Method for directionally producing biomass charcoal by microwave catalytic pyrolysis of biomass

A technology of biomass charcoal and microwave catalysis, which is applied to the preparation of biofuels, biological neural network models, and liquid hydrocarbon mixtures, etc. It can solve the problems of poor image detection accuracy and weak adaptive ability of maximum power control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

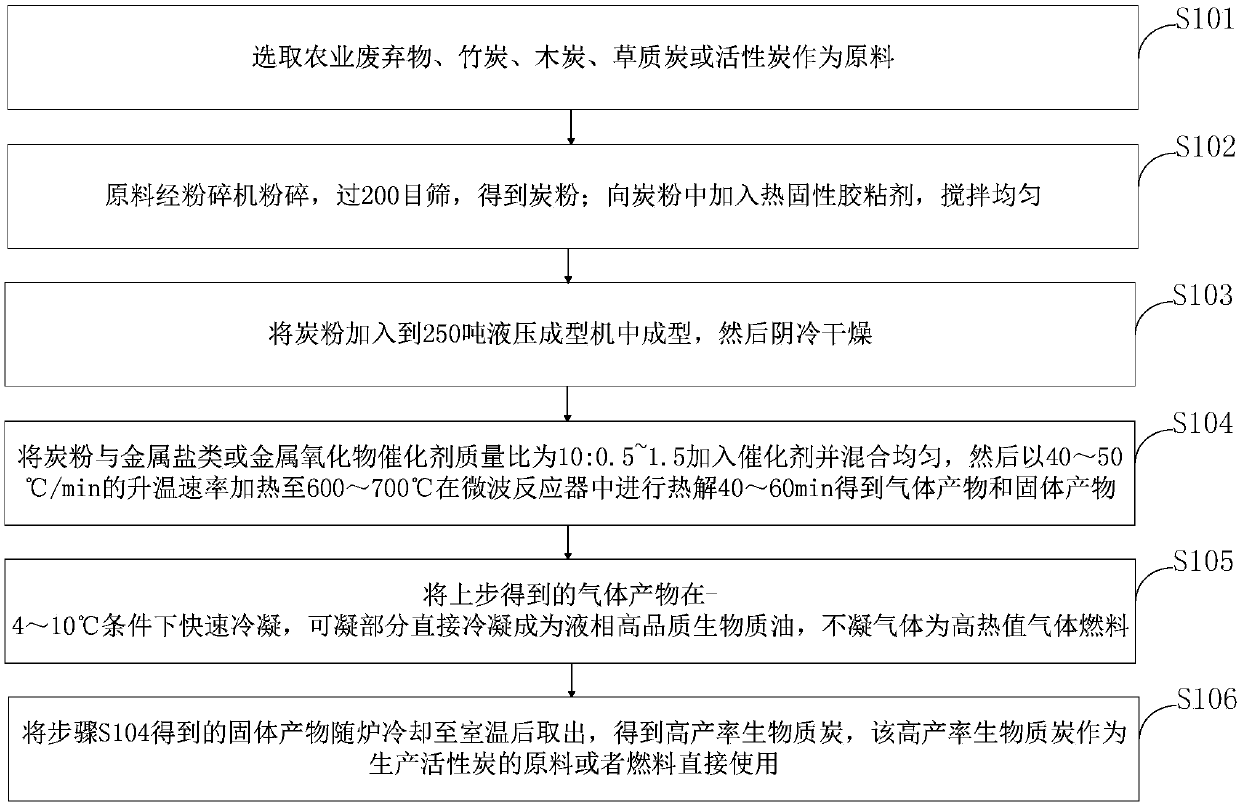

[0179] The method for directional production of biomass charcoal by microwave catalytic pyrolysis of biomass provided in the embodiment of the present invention comprises the following steps:

[0180] Select agricultural waste, bamboo charcoal, charcoal, grass charcoal or activated carbon as raw materials;

[0181] The raw materials are pulverized by a pulverizer and passed through a 200-mesh sieve to obtain carbon powder; add a thermosetting adhesive to the carbon powder and stir evenly;

[0182] Put the charcoal powder into a 250-ton hydraulic molding machine for molding, and then dry it in the shade;

[0183] Add the carbon powder to the metal salt or metal oxide catalyst with a mass ratio of 10:0.5~1.5, add the catalyst and mix evenly, then heat to 600°C at a heating rate of 40 / min and perform pyrolysis in a microwave reactor for 40 minutes to obtain a gas product and solid products;

[0184] Quickly condense the gaseous product obtained in the previous step at -4°C, the...

Embodiment 2

[0187] The method for directional production of biomass charcoal by microwave catalytic pyrolysis of biomass provided in the embodiment of the present invention comprises the following steps:

[0188] Select agricultural waste, bamboo charcoal, charcoal, grass charcoal or activated carbon as raw materials;

[0189] The raw materials are pulverized by a pulverizer and passed through a 200-mesh sieve to obtain carbon powder; add a thermosetting adhesive to the carbon powder and stir evenly;

[0190] Put the charcoal powder into a 250-ton hydraulic molding machine for molding, and then dry it in the shade;

[0191] Add carbon powder to metal salt or metal oxide catalyst with a mass ratio of 10:0.5~1.5, add the catalyst and mix evenly, then heat to 700°C at a heating rate of 60°C / min and perform pyrolysis in a microwave reactor for 60min to obtain gas products and solid products;

[0192] Quickly condense the gaseous product obtained in the previous step at 10°C, the condensable...

Embodiment 3

[0195] The method for directional production of biomass charcoal by microwave catalytic pyrolysis of biomass provided in the embodiment of the present invention comprises the following steps:

[0196] Select agricultural waste, bamboo charcoal, charcoal, grass charcoal or activated carbon as raw materials;

[0197] The raw materials are pulverized by a pulverizer and passed through a 200-mesh sieve to obtain carbon powder; add a thermosetting adhesive to the carbon powder and stir evenly;

[0198] Put the charcoal powder into a 250-ton hydraulic molding machine for molding, and then dry it in the shade;

[0199] Add carbon powder to metal salt or metal oxide catalyst with a mass ratio of 10:0.5~1.5, add the catalyst and mix evenly, then heat to 500°C at a heating rate of 50°C / min and perform pyrolysis in a microwave reactor for 50min to obtain gas products and solid products;

[0200] Quickly condense the gaseous product obtained in the previous step at 5°C, the condensable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com