Resource utilization method of hexavalent chromium contaminated soil

A technology for polluted soil and hexavalent chromium, which is applied in the field of resource utilization of hexavalent chromium polluted soil, can solve problems such as soil yellowing, and achieve the effects of reducing treatment costs, high cylinder compressive strength and bulk density, and good integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for resource utilization of hexavalent chromium-contaminated soil, the method comprising:

[0029] (1) First use a jaw crusher to crush the hexavalent chromium-contaminated soil, then use a ball mill to grind to a size below 100 mesh, and then use a vibrating screener to sieve after grinding, and then grind the particles larger than 100 mesh;

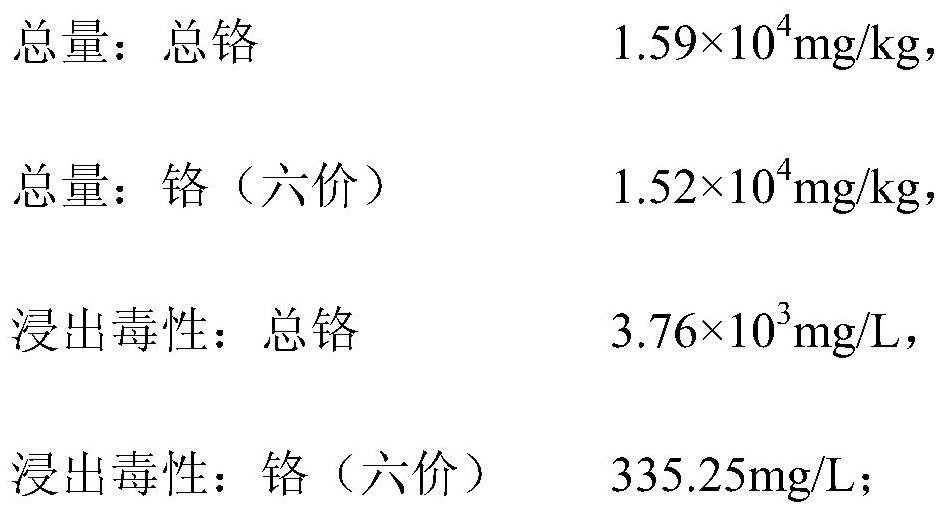

[0030] Among them, refer to USEPA3060A-1996 alkali digestion method of hexavalent chromium, USEPA7196A-1992 Cr in soil 6+ Analytical spectrophotometry, HJ766-2015 Inductively Coupled Plasma Mass Spectrometry for the Determination of Metal Elements in Solid Wastes, Diphenylcarbazide Spectrophotometry for the Determination of Hexavalent Chromium in GB / T15555.4-1995 Solid Wastes, HJ687 - Alkaline digestion flame atomic absorption spectrophotometry specified in 2014 for the determination of hexavalent chromium in solid waste, sulfuric acid and nitric acid method specified in HJ / T299-2007 Solid waste leaching toxicity leachin...

Embodiment 2

[0043] A method for resource utilization of hexavalent chromium-contaminated soil, the method comprising:

[0044] (1) First use a jaw crusher to crush the hexavalent chromium-contaminated soil, then use a ball mill to grind to a size below 100 mesh, and then use a vibrating screener to sieve after grinding, and then grind the particles larger than 100 mesh;

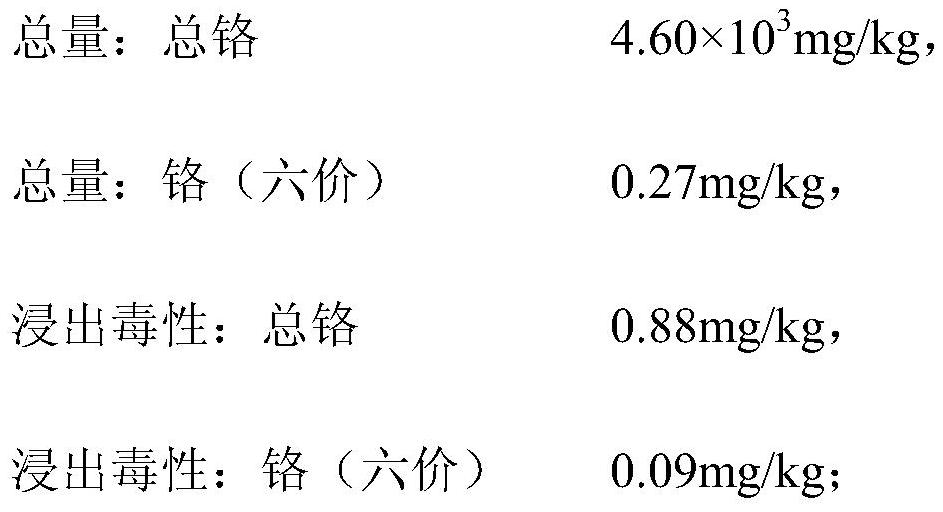

[0045] Wherein, the total chromium, hexavalent chromium and the leached total chromium and hexavalent chromium of polluted soil are detected, and the detection method is the same as in Example 1, and the detection results are as follows:

[0046]

[0047] (2) First use a jaw crusher to crush the blast furnace slag, then use a ball mill to grind to below 100 mesh, and then use a vibrating screener to sieve after grinding, and grind again for particles larger than 100 mesh;

[0048] Among them, the blast furnace slag is a by-product in the matte smelting process, and the blast furnace slag includes FeO, CaO, MgO, C, SiO...

Embodiment 3

[0059] A method for resource utilization of hexavalent chromium-contaminated soil, the method comprising:

[0060] (1) First use a jaw crusher to crush the hexavalent chromium-contaminated soil, then use a ball mill to grind to a size below 100 mesh, and then use a vibrating screener to sieve after grinding, and then grind the particles larger than 100 mesh;

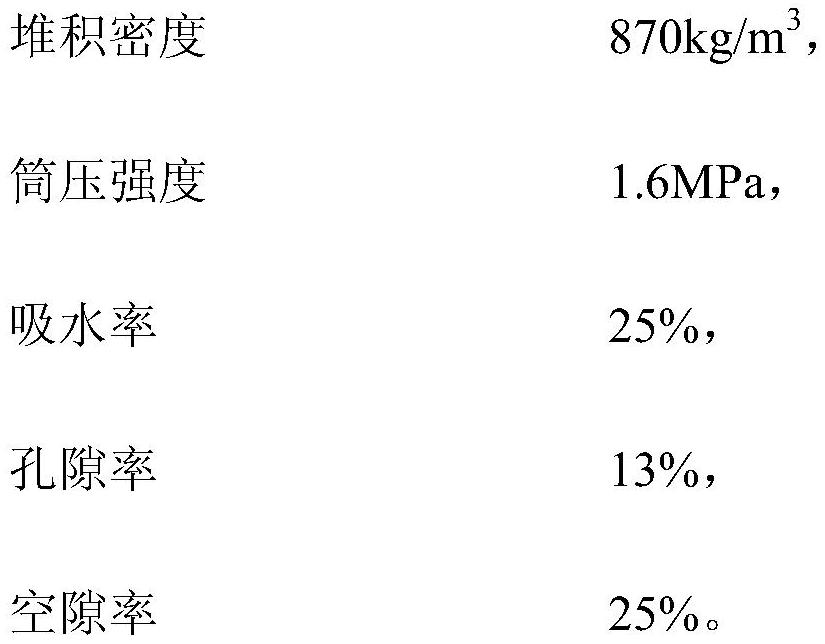

[0061] Wherein, the total chromium, hexavalent chromium and the leached total chromium and hexavalent chromium of polluted soil are detected, and the detection method is the same as in Example 1, and the detection results are as follows:

[0062]

[0063] (2) First use a jaw crusher to crush the blast furnace slag, then use a ball mill to grind to below 100 mesh, and then use a vibrating screener to sieve after grinding, and grind again for particles larger than 100 mesh;

[0064] Among them, the blast furnace slag is a by-product in the matte smelting process, and the blast furnace slag includes FeO, CaO, MgO, C, SiO...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com