Patents

Literature

74results about How to "Fine grain strengthening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

600MPa grade high-strength weathering steel and preparation method thereof

InactiveCN101225498ASimple chemical compositionThe production process is easy to controlMetal rolling arrangementsChemical compositionThin slab

The invention discloses a 600MPa high strength weathering steel and the manufacturing method, which is characterized in that: the 600MPa high strength weathering steel adopts electric stove-thin slab continuous casting and rolling process for preparation; the main chemical components of the refined molten steel for preparing the high strength weathering steel are: C: 0.045 wt % to 0.07wt%, Si: 0.10 wt % to 0.29wt%, Mn: 0.8 wt % to 1.5wt%, P: 0.005 wt% to 0.030wt%, S: 0.002 wt% to 0.008 wt%, Cu: 0.20 wt% to 0.5wt%, Cr: 0.3 wt% to 0.7wt%,Ni: 0.15 wt % to 0.35wt%, Ti: 0.06 wt% to 0.079wt%, Nb: 0.035 wt% to 0.050wt%, Alt: 0.025 wt% to 0.050wt%. The 600MPa high strength weathering steel has the advantages of low cost, strong competitiveness, cold formability, good welding performance and application to tower frame, heavy duty automobile, bridge, container, railway vehicle manufacture.

Owner:GUANGZHOU PEARL RIVER STEEL & IRON

Aluminum alloy subjected to composite microalloying of Sc and Zr and preparation method thereof

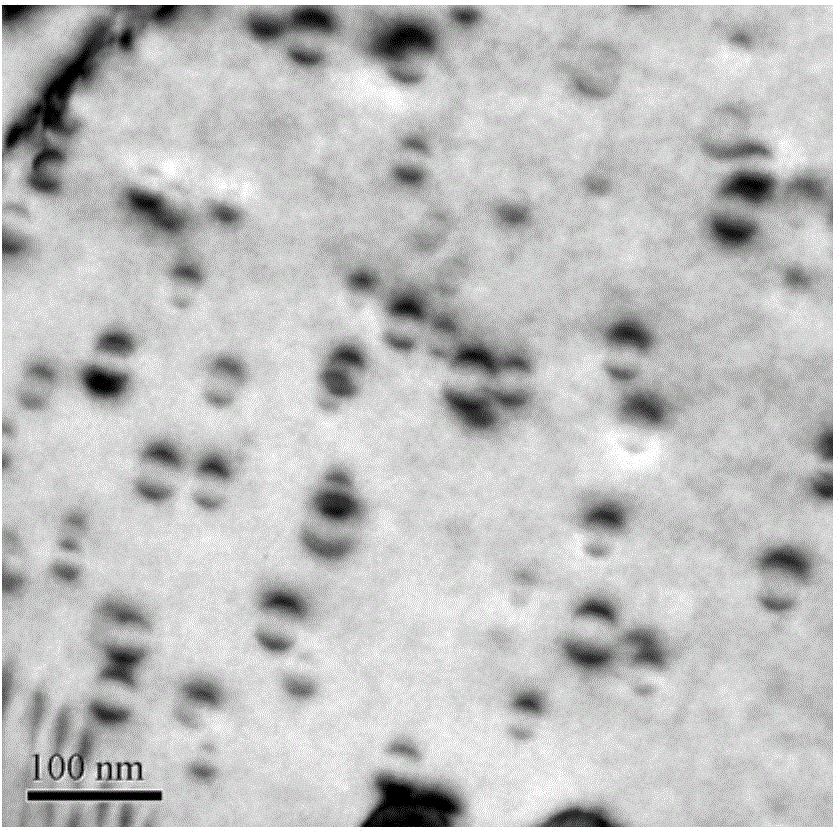

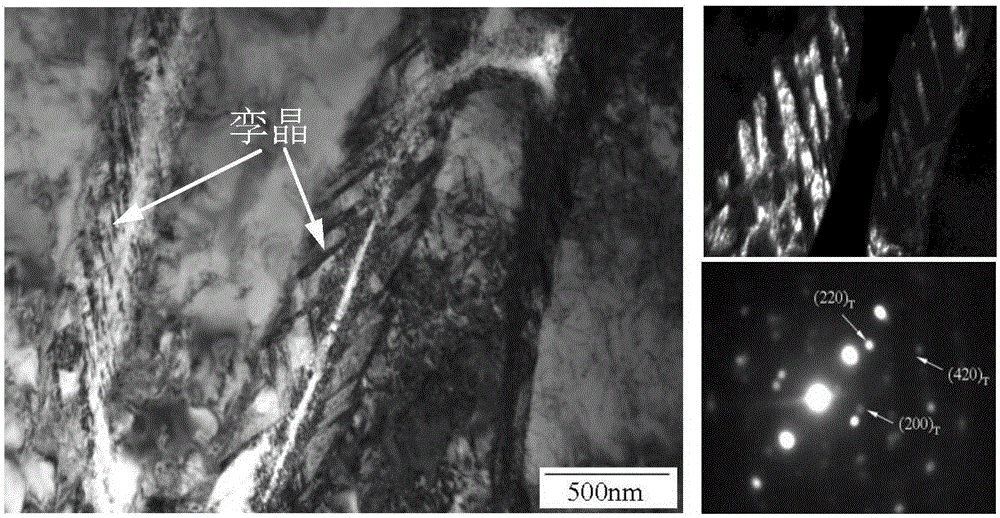

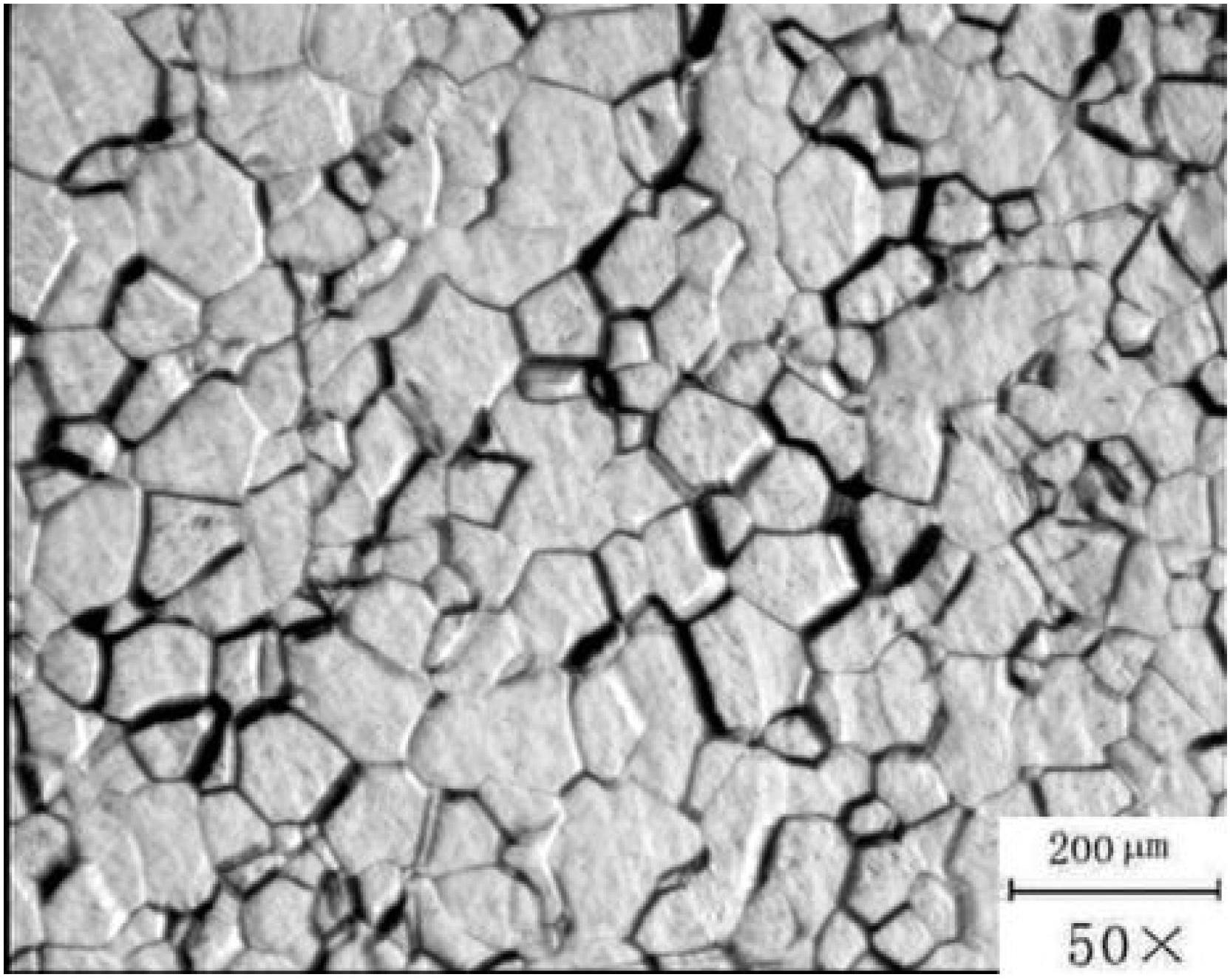

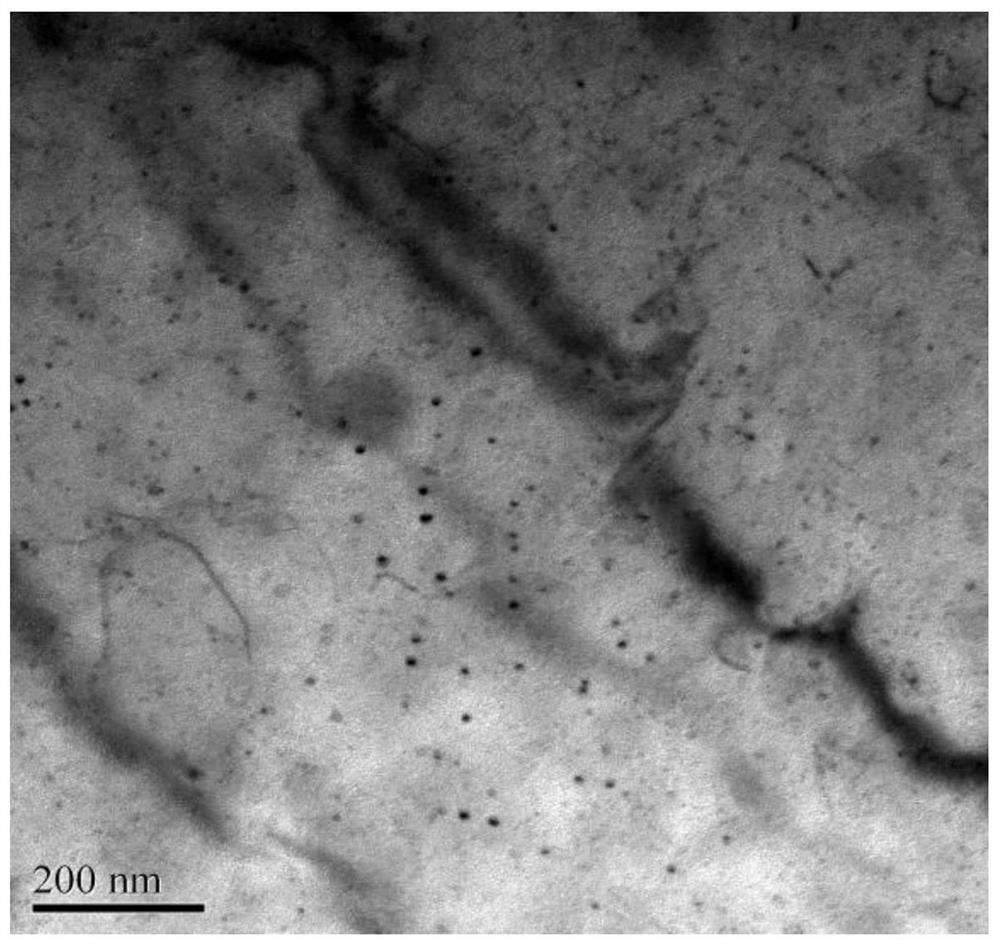

InactiveCN104651683AImprove mechanical propertiesImprove temperature stabilityThermal stabilityDislocation

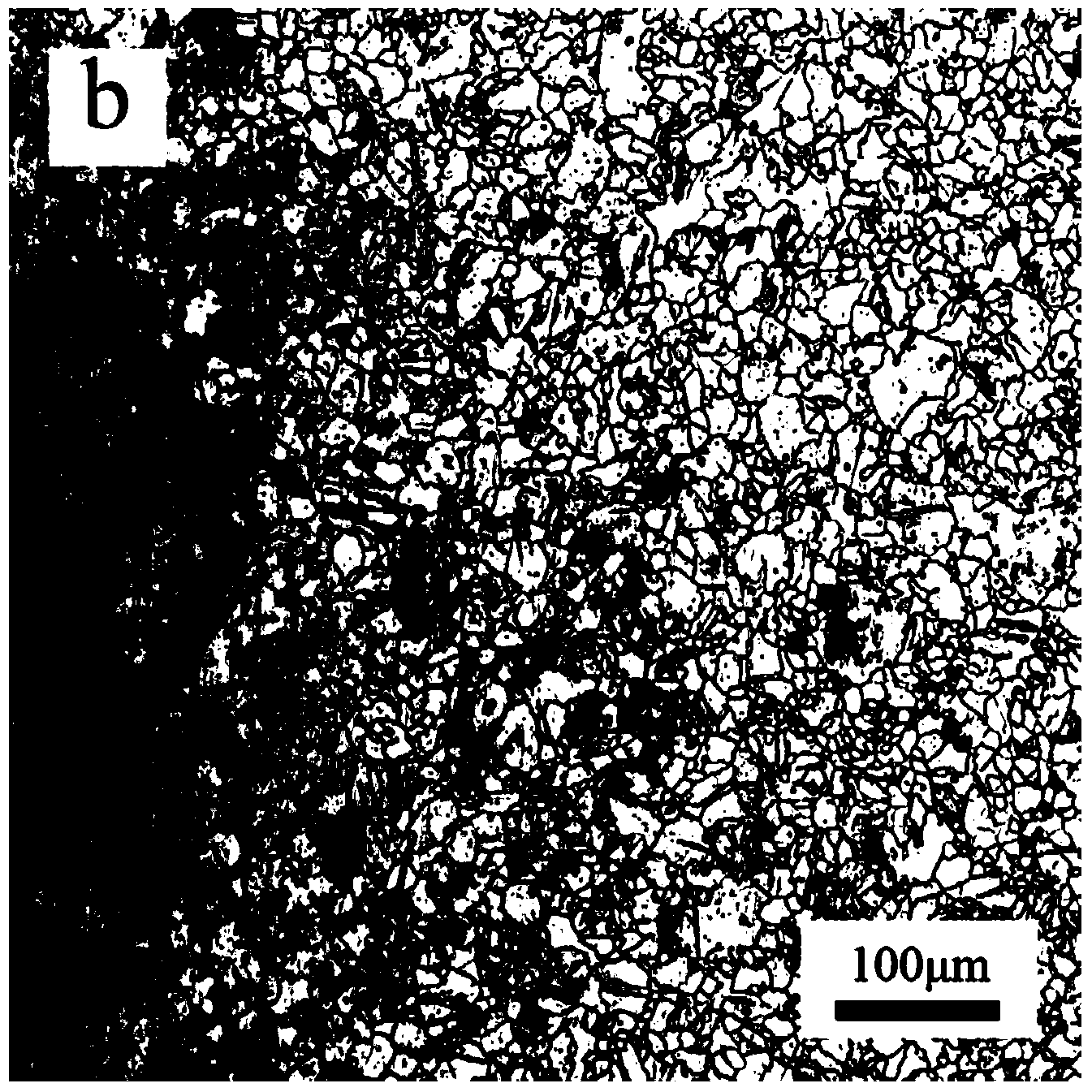

The invention discloses an aluminum alloy subjected to composite microalloying by using Sc and Zr. The alloy matrix refers to an Al-Mg-Mn alloy, wherein the alloy comprises the following components in percentage by mass: 4-6.2 percent of Mg, 0.2-0.6 percent of Mn, 0.2-0.4 percent of Sc, 0.05-0.4 percent of Zr and the balance of Al. The trace Sc and Zr are compounded in the Al-Mg-Mn alloy, so that the comprehensive mechanical properties and the thermal stability can be greatly improved. Compared with an Al-5.8Mg-0.4Mn-0.25Sc-0.1Zr alloy subjected to composition optimization, the alloy in the invention has the advantages that the tensile strength sigma b is improved by nearly 100MPa, the yield strength sigma 0.2 is improved by 40-50 percent, and the alloy has high ductility. The effect of the composite addition of Sc and Zr on the Al-Mg-Mn alloy mainly refers to forming Al3(Sc1-xZrx) second-phase particles in the alloy of Sc and Zr, the primary Al3(Sc1-xZrx) particles have the effects of refining cast grains, and secondary Al3(Sc1-xZrx) particles are subjected to pin dislocations and grain boundary / sub-boundary in the hot and cold processing process, so that the particles have refined crystalline strengthening, dispersion strengthening and substructure strengthening effects on the alloy. The ratio of the components is reasonable, the preparation process is simple, and the method is suitable for industrial production.

Owner:CENT SOUTH UNIV +1

High-plasticity magnesium alloy and preparation method thereof

The invention relates to the field of alloy materials, in particular to high-plasticity magnesium alloy. The magnesium alloy comprises the following components in percentage by weight: 0.5-2 percent of aluminum, 2 percent of manganese, 0.02-0.1 percent of calcium and the balance of magnesium. The preparation method of the high-plasticity magnesium alloy comprises the following steps of: heating up magnesium of the quantity required in the formula to 700-750 DEG C; adding magnesium-calcium intermediate alloy under a protection atmosphere of mixed gas of SF6 and CO2 to obtain Mg-Ca series alloy and preserving heat; adding pure aluminum, preserving heat for 30 minutes, and making partial aluminum and calcium to react to generate Al2Ca to obtain Mg-Al-Ca series alloy; heating up to 750 DEG C, adding magnesium-manganese intermediate alloy and preserving heat for 1 hour to obtain Mg-Al-Ca-Mn series alloy; and cooling to obtain the high-plasticity magnesium alloy. The magnesium alloy has high plasticity, the elongation can reach 25 percent, and the yield strength is 260MPa. The method has simple preparation step and is suitable for large-scale production.

Owner:CHONGQING UNIV

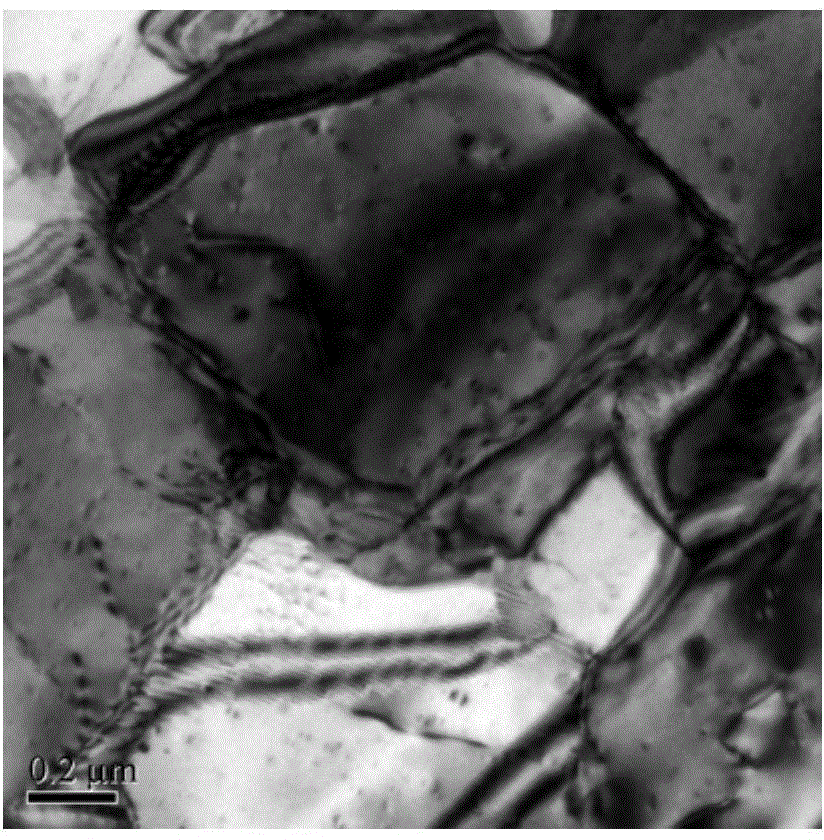

Method for improving weld structure and performance of magnesium alloy

The invention provides a method for improving a weld structure and performance of a magnesium alloy, which comprises the following steps: firstly, placing an magnesium alloy welding plate in a heat treatment furnace to carry out stress relief annealing for a certain time at a temperature of 250 DEG C to 350 DEG C; then, polishing and flattening a weld joint by adopting abrasive paper for metallograph to enable the magnesium alloy welding plate to be at the same height with a base material; and heating the magnesium alloy to a certain temperature higher than a recrystallization temperature and carrying out hot rolling after carrying out heat preservation for a certain time. The method is generally suitable for weld penetration magnesium alloy plates such as an AZ31 magnesium alloy plate, an AZ61 magnesium alloy plate, an AZ80 magnesium alloy plate and the like. Intensity of the weld joint and a heat affected zone of the welded magnesium alloy plate is obviously lower than that of the base material. By a means of carrying out hot rolling after carrying out heat preservation at a certain temperature, the method can effectively improve intensity of a magnesium alloy welding part and enables tissues and performance of the weld joint, the heat affected zone and a base metal to be consistent.

Owner:CHONGQING UNIV

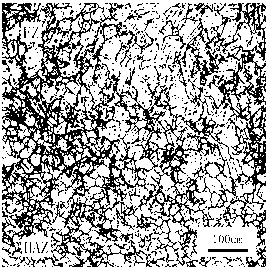

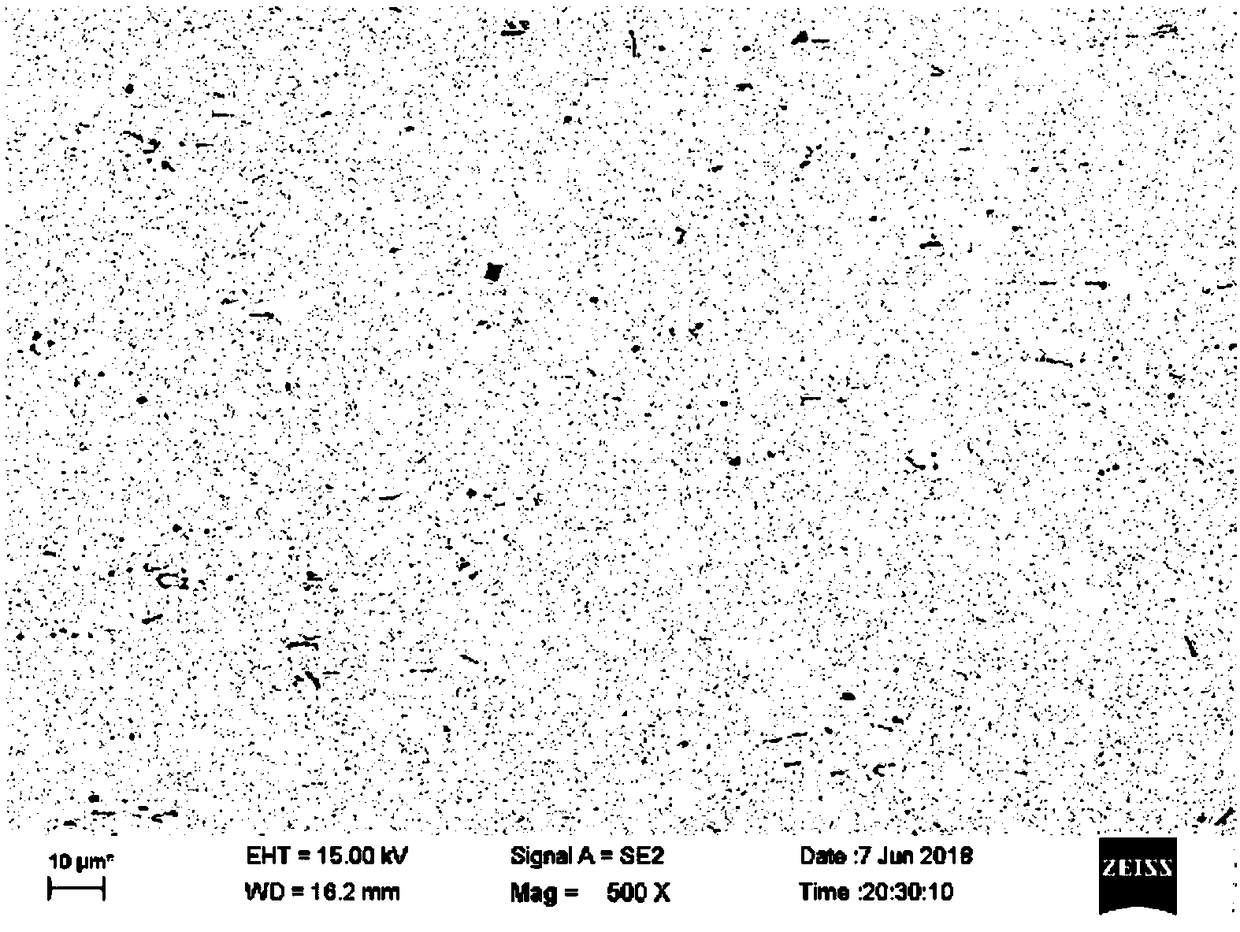

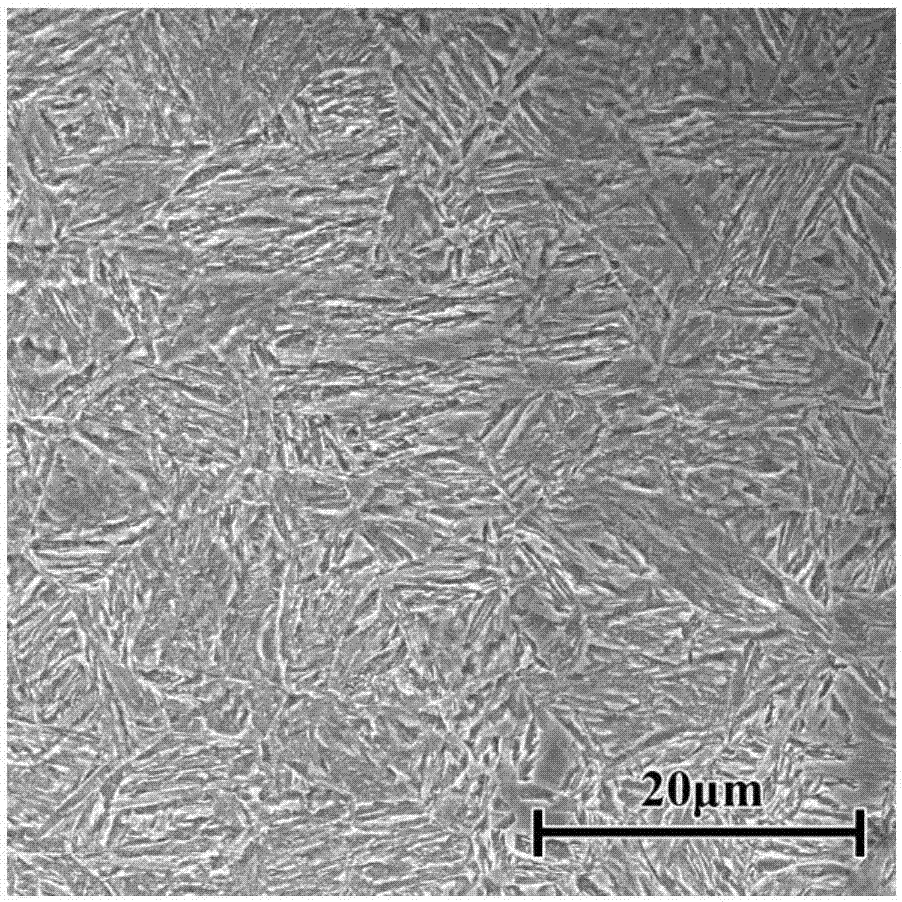

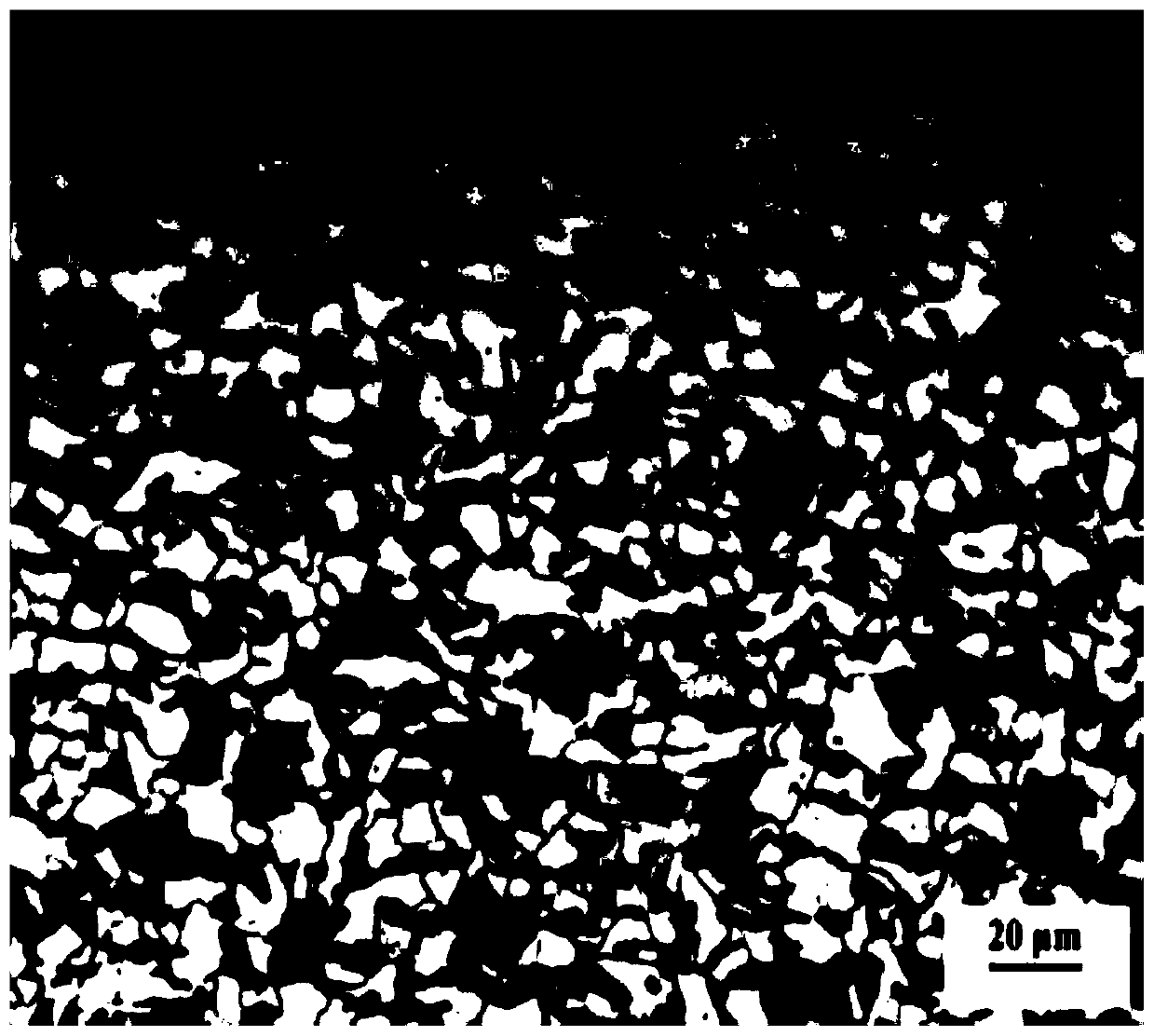

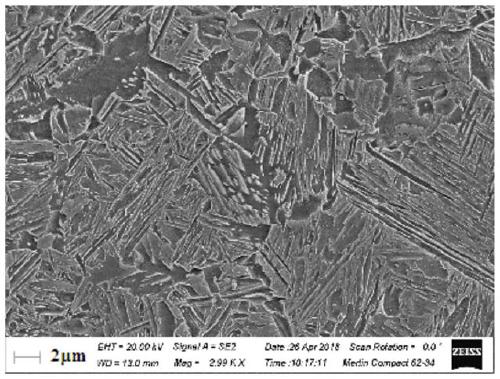

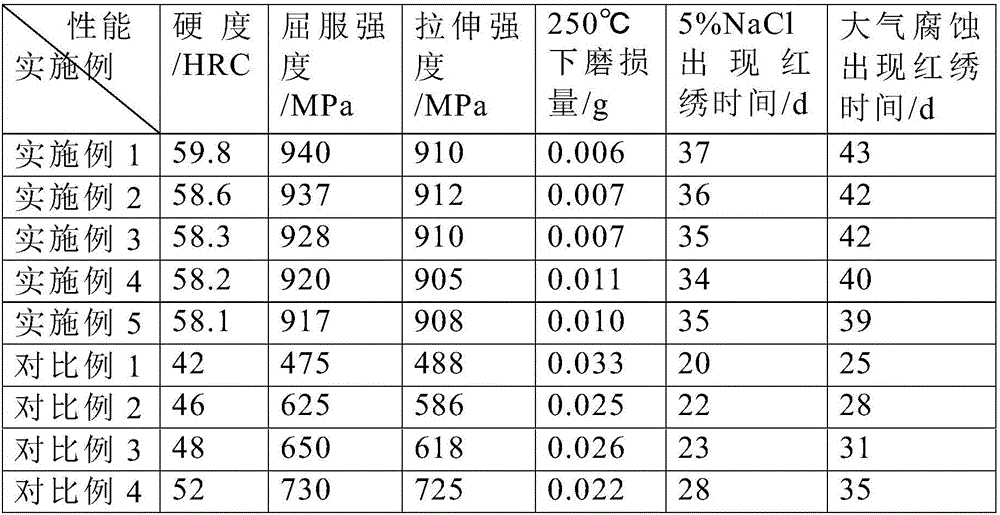

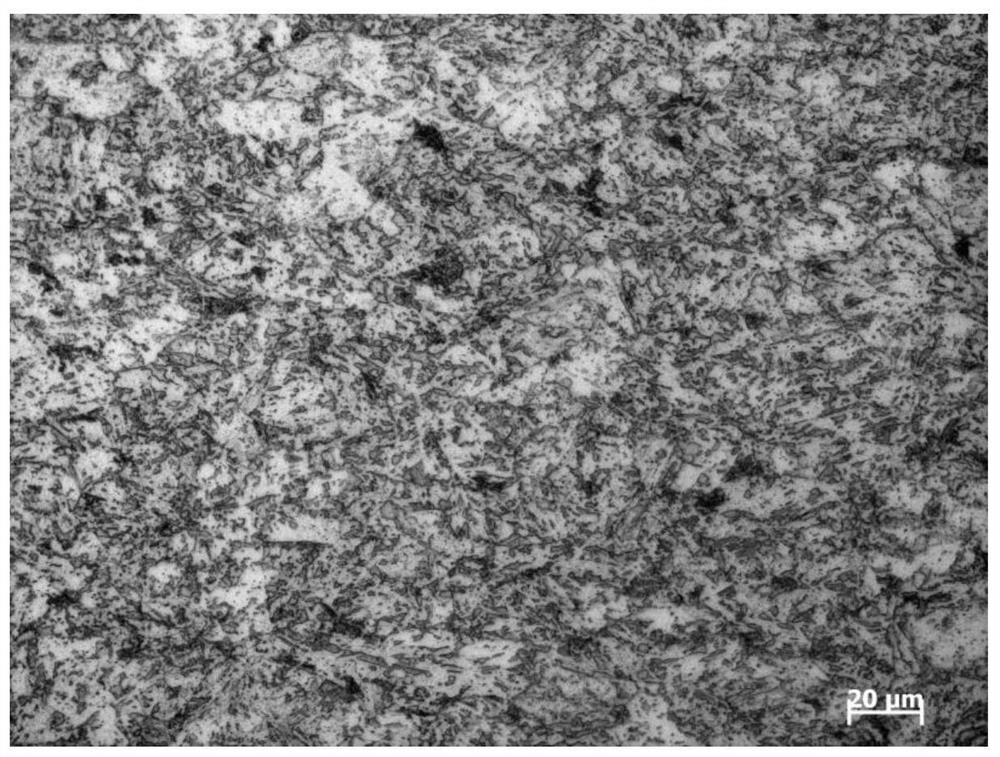

Martensitic wear-resistant steel plate with high wear resistance and manufacturing method thereof

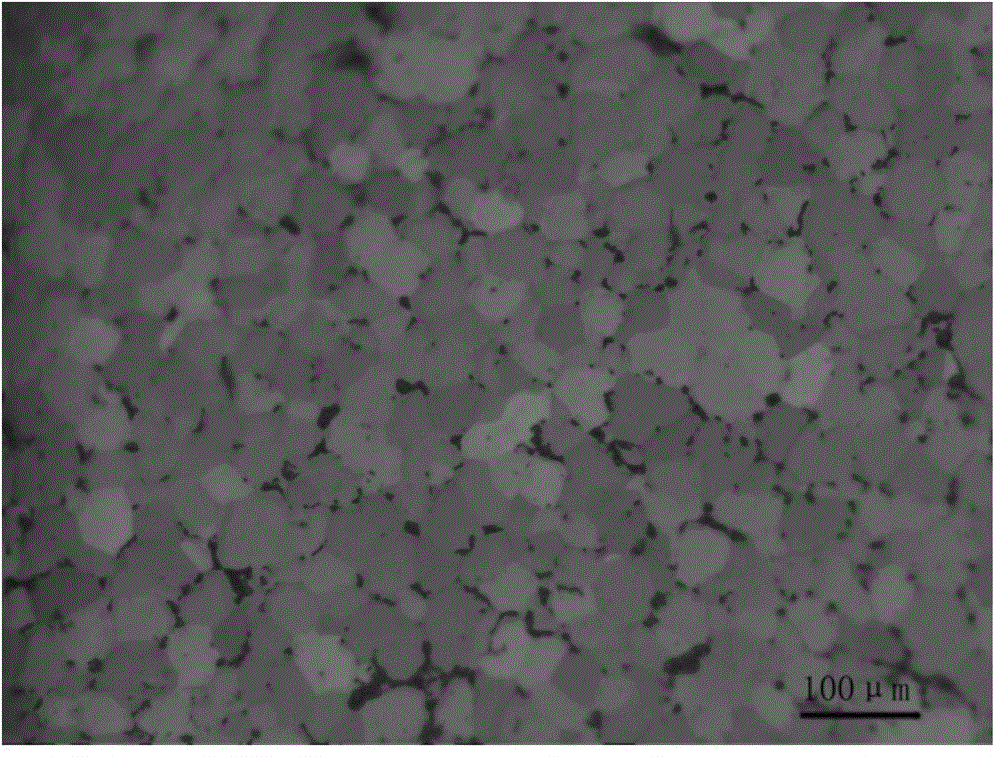

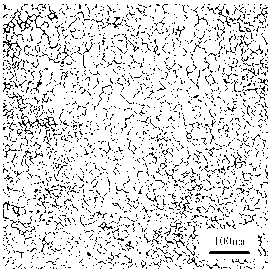

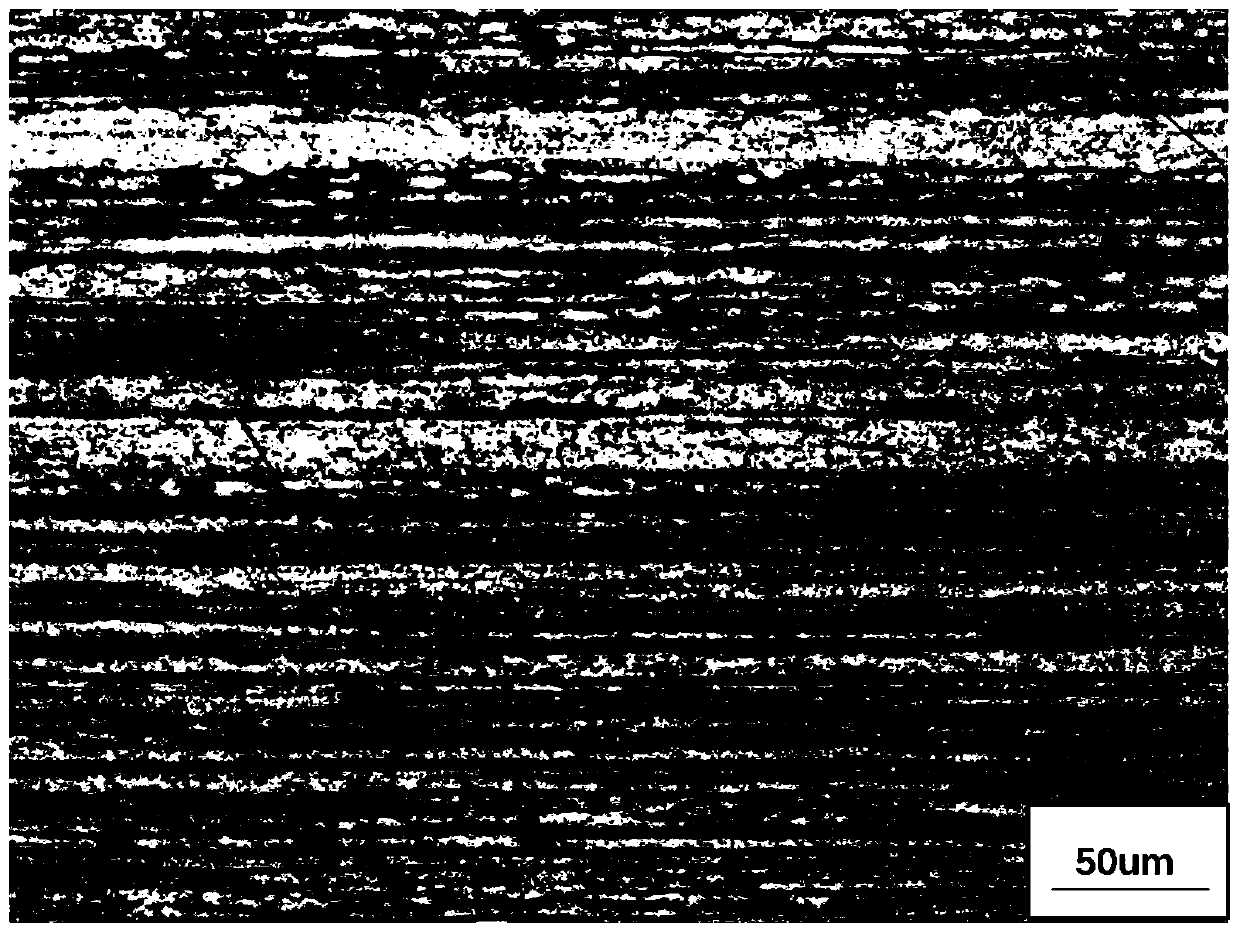

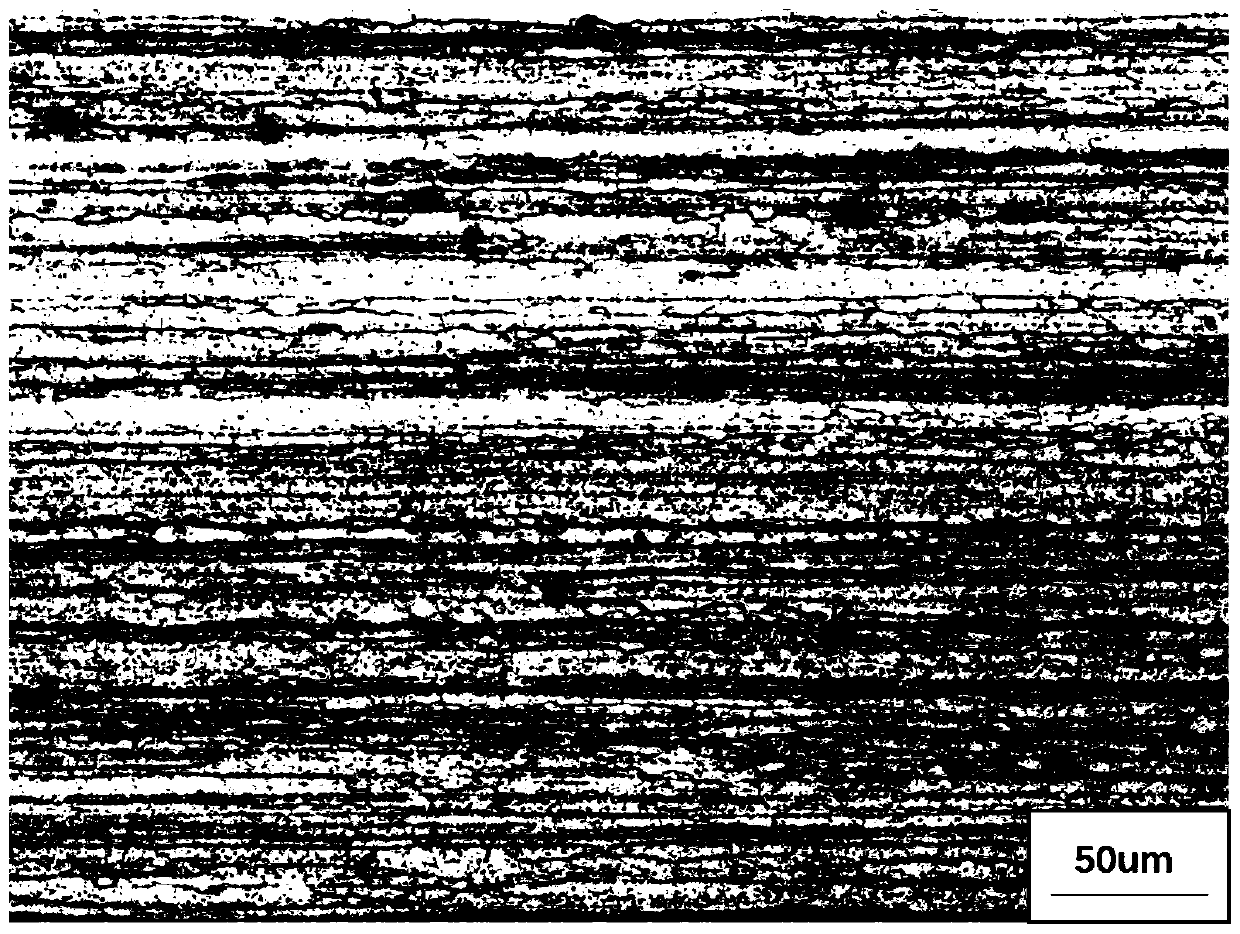

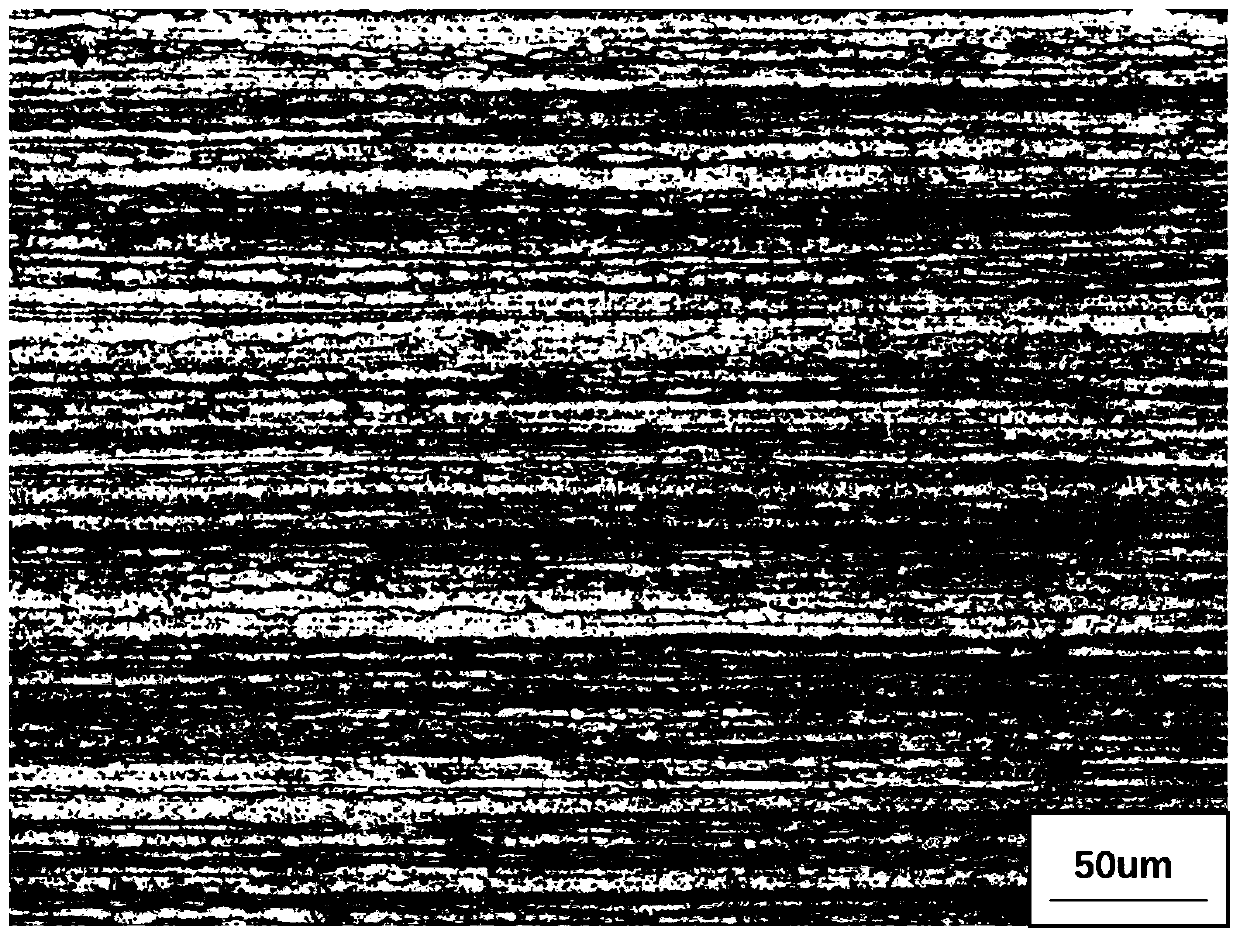

ActiveCN109207853AImproved fine grain strengtheningFine grain strengtheningAustenite grainWear resistant

The invention discloses a martensite wear-resistant steel plate with high wear resistance, belonging to the technical field of steel manufacturing. According to a technical scheme in the invention, the martensite wear-resistant steel plate comprises the following chemical components by weight: 0.32 to 0.38 % of C, 0.02 to 0.30% of Si, 0.8 to 1.0% of Mn, 0.6 to 0.8% of Ti, 0.02 to 0.03% of Nb, 0.15-0.20% of Mo, 0.35-0.45% of Cr, 0.0010-0.0020% of B, no more than 0.003% of S and no more than 0.012% of P, with the balance being Fe and unavoidable impurity elements. In the process of hot continuous rolling in the invention, TiC particles precipitated through continuous casting are gradually fragmented and homogenized along a rolling direction; through rolling fragmentation and solid-state precipitation of nano-sized TiC, most of the micron-sized TiC particles precipitated through continuous casting disappear; and nano-sized TiC can refine original austenite grains and improve ductility andtoughness.

Owner:NORTHEASTERN UNIV +2

Anti-bacterial dual-phase stainless steel and machining process thereof

The invention discloses anti-bacterial dual-phase stainless steel, and belongs to the technical field of dual-phase stainless steel. The stainless steel comprises C, Si, Mn, S, P, Cr, Mo, W, B, Cu, Ag, Nb, N, Ba, Fe and lanthanum cerium mixed rare earth. The invention further discloses a machining process of the anti-bacterial dual-phase stainless steel. The steel has the beneficial effects of being free of nickel, low in production cost, and good in anti-bacterial performance. The colon bacillus and staphylococcus sterilizing rate reaches 99.9%, and the steel can be widely used for the fieldof pharmacy, health care instruments, food processing industry and catering utensils, freezing devices, and sewage treatment and purification devices.

Owner:内蒙古明拓铁素体新材料有限公司

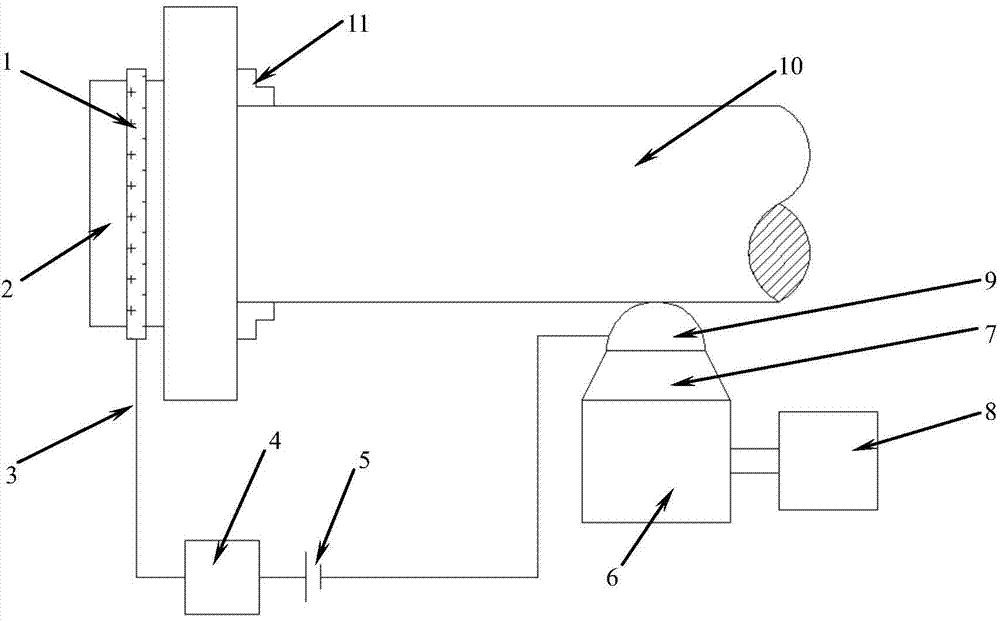

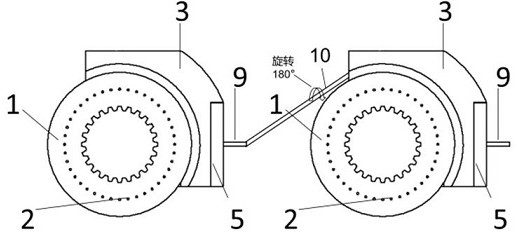

Ultrasonic-vibration surface-enhanced and finishing processing device with electric-contact heating assistance

The invention discloses an ultrasonic-vibration surface-enhanced and finishing processing device with electric-contact heating assistance. The ultrasonic-vibration surface-enhanced and finishing processing device comprises an electric brush, a main shaft, a guide line, an arc-extinguishing device, a power supply, an ultrasonic-vibration generation device, a workpiece and a chuck, wherein a knife head of the ultrasonic generation device, the power supply, the arc-extinguishing device, the electric brush sheathed on the main shaft, the main shaft, the chuck and the workpiece are connected in sequence and in series to form a conducting loop; current generated in the conducting loop is utilized to enable a material of the contact part between the surface of the workpiece and the knife head to generate joule heat for instantaneous warming and softening, and by combination of ultrasonic vibration, finishing processing, surface enhancement, fine-grain enhancement and residual stress elimination are realized. The invention also discloses an ultrasonic-vibration surface-enhanced and finishing processing method with the electric-contact heating assistance utilizing the device. The ultrasonic-vibration surface-enhanced and finishing processing device and method disclosed by the invention have the advantages that the structure is simple, the precise finishing processing and surface enhancement of various conducting materials can be realized, the quality of the processed surface can be improved, the surface roughness is reduced, the surface residual stress can be eliminated, and the ultrasonic vibration also can play a role in enhancing fine grains of the material of the surface of the workpiece.

Owner:SHANDONG UNIV

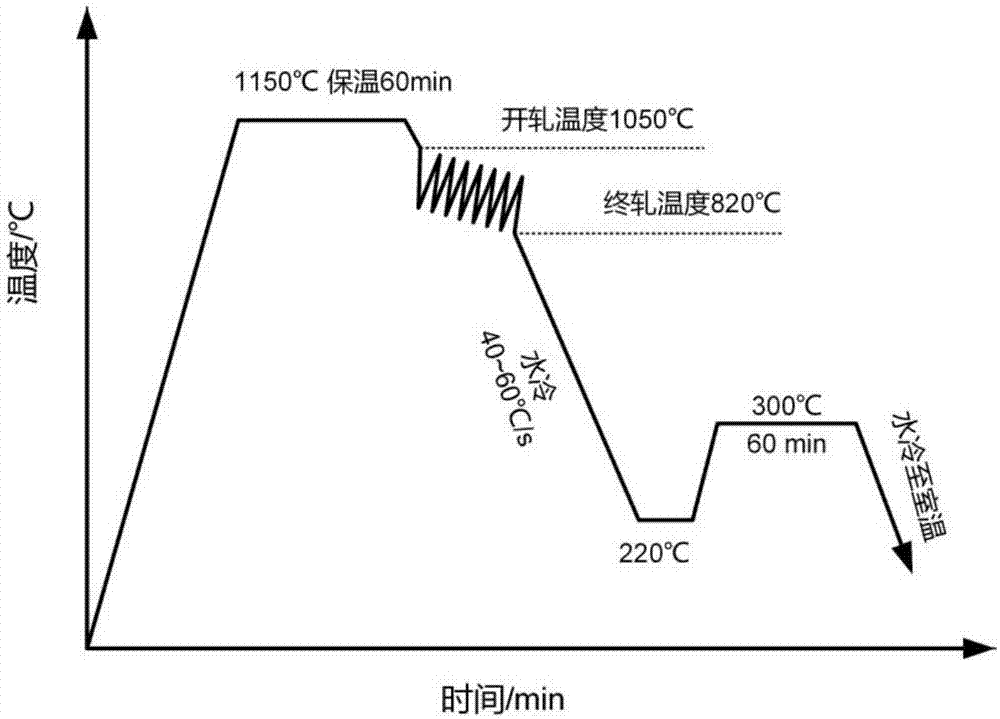

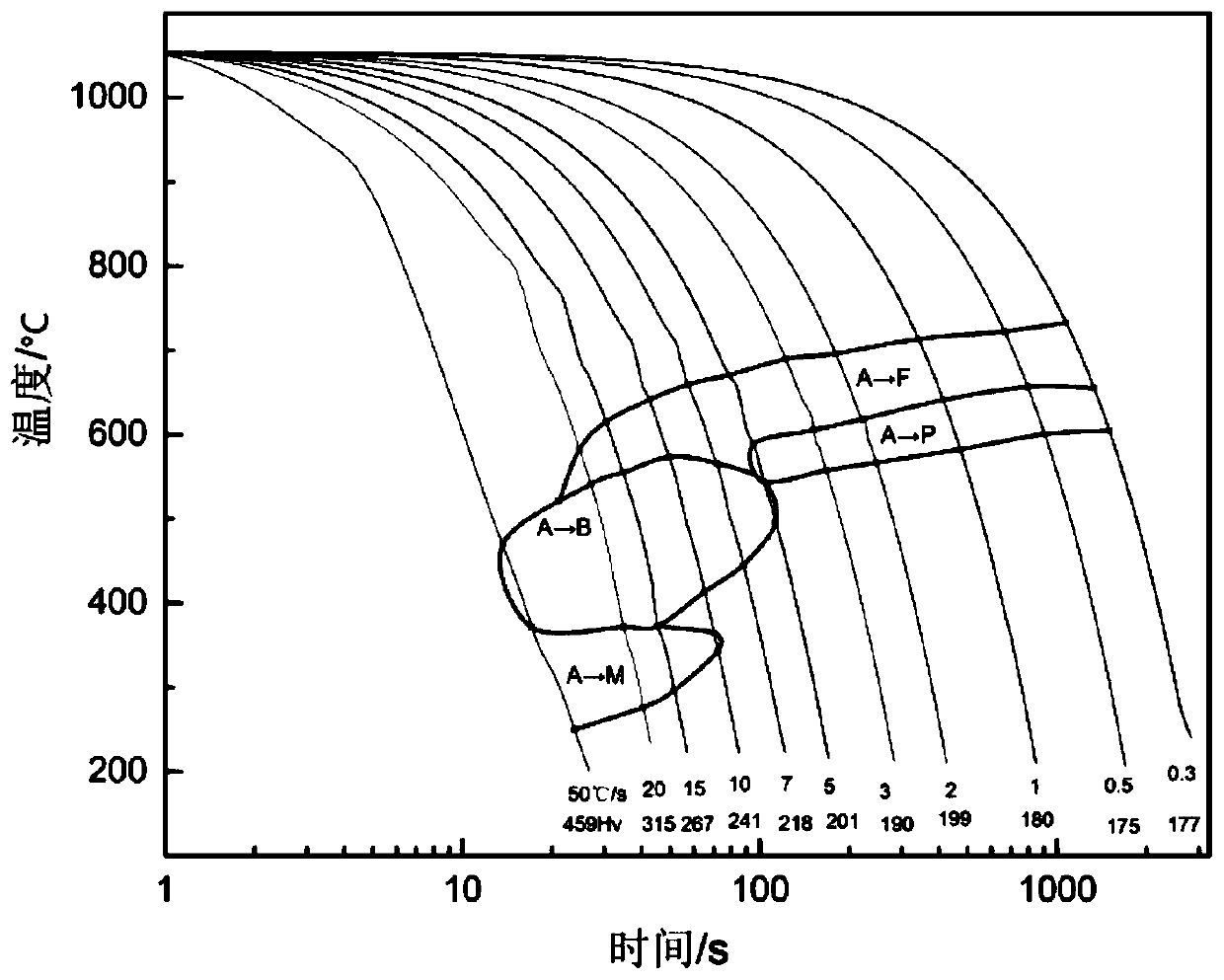

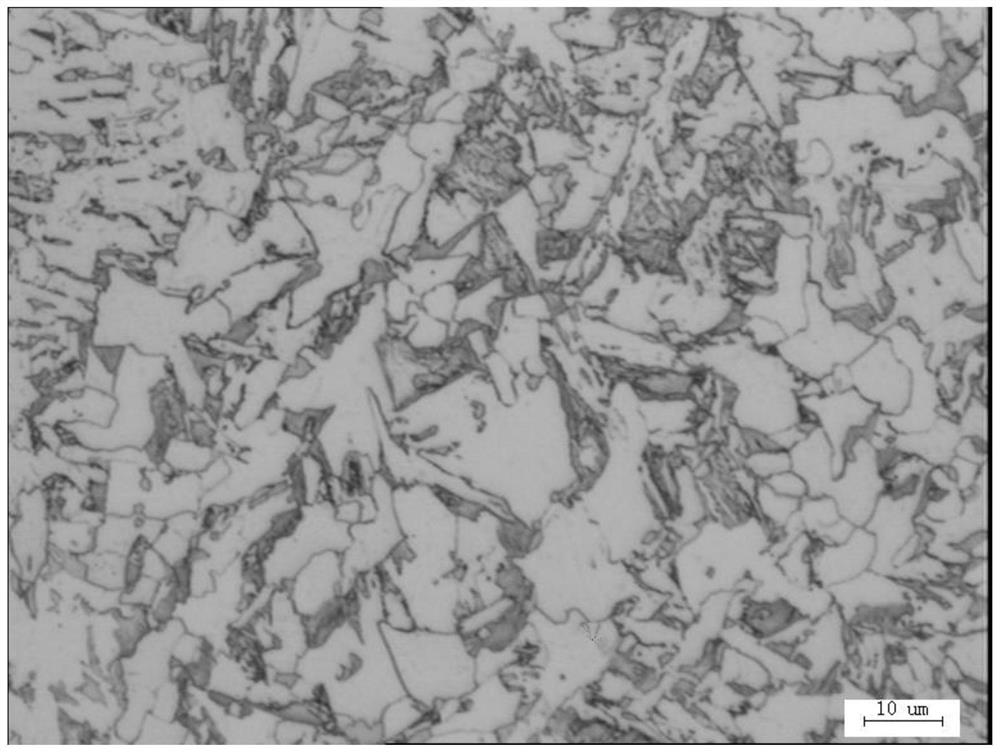

Low alloy high tenacity Q-P-T wear-resistant steel plate and manufacturing method thereof

The invention relates to the field of material heat treatment, and discloses a low alloy high tenacity Q-P-T wear-resistant steel plate and a manufacturing method thereof. The low alloy high tenacityQ-P-T wear-resistant steel plate comprises, by mass, 0.2-0.4% of C, 0.1-0.5% of Si, 0.5-1.5% of Mn, 0.5-1.2% of Cr, 0.1-0.3% of Mo, 0.02-0.08% of Ni, 0.04-0.1% of Cu, 0.001-0.008% of V, 0.01-0.04% ofTi, 0.01-0.05% of Nb, 0.001-0.003% of B, less than 0.015% of P, less than 0.005% of S, less than 0.006% of N, and the balance Fe and inevitable impurities. The low alloy high tenacity Q-P-T wear-resistant steel plate adopts the technique of Q-P-T heat treatment to manufacture the high tenacity wear-resistant steel. Microstructures are martensite, bainite, and retained austenite. Microalloy elements of V, Ti and Nb have effects of fine grain strengthening and precipitation strengthening. Therefore, the wear-resistant steel is good in abrasion performance, and high in tenacity.

Owner:UNIV OF SCI & TECH BEIJING

Magnesium alloy weld joint hot rolling strengthening process

ActiveCN103526142AHigh strengthHigh hardnessFurnace typesHeat treatment furnacesStress reliefUltimate tensile strength

The invention discloses a magnesium alloy weld joint hot rolling strengthening process, which comprises the following steps: 1) welding magnesium alloy pieces on both sides by adopting insert gas arc welding; 2) placing the magnesium alloy welding piece into a heat treatment furnace, and performing postwelding stress relief annealing at 200 to 350 DEG C for 0.5 to 2 hours; and 3) performing hot rolling on the surplus height of the weld joint of the magnesium alloy welding piece for at least two times until the weld joint is in level with a base body, wherein the magnesium alloy welding piece is heated to 350 to 400 DEG C before hot rolling at each time, heat preservation and preheating are performed for 10 minutes to 0.5 hour and hot rolling is performed at 250 to 350 DEG C. According to the process, the operation process is simple, the processing period is short, the weld joint strength is higher than the tensile strength of the base material, the tissue is refined, and the appearance of the welding piece is beautified. The process has a certain straightening effect on the magnesium alloy plate which is deformed after being welded, and is applicable to the complete-penetration magnesium alloy materials such as AZ31, AZ61 and AZ80.

Owner:CHONGQING UNIV

Sc-Ni-RE high-strength heat-resistant aluminium alloy material and preparation method thereof

InactiveCN102021429AGood value for moneyOvercoming cost barriersSolid solutionUltimate tensile strength

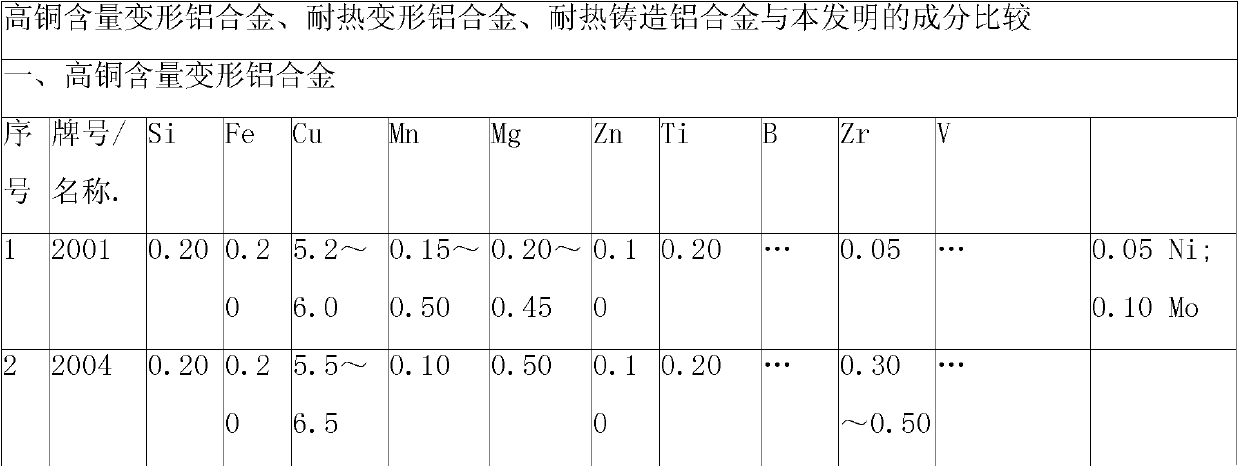

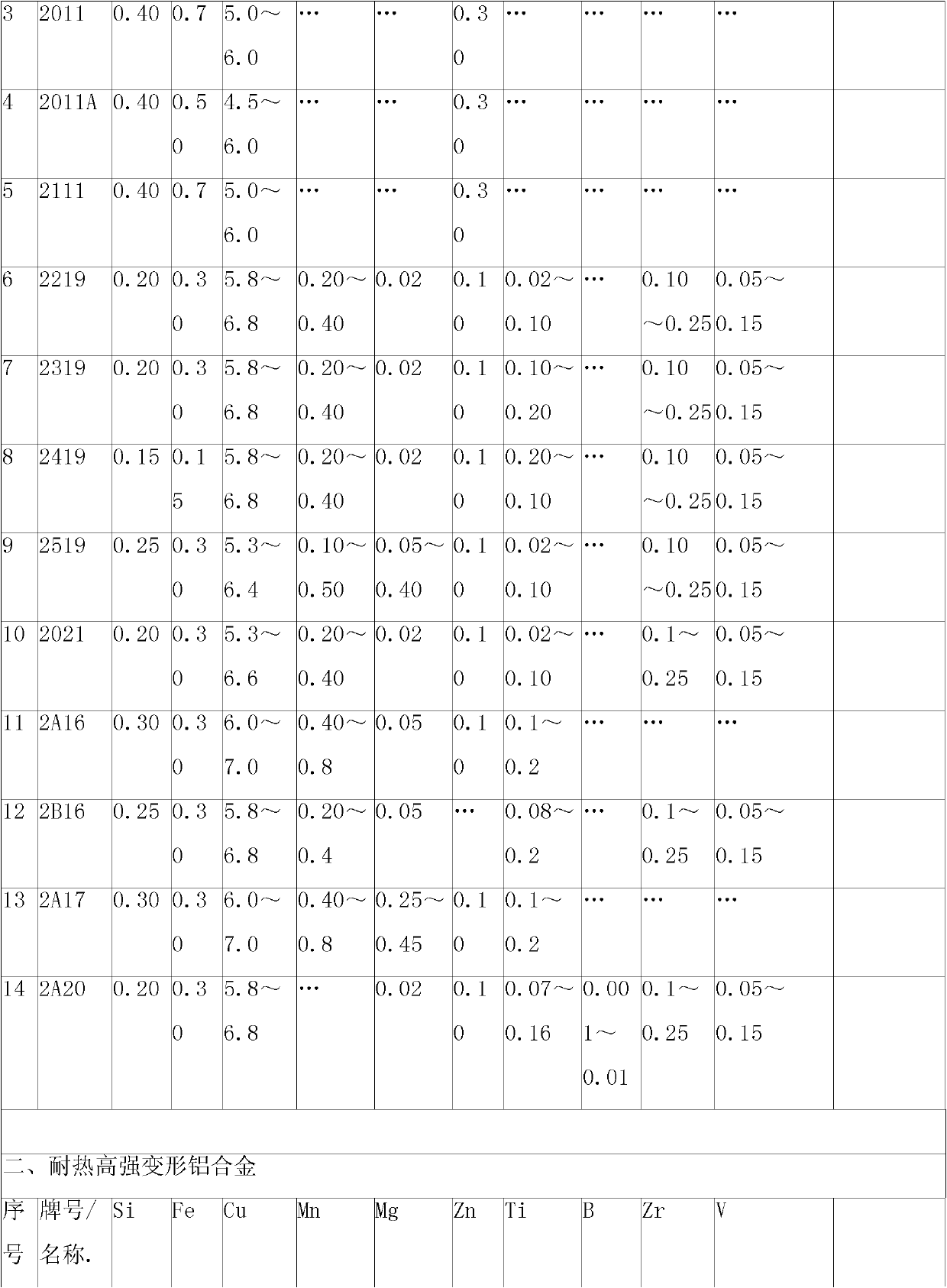

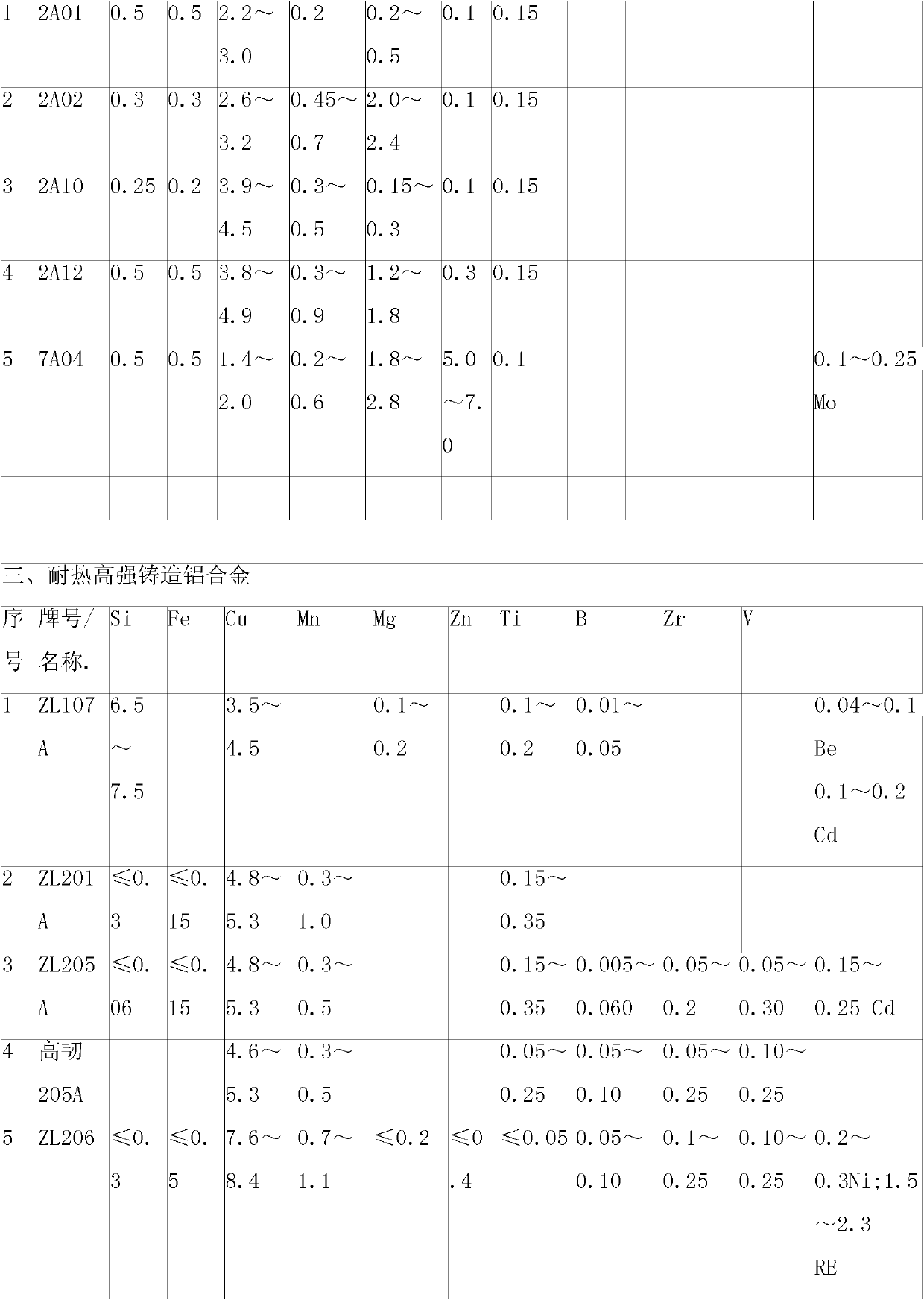

The invention discloses a Sc-Ni-RE high-strength heat-resistant aluminium alloy material and a preparation method thereof. The Sc-Ni-RE high-strength heat-resistant aluminium alloy material comprises the components in percent by weight: 1.0-10.0 percent of Cu, 0.05-1.5 percent of Mn, 0.01-0.5 percent of Cd, 0.01-0.5 percent of Ti, 0.01-0.2 percent of B, 0.01-1.0 percent of Zr, 0.01-1.0 percent ofNi, 0.01-1.0 percent of Sc, 0.05-5 percent of RE and the balance of Al. With an excellent-quality melt, a solid solution and a phase diagram theory as guidance and through preferably selecting alloy principal elements of Cu, Mn and RE, the invention reduces the alloy quasi solid phase temperature range and solves the problems of large heat cracking tendency, low high-temperature strength of the product, and the like during the casting; and preferably, a multielement microalloying element formula is selected, the material base condition is created for carrying out culturing and grain refining on a high-temperature phase and a strengthening phase in the solid solution, and a high-strength heat-resistant aluminium alloy material is finally developed.

Owner:GUIZHOU HUAKE ALUMINUM MATERIAL ENG TECH RES

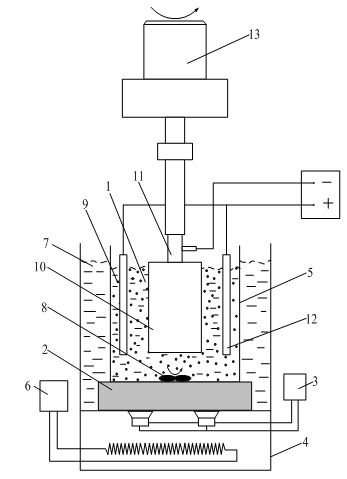

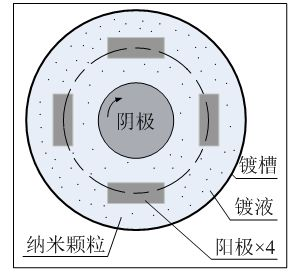

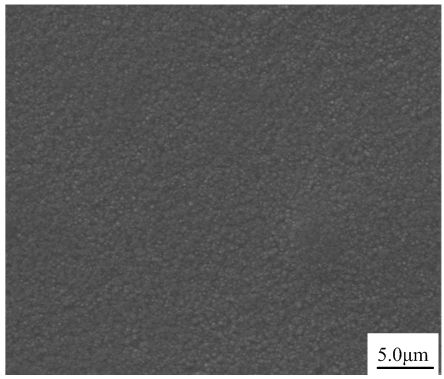

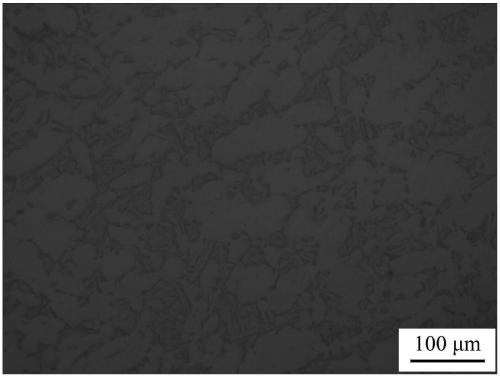

Method for preparing nano composite plating layer

InactiveCN101956225AInhibition of agglomerationStirring speed is fastElectrolytic coatingsLiquid mediumConcentration polarization

The invention discloses a method for preparing a nano composite plating layer, which comprises the following steps of: placing the plating solution added with nano granules in an ultrasonic field of an ultrasonic wave generator, and meanwhile performing plating in a mode of driving a plating cathode to rotate in the ultrasonic field through a cathode connecting rod. By adopting the method of the invention, the cavitation effect of ultrasonic wave and the micro jet flow generated when the ultrasonic wave is propagated in a liquid medium can shatter nano granule aggregates and promote co-deposition of the nano granules and a matrix metal; and the plating cathode rotates at a high speed in the plating solution during plating so as to increase the stirring speed of the plating solution, inhibit the conglobation of the nano granules, reduce the concentration polarization, promote the plating efficiency and enhance the comprehensive performance of the plating layer at the same time. The prepared nano composite plating layer has flat and exquisite surface, uniform and fine granules and dense arrangement; and the hardness, corrosion resistance and abrasion resistance of the nano composite plating layer are greatly improved.

Owner:HENAN UNIV OF SCI & TECH

Recrystallizing high-strength titanium alloy and preparation method thereof

The invention provides a recrystallizing titanium alloy and a preparation method thereof. The high-strength titanium alloy is prepared from the following components of 4.5 to 6.0% of Al (aluminum), 3.7 to 4.7% of Sn (stannum), 0.75 to 2.0% of Mo (molybdenum), 0.2 to 0.35% of Si (silicon), 0.6 to 1.2% of Nd (neodymium), 5 to 50% of Zr (zirconium) and the balance of Ti (titanium). The recrystallizing high-strength titanium alloy has the advantages that after alloying, the crystal lattice is distorted due to the adding of the Zr element, the number of nucleation points is increased in the nucleation process due to the defects, the density of nucleation is increased, the refining function of crystal grains is realized, and the refining of crystals is reinforced; proofed by experiment results,compared with the contrast alloy with yield strength of 880MPa and the tensile strength of 1020MPa, the recrystallizing high-strength titanium alloy has the yield strength of 963 to 1130MPa and the tensile strength of 1100 to 1280MPa, and maintains the equivalent elongation rate.

Owner:YANSHAN UNIV

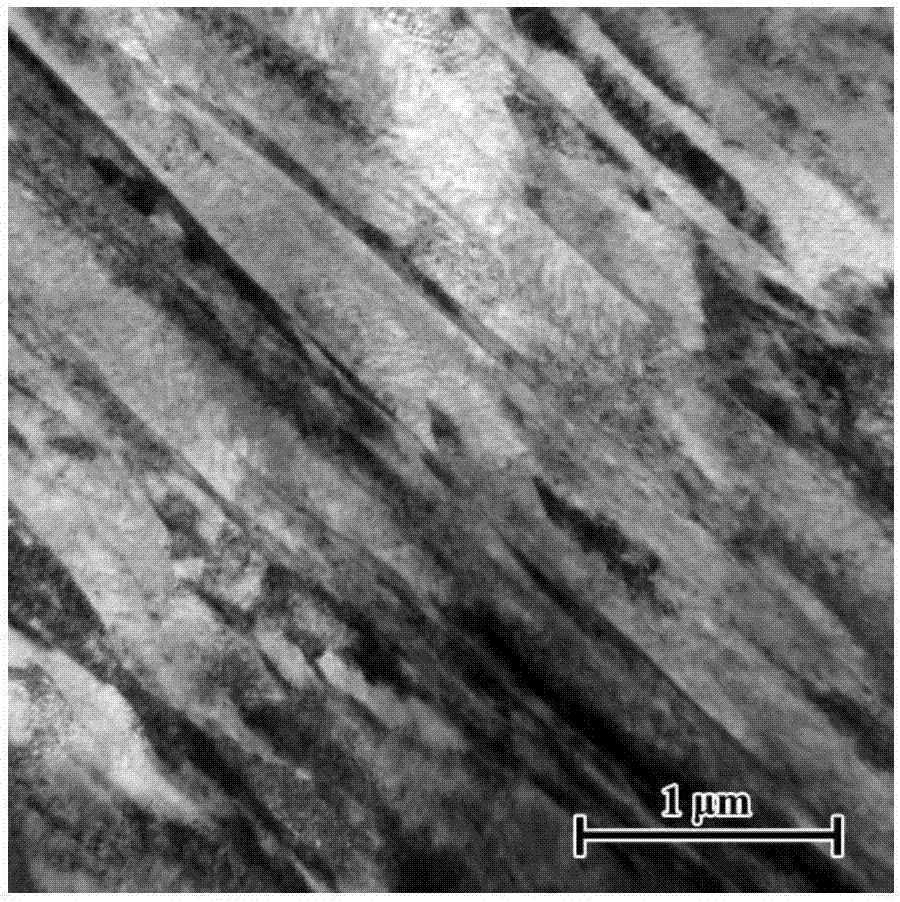

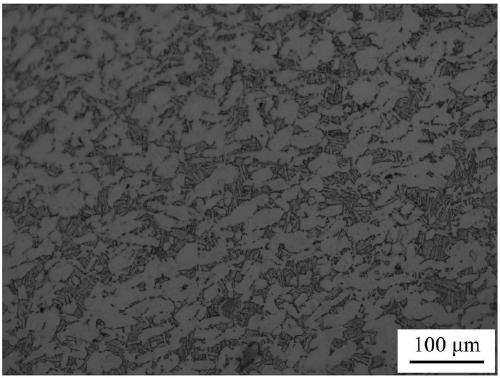

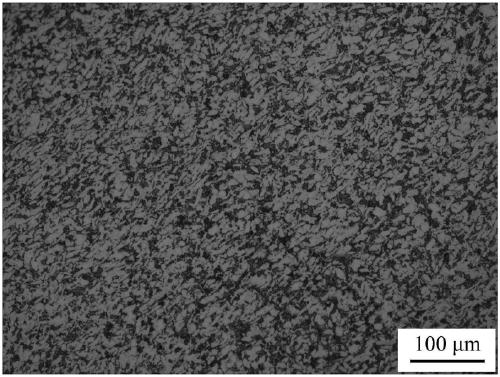

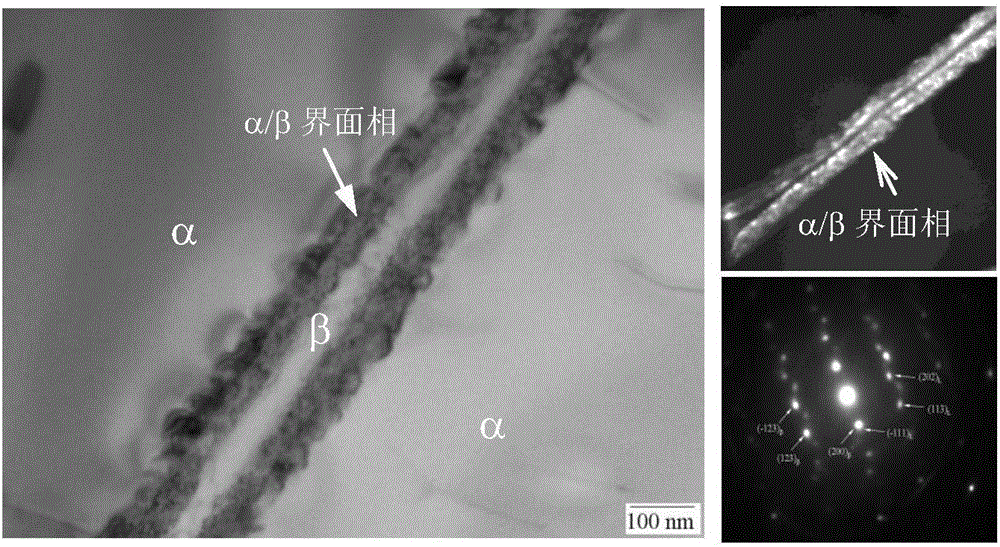

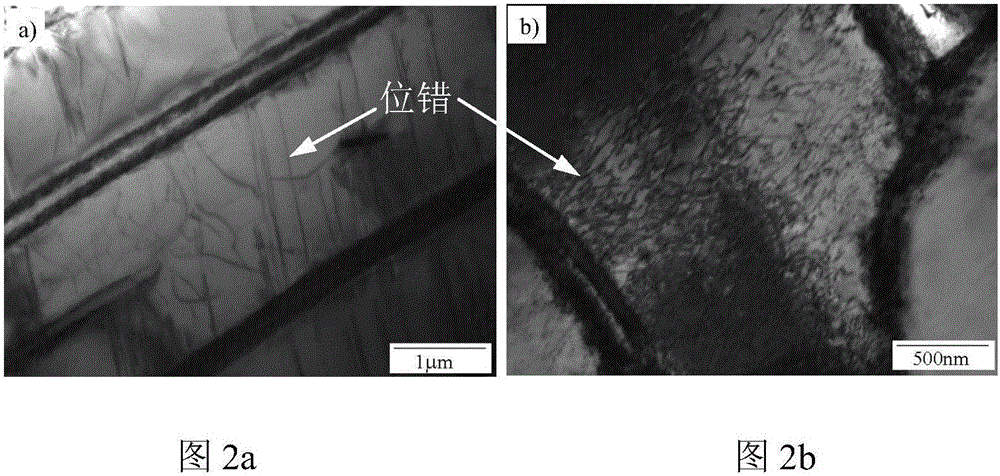

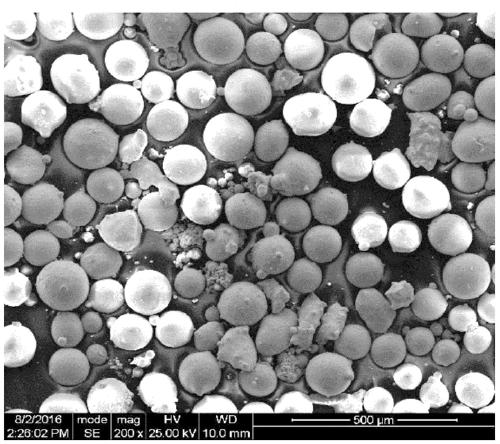

Preparation method capable of synchronously improving strength and plasticity of additive manufactured titanium alloy

ActiveCN106583719AHigh strengthImprove plasticityAdditive manufacturing apparatusIncreasing energy efficiencyDeposition processOxygen content

The invention discloses a preparation method capable of synchronously improving strength and plasticity of an additive manufactured titanium alloy. The preparation method comprises the following steps: (1) Ti-6Al-4V alloy powder with a particle size of -90-+325 meshes is put in a powder feeder, wherein the oxygen content of the powder is not higher than 0.20 wt.%; (2) a substrate is fixed on a worktable of an argon-charged inert atmosphere machining chamber; (3) in the argon-charged inert atmosphere machining chamber, when the oxygen content is lower than 100 ppm, a titanium alloy is formed through additive manufacturing; and (4) under the effect of a laser source, the synchronously fed Ti-6Al-4V alloy powder is continuously molten and deposited on the substrate; in the deposition process, the energy density of the deposition area and the size of the deposition area are controlled to obtain 103-104 k / s cooling speed in the liquid-solid transformation process and to obtain 100-400 k / s cooling speed in the process of converting from a beta phase to an alpha phase; and a Ti-6Al-4V alloy part with an alpha / beta interface phase is prepared.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

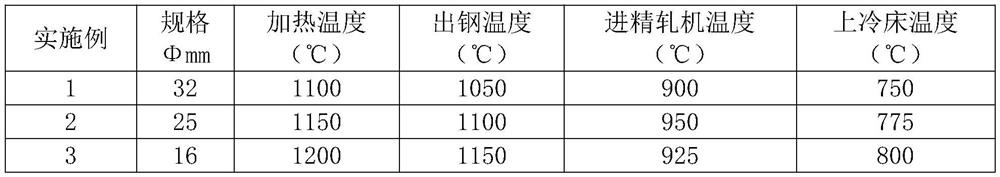

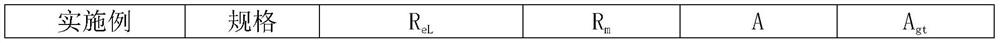

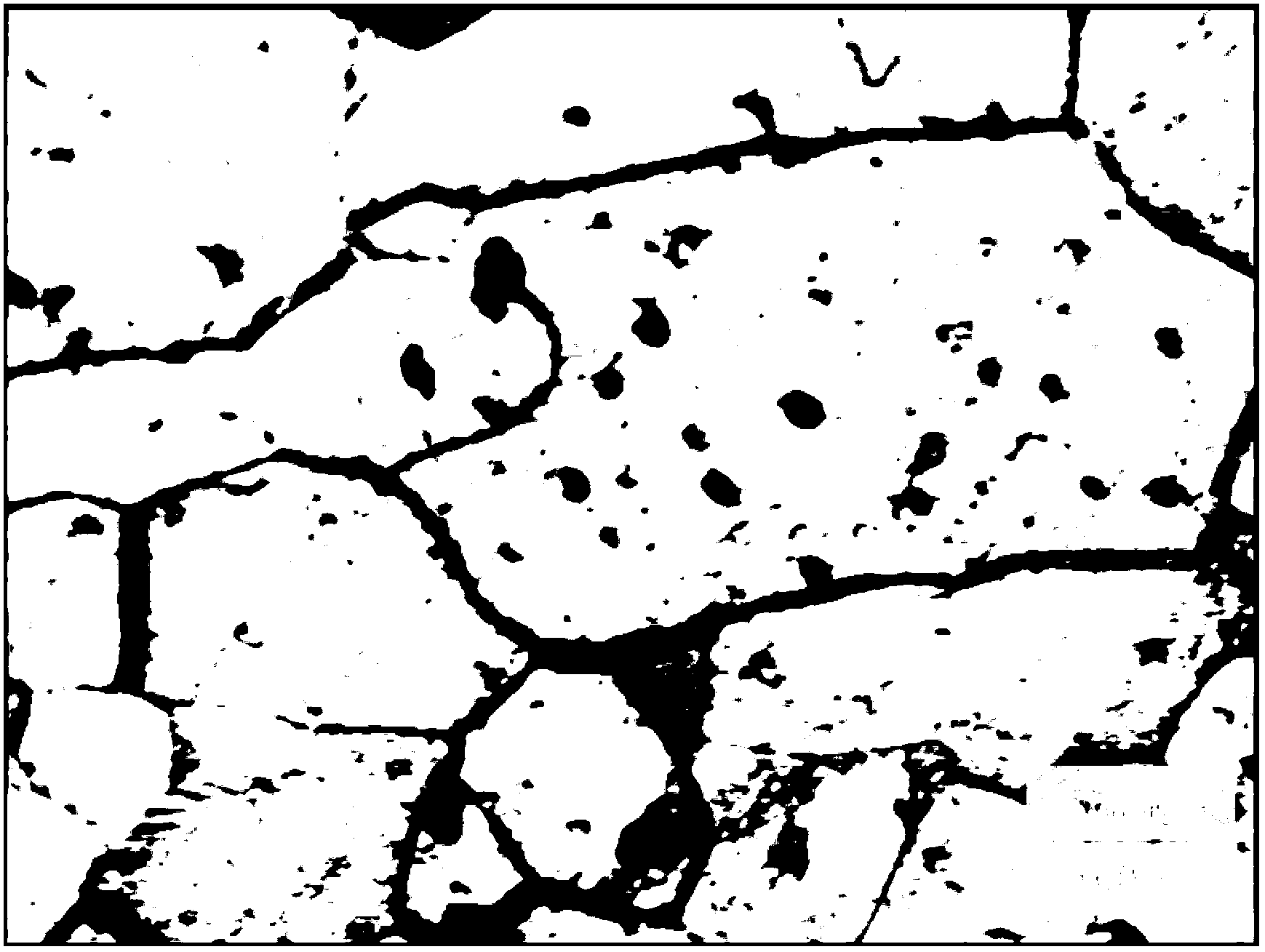

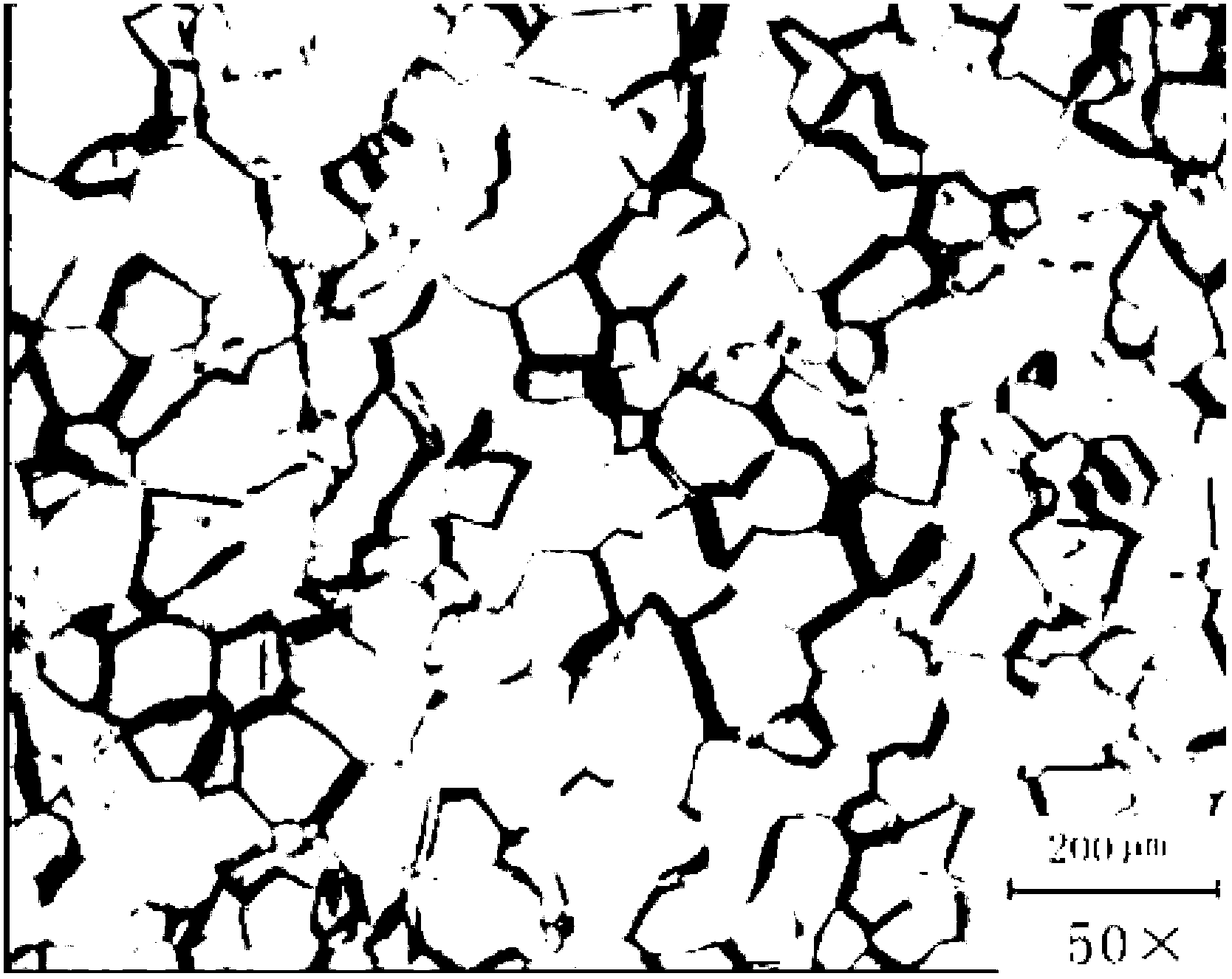

Niobium microalloyed HRB400E hot-rolled ribbed steel bar and efficient manufacturing method thereof

The invention relates to the field of ferrous metallurgy, in particular to a niobium microalloyed HRB400E hot-rolled ribbed steel bar and an efficient manufacturing method thereof. Steel is prepared from the chemical compositions including, by mass, 0.21%-0.25% of C, 0.45%-0.65% of Si, 1.00%-1.25% of Mn, 0.02%-0.025% of Nb, less than or equal to 0.045% of P, less than or equal to 0.045% of S, 0.004%-0.01% of N and the balance Fe and inevitable impurities. When steel rolling is performed, the heating temperature of a billet is 1190-1230 DEG C. When the method is used for steel rolling, the heating temperature of the billet is high, so that the production efficiency is effectively increased. Due to the low Nb and Mn content of the steel, it is guaranteed that the niobium microalloyed HRB400Ehot-rolled ribbed steel bar has a significant yield point.

Owner:SGIS SONGSHAN CO LTD

Ultrahigh-strength high-toughness high-conductivity copper-nickel-tin alloy and preparation method thereof

The invention provides an ultrahigh-strength high-toughness high-conductivity copper-nickel-tin alloy which contains nickel, tine, yttrium, niobium, scandium and cerium elements. The total mass of theyttrium, niobium, scandium and cerium elements is less than or equal to 0.5 percent of the mass of the copper-nickel-tin alloy. The copper-nickel-tin alloy has high strength, toughness and conductivity, and is wide in application range. The invention further provides a preparation method of the copper-nickel-tin alloy. The preparation method of the copper-nickel-tin alloy concretely comprises thesteps of preparing materials according to the mass percent of element compositions, and adopting a gas atomization method for preparing to obtain alloy powder; adopting hot isostatic pressure sintering on the alloy powder to obtain a copper-nickel-tin alloy ingot blank; and carrying out solution treatment and warm deformation strengthening treatment on the copper-nickel-tin alloy ingot blank so as to obtain the ultrahigh-strength high-toughness high-conductivity copper-nickel-tin alloy. According to the preparation method, multiple compound factor strengthening and toughening copper alloys are implemented and utilized, and the obtained copper-nickel-tin alloy has the characteristics of refined crystalline strengthening, strain strengthening, dispersion strengthening and precipitation hardening at the same time so as to obtain high strength, toughness and conductivity.

Owner:CENT SOUTH UNIV

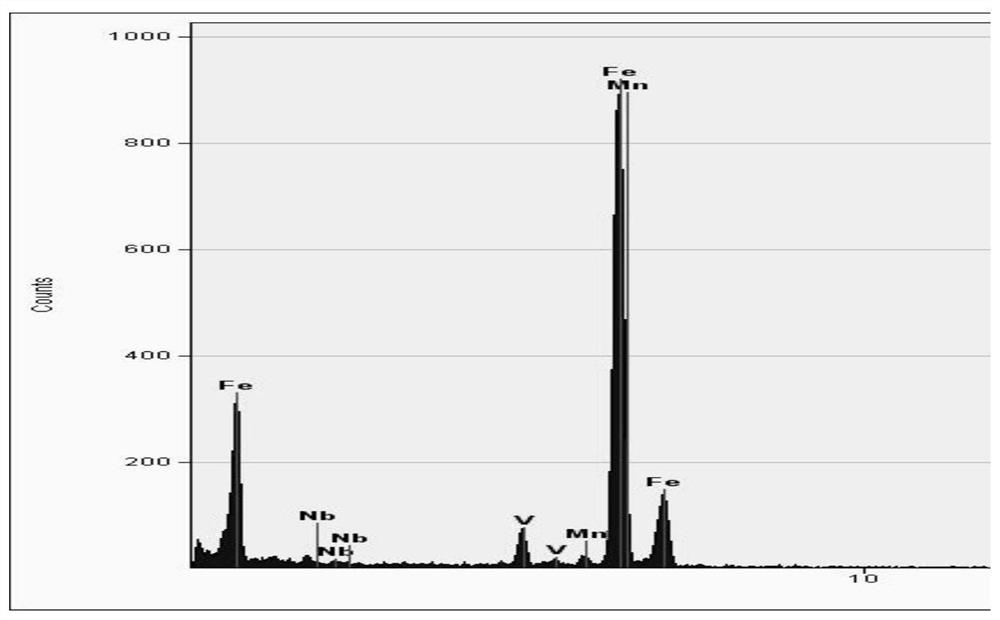

Anti-corrosion crusher hammerhead and preparation method thereof

InactiveCN110257728AHigh hardnessHigh tensile strengthFurnace typesProcess efficiency improvementFerroniobiumManganese

The invention provides an anti-corrosion crusher hammerhead and a preparation method thereof. The crusher hammerhead is prepared from the following components in percentage by mass: 20.68 to 23.20 percent of Cr, 8.64 to 10.32 percent of Ni, 4.19 to 6.08 percent of Nb, 1.58 to 1.84 percent of Mo, 1.25 to 1.57 percent of Mn, 2.04 to 2.65 percent of C, 0.10 to 0.43 percent of Si, 0.22 to 0.37 percent of W, 0.12 to 0.23 percent of V, less than or equal to 0.05 percent of S, less than or equal to 0.008 percent of P, and the balance Fe and inevitable impurities. The preparation method comprises the steps of smelting, casting, austenitizing and isothermally quenching. According to the anti-corrosion crusher hammerhead and the preparation method thereof provided by the invention, during the casting of the cast steel hammerhead, the temperature and the time for austenitizing and isothermally quenching are set, so that the obtained hammerhead has the characteristics of high hardness and high toughness; and on the basis of a traditional chromium manganese cast steel hammerhead, the content of ferronickel ferroniobium is added, and the proportion of the various components are adjusted, so that the cast crusher hammerhead has high hardness, wear resistance and toughness, and has high corrosion resistance at the same time.

Owner:NINGGUO ZHENGXING WEAR RESISTANT MATERIALS

Preparation method of high-strength and high-toughness high-entropy alloy

The invention discloses a preparation method of a high-strength and high-toughness high-entropy alloy, and relates to the technical field of alloy material production. The preparation method comprises the following specific steps that high-entropy alloy powder prepared from the components in atomic percent: 27%-30% of Mn, 8%-12% of Co, 8%-12% of Cr, 0.4%-1.3% of C and the balance of Fe is prepared; the high-entropy alloy powder is subjected to ball milling treatment and then pre-pressed, the pressure ranges from 300 MPa to 500 MPa, the pressure is maintained for 200 seconds to 300 seconds, and a pre-pressed block of the high-entropy alloy is obtained; the pre-pressing block is subjected to vacuum annealing, vacuum hot pressing sintering and cold rolling deformation; and the high-entropy alloy sheet subjected to cold rolling deformation is subjected to constraint carbon distribution treatment at the temperature of 400-550 DEG C, and free carbon elements are diffused. The C-containing unequal-atom FeMnCoCrC high-entropy alloy prepared through the method has excellent strength and plasticity combination, and meanwhile, the problems that a high-entropy alloy prepared through a traditional technology is uneven in component and unstable in structure are solved.

Owner:ZHONGBEI UNIV

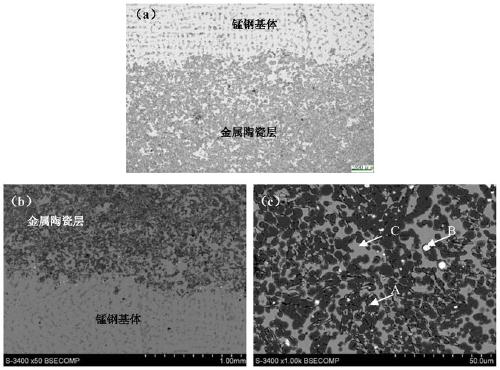

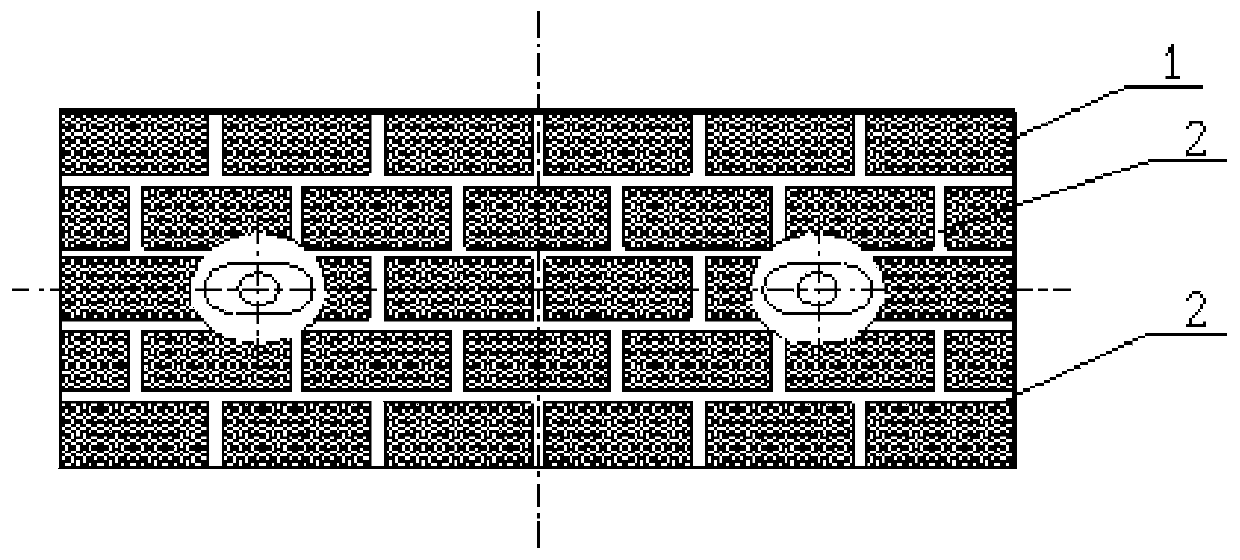

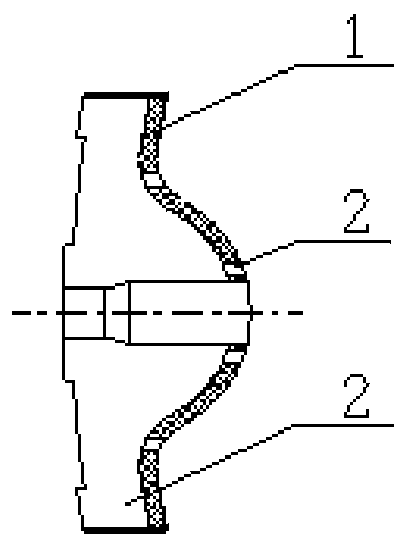

Manganese-steel-based complex phase particle enhanced metal ceramic surface composite material, casting and manufacturing method of casting

ActiveCN111455249AIncrease volume fractionEvenly distributedIncreasing energy efficiencyCeramic particleCermet

The invention discloses a manganese-steel-based complex phase particle enhanced metal ceramic surface composite material, a casting and a manufacturing method of the casting. The casting preparing technology comprises the processes that firstly, prepared titanium powder, tungsten powder, gel graphite powder and an alloy agent are evenly mixed, a proper number of water-based bonding agents are added for uniform stirring, and the mixture is placed in a die to be punched into a prefabricated block; secondly, after the prefabricated block is dried, the prefabricated block is fixed to a foam modelcorresponding to the part, needing to be strengthened, of the casting, coating of a fireproof coating is conducted, and modeling is conducted after drying; and thirdly, austenitic manganese steel metal liquid is poured, the high temperature of alloy liquid is utilized for inducing the metal elements Ti and W in the prefabricated block to generate the high-temperature combustion synthesis reactionwith the C element, in-situ generation of TiC, WC and (Ti, W) C and other complex phase ceramic particle enhanced bodies is achieved, and the particle enhanced manganese-steel-based metal ceramic surface composite casting is manufactured.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

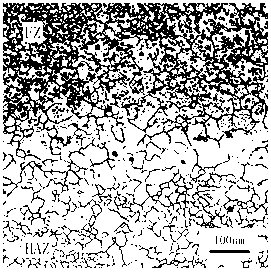

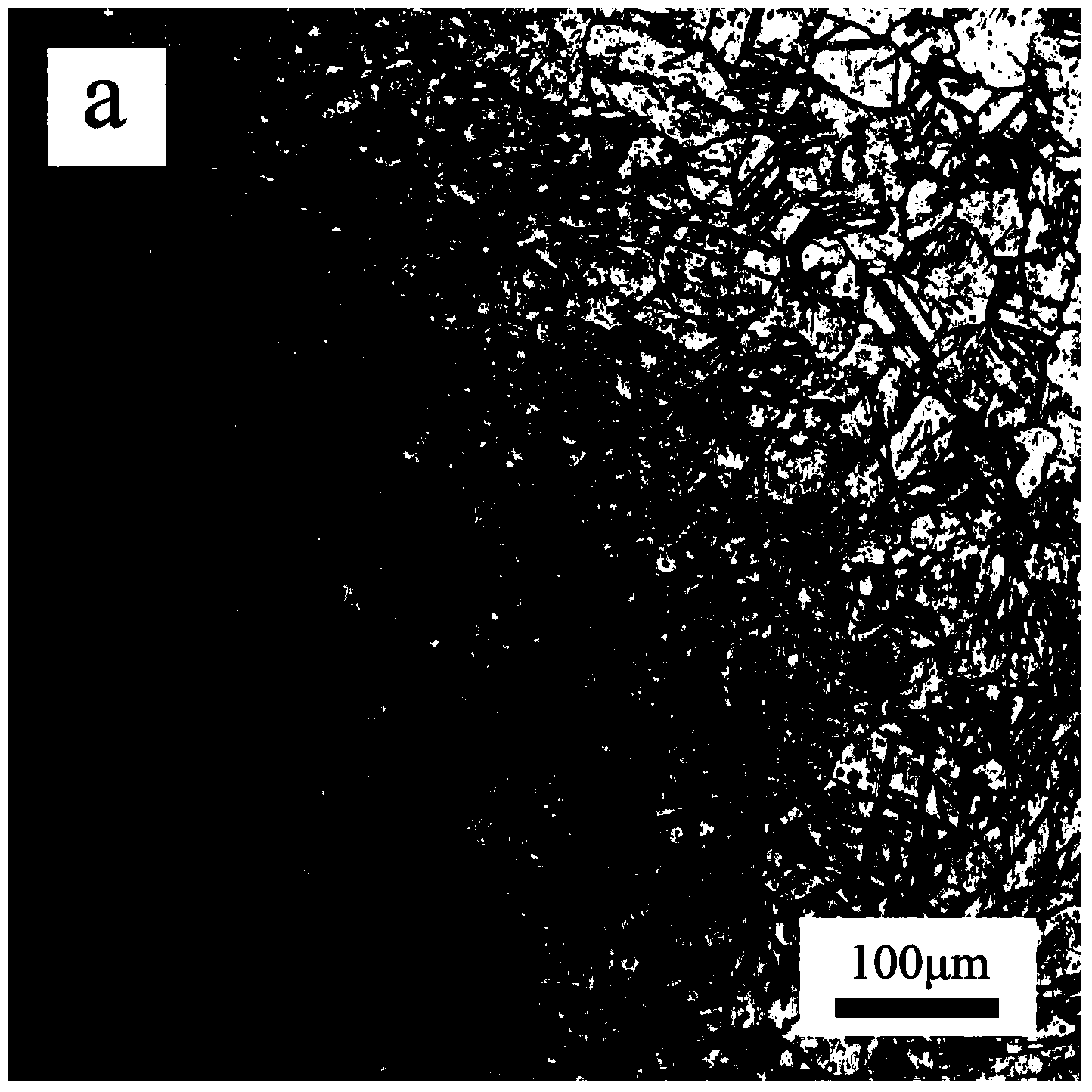

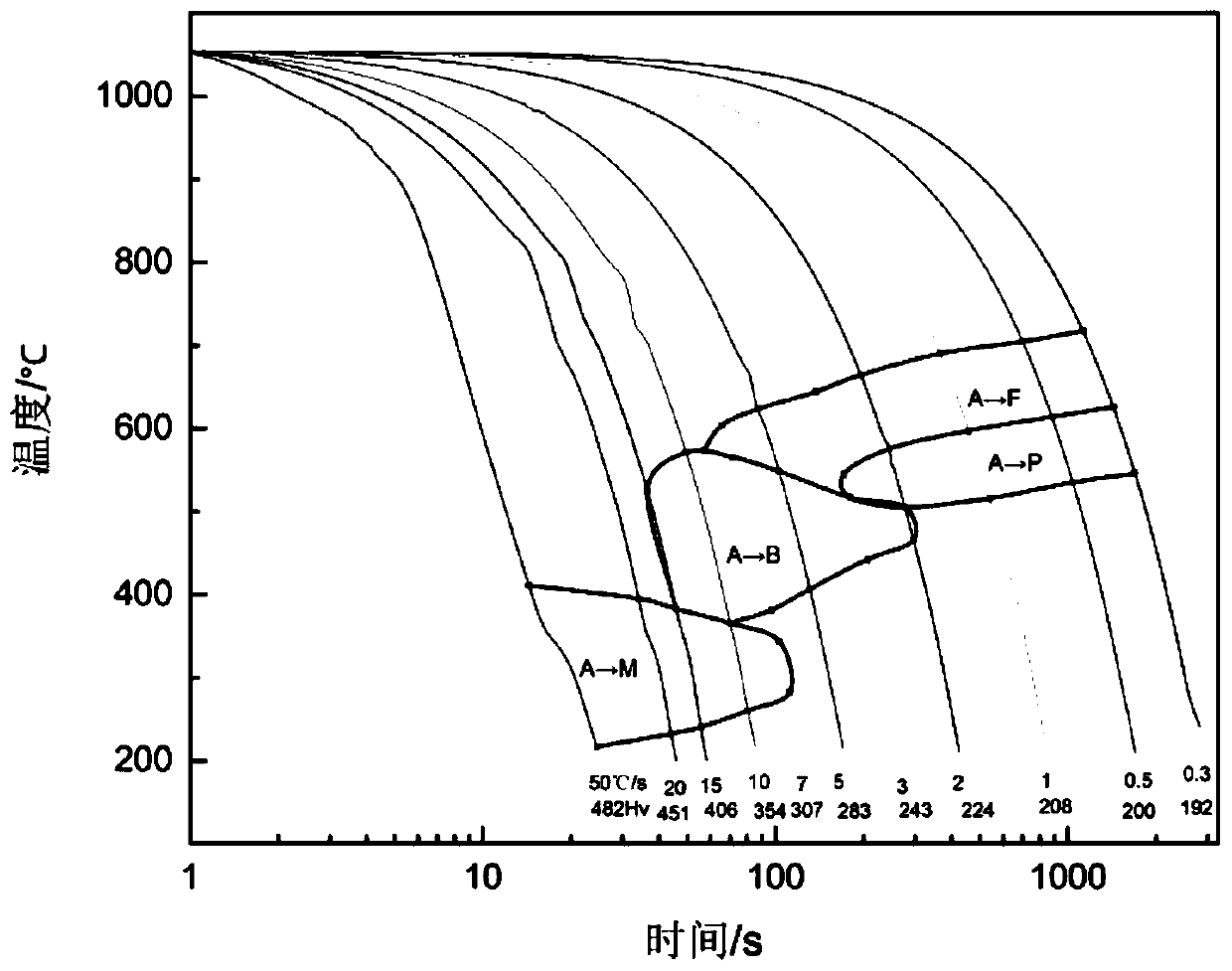

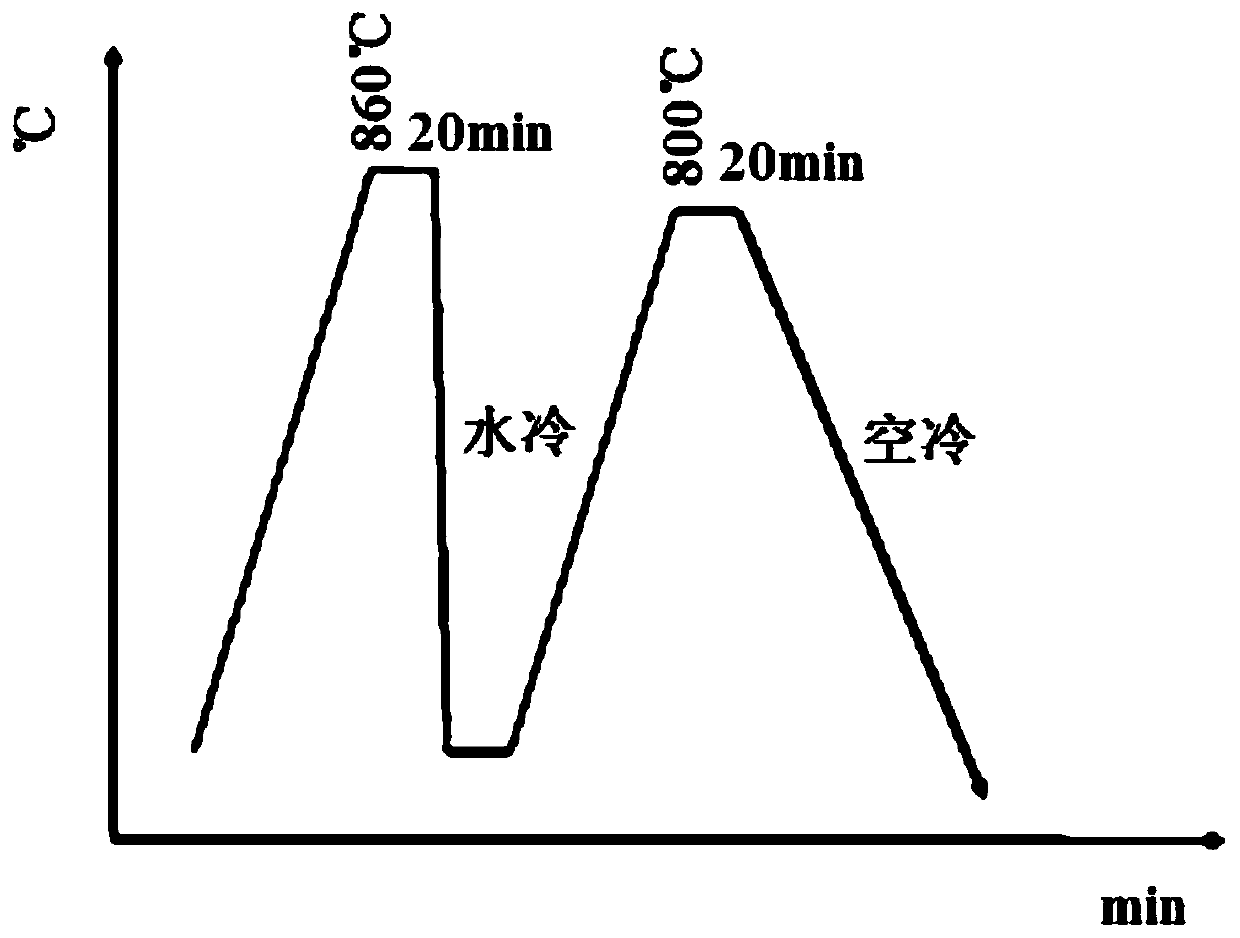

Post heat treatment method for laser additive manufacturing 12CrNi2 alloy steel

InactiveCN109880986ASolve the disadvantages of sub-temperature quenching that is difficult to homogenize the structureSolve the disadvantages of difficult to homogenize tissueIncreasing energy efficiencyRoom temperatureWater cooling

The invention provides a post heat treatment method for a laser additive manufacturing 12CrNi2 alloy steel and relates to the technical field of post heat treatment of the additive manufacturing alloysteel. The purpose of the invention is to solve the problems that traditional laser additive manufacturing is uneven in tissue, difficult to remove residual stresses and low in alloy strength. The method comprises the steps of 1, heating and temperature raising, specifically, the laser additive manufacturing 12CrNi2 alloy steel is heated to 856-866 DEG C; 2, heat preservation, specifically, heatpreservation treatment is performed on the 12CrNi2 alloy steel after the heating and temperature raising under the condition of 856-866 DEG C; 3, cooling, specifically, the 12CrNi2 alloy steel after the heat preservation is water-cooled to the room temperature; and 4, the cooled 12CrNi2 alloy steel is heated to 734-836 DEG C and the heat preservation treatment is performed under this temperature condition, then water-cooling is performed to the room temperature, and the treated 12CrNi2 alloy steel is obtained. By means of the post heat treatment method for the laser additive manufacturing 12CrNi2 alloy steel, the post heat treatment method for the laser additive manufacturing 12CrNi2 alloy steel can be obtained.

Owner:HARBIN INST OF TECH

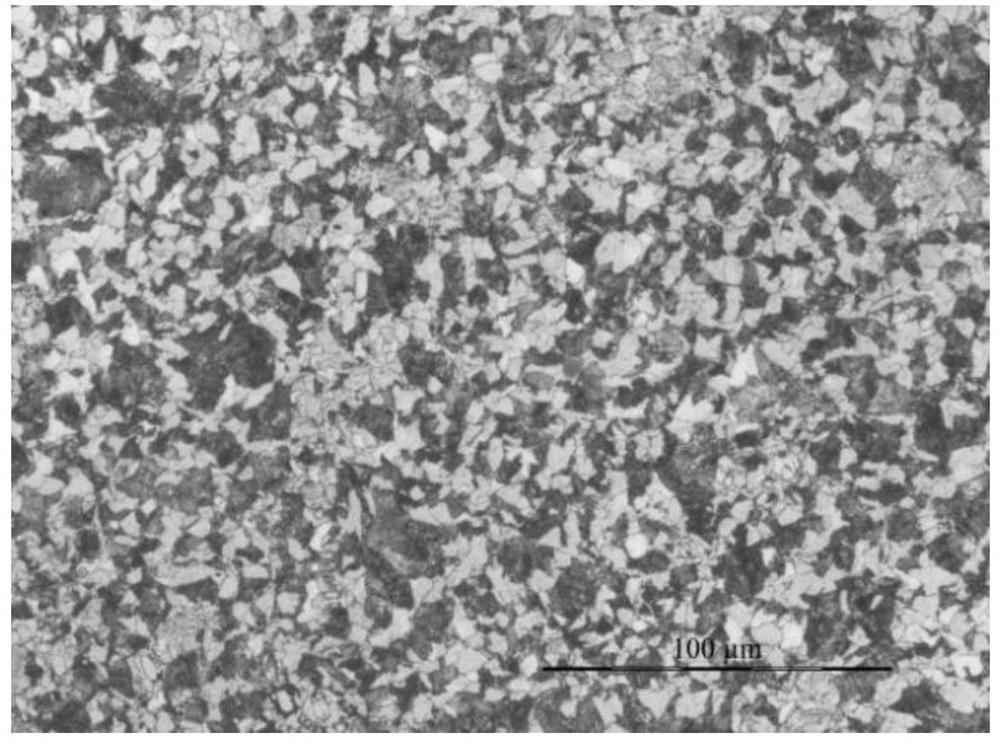

Acicular ferrite type high-strength steel bar and preparation method thereof

PendingCN114015848AStrong precipitation strengtheningReduce toughnessProcess efficiency improvementEarthquake resistanceReinforced concrete

The invention belongs to the technical field of hot-rolled ribbed steel bars for reinforced concrete structures, and particularly relates to an acicular ferrite type high-strength steel bar and a preparation method thereof. Steel in the steel bar comprises the following chemical components in percentage by weight: 0.25 to 0.35 percent of C, 0.40 to 0.80 percent of Si, 1.40 to 1.80 percent of Mn, less than or equal to 0.030 percent of P, less than or equal to 0.030 percent of S, 0.02 to 0.04 percent of Nb, 0.09 to 0.15 percent of V, 0.15 to 0.45 percent of Cr, 0.010 to 0.019 percent of N and the balance of Fe and inevitable impurity elements. Under the condition of existing process equipment of a production plant, the acicular ferrite type high-strength steel bar is prepared by adopting a high C, Si and Mn component design and a V and Nb combined microalloying mode and combining a rolling self-tempering process, the 700MPa-grade reinforcing steel bar with excellent comprehensive performance is produced on the premise of keeping material ductility, the yield strength of the 700MPa-grade reinforcing steel bar is greater than or equal to 700MPa, the tensile strength is greater than or equal to 830MPa, the percentage elongation after fracture is greater than or equal to 14%, the total elongation under the maximum force is greater than or equal to 9%, the anti-seismic performance is good, and the requirements of high-rise and large-span anti-seismic structures are met.

Owner:安徽吾兴新材料有限公司

Forging method for superconducting tantalum bar

InactiveCN102699247AImprove unevennessFine grain strengtheningMetal-working apparatusIngotOxidation resistant

The invention relates to a forging method for a superconducting tantalum bar. The forging method is characterized in that the forging method comprises the following steps: firstly, taking a special superconducting tantalum bar as a raw material, preheating the raw material at the temperature of 150-180 DEG C, preserving the heat for 20-40 minutes, taking out the heated tantalum ingot and uniformly coating the heated tantalum ingot with an oxidation resistant coating, wherein the coating thickness is 2-3 mm and naturally drying in air; heating the dried material at the temperature of 450-500 DEG C, preserving the heat for 210-240 minutes and then taking out the material; secondly, primarily radially upsetting and primarily radially drawing out; thirdly, secondarily radially upsetting and secondarily radially drawing out; and fourthly, triply radially upsetting, stopping forging, carrying out air cooling for 5-10 minutes and then cooling and triply radially drawing out. According to the forging method disclosed by the invention, the forging machining for superconducting products by using a tantalum cast ingot is carried out and a proper hot forging heating process is matched, so that tissues of which the grain size levels and cross section tissue uniformity respectively meet preparation requirements of early-stage tissues are obtained.

Owner:NINGXIA ORIENT TANTALUM IND

635MPa-grade high-strength anti-seismic steel bar and preparation method thereof

The invention belongs to the technical field of hot-rolled ribbed steel bars for reinforced concrete structures, and particularly relates to a 635MPa-grade high-strength anti-seismic steel bar and a preparation method thereof. Steel in a steel bar comprises the following chemical components in percentage by weight: 0.24-0.29 percent of C, 0.70-0.80 percent of Si, 1.50-1.60 percent of Mn, less thanor equal to 0.035 percent of P, less than or equal to 0.035 percent of S, 0.100-0.160 percent of V, 0.010-0.030 percent of Nb and the balance of Fe and inevitable impurity elements. The 635MPa-gradehigh-strength anti-seismic steel bar with high strength and high plasticity is produced by adopting a high-C, Si and Mn component design and a V and Nb combined microalloying manner under the condition of existing process equipment of a production plant and combining steelmaking and steel rolling processes, is stable in performance and good in comprehensive mechanical property, and has yield strength greater than or equal to 635MPa, tensile strength greater than or equal to 795MPa, percentage elongation after fracture greater than or equal to 15%, total elongation under maximal force greater than or equal to 9.0%, the strength-to-yield ratio greater than or equal to 1.25 and the yield-to-yield ratiogreater than or equal to 1.30, good anti-seismic performance is achieved, and the requirements of high-rise and large-span anti-seismic structures are met.

Owner:安徽吾兴新材料有限公司

Al-Zn-Mg-Cr-Mn-Zr-Er medium-strength and high-toughness aluminum alloy plate and preparation method thereof

The invention discloses a preparation method of an Al-Zn-Mg-Cr-Mn-Zr-Er medium-strength and high-toughness aluminum alloy plate. The Al-Zn-Mg-Cr-Mn-Zr-Er medium-strength and high-toughness aluminum alloy plate is prepared from the alloy components: 3.0-4.0% of Zn, 1-2% of Mg, 0.2-0.4% of Mn, 0.1-0.3% of Cr, 0.1-0.3% of Zr, 0.1-0.3% of Er, 0.1-0.5% of Si, less than 0.01% of Cu and the balance of Aland other impurities, and the content of single impurity is not more than 0.1%. The preparation process includes the steps that an alloy prepared according to the composition design is smelted, casted and poured into an ingot with a diameter of 300 mm to 500 mm, the temperature is directly raised to 460 DEG C without homogenization heat treatment after stress relief annealing of the ingot is completed at 220 DEG C to 300 DEG C, after temperature is kept for 3 to 6 hours, hot extruding is carried out, and an aluminum alloy plate with a thickness of 6 to 10 mm is prepared under the condition that the extrusion ratio exceeds 16, wherein the extruded aluminum alloy plate has the tensile strength of more than 350 Mp, the yield strength of more than 300 Mp, the elongation of more than 15% and the ISSRT of less than 0.03 at normal temperature after solid solution aging treatment.

Owner:YANTAI NANSHAN UNIV

Preparation method of Cu-Cr-Zr wear-resistant alloy wire

ActiveCN112845652ASmall sizeIncrease nucleation rateFurnace typesHeat treatment furnacesRefining (metallurgy)Ingot

The invention discloses a preparation method of a Cu-Cr-Zr wear-resistant alloy wire. The method comprises the following steps: S1, powder metallurgy: firstly, preparing a Cu-Cr alloy or Cr-Zr alloy or Cu-Cr-Zr alloy or a combined alloy thereof into powder with the diameter of 50-300 [mu]m, then, carrying out dry pressing or sintering on the powder to prepare a block material, and finally, crushing the block material into particles with the size of 1-10 mm for later use; and S2, smelting: firstly, smelting 50-90% of cast ingot raw materials into an alloy solution under a vacuum condition at the smelting temperature of 1,200to 1,370 DEG C, keeping the vacuum degree at 10<-2> to 10<-5>MPa, keeping the temperature at 1,200 to 1,300 DEG C after complete smelting, and refining to remove impurities and gas. According to the process, the wear-resistant alloy wire with higher tensile strength, better wear resistance, better corrosion resistance and higher conductivity can be prepared, it can be seen from the microscopic structure of the product that the second phase is distributed in a dispersed mode, and the wear resistance and the mechanical property of the material are well improved.

Owner:SUQIAN COLLEGE

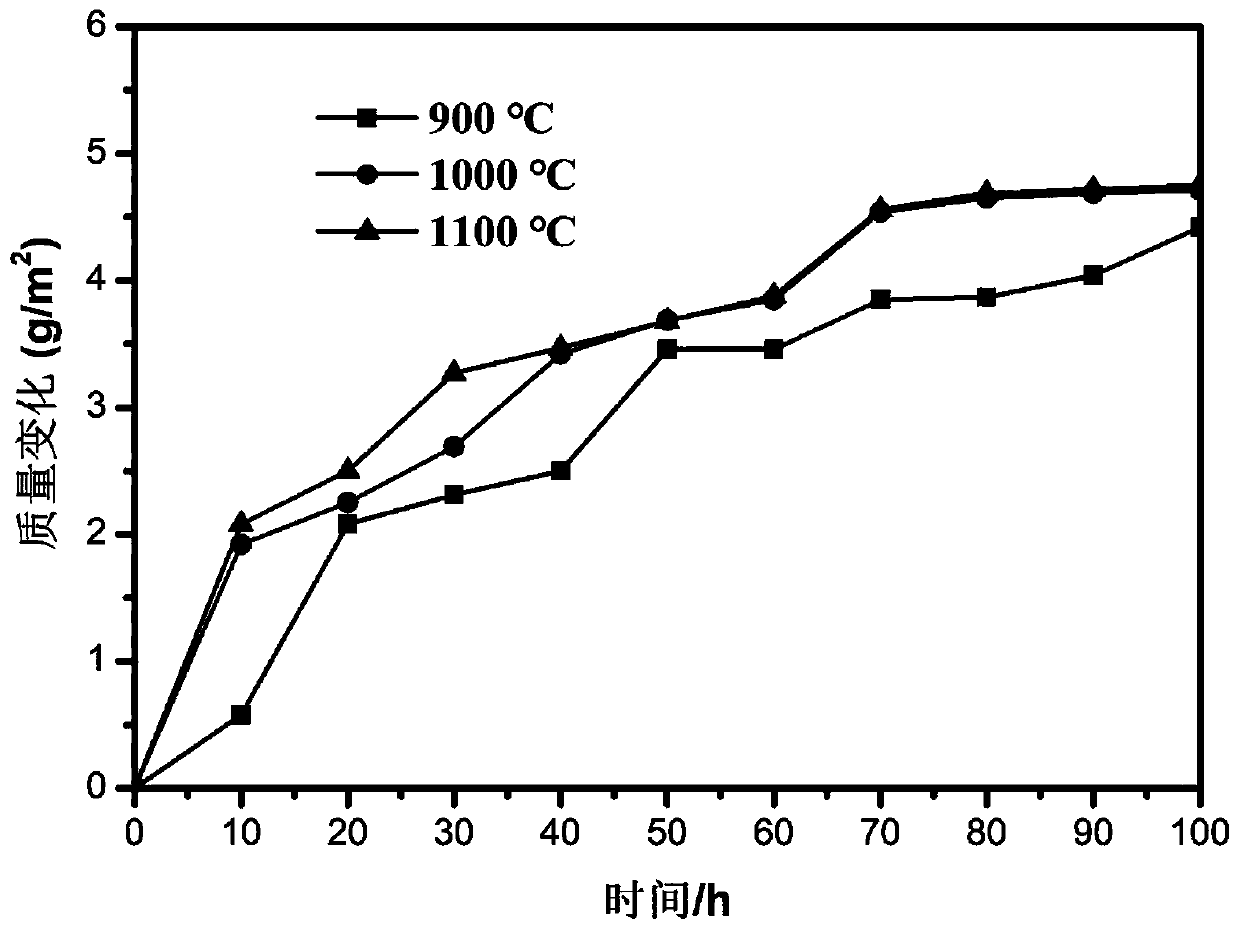

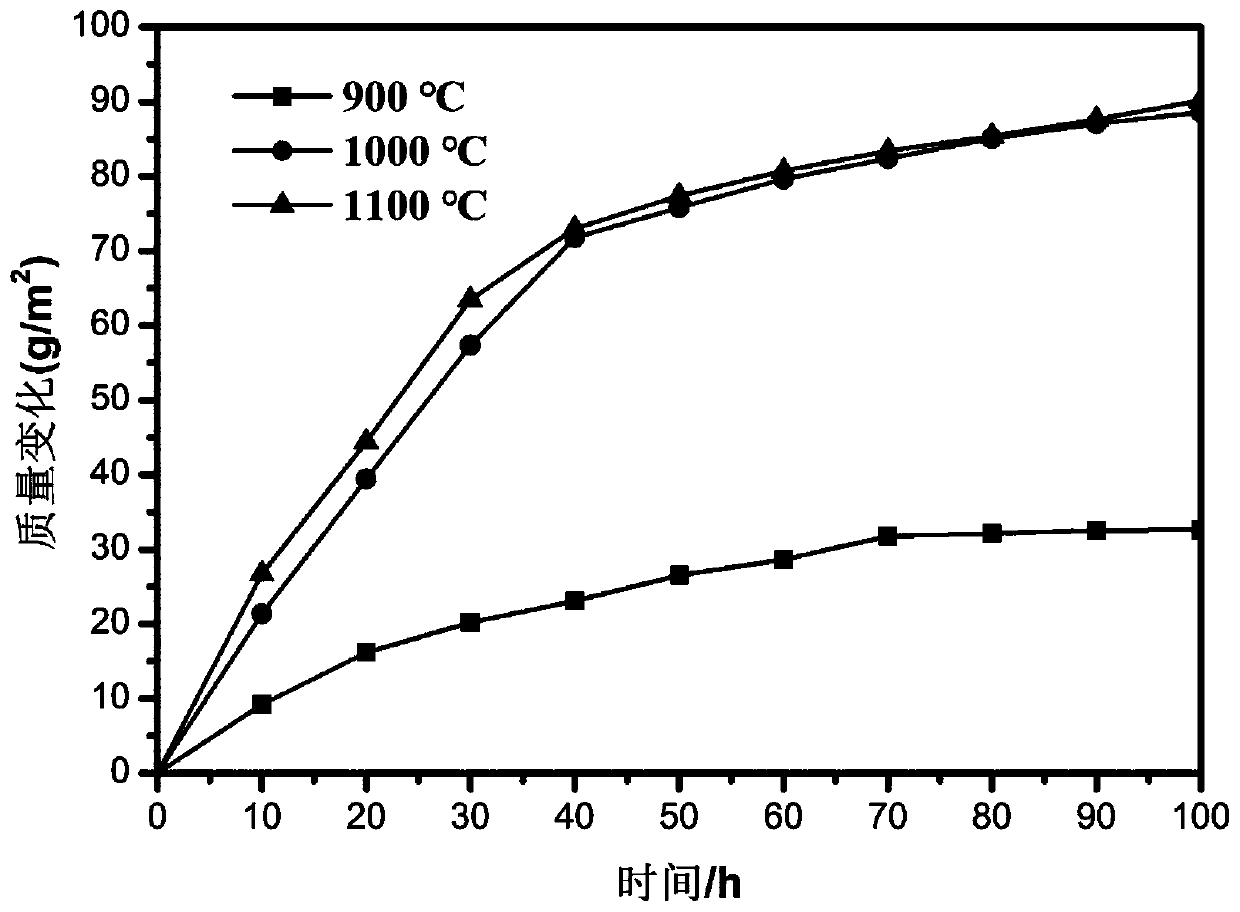

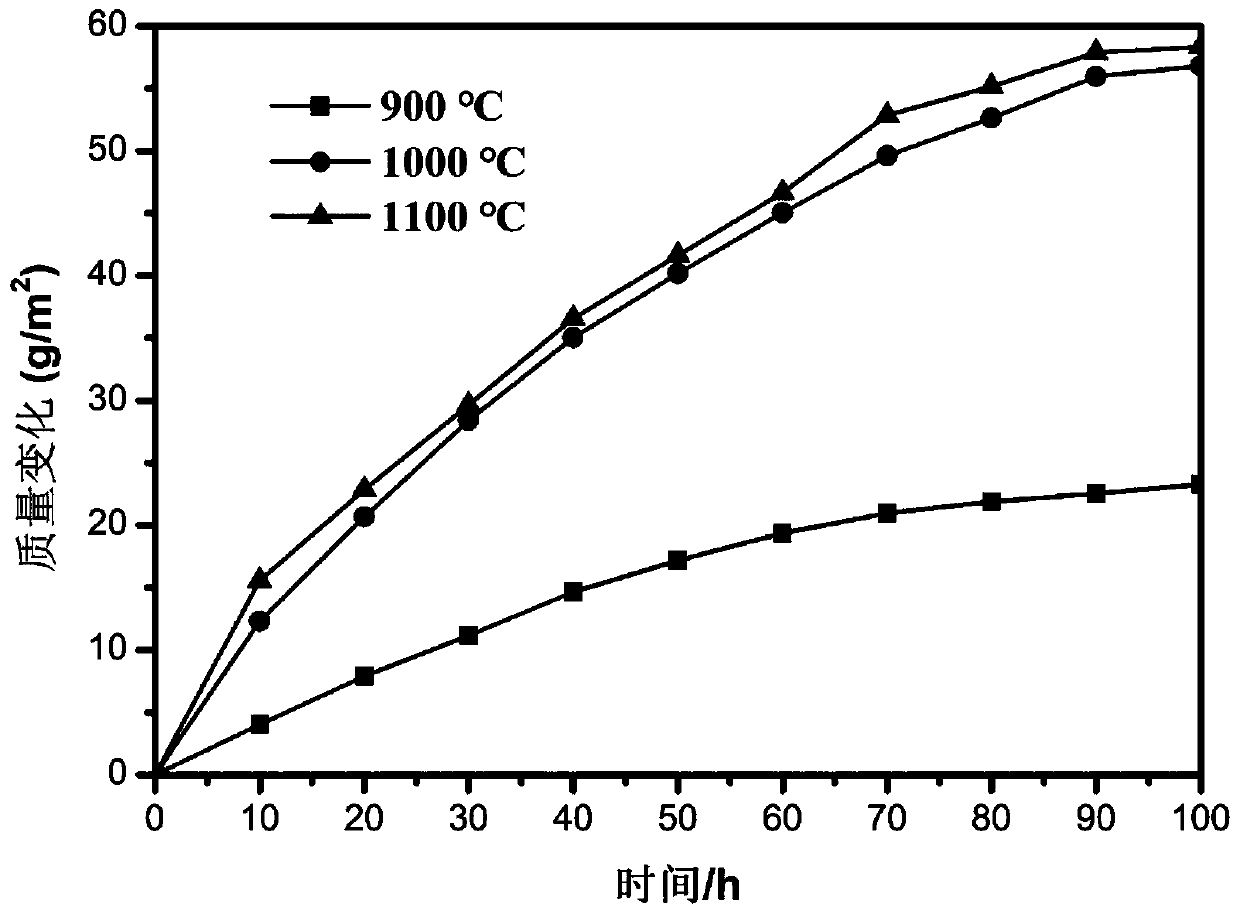

Quaternary MAX phrase enhanced nickel base high temperature oxidation resisting composite material and synthetic method thereof

The invention discloses a quaternary MAX phrase enhanced nickel base high temperature oxidation resisting composite material and a synthetic method thereof. The composite material is prepared throughthe following steps: respectively weighting NiAl, Cr, Ti, Al and a C powder in proportion, then putting the weighted powder into a high energy ball-milling machine for ball milling, so as to prepare auniformly mixed nano-structure mixed powder; putting the well mixed powder into a graphite grinding tool for cold pressing treatment, after cold pressing, carrying out vacuum hot-pressing sintering in a vacuum hot pressure sintering furnace, so as to prepare NiAl-Cr2TiAlC2 composite material. According to the invention, through in-situ reaction of Cr, Ti, Al and C in a sintering process, a novelquaternary MAX phrase (Cr2TiAlC2) is produced, and the high temperature lubrication performance of the composite material is realized, meanwhile, the wettability between MAX phase and NiAl matrix andthe organization structure of the composite material can be effectively improved, and the intensity of the composite material is effectively improved. Moreover, the oxidation resistance of the composite material under a high temperature condition can be remarkably improved, and the high temperature oxidation resisting composite material is prepared successfully.

Owner:XI AN JIAOTONG UNIV +1

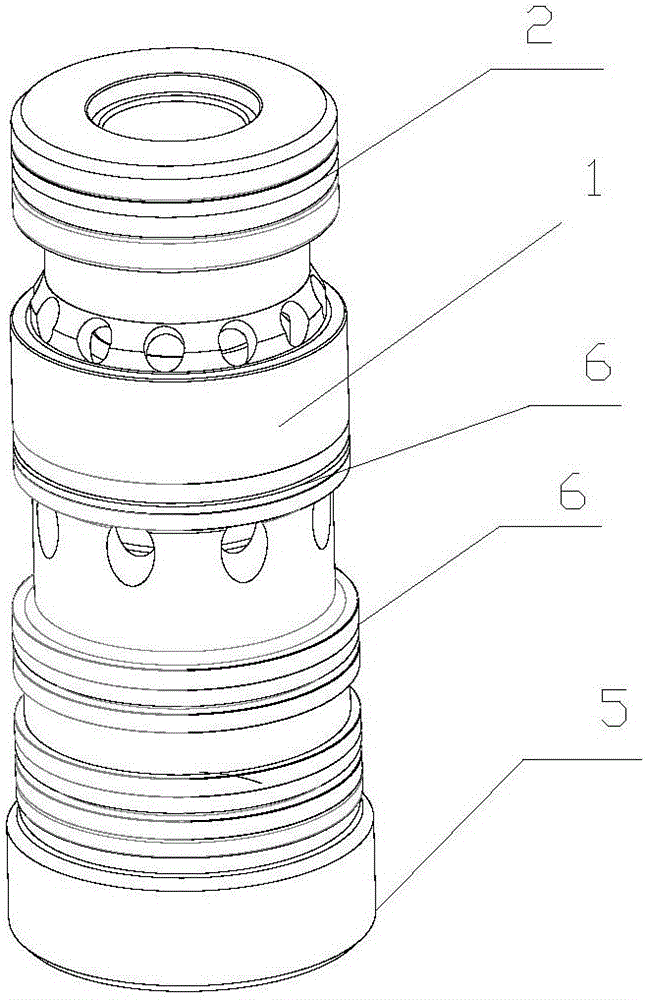

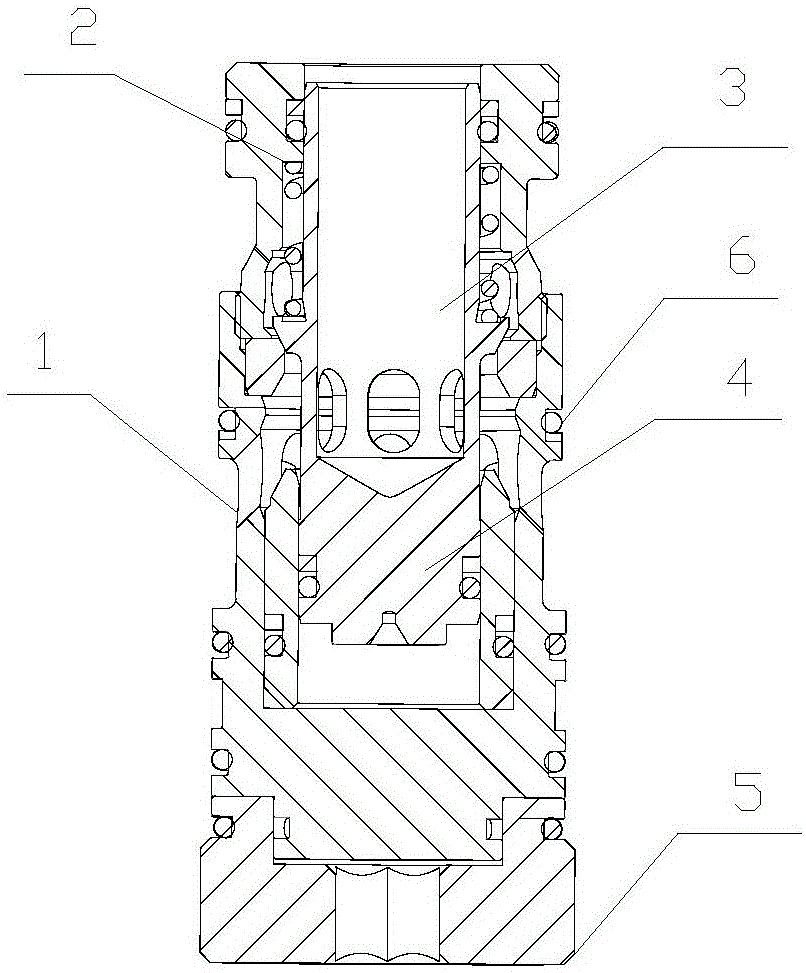

Main valve element for reversing valve

InactiveCN106286885AImprove performanceImprove organizational stabilityServomotor componentsMultiple way valvesMechanical engineeringToughness

The invention relates to a main valve element for a reversing valve. The main valve element comprises a lower valve sleeve, a valve element and an upper valve sleeve internally provided with a piston. The lower valve sleeve is inserted into the upper valve sleeve to be connected with the upper valve sleeve. The valve element is located in the lower valve sleeve and stretches into the piston. The upper valve sleeve is provided with an opening which is covered with an end cover. The upper valve sleeve, the lower valve sleeve and the valve element are all made of alloy steel. The alloy steel comprises 0.10-0.15% of C, 1.5-2.0% of Cr, 0.22-0.35% of Si, 0.8-1.2% of Mn, 0.045-0.06% of Al, 0.03-0.05% of N, 0.25-0.35% of Mo, 0.025-0.04% of Cu, 0.005-0.022% of S, 0.08-0.15% of V, 0.08-0.15% of RE, no more than 0.015% of P and the balance Fe. The main valve element is high in toughness and good in anti-tempering stability, cold-hot-fatigue resistance and high-temperature abrasion resistance.

Owner:NINGBO LONG WALL FLUID KINETIC SCI TECH

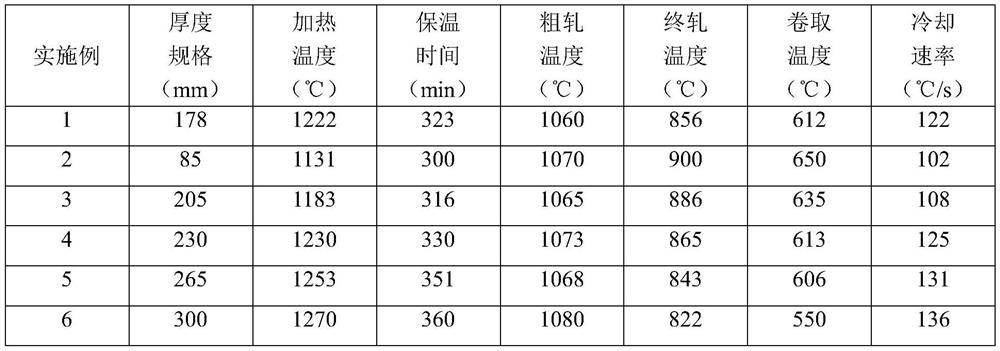

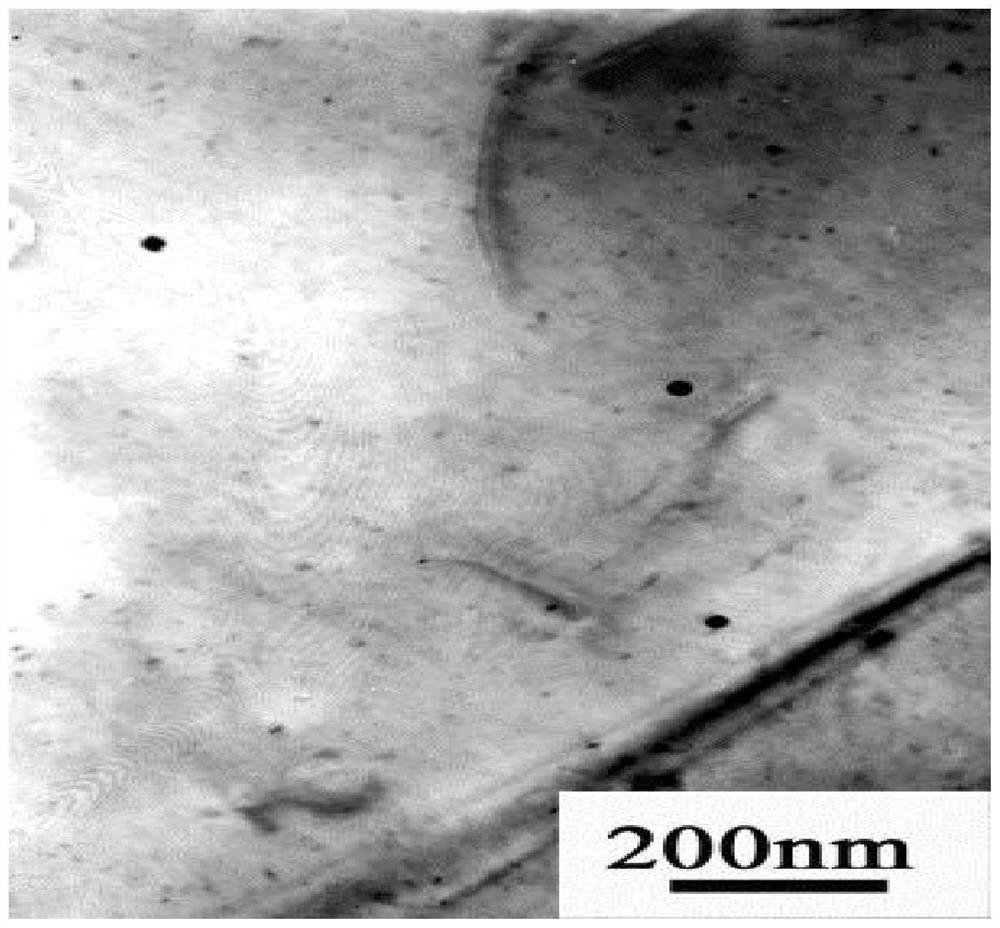

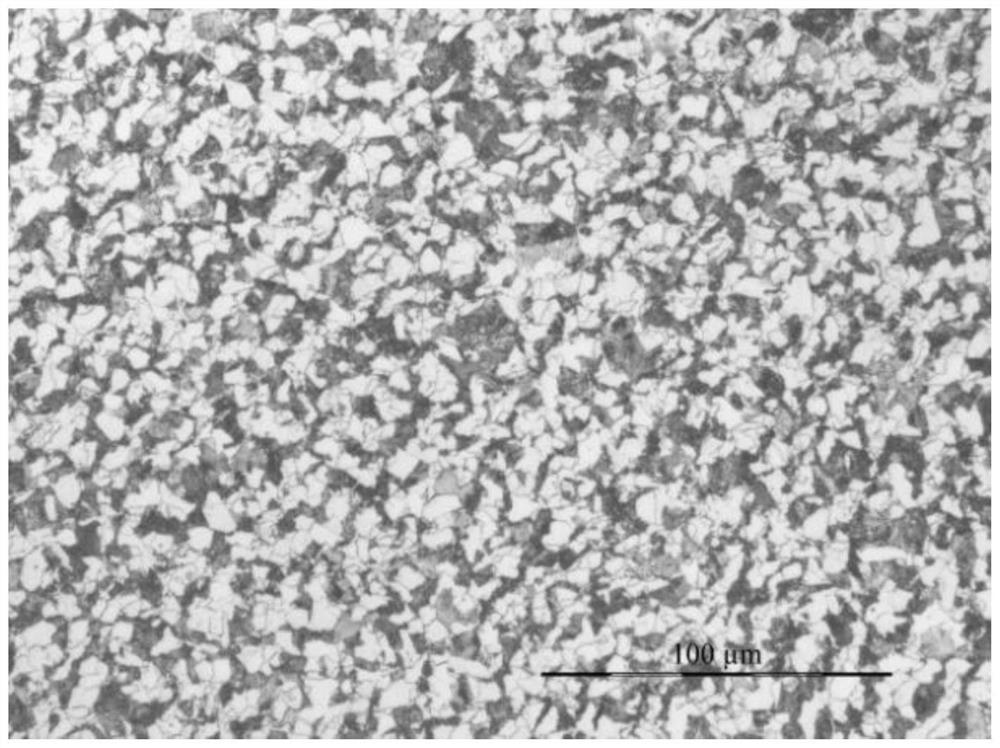

900MPa-grade hot-rolled and pickled complex-phase phase steel with low yield ratio and high hole expansion rate and production method of 900MPa-grade hot-rolled pickling complex phase steel

ActiveCN113549823AFine grain strengtheningWith precipitation strengtheningRare-earth elementSlow cooling

The invention relates to hot-rolled and pickled complex-phase steel, in particular to 900 MPa-grade hot-rolled and pickled complex-phase steel with a low yield ratio and a high hole expansion rate and a production method of the 900 MPa-grade hot-rolled and pickled complex-phase steel. The steel comprises the following chemical components of, in percentage by weight, 0.085%-0.162% of C, 0.08%-0.85% of Si, 1.15%-2.50% of Mn, 0.10%-0.30% of Al, 0.10%-0.75% of Cr, 0.08%-0.65% of Mo, 0.025%-0.070% of Nb, 0.030%-0.155% of Ti, 0.0020%-0.0050% of B, 0.010%-0.060% of rare earth elements La + Ce, P less than or equal to 0.020%, S less than or equal to 0.007% and the balance Fe and inevitable impurities. The method comprises the following steps that (1), a continuous casting slab with the thickness of 80-300mm is put into a heating furnace to be heated to be 1130-1270 DEG C; (2), the initial rolling temperature of rough rolling is not higher than 1080 DEG C, the thickness of an intermediate billet is 25-50 mm, the finish rolling temperature is 840-900 DEG C, the thickness of a finished product is 1.8-5.3 mm, and the total reduction rate is larger than or equal to 85%; (3), after finish rolling, front-section rapid continuous laminar cooling and curling are adopted; (4), after being curled, the steel plate immediately enters a slow cooling cover to be slowly cooled, and a steel coil is taken out and air-cooled to the room temperature; and (5), pickling is carried out . The steel has ultrahigh strength and good formability, and is suitable for manufacturing automobile structural parts, reinforcing parts and safety parts; and the steel has excellent anti-fatigue performance, welding performance and cold forming performance.

Owner:ANGANG STEEL CO LTD

Strengthened coating on surface of transmission component of agricultural machine and preparing method of strengthened coating

ActiveCN110468405AWith variable stiffnessFracture hasMetallic material coating processesHigh entropy alloysShape-memory alloy

The invention provides a strengthened coating on the surface of a transmission component of an agricultural machine. The strengthened coating comprises the following raw materials in parts by weight:10-13.5 parts of high entropy alloy powder, 31-40 parts of hard alloy powder, and 46.5-59 parts of shape memory alloy powder. A preparing method comprises the following specific preparing steps of atfirst, separately grinding the nickel-base high entropy alloy powder, the hard alloy powder and the shape memory alloy powder in fine powders by a ball grinding mill; and then mixing the three alloy fine powders, adding an organic binding agent, sufficiently and uniformly mixing at a room temperature, smearing and heating, thereby obtaining the strengthened coating. The high entropy alloy powder,the hard alloy powder and the shape memory alloy powder are smashed, and are uniformly bound together by the organic binding agent, wherein the hardness of high entropy alloy and the hardness of hardalloy are higher, the high entropy alloy and the hard alloy are mainly used for improving the wear resistance of the transmission component of the agricultural machine, however the shape memory alloyis added to facilitate improving the toughness of the coating and prevent brittle rupture and falling of the coating due to too hard high entropy alloy and hard alloy, so that the service life of thetransmission component of the agricultural machine is effectively prolonged.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

800MPa-grade hot-rolled complex-phase steel and production method thereof

InactiveCN113481436AAchieving fine grain strengtheningRealized with fine grain strengtheningTemperature control deviceWork cooling devicesLaminar coolingHeating furnace

The invention relates to steel for manufacturing automobile structures, in particular to 800MPa-grade hot-rolled complex-phase steel and a production method thereof. The steel comprises the following chemical components in percentage by weight: 0.055%-0.112% of C, 0.08%-0.40% of Si, 1.15%-2.02% of Mn, 0.10%-0.30% of Al, 0.10%-0.62% of Cr, 0.0020%-0.0050% of B, 0.015%-0.056% of V and / or 0.030%-0.145% of Ti, less than or equal to 0.020% of P, less than or equal to 0.007% of S and the balance of Fe and inevitable impurities. The method comprises the following steps that (1) a continuous casting sheet billet with the thickness of 80-300 mm is placed in a heating furnace, and the temperature is kept for 5-6 hours; (2) a controlled rolling means is adopted, the rough rolling temperature is not higher than 1080 DEG C, the thickness of an intermediate billet is 25-50 mm, the finish rolling temperature is controlled, the thickness of a finished product is 2.0-5.0 mm, and the total reduction rate is larger than or equal to 80%; (3) after finish rolling, front-section rapid continuous stream cooling is adopted, and coiling is conducted; and (4) after being coiled, a steel plate immediately enters a slow cooling cover to be slowly cooled to 120 DEG C or below, the slow cooling speed is not larger than 15 DEG C / h, and a steel coil is taken out and air-cooled to the room temperature. The steel has high strength and good formability, and is suitable for manufacturing automobile structural parts, reinforcements and safety parts.

Owner:ANGANG STEEL CO LTD

Ti microalloyed 635MPa-grade hot-rolled ribbed steel bar and preparation method thereof

ActiveCN112111687AImprove plasticityImprove strong plasticityTemperature control deviceFurnace typesSteelmakingRebar

The invention discloses a Ti microalloyed 635MPa-grade hot-rolled ribbed steel bar and a preparation method thereof, and belongs to the technical field of hot-rolled ribbed steel bars for reinforced concrete structures. The steel in the steel bar comprises, by weight, 0.22-0.28% of C, 0.60-0.80% of Si, 1.40-1.60% of Mn, less than or equal to 0.035% of P, less than or equal to 0.035% of S, 0.020-0.040 of Ti, and the balance Fe and inevitable impurity elements. The Ti microalloyed components are combined with steel making and steel rolling processes; the preparation process comprises the steps of carrying out converter smelting, carrying out LF ladle refining, carrying out continuous casting to obtain 150mm<2> steel blanks, carrying out heating by a heating furnace and carrying out rolling on the steel blanks by a rolling mill to form the steel bar; the mechanical performance of the steel is improved by using the principle of precipitation strengthening and fine grain strengthening of titanium in the steel; the 635MPa-grade high-strength steel bar with high strength and high plasticity is produced under the premise of not reducing the ductility index; and the yield strength of the prepared steel bar is greater than or equal to 635MPa, the tensile strength of the prepared steel bar is greater than or equal to 795MPa, and the elongation after fracture of the prepared steel bar is greater than or equal to 15%, and the Ti microalloyed 635MPa-grade hot-rolled ribbed steel bar satisfies the demands of markets and high-rise and long-span building structures on the 635MPa-grade steelbar.

Owner:安徽吾兴新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com