Patents

Literature

131results about "Gasification with fuel pre-distillation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

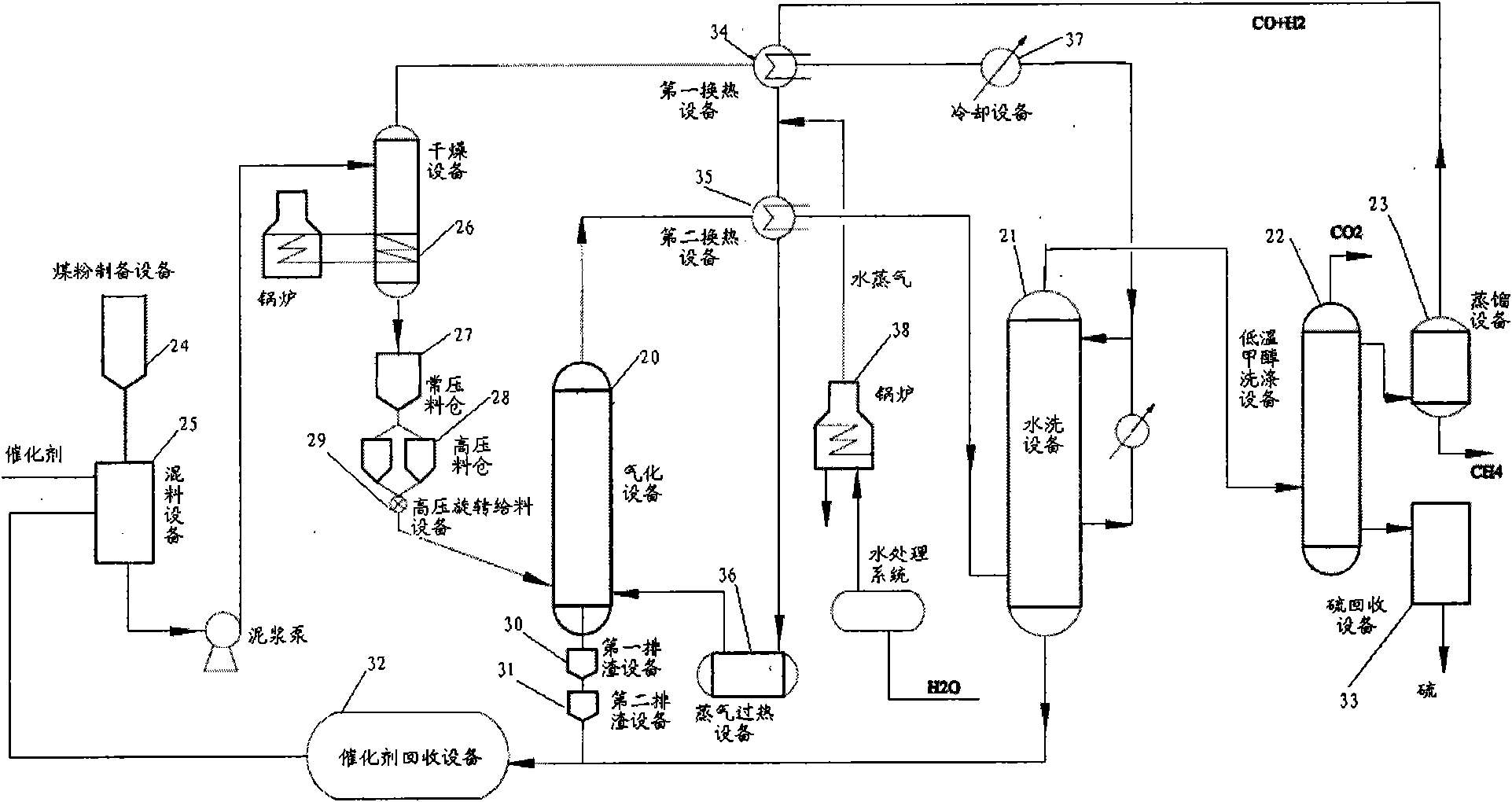

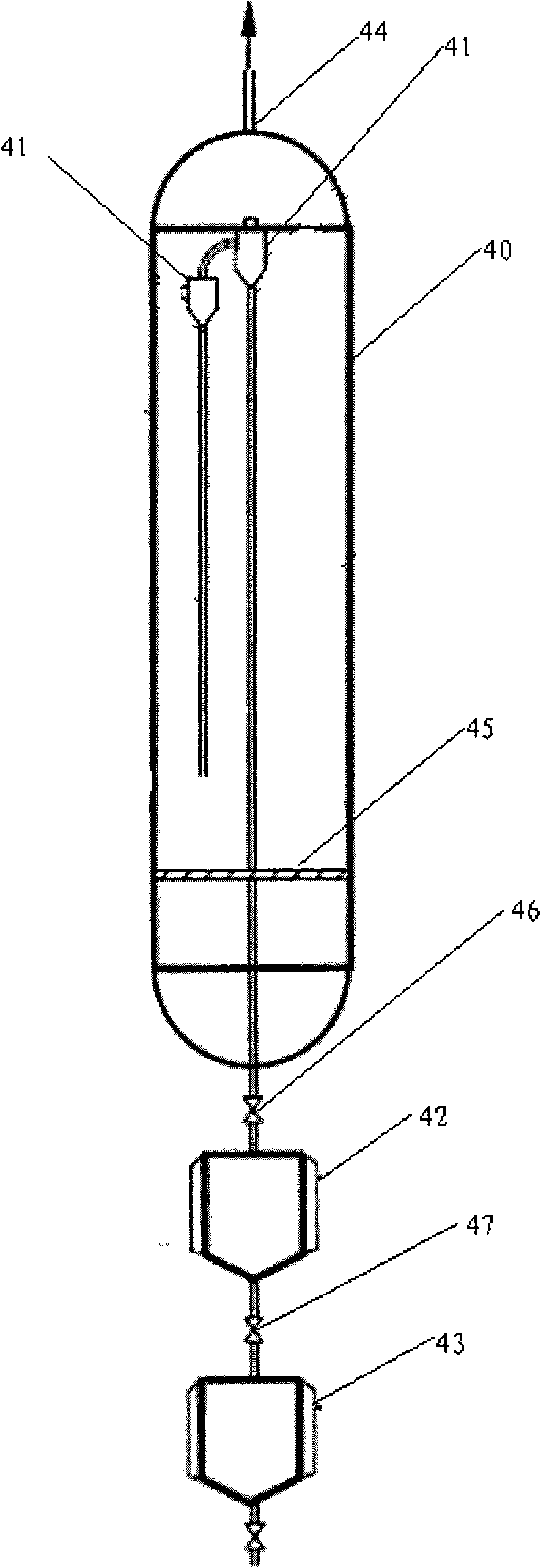

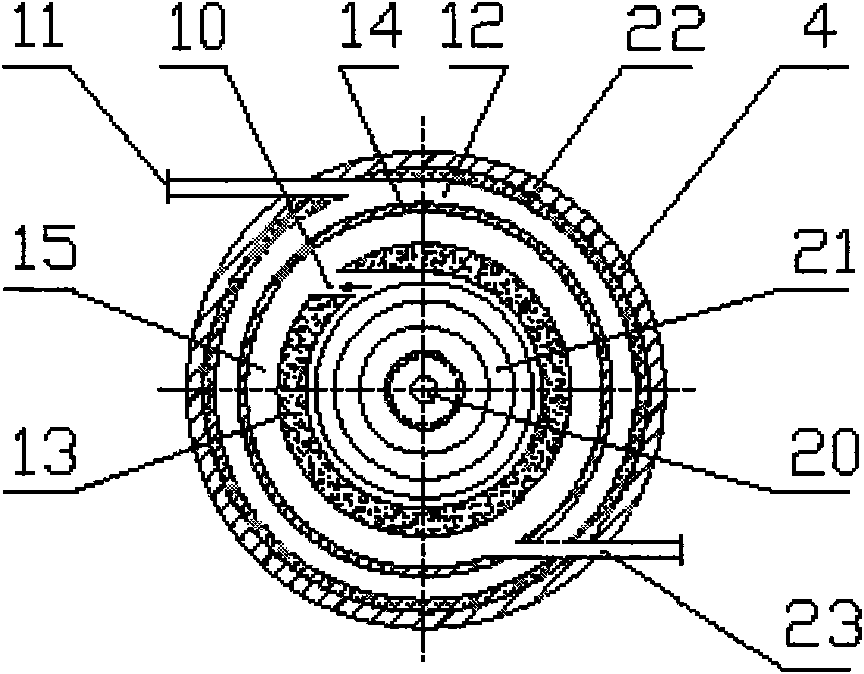

Method, system and equipment for catalytic coal gasification

ActiveCN101555420AContinuous slaggingCombined combustion mitigationGasification with fuel pre-distillationHydrogenProduct gas

The embodiment of the invention discloses a method for catalytic coal gasification. The method comprises the following steps: delivering pulverized coal to gasification equipment under high pressure of high-pressure rotating equipment, allowing a gasification reaction of the coal and a gasification agent in the presence of a catalyst in the gasification equipment, performing gas-solid separation on substances from the gasification reaction, delivering solid obtained from the gas-solid separation to first cinder discharge equipment, and delivering the solid from the first cinder discharge equipment to second cinder discharge equipment; and washing gases obtained from the gas-solid separation to obtain acidic water and purified gases, performing low temperature methanol washing on the purified gases to obtain a mixed gas of methane, hydrogen and carbon monoxide, distilling the mixed gas at low temperature to obtain the methane, delivering the acidic water to a catalyst recovery plant, and returning the recovered catalyst to mixing equipment. The embodiment of the invention further discloses a system and equipment for catalytic coal gasification. The method, the system and the equipment can help realize continuous cinder discharge under high pressure.

Owner:ENN SCI & TECH DEV

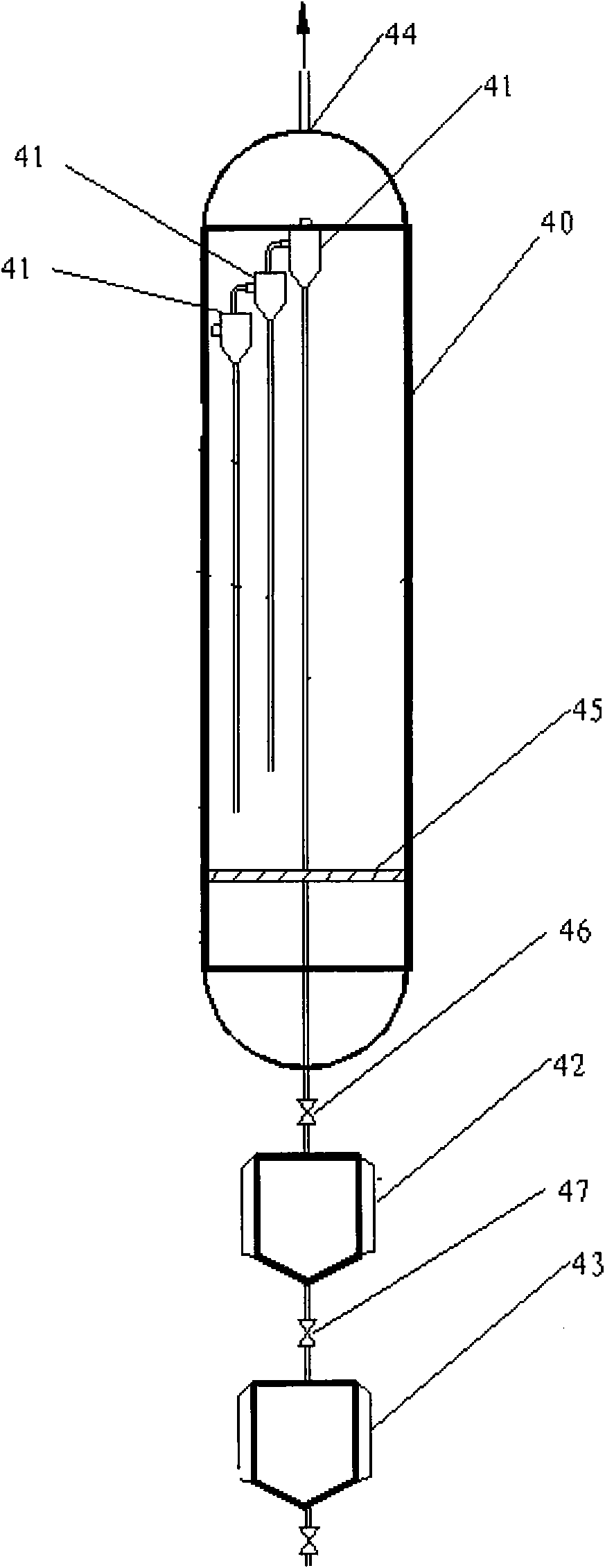

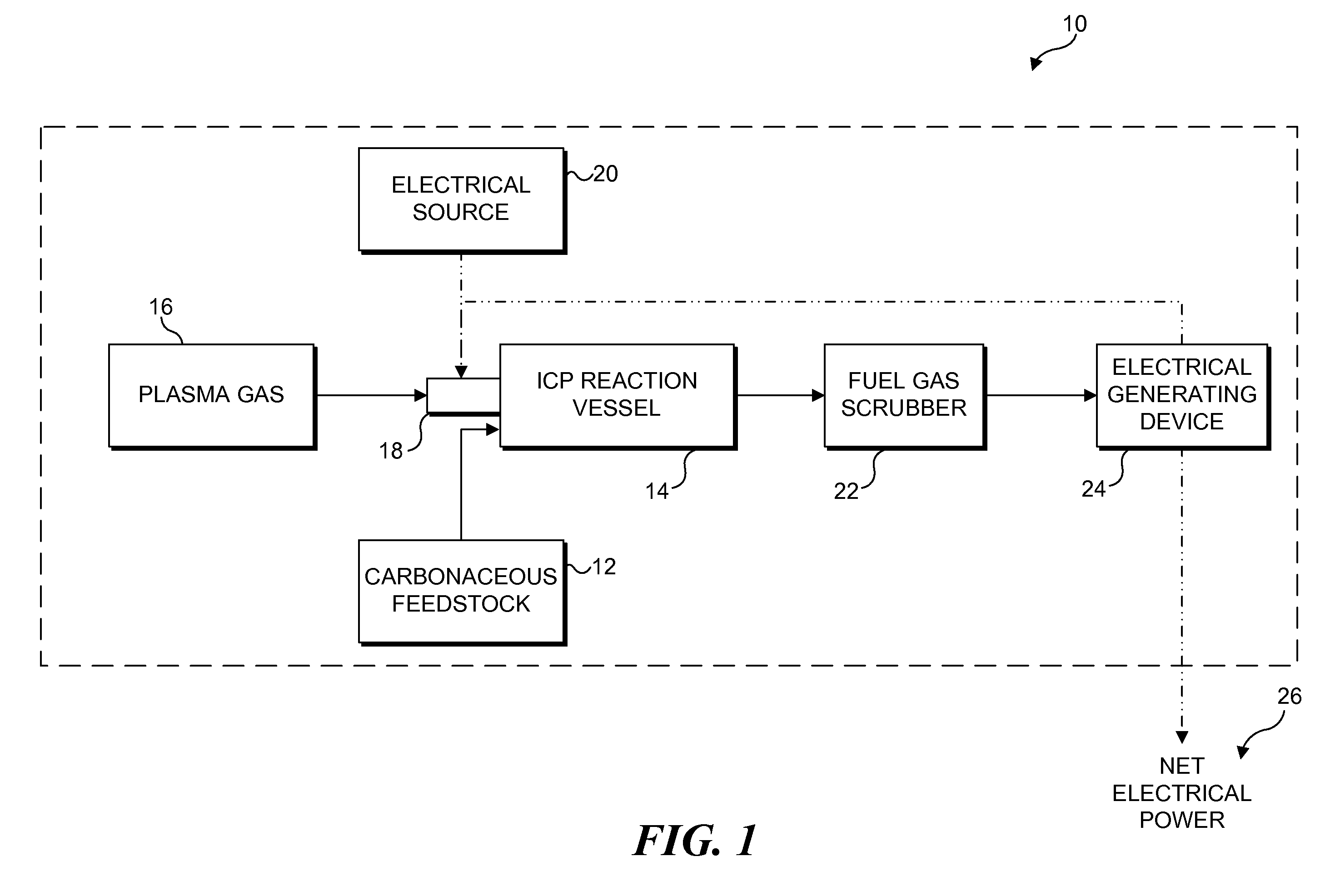

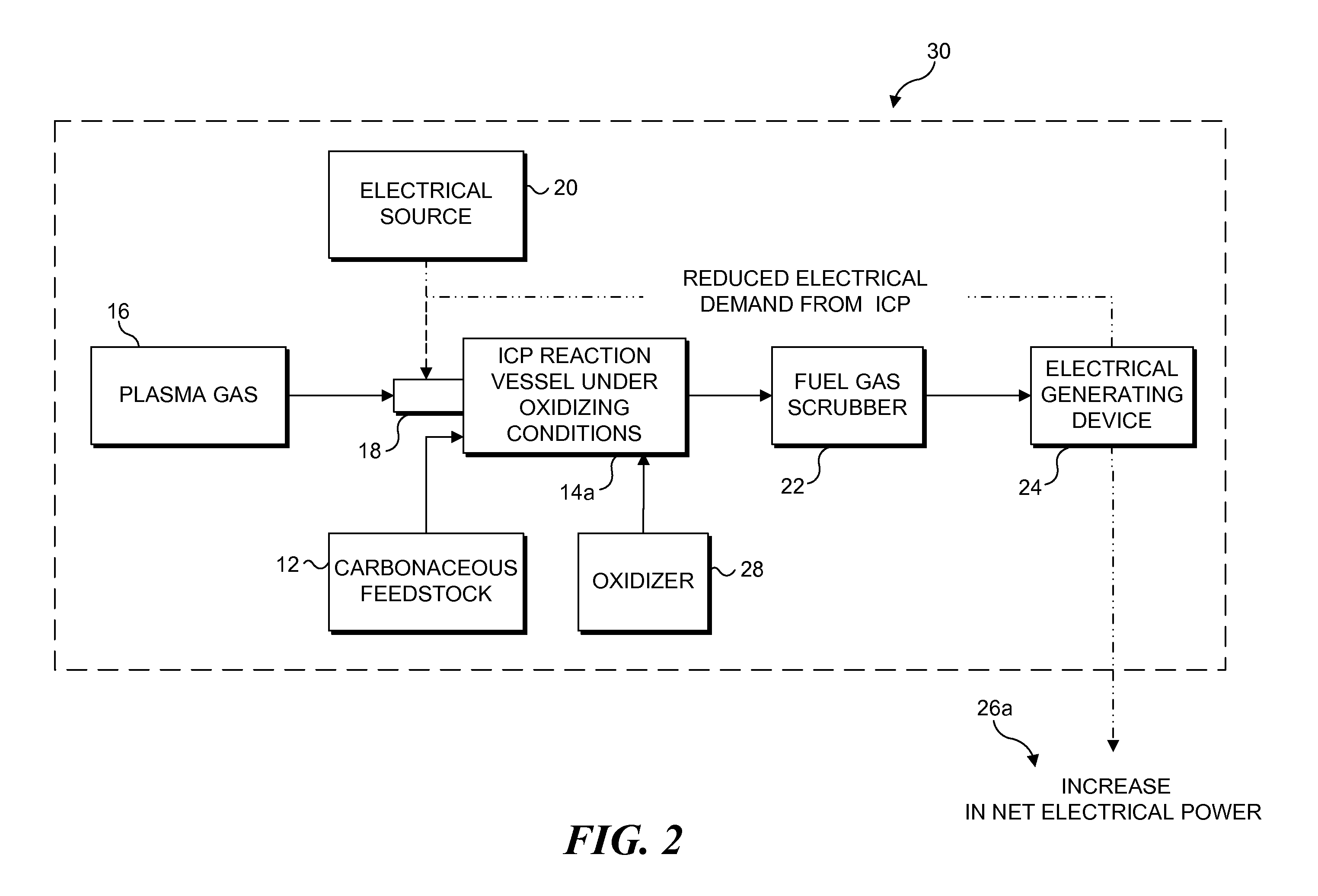

Inductively coupled plasma/partial oxidation reformation of carbonaceous compounds to produce fuel for energy production

InactiveUS20080041829A1Increase the amount of carbonMore electricityElectricity cogenerationFuel cell auxillariesThermal energyPartial oxidation

Owner:SEQUOYAH FINANCE ONE

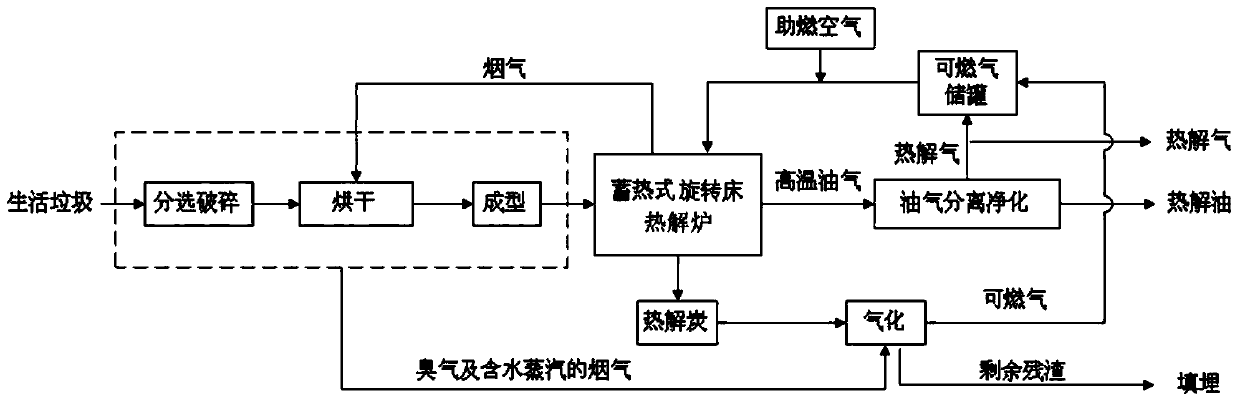

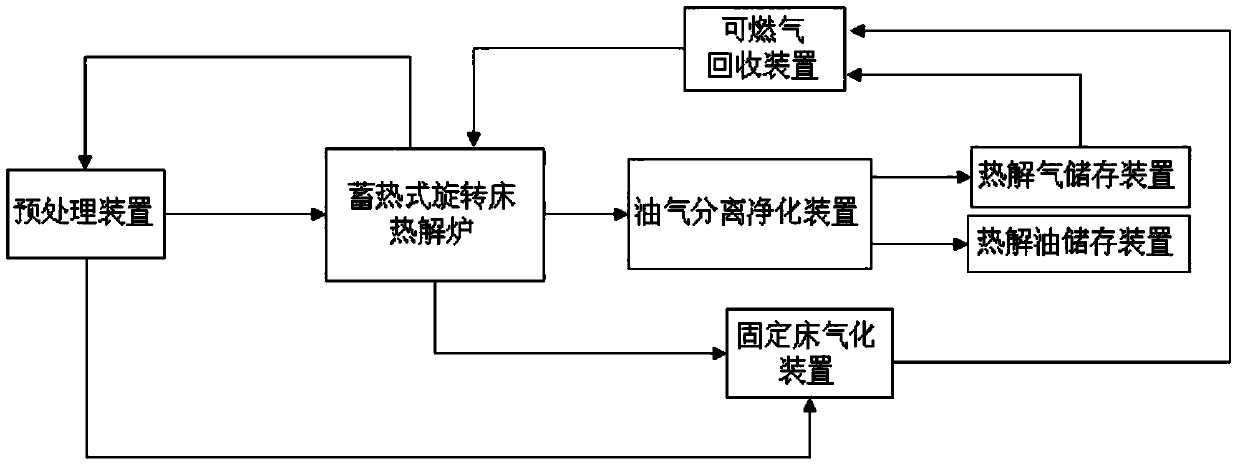

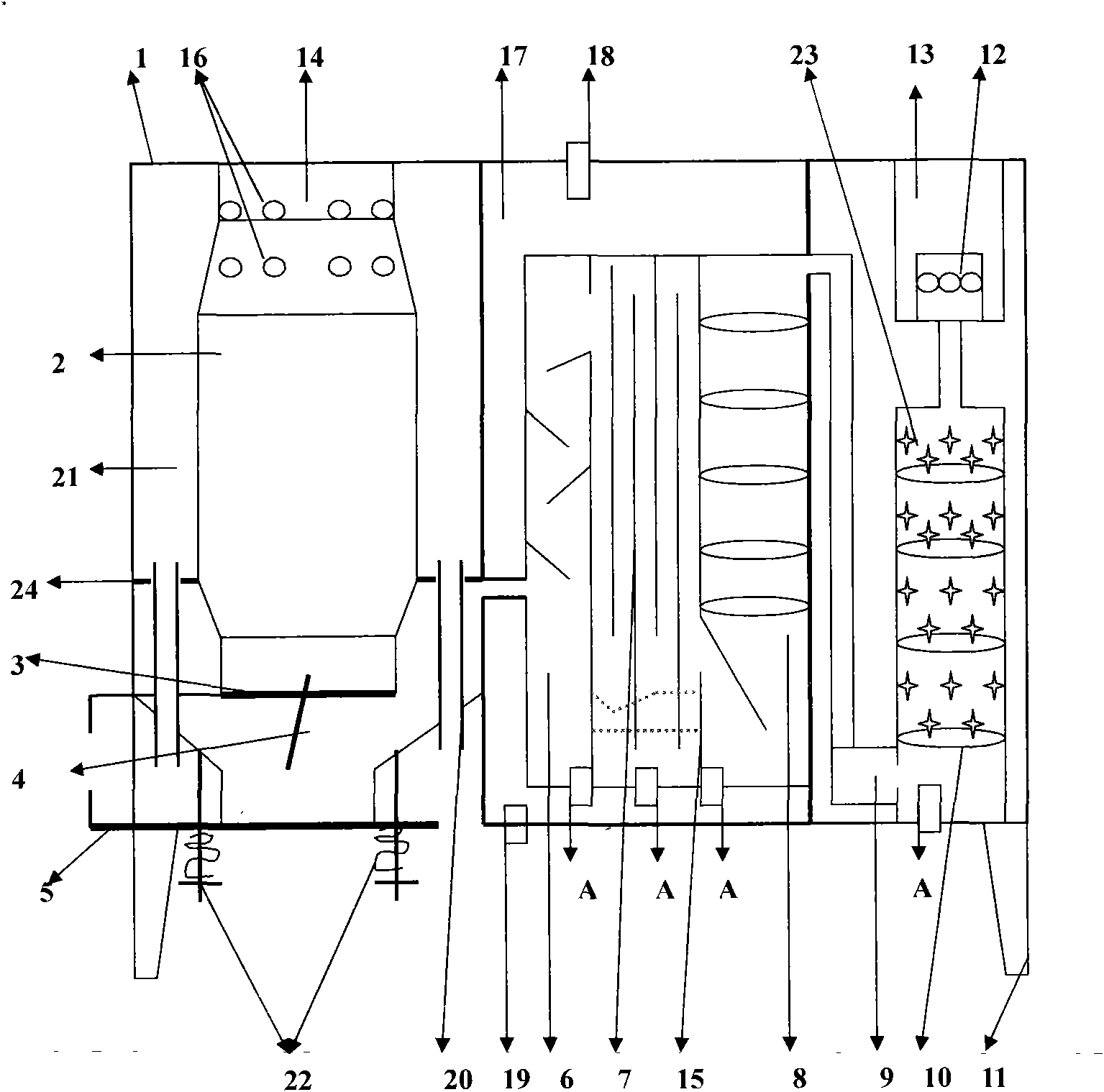

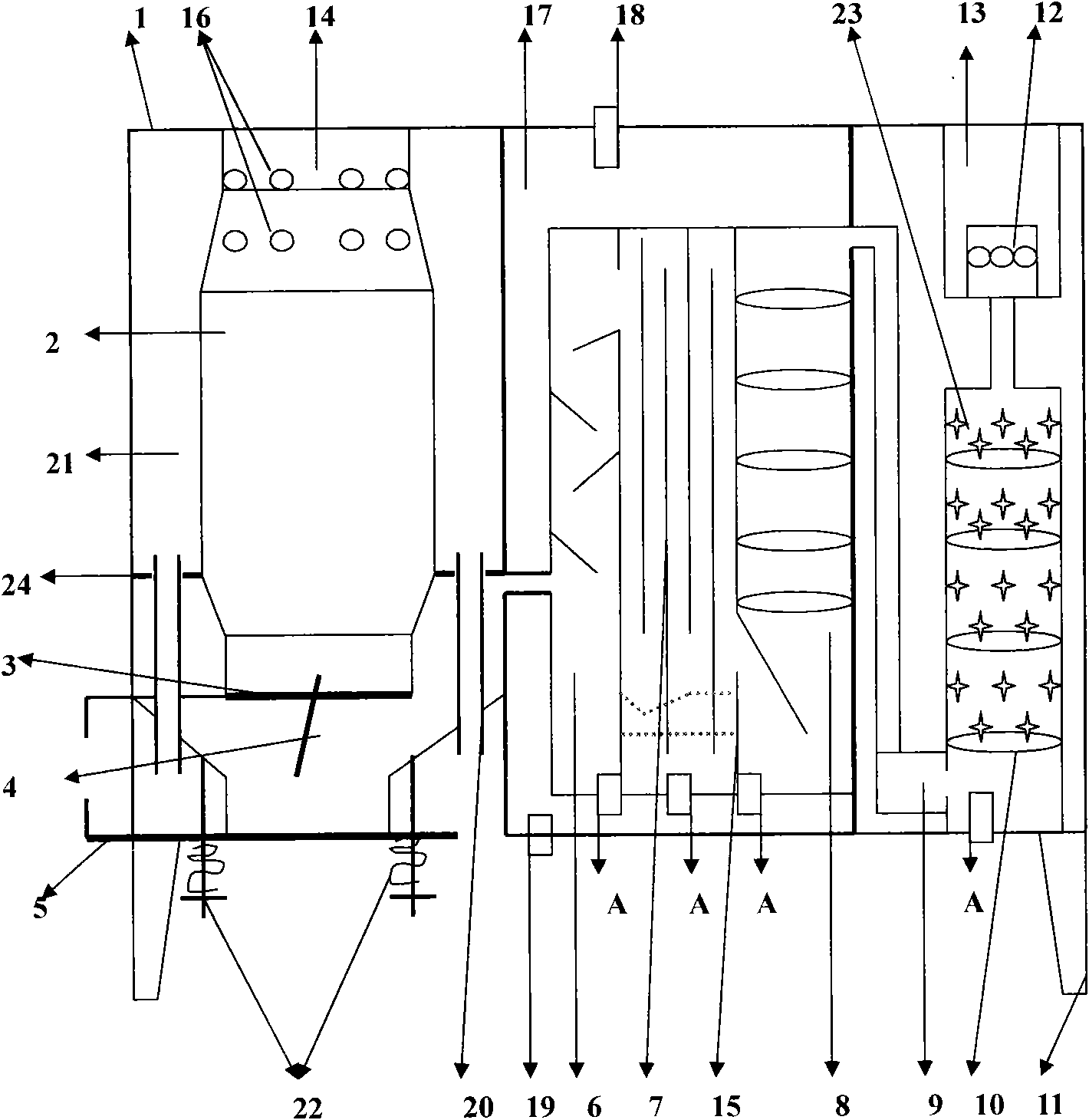

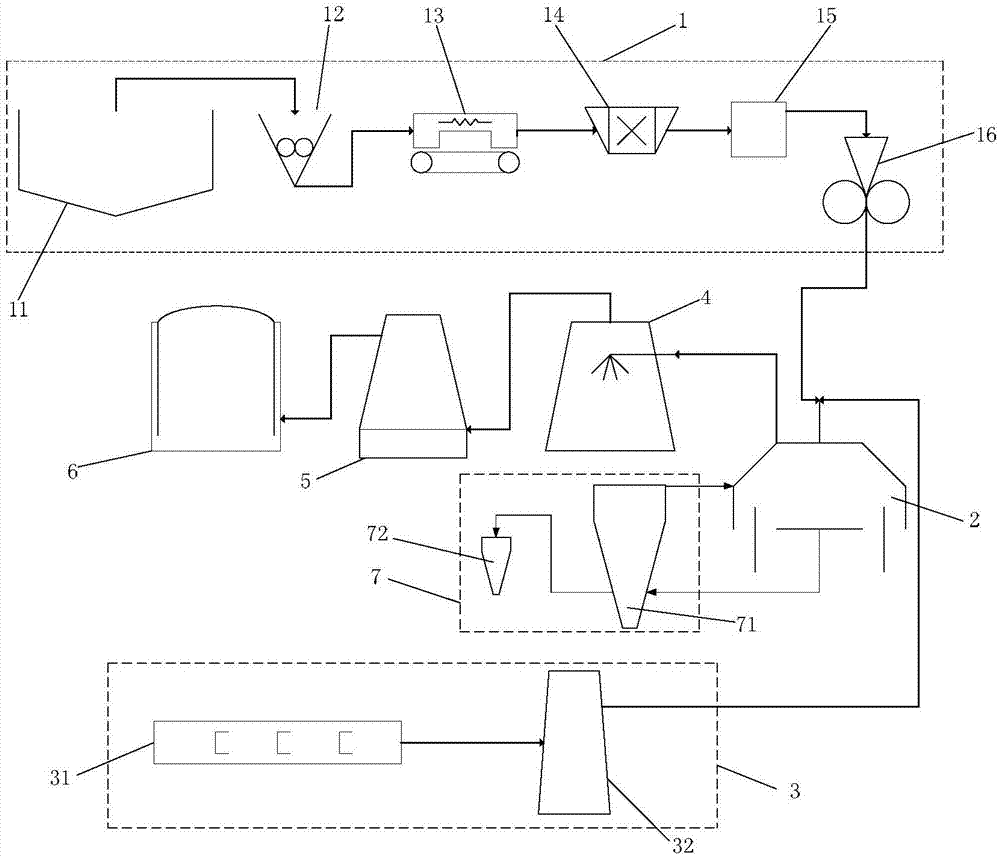

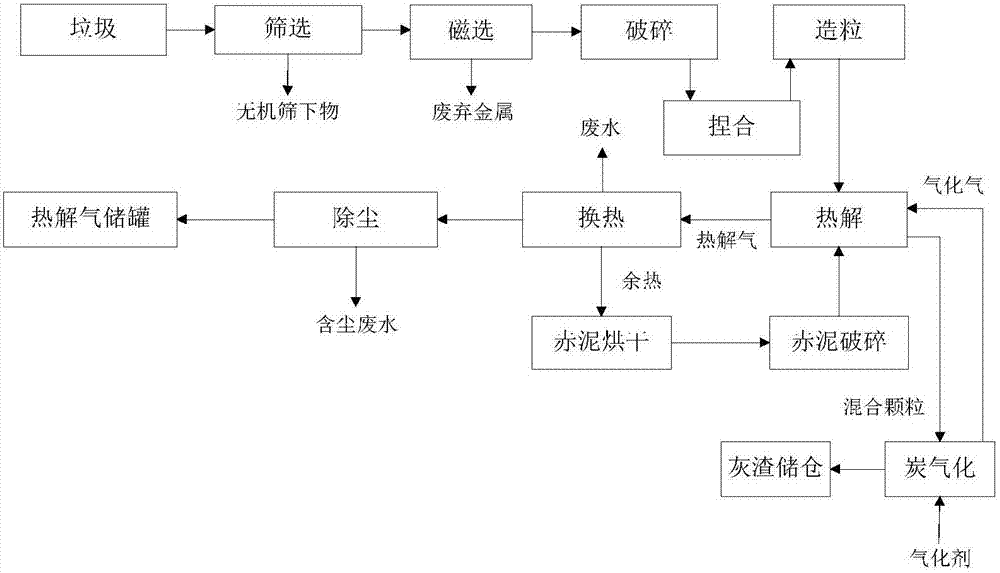

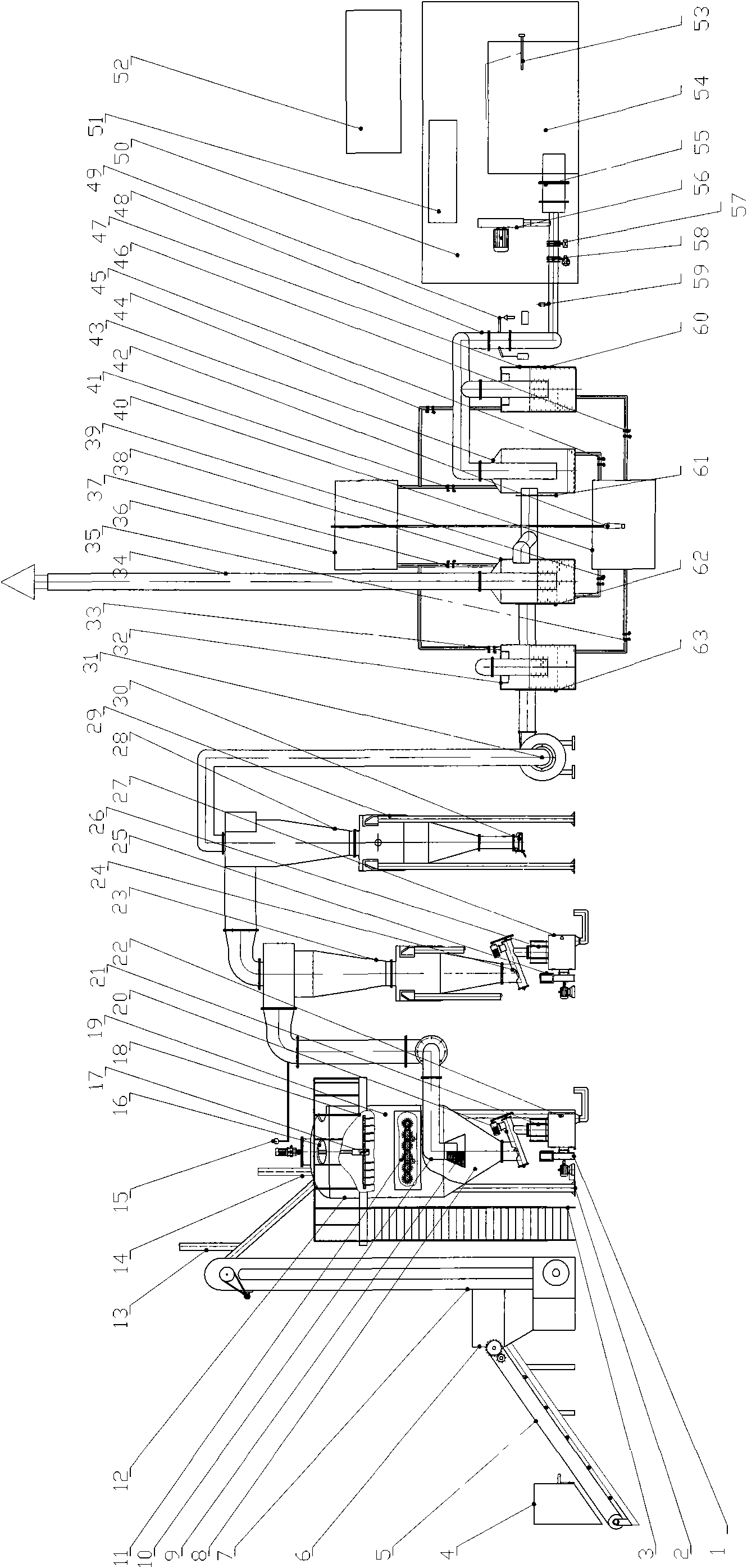

System and method for comprehensively recycling for household refuse pyrolysis

ActiveCN104178226AStable combustionSolve difficult problems that are not well utilizedSolid waste disposalSpecial form destructive distillationCombustorFixed bed

The invention provides a system and a method for comprehensively recycling for household refuse pyrolysis. The system comprises a pretreatment device, a heat accumulating type revolving bed pyrolysis furnace, an oil-gas separating and purifying device, a fixed bed gasifying device, a pyrolysis gas storage device and a combustible gas recycling device. The method comprises the following steps: after carrying out pretreatment such as sorting, crushing, drying and forming on household refuse raw materials, carrying out pyrolysis in the heat accumulating type revolving bed pyrolysis furnace to obtain a high-temperature oil gas and pyrolysis carbon; and gasifying the pyrolysis carbon to produce a gasified combustible gas which is used as a fuel of a heat-accumulating type fuel gas radiant tube combustor. According to the system and the method, the operation cost is low, the economic benefits are good, the produced gasified combustible gas with a low heating value is ventilated into the heat-accumulating type fuel gas radiant tube combustor to combust, so that the problems that the gasified pyrolysis refuse carbon is poor in economic benefits and the recycling for household refuse pyrolysis is difficult to industrially popularize are solved.

Owner:BEIJING SHENYUAN ENVIRONMENTAL PROTECTION CO LTD

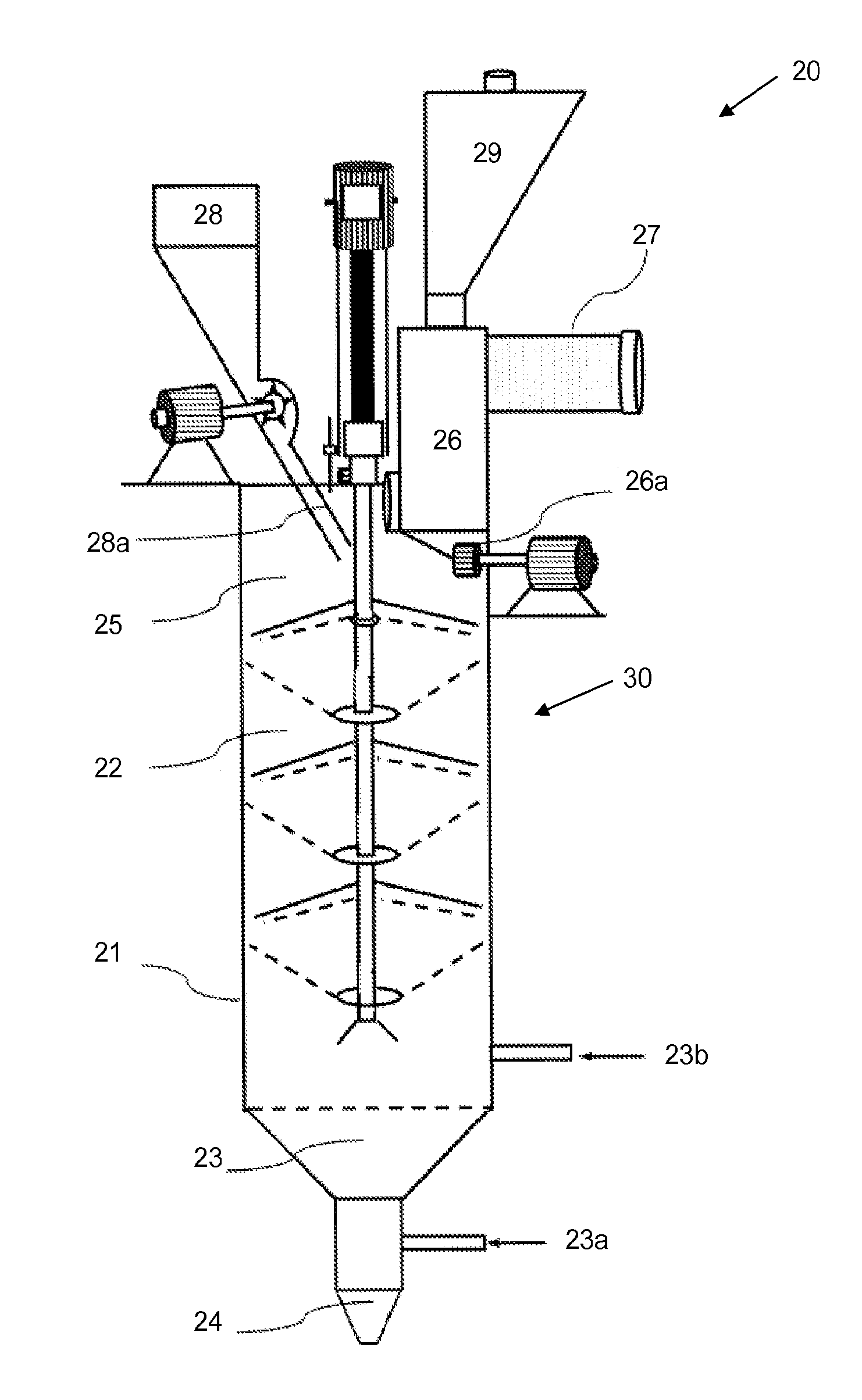

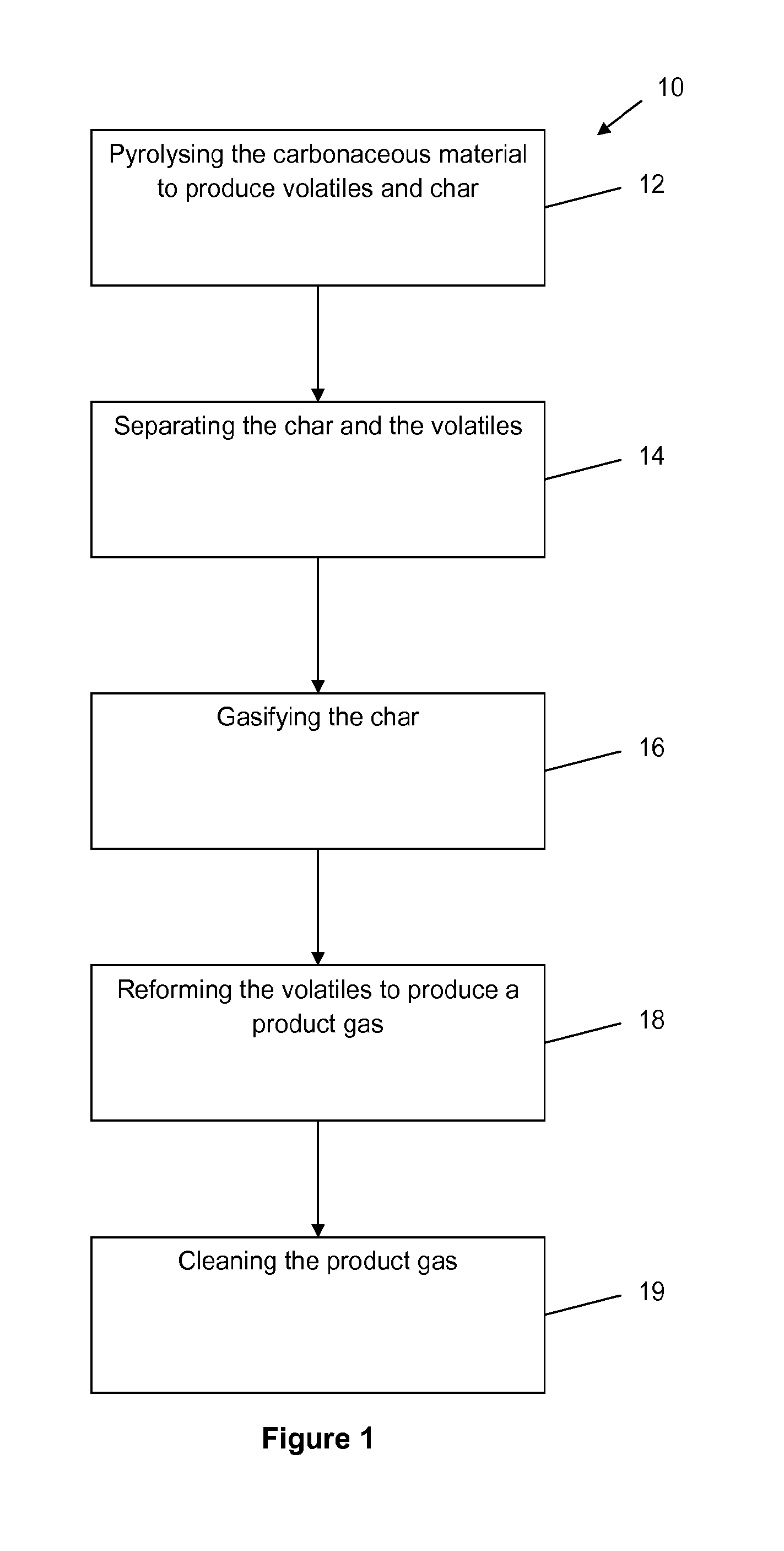

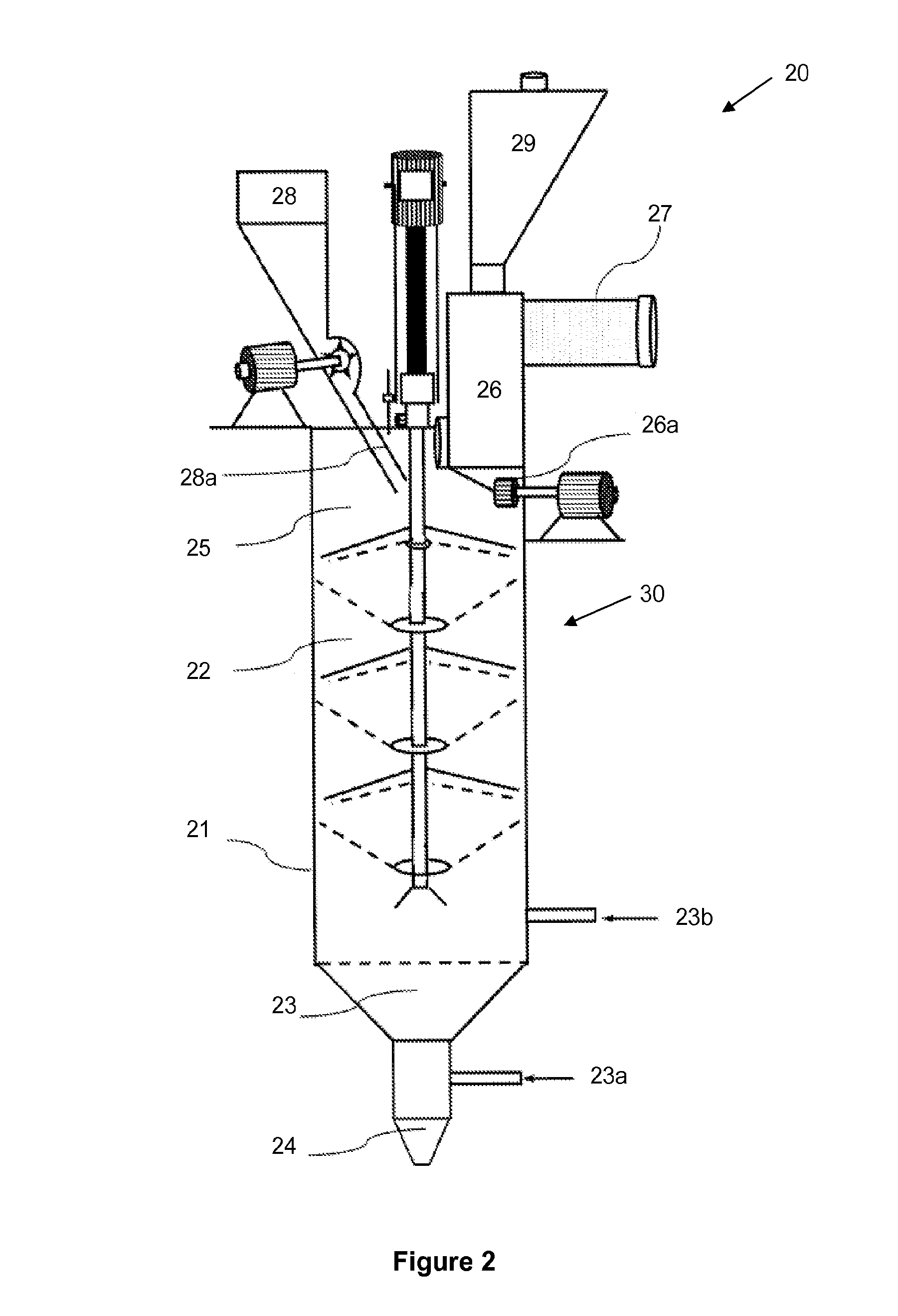

Method of gasifying carbonaceous material and a gasification system

InactiveUS20130306913A1Minimize interactionHigh hydrogen contentCombustible gas coke oven heatingGasifier mechanical detailsProduct gasOrganic chemistry

A method of gasifying carbonaceous material is described. The method comprises a first step of pyrolysing and partially gasifying the carbonaceous material to produce volatiles and char. The volatiles and the char are then separated and, subsequently, the char is gasified and the volatiles are reformed. The raw product gas is then finally cleaned with char or char-supported catalysts or other catalysts.

Owner:CURTAIN UNIV OF TECH

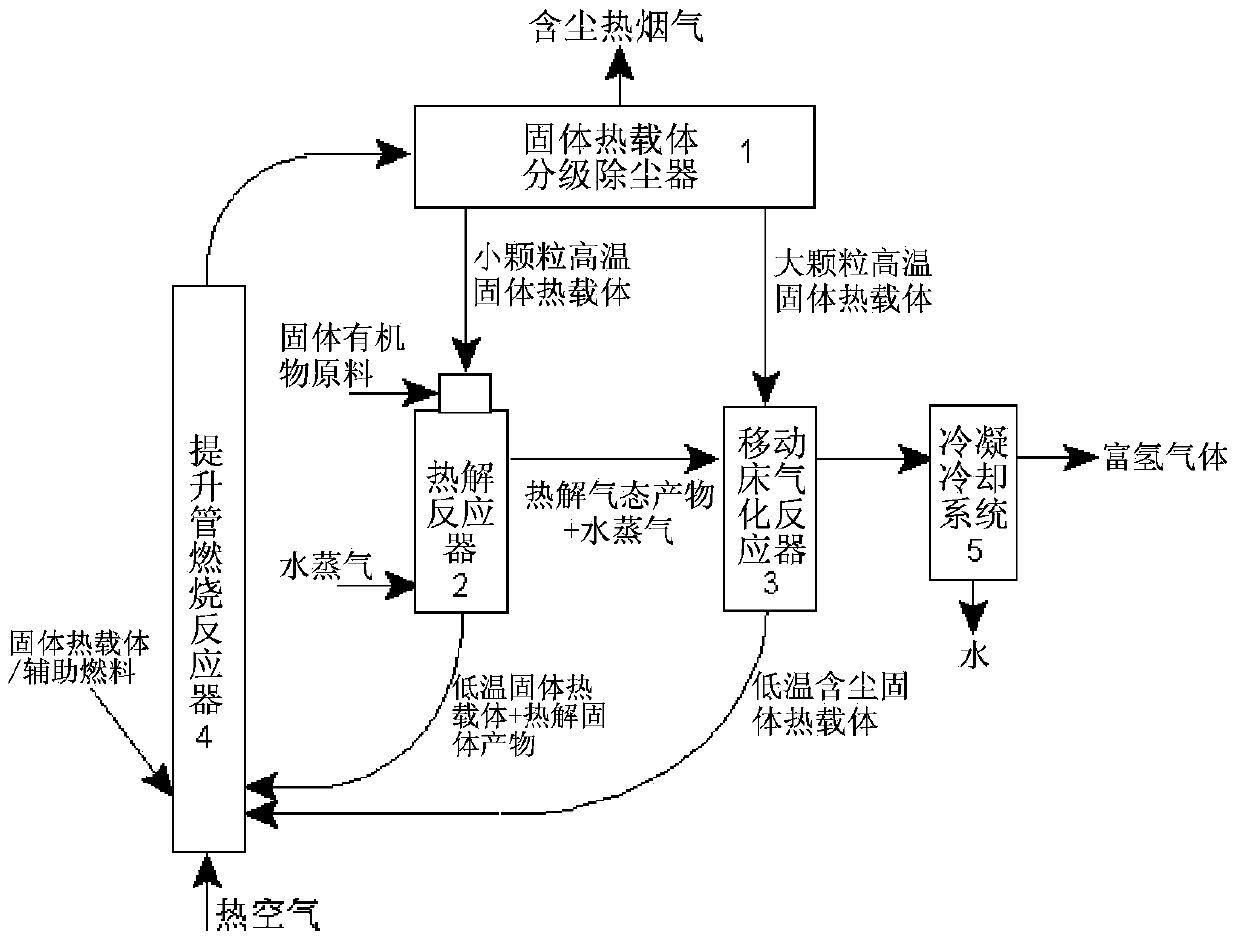

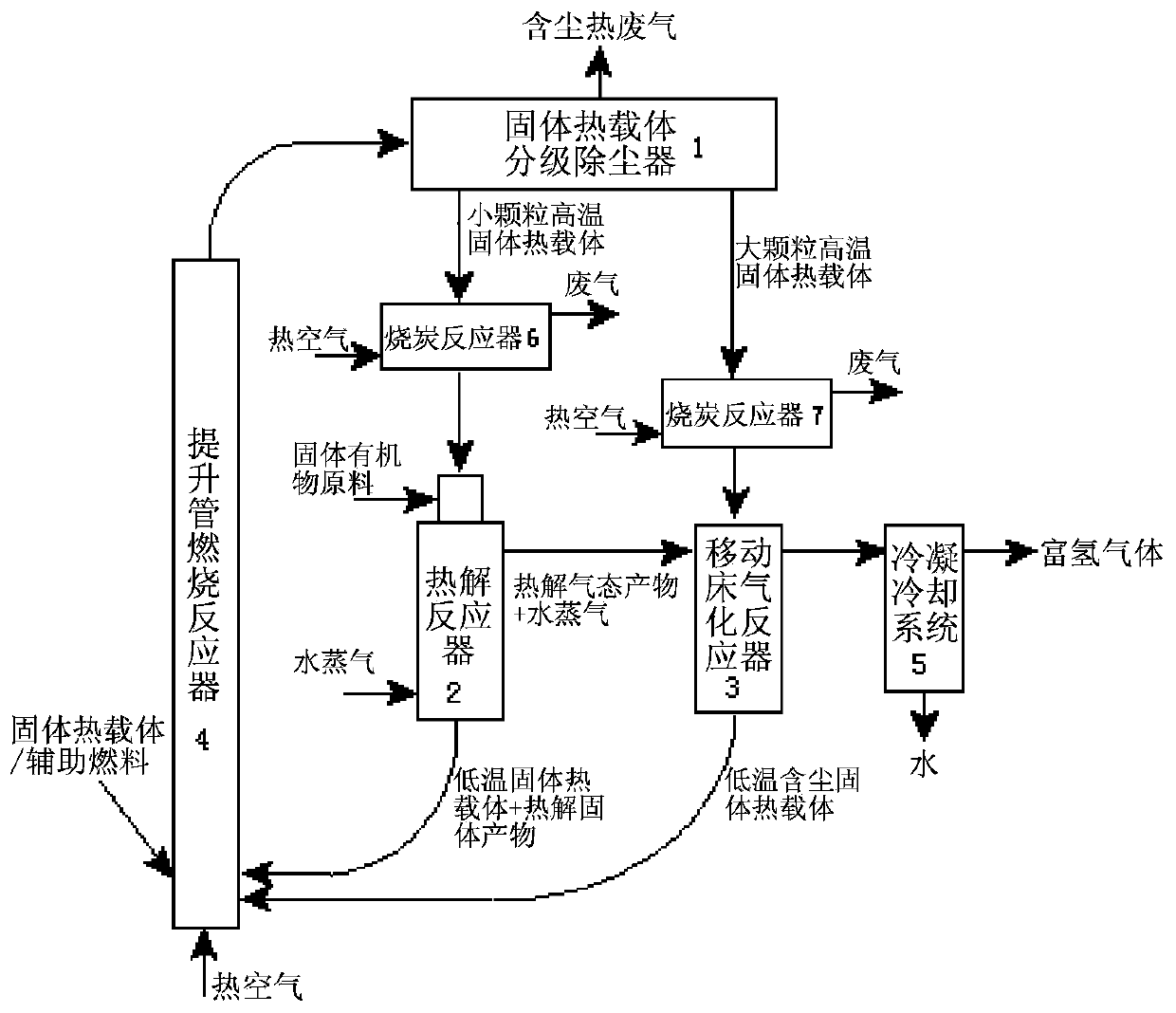

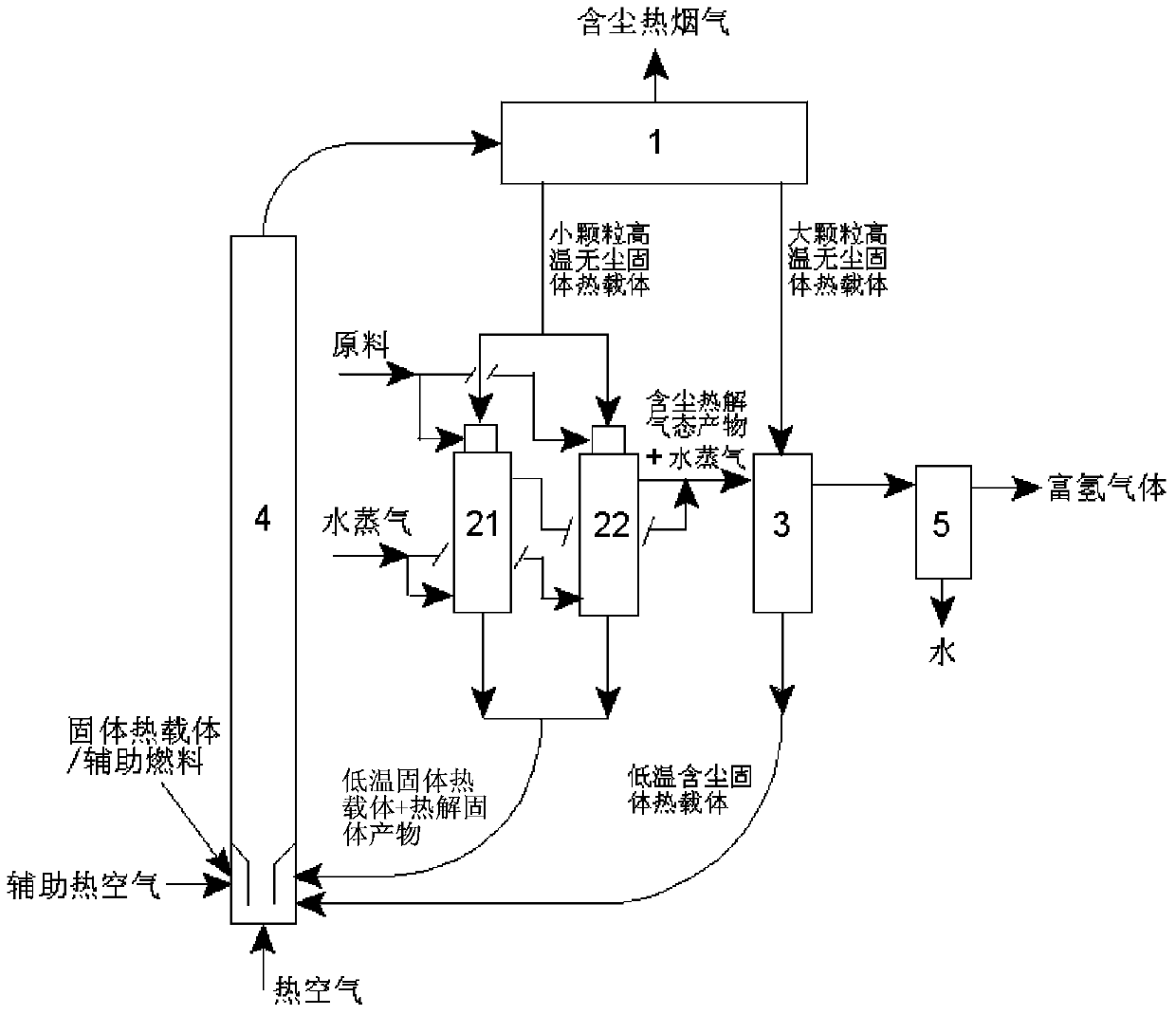

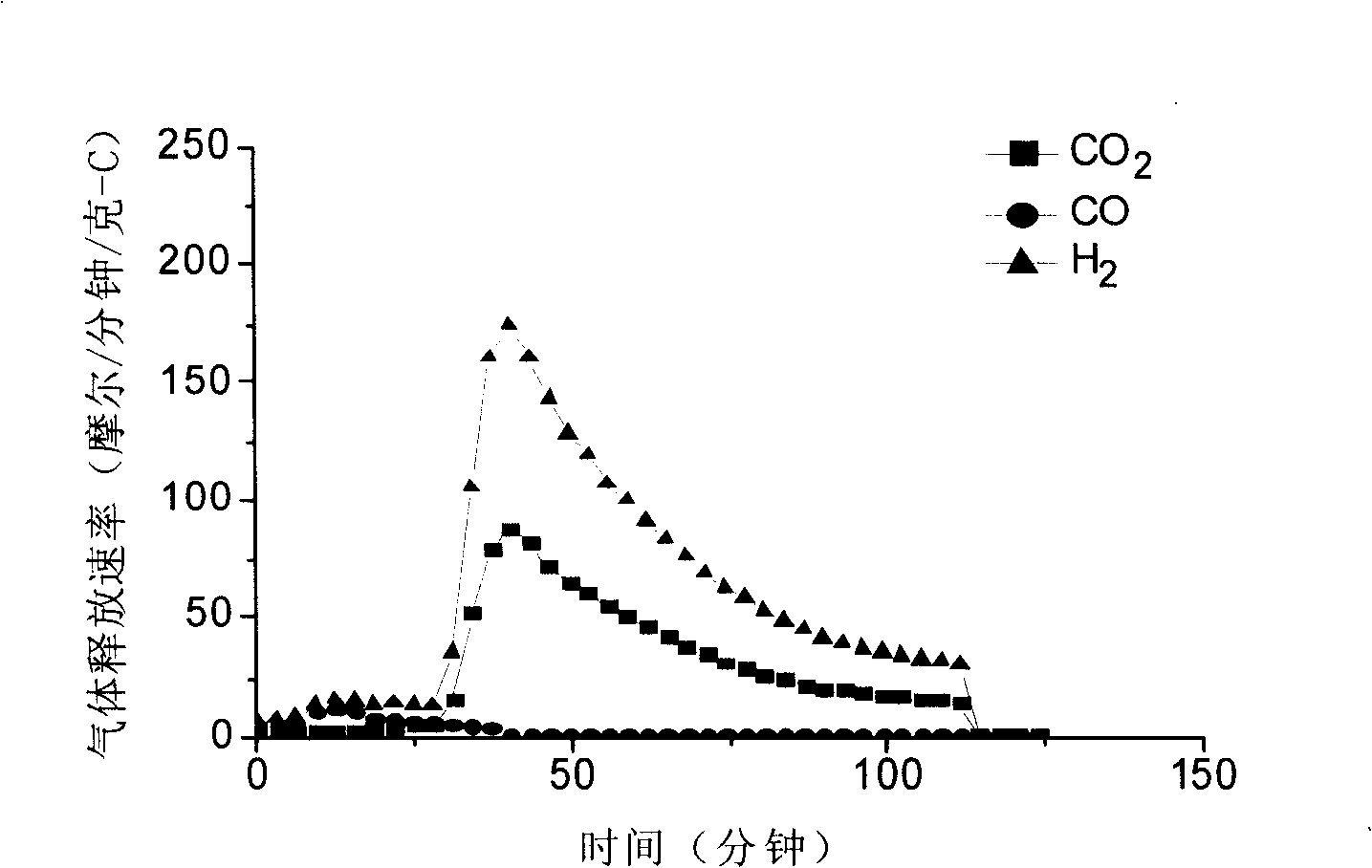

Preparation method for hydrogen-rich gas through steam gasification of solid organic matter

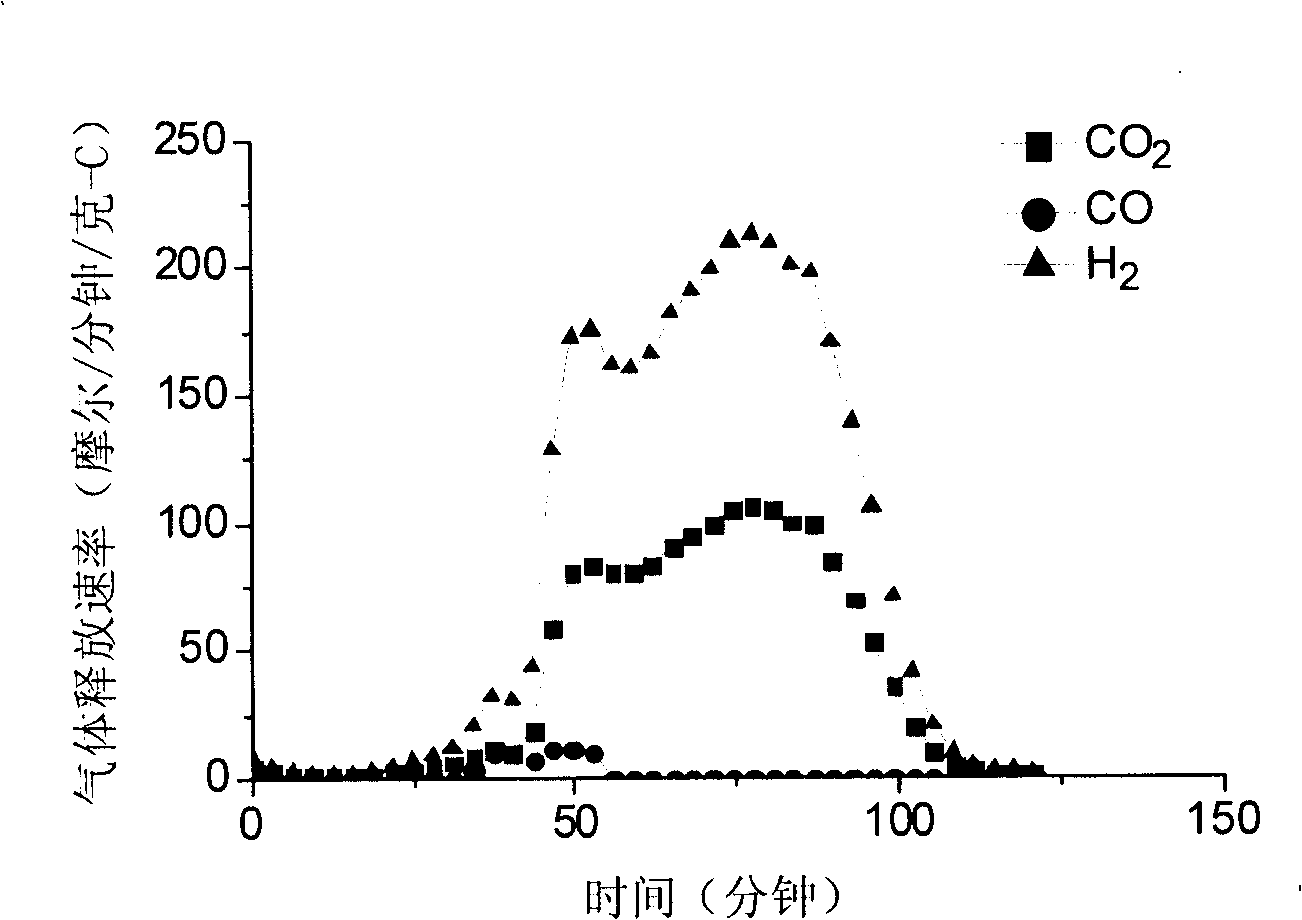

ActiveCN103468322AFast pyrolysisSimple processCombustible gas chemical modificationGasification catalystsWater vaporMoving bed

The invention provides a preparation method for hydrogen-rich gas through steam gasification of a solid organic matter. The method comprises the following steps: heating the raw material--the solid organic matter in a pyrolysis apparatus for pyrolysis; and subjecting a gaseous product produced after pyrolysis and steam to gasification in a moving bed gasification apparatus so as to produce the hydrogen-rich gas. The invention further provides a system for preparing the hydrogen-rich gas from the solid organic matter. The system comprises a solid thermal carrier gradient deduster, the pyrolysis apparatus, the moving bed gasification apparatus and a riser combustion reactor. The method provided by the invention is implemented at normal pressure, has simple process and is applicable to gasification and co-gasification of a variety of organic matters with high content of volatile components, including raw materials with high content of moisture, mineral matters and sulfur.

Owner:ECO ENVIRONMENTAL ENERGY RES INST +1

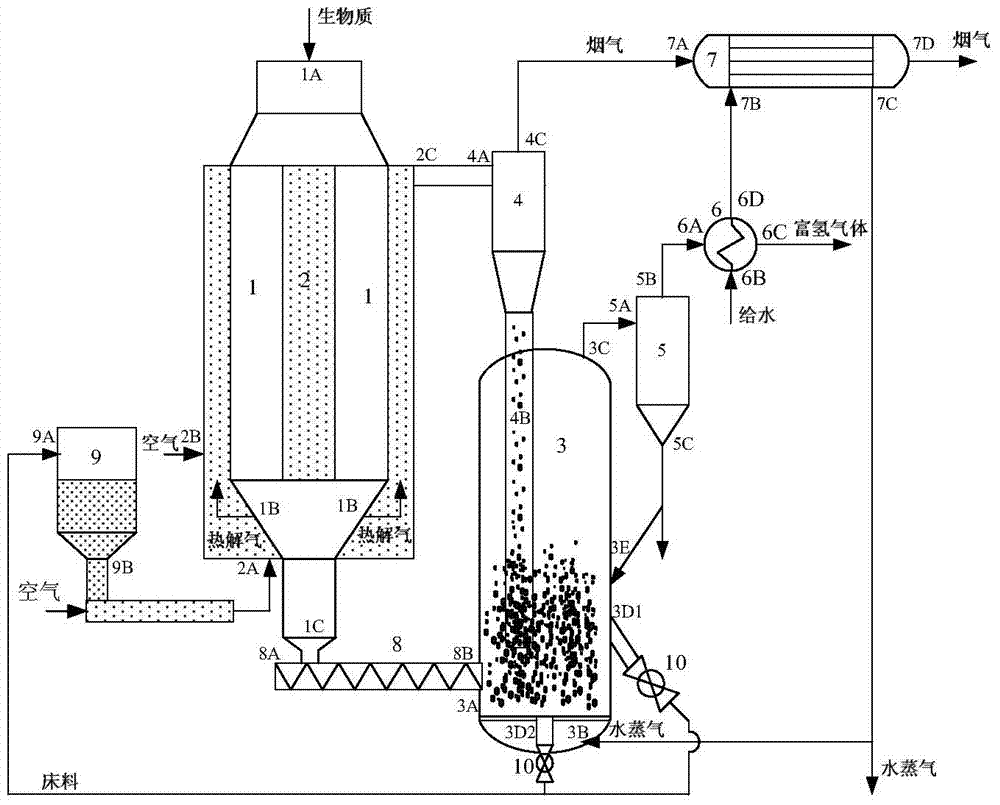

Device and method for preparing hydrogen-rich gas by gasifying biomass

ActiveCN103923705AAvoid mixingEfficient use ofEnergy inputGasification with fuel pre-distillationWater vaporGas cooler

The invention discloses device and method for preparing hydrogen-rich gas by gasifying biomass. The device mainly comprises a pyrolysis reactor, a combustion reactor, a gasification reactor, a gas-solid separator, a gas cooler and an exhaust heat boiler, wherein the pyrolysis reactor is arranged in the combustion reactor. In a process course, the biomass is firstly pyrolyzed in the pyrolysis reactor to generate pyrolysis gas and coke, the pyrolysis gas is directly combusted to provide heat for biomass pyrolysis and gasification, and the coke is subjected to gasification reaction with water vapor to obtain the hydrogen-rich gas. The device and method disclosed by the invention realize the separation of the pyrolysis process and coke gasification process of the biomass and can be used for displacing the hydrogen contained in the water vapor by sufficiently utilizing fixed carbon contained in the biomass. According to the device and method, the obtained hydrogen-rich gas mainly contains H2, CO2 and a small amount of CO, so that the conventionally gasified hydrogen-rich gas product is prevented from being mixed with low-carbon hydrocarbon gas and tar, and the subsequent decontamination and purification utilization are simple, convenient and economic.

Owner:SOUTHEAST UNIV

Biomass vaporizing combustion coupled type cyclone boiler

InactiveCN101625117ABurn fullyGuaranteed gasification effectChemical industrySolid fuel combustionCycloneCombustion chamber

The invention relates to a biomass vaporizing combustion coupled type cyclone boiler, solving the problems of low thermal efficiency, high tar content in vaporizing gas, easy scorification of a high-temperature heating surface and the like existing in the current biomass boiler, and comprising a jacketed type boiler body and a feeding device thereof, a primary air fan, a secondary air fan, a water circulating pump, an ash slurry pond and a flue water fog deduster. The invention has the technical points that the secondary air fan is connected with the jacket of the boiler body, and an atomizing nozzle is arranged on the inner side of an outer boiler wall; secondary air and water vapour tangential jet holes are distributed on the circumference of an inner boiler wall; one end of a small spiral feeder of the feeding device is connected with the inner cavity of a vaporizing combustion chamber, and the other end is connected with the secondary air fan by a feeding air valve; the vaporizing combustion chamber and a complete combustion chamber are communicated. The invention has reasonable structure design and stable operation and strengthens effects of heat transfer and fuel vaporization, which can increase the transformation efficiency of biomass energy and heat values of biomass fuel vaporizing products, and thus, the biomass fuel is completely and sufficiently burnt, thereby saving energy, increasing the heat efficiency of the boiler, protecting environment and reducing environmental pollution.

Owner:辽宁玺丰新能源科技有限公司

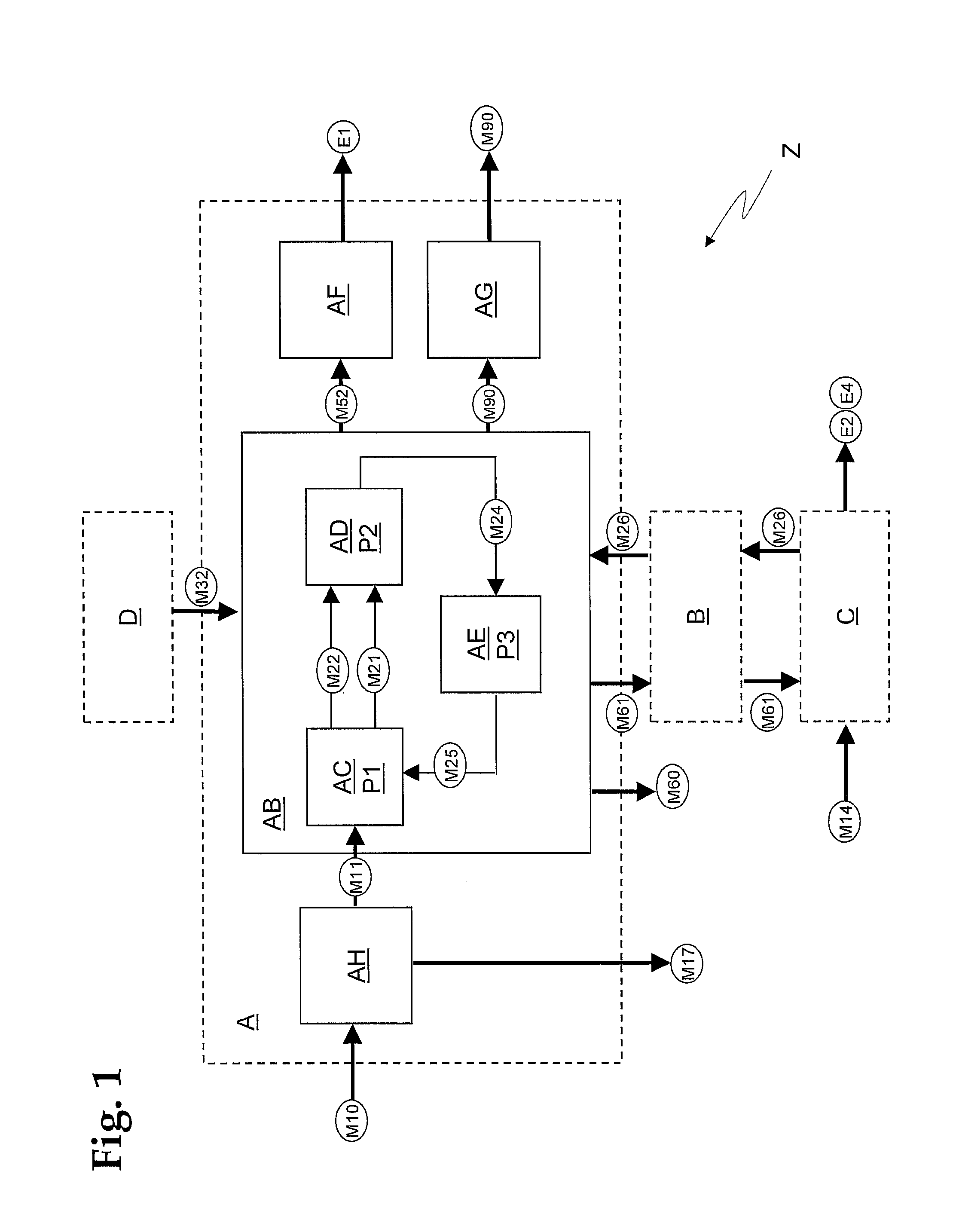

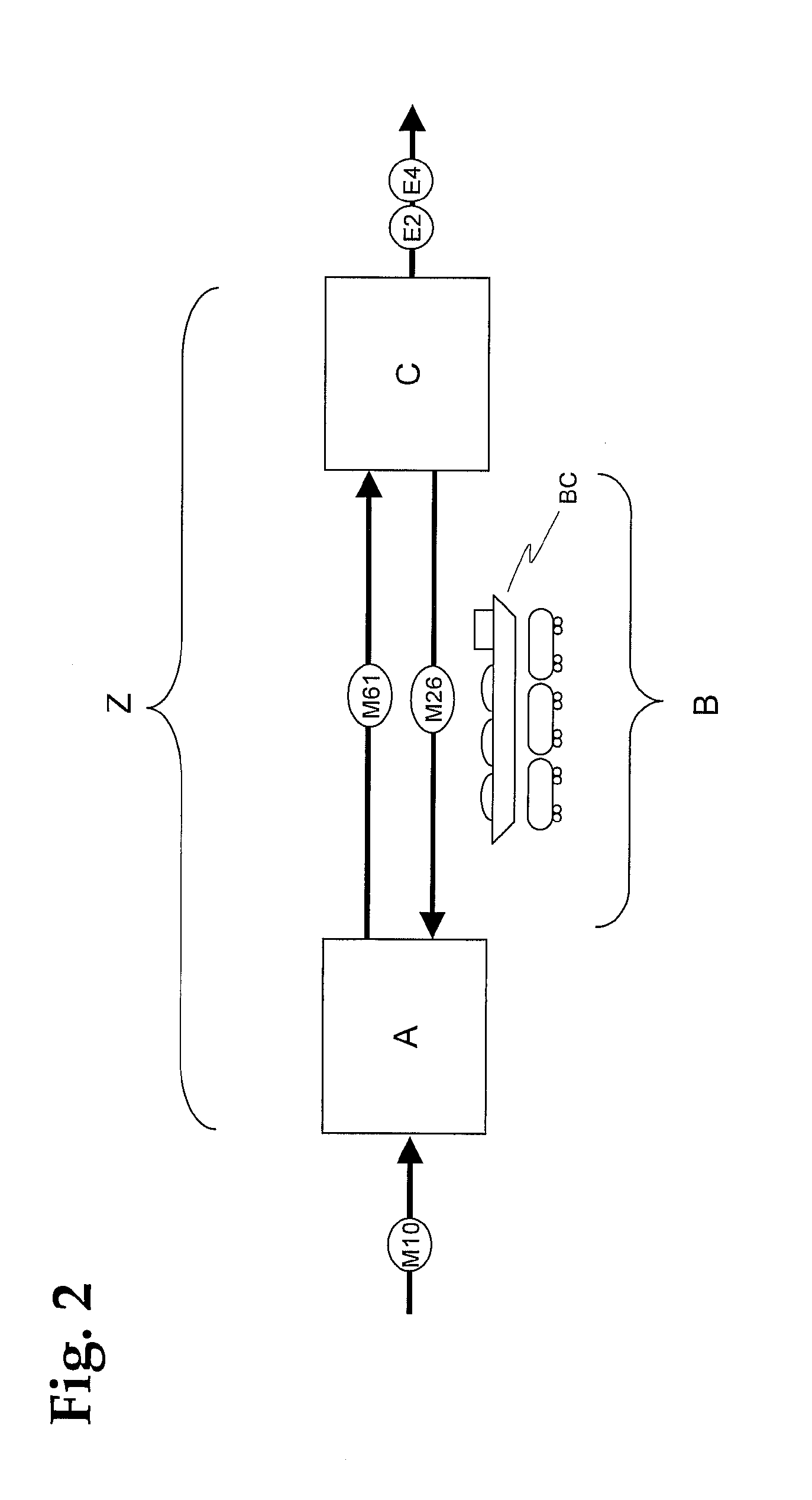

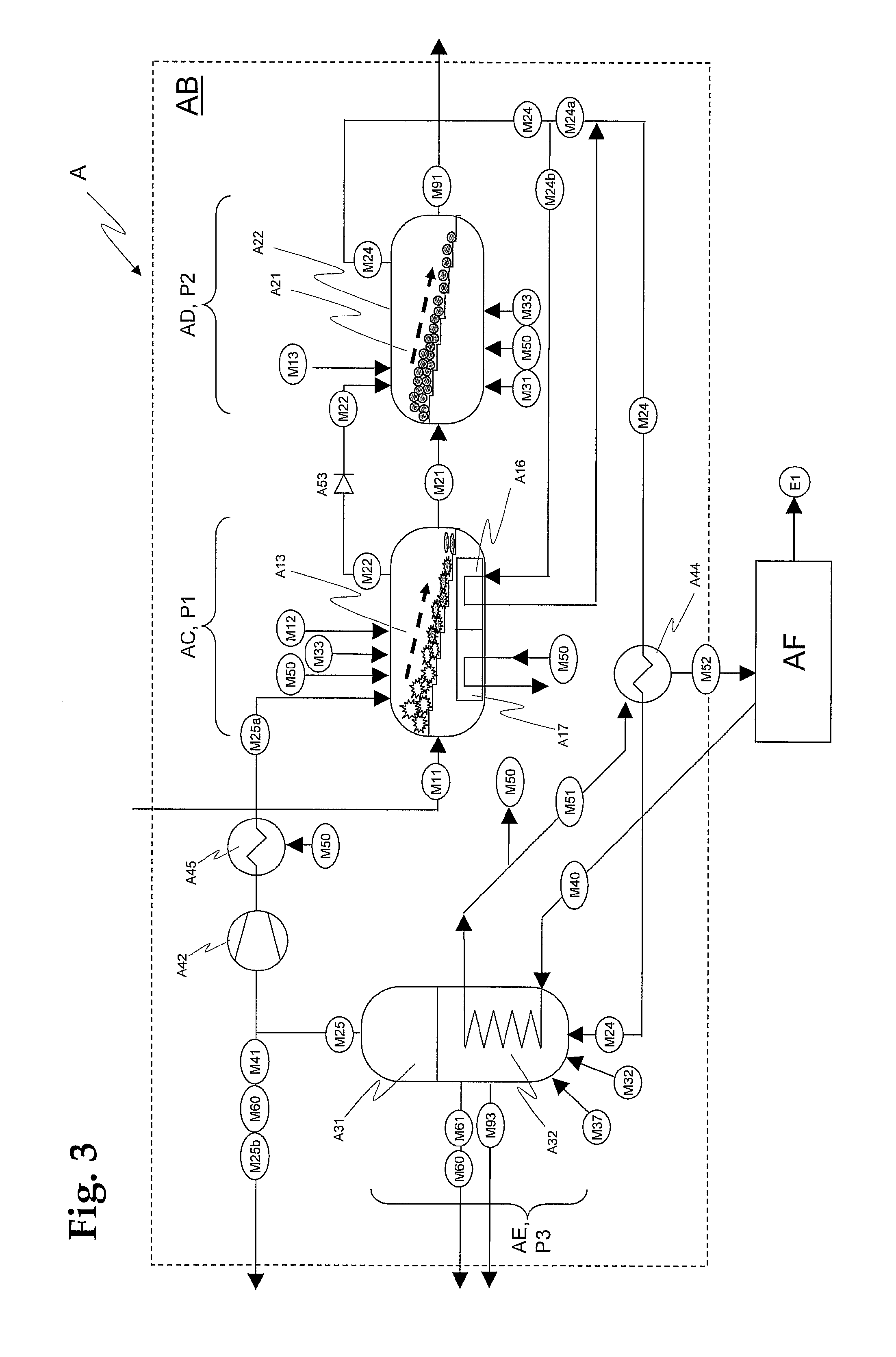

Thermal and chemical utilization of carbonaceous materials, in particular for emission-free generation of energy

ActiveUS20120238645A1Reduce the amount requiredBiofuelsCombustion enginesSyngasHydrocotyle bowlesioides

A process for the generation of energy and / or hydrocarbons and other products utilizing carbonaceous materials. In a first process stage (P1) the carbonaceous materials are supplied and are pyrolysed, wherein pyrolysis coke (M21) and pyrolysis gas (M22) are formed. In a second process stage (P2), the pyrolysis coke (M21) from the first process stage (P1) is gasified, wherein synthesis gas (M24) is formed, and slag and other residues (M91, M92, M93, M94) are removed. In a third process stage (P3), the synthesis gas (M24) from the second process stage (P2) is converted into hydrocarbons and / or other solid, liquid, and / or gaseous products (M60), which are discharged. The three process stages (P1, P2, P3) form a closed cycle. Surplus gas (M25) from the third process stage (P3) is passed as recycle gas into the first process stage (P1), and / or the second process stage (P2), and pyrolysis gas (M22) from the first process stage (P1) is passed into the second process stage (P2), and / or the third process stage (P3),

Owner:RV LIZENZ

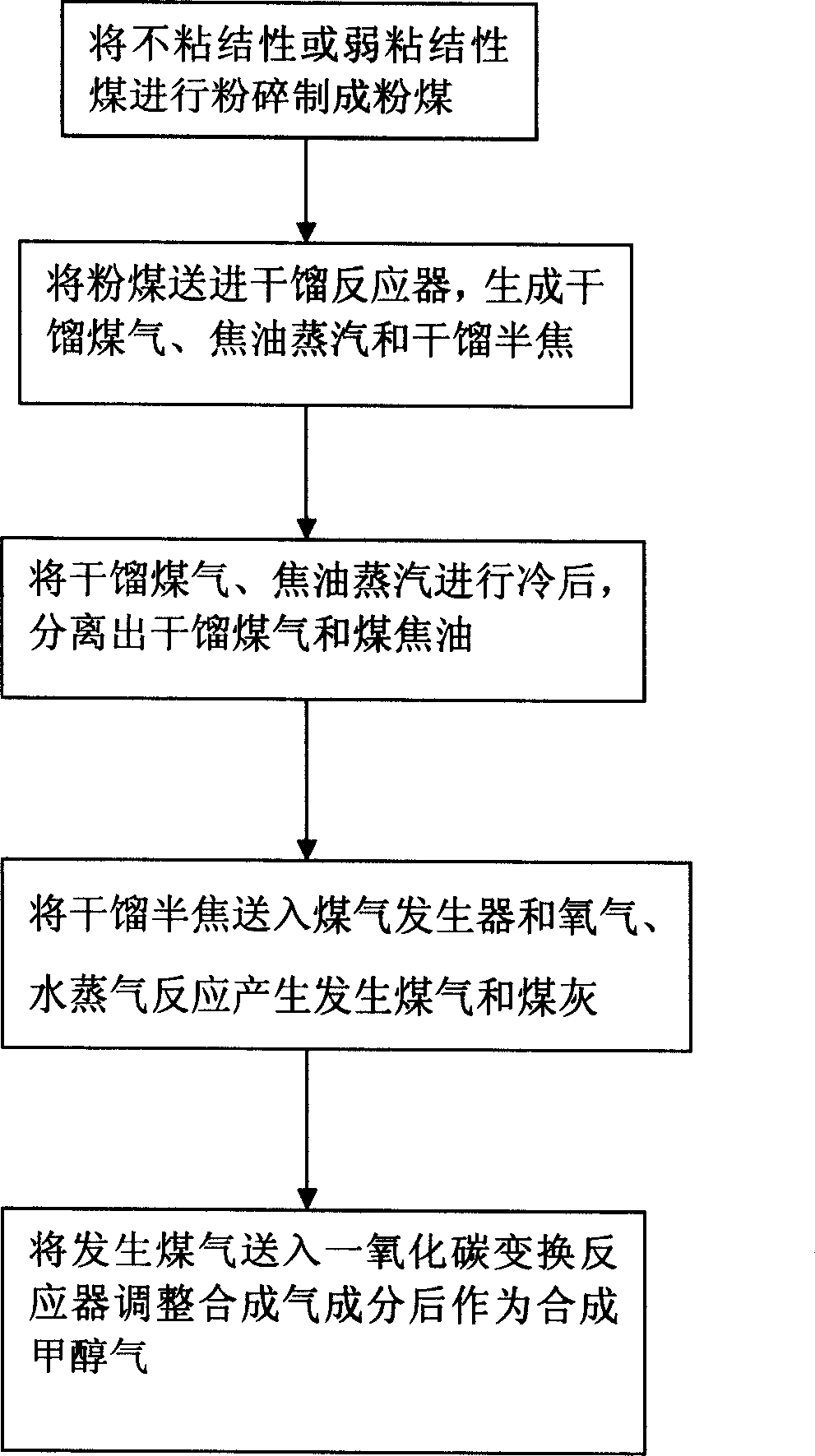

Technology of preparing synthetic gas using non agglomerating or weak agglomerating coal fluidized destructive distillation

ActiveCN1912070AIncrease profitHigh yieldCombined combustion mitigationGasification with fuel pre-distillationLiquid productWater vapor

The invention discloses a process for making synthetic gas by non-adhesive or low-adhesiveness coal fluidized carbonization, comprising the steps of: crushing non-adhesive or low-adhesiveness coal into fine coal; feeding the fine coal into a carbonization reactor and producing coal gas, tar steam and semicoke; cooling the coal gas and tar steam, and extracting the coal gas and coal tar; feeding the semicoke into a coal gas generator to react with oxygen gas and water steam to produce generated coal gas and coal ash; feeding the generated coal gas into a CO conversion reactor to regulate composition of the synthetic gas and act as synthetic methanol gas. And the utilization ratio of raw materials can be 100%. And the oil yield of fine coal fluidized carbonization is high. And the produced semicoke can completely turn into generated coal gas, and finally only coal ash is left. And the yield of liquid products by carbonization and liquid products synthetized by synthetic gas is higher than that of liquid products by coal liquefaction.

Owner:SHAANXI COAL & CHEM IND GRP SHENMU TIANYUAN CHEM IND

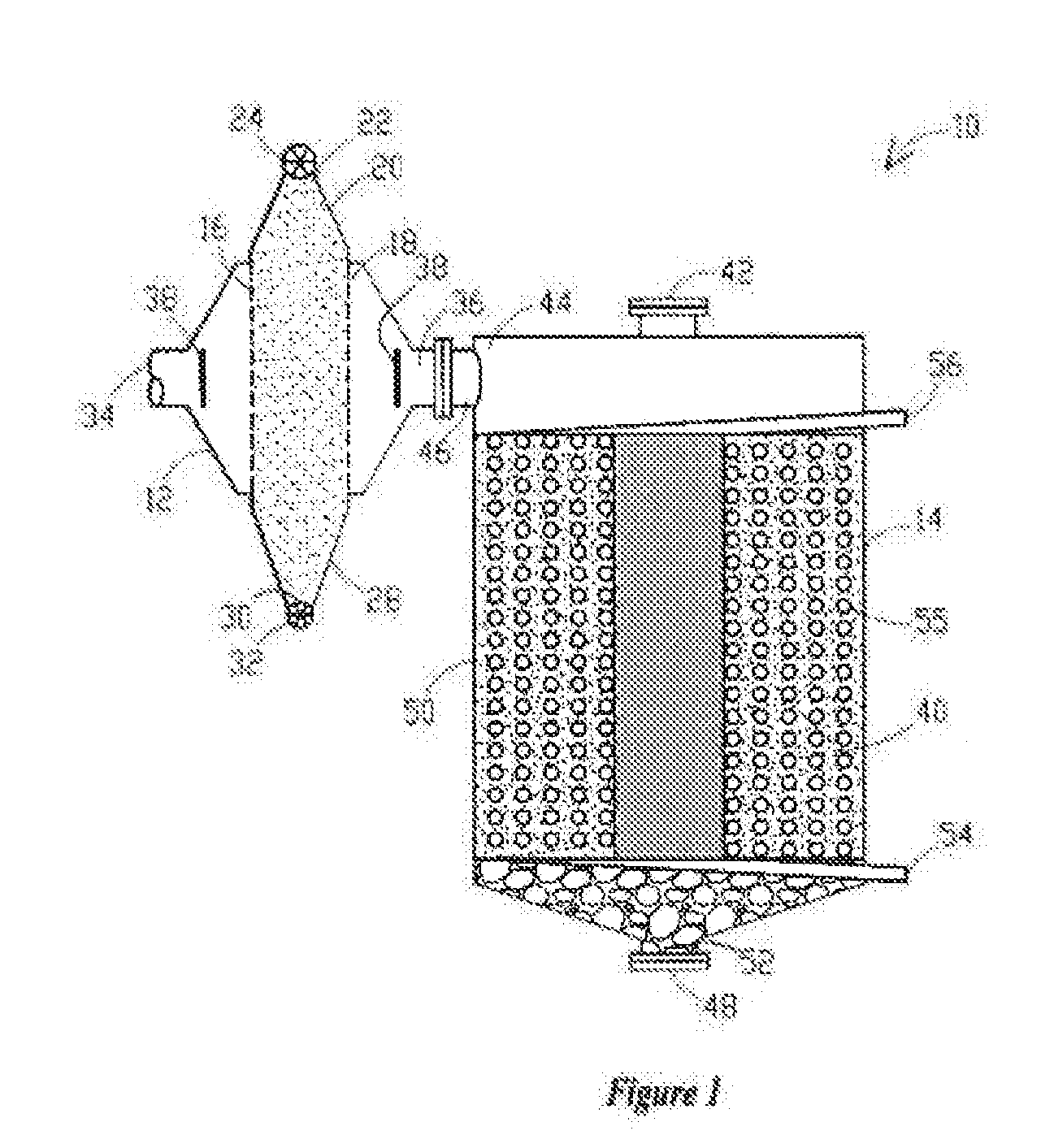

Household up-draft biomass gasification device

InactiveCN101560411ASettlement requires ignition,Resolution timeCombined combustion mitigationGasification with fuel pre-distillationRadiation lossTar

The invention discloses a household up-draft biomass gasification device, which has an upright cylinder structure and is characterized in that the household up-draft biomass gasification device comprises a destructive distillation chamber arranged at the upper section thereof, a main gasification chamber arranged at the middle section thereof and an ash chamber arranged at the lower section thereof; all the sections are respectively separated by a heat storage grille and a heat storage grate; and the main gasification chamber is enclosed by a radiation cylinder on the periphery. The household up-draft biomass gasification device has no need of an external firing heat source, fast firing speed and high temperature of the gasification center, remarkably reduces tar content, reduces radiation loss of a furnace body, and has high gasification efficiency, long fire banking time of the gasification furnace, simple and compact structure, convenient operation and low operating cost.

Owner:安徽喜阳阳新能源科技有限公司

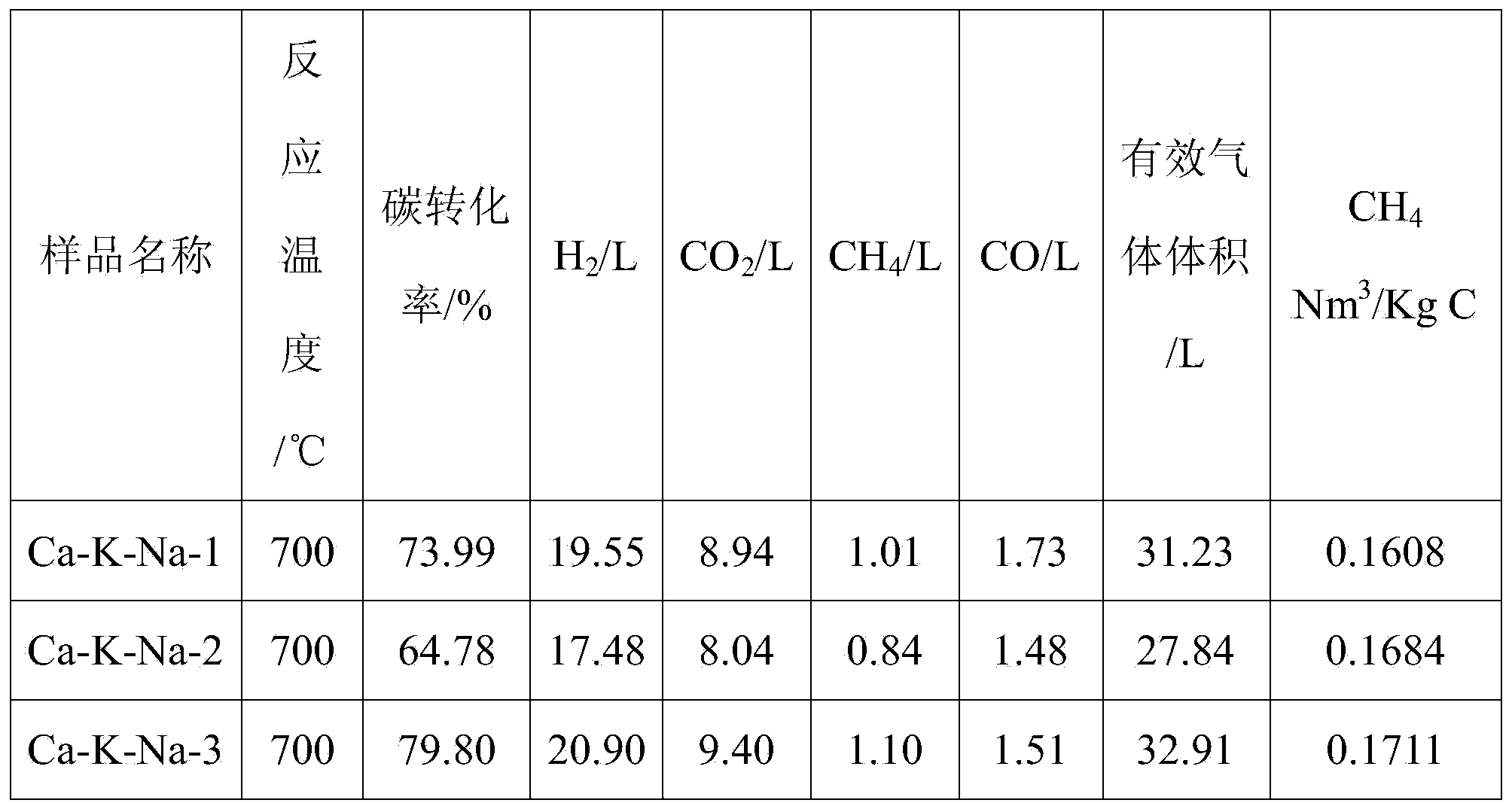

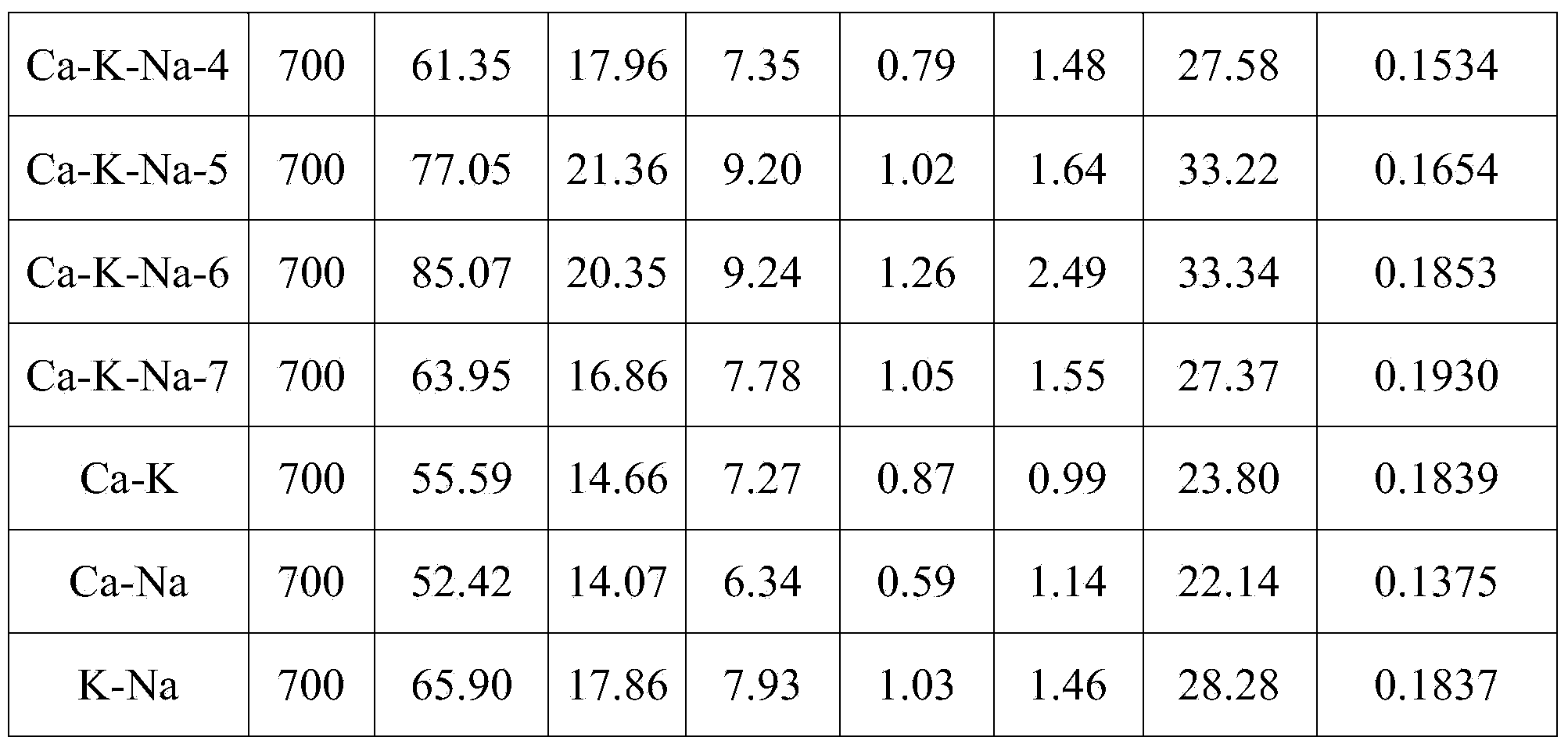

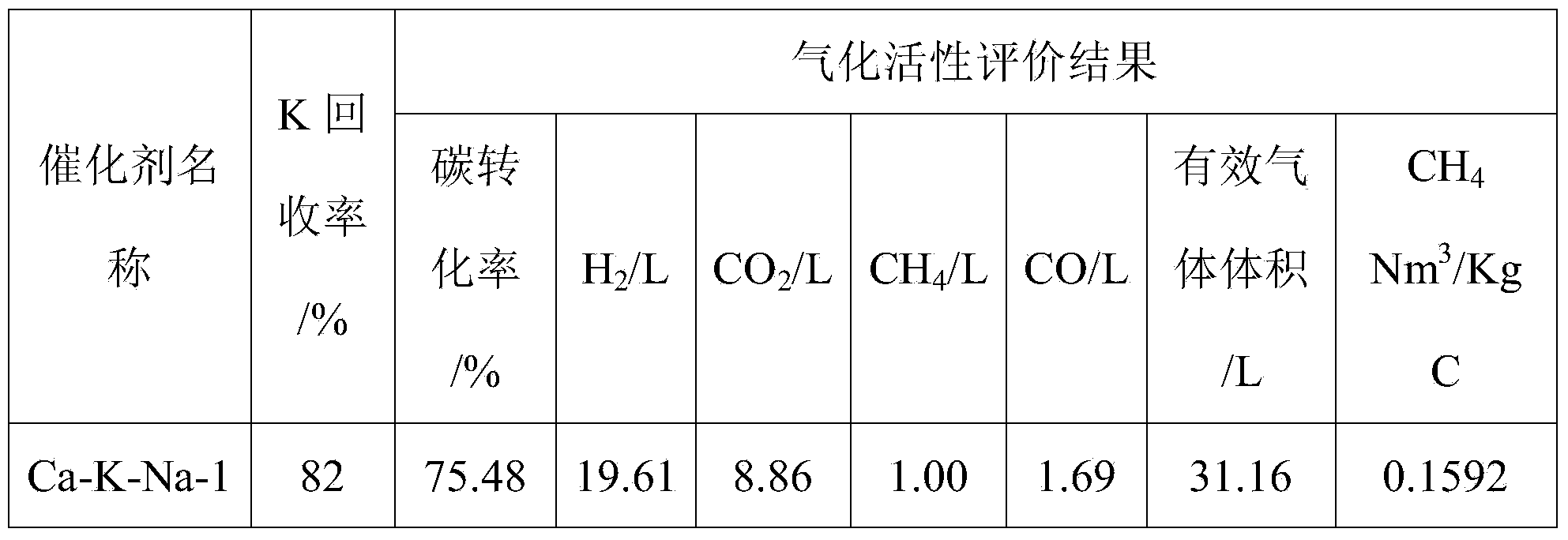

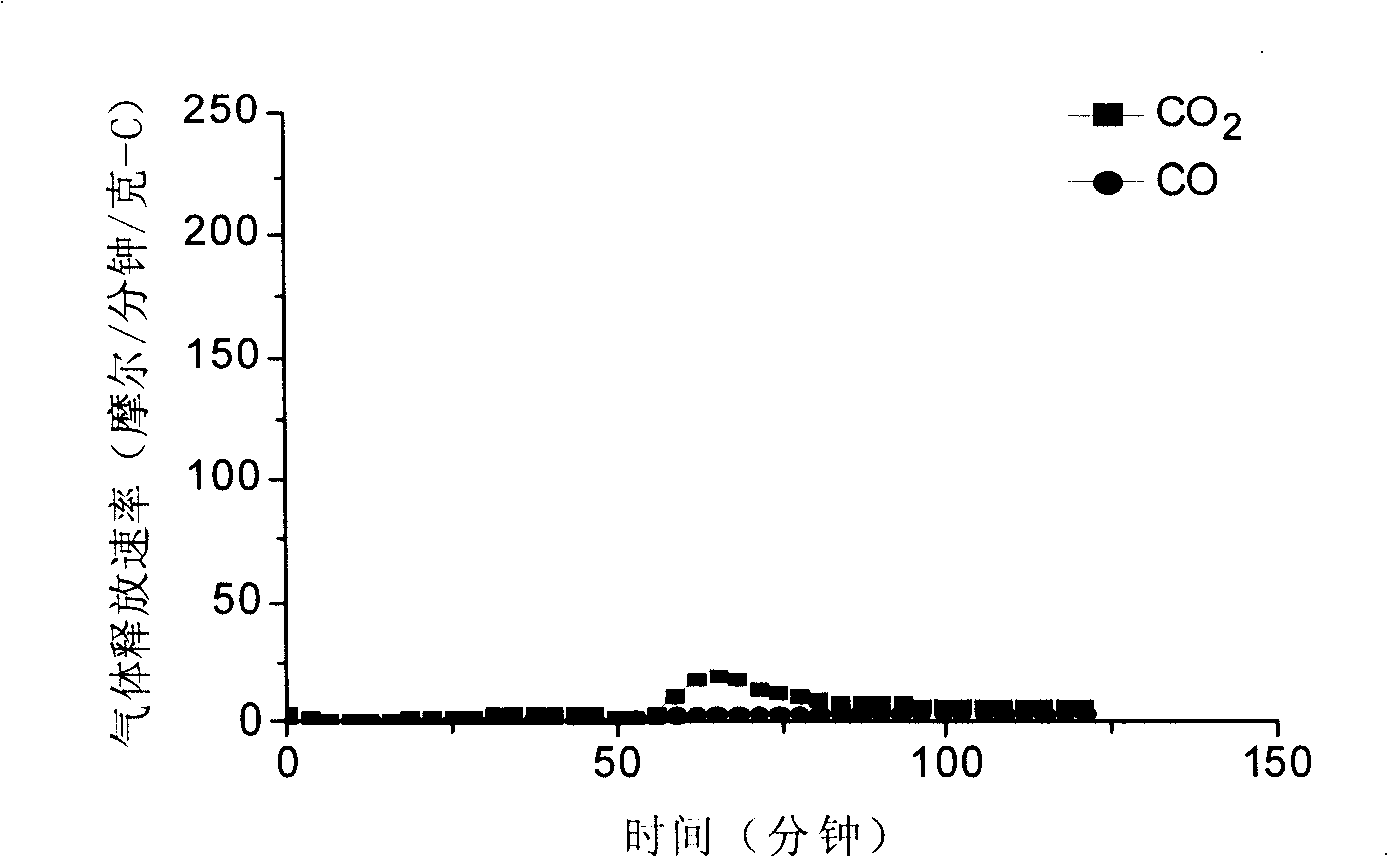

Method for catalytically gasifying coal

ActiveCN103468317AHigh activityImprove stabilityGasification with fuel pre-distillationBulk chemical productionMethanationCoal

The invention relates to a method for catalytically gasifying coal. The method comprises the following steps of (1) adding a Ca-containing compound, a K-containing compound, a Na-containing compound, raw coal and water into a reactor, mixing for 0.1-2.0 hours at a temperature of 50-180 DEG C and a pressure of 0.1-1.0MPa to synchronously realize preparation of a Ca-based catalyst and pretreatment of coal; and (2) gasifying the product in the step (1). According to the method, high gasification and methanation activities can be obtained, and the catalyst is good in stability, cannot be inactivated easily and can be simply recycled.

Owner:ENN SCI & TECH DEV

Process and system for recovering energy from carbon-containing materials

The invention provides processes and systems for generating heat from a carbon-containing material or converting a carbon-containing material to a combustible gaseous fuel, comprising (a) pyrolysing the material in a reactor to produce a carbon-enriched solid and a first gaseous product, (b) burning at least part of the first gaseous product and / or a second gaseous product obtained by reacting the carbon-enriched solid with water vapour to generate heat, and (c) returning combustion products from the burning step to the reactor and / or removing part of the first gaseous product and / or the second gaseous product as a combustible fuel.

Owner:BIDCORP AUSTRALIA

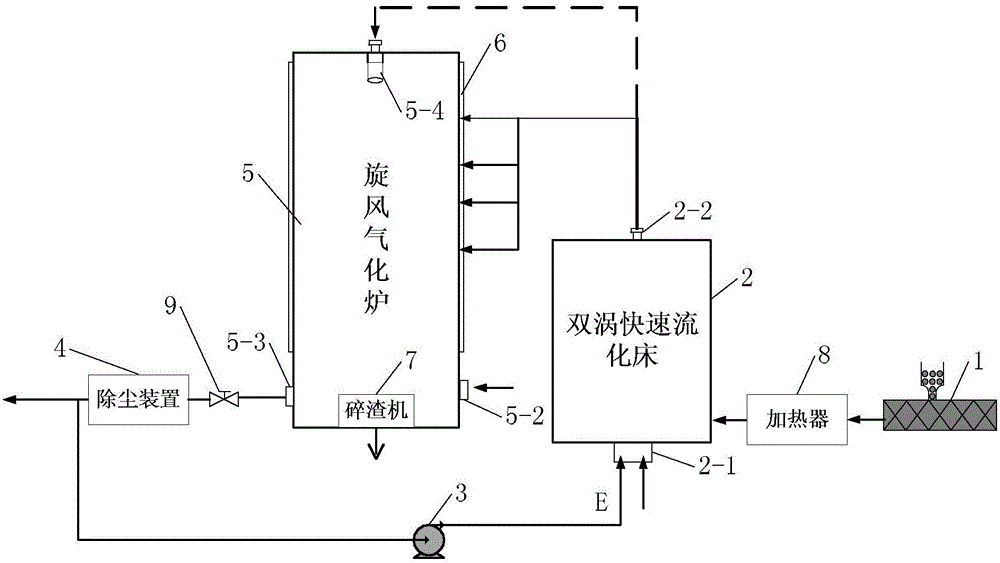

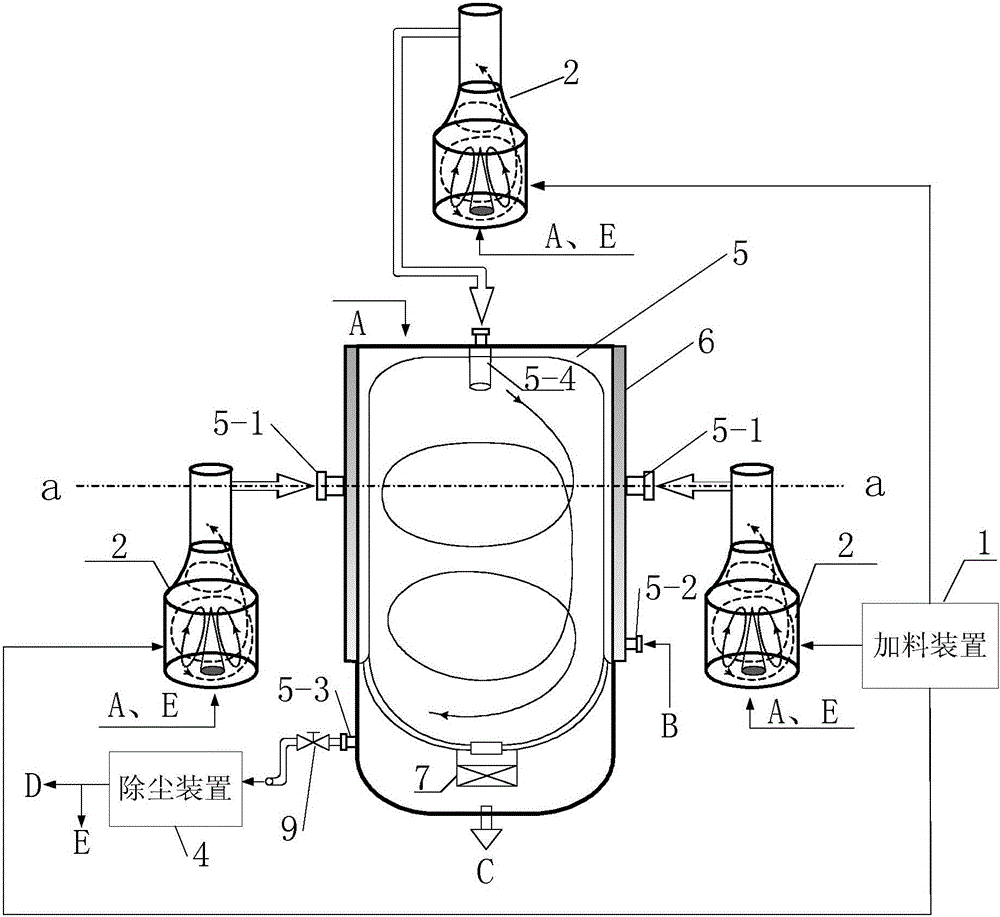

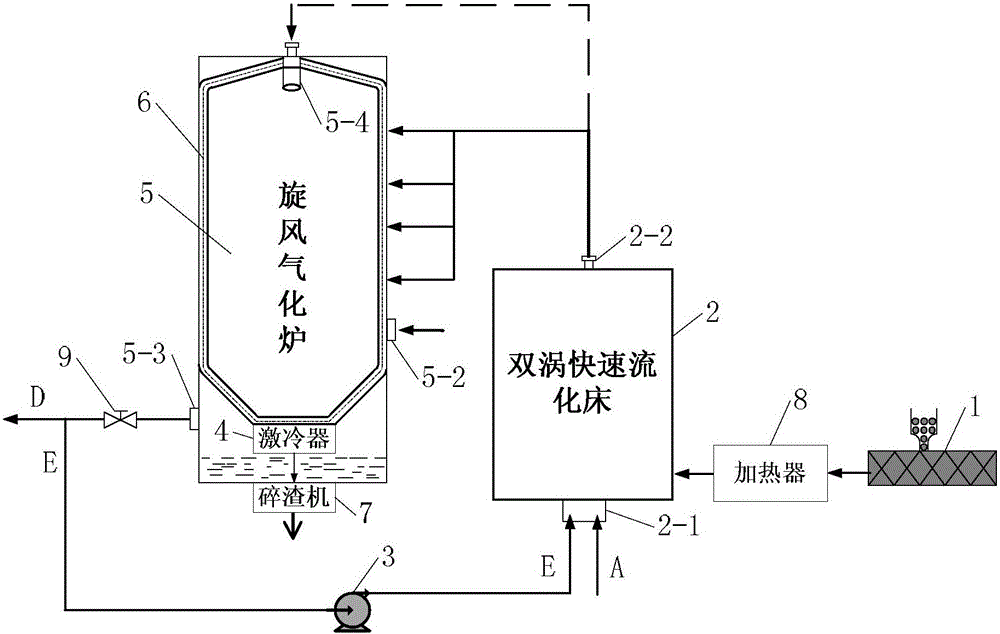

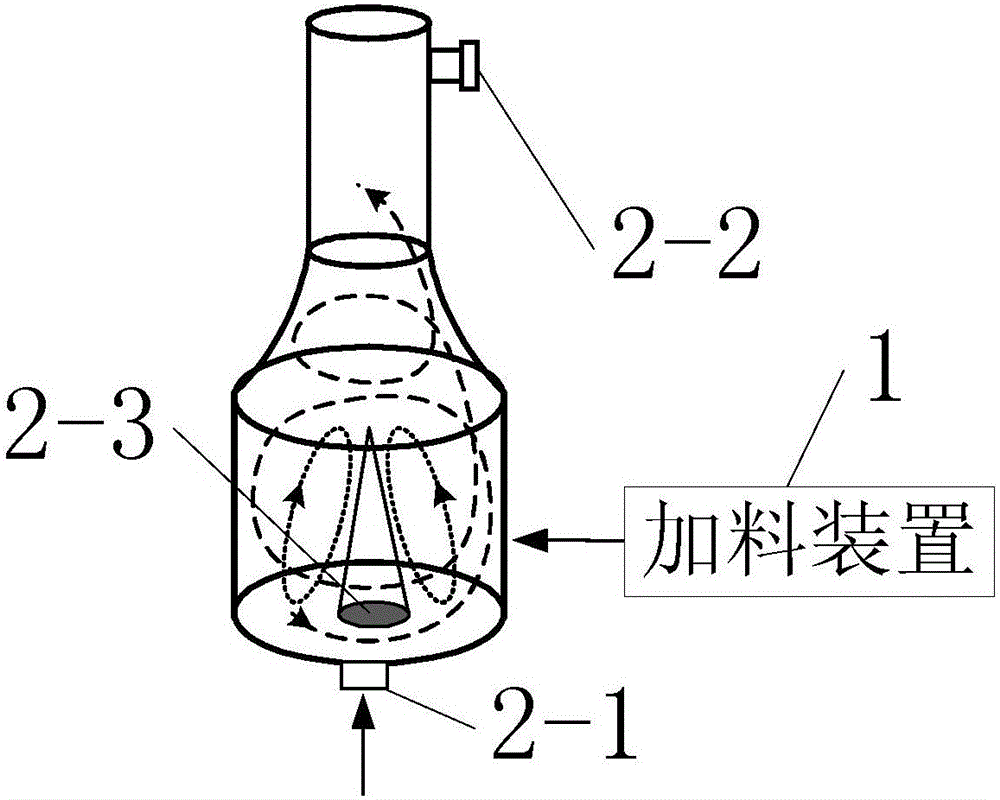

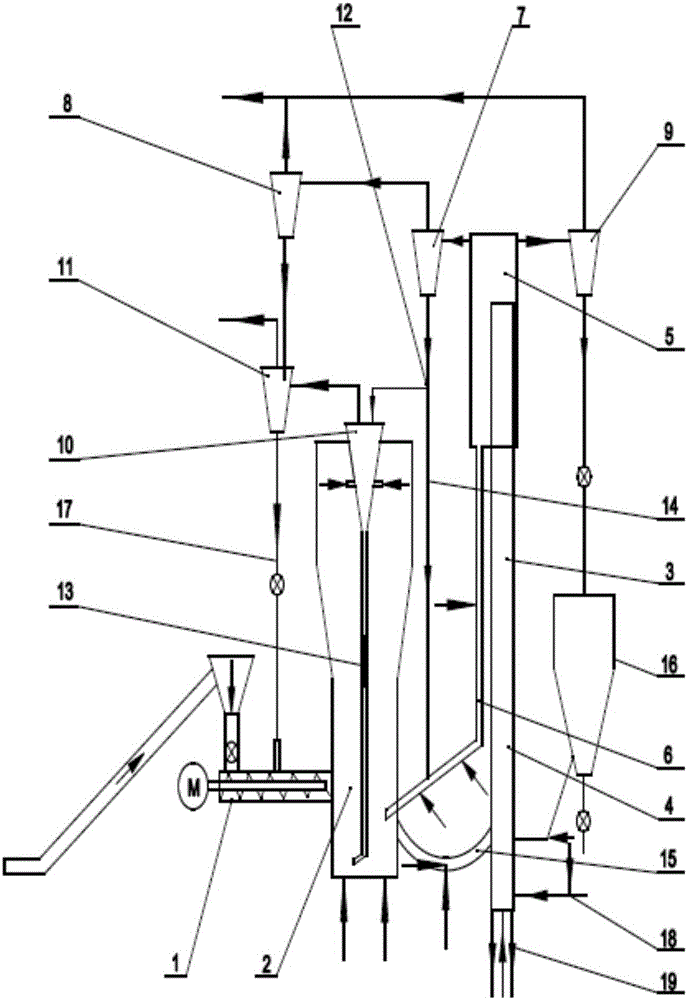

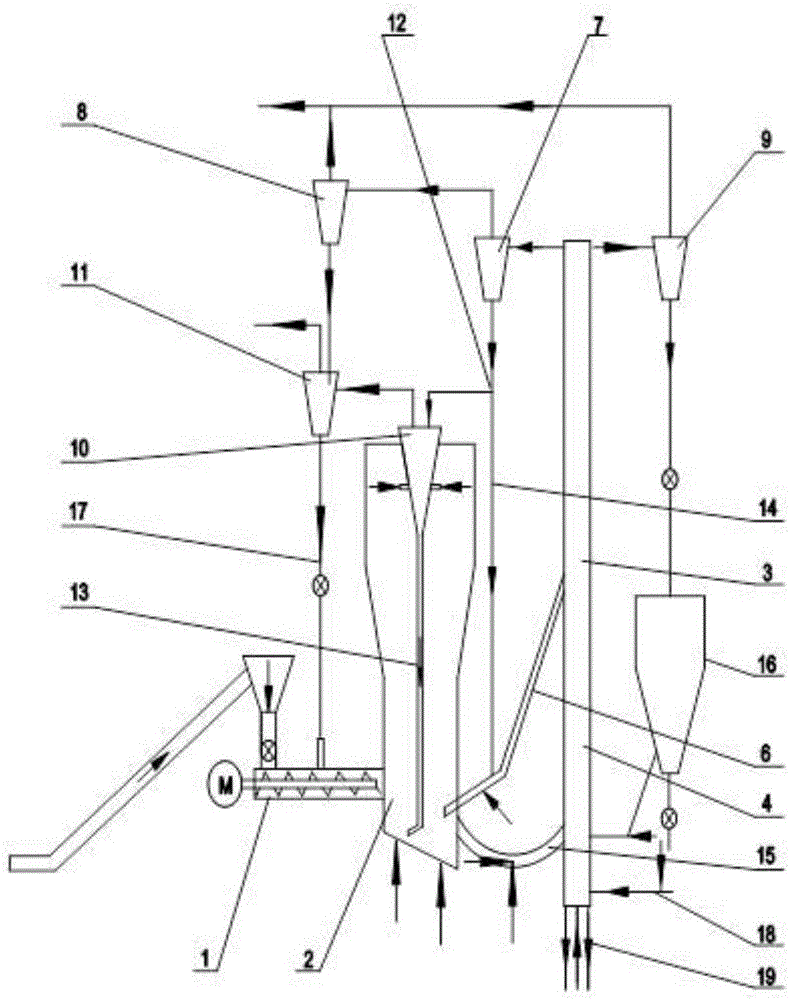

Inferior coal segmented-coupling gasifying device and gasifying method

ActiveCN105861066AReduce energy consumptionAdaptableGasification processes detailsCombined combustion mitigationCycloneSlag

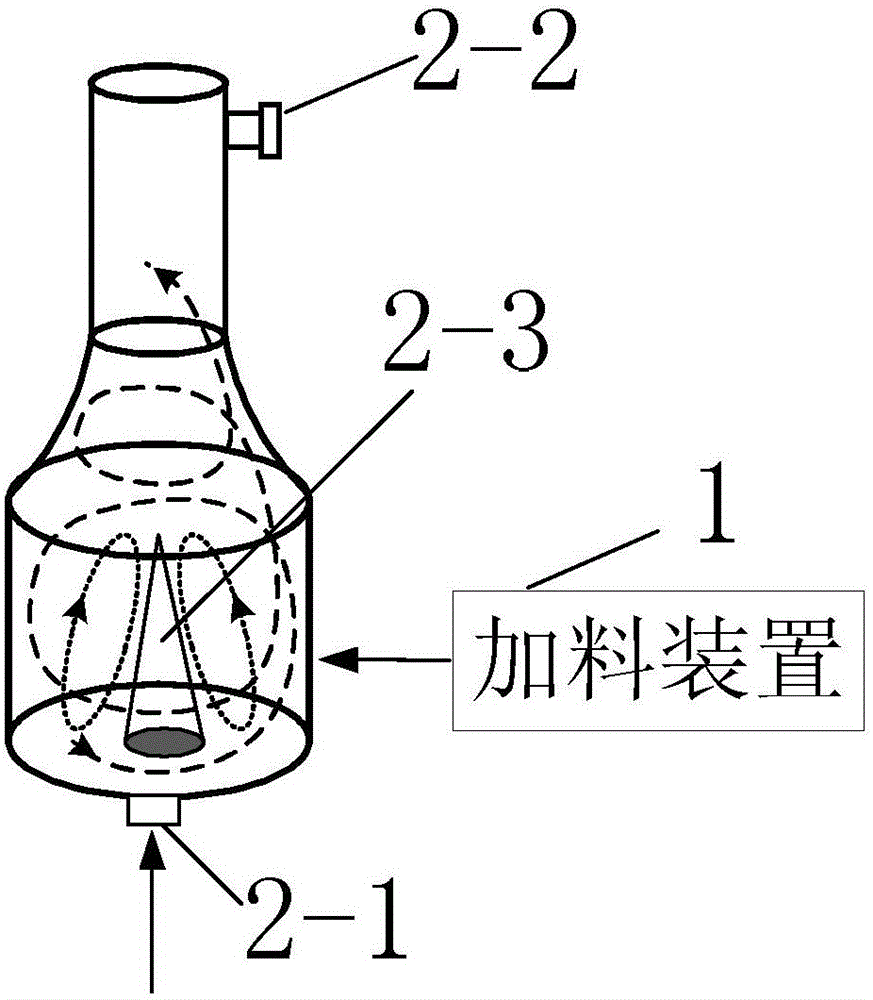

The invention discloses an interior coal segmented-coupling gasifying device and gasifying method and relates to the technical field of clean energy. The problems that existing gasifying device has low raw material adaptability and particularly is hard for realizing economical, reliable, clean and efficient gasification of interior coal and device amplification both are solved. The gasifying device comprises a charging device, a double-vortex fast fluidized bed, a circulating pump, a dust collector, a cyclone gasifier and a water cooling jacket, wherein the water cooling jacket wraps the outer wall of the cyclone gasifier; a slag crusher is arranged at the bottom of the cyclone gasifier; the slag crusher is used for crushing the slag falling to the bottom of the cyclone gasifier and discharging the slag out of the cyclone gasifier; the double-vortex fast fluidized bed is exclusively used for fluidizing, breaking and pyrolyzing a solid material at 500-980 DEG C to produce a raw gas; and the cyclone gasifier is exclusively used for performing carbon conversion of the raw gas introduced into the double-vortex fast fluidized bed at 1,200-1,300 DEG C to finally realize segmented coupling gasifying of inferior coal. The interior coal segmented-coupling gasifying device is mainly used for gasifying inferior coal.

Owner:HARBIN INST OF TECH

High-efficiency low-temperature catalysis gasification method for coal

InactiveCN101319151AAvoid failureImprove catalytic performanceGasification with fuel pre-distillationCalcium hydroxideCoal

The present invention relates to a highly effective low temperature catalytic gasification method for coal. The method comprises the following steps that: an additive is mixed with coal at a pyrolysis temperature of between 500 and 900 DEG C, wherein the additive is selected from calcium hydroxide, lime and limestone, and the weight of the additive is between 5 and 20 percent of the that of the coal, and the pyrolysis lasts 15 to 60 minutes to carry out pretreatment passivation for the coal; and the coal processed by the pretreatment passivation is catalytically gasified.

Owner:EAST CHINA UNIV OF SCI & TECH

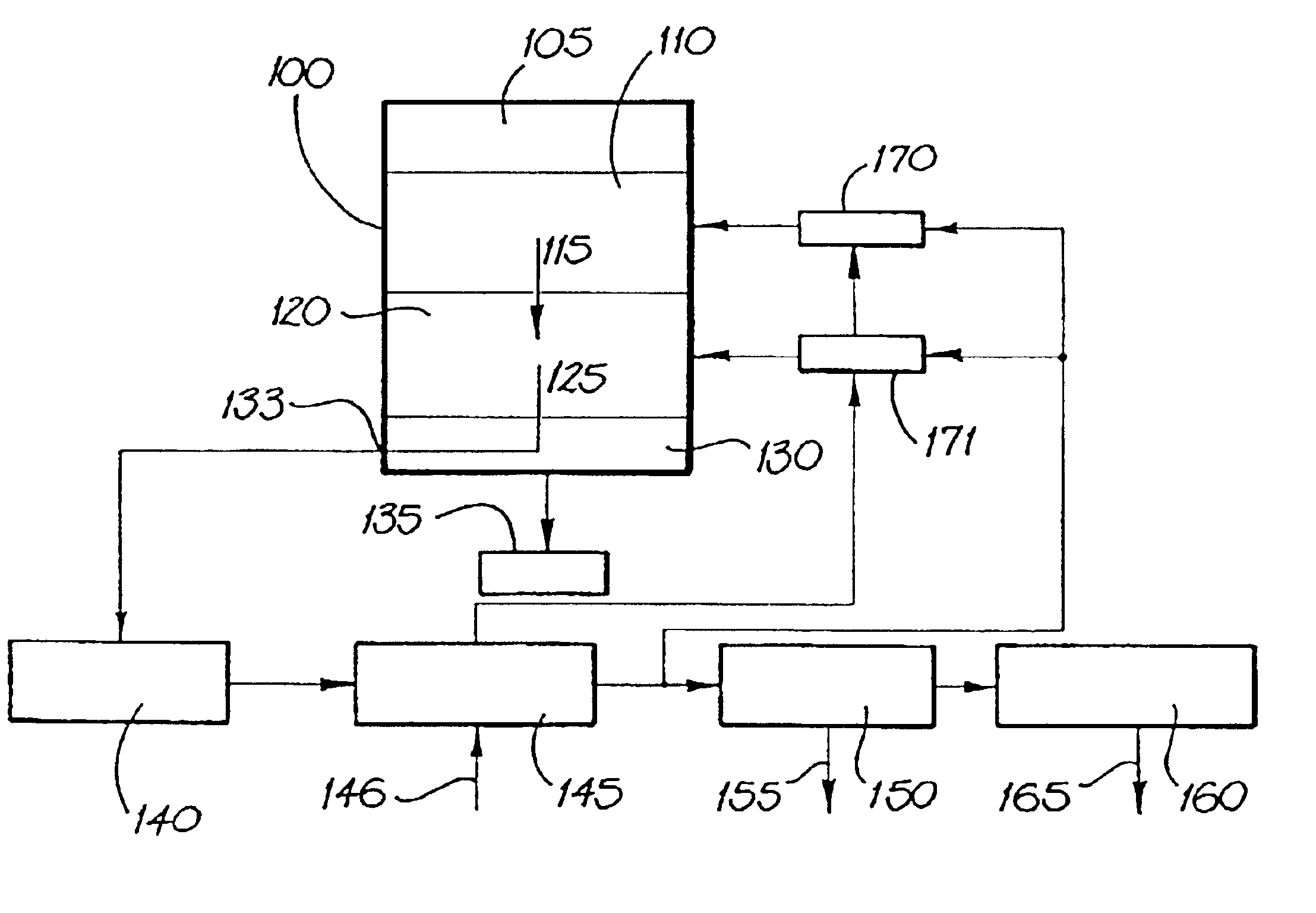

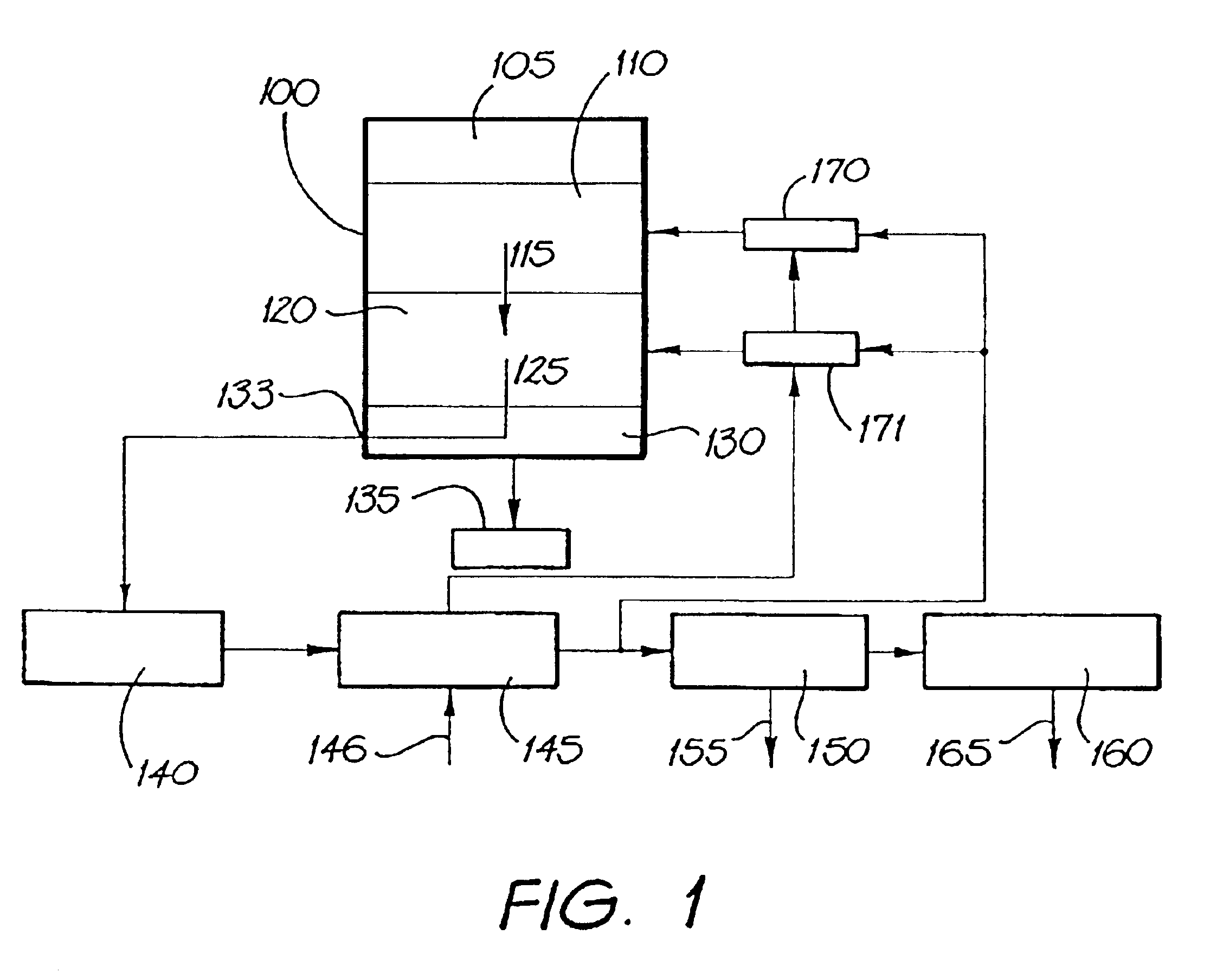

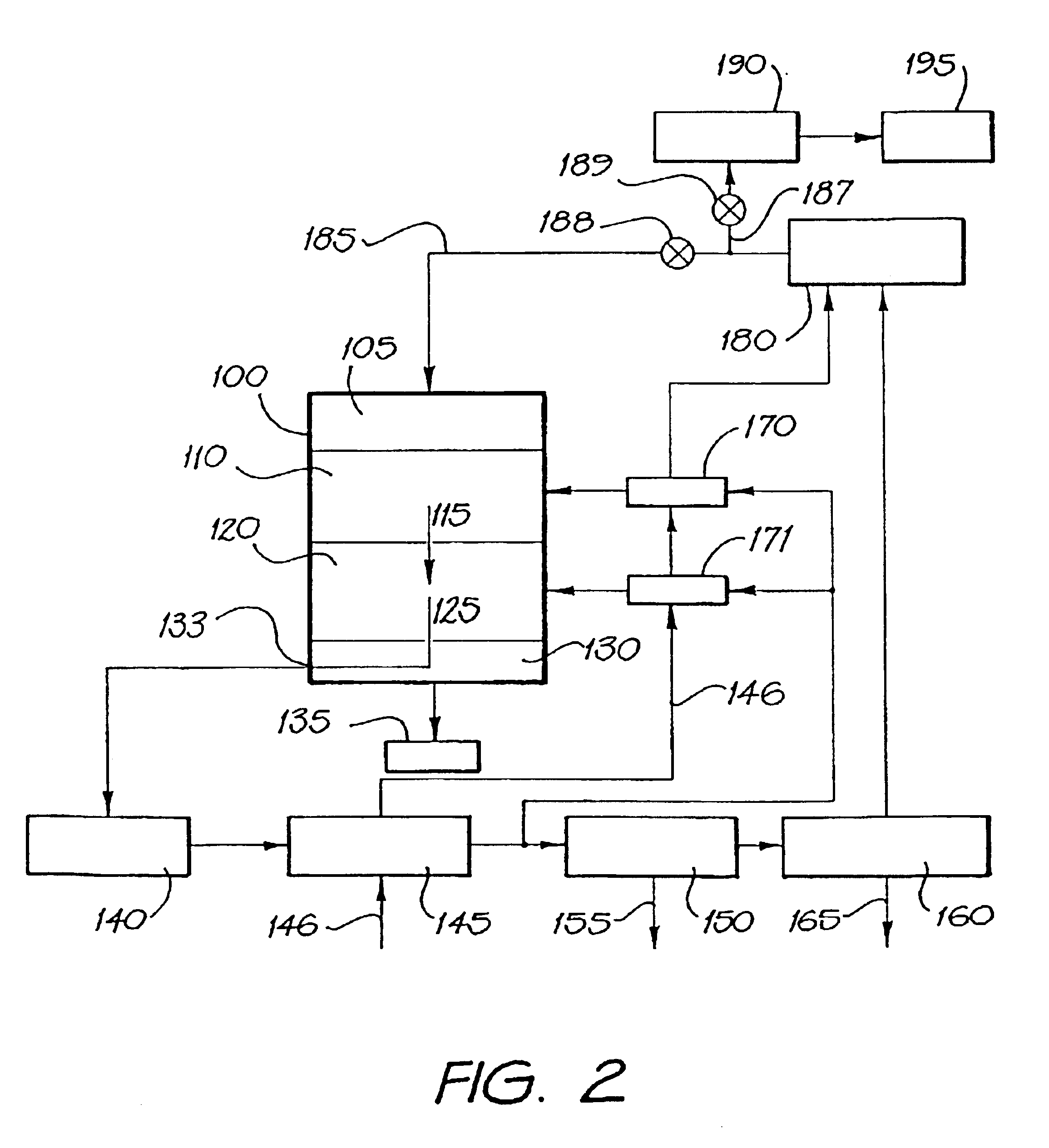

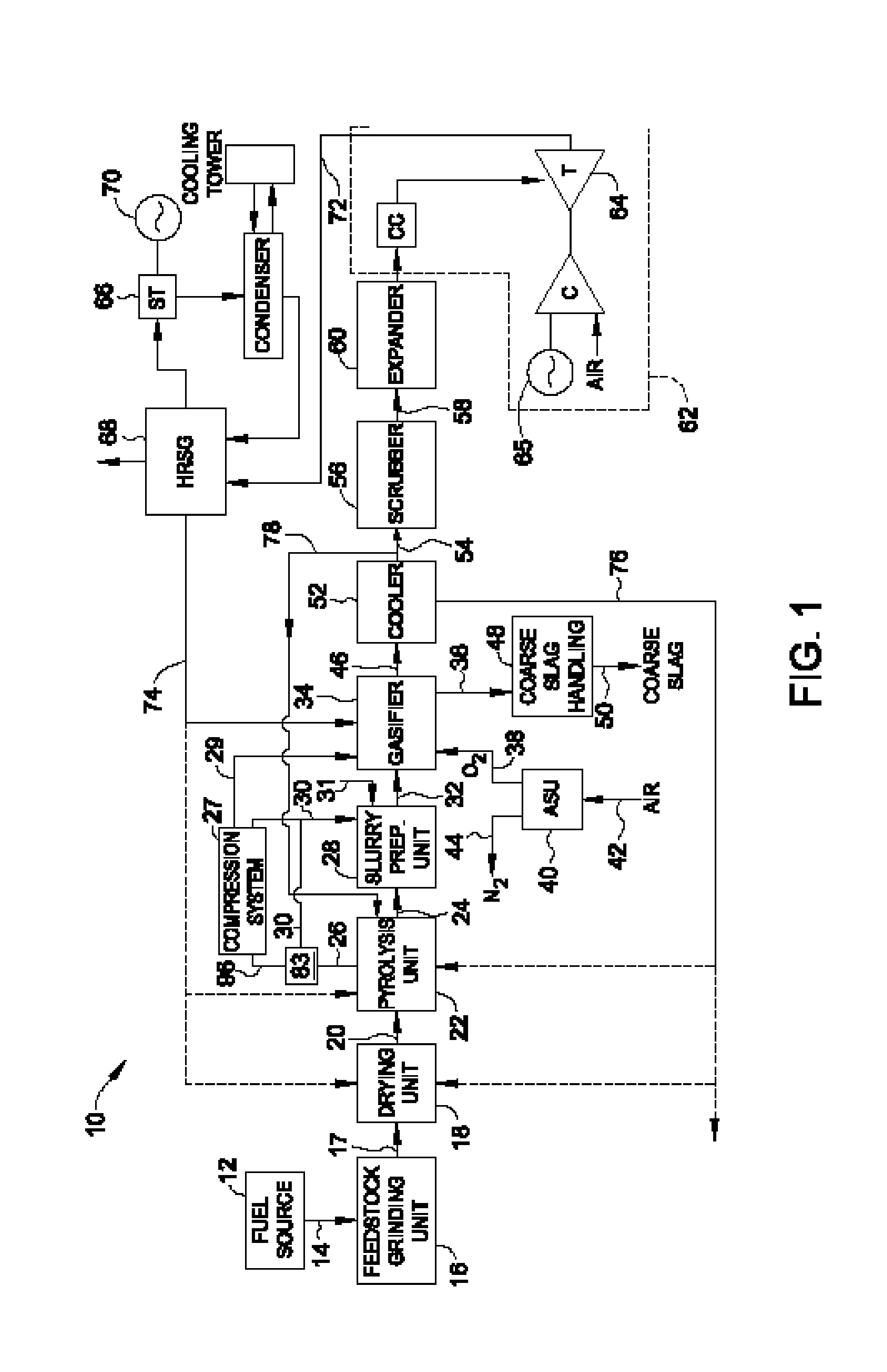

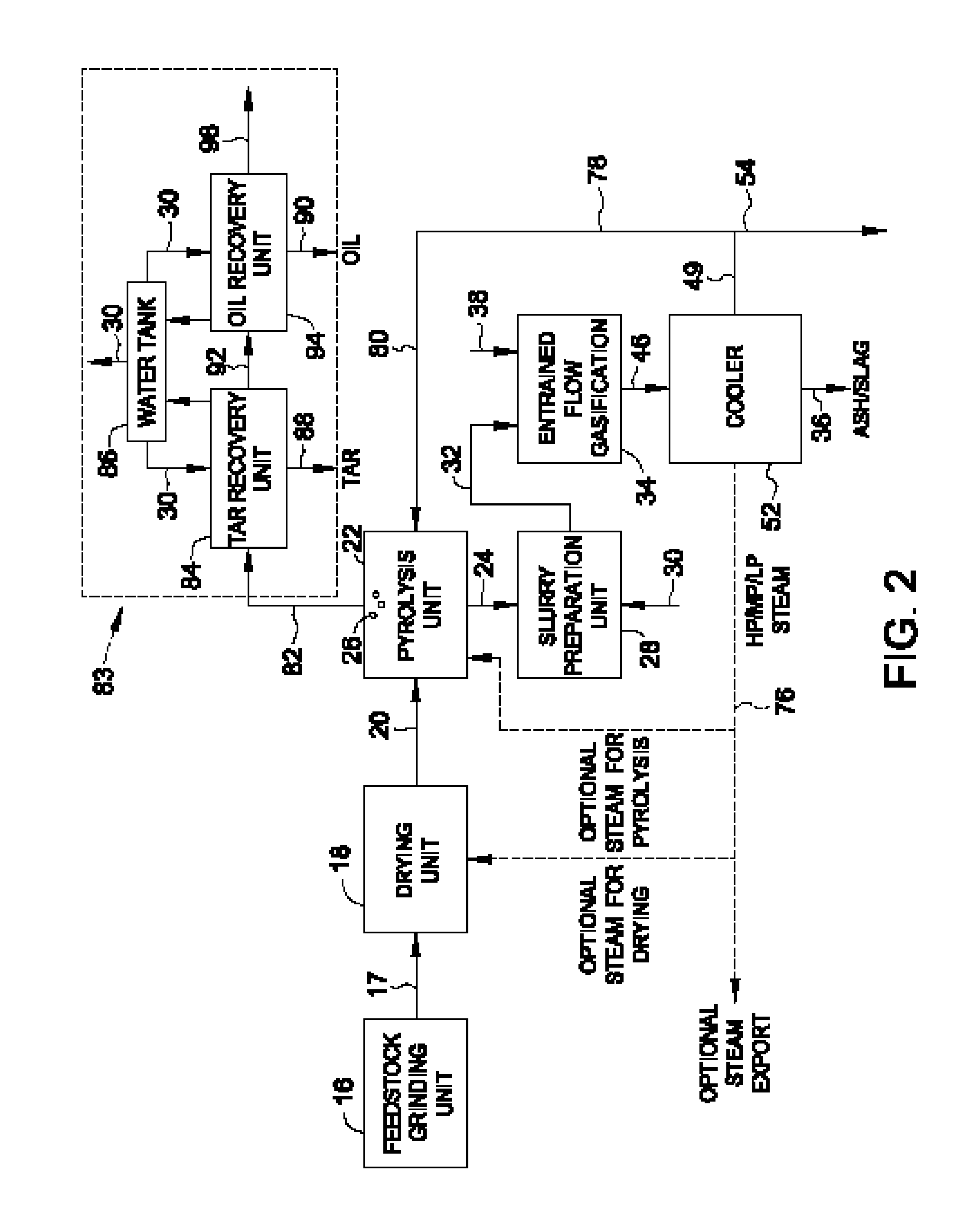

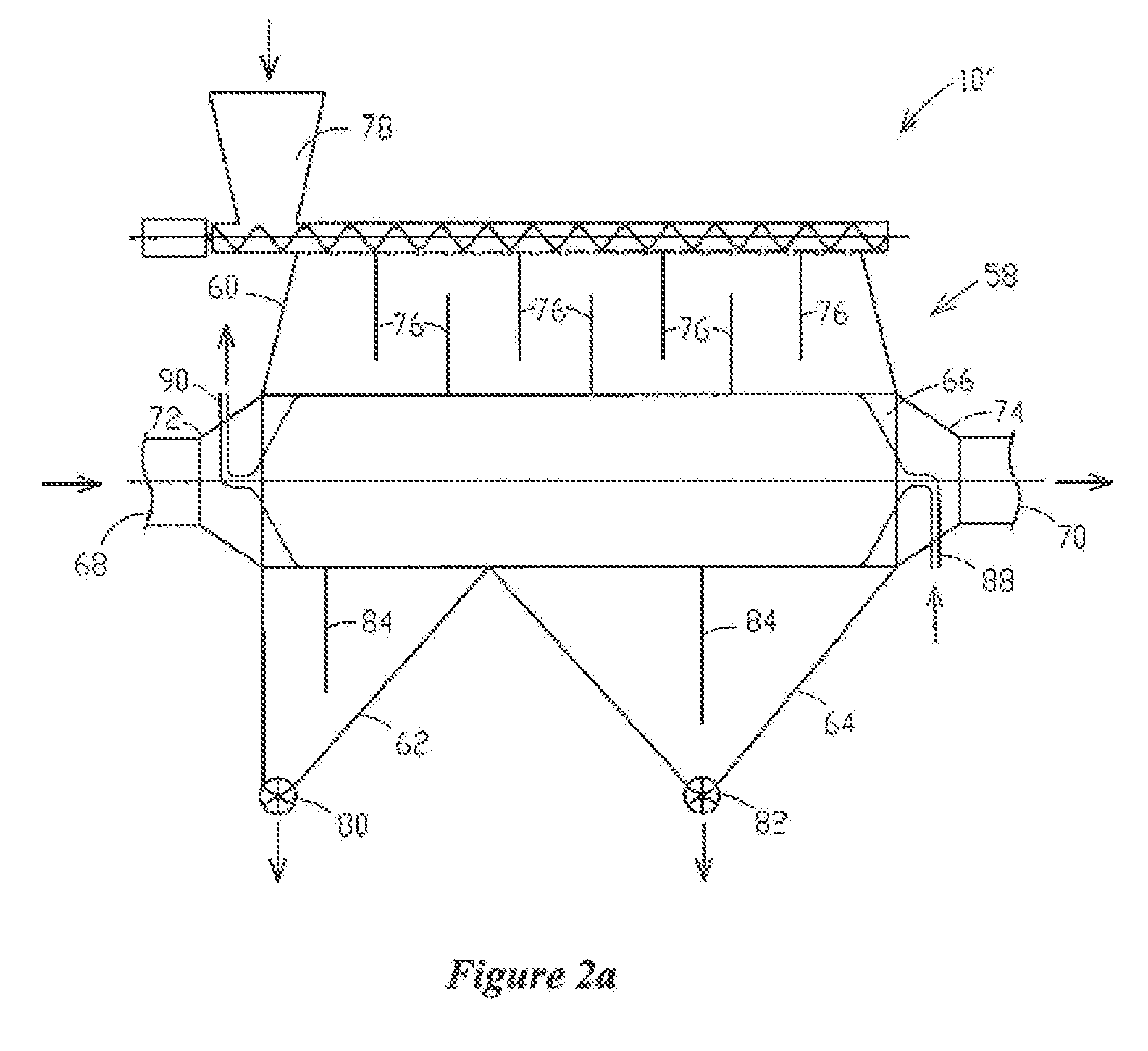

Integrated pyrolysis and entrained flow gasification systems and methods for low rank fuels

In one aspect, a gasification system for use with low rank fuel is provided The system includes a pyrolysis unit positioned to receive a feed of low rank fuel, the pyrolysis unit being configured to pyrolyze the low rank fuel to produce pyrolysis gas and fixed carbon. The system also includes a gasifier configured to produce a syngas stream using the received fixed carbon, a cooler configured to receive and cool the syngas stream, and a first conduit coupled between the cooler and the pyrolysis unit. The first conduit is configured to recycle at least a portion of the syngas stream to the pyrolysis unit such that the recycled syngas stream is mixed with the pyrolysis gas to produce a hydrocarbon-rich syngas stream containing gasification by-products. The system also includes a by-product recovery system coupled to the pyrolysis unit for removing the gasification by-products from the hydrocarbon- rich syngas stream.

Owner:AIR PROD & CHEM INC

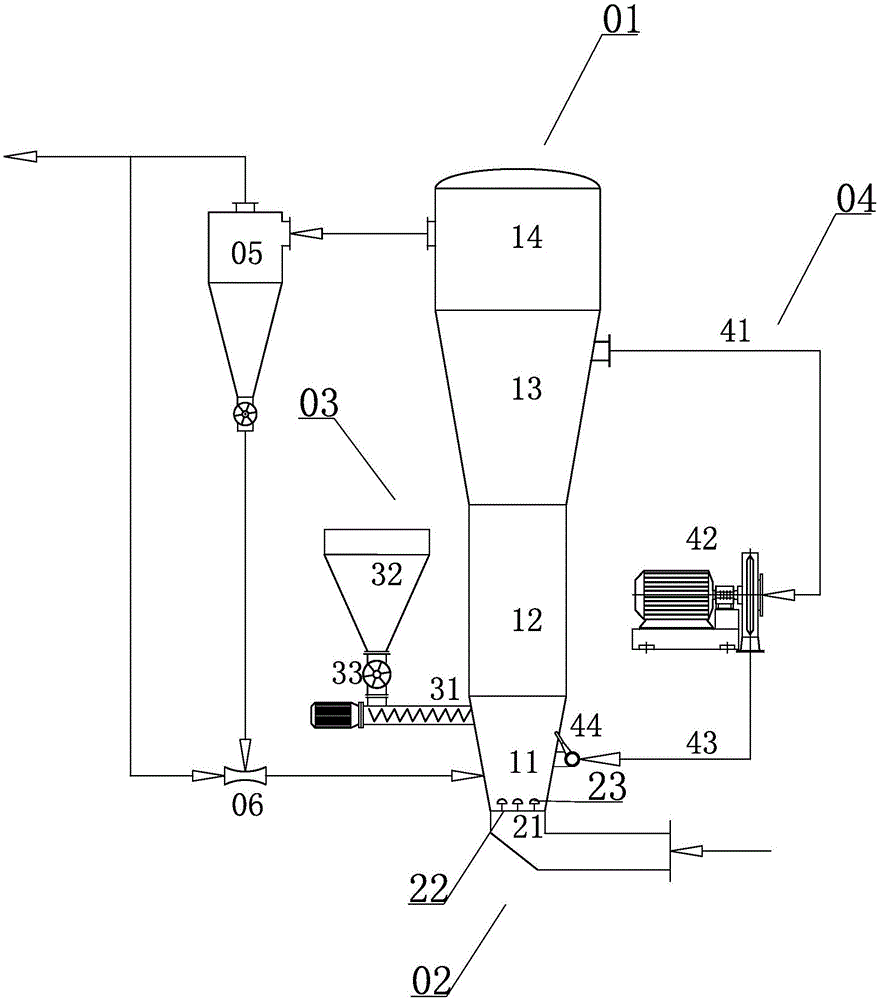

Fluidized bed pyrolysis gasification device by adopting biomass gas recirculation process

InactiveCN106753584AThe requirements for ash content are not highLow volatileChemical industryGasification processes detailsFluidized bed gasifierFluidized bed

The invention discloses a fluidized bed pyrolysis gasification device by adopting a biomass gas recirculation process. The device comprises a fluidized bed gasifying furnace body, and a gasifying agent supply structure, an anti-leakage type feeding structure and a biomass gas circulating structure which are formed in the bottom end of the fluidized bed gasifying furnace body. The fluidized bed gasifying furnace body comprises a conical heating section, a pyrolysis section, a conical diffusion section and a settling section. The gasifying agent supply structure comprises an isobaric air bellow, an air distributor, and a cap arranged on the isobaric air bellow; the biomass gas circulating structure comprises a high-temperature exhaust duct, a dust exhaust fan, an air inlet pipeline and an injection pipe; the high-temperature exhaust duct is formed in the conical diffusion section and is communicated with the upper part of the conical diffusion section; the dust exhaust fan is arranged on the high-temperature exhaust duct; the air inlet pipeline is arranged on the dust exhaust fan and is communicated with the upper part of the conical heating section; and the injection pipe is arranged on the end of the air inlet pipeline and extends into the conical heating section. The device disclosed by the invention has the advantages of high adaptability, high efficiency, energy conservation, flexible operation and simple structure.

Owner:广东国能中林实业有限公司

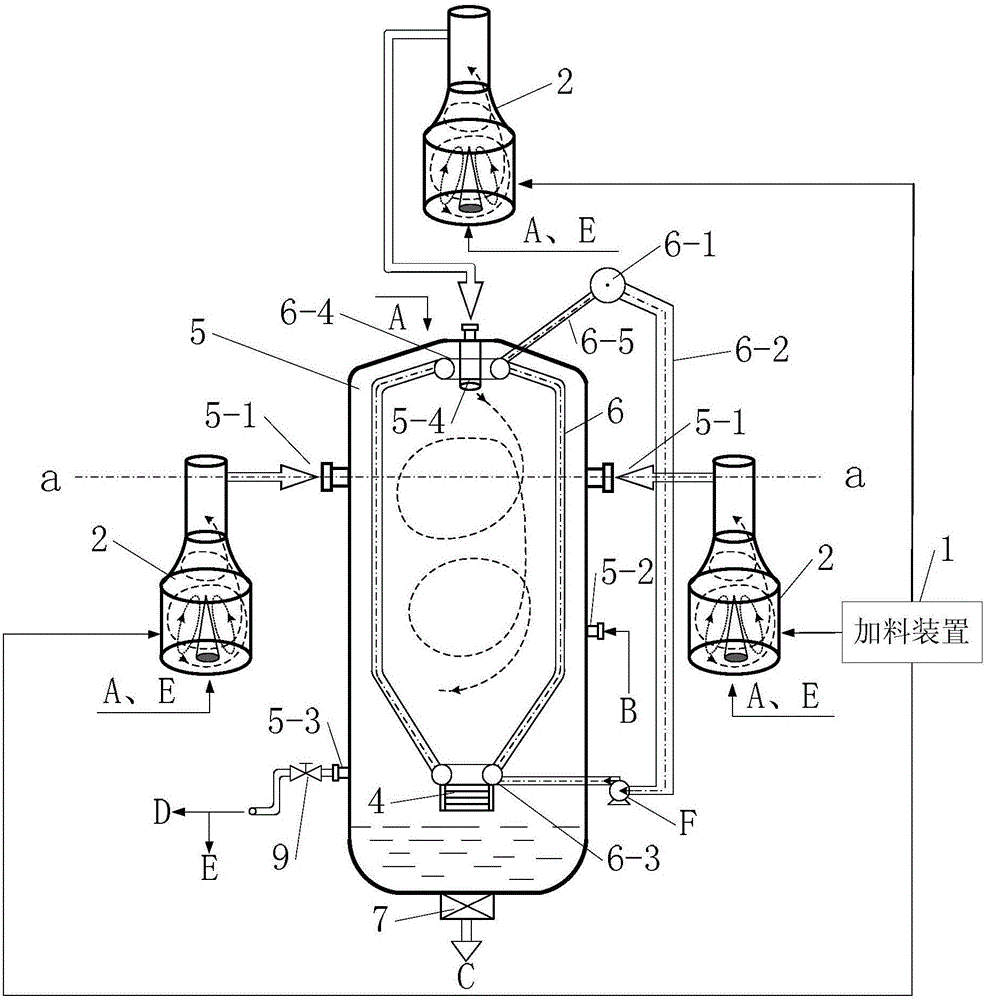

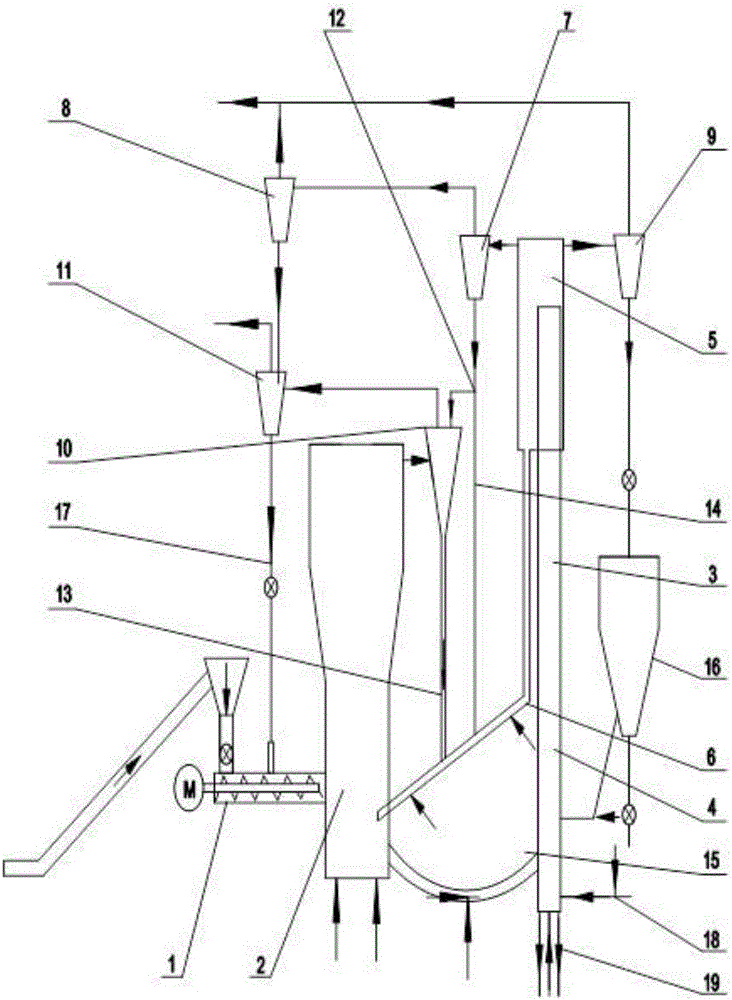

Segmented coupling and gasification device and method of fault coal water-cooling fireplace

ActiveCN106221814AReduced requirements for viscosity-temperature characteristicsImprove slagging characteristicsGasification processes detailsCombined combustion mitigationSlagSolid particle

The invention discloses a segmented coupling and gasification device and method of a fault coal water-cooling fireplace and relates to the technical field of clean energy coal gasification. The problem that an existing gasification device is poor in material adaptability, low in load adaptability, high in oxygen consumption, low in carbon conversion rate, difficult to enlarge and high in preliminary investment and operating cost, makes a slag film thin and non-uniform, needs a standby furnace and makes H2 / CO proportion non-adjustable is solved. The gasification device comprises a charging device, a double-vortex rapid fluidized bed, a gasified gas circulating pump, a cyclone gasification furnace, a water-cooling system, a chilling device and a slag crusher. The gasification method comprises the steps that single-segment gasification is decomposed into two-segment gasification for pyrolysis, carbon conversion and serial coupling, the double-vortex rapid fluidized bed is special used for fluidization, crushing and pyrolysis of low-temperature-segment solid particle material to form raw gas, the cyclone gasification furnace is specially used for weak whirling, combustion and gasification of the raw gas at a high-temperature segment and achieves carbon conversion. The segmented coupling and gasification device and the method are mainly used for clean, efficient, economic and reliable segmented coupling and gasification of low-melting-point fault coal, biomass and their mixtures.

Owner:HARBIN INST OF TECH

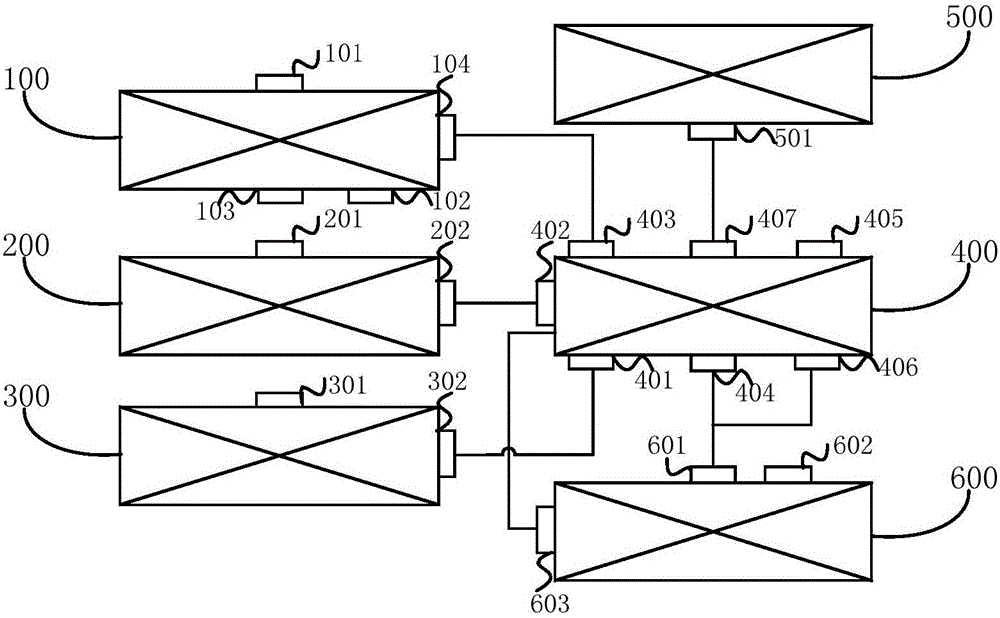

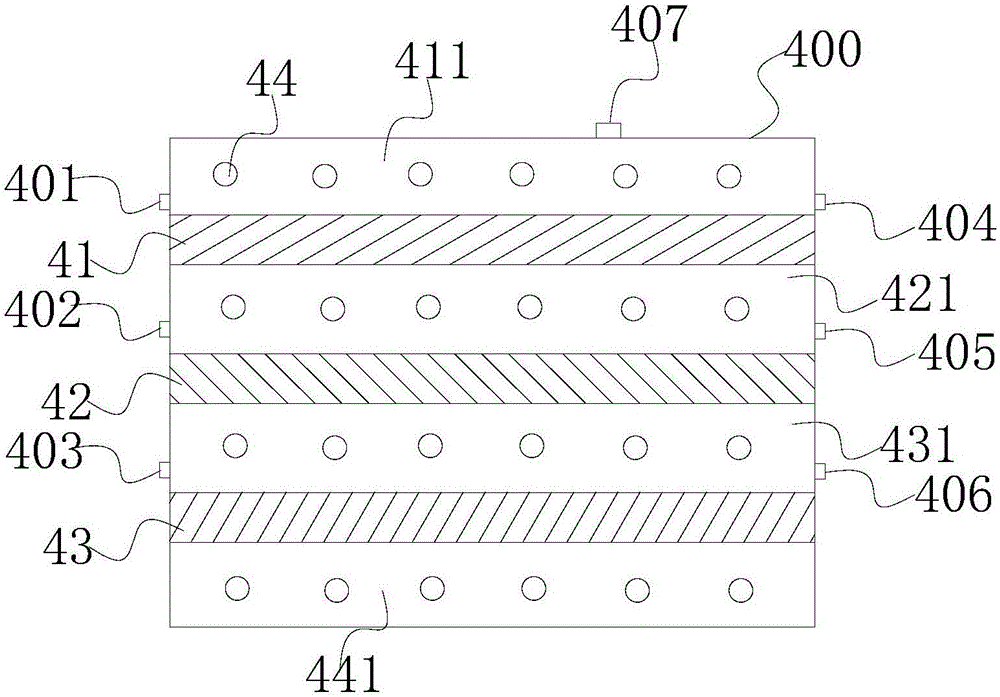

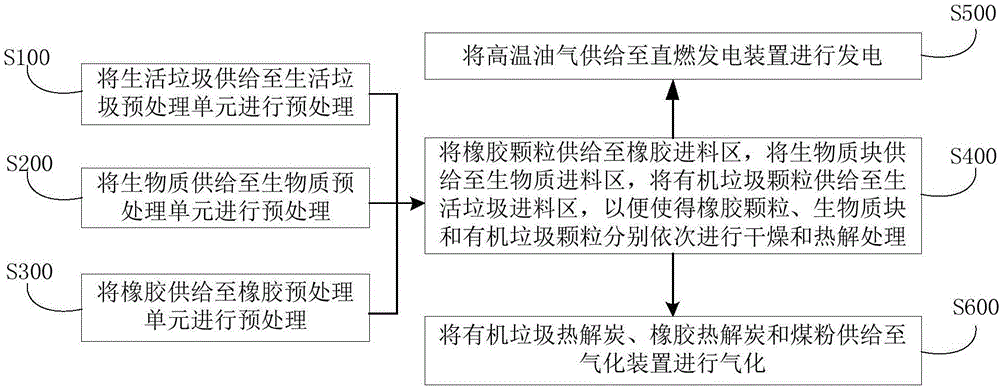

System and method for treating solid waste

The invention discloses a system and a method for treating solid waste. The system comprises a household garbage pretreatment unit, a biomass pretreatment unit, a rubber pretreatment unit, a rotating-bed pyrolyzing furnace, a direct-combustion power generation device and a gasifying device, wherein the household garbage pretreatment unit comprises a household garbage inlet, an inorganic garbage outlet, a stacked filtrate outlet and an organic garbage particle outlet; the biomass pretreatment unit comprises a biomass inlet and a biomass block outlet; the rubber pretreatment unit comprises a rubber inlet and a rubber particle outlet; the rotating-bed pyrolyzing furnace comprises a rubber particle inlet, a biomass block inlet, an organic garbage particle inlet, a rubber pyrolytic carbon outlet, a biomass pyrolytic carbon outlet, an organic garbage pyrolytic carbon outlet and a high-temperature oil gas outlet; the direct-combustion power generation device comprises a high-temperature oil gas inlet; and the gasifying device is provided with a pyrolytic carbon inlet, a pulverized coal inlet and a gasifying coal gas outlet. The system is relatively low in operation cost, and dioxin is not generated in an intermediate process; and meanwhile, high-temperature oil gas and the pyrolytic carbon are efficiently utilized, so that economic benefits are generated.

Owner:SHENWU TECH GRP CO LTD

Three-bed combination pyrolysis gasification and tar cracking integrated system for solid waste

ActiveCN105885950AEasy to operateEmission reductionGasifier feeding meansBiofuelsCycloneFluidized bed

The invention discloses a three-bed combination pyrolysis gasification and tar cracking integrated system for solid waste and belongs to the technical field of solid waste treatment. The system comprises a solid waste feeding system, a pyrolyzer, an oxidizer system, an oxidizer cyclone separator and a cyclone reactor. According to the system, the circulating flow of bed materials among three bed is realized by virtue of a circulating fluidized bed oxidizer, a bubbling or turbulent fluidized bed pyrolyzer and the cyclone reactor which are combined with a gas stripping tube and a sedimentation tube, and the adequate mixing between the hot bed materials and pyrolysis gas is realized by virtue of the cyclone reactor, so that the tar cracking and the gas purification are greatly promoted; by virtue of structural optimization of an oxidizer and the pyrolyzer, the mixed use of different bed materials and the improvements of a bed material circulating flow system, the gas-liquid mixing level and a feeding system, the integral pyrolysis gasification efficiency is greatly improved, the heat value of product gas is greatly increased, the tar content of product gas is greatly reduced, and high-quality clean pyrolysis gas / synthesis gas is prepared.

Owner:BEIJING UNIV OF CHEM TECH

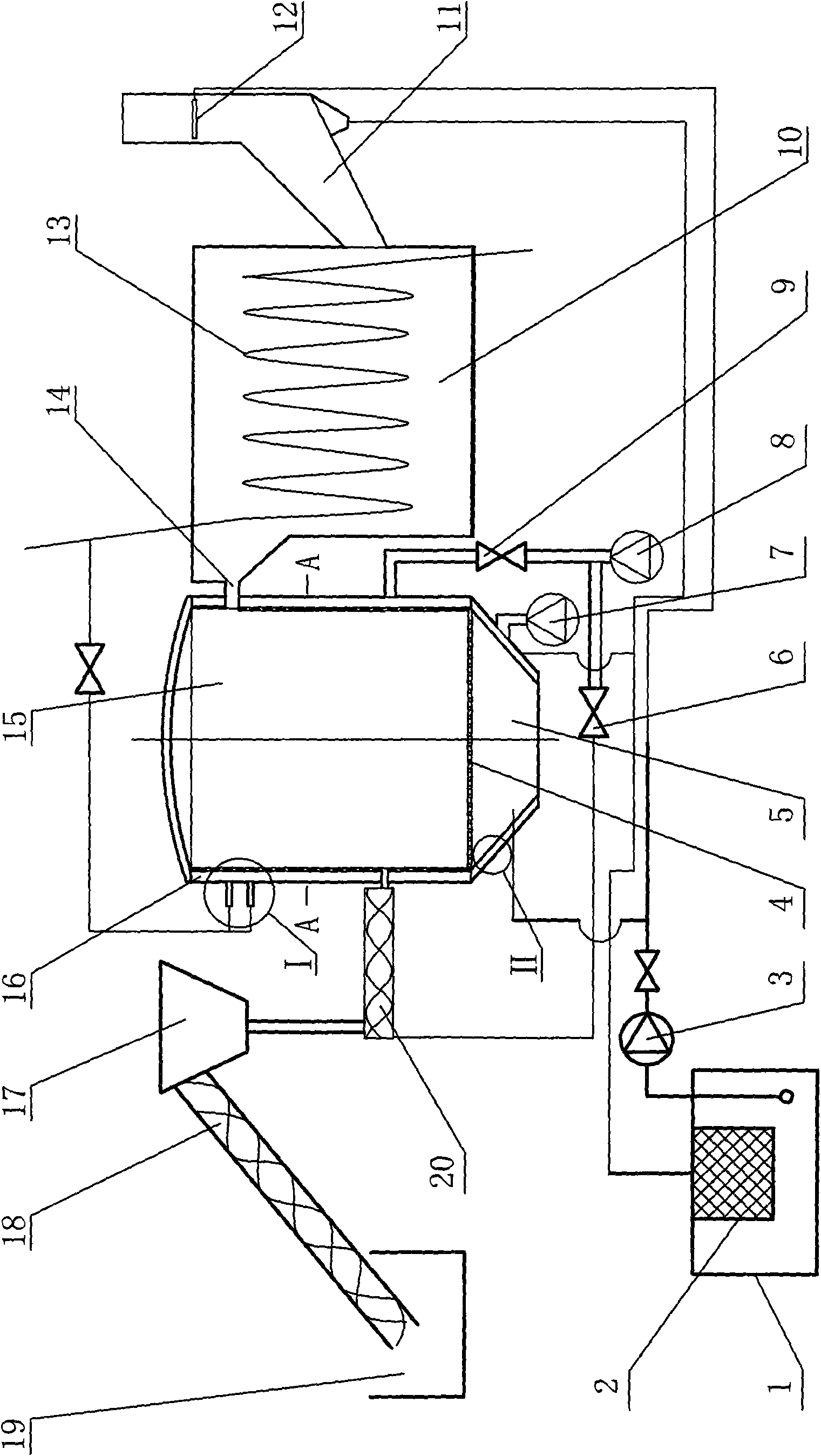

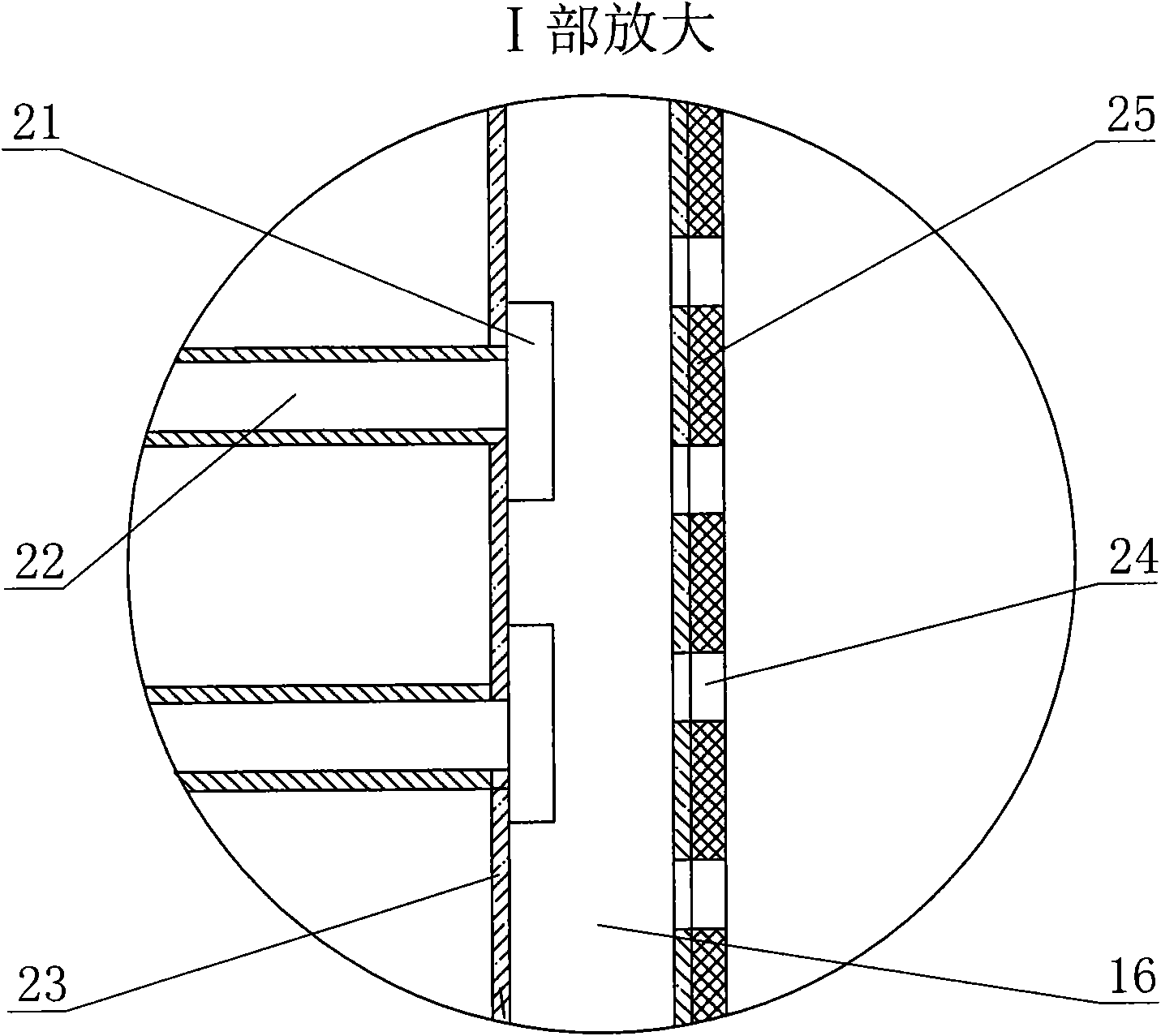

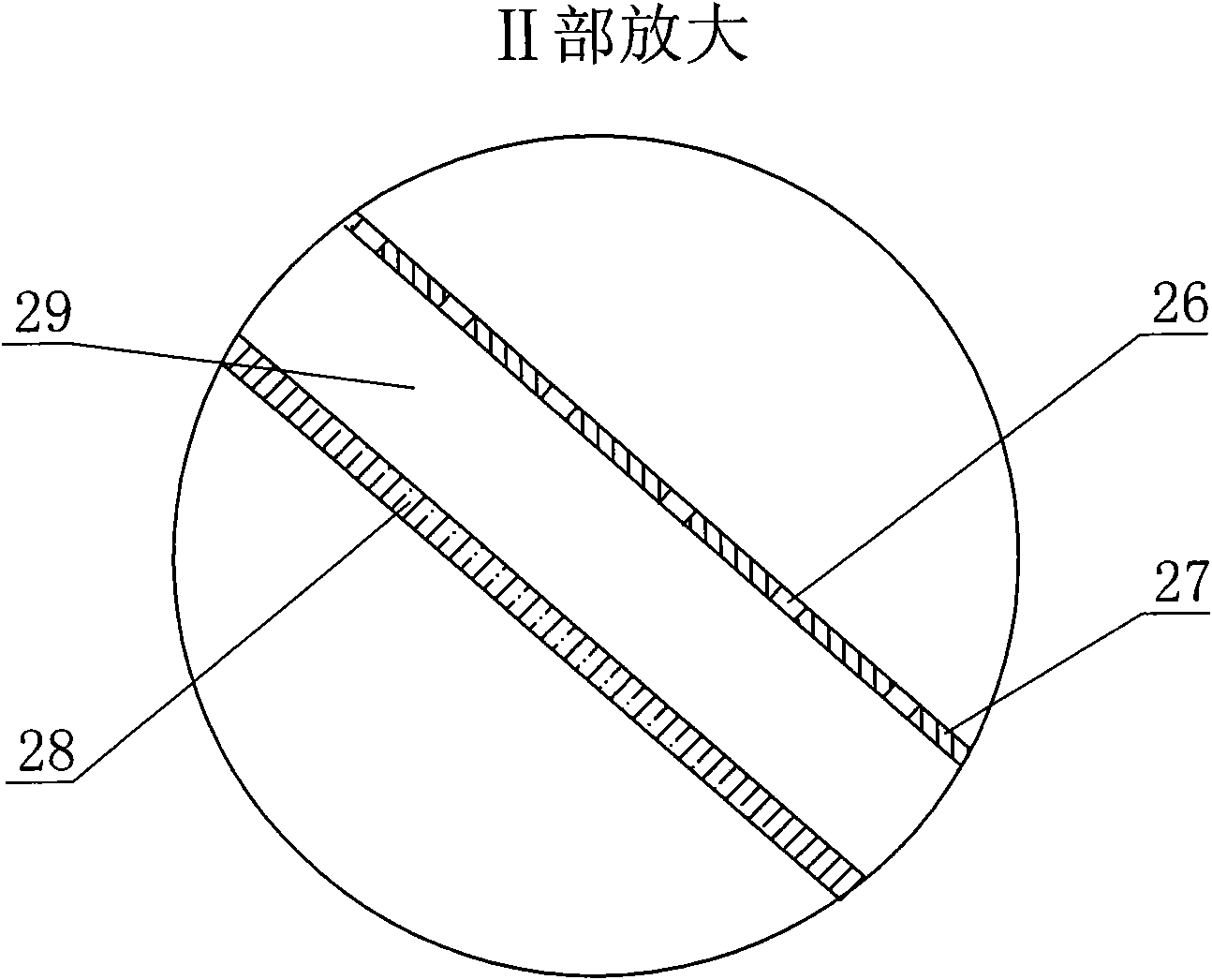

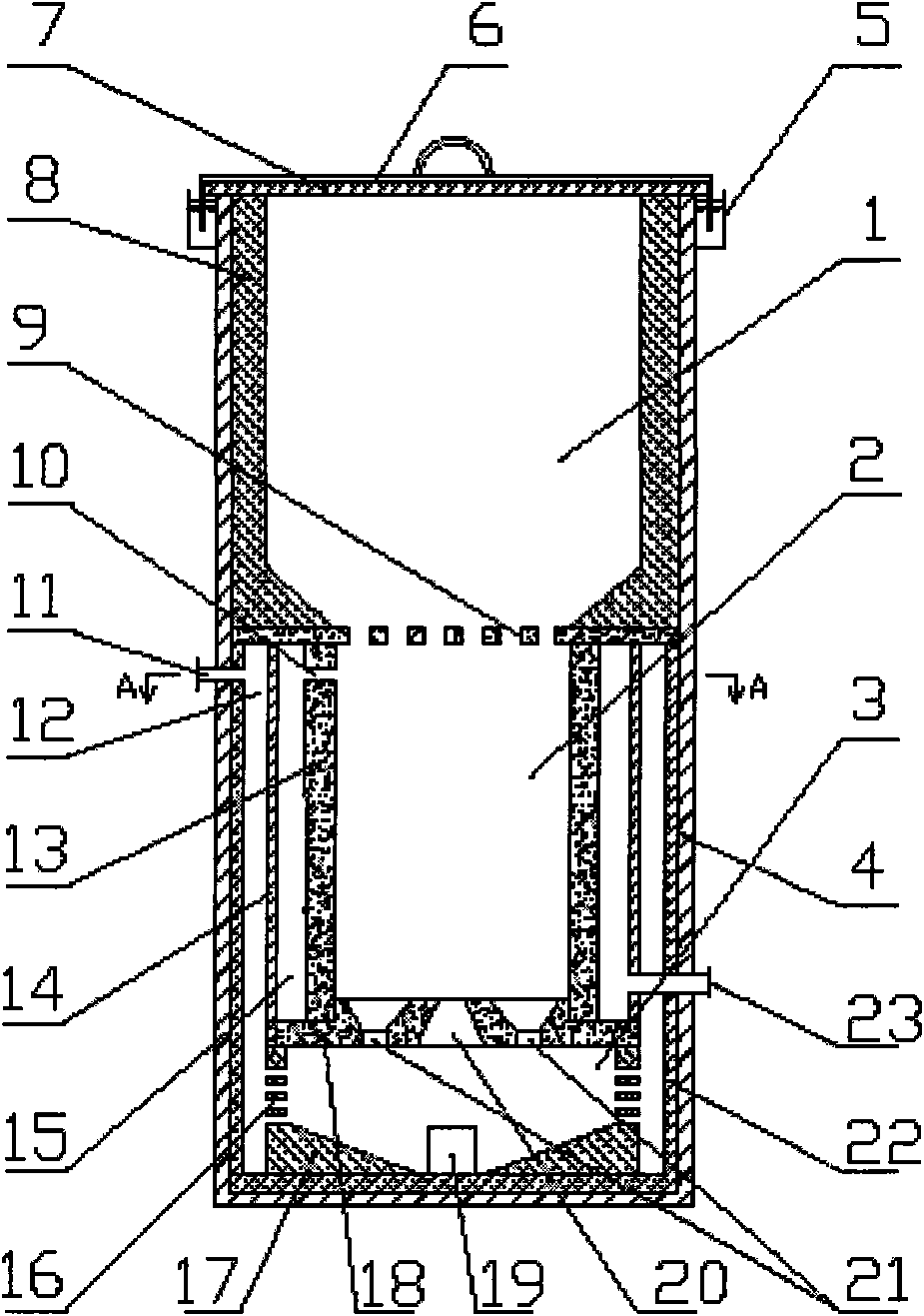

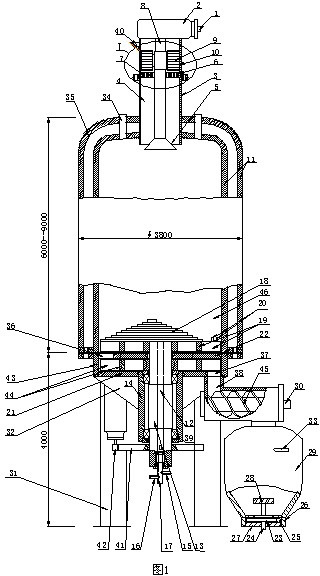

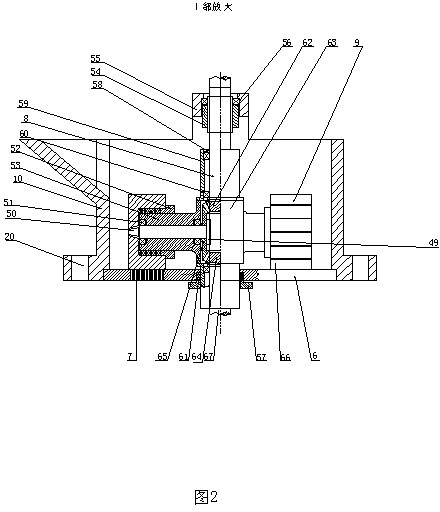

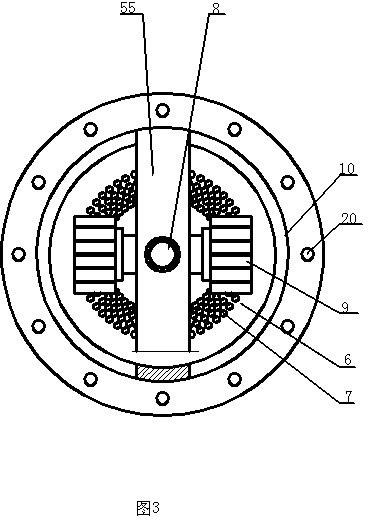

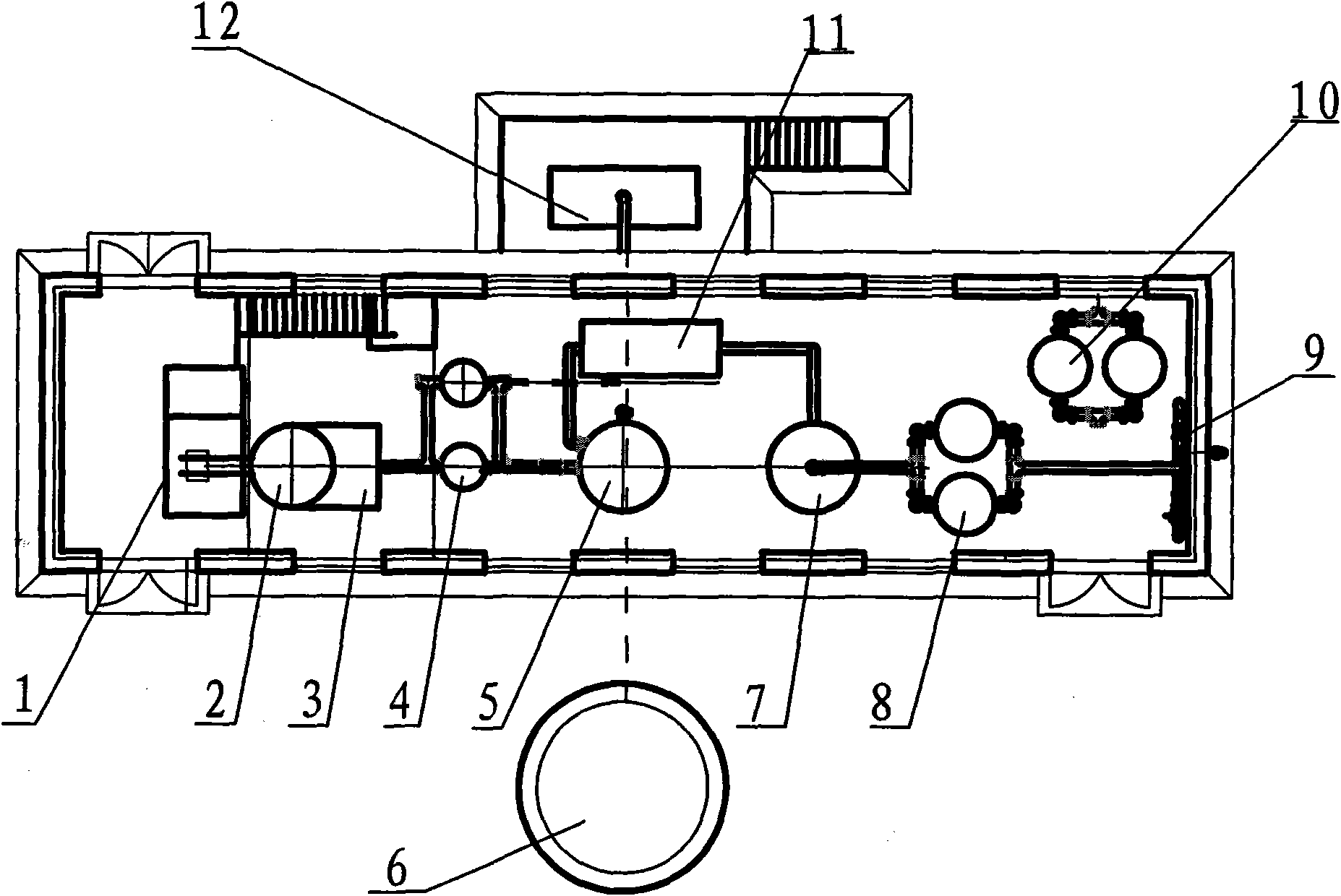

Equipment for preparing fuel gas for gas turbine-steam turbine combined circulating power generation

ActiveCN102634374AInto a stableSolve the problem of easy to reduce the pressure in the furnaceBiofuelsSolid fuelsDrive shaftEngineering

The invention provides equipment for preparing fuel gas for gas turbine-steam turbine combined circulating power generation, comprising a furnace body. An idler wheel extruder is installed at the upper end of the furnace body and is provided with a material receiving barrel, and the material receiving barrel is connected with the furnace body in an airtight mode. A transmission shaft is installed in the material receiving barrel, and two idler wheels are installed on the transmission shaft. A round steel disc is installed on the inner wall of the material receiving barrel below the idler wheels, and a through hole is arranged on the round steel disc. A feed port is arranged at the upper end of the material receiving barrel, the lower end of the material receiving barrel is an opening which is positioned in a fuel gas producer. A fire grate is installed at the lower end of the furnace body, and is connected with a second transmission shaft, and a slagging pipe is installed at one side of the bottom end of the furnace body. An air inlet is arranged in the second transmission shaft and is communicated with a gas mixing pipe, and the gas mixing pipe is respectively connected with a steam pipe and an air pipe. A power transmission piece is installed on the second transmission shaft and is connected with a motor. According to the invention, fuel gas prepared by adopting the equipment has high yield, high cleanliness and high calorific value, and the fuel gas is directly supplied for gas turbine-steam turbine combined circulating power generation.

Owner:孔令增 +1

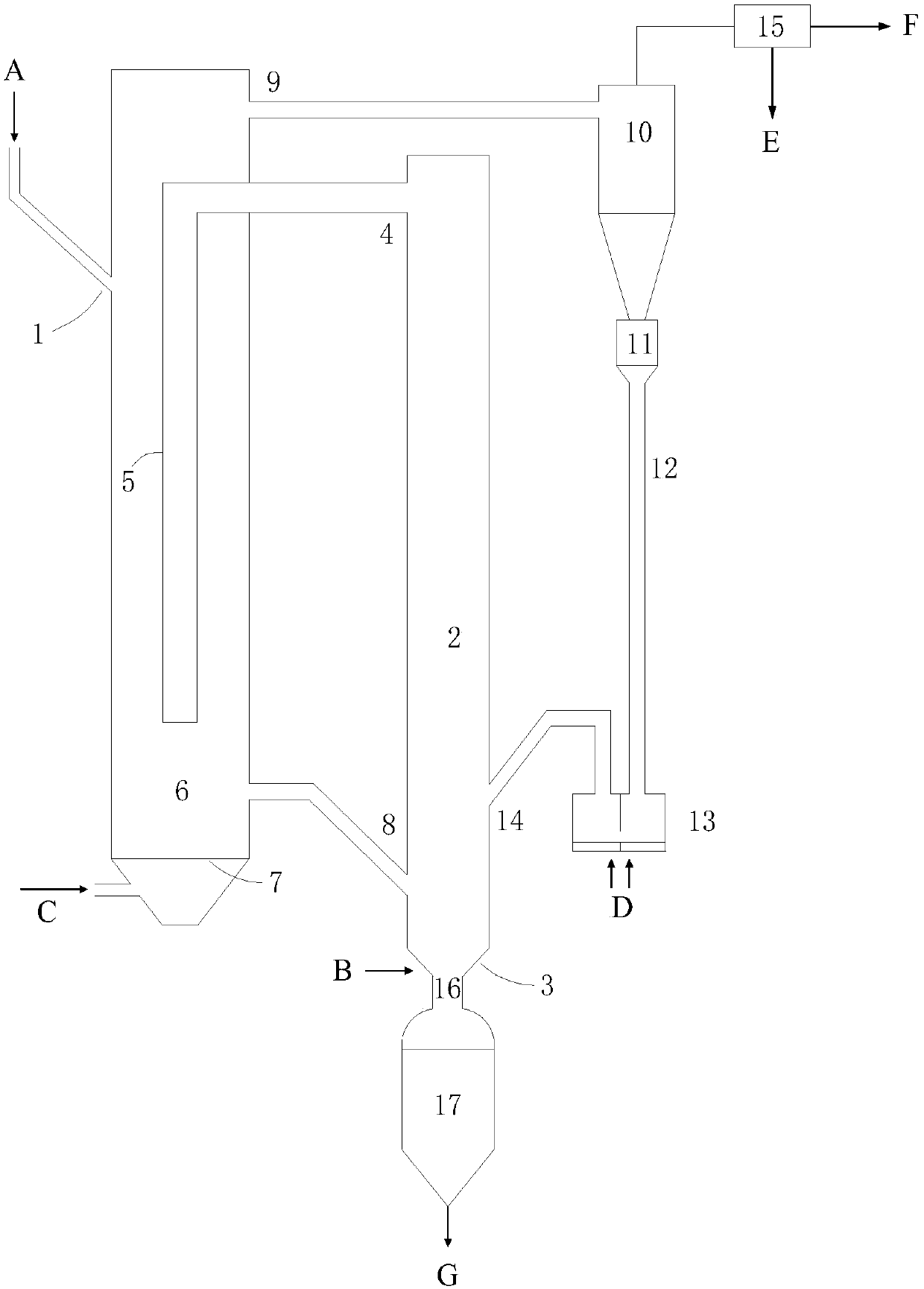

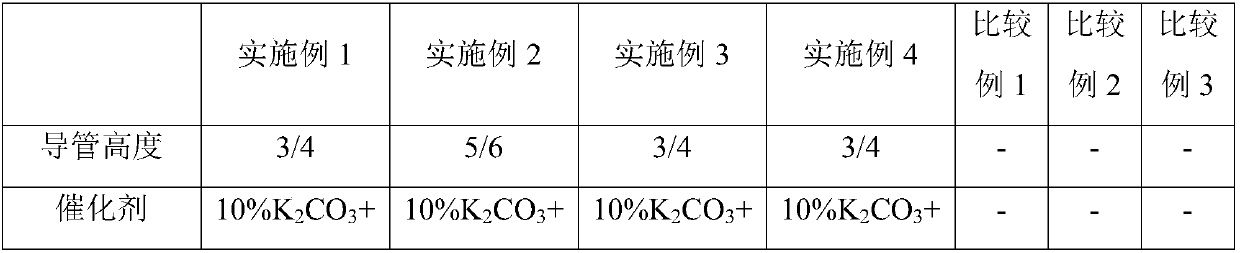

Apparatus and method for producing methane-rich synthesis gas through efficient coal catalytic gasification

ActiveCN107760384AHigh equilibrium concentrationTake advantage ofGasification processes detailsBulk chemical productionCatalytic pyrolysisSyngas

The invention relates to an apparatus and a method for producing methane-rich synthesis gas through efficient coal catalytic gasification. A purpose of the present invention is to solve the problems of low carbon conversion rate, low gasification intensity, low methane yield, high energy consumption and poor gasification furnace operation stability in the prior art. The apparatus comprises a fluidized bed gasification furnace and a fluidized bed pyrolysis methanation furnace, wherein a raw material inlet is positioned on the upper portion of the fluidized bed pyrolysis methanation furnace, thebottom portion of the fluidized bed pyrolysis methanation furnace is connected to the bottom portion of the fluidized bed gasification furnace, and a synthesis gas conduction pipe connected to the outlet above the fluidized bed gasification furnace extends into the bottom portion of the pyrolysis methanation furnace. The method mainly comprises that a catalyst-loading coal sample and high-temperature synthesis gas are subjected to a catalytic pyrolysis and methanation reaction in the fluidized bed pyrolysis methanation furnace, the semi-coke particles obtained after the pyrolysis and fly ashparticles enter the fluidized bed gasification furnace, and a combustion gasification reaction is performed. With the technical scheme of the present invention, the problems in the prior art are wellsolved. The apparatus and the method of the present invention can be used for the coal-to-methane-rich synthesis gas field.

Owner:CHINA PETROLEUM & CHEM CORP +1

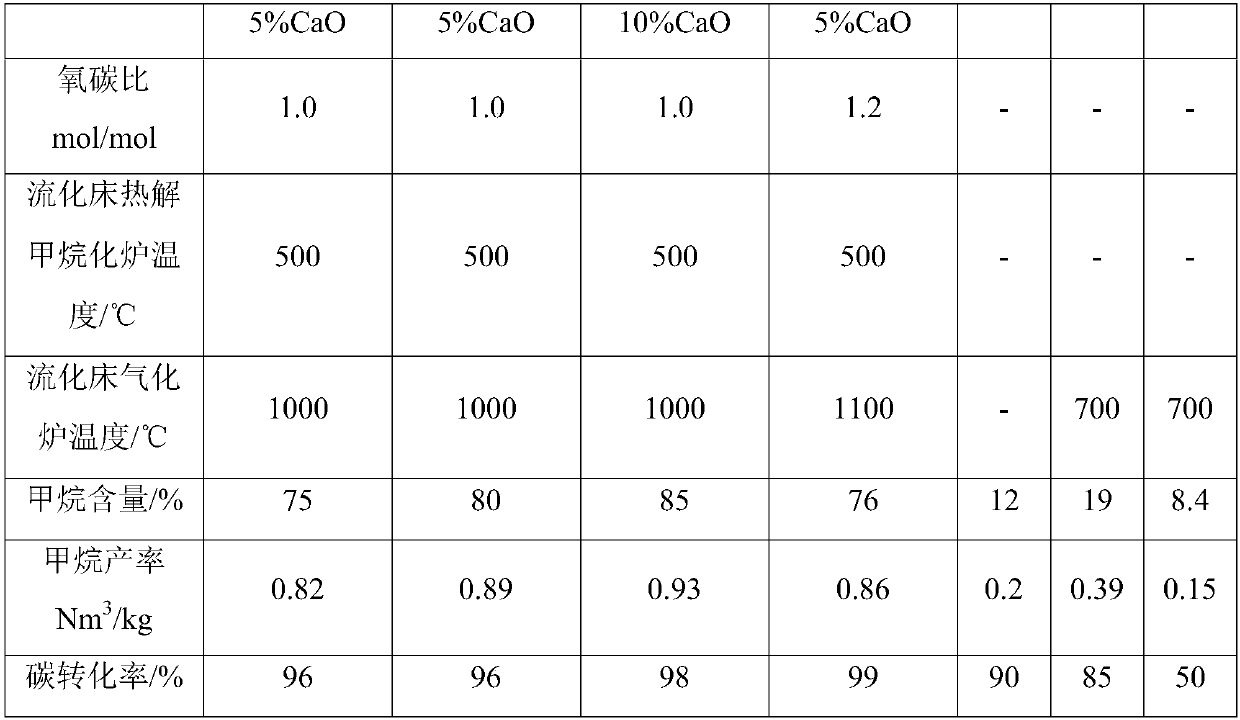

Biomass gasifier and gas preparation method thereof

InactiveCN101654631ANo pollution in the processIncrease gas calorific valueCombined combustion mitigationGasification with fuel pre-distillationFiltrationEngineering

The invention provides a biomass gasifier and a gas preparation method thereof, and the gasifier comprises a feeding cabin, a master / slave furnace, a primary filter connected with a master / slave furnace pipeline, a cooler, a vacuum pump, a desulfurizer, a fine filter, a coke filtering device, a coke accumulating tank and a water pool. The preparation method comprises the following steps: lifting biomass fuel into the feeding cabin; leading the fuel into a master furnace by the feeding cabin through a closed feeder; carrying over cracking catalyst in a jacket of the master furnace; cracking a large number of tar oil through the master furnace; carrying out dustfall on high-temperature subpressure gas; carrying out secondary dustfall through the primary filter; cooling gas at the temperatureof 300 DEG C through the cooler; lowering the temperature below 30 DEG C after circulation cooling; desulfurizing through the desulfurizer, filtering through the fine filter and entering a gas storing device through a control system; feeding in the coke filtering device for further filtering out tar oil and vegetable wax liquid after constant-temperature storing through the gas storing device; and finally supplying qualified gas for users. The invention can crack tar oil, enhance gas heat value, separate tar oil from cooling water, have no pollution on water and environment due to multistagefine filtration of smoke dust, and is applicable to gas supply of biomass gas coke.

Owner:LIAONING SUNRISE BIOMASS ENERGY

Direct-fired half-gasification downdraft type full-gasification multifunctional straw furnace

InactiveCN102052691ANovel structureSimple structureDomestic stoves or rangesLighting and heating apparatusCombustible gasTar

The invention relates to a direct-fired half-gasification downdraft type full-gasification multifunctional straw furnace, belonging to the technical field of cooking and warming equipment. The furnace is innovatively characterized by the invention of a duplex circulative purification device, wherein the device comprises a horizontal slope cross board, a vertical cross board, a staggered round hole and a round disk-type drier purifying mechanism. The furnace is further innovatively characterized by the design of a triple ash cleaning device which can clean furnace ash thoroughly, conveniently and fast. The straws of crops are utilized to produce a combustible gas, the combustible gas is circularly purified and filtered to remove impurities and tar and further enhance the quality of fuel gas and improve cooking and warming effects, thus, the environmental pollution is reduced, and the problems of the traditional gasification furnaces that the quality of the produced gas is poor, the emission of waste gas is too much, the furnace is not available during power failure and in case that the straw is wet, the tar is difficult in processing and the combustible gas has peculiar smell are solved. The straw furnace of the invention realizes stable gas production, good availability during power failure and in case that the straw is wet, good quality of fuel gas, no peculiar smell in the combustible gas, no pollution and the like, can be extensively applied to household cooking, water heating, warming and the like in urban and rural areas, and has extremely wide market prospect.

Owner:宋忠红

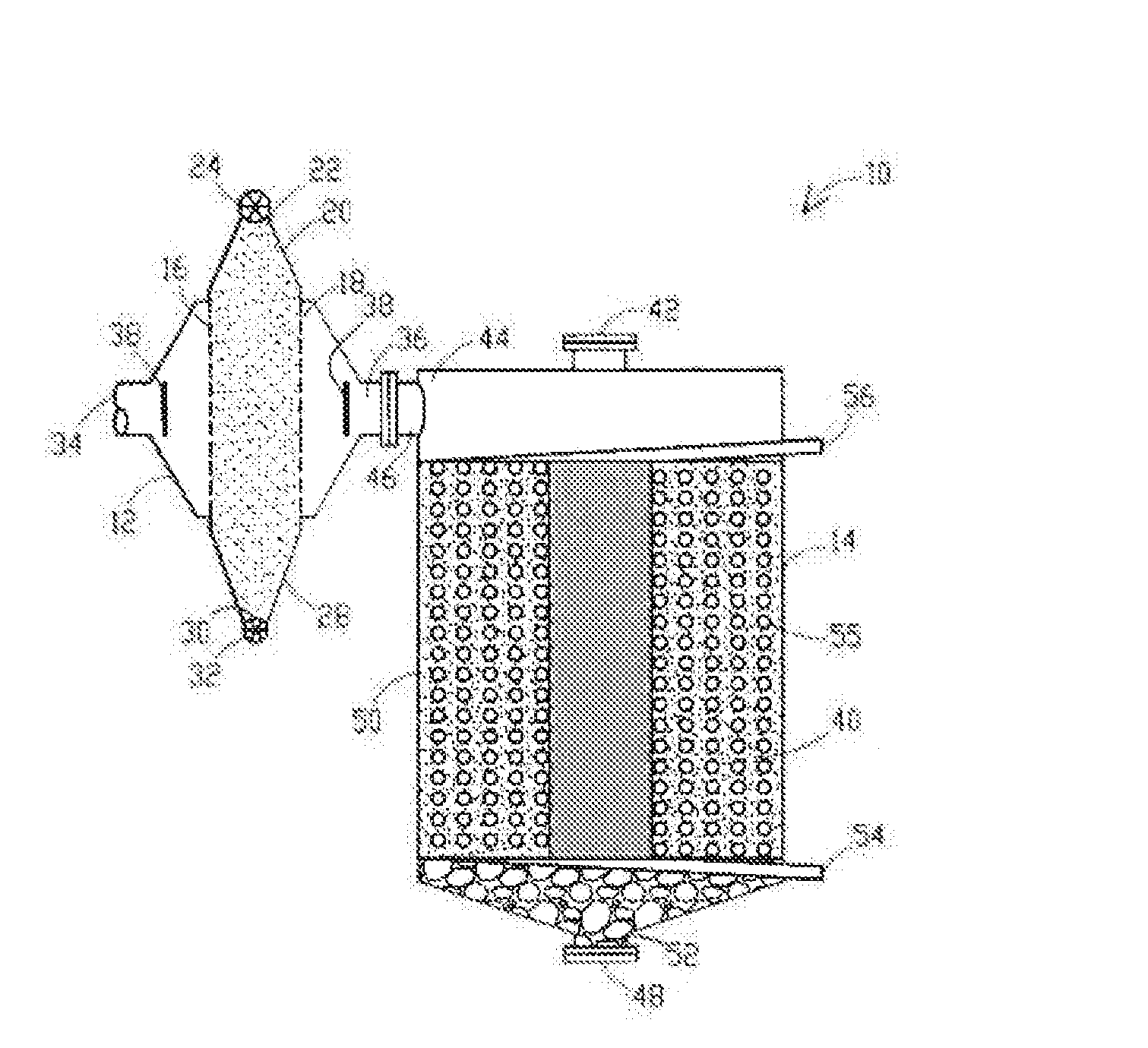

Process and Apparatus for Cleaning Raw Product Gas

ActiveUS20160304345A1Reduce the temperatureGas treatmentHydrogen separation using solid contactProduct gasFine particulate

The present disclosure provides a process for cleaning raw product gas. The process includes contacting the raw product gas with a flow of catalyst to reform organic contaminants and inorganic contaminants in the raw product gas and to remove particulates. Further, the process includes cooling the resulting product gas via heat exchange with a heat exchange medium in the presence of char or a solid adsorbent medium to condense remaining organic contaminants and inorganic contaminants on the char or solid adsorbent medium and to filter out fine particulates.

Owner:RENERGI PTY LTD

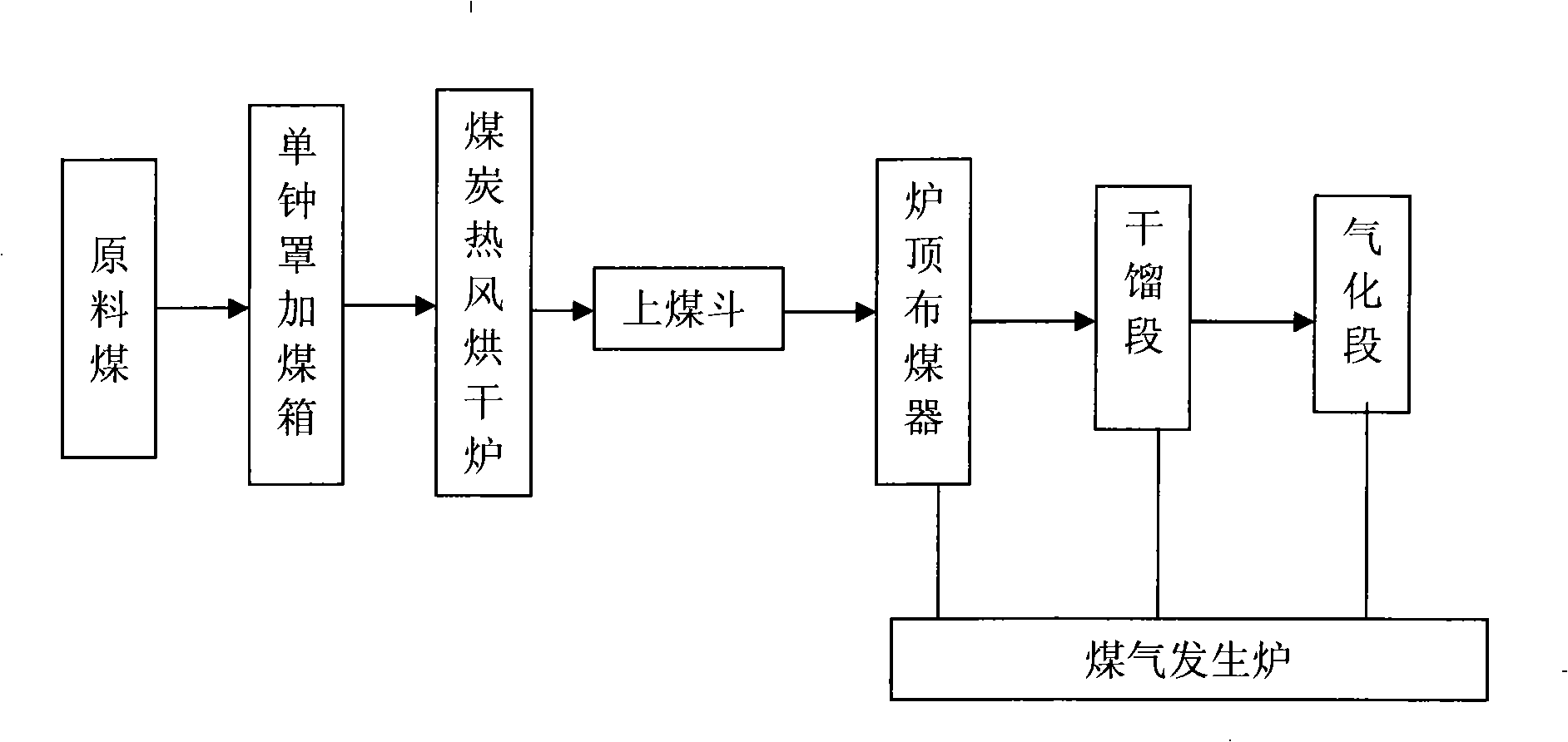

Normal pressure non-phenol method for fixed-bed gas producer

InactiveCN101280224AReduce moisture contentHigh calorific valueGasification with fuel pre-distillationFixed bedPhenol

The invention belongs to the coal gas generation filed, in particular to a normal pressure non-phenol method of the fixed bed coal gas generator; the technical proposal includes that the method includes the steps of dry distillation segment process and gasification segment process in the coal gas generator; the raw coal is dried before the raw coal is fed into the coal gas generator; 95 % water contained in the raw coal is removed through high temperature by the process method before the raw coal is fed into the coal gas generator; finally, the water content of the generated coal gas is lowered greatly; thereby, the generation quantity of the phenol is reduced obviously.

Owner:ZOUPING COUNTY HUAXING HEAT ENERGY ENVIRONMENT PROTECTION EQUIP

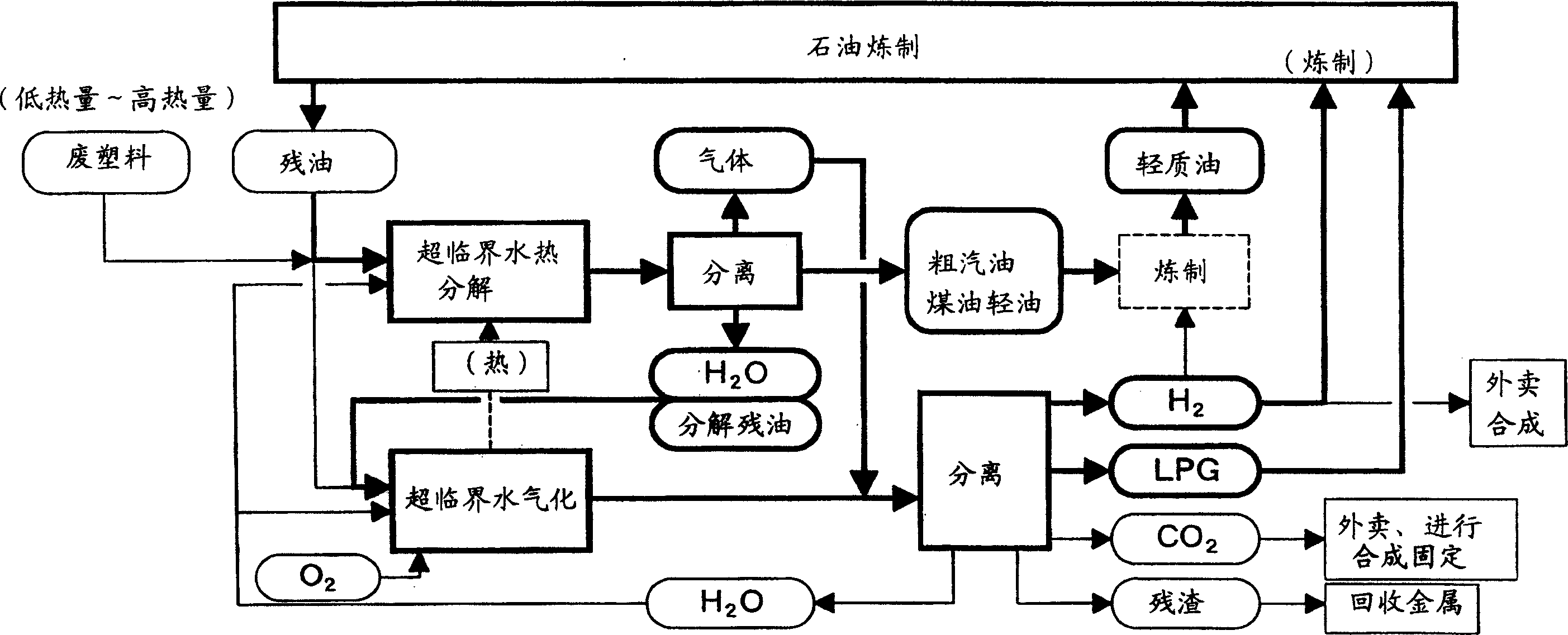

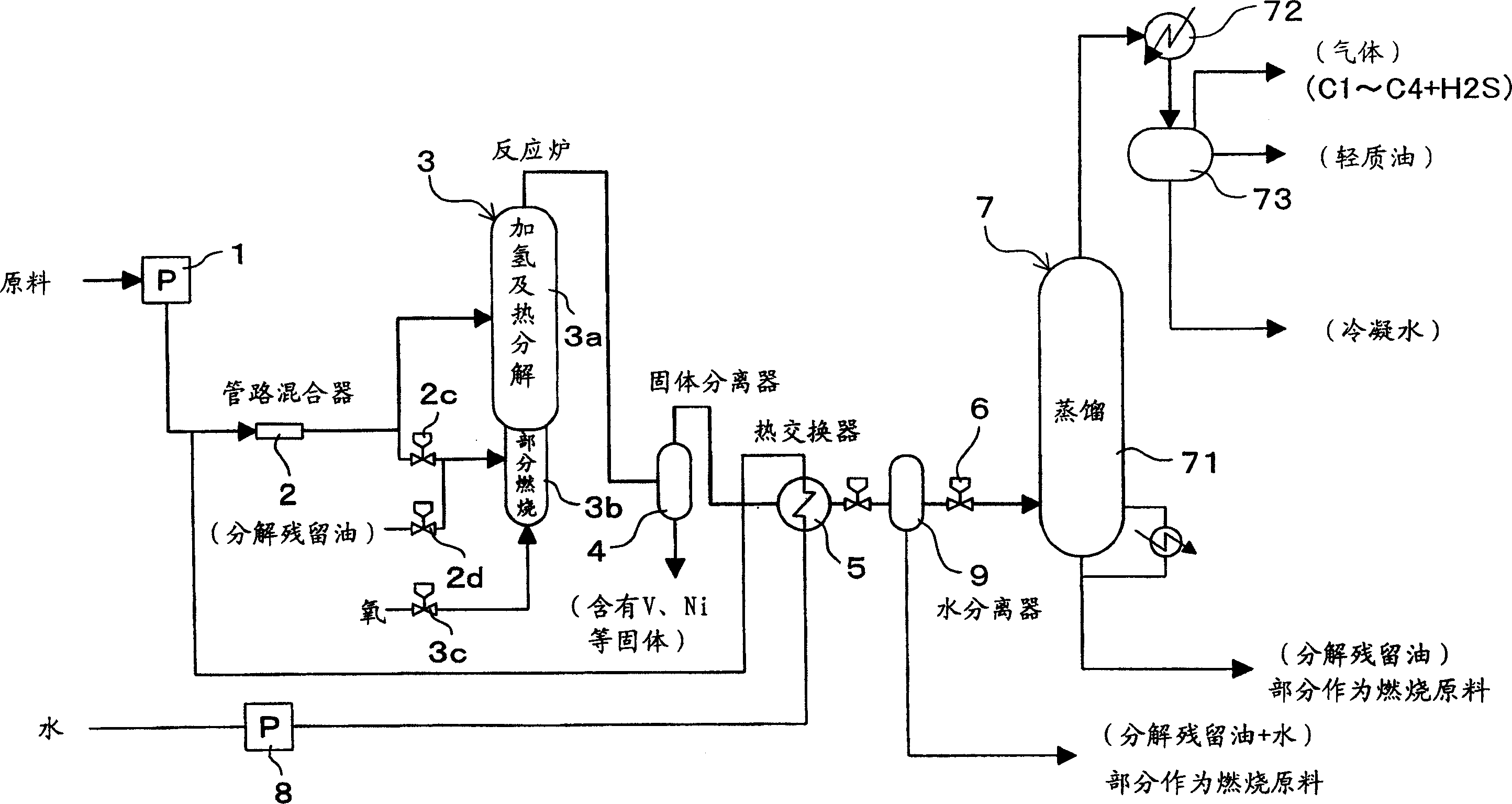

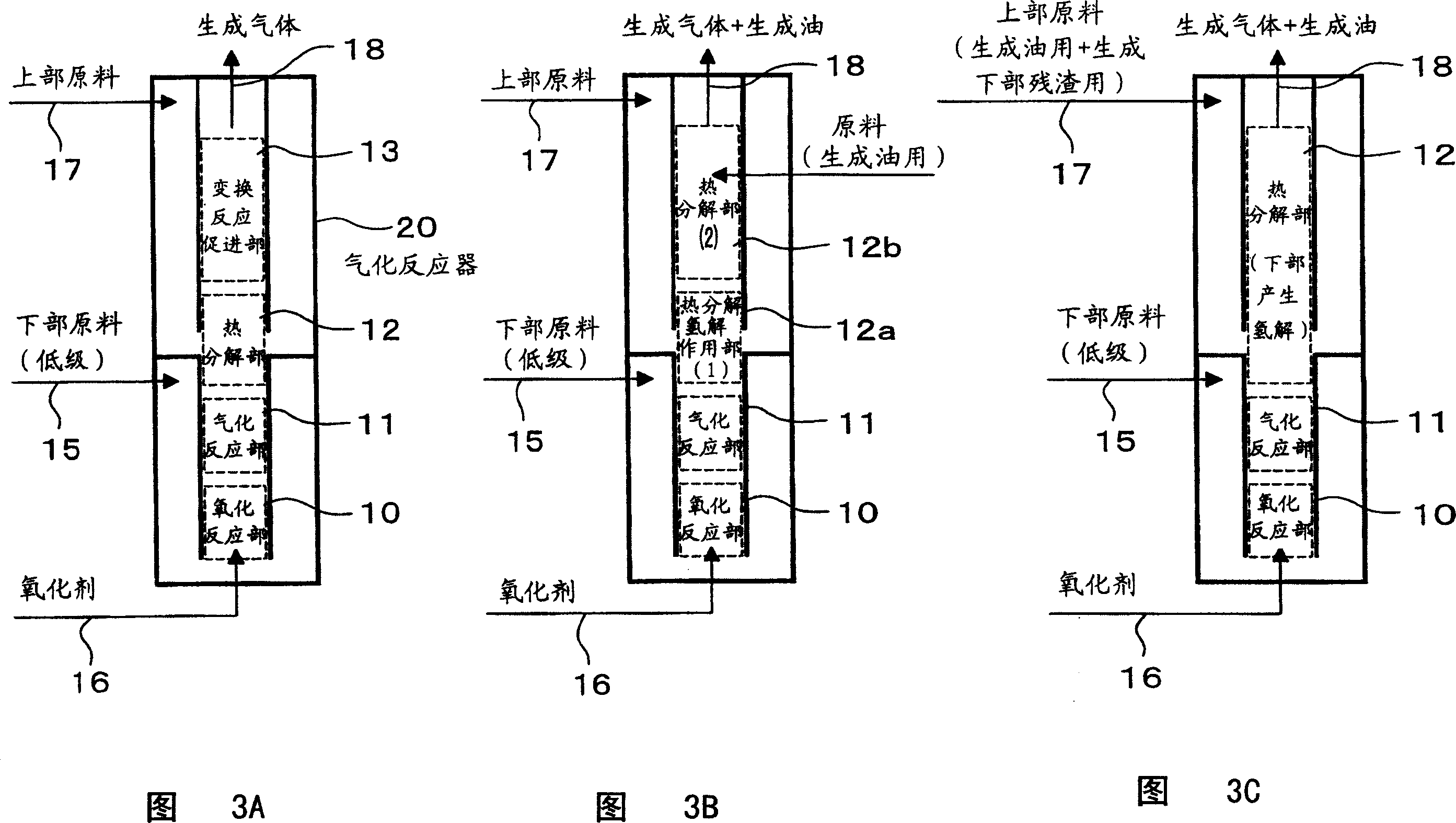

Method and apparatus for recycling hydrocarbon resource

InactiveCN1639056ALow costReduce consumptionThermal non-catalytic crackingGasifier feeding meansMetal impuritiesHigh pressure

The present invention provides a method and an apparatus for effectively performing thermal decomposition without using a catalyst and without supplying hydrogen from the outside, and improving the yield of oil components and pyrolysis gas. In the present invention, the raw material can be fully utilized by gasifying the residue components generated by thermal decomposition to form combustible gas. Furthermore, the present invention provides a method for separately separating metal impurities contained in a raw material as a solid, and is a novel method and apparatus capable of improving availability as resources. In a preferred form of the present invention, nozzles (raw material supply mechanism, oxidant supply mechanism, water supply mechanism) (103) are provided in the reaction vessel (102), and a heat exchanger (104) is provided to A high-temperature and high-pressure generated gas is introduced between the pressure vessel (101) and the reaction vessel (102), and the high-temperature and high-pressure generated gas is generated by reacting oxygen in the raw material and the oxidant in the reaction vessel (102) under water atmosphere conditions. , the pressure vessel (101) is provided with a water inlet (114) communicated with the water supply pipeline (106), and is provided with a discharge pipeline (105) for inserting the generated gas communicated with the heat exchanger (104). ), and a flow path for supplying water between the pressure vessel (101) and the reaction vessel (102) into the reaction vessel (102) is provided in the nozzle (103).

Owner:MITSUBISHI MATERIALS CORP

Garbage pyrolysis system and method

PendingCN106978214AReduce gasification energy consumptionReduce energy consumptionGasification processes detailsGasification with fuel pre-distillationHeat carrierLitter

The invention discloses a garbage pyrolysis system and method. The system includes a garbage pretreatment unit, a pyrolysis furnace, a red mud pretreatment unit, and a carbon gasification unit; the red mud pretreatment unit includes a red mud dryer and a red mud crusher; the garbage particle outlet of the garbage pretreatment unit is connected to a thermal The feed port of the furnace, the dry red mud outlet of the red mud dryer is connected to the dry red mud inlet of the red mud crusher, the red mud particle outlet of the red mud crusher is connected to the feed port of the pyrolysis furnace, and the The discharge port is connected to the pyrolysis charcoal inlet of the charcoal gasification unit. The invention uses red mud as a heat carrier to pyrolyze garbage, reduces pyrolysis energy consumption, improves the pyrolysis gasification rate of garbage, and avoids the problem of tar blockage.

Owner:BEIJING SHENYUAN ENVIRONMENTAL PROTECTION CO LTD

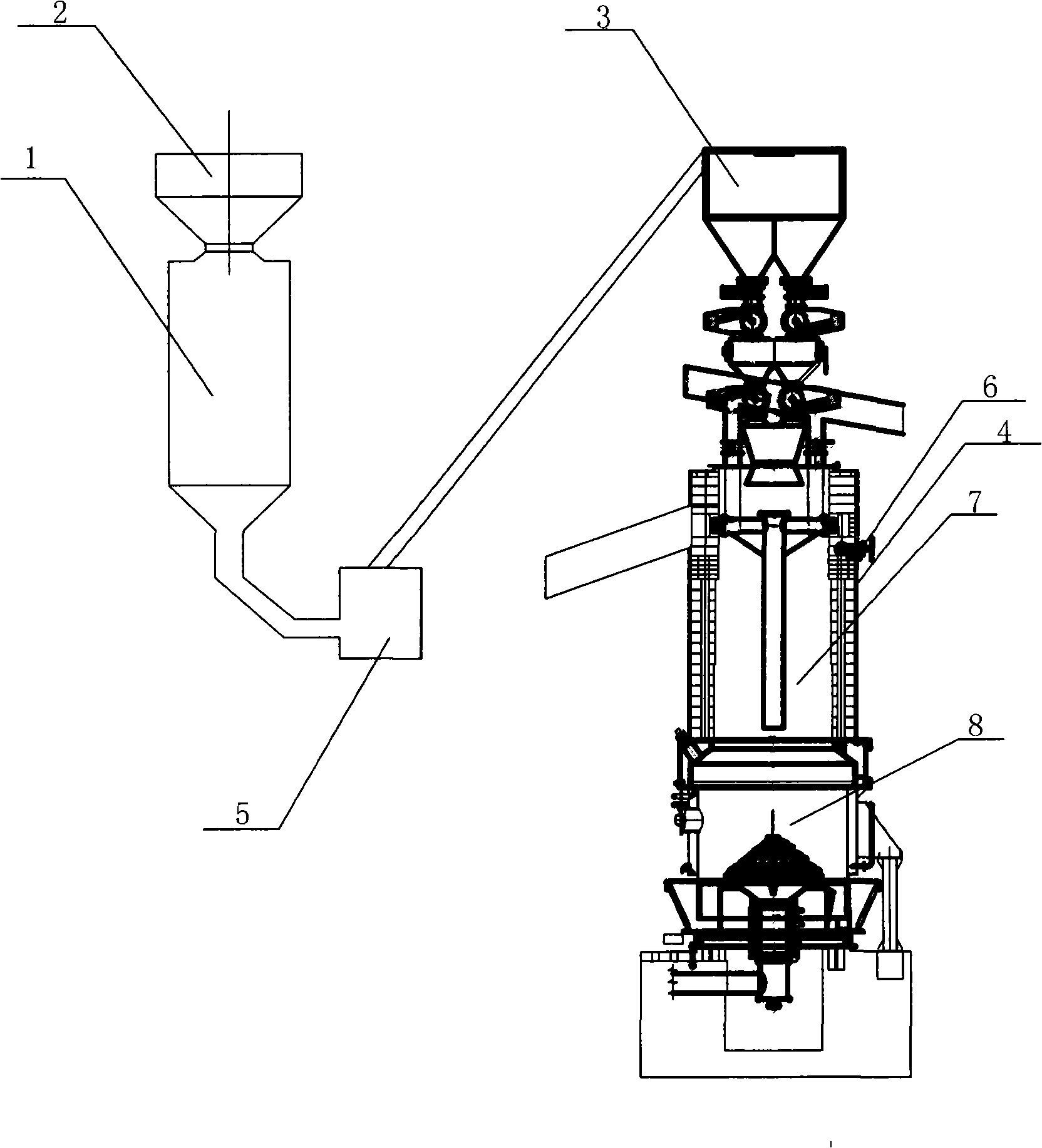

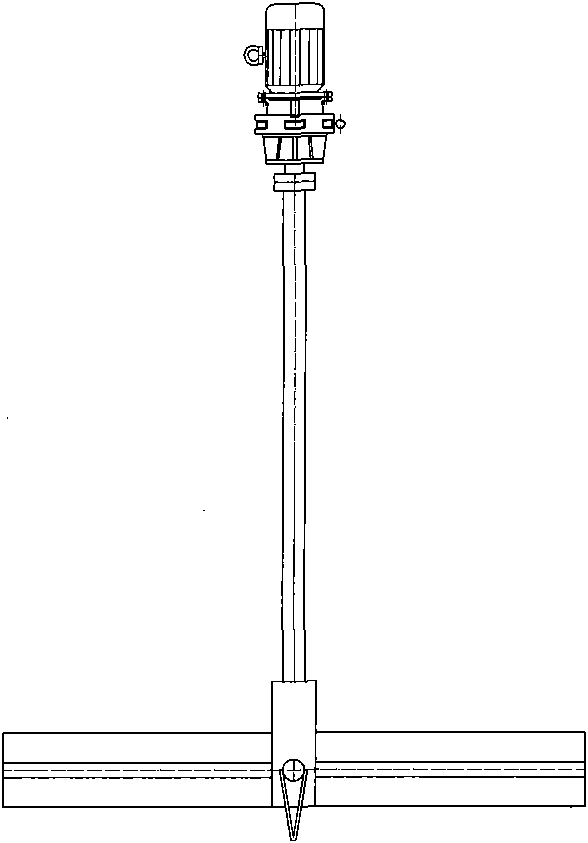

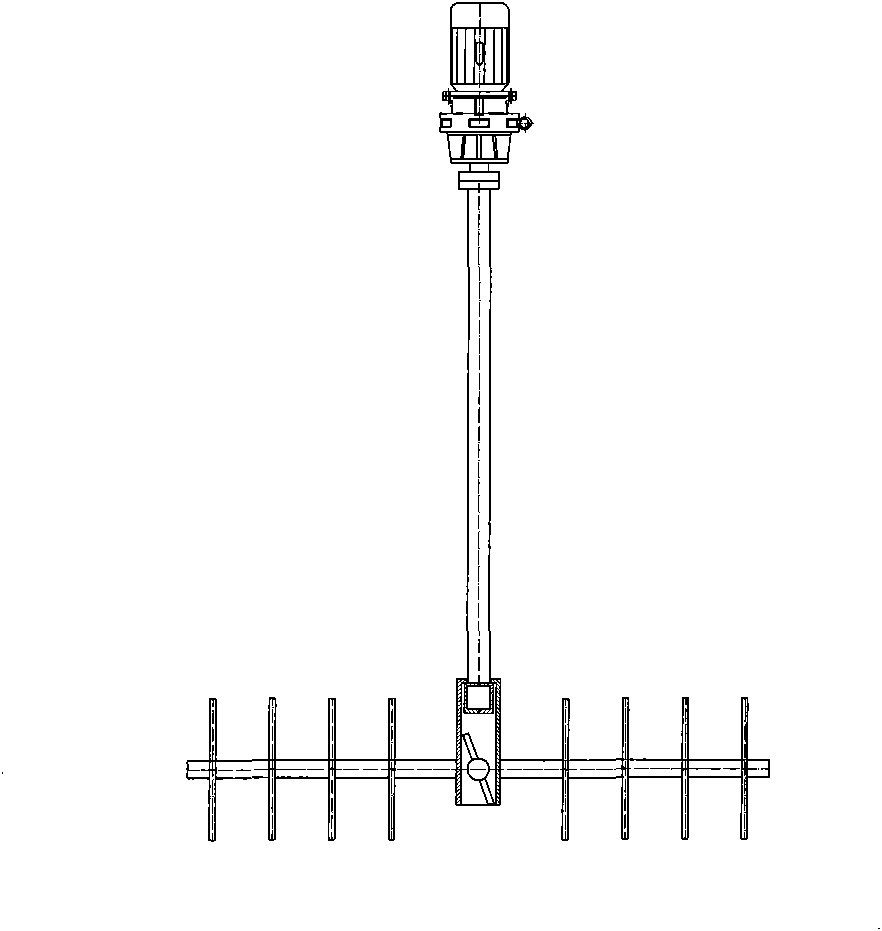

Tobacco stem waste gasification system device and production technology thereof

InactiveCN101592335ASolve runnabilitySolve pollutionCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelTarEngineering

The invention discloses a tobacco stem waste gasification system device capable of continuously operating without secondary pollution. The device comprises a raw material bin, the lower end of the raw material bin is provided with a belt conveyor, the tail end of the belt conveyor is provided with a material lifting machine and is erected on the top of a hopper of the material lifting machine, a discharge outlet of the material lifting machine is connected with a gasification furnace through a pipeline, a fuel preheating pipe is arranged above the pipeline, the upper end of a feed inlet of the gasification furnace is provided with a safe discharge pipe, the other three sides of the top of the gasification furnace are provided with gasification furnace operation ports, the center of the top of the gasification furnace is provided with a kick-out device, the lower end of the kick-out device is provided with parallel switch-plates, the lower end surfaces of the switch-plates are vertically fixed with target pins, the lower parts of the target pins are a gasification cavity of the gasification furnace, the lower part of the gasification cavity is provided with a tipping grate which is vertical to the axial surface of the gasification furnace, the center of the lower part of the tipping grate is provided with a secondary tar cracking bucket, and the top end of the secondary tar cracking bucket is connected with a first dust remover and an air inlet on one side of the upper end of the first dust remover.

Owner:刘善华 +1

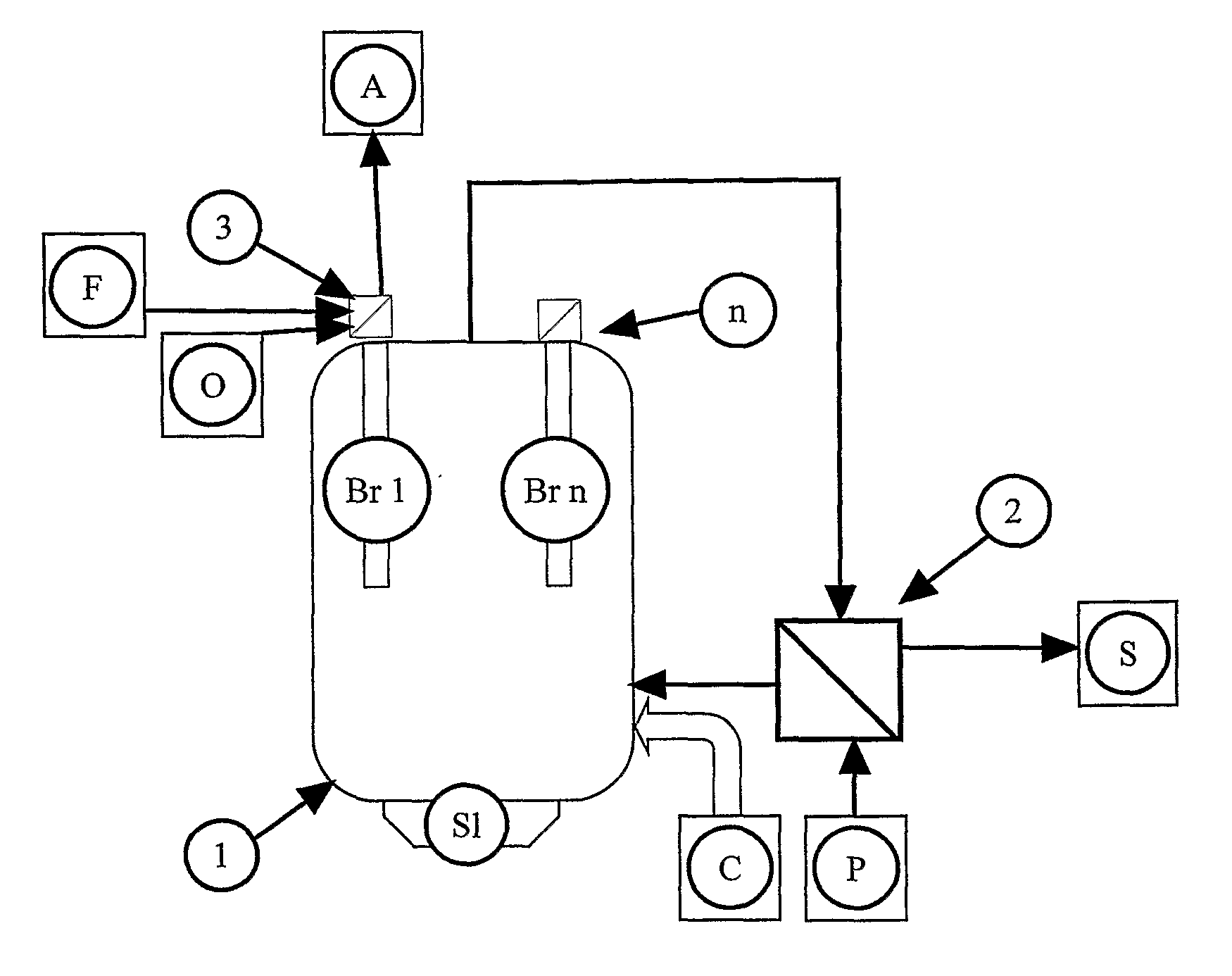

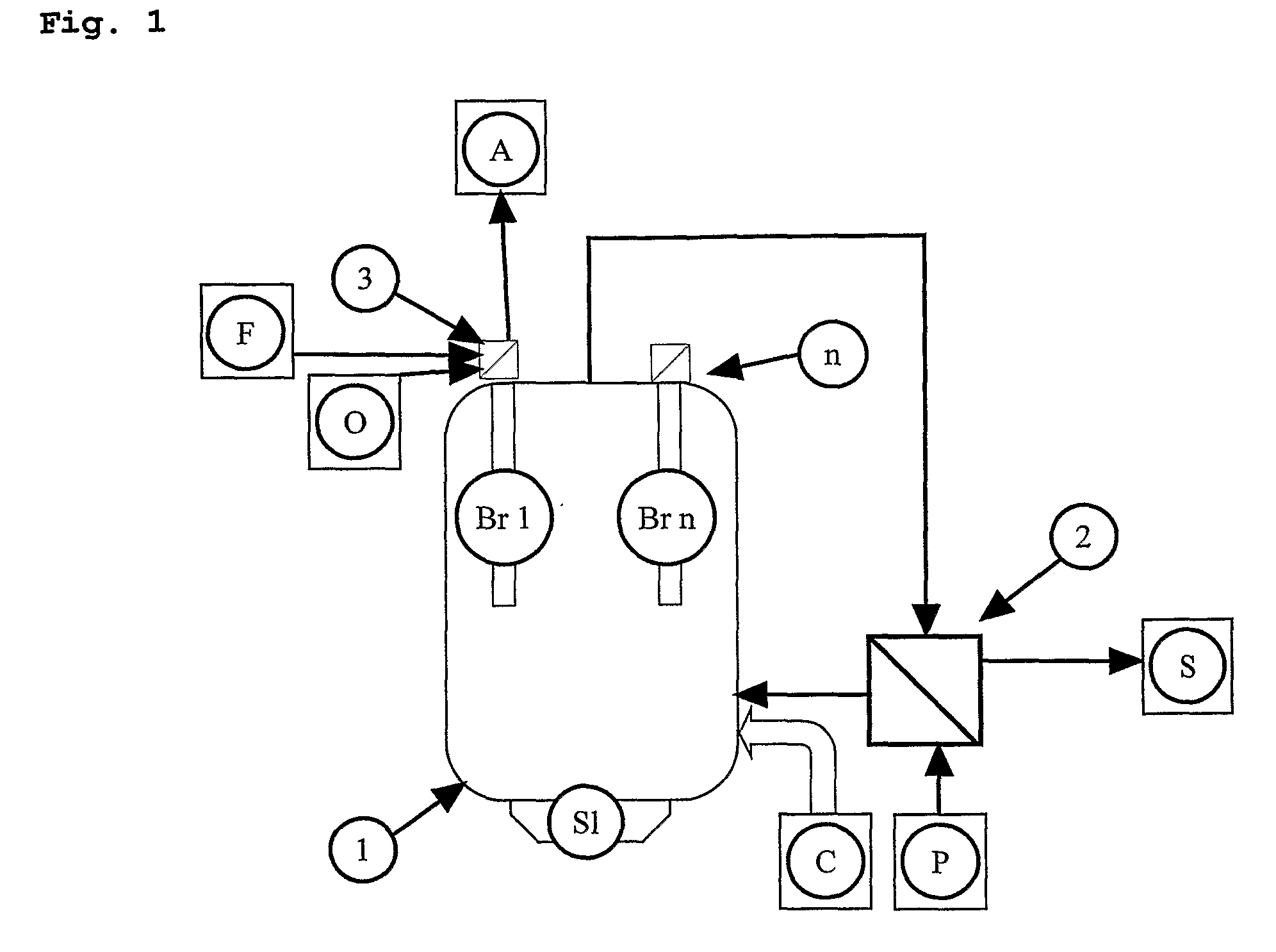

Method and equipment for producing synthesis gas

A method and equipment for producing synthesis gas (S) from solid carbon particles (C), the carbon particles (C) being obtained by pyrolysis, gasification of the carbon particles (C) occurs by indirect heating of the carbon particles (C) in the presence of a process gas (P) in the same space where the carbon particles (C) are present, and the synthesis gas (S) generated during the gasification is discharged from the space. The method is characterised in that the carbon particles (C) and the process gas (P) are located in a reactor (1), and the indirect heating occurs by way of radiant heat from burners (Br1-Brn) located in the reactor (1).

Owner:CORTUS AB

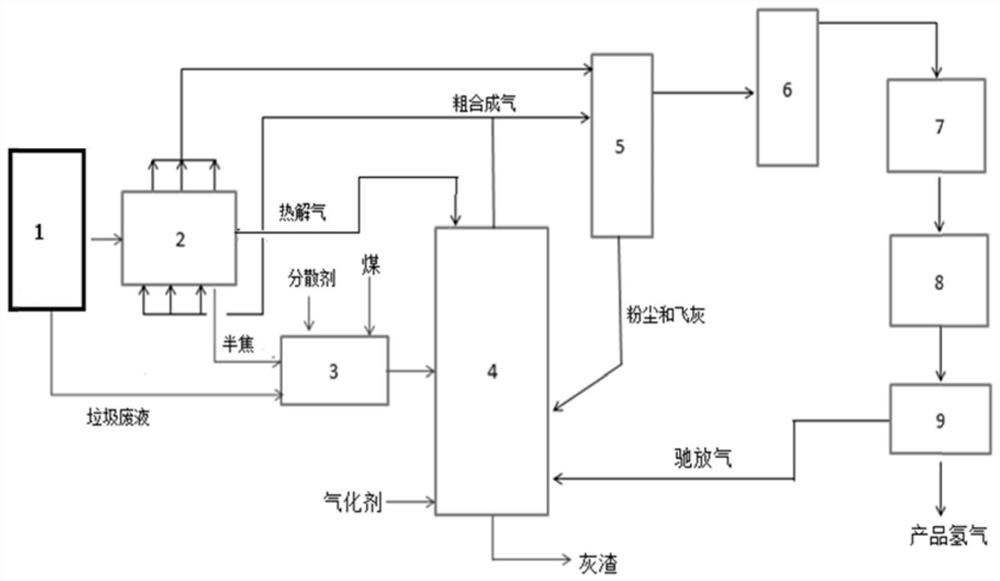

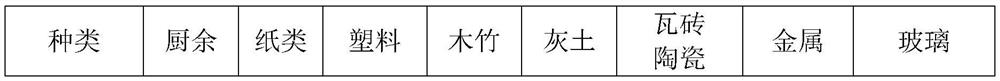

Method for producing hydrogen by converting municipal solid waste

PendingCN112143525APioneering reductionExploitationGasification processes detailsCombined combustion mitigationCoal waterSyngas

The invention relates to the field of municipal solid waste treatment, and discloses a method for producing hydrogen by converting municipal solid waste. The method comprises the following steps: (1)screening the municipal solid waste to remove incombustibles, and draining water to obtain waste liquid and a waste raw material; (2) feeding the waste raw material into a pyrolysis reactor for dryingand pyrolysis reaction to obtain garbage semicoke and pyrolysis gas; (3) mixing the garbage semicoke, the waste liquid, pulverized coal and a dispersing agent to prepare coal water slurry; (4) feeding the coal water slurry and the pyrolysis gas into a gasification furnace for gasification reaction to obtain crude synthesis gas and ash; and (5) indirectly exchanging heat between part of the crudesynthesis gas and the pyrolysis reactor to provide heat, then conducting mixing with the residual crude synthesis gas, and sequentially carrying out purification and shift reaction. According to the method provided by the invention, the difference of different municipal wastes can be reduced, the problem of secondary pollution caused by waste incineration is solved, harmless and full resourceful treatment of municipal domestic wastes is realized, and meanwhile, large-scale, rapid and low-cost preparation of hydrogen can be realized.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com