Regenerative gasification device for high calorific value synthesis gas and gasification production method based on device

A gasification device and synthesis gas technology, applied in the field of gasification, can solve the problems affecting the application field of synthesis gas, the low calorific value of syngas, and the inhibition of application and promotion, so as to reduce the production cost, increase the calorific value of gas, and reduce the system height effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

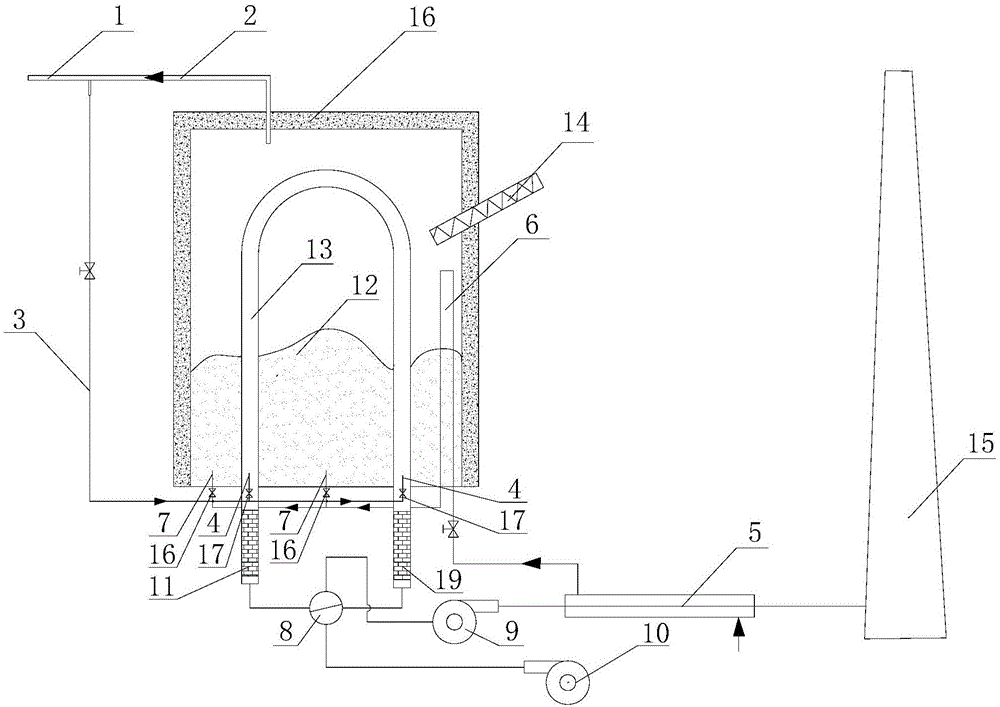

[0028] refer to figure 1 , figure 1 It is a schematic structural diagram of a gasification device for regenerative high calorific value syngas. The direction of the arrow marked on the gas pipeline is the flow direction of the gas. According to the system control requirements, the gas enters the radiant tube through the two ends of the radiant tube respectively according to different timings. The direction of the arrow drawn from the feed water heat exchanger is the flow direction of the superheated steam. .

[0029] The gasification device for regenerative high-calorific value synthesis gas proposed by the present invention includes a gasification chamber 16, a blower 10 and a four-way valve 8. The top of the gasification chamber 16 is provided with a synthesis gas outlet connected to the synthesis gas pipeline 2 for gasification. A radiant tube 13 is arranged inside the chamber 16, and the two ends of the radiant tube 13 are respectively provided with a first heat storage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com