Patents

Literature

98results about How to "Excellent strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

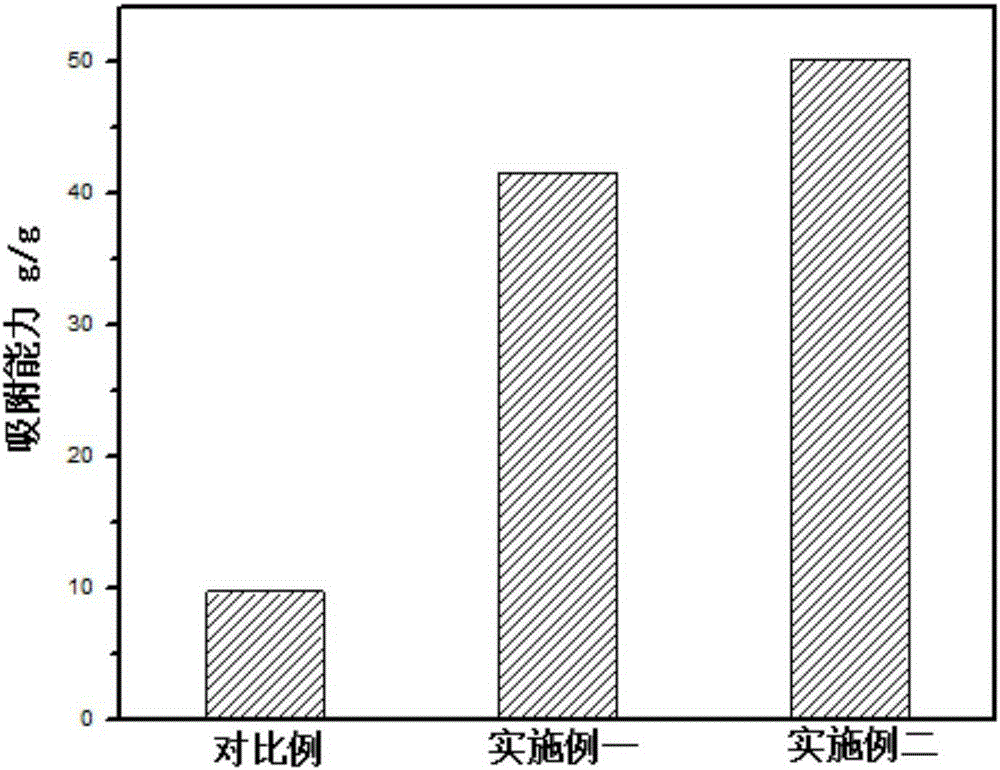

Preparation method of graphene oxide/silicon dioxide hybrid aerogel

A preparation method of graphene oxide / silicon dioxide hybrid aerogel comprises the following steps: A, adding 0.05-0.1 mol of a precursor into 9-18 ml of distilled water and dropwise adding a hydrolyst with its concentration of 0.2-0.6 mol / L into the precursor aqueous solution, wherein molar ratio of the hydrolyst to the precursor is 1:20-1:100; stirring at 20-30 DEG C for 5-8 h; adjusting pH value to 6-7 and stirring for 5-45 min so as to obtain a dispersion containing silicon dioxide microspheres; B, adding water to dilute the silicon dioxide microsphere dispersion by 5-50 times, carrying out iso-volume mixing on the diluted silicon dioxide microsphere dispersion and a graphene oxide dispersion with its concentration being 0.6-2 mg / ml, stirring for 10-30 min, carrying out ultrasonic treatment for 10-30 min so as to obtain graphene oxide / silicon dioxide hybrid aerogel; and C, freezing the hybrid aerogel under liquid nitrogen for 5-10 min, freeze-drying and dewatering to obtain the graphene oxide / silicon dioxide hybrid aerogel. The method is environmentally friendly, and the technology is simple. The prepared hybrid aerogel has advantages of complete gel network structure, high porosity, good adsorptivity, high strength, low density and the like.

Owner:SOUTHWEST JIAOTONG UNIV

Bumper beam for automobile

InactiveUS20080217934A1High degree of freedomExcellent strengthBumpersEngineeringMechanical engineering

A bumper beam includes two tubular bodies formed by tube hydroforming that extend left and right. The tubular bodies are joined to each other in a parallel state. The tubular bodies each have a rectangular vertical cross-section shape including top and bottom and front and rear sides. The tubular bodies are disposed in a line from top to bottom, and opposing surfaces thereof are joined together across the entire length in the longitudinal direction.

Owner:MARUJUN

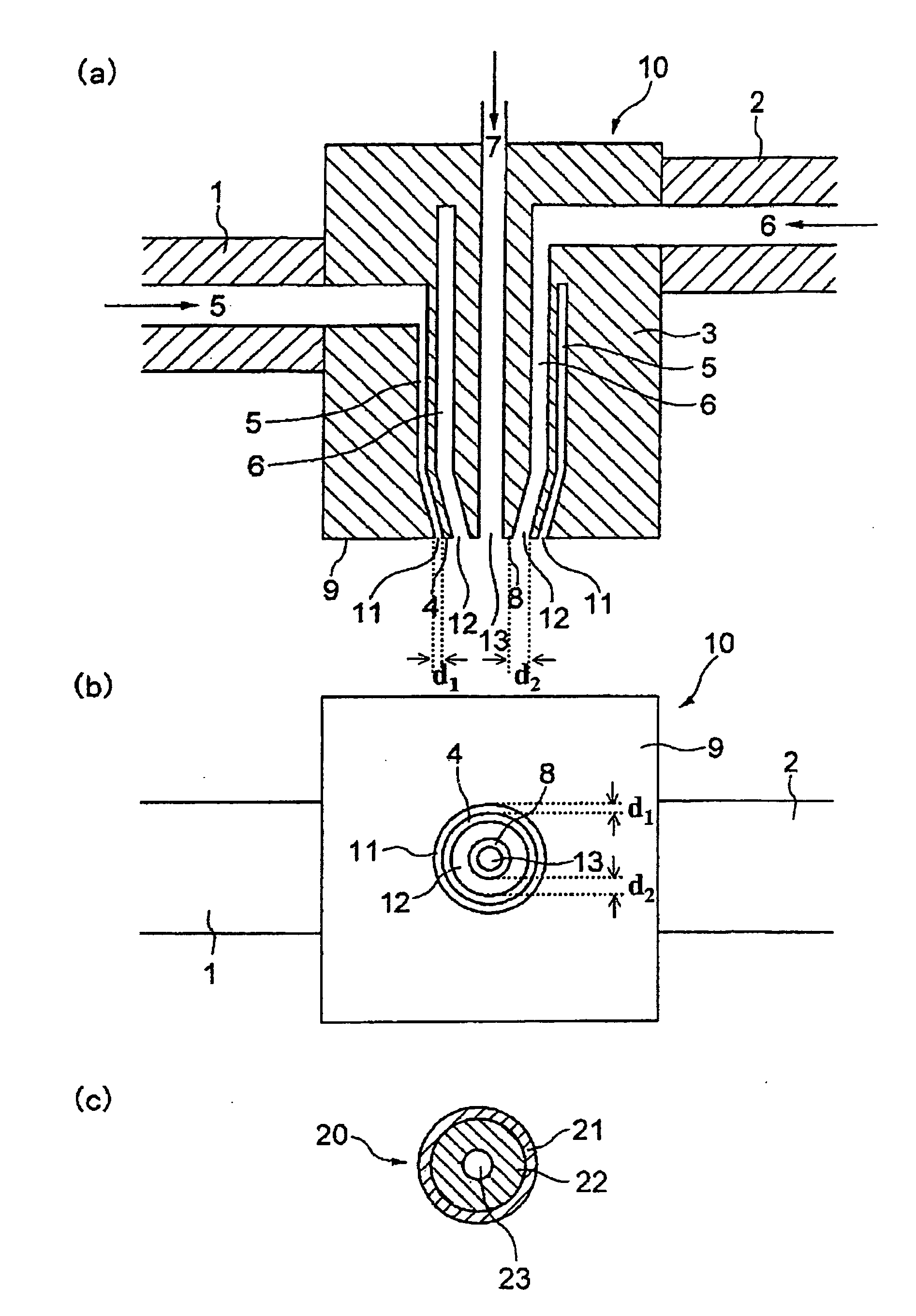

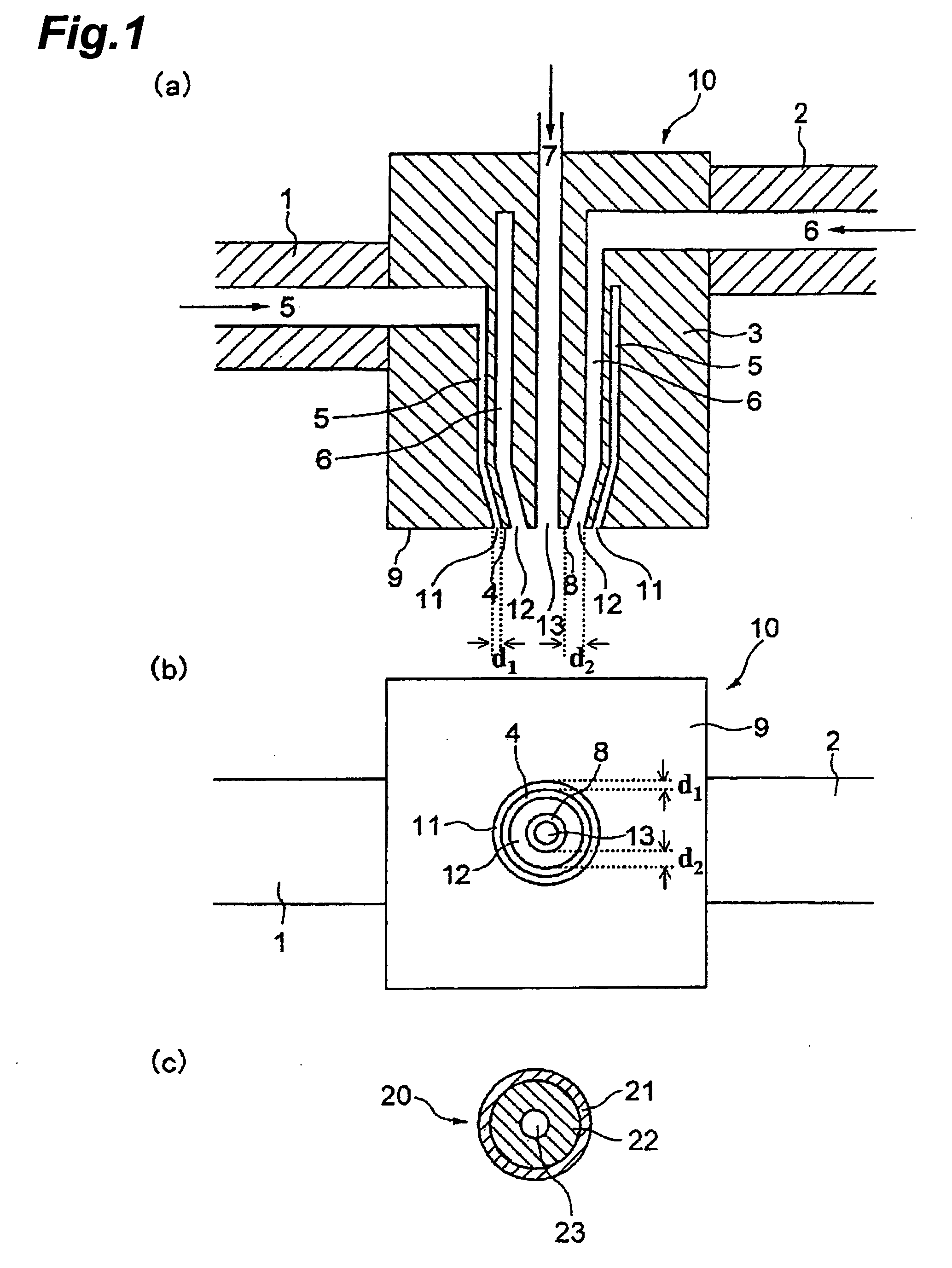

Porous multilayered hollow-fiber membrane and process for producing the same

ActiveUS20090297822A1Excellent strengthHigh water permeabilityMembranesSemi-permeable membranesHollow fibre membraneOrganic fluid

A porous hollow fiber membrane which has high blocking performance and high water permeability suitable for filtration and the like and exhibits excellent strength, and a process for stably producing the porous hollow fiber membrane are disclosed. The process utilizes a hollow fiber molding nozzle having two or more circular discharge ports which are disposed concentrically. Multilayer melt-extrusion is performed by discharging molten mixtures which include a thermoplastic resin and an organic liquid and differ in composition from the adjacent discharge ports. The resulting product is cooled to solidify to obtain a hollow fiber. The organic liquid is then removed from the hollow fiber by extraction to produce a porous hollow fiber membrane. The molten mixture discharged from at least one circular discharge port includes an inorganic fine powder in addition to the thermoplastic resin and the organic liquid. The inorganic fine powder is removed by extraction after cooling in addition to the organic liquid.

Owner:ASAHI KASEI CHEM CORP

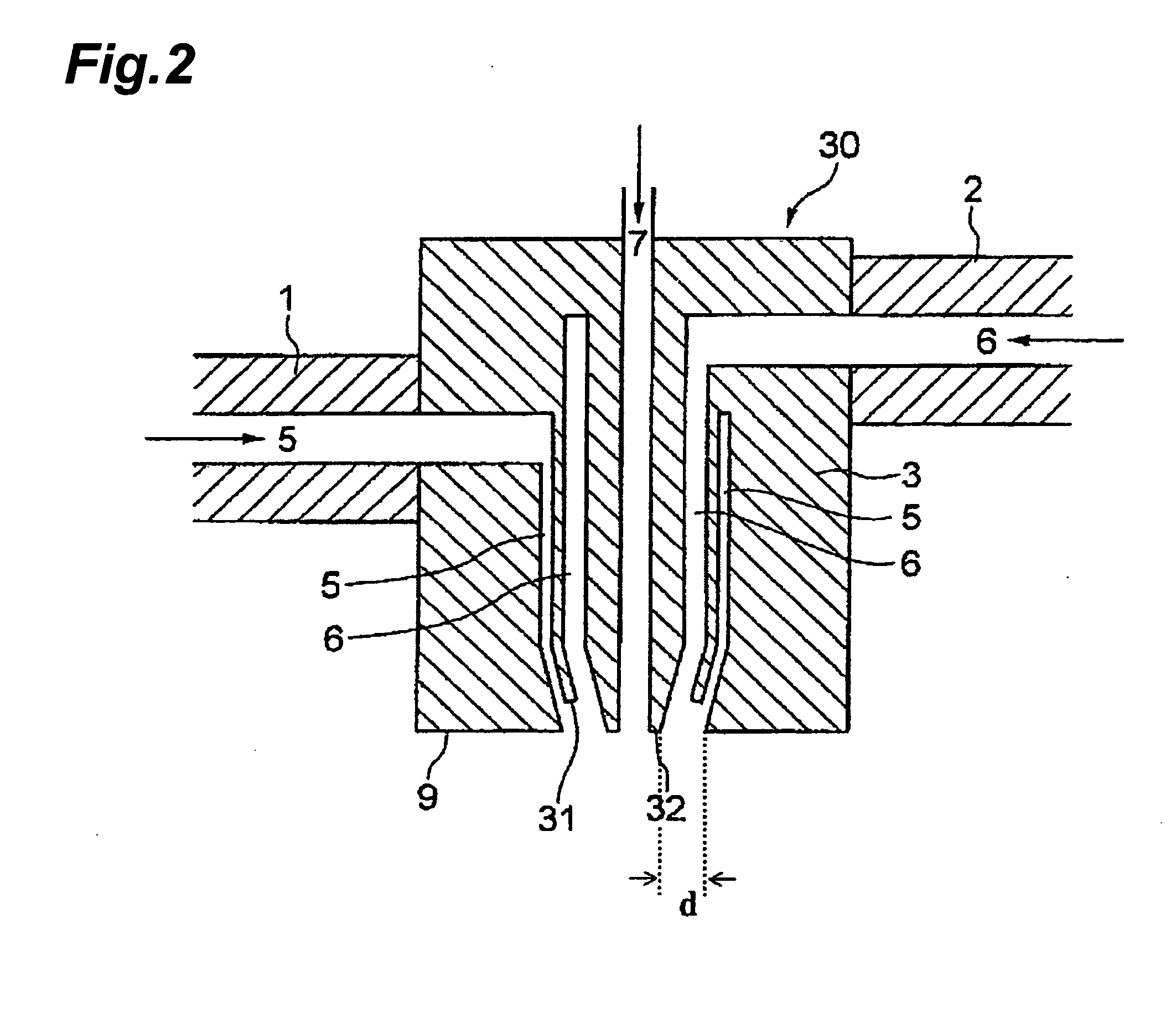

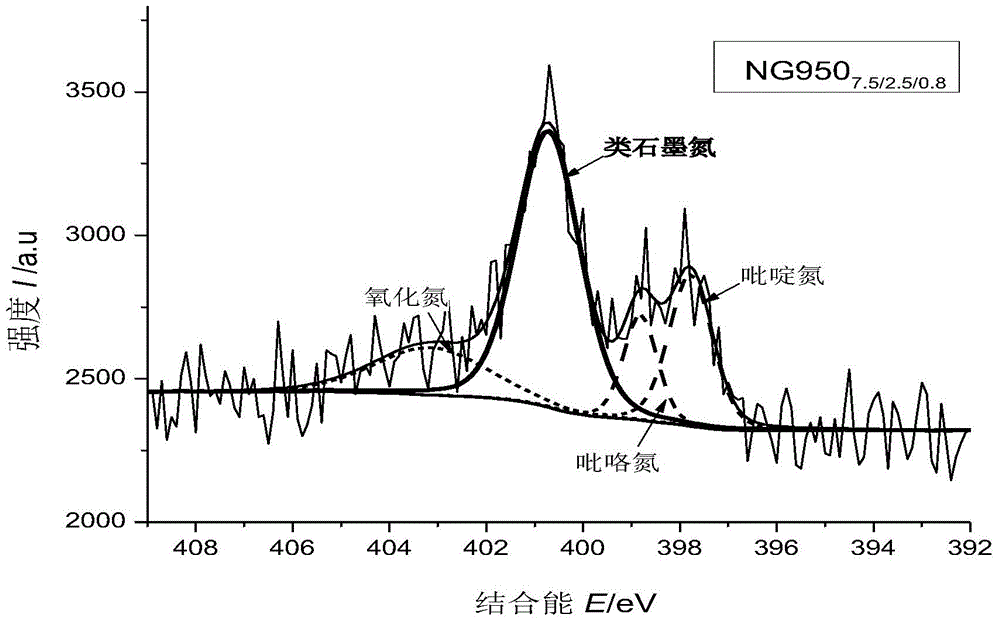

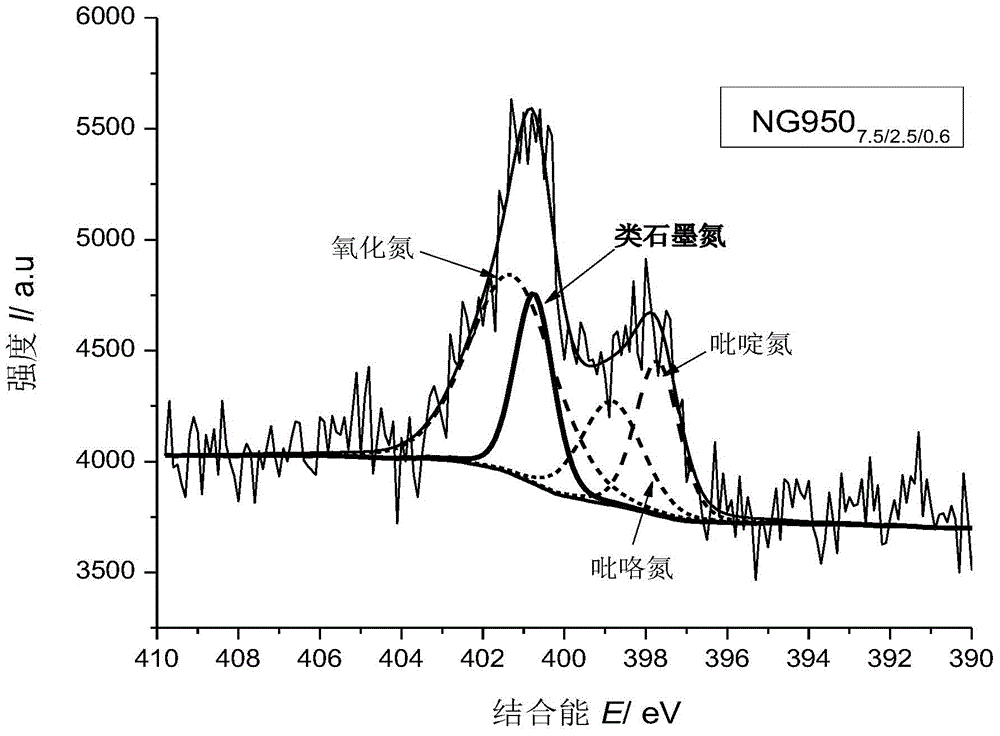

Nitrogen-doped graphene catalyst as well as preparation method and application thereof

InactiveCN104525235AIncrease inertiaImprove hydrophobicityPhysical/chemical process catalystsCell electrodesNitrogen doped grapheneNitrogen gas

The invention discloses a nitrogen-doped graphene catalyst as well as a preparation method and application thereof. The preparation method comprises the following steps: drying and dehydrating glucose and urea, and mixing with melamine, wherein the mass ratio of the urea to melamine is 2-4; uniformly grinding the mixture, and calcining the mixture into a muffle furnace at the temperature of 550 DEG C for 3 hours; cooling and grinding uniformly, adding the mixture into a tube furnace, introducing into nitrogen protection, calcining at the temperature of 850-1000 DEG C for an hour, thereby obtaining the nitrogen-doped graphene catalyst. According to the in-situ nitrogen-doped graphene disclosed by the invention, the used raw materials are low in price, the method is simple, the yield is high, and graphite-like nitrogen doped graphene with the highest ratio is obtained by changing the rate of the raw materials and the temperature, so that the catalyst has a good oxidation-reduction effect, and expensive Pt can be replaced to a certain degree.

Owner:SOUTH CHINA UNIV OF TECH

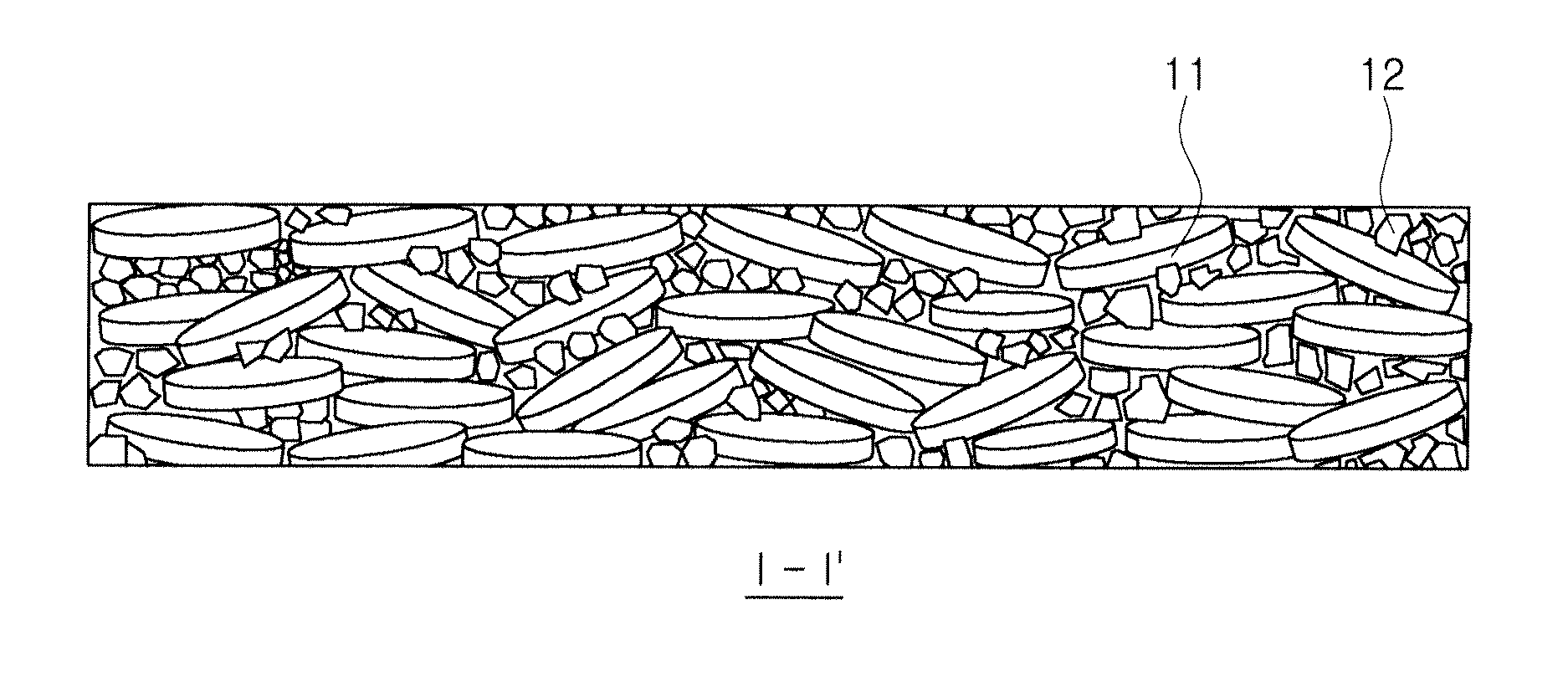

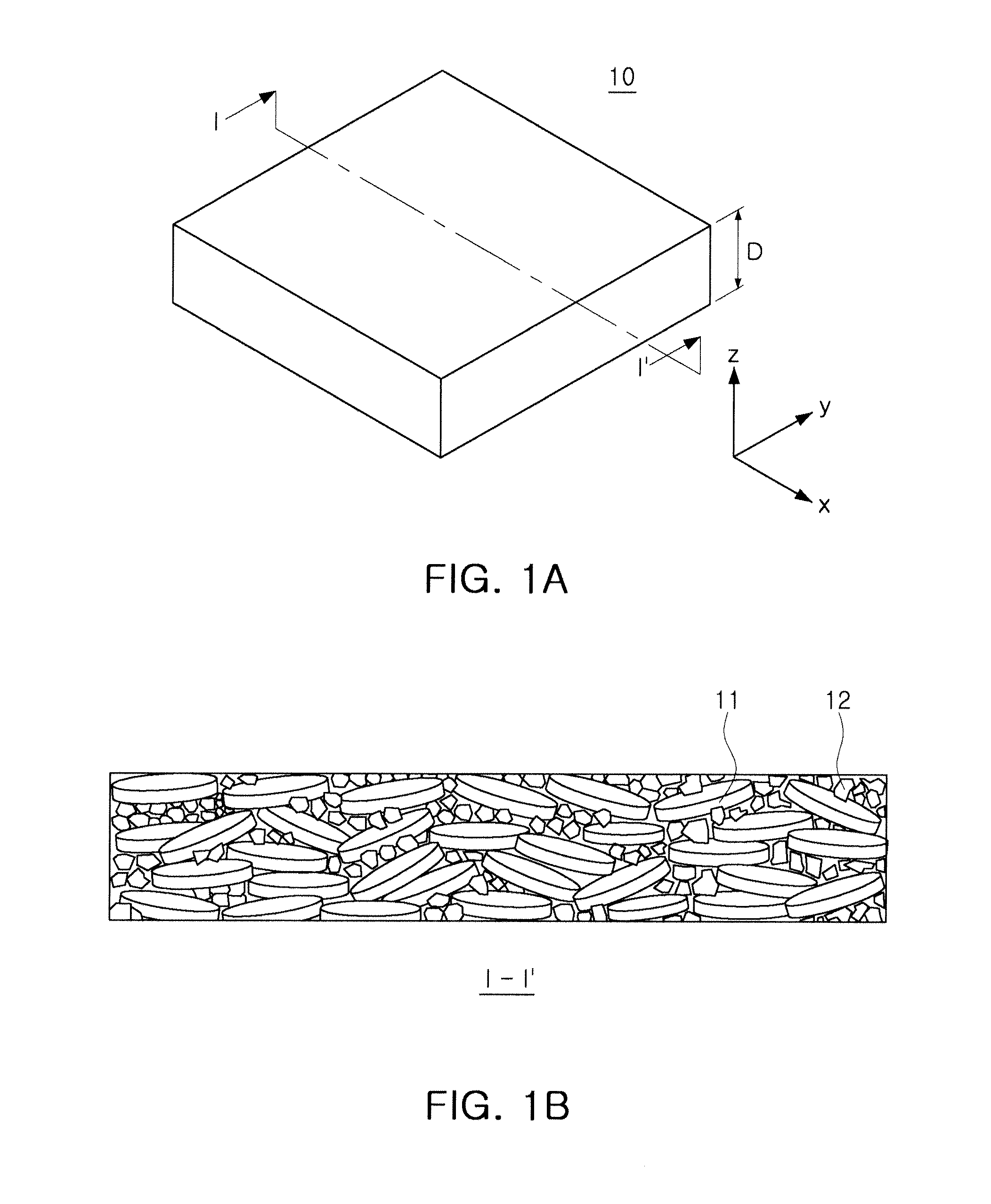

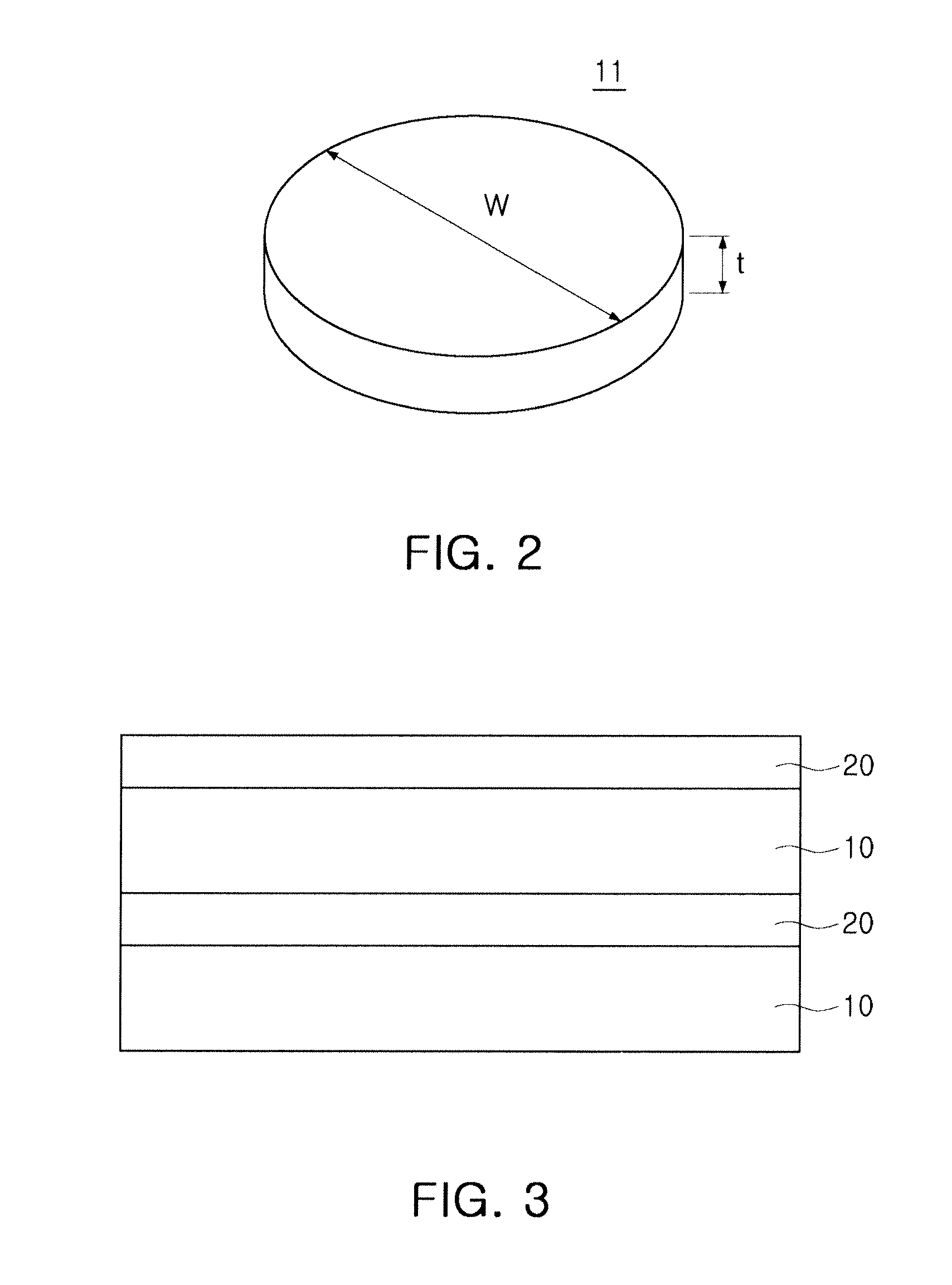

Ltcc composition, ltcc substrate comprising the same and method of manufacturing the same

InactiveUS20120028018A1Excellent strengthHigh strengthStacked capacitorsSynthetic resin layered productsCo-fired ceramicSintering

There is provided a Low Temperature Co-fired Ceramic (LTCC) composition, an LTCC substrate comprising the same, and a method of manufacturing the same. The LTCC composition includes 20 to 70 parts by weight of ceramic powder; and 30 to 80 parts by weight of glass component for low-temperature sintering, wherein the ceramic powder has plate-shaped ceramic powder particles and globular ceramic powder particles, and the ceramic powder has a content ratio of the globular ceramic powder particles with respect to the plate-shaped ceramic powder particles in a range of 0 to 1.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Copolymer resin of chloroethylene-isobutyl vinyl ether-glycidyl acrylate and preparation method thereof

The invention discloses a copolymer resin of chloroethylene-isobutyl vinyl ether-glycidyl acrylate and a preparation method thereof. The copolymer resin is obtained by copolymerization of 65-85 mass parts of chloroethylene, 15-30 mass parts of isobutyl vinyl ether and 0.5-5.0% (corresponding to the total mass of chloroethylene and isobutyl vinyl ether) of glycidyl acrylate. The preparation method comprises the following steps: adding the chloroethylene, isobutyl vinyl ether and glycidyl acrylate into aqueous phase containing emulsifier, a water-soluble redox initiation system and pH regulator, and carrying out emulsion polymerization for 3-10 hours at the temperature of 35-60 DEG C. The invention adds glycidyl acrylate into chloric ether resin to improve the heat stability of chloric ether resin and adhesion with metal; and meanwhile, copolymer has uniform composition and has high dissolving speed in solvent, such as sundex and the like.

Owner:HANGZHOU ELECTROCHEM GROUP +1

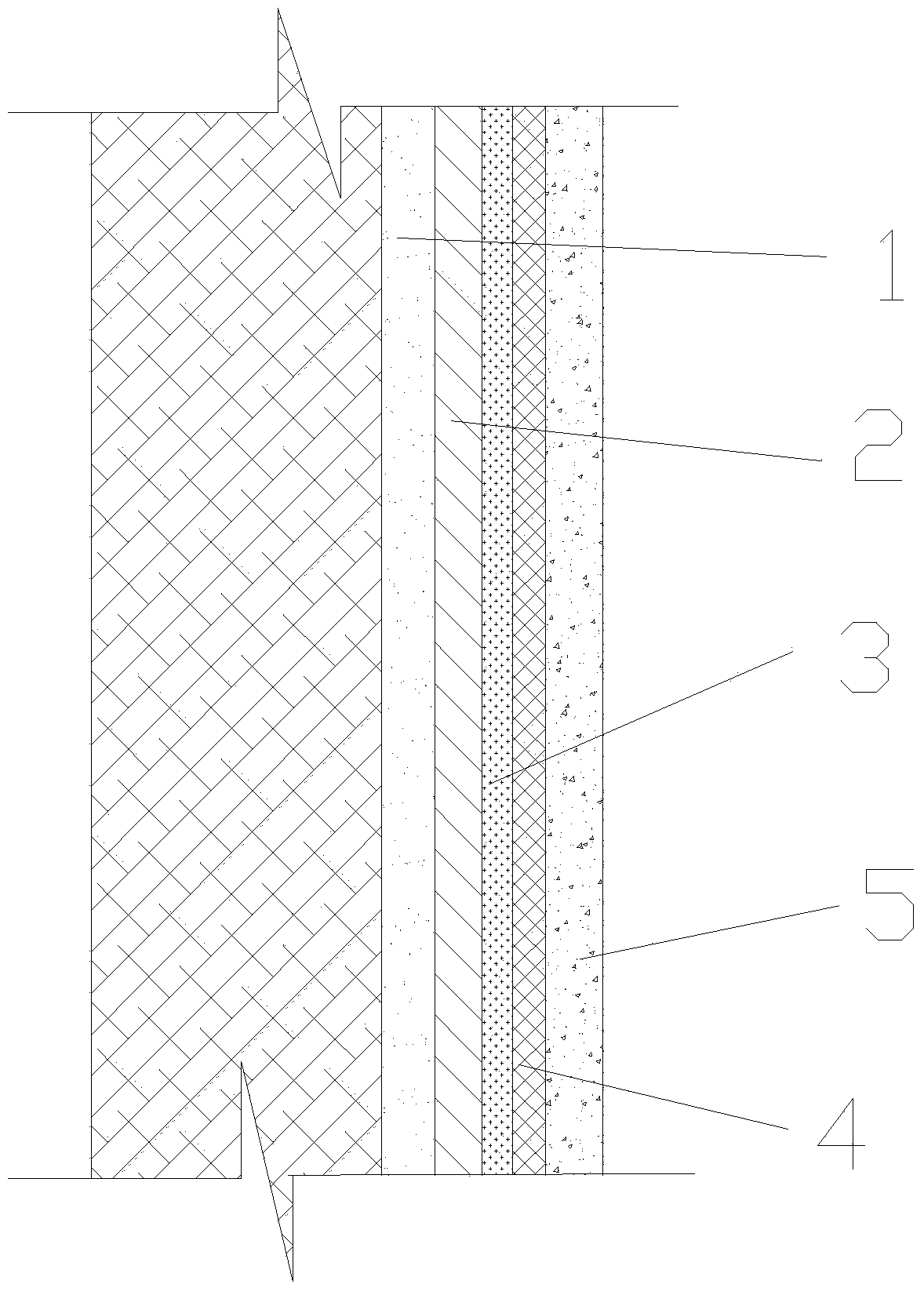

Outer wall waterproof structure

The invention relates to an outer wall waterproof structure which comprises a polymer cement waterproof paint layer, seamed woven polyester cloth and a waterproof anti-crack mortar layer. An insulating layer or a leveling layer of an outer wall is coated with the polymer cement waterproof paint layer. The seamed woven polyester cloth adheres to the polymer cement waterproof paint layer and is coated with the waterproof anti-crack mortar layer. The outer wall waterproof structure is not prone to damage, the anti-crack performance and the waterproof effect are good, the wall can be effectively prevented from falling off, and the service life is long. According to the outer wall waterproof structure, good social benefits and economic benefits further can be achieved, personnel or property loss caused by fall-off of the wall can be avoided, replacement of the outer wall waterproof structure is reduced, and the maintenance cost is reduced.

Owner:SHANDONG YILIN WATERPROOF

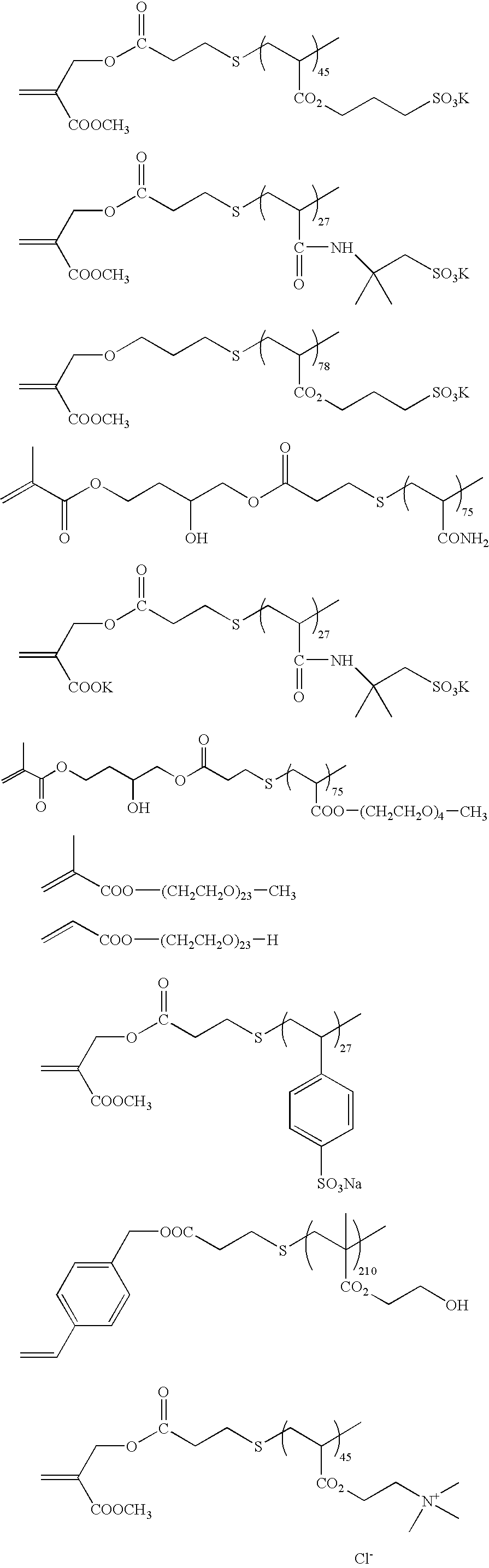

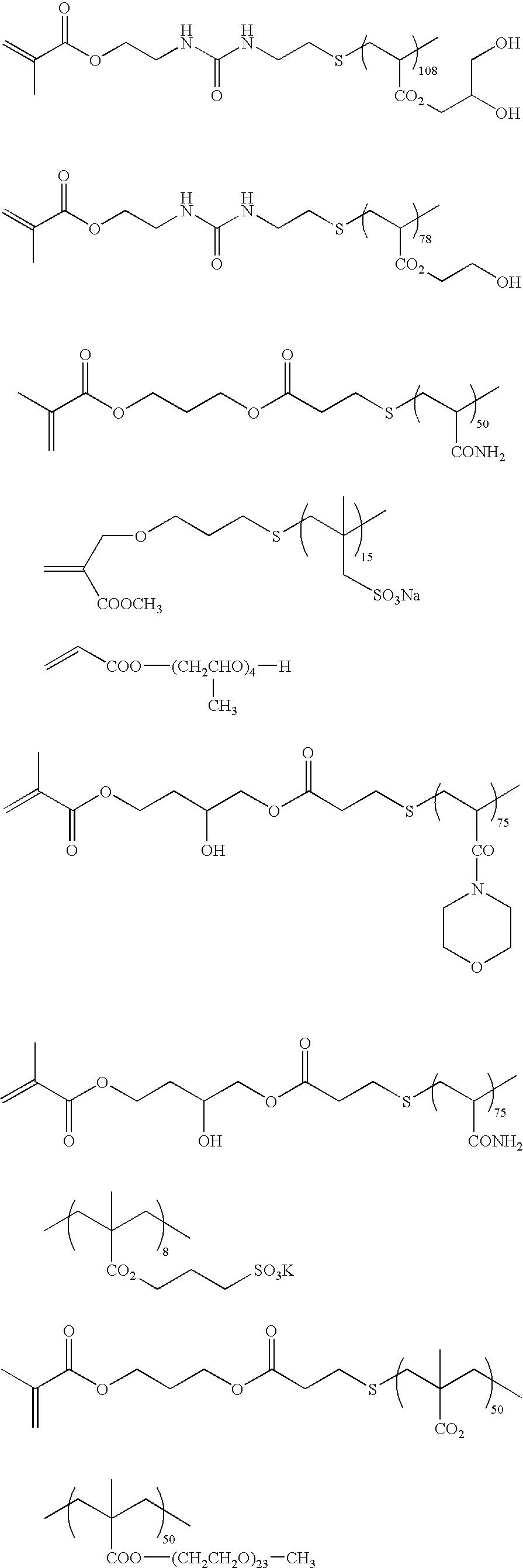

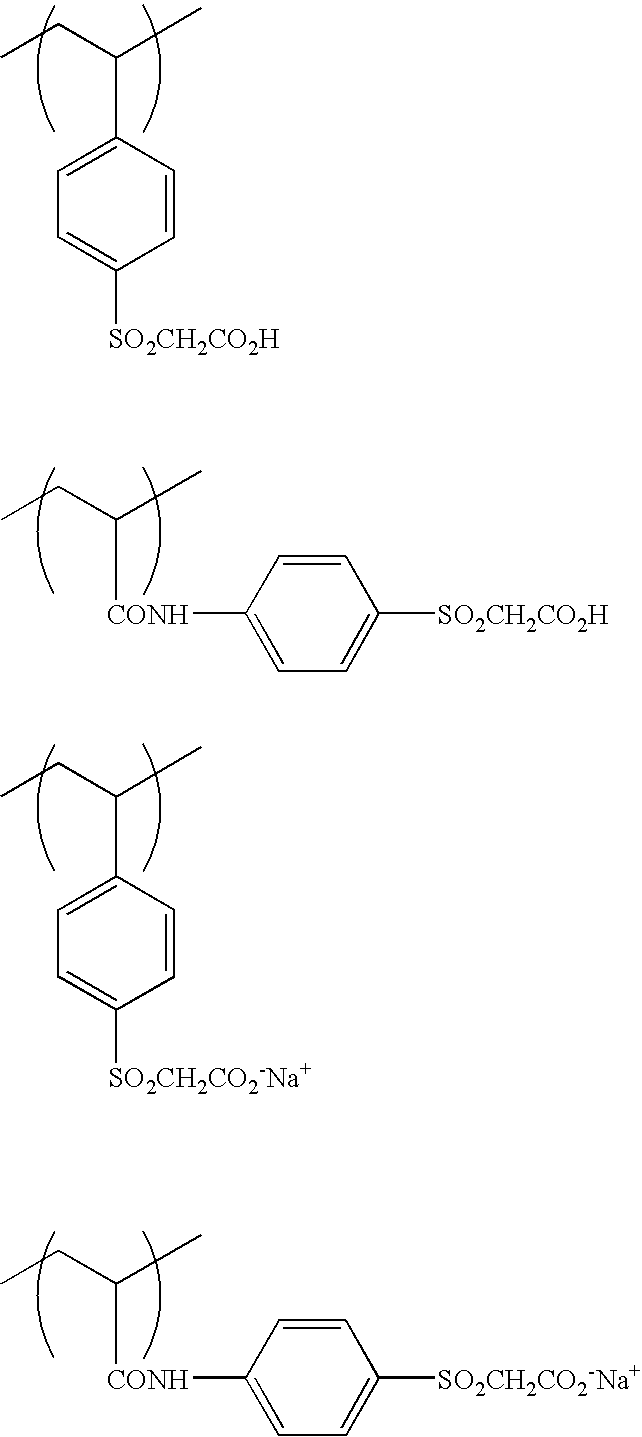

Polymerizable composition, hydrophilic film using it and planographic printing plate precursor

InactiveUS20060046193A1High hydrophilicityExcellent strengthDuplicating/marking methodsPhotomechanical apparatusPolymer chemistryCompound (substance)

A polymerizable composition including a hydrophilic polymer (A) having a radical polymerizable group on the terminal, a radical polymerizable compound (B), and a polymerization initiator (C); a hydrophilic film formed by curing a film by application of light or heat, which film includes the polymerizable composition; and a planographic printing plate precursor including a support and the hydrophilic film formed on or above the support.

Owner:FUJIFILM CORP

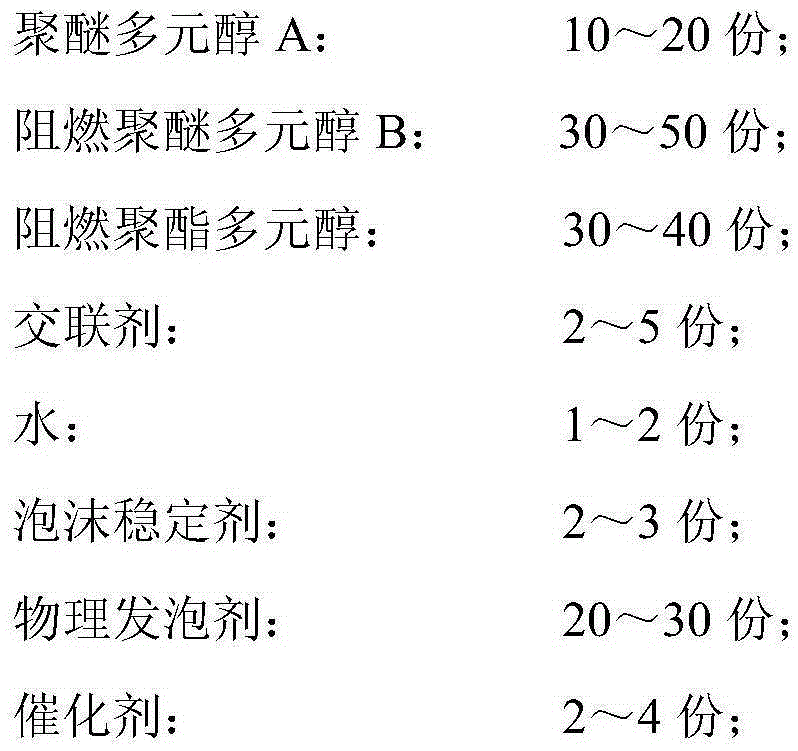

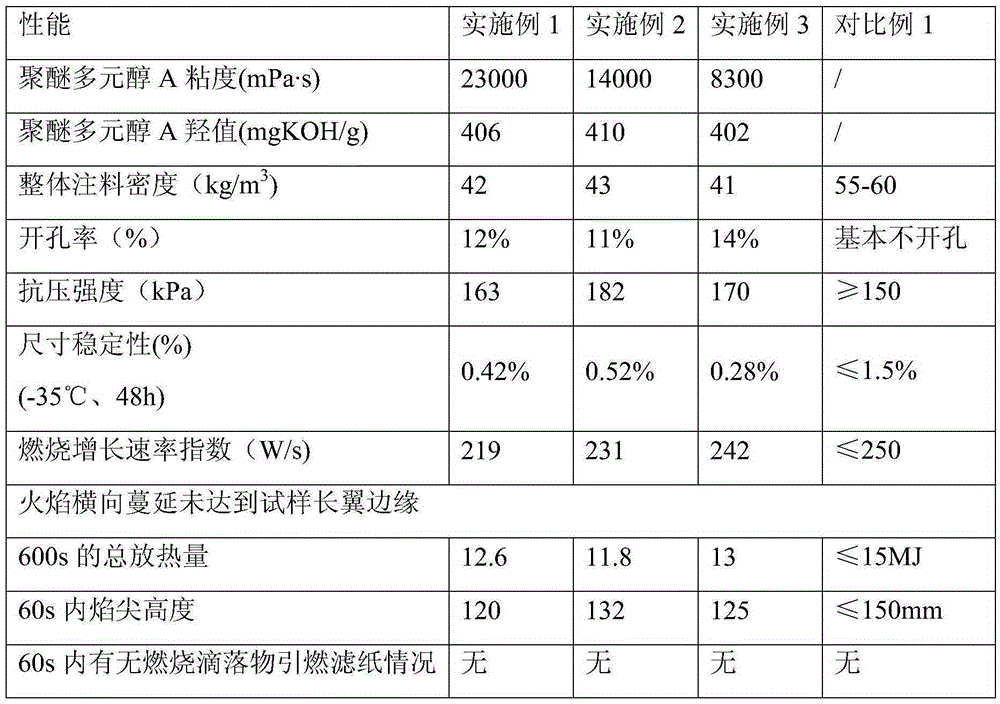

Foamed plastic for low-density and high-flame-retardant continuous slab and preparation method for foamed plastic

The invention belongs to the technical field of polyurethane synthesis and particularly relates to famed plastic for a low-density and high-flame-retardant continuous slab and a preparation method for the foamed plastic. The plastic is composed of a component A and a component B, wherein raw materials of the component A are as follows: 10-20 parts of polyether polyol A, 30-50 parts of flame-retardant polyether polyol B, 30-40 parts of flame-retardant polyester polyol, 2-5 parts of a crosslinking agent, 1-2 parts of water, 2-3 parts of a foam stabilizer, 20-30 parts of a physical foaming agent, 2-4 parts of a catalyst, and 25-40 parts of a flame retardant; and the component B is modified MDI. By selecting specially-prepared polyether polyol A which is reasonably matched with other components, the prepared foamed plastic for the low-density B1 and high-flame-retardant continuous slab has a relatively low heat conductivity coefficient, relatively high strength, certain open porosity and relatively superior foam stability. The preparation method is scientific and reasonable and is easy to implement.

Owner:SHANDONG INOV NEW MATERIALS CO LTD

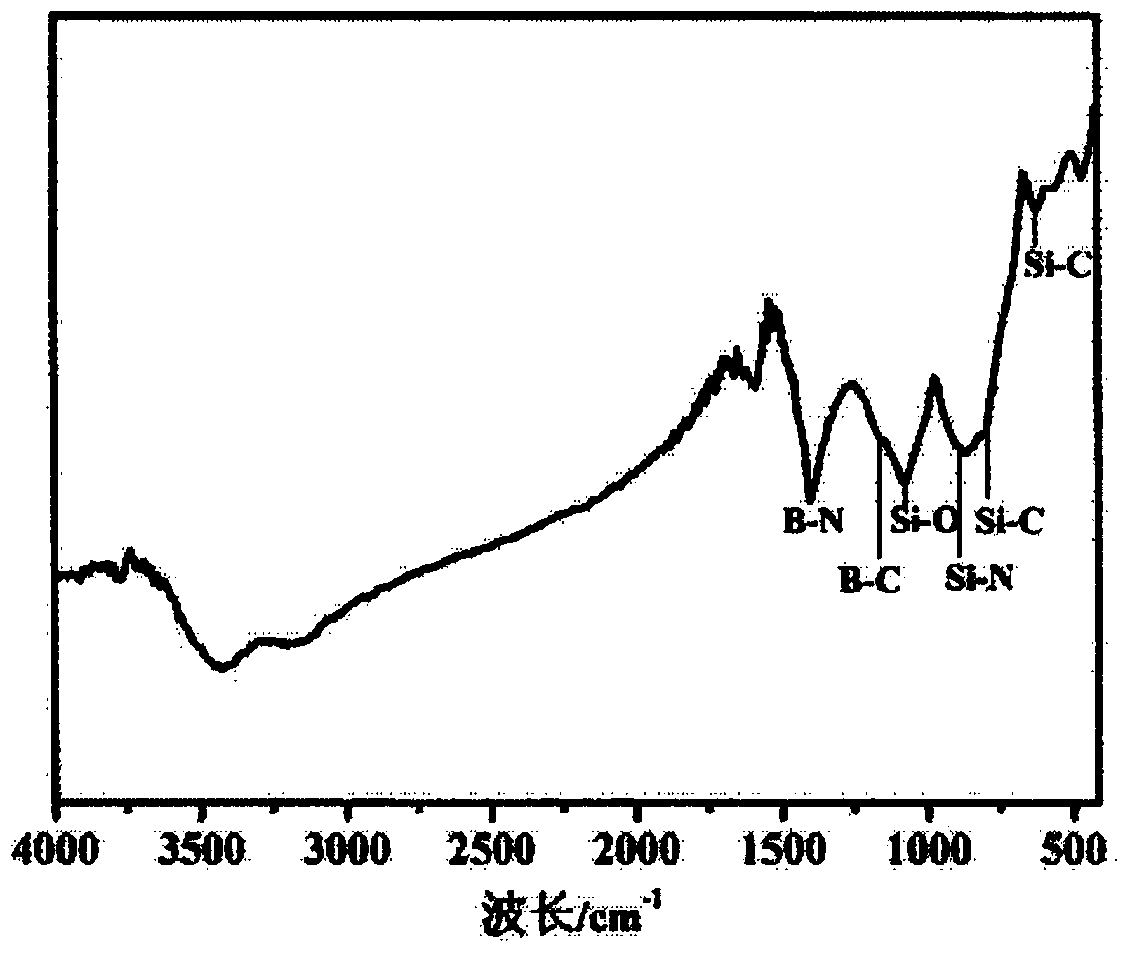

SiBCN composite material and preparation method thereof

The invention relates to a SiBCN composite material and a preparation method thereof. The SiBCN composite material is prepared by mixing and heating polyborosilazane, an organic solvent and a liquid-phase chloride which are used as raw materials. The preparation method comprises the following typical steps: the polyborosilazane and the organic solvent are placed in a reaction kettle, the liquid-phase chloride is added into the reaction kettle and reaction is carried out under the inert or reactive atmosphere condition to obtain a polyborosilazane mixture, and the polyborosilazane mixture is heated and reaction is carried out under the inert or reactive atmosphere, so that the SiBCN composite material is prepared. Through the adoption of the method, the SiBCN composite material can be directly prepared form an undefined structure, so that the mixing uniformity on the atomic scale can be achieved, and the mechanical property of the sintered composite material is remarkably improved.

Owner:山东鑫润建新材料科技产业有限公司

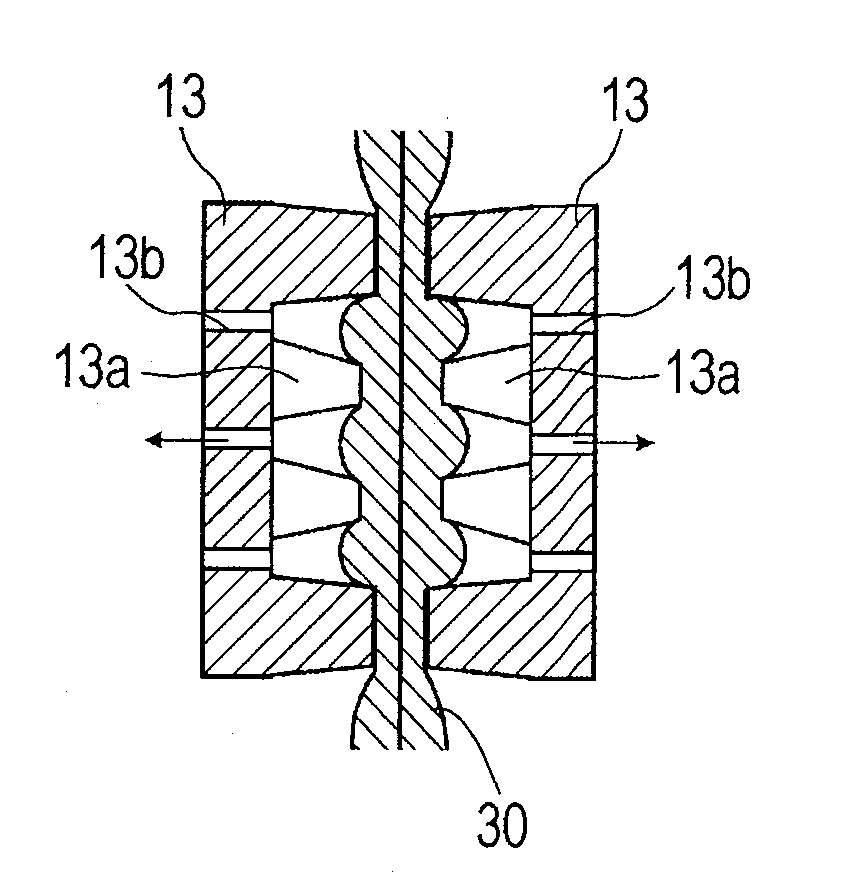

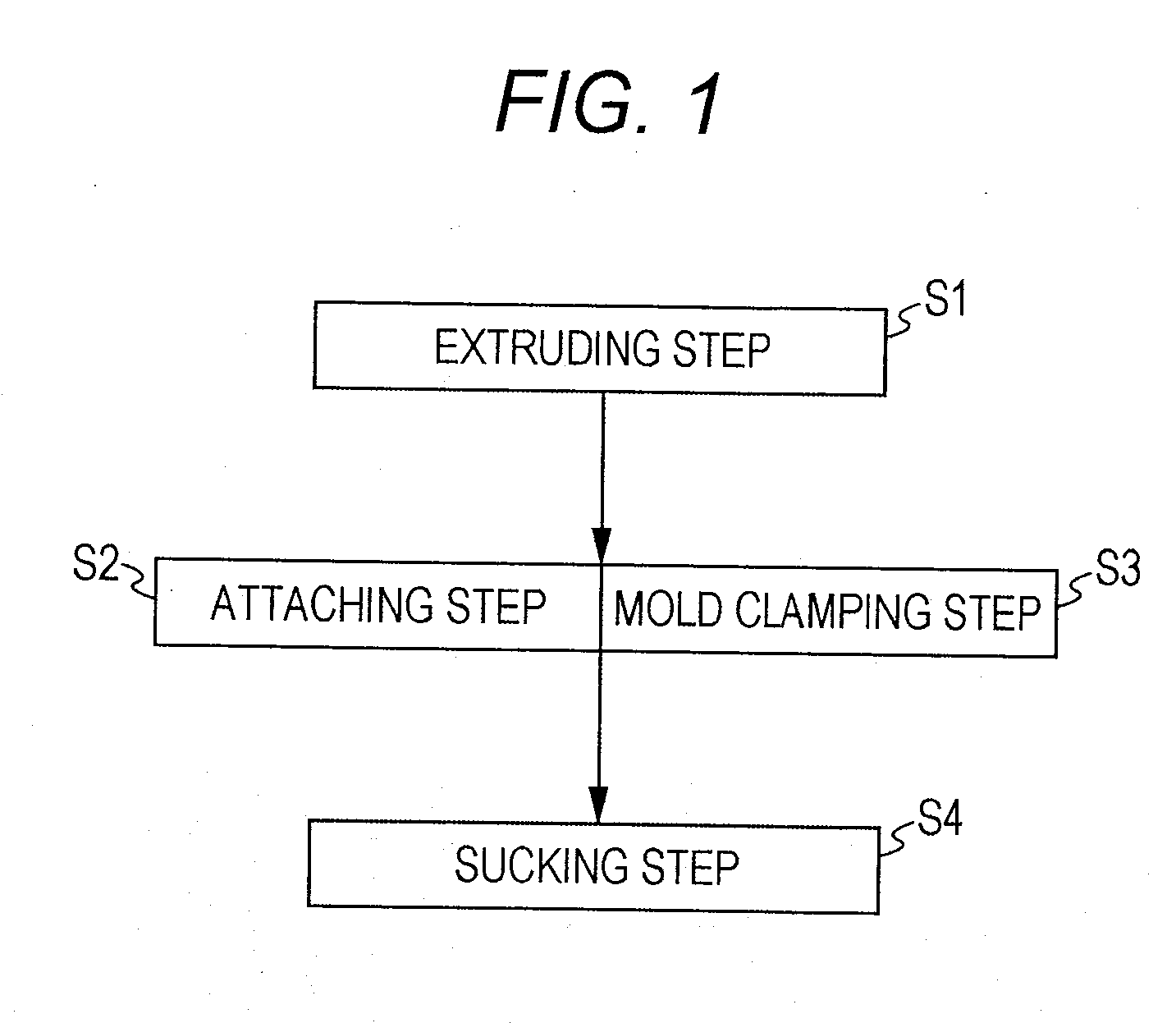

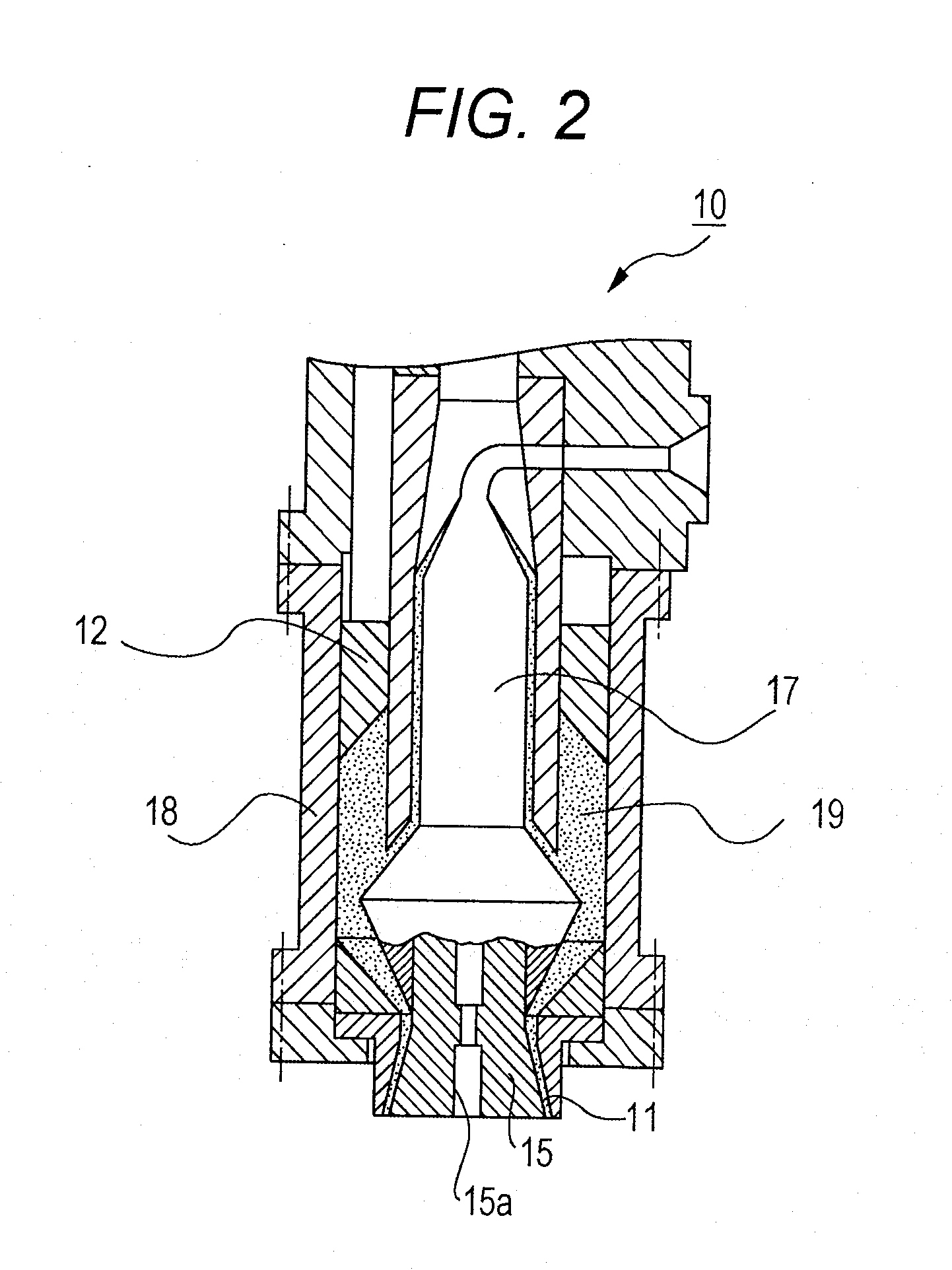

Method for manufacturing molded foam

ActiveUS20110101558A1Excellent strengthHigh strengthSemi-permeable membranesHollow wall articlesComposite materialShell molding

An object of the invention is to provide a method for manufacturing a molded foam which is lightweight and excellent in strength. According to the invention, a method for manufacturing a molded foam from a foamed parison includes: an extruding step of extruding a resin blend containing a foaming agent and a thermoplastic resin to form a foamed parison; an attaching step of closely attaching facing portions of an inner wall surface of the foamed parison to each other to form a foamed parison laminated body; a mold clamping step of sealing and mold clamping the foamed parison laminated body by clamping the foamed parison laminated body by split mold blocks; and a sucking step of sucking air between the split mold blocks to reduce a pressure between the split mold blocks, after the attaching step and the mold clamping step.

Owner:KYORAKU CO LTD

Building polymer powder based on composite silicate

InactiveCN101712537ALarge specific surface areaRich functionalitySolid waste managementPolymer scienceSlag

Owner:高庆越 +1

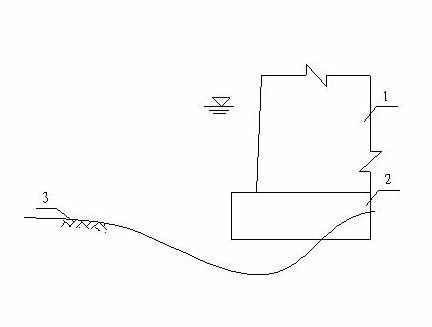

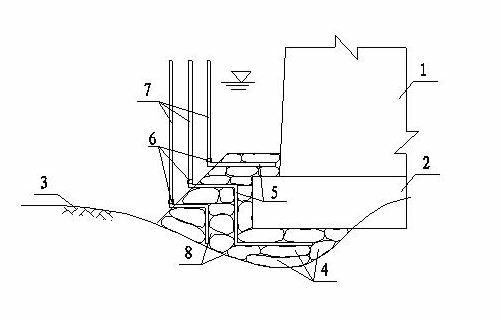

Method for reinforcement and protection of underwater foundation by pressing and pouring grout and matching with bagged dry mix

InactiveCN102134863AAvoid scourExcellent strengthFoundation repairArchitectural engineeringCement grout

The invention relates to a method for reinforcement and protection of an underwater foundation by pressing and pouring grout and matching with bagged dry mix, which comprises the following steps: dry-mixing the mix comprising cement, sand and gravel, bagging according to different weights, stacking the bagged dry mix at the part which is hollow due to flushing and the periphery of the bottom surface of the foundation, simultaneously pre-embedding grout pressing pipes among the well stacked bagged mix, connecting the grout pressing pipes with a grout pouring pipe through two-way joints, performing the operation of pressing and pouring the grout on a working platform on water so as to fill gaps among the bagged dry mix after self-solidification, and finally enabling the bagged mix after the self-solidification and the pressed and poured grout to commonly form integral concrete which is completely jointed with a river bed and the bottom surface of the foundation. The method has the advantages of low cost, good effects and convenience and quickness in construction.

Owner:江西中煤建设集团有限公司

Preparation method of continuous carbon fiber reinforced aluminum-based composite material

The invention provides a preparation method of a continuous carbon fiber reinforced aluminum-based composite material. According to the preparation method provided by the invention, the thickness of an aluminum layer adhered to the surface of the carbon fiber can be controlled by adopting a method of adhering curing aluminum powder to the surface of continuous carbon fiber through organogel, so that the content and the spacing of the carbon fiber in a composite material after hot pressing sintering can be controlled, the carbon fiber can be parallelly distributed in an aluminum matrix, and analuminum-based composite material with high carbon fiber content can be prepared. The preparation method disclosed by the invention is low in cost and easy to operate and is capable of realizing industrialized production; the strength of the carbon fiber reinforced aluminum-based composite material obtained through the preparation method provided by the invention is obviously superior to that of the carbon fiber reinforced aluminum-based composite material prepared through an existing infiltration method, and a wide application prospect is obtained.

Owner:江苏戍卫新材料科技有限公司

Aerated concrete block and preparation method thereof

InactiveCN107162628AEasy to prepareSuitable for industrial productionCeramicwareGlass fiberHigh intensity

The invention discloses an aerated concrete block. The aerated concrete block is prepared from, by weight, 40-60 parts of coal ash, 30-40 parts of levigated quartz powder, 20-30 parts of desulfurized gypsum, 10-30 parts of talc powder, 10-20 parts of sepiolite powder, 5-15 parts of activated silicon material, 15-25 parts of lime, 5-10 parts of mica powder, 2-8 parts of lightweight ceramsite, 5-15 parts of quartz sand, 3-8 parts of gypsum, 5-15 parts of asbestos powder, 4-10 parts of glass fibers, 3-10 parts of aluminum powder, 2-6 parts of an air entraining agent, 1-5 parts of a foam stabilizer, 3-8 parts of a foam homogenizing agent and 60-80 parts of deionized water. The aerated concrete block meets requirements on heat insulation, energy saving and high strength, and a preparation method of the aerated concrete block is simple, convenient and suitable for industrial production.

Owner:HEFEI GUANGMIN BUILDING MATERIAL CO LTD

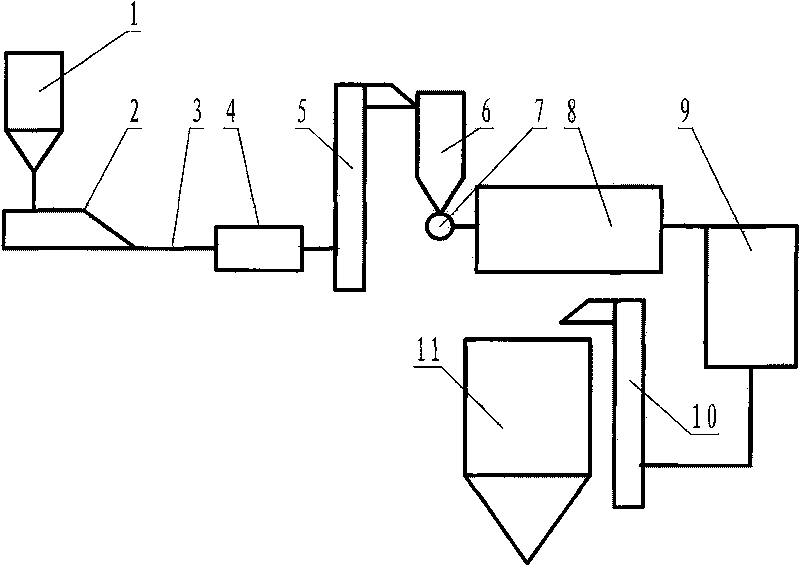

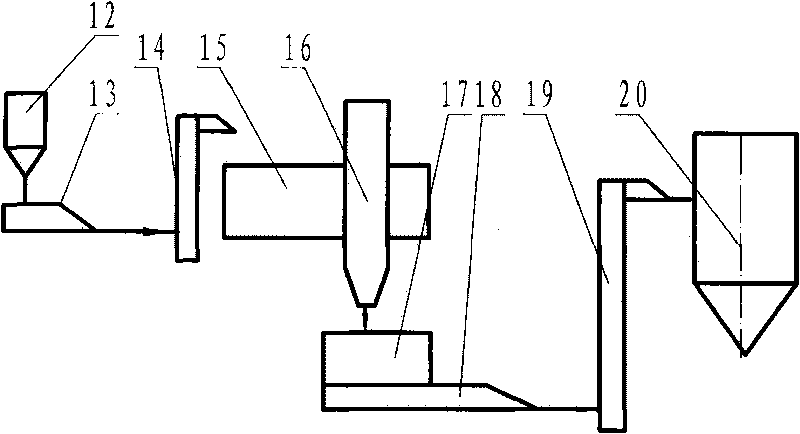

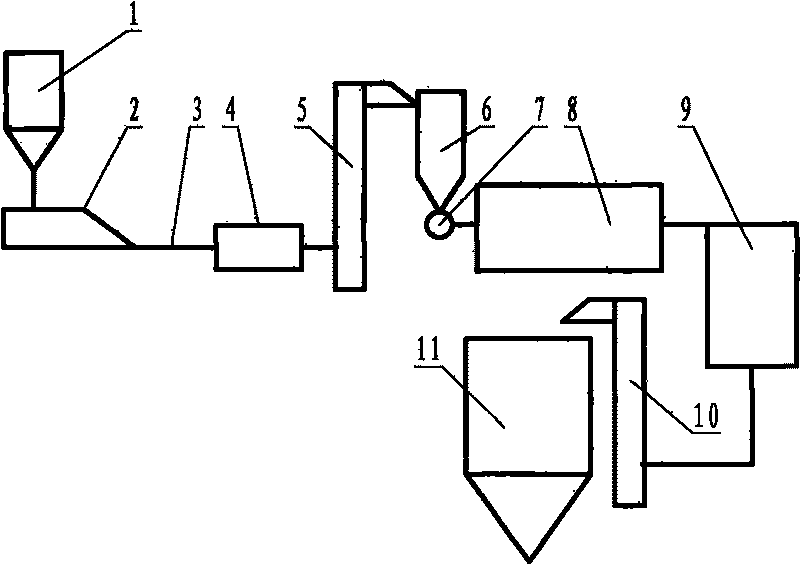

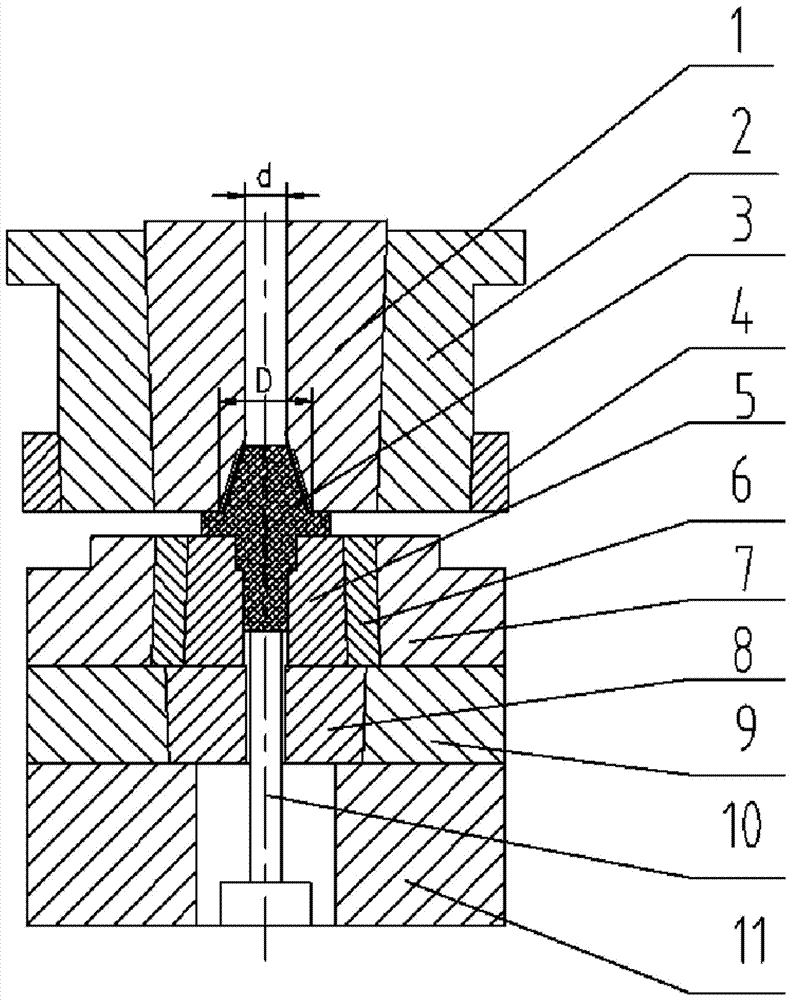

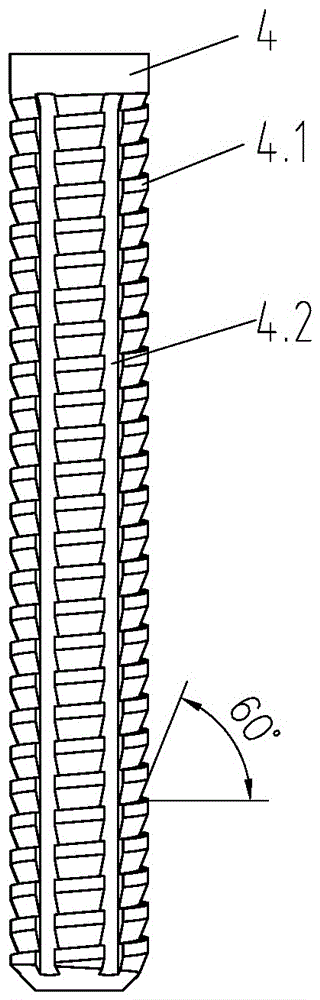

Precise near-net forming technology and device for bevel gear shaft

The invention discloses a precise near-net forming technology and device for a bevel gear shaft. The technology comprises the following steps of (a) precise saw cutting of a bar; (b) annealing treatment; (c) blank lubrication by adopting a high polymer lubricant; (d) conical blank preforming through cold heading: preliminarily preforming the blank according to a bevel angle of the bevel gear shaft and the shape of a shaft step and laying a foundation for next near-net forming of a bevel gear and a step shaft; (e) molybdenum disulfide lubrication: mixing molybdenum disulfide powder and engine oil at a ratio of (30-40wt%):(60-70wt%), coating the surface of the preformed blank with the prepared molybdenum disulfide and directly putting the preformed blank into a near-net forming die for molding; (f) precise near-net forming: forming the bevel gear shaft on a precise near-net forming device; (g) machining according to the requirements; and (h) forming of a product. The forming device comprises four parts, such as a set of combined bevel gear die, a set of combined step shaft die, a reinforcing plate and an ejector stopper.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

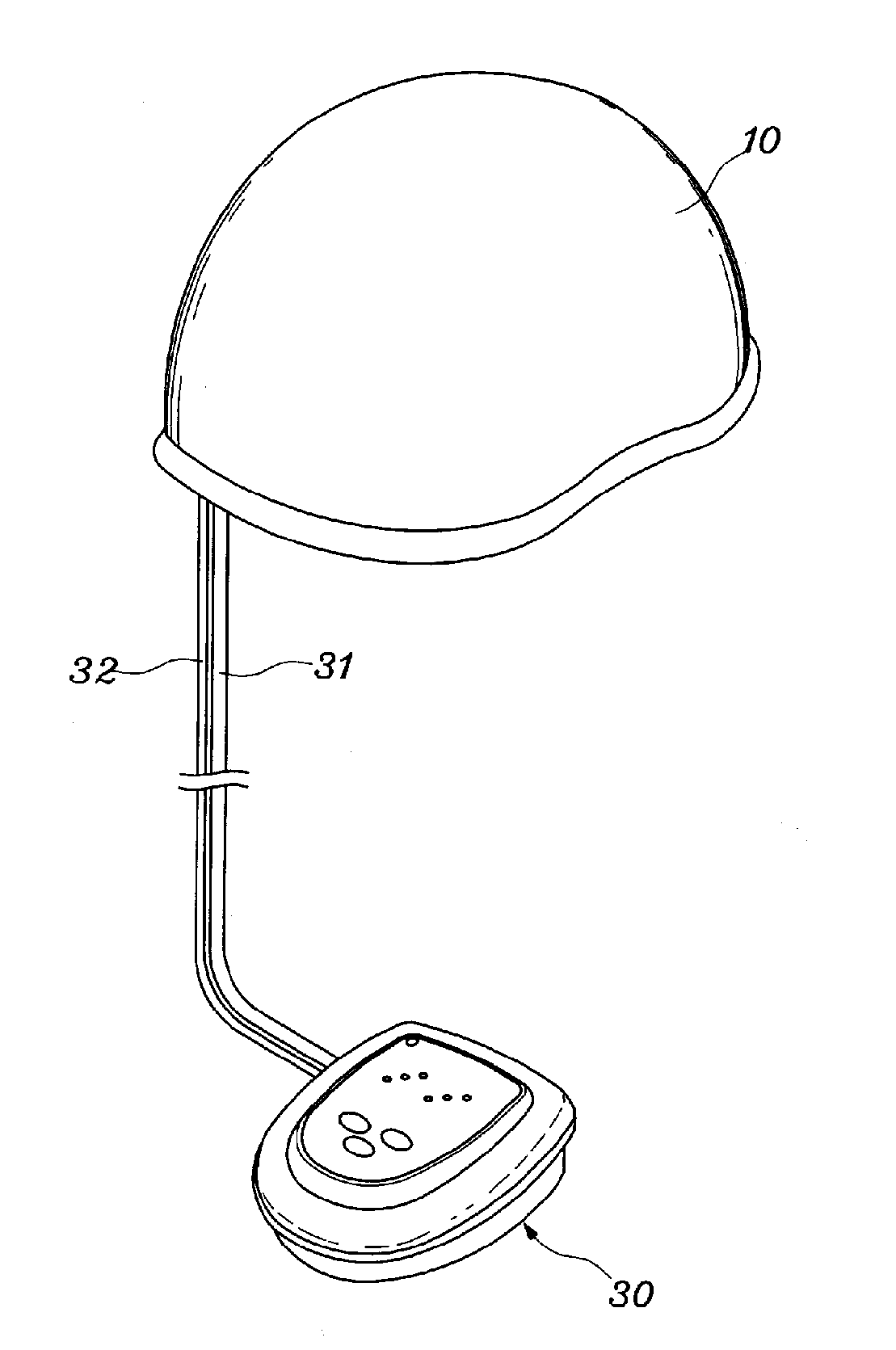

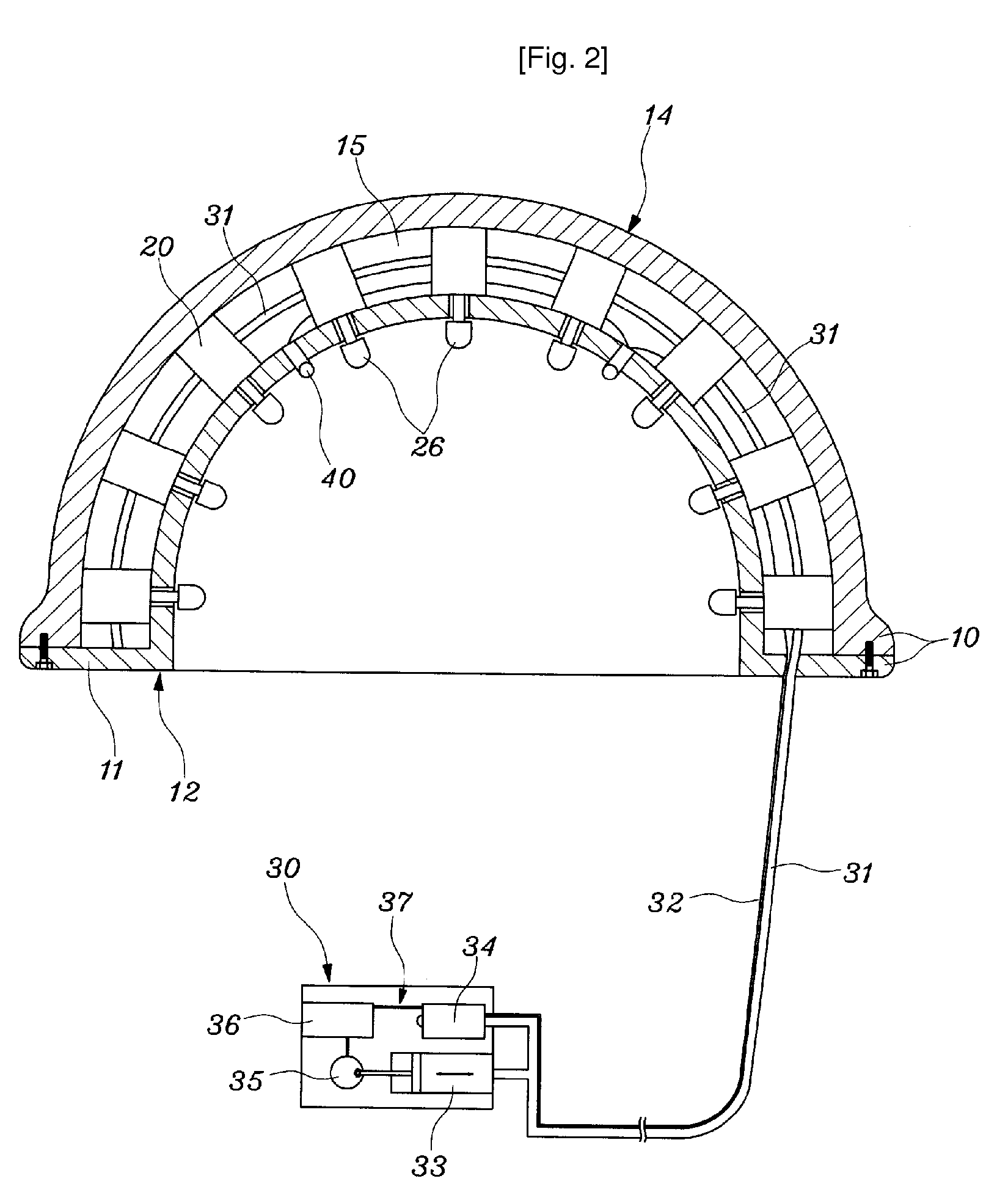

Apparatus for head acupressure using air pressure

InactiveUS20090036808A1Simple to use and carryExcellent strengthPneumatic massageDevices for pressing relfex pointsPneumatic cylinderPneumatic pressure

The present invention relates to a plurality of pneumatic cylinders each having an acupressure probe is radially mounted in a predetermined space portion defined between an inner shell and an outer shell made of an extruded foam synthetic resin material, and an pneumatic pressure generator serving to actuate the pneumatic cylinders is mounted separately from the helmet, so that its whole weight is light, no noise or vibration occurs, and it is very simple to use and carry.

Owner:KI YONG HO

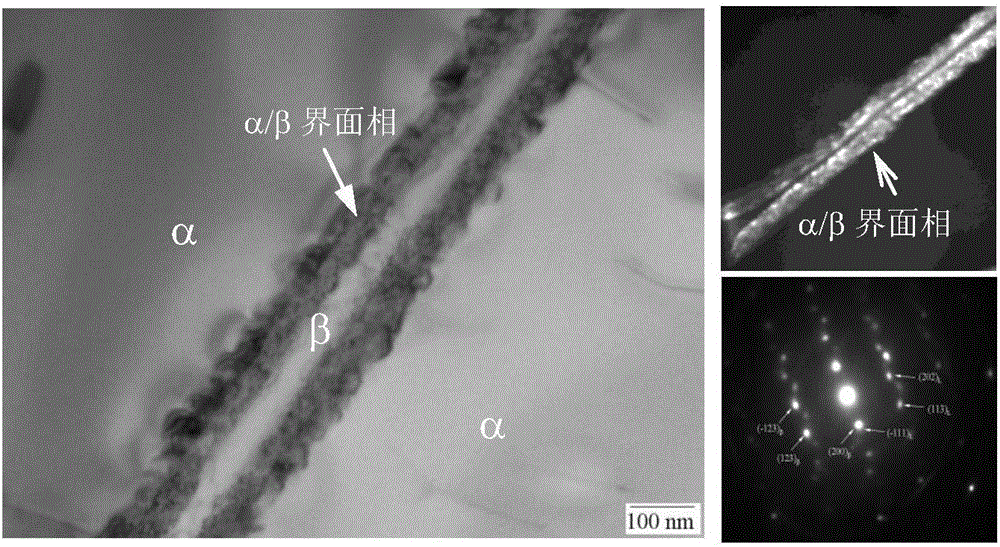

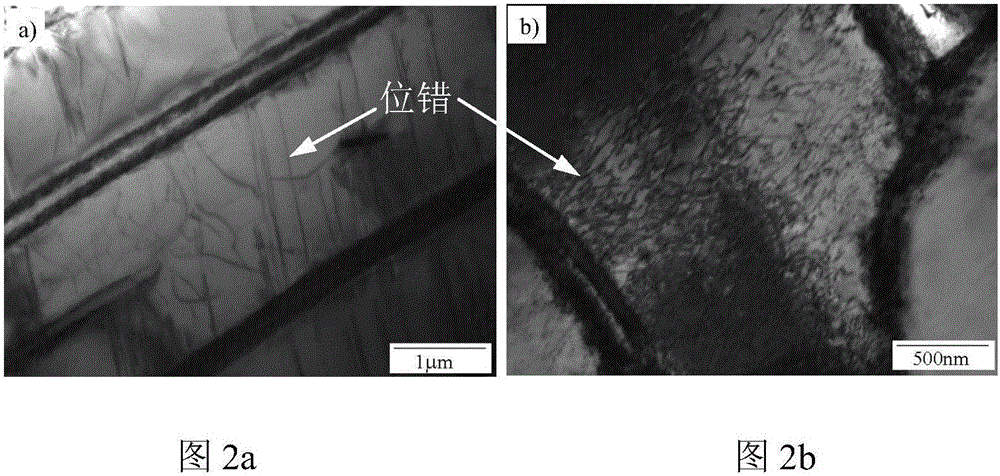

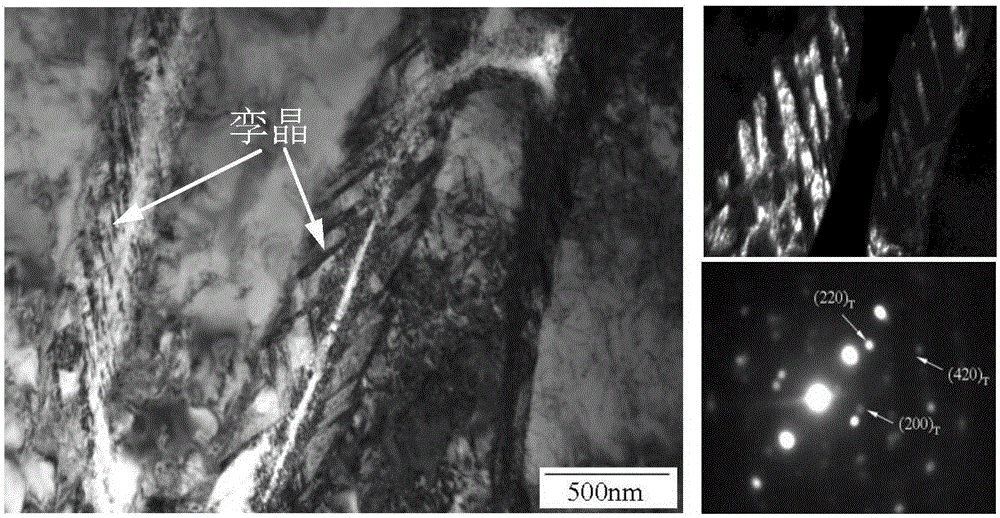

Preparation method capable of synchronously improving strength and plasticity of additive manufactured titanium alloy

ActiveCN106583719AHigh strengthImprove plasticityAdditive manufacturing apparatusIncreasing energy efficiencyDeposition processOxygen content

The invention discloses a preparation method capable of synchronously improving strength and plasticity of an additive manufactured titanium alloy. The preparation method comprises the following steps: (1) Ti-6Al-4V alloy powder with a particle size of -90-+325 meshes is put in a powder feeder, wherein the oxygen content of the powder is not higher than 0.20 wt.%; (2) a substrate is fixed on a worktable of an argon-charged inert atmosphere machining chamber; (3) in the argon-charged inert atmosphere machining chamber, when the oxygen content is lower than 100 ppm, a titanium alloy is formed through additive manufacturing; and (4) under the effect of a laser source, the synchronously fed Ti-6Al-4V alloy powder is continuously molten and deposited on the substrate; in the deposition process, the energy density of the deposition area and the size of the deposition area are controlled to obtain 103-104 k / s cooling speed in the liquid-solid transformation process and to obtain 100-400 k / s cooling speed in the process of converting from a beta phase to an alpha phase; and a Ti-6Al-4V alloy part with an alpha / beta interface phase is prepared.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

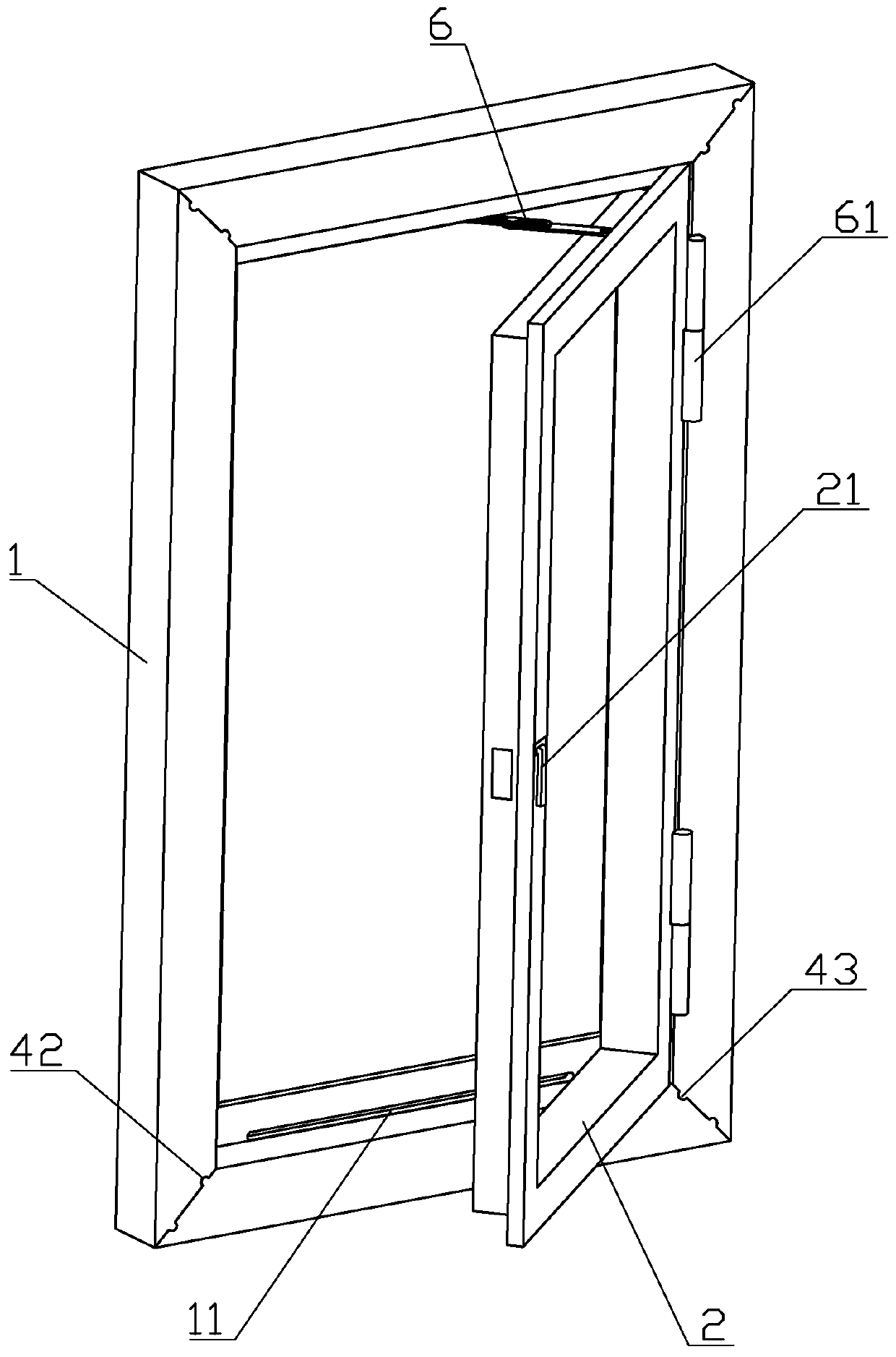

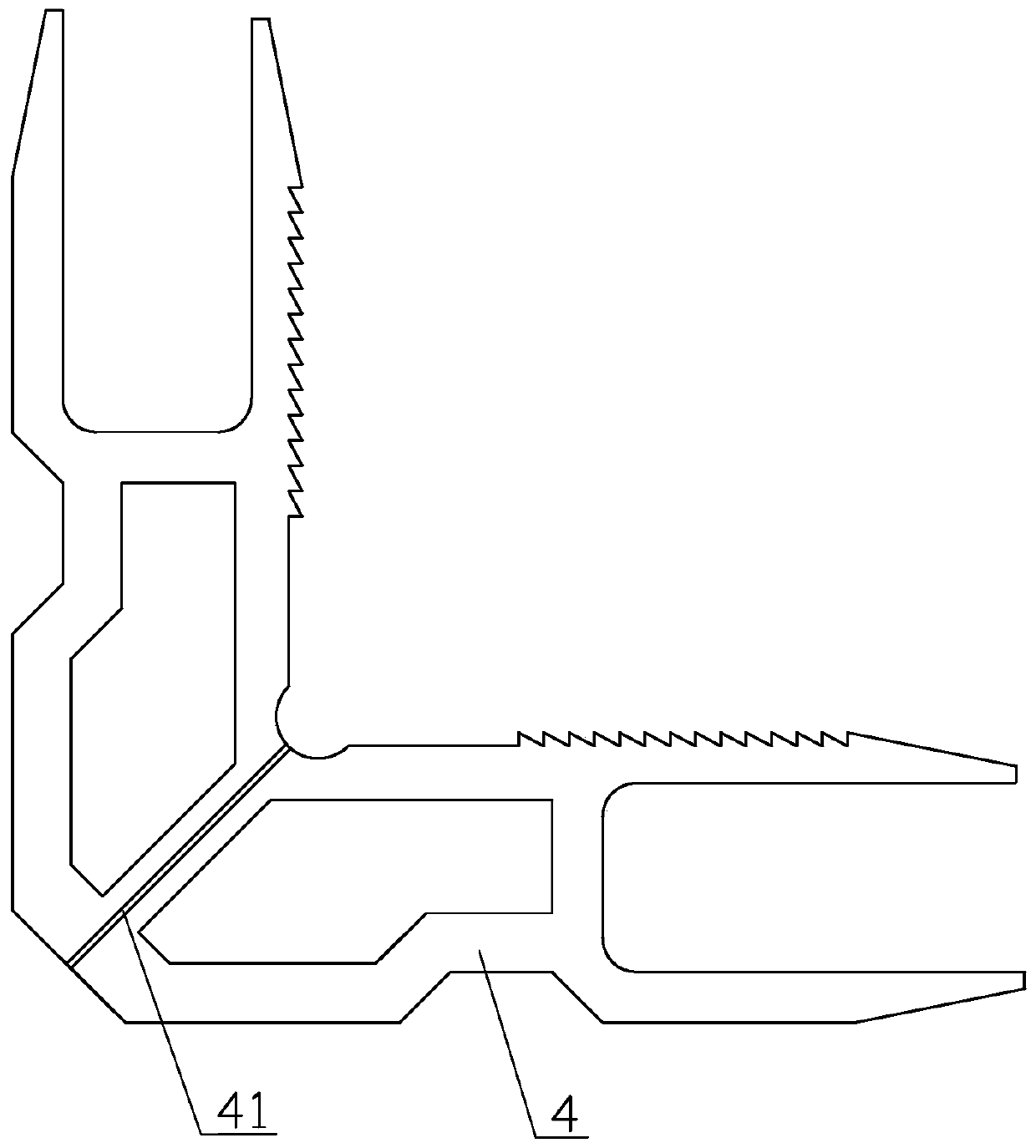

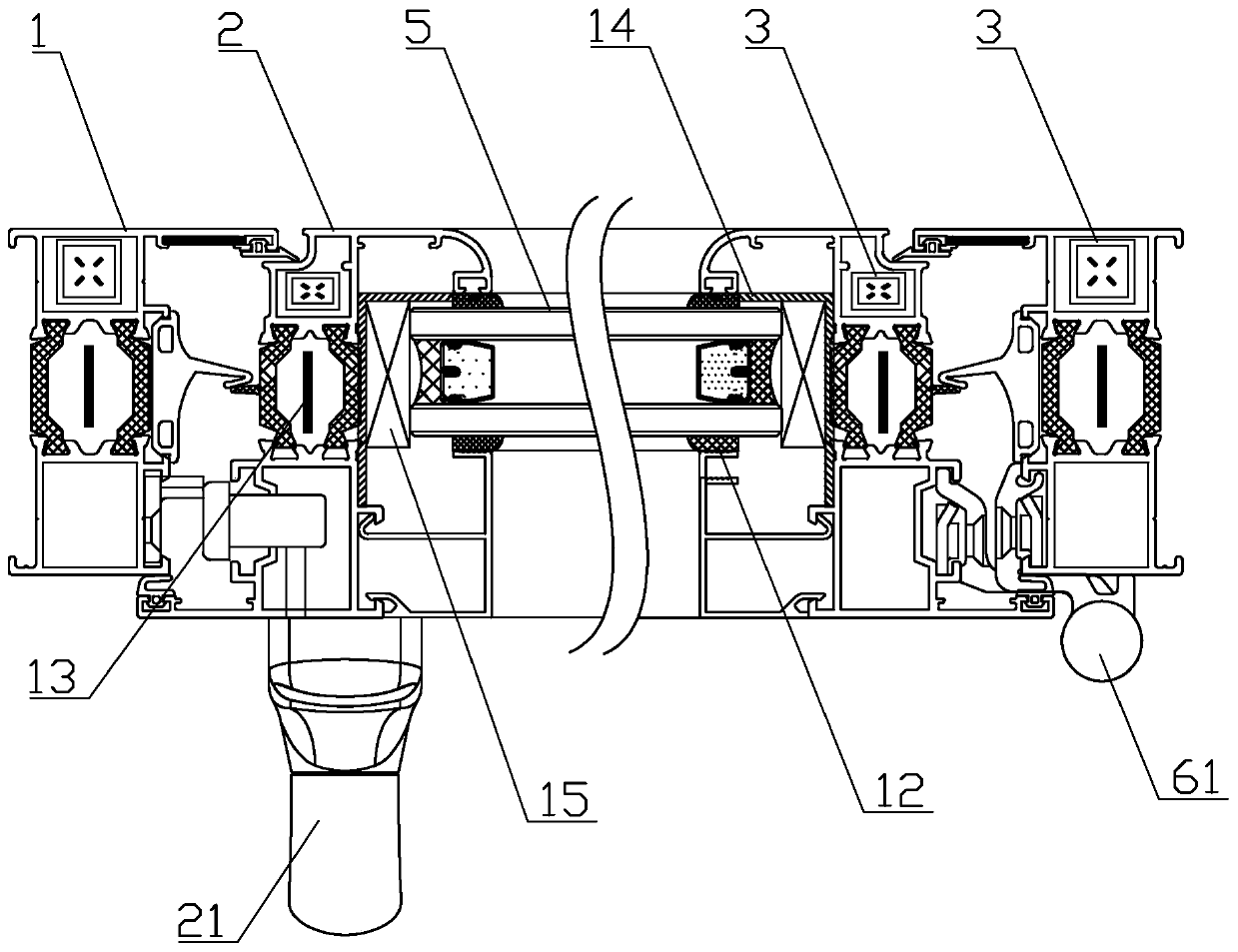

Manufacturing process of high-efficiency and energy-saving aluminum alloy fireproof window

ActiveCN110259351AExcellent strengthExcellent high temperature resistanceFireproof doorsBuilding braking devicesMetallurgy

The invention relates to the technical field of fireproof doors and windows, and discloses a manufacturing process of a high-efficiency and energy-saving aluminum alloy fireproof window. The manufacturing process comprises the following steps that S1, profiles are processed, specifically, all parts of structures are cut, and then slotting and drilling operations are carried out; S2, inner parts are assembled, specifically, steel linings, sliding seats and cross columns are assembled, and then the assembled steel linings, sliding seats and cross columns are put into frames of a window sash and a window frame to assemble the window sash and the window frame; S3, punching is carried out, specifically, corners of the window sash and corners of the window frame are punched; S4, painting is carried out, specifically, antirust paint is sprayed; S5, glass is installed, specifically, double-layer glass is installed into the frame of the window sash and is sealed; and S6, accessories are installed, specifically, hardware accessories of the fireproof window are installed into slots and holes formed in the step S1. According to the manufacturing process of the high-efficiency and energy-saving aluminum alloy fireproof window, the cross columns, the sliding seats and the steel linings are installed in the window frame and the window sash, the steel linings and the cross columns are both made of steel, and the strength and the high-temperature resistance of the steel linings and the cross columns are superior to that of aluminum alloys, when the fireproof window encounters a fire, the strength and the fire resistance of the window frame and the window sash are enhanced by the steel linings and the cross columns, so that the stability of the fireproof window when encountering the fire is improved.

Owner:安徽钟南消防科技有限公司

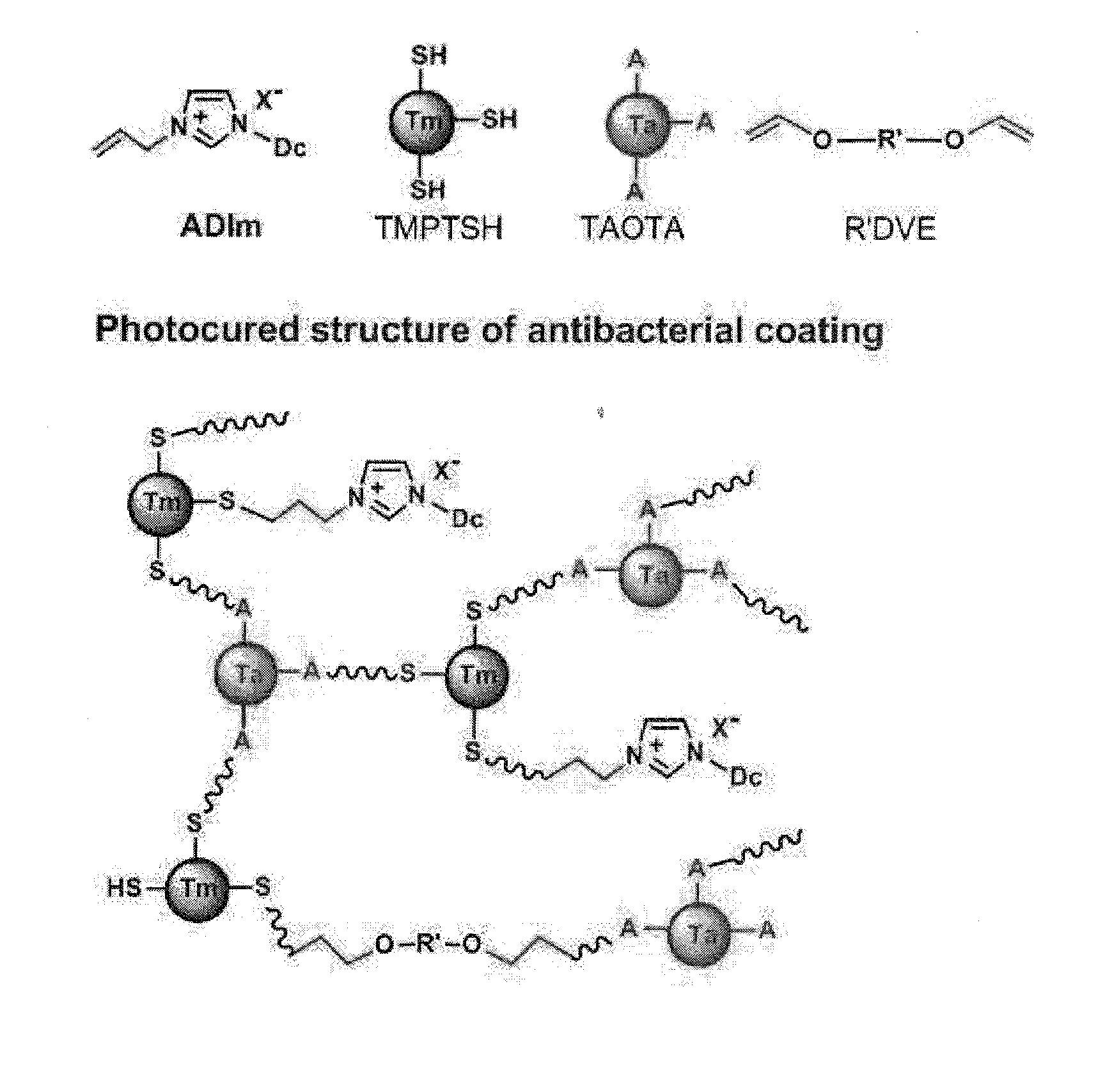

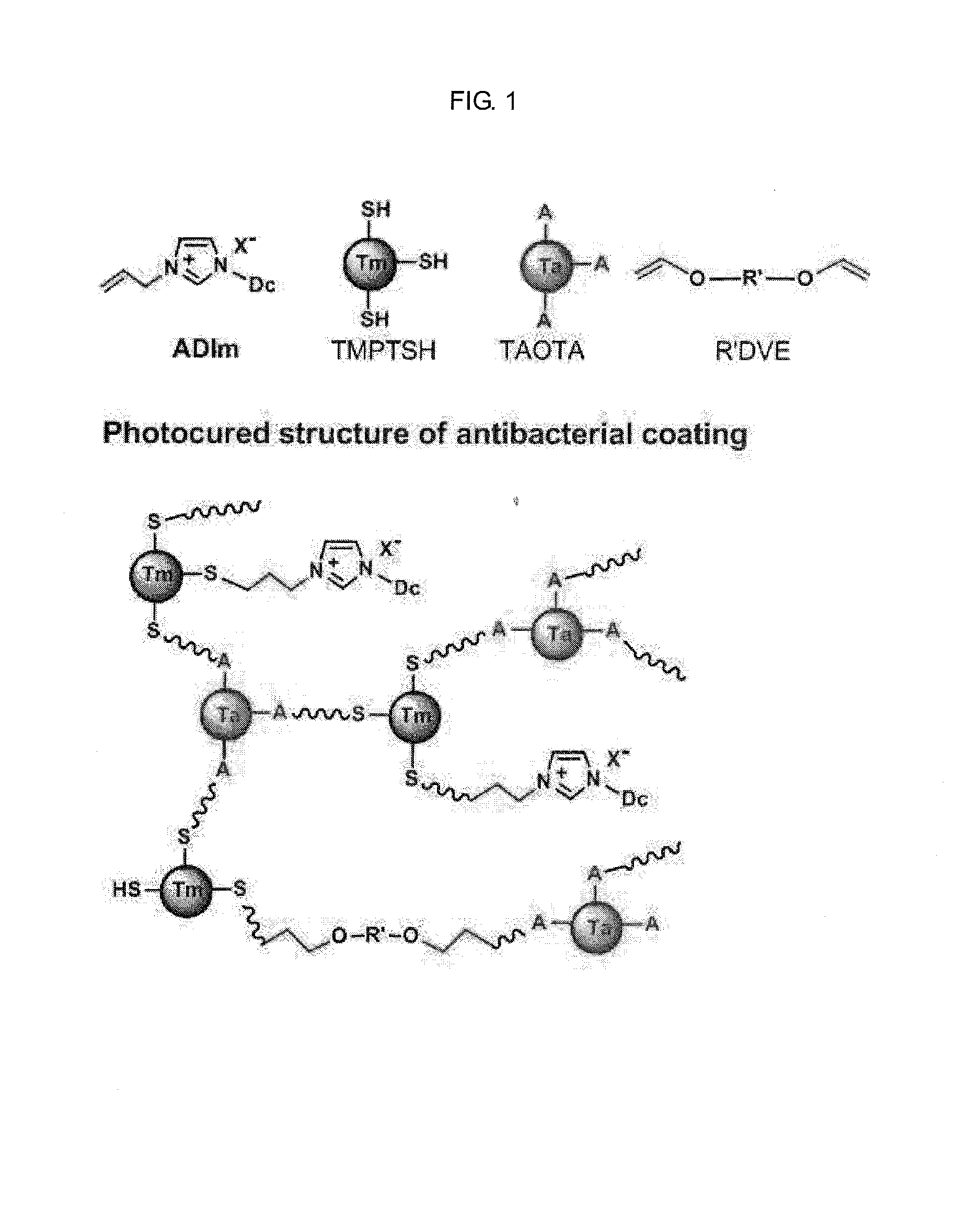

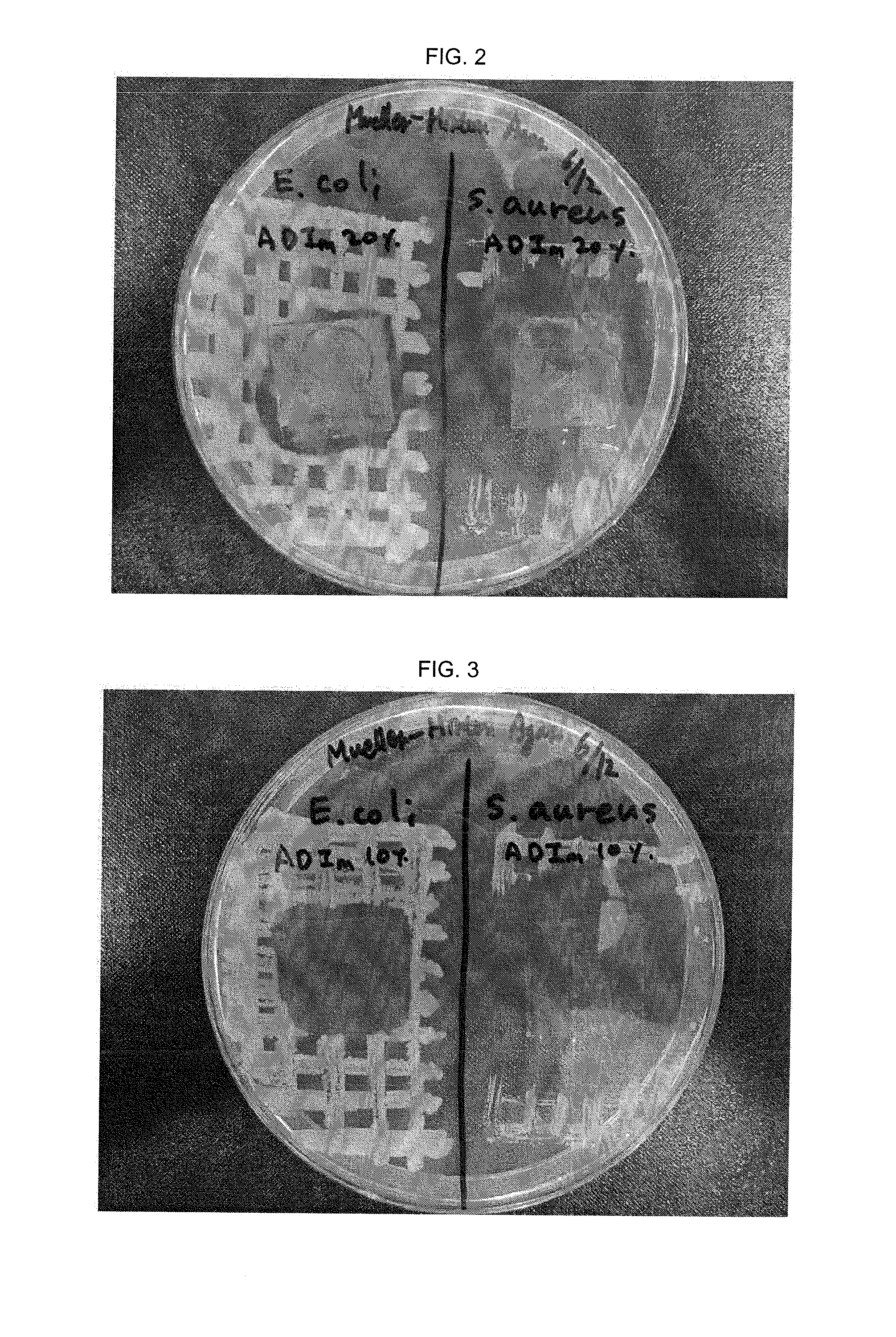

Antibacterial imidazolium compound and antibacterial photocurable thiol-ene compositions comprising the same, and antibacterial polymer coatins prepared therefrom

ActiveUS20140212374A1Excellent antibiosisExcellent strengthBiocideOrganic active ingredientsAntimicrobial polymerAntibiosis

An antibacterial imidazolium compound, a photocurable coating composition, and an antibacterial coating film includes a compound represented by Chemical Formula 1 shown below or derivatives thereof.In Chemical Formula 1, description of X−, R1 and, R2 is the same as in the detailed description of the invention. The antibacterial imidazolium compound has excellent antibiosis over various strains, and is included in a photocurable coating composition so as to provide an antibacterial coating film by a simple method. Also, in the antibacterial coating film, the antibacterial imidazolium compound is included as a monomer and chemically bonded to a polymer chain, and thus, antibacterial performance can be maintained for a long period of time.

Owner:KOREA INST OF SCI & TECH

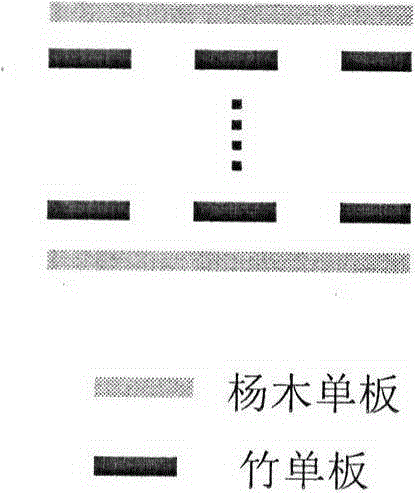

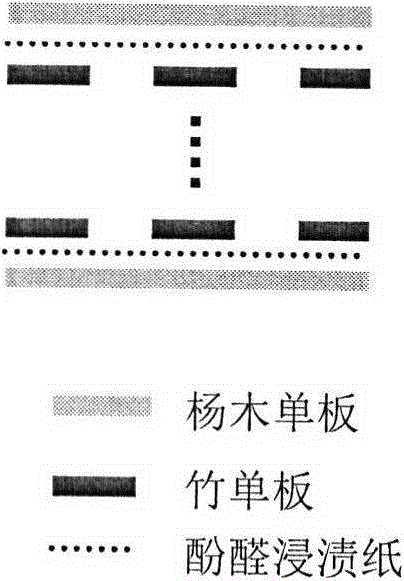

Bamboo and wood composited electrical laminated wood

The invention discloses bamboo and wood composited electrical laminated wood and relates to a process for producing the electrical laminated wood by adopting bamboos and fast-growing wood veneers. The process includes the steps 1), subjecting a thin bamboo veneer to water boiling treatment and soaking a poplar veneer in low-molecular-weight phenolic resin for strengthening treatment; 2), drying the treated bamboo veneer and the fast-growing wood veneer to be 6-8% in moisture content, applying polyvinyl butyral modified phenolic resin class (or polyvinyl butyral class resin / epoxy resin class) and drying the treated bamboo veneer and the fast-growing wood veneer to be 6-10% in moisture content prior to assembling; 3), pressing assembled bamboo veneer and fast-growing wood veneer to obtain an electrical laminated plate under the conditions that hot-press pressure ranges from 3.5MPa to 7.0MPa, time ranges from 1-2min / mm and temperature ranges from 110DEG C to 150DEG C. The bamboo and wood composite electrical laminated wood has the advantages that a medium-density bamboo and a low-density fast-growing wood veneer are composited, the bamboo can share part of compression stress, so that the problems that the electrical laminated wood produced by the low-density bamboo with an overlarge compression ratio is low in impact performance and poor in oil absorbency are solved. The bamboo and wood composited electrical laminated wood is good in dimensional stability, large in resistance, high in intensity and capable of being used for an electrical compression piece, an electrical ring, an insulating plate and the like.

Owner:NANJING FORESTRY UNIV

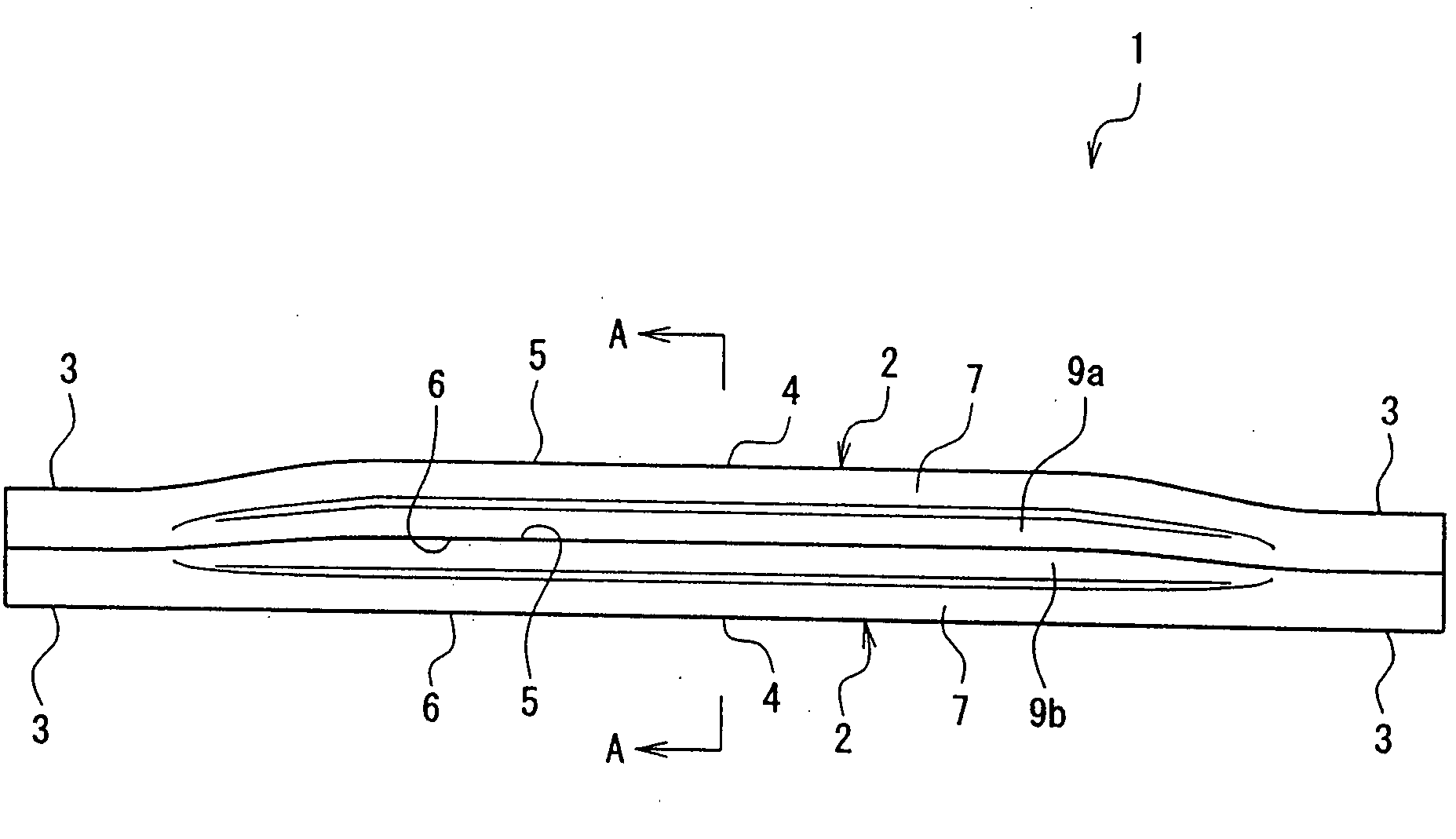

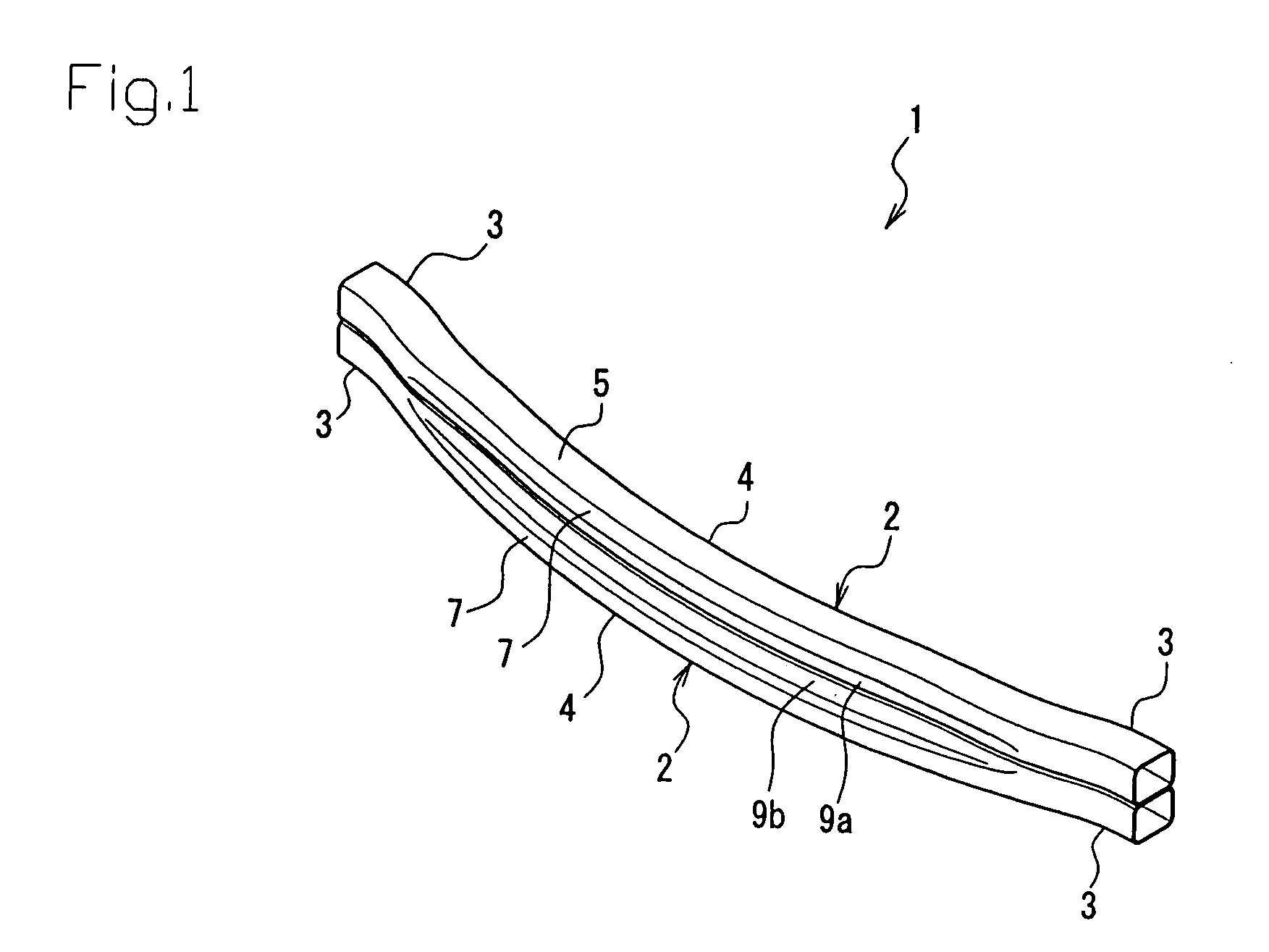

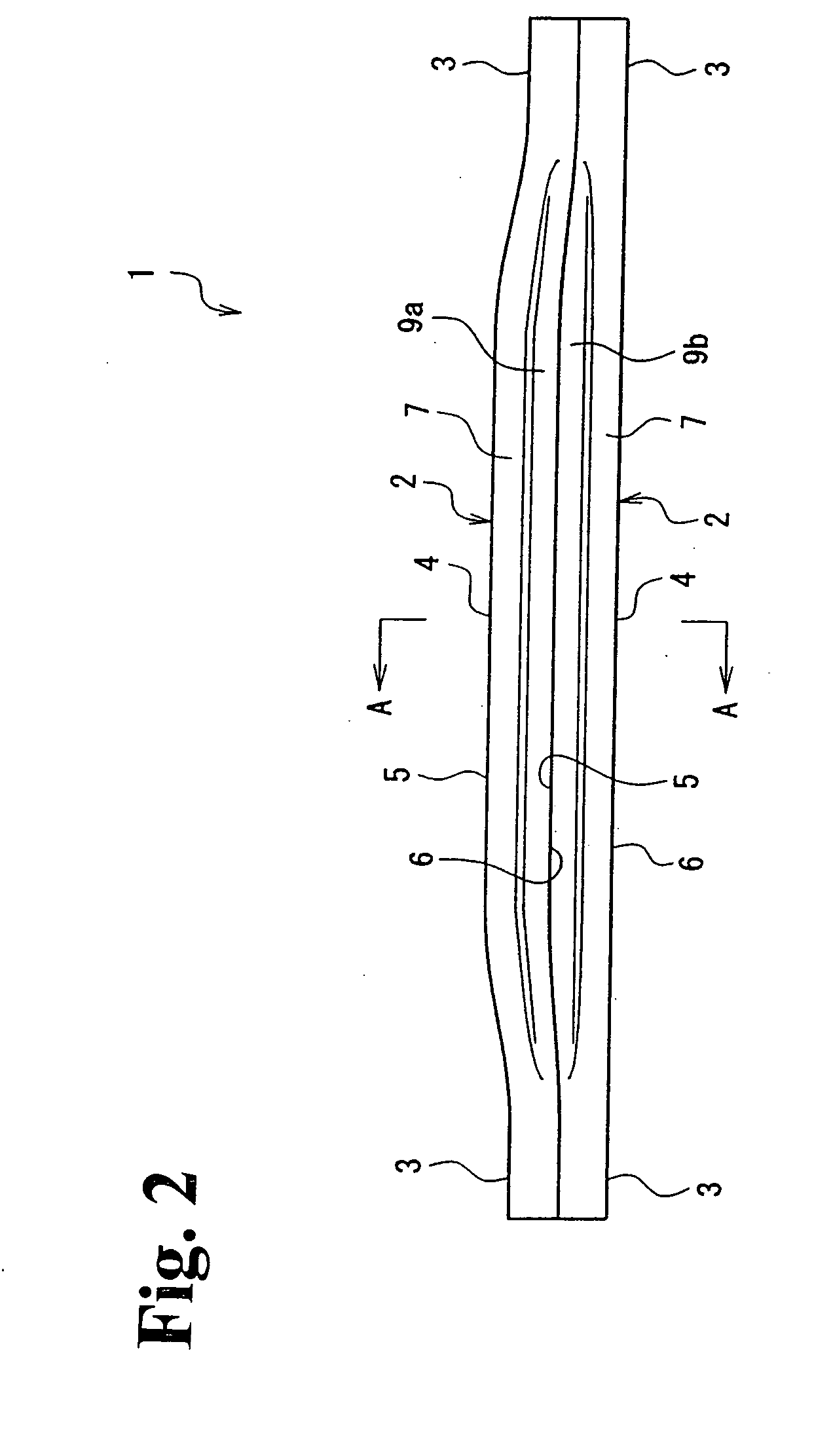

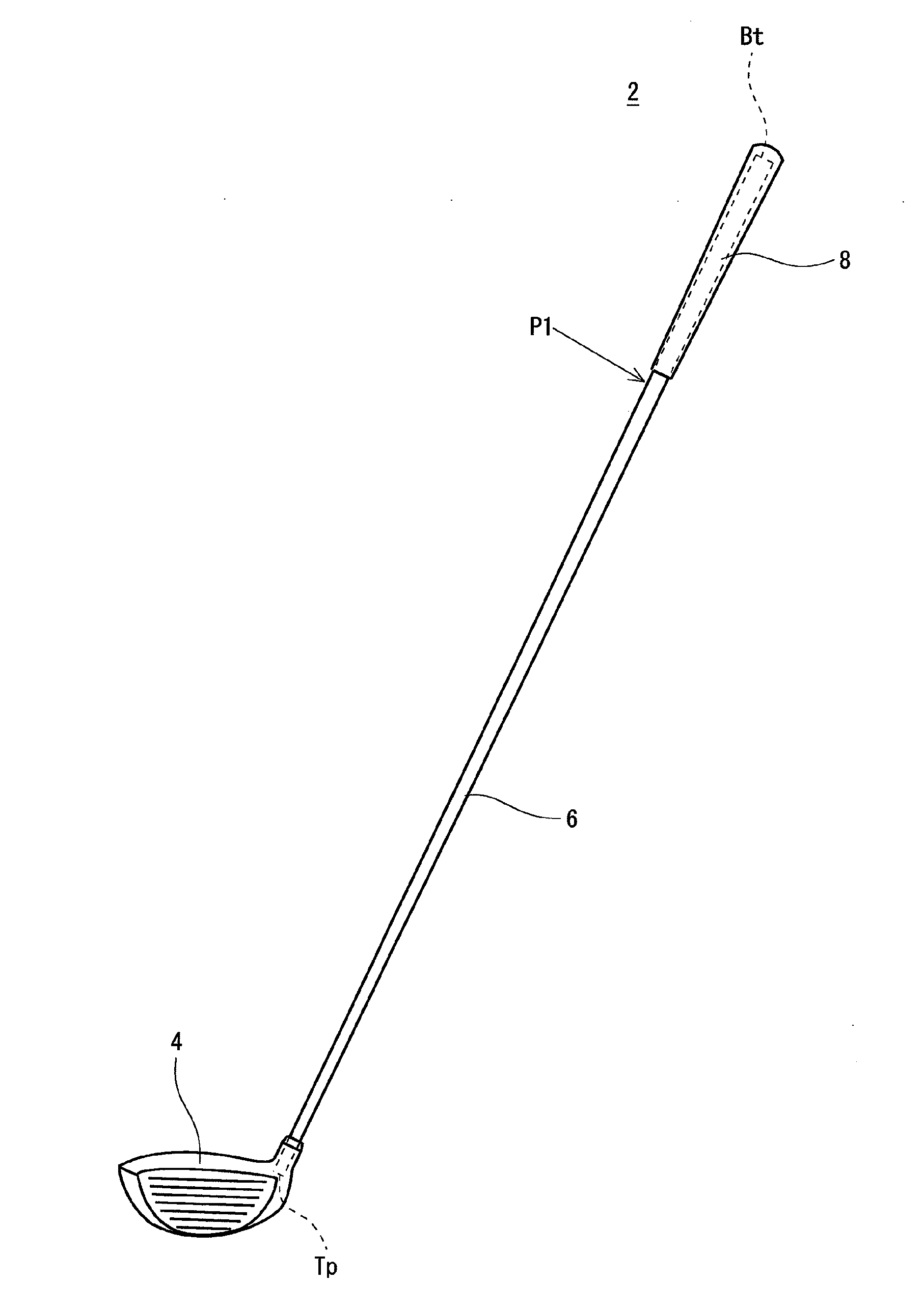

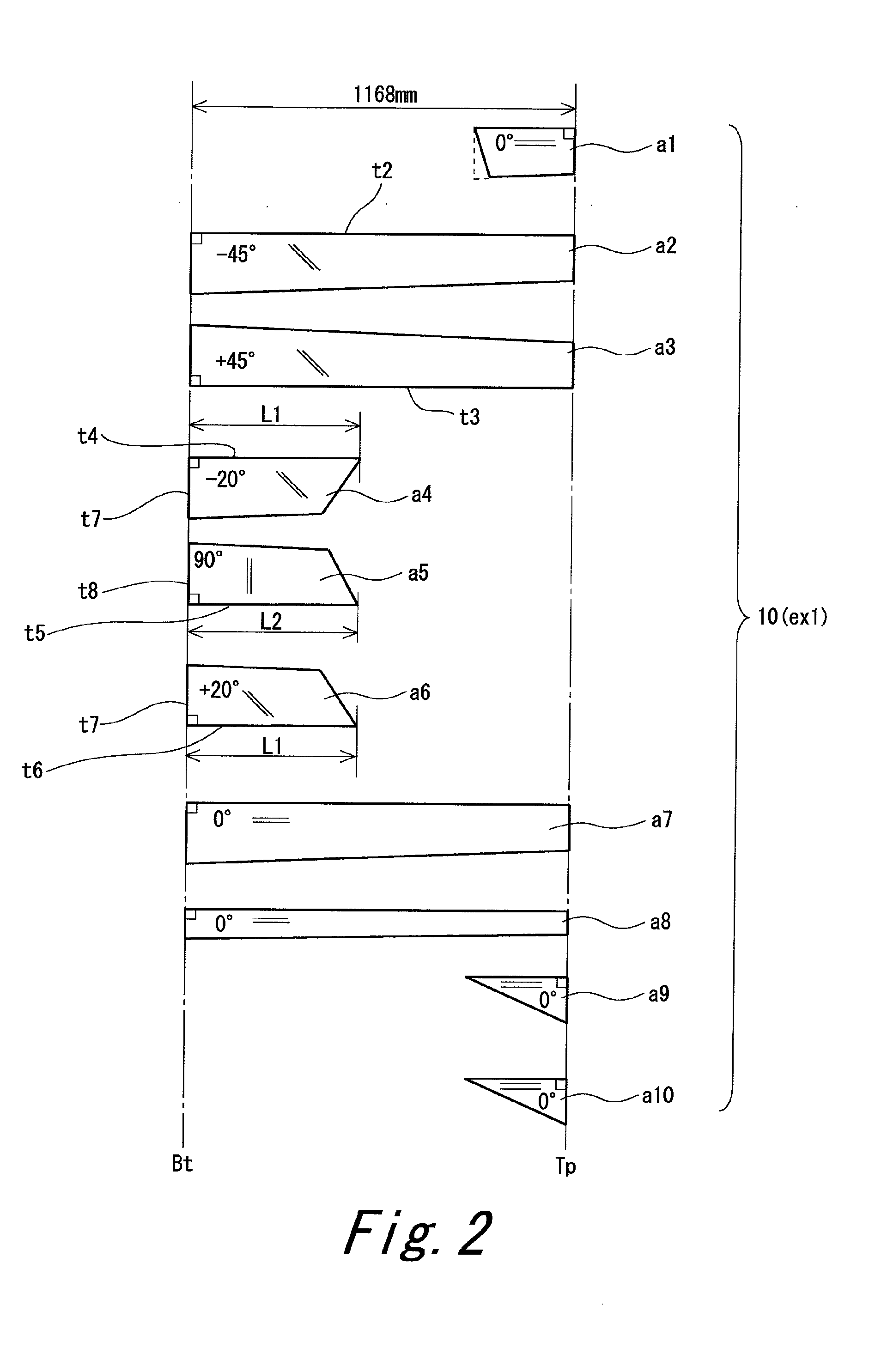

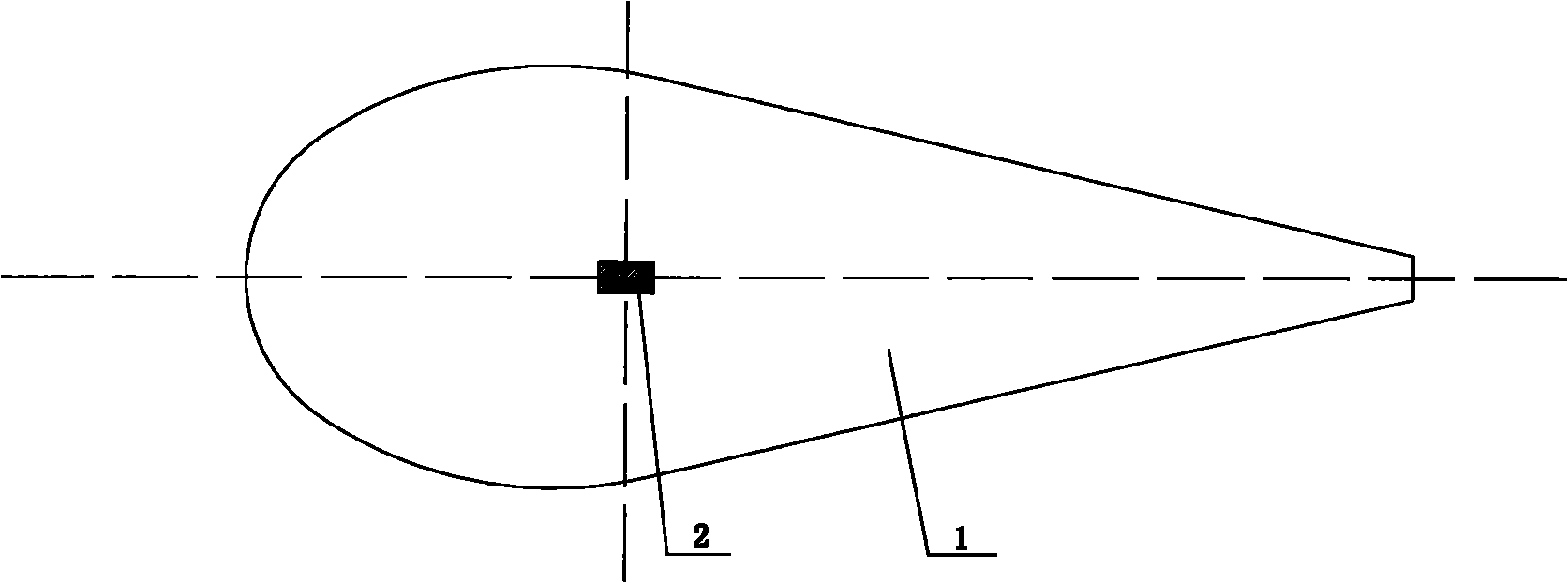

Golf club shaft

ActiveUS20120309558A1Excellent strengthLow flex pointGolf clubsRacket sportsPhysicsTorsional rigidity

A shaft 6 has a plurality of layers a1 to a10. The layers include a bias layer in which an absolute angle θa of a fiber to a shaft axis line is 10 degrees or greater and 70 degrees or less, and a hoop layer in which the angle θa is equal to or greater than 80 degrees. The layers include a full length layer disposed all over in an axis direction of the shaft, and a partial layer partially disposed in the axis direction of the shaft. The partial layer includes back end reinforcing bias layers a4 and a6, and a backend reinforcing hoop layer a5. In the shaft 6, a torsional rigidity value GIt at a point separated by 300 mm from a butt end is 3.5×106 (kgf·mm2 / deg) or greater and 5.0×106 (kgf·me / deg) or less.

Owner:SUMITOMO RUBBER IND LTD

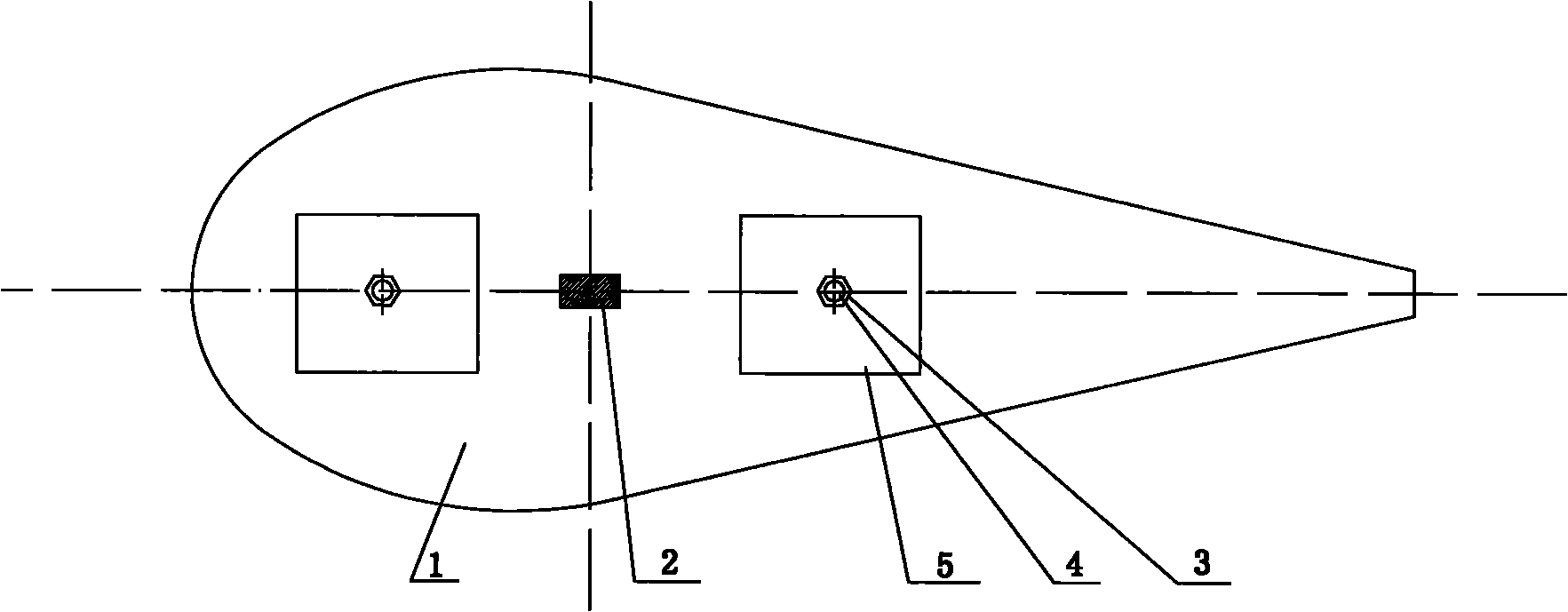

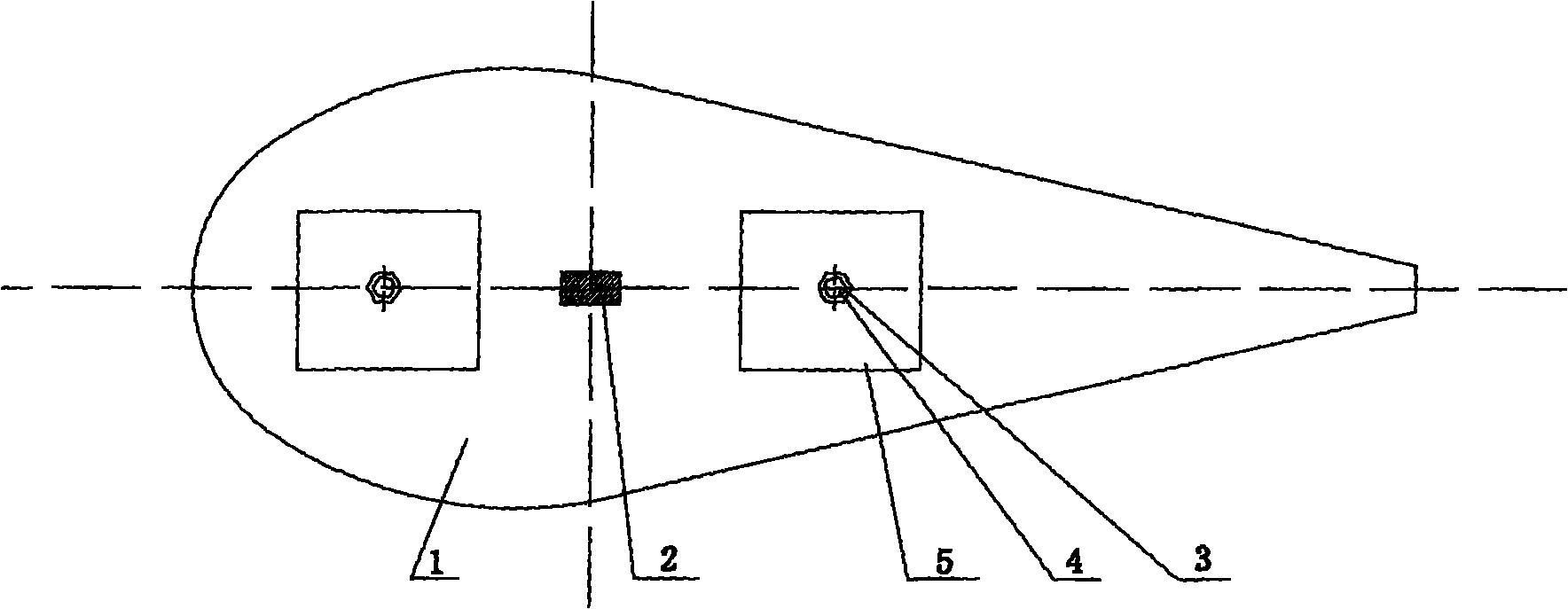

Stiffening rib of flight vehicle aerofoil experimental model

The invention relates to a stiffening rib of a flight vehicle aerofoil experimental model, wherein the original stiffening rib of the flight vehicle aerofoil experimental model, made of laminate plate material is replaced by the stiffening rib made of metal material. Steel material or aluminum material and the corresponding thickness can be selected according to the weight ratio of balance weightto total weight for the stiffening rib of the invention. The stiffening rib of a flight vehicle aerofoil low speed wind tunnel experimental model is provided with two through-holes, wherein a screw rod penetrates through the through-holes of the stiffening rib and a balance weight block, and nuts are used to lock and fix the massive balance weight block. The stiffening rib of the flight vehicle aerofoil experimental model can bear balance weight accounting for more than 50% of total weight, effectively reduce the unsafe factor when the massive balance weight block is fixed and avoid that the flight vehicle aerofoil experimental model is damaged in the wind tunnel experiment; and the stiffening rib has simple structure, high safety, reliable performance, true and accurate experimental result, low cost, high practicability and great use value.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

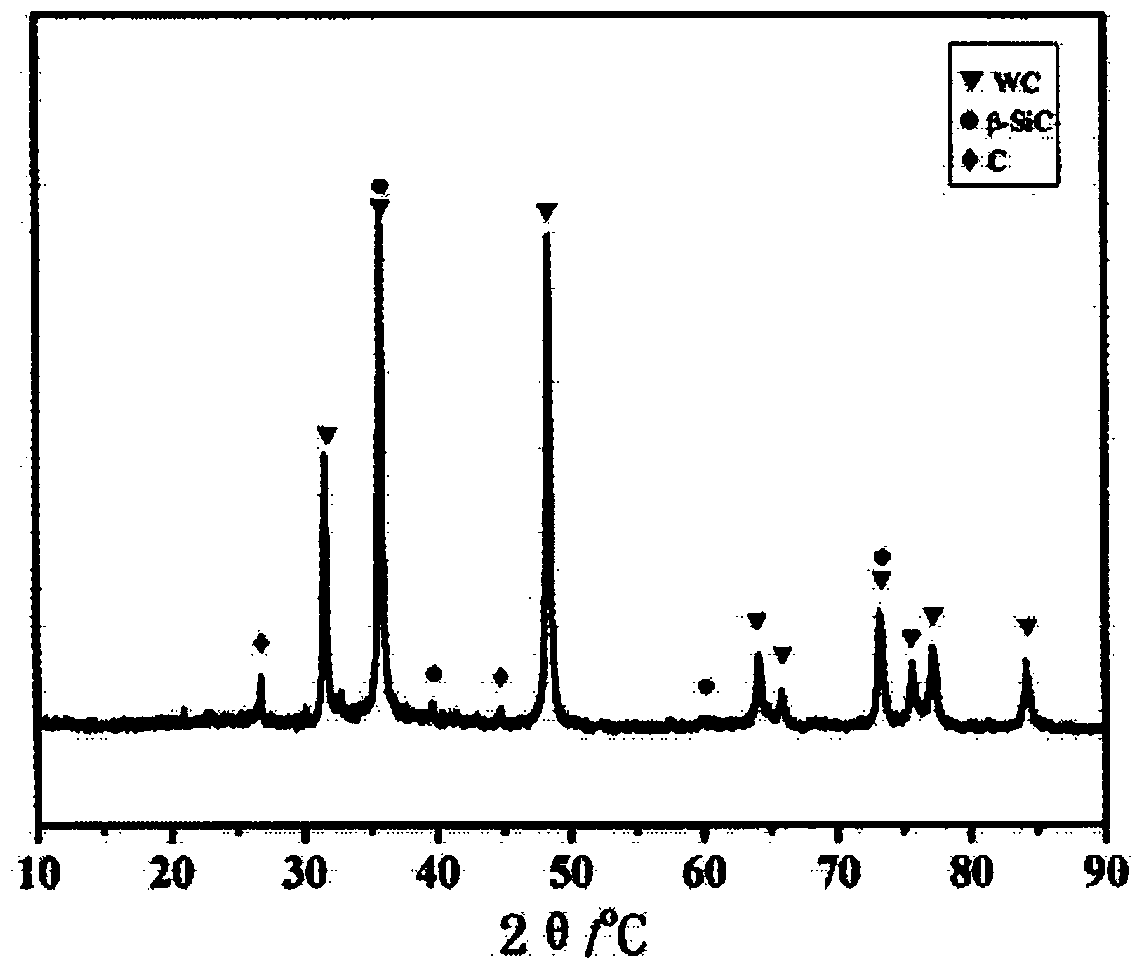

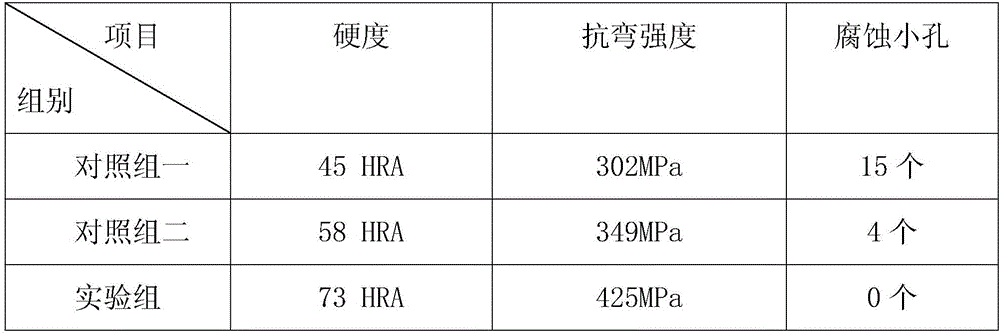

High-strength and high-toughness silicon carbide ceramic bearing plate, manufacturing method and application thereof

The invention discloses a high-strength and high-toughness silicon carbide ceramic bearing plate, a manufacturing method and application thereof. The silicon carbide ceramic bearing plate is preparedfrom the following materials in parts by mass: 70-95 parts of silicon carbide, 2-10 parts of silicon carbide whiskers, 1 to 15 parts of tungsten carbide, 0.5 to 5 parts of boron carbide, 1 to 10 partsof a binder and 0.5 to 10 parts of a lubricant. The manufacturing method comprises burdening, mixing, pulping, spray drying, isostatic pressing, sintering and finish machining. The silicon carbide ceramic bearing plate is applied to the assembly of chemical-mechanical polishing devices. According to the silicon carbide ceramic bearing plate made by the manufacturing method, the strength and toughness are greatly superior to a common corundum ceramic bearing plate at present; a ceramic bearing plate with the same size can be reduced by 1 / 3 in thickness; the ceramic bearing plate is applied tothe chemical-mechanical polishing devices, the stability in the polishing process is greatly improved, the reliability in the operation process is greatly increased, the service life of the ceramic bearing plate is greatly prolonged, and the process manufacturing cost is reduced.

Owner:NANTONG SANZER PRECISION CERAMICS CO LTD

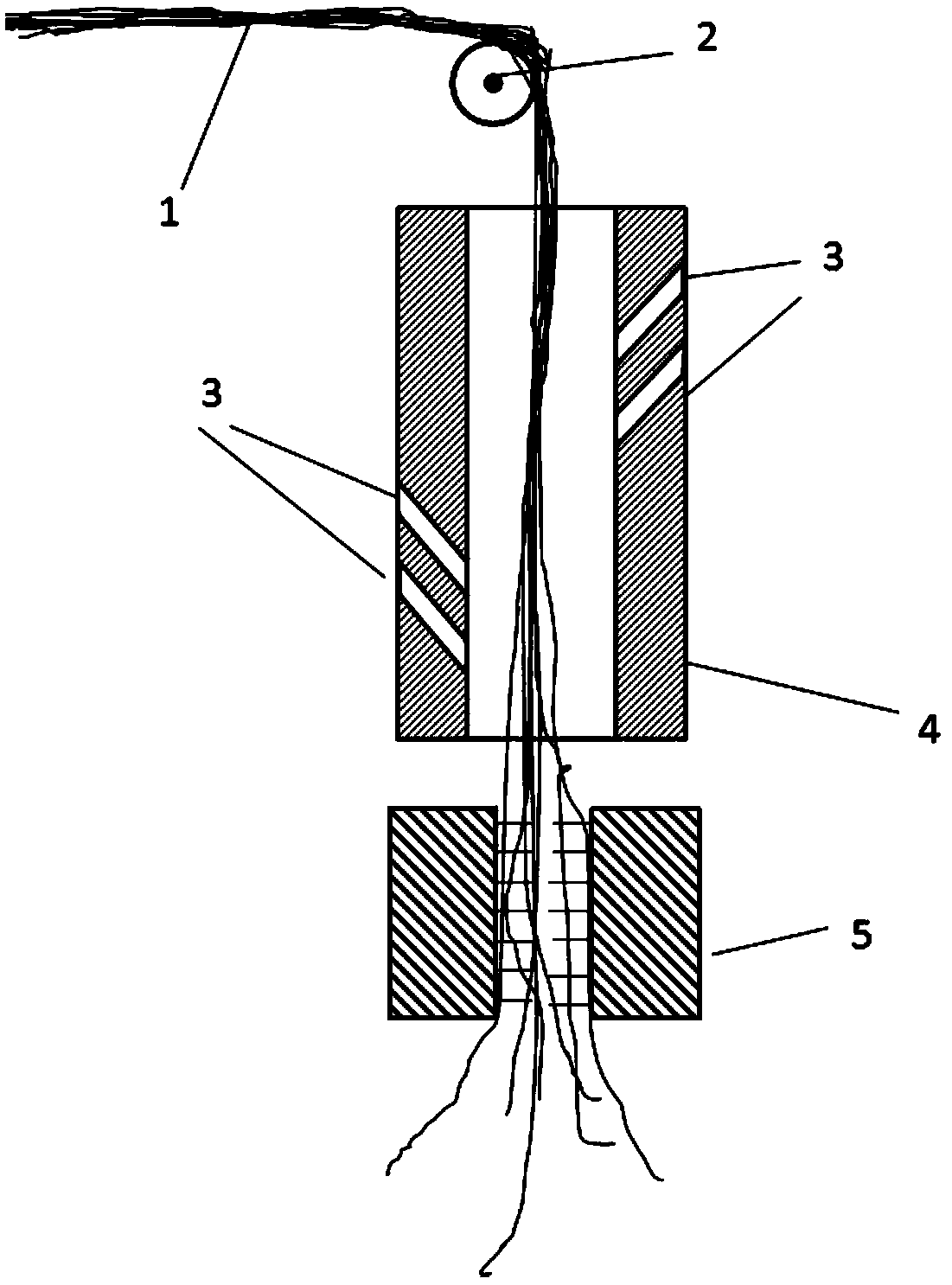

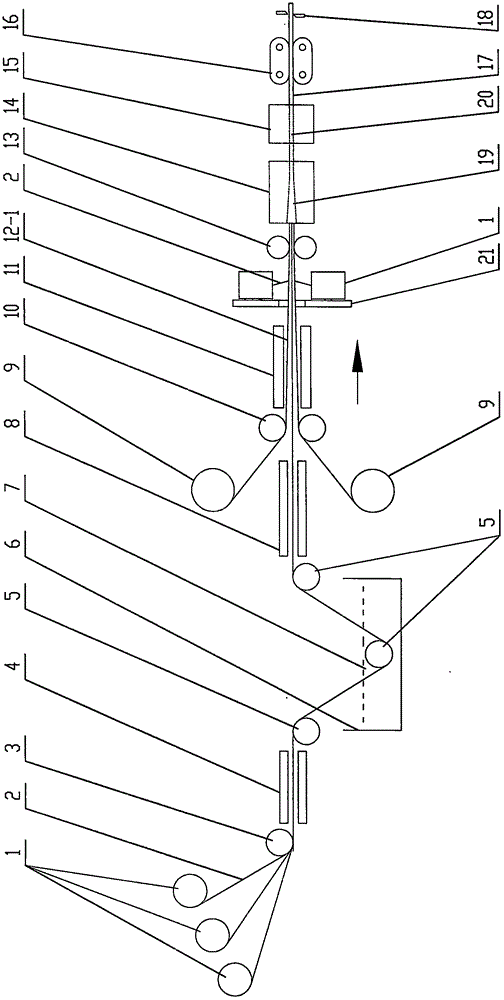

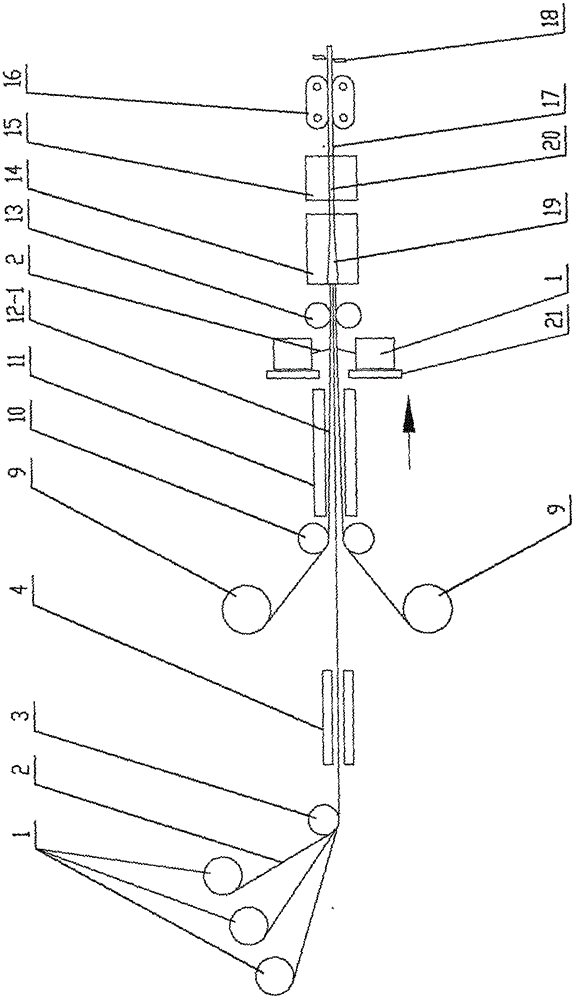

Glass fiber plate or profile or pipe and forming device

The invention discloses a glass fiber plate or profile or pipe and a forming device. The surfaces of glass fiber filaments are sequentially wrapped by surface treating agents and thermoplastic resin. The glass fiber filaments are arranged in the length direction of the plate or profile or pipe and are evenly arranged or arranged in multiple bundles in the above section. The forming device sequentially comprises multiple glass filament unreeling devices, a second heating device, multiple film unreeling devices, a forming die, a cooling sizing device and a traction device. Multiple reels A are arranged on first unreeling discs correspondingly for unreeling. A first heating device comprises a first heater used for heating the glass fiber filaments and a first temperature control device. A steeping device comprises a steeping tank, multiple second guide rollers and a fourth temperature control device. A heating wire or strip-shaped film wraps the glass fiber filaments to form a blank through pulling and extruding. The thermoplastic resin and glass fiber are compounded, forming is easy, the device manufacturing cost is reduced, the operation difficulty is lowered, cost is saved, and the production efficiency is increased by 30% or higher.

Owner:DALIAN HUAGONG INNOVATION TECH

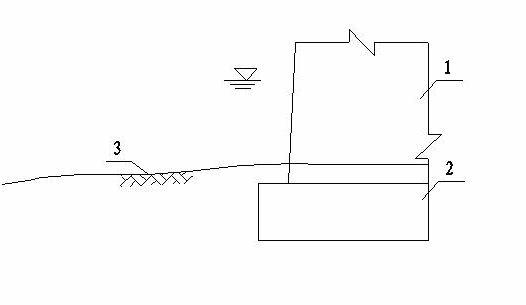

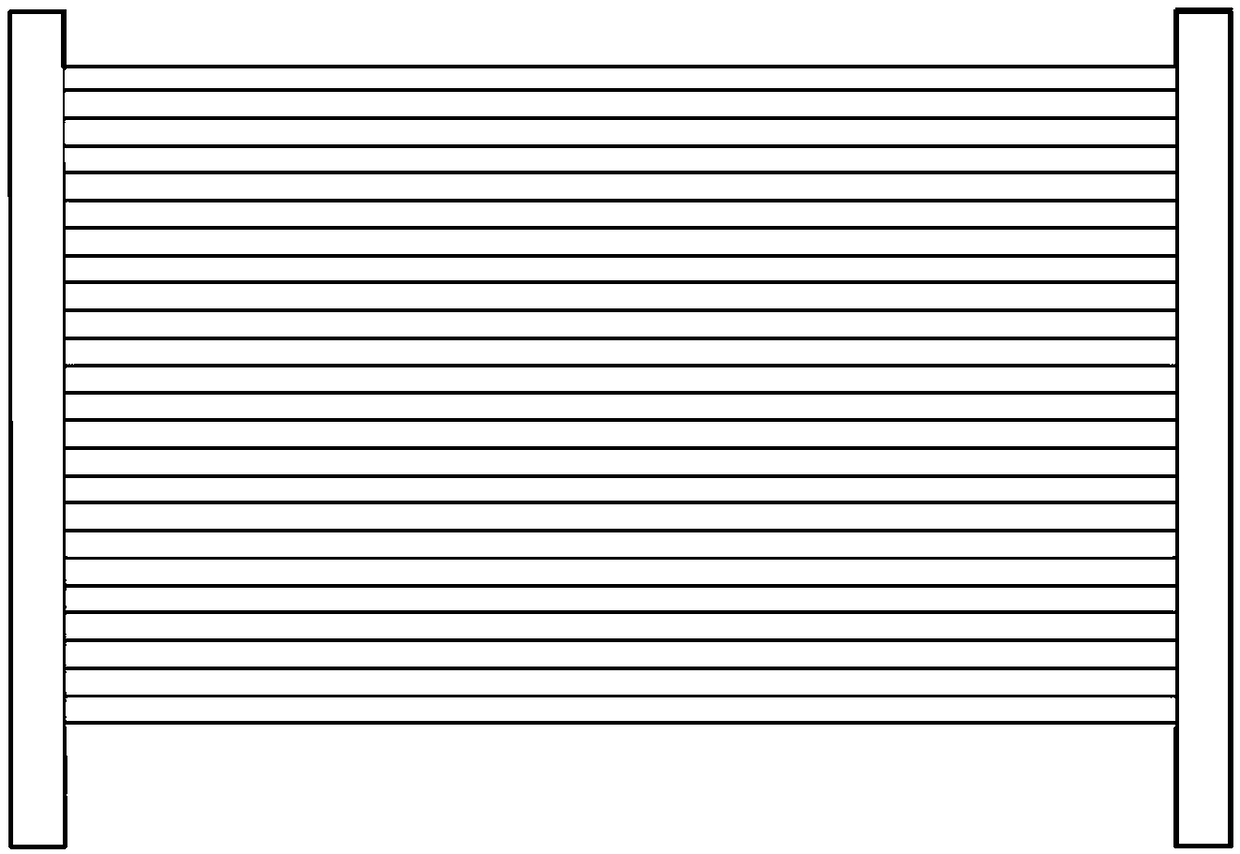

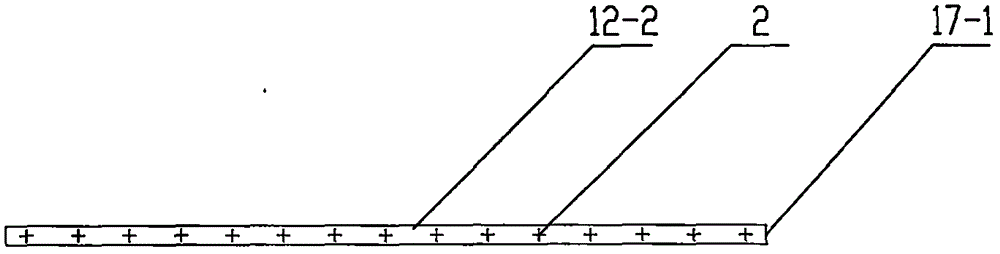

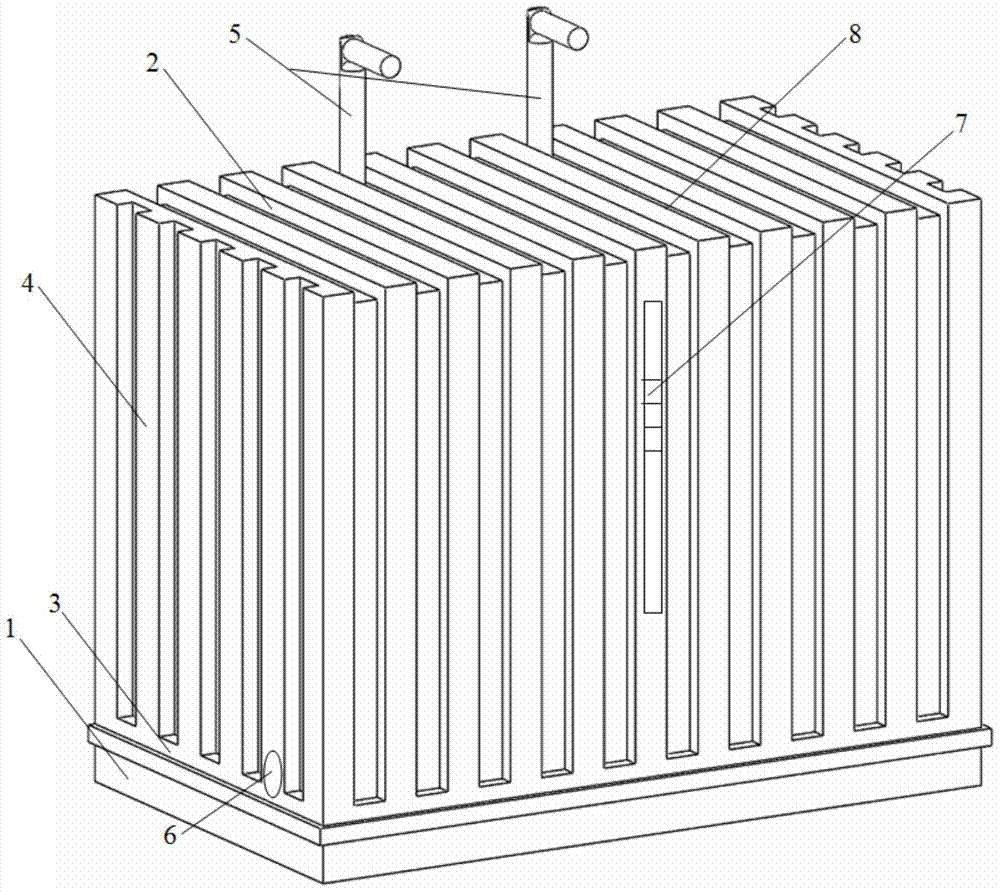

Ribbed plate type stainless steel water tank and production technology thereof

The invention discloses a ribbed plate type stainless steel water tank and a production technology thereof. The ribbed plate type stainless steel water tank comprises a water tank body and a fixing support arranged at the bottom of the water tank body. The water tank body comprises a tank top, a tank bottom and side plates. The tank top and the tank bottom are welded to the side plates. Ventilation devices are further arranged on the tank top, a drain hole is further formed in the tank bottom, and water level observation windows are further arranged on the side plates. The ribbed plate type stainless steel water tank is characterized in that the water tank body is made of SUS304 and 316 food grade stainless steel plates, and reinforcing ribs which are evenly distributed are arranged on the upper portion of the water tank body. The production technology of the ribbed plate type stainless steel water tank comprises the steps of plate shearing, angle and hole punching, rib pressing, edge folding and assembling. The ribbed plate type stainless steel water tank is made of corrugated plates and has excellent strength. No transverse welded joint is arranged on the side wall, and cleaning is convenient. The ribbed plate type stainless steel water tank is made of the SUS304 and 316 food grade stainless steel plates, so that high rotproofness is achieved. The ribbed plate type stainless steel water tank is suitable for being combined on the field, good in sealing property and capable of ensuring that water cannot be polluted for the second time. The ribbed plate type stainless steel water tank is widely applied to hotels, schools, industrial and mining enterprises, public institutions, residential buildings and office buildings and is an ideal product which is used as water storage facilities for public life water, fire protection water and industrial water.

Owner:ANHUI SHUNYU WATER AFFAIRS CO LTD

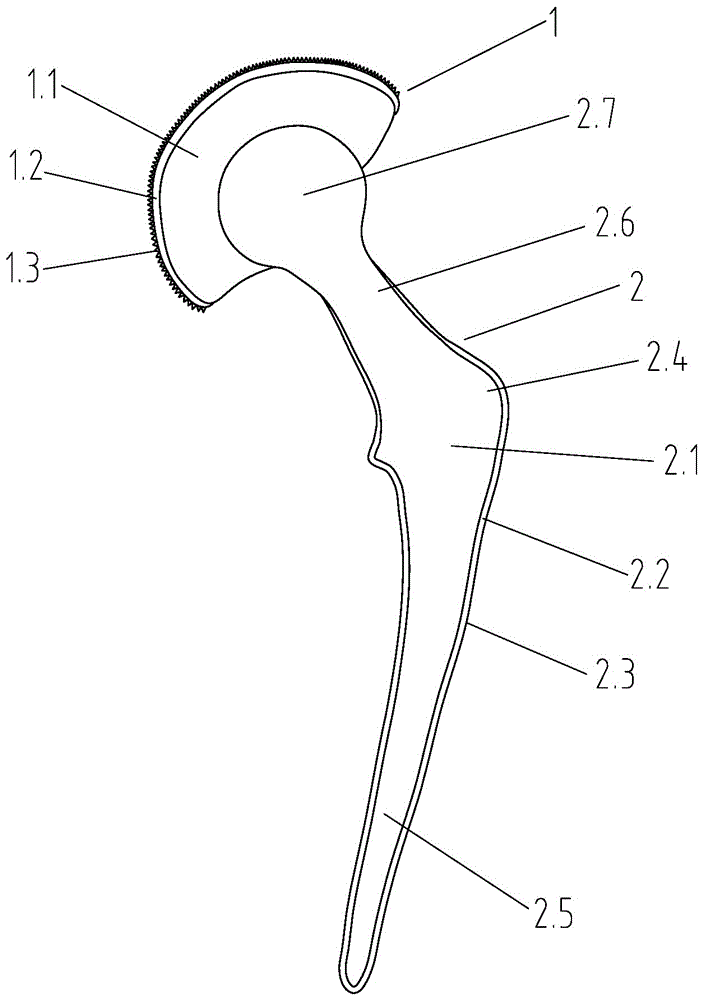

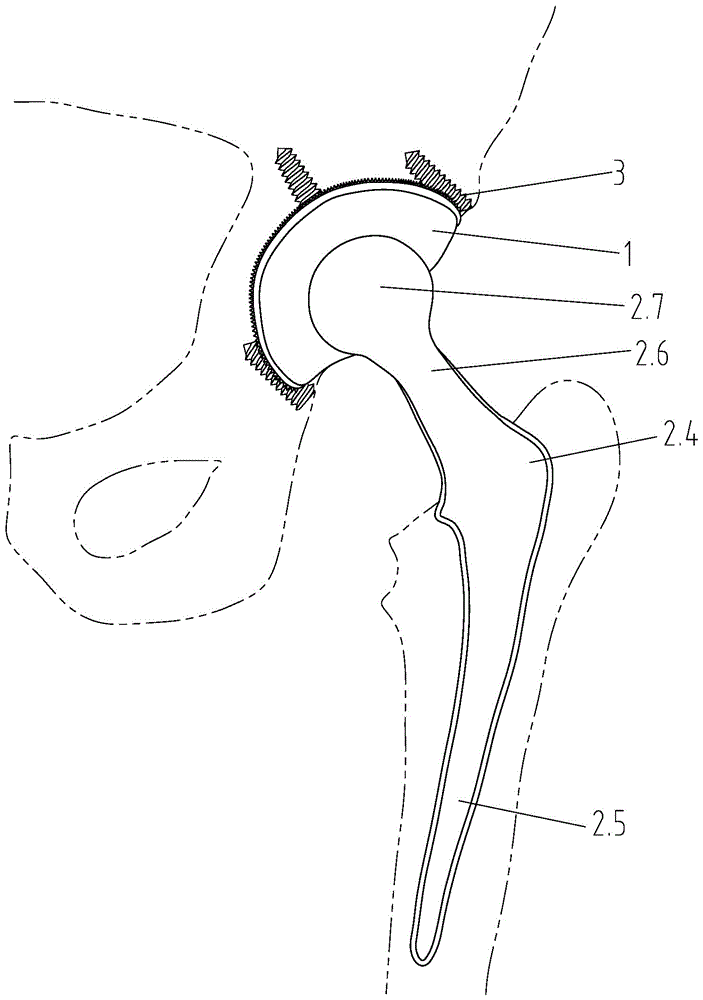

High-toughness super-wear-resistance artificial bone for repairing bone defects and preparation method thereof

ActiveCN105816917AAdequate mechanical propertiesGood biocompatibilityCoatingsProsthesisFiberCarbon fibers

The invention provides a high-toughness super-wear-resistance artificial bone for repairing bone defects. The artificial bone has a structure of inner and outer layers, wherein the inner layer is an artificial bone rack made of PEEK resin, and is compounded with barium glass fibers and calcium carbonate whiskers; the outer layer the outer layer of the artificial bone rack is coated with a hardened compact layer which is sintered by bio-active glass ceramics; and a porous layer formed by bioactive glass ceramics is attached to the surface of the compact layer. The bonding performing of bioactive glass ceramics with bone is higher than that of hydroxyapatite, and the bonding performance of PEEK resin with bioactive glass ceramics is better than that of carbon fibers with hydroxyapatite, so that the artificial bone has enough mechanical performance and good biocompatibility, and has the mechanical performance, biocompatibility and bone bonding strength is superior than those of a conventional artificial bone product.

Owner:NANNING YUEYANG TECH

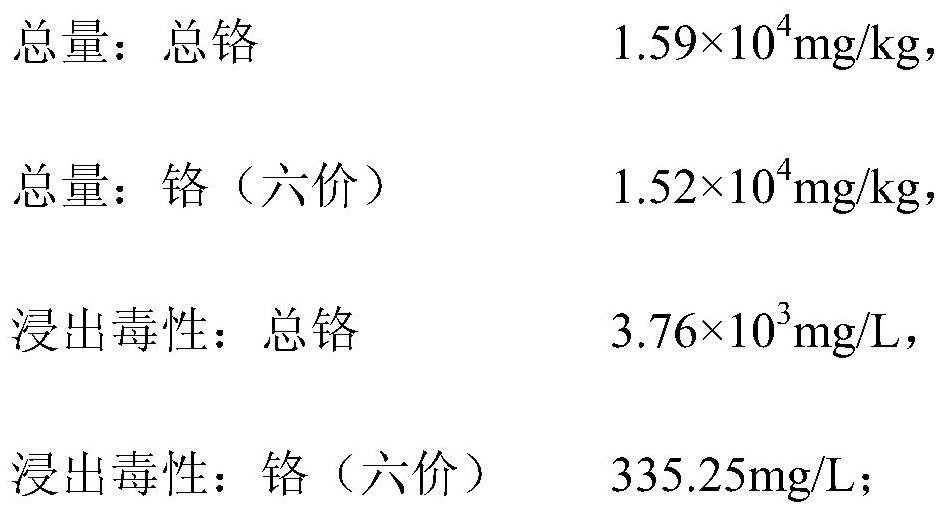

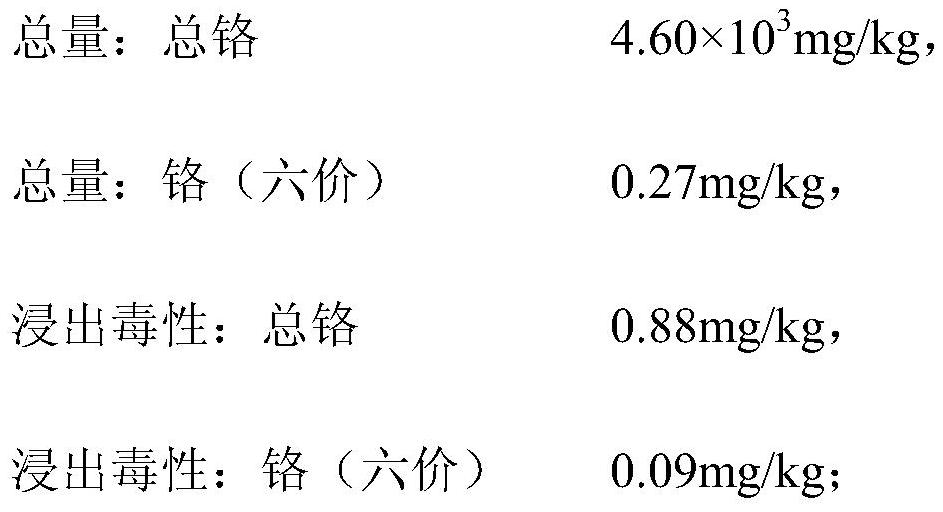

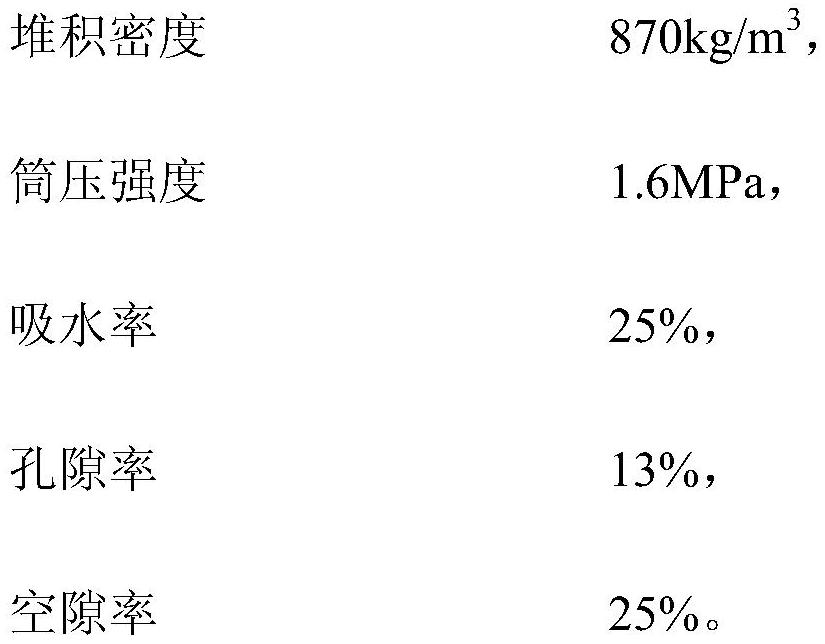

Resource utilization method of hexavalent chromium contaminated soil

ActiveCN111675549ASolve pollutionImprove performanceSievingScreeningChromium contaminationSoil treatment

The invention relates to the technical field of soil treatment, in particular to a resource utilization method of hexavalent chromium contaminated soil. The method comprises the following steps: (1) physically crushing and screening hexavalent chromium contaminated soil, (2) physically crushing and screening blast furnace slag, (3) uniformly stirring and mixing water, the screened hexavalent chromium contaminated soil and blast furnace slag, (4) granulating the mixture to form a ceramsite raw material, (5) drying and roasting the ceramsite raw material, and (6) cooling the roasted ceramsite toobtain a ceramsite product taking hexavalent chromium contaminated soil and blast furnace slag as raw materials. According to the method, the remediation problem of the remediated soil is solved in aresource utilization mode, resources such as raw coal do not need to be purchased additionally, the purpose of treating waste with waste is achieved, and the disposal cost is reduced.

Owner:山东洛尔环保科技有限公司

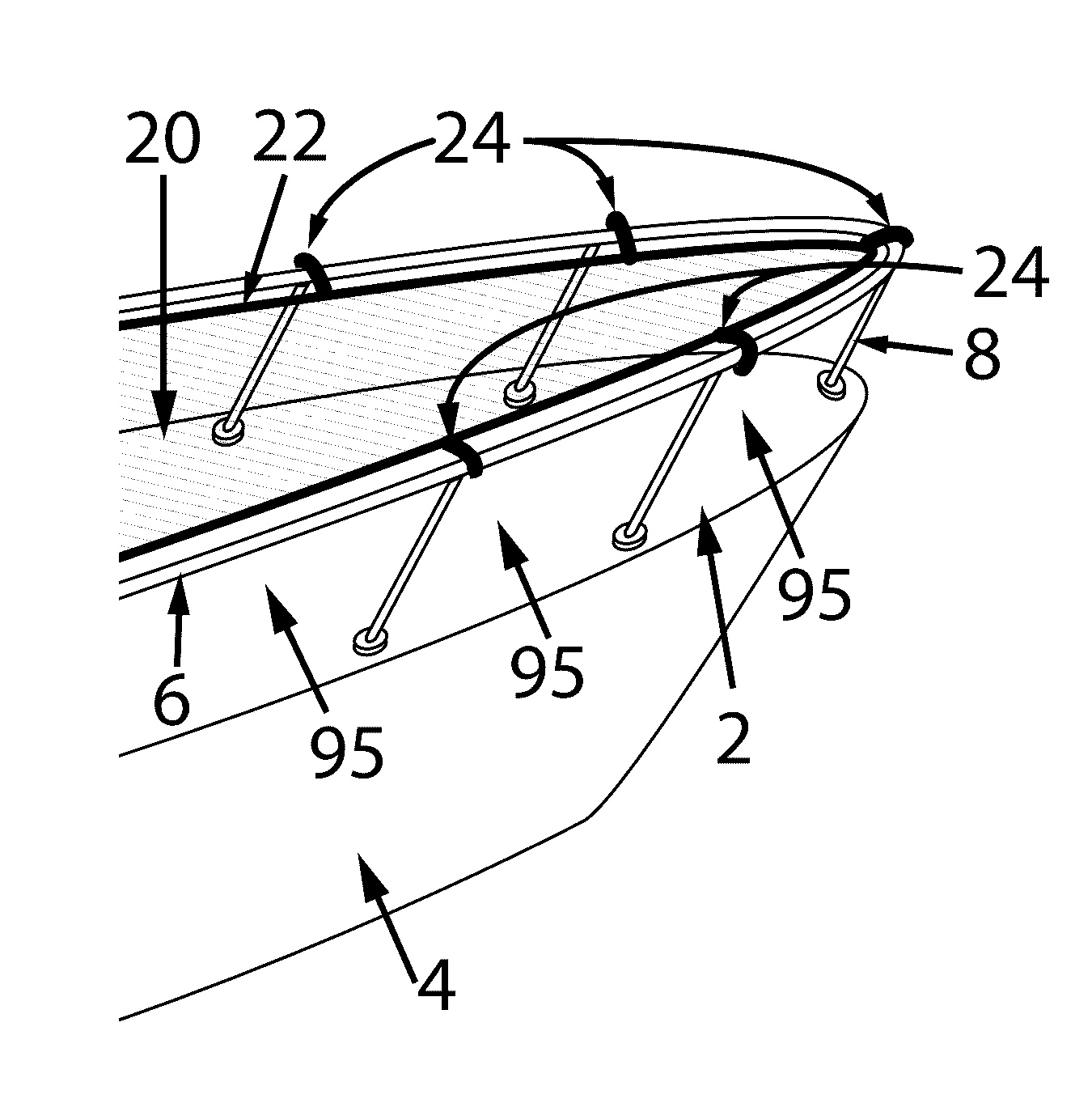

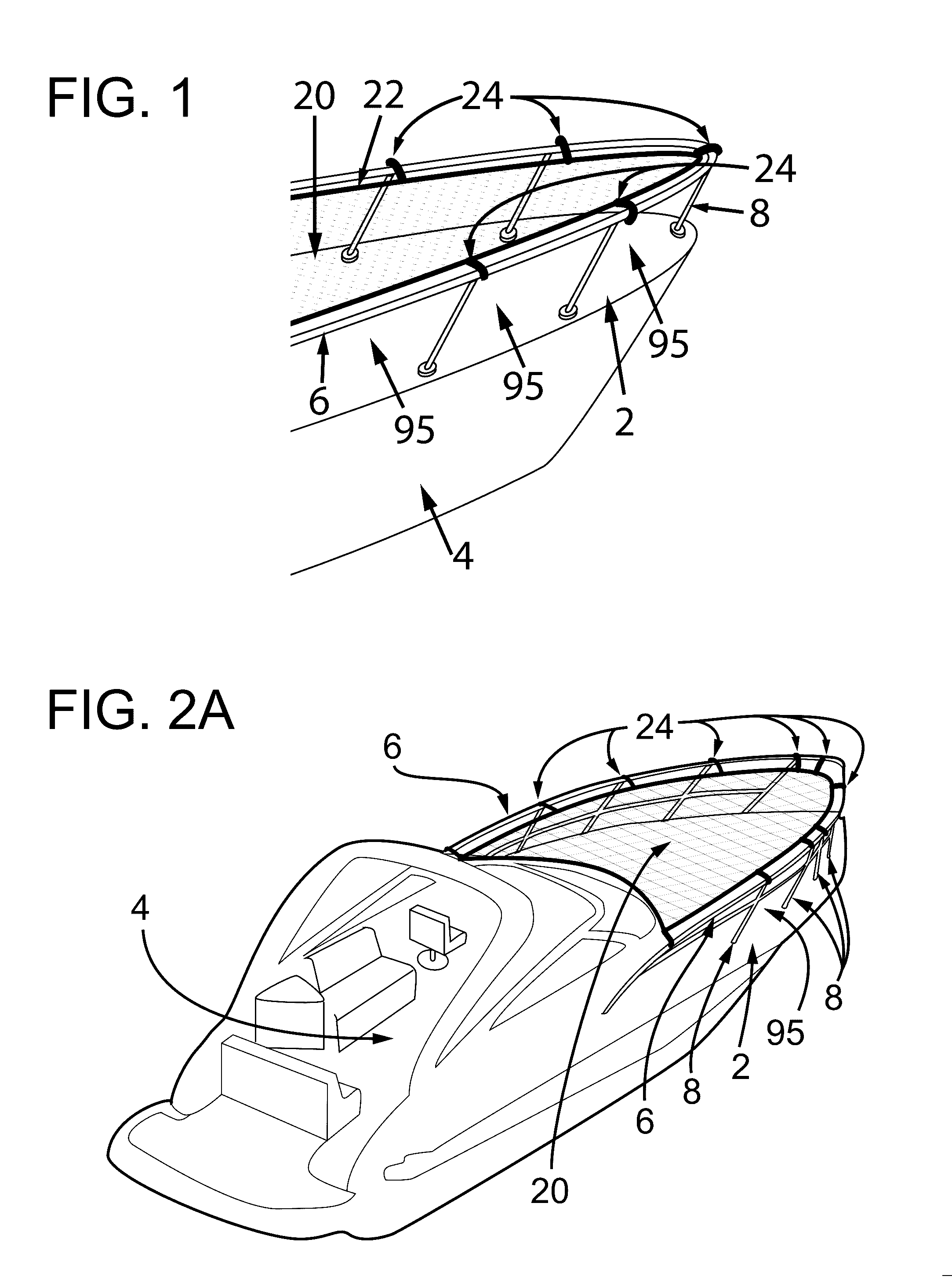

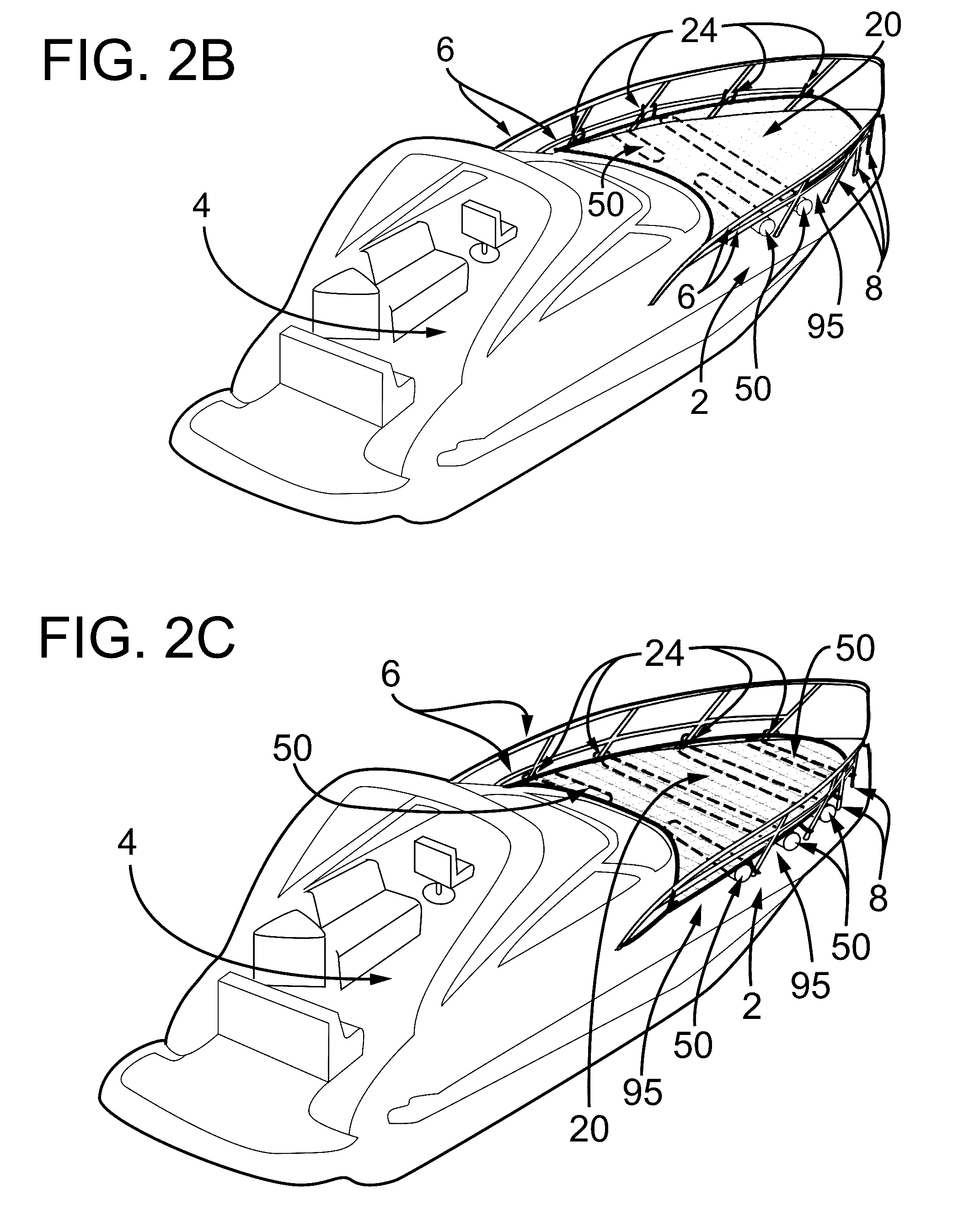

Boat Bow Shade Cover

The shade cover assembly includes a textile contoured to the shape and size of the bow of the vessel to which applied, tautly stretched across above the bow secured by a plurality of quick release fastening devices along the peripheral reinforced edges to the port and starboard the railing / stanchion system on the bow. An insulating air space between the shade cover and the bow surface is present at all times which may require spacers to maintain. For boats with through the windshield access to the bow a quick release fastening system is featured at the aft edge of the shade cover.

Owner:DUPLAIN KEVIN RICHARD

Anti-corrosion scalpel handle and preparation method thereof

The invention discloses an anti-corrosion scalpel handle and a preparation method thereof. The anti-corrosion scalpel handle comprises the raw materials of, by weight, 100-102 parts of aluminum, 110-120 parts of magnesium, 60-62 parts of silver, 2-4 parts of manganese, 1-3 parts of cerium, 1-3 parts of thorium, 2-4 parts of zirconium silicate, 4-6 parts of chromic oxide, 1-3 parts of yttrium oxide, 4-6 parts of tungsten carbide, 6-8 parts of cubic boron nitride, 1-3 parts of tantalum carbide, 1-3 parts of titanium sponge, 1-3 parts of magnesium chloride, 2-4 parts of magnesium carbonate, 1-3 parts of manganese chloride, 1-3 parts of silver chloride, 1-3 parts of carbon hexachloride, 2-4 parts of tungsten hexachloride and 2-4 parts of sodium fluosilicate. The anti-corrosion scalpel handle is high in hardness and good in corrosion resistance.

Owner:张霞

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com