Patents

Literature

730results about How to "Reduce heat consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Novel method for processing calx sodica sintered alumina by dry method

InactiveCN101434403AReduce heat lossImprove economic efficiencyAluminium oxides/hydroxidesWater contentDecomposer

The invention discloses a processing method for sintering alumina by a novel dry soap lime, which comprises the following steps: (1) raw materials, i.e., broken bauxite, limestone, sodium carbonate and coal are sent to a ball mill to be milled until the oversize product of 100<#> is not lager than 5 percent, and raw meal is made into raw meal balls of 30-50mm; (2) clinker sintering: the raw meal of the step (1) is calcined in a vertical kiln at the temperature of 1150-1250 DEG C to prepare the clinker; (3) clinker leaching: the clinker is leached by the lotion of Bayer process, and then the solution is sent to a desilication groove; (4) decomposition: the desiliconized solution is combined with a Bayer solution, and then the mixture is put into a leaf filter and enters a decomposer to be decomposed by adding seed crystal; and (5) roasting: aluminum hydroxide is roasted into alumina at 950-1200 DEG C. The processing method has the beneficial effect that the water content of the raw meal is reduced to 10-15 percent, thus greatly reducing the specific heat consumption in the sintering process by little change and acquiring higher economic benefits.

Owner:CHONGQING BOSAI MINERALS GROUP

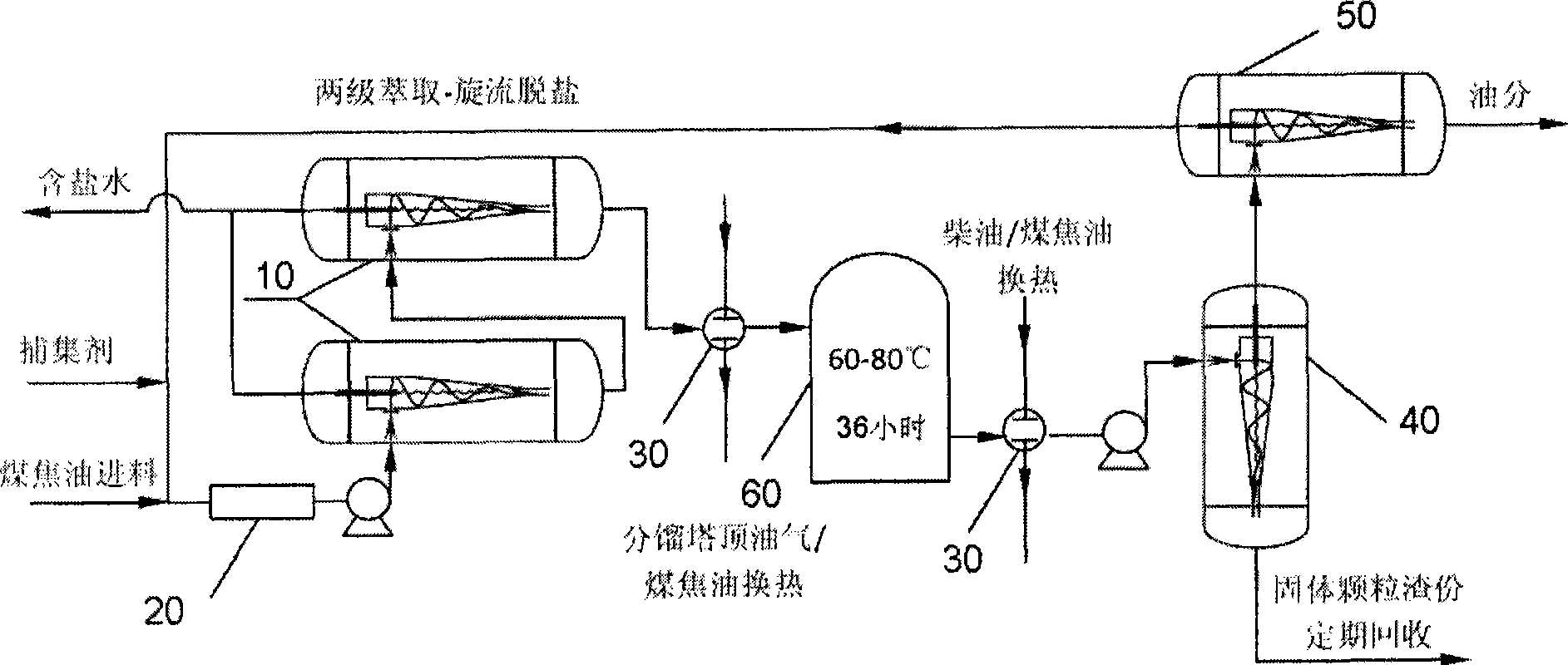

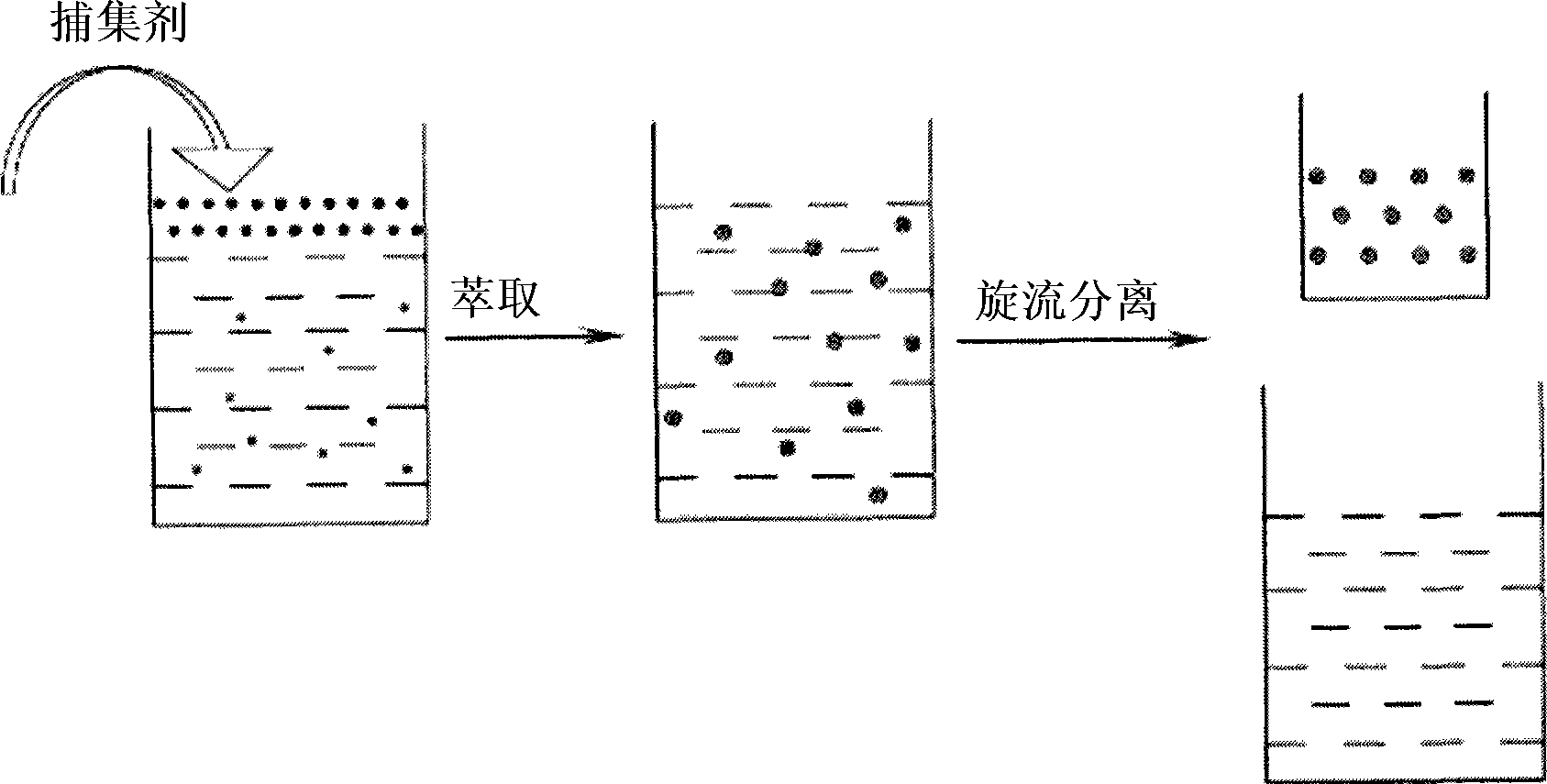

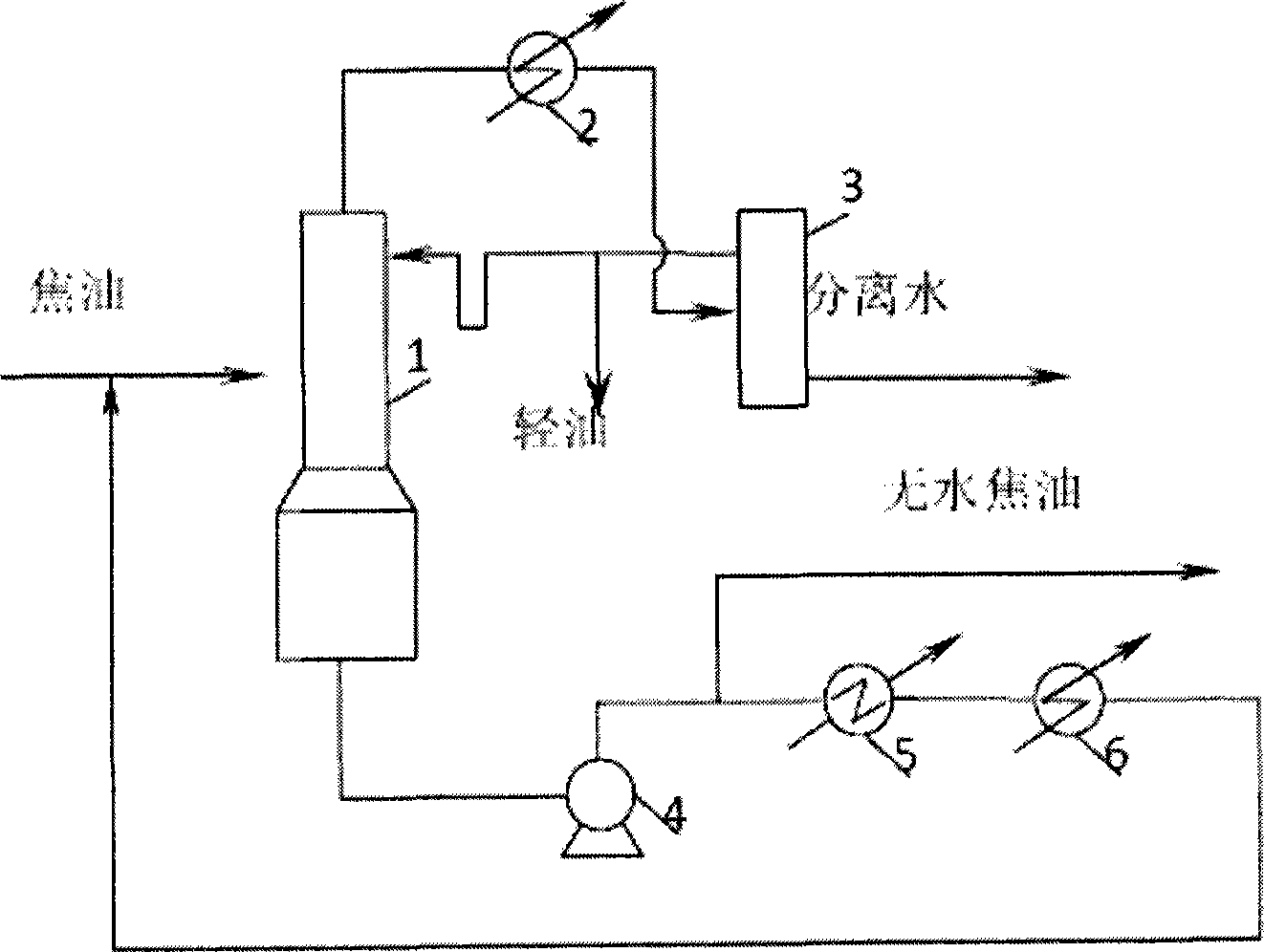

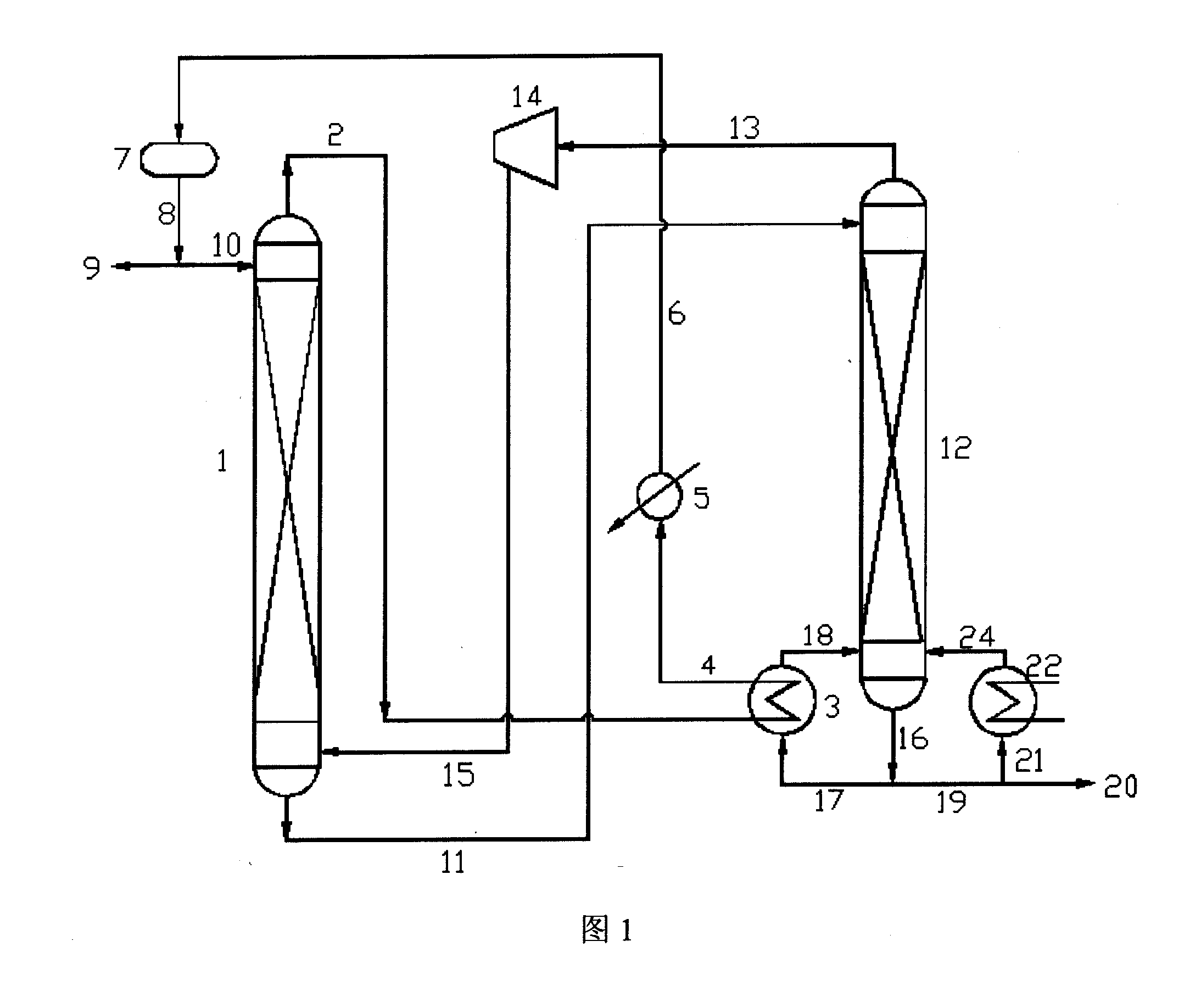

Coal tar coupled rotational flow purification method and apparatus

ActiveCN101475818AReduce heat consumptionReduce resistanceTar working-up by water removalTar working-up by solvent extractionPurification methodsPhysical chemistry

The invention relates to a method and a device for purifying coal tar through coupling rotational flow, wherein the method for purifying the coal tar through coupling rotational flow comprises the following steps: (a) mixing coal tar feed with a trapping agent sufficiently so as to extract out saline matters dispersed in the coal tar; (b) performing liquid-liquid rotational flow separation on thecoal tar in which the dispersed saline matters are extracted out for separating out the saline matters so as to obtain desalinated coal tar; (c) keeping stand and depositing the desalinated coal tar so as to remove the moisture therein and obtain dehydrated coal tar; (d) performing solid-liquid rotational flow separation on the dehydrated coal tar so as to remove solid particles therein and obtain the coal tar without the solid particles; and (e) performing micro rotational flow separation on the coal tar without the solid particles so as to remove the micro moisture therein. The invention also provides a device for purifying the coal tar through the coupling rotational flow.

Owner:EAST CHINA UNIV OF SCI & TECH

Fiberglass radome modified by glass beads and preparation method thereof

The invention discloses a fiberglass radome modified by glass beads, which reduces the DK value thereof, and improves the wave penetration performance of the products. The fiberglass radome modified by glass beads is prepared by the following raw materials in weight portion: 100 portions of unsaturated polyester, 2-10 portions of glass beads, 0.5-2 portions of mold release agent, 0.5-2 portions of curing agent and 0.5-2 portions of accelerator.

Owner:NANJING HUAGE ELECTRONICS & AUTOMOBILE PLASTIC IND

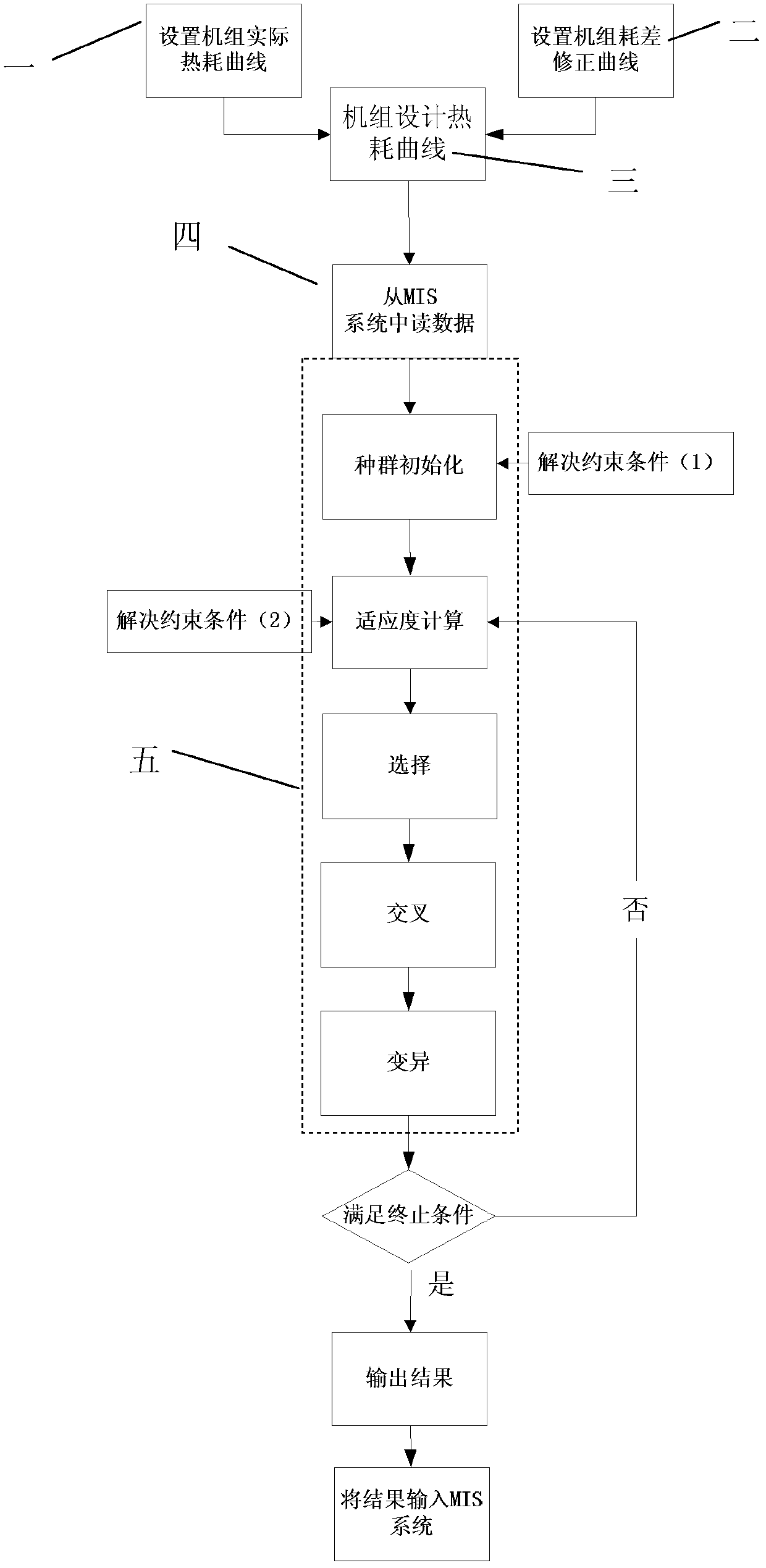

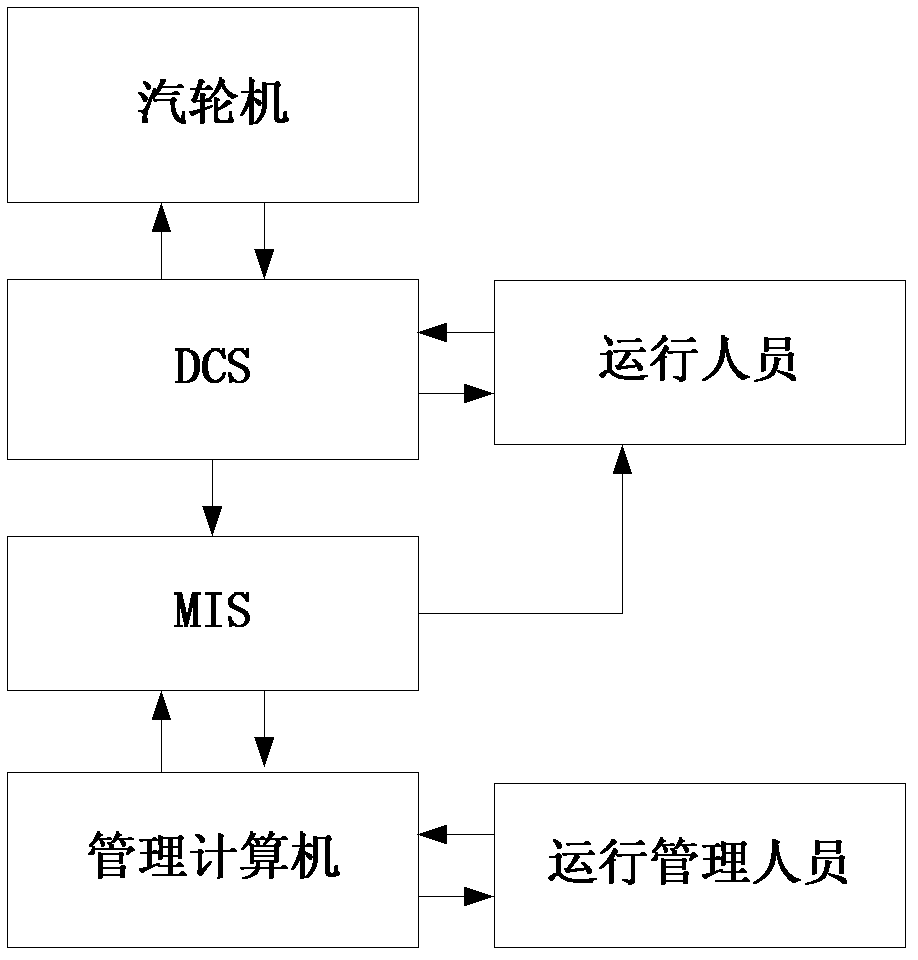

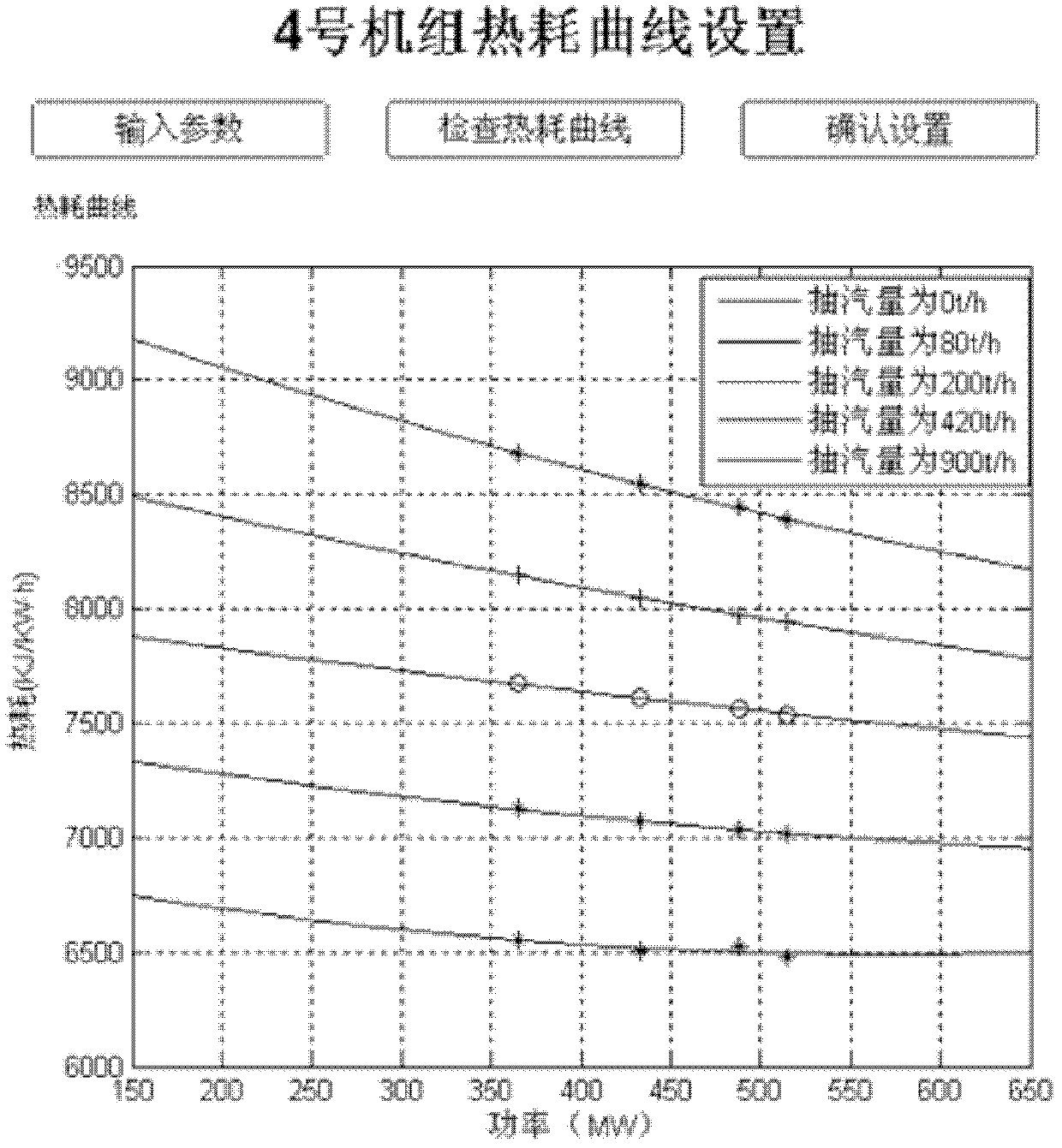

Improved genetic algorithm-based method for distributing and optimizing thermal and electrical load of steam extraction and heating unit

ActiveCN102622530AImprove accuracySolving Equality Constraint ProblemsGenetic modelsSystems intergating technologiesElectricityPower station

The invention provides an improved genetic algorithm-based method for distributing and optimizing thermal and electrical load of a steam extraction and heating unit, and belongs to the technical field of energy saving and monitoring of a power station. The invention aims to distribute and optimize the thermal and electrical load of a plurality of heating units of the power station, optimally distribute the electrical load and the thermal load of the power station when the electrical load and the thermal load meet requirements of users, and reduce total energy consumption and save energy. An actual heat consumption and consumption difference curve of the unit is set, and a design heat consumption curve of the unit is obtained; the electrical load and steam extraction amount of each unit are acquired; and the electrical load and the steam extraction amount value of each unit are obtained based on the improved genetic algorithm when the total thermal consumption values of the units are minimum, and the electrical load, the steam extraction amount value optimal solution and the corresponding minimum total thermal consumption of each unit are output when the total thermal consumption values of the units are minimum by improving genetic coding and fitness function, and selecting, crossing and mutating the genetic algorithm under the condition that the optimization process meets constraint conditions. By the method, the speed of optimization process and accuracy of an optimization result are improved.

Owner:HUADIAN ENERGY COMPANY LIMITED +1

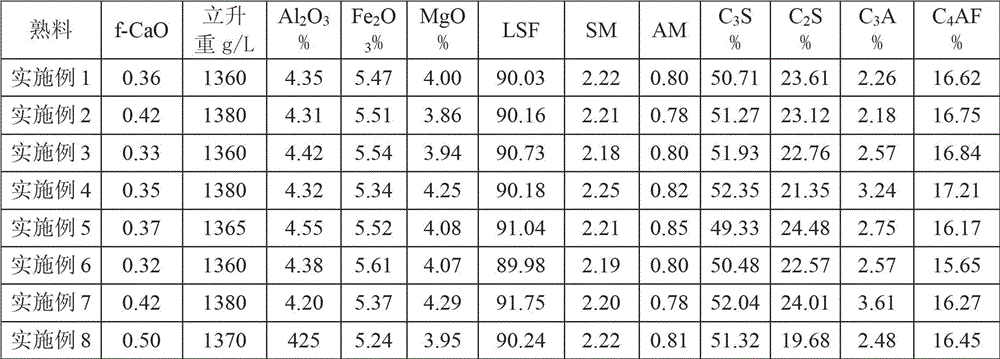

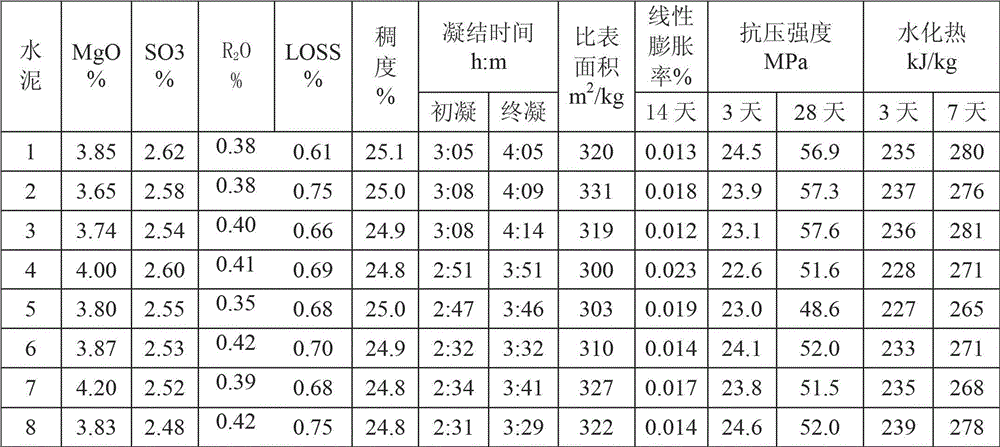

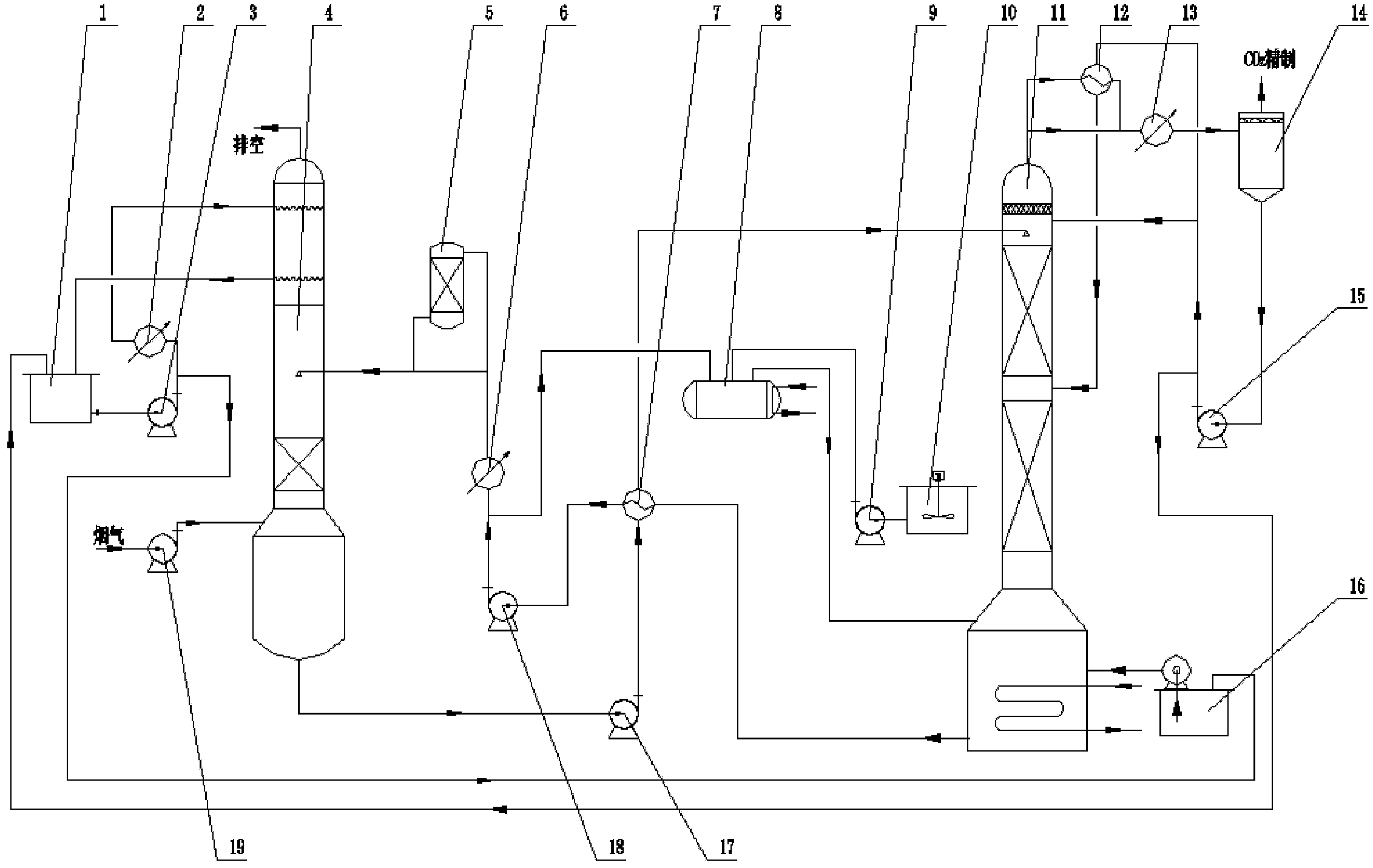

Micro-expansive moderate-heat Portland cement and production method thereof

InactiveCN102976641AHigh strengthHeat of hydration controlClinker productionHigh magnesiumPortland cement

The invention discloses a micro-expansive moderate-heat Portland cement and a production method thereof. The cement contains micro-expansive moderate-heat Portland cement clinker and gypsum in a weight ratio of 92:8-98:2, and also comprises grinding aid which accounts for 0-0.1 wt% of the sum of micro-expansive moderate-heat Portland cement clinker and gypsum. The raw meal of the micro-expansive moderate-heat Portland cement clinker is prepared from the following raw materials in percentage by weight: 65-80% of calcium raw material, 5-20% of silicon correction raw material, 5-15% of iron correction raw material and 3-10% of magnesium correction raw material. The micro-expansive moderate-heat Portland cement clinker is prepared by the following steps: grinding the raw meal, dehydrating the slurry, drying and crushing the filter cake, and firing to obtain the clinker. By adopting the low-aluminum high-iron high-magnesium low-saturation-ratio formula, the invention effectively controls the hydration heat of cement, displays the micro-expansive property, and can compensate the volume shrinkage in the concrete cooling process, thereby reducing or avoiding cracks.

Owner:GUANGXI YUFENG CEMENT

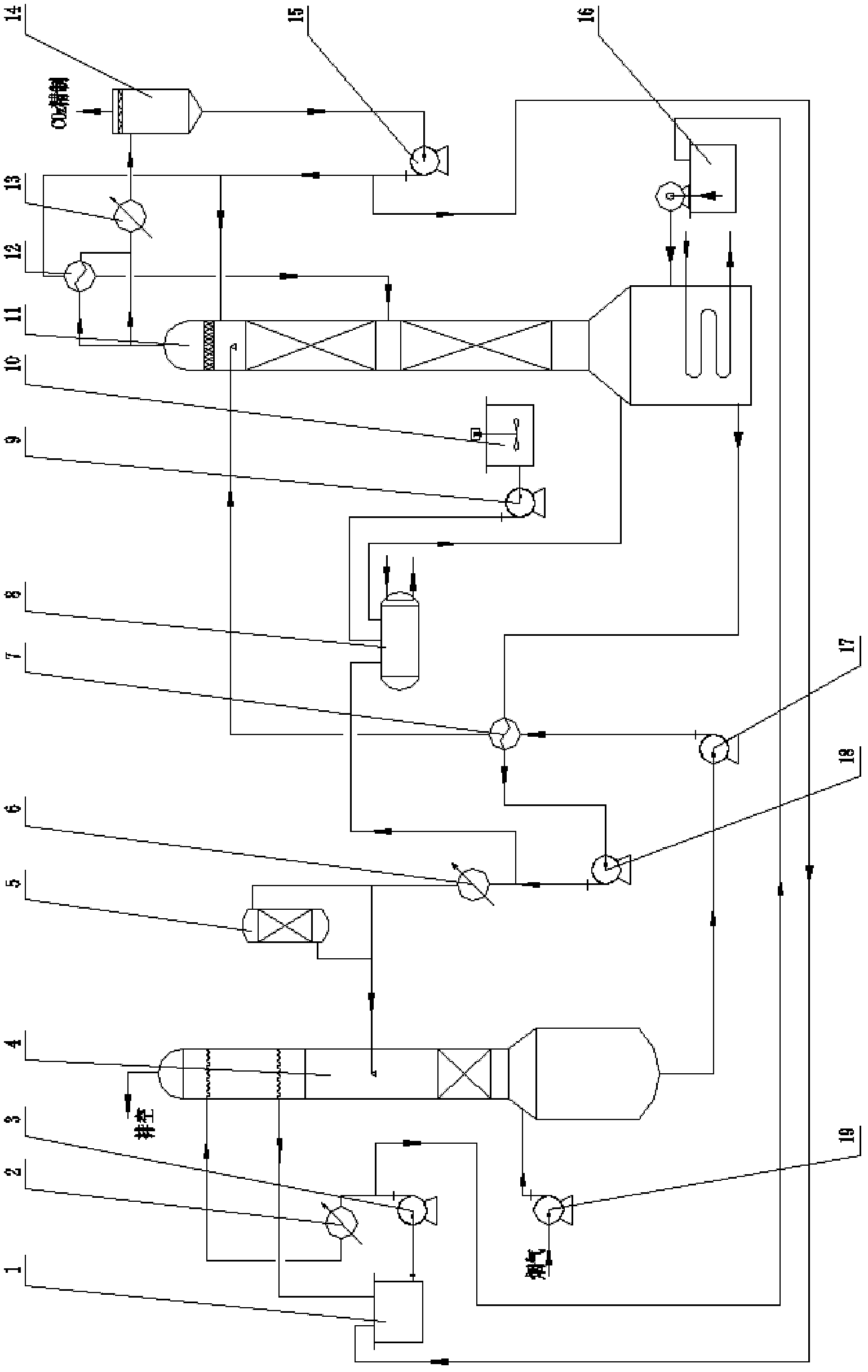

Pneumatic trapping system and process for carbon dioxide (CO2) in smoke

The invention relates to a pneumatic trapping system and process for carbon dioxide (CO2) in smoke. The pneumatic trapping process comprises the following steps that: (1) the smoke enters an absorption tower and is contacted with a serotonin solution in a counterflow manner so as to be absorbed under chemical reaction, the absorbed smoke upwards passes through a washing device, so that an absorbent contained in the smoke is cleaned out, and the smoke is discharged directly; (2) a solution which traps the CO2 is changed into rich liquor, the rich liquor flows to the bottom of the absorption tower and is conveyed to a barren and rich liquor heat exchanger through a rich liquor pump, and the rich liquor subjected to temperature raising enters a desorption tower; (3) the rich liquor is subjected to thermal desorption in the desorption tower to obtain regenerative gas rich in CO2 and solution steam, and the regenerative gas is subjected to heat exchange, condensation and gas and liquor separation to obtain a CO2 product; and (4) desorbed barren liquor is pumped into the barren and rich liquor heat exchanger and a barren liquor cooler by a barren liquor pump, and is reused after being cooled to temperature of an absorption reaction window. By adopting an efficient pneumatic decarbonization technology, the smoke and amine liquor can be contacted with each other fully, so the decarbonization efficiency is up to over 90 percent; and the system and the process are applicable to trapping of the CO2 in a large amount of smoke and can be applied to CO2 trapping devices with yearly output of 1,000,000 tons.

Owner:AEROSPACE ENVIRONMENTAL ENG

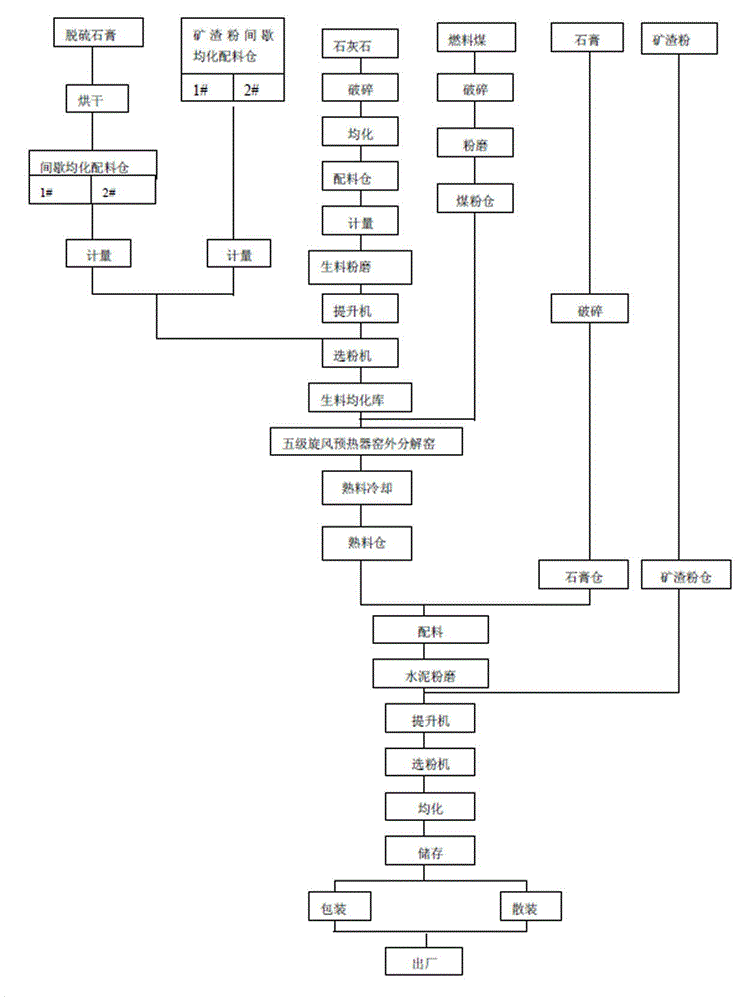

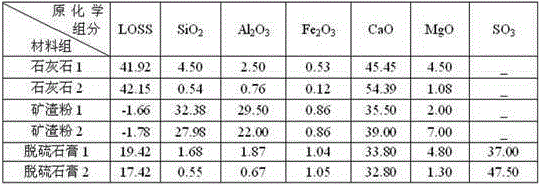

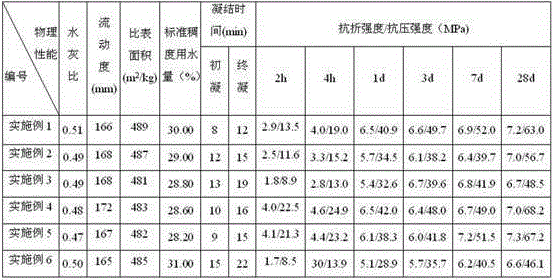

White fast-setting, fast-hardening and high-belite sulphoaluminate cement clinker, and application and production technology thereof

The invention relates to a white fast-setting, fast-hardening and high-belite sulphoaluminate cement clinker, and also relates to an application and a production technology thereof. The mineral component of the cement clinker comprises 0.5-4.6% of f-CaO; the chemical component of the cement clinker comprises 12.9-16.1wt% of SiO2, 12-19wt% of Al2O3, 0.15-1.0wt% of Fe2O3, 49-53wt% of CaO and 12-18.5wt% of SO3; and the clinker rate range Cm is 1.01-1.137, and P is 0.62-1.44. The clinker is produced through calcining 30-50wt% of limestone, 26-46wt% of slag powder and 21.1-40wt% of desulfurized gypsum in a rotary kiln at 1250-1350DEG C. 26-97% Of the clinker, 3-19% of anhydrite and 0-55% of the slag powder, or 5-25% of the clinker, 14.4-19.0% of the anhydrite and 55.8-79% of the slag powder are mixed and ground to form white fast-setting, fast-hardening and high-belite sulphoaluminate cement and high-late strength and high-belite sulphoaluminate cement.

Owner:TANGSHAN POLAR BEAR BUILDING MATERIAL +1

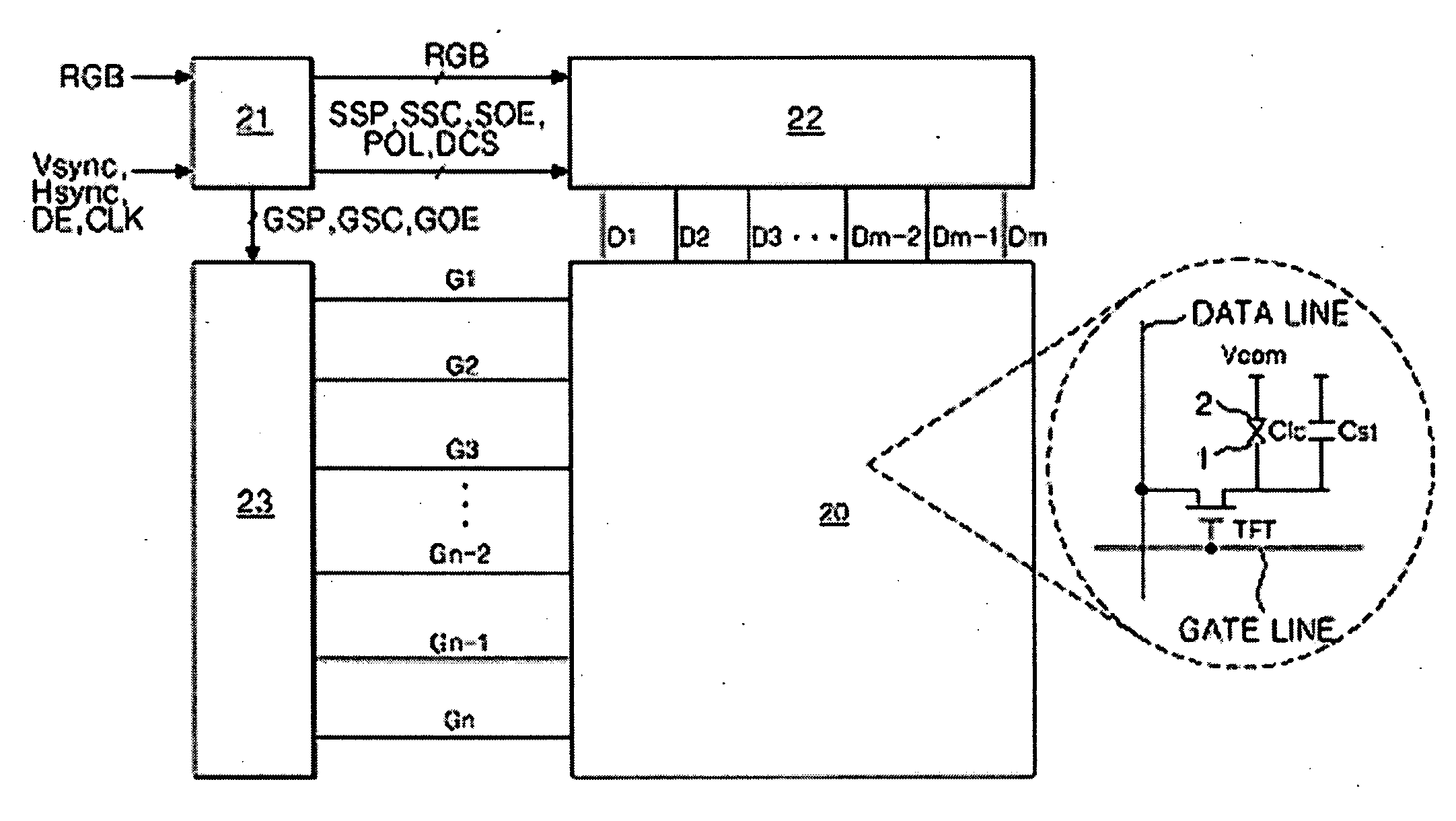

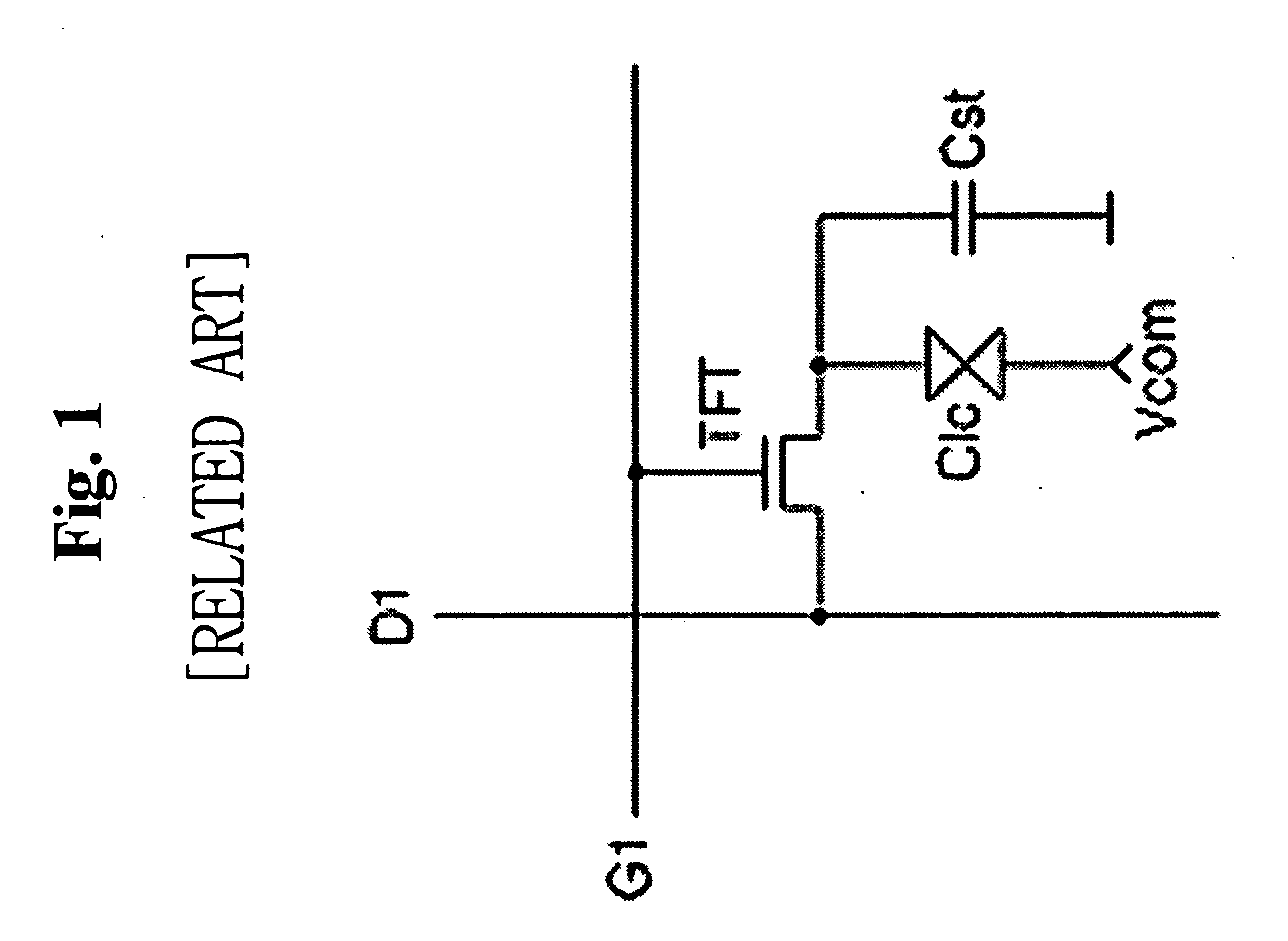

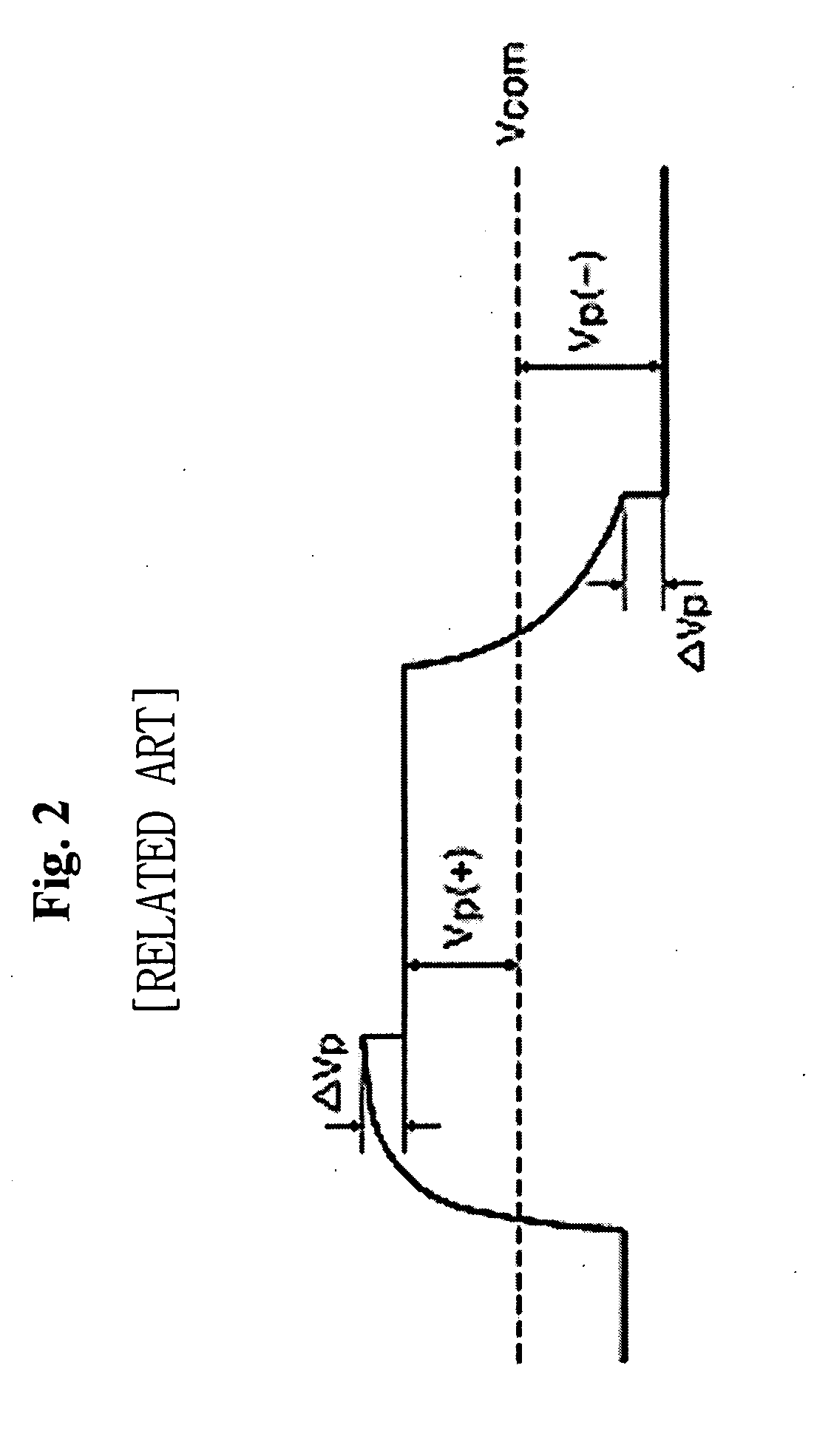

Liquid crystal display and driving method thereof

ActiveUS20090002302A1Reduce heat consumptionLow heat generationCathode-ray tube indicatorsNon-linear opticsDigital videoControl signal

A liquid crystal display includes a liquid crystal display panel having a plurality of data lines, a plurality of gate lines crossing the plurality of data lines, and a plurality of liquid crystal cells, a timing controller to determine gray levels of input digital video data and a time at which a polarity of a data voltage to be supplied to the data lines is inverted, to activate a dynamic charge share control signal to indicate a time at which the gray level of the data voltage is changed from a white gray level to a black gray level and a time at which the polarity of the data voltage is inverted, to detect weakness patterns in which the data of the white gray level and the black gray level are regularly arranged in the input digital video data, and to activate a dot inversion control signal for widening a horizontal polarity inversion period of data voltages to be supplied to the data lines when the weakness patterns are input, a data driving circuit to convert the digital video data from the timing controller into the data voltage, to convert the polarity of the data voltage, to supply any one of a common voltage and a charge share voltage between a positive data voltage and a negative data voltage to the data lines in response to the dynamic charge share control signal, and to widen the horizontal polarity inversion period of the data voltages in response to the dot inversion control signal, and a gate driving circuit to sequentially supply a scan pulse to the gate lines under the control of the timing controller.

Owner:LG DISPLAY CO LTD

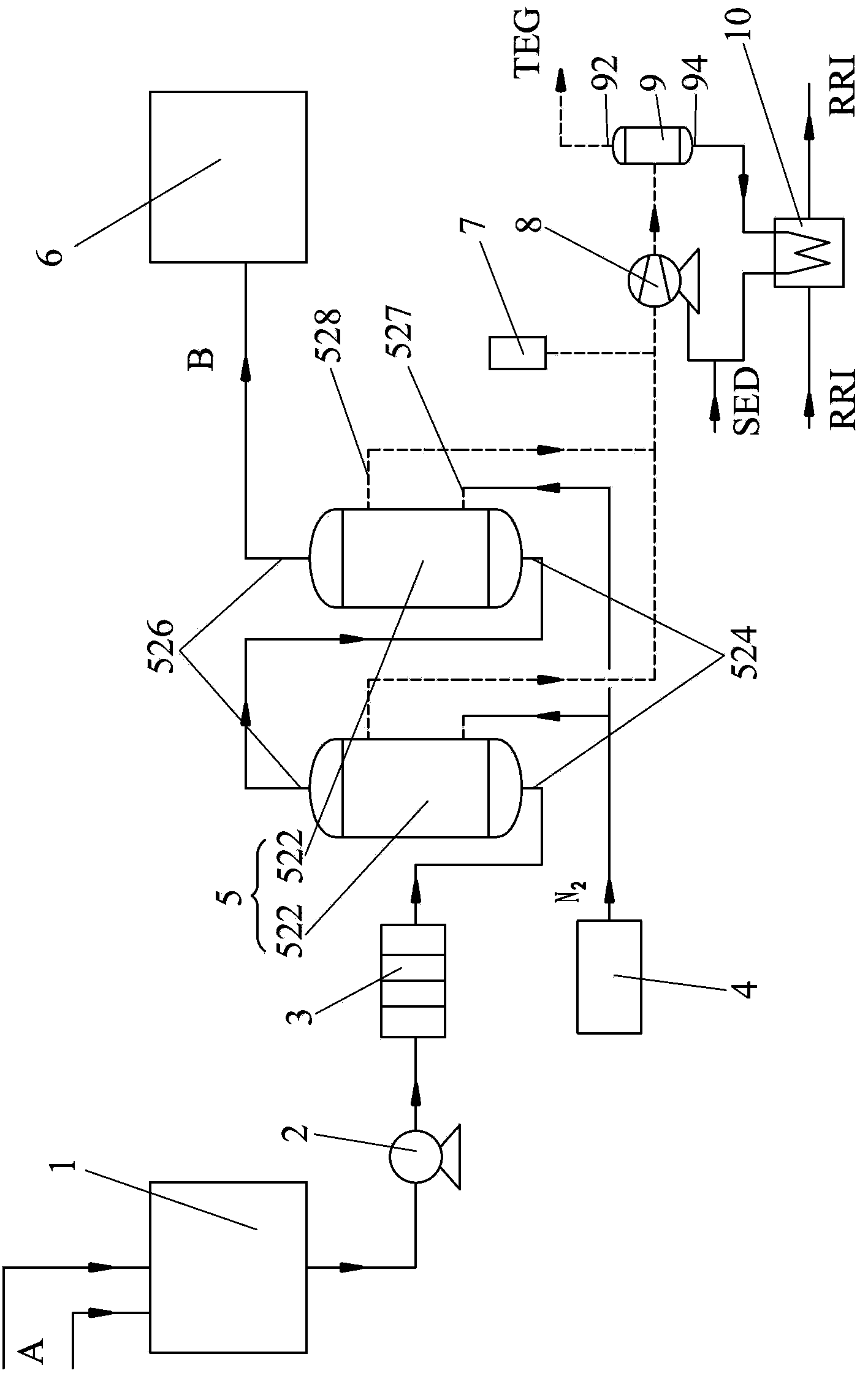

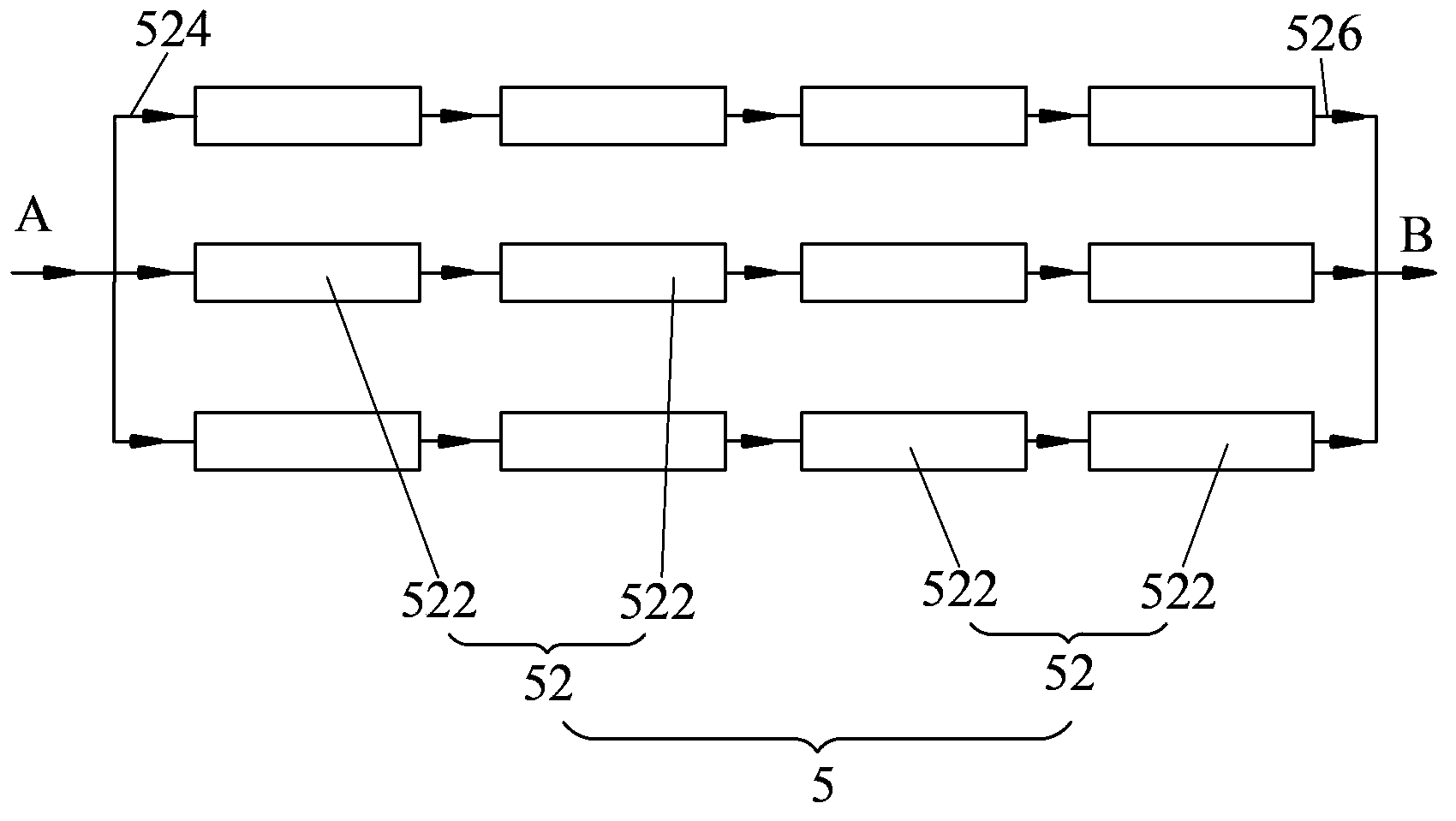

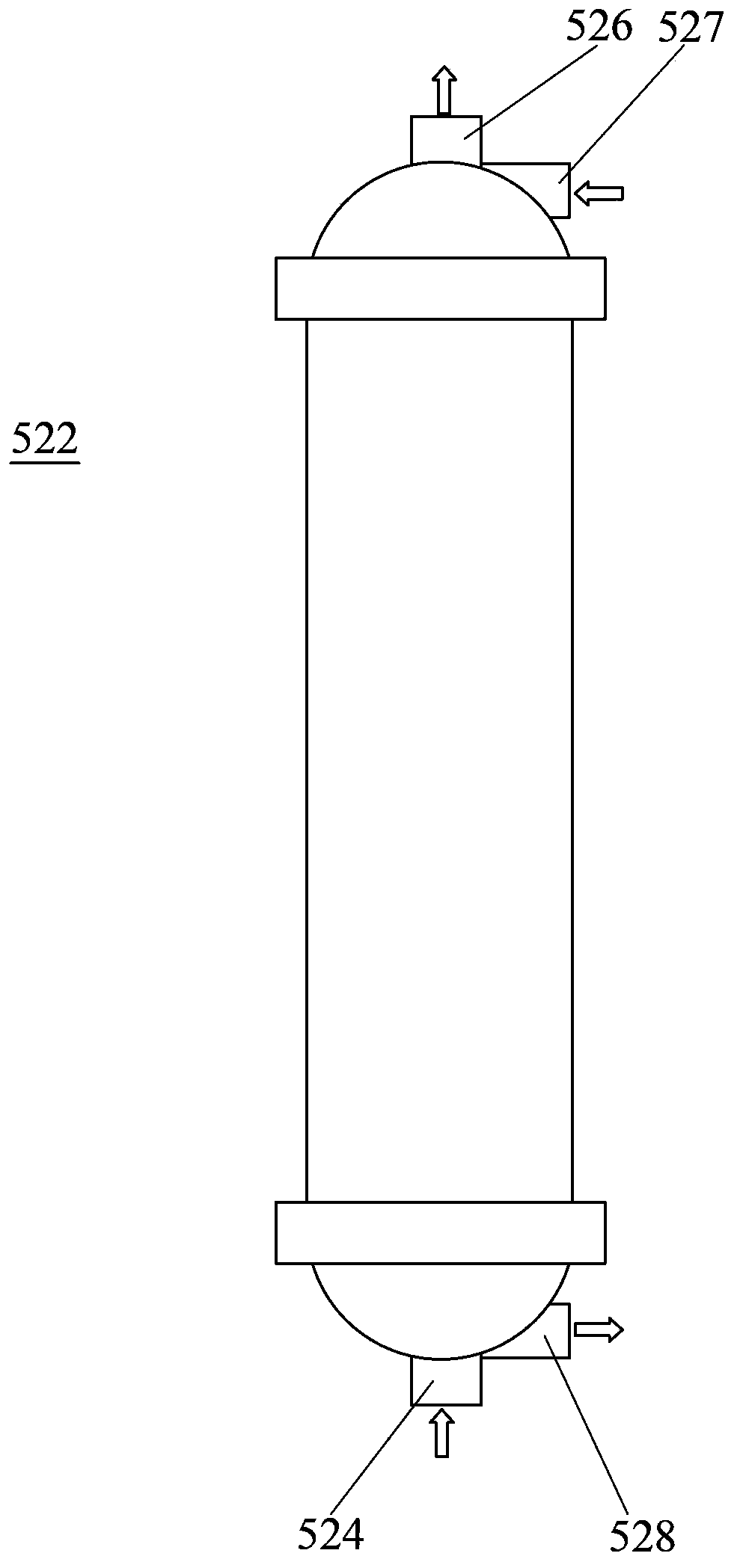

Degasser for removing dissolved gases in reactor coolant of nuclear power station, and method thereof

ActiveCN103405945ALow costLow design process difficultyLiquid degasificationDegasserNuclear engineering

The invention provides a degasser for removing dissolved gases in a reactor coolant of a nuclear power station. The degasser comprises a preposed storage box used for storing the coolant, a degassing membrane unit communicated with the preposed storage box and positioned at the lower reach of the preposed storage box, a vacuum pump and a nitrogen supply device, wherein the vacuum pump and the nitrogen supply device are communicated with the degassing membrane unit; the degassing membrane unit is used for receiving the coolant and removing the dissolved gases in the coolant, and is provided with a gas passage; the vacuum pump is used for vacuumizing the gas passage; the nitrogen supply device is used for inletting nitrogen gases to the gas passage. The degasser is low in energy consumption, low in manufacturing cost, simple in equipment and high in degassing rate. The invention further provides a degassing method for removing the dissolved gases in the reactor coolant of the nuclear power station.

Owner:CHINA NUCLEAR POWER TECH RES INST CO LTD +1

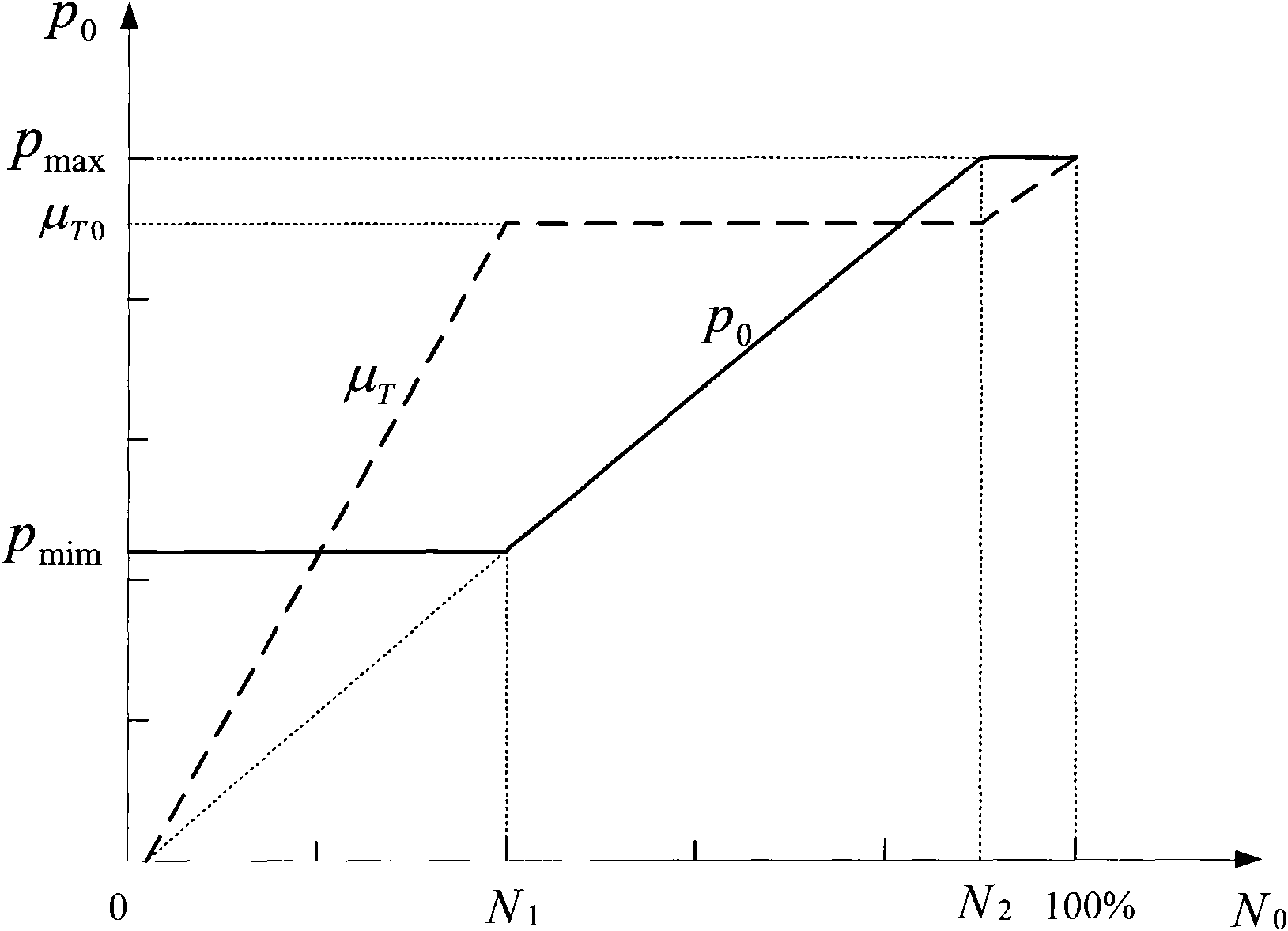

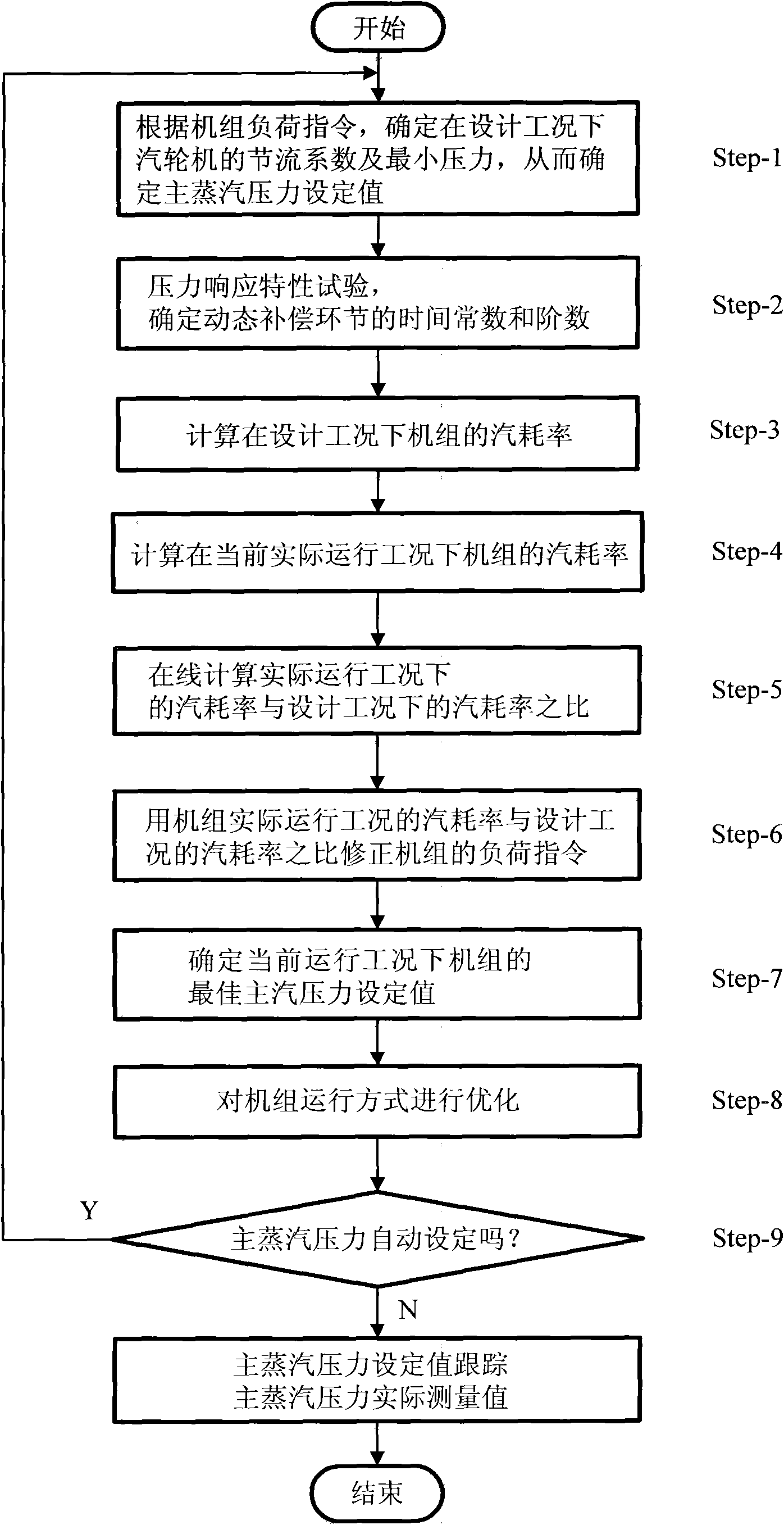

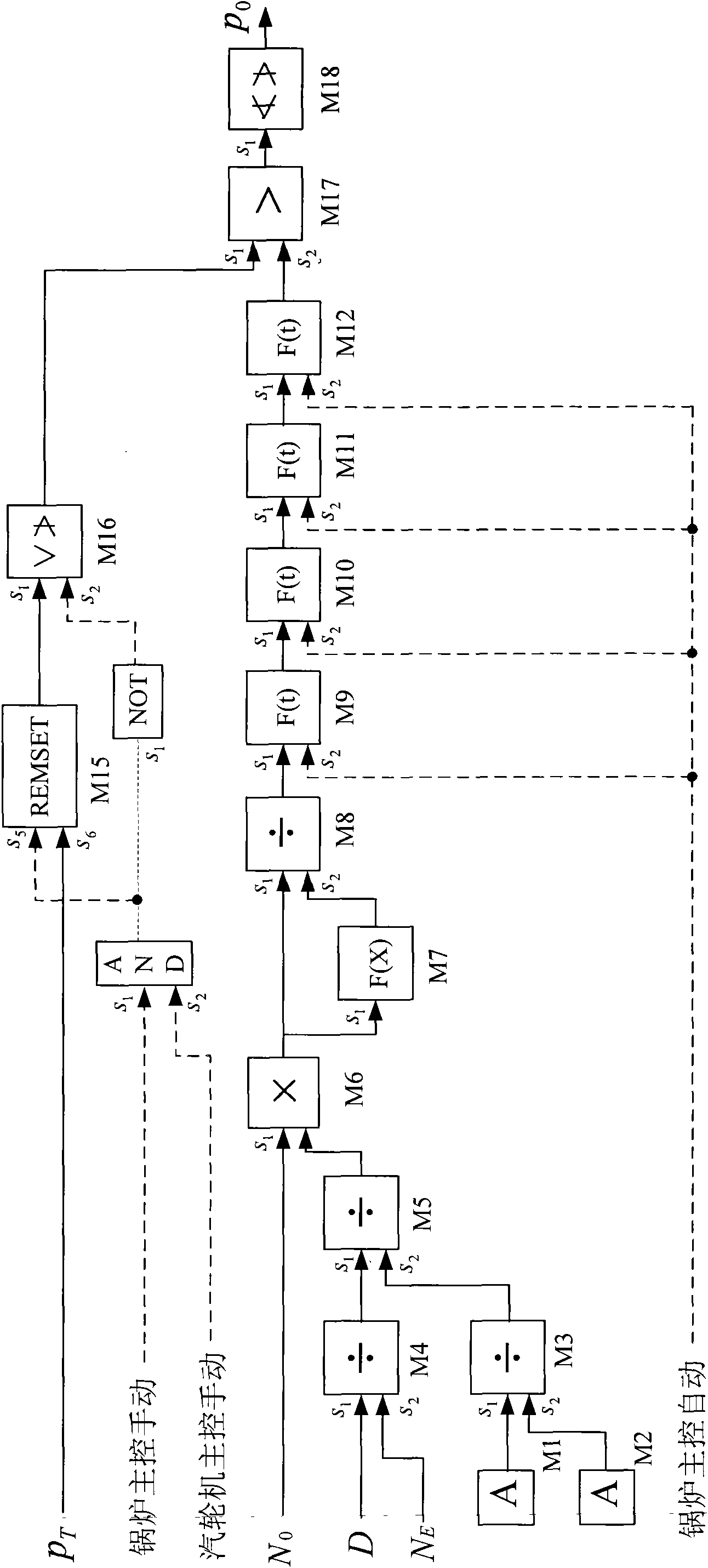

Generating set optimization control method for correcting sliding pressure operation curve by adopting steam consumption rate

ActiveCN101609312AImprove cycle efficiencyBest working pointProgramme control in sequence/logic controllersSteam pressureControl system

The invention discloses a generating set optimization control method for correcting sliding pressure operation curve by adopting steam consumption rate, which comprises the detailed steps of: confirming the throttling coefficients and minimum pressure of a steam turbine under a designed working condition according to the load command of the generating set and confirming the main steam pressure set value; confirming the parameters of dynamic compensation section according to the main steam pressure response characteristics; respectively calculating the steam consumption rate of the generating set under the designed working condition and the actual working condition, working out the steam consumption rate correction coefficients, and implementing online correction on the load command of the generating set; using the corrected load command to divide the throttling coefficients of the steam turbine, then implementing calculation on the dynamic compensation procedure and minimum pressure limitation, and finally obtaining the best main steam pressure set value of the generating set under the current operation condition. The best main steam pressure set value is applied in a cooperation control system of a unit set so as to realize the best cooperation relation between the inlet steam pressure and inlet steam flow of the generating set, thus reducing the throttling loss of the steam turbine and guaranteeing the best thermoeconomic performance of the generating set.

Owner:ELECTRIC POWER RES INST STATE GRID SHANXI ELECTRIC POWER +1

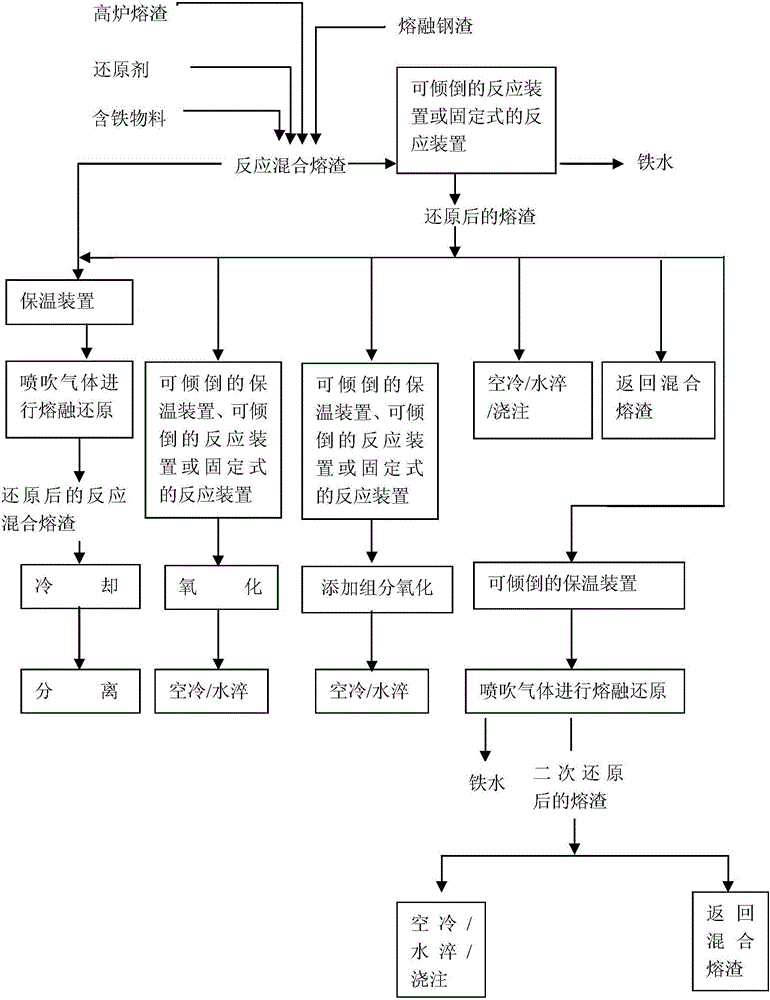

Mixed slag smelting reduction production and thermal refining method

ActiveCN106191344AEasy to removeTake advantage ofRecycling and recovery technologiesProcess efficiency improvementMolten stateReducing agent

The invention discloses a mixed slag smelting reduction production and thermal refining method, and belongs to the field of non-blast furnace iron smelting and comprehensive utilization of resources. The method comprises the following steps: 1) an iron-contained material and a reducing agent are added in mixed slag of blast furnace slag and molten steel slag for heating to reach a molten state; and oxide gas is sprayed for iron smelting by smelting reduction to treat most iron-contained material; and 2) an iron component, a calcium silicon component and a phosphorus component in the mixed slag are separated and recovered according to a reaction device. After smelting reduction, the reduced slag can serve as a cement additive, a cement regulator, a cement clinker or a cement clinker with high production additional value, so that the method realizes efficient comprehensive utilization of the resources, and is a new smelting reduction iron making method. The method uses smelting reduction of the mixed slag for production of pig iron or steel and phosphorus-enriched phases and thermal refining, is short in reaction time, high in metal recovery rate, low in production cost, high in raw material adaptability, high in handling quantity, environment-friendly and high in economic benefit, and can effectively achieve the goal of efficient recycling of metallurgic resources and heat energy.

Owner:NORTHEASTERN UNIV

Pre-heating decomposition method of producing sulfuric acid from phosphogypsum with co-production of cement

ActiveCN105129744AImprove decomposition efficiencyIncrease concentrationSulfur compoundsClinker productionDecompositionPhosphogypsum

The invention relates to the technical field of industrial production of sulfuric acid and cement, the field of industrial solid waste comprehensive utilization, and the field of environment protection and treatment, and particularly relates to a pre-heating decomposition method of producing sulfuric acid from phosphogypsum with co-production of cement. The method includes the steps of powder grinding of raw materials, multi-stage cyclic pre-heating, high-effective decomposition and kiln gas separation and purification. The method is used for preparing a cement raw material from the phosphogypsum subjected to pre-heating decomposition with clay, sand rock, coke and such auxiliary materials in the process of producing the sulfuric acid from the phosphogypsum with co-production of the cement. The method solves the problems that a pre-heating decomposition technology in the prior art is low in decomposition ratio of phosphogypsum, is low in productivity of sulfuric acid and clinker, is liable to cause crusting and blocking in a kiln and is high in production energy consumption, can reduce the decomposition efficiency of the phosphogypsum and accelerate escape of SO2, and further increase the productivity of the sulfuric acid and cement clinker. The pre-heating decomposition method of producing the sulfuric acid from the phosphogypsum with co-production of the cement can significantly reduce sintering temperature and energy consumption of the clinker, can reduce production cost of sulfuric and cement clinker, and can further increase comprehensive utilization rate of the phosphogypsum.

Owner:湖北湖大天沭新能源材料工业研究设计院有限公司

Raw materials combustion adjuvant

Disclosed is a slurry sintering agent which is prepared by using oxidizing agent as the main raw material, and one or more selected from mineralization agent, seed crystal, grinding aid or packing material as the compatible auxiliary raw materials. The sintering agent can reduce deacidized material in the clinker aggregate and improve the sintering quality of the clinker aggregate.

Owner:尹小林

Method for industrial production of ethyl alcohol by using straw or corn or Chinese sorghum straw

InactiveCN101041834AReduce pollutionIncreased degradation rateBiofuelsFermentationBiotechnologyAlcohol

The invention discloses a processing craft with rice straw or corn or sorghum straw to produce industrial alcohol, which comprises the following steps: pressing the rice straw and straw to brick; disposing with 60Co-gama ray of 0.5-2.0X106Gy or electron-beam accelerator; grinding with mechanical; screening through 200 order sieve; leaching with hot water; stripping lignin with alcohol; degrading enzyme; separating 1-2 mu m cord hole film; synchronous-saccharifying saccharomyces cerevisiae and pichia; dispersing and yeasting; dewatering and separating the alcohol; getting the product.

Owner:湖南省原子能农业应用研究所 +1

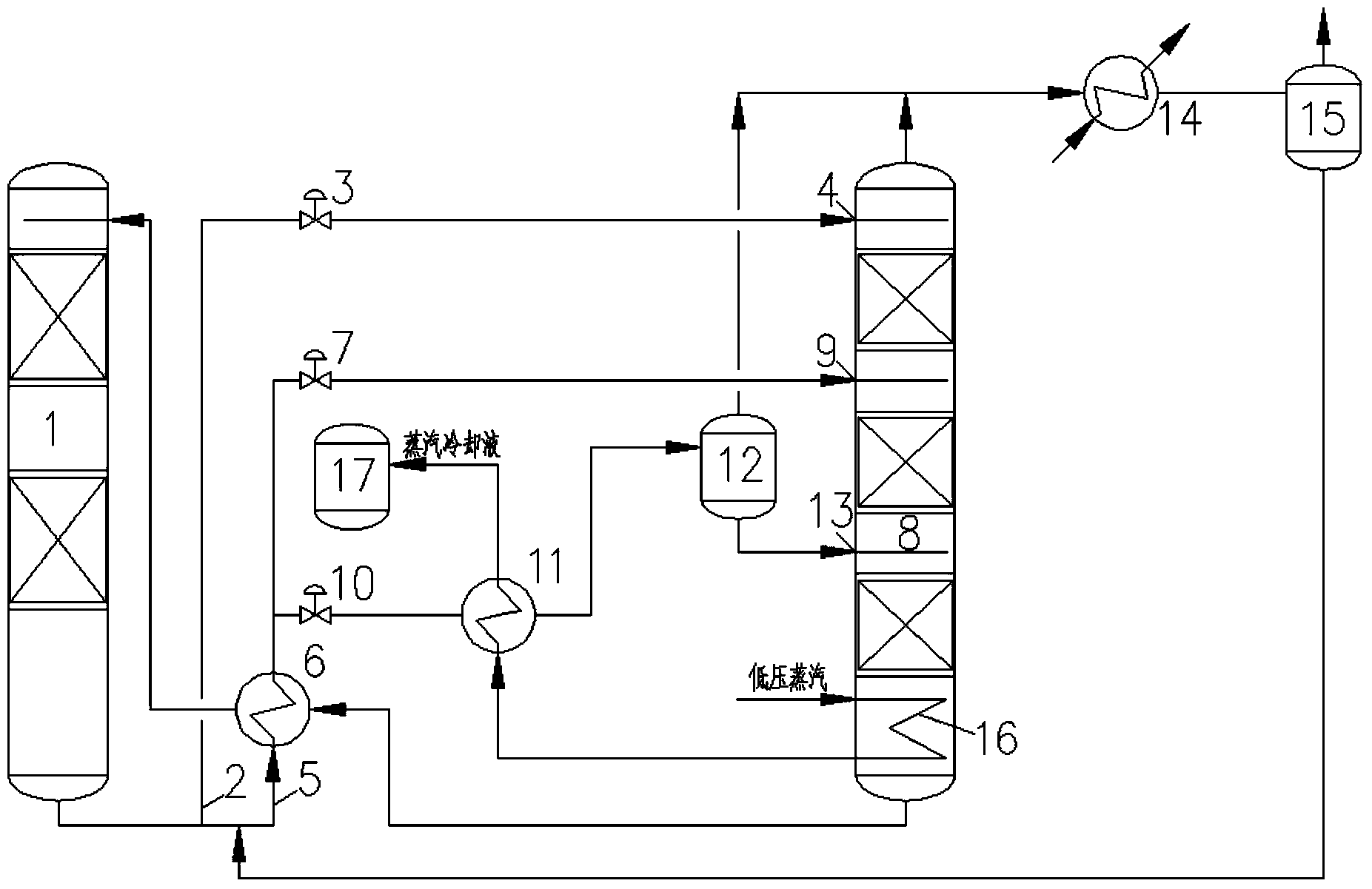

Multistage division regenerative carbon dioxide trapping system and technology

ActiveCN103961979APromote regenerationAbsorb thoroughlyDispersed particle separationSteam condensationTrapping

The invention relates to a multistage division regenerative carbon dioxide trapping system. The system comprises an absorption tower, wherein rich liquor that flows out of the absorption tower is divided into two channels; a first pipeline is communicated with a rich liquor inlet formed in the upper part of a regeneration tower; a second pipeline is communicated with the rich liquor inlet of a rich and poor liquid heat exchanger; rich liquor that flows out of the rich and poor liquid heat exchanger is further divided into two channels; one channel is communicated with a rich liquor inlet formed in the central part of the regeneration tower; the other channel is communicated with the rich liquor inlet of a rich liquor reheater; the rich liquor outlet of the rich liquor reheater is communicated with the rich liquor inlet of a rich liquor flash tank; the rich liquor outlet formed in the bottom of the rich liquor flash tank is communicated with a rich liquor inlet formed in the lower part of the regeneration tower. According to the invention, the regeneration degree of the rich liquor can be increased and steam heat consumption needed during rich liquor regeneration can be reduced; in addition, steam condensates can be recycled in the lyophobic collecting box of main equipment to reduce the desalted water consumption of the trapping system.

Owner:HUANENG CLEAN ENERGY RES INST

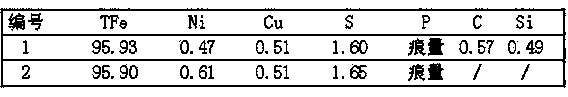

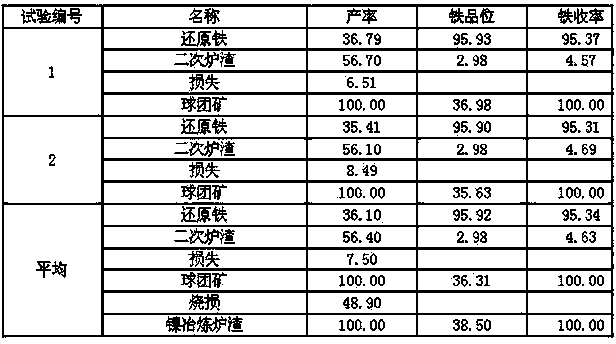

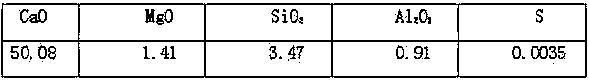

Method for treating nickel smelting furnace slag

The invention method provides a method for treating nickel smelting furnace slag and relates to a method for treating nickel smelting furnace slag by a rotary hearth furnace reduction-gas furnace melting separation combined process. The method is characterized by sequentially comprising the following process steps: (1) adding a reducing agent, a fusing agent and an adhesive into the nickel smelting furnace slag and mixing; (2) pressing into pellets; (3) drying the pressed pellets; (4) charging the dried carbon-containing pellets into a preheating section of a rotary hearth furnace and preheating; (5) reducing the carbon-containing pellets in a reducing section of the rotary hearth furnace to obtain thermal-state metallized pellets; and (6) adding the hot pellets into the gas furnace for melting separation to realize final reduction and scrap iron melting separation. By the method, valuable elements in the nickel smelting furnace slag can be comprehensively recovered, continuity of a preparation process is realized, molten iron for steel-making can be provided, and secondary slag for developing and producing products such as slag micropowder, foamed ceramic and aerated concrete blocks also can be provided, and zero emission of solid wastes is realized.

Owner:JINCHUAN GROUP LIMITED

Differential pressure low-energy-consumption distillation method and equipment

ActiveCN101239247AAchieve rectificationMeet reboil requirementsFractional distillationRefluxDifferential pressure

The present invention provides a rectifying method having differential pressure and lower energy consumption, and an apparatus, including a general knockout tower section, a underpressure knockout tower section, a main reboiler, a reflux accumulator and a compressor, wherein , a compressor is set between the underpressure knockout tower section and the general knockout tower section, the gas material tube on the top of the underpressure knockout tower section is connected to the inlet of the compressor, the outlet of the compressor is connected to the gas inlet ont the bottom of the general knockout tower section; gas material outlet of the general knockout tower section is connected to the heat medium inlet of the main reboiler, heating medium outlet is connected to the reflux accumulator of the general knockout tower section; the liquid outlet on the bottom of the general knockout tower section is connected to the liquid inlet of the underpressure knockout tower section; the liquid material outlet tube on the bottom of the underpressure knockout tower section is connected to the cooling medium inlet of the main reboiler, outlet of the cooling medium is connected to the inlet of the reboiler of the underpressure knockout tower section. The invention realises thermally coupled distillation, matching heat exchange. The minimum heat consumption is realised by differential pressure temperature reduction means, even the cool-heat load are fully matched, the consumption is zero. Ways to achieve the aim only is adding a compressor in the equipment, the dynamic consumption is lower than the original consumption.

Owner:TIANJIN UNIV

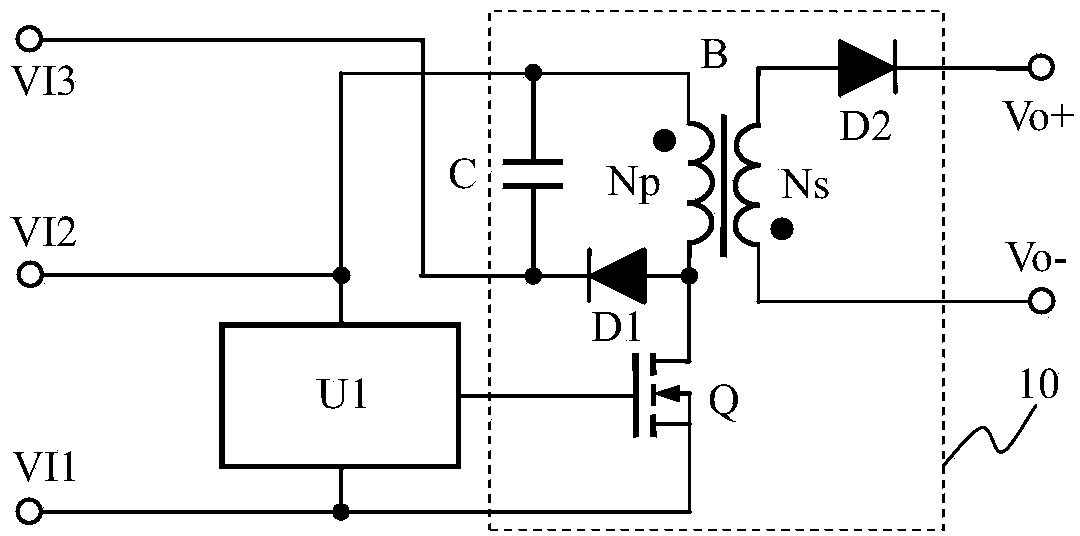

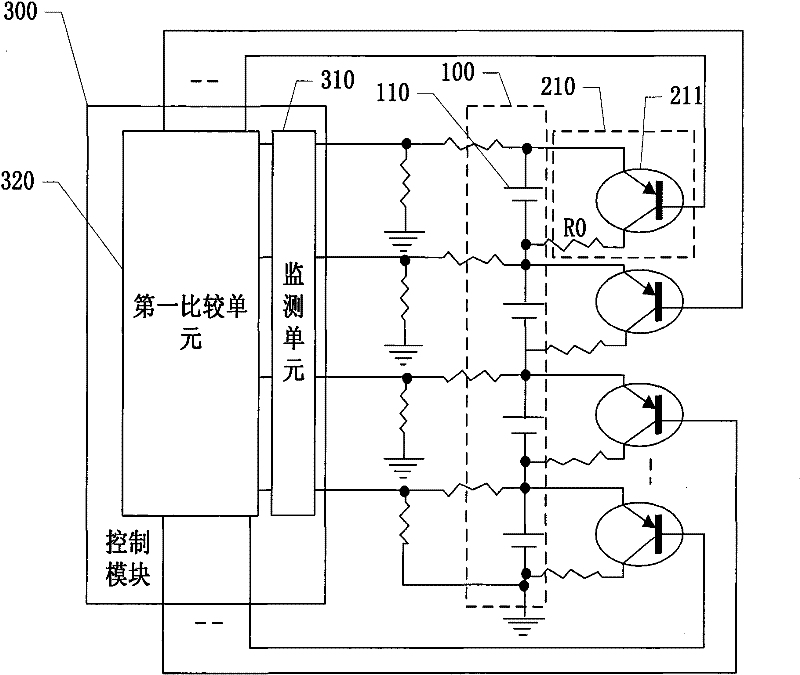

Equalizing charge circuit and battery pack

ActiveCN104201744AReduce power consumptionReduce heat consumptionBatteries circuit arrangementsElectric powerOxide semiconductorCapacitance

An equalizing charge circuit comprises a first input end, a second input end, a third input end, an output plus end, an output minus end, a detection circuit U1 and a flyback DC-DC converter 10. The junction of a drain of an N-MOS (N-channel metal oxide semiconductor) transistor Q and a primary winding NP of a transformer B is further connected with an anode of a diode D1, a cathode of the diode D1 is connected with the third input end, and a capacitor C is parallelly connected between the second input end and the third input end. The output plus end is connected on the anode of the batter pack, and the output minus end is connected on the cathode of the battery pack. When the detection circuit detects that voltage of a battery cell is larger than a set value, the converter 10 starts working, charge current to the battery cell is extracted and returned to charge the chatter pack, energy generated by leakage inductance of the flyback converter can be used for charging a previous battery cell, and accordingly equalizing charge of the battery pack is realized; when the detection circuit U1 composed of a single chip microcomputer is utilized, an infrared receiving head is added to synchronously adjust a set value, and equalizing discharge can be realized. The flyback circuit is high in reliability, simple in composition, low in cost, high in efficiency and easy to maintain.

Owner:MORNSUN GUANGZHOU SCI & TECH

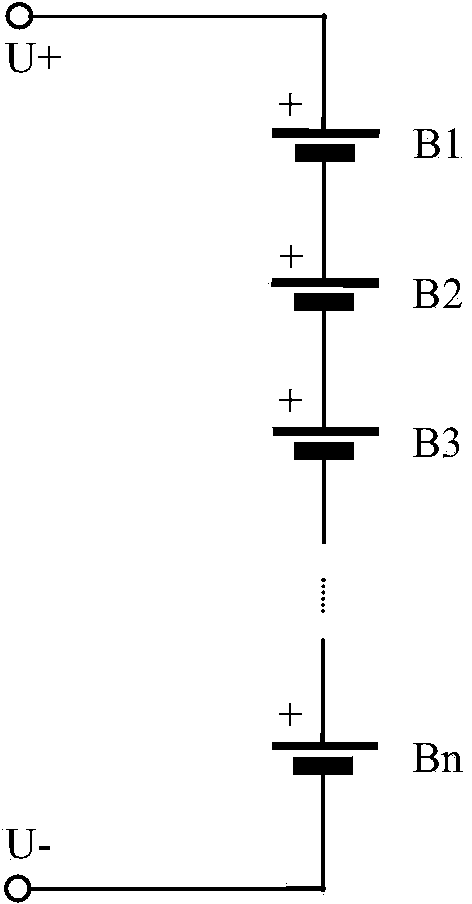

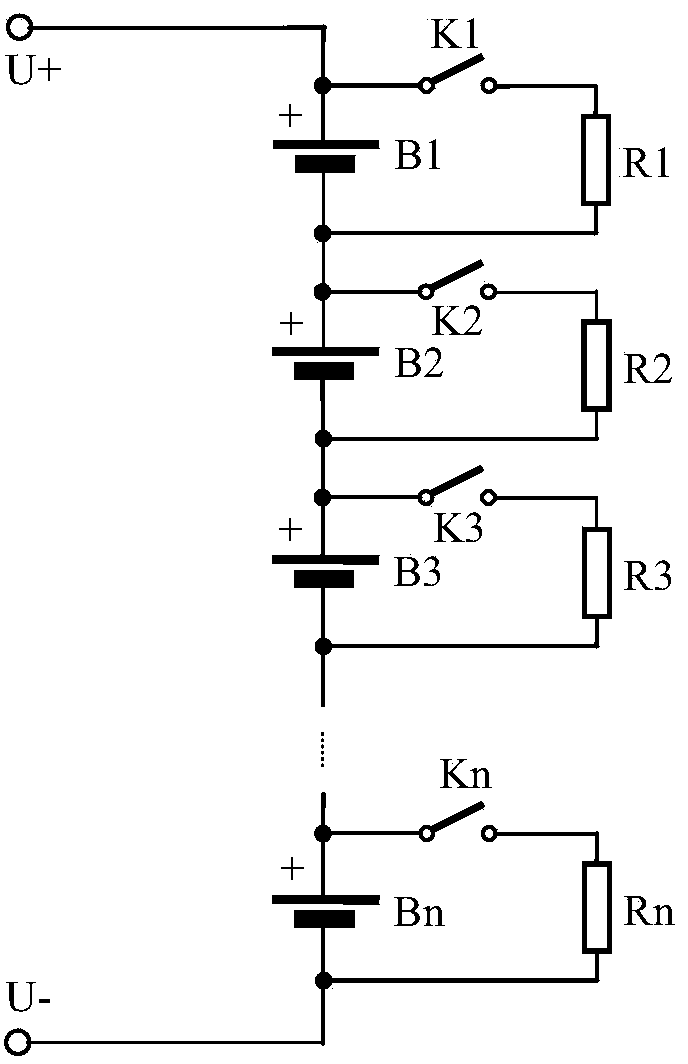

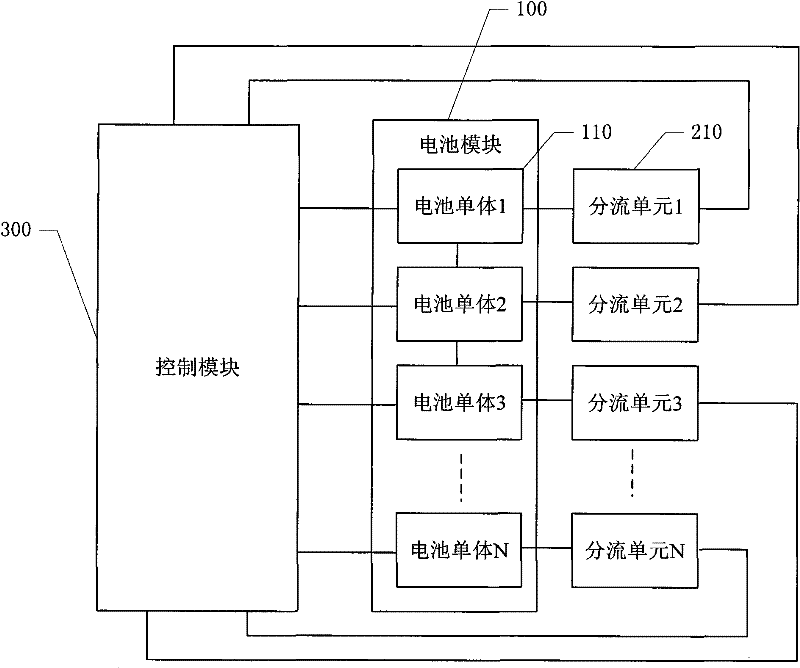

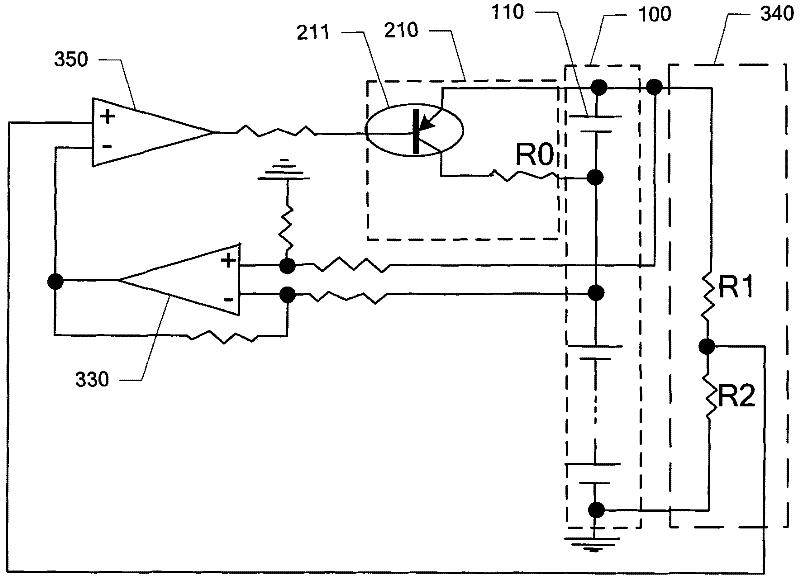

Equalizing charge method and equalizing charge device for battery

ActiveCN101752624AReduce inconsistencyEnsure safetySecondary cells charging/dischargingCharge currentEngineering

The invention relates to the technical field of charge, and discloses an equalizing charge method and an equalizing charge device for a battery. The device comprises a control module; the control module monitors the voltage signal of each single battery; and when the voltage signal of the monitored single battery exceeds a comparison voltage value, a shunt unit connected in parallel with the single battery is controlled to shunt so as to reduce the charge current of the single battery. Because the adopted shunt unit can automatically realize voltage balance between the single batteries, the equalizing charge method and the equalizing charge device for the battery can gradually reduce the inconsistency of a battery pack, ensure that all the single batteries in the battery pack reach consistency after several times of charge cycle, and effectively ensure the safety of each single lithium battery in use and prolong the service life; and the device has the advantages of simple control, low cost, higher efficiency and low heat consumption, can replace an expensive special equalizing chip, and can be widely applied in civilian industry products supplied with power by the lithium battery.

Owner:湖北润升电子实业有限公司

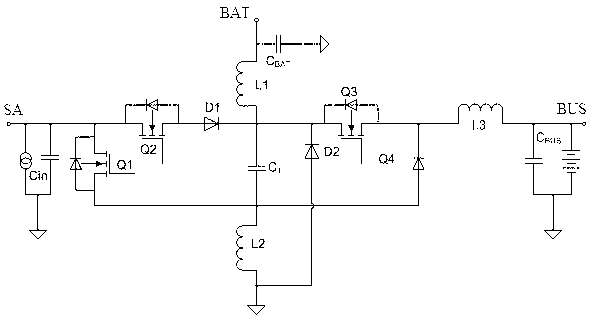

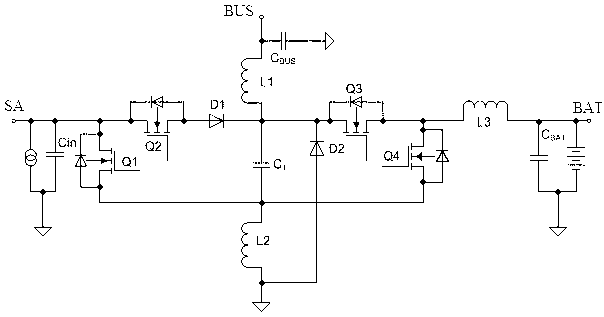

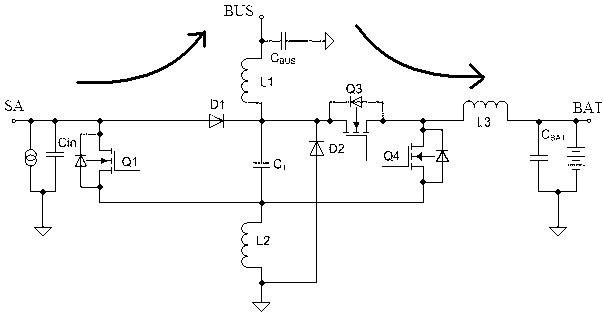

Three-port DC-DC (direct current) converter topology circuit

ActiveCN103199704AReduce heat consumptionImprove efficiencyDc-dc conversionPhotovoltaic energy generationDc dc converterComputer module

The invention provides a three-port DC-DC (direct current) converter topology circuit which comprises a control module, a solar array input end, a bus end and a storage battery end, wherein the input end of the control module is connected with the solar array input end, the bus end and the storage battery end respectively. The three-port DC-DC converter topology circuit also comprises a Buck-Boost circuit connected between the solar array input end and the bus end and a double-direction SuperBuck circuit connected between the bus end and the storage battery end, wherein the control end of the Buck-Boost circuit and the control end of the double-direction SuperBuck circuit are respectively connected with the output end of the control module. The three-port topology structure exchanges a bus port of a three-port topology and a port of a storage battery, primary energy transformation is only needed from a solar battery array to a bus, thus efficiency can be greatly improved, the heat consumption of the integral machine is reduced, heat dissipation measures are reduced, and cost is reduced.

Owner:SHENZHEN AEROSPACE NEW POWER TECH

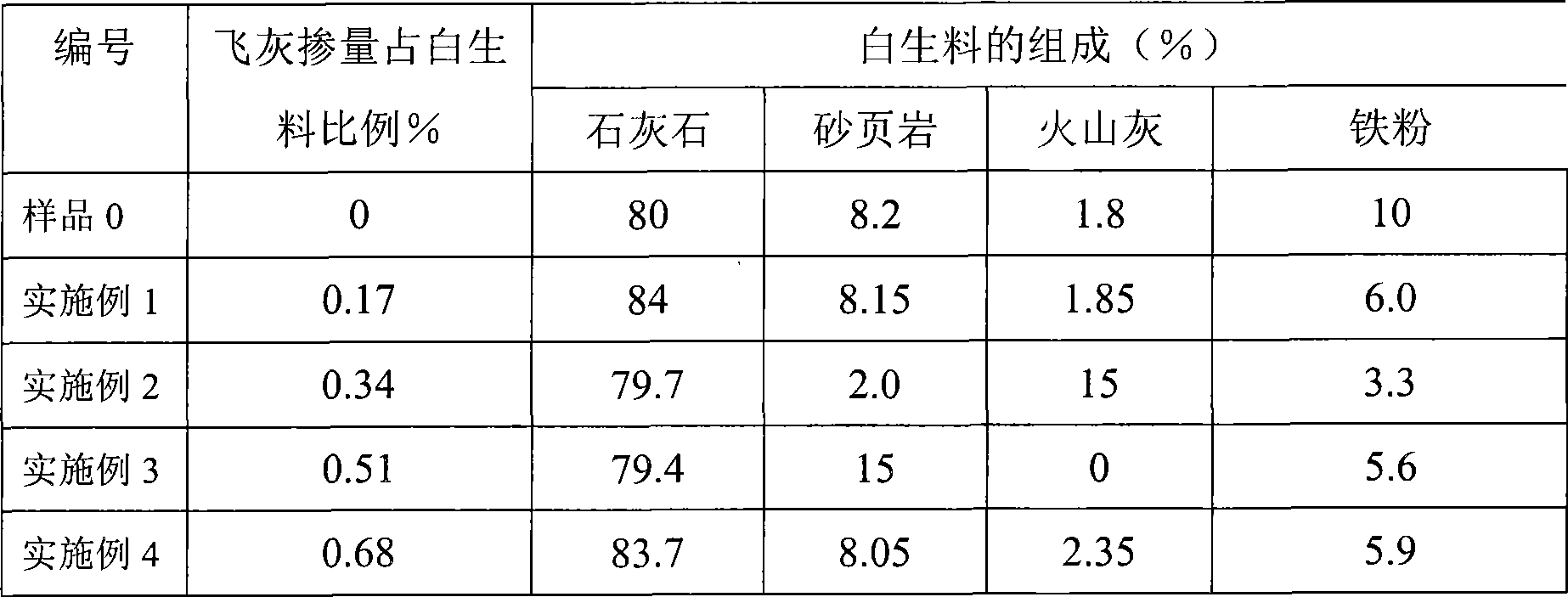

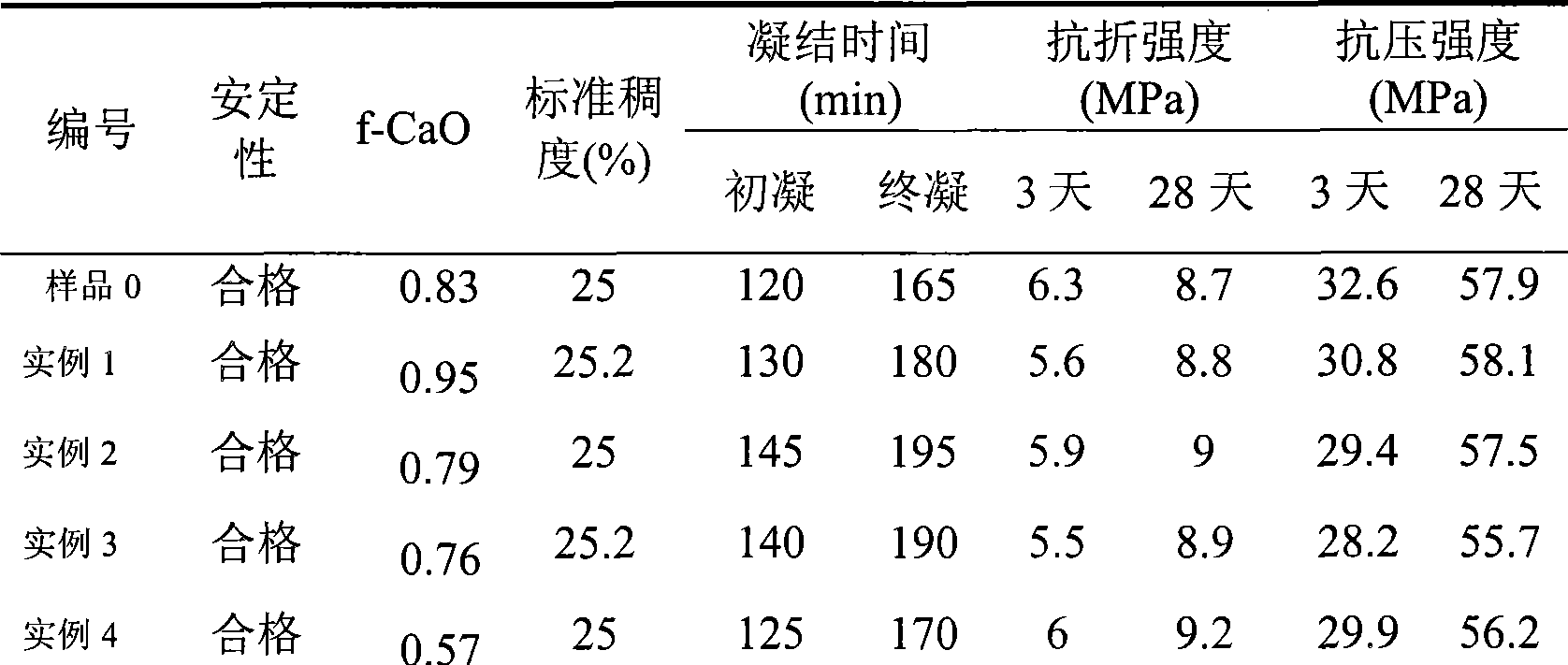

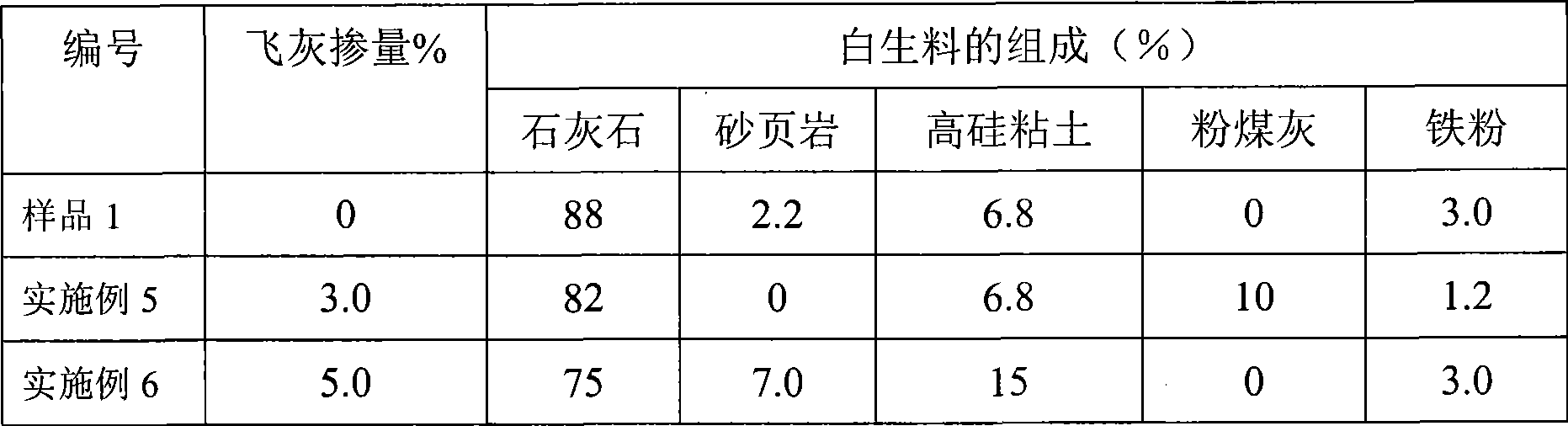

Method for producing portland cement clinker using domestic waste flying ash

The invention relates to a method for producing Portland cement clinker with incineration slag of municipal solid waste. The method solves the problem of crust and blockage caused by chlorine through the reconstruction of the prior kiln which is realized by mounting a by-way air exhaust device. For a kiln system with a kiln row and a furnace row which are independent from each other, the by-way air exhaust device is arranged in an uptake of a kiln end gas chamber in the kiln row close to a five-stage cylinder; while for common industrial kiln, the air exhaust device is arranged between an outlet of decomposing furnace and an inlet of the five-stage cylinder or arranged at an uptake of an outlet of the five-stage cylinder; the fly ash passes through a kiln head, the kiln end gas chamber, or the decomposing furnace and then is sprayed into the kiln. The use frequency of the by-way air exhaust device is between once per four hours and once per three days, the temperature of the air entering the by-way air exhaust device is controlled to be more than 950 DEG C. the method has the advantages of small reconstruction investment, low treatment cost, production of Portland cement clinker having wide application range and meeting JC / T853-1999 standards of Portland Cement Clinker, realization of reclamation, contribution to the development of cyclic economy, and reduction in consumption of natural resources and energy of the cement industry.

Owner:SOUTH CHINA UNIV OF TECH

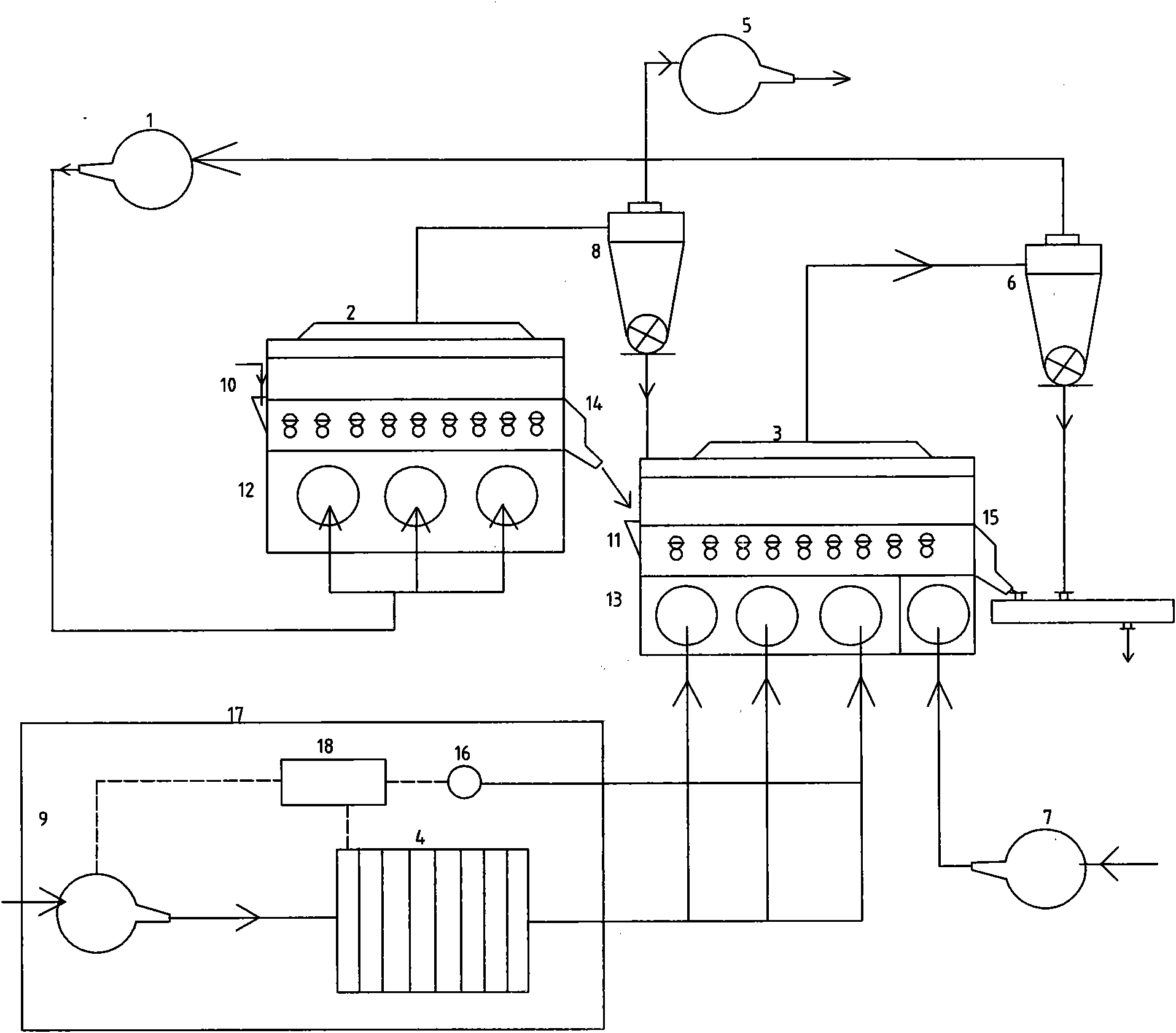

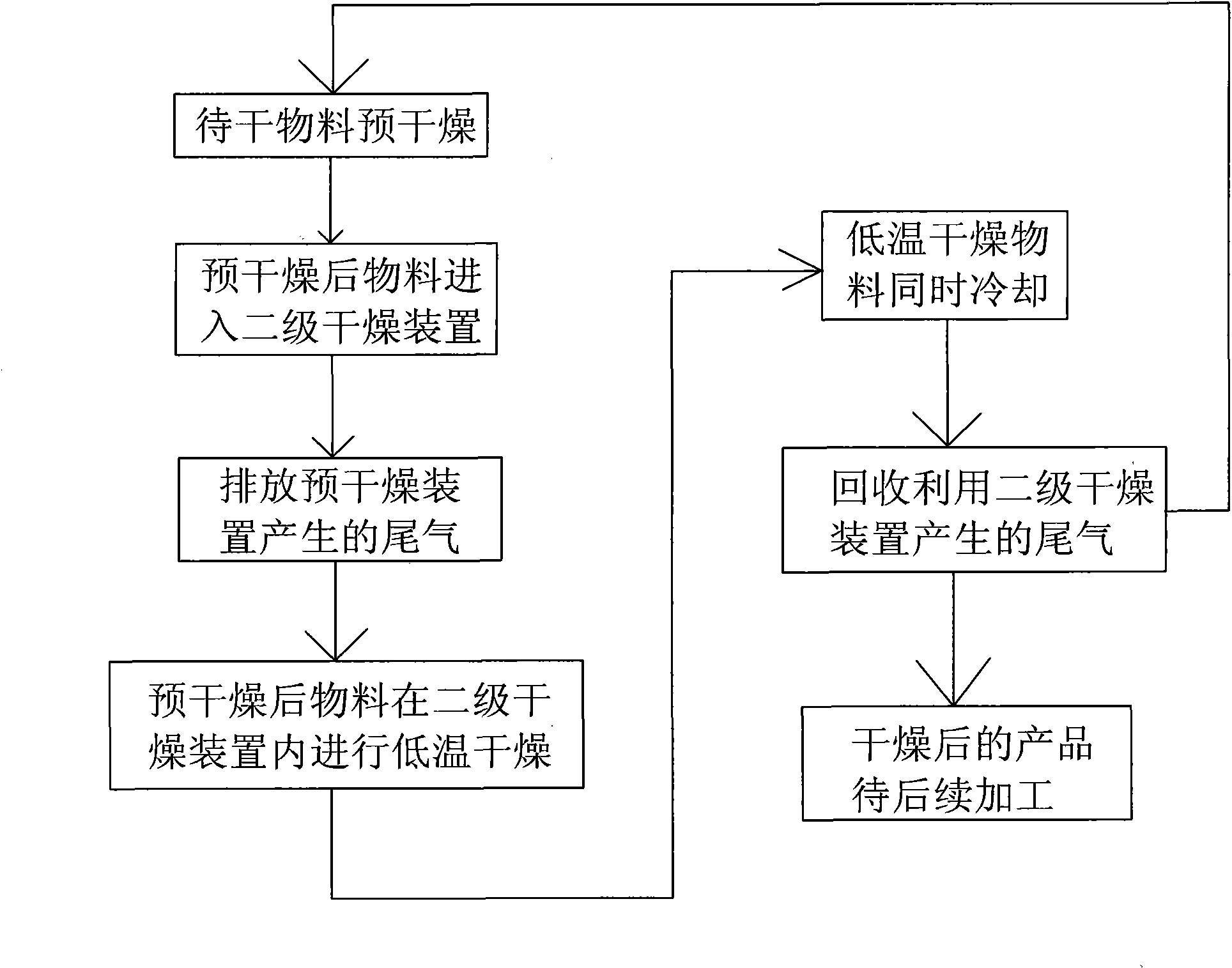

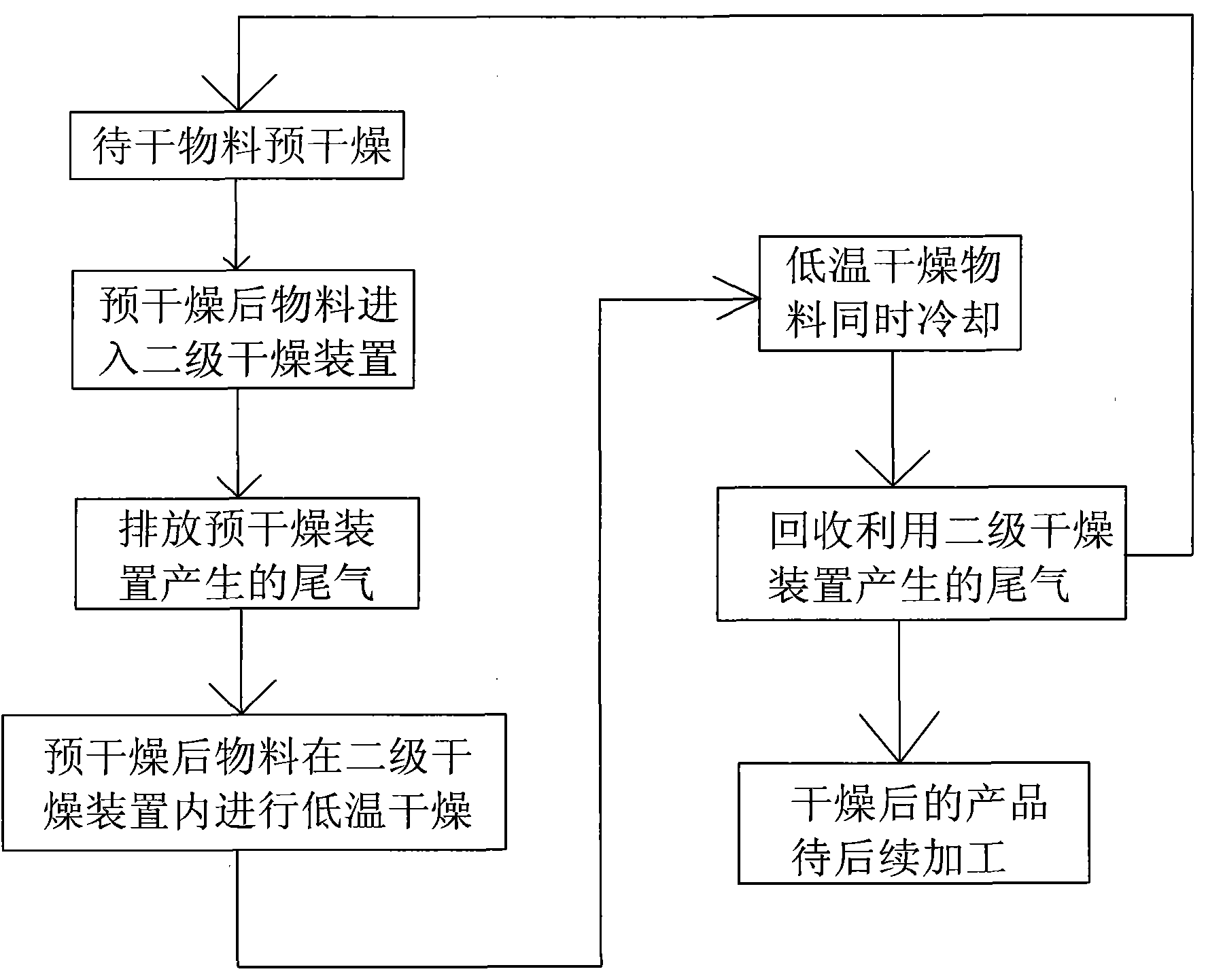

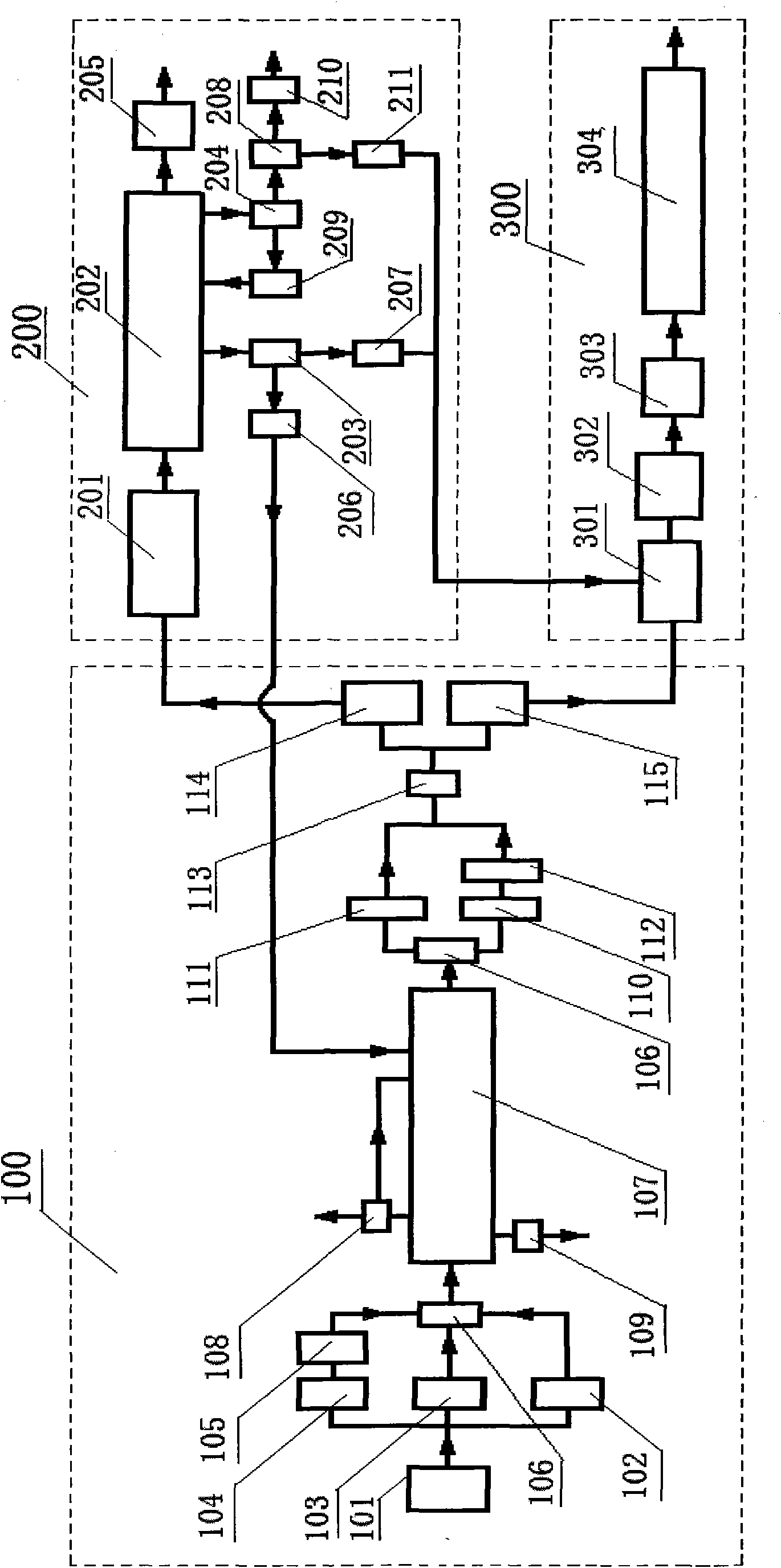

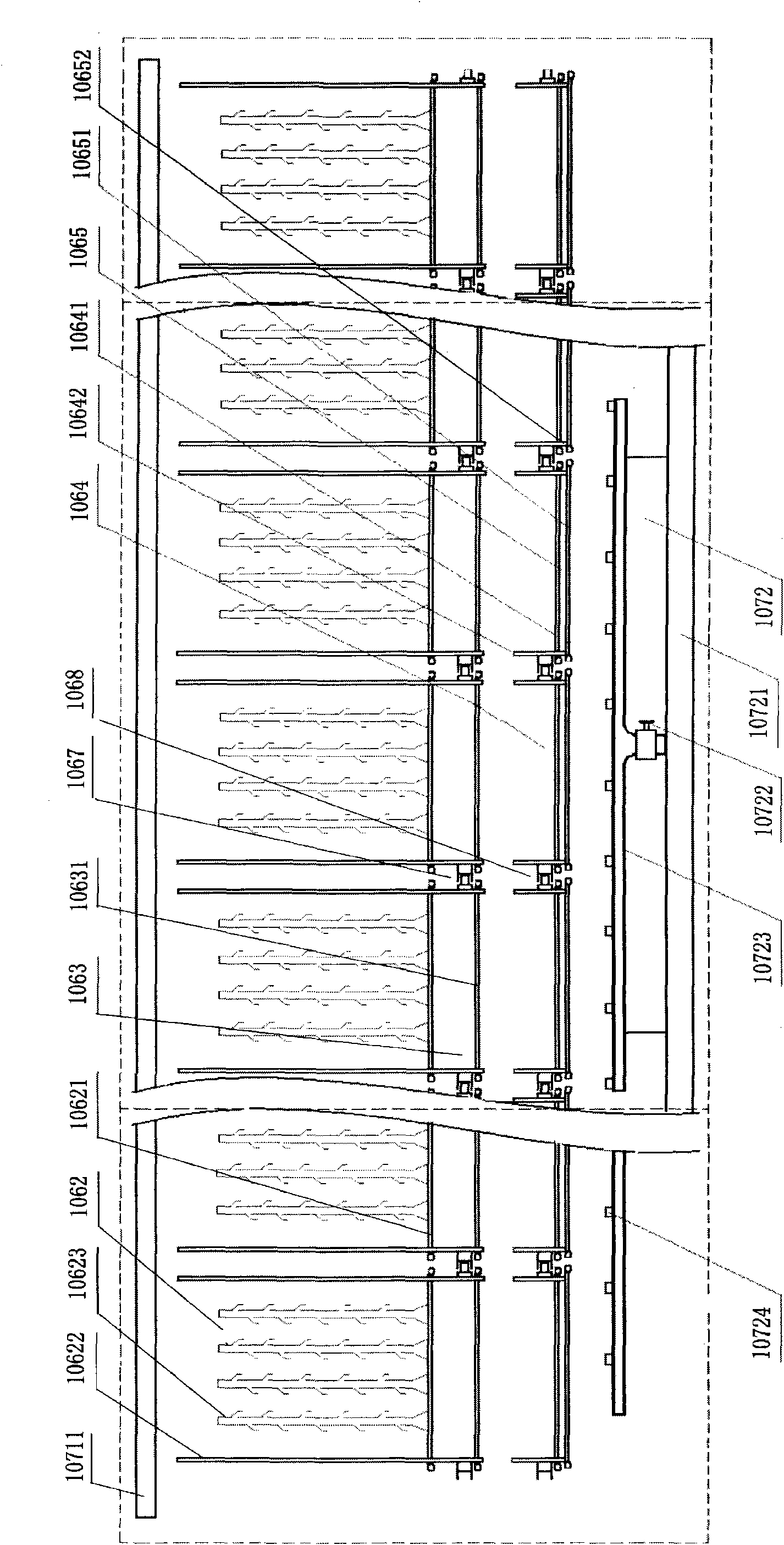

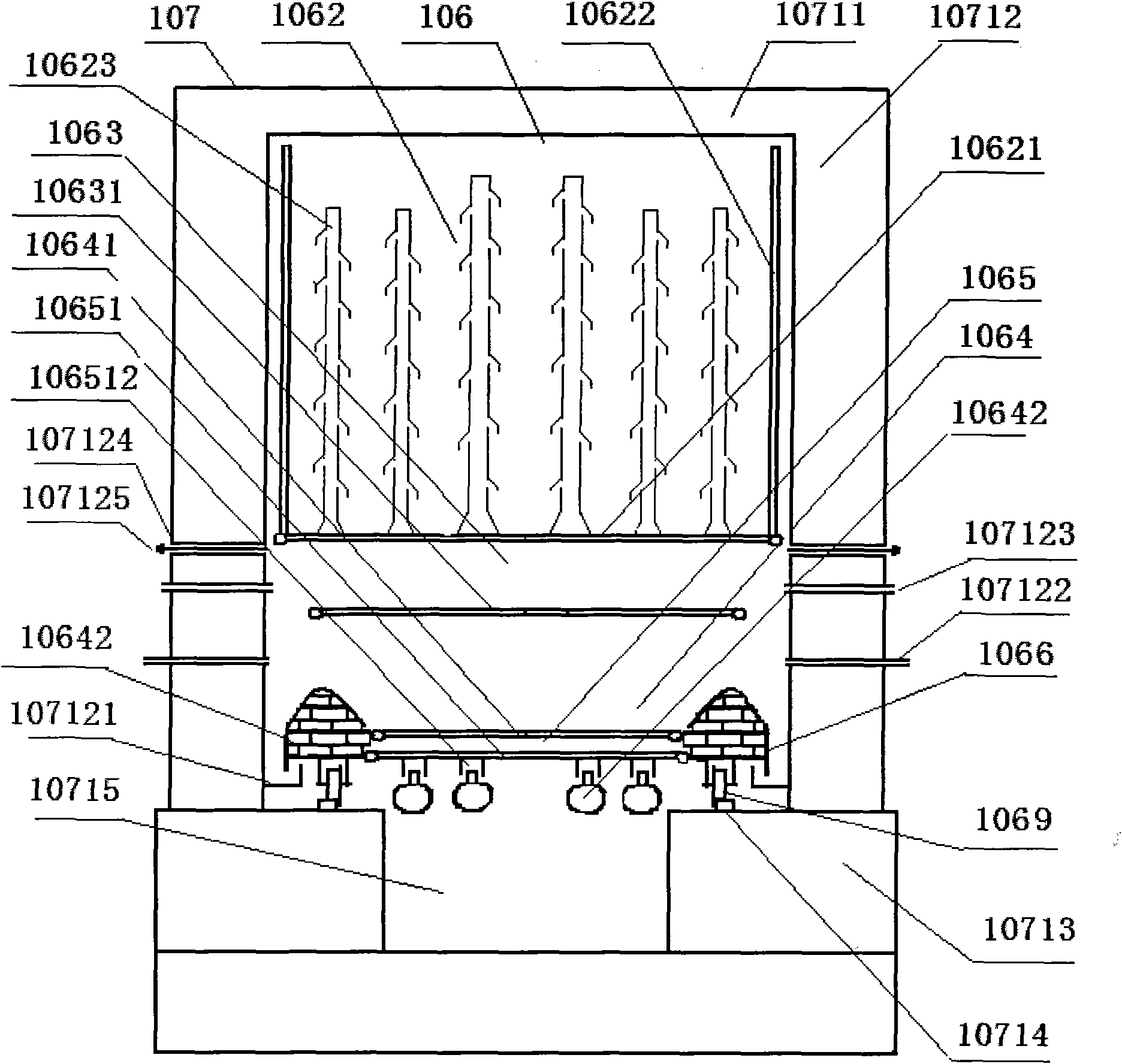

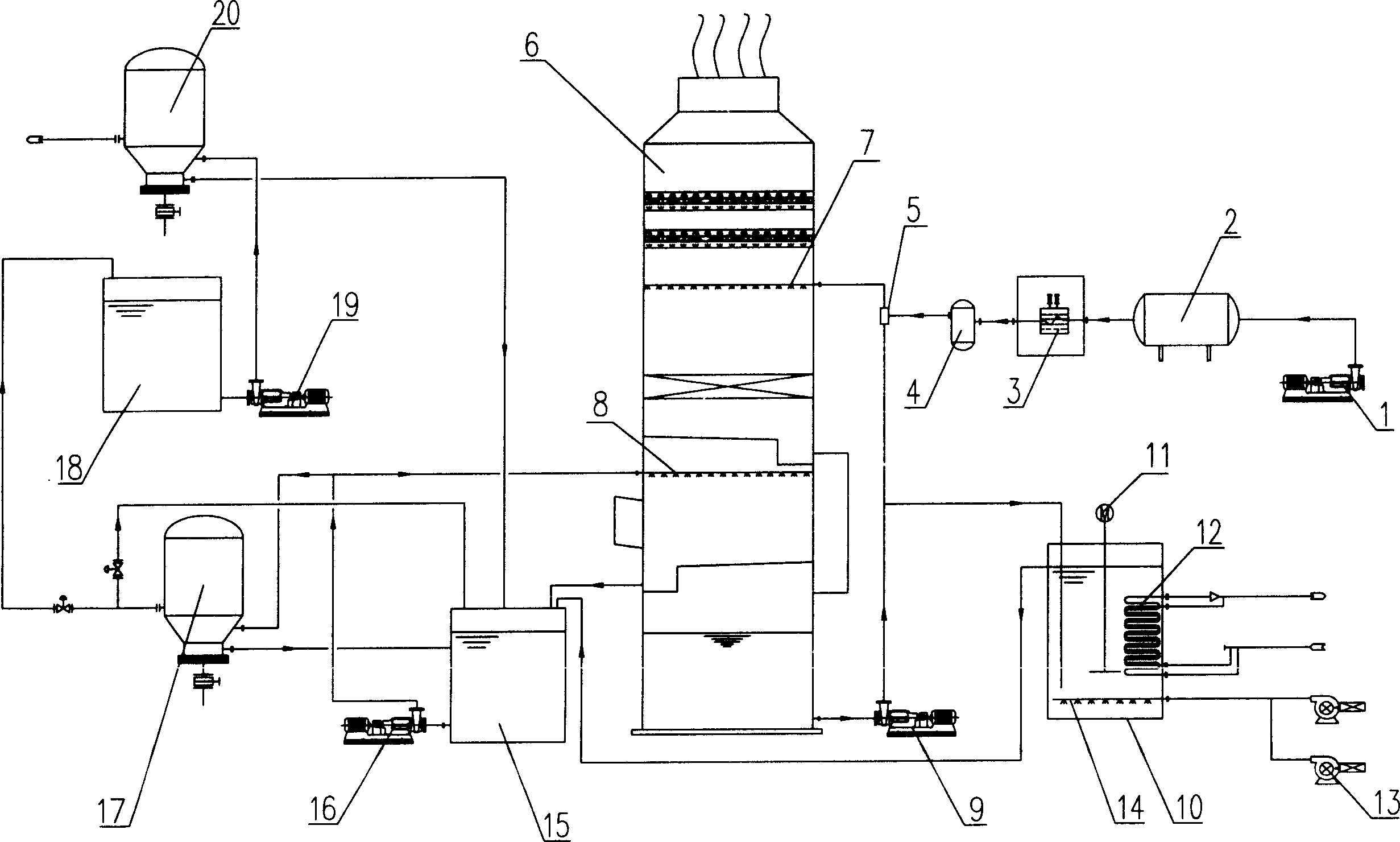

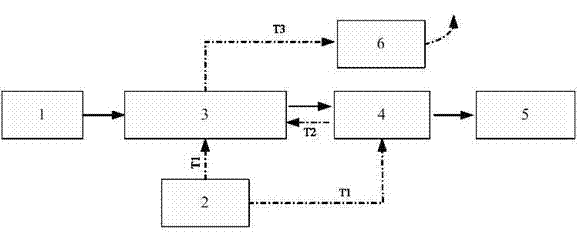

Low-temperature high-efficiency fluidization combined drying process and equipment thereof

InactiveCN101881550AQuality improvementReduce heat consumptionDrying solid materials with heatDrying machine combinationsProcess systemsProcess engineering

The invention discloses a low-temperature high-efficiency fluidization combined drying process and equipment thereof; the drying equipment comprises an afterheat utilization primary pre-heating device, a secondary drying device, cyclone separators, blowers and a temperature control device; the afterheat utilization primary pre-drying device or the secondary drying device comprises a feed opening, a discharge port, a vent and a drying chamber; the discharge port of the afterheat utilization primary pre-drying device is connected with the feed opening of the secondary drying device; the vent of the afterheat utilization primary pre-drying device is sequentially connected with a cyclone separator A, the secondary drying device, a cyclone separator B, a blower A and the drying chamber of the afterheat utilization primary pre-drying device; the vent of the cyclone separator A is connected with the blower B; and the drying chamber of the secondary drying device is respectively connected with a blower C and the temperature control device. The invention quickly and homogeneously dries material to be dried under the premise of meeting the original quality of raw grain, leavening and other products, has the advantages of energy-saving, environment production, low temperature and high efficiency, meets the requirements of continuous and scale production, and has good process system maintenance performance.

Owner:ACAD OF STATE GRAIN ADMINISTRATION

Large-scale brown coal quality-improving process and apparatus

InactiveCN102757833AImprove utilizationComprehensive utilization of product quality improvementSolid fuelsSpecial form destructive distillationBrown coalMicrowave

The invention belongs to the technical field of brown coal quality improving, and relates to a large-scale brown coal quality-improving process and a large-scale brown coal quality-improving apparatus. According to the invention, an interrelated large-scale continuous brown coal quality-improving system is composed of three modules which are a tunnel internal-heat drying module, an external-heating microwave destructive distillation module, and a powdery brown coal molding and drying module. Because of large-amount water discharging, a brown coal block large-capillary framework is collapsed, so that the brown coal is naturally broken into small blocks and powder without mechanical disruption. The small-block brown coal is subjected to destructive distillation under high-temperature hot wind external heating and microwave coupling, until the blocks turn into semi-coke; water-containing coal gas, water-containing coal tar, anhydrous gas, and anhydrous coal tar are respectively obtained by destructive distillation. With a binder of the water-containing coal tar and coal tar pitch (one or a mixture thereof), the powdery brown coal is subjected to kneading and aging; the material is processed into granules by using a vacuum extrusion granulator; and the particles are processed by using a low-temperature microwave drying device, so that high-quality brown coal particles with high strength, low moisture absorption, and high heat value are obtained. The brown coal particles can endure long-distance transportation.

Owner:周灿旭

Solvent for eliminating H2S from gas mixture

InactiveCN1887406APromote absorptionImprove the desorption effectDispersed particle separationSulfolaneOrganic sulfide compound

The present invention is method of adding one kind of secondary amine and one kind of organic amine with steric effect into water or sulfolane solution of N-methyl diethanolamine to obtain the activator for removing H2S from gas mixture with or without CO2. The present invention provides two solution recipes. The recipe I for the solution suitable for removing H2S from gas mixture containing no or less organic sulfide consists of N-methyl diethanolamine 30-50 wt%, secondary amine 1-10 wt%, steric amine 1-15 wt% and water for the rest. The recipe II for the solution suitable for removing H2S from gas mixture containing organic sulfide consists of N-methyl diethanolamine 30-40 wt%, secondary amine 1-5 wt%, steric amine 1-15 wt%, water 5 wt% and sulfolane for the rest.

Owner:HUAXI CHEM INST CHENGDU CITY

Sintering flue gas ammonia method desulfurizing system

ActiveCN101053760AReasonable processEmission complianceDispersed particle separationFurnace typesHigh concentrationCarbonization

The invention relates to an ammonia desulfurization system for sintering flue gas, and the system comprises a gasifying equipment, a absorbing equipment, an oxidation equipment, a concentration equipment and filter equipment etc. The ammonia desulfurization system for sintering flue gas of the invention can removes the SO2 in the flue gas effectively, but also can desulfurizate by reacting with SO2 in the flue gas using carbonization waste water (liquid ammonia gasified). The product of ammonium sulfite is oxidated in a low concentration at the common pressure, and then is concentrated by evaporation by the quantity of heat of the flue gas to greatly save the heat dissipation of concentration by evaporation to arrive at the aim of economize on energy. The ammonia sulfate solution in high concentration is filtrated, and then is send to the ammiaonia sulfate plant to produce chemical fertilizer. The flue gas desulfurization system of the invention has a reasonable process, makes the discharge of the flue gas reach the standard, forms without secondary pollution, treatment the waste gas by waste carbonization waste water, and produces the byproduct-chemical fertilizer.

Owner:CHINA CITY ENVIRONMENT PROTECTION ENGINEERING LIMITED COMPANY

Roasting pretreatment process for extracting vanadium pentoxide from high-carbon scherbinaite-containing coal mine and vanadium pentoxide extracting method

ActiveCN102399976AWide range of applicationsLess investmentProcess efficiency improvementCoalTunnel kiln

The invention discloses a roasting pretreatment process for extracting vanadium pentoxide from a high-carbon scherbinaite-containing coal mine and a vanadium pentoxide extracting method, which comprise the following steps that: the stone coal scherbinaite is used as raw materials, the raw materials are crushed and pressed into blocks and are dried, then, the materials are continuously put into a tunnel kiln capable of regulating the air volume and the pushing speed to be roasted, the temperature is controlled between 400 DEG C and 1000 DEG C in the roasting process, the roasting time lasts 7hto 40h, and the pretreatment process is completed after the roasting. The roasting products are crushed, and then, vanadium pentoxide products are obtained sequentially through leaching, neutralization, oxidization, impurity removal, enrichment, ammonium salt vanadium deposition and calcination. The process has the advantages that the application range is wide, the energy consumption is low, the heat value utilization is sufficient, the equipment investment is low, the environment pollution is little, and the like. The method is suitable for being applied to the vanadium pentoxide extraction from the high-carbon scherbinaite-containing coal mine.

Owner:肃北蒙古族自治县西矿钒科技有限公司

Process for preparing building gypsum powder from phosphogypsum

The invention discloses a process for preparing building gypsum powder from phosphogypsum. The process comprises the technical links of: phosphogypsum drying, fine grinding and powder sorting; suspended dehydration; proper aging and the like. According to the process system disclosed by the invention, the phosphogypsum fine grinding, drying and dehydration process is divided into two relatively independent links, the negative-pressure operation is adopted, and a hot blast stove, a feeding device, a phosphogypsum fine grinding, drying and powder sorting device, a suspended dehydrator, an aging bunker, a dust collecting device, an induced draft fan and the like are provided in the process. The process is stable in production process, capable of saving energy and realizing large-scale production and high in product quality.

Owner:WENGFU (GRP) CO LTD +1

Novel process for leather retanning

ActiveCN101117648ANo adverse effect on hand feelingFeel effectTanning treatmentEngineeringElectric consumption

Owner:鹤山腾泰皮革有限公司

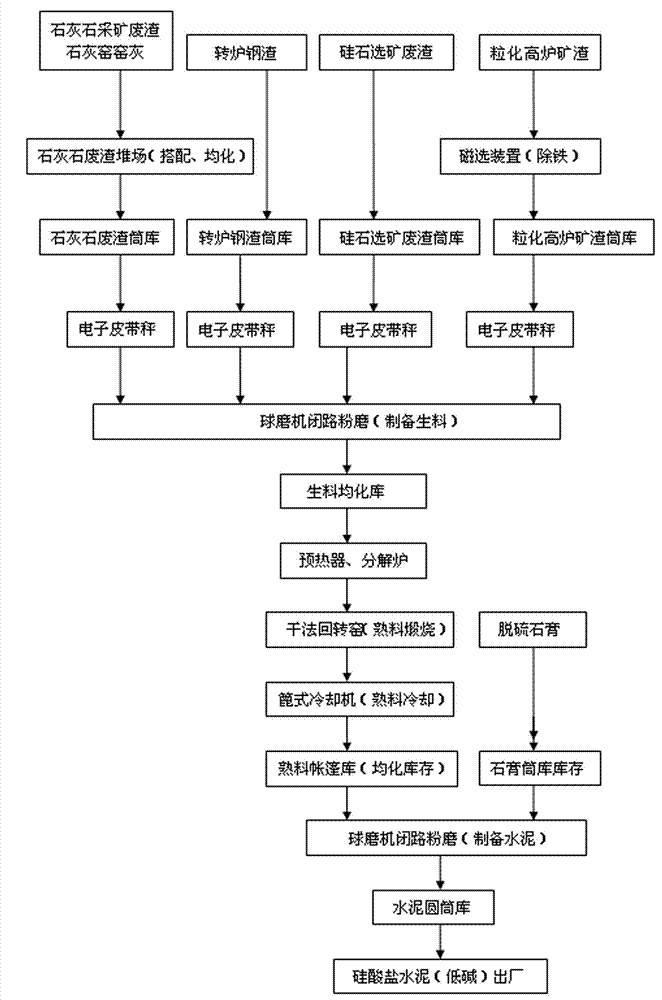

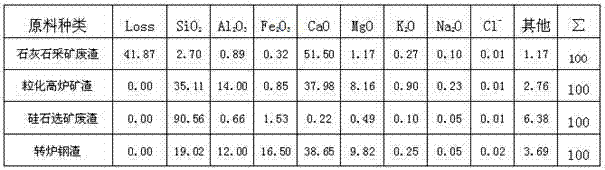

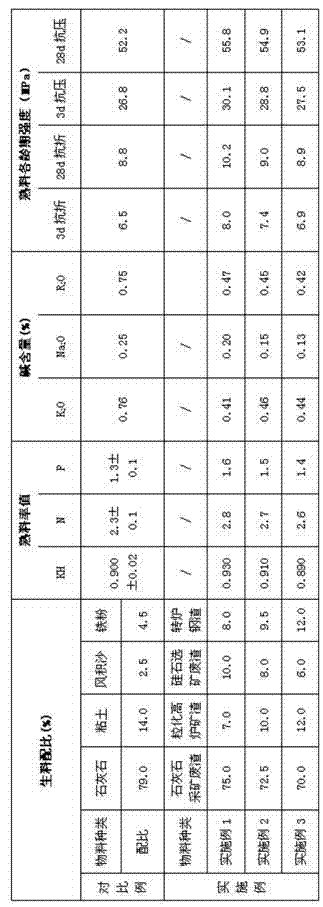

Method for producing low-alkali Portland cement by using industrial solid waste

The invention discloses a method for producing low-alkali Portland cement by using industrial solid waste and aims to overcome the problem that alkali content in cement produced by using traditional methods is high. The method comprises the following steps: A, preparation of the raw materials of 70 to 75% of mining debris of limestone, 7.0 to 12.0% of granulated blast-furnace slag, 6.0 to 10.0% of rejects of silica and 8.0 to 12.0% of converter steel slag; B, clinker calcination; and C, cement grinding. The method provided in the invention has the following characteristics: rejects of silica are used as a silico-regulating material, and not only the characteristic of low alkali content of the rejects of silica is made use of, but also the silica modulus N of the clinker can be adjusted by adjusting the proportion of the rejects of silica so as to inhibit the probability of skinning of a preheater and ring formation in a rotary kiln caused by excessively good burnability of materials. Lime kiln ash, the granulated blast-furnace slag and the converter steel slag are subjected to high temperature calcination, so alkali in the above-mentioned materials greatly volatilizes; therefore, alkali content in the raw materials is decreased, thereby meeting compounding requirements and creating conditions for production of low alkali cement.

Owner:嘉峪关祁连山水泥有限公司

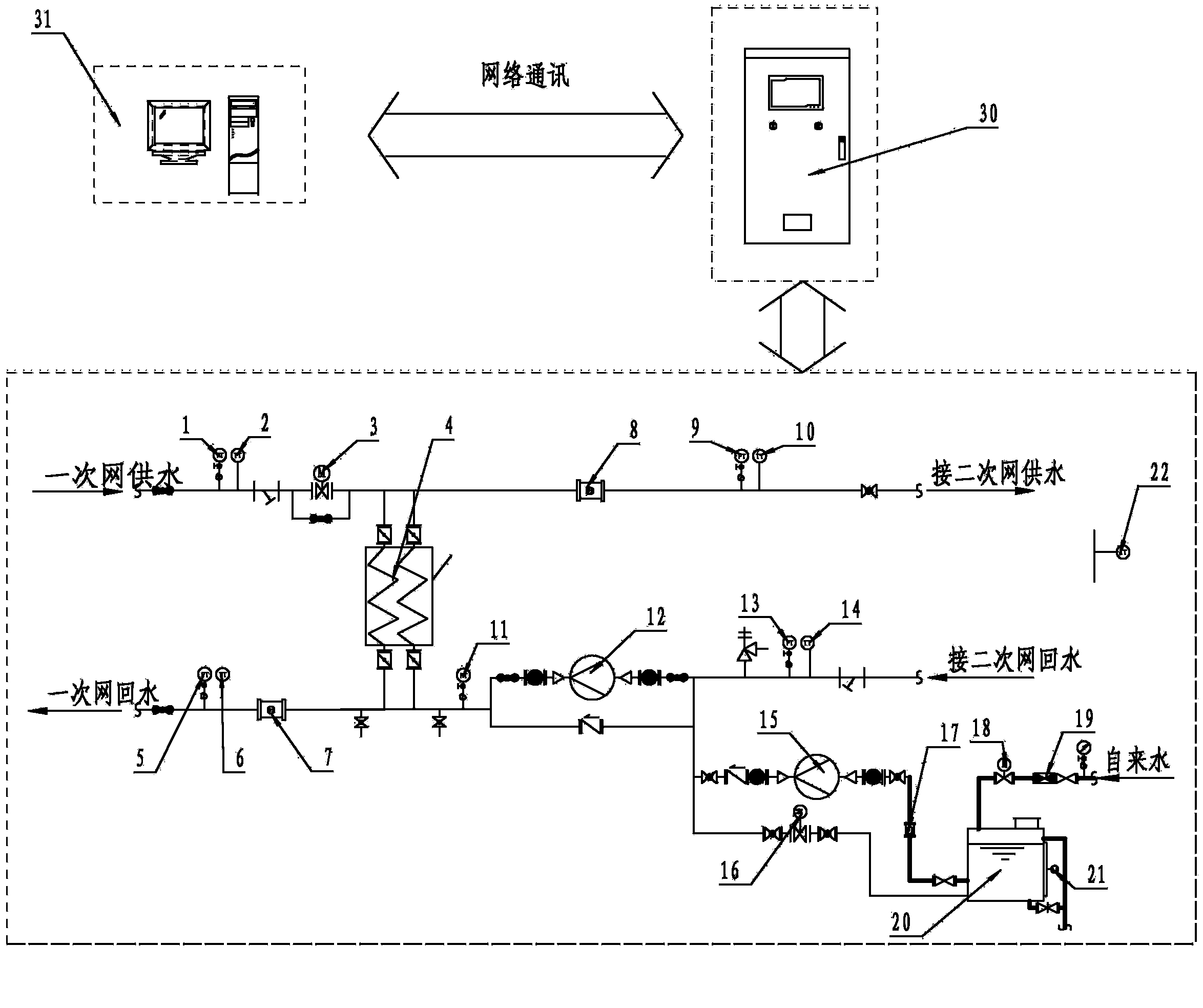

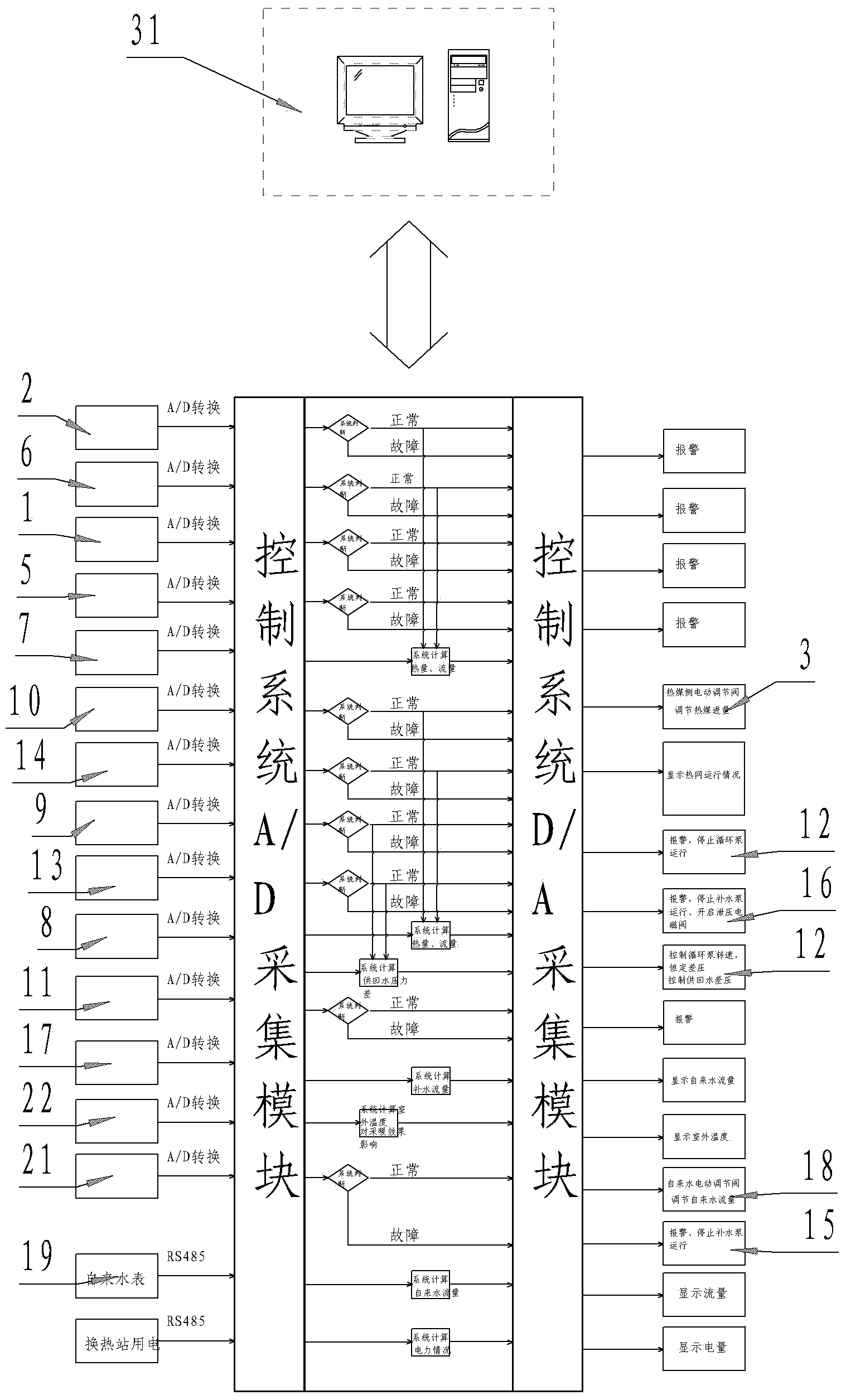

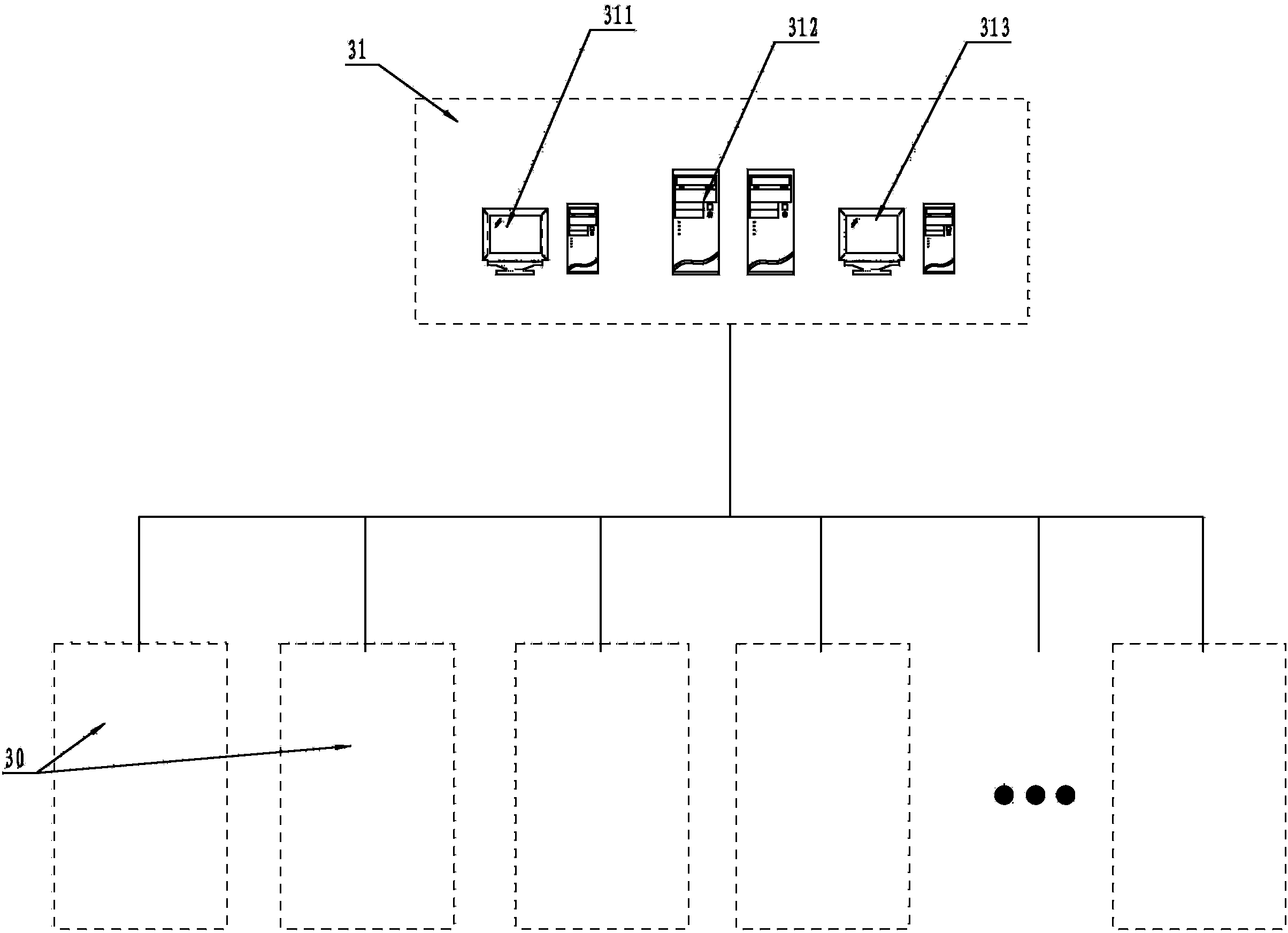

Heat exchanging station intelligent network control system

ActiveCN103759330AImprove efficiencyImprove securityLighting and heating apparatusSpace heating and ventilation detailsBasic premiseEngineering

The invention discloses a heat exchanging station intelligent network control system and belongs to heating heat exchanging equipment, especially program control systems of a heat exchanging station. The heat exchanging station intelligent network control system comprises heat exchanging station local control systems, communication lines and a remote monitoring system. Each heat exchanging station control system mainly comprises a pressure sensor, a temperature sensor, a flow sensor, a liquid level sensor, an outdoor temperature sensor and an intelligent controller. The remote monitoring system comprises a server, an engineer station, an operator station and displaying, printing and inputting equipment. The remote monitoring system is connected with the multiple heat exchanging station local control systems through the communication lines. The heat exchanging station intelligent network control system detects various parameters of heat exchanging stations, the parameters are compared with standard data models, computing is carried out, under the basic premise that the using requirement is guaranteed, each heat exchanging station is adjusted and controlled, energy loss is lowered, and heat exchanging system operation efficiency is improved.

Owner:山东鲁润热能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com