Device for production of fuel oil and fuel gas and/or flue gas power generation through household garbage

A domestic garbage and gas technology, which is applied in the fields of biofuel, petroleum industry, solid waste removal, etc., can solve the problems of low thermal efficiency of indirect heating, low thermal efficiency, long pyrolysis time, etc., and achieve large production scale processing capacity and long equipment life The effect of long life and high calorific value of gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

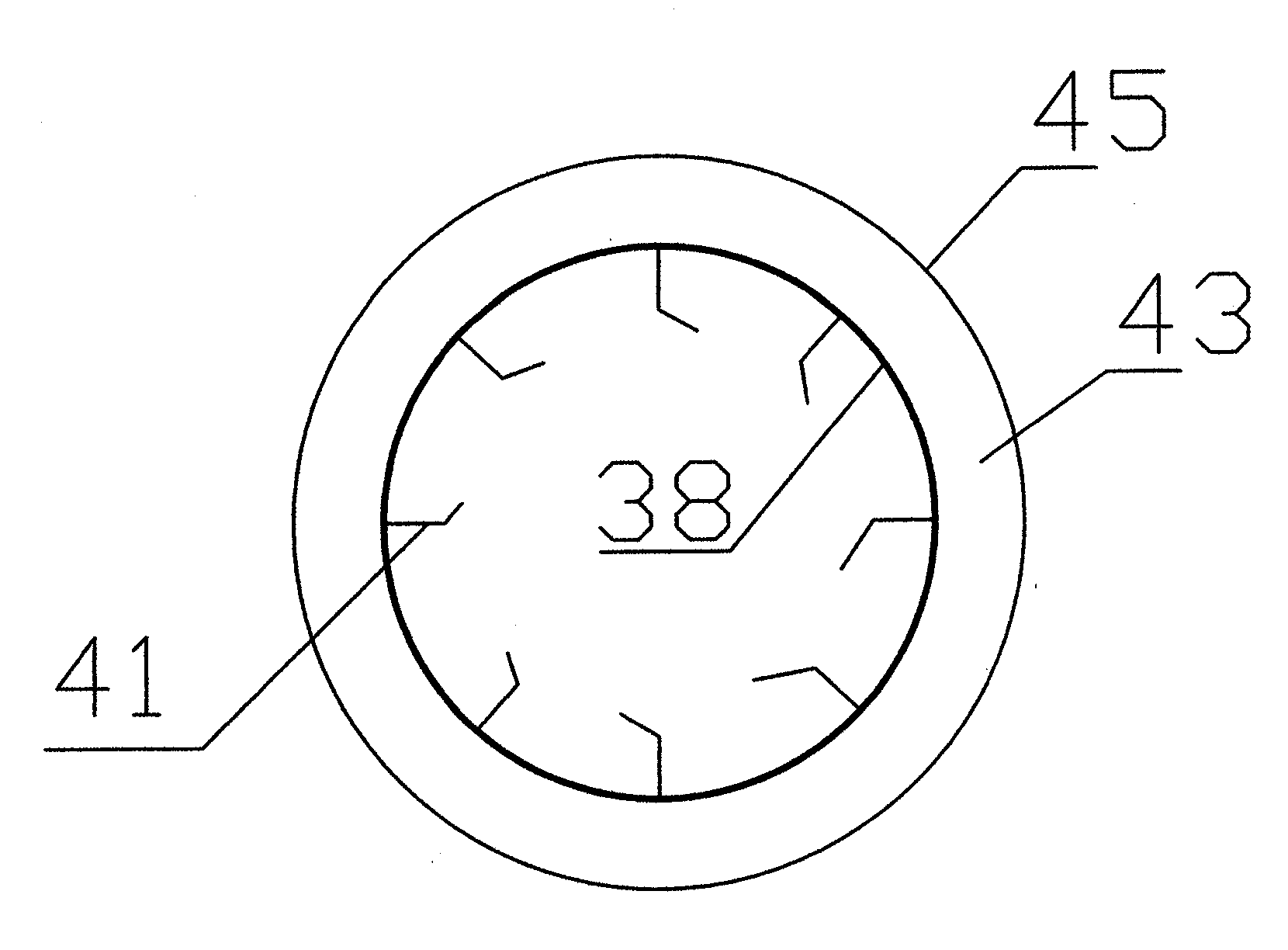

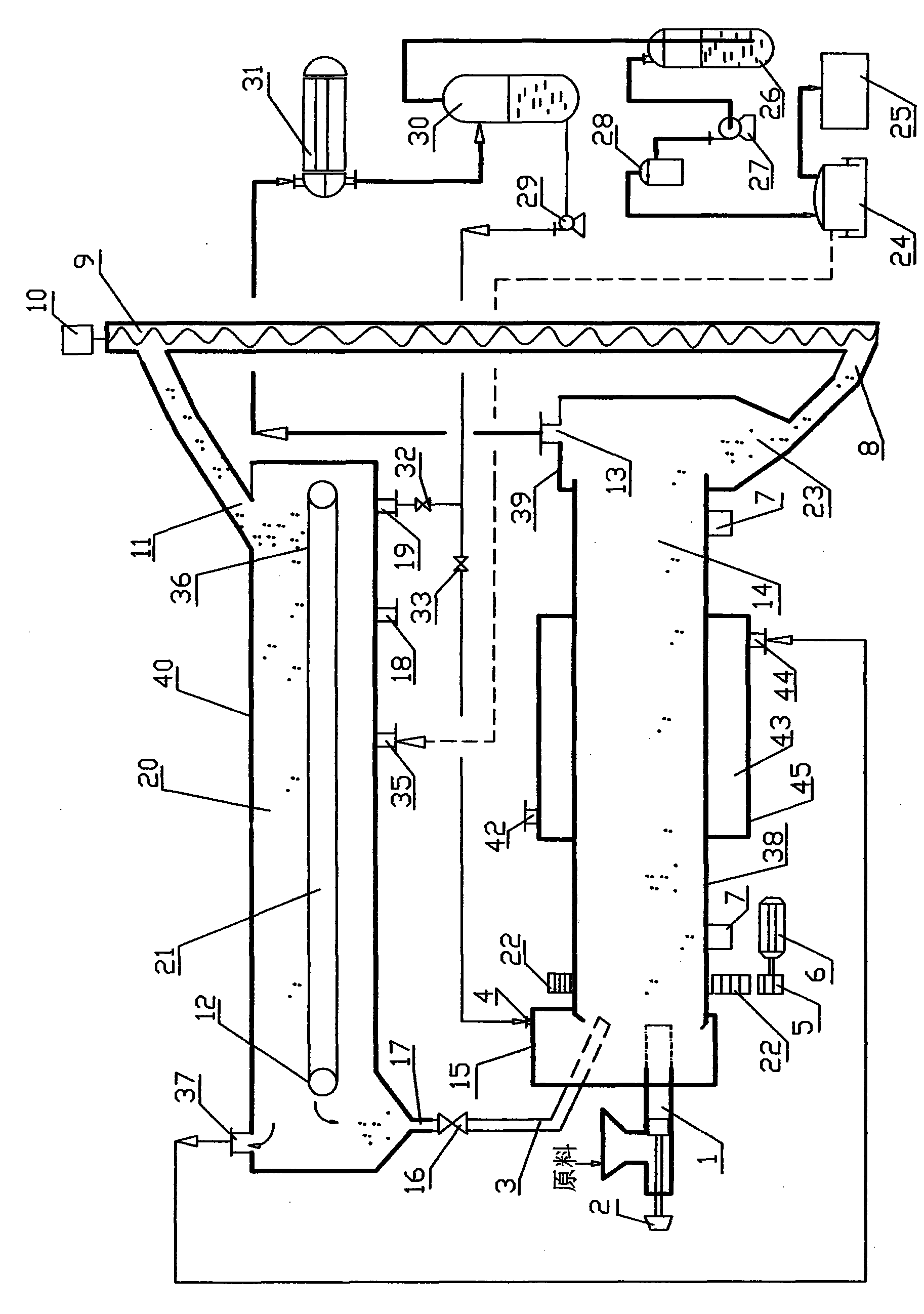

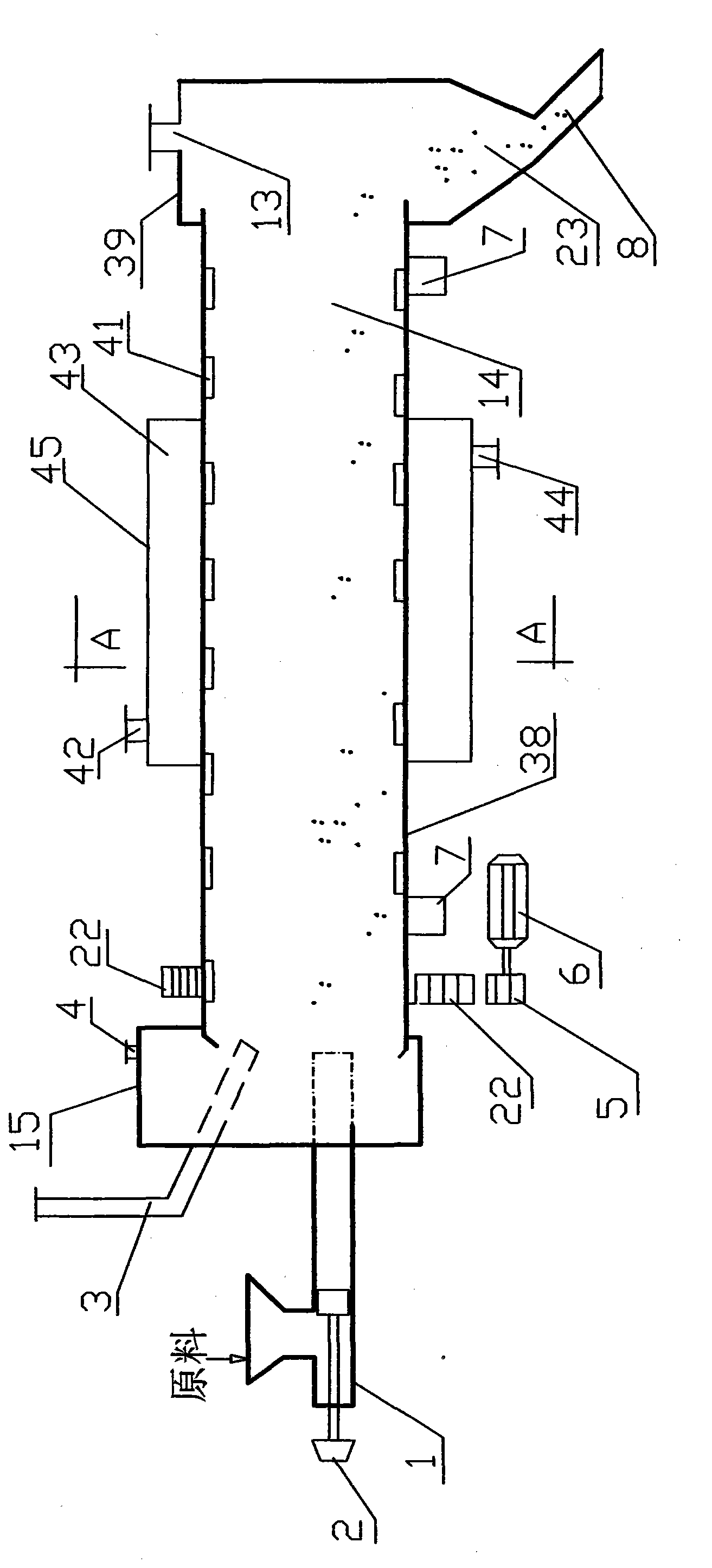

[0036] combined with figure 1 , figure 2 , image 3 and Figure 4 First, heat the granular heat carrier in the incinerator (20) to a high temperature of 700-800°C, then fall into the sealed horizontal rotary pyrolysis reactor (14) through the valve (16), and use the motor ( 6) Drive the gear discs (5, 22) to rotate and drive the horizontal rotary pyrolysis reactor (14) to rotate. At the same time, the motor (2) drives the reciprocating hydraulic feeder (1) to work. The feeder (1) feeds the domestic waste no larger than 30 cm in size after pretreatment and removal of inorganic impurities into the sealed horizontal rotary pyrolysis reactor (14 cm) at a feed rate of 80 kg / min ), and directly mixed with 700-800°C granular heat carrier, use high-temperature granular heat carrier to directly heat the raw material, or / and use high-temperature flue gas to indirectly heat the shell heating chamber of the horizontal rotary pyrolysis reactor Heating, the temperature of the domestic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com