Counterflow burning type coal gasifier device and process thereof

A technology of coal gasification and reverse combustion, which is applied in the chemical industry, petroleum industry, and the manufacture of combustible gas, etc., and can solve problems such as phenol water pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

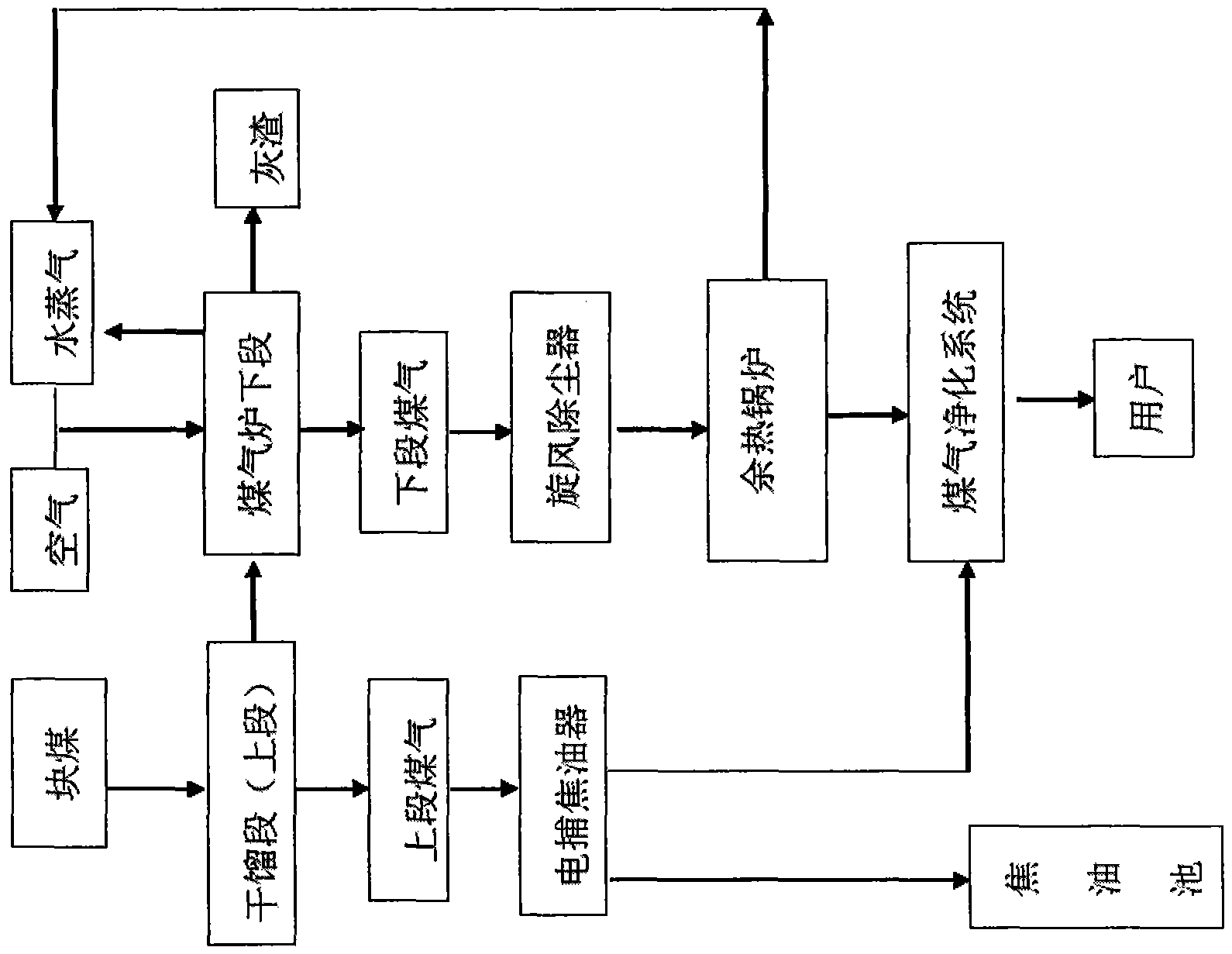

[0062] figure 1 It is a process schematic diagram of an existing two-stage gasifier, and its principle has been described in detail in the content of the invention.

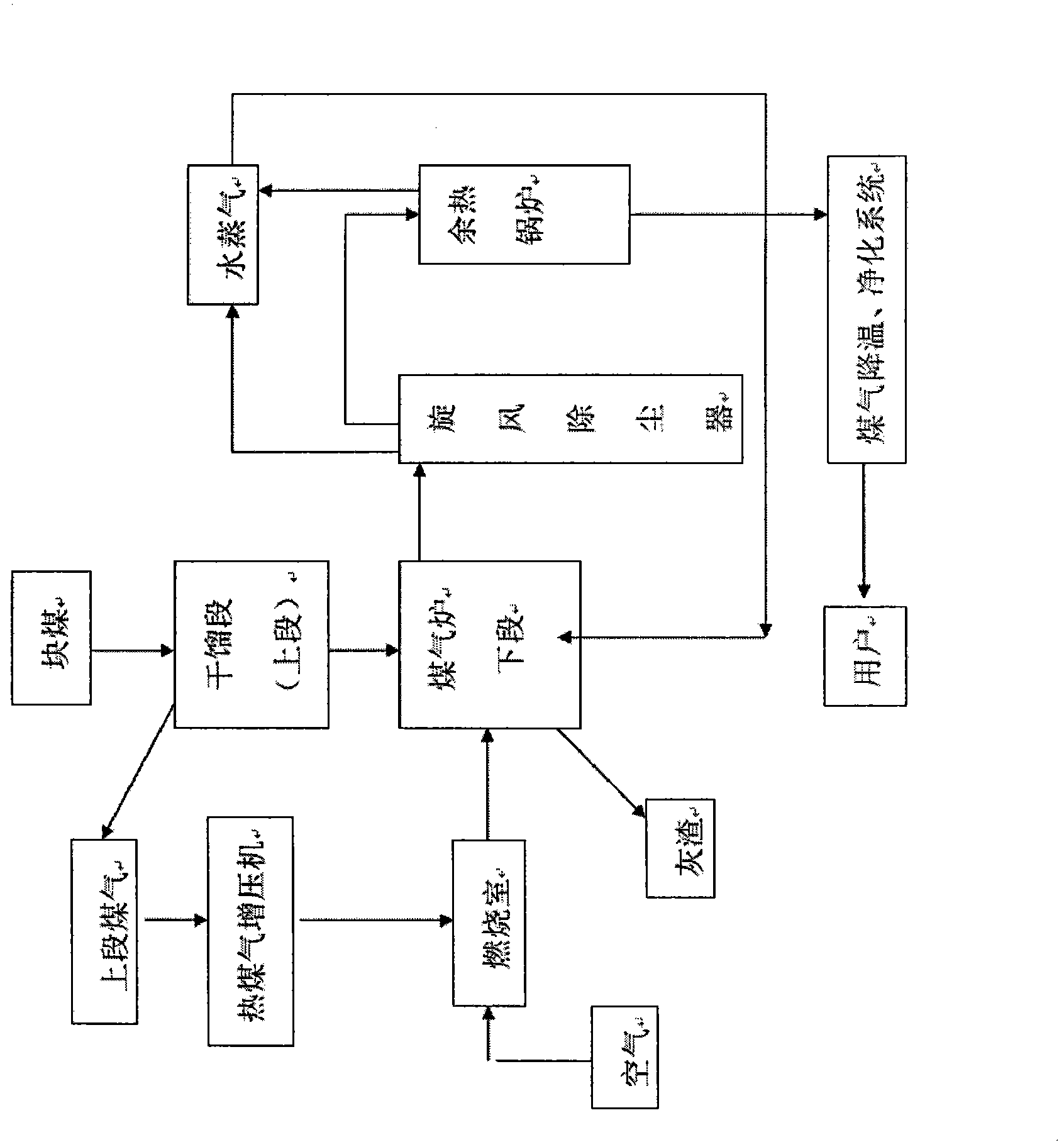

[0063] figure 2 It is a schematic diagram of the process of the present invention.

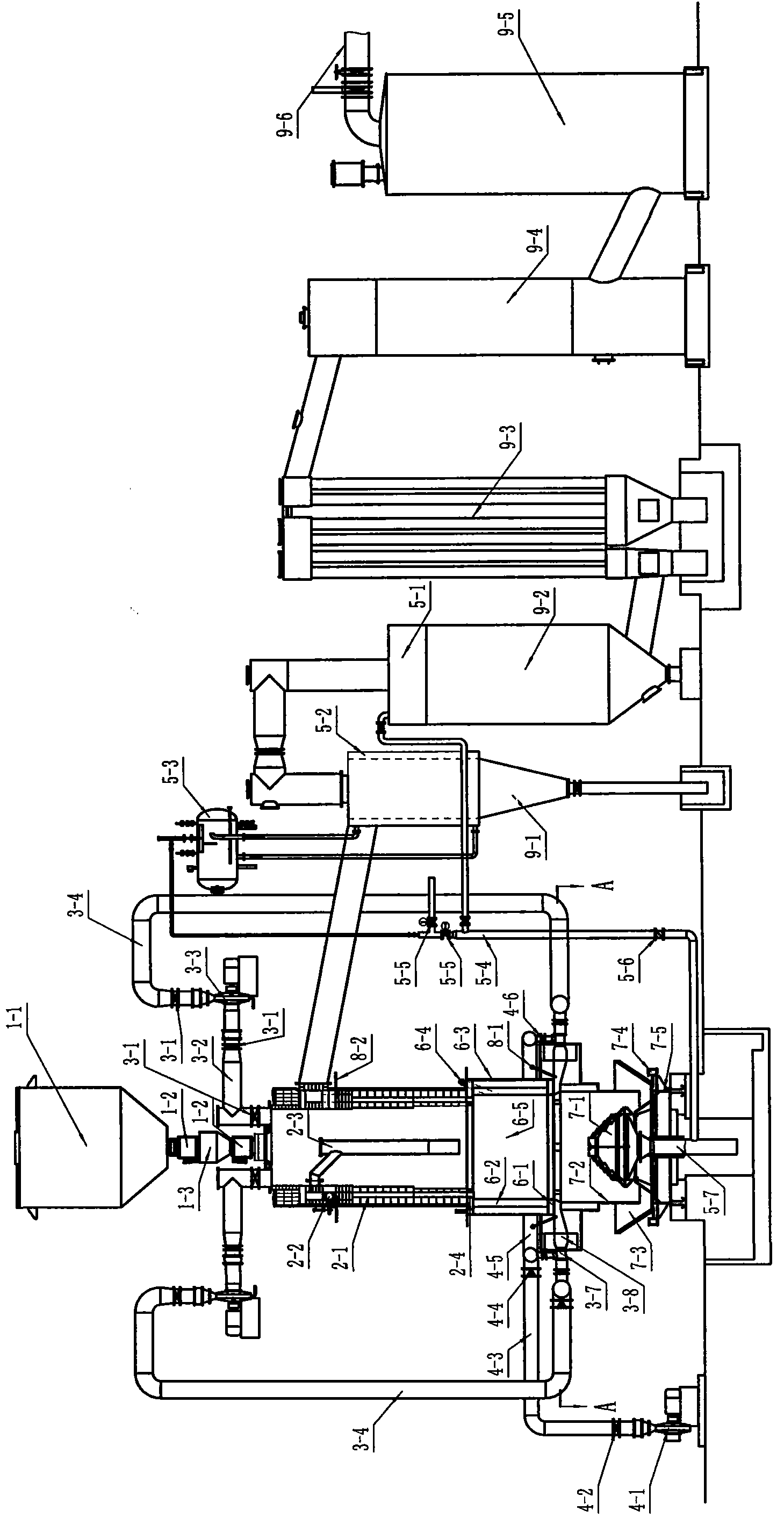

[0064] like image 3 , Figure 4 Shown: the device described in the present invention includes a coal adding system, a dry distillation system, an anti-burning heating system, a combustion-supporting air supply system, a steam supply system, a gas generation system, an ash removal system, an automatic temperature control system and a gas cooling system purification system.

[0065] 1) The coal feeding system of the present invention includes a coal bunker 1-1, two coal feeding valves 1-2 and a buffer coal bunker 1-3. Its structure is the same as that of the prior art and will not be described in detail.

[0066] 2) The retort system of the present invention includes a retort section furnace body, a retort section gas regula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com