Patents

Literature

102results about How to "Strong desulfurization ability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

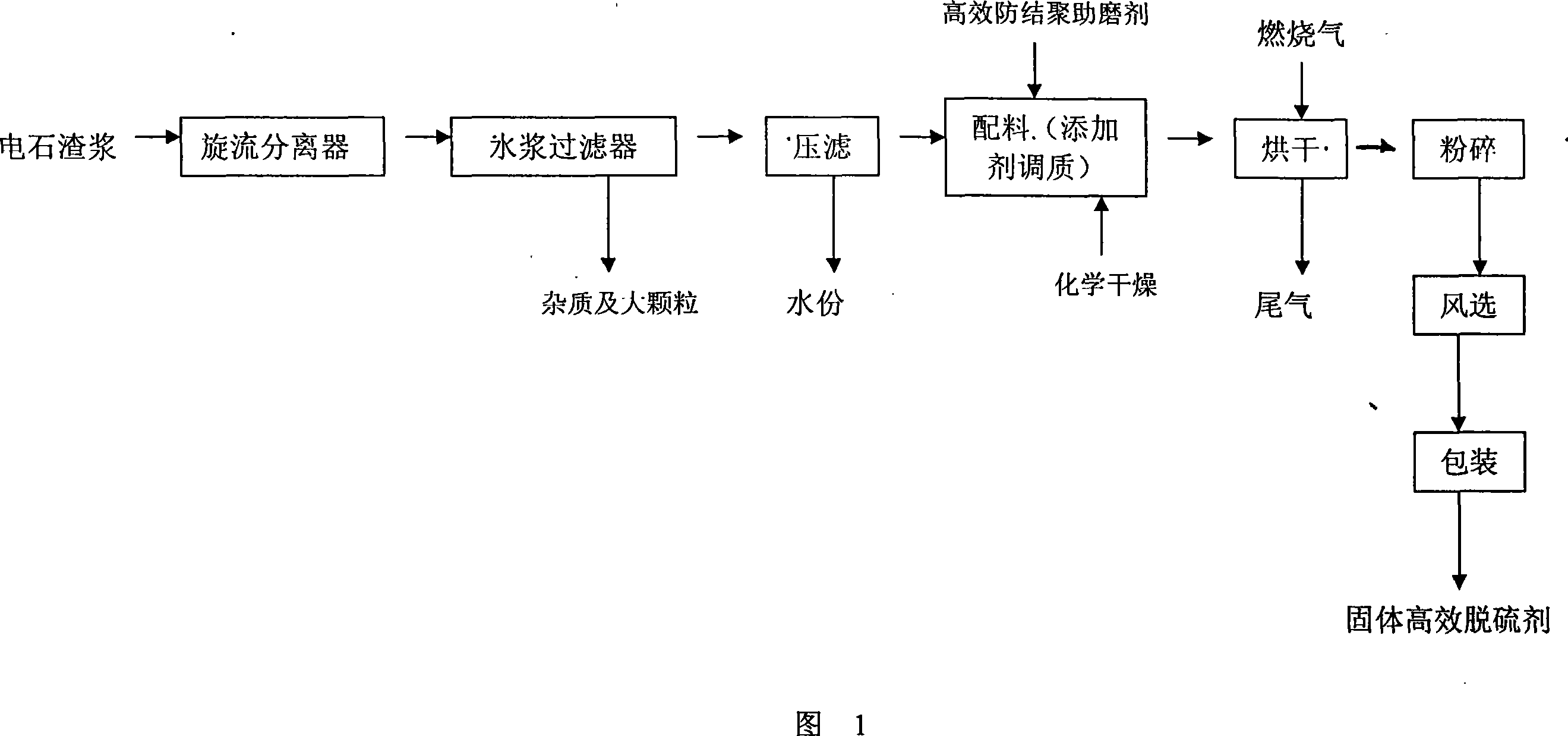

Method for preparing high-performance solid desulfurizing agent by carbide slag slurry

InactiveCN101168117AHigh activityStrong desulfurization abilityDispersed particle separationWinnowingFilter cake

The invention relates to a method of producing a highly-effective solid desulfurizer by carbide slag grout. The invention is characterized in that the carbide slag grout is centrifugally separated, filtered and filter-pressed, then a desiccating agent and a highly-effective anti-coalescing grinding aid are added to a gotten filter cake, and then the filter cake is ground, consequently the process is finished after being packed. The invention produces the highly-effective solid desulfurizer with high activity, high desulfurization and fine grain size by processing purifying, separation, tempering, drying, abrading, winnowing, packing and the like to calcium hydrate which is the main component of the carbide slag grout, thereby achieving the purpose of changing the waste into valuable, realizing the effect of recycling economy, simultaneously saving land resources and eliminating one serious factor of environmental pollution.

Owner:国能英力特能源化工集团股份有限公司 +1

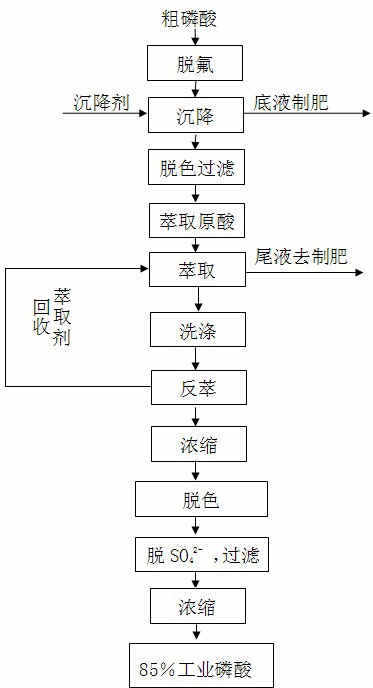

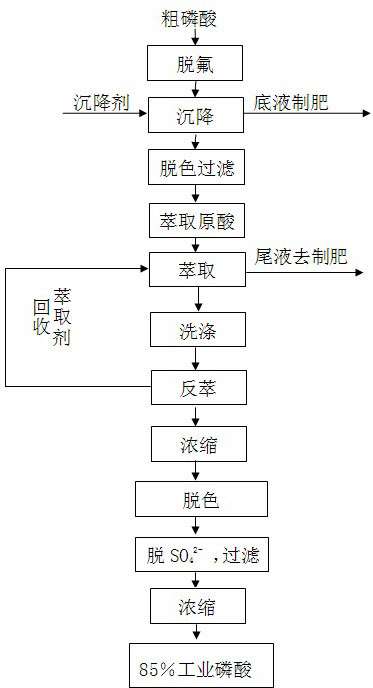

Method of using composite extracting agent for extraction and refining of phosphoric acid prepared through wet process

ActiveCN102616765AHigh selectivityWide extractable concentration rangePhosphorus compoundsAlcoholFiltration

The invention provides a method of using a composite extracting agent for extraction and refining of phosphoric acid prepared through a wet process. The method successively comprises the procedures of pretreatment, extraction and refining and post-treatment, wherein in the procedure of pretreatment, the content of solid in extracted raw acid obtained after condensation, defluorination, sedimentation, decolouring and filtration is less than 0.05 wt%, in the procedure of extraction and refining, a composite extracting agent is used for countercurrent contact extraction and comprises ketone ether, alcohol and ester, the weight ratio of ketone ether to alcohol to ester is 60-80: 15-20: 5-15, the ketone ether comprises ketone and ether and the weight ratio of ketone to ether is 95-60: 5-40, and in the procedure of post-treatment, condensation, decolouring, desulphurization, condensation and filtration are carried out so as to obtain the product of 85% industrial phosphoric acid. The invention has the advantages of low requirements to extracted raw acid, low production cost, a good extraction effect and capability of producing more products of industrial phosphoric acid.

Owner:吴杰

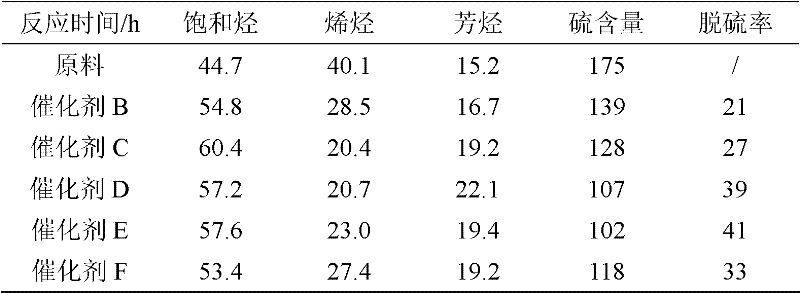

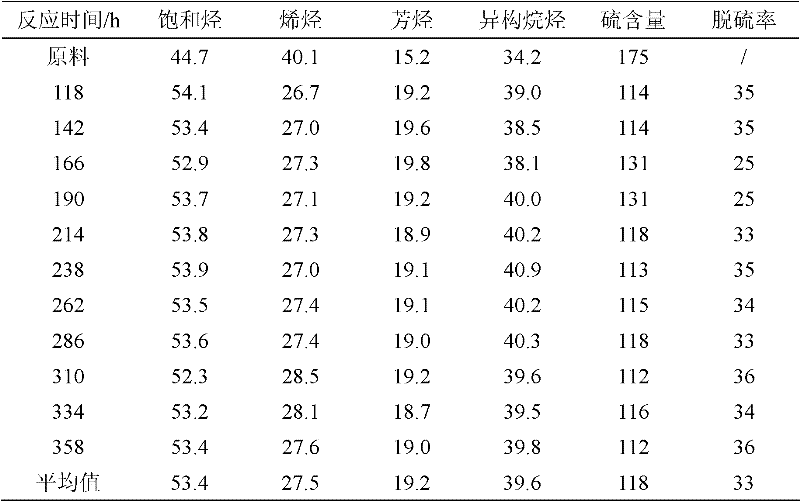

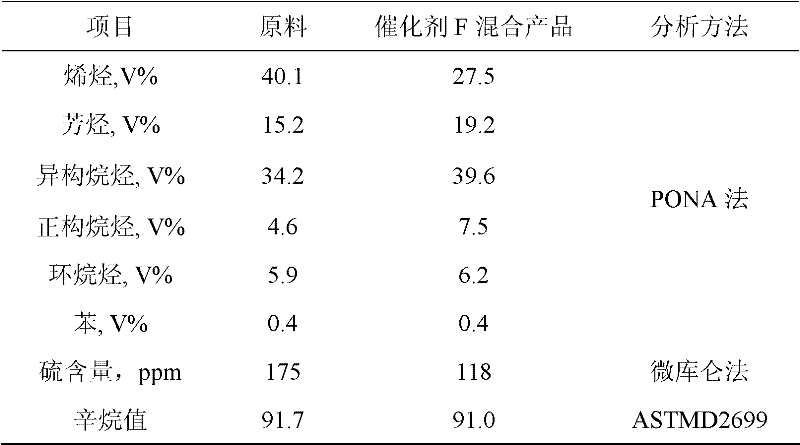

Gasoline aromatization and isomerization reforming catalyst and preparation method and applications thereof

ActiveCN102500409AGood aromatizationGood isomerization activityMolecular sieve catalystsHydrocarbon oils refiningMolecular sieveBenzene

The invention discloses a gasoline aromatization and isomerization reforming catalyst. The catalyst comprises the following components by weight percent: 0.1-5% of oxide of the metal in IIB group, 0.1-3% of lanthanide metal oxide, 0.1-5% of oxide of the element in VA group, 50-80% of nanosized HZSM-5 and 20%-40% of alumina. The preparation method comprises the following steps: using a nanosized ZSM-5 molecular sieve to prepare the nanosized HZSM-5 carrier, performing hydrothermal treatment, and adopting the isovolumetric impregnation method to load an active component I and an active component II and obtain the target catalyst. The catalyst provided by the invention has good aromatization activity and isomerization activity and a certain desulfurization capacity; and the olefin content (V) of the gasoline product which is prepared by using the catalyst provided by the invention is no more than 30%, the aromatic content (V) is no more than 35%, the benzene content (V) is no more than 1% and the loss of the octane value is no more than 1.

Owner:DALIAN UNIV OF TECH

Desulfurizing and dephosphoring refining agent for external refining of molten steel

InactiveCN1974797ASolve the problem of desulfurization and dephosphorization in refining outside the furnaceQuality improvementAdhesiveManganese

The present invention belongs to the field of ferrous alloy smelting treating agent, and is especially treating agent for external refining of molten steel. The treating agent contains BaO 35-70 wt%, BaF2 10-35 wt%, MnO 5-13 wt%, CaO 4-10 wt%, Al2O3 2-10 wt% and adhesive and impurity for the rest. It is used for desulfurzing and dephosphoring in external refining of molten steel. Compared with available technology, the present invention has the advantages of simultaneous external molten steel refining, desulfurzing and dephosphoring, raised production efficiency, improved molten steel quality, etc.

Owner:安徽中实冶金材料工程技术研究有限公司

Deep desulfurizer for refining ultra-low-carbon steel and manufacturing method thereof

The invention discloses an ultralow carbon steel refining deep-desulfurizer and making method, which comprises the following parts: 60%-69% CaO, 11%-20% Al, 5%-10% MgO, 5%-10% SiO2, 1%-5% Al2O3, 0.5%-1.2% Fe2O3, 1%-3% CaF2, 1%-3% B2O3, 1%-3% BaO and impurity. The making technique comprises the following steps: blending; grinding the material with grain size not more than 1mm; inactivating the material; drying; draining the trace element of water; packing.

Owner:ANGANG STEEL CO LTD

Efficient composite desulfurizer

The invention discloses a high-efficiency compound desulfurizing agent, relating to the ladle desulphurization accessory field. In the existing ladle desulphurization, the uniserial desulfurizing agent is uniformly adopted, with narrower function, and non-agreeable desulphurization effect. Aiming at the condition that small and medium-sized steel mills do not have liquid iron pretreatment systems or desulphurization stations, and do not have powder spraying desulphurization devices, the desulfurizing agent of the invention adopts ingredient with multi-components, namely, the compound desulfurizing agent consisting of limestone, calcined soda, fluorite, calcium carbide, magnesium powder and caustic-calcined magnesite, with the weight proportion of 40 to 50, 10 to 20, 5 to 15, 10 to 20, 4 to 6 and 5 to 15 sequentially. The desulfurizing agent has the following advantages that: 1. the integral desulphurization capability is strong, and the sulfur content can be reduced to 20ppm; 2. sulfur substance can be contained, and resulfurization phenomenon can not be generated; 3. the desulfurizing agent can be directly poured, and equipment and investment are not needed to be increased; and 4. the desulphurization speed is high.

Owner:西峡县福盈冶金材料有限公司

Oxidation desulfuration method based on modified MCM-41 anchored heteropolyacid catalyst

InactiveCN102134508AEasy to prepareHigh catalytic activityMolecular sieve catalystsTreatment with plural serial refining stagesFiltrationRoom temperature

Owner:SHANDONG UNIV

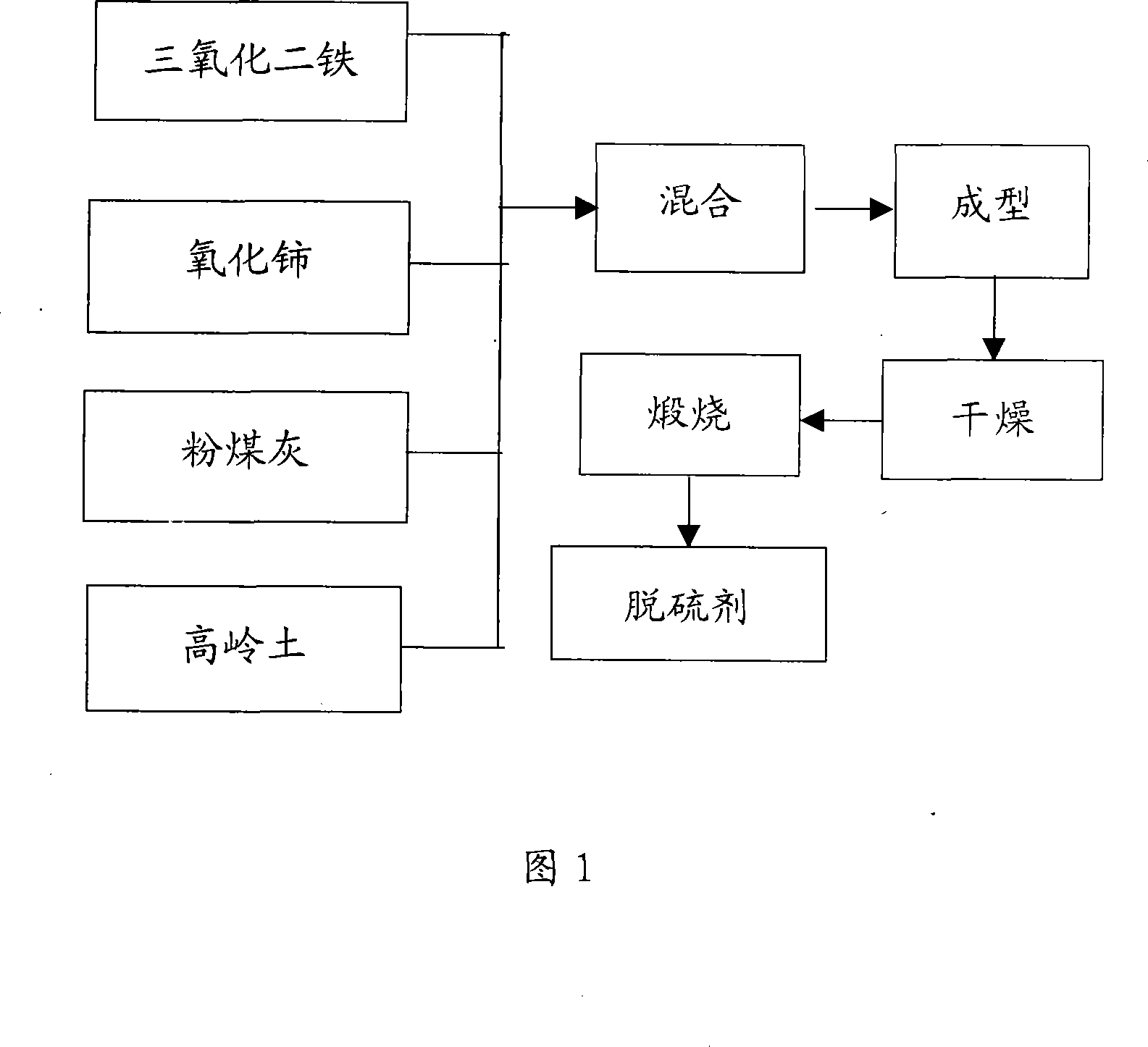

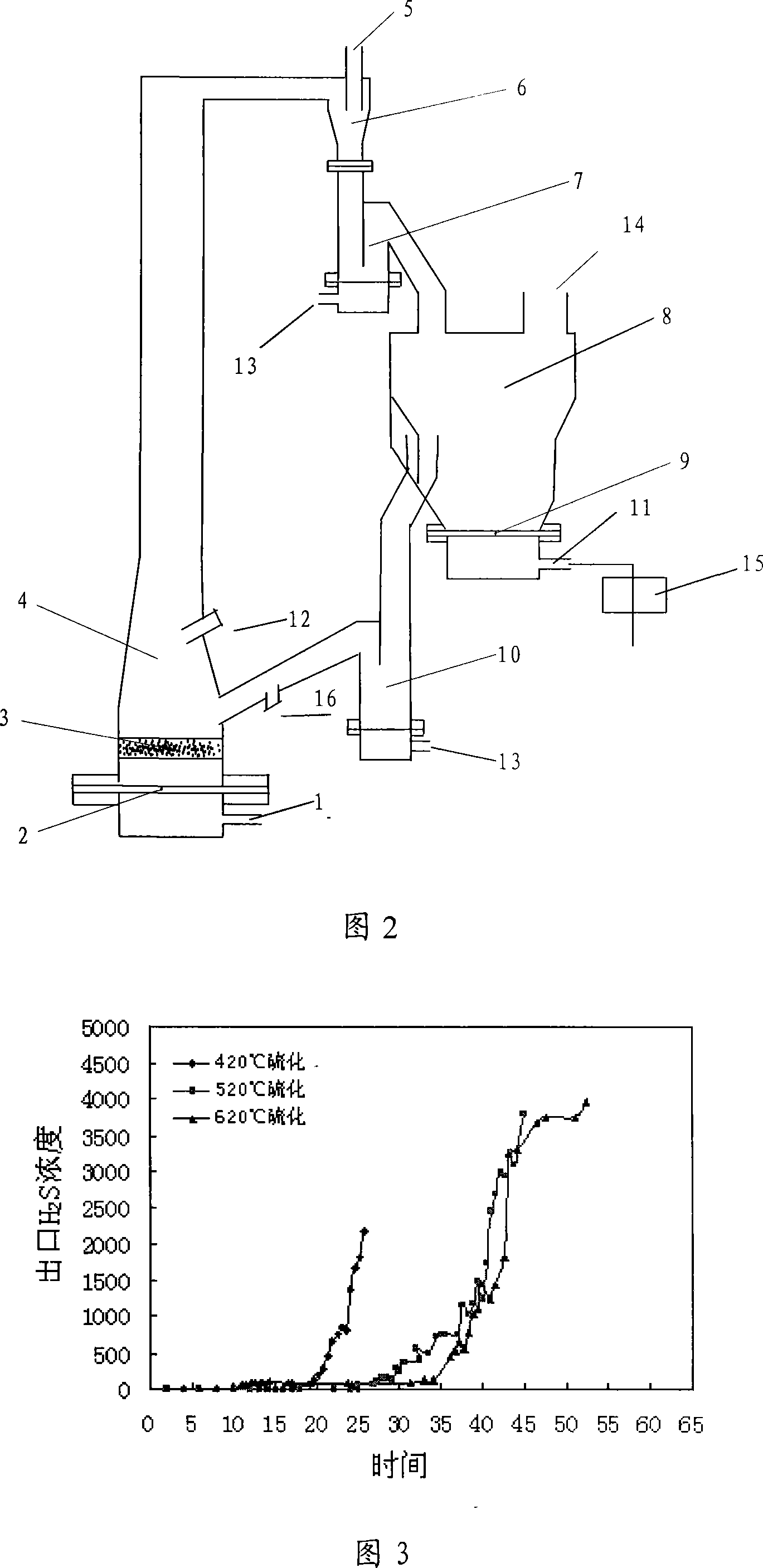

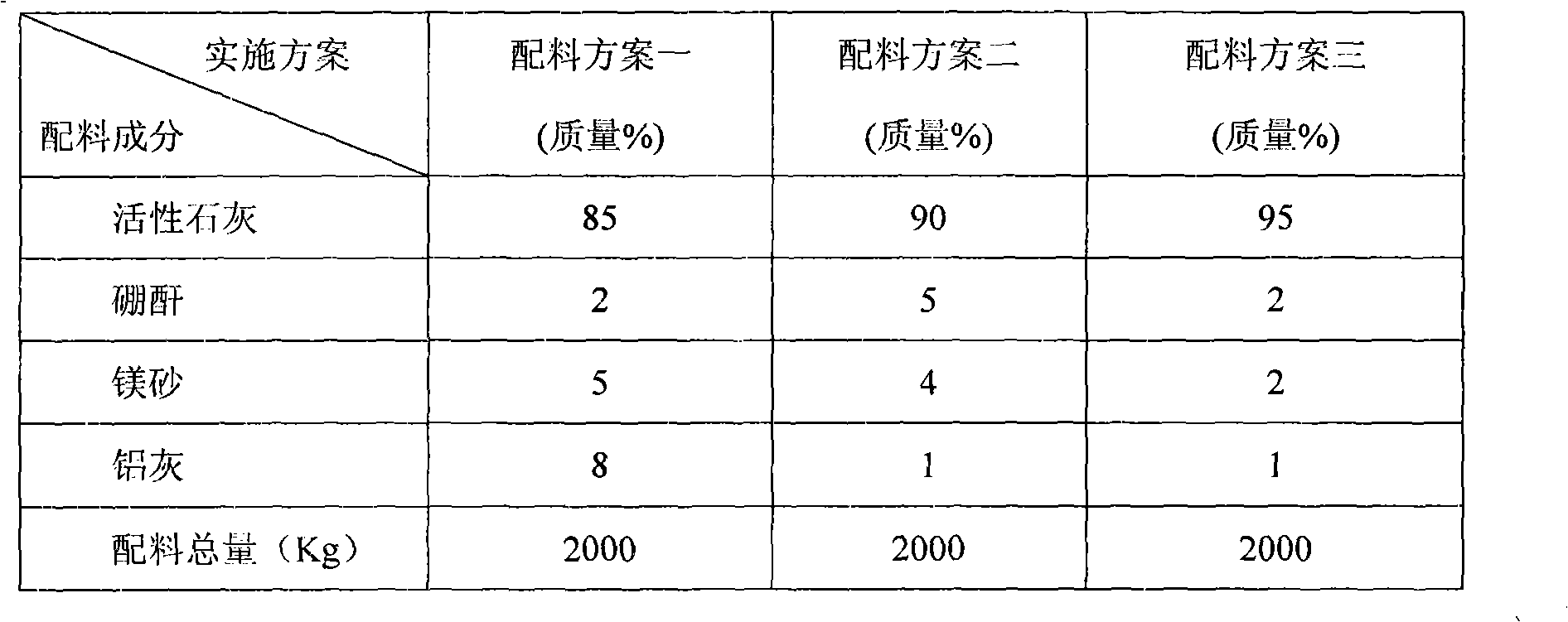

High-temperature coal gas desulfurizer using coal ash as carrier and desulfurization device thereof

InactiveCN101235324ASimple manufacturing processLow costCombustible gas purificationVulcanizationSulfur

The invention aims at solving the problem such as low desulphurization activity of desulfurizer, low mechanical strength, poor regeneration property and higher cost and the like, which discloses a high temperature desulfurizer which uses coal ash as carrier and a desulfurization device , the method comprises utilizing mechanical mixing method to mix multicomponent metal oxide, coal ash and adhesive of the activity component through machine, then extruding into strip shape by utilizing a self-made desulfurizer, drying formed desulfurizer under the temperature of 100-200 DEG C, and calcining under the temperature of 600-1000 DEG C, desulfurizer which is calcined is directly used to desulfurize coal gas under the high temperature. High-temperature desulfuration of hot coal gas adopts a circulating fluidized bed to achieve continuous desulfurization and regeneration, and desulfurizer can effectively remove H2S in high-temperature coal gas under the temperature scope which is 400-750 DEG C. Desulfurizer after being vulcanized can be regenerated in a fluid bed regenerating device. The high temperature desulfurizer has the advantages of simple preparation technique, simple equipment and low cost, which has higher vulcanization activity and sulfur capacity, excellent desulfurizing capacity and higher mechanical strength, and opens up a new approach which utilizes ash from power plant to be carrier to prepare high-temperature coal gas desulfurizer.

Owner:SHENYANG INST OF AERONAUTICAL ENG

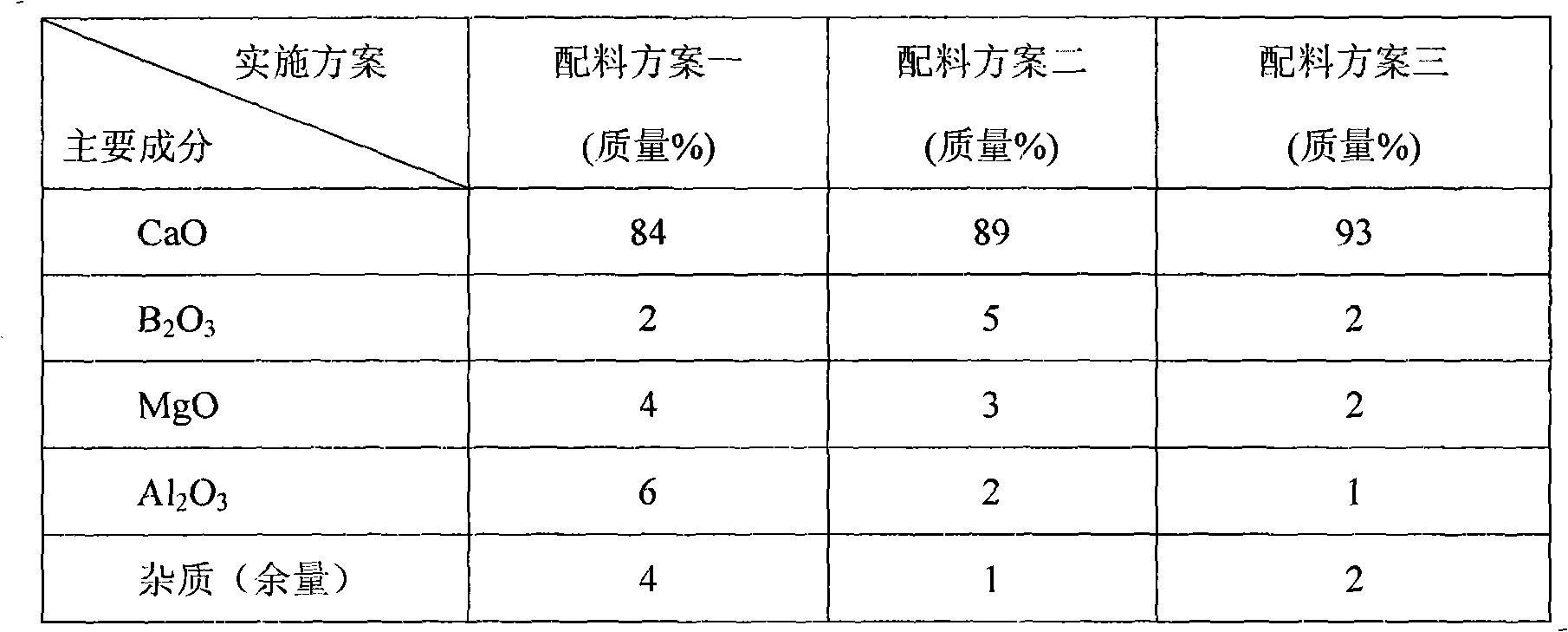

Ultrahigh basicity low aluminum fluorine-free refining slag and preparation method and use method thereof

InactiveCN101643822AEliminate pollutionImprove stabilityProcess efficiency improvementFluorine freeAluminium

The invention relates to an ultrahigh basicity low aluminum fluorine-free refining slag and a preparation method and a use method thereof, belonging to the technical field of steelmaking and refining.The refining slag comprises the following chemical compositions by weight percent: 85-95% of CaO, 2-10% of B2O3, 2-10% of MgO, 1-10% of Al2O3 and less than 5% impurities, wherein the content of harmful impurities such as sulfur, phosphorus and the like is as low as possible. The refining slag is prepared by using industrial reagents, namely active lime, boron anhydride, magnesia and aluminium ashto prepare, premelting at 1350-1450 DEG C, cooling, crushing to 2-10mm and performing moisture proof packaging. The slag series can be used for the refining and slag forming of LF, RH and CAS and therefining slag is added in steel ladle in the process of argon blowing after the molten steel preliminary deoxidation and the reduction treatment of the residue of steel ladle. The refining slag of the invention has strong desulphurizing and dephosphorizing abilities and no pollution, the slag inclusion generated through absorption and deoxidation has higher ability, the deoxidation effect of steel is improved, the spreadability is good, the suction and oxidation of the molten steel are reduced, the refining devices do not adhere to slag, the preparation process is simple, and the product is easy to store and use.

Owner:JIANGSU UNIV

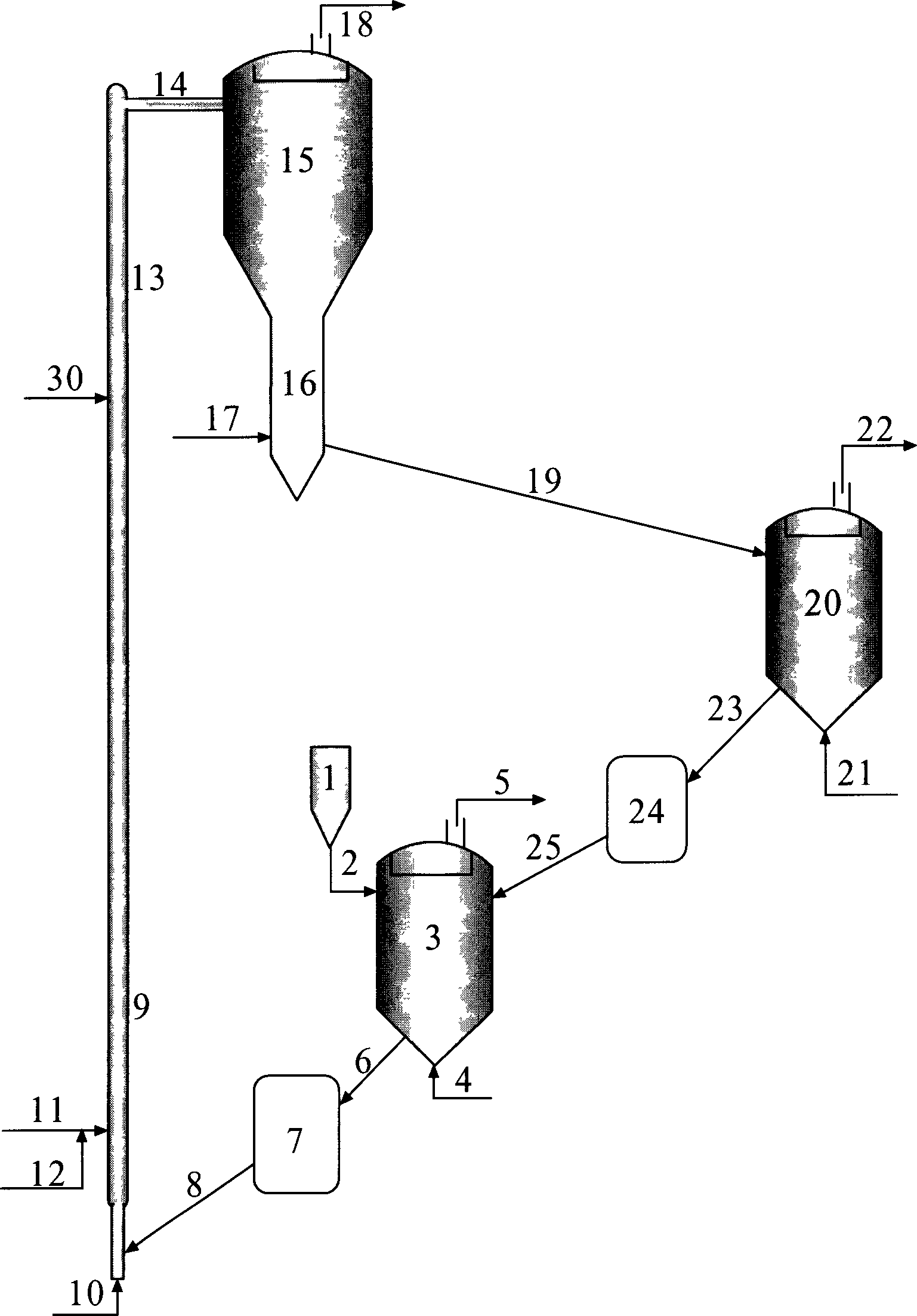

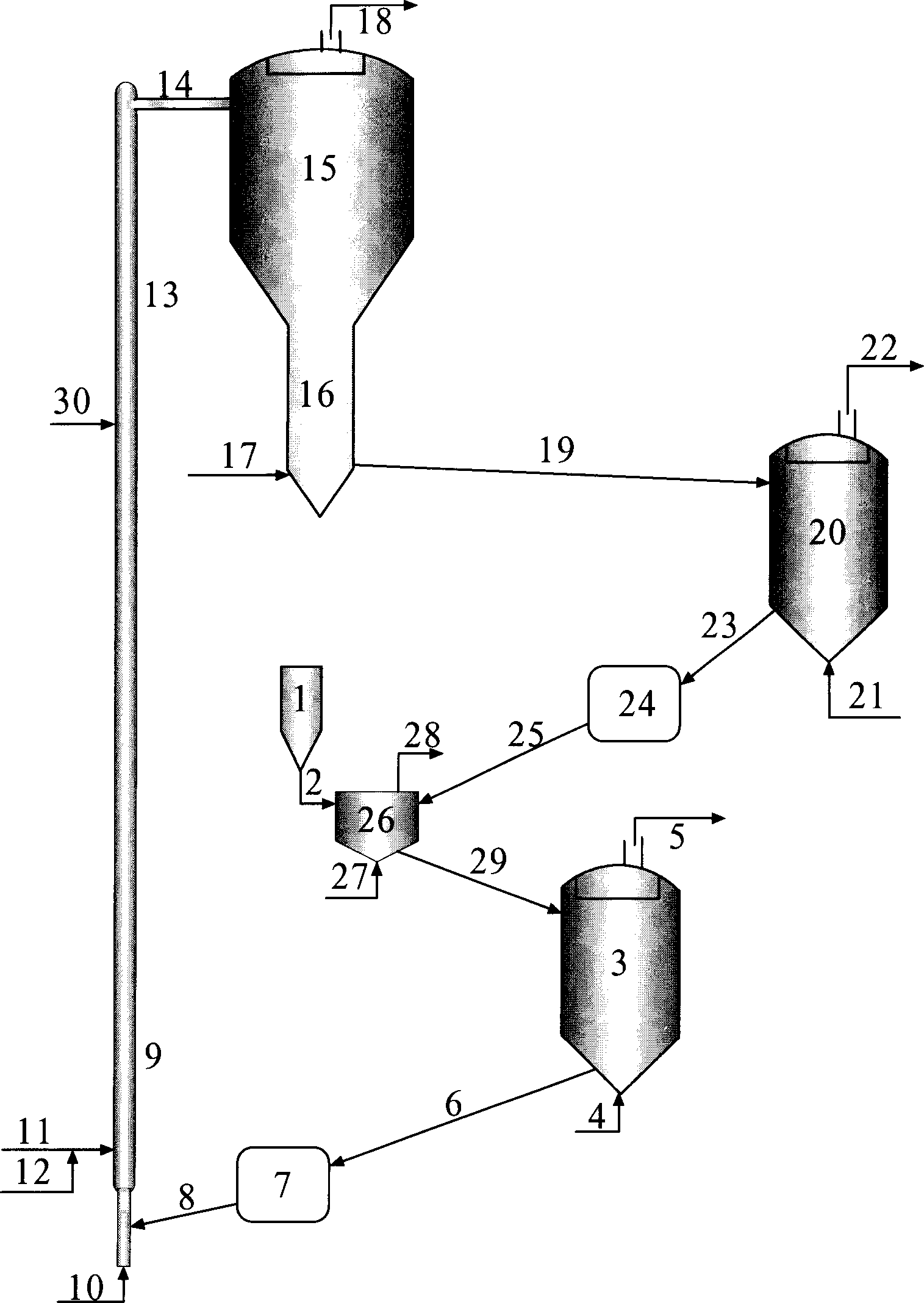

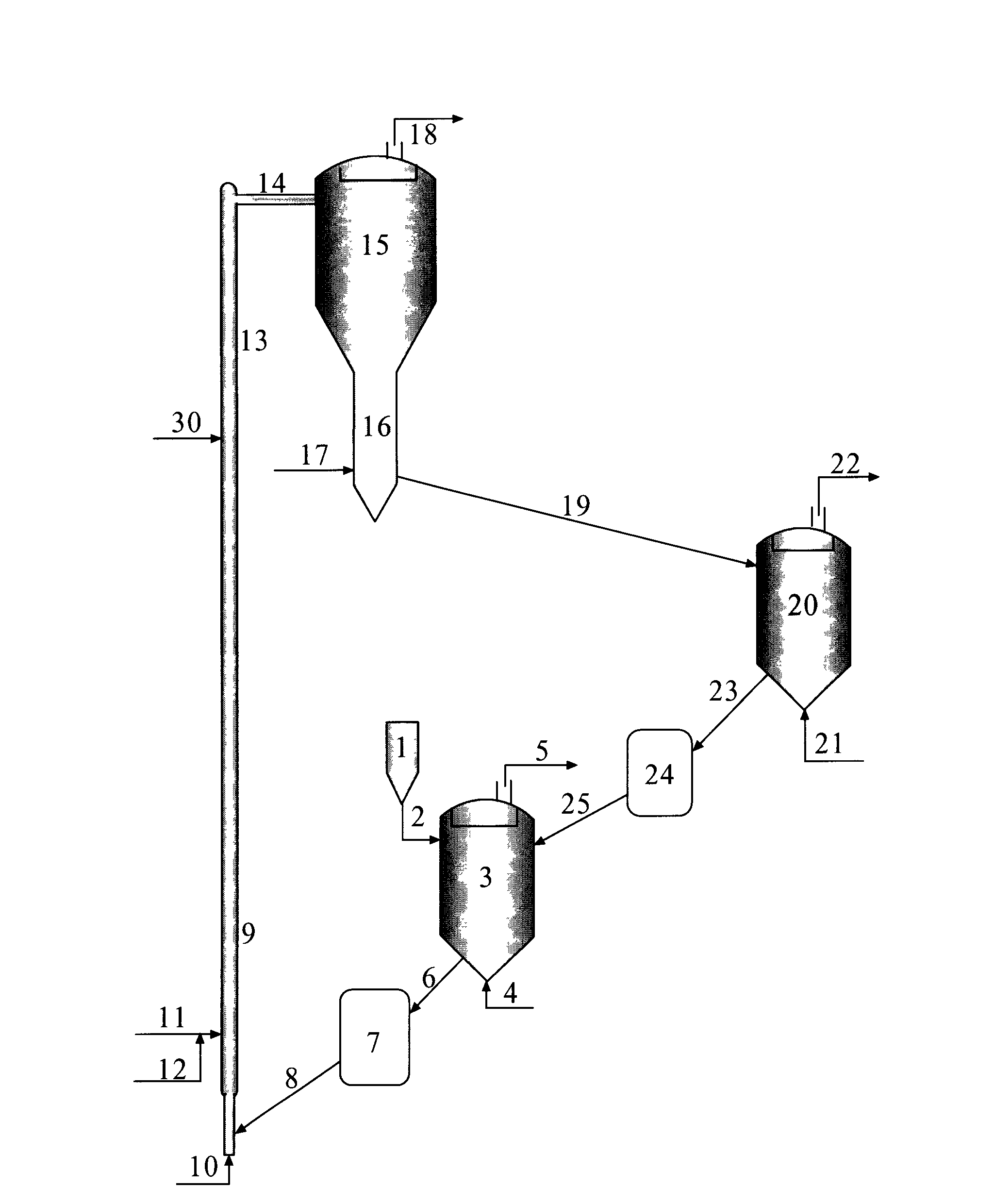

Powder preparation additive for outside-stove refining dephosphorization, removing fine foreign matter and its manufacturing method

The invention relates to an external refining method for microalloy steel and special steel, in particular to a powder additive for external refining desulphurization and fine inclusion removal and a preparation method thereof. The powder additive is the preferred powder additive for refining desulphurization and fine inclusion removal of various microalloy steel or special steel. The powder additive is prepared by mixing raw materials of low melting point premelting slag powder, calcium fluoride, calcium carbonate or magnesium carbonate or a mixture of the calcium carbonate and the magnesium carbonate, calcium oxide or magnesium oxide or a mixture of the calcium oxide and the magnesium oxide, and adhesive according to a formula. The method has scientific formula and simple and reasonable process, can effectively remove inclusions in molten steel, can realize the quick refining desulphurization of the molten steel until the content of sulfur is lower than 0.0030 percent proven by application, is high in efficiency, steady and short in time, can meet the requirements of different molten steel on the content of the sulfur, greatly improves the quality of refining steel, and reduces smelting cost.

Owner:ANGANG STEEL CO LTD

Molten iron desulfurizing agent, preparation method thereof and desulfurization method using molten iron desulfurizing agent

The invention discloses a molten iron desulfurizing agent, a preparation method thereof and a desulfurization method using the molten iron desulfurizing agent. The molten iron desulfurizing agent contains the following ingredients in percentage by weight: 55 to 70 percent of CaO, 5 to 20 percent of Al2O3, 2 to 4 percent of SiO2, 2 to 15 percent of MgO and 2 to 10 percent of CaF2. According to the invention, the molten iron desulfurizing agent is sprayed onto molten iron for desulfurizing, N2 is used as a powder-carrying gas, and the desulphurizing slag is melted based on the dynamic conditions of the gas and the physical heat of the molten iron, thus the desulfurization purpose is achieved; and after the desulfurization and slagging off treatment, the sulfur content of the molten iron can be reduced to below 0.006%.

Owner:HEBEI IRON & STEEL GRP

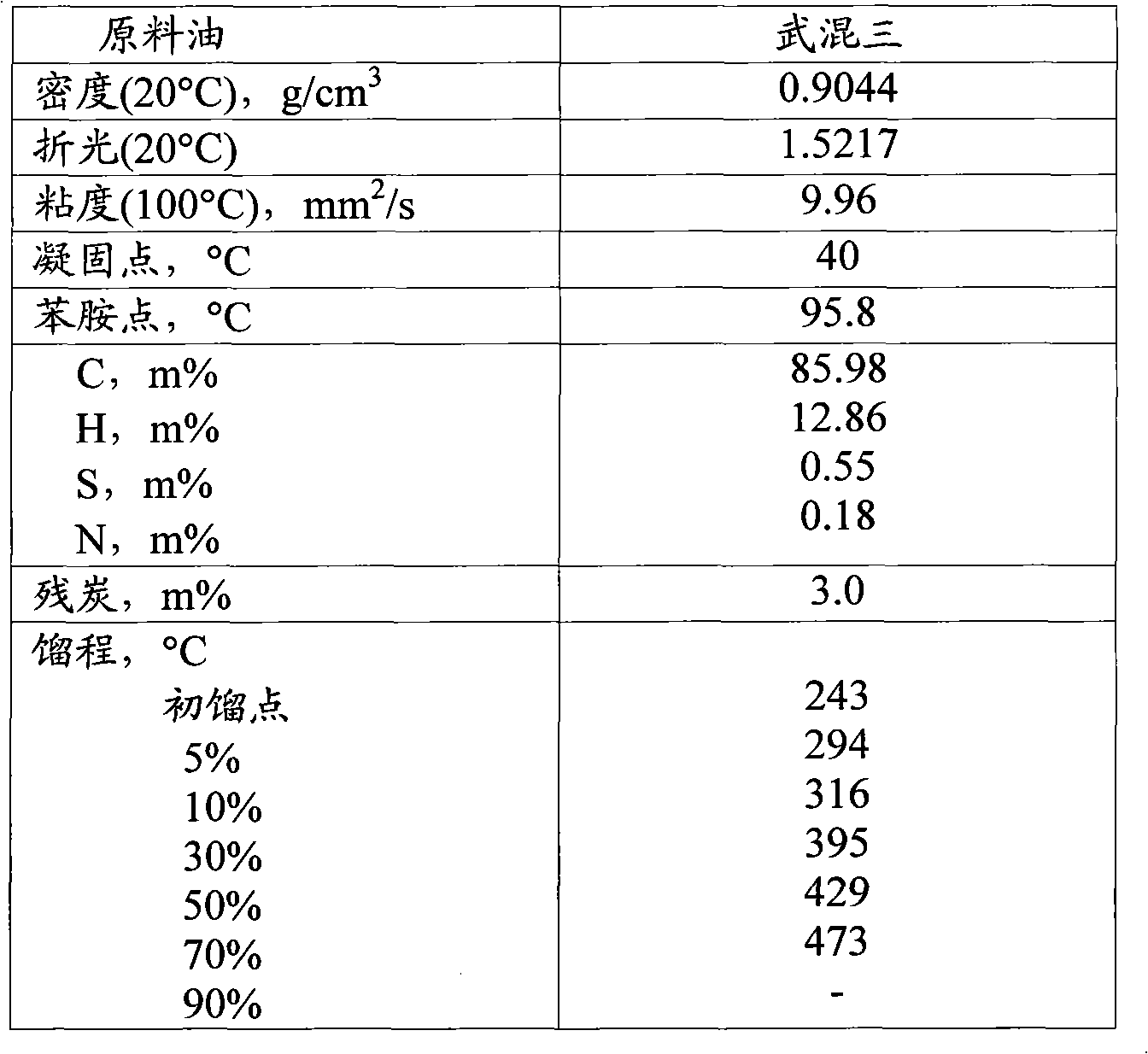

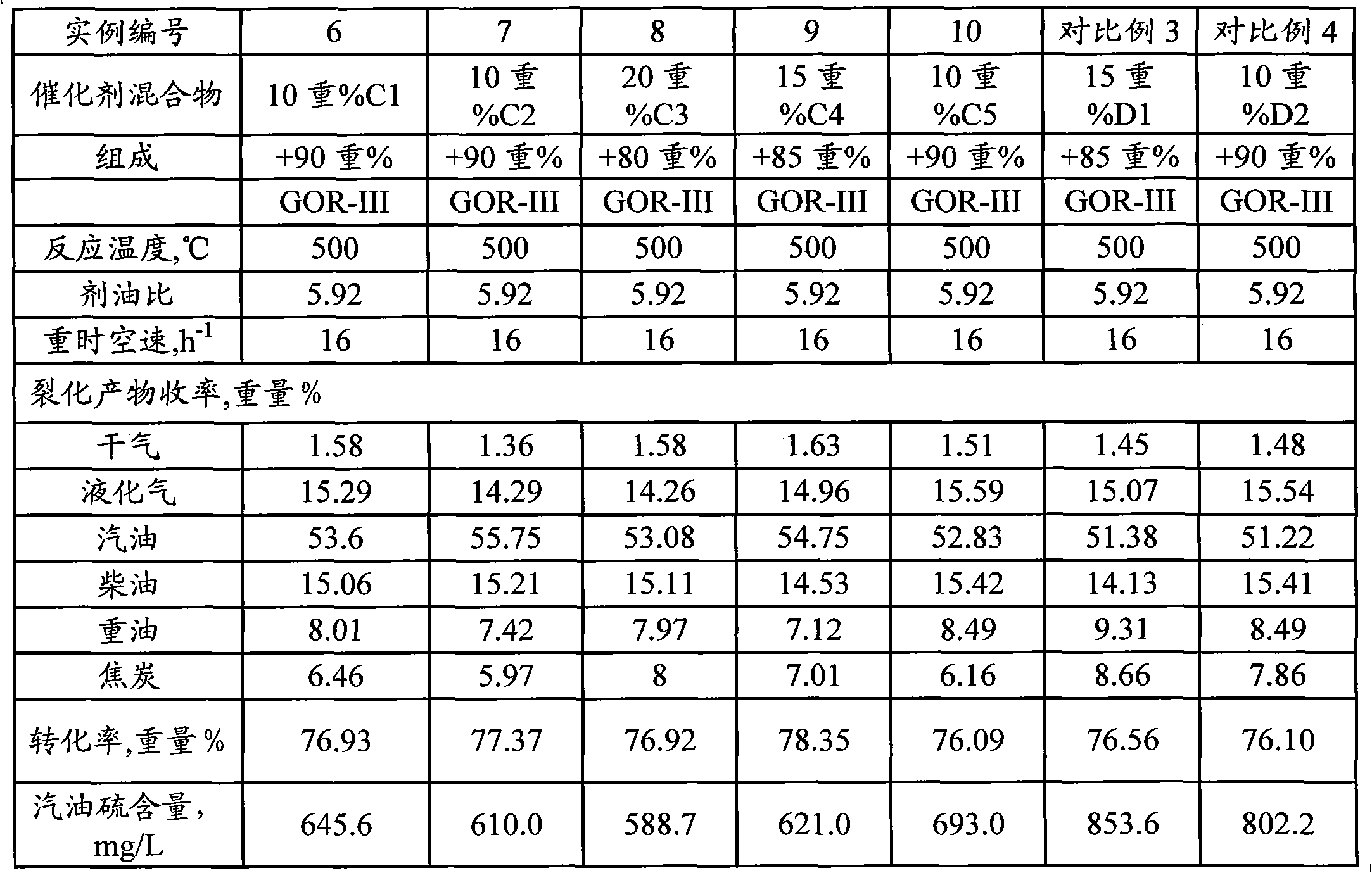

Method for cracking hydrocarbon oil

ActiveCN1600839AStrong desulfurization abilityStrong ability to convert heavy oilHydrocarbon oil crackingChemistryProduct gas

This method aims at cracking hydrocarbon oil, under cracking condition, raw material hydrocarbon oil contactes with catalyst, which is already contacted with reducing gas atmosphere. Then proceeded are procedures of: separating cracking produced from catalyst, regenerating catalyst, said catalyst being contacted with reducing gas atmosphere. In above-said procedures, the catalyst is a mixture of cracking-aid agent and catalytic-cracking catalyst, wherein: said cracking-aid agent comprising a metal component and a carrier; the contact temp. for catalyst, contactint with reducing gas atmosphere being 100-900 deg.C, with contacting time being at least 1 second, the volume of reducing gas atmosphere is that: each ton of metal-contd. cracking catalyst, at one minute contact is not less than 0.03 m3 of reducing gas, the pressure in the reactor being 0.1-0.5 mega Pa.

Owner:CHINA PETROLEUM & CHEM CORP +1

Desulfurating agent for out-of-furnace treatment and preparation method thereof

InactiveCN101649371ASimple processHandling conditions are easy to implementEnergy consumptionAluminium oxide

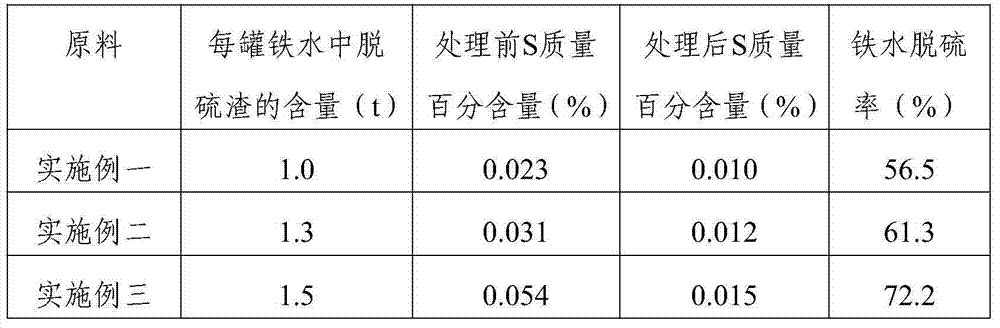

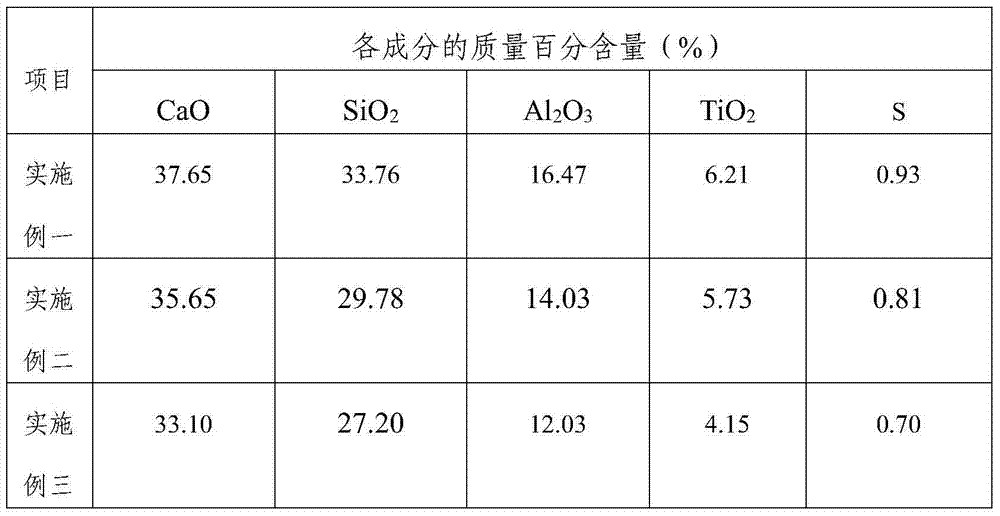

The invention relates to a desulfurating agent for out-of-furnace treatment and a preparation method thereof. The technical scheme is achieved as follows: putting waste residues of out-of-furnace treatment in water with a temperature of 80-374 DEG C according to a solid-to-liquid ratio of 1:(2-8), stirring the waste residues for 2-60 minutes and then filtering and drying the waste residues; then uniformly mixing 30-80 weight percent of the treated waste residues of the out-of-furnace treatment and 20-70 weight percent of additive and then packaging or respectively packaging. The waste residuesof the out-of-furnace treatment comprise the following chemical components by weight: 30-65 percent of CaO, 8-35 percent of SiO2, 2-30 percent of Al2O3, 0.2-3.5 percent of S and the balance of MgO, CaF2, MnO, FeO, P and other impurities. The additive is uniformly mixed and packaged or respectively packaged according to the following components by weight: 70-100 percent of lime, 0-30 percent of one of bauxite, aluminum oxide and fluorite and 1-10 percent of one of aluminum ball and calcium carbide. The invention has the characteristics of simple process, low energy consumption and low cost; and the prepared desulfurating agent for the out-of-furnace treatment has good metallurgical property and strong desulfurating capacity.

Owner:WUHAN UNIV OF SCI & TECH

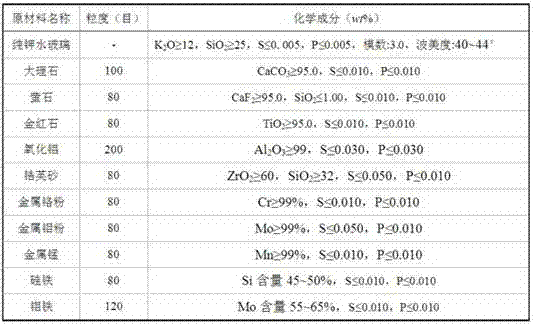

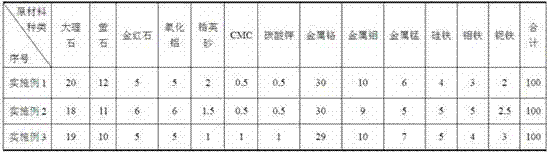

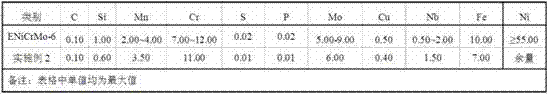

LNG structure as well as nickel-based welding rod for marine 9Ni steel welding, and preparation method thereof

ActiveCN107214434AIncrease alkalinityStrong desulfurization abilityWelding/cutting media/materialsSoldering mediaChemical compositionUltimate tensile strength

The invention discloses an LNG structure as well as a nickel-based welding rod for marine 9Ni steel welding, and a preparation method thereof. The welding rod comprises a nickel-based welding core and a coating coated on the surface of the welding core, wherein the nickel-based welding core comprises the following chemical components with percentage contents: not greater than 0.10% of C, not greater than 0.10% of Si, not greater than 0.10% of Mn, not greater than 0.10% of Cu, not greater than 0.10% of Mg, not greater than 0.005% of S, not greater than 0.40% of Fe and not less than 99.5% of Ni+Co, and the total content of the components is 100%. The welding rod disclosed by the invention is high in manufacturability, and capable of being smoothly coated in a pressing manner during a production process, the coating of the welding rod is high in strength and good in surface quality, and the welding rod is controllable in core shift; and the chemical components of deposited metal meet standards, and weld metal is free from pores and cracks, high in normal-temperature tension and low-temperature toughness, good in mechanical property, and capable of being widely applied.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

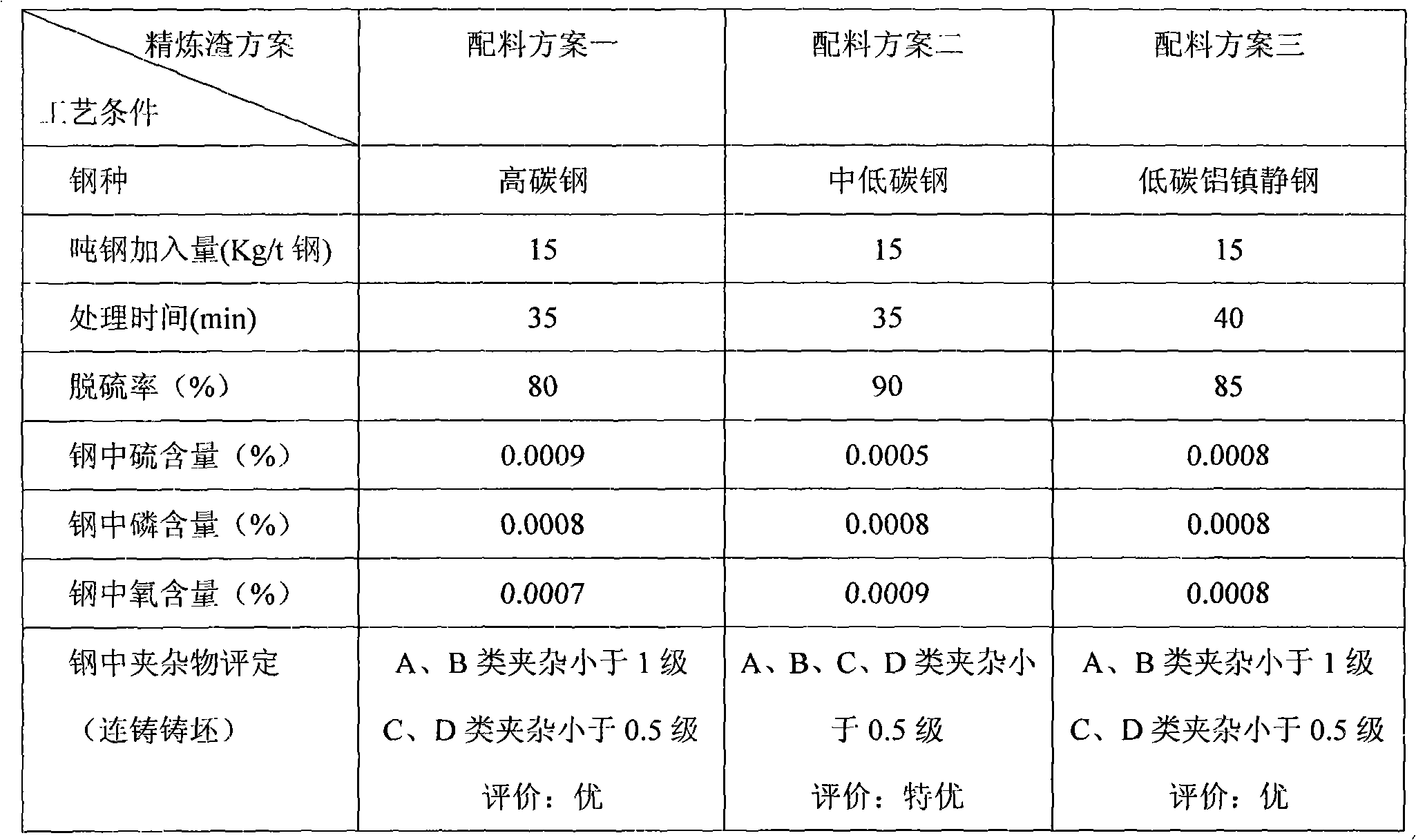

Technique for outside-stove refining dephosphorization

The invention relates to an external refining process for various microalloy steel and special steel, in particular to a process method for external refining desulphurization, which is the preferred process method for desulphurization during the refining processes of various microalloy steel or special steel. The process comprises the following steps of: a. deoxidation: molten steel is firstly subjected to deoxidation treatment to realize that alpha[O] is less than or equal to 0.0003 percent; b. the adjustment of a RH station: the positions of a RH descending tube and a blanking tube are adjusted to ensure that the RH descending tube is positioned at the opposite side of the blanking tube; c. the adding of compound spheres: after a ladle is transported to the RH station, the compound spheres are added into the molten steel at the RH station after temperature measurement sampling, vacuum pumping, clean recycle and refining are finished; and d. continuous casting: the continuous casting adopts the whole-process protection. Proven by application, the process has strong desulphurization ability with a desulphurization rate between 60 and 90 percent, can realize the refining desulphurization of the molten steel until the content of sulfur is lower than 0.0010 percent, greatly improves the purity of the molten steel, and reduces smelting cost.

Owner:ANGANG STEEL CO LTD

Method for desulfurizing molten iron

The invention discloses a method for desulfurizing molten iron, and belongs to the technical field of steelmaking. The method comprises the following steps: when discharging iron from a blast furnace, adding active lime into a molten iron tank, feeding a Ca wire into the molten iron by using a wire feeding machine for desulfurizing after the molten iron arrives at a steel mill, fishing out the desulfurizing residues by using a slag removing rake, and then adding a heat insulation agent into the molten iron. The method for desulfurizing molten iron disclosed by the invention needs less time and can be used for effectively reducing the loss of molten iron temperature in the desulfurizing process, the method of feeding the Ca wire to desulfurize the molten iron is adopted to effectively ensure the full reaction of Ca, so that the desulfurizing effect is good, the application amount of a desulfurizing agent is small and the desulfurizing cost is low.

Owner:SHOUGANG SHUICHENG IRON & STEEL GRP

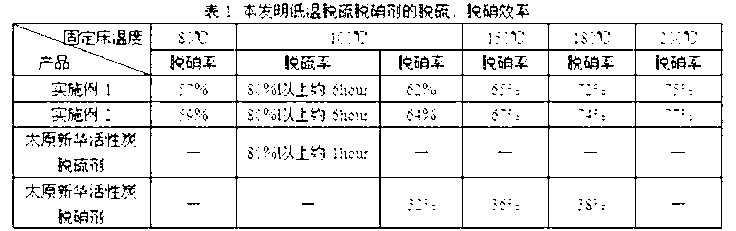

Carbon material low-temperature expansion method and preparation method of low-temperature desulphurization and denitration agent for the same

InactiveCN103341366AStrong desulfurization abilityHigh pore volumeCatalyst carriersDispersed particle separationHydrogen NitrateFlue gas

The invention relates to a carbon material low-temperature expansion method and a preparation method of low-temperature desulphurization and denitration agent for the same, in particular relates to a carbon material ultrasonic acid low-temperature expansion method and a method for preparing low-temperature desulphurization and denitration agent by means of ultrasonic activation by taking the carbon material as a carrier. The invention can be used for overcoming the defects in the existing technology, and provides an ultrasonic acidizing expansion method for expanding the carbon material quickly and efficiently under low temperature, and a quick, efficiency and energy-saving ultrasonic activation preparation method for preparing the low-temperature desulphurization and denitration agent by using the carbon material expanded by the method above. In the preparation method, one or mixture of hydrogen nitrate, sulfuric acid and hydrochloric acid with certain concentration is used as acid treatment agent, by assistance of ultrasonic waves, the carbon material, such as coke or half coke, is subjected to low-temperature acid treatment, after the porous carbon material is treated by acid treatment, vanadate catalyst is loaded on the carbon material, thus, a flue gas desulphurization and denitration agent is prepared. The product can effectively remove SO2 and NOx in the flue gas under low temperature.

Owner:TAIYUAN NORMAL UNIV

Rare earth aluminum calcium silicon iron composite alloy for steel production and preparation method thereof

InactiveCN106834602AEnhanced deoxygenationImprove desulfurization effectSteelmakingChemical composition

The invention discloses a rare earth aluminum calcium silicon iron composite alloy for steel production. The composite alloy comprises the following chemical components in percentage by weight: 1-50% of rare earth, 1-15% of aluminum, 1-5% of silicon, 1-15% of calcium, and the balance of iron. The invention further discloses a preparation method of the rare earth aluminum calcium silicon iron composite alloy for steel production. The rare earth is used as basis, so that the deoxidation and desulfurization effects of steel and iron are greatly improved, and the microalloying effect of molten steel also can be improved.

Owner:BAOTOU RES INST OF RARE EARTHS +1

Electroslag remelting slag system for duplex stainless steel

PendingCN110029229AGood chemical stabilityHigh strengthProcess efficiency improvementSlagSS - Stainless steel

The invention discloses an electroslag remelting slag system for duplex stainless steel. The electroslag remelting slag system is prepared from the following components in percent by weight: 50.0-65.0% of CaF2, 8.0-15.0% of Al2O3, 3.0-10.0% of CeO2, 15.0-20.0% of CaO, 3.0-5.0% of MgO, 1.0-3.0% of SiO2 and the balance impurities which are not more than 1%. According to the slag system, the slag viscosity changes gently as the temperature is reduced, and the high temperature plasticity and the strength of slag can be also improved, so that bleed-out and slag leakage are prevented. The conductivity of the slag can be reduced, the chemical stability of the slag can be improved, and the system has better deoxidizing and desulfurizing effects and inclusion absorption action, thereby playing a role of purifying molten steel deeply. As-cast grains can be refined, and the strength and the toughness of steel are improved. The electroslag remelting slag system is uniform to transfer heat and goodin lubricating effect, and the slag layer is kept stable and is melted uniformly.

Owner:JIANGSU XIHU SPECIAL STEEL

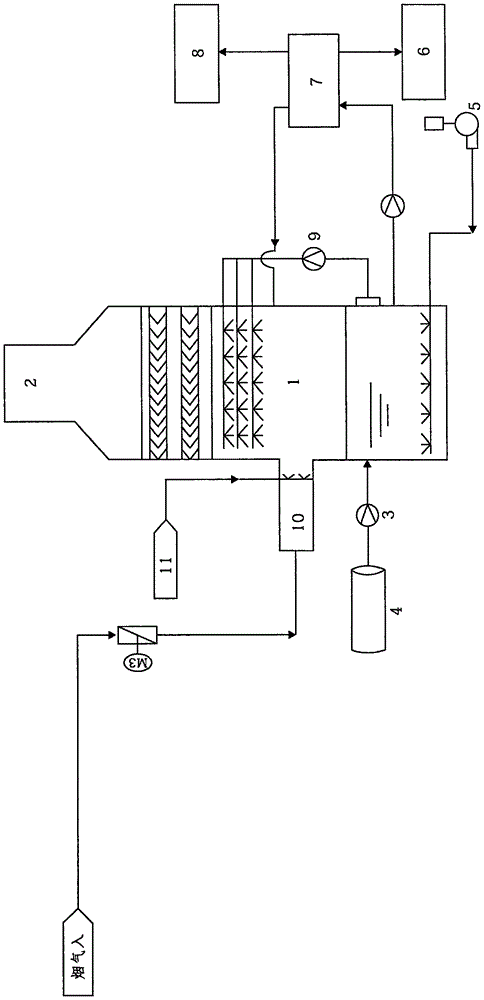

System and method for achieving low-temperature simultaneous desulfurization, denitration and dedusting of flue gas of gas-fired boiler

InactiveCN105771573AAchieve low temperature denitrificationStrong desulfurization abilityGas treatmentUsing liquid separation agentTherapeutic effectAir blower

Provided are a system and method for achieving low-temperature simultaneous desulfurization, denitration and dedusting of flue gas of a gas-fired boiler.The invention aims at solving the problem that at present, when burning is conducted through a gas-fired boiler, exhaust of dust, sulfur dioxide and nitrogen oxide in flue gas is substandard.The invention provides the system and method for achieving low-temperature simultaneous desulfurization, denitration and dedusting of the flue gas of the gas-fired boiler.The system comprises an absorption tower, an ozone generator, a gas distributer, a chimney, an oxygen supply pump, an ammonia water supply tank, an oxidation air blower, a residue storage tank, a catalyst separation and recovery system, a liquid fertilizer storage tank and a circulating pump; for the treatment effect, high desulfurization rate, denitration dedusting rate and dedusting rate are achieved; the system is low in investment cost, low in energy consumption and convenient and rapid to use.

Owner:BEIJING CHANGXIN TAIHE ENERGY SAVING TECH CO LTD

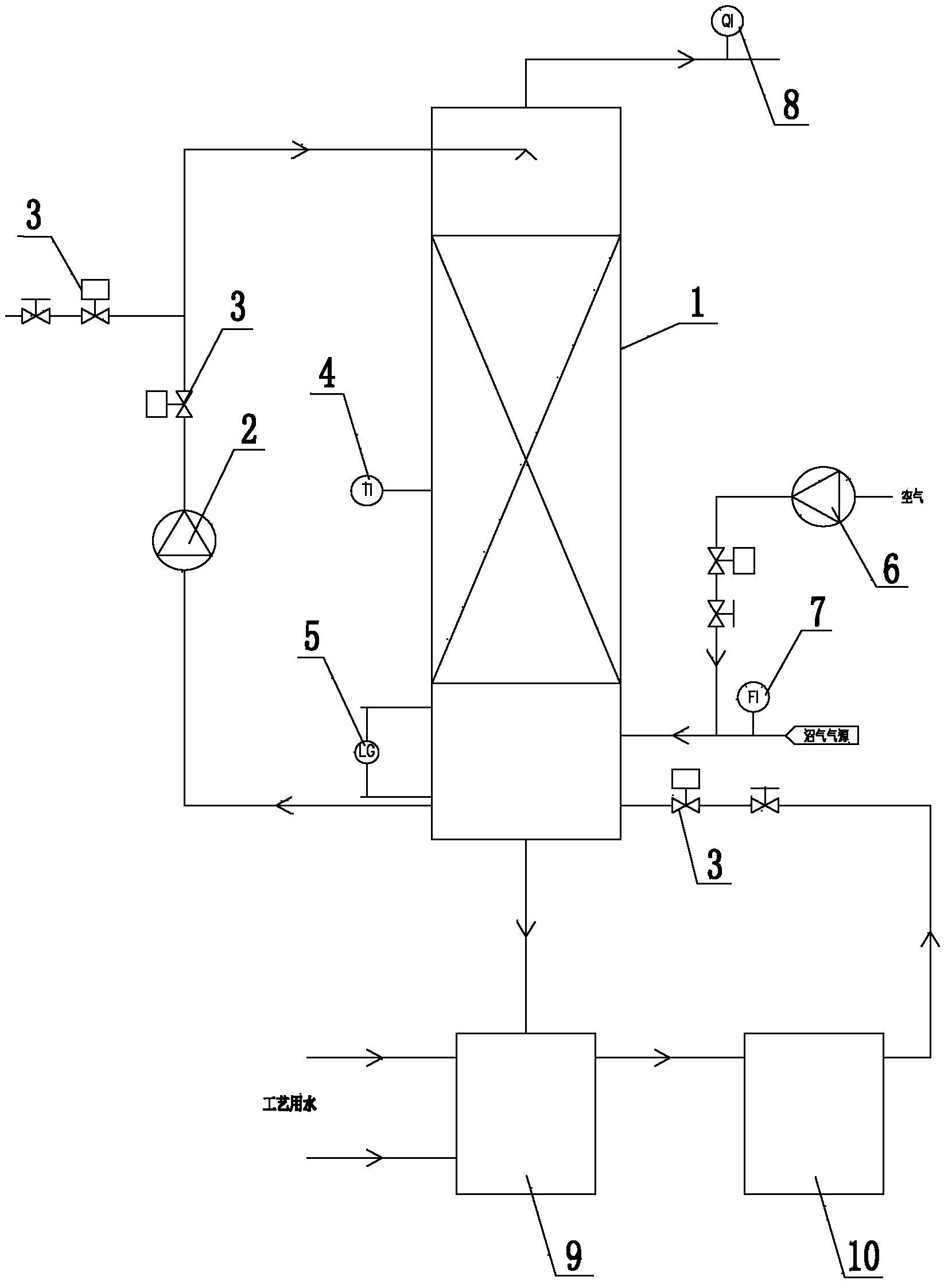

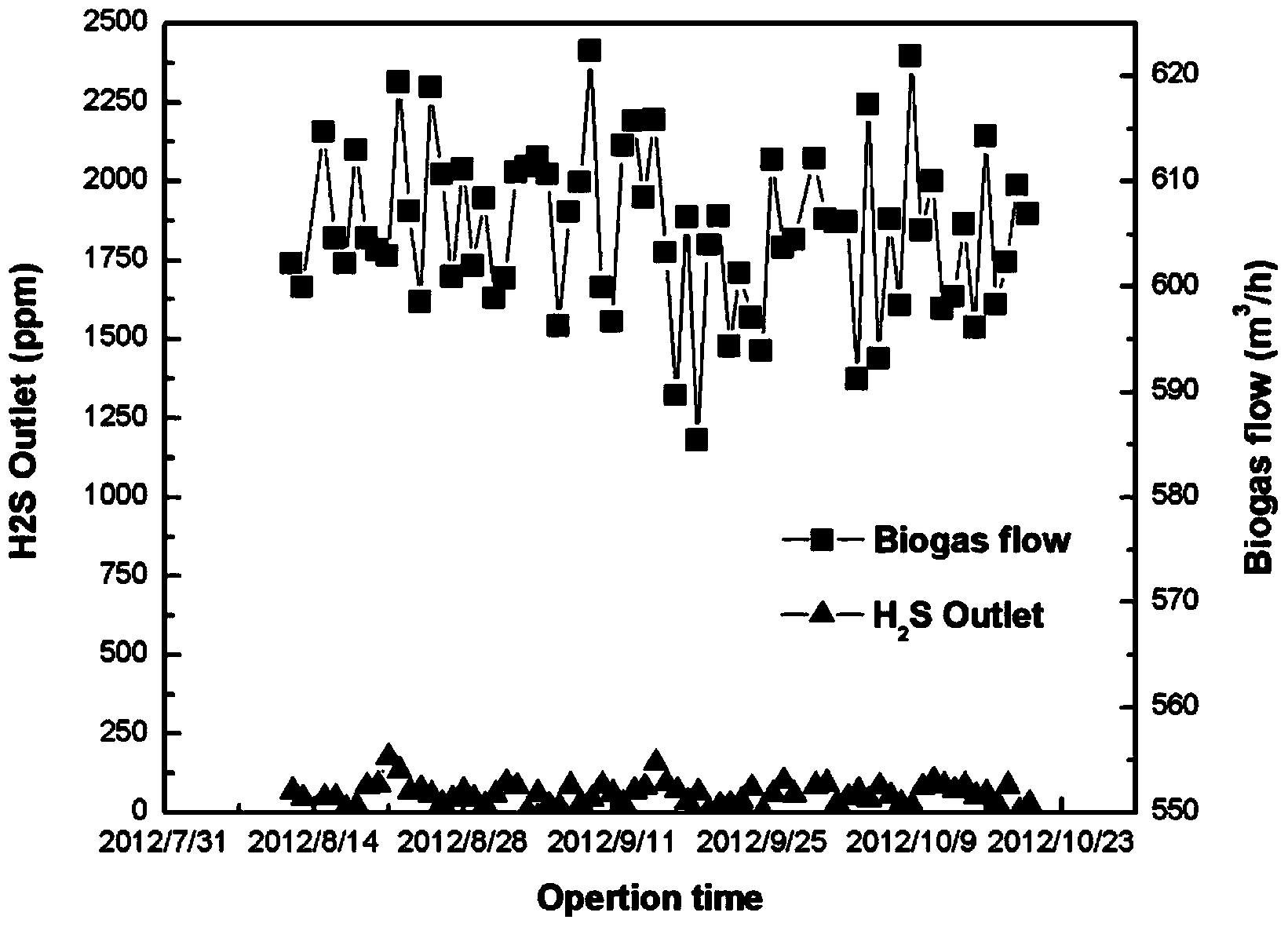

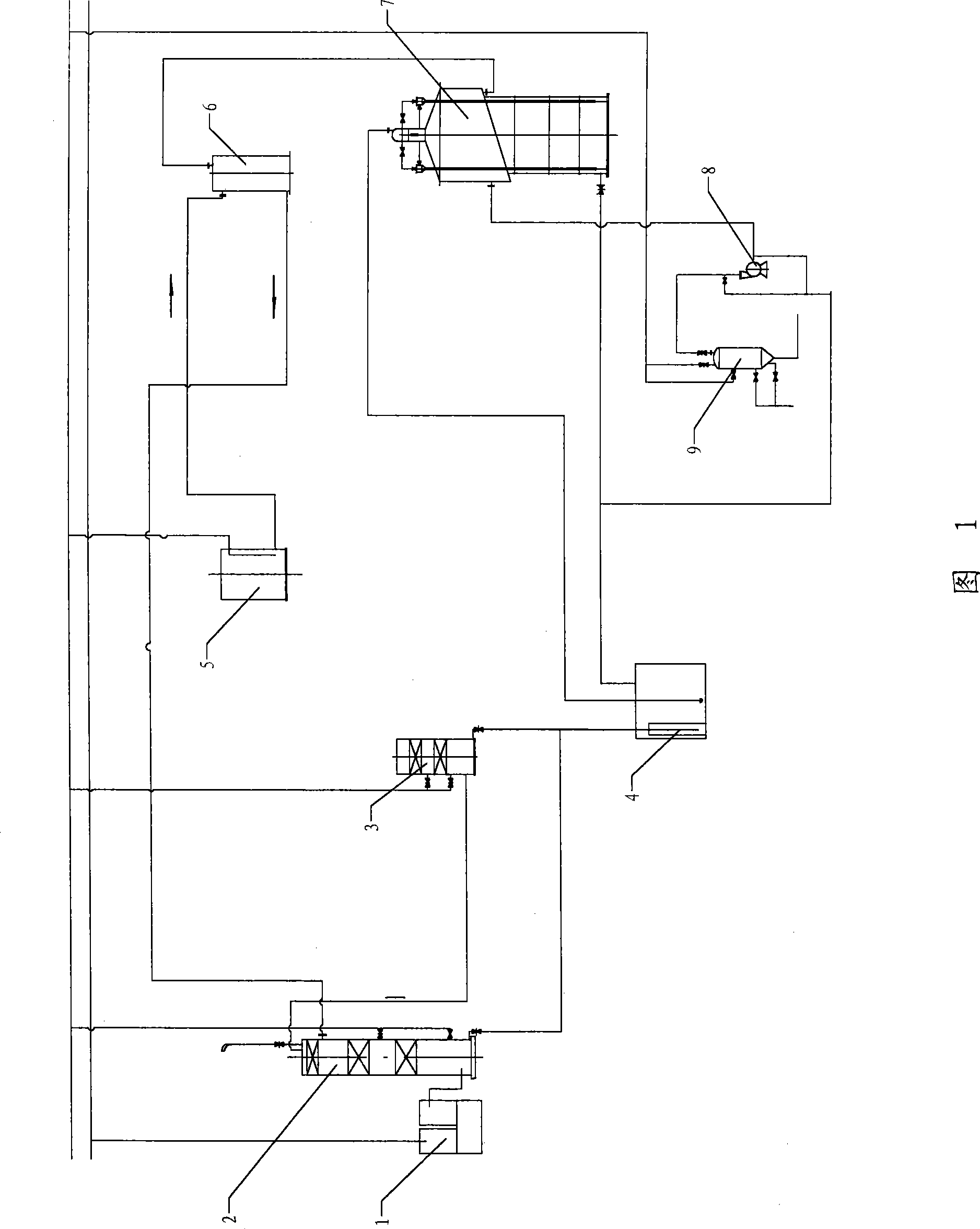

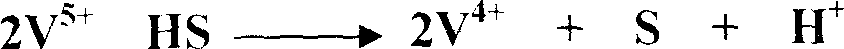

Biological desulfurization device and process

InactiveCN103980972ALow running costGuaranteed uptimeGaseous fuelsDispersed particle separationProgrammable logic controllerProcess engineering

The invention discloses a biological desulfurization device and a desulfurization process thereof. The process comprises the steps: pumping a desulfurization solution into the top of a desulfurization tower by using a circulating pump, and spraying the desulfurization solution to the surface of filler through a sprayer, so as to keep the surface of the filler wet; at an air inlet of the desulfurization tower, proportionally injecting air into raw material biogas containing hydrogen sulfide by a variable-frequency air blower, so as to form mixed gas; enabling the mixed gas to pass through a filler layer, when the hydrogen sulfide in the mixed gas is absorbed by a biomembrane on the surface of the filler; and discharging purified gas from an outlet of the desulfurization tower, thus completing desulfurization. The process is a biological desulfurization process which is low in operating cost, strong in desulfurization capacity and stable and safe in operation; the air injection proportion is controlled and regulated by a PLC (Programmable Logic Controller) and the variable-frequency air blower and can be regulated according to the concentration of hydrogen sulfide at an inlet of the system and the concentration of oxygen gas at an outlet of the system, so that the demand on oxygen gas during desulfurization can be guaranteed, and the problem that the air blower injects too much air into the raw material gas can also be avoided.

Owner:山东恒能环保能源设备有限公司

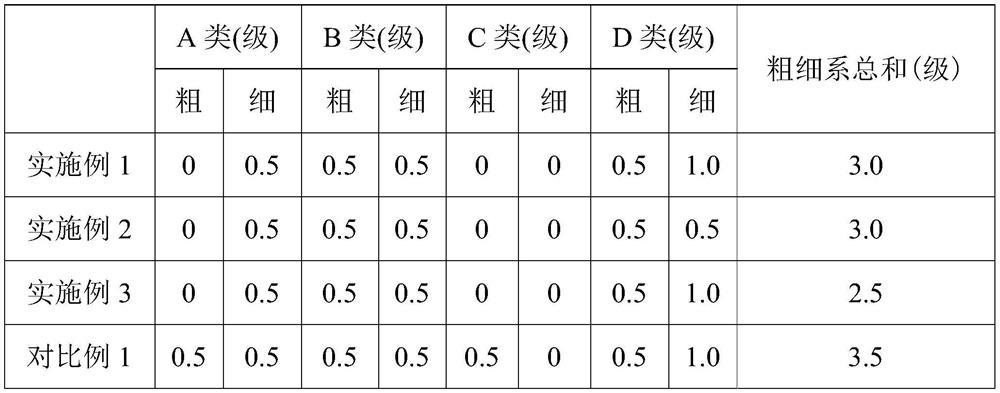

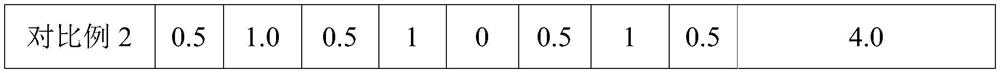

Method for producing low-sulfur and low-phosphorus steel by utilizing semi-molten steel

InactiveCN111926147AImprove componentsStrong desulfurization abilityManufacturing convertersSteelmakingNon-metallic inclusions

The invention relates to a method for producing low-sulfur and low-phosphorus steel by utilizing semi-molten steel. The method comprises the following steps: acquiring low-sulfur and low-phosphorus molten steel by the semi-molten steel through pre-deoxidation, KR desulfurization, converter steelmaking, LF refining and VD vacuum smelting in sequence, and acquiring the low-sulfur and low-phosphorussteel by pouring the low-sulfur and low-phosphorus molten steel, wherein the sulfur content of the molten steel subjected to KR desulfurization is lower than or equal to 0.005%, the rate of slagging-off after KR desulfurization is higher than or equal to 90%, the phosphorus content of the molten steel subjected to converter steelmaking is lower than or equal to 0.004%, 10-30 kg of slagging balls are added into the molten steel per ton during converter steelmaking, the included angle of oxygen gun holes during converter steelmaking is larger than or equal to 13 degrees, and the final temperature of converter steelmaking is lower than or equal to 1620 DEG C. According to the method provided by the invention, the off-site sulfur content is lower than or equal to 0.005% and the rate of dephosphorization during the converter steelmaking of the semi-molten steel reaches 96% or higher. Meanwhile, hydrogen-sulfide-corrosion-resistant continuous-casting round billet non-metallic inclusions produced through the method reach the following levels: class A is lower than or equal to level 0.5; class C is equal to level 0; class B and class C are lower than or equal to level 1.0; and the total thickness of class A, class B, class C and class D is lower than or equal to level 3.0.

Owner:CHENGDE JIANLONG SPECIAL STEEL

Magnesium-and-manganese-containing deoxidizing alloy for steel making and deoxidizing method for steel making

The invention provides a magnesium-and-manganese-containing deoxidizing alloy for steel making and a deoxidizing method for steel making. The deoxidizing alloy comprises the following components in percentage by weight: 15-25% of Mn, 25-50% of Mg, 10-25% of Ca, 5-10% of Si, 1-5% of Ba, and the balance of Fe and other inevitable impurities. According to the deoxidizing method for steel making, the magnesium-and-manganese containing deoxidizing alloy for steel making is used for deoxidizing molten steel. The magnesium-and-manganese containing deoxidizing alloy for steel making and deoxidizing method for steel making disclosed by the invention have the beneficial effects that a strong desulfurization ability is achieved when molten steel is deoxidized, so that most of occluded foreign substances obtained after the molten steel is deoxidized are converted into composite occluded foreign substances, therefore, the quality of the molten steel can be effectively improved and increased.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +2

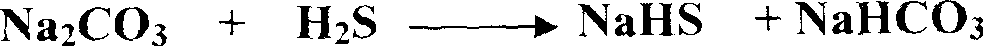

Producer gas desulphurization process

InactiveCN101434873AImprove sulfur recoveryNo sulfur pluggingCombustible gas purificationProducer gasChemistry

The invention provides a desulfurization process of generator gas, comprising the following step: the generator gas containing sulfur is absorbed by a desulfurization solution containing a mimosa extract in a desulfurization tower; the process is characterized in that the desulfurization solution also comprises vanadium pentoxide; and the sulfur content of the generator gas is 1500-2500mg / Nm<3>. The process is suitable for a situation that the content of H2S in the gas is high. The method has high desulfurization rate and the sulfur content of the gas coming out of the tower is not more than 150mg / Nm<3>.

Owner:山东万丰煤化工设备制造有限公司

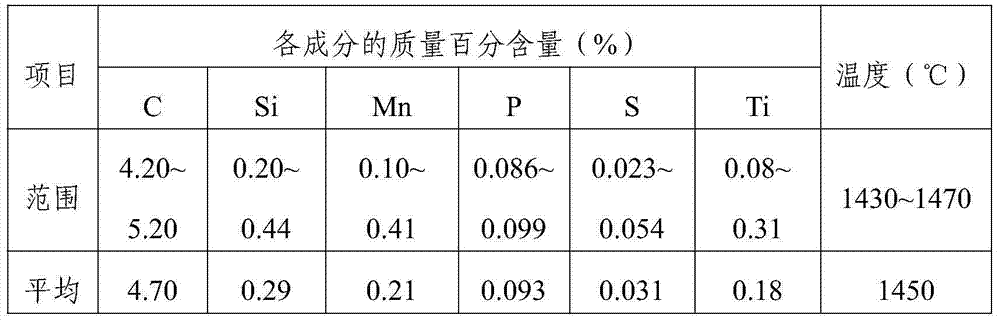

Pure magnesium spheroidizing technology of lost foam ductile cast iron

ActiveCN106636870APrevent defects such as cold insulation wrinkle skinAvoid stickingSulfurFerrosilicon

The invention discloses a pure magnesium spheroidizing technology of lost foam ductile cast iron. The pure magnesium spheroidizing technology comprises the steps that a spheroidizing agent is placed into a lip-pour ladle reaction chamber, a cover of the reaction chamber is closed, and a conventional nucleating agent, ferrosilicon, is added into a lip-pour ladle; after molten iron in a heat-insulated furnace is subjected to deslagging, molten iron is added into the lip-pour ladle, and the temperature of molten iron is controlled to be 1520 DEG C to 1560 DEG C; then, the lip-pour ladle is overturned, and molten iron and the spheroidizing agent react for 60 s to 70 s; and pouring is carried out while stream inoculation is achieved, wherein the addition amount of the stream nucleating agent is 0.08% to 0.15% of the weight of molten iron; the spheroidizing agent is a mixture of pure magnesium ingots and calcium chloride; and the weight ratio of molten iron to the pure magnesium ingots to calcium chloride to ferrosilicon is 1000 to (1.4 to 2.0) to (0.2 to 0.5) to (4 to 8). According to the pure magnesium spheroidizing technology of lost foam ductile cast iron, the spheroidizing problem of high-sulfur high-silicon molten iron can be effectively solved, the spheroidizing grade is high, a required matrix structure can be obtained, the problems that the spheroidizing effect is poor, the quality of castings is not stable, and the rejection rate is high are solved, the technology does not require lip-pour ladle nucleating, the procedures can be decreased, and the labor intensity is reduced.

Owner:桃江新兴管件有限责任公司

Magnesium alloy for steelmaking and steelmaking deoxidization method

InactiveCN103540837AImprove and improve qualityStrong desulfurization abilitySteelmakingMolten steel

The invention provides a magnesium alloy for steelmaking and a steelmaking deoxidization method. The magnesium alloy comprises the following components by weight percent: 15-25% of Al, 15-25% of Mg and the balance of Fe and inevitable impurities. The steelmaking deoxidization method comprises the step of adopting the magnesium alloy for steelmaking to carry out deoxidization treatment on molten steel. The magnesium alloy has the beneficial effects that the magnesium alloy has relatively strong desulfurization capability while deoxidizing molten steel, can convert most inclusions after molten steel deoxidization to complex inclusions, and can effectively improve the molten steel quality.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +2

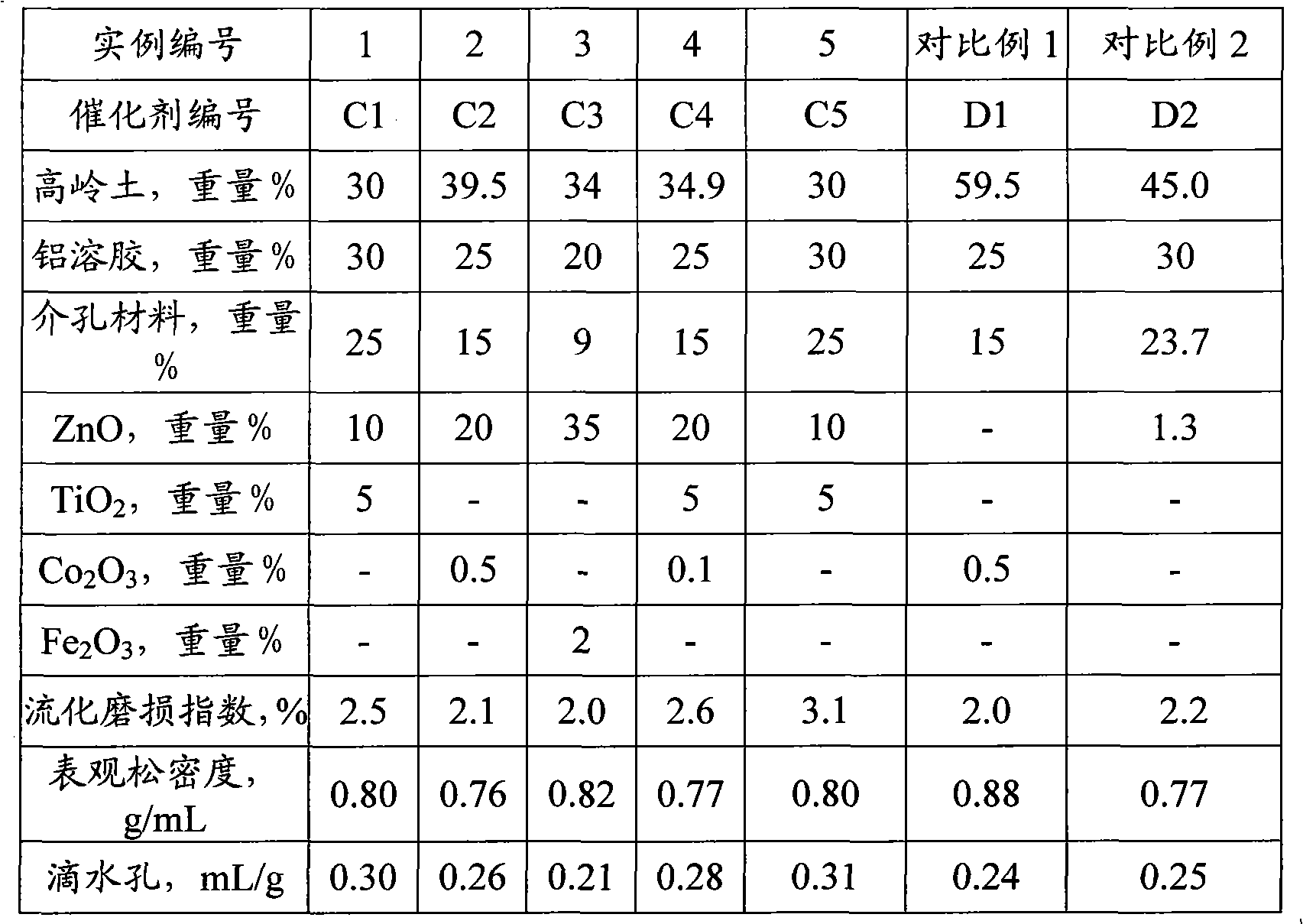

A kind of sulfur reducing additive of hydrocarbon oil cracking product and its preparation and application

ActiveCN102274721AStrong ability to convert heavy oilStrong sulfur reduction performanceCatalytic crackingMetal/metal-oxides/metal-hydroxide catalystsZinc compoundsSulfur

The invention relates to a desulfurization additive for a product obtained by hydrocarbon oil cracking and preparation and application thereof. The additive contains the following components in percentage by weight: 3-40 percent of mesoporous material, 5-50 percent of zinc component in zinc oxide terms, 5-80 percent of clay, 10-50 percent of caking agent in oxide terms and 0.1-10 percent of metal(s), except for zinc, in oxide terms; and the metal(s) except for the zinc is(are) one or a plurality of lanthanide metal, Ti, Co, Ni, Fe, Mn, Ga and Zr. The preparation method of the additive comprises the following steps of: (1) mixing the mesoporous material and deionized water, adding a zinc-containing compound, mixing and pulping, and mixing and pulping the obtained slurry and a compound of the metals except for the zinc; (2) mixing the slurry obtained in the step (1) and the clay; (3) mixing the slurry obtained in the step (2) and the caking agent; and (4) carrying out spray drying on the slurry obtained in the step (3), and roasting. The additive provided by the invention has higher conversion rate and desulfurization performance and high gasoline yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

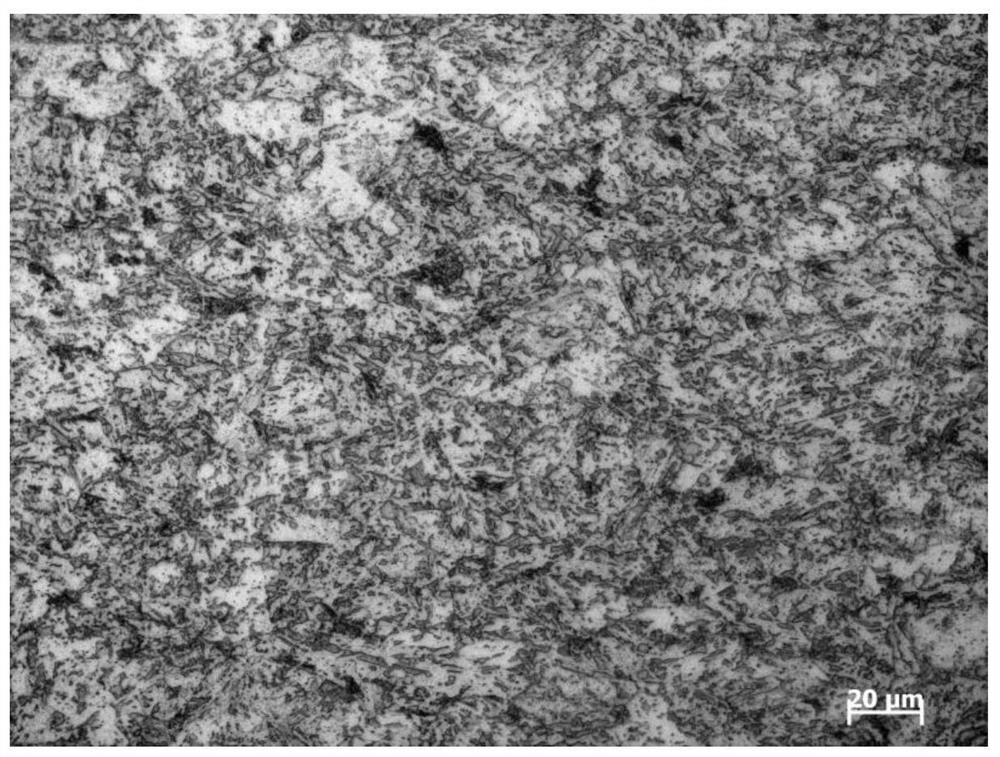

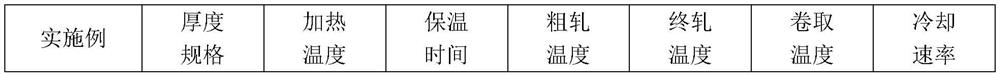

900MPa-grade hot-rolled and pickled complex-phase phase steel with low yield ratio and high hole expansion rate and production method of 900MPa-grade hot-rolled pickling complex phase steel

ActiveCN113549823AFine grain strengtheningWith precipitation strengtheningRare-earth elementSlow cooling

The invention relates to hot-rolled and pickled complex-phase steel, in particular to 900 MPa-grade hot-rolled and pickled complex-phase steel with a low yield ratio and a high hole expansion rate and a production method of the 900 MPa-grade hot-rolled and pickled complex-phase steel. The steel comprises the following chemical components of, in percentage by weight, 0.085%-0.162% of C, 0.08%-0.85% of Si, 1.15%-2.50% of Mn, 0.10%-0.30% of Al, 0.10%-0.75% of Cr, 0.08%-0.65% of Mo, 0.025%-0.070% of Nb, 0.030%-0.155% of Ti, 0.0020%-0.0050% of B, 0.010%-0.060% of rare earth elements La + Ce, P less than or equal to 0.020%, S less than or equal to 0.007% and the balance Fe and inevitable impurities. The method comprises the following steps that (1), a continuous casting slab with the thickness of 80-300mm is put into a heating furnace to be heated to be 1130-1270 DEG C; (2), the initial rolling temperature of rough rolling is not higher than 1080 DEG C, the thickness of an intermediate billet is 25-50 mm, the finish rolling temperature is 840-900 DEG C, the thickness of a finished product is 1.8-5.3 mm, and the total reduction rate is larger than or equal to 85%; (3), after finish rolling, front-section rapid continuous laminar cooling and curling are adopted; (4), after being curled, the steel plate immediately enters a slow cooling cover to be slowly cooled, and a steel coil is taken out and air-cooled to the room temperature; and (5), pickling is carried out . The steel has ultrahigh strength and good formability, and is suitable for manufacturing automobile structural parts, reinforcing parts and safety parts; and the steel has excellent anti-fatigue performance, welding performance and cold forming performance.

Owner:ANGANG STEEL CO LTD

Ultrasonic-assisted ozone oxidation desulfurization method

InactiveCN102703111AImprove desulfurization efficiencyShort reaction timeRefining with oxygen compoundsUltrasonic assistedCatalytic oxidation

The invention discloses an ultrasonic-assisted ozone oxidation desulfurization method. According to the method, ozone is used as an oxidizer, a solid powdery substance is used as a catalyst, acetonitrile is used as an extractant, and ultrasonic waves are used for assisting catalytic oxidation. The method comprises the following steps: under normal pressure conditions, mixing an oil product to be treated with acetonitrile in a volume ratio of 1:(1-3), controlling the reaction temperature at 20-65 DEG C, adding the catalyst solid powdery substance, introducing ozone, and reacting under the ultrasonic action for 50-60 minutes; and after the reaction finishes, stopping the ultrasonic waves, and cooling to room temperature to naturally stratify the reaction mixture, wherein the separated supernatant oil phase is the desulfurized oil product. The ultrasonic-assisted catalytic ozone oxidation desulfurization can be implemented under the conditions of normal temperature and normal pressure, and has the advantages of high desulfurization efficiency and short reaction time. Compared with the traditional technique, the invention has the advantages of low production cost, strong desulfurization capacity, short reaction time, high desulfurization efficiency, low operating cost and the like, and can easily implement industrial production.

Owner:SHANDONG UNIV

Low-cost slag washing method

ActiveCN108018402ANo crusting on the bottom of the bagNo sintering on the bottom of the bagProcess efficiency improvementSlagSulfur

The invention belongs to the technical field of iron and steel metallurgy and in particular relates to a low-cost slag washing method. The low-cost slag washing method comprises the following steps: producing synthetic slag for slag washing in a steel ladle, obtained by casting molten steel, by utilizing refining slag and a deoxidant; then utilizing the produced solid-state synthetic slag with relatively high temperature for slag washing operation of a steel tapping process of the next heat. The method provided by the invention has a simple technology and is low in cost; the consumption of slag production materials is less and the heat of the refining slag is recycled; smooth production is not influenced; compared with cyclic utilization of heat-state refining slag, the low-cost slag washing method has remarkable advantages. Sulfur is effectively removed.

Owner:SHANDONG IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com