Patents

Literature

121results about How to "Increase gas calorific value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-efficiency lignite low-temperature dry distillation quality-enhancing process by using dry distillation coal gas as heat-carrying medium

InactiveCN101812310AReduce in quantityEfficient use ofCoke quenchingChemical industryEconomic benefitsTar

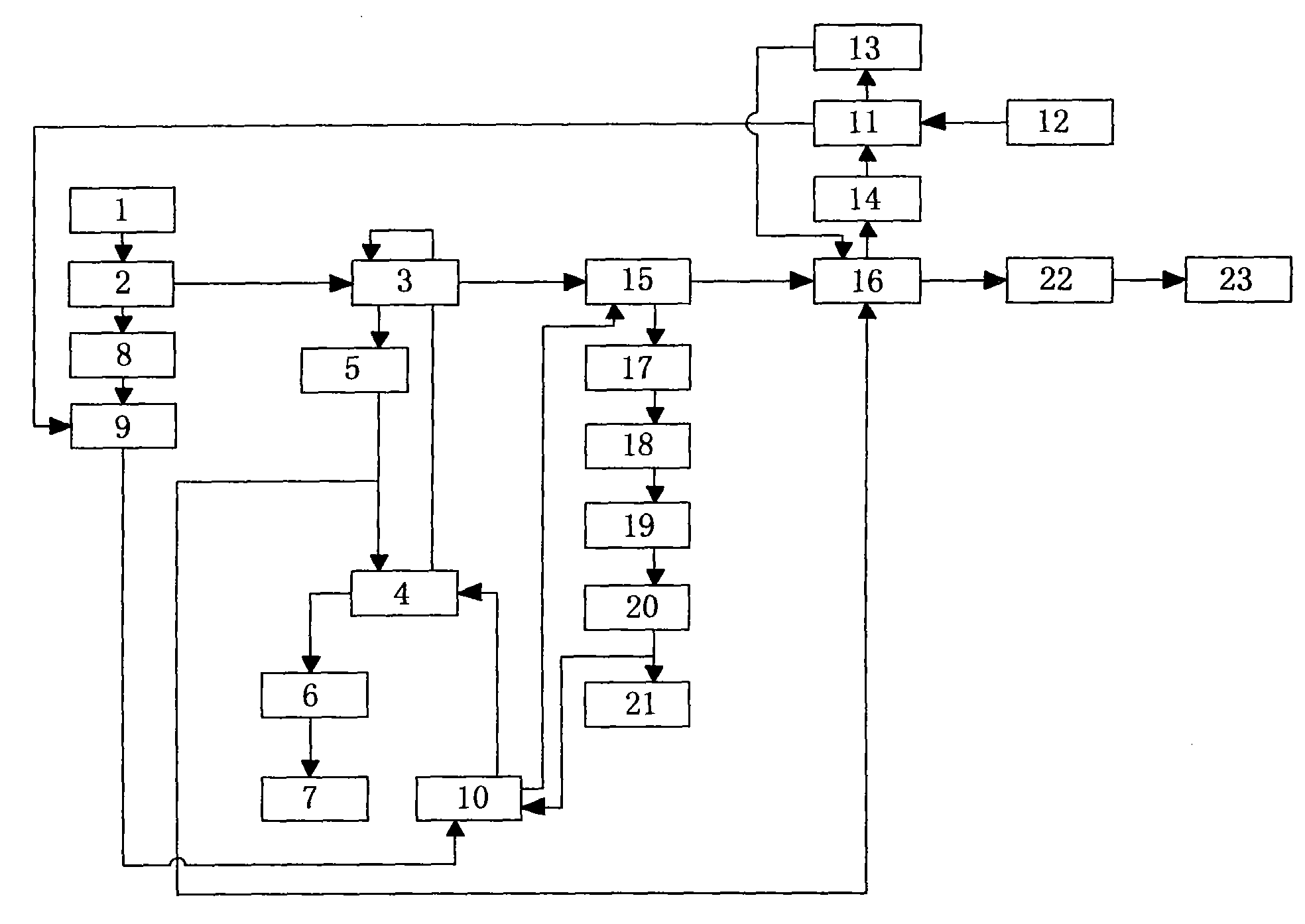

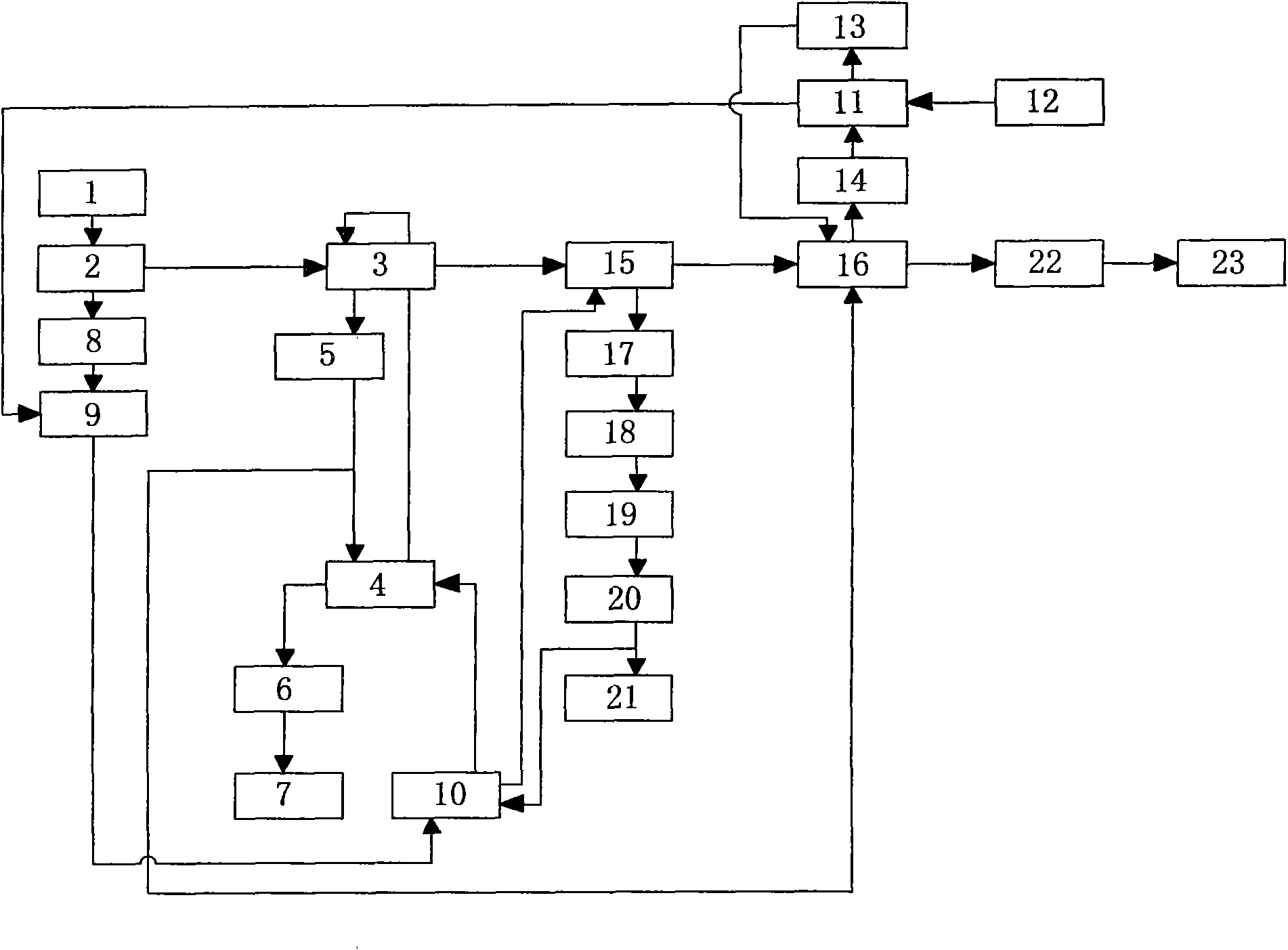

The invention relates to a low-temperature dry distillation process for coal, in particular to a high-efficiency lignite low-temperature dry distillation quality-enhancing process by using dry distillation coal gas as a heat-carrying medium. The process comprises a coal-preparing flow, a drying flow, a dry distillation flow, a heat source flow, a coal gas and tar processing flow and a semicoke cooling transfer flow; in the process, vapor self-generated by a drying tower is used as a drying medium, the coal gas of a generator is taken as a heat source to heat the self-generated dry distillation coal gas, and serves as a dry distillation medium, and the coal gas of the generator is used as fuel of a hot air furnace; the dry distillation semicoke is cooled in a cooling mode of drying fume exhaust plus semi water spraying; and condensation water is used for coke-quenching water, a gasifier of the coal gas of the generator and a tar cooling agent. The process has the advantages of producing high-index dry coal and dry semicoke, high-heating value coal gas and high-quality tar, having a flawless and high-efficiency energy recycling system, not using outside nature water, hardly discharging water to the outside, saving huge cost for sewage treatment, creating the maximum economic benefits for customers and having quite strong competitive power on economy, technology and market.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

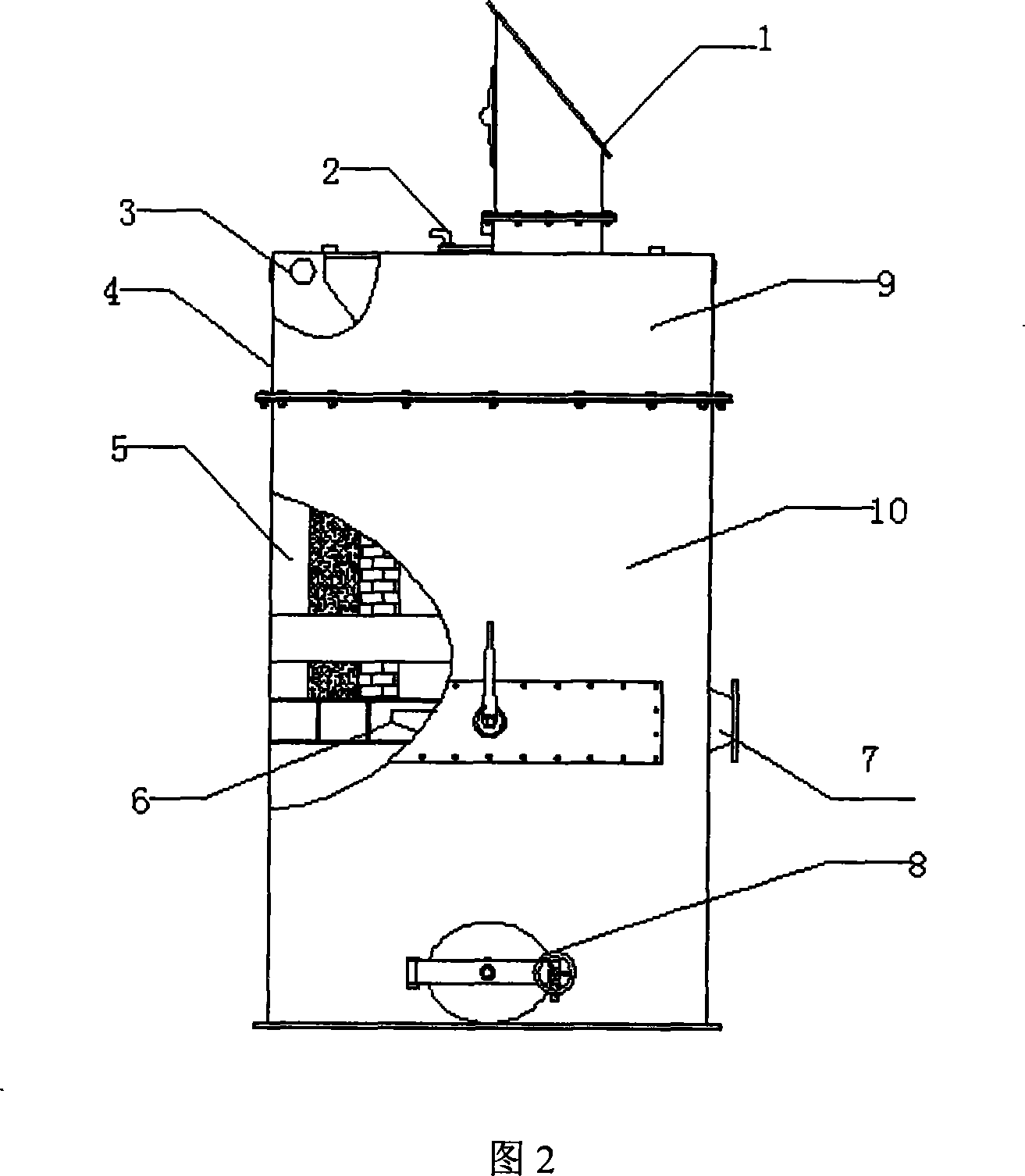

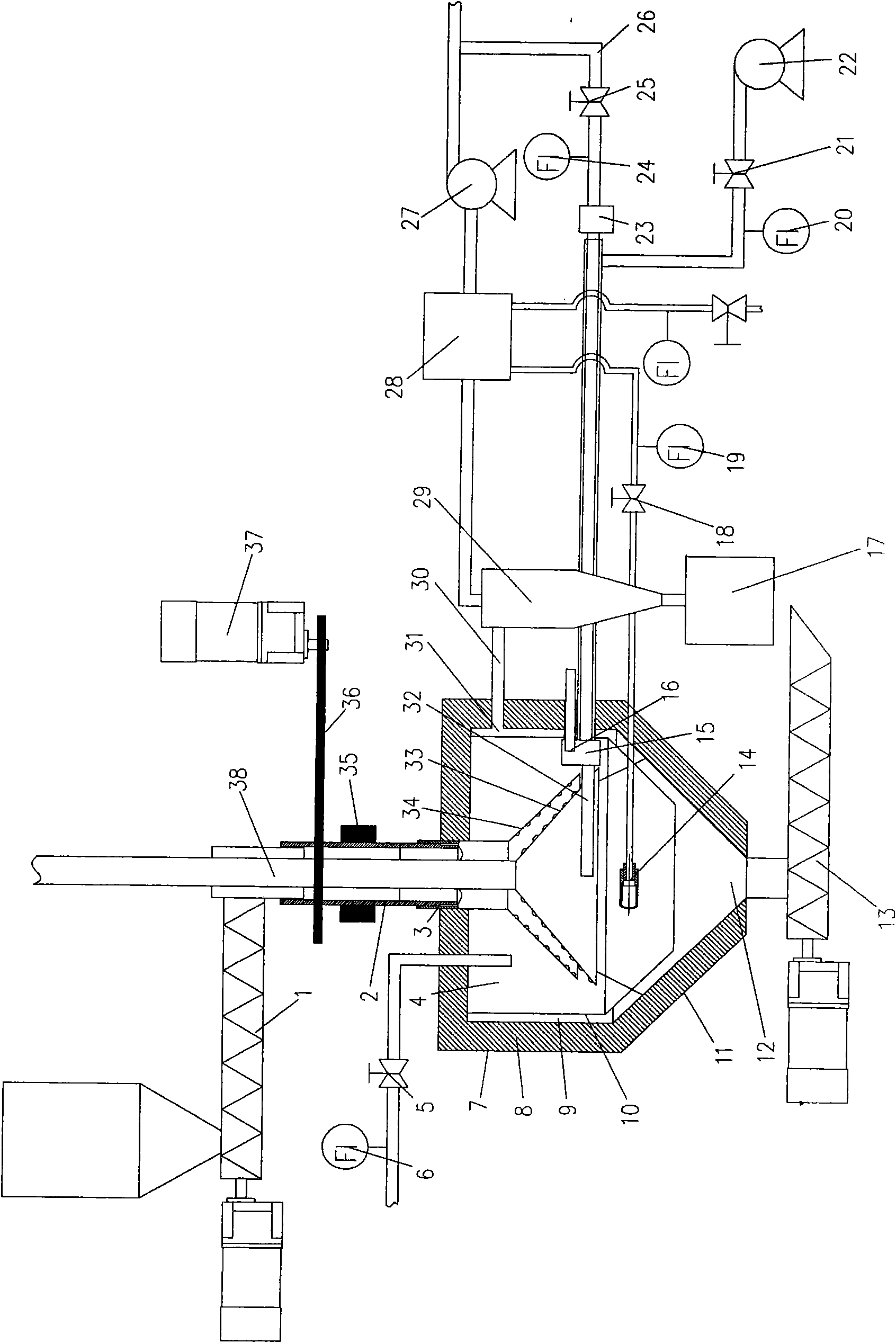

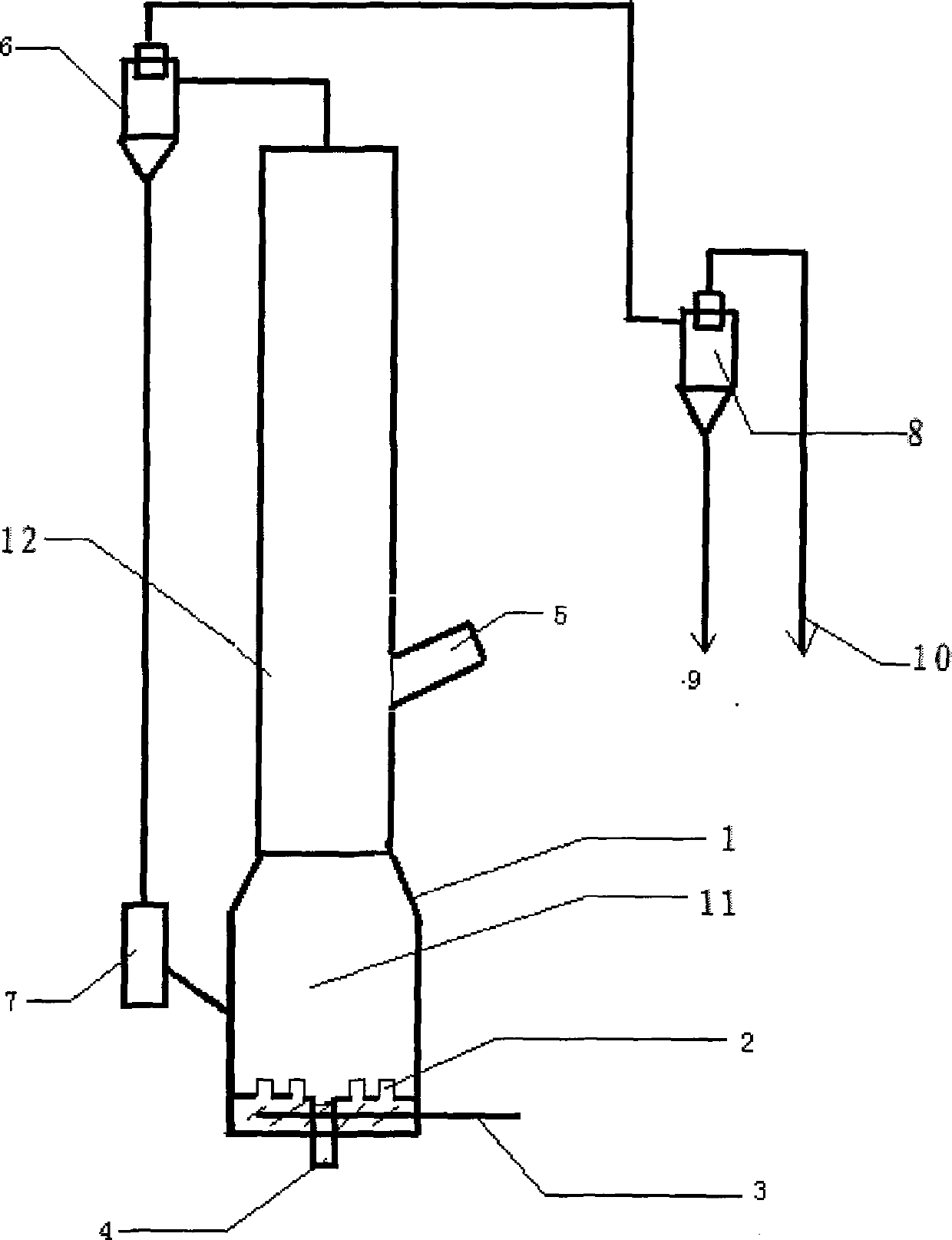

Internal-combustion heating type biomass gasification furnace

ActiveCN101021334AImprove biomass gasification rate and gas calorific valueImprove gasification efficiencyDomestic stoves or rangesLighting and heating apparatusNitrogen gasEngineering

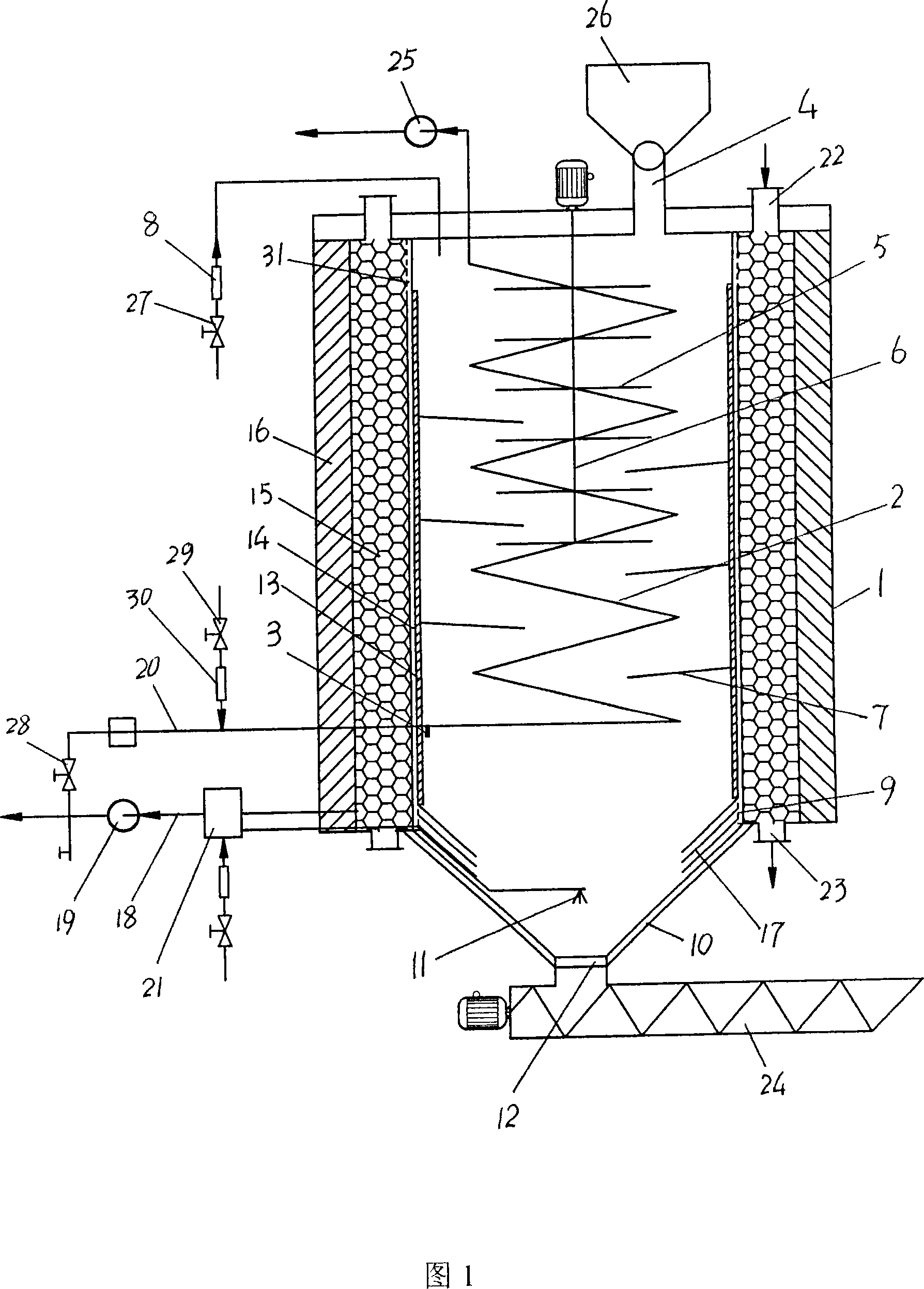

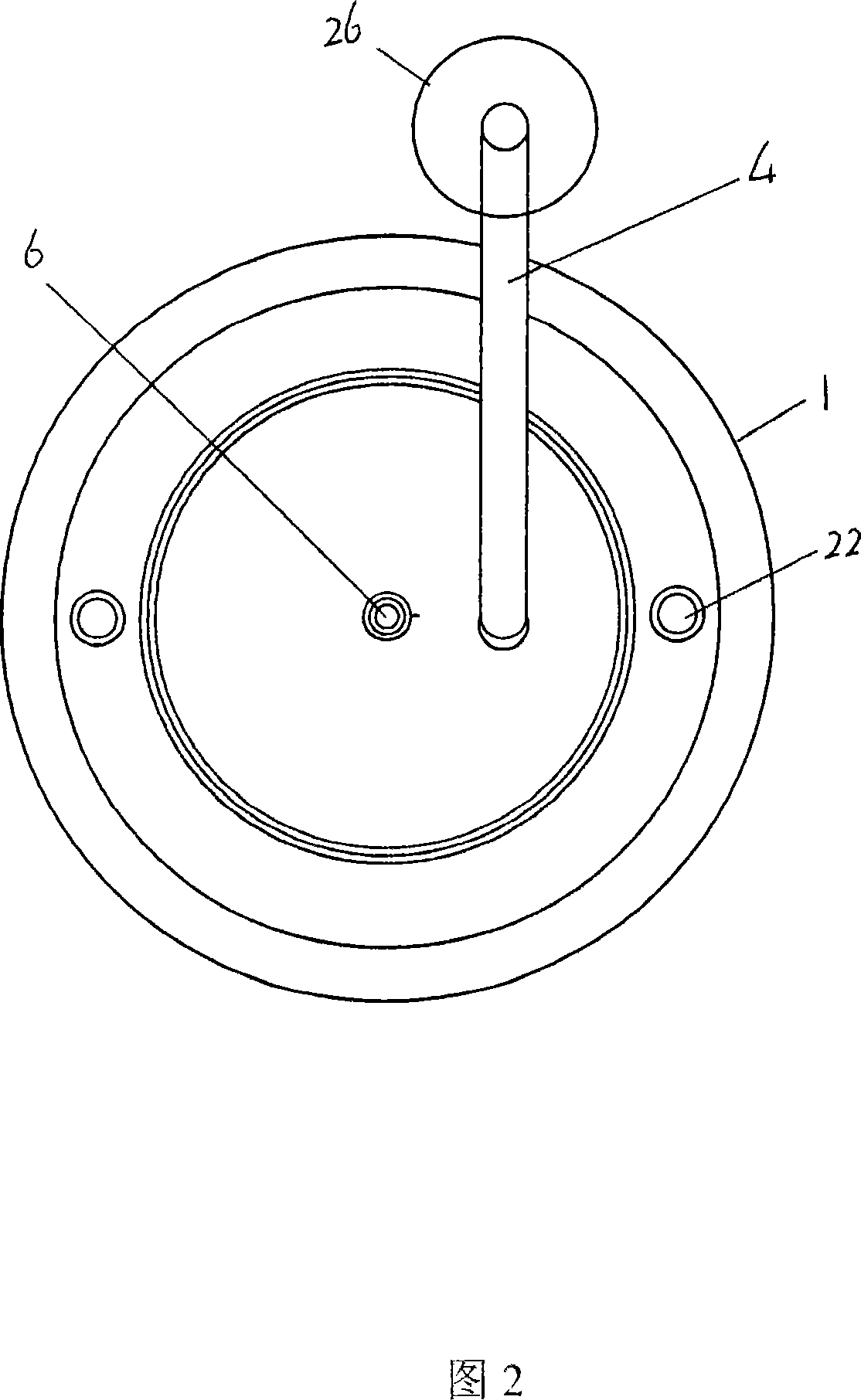

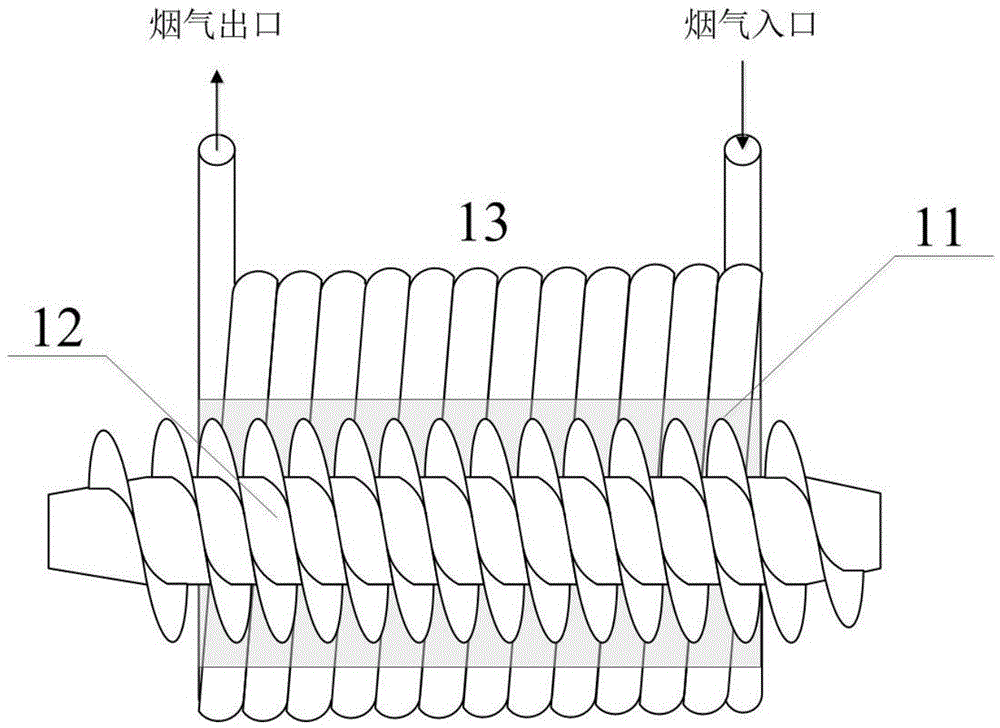

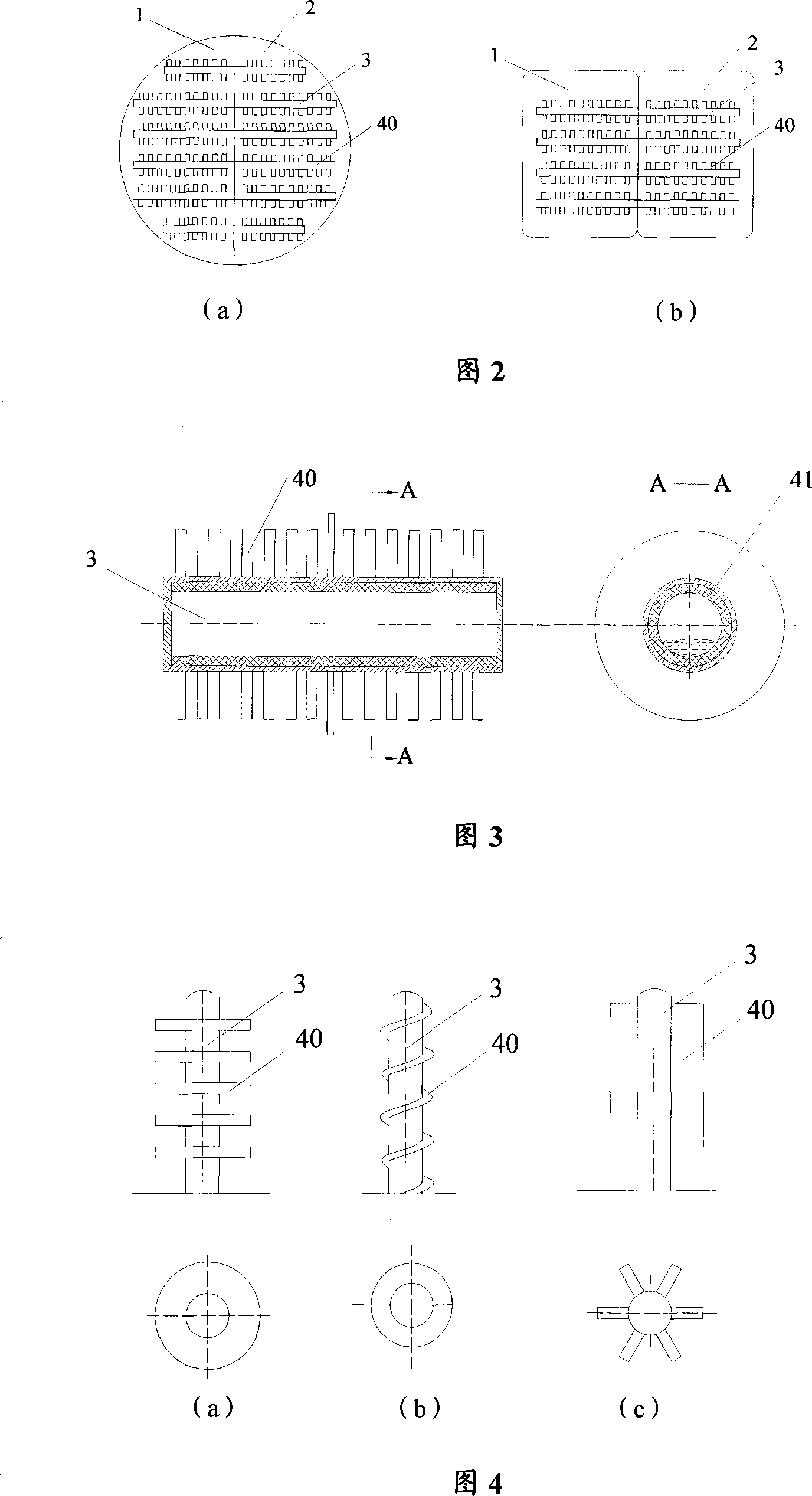

The present invention relates to an internal combustion heated biomass gasification furnace. Its structure is characterized by that it adopts a cylindrical furnace body, in the furnace body interior a coiled internal combustion pipe is set, the internal combustion pipe inlet is positioned in the lower portion of said cylindrical furnace body, and its outlet is extended to the exterior of furnace body from the top portion of cylindrical furnace body, its igniter is positioned in the internal combustion pipe inlet; over the cylindrical furnace body a helical feeding mechanism is set, its helical feeding hole is positioned on the eccentric position of cylindrical furnace body top portion, on the centre axis position of said cylindrical furnace body a stirring shaft with stirring blades is set, on the inside wall of cylindrical furnace body several layers of baffle plates are set, the combustion-supporting air inlet is set in the top portion of said cylindrical furnace body, and the gas outlet in the furnace body is positioned in the lower portion of said furnace body.

Owner:ANHUI WEIDA ENVIRONMENTAL PROTECTION TECH

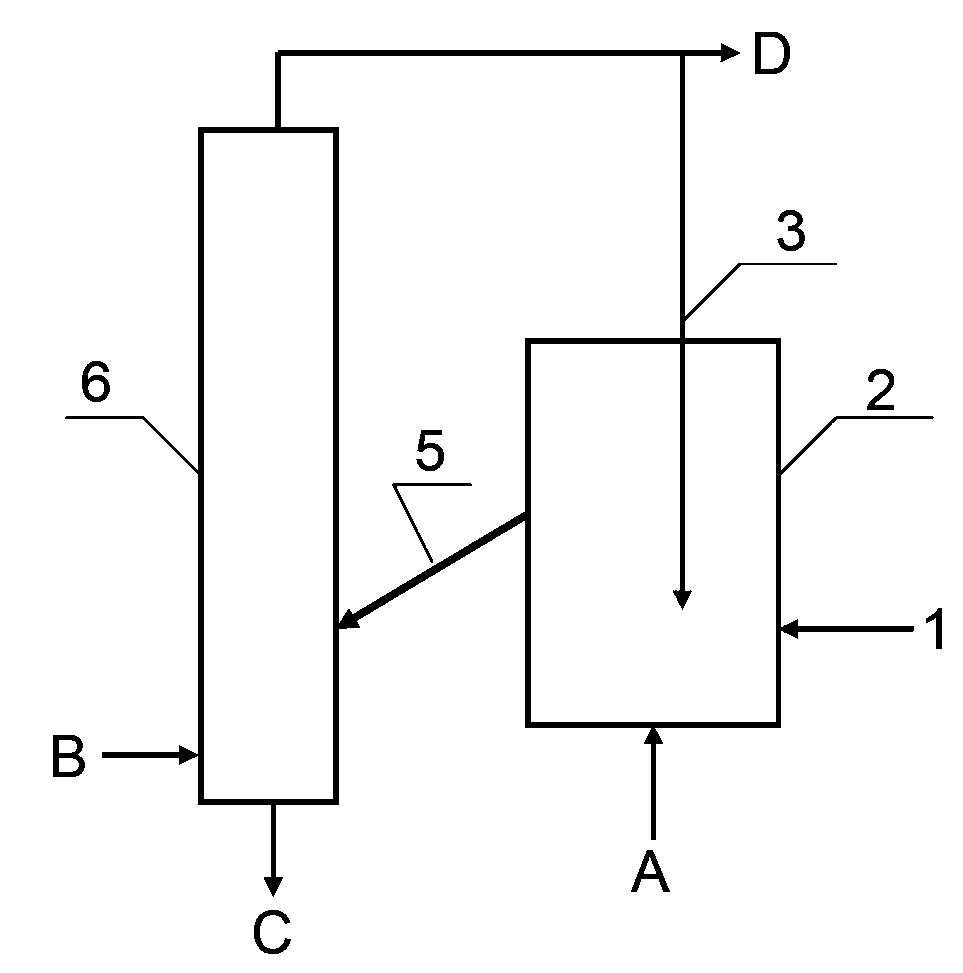

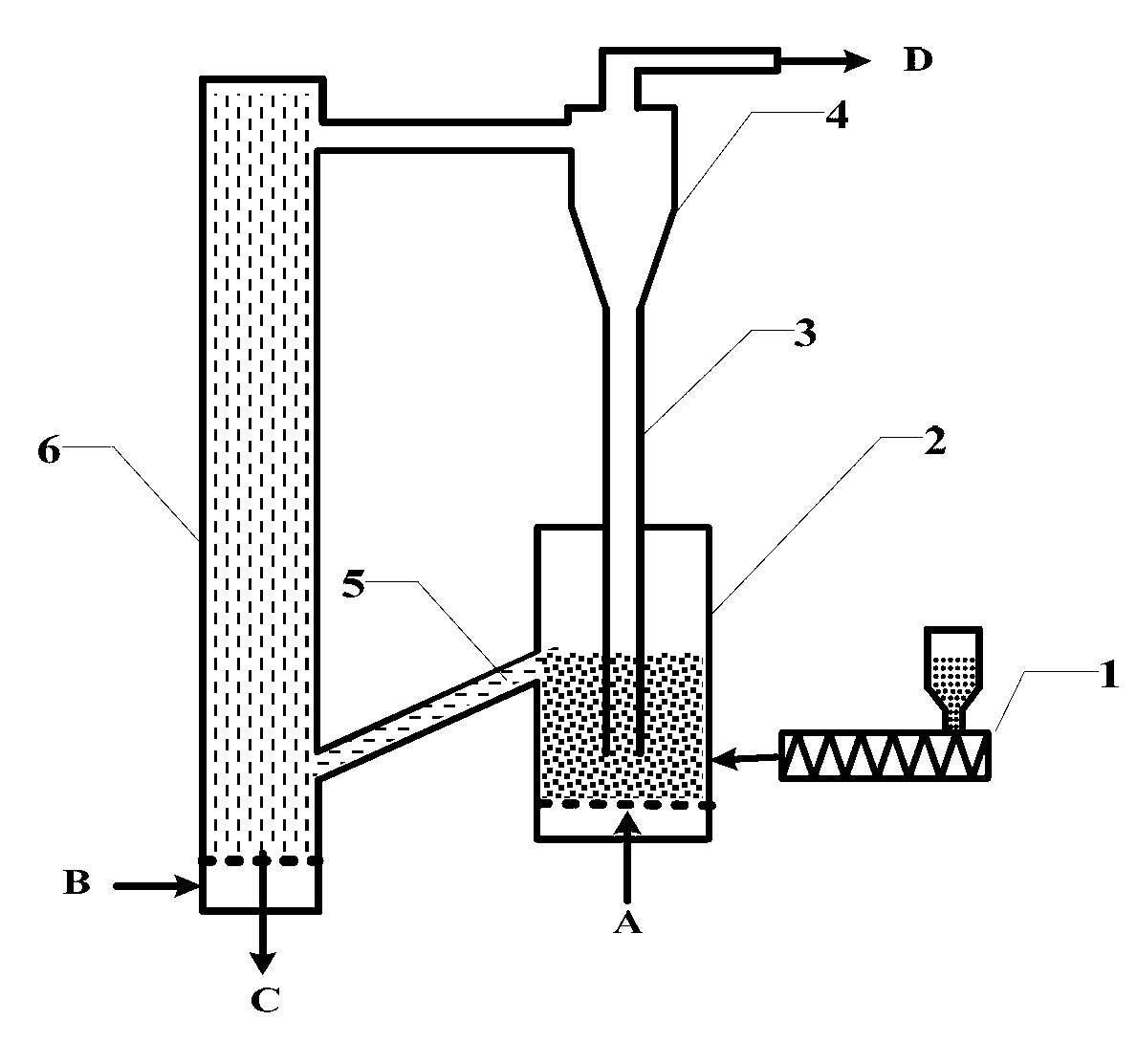

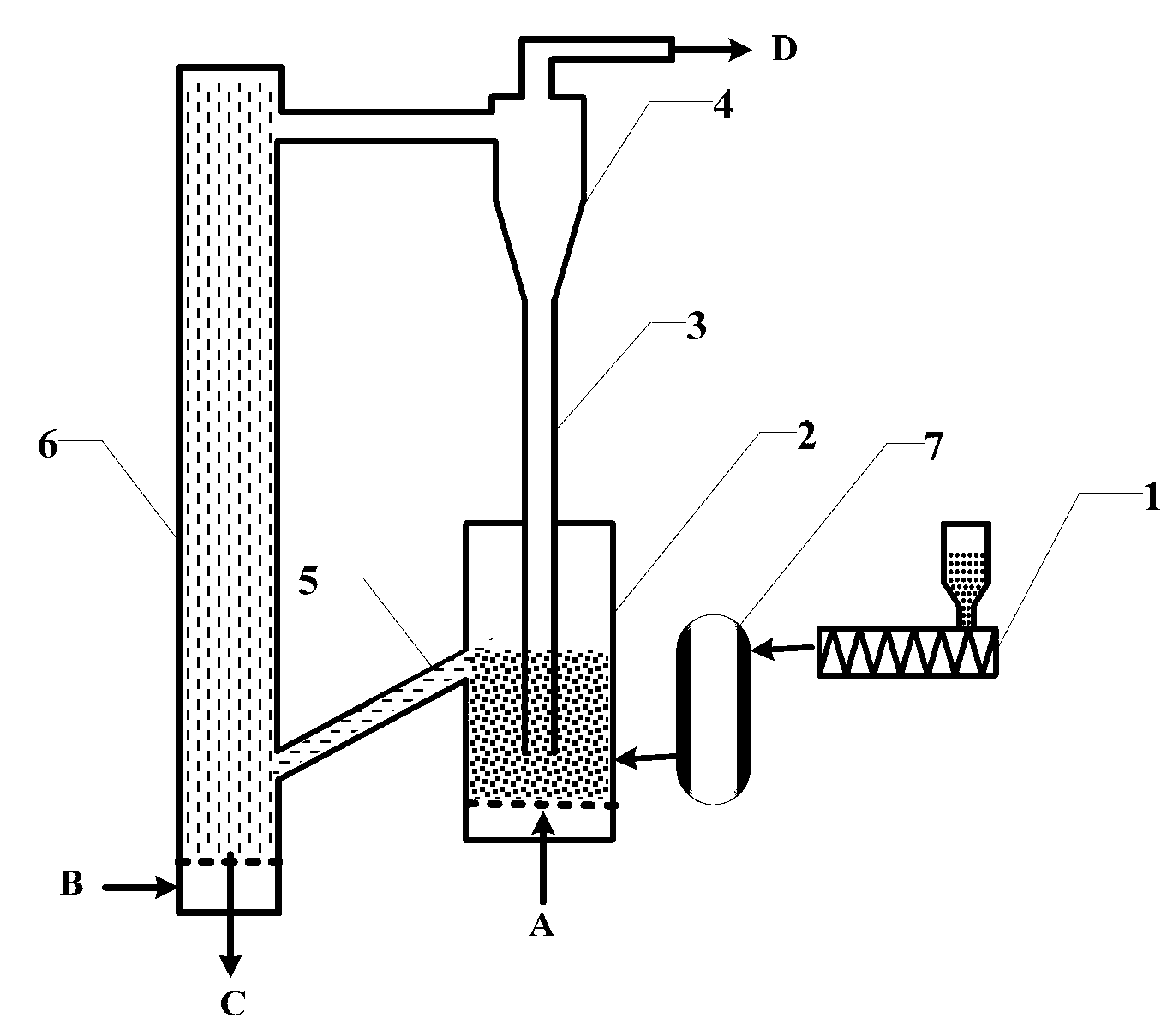

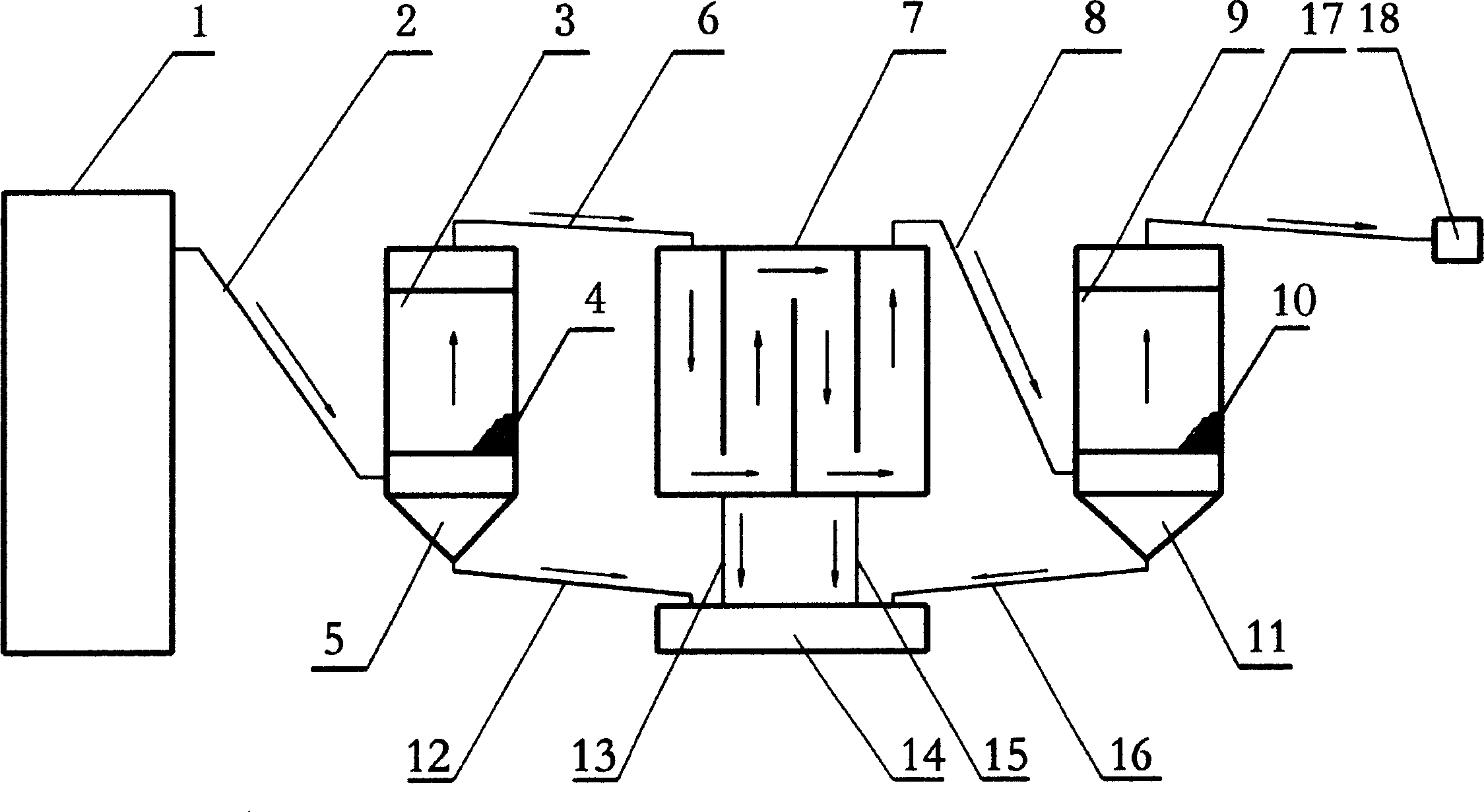

Two-stage gasification method and gasification device for fuels with wide size distribution

ActiveCN102703131AExtensive sources of raw materialsWide particle size distributionCombined combustion mitigationGranular/pulverulent flues gasificationTarProcess engineering

The invention relates to a two-stage gasification method and a gasification device for a fuel with wide size distribution. The two-stage gasification method for the fuel with wide size distribution comprises the steps of 1) adding the fuel to a fluidized bed pyrolyzer by a feeding device; adding a gasifying agent to the fluidized bed pyrolyzer; drying / pyrolyzing or partly gasifying the fuel under semicoking of the pyrolyzer and heating of the gasifying agent; and 2) sending the solid and gas generated in the step 1) to a fluidized bed gasification furnace, adding the gasifying agent to the fluidized bed gasification furnace, finishing complete gasification of semicoke; removing tar by high-temperature pyrolysis, part oxidization and semicoke catalytic reforming in the fluidized bed so as to produce clean gas. With the adoption of the method, the traditional fuel gasification process is divided into a material pyrolysis stage and a semicoke gasification stage, which are performed in an upper fluidized bed pyrolyzer and a lower fluidized bed gasification furnace.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

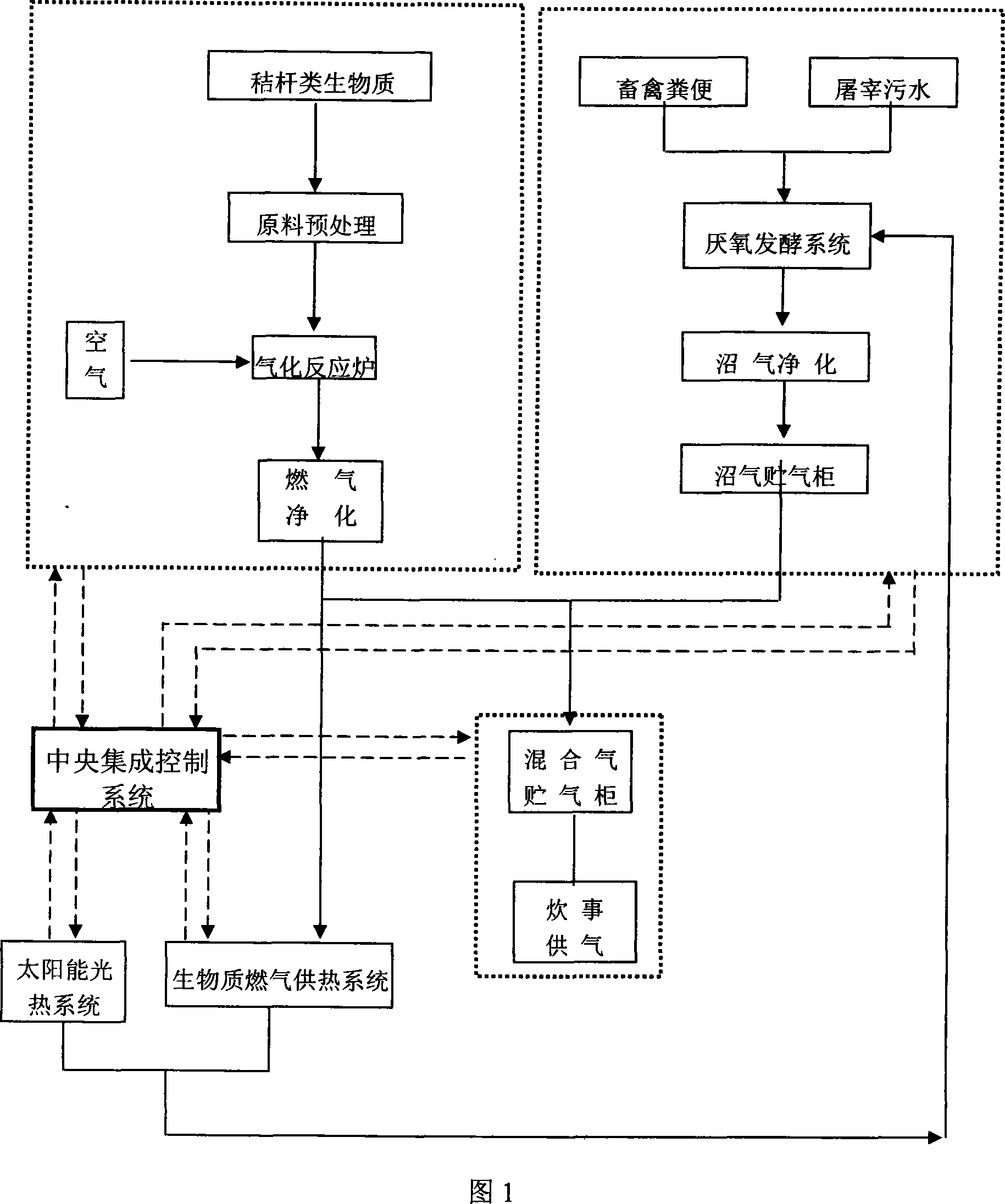

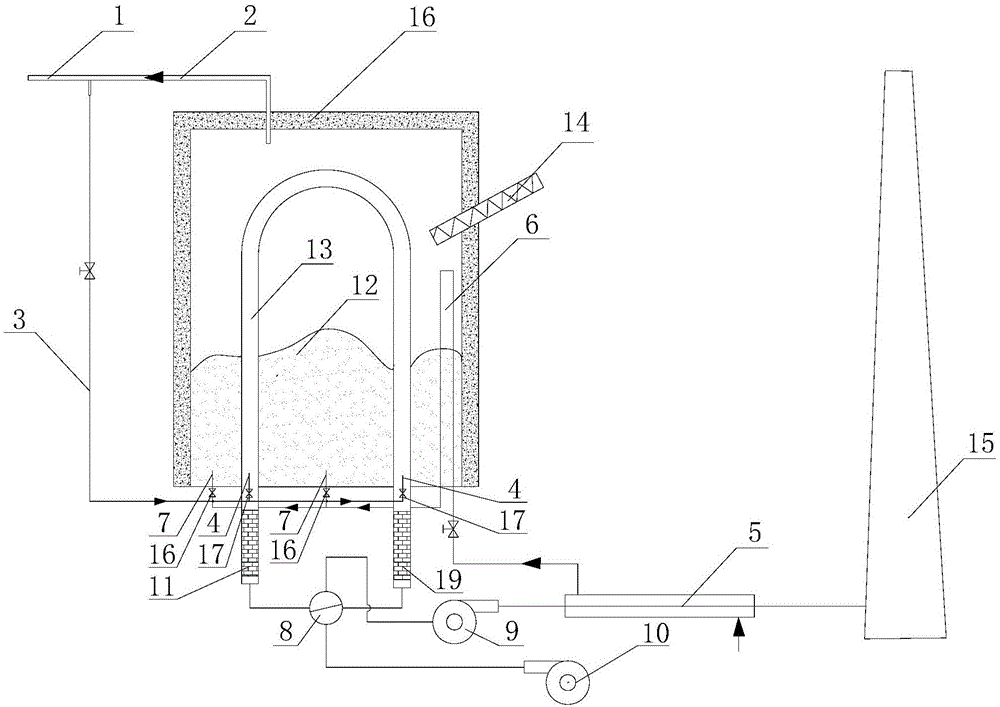

Biological energy-marsh gas fermentation-solar energy integrated utilization system

InactiveCN101063080AEfficient use ofAvoid corrosionSolar heat devicesGas production bioreactorsMarshFermentation

The invention discloses a biological mass energy-marsh gas fermentation-solar energy integrated usage system, which is characterized by the following: comprising biomass evaporated unit, marsh gas anaerobic fermentation unit, central integrated control unit, solar energy light hot unit, biomass gas heat supply unit, biomass fuel and marsh gas automatic mixed unit, fuel transmitting and distributing and user unit; connecting the central control unit and the other units separately; connecting the biomass gasifying unit with the biomass fuel heat supply unit, biomass fuel and marsh gas automatic mixed unit separately; connecting the marsh gas anaerobic fermentation unit with the biomass fuel and marsh automatic mixed unit; connecting the biomass fuel and marsh automatic mixed unit with fuel transmitting and distributing and user unit; connecting the solar energy light hot unit and biomass gas heat supply unit with the marsh gas anaerobic fermentation unit separately. This invention can transform the pollution as marsh gas source.

Owner:浙江网新百川环境科技有限公司

Purifying system for biomass gasifying oven

InactiveCN1667086ASimple structureLow production costSpecial form destructive distillationWater bathsCombustor

This invention discloses a biomass gasification furnace purification system. the main points of its technical proposal is that the system is consisted by catalysis ware, catalyst, labyrinth type gasometer, adsorption filter, adsorption filtering agent, waste tar and waste water collecting pit. Fuel gas current of biomass gasification furnace is transferred to labyrinth type gasometer through catalyst in the catalyst ware, then it istrasferred to adsorption filtering agent in the adsorption filter, the fuel gas current after three times purification is transferred to burner, and the whole purification course is finished. This invention is used to biomass gasification furnace purification system, its structure is simple, cost is low, and operation is simple. Water bath is not used in the system, the waste tar and water is few, and can be value things after proposed. The tar cracking ratio and gas current heating value is high, and the rate of gasification of the furnace can be improved. There is no environmental pollution.

Owner:许庆华

Cracking and gasifying reforming furnace

InactiveCN1888017ACompact structureLow costSpecial form destructive distillationCombined combustion mitigationCatalytic reformingCombustor

The present invention discloses one kind of cracking and gasifying reforming furnace, which includes one dust cloud combustor, one cracking and gasifying chamber and one catalytic reforming chamber. Micron level fuel is burnt in the dust cloud combustor to provide heat for cracking and gasifying and catalytic reforming, the material to be cracked and gasified absorbs heat in the cracking and gasifying chamber to crack and gasify, and the cracked and gasified product is pressurized into the catalytic reforming chamber and reformed to obtain medium heat value fuel gas containing CO and H2 in about 80 %. The cracking and gasifying reforming furnace adopts crop stalks and solid forest waste crushed to micron level as outer heat source, has less investment in apparatus, high heat efficiency, low cost, high gas yield and high heat value of fuel gas product, and may be used in utilizing organic garbage to produce fuel gas.

Owner:HUAZHONG UNIV OF SCI & TECH

Biomass gasification catalyst and its production method

InactiveCN1686606AIncrease gas calorific valueHigh cracking rateOther chemical processesGas purification with selectively adsorptive solidsTarBiomass gasifier

A catalyst used in biomass gasifier or gas furnace for cracking tar and removing uncracked tar and alkali metal is prepared from attapulgite-type clay, high-A alumina, iron oxide, magnesium oxide, calcium oxide and anthracite through proportionally mixing, stirring, grinding, granulating and baking.

Owner:许庆华

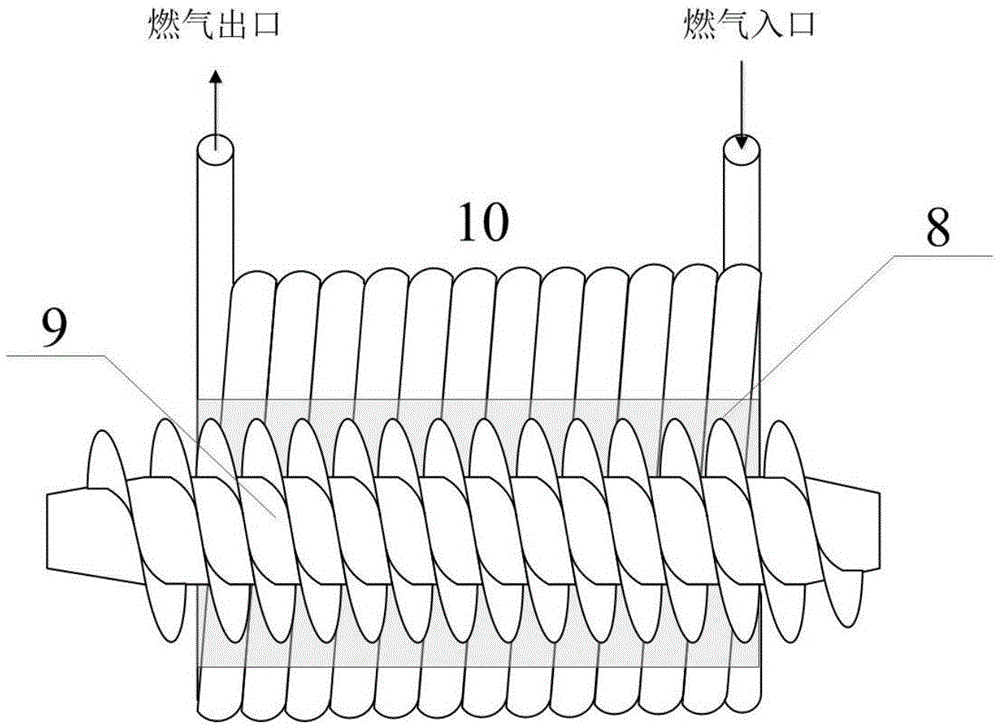

Internal combustion heating moving-bed type biomass pyrolysis liquefying apparatus

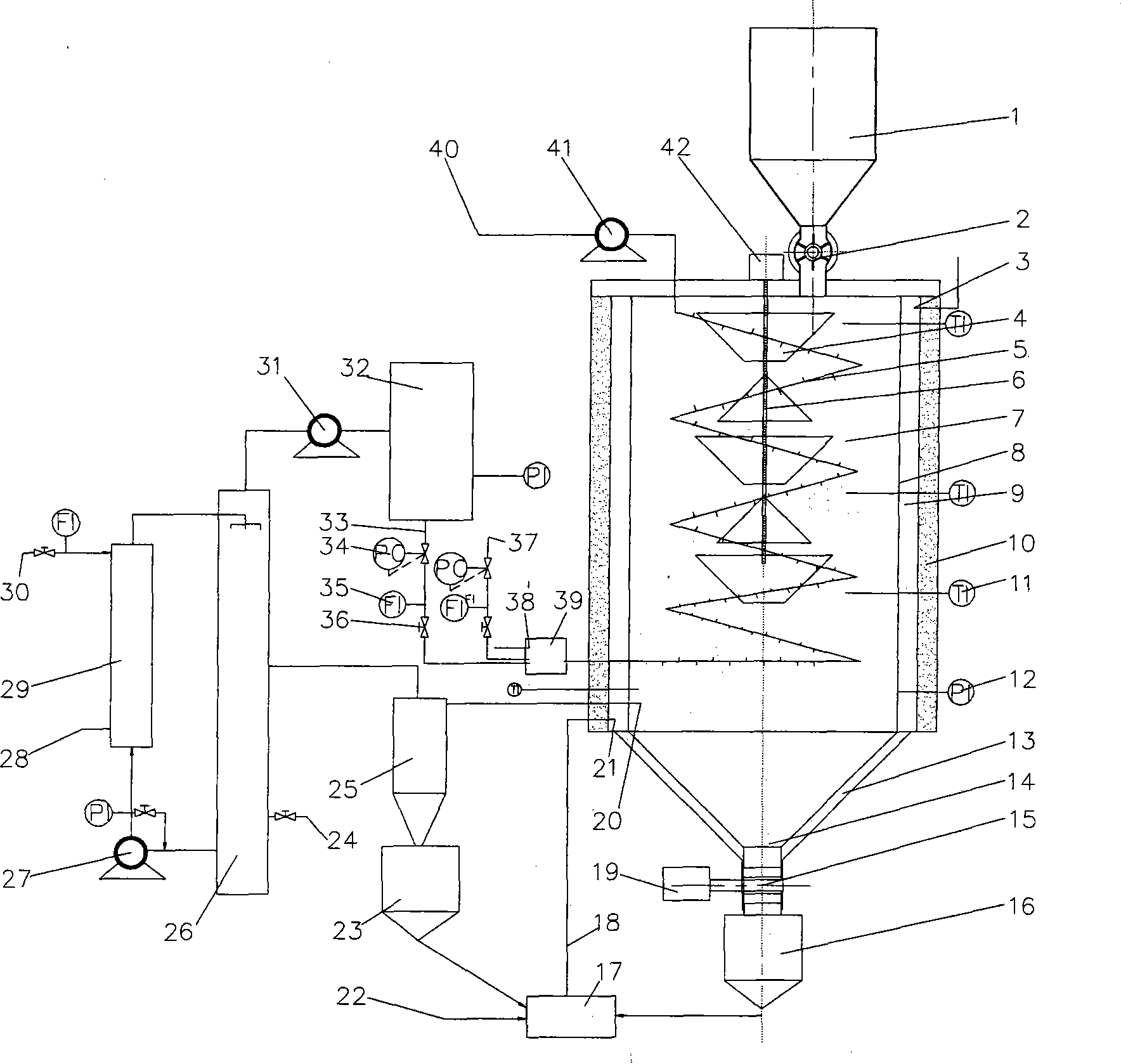

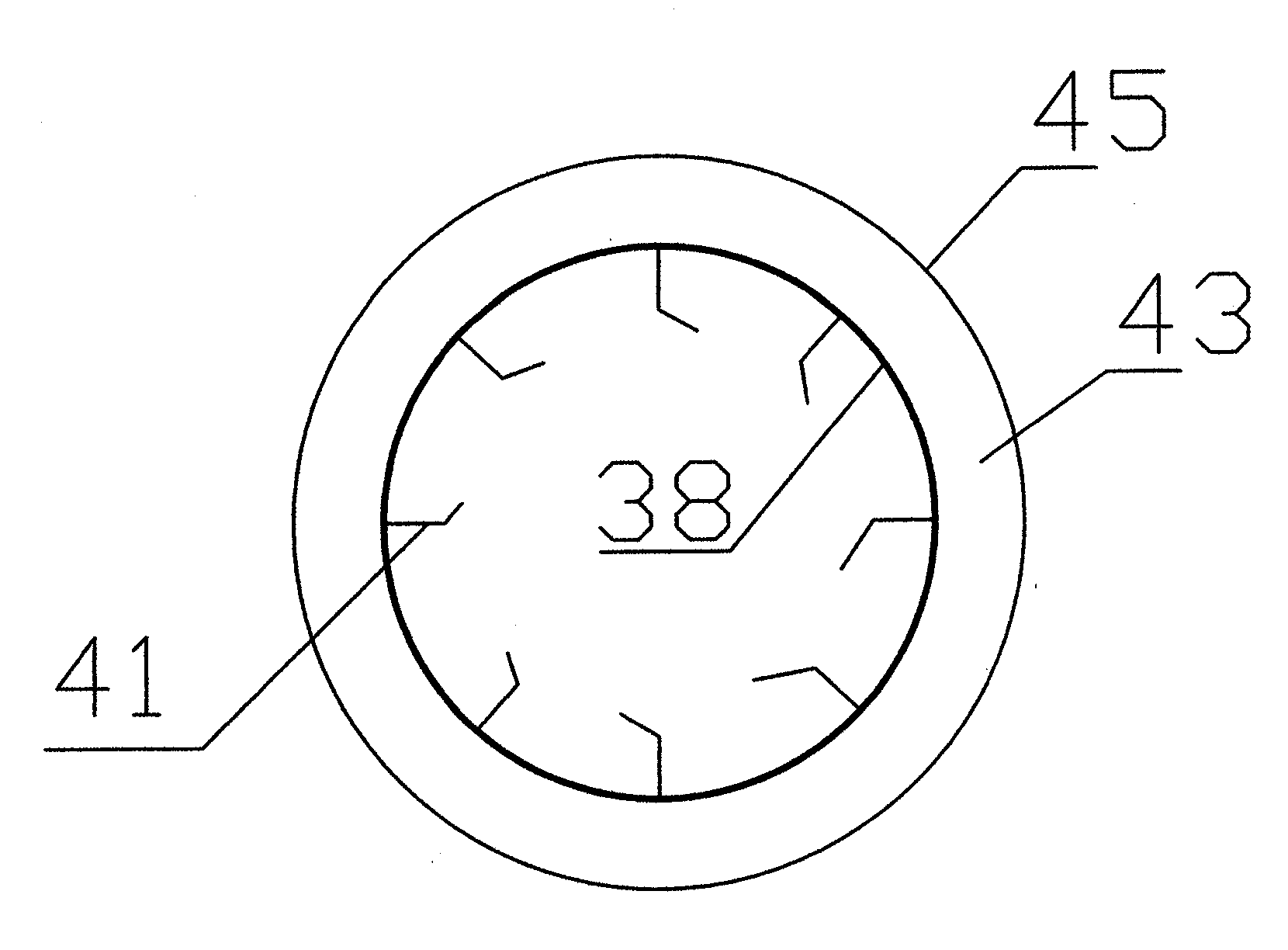

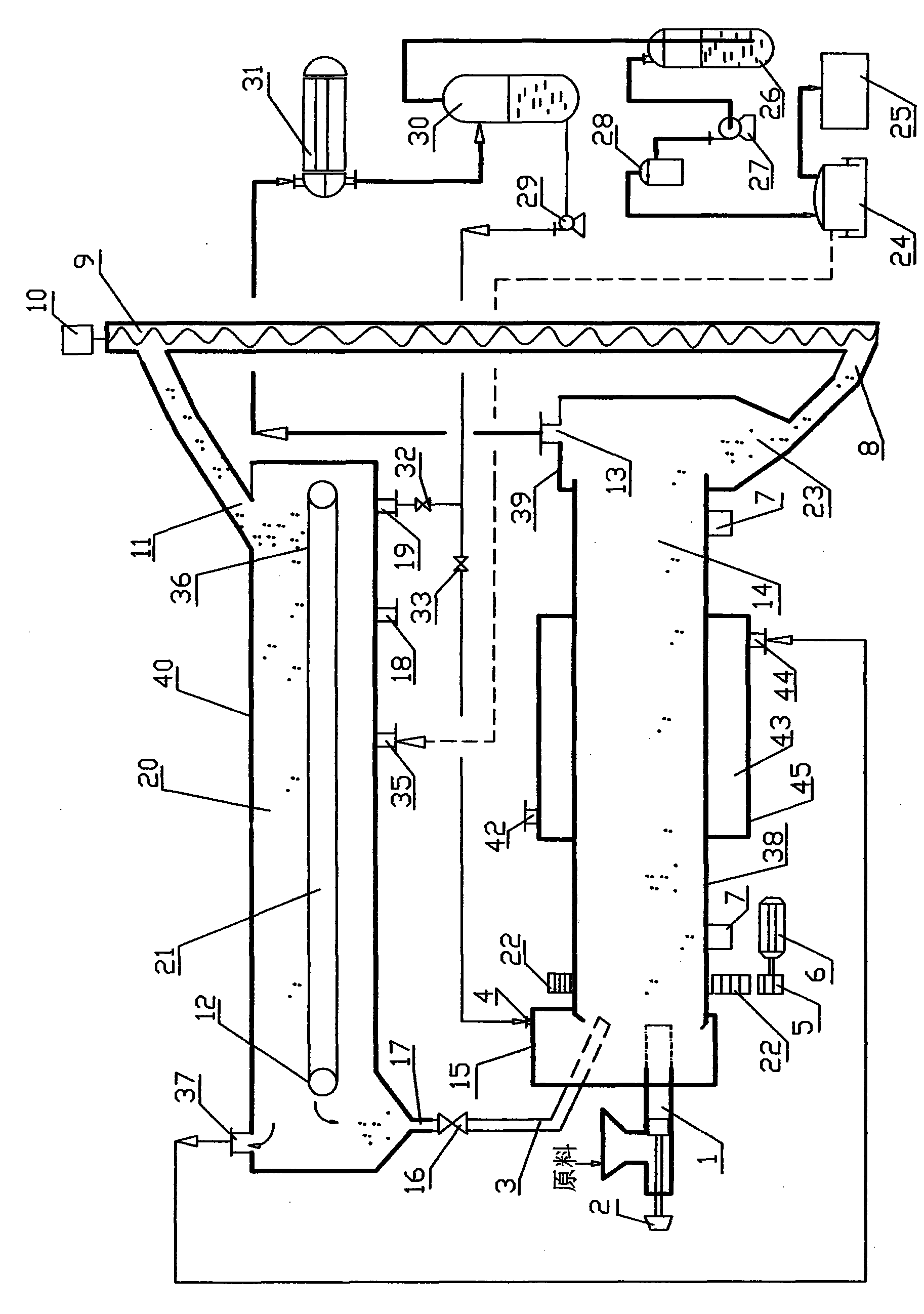

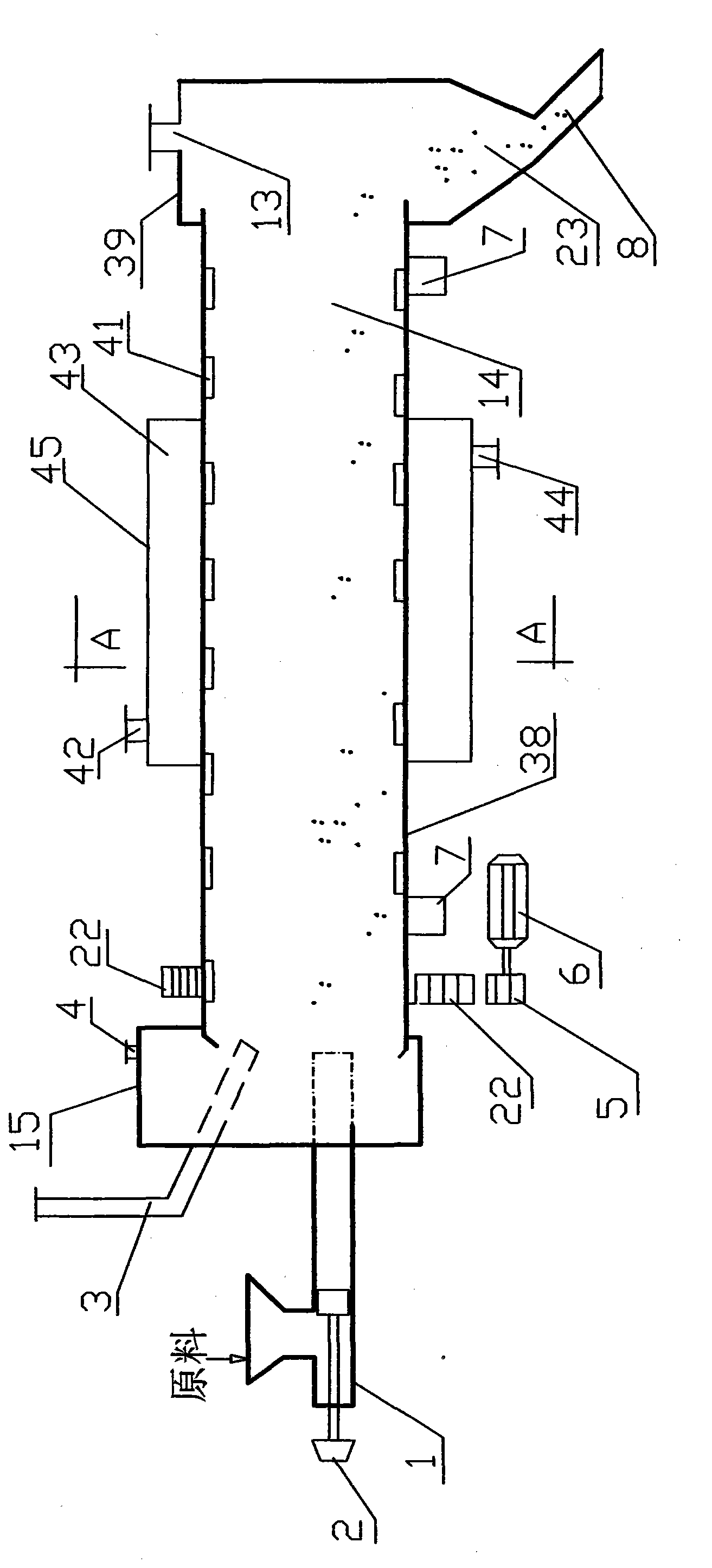

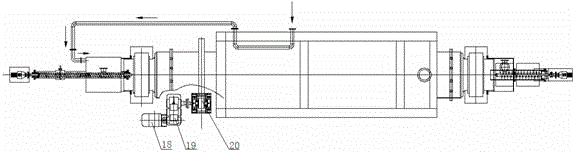

InactiveCN101376814AIncrease profitReduce manufacturing costBiofuelsLiquid hydrocarbon mixture productionBiomassPyrolysis

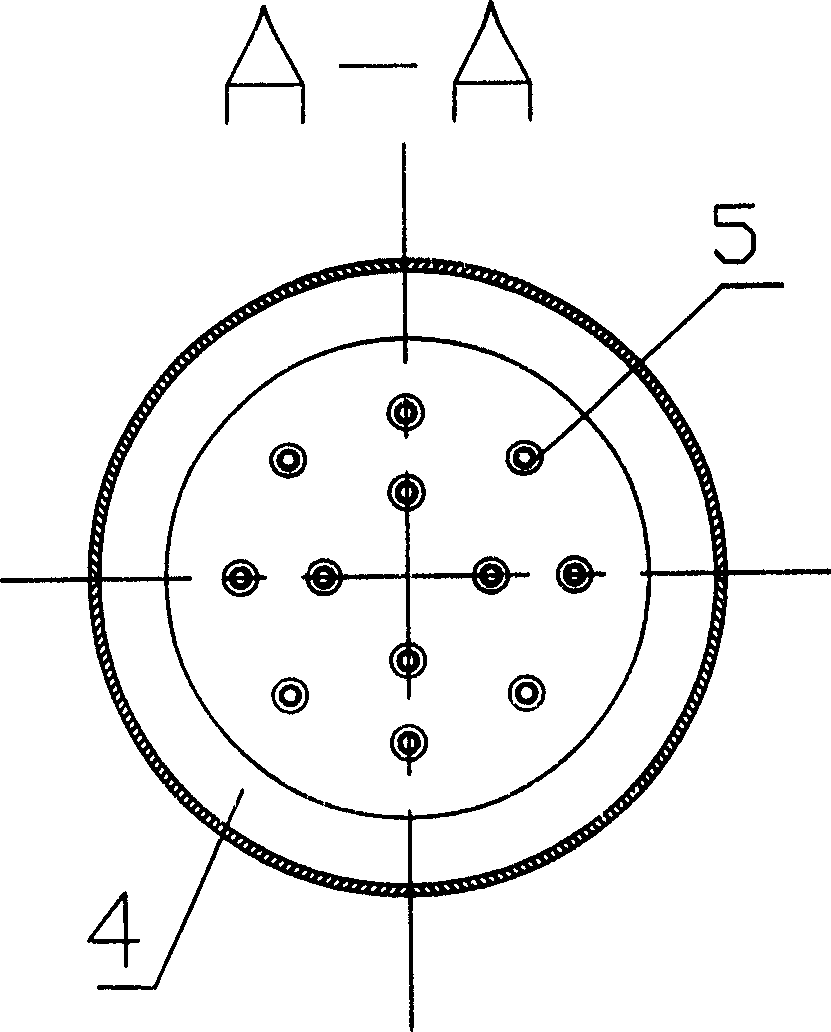

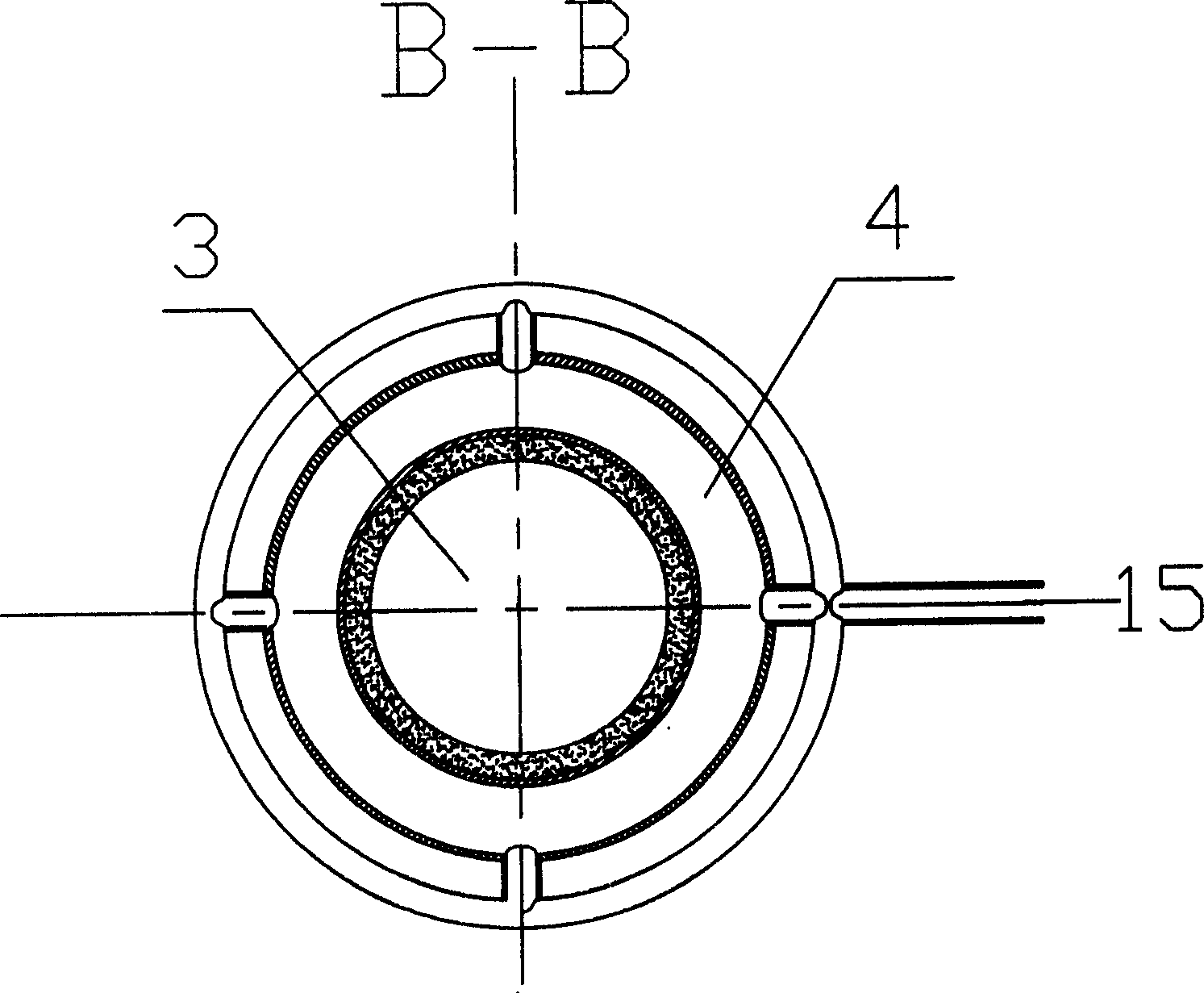

The invention discloses an internal combustion heating movable-bed biomass-pyrolysis liquefaction device which includes a reactor (7); the inside of the reactor is provided with an internal combustion pipeline (5); both the inlet and the outlet of the internal combustion pipeline (5) are arranged outside the reactor (7); a hopper (1) is arranged above the reactor (7); a blanking control valve (2) is arranged on the hopper (1); a rotary shaft (6) is arranged in the center of the reactor (7); conical hoppers (4) are arranged on the rotary shaft (6); conical material dividing umbrellas are arranged between the conical hoppers (4); the material inlet of the hopper (1) is arranged above the conical hoppers (4); a pyrolysis gas outlet (20) is arranged on the reactor (7); the bottom part of the reactor (7) is provided with a slag discharge opening (14); a cyclone separator (23) is connected on the gas pipeline of the pyrolysis gas outlet (20); the flue gas outlet of the cyclone separator (23) is connected into a condenser (26); an oil outlet and an outlet for non-condensable gas are arranged on the condenser (26); the outlet for non-condensable gas is connected to a gas buffer tank (28) through a draught fan. The biomass-pyrolysis liquefaction device reduces the liquefaction cost of bio-oil, has a simple structure and a low processing and manufacture cost as well as is simply and conveniently operated, managed and maintained.

Owner:HEFEI UNIV OF TECH

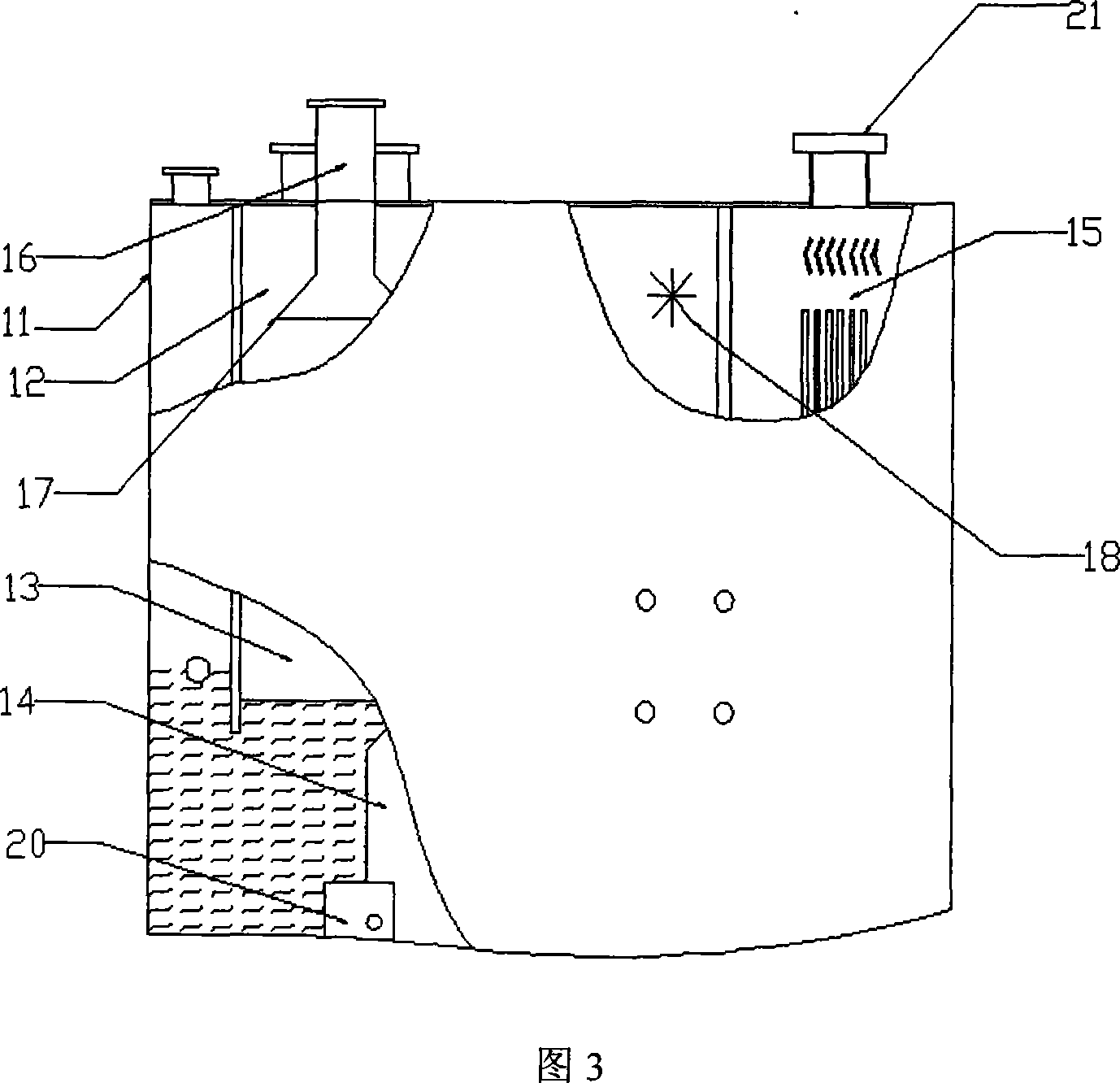

Integration biomass gasification stove catalytic splitting process and device thereof

InactiveCN101338204ANo pollution in the processPromote sustainable developmentSpecial form destructive distillationThermal energyTar

The invention discloses an integrated biomass gasified furnace catalytic cracking method and a device thereof. The technical proposal is characterized in that in the integrated biomass gasified furnace catalytic cracking method, biomass fuel enters a combustion room from a feeding port through a spiral input device to be combusted; a large amount of combustible gas after the combustion rises to an X-type fuel gas buffer room and then enters a tar catalysis cracking chamber; the combustible gas enters a gas purifying chamber after the complete catalysis cracking and the purification filtering and is discharged from an outlet pipe to be used by users. The integrated biomass industrial gasifier consists of a gasifier body, the gas purifying chamber, the tar catalysis cracking chamber, catalyst for the biomass gasifier, the fuel gas buffer room, the spiral input device, the combustion room, a conical recoiling device, an ash storing chamber and a base. The integrated biomass gasifier catalyst cracking method and the device thereof are used for providing heat energy for various industrial and mining enterprises and biomass power plants.

Owner:辽宁东戴河新区乡电电力有限公司

High-temperature low-tar biomass gasifier

InactiveCN101280199ARaise the gasification reaction temperatureIncrease disturbanceCatalytic crackingSpecial form destructive distillationSlagTar

Disclosed is a high temperature low tar biomass gasification device which is characterized in that the gasification device is composed of the sequential connection of a feeding unit, a gasifier, a tar catalytic cracking reaction cylinder and a heat exchanger; the gasifier is designed to the sleeve structure through an inner cylinder and an outer cylinder; an annular hollow cavity is formed between the inner cylinder and the outer cylinder; a preheating hopper which is hoisted on the lower end surface on top of the gasifier and communicated with the feeding unit is arranged in the inner cylinder; the bottom part of the inner cylinder is a slag storage chamber; the annular hollow cavity is used as the preheating cavity of the gasification agent; the inlet of the gasification agent is communicated with the annular hollow cavity; the outlet of the annular hollow cavity is the vent hole arranged on the lateral wall of the slag storage chamber; the combustion gas generated in the inner cylinder leads to the tar catalytic cracking reaction cylinder through the combustion gas outlet; the heat exchange medium is the generated combustion gas in the tar catalytic cracking reaction cylinder and the cold gasification agent; the gasification agent outlet of the heat exchanger is communicated with the gasification agent inlet of the gasifier. The high temperature low tar biomass gasification device has the advantages of avoiding the external heat source, simple and compact structure, improving the heat value of the combustion gas, improving the gasification efficiency and lowering the tar content obviously.

Owner:HEFEI UNIV OF TECH

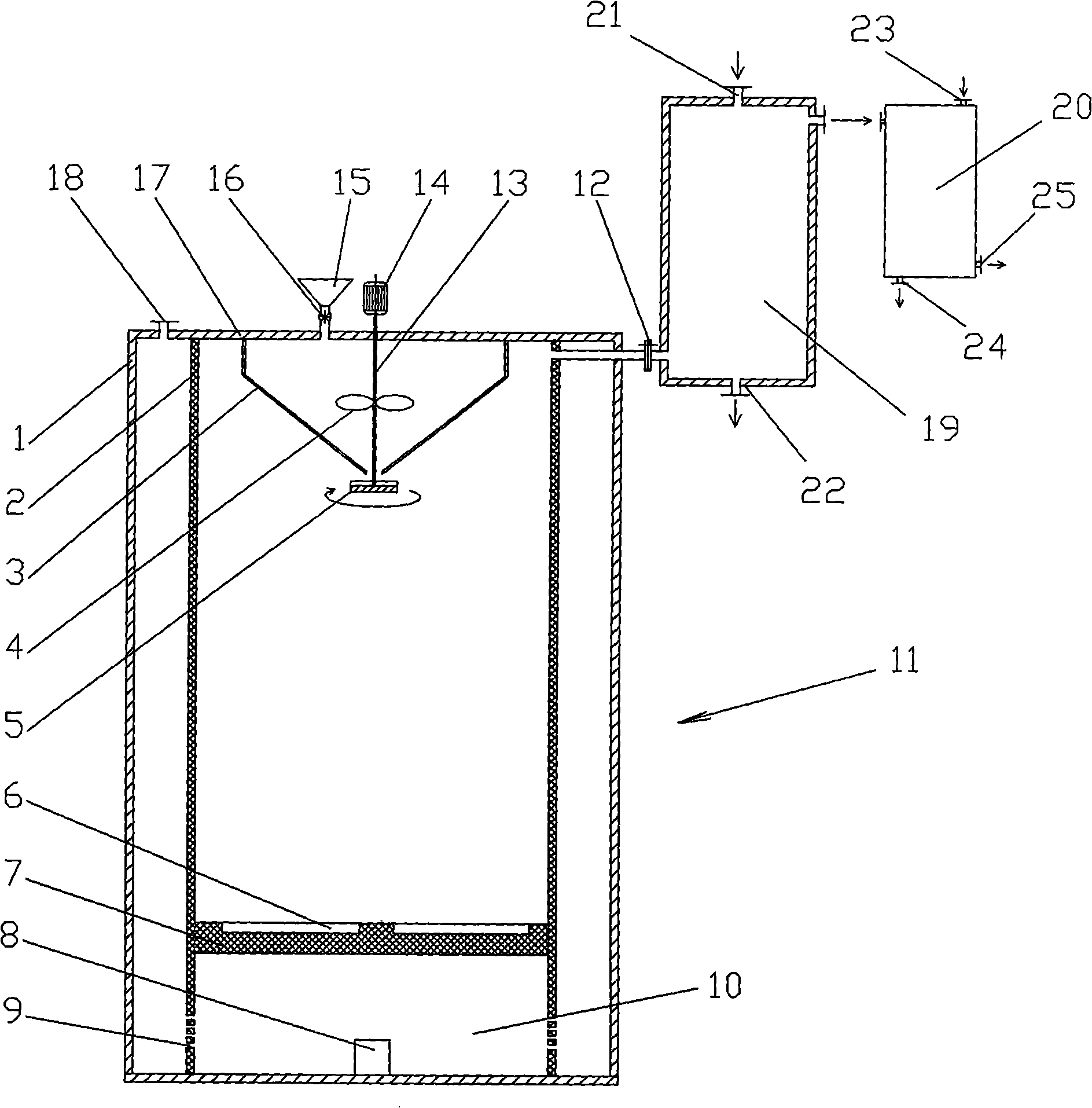

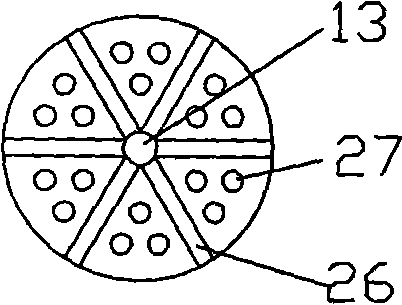

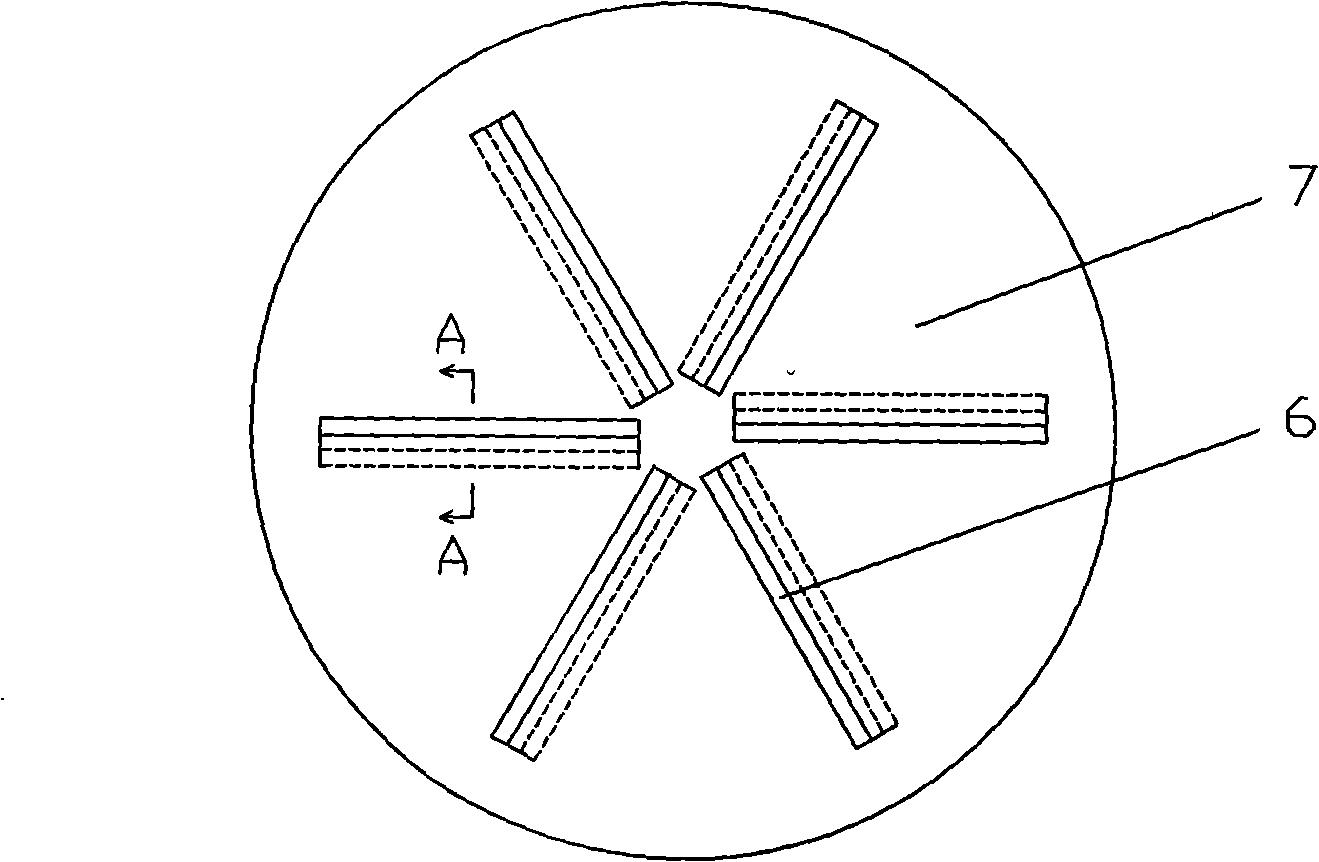

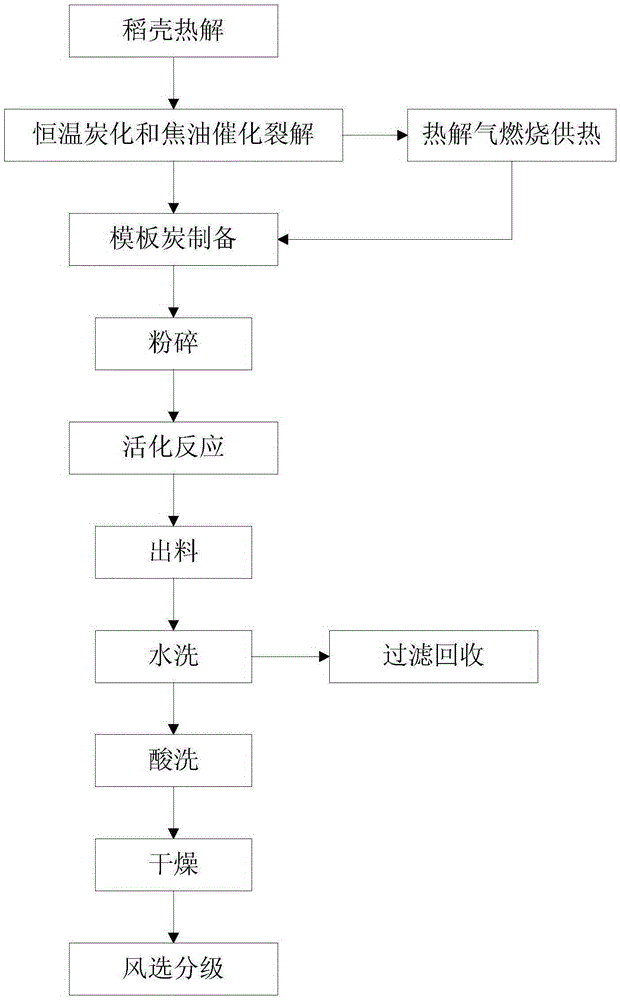

Method for producing capacitive carbon from rice husks

ActiveCN105329892ALow costReduce tar molecular weightCalcium/strontium/barium carbonatesCarbon compoundsTarChemical industry

The invention discloses a method for producing capacitive carbon from rice husks and belongs to the technical field of the biomass energy chemical industry. The method comprises the following steps: 1, the rice husks and a catalyst are mixed uniformly and subjected to pyrolysis, and pyrolytic gas and pyrolytic carbon are produced; 2, the pyrolytic gas and the pyrolytic carbon are subjected to constant-temperature catalytic decoking, volatile components of the pyrolytic carbon are reduced, and tar is pyrolysed into small molecules; 3, a horizontal reaction kettle is adopted and rotated, the pyrolytic carbon and alkali liquor are mixed uniformly, and a mixture is subjected to hot-pressing desilicication, washing and drying; 4, template carbon and an activator are ground, stirred at a high speed for homogenization and uniformly distributed; 5, a push type activation furnace is adopted, the heating rate and activation time are controlled, and an activation material is prepared; 6, the activation material is washed, pickled and washed to be neutral; 7, a product is dried, graded and packaged. The rice husks are adopted to produce the capacitive carbon, biomass is used for producing renewable energy sources and chemicals, the cost is low, the method is environment-friendly, a production process is safe and pollution-free, and large-scale production can be realized.

Owner:旗禾科技(吉林)有限责任公司

Device for production of fuel oil and fuel gas and/or flue gas power generation through household garbage

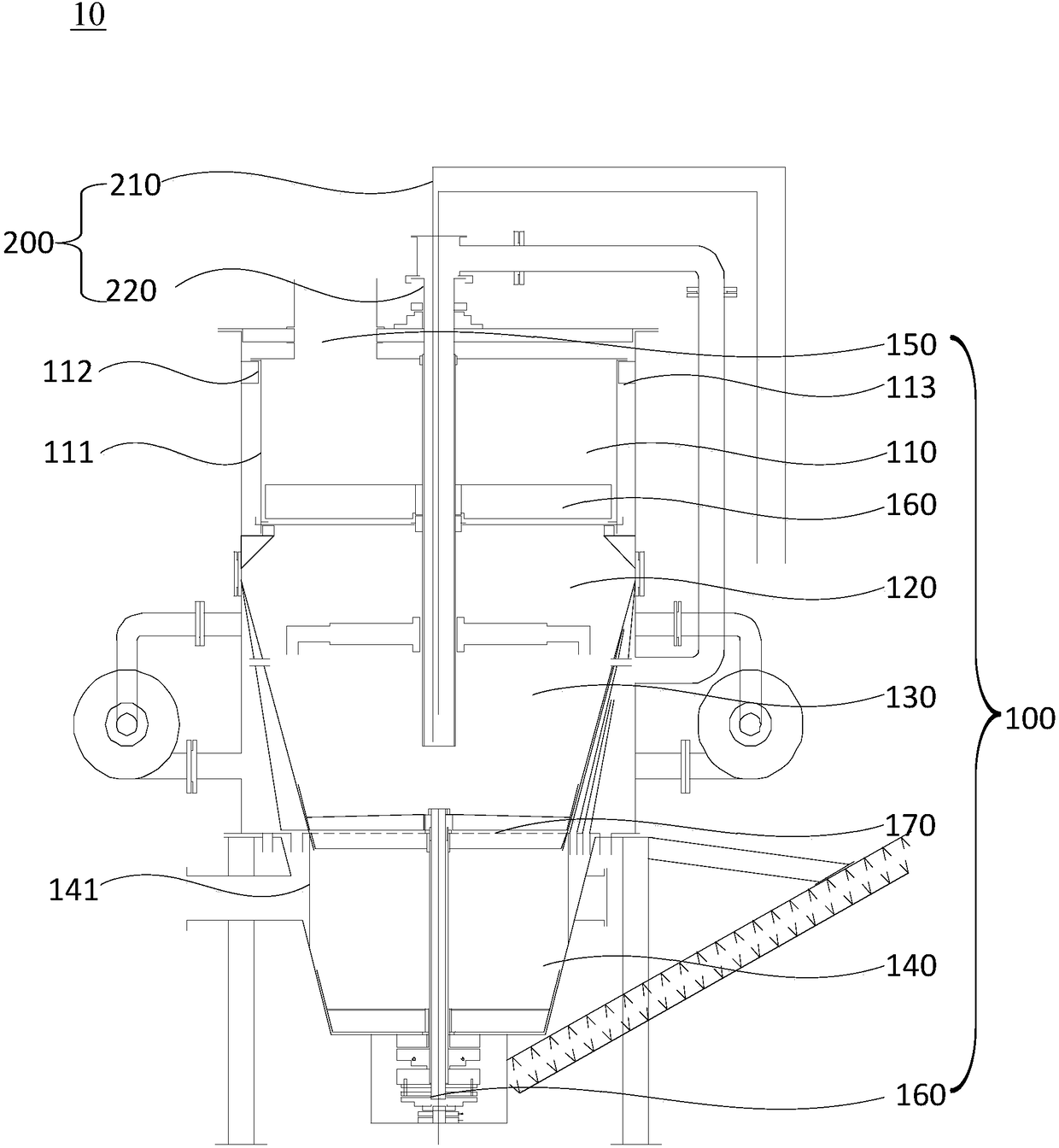

ActiveCN104128349AImprove thermal efficiencyFast heat transferSolid waste disposalBiofuelsHeat carrierVapor–liquid separator

The invention discloses a device for production of fuel oil and fuel gas and / or flue gas power generation through household garbage. The device is mainly composed of a horizontal-type rotating pyrolytic reaction kettle, a material feeding machine, an incinerator, a conveying device, a condenser, a gas-liquid separator, a water-sealing pot, a flue gas purifying device, a flue gas fan, a flue gas cabinet, an oil pump and a flue gas generator set. In the device, a high-temperature granular heat carrier and the household garbage are directly contacted to each other in a sealed and oxygen-free horizontal-type rotating pyrolytic reaction kettle for enabling the household garbage to be subjected to a pyrolytic reaction to produce fuel oil or nitrogen-free high-calorific-value fuel gas. The device can achieve continuous production, is free from coking, is high in heat transmission efficiency and is free of generation of dioxin.

Owner:光大环保能源(沛县)有限公司

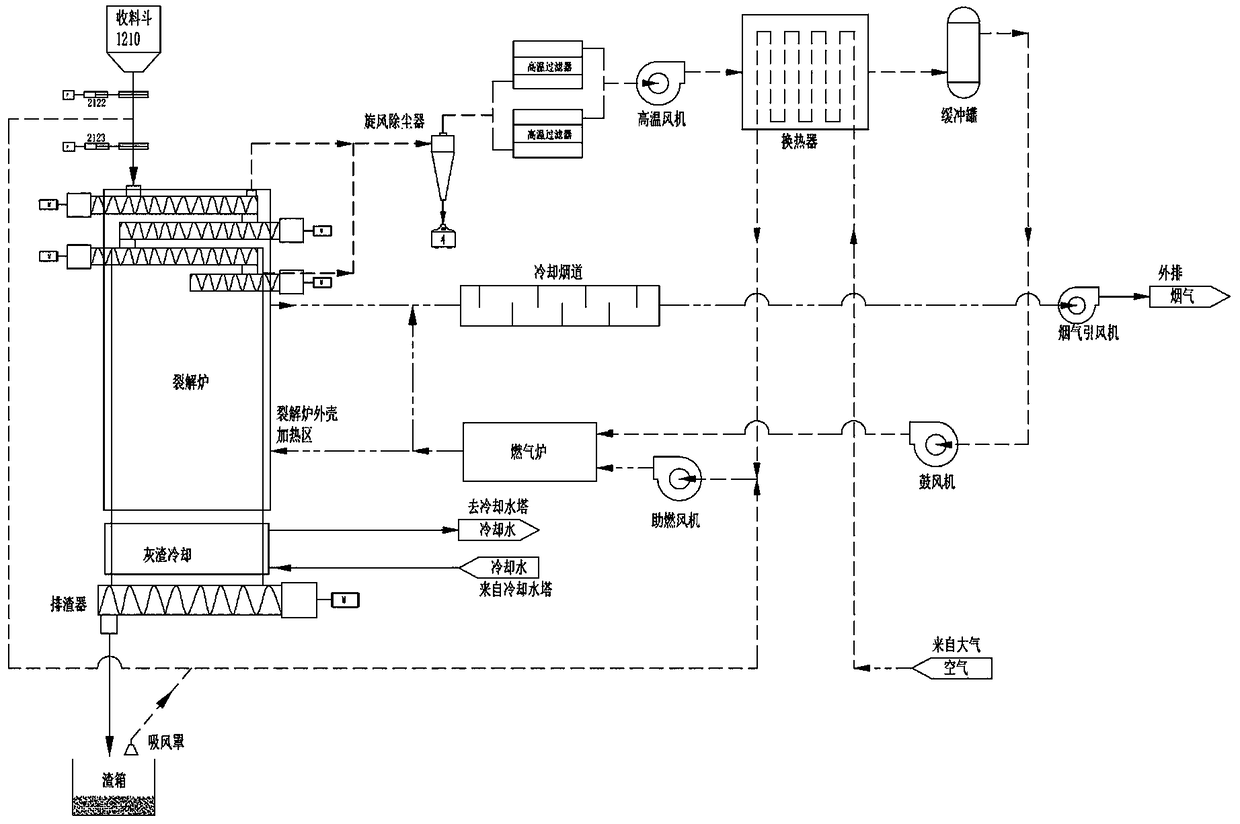

Oxygen-free sticky garbage pyrolyzing method and system

PendingCN108165287AEliminate cloggingEfficient pyrolysisProductsReagentsTemperature controlDecomposition

The invention discloses an oxygen-free sticky garbage pyrolyzing method and an oxygen-free sticky garbage pyrolyzing system. The oxygen-free sticky garbage pyrolyzing method comprises the following steps: performing garbage pretreatment: softening outwardly transported garbage by afterheat, adding a recycling liquid with an additive to increase the fluidity of a material, and sending the materialto a cracking furnace through specific hydraulic conveying equipment; performing garbage cracking decomposition: distilling, carbonizing and decomposing solid waste in the cracking furnace through multi-stage temperature control under an anaerobic condition, and according to the technological temperature and the heating rate, under the action of a catalyst, decomposing organic matters of the solidwaste into combustible gas, carbon and liquid compounds; reprocessing a cracking decomposition product: separating, purifying and synthesizing inorganic matters, the combustible gas, the carbon and the liquid compounds into building materials, fuel gas, regenerated finished products and solvents / oils. Under medium-temperature and low-temperature, catalytic and completely oxygen-free conditions, complex mixed garbage can be treated, the material is continuously fed, high-efficiency pyrolysis is achieved, and the fuel gas, the carbon and other regenerated products are produced.

Owner:深圳新能极科技有限公司

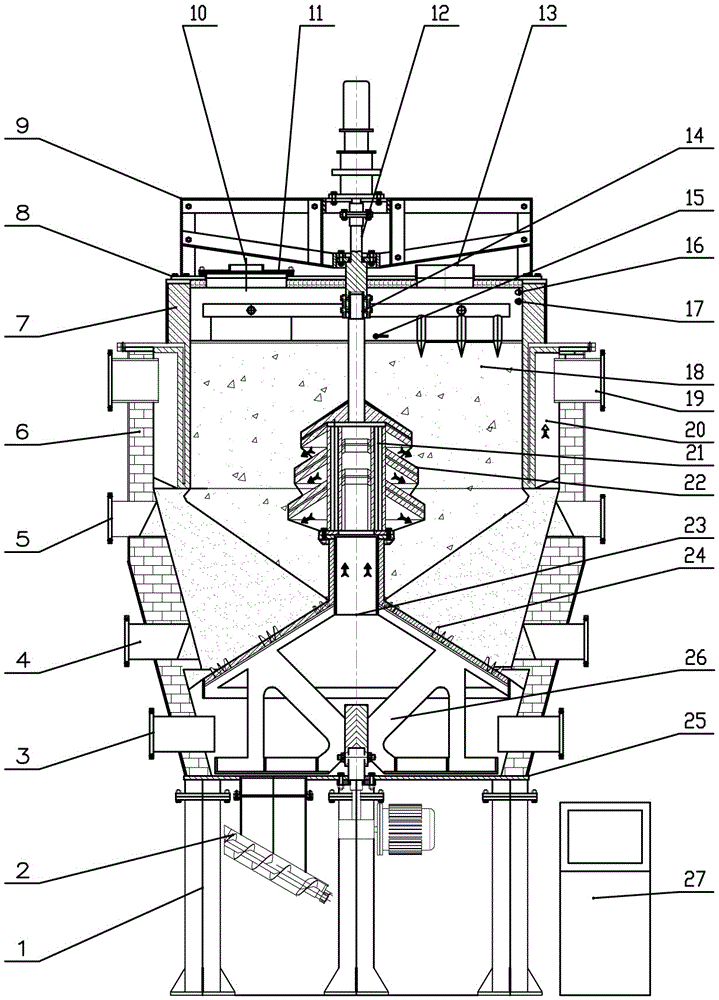

Internal combustion heating rotation conical biomass gasification furnace

InactiveCN101538484AIncrease temperatureImprove efficiencyCombined combustion mitigationCombustible gas productionProcess engineeringBiomass gasifier

The invention provides an internal combustion heating rotation conical biomass gasification furnace which is characterized in that the furnace body is internally provided with two concentric cones, wherein the external cone is a rotation cone and the internal cone is a fixed cone; the top of the rotation cone is connected with a material cylinder at the lower section; the top of the fixed cone is communicated with a smoke gas pipeline; the bottom end surface of the fixed cone is closed and the lower part thereof is tangentially connected with a combustion pipeline; the side wall of the furnace body is arranged as jacket structure; the jacket comprises a high-temperature resistance furnace wall, a combustion gas pipeline, a heat preservation layer and an external wall of the gasification furnace sequentially from inside to outside; the airflow passage in which the combustion gas is led out from the gasification furnace is that the combustion gas is led to the bottom port of the combustion gas pipeline from the bottom of the gasification furnace along the inclined surface of the conical furnace bottom; the delivery outlet of the combustion gas is arranged at the upper part of the combustion gas passage; and a gas transmission pipeline connected on the delivery outlet of the combustion gas outside the gasification furnace is connected with a gas storage cabinet by an induced draft fan. The gasification furnace greatly improves the biomass gasification rate and the heat value of the combustion gas.

Owner:HEFEI UNIV OF TECH

Household garbage pyrolysis and gasification processing system

InactiveCN106338068AImprove heat utilization efficiencyImprove operational efficiencyGasification processes detailsIncinerator apparatusSlagEngineering

The invention discloses a household garbage pyrolysis and gasification processing system. A pyrolysis and gasification furnace is included. A smoke exhaust pipeline is arranged on the middle upper portion of the pyrolysis and gasification furnace and communicates with exhaust gas processing equipment. The exhaust gas processing equipment is connected with an induced draft fan. The upper portion of the pyrolysis and gasification furnace communicates with a furnace bottom through a pyrolysis gas pipeline. An electric air valve is arranged on the pyrolysis gas pipeline, the pyrolysis gas pipeline is connected with a condenser, and the condenser is connected with a gas storage tank. The pyrolysis and gasification furnace adopts fuel as an auxiliary drive heat source, and generated pyrolysis gasified gas serves as a main heat source. By utilizing the pyrolysis and gasification system for processing household garbage, the garbage volume and quantity are remarkably reduced, the performance of ash and slag is stable, the dioxin content of generated exhaust gas is extremely low, then the exhaust gas is further processed so that harmlessness of the exhaust gas can be achieved, and environmental pollution caused by garbage incineration is effectively avoided. The two heat sources are combined, so that the problem that a heat source is additionally arranged for external heating type pyrolysis and gasification of garbage is solved, and dependency on conventional energy such as coal and electricity is reduced; and besides, combustible gas can be supplied externally, and the economic benefit of the system is increased.

Owner:TIANJIN UNIV

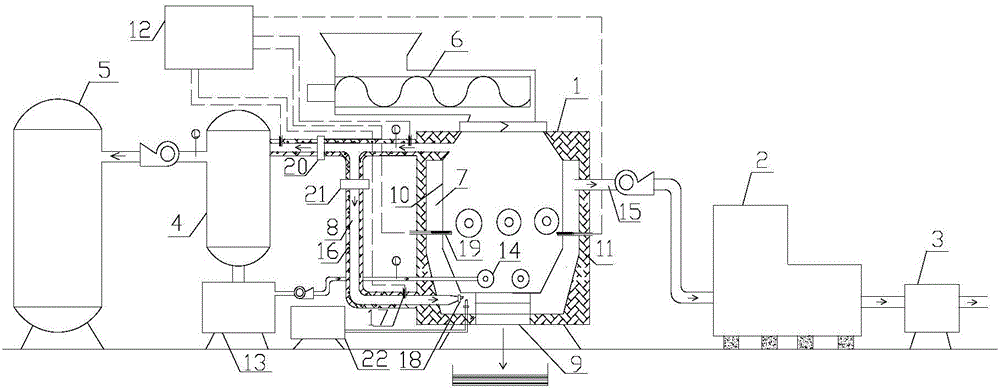

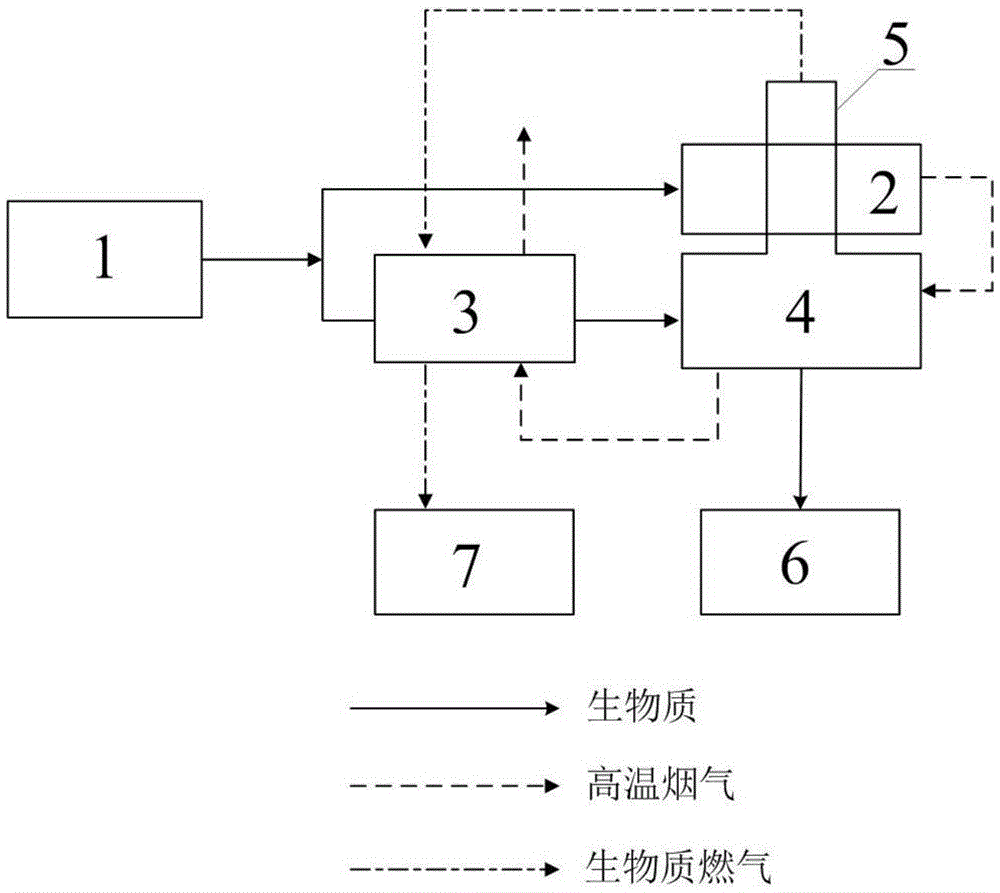

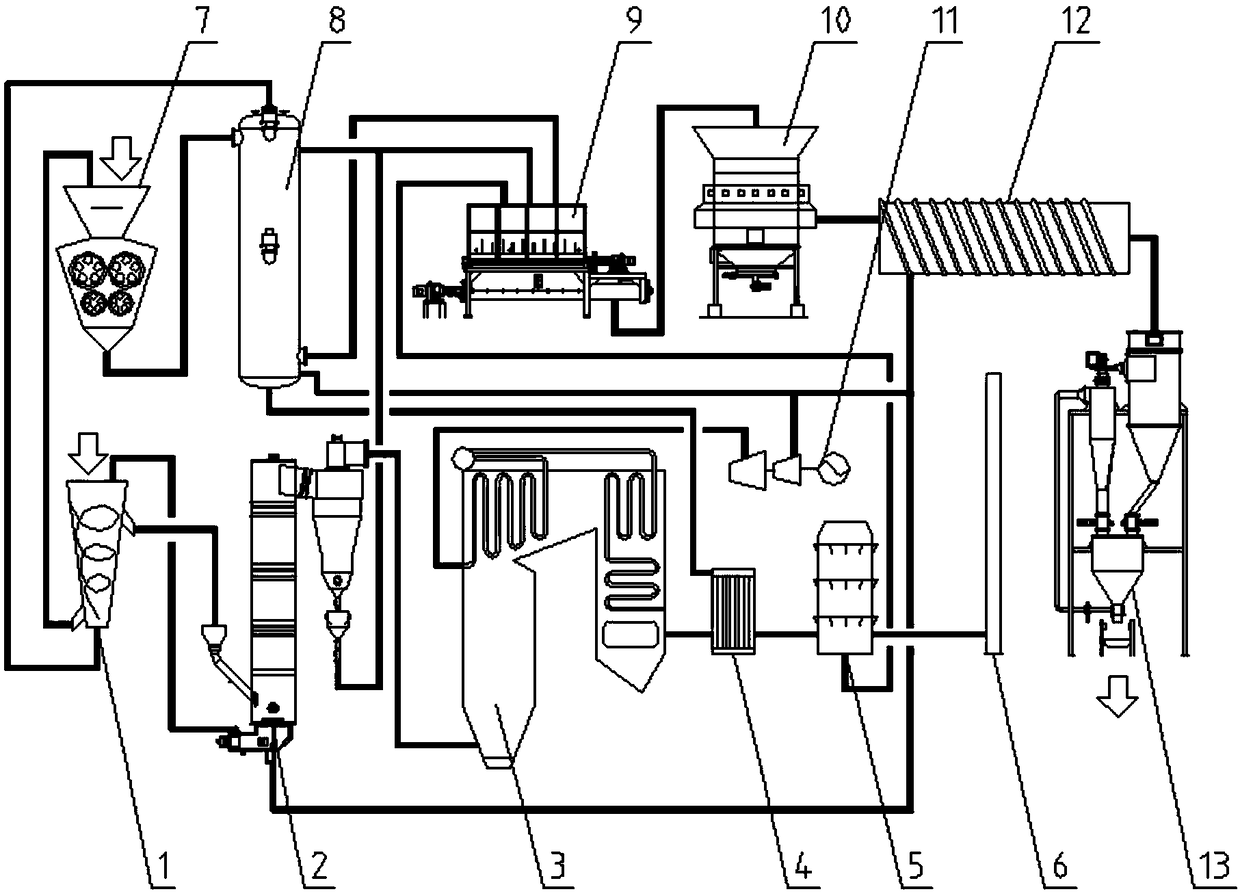

Device and method for producing clean fuel gas and biomass charcoal through continuous biomass carbonization

InactiveCN105542806AReduce tar contentWide range of usesBiofuelsGas purification by catalytic conversionHeat flowFlue gas

The invention discloses a device and method for producing clean fuel gas and biomass charcoal through continuous biomass carbonization. The device mainly comprises a raw material conveying unit, a biomass boiler, a biomass drying unit, a biomass carbonization unit, a catalytic cracking unit, a biomass charcoal storage unit and a biomass gas storage unit. High temperature flue gas generated by the biomass boiler provides heat for the biomass carbonization unit, after sufficient heat exchange is conducted with the biomass carbonization unit, the flue gas provides heat for the biomass drying unit, dried biomass enters the biomass carbonization unit for carbonization, and biomass generated after carbonization enters the biomass charcoal storage unit; biomass fuel gas generated by the biomass carbonization unit enters the catalytic cracking unit to remove tar, and after entering the biomass drying unit to provide heat and conducting sufficient heat exchange with the biomass drying unit, clean fuel gas enters the biomass gas storage unit. The device is compact in process structure, reasonable in material and heat flow direction, environmentally friendly in product, great in controllability and suitable for energy using requirements of villages and towns in China.

Owner:EAST CHINA UNIV OF SCI & TECH

Biomass drum-type carbonization furnace

InactiveCN104877691ASmooth recyclingInnovative designCoke quenchingRotary retortsCombustion chamberFlue gas

A biomass drum-type carbonization furnace comprises a feeding device, a carbonization furnace (7), a combustion chamber (9) and a carbon discharging bin (12), wherein the outlet of a feeding bin (2) of the feeding device is connected with the inlet end of the carbonization furnace (7); the outlet end of the carbonization furnace (7) is connected with the carbon discharging bin (12); a pyrolysis gas outlet (4) is formed in the carbonization furnace (7); a flue gas outlet (8) is formed above the combustion chamber (9); the carbonization furnace (7) is a drum-type carbonization furnace; a rotary power device is arranged below and connected with the carbonization furnace (7); a support device (6) is arranged at the inlet end of the carbonization furnace (7); a support device (11) is arranged at the outlet end of the carbonization furnace (7); the furnace body of the carbonization furnace (7) horizontally penetrates through the combustion chamber (9); and material guiding pieces distributed spirally are arranged on the inner wall of the carbonization furnace (7). A direct heating mode is adopted, the heat efficiency is high, and the energy consumption is low.

Owner:武汉光谷蓝焰新能源股份有限公司

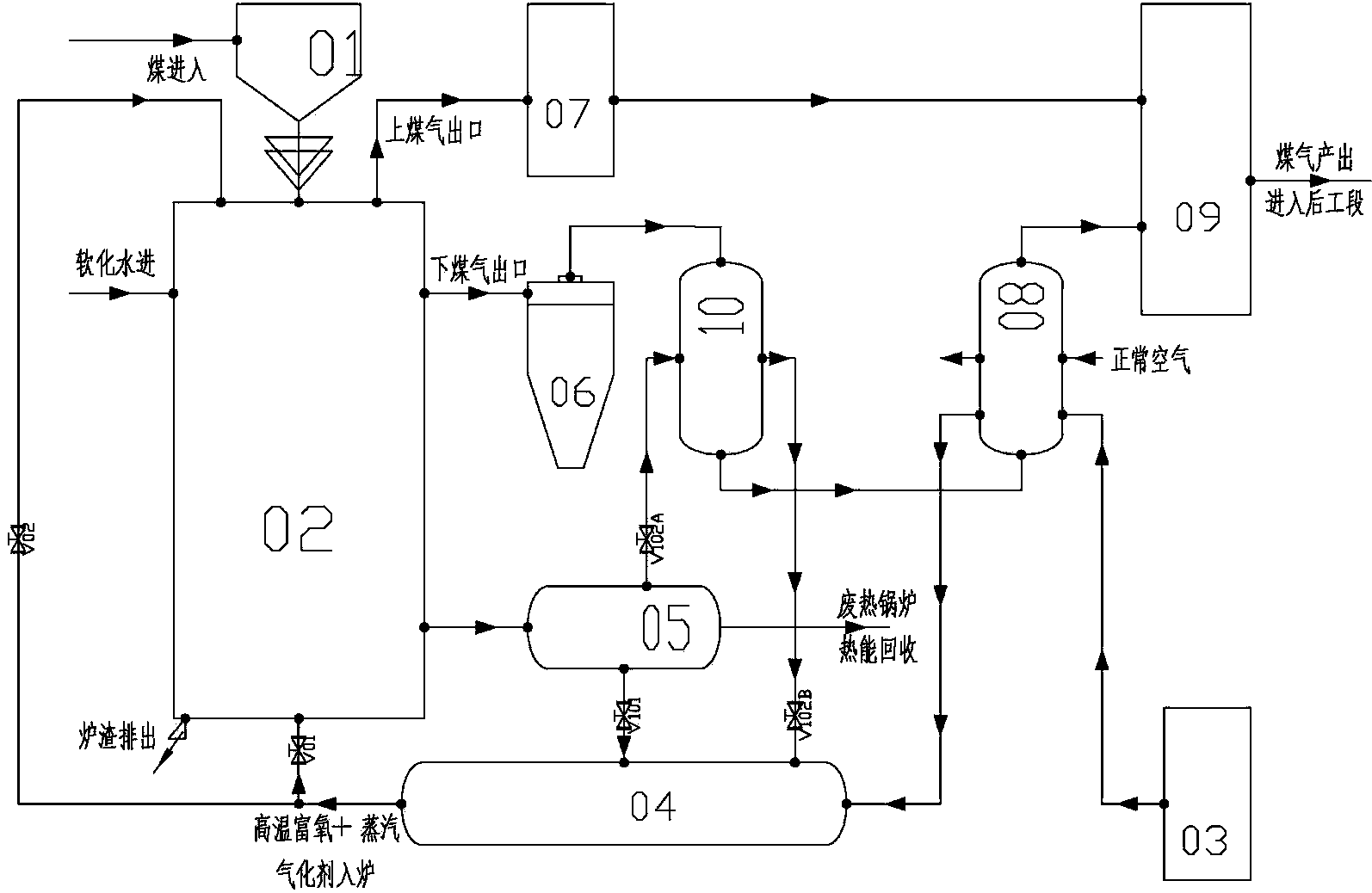

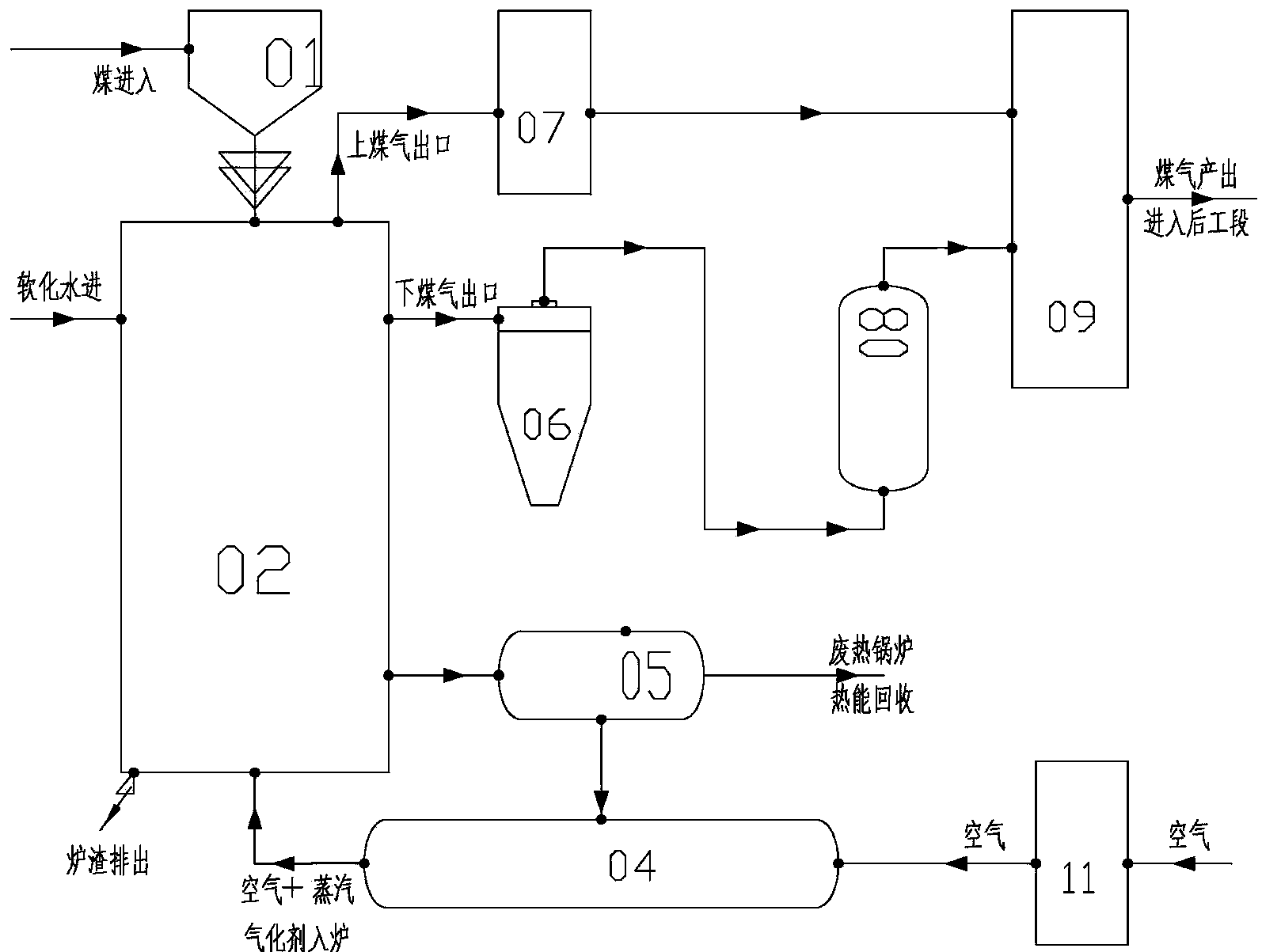

Coal gas production method and device using high-temperature rich oxygen and high temperature steam as gasification agent

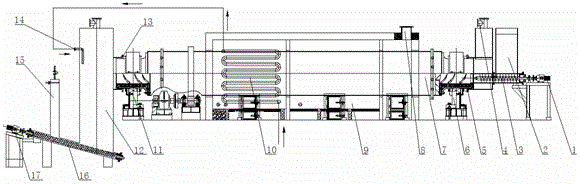

ActiveCN103525465AReduce unit consumptionOvercoming technical defects of furnace gas productionCombustible gas productionFixed bedControl valves

The invention belongs to the technical field of chemical coal made gas, and particularly relates to a coal gas production method and device using high-temperature rich oxygen and high temperature steam as a gasification agent. The coal gas production method and device adopt oxygen-enriched air with the oxygen concentration of 25 ~ 30% and with the oxygen temperature of 120 ~ 220 DEG C and the high temperature steam with the temperature of 120 ~ 220 DEG C as the gasification agent for coal gas production; and accordingly, an oxygen-enriched air source and related a heat exchanger, a control valve and pipelines are additionally arranged in an original coal gas production device. The coal gas production method and device well overcome the technical defects of coal gas production by use of a traditional atmospheric-pressure fixed bed gas producer, increase the coal gas producer yield and the coal gas calorific value, reduce the carbon content of ash, and reduce sensible heat loss, and the coal gas unit consumption is reduced by 10 ~ 30%.

Owner:上海穗杉实业股份有限公司

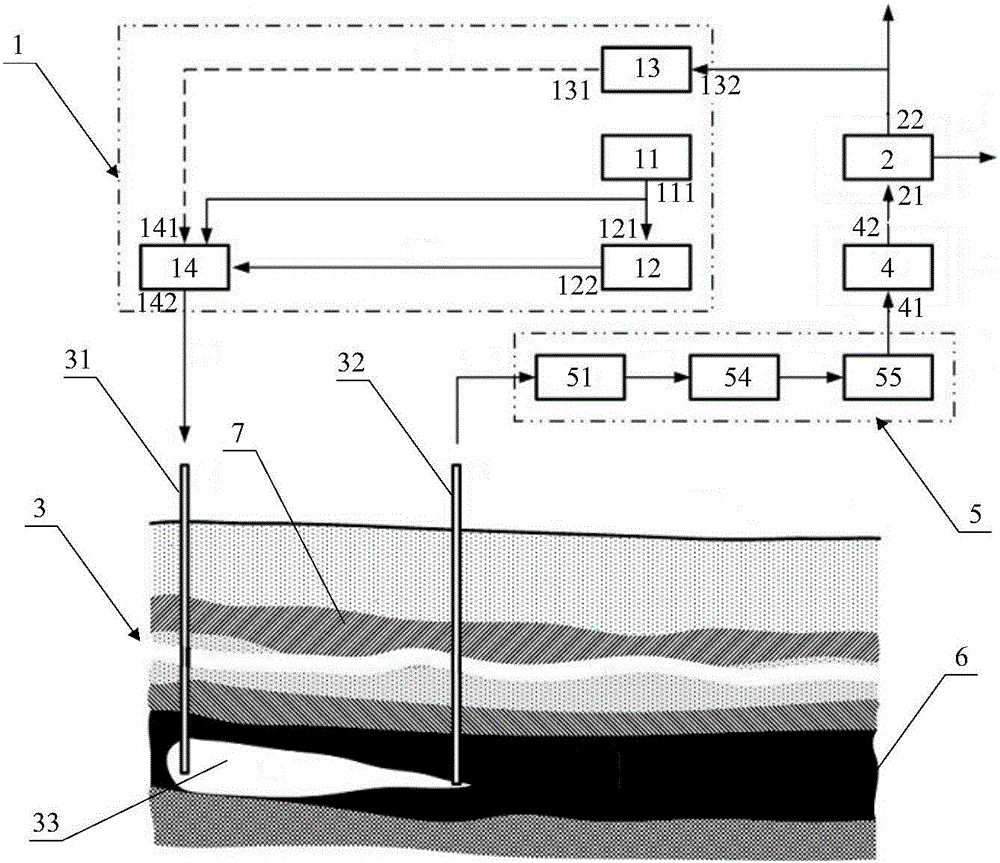

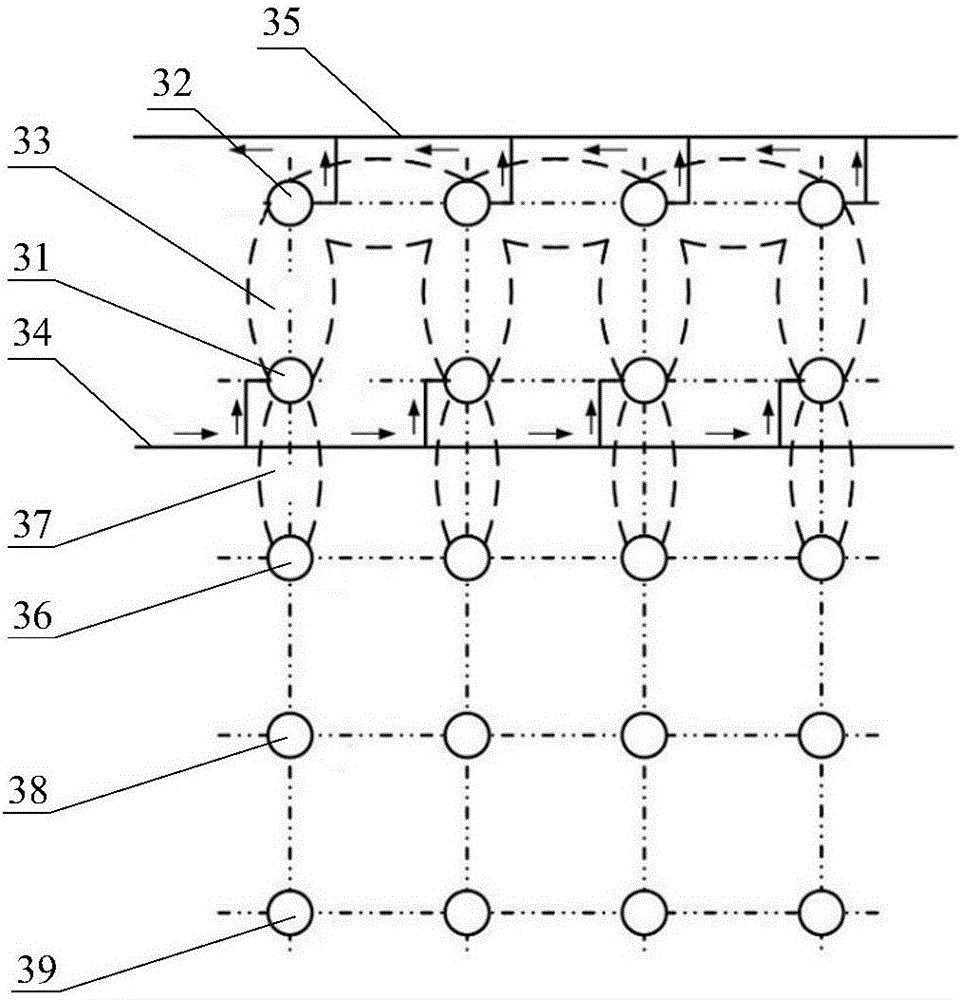

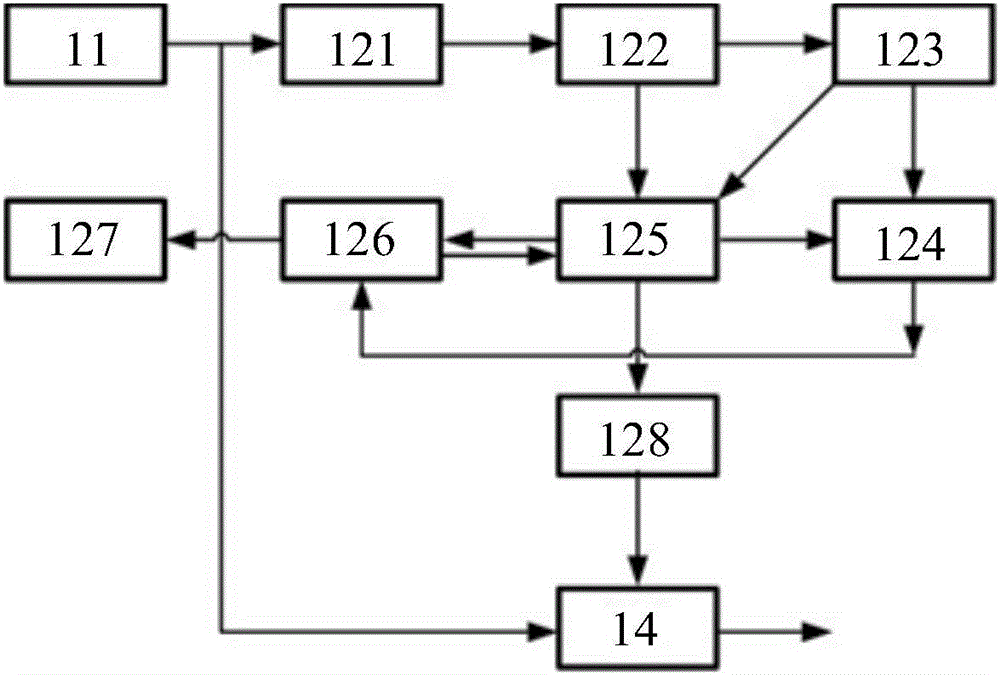

Industrial fuel gas production system and method

PendingCN106593396AHigh calorific valueIncrease gas calorific valueConstructionsFluid removalDecarburizationCarbon dioxide

The invention provides an industrial fuel gas production system and method. The system comprises a transmission and distribution unit and a decarburization unit. A gas outlet of the transmission and distribution unit is used for communicating with a gas inlet of an underground coal gasification system. The transmission and distribution unit is used for preparing a gasifying agent and transmitting the gasifying agent to the underground coal gasification system. The gasifying agent contains oxygen with the preset concentration. A gas inlet of the decarburization unit is used for communicating with a gas outlet of the underground coal gasification system. The decarburization unit is used for receiving gas output by the underground coal gasification system and removing carbon dioxide with the preset concentration in the gas. According to the industrial fuel gas production system, the gasification agent containing the oxygen with the preset concentration is used for gasifying a coal seam, and the heat value of coal gas can be increased; the purpose of further increasing the heat value of the coal gas is achieved by removing the carbon dioxide in the coal gas through the decarburization unit; and meanwhile, the emission load of carbon dioxide in the combustion process of the coal gas is decreased, and accordingly the environment is protected.

Owner:徐斌

Method for simultaneously producing activated carbon and medium heating value (MHV) fuel gas by using eupatorium adenophorum

The invention provides a method for simultaneously producing activated carbon and medium heating value MHV fuel gas by using eupatorium adenophorum. The method comprises the following steps of: drying and heating up eupatorium adenophorum for carbonization; heating up and carrying out heat preservation after crushing, then heating up to 900-1000 DEG C, and feeding carbon dioxide to a furnace for activation, thereby obtaining crude products of the activated carbon and MHV fuel gas; and cooling the crude product of the activated carbon to room temperature under the protection of air isolation, and then drying to obtain the product of the activated carbon. The iodine adsorption capacity of the main quality index of the obtained activated carbon achieves the national primary standard, the adsorption property of the obtained activated carbon is good, and the prepared fuel gas has a heat value up to 11000-13000KJ / m<3>, includes main components C2H2, H2, CH4 and CO, belongs to the MHV fuel gas, and can be used as a gas fuel. According to the method for simultaneously producing activated carbon and medium heating value (MHV) fuel gas by using eupatorium adenophorum, the whole process is shorter in activation time, pollution-free in preparation process, high in comprehensive utilization of resources, and high in added value of the product; the materials are rich in source, and the eupatorium adenophorum resources can be fully converted into biomass energy products.

Owner:KUNMING UNIV OF SCI & TECH

Biomass gasifying furnace

InactiveCN105670694AIncrease gas calorific valueTimely removal of slagGasification processes detailsCombustible gas productionTarPulp and paper industry

A biomass gasifying furnace is characterized in that the main body of the biomass gasifying furnace is a cylindrical gasifying furnace cylinder body, and a residue removal machine and an ash hoist are respectively arranged above and below a gasifying furnace baseboard. The gasifying furnace cylinder body is divided into an external cylinder body and an internal cylinder body, the wall of the external cylinder body and a downward extension wall jacket form a combustion gas channel, the lower end of the combustion gas channel is connected with a hearth, and the sidewall of the external cylinder body is provided with a combustion gas outlet; a flow divider is positioned in the middle portion of the hearth, and the circumference of the hearth is provided with gas outlets; and the residue removal machine is arranged below the flow divider, the upper portion of the residue removal machine is a conical cap, the middle portion of the conical cap is connected with a residue removal machine ventilating tube, and a residue removal machine support medium shaft is supported on a transmission shaft connected with a residue removal machine motor. The sidewall of the external cylinder body is provided with high temperature air inlets, and is connected with the flow divider through the residue removal machine ventilating tube; and the bottom of the gasifying furnace baseboard is connected with an ash discharge machine. The biomass gasifying furnace has the advantages of complete conversion of heat energy of biomass fuels, conversion of tar in the combustion gas into permanent gas molecules in high temperature environment, reduction of damages to devices, and improvement of the calorific value of the combustion gas.

Owner:刘勇

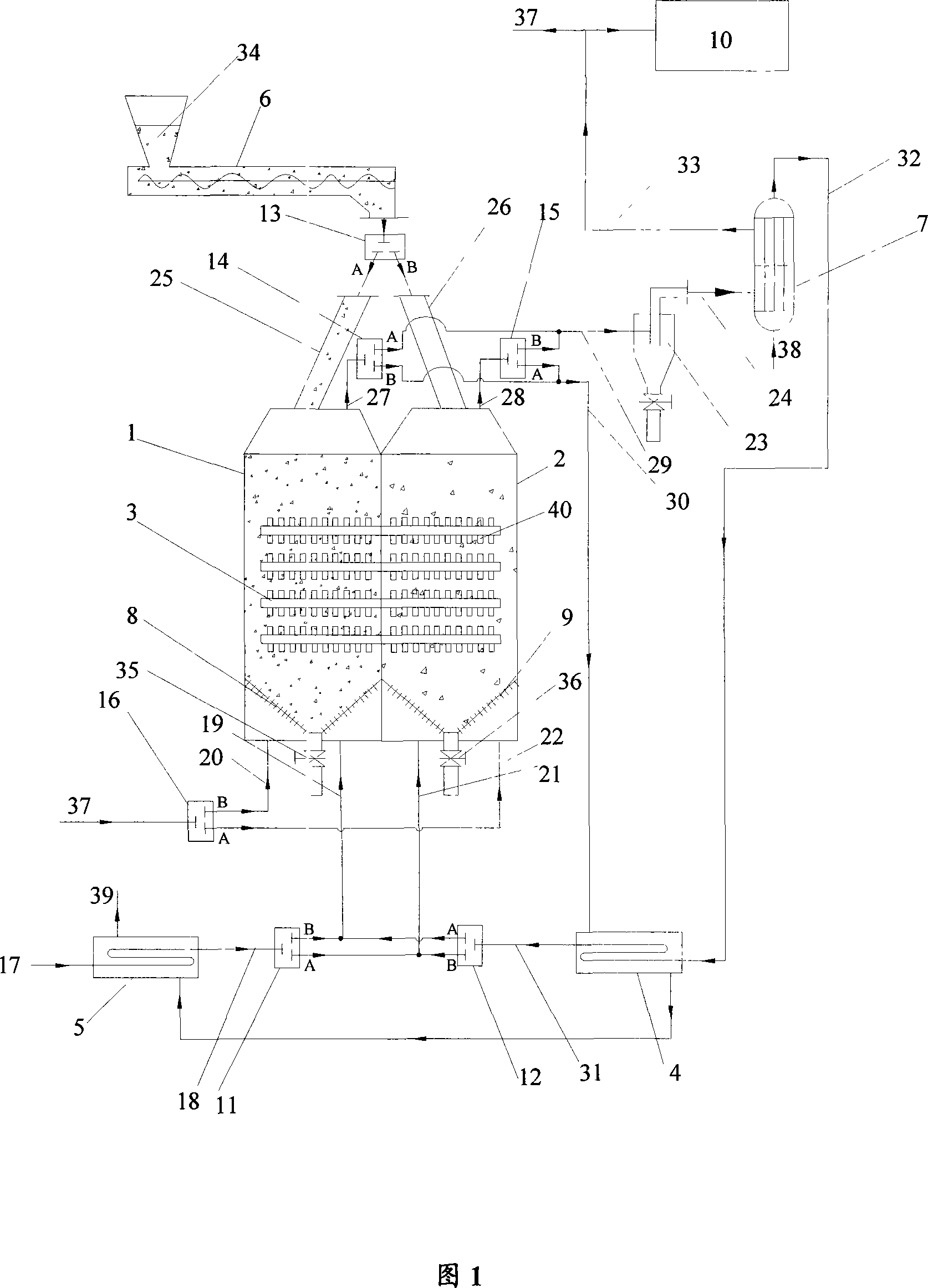

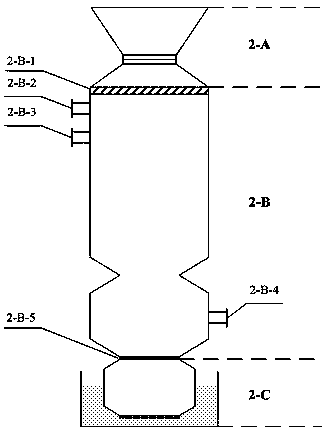

Biomass abnormal circulating fluidized bed gasifier

ActiveCN103102990AIncrease gas calorific valueLarge scale processingProductsReagentsFluidized bed gasifierFluidized bed

The invention provides a biomass abnormal circulating fluidized bed gasifier which consists of a fluidized bed, a gas distributor, an ash discharge tube, a gas inlet tube, a feed inlet, a first-level gas-solid separator, a cinder circulating return tube, a return feeder, a second-level gas-solid separator, a silicon-potassium fertilizer outlet and a gas outlet. The fluidized bed consists of a turbulent fluidized bed and an entrained bed reactor. The gas distributor and the ash discharge tube are arranged at the bottom of the turbulent fluidized bed. A biomass feed inlet is arranged in a position which is 100-2000mm far from the bottom of the entrained bed reactor, and the first-level and second-level gas-liquid separators are arranged at the top. Coarse particle ash of the first-level gas-liquid separator enters into the circulating return tube and is connected with the turbulent fluidized bed at the bottom of the abnormal circulating fluidized bed through the returner. High-temperature refine ash of the second-level gas-liquid separator is fed outwards as the silicon-potassium fertilizer from the silicon-potassium fertilizer outlet, and gas is fed outwards as a product gas from the gas outlet.

Owner:田原宇

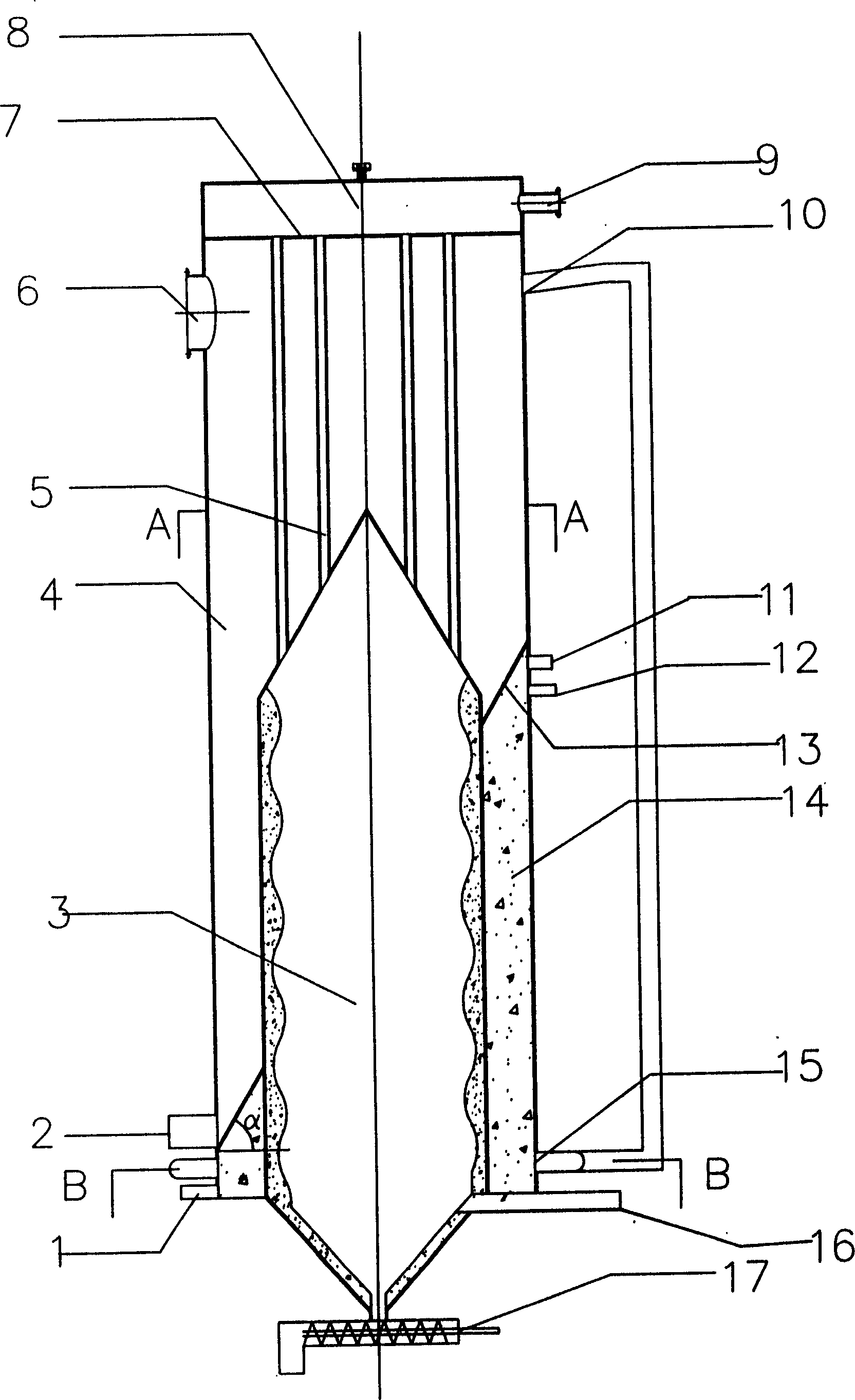

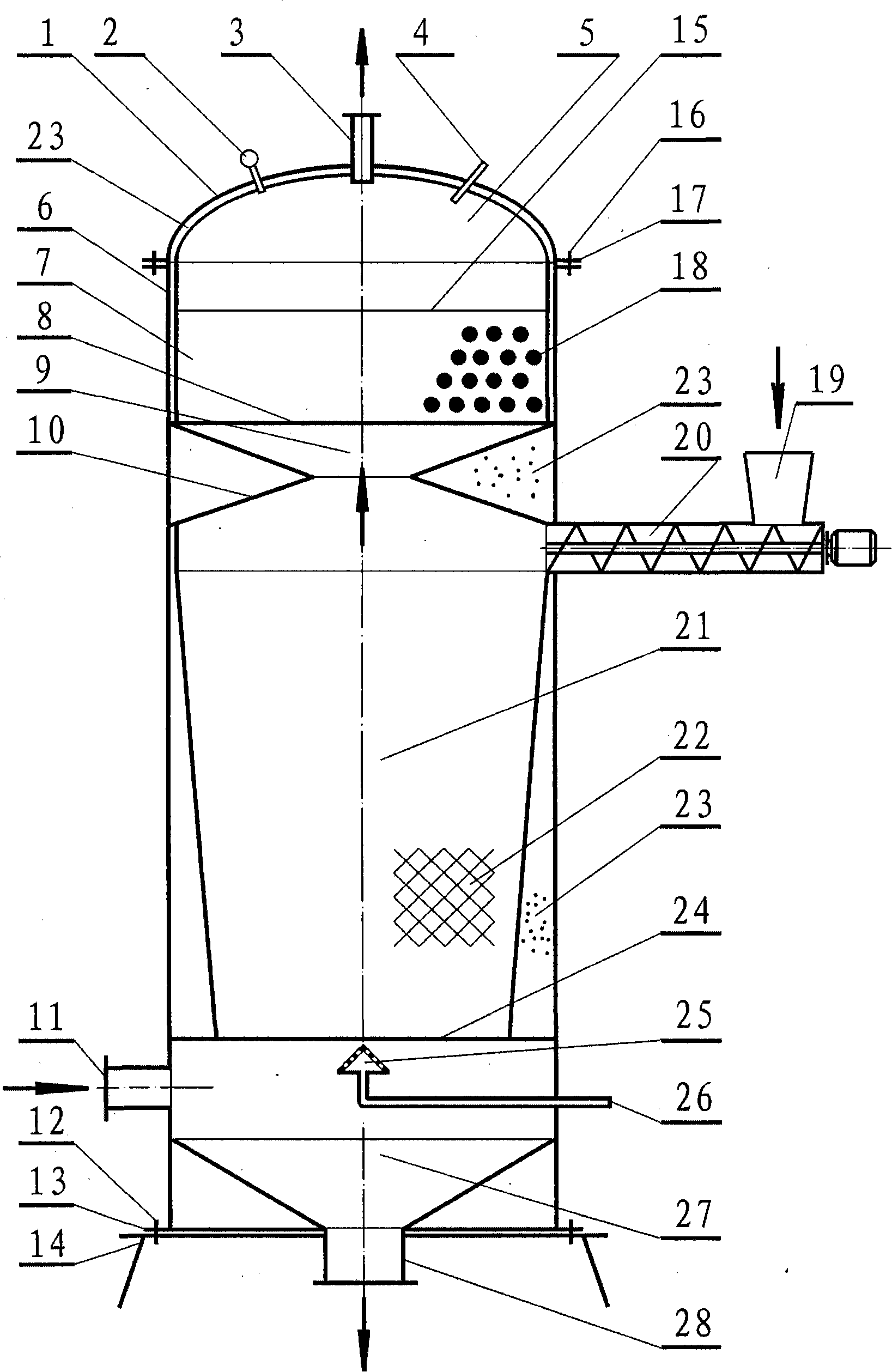

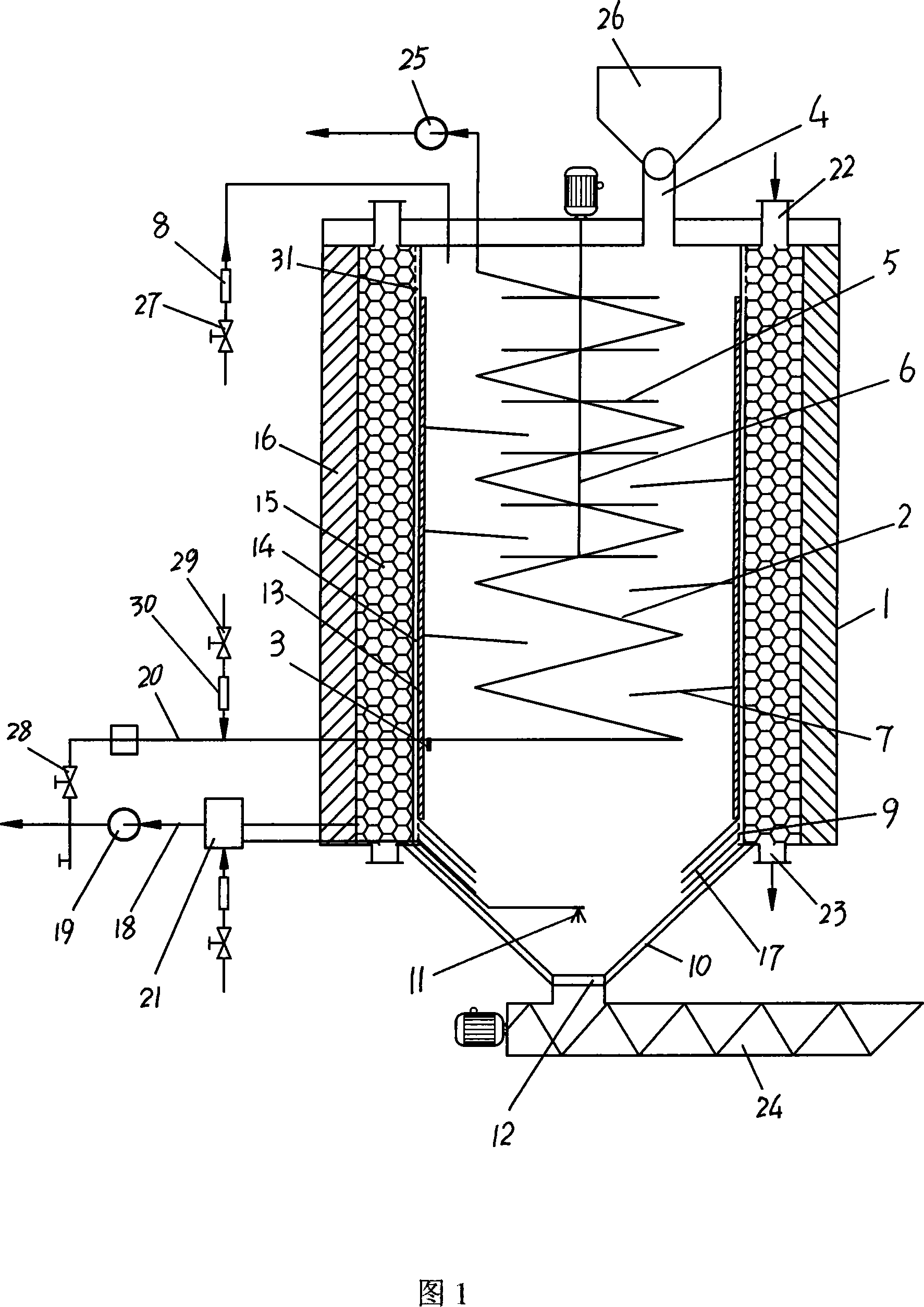

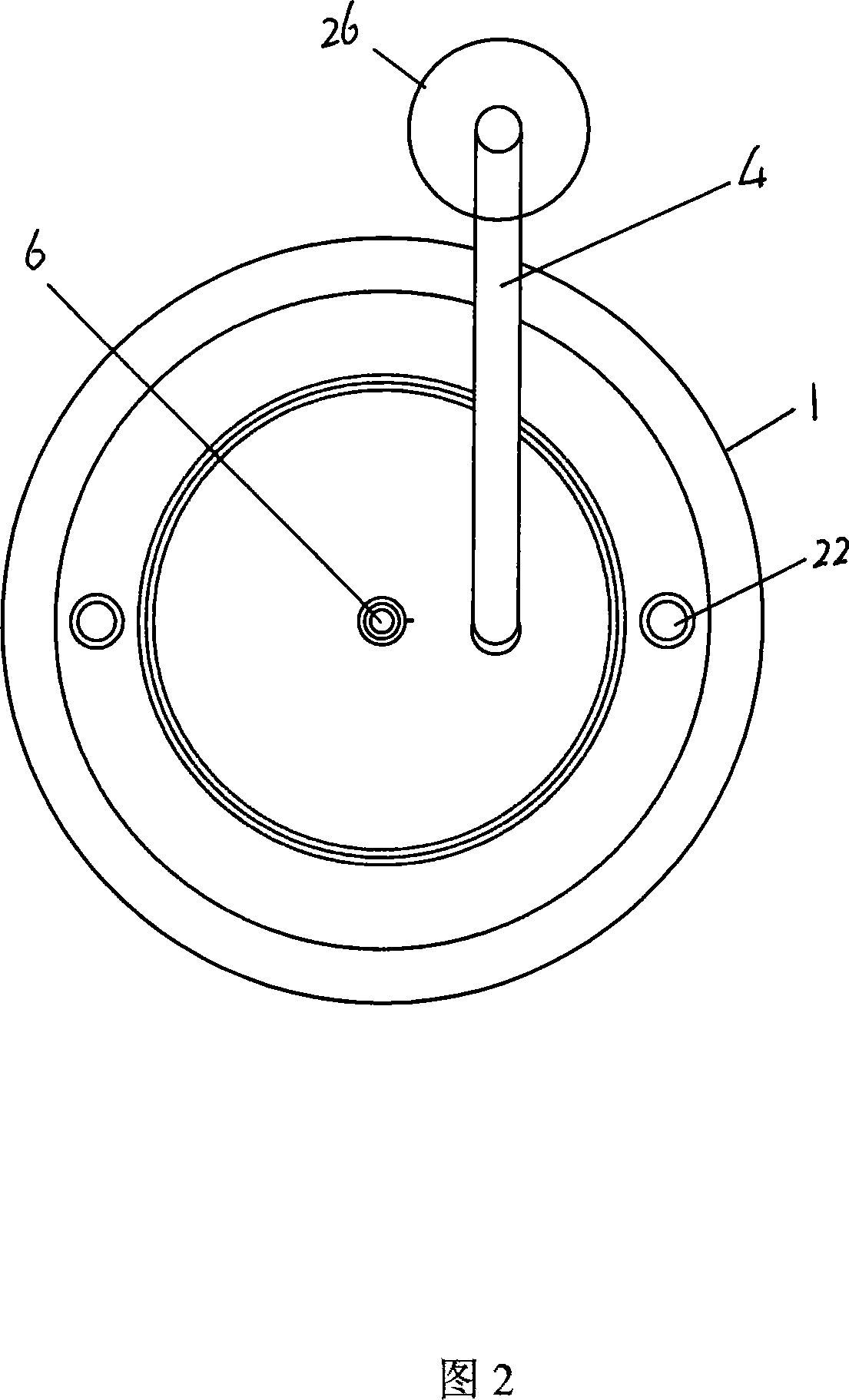

Catalytic cracker of biomass tar

InactiveCN101029249AIncrease temperatureHigh catalytic cracking efficiencyCatalytic crackingTarEngineering

A biomass tar catalytic cracker adopts cylindrical furnace body with conical bottom, jacket structure is arranged at side wall, which consists of high-temperature-resisting furnace wall, gas channel, catalyst bed, thermal-insulating layer and furnace external wall; rectifier board is arranged at bottom of cylindrical furnace body as entrance, exit on top of gas channel leads to catalyst bed by topped filter net, gas-outputting opening is placed at bottom of catalyst bed, and gas pipeline is connected with gas cabinet by induced draft fan. It has high cracking efficiency and prevents tar adhesion and block in gas pipeline system.

Owner:HEFEI UNIV OF TECH

Biomass gasification furnace absorbent and its production method

InactiveCN1686605AIncreased tar cracking rateIncrease gas calorific valueOther chemical processesGas purification with selectively adsorptive solidsTarChemistry

An adsorbent for the adsorptive filter of biomass gasifier is prepared from attapulgite-type clay, high-Al alumina, magnesium oxide, calcium oxide, sodium carbonate and wood dust through proportionally mixing, stirring, grinding, granulating and baking. It can crack the tar and adsorb heavy metals, alkali metals and harmful trace elements.

Owner:许庆华

Double-fixing-bed biological matter reactor system of supplying heat by heat pipe

InactiveCN101070478ARealize indirect gasificationIncrease gas calorific valueEnergy inputIndirect heat exchangersBiomassSuperheater

This invention relates to a double fixed bed live material reactor system which using the heat pipe to provide heat. This invention has the cyclone separator, the steam generator, the steam superheater, the air pre-heater. The technical feature lies in that it has two same fixed beds and the heat transfer part heat pipes. When the lives material reacts, a fixed bed are taken as the combustion chamber, another fixed bed as reaction chamber. After the living material respond finished, the original work for combustion chambers fixed bed transfers to the reaction chamber, the original work for the reaction chamber fixed bed transfers to the combustion chamber. The heat transfer part heat pipe crosses two fixed beds, a section in a fixed bed, a section in another fixed bed. The flaw is resolved existing technical existence's fresh material own combustion produced to include massive N2 to cause calorific value Gao Huo not to take the gasifying agent with the overheated steam to cause the cost which increases. This invention's two fixed bed achievement gasifies the reactor or the combustion chamber in turn, realizing the biological archery target indirect heating gasification, the calorific value's increasing, generally might achieve 10-15MJ / m3.

Owner:NANJING UNIV OF TECH

Biomass gasification reaction system removing tar automatically and method thereof

InactiveCN108315056AEfficient removalAchieve staged gasificationGasification processes detailsCombustible gas productionSlagTar

The invention relates to a biomass gasification reaction system removing tar automatically and a method thereof. The biomass gasification reaction system removing tar automatically comprises a furnacebody and a gasified medium supply device, wherein from top to bottom, a hearth of the furnace body comprises a pretreatment chamber, an oxidation burning chamber, a reductive cracking chamber and a carbonizing activating chamber in sequence, the pretreatment chamber is internally provided with a material storage bin, the upper part of the material storage bin is provided with a material feed port, an isolation part is arranged between the pretreatment chamber and the oxidation burning chamber, the side wall of the oxidation burning chamber is provided with a ventilation port, a fire grate isarranged between the reductive cracking chamber and the carbonizing activating chamber, a product of the reductive cracking chamber enters the carbonizing activating chamber through the fire grate, the carbonizing activating chamber is provided with a slag hole, and the carbonizing activating chamber is further provided with an active carbon taking device. The biomass gasification system removingtar automatically has a wide application range and has high gasification efficiency.

Owner:余军

Regenerative gasification device for high calorific value synthesis gas and gasification production method based on device

ActiveCN106635174AHigh calorific valueEfficient separationGasification processes detailsGranular/pulverulent flues gasificationSyngasFour-way valve

The invention discloses a regenerative gasification device for high calorific value synthesis gas. The regenerative gasification device comprises a gasification chamber, a blower and a four-way valve, wherein a synthesis gas outlet for storing a synthesis gas pipeline is formed in the top end of the gasification chamber; a radiant tube is arranged inside the gasification chamber; a first regenerative chamber and a second regenerative chamber are separately arranged at two ends of the radiant tube and are also arranged outside the gasification chamber; an overheat steam pipeline is also arranged in the gasification chamber; the blower and the four-way valve are arranged outside the gasification chamber; air is fed into the four-way valve by the blower, passes through the four-way valve and then enters the first regenerative chamber; flue gas exhausted from the second regenerative chamber passes through the four-way valve and enters a water feeding heat exchanger by an induced draft fan; an overheat steam outlet is formed on the water feeding heat exchanger. According to the regenerative gasification device disclosed by the invention, heat is provided for the system in the regenerative radiant tube, and gasification is realized in the gasification chamber; nitrogen gas is effectively separated from the synthesis gas, and no nitrogen is contained in the synthesis gas, so that the calorific value of the synthesis gas is improved, and the operation cost is reduced.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

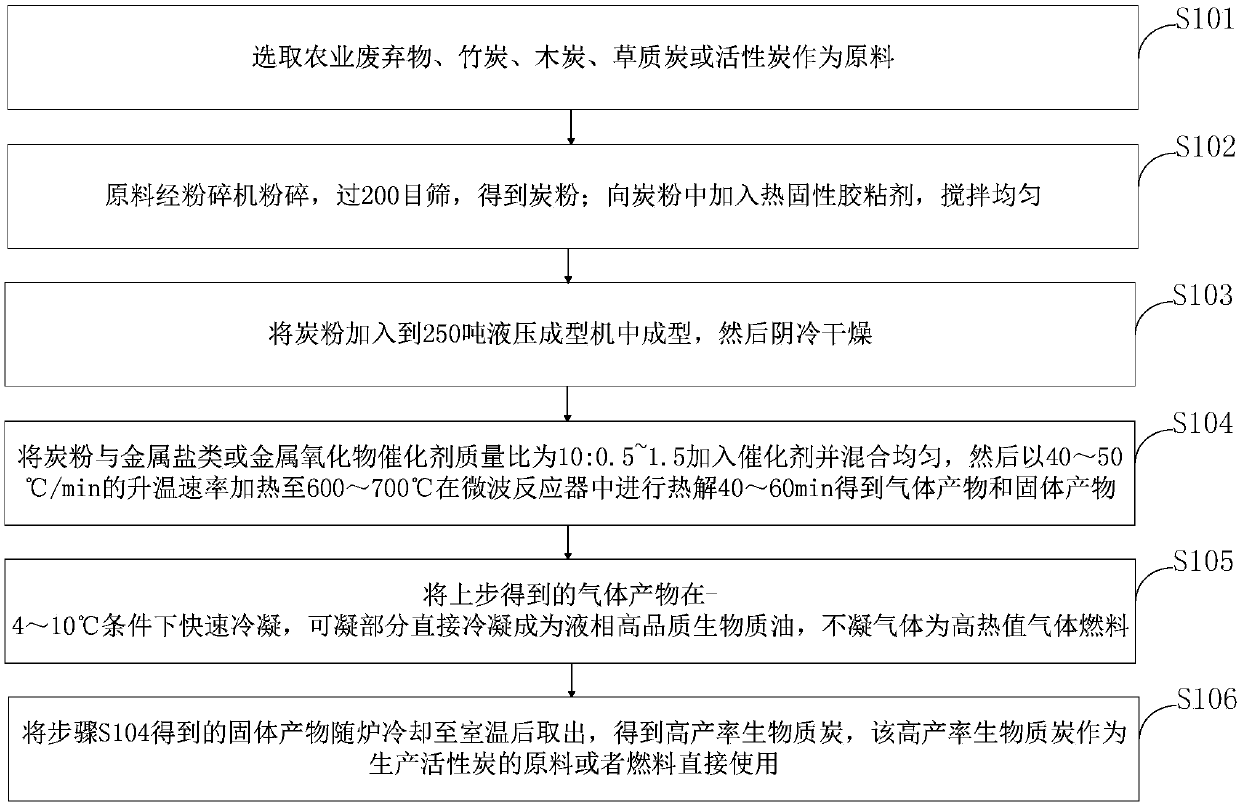

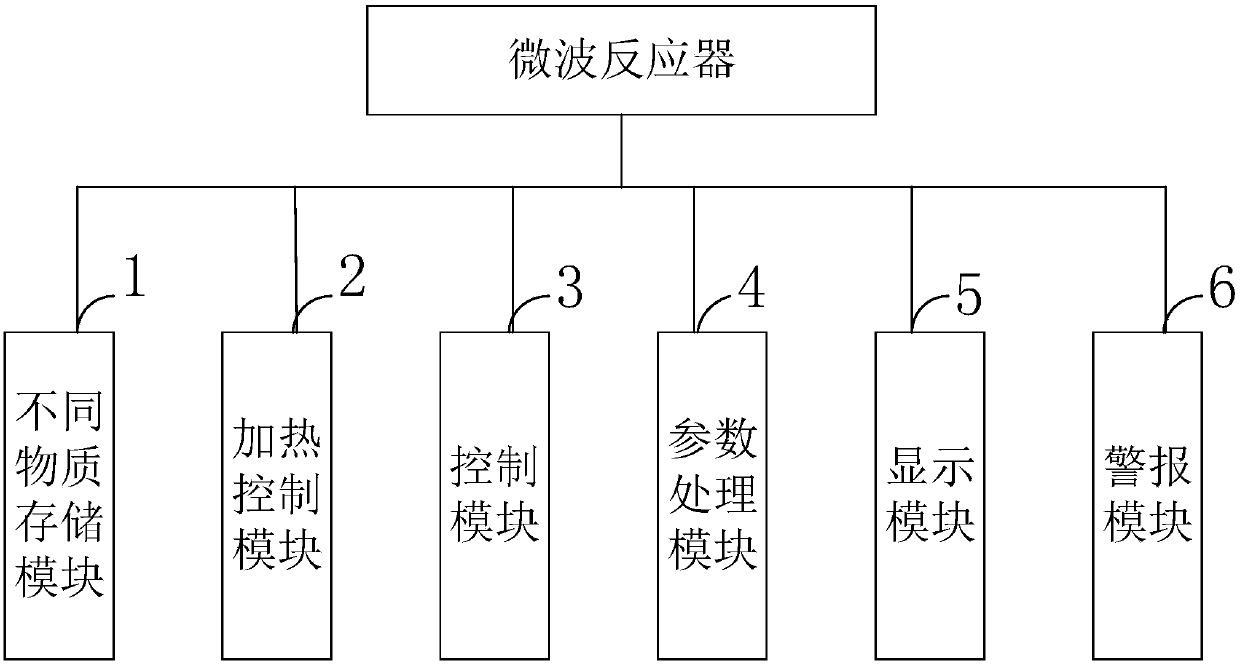

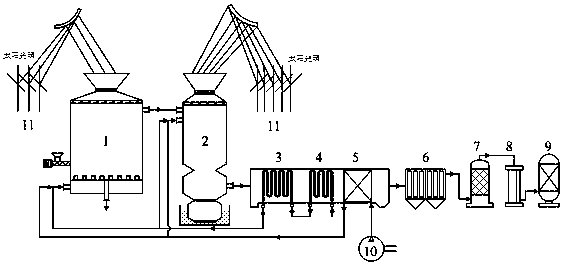

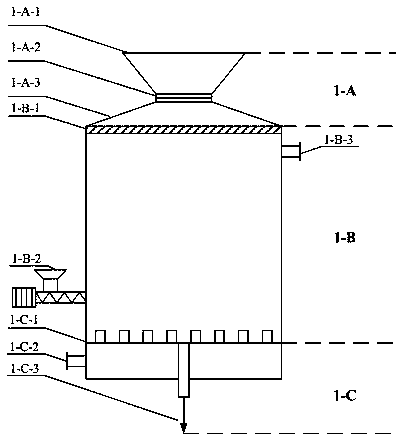

Method for directionally producing biomass charcoal by microwave catalytic pyrolysis of biomass

InactiveCN108251140AReduce usageReduce corrosionBiofuelsLiquid hydrocarbon mixture productionCatalytic pyrolysisAdhesive

The invention belongs to the technical field of biomass charcoal, and discloses a method for directionally producing biomass charcoal by the microwave catalytic pyrolysis of biomass. The method comprises the following steps: selecting agricultural wastes, bamboo charcoal, wood charcoal, grass charcoal or activated carbon as raw materials; smashing the raw materials by a pulverizer, and sieving toobtain powdered carbon; adding thermosetting adhesive into the powdered carbon, and evenly mixing; then, carrying out cold drying; evenly mixing the powdered carbon, metal salt or metal oxide catalyst, then, heating, carrying out pyrolysis for 40-60min in a microwave reactor to obtain a gas product and a solid product; quickly condensing the obtained gas product under a condition of -4 to 10DEG C,directly condensing a coagulable part into liquid-phase high-quality biomass oil, and taking non-condensing gas as high calorific value gas fuel. According to the method, the agricultural wastes aretaken as the raw material so as to be favorable for environment protection and the reuse of agricultural wastes. A preparation process of the biomass charcoal materials does not generate tar.

Owner:HUAIYIN TEACHERS COLLEGE

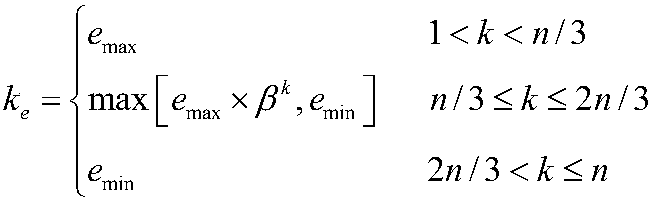

Device and method for preparing high-quality fuel gas by solar-driven solid waste sectional gasification

InactiveCN111548828ATo achieve complementary useRaise the gradeEnergy inputGasification processes detailsAir preheaterHeliostat

The invention discloses a device and a method for preparing high-quality fuel gas by solar-driven solid waste sectional gasification, and belongs to the technical field of solar energy utilization. The device comprises a heliostat field, a solar fluidized bed, a solar melting furnace, a water vapor generator, a coal economizer, an air preheater, a bag-type dust collector, a desulfurizing tower, afuel gas compressor and a gas storage device. Solar energy is gathered by the heliostat field to supply heat, sensible heat of high-temperature combustible gas generated through segmented gasificationof a solar fluidized bed and a solar melting furnace is recycled through the water vapor generator, the coal economizer and the air preheater in sequence, and then the high-temperature combustible gas is subjected to purification treatment through the bag-type dust collector and the desulfurizing tower to form high-quality fuel gas to be compressed, stored or directly utilized. The solar-driven segmented gasification reaction system is realized, the quality of gasified combustible gas can be effectively improved while solid waste is treated, secondary pollutants such as dioxin are prevented from being generated, the gasification efficiency of the system is improved, excessive solar energy is reasonably utilized, and the energy-saving and environment-friendly effects are achieved.

Owner:NANJING INST OF TECH

Cyclic utilization device and method for preparing carbon-based organic fertilizer by carbonizing fluidized bed biomass

InactiveCN109134151AIncrease gas calorific valuePrevent dryingBio-organic fraction processingSteam generation using pressureFluidized bedAgricultural engineering

The invention provides a cyclic utilization device and method for preparing a carbon-based organic fertilizer by carbonizing fluidized bed biomass. The device comprises a winnowing device, wherein thewinnowing device is separately connected to a fluidized bed carbonizing device, an organic matter pre-treatment device and a fermenting device, and the back of the fluidized bed carbonizing device isconnected to a blending device and a fermenting device; one end of the fluidized bed carbonizing device is connected to a boiler, the boiler is connected to a turbine generation unit, and a desulfurizing device is provided with an outlet connected to the inlet of the blending device; the outlet of the organic matter pre-treatment device is connected to the inlet of the fermenting device, the outlet of the fermenting device is connected to the inlet of the blending device, and the bottom of the fermenting device is connected to a denitration device; one side of the blending device is connectedto a forming device; and the outlet of the forming device is connected to a drying device, and the tail part of the drying device is connected to a packaging device. The device can prepare the carbon-based organic fertilizer by only feeding biomass and organic matters, and the electric power and heating powder of the system are self-sufficient, so that the device is suitable for distributed development.

Owner:HEFEI DEBO BIOENERGY SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com