Patents

Literature

111results about How to "Low loss on ignition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oxide solid solution, preparation method of oxide solid solution, lithium ion battery anode material and preparation method of lithium ion battery anode material

ActiveCN102627332AThe composition is determined and reliableImprove stabilityCell electrodesManganese oxides/hydroxidesOXALIC ACID DIHYDRATENickel salt

The invention relates to oxide solid solution, a preparation method of the oxide solid solution, a lithium ion battery anode material and a preparation method of the lithium ion battery anode material. The oxide anode material is prepared by using the oxide solid solution as precursors. The preparation method of the oxide anode material comprises the steps of adding mixed water solution of nickel salt, cobalt salt and manganese salt into oxalic acid or oxalate water solution to produce nickel, cobalt and manganese oxalate co-precipitated products, separating solid from liquid, washing, drying, calcining in an atmosphere of air and decomposing to obtain the oxide solid solution; and mixing and grinding the solid solution and lithium salt, drying and roasting at high temperature to obtain the oxide anode material. The solid solution is an ideal raw material for preparing the oxide anode material, the process stability and the product consistency are improved and the material performance is improved; and the oxide anode material is a high-voltage and high-capacity anode material. The preparation methods are suitable for the large-scale, economic, stable and reliable production of the solid solution and the oxide anode material.

Owner:HUBEI WANRUN NEW ENERGY TECH DEV

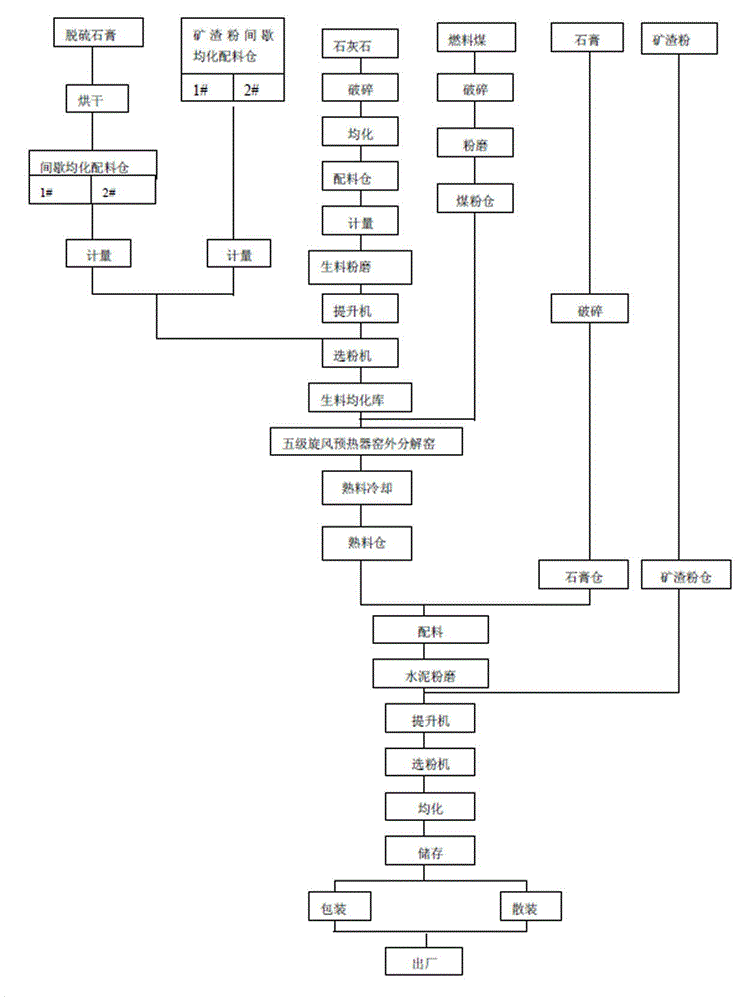

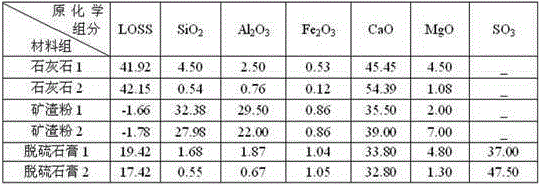

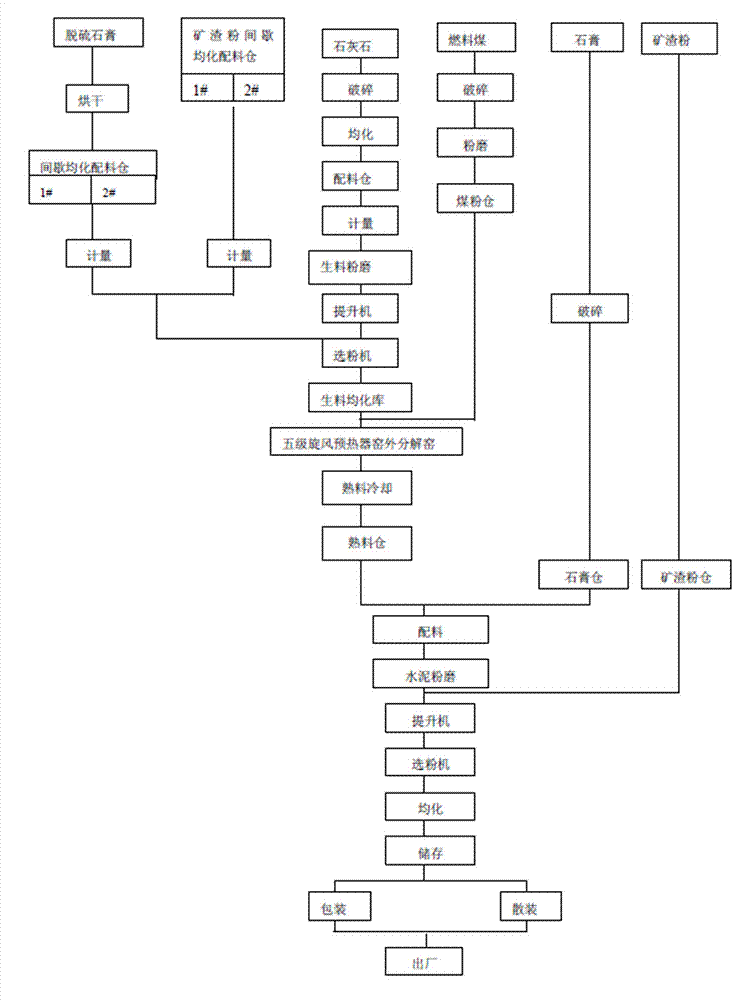

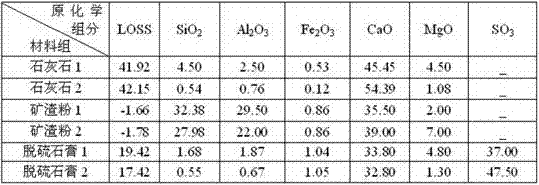

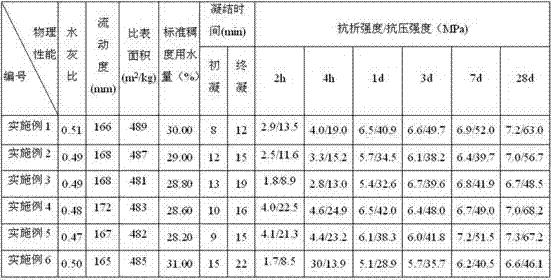

White fast-setting, fast-hardening and high-belite sulphoaluminate cement clinker, and application and production technology thereof

The invention relates to a white fast-setting, fast-hardening and high-belite sulphoaluminate cement clinker, and also relates to an application and a production technology thereof. The mineral component of the cement clinker comprises 0.5-4.6% of f-CaO; the chemical component of the cement clinker comprises 12.9-16.1wt% of SiO2, 12-19wt% of Al2O3, 0.15-1.0wt% of Fe2O3, 49-53wt% of CaO and 12-18.5wt% of SO3; and the clinker rate range Cm is 1.01-1.137, and P is 0.62-1.44. The clinker is produced through calcining 30-50wt% of limestone, 26-46wt% of slag powder and 21.1-40wt% of desulfurized gypsum in a rotary kiln at 1250-1350DEG C. 26-97% Of the clinker, 3-19% of anhydrite and 0-55% of the slag powder, or 5-25% of the clinker, 14.4-19.0% of the anhydrite and 55.8-79% of the slag powder are mixed and ground to form white fast-setting, fast-hardening and high-belite sulphoaluminate cement and high-late strength and high-belite sulphoaluminate cement.

Owner:TANGSHAN POLAR BEAR BUILDING MATERIAL +1

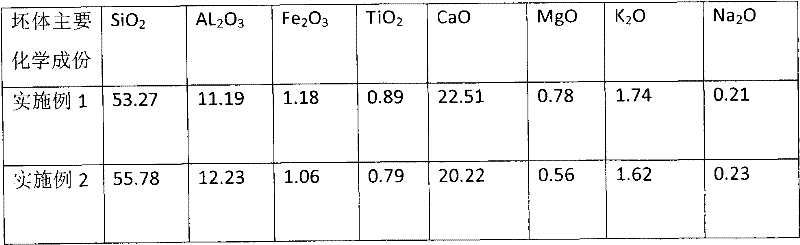

Full polish ceramic product and preparation method thereof

The invention relates to a full polish ceramic product and a preparation method thereof. The full polish ceramic product comprises a ceramic green body and a full polish layer outside the ceramic green body, wherein the full polish layer mainly comprises powder which comprises following components by weight percent: 42-62% of albite, 2-7% of potash feldspar, 0-4% of dolomite, 4-8% of calcite, 0-2% of barium carbonate, 6-8% of aluminum oxide, 3-5% of fired talc, 2-4.6% of zinc oxide, 3-9% of quartz powder, 0.5-2.5% of soochow kaolin, 1-6% of calcined kaolin, 5-10% of aedelforsite, 0.1-3.0% of spodumene, and 0.1-2.8% of borocalcite. The full polish slurry is prepared by burdening and ball milling once. As the full polish slurry contains less wearproof materials like aluminum oxide, the ball milling time is short, and the production efficiency is higher; due to the addition of little amount of spodumene and borocalcite, the abrasion performance and hardness of the fired full polish ceramic product can be improved.

Owner:JIANGSU BAIFU TECH CO LTD +1

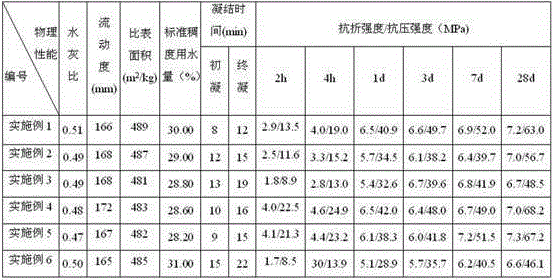

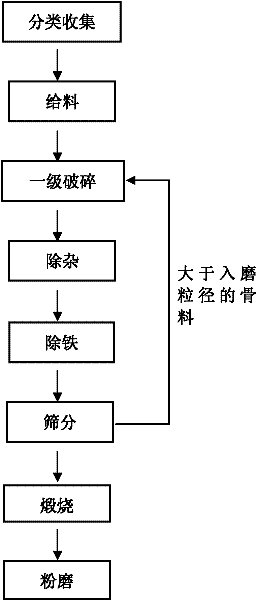

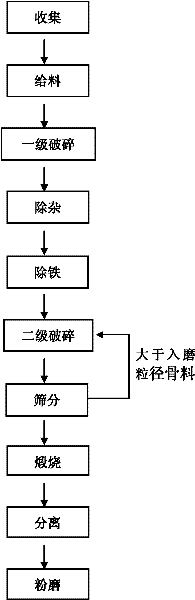

Method for recycling waste clay

InactiveCN102218435AGive full play to the role of materialImprove grindabilityConstruction waste recoverySolid waste disposalLitterIron removal

The invention provides a method for recycling waste clay, which comprises the following steps of: removing impurities from construction waste materials through treatment processes such as crushing, impurity removal, iron removal, sieving and the like, and preparing the materials into a recycled aggregate meeting the requirement of grinding equipment on particle size; burning up combustibles in the recycled aggregate through a calcining process to reduce ignition loss and water content; separating a concrete component from a clay brick component in the recycled aggregate; and grinding the clay brick component to obtain regenerated powder. By the method, waste clay brick resources can be fully utilized by a simple process; moreover, the regenerated clay powder obtained in the production has good performance, wide application range and high added value.

Owner:上海德滨环保科技有限公司

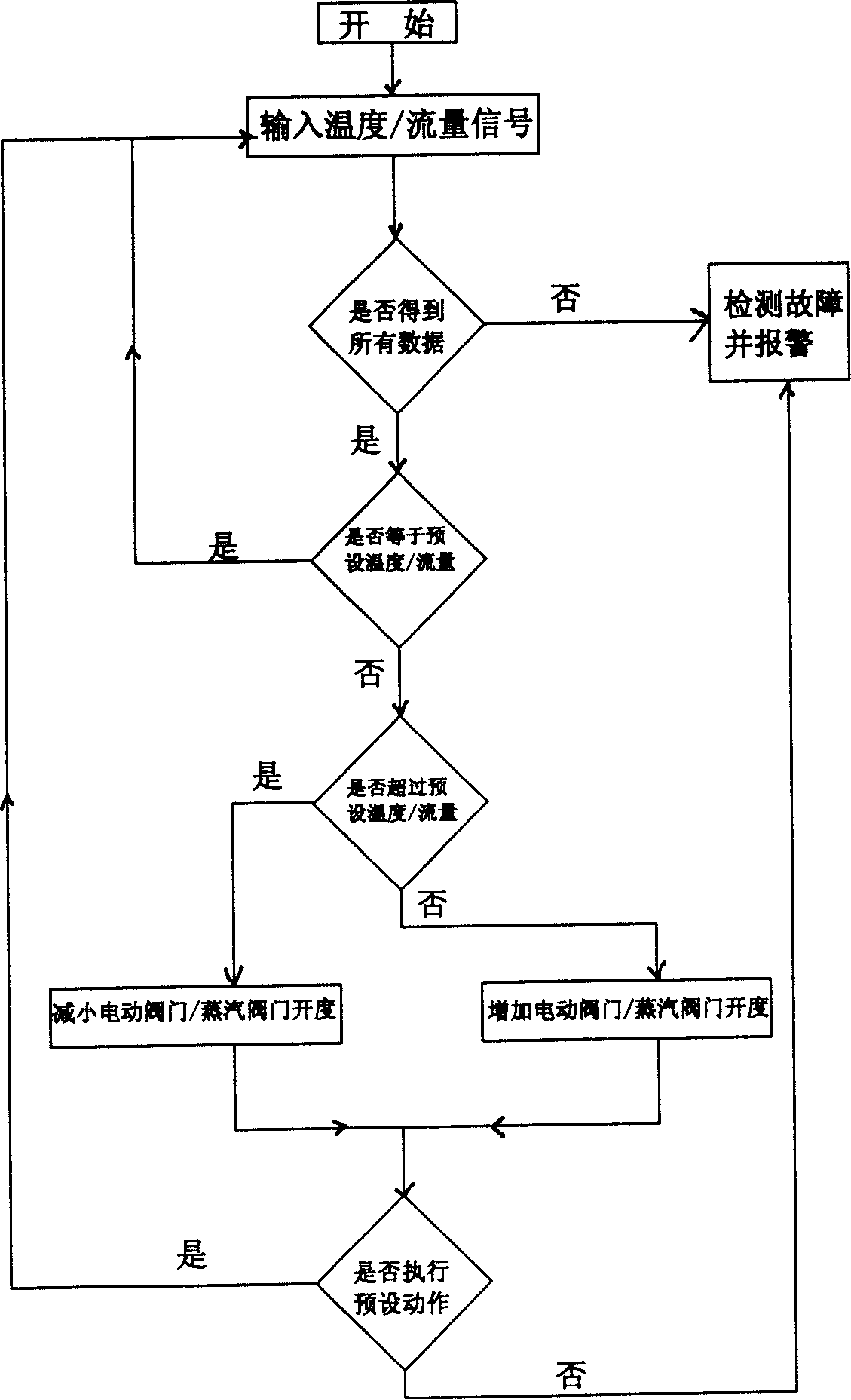

Automatic control system for active carbon processing preparaing procedure

The invention relates to an automatically control system of activated carbon preparing course, and its characteristic: according to the technical parameter signals collected by detecting components and a fixed program, the computer in the control system drives the air quantity regulating valve of carbonization furnace air supply system, the electric regulating value of activation furnace, the electric steam value of activation furnace, the discharging valve of activation furnace and the air and fume gate to implement the automatic control of the temperature of carbonization furnace, the temperature of activation furnace, the steam flow of activation furnace, the activating time, and the mutual conversion between heating and cooling of two half-furnaces. It avoids the liberty of artificial control, replaces artificial and experiential control method with scientific and programmed control method, and effectively controls the conditions of carbonization and activation in producing course, reduces loss rate by burning, etc.

Owner:ACTIVE CARBON FACTORY TAIXI GROUP

Method for manufacturing glazed brick by utilizing silico-calcium slag

InactiveCN102173740AEmission reductionReduce production energy consumptionClaywaresCalcium silicateBrick

The invention relates to a method for manufacturing a glazed brick by utilizing silico-calcium slag, belonging to the technical field of ceramic manufacture. The glazed brick comprises the following raw materials in percentage by weight: 5%-40% of the silico-calcium slag, 0%-10% of Dongsheng clays and 50%-95% of bamboo partridge tower clays. Due to the adoption of the invention, the shortage crisis of raw mineral materials is weakened and the discharge of the silico-calcium slag is reduced, and an energy-saving type ceramic product is produced; the production energy consumption of ceramics can be reduced and the utilization efficiency of resources is enhanced by preparing low-temperature glaze materials adapted to calcium silicate because the firing temperature of a blank body is reduced through the calcium silicate contained in the silico-calcium slag; the invention not only reduces the pollution, but also increases a new member for building materials; and in addition, the novel glazed brick prepared by using the method has various properties which all accord with or surpass the national standard.

Owner:ORDOS CITY TAOERSI CERAMIC

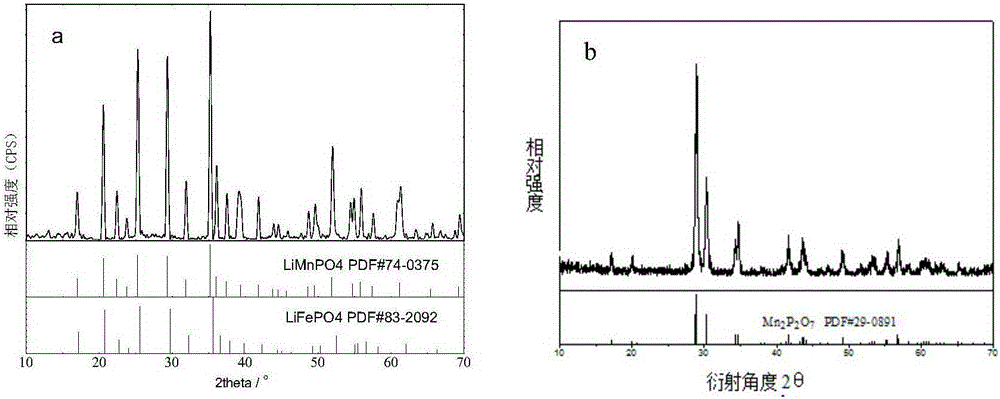

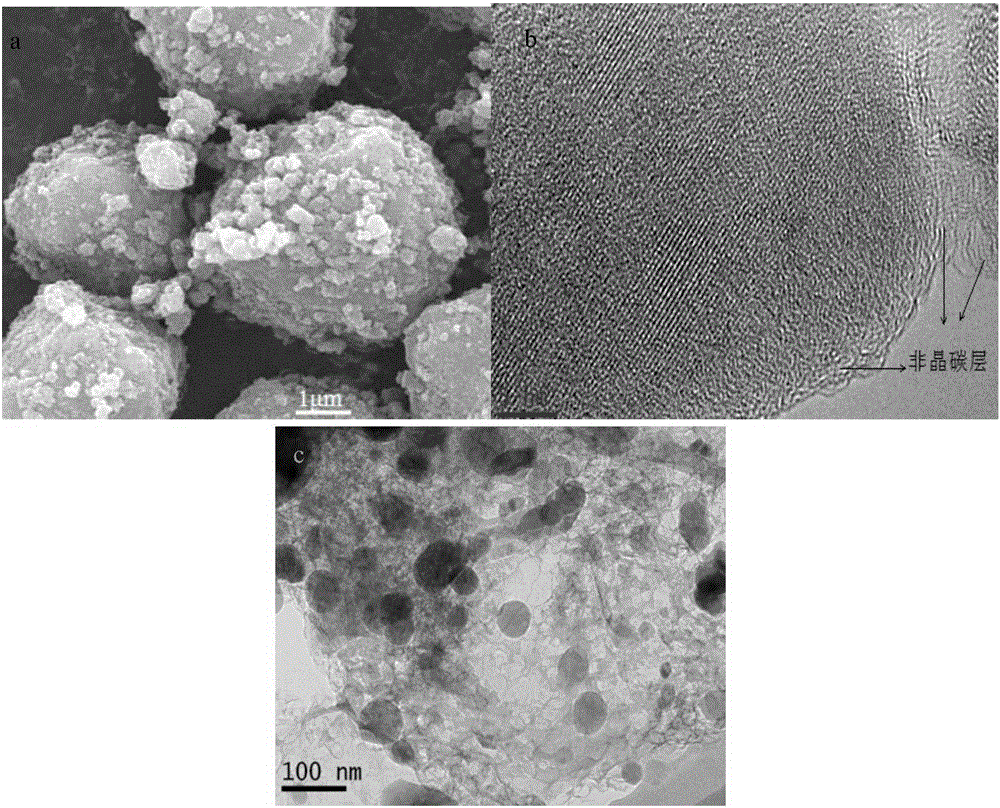

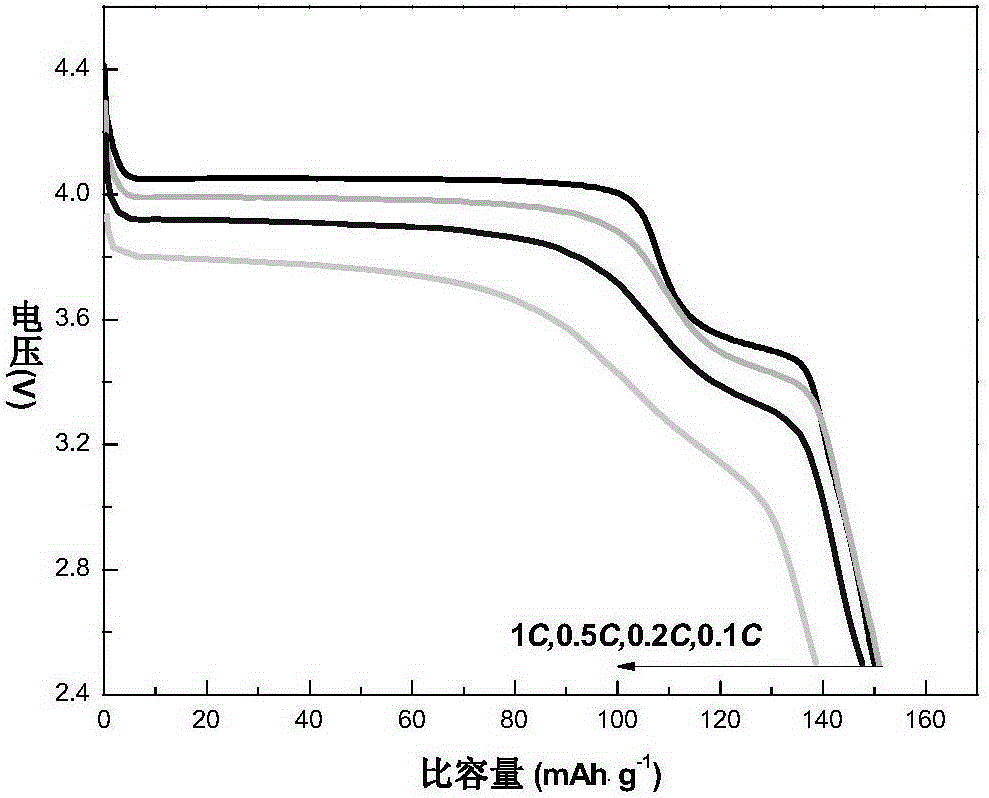

Synthesis method of lithium ion battery composite cathode material LiMn1-xFexPO4/C

InactiveCN105355885AUniform controlAdd lessSecondary cellsPositive electrodesHigh rateSynthesis methods

The invention relates to a synthesis method of lithium ion battery composite cathode material LiMn1-xFexPO4 / C. A manganese source, an iron source, a phosphorus source and an organic carbon source are evenly mixed and processed by a high-energy ball mill. Mixtures are subjected to heat treatment at 500-700 DEG C under the protection of inert atmosphere so that (Mn1-xFex)2P2O7 / C can be prepared; then, pyrophosphate / carbon, a lithium source and a carbon source are mixed, heat treatment is performed at 600-750 DEG C under protection of inert atmosphere, and ferromanganese lithium phosphate / carbon anode materials with a composite conductive network are obtained. The synthesis method is suitable for large-scale industrialized production, the prepared materials are composed of secondary particles of primary nano-crystals covered with amorphous carbon, distribution is uniform, and the uniform conductive network is formed on the surfaces of phosphate particles in an in-situ mode. The obtained composite cathode material has high rate capacity and high compaction intensity and has good application prospects in the aspect of high-energy-density lithium ion batteries.

Owner:CENT SOUTH UNIV

Compression-resistant, abrasion-resistant and corrosion-resistant transformer seal ring as well as production method thereof

The invention discloses a compression-resistant, abrasion-resistant and corrosion-resistant transformer seal ring as well as a production method thereof. Chemigum is adopted as a main raw material, and forms synthetic rubber with high-tenacity reclaimed rubber and coumarone resin, and the synthetic rubber has extremely good oil resistance, abrasion resistance and thermal resistance; the synthetic rubber is matched with carbon black, ceramic micro powder, silicon powder, manganese powder, teflon, zinc oxide, argil, vulcanizing activators and hot-oxygen aging resistant agents, so that the performance of tearing resistance, self-lubricating effect, compression deformation resistance, thermal resistance, corrosion resistance, abrasion resistance and the like of the seal ring can be improved effectively, and the service life of the seal ring is prolonged. The favorable seal effect can be protected in severe cold and hot climate environments, and the service life of the seal ring is more than twice that of a traditional seal ring.

Owner:STATE GRID CORP OF CHINA +1

Preparation method of high specific surface area titanium dioxide for denitration catalyst

InactiveCN106379936ALarge specific surface areaHigh specific surface areaPhysical/chemical process catalystsTitanium dioxideHigh-speed grindingSlurry

The invention relates to a preparation method of high specific surface area titanium dioxide for a denitration catalyst. The preparation method comprises the following steps: (1) taking concentrated titanium liquid in the sulfuric acid method titanium dioxide production process as the raw material, adding a seed crystal, and carrying out pressurized hydrolysis to obtain meta-titanic acid with a high specific surface area; (2) washing the obtained meta-titanic acid for the first time, bleaching the meta-titanic acid, washing the meta-titanic acid for a second time, beating qualified meta-titanic acid after water washing, and controlling the concentration (calculated by titanium dioxide) to be in a range of 120 to 200 g / L; (3) adding an alkaline substance into the meta-titanic acid slurry obtained in the step (2) under stirring so as to adjust the pH value of the slurry to a range of 6.5 to 7.5; (4) subjecting the slurry obtained in the step (3) to aging, which lasts for 30 to 60 minutes, carrying out suction filtration in a vacuum suction device, and washing the filter cake by water, wherein the solid content of filter cake is more than 35%; (5) placing the filter cake obtained in the step (4) in an electric oven to dry the filter cake, wherein the temperature is controlled in a range of 105 to 150 DEG C, and the drying time lasts for 10 to 20 hours; and (6) grinding the material obtained in the step (5) by a high speed grinding machine to obtain the high specific surface area titanium dioxide.

Owner:NANJING TITANIUM DIOXIDE CHEM

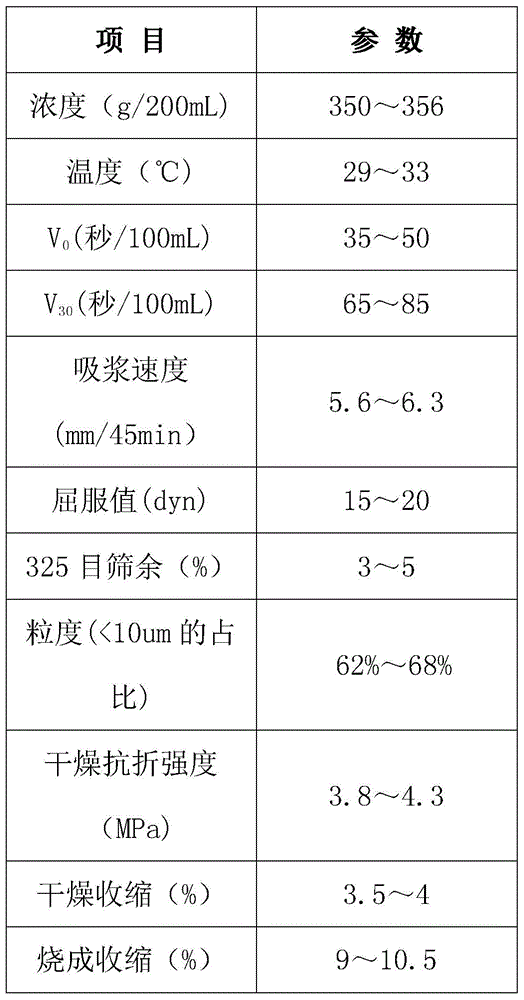

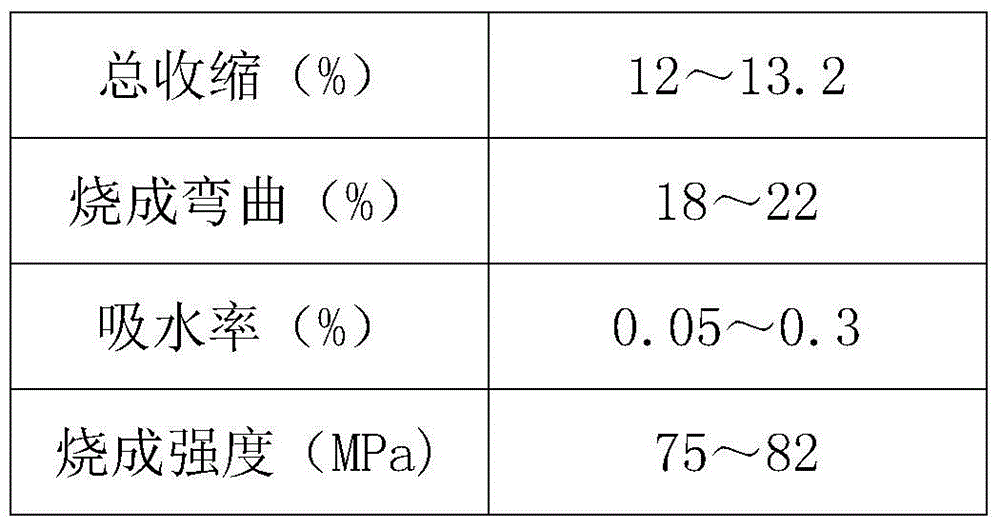

Sanitary ceramics slip and preparation technology thereof

The invention discloses sanitary ceramics slip and a preparation technology thereof. The sanitary ceramics slip mainly comprises, by weight, 30-70 parts of illite-structure clay, 5-15 parts of kaolin, 6-14 parts of ball clay, 8-13 parts of potassium feldspar, 5-10 parts of pyrophyllite, 5-10 parts of sericite, 0.1-3 parts of dolomite and 40-45 parts of water. Sanitary ceramics prepared from the sanitary ceramics slip are low in firing temperature, little in energy consumption and high in strength, and slip casting qualified rate, semi-finished product qualified rate and firing qualified rate can reach 98%, 96% and 92% respectively.

Owner:福建科福材料有限公司

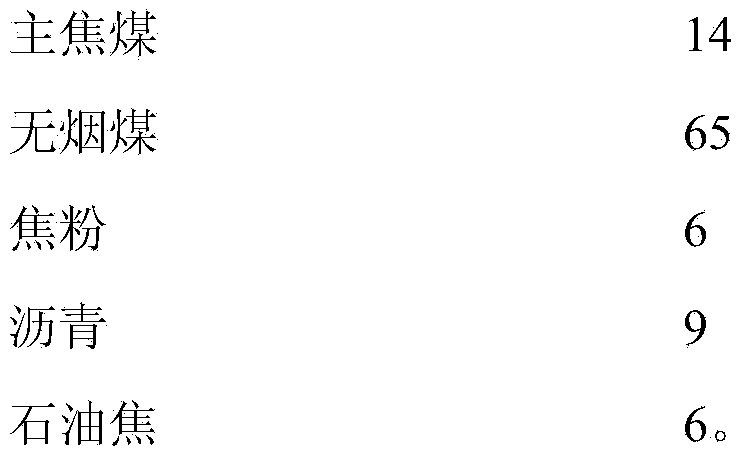

Method for preparing coke

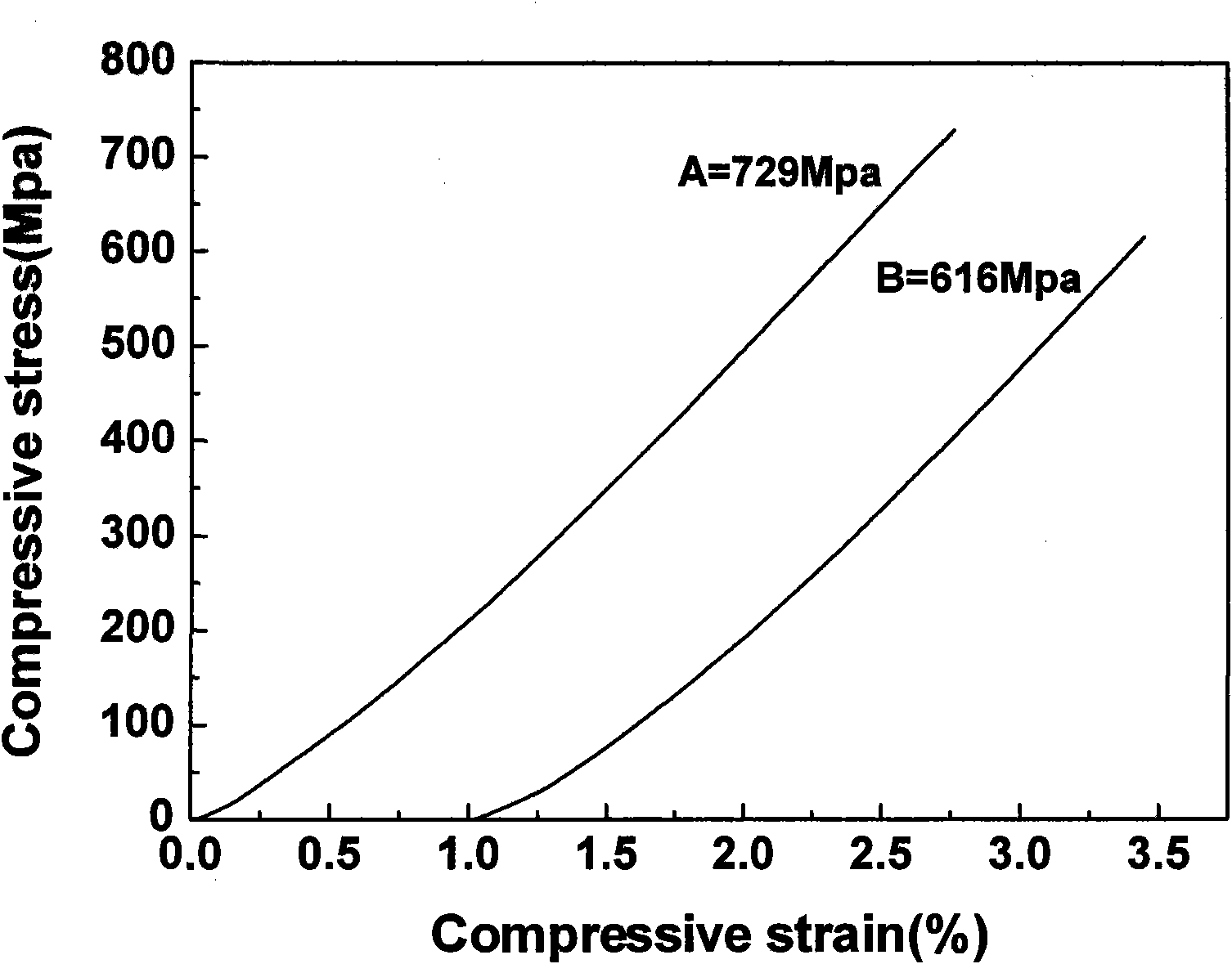

ActiveCN104194813AQuality improvementHigh strengthSpecial form destructive distillationPorosityCoke oven

The invention provides a method for preparing coke. The invention provides a preparation method of formed coke in a vertical coke oven. The method comprises the step of carrying out dry distillation on the raw materials including coking coal, anthracite, coke powder, asphalt and petroleum coke. The formed coke is prepared by stirring blending coal at high temperature and high pressure according to a certain proportion and carrying out forming, charging and carbonizing processes. The method has the beneficial effects that a formula effectively solves the problem of impacts of plastic mass change under the conditions of high temperature and rapid heating; the coke quality reaches the A-level rate, which is above 95%, in the national standard; the coke has the characteristics of uniform product specification, high lumpiness, high strength, lower porosity and reactivity and low ash content and sulfur content.

Owner:SHANDONG JUMING ENERGY

Producing method of low-fluorine high-purity tantalic oxide

The invention provides a preparation method of low-fluorine high-purity tantalic oxide, which comprises the following steps: preparing high-purity tantalic liquid from impure tantalic liquid materials by adopting a liquid-liquid extraction method; neutralizing the high-purity tantalic liquid by purified ammonia to obtain high-purity tantalum hydroxide which is then washed, filtered, dried; sectionally calcining the high-purity tantalum hydroxide according to the following steps: heating to 180-230 DEG C, and carrying out heat preservation for 2-3 hours; heating to 480-530 DEG C, and carrying out heat preservation for 4-6 hours; heating to 620-680 DEG C, and carrying out heat preservation for 2-3 hours; heating to 790-840 DEG C, and carrying out heat preservation for 3-5 hours; reducing temperature to 180-230 DEG C, and then discharging the high-purity tantalum hydroxide from a furnace and screening to obtain the high-purity tantalic oxide. The invention has the advantages that the prepared high-purity tantalic oxide product has good consistency and evenness, low fluorine content, less ignition loss and protection function to a furnace hearth, and the service life of a roasting hearth can be prolonged.

Owner:ZHAOQING DUOLUSN RARE METAL

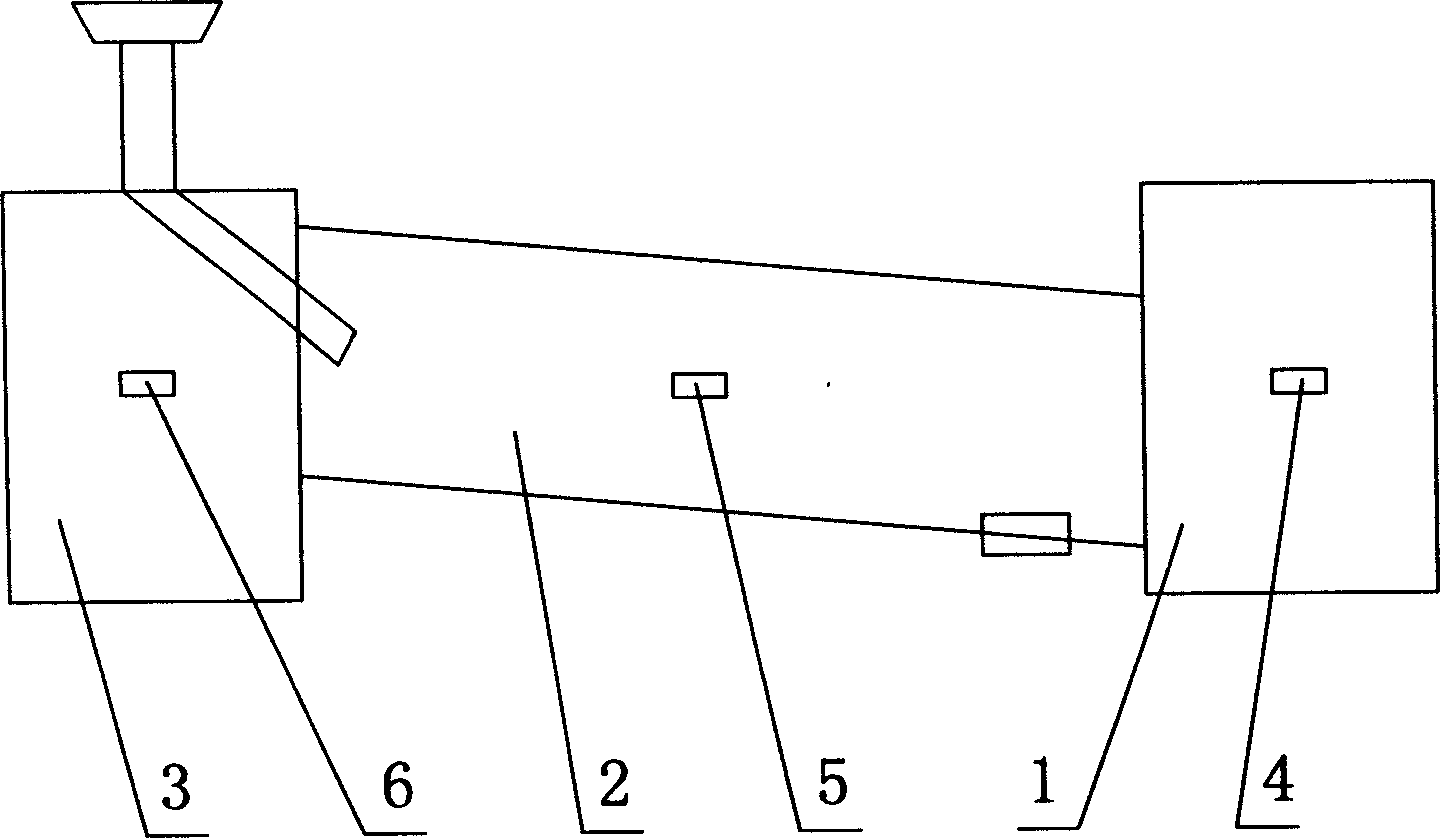

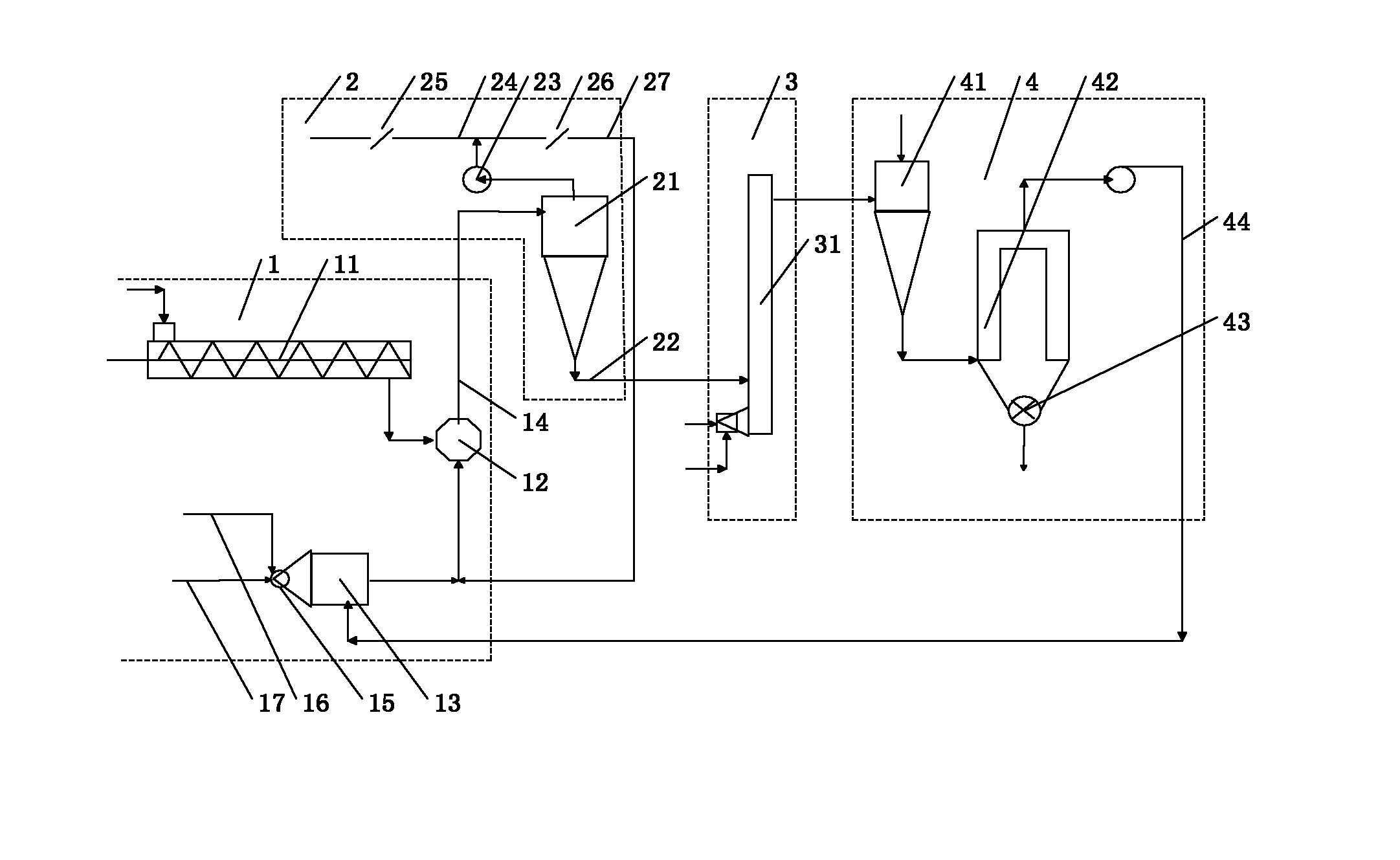

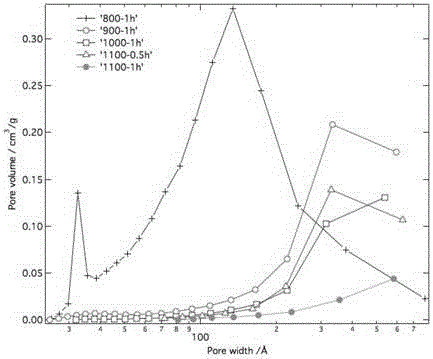

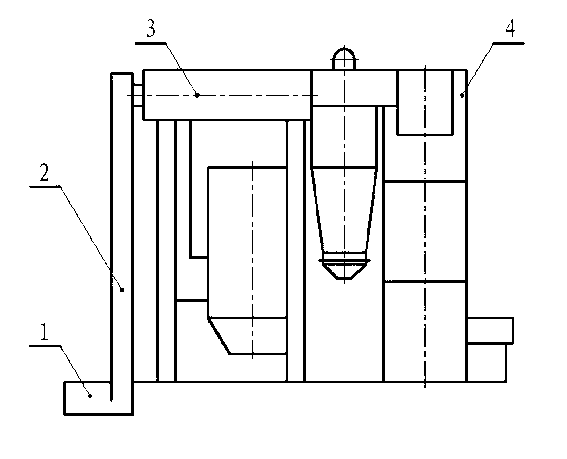

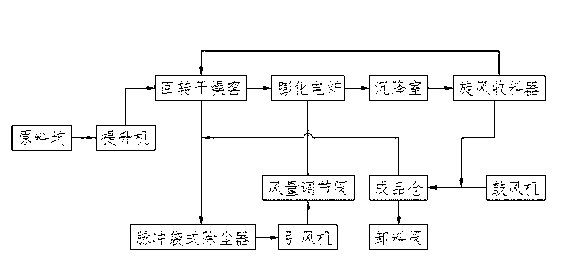

Production line for regenerating wood based powdered activated carbon

ActiveCN102553554AAchieve regenerationLow loss on ignitionCombustible gas purificationFilter regenerationProduction lineActivated carbon

The invention relates to a production line for regenerating wood based powdered activated carbon. The production line comprises a grinding and drying device, a cyclone seperation device, a high-temperature shaft kiln activation furnace and a cooling bag filtering device, wherein the grinding and drying device is used for heating, drying and mechanically grinding peat, the cyclone seperation device is used for separating out peat grains, the high-temperature shaft kiln activation furnace is used for reactivating the peat grains, the cooling bag filtering device is used for carrying out cooling temperature reduction on the activated peat, and the activated peat is led to pass through a bag filter and then is discharged, thereby the activated carbon is completely regenerated, the ignition lost rate is low, the regeneration cost is low, the regeneration quality is good, and the large-scale automation control production is realized.

Owner:福建省芝星炭业股份有限公司

Preparation method for magnesium oxide for concrete

The invention relates to a preparation method for magnesium oxide for concrete. According to the method, the magnesium oxide for the concrete is prepared by controlling calcining and grinding by taking magnesium-containing mineral resources, such as magnesite and dolomite, as raw materials. Through the preparation method, industrial stable production of rotary equipment for the magnesium oxide for the concrete is realized; by controlling the condition of calcining, and the magnesium oxide for the concrete with different activity ranges is prepared; the weight uniformity and stability in the production of the magnesium oxide for the concrete are remarkably improved; the expansibility of the magnesium oxide when used in the concrete is improved; the expansion of the concrete or a building can be controlled.

Owner:武汉三源特种建材有限责任公司

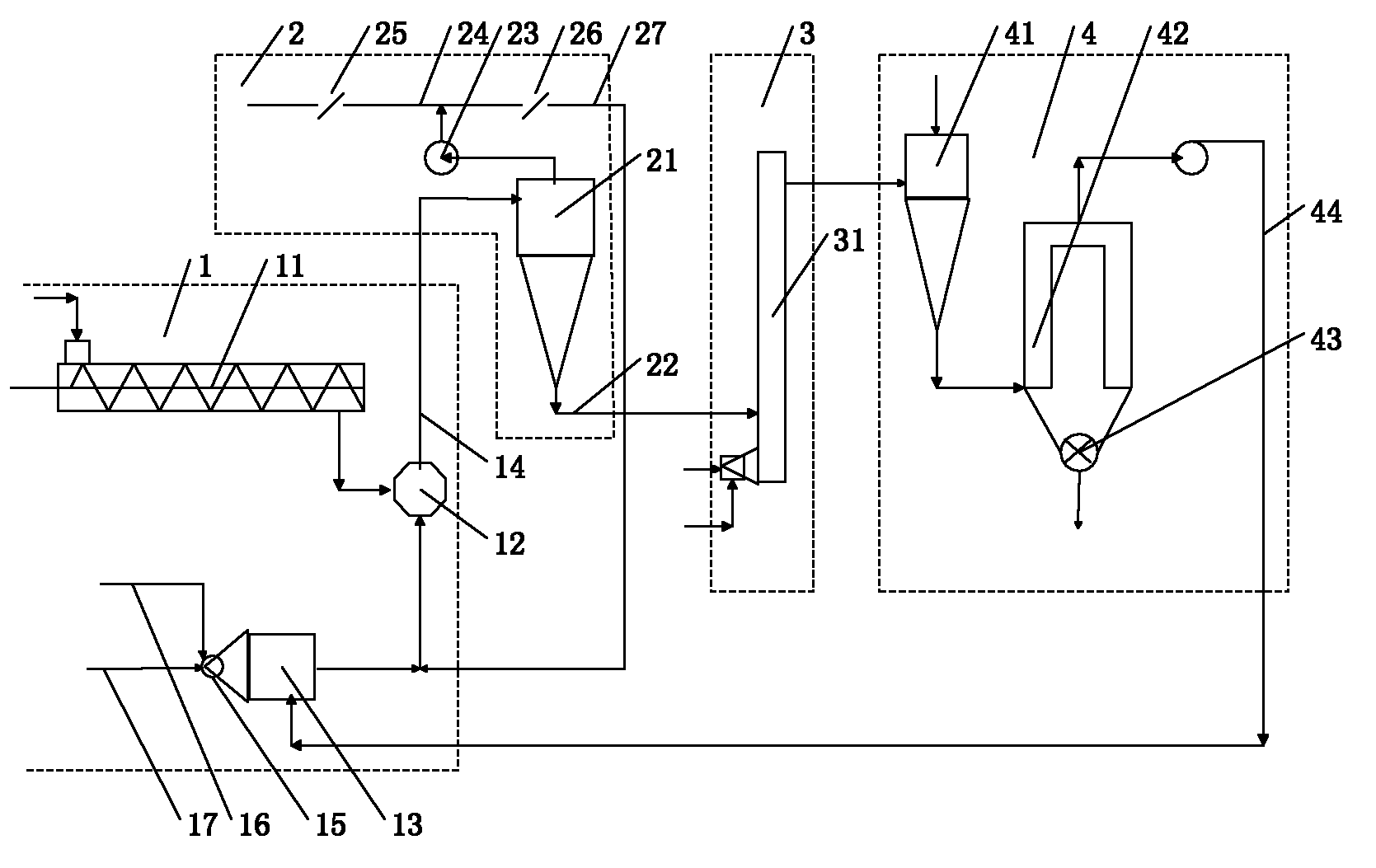

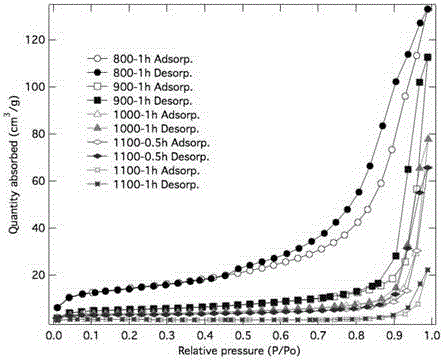

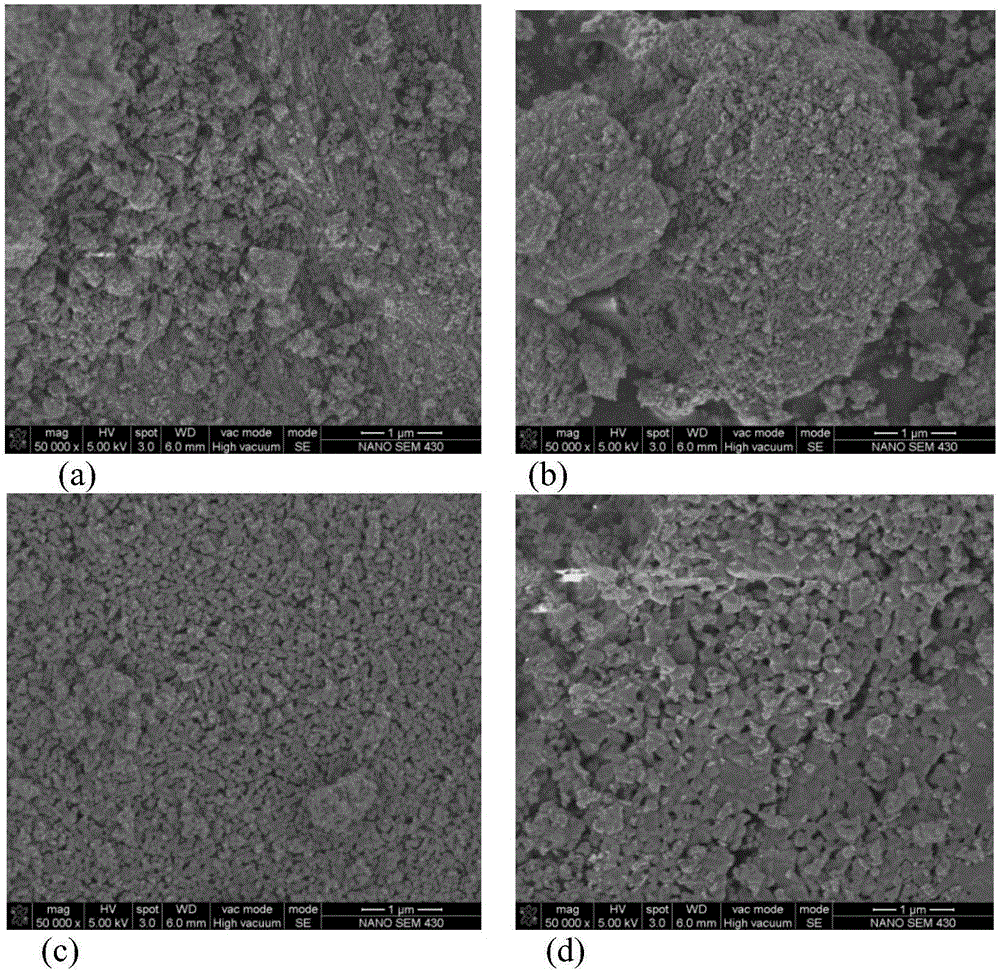

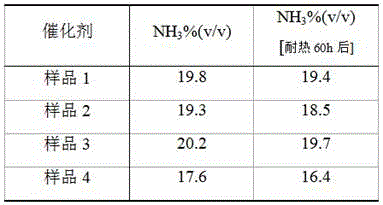

Modified active carbon, and preparation method and application thereof

ActiveCN106362719AIncrease the number ofGood dispersionMetal/metal-oxides/metal-hydroxide catalystsBulk chemical productionDispersityMethanation

The invention provides modified active carbon, and a preparation method and application thereof, belonging to the field of preparation of catalyst carriers. The preparation method comprises the following steps: subjecting graphitized active carbon to treatment with HNO3 and then carrying out high-heat treatment in an ammonia gas atmosphere so as to obtain an active carbon carrier with high mesoporosity. The carrier has the characteristics of a great pore volume, high mesoporosity (no less than 97%), good conductivity, etc. When used as a carrier for an ammonia-synthesis catalyst, the carrier can substantially improve the dispersity of the precious metal ruthenium and improves anti-methanation capability, heat stability and activity of the catalyst. The carrier has wide application prospect in the field of catalysis.

Owner:FUZHOU UNIV

Production formula for alkali-resistant glass marble, production method and production kiln thereof

ActiveCN101531457AMix well and evenlyControl moisture contentGlass furnace apparatusGlass shaping apparatusProduction rateCLARITY

The invention relates to a production formula for alkali-resistant glass marble in building material industry, a production method and a production kiln thereof. The invention is reasonable in selecting weight proportions of ingredients, which is favorable for the control of quality system, and the produced finished product of the glass marble has high clarity and good quality; the entire technological process consists of screening, weighting and mixing raw materials, founding and discharging, the technology is simple and the operation is convenient; using a horseshoe-fired furnace for producing the alkali-resistant glass marble solves the technical prejudice in a long term that the horseshoe-fired furnace is unsuitable for the production of the alkali-resistant glass marble; a general glass marble kiln is utilized to realize the production of the alkali-resistant glass marble without improving kiln refractory, which has the advantages of large production scale, easy control and regulation for the production process, good scale effect and prominent energy-saving effect; the cost is dramatically reduced while the production rate is greatly improved in contrast to a full-electric melting kiln.

Owner:ZIGONG DENGGUAN GLASS FIBER

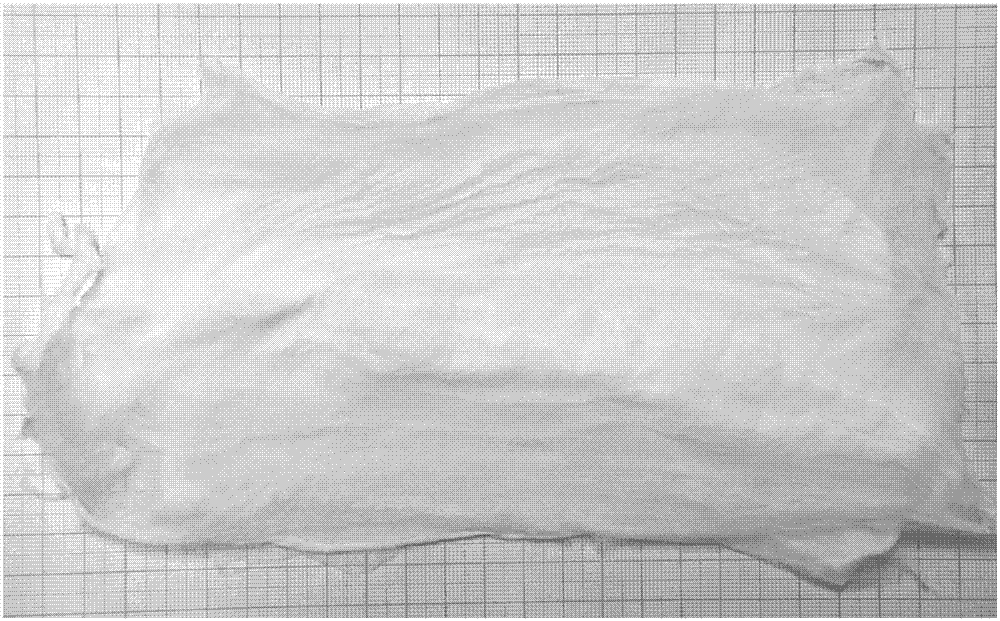

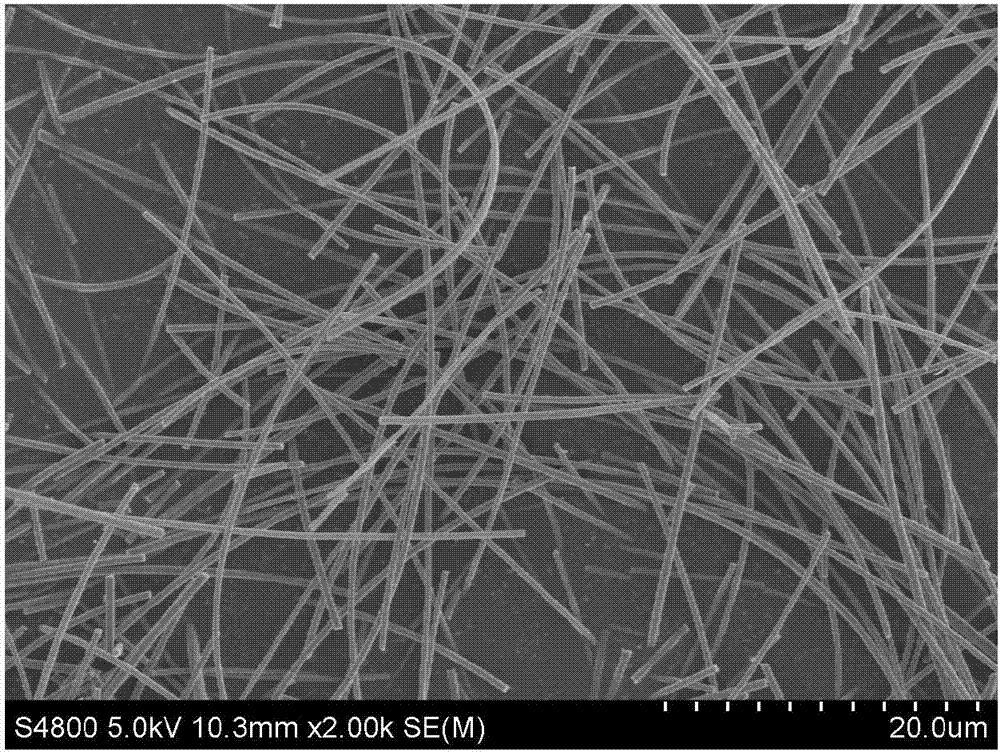

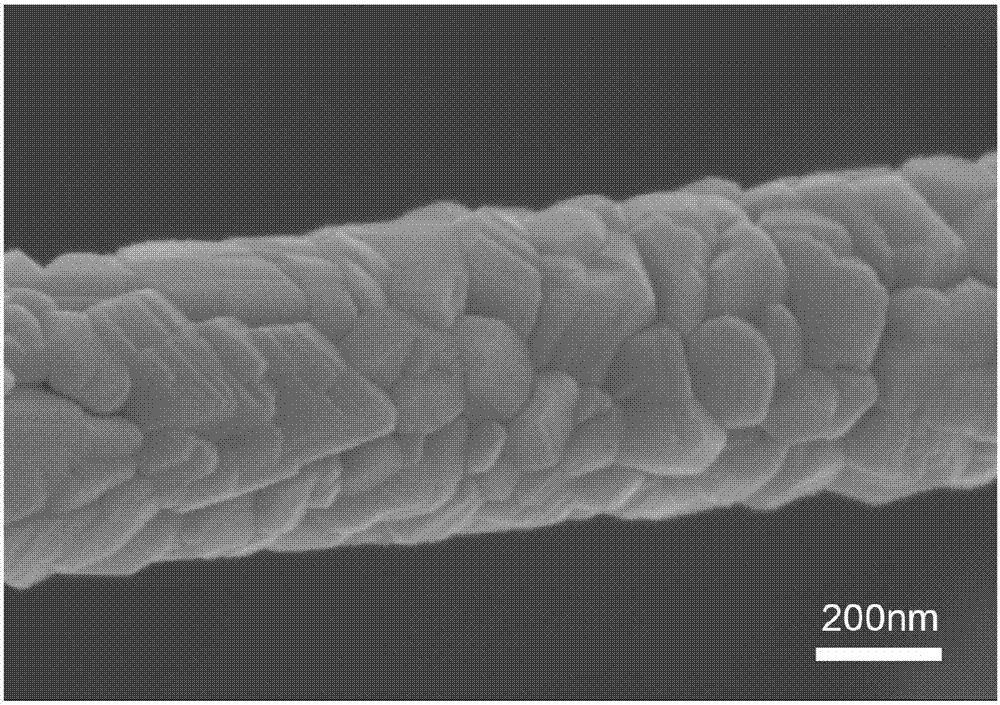

Polyvinyl acetateoxotitaniumprecursor sol spinning solution and preparation method of titanium oxide nano fiber photocatalyst

ActiveCN106978652ALow loss on ignitionImprove performancePhysical/chemical process catalystsElectro-spinningElectrospinningSolvent

The invention relates to a polyvinyl acetate oxotitanium precursor sol spinning solution and a preparation method of a titanium oxide nano fiber photocatalyst. The preparation method comprises the following steps: preparing a polyvinyl acetate oxotitanium precursor sol spinning solution, electrostatically spinning, and thermally treating; to be specific, tetrabutyl titanate and glacial acetic acid are used as raw materials to prepare a polyvinyl acetate oxotitanium precursor, and then the precursor, aids and solvent are uniformly mixed according to a certain ratio to obtain a spinning solution; the spinning solution is prepared into polyvinyl acetate oxotitanium precursor fibers by virtue of an electrostatic spinning technology; and the precursor fibers are thermally treated in a muffle furnace to obtain solid titanium oxide nano fibers or mesoporous titanium oxide nano fibers. The method has the characteristics of simple process flow, excellent fiber quality, environmental friendliness and the like, the industrialized production is facilitated, and the obtained titanium oxide nano fibers have excellent catalytic performance and can be used as a photocatalytic material for degrading organic pollutants.

Owner:SHANDONG UNIV

Preparation method of strong-acidity polystyrene cationic exchange resin

InactiveCN107652406AImprove stabilityImprove adsorption capacityCation exchanger materialsOther chemical processesIce waterMicrosphere

The invention discloses a preparation method of strong-acidity polystyrene cationic exchange resin, comprising the steps of mixing well methyl styrene, methylene bisacrylamide, and methylbenzene, adding pre-processed rice hull and gelatin solution, mixing well, adding tert-butyl peroxy-2-ethylhexanoate, heating and stirring, heating, holding the temperature, aging, and filtering to obtain polystyrene microspheres; feeding the polystyrene microspheres into n-heptane for swelling, dropwise adding sulfuric acid solution while stirring, adjusting the temperature after dropwise adding, stirring, washing with ice water, and filtering to obtain the strong-acidity polystyrene cationic exchange resin. The pre-processed rice hull is prepared by: stirring rice hull and kaolin, feeding into an anaerobic muffle furnace, heating for calcining, cooling, grinding, adding nitric acid solution, stirring, washing until neutrality, drying, adding hyperbranched polysiloxane and acetone, ultrasonically treating, treating with microwave, and drying by spraying.

Owner:ANHUI WANDONG CHEM

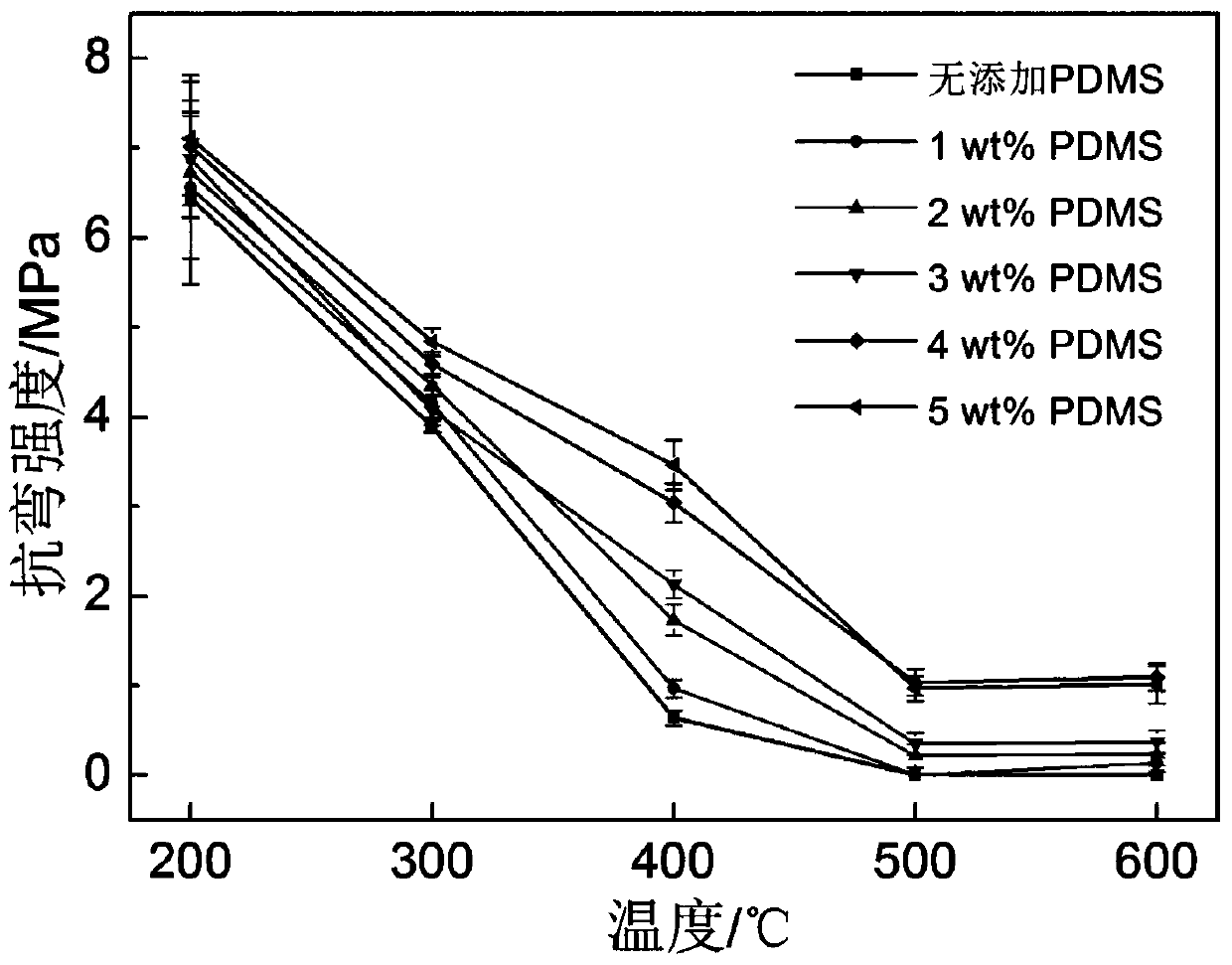

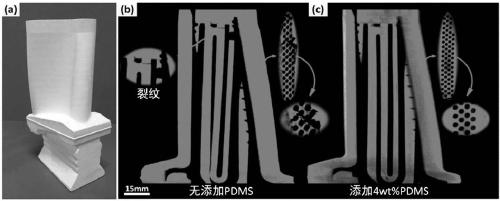

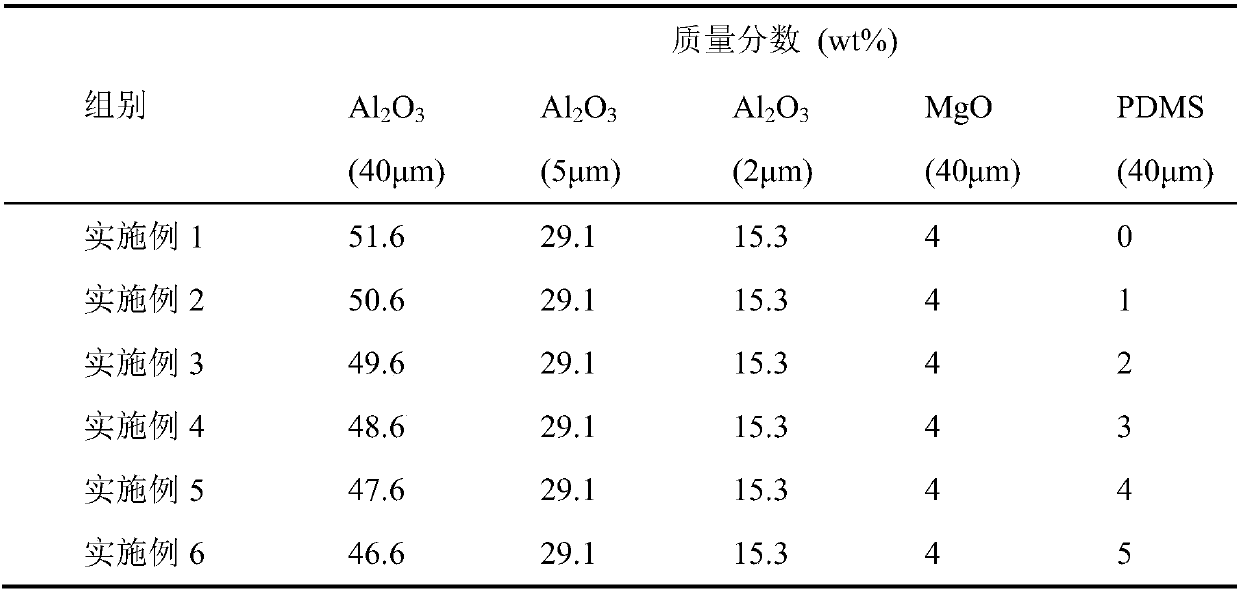

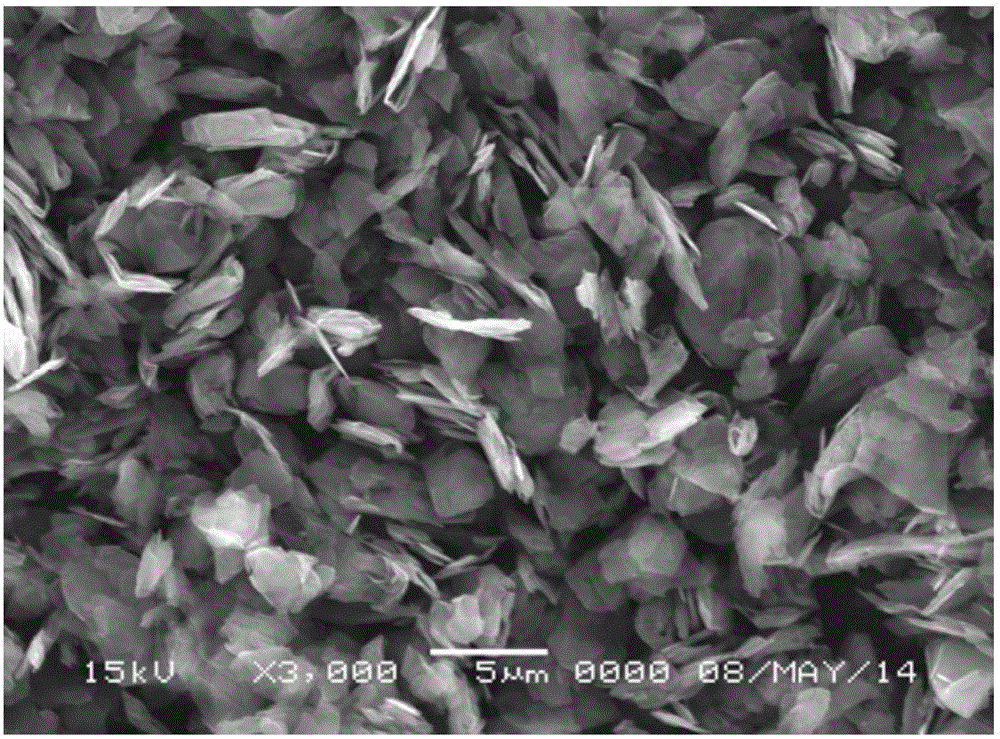

Method for improving degreasing strength of additive manufacturing formed ceramic part

InactiveCN109534794AImprove degreasing strengthSufficient strength marginUltrasound attenuationPrill

The invention discloses a method for improving the degreasing strength of an additive manufacturing formed ceramic part. The method comprises the following steps that polydimethylsiloxane is added into a ceramic powder material, and required raw material powder is obtained after even dispersing; the powder material and a liquid phase solvent are mixed, and ceramic slurry is prepared after even ball-milling; a ceramic part blank is formed through an additive manufacturing method, and after the blank is dried, degreasing and glue discharging are conducted; and in the degreasing heating process,the polydimethylsiloxane is softened and molten to permeate into adjacent ceramic particle gaps, and ceramic particles are wrapped. The polydimethylsiloxane is simple in molecular structure, low in carbon content and low in pyrolysis ignition lost rate, thus the wrapping bonding effect on the ceramic particles is small along with thermal attenuation of the temperature, the degreasing strength of the part can be established, and it is ensured that the blank has the sufficient strength margin to resist damage of gravity and thermal stress in a degreasing technology. The method can be used for improving the degreasing strength of the additive manufacturing ceramic part, and is especially suitable for additive manufacturing forming of ceramic parts of complex structures.

Owner:XI AN JIAOTONG UNIV

Graphite mixture, graphite film for heat conducting, and preparation method and application of graphite mixture, graphite film

ActiveCN106832926AWith Z-oriented magnetic structureImprove thermal conductivitySecondary cellsHeat-exchange elementsPolymer scienceHeat conducting

The invention relates to the field of battery heat-conducting materials, and particularly relates to a graphite mixture, graphite film for heat conducting, and a preparation method of the graphite mixture and the graphite film. The graphite mixture for heat conducting comprises a polyimide polymer and a magnetic-conductive material, the magnetic-conductive material comprises graphite. In addition, the preparation method of the graphite mixture for heat conducting comprises the following steps: adding the magnetic-conductive material into the polyimide polymer solution, to obtain the graphite mixture for heat conducting. The invention also provides a graphite film for heat conducting, which is prepared from the graphite mixture for heat conducting. The prepared heat-conducting film with the heat conductivity of 300-2000W / m.K and can widely replace or can be used in various heat-radiating environments by combining aluminum / copper heat-radiating materials, and compared with the existing same type heat-radiating material, the heat-radiating film material prepared by using the technology shows excellent heat-radiating performance, is beneficial to light weight and small size of the product, and has obvious economic effects.

Owner:祝巧凤

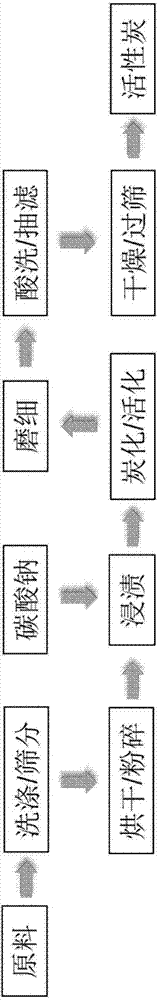

Powder active carbon prepared by using turf as raw material and preparation method of powder active carbon

The invention provides a powder active carbon, which is prepared by using turf as a raw material. The powder active carbon is characterized in that the specific surface area of the powder active carbon is 1200-1400 m<2> / g, the iodine adsorption capacity is 1000-1200mg / g, and the methylene blue absorbing value is 130-200mg / g. The powder active carbon is prepared by the method provided by the invention. The preparation method comprises the following steps of 1) removing impurities by using a turf sieve, drying and crushing the sieved turf; 2) putting the crushed turf into sodium carbonate solution with a weight ratio of (3-5) to 1, mixing the mixture evenly into mud immersion, and drying the mixture; 3) raising the temperature of the dried mixture to 500 DEG C a program of 10 DEG C / min, taking out the cooled mixture to be grinded, and washing away excessive anhydrous sodium carbonate and surface residue with dilute nitric acid, and washing the mixture with deionized water to a pH value of 4.5-4.8, performing suction filtering and drying for the mixture to obtain powder active carbon. The invention further discloses a method for preparing the powder active carbon.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Nonluminous glaze

The invention relates to nonluminous glaze. The nonluminous glaze is prepared by adding a proper amount of aluminum powder into slaked talc, quartz and feldspar to generate metal aluminum oxide without glossiness, so that the production cost of the nonluminous glaze can be effectively reduced; the added slaked talc is subjected to high-temperature calcination, so the impurity content is low, the loss on ignition is small and new grain which people do not like is avoided; a proper amount of silicon micropowder is added into the nonluminous glaze, the temperature resistance and the acid and alkali resistance of the glaze layer can be improved and the effect of improving the mechanical strength of the glaze layer is achieved; and the nonluminous glaze is obtained by performing wet ball milling by a wet ball mill, the raw materials for forming the nonluminous glaze are stirred and mixed uniformly, slurry with the physical and chemical properties tending to be uniform and consistent can beobtained, and glazing is fertilized.

Owner:GUANGXI NANSHAN PORCELAIN

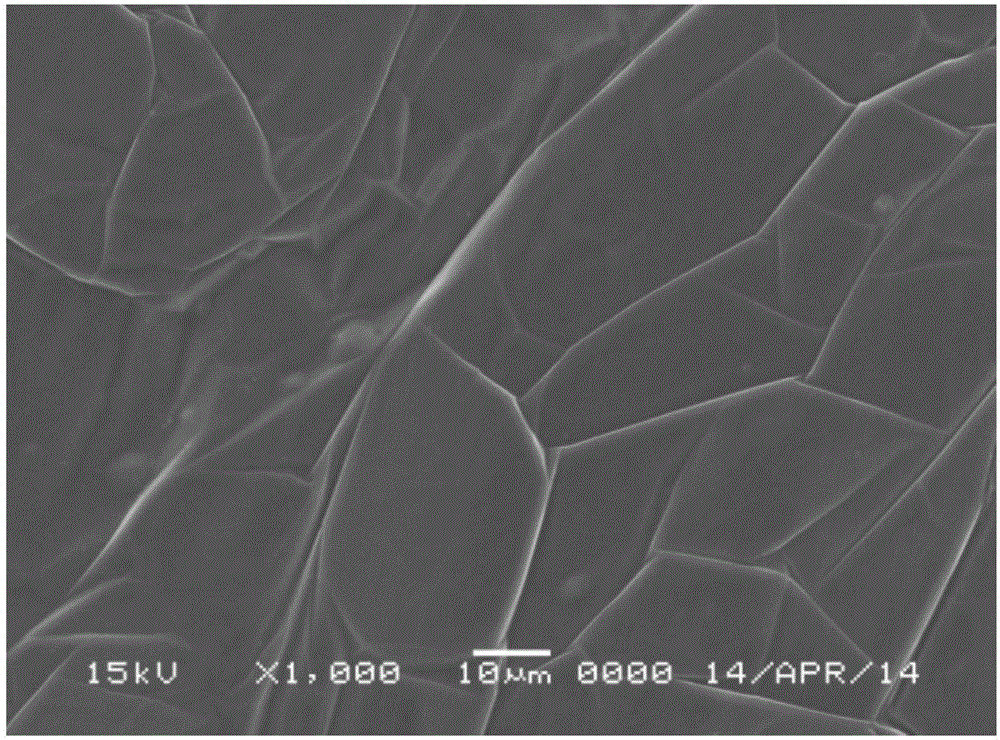

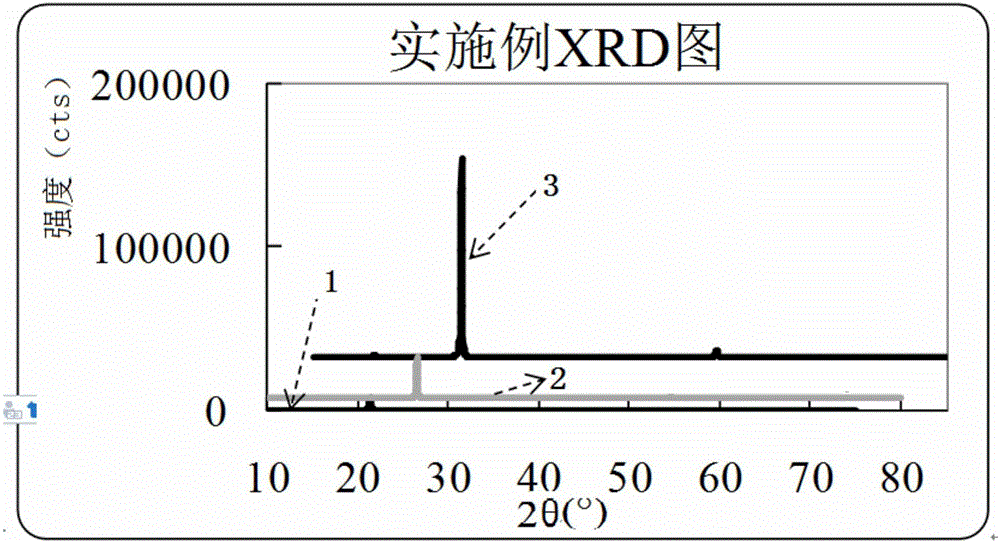

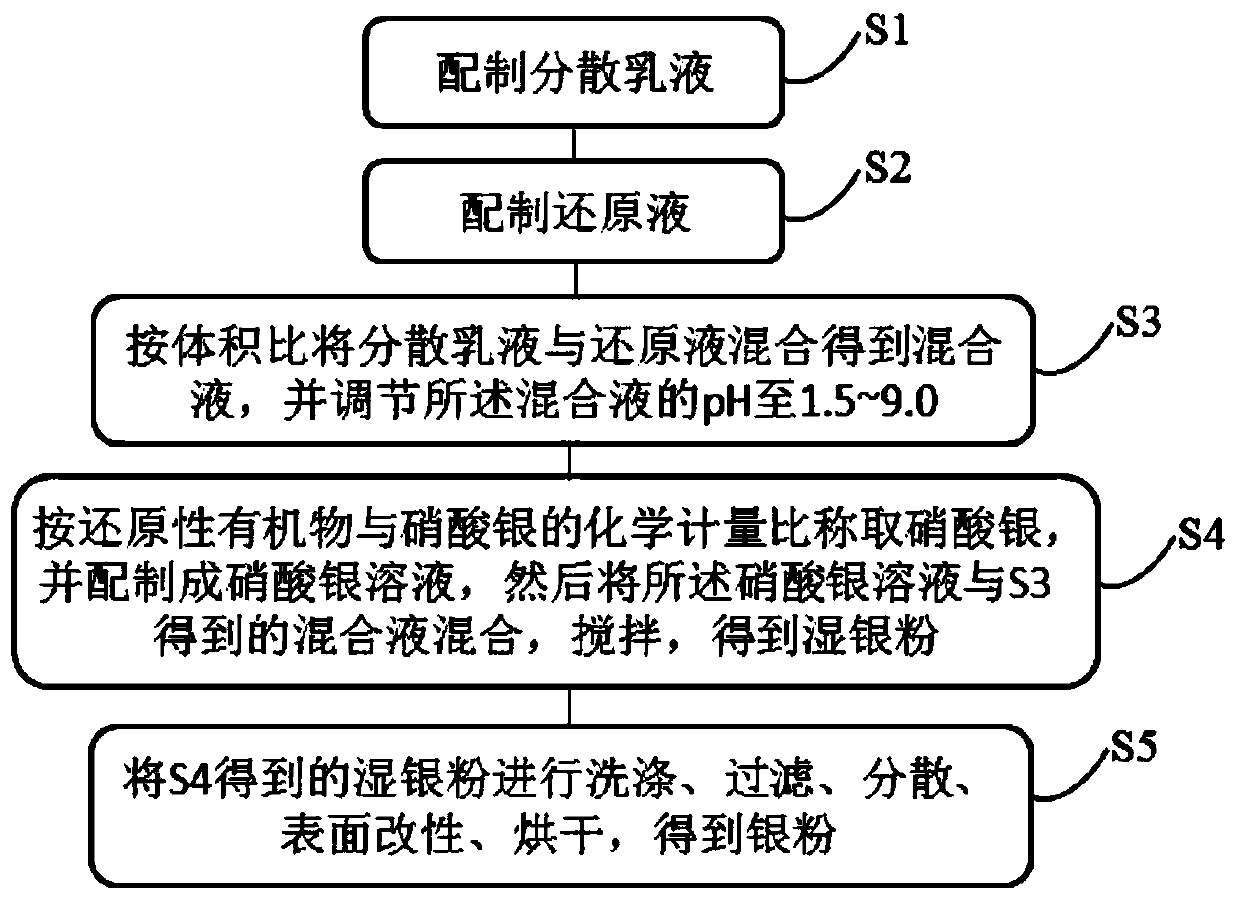

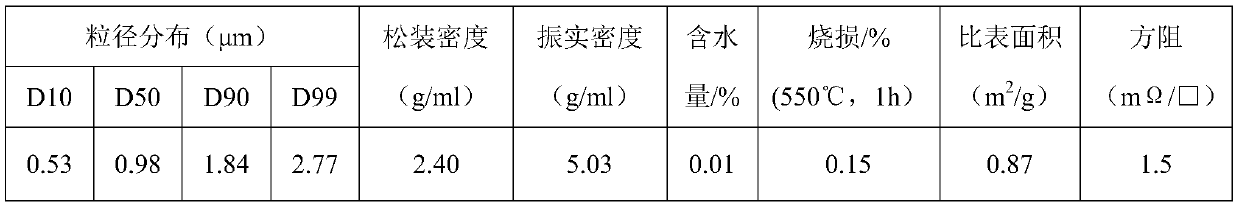

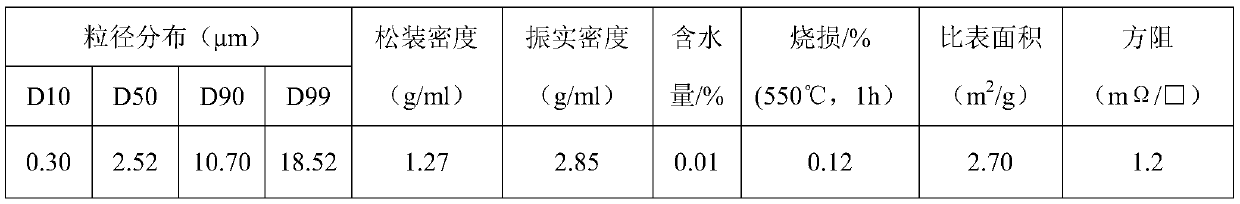

Preparation method of micron/submicron order silver powder

PendingCN110947980ALow loss on ignitionGood dispersionTransportation and packagingMetal-working apparatusEmulsionOrganic matter

The invention discloses a preparation method of micron / submicron order silver powder. The preparation method comprises the following steps that S1, a dispersion emulsion is prepared; S2, a reducing liquid is prepared; S3, the dispersion emulsion is mixed with the reducing liquid according to the volume ratio to obtain a mixed solution, and the pH of the mixed solution is adjusted; S4, silver nitrate is weighed according to the stoichiometric ratio of a reducing organic matter to the silver nitrate, a silver nitrate solution is prepared, then the silver nitrate solution is mixed with the mixedsolution obtained in the step S3, and stirring is carried out to obtain wet silver powder; and S5, washing, filtering, dispersing, surface modification and drying are carried out on the wet silver powder obtained in the step S4 to obtain the silver powder. According to the preparation method, firstly, a dispersing agent is prepared into the dispersion emulsion so that the burning weight loss of the silver powder can be effectively reduced; and meanwhile, the surface modification is carried out on the wet silver powder in the subsequent step by adopting a substance containing a mercapto group so that the dispersibility and the sintering activity of the silver powder can be effectively improved.

Owner:CHANGSHA ADVANCED MATERIALS IND RES INST CO LTD

Rubber reinforcing method

InactiveCN102634075AEliminate pollutionEasy to recyclePigmenting treatmentPlastic recyclingPolymer scienceVulcanization

The invention relates to a rubber reinforcing method. According to the method, 100 parts of rubber needing to be reinforced needs to be added with the following compositions in part by weight: 50-60 parts of reinforcement regenerable carbon black, 2-4 parts of zinc oxide, 0.4-0.8 parts of accelerator DM, 2-4 parts of sulphur, and 3-5 parts of stearic acid, then mixed melting and vulcanization are conducted according to the characteristics of rubber needing to be reinforced, so that the reinforcement on the rubber is completed. The reinforcement regenerable carbon black adopts regenerable carbon black to conduct temperature rise and themolysis and carbonization on macromolecular wastes under inert atmosphere to obtain thermolysis carbon black, mixed gas of oxidizing gas and inert gas are introduced so as to conduct oxidation and thermolysis on the carbon black in cooling process, ZnS produced by thermolysis is oxidized into important composition ZnO in the reinforced rubber, and then magnetic separation, crushing, grading and pelletizing are carried out, so that the reinforced rubber is obtained. With the rubber reinforcing method, waste superpolymer pollution is eliminated, cyclic utilization of the regenerable resources can be promoted, no secondary pollution is caused; and according to the method, process line is simple, the ignition lost is low, the equipment investment and the operation cost are low, and the environment is friendly.

Owner:HANGZHOU DIANZI UNIV

A pressure-resistant, wear-resistant and corrosion-resistant transformer sealing ring and its production method

The invention discloses a compression-resistant, abrasion-resistant and corrosion-resistant transformer seal ring as well as a production method thereof. Chemigum is adopted as a main raw material, and forms synthetic rubber with high-tenacity reclaimed rubber and coumarone resin, and the synthetic rubber has extremely good oil resistance, abrasion resistance and thermal resistance; the synthetic rubber is matched with carbon black, ceramic micro powder, silicon powder, manganese powder, teflon, zinc oxide, argil, vulcanizing activators and hot-oxygen aging resistant agents, so that the performance of tearing resistance, self-lubricating effect, compression deformation resistance, thermal resistance, corrosion resistance, abrasion resistance and the like of the seal ring can be improved effectively, and the service life of the seal ring is prolonged. The favorable seal effect can be protected in severe cold and hot climate environments, and the service life of the seal ring is more than twice that of a traditional seal ring.

Owner:STATE GRID CORP OF CHINA +1

A white fast setting rapid hardening high belite sulfoaluminate cement clinker, its application and its production process

The invention relates to a white fast-setting, fast-hardening and high-belite sulphoaluminate cement clinker, and also relates to an application and a production technology thereof. The mineral component of the cement clinker comprises 0.5-4.6% of f-CaO; the chemical component of the cement clinker comprises 12.9-16.1wt% of SiO2, 12-19wt% of Al2O3, 0.15-1.0wt% of Fe2O3, 49-53wt% of CaO and 12-18.5wt% of SO3; and the clinker rate range Cm is 1.01-1.137, and P is 0.62-1.44. The clinker is produced through calcining 30-50wt% of limestone, 26-46wt% of slag powder and 21.1-40wt% of desulfurized gypsum in a rotary kiln at 1250-1350DEG C. 26-97% Of the clinker, 3-19% of anhydrite and 0-55% of the slag powder, or 5-25% of the clinker, 14.4-19.0% of the anhydrite and 55.8-79% of the slag powder are mixed and ground to form white fast-setting, fast-hardening and high-belite sulphoaluminate cement and high-late strength and high-belite sulphoaluminate cement.

Owner:TANGSHAN POLAR BEAR BUILDING MATERIAL +1

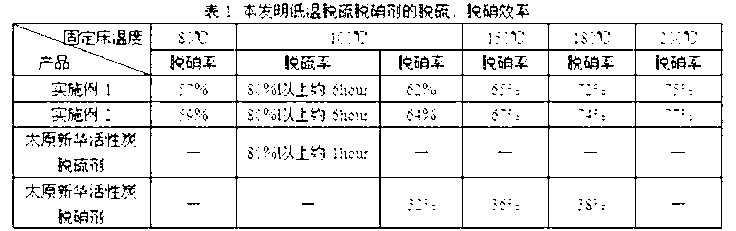

Carbon material low-temperature expansion method and preparation method of low-temperature desulphurization and denitration agent for the same

InactiveCN103341366AStrong desulfurization abilityHigh pore volumeCatalyst carriersDispersed particle separationHydrogen NitrateFlue gas

The invention relates to a carbon material low-temperature expansion method and a preparation method of low-temperature desulphurization and denitration agent for the same, in particular relates to a carbon material ultrasonic acid low-temperature expansion method and a method for preparing low-temperature desulphurization and denitration agent by means of ultrasonic activation by taking the carbon material as a carrier. The invention can be used for overcoming the defects in the existing technology, and provides an ultrasonic acidizing expansion method for expanding the carbon material quickly and efficiently under low temperature, and a quick, efficiency and energy-saving ultrasonic activation preparation method for preparing the low-temperature desulphurization and denitration agent by using the carbon material expanded by the method above. In the preparation method, one or mixture of hydrogen nitrate, sulfuric acid and hydrochloric acid with certain concentration is used as acid treatment agent, by assistance of ultrasonic waves, the carbon material, such as coke or half coke, is subjected to low-temperature acid treatment, after the porous carbon material is treated by acid treatment, vanadate catalyst is loaded on the carbon material, thus, a flue gas desulphurization and denitration agent is prepared. The product can effectively remove SO2 and NOx in the flue gas under low temperature.

Owner:TAIYUAN NORMAL UNIV

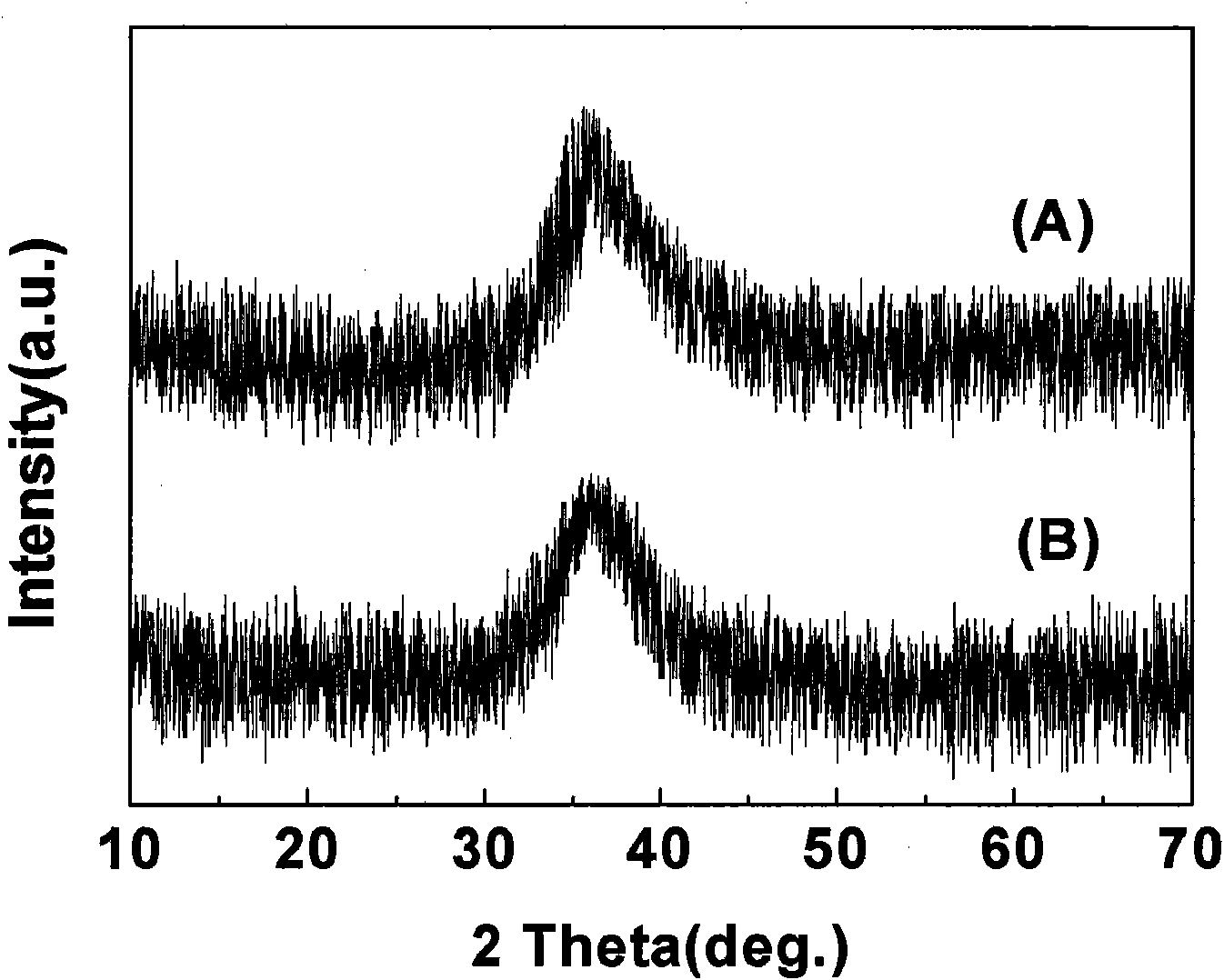

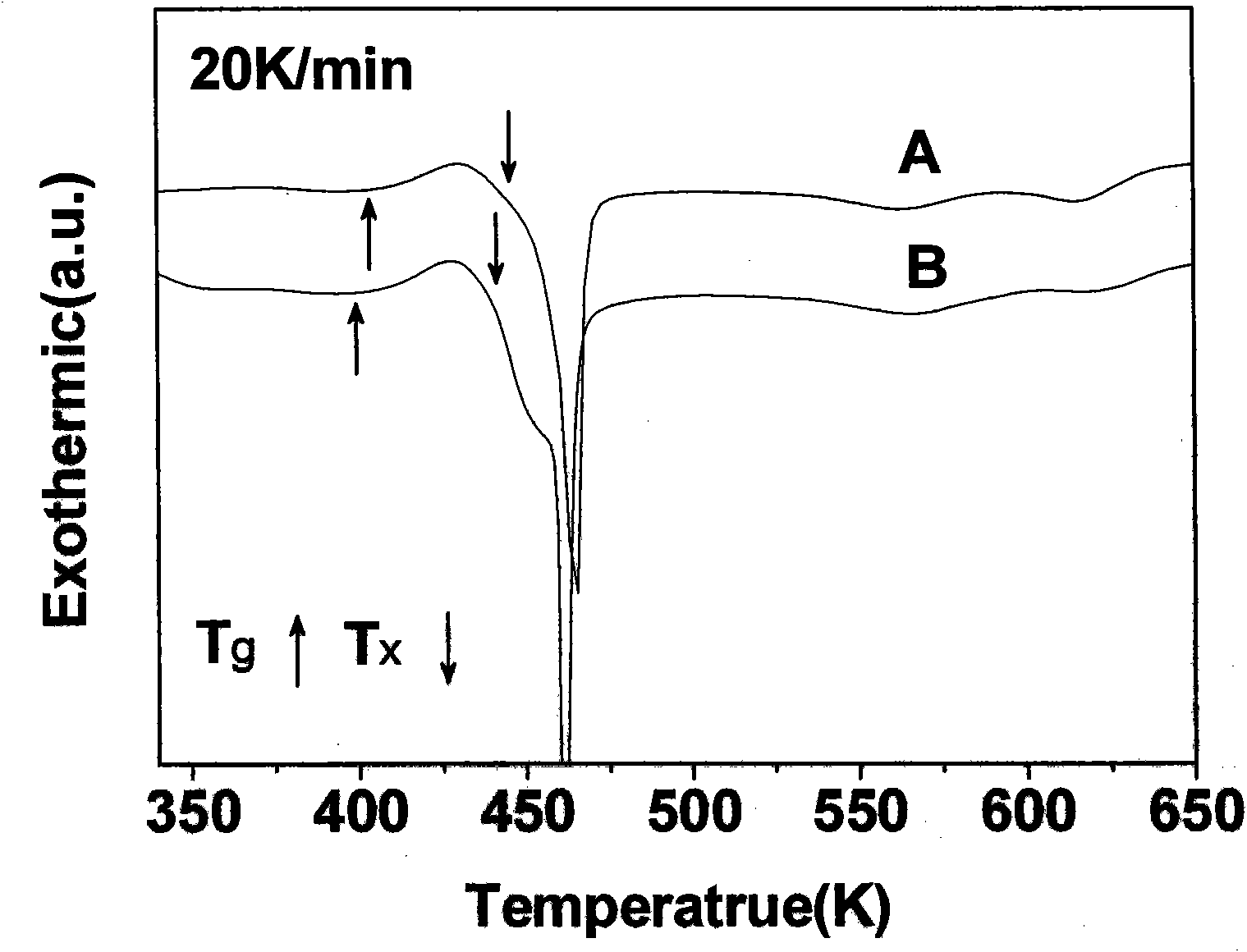

Preparation method of Mg-Li matrix Mg-Li-Cu-Ni-Y series bulk amorphous alloy

The invention provides a preparation method of Mg-Li matrix Mg-Li-Cu-Ni-Y series bulk amorphous alloy. The method comprises the following steps: mixing high purity magnesium block, lithium block, nickel block, high purity copper ingot and high purity yttrium block according to a nominal formulation-Mg65LixCu20-xNi5Y10 (0<x<5at.%), wherein firstly smelting by using the vacuum induction melting method to obtain Cu-Ni-Y ternary alloy, secondly polishing the Cu-Ni-Y alloy, grinding the alloy to mix with magnesium block and lithium block and then using the same smelting method to prepare Mg-Li-Cu-Ni-Y quinary master alloy; and (2) after grinding the Mg-Li-Cu-Ni-Y quinary master alloy prepared by smelting, and performing vacuum rapid quenching on an ultrafast quenching device to prepare the high-strength Mg-Li matrix Mg-Li-Cu-Ni-Y series bulk amorphous alloy. The preparation method of the invention avoids large ignition loss of Mg and Li and impurity elements and increases the purity of the amorphous alloy, and the obtained Mg-Li matrix amorphous alloy has high strength, low density and good corrosion resistance.

Owner:HARBIN ENG UNIV

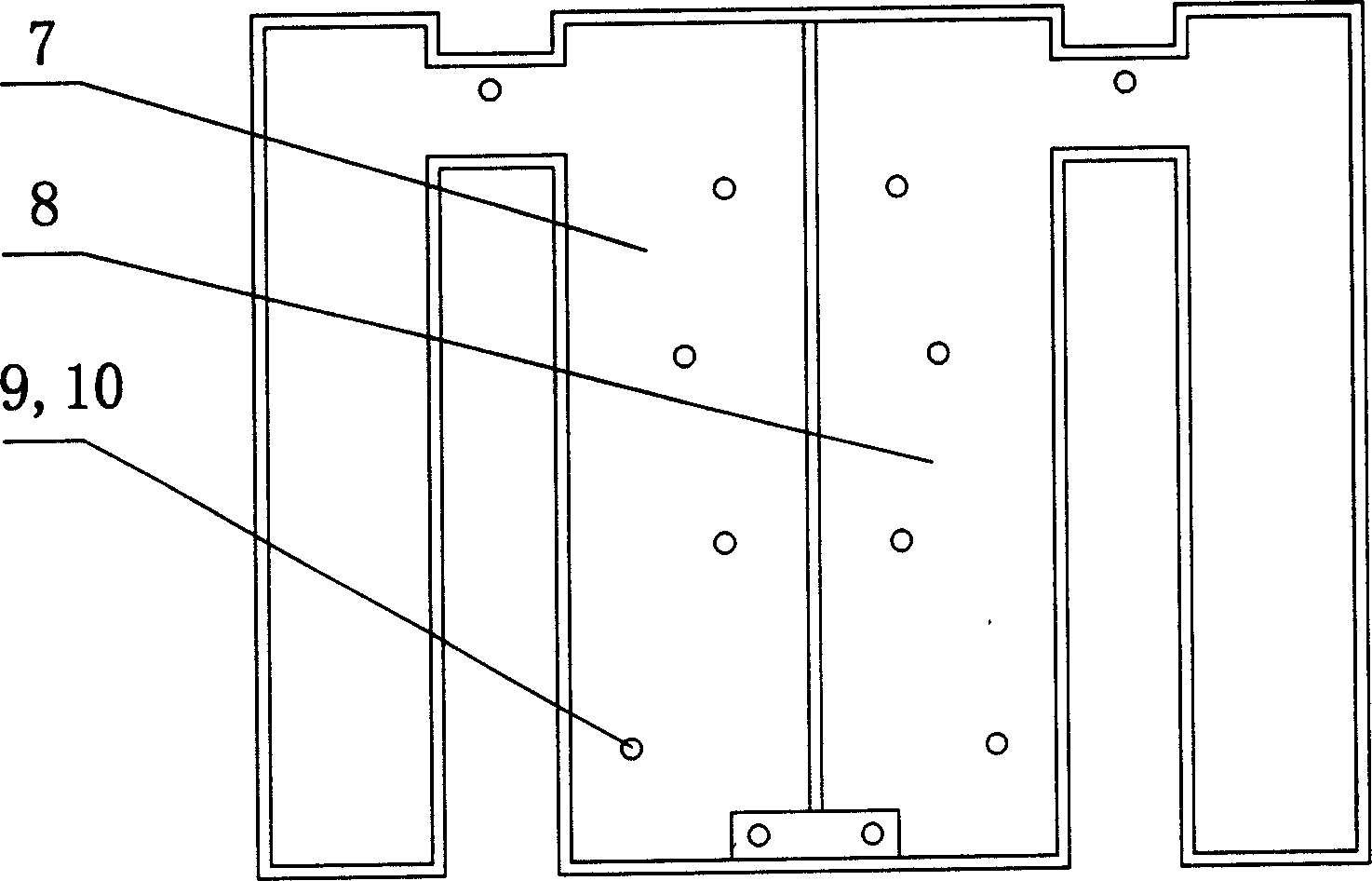

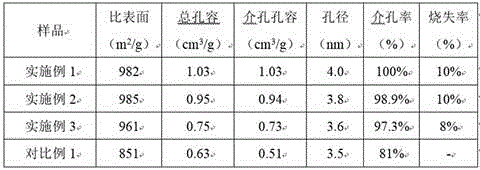

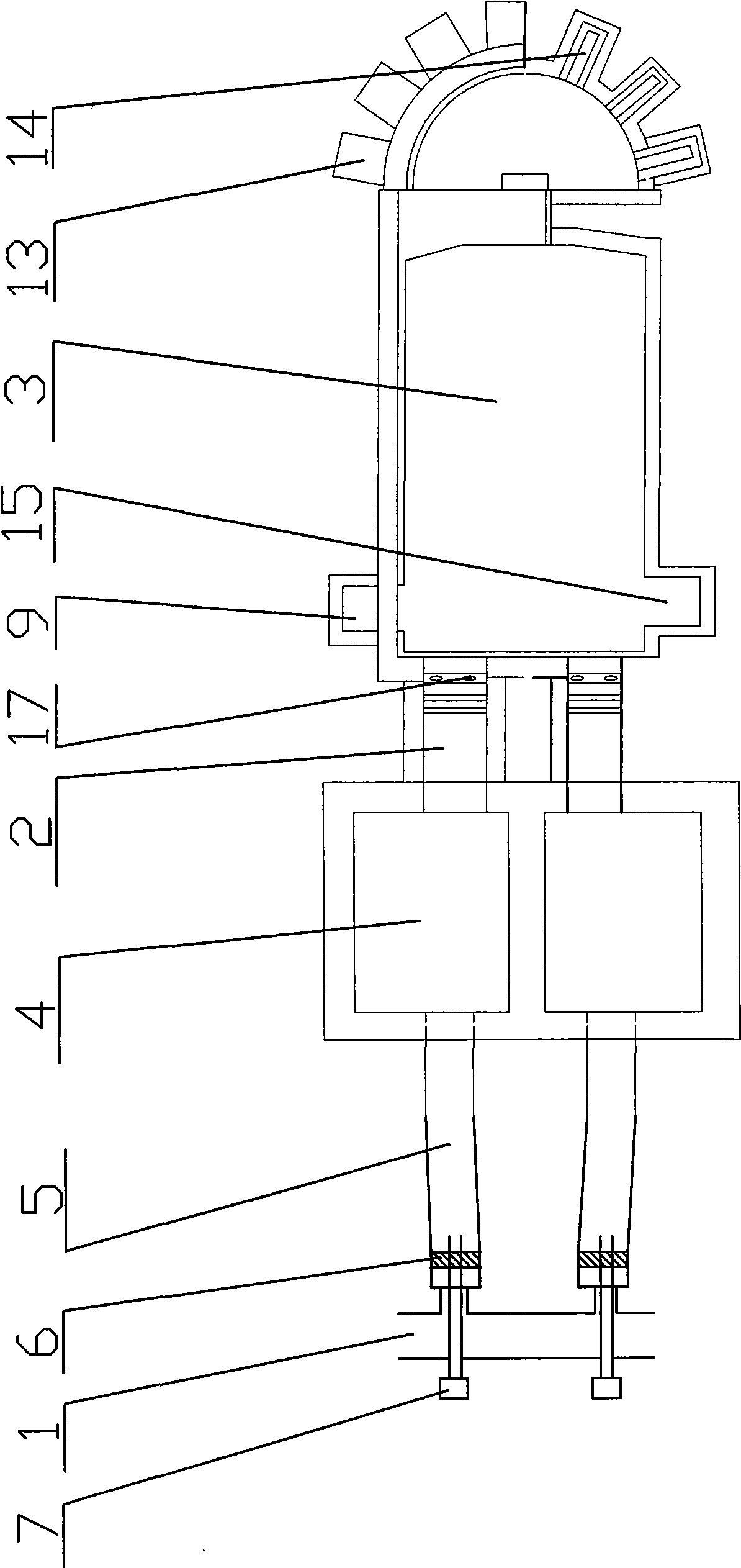

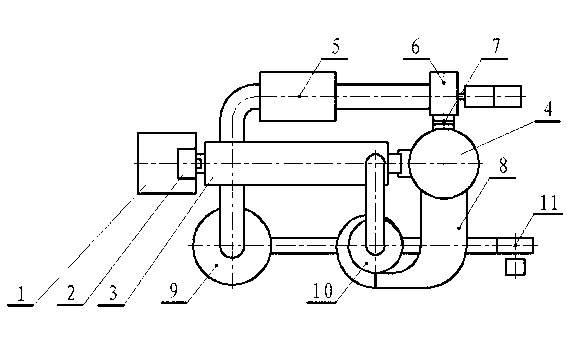

Perlite production equipment

Perlite production equipment mainly comprises a raw material pit, an elevator, a rotary drying kiln, an expansion furnace, a dust remover, an induced draft fan, an air volume regulating valve, a settling chamber, a finished product bin, a cyclone material collector, an air blower and a communication air pipe. The lower end of the elevator is positioned in the raw material pit, the upper end of the elevator is connected with the rotary drying kiln, a discharge outlet of the rotary drying kiln is connected with a feed inlet of the expansion finance, the rotary drying kiln is communicated with the dust remover by a pipeline, the dust remover is connected with the induced draft fan by an air pipe and communicated with the expansion furnace via the air volume regulating valve, the expansion valve is communicated with the settling chamber, the settling chamber is communicated with the cyclone material collector, one side of the cyclone material collector is communicated with the finished product bin by an air pipe while the other side of the cyclone material collector is communicated with the air blower, the cyclone material collector is further communicated with the rotary drying kiln by an air pipe, and an integral system is in a closed-loop control state. The perlite production equipment is fast in temperature rise and easy in temperature control, ignition loss of a furnace body is little, the service life of the perlite production equipment is prolonged, expansion efficiency is improved, energy consumption is low, utilization rate is high, repair workload is low, automatic control is realized, labor is saved, an operating environment is enhanced, and emission of greenhouse gases is reduced.

Owner:ZUNYI CITY GUI KE TECH

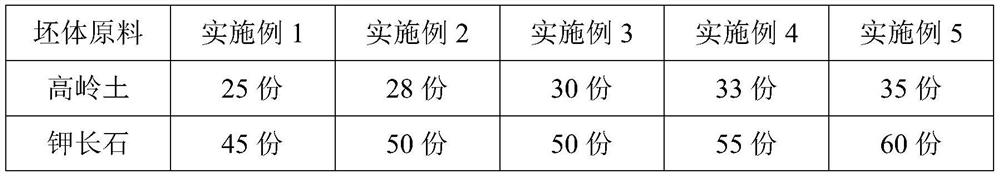

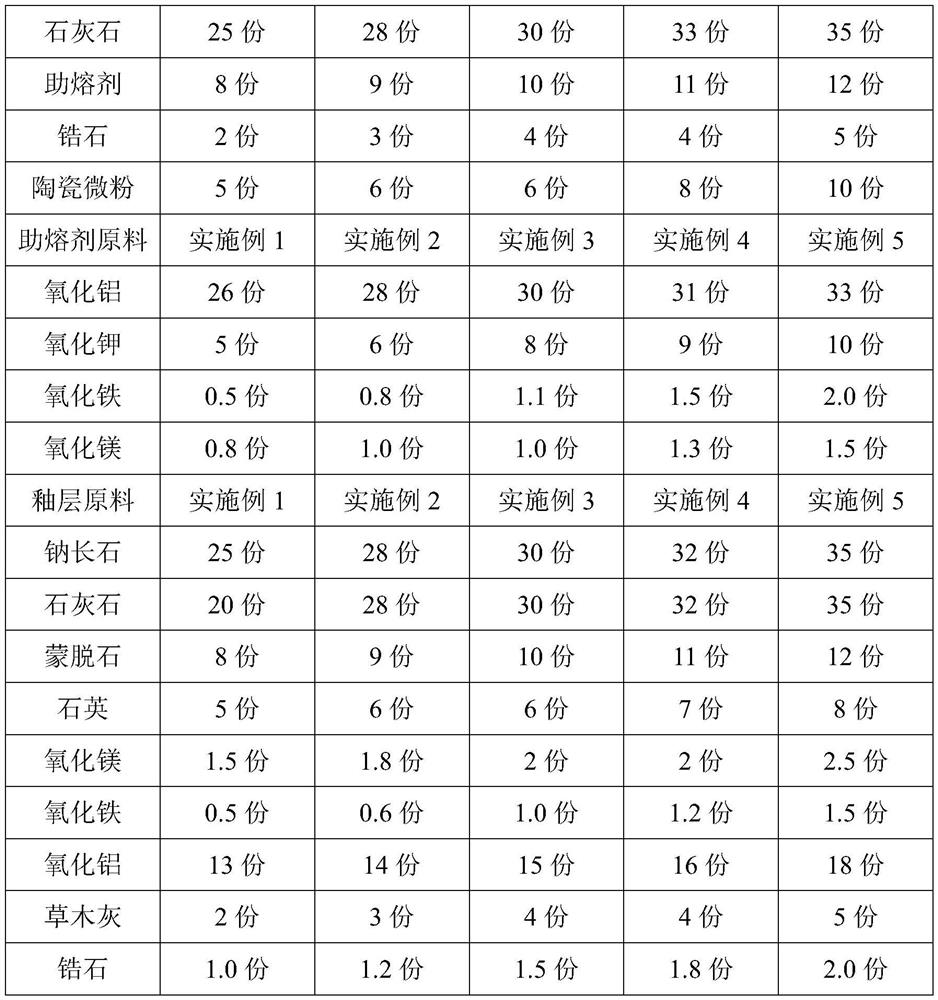

High-strength white porcelain glaze ceramic product and preparation method thereof

The invention provides a high-strength white porcelain glaze ceramic product and a preparation method thereof, the high-strength white porcelain glaze ceramic product comprises a body material and glaze, the body material comprises the following raw materials: kaolin, potassium feldspar, limestone, a fluxing agent, zircon and ceramic micropowder; and the glaze comprises the following raw materials: albite, limestone, montmorillonite, quartz, magnesium oxide, iron oxide, aluminum oxide, plant ash and zircon. The preparation method of the high-strength white porcelain glaze ceramic product comprises the following steps: 1, preparing raw materials; 2, performing biscuit firing of the green body; 3, preparing glaze water; and 4, glazing and firing. The ceramic product manufactured by adopting the raw materials and the manufacturing process provided by the invention is smooth and bright in color and luster, is milky white like congealed fat, shows pink or milky white in glaze under illumination, and has the characteristics of high glaze brightness, fine porcelain, firmness, durability, easiness in cleaning and difficulty in breaking.

Owner:FUJIAN DEHUA FIVE CONTINENTS CERAMIC MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com