Multistage division regenerative carbon dioxide trapping system and technology

A carbon dioxide and split regeneration technology, applied in the field of flue gas purification, can solve the problems of incomplete regeneration, increased circulating pumps, and low desorption degree, and achieve the goals of reducing desalted water consumption, reducing evaporation heat loss, and increasing rich liquid regeneration degree Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

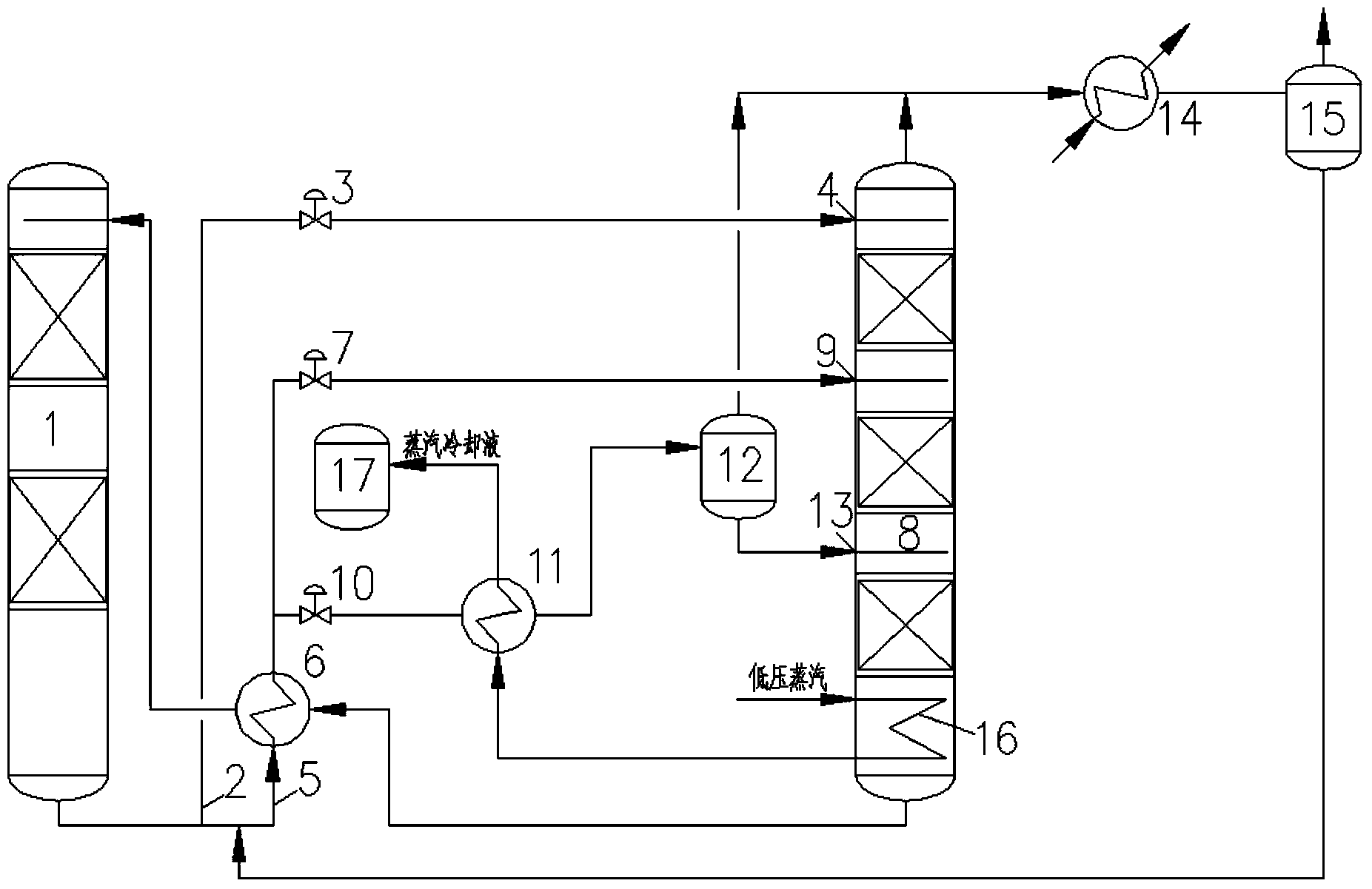

[0016] Such as figure 1 As shown, a carbon dioxide capture and treatment system for multi-stage split flow regeneration of the present invention includes an absorption tower 1, and the rich liquid coming out of the absorption tower 1 is divided into two paths, the first pipeline 2 is provided with a first regulating valve 3, and is connected with the regeneration The upper rich liquid inlet 4 of the tower 8 is connected, the second pipeline 5 is connected with the rich liquid inlet pipeline of the lean and rich liquid heat exchanger 6, and the rich liquid at the outlet of the lean and rich liquid heat exchanger 6 is divided into two paths, and one path The second regulating valve 7 is also communicated with the middle rich liquid inlet 9 of the regeneration tower 8, and the third regulating valve 10 is arranged on the other side and communicated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com