Patents

Literature

1270 results about "Steam condensation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Condensation of steam. Steam is to be condensed in the condenser of a steam power plant at a temperature of 50 degrees Celcius with cooling water from a nearby lake, which enters the tubes of the condenser at 18 degrees Celcius at a rate of 101kg/s and leaves at 27 degrees Celcius.

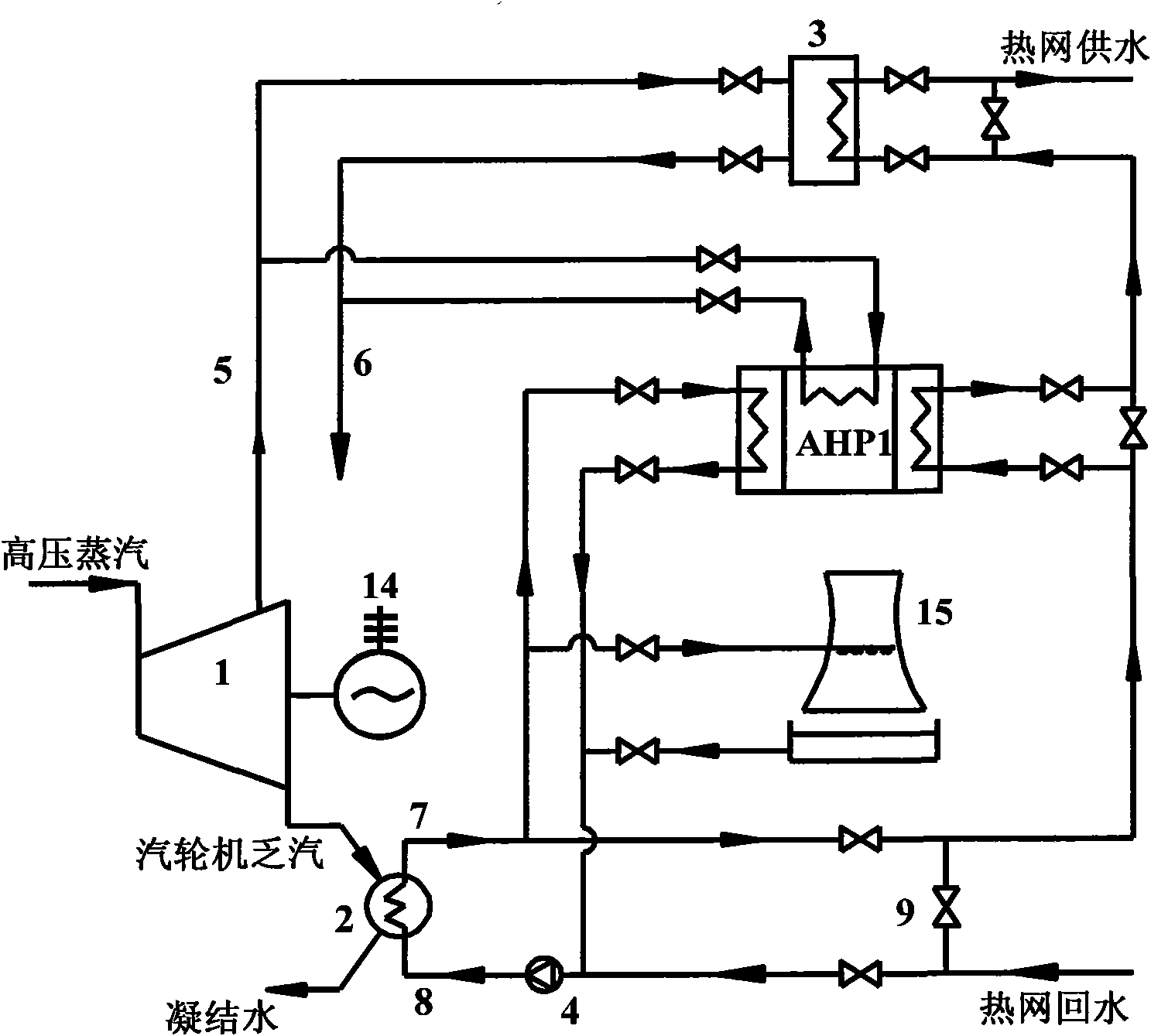

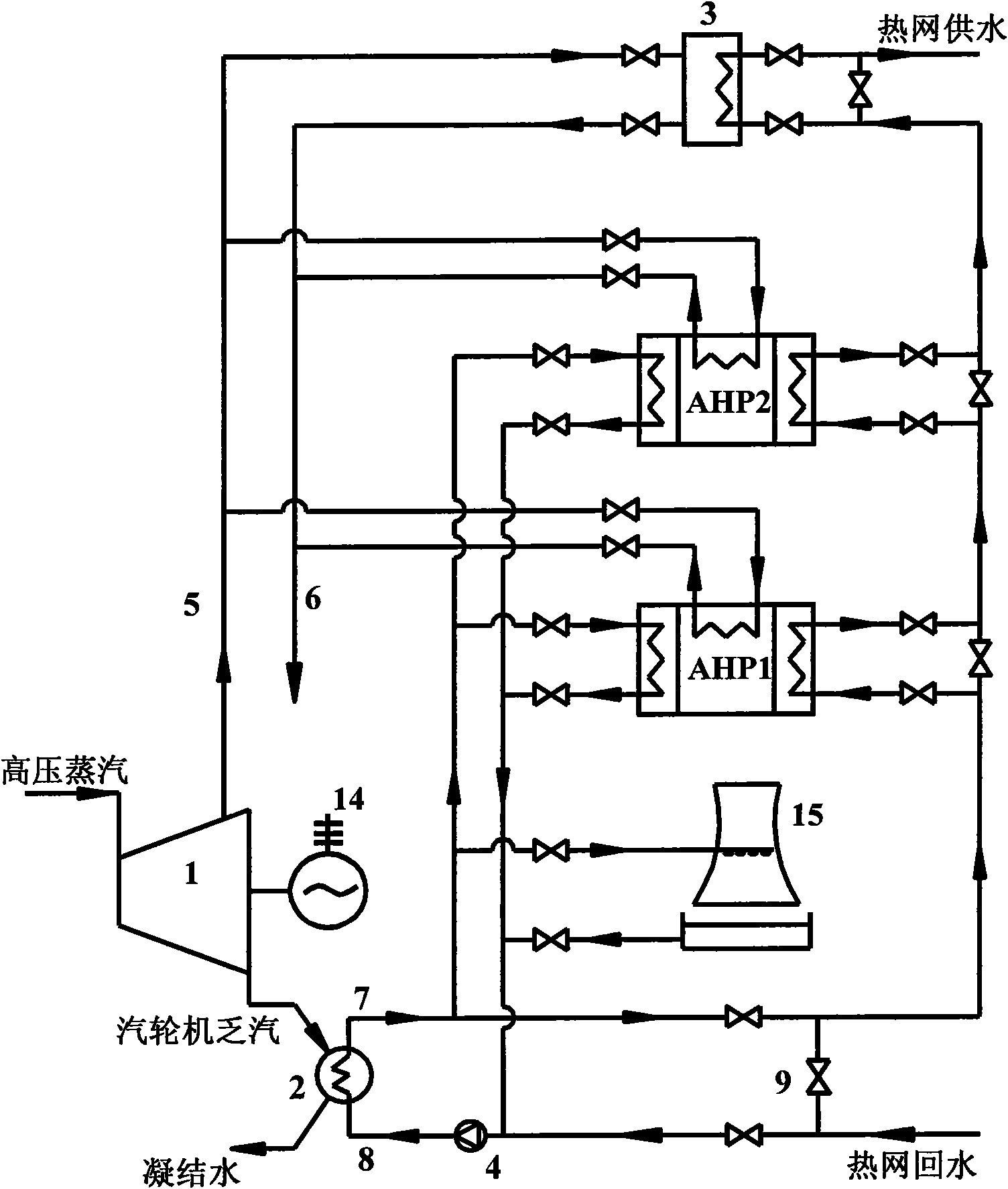

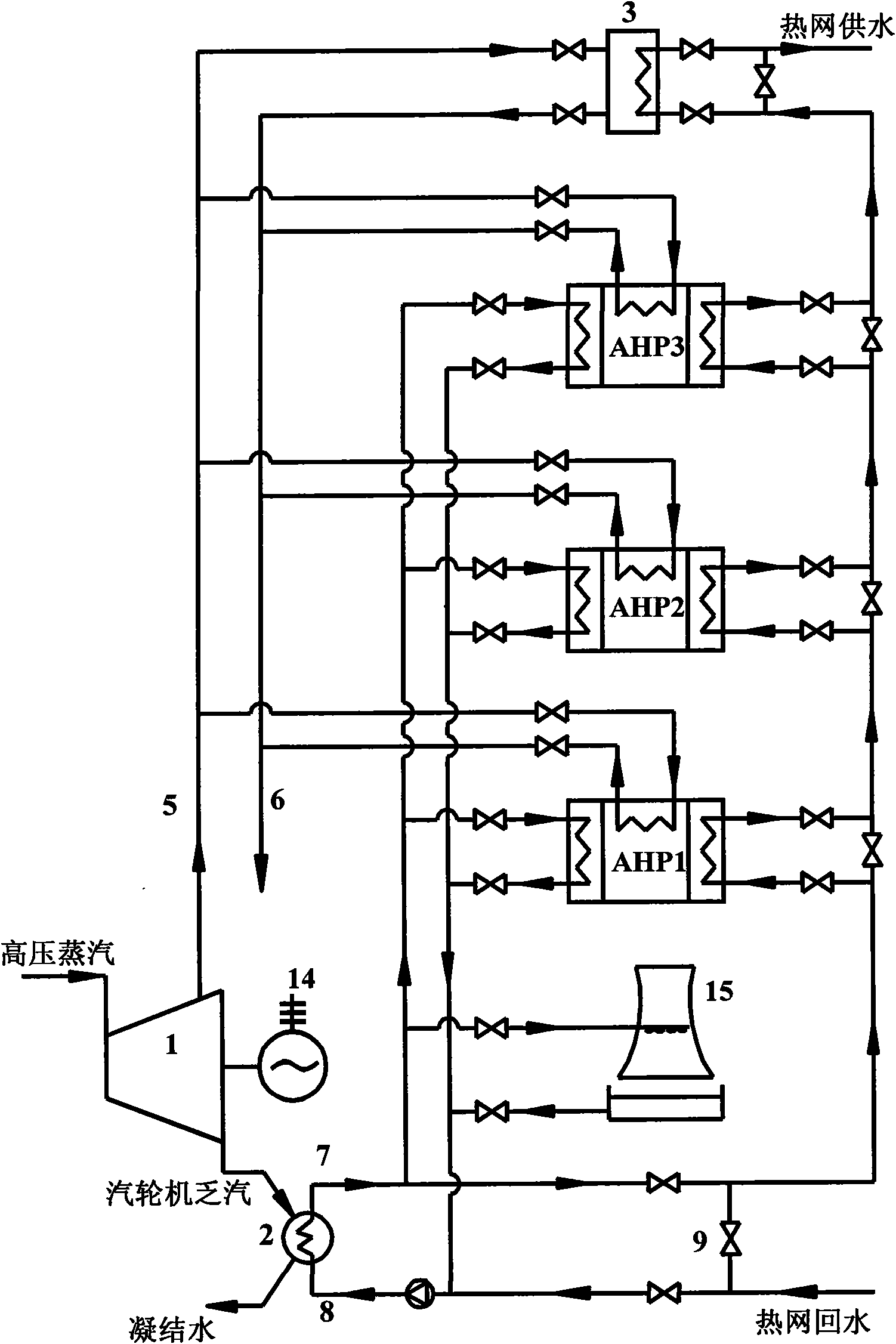

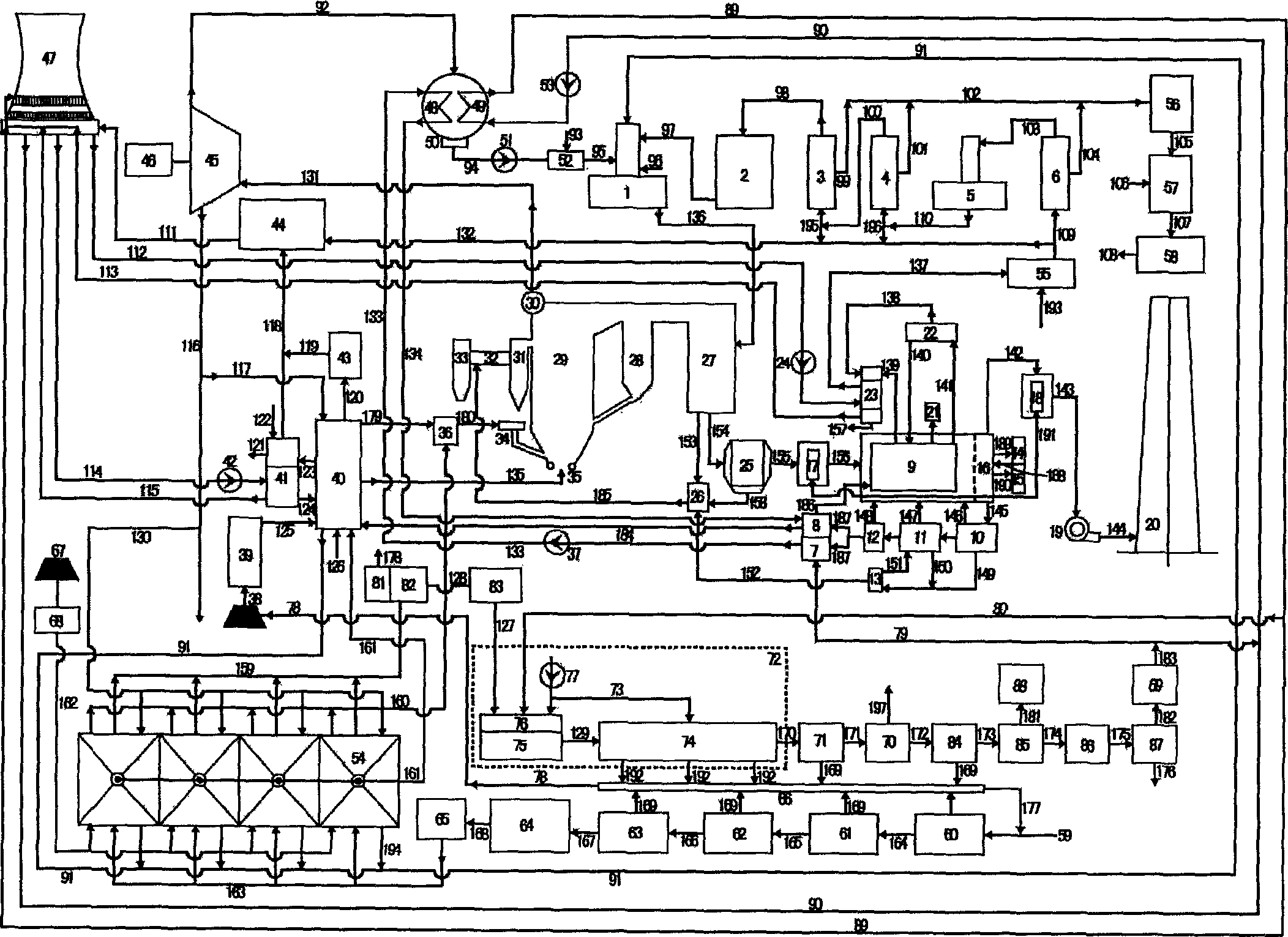

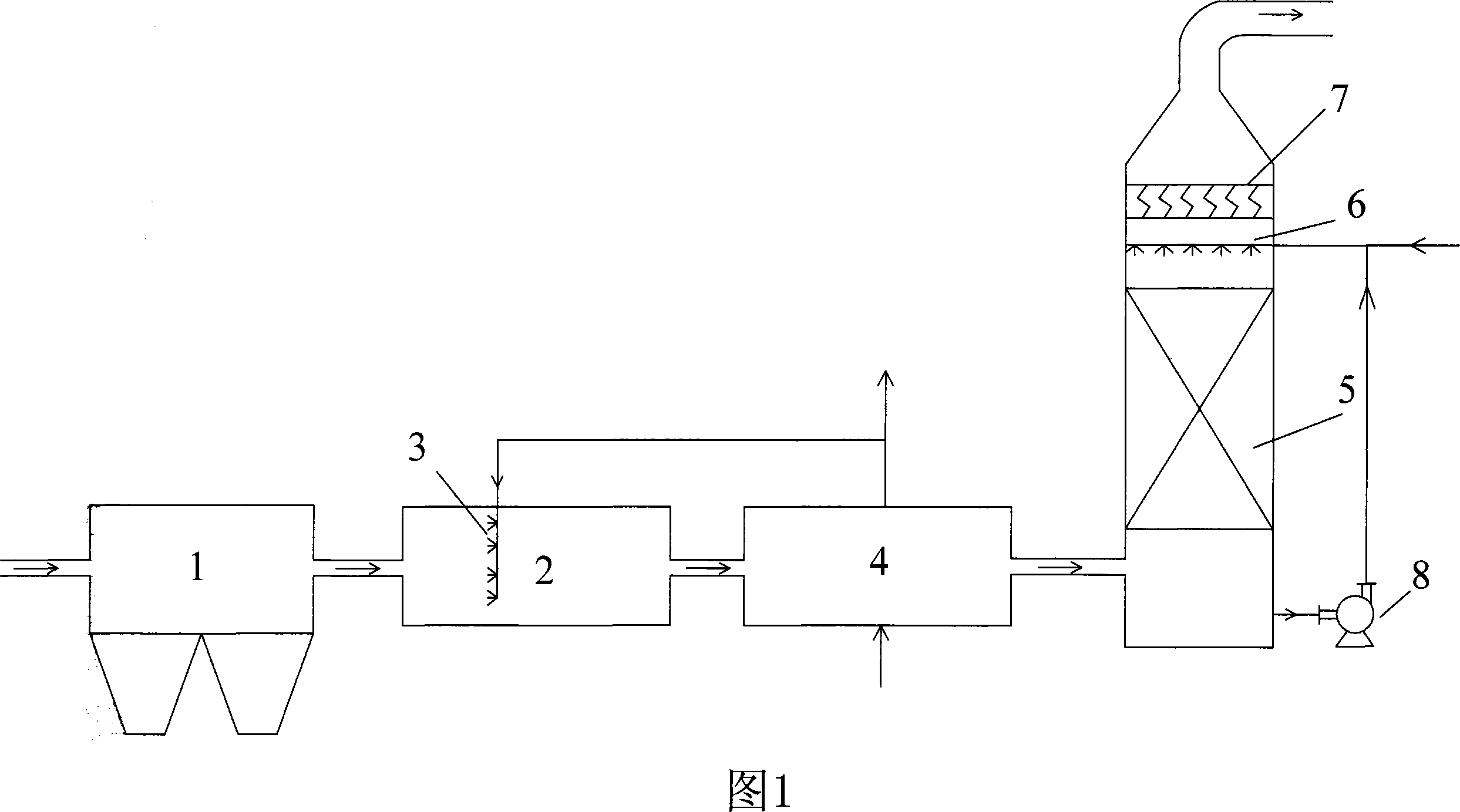

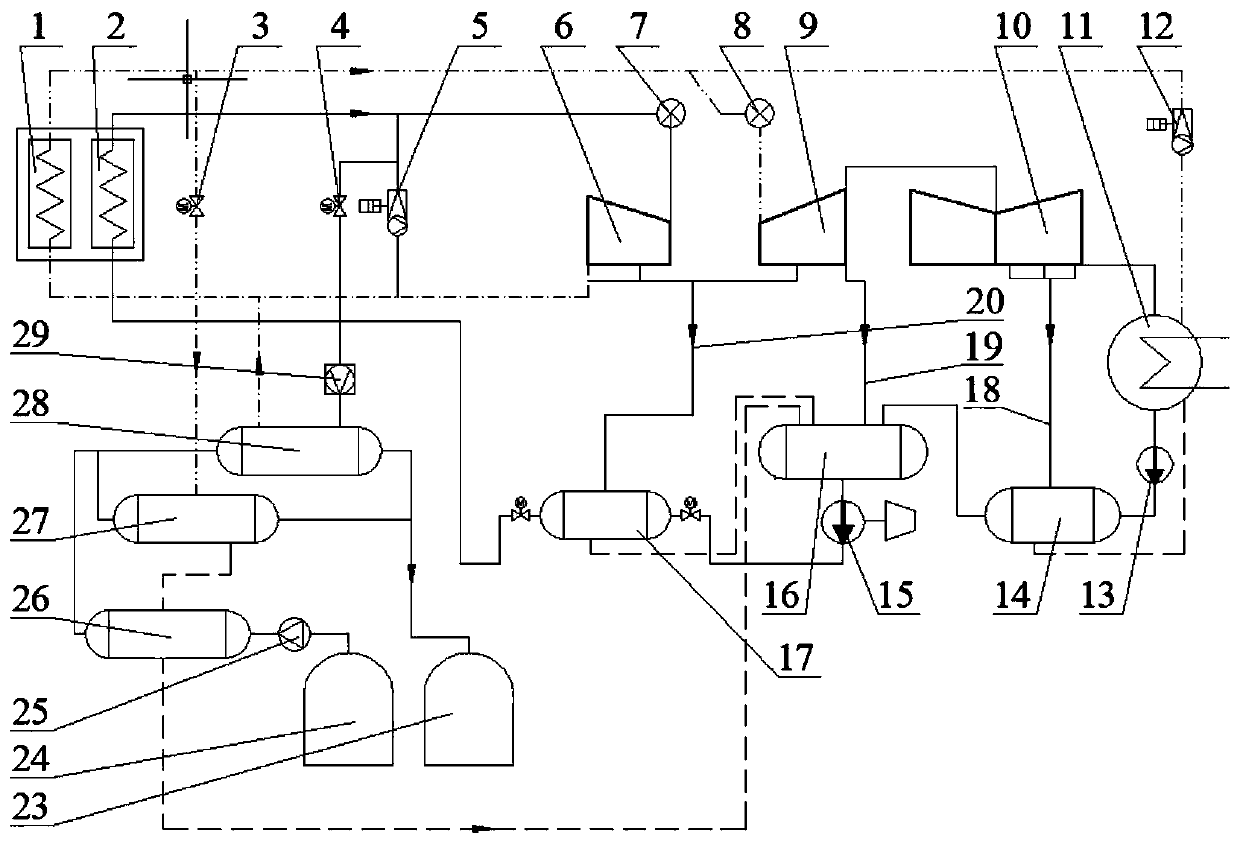

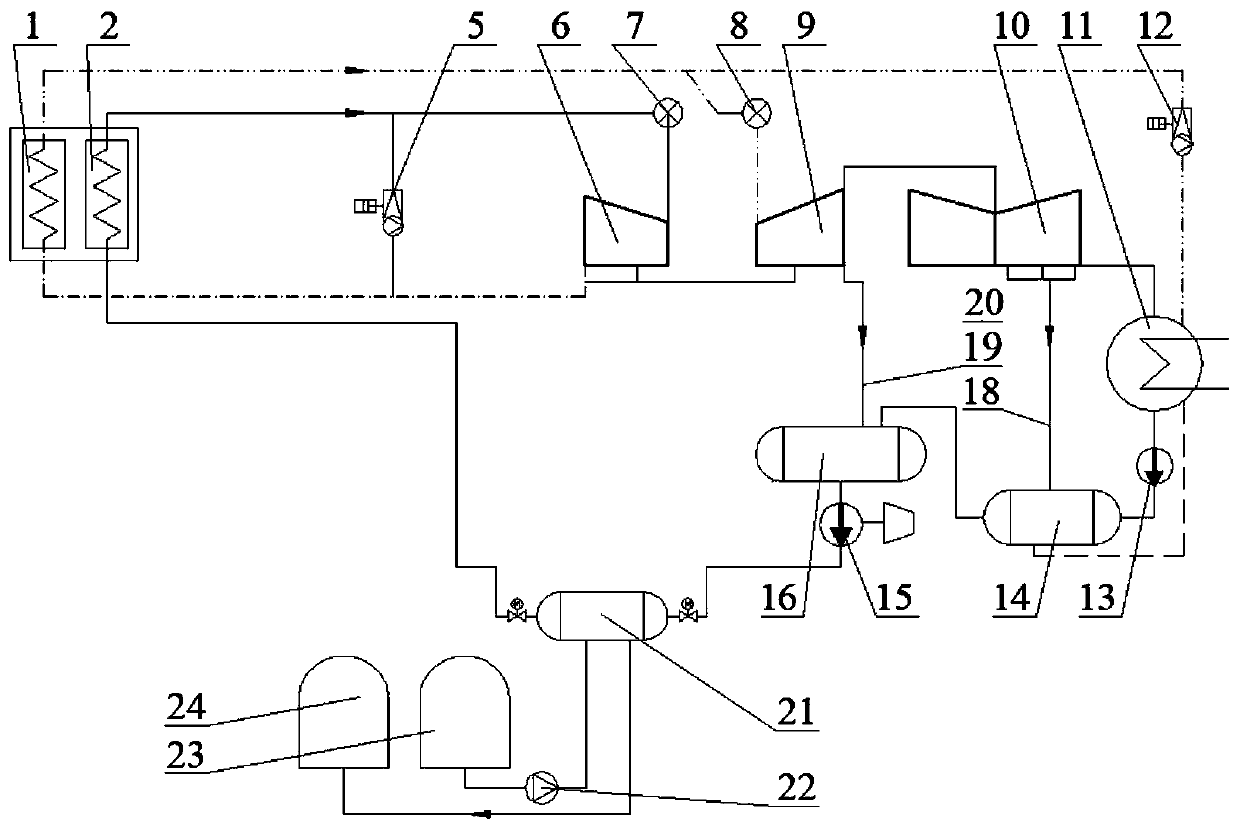

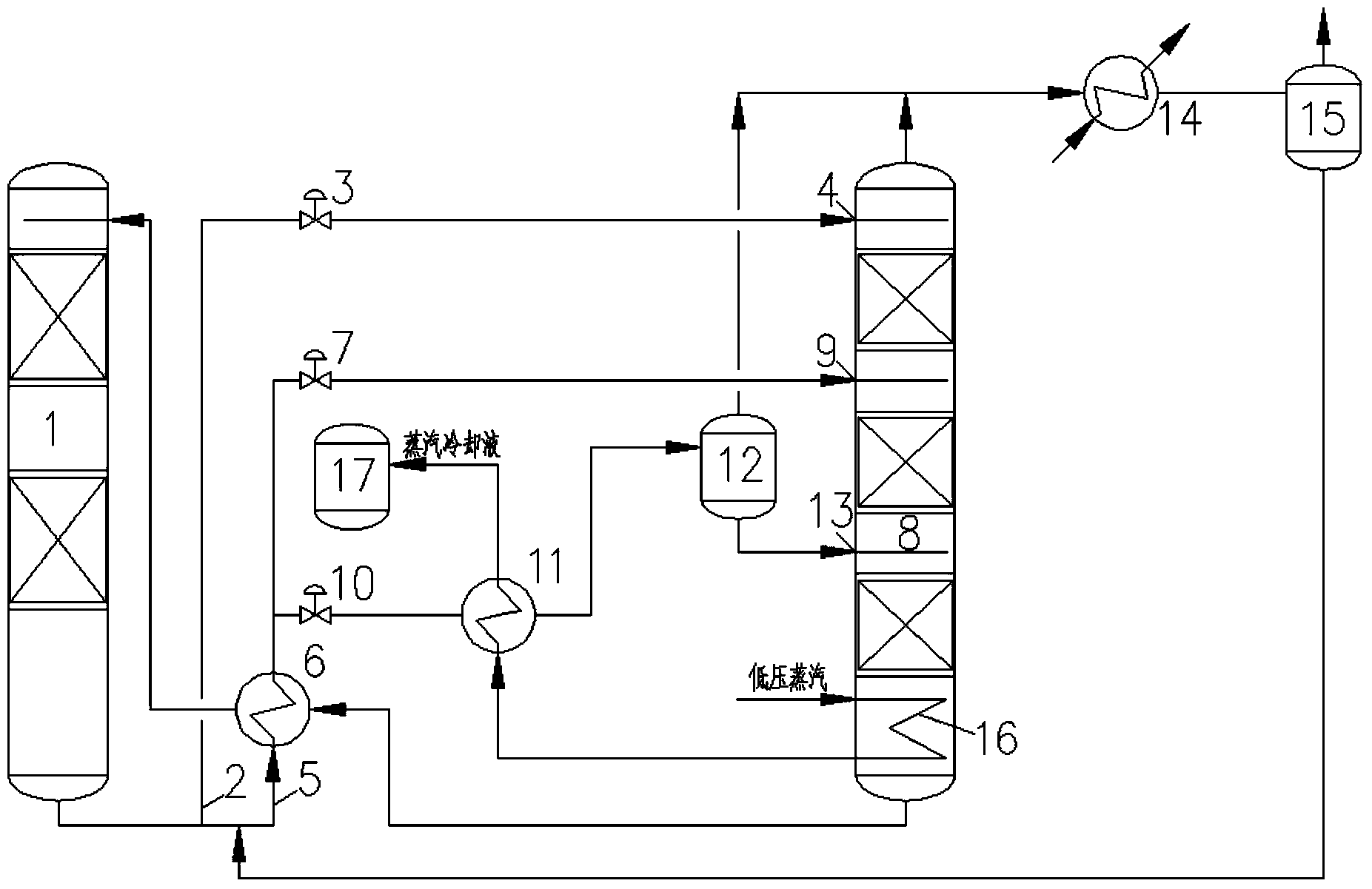

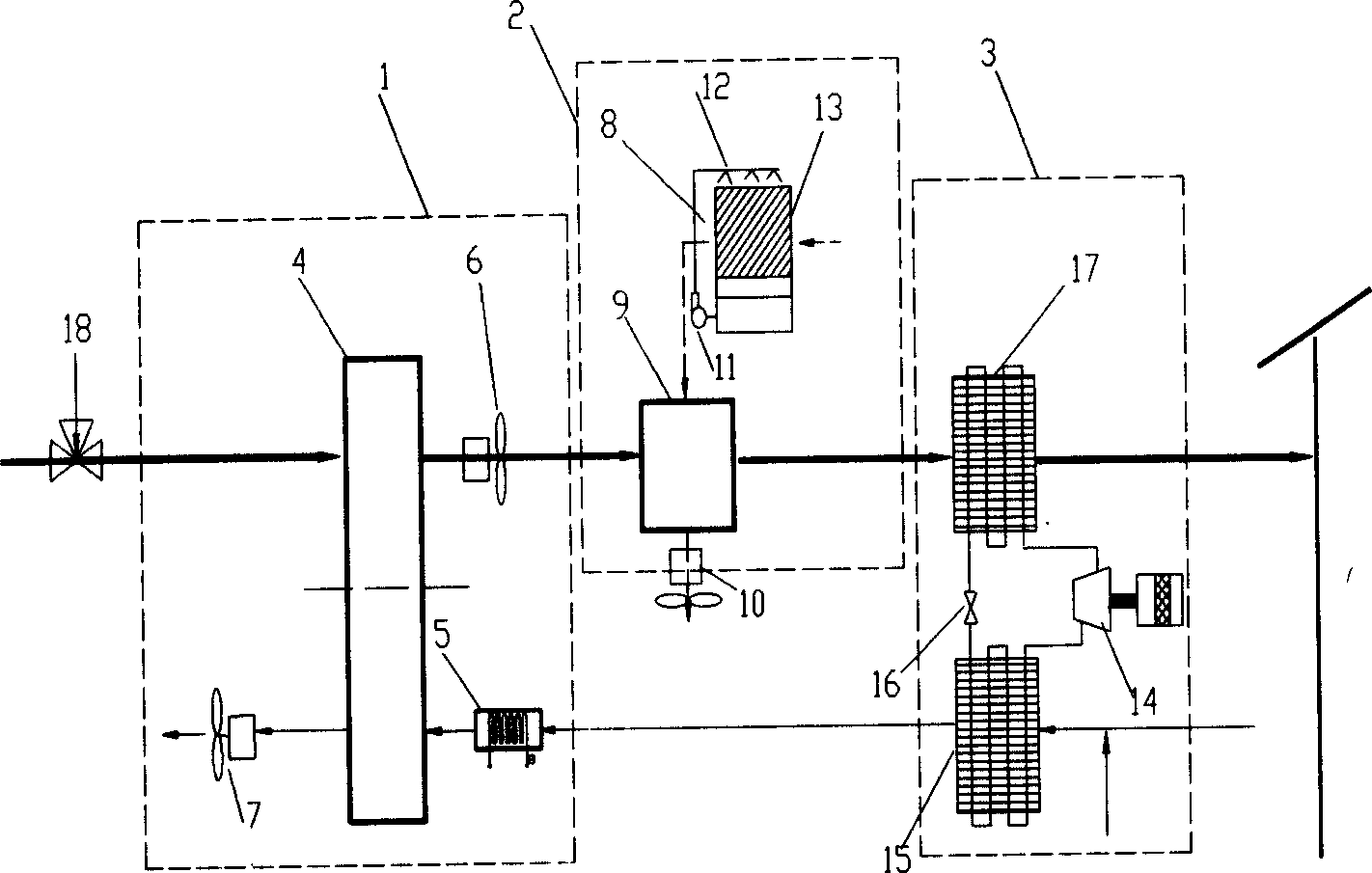

Method for recovering waste heat of thermal power plant and heating and supplying heat to hot water in a stepping way

ActiveCN101619662AImprove utilization efficiencyReduce exergy lossSteam useCombined combustion mitigationCooling towerSteam condensation

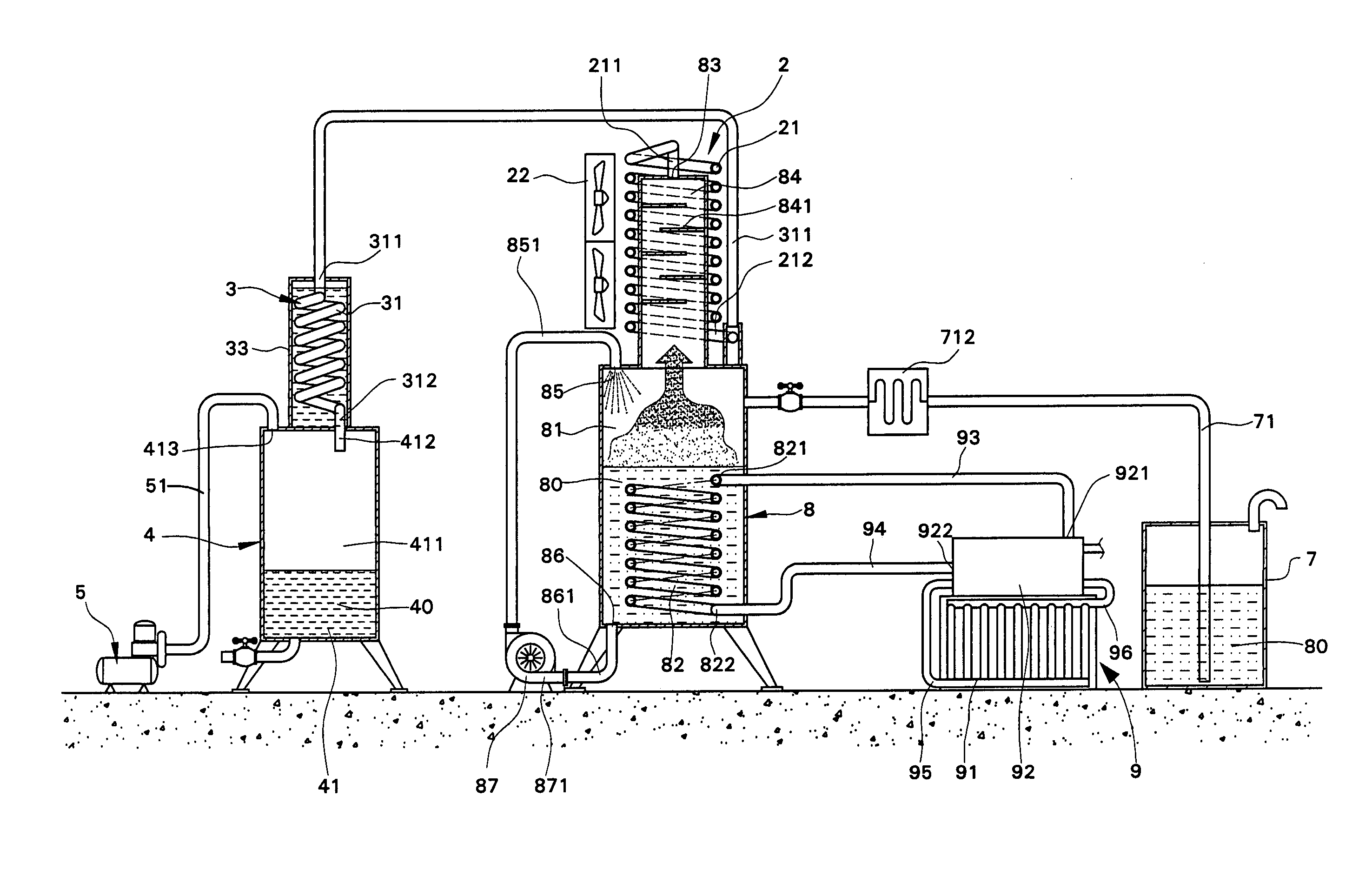

The invention discloses a method for recovering the waste heat of a thermal power plant and heating and supplying heat to hot water in a stepping way. In the method, low-temperature heat-net return water is firstly mixed with circulating cooling water positioned on an outlet of a cooling condenser or exchanges heat with the circulating cooling water positioned on the outlet of the cooling condenser to be increased in temperature and then sequentially delivered into an each-step vapour absorption type heat pump and a vapor-water heat exchanger in a series connection way to be gradually heated to be increased in temperature to heat supplying temperature and finally discharged through a water supplying pipeline; the circulating cooling water absorbs the waste steam condensation heat of a steam turbine in the cooling condenser, then one path of the circulating cooling water is directly mixed with the low-temperature heat-net return water or heats the low-temperature heat-net return water through the heat changer, the other path of the circulating cooling water is delivered into an each-step absorption type heat pump unit to be used as a low-order heat source of the absorption type heat pump unit, and the redundant heat of the circulating cooling water is discharged to the environment through a cooling tower. The invention uses the steam extraction of the steam turbine as a driving heat source of the absorption type heat pump so that the low-temperature heat-net return water is heated in a stepping way, thereby reducing the effective energy loss; the waste heat of the discharged steam of the steam turbine is sufficiently recovered in a direct heating way and an absorption type heat pump temperature increasing heating way, therefore, the comprehensive energy usage efficiency of the thermal power plant is enhanced.

Owner:TSINGHUA UNIV +1

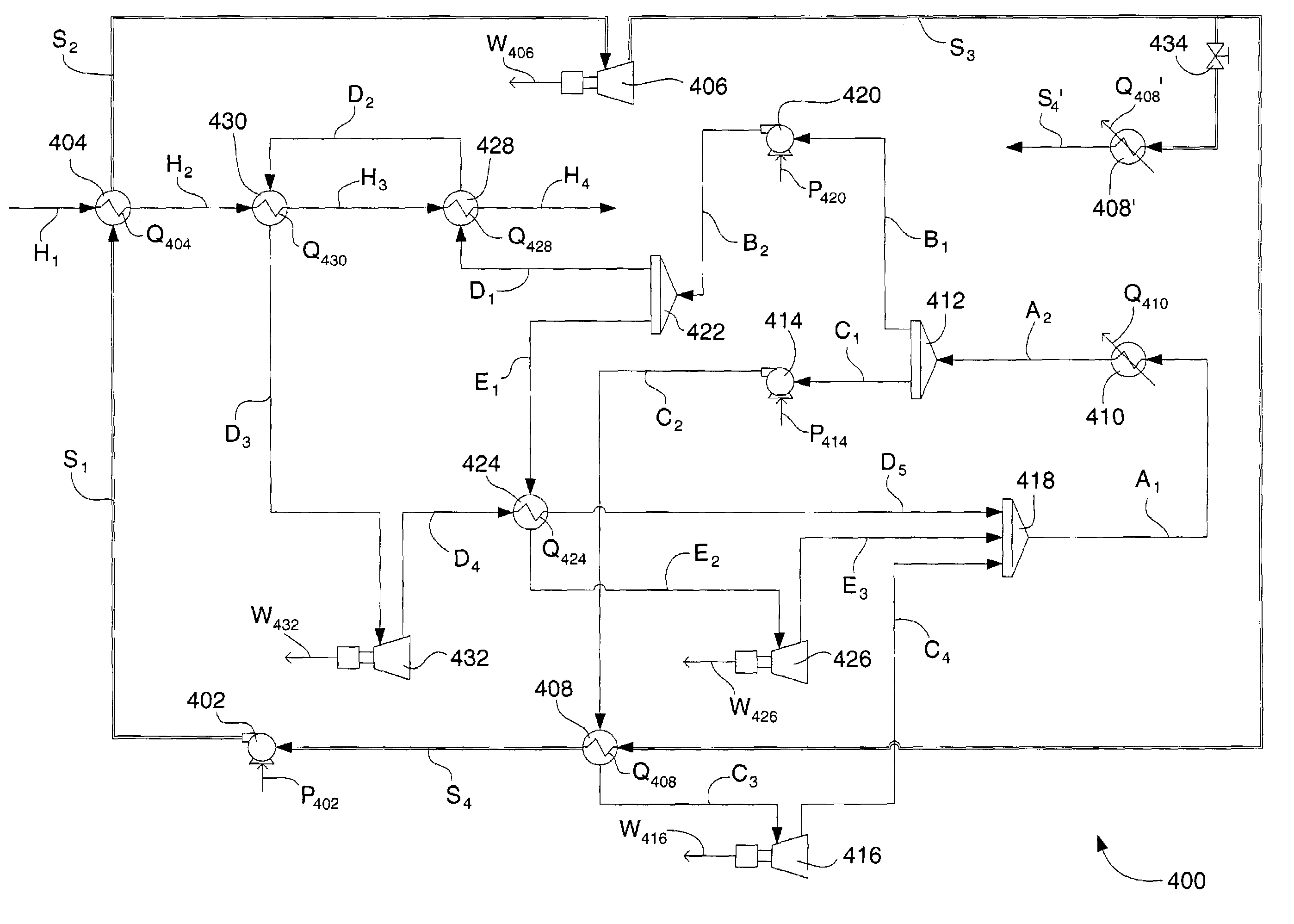

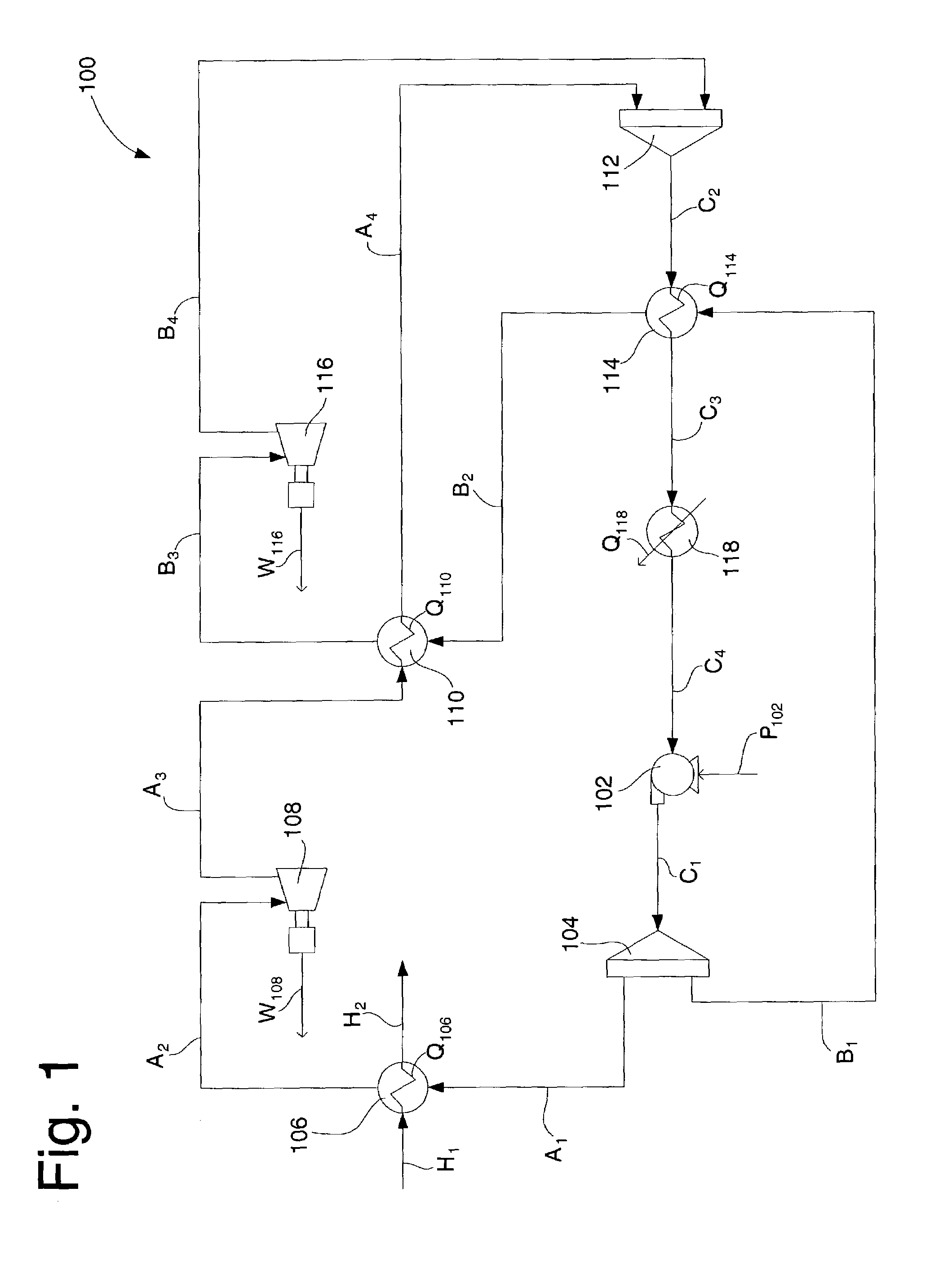

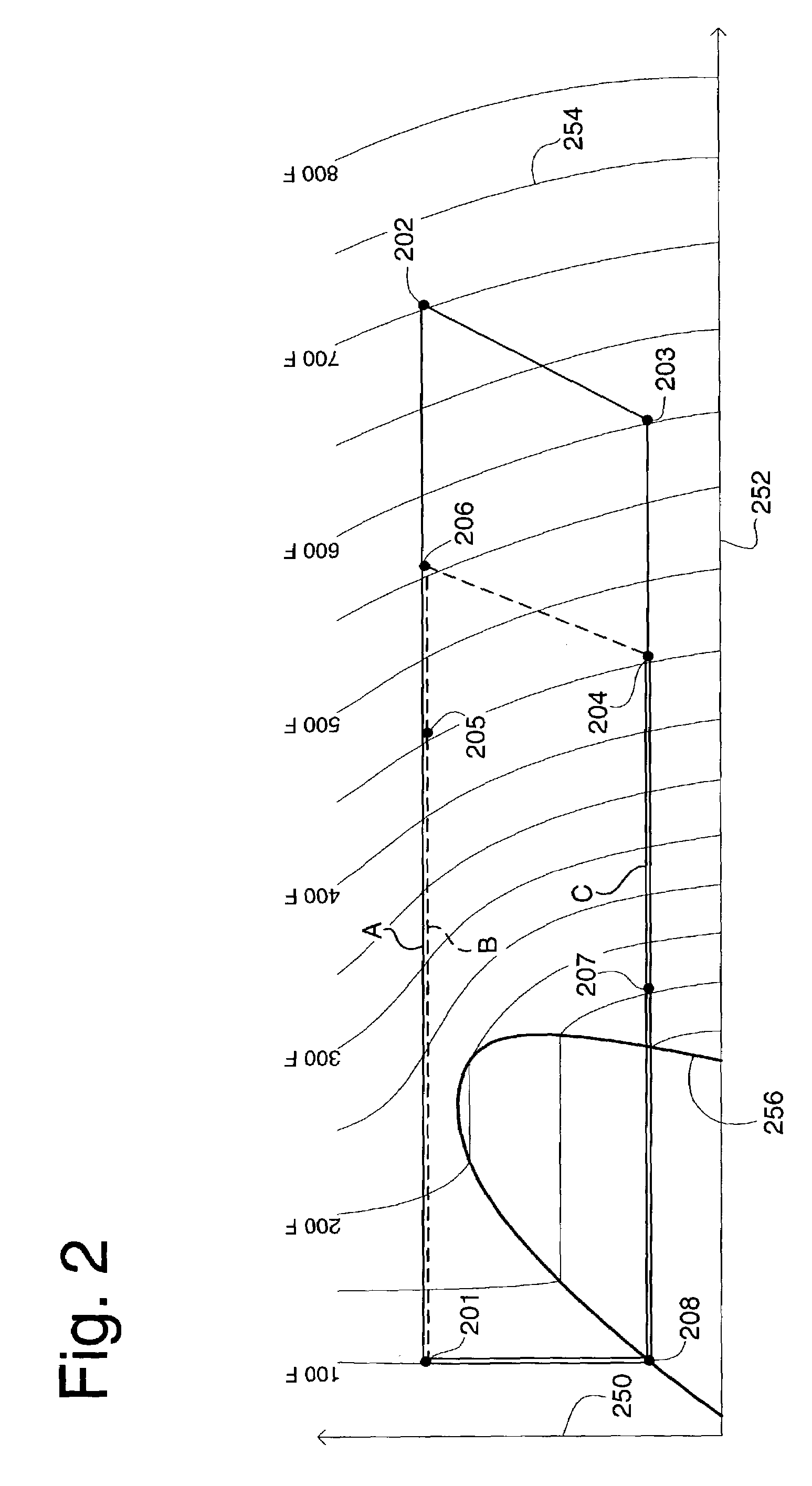

Cascading closed loop cycle power generation

InactiveUS7096665B2Improve power efficiencyIncrease pressureEnergy industrySteam accumulatorsLiquid propaneSteam condensation

Owner:UNIVERSAL TECH

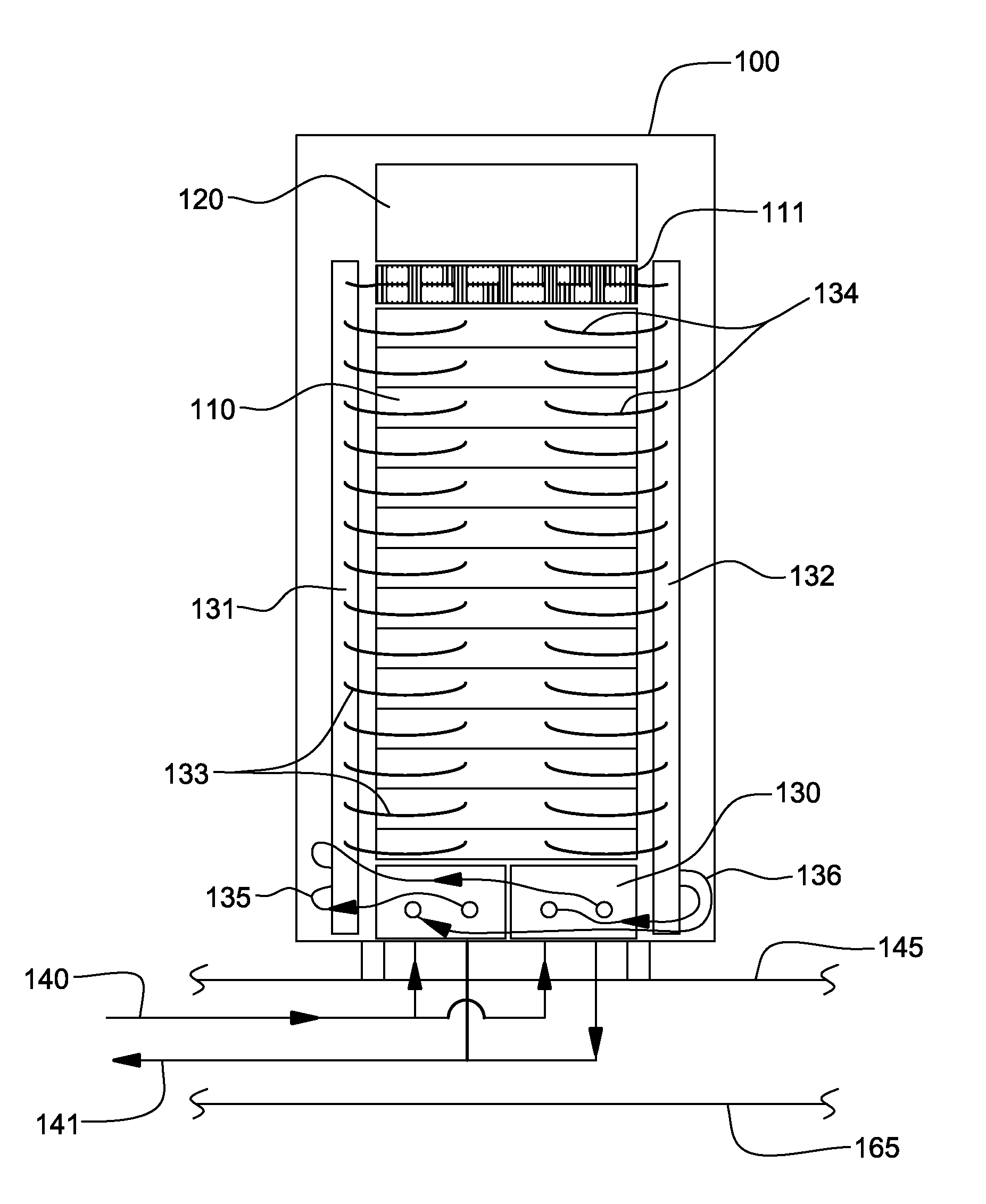

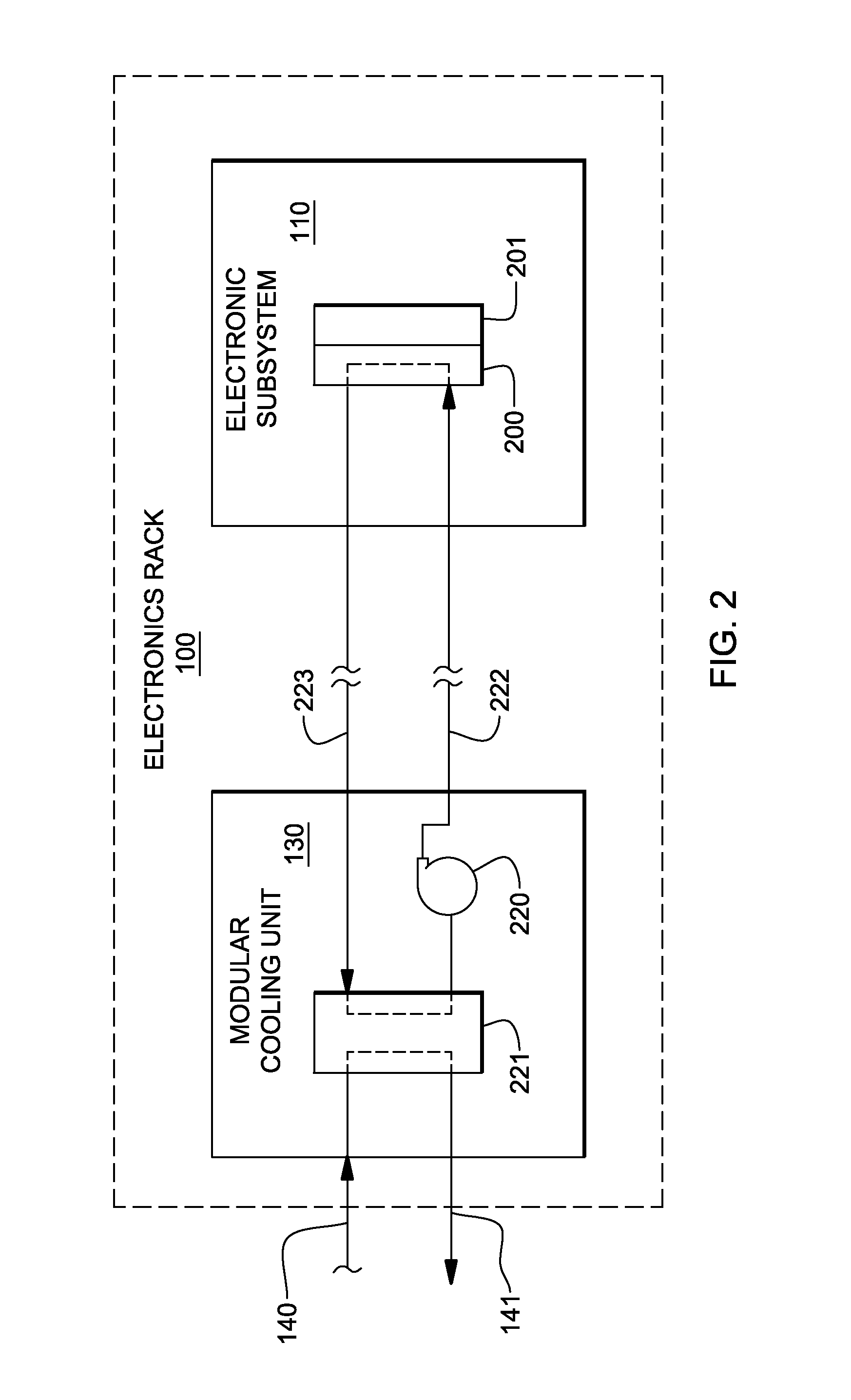

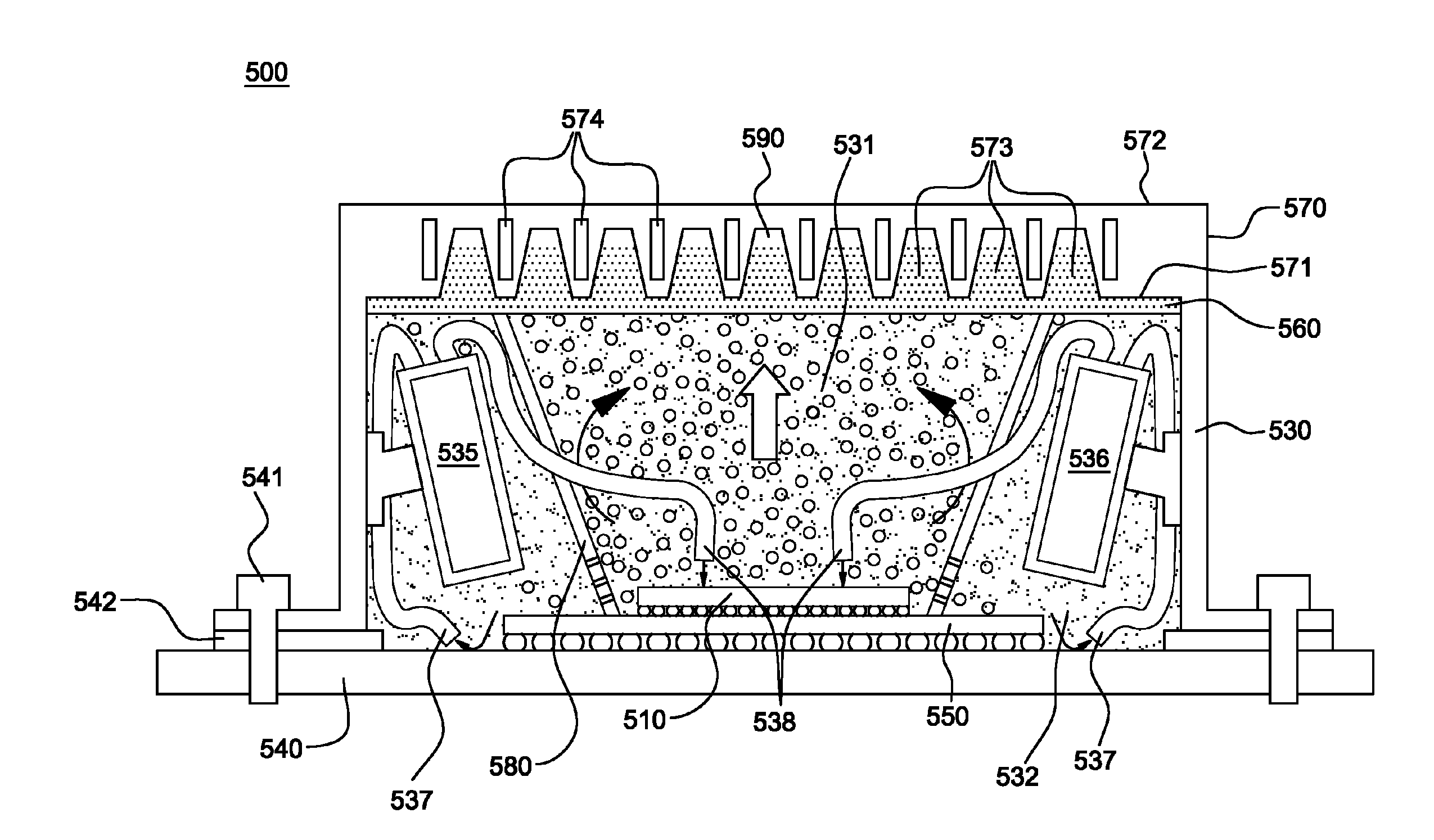

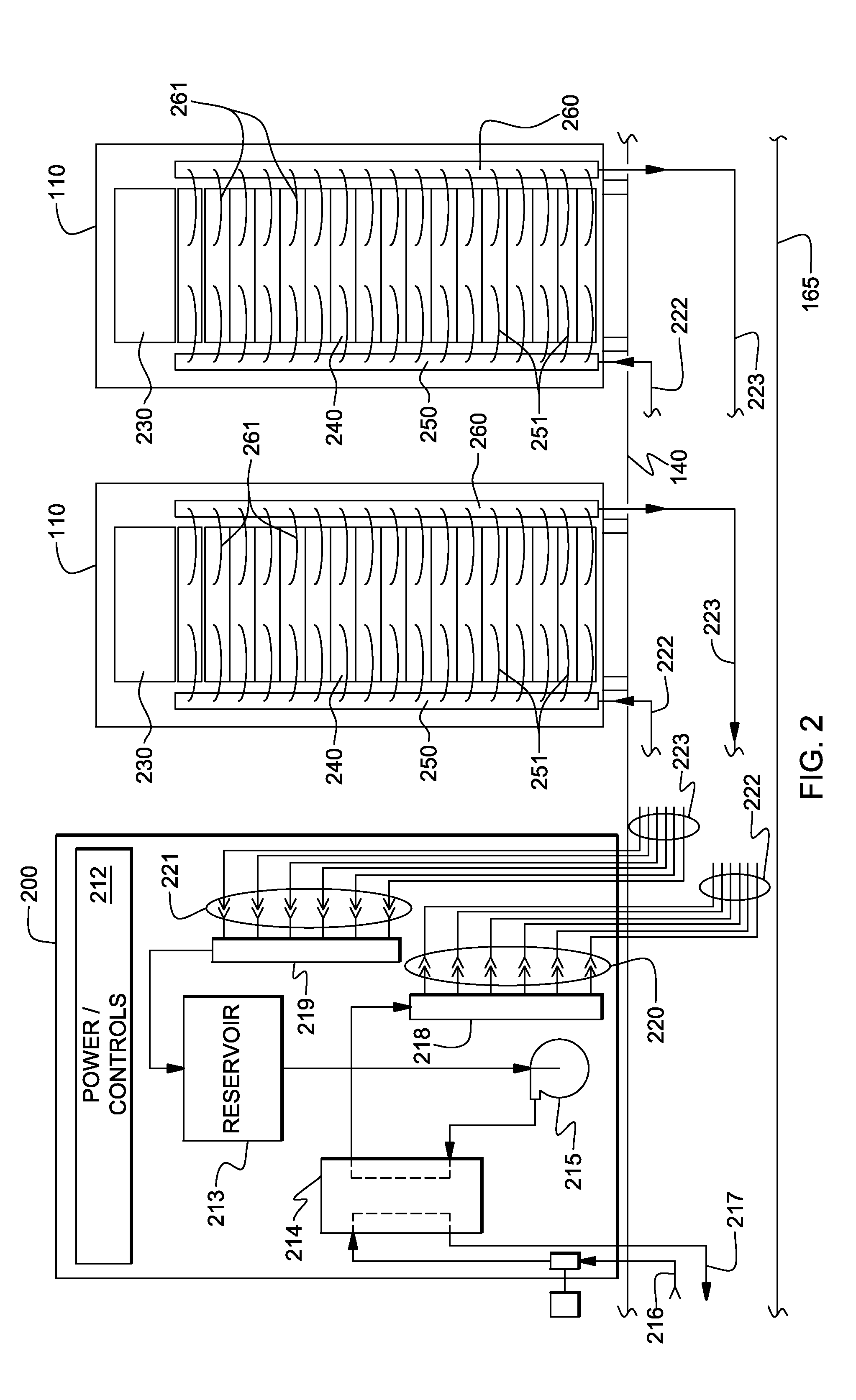

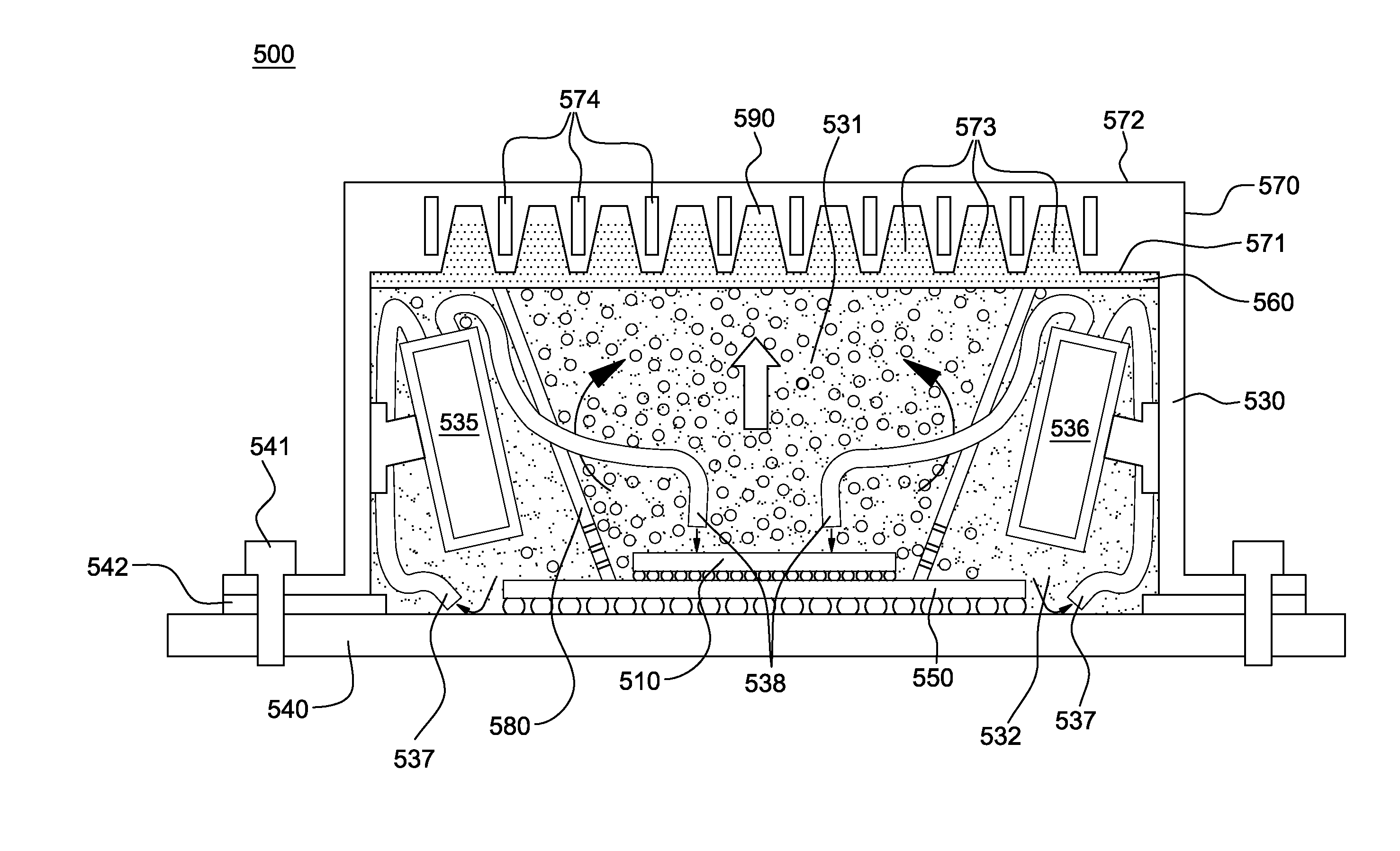

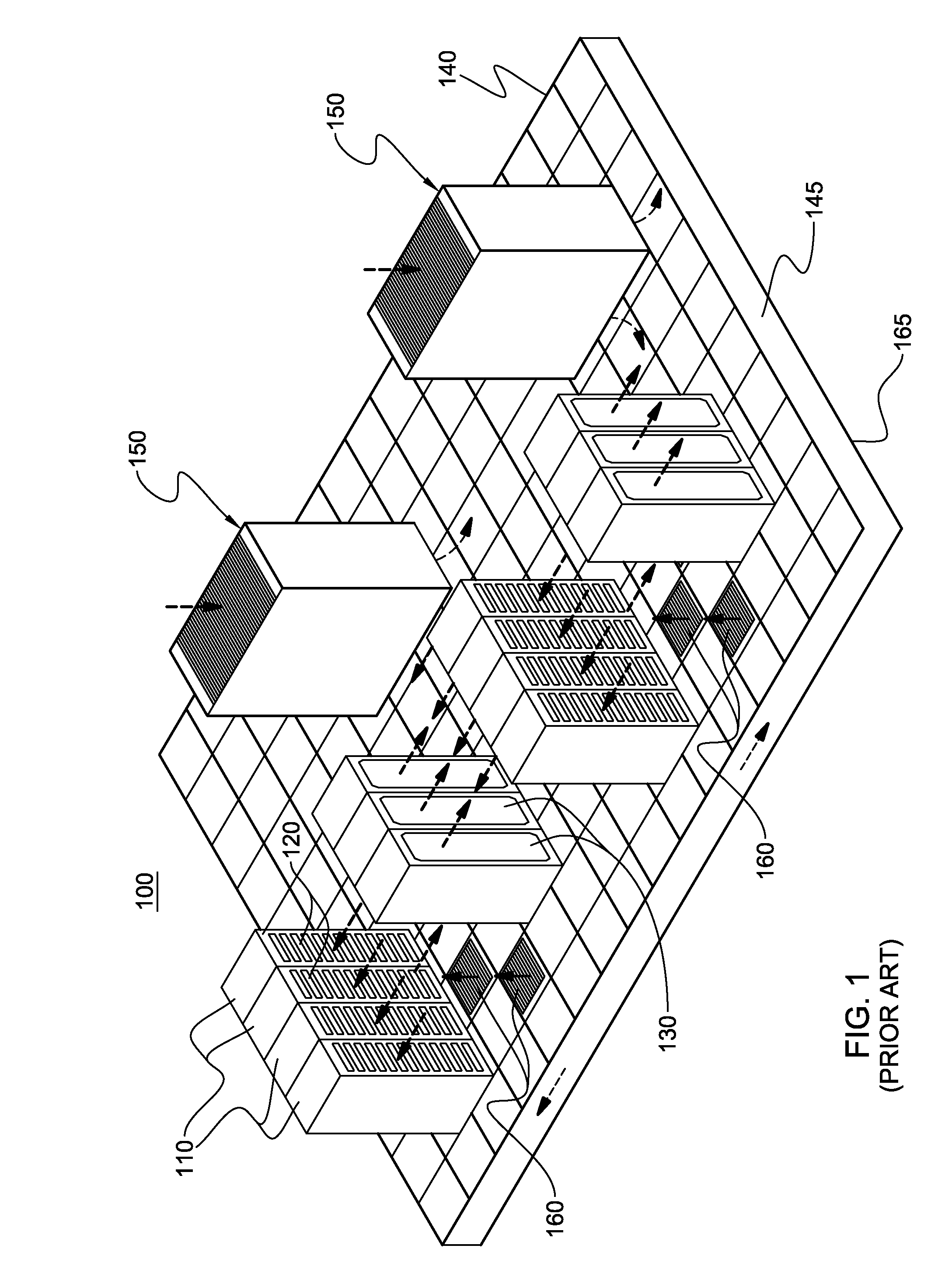

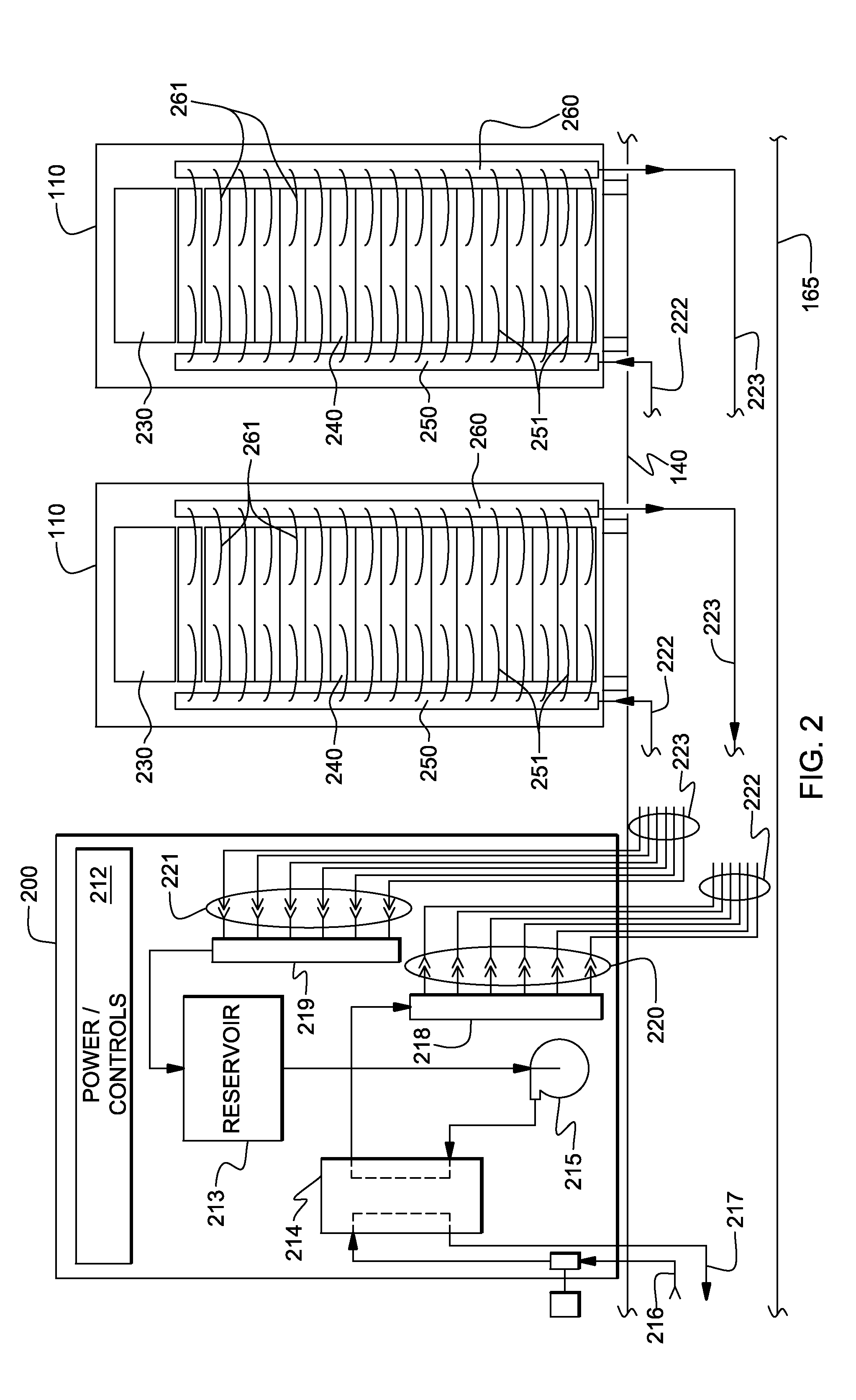

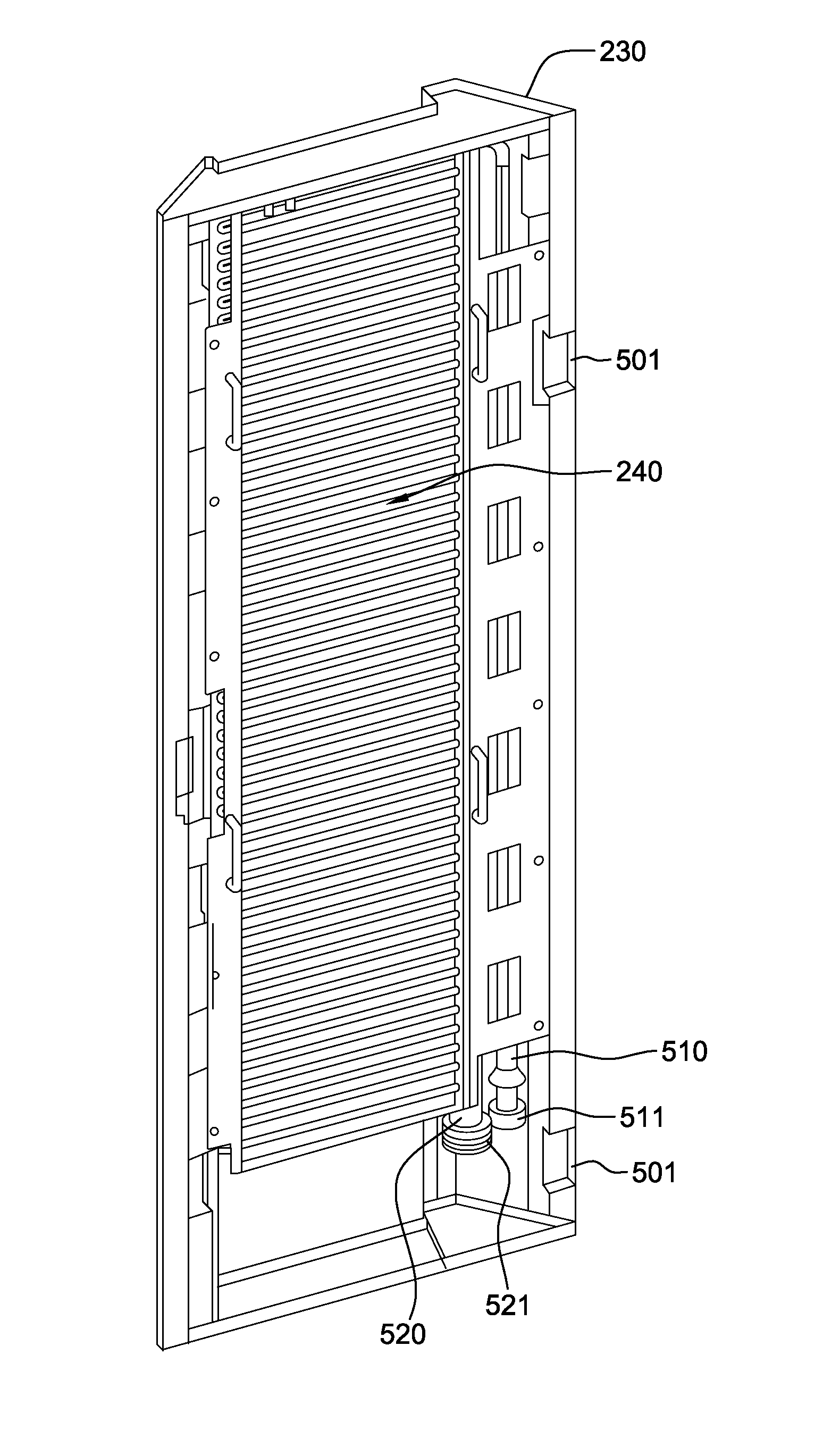

Valve controlled, node-level vapor condensation for two-phase heat sink(s)

ActiveUS20130027884A1Easy to condenseEasy extractionDigital data processing detailsIndirect heat exchangersSteam condensationAutomatic control

A cooling apparatus and method are provided for cooling one or more electronic components of an electronic subsystem of an electronics rack. The cooling apparatus includes a heat sink, which is configured to couple to an electronic component, and which includes a coolant-carrying channel for coolant to flow therethrough. The coolant provides two-phase cooling to the electronic component, and is discharged from the heat sink as coolant exhaust which comprises coolant vapor to be condensed. The cooling apparatus further includes a node-level condensation module, associated with the electronic subsystem, and coupled in fluid communication with the heat sink to receive the coolant exhaust from the heat sink. The condensation module is liquid-cooled, and facilitates condensing of the coolant vapor in the coolant exhaust. A controller automatically controls the liquid-cooling of the heat sink and / or the liquid-cooling of the node-level condensation module.

Owner:IBM CORP

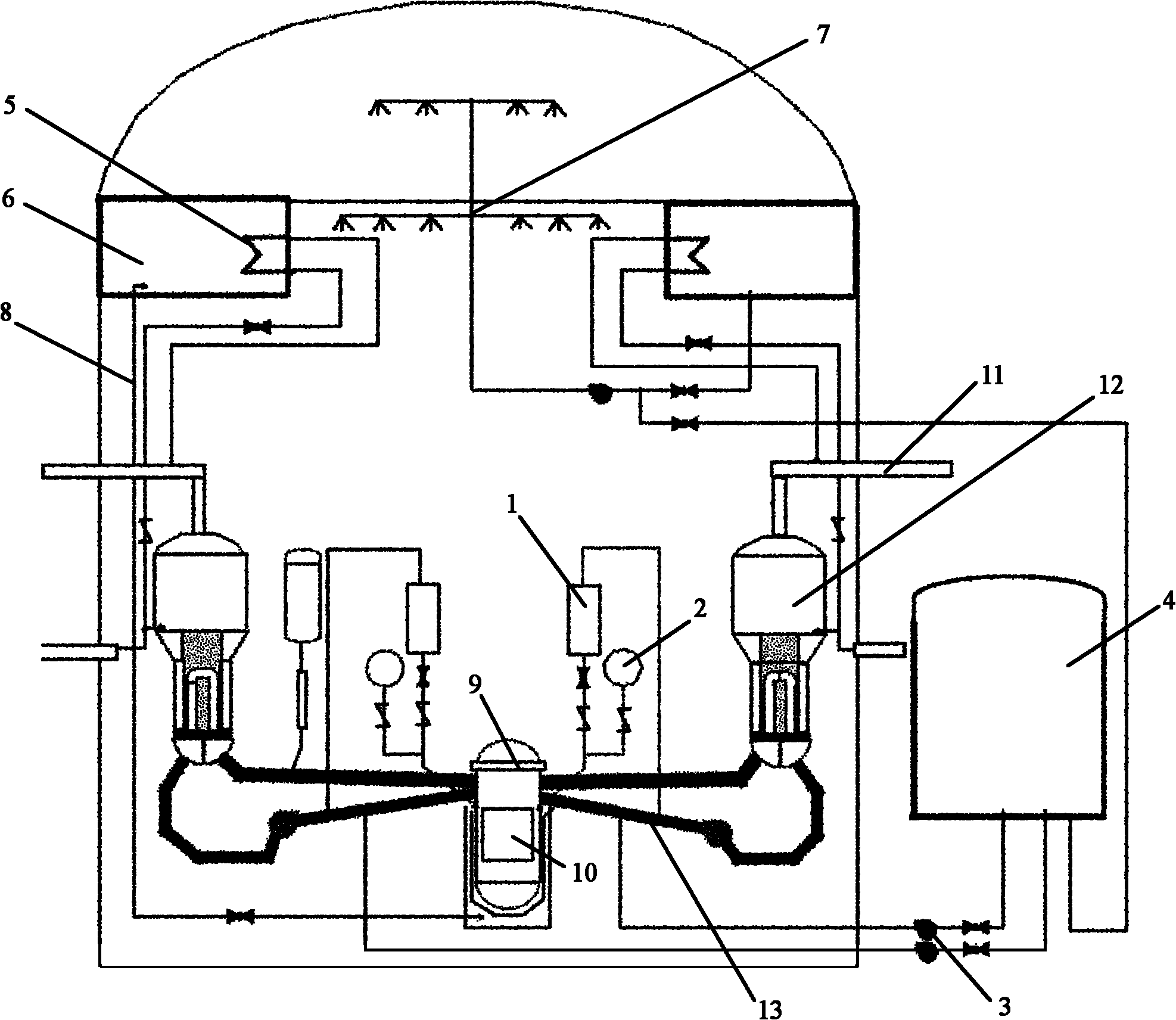

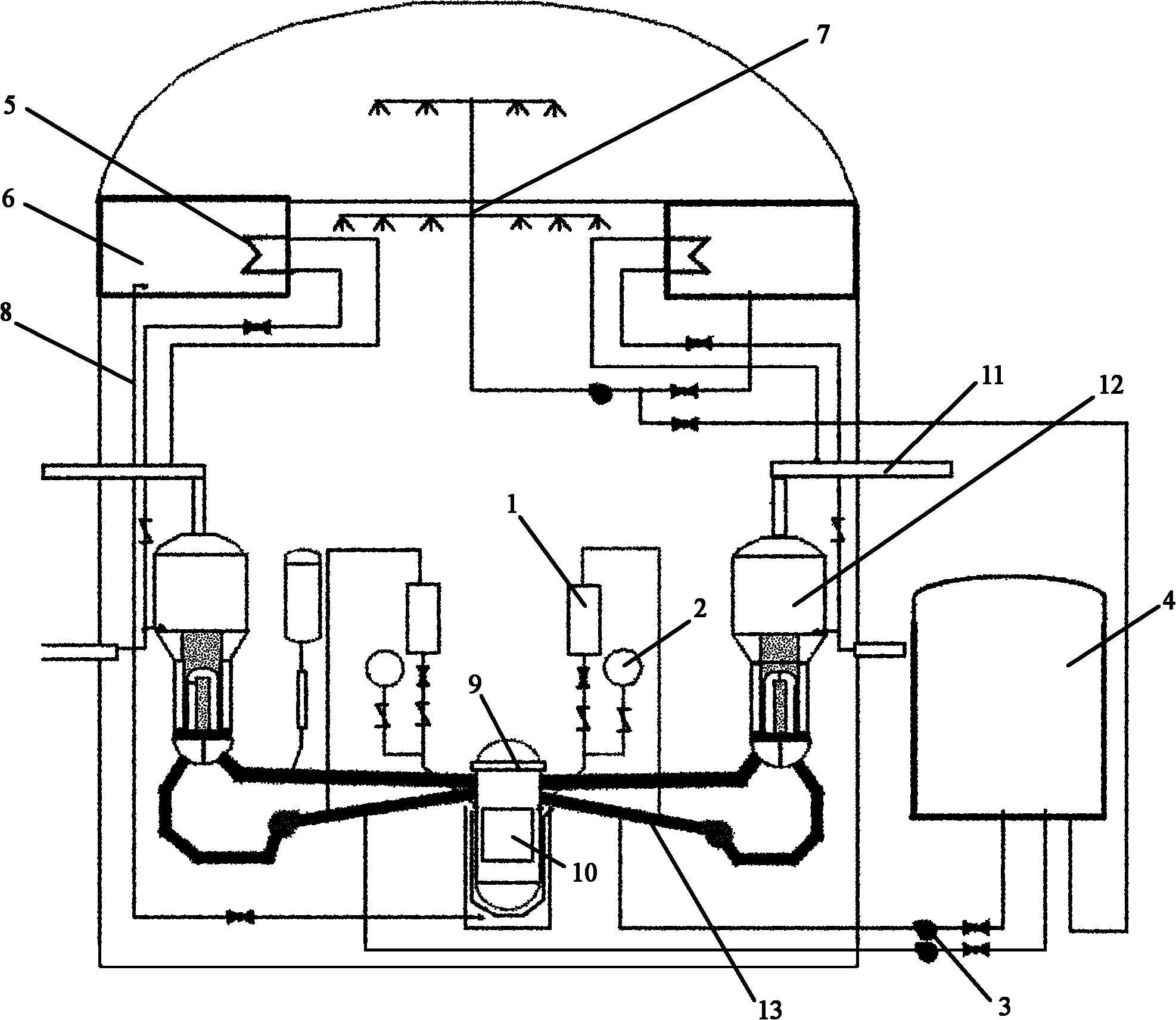

Nuclear power station non-active engineering safety system

InactiveCN102163469AReduce the risk of secondary side radioactive leakage in accidents such as rupture (SGTR)Prevent and Mitigate MeltthroughNuclear energy generationEmergency protection arrangementsActive safetySteam condensation

The invention belongs to a nuclear power station safety system, and in particular relates to a nuclear power station non-active engineering safety system. The system comprises a secondary non-active residual heat removal exchanger, a steam condensation water tank, a non-active reactor cavity water injection system, a non-active high pressure reactor core water supplementing tank and related valves and pipelines. When a nuclear power station is in a design basis accident or a hyper design basis accident, a series of non-active and active safety devices are invested in steps, and a reactor primary circuit and a reactor core are timely, rapidly and effectively cooled, thus a nuclear power station smoothly enters into a safe cold shut-down amplifier state, a reactor disaster consequence is inhibited or alleviated, incident harm is reduced, and the safety of the nuclear power station is improved.

Owner:CHINA NUCLEAR POWER ENG CO LTD

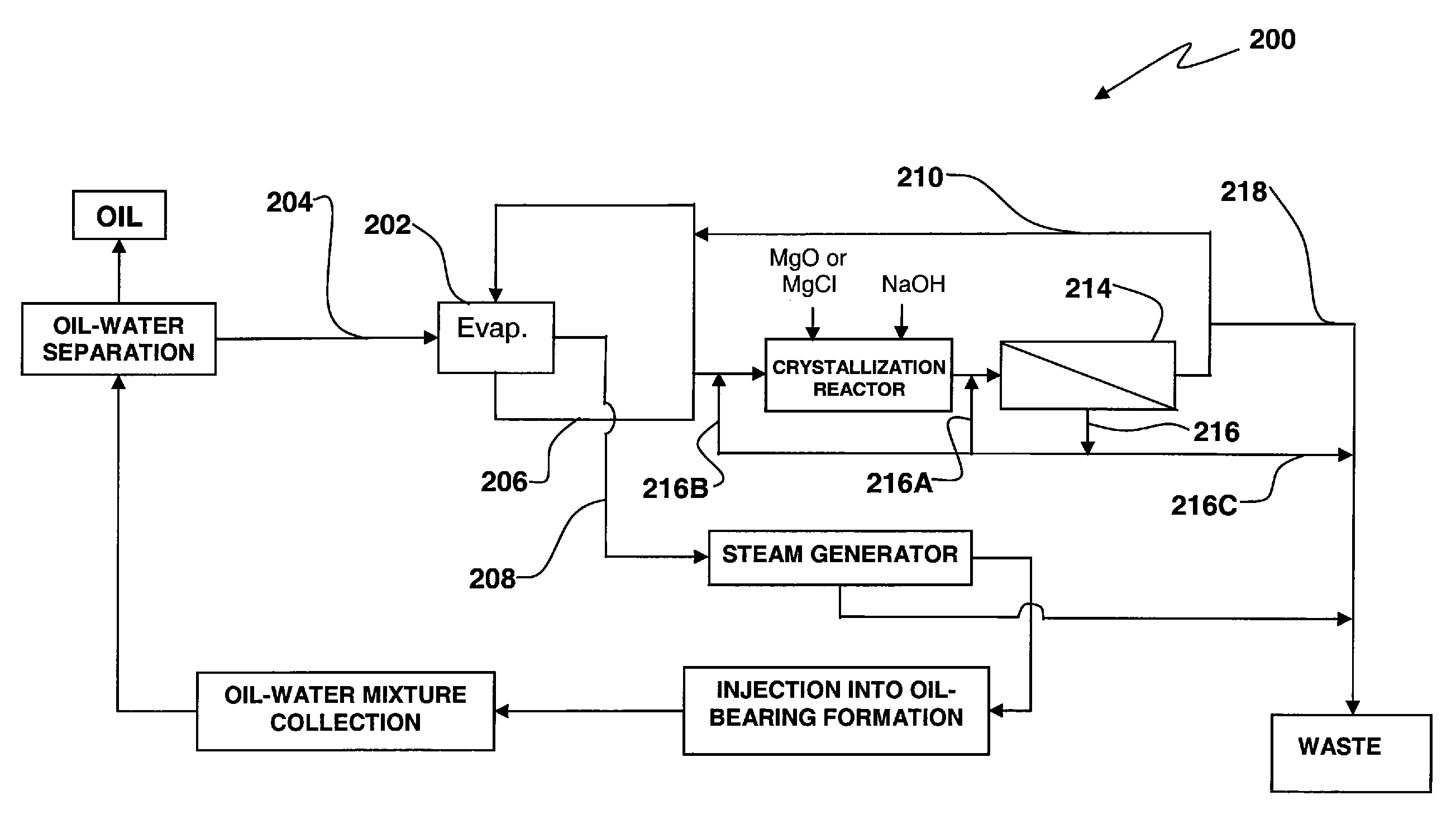

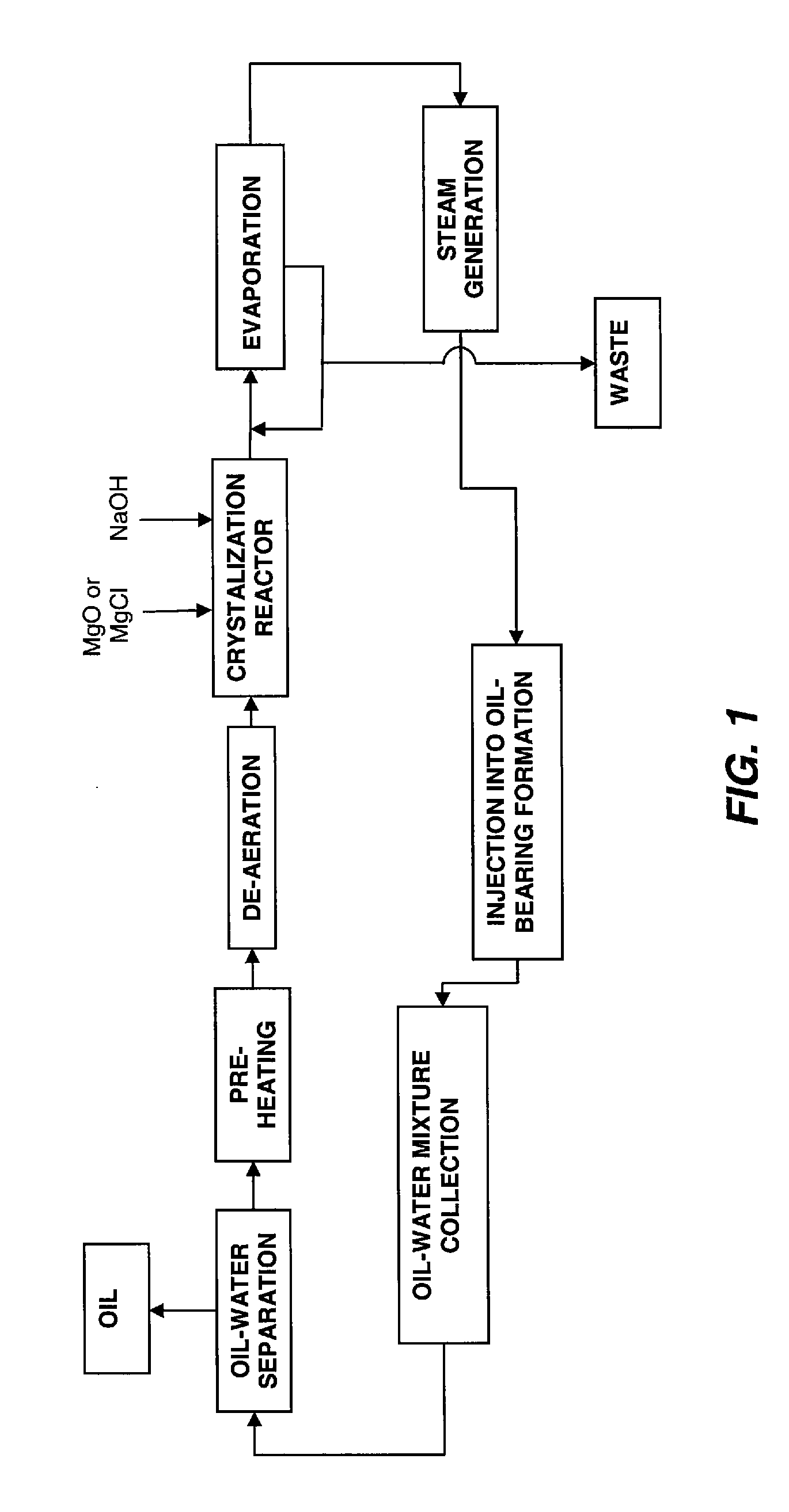

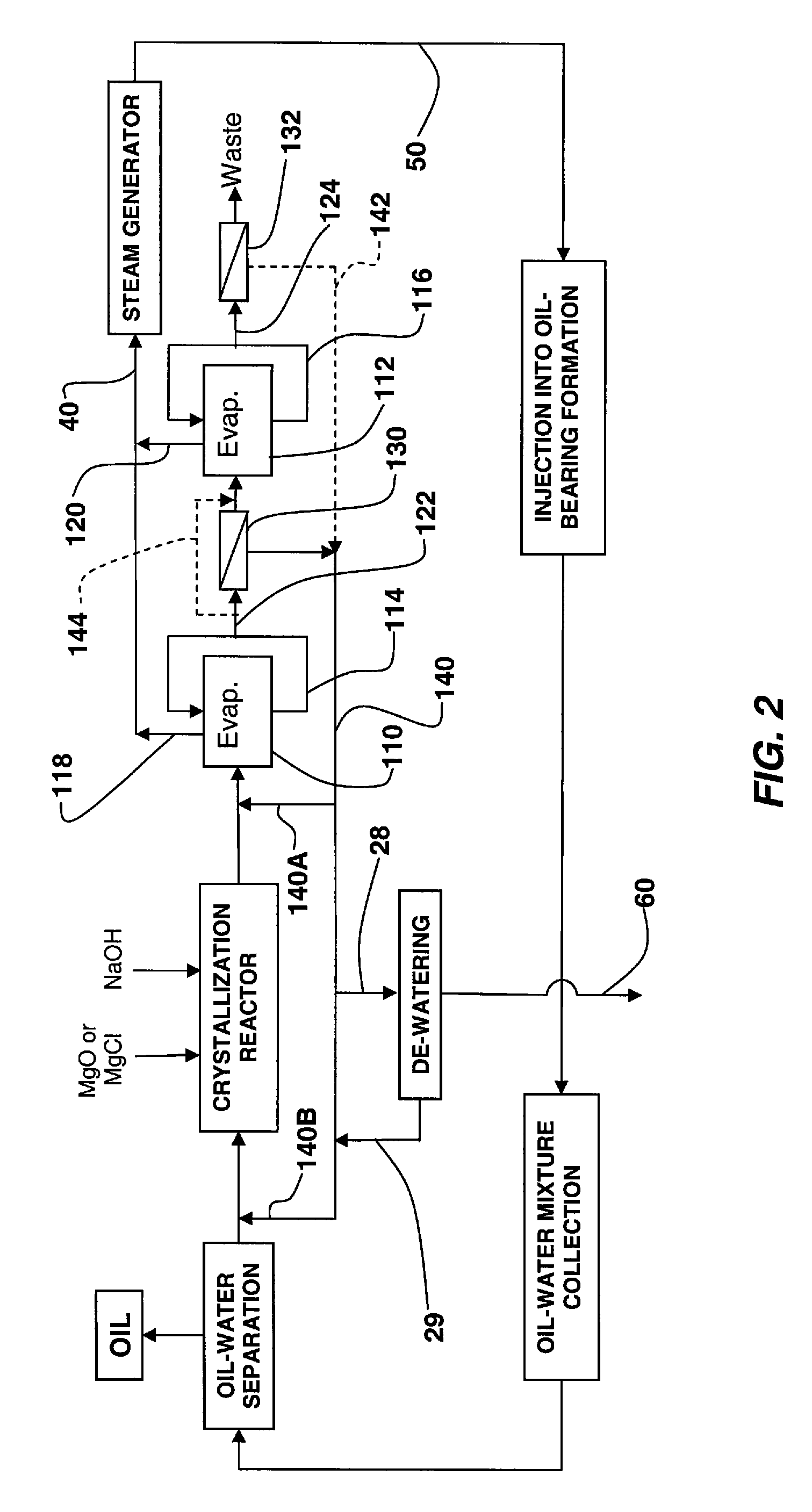

Process for Removing Silica in Heavy Oil Recovery

A process for recovery oil includes recovering an oil / water mixture from an oil well. Thereafter, the method includes separating oil from the oil / water mixture to produce an oil product and produced water having dissolved silica therein. The produced water is directed to an evaporator and produces steam and a concentrated brine. The method or process entails mixing a precipitant or crystallizing reagent with the produced water or the concentrated brine and causing the silica to precipitate from the produced water or the concentrated brine. Steam produced by the evaporator is condensed to form a distillate which is directed to steam generator. At the steam generator the distillate is heated to produce steam which is injected into an injection well, giving rise to the formation of the oil / water mixture.

Owner:VEOLIA WATER TECH INC

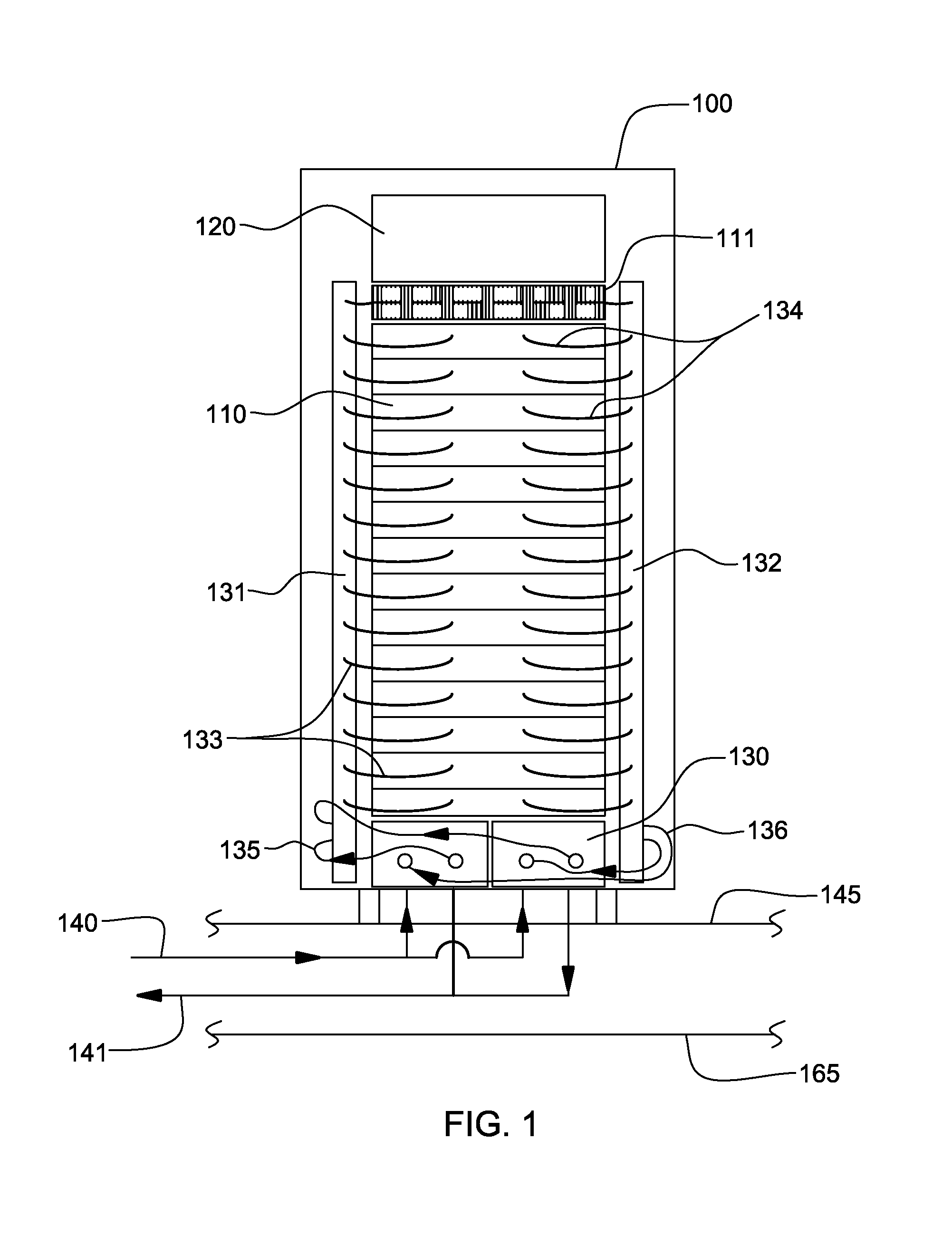

Condenser block structures with cavities facilitating vapor condensation cooling of coolant

InactiveUS8059405B2Improve cooling effectIncrease surface areaDigital data processing detailsIndirect heat exchangersSteam condensationCondensation heat transfer

Condenser structures and cooling apparatuses are provided which facilitate vapor condensation heat transfer of a coolant employed in cooling an electronic device. The condenser structure includes a thermally conductive condenser block with multiple exposed cavities therein extending from a first main surface towards a second main surface. The condenser block is a monolithic structure, and the first main surface is a coolant vapor condensate formation surface when the condenser structure is operationally facilitating cooling of an electronic device. The exposed cavities extend from the first main surface into the condenser block to increase a condensation surface area of the condenser block, thereby facilitating coolant vapor condensate formation on the condenser block, and thus cooling of the electronic device using a two-phase coolant. The condenser structure also includes coolant-carrying channels for facilitating cooling of the condenser block, and thus vapor condensate formation on the condenser block.

Owner:IBM CORP

Sewage-refuse treatment clean-production system at the center of generating plant

InactiveCN1743284AImprove efficiencyComplete desulfurizationWater/sewage treatment by irradiationSolid waste disposalSteam condensationCoal

This sewage and garbage treatment system centrally designed for power plant includes sewage treatment unit, fuel processing unit, garbage combustion boiler, fly ash processing unit, smoke processing unit, the de-oxygenating draining steam of turbine steam-extraction heat-supply boiler and circulated water cooling unit. The effluent of sewage treatment unit with coal as filter is led into magnetic water strainer, and condensed water from the domestic garbage dehydration-drying condensed water-recovering combustion-supporting device is cleared by the coal filtration and normal water treatment system to feedback the circulated water-cooling system, the steam condensed water is heated and delivered into the de-oxygenating device. Treated sewage is introduced into multi-medium condenser and the distillation-desalination device; discharged smoke from fly ash incineration device is led into garbage combustion boiler; acid water discharged from distillation unit and alkaline water from coal filter are neutralized and discharged. Water distillation system and the circulation cooling water of the steam turbine condensator are led to the air- water cooling tower.

Owner:徐宝安

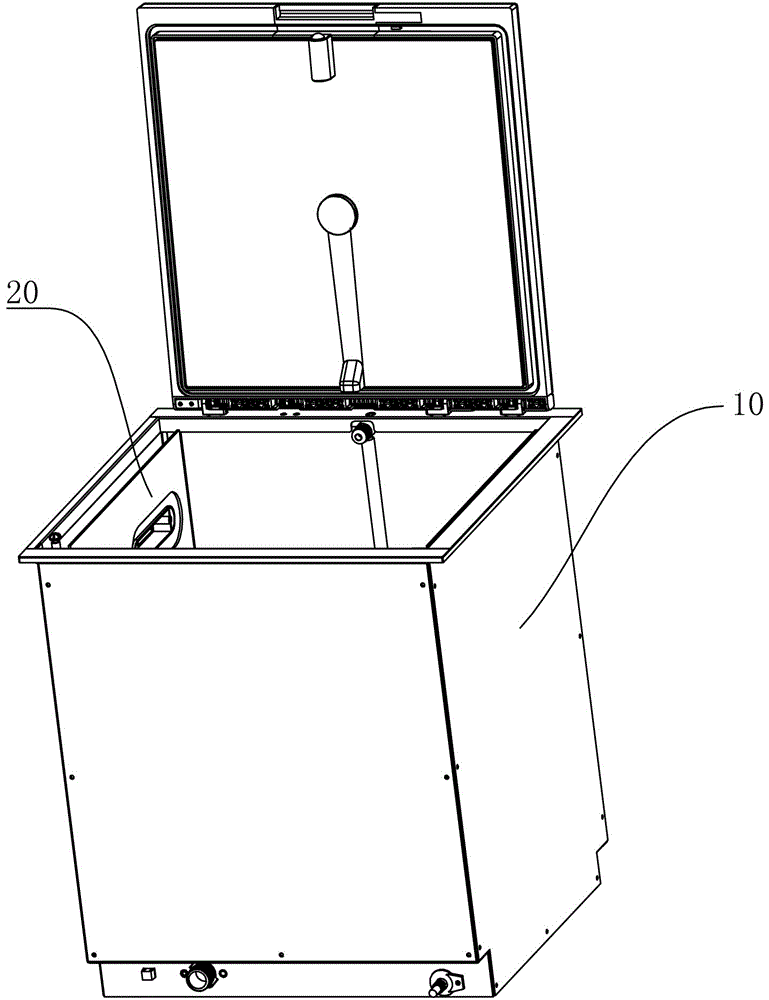

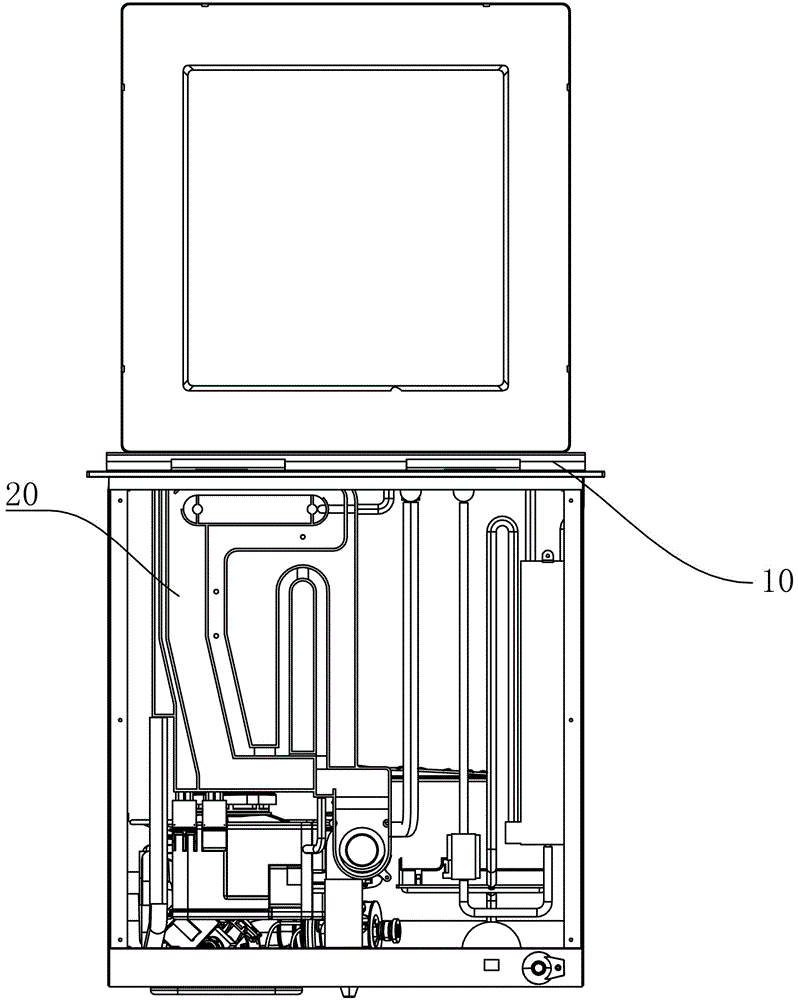

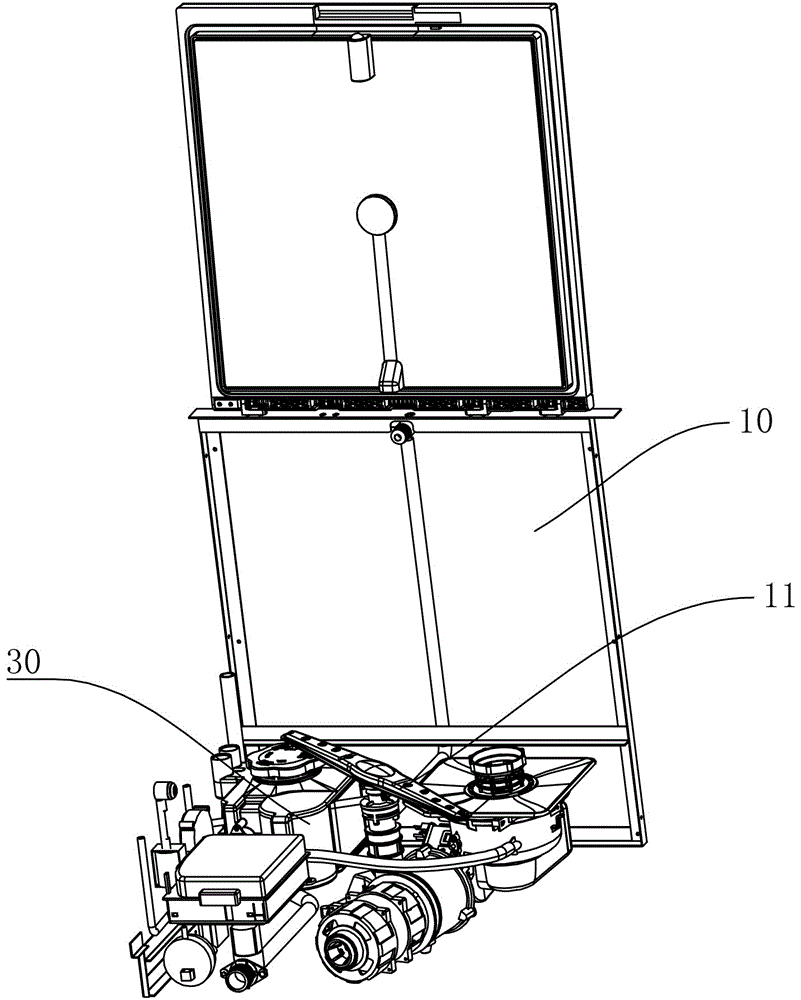

Respirator with condensing and drying functions and dish-washing machine using same

PendingCN106821265AStable jobSafe and reliable workTableware washing/rinsing machine detailsWater savingWater storage

The invention discloses a respirator with condensing and drying functions. The respirator comprises a box body and a cover body which are mutually buckled, wherein the box body is provided with a steam inlet communicated with an inner container of a dish-washing machine and a steam outlet communicated with the outside; the box body is provided with a water diversion port and a water draining outlet; a water storing chamber is formed between the water diversion port and the water draining outlet in the box body; a condensation channel is arranged between the steam inlet and the steam outlet in the box body and arranged in the water storing chamber; a condensation water draining opening is formed below the condensation channel; a fan is arranged at the tail end of the condensation channel. According to the respirator disclosed by the invention, siphon can be prevented, condensation water generated by condensing steam can be drained and repeatedly utilized, and uncondensed steam is exhausted by the fan, so that tableware in the dish-washing machine can be quickly dried. The invention also provides the dish-washing machine using the respirator with the condensing and drying functions; the exhaust quantity of the steam can be reduced, and steam condensation water generated in the respirator can be repeatedly utilized, so that the dish-washing machine realizes better water-saving and energy-saving functions.

Owner:FENGHUA EAGURT MACHINERY MFR

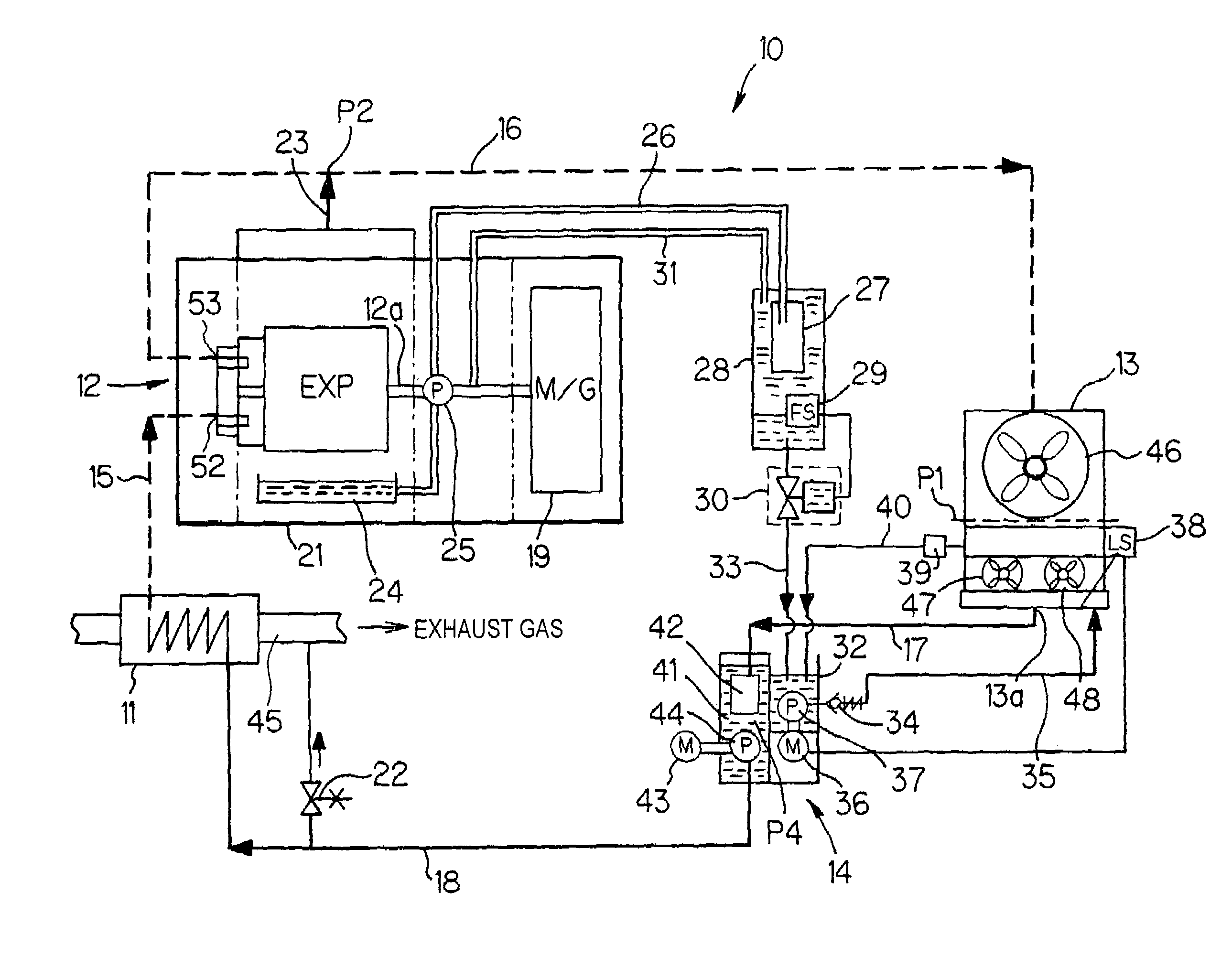

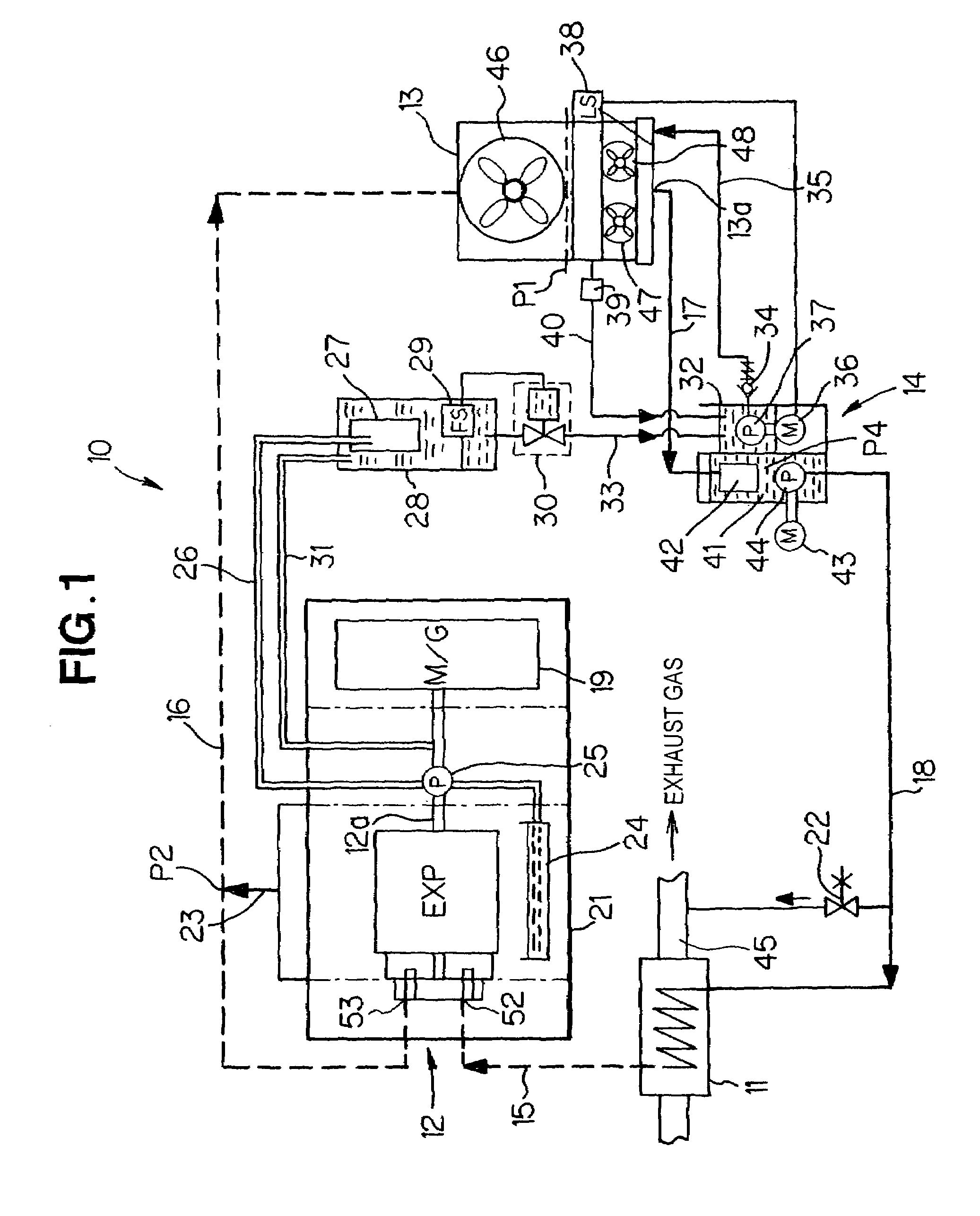

Non-condensing gas discharge device of condenser

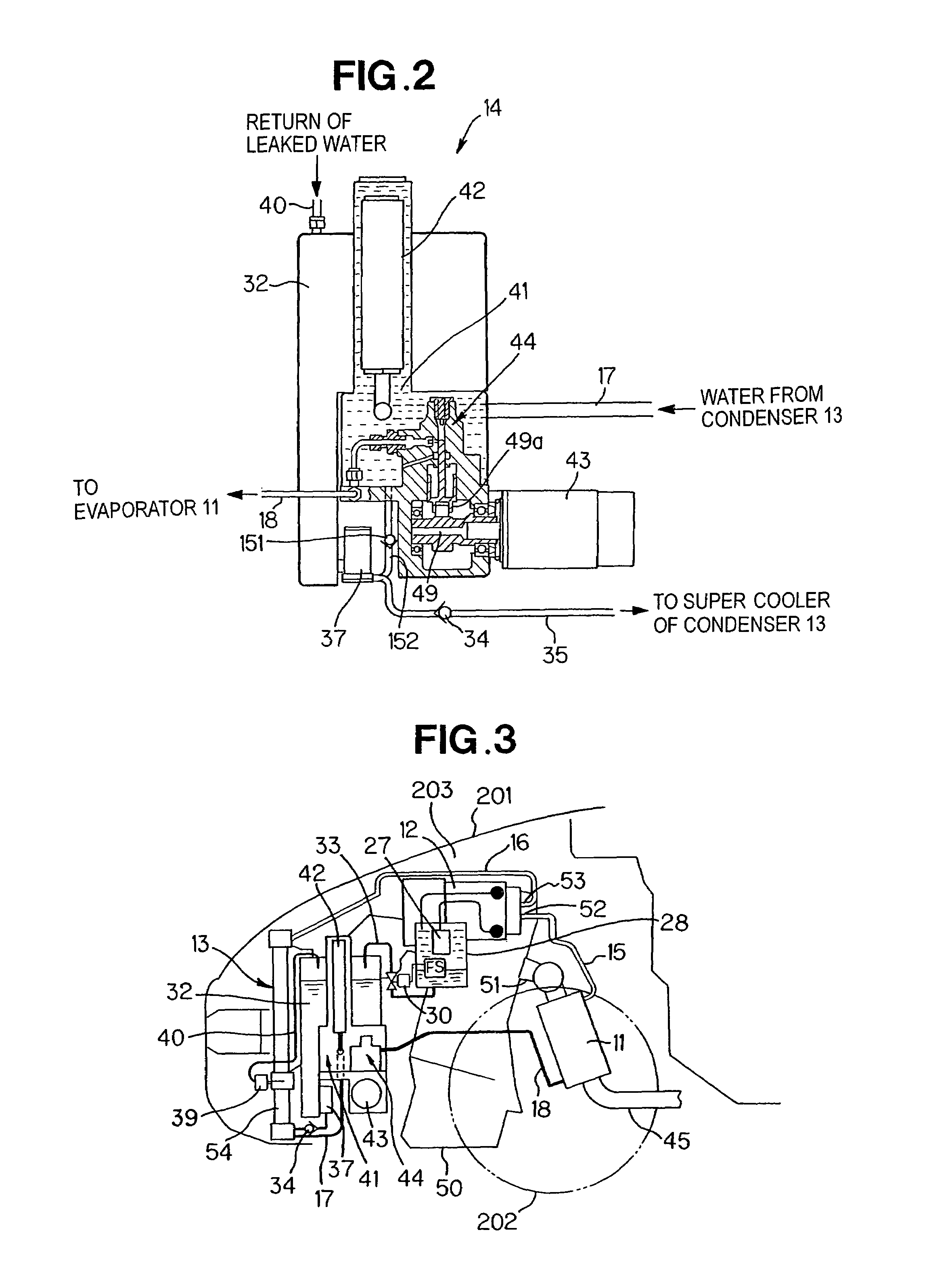

InactiveUS7131290B2Improve efficiencyImprove responseCompression machines with several evaporatorsVapor condensationSteam condensationGas phase

Owner:HONDA MOTOR CO LTD

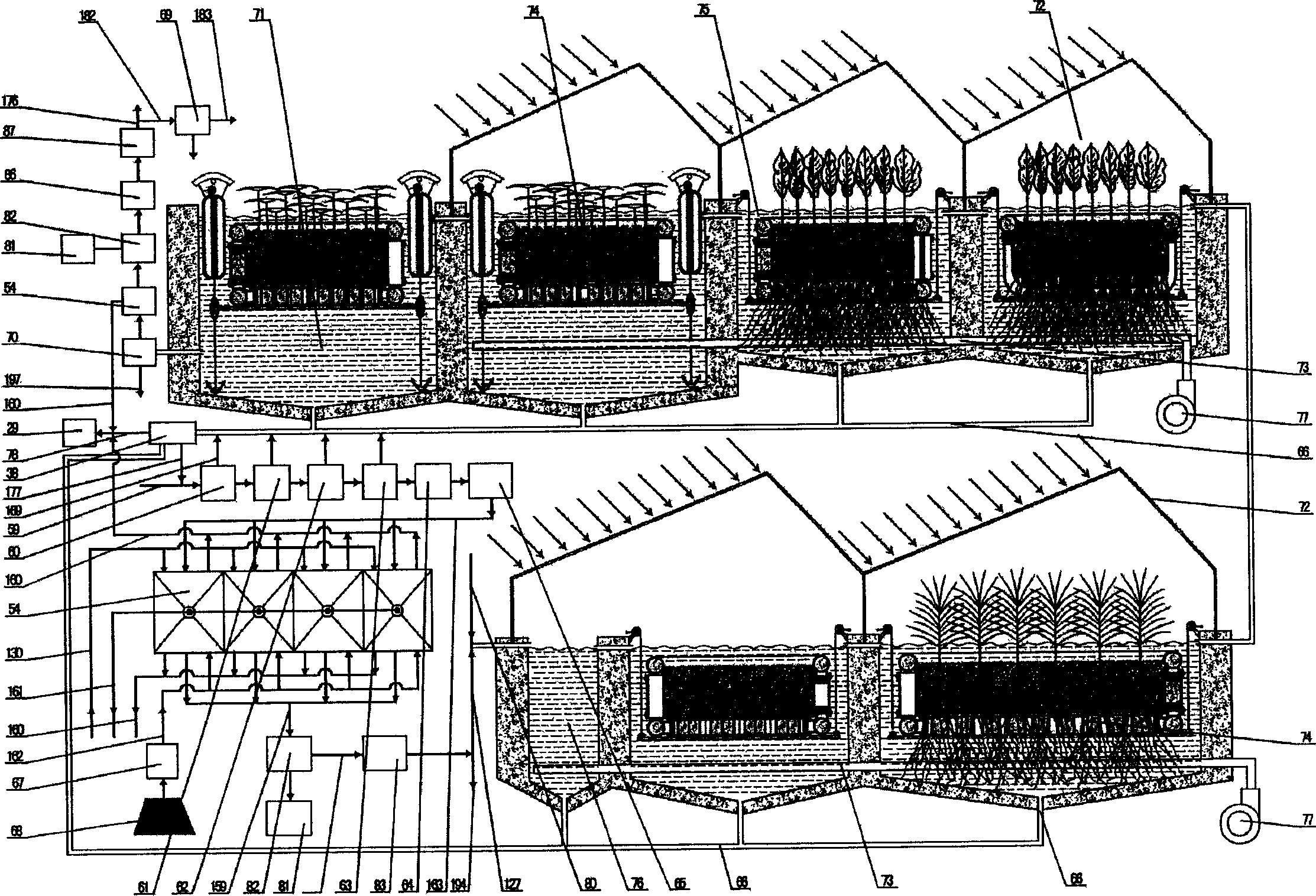

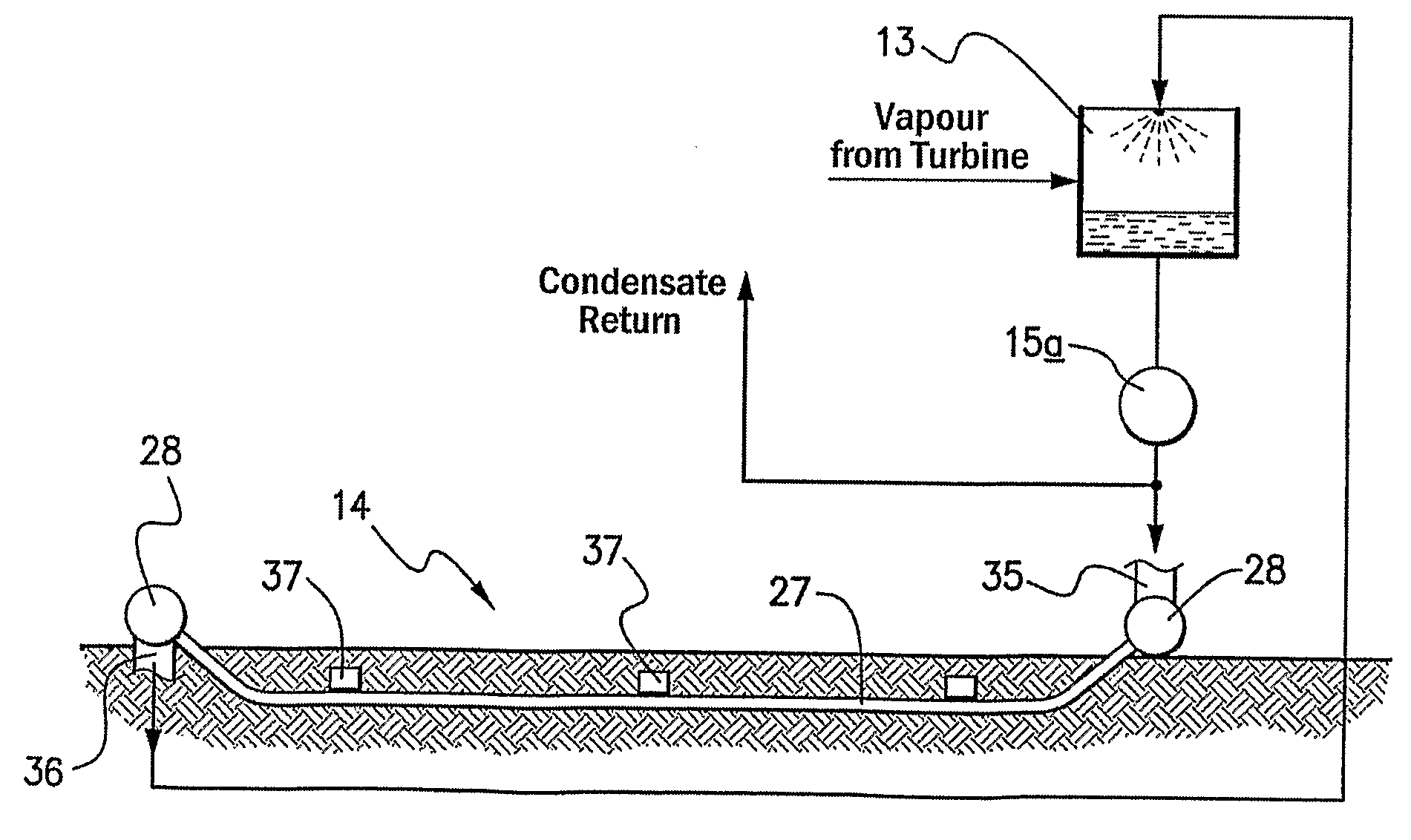

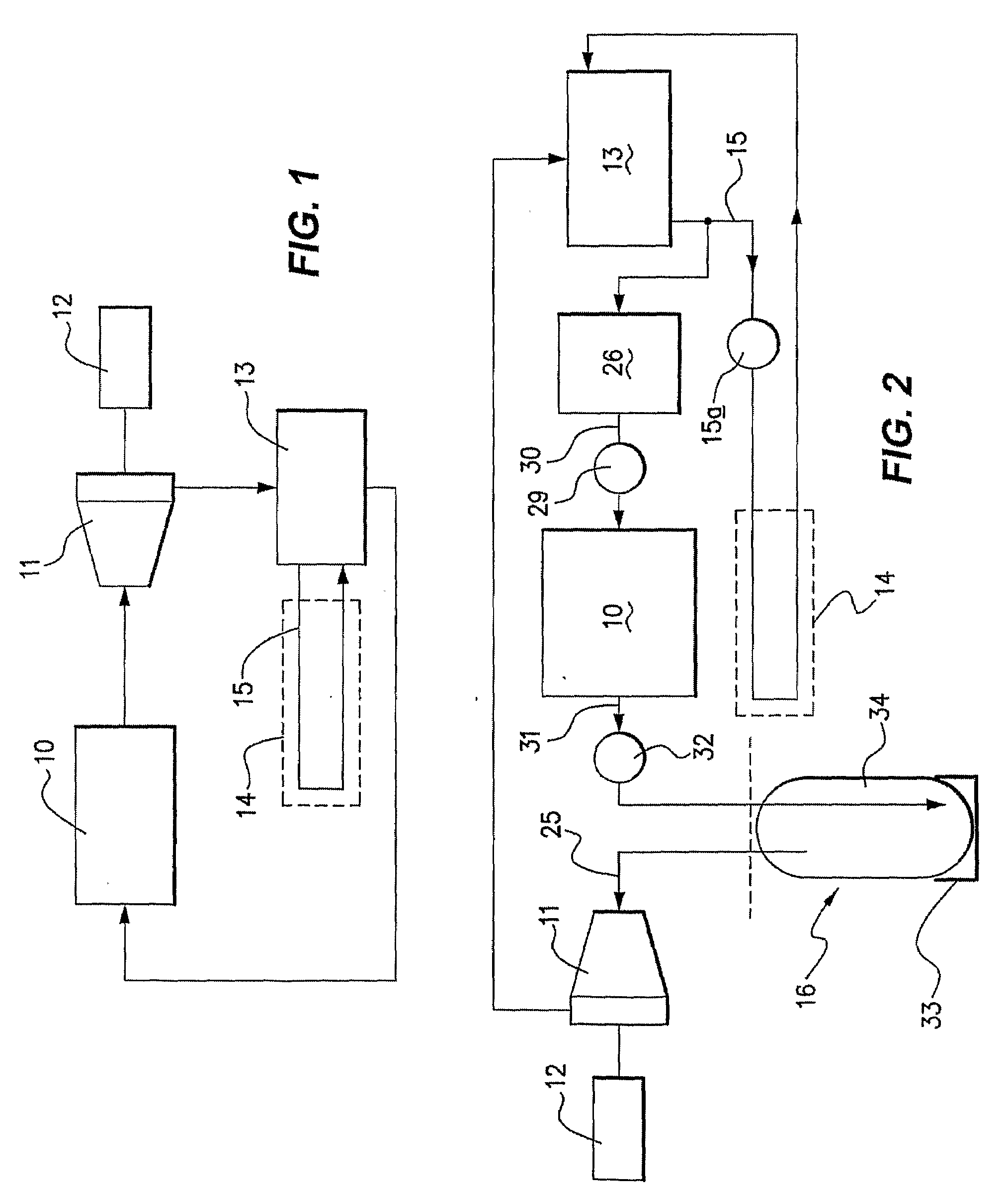

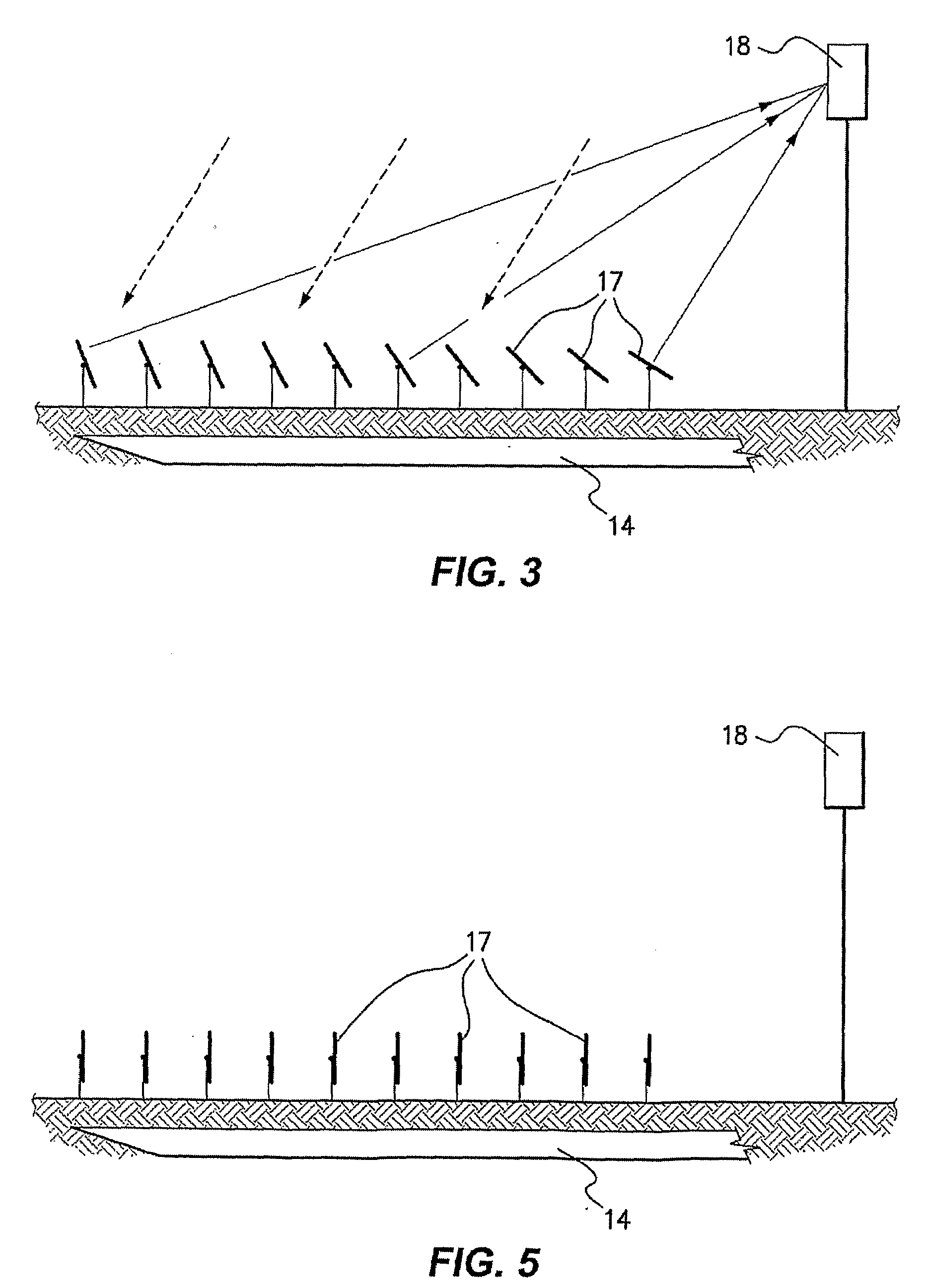

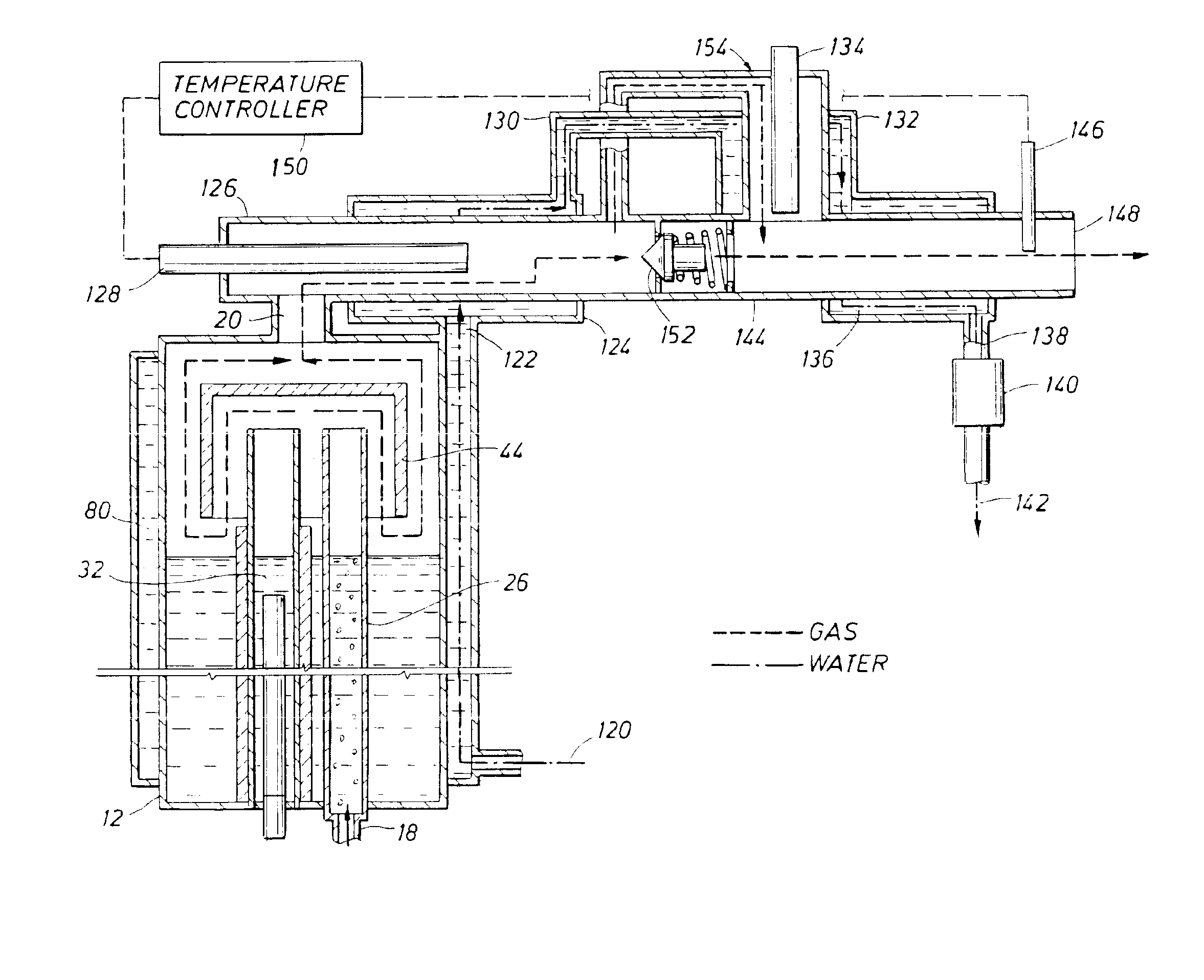

Thermal power plant incorporating subterranean cooling of condenser coolant

InactiveUS20090158736A1Facilitate maximum heat dissipationMaximize shadeSolar heating energyAuxillary drivesPower stationSteam condensation

A thermal power plant is disclosed that comprises a heating system (10) that utilizes solar radiation for heating a working fluid, a turbine (11) to which, in operation, the working fluid is delivered, a condenser (13) located downstream from the turbine and arranged for condensing vapour exhausted from the turbine, and a cooling system (14) associated with the condenser. The heating system comprises a field of reflectors (17) that, during diurnal periods, are arranged (for example by pivoting) to reflect incident solar radiation to a receiver (18) for heating the working fluid. The cooling system (14) is arranged in operation of the power plant to transport a coolant fluid to which heat is transferred during vapour condensing and it comprises a subterranean heat exchanger incorporating conduits (27) through which the coolant is recirculated when cycling through the condenser. In one embodiment of the power plant the cooling system / subterranean heat exchanger (14) is positioned within ground that is located at least in part below the field of reflectors (17). Also disclosed is a method of operating a thermal power plant.

Owner:AREVA SOLAR

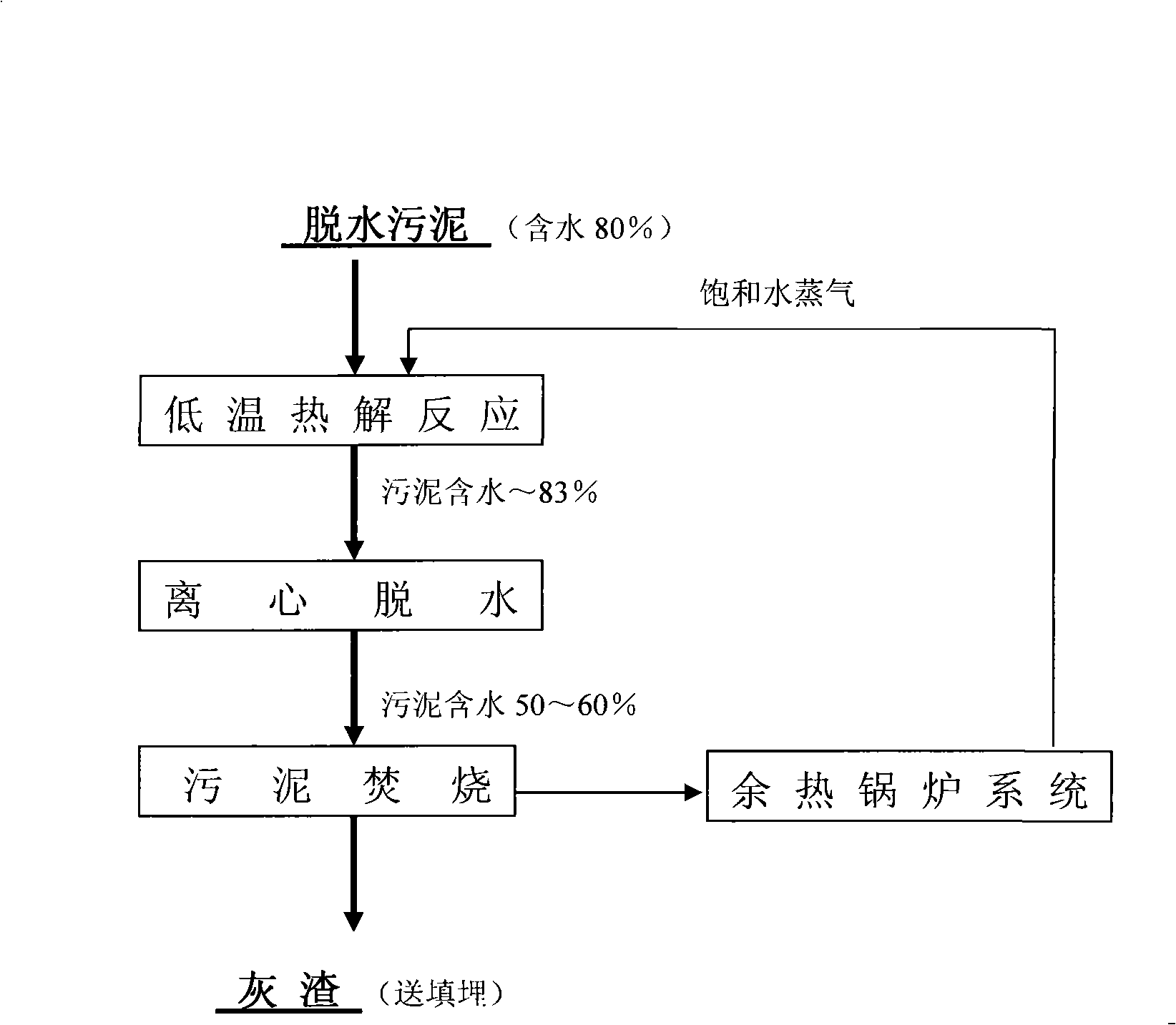

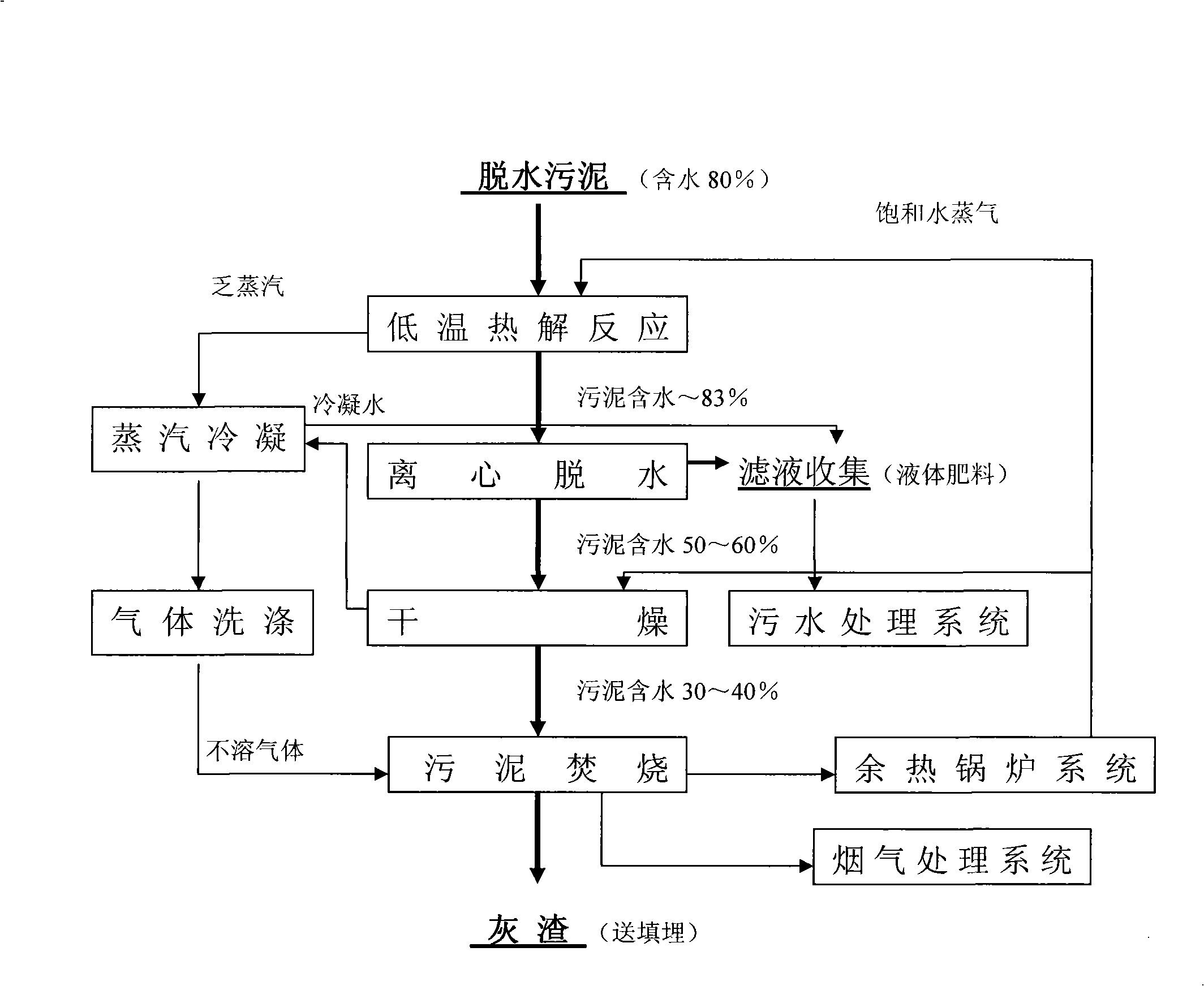

Wet sludge anhydration burning processing system and process

ActiveCN101290121AThoroughly deodorizedHarmlessDrying using combination processesSludge treatment by oxidationSteam condensationResource utilization

The invention relates to a wet sludge drying and incineration processing system. The system comprises a low-temperature pyrolytic reaction device, a centrifuging filtering device, a steam condensation device, a filtrate recovery device and a sludge incineration device; the low-temperature pyrolytic reaction device is used for carrying out low-temperature pyrolytic reaction between wet sludge and saturated steam in order to convert macromolecular organics in the wet sludge into low-molecular organics and destroy a sludge water-holding structure; the centrifuging device is used for carrying out centrifuging filtering to the wet sludge after pyrogenation; the steam condensation device is used for condensing and collecting bled steam converted from saturated steam in the low-temperature pyrolytic reaction device; the filtrate recovery device is used for collecting filtrate produced in the centrifuging device and for collecting condensed fluid from the steam condensation device; the sludge incineration device is used for incinerating semidry sludge after being dehydrated in the centrifuging device and insoluble gas remained in the steam condensation device as fuel. The system also relates to a process for carrying out the processing of wet sludge drying and incineration by adopting the processing system. The system and the process can solve the problem of sludge resource regeneration in a mode of environmental protection, energy conservation, high resource utilization rate and low operating cost.

Owner:SHENZHEN ECO SOLUTION TECH CORP

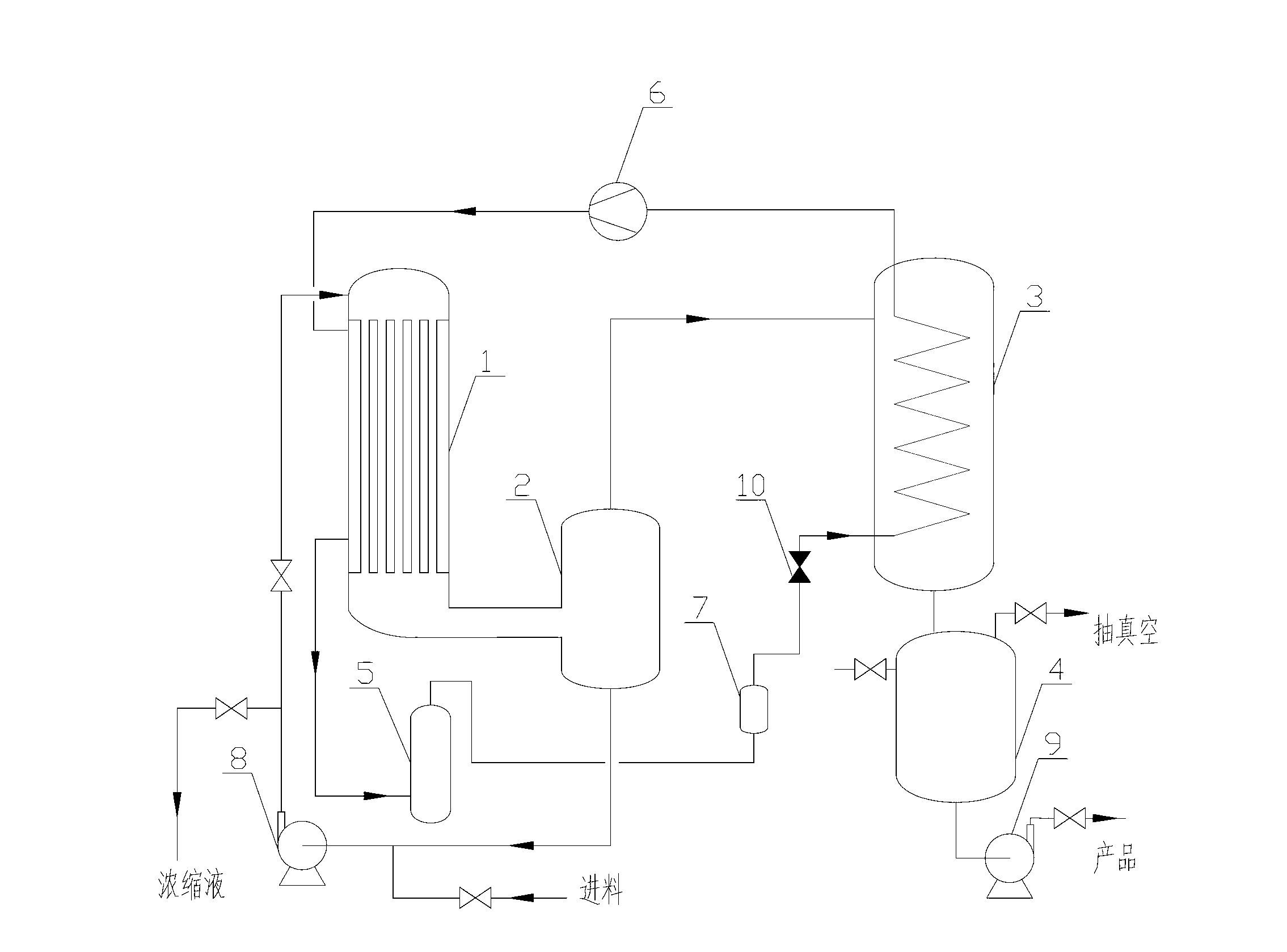

Heat pump type low-temperature evaporating device and method

InactiveCN102698451AEvaporator accessoriesMultiple-effect evaporationSteam condensationChemical separation

The invention relates to a heat pump type low-temperature evaporating device and method, belonging to the technical fields of chemical separation, energy conservation and emission reduction. The method is characterized in that a solvent is evaporated and condensed in the heating circulation process of a heat-carrying medium, so that the aim that a thermosensitive material liquid is evaporated and concentrated or an organic solvent is recovered at the low temperature can be achieved; the heat pump type low-temperature evaporating device mainly comprises a material liquid evaporator, a gas-liquid separator, a secondary steam condenser, a condensate tank, a heat medium storage tank, a heat medium steam compressor, a filter, a material liquid pump, a condensate pump, a throttling device and a pipeline valve, wherein a single-effect or multi-effect falling-film evaporator is used as the material liquid evaporator. The material liquid evaporating temperature is controlled to be within the range of 25-60 DEG C by adjusting the system vacuum degree; and the system heating capacity is controlled to be matched with the evaporation capacity by adjusting the input power of the compressor at the variable frequency. The heat pump type low-temperature evaporating device and method have the beneficial effects and advantages that the gas emission is reduced, so that the environment is protected, and the energy is saved; and furthermore, the active ingredients of the material liquid can be maintained by low-temperature evaporation, equipment is seldom corroded, and a pipeline is not easily blocked, so that the equipment cost is lowered.

Owner:DALIAN UNIV OF TECH

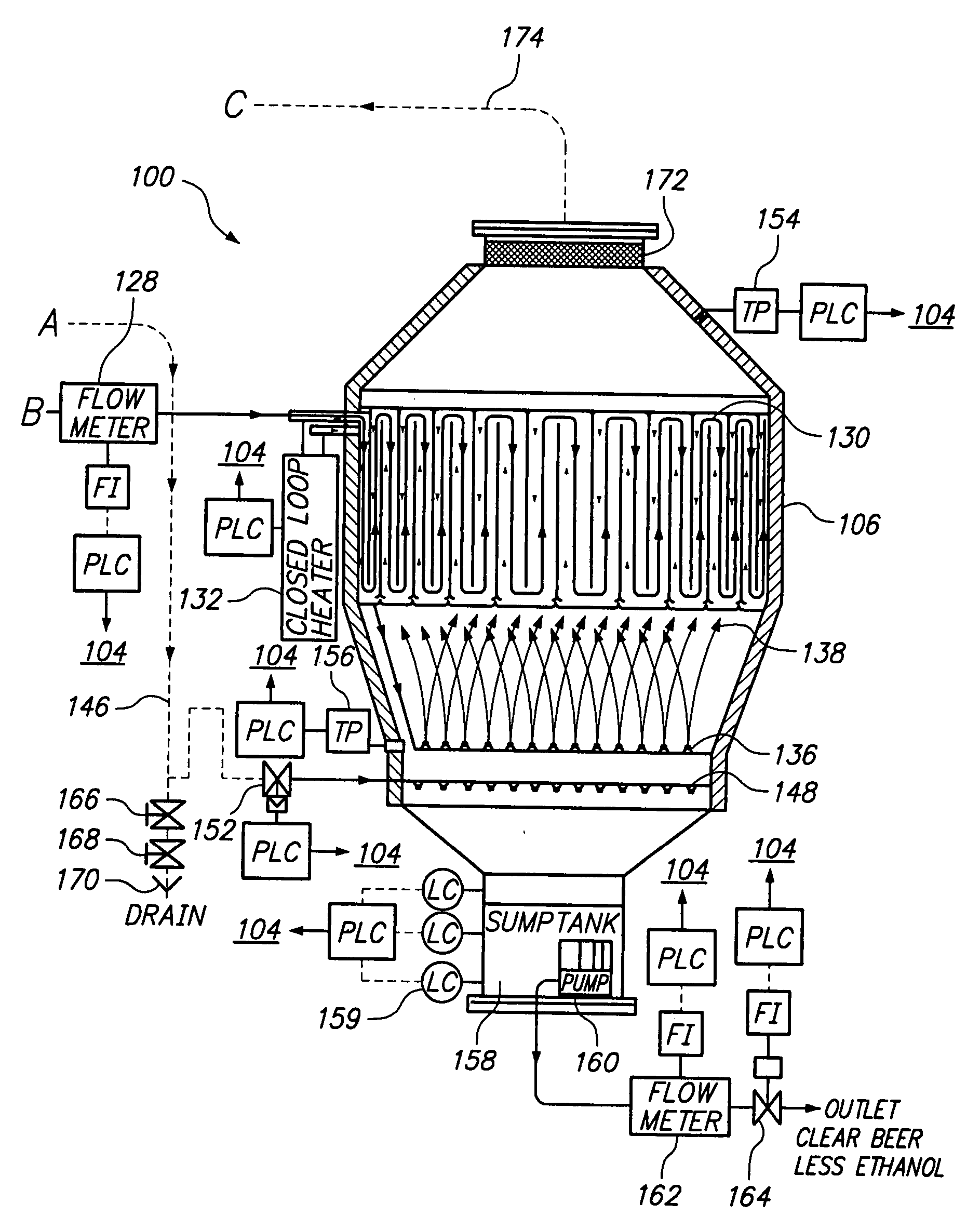

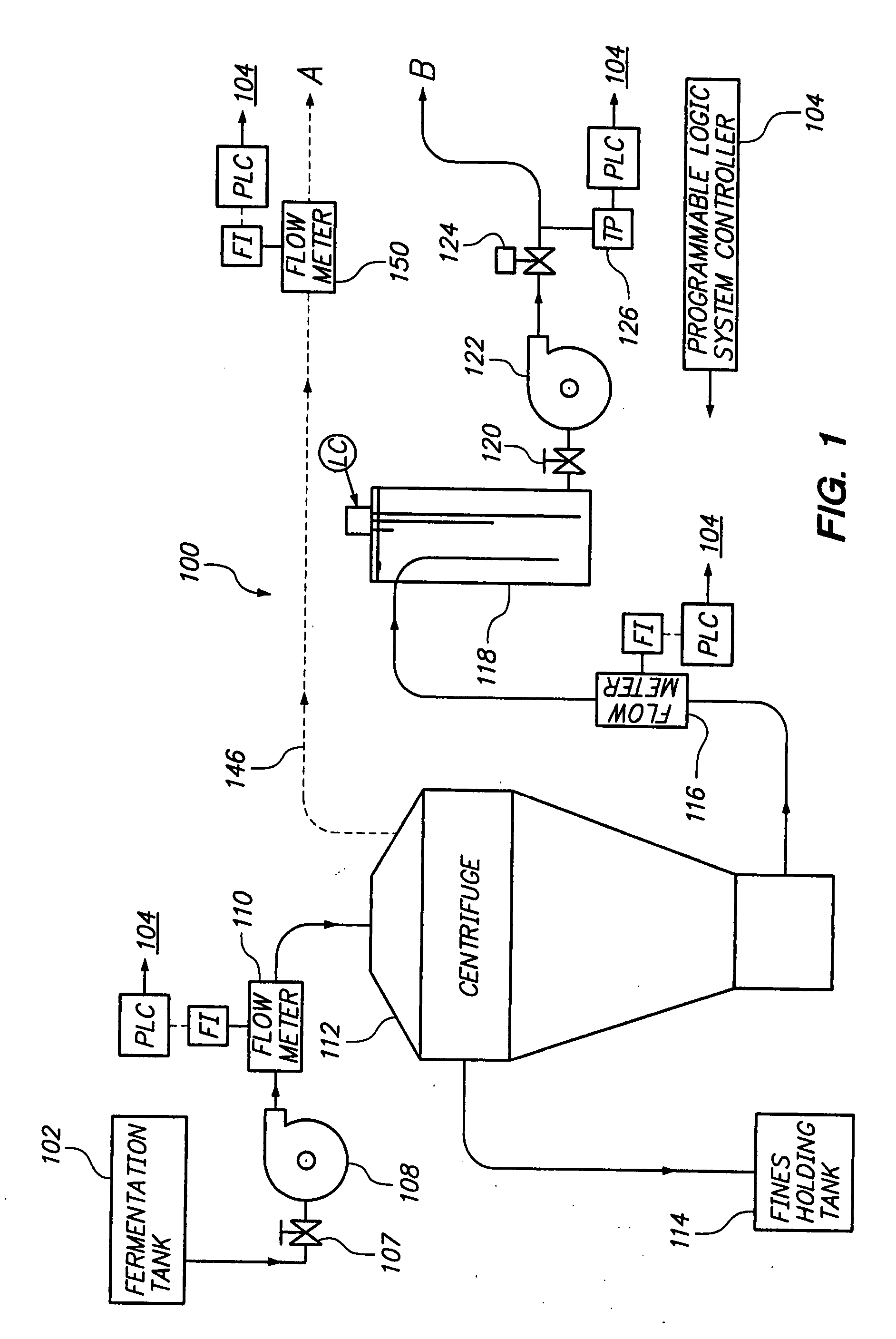

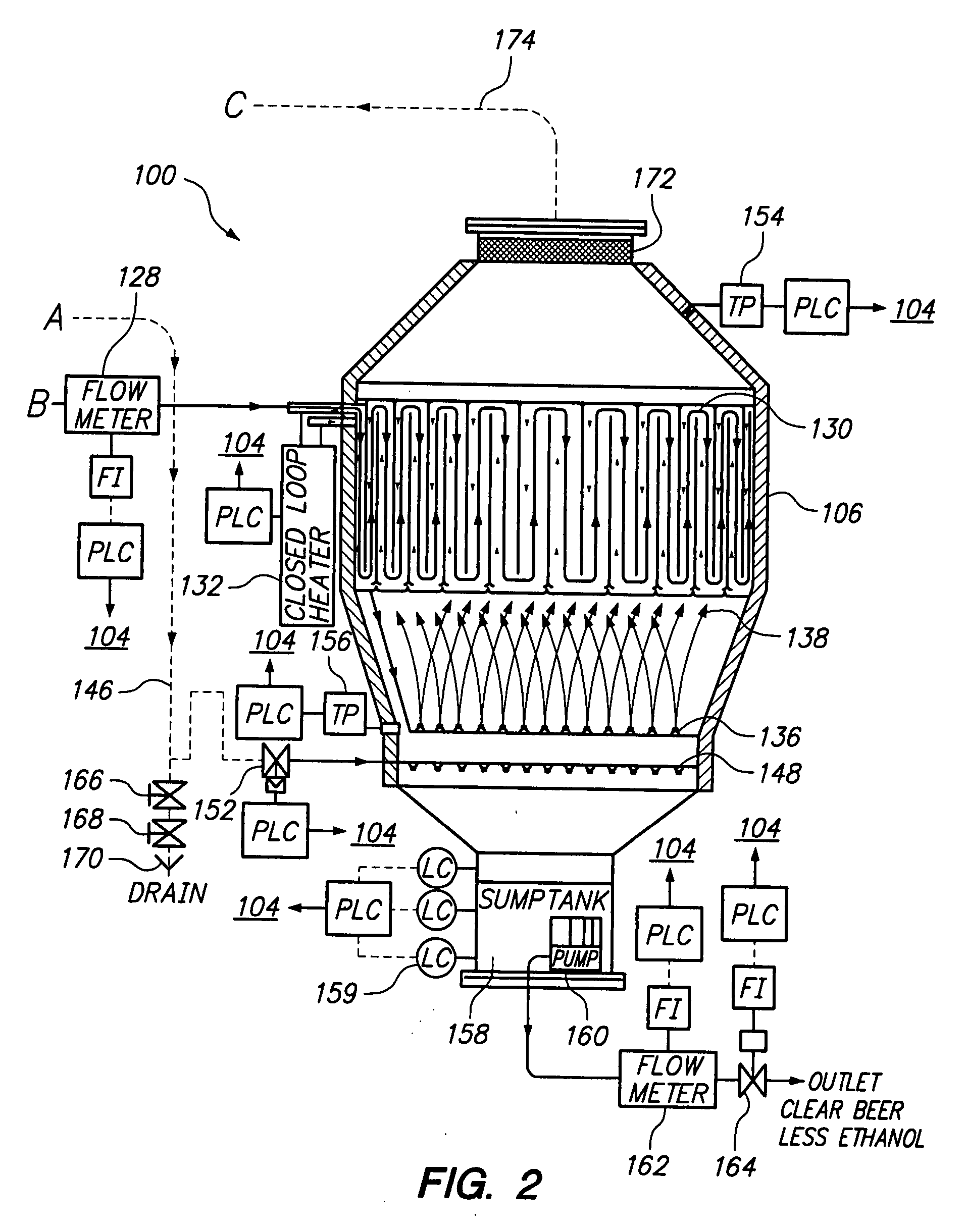

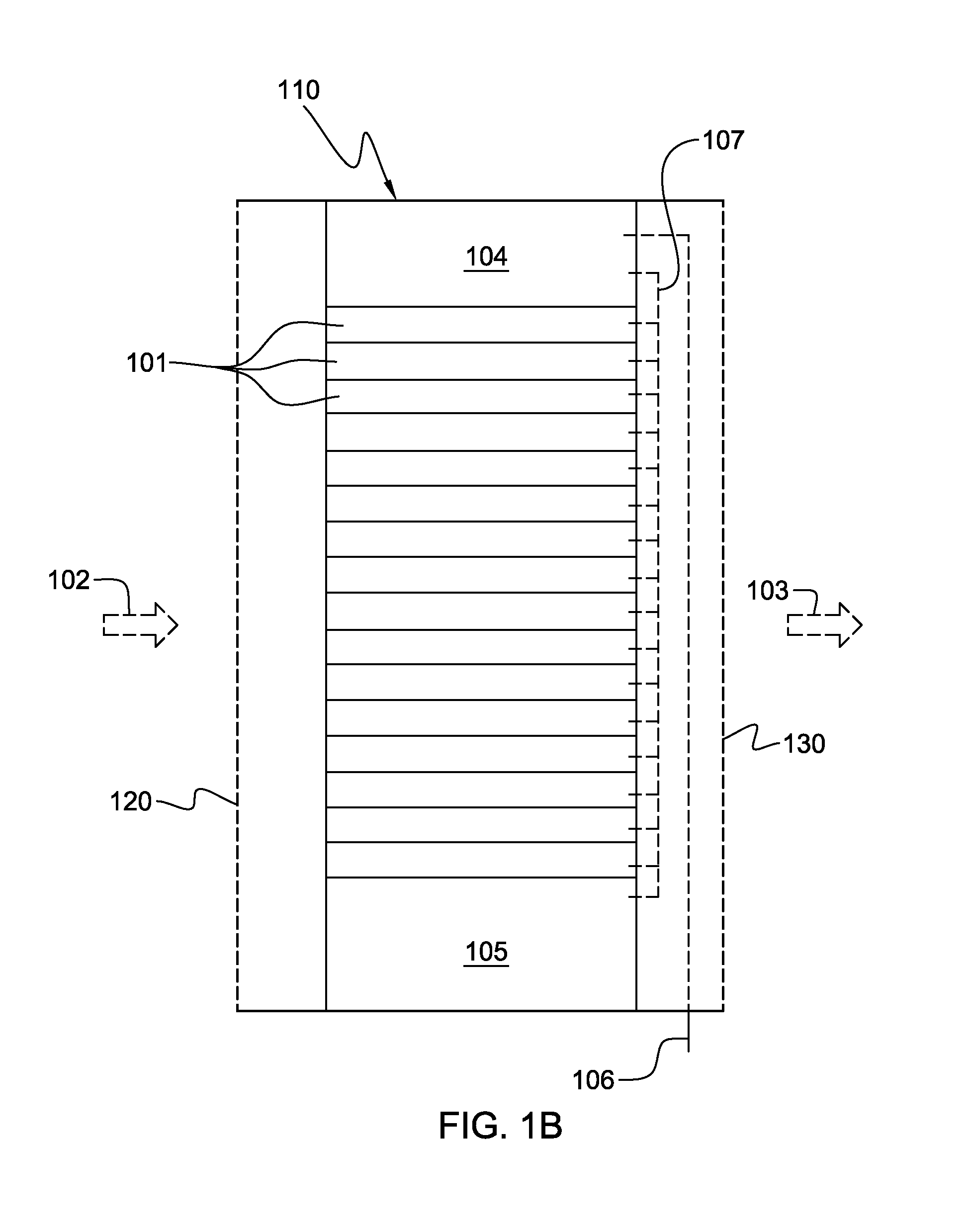

Closed system for continuous removal of ethanol and other compounds

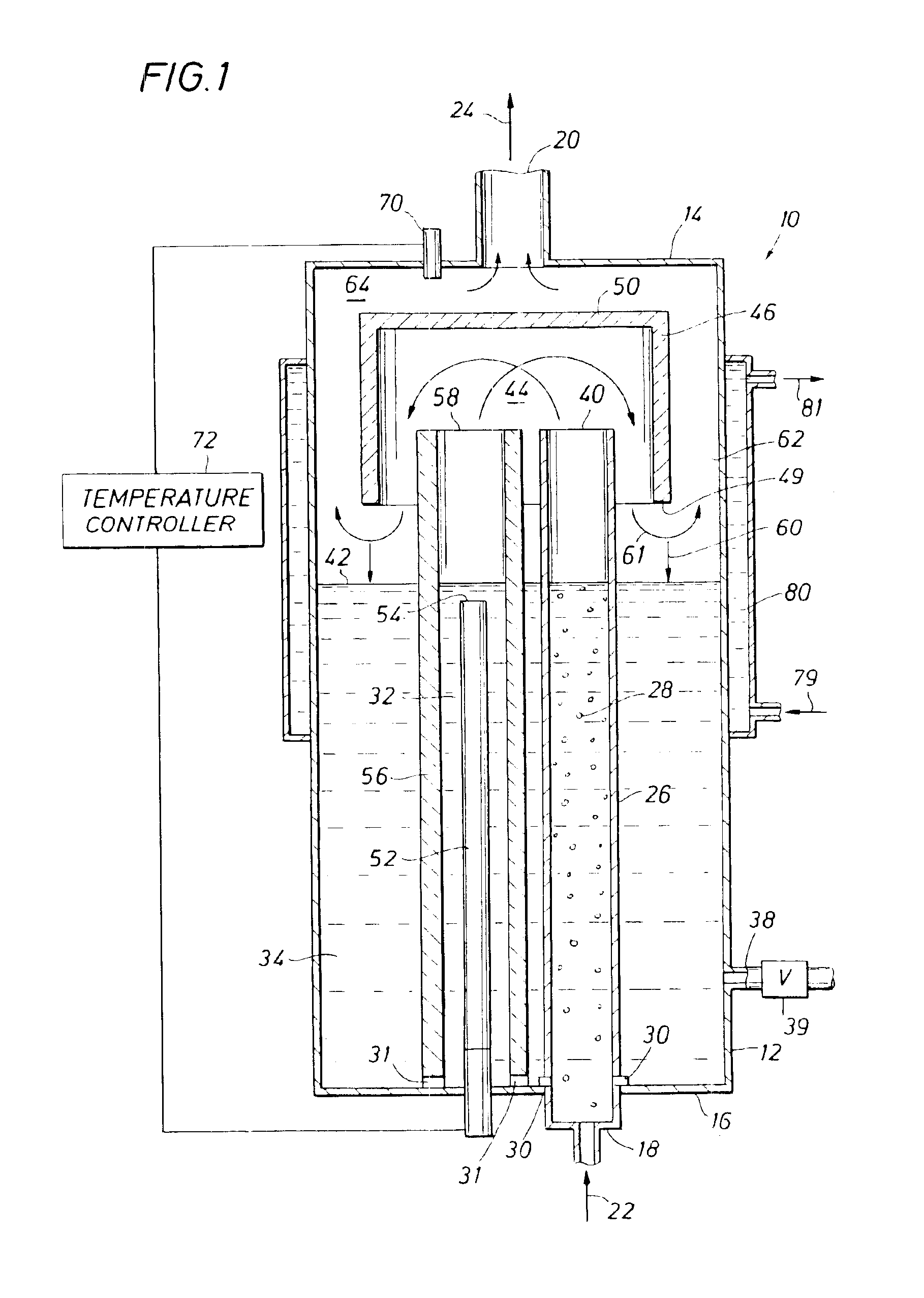

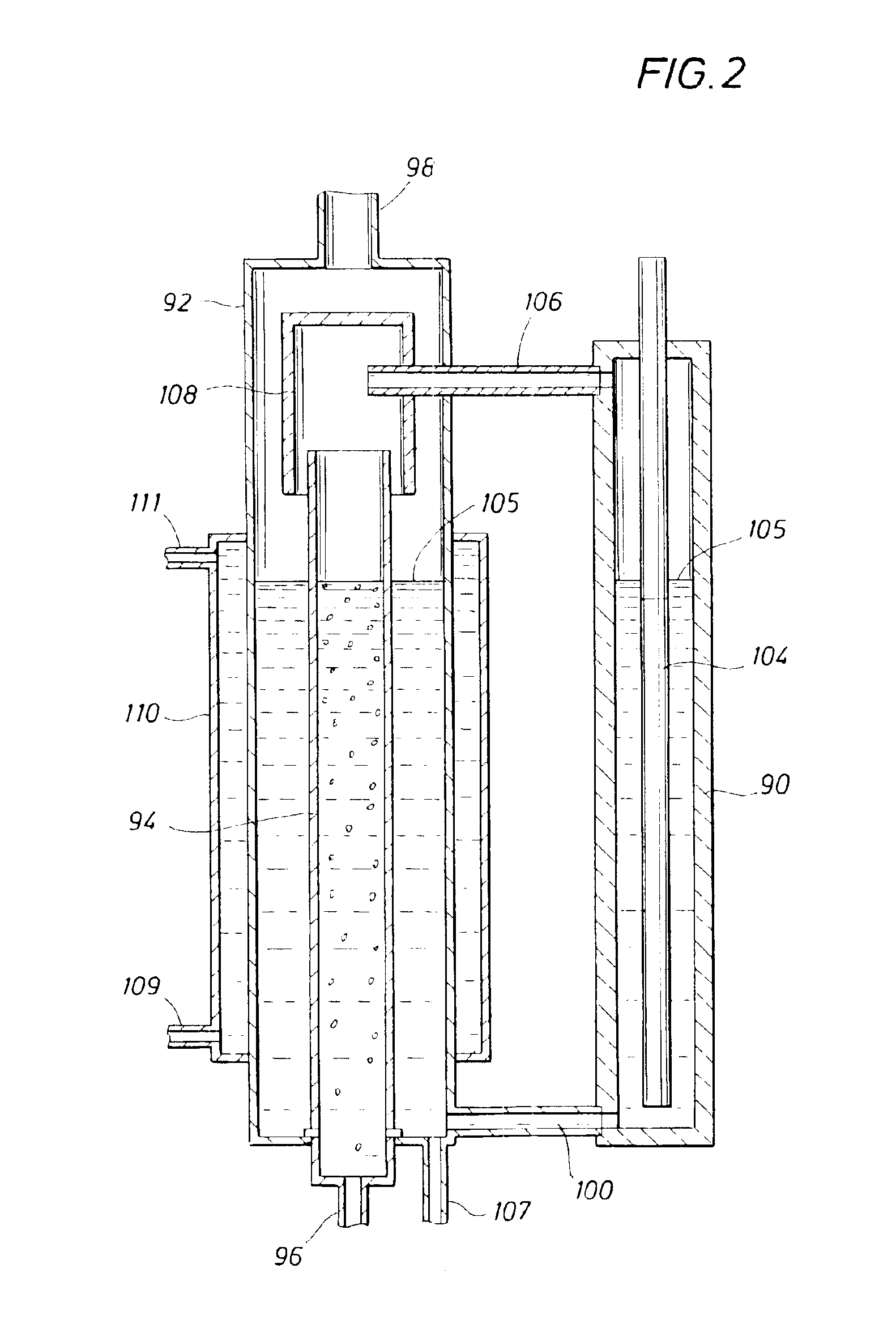

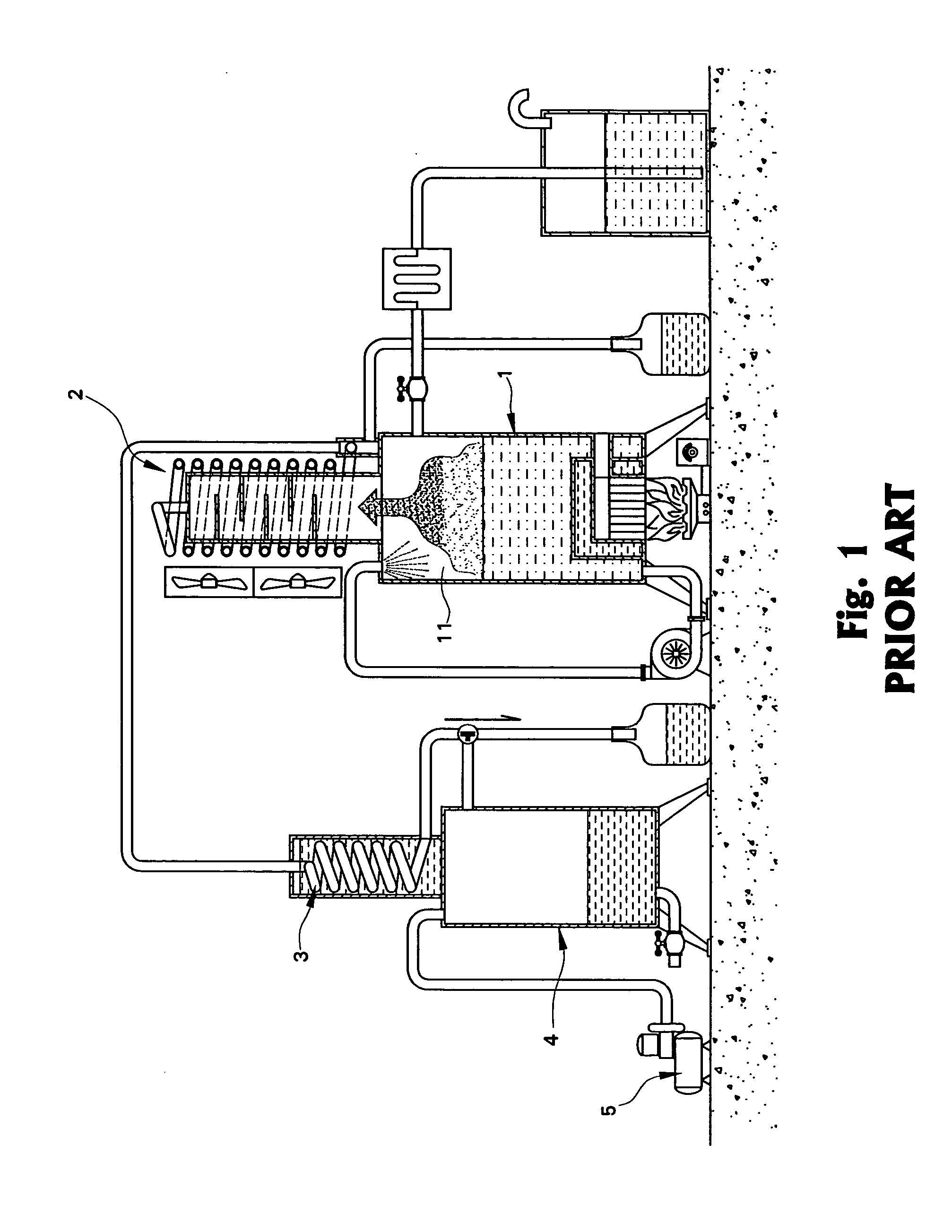

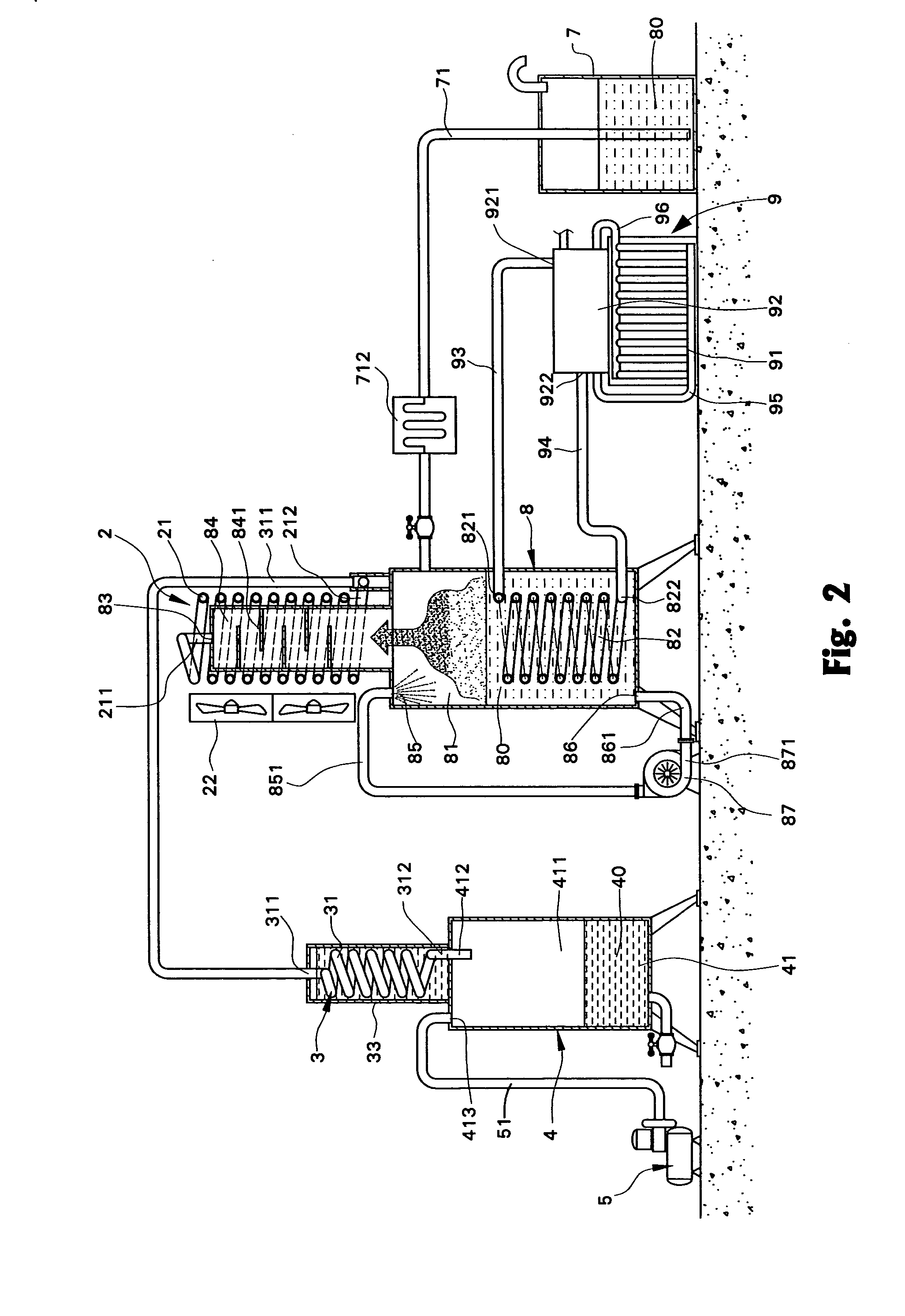

InactiveUS20080011597A1Equally distributedPrevent channelingFermented solutions distillation/rectificationRetortsSteam condensationClosed loop

A closed system for continuous removal of ethanol and other compounds in an aqueous solution includes a centrifuge for removing debris for providing a filtered aqueous solution. A transfer pump and flow control valve control the flow and pressure of the filtered solution. A vacuum pump provides a negative pressure within a boil chamber. An internal heating element within the boil chamber receives the filtered solution preheated by a closed loop heater for maintaining the internal boil chamber temperature. An internal up-spray header sprays droplets of the filtered solution in the boil chamber for controlling the surface area and contact time of the droplets within the boil chamber. The heated vacuum environment within the boil chamber results in the ethanol within the sprayed droplets and a stream of centrifuge off-gas, to be extracted as a vapor and prevent recombination with the filtered solution. A condenser condenses the vapor to liquid ethanol.

Owner:SPANI WAYNE W

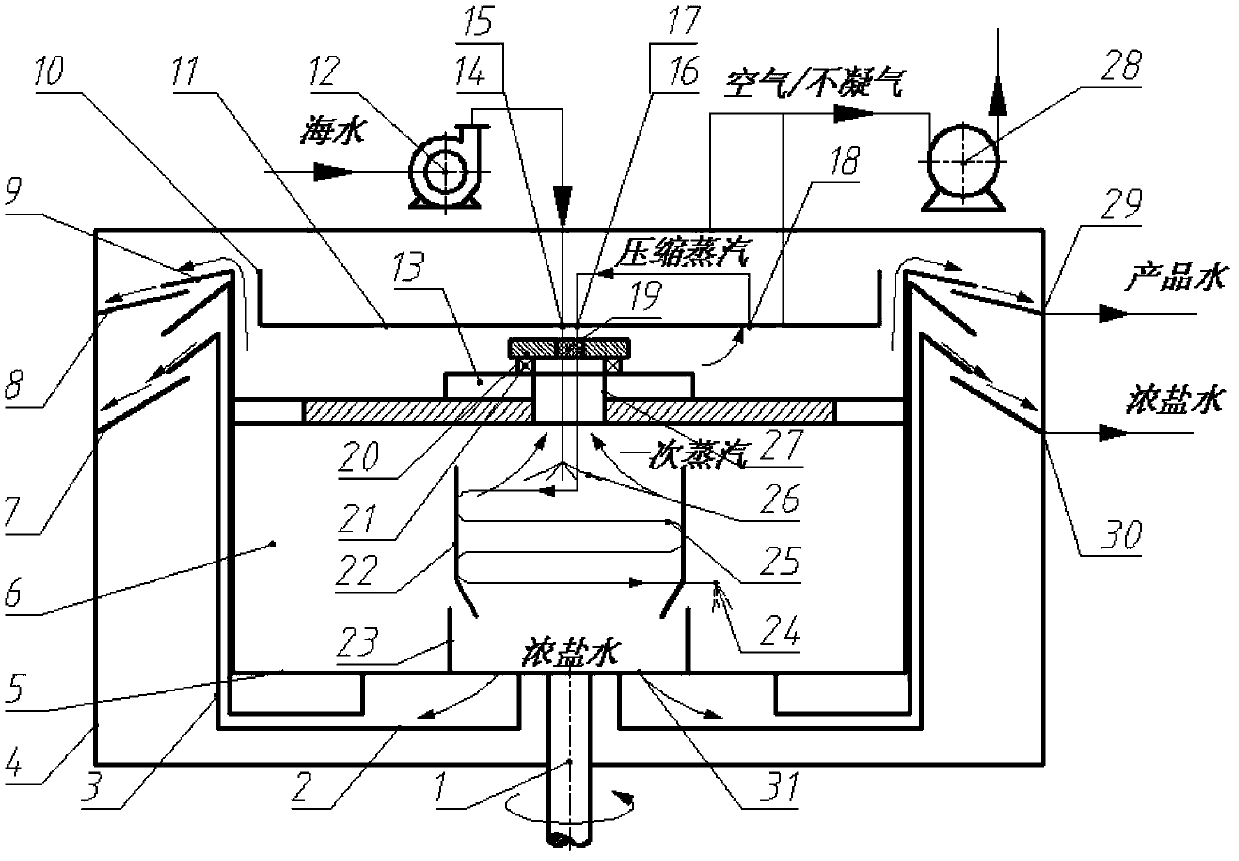

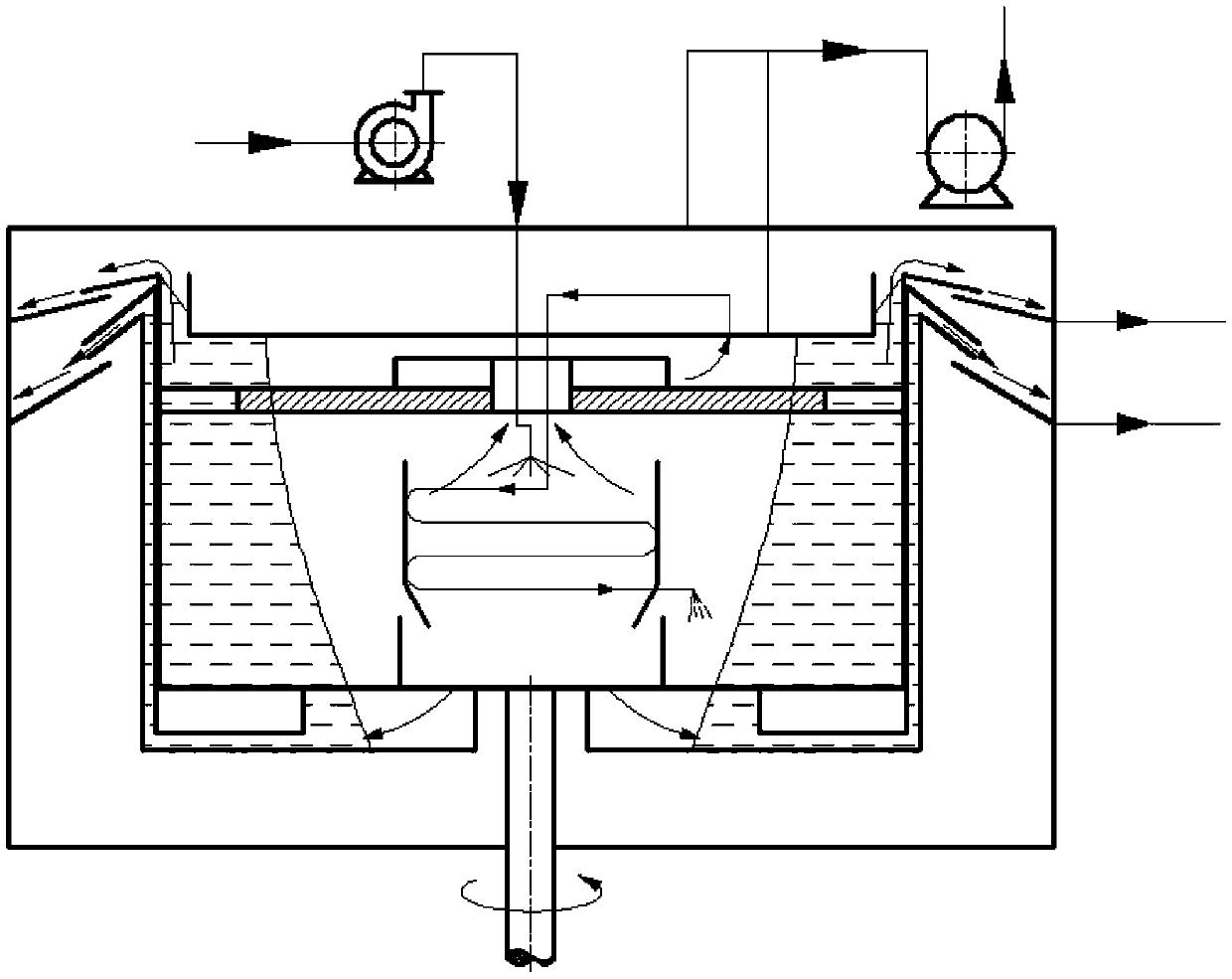

A vacuum vapor compression distillation sea water desalination device

InactiveCN103387270AIncrease water production rateIncrease heat and mass transfer rateGeneral water supply conservationSeawater treatmentWater desalinationSteam condensation

The present invention relates to a vacuum vapor compression distillation sea water desalination device comprising: a sea water pump, a seal chamber, a vacuum evaporation chamber and a vacuum pump and other components. In operation, a drive shaft drives the vacuum evaporation chamber filled with fresh water to rotate, after the formation of a vacuum area without water, sea water is fed in, and at the same time working vapor is fed in a vapor pipe coil, heat transfer between the vapor in the vapor pipe coil and the outside sea water enable the condensation of the vapor to obtain fresh water, while the sea water volatilizes to form primary vapor; and after temperature and pressure rise via a impeller, the primary vapor is fed in the vapor pipe coil as the working vapor for continuous vapor compression distillation to achieve sea water desalination. According to the device of the invention, centrifugal force is employed to replace the gravity to obtain a vacuum environment, operations are all in room temperature, no external heat source is required, and circular energy supply is achieved by the utilization of latent heat of the vapor; the water production rate and the energy utilization rate of the system are high; and the device has advantages of a simple process, a compact structure, little corrosion and scaling, etc.

Owner:HAINAN UNIVERSITY +1

Condenser block structures with cavities facilitating vapor condensation cooling of coolant

InactiveUS20100328891A1Improve cooling effectIncrease surface areaDigital data processing detailsIndirect heat exchangersSteam condensationCondensation heat transfer

Condenser structures and cooling apparatuses are provided which facilitate vapor condensation heat transfer of a coolant employed in cooling an electronic device. The condenser structure includes a thermally conductive condenser block with multiple exposed cavities therein extending from a first main surface towards a second main surface. The condenser block is a monolithic structure, and the first main surface is a coolant vapor condensate formation surface when the condenser structure is operationally facilitating cooling of an electronic device. The exposed cavities extend from the first main surface into the condenser block to increase a condensation surface area of the condenser block, thereby facilitating coolant vapor condensate formation on the condenser block, and thus cooling of the electronic device using a two-phase coolant. The condenser structure also includes coolant-carrying channels for facilitating cooling of the condenser block, and thus vapor condensate formation on the condenser block.

Owner:IBM CORP

Dew point humidifier (DPH) and related gas temperature control

InactiveUS6863268B2The process is simple and easy to controlSimple and economic and effectiveFlow mixersSpace heating and ventilationThermal energySteam condensation

A method of humidifying gases to 100% relative humidity and a humidifier to carry out such a method are provided to humidify gases for fuel cells and for other applications. The humidification of gases is thermally controlled and thermal energy is managed to provide an efficient system. A pre-humidifier accommodates a wide range of flow rates of dry gas to initially humidify and pre-heat the gas, and a boiler provides steam to mix with the effluent from the pre-humidifier to humidify the gas to saturation. A thermal insulator between the boiler and bulk water and / or pre-humidifier enhances the steam generation from the boiler and prevents direct heating of water or gases by heat from the boiler. Above the boiler, bulk water, and pre-humidifier, a mixing chamber further functions as a condenser and water separator. The mixing chamber provides a space for mixing gases and steam and separates saturated gases from condensed water. By vapor condensation during the mixing, the gas can be humidified completely to its dew point at given temperature and pressure conditions.

Owner:ZHANG CHAOJIONG

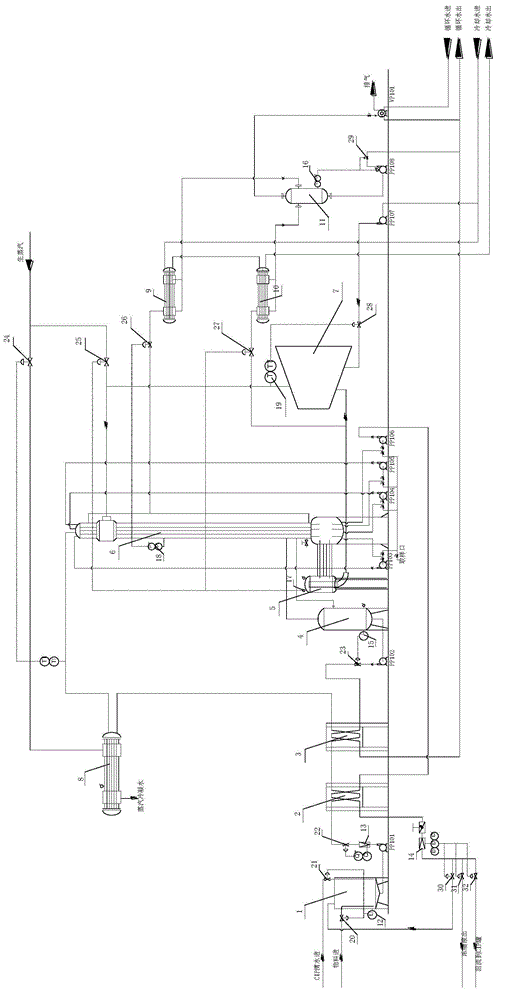

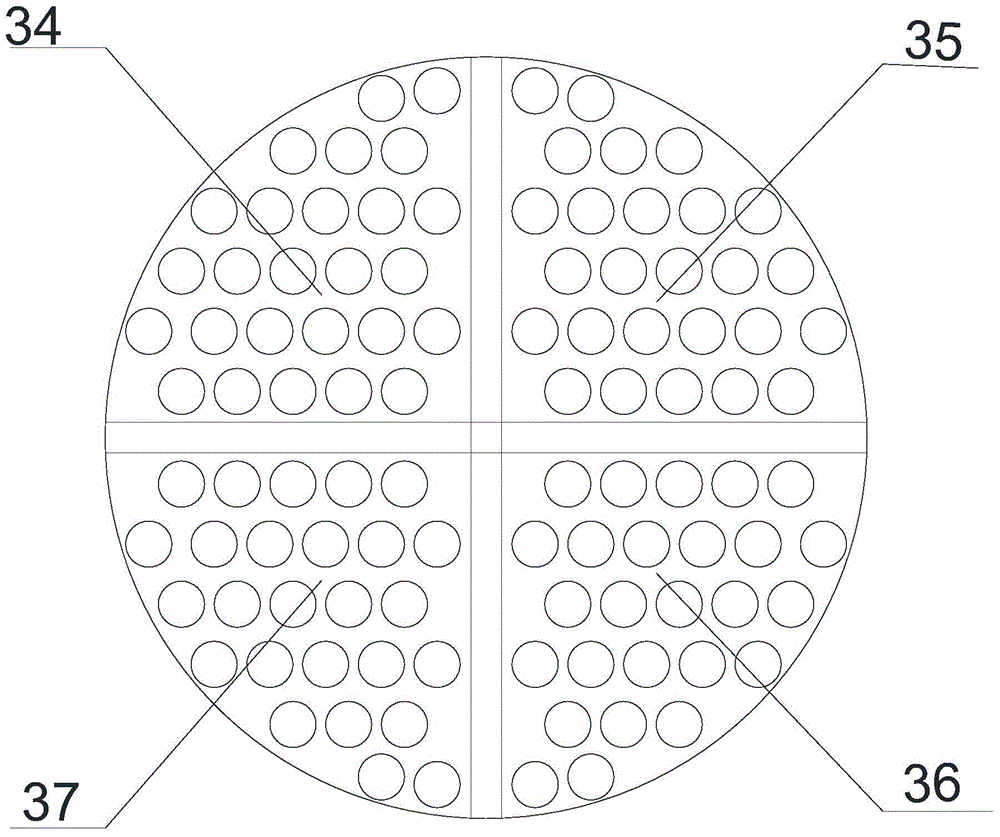

MVR continuous evaporation system

InactiveCN104667550AStable feed flowThere will be no cut-off stateEvaporator accessoriesMultiple-effect evaporationVapor–liquid separatorSteam condensation

The invention discloses an MVR continuous evaporation system. The system can be applied to the requirements on different evaporation pressures, and automatic control of continuous and stable feeding and continuous discharging can be realized. The system disclosed by the invention comprises a raw material balance tank, a main body evaporator, a gas-liquid separator, a condensate storage tank, a steam compressor, a vacuum system and at least three heat exchange devices which are connected by virtue of pipelines, control valves and related pumps, wherein the bottom of the raw material balance tank is connected with the inlet of a feeding pump and is connected with an interval inlet of the top end of the main body evaporator by virtue of a heat exchange device; multiple evaporation intervals are contained in the main body evaporator; a gas-liquid collection cavity is formed in the bottom end of the main body evaporator and is connected with the next evaporation interval by virtue of a booster pump; the concentrated solution in the final evaporation interval is used for preheating the raw materials by virtue of the heat exchange devices; the shell pass of the main body evaporator is connected with the condensate storage tank; and steam condensate is connected with the heat exchange devices by virtue of the condensate storage tank, and the raw materials can be preheated.

Owner:NANJING UNIV OF TECH

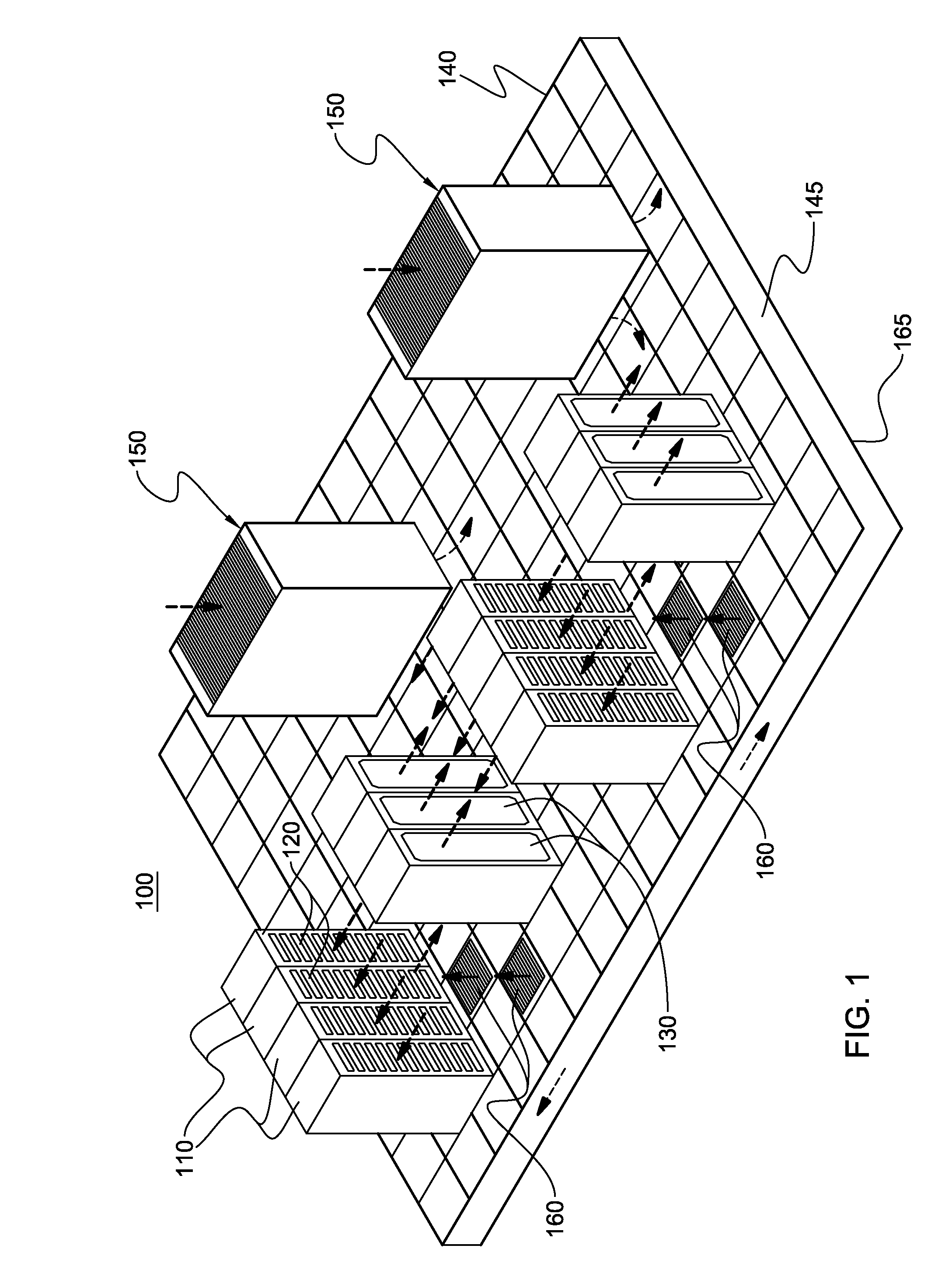

Air-cooling and vapor-condensing door assembly

InactiveUS20140133099A1Heat exchanger casingsCooling/ventilation/heating modificationsSteam condensationEngineering

A method is provided which includes providing a cooling apparatus which includes a door assembly coupled to the electronics rack at an inlet or air outlet side of the rack. The door assembly includes: an airflow opening configured to facilitate ingress or egress of airflow through the electronics rack with the door assembly mounted to the rack; an air-to-coolant heat exchanger disposed so that airflow through the airflow opening passes across the air-to-coolant heat exchanger, the air-to-coolant heat exchanger being configured to extract heat from the airflow passing thereacross; and a vapor condenser configured to facilitate condensing of dielectric fluid vapor egressing from at least one immersion-cooled electronic component section of the electronics rack. The cooling apparatus, including the door assembly, facilitates air-cooling and immersion-cooling of different electronic components of the electronics rack.

Owner:IBM CORP

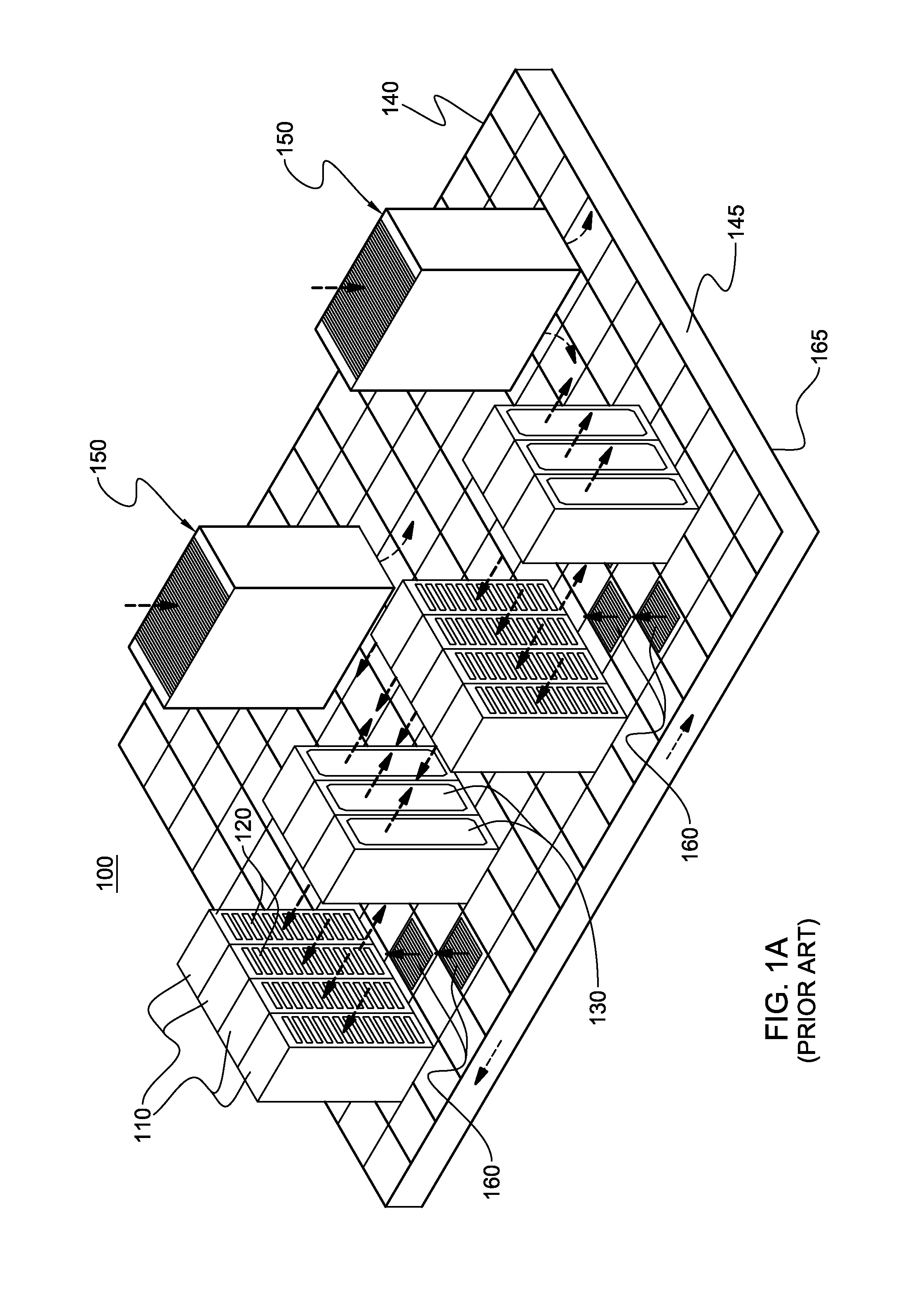

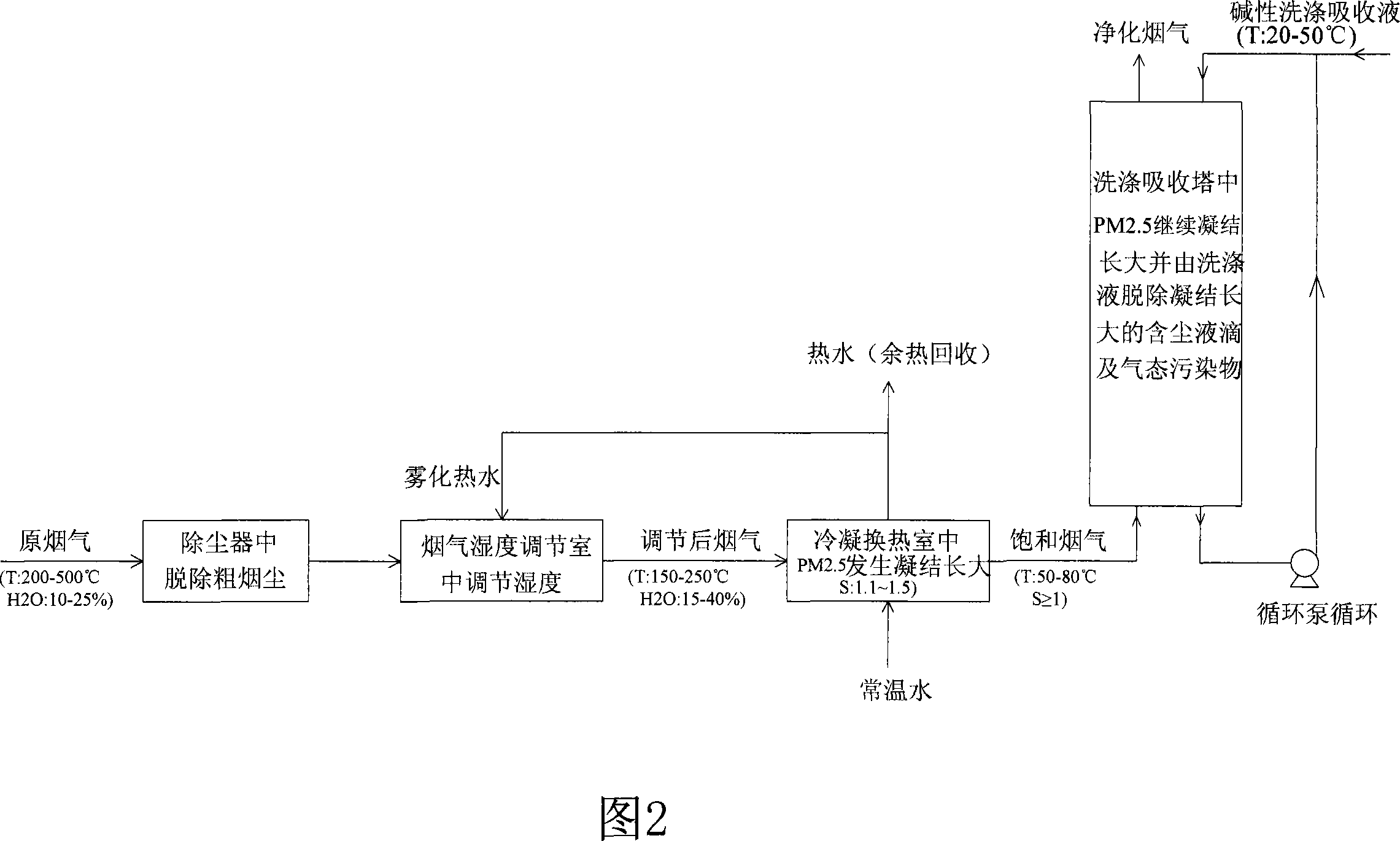

Method of removing PM2.5 and gaseous pollutant using steam phase transition and device thereof

InactiveCN101224367ALarge granularityQuality improvementAuxillary pretreatmentUsing liquid separation agentSteam condensationPollution

The invention relates to a method and a device which adopt steam phase changing to cooperatively remove PM2.5 and gas pollutions from a high temperature and high humidity flue gas. The invention comprises a dust catcher, a flue gas humidity regulating chamber, a condensing heat exchanger and a washing absorption tower. The method is that the flue gas enters the flue gas humidity regulating chamber after coarse dust removing in the dust catcher, and atomized hot water is sprayed to regulate the humidity of the flue gas; after humidity regulation, the flue gas is induced into the condensing heat exchanger to reach supersaturation, and the supersaturation steam takes the PM2.5 as condensing core to generate phase changing, thus increasing the granularity of the PM2.5; then the steam enters the washing absorption tower, and in the tower, the flue gas reversely contact a middle-lower temperature alkalescent washing-adsorbing liquid to be further subject to the phase changing of the steam taking PM2.5 as condensing core, and the alkalescent washing-adsorbing is adopted for removing the growing dust-drop and gas pollutions. Taking the characteristics of the high temperature and high humidity flue gas into account, the invention adopts the steam phase changing theory to lead the PM2.5 to be condensed and to grow so as not only to cooperatively remove PM2.5 and gas pollution, but to recycle the gasifying potential heat released by steam condensing and the sensible heat caused by temperature reduction of the flue gas.

Owner:SOUTHEAST UNIV

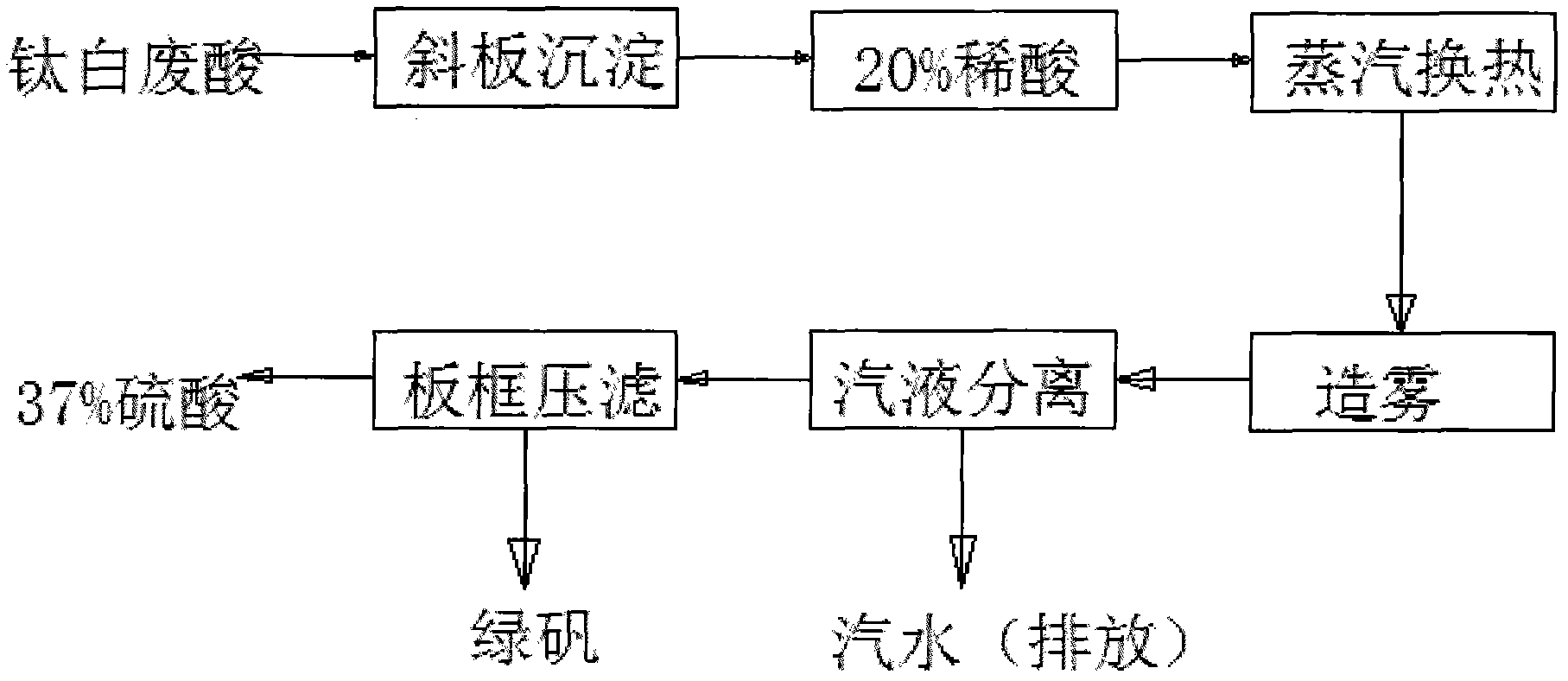

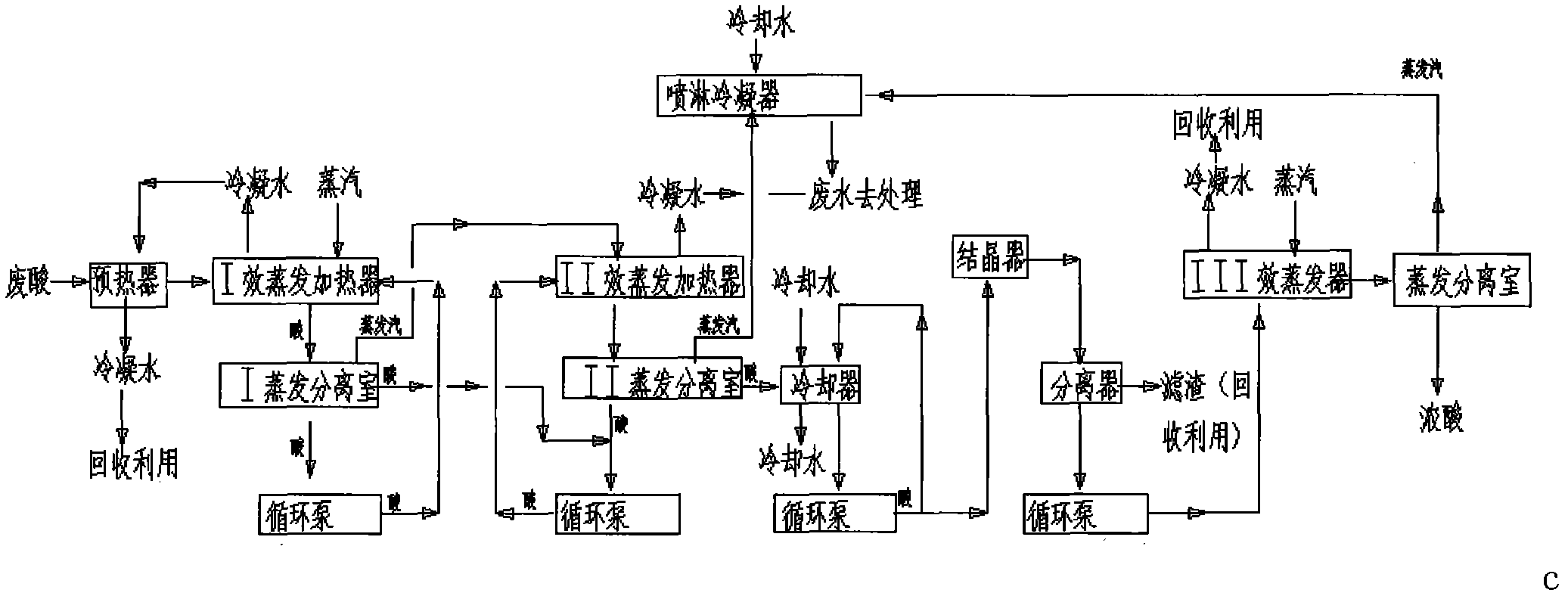

Waste acid concentration multistage treatment method

ActiveCN101935077ATake advantage ofReduce heat transfer areaMultistage water/sewage treatmentWater/sewage treatment by heatingSteam condensationSpray cooling

The invention relates to a waste acid concentration multistage treatment method which comprises the following steps of: heating 20-22% waste acid by a preheater, evaporating by a one-effect evaporation heater and a double-effect evaporation heater, cooling by a cooler and crystallizing by a crystallizer; heating by a triple-effect evaporation heater and separating by a separator to obtain 65% concentrated acid. The secondary steam part is used as a heat source part of the next stage heater and is condensed by spraying cooling water, wherein the one-effect evaporation heater and the double-effect evaporation heater are falling film graphite tube array evaporation heaters; the triple-effect evaporation heater is a floating head tube array graphite heat exchange. The water evaporation capability of the method is increased from 2.5 tons to 10 tons, and the stage number is 3 or more. A large amount of steam and cooling water is saved, and the pollution to the environment is reduced. The heat exchange area of equipment is reduced by 30%, and materials are saved and manufacturing cost is reduced correspondingly. The heat of steam is fully utilized, more than 35% of steam is saved, and more than 30% of cooling water can be saved. The condensed water part of the steam is used as the hear source part of the preheater and is recycled for other uses.

Owner:NANTONG JINGTONG GRAPHITE EQUIP

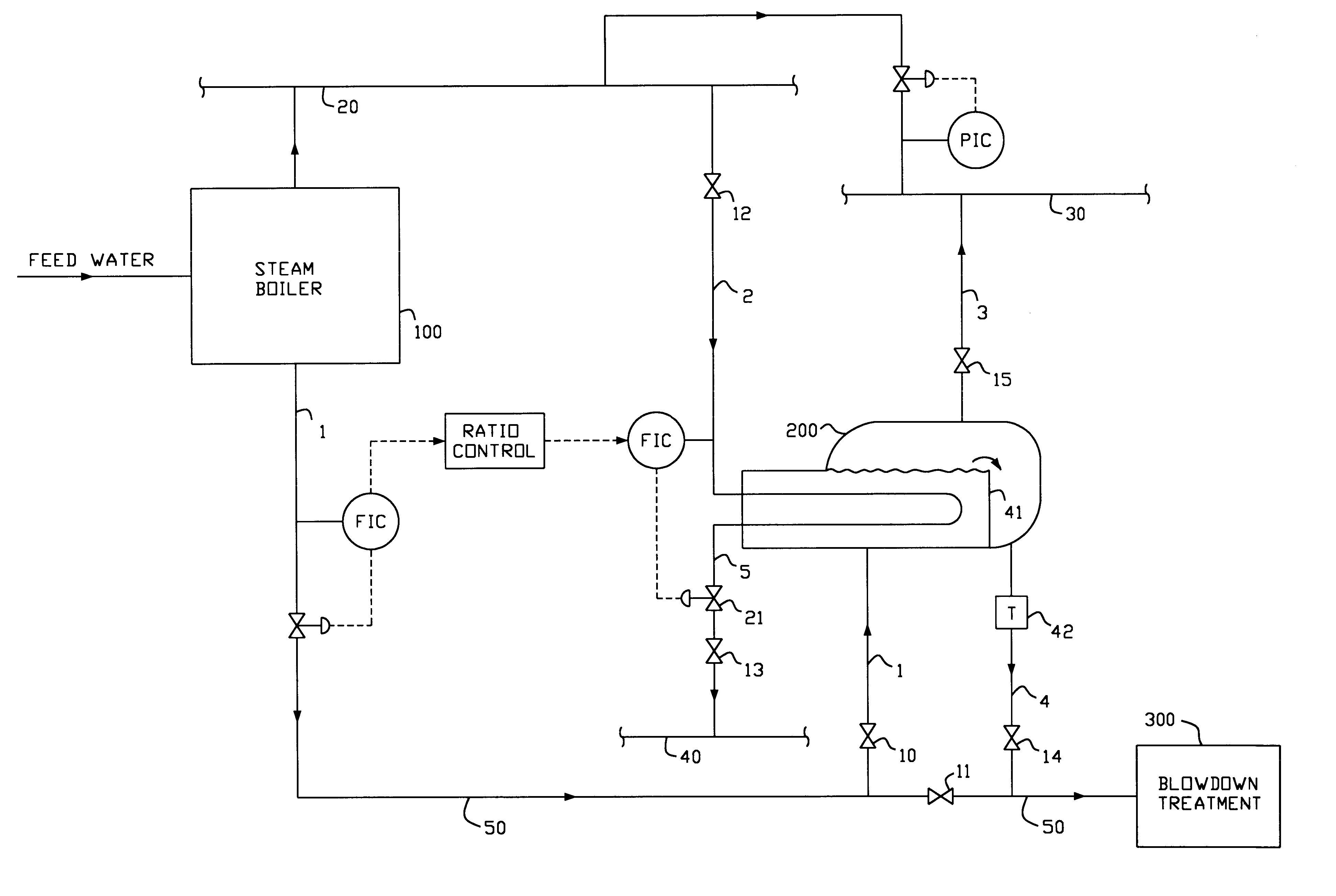

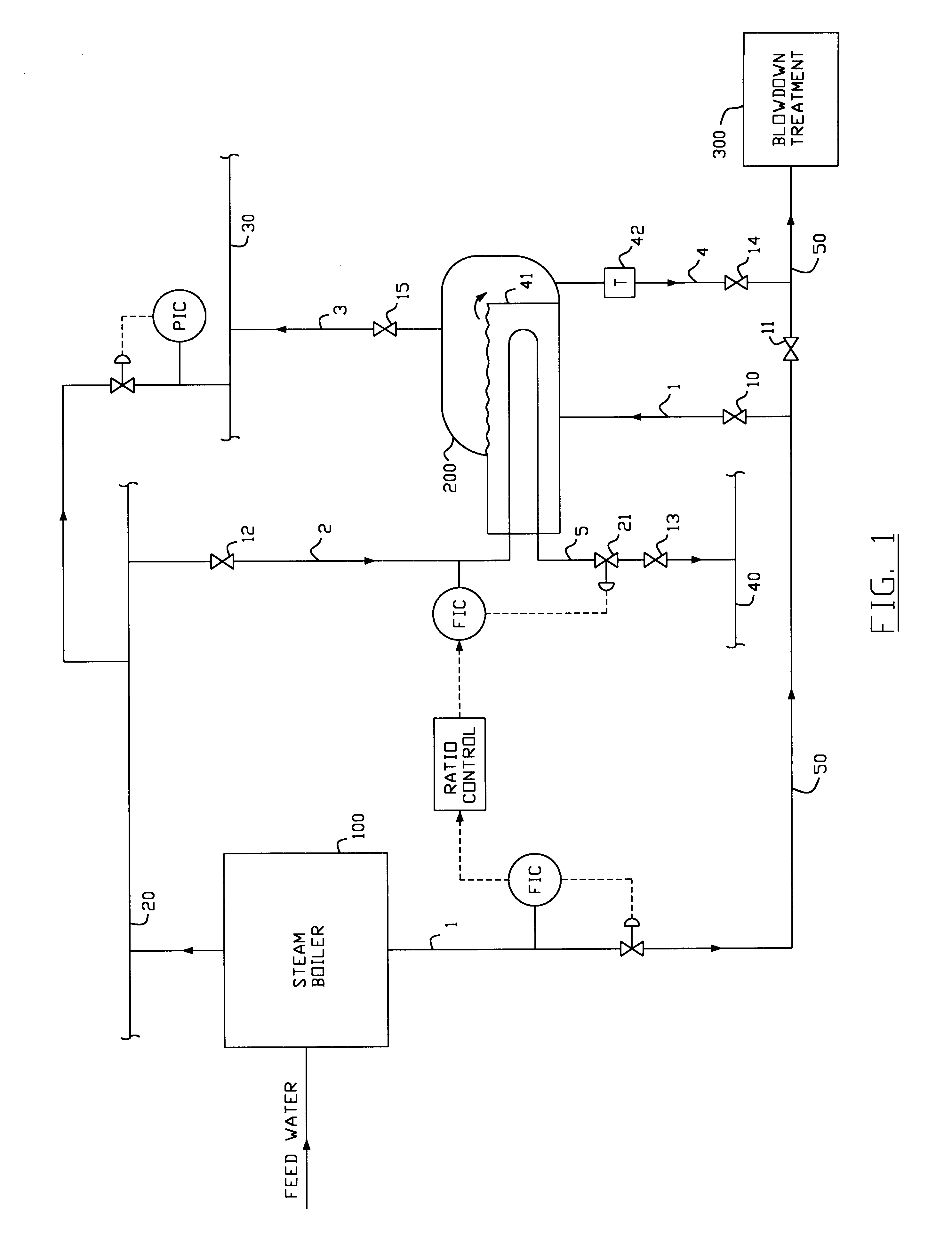

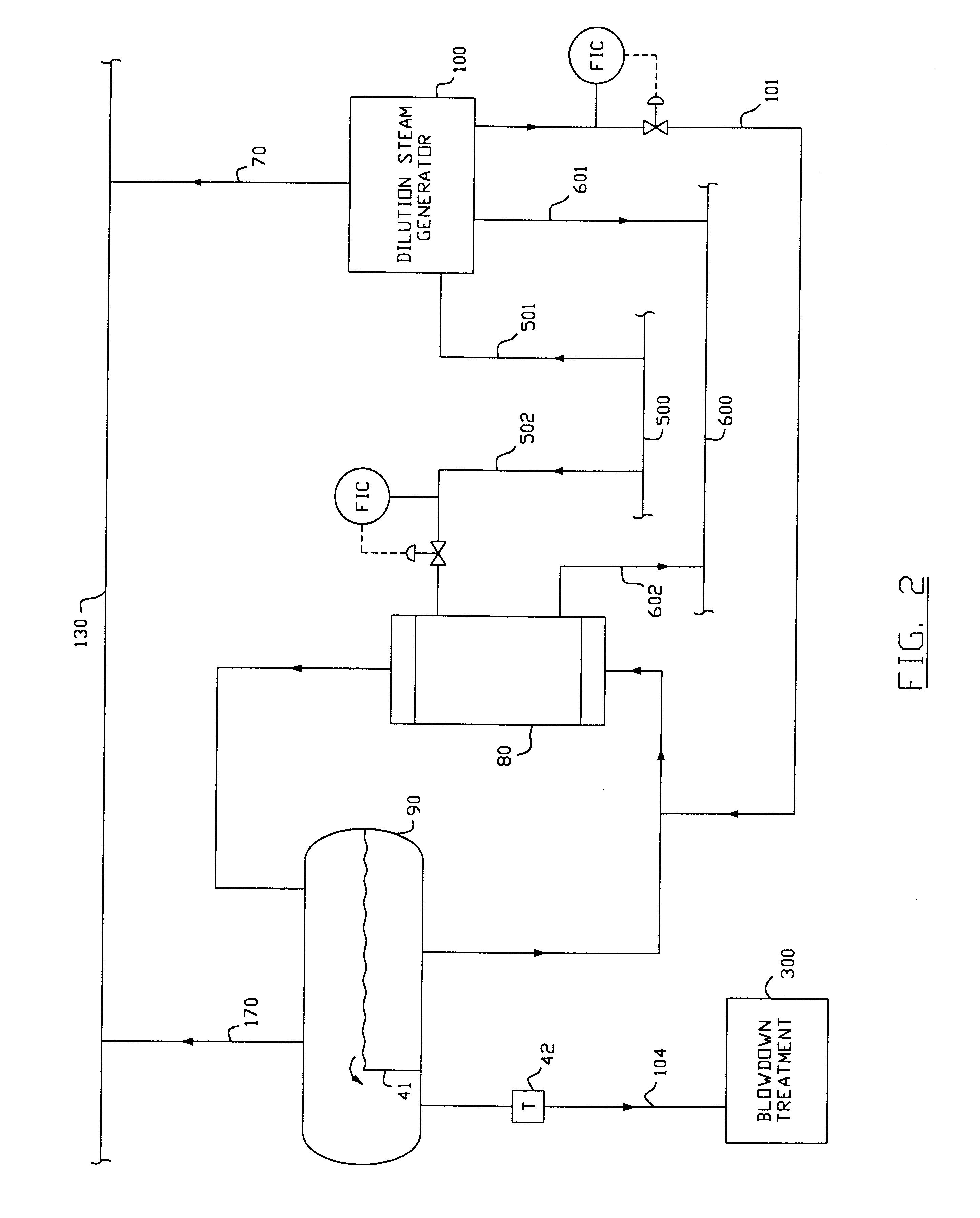

Methods for recycling process wastewater streams

InactiveUS6371058B1High mean blowdown rateChemical treatment costDrying using combination processesSteam separation arrangementsShell and tube heat exchangerWastewater

This invention provides cost-effective alternatives to reduce the cost associated with customary blowdown from steam generating equipment. By selectively recycling process blowdown streams using secondary vaporizers, the net result is a partial replacement of wastewater stream with almost an equivalent quantity of clean steam condensate. The heat transfer is carried out by indirect contact devices, such as shell and tube heat exchanger and the like, without mixing of the two process streams to allow condensate recovery while avoiding cross contamination. This invention carries economic as well as environmental credits. A condensate recovery apparatus can be designed to enable easy connection to existing equipment already in service, as well as easy removal, without causing process disruption.

Owner:TUNG PETER

Solar distilling apparatus for alcohol

InactiveUS20060037853A1Reduce the temperatureFermented solutions distillation/rectificationGeneral water supply conservationAlcoholSteam condensation

A distilling apparatus for alcohol includes an evaporation tank having a compartment for receiving fermented alcoholic liquid. A heating tube is mounted in the compartment for heating the fermented liquid into steam. A condensing device is communicated with the evaporation tank for receiving and condensing steam from the evaporation tank. A collecting tank is communicated with the condensing device for collecting condensed liquid from the condensing device. A negative pressure creating device creates a negative pressure in the evaporation tank, allowing the fermented alcoholic liquid in the evaporation tank to evaporate at a low temperature. A solar energy collecting device includes a solar energy collector and a water tank containing water heated by the solar energy collector. Hot water in the water tank flows into the heating tube for heating the fermented alcoholic liquid in the evaporation tank.

Owner:ROAN TONY +1

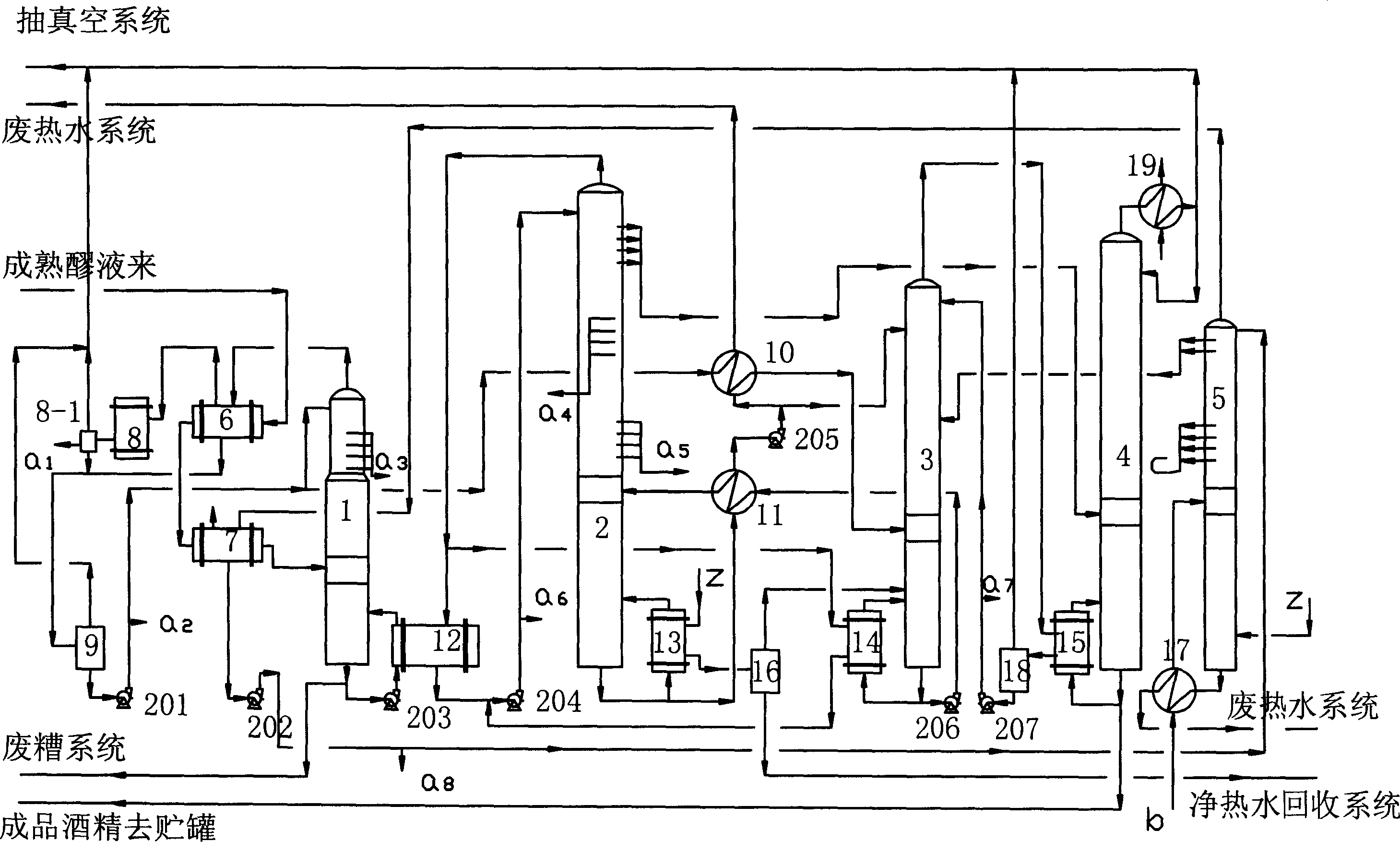

Alcohol quinque-towel differential pressure distilling arrangement and technique thereof

ActiveCN1736527APrevent scalingPrevent precipitationDistillation separationSteam condensationAqueous alcohol

The invention discloses a five-tower differential pressure distilling apparatus and the technique for alcohol: the fractionating tower operating with positive pressure, some alcohol vapor in the head tower flowing into the reboiler of crude distillation column, and the other into the reboiler of water scrubber; the leaving distilled water in the still of fractionating tower preheating the weak alcohol liquid from the bottom of water scrubber, then partly inpouring to crude alcohol preheater to preheat crude alcohol, and partly inpouring to water scrubber according to the requirement of flowmeter; by flash distillation the condensate water in the reboiler of fractionating tower generating indirect steam which enters directly into the still of water scrubber; the water scrubber operating with negative pressure, and the alcohol vapor in the head into the reboiler of the methanol heating tower. The significance effect is that: the energy saving effect is perfect when used to produce excellent edible alcohol and the vapor consuming index approaching the advanced lever of 2.3- 2.6 t / t.

Owner:广东省博罗中科天元高新技术工程有限公司

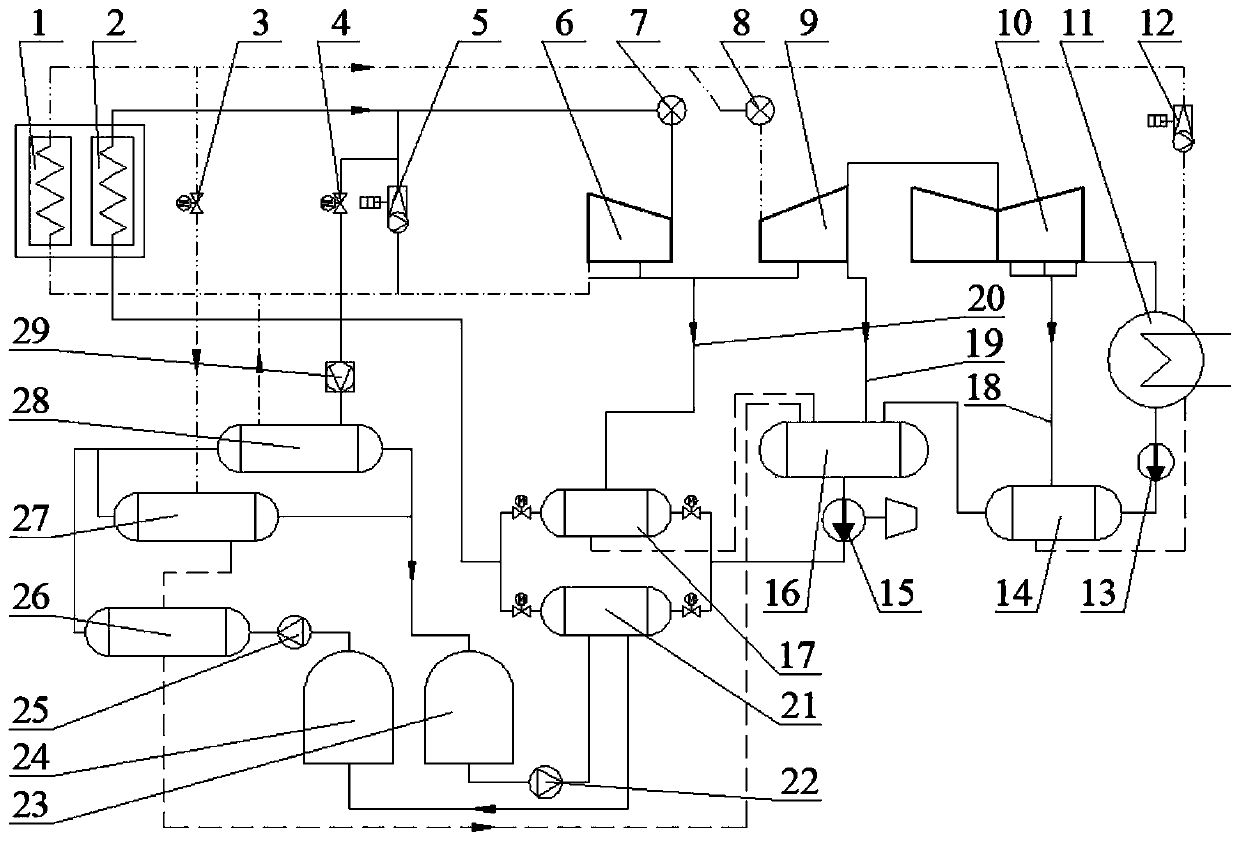

Deep peak shaving system of thermal power plant

PendingCN110006026AImprove operational efficiencyImprove economyLiquid degasificationHeat storage plantsSteam pressureSteam condensation

The invention discloses a deep peak shaving system of a thermal power plant. The deep peak shaving system comprises a superheater, a reheater, a high-pressure cylinder, a reheating steam electric regulating valve, a main steam electric regulating valve, a medium-pressure cylinder, a low-pressure cylinder, a condenser, a condensation water pump, a low-pressure heating water feeding heat exchanger,a water feeding pump set, a deaerator, a high-pressure heating water feeding heat exchanger, a steam turbine low-pressure steam extraction system, four-stage extraction, a steam turbine high-pressuresteam extraction system, a high-temperature molten salt water feeding heat exchanger, a high-temperature molten salt pump, a high-temperature molten salt storage tank, a low-temperature molten salt storage tank, a low-temperature molten salt pump, a molten salt preheater, a steam condensation type heat exchanger, a steam non-condensation type heat exchanger, a steam pressure reduction device and the like. According to the system, the molten salt heat storage technology is utilized, redundant steam heat is stored during load reducing peak shaving of a unit, in the process of load increasing peak shaving of the unit, high-temperature molten salt is used for heating high-pressure fed water to reduce steam extraction of a steam turbine, the output of the steam turbine is increased, the heat efficiency of the unit is improved, and the flexible and deep peak shaving of the thermal power plant is realized.

Owner:BEIJING UNIV OF TECH

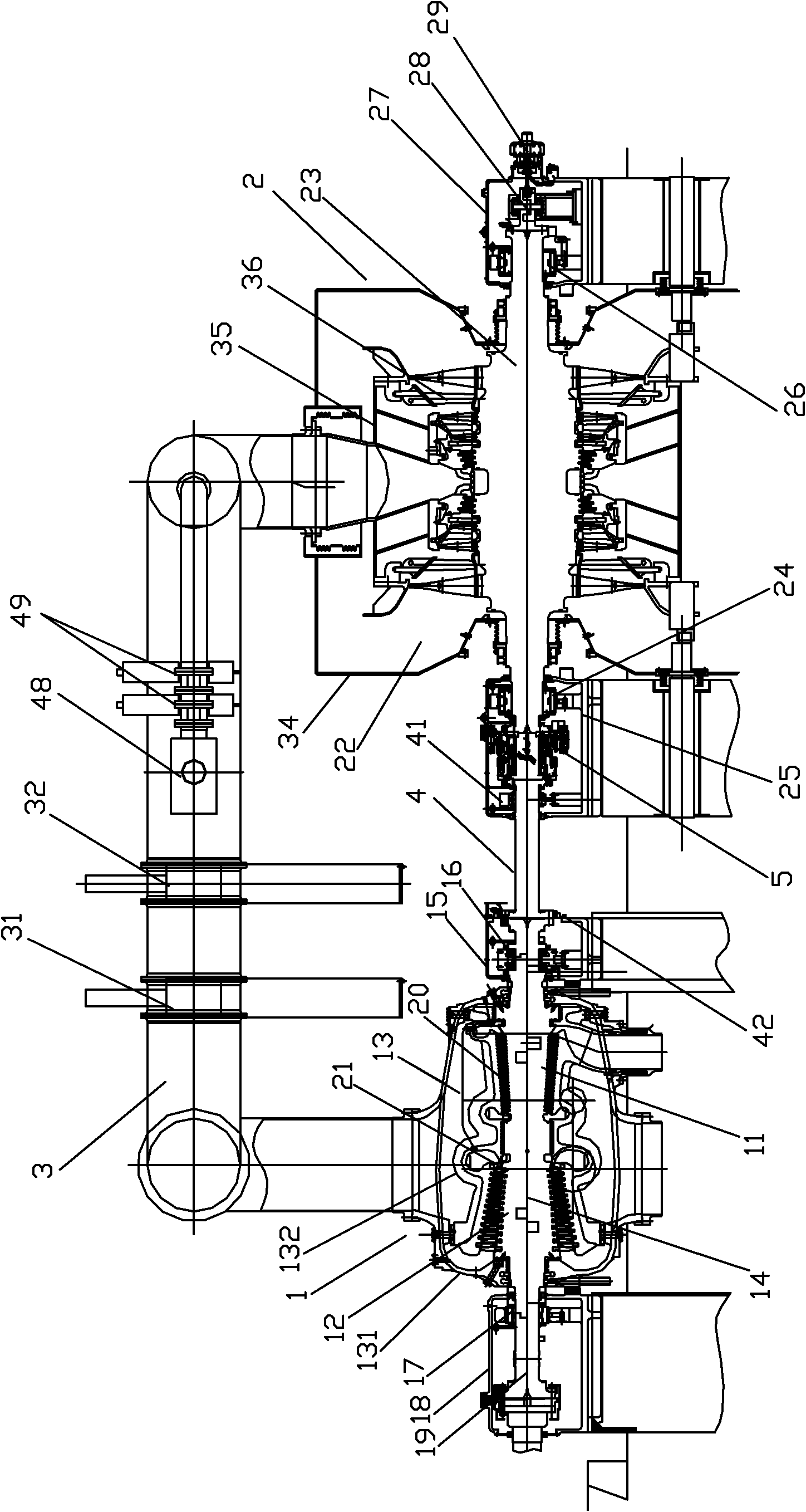

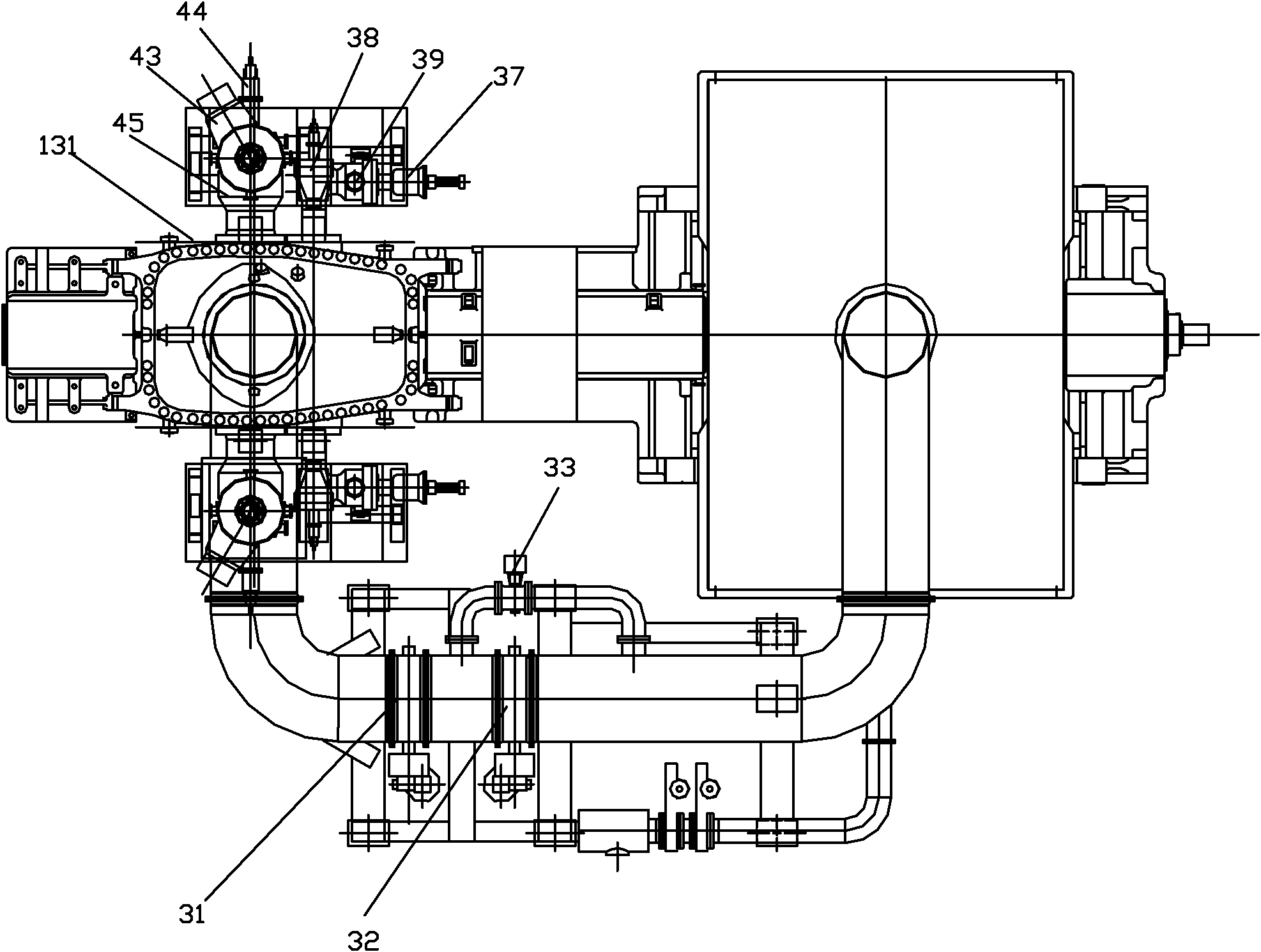

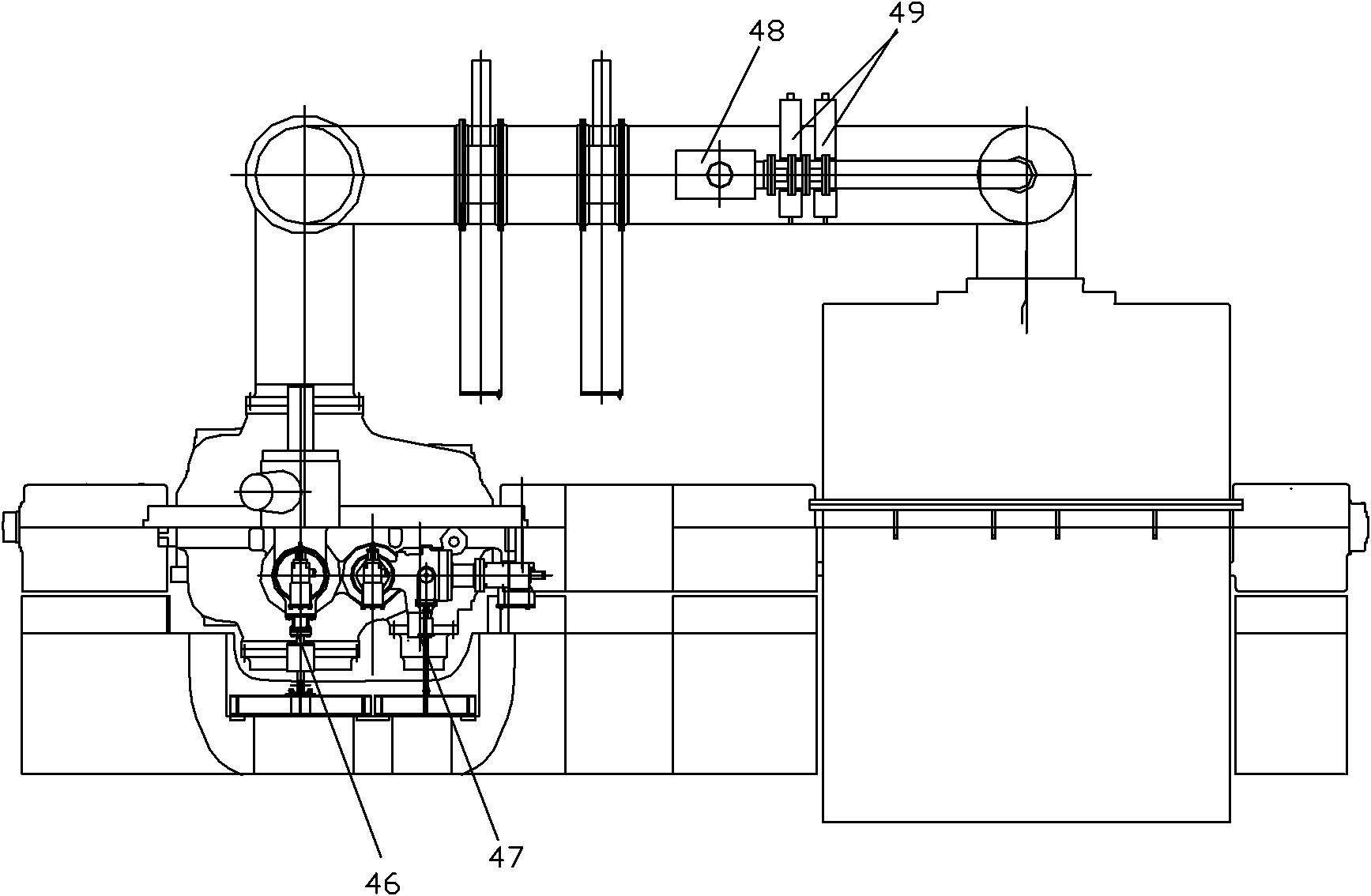

Double-cylinder coaxial combined cycle heat supply gas turbine

ActiveCN102140938AFlexible operationImprove utilization efficiencyBlade accessoriesMachines/enginesSteam condensationEngineering

The invention discloses a double-cylinder coaxial combined cycle heat supply gas turbine. The double-cylinder coaxial combined cycle heat supply gas turbine comprises a high pressure module and a low pressure module which are distributed coaxially; a high and medium pressure rotor is arranged in the high pressure module; a low pressure rotor is arranged in the low pressure module; one end of the high and medium pressure rotor close to a medium pressure cylinder is connected with a motor; one end of the high and medium pressure rotor close to a high pressure cylinder is coaxially connected with an intermediate shaft; the other end of the intermediate shaft is connected with the low pressure rotor through an autosynchronous clutch; and the high pressure module and the low pressure module are communicated through a low pressure communication pipe which is provided with a low pressure valve bank. The gas turbine can realize the on-line paralleling or disconnection of the high and medium pressure module and the low pressure module, is suitable for single backpressure running of the high pressure module, steam extraction and condensation running of the high pressure module and the low pressure module and steam condensation running of the high pressure module and the low pressure module, and can improve the energy utilization rate to the maximum extent according requirements; and the running mode of the gas turbine is very flexible.

Owner:SHANGHAI ELECTRIC POWER GENERATION EQUIPMENT CO LTD

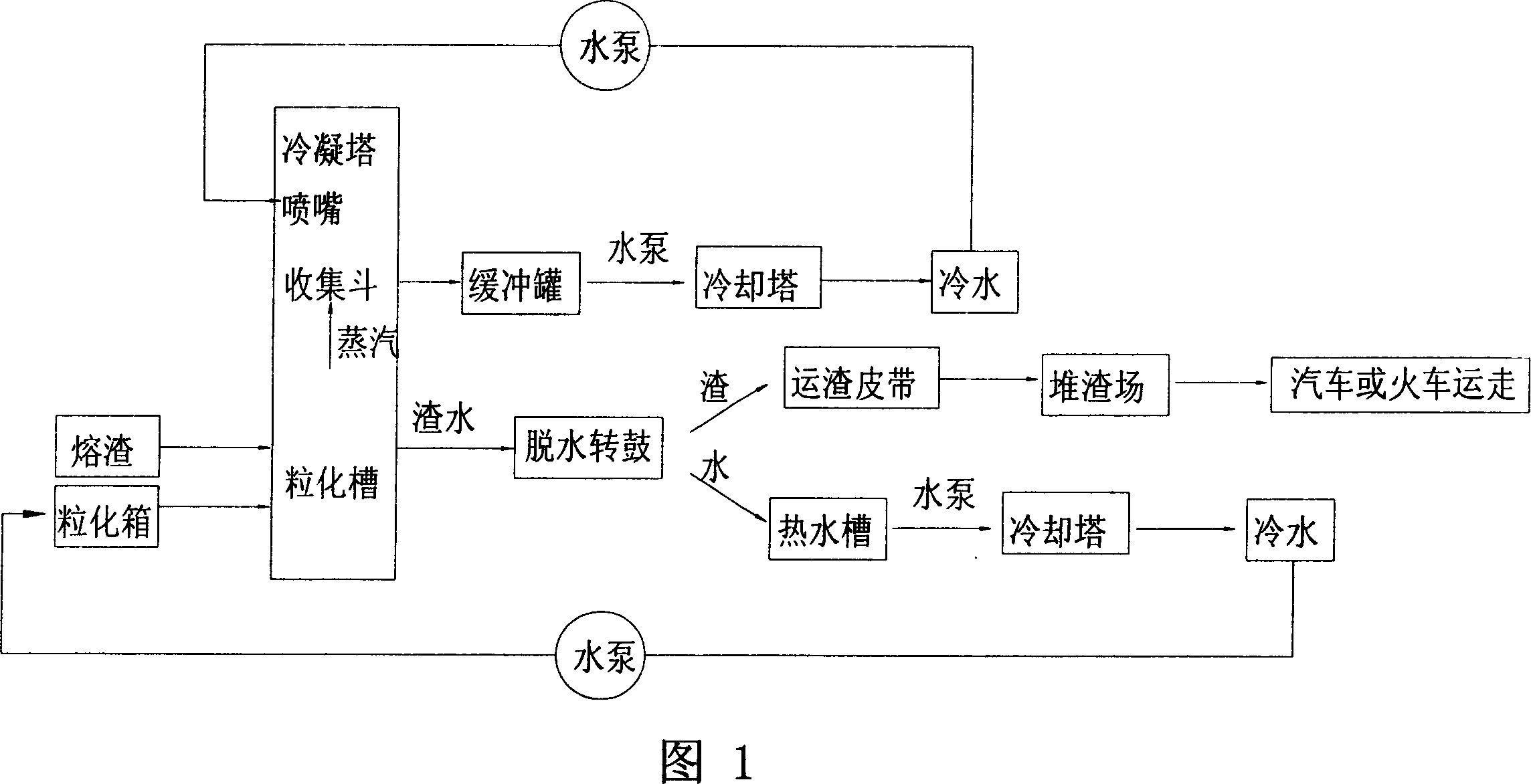

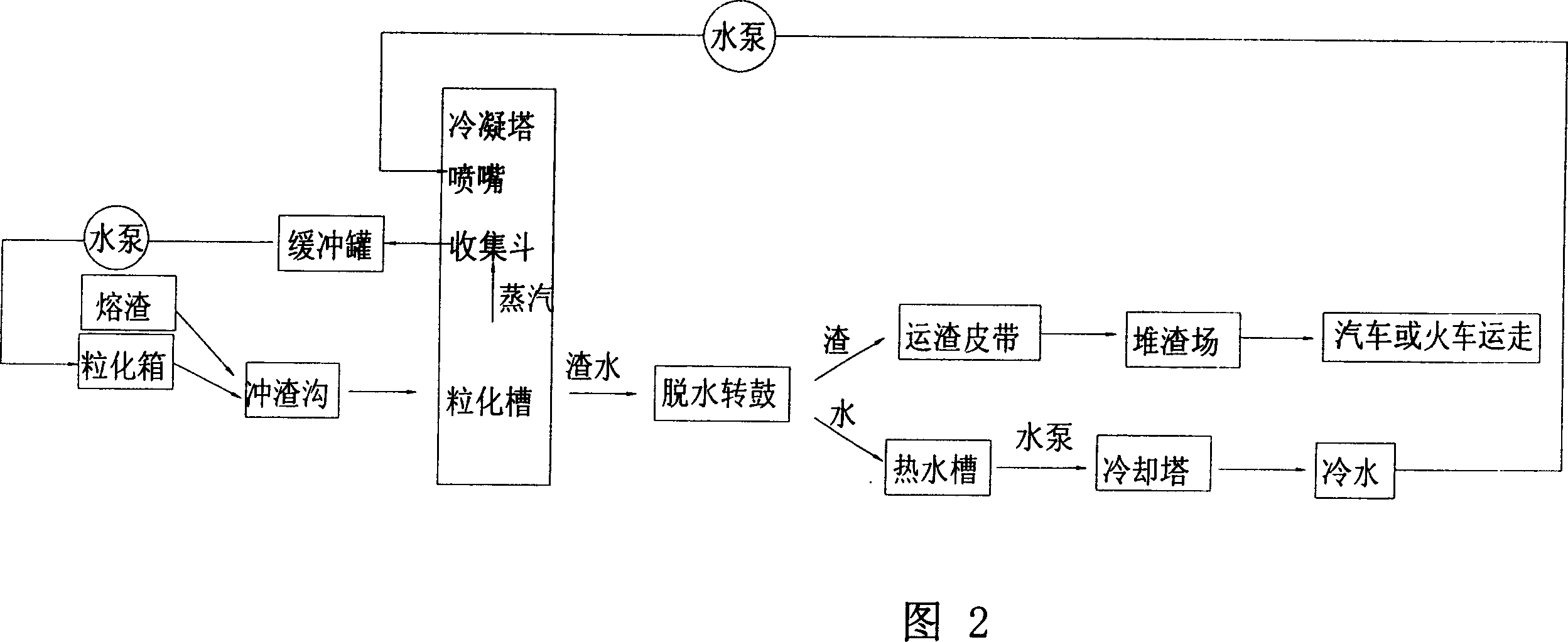

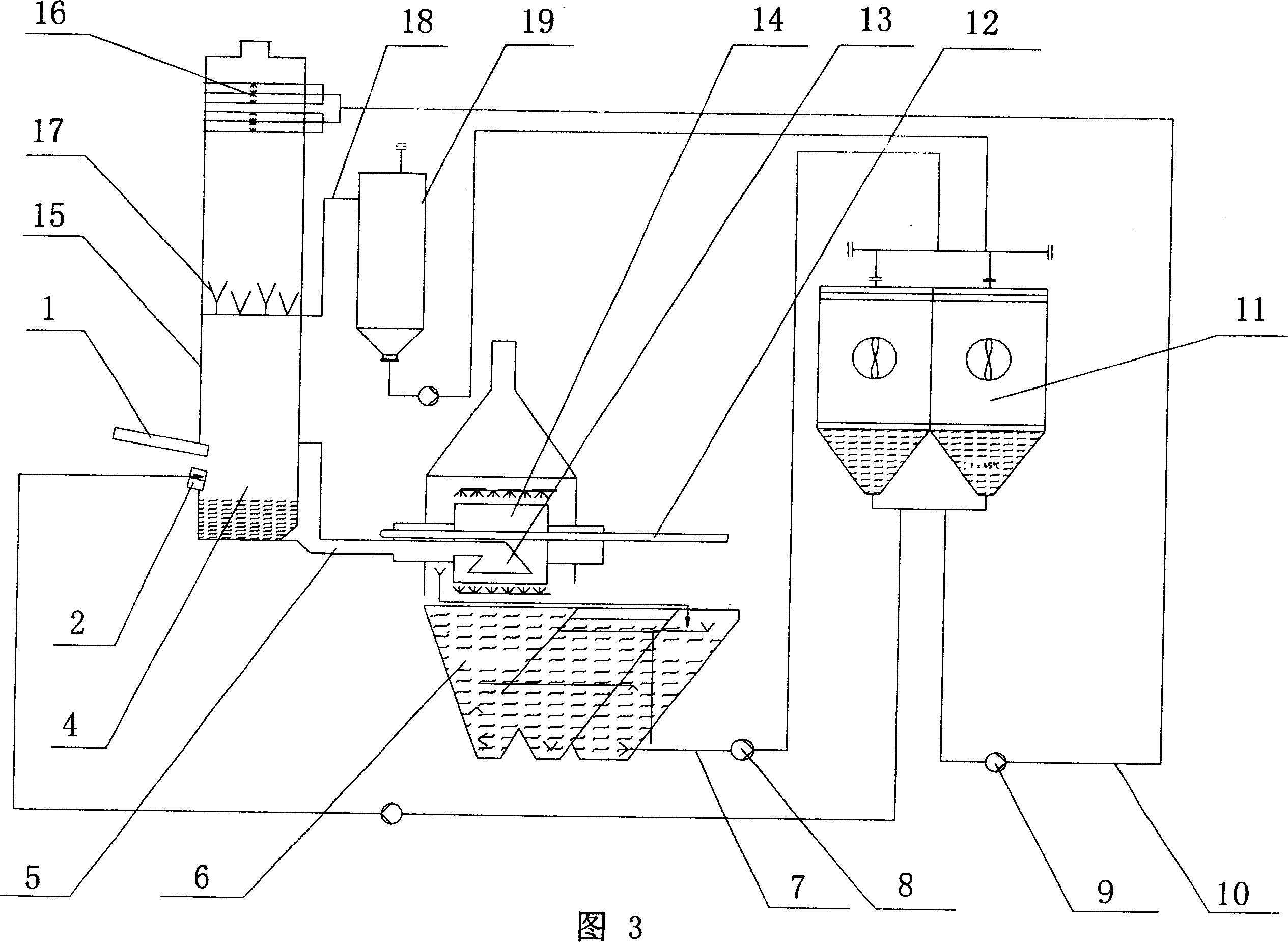

Environment friendly blast furnace slag treating process and system

InactiveCN1986836AImprove protectionReduce trafficRecycling and recovery technologiesCooling towerSteam condensation

The present invention is environment friendly blast furnace slag treating process and system. The blast furnace slag treating process includes water quenching the red slag for fast cooling with the granulating tank sprayed cooling water and collecting in the collecting pipeline; conveying to the distributor of dewatering drum and separating into water granulated slag falling to the belt conveyer for being transported to the slag yard and filtered hot water; collecting hot water, pumping to cooling tower for cooling and condensing through the atomizing nozzle in the condensing tower; and collecting the condensated water and returning through the third water pipe, the buffering tank and the fourth water pipe to the granulating tank for reuse. The present invention has the advantages of simple system composition, environment friendship, low power consumption, etc.

Owner:WISDRI ENG & RES INC LTD

Multistage division regenerative carbon dioxide trapping system and technology

ActiveCN103961979APromote regenerationAbsorb thoroughlyDispersed particle separationSteam condensationTrapping

The invention relates to a multistage division regenerative carbon dioxide trapping system. The system comprises an absorption tower, wherein rich liquor that flows out of the absorption tower is divided into two channels; a first pipeline is communicated with a rich liquor inlet formed in the upper part of a regeneration tower; a second pipeline is communicated with the rich liquor inlet of a rich and poor liquid heat exchanger; rich liquor that flows out of the rich and poor liquid heat exchanger is further divided into two channels; one channel is communicated with a rich liquor inlet formed in the central part of the regeneration tower; the other channel is communicated with the rich liquor inlet of a rich liquor reheater; the rich liquor outlet of the rich liquor reheater is communicated with the rich liquor inlet of a rich liquor flash tank; the rich liquor outlet formed in the bottom of the rich liquor flash tank is communicated with a rich liquor inlet formed in the lower part of the regeneration tower. According to the invention, the regeneration degree of the rich liquor can be increased and steam heat consumption needed during rich liquor regeneration can be reduced; in addition, steam condensates can be recycled in the lyophobic collecting box of main equipment to reduce the desalted water consumption of the trapping system.

Owner:HUANENG CLEAN ENERGY RES INST

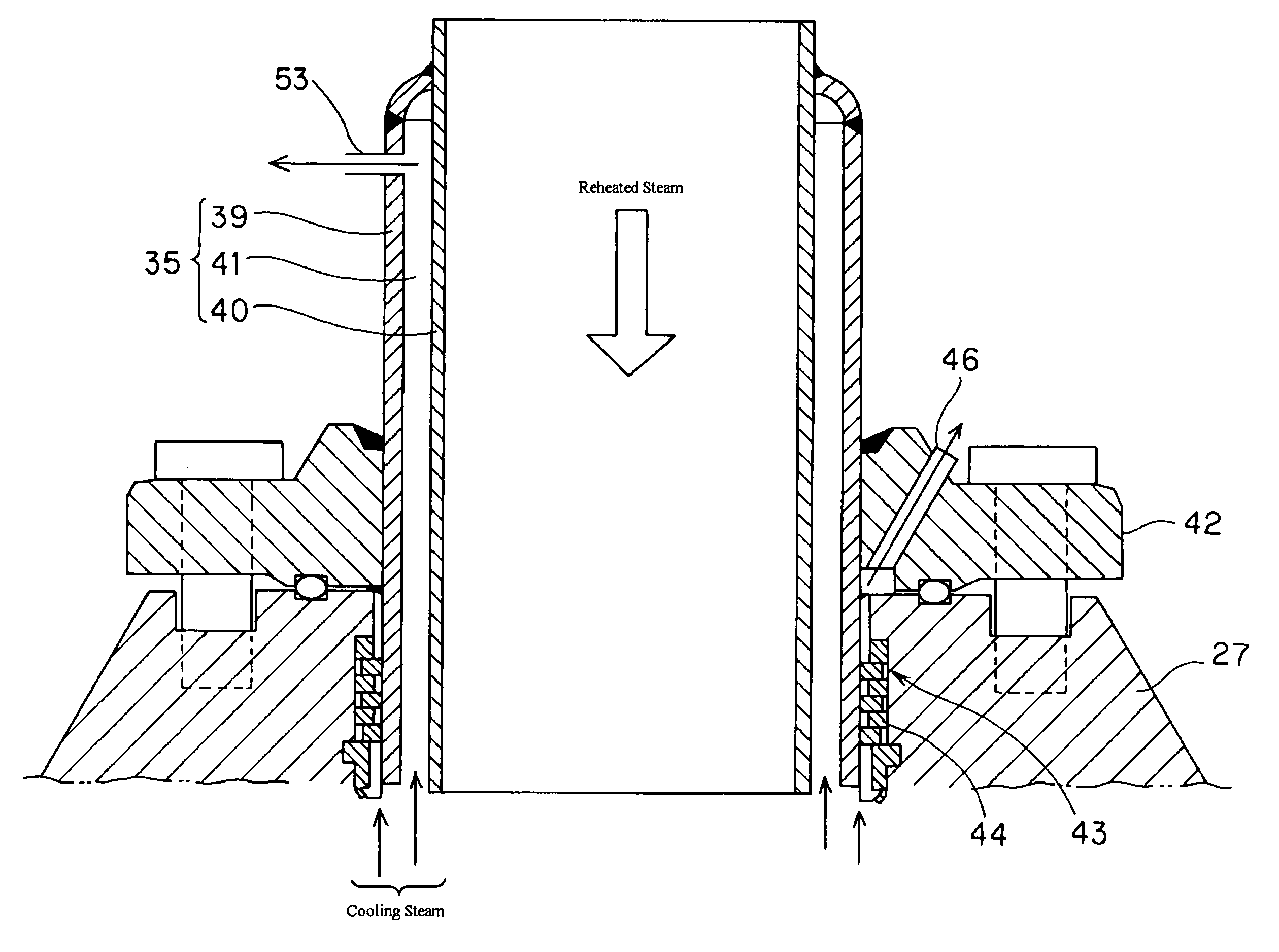

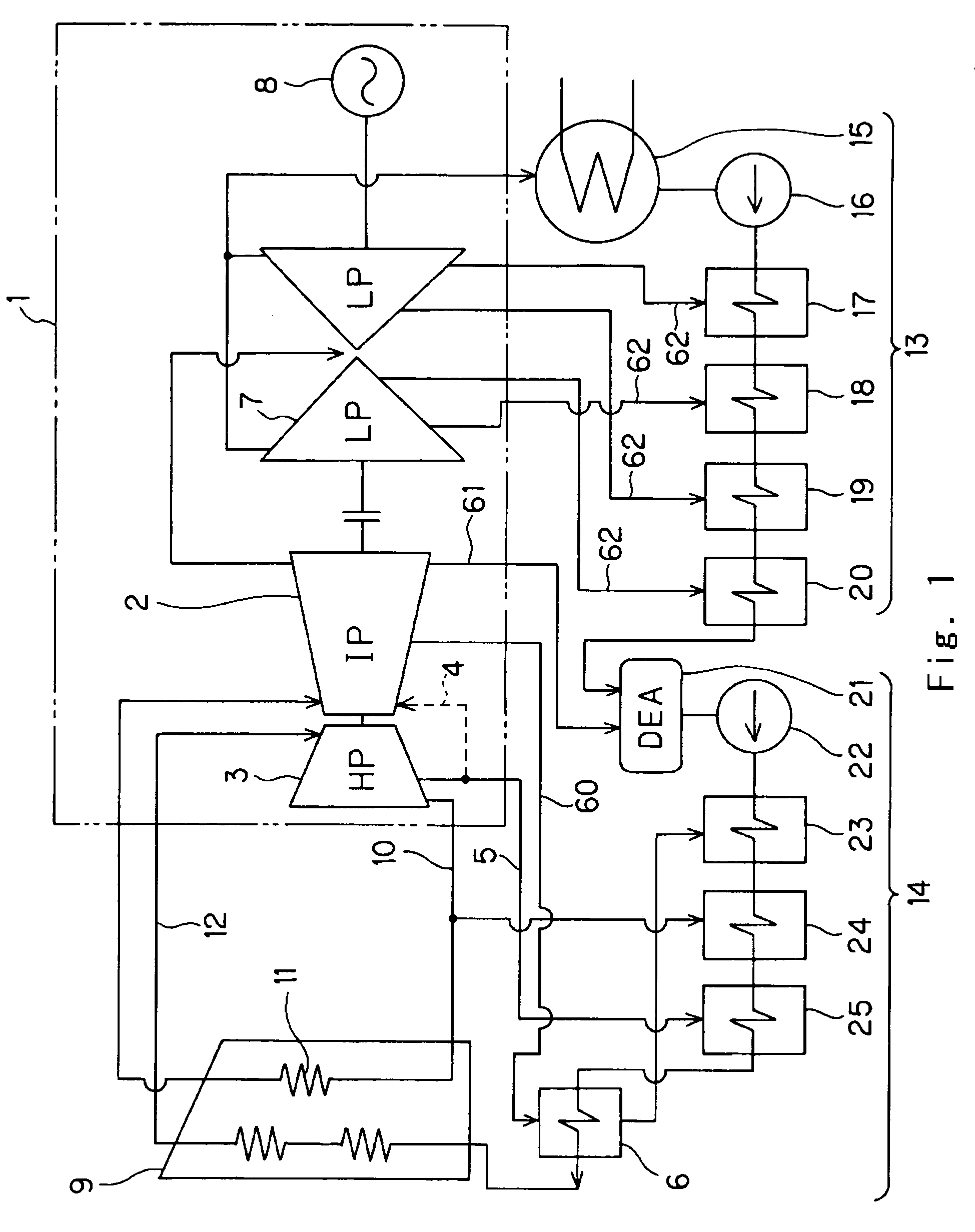

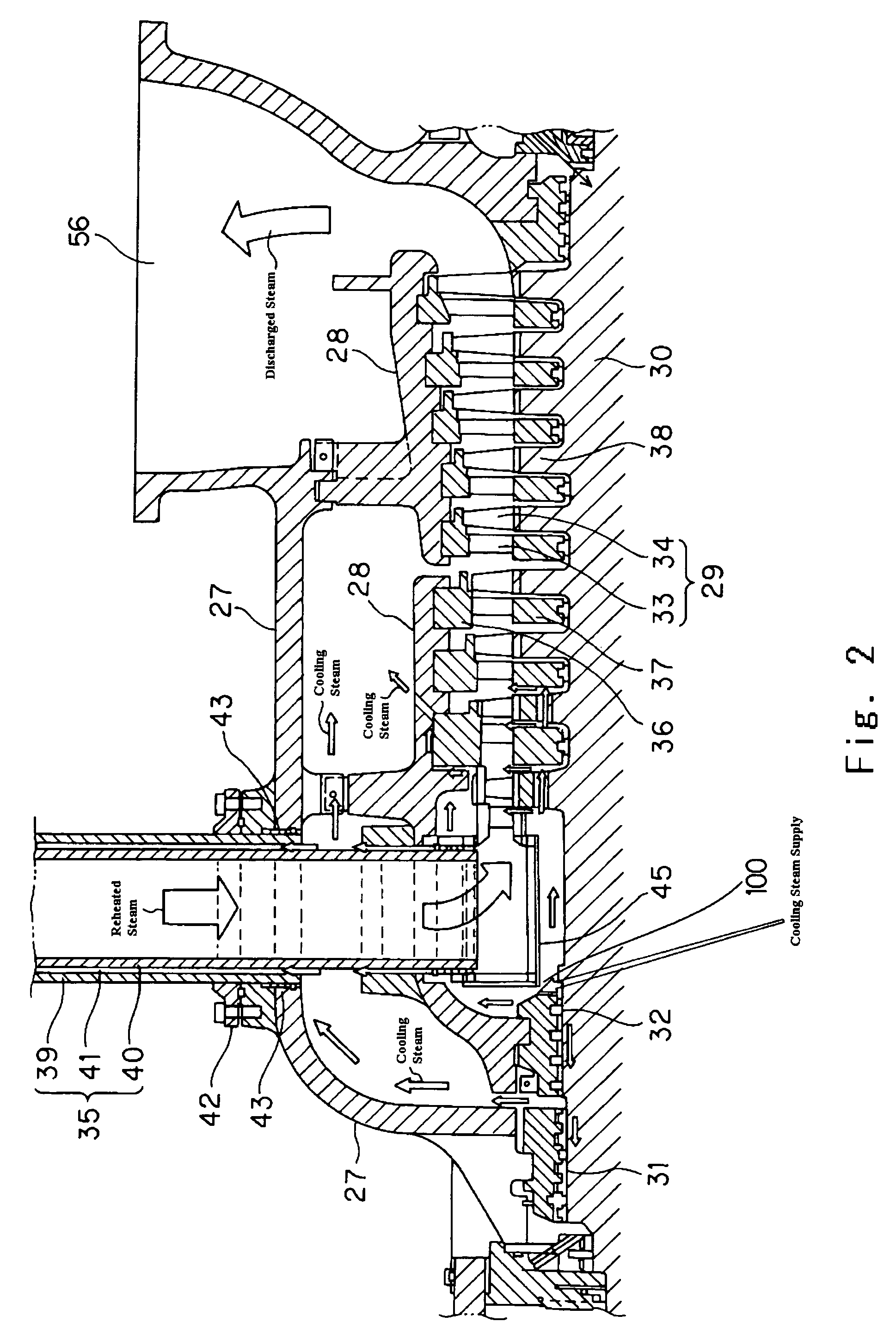

Steam turbine, steam turbine plant and method of operating a steam turbine in a steam turbine plant

ActiveUS7003956B2Improves plant thermal efficiencyIncrease temperatureLiquid degasificationPump componentsSteam condensationEngineering

A steam turbine and steam turbine plant that can utilize a relatively higher reheated steam, such as about 1300 degrees Fahrenheit or higher, is provided. A steam turbine plant includes a steam generator generating high pressure steam and reheated steam, a high pressure turbine driven by the high pressure steam generated by the steam generator, and an intermediate pressure turbine driven by the reheated steam. A steam bleed line coupled with the high pressure turbine bleeds steam from the high pressure turbine as cooling steam. The intermediate pressure turbine includes a heated steam inlet for receiving the reheated steam, and a cooling steam inlet for receiving the cooling steam. The cooling steam cools components of the intermediate pressure turbine that receive the reheated steam. A low pressure turbine is driven by steam discharged from the intermediate pressure turbine, and a condenser condenses steam discharged from the low pressure turbine into water as a condensate. A plurality of feedwater heaters heat the condensate to produce feedwater provided to the steam generator.

Owner:KK TOSHIBA

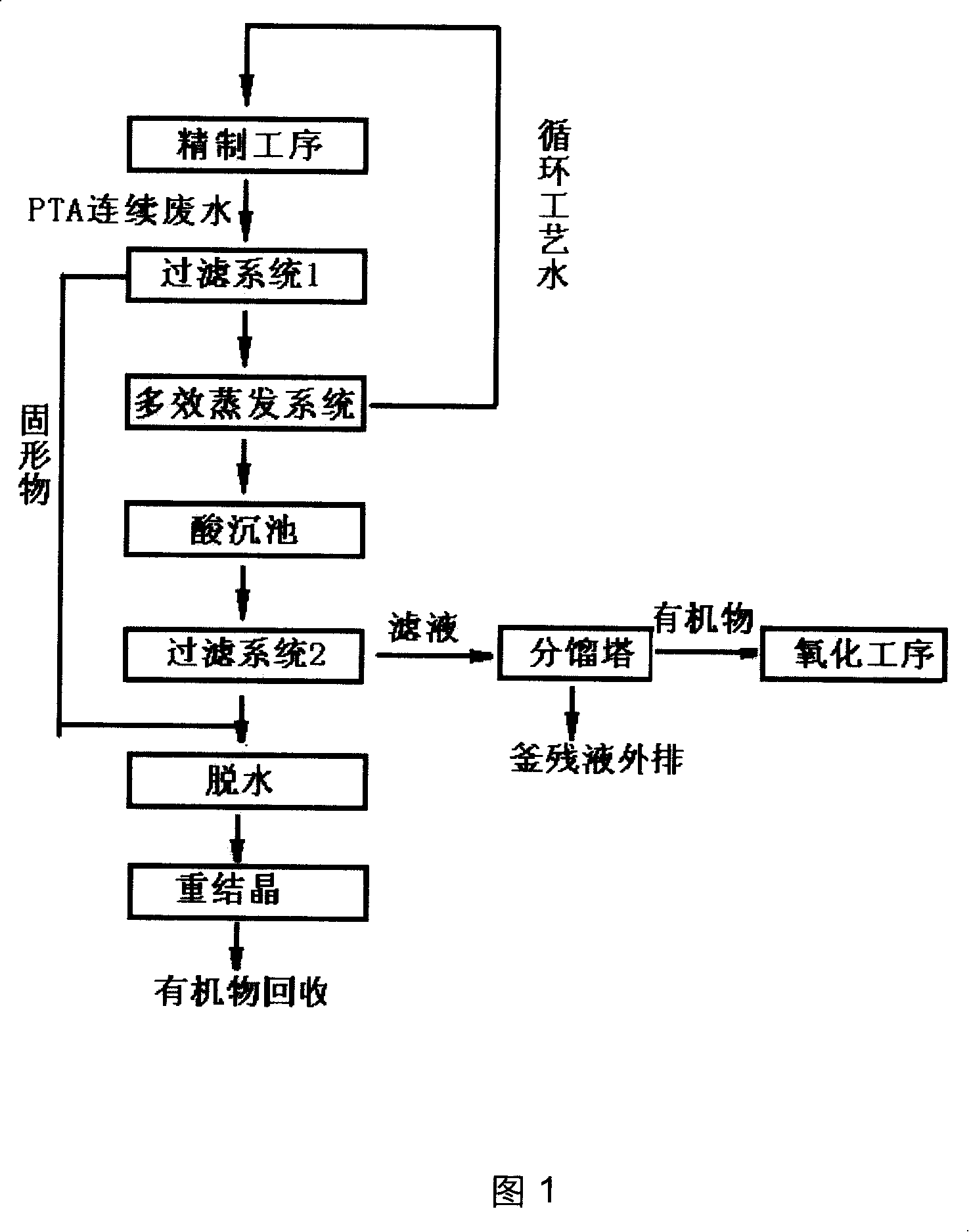

Method of processing p-benzene dicarboxylic acid production wastewater

ActiveCN101152969AEnable direct reuseAchieve recyclingMultistage water/sewage treatmentWater/sewage treatment by heatingSteam condensationEvaporation

The present invention provides a disposal of the phthalic acid production wastewater. The steps are: a. the process wastewater output from a refining process is filtered; filtrate and a solid-form object are gained; b. the filtrate is sent to and processed in a multi-effect evaporation system; steaming condensation water and condensation water with organic compound are gained; then the steaming condensation water is recycled back to the refining process and is reused; c. a solid-liquid mixture is gained by adding acid to the condensation water and precipitating; the solid-form object and the filtrate are gained by processing a solid-liquid separation to the mixture; d. water and various organic compounds are gained by fractionating the filtrate; the water is recycled back to the refining process and is reused; the organic compounds are recycled back to a xylene oxidation process; e. various organic compounds are gained though the combination and re-crystallization of the solid-form object in the step a and the solid-form object in the step c. With the present invention, the majority of the PTA wastewater is capable of being recycled and reused in the production after being disposed; in addition, the majority of the organic compounds in wastewater are reclaimed. So the economically using of the PTA wastewater and the organic compounds in wastewater is realized.

Owner:CHINA PETROLEUM & CHEM CORP

Hybrid dehumidifying air-conditioner

InactiveCN1570495AImprove mass transfer efficiencyImprove heat transfer performanceAir treatment detailsLighting and heating apparatusSteam condensationEngineering

The invention relates to a mixing humidity-removal air conditioner. It belongs to refrigeration and air conditioner technology field. The air conditioner includes desiccant humidity-removal subsystem, indirect evaporation refrigeration device and steam condensation refrigeration subsystem. Reel of desiccant humidity-removal subsystem is separated humidity-removal zone and regeneration zone by insulation heat preservation board. Exit of humidity-removal connects with fan through air conduit. Entry of regeneration connects with regeneration heater through air conduit. Exit of regeneration connects with regeneration wind fan. Two ends of sensible heat exchanger respectively connect with fan and direct evaporation condensation device. Two ends of air condition compressor of evaporation condensation subsystem respectively connect with evaporator and condensator. The other end of condensator connects with throttle device. The other end of throttle device connects with evaporator to form a loop. Adopting the invention, deep dry and evaporation condensation are reduced; evaporator's size is reduced; energy consumption and noise are reduced and heat pollution is lightened for fully using waste heat produced by system.

Owner:SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com