Biomass gasification reaction system removing tar automatically and method thereof

A technology of gasification reaction and biomass, which is applied in the direction of gasification process, petroleum industry, and manufacture of combustible gas, etc. It can solve the problems of inability to process raw materials containing tar, affect the service life of the gasifier, and narrow the scope of application, and achieve The effect of wide application range of raw materials, less energy consumption and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

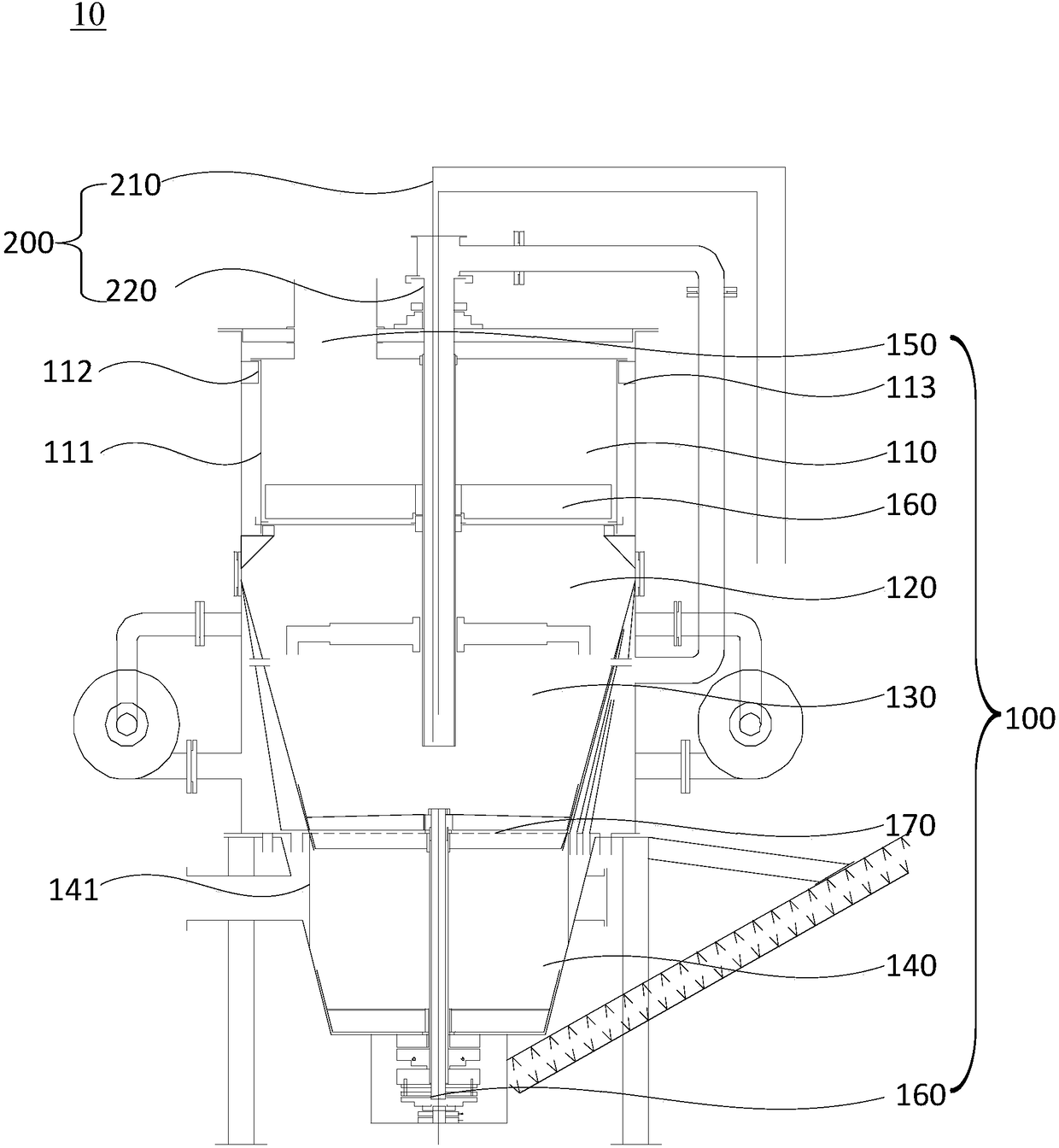

[0055] 1) Add construction residues into the storage bin 111 of the pretreatment chamber 110 of the furnace body 100 from the feed port 150, evaporate and dry at a temperature of 150°C, and then undergo a pyrolysis reaction at a temperature of 450°C. Combustible gas, tar and charcoal are generated from the pyrolysis of construction residues.

[0056] 2) The combustible gas, tar and char enter into the oxidation incineration chamber 120 through the separator 160, and undergo an oxidation reaction under the temperature of 1100°C and the action of air to obtain carbon dioxide, water vapor, char and tar.

[0057] 3) The carbon dioxide, water vapor and tar enter the reduction cracking chamber 130 downward, and a reduction reaction occurs at a temperature of 1000°C. Under the high-temperature anaerobic state, the carbon dioxide, water vapor and carbon undergo a reduction reaction to obtain carbon monoxide, hydrogen, and methane And carbon, tar and water vapor are reacted and cracked...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com