Preparation method capable of synchronously improving strength and plasticity of additive manufactured titanium alloy

An additive manufacturing and titanium alloy technology, which is applied in the field of preparation that can simultaneously improve the strength and plasticity of additively manufactured titanium alloys, can solve problems such as reducing material strength, reduce plug stress, hinder dislocation movement, and reduce dislocation. The effect of wrong slip length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

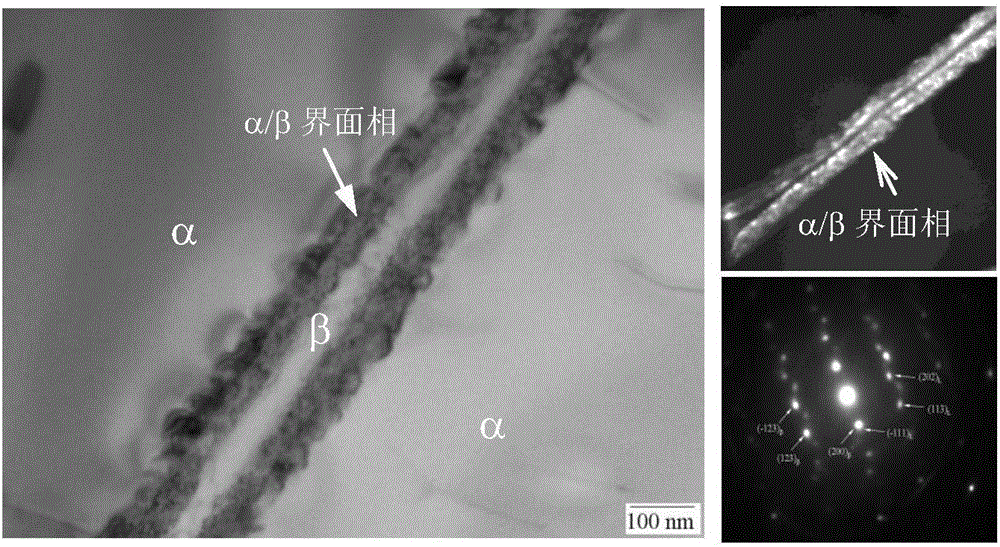

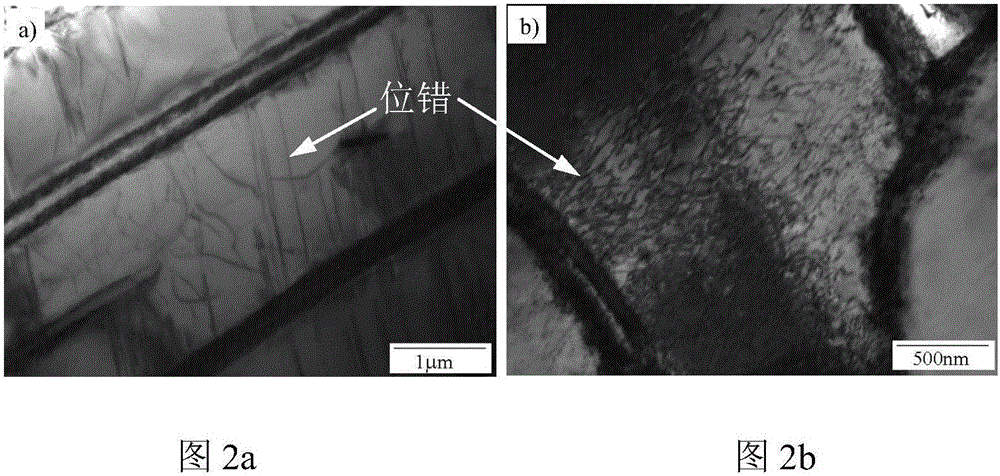

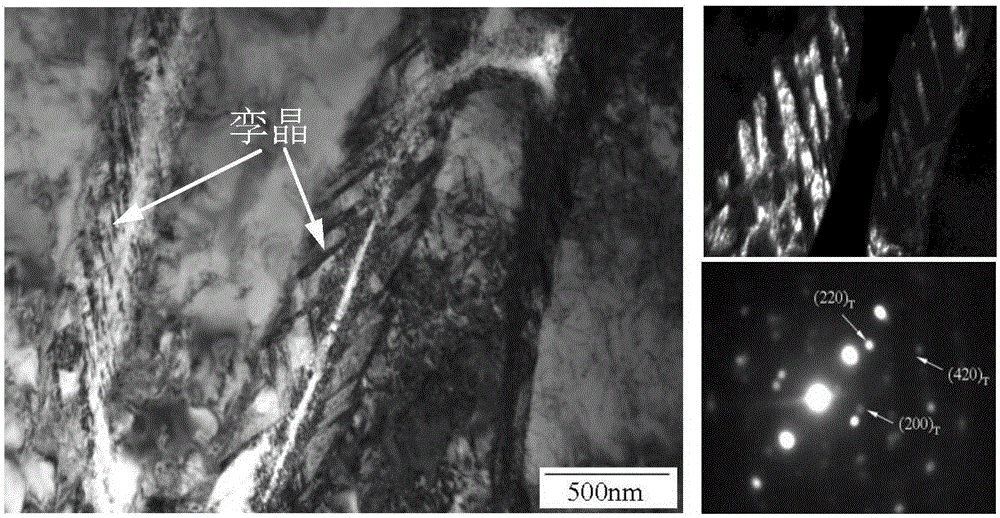

[0027] Specifically, the invention improves the strength and plasticity of the titanium alloy by forming the α / β interface phase during the laser cladding deposition and selective laser melting process of additive manufacturing, and its effect is similar to "fine grain strengthening"; it can be used for strengthening and toughening The preparation of titanium alloy material provides a preparation method for the strengthening and toughening of titanium alloy (Ti-6Al-4V) by additive manufacturing.

[0028] Among the present invention, the Ti-6Al-4V titanium alloy is realized in this way: in an argon-filled inert atmosphere protection chamber, with a high-energy all-solid-state laser as a laser source, the Ti-6Al-4V (O≤0.20wt.%) ) alloy powders were continuously melted and deposited layer by lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com