Biomass gasifying furnace

A technology of gasification furnace and biomass, which is applied in the direction of gasification process, manufacture of combustible gas, petroleum industry, etc. It can solve the problems of temporary solution, blockage, hindering the development of biomass gasification market, etc., and achieve the effect of increasing calorific value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

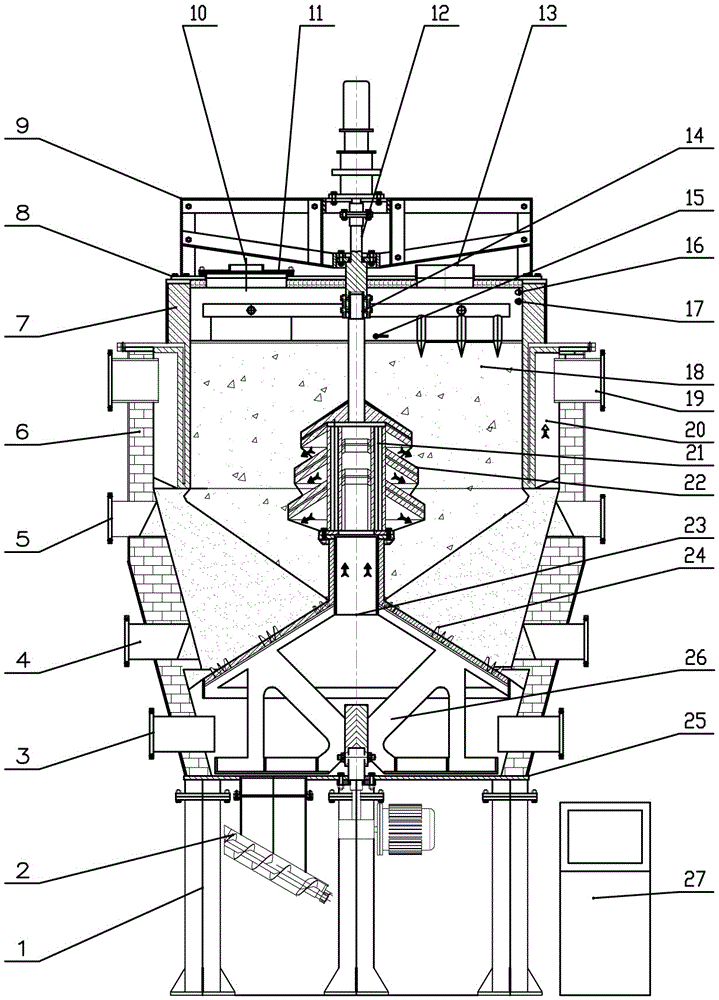

[0023] Such as figure 1 As shown, a biomass gasification furnace suitable for high-temperature gasification agent, its main body is a cylindrical gasification furnace body supported by gasification furnace feet, and the top cover 8 of the gasification furnace is designed with a feeding port 13, Feeding device 12, manhole 11, safety explosion-proof opening 10 feeding port and manhole are closed by a cover; feeding port and feeding device are realized as furnace feeding and uniform material distribution; slag remover 26 and The ash machine 2 and the cylinder body of the gasifier are divided into an outer cylinder body 6 and an inner cylinder body 7. The cylinder walls of the inner cylinder body 7 and the outer cylinder body 6 are composed of metal cylinder walls and refractory materials, and the inner cylinder body is supported on On the outer cylinder, the two are airtightly connected, and the jacket between the outer cylinder wall and the downwardly extending outer cylinder wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com