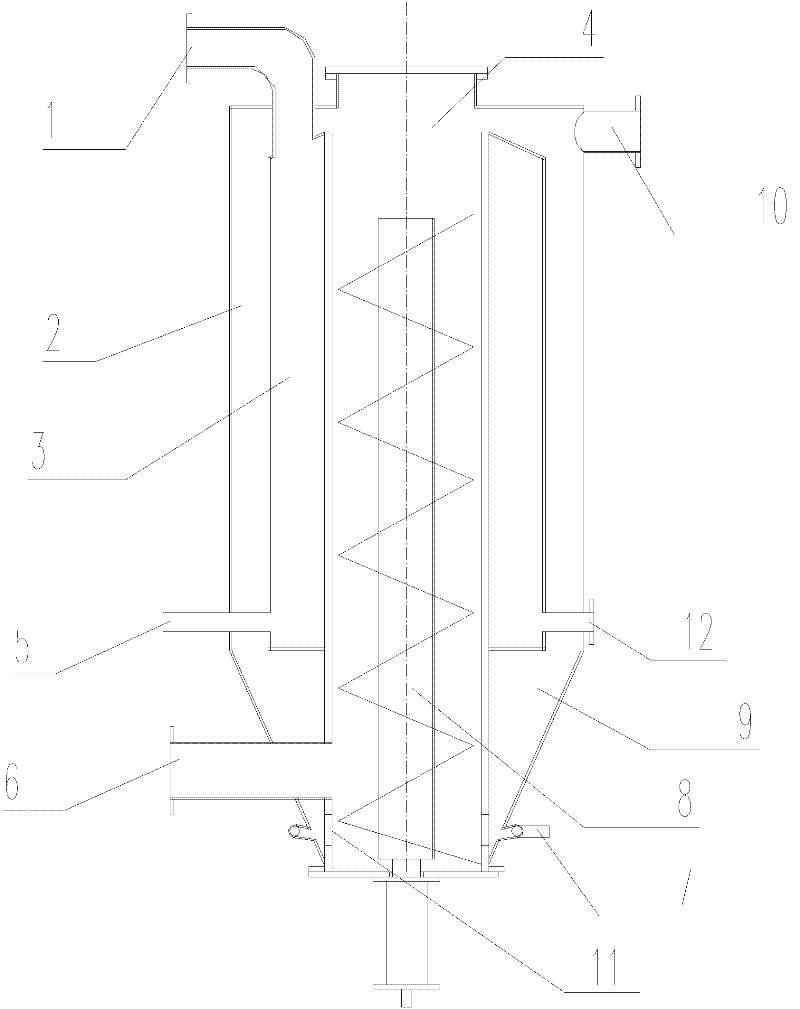

Internal circulation external heating type gasification device

ActiveCN102260536AReduce heat lossExtended stayGranular/pulverulent flues gasificationWater vaporResidual carbon

The invention discloses an internal circulation external heating type gasification device. The device comprises a central gasification chamber, an annular heating chamber, a peripheral gasification chamber, a residual carbon reflux chamber and the like. Biomass micron fuel enters the annular heating chamber and is efficiently burned, so that the required heat is provided for the central gasification chamber, the peripheral gasification chamber and the residual carbon reflux chamber. Cracking and gasification raw materials absorb the heat in the down-up movement process of the central gasification chamber to be cracked and gasified, and an initial cracking product then enters the peripheral gasification chamber and is further gasified; and residual carbon refluxes through the residual carbon reflux chamber and enters the central gasification chamber to carry out a water gas reaction with water vapor, so that medium-calorific-value gas of which the content of CO and the content of H2 are equal and CO and H2 account for about 80 percent of the total amount is obtained. In the device, an internal circulation external heating mode is used for gasification; and the device has the advantages of high heat utilization rate, heat transfer efficiency and gasification efficiency and the like, and the calorific value of gas is high. The internal circulation external heating type gasification device can be widely applied to the preparation of the gas by cracking and gasifying municipal organic refuse, agricultural and forest residues and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

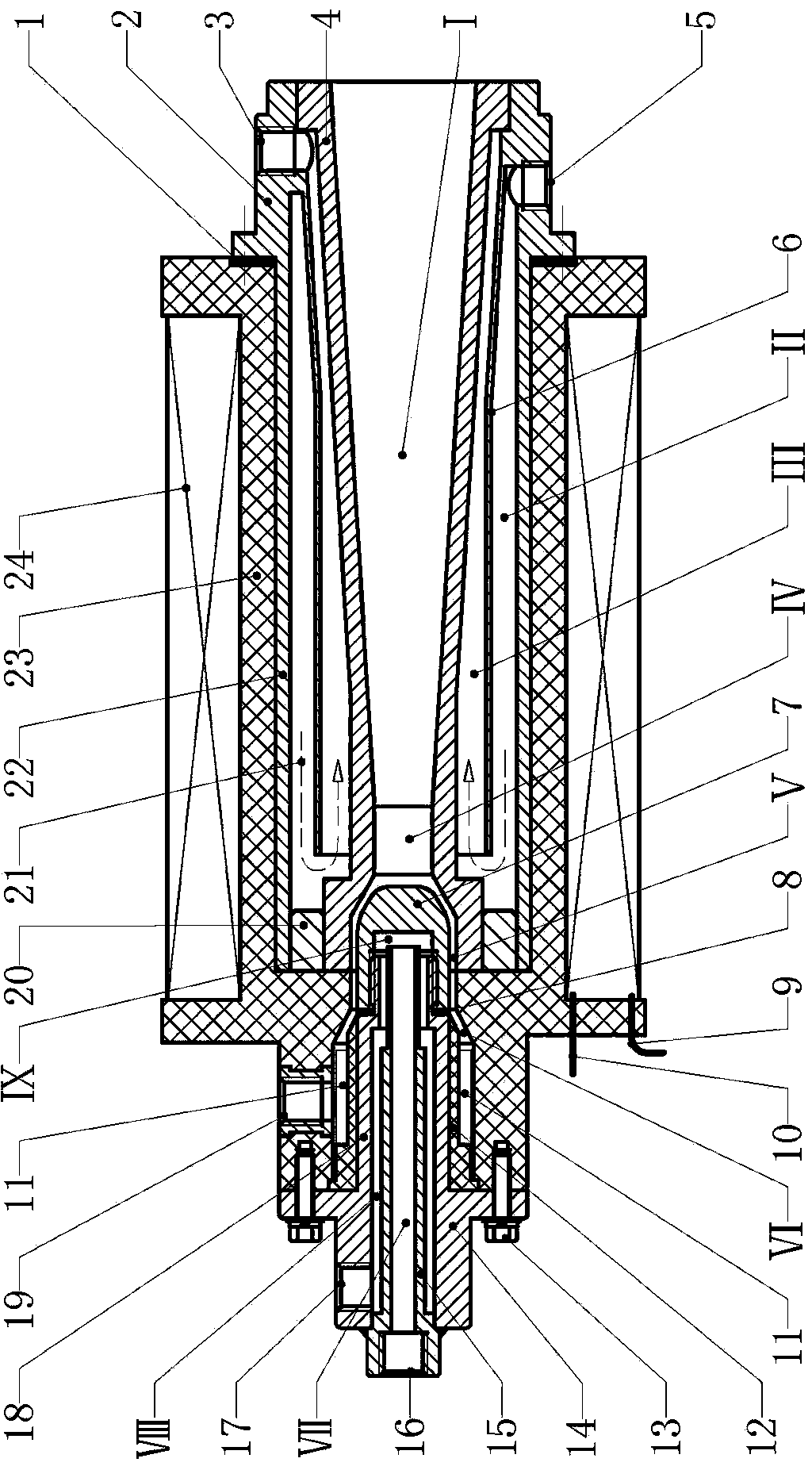

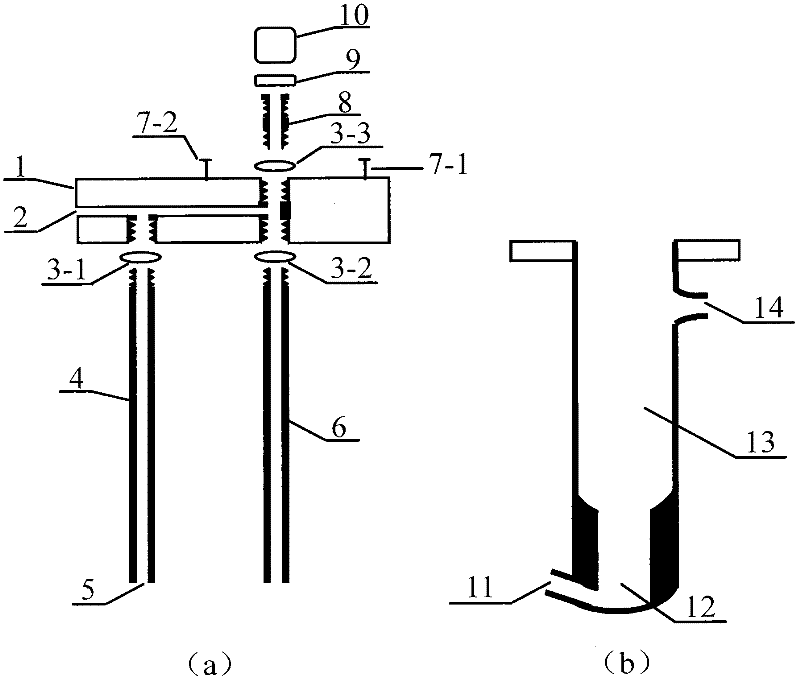

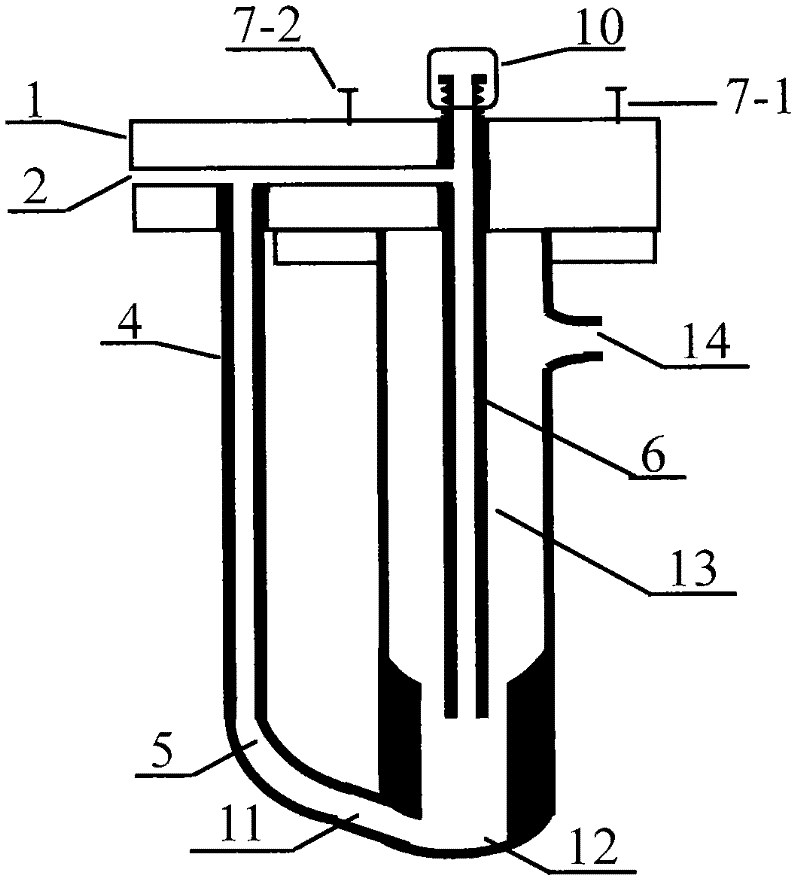

Plasma torch for dielectric heating

ActiveCN103906337AEasy to installAvoid parasitic arcingPlasma techniqueEcological environmentHydrogen

The invention provides a plasma torch for dielectric heating, and relates to plasma equipment. The plasma torch is mainly composed of a front torch body, an anode, a rear torch body, a cathode and an insulation frame. The front torch body is provided with a guide sleeve and a cylinder extending backwards, and the guide sleeve is arranged in the inner space of the cylinder; the anode is embedded into the front torch body, the space between the cylinder of the front torch body and the wall of the anode forms a cooling water jacket, a cathode base is arranged on a rotary body structure of the rear torch body, the cathode is installed at the front end of the cathode base, and a cooling cavity is formed in the cathode. The front torch body is installed at the front end of the insulation frame, the extending cylinder of the front torch body is inserted into a front inserting port of the insulation frame, the rear torch body is installed at the rear end of the insulation frame, the cathode base on the rear torch body enters a rear inserting port of the insulation frame, the head of the cathode stretches into a cylindrical space in the rear portion of the anode, and the space between the head of the cathode and the wall of the rear portion of the anode forms an ionization channel. The plasma torch is used for pyrolyzing water to manufacture hydrogen or used for processing harmful substances, thereby reducing the dependence on coal and oil of people and preserving the ecological environment.

Owner:JIANGSU YAFENG ALLOY MATERIAL

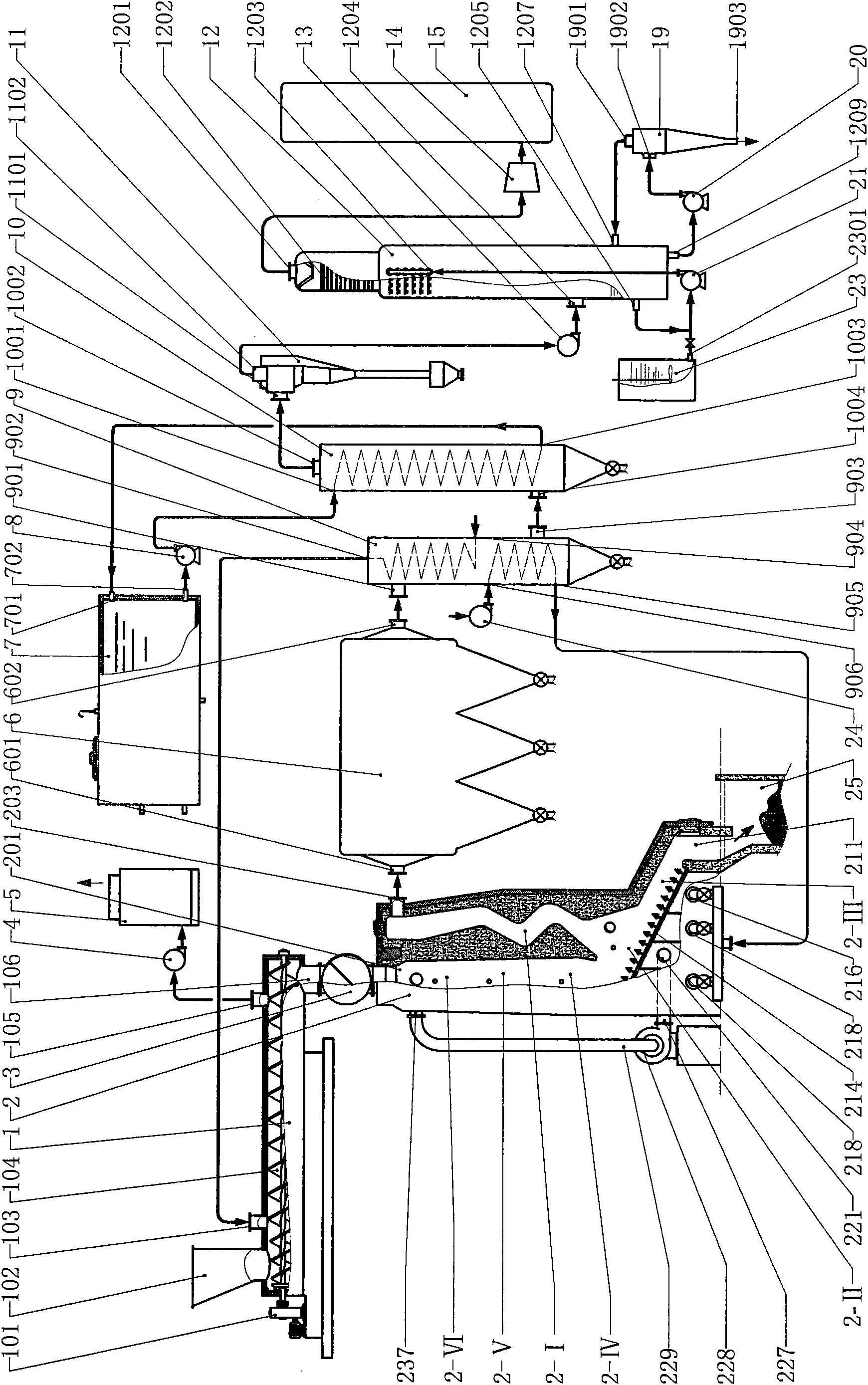

Gasification system of garbage and organic waste and device thereof

InactiveCN101560408AEliminate pollutionIncrease the low calorific valueWaste based fuelCombined combustion mitigationHydrogenGas phase

The invention discloses a gasification system of garbage and organic waste and a device thereof, and relates to a garbage treatment device. The gasification system mainly consists of a blast drier, a gas phase circulation gasification furnace, a dusting / purification device, a compressor, a gas receiver and connection pipelines, wherein, the gasification furnace is equipped with a baking zone, a pyrolysis zone, a first gasification zone, a second gasification zone, a burnout zone and a heat storage chamber, a recirculating blower and a recirculating wind pipeline form a gas phase circulation loop outside the furnace. In the system, a discharge port of the blast drier is connected to a feed inlet of the gasification furnace, a synthesis gas output interface of the gasification furnace is connected to the dusting / purification device by an induced draft fan, the dusting / purification device is connected to the compressor, and the compressor is connected to the gas receiver. The system utilizes a technical measure of arranging the heat storage chamber in a gas phase circulation gasification furnace to enhance gasification rate and quality of refuse fuel and decompose dioxin with severe toxicity and eliminate coke tar, convert garbage and organic waste into secondary clean energy which comprises producer city coal gas, hydrogen, methanol and dimethyl ether liquefied gas.

Owner:周开根

Biomass gasification catalyst and its production method

InactiveCN1686606AIncrease gas calorific valueHigh cracking rateOther chemical processesGas purification with selectively adsorptive solidsTarBiomass gasifier

A catalyst used in biomass gasifier or gas furnace for cracking tar and removing uncracked tar and alkali metal is prepared from attapulgite-type clay, high-A alumina, iron oxide, magnesium oxide, calcium oxide and anthracite through proportionally mixing, stirring, grinding, granulating and baking.

Owner:许庆华

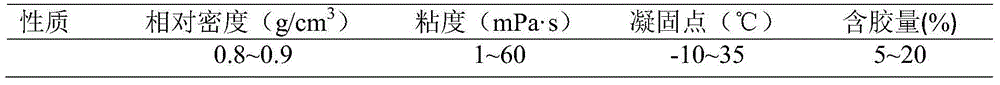

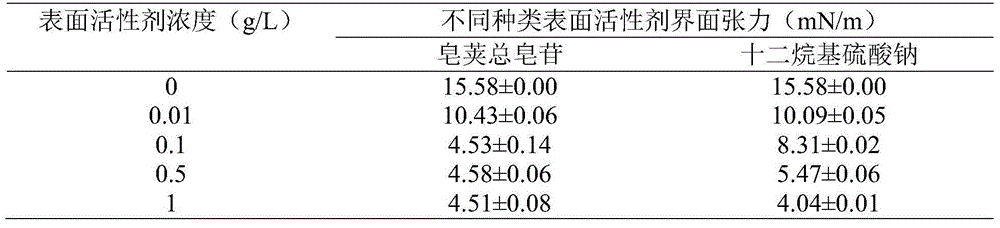

Application of plant source surface active agent

InactiveCN104874329AHas an activation effectIncrease gasification rateNon-ionic surface-active compoundsOther chemical processesEmulsionResource utilization

The invention relates to a total saponnis extraction technology of a honeylocust extract and an application field thereof. The total saponnis extraction technology is characterized in that the total saponnis is a plant source nonionic type surface active agent, and has the interfacial tension reduction property, emulsion activity, wetting property, temperature-resistant and salt-tolerant property, dispersant solubilizing and the like, so as to provide the applicability in the fields of recovery, storage and transportation of crude oil; the green surface active agent from the plant, namely the honeylocust, is applied to the bulk industrial purpose, so the resource utilization rate of the honeylocust is improved, the recovery rate of crude oil is improved, the storage and transportation cost of crude oil is reduced, and the pollution to the environment is reduced.

Owner:SHENYANG INST OF APPL ECOLOGY CHINESE ACAD OF SCI

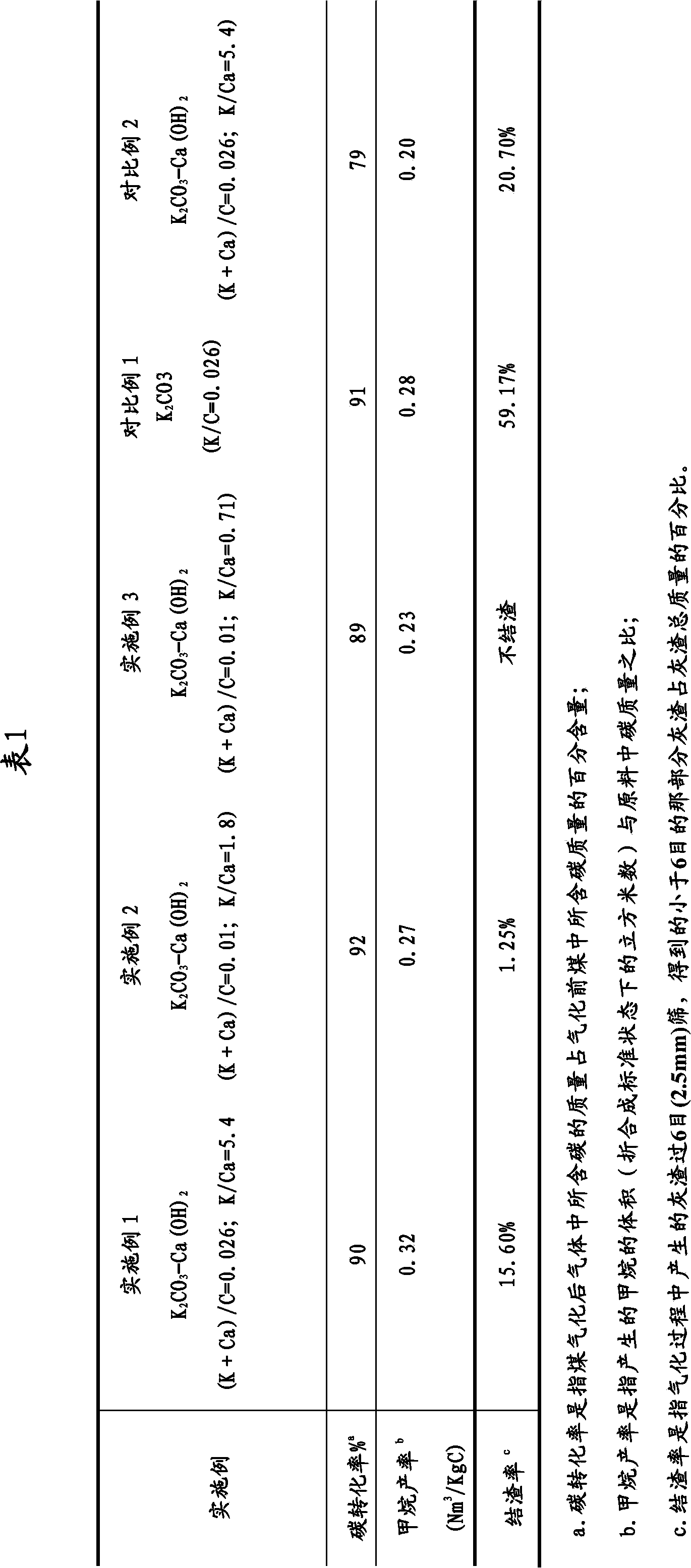

Gasification raw material, preparation method of the gasification raw material, and catalytic gasification method adopting the gasification raw material

The invention discloses a gasification raw material. The gasification raw material comprises a first carbon-containing material, an alkali metal catalyst loaded on the first carbon-containing material, a second carbon-containing material, and an alkaline-earth metal catalyst loaded on the second carbon-containing material, wherein the first carbon-containing material and the second carbon-containing material are same or different. The invention also discloses a preparation method of the gasification raw material and a catalytic gasification method adopting the gasification raw material.

Owner:ENN SCI & TECH DEV

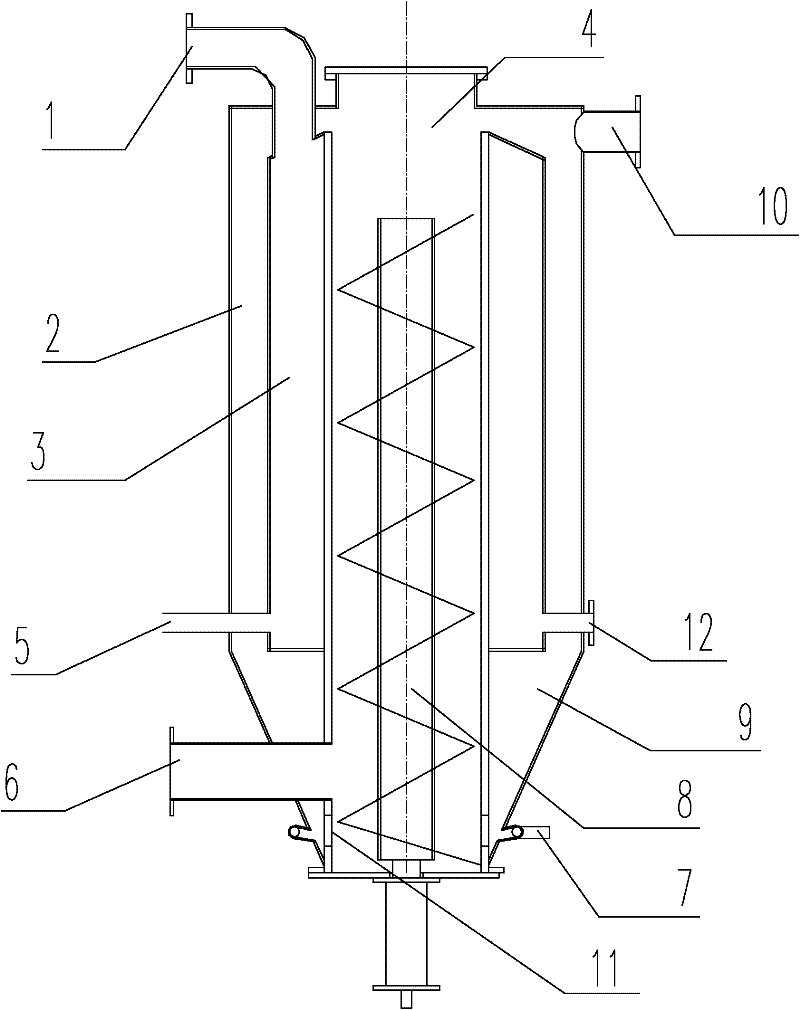

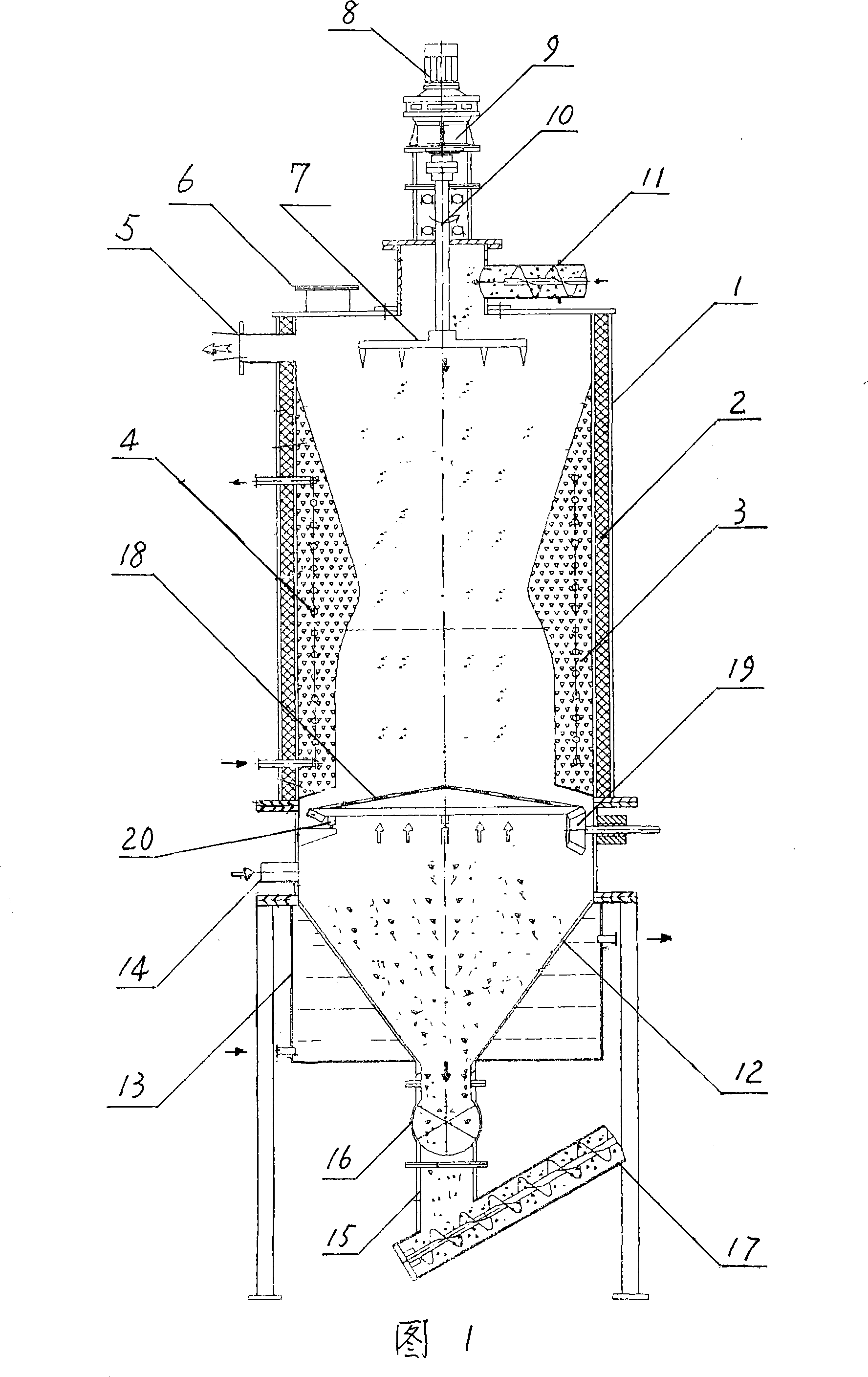

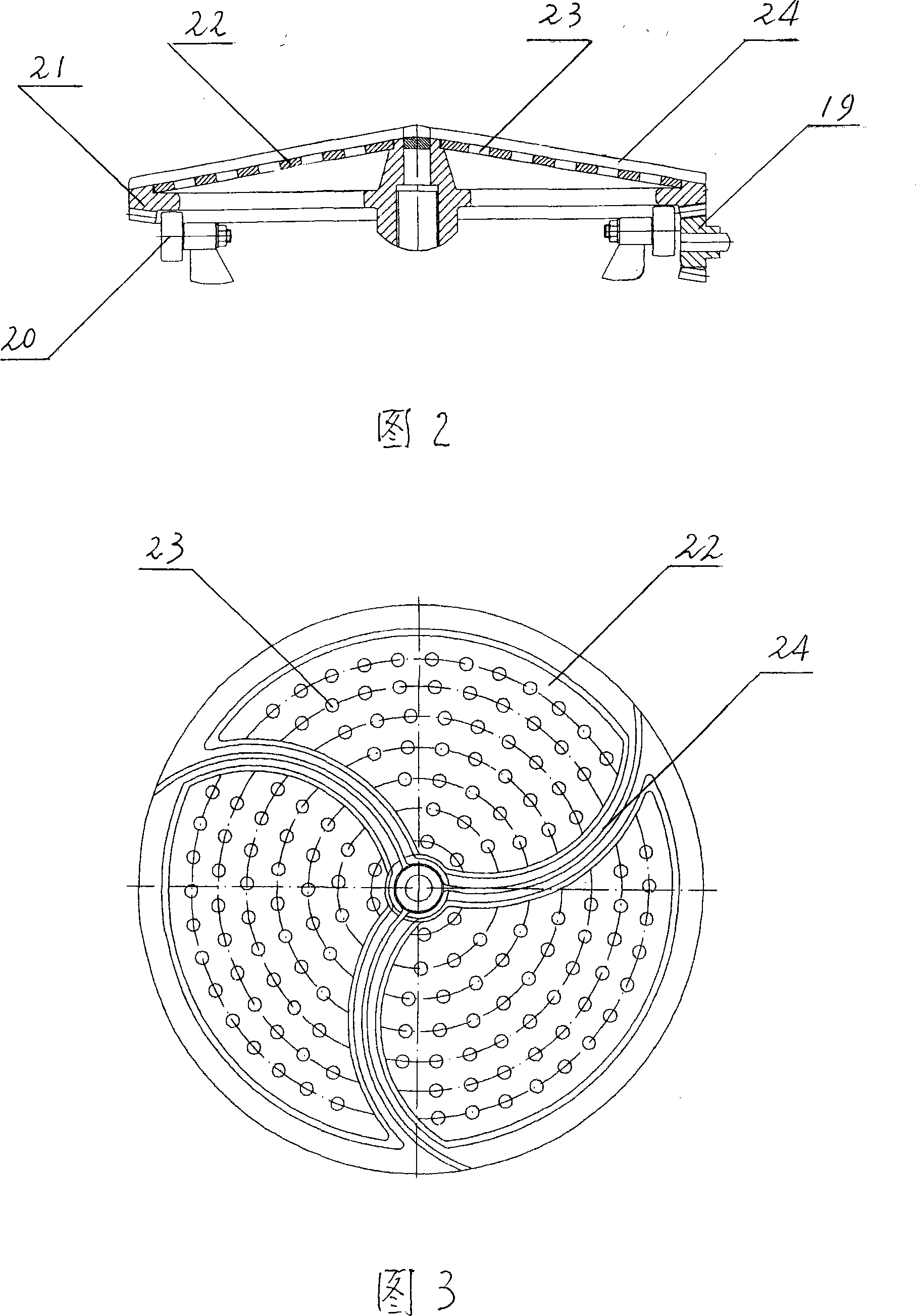

Solid biomass semi-water coal-gas producer

InactiveCN101230281AIncrease gasification rateQuality improvementSpecial form destructive distillationWater vaporCombustible gas

The invention provides a solid biomass semiwater gas generating furnace, which includes a furnace body, a transmission mechanism, a feeding mechanism and a residue discharging mechanism. A head preserving layer 2 and a fire resisting layer 3 are arranged in the furnace body, a heat exchanger pipe 4 is arranged in the fire resisting layer 3, and a material homogenizing harrow is arranged on the hearth. A clinker chamber 12 and a cooling water tank 13 are arranged on the underside of the furnace body 1, a gasification agent inlet 14 is arranged on the clinker chamber 12, and a clinker outlet 15 is arranged on the bottom of the clinker chamber which is connected with a spiral clinker discharger 17. A rotatable furnace grate is arranged on the interface of the hearth and the clinker chamber 12. The invention can feed material and discharge clinker continuously, ensures the continuous stability of the gasification process, uses the vapor generated by residual heat to participate in gasification reaction, improves the carbon utilization rate, and improves the gasification rate of the solid biomass. Compared with gasification furnace with uniform section, the gasification strength of the invention is improved by 1.5-2.0 times, and the combustible gas calorific value is doubled.

Owner:合肥天焱绿色能源开发有限公司

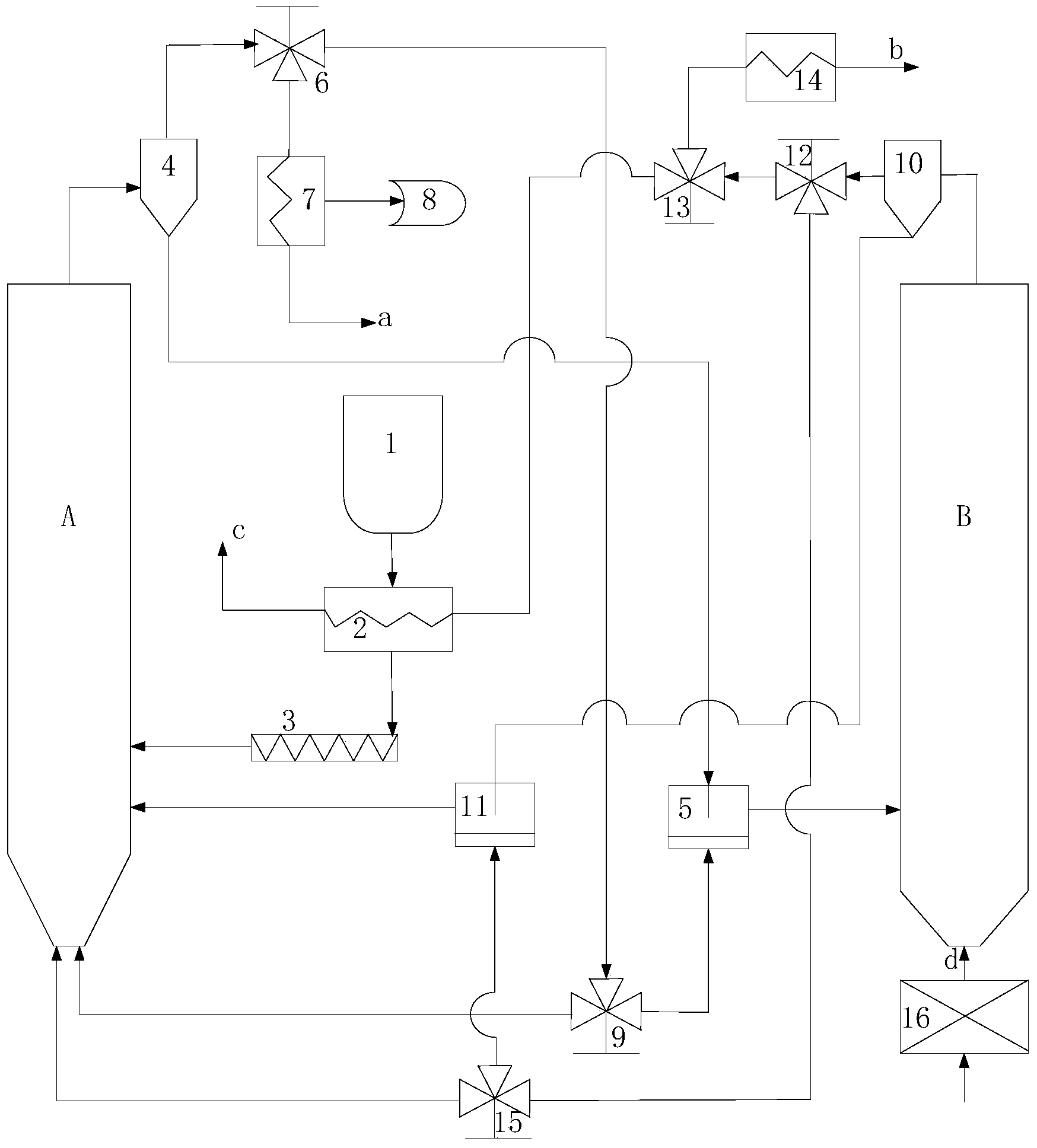

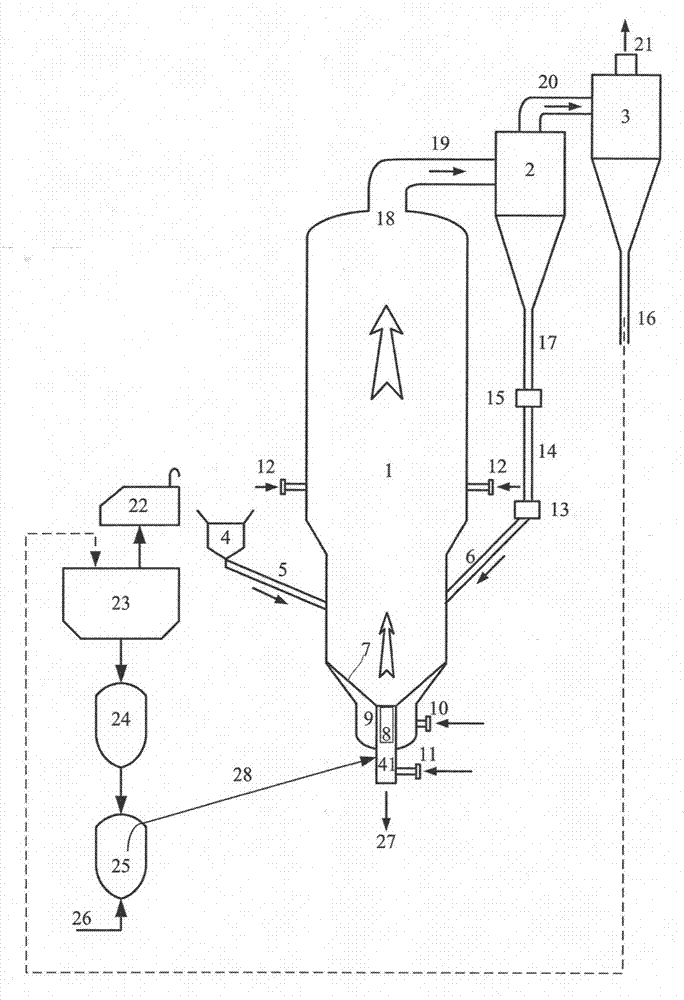

Double-rapid fluidized bed gasification method and device for biomasses

ActiveCN103725328ARealization of gasificationReduce contentGranular/pulverulent flues gasificationTarProcess engineering

The invention provides a double-rapid fluidized bed gasification method and device for biomasses. According to the method, a biomass pyrolysis and gasification process is mutually coupled with a coke and combustible gas combustion process, wherein the pyrolysis and gasification of the biomasses is finished by a rapid fluidized bed gasification furnace A; the combustion of coke and combustible gas is finished by a rapid fluidized bed gasification furnace B, so as to gasify the biomasses by components of the biomasses; a combustion improver, namely pure nitrogen, does not need to be additionally provided. The device mainly comprises the rapid fluidized bed gasification furnace A, the rapid fluidized bed gasification furnace B, a hopper, a dryer, a spiral feeder, a cyclone separator, a material returning device, a three-way valve, a condenser, a tar collector and an air separator. The double-rapid fluidized bed gasification method and device for the biomasses are suitable for various biomasses including saw dust, rice husks and the like. The content of the tar can be effectively reduced.

Owner:SOUTHEAST UNIV

Method and equipment for gasifying coal by using plasma

InactiveCN101781584AIncrease gasification rateReduce coal consumptionGranular/pulverulent flues gasificationChemical reactionWater vapor

The invention provides method and equipment for gasifying coal, relating to a coal chemical industry technique and gasification furnace equipment. The invention is characterized in that a fluidized bed gasification furnace is designed into a three-section working mode, the upper section is a suspended preheating section, the middle section is a turbulent flow pyrolyzing section, the lower section is a bubbled gasifying section, a plasma torch is arranged at the bubbled gasifying section, and water vapor is heated to be greater than 4000 DEG C in the plasma torch, is decomposed into active chemicals H., O., H2., HO., O2. and then is directly sprayed to carbon coke of the bubbled gasifying section for chemical reaction to generate synthesis gas of CO and H2 and release heat; and pyrolysis gas, the water vapor and fluidized gas in the furnace are mixed, are discharged out of the furnace through an outlet of the suspended preheating section and then return the bubbled gasifying section of the gasification furnace through a fluidized air pipe and a fluidized fan, and soot, gaseous tar, CmHn and CH4 in the pyrolysis gas react with the water vapor to generate the synthesis gas of the CO and the H2. Compared with the conventional coal gasification technique, the invention reduces the consumption of coal resources and the discharge of greenhouse gases.

Owner:周开根

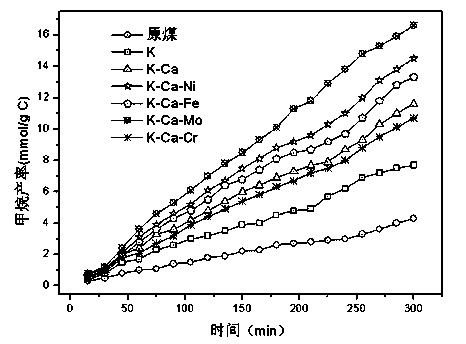

Catalyst for medium and low temperature catalytic coal gasification for producing natural gas and preparation method thereof

InactiveCN104174402AIncrease gasification rateSolve poisoning inactivationGaseous fuelsMetal/metal-oxides/metal-hydroxide catalystsChemistryCalcium EDTA

The invention relates to a catalyst for medium and low temperature catalytic coal gasification for producing natural gas and a preparation method thereof, and in particular, the catalyst consists mainly of alkali metals, alkaline earth metals, and transition metals; the alkali metals are mainly potassium salts, such as potassium carbonate, potassium sulfate or potassium nitrate and the like, the potassium / carbon mass fraction is 1-20%; the alkaline earth metals are calcium salts, the calcium / potassium mass fraction is 10-50%; the transition metals are mainly one or two of iron, nickel, molybdenum, cobalt and cadmium, can be salts or oxides thereof, and the transition metal / potassium mass fraction is 5-30%. The catalyst is helpful to solve the problem of poisoning deactivation and unstable catalyst activity and other problems caused for the reason that the catalyst for the medium and low temperature catalytic coal gasification for producing the natural gas is easy to react with minerals in coal, and the problems are solved, so that future realization of industrialization can be facilitated.

Owner:CHINA PETROLEUM & CHEM CORP +1

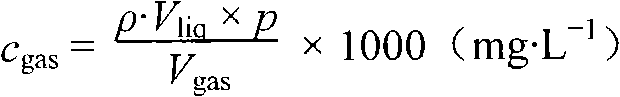

Liquid organic atomization and gasification device

InactiveCN102172504AThe result is accurateReliable resultsAlarmsChemical/physical/physico-chemical processesGas phaseEquation of state

The invention discloses a liquid organic atomization and gasification device, which is mainly used for preparing a standard gas required in processes of manufacturing, production, verification and calibration of gas alarms from a liquid organic material. A liquid standard material is atomized in an atomizing air pipe through the inlet of an injector and is evaporated and gasified in an evaporating tube under the action of the gas in a blowing air pipe, and thus, the liquid standard organic substance is converted into a gaseous substance. The pushing rate of the injector is controlled by using an injection pump, so that the pushing rate of the injector is smaller than the maximum evaporation rate of the liquid standard substance. The temperature and pressure in an atomizing and gasifying system are measured, the concentration of the standard material from the outlet of the atomization and gasification device in a gas phase can be obtained by using the pushing rate of the injector and the flow metered by a flowmeter, and by conversion according to an equation of state of gas.

Owner:中国人民解放军防化指挥工程学院

Heat exchanger for distillation

ActiveCN101696859AIncrease gasification rateSave energyStationary tubular conduit assembliesPlate heat exchangerDistillation

The invention relates to a heat exchanger for distillation. The technical scheme is that: the heat exchanger consists of a shell pass and a tube pass, wherein in the shell pass, an upper cylinder body of the shell pass and a lower cylinder body of the shell pass are connected into one body by an expansion joint, both ends of the shell pass are connected with an upper tube plate and a lower tube plate, a heat exchange tube and a central tube pass a baffle plate, both ends of the heat exchange tube and the central tube are connected with the upper tube plate and the lower tube plate, the central tube is arranged on the axis of the upper tube plate and the lower tube plate, a baffle plate is fixed by a distance tube, a lower cylinder of the shell pass is provided with an exhaust and a steam outlet of the shell pass, an upper cylinder of the shell pass is provided with a steam exhaust and a steam inlet of the shell and a shock proof plate is arranged in the upper cylinder body of the shell pass; and in the tube pass, both ends of a lower tube pass cylinder body are connected with a lower tube pass flat cover and the lower tube plate by flanges, and the lower tube pass is provided with a tube pass exhaust and a material charge port; both ends of an upper tube pass cylinder body are connected with an upper flat cover and the upper tube plate by flanges, and the upper tube pass is provided with a material discharge port and a fixed gas discharge port; and the pads are arranged between the upper tube pass flanges and the upper tube plate and between the lower tube pass flanges and the lower tube plate. The heat exchanger is high in gasification rate and good in heat exchange effect.

Owner:沈阳东方钛业股份有限公司

Compound circulating fluidized bed gasification reaction device

ActiveCN104498103AImprove adaptabilityIncrease temperatureGasifier feeding meansGasification processes detailsCycloneFluidized bed

The invention provides a compound circulating fluidized bed gasification reaction device. The compound circulating fluidized bed gasification reaction device comprises a reactor body, a multistage cyclone separator, a particle fuel feeding system, a powder fuel feeding system, a central jet flow gasification burner nozzle and a material returning system, wherein the outlet of the reactor is connected with a primary cyclone separator; the primary cyclone separator is connected with a secondary cyclone separator; crude particles separated by the primary cyclone separator are returned to a gasification furnace body by virtue of the material returning system; fine particles separated by the secondary cyclone separator enter the central jet flow gasification burner nozzle by virtue of the powder fuel feeding system and are finally sprayed to the gasification furnace body. A circulating fluidized bed reactor is used as a gas reaction body; the slag is continuously discharged by gasifying at a medium-high temperature; by virtue of application of high-temperature jet flow two-stage grading gasification, the carbon conversion rate and the cold gas efficiency are increased; a simplified slag discharging device is combined with the design of an air distributing plate; the operation stability and the running stability are improved; the compound circulating fluidized bed gasification reaction device is suitable for gasifying and converting various carbon-containing solid fuels and has large-scale popularization and application prospects.

Owner:SHANGHAI BOILER WORKS

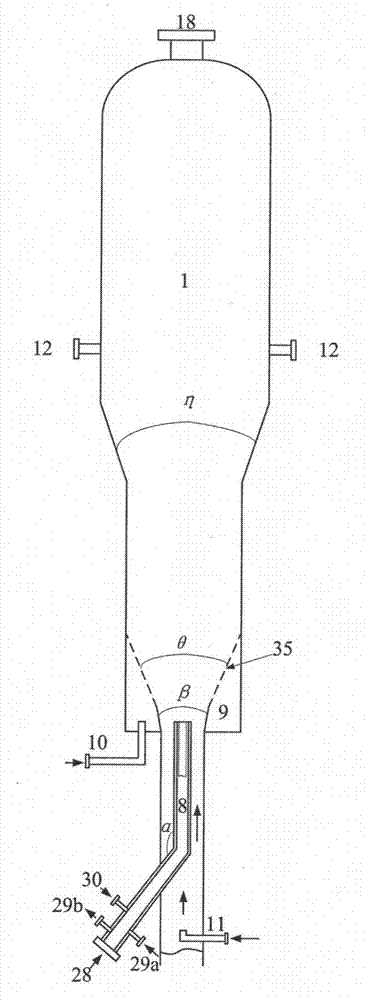

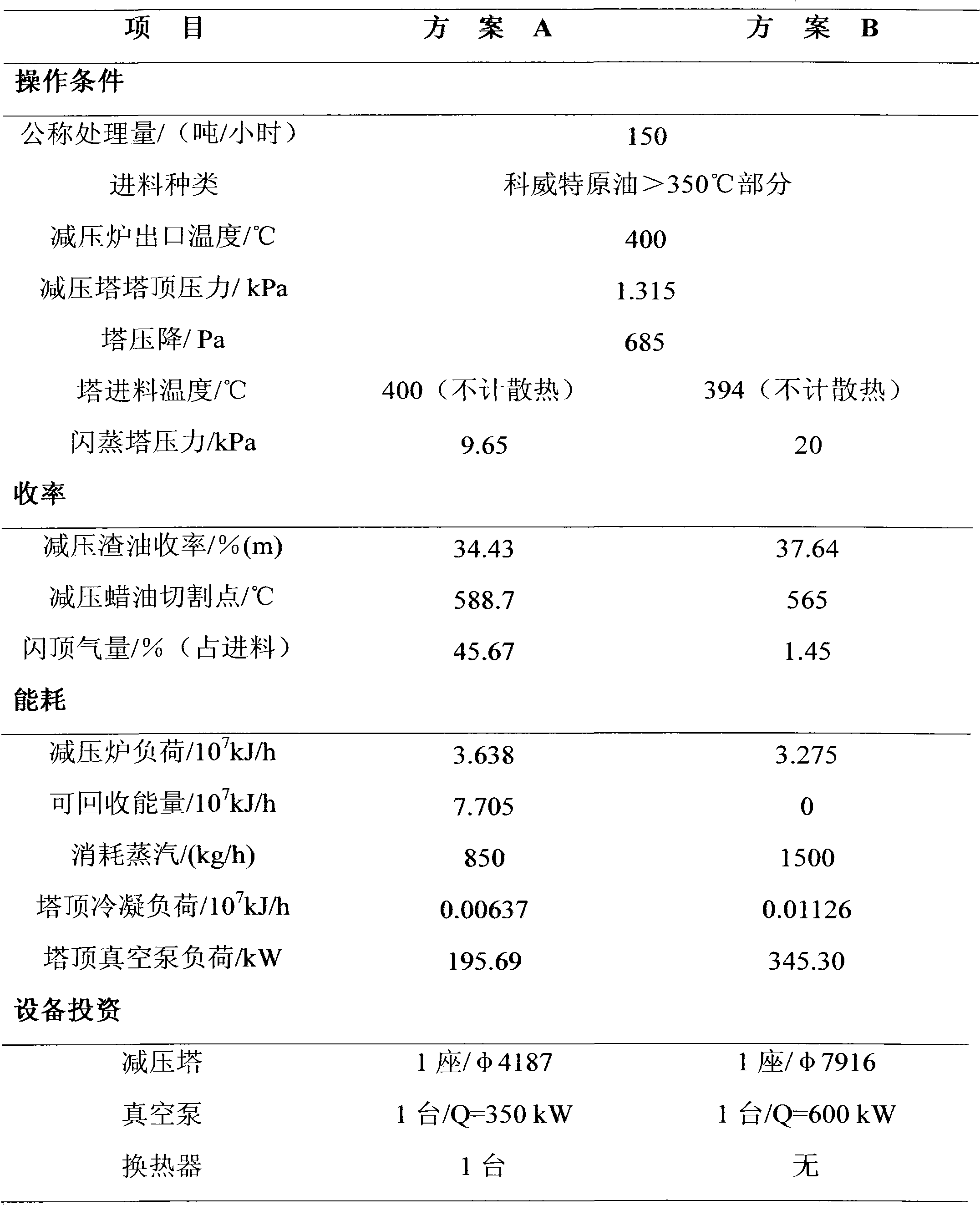

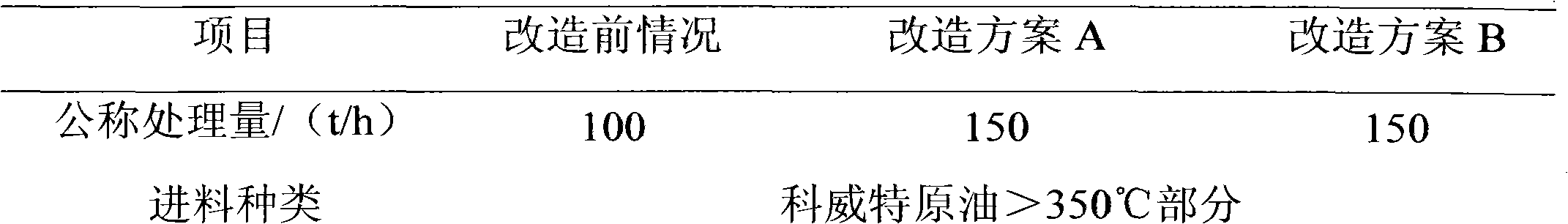

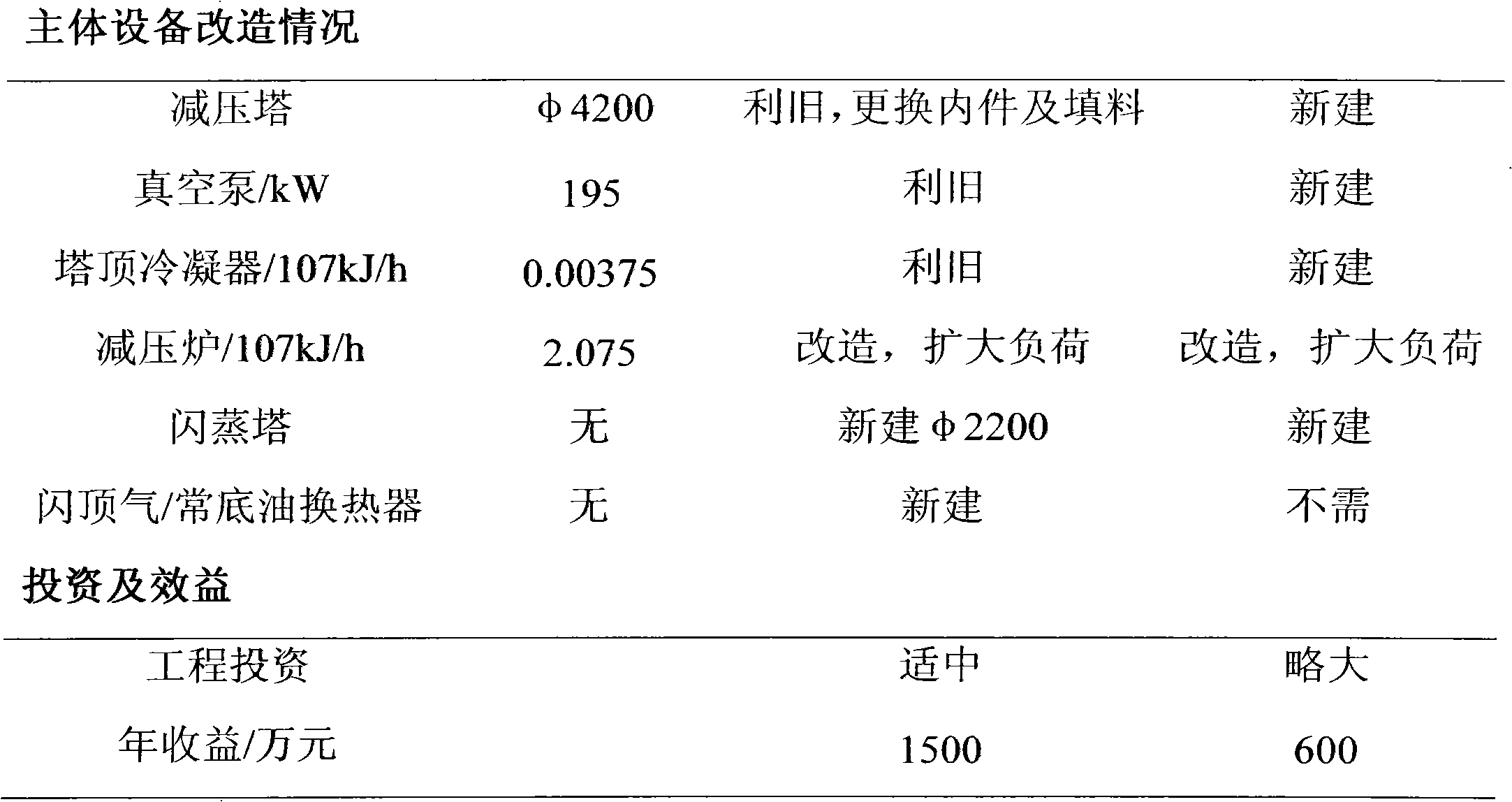

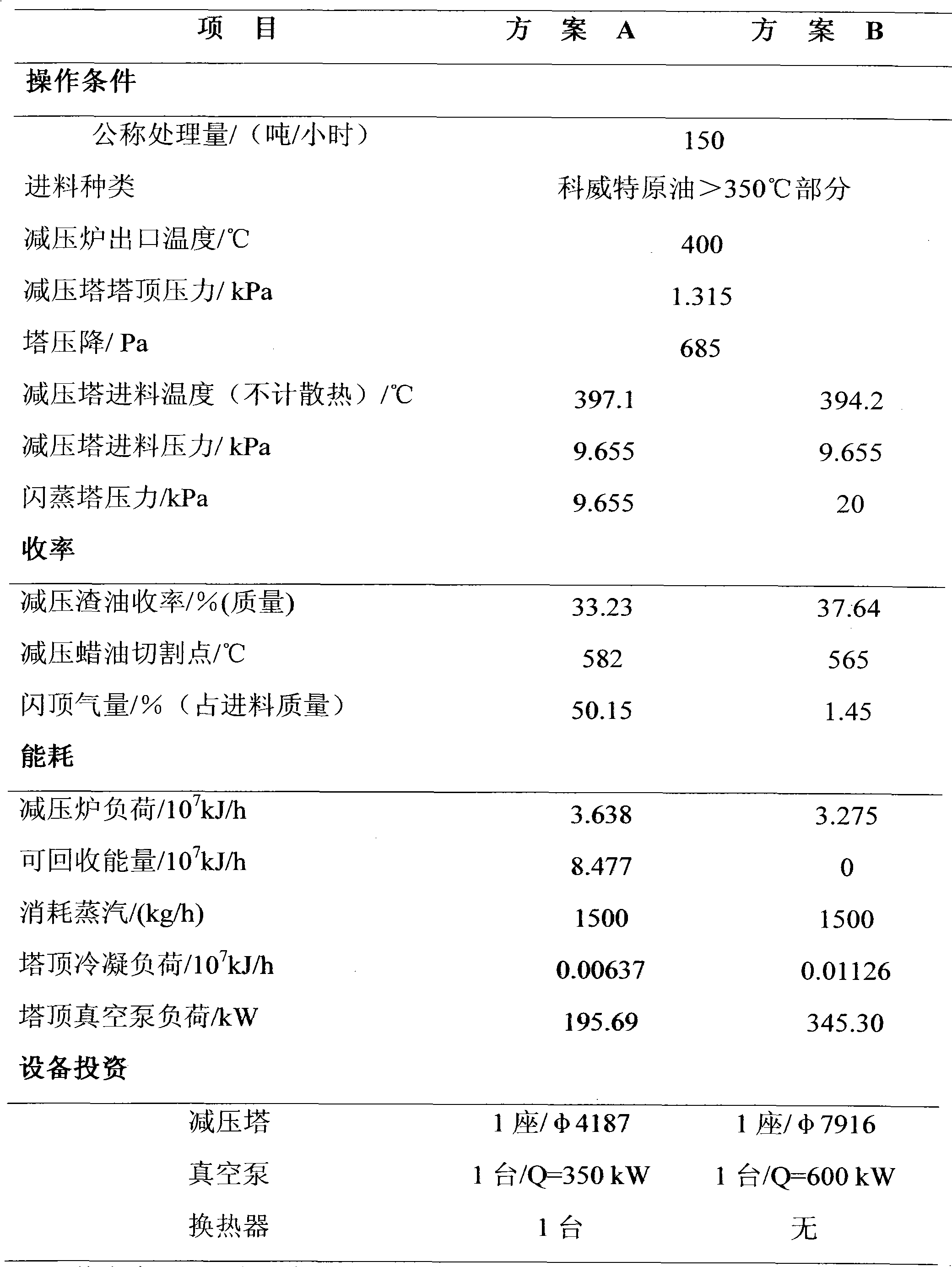

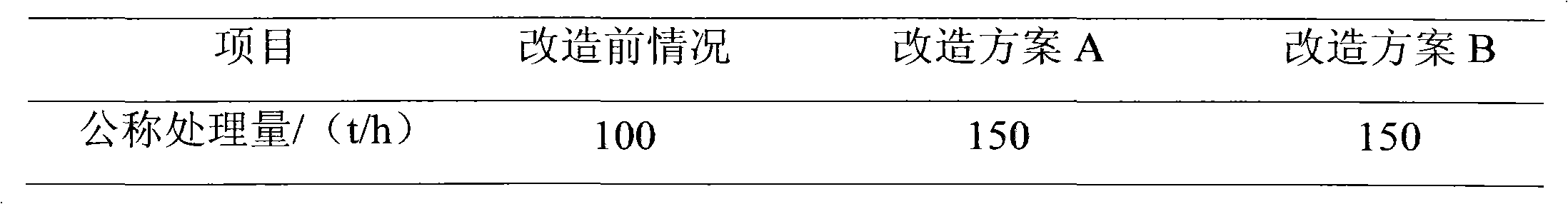

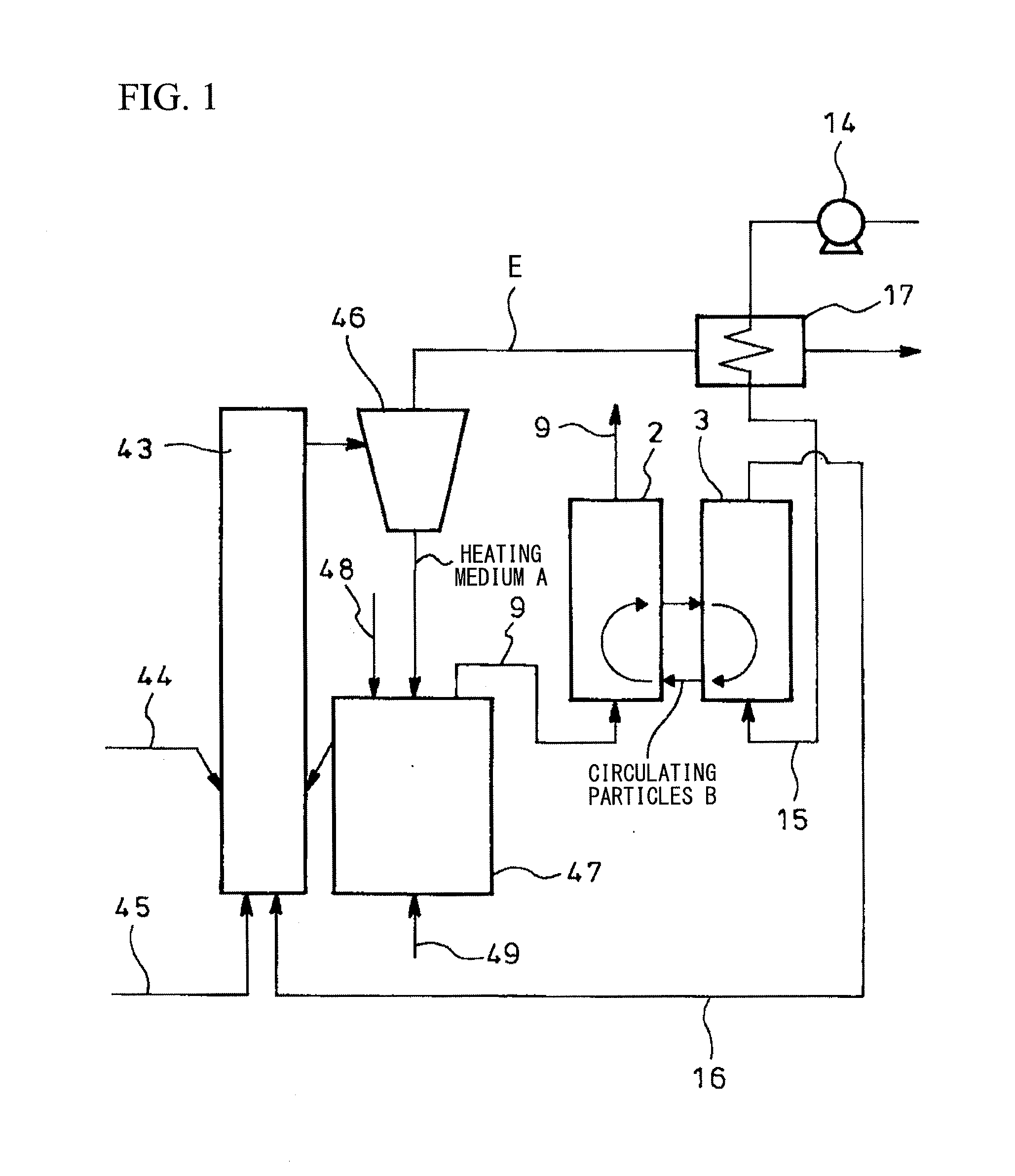

Reduced pressure distillation method and device

ActiveCN102309863AIncrease gasification rateShort processVacuum distillation separationVacuum distillationChemistryLiquid phase

The invention discloses a reduced pressure distillation method and a reduced pressure distillation device. A flash tower is arranged between a reduced pressure furnace and a reduced pressure distillation tower, an oil transfer line is canceled, a reduced pressure distillation raw material is heated in the reduced pressure furnace and then directly enters the flash tower, and gas-liquid separation is performed in the flash tower; the liquid phase, namely flash bottom oil, discharged from the bottom of the flash tower is introduced into the reduced pressure distillation tower; and the gas phase, namely flash top gas, discharged from the top of the flash tower is condensed into liquid phase, and the liquid phase is led out of the device. According to the reduced pressure distillation method and the reduced pressure distillation device using the flash tower in back of the reduced pressure furnace, on the one hand, the yield of reduced pressure distillate is improved; and on the other hand, the conventional reduced pressure oil transfer line is canceled, the operation load of the reduced pressure tower is reduced, and the diameter of the reduced pressure tower can be properly reduced so that the equipment investment is saved and the operation cost is lowered.

Owner:CHINA PETROLEUM & CHEM CORP +1

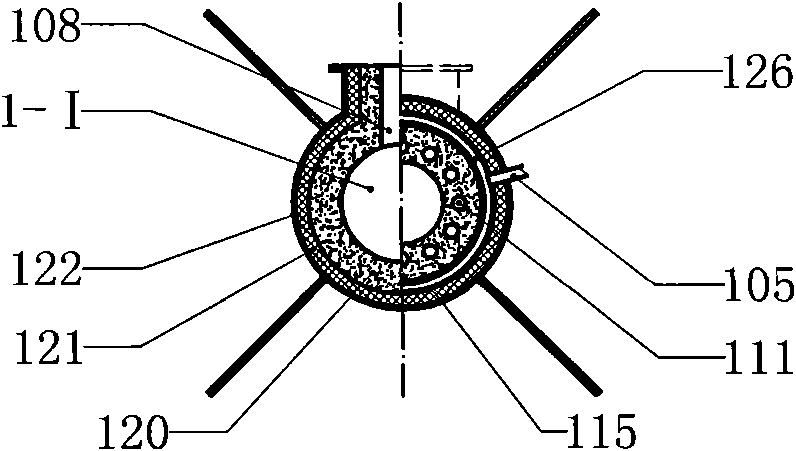

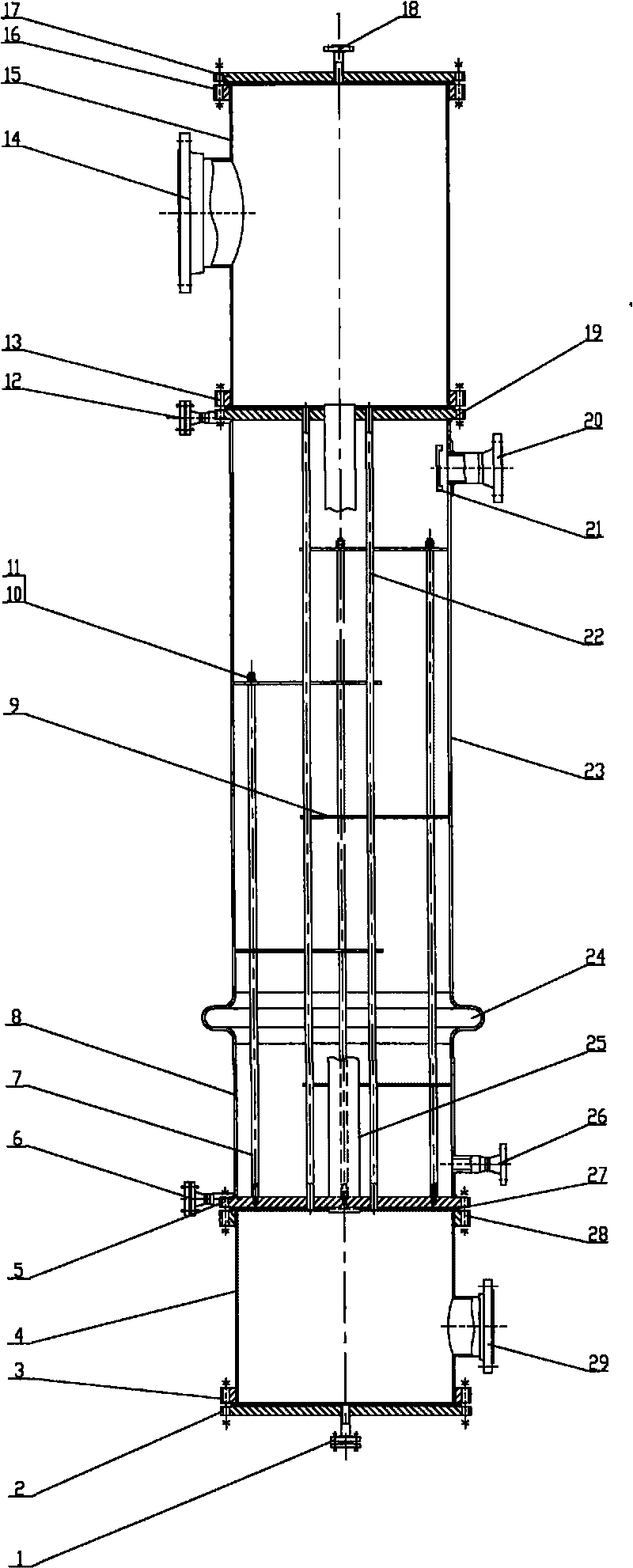

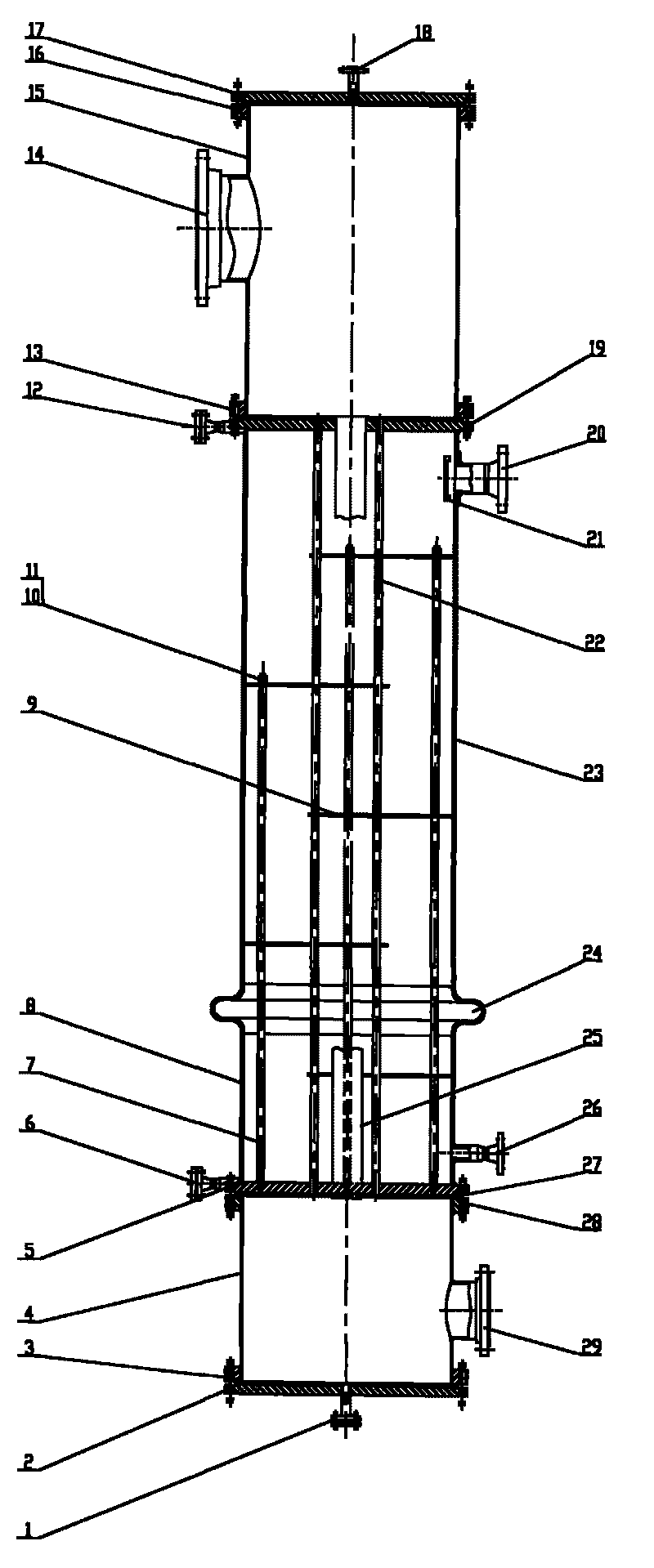

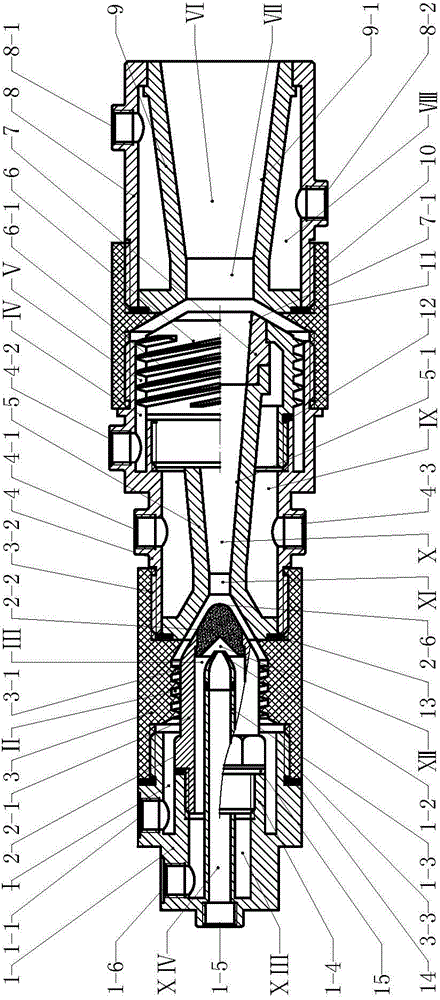

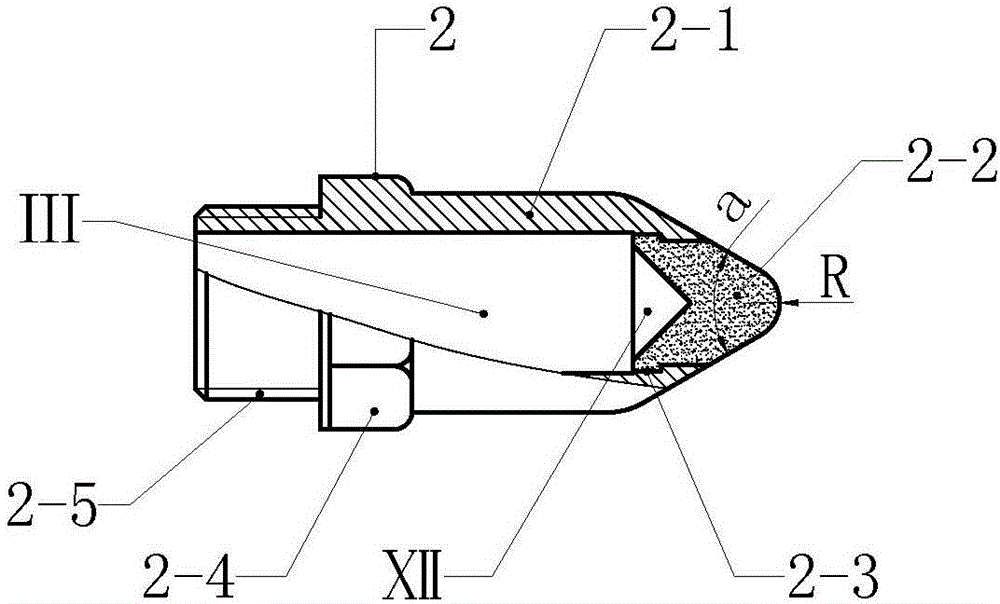

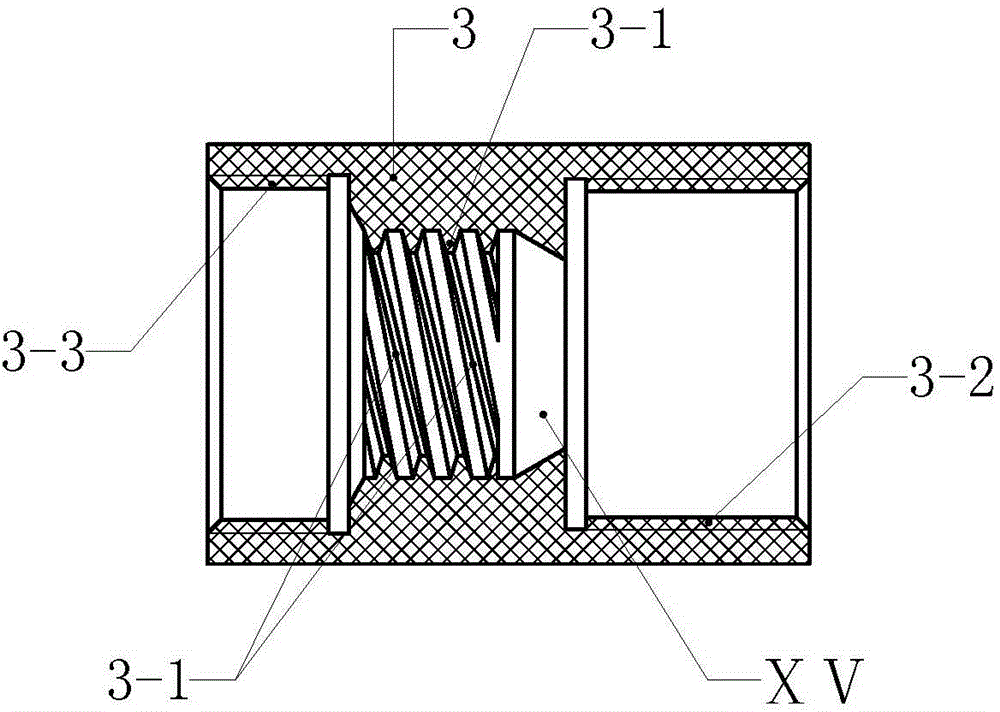

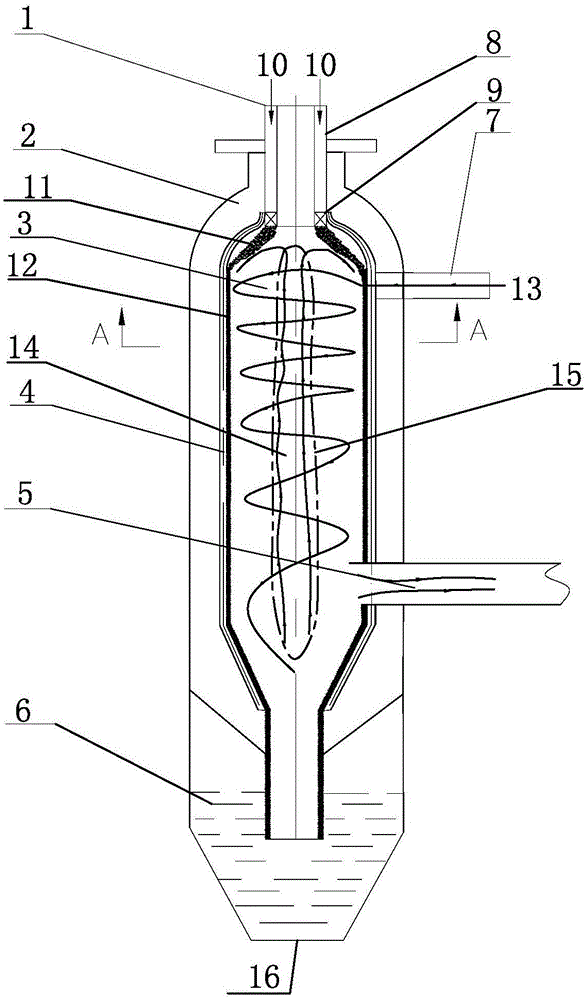

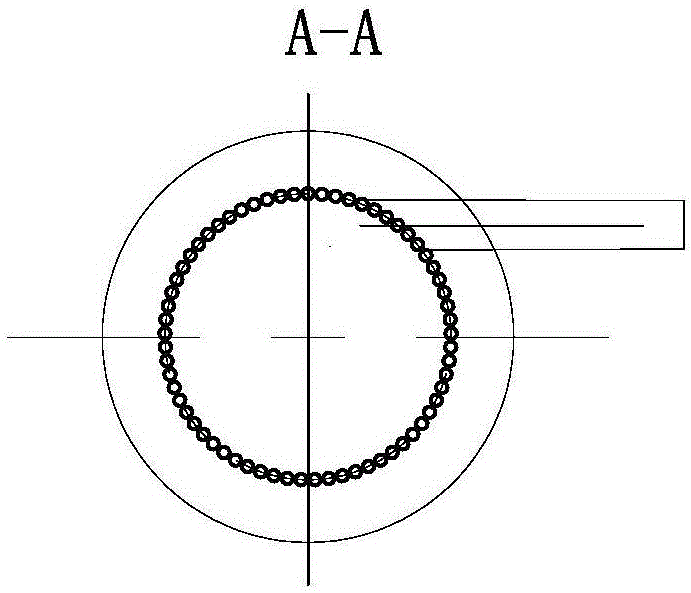

Double-pole electric arc plasma torch used for water pyrolysis

ActiveCN104470187AHigh processing temperatureImprove heating efficiencyPlasma techniqueMaterials scienceMicroporous membranes

The invention relates to a plasma torch, in particular to a double-pole electric arc plasma torch used for water pyrolysis. The double-pole electric arc plasma torch is composed of a backseat, a cathode, a spiral fluid director, a middle electrode assembly, an insulating connecting piece and an anode assembly. A water supply flow guide pipe and a cathode connecting rod are arranged in a revolution body of the backseat; the cathode is composed of a microporous membrane cathode head and a cathode sleeve, and micropores of the microporous membrane cathode head form a filtering channel for water molecules; the middle electrode assembly comprises a middle electrode and an annular electrode; the cathode is connected to the front end of the cathode connecting rod, the spiral fluid director is installed on the backseat, the middle electrode assembly is connected between the spiral fluid director and the insulating connecting piece, and an anode sleeve and an anode are installed at the front end of the insulating connecting piece; the head of the cathode enters the entrance space in the rear end of the middle electrode, a first discharging area is formed by the entrance space in the rear end of the middle electrode, and a second discharging area is formed by the space between the annular electrode and the rear end of the anode. The higher processing temperature of the plasma torch can be reached, and the heating efficiency and the decomposition capacity of the plasma torch are improved.

Owner:中恒华创(山东)技术服务有限公司

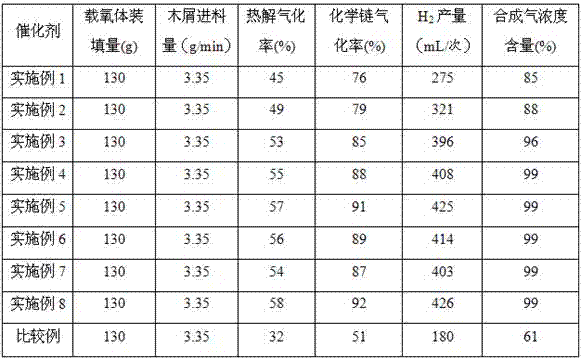

Oxygen carrier for preparing syngas from biomass, preparation method and applications thereof

ActiveCN107537503AEasy to prepareRaw materials are cheap and easy to getMetal/metal-oxides/metal-hydroxide catalystsBulk chemical productionLanthanumOxygen

The present invention discloses an oxygen carrier for preparing syngas from biomass, wherein the oxygen carrier comprises 5-65% of Fe2O3, 5-35% of NiO and 30-90% of LaNiO3, wherein perovskite structure LaNiO3 or a LaNiO3 and NiO mixture with a perovskite structure is prepared through a complexing reaction by using the soluble salt of nickel and lanthanum as a precursor and using citric acid as a complexing agent, and loads an active component and an auxiliary agent through impregnating. According to the present invention, the oxygen carrier can be used for producing syngas by using biomass asthe raw material, has high activity, and can promote the gasification of the tar generated after biomass pyrolysis so as to improve the whole gasification rate of biomass; the syngas can be obtained by using the biomass as the raw material, such that the yield of the syngas is high and can achieve more than 95%; and through the chemical looping cycle reaction, the pure hydrogen gas can be obtainedwithout the gas separation process so as to improve the economy of the biomass-to-hydrogen production technology.

Owner:CHINA PETROLEUM & CHEM CORP +1

Internal combustion heating rotation conical biomass gasification furnace

InactiveCN101538484AIncrease temperatureImprove efficiencyCombined combustion mitigationCombustible gas productionProcess engineeringBiomass gasifier

The invention provides an internal combustion heating rotation conical biomass gasification furnace which is characterized in that the furnace body is internally provided with two concentric cones, wherein the external cone is a rotation cone and the internal cone is a fixed cone; the top of the rotation cone is connected with a material cylinder at the lower section; the top of the fixed cone is communicated with a smoke gas pipeline; the bottom end surface of the fixed cone is closed and the lower part thereof is tangentially connected with a combustion pipeline; the side wall of the furnace body is arranged as jacket structure; the jacket comprises a high-temperature resistance furnace wall, a combustion gas pipeline, a heat preservation layer and an external wall of the gasification furnace sequentially from inside to outside; the airflow passage in which the combustion gas is led out from the gasification furnace is that the combustion gas is led to the bottom port of the combustion gas pipeline from the bottom of the gasification furnace along the inclined surface of the conical furnace bottom; the delivery outlet of the combustion gas is arranged at the upper part of the combustion gas passage; and a gas transmission pipeline connected on the delivery outlet of the combustion gas outside the gasification furnace is connected with a gas storage cabinet by an induced draft fan. The gasification furnace greatly improves the biomass gasification rate and the heat value of the combustion gas.

Owner:HEFEI UNIV OF TECH

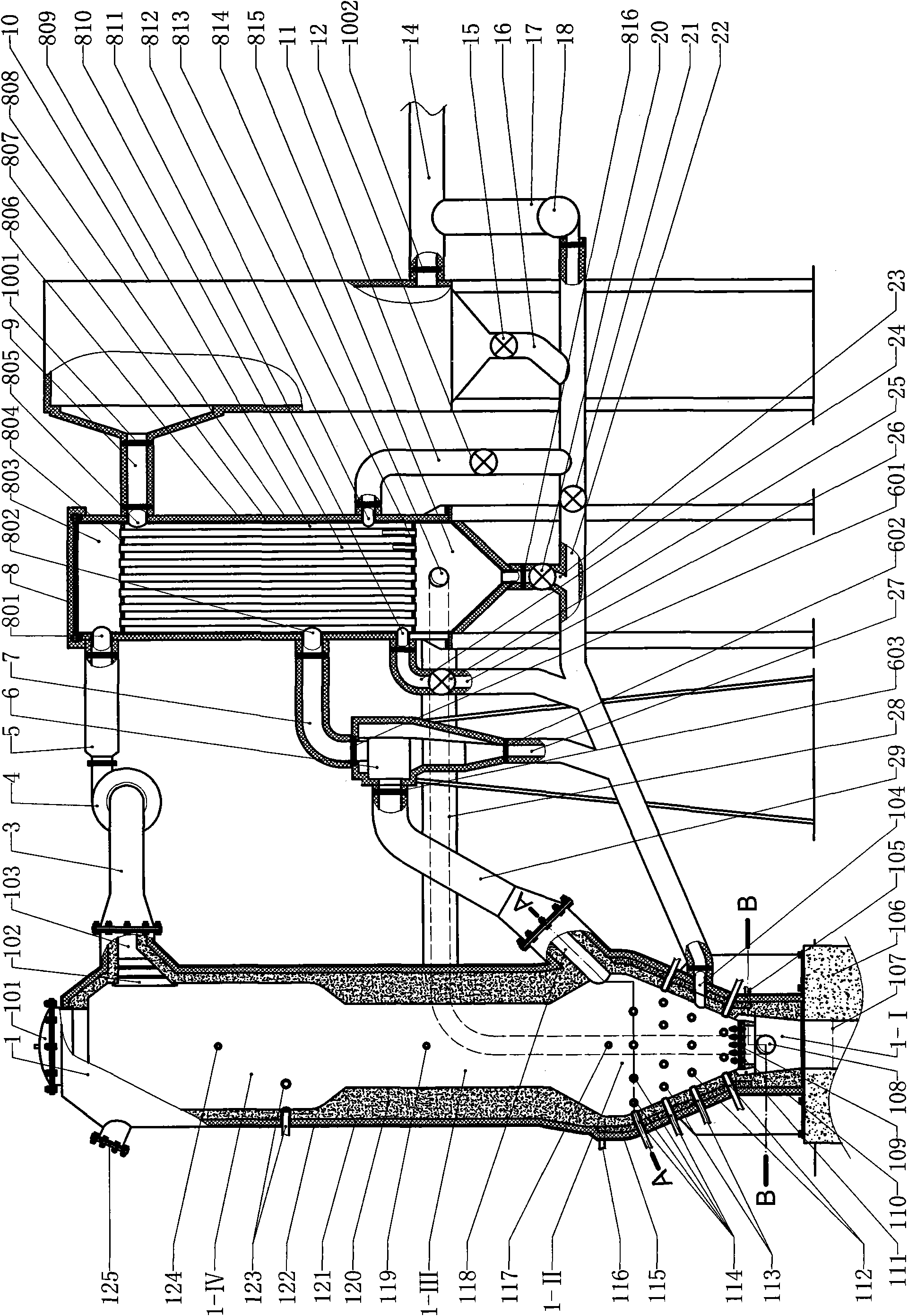

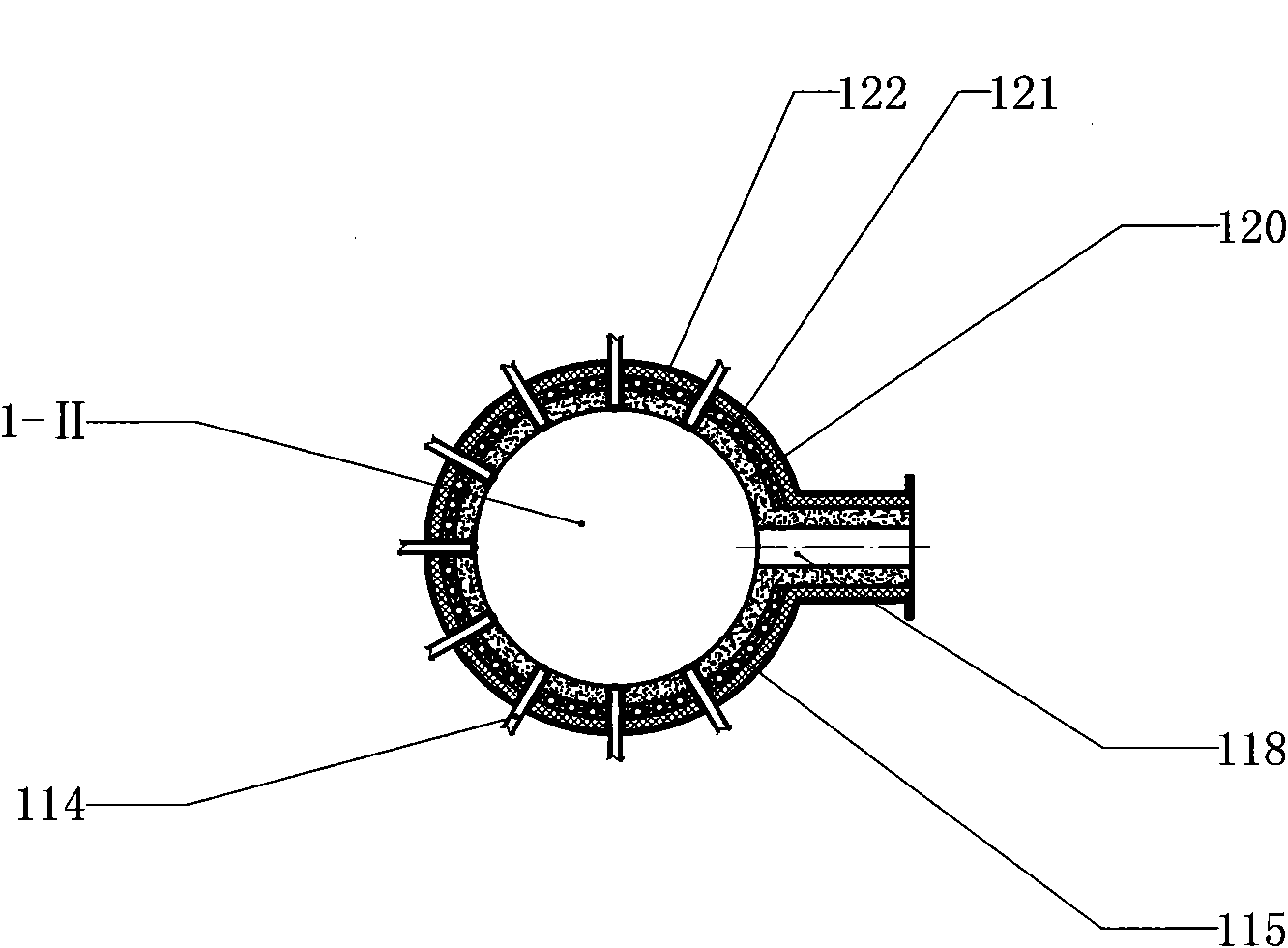

Gasifying agent strongly-rotating pulverized coal gasifying device and gasifying method

InactiveCN105132035AUniform thicknessWell mixedGranular/pulverulent flues gasificationHearthEngineering

The invention relates to a pulverized coal gasifying device and gasifying method, in particular to a gasifying agent strongly-rotating pulverized coal gasifying device and gasifying method. The invention aims at solving the problems that cinders are not uniformly hung on the wall surface of the gasifier in the prior art and the inner wall surface of the gasifier is burned out and corroded. A water-cooled wall of the device is installed in a gasifier body, the water-cooled wall consists of a plurality of vertical circular pipes, the water-cooled wall forms a rotary body gasifying hearth, a cinder basin is arranged at the bottom portion of the gasifier body, a synthesis gas passage is inserted into the lower portion of the gasifier body, a gasifying agent spray outlet is formed in the upper portion of the gasifier body, the gasifying agent spray outlet is inserted into the gasifying hearth along the tangential direction of the gasifying hearth, a pulverized coal burner is installed at the top portion of the gasifier body, the axis of the pulverized coal burner and the axis of the gasifying hearth are overlapped, and a pulverized coal passage with an annular cross section is arranged in the pulverized coal burner. The gasifying agent strongly-rotating pulverized coal gasifying device and gasifying method are used for the field of coal gasification.

Owner:HARBIN INST OF TECH

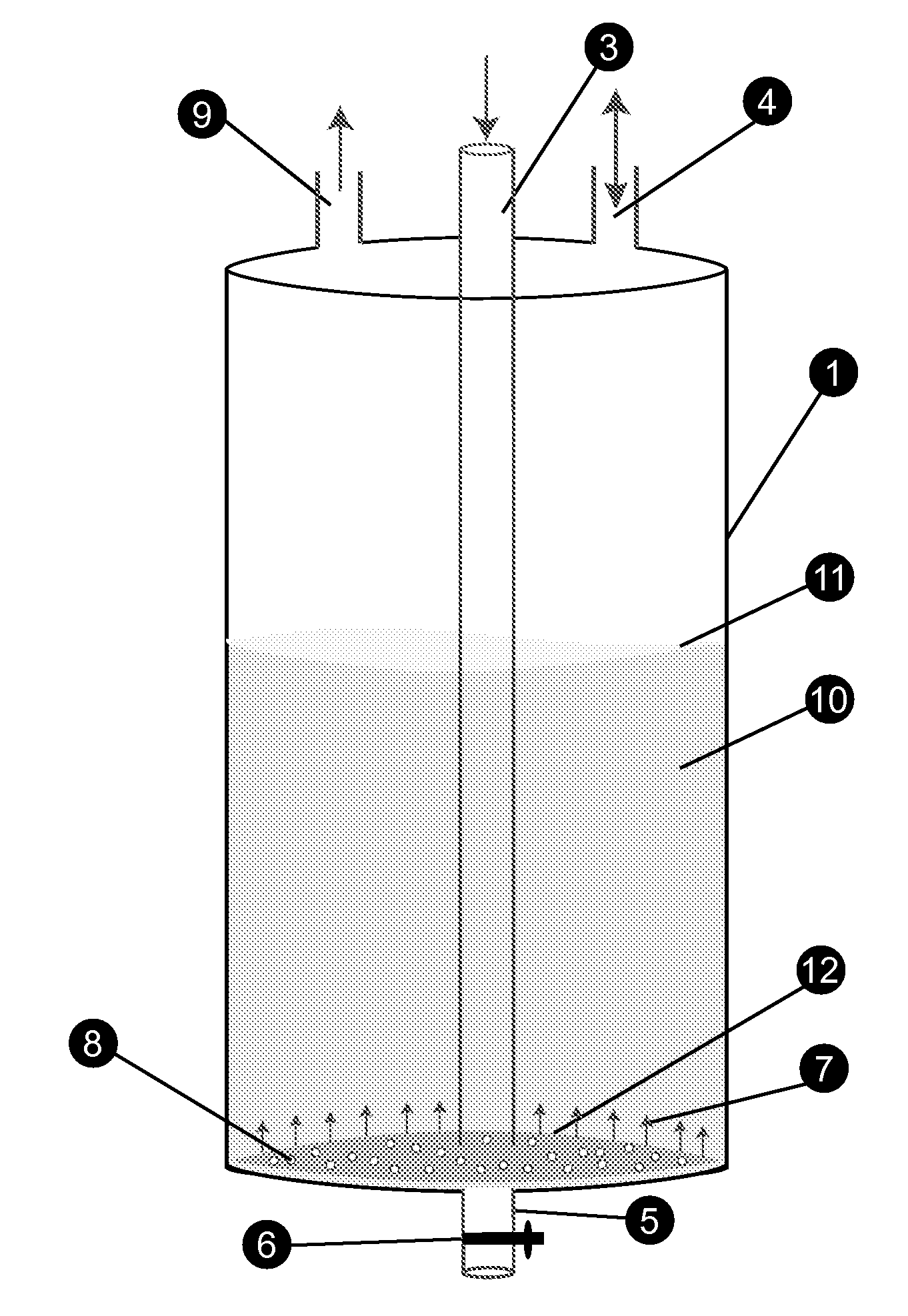

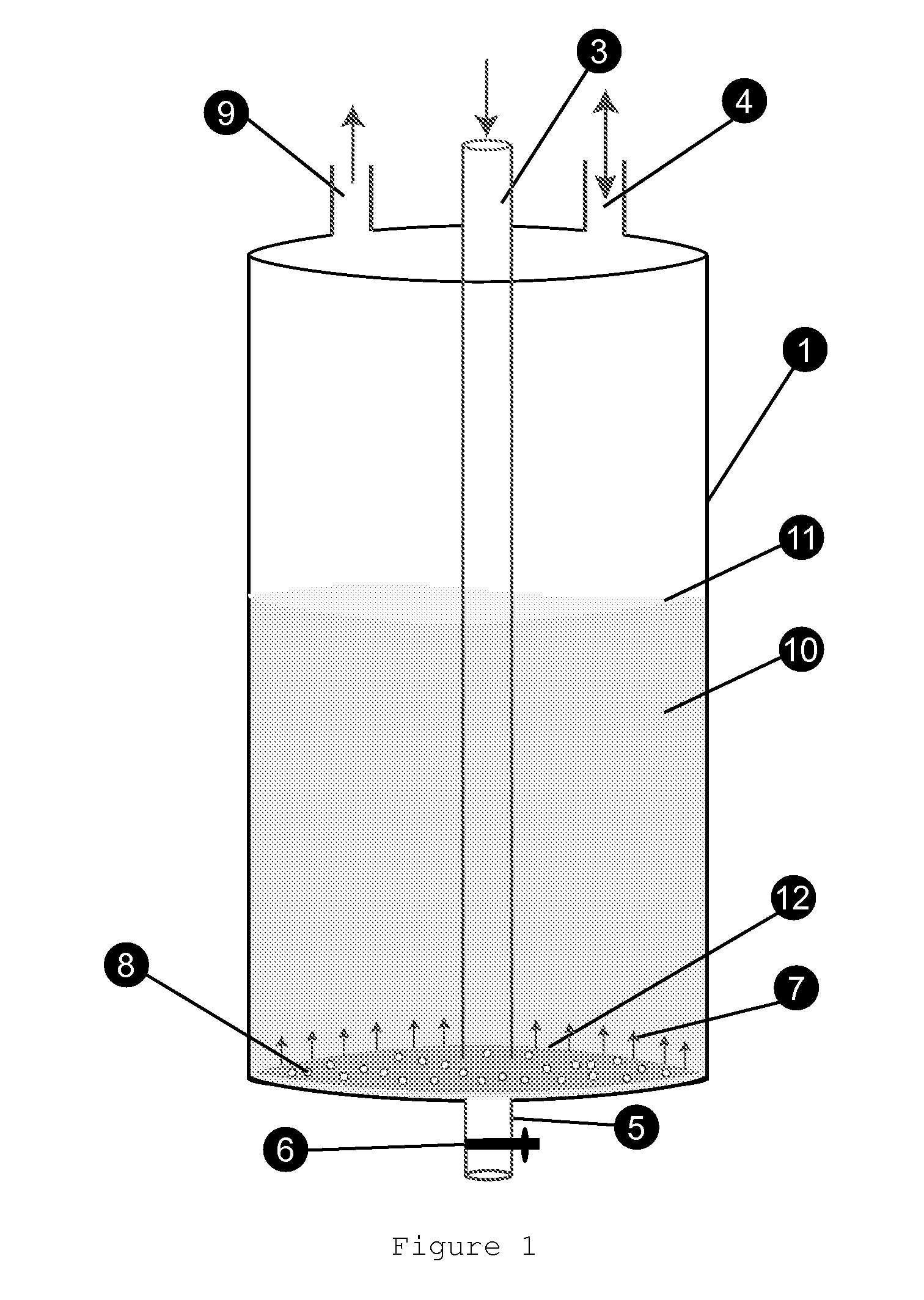

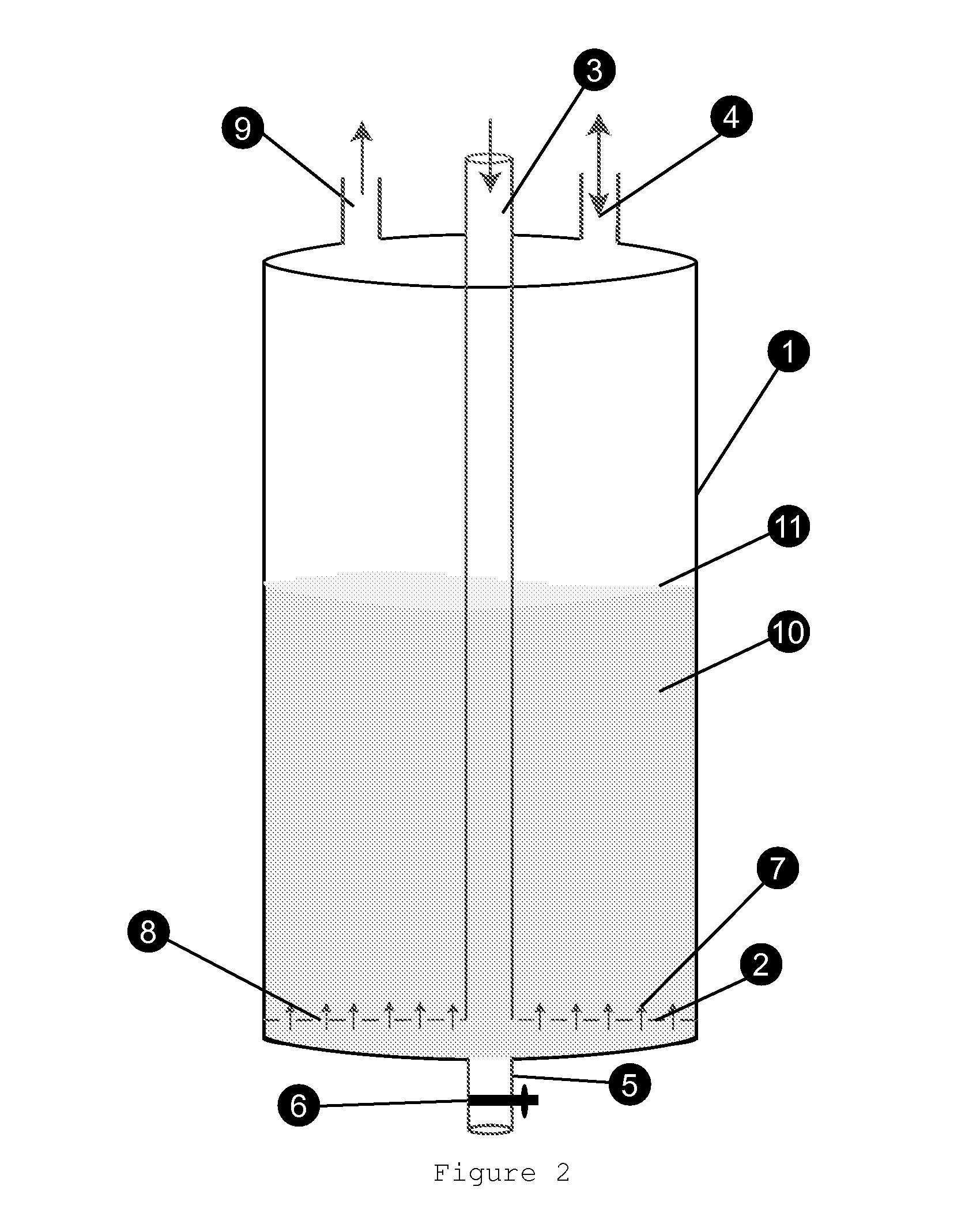

Stationary Bubble Reactors

Owner:ADELLO BIOLOGICS LLC

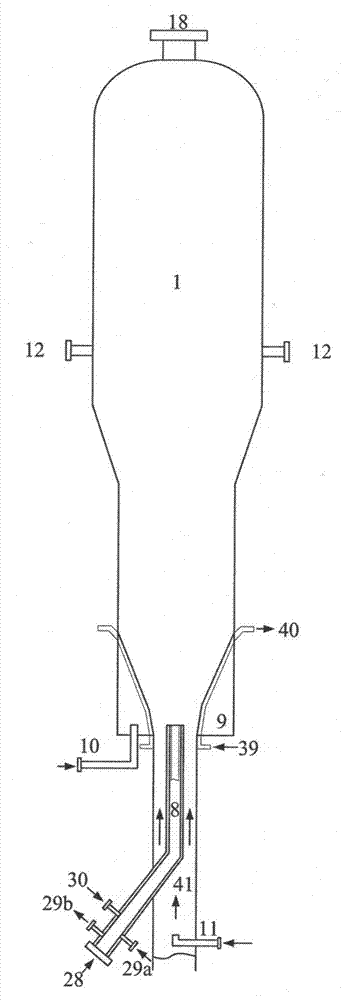

Crude oil pressure-reduced distillation method and device

InactiveCN102311754AEasy to separateGood stripping effectVacuum distillation separationVacuum distillationHydrogenGas phase

The invention discloses a crude oil pressure-reduced distillation method and a crude oil pressure-reduced distillation device. A flash tower is arranged between a reduced-pressure furnace and a reduced-pressure distillation tower, an oil transfer line is eliminated, a reduced-pressure distillation raw material is heated in the reduced-pressure furnace and directly enter the flash tower, a small amount of stripping gas is introduced into the flash tower, and the liquid phase, namely flash bottom oil, obtained by gas-liquid separation in the flash tower is introduced into the reduced-pressure distillation tower; and a gas phase, namely flash top gas, discharged from the top of the flash tower is condensed into a liquid phase to be led out of the device. A high-temperature hydrogen or inert gas is introduced into the bottom of the flash tower. When the pressure-reduced distillation method and the pressure-reduced distillation device, in which the flash tower for high-temperature hydrogen or inert gas stripping flash tower is arranged behind the reduced-pressure furnace, are used, the yield of a reduced-pressure fraction oil is increased, the conventional reduced-pressure oil transfer line is not used, the operation load of the reduced-pressure furnace is lowered, and the tower diameter of the reduced-pressure tower can be reduced properly; therefore, equipment investment is reduced, and operation cost is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

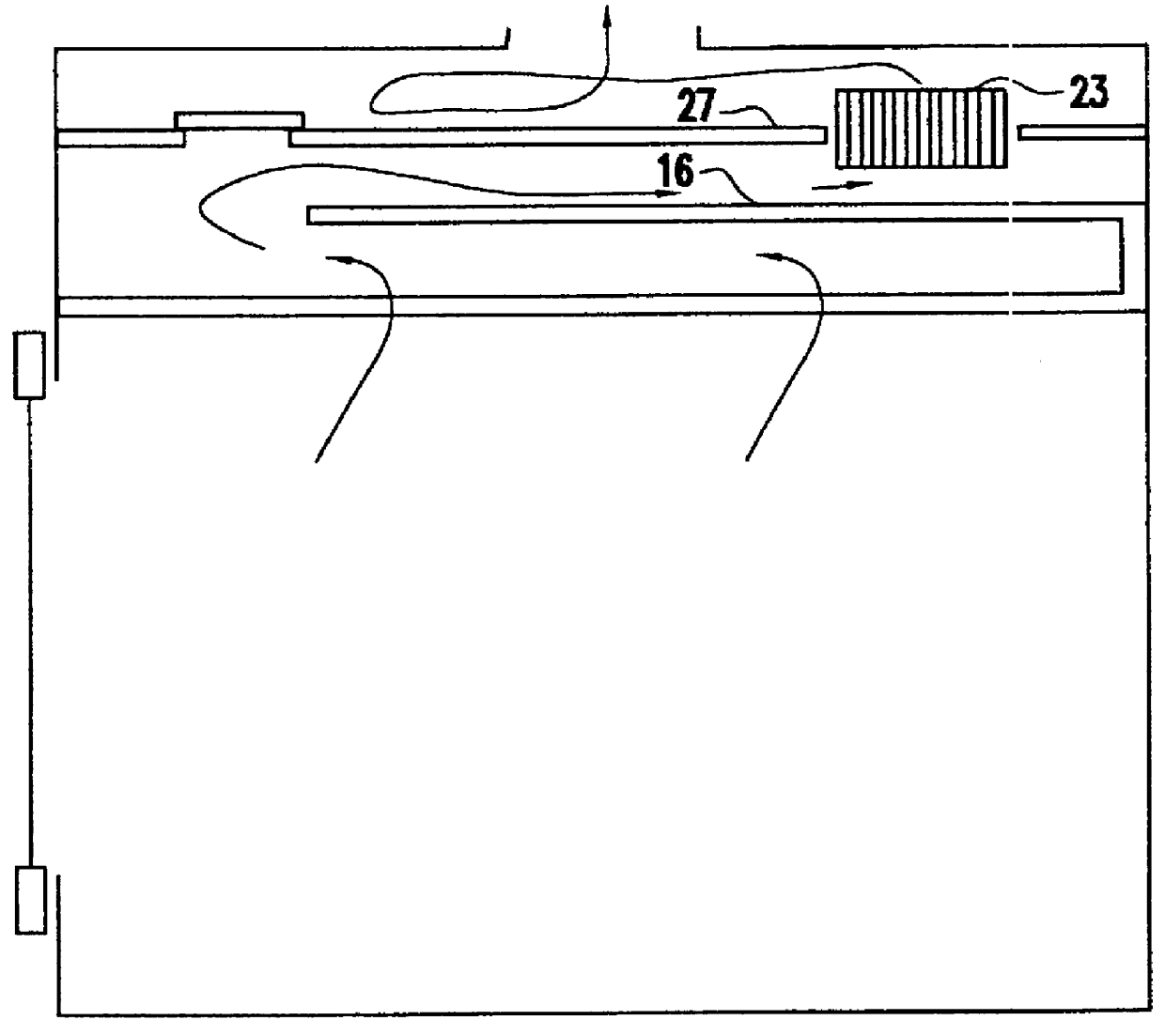

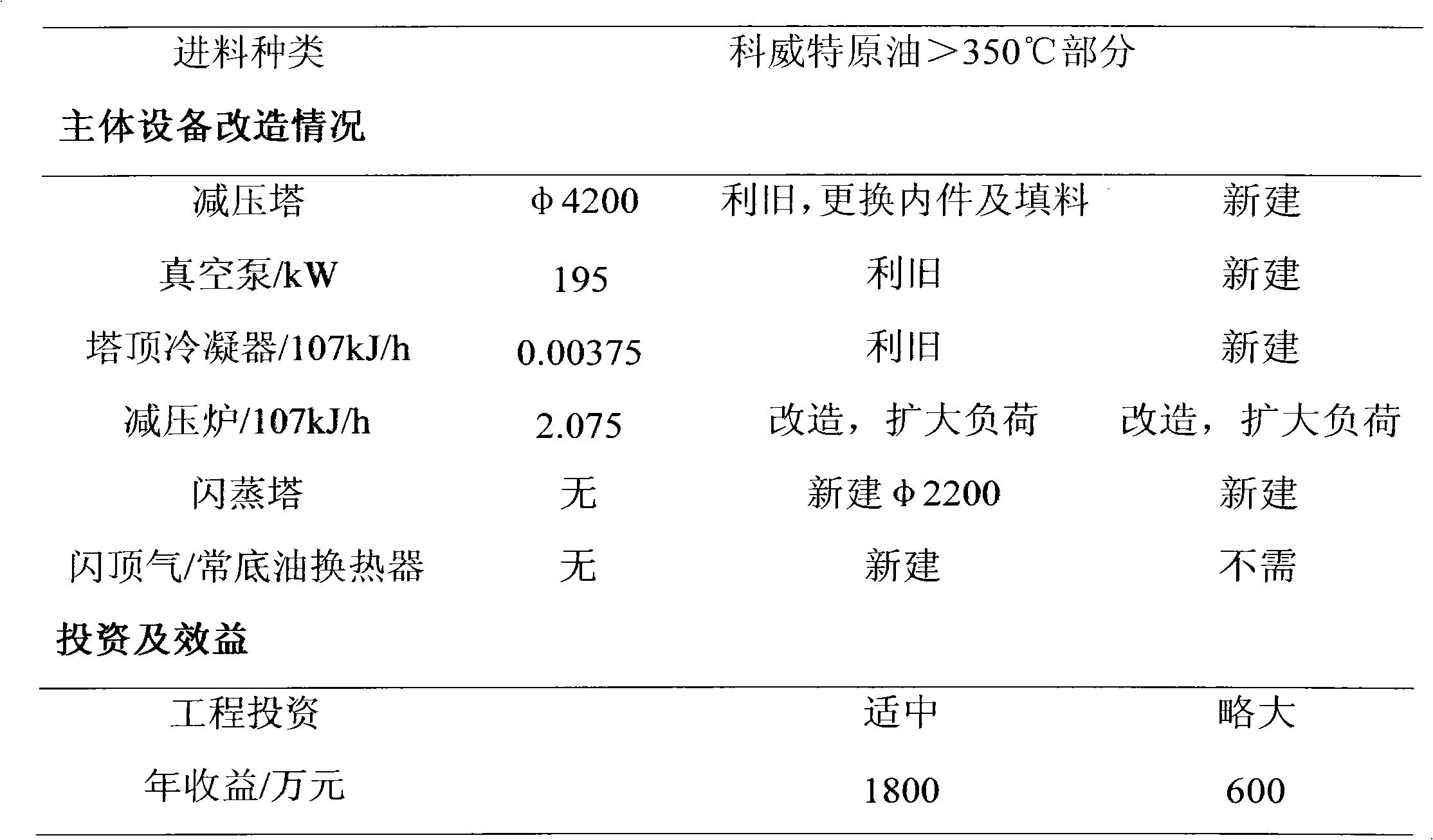

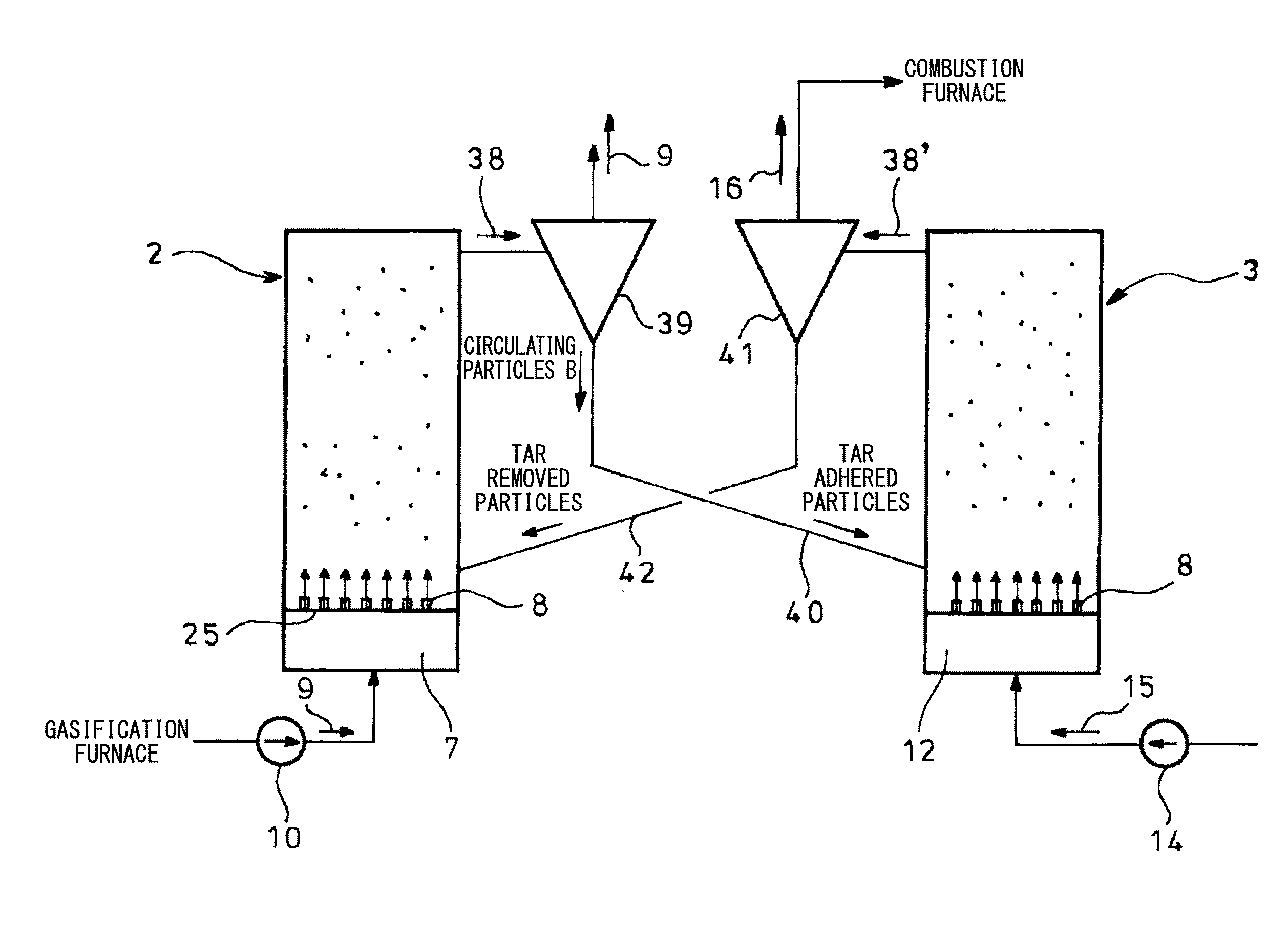

Tar removal device

ActiveUS20140017140A1Increase thermal efficiencyGasification rate be improveFluidized bed combustionGasification processes detailsTarProcess engineering

A tar removal device removes tar contained in a gasification gas (9) generated in a gasification furnace of a two-towered gasifier having a combustion furnace (43) heating a heating medium (A) and the gasification furnace (47) introducing the heating medium (A) heated in the combustion furnace to perform gasification of a starting material (48).The tar removal device includes a tar separation unit (2) that introduces the gasification gas from the gasification furnace to fluidize the circulating particles (B) so as to adhere the tar in the gasification gas to the circulating particles, and a tar combustion unit (3) that introduces the circulating particles to which the tar is adhered at the tar separation unit, fluidizes the circulating particles using air (15) so as to burn the tar adhered to the circulating particles, supplies the combustion gas (16) in which the tar is burnt to the combustion furnace as a gas for combustion, and returns the circulating particles from which the tar is burnt and removed to the combustion furnace.

Owner:IHI CORP

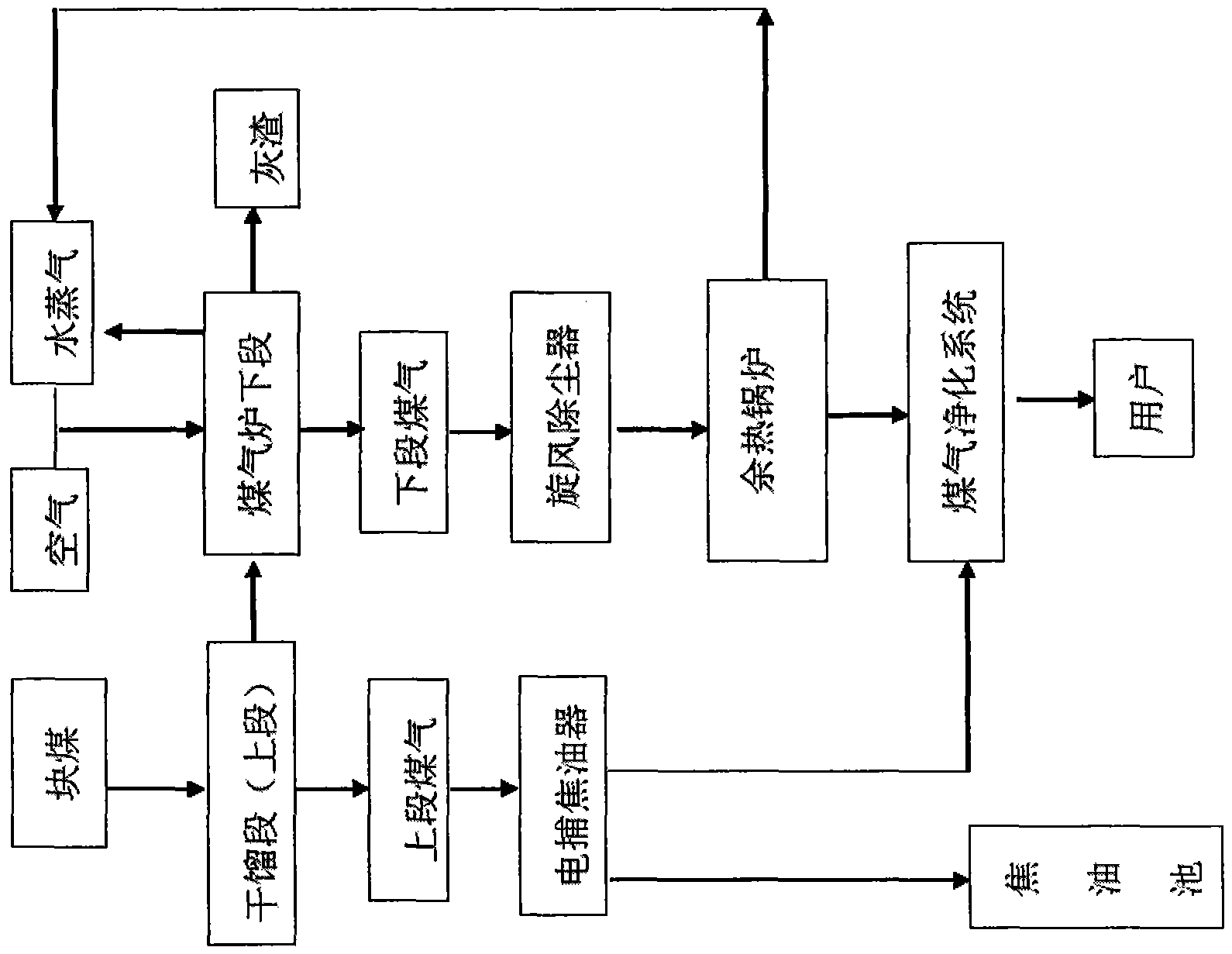

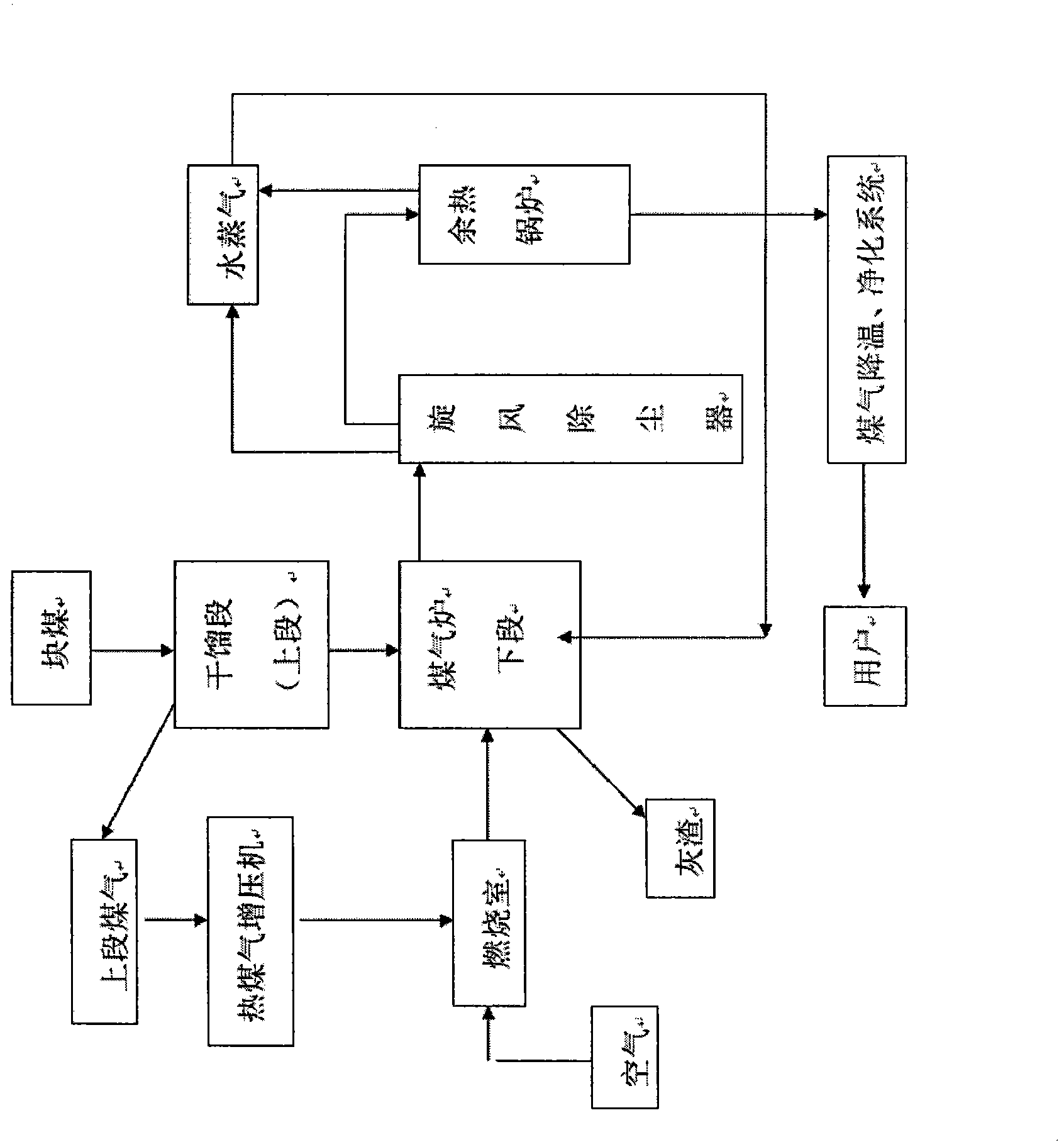

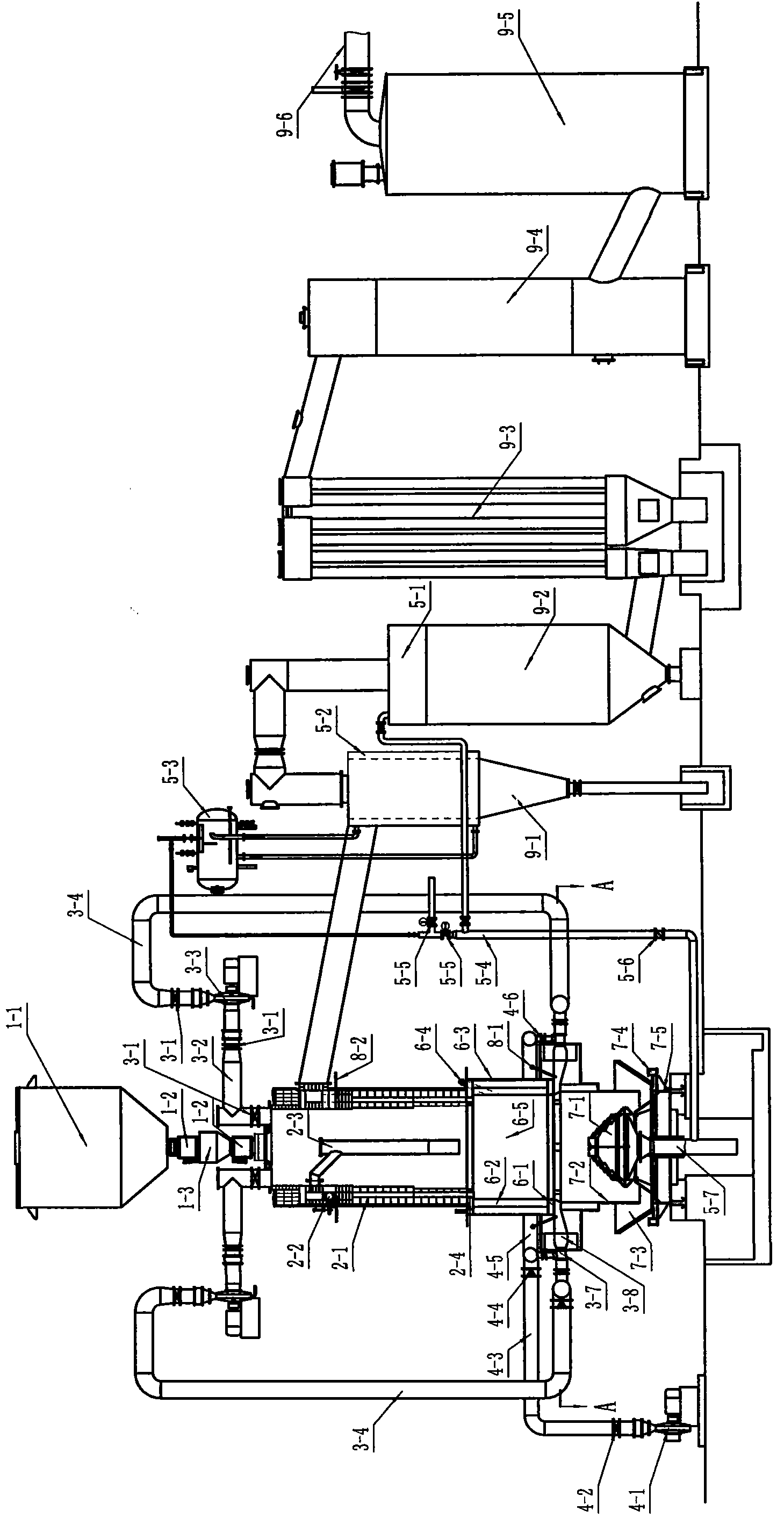

Counterflow burning type coal gasifier device and process thereof

ActiveCN103642530AImprove reliabilityReduce labor intensityChemical industryGasification with fuel pre-distillationThermal energyCombustion chamber

The invention specifically relates to a novel counterflow burning type coal gasifier device and a process thereof. The device is composed of following nine major systems: a coal charging system, a dry distillation system, a counterflow burning heating system, a combustion supporting air supply system, a steam supply system, a gas generation system, an ash removal system, an automatic temperature control system and a gas cooling purification system; the process comprises the following steps: 1) generating upper section gas containing dry distillation gas, tar gas, phenol organic matter gasses and water steam; 2) feeding the upper section gas into a combustion chamber for combustion through a hot gas supercharger; 3) introducing high temperature gas generated after combustion in the combustion chamber and containing water vapor and CO2 into the hearth at the lower section of the coal gasifier to contact with coke, and generating to generate lower section gas; 4) cooling and separating dust from the generated lower section gas and then transmitting the gas to the user end. The device and the process provided by the invention are free of discharge of pollutants such as tar and carbolisata aqua, and have the advantages of high heat utilization rate, energy conservation and environmental friendliness; the generated gas is high in cleanness and combustion value.

Owner:淄博硕丰环保设备有限公司

A kind of underground coal gasification system and process with retreating gas injection point

InactiveCN103277082BImplement fixed-point injectionImprove stabilityConstructionsCoal gasificationThermodynamicsCombustion

The invention discloses a gas injection point retreating type coal underground gasification system and process. The gas injection point retreating type coal underground gasification system comprises an airway arranged in a coal layer and multiple coal underground gasification units, wherein the airway is connected to the multiple coal underground gasification units; and the technical steps are sequentially as follows: a step of cold-state testing, a step of ignition on a gasification working surface, a step of debugging of the gasification working surface and a step of gasification normal production process. According to the invention, mud can be prevented from blocking the gas injection point efficiently, and the coal layer can be exploited to the maximum extent, so that possibility of thoroughly cutting off the leakage of a gasification agent to a combustion space area is realized while safe retreating in the coal underground gasification process is realized, filling of the combustion space area is realized, collapse of the ground surface caused by the gasification is removed, stability of the gasification channel structure is guaranteed, problem of the short circuit of the gasification agent caused by a channel which is resulted from collapse of a coal layer plate in the gasification area in the early stage and the gasification channel at the later stage of the underground gasification is solved, the quality of the coal gas is improved, and safe and reliable coal gas production and high gasification rate are achieved.

Owner:HENAN ZHONGKUANG KENENG COAL CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com