Patents

Literature

114results about How to "Solve the whereabouts problem" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Organic fertilizer for killing underground injurious insect and preparation method thereof

InactiveCN101781153AImprove aggregate structurePromote growthBio-organic fraction processingOrganic fertiliser preparationFecesLivestock manure

The invention belongs to organic fertilizer, and in particular relates to organic fertilizer for killing underground injurious insects and a preparation method thereof. The organic fertilizer comprises the following components in part by weight: 1000 parts of tobacco stalk, 25 to 30 parts of dry livestock manure, 5 to 10 parts of urea and 3 to 5 parts of solid high-efficient microorganism zymogeneous bacteria. The preparation method comprises the following steps that: the tobacco stalk is smashed; the livestock manure is dried and dehydrated; the urea is added to be uniformly mixed; the zymogeneous bacteria is inoculated; the moisture and the pH value are adjusted, fermentation stocks are piled up, and black plastic film covers the fermentation stocks, so the fermentation stocks are undertaken the anaerobic fermentation; after the temperature is increased, the stocks are turned for a plurality of times until the materials are fermented and matured and the size is reduced to two thirds of that of the original stocks; and the fermented stocks are naturally ventilated and dried and are bagged to store. The organic fertilizer has the advantages that the fertilizer efficiency is high, the underground injurious insects can be killed, the content of the organic colloid of the soil is increased after the application of the fertilizer, the fertilizer and water maintaining capacity of the soil is improved, the period of validity of the fertilizer is prolonged, and the probiotics in the soil can be compensated.

Owner:王德生

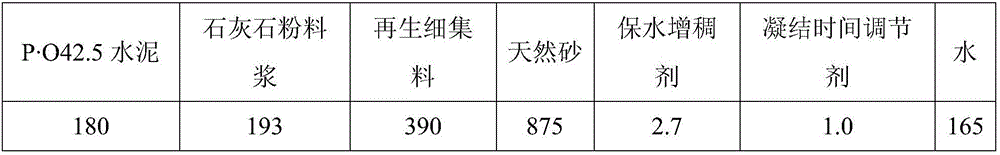

Recycled wet-mixed mortar and preparation method thereof

ActiveCN105948653AGreat social significanceImprove the state of the mixtureSolid waste managementSetting timeMoisture

The invention discloses recycled wet-mixed mortar and a preparation method thereof. The recycled wet-mixed mortar is prepared from the components in parts by weight as follows: 180-260 parts of cement, 130-240 parts of limestone flour slurry with the moisture content being 30%-60%, 380-650 parts of recycled fine aggregate, 650-900 parts of natural medium sand, 2.7-3.9 parts of a water-retention thickener, 0-3.0 parts of a setting time regulator and 120-210 parts of water. The recycled fine aggregate produced with waste concrete test cubes through crushing is applied to wet-mixed mortar, a technical method of pre-stirring of the recycled fine aggregate and stone powder slurry as well as utilization of a special additive is used, the problems of high water absorptivity of the recycled fine aggregate, and quick workability loss, reduced strength and the like are solved; not only is the problem of treatment of waste concrete test cubes solved, but also higher economic benefit is produced.

Owner:XIAMEN TIANRUN JINLONG BUILDING MATERIAL

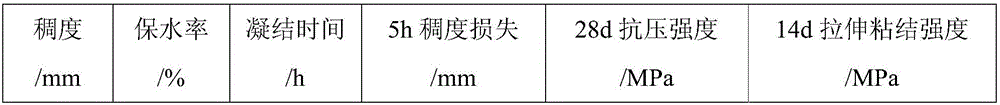

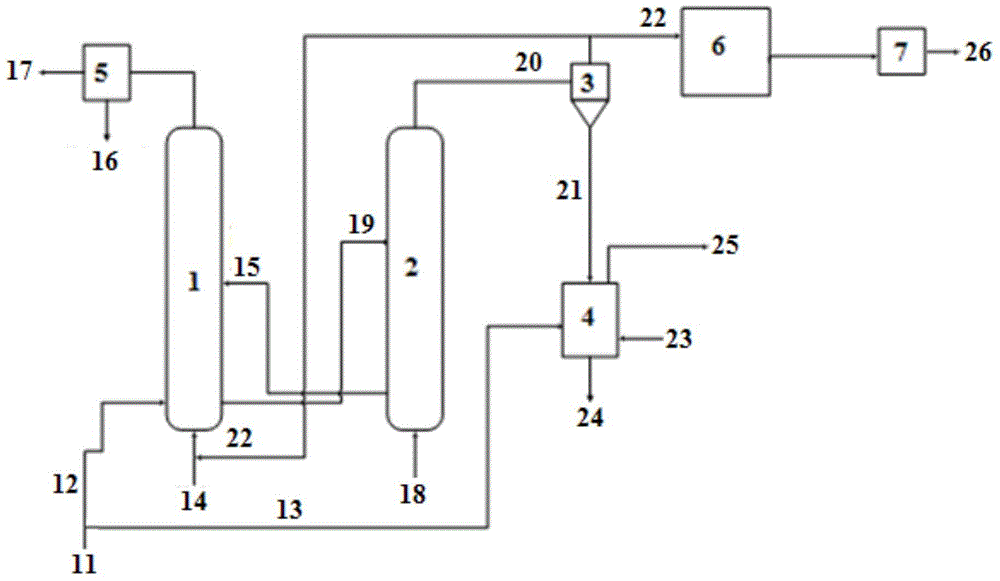

Heavy hydrocarbon removing process and device of natural gas

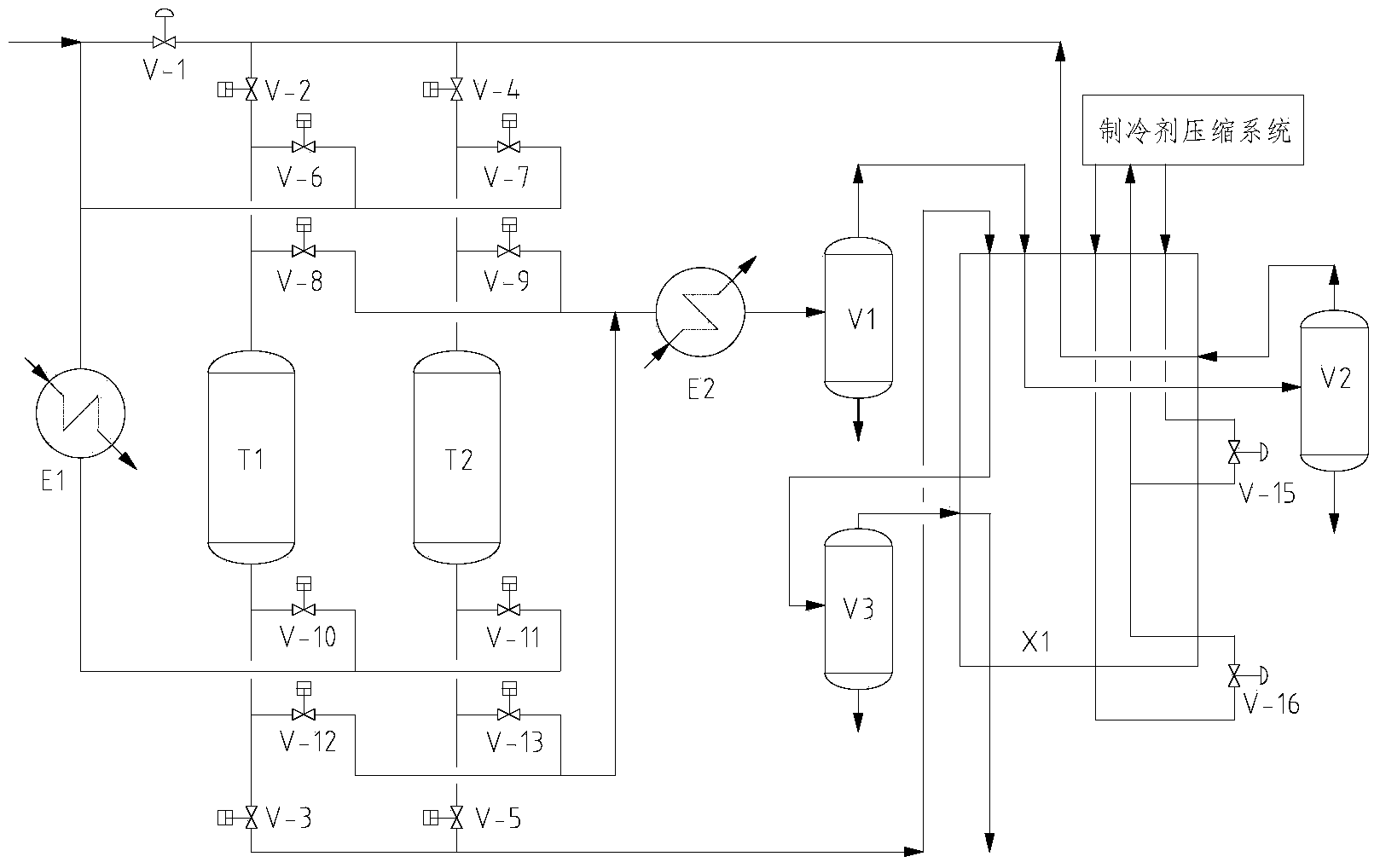

The invention relates to a heavy hydrocarbon removing process of natural gas, i.e. a heavy hydrocarbon removing process by adopting the combination of an adsorbent and low-temperature separation. According to the heavy hydrocarbon removing process disclosed by the invention, most heavy hydrocarbons in the natural gas are removed by an adsorbent bed layer of a heavy hydrocarbon removing tower, then the natural gas enters a cold box for further low-temperature separation to remove residual heavy hydrocarbons, and C6 and C6<+> heavy hydrocarbon components in the natural gas after treating are removed until the soluble degree of LNG (Liquefied Natural Gas); regeneration gas used for regeneration of the heavy hydrocarbon removing tower is taken from process gas, and is regenerated by sequentially pre-cooling, partial heavy hydrocarbon separation and low-temperature heavy hydrocarbon separation in the cold box, so that excessive heavy hydrocarbons are not carried when the regeneration gas is returned to the process gas, the load of the heavy hydrocarbon removing tower and the device investment cost are lowered, and the source and destination problems of the regeneration gas are solved. In addition, with the adoption of the heavy hydrocarbon removing process, the purification effect is good, and an operation index of each part is clearer and is easily controlled. The invention also relates to a device used by the process.

Owner:XINDI ENERGY ENG TECH

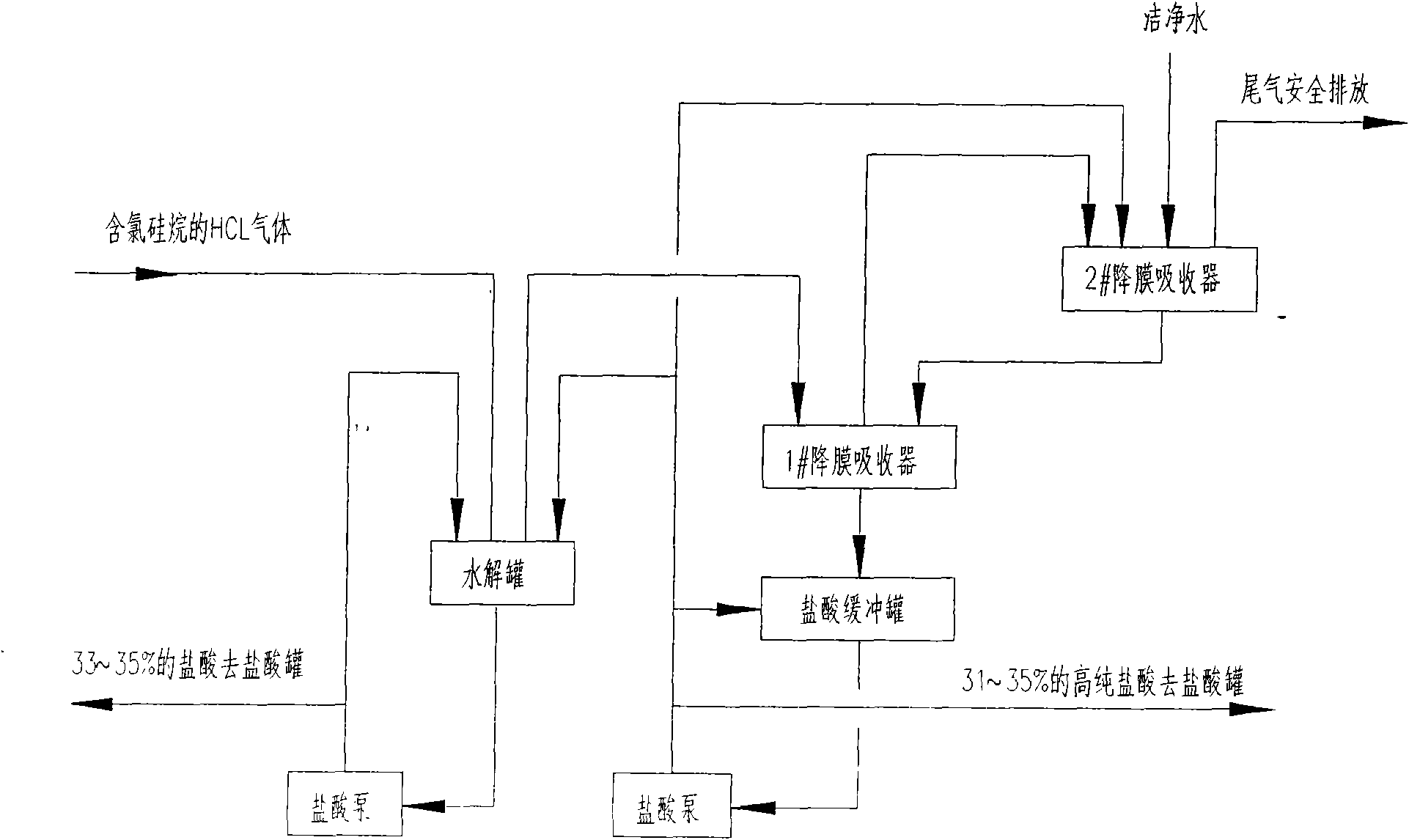

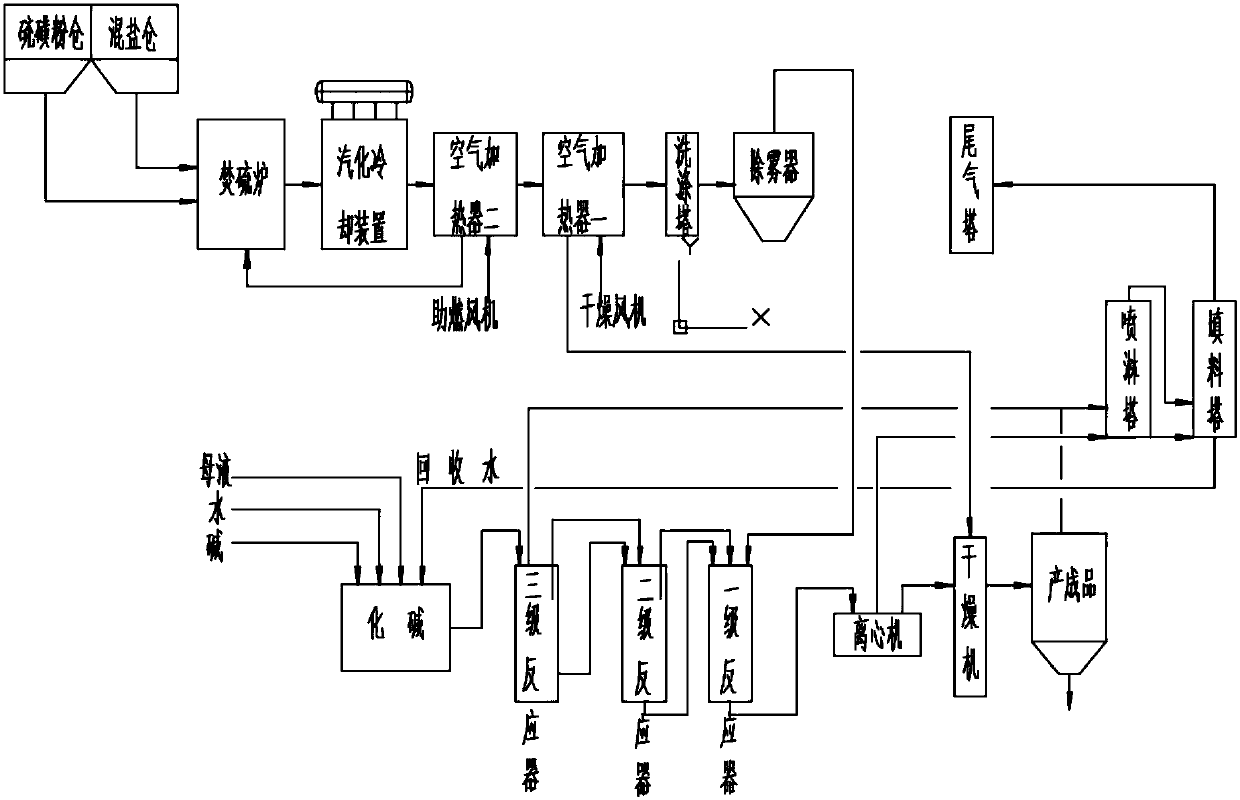

Method for producing high-purity concentrated hydrochloric acid by adopting hydrogen chloride gas containing chlorosilane

ActiveCN101628710AHigh purityImprove production stabilityChlorine/hydrogen-chloride purificationPhysical chemistryWater circulation

The invention discloses a method for producing high-purity concentrated hydrochloric acid by adopting hydrogen chloride gas containing chlorosilane, which comprises the following steps: injecting hydrogen chloride gas containing chlorosilane into a hydrolyzer, carrying out hydrolyzation reaction with water in concentrated hydrochloric acid in the hydrolyzer, removing chlorosilane in the gas, adopting water circulation to absorb hydrogen chloride in the gas in falling film absorbers after the gas passes through at least two serial falling film absorbers in sequence to obtain concentrate hydrochloric acid, and discharging tail gases after the hydrogen chloride is absorbed. By utilizing the method, the high-purity concentrated hydrochloric acid is produced by adopting hydrogen chloride gas containing chlorosilane, thus the problem that pure hydrochloric acid can not be obtained in the traditional method that water is directly used for absorbing hydrochloric acid is solved; the production stability, the mutual independence and the flexible operability of a polysilicon production device are increased; and meanwhile, the high-purity hydrochloric acid can be also obtained, recycled and sold as a by-product.

Owner:SINOPEC NANJING ENG & CONSTR

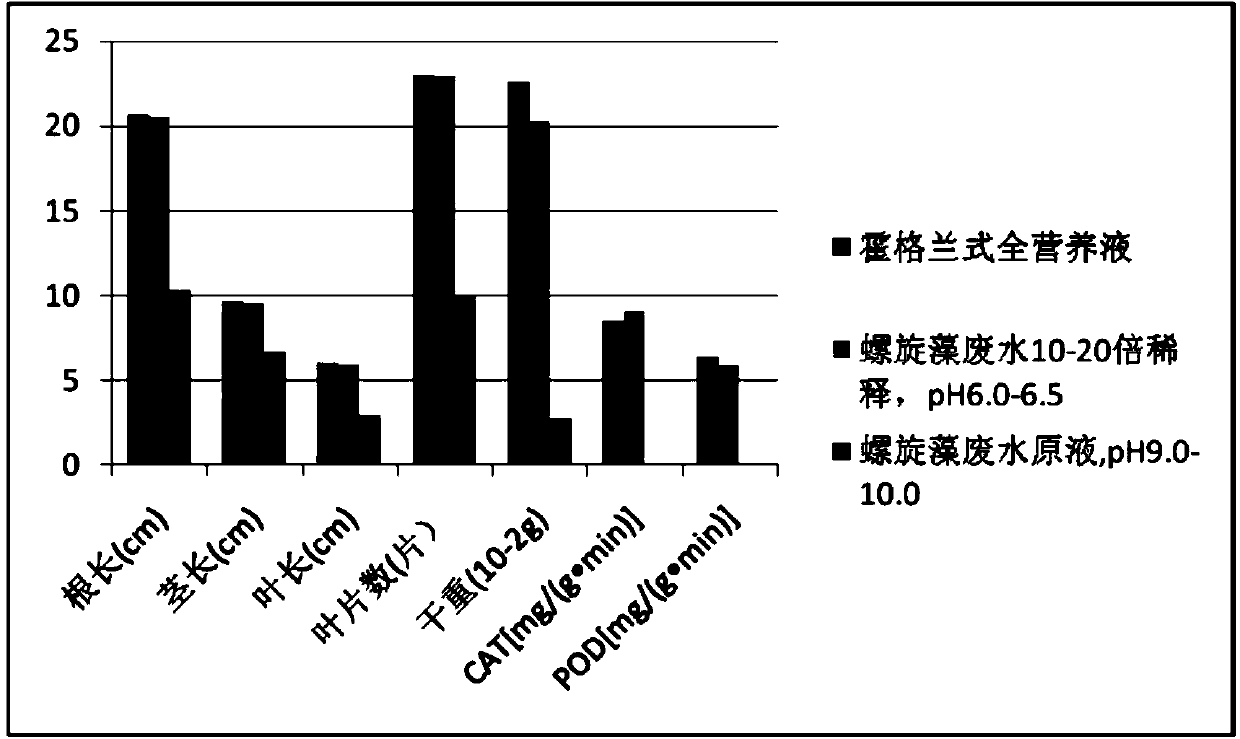

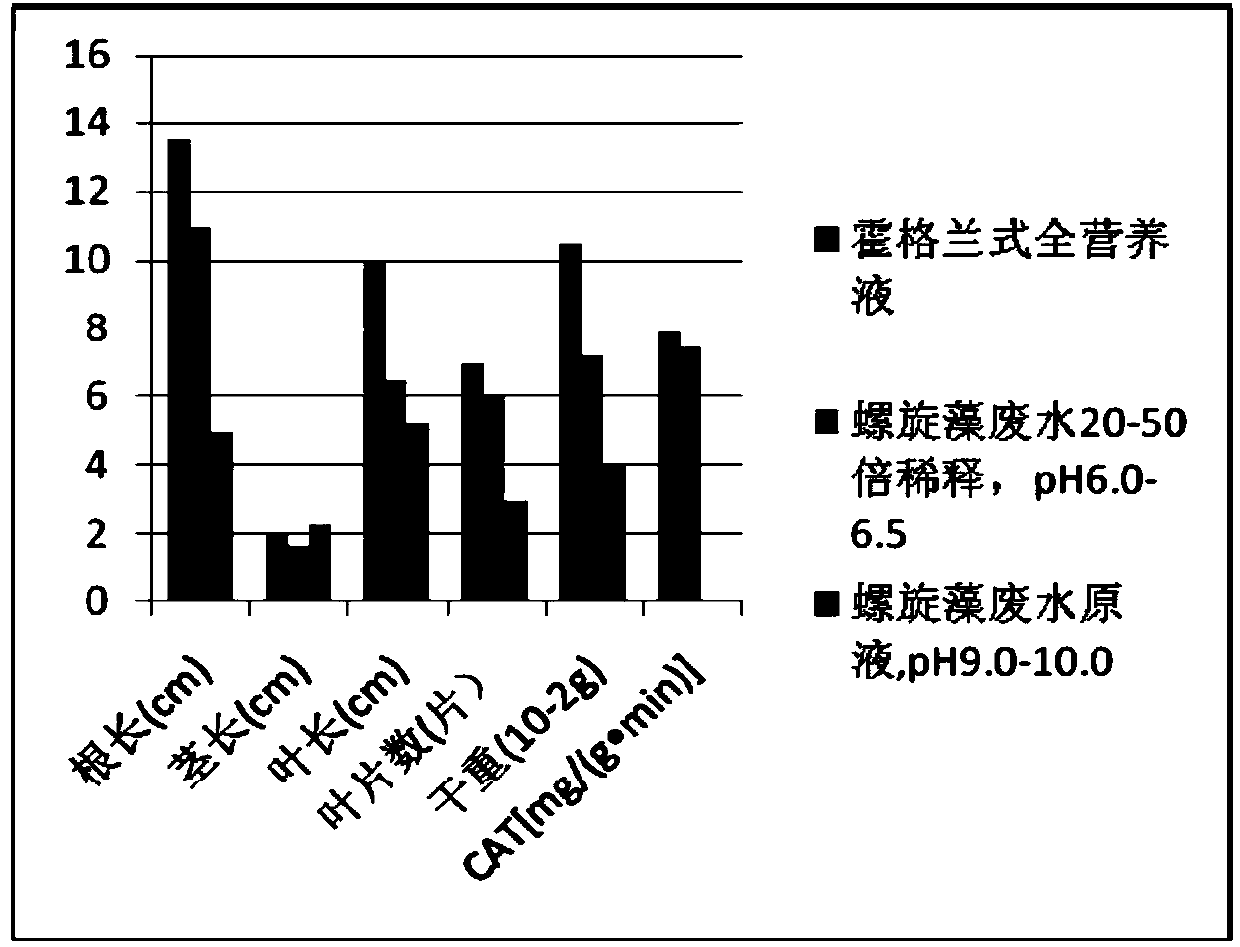

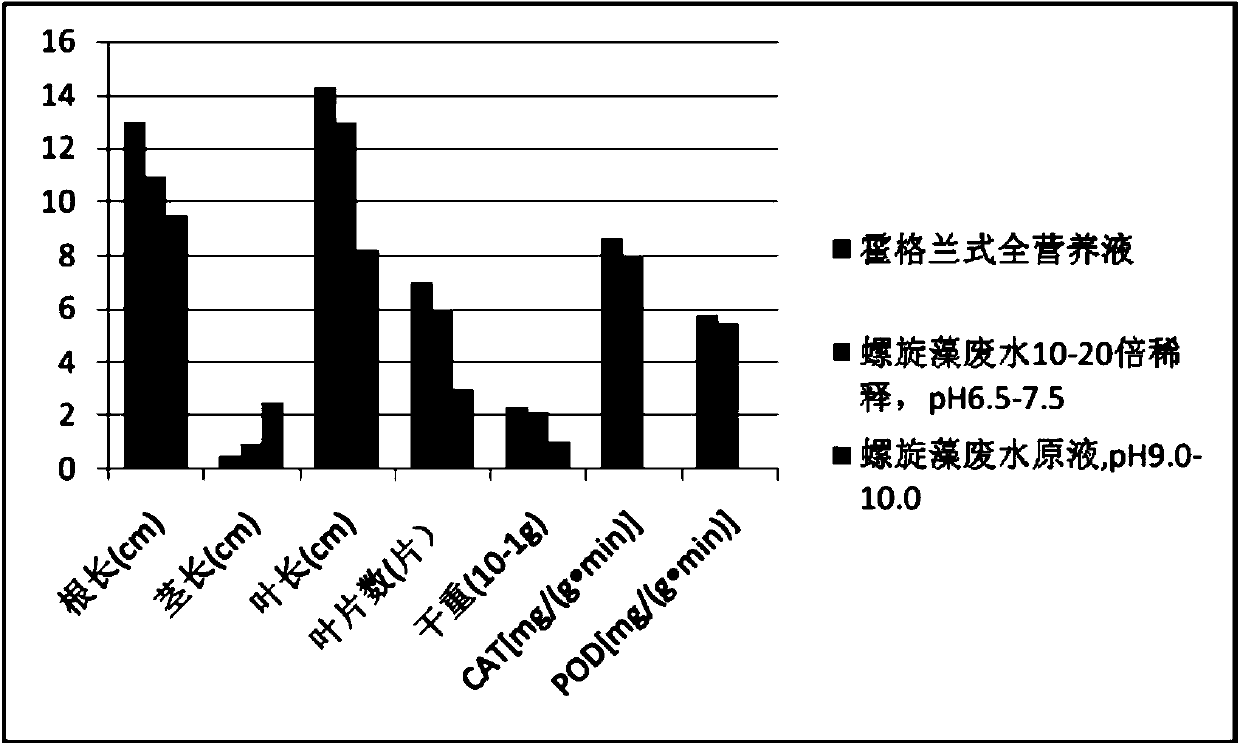

Method for cultivating vegetables in water mode through spiral seaweed cultivation waste water

InactiveCN103988768ARealize resource utilizationSolve the whereabouts problemMultistage water/sewage treatmentCultivating equipmentsPetri dishSprouted Seeds

The invention discloses a method for cultivating vegetables in a water mode through spiral seaweed cultivation waste water. The method includes the following steps: carrying out processing such as filtering, diluting and pH adjustment on the collected spiral seaweed waste water; comparing the preprocessed spiral seaweed waste water with a standard total nutrient solution, and adding microelements necessary for plant growth to obtain a spiral seaweed waste water nutrient solution; soaking vegetable seeds into a clean culture dish, and placing the culture dish into a constant temperature illumination incubator till the seeds are sprouted; selecting sprouted seeds with the good growth conditions according to the sprouting states of the seeds, and transplanting the selected seeds into a Hogland type nutrient solution to cultivate seedlings; when the seedlings are grown to form plants, carrying out spiral seaweed waste water cultivation through plastic thin plates and water grooves; carrying out harvesting or transplanting. According to the method, the vegetables are cultivated in a water-planted mode through the spiral seaweed cultivation waste water, environment pollution caused by direct discharging of the spiral seaweed cultivation waste water is reduced, the waste water is changed into wealth, waste of water resources is reduced, and resource utilization of the spiral seaweed waste water is sufficiently achieved; meanwhile, the direction problem of the spiral seaweed cultivation waste water is solved, and the sustainable development of a spiral seaweed enterprise is also facilitated.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Coal pyrolysis and gasification coproduction method

ActiveCN105441138ASolve the whereabouts problemImprove carbon conversionSpecial form destructive distillationGranular/pulverulent flues gasificationCoal pyrolysisProcess engineering

The invention relates to a coal pyrolysis and gasification coproduction method. The method comprises the following steps: 1, separating coarse coal dusts and fine coal dusts from raw coal; 2, pyrolyzing the coarse coal dusts in a fluidized bed mode to obtain coal tar and semicoke; 3, gasifying the semicoke generated after pyrolysis in a fluidized bed mode to obtain a gas flow and high temperature semicoke, separating a product gas and solid particles from the gas flow, and returning at least parts of the high temperature semicoke and / or at least parts of the product gas to the above pyrolysis process in order to be used as a heat source in the pyrolysis process; and 4, carrying out coal dust gasification on the fine coal dusts separated in step 1 and the solid particles separated in step 3. The coal pyrolysis and gasification coproduction method realizes combined supply of heat, gas, oil and a chemical substance, and also realizes a high carbon conversion rate.

Owner:CHINA PETROLEUM & CHEM CORP +1

Cultivation method of pleurotus geesteranus

InactiveCN106927943AReduce odorFast growthCalcareous fertilisersAnimal corpse fertilisersPassion fruitCompost

The invention relates to a cultivation method of pleurotus geesteranus and belongs to the technical field of cultivation of the pleurotus geesteranus. The cultivation method of the pleurotus geesteranus comprises the following steps: (1) batching: preparing a cultivation material by mixing and composting cottonseed hulls, corn straws, wheat bran, sawdust, peanut cake powder, grape residues, pitaya stems, passion fruit peel, banana peel, bee pupae, beancurd, durian peel, pineapple peel, expired yogurt, coffee residues and lime, and adjusting the moisture content to be 65 to 70 percent and the pH value to be 8 to 10; (2) bagging; (3) sterilizing; (4) inoculating; (5) performing mycelium culture; (6) performing fruiting management; and (7) harvesting. According to the cultivation method of the pleurotus geesteranus, the raw materials of the cultivation materials are wide in source and rich in nutrient, and the yield of the pleurotus geesteranus can be increased.

Owner:陆川县新英食用菌专业合作社

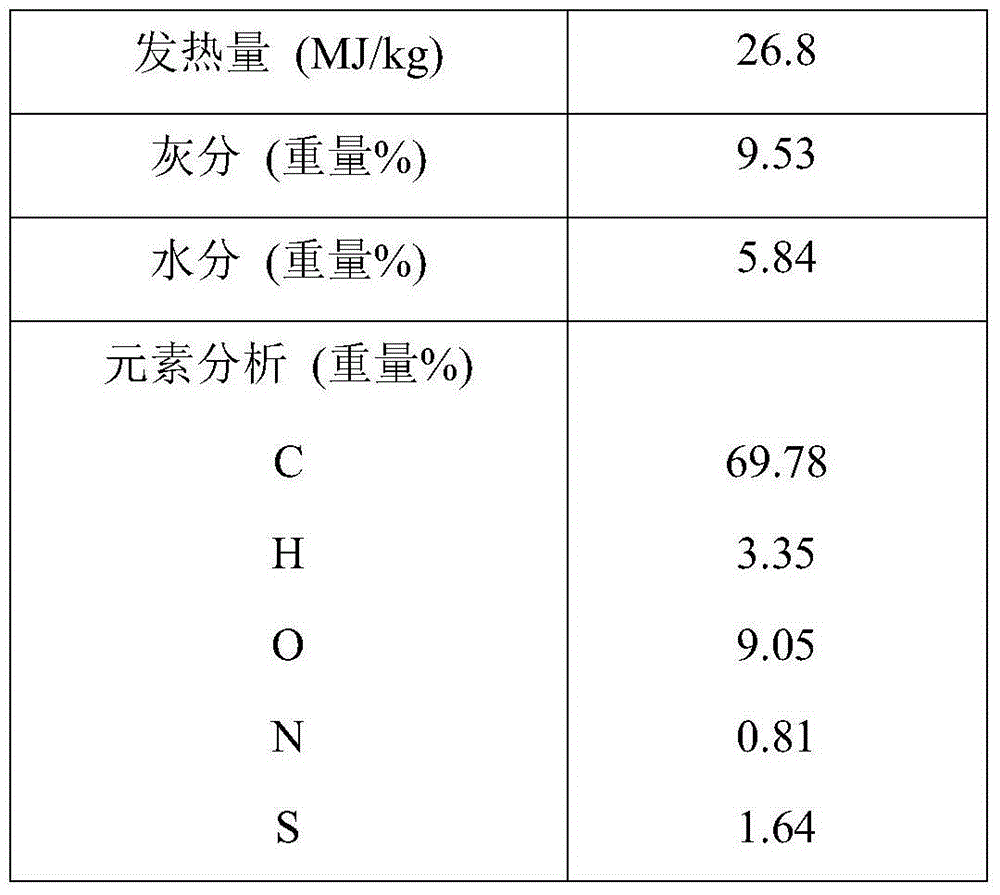

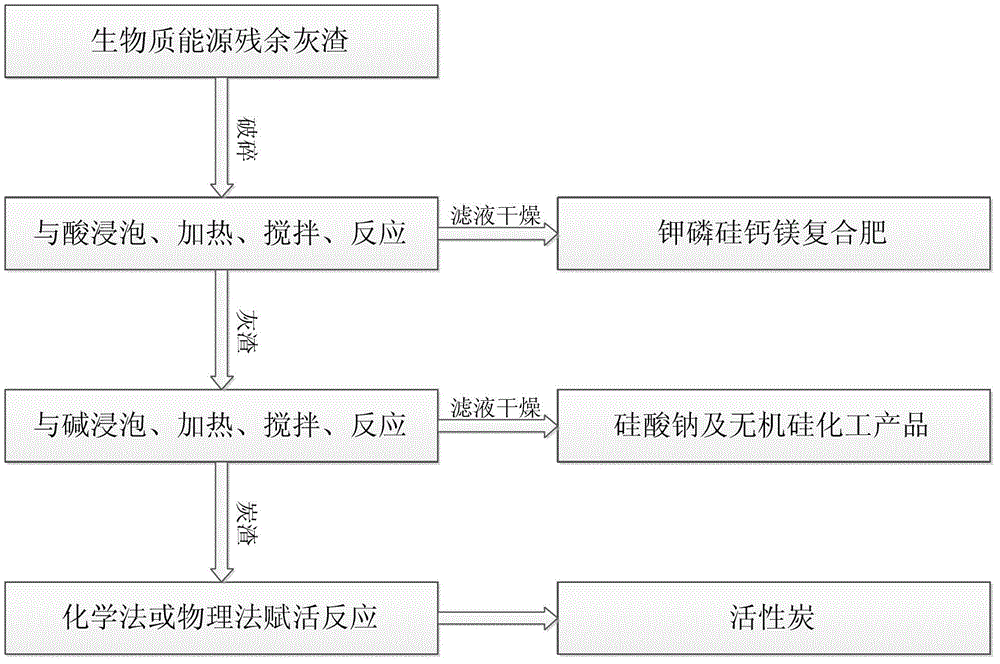

Method and system for comprehensively utilizing biomass ash

ActiveCN103332994AIncrease added valueSolve the whereabouts problemCarbon compoundsAlkali metal silicatesFertilizerChemistry

The invention discloses a method and a system for comprehensively utilizing biomass ash. The method comprises the following steps: reacting biomass ash with acid, and extracting elements including potassium, phosphorus, silicon, calcium and magnesium and the like from the biomass ash to prepare a potassium-based compound fertilizer; reacting residual biomass ash left after the acid reaction with alkali, and extracting a silicon element from the biomass ash to prepare an inorganic silicon compound; and performing a reactivating reaction on the residual biomass ash left after the acid-alkali reaction to prepare active carbon, wherein the sequences of the acid reaction and the alkali reaction can be changed according to different types of biomass ash. According to the method, deep processing of biomass ash is performed with a simple process at low production cost, and the obtained high-quality potassium-based compound fertilizers, relevant inorganic silicon compounds and active carbon products are free from residual ash, so that the comprehensive utilization of the biomass ash is utilized, the problem of treatment of the biomass ash is solved, the additional value of the biomass ash is increased greatly, and the industrialization and sustainable development of biomass energy is facilitated.

Owner:联智同达(苏州)环境科技有限公司

Preparation method of source phosphorus adsorption material in water

InactiveCN105413623AImprove adsorption capacityLarge adsorption capacityOther chemical processesWater contaminantsSoil scienceSludge

The invention provides a preparation method of source phosphorus adsorption material in water. The preparation method includes the following steps that dredged sediment in the water is dried for 2-4 hours at the temperature of 110 DEG C after being filtered with an iron mesh with the hole diameter being 1-2 mm, then ground and sieved with a 100-mesh sieve, and processed dredged sediment in the water is obtained; sludge in a water treatment plant is dried for 2-4 hours at the temperature of 110 DEG C after being filtered with an iron mesh with the hole diameter being 1-2 mm, then ground and sieved with a 100-mesh sieve, and processed sludge in the water treatment plant is obtained; the processed dredged sediment in the water and the processed sludge in the water treatment plant are mixed to be uniform with a stirrer, a mixed material is obtained, the weight ratio of the processed dredged sediment in the water to the processed sludge in the water treatment plant is (2-3):1, the stirring speed of the stirrer is 100 RPM, and the stirring time is 10 min; the mixed material is burnt for 2-4 hours at the temperature of 550 DEG C, and the source phosphorus adsorption material in water can be obtained. The adsorption material prepared through the method is high in adsorption capacity of phosphorus and large in adsorption volume.

Owner:SUZHOU UNIV OF SCI & TECH

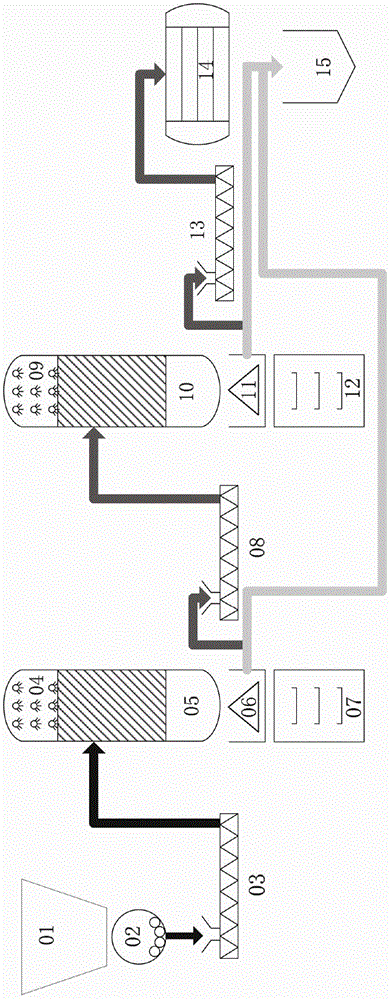

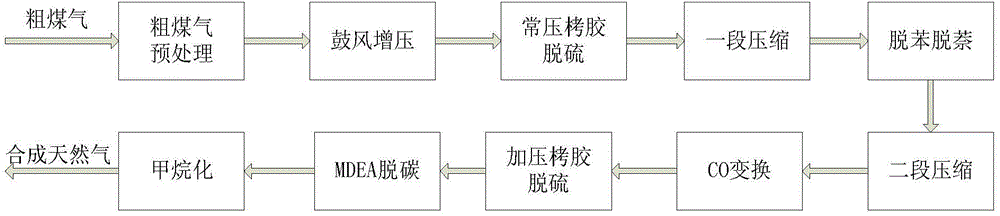

Technology for producing natural gas through underground coal gasification

The invention relates to a technology for producing natural gas through underground coal gasification and provides a solution for producing qualified natural gas through underground coal gasification. The technical scheme is as follows: the technology comprises the following steps of: pretreating raw gas produced through underground coal gasification to remove dust and impurities as well as oil tar; carrying out constant-pressure tannin extract desulfurization after supercharging through an air blower; compressing the desulfurized raw gas by using a reciprocating compressor in a two-stage compression manner, wherein the raw gas is subjected to debenzolization and naphthalene removal after being compressed at the first stage of the compressor, then the raw gas is compressed at the second stage of the compressor, and the pressure of the compressed raw gas is 2.5-3.5MPaG; and carrying out CO transformation, pressurized tannin extract desulfurization, and MDEA (Methyldiethanolamine) decarburization on the compressed raw gas; and finally carrying out methanation reaction on the purified gas to generate the synthetic natural gas meeting the national standard heat value requirements. The technology has the advantages of being low in equipment and investment cost, high in reliability, stable in running and capable of producing the synthetic natural gas meeting the national standard heat value requirements.

Owner:WUHUAN ENG

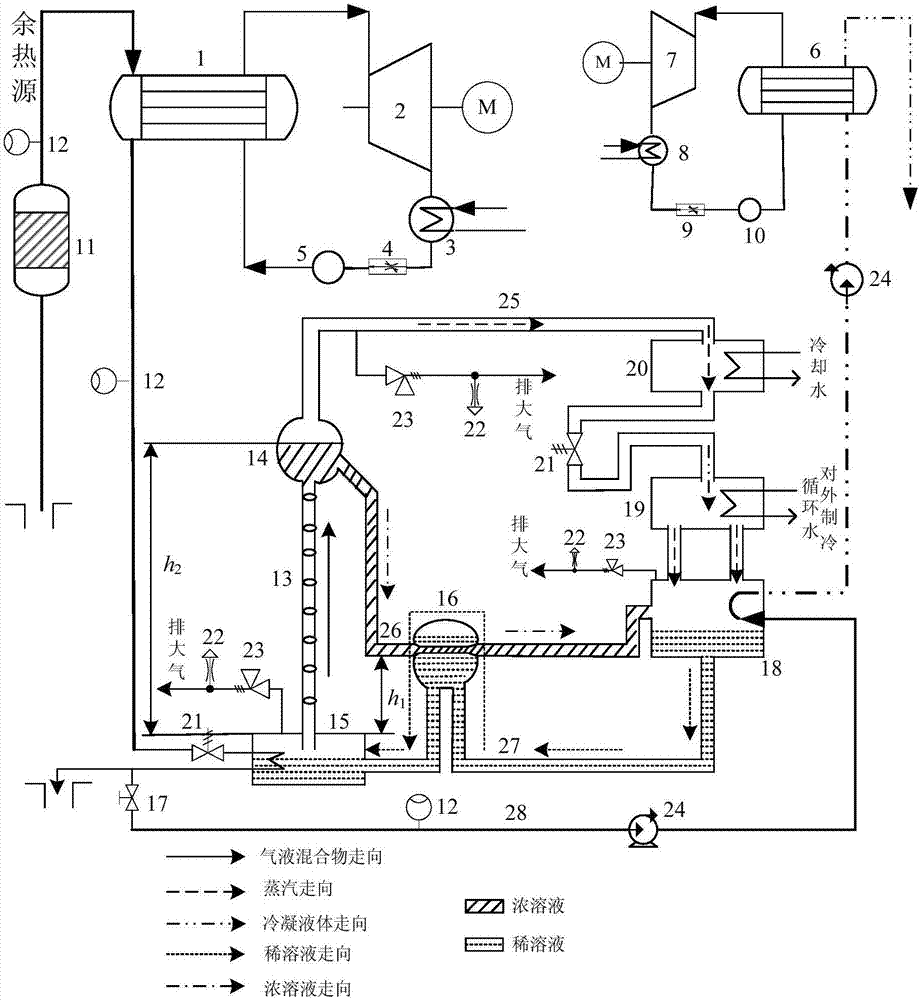

Combined power generation system based on organic Rankine cycle and absorption type heat pump cycle

ActiveCN107100685AReduce investmentSolve the whereabouts problemHeat pumpsSteam engine plantsSiphonOrganic Rankine cycle

A combined power generation system based on an organic Rankine cycle and an absorption type heat pump cycle comprises a first organic Rankine cycle module, an absorption type heat pump module and a second organic Rankine cycle module; after finishing cycle power generation in the first organic Rankine cycle module, a primary heat source becomes low-temperature hot fluid at a certain temperature; the low-temperature hot fluid enters the absorption type heat pump module, then the grade of the low-temperature hot fluid is increased, and outward refrigeration to a certain degree can be realized while the low-temperature hot fluid becomes a high-temperature secondary heat source; and in the absorption type heat pump module, a siphon tube is used as a main tool for delivering a refrigerant solution, flowing of the solution is realized by height difference, investment on working medium pumps is reduced, and after two-time heat exchange is finished, waste heat enters the second organic Rankine cycle module for power generation, and then can be fully utilized. The problem that energy which is still in an available state at the tail end of the conventional low-grade heat source recycling system is wasted can be solved; the recycling rate of the energy is improved; and power output is increased.

Owner:LIAONING TECHNICAL UNIVERSITY

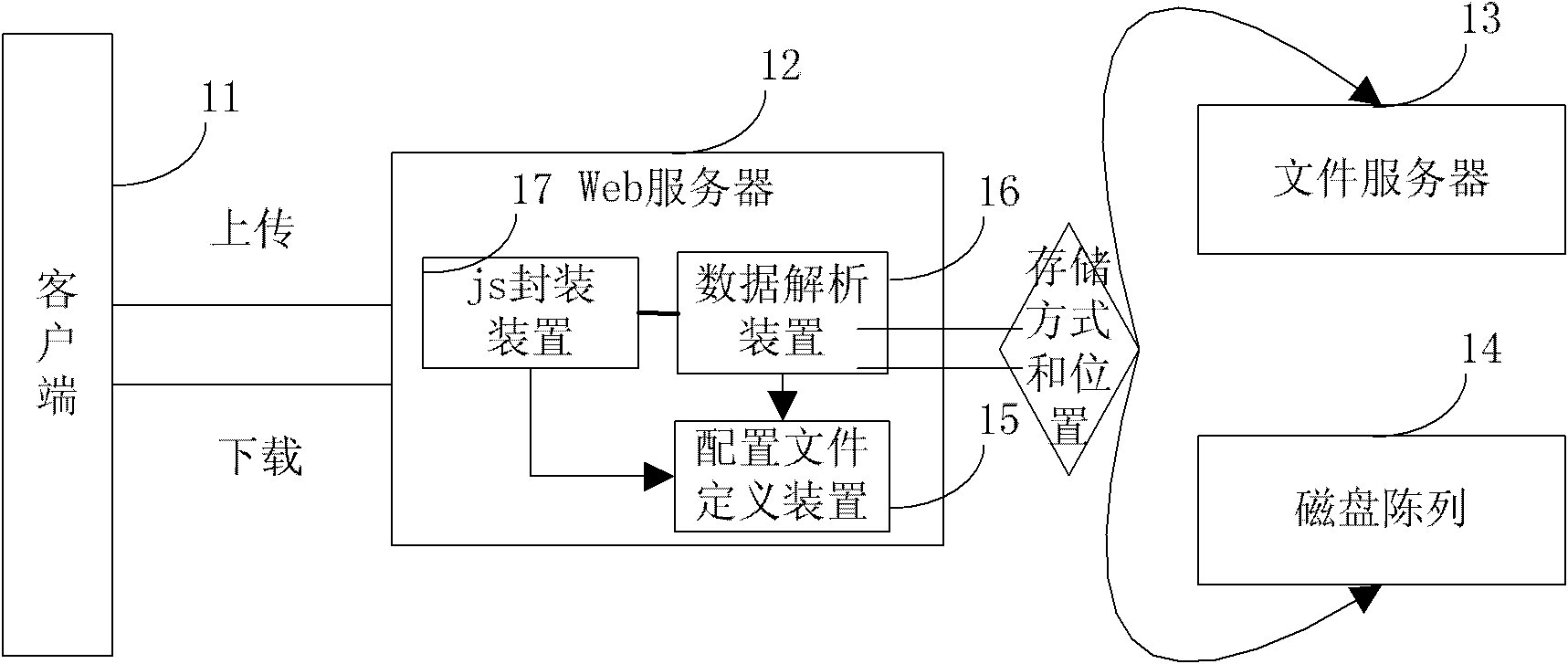

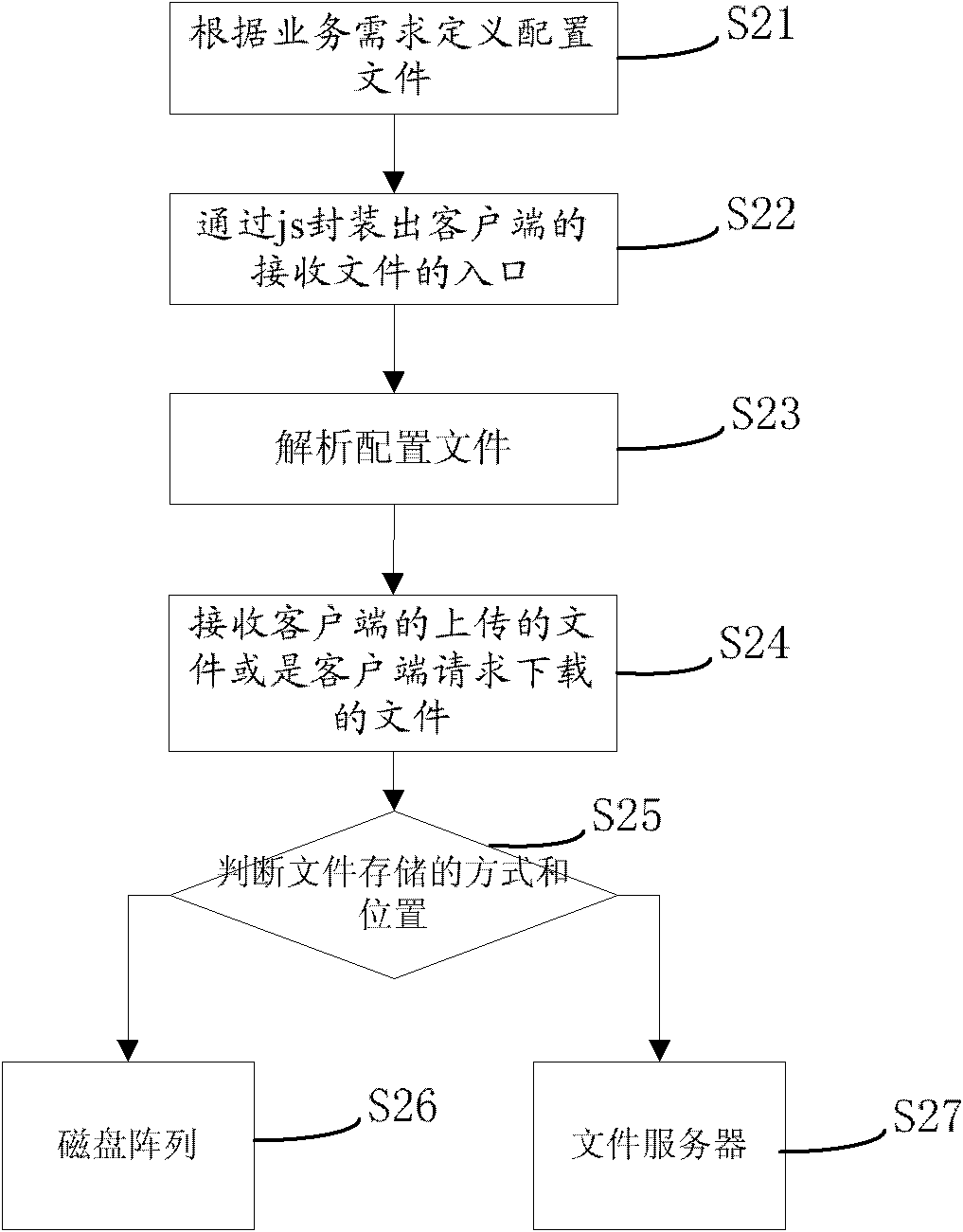

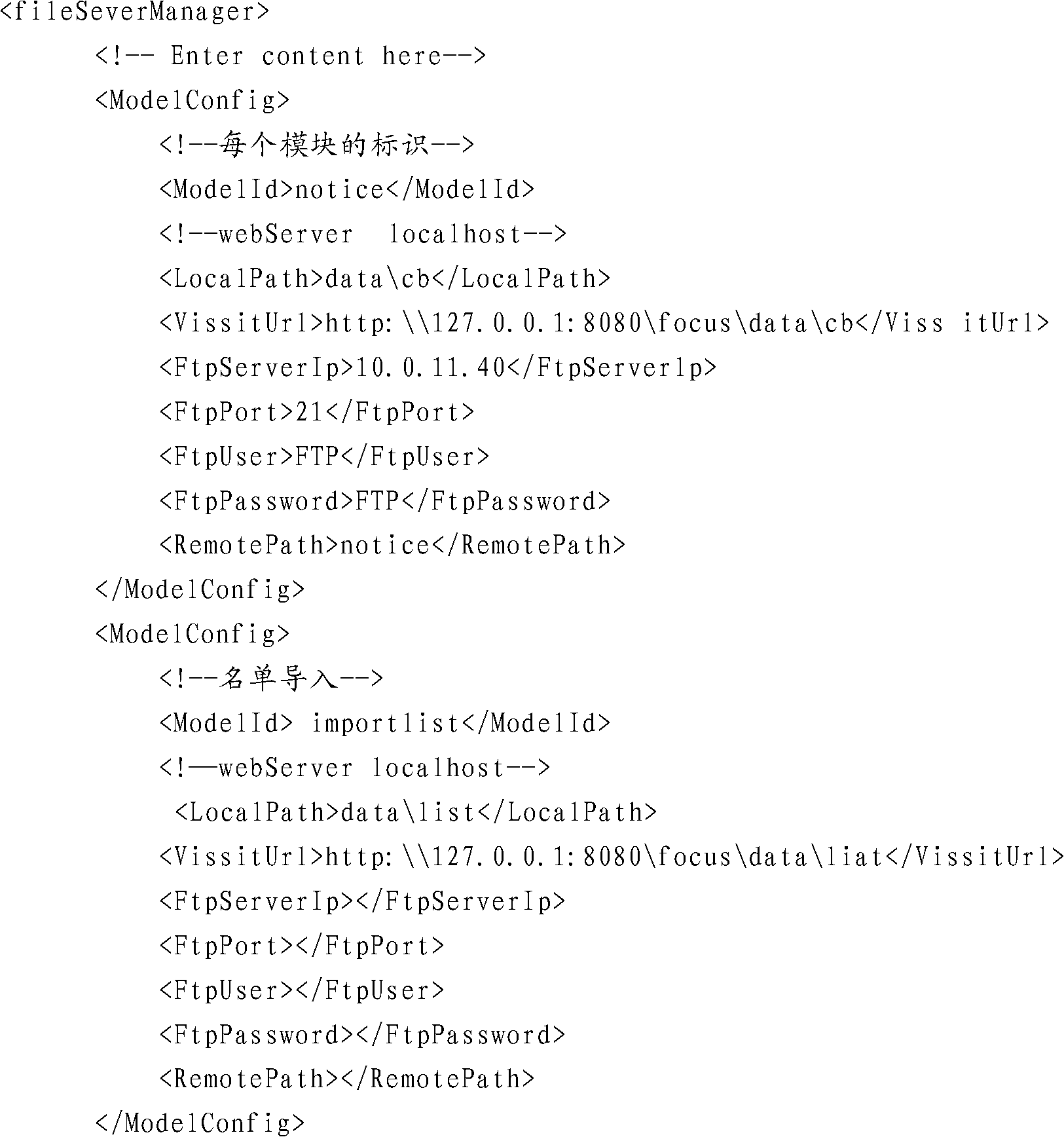

Networked file storing method and system based on HTTP (Hyper Text Transport Protocol)

The invention relates to a networked file storing method and system based on an HTTP (Hyper Text Transport Protocol), belonging to the technical field of network storage. The networked file storing method comprises the following steps that: a configuration file is defined according to a business requirement, and the configuration information of file storage in the business requirement is defined in the configuration file; then an entrance for a client to receive the file is packaged through js; the configuration file is parsed; the command of the client is received; and the storing mode and position of the file are judged through the configuration information corresponding to the parsed business type according to the command of the client, so as to carry out storage or download processing. Therefore, the invention provides an efficient, low-cost and cross-platform technical scheme for the storage of the networked file based on the HTTP.

Owner:FOUNDER INTERNATIONAL CO LTD

Treatment method for landfill leachate membrane treatment evaporated and concentrated liquor

InactiveCN108911324AFast curingStrong penetration resistanceWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentSulfateTherapeutic effect

The invention discloses a treatment method for landfill leachate membrane treatment evaporated and concentrated liquor. The treatment method is characterized in that sulfate aluminum cement is adopted, and has high curing speed and strong permeability resistance in comparison with conventional silicate cement. Silicate cement, a heavy metal ion chelating agent and an additive are taken as curing agent main components, and can be effectively combined with pollutants such as organic substances and heavy metal in landfill leachate membrane treatment evaporated and concentrated liquor, so that thepollutants are cured in a curing body, and therefore, the harmless and stable purpose is achieved. The treatment method is simple in process, is high in practicability, is good in treatment effect, is taken as a deep treatment technology, makes up the defects of an existing landfill leachate membrane treatment evaporated and concentrated liquor treatment technology, and effectively solves the treatment problem of the landfill leachate membrane treatment evaporated and concentrated liquor.

Owner:武汉天源环保股份有限公司

Pakchoi water culture method

InactiveCN107173197AGood insecticidal and bactericidal biological activityAvoid harmCultivating equipmentsSoilless cultivationManganeseNutrient solution

The invention discloses a pakchoi water culture method. The method comprises the following steps of seed treatment and germination accelerating, sowing, transplanting, management and harvesting. A water culture nutrient solution is prepared by adding 30-50 mL of tofu waste water, 10-20 mL of tea bran water, 20-30 mL of molasses fermentation liquor, 220-250 mg of ammonium nitrate, 5-8 mg of sodium molybdate, 3-5 mg of borax, 3-5 mg of calcium nitrate, 6-10 mg of ferrous sulfate, 1-3 mg of manganese sulfate, 1-3 mg of zinc sulfate and 1-3 mg of copper sulfate into each liter of pigsty liquid dung. The pH value of the nutrient solution is adjusted to be 5.8-6.5 by using citric acid. The electric conductivity is controlled to be 1.5-2.5 mS / cm, and the dissolved oxygen amount is 4-5 mg / L. Waste water resources are fully utilized, waste is turned into wealth, organic, safe and pollution-free pakchoi is harvested, and the popularization value is relatively high.

Owner:广西横县锦绿物流有限公司

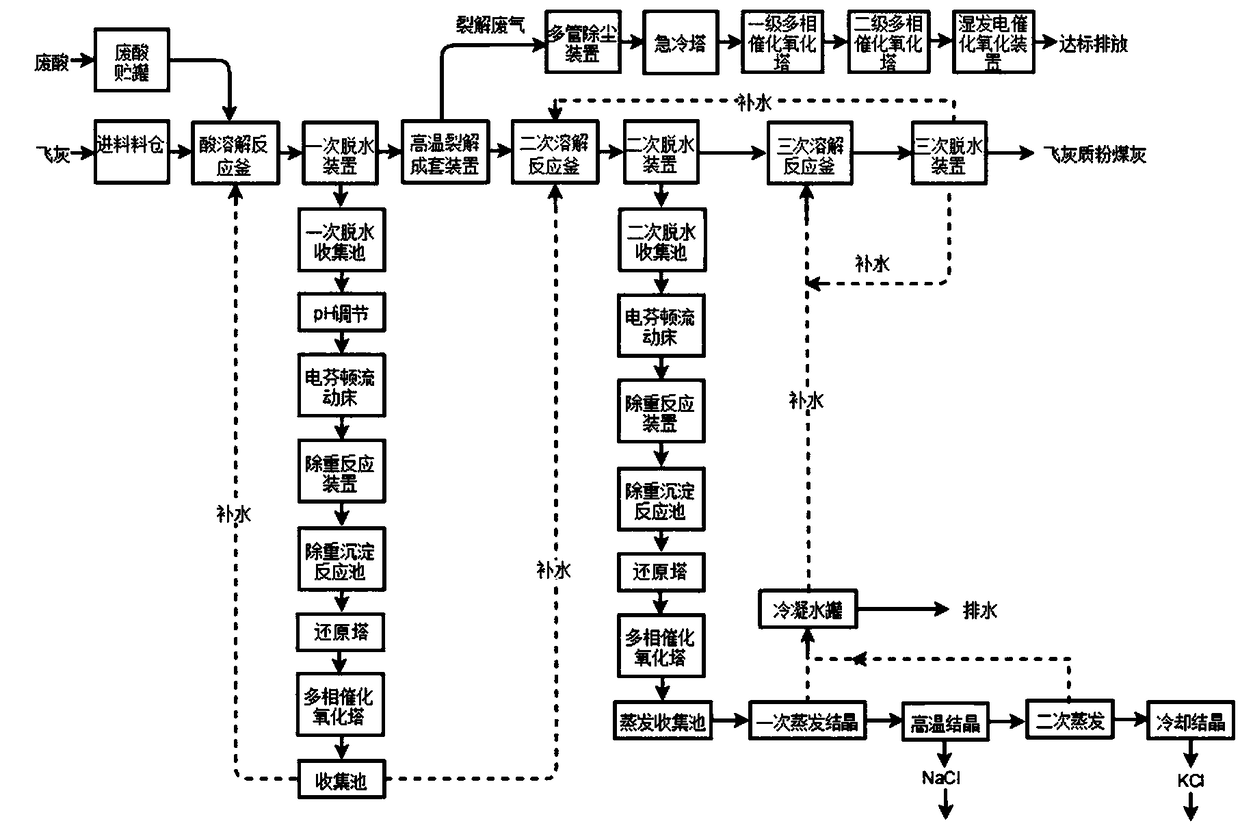

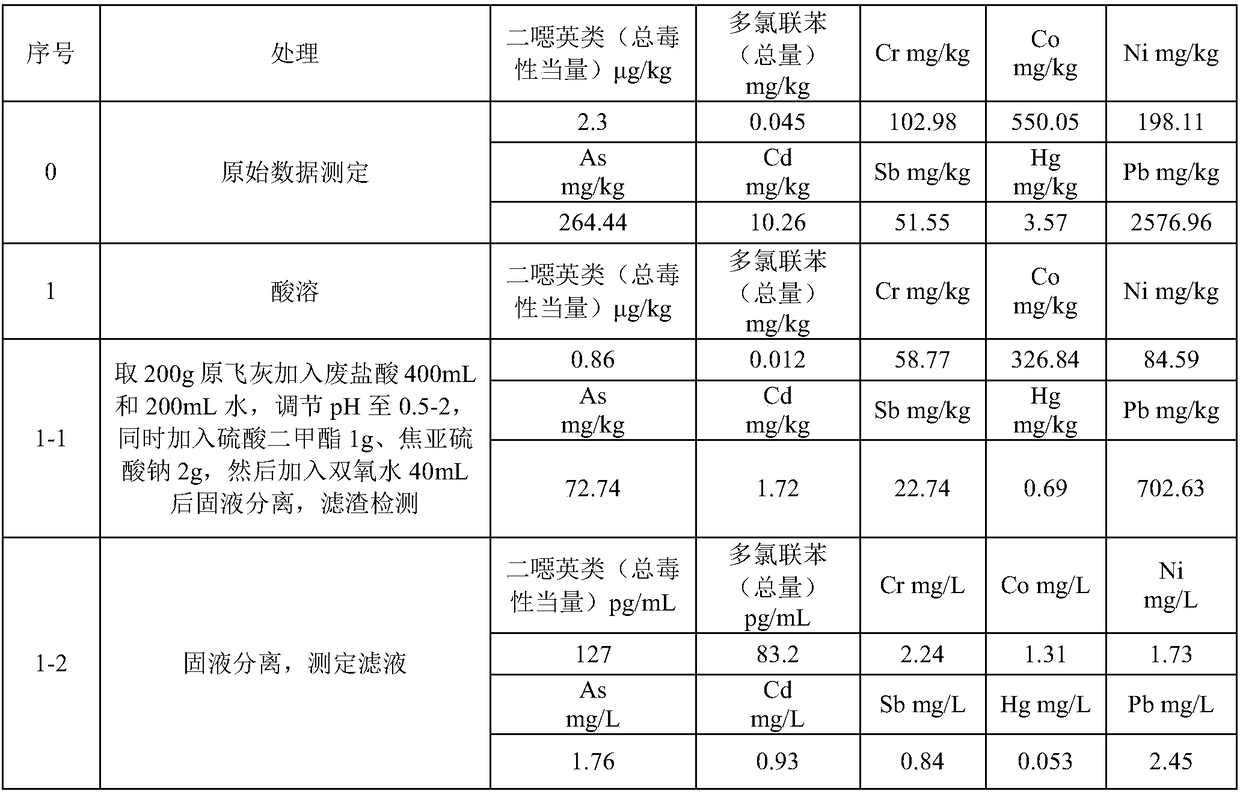

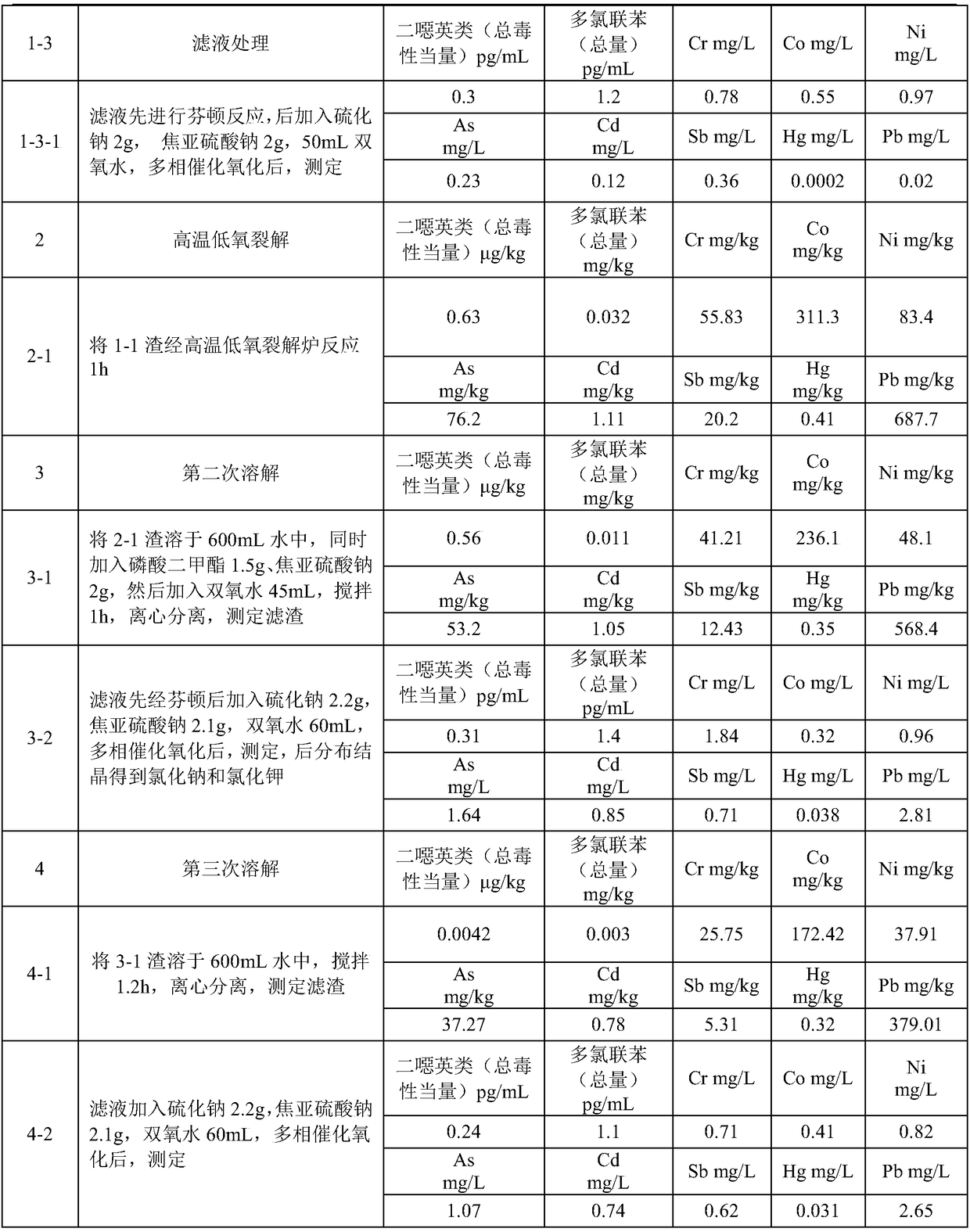

Waste acid cooperative disposal process in domestic waste incineration fly ash resource refining process

ActiveCN109226175ARealize dual resource utilizationAchieve recyclingWater treatment compoundsSolid waste disposalHeavy metalsResource utilization

The invention belongs to the technical field of dangerous solid waste disposal and resource utilization, and particularly relates to a waste acid cooperative disposal process in the domestic waste incineration fly ash resource refining process. In the process disclosed by the invention, fly ash is dissolved with a great amount of waste acid, leaching is repeatedly carried out, dioxin, heavy metalsand salt in the fly ash can be dissolved in filtrate, then by carrying out treatment on the filtrate, content of the dioxin, the heavy metals and the salt in the filtrate is reduced and meanwhile, sodium chloride salt and potassium chloride salt are separated out, thereby implementing resource comprehensive utilization of the waste acid and the fly ash.

Owner:韩正昌

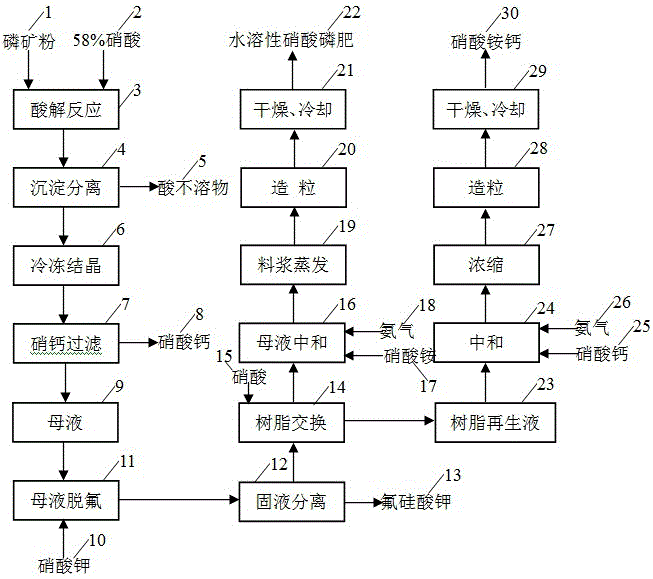

Production method of high-concentration water-soluble nitrophosphate fertilizer

PendingCN106565282ATo achieve the purpose of continuous useMeet integration needsAmmonium nitrate fertilisersNitrate fertilisersSolubilityHigh concentration

The invention discloses a production method of a high-concentration water-soluble nitrophosphate fertilizer. The method is characterized in that a resin exchange procedure is added on the basis of the freezing nitrophosphate fertilizer technological process to remove metal ions like calcium ions, magnesium ions, aluminum ions and iron ions in a defluorination mother liquid, and the water-soluble nitrophosphate fertilizer is prepared; and besides, a calcium ammonium nitrate production procedure is added after the resin exchange procedure, and a by-product generated from resin exchange is converted into a calcium ammonium nitrate product. According to the method, while the freezing nitrophosphate fertilizer technology is utilized to produce the water-soluble fertilizer, the production expense is reduced and operation is simplified; besides, generation of reproduced calcium sulfate and accumulation of magnesium aluminum iron phosphate deposits are avoided, and the requirements of effective resource utilization and zero emission are achieved; and the obtained product is good in physical and chemical properties, high in water solubility and wide in application range, fertilizer flushing, drip irrigation, topdressing and soilless culture of crops are facilitated, and the requirement of integration of water and fertilizers is met.

Owner:GUIZHOU BATIAN ECOTYPIC ENG CO LTD +1

Renewable-aggregate industrial mortar and preparation method thereof

InactiveCN103420655AExcellent heat preservation functionImprove thermal insulation function and building energy-saving levelSolid waste managementThermal insulationCoal

The invention discloses an industrial mortar using renewable aggregates as a main filling raw material and a preparation method of the industrial mortar. The production formula of the industrial mortar is that 10-30 percent of silicate cement, 10-20 percent of calcium oxide, 10-15 percent of renewable concrete aggregate of which particle size is smaller than or equal to 5 mm, 5-10 percent of renewable clay brick aggregate of which particle size is smaller than or equal to 5 mm, 2-3 percent of renewable glass aggregate of which particle size is smaller than or equal to 5 mm, 10-20 percent of natural yellow sand, 15-25 percent of coal ash, 4-6 percent of water-reducing agent and a proper quantity of water are adopted, wherein the water-reducing rate of the water-reducing agent is required to be greater than 12 percent; preferably, the formula does not contain other components. Through the process of the method, the cost is effectively reduced; the mortar can be used in building surfaces and wall surfaces for plastering, is conducive to improving thermal insulation performance and energy-saving level of buildings, and has higher pressure resistance and tensile strength compared with existing similar products.

Owner:LANGFANG RONGSHENG CONCRETE

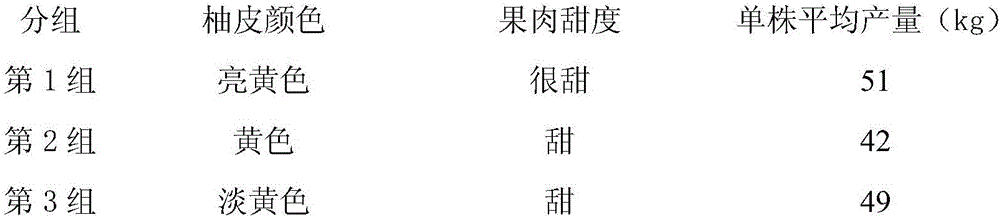

Honey pomelo planting method

InactiveCN106332721APromote growthIncrease photosynthesis rateCalcareous fertilisersBio-organic fraction processingHorticultureEdible mushroom

The invention relates to a honey pomelo planting method and belongs to the technical field of crop cultivation. The honey pomelo planting method comprises the following steps: (1) performing seed and seedling cultivation; (2) performing fixed plant; (3) performing fertilization management: applying fertilizer for 3 to 4 times every year, wherein the fertilizer is prepared by mixing and fermenting the following raw materials in parts by weight: 5 to 15 parts of straws, 15 to 25 parts of bagasse, 5 to 10 parts of corn straws, 5 to 15 parts of chicken manure, 5 to 15 parts of goose manure, 5 to 15 parts of pig manure, 5 to 15 parts of horse manure, 5 to 9 parts of edible mushroom residues, 3 to 8 parts of egg shells, 5 to 10 parts of grape pomace, 7 to 12 parts of magnesium powder, 5 to 15 parts of plant ash and 10 to 15 parts of pond sludge; (4) pruning; (5) preventing and controlling plant diseases and insect pests; (6) performing fruit thinning and bagging. By the honey pomelo planting method, the content of each component of the fertilizer is adjusted to enable the fertilizer to accord with the nutritional requirement characteristics of the honey pomelos, so that the yield of the honey pomelos is increased.

Owner:广西盛元现代林业科技有限公司

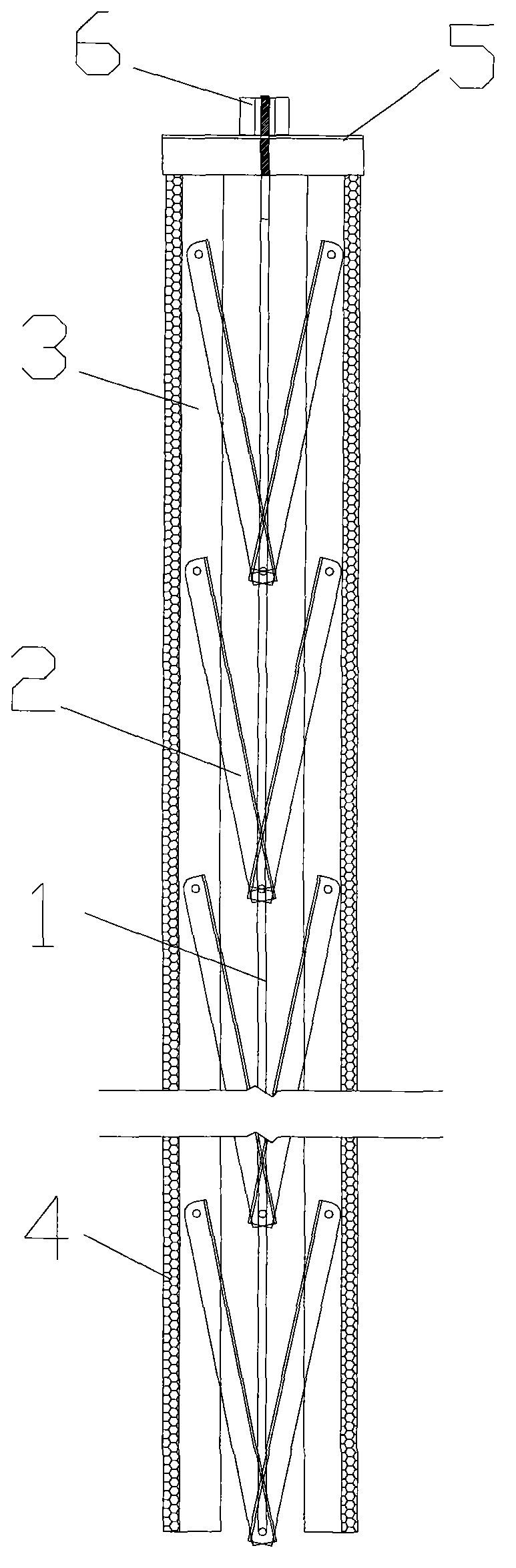

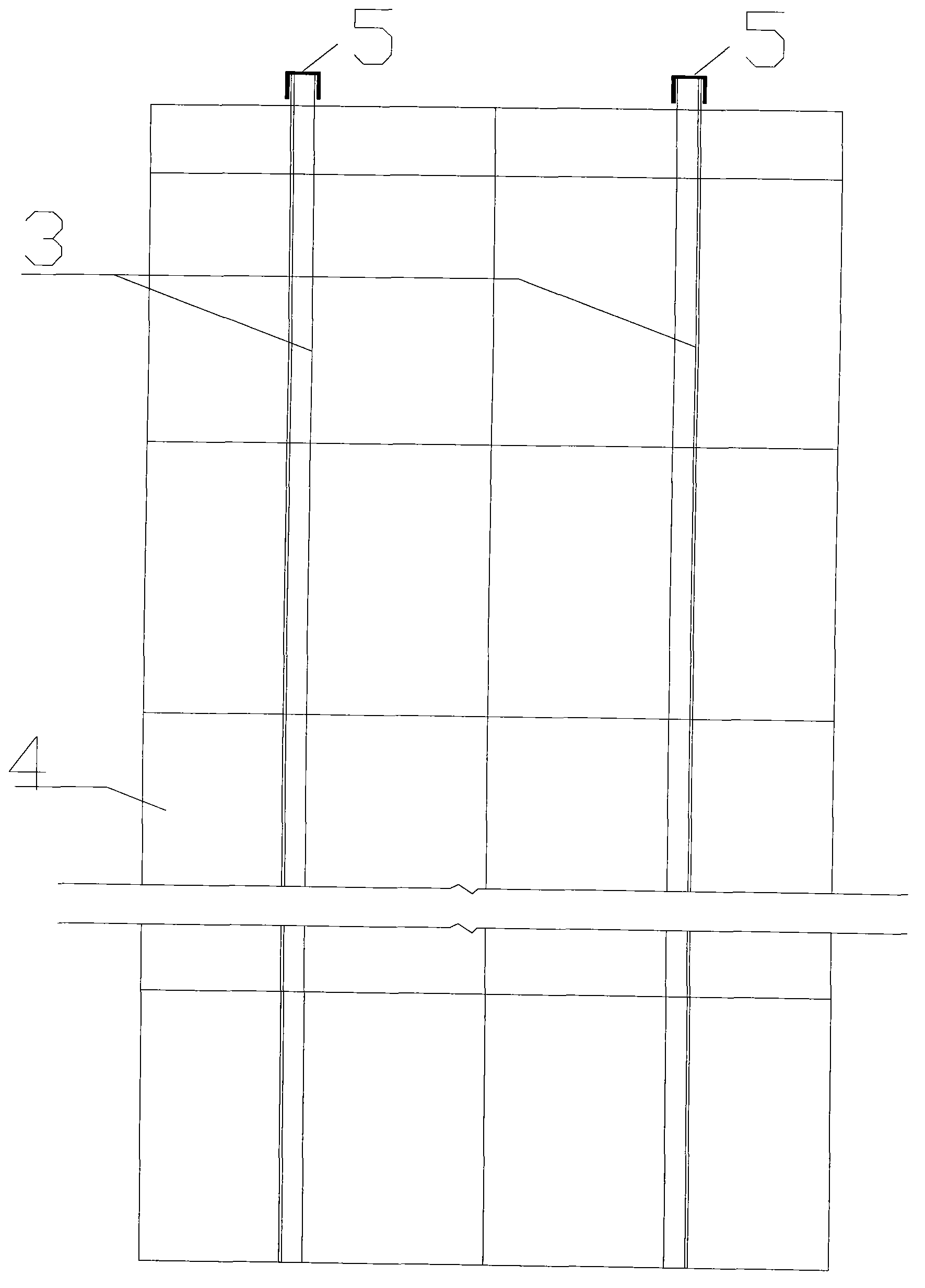

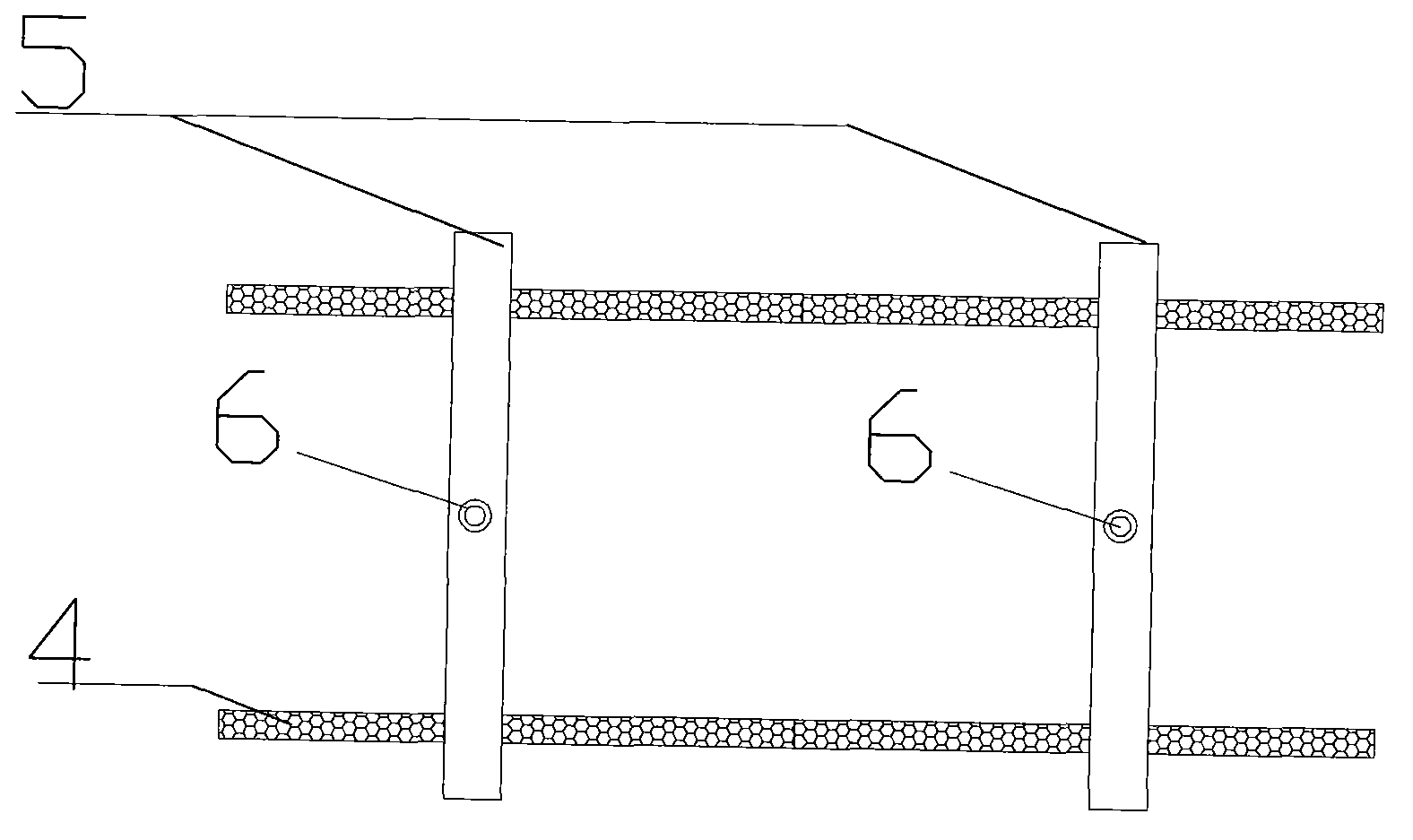

Double concrete wall plate scissor type keel supporting template system

InactiveCN103541544ASolve the whereabouts problemSpacing controlAuxillary members of forms/shuttering/falseworksSupporting systemKeel

The invention discloses a double concrete wall plate scissor type keel supporting template system which comprises a central pull rod, hinge rods, main keels, template panels, a fixing baffle and fastening screws, a pair of main keels is hinged to a connecting rod system composed of the hinge rods and the central pull rod. The template panels are fixed on the main keels. A plurality of pairs of hinge rods are arranged on the central pull rod. The fixed baffle is arranged on the upper portion of the central pull rod. The fastening screws are arranged at the upper end of the central pull rod. The pair of main keels is located on the two sides of the central pull rod. Hinges are connected to the hinge rods. Two keel systems are connected through the template panels to form the scissor type supporting template system. The double concrete wall plate scissor type keel supporting template system solves the problems that two adjacent concrete wall bodies can not be constructed at the same time, supporting keels and templates between the two walls are hard to detach, and the project progress is influenced. The supporting system utilizes the screws at the upper end of the central pull rod of the rotating system, the interval between two wall plate templates, the two wall templates and the supporting system are made to form an organic integrity.

Owner:谢月实 +1

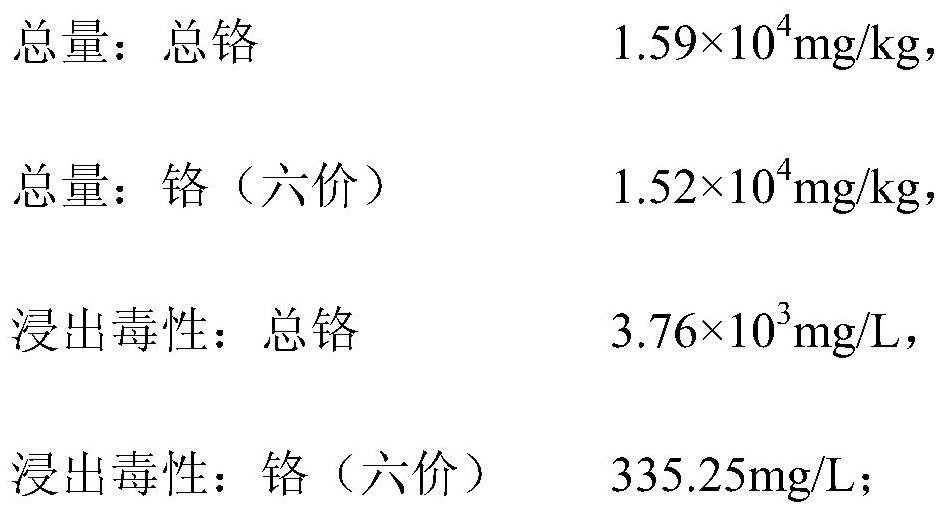

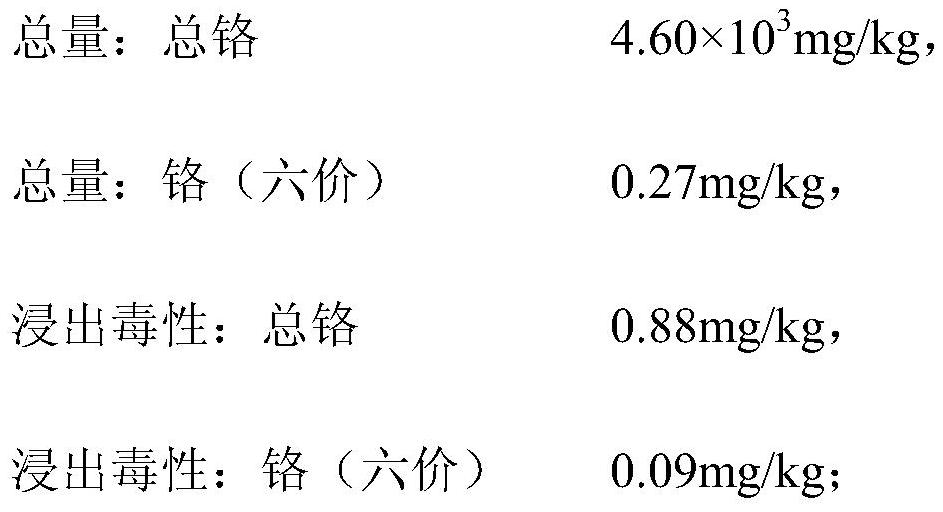

Resource utilization method of hexavalent chromium contaminated soil

ActiveCN111675549ASolve pollutionImprove performanceSievingScreeningChromium contaminationSoil treatment

The invention relates to the technical field of soil treatment, in particular to a resource utilization method of hexavalent chromium contaminated soil. The method comprises the following steps: (1) physically crushing and screening hexavalent chromium contaminated soil, (2) physically crushing and screening blast furnace slag, (3) uniformly stirring and mixing water, the screened hexavalent chromium contaminated soil and blast furnace slag, (4) granulating the mixture to form a ceramsite raw material, (5) drying and roasting the ceramsite raw material, and (6) cooling the roasted ceramsite toobtain a ceramsite product taking hexavalent chromium contaminated soil and blast furnace slag as raw materials. According to the method, the remediation problem of the remediated soil is solved in aresource utilization mode, resources such as raw coal do not need to be purchased additionally, the purpose of treating waste with waste is achieved, and the disposal cost is reduced.

Owner:山东洛尔环保科技有限公司

Copper slag-base low silicon iron tailing filling material and preparation technology thereof

InactiveCN105541255ASolve the technical problems that can only be prepared with high-silicon aggregatesSolve the whereabouts problemSolid waste managementMaterial resourcesWater reducer

The invention belongs to the field of filling cementing material preparation and particularly relates to a copper slag-base low silicon iron tailing filling material. The filling cementing material is prepared from 15-25wt% of copper slag materials, 3-8wt% of cement clinker, 0.3-0.8wt% of sodium hydroxide and 70-80wt% of low silicon iron tailings. The copper slag materials are prepared from 75-80wt% of copper slag, 3-6wt% of lime, 15-18wt% of gypsum and 0.3-0.8wt% of naphthalene water reducer. The filling cement material is prepared through the copper slag and the low silicon iron tailings, the local ecological environment problems and slag waste problems of mines are solved, and manpower and material resources can be greatly saved. The cost is low, the equipment investment is small, the filling effect is good, and the copper slag-base low silicon iron tailing filling material has wide application prospects in the fields of mine backfilling, building materials and others.

Owner:FUZHOU UNIV

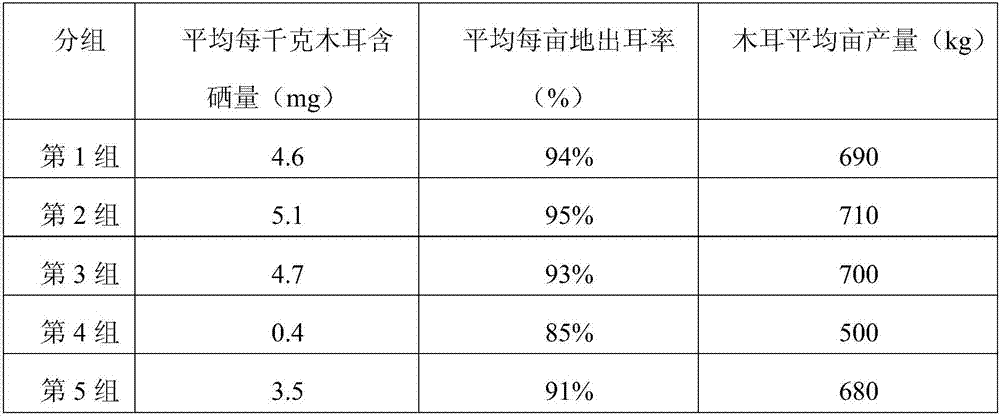

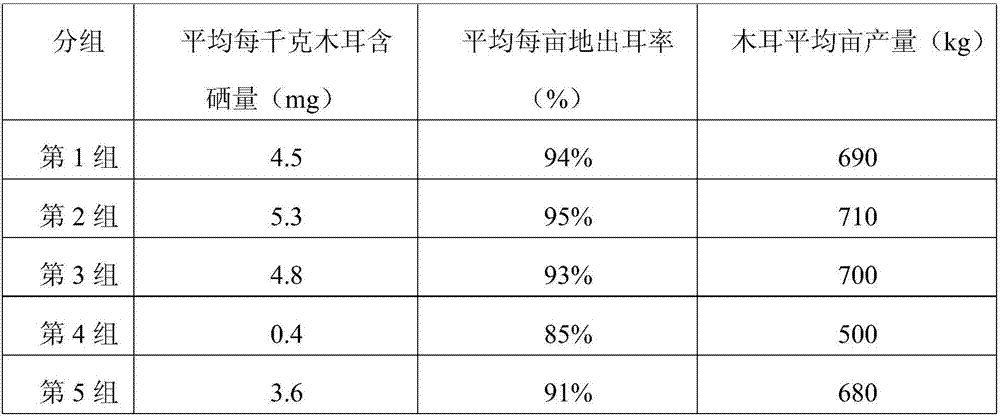

Special selenium-enriched organic fertilizer for agaric and preparation method of organic fertilizer

InactiveCN107056526ARich in nutrientsHigh activityBio-organic fraction processingAnimal corpse fertilisersAgaricAdditive ingredient

The invention discloses a special selenium-enriched organic fertilizer for agaric and relates to the field of fertilizers. The organic fertilizer specifically comprises the following raw materials: chicken manure, duck manure, pig manure, selenium-enriched corncob, wheat bran, bean dregs, humic acid, bone meal, scoria, lotus seed skin, garlic, mangosteen fruit skin, lycium ruthenicum residues, selenium-enriched waste tea leaves, overdue milk and purple sweet potatoes. A preparation method of the special selenium-enriched organic fertilizer for agaric comprises the following steps: (1) pretreating the raw materials; (2) mixing and stirring; (3) performing composting fermentation; and (4) bagging and sterilizing. The special selenium-enriched organic fertilizer for agaric disclosed by the invention is prepared from raw materials readily available and is rich in nutritional ingredients, the yield of agaric can be improved, and the harvested agaric is rich in selenium.

Owner:广西丰兄农业开发有限公司

Method for preparing sodium pyrosulfite from coking desulfurization waste liquid and crude sulfur

InactiveCN109607575ASolve the whereabouts problemReduce restrictionsAlkali metal sulfite preparationSulfurDirect combustion

The invention discloses a method for preparing sodium pyrosulfite from coking desulfurization waste liquid and crude sulfur, which comprises a raw material pretreatment step, a sulfur burning step, afurnace gas purification step and a finished product step. The invention adopts the technology of a sulfur melting kettle to prepare sulfur, and the desulfurization waste liquid is subjected to concentrated crystallization to directly prepare mixed salt, and then the mixed salt is respectively sent to an incinerator for direct combustion, thereby not only innocuously treating the desulfurization waste liquid, but also comprehensively utilizing the sulfur resources; the low pressure saturated steam from coking plant is used to produce massive sulfur by using the technology of the sulfur meltingkettle, and the desulfurization waste liquid is also concentrated and crystallized by using the low pressure saturated steam to produce mixed salt, the method has features of low investment, low energy consumption which is only 30%-40% of that of direct hot air drying and no exhaust emission.

Owner:朱华东

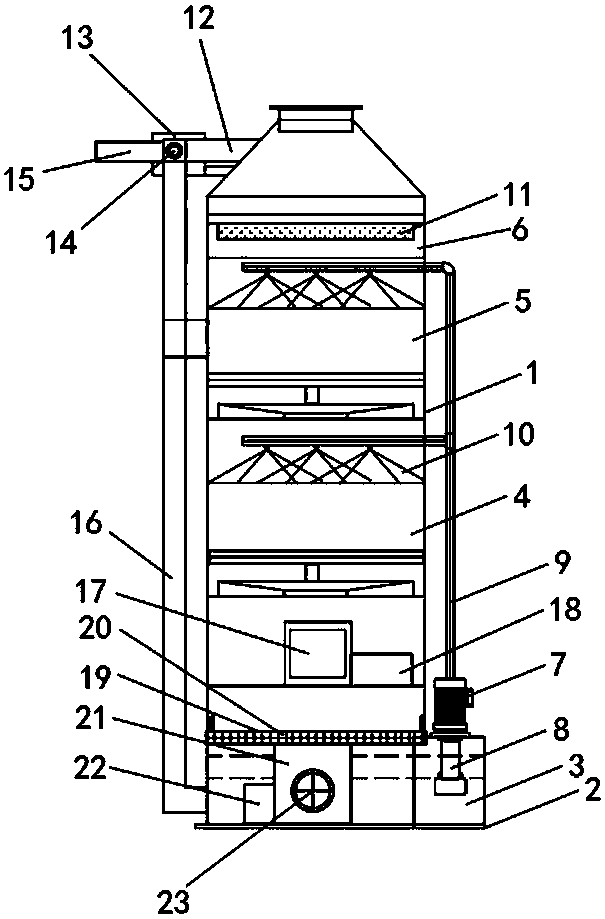

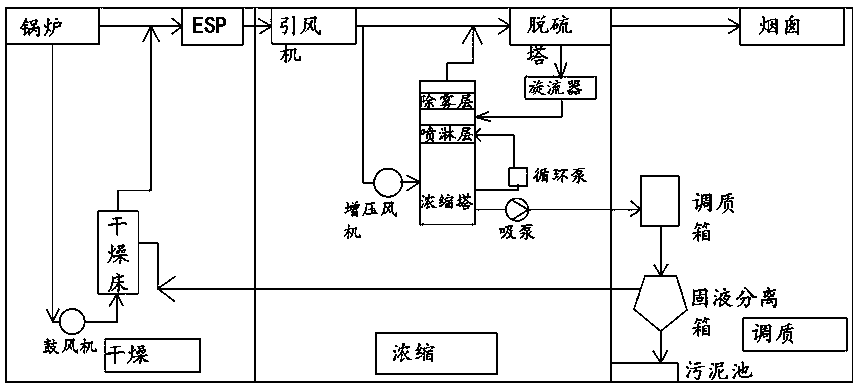

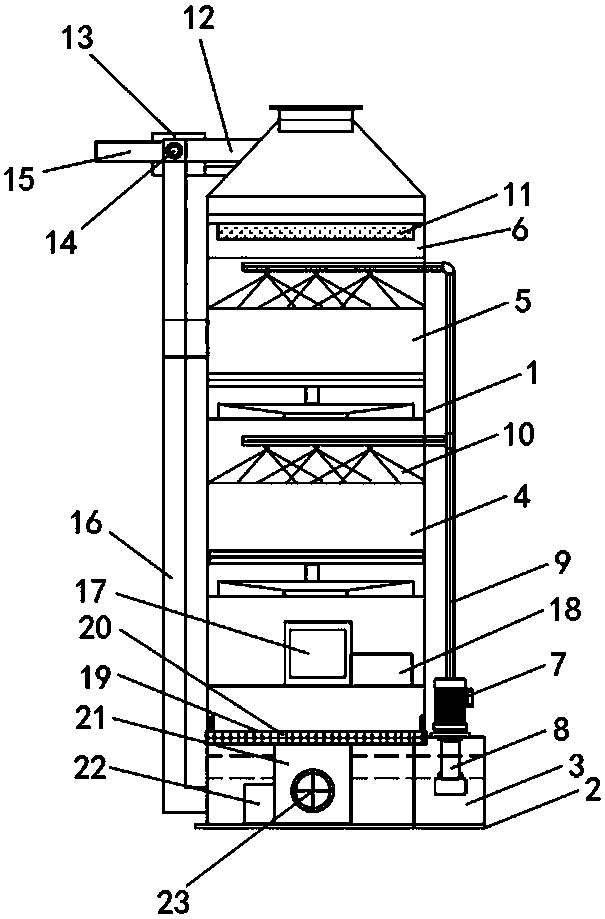

Zero-emission and low-energy-consumption concentration tower

InactiveCN111138016AReduce energy consumptionSolve the problem of energy consumptionTreatment involving filtrationWaste water treatment from gaseous effluentsCirculator pumpEngineering

The invention discloses a zero-emission and low-energy-consumption concentration tower. The zero-emission and low-energy-consumption concentration tower can solve the problems of high desulfurizationwastewater operation cost, complex treatment process and real zero emission of desulfurization wastewater, which are not solved by a traditional wastewater treatment method for a concentration tower.The zero-emission and low-energy-consumption concentration tower comprises a tower body and a bottom pool, wherein a first spraying layer, a second spraying layer and a demisting layer are sequentially arranged in the tower body from bottom to top; a demister is mounted in the demisting layer; a connecting pipe is connected with and arranged on the side wall of the top part of the demisting layer;one end of the connecting pipe is connected with a gas circulating pump; a guide pipe and a gas circulating pipe which are perpendicular to each other are connected with and arranged on the side wallof the gas circulating pump; the bottom end of the gas circulating pipe is guided into the bottom pool; an electromagnetic valve is installed at the joint of the guide pipe and the gas circulating pipe; a plurality of spray heads are installed in the first spray layer and the second spray layer; a tower tray is installed at the bottom part of the interior of the tower body; and a PLC is installedon the outer wall of the tower body.

Owner:LIBAO TECH

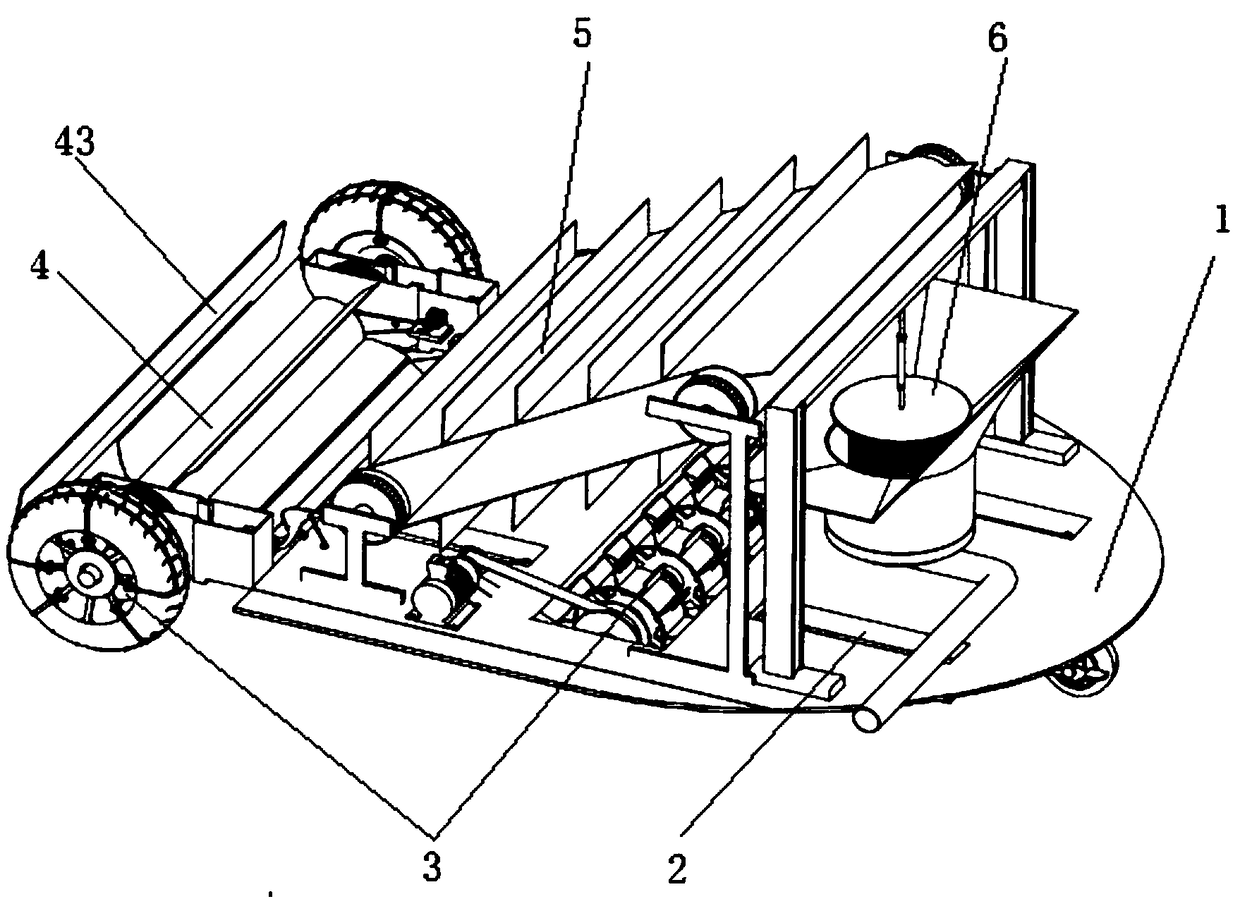

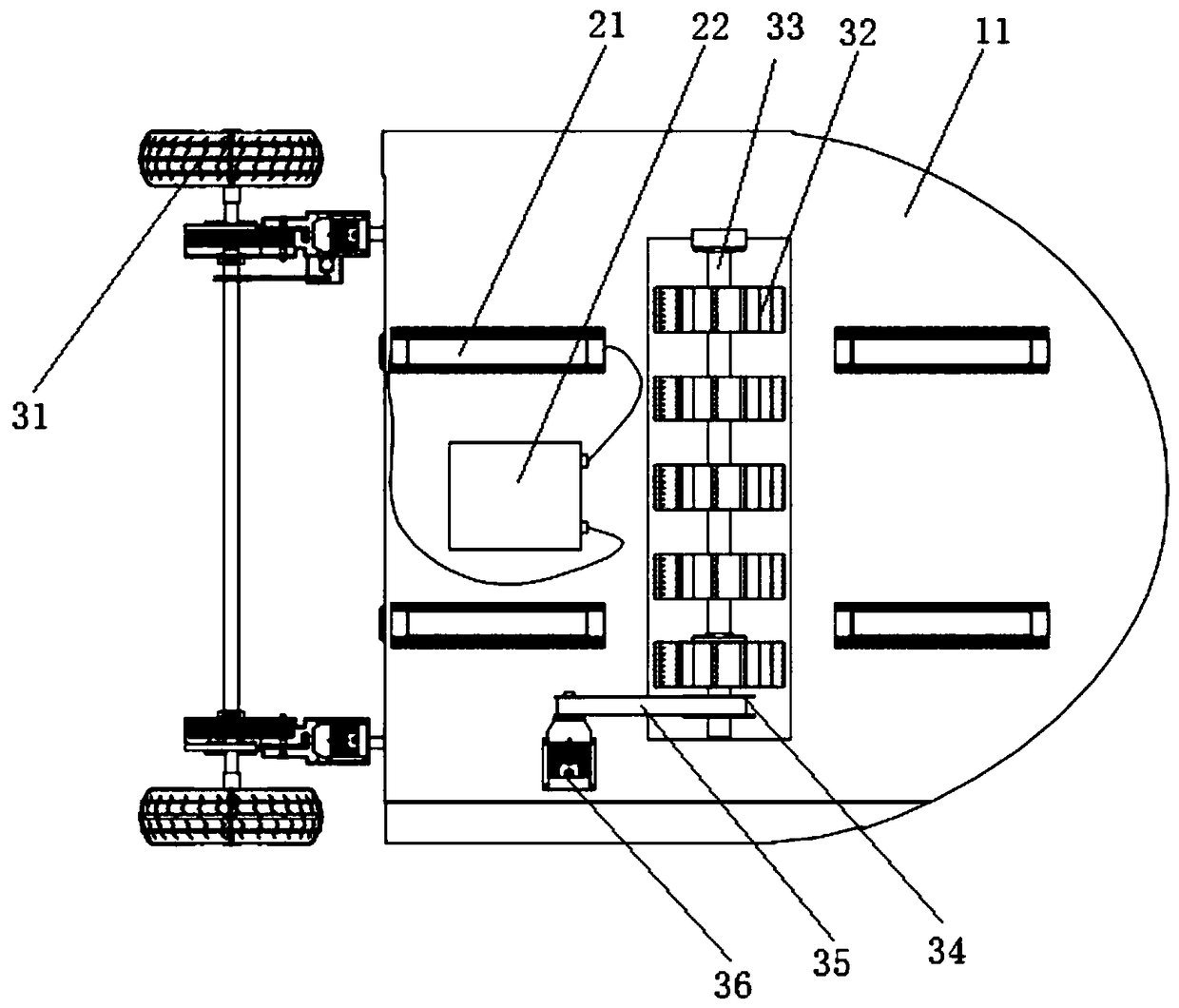

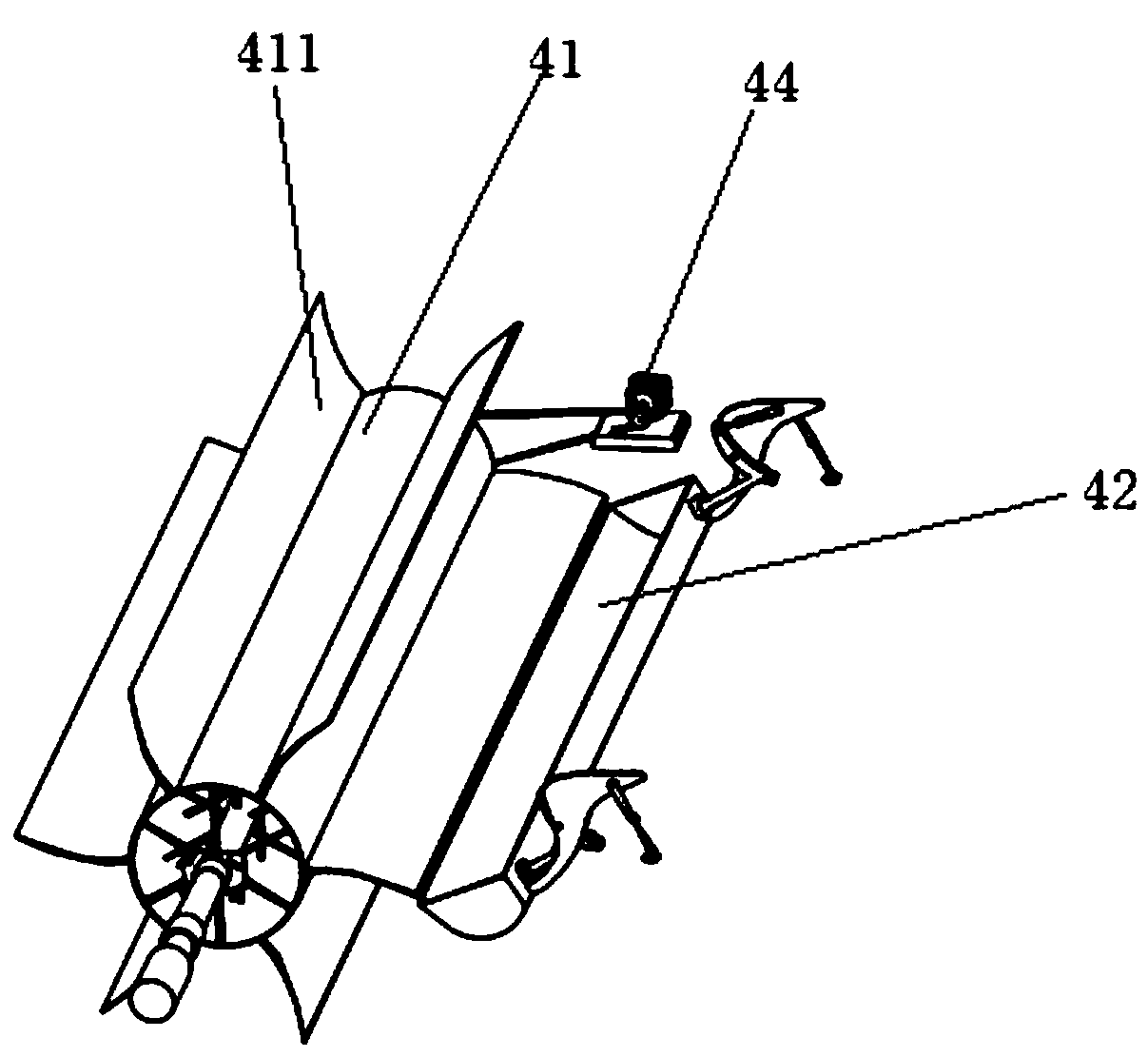

Hand-push double-tooth multifunctional ice breaking machine

ActiveCN109487746AFilling the gap in mechanical deicingSolve the whereabouts problemSnow cleaningDouble teethEngineering

The invention discloses a hand-push double-tooth multifunctional ice breaking machine. The machine comprises a trolley, a hot melting module, an ice breaking module, a collecting module, a transportation module and a crushing module. The hot melting module, the ice breaking module, the collecting module, the transportation module and the crushing module work cooperatively to form the multifunctional ice breaking machine. Road ice breaking, ice block collecting, ice breaking and cleaning are integrated. The invention discloses a double-tooth ice breaking wheel. Sharp teeth and an impact gear are used for ice breaking alternately, point-plane combination is achieved, and the ice breaking efficiency is greatly improved. According to the machine, compacted ice and snow of a road can be treatedin a large range, an ice layer of a certain area can be broken in pertinence, and accumulated snow is removed. Meanwhile, the machine is suitable for the road environment, communities and the like and also applicable to solving the problems about snow accumulation and ice accumulation, and the travel safety of people is guaranteed.

Owner:WUHAN UNIV OF TECH

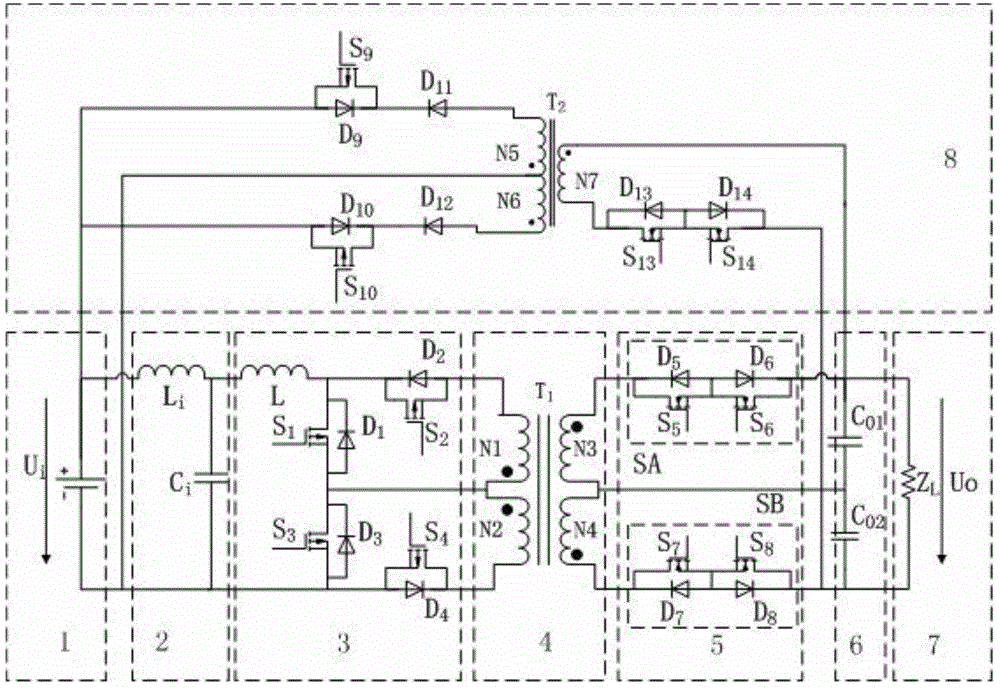

High-frequency isolated type boost three-level inverter

The invention provides a high-frequency isolated type boost three-level inverting circuit which is composed of a Boost inverting circuit and a flyback type energy feedback circuit. The Boost inverting circuit is composed of an input direct-current power supply unit, an input filter, a high-frequency inverter, a high-frequency transformer, a frequency converter, an output filtering capacitor and an output alternating-current load which are sequentially connected. A Boost converter can only increase the voltage and can not decrease the voltage, so that the output voltage can not be decreased, and the voltage can not meet the requirement for the output sine waveform. In order to ensure the quality of the output sine waveform in the period and solve the problem of the orientation of reactive energy of the output filtering capacitor and the load, the high-frequency electrical isolation flyback type converter energy feedback circuit is added between the output load and an input power supply. The inverter has the advantages that the number of power conversion stages is small, the number of power switching devices is small, input ripple waves are small, the voltage stress of a power switching tube is low, the dual-directional power stream and high-frequency electrical isolation are achieved, and the spectrum characteristic of the voltage at the front end of the output filter is good.

Owner:NANJING UNIV OF SCI & TECH

Method for preparing matrix especially for facility cultivation of strawberries by using mushroom residue of agaricus bisporus

PendingCN108849390ASuitable for growthLower substrate costGrowth substratesCulture mediaFragariaContinuous fermentation

The invention provides a method for preparing matrix especially for the facility cultivation of strawberries by using the mushroom residue of agaricus bisporus, which comprises the following steps of:adding EM fungus stock solution into the mushroom residue of the agaricus bisporus, adding water to adjust the moisture content, stacking into material piles for fermentation, carrying out pile turning treatment when the center temperature of the material pile is more than or equal to 60-65 DEG C during the continuous fermentation period; stopping fermentation when the center temperature of the material pile does not exceed the above-mentioned temperature after 24 hours; after the fermentation, crushing the mushroom residue of the agaricus bisporus and then washing the mushroom residue by water and airing; taking 5.8-6.2 parts of the washed and aired mushroom residue of the agaricus bisporus, mixing the mushroom residue with 3.8-4.2 parts of cultivation matrix evenly to obtain the matrixespecially for the facility cultivation of strawberries. According to the invention, the cost of strawberry matrix cultivation can be greatly reduced, and the fruit yield and fruit quality of the strawberries cultivated in facilities can be improved.

Owner:NINGBO ACAD OF AGRI SCI

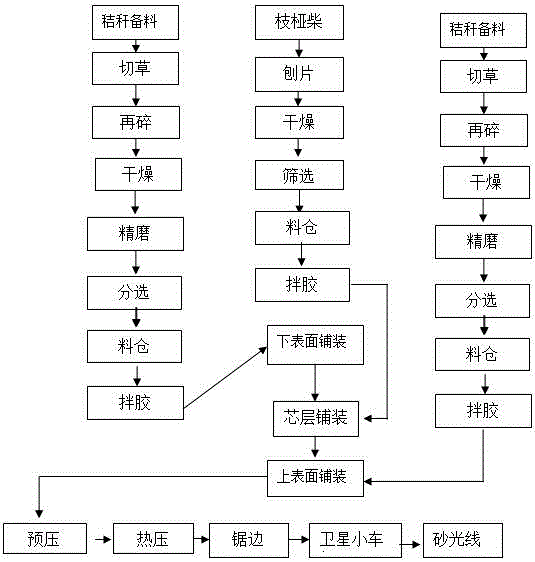

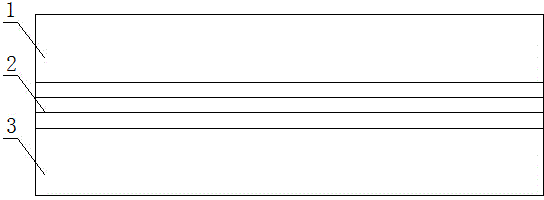

Grass tree structural board and production technology thereof

ActiveCN104960066AIncrease valueReduce manufacturing costWood working apparatusFlat articlesFiberEngineering

The invention discloses a grass tree structural board adopting straw and branch firewood as raw materials and a production technology thereof. Waste generated in the agricultural production process is fully utilized, crop straw of wheat straw, straw, cornstalks, sorghum stalks and the like and branch firewood waste abandoned in the production construction and updating modification process are used as raw materials, the novel artificial plate manufactured through the brand-new production technology is used for replacing traditional solid wood products to turn the straw into wealth, and the value of the crop straw is greatly improved. Meanwhile, the production cost of the plate is effectively lowered, and great economic benefits and social value are achieved. One-time hot press molding is achieved, and the problems that due to the fact that stacked gaps exist between wood sheets of an existing oriented strand board, the surface of a plate is uneven, and the plate cannot be directly used for producing surface decorative plates are solved. The density of a fiber surface plate layer can be 0.8 g / cm<3>, the density of a wood shaving core plate layer can be 0.78 g / cm<3>, the static bending intensity of the plate can reach 35.4 MPa effectively, and the thickness swelling rate of water absorption is smaller than 2% within 36 hours.

Owner:湖北益嘉林业发展有限公司

Soil amendment suitable for chinaroot greenbrier growth and preparation method thereof

InactiveCN105367352ALow cost of preparationEnvironmentally friendlyExcrement fertilisersInvertebrate treatmentNutrientMicrobial agent

The invention relates to a soil amendment suitable for chinaroot greenbrier growth and a preparation method thereof. The preparation method includes the following steps that 1-2 parts of a multifunctional microbial agent and water are mixed in the proportion of 1:2; the mixed liquid and 1-3 parts of a multifunctional bacterium accelerator are mixed according to the proportion of 1:1, the obtained mixed liquid is mixed with 25-35 parts of shield soil, 25-35 parts of bone meal, 20-30 parts of straw, 8-10 parts of earthworms, 3-5 parts of animal faeces, 2-5 parts of urea and 5-10 parts of a soil structure amendment, high-temperature fermentation is conducted, turning and piling are carried out every two days, the mixture makes full contact with air, the compost effect is promoted, and the shield soil amendment is obtained after 1-2 months of composting. The prepared soil amendment provides needed microorganisms, microelements and nutrients for bock greenbrier rhizome and has no pollution to the environment. The yield of the bock greenbrier rhizome is guaranteed, the quality of the bock greenbrier rhizome is guaranteed, and economic benefits of the bock greenbrier rhizome are improved.

Owner:JIANGSU GAIYA ENVIRONMENTAL SCI & TECH CO LTD

Culture method of selenium-rich edible fungus

InactiveCN106966778AKeep looseHigh activityBio-organic fraction processingAnimal corpse fertilisersAgaricBiotechnology

Relating to the technical field of edible fungus cultivation, the invention provides a culture method of selenium-rich edible fungus. The method includes the steps of: (1) blending: taking chicken manure, duck manure, pig manure, selenium-rich cob, wheat bran, bean dregs, humic acid, bone meal, volcanic cinder, lotus seed skin, garlic, mangosteen skin, Lycium ruthenicum residue, selenium-rich waste tea, expired milk and purple sweet potato, conducting fermentation to prepare a culture material, adjusting the moisture content of the culture material to 60-70%, and adjusting the pH value of the culture material to 5.3-6.3; (2) bagging; (3) sterilization; (4) inoculation; (5) mycelium culture; (6) fungus yield management; and (7) harvesting. The culture method of selenium-rich edible fungus provided by the invention can produce selenium-rich edible fungus with high yield.

Owner:广西丰兄农业开发有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com