Purifying system for biomass gasifying oven

A purification system and a gasifier technology, which are applied in the field of biomass gasifiers, can solve the problems that the tar cracking rate, the gasification rate and the comprehensive economic benefit of the gas calorific value cannot be improved, and achieve low production cost, simple structure, The effect of increasing the vaporization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with embodiment the present invention will be further described:

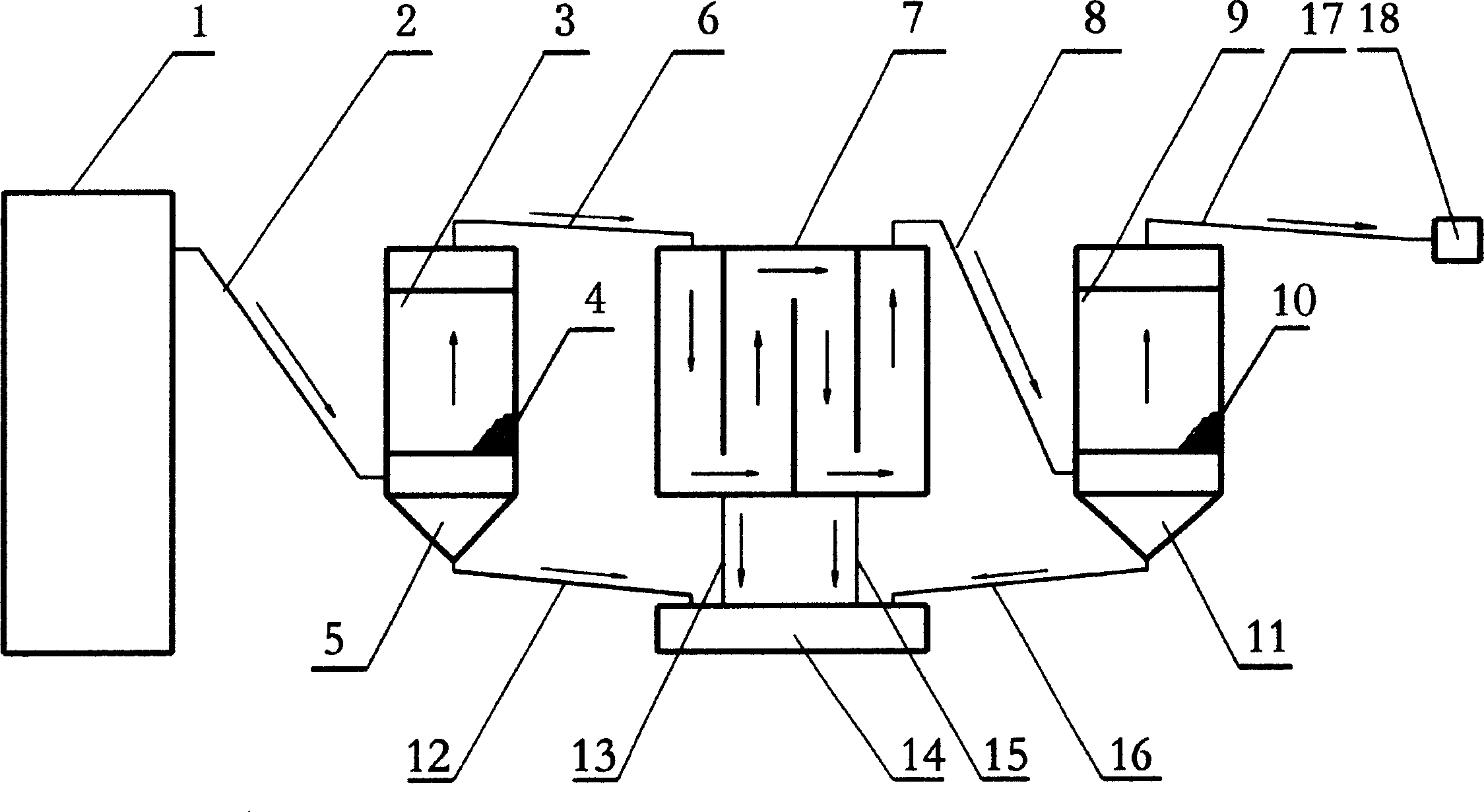

[0025] figure 1 It is a schematic diagram of the biomass gasification furnace purification system.

[0026] When the gas flow of the biomass gasification furnace 1 passes through the pipeline 2 and flows through the catalyst 4 of the biomass gasification furnace in the catalytic converter 3, the tar in the gas flow is catalytically cracked, and the cracked tar is decomposed into combustible Gas and other substances are transported from the pipeline 6 to the labyrinth gas holder 7 along with the gas flow, and tar, alkali metals, heavy metals, waste water and dust that have not been cracked are blocked by numerous particle catalysts in the labyrinth. Combined with the effect of gravity, it flows into the waste tar and waste water chamber 5, and flows from the lower pipe 12 of the catalytic converter to the collection pool 14 of waste tar and waste water.

[0027] The gas flow purifie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com